Page 1

S

$JLOHQW7HFKQRORJLHV$$WWHQXDWRU2SHUDWLQJDQG

3URJUDPPLQJ*XLGH

S1

Page 2

Notices

Copyright © 1994-2000 Agilent

Technologies Deutschland GmbH.

All rights reserv ed.

No part of this manual may be

reproduced in any form or by any

means (including electronic

storage and retrieval or translation

into a foreign language) without

prior agreement and written

consent from Agilent Technologies,

Inc. as governed by United States

and international copyright laws.

Warranty

The material contained in this

document is subject to change without

notice. Agilent Technologies makes

no warranty of any kind with regard to

this material, including, but not

limited to, the implied warranties of

merchantability and fitness for a

particular purpose. Agilent

Technologies shall not be liable for

errors contained herein or for

incidental or consequential damages in

connection with the furnishing,

performance, or use of this material.

Edition/Print Date

All Editions and Updates of this

manual and their creation dates are

listed below.

08156-91011: E0500

Second Edition ………… May 2000

First Edition W0194, E0694, E0696,

E1098

continually increasing customer

satisfaction through improved

process control.

Assistance

Product maintenance agreements

and other customer assistance

agreements are available for

Agilent Technologies products.

For any assistance, contact your

nearest Agilent Technologies Sales

and Service Office (see “Service

and Support” on page 9).

ISO 9001 Certification

Produced to ISO 9001 international

quality system standard as part of

Agilent Technologies’ objective of

Agilent Technologies GmbH

Herrenberger Str. 130

71034 Böblingen

Germany

Page 3

6DIHW\6XPPDU\

The following general safety precautions must be observed during

all phases of operation of this instrument. Failure to comply with

these precautions or with specific warnings elsewhere in this

manual violates safety standards of design, manufacture, and

intended use of the instrument. Agilent Technologies assumes no

liability for the customer’s failure to comply with these

requirements.

*(1(5$/

This product is a Safety Class 1 instrument (provided with a

protective earth terminal). The protective features of this product

may be impaired if it is used in a manner not specified in the

operation instructions.

All Light Emitting Diodes (LEDs) used in this product are Class 1

LEDs as per IEC 60825-1.

(19,5210(17$/&21',7,216

This instrument is intended for indoor use in an installation category

II, pollution degree 2 environment. It is designed to operate at a

maximum relative humidity of 95% and at altitudes of up to 2000

meters. Refer to the specifications tables for the ac mains voltage

requirements and ambient operating temperature range.

%()25($33/<,1*32:(5

Verify that the product is set to match the available line voltage, the

correct fuse is installed, and all safety precautions are taken. Note

the instrument’s external markings described under Safety Symbols.

Page 4

*5281'7+(,167580(17

To minimize shock hazard, the instrument chassis and cover must

be connected to an electrical protective earth ground. The

instrument must be connected to the ac power mains through a

grounded power cable, with the ground wire firmly connected to an

electrical ground (safety ground) at the power outlet. Any

interruption of the protective (grounding) conductor or

disconnection of the protective earth terminal will cause a potential

shock hazard that could result in personal injury.

)86(6

Only fuses with the required rated current, voltage, and specified

type (normal blow, time delay, etc.) should be used. Do not use

repaired fuses or short-circuited fuse holders. To do so could cause

a shock or fire hazard.

'212723(5$7(,1$1(;3/26,9($70263+(5(

Do not operate the instrument in the presence of flammable gases or

fumes.

'21275(029(7+(,167580(17&29(5

Operating personnel must not remove instrument covers.

Component replacement and internal adjustments must be made

only by qualified service personnel.

Instruments that appear damaged or defective should be made

inoperative and secured against unintended operation until they can

be repaired by qualified service personnel.

Page 5

2WKHU6DIHW\,QIRUPDWLRQ

• Adjustments described in this manual are performed with power

supplied to the instrument while protective covers are removed.

Be aware that energy at many points, if contacted, result in

personal injury.

• Do not install substitute parts or perform any unauthorized

modification to the instrument.

• Be aware that capacitors inside the instrument may still be

charged even if the instrument has been connected from its

source of supply.

:$51,1* To avoid hazardous electrical shock, do not operate the instrument

if there are any signs of damage to any portion of the outer

enclosure (covers, panels, and so on).

:$51,1* To avoid the possibility of injury or death, you must observe the

following precautions before powering on the instrument.

– If this instrument is to be energized via an autotransformer for

voltage reduction, ensure that the Common terminal connects

to the earthed pole of the power source.

– Insert the power cable plug only into a socket outlet provided

with a protective earth contact. Do not negate this protective

action by the using an extension cord without a protective

conductor.

– Before switching on the instrument, the protective earth

terminal of the instrument must be connected to a protective

conductor. You can do this by using the power cord supplied

with the instrument.

– It is prohibited to interrupt the protective earth connection

intentionally.

Page 6

• The following work should be carried out by a qualified

electrician. All local electrical codes must be strictly observed:

If the plug on the cable does not fit the power outlet, or if the cable

is to be attached to a terminal block, cut the cable at the plug end

and rewire it.

The color coding used in the cable depends on the cable supplied. If

you are connecting a new plug, it should meet the local safety

requirements and include the following features:

• Adequate load-carrying capacity (see table of specifications).

• Ground connection.

• Cable clamp.

:$51,1* To avoid the possibility of injury or death, please note that the

Agilent 8156A does not have a floating earth.

:$51,1* The Agilent 8156A is not designed for outdoor use. To prevent

potential fire or shock hazard, do not expose the instrument to rain

or other excessive moisture.

:DUQLQJVDQG&DXWLRQV

:$51,1* The WARNING sign denotes a hazard. It calls attention to a

procedure, practice, or the like, which, if not correctly performed or

adhered to, could result in personal injury. Do not proceed beyond a

WARNING sign until the indicated conditions are fully understood

and met.

Page 7

&$87,21 The CAUTION sign denotes a hazard. It calls attention to an

operating procedure, or the like, which, if not correctly performed

or adhered to, could result in damage to or destruction of part or all

of the product. Do not proceed beyond a CAUTION sign until the

indicated conditions are fully understood and met.

6DIHW\6\PEROV

&DXWLRQUHIHUWRDFFRPSDQ\LQJGRFXPHQWV

:DUQLQJULVNRIHOHFWULFVKRFN

)UDPHRUFKDVVLVWHUPLQDO

3URWHFWLYHHDUWKJURXQGWHUPLQDO

+D]DUGRXVODVHUUDGLDWLRQ

Page 8

$ERXW7KLV0DQXDO

7KH6WUXFWXUHRIWKLV0DQXDO

This manual is divided into 4 parts:

• Chapter 1 tells you how to set up your Attenuator.

• Chapters 2 to 6 shows you what you can do with your Attenuator.

• Chapters 7 to 9 show you how you can remotely program your

Attenuator, using GPIB commands.

• The appendices contain additional information not required for

routine day-to-day use.

Page 9

6HUYLFHDQG6XSSRUW

Any adjustment, maintenance, or repair of this product must be

performed by qualified personnel. Contact your customer engineer

through your local Agilent Technologies Service Center. You can

find a list of local service representatives on the Web at:

http://www.agilent-tech.com/services/English/index.html

If you do not have access to the Internet, one of these centers can

direct you to your nearest representative:

8QLWHG6WDWHV 7HVWDQG0HDVXUHPHQW&DOO&HQWHU

7ROOIUHHLQ86

&DQDGD

(XURSH

-DSDQ 0HDVXUHPHQW$VVLVWDQFH&HQWHU

)$;

/DWLQ$PHULFD

)$;

$XVWUDOLD1HZ

=HDODQG

$VLD3DFLILF

$XVWUDOLD

1HZ=HDODQG

)$;

Page 10

Page 11

Table of Contents

1 Getting Started

1.1 Using the Attenuator ..............................................29

Using the Modify Keys ...................................................... 29

1.2 Making an Attenuation Sweep ..............................30

Making an Automatic Sweep ............................................ 30

1.3 The Manual Sweep .................................................31

1.4 Using your Attenuator as a Variable Back Reflector

32

1.5 Using the Through-Power Mode ..........................33

1.6 Selecting the Wavelength Calibration and Its Function

33

2 Using the Attenuator

2.1 Setting Up the Hardware ......................................37

2.2 Setting Up the Attenuation .....................................38

Entering the Attenuation Factor ........................................ 38

Entering a Calibration Factor ............................................ 39

Entering the Wavelength ............................ ..... .................. 40

2.3 Example, Setting the Calibration ..........................42

3 Making an Attenuation Sweep

3.1 Configuring the Hardware ....................................47

11

Page 12

Table of Contents

3.2 The Automatic Sweep ............................................48

Setting Up an Automatic Sweep ........................................48

Executing the Automatic Sweep ........................................50

3.3 The Manual Sweep .................................................51

Setting Up a Manual Sweep ...............................................51

Executing the Manual Sweep .............................................53

3.4 Example, an Automatic Attenuation Sweep .........54

4 Using your Attenuator as a Variable Back Re-

flector

4.1 Configuring the Hardware ....................................59

4.2 Setting Up the Software .........................................60

Editing the Setup .................................................................60

Executing the Back Reflector Application .........................61

4.3 Example, Setting a Return Loss ............................62

5 Setting Up the System

5.1 Setting the GPIB Address .....................................67

Resetting the GPIB Address ...............................................67

5.2 Selecting the Wavelength Calibration and Its Function

67

Setting the Function of the Wavelength Calibration ..........68

Selecting the Wavelength Calibration Data .......................69

12

Page 13

Table of Contents

5.3 Selecting the Through-Power Mode .....................70

Deselecting the Through-Power Mode ............................... 71

Resetting the Through-Power Mode .................................. 71

5.4 Setting the Display Brightness ..............................71

Resetting the Display Brightness .......................................71

5.5 Selecting the Setting used at Power-On ...............72

Resetting the Power-On Setting ........................................ 72

5.6 Locking Out ENB/DIS .............................................72

Resetting the ENB/DIS Lock Out ....................................... 73

5.7 Selecting the Shutter State at Power On ..............73

Resetting the Shutter State at Power On ............................ 73

5.8 Setting the Display Resolution ..............................74

Resetting the Display Resolution ...................................... 74

6 Storing and Recalling Settings

6.1 Storing the Setting .................................................77

6.2 Recalling a Setting ..................................................77

Resetting the Instrument .................................................... 77

Recalling a User Setting .................................................... 77

7 Programming the Attenuator

7.1 GPIB Interface .......................................................81

7.2 Setting the GPIB Address .....................................83

13

Page 14

Table of Contents

7.3 Returning the Instrument to Local Control ........83

7.4 How the Attenuator Receives and Transmits Messages

83

How the Input Queue Works ..............................................83

The Output Queue ..............................................................84

The Error Queue .................................................................84

7.5 Some Notes about Programming and Syntax Diagram

Conventions ..................................................................85

Short Form and Long Form ................................................85

Command and Query Syntax .............................................86

8 Remote Commands

8.1 Units ........................................................................89

8.2 Command Summary ..............................................89

8.3 The Common Commands .....................................93

Common Status Information ..............................................93

*CLS ...................................................................................95

*ESE ............................. ......................................................95

*ESR? .................................................................................. 96

*IDN? .................................................................................97

*OPC ..................................................................................98

*OPT? ................................................................................98

*RCL ..................................................................................99

*RST ..................................................................................99

*SAV ..................................................................................100

*SRE ..................................................................................101

*STB? .................................................................................102

14

Page 15

Table of Contents

*TST? ................................................... ...... ..... .................. 103

*WAI ................................................................................. 104

8.4 DISPlay Commands ................................................104

:DISPlay:BRIGhtness ............................................ ...... ..... .104

:DISPlay:ENABle .............................................................. 105

8.5 INPut Commands ...................................................106

:INPut:ATTenuation .......................................................... 106

:INPut:LCMode ................................................................. 107

:INPut:OFFSet ................................................................... 107

:INPut:OFFSet:DISPlay .................................................... 108

:INPut:WAVelength .......................................................... 109

8.6 OUTPut Commands ...............................................110

:OUTPut:APMode ............................................................. 110

:OUTPut:POWer ............................................................... 112

:OUTPut:[:STATe] ............................................................ 113

:OUTPut:[:STATe]:APOWeron ........................................114

8.7 STATus Commands ...............................................114

:STATus:OPERation:CONDition? ....................................116

:STATus:OPERation:ENABle .......................................... 117

:STATus:OPERation[:EVENt]? ........................................ 117

:STATus:OPERation:NTRansition ................................... 118

:STATus:OPERation:PTRansition .................................... 118

:STATus:QUEStionable:CONDition? ...............................119

:STATus:QUEStionable:ENABle ..................................... 119

:STATus:QUEStionable[:EVENt]? ................................... 120

:STATus:QUEStionable:NTRansition .............................. 1 20

:STATus:QUEStionable:PTRansition ............................... 121

:STATus:PRESet ........... ...... ...... ........................................122

8.8 SYSTem Commands ...............................................122

15

Page 16

Table of Contents

:SYSTem:ERRor? ..............................................................122

8.9 User Calibration Commands .................................123

Entering the User Calibration Data ....................................123

9 Programming Examples

9.1 Example 1 - Checking Communication ................131

9.2 Example 2 - Status Registers and Queues ............132

9.3 Example 3 - Measuring and Including the Insertion

Loss .................................................................................135

9.4 Example 4 - Running an Attenuation Sweep ........139

A Installation

A.1 Safety Considerations ...........................................143

A.2 Initial Inspection ...................................................143

A.3 AC Line Power Supply Requirements ................144

Line Power Cable ...............................................................144

Replacing the Battery .........................................................146

Replacing the Fuse .............................................................146

A.4 Operating and Storage Environment ...................148

Temperature ........................................................................148

Humidity ............................................................................148

Instrument Positioning and Cooling ...................................148

A.5 Switching on the Attenuator .................................149

16

Page 17

Table of Contents

A.6 Monitor Output ......................................................149

A.7 Optical Output ......................................................150

Disabling the Optical Output ............................................. 150

A.8 GPIB Interface ......................................................150

Connector ........................................................................... 151

GPIB Logic Levels ......................... ................................... 152

A.9 Claims and Repackaging .......................................152

Return Shipments to Agilent Technologies ........................ 152

B Accessories

B.1 Instrument and Options .......................................157

B.2 GPIB Cables and Adapters ..................................157

B.3 Connector Interfaces and Other Accessories ......158

Straight Contact Connector ................................................158

Option 201, Angled Contact Connector ............................. 160

C Specifications

C.1 Definition of Terms ...............................................165

C.2 Specifications ..........................................................167

Supplementary Performance Characteristics ...................... 169

C.3 Other Specifications ...............................................171

C.4 Declaration of Conformity ....................................172

17

Page 18

Table of Contents

D Performance Tests

D.1 Equipment Required .............................................175

D.2 Test Record .............................................................177

D.3 Test Failure .............................................................177

D.4 Instrument Specification .......................................177

D.5 Performance Test ...................................................178

I. Total Insertion Loss Test .................................................179

II. Linearity/Attenuation Accuracy Test .............................182

III. Attenuation Repeatability Test ......................................184

IV. Return Loss Test ...........................................................185

D.6 V. Polarization Dependent Loss (PDL): Optional 191

Polarization Dependant Loss Test (Mueller method) .........192

E Cleaning Information

Cleaning Instructions for this Instrument ............................248

E.1 Safety Precautions ..................................................249

E.2 Why is it important to clean optical devices ? .....249

E.3 What do I need for proper cleaning? ...................250

Standard Cleaning Equipment .............................................250

Additional Cleaning Equipment ..........................................253

E.4 Preserving Connectors ...........................................256

Making Connections ...........................................................256

Dust Caps and Shutter Caps ................................................256

Immersion Oil and Other Index Matching Compounds ......256

18

Page 19

Table of Contents

E.5 Cleaning Instrument Housings .............................257

E.6 Which Cleaning Procedure should I use ? ...........257

Light dirt ............................................................................. 257

Heavy dirt ........................................................................... 257

E.7 How to clean connectors ........................................258

Preferred Procedure .............. ..............................................258

Procedure for Stubborn Dirt ...............................................258

An Alternative Procedure ...................... ............................. 259

E.8 How to clean connector adapters ..........................259

Preferred Procedure .............. ..............................................259

Procedure for Stubborn Dirt ...............................................260

E.9 How to clean connector interfaces ........................260

Preferred Procedure .............. ..............................................260

Procedure for Stubborn Dirt ...............................................261

E.10 How to clean bare fiber adapters ........................261

Preferred Procedure .............. ..............................................261

Procedure for Stubborn Dirt ...............................................262

E.11 How to clean lenses ...............................................262

Preferred Procedure .............. ..............................................262

Procedure for Stubborn Dirt ...............................................263

E.12 How to clean instruments with a fixed connector inter-

face ..................................................................................263

E.13 How to clean instruments with an optical glass plate

264

E.14 How to clean instruments with a physical contact in-

terface .............................................................................264

Preferred Procedure .............. ..............................................265

Procedure for Stubborn Dirt ...............................................265

19

Page 20

Table of Contents

E.15 How to clean instruments with a recessed lens inter-

face ..................................................................................265

Preferred Procedure .................................................... ...... ...266

Procedure for Stubborn Dirt ................................................266

E.16 How to clean optical devices which are sensitive to me-

chanical stress and pressure .........................................267

Preferred Procedure .................................................... ...... ...267

Procedure for Stubborn Dirt ................................................267

Alternative Procedure ............................................ ..... ...... ...267

E.17 How to clean metal filters or attenuator gratings 268

Preferred Procedure .................................................... ...... ...268

Procedure for Stubborn Dirt ................................................268

E.18 Additional Cleaning Information .......................268

How to clean bare fiber ends ...............................................269

How to clean large area lenses and mirrors .........................269

Preferred Procedure .................................................... ...... ...269

Procedure for Stubborn Dirt ................................................270

Alternative Procedure A .................................. ...... ..... .........270

Alternative Procedure B ......................................................271

E.19 Other Cleaning Hints ...........................................271

Making the connection ........................................................271

Lens cleaning papers ...........................................................271

Immersion oil and other index matching compounds .........272

Cleaning the housing and the mainframe ............................272

F Error messages

F.1 Display Messages ...................................................275

20

Page 21

Table of Contents

F.2 GPIB Messages .......................................................276

Command Errors .................................................................276

Execution Errors ..................................................... ............ 280

Device-Specific Errors ....................................................... 281

Query Errors ....................................................................... 282

Instrument Specific Errors .................................................. 283

21

Page 22

Table of Contents

22

Page 23

List of Figures

Figure 1-1 The Attenuator Keys ................................................................................ 29

Figure 1-2 The Modify Keys ..................................................................................... 30

Figure 1-3 The Parameters for an Automatic Sweep ................................................. 31

Figure 1-4 The Hardware Configuration for the Back Reflector (Options 201 and 203) 32

Figure 2-1 The Hardware Configuration for the Attenuator ...................................... 37

Figure 2-2 The Attenuation Factor on the Display .................................................... 38

Figure 2-3 The Calibration Factor on the Display ..................................................... 39

Figure 2-4 The Wavelength on the Display ............................................................... 41

Figure 2-5 Hardware Configuration for Attenuation Example - A ........................... 42

Figure 2-6 Hardware Configuration for Attenuation Example - B ............................ 43

Figure 3-1 The Hardware Configuration for the Attenuator ...................................... 47

Figure 3-2 The Parameters for an Automatic Sweep ................................................. 49

Figure 3-3 Selecting the Automatic Sweep Application ........................................... 49

Figure 3-4 Running the Automatic Sweep ................................................................ 51

Figure 3-5 Editing the STOP Parameter .................................................................... 52

Figure 3-6 Running the Manual Sweep ..................................................................... 53

Figure 4-1 The Hardware Configuration for the Back Reflector ............................... 59

Figure 4-2 Editing the Value for the Reference Return Loss .................................... 61

Figure 4-3 Executing the Back Reflector Application ............................................... 62

Figure 4-4 Hardware Configuration for Variable Return Loss .................................. 63

Figure 5-1 The LAMBDCAL Indicator on the Display ................................................ 68

Figure 5-2 The USERCAL Indicator on the Display .................................................. 69

Figure 5-3 The Display in Through-Power Mode ..................................................... 70

Figure 6-1 The Display when Recalling the Default Setting ..................................... 77

Figure 8-1 Common Status Registers ........................................................................ 94

Figure 8-2 The Status Registers ................................................................................. 116

Figure 9-1 Hardware Configuration for Attenuation Example - A ........................... 135

Figure 9-2 Hardware Configuration for Attenuation Example - B ............................ 136

Figure A-1 Line Power Cables - Plug Identification ................................................. 144

Figure A-2 Rear Panel Markings ............................................................................... 145

Figure A-3 Releasing the Fuse Holder ...................................................................... 147

Figure A-4 The Fuse Holder ...................................................................................... 147

Figure A-5 Correct Positioning of the Attenuator ..................................................... 149

Figure A-6 GPIB Connector ...................................................................................... 151

Figure B-1 Straight Contact Connector Configuration .............................................. 159

23

Page 24

List of Figures

Figure B-2 Angled Contact Connector Configuration .............................................. 160

Figure D-1 Total Insertion Loss Test Setup 1, Options 100, 101, 121 ...................... 179

Figure D-2 Total Insertion Loss Test Setup 1, Options 201, 221 .............................. 180

Figure D-3 Total Insertion Loss Test Setup 1, Option 350 ....................................... 180

Figure D-4 Total Insertion Loss Test Setup 2, Options 100, 101, 121 ...................... 181

Figure D-5 Total Insertion Loss Test Setup 2, Options 201, 221 .............................. 181

Figure D-6 Total Insertion Loss Test Setup 2, Option 350 ....................................... 182

Figure D-7 Return Loss Test Setup 1, Options 100, 101, 121 .................................. 185

Figure D-8 Return Loss Test Setup 2, Options 100, 101 .......................................... 187

Figure D-9 Return Loss Test Setup 2, Option 121 .................................................... 187

Figure D-10 Return Loss Test Setup 1, Options 201, 221 ........................................ 188

Figure D-11 Return Loss Test Setup 2, Option 201 .................................................. 189

Figure D-12 Return Loss Test Setup 2, Option 221 .................................................. 190

Figure D-13 PDL Test Setup 1: Reference Measurement ......................................... 192

Figure D-14 PDL Test Setup 2: Power after DUT .................................................... 198

24

Page 25

List of Tables

Table 7-1 GPIB Capabilities ...................................................................................... 82

Table 8-1 Units and Allowed Mnemonics ................................................................. 89

Table 8-2 Common Command Summary .................................................................. 89

Table 8-3 Command List ........................................................................................... 90

Table 8-4 The Event Status Enable Register .............................................................. 96

Table 8-5 The Standard Event Status Register........................................................... 97

Table 8-6 Reset State (Default Setting) ..................................................................... 100

Table 8-7 The Service Request Enable Register ........................................................ 101

Table 8-8 The Status Byte Register............................................................................ 102

Table 8-9 The Self Test Results.................................................................................. 103

Table A-1 Temperature .............................................................................................. 148

Table C-1 Specifications - Options 100, 101 and 201................................................ 167

Table C-2 Monitor Output Options ........................................................................... 168

Table C-3 Multimode Options ................................................................................... 169

Table D-1 Equipment Required for the Agilent 8156A (1310/1550nm) ................... 176

Table D-2 Equipment for the PDL test 1.................................................................... 191

Table D-3 Performance Test Agilent 8156A ............................................................. 200

25

Page 26

List of Tables

26

Page 27

1

1 Getting Start e d

Page 28

Getting Start e d

This chapter introduces the features of the Agilent Technologies

8156A. More detail is given on these features in the following

chapters.

The main features of the Agilent 8156A, other than its use as an

attenuator, are its built-in sweep and back reflector applications, its

through-power mode (which displays the power at the output of the

instrument, rather than the amount of attenuation set) and its

selection of wavelength calibration possibilities.

28

Page 29

Getting Started

Using the Attenuator

1.1 Using the Attenuator

NOTE Before using the instrument, you should make sure that it is properly

warmed up. The instrument is properly warmed up when it has been

switched on for a minimum of 45 minutes. Failure to do this can cause

errors of up to 0.04dB in the attenuation.

Set the attenuation of the filter using A

(wavelength), and C

Figure 1-1 The Attenuator Keys

The attenuation factor and the calibration factor set the position of

the filter. The calibration factor allows you to of fset the value of the

attenuation factor.

Att(dB) = Cal(dB) + Attenuation

In addition, you can use D

attenuation factor to the calibration factor.

TT (attenuation factor), λ

AL (calibration factor).

(dB)

filter

ISP→CAL to transfer the current

Using the Modify Keys

There are four modify keys on the front panel of the attenuator.

29

Page 30

Getting Started

Making an Attenuation Sweep

Figure 1-2 The Modify Keys

Editing a Number

Use

⇐ and ⇒ to move the cursor from digit to digit when editing a

number. Use

number.

⇑ and ⇓ to change the value of a digit when editing a

Editing a Non-Numeric Parameter

⇑ or ⇒ to increment the parameter.

Use

⇓ or ⇐ to decrement the parameter.

Use

1.2 Making an Attenuation Sweep

There are two types of attenuation sweep, automatic and manual.

Making an Automatic Sweep

An automatic sweep is one where stepping from one attenuation

factor to the next is done by the instrument.

To select the automatic sweep press SWP, and make sure that

SWEEP is set to AUTO. By pressing S

30

WP repeatedly you view and

Page 31

Getting Started

The Manual Sweep

can edit the parameters for the sweep. START is the attenuation

factor at which the sweep begins, STOP is the attenuation factor

that ends the sweep, STEP is the size of the attenuation factor

change, and DWELL is the time taken for each attenuation factor.

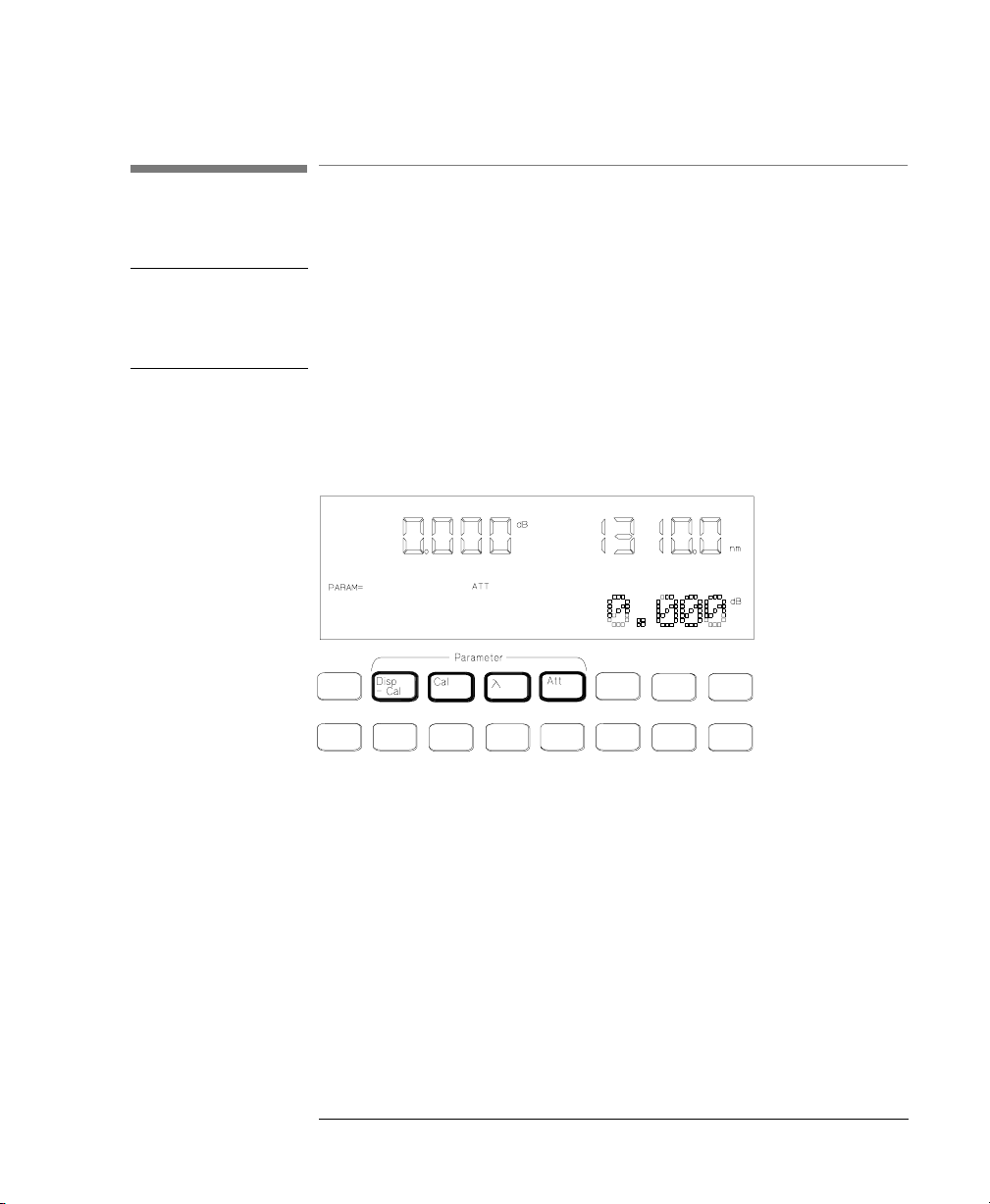

Figure 1-3 The Parameters for an Automatic Sweep

If you have set up your sweep, then you press E

XEC to run it.

1.3 The Manual Sweep

A manual sweep is one where stepping from one attenuation factor

to the next is done by the user.

T o select the manual sweep press SWP, and make sure that SWEEP

is set to MANUAL. By pressing S

edit the parameters for the sweep. START is the attenuation factor

at which the sweep begins, STOP is the attenuation factor that ends

the sweep, and STEP is the size of the attenuation factor change.

If you have set up your sweep, then you press E

to the next attenuation factor in the sweep, press

the previous attenuation factor in the sweep, press

31

WP repeatedly you can view and

XEC to run it. To go

⇑ or ⇒. To go to

⇓ or ⇐.

Page 32

Getting Started

Using your Attenuator as a Variable Back Reflector

1.4 Using your Attenuator as a Variable Back Reflector

NOTE Before using the instrument, you should make sure that it is properly

warmed up. The instrument is properly warmed up when it has been

switched on for a minimum of 45 minutes. Failure to do this can cause

errors of up to 0.04dB in the attenuation.

To use the attenuator as a back reflector, you need to set up the

hardware as shown in the figure below.

Figure 1-4 The Hardware Configuration for the Back Reflector (Options 201 and

203)

RL dB() 10 10

log–=

Press B

enter measured values for the insertion loss of the attenuator (INS

LOSS), the return loss of the attenuator (RL INPUT), and the

reference return loss you are using (RL REF). Th e r et urn los s ( RL)

is calculated according to the equation

RLInput dB

------------------------------------- -

()–

10

You edit the value for the return loss while the application is

running.

32

ACK REFL to start operation as a back reflector. You need to

RLInput dB()–

------------------------------------- -

110

–

+

10

10

()InsLoss dB()+()RLRef dB()+()–

2 Att dB

---------------------------------------------------------------------------------------------------------------10

Page 33

Getting Started

Using the Through-Power Mode

1.5 Using the Through-Power Mode

NOTE Before using the instrument, you should make sure that it is properly

warmed up. The instrument is properly warmed up when it has been

switched on for a minimum of 45 minutes. Failure to do this can cause

errors of up to 0.04dB in the attenuation.

In the through-power mode, the instrument shows the power that

gets through the attenuator on the display (that is the power at the

output) rather than the attenuation.

When you select the through-power mode the attenuation factor (in

dB) becomes the value for the through-power (in dBm). Set the

calibration factor (see “Entering a Calibration Factor” on page 39)

to get the attenuation factor to the value of the through-power.

After measuring and setting this base power value, press S

repeatedly until THRUPOWR is shown at the bottom of the display.

Select ON to select the through-power mode.

Edit the through-power factor by pressing A

Modify key s .

TT, and then the

YST

1.6 Selecting the Wavelength Calibration and Its Function

The attenuation at any point on the filter is wavelength dependent.

This dependence is measured and stored in the instrument, and is

used, with the value for the wavelength entered by the user to

compensate for the dependence. This is the wavelength calibration

data.

There are two ways in which this data can be used:

33

Page 34

Getting Started

Selecting the Wavelength Calibration and Its Function

• to reposition the filter so that the attenuation stays constant, or

• to change the attenuation factor on the display to show the

wavelength dependence. You use this to set the wavelength for

an unknown source (you alter the wavelength until the displayed

attenuation matches the measured attenuation).

To set the function of the calibration data press S

YST repeatedly

until LAMBDCAL is shown at the bottom of the display. Set

LAMBDCAL to OFF to use the calibration data to reposition the

filter, and set LAMBDCAL to ON to use the calibration data to

change the attenuation factor.

As well as the wavelength calibration data measured for and stored

in your instrument in the factory, there is space reserved in memory

for a set of your own user calibration data. (You load this data into

the instrument over the GPIB. See “User Calibration Commands”

on page 123)

YST repeatedly until USERCAL is shown at the bottom of the

Press S

display. OFF selects the factory-made wavelength calibration data.

ON selects the user wavelength calibration data.

34

Page 35

2

2 Using the Attenuator

Page 36

Using the Attenuator

This chapter describes the use of the Agilent Technologies 8156A

as an attenuator. There is an example given at the end of this

chapter.

36

Page 37

Using the Attenuator

Setting Up the Hardware

2.1 Setting Up the Hardware

To use the attenuator, you need to set up the hardware as shown in

the figure below.

Figure 2-1 The Hardware Configuration for the Attenuator

NOTE Before using the instrument, you should make sure that it is properly

warmed up. The instrument is properly warmed up when it has been

switched on for a minimum of 45 minutes. Failure to do this can cause

errors of up to 0.04dB in the attenuation.

The connector interface you need depends on the connector type

you are using (see “Connector Interfaces and Other Accessories”

on page 158).

If you have option 121 or option 221, then the Monitor Output

provides a signal for monitoring the power getting through the

attenuator. The signal level is approximately 5% of the output

power level. For the most accurate results, you should measure the

coupling ratio, and its wavelength dependence, for the Monitor

Output yourself.

37

Page 38

Using the Attenuator

Setting Up the Attenuation

2.2 Setting Up the Attenuation

The attenuation can be set in two different ways. This section

describes how to set the attenuation by specifying the attenuation

factor and an offset (called a calibration factor).

“Selecting the Through-Power Mode” on page 70 describes how to

set the attenuation by specifying the power that gets through.

Entering the Attenuation Factor

The attenuation factor is shown at the top left of the display.

Figure 2-2 The Attenuation Factor on the Display

Edit the attenuation factor using the modify keys.

The filter attenuation is changed while you edit the attenuation

factor according to the equation:

(dB) = Att(dB) - Cal (dB)

Att

filter

To edit the attenuation factor,

1. press A

2. edit the factor using the Modify keys (see “Using the Modify

38

TT, and

Keys” on page 29).

Page 39

Using the Attenuator

Setting Up the Attenuation

Resetting the Attenuation Factor

To reset the attenuation factor, press and hold A

resets (this takes approximately two seconds). The attenuation

factor resets so that the filter attenuation is zero, that is

Att(dB) = Cal(dB)

Entering a Calibration Factor

The calibration factor is shown at the bottom left of the display

Figure 2-3 The Calibration Factor on the Display

This factor does not affect the filter attenuation. It is used to offset

the values for the attenuation factor.

There are two ways of entering the calibration factor.

• by editing, and

• by transferring

TT until the value

Att

NEW

(dB) = Att

(dB) + Cal

filter

Editing the Calibration Factor

You would use this, for example, to enter an offset to compensate

for the insertion loss (attenuation) of your hardware setup.

The filter attenuation stays constant while you edit the calibration

factor. This means that the attenuation factor, shown on the display ,

changes according to the formula below (from equation (1)):

(dB) = Att

NEW

OLD

(dB) -Cal

(dB) + Cal

OLD

NEW

(dB)

To edit an external calibration factor,

39

Page 40

Using the Attenuator

Setting Up the Attenuation

1. press CAL, and

2. edit the factor using the Modify keys (see “Using the Modify

Keys” on page 29).

Resetting the Calibration Factor To reset the calibration factor, press and hold C

AL until the value

resets to zero (this takes approximately two seconds). The

calibration factor resets to zero.

Transferring to the Calibration Factor

You can transfer the attenuation factor shown on the display into

the calibration factor, so that the attenuation factor is reset to zero.

You would use this, for example, after you have set the power

through the attenuator at a specific level. When you have reset the

attenuation factor, you can edit it to get a relative attenuation.

The filter attenuation stays constant when you transfer to the

calibration factor. This means that the new calibration factor is

calculated from the attenuation factor and the old calibration factor

according to the formula below (from equation (1)):

Cal

(dB) = -Att

NEW

To transfer to the calibration factor, press D

(dB) = Cal

filter

OLD

(dB) - Att

ISP→CAL.

OLD

(dB)

Entering the Wavelength

The attenuation at any point on the filter is wavelength dependent.

This dependence is measured and stored in the instrument, and is

used, with the value for the wavelength entered by the user, to

compensate for the dependence. This is the wavelength calibration

data.

NOTE There are two ways of using the wavelength calibration data,

• to reposition the filter so that the attenuation stays constant, or

• to change the attenuation factor on the display to show the

wavelength dependence. You use this to set the wavelength for an

40

Page 41

Using the Attenuator

Setting Up the Attenuation

unknown source (you alter the wavelength until the displayed

attenuation matches the mea sured attenuation).

There are two sets of wavelength calibration data, one made in the

factory, individually, for your instrument. The user defines the other.

For more details on these topics, see “Selecting the Wavelength

Calibration and Its Function” on page 67.

The wavelength is shown at the top right of the display.

Figure 2-4 The Wavelength on the Display

Edit the wavelength using the modify keys.

To edit the wavelength,

1. press

λ, and

2. edit the value using the Modify keys (see “Using the Modify

Keys” on page 29).

Resetting the Wavelength To reset the wavelength, press and hold A

TT until the value resets

(this takes approximately two seconds). The wavelength resets to

1310nm.

41

Page 42

Using the Attenuator

Example, Setting the Calibration

2.3 Example, Setting the Calibration

This example uses the Agilent 8156A Attenuator, with a HP 8153A

multimeter with one source and one sensor. The connectors for this

system are all HMS-10.

We set up the hardware, and measure the insertion loss of the

system and use this value to set a calibration factor.

1. Configure the hardware as shown in the figure below, making

sure that all the connectors are clean:

Figure 2-5 Hardware Configuration for Attenuation Example - A

a. Make sure that the power sensor is inst alled in the

multimeter mainframe in channel A, and the source is in

channel B.

b. Connect both instruments to the electric supply.

c. Switch on both instruments.

42

Page 43

Using the Attenuator

Example, Setting the Calibration

NOTE Under normal circumstances you should leave the instruments to

warmup. (The multimeter needs around 20 minutes to warmup. The

attenuator needs around 45 minutes with the shutter open to warmup.)

Warming up is necessary for accuracy of the sensor, and the output

power of the source.

d. Connect a patchcord from the source to the input of the

sensor.

2. Measure the insertion loss of the Hardware setup:

a. On the multimeter:

i. Set the wavelength for the sensor to that of the source.

ii. Activate the source, by pressing the gray button on its

front panel.

iii. Start the loss application (press M

XEC).

and E

ODE and then LOSS,

b. Reconfigure the hardware to include the attenuator:

i. Disconnect the source from the sensor, and connect it to

the input of the attenuator.

Figure 2-6 Hardware Configuration for Attenuation Exam ple - B

ii. Connect a patchcord from the output of the attenuator to

the sensor.

43

Page 44

Using the Attenuator

Example, Setting the Calibration

c. Set the wavelength on the attenuator to that of the source:

i. Press

λ.

ii. Use the m odif y keys to edit the value for the

wavelength.

d. Reset the calibration factor, by pressing and holding C

AL

for two seconds.

e. Reset the attenuation factor, by pressing and holding ATT

for two seconds.

f. Enable the output of the attenuator (press ENB/DIS so that

the LED lights).

g. Note the value for the loss read by the multimeter.

3. Enter the insertion loss of the hardware setup.

a. Press C

AL.

b. Edit the calibration factor so that it has the value shown on

the multimeter display, using the modify keys.

You should notice that the value for the attenuation factor changes,

and always has the same value as that for the calibration factor. This

is because the filter attenuation stays at zero (you should also notice

that the display on the multimeter does not change).

The attenuator now shows its full attenuation (including its own

insertion loss) on the display.

44

Page 45

3

3 Making an Attenuation

Sweep

Page 46

Making an Attenuation

Sweep

This chapter describes how to make an attenuation sweep with the

Agilent T echnologies 8156A Attenuator. An example is given at the

end of the chapter.

46

Page 47

Making an Attenuation Sweep

Configuring the Hardware

3.1 Configuring the Hardware

To use the attenuator for a sweep, you need to set up the hardware

as shown in the figure below. (This is the configuration as giv en for

simple attenuation in chapter 2).

Figure 3-1 The Hardware Configuration for the Attenuator

NOTE Before using the instrument, you should make sure that it is properly

warmed up. The instrument is properly warmed up when it has been

switched on for a minimum of 45 minutes. Failure to do this can cause

errors of up to 0.04dB in the attenuation.

The connector interface you need depends on the connector type

you are using (see “Connector Interfaces and Other Accessories”

on page 158).

If you have option 121 or option 221 (the monito r outpu t ), then th e

Monitor Output provides a signal for monitoring the power getting

through the attenuator. The signal level is approximately 5% of the

output power level. For the most accurate results, you should

measure the coupling ratio, and its wavelength dependence, for the

Monitor Output yourself.

47

Page 48

Making an Attenuation Sweep

The Automatic Sweep

3.2 The Automatic Sweep

An automatic sweep is one where stepping from one attenuation

factor to the next is done by the instrument.

Setting Up an Automatic Sweep

There are four parameters for the automatic sweep

• START is the attenuation factor at which the sweep begins.

• STOP is the attenuation factor that ends the sweep. If START

and STEP are such that the sweep does not end exactly at

STOP, then the sweep ends at the immediately previous value.

• STEP is the size of the attenuation factor change. This value is

always positive, even for a sweep of decreasing attenuation

factor. STEP cannot be set to a value greater than the difference

between START and STOP.

• DWELL is the time taken for each attenuation factor.

NOTE The dwell time includes the time it takes for the filter attenuation to

change. The time taken to change depends on the size of the attenuation

factor change, and is in the range 20 to 400ms (typical value is 200ms).

48

Page 49

Making an Attenuation Sweep

The Automatic Sweep

Figure 3-2 The Parameters for an Automatic Sweep

Starting the Setting Up

T o select the automatic sweep

1. Press S

2. If it is not already set, use

WP.

⇑ or ⇓ to set SWEEP to AUTO.

Figure 3-3 Selecting the Automatic Sweep Application

Editing the Parameters

To edit the value of the parameters

3. Press S

4. Edit the value of START with the Modify keys.

5. Press S

49

WP again to get START.

WP again to get STOP.

Page 50

Making an Attenuation Sweep

The Automatic Sweep

6. Edit the value of STOP with the Modify keys.

7. Press S

WP again to get STEP.

8. Edit the value of STEP with the Modify keys.

9. Press S

WP again to get DWELL.

10. Edit the value of DWELL with the Modify keys.

See “Using the Modify Keys” on page 29 for information on

editing with the Modify keys.

Resetting the Parameters

To reset any of the sweep parameters, press and hold SWP until the

value resets (this takes approximat el y two second s).

START and STOP reset so that the filter attenuation (inside th e

instrument) is zero, that is

Start = Cal

or

Stop = Cal

See “Entering a Calibration Factor” on page 39 for information

about setting the calibration factor, Cal.

STEP resets to zero.

DWELL resets to 0.2 seconds.

Executing the Automatic Sweep

If you have just set up your sweep, then you only need to press

XEC to run the application.

E

If you have already set up the sweep, and are currently operating

the instrument as an attenuator,

1. Press S

2. Press E

50

WP, and then,

XEC.

Page 51

Making an Attenuation Sweep

The Manual Sweep

Figure 3-4 Running the Automatic Sweep

If there is something wrong with a parameter (if STEP is zero, for

example), this parameter is shown on the display for editing. Edit

the parameter, and press E

Repeating the Sweep

When the sweep is finished (SWEEP READY is shown at the

bottom of the display), you can press E

Restarting the Sweep

XEC again.

XEC to start it again.

To restart the sweep at any time while it is runnin g, p ress EXEC.

3.3 The Manual Sweep

A manual sweep is one where stepping from one attenuation factor

to the next is done by the user.

Setting Up a Manual Sweep

There are three parameters for a manual sweep

• START is the attenuation factor at which the sweep begins.

• STOP is the attenuation factor that ends the sweep. If START

and STEP are such that the sweep does not end exactly at STOP,

then the sweep ends at the immediately previous value.

51

Page 52

Making an Attenuation Sweep

The Manual Sweep

• STEP is the size of the attenuation factor change. This value is

always positive, even for a sweep of decreasing attenuation

factor. STEP cannot be set to a value greater than the difference

between START and STOP.

Starting the Setting Up

T o select the manual sweep

1. Press S

WP.

2. If it is not already set, use the modify keys to set SWEEP to

MANUAL.

Editing the Parameters

To edit the value of the parameters

3. Press S

4. Edit the value of START with the Modify keys.

5. Press S

6. Edit the value of STOP with the Modify keys.

Figure 3-5 Editing the STOP Parameter

7. Press S

WP again to get START.

WP again to get STOP.

WP again to get STEP.

8. Edit the value of STEP with the Modify keys.

See “Using the Modify Keys” on page 29 for information on

editing with the Modify keys.

52

Page 53

Making an Attenuation Sweep

The Manual Sweep

Resetting the Parameters

T o res et any of the sweep parameters, press and hold SWP until the

value resets (this takes approximat el y two second s).

START and STOP reset so that the filter attenuation (inside the

instrument) is zero, that is

Start = Cal

or

Stop = Cal

See “Entering a Calibration Factor” on page 39 for information

about setting the calibration factor, Cal.

STEP resets to zero.

Executing the Manual Sweep

If you have just set up your sweep, then you only need to press

XEC to run the application.

E

If you have already set up the sweep, and are currently operating

the instrument as an attenuator,

1. Press S

2. Press E

WP, and then,

XEC.

Figure 3-6 Running the Manual Sweep

If there is something wrong with a parameter (if STEP is zero, for

example), this parameter is shown on the display for editing. Edit

the parameter, and press E

53

XEC again.

Page 54

Making an Attenuation Sweep

Example, an Automatic Attenuation Sweep

Changing the Attenuation in a Manual Sweep

To go to the next attenuation factor in the sweep, press ⇑ or ⇒.

To go to the previous attenuation factor in the sweep, press

⇓ or ⇐.

3.4 Example, an Automatic Attenuation Sweep

This example uses the Agilent 8156A Attenuator on its own.

W e set up the instrument to sweep from 5dB to 0dB with an interval

of 0.5dB, dwelling for a second at each attenuation factor.

1. First we want to reset the instrument.

NOTE If someone else is using this instrument, please check with them before

resetting, or store their setting for later recall.

a. Press R

b. Press E

2. Start the automatic sweep application.

a. Press S

b. If the sweep parameter is set to MANUAL, press

it to AUTO.

ECALL.

XEC.

WP.

⇑, or ⇓ to set

3. Set the start attenuation factor.

a. Press S

WP.

b. Use the Modify keys to set START to 5.000dB.

4. Set the attenuation factor step size.

a. Press S

WP, to get the stop parameter. We do not need to edit

this parameter.

b. Press SWP to get the step parameter.

54

Page 55

Making an Attenuation Sweep

Example, an Automatic Attenuat ion Sweep

c. Use the Modify keys to set STEP to 0.500dB.

5. Set the dwell time.

a. Press S

WP.

b. Use the Modify keys to set DWELL to 1.00s.

6. Execute the sweep

a. Press S

WP.

b. Make sure the output is enabled (press E

LED lights).

c. Press EXEC.

NB/DIS until the

55

Page 56

Making an Attenuation Sweep

Example, an Automatic Attenuation Sweep

56

Page 57

4

4 Using your Attenuator as a

Variable Back Reflector

Page 58

Using your Attenuator

as a Variable Back

Reflector

This chapter describes how you can use your attenuator as a

variable back reflector. An example using the back reflector kit

(option 203 with option 201) is given at the end of the chapter.

58

Page 59

Using your Attenuator as a Variable Back Reflector

Configuring the Hardware

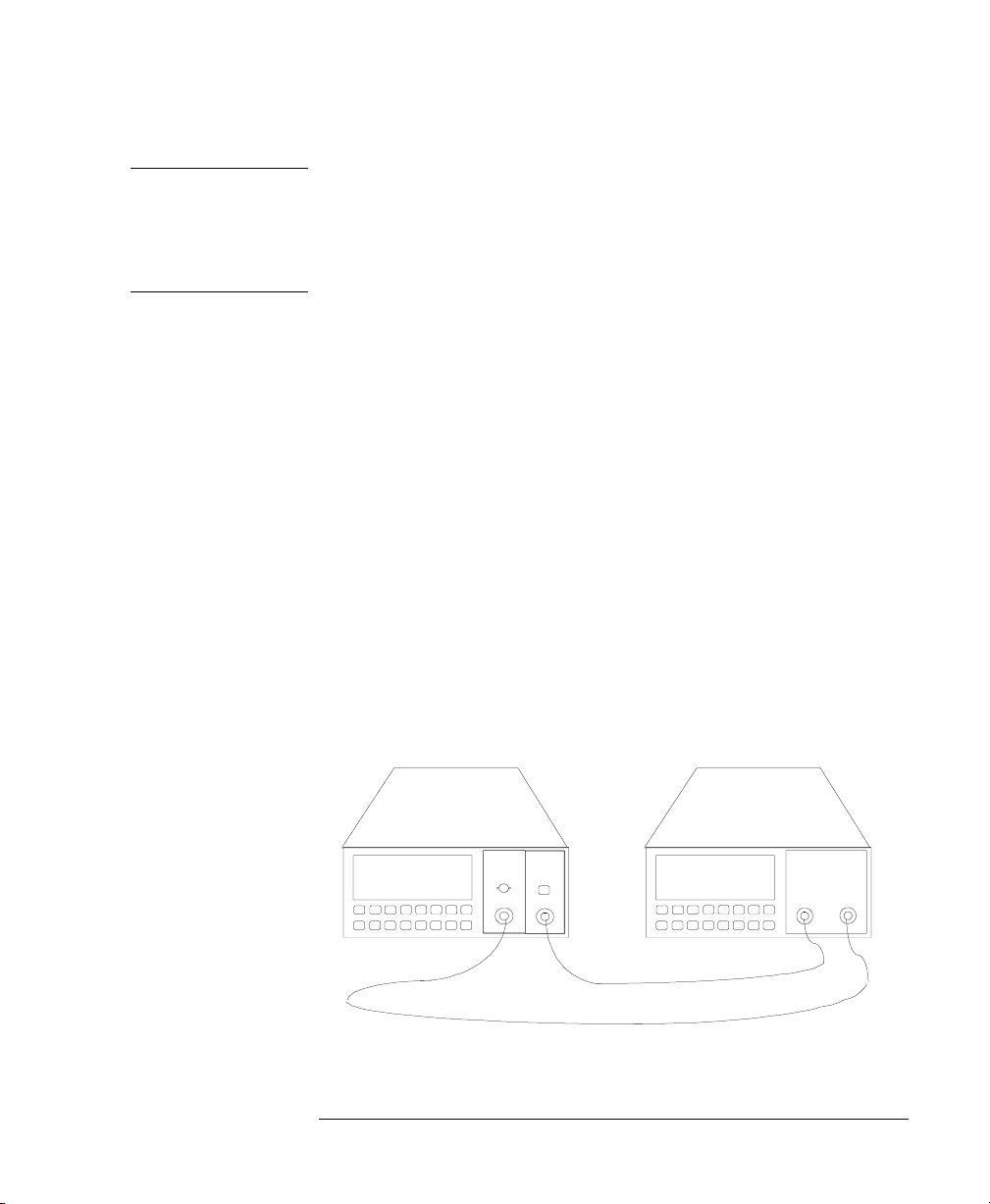

4.1 Configuring the Hardware

To use the attenuator as a back reflector, you need to set up the

hardware as shown in the figure below.

NOTE If this your first time to use the att enuat or as a back r ef lector, you first

need to make some measurements. These require other setups before

setting up the hardware as shown below (see “Setting Up the Software”

on page 60).

Figure 4-1 The Hardware Configuration for the Back Reflector

NOTE Before using the instrument, you should make sure that it is properly

warmed up. The instrument is properly warmed up when it has been

switched on for a minimum of 45 minutes. Failure to do this can cause

errors of up to 0.04dB in the attenuation.

If you are not using option 201, the connector interfaces you need

depends on the connector type you are using. Option 121 or option

221 (the monitor output) is of no use when using the attenuator as a

back reflector. The disruption to the back r eflection performance b y

leaving this output open is negligible, though you may want to

terminate it to eliminate any small effect it might have.

59

Page 60

Using your Attenuator as a Variable Back Reflector

Setting Up the Software

4.2 Setting Up the Software

There are four factors that influence the back reflection of the

attenuator. These are

1. the insertion loss of the attenuator (INS LOSS),

2. the return loss of the attenuator (RL INPUT),

3. the reference return loss you are using (RL REF), and

4. the filter attenuation.

The return loss (RL) is calculated according to the equation

RL dB() 10 10

log–=

RLInput dB

------------------------------------- -

()–

10

You edit the values for the insertion loss, the reference return loss,

and the return loss of the attenuator while you are setting up the

application.

You edit the value for the return loss while the application is

executing. The instrument calculates and sets the req uired value for

the filter attenuation.

Editing the Setup

Before you start setting up the back reflector application, you may

need to measure the following values, if you do not already know

them:

• The insertion loss of the instrument (see “Example, Setting the

• The return loss of the instrument (with the output properly

• The reference return loss value.

RLInput dB()–

------------------------------------- -

110

–

+

10

10

()InsLoss dB()+()RLRef dB()+()–

2 Att dB

----------------------------------------------------------------------------------------------------------------

Calibration” on page 42,

terminated), and

10

60

Page 61

Using your Attenuator as a Variable Back Reflector

Setting Up the Software

To start setting up the Back Reflector application

1. Press B

ACK REFL.

After pressing this the first parameter (INS LOSS) is ready to for

editing.

2. Edit the value insertion loss with the Modify keys.

3. Press B

ACK REFL.

4. Edit the value reference return loss with the Modify keys.

Figure 4-2 Editing the Value for the Reference Return Loss

5. Press B

ACK REFL.

6. Edit the value attenuator return loss with the Modify keys.

See “Using the Modify Keys” on page 29 for information on

editing with the Modify keys.

Resetting the Parameters

T o rese t any of the back reflector parameters , press and hold BACK

EFL until the value resets (this takes approximately two seconds).

R

INS LOSS resets to 2.000dB.

RL REF resets to 14.700dB (the return loss for the glass/air

interface at an open connector)

RL INPUT resets to 60.000dB.

Executing the Back Reflector Application

If you have just set up the application, then you only need to press

XEC to run the application.

E

61

Page 62

Using your Attenuator as a Variable Back Reflector

Example, Setting a Return Loss

If you have already set up the application, and are currently

operating the instrument as an attenuator,

1. Press BACK REFL, and then,

2. Press E

Figure 4-3 Executing the Back Reflector Application

The value shown at the top left of the display is the return loss of

the instrument. You can edit the value of the return loss with the

Modify keys.

XEC.

4.3 Example, Setting a Return Loss

This example uses the Ahilent T echnolog ies 8156A Attenuator with

options 201, and 203.

Assuming an insertion loss of 2.00d B and a return los s of 60.000 dB

for the instrument we set up the instrument to have a return loss of

20dB.

62

Page 63

Using your Attenuator as a Variable Back Reflector

Example, Setting a Return Loss

1. Configure the hardware as shown in the figure below:

Figure 4-4 Hardware Configuration for Variable Return Loss

a. Connect the instrument to the electric supply.

b. Switch on the instrument.

2. Reset the instrument.

NOTE If someone else is using this instrument, please check with them before

resetting, or store their setting for later recall.

a. Press R

b. Press E

ECALL.

XEC.

3. Set the return loss reference value for the Agilent 81000BR

reference reflector.

a. Press BACK REFL twice to select the RL REF parameter.

b. Edit the value, with the Modify keys to set it to 0.180dB

4. Press E

XEC to start the application

5. Edit the return loss value, with the Modify keys, to set it to

20.000dB.

63

Page 64

Using your Attenuator as a Variable Back Reflector

Example, Setting a Return Loss

64

Page 65

5

5 Setting Up the System

Page 66

Setting Up the System

This chapter describes how to set the various system parameters for

your attenuator.

66

Page 67

Setting Up the System

Setting the GPIB Address

5.1 Setting the GPIB Address

To set the GPIB address of the attenuator

1. Press S

2. Edit the value for ADDRESS using the Modify keys.

YST.

Resetting the GPIB Address

To reset ADDRESS, press and hold SYST until the value resets (this

takes approximately two seconds).

ADDRESS resets to 28.

5.2 Selecting the Wavelength Calibration and Its Function

The attenuation at any point on the filter is wavelength dependent.

This dependence is measured and stored in the instrument, and is

used, with the value for the wavelength entered by the user to

compensate for the dependence. This is the wavelength calibration

data.

As well as the wavelength calibration data measured for and stored

in your instrument in the factory, there is space reserved in memory

for a set of your own user calibration data.

There are two choices concerning the use of waveleng th calibration

data.

• Whether or not the data should be used to position the filter to

compensate for wavelength dependence.

• Whether the factory-made wavelength calibration data is used,

or the data entered by the user.

67

Page 68

Setting Up the System

Selecting the Wavelength Calibration and Its Function

Setting the Function of the Wavelength Calibration

This compensation can be used

• to reposition the filter so that the attenuation stays constant, or

• to change the attenuation factor on the display to show the

wavelength dependence. You use this to set the wavelength for

an unknown source (you alter the wavelength until the displayed

attenuation matches the measured attenuation).

To set the function of the wavelength calibration data

1. Press S

of the display.

2. Select the wavelength calibration data function using the Modify

keys. Set LAMBDCAL to OFF so that the function of the

wavelength calibration data is not visible to the user. This keeps

the attenuation value fixed, and alters the filter position. Set

LAMBDCAL to ON to keep the filter position fixed, and for the

function of the wavelength calibration data to be visible to the

user.

While it is ON, LAMBDCAL is shown at the bottom left of the

display (U/L-CAL is shown if the USERCAL is also on).

Figure 5-1 The LAMBDCAL Indicator on the Display

YST repeatedly until LAMBDCAL is shown at the bottom

Resetting the Function of the Wavelength Calibration Data

To reset LAMBDCAL, press and hold SYST until the value resets

(this takes approximately two seconds).

LAMBDCAL resets to OFF.

68

Page 69

Setting Up the System

Selecting the Wavelength Calibration and Its Function

Selecting the Wavelength Calibration Data

You enter the user wavelength calibration data over the GPIB (see

“User Calibration Commands” on page 123).

Using your own wavelength calibration data, you can use the

attenuator to compensate for the total wavelength dependence of

your hardware configuration.

NOTE If you are using the instrument in an environment where the

temperature changes, you should not use the user wavelength

calibration data, as it lacks correction for temperature changes.

To select the wavelength calibration data to use

1. Press S

2. Select the wavelength calibration data using the Modify keys.

Figure 5-2 The USERCAL Indicator on the Display

YST repeatedly until USERCAL is shown at the bottom of

the display.

OFF means that the instrument uses the factory-made

wavelength calibration data

ON means that the user wavelength calibration data is used.

While it is ON, USERCAL is shown at the bottom left of the

display (U/L-CAL is shown if the LAMBDCAL is also on).

Resetting the Wavelength Calibration Data Set

To reset USERCAL, press and hold SYST until the value resets (this

takes approximately two seconds).

USERCAL resets to OFF.

69

Page 70

Setting Up the System

Selecting the Through-Power Mode

5.3 Selecting the Through-Power Mode

In the through-power mode, the instrument shows th e po wer that

gets through the attenuator on the display (that is the power at the

output) rather than the attenuation.

When you select the through- power mod e the attenuation facto r ( in

dB) becomes the value for the through-power (in dBm). That is, if

the attenuation factor is at 32.000dB, and you switch the absolute

power mode on, then the base value for the through-power is

32.000dBm.

Measure the power at the output of the attenuator, and then use the

calibration factor (see “Entering a Calibration Factor” on page 39)

to set the attenuation factor to the required value for use as the base

value for the through-power

= (ThrouhgPower

Cal

New

- Att) + Cal

Base

After setting the calibration factor,

1. Press S

YST repeatedly until THRUPOWR is shown at the bottom

of the display.

2. Select ON to switch on the through-power mode.

The through-power factor is shown at the upper left on the display,

and you can edit it by pressing A

“Using the Modify Keys” on page 29).

Figure 5-3 The Display in Through-Power Mode

70

Current

TT, and using the Modif y keys (see

Page 71

Setting Up the System

Setting the Display Brightness

Deselecting the Through-Power Mode

When you switch the through-power mode off, the last set

calibration factor becomes active, and the attenuation factor is set

so that the filter attenuation does not change.

1. Press S

2. Select OFF to switch off the through-power mode.

YST repeatedly until THRUPOWR is shown at the bottom

of the display.

Resetting the Through-Power Mode

To reset THRUPOWR, press and hold SYST until the value resets

(this takes approximately two seconds).

THRUPOWR resets to OFF.

5.4 Setting the Display Brightness

This parameter sets the brightness of the display. To set the

brightness,

1. Press SYST repeatedly until BRIGHT is shown at the bottom of

the display.

2. Use Modify keys to set the brightness.

Resetting the Display Brightness

To reset BRIGHT, press and hold SYST until the value resets (this

takes approximately two seconds).

BRIGHT resets to full brightness.

71

Page 72

Setting Up the System

Selecting the Setting used at Power-On

5.5 Selecting the Setting used at Power-On

This parameter selects the instrument setting that is used at poweron.

1. Press SYST repeatedly until P ON SET is shown at the bottom

of the display.

2. Use Modify keys to select the setting.

LAST is the setting that was in use when the instrument was

switched off.

DEFAULT is the default setting.

a number is the number of the setting location where the u ser has

saved a setting.

Resetting the Power-On Setting

To reset P ON SET press and hold SYST until the value resets (this

takes approximately two seconds).

P ON SET is reset to LAST.

5.6 Locking Out ENB /DIS

This selects how the shutter enabling and disabling key operates

while the instrument is being operated over the GPIB.

1. Press SYST repeatedly until SHUTTER is shown at the bottom of

the display.

2. Use Modify keys to select the setting.

NORMAL means that the shutter can be enabled and disabled as

usual with E

72

NB/DIS.

Page 73

Setting Up the System

Selecting the Shutter State at Power On

LOCKOUT means that the shutter cannot be enabled or disabled

(Local Lock Out) while the instrument is being operated over the

GPIB.

Resetting the ENB/DIS Lock Out

To reset SHUTTER, press and hold SYST until the value resets (this

takes approximately two seconds).

SHUTTER resets to NORMAL.

5.7 Selecting the Shutter State at Power On

This selects whether the shutter is open or closed at power-on.

1. Press S

2. Use Modify keys to select the setting.

YST repeatedly until SHUTTER@ PON is shown at the

bottom of the display.

DIS means that the shutter is disabled at power-on.

LAST means that the shutter is the set to the state that was in use

when the instrument was switched off.

Resetting the Shutter State at Power On

To reset SHUTTER@ PON press and hold SYST until the value

resets (this takes approximately two seconds).

SHUTTER@ PON resets to LAST.

73

Page 74

Setting Up the System

Setting the Display Resolution

5.8 Setting the Display Resolution

This parameter sets the resolution of the attenuation factor and the

calibration factor on the screen.

1. Press SYST repeatedly until RESOLUT is shown at the bottom of

the display.

2. Use Modify keys to select the setting.

1/100 sets a resolution of 0.01.

1/1000 sets a resolution of 0.001.

Resetting the Display Resolution