Page 1

Enhancing

Automotive Electronic Test

with LXI

Page 2

Steve Stetler

Business Development Manager, Agilent Technologies

steve_stetler@agilent.com

The automotive industry’s highly

competitive nature puts intense

pressure on electronic manufacturers

to boost quality while lowering costs.

Activities such as electronic functional

test are often viewed as necessary

evils that must provide a high return

on investment.

Enter LAN eXtensions

for Instrumentation (LXI),

an architecture for nextgeneration test systems based on

proven, widely used standards

such as Ethernet. Combined

with the time-tested principles

of providing just enough cooling,

power, shielding and physical

size to provide superb measurements in modular and

traditional form factors, LXI’s

appeal is bolstered by its availability in bench-top instruments,

providing excellent performance

at competitive prices.

System designers who test

automotive electronics can use

LXI to maximize performance,

minimize cost and plan for the

future. There are at least nine

good reasons to consider LXI

for present and future test sys-

Figure 1. Agilent’s LXI-compatible 34980A LXI multi-function switch/measure unit allows

for insertion and removal of plug-in cards while power is on.

tems, as described in the April

2006 edition of LXI ConneXion

magazine1:

1. Ease of use

2. Performance

3. Cost

4. Scalability

5. Longevity

6. Flexibility

7. Rack space

8. Distributed systems

1. Ease of use

With the year-to-year changes

in new car models, automotive

electronics manufacturers must

bring new products to market

quickly. Rapid test system

creation depends on getting

instruments connected and

systems running as soon as

possible, which not only saves

time but also enables manufacturers to focus on verifying the

functionality of a module and

its subassemblies.

9. IEEE-1588 synchronization

2

Page 3

Many of these systems are

created with VXI- or PXIbased hardware and controlled

with either an embedded PC

or standalone PC connected

through an interface card and

cable. LXI solves four key problems developers would typically

face under these methods:

• Interface: Rather than an

MXI or GPIB interface,

LXI uses Ethernet,

eliminating the need to

install an additional

interface card in the PC.

In addition, there are no

proprietary cables or

software.

• PC configuration: Because

a PXI cardcage is an exten sion of the PC backplane,

the whole system must be

rebooted every time a card

is inserted or removed. With

LXI, PCs do not require

rebooting when connecting

or disconnecting instruments.

What’s more, some modular

LXI instruments allow for

“hot-docking” of cards while

the power is on (Figure 1).

• Drivers: When a PXI system

reboots, the PC uses an

instrument discovery process

to identify newly connected

devices, which usually requires

operators to download and

install device drivers. The

LXI standard specifies the

use of IVI-COM drivers,

making it easier to work in

a variety of development

environments. And some

LXI instruments can be

programmed directly through

Standard Commands for

Programmable Instruments

(SCPI) when greater func tionality or performance

is required.

• User interface: With no front

panel interface, using

PC-based system software

to diagnose problems in

PXI and VXI devices can be

difficult. With benchtop LXI

instruments, the front panel

interface makes it easy for

developers to experiment

with an instrument. While

most modular LXI instruments

lack a front panel, their

built-in Web interface makes

it possible to learn the capa bilities by simply opening a

Web browser on the connected

PC. The browser function

also makes it easier to see

what’s happening with the

equipment, simplifying system

support and ensuring greater

uptime.

2. Performance

Automotive electronics testing includes everything from

complex power train control

modules requiring hundreds

of tests, to simple airbag squib

modules, to telematic/infotainment modules that may involve

time-consuming transfers of

huge data files. These tests

often challenge GPIB’s maximum data rate of roughly

1 MB/s. With LAN, I/O transfer

speed is becoming a non-issue

with 1-Gbit/s connections

becoming commonplace and

10-Gbit/s on the way.

I/O performance should not

be an issue for LXI devices in

typical automotive applications

that require both transactional

programming and transfers of

large data blocks such as waveforms captured by digitizers.

In transactional programming,

there is a well-understood

issue around LAN latency.

Instrumentation vendors are

reducing the number of required

communication cycles by

preloading instructions to

LXI devices.

2

3

Page 4

3. Cost

Minimizing the overall cost

of test requires fast, reliable

testing at as low a price as possible. Some trade publications

have suggested that functional

test adds no value: At this late

stage, most manufacturers have

inspected incoming parts, performed X-ray inspection and

completed in-circuit test. While

these steps do improve product

quality, they do not eliminate

the need for functional test

because they cannot detect

faults due to post-assembly

product failures, design errors

or inaccessible nodes.

Automakers’ seemingly conflicting requirements compound

matters. Instruments that deliver

the necessary capabilities and

performance at an attractive

price can solve these issues,

as can careful consideration of

both initial hardware cost and

recurring costs such as spares,

warranties, local versus returnto-factory repair options and

availability of rental equipment.

In many cases, an instrumentby-instrument price comparison

will show up to 40 percent

reductions in the cost of LXI

versus PXI hardware.

3

It is also worthwhile to account

for the learning-curve costs of

cardcage instruments versus

LXI. Cardcage instruments

require the use of different

software drivers for each development environment such as

LabVIEW, Visual Basic and

C++. LXI instruments generally

offer a choice, enabling use of

either drivers or SCPI.

4. Scalability

Figure 2 shows a typical automotive electronic functional

test system built with LXI

devices: expandable reed relay

matrix, many armature-relay

load switches, many channels

of arbitrary waveform output

and many channels of D/A

conversion. In a cardcage-based

system, these devices can quickly

fill every slot, and the addition

of just one more device requires

another cardcage and computer

interface. For systems requiring

just a few cards, the cardcage

adds cost and consumes space,

though the empty slots allow

for future expansion. LXI

instruments provide the desired

functionality, making it easy to

upgrade functionality without

adding a cardcage or computer

interface. At most, the system

may require the addition of a

low-cost LAN switch to provide

ports for added LXI devices.

Figure 2. In an automotive test system, LXI

components enable greater scalability and

flexibility to meet present and future needs.

4

Page 5

5. Longevity

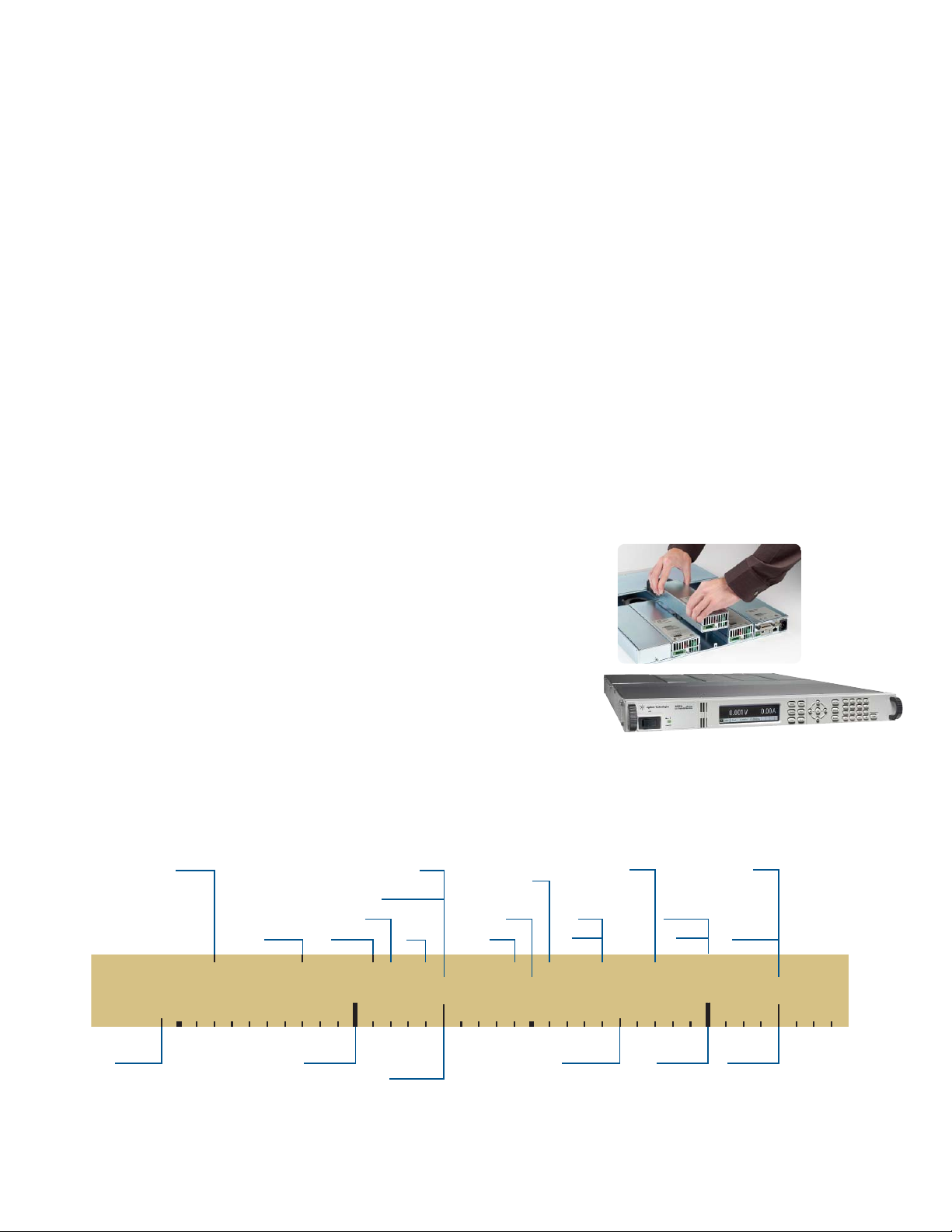

Figure 3 provides a comparison of various interfaces over

the past 30-plus years. Most

noteworthy is the continuous

improvement in LAN performance while maintaining

backward compatibility, suggesting that it will continue

as a dominant force in the

computer industry for a long

time to come.

Extensions designed into the

LXI Standard ensure that it

will meet the foreseeable needs

of the test and measurement

industry, a critical requirement

of the automotive electronics industry that supports an

active aftermarket and long

product lifetimes.

6. Flexibility

Cardcage-based solutions limit

the optimal instrumentation

placement in a test rack. For

example, system creators will

find it useful to put switching

in one low-cost subsystem and

stimulus/measurement instruments in another, simplifying

service and avoiding use of

high-cost, high-performance

backplanes to control slow

relays (often the case in PXI

or VXI cardcages).

LXI instrumentation enables

a better approach: A modular

switch/measure unit equipped

with an internal digital multimeter (DMM) and a selection

of switching cards offers a

low-cost method of creating a

dedicated switching subsystem.

The use of LAN also makes it

possible to place the LXI-based

subsystem farther from the

host PC and closer to the unit

under test.

Few cardcage-based power

supplies meet the current

requirements of many automotive electronic modules and

require external power supplies

based on different architectures.

Agilent has updated existing

designs to be LXI compliant,

housing them in compact, rackfriendly enclosures. Examples

include the Agilent N5700

series of high-power supplies

and the Agilent N6700 series

of modular supplies (Figure 4).

Figure 4. Some LXI-compliant power supplies

have size, power and functionality advantages over GPIB and PXI alternatives.

GPIB

VME

TRS 80

72 77 82

IBM PC

81 84 89

1970 1980 1990 2000

69

ARPAnet

3 Mb/s

Figure 3. LAN has evolved – and maintained backward compatibility – while other interfaces have come and gone.

Ethernet

10 Mb/s

VXI

Windows

ISA

IEEE

802.3

Standard

®

85

Worldwide

Web

EISA

5

PCI

cPCI

MCA

91

Ethernet

100 Mb/s

PXI

Rapid IO

PCI-X

94 97

95

Ethernet

Gbit

LXI

PCI

Express

04

10 Gbit

Ethernet

Page 6

7. Rack space

An LXI-based functional test

system could be assembled in

a rack as small as 750 mm tall

(Figure 5). This space efficiency

is due in part to LXI-based

devices such as an eight-slot

switch/measure unit with a

built-in DMM (second position

in rack) and a 1U modular

power system (lowest position

in rack).

To achieve maximum density,

system developers often use

cardcage-based instrumentation.

With VXI, a C-size cardcage can

hold up to 12 high-performance

instruments in about 6U, but this

is often an expensive solution.

PXI also provides high density,

but its compact 4U size has

four key shortcomings that are

addressed by LXI:

Card size: Due to PXI card size,

it may be necessary to use

more than one slot to achieve

the needed functionality. LXI

instruments, on the other

hand, can be created in a

variety of sizes to ensure

they fulfill their intended use.

Shielding: PXI cards are susceptible to interference. For

example, a Signal Conditioning

eXtensions for Instrumentation

(SCXI) power supply that emits

high levels of magnetic interference can lower the performance of an adjacent PXI

DMM, potentially lowering

DMM performance by a full

digit of resolution. LXI devices

are inherently shielded because

they are fully self-contained.

Cooling and power: Cardcages

must provide sufficient cooling

and power supply capacity to

handle a maximum number of

instruments or relays at one

time. In demanding systems,

it may be necessary to upgrade

to one or more higher-cost

mainframes capable of providing

the required cooling and power.

Automotive electronics applications also often require instrumentation output voltages that

exceed the voltage capability

of many PXI mainframes. LXI

instruments are generally designed

to provide the required power,

voltage and cooling for their

target application.

8. Distributed systems

Automotive production test

systems typically co-locate all

instruments. However, there is

an inherent benefit to applications such as durability test

systems, R&D test systems and

production validation systems

when operators can place LXI

instruments where the measurement needs to be made.

Figure 5. With LXI, a functional test

system can fit into a rack that is just

750 mm tall.

6

Production test systems also

can benefit from a remote testhead. With off-the-shelf LXI

switch modules, it is possible

to create a test fixture that

automatically adapts to any

engine control module coming

down the line, for example.

Page 7

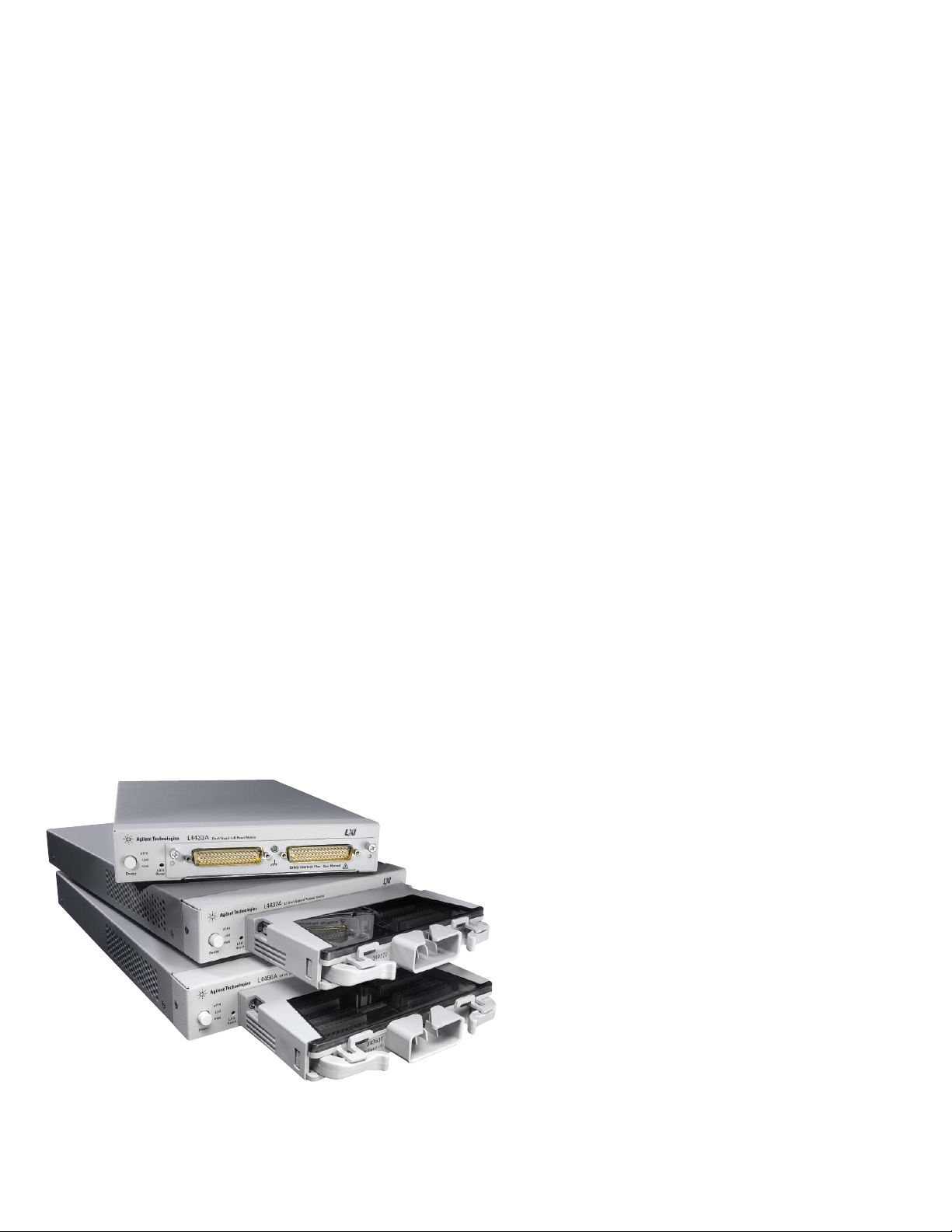

The ability to put the stimulus

and measurement instruments

where they are needed — with

minimal or no cabling back to

the core of the system — is a

feature unique to LXI. Modules

such as the Agilent L4400A

series are designed for this

type of remote or distributed

application (Figure 6).

Another factor that favors LXI

is remote debugging and troubleshooting. Service technicians

with remote access privileges

can diagnose a test system from

practically anywhere using a Web

browser. If a LAN-connected

webcam is added to the system,

the remote technician can even

see what is happening as they

troubleshoot.

9. IEEE-1588 synchronization

In high-volume production

lines, the ability to shave even

one second of test time per

module may be worth thousands

of dollars. In such cases, any

change to hardware or software

that causes an increase in test

execution time is unacceptable.

LXI addresses test time

through extensive triggering

capabilities, beginning with

a standardized trigger bus in

Class A LXI instruments. LXI

also provides a new way to

improve test execution time:

self-triggered measurements

based on a precise real-time

clock are synchronized from

instrument to instrument. With

this capability, measurements

can be performed without

intervention from the host

computer, minimizing or even

eliminating trigger wiring in a

test system and reducing I/O

bottlenecks.4

Conclusion

LXI is built for the long

haul and is well-suited to

automotive electronic test.

Its main benefits are in cost,

scalability and ease-of-use,

but LXI also offers advantages

in performance, longevity,

flexibility, synchronization

and rack space. More information is available online at

www.lxistandard.org and

www.agilent.com/find/lxi.

References

1. LXI ConneXion, April 2006,

Stefan Kopp; available from

www.lxiconnexion.com

2. LAN latency issue, The Appli-

cation of IEEE 1588 to Test

and Measurement Systems

by John C. Eidson; available

from www.lxistandard.org

3. Agilent application note

A Comparison Between PXI

and the Agilent 34980A for

Switch/Measure Applications

shows a 40 percent savings;

publication number

5989-5852EN available

from www.agilent.com

Figure 6. LXI-based switching modules enable the creation of powerful remote test systems.

7

4. Online article, “Making High

Speed Measurements Through

Triggering,” available from

www.agilent.com

Page 8

www.agilent.com/find/emailupdates

Get the latest information on the

products and applications you select.

www.agilent.com/find/agilentdirect

Quickly choose and use your test

equipment solutions with confidence.

www.agilent.com/find/open

Agilent Open simplifies the process

of connecting and programming

test systems to help engineers

design, validate and manufacture

electronic products. Agilent offers

open connectivity for a broad range

of system-ready instruments, open

industry software, PC-standard I/O

and global support, which are

combined to more easily integrate

test system development.

Remove all doubt

Our repair and calibration services

will get your equipment back to you,

performing like new, when promised. You will get full value out of

your Agilent equipment throughout its lifetime. Your equipment

will be serviced by Agilent-trained

technicians using the latest factory

calibration procedures, automated

repair diagnostics and genuine parts.

You will always have the utmost

confidence in your measurements.

Agilent offers a wide range of additional expert test and measurement services for your equipment,

including initial start-up assistance

onsite education and training, as

well as design, system integration,

and project management.

For more information on repair and

calibration services, go to:

www.agilent.com

For more information on Agilent Technologies’

products, applications or services, please

contact your local Agilent office. The complete

list is available at:

www.agilent.com/find/contactus

Americas

Canada (877) 894-4414

Latin America 305 269 7500

United States (800) 829-4444

Asia Pacific

Australia 1 800 629 485

China 800 810 0189

Hong Kong 800 938 693

India 1 800 112 929

Japan 81 426 56 7832

Korea 080 769 0800

Malaysia 1 800 888 848

Singapore 1 800 375 8100

Taiwan 0800 047 866

Thailand 1 800 226 008

www.lxistandard.org

LXI is the LAN-based successor to

GPIB, providing faster, more efficient

connectivity. Agilent is a founding

member of the LXI consortium.

www.agilent.com/find/removealldoubt

Europe

Austria 0820 87 44 11

Belgium 32 (0) 2 404 93 40

Denmark 45 70 13 15 15

Finland 358 (0) 10 855 2100

France 0825 010 700

Germany 01805 24 6333*

*0.14 €/minute

Ireland 1890 924 204

Italy 39 02 92 60 8484

Netherlands 31 (0) 20 547 2111

Spain 34 (91) 631 3300

Sweden 0200-88 22 55

Switzerland (French) 41 (21) 8113811(Opt 2)

Switzerland (German) 0800 80 53 53 (Opt 1)

United Kingdom 44 (0) 118 9276201

Other European Countries:

www.agilent.com/find/contactus

Revised: May 7, 2007

Product specifications and descriptions

in this document subject to change

without notice.

Windows and MS Windows are

U.S.registered trademarks of

Microsoft Corporation.

© Agilent Technologies, Inc. 2007

Printed in USA, October 8, 2007

5989-7173EN

Loading...

Loading...