Page 1

Programming Guide

Dynamic Measurement DC Source

Agilent Models 66312A, 66332A

System DC Power Supply

Agilent Models 6631B, 6632B, 6633B, 6634B

6611C, 6612C, 6613C, 6614C

Agilent Part No. 5962-8198 Printed in U.S.A.

Microfiche No 5962-8199 January, 2000

Page 2

Safety Guidelines

The beginning of the Operating Guide has a Safety Summary page. Be sure you are familiar with the

information on this page before programming the dc source for operation from a controller.

Printing History

The edition and current revision of this manual are indicated below. Reprints of this guide containing minor

corrections and updates may have the same printing date. Revised editions are identified by a new

printing date. A revised edition incorporates all new or corrected material since the previous printing date.

Changes to the manual occurring between revisions are covered by change sheets shipped with the

guide.

This document contains proprietary information protected by copyright. All rights are reserved. No part of

this document may be photocopied, reproduced, or translated into another language without the prior

consent of Agilent Technologies. The information contained in this document is subject to change without

notice.

Copyright 1997 Agilent Technologies Edition 1 November, 1997

Update 1 December, 1998

Update 2 January, 2000

2

Page 3

Table of Contents

Safety Guidelines 2

Printing History 2

Table of Contents 3

1 - GENERAL INFORMATION 7

About this Guide 7

Documentation Summary 7

External References 8

GPIB References 8

SCPI References 8

2 - INTRODUCTION TO PROGRAMMING 9

VXIplug&play Power Products Instrument Drivers 9

Supported Applications 9

System Requirements 9

Downloading and Installing the Driver 9

Accessing Online Help 10

GPIB Capabilities of the DC Source 10

GPIB Address 10

RS-232 Capabilities of the DC Source 10

RS-232 Data Format 10

RS-232 Flow Control 11

RS-232 Programming Example 11

RS-232 Troubleshooting 12

Introduction to SCPI 12

Conventions Used in This Guide 12

Types of SCPI Commands 13

Multiple Commands in a Message 13

Moving Among Subsystems 14

Including Common Commands 14

Using Queries 14

Types of SCPI Messages 14

The Message Unit 15

Headers 15

Query Indicator 15

Message Unit Separator 15

Root Specifier 15

Message Terminator 15

SCPI Data Formats 16

Numerical Data Formats 16

Suffixes and Multipliers 16

Response Data Types 16

SCPI Command Completion 17

Using Device Clear 17

3 - PROGRAMMING THE DC SOURCE 19

Introduction 19

Programming the Output 19

Power-on Initialization 19

Enabling the Output 19

Output Voltage 20

Output Current 20

Triggering Output Changes 21

SCPI Triggering Nomenclature 21

3

Page 4

Output Trigger System Model 21

Setting the Voltage or Current Trigger Levels 21

Initiating the Output Trigger System 22

Generating Triggers 22

Making Measurements 23

Voltage and Current Measurements 23

Internally Triggered Measurements 25

SCPI Triggering Nomenclature 25

Measurement Trigger System Model 25

Initiating the Measurement Trigger System (Agilent 66312A, 66332A Only) 25

Selecting the Measurement Trigger Source (Agilent 66312A, 66332A Only) 26

Generating Measurement Triggers (Agilent 66312A, 66332A Only) 26

Measuring Output Pulses (Agilent 66312A, 66332A Only) 28

Current Detector 28

Pulse Measurement Queries 28

Controlling Measurement Samples 29

Varying the Voltage or Current Sampling Rate 29

Multiple Measurements (Agilent 66312A, 66332A Only) 29

Pre-event and Post-event Triggering (Agilent 66312A, 66332A Only) 30

Pulse Measurement Example (Agilent 66312A, 66332A only) 30

Programming the Status Registers 32

Power-On Conditions 32

Operation Status Group 33

Questionable Status Group 34

Standard Event Status Group 34

Status Byte Register 34

Determining the Cause of a Service Interrupt 35

Servicing Operation Status and Questionable Status Events 35

Monitoring Both Phases of a Status Transition 36

Inhibit/Fault Indicator 36

Remote Inhibit (RI) 36

Discrete Fault Indicator (DFI) 36

Using the Inhibit/Fault Port as a Digital I/O 37

DFI Programming Example 37

4 - LANGUAGE DICTIONARY 39

Introduction 39

Subsystem Commands 39

Common Commands 43

Programming Parameters 43

Calibration Commands 44

CALibrate:CURRent 44

CALibrate:CURRent:NEGative 44

CALibrate:CURRent:MEASure:LOWRange 44

CALibrate:CURRent:MEASure:AC 44

CALibrate:DATA 45

CALibrate:LEVel 45

CALibrate:PASSword 45

CALibrate:SAVE 45

CALibrate:STATe 46

CALibrate:VOLTage 46

CALibrate:VOLTage:PROTection 46

Measurement Commands 47

MEASure:ARRay:CURRent? FETCh:ARRay:CURRent? 47

MEASure:ARRay:VOLTage? FETCh:ARRay:VOLTage? 47

4

Page 5

MEASure:CURRent? FETCh:CURRent? 48

MEASure:CURRent:ACDC? FETCh:CURRent:ACDC? 48

MEASure:CURRent:HIGH? FETCh:CURRent:HIGH? 48

MEASure:CURRent:LOW? FETCh:CURRent:LOW? 49

MEASure:CURRent:MAXimum? FETCh:CURRent: MAXimum? 49

MEASure:CURRent:MINimum? FETCh:CURRent:MINimum? 49

MEASure:VOLTage? FETCh:VOLTage? 50

MEASure:VOLTage:ACDC? FETCh:VOLTage:ACDC? 50

MEASure:VOLTage:HIGH? FETCh:VOLTage:HIGH? 50

MEASure:VOLTage:LOW? FETCh:VOLTage:LOW? 51

MEASure:VOLTage:MAXimum? FETCh:VOLTage:MAXimum? 51

MEASure:VOLTage:MINimum? FETCh:VOLTage:MINimum? 51

SENSe:CURRent:RANGe 52

SENSe:CURRent:DETector 52

SENSe:FUNCtion 53

SENSe:SWEep:OFFSet:POINts 53

SENSe:SWEep:POINts 53

SENSe:SWEep:TINTerval 53

SENSe:WINDow 54

Output Commands 55

OUTPut 55

OUTPut:DFI 55

OUTPut:DFI:SOURce 55

OUTPut:PON:STATe 56

OUTPut:PROTection:CLEar 56

OUTPut:PROTection:DELay 56

OUTPut:RELay 57

OUTPut:RELay:POLarity 57

OUTPut:RI:MODE 57

[SOURce:]CURRent 58

[SOURce:]CURRent:TRIGger 58

[SOURce:]CURRent:PROTection:STATe 58

[SOURce:]DIGital:DATA 59

[SOURce:]DIGital:FUNCtion 59

[SOURce:]VOLTage:ALC:BANDwidth? [SOURce:]VOLTage:ALC:BWIDth? 60

[SOURce:]VOLTage:TRIGger 60

[SOURce:]VOLTage:PROTection 60

Status Commands 61

STATus:PRESet 61

STATus:OPERation? 61

STATus:OPERation:CONDition? 61

STATus:OPERation:ENABle 62

STATus:OPERation:NTR STATus:OPERation:PTR 62

STATus:QUEStionable? 63

STATus:QUEStionable:CONDition? 63

STATus:QUEStionable:ENABle 63

STATus:QUEStionable:NTR STATus:QUEStionable:PTR 64

*CLS 64

*ESE 65

*ESR? 65

*OPC 65

*PSC 66

*SRE 66

*STB? 67

*WAI 67

5

Page 6

System Commands 68

DISPlay 68

DISPlay:MODE 68

DISPlay:TEXT 68

SYSTem:ERRor? 69

SYSTem:LANGuage 69

SYSTem:VERSion? 69

SYSTem:LOCal 70

SYSTem:REMote 70

SYSTem:RWLock 70

*IDN? 70

*OPT? 71

*RCL 71

*RST 71

*SAV 72

*TST? 72

Trigger Commands 73

ABORt 73

INITiate:SEQuence INITiate:NAME 73

INITiate:CONTinuous:SEQuence1 INITiate:CONTinuous:NAME 73

TRIGger 74

TRIGger:SOURce 74

TRIGger:SEQuence2 TRIGger:ACQuire 74

TRIGger:SEQuence2:COUNt:CURRent TRIGger:ACQuire:COUNt:CURRent 75

TRIGger:SEQuence2:COUNt:VOLTage TRIGger:ACQuire:COUNt:VOLTage 75

TRIGger:SEQuence2:HYSTeresis:CURRent TRIGger:ACQuire:HYSTeresis:CURRent 76

TRIGger:SEQuence2:HYSTeresis:VOLTage TRIGger:ACQuire:HYSTeresis:VOLTage 76

TRIGger:SEQuence2:LEVel:CURRent TRIGger:ACQuire:LEVel:CURRent 77

TRIGger:SEQuence2:LEVel:VOLTage TRIGger:ACQuire:LEVel:VOLTage 77

TRIGger:SEQuence2:SLOPe:CURRent TRIGger:ACQuire:SLOPe:CURRent 78

TRIGger:SEQuence2:SLOPe:VOLTage TRIGger:ACQuire:SLOPe:VOLTage 78

TRIGger:SEQuence2:SOURce TRIGger:ACQuire:SOURce 79

TRIGger:SEQuence1:DEFine TRIGger:SEQuence2:DEFine 79

*TRG 79

A - SCPI CONFORMANCE INFORMATION 81

SCPI Version 81

SCPI Confirmed Commands 81

Non-SCPI Commands 81

B - COMPATIBILITY LANGUAGE 83

Introduction 83

C - ERROR MESSAGES 89

Error Number List 89

D - EXAMPLE PROGRAMS 93

Introduction 93

Assigning the GPIB Address in Programs 93

Types of DOS Drivers 93

Error Handling 94

BASIC Controllers 94

Example 1. HP Vectra PC Controller Using Agilent 82335 Interface 94

Example 2. IBM Controller Using National Interface 96

Example 3. Controller Using BASIC 98

INDEX 99

6

Page 7

General Information

About this Guide

This guide provides remote programming information for the following series of GPIB programmable dc

power supplies:

•

Agilent 66312A

•

Agilent 66332A

•

Agilent 6631B/6632B/6633B/6634B

•

Agilent 6611C/6612C/6613C/6614C

You will find the following information in the rest of this guide:

Chapter 1 Introduction to this guide.

Chapter 2 Introduction to SCPI messages structure, syntax, and data formats. Examples of SCPI

programs

Chapter 3 Introducton to Programming the dc source with SCPI commands.

Chapter 4 Dictionary of SCPI commands.

Appendix A SCPI conformance information.

1

Appendix B Use of the alternate Comptibility programming language.

Appendix C Error messages

Documentation Summary

The following documents that are related to this Programming Guide have additional helpful information

for using the dc source.

♦

User’s Guide for Agilent 66312A and Agilent 6611C/6612C/6613C/3314C. Includes specifications

and supplemental characteristics, how to use the front panel, how to connect to the instrument,

and calibration procedures.

♦

User’s Guide for Agilent 66332A and Agilent 6631B/6632B/6633B/6634B. Includes specifications

and supplemental characteristics, how to use the front panel, how to connect to the instrument,

and calibration procedures.

7

Page 8

1 - General Information

External References

GPIB References

The most important GPIB documents are your controller programming manuals - BASIC, GPIB Command

Library for MS DOS, etc. Refer to these for all non-SCPI commands (for example: Local Lockout).

The following are two formal documents concerning the GPIB interface:

♦

ANSI/IEEE Std. 488.1-1987 IEEE Standard Digital Interface for Programmable Instrumentation

Defines the technical details of the GPIB interface. While much of the information is beyond the

need of most programmers, it can serve to clarify terms used in this guide and in related

documents.

♦

ANSI/IEEE Std. 488.2-1987 IEEE Standard Codes, Formats, Protocols, and Common

Commands

programming. Helpful for finding precise definitions of certain types of SCPI message formats,

data types, or common commands.

The above two documents are available from the IEEE (Institute of Electrical and Electronics Engineers),

345 East 47th Street, New York, NY 10017, USA. The WEB address is www.ieee.org.

. Recommended as a reference only if you intend to do fairly sophisticated

.

SCPI References

The following documents will assist you with programming in SCPI:

♦

Standard Commands for Programmable Instruments Volume 1, Syntax and Style

♦

Standard Commands for Programmable Instruments Volume 2, Command References

♦

Standard Commands for Programmable Instruments Volume 3, Data Interchange Format

♦

Standard Commands for Programmable Instruments Volume 4, Instrument Classes

To obtain a copy of the above documents, contact: Fred Bode, Executive Director, SCPI Consortium,

8380 Hercules Drive, Suite P3, Ls Mesa, CA 91942, USA

8

Page 9

Introduction to Programming

VXI

plug&play

VXI

plug&play

Web at http://www.agilent.com/find/drivers. These instrument drivers provide a high-level programming

interface to your Agilent Technologies instrument. VXI

programming your instrument with SCPI command strings. Because the instrument driver’s function

calls work together on top of the VISA I/O library, a single instrument driver can be used with multiple

application environments.

Supported Applications

ñ Agilent VEE

ñ Microsoft Visual BASIC

ñ Microsoft Visual C/C++

ñ Borland C/C++

ñ National Instruments LabVIEW

ñ National Instruments LabWindows/CVI

instrument drivers for Microsoft Windows 95 and Windows NT are now available on the

Power Products Instrument Drivers

plug&play

instrument drivers are an alternative to

2

System Requirements

The VXI

ñ Microsoft Windows 95

ñ Microsoft Windows NT 4.0

ñ HP VISA revision F.01.02

ñ National Instruments VISA 1.1

plug&play

Power Products instrument driver complies with the following:

Downloading and Installing the Driver

NOTE: Before installing the VXIplug&play instrument driver, make sure that you have one of the

supported applications installed and running on your computer.

1.Access Agilent Technologies’ Web site at http://www.agilent.com/find/drivers.

2. Select the instrument for which you need the driver.

3. Click on the driver, either Windows 95 or Windows NT, and download the executable file to your

pc.

4.Locate the file that you downloaded from the Web. From the Start menu select Run

<path>:\agxxxx.exe - where <path> is the directory path where the file is located, and agxxxx is

the instrument driver that you downloaded .

5.Follow the directions on the screen to install the software. The default installation selections will

work in most cases. The readme.txt file contains product updates or corrections that are not

documented in the on-line help. If you decide to install this file, use any text editor to open and

read it.

9

Page 10

2 - Introduction to Programming

6.To use the VXI

under “Introduction to Programming”.

plug&play

instrument driver, follow the directions in the VXI

plug&play

online help

Accessing Online Help

A comprehensive online programming reference is provided with the driver. It describes how to get

started using the instrument driver with Agilent VEE, LabVIEW, and LabWindows. It includes complete

descriptions of all function calls as well as example programs in C/C++ and Visual BASIC.

ñ To access the online help when you have chosen the default Vxipnp start folder, click on the Start

button and select Programs | Vxipnp | Agxxxx Help (32-bit).

- where agxxxx is the instrument driver.

GPIB Capabilities of the DC Source

All dc source functions except for setting the GPIB address are programmable over the GPIB. The IEEE

488.2 capabilities of the dc source are listed in the Specifications Table of the User's Guide.

GPIB Address

The dc source operates from an GPIB address that is set from the front panel. To set the GPIB address,

press the Address key on the front panel and enter the address using the Entry keys. The GPIB address

is stored in non-volatile memory.

RS-232 Capabilities of the DC Source

The dc source provides an RS-232 programming interface, which is activated by commands located under

the front panel Address key. All SCPI and COMPatibility commands are available through RS-232

programming. When the RS-232 interface is selected, the GPIB interface is disabled.

The EIA RS-232 Standard defines the interconnections between Data Terminal Equipment (DTE) and

Data Communications Equipment (DCE). The dc source is designed to be a DTE. It can be connected to

another DTE such as a PC COM port through a null modem cable.

NOTE: The RS-232 settings in your program must match the settings specified in the front panel

Address menu. Press the front panel Address key if you need to change the settings.

RS-232 Data Format

The RS-232 data is a 10-bit word with one start bit and one stop bit. The number of start and stop bits is

not programmable. However, the following parity options are selectable using the front panel Address key:

EVEN Seven data bits with even parity

ODD Seven data bits with odd parity

MARK Seven data bits with mark parity (parity is always true)

SPACE Seven data bits with space parity (parity is always false)

NONE Eight data bits without parity

Parity options are stored in non-volatile memory.

10

Page 11

Introduction to Programming - 2

Baud Rate

The front panel Address key lets you select one of the following baud rates, which is stored in non-volatile

memory:

300 600 1200 2400 4800 9600

RS-232 Flow Control

The RS-232 interface supports several flow control options that are selected using the front panel Address

key. For each case, the dc source will send a maximum of five characters after holdoff is asserted by the

controller. The dc source is capable of receiving as many as fifteen additional characters after it asserts

holdoff.

XON-XOFF A software handshake that uses the ASCII control code DC3 (decimal code

19) to assert hold-off, and control code DC1 (decimal code 17) to release

hold-off.

RTS-CTS The dc source asserts its Request to Send (RTS) line to signal hold-off

when its input buffer is almost full, and it interprets its Clear to Send (CTS)

line as a hold-off signal from the controller.

DTR-DSR The dc source asserts its Data Terminal Ready (DTR) line to signal hold-off

when its input buffer is almost full, and it interprets its Data Set Ready

(DSR) line as a hold-off signal from the controller.

NONE There is no flow control.

Flow control options are stored in non-volatile memory.

RS-232 Programming Example

The following program illustrates how to program the power supply using RS-232 to set the output voltage

and current and to readback the model number and output voltage. The program was written to run on any

controller using Microsoft QBasic.

NOTE: The power supply must be configured for RS232 and the same baud rate and parity as

the controller.

‘ Program to write and read via RS232.

‘ Configure the power supply for 9600 baud, even parity and RS232

‘ Configure serial port for:”

‘ 9600 baud

‘ 7 bit data

‘ 2 stop bits

‘ Ignore request to send

‘ Ignore carrier detect

‘ Even parity ‘ Needed with Vectra basic, ignored with QBasic

‘ Send line feed

‘ Reserve 1000 character buffer for serial I/O

‘

DECLARE FUNCTION gets$ ()

CLS ‘ Clears screen

LOCATE 1, 1 ‘ Position curser at top left

‘ Configure Com Port

OPEN “com1:9600,e,7,2,rs,cd,pe,lf” FOR RANDOM AS #1 LEN = 1000

PRINT #1, “OUTPUT ON” ‘ Turn on output then set voltage and current

PRINT #1, “VOLT 6” ‘ Set voltage to 6 volts

PRINT #1, “CURR .5” ‘ Set current to 0.5 amps

PRINT #1, “*IDN?” ‘ Query the power supply identification string

PRINT gets$ ‘ Go to gets$ Function and print data returned

PRINT #1, MEAS”VOLT?”; volt ‘ Query the power supply voltage

Volt = VAL (gets$) ‘ Convert gets$ string to a value

PRINT gets$ ‘ Print the value of the voltage

END ‘ End of main program

11

Page 12

2 - Introduction to Programming

FUNCTION gets$ ‘ Get a new line feed terminated string from device #1

C$ = “” ‘ Set C$ to null

WHILE c$ <> CHR$ (10) ‘ Set loop to stop at Line Feed

C$ = INPUT$ (1, #1) ‘ Read 1 bit into file #1

Resp$ = resp$ + c$ ‘ Concantenate bit with previous bits

WEND ‘ End of WHILE loop

gets$ = resp$ ‘ Assign response to gets$

END FUNCTION

RS-232 Troubleshooting

If you are having trouble communicating over the RS-232 interface, check the following:

♦

The computer and the dc source must be configured for the same baud rate, parity, number of

data bits, and flow control options. Note that the dc source is configured for 1 start bit and 1 stop

bit (these values are fixed).

♦

The correct interface cables or adaptors must be used, as described under RS-232 Connector.

Note that even if the cable has the proper connectors for your system, the internal wiring may be

incorrect.

♦

The interface cable must be connected to the correct serial port on your computer (COM1, COM2,

etc.).

Introduction to SCPI

SCPI (Standard Commands for Programmable Instruments) is a programming language for controlling

instrument functions over the GPIB. SCPI is layered on top of the hardware-portion of IEEE 488.2. The

same SCPI commands and parameters control the same functions in different classes of instruments. For

example, you would use the same DISPlay command to control the dc source display and the display of a

SCPI-compatible multimeter.

Conventions Used in This Guide

Angle brackets < > Items within angle brackets are parameter abbreviations. For example,

<NR1> indicates a specific form of numerical data.

Vertical bar | Vertical bars separate alternative parameters. For example, NORM | TEXT

indicates that either "TEXT" or "NORM" can be used as a parameter.

Square Brackets [ ] Items within square brackets are optional. The representation [SOURce:].

VOLTage means that SOURce: may be omitted.

Braces { } Braces indicate parameters that may be repeated zero or more times. It is

used especially for showing arrays. The notation <A>{<,B>} shows that

parameter "A" must be entered, while parameter "B" may be omitted or

may be entered one or more times.

Boldface font

Computer font Computer font is used to show program lines in text.

Boldface font is used to emphasize syntax in command definitions.

TRIGger:COUNt:CURRent <NRf> shows command definition.

TRIGger:COUNt:CURRent 10 shows a program line.

12

Page 13

Types of SCPI Commands

SCPI has two types of commands, common and subsystem.

♦

Common commands generally are not related to specfic operation but to controlling overall dc

source functions, such as reset, status, and synchronization. All common commands consist of a

three-letter nmemonic preceded by an asterisk: *RST *IDN? *SRE 8

♦

Subsystem commands perform specific dc source functions. They are organized into an inverted

tree structure with the "root" at the top. The following figure shows a portion of a subsystem

command tree, from which you access the commands located along the various paths. You can

see the complete tree in Table 4-1.

ROOT

Introduction to Programming - 2

:OUTPut

:STATus

[:STATe]

:DFI

:PON

:PROTection

:OPERation

[:STATe]

:SOURce

:STATe

:CLEar

:DELay

?

[:EVEN]

:CONDition?

Figure 2-1. Partial Command Tree

Multiple Commands in a Message

Multiple SCPI commands can be combined and sent as a single message with one message terminator.

There are two important considerations when sending several commands within a single message:

♦

Use a semicolon to separate commands within a message.

♦

There is an implied header path that affects how commands are interpreted by the dc source.

The header path can be thought of as a string that gets inserted before each command within a message.

For the first command in a message, the header path is a null string. For each subsequent command the

header path is defined as the characters that make up the headers of the previous command in the

message up to and including the last colon seperator. An example of a message with two commands is:

CURR:LEV 3;PROT:STAT OFF

which shows the use of the semicolon separating the two commands, and also illustrates the header path

concept. Note that with the second command, the leading header "CURR" was omitted because after the

"CURR:LEV 3" command, the header path was became defined as "CURR" and thus the instrument

interpreted the second command as:

CURR:PROT:STAT OFF

In fact, it would have been syntactically incorrect to include the "CURR" explicitly in the second command,

since the result after combining it with the header path would be:

CURR:CURR:PROT:STAT OFF

which is incorrect.

13

Page 14

2 - Introduction to Programming

Moving Among Subsystems

In order to combine commands from different subsystems, you need to be able to reset the header path to

a null string within a message. You do this by beginning the command with a colon (:), which discards any

previous header path. For example, you could clear the output protection and check the status of the

Operation Condition register in one message by using a root specifier as follows:

OUTPut:PROTection:CLEAr;:STATus:OPERation:CONDition?

The following message shows how to combine commands from different subsystems as well as within the

same subsystem:

VOLTage:LEVel 20;PROTection 28; :CURRent:LEVel 3;PROTection:STATe ON

Note the use of the optional header LEVel to maintain the correct path within the voltage and current

subsystems, and the use of the root specifier to move between subsytems.

Including Common Commands

You can combine common commands with system commands in the same message. Treat the common

command as a message unit by separating it with a semicolon (the message unit separator). Common

commands

VOLTage:TRIGgered 17.5;:INITialize;*TRG

OUTPut OFF;*RCL 2;OUTPut ON

do not affect the header path

; you may insert them anywhere in the message.

Using Queries

Observe the following precautions with queries:

♦

Set up the proper number of variables for the returned data.

♦

Read back all the results of a query before sending another command to the dc source. Otherwise

a

Query Interrupted

error will occur and the unreturned data will be lost.

Types of SCPI Messages

There are two types of SCPI messages, program and response.

♦

program message

A

controller to the dc source. The message, which may be sent at any time, requests the dc source

to perform some action.

♦

response message

A

controller. The dc source sends the message only when commanded by a program message

called a "query."

The following figure illustrates SCPI message structure:

consists of one or more properly formatted SCPI commands sent from the

consists of data in a specific SCPI format sent from the dc source to the

14

Page 15

Ke

y

y

g

g

Query Indicator

Root Specifier

Data

words

Messa

Introduction to Programming - 2

e Unit

VOLT

word Separator

Ke

:LEV 20

Messa

e Unit Separators

PROT 21;; : CURR?

Message Terminator

<NL>

Figure 2-2. Command Message Structure

The Message Unit

The simplest SCPI command is a single message unit consisting of a command header (or keyword)

followed by a message terminator. The message unit may include a parameter after the header. The

parameter can be numeric or a string.

ABORt<NL>

VOLTage 20<NL>

Headers

Headers, also referred to as keywords, are instructions recognized by the dc source. Headers may be

either in the long form or the short form. In the long form, the header is completely spelled out, such as

VOLTAGE, STATUS, and DELAY. In the short form, the header has only the first three or four letters,

such as VOLT, STAT, and DEL.

Query Indicator

Following a header with a question mark turns it into a query (VOLTage?, VOLTage:PROTection?). If a

query contains a parameter, place the query indicator at the end of the last header

(VOLTage:PROTection? MAX).

Message Unit Separator

When two or more message units are combined into a compound message, separate the units with a

semicolon (STATus:OPERation?;QUEStionable?).

Root Specifier

When it precedes the first header of a message unit, the colon becomes the root specifier. It tells the

command parser that this is the root or the top node of the command tree.

Message Terminator

A terminator informs SCPI that it has reached the end of a message. Three permitted messages

terminators are:

♦ newline (<NL>), which is ASCII decimal 10 or hex 0A.

♦ end or identify (<END>)

♦ both of the above (<NL><END>).

In the examples of this guide, there is an assumed message terminator at the end of each message.

15

Page 16

2 - Introduction to Programming

NOTE:

All RS-232 response data sent by the dc source is terminated by the ASCII character pair

<carriage return><newline>. This differs from GPIB response data which is terminated by

the single character <newline> with EOI asserted.

SCPI Data Formats

All data programmed to or returned from the dc source is ASCII. The data may be numerical or character

string.

Numerical Data Formats

Symbol Data Form

Talking Formats

<NR1> Digits with an implied decimal point assumed at the right of the least-significant digit.

Examples: 273

<NR2>

<NR3>

Listening Formats

<Nrf>

Digits with an explicit decimal point. Example: .0273

Digits with an explicit decimal point and an exponent. Example: 2.73E+2

Extended format that includes <NR1>, <NR2> and <NR3>. Examples: 273 273. 2.73E2

<Nrf+>

<Bool>

Expanded decimal format that includes <NRf> and MIN MAX. Examples: 273 273.

2.73E2 MAX. MIN and MAX are the minimum and maximum limit values that are

implicit in the range specification for the parameter.

Boolean Data. Example: 0 | 1 or ON | OFF

Suffixes and Multipliers

Class Suffix Unit Unit with Multiplier

Current A ampere MA (milliampere)

Amplitude V volt MV (millivolt)

Time S second MS (millisecond)

Common Multipliers

1E3 K kilo

1E-3 M milli

1E-6 U micro

Response Data Types

Character strings returned by query statements may take either of the the following forms, depending on

the length of the returned string:

<CRD> Character Response Data. Permits the return of character strings.

<AARD> Arbitrary ASCII Response Data. Permits the return of undelimited 7-bit ASCII. This data type

has an implied message terminator.

<SRD> String Response Data. Returns string parameters enclosed in double quotes.

16

Page 17

Introduction to Programming - 2

SCPI Command Completion

SCPI commands sent to the dc source are processed either sequentially or in parallel. Sequential

commands finish execution before a subsequent command begins. Parallel commands allow other

commands to begin executing while the parallel command is still executing. Commands that affect trigger

actions are among the parallel commands.

The *WAI, *OPC, and *OPC? common commands provide different ways of indicating when all

transmitted commands, including any parallel ones, have completed their operations. The syntax and

parameters for these commands are described in chapter 4. Some practical considerations for using

these commands are as follows:

*WAI

*OPC?

*OPC

This prevents the dc source from processing subsequent commands until all pending

operations are completed.

This places a 1 in the Output Queue when all pending operations have completed.

Because it requires your program to read the returned value before executing the next

program statement, *OPC? can be used to cause the controller to wait for commands

to complete before proceeding with its program.

This sets the OPC status bit when all pending operations have completed. Since your

program can read this status bit on an interrupt basis, *OPC allows subsequent

commands to be executed.

NOTE: The trigger subsystem must be in the Idle state in order for the status OPC bit to be true.

Therefore, as far as triggers are concerned, OPC is false whenever the trigger subsystem

is in the Initiated state.

Using Device Clear

You can send a device clear at any time abort a SCPI command that may be hanging up the GPIB

interface. The status registers, the error queue, and all configuration states are left unchanged when a

device clear message is received. Device clear performs the following actions:

♦

The input and output buffers of the dc source are cleared.

♦

The dc source is prepared to accept a new command string.

The following statement shows how to send a device clear over the GPIB interface using

CLEAR 705

The following statement shows how to send a device clear over the GPIB interface using the GPIB

command library for

IOCLEAR (705)

C

IEEE-488 Device Clear

or

QuickBASIC

:

Agilent BASIC:

NOTE: For RS-232 operation, sending a Break will perform the same operation as the IEE-488

device clear message.

17

Page 18

Page 19

Programming the DC Source

Introduction

This chapter contains examples on how to program your dc source. Simple examples show you how to

program:

u output functions such as voltage and current

u internal and external triggers

u measurement functions

u the status and protection functions

NOTE: These examples in this chapter show which commands are used to perform a particular

function, but do not show the commands being used in any particular programming

environment. Refer to Appendix D for some examples of SCPI commands in a specific

programming environment.

3

Programming the Output

Power-on Initialization

When the dc source is first turned on, it wakes up with the output state set OFF. In this state the output

voltage is set to 0. The following commands are given implicitly at power-on:

*RST

*CLS

STATus:PRESet

*SRE 0

*ESE 0

*RST is a convenient way to program all parameters to a known state. Refer to the *RST command in

chapter 4 to see how each programmable parameter is set by *RST. Refer to the *PSC command in

chapter 4 for more information on the power-on initialization of the *ESE and the *SRE registers.

Enabling the Output

To enable the output, use the command:

OUTPut ON

19

Page 20

3 - Programming the DC Source

Output Voltage

The output voltage is controlled with the VOLTage command. For example, to set the output voltage to 25

volts, use:

VOLTage 125

The dc source can be programmed to turn off its output if the output voltage exceeds a preset peak

voltage limit. This protection feature is implemented with the VOLTage:PROTection command as

explained in chapter 4.

Maximum Voltage

The maximum rms output voltage that can be programmed can be queried with:

VOLTage? MAX

Output Current

All models have a programmable current function. The command to program the current is:

CURRent <n>

where <n> is the current limit in amperes.

If the load attempts to draw more current than the programmed limit, the output voltage is reduced to keep

the current within the limit.

Maximum Current

The maximum output current that can be programmed can be queried with:

CURRent? MAX

Overcurrent Protection

The dc source can also be programmed to turn off its output if the current limit is reached. As explained in

chapter 4, this protection feature is implemented the following command:

CURRent:PROTection:STATe ON | OFF

NOTE: Use OUTP:PROT:DEL to prevent momentary current limit conditions caused by

programmed output changes from tripping the overcurrent protection.

20

Page 21

Programming the DC Source - 3

INITIATED STATE

IDLE STATE

TRIGGER RECEIVED

INITiate[:IMMediate]

Triggering Output Changes

The dc source has two independent trigger systems. One is used for generating output changes, and the

other is used for triggering measurements. This section describes the output trigger system. The

measurement trigger system is described under "Triggering Measurements".

SCPI Triggering Nomenclature

In SCPI terms, trigger systems are called sequences. When more than one trigger system exists, they are

differentiated by naming them SEQuence1 and SEQuence2. SEQuence1 is the transient trigger system

and SEQuence2 is the measurement trigger system. The dc source uses aliases with more descriptive

names for these sequences. These aliases can be used instead of the sequence forms.

Sequence Form Alias

SEQuence1 TRANsient

SEQuence2 ACQuire

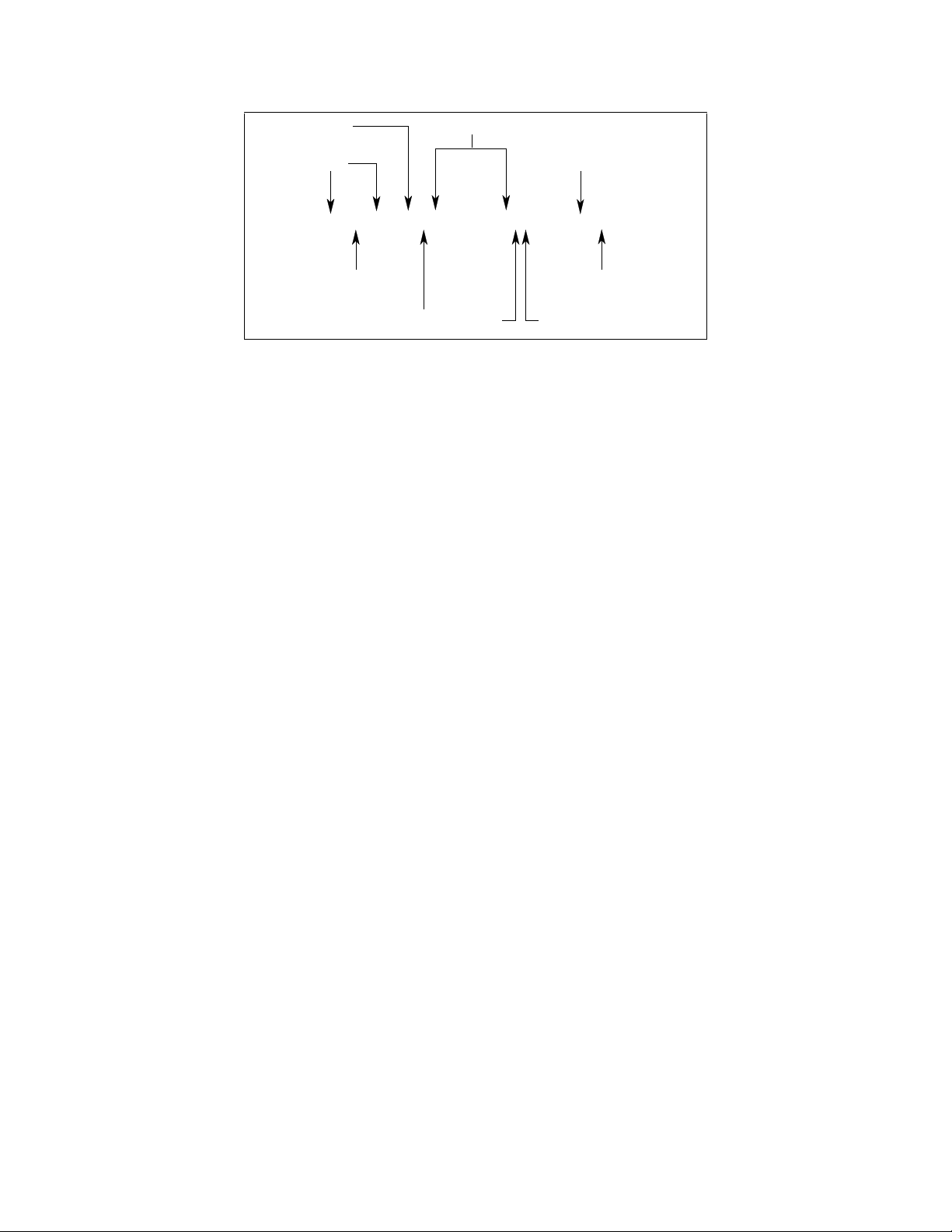

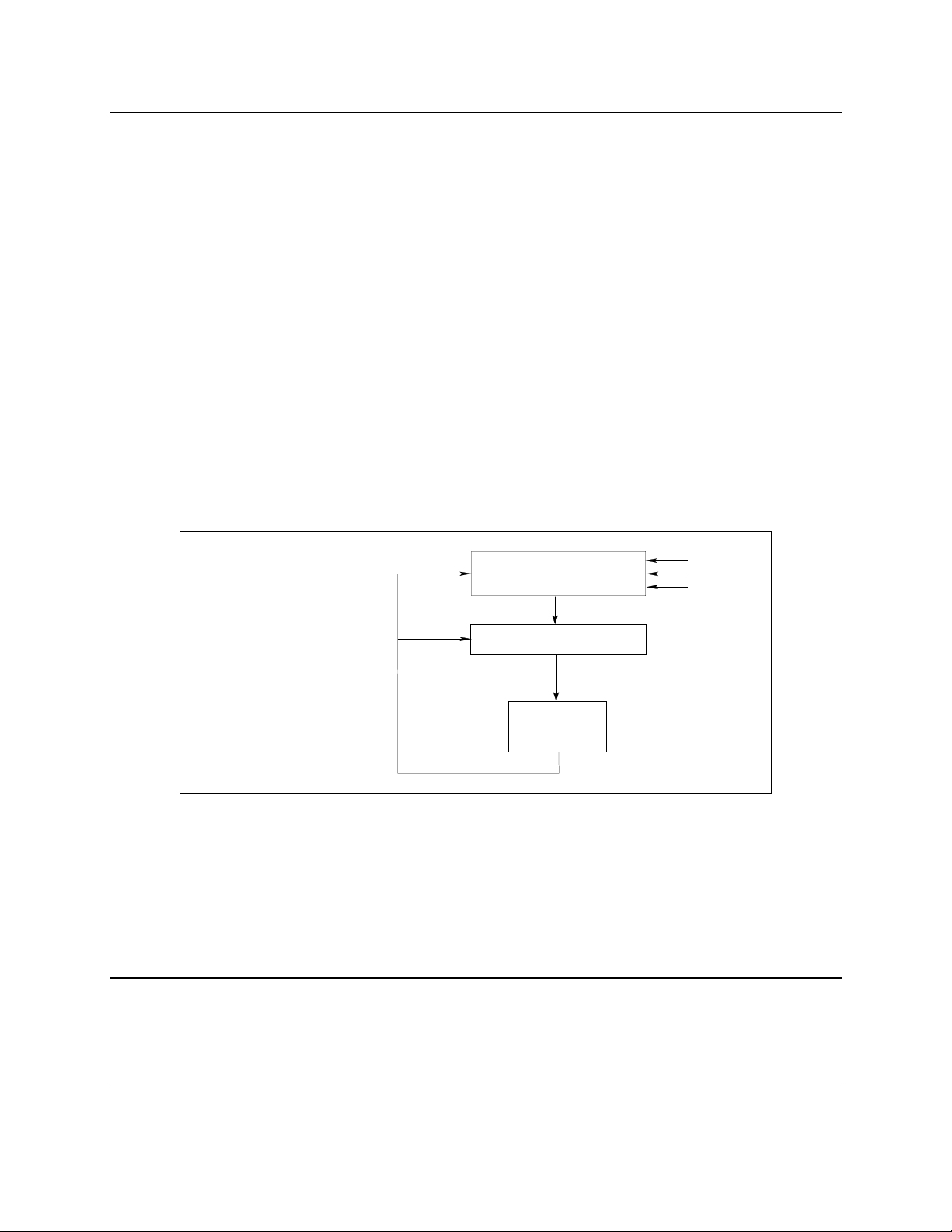

Output Trigger System Model

Figure 3-1 is a model of the output trigger system. The rectangular boxes represent states. The arrows

show the transitions between states. These are labeled with the input or event that causes the transition

to occur.

ABORt

INITiate:CONTinuous OFF

INITiate:CONTinuous ON

OUTPUT

LEVEL

CHANGE

*RST

*RCL

Figure 3-1. Model of Output Triggers

Setting the Voltage or Current Trigger Levels

To program output trigger levels, you must first specify a voltage or current trigger level that the output will

go to once a trigger signal is received. Use the following commands to set the output trigger level:

VOLTage:TRIGgered <n> or

CURRent:TRIGgered <n>

NOTE: Until they are programmed, uninitialized trigger levels will assume their corresponding

immediate levels. For example, if a dc source is powered up and VOLTage:LEVel is

programmed to 6, then VOLTage:LEVel:TRIGger will also be 6 until you program it to

another value. Once you program VOLTage:LEVel:TRIGger to a value, it will remain at

that value regardless of how you subsequently reprogram VOLTage:LEVel.

21

Page 22

3 - Programming the DC Source

Initiating the Output Trigger System

When the dc source is turned on, the trigger subsystem is in the idle state. In this state, the trigger

subsystem ignores all triggers. Sending the following commands at any time returns the trigger system to

the Idle state:

ABORt

*RST

*RCL

The INITiate commands move the trigger system from the Idle state to the Initiated state. This enables

the dc source to receive triggers. To initiate for a single triggered action, use:

INITiate:SEQuence1or

INITiate:NAME TRANsient

After a trigger is received and the action completes, the trigger system will return to the Idle state. Thus it

will be necessary to initiate the system each time a triggered action is desired.

To keep a trigger system initiated for multiple actions without having to send an initiate command for each

trigger, use:

INITiate:CONTinuous:SEQuence1 ON or

INITiate:CONTinuous:NAME TRANsient, ON

Generating Triggers

You can only program output triggers over the GPIB bus. Since BUS is the only trigger source for output

triggers, the following command is provided for completeness only:

TRIGger:SOURce BUS

After you have specified the appropriate trigger source, you can generate triggers as follows:

Single Triggers Send one of the following commands over the GPIB:

TRIGger:IMMediate

*TRG

a group execute trigger

Continuous Triggers Send the following command over the GPIB:

INITiate:CONTinuous:SEQuence1 ON

When the trigger system enters the Output Change state upon receipt of a trigger (see figure 3-1), the

triggered functions are set to their programmed trigger levels. When the triggered actions are completed,

the trigger system returns to the Idle state.

22

Page 23

Programming the DC Source - 3

Making Measurements

The dc source has the ability to make several types of voltage or current measurements. The

measurement capabilities of the Agilent 66312A and Agilent 66332A models are particulary useful for

loads that draw current in pulses.

NOTE: You cannot measure output voltage and current simultaneously.

All measurements are performed by digitizing the instantaneous output voltage or current for a defined

number of samples and sample interval, storing the results in a buffer, and then calculating the measured

result. Many parameters of the measurement are programmable. These include the number of samples,

the time interval between samples, the bandwidth, and the method of triggering. Note that there is a

tradeoff between these parameters and the speed, accuracy, and stability of the measurement in the

presence of noise.

There are two ways to make measurements:

♦

Use the MEASure commands to immediately start acquiring new voltage or current data, and

return measurement calculations from this data as soon as the buffer is full. This is the easiest

way to make measurements, since it requires no explicit trigger programming.

♦

Use an acquisition trigger to acquire the data. Then use the FETCh commands to return

calculations from the data that was retrieved by the acquisition trigger. This method gives you the

flexibility to synchronize the data acquisition with a transition in the output voltage or current.

FETCh commands do not trigger the acquisition of new measurement data, but they can be used

to return many different calculations from the data that was retrieved by the acquisition trigger.

Note that if you take a voltage measurement, you can fetch only voltage data.

Making triggered measurements with the acquisition trigger system is discussed under "Triggering

Measurements".

NOTE: For each MEASure form of the query, there is a corresponding query that begins with the

header FETCh. FETCh queries perform the same calculation as their MEASure

counterparts, but do not cause new data to be acquired. Data acquired by an explicit

trigger or a previously programmed MEASure command are used.

Voltage and Current Measurements

The SCPI language provides a number of MEASure and FETCh queries which return various

measurement parameters of voltage and current waveforms.

DC Measurements

To measure the dc output voltage or current, use:

MEASure:VOLTage? or

MEASure:CURRent?

Dc voltage and current is measured by acquiring a number of readings at the selected time interval,

applying a Hanning window function to the readings, and averaging the readings. Windowing is a signal

conditioning process that reduces the error in dc measurements made in the presence of periodic signals

such as line ripple. At power-on and after a *RST command, the following parameters are set:

SENSe:SWEep:TINTerval 15.6E-6

SENSe:SWEep:POINts 2048

23

Page 24

3 - Programming the DC Source

This results in a data acquisition time of 32 milliseconds. Adding a command processing overhead of

about 20 milliseconds results in a total measurement time of about 50 milliseconds per measurement

sample.

Ripple rejection is a function of the number of cycles of the ripple frequency contained in the acquisition

window. More cycles in the aquisition window results in better ripple rejection. If you increase the time

interval for each measurement to 45 microseconds for example, this results in 5.53 cycles in the

acquisition window at 60 Hz, for a ripple rejection of about 70 dB.

Note that the speed of the measurement can be increased by reducing the number of sample points. For

example, the commands

SENSe:SWEep:TINTerval 15E-6

SENSe:SWEep:POINts 1024

speeds up the acquisition period to 16 milliseconds; however, the tradeoff is reduced measurement

accuracy.

RMS Measurements (Agilent 66312A, 66332A Only)

To read the rms content of a voltage or current waveform, use:

MEASure:VOLTage:ACDC? or

MEASure:CURRent:ACDC?

This returns the total rms measurement, including the dc portion.

Making rms measurements on ac waveforms for which a non-integral number of cycles of data has been

acquired may result in measurement errors due to the last partial cycle of acquired data. The instrument

reduces this error by using a Hanning window function when making the measurement.

Minimum and Maximum Measurements (Agilent 66312A, 66332A Only)

To measure the maximum or minimum voltage or current of a pulse or ac waveform, use:

MEASure:VOLTage:MAXimum?

MEASure:VOLTage:MINimum?

MEASure:CURRent:MAXimum?

MEASure:CURRent:MINimum?

Current Ranges

The dc source has two current measurement ranges. The command that controls the ranges is:

SENSe:CURRent:RANGe MIN | MAX

When the range is set to MIN, the maximum current that can be measured is 20 milliamperes.

Returning Measurement Data From the Data Buffer (Agilent 66312A, 66332A Only)

The MEASure and FETCh queries can also return all data values of the instantaneous voltage or current

buffer. The commands are:

MEASure:ARRay:CURRent?

MEASure:ARRay:VOLTage?

24

Page 25

Programming the DC Source - 3

[

]

Internally Triggered Measurements

You can use the data acquisition trigger system to synchronize the timing of the voltage and current data

acquisition with a BUS or internal trigger source. Then use the FETCh commands to return different

calculations from the data acquired by the measurement trigger.

SCPI Triggering Nomenclature

As previously explained under "Triggering Output Changes", the dc source uses the following sequence

name and alias for the measurement trigger system. This alias can be used instead of the sequence form.

Sequence Form Alias

SEQuence2 ACQuire

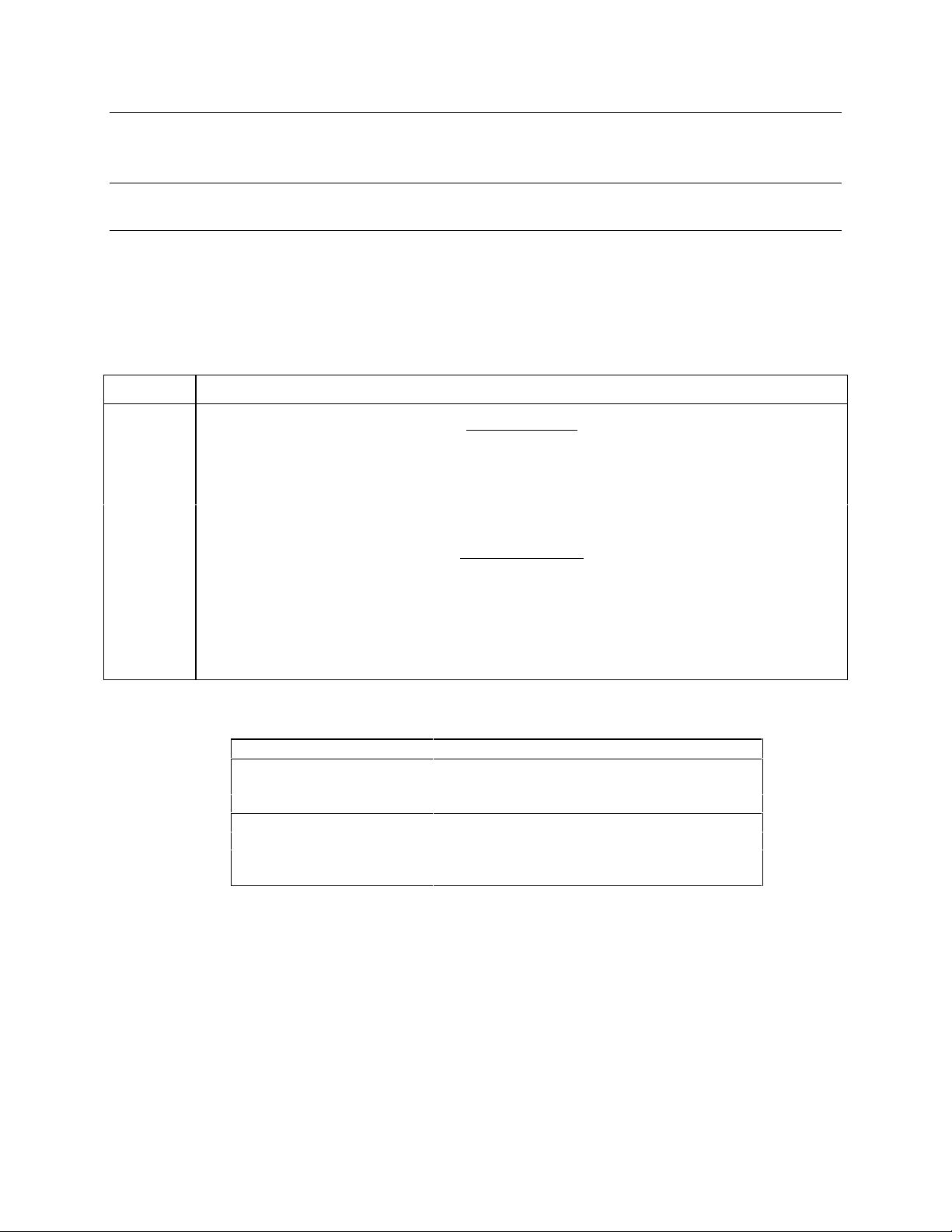

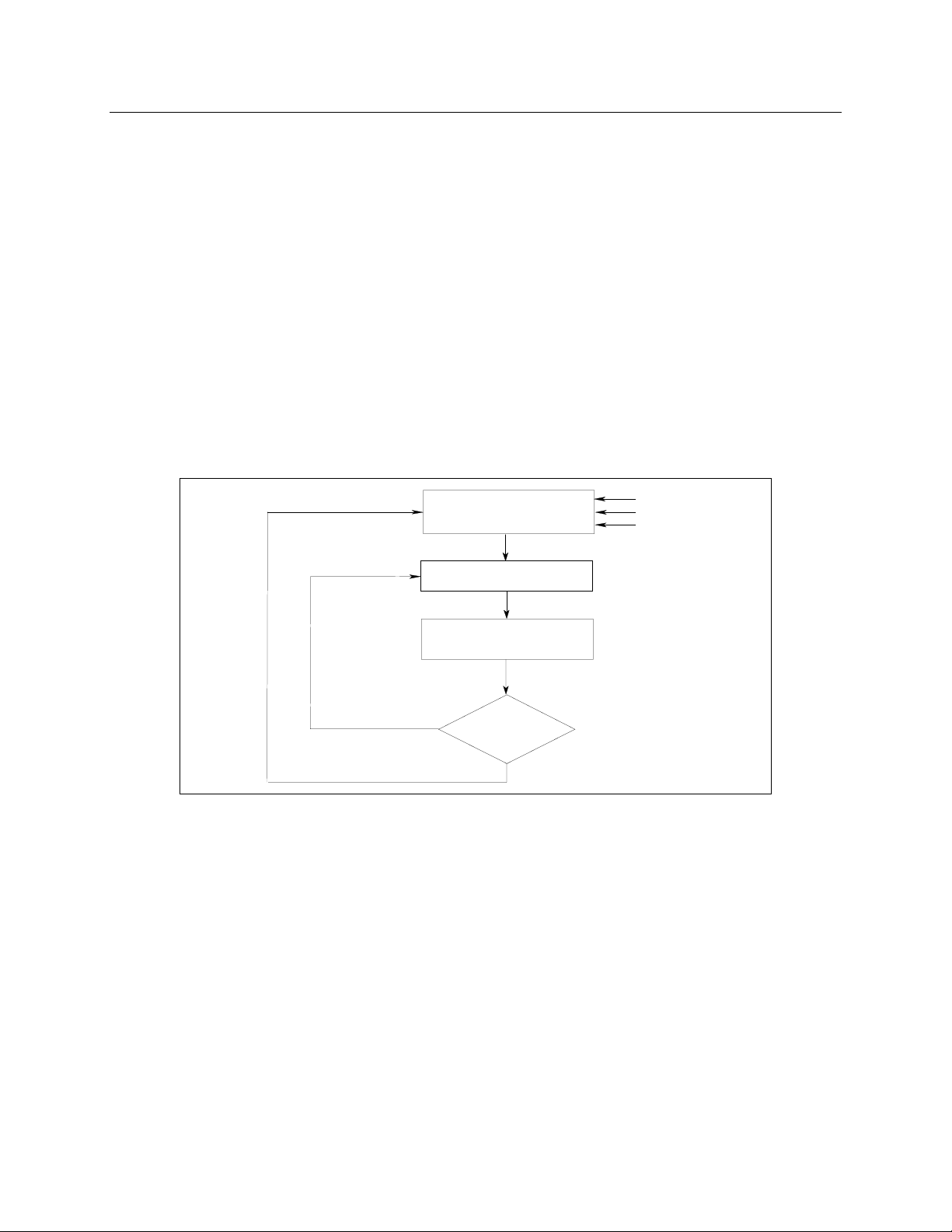

Measurement Trigger System Model

Figure 3-2 is a model of the measurement trigger system. The rectangular boxes represent states. The

arrows show the transitions between states. These are labeled with the input or event that causes the

transition to occur.

IDLE STATE

INITIATED STATE

SENSe:SWEep:POINts

ACQUIRED

NO

TRIGger:COUNt

COMPLETE?

YES

INITiate

:IMMediate

TRIGGER RECEIVED

ABORt

*RST

*RCL

Figure 3-2. Model of Measurement Triggers

Initiating the Measurement Trigger System (Agilent 66312A, 66332A Only)

When the dc source is turned on, the trigger system is in the idle state. In this state, the trigger system

ignores all triggers. Sending the following commands at any time returns the trigger system to the Idle

state:

ABORt

*RST

*RCL

The INITiate commands move the trigger system from the Idle state to the Initiated state. This enables

the dc source to receive triggers. To initiate for a measurement trigger, use:

25

Page 26

3 - Programming the DC Source

INITiate:SEQuence2 or

INITiate:NAME ACQuire

After a trigger is received and the data acquisition completes, the trigger system will return to the Idle state

(unless multiple measurements are desired). Thus it will be necessary to initiate the system each time a

triggered acquisition is desired.

NOTE: You cannot initiate measurement triggers continuously. Otherwise, the measurement data

in the data buffer would continuously be overwritten by each triggered measurement.

Selecting the Measurement Trigger Source (Agilent 66312A, 66332A Only)

The trigger system is waiting for a trigger signal in the Initiated state. Before you generate a trigger, you

must select a trigger source. The following measurement trigger sources can be selected:

BUS - selects GPIB bus triggers.

INTernal - selects the dc source’s output as the measurement trigger.

To select GPIB bus triggers (group execute trigger, device trigger, or *TRG command), use:

TRIGger:SEQuence2:SOURce BUS or

TRIGger:ACQuire:SOURce BUS

To select internal triggers (measurements triggered off the output signal) use:

TRIGger:SEQuence2:SOURce INTernal or

TRIGger:ACQuire:SOURce INTernal

Generating Measurement Triggers (Agilent 66312A, 66332A Only)

There is only one measurement converter in the dc source. Before you generate a measurement trigger,

you must specify a measurement acquistion of either voltage or current. To specify a measurement

acquisition use:

SENSe:FUNCtion "CURRent" or

SENSe:FUNCtion "VOLTage"

Providing that you have specified the appropriate trigger source and a measurement acquisition, you can

generate triggers as follows:

GPIB Triggers Send one of the following commands over the GPIB:

TRIGger:IMMediate (not affected by the trigger source setting)

*TRG

a group execute trigger

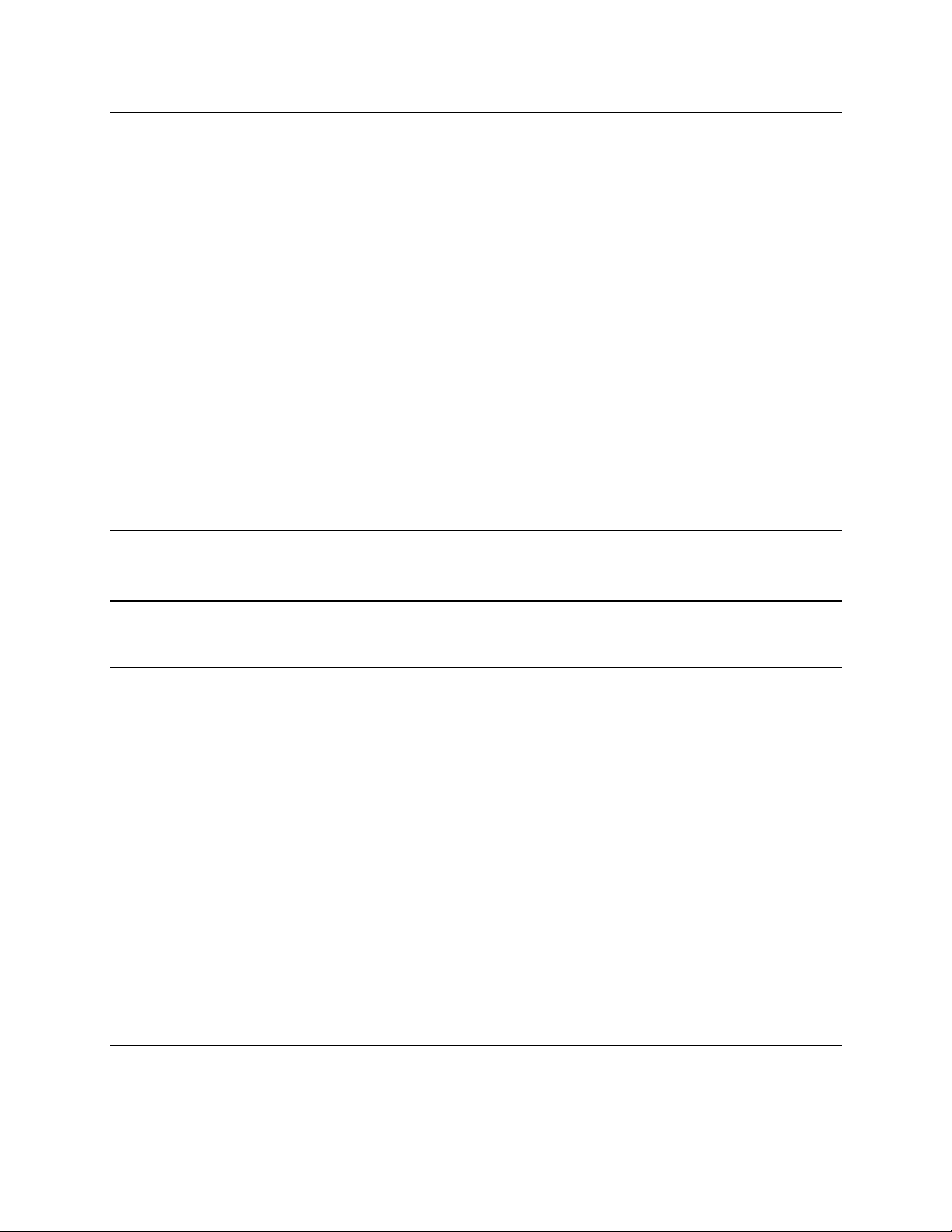

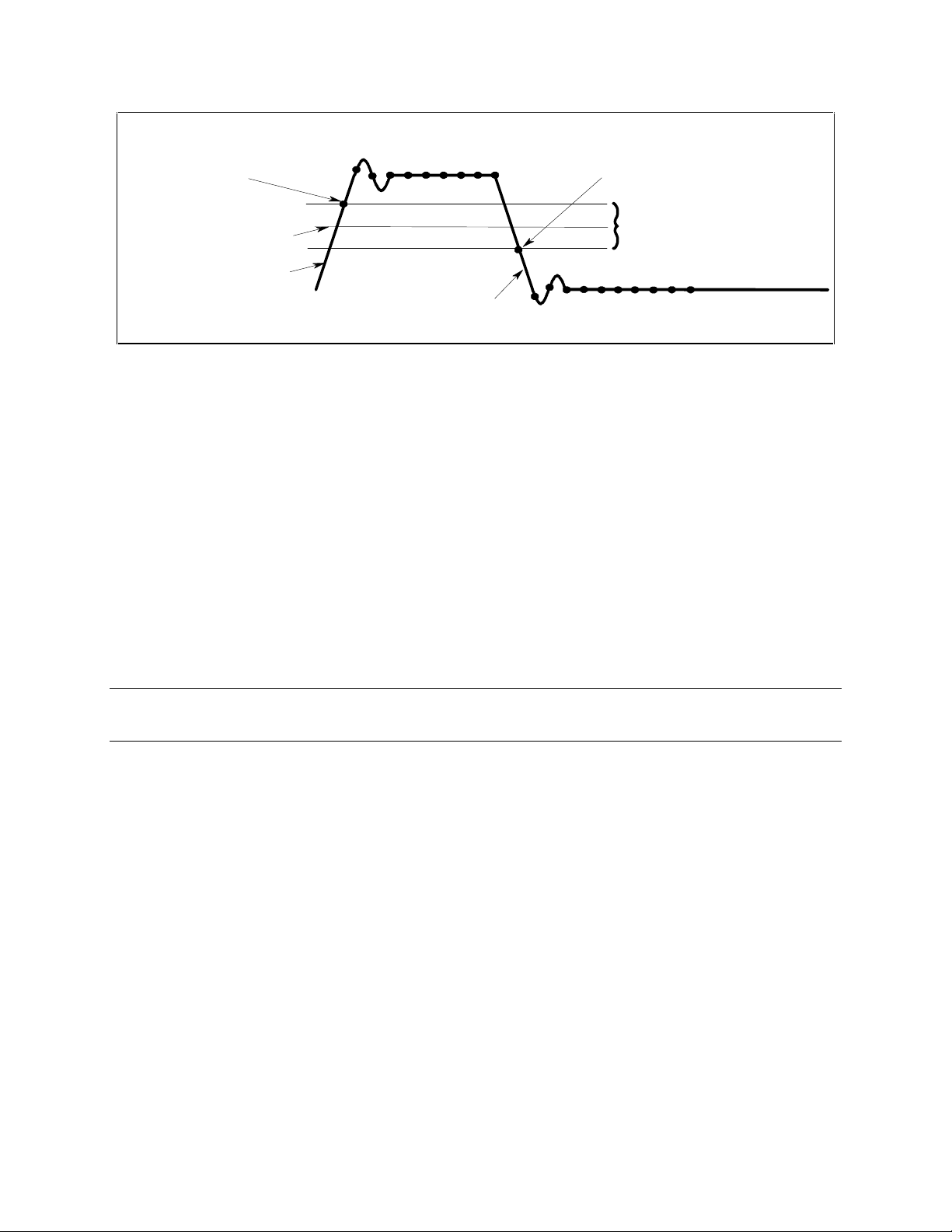

Internal Triggers To trigger off of the output signal, you must specify the output level that generates

the trigger, the rising or falling edge of the slope, and a hysteresis to qualify trigger

conditions. This is illustrated in figure 3-3.

26

Page 27

Q

>

TRIG:ACQ:HYST:CURR <value>

Trigger occurs on rising edge

g

TRIG :AC Q :HYST:V O LT

Trigger occu rs on falling edg e

when signal crosses negative

nal crosses positive

when si

hysteresis band limit

Programming the DC Source - 3

hysteresis band limit

TRIG:A C

TRIG:ACQ:LEV:VOLT

TRIG:ACQ:SLOP:CURR

TRIG:ACQ:SLOP:VOLT

:LEV:CURR <level

TRIG:ACQ:SLOP:CURR NEG

TRIG:ACQ:SLOP:VOLT

Figure 3-3. Trigger Commands Used to Measure Output Pulses

To specify the output level that will generate triggers for both positive- and negative-going signals use:

TRIGger:SEQuence2:LEVel:CURRent <value> or

TRIGger:ACQuire:LEVel:CURRent <value>

To specify the slope on which triggering occurs use the following commands. You can specify a POSitive,

a NEGative, or EITHer type of slope.

TRIGger:SEQuence2:SLOPe:CURRent <slope> or

TRIGger:ACQuire:SLOPe:CURRent <slope>

To specify a hysteresis band to qualify the positive- or negative-going signal use:

TRIGger:SEQuence2:HYSTeresis:CURRent <value> or

TRIGger:ACQuire:HYSTeresis:CURRent <value>

NOTE: When using internal triggers, do not INITiate the measurement until after you have

specified the slope, level, and hysteresis.

When the acquisition finishes, any of the FETCh queries can be used to return the results. Once the

measurement trigger is initiated, if a FETCh query is sent before the data acquisition is triggered or before

it is finished, the response data will be delayed until the trigger occurs and the acquisition completes. This

may tie up the controller if the trigger condition does not occur immediately.

One way to wait for results without tying up the controller is to use the SCPI command completion

commands. For example, you can send the *OPC command after INITialize, then occasionally poll the

OPC status bit in the standard event status register for status completion while doing other tasks. You can

also set up an SRQ condition on the OPC status bit going true, and do other tasks until an SRQ interrupt

occurs.

27

Page 28

3 - Programming the DC Source

Measuring Output Pulses (Agilent 66312A, 66332A Only)

Current Detector

Check that the current detector is set to ACDC when measuring current pulses or other waveforms with a

frequency content greater than a few kilohertz.

SENSe:CURRent:DETect ACDC

Only select DC as the measurement detector if you are making only DC current measurements and you

require a measurement offset better than 2mA on the High current measurement range. Note that this

selection gives inaccurate results on current waveforms that have ac content.

SENSe:CURRent:DETect DC

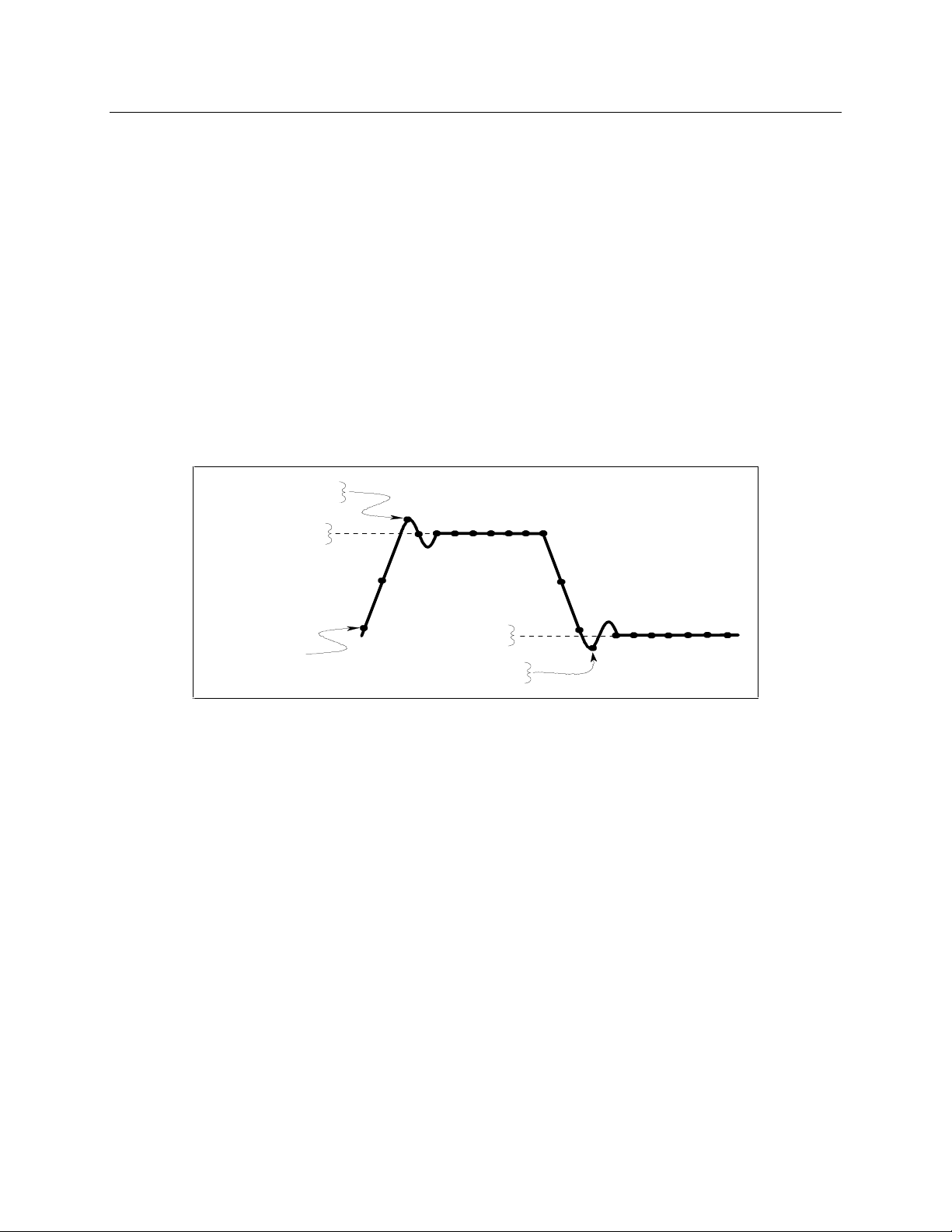

Pulse Measurement Queries

The dc source has several measurement queries that return key parameters of pulsewaveforms as shown

in Figure 3-4.

FETC:CURR:MAX?

FETC:VOLT:MAX?

FETC:CURR:HIGH?

FETC:VOLT:HIGH?

FETC:CURR:LOW?

DATA POINTS

FETC:VOLT:LOW?

FETC:CURR:MIN?

FETC:VOLT:MIN?

Figure 3-4. Measurement Commands Used to Return Pulse Data

To return the maximum or minimum value of a pulse waveform use the following commands. Note that

the data points of the measurement sample may not coincide with the actual maximum or minimum point

on the waveform.

FETCh:VOLTage:MAXimum? or

FETCh:VOLTage:MINimum?

FETCh:CURRent:MAXimum? or

FETCh:CURRent:MINimum?

The average value of the high level or low level of a pulse can also be measured. To return the average

value of the high level, use:

FETCh:CURRent:HIGH? or

FETCh:VOLTage:HIGH?

To return the average value of the low level, use:

FETCh:CURRent:LOW? or

FETCh:VOLTage:LOW?

28

Page 29

Programming the DC Source - 3

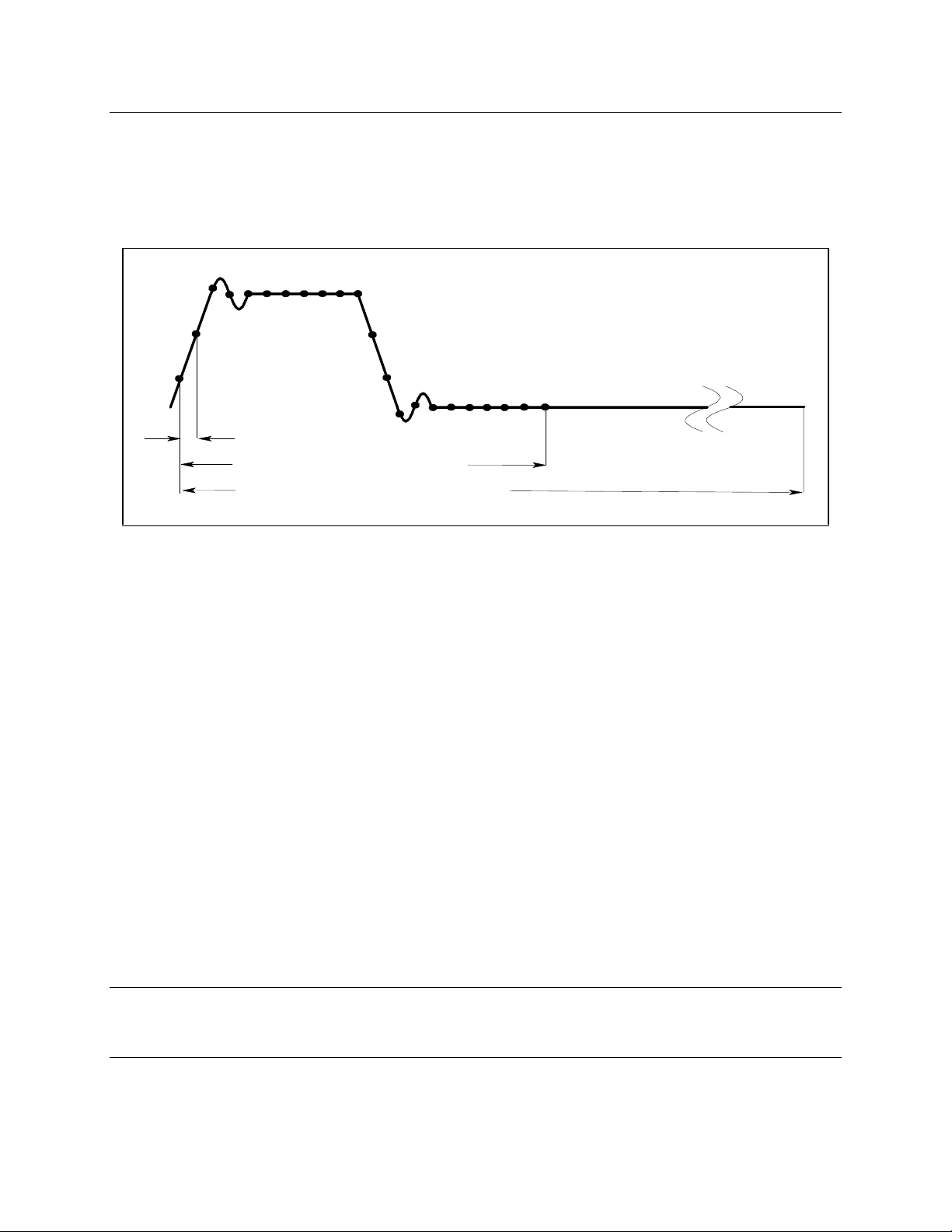

Controlling Measurement Samples

Varying the Voltage or Current Sampling Rate

You can vary both the number of data points in a measurement sample, as well as the time between

samples. This is illustrated in Figure 3-5.

<

p

>

<

p

>

Figure 3-5. Sense Commands Used to Vary the Sampling Rate

At *RST, the output voltage or current sampling rate is 15.6 microseconds. This means that it takes about

32 milliseconds to fill up 2048 data points in the data buffer. You can vary this data sampling rate with:

SENSe:SWEep:TINTerval <sample_period>

SENSe:SWEep:POINts <points>

For example, to set the time interval to 46.8 microseconds per sample with 1500 samples, use

SENSe:SWEep:TINTerval 46.8E-6;POINts 1500.

Multiple Measurements (Agilent 66312A, 66332A Only)

The instrument also has the ability to set up several acquisition triggers in succession and average the

results from each acquisition in the returned measurement. To set up the trigger system for a number of

sequential aquisitions use:

TRIGger:ACQuire:COUNt:CURRent <number> or

TRIGger:ACQuire:COUNt:VOLTage <number>

With this setup, the instrument performs each acquisition sequentially, storing the digitized readings in the

internal measurement buffer. It is only necessary to initialize the measurement once at the start; after

each completed aquisition the instrument will wait for the next valid trigger condition to start another. The

results returned by MEASure or FETCh will be the average of the total data acquired.

NOTE: The total number of data points cannot exceed 4096. This means that the product of the

trigger count multiplied by the sweep points cannot exceed 4096; otherwise an error will

occur.

29

Page 30

3 - Programming the DC Source

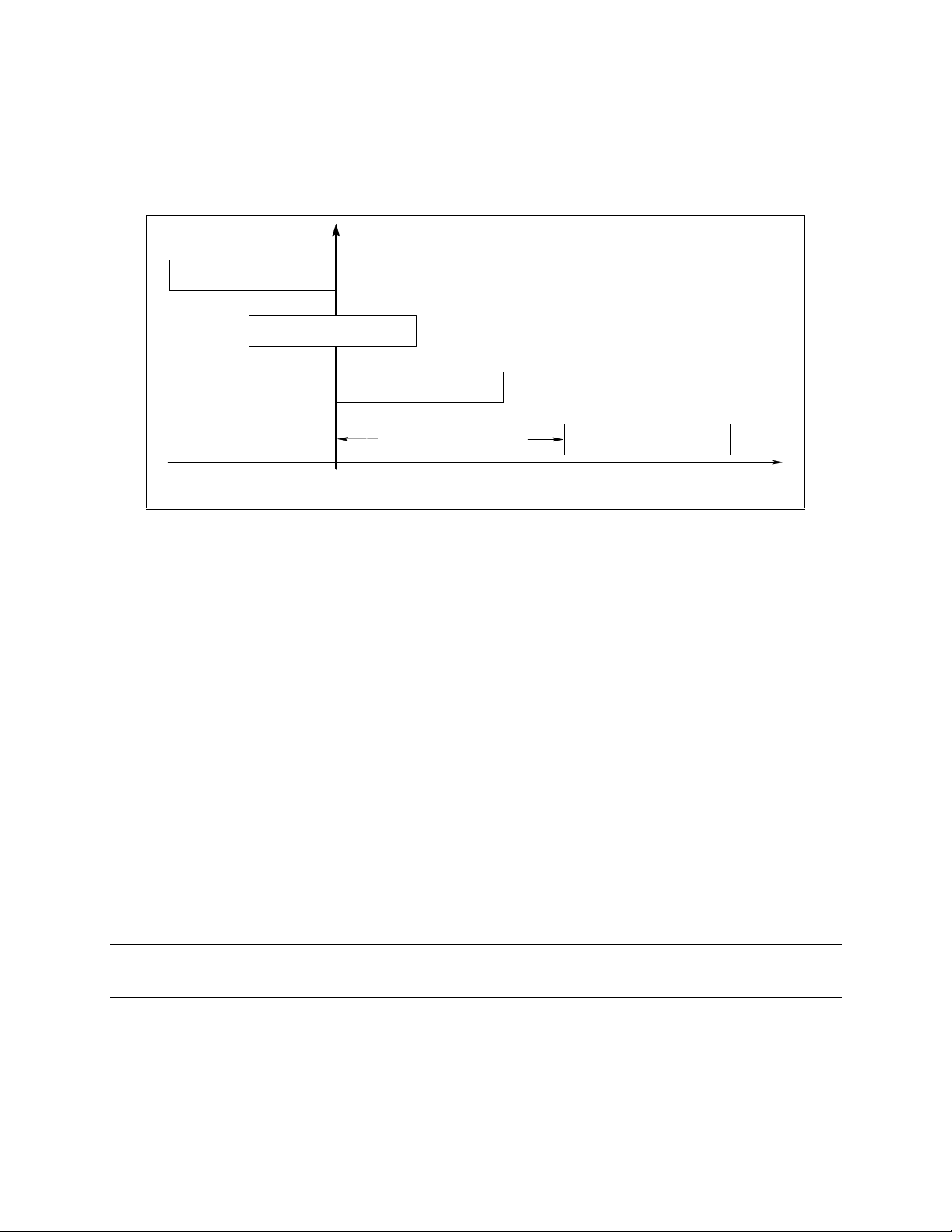

Pre-event and Post-event Triggering (Agilent 66312A, 66332A Only)

When a measurement is initiated, the dc source continuously samples either the instantaneous output

voltage or current. As shown in figure 3-6, you can move the block of data being read into the acquisition

buffer with reference to the acquisition trigger. This permits pre-event or post-event data sampling.

=-

=-

=

=

Figure 3-6. Pre-event and Post-event Triggering

To offset the beginning of the acquisition buffer relative to the acquisition trigger, use:

SENSe:SWEep:OFFSet:POINts <offset>

The range for the offset is -4096 to 2,000,000,000 points. As shown in the figure, when the offset is

negative, the values at the beginning of the data record represent samples taken prior to the trigger. When

the value is 0, all of the values are taken after the trigger. Values greater than zero can be used to

program a delay time from the receipt of the trigger until the data points that are entered into the buffer are

valid. (Delay time = Offset X Sample period)

Pulse Measurement Example (Agilent 66312A, 66332A only)

The following program illustrates how to make a pulse measurement over the GPIB. The measurement

function is set to ACDC, which gives the best results for current waveforms that have ac content. The

measurement incorporates 100 readings taken at time intervals of 20 microseconds, for a total

measurement time of 2 milliseconds. The trigger point for the pulse measurement occurs at 0.1 amperes

on the positive slope of the current pulse. The measurement offset is programmed so that 20

measurement points prior to the trigger are also returned as part of the measurement sample.

Because measurement triggers are initiated by the current pulse, a FETCh command is used to return the

measurement data. FETCh commands are also used to return the MAXimum, MINimum, HIGH, and LOW

values of the measurement.

NOTE: MEASure commands cannot be used to return data in this example because they always

acquire NEW measurement data each time they are used.

The program can be run on any controller operating under Agilent BASIC. To generate output pulses, an

electronic load is programmed to generate 3-ampere pulses with a duty cycle of 100 microseconds at

1000 Hz. The power supply address is 705, and the load address is 706. If required, change these

parameters in the appropriate statements.

30

Page 31

Programming the DC Source - 3

10 !Rev A.00.00

20 OPTION BASE 1

30 DIM Curr_array(100)

40 !

50 ASSIGN @Ps TO 705

60 ASSIGN @Ld TO 706

80 OUTPUT @Ps;"*RST" ! Sets supply to default values

90 OUTPUT @Ps;"OUTP ON" ! Turn on power supply output

100 OUTPUT @Ps;"VOLT 5;CURR 5" ! Program power supply to 5 volts, 5 amps

110 !

120 OUTPUT @Ld;"CURR:LEVEL 0" ! Set up electronic load to produce pulses

130 OUTPUT @Ld;"CURR:TLEVEL 3"

140 !

150 OUTPUT @Ld;"TRAN:FREQ 1000"

160 OUTPUT @Ld;"TRAN:DCYCLE 10"

170 OUTPUT @Ld;"TRAN:MODE CONT"

180 OUTPUT @Ld;"TRAN:STATE ON"

190 !

200 OUTPUT @Ps;"SENS:CURR:DET ACDC" ! Set meter to ACDC

210 OUTPUT @Ps;"SENS:CURR:RANG MAX" ! High Current range

220 OUTPUT @Ps;"TRIG:ACQ:SOUR INT" ! Set to trigger on pulse

230 OUTPUT @Ps;"SENS:FUNC ""CURR""" ! Acquire current reading

240 OUTPUT @Ps;"TRIG:ACQ:LEV:CURR .1" ! Trigger at 0.1 amps

250 OUTPUT @Ps;"TRIG:ACQ:SLOPE:CURR POS" ! Trigger on positive slope

260 OUTPUT @Ps;"TRIG:ACQ:HYST:CURR .05" ! Set hysteresis of trigger

270 OUTPUT @Ps;"SENS:SWE:TINT 20E-6" ! Set sample time interval to 20us

280 OUTPUT @Ps;"SENS:SWE:POIN 100" ! Set number of measurement samples in sweep

290 OUTPUT 705;"SENS:SWE:OFFS:POIN -20" ! Number of sample points before trigger

300 OUTPUT @Ps;"INIT:NAME ACQ" ! Initiate the trigger system.

310 ! Controller now waits for trigger to occur.

320 OUTPUT @Ps;"FETCH:ARRAY:CURR?" ! Get the data after measurement completes.

330 !

340 ENTER @Ps;Curr_array(*) ! Enters all 100 data points

350 PRINT Curr_array(*) ! Print all data points

360 !

370 OUTPUT @Ps;"FETCH:CURR:MAX?" ! Get more data from previous measurement.

380 ENTER @Ps;Curr_max

390 PRINT "MAX CURRENT",Curr_max

400 !

410 OUTPUT @Ps;"FETCH:CURR:MIN?"

420 ENTER @Ps;Curr_min

430 PRINT "MIN CURRENT",Curr_min

440 !

450 OUTPUT @Ps;"FETCH:CURR:HIGH?"

460 ENTER @Ps;Curr_hi

470 PRINT "HIGH CURRENT",Curr_hi

480 !

490 OUTPUT @Ps;"FETCH:CURR:LOW?"

500 ENTER @Ps;Curr_low

510 PRINT "LOW CURRENT",Curr_low

520 !

530 END

When this program runs, it returns 100 measurement data points as well as the MIN, MAX, HIGH, and

LOW data in the following format:

.030585 .031869 .0344369 .031655 .0320829 .0325109 .0333669 .0340089

.0320825 .031449 .031227 .031441 .0337949 .0327249 .031869 .031655

.0327249 .031013 .0325109 .0333669 3.09751 3.1814 3.14266 3.13667

3.13817 3.13624 .977283 .0667496 .0245932 .0280171 .031013 .031655

.0331529 .0350788 .0348648 .0327249 .031227 .0327249 .031227 .030799

.031869 .0329389 .030371 .031655 .031869 .0329389 .031869 .0322869

.0320829 .0325109 .0333669 .0340089 .0348648 .0327249 .031227 .0327249

.0320829 .030371 .031449 .031227 .031441 .0337949 .031449 .0333669

.031441 .0337949 .030371 .031655 .031869 .0329389 .031869 .0293011

.031441 .0337949 .0327249 .031869 .031655 .031655 .0320829 .031227

.0322969 .031655 .0327249 .0340089 2.97661 3.18632 3.14523 3.13496

3.13453 3.13731 1.32438 .0836549 .0258772 .0284451 .0275891 .0329389

.0329389 .0333669 .0322969 .0333669

MAX CURRENT 3.18632

MIN CURRENT .0245932

HIGH CURRENT 3.1371

LOW CURRENT .0314077

31

Page 32

3 - Programming the DC Source

Programming the Status Registers

You can use status register programming to determine the operating condition of the dc source at any

time. For example, you may program the dc source to generate an interrupt (assert SRQ) when an event

such as a current limit occurs. When the interrupt occurs, your program can then act on the event in the

appropriate fashion.

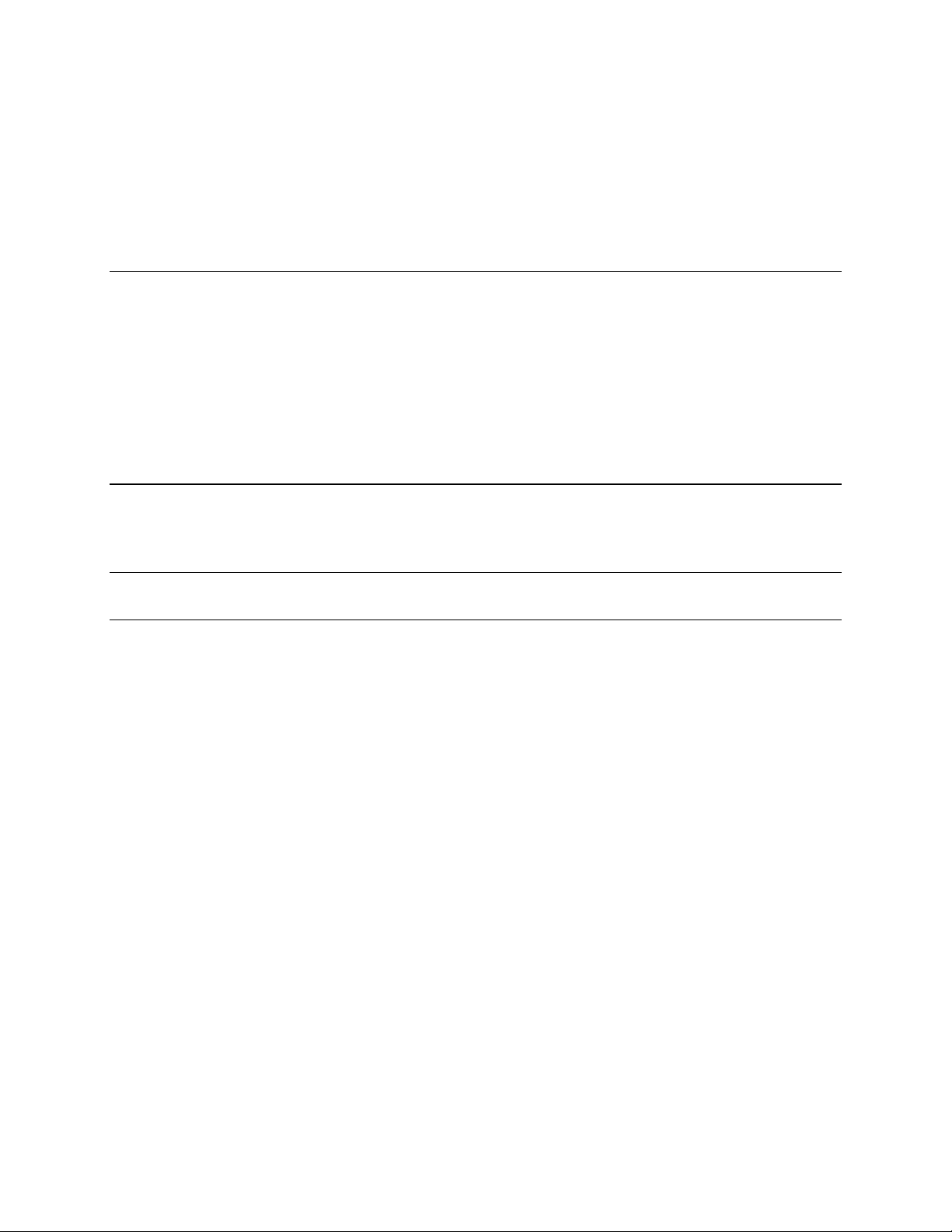

Figure 3-7 shows the status register structure of the dc source. Table 3-1 defines the status bits. The

Standard Event, Status Byte, and Service Request Enable registers and the Output Queue perform

standard GPIB functions as defined in the

Instrumentation

. The Operation Status and Questionable Status registers implement functions that are

specific to the dc source.

Power-On Conditions

Refer to the *RST command description in chapter 4 for the power-on conditions of the status registers.

QUESTIONABLE STATUS

OCP

N.U.

N.U.

Unreg

N.U.

MeasOvld

N.U.

OPC

N.U.

QYE

DDE

EXE

CME

N.U.

PON

CONDITION

0

OV

1

2

FS

3

4

OT

5-8

9

RI

10

1024

11-13

14

15

STANDARD EVENT STATUS

EVENT ENABLE

0

1

2

3

4

5

6

7

1

2

4

16

512

1

4

8

16

32

128

PTR/NTR

1

2

444

16

512

1024

16384 16384 1638416384

1

4

8

16

32

128

EVENT

1

2

16

512

1024

LOGICAL OR

IEEE 488.2 Standard Digital Interface for Programmable

ENABLE

1

2

16

512

1024

OUTPUT QUEUE

DATA

DATA

DATA

LOGICAL OR

QUEUE

NOT

EMPTY

OFF

N.U.

QUES

MAV

ESB

MSS

OPER

OUTPut:DFI:SOURce

STATUS BYTE

0-2

3

4

5

6

7

8

16

32

64

128

SERVICE

REQUEST

ENABLE

FLT

8

16

32

128

LOGICAL OR

CAL

N.U.

WTG

N.U.

CV

N.U.

CC+

CCN.U.

32

0

1-4

5

6,7

8

9

10

11

12-15

CONDITION

1

32

256

512

1024

2048

OPERATIO N STATUS

PTR/NTR

1

32

256

512

1024

2048

EVENT

1

32

256

512

1024

2048

ENABLE

1

32

256

512

1024

2048

LOGICAL OR

Figure 3-7. DC Source Status Model

RQS

SERVICE

REQUEST

GENERATION

),**$/

Page 33

Table 3-1. Bit Configurations of Status Registers

Bit Signal Meaning

0

5

8

10

11

0

1

2

4

9

10

14

0

2

3

4

5

7

3

4

5

6

7

CAL

WTG

CV

CC+

CC-

OV

OCP

FS

OT

RI

Unreg

MeasOvld

OPC

QYE

DDE

EXE

CME

PON

QUES

MAV

ESB

MSS

RQS

OPER

Operation Status Group

The dc source is computing new calibration constants

The dc source is waiting for a trigger

The dc source is in constant voltage mode

The dc source is in constant current mode

The dc source is in negative constant current mode

Questionable Status Group

The overvoltage protection has tripped

The overcurrent protection has tripped

The fuse is blown

The overtemperature protection has tripped

The remote inhibit state is active

The output is unregulated

Current measurement exceeded capability of low range

Standard Event Status Group

Operation complete

Query error

Device-dependent error

Execution error

Command error

Power-on

Status Byte and Service Request Enable Registers

Questionable status summary bit

Message Available summary bit

Event Status Summary bit

Master Status Summary bit

Request Service bit

Operation status summary bit

Programming the DC Source - 3

Operation Status Group

The Operation Status registers record signals that occur during normal operation. As shown below, the

group consists of a Condition, PTR/NTR, Event, and Enable register. The outputs of the Operation Status

register group are logically-ORed into the OPER(ation) summary bit (7) of the Status Byte register.

Register Command Description

Condition

PTR Filter

NTR Filter

Event

Enable

STAT:OPER:COND?

STAT:OPER:PTR <n>

STAT:OPER:NTR <n>

STAT:OPER:EVEN?

STAT:OPER:ENAB <n>

A register that holds real-time status of the circuits being

monitored. It is a read-only register.

A positive transistion filter that functions as described under

STAT:OPER:NTR|PTR commands in chapter 4. It is a

read/write register.

A negative transition filter that functions as described under

STAT:OPER:NTR|PTR commands in chapter 4. It is a

read/write register.

A register that latches any condition that is passed through the

PTR or NTR filters. It is a read-only register that is cleared

when read.

A register that functions as a mask for enabling specific bits

from the Event register. It is a read/write register.

33

Page 34

3 - Programming the DC Source

Questionable Status Group

The Questionable Status registers record signals that indicate abnormal operation of the dc source. As

shown in figure 3-7, the group consists of the same type of registers as the Status Operation group. The

outputs of the Questionable Status group are logically-ORed into the QUEStionable summary bit (3) of the

Status Byte register.

Register Command Description

Condition STAT:QUES:COND? A register that holds real-time status of the circuits being

monitored. It is a read-only register.

PTR Filter STAT:QUES:PTR <n> A positive transistion filter that functions as described under

STAT:QUES:NTR|PTR commands in chapter 4. It is a

read/write register.

NTR Filter STAT:QUES:NTR <n> A negative transition filter that functions as described under

STAT:QUES:NTR|PTR commands in chapter 4. It is a

read/write register.

Event STAT:QUES:EVEN? A register that latches any condition that is passed through the

PTR or NTR filters. It is a read-only register that is cleared

when read.

Enable STAT:QUES:ENAB <n> A register that functions as a mask for enabling specific bits

from the Event register. It is a read/write register..

Standard Event Status Group

This group consists of an Event register and an Enable register that are programmed by Common

commands. The Standard Event event register latches events relating to instrument communication status

(see figure 3-7). It is a read-only register that is cleared when read. The Standard Event enable register

functions similarly to the enable registers of the Operation and Questionable status groups.

Command Action

*ESE

*PSC ON

*ESR?

The PON (Power On) Bit

The PON bit in the Standard Event event register is set whenever the dc source is turned on. The most

common use for PON is to generate an SRQ at power-on following an unexpected loss of power. To do

this, bit 7 of the Standard Event enable register must be set so that a power-on event registers in the ESB

(Standard Event Summary Bit), bit 5 of the Service Request Enable register must be set to permit an SRQ

to be generated, and *PSC OFF must be sent. The commands to accomplish these conditions are:

*PSC OFF *ESE 128 *SRE 32

programs specific bits in the Standard Event enable register.

clears the Standard Event enable register at power-on.

reads and clears the Standard Event event register.

Status Byte Register

This register summarizes the information from all other status groups as defined in the

Standard Digital Interface for Programmable Instrumentation

Command Action

*STB? reads the data in the register but does not clear it (returns MSS in bit 6)

serial poll clears RQS inside the register and returns it in bit position 6 of the response.

. The bit configuration is shown in Table 3-1.

IEEE 488.2

34

Page 35

Programming the DC Source - 3

The MSS Bit

This is a real-time (unlatched) summary of all Status Byte register bits that are enabled by the Service

Request Enable register. MSS is set whenever the dc source has one or more reasons for requesting

service. *STB? reads the MSS in bit position 6 of the response but does not clear any of the bits in the

Status Byte register.

The RQS Bit

The RQS bit is a latched version of the MSS bit. Whenever the dc source requests service, it sets the

SRQ interrupt line true and latches RQS into bit 6 of the Status Byte register. When the controller does a

serial poll, RQS is cleared inside the register and returned in bit position 6 of the response. The remaining

bits of the Status Byte register are not disturbed.

The MAV Bit and Output Queue

The Output Queue is a first-in, first-out (FIFO) data register that stores dc source-to-controller messages

until the controller reads them. Whenever the queue holds one or more bytes, it sets the MAV bit (4) of the

Status Byte register.

Determining the Cause of a Service Interrupt

You can determine the reason for an SRQ by the following actions:

Step 1 Determine which summary bits are active. Use:

*STB? or serial poll

Step 2

Step 3 Remove the specific condition that caused the event. If this is not possible, the event

Read the corresponding Event register for each summary bit to determine which events

caused the summary bit to be set. Use:

STATus:QUEStionable:EVENt?

STATus:OPERation:EVENt?

ESR?

When an Event register is read, it is cleared. This also clears the corresponding

summary bit.

may be disabled by programming the corresponding bit of the status group Enable

register or NTR|PTR filter. A faster way to prevent the interrupt is to disable the service

request by programming the appropriate bit of the Service Request Enable register

Servicing Operation Status and Questionable Status Events

This example assumes you want a service request generated whenever the dc source switches to the CC

(constant current) operating mode, or whenever the dc source’s overvoltage, overcurrent, or

overtemperature circuits have tripped. From figure 3-7, note the required path for a condition at bit 10

(CC) of the Operation Status register to set bit 6 (RQS) of the Status Byte register. Also note the required

path for Questionable Status conditions at bits 0, 1, and 4 to generate a service request (RQS) at the

Status Byte register. The required register programming is as follows:

Step 1 Program the Operation Status PTR register to allow a positive transition at bit 10 to be

latched into the Operation Status Event register, and allow the latched event to be

summed into the Operation summary bit. Use:

STATus:OPERation:PTR 1024;ENABle 1024

Step 2

Program the Questionable Status PTR register to allow a positive transition at bits 0,

1, or 4 to be latched into the Questionable Status Event register, and allow the latched

35

Page 36

3 - Programming the DC Source

event to be summed into the Questionable summary bit. Use:

STATus:QUEStionable:PTR 19;ENABle 19 (1 + 2 + 16 = 19)

Step 3

Step 4

Program the Service Request Enable register to allow both the Operation and the

Questionable summary bits from the Status Byte register to generate RQS. Use:

*SRE 136 (8 + 128 = 136)

When you service the request, read the event registers to determine which Operation

Status and Questionable Status Event register bits are set, and clear the registers for

the next event. Use:

STATus:OPERation:EVENt;QUEStionable:EVENt?

Monitoring Both Phases of a Status Transition

You can monitor a status signal for both its positive and negative transitions. For example, to generate

RQS when the dc source either enters the CC+ (constant current) condition or leaves that condition,

program the Operational Status PTR/NTR filter as follows:

STATus:OPERational:PTR 1024;NTR 1024

STATus:OPERational:ENABle 1024;*SRE 128

The PTR filter will cause the OPERational summary bit to set RQS when CC+ occurs. When the

controller subsequently reads the event register with STATus:OPERational:EVEN?, the register is cleared.

When CC+ subsequently goes false, the NTR filter causes the OPERational summary bit to again set

RQS.

Inhibit/Fault Indicator

The remote inhibit(INH) and discrete fault(FLT) indicators are implemented through the respective INH

and FLT connections on the rear panel. Refer to Table 1-2 for the electrical parameters.

Remote Inhibit (RI)

Remote inhibit is an external, chassis-referenced logic signal routed through the rear panel INH

connection, which allows an external device to signal a fault. To select an operating modes for the remote

inhibit signal, use:

OUTPut:RI:MODE LATChing | LIVE | OFF

Discrete Fault Indicator (DFI)

The discrete fault indicator is an open-collector logic signal connected to the rear panel FLT connection,

that can be used to signal external devices when a fault condition is detected. To select the internal fault

source that drives this signal, use:

OUTPut:DFI:SOURce QUEStionable | OPERation | ESB | RQS | OFF

To enable or disable the DFI output, use:

OUTPut:DFI:STATe ON | OFF

36

Page 37

Programming the DC Source - 3

Using the Inhibit/Fault Port as a Digital I/O

You can configure the inhibit/fault port to provide a digital input/output to be used with custom digital

interface circuits or relay circuits. As shipped from the factory, the port is shipped for inhibit/fault operation.

You can change the configuration of the port to operate as a general purpose digital input output port with

the following command:

[SOURce:]DIGital:FUNCtion RIDFi | DIGio

The following table shows the bin assignments of the mating plug when used in RI/DFImode as well as

Digital I/O mode. Refer to Table 1-2 for the electrical characteristics of the port.

Pin FAULT/INHIBIT DIGITAL I/O Bit Weight

1 FLT Output OUT 0 0

2 FLT Output OUT 1 1

3 INH Input IN/OUT 2 2

4 INH Common Common not programmable

To program the digital I/O port use:

[SOURce:]DIGital:DATA <data>

where the data is an integer from 0 to 7 that sets pins 1 to 3 according to their binary weight. Refer to the

DIGital:DATA command for more information.

DFI Programming Example

The following program illustrates how to program the DFI port so that it goes low when an OCP condition

turns off the output of the unit. To clear an overcurrent condition, the cause of the condition must first be

removed and then an OUTput:PROTection:CLEar command must be sent. Note that the status event

register will not clear the DFI port until the register is read.