Page 1

Operating Manual

Agilent 7673 Automatic Liquid Sampler

Page 2

© Agilent Technologies 1995-2000

Target® is a registered trademark and DP™ is a

trademark of National Scientific Company.

HP-UX™ is a registered trademark of the

Hewlett-Packard Company.

All Rights Reserved.

Reproduction, adaptation, or translation without

permission is prohibited, except as allowed under

the copyright laws.

Part number G1513-90107

First edition, MAY 2000

Printed in USA

Safety Information

The Agilent Automatic Liquid Sampler meets the

following IEC (International Electrotechnical

Commission) classifications: Safety Class 1,

Transient Overvoltage Category II, and Pollutions

Degree 2. This unit has been designed and tested

in accordance with recognized safety standards

and designed for use indoors. Whenever the safety

protection of the Automatic Liquid Sampler has

been compromised, disconnect the unit from all

power sources and secure the unit against

unintended operation.

The recyclable carbon mono-fluoride lithium

battery is a BR-2/3 A 1,2OO mAh. Fuses F001 and

F002 are 3 A, 250 Vac, IEC 127 Type T. Fuses

F201 and F202 are 10 A, 250 Vac, IEC 127 Type

T. Fuse F101 is a 0.5 A, 250 Vac.

Warnings in this manual or on the instrument must

be observed during all phases of operation, service,

and repair of this instruments. Failure to comply

with these precautions violates safety standards

of design and the intended use of the instrument.

Agilent Technologies assumes no liability for the

customer’s failure to comply with these

requirements. Refer servicing to qualified service

personnel. Substituting parts or performing any

unauthorized modification to the instrument may

result in a safety hazard. Disconnect the AC power

cord before removing covers. The customer should

not attempt to replace the battery or fuses in this

instrument.

Safety Symbols

This manual contains safety information that

should be followed by the user to ensure safe

operation.

WARNING

A warning calls attention to a condition or possible

situation that could cause injury to the user.

CAUTION

A caution calls attention to a condition or possible

situation that could damage or destroy the product

or the user’s work.

Sound Emission Certification for Federal

Republic of Germany

If Test and Measurement Equipment is operated

with unscreened cables and/or used for

measurements in open set-ups, users have to

assure that under these operating conditions the

Radio Interference Limits are still met at the border

of their premises.The following information is

provided to comply with the requirements of the

German Sound Emission Directive dated

January 18, 1991:

Sound pressure Lp < 70db(A)

During normal operation

At the operator position

According to ISO 7779 (Type Test)

When operating the Automatic Liquid Sampler with

cryo valve option, the sound pressure ≈ 78 db(A)

during cryo valve operation for short burst pulses.

Schallemission

Werden Meß-und Testgeräte mit ungeschirmten

Kabeln und/oder in offenen Meßaufbauten

verwendet, so ist vom Betreiber sicherzustellen,

daß die Funk-Entströbedingungen unter

Betriebsbedingungen an seiner Grundstücksgrenze

eingehalten werden. Diese Information steht im

Zusammenhang mit den Anforderungen der

Maschinenlärminformation sverordnung vom

18 Januar 1991.

Schalldruckpegel LP < 70 dB(A)

Am Arbeitsplatz

Normaler Betrieb

Nach DIN 45635 T. 19

(Typprüfung)

Bei Betrieb des Automatischer

Slüssigkeitsprobengeber mit Cryo Ventil Option

treten beim Oeffnen des Ventils impulsfoermig

Schalldrucke Lp bis ca. 78 dB(A) auf.

Agilent Technologies, Inc.

2850 Centerville Road

Wilmington, DE 19808-1610

USA

Page 3

Contents

Chapter 1 Setting Up

The modules of the automatic liquid sampler ....................................................... 3

Preparing the site ...................................................................................................... 5

Installing the injectors ..............................................................................................7

Installing the tray .....................................................................................................13

Installing the controller .......................................................................................... 17

Environmental considerations ......................................................................... 5

Space considerations ........................................................................................ 5

Electrical power requirements ........................................................................6

Connecting the controller power cord ...........................................................7

Behind the door to the control switches ........................................................9

Before you start ............................................................................................... 10

Mounting the injectors .................................................................................... 11

Checking your work ........................................................................................13

Before you start ............................................................................................... 14

Mounting the tray ............................................................................................ 15

Checking your work ........................................................................................16

Connecting cables to other instruments ...................................................... 18

Setting the configuration switches ................................................................19

Configuration switch definitions ................................................................... 19

Connecting the injector cables ......................................................................21

Connecting the tray cable ...............................................................................22

Connecting the controller power cord .........................................................22

Checking your work ........................................................................................23

Chapter 2 Preparing for Operation

Preparing sample vials ............................................................................................ 26

Selecting and labeling sample vials ...............................................................26

Specifications ...................................................................................................27

Sample caps and septum ................................................................................ 28

Filling sample vials .......................................................................................... 29

Crimp capping sample vials ........................................................................... 30

Placing sample vials in the standard injector turret ...................................32

Placing sample vials in a tray .........................................................................33

Using the injector fan .............................................................................................. 34

Turning the fan off ........................................................................................... 34

Preparing the solvent and waste bottles .............................................................. 36

Selecting the bottles ........................................................................................ 36

i

Page 4

Contents

Filling and placing the bottles ........................................................................37

Do you need to read further? .........................................................................40

Estimating the maximum number of sample vials ......................................42

Controlling sample carryover .........................................................................47

Selecting and installing syringes ............................................................................49

Selecting syringes ............................................................................................49

Inspecting syringes ..........................................................................................51

Installing syringes ............................................................................................52

Checking your work ........................................................................................53

Maintaining the inlet ................................................................................................54

Changing septa .................................................................................................54

Changing or cleaning liners ............................................................................55

Suggestions for packed inlets with 530-µm columns ..................................55

Adapting for cool on-column injection .................................................................55

Chapter 3 Operation

Setting the run parameters .....................................................................................59

Description of the parameters .......................................................................59

Injection mode ...............................................................................................63

What happens during a run? ...................................................................................66

Checklist ...................................................................................................................68

Running the samples ...............................................................................................69

Starting a run or sequence ..............................................................................69

Stopping or interrupting a run or sequence ..................................................69

Using two injectors ..................................................................................................70

With a tray .........................................................................................................70

Without a tray ...................................................................................................72

Four methods of control .........................................................................................73

Examples of operation ............................................................................................74

Preparing the GC and controlling device ......................................................74

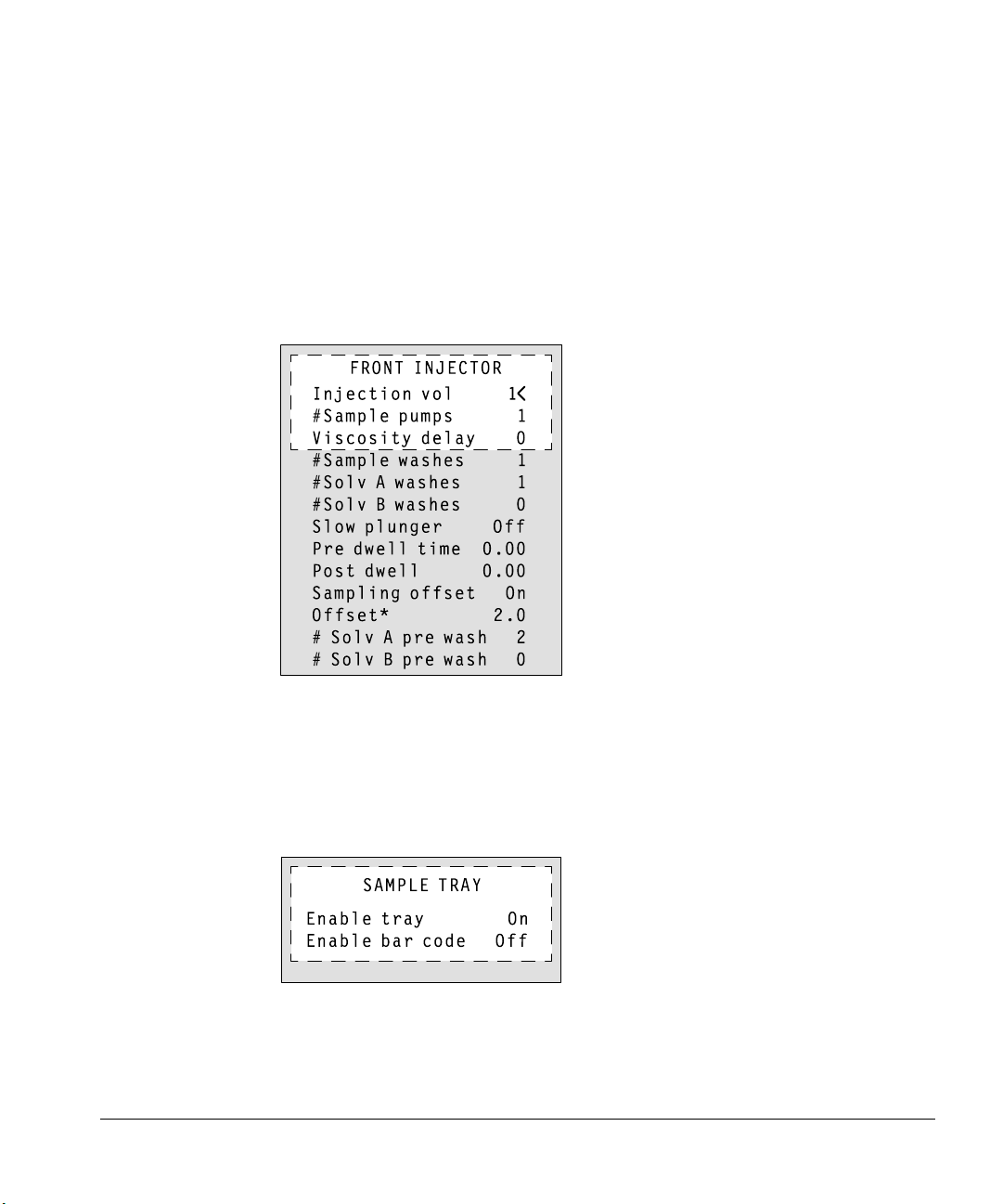

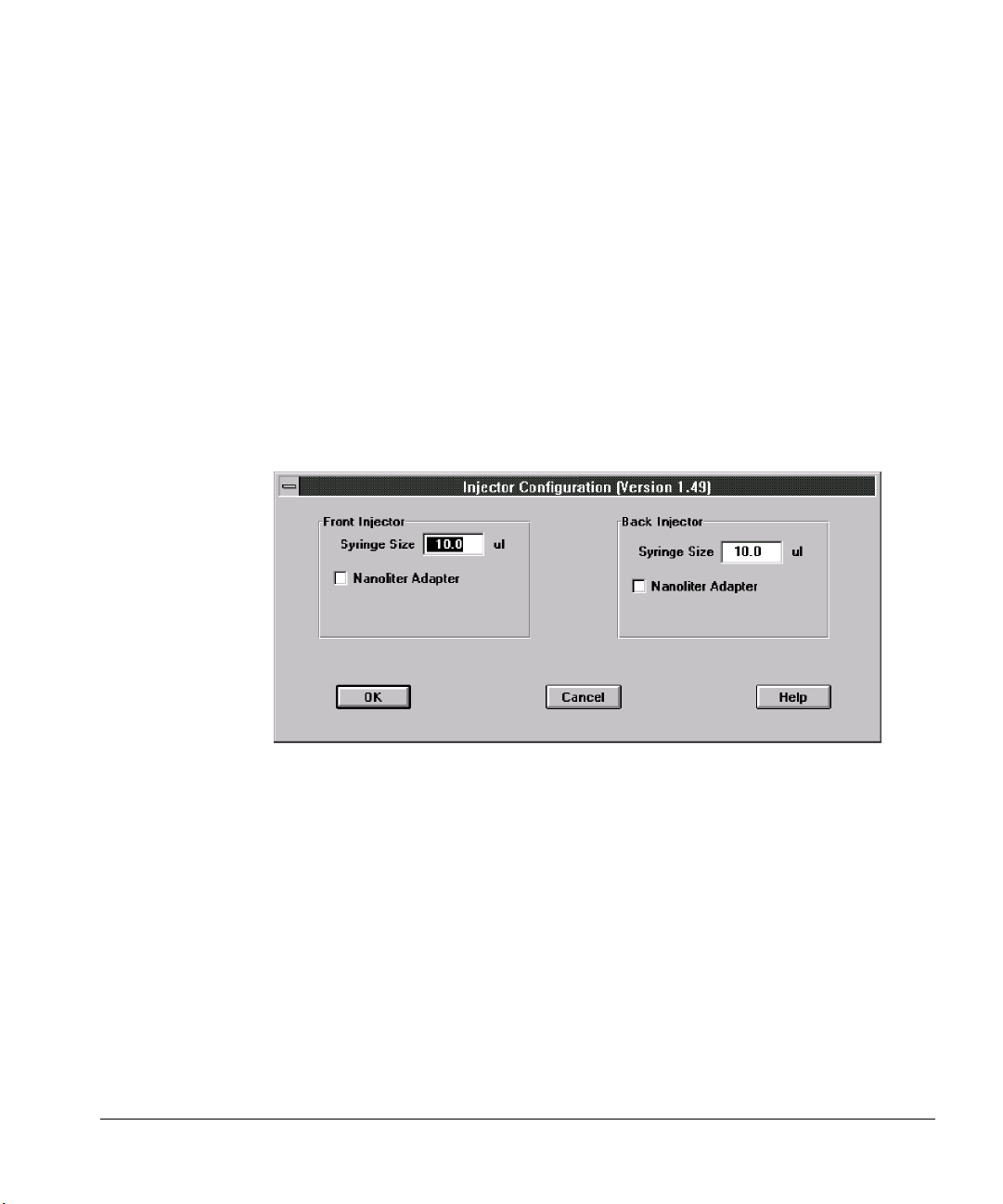

6890 Series GC Control ...........................................................................................75

Configure tower position ................................................................................75

Configure waste bottle position with a tray .................................................75

Configure the injector .....................................................................................75

Injector parameter setpoints ..........................................................................76

Sample tray setpoints ......................................................................................76

Storing injector setpoints ................................................................................77

Operating in cool on-column mode ...............................................................77

ii

Page 5

Contents

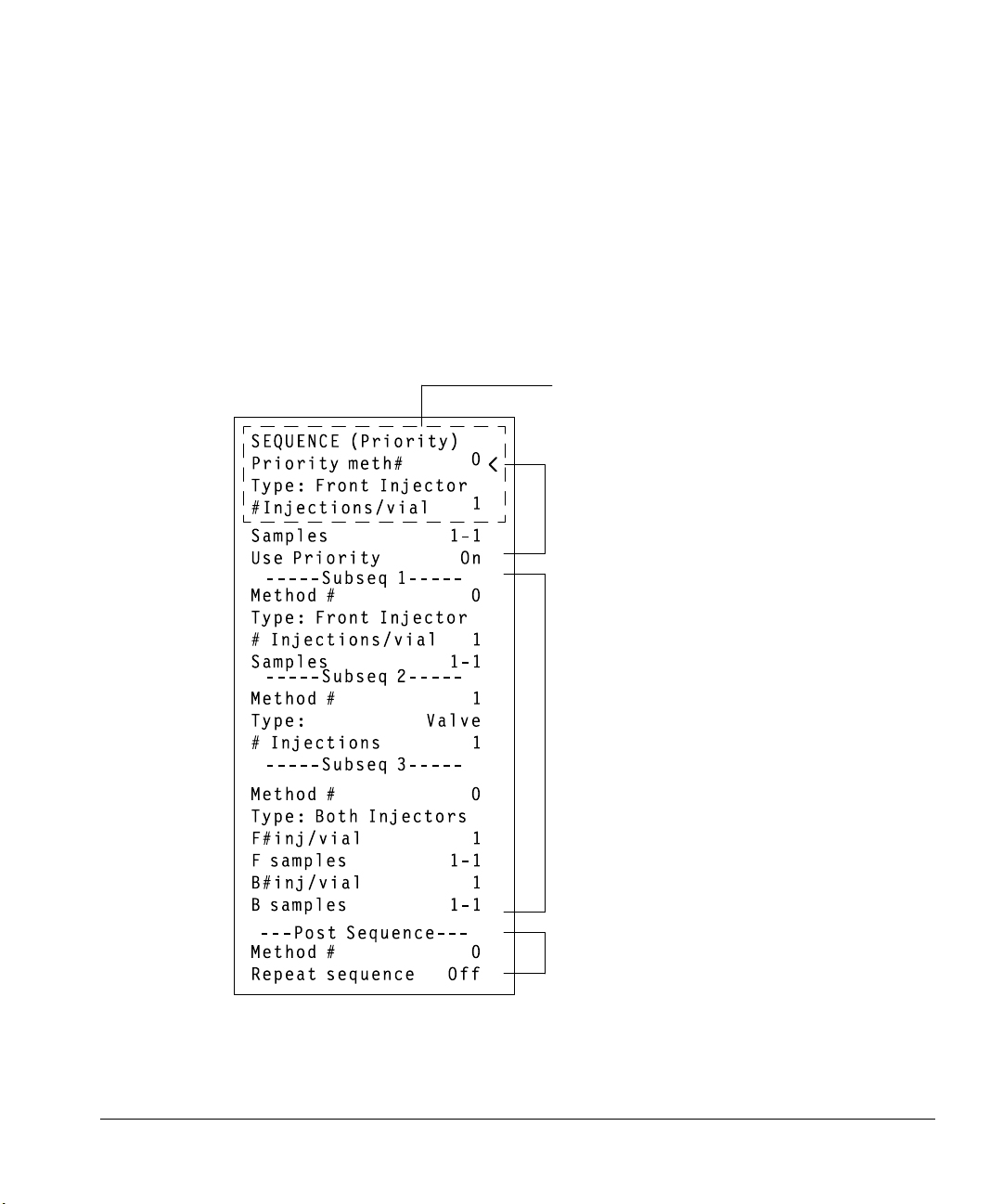

Creating a sequence ........................................................................................78

Storing a sequence ..........................................................................................79

Starting/running a sequence ...........................................................................80

Special considerations when using an integrator with a 6890 Series GC ........ 81

3396 integrator with a 5890 GC .............................................................................. 83

Checking your work ........................................................................................85

Multitechnique ChemStation control with a 6890

Series GC ..................................................................................................................86

Injector parameters ......................................................................................... 86

Washes .............................................................................................................. 87

Position .............................................................................................................87

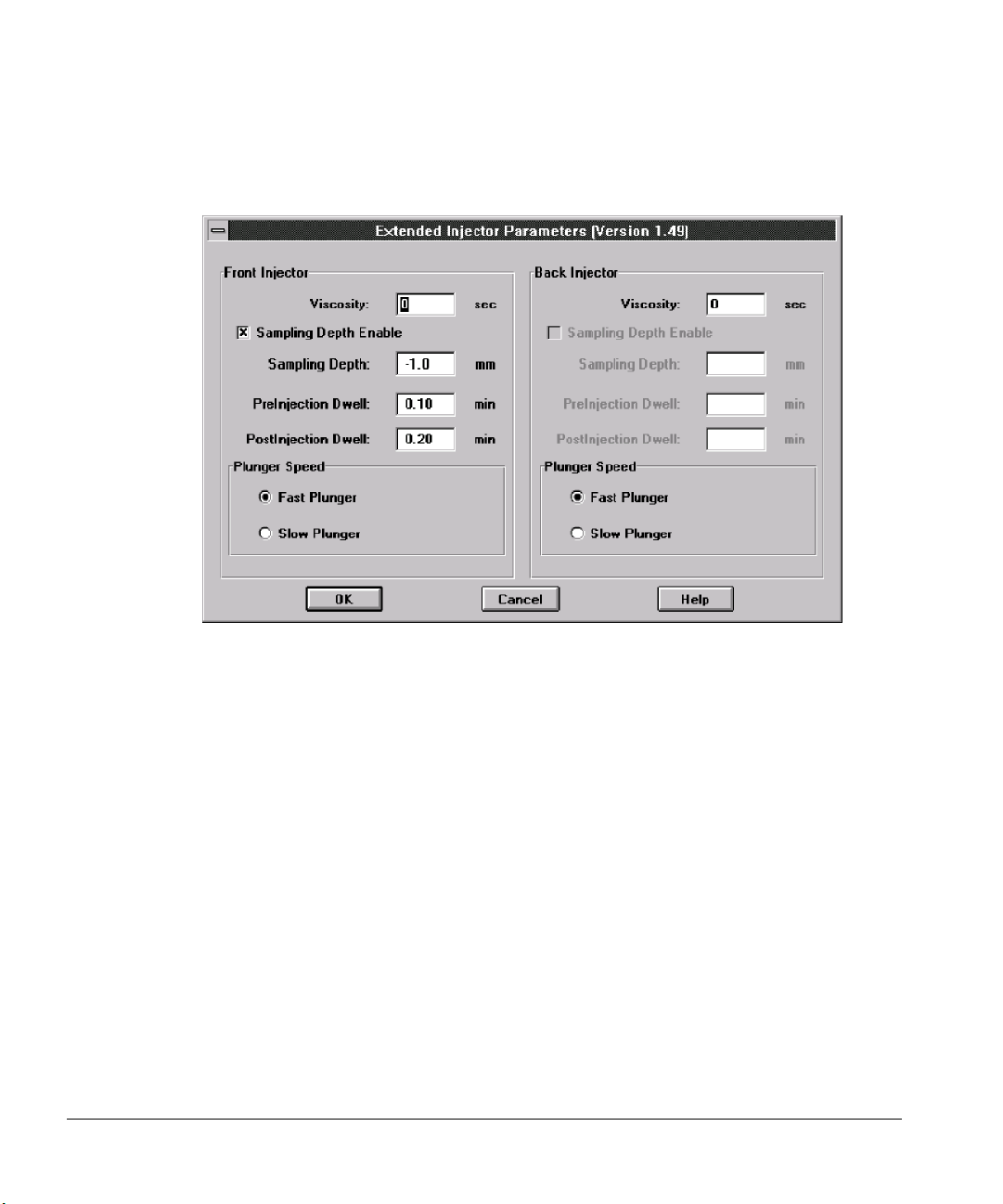

Extended Injector Parameters dialog box ...................................................88

Start a Run ........................................................................................................ 90

Start a sequence ...............................................................................................90

Chapter 4 Standalone Control

Setting the run parameters ..................................................................................... 92

Sample size ....................................................................................................... 95

Injection ............................................................................................................ 96

Number of injections per vial ........................................................................ 97

Number of sample prewashes ....................................................................... 98

On-column injection mode .............................................................................99

Number of solvent postwashes ...................................................................100

Example of setting the injector switches ................................................... 101

Setting the position of the last vial ..............................................................102

Running the samples ............................................................................................. 103

Starting a run or sequence ............................................................................ 103

What happens during a run? ........................................................................ 103

Stopping or interrupting a run or sequence ............................................... 104

Using two injectors ............................................................................................... 106

Synchronous mode ........................................................................................106

Asynchronous mode ..................................................................................... 107

Example of standalone control setup ................................................................. 109

Checking your work ..............................................................................................112

Standalone control ........................................................................................ 112

iii

Page 6

Contents

Chapter 5 Preventive Maintenance and Troubleshooting

Preventive maintenance ........................................................................................114

Regular basis (before you start a sequence ................................................114

Occasional basis .............................................................................................114

Turret exchange .............................................................................................115

Alignment procedure .....................................................................................116

Troubleshooting .....................................................................................................118

Bent syringe needle ...............................................................................................119

Dropped sample vial ..............................................................................................120

Chromatographic symptoms ................................................................................121

Variability ........................................................................................................121

Contamination or ghost peaks .....................................................................124

Peak area discrimination (smaller or larger peaks than expected) ........126

Sample carryover ...........................................................................................128

No signal/no peaks .........................................................................................129

Fault light symptoms .............................................................................................130

Fault light locations, colors, and patterns ..................................................131

Responding to the fault lights ......................................................................133

Power error .....................................................................................................133

Injector door open/not mounted ..................................................................134

Syringe error ...................................................................................................135

Turret error .....................................................................................................136

Plunger error ..................................................................................................137

Incomplete injection ......................................................................................138

Bottle in gripper .............................................................................................139

Hard tray/injector error .................................................................................140

Align LED is On ..............................................................................................141

Other patterns ................................................................................................142

Error messages ......................................................................................................145

Contacting Agilent Technologies .........................................................................147

Obtaining Agilent Technologies service .....................................................147

Shipment or storage ......................................................................................148

iv

Page 7

Contents

Chapter 6 Special Topics

Performing cool on-column injection onto 250-µm and 320-µm columns ..... 151

Installing the needle into the syringe barrel ..............................................151

Checking the needle-to-column size ........................................................... 152

Preparing the cool on-column inlet .............................................................153

Using retention gaps and other precolumns ..............................................158

Preparing the injector ................................................................................... 160

Replacing the needle guide in the needle support foot ............................ 165

Troubleshooting 250-µm and 320-µm systems ........................................... 167

Controlling sample vial temperatures ......................................................... 168

Tray control commands ................................................................................ 174

Glossary ...................................................................................... 182

Index ........................................................................................... 191

v

Page 8

Contents

vi

Page 9

1

Setting Up

Page 10

Setting Up

The purpose of this chapter is to:

• Introduce you to the names of the major parts associated with installing

• Help you set up the automatic liquid sampler and turn on the power.

You must complete the following tasks during installation to be ready to turn

on the power.

1. Install the mounting brackets for the injector and tray, along with any

2. Mount the injector and tray on the brackets.

3. Verify that the controller switch settings are correct.

4. Connect the cables for the injector and tray to the controller.

5. Connect the communication cables for the controller, the GC, and the data

the automatic liquid sampler and some preventive maintenance tips.

upgrade parts for the gas chromatograph (GC). Instructions for these

installations are contained in link manuals that are packaged with the

brackets or upgrade parts.

handling device.

6. Install the power cord for the controller.

The instructions for tasks 2 through 6 start on page 11.

2

Page 11

Setting Up

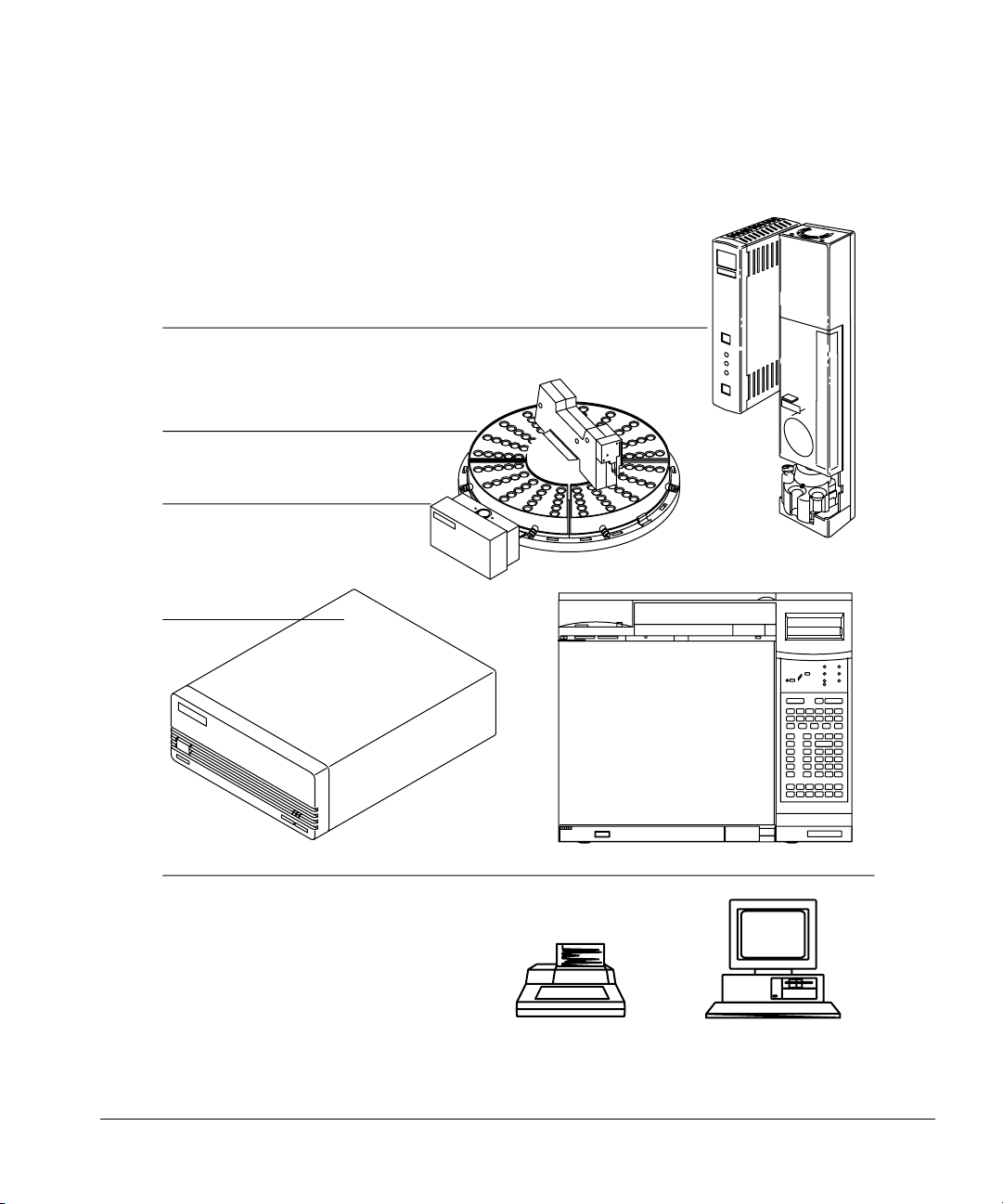

"6890" [type C] tower, tray and controller

The modules of the automatic liquid sampler

The modules of the automatic liquid sampler

The automatic liquid sampler is made up of three modules:

The G1512A controller and communications module supplies

power and communications to the injector and tray.

The G1513A injector module removes a volume of sample from

a vial and injects it into the inlet.

The 18596C tray module moves sample vials to and from the

injector and the bar code reader.

The automatic liquid sampler works with the PrepStation system to automate

sample preparation procedures. The G1296A/G1926A bar code reader module

is also available. It reads the vial numbers and special instructions for running

a method. It can also be used for agitating the sample vial.

The automatic liquid sampler becomes part of your gas chromatography

system. It introduces sample to an inlet or a column on your GC.

The automatic liquid sampler, with or without the tray, can be controlled by a

variety of integrators and computers, including:

• 6890 Series GC

• Its own electronics (standalone control)

• 3396 integrators plus older models

• Most Agilent laboratory automation systems

• Most Agilent ChemStation systems

• Suitably programmed external computers

3

Page 12

Setting Up

The modules of the automatic liquid sampler

Figure 1 illustrates how the automatic liquid sampler is an integral part of the

analytical system.

One or two injectors

With or without the tray

With or with out the bar

code reader

Controller

Controller configured to communicate with:

• 6890 Series GC

•Integrator

• Personal computer

• Workstation

• Lab data system

• Injector’s control switches

Figure 1. The automatic liquid sampler as part of your analytical system

4

Page 13

Setting Up

Preparing the site

Preparing the site

The automatic liquid sampler has certain environmental, space, and electrical

power requirements.

Environmental considerations

The automatic liquid sampler is designed to operate within ranges of

temperature and relative humidity.

• Temperature range: 0° to 55°C

• Relative humidity range: 5% to 95% at 40°C

• Altitude ranges: up to 2,300 m

Agilent Technologies recommends an environment comfortable for the

operators (reasonably constant temperature and humidity) for optimum

performance and instrument lifetime.

Caution Do not place any instruments that release heat on top of or underneath the

controller. For example, do not place an integrator on top of the controller.

The additional heat can cause damage to its electrical components.

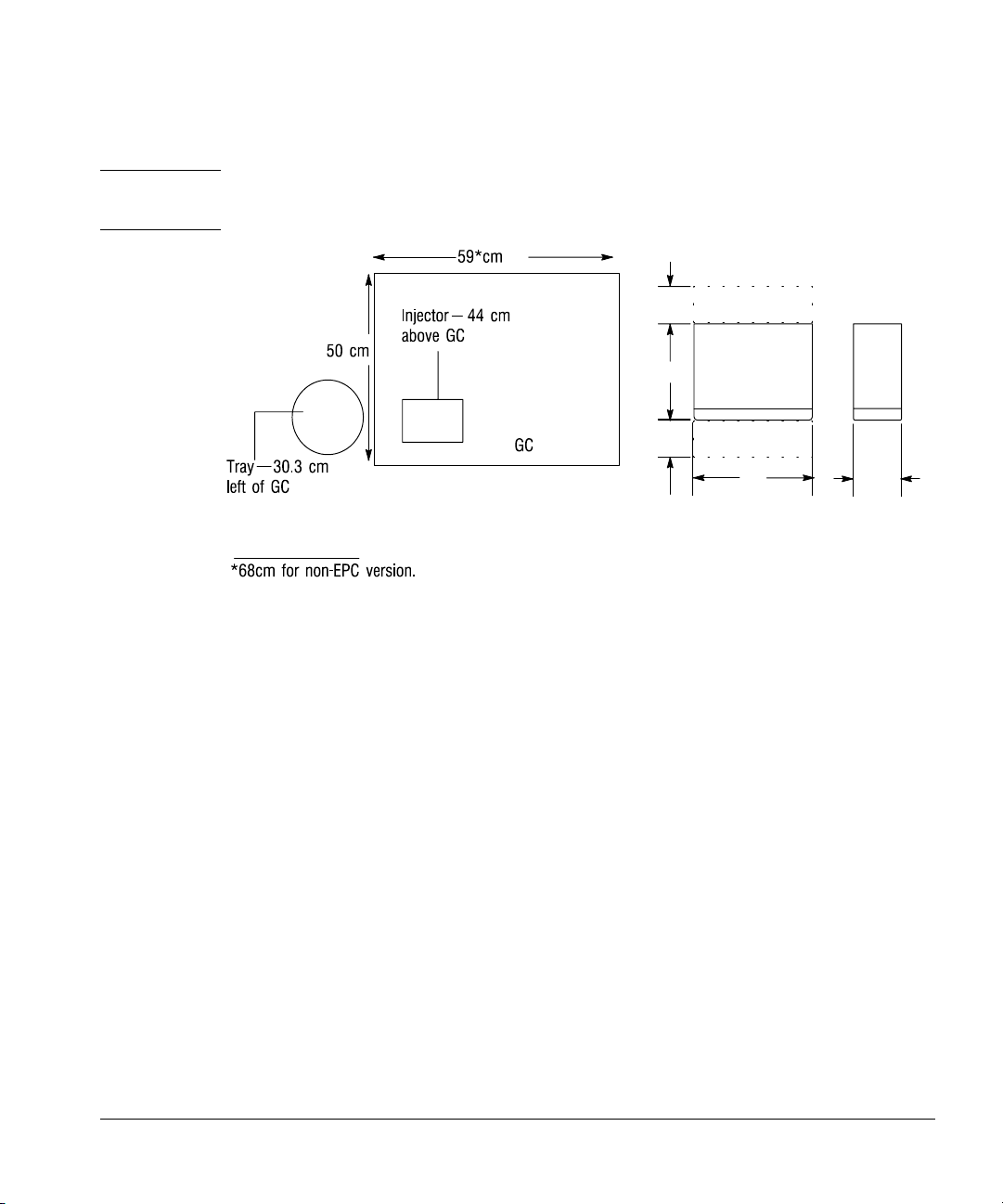

Space considerations

The injector and tray increase the space requirements for the GC. The exact

amount depends on the model of the GC. Figure 2 shows the space

requirements for the components with a 6890 Series GC.

Installed on the 6890 Series GC, the injector adds 44 cm (17 in.) in height. The

tray adds 30.3 cm (9 in.) to the left side and 3 cm (2 in.) to the front. The

controller requires a clear surface about 33 cm (13 in.) wide and 38 cm

(15.2 in.) deep. About 20 cm (8 in.) of the depth is required for cabling. If you

place the controller on its right-hand side (i.e., power switch up), it needs a

clear surface of 38 cm (15.2 in.) deep and 14 cm (6 in.) wide.

5

Page 14

Setting Up

Preparing the site

WARNING Place the G1512A controller where you can easily unplug it from the power

source.

Ventilation and cabling space

10

Top Views

Figure 2. Space considerations

Electrical power requirements

The controller is the power source for the injector and tray. The controller has

an autoranging power supply:

• 100–240 Vac single phase

• 48–66 Hz maximum

•320 VA maximum

The automatic liquid sampler requires a proper earth ground. To protect users,

the metal instrument panels and cabinet are grounded through the threeconductor power line cord in accordance with International Electrotechnical

Commission (IEC) requirements.

30

10

Ventilation space

33

All dimensions in centimeters

or

14

The power cord must be plugged into a receptacle connected to a suitable

earth ground. The receptacle ground should be verified.

6

Page 15

Setting Up

Installing the injectors

WARNING Any interruption of the grounding conductor or disconnection of the power

cord could cause a shock that results in personal injury.

Connecting the controller power cord

1. Check the on/off button on the front of the controller. It must be off or

flush with the front panel before you plug in the power cord. The symbol

“ ” indicates standby. The symbol “|” indicates on.

2. Plug the female end of the power cord into the AC power receptacle on the

back of the controller.

3. Plug the male end of the power cord into the AC power receptacle of your

facility.

Installing the injectors

The injector contains the syringe, a syringe carriage, a six-position standard

turret, a cooling fan that you can turn off, parameter switches, and a last

sample vial switch.

The turret rotates sample vials and solvent and waste bottles into position

under the syringe. Without a tray, you load the sample vials manually into the

turret (maximum of three samples). With a tray, the robotic arm loads the vials

(up to 100 samples). You load the solvent and wash bottles manually (the

quantities of each depend on your controlling device). For more information on

the fan, see “Using the injector fan” on page 34.

7

Page 16

Setting Up

Installing the injectors

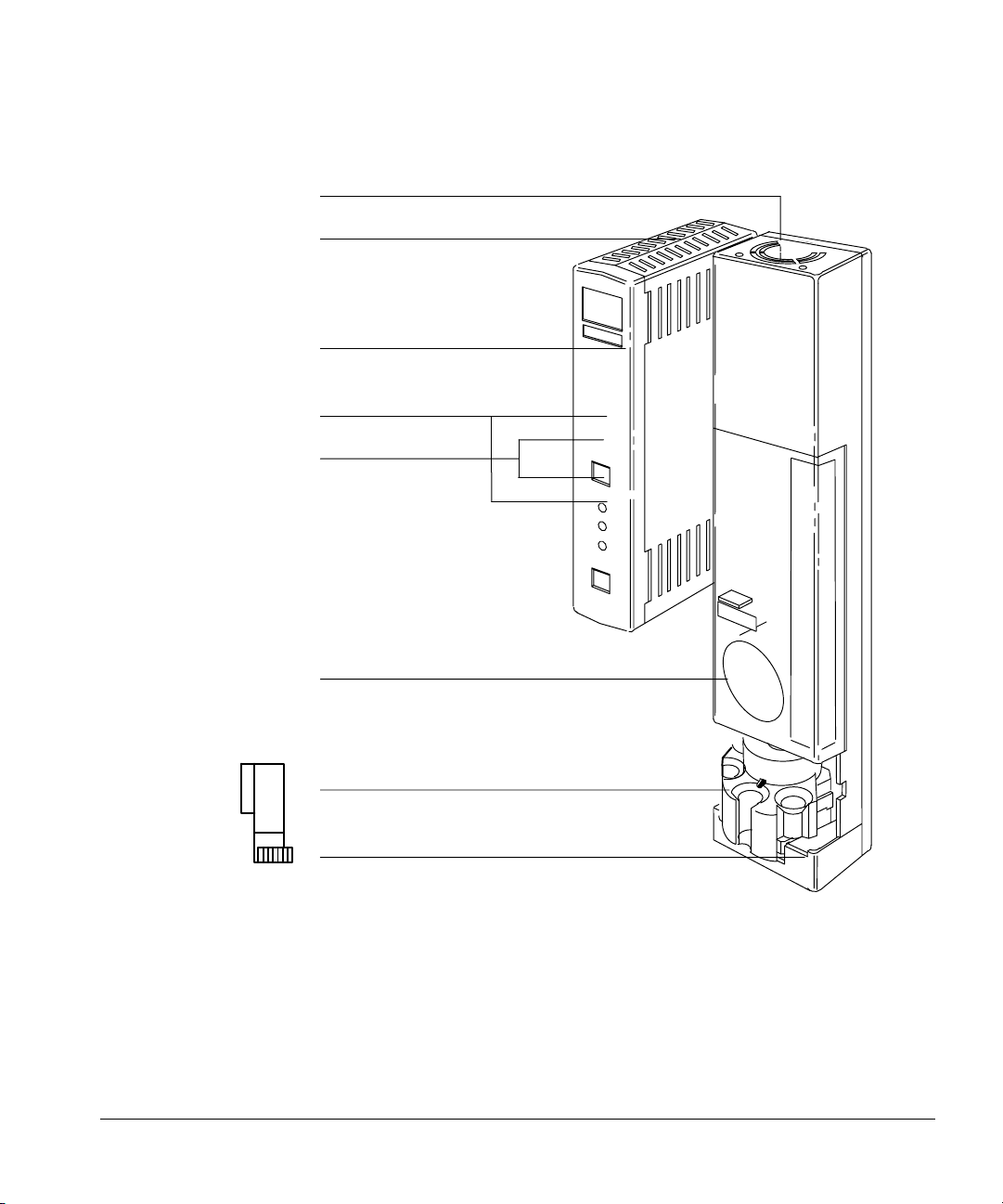

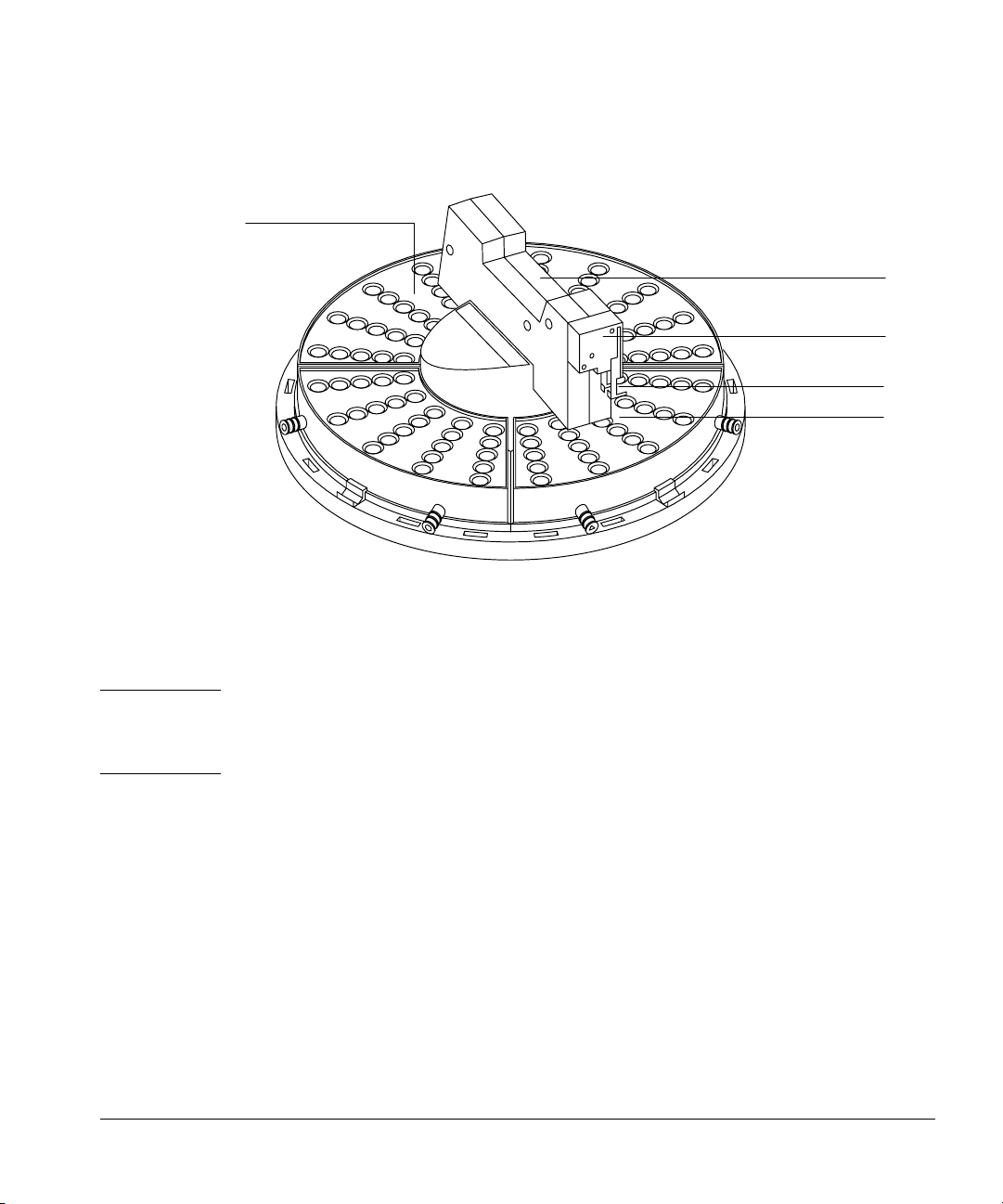

Fan

Electronics assembly

Door to control switches

Start/stop buttons

Fault LEDs

Door to syringe

Turret

Base

Figure 3. G1513A injector module

8

Page 17

Setting Up

Installing the injectors

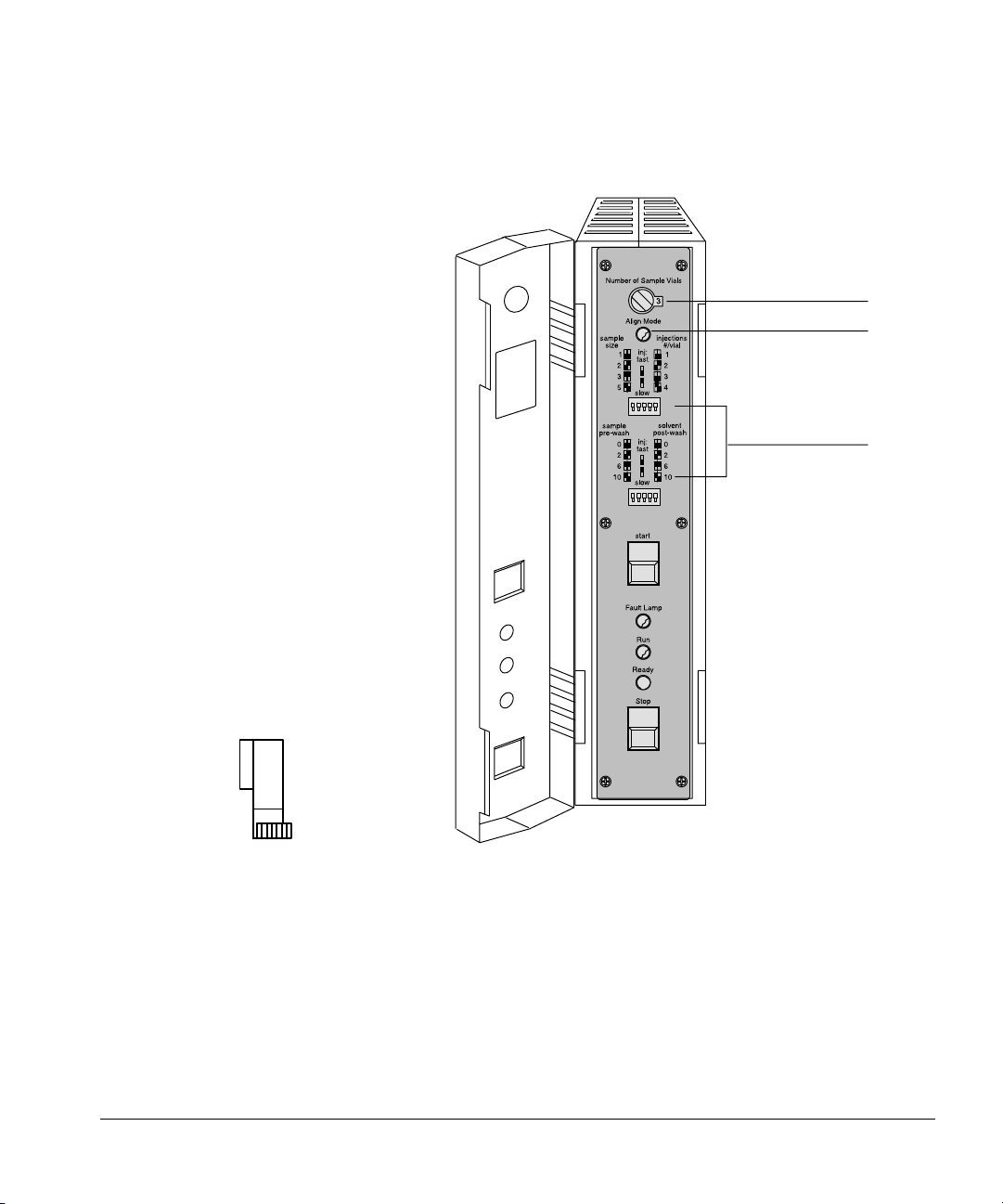

Behind the door to the control switches

There are control switches behind the door on the injector’s front panel.

• You use the rotary switch to set the number of sample vials when no tray is

installed and the remaining ten switches to set six injector parameters

when the system cannot be controlled by the 6890 Series GC, a computer,

or an integrator. For example, you can set the number of injections per

sample vial or the number of syringe washes. For more information, see

“Setting the run parameters” on page 59.

• The injection switch can be used to set fast or slow injection with or

without an integrator or computer controlling the system having any affect

on that setting. However, it will be overridden by settings from the 6890

Series GC and the ChemStation.

• The Align LED is a diagnostic LED to warn users to perform the alignment

procedure. See Chapter 5, Preventive Maintenance and Troubleshooting.

9

Page 18

Setting Up

Installing the injectors

Rotary switch

Align LED

Control switches

10

Figure 4. The parameter control switches

Before you start

To install an injector, you must first:

• Install the tray’s mounting bracket before mounting the injectors (if your

automatic liquid sampler includes a tray). The instructions and hardware

are packaged together with the tray.

• Open the front panel, and remove the foam packing materials.

Page 19

Setting Up

Installing the injectors

• Install the injector mounting posts in the front and back locations of the

injection bracket on the GC.

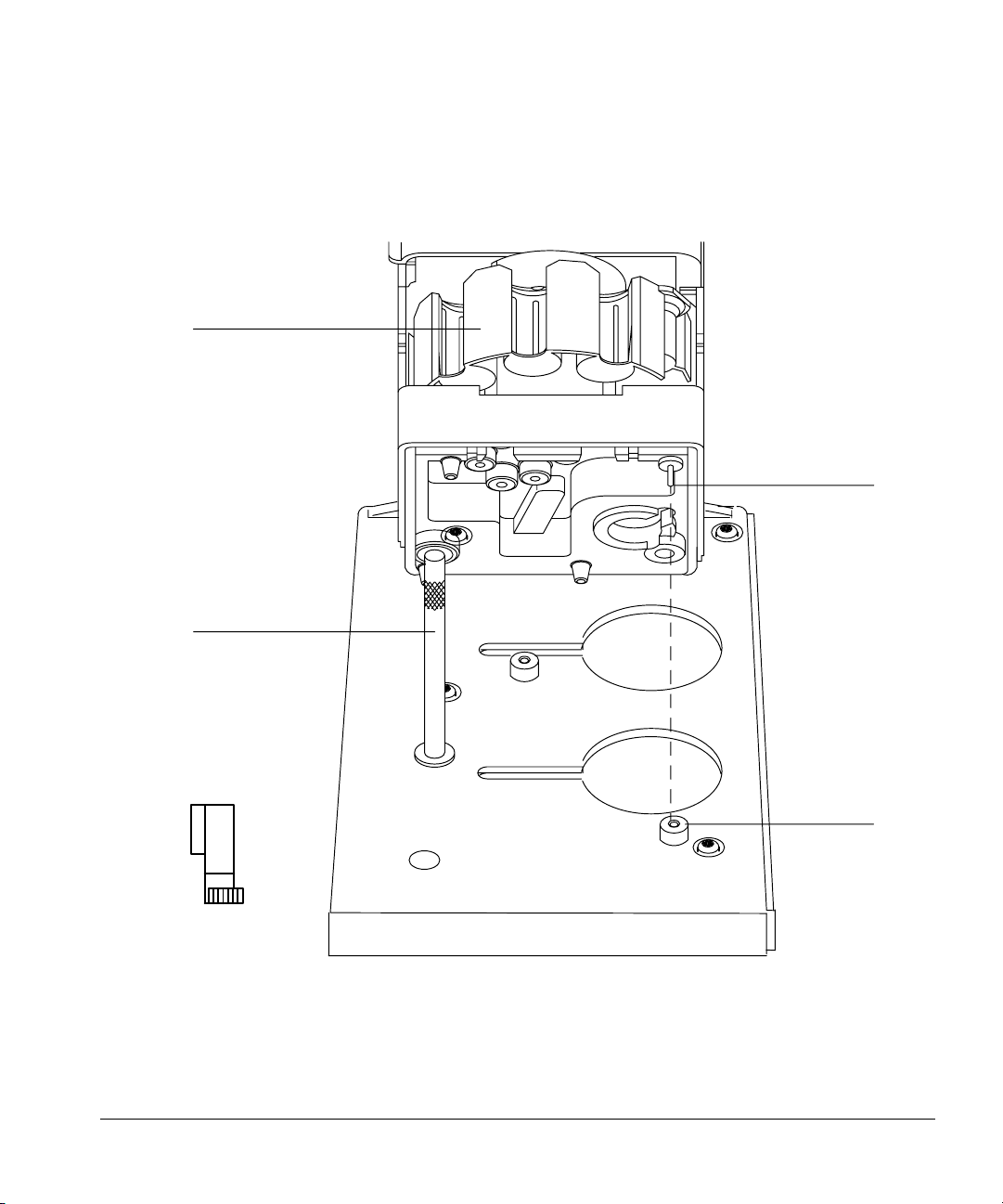

Mounting the injectors

The first part of each step describes how to mount the injector over the front

inlet (injection port).

1. Hold the injector with both hands so the cable points toward you. Line up

the hole in the base of the injector that is nearest the cable with the

mounting post on the bracket. Lower the injector about an inch on to the

post.

Cable

Hole

Front mounting post

Figure 5. Lining up the injector with the mounting post

Door

Turret

Injector base

Mounting pin

Back disk

Front disk

11

Page 20

Setting Up

Installing the injectors

2. Turn the injector so that the turret is facing toward you. Lower the injector

Turret

so that the pin in the base enters the hole in the disk on the mounting

bracket.

Mounting pin

Front mounting post

Disk

Figure 6. Lowering the injector. The injector in this diagram is angled back to illustrate

the position of the mounting pin.

12

Page 21

Setting Up

Installing the tray

Checking your work

❐ Be sure the mounting pin is seated in the hole of the disk. The injector’s feet

should touch the mounting bracket. Be sure the gas lines are not routed

under the feet or the mounting pin.

❐ Turn the turret so you can see the inlet of the GC, and open the door to the

syringe. Be sure the inlet is flush with the surface of the hole in the injector’s

base. This check does not apply to on-column inlets.

❐ If your system does not include a tray, read “Placing sample vials in the

standard injector turret” in chapter 2.

For information on installing syringes, see “Selecting and installing syringes” in

chapter 2. See this section for instructions on how to align the syringe to the

inlet. Alignment is critical when injecting onto a 320- or 250-µm column.

Chapter 6, “Special Topics,” contains more information on use of 320- and

250-µm columns.

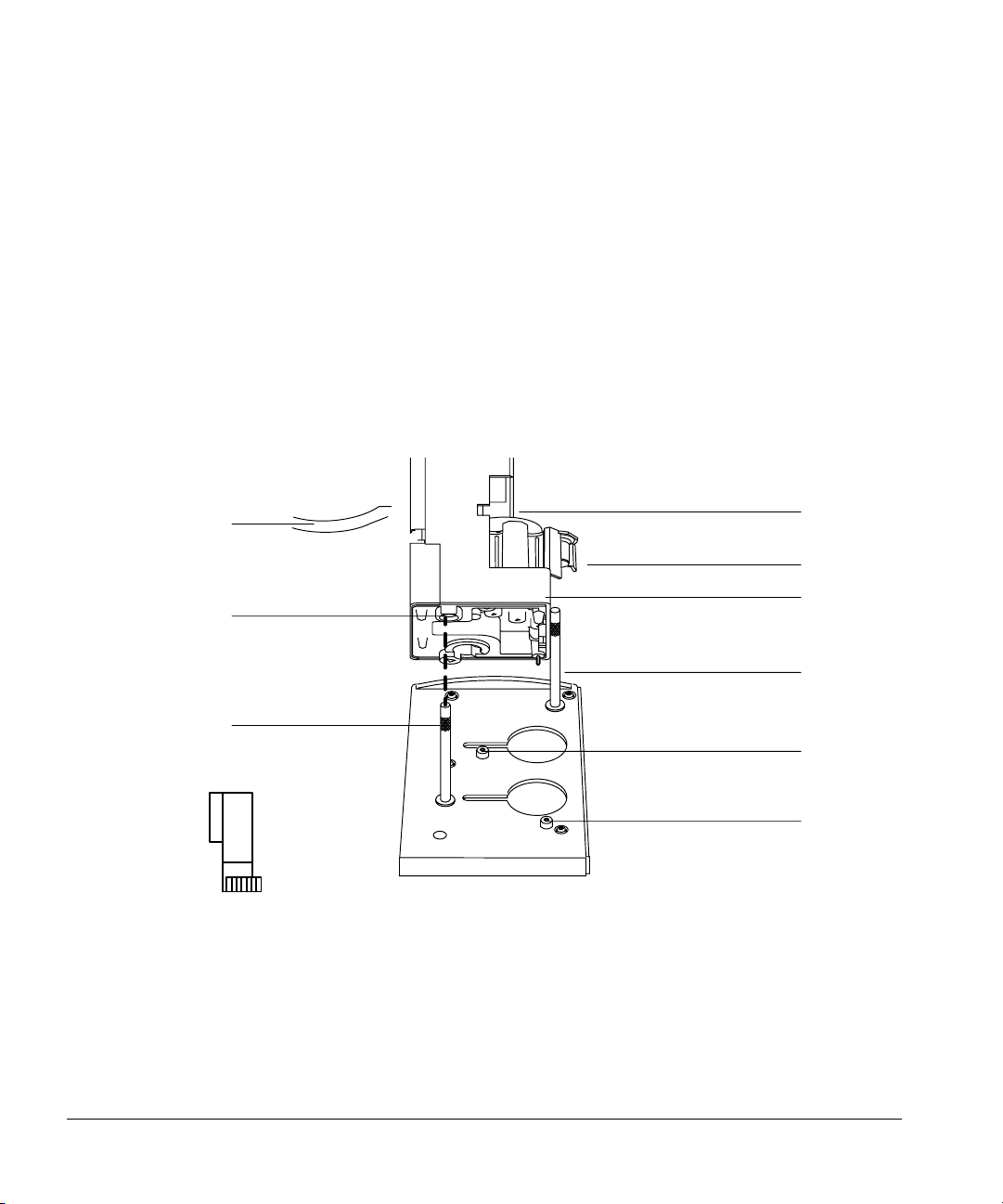

Installing the tray

The tray delivers samples to one or two injectors depending on the

configuration of the gas chromatography system. The arm and gripper

mechanism in the center of the tray loads sample vials into the injector turret

and then returns them to the tray after each injection. It can also transport

sample vials to and from the G1296A/G1926A bar code reader.

Each of the four removable tray quadrants holds 25 vials. Each is hollow and

has fittings so that you can circulate a temperature-controlled fluid through it.

13

Page 22

Setting Up

Installing the tray

Quadrant

Arm

Gripper

Gripper jaws

Sample vial

Figure 7. 18596B tray module

Before you start

Caution Do not remove the tray’s arm back and forth. Do not move the tray’s gripper up

and down. These movements could damage the tray arm. If you need to move

the arm, turn it in a clockwise or counterclockwise direction.

To install a tray, you must first install the tray mounting bracket. The mounting

bracket for the tray attaches to the injector mounting bracket and the GC. The

instructions and hardware are packaged together with the tray.

14

Page 23

Setting Up

Installing the tray

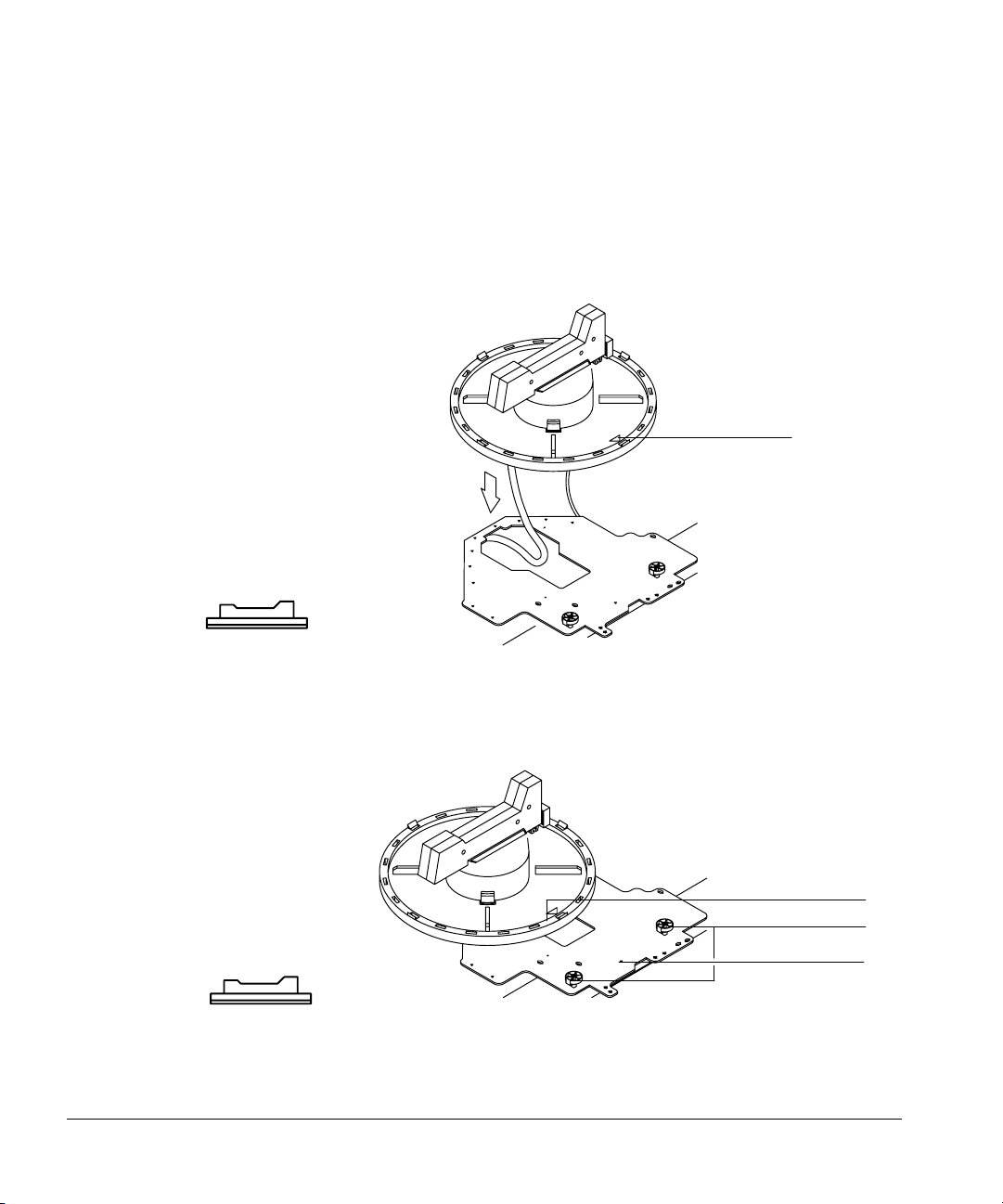

Mounting the tray

1. Thread the cable through the hole in the mounting bracket. Lower the tray

onto the bracket. Position the tray so that it sits flat on the bracket with

the raised arrow pointing toward the right (the front injector). Move the

injector cable out of the way.

Arrow

Figure 8. Threading the tray cable

2. Line up the arrow on the tray base with the alignment pin on the mounting

bracket. Slide the tray to the right until the edge is under the two tray

locks.

Arrow

Tray locks

Alignment pin

Figure 9. Attaching the tray

15

Page 24

Setting Up

Installing the tray

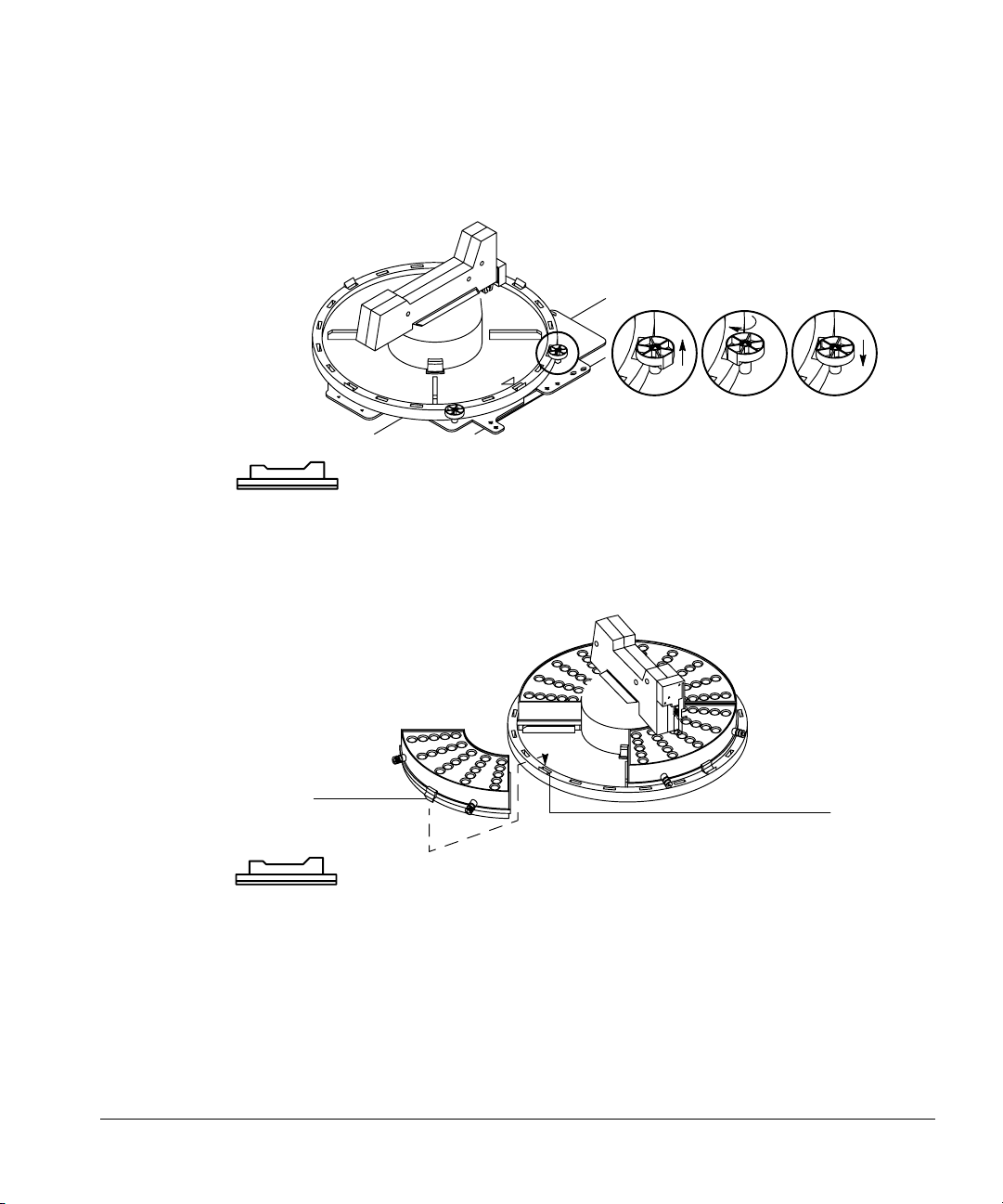

3. Lock the tray into place by pulling each lock up (A), turning each lock (B),

and inserting each tab into a slot in the tray (C).

A B C

Figure 10. Locking the tray

4. Snap the tab of each tray quadrant into a slot on the base of the tray. The

numbers on the quadrants should match the numbers on the base.

16

Ta b

Slot

Figure 11. Inserting the tray quadrants

Checking your work

❐ Be sure the tray base is all the way to the right and locked into place.

❐ Be sure the quadrants are seated on the tray base.

Page 25

Setting Up

Installing the controller

Installing the controller

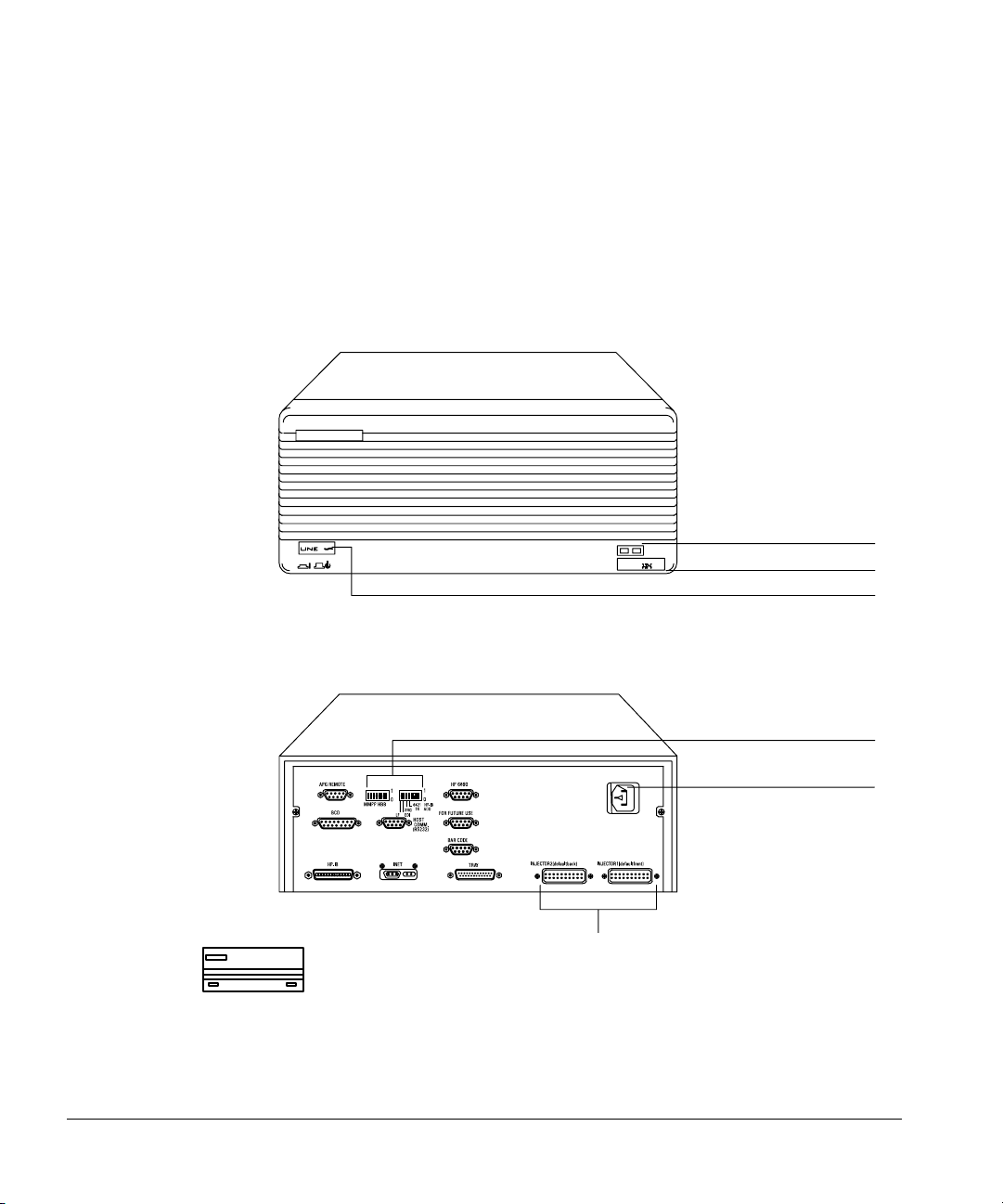

The G1512A controller provides power and the communication interface for

18593A/B or G1513A injectors and for the 18596A or 18596B/C tray.

There are 11 connectors and two sets of switches for defining the

communication type.

Fault LED

Serial number

On/off button

Injector connectors

Figure 12. G1512A controller and communications module

Configuration switches

AC power receptacle

17

Page 26

Setting Up

Installing the controller

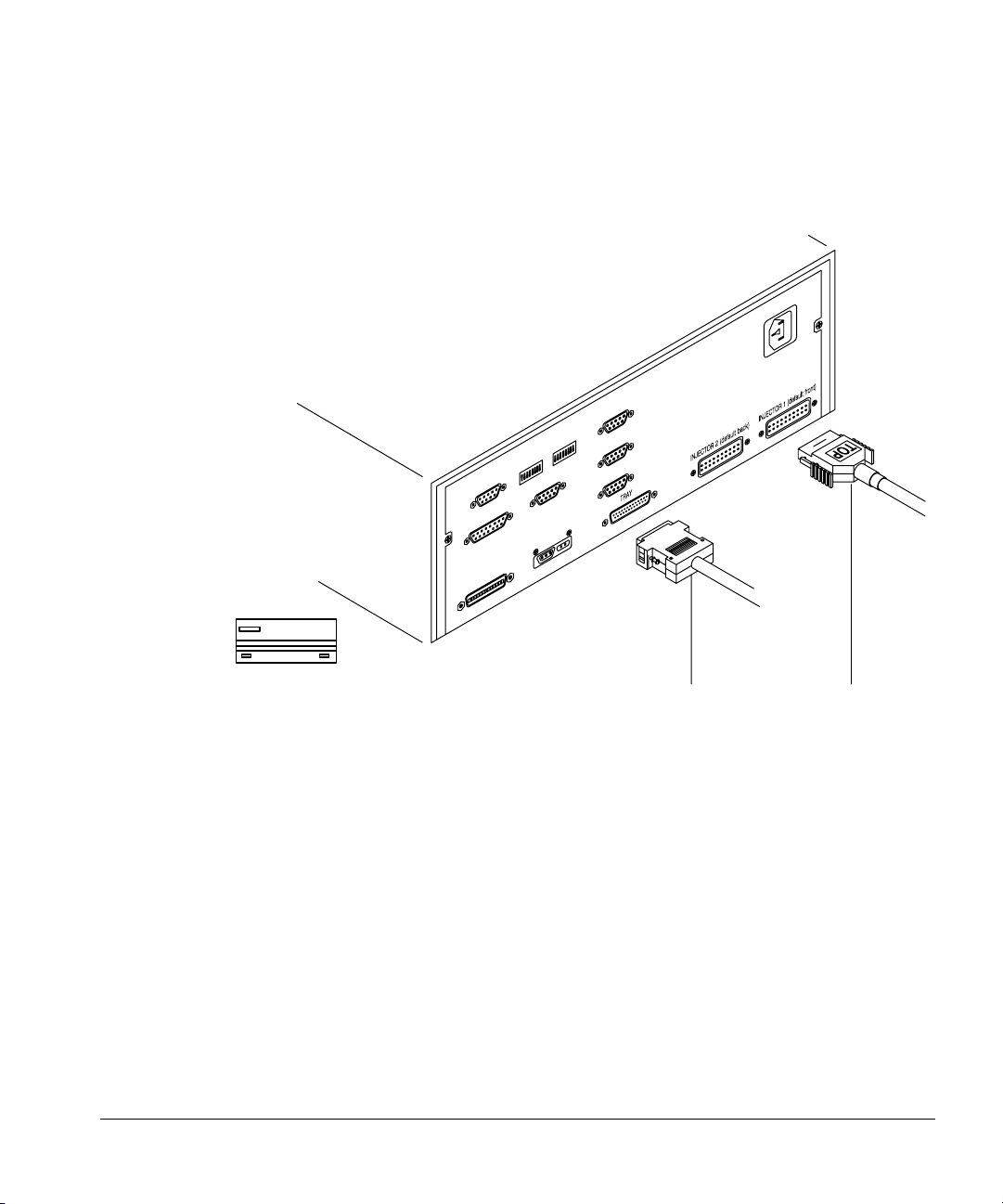

This section covers connecting the injector and tray cables to the controller,

connecting the controller to the GC, connecting the controller to the data

handling device, and plugging in the controller.

Find the power cord in the controller box. Check the shape of the plug and the

source voltage listed on the packing contents sheet. Verify that the power cord

is appropriate for the power source at your facility.

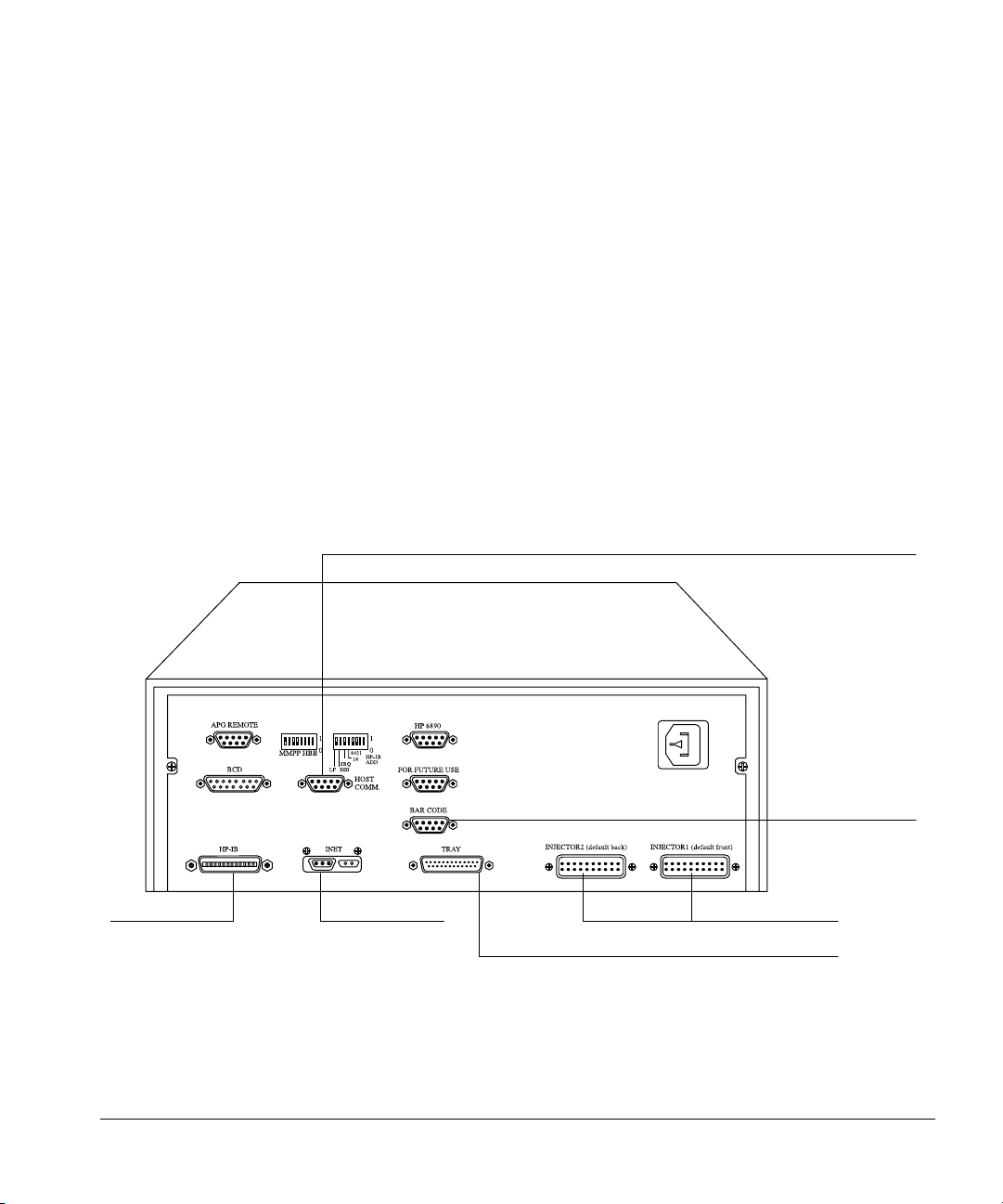

Connecting cables to other instruments

The automatic liquid sampler communicates to other instruments via cables

that connect to the various connectors on the controller. Figure 13 shows the

connectors on the back of the controller and what they are used for.

RS-232-C to computer

Connect to a

computer

Connect to the

Instrument

Network

Figure 13. Common cable connections

18

Connect to the

bar code reader

Connect to the injector modules

Connect to the tray module

Page 27

Setting Up

Installing the controller

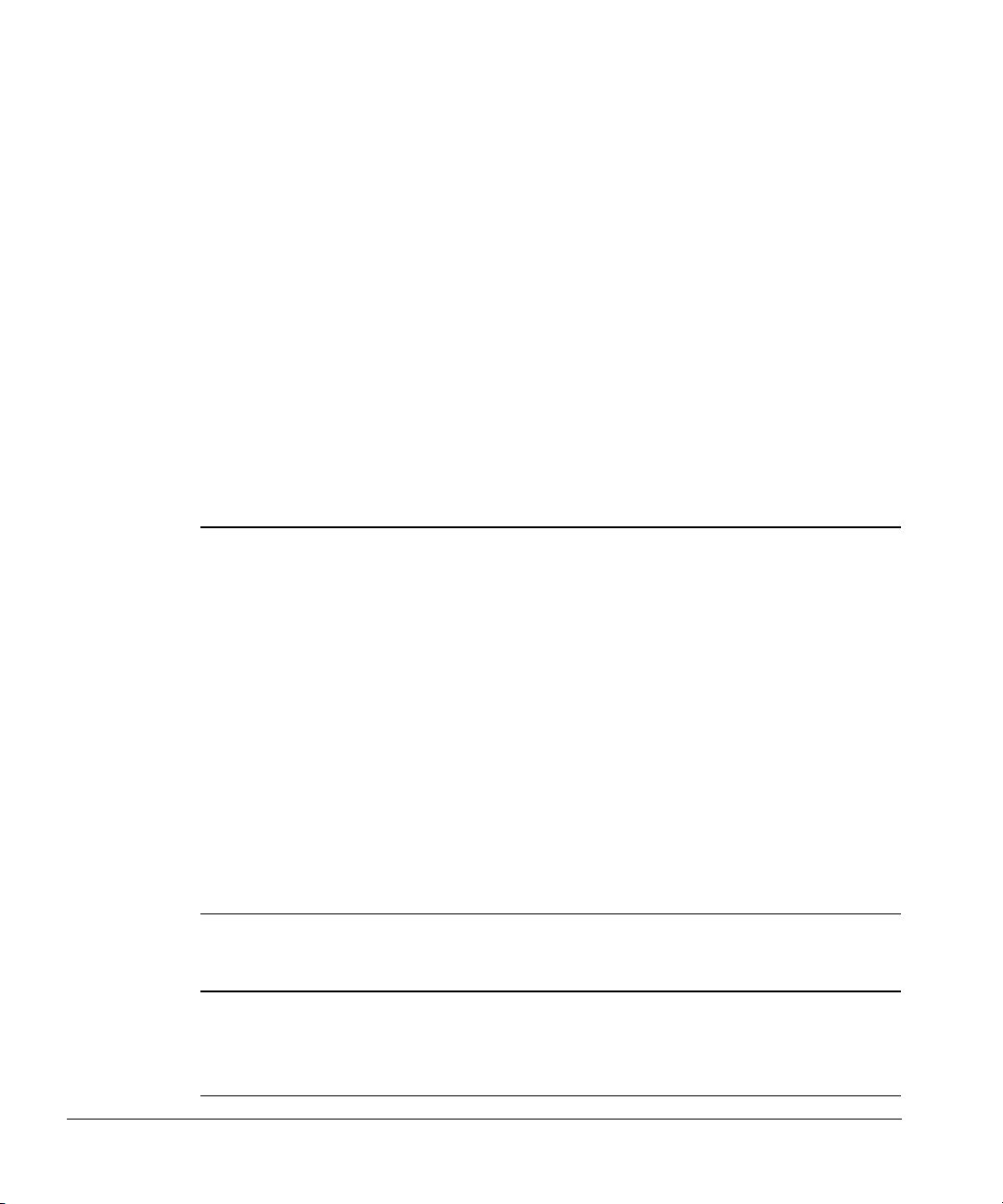

Setting the configuration switches

There are 16 switches on the back of the controller. Figure 14 and Figure 15

show the switches and settings for five common types of communications.

When you are using ChemStation software, you must set the GPIB address

switches to a unique address. The address for the first sampler is usually set to

“8.” For a complete list of address switches, see Table 3.

Configuration switch definitions

The following tables describe the configuration switches and their settings.

Table 1. Left-hand Switch Settings

Switch Description Possible Values

MM Communication mode type 00—INET, standalone

10—3365 ChemStation, MS ChemStation

(Rev 3.65 and lower)

11—ChemStation, MS ChemStation

(Rev 3.71 and higher)

01—Asynchronous standalone

PP The bar code reader position 00—Front

01—Back

10—Right

11—Left

H RS-232-C host handshake 0—XON/XOFF

1—RTS/CTS

BB RS-232-C host baud rate 00—2400

01—9600

10—19.2 K

11—38.4 K

Table 2. Right-hand Switch Settings

Switch Description Possible Values

LF Controller termination

message

16,8,4,2,1 GPIB address of controller 00000=0, 00001=1, 00010=2, 00011=3, etc.

0—Line feed only

1—Carriage return and line feed

(see Figure 14)

19

Page 28

Setting Up

Installing the controller

Communication mode Baud rate

Bar code reader position Handshake

Figure 14. Setting the address switches

ChemStation

6890 Series GC

MSD ChemStation

(rev 3.70 and above)

3365 ChemStation

MSD ChemStation

(rev 3.65 and below)

HP-UX ChemStations

Integrator with INET

Synchronous standalone

1

0

LFBBHPPMM124816

1

0

LFBBHPPMM124816

1

0

LFBBHPPMM124816

1

0

LFBBHPPMM124816

GPIB address

1

0

1

Address = 10

0

1

Address = 8

0

1

0

Asynchronous standalone

35900 Loop

RS-232-C, described in

serial interface manual,

part no. 18594-90300

Figure 15. Examples of switch settings

20

1

0

1

0

1

0

1

0

LFBBHPPMM124816

1

0

LFBBHPPMM124816

1

0

LFBBHPPMM124816

Page 29

Table 3. Possible GPIB Address Switch Settings

Setting Up

Installing the controller

Switch

GPIB Address

0 00000 15 01111

1 00001 16 10000

2 00010 17 10001

3 00011 18 10010

4 00100 19 10011

5 00101 20 10100

6 00110 21 10101

7 00111 22 10110

8 01000 23 10111

9 01001 24 11000

10 01010 25 11001

11 01011 26 11010

12 01100 27 11011

13 01101 28 11100

14 01110 29 11101

Settings GPIB Address

Switch

Settings

Connecting the injector cables

With the power off, plug each injector cable into the connector on the back

panel of the controller associated with the position of the injector, front or

21

Page 30

Setting Up

Installing the controller

back. Be sure the spring clamps on either side of the plug snap onto the

connector. Note the TOP label on the connector for orientation purposes.

22

Tray Injector

Figure 16. Connecting the injector and tray cables

Connecting the tray cable

Plug the cable into the tray connector on the back panel of the controller.

Secure the plug to the connector with a small flathead screwdriver.

Connecting the controller power cord

1. Check the on/off button on the front of the controller. It must be off or

flush with the front panel before you plug in the power cord.

2. Plug the female end of the power cord into the AC power receptacle on the

back of the controller.

3. Plug the male end of the power cord into the AC power receptacle of

your facility.

Page 31

Setting Up

Installing the controller

Checking your work

❐ Be sure the injector and tray plugs are fastened securely.

❐ Be sure all the communication cables are installed and fastened

securely.

❐ Be sure any external control or data handling devices are configured

correctly by referring to the appropriate manual.

❐ Turn the controller on. Listen for a single beep. This means the system

initialized correctly.

• On the injector, the red, yellow, and green lights flash on together.

The red and yellow lights go off. The green light stays on. If the red

light stays on, be sure the injector is mounted correctly and the door

to the syringe chamber is closed.

• On the controller, the yellow and green lights flash on together. The

green light stays on while the yellow light goes off.

To test the operation of the automatic liquid sampler, turn to chapter 2,

“Preparing for Operation.”

23

Page 32

6890A GC

this page is from

"Agilent 7683B Automatic Liquid Sampler

Installation, Operation and Maintenance"

Installation 2

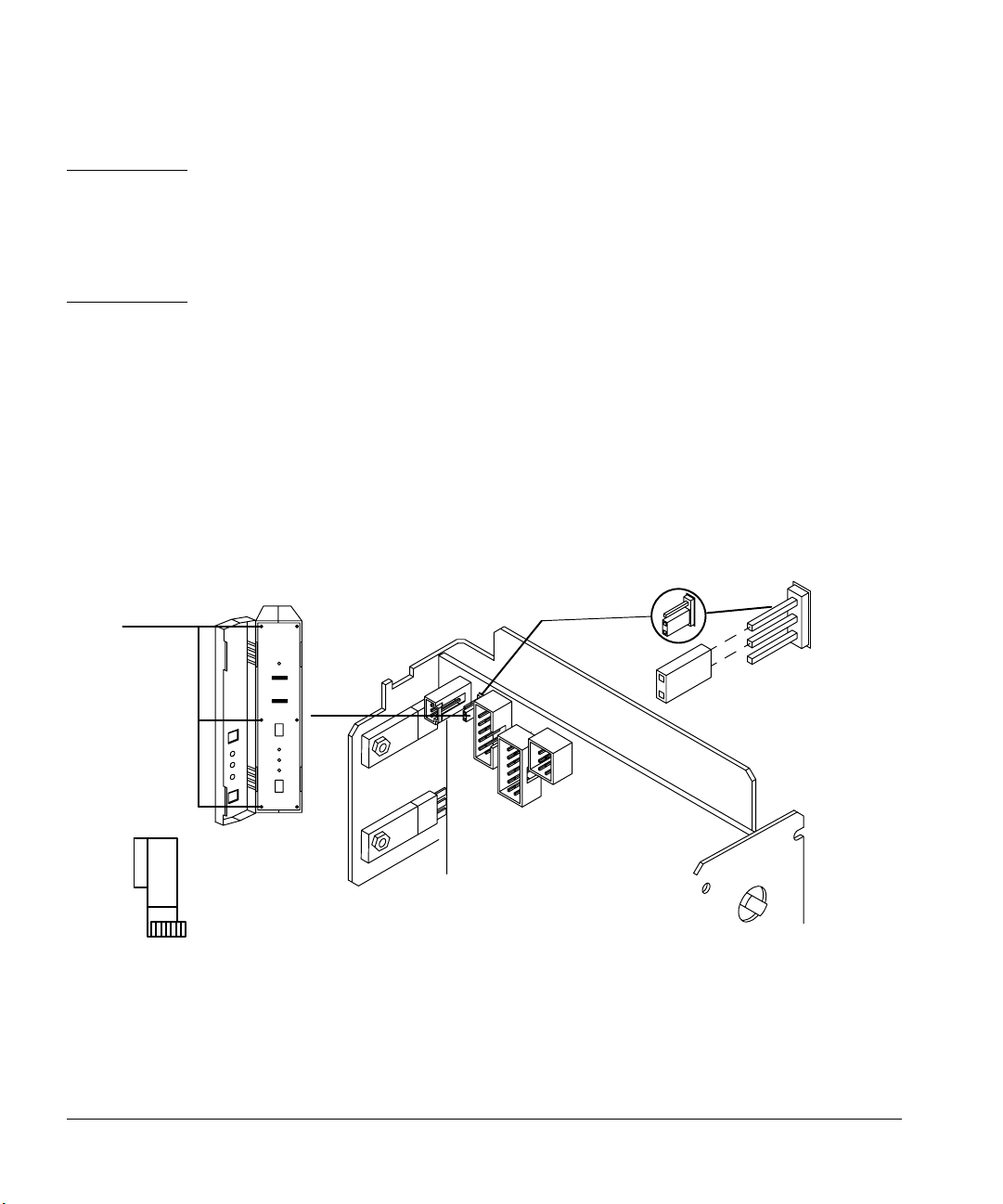

Follow the instructions below to properly wire the G2912A controller. See

“Procedure 8. Install the G2912A ALS Controller” on page 55 for installation

instructions for the G2912A controller including the power supply cord.

G2912A Controller

Front

Injector

Back

Injector

Tr ay

5890

Remote

6890

Remote

RS-232

Inj1 Inj2

Front

Power cords not shown

Back

Injectors

G2614-60610

Tr ay

Bar Code

Reader

G1530-60930

G1530-60600

Sampler

6890A GC

Remote

Figure 18 Cables for 6890A GC

1 Connect the injector(s) to the controller.

2 Connect the tray to the controller with G2614-60610 cable.

3 Connect the controller to the GC with a G1530-60930 cable and a

G1530-60600 cable.

4 Connect the Bar Code Reader to the tray, if desired.

5 Connect the power cords.

Installation, Operation, and Maintenance 47

Part 1, Installation

Page 33

Setting Up

Installing the controller

24

Page 34

2

Preparing for Operation

Page 35

Preparing for Operation

This chapter contains detailed information for preparing the automatic liquid

sampler for operation, including:

• Preparing sample vials

• Using the injector fan

• Preparing the solvent and waste bottles

• Selecting and installing syringes

• Maintaining the inlet

• Adapting for cool on-column injection

To optimize your sampler operation, it is important to have thorough

preparation of your samples, sample vials, syringes, and inlets. Regular

maintenance also keeps your equipment and analysis running smoothly. For

more information, see chapter 5, “Preventive Maintenance and

Troubleshooting.”

Preparing sample vials

26

This section explains how to select, label, fill, cap, and place the sample vials.

Selecting and labeling sample vials

The injector and the tray use glass sample vials and crimp caps or Target® DP

screw-cap vials that meet a set of specifications. These are available with a

write-on spot for easy labeling. If you choose to make your own labels, read the

following specifications for location and thickness of labels.

™

Page 36

Preparing for Operation

Preparing sample vials

The location and thickness of a vial label can affect the delivery of the bottles

to and from the injector. Agilent Technologies recommends the position and

maximum label thickness shown in the following diagram.

No label

5.6 0.6

20.5 1.0

No label

All measurements in millimeters

.2

.44

Figure 17. Label specifications

Caution The correct sample vial dimensions are critical for proper operation. Vials that

do not meet specifications may cause sampler errors. Service calls and repairs

found to be due to vials and microvials that do not meet these specifications

are not covered under warranty or the service contract.

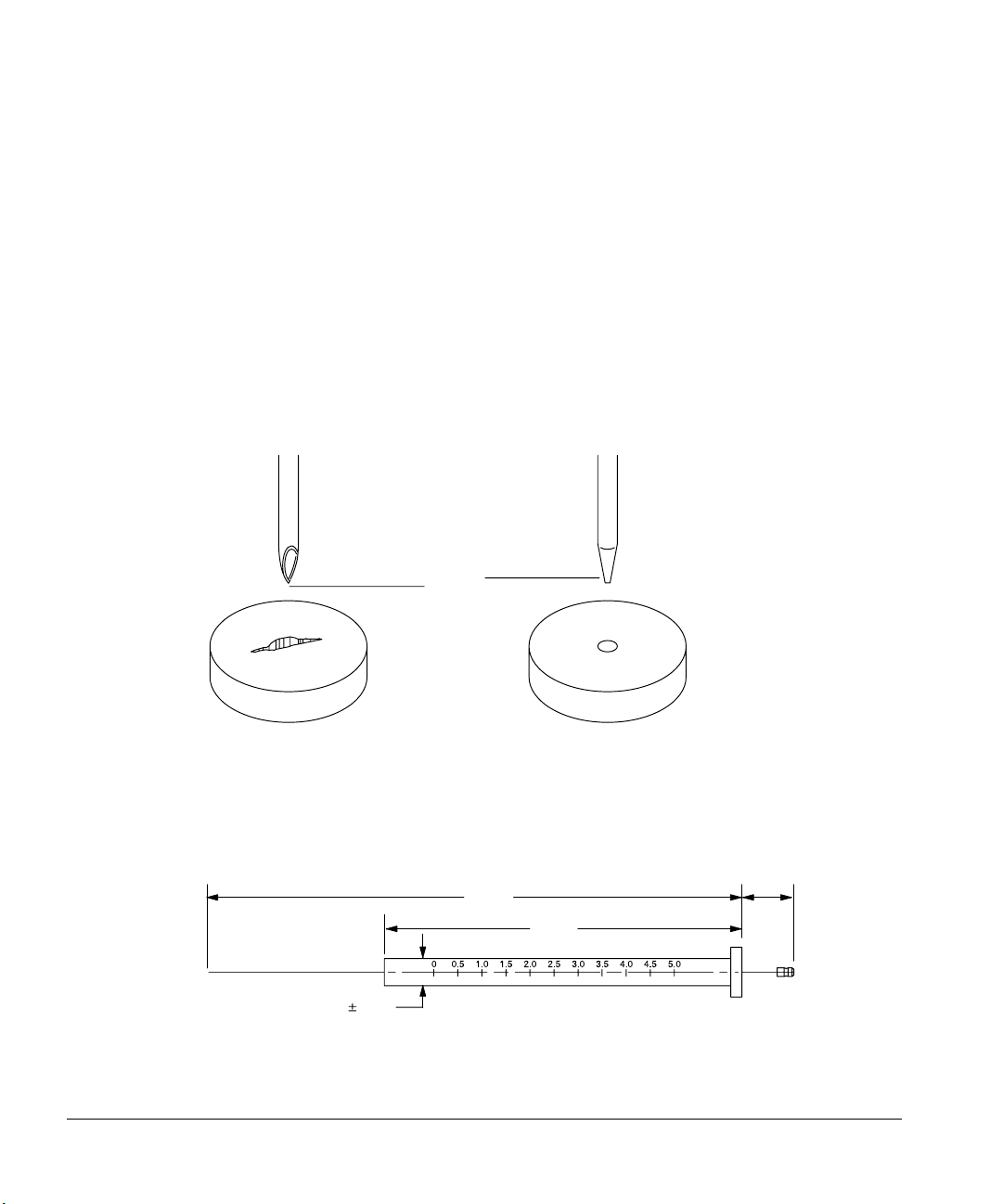

Specifications

Figure 18 illustrates most of the critical dimensions for the sample vials and

microvial inserts. These dimensions do not make up a complete set of

27

Page 37

Preparing for Operation

Preparing sample vials

specifications. Some of the dimensions are too difficult to measure without

special instruments.

Microvial insert

5 minimum

All dimensions in millimeters

Crimp cap sample vial

3.5

28.4

Figure 18. Dimensions for sample vials and microvial inserts

Sample caps and septum

Although septa come in different colors, the characteristics are measured by

inertness and type of composition. There are two basic types of septa used

with both crimp caps and screw-on caps. Each has different resealing

characteristics and a different resistance to interaction with solvents.

8.2 maximum

11.7 0.2

3.7

28

• A general-purpose rubber formulation made from natural rubber is coated

with Teflon on the sample side. It has a pH range of 4.0–7.5. It is least

resistant to solvents after puncture, however, it is more easily cored. This

coring may place septum pieces in the solvent that affect your

chromatograms.

• A high-quality, low-extractable silicone rubber, coated with Teflon on one

or both sides, is somewhat resistant to solvents after puncture.

Refer to your Agilent analytical supplies catalog for more information.

Page 38

Preparing for Operation

34.5 mm

Preparing sample vials

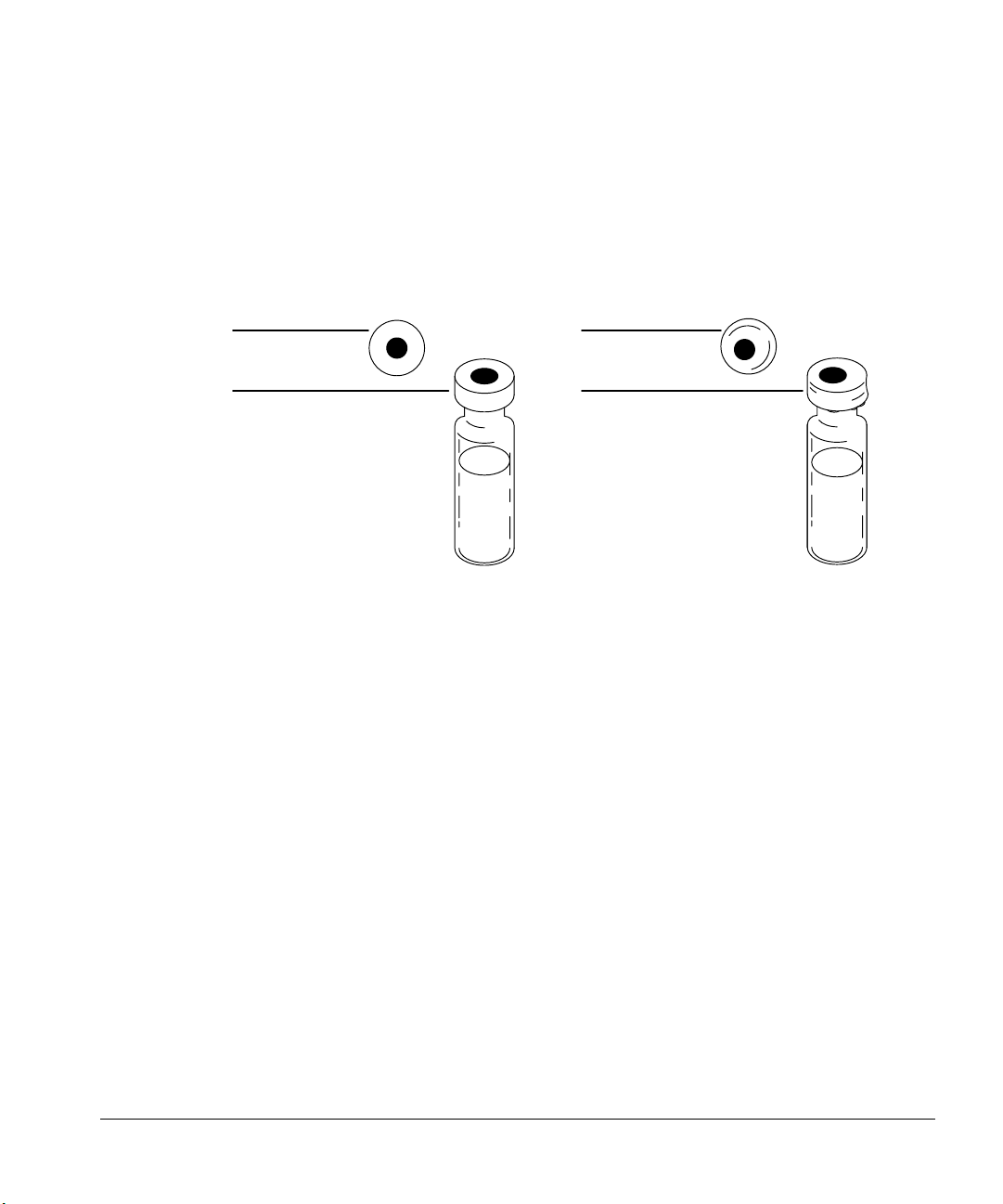

Figure 19 illustrates the recommended and minimum diameter for vial cap

apertures.

5.58 (0.220 in.) recommended

4.65 (0.183 in.) minimum

All dimensions in millimeters

Figure 19. Specifications of vial cap aperture

Use amber glass vials for light-sensitive samples.

The last specification to consider is the total height of the capped vial.

Figure 20 illustrates the recommended maximum height of a crimp capped or

screw capped vial.

Figure 20. Maximum height of a vial with cap

Filling sample vials

Follow these recommendations to obtain reliable, high performance with the

sampler and prevent contamination or injection volume problems.

Recommended volumes for a maximum of five injections per vial are:

• 1 ml for the 2-ml vial

• 50 µl for the 100-µl vial

29

Page 39

Preparing for Operation

Preparing sample vials

For large volumes and multiple injections, you will have to decide how to

divide the sample among several vials to obtain reliable results. You have to be

aware when sample volume is low. For example, if the vials are less than half

full, contaminants from the previous sample injection or solvent washes may

affect the sample. Due to the various parameter settings available, the many

suppliers of consumables, and the choices of vials, microvials, vial caps, and

septa, some method development will need to be done to optimize your

analysis.

1 ml

3.6 mm*

2-ml vial

*Needle position based on standard sampling depth. See chapter 3 for more information on setting parameters

for sampling depth.

50 ml

100-ml vial

Figure 21. Recommended volumes for sample vials

Caution If the vials are more than half full, a vacuum may interfere with the syringe

delivering a precise volume.

Do not inject air into the vial to compensate for the vacuum. Injecting air into

the vial often damages the cap septum so that it is no longer airtight.

Crimp capping sample vials

Use a crimper to put on the airtight crimp caps.

1. Clean off the inside surfaces of the crimper jaws.

2. Place the crimp cap over the top of the vial.

30

Page 40

Preparing for Operation

Preparing sample vials

3. Lift the vial into the crimper, and squeeze the handle until the bottom grip

reaches the adjuster screw.

Handle

Adjuster screw

Jaws

Crimp cap

Sample vial

Figure 22. Crimping caps

Caution Vials that do not have properly crimped caps may cause sampler errors.

When a tray is not installed, you may be able to use sample vials with no caps,

snap-on caps, or screw-on caps depending on your application. If a tray is

installed, sample vials must have crimp caps or Target

Check that your vial is crimped as follows:

1. Cap has no metal folds or wrinkles on the part of the cap that wraps under

the neck of the vial.

• If there are folds or wrinkles, flatten any wrinkles by turning the vial

about 10° and crimping it again. Adjust the crimper for a looser crimp

by turning the adjusting screw clockwise.

2. Cap is too tight to turn by hand.

• If the cap is loose, adjust the crimper for a tighter crimp by turning the

adjusting screw counterclockwise. Crimp the cap again.

®

DP™ screw-cap vials.

31

Page 41

Preparing for Operation

Preparing sample vials

3. Cap has a flat septum centered over the top of the vial.

• If the septum is not flat, remove the cap, turn the adjusting screw

clockwise, and try again.

• If the cap is not centered, remove the cap, and make sure the new cap

is flat on the top of the vial before you squeeze the crimper.

Centered

No folds or wrinkles

Off center

Folds and wrinkles

Figure 23. Acceptable and unacceptable caps

There are three reasons for crimping the cap properly:

• The syringe tends to core a curved vial septum and drop small pieces of

the material into the sample.

• The syringe needle could hit the metal part of the uncentered cap.

• The tray gripper may drop a vial if the cap has folds or wrinkles in it.

Placing sample vials in the standard injector turret

If you do not use the tray, you can place one, two, or three vials in the injector

turret. For two or three sample vials, you must convert some of the bottle

positions to sample vial positions with sample inserts.

32

1. Place the appropriate sample inserts in bottle positions 2 and 3 on the

turret.

• For one sample, no inserts are needed. Position one is molded into the

turret.

Page 42

2. Place the sample vials into the sample inserts.

Preparing for Operation

Preparing sample vials

White sample insert

for sample 3

Turret

White sample insert

for sample 2

Sample 1

Figure 24. Placing sample inserts for three sample vials

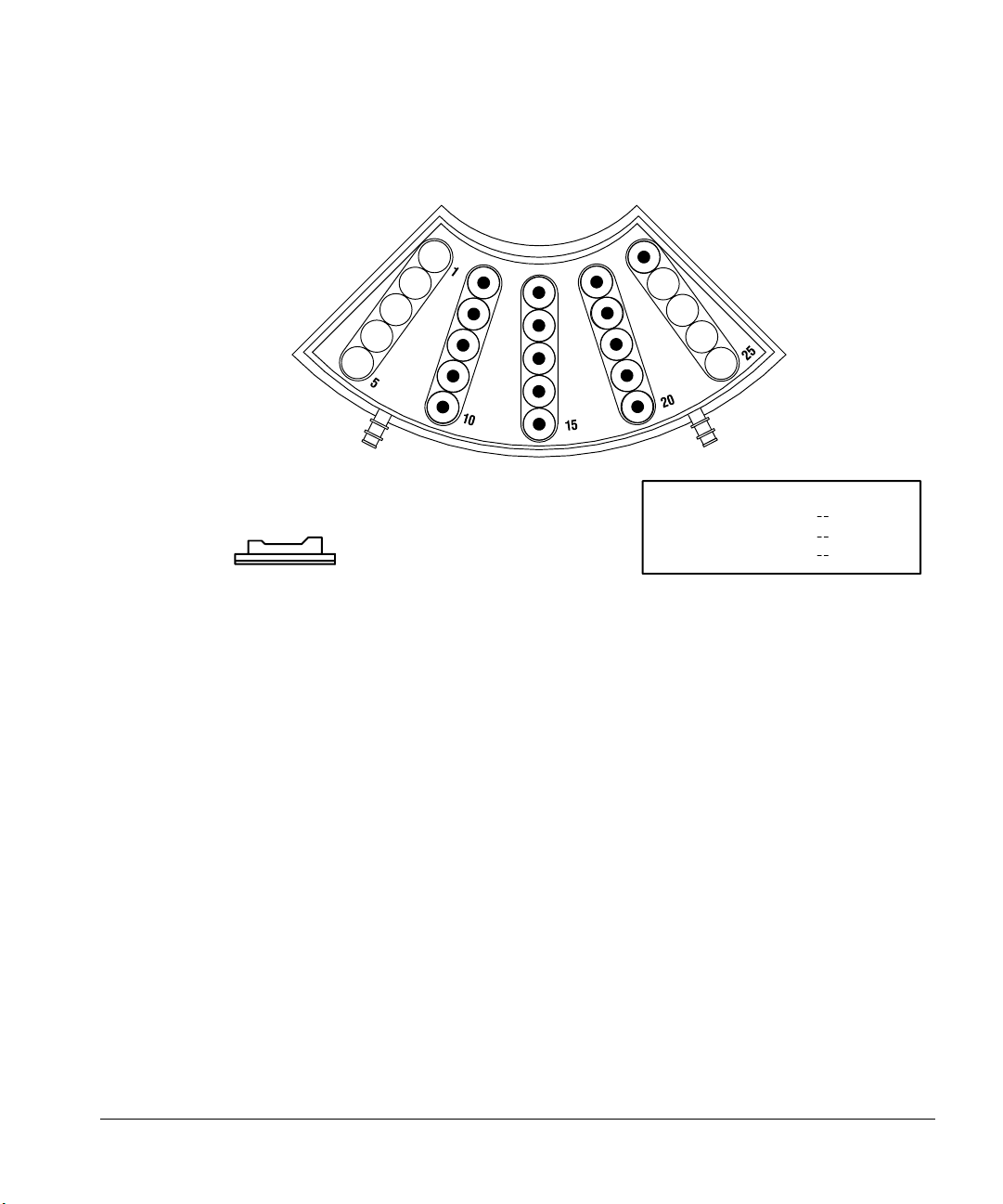

Placing sample vials in a tray

You can place up to 100 samples in the tray’s four quadrants. The tray gripper

picks up the vials and delivers them to the sample vial position in the turret.

When you are not using the external control instruments, place the first bottle

in quadrant position 1. The tray continues to deliver vials until it delivers the

last one in the series or until it encounters an empty position. For more

information, see chapter 4, “Standalone Control.”

When you are using another instrument such as an integrator or ChemStation

to control the tray, the first and last bottle positions are defined when you set

the sequence parameters. The tray begins picking up sample vials at the

position that corresponds to the “first bottle” and stops after it replaces the vial

that corresponds to the “last bottle.”

33

Page 43

Preparing for Operation

Using the injector fan

For more information, see “Setting the run parameters” in chapter 3.

Figure 25. Specifying tray positions with a 3396 integrator and 5890 or 6890 GC

FRONT INJECTOR

INJ/BOTTLE

FIRST BOTTLE

LAST BOTTLE

1 >

1 >

5 >

@

6

21

34

Using the injector fan

The purpose of the fan is to push cool air over the samples and solvent to keep

them cooler. Also, some samples may boil out of the syringe if heat builds up in

the injector.

For a particular application, you may want the area around the samples to be

warm. Heat can help the delivery of viscous, high-boiling samples.

The default position of the fan is on. If your analysis requires the fan to be off,

use the instructions “Turning the fan off” below.

Turning the fan off

To turn the fan off, follow these steps.

1. Turn the controller power switch off.

2. Put on a grounded wrist strap.

Page 44

Preparing for Operation

Using the injector fan

Caution This procedure requires protection against electrostatic discharge. Use a static

control wrist strap connected to a ground (part no. 9300-0969 for large wrists

or part no. 9300-0970 for small wrists). If you do not use static protection, you

may damage the electronics of the injector. Do not touch any of the electrical

components, especially the microprocessor.

3. Open the door to the injector electronics assembly, and remove the three

screws on the left edge of the panel with a No. 1 Point Pozidrive

screwdriver.

4. Open the left-hand side of the assembly. Remove the blue ribbon cable

(P3) so P6 is more visible. Locate the P6 jumper switch on the top left

front corner of the printed circuit board.

5. Connect the P6 jumper so that it covers the top two prongs on the circuit

board labeled OFF. See Figure 26. Return the ribbon cable to its original

position.

OFF

Screws

P6

Figure 26. P6 jumper setting

6. Close the left-hand side of the assembly, and replace the three screws on

the left edge of the front panel.

ON

35

Page 45

Preparing for Operation

Preparing the solvent and waste bottles

7. Restore the power. The fan should now be off. If it is still running, reopen

the injector, and check the position of the P6 jumper according to the

instructions in step 5.

Preparing the solvent and waste bottles

The solvent bottles hold solvent for rinsing the syringe between injections. The

injector dispenses the solvent washes and sample washes into waste bottles.

The first two parts of this section explain how to select, fill, and place the

solvent and waste bottles. The last two parts of this section explain how to

estimate the maximum number of vials you can run at one time and how the

injector controls carryover.

For information on how to set the number of washes, see “Setting the run

parameters” in chapter 3.

36

Selecting the bottles

The injector uses 4-ml bottles with diffusion caps to hold the solvent and

waste. You can use diffusion caps or septa on these bottles to reduce

evaporation and diffusion of your solvents and waste. Agilent Technologies

recommends diffusion caps over septa for two reasons:

• The diffusion cap allows multiple entrances into a bottle without

contaminating the liquid inside the bottle with small pieces of septum

material.

Page 46

Preparing for Operation

Preparing the solvent and waste bottles

• For many common solvents, the rate of diffusion out of the bottle is less

with a diffusion cap than with a septum that has been punctured with a

standard syringe needle.

Diffusion cap

Agilent Technologies recommends

using a diffusion cap instead of a

septum to reduce solvent

contamination and evaporation.

Figure 27. 4-ml bottle used for solvent and waste

Filling and placing the bottles

Before each sequence or group of sequences, prepare your solvent and waste

bottles by doing the following:

1. Rinse and fill each solvent bottle with 4 to 4.5 ml of fresh solvent. The

liquid level should be near the shoulder of the bottle. If the solvent bottle is

filled with 4.5 ml of solvent, the syringe can reach about 2 ml or about 250

washes for a 10-µl syringe.

4.5 ml maximum

2.5 ml minimum

18.5 mm

Figure 28. Shows position of the syringe tip when withdrawing solvent

37

Page 47

Preparing for Operation

Preparing the solvent and waste bottles

2. Empty and rinse each waste bottle. The syringe can dispense about 4 ml of

waste into the waste bottle or about 500 washes for a 10-µl syringe.

4 ml maximum

Figure 29. Shows position of syringe tip when dispensing waste

3. Place the bottles in the appropriate positions on the injector turret

according to the table on page 40. The positions are labeled on the turret,

Solvent A, Waste A, Solvent B, and Waste B.

Caution Do not refill a solvent bottle that still has solvent left in the bottle. The solvent

from the last analysis may be contaminated.

38

Figure 30 shows an example of the turret positions used with and without a

tray.

• If a tray is installed, place four bottles in turret positions solvent A, waste

A, solvent B, and waste B.

Page 48

Preparing for Operation

Preparing the solvent and waste bottles

• If a tray is not installed, place two or three bottles (solvent A, waste A, and

solvent B) in the turret positions. Position 3 in the turret can be used as

sample 3 or solvent B. Make sure you have the correct vial in the turret.

Top view with a tray Top view without a tray

Solvent A Solvent A

Waste B

Solvent B

Waste A Waste A

Figure 30. Examples with and without a tray

Solvent B

39

Page 49

Preparing for Operation

Preparing the solvent and waste bottles

Caution When a tray is installed, place a waste bottle in both waste position A and

waste position B. The injector alternates dispensing waste between the two

positions. With the 6890 Series GC, you can choose A, B, or both.

System Solvent Waste

Standalone With a tray

Without a tray

3365/5890 With a tray

Without a tray

3366/5890 With a tray

Without a tray

3396/6890 With a tray

Without a tray

Multitechnique

ChemStation/5890

Multitechnique

ChemStation/6890

With a tray

Without a tray

With a tray

Without a tray

A & B

A

A, B, or both

A, B, or both

A, B, or both

A

A, B, or both

A, B, or both

A, B, or both

A, B, or both

A, B, or both

A, B, or both

A & B

A

A & B

A

A & B

A

A, B or both

A

A & B

A

A, B or both

A

Do you need to read further?

The volumes of the solvent and waste bottles determine the number of sample

vials that you can run at one time. If your application requires more than the

maximum number of washes listed in Figure 31, you must read the next section

entitled, “Estimating the maximum number of sample vials.” The total number

of washes includes all solvent (pre- and post-injection) and sample washes

using the default needle depth. This is critical to your solvent supply if solvent

prewashes are not part of your solvent needed estimation.

40

Page 50

Preparing for Operation

Preparing the solvent and waste bottles

Number of Bottles Solvent Limit Waste Limit

Syringe size 5 µl 10 µl 5 µl 10 µl

Two bottles 1,000 500 2,000 1,000

One bottle 500 250 1,000 500

Note: Wash volume is 0.8 times the syringe volume.

Figure 31. The maximum number of washes (pre- and post-injection)

Caution Do not exceed the solvent and waste limits of the bottles. If you exceed these

limits, sample carryover may affect your analysis.

Example 1 (tray not installed): Your application requires 10 sample

washes and 10 solvent washes with a 10-µl syringe. For three sample vials (five

injections per vial), you need 150 solvent washes, and you need to dispense 300

syringe volumes of waste. With this example, you are limited to one bottle for

solvent and one bottle for waste.

Figure 31 shows that you can have up to 250 washes from one solvent bottle

and can dispense up to 500 washes into the waste bottle. You are within the

limits and do not have to read any further.

Example 2 (tray installed): Your application requires three sample washes

and three solvent washes with a 10-µl syringe. For 40 sample vials (two

injections per vial), you need 240 solvent washes, and you need to dispense 480

syringe volumes of waste. With this example, you are using two bottles for

solvent and two bottles for waste.

Figure 31 shows that you can have up to 250 washes from each solvent bottle

and can dispense up to 1,000 washes into the waste bottles. You are within the

limits and do not have to read any further.

Example 2b (tray installed): Your application requires three sample washes

and three solvent washes with a 10-µl syringe. If you had 60 samples, you

would need 360 washes from the solvent bottles. You would have to place

41

Page 51

Preparing for Operation

Preparing the solvent and waste bottles

solvent bottles in both positions and set the run parameters for solvent washes

from both positions (e.g., one from solvent A and two from solvent B).

Example 3 (tray installed): Your application requires three sample washes,

three solvent A washes, and three solvent B washes with a 10-µl syringe. For

100 sample vials (two injections per vial), you need 600 solvent washes and

need to dispense 1,200 syringe volumes of waste. With this example, you are

using two bottles for solvent and two bottles for waste.

Figure 31 shows that you can have up to 250 washes from each solvent bottle

and can dispense up to 1,000 washes into the waste bottles. You would exceed

the solvent and waste capacity of the bottles. Read the next section to estimate

the maximum number of sample vials you can run at one time.

Estimating the maximum number of sample vials

This section contains equations and tables for estimating the maximum

number of sample vials you can run before you must replace the solvent or

empty the waste bottles.

Caution The number of sample vials given in the equations and tables are estimates.

Characteristics of the solvent, such as the evaporation rate and surface

tension, may affect the capacity of the bottles.

If you use either the tables or the equations, you must know the following

parameters for your application:

• The number of injections per vial.

• The number of solvent washes per pre- and post-injection required from

each solvent bottle.

• The number of sample wastes and solvent washes per injection that the

injector dispenses into each waste bottle. When the tray is installed, you

must use two waste bottles. The injector dispenses the waste equally

between the two bottles unless you have specified differently on the

6890 Series GC.

• The syringe size, 5 µl or 10 µl.

42

Page 52

Preparing for Operation

Preparing the solvent and waste bottles

Using the equation to estimate

1. Substitute the parameters of your application into both equations.

• If you are using a 5-µl syringe, substitute 0.004 ml/wash for the

0.008 ml/wash in each equation.

• If a tray is installed or both waste bottles are being used, substitute

8.0 ml of waste for the 4.0 ml of waste in the second equation.

2. Calculate the answers for both equations. Use the smaller of the two

answers for the estimate.

• Equation S estimates the maximum number of vials from the volume

of solvent available from the bottle associated with the largest

number of washes.

Equation S

Maximum

Number

of Vials

=

0.008 ml/wash Number

××

2.0 ml of solvent

injections/vial

Largest number solvent

washes from a bottle

• Equation W estimates the maximum number of vials from the waste

bottle capacity.

Equation W

Maximum

Number

of Vials

=

0.008 ml/wash Number

××

4.0 ml of waste

injections/vial

Number solvent and

sample washes/injection

Equation method example

Assume a tray is installed and your application parameters are:

• Two injections per vial

• Three washes from solvent bottle A

• Two washes from solvent bottle B

• Two sample washes

• 10-µl syringe

43

Page 53

Preparing for Operation

Preparing the solvent and waste bottles

1. Substitute the parameters of your application into equations S and W.

S: Maximum number of vials = 2.0 ( 0.008 x 2 x 3 ) = 41

W: Maximum number of vials = 8.0 ( 0.008 x 2 x 7 ) = 71

2. Calculate the answers for both equations. Use the smaller of the two

answers, answer (41).

Using the table to estimate

1. Go to the S table in Figure 32. In the left-hand column, find the largest

number of solvent washes you need from a solvent bottle. If you use a tray,

you can divide the solvent washes between both waste bottles.

2. Read across this row to the column with the number of injections you are

taking from each vial. The intersection of row and column is the maximum

number of vials that you can run from the limiting bottle.

• When you are using a 5-µl syringe, multiply the maximum number of

vials listed in the figure by 2.

44

Page 54

Preparing for Operation

Preparing the solvent and waste bottles

S

Number

of

solvent

washes

per

injection

123456

1 100+100+83625041

2 100+6241312520

3 834127201613

4 623120151210

5 50251612108

6 412013108 6

7 3517118 7 5

8 3115107 6 5

927139654

1025128654

1122117543

1220106543

131996433

141785432

151685432

Number of injections per vial

Figure 32. Maximum number of sample vials with one solvent bottle and a 10-µl

syringe

3. Go to the W table in Figure 33. In the left-hand column, find the number of

solvent wastes and sample washes you need.

4. Read across this row to the column with the number of injections you are

making from each vial. The intersection of row and column is the

maximum number of vials that you can run with one bottle.

• If a tray is installed, multiply the maximum number of vials listed in

the figure by 2.

45

Page 55

Preparing for Operation

Preparing the solvent and waste bottles

W

Number

of pre-and

post-solvent washes

+

sample washes

per injection

123456

1 100+ 100+ 100+ 100+ 100 83

2 100+100+83625041

3 100+8355413327

4 100+6241312520

5 100 50 33 25 20 16

6 834127201613

7 713523171411

8 623120151210

9 55271813119

10 50 25 16 12 10 8

11 45 22 15 11 9 7

12 41 20 13 10 8 6

13 38 19 12 9 7 6

14 35 17 11 8 7 5

15 33 16 11 8 6 5

Number of injections per vial

Figure 33. Maximum number of sample vials with one waste bottle and a 10-µl

syringe

46

5. Compare the answers from both tables. Use the smaller of the two

answers for the estimate.

Table method example

Assume a tray is installed and your application parameters are:

• Two injections per vial

• Three washes from solvent bottle A

• Two washes from solvent bottle B

• Two sample washes

• 10-µl syringe

Page 56

Preparing for Operation

Preparing the solvent and waste bottles

1. Go to the S table in Figure 32. In the left-hand column, find the largest

number of solvent washes you need from a solvent bottle, answer (3).

2. Read across this row to the column indicating the number of injections

you are taking from each vial, answer (2).

The intersection of row and column is the maximum number of vials that

you can run from the limiting bottle, answer (41).

3. Go to the W table in Figure 33. In the left-hand column, find the number of

solvent and sample washes you need, answer (7).

4. Read across this row to the column indicating the number of injections

you are making from each vial, answer (2).

The intersection of row and column is the maximum number of vials for

one bottle, answer (35).

• Because a tray is installed, multiply the maximum number of vials

listed in the table by 2, answer (70).

5. Compare the answers from both tables. Use the smaller of the two

answers for the maximum vial estimate, answer (41).

Controlling sample carryover

This section describes the features of the injector used to control carryover.

For an explanation of sample carryover, see the Glossary.

You can use solvent washes, sample washes, and pumps to control carryover

because each dilutes the concentration of sample left in the syringe. The

effectiveness of each depends on your application.

You may be able to adjust your application for a more efficient use of solvent

and sample and increase the number of sample vials you can run at one time.

• Solvent washes

The injector fills the syringe to eight-tenths of its volume (4 µl with the 5-µl

syringe and 8 µl with the 10-µl syringe) from either the solvent A or solvent

B position. Then it dispenses the syringe contents into one of the waste

bottles. Solvent washes can be set to occur before taking a sample

(preinjection solvent wash) or immediately after the injection

(postinjection solvent wash).

47

Page 57

Preparing for Operation

Preparing the solvent and waste bottles

• Sample washes

The injector fills the syringe to eight-tenths of its volume with the next

sample and dispenses the contents into one of the waste bottles. Sample

washes occur before the injection. When sample is limited, you can use a

solvent prewash to wet the syringe before drawing sample.

• Pumps

The injector fills the syringe to eight-tenths of its volume with the next

sample and dispenses it back into the sample vial. Pumps occur after the

sample washes and immediately before the injection. Pumps serve to

eliminate bubbles. If the needle contains solvent from a previous wash, the

pumps may add a small amount of solvent that mixes with the sample and

can dilute a small volume.

The number and type of washes are determined with the run parameters. See

“Setting the run parameters” in chapter 3 for details.

Under ideal conditions, four washes reduce the carryover to one part in 10,000.

The actual number and type of washes you need depends on many factors,

including:

48

• The percentage of carryover that you can accept

• The viscosity and solubility of the analyte(s)

• The volatility of the solvent(s)

• The extent of wear in the syringe barrel

The number and type of washes is often set for you as a standard method. You

can also determine the number and type of washes experimentally.

To measure the percentage of carryover in your procedure, run a solvent blank

after a sample, and compare the peak areas of the components.

Page 58

Preparing for Operation

Selecting and installing syringes

Selecting and installing syringes

Selecting syringes

Select the type of syringe you need based on the inlet (injection port) you are

using and the volume of sample you want to inject.

1. The syringe needle must have a cone tip. Do not use sharp-tipped needles.

These needles tear the inlet septum causing leaks. Also, sharp-tipped

needles wipe off on the septum as they exit resulting in a large solvent tail

on the chromatogram.

Sharp tip

Cone tip

Figure 34. Needle tip

Figure 35 illustrates some of the critical syringe dimensions. These

dimensions do not make up a complete set of specifications. Some of the

dimensions are too difficult to measure without special instruments.

126.5

84.5

6.6 0.1

All dimensions in millimeters

12.5

Figure 35. Syringe dimensions

49

Page 59

Preparing for Operation

Selecting and installing syringes

Figure 36 illustrates the shapes of the two fixed needles:

Figure 36. Needle shapes

2. Select the appropriate syringe needle gauge. If you need more help in

making your selection, refer to chapter 6, “Special Topics.”

23/26 gauge tapered needle

23 gauge or 26 gauge straight needle

50

Inlet Needle Gauge Column Type

Packed, split, or

splitless

Cool on-column 23/26 gauge tapered, 26 gauge, 530 µm

23 gauge or 23/26 gauge tapered

32/26 gauge 320 µm

32/26 gauge 250 µm

Figure 37. Needle gauge selection

3. Select the 5-µl or 10-µl syringe. Figure 38 shows the range of volumes you

can inject according to the sample volume setting, the syringe size, and

whether the nanoliter adapter, accessory 18599N, is installed.

Page 60

Preparing for Operation

Selecting and installing syringes

Sample Volume Setting Standard Injection With Nanoliter Adapter

Syringe

Size

1 0.5 1.0 0.1 0.2

2 1.0 2.0 .05 1.0

3 1.5 3.0 1.0 2.0

4 2.0 4.0 1.5 3.0

5 2.5 5.0 2.0 4.0

5 µl 10 µl 5 µl 10 µl

Figure 38. Injection volumes depend on sample volume setting, syringe size and

injection type

Caution Failure to use an on-column syringe when injecting into an on-column inlet

could damage the injector, syringe and column.

Inspecting syringes

Before installing the syringe:

1. Roll the syringe on the edge of a clean flat surface. If the tip of the needle

seems to follow a circular motion, bend it slightly near where it connects

to the syringe barrel, and check it again.

Bend here if necessary

Figure 39. Syringe parts and needle inspection

2. Check for a rough needle. The needle may contain closely spaced

concentric ridges that act like a miniature file and abrade pieces of the

septum into the inlet. The ridges are easy to see under 10X magnification.

51

Page 61

Preparing for Operation

Selecting and installing syringes

If there are ridges, polish the needle by pulling it through a folded piece of

fine emery paper between your finger and thumb until the ridges are gone.

Be careful not to modify the special blunt tip of the syringe.

3. Check for a sticky plunger. Slide the plunger of the syringe up and down a

few times. It should move smoothly without sticking or binding. If it is

sticky, remove the plunger, and clean it with solvent.

Installing syringes

After completing this task, check your work with the following instructions:

1. Open the injector door.

2. Pass the syringe needle through the hole in the needle support foot.

3. Align the syringe barrel with the flange guide and syringe clip. Press the

syringe in place, keeping the needle in the hole of the needle support foot.

4. Close the syringe latch by swinging it clockwise.

52

Plunger carrier

Plunger screw

Slide

Flange guide

Syringe latch

Syringe clip

Needle support foot

Flange

Figure 40. Installing the syringe in the syringe carriage and needle support

Page 62

Preparing for Operation

Selecting and installing syringes

5. Move the plunger carrier loop down and tighten the plunger screw.

Checking your work

❐ Move the plunger carrier up and down. If the syringe plunger does not move

along with the carrier, repeat the previous steps. Be sure the plunger carrier

screw is tight.

❐ Check that the needle is aligned with the needle guide in the foot by moving

the slide up and down. The needle should slide smoothly in the needle guide.

Plunger carrier

Plunger carrier screw

Slide

Flange guide

Syringe latch

Syringe clip

Needle support foot

Figure 41. Plunger carrier and needle support with needle installed

Caution Failure to use the on-column syringe when injecting into an on-column inlet

could damage the injector, syringe, and column.

53

Page 63

Preparing for Operation

Maintaining the inlet

Caution Do not operate the injector without a syringe in place because the syringe latch

may interfere with the motor if it is allowed to swing freely.

❐ To check the alignment of the syringe needle to ensure an average septum

life of 200 injections, follow these instructions:

1. Pull down the syringe carriage until the needle tip is near the top of the

inlet septum nut. The needle should be centered exactly over the hole in