Page 1

User’s Guide

Agilent Technologies

8719ET/20ET/22ET

8719ES/20ES/22ES

Network Analyzers

Part Number: 08720-90392

Printed in U SA

June 2002

Supersede s: February 2001

© Copyright 1999–2002 Agilent Technologies, Inc.

Page 2

Notice

The information contained in this document is subject to change without notice.

Agilent Technologies makes no warranty of any kind with regard to this material,

including but not limited to, the implied warranties of merchantability and fitness for a

particular purpose. Agilent Technologies shall not be liable for errors contained herein or

for incidental or consequent ial damages in connect ion with the furnishing , performance, or

use of this material.

Certification

Agilent Technologie s certi f ies that this produc t m et i ts p ub lis hed speci fi c ations a t the time

of shipment from the factory. Agilent Technologies further certifies that its calibration

measurements are traceable to the United States National Institute of Standards and

Technology, to the extent allowed by the Institute’s calibration facility, and to the

calibration facilities of other International Standards Organization members.

Regulatory Inf ormation

The regulatory information is located in Chapter 8 , “Safety and Regulatory Information.”

Warranty

THE MATERIAL CONTAINED IN THIS DOCUMENT IS PROVIDED “ AS IS,” AND IS SUBJECT TO BEING

CHANGED, WITHOUT NOTICE, IN FUTURE EDITIONS. FURTHER, TO THE MAXIMUM EXTENT

PERMITTED BY APPLICABLE LAW, AGILENT DISCLAIMS ALL WARRANTIES, EITHER EXPRESS OR

IMPLIED WITH REGARD TO THIS MANUAL AND ANY INFORMATION CONTAINED HEREIN,

INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE. AGILENT SHALL NOT BE LIABLE FOR ERRORS OR FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES IN CONNECTION WITH THE FURNISHING, USE OR

PERFORMANCE OF THIS DOCUMENT OR ANY INFORMATION CONTAINED HEREIN. SHOULD

AGILENT AND THE USER HAVE A SEPARATE WRITTEN AGREEMENT WITH WARRANTY TERMS

COVERING THE MATERIAL IN THIS DOCUMENT THAT CONFLICT WITH THESE TERMS, THE

WARRANTY TERMS IN THE SEPARATE AGREEMENT WILL CONTROL.

Assistance

Product maintenance agreements and other customer assistance agreements are availa ble

for Agilent Technologies products. For any assistance, contact your nearest Agilent

Technologies sales or service office. See Table 8-1 for the nearest office.

ii

Page 3

Safety Note s

Front-Panel Key

SOFTKEY

The following safety notes are used throughout this manual. Familiarize your self with

each of the notes and its meaning before operating this instrument. All pertinent safety

notes for using this product are located in Chapter 8 , “Safety and Regulatory

Information.”

WARNING Warning denotes a hazard. It calls attention to a procedure which, if

not correctly performed or adhered to, could result in injury or loss

of life. Do not proceed beyond a warning note until the indicated

conditions are fully un derstood and met.

CAUTION Caution denotes a hazard. It calls attention to a procedure that, if not

correctly performed or adhered to , would result in damage to or destructi on of

the instrument. Do not proceed beyond a caution sign until the indicated

conditions are fully understood and met.

How to Use This Guide

This guide uses the following conventions:

This represents a key physically located on the

instrument.

This represents a “softkey,” a key whose label is

determined by the instrument’s firmware.

Screen Text This represents text displayed on the instrument’s screen.

iii

Page 4

Documentation Map

The Installation an d Quick Start Guide pr ovides procedures for

installing, configuring, and verifying the operation of the analyzer. It

also will help you familiarize yourself with the basic operation of the

analyzer.

The User’s Guide shows how to make measurements, explains

commonly-used features, and tells you how to get the most

perform ance from your ana ly z e r.

The Reference Guide provides re fere n ce inform at i on, su ch as

specifications, menu maps, and key definitions.

The Programm er’s Guide provides general GPIB programming

informat ion, a comm an d reference, and e xample pr og ra ms. T he

Programmer’s Gui de contains a CD-ROM with example programs.

The CD-ROM provides the Installa tio n and Qu ick Start Guide , the

User’s Guid e, the Referen ce Guide , and the Progra mmer’s Guid e in

PDF format for v ie wing or p rin t ing from a PC.

The Service Guide pr ovides information on calibrating,

troubleshooting, and servicing your analyzer . The Serv ic e Gu ide i s not

part of a standard shipment and is available only as Option 0BW, or

by ordering part number 08720-90397. A CD-ROM with the Service

Guide in PDF format is included for viewing or printing from a PC.

iv

Page 5

Contents

1. Making Measurements

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

More Instrument Functions Not Described in This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Making a Basic Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Step 1. Connect the device under test and any required test equipment. . . . . . . . . . . . . .1-4

Step 2. Choose the measurement parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Step 3. Perform and apply the appropriate error-correction. . . . . . . . . . . . . . . . . . . . . . . .1-5

Step 4. Measure the device under test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Step 5. Output the measurement results. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Measuring Magnitude and Insertion Phase Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Measuring the Magnitude Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Measuring Insertion Phase Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Using Display Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

Titling the Active Channel Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

Viewing Both Primary Measurement Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

Viewing Four Measurement Channels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

Customizing the Four-Channel Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

Using Memory Traces and Memory Math Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-19

Blanking the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-21

Adjusting the Colors of the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-22

Using Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 2 4

To Use Continuous and Discrete Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-24

To Activate Display Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-25

To Move Marker Information Off the Grids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-26

To Use Delta (∆) Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-28

To Activate a Fixed Marker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-29

To Couple and Un co u p le Display M a rkers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1- 3 1

To Use Polar Format Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-32

To Use Smith Chart Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-33

To Set Measurement Parameters Using Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-34

Setting the CW Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-38

To Search for a Specific Amplitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-39

To Calculate the Statistics of the Measurement Data . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-42

Measuring Electrical Length and Phase Distortion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-43

Measuring Electrical Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-43

Measuring Phase Distortion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-45

Characterizing a Duplexer (ES Analyzers Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-49

Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-49

Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-49

Measuring Amplifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-52

Measuring Gain Compression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-53

Measuring Gain and Rev erse Isolatio n Sim ultan eo usly (ES An alyze r s Only ) . . . . . . . . .1-57

Making High Power Measurements with Optio n 085 (ES Analyz ers On ly) . . . . . . . . . . .1-59

Making High Power Measurements with Optio n 012 (ES Analyz ers On ly) . . . . . . . . . . .1-65

Using the Swept List Mode to Test a Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-67

Connect the Device Under Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-67

Observe the Characteristics of the Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-68

Choose the Measurement Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-68

Calibrate and Measure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-70

Contents-v

Page 6

Contents

Using Limit Lines to Test a Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-72

Setting Up the Measurement Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-72

Creating Flat Limit Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-73

Creating a Sloping Limit Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-75

Creating Single Point Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-77

Editing Limit Segments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-78

Running a Limit Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-79

Offsetting Limit Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-79

Using Ripple Limits to Test a Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-81

Setting Up the List of Ripple Limits to Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-81

Editing Ripple Test Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-84

Running the Ripple Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-86

Using Bandwidth Limits to Test a Bandpass Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-92

Setting Up Bandwidth Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-92

Running a Bandwidth Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-94

Using Test Sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-98

How to Use Test Sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-98

Creating a Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-98

Running a Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-100

Stopping a Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-100

Editing a Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-100

Clearing a Sequence from Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-102

Changing the Sequence Title . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-103

Naming Files Generated by a Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-103

Storing a Sequence on a Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-104

Loading a Sequence from Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-104

Purging a Sequence from Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-104

Printing a Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-105

In-Depth Sequencing Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-105

Using Test Sequencing to Test a Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-114

Cascading Multiple Example Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-114

Loop Counter Example Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-115

Generating Files in a Loop Counter Example Sequence . . . . . . . . . . . . . . . . . . . . . . . . . 1-116

Limit Test Example Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-118

2. Making Mixer Measurements (Option 089 Only)

Using This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Mixer Measure men t Ca pabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Measurement Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Minimizing Source and Load Mismatches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Reducing the Effect of Spurious Responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Eliminating Unwanted Mixing and Leakage Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

How RF and IF Are Defined . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Frequency Offset Mode Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

LO Frequency Accuracy and Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Differences Between Internal and External R Channel Inputs . . . . . . . . . . . . . . . . . . . .2-10

Power Meter Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Conversion Loss Using the Frequency Offset Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Sett i n g M easu rement Parameter s for the Pow e r M eter Ca libration . . . . . . . . . . . . . . . . 2-14

Contents-vi

Page 7

Contents

Performing a Power Meter (Source) Calibration Over the RF Range . . . . . . . . . . . . . . . .2-15

Setting the Analyzer to Make an R Channel Measurement. . . . . . . . . . . . . . . . . . . . . . . .2-17

High Dynamic Range Swept RF/IF Conversion Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-20

Set Me a s urem e n t Par a mete rs for the I F Rang e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2- 2 0

Perform a Power Meter Calibration Over the IF Range. . . . . . . . . . . . . . . . . . . . . . . . . . .2-20

Perform a Receiver Calibration Over the IF Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

Set the Analyzer to the RF Frequency Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

Perform a Power Meter Calibration Over the RF Range . . . . . . . . . . . . . . . . . . . . . . . . . .2-23

Perform t he Hi gh Dynami c R a nge Me a sure ment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2 4

Fixed IF Mixer Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

Tuned Receiver Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

Sequence 1 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

Sequence 2 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

Phase or Group Delay Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-35

Phase Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-35

Phase Linearity and Group Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-35

Amplitude and Phase Tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-39

Conversion Co m pres s i o n U s i ng the Frequ e n cy Off s e t M o de . . . . . . . . . . . . . . . . . . . . . . . .2- 4 0

Isolation Example Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-45

LO to RF Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-45

RF Feedthrough . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-47

SWR / Return Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-50

3. Making Time Domain Measurements

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Introduction to Time Domain Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Making Transmission Response Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Making Reflection Response Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Time Domain Bandpass Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Adjusting the Relative Velocity Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Reflection Measurements Using Bandpass Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Transmission Measurements Using Bandpass Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

Time Domain Low Pass Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

Setti ng the Frequenc y Ra nge fo r T i me Do m a in Low Pass . . . . . . . . . . . . . . . . . . . . . . . .3 - 1 5

Reflection Measurements in Time Domain Low Pa ss . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

Fault Location Measurements Using Low Pass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Transmiss ion M easur emen t s in Tim e Dom a i n Low Pass . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1 9

Transforming CW Time Measurements into the Frequency Domain . . . . . . . . . . . . . . . . .3-22

Forward Transform Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Masking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

Windowing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 3 0

Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-32

Response Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-32

Range Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-34

Gating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-35

Setting the Gate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-35

Selecting Gate Shape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-36

Contents-vii

Page 8

Contents

4. Printing, Plotting, and Saving Mea sureme nt Resul ts

Using This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Printing or Plotting Your Measurement Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Configuring a Print Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Defining a Print Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

If You Are Using a Color Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

To Reset the Printing Parameters to Default Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Printing One Measurement Per Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Printing Multiple Measurements Per Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

Configuring a Plot Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

If You Are Plotting to an HPGL/2 Compatible Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

If You Are Plotting to a Pen Plotter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-12

If You Are Plotting Measurement Results to a Disk Drive . . . . . . . . . . . . . . . . . . . . . . . .4-13

Defining a Plot Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

Choosing Display Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Selecting Auto-Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

Selecting Pen Numbers and Colors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-16

Selecting Line Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-17

Choosing Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4- 1 7

Choosing Plot Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

To Reset the Plotting Parameters to Default Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Plotting One Measurement Per Page Using a Pen Plotter . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Plotting Multiple Measurements Per Page Using a Pen Plotter . . . . . . . . . . . . . . . . . . . . .4-20

If You Are Plotting to an HPGL Compatible Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

To View Plot Files on a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-22

Using Ami Pro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4- 2 3

Using Freelance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Converting HPGL Files for Use with Other PC Applications . . . . . . . . . . . . . . . . . . . . . . 4-24

Outputting Plot Files from a PC to a Plotter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-24

Outputting Plot Files from a PC to an HPGL Compatible Printer . . . . . . . . . . . . . . . . . . .4-25

Step 1. Store the HPGL initialization sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-25

Step 2. Store the exit HPGL mode and form feed sequence. . . . . . . . . . . . . . . . . . . . . . . .4-26

Step 3. Send the HPGL initialization sequence to the printer. . . . . . . . . . . . . . . . . . . . .4-26

Step 4. Send the plot file to the printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-26

Step 5 . Se nd the exit HPGL mode a n d f orm fee d sequ ence t o the printer. . . . . . . . . . . . 4- 2 6

Outputting Single Page Plots Using a Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Outputting Multiple Plots to a Single Page Using a Printer . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Plotting Multiple Measurements Per Page from Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

To Plot Multiple Measurements on a Full Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-29

To Plot Measu remen t s in Page Q u a d rant s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3 0

Titling the Displayed Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Configuring the Analyzer to Produce a Time Stamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

Aborting a Print or Plot Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

Printing or Plotting the List Values or Operating Parameters . . . . . . . . . . . . . . . . . . . . . .4-34

If You Want a Single Page of Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

If You Want the Entire List of Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

Solving Problems with Printing or Plotting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

Saving and Recalling I nst ru m ent State s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-36

Places Where You Can Save . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Contents-viii

Page 9

Contents

What You Can Save to the Analyzer’s Internal Memory . . . . . . . . . . . . . . . . . . . . . . . . . .4-36

What You Can Save to a Floppy Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-37

What You Can Save to a Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-37

Saving an Instrument State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-38

Saving Measurement Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-39

ASCII Data Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-41

Saving in Textual (CSV) Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-44

Saving in Graphical (JPEG) Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-46

Instrument State Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-47

Saving Time Gated Frequency Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-49

Differences between Raw, Data, and Format Arrays . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-49

Re-Saving an Instrument State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-51

Deleting a File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5 2

To Delete an Instrument State File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-52

To Delete all Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-52

Renaming a File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-53

Recalling a File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-54

Formatting a Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-54

Solving Problems with Saving or Recalling Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-55

If You Are Using an External Disk Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-55

5. Optimizing Measurement Results

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Taking Care of Microwave Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Increasing Measurement Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Interconnecting Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Improper Calibration Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Sweeping Too Fast for Electrically Long Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Connector Rep eatability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Temperature Drift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Frequency Drift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Performance Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Reference Plane and Port Extensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Maintaining Test Port Output Power During Sweep Retrace . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Making Accurate Measurements of Electrically Long Devices . . . . . . . . . . . . . . . . . . . . . . . .5-8

The Cause of Measurement Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

To Improve Measurement Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Increasing Sweep Speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

To Use Swept List Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

To Decrease the Frequency Span . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

To Set the Auto Sweep Time Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

To Widen the System Bandwidth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

To Reduce the Averaging Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

To Reduce the Number of Measurement Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

To Set the Sweep Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

To View a Single Me a sur em ent C h a nnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5- 1 3

To Activate Chop Sweep Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

To Use External Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

To Use Fast 2-Port Calibration (ES Analyzers Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

Contents-ix

Page 10

Contents

Increasing Dynamic Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

Increase the Test Port Input Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Reduce the Receiver Noise Floor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Reduce the Receiver Crosstalk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Reducing Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 6

To Activate Averaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16

To Change System Bandwidth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16

To Use Direct Sampler Access Configurations (Opt ion 012 On ly). . . . . . . . . . . . . . . . . . .5-17

Reducing Receiver Crosstalk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-18

Reducing Recall Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 1 8

6. Calibrating for Increased Measurement Accuracy

How to Use This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Calibration Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Measurement Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Device Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Clarifying Type-N Connector Sex . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Omitting Isolation Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

Saving Calibration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

Restarting a Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

The Calibration Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

Frequency Response of Calibration Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Interpolated Error Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Error-Correction Stimulus State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

Procedures for Error Correcting Your Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

Types of Error Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

Frequency Response Error Corrections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Response Error Correction for Reflection Measurements . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Resp o n se Error Correction for Tran smiss i o n M e a suremen ts . . . . . . . . . . . . . . . . . . . . . . 6-14

Receiver Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-15

Frequency Res ponse and Isolation Error Corrections . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-17

Response and Isolation Error Correction for Transmission Measurements . . . . . . . . . .6-17

Response and Isolation Error Correction for Reflection Measurements . . . . . . . . . . . . .6-19

Enhanced Frequency Response Error Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Enhanced Reflection Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-25

One-Port Reflection Error Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

Full Two-Port Error Correction (ES Analyzers Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-29

Power Meter Measurement Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-33

Loss of Power Meter Calibration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-33

Interpolation in Power Meter Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-34

Entering the Power Sensor Calibration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-34

Compensating for Directional Coupler Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-35

Using Sample-and-Sweep Correction Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-36

Using Continuous Correction Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-38

Calibrating for Noninsertable Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-40

Adapter Removal Calibration (ES Analyzers Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-41

Perform the 2-Port Error Corrections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-42

Verify the Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6- 4 5

Contents-x

Page 11

Contents

Matched Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 -45

Modify the Cal Kit Thru Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-46

Minimizing Error When Using Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-47

Making Non-Coaxial Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-48

Fixtures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4 8

Calibrating for Non-Coaxial Devices (ES Analyzers Only) . . . . . . . . . . . . . . . . . . . . . . . . . .6-50

TRL Error Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-50

LRM Error Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-54

Create a User-Defined LRM Calibration Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-54

Perform the LRM Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-56

Calibrating Using Electronic Calibration (ECal) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-58

Set Up the Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-58

Connect the ECal Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-59

Select the ECal Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-60

Perform the Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-62

Display the Module Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-64

Perform the Confidence Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-65

Investigating the Calibration Results Using the ECal Service Menu . . . . . . . . . . . . . . . .6-67

Adapter Removal Using ECal (ES Analyzers Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-69

Perform the 2-Port Error Corrections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-71

Determine the Electrical Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-73

Remove the Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-74

Verify the Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6- 7 5

7. Operating Concepts

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Where to Find More Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

The Built-In Synthesized Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

The Built-In Test Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

The Receiver Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

The Microprocessor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

Required Peripheral Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 5

Processing Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

Output Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-9

Understanding the Power Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-9

Power Coupling Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-10

Sweep Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-11

Manual Sweep Time Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-11

Auto Sweep Time Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-11

Minimum Sweep Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-11

Source Attenuator Switch Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-13

Allowing Repetitive Switching of the Attenuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-13

Channel Stimulus Coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-14

Sweep Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-15

Linear Frequency Sweep (Hz) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-15

Logarithmic Frequency Sweep (Hz) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-15

Stepped List Frequency Sweep (Hz) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-15

Contents-xi

Page 12

Contents

Swept List Frequency Sweep (Hz) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

Power Sweep (dBm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-19

CW Time Sweep (Seconds) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-19

Selecting Sweep Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-19

S-Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

Understanding S-Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

The S-Parameter Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-22

Analyzer Display Formats. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-24

Log Magnitude Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

Phase Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2 4

Group Delay Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

Smith Chart Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-26

Polar Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7- 2 7

Linear Magnitude Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-27

SWR Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 2 8

Real Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7- 2 9

Imaginary Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-29

Group Delay Principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-29

Electrical Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-33

Noise Reduction Techniques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-34

Averaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-34

Smoothing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3 5

IF Bandwidth Reduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-35

Measurement Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-37

What Is Accuracy Enhancement? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-37

What Causes Measurement Errors? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-38

Characterizing Microwave Systematic Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-41

How Effective Is Accuracy Enhancement? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-51

Calibration Routines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 5 4

Response Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-54

Response and Isolation Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-54

Enhanced Response Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-54

S11 and S22 One-Port Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-55

Full Two- Por t Calibration (ES M odels Only ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-55

TRL*/LRM* Two-Port Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-55

E-CAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-56

Modifying Calibration Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-57

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-57

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-58

Modify Calibration Kit Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-58

Verify Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-65

Saving Modified Calibration Kits to a Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-65

Modifying and Saving a Ca libr atio n Kit from the Calibrat io n Kit Se lection Menu. . . . . 7-66

TRL*/LRM* Calibration (ES Models Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-67

Why Use TRL Calibration? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-67

TRL Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-68

How TRL*/LRM* Calibration Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-68

Improving Raw Source Match and Load Match for TRL*/LRM* Calibration . . . . . . . . . 7-71

How True TRL/LRM Works (Option 400 Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-72

Contents-xii

Page 13

Contents

The TRL Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-72

GPIB Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-78

Local Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-78

GPIB STATUS Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-79

System Controller Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-79

Talker/Listener Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-79

Pass Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-7 9

Address Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 -80

Using the Parallel Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-80

Limit Line Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-82

Edit Limits Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-83

Edit Segment Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-83

Offset Limits Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8 3

Knowing the Instrument Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-84

Network Analyzer Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-84

Tuned Receiver Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-84

Frequency Offset Operation (Op tion 089) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-85

8. Sa fety and Regu latory Inf ormation

General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

Shipment for Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-4

Instrument Markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-4

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-5

Safety Earth Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-5

Before Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8- 5

Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-6

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-7

Compliance with German FTZ Emissions Requirements . . . . . . . . . . . . . . . . . . . . . . . . . .8-8

Compliance with German Noise Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-8

Compliance with Canadian EMC Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-8

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-9

Contents-xiii

Page 14

Contents

Contents-xiv

Page 15

1 Making Measurements

1-1

Page 16

Making Measurements

Using This Chapter

Using This Chapter

This chapter contains the following example procedures for making measurements. Mixer

and time domain measurements are covered in Chapter 2 , "Making Mixer Measurements

(Option 089 Only) " and Chapter 3 , “Making Time Domain Measurements.” This chapter

also describes how to use most display, marker, and sequencing functions.

• "Making a Basic Measurement" on page 1-4

• "Measuring Magnitude and Insertion Phase Response" on page 1-7

• "Measuring Electrical Length and Phase Distortion" on page 1-43

— Electr ical Length

— Phase Distortion (deviation from linear phase, group delay)

• Characterizing a Duplexer (ES Analyzers Only)

• "Measuring Amplifiers" on page 1-52

— Measuring Gain Compression

— Measuring Gain Compression and Reverse Isolation Simultaneously

(ES Analyzers Only)

— Making High Power Measurements (ES Analyzers Only)

• "Using the Swept List Mode to Test a Device" on page 1-67

• "Using Limit Lines to Test a Device" on page 1-72

• "Using Test Sequencing to Test a Device" on page 1-114

The following chapters describe how to use more instrument functions (as indicated by

their chapter titles):

• Chapter 4 , "Printing, Plotting, and Saving Measurement Results"

• Chapter 5 , "Optimizing Measurement Results"

• Chapter 6 , "Calibrating for Increased Measurement Accuracy"

1-2

Page 17

Making Measurements

More Instrument Functions Not Described in This Guide

More Instrument Functions Not Described in This Guide

To learn about instrument functions not covered in this user’s guide, refer to the following

chapters in the reference guide.

“Menu Maps” contains maps of the instrument menu structure.

“Hardkey/Softkey Reference” contains descriptions of all instrument functions.

1-3

Page 18

Making Measurements

PRESET : FACTORY

Making a Basic Measurement

Making a Basic Measurement

There are five basic steps when you are making a measurement.

1. Connect the device under test and any required test equipment.

CAUTION Damage may result to the device under test (DUT) if it is sensitive to the

analyzer’s default output power lev el. To avoid damaging a sensitive DUT, be

sure to lower the output power before connecting the DUT to the analyzer.

2. Choose the measurement parameters.

3. Perform and apply the appropriate error-correction.

4. Measure the device under test (DUT).

5. Output the measurement results.

This example procedure shows you how to measure the transmission response of a

bandpass filt e r.

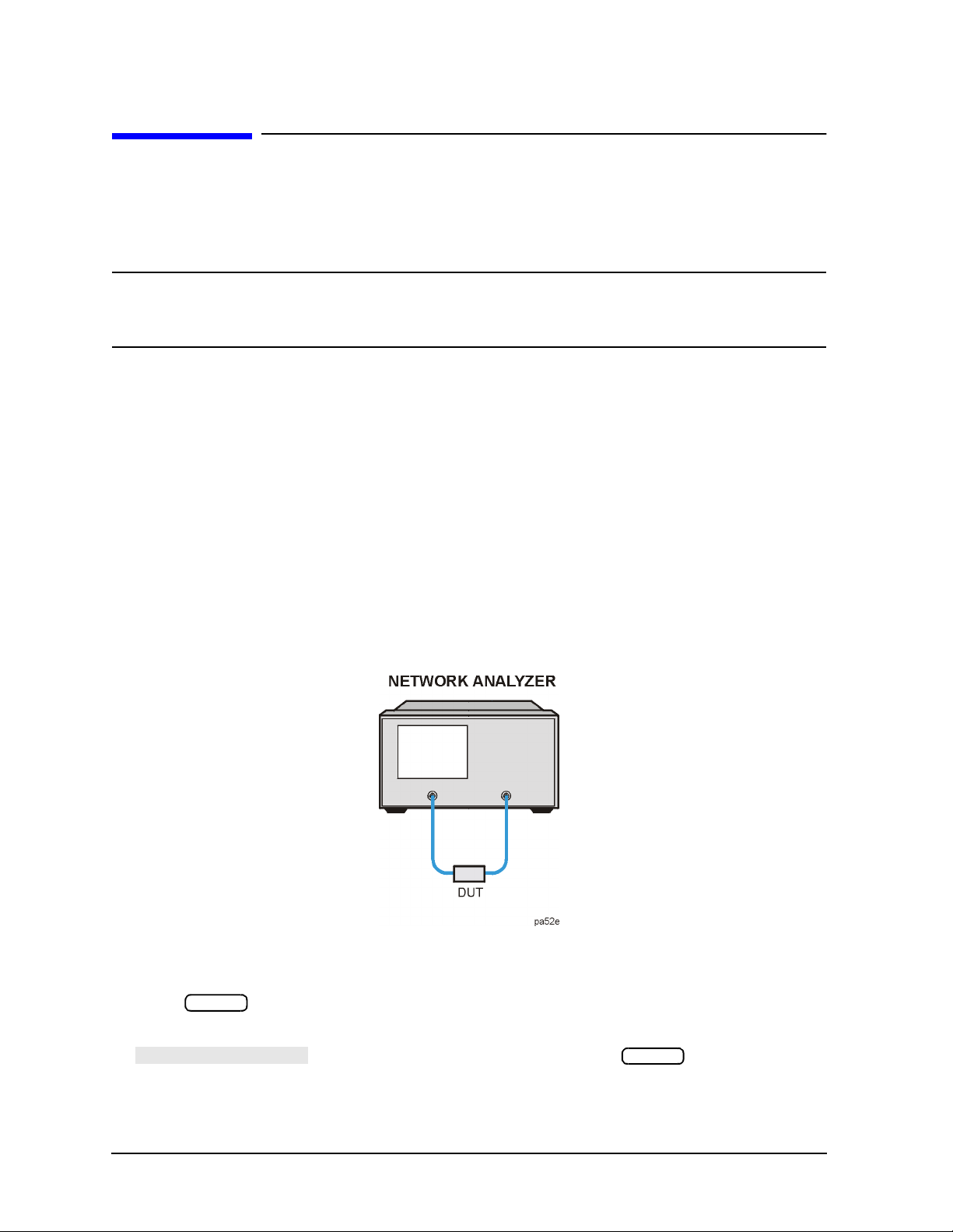

Step 1. Connect the device under test and any required test equipment.

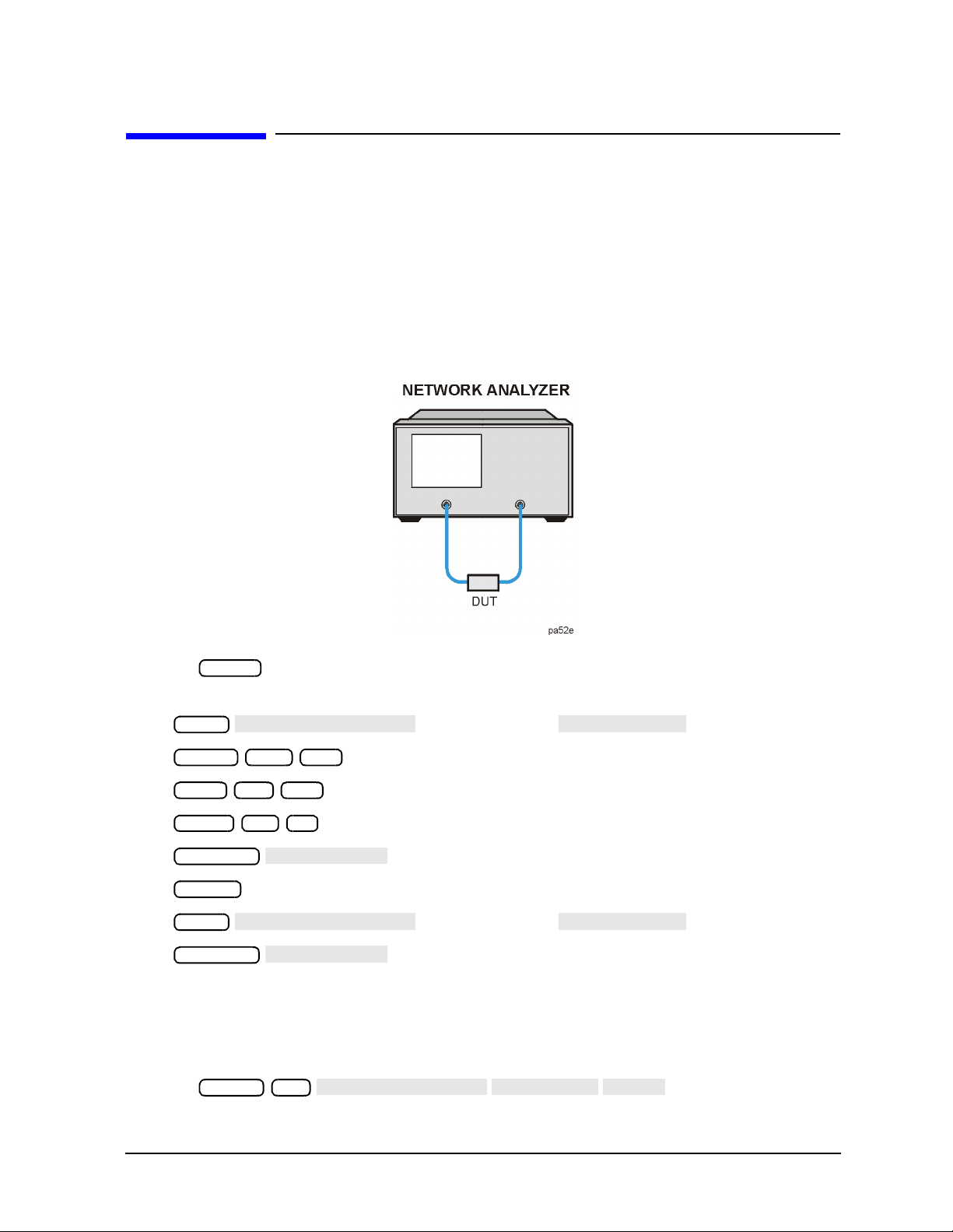

Make the connections as shown in Figure 1-1.

Figure 1-1 Basic Measurement Setup

Step 2. Choose the measurement parameters.

Press .

Preset

To set preset the analyzer to the “Factory Preset” conditions, press the

1-4

softkey if it is not selected. Then press .

Preset

Page 19

Setting the Frequency Range

POWER RANGE MAN

POWER RANGES

Sweep Setup

NUMBER OF POINTS

Trans: FWD S21 (B/R)

TRANSMISSN

AUTOSCALE

SELECT DISK

INTERNAL MEMORY

RETURN

SAVE STATE

Marker Search

SEARCH: MAX

To se t the center frequency to 134 MHz, press:

Making Measurements

Making a Basic Measurement

Center 134 M/µ

To set the span to 30 MHz, press:

Span 30 M/µ

NOTE You could also press the and keys and enter the frequency

Start Stop

range limits as start frequency and stop frequency values.

Setting the Source Power

To change the power level to −5 dBm, press:

Power −5 x1

NOTE You could a lso pres s and select

one of the power ranges to keep the power setting within the defined range.

Setting the Measurement

To change the number of measurement data points to 101, press:

To select the transmission measurement, press:

Meas

or on ET models:

To view the data trace, press:

Scale Ref

Step 3. Perform and apply the appropriate error-correction.

Refer to the Chapter 5 , “Optimizing Measurement Results,” for procedures on

correcting measurement errors.

To save the instrument state and error- correction in the analyzer internal memory,

press:

Save/Recall

Step 4. Measure the device under test.

Replace any standard used for error-correction with the device under test.

To measure the insertion loss of the bandpass filter, press:

1-5

Page 20

Making Measurements

PRINT MONOCHROME

PLOT

Making a Basic Measurement

Step 5. Output the measurement results.

To create a printed copy of the measurement results, press:

(or )

Copy

Refer to Chapter 4 , “Printing, Plotting, and Saving Measurement Results ,” for

procedures on how to set up a printer and define a print, plot, or save results.

1-6

Page 21

Making Measurements

Trans:FWD S21 (B/R)

TRANSMISSN

AUTO SCALE

Trans:FWD S21 (B/R)

TRANSMISSN

AUTO SCALE

CALIBRATE MENU

RESPONSE

THRU

Measuring Magnitude and Insertion Phase Response

Measuring Magnitud e and Insertion Phase Response

This measurement example shows you how to measure the maximum amplitude of a

surface acoustic wave (SAW) filter and then how to view the measurement data in the

phase format, which provides information about the phase response.

Measuring the Magnitude Response

1. Connect your test device as shown in Figure 1-2.

Figure 1-2 Device Connections for Measuring a Magnitude Response

2. Press and choose the measurement settings. For this example the

Preset

measurement parameters are set as follows:

Meas

Center 134 M/µ

Span 50 M/µ

Power −3 x1

Scale Ref

Chan 2

Meas

Scale Ref

or on ET models:

or on ET models:

You may also want to select settings for the number of data points, averaging, and IF

bandwidth.

3. Remove the device and connect the power cables together (thru) and perfo rm a response

calibration using the following key presses.

Press .

Chan 1 Cal

1-7

Page 22

Making Measurements

AUTO SCALE

Marker Search

SEARCH: MAX

DUAL | QUAD SETUP

DUAL CHAN ON

PHASE

Measuring Magnitude and Insertion Phase Response

If the channels are coupled (the default condition), this calibration is valid for both

channels.

4. Reconnect your test device.

5. To better view the measurement trace, press:

Scale Ref

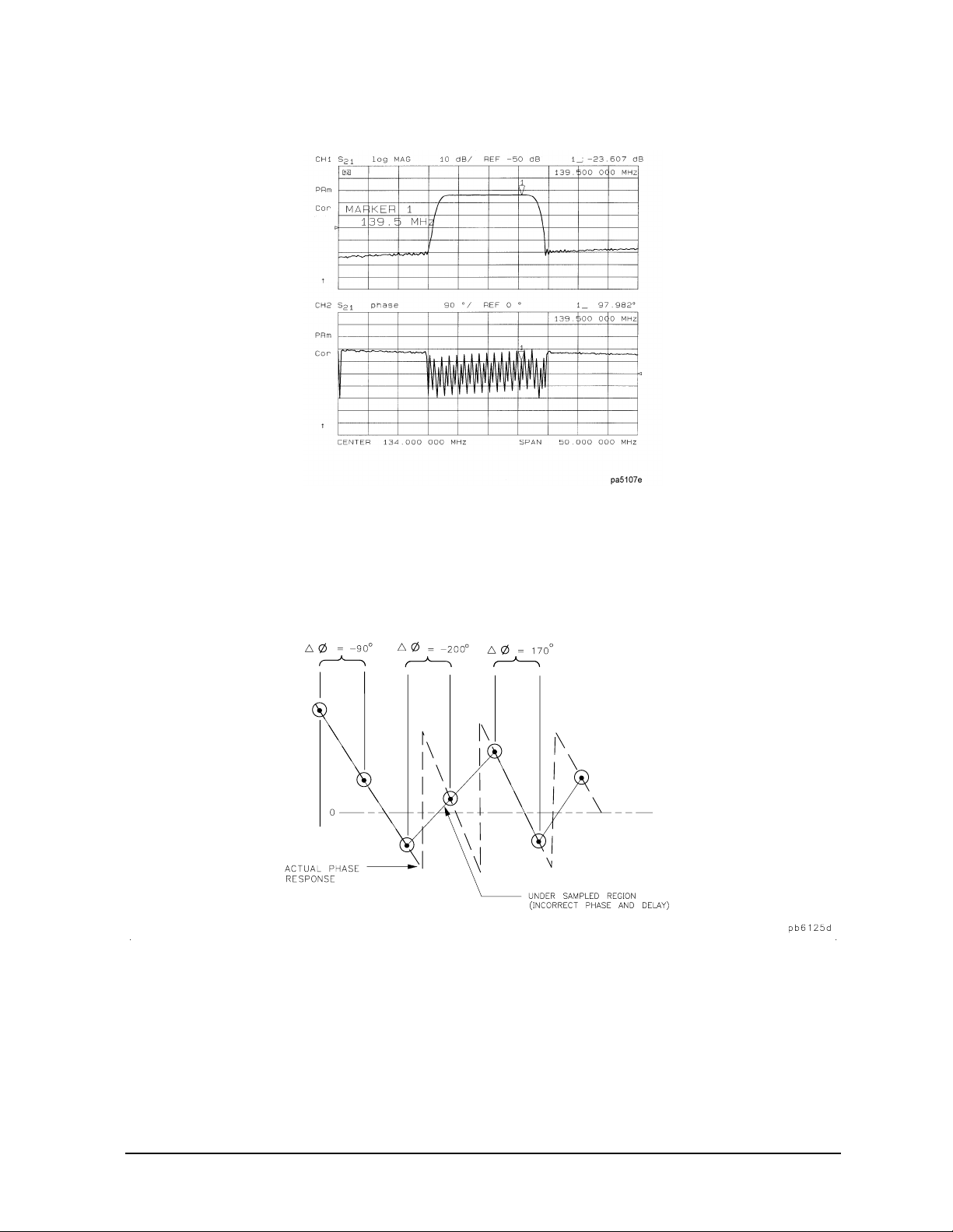

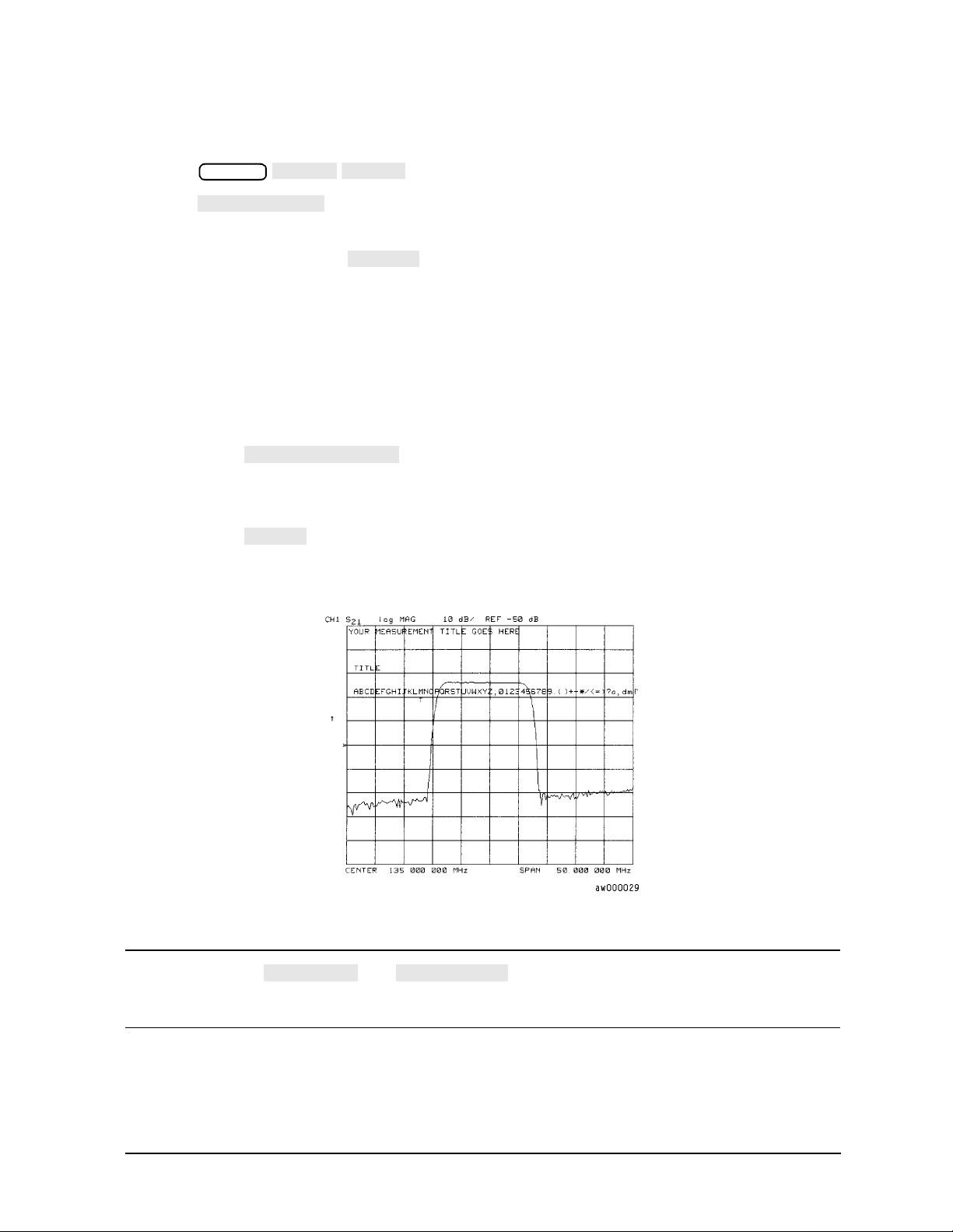

6. To locat e the maximum amplitude of the device resp onse, as shown in Figure 1-3 , p r ess :

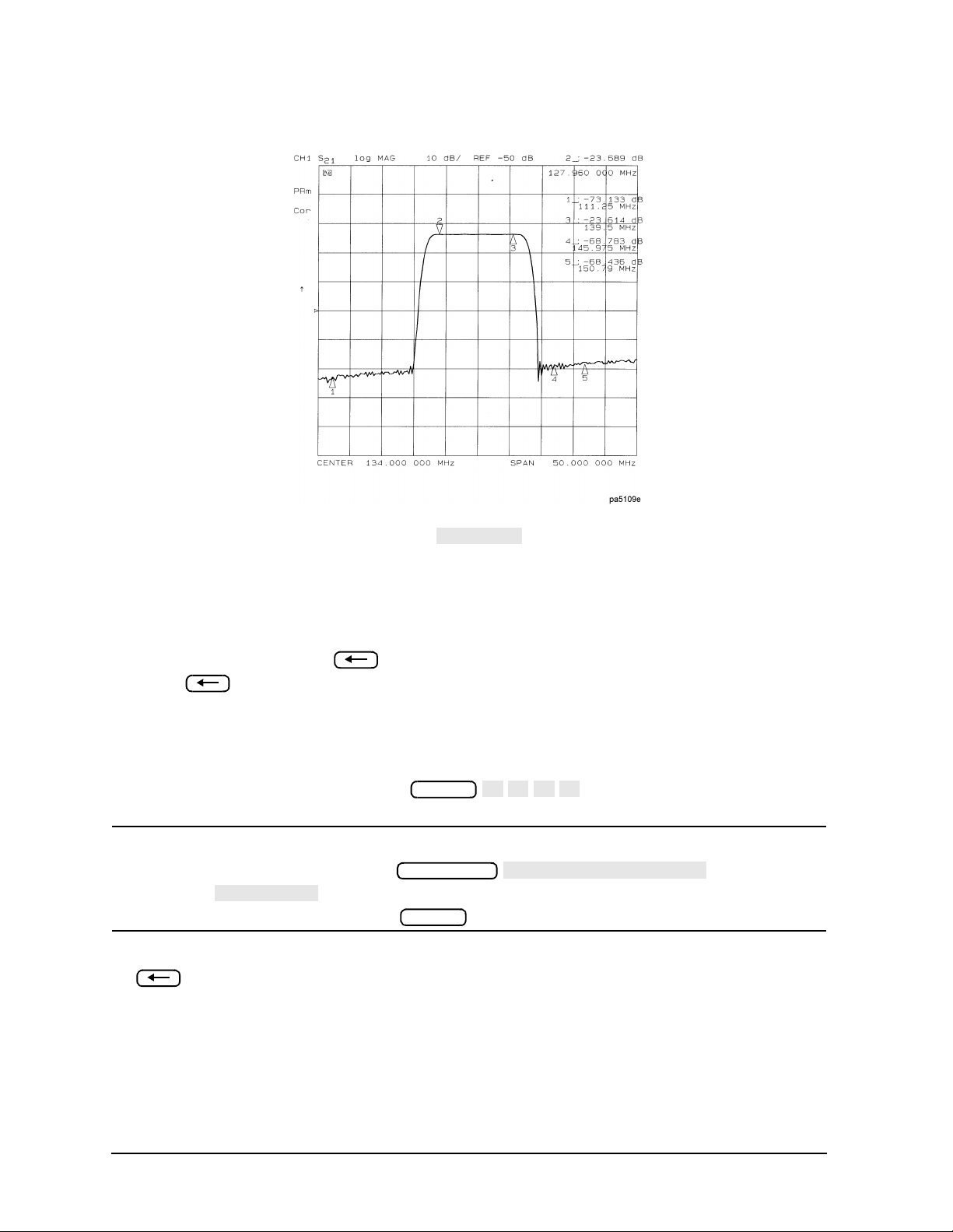

Figure 1-3 Example Magnitude Response Measurement Results

Measuring Insertion Phase Response

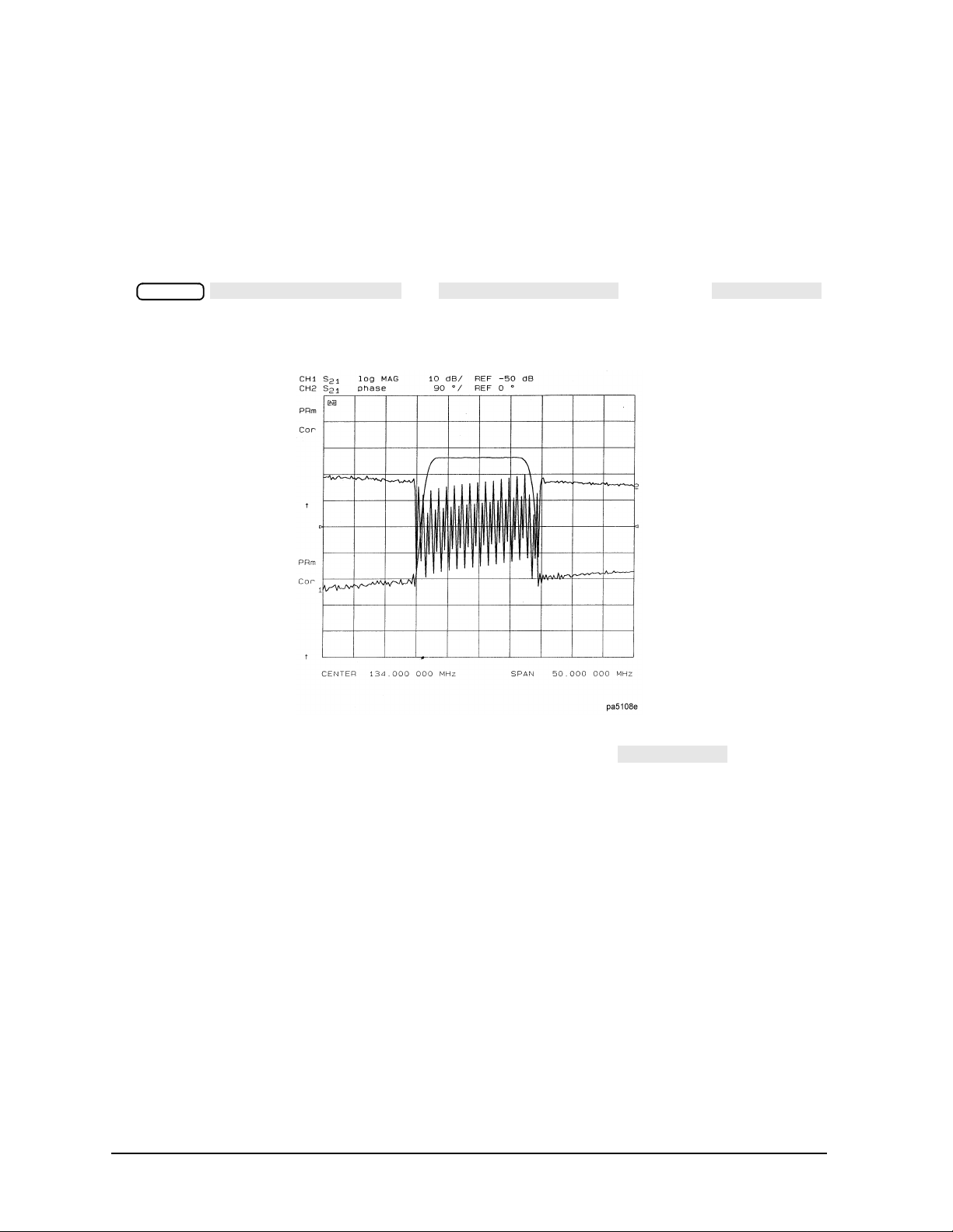

7. To view both the magnitude and phase response of the device, as shown in Figure 1-4,

press:

Chan 2

Display

Format

The channel 2 portion of Figure 1-4 shows the insertion phase response of the device under

test. The ana lyz er measures and displays phas e over the range o f −180° to +180°. As phase

changes beyond these values, a sharp 360° transition occurs in the displayed data.

1-8

Page 23

Measuring Magnitude and Insertion Phase Response

Figure 1-4 Example Insertion Phase Response Measurement

Making Measurements

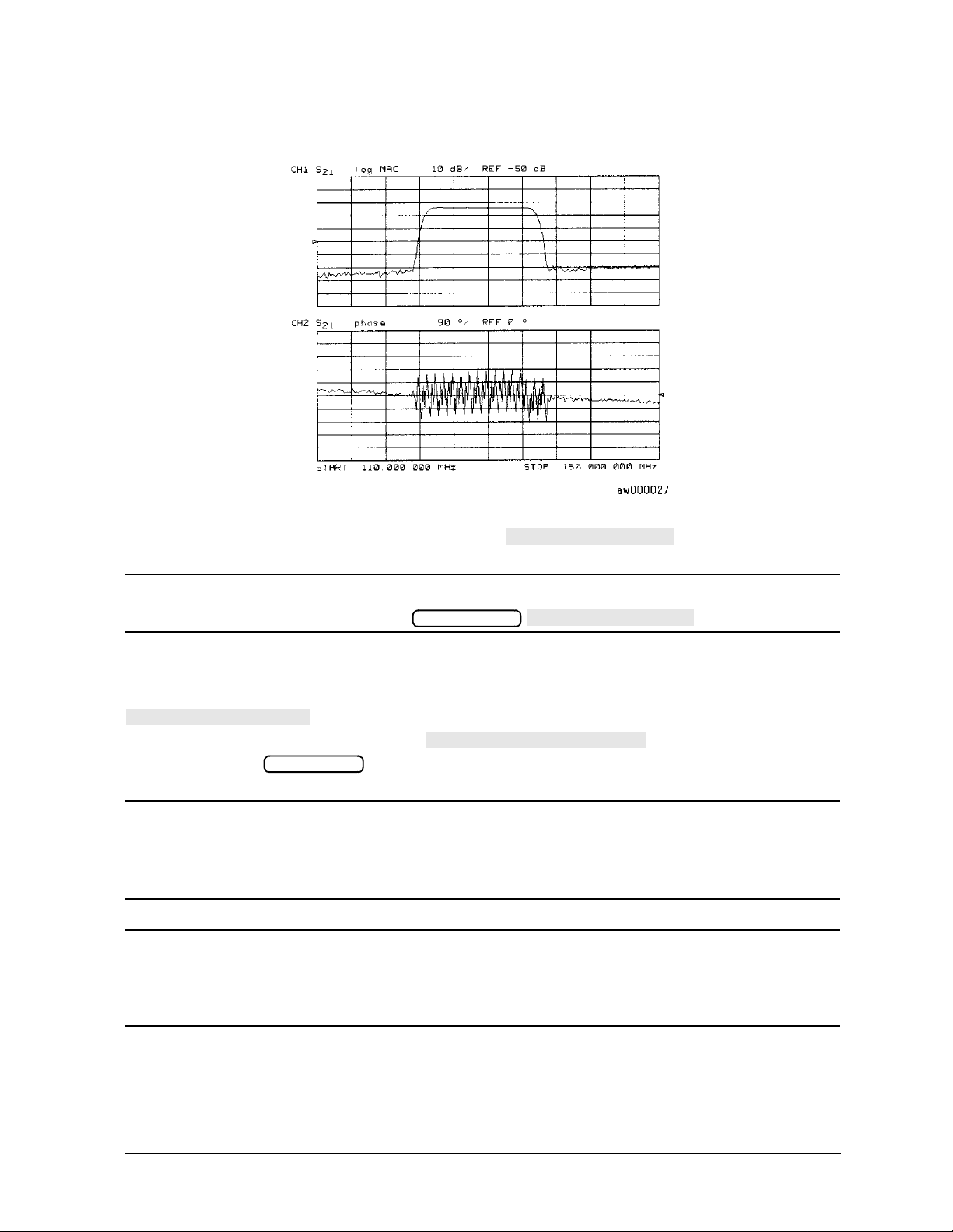

The phase response shown in Figure 1-5 is undersampled; that is, there is more than 180°

phase delay between frequency points. If the ∆Φ ≥ 180°, incorrect phase and delay

inform at io n may result . Figu re 1-5 shows an example of phase samples being with

∆Φ less than 180° and greater than 180°.

Figure 1 -5 Phase Samples

Undersampling may arise when measuring devices with long electrical length. To correct

this problem, the frequency span should be reduced, or the number of points increased

until ∆Φ is less than 180° per point. Electrical delay may also be used to compensate for

this effect (as shown in the next example procedure).

1-9

Page 24

Making Measurements

Using Display Functions

Using Display Functions

This section provides the necessary information for using the display functions. These

functions are very helpful for displaying measurement data so that it will be easy to read.

This section covers the following topics:

• Adding titles to your measurements

• Viewing both primary channels at the same time

• Viewing and customizing four-channel measurements

• Using the memory traces

• Using the memory math functions

• Blanking the analyzer’s display

• Changing the colors of the display

1-10

Page 25

Titling the Active Channel Display

MORE

TITLE

ERASE TITLE

ENTER

SELECT LETTER

DONE

NEWLINE

FORMFEED

Making Measurements

Using Display Functions

1. Press to access the title menu.

Display

2. Press and enter the title you want for your measurement display.

• If you have a DIN keyboard attached to the analyzer, type the titl e you w ant from the

keyboard. Then press to enter the title into the analyzer. You can enter a

title that has a maximum of 50 characters. (For more information on using a

keyboard with the analyzer, refer to the “Options and Accessories” chapter in the

reference guide.)

• If you do not have a DIN keyboard attached to the analyzer, enter the title from the

analyzer front panel.

a. Turn the front panel knob to move the arrow pointer to the first character of the

title.

b. Press .

c. Repeat the previous two steps to enter the re st of the char acter s in yo ur title. You

can enter a title that has a maximum of 50 characters.

d. Press to complete the title entry.

Figure 1-6 Example of a Display Title

CAUTION The and keys are not intended for creatin g display

titles. Those keys are for creating commands to send to peripherals during a

sequence program.

1-11

Page 26

Making Measurements

DUAL | QUAD SETUP

DUAL CH AN on O FF

SPLIT DISP

SPLIT DISP

Using Display Functions

Viewing Both Primary Measurement Channels

In some cases, you may want to view more than one measured parameter at a time.

Simultaneous gain and phase measurements, for example, are useful in evaluating

stability in negative feedback amplifiers. You can easily make such measurements using

the dual channel display.

1. To see channels 1 and 2 in the same grid, press:

Display

, set to ON, and

to 1X.

Figure 1-7 Example of Viewing Channel 1 and 2 Simultaneously

2. To view the measurements on separate graticules, press: Set to 2X. The

analyzer shows channel 1 on the upper half of the display and channel 2 on the lower

half of the display. The analyzer defaults to measuring S

on channel 1 and S21 on

11

channel 2.

1-12

Page 27

Figure 1-8 Example Dual Channel with Split Display On

SPLIT DISPLAY 1X

COUPLED CH OFF

COUPLED CH ON off

MARKERS: UNCOUPLED

Making Measurements

Using Display Functions

3. To return to a single-graticule display, press: .

NOTE You can control the stimulus functions of the two channels independent of

each other by pressing .

Sweep Setup

Dual Channel Mode with Decoupled Stimulus

The stimulus functions of the two channels can be controlled independently using

in the stimulus menu. In addition, the markers can be controlled

independently for each channel using in the marker mode

menu, under the key.

Marker Fctn

NOTE ES models onl y: For dual channel, if chann els are unc oupled and you have full

2-port calibrations on both channels, you will not be able to select a

non-ratioed measurement. For example, you can measure S

or B/R, but not

21

input B.

NOTE Auxiliary channels 3 and 4 are permanently coupled by stimulus to primary

channels 1 and 2, respectively. Decoupling the primary channels’ stimulus

from each other does not affect the stimulus coupling between the auxiliary

channels and their primary channels.

Dual Channel Mode with Decoupled Channel Power

By decoupling the channel power or port power and using the dual channel mode, you can

simultaneously view two measurements (or two sets of measurements, if both auxiliary

channels are enabled) having different power levels.

1-13

Page 28

Making Measurements

MEASURE RESTART

AUX CHAN

AUX CHAN

DUAL | QUAD SETUP

DUAL CHAN

AUX CHAN

SPLIT DISP

4X

Using Display Functions

However, there are two configurations that will not sweep continuously.

1. For analyzers with source attenuators, with channel 1 having one attenuation value

and channel 2 set to a different at tenua tion val ue, then continuous sweep is disa bled to

avoid wear on the attenuator. A similar situation where this occurs is when a 2-port cal

is active and the port 1 attenuation value is not equal to the port 2 attenuation value.

Since one attenuator is used for bot h measure ments, this woul d c ause the attenuator to

continuously switch power ranges , so continuous sweep is not all owed. (The exceptio n is

analyzers configured with option 400. Option 400 analyzers have two attenuators and

can allow different attenuation settings on each port.)

2. For ES analyzers with Option 007 or 085 (options using a mechanical transfer switch),

channel 1 is driving one test port and channel 2 is driving the other test port. This

would cause the test port transfer switch to continually cycle. The instrument will not

allow the transfer switch or attenuator to c ontinuously switc h ranges in order to update

these measurements without the direct intervention of the operator.

If one of these conditions exist, the test set hold mode will engage, and the status notation

tsH will appear on the left side of the screen. The hold mode leaves the measurement

function in only one of the two measurements. To update both measurement setups, press

Sweep Setup

. Refer to "Source Attenuator Switch Protection" on

page 7-13.

Viewing Four Measurement Channels

Four m easur ement c hannels c an be viewed simultaneously by enabli ng aux il iar y cha nnels

3 and 4. Although independent of other channels in most variables, channels 3 and 4 are

permanently coupled to channels 1 and 2 respectively by stimulus. That is, if channel 1 is

set for a center frequency of 200 MHz and a span of 50 MHz, channel 3 will have the same

stimulus values.

NOTE Channels 1 and 2 are referred to as primary channels and channels 3 and 4

are referre d t o as au xiliary channels.

Channel 3 or 4 are activated when the Chan 3 or Chan 4 keys are pressed. Alternatively,

you can enable the auxiliary setting to ON. For example, if channel 1 is

active, pressing to ON enables channel 3 and its trace appears on the display.

Channel 4 is similarly enabled and viewed when channel 2 is active.

1. Press to select the type of display of the data. This example uses the log mag

format.

2. If channel 1 is not active, make it active by pressing .

3. Press , set to ON, set to

ON, and set to .

Format

Chan 1

Display

The display will appear as show n in Figure 1-9. Channel 1 is in the upper-left quadrant

of the display, channel 2 is in the upper-right quadrant, and channel 3 is in the lower

half of the display.

1-14

Page 29

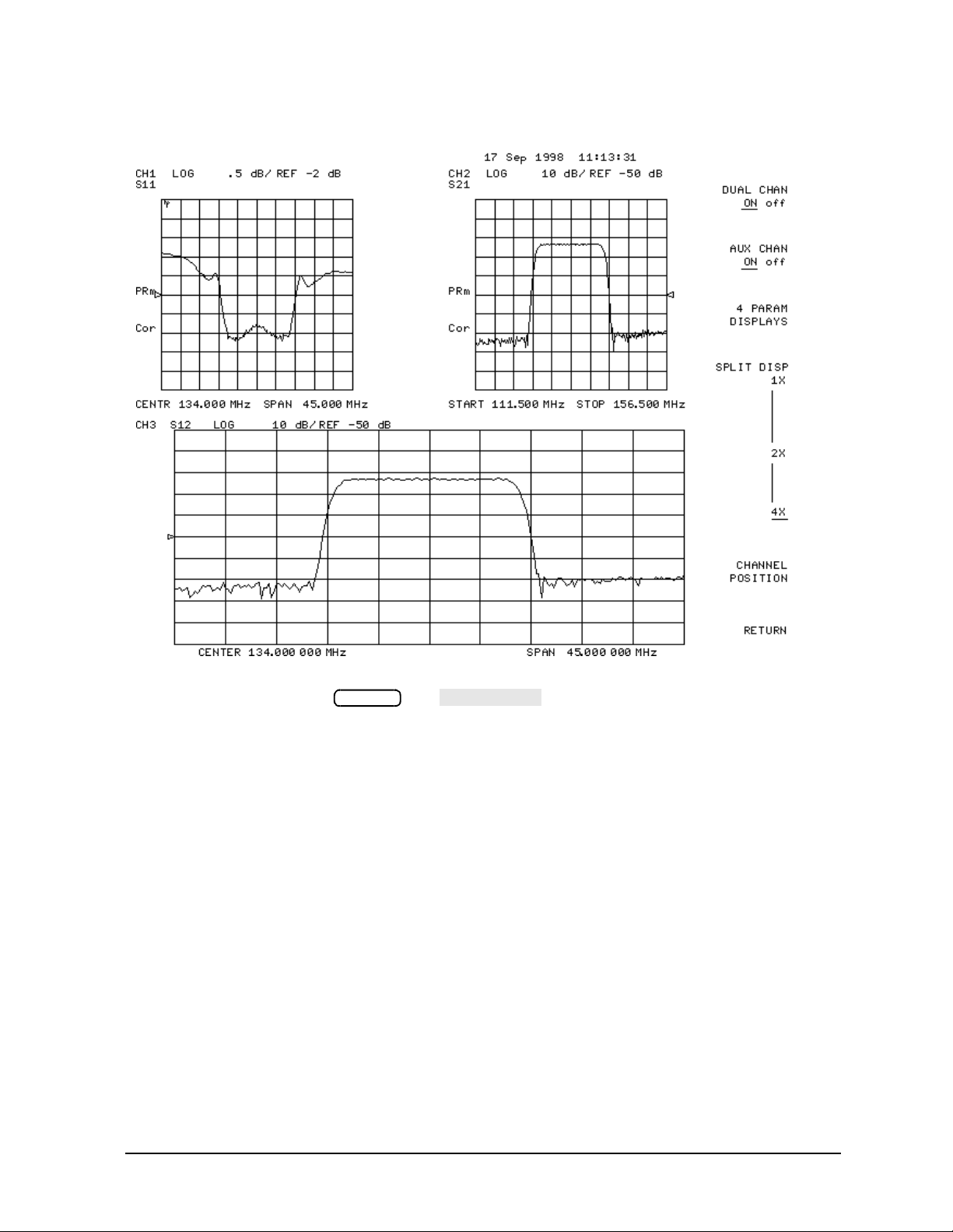

Figure 1-9 Three-Channel Display

Chan 2

AUX CHAN

Making Measurements

Using Display Functions

4. Press Chan 4 (or press , set to ON).

This enables channel 4 and the screen now displays four separate grids as shown in

Figure 1-1 0. Channel 4 is in the lower-right quadrant of the screen.

1-15

Page 30

Making Measurements

MARKER 1

MARKER 2

MARKER MODE MENU

MARKERS:

Using Display Functions

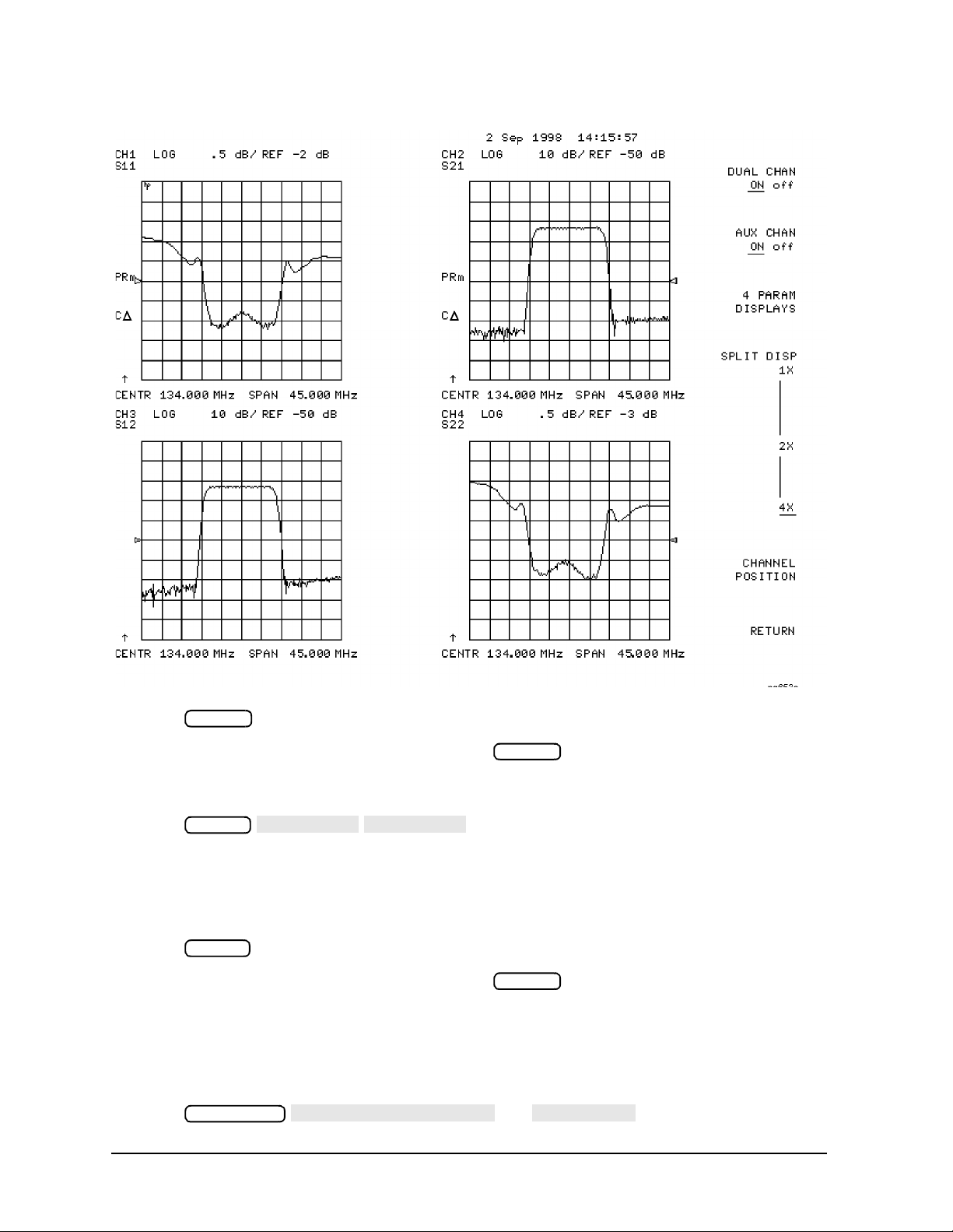

Figure 1-10 Four-Channel Display

5. Press .

Observe that the amber LED adjacent to the key is lit and the CH4 indicator

Chan 4

Chan 4

on the display has a box around it. This indicates that channel 4 is now active and can

be configured.

6. Press .

Marker

Markers 1 and 2 appear on all four channel traces. Rotating the front panel control

knob moves marker 2 on all four channel traces. Note that the active function, in this

case the marker frequency, is the same color and in the same grid as the active channel

(channel 4).

7. Press .

Observe that the amber LED adjacent to the key is lit. This indicates that

Chan 3

Chan 3

channel 3 is now active and can be configured.

8. Rotate the front panel control knob and notice that marker 2 still moves on all four

channel traces.

9. To independently control the channel markers:

Press , set to UNCOUPLED.

Marker Fctn

Rotate the front panel control knob. Marker 2 moves only on the channel 3 trace.

1-16

Page 31

Making Measurements

Format

SMITH CHART

DUAL CH AN on O FF

SPLIT DISP 1X 2X 4X

CHANNEL POSITION

DUAL|Q UAD SE TUP

CHANNEL POSITION

CHANNEL POSITION

SPLIT DISP 1X 2X 4X

SPLIT DISP 2X

CHANNEL POSITION

SPLIT DISP 4X

CHANNEL POSITION

Using Display Functions

Once made active, a channel can be confi gured independentl y of the other channel s in most

variables except stimulus. For example, once channel 3 is active, you can change its format

to a Smith chart by pressing .

Customizing the Four-Channel Display

When one or both auxiliary channels are enabled, and

interact to produce different display configurations according to

Table 1-1.

Table 1-1 Customizing the Display

Split Display Dual Channel Aux Channels On Number of Graticules

1X Don’t Care Do n’t Care 1

1X/2X/4X Off None

2X/4X Off 3 or 4 2

2X On Don’t Care

4X On 3 or 4 3

4X On Both on 4

Channel Position So ftkey

gives you options for arranging the display of the channels. Press

Display

, to use .

works with . When is

selected, gives you two choices for a two-graticule display:

• Channels 1 and 2 overlaid in the top graticule, and channels 3 and 4 are overlaid in the

bottom graticule.

• Channels 1 and 3 are overlaid in the top graticule, and channels 2 and 4 are overla id in

the bottom graticule.

When is selected, g ives you two choices for a

four-graticul e di spl ay:

• Channels 1 and 2 are in separate graticules in the upper half of the display, channels 3

and 4 are in separate graticules in the lower half of the display.

• Channels 1 and 3 are in the upper half of the display, channels 2 and 4 are in the lower

half of the display.

1-17

Page 32

Making Measurements

4 PARAM DISPLAYS

4 PARAM DISPLAYS

SETUP A

SETUP F