Page 1

..':.+:..

..e:*..

.

Agilent Technologies, Inc

24001

E

Mission

Liberty Lake, WA

99019

www

..

Agilent Technologies

'

Innovating

June

Dear Customer,

As

semiconductor products, health care solutions, and chemical analysis became a new company,

Agilent Technologies. Now, many

Agilent Technologies.

the

8,2000

of

November

HPWay

1,

1999,

four

of

Hewlett-Packard's businesses, test and measurement,

of

your Hewlett-Packard products and services are

agilent corn

in

the care of

At

Agilent Technologies, we are working diligently

you. However, as

shipment may be labeled with either the Hewlett-Packard name and logo, the Agilent Technologies

name and logo,

(HP), but applies to your Agilent Technologies product. Hewlett-Packard and Agilent branded

products with the same model number are interchangeable.

Whatever logo you see, the information, products, and services come from the same reliable source.

If

you have questions about Agilent Technologies products and services, please visit our website at

http://www.aqilent.com.

a

result of this transition, the products and related documentation contained in this

or

a combination of both. Information in this package may refer to Hewlett-Packard

to

make this transition

as

smooth as possible for

Sincerely,

Rebranding Team

Page 2

HP

8904A

MULTIFUNCTION SYNTHESIZER

(Including Options

Service Manual

SERIAL

This

2712A

manual

serial numbers prefixed

to

2948A

For

numbers, refer

THIS

This

Government pursuant

der the clause at

and all MAJOR

additional important information about serial

MANUAL"

material may

applies directly

SEW

rev.OlJUL91

to

"INSTRUMENTS

in

Fourth

be

DFARS

001,

002,

NUMBERS

to

instruments

PREFIXES

changes

Section

reproduced by

to

that

apply to

COVERED

1.

Edition

the Copyright License

52.227-7013

003,

with

your

or

for the

(APR 1988).

U.S.

and

instrument.

BY

un-

004)

Copyright@ HEWLETT-PACKARD COMPANY

EAST 24001 MISSION AVENUE, TAF C-34, SPOKANE, WASHINGTON, U.S.A.

Service Manual HP Part 08904-90008

Other Documents Availiable:

Operation and Calibration Manual HP Part 08904-90007

Operation and Application Guide HP Part 5953-8491

Microfiche Service Manual HP Part 08904-90020

Microfiche OperationlCalibration Manual HP Part 08904-90019

1987

99220

Printed In

U.S.A.:

June

1992

HEWLETT

PACKARD

Page 3

1

Regulatory

Information

(Updated March

1999)

1

Page 4

Regulatory

Safety Considerations

GENERAL

This

markings and instructions before operation.

This

"Safety Requirements for Electronic Measuring Apparatus," and

safe condition.

must

condition.

SAFETY EARTH GROUND

A

uninterruptible safety earth ground must be provided from the main power source to the

product input wiring terminals, power cord, or supplied power cord set.

Information

product and related documentation must be reviewed for familiarization with safety

product

be followed by the user to ensure safe operation and to maintain the product in a safe

(Updated

has

been designed and tested in accordance with

This

March

1999)

instruction documentation contains information and warnings which

IEC

Publication

has

1010,

been supplied

in

a

SAFETY

A

Indicates instrument damage can occur if indicated operating limits are exceeded.

r;n

Indicates hazardous voltages.

Indicates earth (ground) terminal

1-

-

WARNING

~ ~ ~

CAUTION

SYMBOLS

~~ ~ ~

A

WARNING note denotes a hazard. It

practice,

could result in personal injury.

sign

A

CAUTION note denotes a hazard. It calls attention to an operation

procedure, practice, or the like, which, if not correctly performed or adhered

to, could result in damage to or destruction

not proceed beyond an CAUTION note until the indicated conditions are fully

understood and met.

or

the like, which, if not correctly performed or adhered to,

Do

until the indicated conditions are

calls

attention to a procedure,

not proceed beyond a WARNING

fully

understood and met.

of

part or

all

of the product.

Do

2

Chapter

1

Page 5

Safety Considerations for this Instrument

~

WARNING

This product is a Safety Class I instrument (provided with

protective earthing ground incorporated in the power cord). The

mains plug shall only be inserted in a socket outlet provided with a

protective earth contact. Any interruption

conductor inside

or

outside

product dangerous. Intentional interruption is prohibited.

Regulatory Information (Updated March

of

the protective

of

the product is likely to make the

1999)

a

Whenever

it

is likely that the protection has been impaired, the

instrument must be made inoperative and be secured against any

unintended operation.

If

this instrument is to be energized via an auto transformer

(for

voltage reduction), make sure the common terminal is connected to

the earth terminal

If

this product is not used as specified, the protection provided by

of

the power source.

the equipment could be impaired. This product must be used in a

normal condition (in which all means

No

operator serviceable parts in this product. Refer servicing to

qualified personnel.

To

prevent electrical shock, do not remove

for

protection are intact) only.

covers.

Servicing instructions are

for

use by qualified personnel only.

To

avoid electrical shock, do not perform any servicing unless you are

qualified to do

The opening

dangerous voltages. Disconnect the product from

while

it

is

The power cord is connected

live for

5

seconds after disconnecting the plug from its power supply.

so.

of

covers

being opened.

or

removal

of

parts is likely

to

internal capacitors that my remain

to

expose

all

voltage sources

Chapter

For

Continued protection against fire hazard, replace the line fuse(s)

only with

example, normal blow

250

V

fuse(s)

or

the same current rating and type (for

or

time delay).

Do

not use repaired fuses

short circuited fuseholders.

Always use the three-prong ac power cord supplied with this

product. Failure to ensure adequate earth grounding by not using

this cord may cause product damage.

This product is designed

Pollution Degree

INDOOR

USE

2

per

ONLY.

for

IEC

use in Installation Category

1010

and

IEC

664

respectively. FOR

This product has autoranging line voltage input, be sure the supply

voltage

1

is

within the specified range.

I1

or

and

3

Page 6

Regulatory Information (Updated March

To

prevent electrical shock, disconnect instrument from mains (line)

before cleaning. Use

to

clean the external case parts.

Ventilation Requirements: When installing the product in a cabinet,

the convection into and out of the product must not be restricted.

The ambient temperature (outside the cabinet) must be less than the

maximum operating temperature

watts dissipated in the cabinet.

cabinet is greater than

used.

1999)

a

dry cloth or one slightly dampened with water

Do

not attempt to clean internally.

of

the product by

If

the total power dissipated in the

800

watts, then forced convection must be

4"

C

for

every

100

Product

CE

accompanied by

CSA - the CSA mark

-

the

Markings

CE mark

a

is

year indicated the year the design

a

registered trademark

is

a

registered trademark

of

the

European Community. A CE mark

was

proven.

of

the Canadian Standards Association.

Chapter

1

Page 7

Model 8904A Contents

CONTENTS

Section

Introduction to This Section

Reference Designations and Abbreviations Used in This Manual

Replaceable

Mechanical and Chassis

Section

Introduction

Option Conversions

Instrument Modifications

Section

6

.

Replaceable Parts

............................................

Parts

List

................................................

Ordering Parts

Replaceable Parts List Updating (Manual Updates)

7

...................................................

.............................

Part

Locations and Reference Designations

.

Instrument Changes

to

This Section

............................................

..................................................

..............................................

Firmware Updates (A2U12 and A2U13)

Hardware Modifications

Modification for Possible Ground Wire Shock Hazard

Modification for Output Overvoltage Protection Improvement

Modification for Potential Power Supply Short

8

.

Service

.............................................

....................................

............................

...............................

........................

......................

.......................

6.1

6.1

6.1

6.1

6.2

6.2

7.1

7.1

7.1

7.8

7.8

7.9

7-13

7-14

Introduction to This Section

How the Section is Organized

Safety Considerations

Before Applying Power

Safety

Service Tools, Helps, and Information

Printed Circuit Board Extractor

Assembly, Parts. and Cable Locations

Other Service Documents

Recommended

Schematic Symbology and Schematic Diagram Notes

Principles of Operation

Overall

A2

A3 Output Assembly (Service Sheets

Troubleshooting

General

A2

A2

A2

A3

.......................................................

.....................................................

Digital Assembly

.....................................................

Digital Assembly to A3

Digital Assembly to

Digital Assembly

or

A10 Output Assembly

................................................

Test

Equipment and Accessories

..................................................

............................................

............................................

.............................................

.......................................

........................................

.....................................

............................................

..............................................

..............................................

1

through

(or

A10) Output Assembly Interface

A1

Keyboard Assembly Interface

to

A5 Display Assembly Interface

.........................................

...............................

...............................

4)

.............................

......................

.........................

...........................

8.1

8.1

8.1

8.1

8-1

8-3

8.3

8.3

8.3

8.3

8.3

8-15

8-15

8-23

8-24

8-29

8-29

8-30

8-38

8-41

8-42

reu.200CT88

Page 8

Contents

Model

8904A

Section

8

.

Service (cont’d)

How

to

Restore the Serial Number

How

to

How

Service Sheets 1 through 4 (schematics)

Restore Options

to Replace the Memory Backup Battery

001

and

in

a Replacement A2

003

in

a

Replacement

...................................

Digital

A2

Digital

Assembly

Assembly

................

..............

...............................

8-43

8-46

8-48.1

8-50

reu.200CT88

Page 9

Model

8904A

Replaceable

Parts

Section

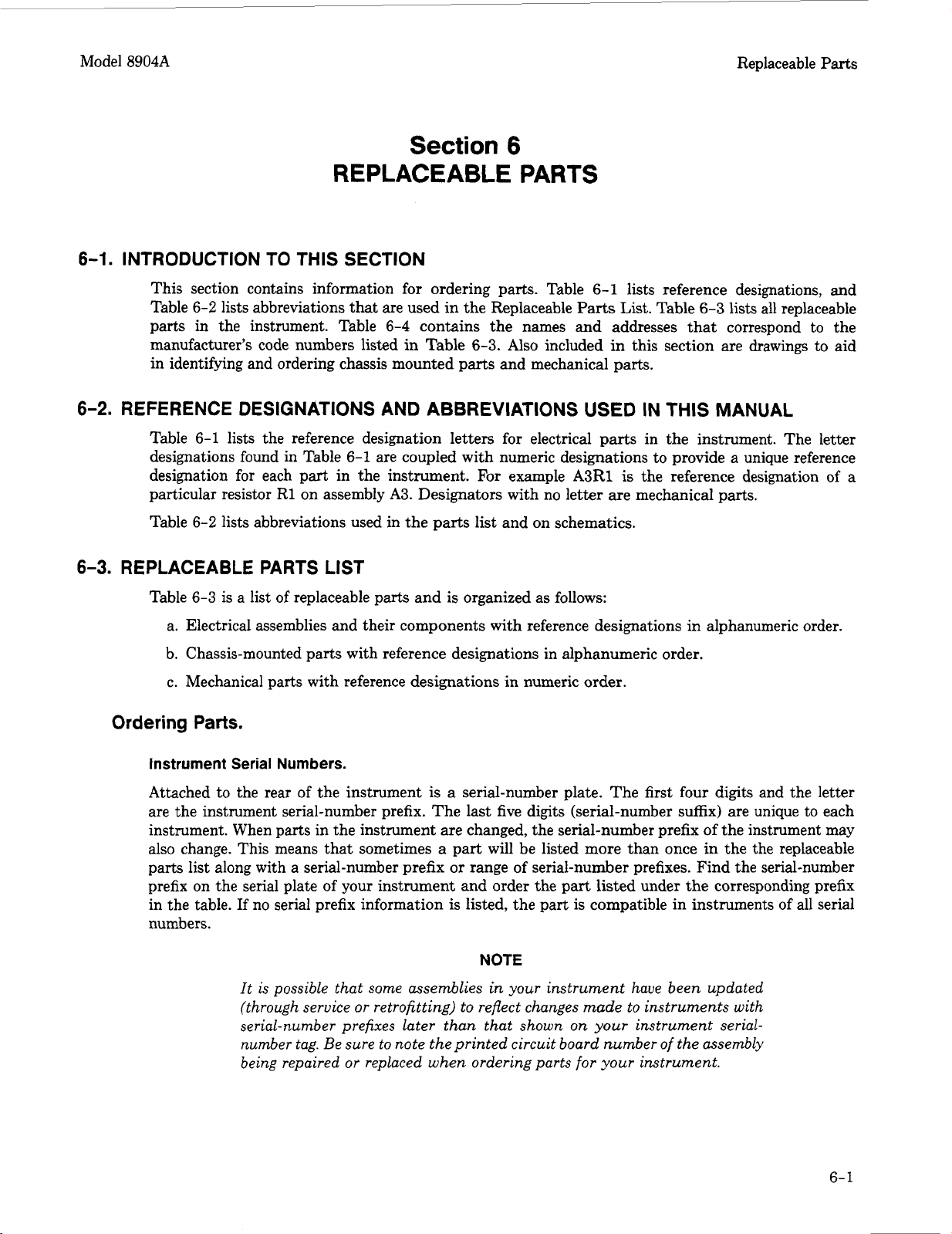

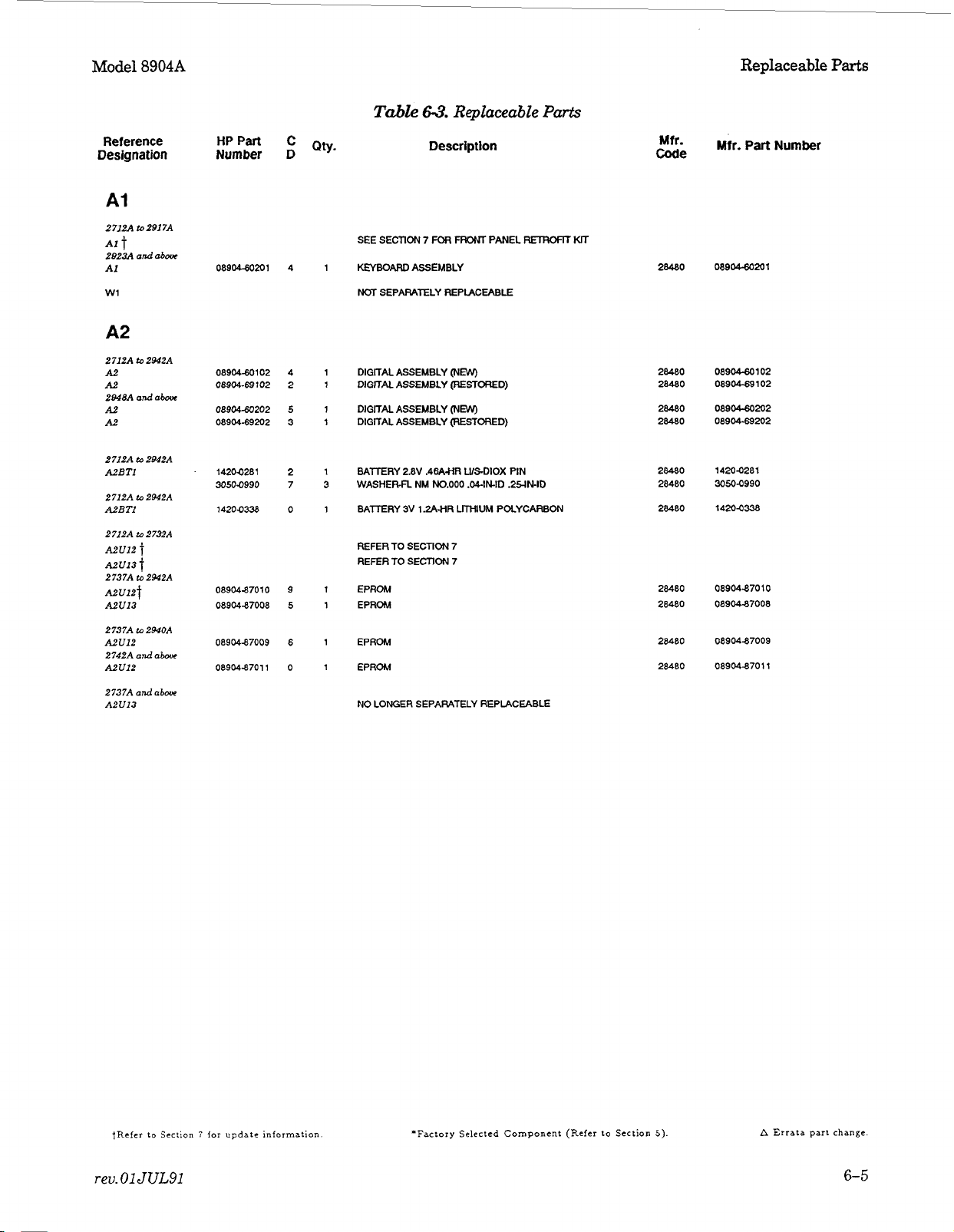

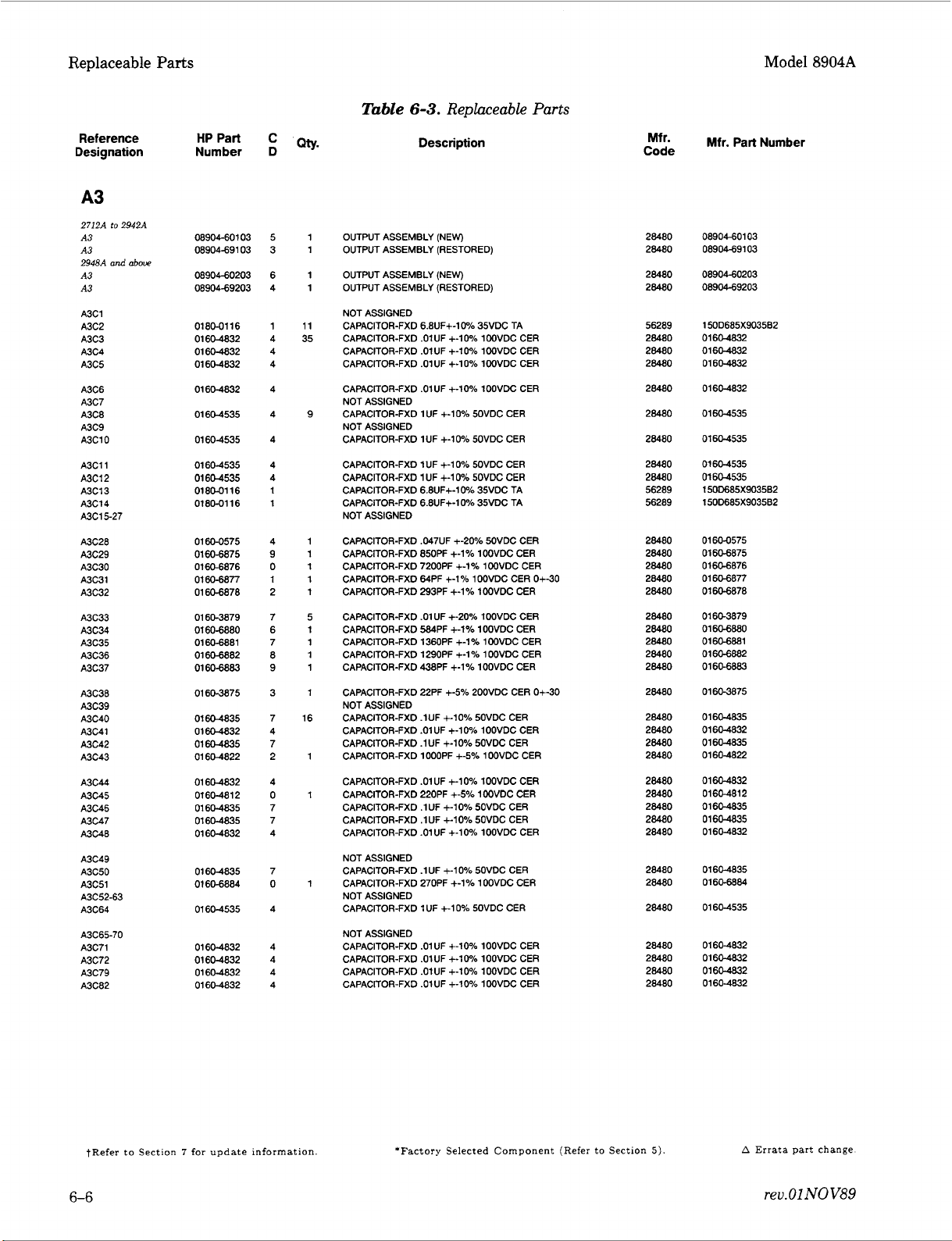

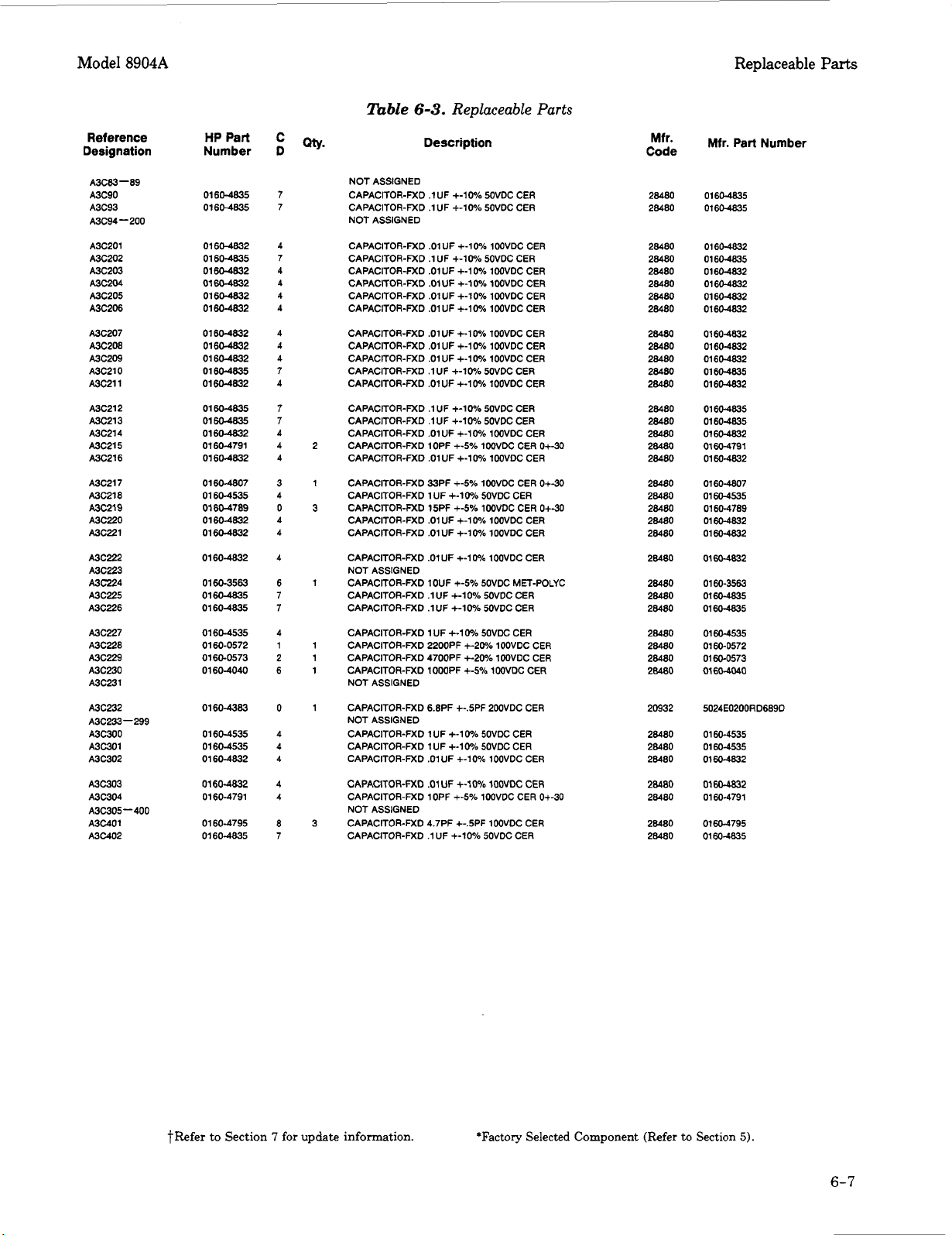

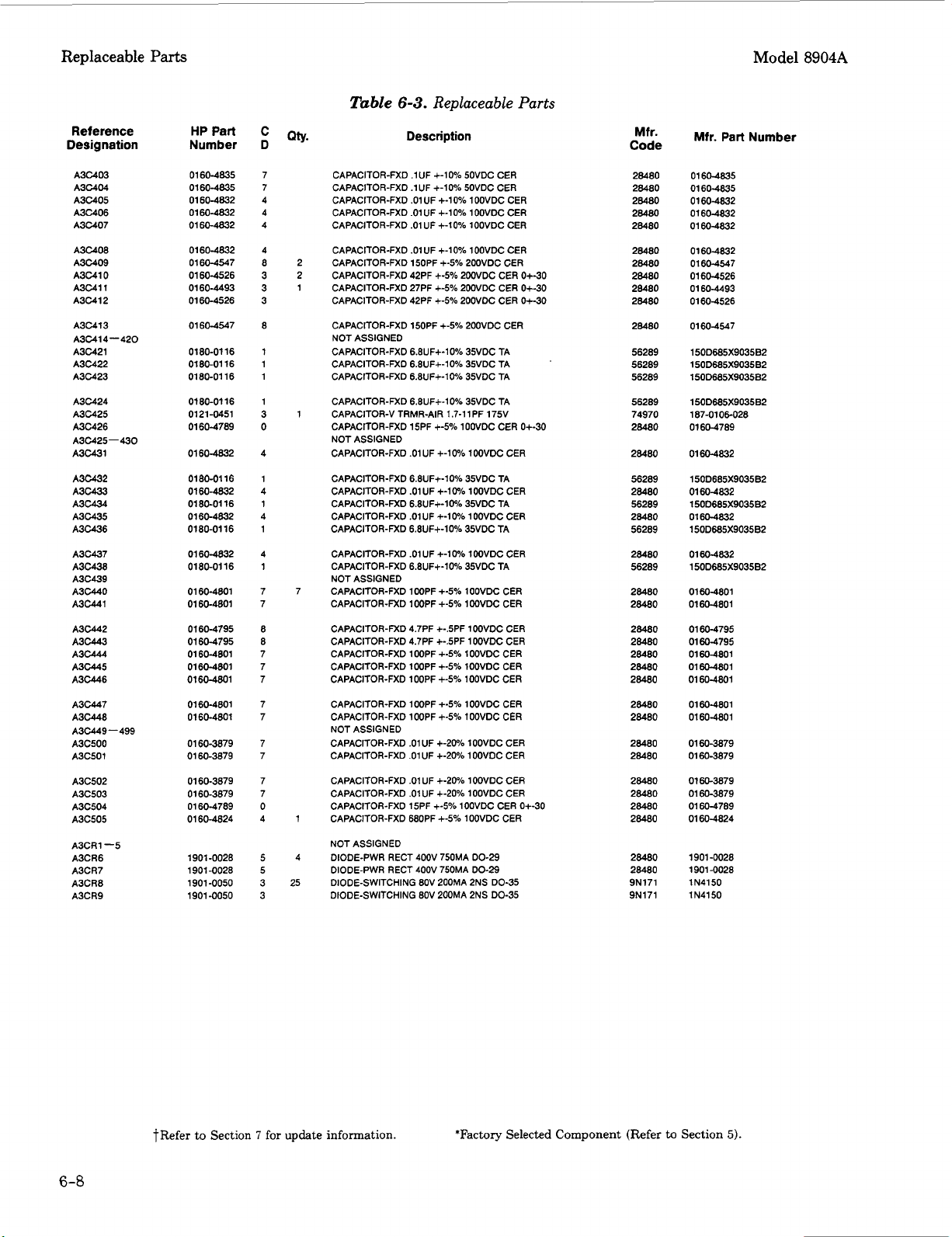

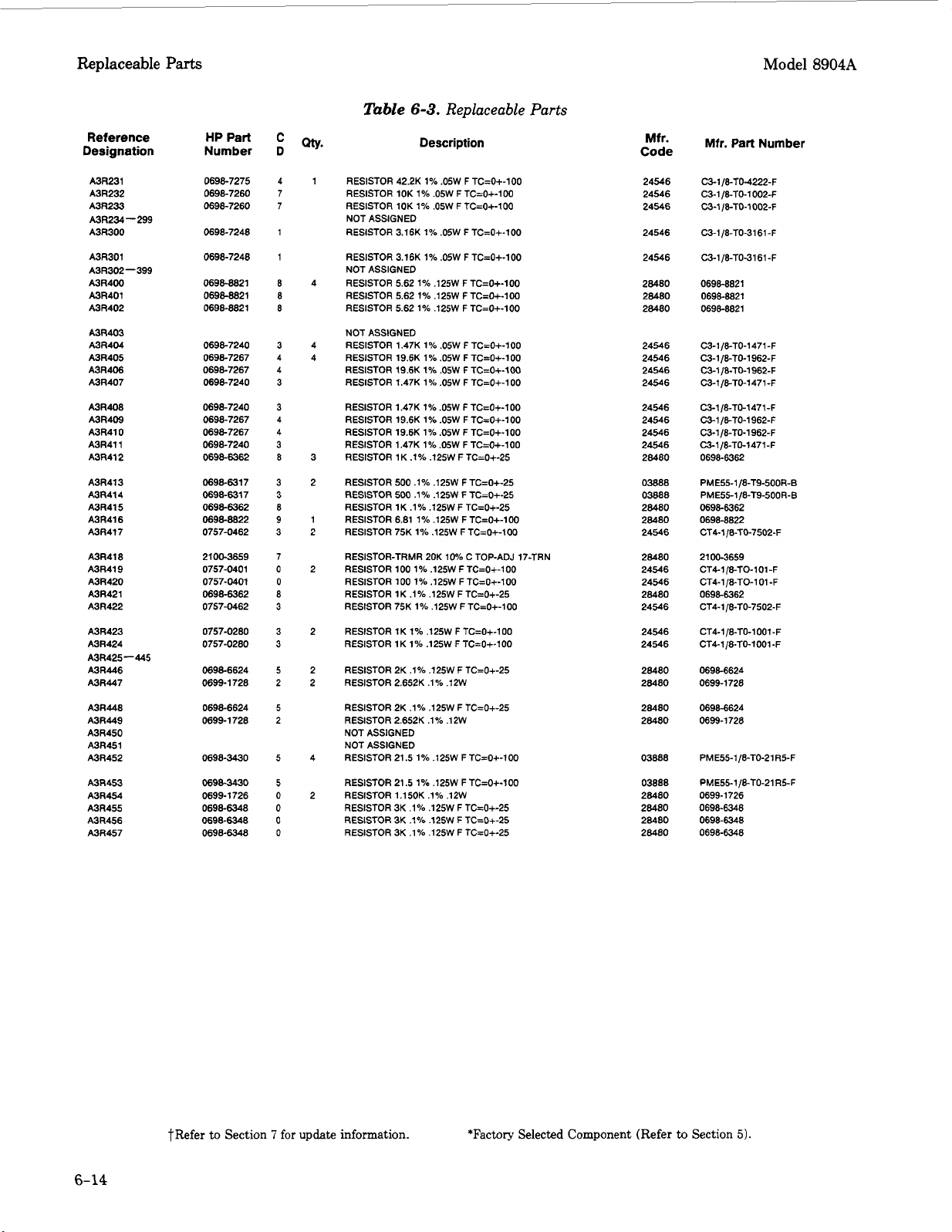

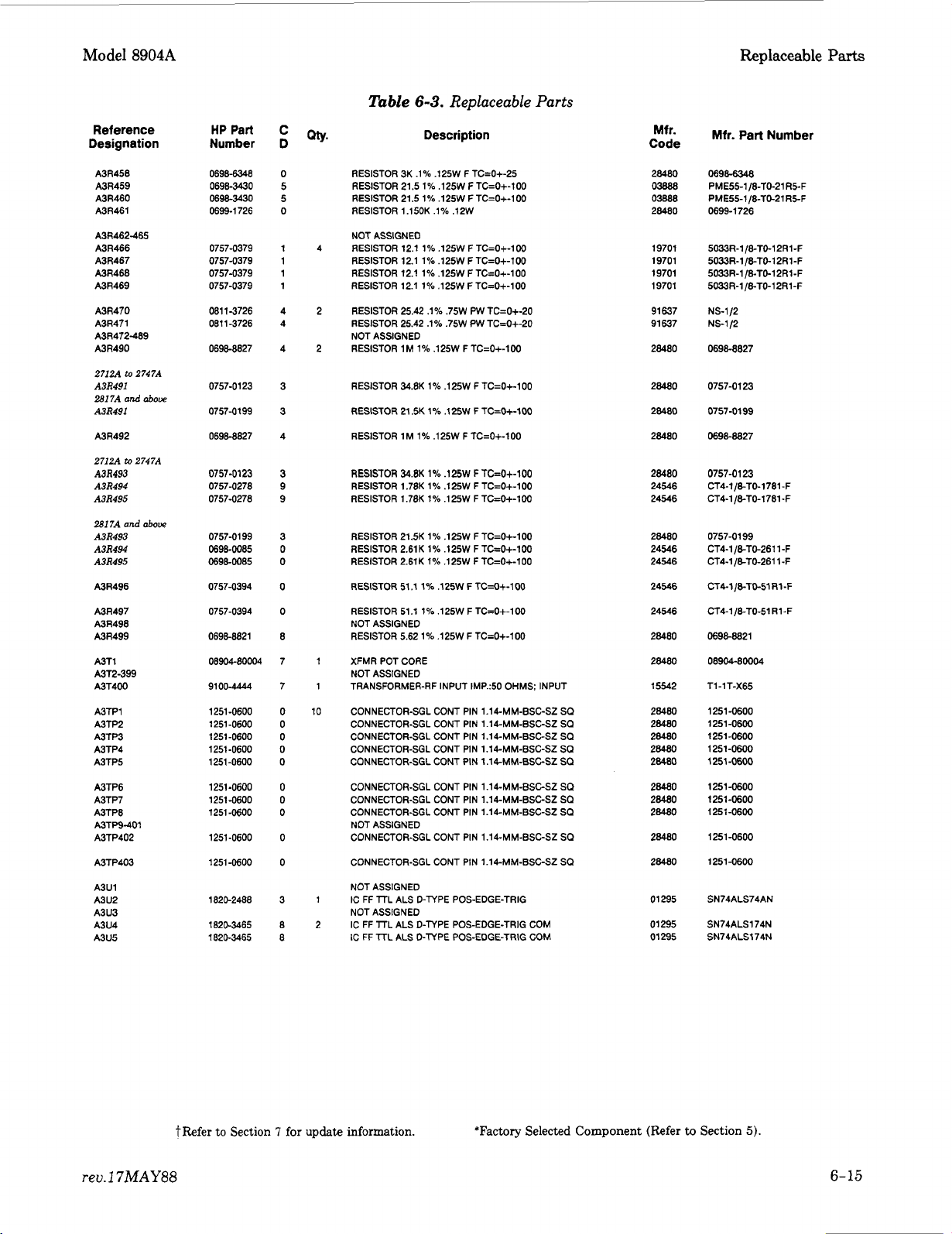

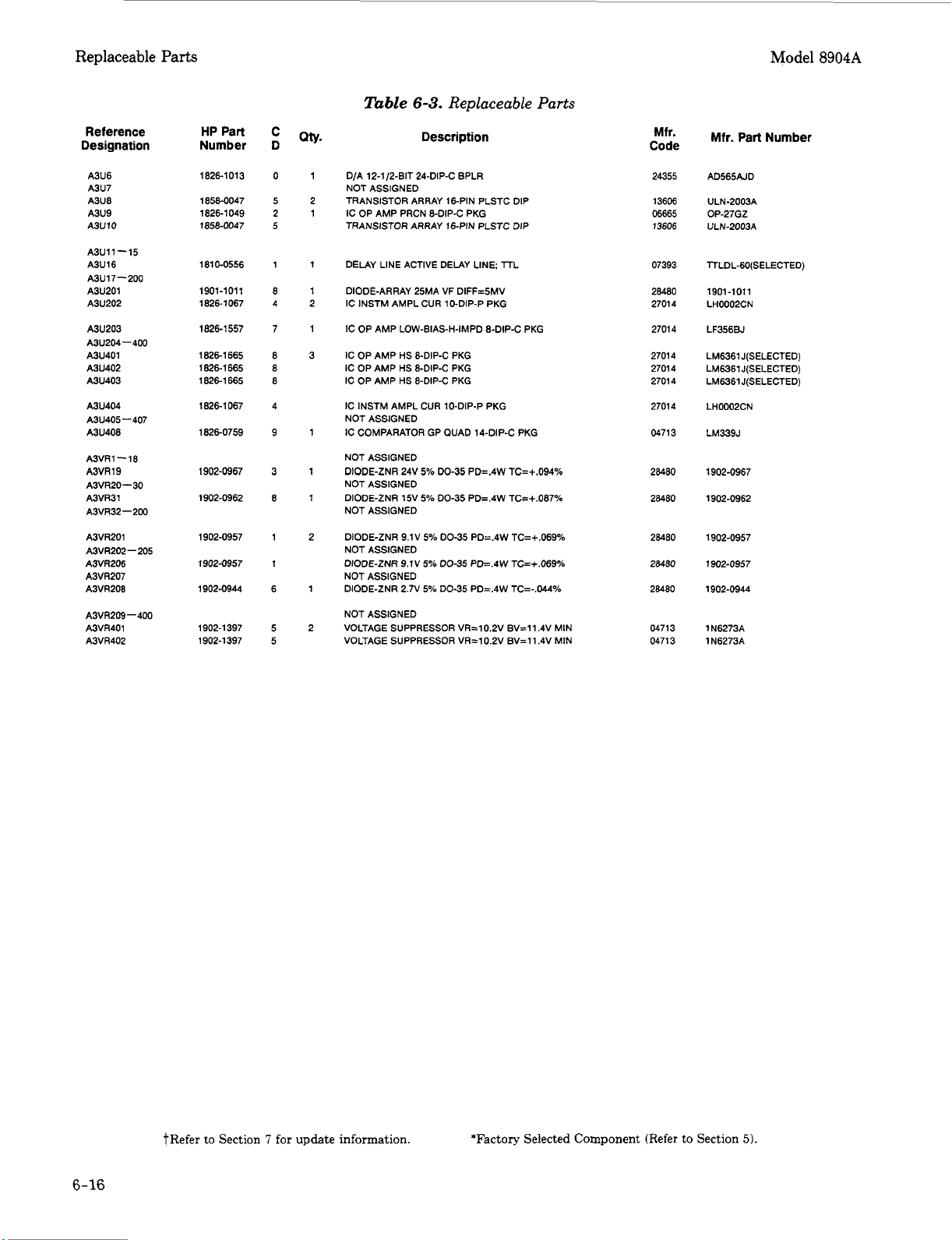

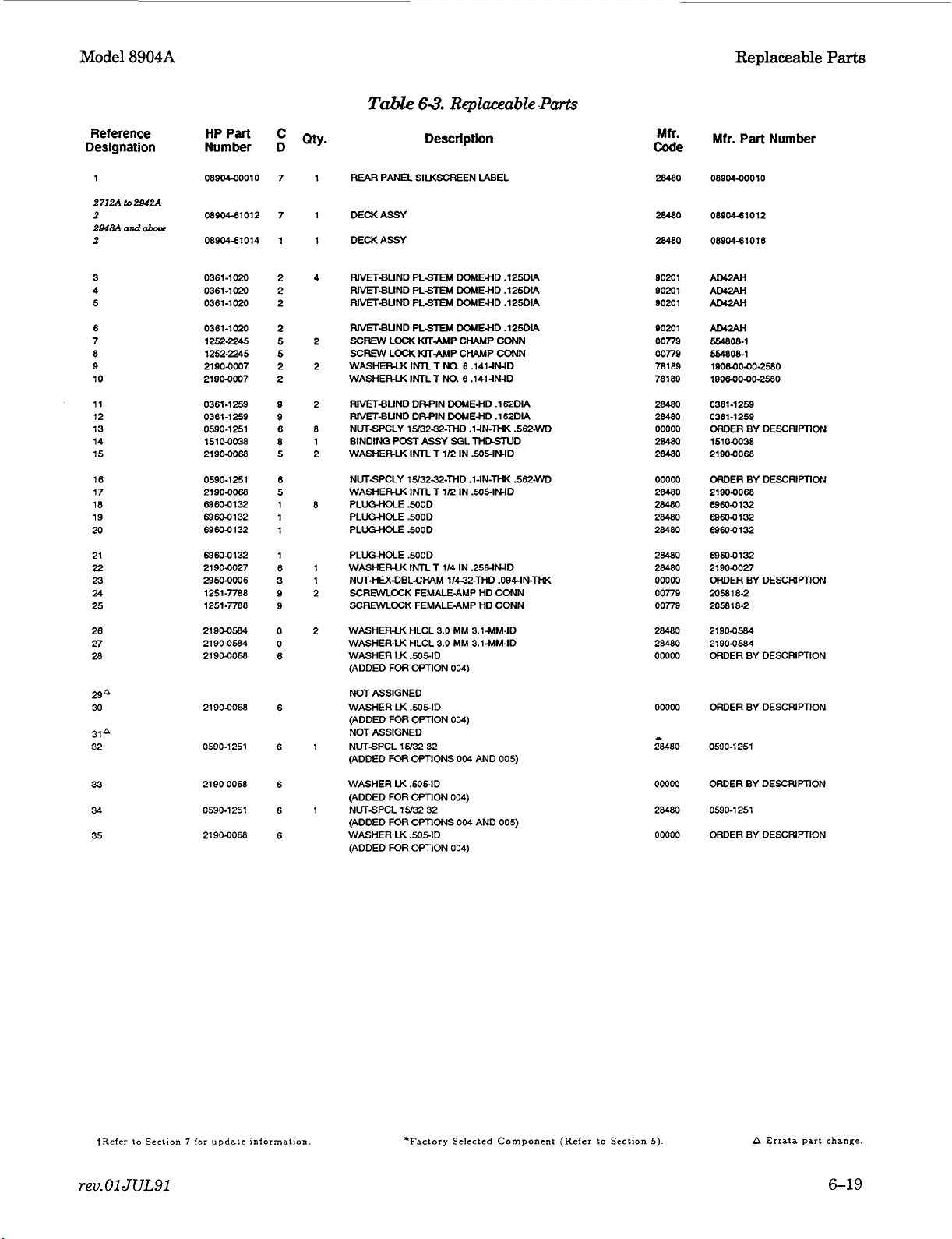

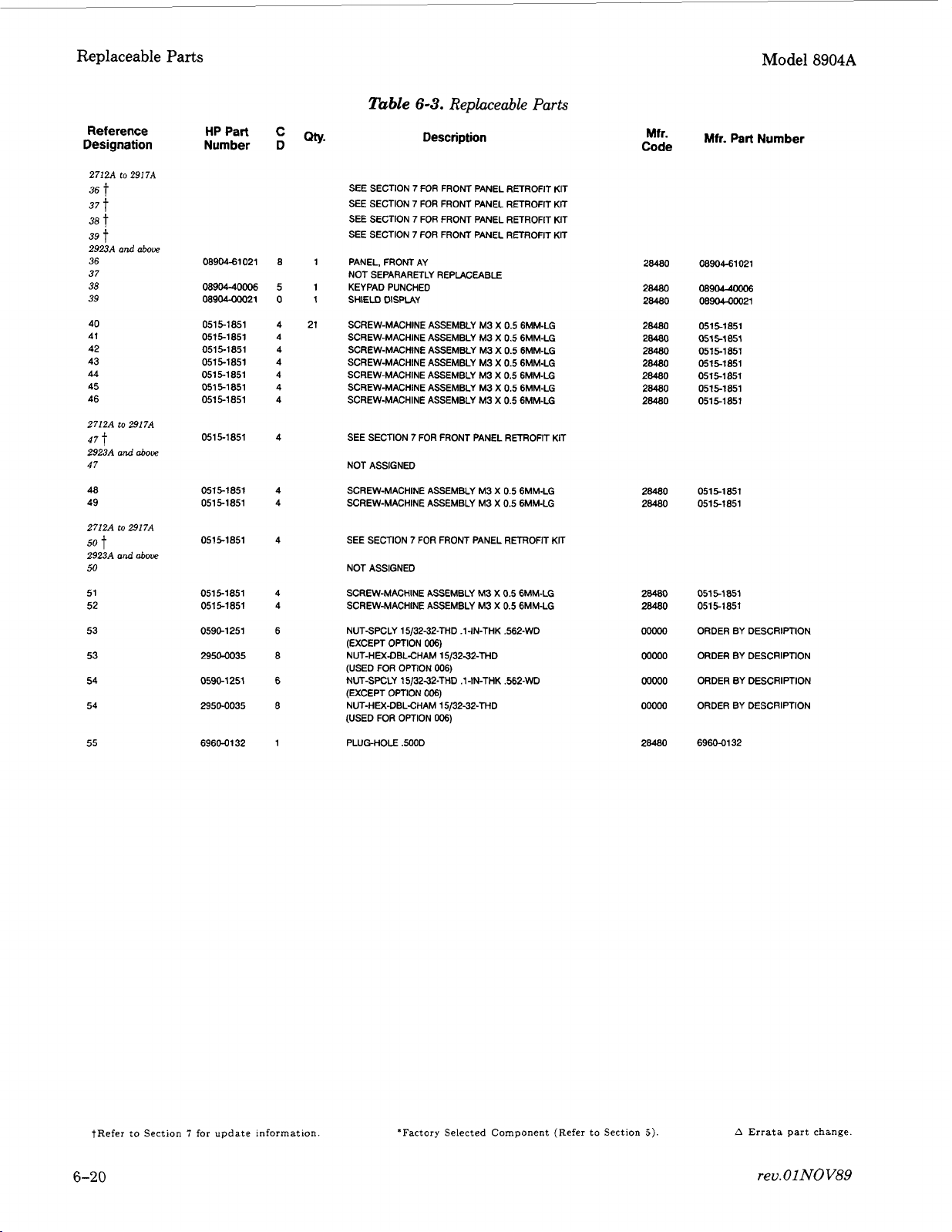

REPLACEABLE PARTS

6-1.

INTRODUCTION TO THIS SECTION

This section contains information for ordering parts. Table 6- 1 lists reference designations, and

Table 6-2 lists abbreviations that are used in the Replaceable

parts in the instrument. Table 6-4 contains the names and addresses that correspond

manufacturer’s code numbers listed in Table 6-3.

in identifying and ordering chassis mounted parts and mechanical parts.

6-2.

REFERENCE DESIGNATIONS AND ABBREVIATIONS

Table 6-1 lists the reference designation letters

designations found in Table 6-1 are coupled with numeric designations to provide a unique reference

designation for each part in the instrument.

particular resistor

Table 6-2 lists abbreviations used in the parts list and on schematics.

6-3.

REPLACEABLE PARTS LIST

R1

on assembly A3. Designators with no letter are mechanical parts.

For

6

Parts

List. Table 6-3 lists all replaceable

Also

included in this section are drawings to aid

USED

for

electrical

example A3R1

IN

THIS

parts

in the instrument. The letter

is

the reference designation

MANUAL

to

the

of

a

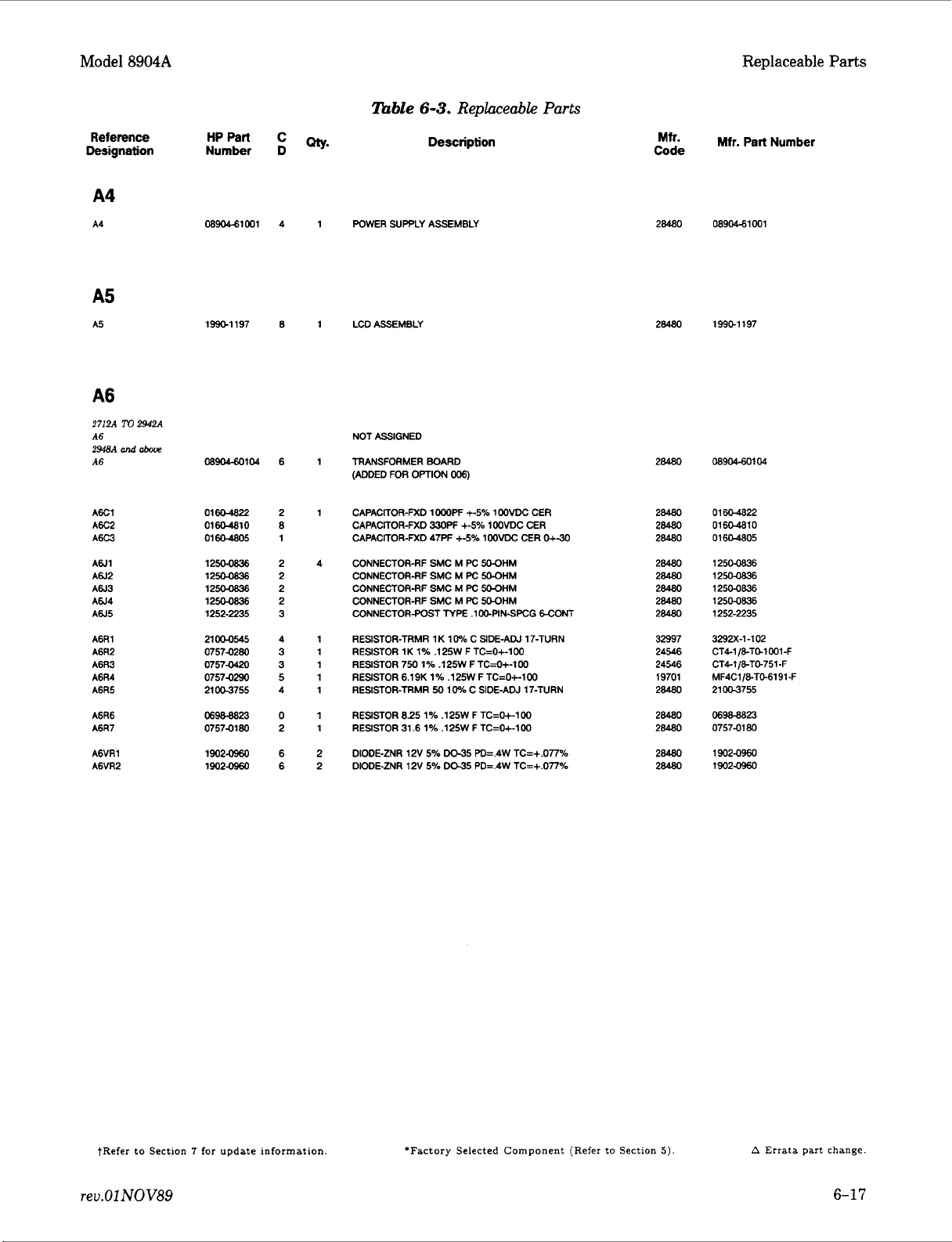

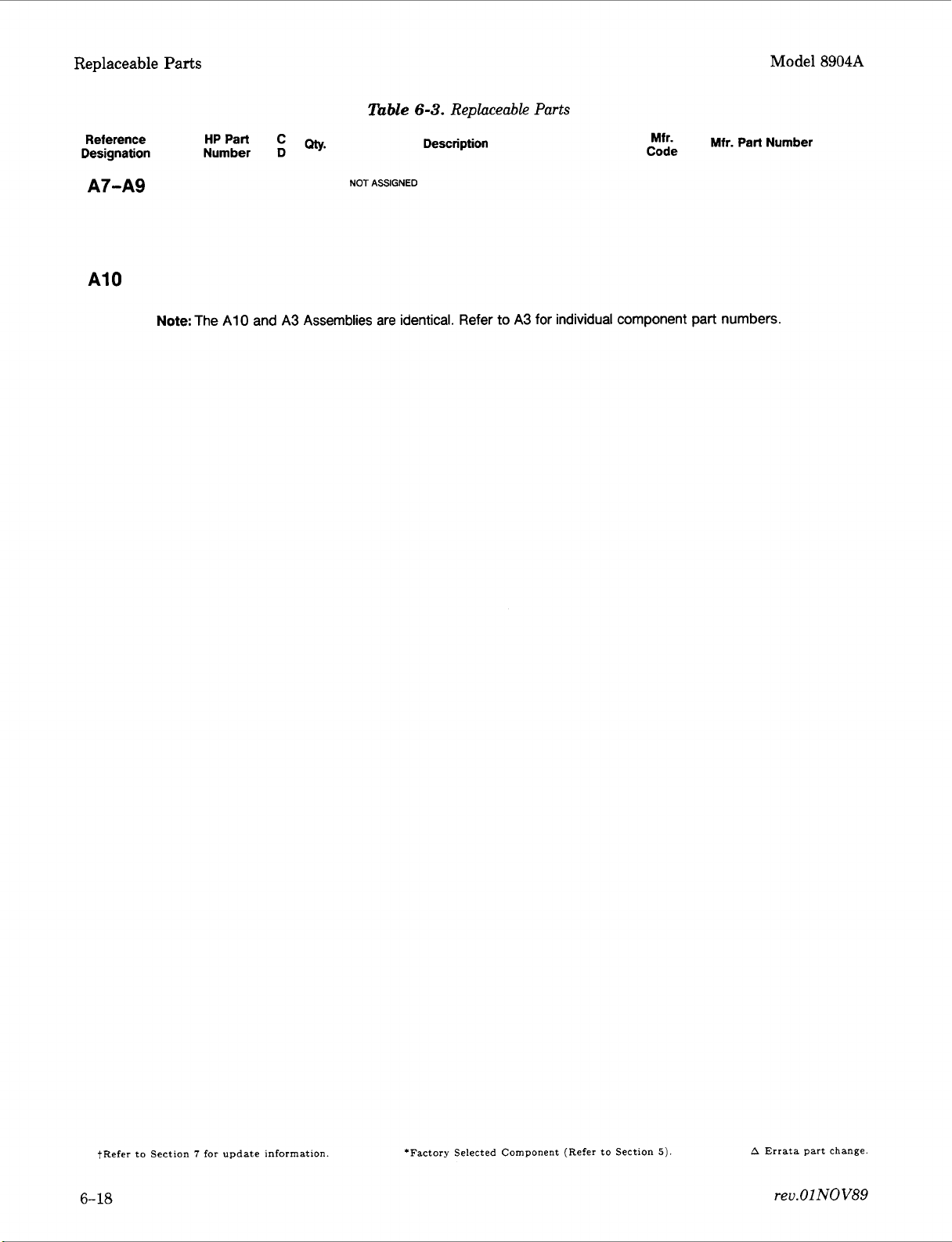

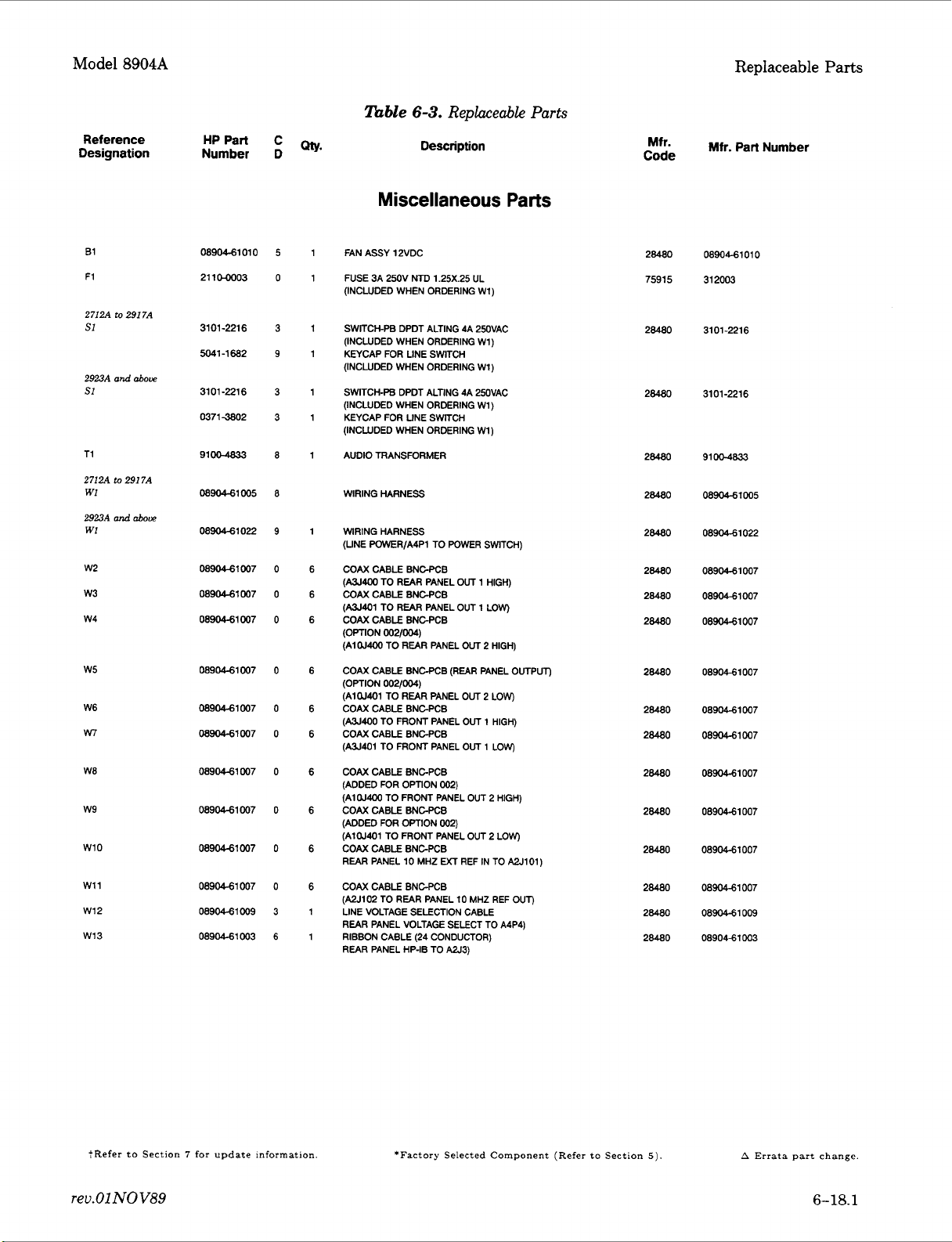

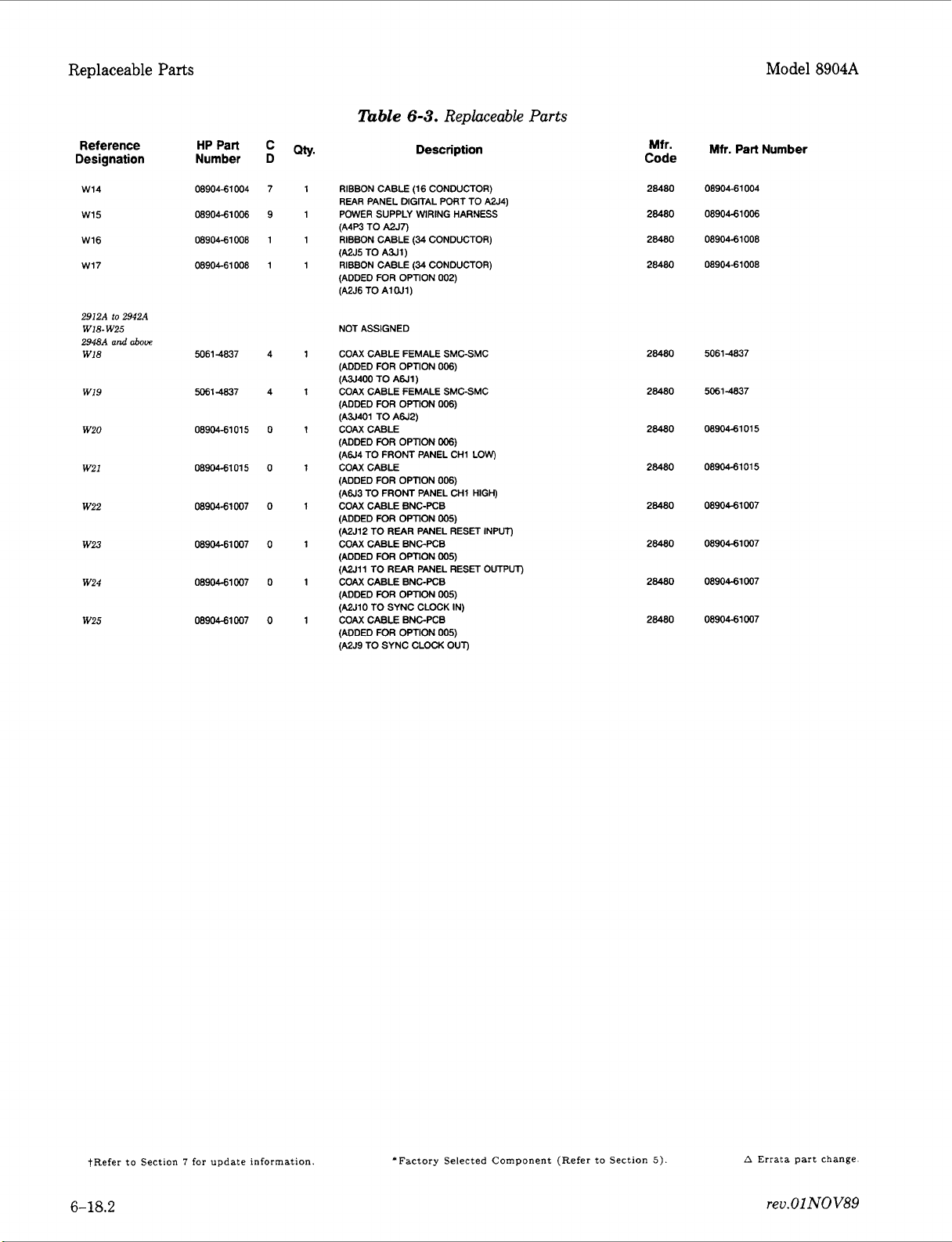

Table 6-3 is a list

a. Electrical assemblies and their components with reference designations in alphanumeric order.

b. Chassis-mounted parts with reference designations in alphanumeric order.

c. Mechanical parts with reference designations

Ordering

Parts.

Instrument Serial Numbers.

Attached to the rear

are the instrument serial-number prefix. The last five digits (serial-number suffix) are unique to each

instrument. When parts in the instrument are changed, the serial-number prefix of the instrument may

also change. This means that sometimes a part will be listed more than once in the the replaceable

parts list along with a serial-number prefix

prefix on the serial plate of your instrument and order the part listed under the corresponding prefix

in the table. If no serial prefix information is listed, the part is compatible in instruments of all serial

numbers.

of

replaceable parts and is organized as follows:

in

numeric order.

of

the instrument is a serial-number plate. The first four digits and the letter

or

range of serial-number prefixes. Find the serial-number

NOTE

It is possible that some assemblies

or

(through service

serial-number prefixes later than that shown on

number tag. Be sure to note the printed circuit board number

being repaired

retrofitting) to reflect changes made to instruments with

or

replaced when ordering parts

in

your instrument have been updated

your

instrument serial-

for

your

instrument.

of

the

assembly

6-

1

Page 10

Replaceable

Parts

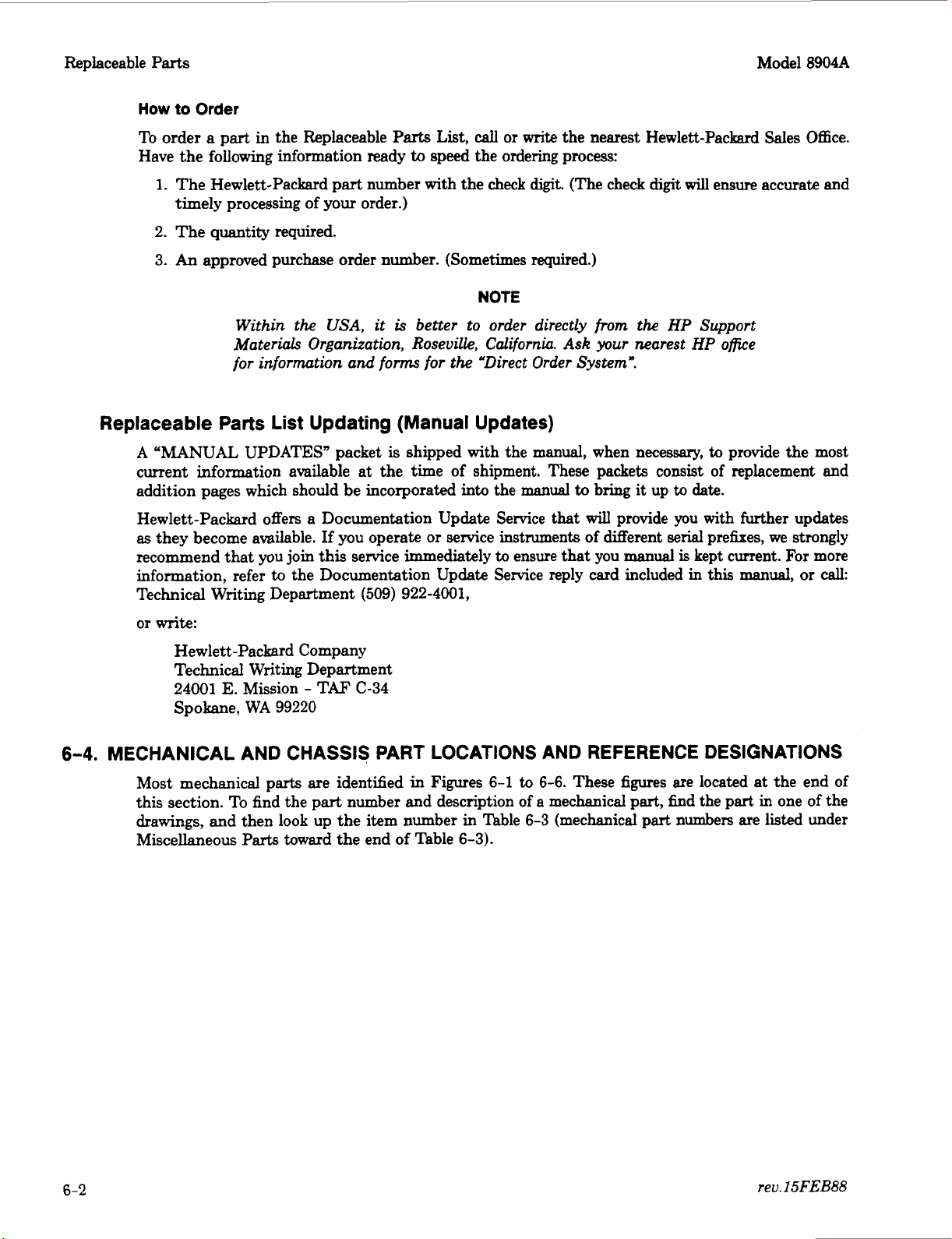

How

to

Order

Model

8904A

To order a part in the Replaceable

Have the following information ready

1.

The Hewlett-Packard

timely processing of your order.)

2.

The quantity required.

3.

An

approved purchase order number. (Sometimes required.)

Within the

Mater& Organization, RoseviUe, California.

for

information

part

USA,

Parts

List,

call

to

speed the ordering process:

number with the check

it

is

better to order directly

and

form

for

the uDirect Order Systems.

or write the nearest Hewlett-Packard Sales Office.

digit.

NOTE

Replaceable Parts List Updating (Manual Updates)

A

“MANUAL

current information available

addition pages which should be incorporated into the

Hewlett-Packard offers a Documentation Update Service

as

they become available.

recommend that

information, refer

Technical Writing Department

UPDATES‘ packet

If

you operate or service instruments

you

join this service immediately

to

the Documentation Update Service reply card included

is

at

the time of shipment. These packets consist of replacement and

(509) 922-4001,

shipped with the manual, when necessary,

manual

that

to

ensure that you

(The check

from

Ask

your

to

bring

will

provide you with further updates

of

different

manual

digit

the

HP

nearest

it

up

to

serial

will

ensure accurate and

Support

HP

office

to

provide the most

date.

prefixes, we strongly

is

kept current. For more

in

this

manual,

or calk

or

write:

Hewlett-Packard

Technical Writing Department

24001

Spokane, WA

6-4.

MECHANICAL AND CHASSIS PART LOCATIONS AND REFERENCE DESIGNATIONS

Most mechanical parts are identified in Figures

this section. To find the part number and description of

drawings, and then look up the item number in Table

Miscellaneous

E.

Mission

Parts

Company

-

TAF

C-34

99220

toward the end of Table

6-1

6-3).

to

6-6.

These

a

mechanical part,

6-3

(mechanical

figures

are located

find

part

numbers are listed under

the part

at

the end of

in

one of the

6-2

rev.15FEB88

Page 11

Model

8904A

Replaceable

Parts

A

AT

........

.

.....

attenuator; isolator;

.............

B

..

................

BT

.

..............

c

..

...............

CP

.

CR

.

...........

thyristor: varactor

......

DC

.

DL

.

,

..............

...........

DS

.

signaling device

(audible or visual);

lamp; LED

ac

........

ACCESS

ADJ

AID

AL

ALC

APC

ASSY

AUX

avg

AWG American wire

BAL

BCD

BD

BECU

BFO

BKDN

BP

BPF

BRS

BWO

CAL

ccw

CER

CHAN

cm

..............

CMO

COAX

alternating current

.........

............

........

..............

.........

control

amplitude modulation

...........

.......

control

............

..............

. .....

...............

..........

decimal

.................

......

.........

..........

..............

.........

................

.......

oscillator

..............

.......

counter-clockwise

..............

.............

.....

cabinet mount only

..............

assembly

termination

fan: motor

battery

capacitor

coupler

diode; diode

directional coupler

delay line

annunciator:

accessory

adjustment

analog-to-digital

aluminum

automatic level

amplifier

automatic phase

assembly

auxiliary

average

balance

binary coded

beryllium copper

backware-wave

board

beat frequency

breakdown

bandpass

bandpass filter

brass

calibrate

ceramic

channel

centimeter

coaxial

nable

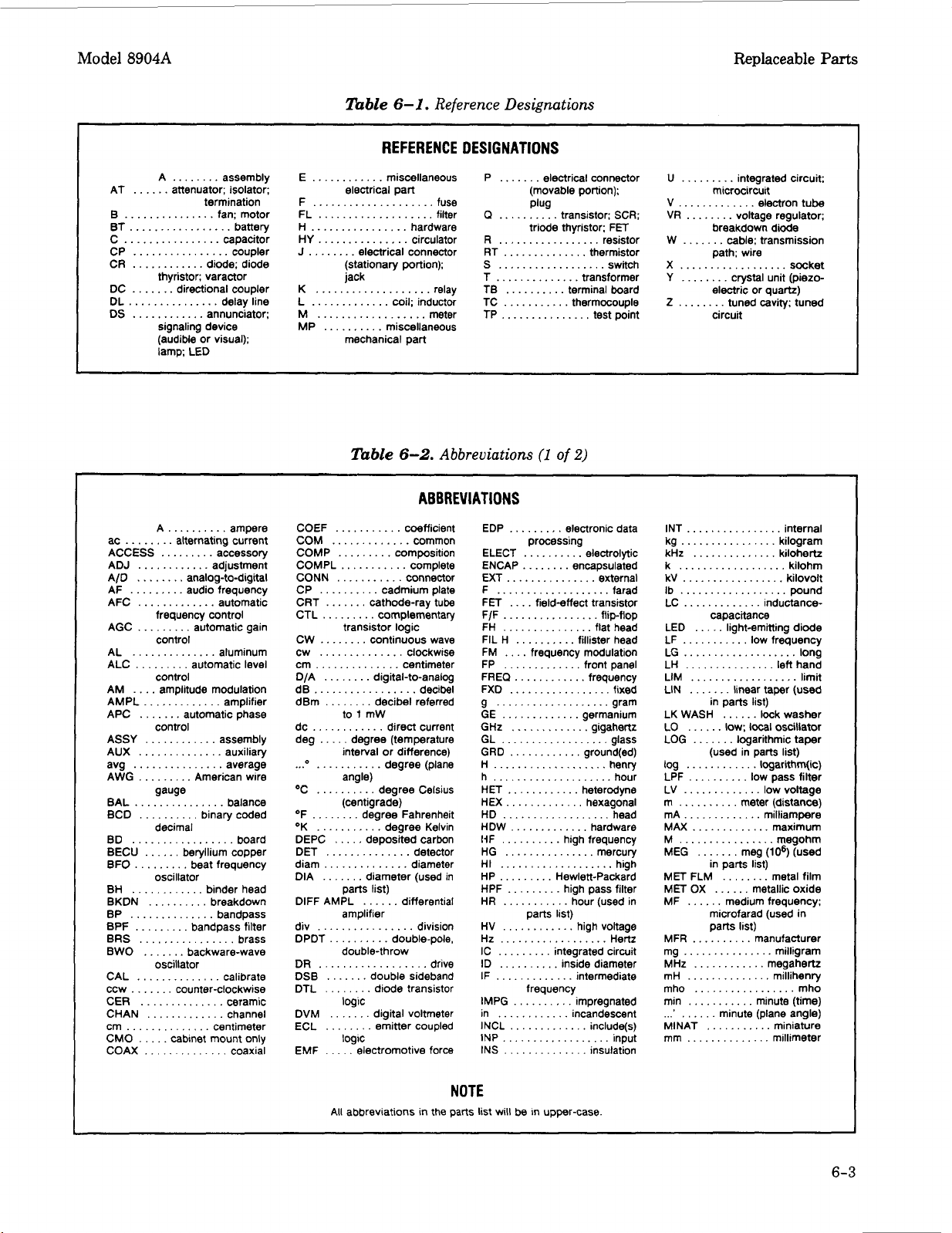

REFERENCE DESIGNATIONS

E

............

F

....................

FL

...................

................

H

...............

HY

J

........

K

...................

L

.............

..................

M

..........

MP

miscellaneous

electrical part

electrical connector

(stationary portion);

jack

miscellaneous

mechanical part

Table

COEF

...........

COM

.............

COMP

.........

COMPL

...........

CONN

...........

CP

..........

CRT

.......

CTL

.........

CW

........

..............

cw

..............

cm

........

D/A

dB

.................

dBm

........

dc

............

deg

.....

...'

...........

OC

..........

........

OF

OK

...........

DEPC

DET

..............

diam

..............

.......

DIA

DlFF

AMPL

div

................

..........

DPDT

DR

..................

DSB

.......

........

DTL

DVM

.......

........

ECL

EMF

.....

cadmium plate

cathode-ray tube

complementary

transistor logic

continuous wave

digital-to-analog

decibel referred

to 1 mW

direct current

degree (temperature

interval or difference)

degree (plane

angle)

degree Celsius

(centigrade)

degree Fahrenheit

.....

degree Kelvin

deposited carbon

diameter (used in

parts list)

......

amplifier

double-throw

double sideband

diode transistor

logic

digital voltmeter

emitter coupled

logic

electromotive force

6-1.

Reference Designations

P

.......

fuse

filter

hardware

circulator

relay

coil; inductor

meter

6-2.

Q

..........

R

.................

RT

S

..................

..............

T

TB

TC

TP

...............

Abbreviations

ABBREVIATIONS

coefficient

common

composition

complete

connector

clockwise

centimeter

decibel

detector

diameter

differential

division

double-pole,

drive

EDP

ELECT

ENCAP

EXT

F

...................

FET

FM

FP

FREQ

FXD

g

...................

.............

GE

GHz

GL

..................

GRD

....

H

....

h

HET

HEX

HD

IiF

..........

HG

...................

HI

.........

HP

HPF

HR

HV

..................

Hz

IC

.........

..........

ID

IF

.............

IMPG

............

in

INCL

INP..

INS

electrical connector

(movable portion);

Plug

transistor; SCR;

triode thyristor; FET

..............

..........

...........

(1

.........

processing

..........

........

...............

....

field-effect transistor

....

frequency modulation

.............

............

.................

............

............

._ . .

.............

..................

...............

.........

...........

............

..............

Hewlett-Packard

parts list)

integrated circuit

frequency

..........

.............

................

resistor

thermistor

switch

transformer

terminal board

thermocouple

test point

of

2)

electronic data

electrolytic

encapsulated

external

.......

flip-flop

front panel

frequency

gram

germanium

.gigahertz

glass

ground(ed)

......

henry

.......

heterodyne

hexagonal

head

high frequency

mercury

high pass filter

hour (used in

high voltage

Hertz

inside diameter

intermediate

impregnated

incandescent

include(s)

input

insulation

farad

fixed

hour

high

U

.........

V

.............

VR

........

.......

W

X

..................

Y

........

2

........

INT

................

................

kg

k

..................

.................

kV

..................

Ib

.............

LC

LED

LH

...............

LIM

.......

LIN

LK WASH

LO

......

LOG

log

'

LPF

LV

.

m

..........

.............

mA

MAX

M

................

MEG

MET FLM

MET

OX

......

MF

...............

mg

mH

..............

mho

...........

min

..........

MlNAT

..............

mm

integrated circuit;

microcircuit

voltage regulator;

breakdown

cable: transmission

path; wire

crystal unit (piezo-

electric or quartz)

tuned cavity; tuned

circuit

capacitance

.....

light-emitting diode

..................

linear taper (used

in parts list)

......

low;

.......

local

logarithmic taper

(used in parts list)

...

.

low pass filter

...

meter (distance)

.............

.......

meg

in parts list)

........

......

metallic oxide

medium frequency;

microfarad (used

manufacturer

.................

minute (plane angle)

...........

electron tube

diode

socket

internal

kilogram

kilohm

kilovolt

pound

inductance-

left

hand

limit

lock washer

oscillator

lcgarithm(ic)

low voltage

milliampere

maximum

megohm

(lo6)

(used

metal film

in

milligram

millihenry

mho

minute (time)

miniature

millimeter

All abbreviations

NOTE

in

the parts list will

b%

in upper-case.

6-3

Page 12

Replaceable

MOM

mV

mVac

mVpp

mVrms

mW

MUX

MY

&

pF

pH

pV

pVac

pVdc

@Vpk

pVp-p

pvrms

pW

N/O

NOM

NORM

NPN negative-positive-

NPO

NRFR

NSR

ns

nW

OBD

Parts

MOD

....

...........

device)

................

...........

.......

to-peak

.........

...............

.............

.................

............

..............

.............

...............

..........

..........

........

..............

..........

..............

.......

.........

.............

.....

....

microvolt. peak

.......

microvolt, peak-

to-peak

........

.............

negative-positive

zero (zero temperature coefficient)

.....

not recommended

for field replacement

replaceable

order by description

modulator

momentary

millivolt

millivolt, ac

millivolt, peak-

millivolt, rms

milliwan

multiplex

mylar

microampere

microfarad

microhenry

microvolt

microvolt, ac

microvolt, dc

microvolt, rms

microwatt

normally open

nominal

normal

not separately

nanosecond

...

nanowatt

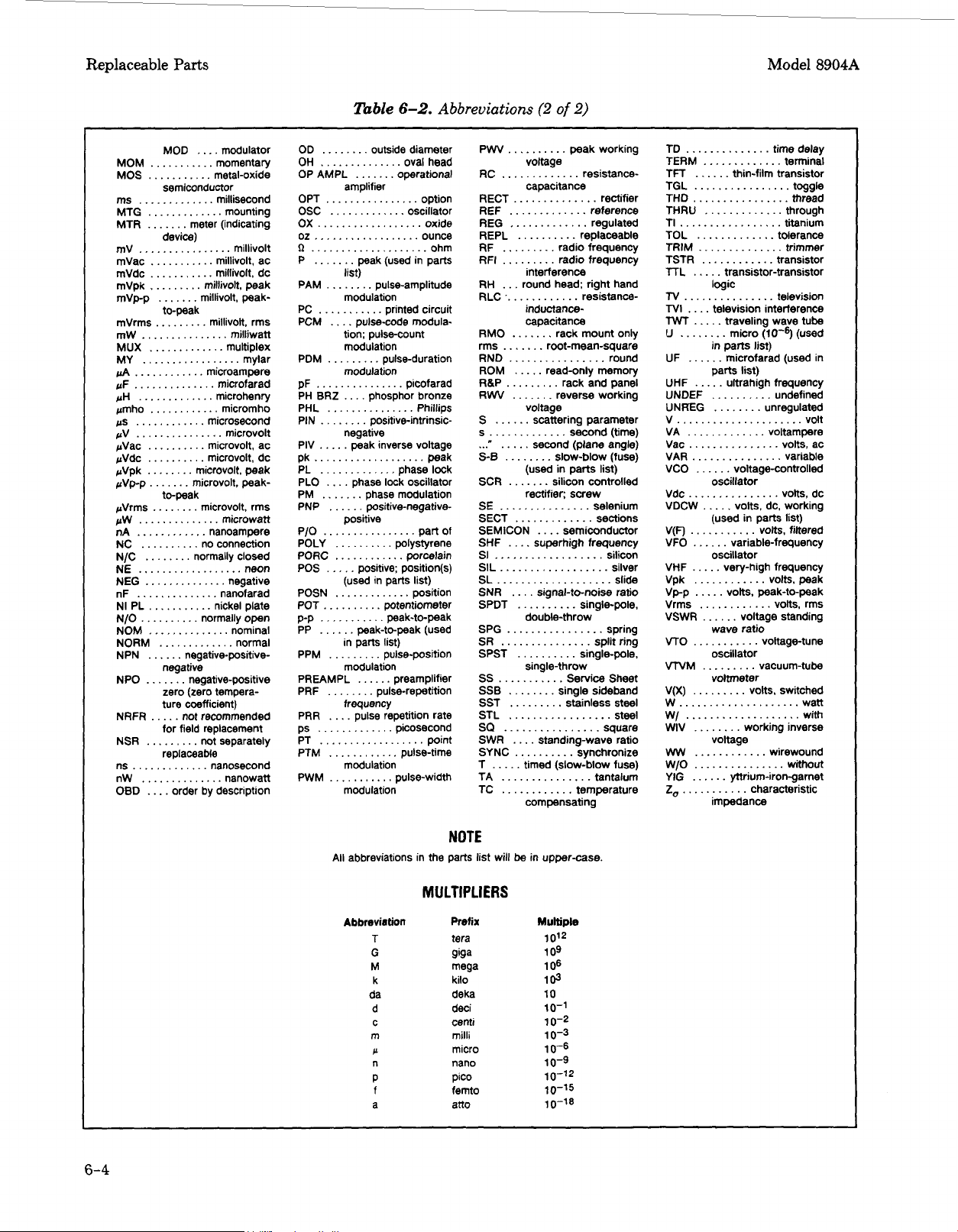

Table

6-2.

OD

........

OH

..............

OP AMPL

OX..

outside diameter

.......

amplifier

operational

.........

.......

................

......

peak

(used

........

PAM

...........

PC

PCM

PDM

.........

pF ...............

PH

BRZ

PHL

...............

PIN

........

PLO

....

PM

.......

PNP

P/O

................

POLY

PORC

. , . , .

POS

POSN

p-p

...........

PPM

PREAMPL

PRF

........

PRR

ps

.............

..................

PT

PTM

PWM

pulse-amplitude

modulation

....

......

..........

............

.............

.........

....

printed circuit

pulse-code modulation; pulse-count

modulation

pulse-duration

modulation

....

phosphor bronze

positive-intrinsic-

negative

phase lock oscillator

phase modulation

positive-negative-

positive

polystyrene

positive: position(s)

(used in parts list)

peak-to-peak

in parts list)

pulse-position

modulation

......

preamplifier

pulse-repetition

frequency

pulse repetition rate

picosecond

............

modulation

...........

modulation

pulse-width

Abbreviations

oval head

option

oscillator

oxide

ounce

in parts

picofarad

Phillips

ltage

peak

lock

part of

porcelain

position

point

pulse-time

(2

of

2)

RECT

..............

REG

.............

..........

REPL

RH

RLC

RMO

rms

RND

ROM

R&P

RWV

S

S

...

S-B

SCR

SE

SECT

SI

SIL..

SL

SNR

SPDT

SPG

SR

SPST single-pole,

SS ...........

SSB

STL

SWR

SYNC

T

TA tantalum

TC

interference

...

round head; right hand

.............

inductancecapacitance

.......

.......

root-mean-square

................

.....

read-only memory

.........

.......

voltage

........

(used

.......

silicon controlled

rectifier; screw

...............

.............

..................

................

...................

....

signal-to-noise ratio

..........

double-throw

................

...............

........

.........

....

standing-wave ratio

..........

.....

timed (slow-blow fuse)

............

compensating

rectifier

....

reference

regulated

replaceable

resistance-

rack mount only

round

rack and panel

reverse working

ng parameter

second (time)

(plane angle)

slow-blow (fuse)

in

parts list)

selenium

sections

silicon

silver

slide

single-pole,

spring

splitring

W

Service Sheet

single sideband

synchronize

temperature

Model

TD

..............

.............

TERM

TFT

......

................

TGL toggle

THD

................

THRU

.............

.................

TI

TOL

.............

TTL

.....

transistor-transistor

N

TVI

TWT

U

UF

UHF

UNDEF

UNFEG

v

VA

Vac

VAR

VCO

Vdc

VDCW

VHF

Vrms

VSWR

VTO

VTVM

V(X)

w..

wl

WIV

WW

W/O

logic

...............

....

television interference

.....

traveling wave tube

........

in

parts list)

......

microfarad (used in

parts list)

.....

ultrahigh frequency

..........

........

.....................

.............

...............

...............

......

oscillator

...............

.....

(used

oscillator

.....

very-high frequency

............

......

wave ratio

...........

oscillator

.........

voltmeter

.........

..................

...................

........

voltage

............

...............

YIG

......

Z,

...........

impedance

time delay

thin-film transistor

micro (used

voltage-controlled

volts, dc, working

yttrium-iron-garnet

terminal

thread

through

titanium

tolerance

television

undefined

unregulated

volt

voltampere

volts, ac

variable

volts, dc

in

parts list)

volts, rms

voltage standing

voltage-tune

vacuum-tube

volts, switched

working inverse

characteristic

wan

with

wirewound

without

8904A

6-4

NOTE

All abbreviations in the parts list will

MULTIPLIERS

Abbreviation

T

G

M

k

da

d

C

m

P

n

P

f

a

Prefix

tera

gigs

mega

kilo

deka

deci

centi

milli

micro

nano

pic0

femto

ano

be

in

upper-case.

Multiple

10’2

1

09

1

06

103

10

10-1

10-2

10-3

10-6

10-9

10-12

10-’5

10-18

Page 13

Model

8904A

ReplaceabIe

Parts

Reference

Designation

A1

2

71ZA

to

291

7A

Alt

2025%

and abwo

AI

w1

A2

2712A

to

2942A

A2

A2

2048A and ah

A2

A2

2712A

to

2M2A

A2BTl

2712A

to

2942A

A2BTl

2

712A

to

2

732A

A2u12

i.

A2U13

t

2737A

to

2942A

AZUlZt

A2U13

2737A

to

294OA

A2u12

2742A

and ah

A2u12

2737A

andabwo

A2U13

HPPart

Number

08904-60201 4 1

0890480102 4 1

08904-69102 2

08904-60202

08904-89202

14200281

3050.0990

14200238

0890487010 9 1

0~90487008

0890487009

0890487011

C

D

5

3

2

7

0

5

6

0

Qty.

SEE SECTION

KEYBOARD

NOT

DIGITAL ASSEMBLY

DIGITAL ASSEMBLY

1

1

DIGITAL ASSEMBLY

DIGITAL ASSEMBLY

1

BA'ITERY

1

WASHERFL NM

3

BAlTERY

1

REFER

REFER

EPROM

EPROM

1

EPROM

1

EPROM

1

NO

Table

63'.

Replaceable Parts

Description

7

KXI

FRONT

PANEL

RETRoFlT

ASSEMBLY

SEPARATELY REPLACEABLE

(NW

(RESTORED)

(NEW)

(RESTORED)

2.8V

.46A%IR

US-DIOX

.WlN-ID

PIN

.25-IN-ID

NO.000

3V

1.2AHR

LMIUM POLYCARBON

TO

SECTION

SECTION

7

7

TO

LONGER SEPARATELY REPLACEABLE

WT

llfr-

Code

28480 08804-60201

28480 08904-60102

28480 089066Q102

28480 08904-60202

28480 08904-69202

28480 14200281

28480 30504990

28480 14204338

28480 0890487010

28480 08904-87008

28480 0890487009

28480 089048701 1

Mtr. Part Number

tRefer to Section

rev.

01

JUL91

i

for

update information

*Factory Selected Component

(Refer

to

Section

5).

A

Errata part change.

6-5

Page 14

Replaceable Parts

Model

8904A

Reference

Designation

A3

2712A

to

2942A

A3

A3

and

2948A

A3

A3

A3C1

A3C2

A3C3

A3C4

A3C5

A3C6

A3C7

A3C8

A3C9

A3C10

A3C11

A3C12

A3C13

A3C14

A3C15-27

A3C28

A3C29

A3C30

A3C31

A3C32

A3C33

A3C34

A3C35

A3C36

A3C37

A3C38

A3C39

A3C40

A3C41

A3C42

A3C43

A3C44

A3C45

A3C46

A3C47

A3C48

A3C49

A3C50

A3C51

A3C52-63

A3C64

A3C65-70

A3C71

A3C72

A3C79

A3C82

abow

HPPart C

Number

08904-60103

08904-69103 3

0890440203

08904-69203 4

01804116

0160-4832 4 35

0160-4832 4

0160-4832 4

0160-4832 4

0160-4535 4

01604535 4

0160-4535 4

0160-4535 4

01804116

01804116

01600575 4

0160-6875 9

0160-6876

0160-6877

0160-6878

0160-3879 7 5

0160-6880

0160-6881 7

0160-6882

0160-6883 9

0160-3875 3

0160435 7 16

0160-4832 4

0160-4835 7

0160-4822

0160-4832 4

0160-4812

0160-4835 7

01604835 7

01604832 4

0160-4835 7

01606884

0160-4535 4

01604832 4

0160-4832 4

0160-4832 4

0160-4832 4

Q~.

D

5

6

1

11

1

1

0

1

2

6

8

2

0

0

fible

6-3.

Replaceable

Description

OUTPUT ASSEMBLY (NEW)

1

OUTPUT ASSEMBLY (RESTORED)

1

OUTPUT ASSEMBLY (NEW)

1

OUTPUT ASSEMBLY (RESTORED)

1

NOT ASSIGNED

CAPACITOR-FXD 6.8UF+-10% 35VDC TA

CAPACITOR-FXD .OlUF

CAPACITOR-FXD .OlUF

CAPACITOR-FXD .OlUF +-lo%

CAPACITOR-FXD .OlUF

NOT ASSIGNED

CAPACITOR-FXD 1UF +-10% 50VDC CER

9

NOT ASSIGNED

CAPACITOR-FXD 1UF +-1O% 5OVDC CER

CAPACITOR-FXD 1UF +-lo% 50VDC CER

CAPACITOR-FXD 1 UF +-lo% 50VDC CER

CAPACITOR-FXD 6.8UF+-10°/o 35VDC TA

CAPACITOR-FXD 6.8UF+-10% 35VDC TA

NOT ASSIGNED

CAPACITOR-FXD .047UF

1

CAPACITOR-FXD 850PF +-1% 100VDC CER

1

CAPACITOR-FXD 7200PF +-1%

1

CAPACITOR-FXD 64PF +-1% 1 OOVDC CER

1

CAPACITOR-FXD 293PF +-1% 1WVDC CER

1

CAPACITOR-FXD .OlUF

CAPACITOR-FXD 584PF

1

CAPACITOR-FXD 1360PF +-1%

1

CAPACITOR-FXD 129OPF +-1%

1

CAPACITOR-FXD 438PF +-1% 100VDC CER

1

CAPACITOR-FXD 22PF +-5% POOVDC CER 0+-30

1

NOT ASSIGNED

CAPACITOR-FXD .1UF +-10% 5OVDC CER

CAPACITOR-FXD .OlUF +-10% 100VDC CER

CAPACITOR-FXD .1UF +-lo% 50VDC CER

CAPACITOR-FXD lOOOPF

1

CAPACITOR-FXD .OlUF t10% 1 WVDC CER

CAPACITOR-FXD 220PF +-5% 1WVDC CER

1

CAPACITOR-FXD .1UF +-lo% 5OVDC CER

CAPACITOR-FXD .1UF +-lo% 50VDC CER

CAPACITOR-FXD .OlUF +-lo% 100VDC CER

NOT ASSIGNED

CAPACITOR-FXD

CAPACITOR-FXD 270PF +-1%

1

NOT ASSIGNED

CAPACITOR-FXD

NOT ASSIGNED

CAPACITOR-FXD .OlUF

CAPACITOR-FXD .OlUF

CAPACITOR-FXD

CAPACITOR-FXD .OlUF +-lo% 1 WVDC CER

+-1O%

+-loo/.

+-1oO/c

+-20%

+-20%

+-1%

+-5%

.1

UF +-lo% 5OVDC CER

1

UF +-lo% 50VDC CER

+-loo/.

+-1O%

.OWF

+-io%

lWVDC CER

lWVDC CER

1

WVDC CER

lOOVDC CER

5OVDC CER

1

WVDC CER

1WVDC CER

100VDC CER

1

WVDC CER

1

WVDC CER

lOOVDC CER

1

WVDC CER

lOOVDC CER

lOOVDC CER

IOOVDC

CER

Parts

0+30

Mfr-

Code

28480

28480

28480

28480

56289

28480

28480

28480

28480

28480

28480

28480

28480

56289

56289

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

Mfr. Part Number

08904-60103

08904-69103

08904-60203

08904-69203

150D685X903562

01 60-4832

01604832

60-4832

01

01 604832

0160-4535

0160-4535

0160-4535

0160-44535

150D685X9035B2

150D685X903562

01 60-0575

01606875

01606876

01 60-6877

0160-6878

0160-3879

60-6880

01

0160-6881

01 60-6882

01 60-6883

01604875

01 60-4835

01 60-4832

01 60-4835

01 60-4822

0160-4832

01604812

01604835

0160-4835

0160-4832

01604835

01 60-6884

01 60-4535

0160-4832

01 60-4832

01 60-4832

01 60-4832

?Refer to Section 7 for update information.

6-6

'Factory Selected Component (Refer to Section

5).

A

Errata part change

reu.OlNOV89

Page 15

Model

8904A

Replaceable

Parts

Reference

Designation

A3C83-89

A3C90

A3C93

A3c94-200

A3C201

A3c202

Ax203

Ax204

A3C205

A3C206

Ax207

A3c208

A3c209

A3C210

A3c211

A3c212

A3C213

A3C214

A3C215

Ax216

A3C217

A3C218

A3C219

A3C220

A3c221

A3C222

A3C223

A3C224

A3C225

A3C226

A3c227

A3C228

A3C229

A3C230

A3C231

A3C232

A3C233-299

A3C300

A3c301

A3C302

A3C303

A3c304

A3C305-400

A3C401

A3C402

HP Part

Number

01604835

01604B35

01 604832

01 604835

01 60-4832

01 60-4832

01 604832

01 60-4832

01 604832

01 604832

01 604832

01 60-4835

01 604832

01 60-4835

01

6c-4635

01 604832

0160-4791

01 60-4832

01 60-4807

01 60-4535

01 604789

01 604832

01 604832

01 60-4832

01609563

0160-4835

01 60-4835

01 604535

0160-0572

0160-0573

01 604040

01 60-4383

01604535

01 60-4535

01 604832

01604832

01 60-4791

01 60-4795

01604835

C

D

8

7

Table

7

7

NOT ASSIGNED

CAPACITOR-FXD .1UF +-lo% 50VDC CER

CAPACITOR-FXD .1UF +-1O% 5OVDC CER

NOT ASSIGNED

CAPACITOR-FXD .OlUF +-lo% lWVDC CER

CAPACITOR-FXD .1 UF +-1O% 5OVDC CER

CAPACITOR-FXD .OlUF +-lo% 1 WVDC CER

CAPACITOR-FXD .OlUF

CAPACITOR-FXD .OlUF +-lo% 1WVDC CER

CAPACITOR-FXD .OlUF +-lo% lWVDC CER

CAPACITOR-FXD .01 UF +-1O% 1 WVDC CER

CAPACITOR-FXD .OlUF +-1O% 100VDC CER

CAPACITOR-FXD .OlUF +-1O% lOOVDC CER

CAPACITOR-FXD .1 UF +-IO% 5OVDC CER

CAPACITOR-FXD .OlUF +-loo/. 1OOVDC CER

CAPACITOR-FXD .1 UF +-10% 5OVDC CER

CAPACITOR-FXD .1UF +-lo% 5OVDC CER

CAPACITOR-FXD .OlUF +-1O% 1 OOVDC CER

CAPACITOR-FXD 1OPF +-5% 1OOVDC CER

2

CAPACITOR-FXD .OlUF

1

CAPACITOR-FXD 33PF +-5% l00VDC CER

CAPACITOR-FXD 1UF +-1O% 5OVDC CER

CAPACITOR-FXD 15PF +-5% 1WVDC CER

3

CAPACITOR-FXD .01 UF +-lo% lOOVDC CER

CAPACITOR-FXD .OlUF +-lo% lOOVDC CER

CAPACITOR-FXD .OlUF

NOT ASSIGNED

1

CAPACITOR-FXD lOUF +-5% 50VDC MET-POLYC

CAPACITOR-FXD .1 UF +-lo% 50VDC CER

CAPACITOR-FXD .1UF +-lo% 50VDC CER

CAPACITOR-FXD 1UF

CAPACITOR-FXD 22OOPF +-20% 100VDC CER

CAPACITOR-FXD 4700PF +-20% lWVDC CER

CAPACITOR-FXD 1OOOPF +-5% lWVDC CER

NOT ASSIGNED

1

CAPACITOR-FXD 6.8PF +-.5PF 2OOVDC CER

NOT ASSIGNED

CAPACITOR-FXD 1 UF +-lo% 5OVDC CER

CAPACITOR-FXD 1UF +-loo/. 50VDC CER

CAPACITOR-FXD .OlUF +-lo% lOOVDC CER

CAPACITOR-FXD

CAPACITOR-FXD lOPF +-5% lOOVDC CER 0+-30

NOT ASSIGNED

CAPACITOR-FXD 4.7PF +-.5PF 100VDC CER

3

CAPACITOR-FXD .1 UF +-lo% 5OVDC CER

6-3.

Replaceable Parts

Description

+-lo"/.

lMWDC CER

+-loo/.

lOOVDC CER

+-lo%

lOOVDC CER

+-1O%

5OVDC CER

.OlUF

+-IO%

1OOVDC CER

0+30

0+30

0+30

Mfr*

Code

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

20932

28480

28480

28480

28480

28480

28480

28480

Mfr. Part Number

0160-4835

0160-4835

01 60-4832

01604835

0160-4832

01 604832

01 60-4832

0160-4832

01 60-4832

01 60-4832

0160-4832

0160-4835

01 60-4832

01 60-4835

01 60-4835

0160-4832

0160-4791

01 €0-4832

0160-4807

01 60-4535

01 60-4789

01 60-4832

01 60-4832

01

60-4832

01 60-3563

0160-4835

0160-4835

01 604535

0160-0572

01 60-0573

0160-4040

5024E0200RD689D

01 60-4535

01 60-4535

0160-4832

01604832

0160-4791

0160-4795

0160-4835

?&fer to Section 7 for

update

information. *Factory Selected Component (Refer

to

Section

5).

6-7

Page 16

Replaceable

Parts

Model

8904A

Reference

Designation

A3C403

A3C404

A3C405

A3C406

A3C407

A3C408

A3C409

A3C410

1

A3C41

A3C412

A3C413

A3C414-420

A3C421

A3C422

A3C423

A3C424

A3C425

A3C426

A3C425-430

A3C431

A3C432

A3C433

A3C434

A3C435

A3C436

A3C437

A3C438

AX439

A3C440

MC441

A3W2

A3C443

A30614

A3C445

A3C446

A3C447

A3C448

A3C449-499

AX500

A3C501

A3C502

AX503

AX504

AX505

A3CR1-5

A3CR6

A3CR7

A3CR8

A3CR9

HP Part

Number

01

60-4835

01 60-4835

01 60-4832

60-4832

01

01

60-4832

0160-4832

0160-4547

01 60-4526

0160-4493

0160-4526

01 60-4547

0180-0116

16

01 80-01

0180-0116

01 80-01 16

0121-0451

01 60-4789

01

60-4832

0180-0116

01604832

01 80-01 16

01 60-4832

0180-01 16

01 60-4832

16

0180-01

01604801

01 60-4801

01604795

01 60-4795

01 60-4801

0160-4801

0160-4801

01 604801

01 60-4801

01 60-3879

01 60-3879

01 60-3879

0160-3879

01 60-4789

01 60-4824

1901

-0028

1 901

-0028

1 901

-0050

1901 -0050

C

D

7

7

4

4

4

4

8

3

3

3

8

1

1

1

1

3

0

4

1

4

1

4

1

4

1

7

7

8

8

7

7

7

7

7

7

7

7

7

0

4

5

5

3

3

Table

QW.

CAPACITOR-FXD .1UF

CAPACITOR-FXD .1UF +-lo% 5OVDC CER

CAPACITOR-FXD .OlUF +-lo% 100VDC CER

CAPACITOR-FXD .OlUF +-lo% lOOVDC CER

CAPACITOR-FXD .OlUF +-lo% lOOVDC CER

CAPACITOR-FXD .OlUF +-lo% lOOVDC CER

2

CAPACITOR-FXD 150PF +-5% ZOOVDC CER

2

CAPACITOR-FXD 42PF +-5% POOVDC CER

1

CAPACITOR-FXD 27PF +-5% ZOOVDC CER

CAPACITOR-FXD 42PF +-5% ZOOVDC CER

CAPACITOR-FXD 150PF +-5% POOVDC CER

NOT ASSIGNED

CAPACITOR-FXD 6.8UF+-1Oo/o 35VDC TA

CAPACITOR-FXD 6.8UF+-1O0/- 35VDC TA

CAPACITOR-FXD 6.8UF+-llW 35VDC TA

CAPACITOR-FXD 6.8UF+-10°/e 35VDC TA

1

CAPACITOR-V TRMR-AIR 1.7-1 1PF 175V

CAPACITOR-FXD 15PF +-5% lOOVDC CER

NOT ASSIGNED

CAPACITOR-FXD .OlUF +-10% lOOVDC CER

CAPACITOR-FXD 6.8UF+-1Oo/o 35VDC TA

CAPACITOR-FXD .OlUF +-lo% lOOVDC CER

CAPACITOR-FXD 6.8UF+-10% 35VDC TA

CAPACITOR-FXD .OlUF

CAPACITOR-FXD 6.8UF+-1Oo/o 35VDC TA

CAPACITOR-FXD .OlUF

CAPACITOR-FXD 6.8UF+-1Oo/o 35VDC TA

NOT ASSIGNED

7

CAPACITOR-FXD lOOPF +-5% lOOVDC CER

CAPACITOR-FXD 1OOPF +-5% lOOVDC CER

CAPACITOR-FXD 4.7PF +-SPF 1 OOVDC CER

CAPACITOR-FXD 4.7PF +-.5PF 1 OOVDC CER

CAPACITOR-FXD lOOPF +-5% lOOVDC CER

CAPACITOR-FXD lOOPF

CAPACITOR-FXD 1OOPF +-5% lOOVDC CER

CAPACITOR-FXD lOOPF

CAPACITOR-FXD lOOPF +-5% 1OOVDC CER

NOT ASSIGNED

CAPACITOR-FXD .OlUF

CAPACITOR-FXD .OlUF

CAPACITOR-FXD .OlUF

CAPACITOR-FXD .OlUF

CAPACITOR-FXD 15PF

1

CAPACITOR-FXD 680PF +-5% lOOVDC CER

NOT ASSIGNED

4

DIODE-PWR RECT 400" 750MA DO-29

DIODE-PWR RECT 400V 750MA DO-29

DIODE-SWITCHING 8OV 200MA 2NS DO-35

25

DIODE-SWITCHING 8OV 200MA

6-3.

Description

Replaceable Parts

+-lo%

5OVDC CER

0+-30

0+-30

0+-30

0+-30

+-lo%

lOOVDC CER

+-10%

lOOVDC CER

+-5%

lOOVDC CER

+-5%

lOOVDC CER

+-2O%

lOOVDC CER

+-20%

lOOVDC CER

+-20%

lOOVDC CER

+-20%

100VDC CER

+-5%

lOOVDC CER

2NS

0+-30

DO-35

Mfr.

Code

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

56289

56289

56289

56289

74970

28480

28480

56289

28480

56289

28480

56289

28480

56289

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

28480

26480

28480

28480

28480

28480

28480

9N171

9N171

Mfr. Part Number

01

60-4835

0160-4835

60-4832

01

0160-4832

60-4832

01

0160-4832

01604547

01 60-4526

01 60-4493

01604526

01604547

150D685X903562

150D685X903582

150D685X9035B2

150D685X903562

187-0106-028

0160-4789

01

60-4832

150D685X9035B2

01604832

150D685X903582

60-4832

01

150D685X903562

01604832

150D685X9035B2

0160-4801

0160-4801

01 60-4795

01604795

0160-4801

0160-4801

01 60-4801

01 604801

0160-4801

01 60-3879

01604879

01 60-3879

0160-3879

01 60-4789

01 60-4824

1901

-0028

1901

-0028

1

N4150

1

N4150

6-8

tRefer

to

Section

7

for

update information.

'Factory Selected Component (Refer

to

Section

5).

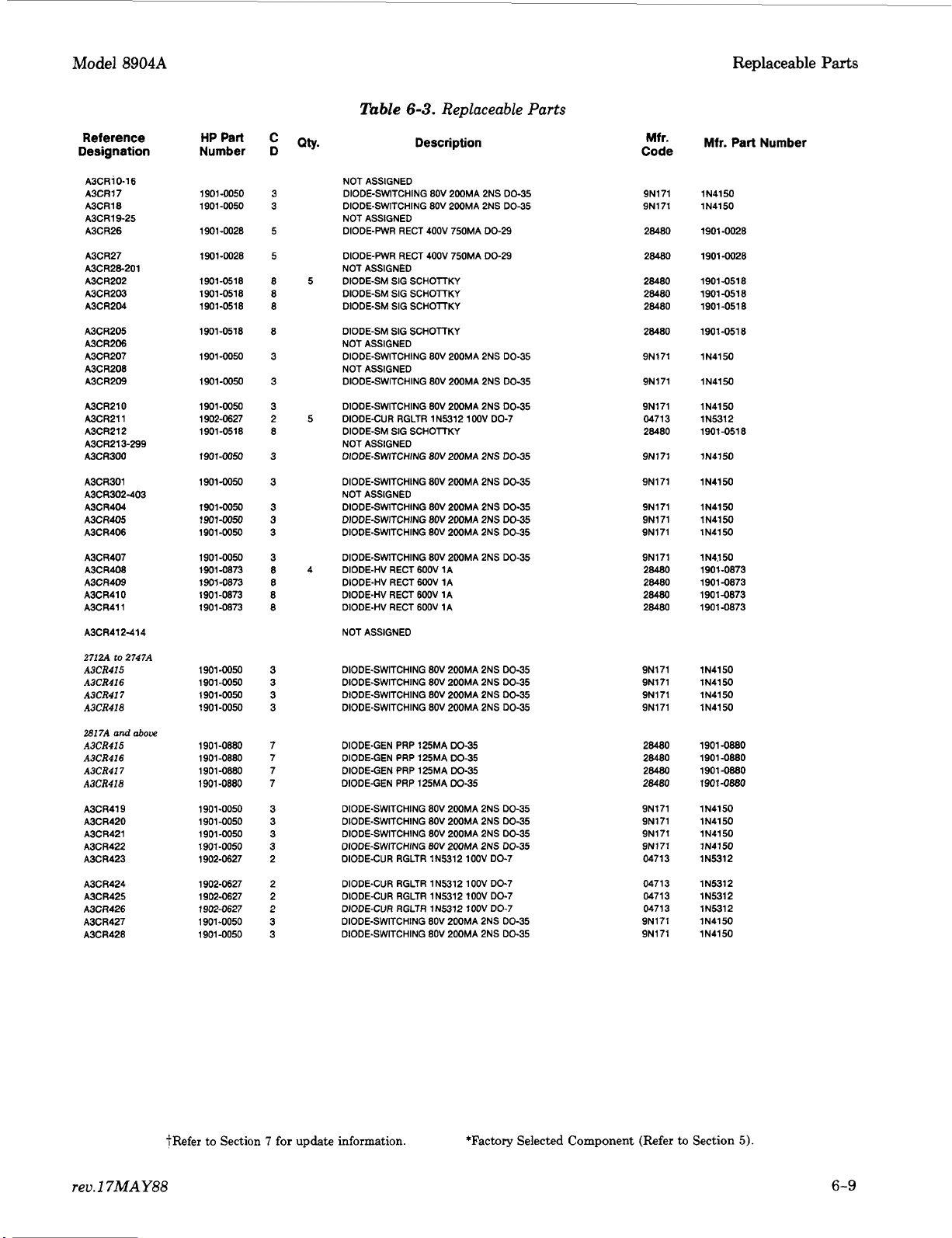

Page 17

Model

8904A

Replaceable

Parts

Reference

Designation

A3CRlO-16

A3CR17

MCRl8

A3CRl9-25

A3CR26

A3CR27

A3CR28-201

A3CR2M

A3CR203

A3CR204

A3CR205

A3CR206

A3CR207

A3CR208

A3CR209

A3CR210

A3CR211

A3CR212

A3CR213-299

A3CR300

A3CR301

A3CR302-403

A3CR404

A3CR405

A3CR406

A3CR407

A3CR408

A3CR409

A3CR410

A3CR411

A3CR412414

2712A

to

2747A

A3CR415

A3CR416

A3CR417

A3CR418

2817A

and

A3CR415

A3CR.116

A3CR417

A3CR416

A3CR419

A3CR420

A3CR421

A3CR422

A3CR423

A3C R424

A3CR425

A3CR426

A3CR427

A3CR428

above

HP

Part

Number

1901 -0050

1901

-0050

1901

-0028

1901

-0028

1901 -051

1901 -051

1901-0518

1901-0518

1901-0050

1901 -0050

1901-0050

1902-0627

1901-0518

1901-0050

1901-0050

1901-0050

1901-0050

1901-0050

1901 -0050

1901-0873

1901-0873

1901-0873

1901 -0873

1901 -0050

1901-0050

1901 -0050

1901-0050

1901 -0880

-0880

1901

1901 -0880

1901-0860

1901 -0050

1901 -0050

1901-0050

1901-0050

1902-0627

1902-0627

1902-0627

1902-0627

1901-0050

1901 -0050

C

Qty.

D

8

8

3

3

3

3

3

3

3

84

8

8

8

%Me

6-3.

Replaceable Parts

Description

NOT ASSIGNED

DIODE-SWITCHING 8OV 2WMA 2NS 00-35

DIODE-SWITCHING 8OV 200MA 2NS DO-35

NOT ASSIGNED

DIODE-PWR RECT 400V 750MA DO-29

DIODE-PWR RECT 400V 750MA DO-29

NOT ASSIGNED

5 DIODE-SM SIG SCHOTTKY

DIODE-SM SIG SCHOTTKY

DIODE-SM SIG SCHOTTKY

DIODE-SM SIG SCHOTTKY

NOT ASSIGNED

DIODE-SWITCHING 8OV 200MA 2NS DO-35

NOT ASSIGNED

DIODE-SWITCHING 8OV 200MA 2NS DO-35

DIODE-SWITCHING 8OV 200MA 2NS DO35

DIODE-CUR RGLTR 1N5312 1WV DO-7

5

DIODE-SM SIG SCHOTTKY

NOT ASSIGNED

DIODE-SWITCHING 8OV 200MA 2NS DO-35

DIODE-SWITCHING 8OV 200MA 2NS DO-35

NOT ASSIGNED

DIODE-SWITCHING 8OV 200MA 2NS DO35

DIODE-SWITCHING 8OV 200MA 2NS DO35

DIODE-SWITCHING 8OV 200MA 2NS DO35

DIODE-SWITCHING 8OV 200MA 2NS DO-35

DIODE-HV RECT WOV 1A

DIODE-HV RECT 600V 1A

DIODE-HV RECT 600V 1A

DIODE-HV RECT 600V 1A

NOT ASSIGNED

DIODE-SWITCHING 8OV 200MA 2NS DO35

DIODE-SWITCHING 8OV 200MA 2NS DO35

DIODE-SWITCHING

DIODE-SWITCHING 8OV 200MA 2NS DO35

DIODE-GEN PRP 125MA DO-35

DIODE-GEN PRP 125MA 00-35

DIODE-GEN PRP 125MA DO-35

DIODE-GEN PRP 125MA DO45

DIODE-SWITCHING 8OV 200MA 2NS DO-35

DIODE-SWITCHING 8OV 200MA 2NS DO35

DIODE-SWITCHING 8OV 200MA 2NS DO-35

DIODE-SWITCHING 8OV 200MA 2NS DO45

DIODE-CUR RGLTR 1N5312 1OOV DO-7

DIODE-CUR RGLTR 1N5312 1OOV DO-7

DIODE-CUR RGLTR 1N5312 1OOV DO-7

DIODE-CUR RGLTR 1NS312 lOOV DO-7

DIODE-SWITCHING 8OV 200MA 2NS DO35

DIODE-SWITCHING 8OV 200MA 2NS DO-35

8OV

200MA 2NS 00-35

Mfr*

Code

9N171 1N4150

9N171 1N4150

28480

28480

28480 1901 -051

28480

28480 1901 -051 8

Mfr. Part Number

1901-0028

1901-0028

1901-0518

28480 1901-0518

9N171 1N4150

9N171 1N4150

9N171 1N4150

04713 1N5312

28480 1901-0518

9N171 1N4150

9N171 1N4150

9N171 1N4150

9N171 1N4150

9N171 1N4150

9N171 1N4150

28480 1901-0873

28480 19014873

28480

28480 1901 -0873

9N171 1N4150

9N171 1N4150

9N171 1N4150

9N171 1N4150

28480 1901

28480

28480 1901-0880

28480 1901-0880

9N171 1N4150

9N171 1N4150

9N171 1N4150

9N171 1N4150

04713 1N5312

04713 1N5312

04713 1N5312

04713 1N5312

9N171 1N4150

9N171 1N4150

19014873

-0880

1901-0880

8

rev.

1

7MAY88

thfer to Section 7 for update information.

*Factory Selected Component (Refer

to

Section

5).

6-9

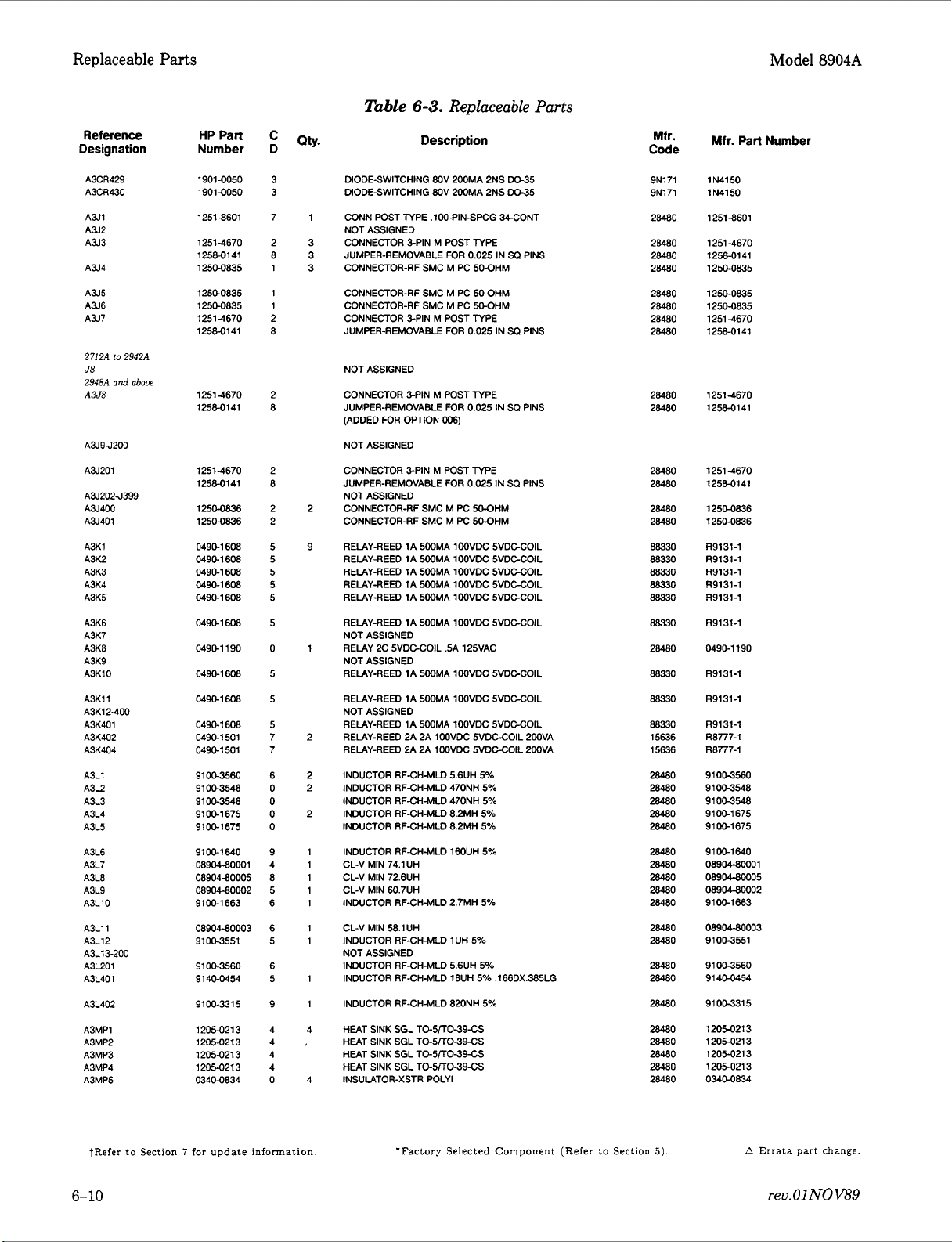

Page 18

Replaceable Parts Model

8904A

Reference

Designation

A3CR429

A3CR430

A31

A32

A33

A34

A35

A36

A37

2712A

to

2942A

J8

and

2948A

A3J8

A394200

A3201

A3202J399

A3400

A3401

A3K1

A3K2

A3K3

A3K4

A3K5

A3K6

A3K7

A3K8

A3K9

A3K10

A3K11

A3K12-400

A3K401

A3K402

A3K404

A3L1

A3L2

A3L3

A3L4

A3L5

A3L6

A3L7

A3L8

A3L9

A3L10

A3L11

A3L12

A3L13-200

A3L201

A3L401

A3L402

A3MPl

A3MP2

A3MP3

A3MP4

A3MP5

abom

HP Part

Number

19010050

1901 -0050

12518601

1251-4670

12580141

1250-0835

1250-0835

1250-0835

12514670

12580141

1251-4670

12580141

12514670

12580141

1250-0836

12500836

0490-1 608

04901608

608

0490-1

0490-1 608

608

04901

0490-1608

0490-1 190

0490-1

608

0490-1 608

0490-1 608

0490-1501

0490-1501

91 00-3560

91 003548

9100-3548

9100-1675

9100-1675

91

00-1

640

08904-80001

08904-80005

08904-80002

9100-1 663

08904-80003

91003551

91003560

91 40-0454

91 00-331 5

1205-0213

1205-021

3

1205-021 3

1 205-021 3

03400834

C

D

5

5

5

5

5

0

5

5

5

7

7

6

0

0

0

0

9

4

8

5

6

6

5

6

5

9

4

4

4

4

0

3

3

7

2

8

1

1

1

2

8

2

8

2

8

2

2

5

Table

QW

DIODE-SWITCHING 8OV 200MA 2NS DO-35

DIODE-SWITCHING 80V 200MA 2NS DO45

1

CONN-POST TYPE ,100-PIN-SPCG WONT

NOT ASSIGNED

3

CONNECTOR SPIN M POST TYPE

JUMPER-REMOVABLE

3

CONNECTOR-RF SMC M PC 5WHM

3

CONNECTOR-RF SMC M PC WHM

CONNECTOR-RF SMC

CONNECTOR SPIN

JUMPER-REMOVABLE

NOT ASSIGNED

CONNECTOR SPIN

JUMPER-REMOVABLE FOR 0.025

(ADDED FOR OPTION

NOT ASSIGNED

CONNECTOR 3-PIN

JUMPER-REMOVABLE

NOT ASSIGNED

2

CONNECTOR-RF SMC M PC 5WHM

CONNECTOR-RF SMC

RELAY-REED 1A 500MA l00VDC 5VDCCOlL

9

RELAY-REED 1A 500MA lOOVDC 5VDC-COIL

RELAY-REED 1A 500MA 100VDC 5VDC-COlL

RELAY-REED 1A 500MA 100VDC 5VDC-COIL

RELAY-REED 1A 500MA l00VDC 5VDC-COIL

RELAY-REED 1A 500MA lOOVDC 5VDC-COIL

NOT ASSIGNED

1

RELAY 2C 5VDCCOlL .5A 125VAC

NOT ASSIGNED

RELAY-REED 1A 500MA l00VDC 5VDCCOIL

RELAY-REED 1A 500MA l00VDC 5VDCCOIL

NOT ASSIGNED

RELAY-REED 1A 500MA l00VDC 5VDGCOlL

2

RELAY-REED

RELAY-REED 2A 2A 100VDC 5VDCCOlL 200VA

INDUCTOR RF-CH-MLD 5.6UH 5%

2

INDUCTOR RF-CH-MLD 470NH 5%

2

INDUCTOR RF-CH-MLD 470NH 5%

INDUCTOR RF-CH-MLD 8.2MH 5%

2

INDUCTOR RF-CH-MLD 8.2MH 5%

1

INDUCTOR RF-CH-MLD 160UH

CL-V MIN 74.1UH

1

CL-V MIN 72.6UH

1

CL-V MIN 60.7UH

1

INDUCTOR RF-CH-MLD 2.7MH 5%

1

CL-V MIN 58.1UH

1

1

INDUCTOR RF-CH-MLD 1 UH 5%

NOT ASSIGNED

INDUCTOR RF-CH-MLD 5.6UH 5%

INDUCTOR RF-CH-MLD l8UH 5% .166DX.385LG

1

INDUCTOR RF-CH-MLD 820NH 5%

1

HEAT SINK SGL TO-5/T039-CS

4

HEAT SINK SGL TO-5/T0-39-CS

HEAT SINK SGL TO-5fl039-CS

HEAT SINK SGL TO-5/TO-39-CS

INSULATOR-XSTR POLY1

4

6-3.

Replaceable

Description

FOR

M

M

POST TYPE

FOR

M

POST TYPE

006)

M

POST TYPE

FOR

M

PC 5WHM

2A

2A lOOVDC 5VDCCOlL 200VA

0.025

IN

PC MOHM

0.025

IN

IN

0.025

IN

5%

sa

sa

sa

sa

Parts

PINS

PINS

PINS

PINS

Mfr*

Code

9N171 1N4150

9N171 1N4150

28480 12518601

28480 12514670

28480 12580141

28480 1250-0835

28480 12500835

28480 12500835

28480 12514670

28480

28480 12514670

28480

28480 12514670

28480 12580141

28480 1250-0836

28480

88330 R9131-1

88330

88330

88330

88330

88330

28480

88330

88330

88330 R9131-1

15636 R8777-1

15636 R8777-1

28480 91003560

28480

28480

28480 9100-1675

28480 9100-1675

28480 9100-1640

28480 08904-80001

28480 08904-80005

28480 08904-80002

28480

28480 08904-80003

28480 91003551

28480 9100-3560

28480 9140-0454

28480 91003315

28480

28480 1205-0213

28480 1205-0213

28480 12050213

28480

Mfr.

Part Number

1258-0141

12580141

12500836

R9131-1

R9131-1

R9131-1

R9131-1

R9131-1

0490-1190

R9131-1

R9131-1

91003548

91003548

91001663

1205-0213

03400834

tRefer to Section 7 for update information.

6-10

'Factory Selected Component (Refer to Section

5)

A

Errata part change.

rev.

01

NO

V89

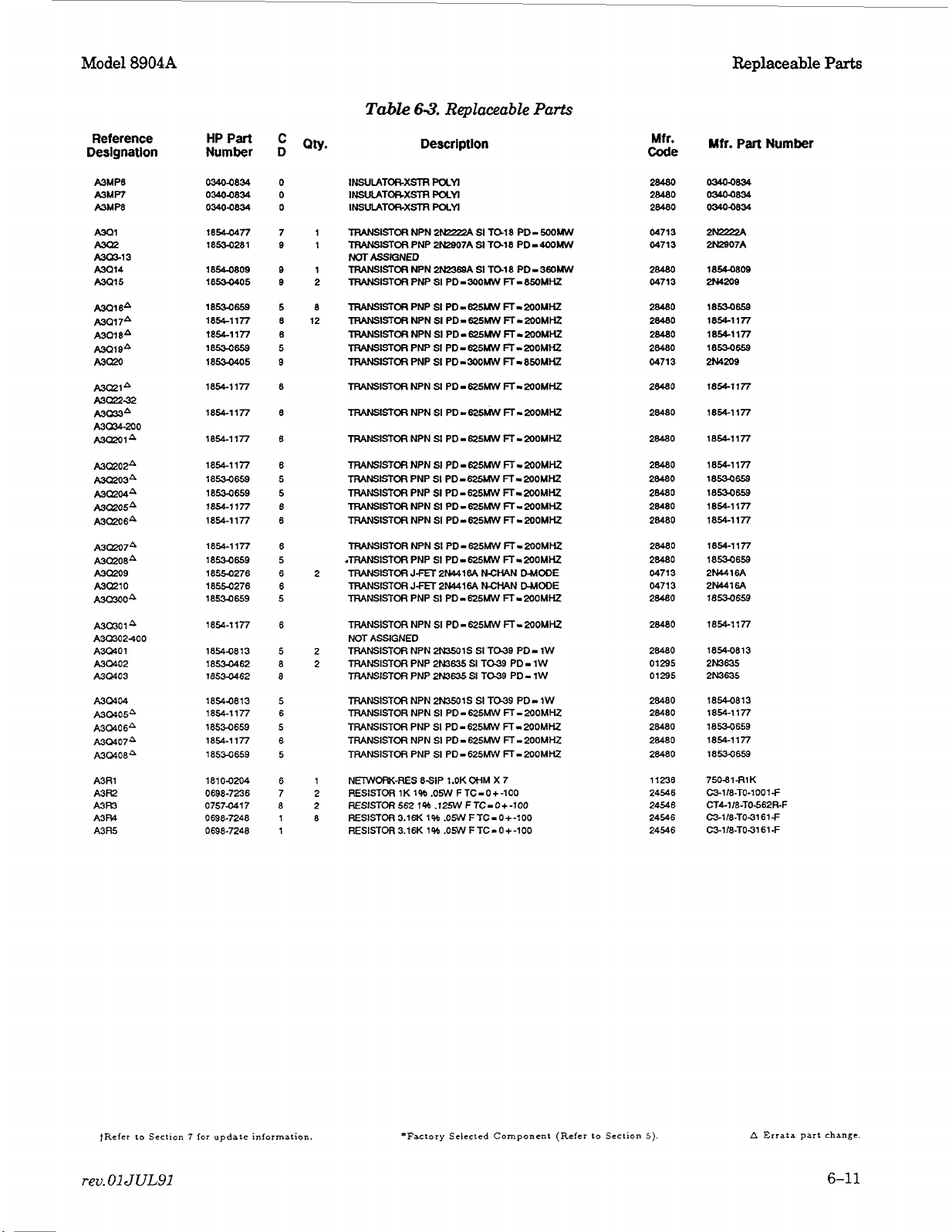

Page 19

Model

8904A

Replaceable

Parts

Reference

Designation

MMP8

A3MP7

A3MP8

A301

A3Q2

-13

A3014

A301 5

A301BA

A3Q17A

A301 8A

m19A

A3m

A3Q2lA

A3oi232

A3033A

A3a34-200

A3(1xlA

A30202A

A3Qzo3A

A30204A

A3am5A

A30206A

A3(1207A

A30208A

A30209

A3021

0

A30300A

A3QjOl

A

A3Qj02400

A-01

A30102

A30403

A30104

A30405A

A3040SA

A30107A

A30408&

A3R1

A3R2

A3m

A3R4

A3R5

HP

Part

Number

03404834

03404834

03404834

18544477

18530281

1854-0809

18530405

18530659

1854-1177

i854-iin

16534659

185SC405

1854-1177

1854-1177

1854-1177

1854-1177

18530659

18534659

1854-1177

1854-1177

1854-1177

18530659

18550276

18554276

18530659

1854-1177

185448 13

1853-0462

1853-0462

18544813

1854-1177

18534659

1854-1 177

18534659

181 OO2O4

0698-7236

07574417

0698-7248

0698-7248

D

C

e

8

6

5

6

6

5

6

5

8

8

5

6

5

6

5

Table

QW.

INSUIATORXSFI

INSUIATORXSlR

INSUIATORXSFI

TRANSISTOR

1

TRANSISTOR

1

NOT

TRANSISTOR

1

TRANSISTOR PNP

2

TRANSISTOR

8

TRANSISTOR

12

TRANSISTOR

TRANSISTORPNPSI PD-625W

TRANSISTORPNPSI PD-WOMW FT-850MHZ

TRANSISTOR

TRANSISTOR

TRANSISTOR

TRANSISTOR NPN

TRANSISTORPNPSI

TRANSISTOR

TRANSISTOR NPN

TRANSISTORNPNSIPD-625MWFT-MOMHZ

TRANSISTOR NPN

.TTRANSISTOR PNP

TRANSISTOR

2

TRANSISTOR

TRANSISTOR PNP

TRANSISTOR NPN

NOT ASSIGNED

TRANSISTOR NPN 2N3501S

2

TRANSISTOR PNP 2M3635

2

TRANSISTOR PNP 2N3635

TRANSISTOR NPN 2W1S

TRANSISTOR NPN

TRANSISTOR PNP

TRANSISTOR NPN

TRANSISTOR PNP

NETWOF1K-RES 8-SIP 1.OK

RESISTOR 1K 1%

RESISTOR562 1% .125WFTC-0+-100

RESlSTOR3.16K 1% .05WFTC-0+-100

RESlSTOR3.16K 1% .05WFTC-O+-100

AsSloNED

63.

Replaceable

Description

POLW

POLYI

POLW

NPN

zttza~

PNP 2W907A

NPN 2Ft23WA

SI

PD-300MW

PNP

SI

PD - 625MW

NPN

SI

PD-625W

NPN

SI

PD-625MW

NPN

SI

PD - 625MW

NPN

SI

PD - 625MW

NPN

SI

PD-625MW FT-200MHZ

SI

PD - 625MW

PD-625MWFT-X)OMHZ

PNP

SI

PD-625MW

SI

PD-625MW

SI

PD-625MW

SI

PD-625MW

J-FET

2N4416A NCHAN

Jm

2N4416A NCHAN

SI

PD-625MW

SI

PD-625MW

SI

PD- 625MW

SI

PD-625MW

SI

PD-625MW FT-2OOMHZ

SI

PD - 625MW

.OW

FTC-0+-100

SI

TOKI

PD-

SI

TO18 PD-400MW

SI

TO18 PD

FT-85OMHZ

FT-

FT-20OMHZ

FT-200MHZ

FT-ZOOMHZ

FT-

FT-

FT

-

FT-200MHZ

FT-200MHZ

R-200MHZ

FT-MOMHZ

WODE

MODE

FT-200MHZ

FT-rnOMHZ

SI

TO39 PD- 1W

SI

To39 PD - 1W

SI

To39 PD - 1W

SI

TO39 PD- 1W

FT-200MHZ

FT-200MHZ

FT

-

OHM

X 7

Parts

mow

-

360w

200MHZ

MOMHZ

200MHZ

200MHZ

200MHZ

Mfr.

Code

28480

28480

28480

04713

04713

28480

04713

28480

28480

28480

28480

04713

28480

28480 18561177

28480

28480

28480

28480

28480

28480

28480

28480

04713

04713

28480

28480

28480

01295

01295

28480

28480

28480

28480

28480

11238

24546

24546

24546

24546

Mtr.

Part

03406834

03406834

03404834

2N2222A

m07A

1864-0809

%209

18534659

1854-1177

18561177

18534659

2N4209

1854-1 177

1654-1177

1854-1177

1853-0659

18530659

1854-1177

1854-1177

1854-1177

1853-0659

2N4416A

2N4416A

1853-0659

18561177

18544813

2N333635

2N3635

18544813

1854-1177

18530659

1854-1177

18530659

75081-FilK

C3-1 18-TO-1

CTkll8-TOS62R-F

C3-118-TO3161-F

C2-118-TO-3161-F

Number

00

1

C

tRefer to Section

rev.

01

JUL91

7

lor

update information.

*Factory Selected Component

(Refer

to Section

5)

A

Errata part change.

6-11

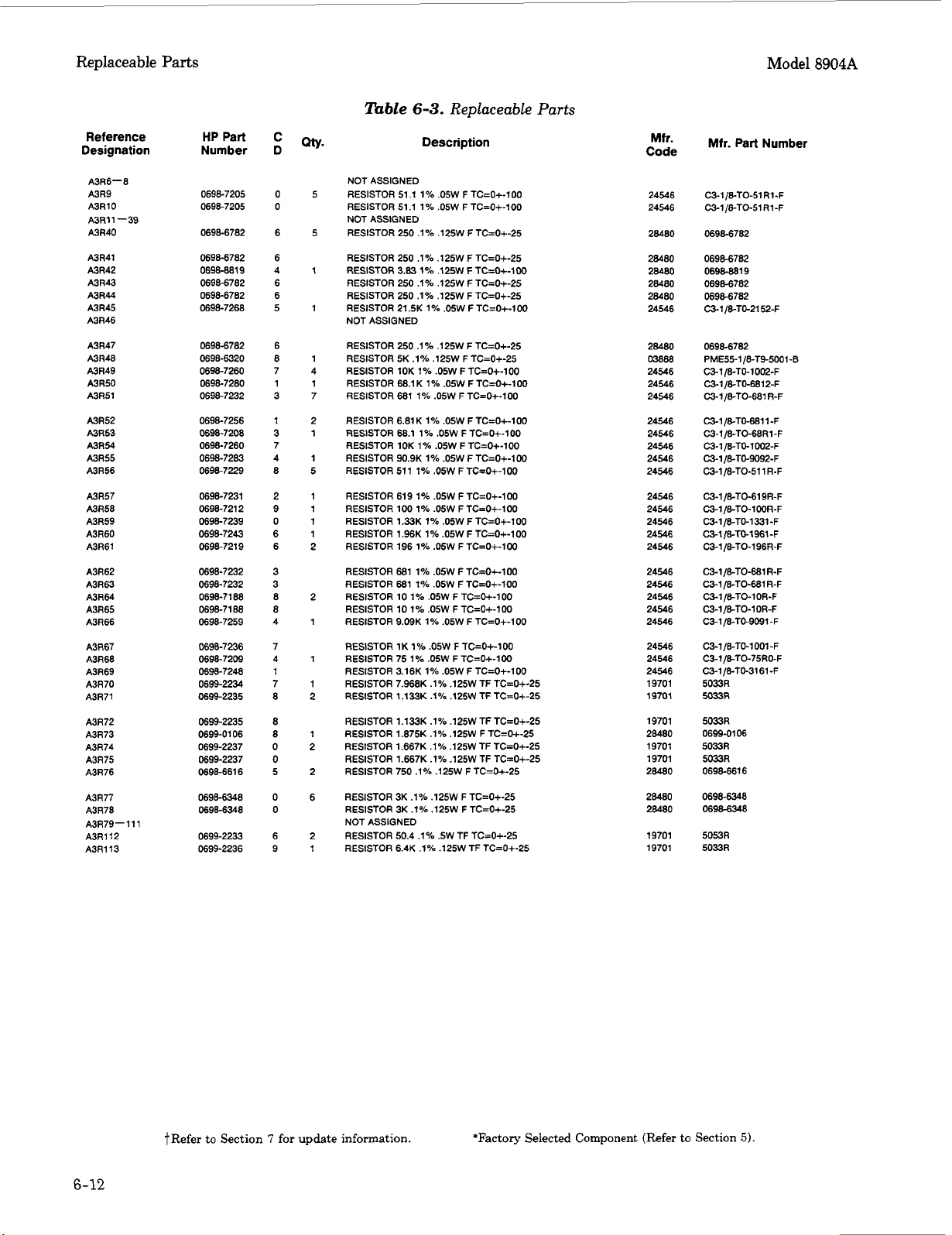

Page 20

Replaceable Parts Model

8904A

Reference

Designation

A3R6-8

A3R9

A3R10

A3Rll-39

A3R40

A3R41

A31342

A3R43

A3R44

A3R45

A3R46

A3R47

A3R48

A3R49

A3R50

A3R51

A3R52

A3R53

A3R54

A3R55

A3R56

A3R57

A3R58

A3R59

A3R60

A3R61

A3R62

A3R63

A3R64

A3R65

A3R66

A3R67

A3R68

A3R69

A3R70

A3R71

A3R72

A3R73

A3R74

A3R75

A3R76

A3R77

A3R78

A3R79-111

A3R112

A3R113

HP

Part

Number

0698-7205

0698-7205

0698-6782

0698-6782

0698-8819

0698-6782

0698-6782

0698-7268

0698-6782

0698-6320

0698-7260

0698-7280

0698-7232

0698-7256

0698-7208

0698-7260

0698-7283

0698-7229

0698-7231

0698-7212

0698-7239

0698-7243

0698-7219

0698-7232

0698-7232

88

0698-71

0698-71 88

0698-7259

0698-7236

0698-7209

0698-7248

0699-2234

0699-2235

0699-2235

0699-01 06

0699-2237

0699-2237

0698-6616

0698-6348

0698-6348

0699-2233

0699-2236

Table

05

0

65

6

41

6

6

51

6

81

74

11

37

12

31

7

41

85

21

91

01

61

62

3

3

82

8

41

7

41

1

71

82

8

81

02

0

52

06

0

62

91

NOT ASSIGNED

RESISTOR 51.1 1% .05W F TC=0+-100

RESISTOR 51.1 1% .05W F TC=O+-100

NOT ASSIGNED

RESISTOR 250 .1% .125W F TC=0+-25

RESISTOR 250 .1% .125W F TC=0+-25

RESISTOR 3.83 1% .125W F TC=O+-100

RESISTOR 250

RESISTOR 250.1% .125W

RESISTOR 21.5K 1% .05W

NOT ASSIGNED

RESISTOR 250 .l% .125W F TC=0+-25

RESISTOR 5K .1% .125W F TC=0+-25

RESISTOR 10K 1% .05W FTC=O+-100

RESISTOR 68.1 K 1% .05W F TC=0+-100

RESISTOR 681 1% .05W

RESISTOR 6.81 K 1% .05W F TC=0+-100

RESISTOR 68.1

RESISTOR 10K 1% .05W FTC=0+-100

RESISTOR 90.9K 1% .05W F TC=O+-lOO

RESISTOR 511 1% .OSW

RESISTOR 619 1% .05W F TC=0+-100

RESISTOR 100 1% .05W F TC=O+-100

RESISTOR 1.33K 1% .05W F TC=O+-100

RESISTOR 1.96K 1% .05W F TC=0+-100

RESISTOR 196 1% .05W F TC=0+-100

RESISTOR 681 1% .05W FTC=O+-100

RESISTOR 681 1% .05W F TC=O+-lOO

RESISTOR 10 1% .05W F TC=O+-100

RESISTOR 10 1% .05W F TC=0+-100

RESISTOR 9.09K 1% .05W F TC=0+-100

RESISTOR

RESISTOR 75 1% .05W F TC=O+-100

RESISTOR 3.16K 1% .05W F TC=O+-lOO

RESISTOR 7.968K .1% .125W TF TC=0+-25

RESISTOR 1.133K .1% .125W TF TC=0+-25

RESISTOR 1.133K .1% .125W TF TC=0+-25

RESISTOR 1.875K .1% .125W

RESISTOR 1.667K .1% .125W TF TC=0+-25

RESISTOR 1.667K .1% .125W TF TC=0+-25

RESISTOR 750.1% .125W

RESISTOR 3K .1% .125W F TC=0+-25

RESISTOR 3K .1% .125W F TC=0+-25

NOT ASSIGNED

RESISTOR 50.4 .1% .5W TF TC=0+-25

RESISTOR 6.4K

6-3.

Replaceable

Description

.1%

.125W F TC=0+-25

F

F

F

TC=0+-100

1%

.05W FTC=O+-100

F

TC=O+-lOO

1K

1% .05W F TC=0+-100

F

.1%

.125W TF TC=0+-25

TC=O+-25

TC=0+-100

F

TC=0+-25

TC=0+-25

Parts

Mfr.

Code

24546 C~-I/~TO-~IRI-F

24546 C3-1/8-TO-51Rl-F

28480 0698-6782

28480 0698-6782

28480 0698-6819

28480

28480 0698-6782

24546 C3-1/8-TO-2152-F

28480

03888

24546 C3-1/8-T0-1002-F

24546 C3-1/8-TO-6812-F

24546 C3-1/8-TO-681R-F

24546 C3-1 /ET091 1 -F

24546 C3-l/ETO-68Rl-F

24546 C3-1/8-TO-1002-F

24546 C3-1/8-TO-9092-F

24546 C3-1 /E-TO-51 1 R-F

24546 C3-l/ETO-619R-F

24546 C3-1/8-TO-100R-F

24546 C3-1/8-TO-1331-F

24546 C3-1/8-T&1961-F

24546 C3-1/8-TO-196R-F

24546 C3-1/8-TO-681 R-F

24546 Wl/ET0-681 R-F

24546 C3-l/ETO-lOR-F

24546 C3-1/8-TO-lOR-F

24546 C3-1 /ETO-9091 -F

24546 C3-1/8-TO-lOOl-F

24546 C3-1/ETO-75RO-F

24546 C51/aTO-3161-F

19701 5033R

19701

19701 5033R

28480 0699-0106

19701 5033R

19701 5033R

28480 0698-6616

28480

28480 0698-6348

19701 5053R

19701 5033R

Mfr.

Part

Number

06984782

0698-6782

PME55-1 /8-T9-500l-B

5033R

0698-6348

6-12

?Refer

to

Section 7 for update information.

*Factory Selected Component (&fer

to

Section

5).

Page 21

Model

8904A

Replaceable Parts

Reference

Designation

A3R114

A3R115- 121

A3R122

A3R123

A3R124

A3R125

A3R126

A3R127- 135

A3R136

A3R139

A3R140

A3R141

A3R142

A3R 143

-

A3R201

A3R202

A3R203

A3R204

A3R205

A3R206

A3R207

A3R208

A3R209

A3R210

A3R211

A3R212

A3R213

A3R214

A3R215

A3R216

A3R217

A3R218

A3R219

A3R220

A3R221

A3R222

A3R223

A3R224

A3R225

A3R226

A3R227

A3R228

A3R229

A3R230

200

!Cable

HP

Part

Number

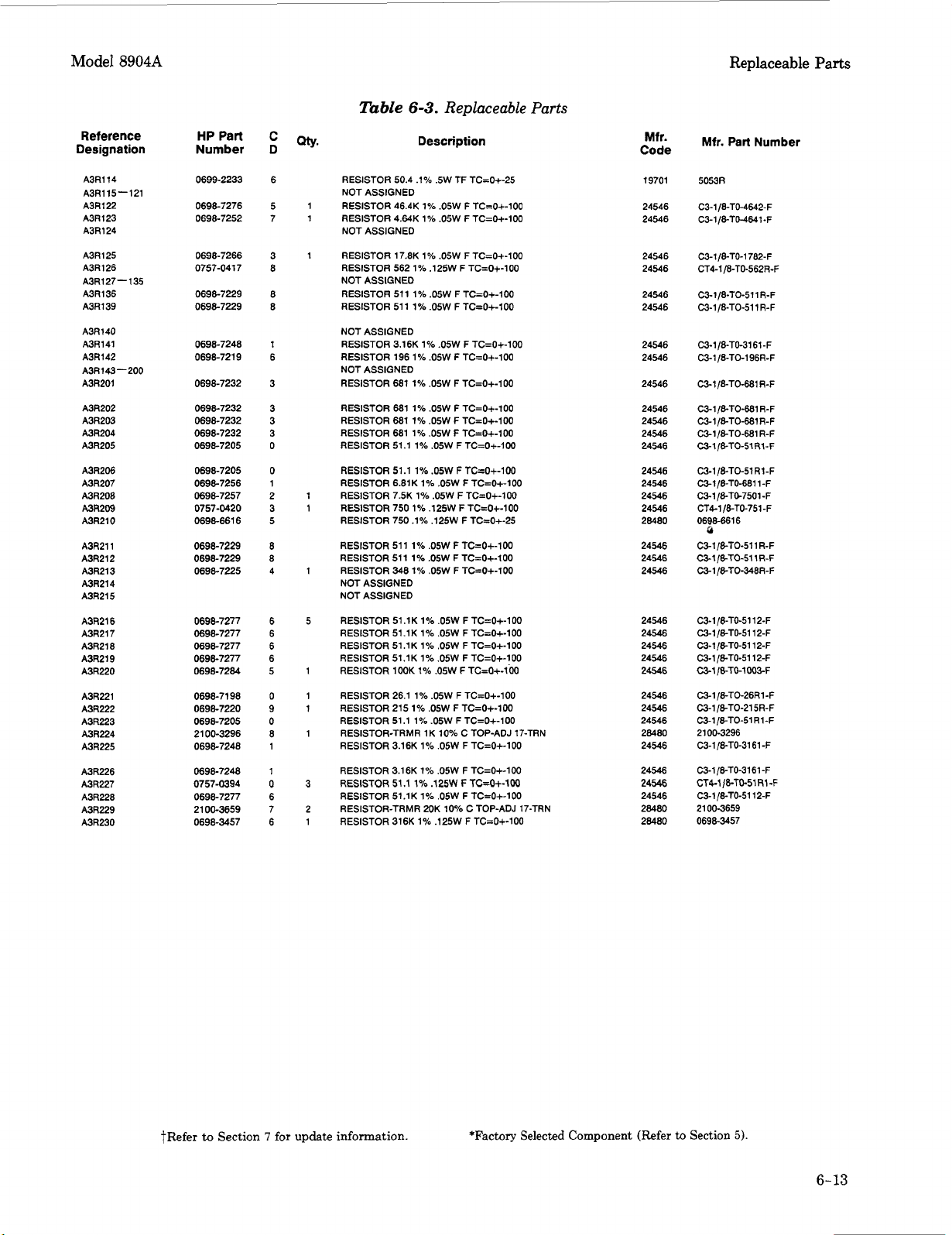

0699-2233 6 RESISTOR 50.4

0698-7276

0698-7252 5 7

0698-7266

0757-041 7

0698-7229

0698-7229

0698-7248

0698-721

0698-7232

0698-7232

0698-7232

0698-7232

0698-7205

0698-7205

0698-7256

0698-7257

0757-0420

0698-661 6

0698-7229

0698-7229

0698-7225

0698-7277

0698-7277

0698-7277

0698-7277

0698-7284

0698-7198

0698-7220

0698-7205

21 00-3296

0698-7248

0698-7248

0757-0394

0698-7277

21 00-3659

0698-3457

C

D

NOT ASSIGNED

1

RESISTOR 46.4K 1% .05W F TC=0+-100

1

RESISTOR 4.64K 1% .05W F TC=0+-100

NOT ASSIGNED

1

RESISTOR 17.8K 1% .05W F TC=0+-100

RESISTOR 562 1% ,125W F TC=0+-100

NOT ASSIGNED

RESISTOR 511 1% .05W F TC=O+-100

RESISTOR 511 1% .05W F TC=0+-100

1

9

6

NOT ASSIGNED

RESISTOR 3.16K 1% .05W F TC=0+-100

RESISTOR 196 1% .05W F TC=0+-100

NOT ASSIGNED