Page 1

Agilent 81480A and

Agilent 81680A, 81640A, 81682A, 81642A, & 81689A

Tunable Laser Modules

User’s Guide

S1

Page 2

Notices

This document contains proprietary information that is

protected by copyright. All rights are reserved.

No part of t his doc ument ma y reprodu ced in (inc luding

electronic storage and retrieval or translation into a

foreign language) without prior agreement and written

consen t fro m Agilent T echno logie s Deu tschlan d Gm bH

as governed by United States and international

copywright laws.

Copyr ight 20 01 by:

Agilent Technologies Deutschland GmbH

Herrenberger Str. 130

71034 Böblingen

Germany

Subject Matter

The material in this document is subject to change

without notice.

Agilent Technologies makes n o warran ty of an y kind

with rega rd to this p rint ed ma teri al, inclu ding , but not

limited to, the implied warranties of merchantability

and fitness for a particular purpose.

Agilent Technologies shall not be liable for errors

contained herein or for incidental or consequential

damages in connection with the furnishing,

performance, or use of this material.

Printing History

New editions are complete revisions of the guide

reflecting alterations in the functionality of the

instrument. Updates are occasionally made to the guide

betwee n editio ns. The date on the titl e page changes

when an updated guide is published. To find out the

current revision of the guide, or to purchase an updated

guide, contact your Agilent Technologies representative.

Control Serial Number: First Edition applies directly to

all instruments.

Warranty

This Agilent Technologies instrument product is

war rante d agains t defect s in m ate rial and workm anship

for a period of one year from date of shipment. During

the warranty period, Agilent will, at its option, either

repair or replace products that prove to be defective.

For warranty service or repair, this product must be

returned to a service facility designated by Agilent.

Buyer shall prepay shipping charges to Agilent and

Agilent shall pay shipping charges to return the product

to Bu yer. How ever, Buye r shall pa y all shi pping char ges,

duties, and taxes for products returned to Agilent from

another country.

Agilent warrants that its software and firmware

designated by Agilent for use with an instrument will

execute its programming instructions when properly

installed on that instrument. Agilent does not warrant

that the operation of the instrument, software, or

firm ware wil l be un inte rrupted or e rror fr ee.

Exclusive Remedies

The remedies provided herein are Buyer’s sole and

exclus ive remed ies. Agi lent Tech nologies shall no t be

liable for any direct, indirect, special, incidental, or

conse quent ial damag es whe ther based on contra ct, tort,

or any other legal theory.

Assistance

Product maintena nce agreem ents and other cus tomer

assistance agreements are available for Agilent

Technologies products. For any assistance contact your

nearest Agilent Technologies Sales and Service Office.

Certification

Agilent Technologies Inc. certifies that this product met

its published specifications at the time of shipment from

the factory.

Agilent Technologies further certifies that its calibration

measurements are traceable to the United States

National Institute of Standards and Technology, NIST

(formerly the United States National Bureau of

Sta ndar ds, N BS) t o the exte nt allowed by the In sti tutes ’s

calibration facility, and to the calibration facilities of

other International Standards Organization members.

ISO 9001 Certification

Produced to ISO 9001 international quality system

standard as part of our objective of continually

increasin g custome r satisfac tion throug h improved

process c ontrol.

Sixth Edition

81680-90014 E0101

First Edition:

E0599: May 1999

Second Edition:

E1099: October 1999

Third Edition:

E1299: December 1999

Fourth Edition:

E0300: March 2000

Fifth Edition:

E0900: September 2000

Sixth Edition:

E0101: January 2001

Limitation of Warranty

The foregoing warranty shall not apply to defects

resulting from improper or inadequate maintenance by

Buyer, Buyer-supplied software or interfacing,

unauthorized modification or misuse, operation outside

of the environmental specifications for the product, or

improper site preparation or maintenance.

No oth er warran ty is expre ssed or implied. Agilent

Technologies specifically disclaims the implied

warranties of Merchantability and Fitness for a

Particular Purpose.

2 Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide,

Sixth Edition

Page 3

Safety Summary

WARNING The WARNING sign denotes a hazard. It calls attention to a procedure,

Safety Summary

The following general safety precautions must be observed during all

phases of operation, service, and repair of this instrument. Failure to

comply with these precautions or with specific warnings elsewhere in

this manual violates safety standards of design, manufacture, and

intended use of the instrument. Agilent Technologies Inc. assumes no

liability for the customer’s failure to comply with these requirements.

Before operation, review the instrument and manual, including the

red safety page, for safety markings and instructions. You must follow

these to ensure safe operation and to maintain the instrument in safe

condition.

practice or the like, which, if not correctly performed or adhered to,

could result in injury or loss of life. Do not proceed beyond a

WAR N I NG sign u ntil th e indica t ed conditions ar e fully u nd ersto od a nd

met.

Safety Symbols

The apparatus will be marked with this symbol when it is necessary

for the user to refer to the instruction manual in order to protect the

apparatus against damage.

Hazardous laser radiation.

Initial Inspection

Inspect the shipping container for damage. If there is damage to the

container or cushioning, keep them until you have checked the

contents of the shipment for completeness and verified the instrument

both mechanically and electrically.

The Performance Tests give procedures for checking the operation of

the instrument. If the contents are incomplete, mechanical damage or

defect is apparent, or if an instrument does not pass the operator’s

checks, notify the nearest Agilent Technologies Sales/Service Office.

WARNING To avoid hazardous electrical shock, do not perform electrical tests

when there are signs of shipping damage to any portion of the outer

enclosure (covers, panels, etc.).

Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide, Sixth Edition 3

Page 4

Safety Summary

WARNING You MUST return instruments with malfunctioning laser modules to

an Agilent Technologies Sales/Service Center for repair and

calibration.

Line Power Requirements

The Agilent 81480A, Agilent 81680A, Agilent 81640A, Agilent 81682A,

Agilent 81642A, & Agilent 81689A Tunable Laser Modules operate

when installed in the Agilent 8164A Lightwave Measurement System.

The Agilent 81689A also operates when installed in the Agilent 8163A

Lightwave Multimeter or Agilent 8166A Lightwave Multichannel

System.

Operating Environment

The safety information in the Agilent 8163A Lightwave Multimeter,

Agilent 8164A Lightwave Measurement System, & Agilent 8166A

Lightwave Multichannel System User’s Guide summarizes the

operating ranges for the Agilent 81480A, Agilent 81680A,

Agilent 81640A, Agilent 81682A, Agilent 81642A, & Agilent 81689A

Tunable Laser Modules. In order for these modules to meet

specifications, the operating environment must be within the limits

specified for your mainframe.

Input/Output Signals

CAUTION There are two BNC connectors on the front panel of the

Agilent 81480A, Agilent 81680A, Agilent 81640A, Agilent 81682A, and

Agilent 81642A; a BNC input connector and a BNC output connector.

There is one BNC connector on the front panel of the Agilent 81689A a BNC input connector.

An absolute maximum of ±6 V can be applied as an external voltage to

any BNC connector.

Storage and Shipment

This module can be stored or shipped at temperatures between

−40°C and +70°C. Protect the module from temperature extremes that

may cause condensation within it.

4 Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide,

Sixth Edition

Page 5

Safety Summary

Initial Safety Information for Tunable Laser Modules

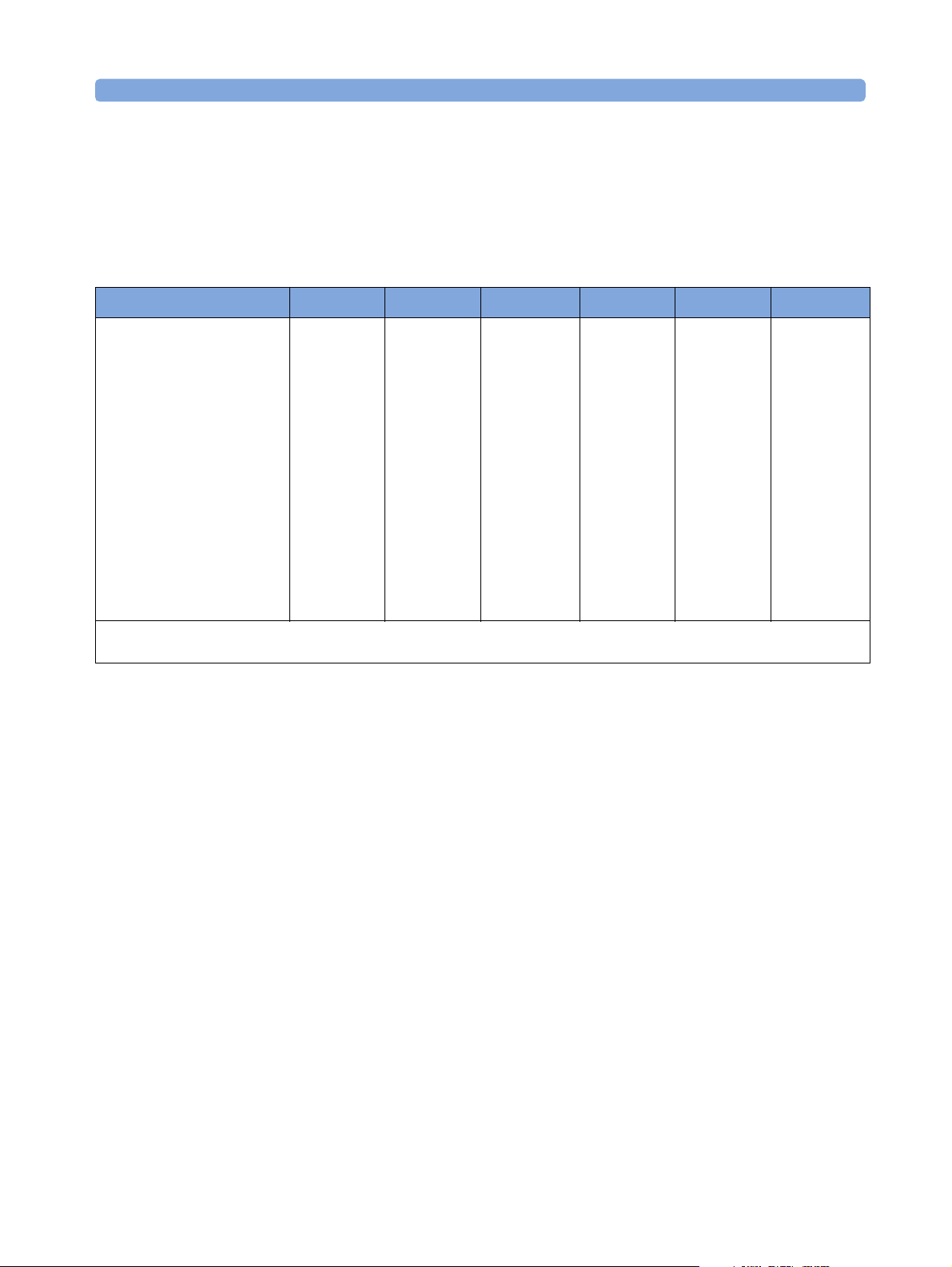

The Specifications for these modules are as follows:

Table 1 Tunable Laser Modules Laser Safety Information

Agilent 81480A Agilent 81680A Agilent 81640A Agilent 81682A Agilent 81642A Agilent 81689A

Laser Type FP-Laser

InGaAsP

Wav elengt h range 1370-1480 nm 1400-1670 nm 1400-1670 nm 1400-1670 nm 1400-1670 nm 1400-1670 nm

Max. CW output power* <15 mW <15 mW <15 mW <15 mW <15 mW <15 mW

Beam waist diameter 9 µm9 µm9 µm9 µm9 µm9 µm

Numerical aperture 0.1 0.1 0.1 0.1 0.1 0.1

Laser Class according to

IEC 60825-1 (1998)- International

Max. permissible CW output

power - IEC**

Laser Class according to

FDA 21 CFR 1040.10 (1995) - USA

Max. permissible CW output

power - FDA**

* Max. CW output power is defined as the highest possible optical power that the laser source can produce at its output connector.

** Max. permissible CW output power is the highest optical power that is permitted within the appropriate laser class.

3A 3A 3A 3A 3A 3A

50 mW 50 mW 50 mW 50 mW 50 mW 50 mW

IIIb IIIb IIIb IIIb IIIb IIIb

500 mW 500 mW 500 mW 500 mW 500 mW 500 mW

FP-Laser

InGaAsP

FP-Laser

InGaAsP

FP-Laser

InGaAsP

FP-Laser

InGaAsP

FP-Laser

InGaAsP

Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide, Sixth Edition 5

Page 6

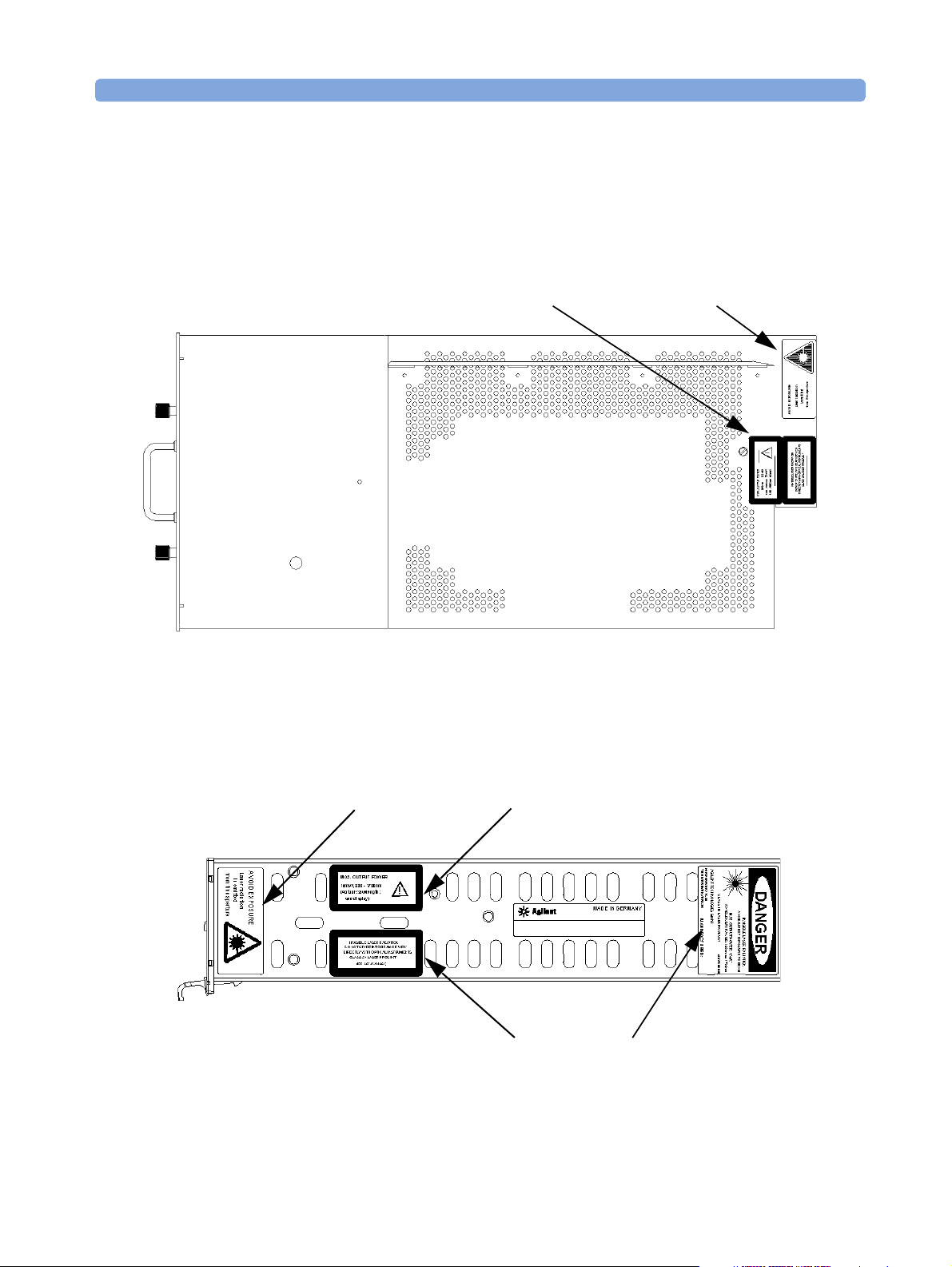

Laser Safety Labels

These laser safety warning labels are fixed on the outside of the

Agilent 8164A Lightwave Measurement System before shipment.

Safety Summary

Figure 1 USA Safety Labels (81480A, 81680A, 81640A, 81682A, 81642A, 81689A)

These laser safety warning labels are fixed on the outside of the Agilent 8164A

Lightwave Measurement System before shipment.

Figure 2 Non-USA Safety Labels (81480A, 81680A, 81640A, 81682A, 81642A, 81689A)

6 Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide,

Sixth Edition

Page 7

Safety Summary

A sheet of laser safety warning labels are included with the

instrument. You MUST stick the labels in the local language onto the

outside of the instrument, in a position where they are clearly visible

to anyone using the instrument.

Top Vi e w

See page 6See page 6

Figure 3 Position of Safety Labels on Backloadable Tunable Laser Modules

These labels are applied in these positions to every Agilent 81480A,

Agilent 81680A, Agilent 81640A, Agilent 81682A, and Agilent 81642A

Tunable Laser Module before shipment.

See page 6

Figure 4 Position of Safety Labels on Agilent 81689A Tunable Laser Module

These labels are applied in these positions to every Agilent 81689A

Tunable Laser Module before shipment.

Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide, Sixth Edition 7

See page 6

See page 6

See page 6

Page 8

Safety Summary

WARNING Please pay attention to the following laser safety warnings:

• Under no circumstances look into the end of an optical cable

attached to the optical output when the device is operational. The

laser radiation can seriously damage your eyesight.

• Do not enable the laser when there is no fiber attached to the optical

output connector.

• The laser is enabled by pressing the gray button close to the optical

output connector on the front panel of the module. The laser is on

when the green LED on the front panel of the instrument is lit.

• The use of optical instruments with this product will increase eye

hazard.

• The laser module has a built-in safety circuitry which will disable

the optical output in the case of a fault condition.

WARNING Refer Servicing only to qualified and authorized personnel.

8 Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide,

Sixth Edition

Page 9

The Structure of this Manual

The Structure of this Manual

This manual is divided into two categories:

• Getting Started

This section gives an introduction to the Tunable Laser modules.

and aims to make these modules familiar to you:

– “Getting Started with Tunable Laser Sources” on page 21.

• Additional Information

This is supporting information of a non-operational nature. this

contains information concerning accessories, specifications, and

performance tests:

– “Accessories” on page 31,

– “Specifications” on page 39, and

– “Performance Tests” on page 57.

Conventions used in this manual

• Hardkeys are indicated by italics, for example, Config, or Channel.

• Softkeys are indicated by normal text enclosed in square brackets,

for example, [Zoom] or [Cancel].

• Parameters are indicated by italics enclosed by square brackets, for

example, [Range Mode], or [MinMax Mode].

• Menu items are indicated by italics enclosed in brackets, for

example, <MinMax>, or <Continuous>.

Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide, Sixth Edition 9

Page 10

The Structure of this Manual

10 Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide,

Sixth Edition

Page 11

Tabl e of C o nt e nts

Tab l e o f Co n t e n t s

Safety Summary 3

Safety Symbols 3

Initial Inspection 3

Line Power Requirements 4

Operating Environment 4

Input/Output Signals 4

Storage and Shipment 4

Initial Safety Information for Tunable Laser Modules 5

Laser Safety Labels 6

The Structure of this Manual 9

Conventions used in this manual 9

Getting Started with Tunable Laser Sources 21

What is a Tunable Laser ? 23

Agilent 81480A, 81680A/82A/40A/42A Tunable Laser Modules

24

Agilent 81689A Tunable Laser Module 26

Optical Output 27

Polarization Maintaining Fiber 27

Angled and Straight Contact Connectors 27

Signal Input and Output 29

Accessories 31

Modules and Options 33

Modules 34

User’s Guides 35

Options 35

Option 003 - Agilent 81682A, Agilent 81642A 35

Option 021 - Agilent 81689A 35

Option 022 - Agilent 81689A 36

Option 071 - All Tunable Laser Modules 36

Option 072 - All Tunable Laser Modules 36

Connector Interfaces and Other Accessories 36

Options 071, 021: Straight Contact Connectors 36

Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide, Sixth Edition 11

Page 12

Table o f Co n ten t s

Specifications 39

Options 072, 022: Angled Contact Connectors 37

Definition of Terms 41

Absolute Wavelength Accuracy 41

Effective Linewidth 41

Linewidth 42

Minimum Output Power 42

Mode-Hop Free Tuning Range 42

Modulation Extinction Ratio 42

Modulation Frequency Range 43

Output Power 43

Output Isolation 43

Peak Power 43

Polarization Extinction Ratio 43

Power Flatness Over Modulation 44

Power Flatness Versus Wavelength 44

Power Linearity 44

Power Repeatability 44

Power Stability 45

Relative Intensity Noise (RIN) 45

Relative Wavelength Accuracy 45

Return Loss 45

Sidemode Suppression Ratio 46

Signal-to-Source Spontaneous Emission (SSE) Ratio 46

Signal-to-Total-Source Spontaneous Emission 46

Wavelength Range 47

Wavelength Repeatability 47

Wavelength Resolution 47

Wavelength Stability 47

Tunable Laser Module Specifications 48

Supplementary Performance Characteristics 54

Operating Modes 54

Internal Digital Modulation 1 54

External Digital Modulation 1 54

External Analog Modulation 1 54

External Wavelength Locking (Agilent 81680A/40A/82A/42A) 54

Coherence Control (Agilent 81680A/40A/82A/42A) 54

Continuous Sweep (Agilent 81680A/40A/82A/42A) 55

12 Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide,

Sixth Edition

Page 13

Tab l e o f Co n t e n t s

Stepped Mode (Agilent 81680A/40A/82A/42A) 55

General 55

Output Isolation (typ.): 55

Return loss (typ.): 55

Polarization Maintaining Fiber (Options 071, 072): 55

Laser Class: 55

Recalibration Period: 56

Warm-up Time: 56

Environmental 56

Storage Temperature: 56

Operating Temperature: 56

Humidity: 56

Performance Tests 57

Required Test Equipment 59

Test Record 60

Test Failure 60

Instrument Specification 60

Performance Test Instructions 61

General Test Setup 61

Wavelength Tests 61

General Settings of Wavelength Meters for all Wavelength Tests 62

Wavelength Accuracy 62

Relative Wavelength Accuracy 62

Absolute Wavelength Accuracy 64

Mode Hop Free Tuning 64

Wavelength Repeatability 65

Power Tests 67

Calibration of the Agilent 81001FF Attenuation Filter 67

Maximum Output Power 69

Power Linearity 71

Power Linearity - Low Power Test 71

Example (Agilent 81680A Output 1) 73

Power Linearity - High Power Test 73

Power Linearity - Test Using Attenuation 75

Power Flatness over Wavelength 76

Power Flatness over Wavelength - Without Attenuation 76

Power Flatness over Wavelength - Using Attenuation 77

Power Stability 79

Signal-to-Source Spontaneous Emission 81

Signal-to-Source Spontaneous Emission Tests - High Power Outputs

Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide, Sixth Edition 13

Page 14

Table o f Co n ten t s

81

Signal-to-Source Spontaneous Emission Tests - Low SSE Outputs 83

Signal-to-Total-Source Spontaneous Emission 88

Signal to Total SSE Tests - Low SSE Outputs 89

Optional Test 95

S i gna l t o To t al SS E Tes t s - H ig h P o we r Ou t pu ts 95

Te st Re c o r d 99

Agilent 81480A Performance Test 99

Test Equipment Used 100

Relative Wavelength Accuracy 101

Mode Hop Free Tuning 103

Wavelength Repeatability 104

Maximum Power Test 105

Power Linearity Output 1, Low SSE 106

Power Linearity Output 2, High Power Upper Power Levels 106

Power Linearity Output 2, High Power by attenuator 107

Power Flatness 108

Power Stability 109

Signal-to-Source Spontaneous Emission - 81480A Output 2, High

Power 109

Signal-to-Source Spontaneous Emission - 81480A Output 1, Low SSE

110

Signal-to-Total-Source Spontaneous Emission - 81480A Output 1, Low

SSE 111

Optional Test: Signal-to-Total-Source Spontaneous Emission - 81480A

Output 2, High Power 111

Agilent 81680A Performance Test 113

Test Equipment Used 114

Relative Wavelength Accuracy 115

Mode Hop Free Tuning 117

Wavelength Repeatability 118

Maximum Power Test 119

Power Linearity Output 1, Low SSE 120

Power Linearity Output 2, High Power Upper Power Levels 120

Power Linearity Output 2, High Power by attenuator 121

Power Flatness 122

Power Stability 123

Signal-to-Source Spontaneous Emission - 81680A Output 2, High

Power 123

Signal-to-Source Spontaneous Emission - 81680A Output 1, Low SSE

124

Signal-to-Total-Source Spontaneous Emission - 81680A Output 1, Low

SSE 125

Optional Test: Signal-to-Total-Source Spontaneous Emission - 81680A

14 Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide,

Sixth Edition

Page 15

Tab l e o f Co n t e n t s

Output 2, High Power 125

Agilent 81640A Performance Test 127

Te s t E q ui pm en t Us e d 1 2 8

Relative Wavelength Accuracy 129

Relative Wavelength Accuracy Summary of all Repetitions 130

Relative Wavelength Accuracy Result 130

Absolute Wavelength Accuracy Result 130

Mode Hop Free Tuning 131

Wavelength Repeatability 132

Maximum Power Test 133

Power Linearity Output 1, Low SSE134

Power Linearity Output 2, High Power Upper Power Levels 134

Power Linearity Output 2, High Power by Attenuator 135

Power Flatness 136

Power Stability 137

Signal-to-Source Spontaneous Emission - 81640A Output 2, High

Power 137

Signal-to-Source Spontaneous Emission - 81640A Output 1, Low SSE

138

Signal-to-Total-Source Spontaneous Emission - 81640A Output 1, Low

SSE 139

Optional Test - Signal-to-Total-Source Spontaneous Emission - 81640A

Output 2, High Power 139

Agilent 81682A Performance Test 141

Te s t E q ui pm en t Us e d 1 4 2

Relative Wavelength Accuracy 143

Mode Hop Free Tuning 145

Wavelength Repeatability 146

Maximum Power Test 147

Power Linearity - 81682A 147

Power Linearity 81682A #003 Upper Power Levels 148

Power Linearity 81682A #003 by Attenuator 149

Power Flatness 150

Power Stability 151

Signal-to-Source Spontaneous Emission - 81682A 151

Optional Test: Signal-to-Total-Source Spontaneous Emission - 81682A

152

Agilent 81642A Performance Test 153

Te s t E q ui pm en t Us e d 1 5 4

Relative Wavelength Accuracy 155

Mode Hop Free Tuning 157

Wavelength Repeatability 158

Maximum Power Test 159

Power Linearity - 81642A 159

Power Linearity 81642A #003 Upper Power Levels 160

Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide, Sixth Edition 15

Page 16

Table o f Co n ten t s

Cleaning Information 171

Power Linearity 81642A #003 by Attenuator 161

Power Flatness 162

Power Stability 163

Signal-to-Source Spontaneous Emission - 81642A 163

Optional Test: Signal-to-Total-Source Spontaneous Emission - 81642A

164

Agilent 81689A Performance Test 165

Tes t E qui pme nt U s ed 1 66

Relative Wavelength Accuracy 167

Wavelength Repeatability 168

Maximum Power Test 169

Power Linearity 169

Power Flatness 170

Power Stability 170

Signal-to-Source Spontaneous Emission 170

Safety Precautions 173

Why is it important to clean optical devices? 173

What do I need for proper cleaning? 174

Standard Cleaning Equipment 174

Dust and shutter caps 174

Isopropyl alcohol 175

Cotton swabs 175

Soft tissues 176

Pipe cleaner 176

Compressed air 176

Additional Cleaning Equipment 177

Microscope with a magnification range about 50X up to 300X 177

Ultrasonic bath 177

Warm water and liquid soap 178

Premoistened cleaning wipes 178

Polymer film 178

Infrared Sensor Card 178

Preserving Connectors 179

Cleaning Instrument Housings 179

Which Cleaning Procedure should I use ? 180

How to clean connectors 180

How to clean connector adapters 181

How to clean connector interfaces 182

16 Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide,

Sixth Edition

Page 17

Tab l e o f Co n t e n t s

How to clean bare fiber adapters

183

How to clean lenses 184

How to clean instruments with a fixed connector interface

184

How to clean instruments with an optical glass plate 185

How to clean instruments with a physical contact interface

185

How to clean instruments with a recessed lens interface

186

How to clean optical devices which are sensitive to

mechanical stress and pressure

187

How to clean metal filters or attenuator gratings 188

Additional Cleaning Information 189

How to clean bare fiber ends 189

How to clean large area lenses and mirrors 189

Other Cleaning Hints 191

Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide, Sixth Edition 17

Page 18

Table o f Co n ten t s

18 Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide,

Sixth Edition

Page 19

List of Figures

Figure 1 USA Safety Labels (81480A, 81680A, 81640A, 81682A, 81642A, 81689A) . . 6

Figure 2 Non-USA Safety Labels (81480A, 81680A, 81640A, 81682A, 81642A, 81689A) 6

Figure 3 Position of Safety Labels on Backloadable Tunable Laser Modules . . . 7

Figure 4 Position of Safety Labels on Agilent 81689A Tunable Laser Module . . . 7

Figure 5 Agilent 81480A Tunable Laser Module (straight contact connectors) . . . 24

Figure 6 Agilent 81680A Tunable Laser Module (straight contact connectors) . . . 24

Figure 7 Agilent 81682A Tunable Laser Module (straight contact connector) . . . 24

Figure 8 Agilent 81640A Tunable Laser Module (straight contact connectors) . . . 24

Figure 9 Agilent 81642A Tunable Laser Module (straight contact connectors) . . . 24

Figure 10 Agilent 81689A Tunable Laser Module . . . . . . . . . . 26

Figure 11 PMF Output Connector . . . . . . . . . . . . . . 27

Figure 12 Angled and Straight Contact Connector Symbols . . . . . . . . 28

Figure 13 Agilent 81682A Tunable Laser Module (angled contact connector) . . . 28

Figure 14 Mainframes, Tunable Laser Modules, and Options . . . . . . . 33

Figure 15 Options 021, 071: Single-mode fiber/PMF with Straight Contact Connectors . 37

Figure 16 Options 022, 072: Single-mode fiber/PMF with Angled Contact Connectors . 38

Figure 17 Test Setup for Wavelength Tests . . . . . . . . . . . . 61

Figure 18 Calibration of the Agilent 81001FF Attenuation Filter, Reference Setup . . 67

Figure 19 Test Setup for Calibrating the Agilent 81001FF Attenuation Filter . . . . 68

Figure 20 Test Setup for the Maximum Output Power Tests. . . . . . . . 69

Figure 21 Test Setup for Low Power Linearity Tests. . . . . . . . . . 71

Figure 22 Test Setup for the Source Spontaneous Emission Test - High Power Outputs . 81

Figure 23 Transmission Characteristic of Fiber Bragg Grating . . . . . . . 84

Figure 24 Signal-to-Spectral SSE Measurement . . . . . . . . . . 84

Figure 25 Test Setup for Source Spontaneous Emission Test . . . . . . . 85

List of Figures

Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide, Sixth Edition 19

Page 20

List of Figures

20 Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide,

Sixth Edition

Page 21

Getting Started with Tunable Laser Sources

Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide, Sixth Edition 21

Page 22

Getting Started with Tunable Laser Sources

This chapter describes the Agilent 81480A, Agilent 81680A,

Agilent 81640A, Agilent 81682A, Agilent 81642A, and Agilent 81689A

Tunable Laser modules.

22 Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide,

Sixth Edition

Page 23

What is a Tunable Laser ? Getting Started with Tunable Laser Sources

What is a Tunable Laser ?

A Tunable Laser is a laser source for which the wavelength can be

varied through a specified range. The Agilent Technologies range of

Tunable Laser modules also allow you to set the output power, and to

choose between continuous wave or modulated power.

Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide, Sixth Edition 23

Page 24

Getting Started with Tunable Laser Sources What is a Tunable Laser ?

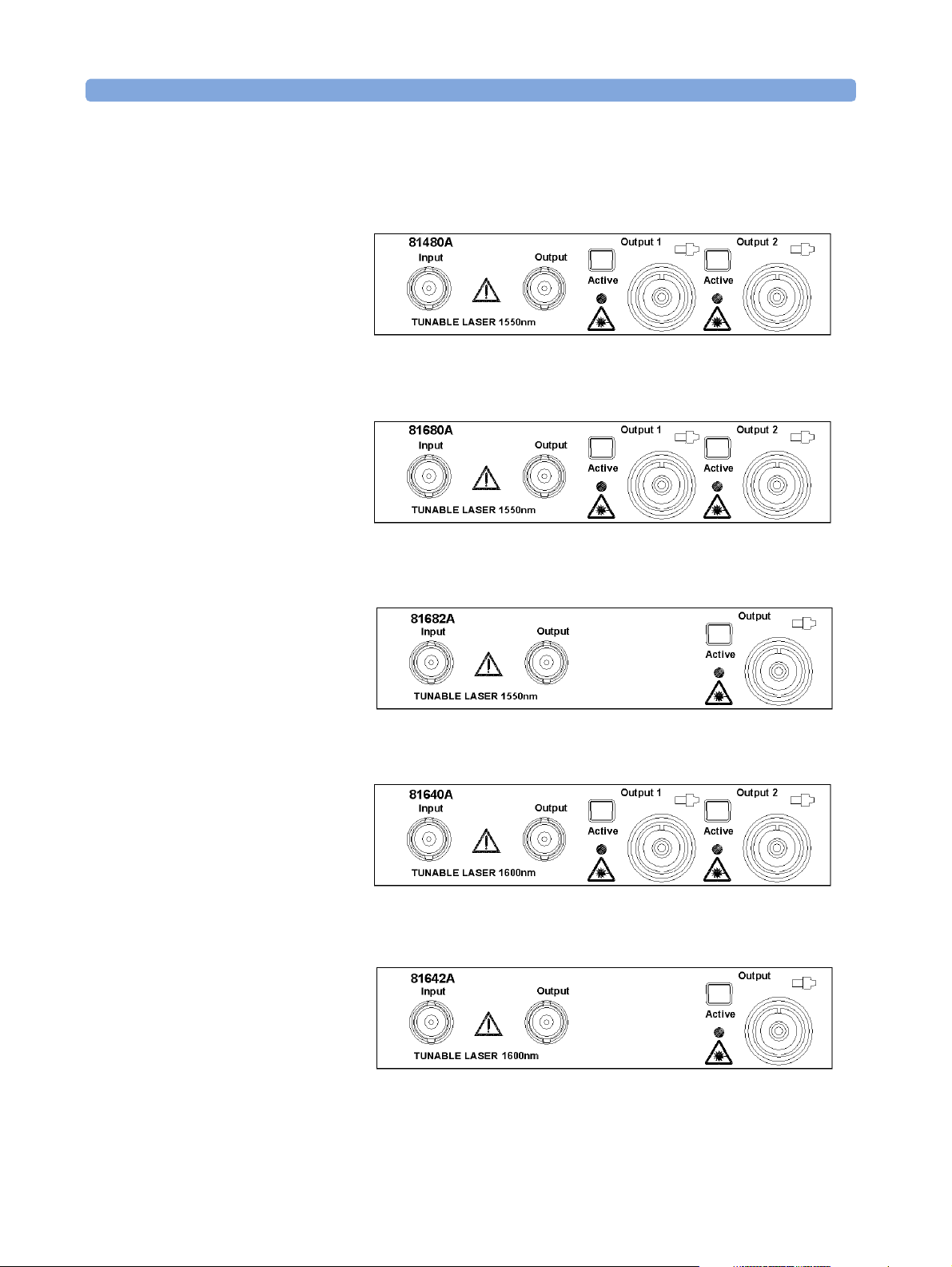

Agilent 81480A, 81680A/82A/40A/42A

Tunable Las er Modules

Figure 5 Agilent 81480A Tunable Laser Module (straight contact connectors)

Figure 6 Agilent 81680A Tunable Laser Module (straight contact connectors)

Figure 7 Agilent 81682A Tunable Laser Module (straight contact connector)

Figure 8 Agilent 81640A Tunable Laser Module (straight contact connectors)

Figure 9 Agilent 81642A Tunable Laser Module (straight contact connectors)

24 Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide,

Sixth Edition

Page 25

What is a Tunable Laser ? Getting Started with Tunable Laser Sources

The Agilent 81480A and 81680A/82A/40A/42A Tunable Laser

modules are back-loadable modules. To fit these modules into the

Agile nt 8164A mainframe see “How to Fit and Remove Modules” in th e

Agilent 8163A Lightwave Multimeter, Agilent 8164A, Lightwave

Measurement System, & Agilent 8166A Lightwave Multichannel

SystemUser’s Guide.

The Agilent 81480A and 81680A/82A/40A/42A Tunable Laser

modules have a built-in wavelength control loop to ensure high

wavelength accuracy. As these modules are all mode-hop free tunable

with continuous output power, they qualify for the test of the most

critical dense-Wavelength Division Multiplexer (dWDM) components.

The Agilent 81480A and Agilent 81640A/80A Tunable Laser modules

are equipped with two optical outputs:

• Output 1, the Low SSE output, delivers a signal with ultra-low

source spontaneous emission (SSE). It enables accurate crosstalk

measurement of DWDM components with many channels at narrow

spacing. You can characterize steep notch filt ers such as Fiber

Bragg Gratings by using this output and a power sensor module.

• Output 2, the High Power output, delivers a signal with high optical

power. You can adjust the signal by more than 60 dB by using the in-

built optical attenuator.

The Agilent 81682A/42A Tunable Laser module delivers a signal with

high optical power. If you choose O ption 0 03 , you can adjust the signal

by more than 60 dB by using the in-built optical attenuator.

Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide, Sixth Edition 25

Page 26

Getting Started with Tunable Laser Sources What is a Tunable Laser ?

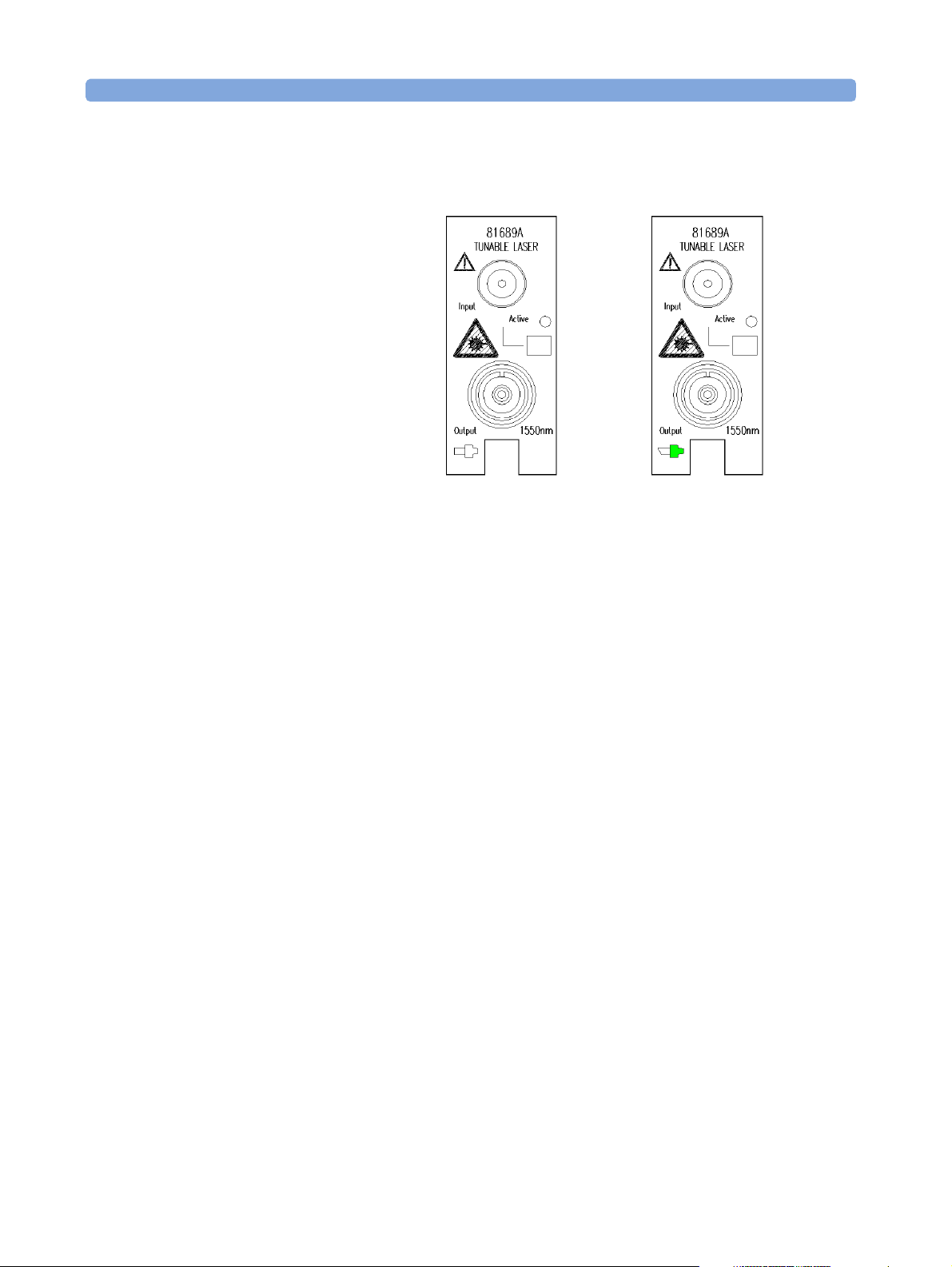

Agilent 81689A Tunable Laser Module

Agilent 81689A with

Straight Contact Connector

Figure 10 Agilent 81689A Tunable Laser Module

The Agilent 81689A Tunable Laser module is a front-loadable module.

To insert this module into the Agilent 8163A Lightwave Multimeter,

Agilent 8164A Lightwave Measurement System or Agilent 8166A

Lightwave Multichannel System see “How to Fit and Remove Modu les”

in the Agilent 8163A Lightwave Multimeter, Agilent 8164A Lightwave

Measurement System, & Agilent 8166A Lightwave Multichannel

System User’s Guide.

You can use the Agilent 81689A Tunable Laser module to set up a

realistic multi-channel test-bed for DWDM transmission systems. Its

continuous, mode-hop free tuning makes it quick and easy to set even

the most complex configurations to the target wavelengths and power

levels.

The Agilent 8163A Lightwave Multimeter, a Power Sensor module,and

a Agilent 81689A Tunable Laser module together represent a smart

loss-test set with selectable wavelength.

Agilent 81689A with

Angled Contact Connector

26 Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide,

Sixth Edition

Page 27

Optical Output Getting Started with Tunable Laser Sources

Optical Output

Polarization Maintaining Fiber

If you have an instrument with a polarization maintaining fiber (PMF),

the PMF is aligned to maintain the state of polarization.

The fiber is of Panda type, with TE mode in the slow axis in line with

the connector key. A well defined state of polarization ensures

constant measurement conditions.

The Agilent 81480A and 81680A/40A/82A/42A Tunable Laser

modules are equipped with PMF outputs as standard.

For the Agilent 81689A Tunable Laser module, PMF output is available

as an option.

Stress Rods

Figure 11 PMF Output Connector

Angled and Straight Contact Connectors

Angled contact connectors help you to control return lo ss. With angled

fiber endfaces, reflected light tends to reflect into the cladding,

reducing the amount of light that reflects back to the source.

E

Connector Key

Fiber Cladding

H

Fiber Core

(8-µm Diameter)

Slow Axis (Polarization Axis)

Not to Scale

The Agilent 81480 and 81680A/40A/82A/42A/89A Tunable Laser

modules can have the following connector interface options:

• Option 071, Polarization-maintaining fiber straight contact

connectors, or

• Option 072, Polarization-maintaining fiber angled contact

connectors.

Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide, Sixth Edition 27

Page 28

Getting Started with Tunable Laser Sources Optical Output

Two additional connector interface options are available for the

Agilent 81689A Tunable Laser module:

• Option 021, Standard single-mode fiber straight contact connectors,

or

• Option 022, Standard single-mode fiber angled contact connectors.

CAUTION If the contact connector on your instrument is angled, you can only

use cables with angled connectors with the instrument.

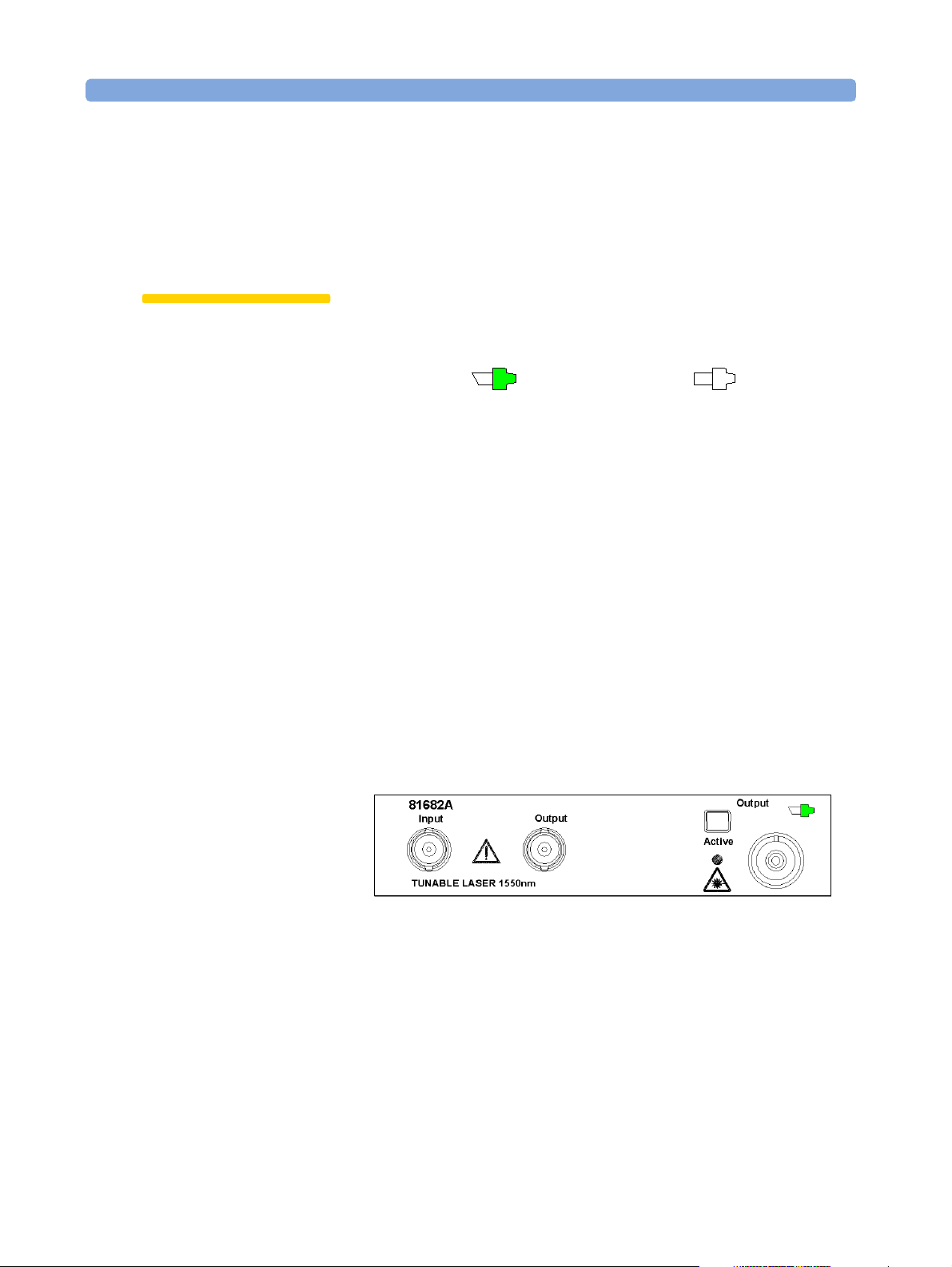

Angled Contact

Connector Symbol

Figure 12 Angled and Straight Contact Connector Symbols

Figure 12 shows the symbols that tell you whether the contact

connector of your Tunable Laser module is angled or straight. The

angled contact connector symbol is colored green.

Figure 7 and Figure 13 show the front panel of the Agilent 81682A

Tunable Laser module with straight and angled contact connectors

respectively.

You should connect straight contact fiber end connectors with neutral

sleeves to straight contact connectors and connect angled contact fiber

end connectors with green sleeves to angled contact connectors.

NOTE You cannot connect angled non-contact fiber end connectors with

orange sleeves directly to the instrument.

Straight Contact

Connector Symbol

Figure 13 Agilent 81682A Tunable Laser Module (angled contact connector)

See “Accessories” on page 31 for further details on connector

interfaces and accessories.

28 Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide,

Sixth Edition

Page 29

Signal Input and Output Getting Started with Tunable Laser Sources

Signal Input and Output

CAUTION There are two BNC connectors on the front panel of the

Agilent 81480A, Agilent 81680A, Agilent 81680A, Agilent 81640A,

Agilent 81682A, and Agilent 81642A - a BNC input connector and a

BNC output connector.

There is one BNC connector on the front panel of the Agilent 81689A a BNC input connector.

An absolute maximum of ±6 V can be applied as an external voltage to

any BNC connector.

Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide, Sixth Edition 29

Page 30

Getting Started with Tunable Laser Sources Signal Input and Output

30 Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide,

Sixth Edition

Page 31

Accessories

Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide, Sixth Edition 31

Page 32

Accessories

The Agilent 81480A and 81680A/40A/82A/42A/89A Tunable Laser

Source Modules are available in various configurations for the best

possible match to the most common applications.

This chapter provides information on the available options and

accessories.

32 Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide,

Sixth Edition

Page 33

Modules and Options Accessories

Modules and Options

Figure 14 shows all the options that are available for all Tunable Laser

modules and the instruments that support these modules.

Agilent 8164A

Lightwave Measurement System

Agilent 81480A

Tuna ble Laser

1400 nm

Low SSE

Agilent 81680A

Tuna ble Laser

1550 nm

Low SSE

Option 071

PMF,

Panda-type,

Straight

Contact

Option 072

PMF,

Panda-type,

Angled

Contact

Agilent 81640A

Tuna ble La se r

1600 nm

Low SSE

Agilent 81682A

Tunable Laser

1550 nm

+ 8 dBm

Option 003

Attenuator

Agilent 81645A

Filler Module

Agilent 81642A

Tunable Laser

1600 nm

+ 7 dBm

Option 021

Single-mode

fiber,

Straight

Contact

Agilent 81689A

Compact

Tuna ble Laser

1550 nm

Option 022

Single-mode

fiber,

Angled

Contact

Agilent 8163A

Lightwave Multimeter

Agilent 8163A

Lightwave

Multimeter

Modules

Option 071

PMF,

Panda-type,

Straight

Contact

Option 072

PMF,

Panda-type,

Angled

Contact

HP 8153A

Lightwave

Multimeter

Modules

Figure 14 Mainframes, Tunable Laser Modules, and Options

Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide, Sixth Edition 33

Page 34

Accessories Modules

Modules

The Agilent 8164A Lightwave Measurement System supports the

Agilent 81480A and 81680A/40A/82A/42A/89A Tunable Laser

modules. In addition, the Agilent 8163A Lightwave Multimeter

supports the Agilent 81689A Tunable Laser module.

Tunable Laser Modules

Model No. Description

Agilent 81480A Tunable Laser for the Test of Critical dense-WDM Components

Agilent 81680A Tunable Laser for the Test of Critical dense-WDM Components

Agilent 81640A Tunable Laser for the Test of Critical Components in both

dense-WDM Bands, the C and L bands

Agilent 81682A Tunable Laser for the Test of Optical Amplifiers and Passive

Components

Agilent 81642A Tunable Laser for the Test of Optical Amplifiers and Passive

Components in both dense-WDM Bands.

Agilent 81689A Tunable Laser for Multi-Channel Test Applications

Filler Module

Filler Module

Model No. Description

Agilent 81645A Filler Module

The Agilent 81645A Filler Module is required to operate the

Agile nt 8164A mainframe if it is used without a back-loadable Tunable

Laser module. It can be used to:

• prevent dust pollution and

• optimize cooling by guiding the air flow.

See the "Installation and Maintenance" chapter of the Agilent 81480A,

Agilent 81680A, Agilent 81682A, Agilent 81640A, & Agilent 81689A

Tunable Laser Modules User’s Guide for more details on installing the

Agilent 81645A Filler Module.

34 Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide,

Sixth Edition

Page 35

Modules Accessories

User’s Guides

User’s Guides

Opt Description Part No.

Agilent 81480A, Agilent 81680A, Agilent 81682A, Agilent 81640A, &

Agilent 81689A Tunable Laser Modules User’s Guide

ABJ Japanese Agilent 81480A, Agilent 81680A, Agilent 81682A,

Agilent 81640A, & Agilent 81689A Tunable Laser Modules User’s

Guide

ABF French Agilent 81480A, Agilent 81680A, Agilent 81682A,

Agilent 81640A, & Agilent 81689A Tunable Laser Modules User’s

Guide

AB0 Traditional Chinese (Taiwan) Agilent 81480A, Agilent 81680A,

Agilent 81682A, Agilent 81640A, & Agilent 81689A Tunable Laser

Modules

User’s Guide

AB1 Korean Agilent 81480A, Agilent 81680A, Agilent 81682A,

Agilent 81640A, & Agilent 81689A Tunable Laser Modules User’s

Guide

8164A 0B2 Agilent 8163A Lightwave Multimeter, Agilent 8164A Lightwave

Measurement System, & Agilent 8166A Lightwave Multichannel

System Programming Guide

8164A 0BF Agilent 8163A Lightwave Multimeter, Agilent 8164A Lightwave

Measurement System, & Agilent 8166A Lightwave Multichannel

System User’s Guide

81680-90014

81680-91514

81680-91214

81680-91714

81680-91814

08164-91016

08164-91011

Options

Option 003 - Agilent 81682A, Agilent 81642A

Built-in optical attenuator with 60 dB attenuation range.

NOTE The Agilent 81640A/80A Tunable Laser Modules have a built-in optical

attenuator as standard for Output 2, the High Power output.

A built-in optical attenuator is not available for the Agilent 81689A.

Option 021 - Agilent 81689A

Standard single-mode fiber, for straight contact connectors.

Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide, Sixth Edition 35

Page 36

Accessories Connector Interfaces and Other Accessories

Option 022 - Agilent 81689A

Standard single-mode fiber, for angled contact connectors.

Option 071 - All Tunable Laser Modules

Polarization-maintaining fiber, Panda-type, for straight contact

connectors.

Option 072 - All Tunable Laser Modules

Polarization-maintaining fiber, Panda-type, for angled contact

connectors.

Connector Interfaces and Other Accessories

The Agilent 81480A and 81680A/40A/82A/42A/89A Tunable Laser

modules are supplied with one of two connector interface options:

• Option 071, Polarization-maintaining fiber straight contact

connectors, or

• Option 072, Polarization-maintaining fiber angled contact

connectors.

Two additional connector interface options are available for the

Agilent 81689A Tunable Laser module:

• Option 021, Standard single-mode fiber straight contact connectors,

or

• Option 022, Standard single-mode fiber angled contact connectors.

Options 071, 021: Straight Contact Connectors

If you want to use straight connectors (such as FC/PC, Diamond HMS10, DIN, Biconic, SC, ST or D4) to connect to the instrument, you must

do the following:

36 Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide,

Sixth Edition

Page 37

Connector Interfaces and Other Accessories Accessories

1 Attach your connector interface to the interface adapter.

See Table 2 for a list of the available connector interfaces.

2 Connect your cable (see Figure 15).

Agilent 810

00AI

Connector

Interface

Diamond

HMS-10

Agilent 810

00FI

Connector

Interface

FC/PC/SPC

Agilent 810

00GI

Connector

Interface

D4

Agilent 810

00HI

Connector

Interface

Diamond

E-2000

Agilent 810

00KI

Connector

Interface

SC

Agilent 810

00SI

Connector

Interface

DIN 47256

Agilent 810

00VI

Connector

Interface

ST

Agilent 8100

Connector

Interface

Biconic

Figure 15 Options 021, 071: Single-mode fiber/PMF with Straight Contact Connectors

Table 2 Straight Contact Connector Interfaces

Description Model No.

Biconic Agilent 81000 WI

D4 Agilent 81000 GI

Diamond HMS-10 Agilent 81000 AI

DIN 47256 Agilent 81000 SI

FC / PC / SPC Agilent 81000 FI

SC Agilent 81000 KI

ST Agilent 81000 VI

Diamond E-2000 Agilent 81000 HI

Options 072, 022: Angled Contact

0WI

Connectors

If you want to use angled connectors (such as FC/APC, Diamond HRL10, or SC/APC) to connect to the instrument, you must do the

following:

1 Attach your connector interface to the interface adapter.

See Table 3 for a list of the available connector interfaces.

Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide, Sixth Edition 37

Page 38

Accessories Connector Interfaces and Other Accessories

2 Connect your cable (see Figure 16).

Agilent 8100

0NI

Connector

Interface

FC/APC

Agilent 8100

0KI

Connector

Interface

SC/APC

Agilent 8100

0HI

Connector

Interface

Diamond

E-2108.6

Agilent 8100

0SI

Connector

Interface DIN

47256/4108.6

Figure 16 Options 022, 072: Single-mode fiber/PMF with Angled Contact Connectors

Table 3 Angled Contact Connector Interfaces

Description Model No.

DIN 47256-4108.6 Agilent 81000 SI

FC / APC Agilent 81000 NI

SC / APC Agilent 81000 KI

Diamond E-2108.6 Agilent 81000 HI

38 Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide,

Sixth Edition

Page 39

Specifications

Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide, Sixth Edition 39

Page 40

Specifications

The Agilent 81480A, Agilent 81680A, Agilent 81640A, Agilent 81682A,

Agilent 81642A and Agilent 81689A Tunable Laser modules are

produced to the ISO 9001 international quality system standard as

part of Agilent Technologies’ commitment to continually increasing

customer satisfaction through improved quality control.

Specifications describe the modules’ warranted performance.

Supplementary performance characteristics describe the modules

non-warranted typical performance.

Because of the modular nature of the instrument, these performance

specifications apply to these modules rather than the mainframe unit.

40 Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide,

Sixth Edition

Page 41

Definition of Terms Specifications

Definition of Terms

This section defines terms that are used both in this chapter and

“Performance Tests” on page 57.

Generally, all specifications apply for the given environmental

conditions and after warmup time.

Measurement principles are indicated. Alternative measurement

principles of equal value are also acceptable.

Absolute Wavelength Accuracy

The maximum difference between the actual wavelength and the

displayed wavelength of the TLS. Wavelength is defined as wavelength

in vacuum.

Conditions: constant power level, temperature within operating

temperature range, coherence control off, measured at high power

output.

Validity: within given time span after wavelength zeroing, at a given

maximum temperature difference between calibration and

measurement.

Measurement with wavelength meter. Averaging time given by

wavelength meter, ≥1 s.

NOTE The abso lute wavelength accuracy of Output 1, the Lo w SSE Ou tput, of

the Agilent 81680A/40A Tunable Laser modules is the same as the

absolute wavelength accuracy of Output 2, the High Power Output

(guaranteed by design).

Effective Linewidth

The time-averaged 3-dB width of the optical spectrum, expressed in

Hertz.

Conditions: temperature within operating temperature range,

coherence control on, power set to specified value.

Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide, Sixth Edition 41

Page 42

Specifications Definition of Terms

Measurement with heterodyning technique: the output of the laser

under test is mixed with another laser of the same type on a wide

bandwidth photodetector. The electrical noise spectrum of the

photodetector current is measured with an Agilent Lightwave Signal

Analyzer, and the linewidth is calculated from the heterodyne

spectrum (Lightwave signal analyzer settings: resolution bandwidth

1 MHz; video bandwidth 10 kHz; sweep time 20 ms; single scan).

Linewidth

The 3-dB width of the optical spectrum, expressed in Hertz.

Conditions: temperature within operating temperature range,

coherence control off, power set to maximum flat power (maximum

attainable power within given wavelength range).

Measurement with self-heterodyning technique: the output of the

laser under test is sent through a Mach-Zehnder interferometer in

which the length difference of the two arms is longer than the

coherence length of the laser. The electrical noise spectrum of the

photodetector current is measured with an Agilent Lightwave Signal

Analyzer, and the linewidth is calculated from the heterodyne

spectrum (Lightwave signal analyzer settings: resolution bandwidth 1

MHz; video bandwidth 10 kHz; sweep time 20 ms; single scan).

Minimum Output Power

The minimum output power for which the specifications apply.

Mode-Hop Free Tuning Range

The tuning range for which no abrupt wavelength change occurs

during fine wavelength stepping. Abrupt change is defined as change

of more than 25 pm.

Conditions: within specified wavelength range, at specified

temperature range and output power. Tuning from outside into the

mode-hop free tuning range is not allowed.

Modulation Extinction Ratio

The ratio of total power in on-state to total power in off-state,

expressed in dB.

Conditions: Internal or external modulation, tunable laser at highest

power setting.

42 Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide,

Sixth Edition

Page 43

Definition of Terms Specifications

Measurement with optical spectrum analyzer. Tunable laser switched

on and off.

Modulation Frequency Range

The range of frequencies for which the modulation index is above − 3

dB of the highest modulation index. In this context, modulation index

is defined as the AC power amplitude (peak-to-peak) divided by the

average power.

Output Power

The achievable output power for the specified TLS tuning range.

Conditions: temperature within operating temperature range.

Measurement with power meter at the end of a single-mode fiber

patchcord.

Output Isolation

The insertion loss of the built-in isolator in the backward direction.

Measurement: Cannot be measured from the outside. This

characteristic is based on known isolator characteristics.

Peak Power

The highest optical power within specified wavelength range.

Polarization Extinction Ratio

The ratio of optical power in the slow axis of the polarizationmaintaining fiber to optical power in the fast axis within a specified

wavelength range.

Conditions: only applicable for TLS with polarization maintaining

fiber with the TE mode in slow axis and oriented in line with

connector key, at constant power level.

Measurement with a polarization analyzer at the end of a polarizationmaintaining patchcord, by sweeping the wavelength, thereby creating

circular traces on the Poincaré sphere, then calculating the

polarization extinction ratio from the circle diameters.

Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide, Sixth Edition 43

Page 44

Specifications Definition of Terms

Power Flatness Over Modulation

When changing the wavelength and modulation frequency, and

measuring the differences between actual and displayed power levels

(in dB), the power flatness is ± half the span between the maximum

and the minimum value of all differences.

Conditions: uninterrupted line voltage, constant power setting,

temperature within ±2 K, external modulation ON.

Measurement with optical power meter.

Power Flatness Versus Wavelength

When changing the wavelength at constant power setting and

recording the differences between actual and displayed power levels,

the power flatness is ± half the span (in dB) between the maximum

and the minimum of the measured power levels.

Conditions: uninterrupted TLS output power, constant power setting,

temperature within ±1K.

Measurement with optical power meter.

Power Linearity

When changing the power level and measuring the differences (in dB)

between actual and displayed power levels, the power linearity is ±

half the span (in dB) between the maximum and the minimum value of

all differences.

Conditions: power levels from within specified output power range,

uninterrupted TLS output power, at fixed wavelength settings and

stable temperature.

Measurement with optical power meter.

Power Repeatability

The random uncertainty in reproducing the power level after changing

and re-setting the power level. The power repeatability is ± half the

span (in dB) between the highest and lowest actual power.

Conditions: uninterrupted TLS output power, constant wavelength,

temperature within ±1 K, short time span.

Measurement with optical power meter.

NOTE The long-term power repeatability can be obtained by taken the power

repeatability and power stability into account.

44 Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide,

Sixth Edition

Page 45

Definition of Terms Specifications

Power Stability

The change of the power level during given time span, expressed as ±

half the span (in dB) between the highest and lowest actual power.

Conditions: uninterrupted TLS output power, constant wavelength

and power level settings, temperature within ±1 K, time span as

specified.

Measurement with optical power meter.

Relative Intensity Noise (RIN)

The square of the (spectrally resolved) RMS optical power amplitude

divided by the measurement bandwidth and the square of the average

optical power, expressed in dB/Hz.

Conditions: at specified output power, coherence control off,

temperature within operating temperature range, frequency range 0.1

to 6 GHz.

Measurement with Agilent Lightwave Signal Analyzer.

Relative Wavelength Accuracy

When randomly changing the wavelength and measuring the

differences between the actual and displayed wavelengths, the relative

wavelength accuracy is ± half the span between the maximum and the

minimum value of all differences.

Conditions: uninterrupted TLS output power, constant power level,

temperature within operating temperature range, observation time 10

minutes maximum (constant temperature), coherence control off,

measured at high power output.

Measurement with wavelength meter. Averaging time given by

wavelength meter, ≥1 s.

NOTE The relative wavelength accuracy of Output 1, the Low SSE Output, of

the Agilent 81640A/80A Tunable Laser modules is the same as the

relative wavelength accuracy of Output 2, the High Power Output

(guaranteed by design).

Return Loss

The ratio of optical power incident to the TLS outpu t port, at the TLS's

own wavelength, to the power reflected from the TLS output port.

Conditions: TLS disabled.

Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide, Sixth Edition 45

Page 46

Specifications Definition of Terms

Sidemode Suppression Ratio

The ratio of average signal power to the optical power of the highest

sidemode within a distance from 0.1 to 6 GHz to the signal's optical

frequency, expressed in dB.

Conditions: at a specified output power and wavelength range,

temperature within operating temperature range, coherence control

off.

Measurement with the Agilent Lightwave Signal Analyzer, by

analyzing the heterodyning between the main signal and the highest

sidemode.

Signal-to-Source Spontaneous Emission (SSE) Ratio

The ratio of signal power to maximum spontaneous e mission power in

1 nanometer bandwidth within a ±3 nm window around the signal

wavelength, where ±1 nm around the signal wavelength are excluded,

at the specified output power, expressed in dB/nm.

Conditions: output power set to specified values, at temperatures

within operating temperature range, coherence control off.

Measurement with optical spectrum analyzer (OSA) at 0.5 nm

resolution bandwidth (to address the possibility of higher SSE within

a narrower bandwidth), then extrapolated to 1 nm bandwidth. On

low-SSE output (if applicable), with fiber Bragg grating inserted

between the TLS and the OSA in order to suppress the signal, thereby

enhancing the dynamic range of the OSA.

NOTE The specified signal-to-SSE ratio is also applicable to output powers

higher than the specified values.

Signal-to-Total-Source Spontaneous Emission

The ratio of signal power to total spontaneous emission power, at the

specified achievable output power, expressed in dB.

Conditions: output power set to specified values, at temperatures

within operating temperature range, coherence control off.

Measurement with optical spectrum analyzer, by integrating the

source spontaneous emission and excluding the remnant signal. On

low-SSE output (if applicable), with fiber Bragg grating inserted

between the TLS and the OSA in order to suppress the signal, thereby

enhancing the dynamic range of the OSA.

46 Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide,

Sixth Edition

Page 47

Definition of Terms Specifications

NOTE The specified signal-to-total-SSE ratio is also applicable to output

powers higher than the specified values.

Wavelength Range

The range of wavelengths for which the specifications apply.

Wavelength Repeatability

The random uncertainty in reproducing a wavelength after detuning

and re-setting the wavelength. The wavelength repeatability is ± half

the span between the maximum and the minimum value of all actual

values of this wavelengths.

Conditions: uninterrupted TLS output power, constant power level,

temperature within operating temperature range, coherence control

off, short time span.

Measurement wit h w a veleng th m eter a t high power o u t put. Ave r a ging

time given by wavelength meter, ≥1 s.

NOTE The wavelength repeatability of Output 1, the Low SSE Output, of the

Agile nt 81680A/40A Tunable Laser modules is the same as th e relative

wavelength accuracy of Output 2, the High Power Output (guaranteed

by design).

NOTE The long-term wavelength repeatability can be obtained by taken the

wavelength repeatability and wavelength stability into account.

Wavelength Resolution

The smallest possible displayed wavelength increment/decrement.

Wavelength Stability

The change of wavelength during given time span, expressed as ± half

the span between the maximum and the minimum of all actual

wavelengths.

Conditions: uninterrupted TLS output power, constant wavelength

and power level settings, coherence control off, temperature within ±1

K, time span as specified.

Measurement with wavelength meter. Averaging time given by

wavelength meter, ≥1 s.

Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide, Sixth Edition 47

Page 48

Specifications Tunable Laser Module Specifications

Tunable Laser Module Specifications

Agilent 81480A

Agilent 81480A

Output 1

(Low SSE)

Wavelength range 1370 nm to 1480 nm

Wavelength resolution 0.1 pm, 15 MHz at 1450 nm

Mode-hop free tuning range

Absolute wavelength accuracy

Relative wavelength accuracy

Wavelength repeatability

Wavelength stability (typ., 24 hours at

constant temperature)

Tuning speed (typ. for a 1/10/100 nm step) 400 ms/ 600 ms/ 2.8 s

Linewidth (typ.), coherence control off 100 kHz

Effective linewidth (typ.), coherence ctrl. on> 50 MHz (1420 - 1470 nm), at maximum flat output power)

Output power

(continuous power during tuning)

3

9

1, 2, 9

1, 2, 9

2, 9

2, 9

full wavelength range

±0.01 nm

±5 pm, typ. ±2 pm

±1 pm, typ. ±0.5 pm

< ±1 pm

> -4.5 dBm peak typ

> -7 dBm (1420 – 1470 nm)

> +5.5 dBm peak typ

> +3 dBm (1420 - 1470 nm)

Agilent 81480A

Output 2

(High Power)

Minimum output power

Power stability

Power repeatability (typ.)

Power linearity

3

3

3

3, 9

> -13 dBm (1370 – 1480 nm)[9]

-13 dBm -3 dBm

±0.01 dB, 1 hour (1420nm-1480nm)

typ. ±0.01 dB, 1 hour (1370nm-1420nm) [9]

typ. ±0.03 dB, 24 hours

±0.01 dB

±0.1 dB (1420nm-1480nm)

typ. ±0.1dB (1370nm-1420nm) [9]

> -3 dBm (1370 - 1480 nm)[9]

(-60 dBm in attenuation mode)

±0.3 dB (1420nm-1480nm)

typ. ±0.3 dB (1370nm-1420nm) [9]

48 Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide,

Sixth Edition

Page 49

Tunable Laser Module Specifications Specifications

Power flatness versus wavelength

Side-mode suppression ratio (typ.)

Signal-to-Source Spontaneous Emission

5, 8

Ratio

Signal-to-Total-Source Spontaneous

Emission ratio

6, 8

3, 9

4, 8, 9

±0.2 dB, typ. ±0.1 dB

(1420-1480nm)

±0.2 dB typ (1370nm-1420nm)

> 40 dBc (1380 - 1480 nm)

> 61 dB/nm [7]

(1420 – 1470 nm)

> 55 dB/nm [7] [9]

(typ., 1370 – 1480 nm)

> 58 dB

(1420 – 1470 nm) [7]

±0.3 dB, typ. ±0.2 dB

(1420nm-1480nm)

±0.3 dB typ (1370nm-1420nm)

> 40 dB/ nm

(1420 – 1470 nm)

> 35 dB/ nm

(1370 – 1480 nm)

> 28 dB

(typ., 1420 - 1470 nm )

> 53 dB

(typ., 1370 - 1480 nm) [7] [9]

Relative intensity noise (RIN, typ.)

8

-145 dB/Hz (1420 - 1470 nm)

1. Valid for one month and within a ±5 K temperature range after automatic wavelength zeroing.

2. At CW operation. Measured with wavelength meter based on wavelength in vacuum.

3. Applies to the selected output.

4. Measured by heterodyning method.

5. Measured with optical spectrum analyzer at 1 nm resolution bandwidth.

6. Measured with optical spectrum analyzer.

7. Measured with fiber Bragg grating to suppress the signal.

8. Output power as specified per wavelength range and output port.

9. Wavelength must not be equal to any water absorption line

Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide, Sixth Edition 49

Page 50

Specifications Tunable Laser Module Specifications

Agilent 81680A and Agilent 81640A

Agilent 81680A

Output 1

(Low SSE)

Agilent 81680A

Output 2

(High Power)

Agilent 81640A

Output 1

(Low SSE)

Agilent 81640A

Output 2

(High Power)

Wavelength range 1460 nm to 1580 nm 1510 nm to 1640 nm

Wavelength resolution 0.1 pm, 12.5 MHz at 1550 nm

Mode hop free tuning range 1460 nm to 1580 nm 1510 nm to 1640 nm

Absolute

wavelength accuracy

Relative wavelength accuracy

Wavelength repeatability

Wavelength stability (typ., 24 hours

at constant temperature)

Tuning speed

1, 2

1, 2

2

2

± 0.01 nm ± 0.015 nm

± 5pm, typ. ± 2pm ± 7pm, typ. ± 3pm

± 1 pm, typ. ± 0.5 pm

≤± 1 pm

400 ms/600 ms/2.8 s

(typ. for a 1/10/100 nm step)

Linewidth (typ.), coherence control

100 kHz

off.

Effective Linewidth (typ.), coherence

control on

Output power

3

>50 MHz (1480 to 1580 nm, at maximum

flat output power)

≥ −4 dBm peak typ.

≥ 6 dBm peak typ.

>50 MHz (1520 to 1620 nm, at maximum

flat output power)

≥ −5 dBm peak typ.

≥ 4 dBm peak typ.

(continuous power during tuning)

Minimum output power

Power stability

3

Power repeatability (typ.)

Power linearity

3

3

3

Power flatness versus wavelength

Side-mode Suppression ratio (typ.)

4,8

(1520-1570 nm)

(1480-1580 nm)

(1460-1580 nm)

3

≥ −6 dBm

≥ −10 dBm

≥ −13 dBm

−13 dBm −3 dBm

± 0.1 dB ± 0.3 dB ± 0.1 dB ± 0.3 dB

± 0.2 dB,

typ.

± 0.1 dB

≥ 40 dBc

(1480-1580 nm)

≥ 5 dBm

(1520-1570 nm)

≥ 1 dBm

(1480-1580 nm)

≥ −3 dBm

(1460-1580 nm)

(−60 dBm in atten-

uation mode)

± 0.01 dB, 1 hour.

typ.

± 0.03 dB, 24 hours

± 0.01 dB

± 0.3 dB,

typ.

± 0.15 dB

≥ −7 dBm

(1530-1610 nm)

(1530-1610 nm)

≥ −9 dBm

(1520-1620 nm)

(1520-1620 nm)

≥ −13 dBm

(1510-1640 nm)

(1510-1640 nm)

−13 dBm −5 dBm

(−60 dBm in atten-

uation mode)

± 0.2 dB,

typ.

± 0.1 dB

typ.

≥ 40 dBc

(1530-1610 nm)

≥ 2 dBm

≥ 0 dBm

≥ −5 dBm

± 0.3 dB,

± 0.15 dB

50 Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide,

Sixth Edition

Page 51

Tunable Laser Module Specifications Specifications

Signal-to-Source Spontaneous Emission Ratio

Signal-to-Total-Source Spontaneous

Emission

Relative Intensity noise (RIN, typ.)

1. Valid for one month and within a

5,8

Ratio

6,8

8

±5 K temperature range after wavelength zeroing.

Agilent 81680A

Output 1

(Low SSE)

≥ 63 dB/nm

(1520-1570 nm)

≥ 58 dB/nm

1480-1580 nm)

≥ 53 dB/nm

7

(typ.,

7

(typ.,

1460-1580 nm)

7

≥ 60 dB

(1520-1570 nm)

(typ., 1480-1580 nm)

≥ 50 dB

7

− 145 dB/Hz (1480-1580 nm) − 145 dB/Hz (1530-1610 nm)

7

Agilent 81680A

Output 2

(High Power)

≥ 45 dB/nm

(1520-1570 nm)

≥ 40 dB/nm

(1480-1580 nm)

≥ 35 dB/nm

(1460-1580 nm)

≥ 30 dB

(typ., 1520-1570

nm)

Agilent 81640A

≥ 60 dB/nm

(1530-1610 nm)

≥ 55 dB/nm

1520-1620 nm)

≥ 50 dB/nm

(typ., 1510-1640 nm)

(1530-1610 nm)

(typ., 1510-1640 nm)

2. At CW operation. Measured with wavelength meter based on wavelength in vacuum.

3. Applies to the selected output.

4. Measured by heterodyning method.

5. Measured with optical spectrum analyzer at 1 nm resolution bandwidth.

6. Measured with optical spectrum analyzer.

Output 1

(Low SSE)

7

7

≥ 55 dB

7

≥ 45 dB

7

(typ.,

7

Agilent 81640A

Output 2

(High Power)

≥ 45 dB/nm

(1530-1610 nm)

≥ 40 dB/nm

(1520-1620 nm)

≥ 35 dB/nm

(1510-1640 nm)

≥ 27 dB

(typ., 1530-1610

nm)

7. Measured with Fiber Bragg Grating to supress the signal.

8. Output power as specified per wavelength range and ouput port.

9. Warm up time: 1 hour

Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide, Sixth Edition 51

Page 52

Specifications Tunable Laser Module Specifications

Agilent 81682A, Agilent 81642A

and Agilent 81689A

Agilent 81682A Agilent 81642A Agilent 81689A

Wavelength range 1460 nm to 1580 nm 1510 nm to 1640 nm 1525 nm to 1575 nm

Wavelength resolution 0.1 pm, 12.5 MHz at

1550 nm

0.1 pm, 12.5 MHz at

1550 nm

Mode hop-free tuning range 1460 nm to 1580 nm full wavelength range

Absolute wavelength accuracy

± 0.01 nm

1, 2

Relative wavelength accuracy ± 5pm, typ. ± 2pm

Wavelength repeatability

Wavelength stability (typ, over 24 hours

± 1pm, typ. ± 0.5 pm

< ± 1pm

2

1, 2

± 0.015 nm

± 7pm, typ. ± 3pm

2

± 1pm, typ. ± 0.5 pm

< ± 1pm

1, 2

1, 2

2

at constant temperature)

Tuning speed 400 ms/600 ms/2.8 s

(typ. for a 1/10/100 nm

step)

Linewidth (typ.) 100 kHz,

coherence control off

Effective Linewidth (typ.), coherence

control on

> 50 MHz (1480 -

1580 nm, at maximum flat

output power)

Output power

(continuous power during tuning)

≥ 8dBm peak typ.

≥ 6 dBm (1520 - 1570 nm)

≥ 2 dBm (1480 - 1580 nm)

400 ms/600 ms/2.8 s

(typ. for a 1/10/100 nm

step)

100 kHz,

coherence control off

> 50 MHz (1520 -

1620 nm, at maximum flat

output power)

≥ 7 dBm peak typ.

≥ 6 dBm (1560 - 1610 nm)

≥ 4 dBm (1530 - 1610 nm)

0.01 nm, 1.25 GHz at

1550 nm

± 0.3 nm, typ.

± 0.3 nm

2

± 0.05 nm

< ± 0.02 nm

< 10 sec/ 50 nm (typ.)

20 MHz

- -

≥ 6dBm (1525-1575nm)

2

2

2

2

3

≥ −3 dBm (1460-1580 nm)

≥ 2 dBm (1520 - 1620 nm)

≥ −3 dBm (1510-1640 nm)

/with option #003 reduce by 1.5 dB

Minimum output power

/with option #003

−3dBm

−4.5 dBm (−60 dBm in

attenuation mode)

Power stability

± 0.01 dB, 1 hour

typ. ±0.03 dB, 24 hours

4

4

10

10

reduce by 1.5 dB

−3dBm

−4.5 dBm (−60 dBm in

attenuation mode)

± 0.01 dB, 1 hour

typ. ±0.03 dB, 24 hours

Power repeatability (typ.) ± 0.01 dB ± 0.01 dB ± 0.02 dB

Power linearity (typ.)

/with option #003

Power flatness versus wavelength

/with option #003

± 0.1 dB

± 0.2 dB

± 0.2 dB, typ. ± 0.1 dB

± 0.3 dB, typ. ±0.2 dB

4

± 0.3 dB

± 0.3 dB

± 0.3 dB, typ. ± 0.15 dB

4

± 0.3 dB

4

- -

−3dBm

4

10

10

4

4

± 0.03 dB, 1 hour

± 0.06 dB, 24 hours

± 0.1 dB

± 0.3 dB

9

9

9

52 Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide,

Sixth Edition

Page 53

Tunable Laser Module Specifications Specifications

Agilent 81682A Agilent 81642A Agilent 81689A

Side-mode Suppression ratio (typ.) ≥ 40 dBc

(1480 - 1580 nm)

Signal-to-Source Spontaneous Emission

Ratio

≥ 45 dB/nm

(1520 - 1570 nm)

≥ 40 dB/nm

(1480 - 1580 nm)

≥ 35 dB/nm

(1460 - 1580 nm)

Signal-to-Total-Source Spontaneous

Emission Ratio

Relative Intensity noise

(RIN, typ.)

≥ 30 dB

(1520 - 1570 nm)

−145 dB/Hz

(1460 - 1580 nm)

5,8

6,8

6,8

6,8

7,8

8

≥ 40 dBc

(1530 - 1610 nm)

≥ 45 dB/nm

(1530 - 1610 nm)

≥ 40 dB/nm

(1520 - 1620 nm)

≥ 35 dB/nm

(1510 - 1640 nm)

≥ 27 dB

(1530 - 1610 nm)

−145 dB/Hz

(1530 - 1610 nm)

> 40 dBc (1525 - 1575 nm

5,8

6,8

6,8

6,8

7,8

8

at 0 dBm)

≥ 39 dB/nm

(1525 - 1575 nm at

6dBm)

< −140 dB/Hz

(100 MHz - 2.5 GHz)

5

6

- -

Dimensions - - - - 75 mm H, 32 mm W, 335

mm D

(2.8” × 1.3” × 13.2”

Weight - - - - 1 kg

1. Valid for one month and within a

±5 K temperature range after automatic wavelength zeroing.

2. At CW operation. Measured with wavelength meter based on wavelength in vacuum.

3. Measured by heterodyning method with 20 ms sweep time, 50 MHz span, 1 MHz resolution.

4. Option #003: built-in optical attenuator.

5. Measured by heterodyning method.

6. Measured with optical spectrum analyzer at 1 nm resolution bandwidth.

7. Measured with optical spectrum analyzer.

8. Output power as specified per wavelength range.

9. 500 ms after changing power.

10. Warm up time: 1 hour

Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide, Sixth Edition 53

Page 54

Specifications Supplementary Performance Characteristics

Supplementary Performance Characteristics

Operating Modes

Internal Digital Modulation

50% duty cycle, 200 Hz to 300 kHz. Modulation output: TTL reference

signal.

1

Agilent 81480A, Agilent 81680A/40A/82/42A: displayed wavelength

represents average wavelength while digital modulation is active.

External Digital Modulation

> 45% duty cycle, fall time < 300 ns, 200 Hz to 1 MHz. Modulation input:

TTL signal.

External Analog Modulation

≤ 15% modulation depth, 5 kHz to 20 MHz.

Modulation input: 5 Vp-p.

1

1

1

External Wavelength Locking (Agilent 81480A, Agilent

81680A/40A/82A/42A)

> ±70 pm at 10 Hz

±7 pm at 100 Hz

>

Modulation input:

±5 V

Coherence Control (Agilent 81480A, Agilent

81680A/40A/82A/42A)

For measurements on components with 2-meter long patchcords and connectors

with 14 dB return loss, the effective linewidth results in a typical power stability of <

the test setup.

±0.025 dB over 1 minute by drastically reducing interference effects in

54 Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide,

Sixth Edition

Page 55

Supplementary Performance Characteristics Specifications

Continuous Sweep (Agilent 81680A/40A/82A/42A)

Tuning velocity adjustable to: 40 nm/s, 5 nm/s, 0.5 nm/s.

Mode-hop free span:

• Agilent 81480A:

1420 - 1470 nm at flat output power ≥ 0 dBm

• Agilent 81680A/82A:

1520 - 1570 nm at flat output power ≥ 3 dBm

• Agilent 81640A:

Any 50 nm within 1520 - 1620 nm at flat output power ≥ 0 dBm

• Agilent 81642A:

Any 50 nm within 1520 - 1620 nm at flat output power ≥ 2 dBm

Ambient temperature within +20°C and +30°C.

Stepped Mode (Agilent 81680A/40A/82A/42A)

Full instrument performance (Agilent 81680A/40A/82A/42A).

Please note that the laser is turned off for 3 µs after each wavelength

tuning in the range 1620-1640nm (Agilent 81640A only).

General

Output Isolation (typ.):

50 dB (for Agilent 81689A: 38 dB)

Return loss (typ.):

60 dB (options 022, 072);

40 dB (options 021, 071).

Polarization Maintaining Fiber (Options 071, 072):

Fiber type: Panda.

Orientation: TE mode in slow axis, in line with connector key.

Extinction Ratio: 16 dB typ.

Laser Class:

Class IIIb according to FDA 21 CFR 1040.10,

Class 3A according to IEC 825 - 1; 1993.

Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide, Sixth Edition 55

Page 56

Specifications Supplementary Performance Characteristics

Recalibration Period:

2 years.

Warm-up Time:

< 20 min (< 40 min for Agilent 81689A), immediate operation after

boot-up.

Environmental

Storage Temperature:

−40°C to +70°C.

Operating Temperature:

+10°C to +35°C (+15°C to +35°C for Agilent 81689A).

Humidity:

< 80% R. H. at +10°C to +35°C (+15×°C to +35°C for Agilent 81689A).

Specifications are valid in non-condensing conditions.

56 Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide,

Sixth Edition

Page 57

Performance Tests

Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide, Sixth Edition 57

Page 58

Performance Tests

The procedures in this section tests the optical performance of the

instrument. The complete specifications to which the Agilent 81480A,

Agilent 81680A, Agilent 81640A, Agilent 81682A, Agilent 81642A and

Agilent 81689A are tested are given in “Specifications” on page 39. All

tests can be performed without access to the interior of the

instrument. The performance tests refer specifically to tests using the

Diamond HMS-10/Agilent connector.

58 Agilent 81480A and 81680A, 40A, 82A, 42A, & 89A Tunable Laser Modules User’s Guide,

Sixth Edition

Page 59

Required Test Equipment Performance Tests

Required Test Equipment