Page 1

S

Agilent 81101A 50 MHz Pulse Generator

Quick Start Guide

S1

Page 2

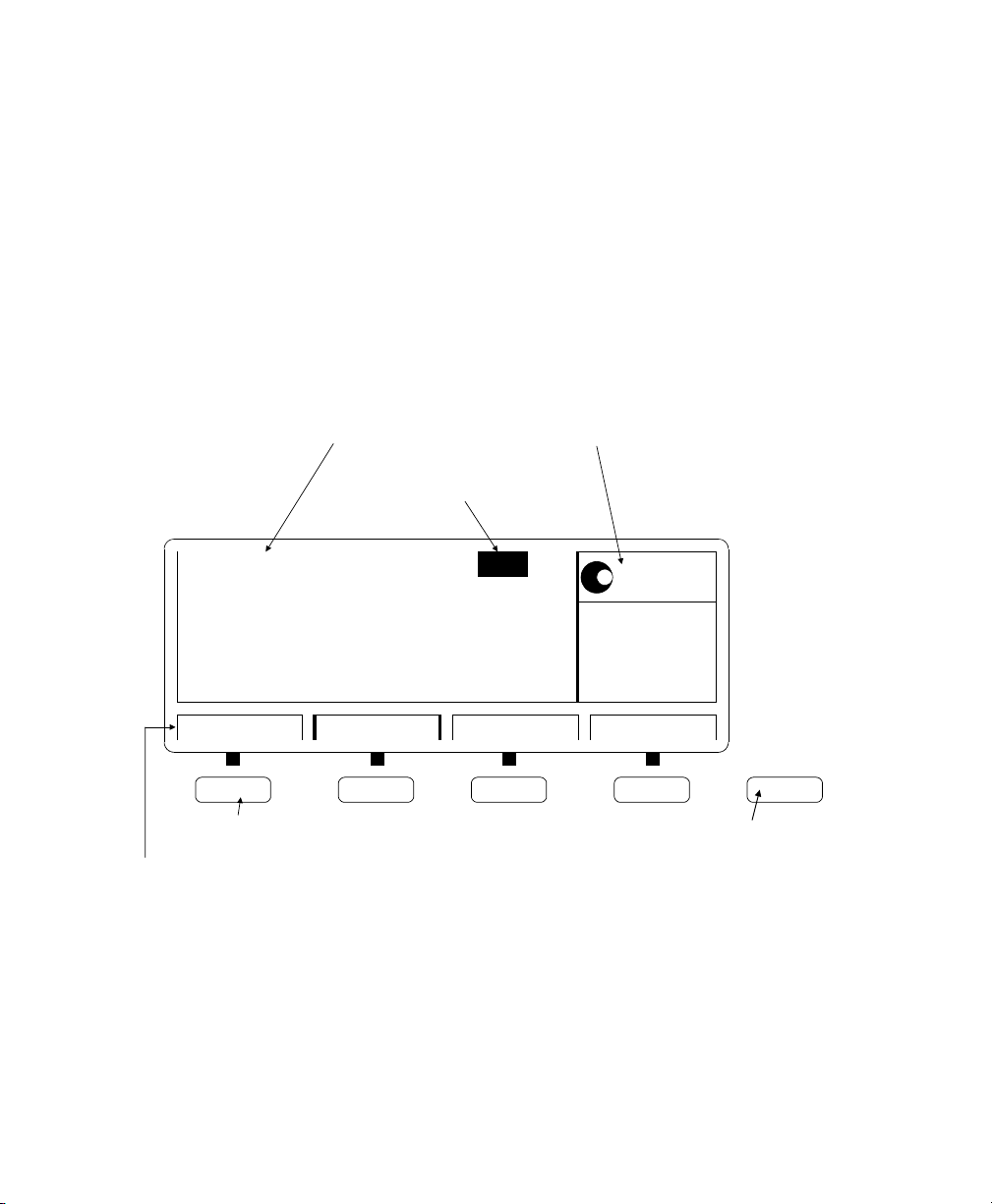

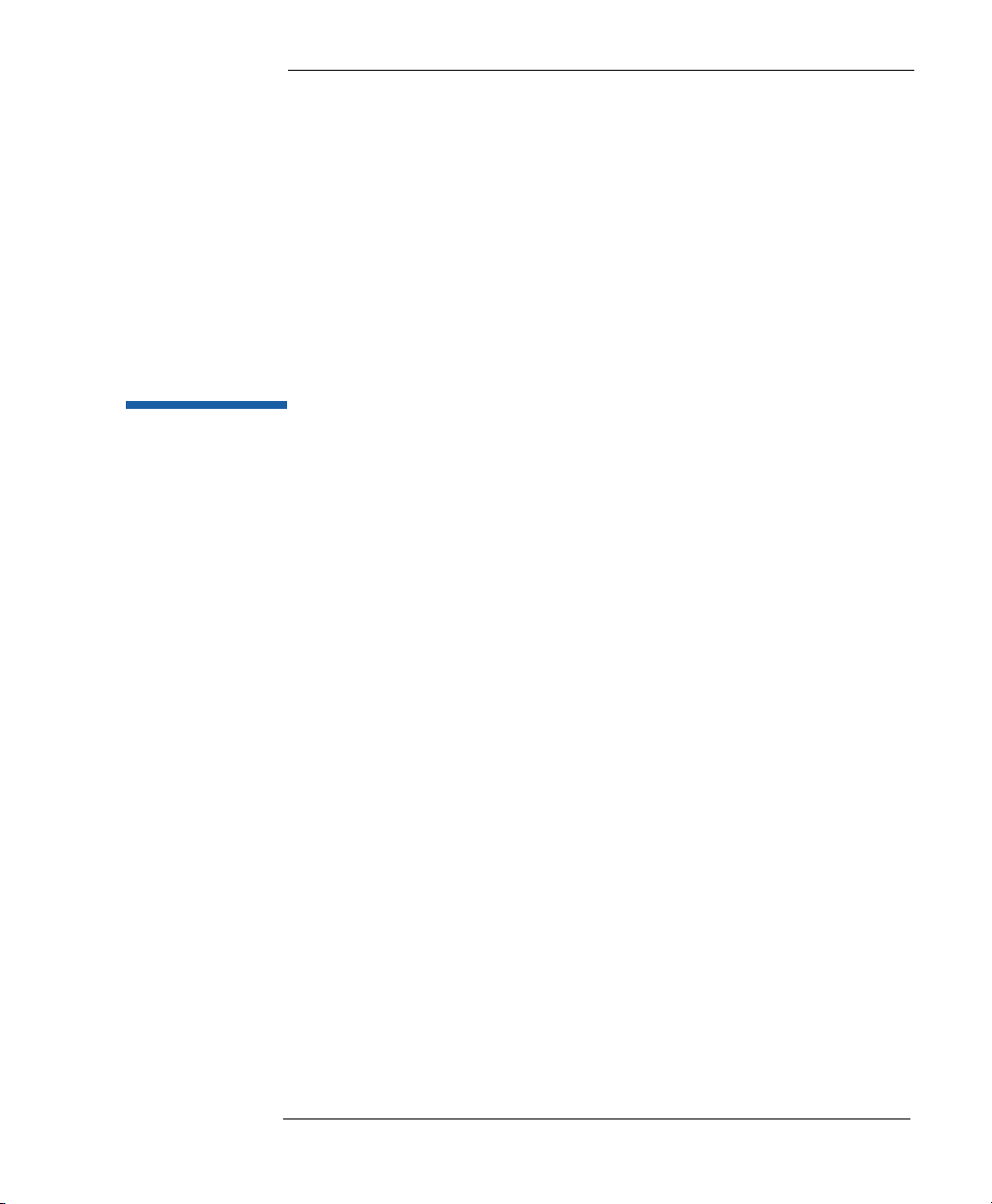

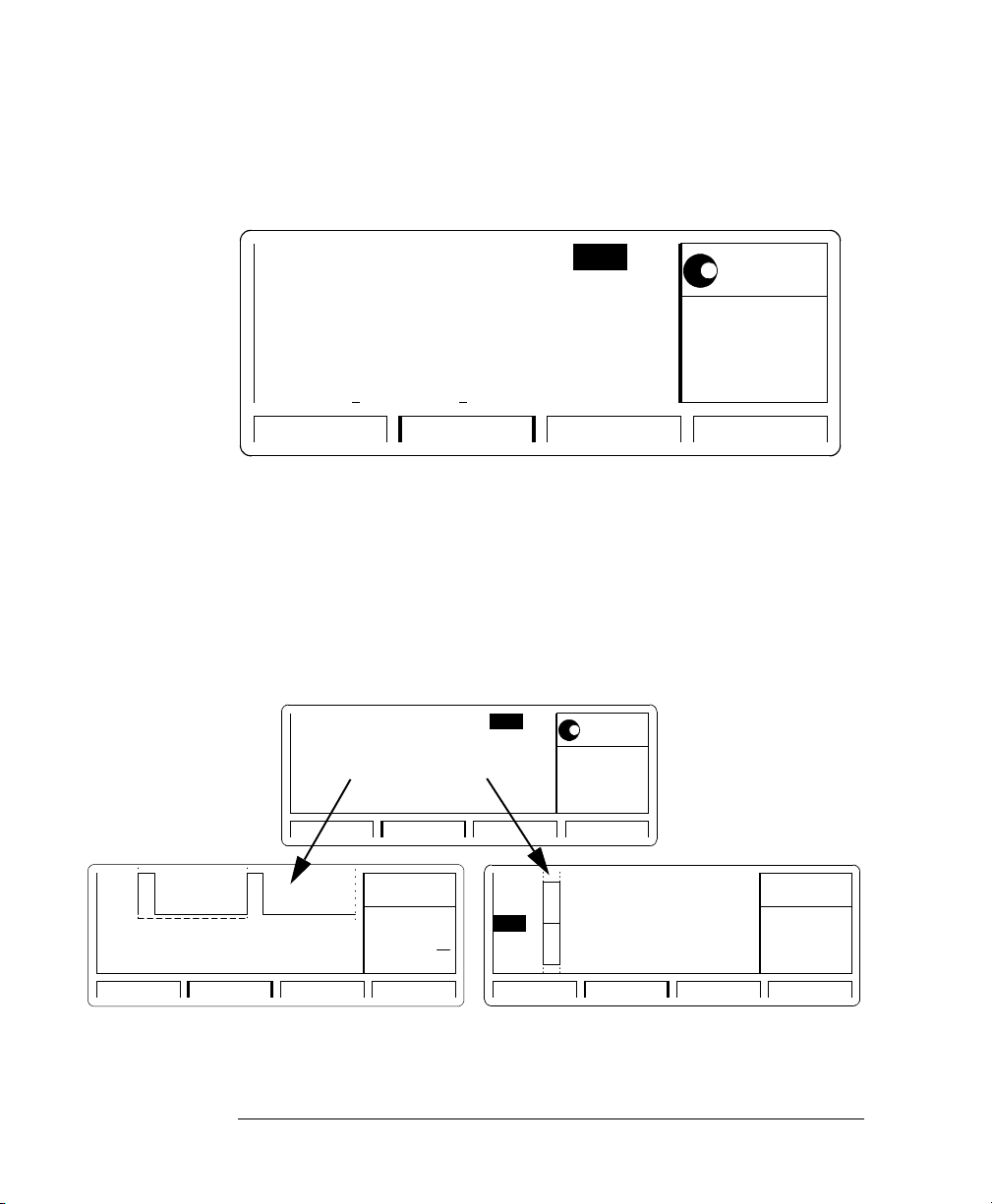

Front Panel Display and Softkeys

Mode / Parameter Area Modify / Enter Area

Use the CURSOR keys to move

the entry focus to a mode,

parameter format, or

parameter value

Entry Focus

Use the KNOB to select a

mode or modify parameters

and formats

Press ENTER or a UNIT key to

confirm parameter changes

Per 1.000µµµµs Normal

Delay1 0ps

Width

LeadE

TraiE

100.0ns

5.00ns

=LeadE

OUTPUT TRG-LEVLIMITSMODE/TRG

Press a SOFTKEY to access

the required entry screen

Screen Selection Area

OFF

Offset

Amplit

+0.0mV

1.00V

50ΩΩΩΩ into 50.0ΩΩΩΩ

MODE/TRG TRG-LEV MEMCARD CONFIG

MODIFY

*OFF

ON

Press MORE key to access

the additional screen menus:

GRAPH

MORE

Page 3

Quick Start Guide

Agilent 81101A 50 MHz

Pulse Generator

Part No. 81101-91020

Printed in Germany March 2000

Edition 1.1, E0300

Page 4

Notice

Notice

Copyright

1998 Agilent Technologies 1998, 2000. All rights reserved.

No part of this manual may be reproduced in any form or by any means

(including electronic storage and retrieval or translation into a foreign

language) without prior agreement and written consent from Agilent

Technologies Inc. as governed by United States and international

copyright laws.

Notice

The material contained in this document is subject to change without

notice. Agilent Technologies makes no warranty of any kind with regard

to this material, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. Agilent

Technologies shall not be liable for errors contained herein or for

incidental or consequential damages in connection with the furnishing,

performance, or use of this material.

Warranty

This Agilent Technologies product has a warranty against defects in

material and workmanship for a period of three years from date of

shipment. During the warranty period, Agilent Technologies will, at its

option, either repair or replace products that prove to be defective. For

warranty service or repair, this product must be returned to a service

facility designated by Agilent Technologies. The Buyer shall pay Agilent

Technologies round-trip travel expenses. For products returned to

Agilent Technologies for warranty service, the Buyer shall prepay

shipping charges to Agilent Technologies and Agilent Technologies shall

pay shipping charges to return the product to the Buyer. However, the

Buyer shall pay all shipping charges, duties and taxes for products

returned to Agilent Technologies from another country.

4

Page 5

Notice

Agilent Technologies warrants that its software and firmware designated

by Agilent Technologies for use with an instrument will execute its

programming instructions when properly installed on that instrument.

Agilent Technologies does not warrant that the operation of the

instrument software, or firmware, will be uninterrupted or error free.

Limitation of Warranty

The foregoing warranty shall not apply to defects resulting from

improper or inadequate maintenance by the Buyer, Buyer-supplied

software or interfacing, unauthorized modification or misuse, operation

outside of the environmental specifications for the product, or improper

site preparation or maintenance. No other warranty is expressed or

implied. Agilent Technologies specifically disclaims the implied

warranties of merchantability and fitness for a particular purpose.

Exclusive Remedies

The remedies supplied are the Buyer's sole and exclusive remedies.

Agilent Technologies shall not be liable for any direct, indirect, special,

incidental, or consequential damages, whether based on contract, tort or

any other legal theory.

Certification

Agilent Technologies certifies that this product met its published

specifications at the time of shipment. Agilent Technologies further

certifies that its calibration measurements are traceable to the United

States Institute of Standards and Technology, to the extent allowed by

the Institute's calibrating facility, and to the calibration facilities of other

International Standards Organization members.

Services and Support

Any adjustment, maintenance, or repair of this product must be

performed by qualified personnel. Contact your customer engineer

through your local Agilent Technologies Service Center. You can find a

list of local service representatives on the Web at:

http://www.agilent.com/Service/English/index.html

5

Page 6

Safety Summary

Safety Summary

The following general safety precautions must be observed during all

phases of operation of this instrument. Failure to comply with these

precautions or with specific warnings elsewhere in this manual violates

safety standards of design, manufacture, and intended use of the

instrument. Agilent Technologies Inc. assumes no liability for the

customer's failure to comply with these requirements.

General

This product is a Safety Class 1 instrument (provided with a protective

earth terminal). The protective features of this product may be impaired

if it is used in a manner not specified in the operation instructions.

All Light Emitting Diodes (LEDs) used in this product are Class 1 LEDs

as per IEC 60825-1.

Environmental Conditions

This instrument is intended for indoor use in an installation category II,

pollution degree 2 environment. It is designed to operate at a maximum

relative humidity of 95% and at altitudes of up to 2000 meters. Refer to

the specifications tables for the ac mains voltage requirements and

ambient operating temperature range.

Before Applying Power

Verify that the product is set to match the available line voltage, the

correct fuse is installed, and all safety precautions are taken. Note the

instrument's external markings described under Safety Symbols on

page 8.

6

Page 7

Safety Summary

Ground the Instrument

To minimize shock hazard, the instrument chassis and cover must be

connected to an electrical protective earth ground. The instrument must

be connected to the ac power mains through a grounded power cable,

with the ground wire firmly connected to an electrical ground (safety

ground) at the power outlet. Any interruption of the protective

(grounding) conductor or disconnection of the protective earth terminal

will cause a potential shock hazard that could result in personal injury.

Fuses

Only fuses with the required rated current, voltage, and specified type

(normal blow, time delay, etc.) should be used. Do not use repaired fuses

or short-circuited fuse holders. To do so could cause a shock or fire

hazard.

Do Not Operate in an Explosive Atmosphere

Do not operate the instrument in the presence of flammable gases or

fumes.

Do Not Remove the Instrument Cover

Operating personnel must not remove instrument covers. Component

replacement and internal adjustments must be made only by qualified

service personnel.

Instruments that appear damaged or defective should be made

inoperative and secured against unintended operation until they can be

repaired by qualified service personnel.

7

Page 8

Safety Summary

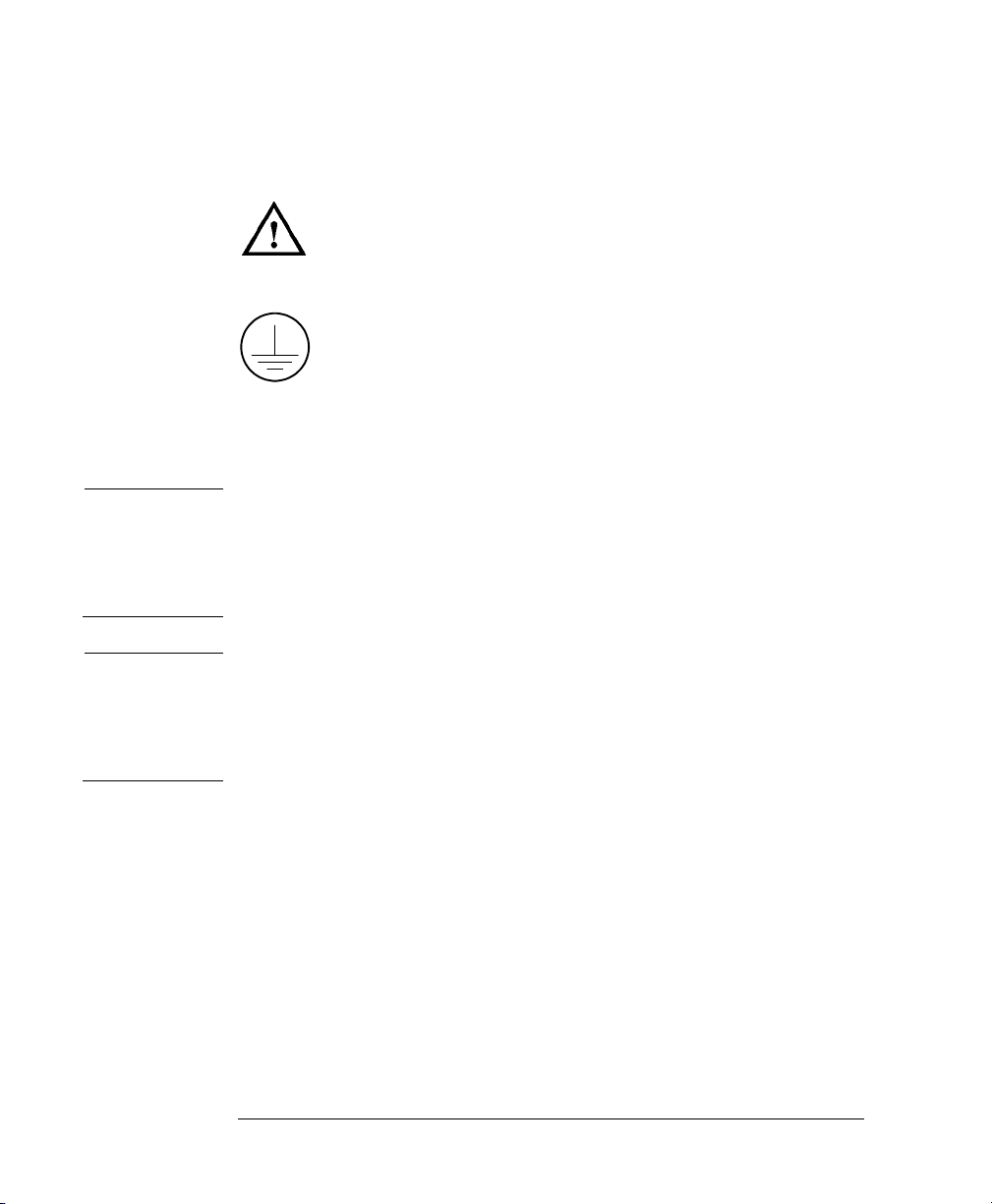

Safety Symbols

Caution (refer to accompanying documents)

Protective earth (ground) terminal

In the manuals:

WARNING

CAUTION

The WARNING sign denotes a hazard. It calls attention to a

procedure, practice, or the like, which, if not correctly performed

or adhered to, could result in personal injury. Do not proceed

beyond a WARNING sign until the indicated conditions are fully

understood and met.

The CAUTION sign denotes a hazard. It calls attention to an operating

procedure, or the like, which, if not correctly performed or adhered to,

could result in damage to or destruction of part or all of the product. Do

not proceed beyond a CAUTION sign until the indicated conditions are

fully understood and met.

8

Page 9

About this Book

About this Book

This quick start guide helps you to quickly get familiar with the features

and the user interface of the Agilent 81101A Pulse Generator.

Chapter 1 Introducing the Agilent 81101A Pulse Generator on page

15 gives a general overview of the Agilent 81101A, its features, the user

interface, and the steps required for operating the instrument.

For getting started Chapter 2 Getting Started on page 29 gives the

setup information for some real-world signal examples, which can easily

be used by varying only some parameter values.

Chapter 3 Using the Agilent 81101A on page 43 provides complete

information on the user interface screens.

Installation and maintenance are described in Appendix A Installation

& Maintenance on page 75.

For specifications and information on operating the instrument by means

of remote control, please refer to the Reference Guide, p/n 81101-91021.

9

Page 10

About this Book

Conventions Used in this Book

This book uses certain conventions to indicate elements of the

Agilent 81101As user interface. The following table shows some

examples:

Softkeys Press the MODE/TRG softkey to access the Mode/

Trigger screen.

Hardkeys Press the MORE key to switch to the alternative

softkey layout.

Alternate Keys Press SHIFT + 0 (ON/OFF) to switch on the output.

The alternate key labelwhich is selected by

pressing the SHIFT keyis given in parentheses.

Screen Quotes Move the entry focus down to P

turn the knob to select

INTERNAL

ULSE-PERIOD

PLL.

and

Entry Focus The highlight field, that can be moved with the

cursor keys, to change modes, parameters, or

parameter formats.

10

Page 11

Contents

Notice ......................................................................................... 4

Safety Summary ......................................................................... 6

About this Book ......................................................................... 9

Chapter 1

Chapter 2

Introducing the Agilent 81101A Pulse Generator

What you can do with the Agilent 81101A ............................ 16

The Front Panel ....................................................................... 18

Operating the Agilent 81101A ................................................ 20

Switching On the Instrument .............................................................. 20

The Basic Screens ................................................................................. 21

Adjusting Parameters ........................................................................... 23

Switching the Output On and Off ....................................................... 26

Using the Special Function Keys ........................................................ 26

Help is Available ...................................................................... 27

The Rear Panel ........................................................................ 28

Getting Started

Setting Up a Clock Signal ....................................................... 30

Setting Up a Pulse Signal ........................................................ 35

Setting Up a Burst Signal ....................................................... 39

xi

Page 12

Contents

Chapter 3

Using the Agilent 81101A

The Mode/Trigger Screen ....................................................... 44

Overview ................................................................................................. 44

Continuous Pulses Mode ...................................................................... 46

Continuous Burst Mode ........................................................................ 47

Triggered Pulses Mode ......................................................................... 48

Triggered Burst Mode ........................................................................... 50

Gated Pulses Mode ................................................................................ 52

Gated Burst Mode ................................................................................. 54

External Width Mode ............................................................................ 55

The Output Screen ................................................................. 56

Timing Parameters ................................................................................ 56

Level Parameters ................................................................................... 61

The Limits Screen ................................................................... 64

The Trigger-Level Screen ....................................................... 65

Threshold and Impedance Parameters ............................................... 65

Trigger and Strobe Level Parameters ................................................. 66

Appendix A

The Memory Card Screen ....................................................... 67

The Configuration Screen ...................................................... 70

Warnings and Errors .............................................................. 72

Installation & Maintenance

Initial Inspection .................................................................... 76

Standard Deliverables ........................................................................... 77

Options and Accessories: ..................................................................... 78

xii

Page 13

Contents

Power Requirements ............................................................... 80

Power Cable ............................................................................. 82

Ventilation Requirements ....................................................... 83

Thermal Protection ............................................................................... 83

Battery ..................................................................................... 84

Battery Replacement ............................................................................ 85

Operating Environment .......................................................... 86

Cleaning Recommendation ..................................................... 87

Acoustic Noise Emission ......................................................... 88

xiii

Page 14

Contents

xiv

Page 15

1Introducing the

Agilent 81101A Pulse

1

Generator

The purpose of the introduction chapter is to give a general overview of

the Agilent 81101A.

The main features and use models are described in What you can do

with the Agilent 81101A on page 16.

Operating the instrument via the front panel user interface is described in

The Front Panel on page 18 and Operating the Agilent 81101A on

page 20.

Help is Available on page 27 shortly introduces the Agilent 81101As

on-line help system.

Finally, The Rear Panel on page 28 takes a look at the back of the

Agilent 81101A.

15

Page 16

Introducing the Agilent 81101A Pulse Generator

What you can do with the Agilent 81101A

What you can do with the

Agilent 81101A

This section introduces the basic features and use models of the

Agilent 81101A Pulse Generator.

Basic Features

The Agilent 81101A is a single-channel pulse generator with variable

transition times. It is capable of generating all standard pulses and bursts

of pulses needed to test current logic technologies (for example, TTL,

CMOS, ECL, PECL, LVDS, GTL) and other digital designs up to 50 MHz.

The instrument features two internal oscillators:

a synchronously triggerable internal oscillator

an accurate, stable internal PLL

For even more accuracy, an external frequency reference can be

connected.

Any timing parameter can be varied without glitch or drop out. This

contributes to more accurate and confident characterizations of the

device under test (DUT).

Complete signal setups can be stored locally (9 internal non-volatile

registers available) or on a memory card.

Benchtop Testing

The Agilent 81101A features a graphic display showing all pulse

parameters at a glance. The cursor keys and the modify knob allow fast

and simple operation.

The user interface is designed to minimize the time invested in getting

familiar with the instrument. After familiarization, the instrument

supports quick setups of signals. This leaves you free to concentrate on

the measurement task and testing of the DUT.

16

Page 17

Introducing the Agilent 81101A Pulse Generator

What you can do with the Agilent 81101A

Automated Testing

The Agilent 81101A features an GP-IB/SCPI-conform command structure

for all features. Using this programming interface, the instrument can be

easily integrated into all phases of test system development such as

planning rack integration and test program generation.

Programs designed for the Agilent 81101A are compatible with all other

models of the Agilent 81100 family.

NOTE

For a command reference list, please refer to the Reference Guide, part

number 81101-91021.

17

Page 18

Introducing the Agilent 81101A Pulse Generator

The Front Panel

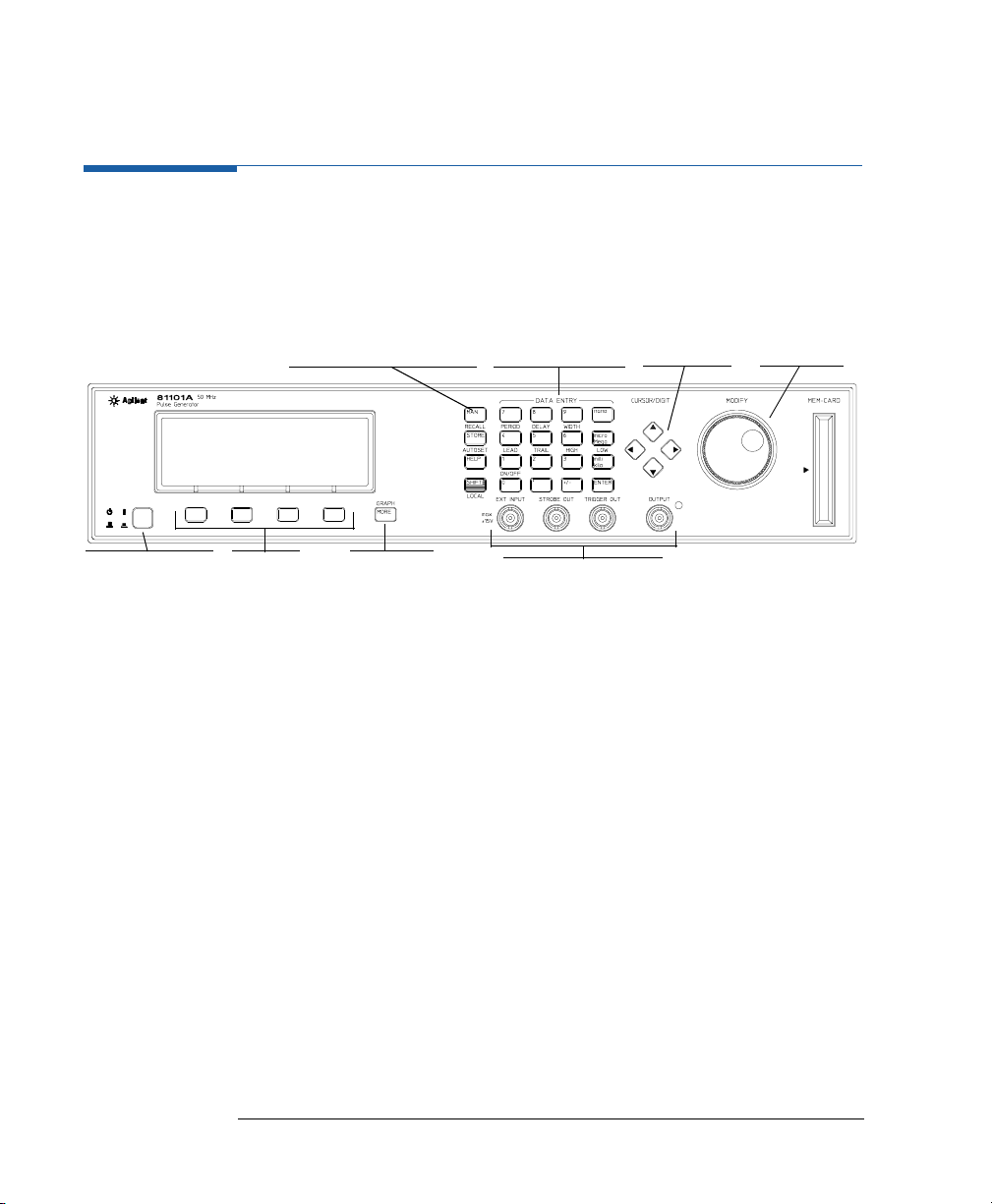

The Front Panel

When used for benchtop testing, the instrument is mainly operated from

the front panel.

Front Panel

Switch

NOTE

Special Function Keys Data Entry Keys

Softkeys MORE Key Inputs and Outputs

front panel switch

The

When the front panel switch is off, the instrument is in standby mode.

The instrument is disconnected from the AC line power only by

disconnecting the power cord.

The four keys below the display are the

keys). The current function of each softkey is indicated in the

corresponding box on the display.

Pressing the MORE key changes the softkey layout.

The other keys (

and the

operating the instrument (see Operating the Agilent 81101A on

page 20).

special function keys, data entry keys, cursor keys

rotary knob

is used to switch on and off the instrument.

are used to select and modify parameters when

Cursor Keys

softkeys

(software-controlled

Rotary Knob

)

18

Page 19

Introducing the Agilent 81101A Pulse Generator

The Front Panel

The major inputs and outputs of the instrument are available at the front

panel:

The external input (EXT INPUT) can be used to connect an external

arming source (triggered or gated modes), or to perform pulse

recovery (external width mode). For details, please refer to The

Mode/Trigger Screen on page 44.

The strobe output (STROBE OUT) provides a signal indicating the

duration of a burst.

In burst mode, the STROBE OUT signal marks the start and end of

each burst of pulses generated. The rising edge of the STROBE signal

is synchronized to the start of the first pulse period in a burst, the

falling edge is synchronized to the start of the last pulse period in the

burst. (see The Mode/Trigger Screen on page 44).

You can set the output levels to TTL or ECL (see The Trigger-Level

Screen on page 65)

The trigger signal (TRIGGER OUT) marks the start of each pulse

period (see The Mode/Trigger Screen on page 44). You can set the

output levels to TTL or ECL (see The Trigger-Level Screen on

page 65).

NOTE

NOTE

The OUTPUT provides the signal output, the indicator shows the

current state of the output (on or off).

An input connector for external frequency reference (CLOCK/REF INP.)

is available at the rear panel (see The Rear Panel on page 28). When

the rear panel option UN2 is ordered, all input and output connectors are

available at the rear panel.

For information on the use of the memory card slot, refer to The

Memory Card Screen on page 67.

19

Page 20

Introducing the Agilent 81101A Pulse Generator

Operating the Agilent 81101A

Operating the Agilent 81101A

This section guides you through the first steps when operating the

Agilent 81101A via the user interface.

NOTE

For information on operating the Agilent 81101A via remote control,

please refer to the Reference Guide, part number 81101-91021.

Switching On the Instrument

After switching on the instrument the display indicates that the

instrument selftest is running. This can take several seconds to complete.

If the selftest fails, you see a flashing E at the bottom of the screen. Press

the HELP key to see a list of the selftest error messages. Use the knob or

the cursor keys to scroll through the list if necessary.

To return to normal operation press HELP again. Note that the selftest

error messages are removed from the error queue after this.

20

Page 21

Introducing the Agilent 81101A Pulse Generator

Operating the Agilent 81101A

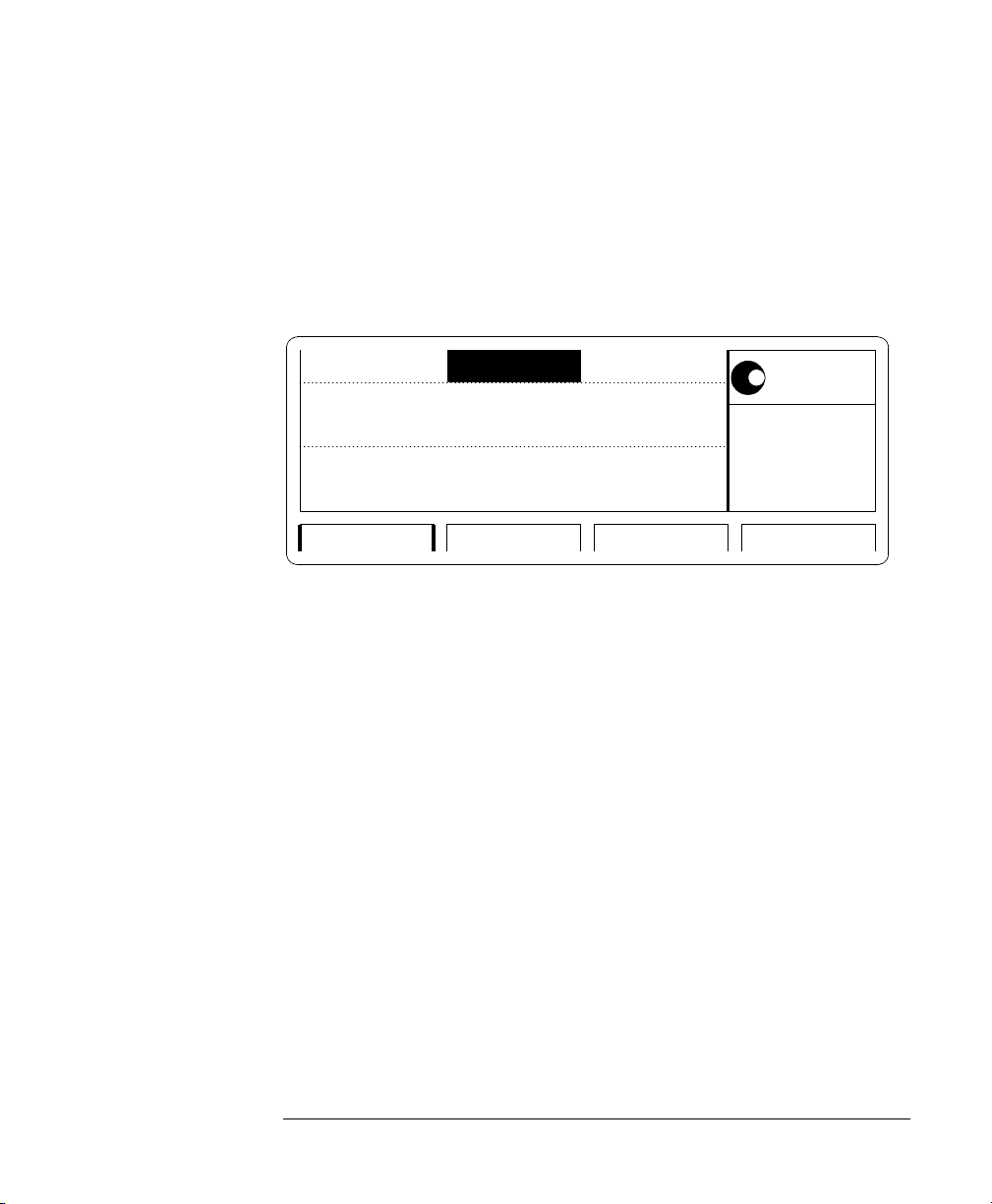

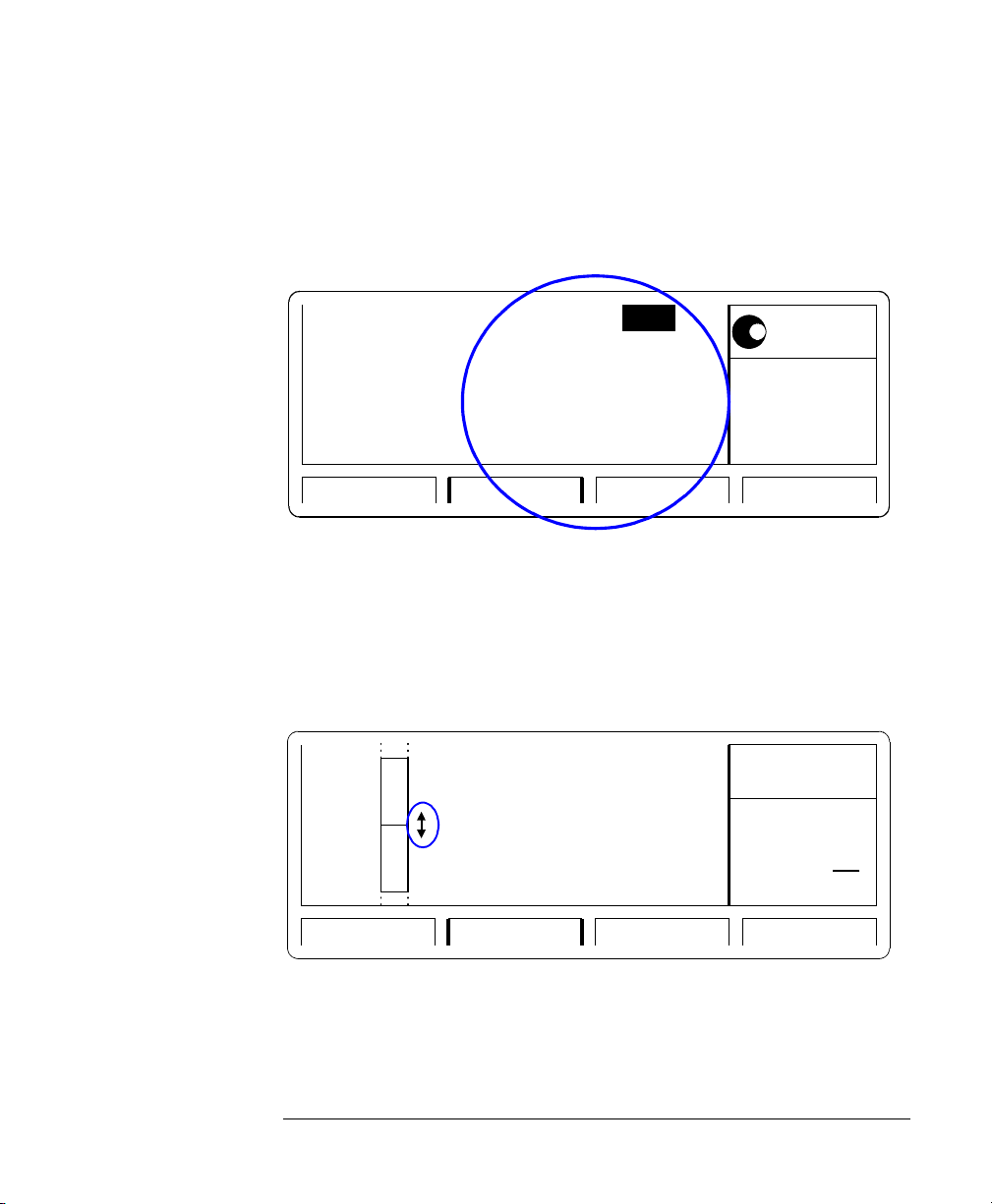

The Basic Screens

The major parameters for pulse generation can be set up in only two

screens.

Mode/Trigger screen

The

and trigger modes with respect to the signal required.

allows you to set the fundamental operating

Press the MODE/

TRG softkey to

access this screen.

CONTINUOUS

PULSES

MODIFY

Single-Pulses at Out1

*PulseStrm

Burst

Pulse-Period: internal Osc

OUTPUT TRG-LEVLIMITSMODE/TRG

In this screen, you can set up the signal to be triggered or continuous,

and to be a pulse stream or a burst (several pulses followed by a pause)

consisting of single or double pulses.

In the lower section you can specify the frequency source for the pulse

period and the trigger source.

21

Page 22

Introducing the Agilent 81101A Pulse Generator

Operating the Agilent 81101A

Output screen

The

for the signal to be generated.

allows you to specify timing and level parameters

Press the OUTPUT

softkey to access

this screen.

Per 1.000

Delay

Width

LeadE

TraiE

µµµµ

s Normal

0ps

100.0ns

5.00ns

=LeadE

Offset

Amplit

ΩΩΩΩ

50

into 50.0

OFF

1

+0.0mV

1.00V

ΩΩΩΩ

MODIFY

*OFF

ON

OUTPUT TRG-LEVLIMITSMODE/TRG

In the left part of this screen, you can set up the timing for the signal

(period, pulse width, transition times, ...). The right part is for the levels

(normal or inverted signal, offset and amplitude, impedance, ...).

Furthermore, you can switch on and off the output.

Pressing SHIFT + MORE (GRAPH) when the Output screen is displayed,

toggles between the textual display and a graphical representation of the

parameters. Depending on the current cursor position (left or right part),

the timing parameters or the level parameters are visualized.

Per 1.000µµµµs Normal

Delay1 0ps

Width

LeadE

TraiE

100.0ns

5.00ns

=LeadE

Offset

Amplit

50

OUTPUT TRG-LEVLIMITSMODE/TRG

OFF

+0.0mV

1.00V

ΩΩΩΩ

into 50.0

MODIFY

*OFF

ON

ΩΩΩΩ

1

OFF

PERIOD

1

OFF

+11V

1.000

µµµµ

s

OUTPUT TRG-LEVLIMITSMODE/TRG

-11V

OUTPUT TRG-LEVLIMITSMODE/TRG

Output 1

*OFF

ON

22

Page 23

Introducing the Agilent 81101A Pulse Generator

Operating the Agilent 81101A

Adjusting Parameters

Adjusting parameters within a screen, requires two steps:

selecting the parameter

adjusting its value

Some parameters allow different formats of their values. For example,

the pulse width can be displayed and entered as an absolute value, as

duty cycle (percentage of the period), or as the delay of the trailing edge.

The following sections show the standard procedure for adjusting

parameters, and list some features useful for the advanced user.

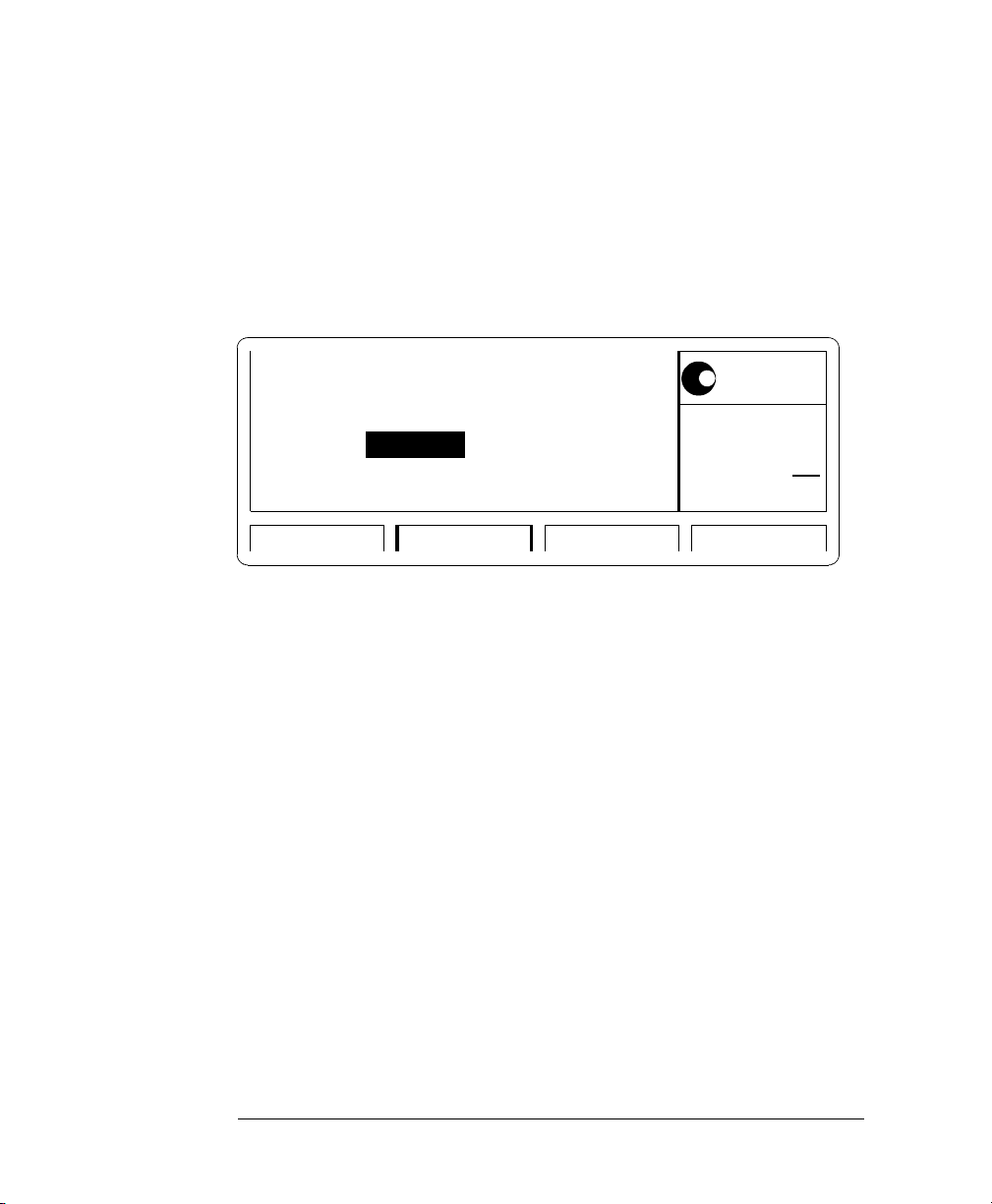

Standard Procedure

To experience the standard procedure for adjusting parameters, consider

the following example where the duty cycle is set to 50%.

1

Press the OUTPUT softkey to access the Output screen.

2

Use the cursor keys to select the W

parameter.

IDTH

Selection Cursor Modify/Enter Area

Per 1.000

Delay

Width

LeadE

TraiE

µµµµ

s Normal OFF

0ps

100.0ns

5.00ns

=LeadE

Offset

Amplit

50

ΩΩΩΩ

into 50.0

1

+0.0mV

1.00V

ΩΩΩΩ

MODIFY

*Width

DutyCycle

TrailDel

OUTPUT TRG-LEVLIMITSMODE/TRG

The available formats for the pulse width parameter are displayed in

the Modify/Enter area.

23

Page 24

Introducing the Agilent 81101A Pulse Generator

Operating the Agilent 81101A

3

When changing the

parameter format,

the instrument

automatically

recalculates the

value.

Turn the knob to select D

The selected setting is indicated by an *.

4

Move the cursor to the right to select the duty cycle value.

5

Use the data entry keys or the knob to enter the required value: 50.

6

Press the ENTER key to confirm your selection.

UTYCYCLE

.

Per 1.000

Delay1 0.0ps

DtyCyc

LeadE

TraiE

µµµµ

s Normal OFF

50.00%

6.00ns

=LeadE

Offset

Amplit

50

ΩΩΩΩ

into 50.0

+0.0mV

1.00V

MODIFY

50.00

ΩΩΩΩ

%

OUTPUT TRG-LEVLIMITSMODE/TRG

If you need to specify a unit for a parameter, simply press the appropriate

unit key (

With this small example, you have learned the basic steps required for

adjusting parameters. For a complete reference of parameters and

formats available in the individual screens, refer to Chapter 3 Using the

Agilent 81101A on page 43.

NANO, MICRO/MEGA, MILLI/KILO

) instead of the ENTER key.

24

Page 25

SHIFT

Introducing the Agilent 81101A Pulse Generator

Operating the Agilent 81101A

Advanced Procedures

The following features can be used to make operation more comfortable.

Selecting parameters

Most keys of the front panel have an additional function. The SHIFT

key provides fast access to the additional functions of the data entry

keys and the special function keys.

For example, it is possible to quickly access the pulse width

parameter by pressing SHIFT + 6 (WIDTH). The entry focus will be

positioned on the corresponding editing field.

Changing the step size

SHIFT

SHIFT

NOTE

When modifying a value in the Modify/Enter area, pressing the SHIFT

key followed by cursor left/right moves the cursor to a different digit

in the displayed number.

Thus, you can change the step size for parameter change before you

vary the value either with the up/down cursor keys or the knob.

Overprogramming

Pressing the SHIFT key while turning the knob, it is possible to exceed

specified parameter ranges to utilize the instrument to its limits.

Proper operation of the instrument outside of the specified ranges is not

guaranteed. It is recommended to have the output switched on when

overprogramming to have the internal error check system activated. This

error check system warns you about impossible settings.

25

Page 26

Introducing the Agilent 81101A Pulse Generator

Operating the Agilent 81101A

Switching the Output On and Off

When you switch the instrument on, the output is switched off to protect

the device under test. The LED indicator next to the output connector

indicates the output state.

ON/OFF

0

MAN

RECALL

STORE

SHIFT

LOCAL

To switch the output on or off

either press SHIFT + 0 (ON/OFF),

or move the cursor to the ON/OFF parameter in the Output screen

and select the appropriate value by turning the knob.

Using the Special Function Keys

The instrument provides the following special function keys:

The MAN key can be used in triggered or gated mode to manually

trigger the instrument if there is no other source available (see The

Mode/Trigger Screen on page 44).

The STORE key can be used to store/recall to/from 1 to 9 individual

settings in the instrument memory.

In the internal memory location 0 there is a default setting stored.

Pressing SHIFT + STORE (RECALL) and selecting 0 resets the instrument to

the default setting.

The SHIFT key provides fast access to additional functions.

When the front panel controls are locked in remote control, pressing

the SHIFT key unlocks the front panel controls.

HELP

The HELP key provides access to the instruments on-line help or in

warning or error state, access to Warning/Error Report screen.

Pressing SHIFT + HELP (AUTOSET) sets the instrument to a valid

setting based on the current period setting.

26

Page 27

Help

Introducing the Agilent 81101A Pulse Generator

Help is Available

Help is Available

Whenever you are in doubt or the instrument signals warnings or errors,

press the HELP key.

If there are no warnings or errors pending, pressing the HELP key

displays information on the currently selected parameter, the parameter

help. More information is available within the help system:

Parameter Help

The help information gives a short description of the parameter or

setting options and the corresponding SCPI command(s) syntax for

programming the parameter or setting.

If there is more than one screen available (indicated by small arrows),

use the knob or the cursor keys to scroll through the help

information.

To access parameter help from other screens of the help system,

press the ON FIELD softkey.

Warnings and

Errors

Exit Help

Concept Help

Pressing the CONCEPT softkey within the help system displays a short

description of the instrument.

Serial Numbers and Software Revision

Pressing the SERIAL # softkey within the help system displays

information on serial numbers and software revision codes of the

instrument.

If there are warnings or errors pending (indicated by a flushing W or E),

pressing the HELP key displays a list of the current messages. Using the

ERROR QU and WARNING softkeys, you can toggle between both lists. For

more information on warnings and errors, see Warnings and Errors on

page 72.

To exit from the help system, press the HELP key again, or press the EXIT

HELP softkey.

27

Page 28

Introducing the Agilent 81101A Pulse Generator

The Rear Panel

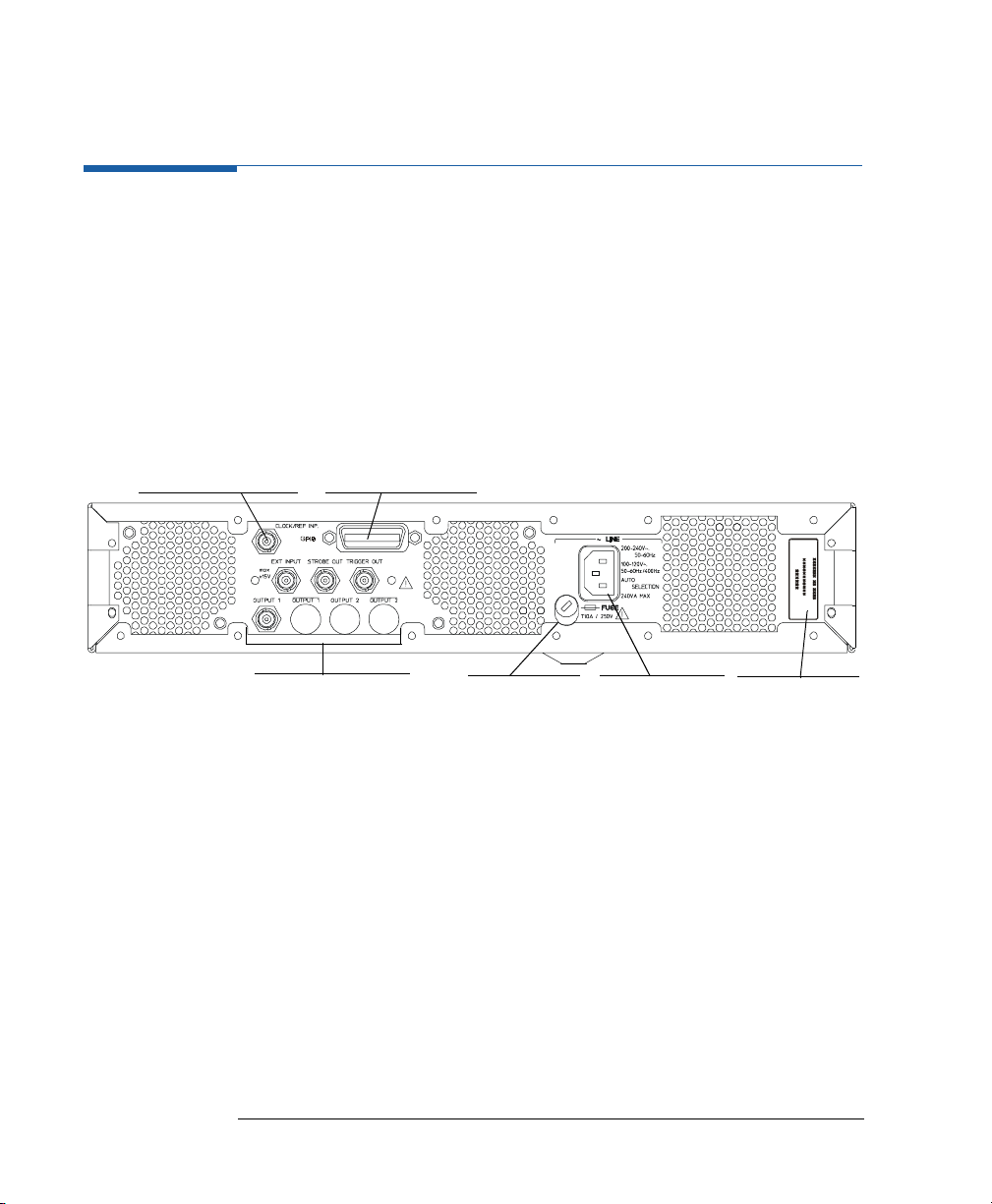

The Rear Panel

The rear panel always provides two connectors:

The input connector for external frequency reference (CLOCK/REF

INP.). This input can be used if a higher frequency accuracy is

required, or if you need frequency locking.

The GP-IB connector providing the interface for remote control.

The following figure shows the rear panel view with the option UN2.

GP-IB ConnectorExternal Reference

Inputs and Outputs

With option UN2 the major inputs and outputs of the instrument (as

described in The Front Panel on page 18) are available at the rear

panel:

external input (EXT INPUT)

strobe output (STROBE OUT)

trigger signal (TRIGGER OUT)

signal output (OUTPUT)

28

Fuse Holder AC Line Socket

Serial Number

Page 29

2

2Getting Started

The intention of this chapter is to give the necessary steps to set up

generic signals for first-time users of the Agilent 81101A.

This chapter provides examples for the following types of signals:

“Setting Up a Clock Signal” on page 30

“Setting Up a Pulse Signal” on page 35

“Setting Up a Burst Signal” on page 39

At the end of each example, the required set of device commands is listed

to provide programming examples. For further information on the

commands and a complete command reference please refer to the

Reference Guide, p/n 81101-91021.

The examples are intended to be performed one after the other.

Therefore, the first example provides the most detailed instructions,

while the other examples are described on a higher level.

29

Page 30

Getting Started

Setting Up a Clock Signal

Setting Up a Clock Signal

Ta sk

Instructions

Set up a continuous clock signal with 25 MHz frequency with PLL

accuracy, a duty cycle of 50 %, 6 ns transition times, a high level of 2.5 V

and low level of 0 V.

Duty Cycle = 50 %

2.5 V

0.0 V

f = 25 MHz

To set the

1

Reset all parameters and modes by pressing SHIFT + STORE (RECALL) + 0.

2

Press the MODE/TRG softkey to enter the Mode/Trigger screen.

Trigger mode CONTINUOUS and operating mode PULSES are

selected by default.

3

Move the entry focus down to P

select

operating mode and trigger mode

ULSE-PERIOD

INTERNAL

PLL.

as required:

and turn the knob to

CONTINUOUS PULSES

Single-Pulses at Out1

Pulse-Period: internal PLL

OUTPUT TRG-LEVLIMITSMODE/TRG

30

MODIFY

intOsc

intPLL

*CLK-IN

Page 31

Getting Started

Setting Up a Clock Signal

To set the

1

Press the OUTPUT softkey to enter the Output screen.

2

Press SHIFT + 0 (ON/OFF).

This turns on the Output and activates the internal error check to

detect parameter conflicts.

3

Move the entry focus to P

4

Move the entry focus to the right (to the frequency entry field) and

enter a value of 25 MHz by pressing 2 + 5 +

A warning is displayed, indicating a potential conflict in your settings.

You can ignore this, because the conflict will be solved in the next

steps.

5

Move the entry focus down to W

6

Move the entry focus to the right and enter 50 % by typing 5 + 0 +

ENTER.

7

Move the entry focus down to the leading edge entry field and press 6

+

The trailing edge is set to be the same as the leading edge (T

L

Freq 25.00MHz Normal ON

timing parameters

.

NANO

E) by default.

EAD

as required:

and turn the knob to select F

ER

MICRO/MEGA

and select D

IDTH

UTYCYC

REQ

.

le.

RAI

MODIFY

.

E =

Delay1 0.0ps

DtyCyc

LeadE

TraiE

50.00%

6.00ns

=LeadE

Offset

Amplit

ΩΩΩΩ

50

into 50.0

+0.0mV

1.00V

ΩΩΩΩ

OUTPUT TRG-LEVLIMITSMODE/TRG

8

Press SHIFT + MORE (GRAPH) to see a preview of your signal.

6.00

ns

31

Page 32

Getting Started

Setting Up a Clock Signal

1

ON

LeadEdge1

6.00

ns

OUTPUT TRG-LEVLIMITSMODE/TRG

You can modify the parameter displayed in the Modify/Enter area, and

immediately check how your changes affect the signal. Use the cursor

keys to switch to another parameter.

9

Press SHIFT + MORE (GRAPH) to return to the textual screen.

To set the

1

Move the entry focus to O

select H

2

Move the entry focus to the high level entry field, enter 2.5 and press

the ENTER key.

In the same way, enter 0 for the low level. The impedance is 50Ω

source into 50Ω load by default.

level parameters

IGH-LOW

.

as required:

FFSET/AMPLITUDE

and turn the knob to

NOTE

Freq 25.00MHz Normal ON

Delay1 0.0ps

DtyCyc

LeadE

TraiE

50.00%

6.00ns

=LeadE

High

Low

ΩΩΩΩ

50

into 50.0

+2.50V

+0.00V

ΩΩΩΩ

MODIFY

+2.50

V

OUTPUT TRG-LEVLIMITSMODE/TRG

There is also a graphical screen available for the level parameters.

32

Page 33

Getting Started

Setting Up a Clock Signal

Here is the signal as displayed on an Agilent 54810A Infinium

oscilloscope. Use the generator’s TRIGGER OUT to trigger the scope.

33

Page 34

Getting Started

Setting Up a Clock Signal

Programming

Example

If you want to include this clock signal in your GP-IB program, use the

following command lines. The comment lines starting with a # are not

required.

# Reset the instrument to start from a defined, default status.

*RST

# Switch off the automatic display update to increase programming

# speed.

:DISPlay OFF

# Internal PLL has to be set as period source.

:ARM:SOURce INT2

# Set the frequency to 25 MHz, the duty cycle to 50 % and the

# leading and trailing edge to 6 ns.

:FREQuency 25 MHZ

:PULSe:DCYCle 50

:PULSe:TRANsition 6NS

# Set the high level to 2.5 Volts, the low level to 0.0 Volts.

:VOLTage:HIGH 2.5V

:VOLTage:LOW 0V

# Enable the output.

:OUTPut ON

34

Page 35

Setting Up a Pulse Signal

Getting Started

Setting Up a Pulse Signal

Ta sk

Instructions

Set up a continuous pulse signal with 50 ns period, a pulse width of 30 ns,

a leading edge of 6 ns, a trailing edge of 10 ns, an amplitude of 3.3 V and

an offset of 1.65 V (high level 3.3 V, low level 0.0 V).

Pulse Width = 30 ns

3.3 V

50 %

0.0 V

Period = 50 ns

To set the

1

Reset all parameters and modes by pressing SHIFT + STORE + 0.

2

Press the MODE/TRG softkey to enter the Mode/Trigger screen.

The default settings can be used for this example. For reference the

Mode/Trigger screen is displayed. There is nothing to change.

CONTINUOUS

operating mode and trigger mode

PULSES

as required:

MODIFY

Single-Pulses at Out1

*PulseStrm

Burst

Pulse-Period: internal Osc

OUTPUT TRG-LEVLIMITSMODE/TRG

35

Page 36

Getting Started

Setting Up a Pulse Signal

To set the

1

Press the OUTPUT softkey to enter the Output screen.

2

Switch on the output.

3

Enter a period of 50

A warning is shown, which you may ignore, because the parameter

conflict will be solved in the next steps.

4

Enter a pulse width of 30

5

Enter 6

6

For the trailing edge, select A

Per 50.00ns Normal ON

Delay1 0.0ps

Width

LeadE

TraiE

timing parameters

.

NS

for the leading edge.

NS

Offset

30.00ns

6.00ns

Amplit

50

10.0ns

as required:

.

NS

BSOLUTE

+0.0mV

1.00V

ΩΩΩΩ

into 50.0

and enter a value of 10 NS.

MODIFY

10.0

ΩΩΩΩ

ns

OUTPUT TRG-LEVLIMITSMODE/TRG

To set the

1

Enter an offset of 1.65 V.

2

Enter an amplitude of 3.30 V.

level parameters

as required:

Per 50.00ns Normal ON

Delay1 0.0ps

Width

LeadE

TraiE

30.00ns

6.00ns

10.0ns

Offset

Amplit

50

ΩΩΩΩ

into 50.0

OUTPUT TRG-LEVLIMITSMODE/TRG

36

+1.65V

3.30V

ΩΩΩΩ

MODIFY

3.30

V

Page 37

Getting Started

Setting Up a Pulse Signal

Here is the figure as displayed on the Agilent 54810A Infinium

oscilloscope. Use the generator’s TRIGGER OUT to trigger the scope.

37

Page 38

Getting Started

Setting Up a Pulse Signal

Programming

Example

If you want to include this pulse signal in your GP-IB program, use the

following command lines. The comment lines starting with a # are not

required.

# Reset the instrument to start from a defined, default status.

*RST

# Switch off the automatic display update to increase programming

# speed.

:DISPlay OFF

# Pulse stream operating mode is required, but as we start

# from a default status it is not necessary to send a command for

# setting the instrument into pulse stream operating mode.

# Set the period to 50 ns, the pulse width to 20 ns, the leading

# edge to 6 ns and the trailing edge to 10 ns.

:PULSe:PERiod 50NS

:PULSe:WIDTh 30NS

:PULSe:TRANsition 6NS

:PULSe:TRANsition:TRAiling:AUTO OFF

:PULSe:TRANsition:TRAiling 10NS

# Set the amplitude to 3.3 Volts, the offset to 1.65 Volts.

:VOLTage 3.3V

:VOLTage:OFFSet 1.65V

# Enable the output

:OUTPut ON

38

Page 39

Setting Up a Burst Signal

Getting Started

Setting Up a Burst Signal

Ta sk

Instructions

Set up a burst signal with a burst repetition of 2 µs. Each burst consists of

two double-pulses at a period of 500 ns. The pulse width is 100 ns, the

delay between the two pulses of a double-pulse is 200 ns. The levels are

2 Vpp amplitude and 0 V offset.

Double Pulse Delay = 200 ns

1 V

0 V

1 V

Pulse Period = 500 ns

Burst Repetition = 2 µs

To set the

1

Reset all parameters and modes by pressing SHIFT + STORE + 0.

2

Press the MODE/TRG softkey to enter the Mode/Trigger screen.

operating mode and trigger mode

as required:

The internal PLL is used to trigger the startable internal oscillator.

The PLL defines the burst repetition, the oscillator generates the

pulse period. This requires the following settings:

3

Move to CONTINUOUS and turn the knob to select T

4

Move to PULSES and select B

5

Move down and select D

6

Move left and select a burst length of 2.

7

Move down and select T

(burst repetition)

.

OUBLE

RG’D BY

.

URST

(D

OUBLE-PULSES AT OUT

: PLL and set the period to 2.000µs

RIGGERED

1).

.

39

Page 40

Getting Started

Setting Up a Burst Signal

TRIGGERED BURSTS OF

2-Double-Pulses at Out1

Pulse-Period: internal Osc

Trg'd by: PLL ->

Per 2.000

µµµµ

s

OUTPUT TRG-LEVLIMITSMODE/TRG

To set the

1

Press the OUTPUT softkey to enter the Output menu.

2

Switch on the Output.

3

Enter a pulse period of 500

4

Enter a double-pulse delay (D

To set the

1

Enter an amplitude of 2.00 V.

timing parameters

level parameters

as required:

.

NS

BLDEL

as required:

) of 200NS.

Per 500.0ns Normal ON

MODIFY

2.000

s

µµµµ

MODIFY

DblDel1 200.0ns

Width

LeadE

TraiE

40

100.0ns

5.00ns

=LeadE

OUTPUT TRG-LEVLIMITSMODE/TRG

Offset

Amplit

50

ΩΩΩΩ

into 50.0

+0.0mV

2.00V

ΩΩΩΩ

2.00

V

Page 41

Getting Started

Setting Up a Burst Signal

The following figure shows the signals as displayed on the

Agilent 54810A Infinium Oscilloscope if you connect OUTPUT to

channel 1, STROBE OUT to channel 2, and use the generator’s

TRIGGER OUT to trigger the scope.

41

Page 42

Getting Started

Setting Up a Burst Signal

Programming

example

If you want to include this burst signal in your GP-IB program use the

following command lines. The comment lines starting with a # are not

required.

# Reset the instrument to start from a defined, default status.

*RST

# Switch off the automatic display update to increase programming

# speed.

:DISPlay OFF

# Set the instrument to burst mode by selecting a burst count

# of 2. Choose double pulses. Select triggered mode by selecting

# PLL as the trigger source and set the burst repetition to 2 µs.

:TRIGger:COUNt 2 # Set Burst mode with burst count of 2

:ARM:SOURce INT2 # Set Triggered mode with PLL as

# trigger source

:ARM:PERiod 2US # Set burst repetition of 2 µs

:PULSe:DOUBle ON # second channel generates double pulses

# per period

# Set the double pulse delay to 200 ns and the width to 100 ns.

:PULSe:PERiod 500NS

:PULSe:WIDTh 100NS

:PULSe:DOUBle:DELay 200NS

# Set the output amplitude to 2 Volts and the offset to

# 0.0 Volts.

:VOLTage 2V

# Enable the output.

:OUTPut ON

42

Page 43

3

3Using the Agilent 81101A

This chapter provides complete reference information for using the

Agilent 81101A by means of the user interface screens.

Each screen is described in detail. To access the individual screens, use

the softkeys below the screen. There are two softkey layouts:

the default layout

OUTPUT TRG-LEVLIMITSMODE/TRG

the alternative layout displayed after pressing the MORE key

TRG-LEV CONFIGMEMCARDMODE/TRG

At the end of this chapter, Warnings and Errors on page 72 provides

details on the instruments warning and error messaging system.

NOTE

NOTE

For general information on using the Agilent 81101A and information on

the instruments hardkeys, please refer to Chapter 1 Introducing the

Agilent 81101A Pulse Generator on page 15.

For information on using the Agilent 81101A via remote control, please

refer to the Reference Guide, part number 81101-91021.

43

Page 44

Using the Agilent 81101A

The Mode/Trigger Screen

The Mode/Trigger Screen

This section describes the Mode/Trigger screen, starting with an

overview of the available parameter combinations, followed by detailed

descriptions of each combination.

Overview

To access the Mode/Trigger screen, press the MODE/TRG softkey.

The following figure shows a typical Mode/Trigger screen, where the

individual parameters are indicated. The parameter combinations are

listed in the table on the next page.

➀

TRIGGERED BURSTS OF

2-Double-Pulses at Out1

➃

➄

Pulse-Period: internal Osc

Trg'd by: PLL ->

In this screen, you can set up the signal to be triggered or continuous,

and to be a pulse stream or a burst (several pulses followed by a pause)

consisting of single or double pulses.

44

➁

Per 2.000

OUTPUT TRG-LEVLIMITSMODE/TRG

➅

➂

MODIFY

2.000

µµµµ

s

µµµµ

s

Page 45

Using the Agilent 81101A

The Mode/Trigger Screen

Furthermore, you can specify the pulse and trigger sources.

The following table provides a list of possible parameter combinations.

The rows refer to the numbers in the figure.

Trigger Mode Continuous Triggered Gated Ext. Width

➀

Pulse Mode Pulses Burst Pulses Burst Pulses Burst

➁

Pulse Type

➂

Length

➃

Period Source

➄

Arming Source

➅

Trigger Out

Strobe Out

Single/Double Single/Double Single/Double

265536 265536 265536

internal Osc.

internal PLL

CLK-IN

not used

on 1st

↑

on last

↓

MAN

key

Ext. Input

marks each pulse period generated

not used

internal Osc.

internal PLL

CLK-IN

MAN

key

Ext. Input

PLL

on1st

↑

on last

↓

internal Osc.

internal PLL

CLK-IN

MAN

key

Ext. Input

not used

↑

↓

on 1st

on last

MAN

key

Ext. Input

not used

The pulse period source can be selected from internal oscillator, internal

PLL, and external CLK-IN:

If you have to trigger after an external event, use the startable

oscillator (

internal Osc.

), which starts on the external signal with a

fixed latency.

If you do not have to trigger but need a high accuracy frequency, then

use the

For even more accuracy, you can use the external CLK-IN.

internal PLL

clock generation circuitry.

In triggered/gated mode the internal PLL can be used as an arming

source. However, the internal PLL cannot be used as pulse and arming

source at the same time.

The following sections explain the individual mode combinations in

more detail. For each combination of trigger mode and pulse mode,

typical timing diagrams are provided, showing single and double pulses.

45

Page 46

Using the Agilent 81101A

The Mode/Trigger Screen

Continuous Pulses Mode

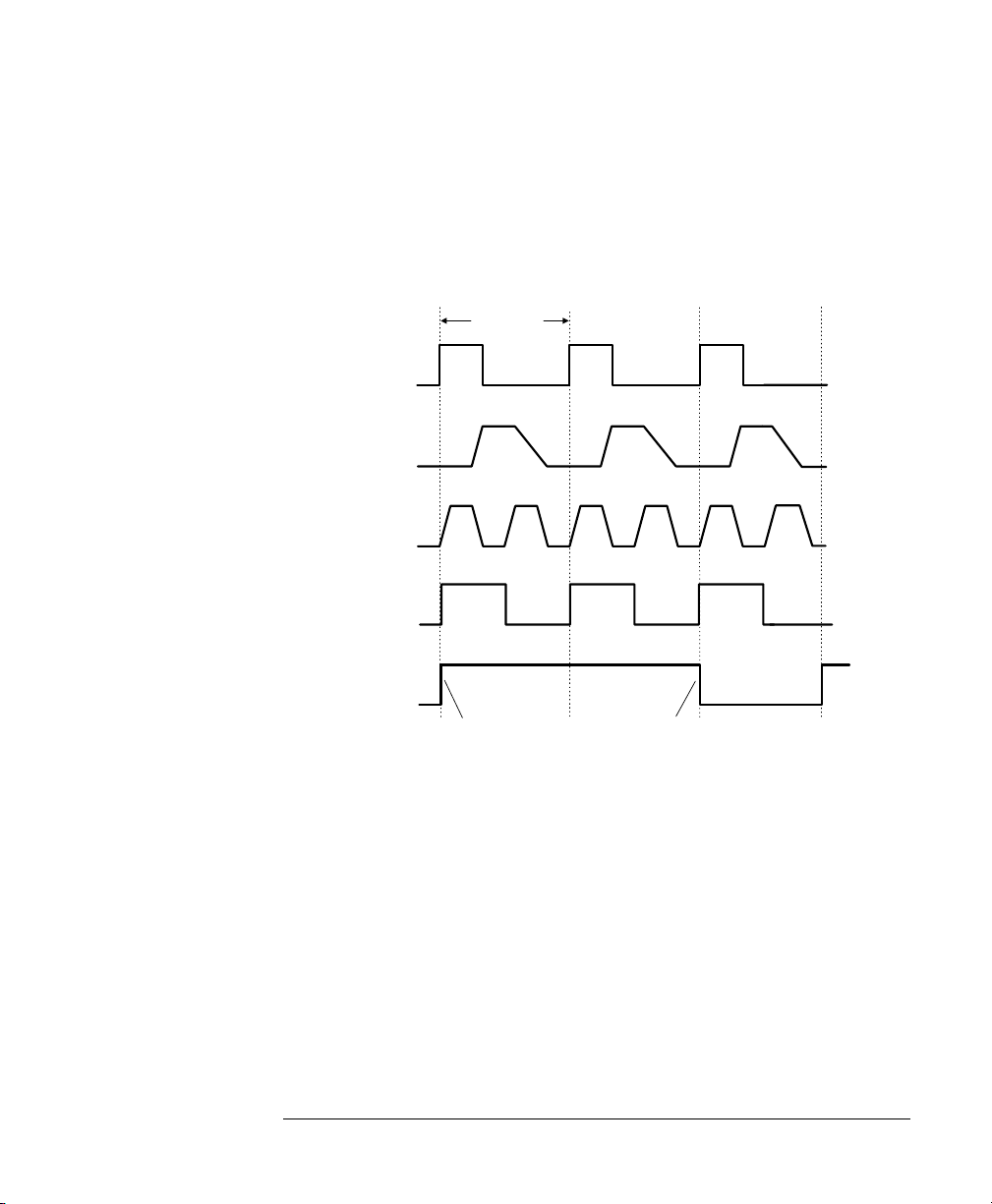

The following figure shows typical timings for trigger mode

CONTINUOUS and pulse mode PULSES.

Period Source

int Osc, int PLL or Ext Clock

TRIGGER OUT

OUTPUT

Single Pulse

OUTPUT

Double Pulse

Period

Characteristics

NOTE

Pulse periods are generated continuously.

You can select single pulses or double pulses per pulse period.

For the pulse period source you can select from

internal Osc (VFO)

internal PLL (higher accuracy)

external CLK-IN (external signal), synchronize to rising or falling

edge

TRIGGER OUT marks each pulse period.

STROBE OUT is not used in continuous pulse mode.

46

Page 47

Using the Agilent 81101A

The Mode/Trigger Screen

Continuous Burst Mode

The following figure shows typical timings for trigger mode

CONTINUOUS and pulse mode BURST.

Burst of 3

Period

Period Source

int Osc, int PLL or Ext Clock

OUTPUT

Single Pulse

OUTPUT

Double Pulse

TRIGGER OUT

Characteristics

STROBE OUT

1st period

A burst of pulse periods is repeated continuously.

You can select the number of pulse periods per burst in the range of

last period

265536.

You can select single pulses or double pulses per pulse period.

For the pulse period source you can select from

internal Osc (VFO)

internal PLL (higher accuracy)

external CLK-IN, synchronize to rising or falling edge.

TRIGGER OUT marks each pulse period.

STROBE OUT rises at the start of the first pulse period in a burst, and

falls at the start of the last pulse period.

47

Page 48

Using the Agilent 81101A

The Mode/Trigger Screen

Triggered Pulses Mode

The following figure shows typical timings for trigger mode TRIGGERED

and pulse mode PULSES. The pulses are triggered by the rising edge of

the arming source.

Arming Source

Trg'd by: Ext Input or MAN Key

TRIGGER OUT

OUTPUT

Single Pulses

OUTPUT

Double Pulses

Trg'd by:

Characteristics

NOTE

STROBE OUT

Single pulse periods are triggered by (T

RG'D BY

) an active edge at the

selected arming source:

MAN key on front panel, triggered by press or release or both.

EXT INPUT triggered by rising or falling or both edges.

You can select single pulses or double pulses per pulse period.

TRIGGER OUT marks each pulse period.

STROBE OUT is not used in triggered pulse mode.

The PLL cannot be selected as the arming source. Select continuous

pulse mode with the PLL as period source to achieve the same result.

48

Page 49

Using the Agilent 81101A

The Mode/Trigger Screen

In contrast to the previous figure, this figure shows a timing diagram

where the pulses are triggered by both rising and falling edges of the

arming source.

Trg'd by:

Arming Source

(Trg'd by:)

Ext INPUT or MAN Key

OUTPUT

Single Pulses

OUTPUT

Double Pulses

TRIGGER OUT

STROBE OUT

Minimum Width

49

Page 50

Using the Agilent 81101A

The Mode/Trigger Screen

Triggered Burst Mode

The following figures show typical timings for trigger mode TRIGGERED

and pulse mode BURST. The bursts are triggered by the rising edge of the

arming source.

For the first example, the synchronously triggerable internal oscillator is

used to source the period.

Characteristics

Trg'd by:

ARMING SOURCE

(Trg'd by:) EXT INPUT

or MAN Key

or PLL

PERIOD SOURCE

internal Osc.

OUTPUT

Single Pulses

OUTPUT

Double Pulses

TRIGGER OUT

STROBE OUT

A burst of pulse periods is triggered by an active edge at the selected

Period

1st period

Burst of 3

last period

Oscillator starts synchronously

1st period

arming source

MAN key on front panel, triggered by press or release or both.

EXT INPUT triggered by rising or falling or both edges.

PLL (internally triggered bursts)

When using the internal PLL as the arming source, you must specify

the triggering period.

You can select the number of pulse periods per burst in the range of

265536.

You can select single pulses or double pulses per pulse period.

50

Page 51

Using the Agilent 81101A

The Mode/Trigger Screen

TRIGGER OUT marks each pulse period.

STROBE OUT rises at the start of the first pulse period in a burst and

falls at the start of the last pulse period.

NOTE

For the second example, either the internal PLL or an external CLK-IN

or MAN Key

OUTPUT

Single Pulses

OUTPUT

Double Pulses

Trg'd by:

Period

1st period

PLL/CLK-IN NOT synchronous to EXT INPUT

DELAY = n * Period, 1 < n ≤ 2

Burst of 3

last period

1st period

are used to source the periodboth cannot be triggered synchronously.

ARMING SOURCE

(Trg'd by:) EXT INPUT

PERIOD SOURCE

internal PLL or CLK-IN.

TRIGGER OUT

STROBE OUT

You cannot use the PLL as both pulse period source and arming

(T

RG'DBY

) source at the same time.

51

Page 52

Using the Agilent 81101A

The Mode/Trigger Screen

Gated Pulses Mode

The following figures show typical timings for trigger mode GATED and

pulse mode PULSES.

For the first example, the synchronously triggerable internal oscillator is

used to source the period.

Characteristics

Gated by:

ARMING SOURCE

(Gated by:) EXT INPUT

or MAN Key

Period

PERIOD SOURCE

internal Osc

OUTPUT

Single Pulses

OUTPUT

Double Pulses

TRIGGER OUT

STROBE OUT

Pulse periods are gated by (enabled by) an active level at the selected

Oscillator starts synchronously

arming source:

MAN key on the front panel, gated while pressed or released or

both.

EXT INPUT (external signal) gated by high, low or both levels.

You can select single pulses or double pulses per pulse period.

TRIGGER OUT marks each pulse period.

STROBE OUT is not used in gated pulses mode.

52

Page 53

Using the Agilent 81101A

The Mode/Trigger Screen

For the second example, either the internal PLL or an external CLK-IN

are used to source the periodboth cannot be triggered synchronously.

ARMING SOURCE

(Gated by:) EXT INPUT

or MAN Key

PERIOD SOURCE

internal PLL or CLK-IN

OUTPUT

Single Pulses

OUTPUT

Double Pulses

TRIGGER OUT

STROBE OUT

Gated by:

Period

PLL/CLK-IN NOT Synchronous to EXT INPUT

DELAY = n * Period, 1 < n ≤ 2

53

Page 54

Using the Agilent 81101A

The Mode/Trigger Screen

Gated Burst Mode

The following figures show typical timings for trigger mode GATED and

pulse mode BURST.

For the first example, the synchronously triggerable internal oscillator is

used to source the period.

Characteristics

Gated by:

ARMING SOURCE

(Gated by:) EXT INPUT

or MAN Key

PERIOD SOURCE

internal Osc.

OUTPUT

Single Pulses

OUTPUT

Double Pulses

TRIGGER OUT

STROBE OUT

1st period

Bursts of pulse periods are gated by (enabled by) an active level at

Period

Oscillator starts synchronously

Burst of 3

last period

1st period

last period

the selected arming source:

MAN key on the front panel, gated while pressed or released or

both.

EXT INPUT (external signal) gated by high, low or both levels.

You can select single pulses or double pulses per pulse period.

TRIGGER OUT marks each pulse period.

STROBE OUT rises at the start of the first pulse period in a burst and

falls at the start of the last pulse period.

54

Page 55

Using the Agilent 81101A

The Mode/Trigger Screen

For the second example, either the internal PLL or an external CLK-IN

are used to source the periodboth cannot be triggered synchronously.

ARMING SOURCE

(Gated by:) EXT INPUT

or MAN Key

PERIOD SOURCE

internal PLL. or CLK-IN

OUTPUT

Single Pulses

OUTPUT

Double Pulses

TRIGGER OUT

STROBE OUT

Gated by:

Period

1st period

PLL/CLK-IN NOT Synchronous to EXT INPUT

DELAY = n * Period, 1 < n

Burst of 3

last period

2

≤

1st period

last period

External Width Mode

In external width mode, the pulse width is determined by an external

signal. You can choose between:

MANK

: Pressing the key generates a leading edge, releasing the key

EY

generates a trailing edge.

EXT-IN: A rising edge at the EXT INPUT generates a leading edge, a

falling edge generates a trailing edge.

The threshold and impedance of the EXT INPUT can be set on the

Trigger Level screen.

The period, delay, and width of the output pulse are not programmable in

this mode, because they are determined by the external signal.

The TRIGGER OUT rises and falls parallel to the OUTPUT signal.

55

Page 56

Using the Agilent 81101A

The Output Screen

The Output Screen

The Output screen shows both timing and level parameters on one

screen.

To access the Output screen, press the OUTPUT softkey.

Timing Parameters

You can use the left part of the Output screen to view and control the

pulse timing parameters.

NOTE

1.000

Per

Delay

Width

LeadE

TraiE

0ps

100.0ns

5.00ns

=LeadE

µµµµ

s Normal OFF

Offset

Amplit

50

ΩΩΩΩ

+0.0mV

1.00V

into 50.0

1

*Period

Frequency

ΩΩΩΩ

MODIFY

OUTPUT TRG-LEVLIMITSMODE/TRG

The individual timing parameters are described in more detail in the

following. All parameters can be entered in different formats.

With the Agilent 81101A you can vary timing parameters without the risk

of glitches or drop outs, which could cause measurement errors. This

applies to continuous mode with timing values < 100 ms (frequency

< 10 Hz), and consecutive values between one-half and twice the

previous value.

56

Page 57

Using the Agilent 81101A

The Output Screen

When you press SHIFT + MORE (GRAPH) while one of the timing parameters is

selected, you will see a graphical representation of the timing

parameters. The currently selected parameter is displayed in the Modify/

Enter area and is indicated by dashed or bold lines in the graphical

display.

1

OFF

NOTE

Width1

100.0

ns

OUTPUT TRG-LEVLIMITSMODE/TRG

1

OFF

PERIOD

1.000

µµµµ

s

OUTPUT TRG-LEVLIMITSMODE/TRG

Use the left/right cursor keys to toggle between the individual timing

parameters.

Note that in graphics mode you can only adjust the values of each

parameter, not the parameter format. If you want to change the format of

a parameter, for example W

select the parameter name with the cursor.

Pulse Period Parameter

to DTYCYC, you must be in text mode to

IDTH

Set the pulse period as either P

If you select the CLK-IN as the pulse period source on the Mode/Trigger

screen, the pulse period/frequency is determined from the signal applied

to the CLOCK/REF INP. connector:

M

EAS ONCE

The external signal is measured only once. Press ENTER to measure

again.

ERIOD

or F

REQUENCY

.

57

Page 58

Using the Agilent 81101A

The Output Screen

Pulse Delay Parameter

Delay the leading edge of the pulse within the pulse period. There are

three delay formats available:

M

EAS CONT

The external signal is continuously measured until the instrument

receives a command via GP-IB.

To invoke continuous measurements again, you have to bring the

instrument in local operating mode by pressing SHIFT (LOCAL) and start

continuous measurement again.

D

or DBLDEL (select A

ELAY

D

is the absolute delay from the start of a pulse period to the

ELAY

BSOLUTE

)

start of the leading edge of the pulse.

If double pulses are selected on the Mode/Trigger screen, the D

BLDEL

parameter specifies the delay between the first and second pulse in

each pulse period.

The absolute delay is independent of the pulse period. So the leading

edge does not move relative to the start of the period if you change

the period.

D

% (select % OF P

ELAY

ERIOD

)

The delay from the start of the pulse period to the start of the leading

edge expressed as a percentage of the pulse period. In this format, if

you change the period, the leading edge moves relative to the start of

the period in order to maintain the percentage delay.

P

HASE

(select P

HASE

)

The phase delay in degrees from the start of the pulse period to the

start of the leading edge (360° = 1 pulse period). In this format, if you

change the period, the leading edge moves relative to the start of the

period in order to maintain the phase delay.

58

Page 59

Using the Agilent 81101A

The Output Screen

Pulse Width Parameter

Set the width of the output pulse. There are three width formats

available:

W

(select W

IDTH

The absolute pulse width measured from the start of the leading edge

to the start of the trailing edge. In this format, the pulse width is

independent of changes in pulse period and delay.

IDTH

)

NOTE

D

TYCYC

(select D

UTYCYCLE

)

The duty cycle is the pulse width measured from the start of the

leading edge to the start of the trailing edge expressed as a

percentage of the period. In this format, if you adjust the period, the

absolute width is adjusted to maintain the duty cycle.

T

RADEL

(select T

RAILDEL

)

The trailing delay is the absolute delay from the start of the pulseperiod to the start of the trailing edge. In this format the trailing edge

remains fixed relative to the start of the pulse period if you adjust the

pulse delay (leading edge delay) or the pulse period.

You cannot have the width format set to D

edge format set to percentage of width (L

EADED

and the leading/trailing-

TYCYC

%/T

E%) at the same

RAIL

time.

Leading Edge Parameter

Set the leading edge transition time of the pulse, measured from 10% to

90% of the pulse amplitude. There are two formats available:

L

E (select A

EAD

BSOLUTE

The absolute transition time measured from 10% to 90% of the pulse

amplitude. In this format the leading edge is independent of the pulse

width.

)

L

E% (select % OF WID)

EAD

The absolute transition time expressed as a percentage of the pulse

width. In this format, if you adjust the pulse width, the transition time

is adjusted to maintain the edge time as a percentage of the width.

59

Page 60

Using the Agilent 81101A

The Output Screen

NOTE

NOTE

The leading and trailing edges are independently programmable within

certain ranges only, see Transition Times in the Reference Guide.

You cannot have the width format set to D

edge format set to percentage of width (L

EAD

and the leading/trailing-

TYCYC

E%/T

E%) at the same

RAI

time.

Pulse Trailing Edge Parameter

Set the trailing edge transition-time of the pulse, measured from 10% to

90% of the pulse amplitude. There are three formats available:

=L

E (select =L

EAD

The trailing edge transition time is coupled directly to the leading

edge to maintain a symmetrical pulse.

T

E (select A

RAI

BSOLUTE

The absolute transition time measured from 90% to 10% of the pulse

amplitude. In this format the trailing edge is independent of the

leading edge and the pulse width.

T

E% (select % OF WID)

RAI

The trailing edge transition time expressed as a percentage of the

pulse width. In this format, if you adjust the pulse width, the

transition time is adjusted to maintain the edge time as a percentage

of the width.

EAD

E)

)

NOTE

NOTE

The leading and trailing edges are independently programmable within

certain ranges only, see Transition Times in the Reference Guide.

You cannot have the width format set to D

edge format set to percentage of width (L

EAD

and the leading/trailing

TYCYC

E%/T

E%) at the same

RAI

time.

60

Page 61

Using the Agilent 81101A

The Output Screen

Level Parameters

You can use the right part of the Output screen to view and control the

pulse level parameters and to enable or disable the outputs.

Per 1.000

Delay1 0ps

Width

LeadE

TraiE

The individual level parameters are described in more detail in the

following. All parameters can be entered in different formats.

When you press SHIFT + MORE (GRAPH) while one of the level parameters is

selected, you will see a graphical representation of the level parameters.

The currently selected parameter is displayed in the Modify/Enter area

and is indicated in the graphical display.

1

OFF

µµµµ

s Normal

100.0ns

5.00ns

=LeadE

OUTPUT TRG-LEVLIMITSMODE/TRG

+11V

Offset

Amplit

ΩΩΩΩ

50

into 50.0

OFF

+0.0mV

1.00V

ΩΩΩΩ

MODIFY

*OFF

ON

Amplitude1

1.00

-11V

V

OUTPUT TRG-LEVLIMITSMODE/TRG

When output limits are on, the limits are indicated on the Output screen

in graphics mode (see The Limits Screen on page 64).

61

Page 62

Using the Agilent 81101A

The Output Screen

NOTE

NOTE

NOTE

Note that in graphics mode you can only adjust the values of each

parameter, not the parameter format. If you want to change the format of

a parameter, for example O

FFS-AMPL

to H

IGH-LOW

, you must be in text

mode to select the parameter name with the cursor.

When the output is switched on, the instrument monitors the actual

voltage and current levels at the output. The output is automatically

switched off if voltage levels or power dissipation reach levels which

could damage the output circuits.

Normal/Complement Parameter

Switch the output between normal and complement mode:

N

ORMAL

Pulse leading edge rises from low to high level, trailing edge falls from

high to low level.

C

OMPLMNT

Pulse leading edge falls from high to low level, trailing edge rises from

low to high level.

This parameter is only available in text mode.

Offset/Amplitude, High/Low Level Parameters

Set and display the pulse levels in terms of either offset and amplitude, or

high and low level. You can quickly set TTL or ECL output levels using

the S

TTL and SET ECL formats.

ET

S

TTL

ET

Select high and low level formats and automatically set the levels to

the default TTL levels:

TTL-HI: +2.50 V

TTL-LOW: +0.0 mV

The default levels are set once and can be adjusted afterwards by

moving the entry focus to the values as normal.

H

IGH-LOW

Select high and low level format for the pulse levels.

62

Page 63

Using the Agilent 81101A

The Output Screen

O

FFS-AMPL

Select offset and amplitude format for the pulse levels. Offset is

measured from 0V to the middle of the pulse amplitude. Pulse

amplitude is the difference between the high and low levels of the

pulse.

S

ECL

ET

Select high and low level format and automatically set the levels to

the default ECL levels:

ECL-HI: 850 mV

ECL-LOW: 1.80 V

These default levels are set once and can be adjusted afterwards by

moving the entry focus to the value as normal.

Voltage/Current Mode (mV/V/mA/A)

Move the entry focus onto the level units to select between setting the

pulse levels

IN VOLTS

or IN A

MPERES

.

NOTE

NOTE

NOTE

This parameter is only available in text mode.

Output Source Impedance Parameter (50Ω into)

Select an output source impedance of 50 Ω or 1 kΩ.

This parameter is only available in text mode

Load Impedance Parameter (50.0Ω)

Adjust the load impedance value expected at the output to compensate

for non-50Ω loads. The displayed level parameters are then calculated

using this value and therefore represent the levels at a non-50Ω static

load.

This parameter is only available in text mode.

63

Page 64

Using the Agilent 81101A

The Limits Screen

The Limits Screen

Use the Limits screen to set up voltage and current limits for the pulse

level parameters to prevent accidental damage of the device under test.

To access the Limit screen, press the LIMIT softkey.

Limits OFF

1

High-V +500mV

Low-V -500mV

High-A +10.0mA

Low-A -10.0mA

OUTPUT TRG-LEVLIMITSMODE/TRG

After you switch on the limits, the pulse level parameters on the OUTPUT

screen cannot be adjusted outside the ranges specified on the LIMITS

screen if the output is switched on. Note that because current and

voltage limits apply, the available ranges of the impedance parameters

are also affected.

When output limits are on, the limits are indicated on the OUTPUT screen

in graphics mode, and the level bar is scaled accordingly:

+1V

1

OFF

MODIFY

*OFF

ON

Amplitude1

500

-1V

mV

64

OUTPUT TRG-LEVLIMITSMODE/TRG

Page 65

Using the Agilent 81101A

The Trigger-Level Screen

The Trigger-Level Screen

Use the Trigger-Level screen to

set the triggering threshold and input impedance for the EXT INPUT

connector,

set the triggering threshold and input impedance for the

CLOCK/REF INP. connector,

set the output levels for the STROBE OUT and TRIGGER OUT

connectors.

To access the Trigger-Level screen, press the TRG-LEV softkey.

EXT-IN: Threshold

+1.0V 50

CLK-IN: Threshold +1.0V 50

ΩΩΩΩ

ΩΩΩΩ

MODIFY

Set TTL

Set ECL

TRIGGER-OUT: TTL

*Voltage

STROBE-OUT : TTL

OUTPUT TRG-LEVLIMITSMODE/TRG

Threshold and Impedance Parameters

You can individually specify threshold and input impedance of the EXTIN and the CLK-IN connectors.

EXT-IN and CLK-IN Threshold Parameters

Move the entry focus to EXT-IN or CLK-IN to quickly set the triggering

threshold of the external input or the clock input to a TTL- or ECLcompatible level:

65

Page 66

Using the Agilent 81101A

The Trigger-Level Screen

S

Set the input threshold to +2.5 V.

You can adjust the threshold by moving the entry focus to the value.

S

Set the input threshold to 1.3 V.

You can adjust the threshold by moving the entry focus to the value.

V

Set any threshold level in the range of 10.0 V to +10.0 V. Move the

entry focus to the value to adjust it.

EXT-IN and CLK-IN Impedance Parameters

Toggle the input impedance of the external input connector or the clock

input connector between 50Ω and 10 kΩ.

Trigger and Strobe Level Parameters

TTL

ET

ECL

ET

OLTAGE

You can individually set the output levels of the TRIGGER OUT

connector and the STROBE OUT connector.

Set the output levels (into 50 Ω) to

TTL

High level: +2.50 V

Low level: 0 V

ECL

High level: 0.85 V

Low level: 1.80 V

66

Page 67

Using the Agilent 81101A

The Memory Card Screen

The Memory Card Screen

Use the Memory Card screen to

store instrument settings to the memory card,

recall instrument settings from the memory card,

delete files from the memory card,

format a memory card.

To access the Memory Card screen, press the MEMCARD softkey. If the

MEMCARD softkey is not displayed, press MORE.

Dir Path \

Filename TESTVI.TXT

MODIFY

*BURSTS

PULSES

Perform Operation

TRG-LEV CONFIGMEMCARDMODE/TRG

Directory Path Parameter

Move the entry focus to DIR P

card, or to view the sub-directories of the current directory (the name of

the current directory is displayed next to D

All sub-directories of the current directory are listed in the Modify/Enter

area.

To change the directory, turn the knob to select the directory name and

press the ENTER key.

Note that when you are in a sub-directory you can return to the parentdirectory by selecting .. from the directory list.

to change the directory on the memory

ATH

IR PATH

).

67

Page 68

Using the Agilent 81101A

The Memory Card Screen

Filename Parameter

CAUTION

Move the entry focus to the F

ILENAME

parameter to select a file from the

current directory. Use the knob to scroll through the filenames listed in

the Modify/Enter area.

Memory Card Operations

Move the entry focus to P

ERFORM OPERATION

the required operation. Press the ENTER key to perform the operation.

R

EADCARD

Read the DOS file system information from the memory card after

inserting a new card.

R

ECALL

Recall the selected file as the current instrument setting.

S

TORE

Store the current instrument setting to the memory card.

Press ENTER once to start editing the filename for the setting in the

Modify/Enter area. The currently selected filename is used as default.

If you do not modify the filename, the existing file will be overwritten

when you press ENTER.