Page 1

Service Guide

Publication number 01680-97016

October 2005

For Safety information, Warranties, and Regulatory information, see the pages at the end

of the book.

© Copyright Agilent Technologies 2001, 2004-2005

All Rights Reserved.

Agilent Technologies 1680/90-Series

Logic Analyzer

Page 2

The Agilent 1680/90-Series Logic Analyzer–At a Glance

Features

Some of the main features of the Agilent 1680A,AD-Series Logic Analyzers are as

follows:

• Standalone benchtop logic analyzer

• Microsoft Windows® XP Professional operating system

• 132 data channels and 4 clock/data channels on the Agilent 1680A,AD

• 98 data channels and 4 clock/data channels on the Agilent 1681A,AD

• 64 data channels and 4 clock/data channels on the Agilent 1682A,AD

• 32 data channels and 2 clock/data channels on the Agilent 1683A,AD

• 12.1-inch LCD display

• 3.5-inch flexible disk drive

• 80GB hard disk drive

• Centronics and LAN interfaces

• IEEE 1394 interface for hosted control

• Variable setup/hold time

• 512K acquisition memory in the Agilent 1680A-series

• 2M acquisition memory in the Agilent 1680AD-series

•Marker Measurements

•PS/2 Mouse

• PS/2 keyboard support

Some of the main features of the Agilent 1690A,AD-Series Logic Analyzers are as

follows:

• Hosted benchtop logic analyzer

• 132 data channels and 4 clock/data channels on the Agilent 1690A,AD

• 98 data channels and 4 clock/data channels on the Agilent 1691A,AD

• 64 data channels and 4 clock/data channels on the Agilent 1692A,AD

• 32 data channels and 2 clock/data channels on the Agilent 1693A,AD

• IEEE 1394 interface for hosted control

• Variable setup/hold time

• 512K acquisition memory in the Agilent 1690A-series

• 2M acquisition memory in the Agilent 1690AD-series

•Marker Measurements

2

Page 3

Service Strategy

The service strategy for this instrument is the replacement of defective

assemblies. This service guide contains information for finding a defective

assembly by testing and servicing the Agilent 1680/90-series logic analyzers.

This logic analyzer can be returned to Agilent for all service work, including

troubleshooting. Contact your nearest Agilent Technologies Sales Office for

details.

Agilent Technologies 1680-Series Logic Analyzer

Agilent Technologies 1690-Series Logic Analyzer

3

Page 4

In This Book

This book is the service guide for the Agilent 1680/90-Series Logic Analyzers and

is divided into eight chapters.

Chapter 1 contains information about the logic analyzer and includes accessories,

specifications and characteristics, and equipment required for servicing.

Chapter 2 tells how to prepare the logic analyzer for use.

Chapter 3 gives instructions on how to test the performance of the logic analyzer.

Chapter 4 contains calibration instructions for the logic analyzer.

Chapter 5 contains self-tests and flowcharts for troubleshooting the logic

analyzer.

Chapter 6 tells how to replace assemblies of the logic analyzer and how to return

them to Agilent Technologies.

Chapter 7 lists replaceable parts, shows an exploded view, and gives ordering

information.

Chapter 8 explains how the logic analyzer works and what the self-tests are

checking.

4

Page 5

Contents

The Agilent 1680/90-Series Logic Analyzer–At a Glance

Features 2

Service Strategy 3

In This Book

1 General Information

Accessories 10

Specifications 11

Characteristics 11

Recommended Test Equipment 14

2 Preparing for Use

Power Requirements 16

Operating Environment 16

Storage 16

To inspect the logic analyzer 16

To apply power 17

To connect the 1690A,AD-series logic analyzer to a host PC 17

To start the user interface 18

To clean the logic analyzer 18

To test the logic analyzer 18

3 Testing Performance

The Logic Analyzer Interface 20

Test Strategy 20

Test Interval 20

Performance Test Record 20

Test Equipment 20

To make the test connectors 21

To set up the test equipment and the logic analyzer 23

Set up the test equipment 23

Set up the 1680A,AD-series logic analyzer 24

Set up the 1690A,AD-series logic analyzer 25

To perform the logic analyzer self-tests 25

5

Page 6

Contents

To test the threshold accuracy 28

Set up the equipment 28

Connect and configure the logic analyzer 29

Test the ECL Threshold 30

Test the 0 V User Threshold 31

Test the next pod 32

To set up the logic analyzer for the state mode tests 33

To test the single-clock, single-edge, state acquisition 37

Set up the equipment 37

Connect and configure the logic analyzer 37

Verify the test signal 40

Check the setup/hold combination 41

Test the next channels (1680/81A,AD and 1690/91A,AD) 47

To test the multiple-clock state acquisition 48

Set up the equipment 48

Connect and configure the logic analyzer 49

Verify the test signal 51

Check the setup/hold with single clock edges, multiple clocks 52

Test the next channels (1680/81A, AD and 1690/91A, AD) 56

To test the single-clock, multiple-edge, state acquisition 57

Set up the equipment 57

Connect and configure the logic analyzer 58

Verify the test signal 60

Check the setup/hold with single clock, multiple clock edges 61

Test the next channels (1680/81A,AD and 1690/91A,AD) 65

To test the time interval accuracy 66

Set up the equipment 66

Connect and configure the logic analyzer 67

Acquire and verify the test data 69

Performance Test Record 71

4 Calibrating and Adjusting

Logic analyzer calibration 76

6

Page 7

Contents

5 Troubleshooting

To install the fan guard 78

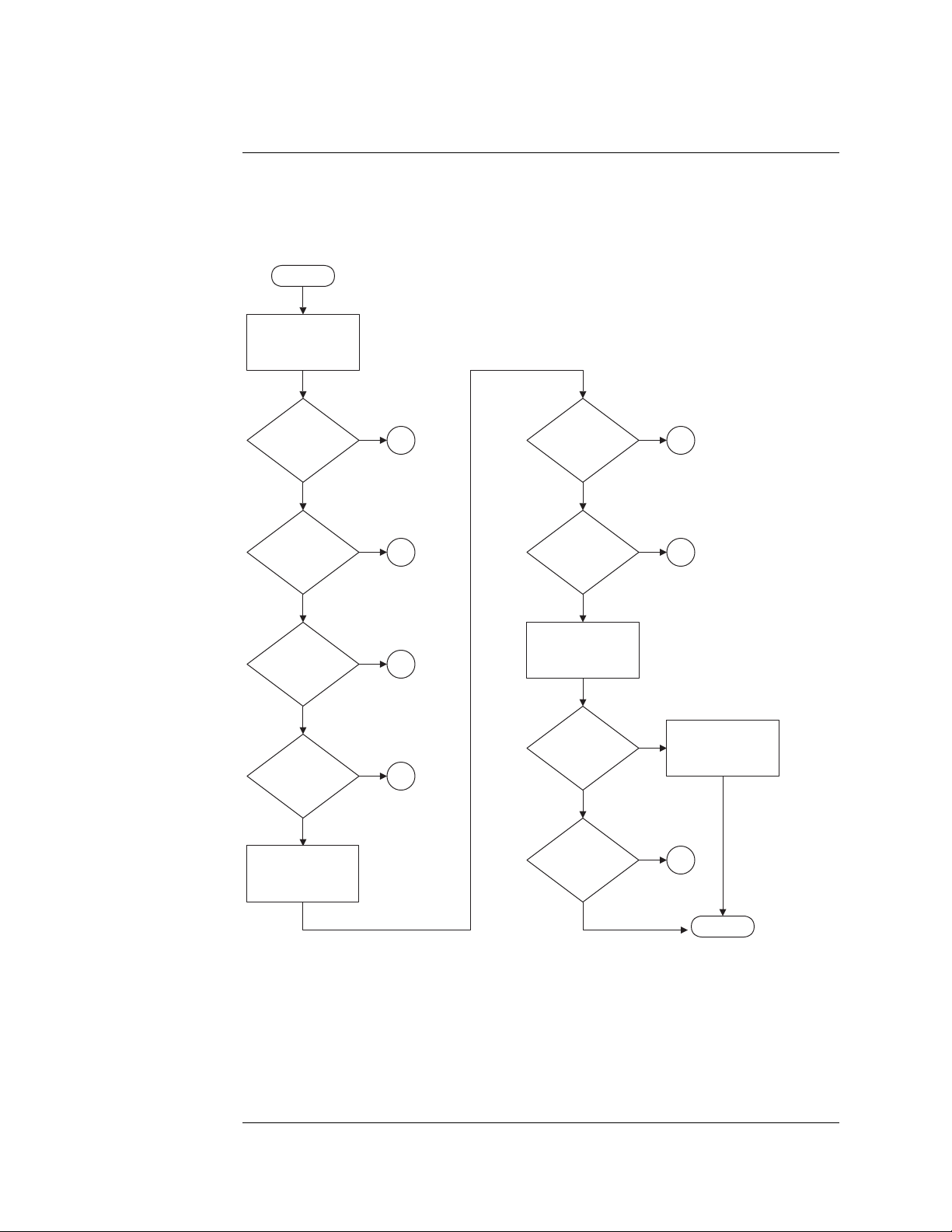

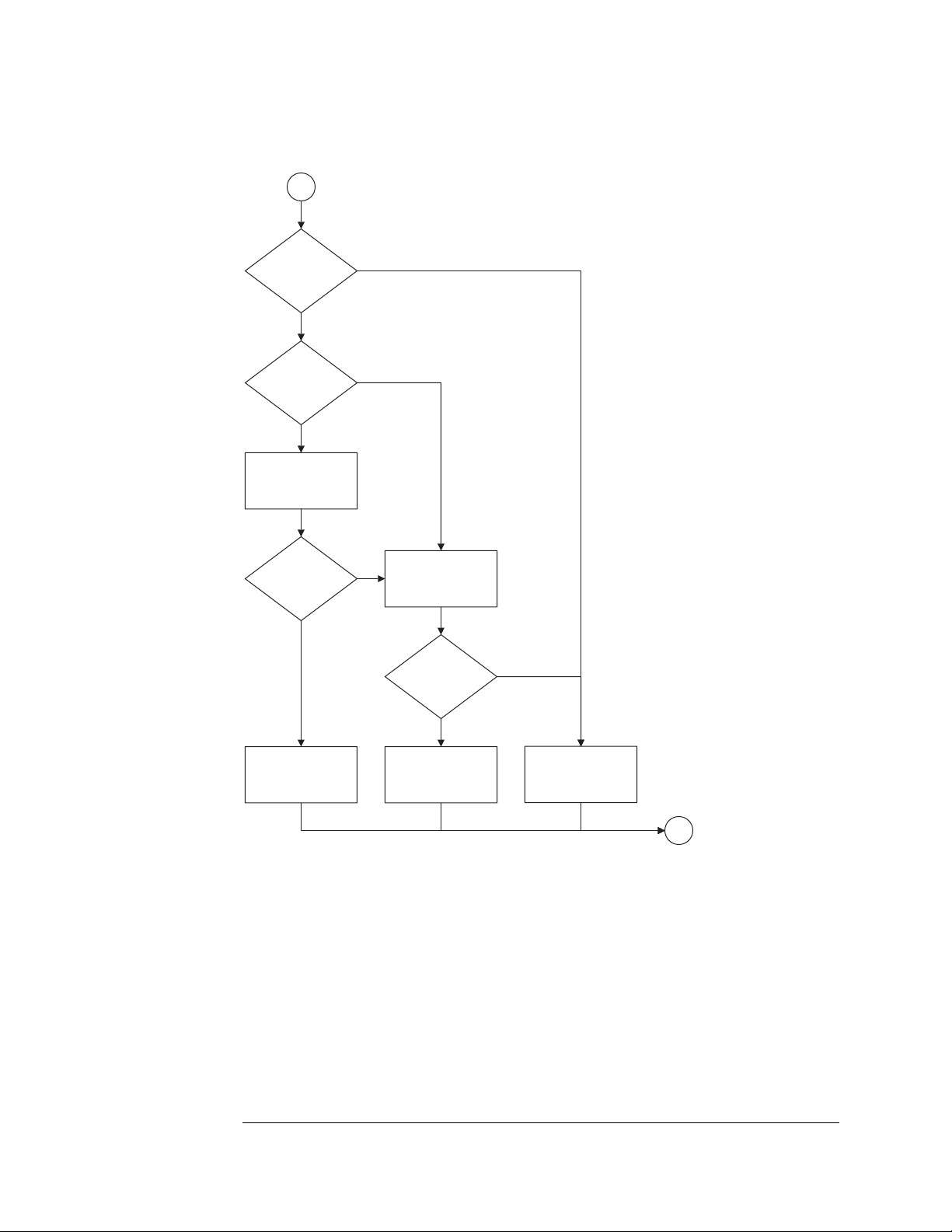

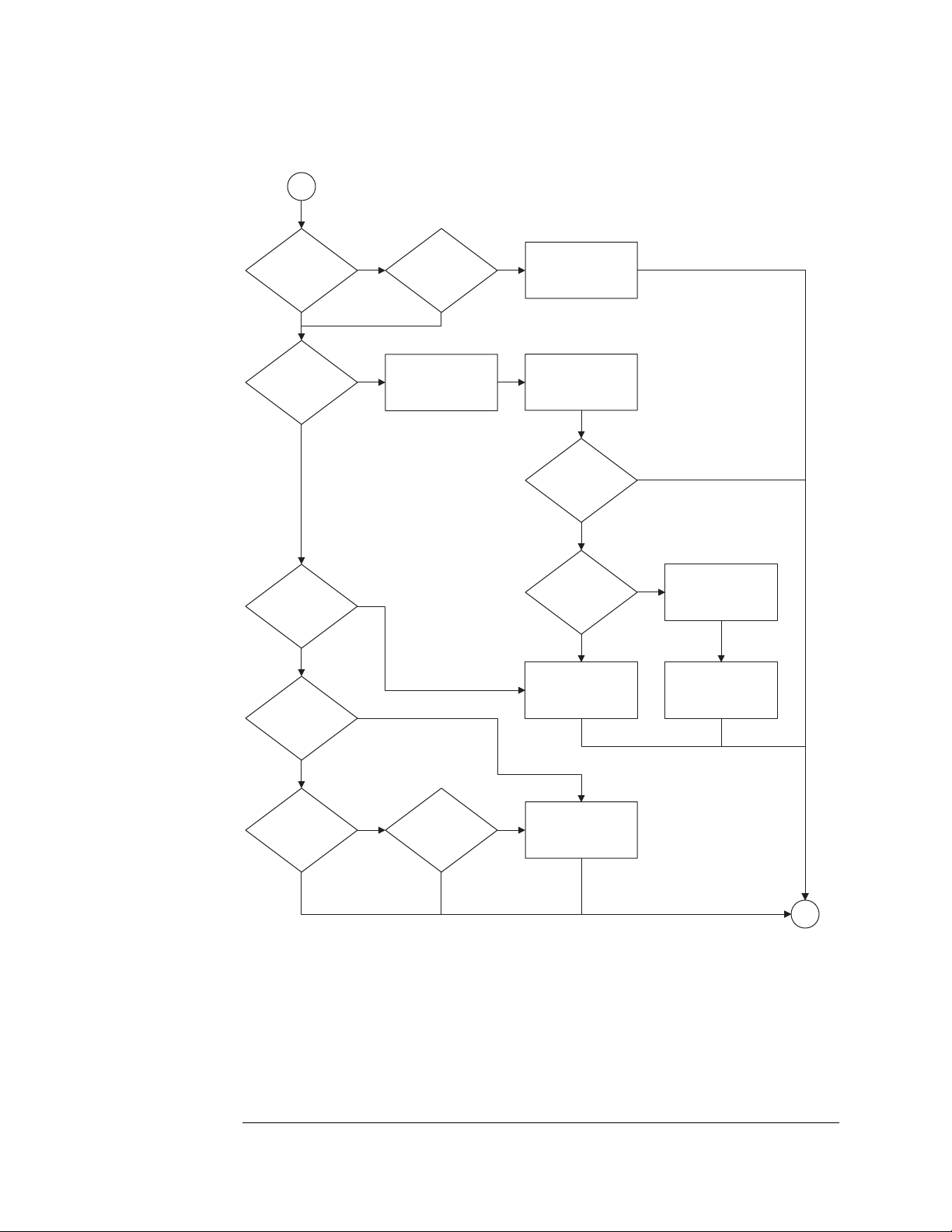

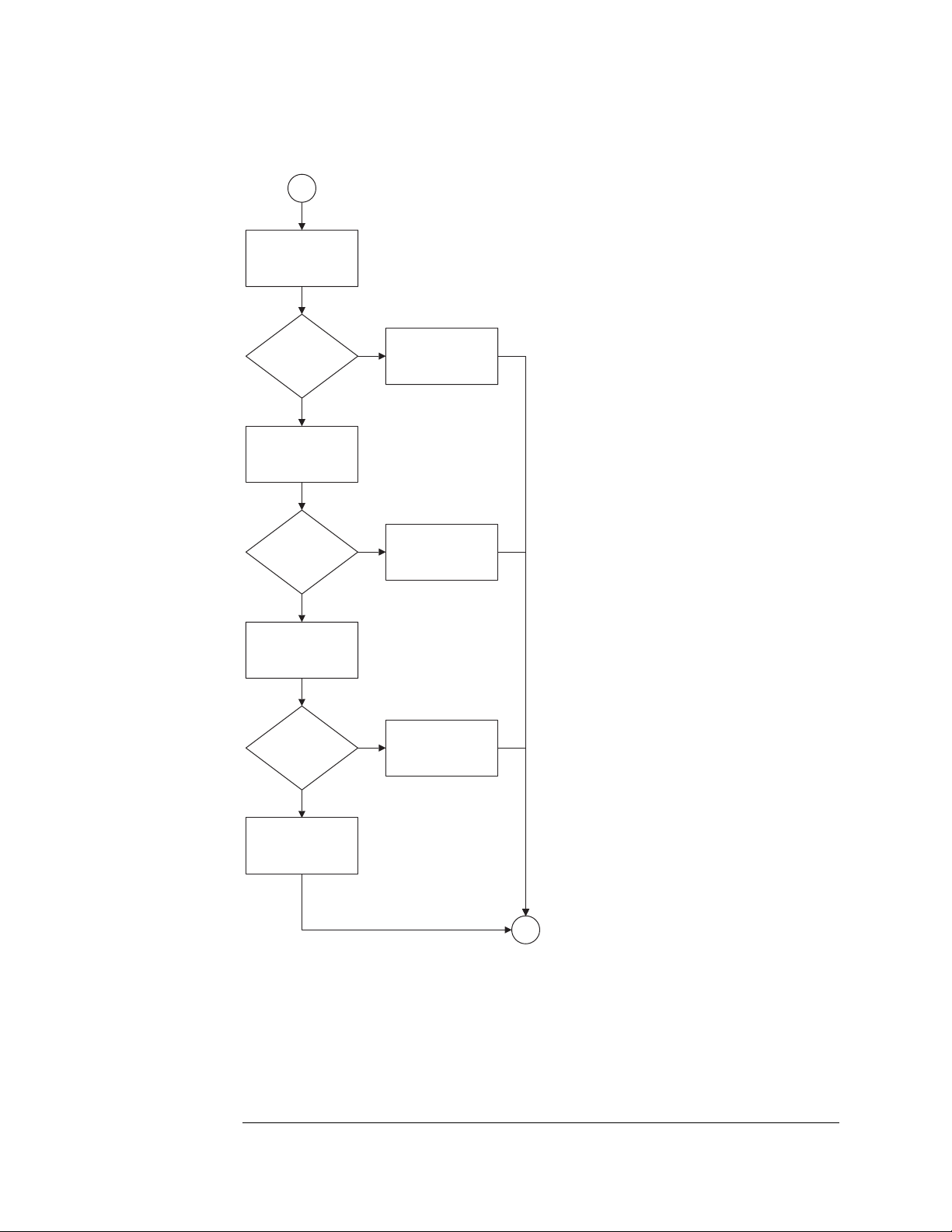

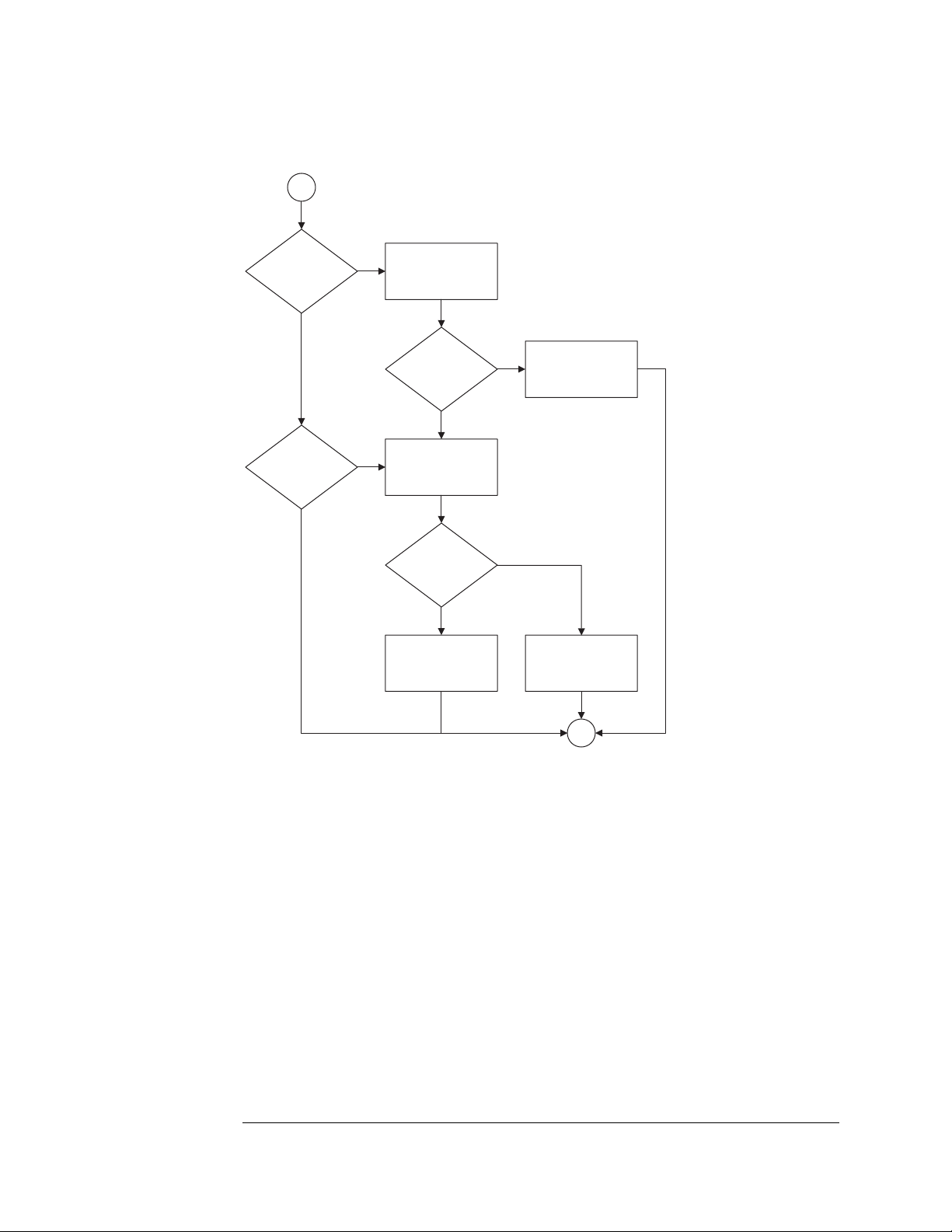

To use the flowcharts 79

Troubleshooting the Agilent 1680A,AD-series 80

To check the power-up tests 87

To test the power supply voltages 87

To test the LCD display signals 89

To test disk drive voltages 90

To verify the CD-ROM 92

To recover the operating system 93

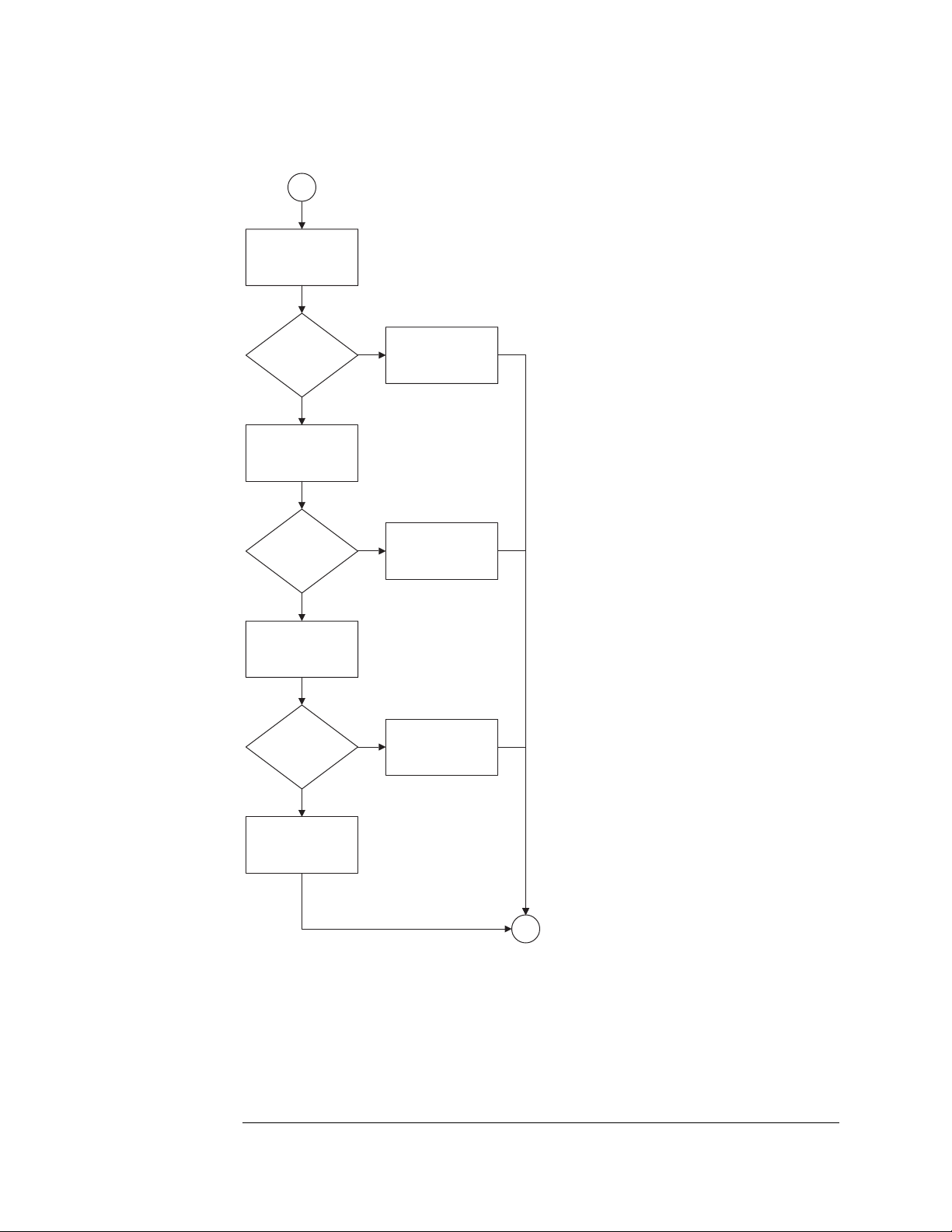

Troubleshooting the Agilent 1690A,AD-series 95

To verify connectivity 99

To test the power supply voltages 100

General Troubleshooting 103

To run the self-tests 103

Acquisition board status LEDs 106

To test the logic analyzer probe cables 107

To check the BNC Trigger input/output signals 110

To test the auxiliary power 112

6 Replacing Assemblies

1680A,AD-series disassembly/assembly 114

Prepare the instrument for disassembly 114

To remove the chassis from the sleeve 114

To remove the acquisition board 115

To remove the power supply 117

To remove the hard disk drive 118

To remove the CD-ROM drive assembly 119

To remove the flexible disk drive 120

To remove the PCI boards 122

To remove the motherboard 123

To remove the front panel assembly 126

To disassemble the front panel assembly 128

To remove the distribution board 129

To remove the inverter board 130

To remove the fans 131

To remove the cable tray 132

7

Page 8

Contents

1690A,AD-series disassembly/assembly 133

Prepare the instrument for disassembly 133

To remove the chassis from the sleeve 133

To remove the fascia 134

To remove the acquisition board 136

To remove the deck 137

To remove the power supply 137

To remove the distribution board 138

To remove the fans 139

To remove the line filter 140

To remove the front panel and front frame 141

7 Replaceable Parts

Replaceable Parts Ordering 144

Replaceable Parts List 145

Exploded View 146

Agilent 1680A,AD-Series Replaceable Parts 147

Exploded View 153

Agilent 1690A,AD-Series Replaceable Parts 154

Power Cables and Plug Configurations 157

8 Theory of Operation

Block-Level Theory 160

Agilent 1680A,AD-series Logic Analyzer Theory 161

Power Supply 162

Acquisition Board 162

Power Distribution Board 165

Front Panel Board 165

Agilent 1690A,AD-series Logic Analyzer Theory 166

Acquisition Board 166

Power Supply 166

Power Distribution Board 166

Self-Tests Descriptions 167

Power-up Self-Tests (1680A,AD-series) 167

Connectivity Tests (1690A,AD-series) 167

Acquisition Board Self Tests 168

Logic Analyzer Self-Tests 169

8

Page 9

1

General Information

This chapter lists the accessories, the specifications and characteristics, and the

recommended test equipment.

9

Page 10

Chapter 1: General Information

Accessories

The following accessory is supplied with the Agilent 1680/90-series logic

analyzers. The part number is current as of the print date of this edition of the

Service Guide, but further upgrades may change the part number. Do not be

concerned if the accessory you receive has a different part number.

Accessories Supplied Agilent Part Number Qty

3-button Corded Mouse 1150-7845 1

Mini Keyboard 1150-7809 1

Accessories Available

For probing information, see Probing Solutions for Logic Analysis Systems

(publication 5968-4632E) available at:

http://www.agilent.com/find/logic_analyzer_probes

10

Page 11

Chapter 1: General Information

Specifications

The specifications are the performance standards against which the product is

tested.

Maximum State Speed (selectable) 200 MHz

Minimum Master to Master Clock Time* 5.000 ns

Threshold Accuracy ± (65 mV + 1.5% of threshold setting)

Setup/Hold Time

Single Clock, Single Edge 4.5/-2.0 ns through -2.0/4.5 ns, adjustable in 100 ps

Single Clock, Multiple Edges 5.0/-2.0 ns through -1.5/4.5 ns, adjustable in 100 ps

Multiple Clocks, Multiple Edges 5.0/-2.0 ns through -1.5/4.5 ns, adjustable in 100 ps

* Specified for an input signal VH = −0.9 V, VL = −1.7 V, slew rate = 1 V/ns, and threshold = −1.3 V.

*

increments

increments

increments

Characteristics

These characteristics are not specifications, but are included as additional

information.

Full Channel Half Channel

Maximum State Clock Rate 150 MHz not applicable

Maximum Conventional Timing Rate 250 MHz 500 MHz

Memory Depth (1680A, or 1690A-series) 512 K 1024 K

Memory Depth (1680AD or 1690AD-series) 2048 K 4196 K

Channel Count

1680A,AD or 1690A,AD 136 68

1681A,AD or 1691A,AD 102 51

1682A,AD or 1692A,AD 68 34

1683A,AD or 1693A,AD 34 17

11

Page 12

Chapter 1: General Information

Probes

Maximum Input Voltage + 40V Peak AC+DC, CAT 1

Auxiliary Power

Power Through Cables 1/3 amp at 5 V maximum per cable, CAT 1

Operating Environment (for indoor use only)

Temperat ure:

• Instrument: 0° C to 55° C (+32° F to 131° F).

• Probe lead sets and cables: 0° C to 65° C (+32° F to 149° F).

• Disk media: 10° C to 40° C (+50° F to 104° F).

Humidity: Instrument, probe lead sets, and cables, up to 80% relative humidity at

+40° C (+122° F).

Altitude: To 3067 m (10,000 ft).

Vibration:

• Operating: Random vibration 5 to 500 Hz, 10 minutes per axis, 0.3 g (rms).

• Non-operating: Random vibration 5 to 500 Hz, 10 minutes per axis, 2.41 g (rms); and

swept sine resonant search, 5 to 500 Hz, 0.75 g (0-peak), 5 minute resonant dwell at 4

resonances per axis.

12

Page 13

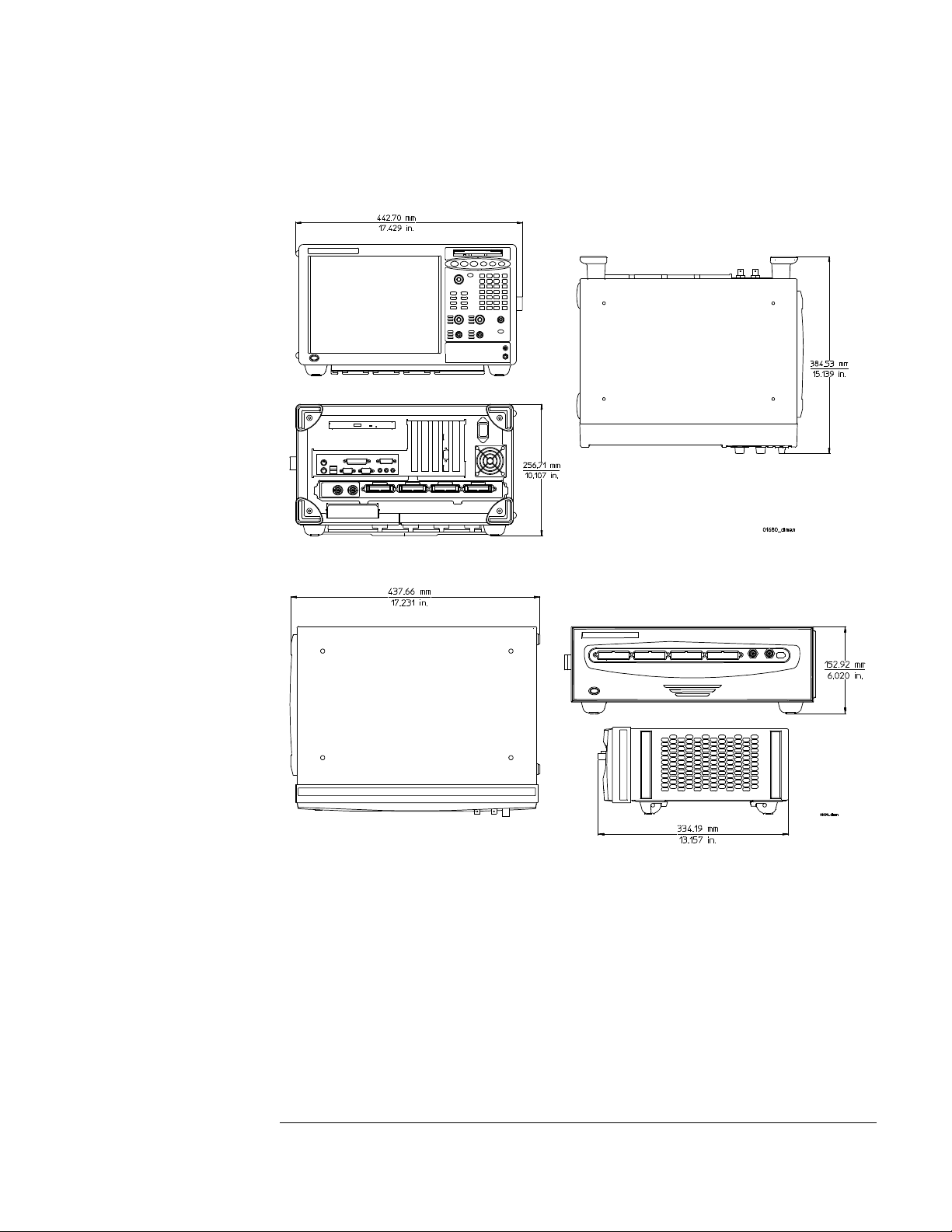

Dimensions

1680A,AD-Series

Chapter 1: General Information

1690A,AD-Series

13

Page 14

Chapter 1: General Information

Recommended Test Equipment

Equipment Required

Equipment Critical Specifications Recommended Model/Part

Pulse Generator 200 MHz, 2.5 ns pulse width,

8133A Option 003 P,T

Use

<600 ps rise time

Digitizing Oscilloscope ≥6 GHz bandwidth,

<58 ps rise time

Function Generator

Accuracy (5)(10

-6

) frequency,

54750A mainframe with 54751A

plug-in module

33250A P

P

DC offset voltage ±1.6 V

Digital Multimeter 0.1 mV resolution, 0.005%

3458A P

accuracy

BNC-Banana Cable 11001-60001 P

BNC Tee BNC (m)(f)(f) 1250-0781 P

Cable BNC (m)(m) 48 inch 8120-1840 P,T

SMA Coax Cable (Qty 3) 18 GHz bandwidth 8120-4948 P

Adapter (Qty 4) SMA(m)-BNC(f) 1250-1200 P, T

Adapter SMA(f)-BNC(m) 1250-2015 P

Coupler (Qty 4) BNC (m)(m) 1250-0216 P, T

20:1 Probes (Qty 2) 54006A P

BNC Coax Cable BNC(m)(m), >2 GHz

10503A T

bandwidth, >1 meter length

BNC Test Connector, 17x2 (Qty

**

1)

BNC Test Connector, 6x2 (Qty

**

4)

P

P, T

Digitizing Oscilloscope > 100 MHz Bandwidth 54600B T

BNC Shorting Cap 1250-0774 T

BNC-Banana Adapter 1251-2277 T

*

*A = Adjustment P = Performance Tests T = Troubleshooting

**Instructions for making these test connectors are in chapter 3, "Testing Performance."

14

Page 15

2

Preparing for Use

This chapter gives you instructions for preparing the logic analyzer for use.

15

Page 16

Chapter 2: Preparing for Use

Power Requirements

The logic analyzer requires a power source of either 115 Vac or 230 Vac, –22 % to

+10 %, single phase, 48 to 66 Hz, CAT II pollution degree 2, 140/400 Watts

nominal maximum power (1680A/AD-series), and 76/200 Watts nominal

maximum power (1690A/AD-series).

Operating Environment

The operating environment is listed in chapter 1. The logic analyzer will operate

at all specifications within the temperature and humidity range given in chapter

1. However, reliability is enhanced when operating the logic analyzer within the

following ranges:

• Temperature: +20° C to +35° C (+68° F to +95° F)

• Humidity: 20% to 80% noncondensing

Note the recommended noncondensing humidity. Condensation within the

instrument can cause poor operation or malfunction. Provide protection against

internal condensation.

Storage

Store or ship the logic analyzer in environments within the following limits:

• Temperature: -40° C to +75° C

• Humidity: Up to 90% at 65° C

• Altitude: Up to 15,300 meters (50,000 feet)

Protect the logic analyzer from temperature extremes which cause condensation

on the instrument.

To inspect the logic analyzer

1 Inspect the shipping container for damage.

If the shipping container or cushioning material is damaged, keep them until you

have checked the contents of the shipment and checked the instrument

mechanically and electrically.

2 Check the supplied accessories.

Accessories supplied with the logic analyzer are listed in “Accessories” on

page 10.

16

Page 17

Chapter 2: Preparing for Use

3 Inspect the product for physical damage.

Check the logic analyzer and the supplied accessories for obvious physical or

mechanical defects. If you find any defects, contact your nearest Agilent

Technologies Sales Office. Arrangements for repair or replacement are made, at

Agilent Technologies' option, without waiting for a claim settlement.

To apply power

These steps are required for all 1680A,AD and 1690A,AD-series logic analyzers.

1 Connect the power cord to the instrument and to the power source.

This instrument autodetects the line voltage from 115 VAC to 230 VAC. It is

equipped with a three-wire power cable. When connected to an appropriate AC

power outlet, this cable grounds the instrument cabinet. The type of power cable

plug shipped with the instrument depends on the country of destination. Refer to

chapter 7, "Replaceable Parts," for option numbers of available power cables.

2 Turn on the power switch located on the front panel.

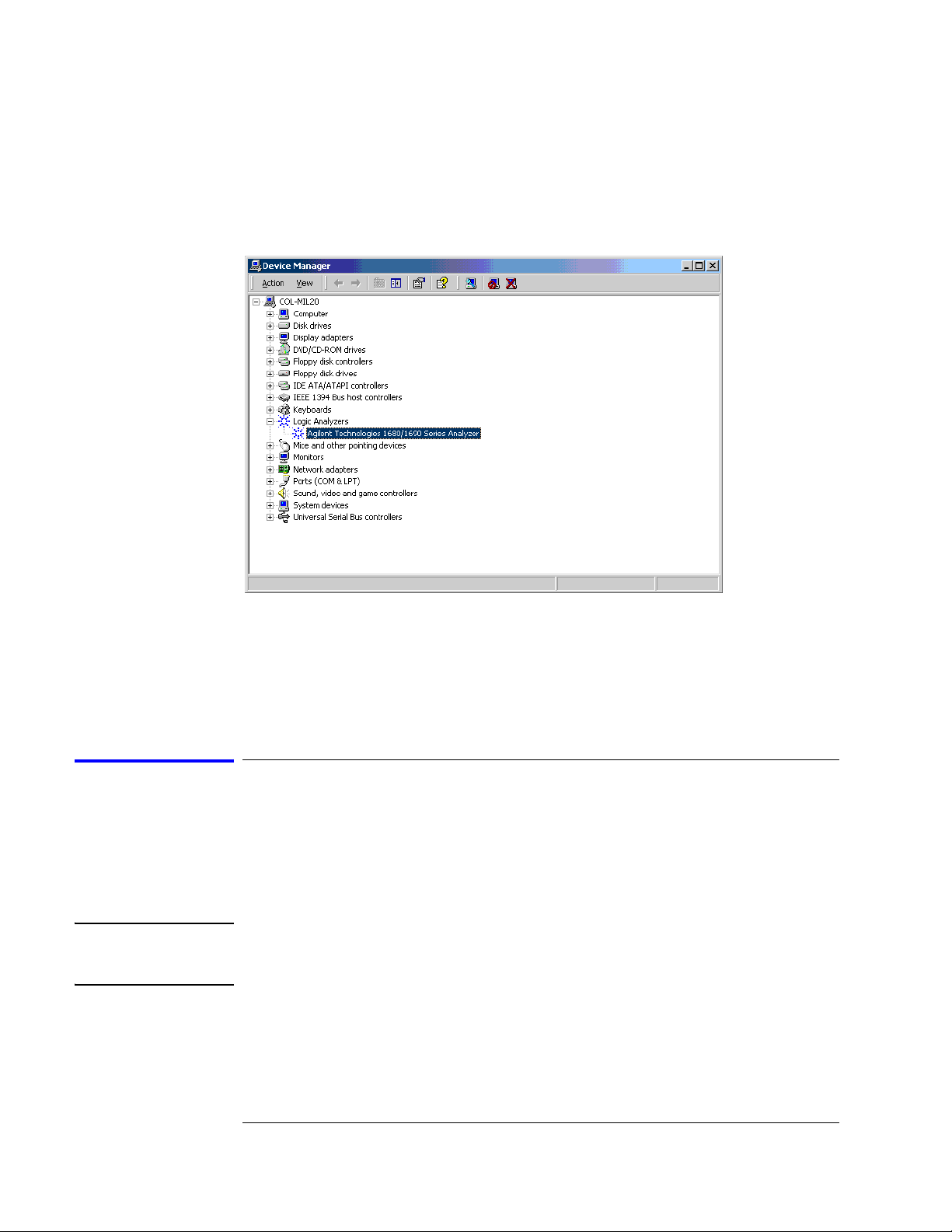

To connect the 1690A,AD-series logic analyzer to a host PC

These steps are required for the Agilent 1690A,AD-series hosted logic analyzer.

The logic analyzer user interface requires a host computer (PC) with the

following characteristics (or better):

Intel Celeron, AMD K6-II 500 MHz

Windows 2000 Professional or Windows XP Professional

128MB RAM

IEEE 1394 PCI card

1 Connect one end of the 6-pin IEEE 1394 cable to the IEEE 1394 port on

the host PC.

2 Connect the free end of the IEEE 1394 cable to the IEEE 1394 port on the

logic analyzer.

3 Apply power to the PC if it is not turned on.

17

Page 18

Chapter 2: Preparing for Use

To start the user interface

Start the Agilent Logic Analyzer application from the Start menu or using a

shortcut. On the desktop, the Agilent Logic Analyzer icon looks like:

Refer to the Agilent Logic Analyzer on-line help for information on how to

operate the user interface. Also, refer to the window icon reference on the inside

front cover of this service manual for a brief explanation of the Agilent Logic

Analyzer standard icons.

To clean the logic analyzer

With the instrument turned off and unplugged, use mild soap and water to clean

the front and cabinet of the logic analyzer. Harsh soap might damage the waterbase paint.

To test the logic analyzer

• If you require a test to verify the specifications, start at the beginning of

chapter 3, "Testing Performance."

• If you require a test to initially accept the operation, perform the self-tests

in chapter 3.

• If the logic analyzer does not operate correctly, go to the beginning of

chapter 5, "Troubleshooting."

18

Page 19

3

Testing Performance

This chapter tells you how to test the performance of the logic analyzer against

the specifications listed in chapter 1.

19

Page 20

Chapter 3: Testing Performance

The Logic Analyzer Interface

To select a field on the logic analyzer screen, use the arrow keys to highlight the

field, then press the Select key. Provided on the inside front cover of this manual

is a list of logic analyzer icons that can be referenced while performing test

procedures. For more information about the logic analyzer interface, refer to the

Agilent Logic Analyzer application’s online help.

Test Strategy

For a complete test, start at the beginning with the software tests and continue

through to the end of the chapter. For an individual test, follow the procedure in

the test. The examples in this chapter were performed using an Agilent 1680AD.

Other analyzers in the series will have appropriate pods showing on the screen.

The performance verification procedures starting on page 3–8 are each shown

from power-up. To exactly duplicate the setups in the tests, save the power-up

configuration to a file on a disk, then load that file at the start of each test.

If a test fails, check the test equipment setup, check the connections, and verify

adequate grounding. If a test still fails, the most probable cause of failure would

be the acquisition board.

Test Interval

Test the performance of the logic analyzer against specifications at two-year

intervals.

Performance Test Record

A performance test record for recording the results of each procedure is located

at the end of this chapter. Use the performance test record to gauge the

performance of the logic analyzer over time.

Test Equipment

Each procedure lists the recommended test equipment. You can use equipment

that satisfies the specifications given. However, the procedures are based on

using the recommended model or part number. Before testing the performance

of the logic analyzer, warm-up the instrument and the test equipment for 30

minutes.

20

Page 21

Chapter 3: Testing Performance

To make the test connectors

To make the test connectors

The test connectors connect the logic analyzer to the test equipment.

Materials Required

Description Recommended Part Qty

BNC (f) Connector 1250-0698 5

100 Ω 1% resistor 0698-7212 8

Berg Strip, 17-by-2 1

Berg Strip, 6-by-2 4

20:1 Probe 54006A 2

Jumper wire

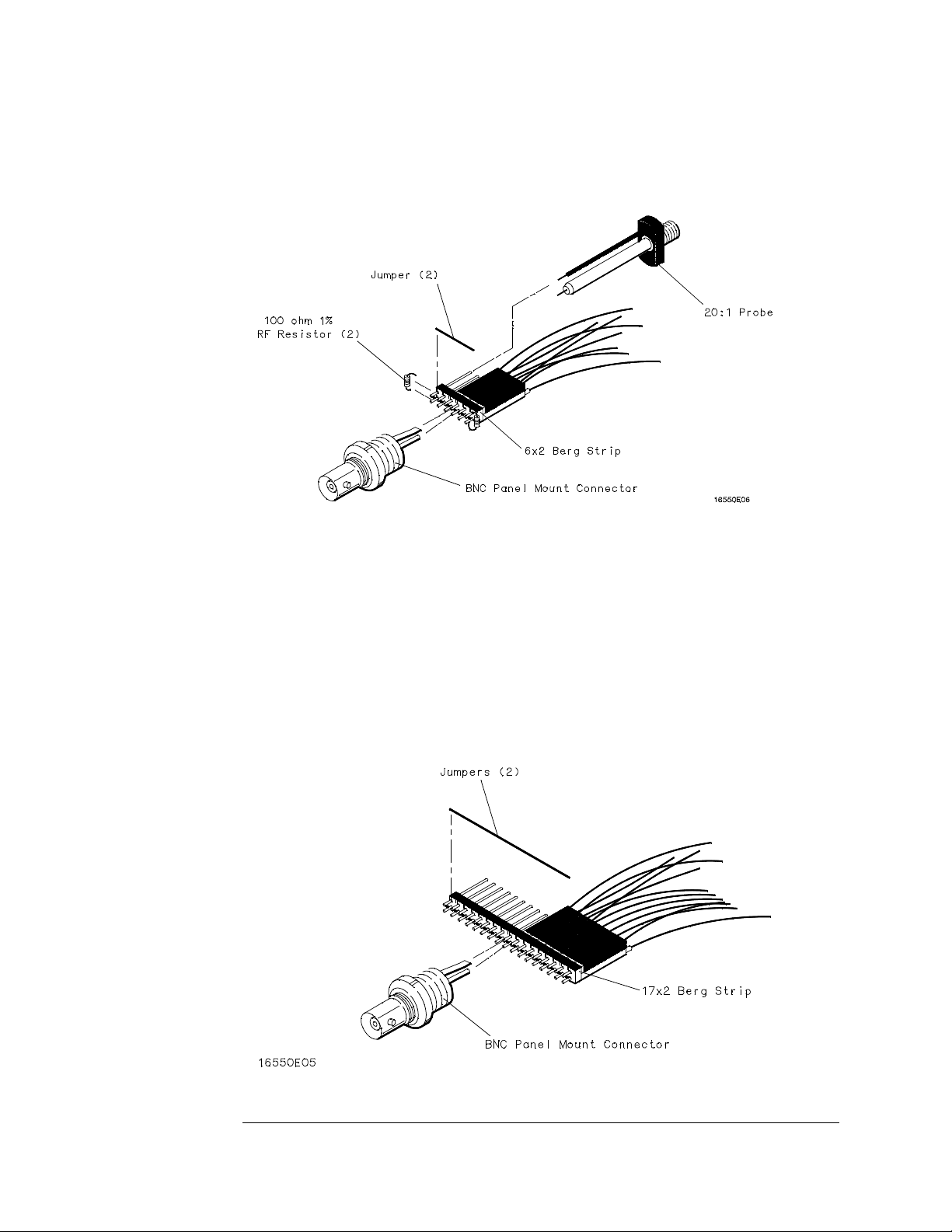

1 Build four test connectors using BNC connectors and 6-by-2 sections of

Berg strip:

a Solder a jumper wire to all pins on one side of the Berg strip.

b Solder a jumper wire to all pins on the other side of the Berg strip.

c Solder two resistors to the Berg strip, one at each end between the end

pins.

d Solder the center of the BNC connector to the center pin of one row on

the Berg strip.

e Solder the ground tab of the BNC connector to the center pin of the

other row on the Berg strip.

21

Page 22

Chapter 3: Testing Performance

To make the test connectors

f On two of the test connectors, solder a 20:1 probe. The probe ground

goes to the same row of pins on the test connector as the BNC ground

tab.

2 Build one test connector using a BNC connector and a 17-by-2 section of

Berg strip:

a Solder a jumper wire to all pins on one side of the Berg strip.

b Solder a jumper wire to all pins on the other side of the Berg strip.

c Solder the center of the BNC connector to the center pin of one row on

the Berg strip.

d Solder the ground tab of the BNC connector to the center pin of the

other row on the Berg strip.

22

Page 23

Chapter 3: Testing Performance

To set up the test equipment and the logic analyzer

To set up the test equipment and the logic analyzer

Before testing the specifications of the Agilent 1680A,AD-series or 1690A,ADseries logic analyzer, the test equipment and the logic analyzer must be set up

and configured.

These instructions include detailed steps for initially setting up the required test

equipment and the logic analyzer. Before performing any or all of the tests in this

chapter, the following steps must be done.

Equipment Required

Equipment Critical Specifications

Pulse Generator 200 Mhz, 2.5 ns pulse width, <600 ps rise time 8133A option 003

Digitizing Oscilloscope ≥ 6 GHz bandwidth, < 58 ps rise time 54750A w/ 54751A

Digital Multimeter 0.1 mV resolution, 0.005% accuracy 3458A

Function Generator DC offset voltage ±1.5 V 3325B Option 002

Recommended HP/Agilent

Model/Part

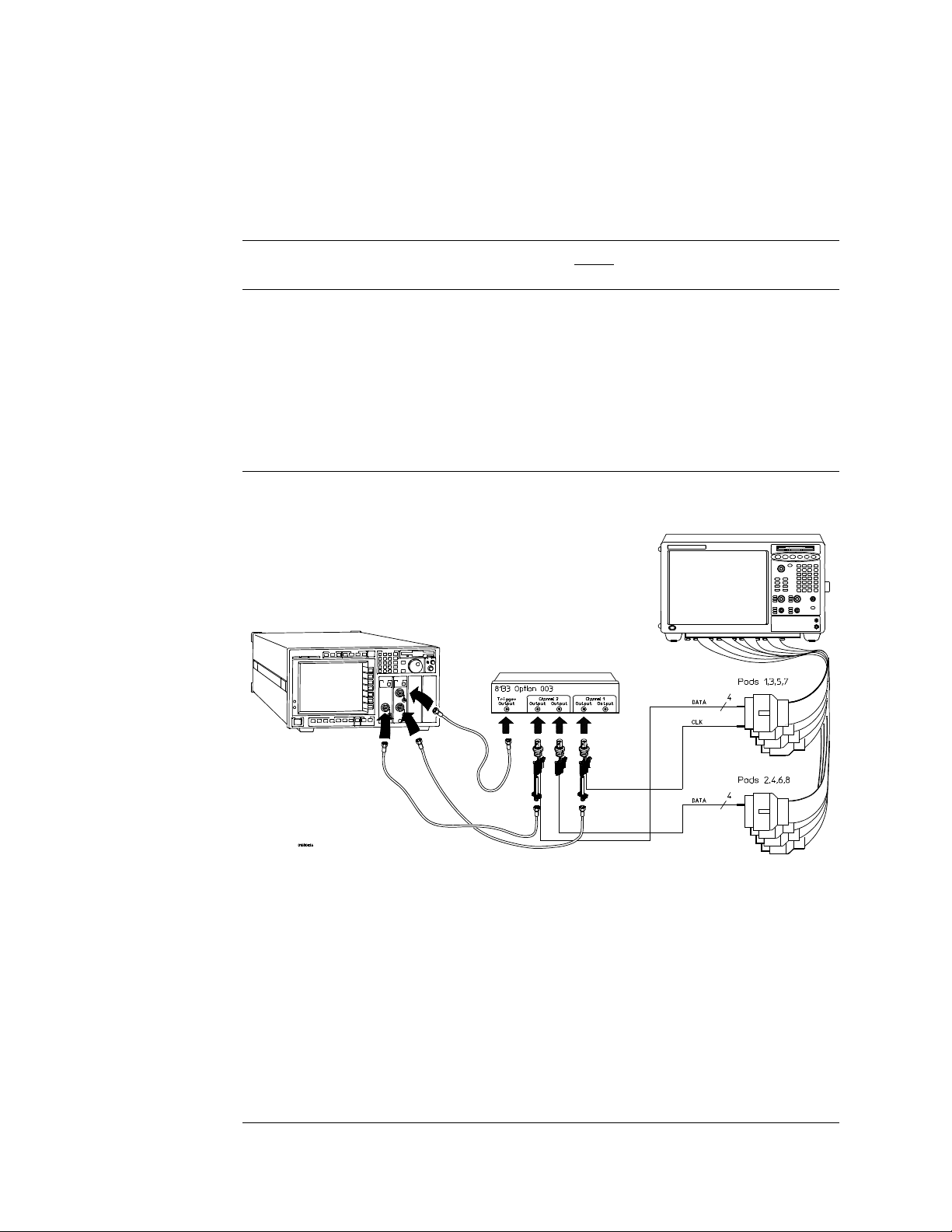

Set up the test equipment

1 Turn on the required test equipment listed in the table above. Let them

warm up for 30 minutes before beginning any test.

2 Set up the pulse generator according to the following table.

Pulse Generator Setup

Timebase Channel 2 Trigger Channel 1

Mode: Int

Period: 5.000 ns

Mode: Pulse

Divide: Pulse ÷ 2

Width: 2.500 ns

Ampl: 0.80 V

Offs: -1.30 V

COMP: Disabled

(LED Off)

Divide: Divide ÷ 2

Ampl: 0.50 V

Offs: 0.00 V

Mode: Square

Delay: 0.0 ps

Ampl: 0.80 V

Offs: -1.30 V

COMP: Disabled

(LED Off)

3 Set up the oscilloscope:

a Select Setup, then select Default Setup.

23

Page 24

Chapter 3: Testing Performance

To set up the test equipment and the logic analyzer

b Configure the oscilloscope according to the following table.

Oscilloscope Setup

Acquisition Display Trigger [Shift] ∆ Time

Averaging: On

# of averages: 16

Channel 1 Channel 2 Define meas

Graticule graphs: 2 Level: 0.0 V Stop src: channel 2 [Enter]

External Scale

Attenuation: 20.00:1

Scale: 200 mV/div

Offset: - 1.300 V

External Scale

Attenuation: 20.00:1

Scale: 200 mV/div

Offset: - 1.300 V

Thresholds: user-defined

Units: Volts

Upper: - 980 mV

Middle: -1.30 V

Lower: -1.62 V

Set up the 1680A,AD-series logic analyzer

Power-up self tests are done on the logic analyzer system components when

power is applied. Any problems reported by the logic analyzer during boot must

be cleared before going further. For more information, refer to Chapter 5 and

Chapter 8.

1 Turn on the logic analyzer:

a Connect a keyboard and mouse to the rear panel of the logic analyzer.

b Plug in a power cord to the rear panel power connector of the logic

analyzer.

c Turn on the power switch on the logic analyzer front panel.

2 Set up the logic analyzer:

a Wait for the logic analyzer boot up to complete.

b On the logic analyzer desktop, double-click the Agilent Logic Analyzer

icon to launch the application.

24

Page 25

Chapter 3: Testing Performance

To set up the test equipment and the logic analyzer

Set up the 1690A,AD-series logic analyzer

Power-up self tests are done on the logic analyzer system components when

power is applied. Logic analyzer peripheral communication tests are done when

the host PC recognizes the hosted logic analyzer hardware. Any problems

reported should be cleared before going further. For more information, refer to

Chapter 5 and Chapter 8.

1 Connect the logic analyzer to the host PC.

2 Set up the logic analyzer:

a Wait for the logic analyzer power-up to complete.

b On the host PC desktop, double-click the Agilent Logic Analyzer icon to

launch the application.

c In the Agilent Logic Analyzer application window, ensure the

application reports “Online.”

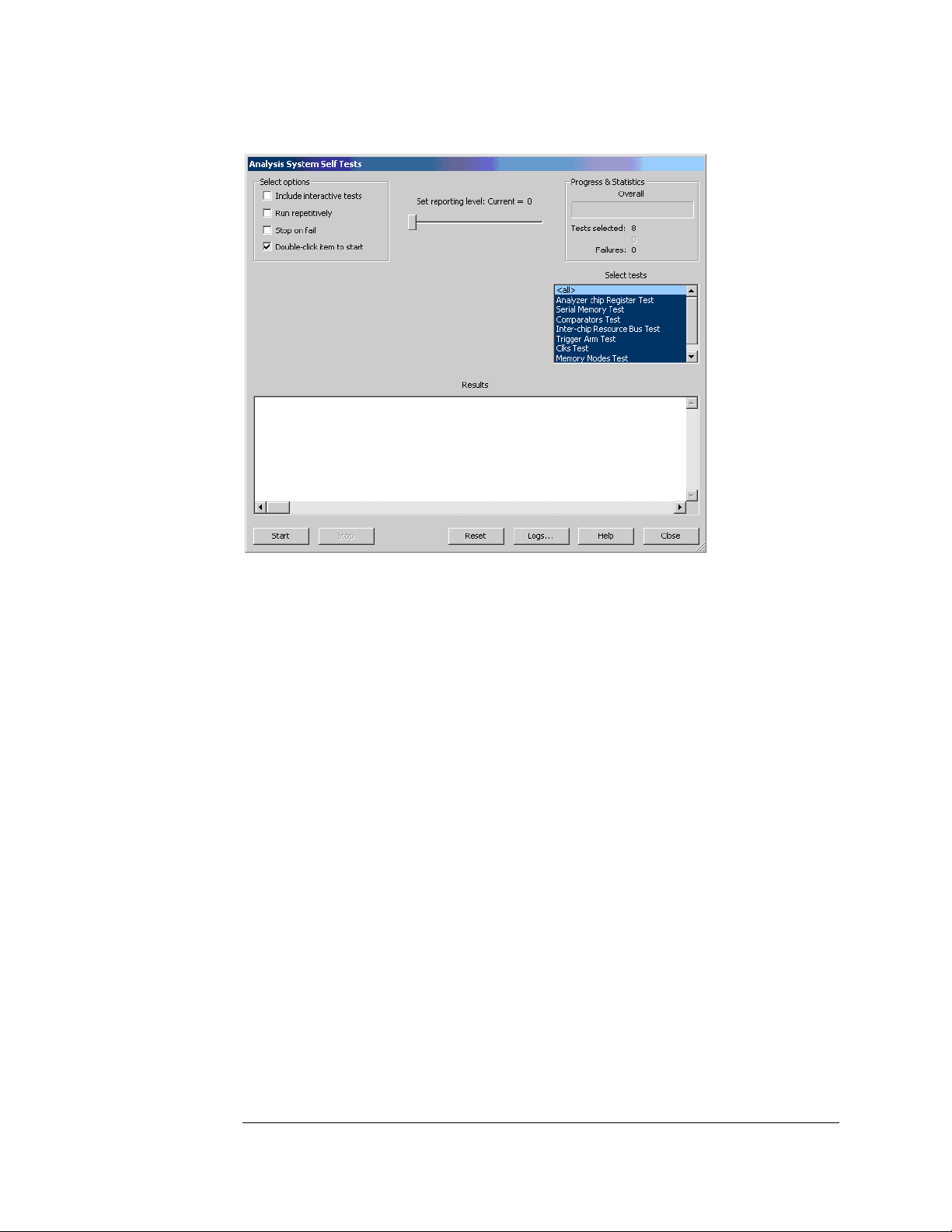

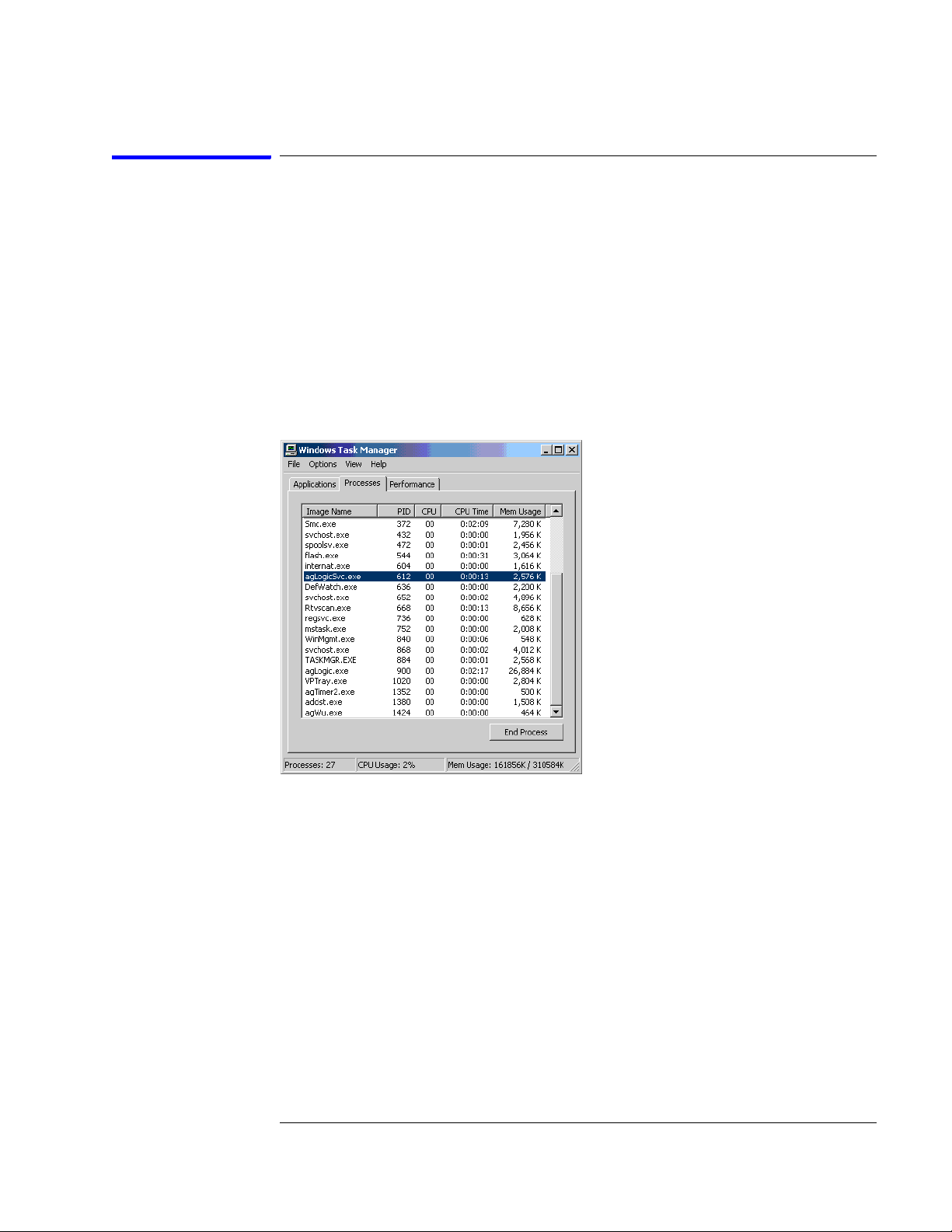

To perform the logic analyzer self-tests

The Self Test menu checks the major hardware functions of the logic analyzer to

verify that it is working correctly. Self-tests can be performed all at once or one at

a time. While testing the performance of the logic analyzer, run the self-tests all at

once. Refer to Chapter 8 for more information on the logic analyzer self-tests.

CAUTION: Because the most recently acquired data will be lost, be sure to save important data

before running self tests.

1 In the Agilent Logic Analyzer application, choose Help>Self Test... from

the main menu.

CAUTION: If you have acquired data, a warning message appears, "Running self-tests will invalidate

acquired data"; click OK to continue.

25

Page 26

Chapter 3: Testing Performance

To set up the test equipment and the logic analyzer

2 In the Analysis System Self Tests dialog, select the self test options:

• Include interactive tests — causes interactive tests to appear in the selection lists.

• Run repetitively — runs the selected tests repetitively until you click Stop.

• Stop on fail — if you are running multiple tests or running tests repetitively, this

causes the tests to stop if there is a failure.

• Double-click item to start — lets you double-click a test to start it.

3 Set the reporting level.

Higher levels produce increasingly verbose output.

4 Select the tests you want to run.

5 Click Start.

As the tests are running, the results are reported in the lower part of the dialog

and saved to a log file.

26

Page 27

Chapter 3: Testing Performance

To set up the test equipment and the logic analyzer

To stop running test, click Stop.

To reset the self-test options, click Reset.

To view the log file, click Logs..., select the log file you want to view, and click

Open.

If, after completing the self tests, you have failures or you have questions about

the performance of the logic analysis system, contact Agilent Technologies sales

or support at http://www.agilent.com/find/contactus.

6 Click Close to close the Analysis System Self Tests dialog.

27

Page 28

Chapter 3: Testing Performance

To test the threshold accuracy

To test the threshold accuracy

Testing the threshold accuracy verifies the performance of the following

specification:

• Clock and data channel threshold accuracy.

These instructions include detailed steps for testing the threshold settings of

pod 1. After testing pod 1, connect and test the rest of the pods one at a time. To

test the next pod, follow the detailed steps for pod 1, substituting the next pod

for pod 1 in the instructions.

Each threshold test tells you to record a pass/fail reading in the performance test

record located at the end of this chapter.

Equipment Required

Equipment Critical Specifications Recommended Model/Part

Digital Multimeter 0.1 mV resolution, 0.005% accuracy 3458A

Function Generator

BNC-Banana Cable 11001-60001

BNC Tee 1250-0781

BNC Cable 8120-1840

BNC Test Connector, 17x2

Accuracy (5)(10

DC offset voltage ±1.5 V

-6

) frequency,

33250A

Set up the equipment

1 If you have not already done so, do the procedure “To set up the test

equipment and the logic analyzer” on page 23.

2 Set up the DC source to deliver a DC voltage on the output:

a In the function generator Utility menu, activate the DC Level. All AC

voltage functions will be disabled.

b Enable the high impedance load under the Output Setup menu.

3 Using a BNC-banana cable, connect the voltmeter to one side of the BNC

Tee.

4 Connect the BNC Tee to the output of the DC source. Set up the logic

analyzer.

28

Page 29

Chapter 3: Testing Performance

To test the threshold accuracy

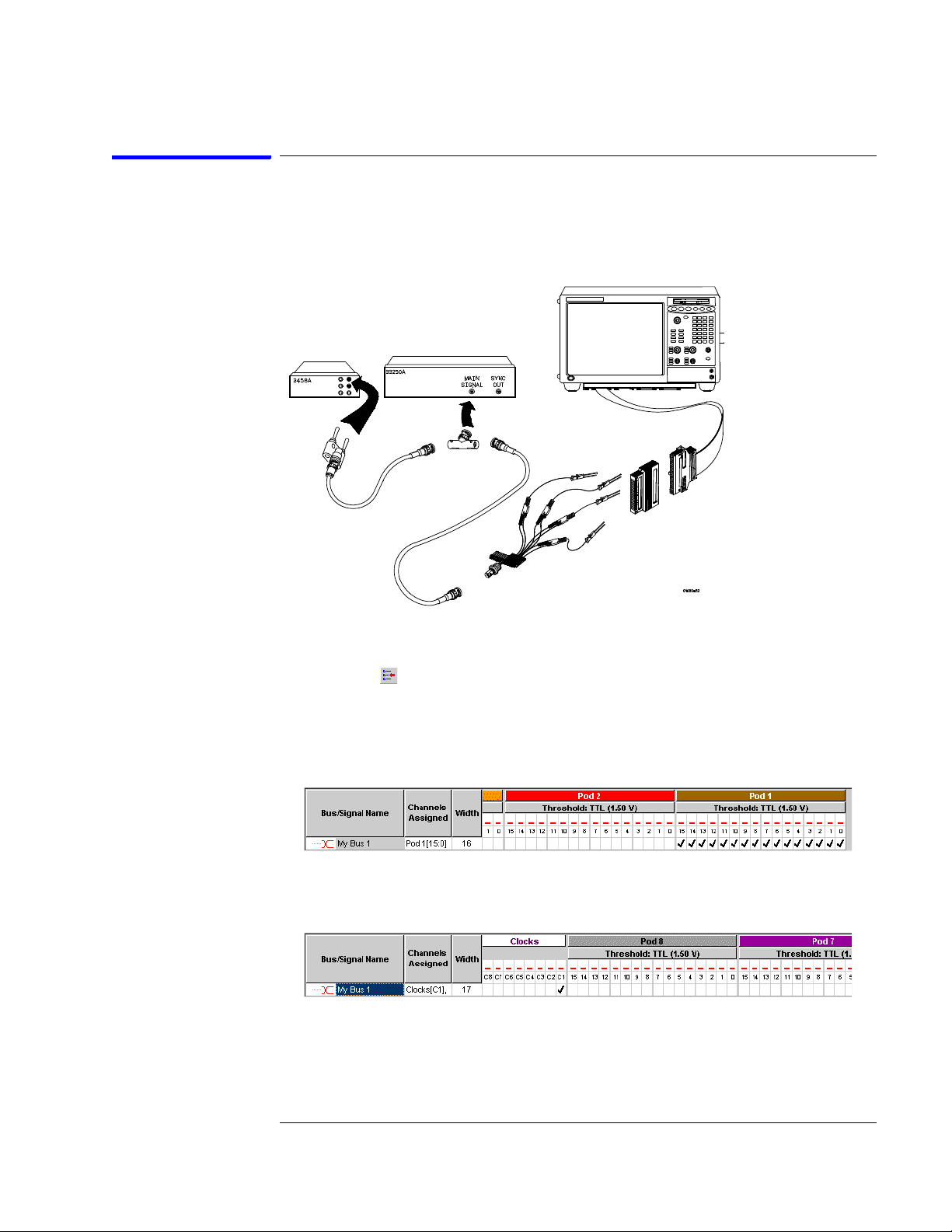

Connect and configure the logic analyzer

1 Using the 17-by-2 test connector, BNC cable, and probe tip assembly,

connect the data and clock channels of Pod 1 to the free side of the BNC

Tee.

2 Configure the logic analyzer:

a Click the Bus/Signal Setup icon. The Analyzer Setup dialog opens.

b In the Buses/Signals tab, click Delete All at the bottom of the dialog.

c Using the mouse, activate all Pod 1 channels. Assign channels to bus/

signal name My Bus 1.

d Scroll the channel assignments to the left. Assign the clock/data

channel for the Pod 1 (that is, C1) to My Bus 1.

3 Activate the DC source output.

29

Page 30

Chapter 3: Testing Performance

To test the threshold accuracy

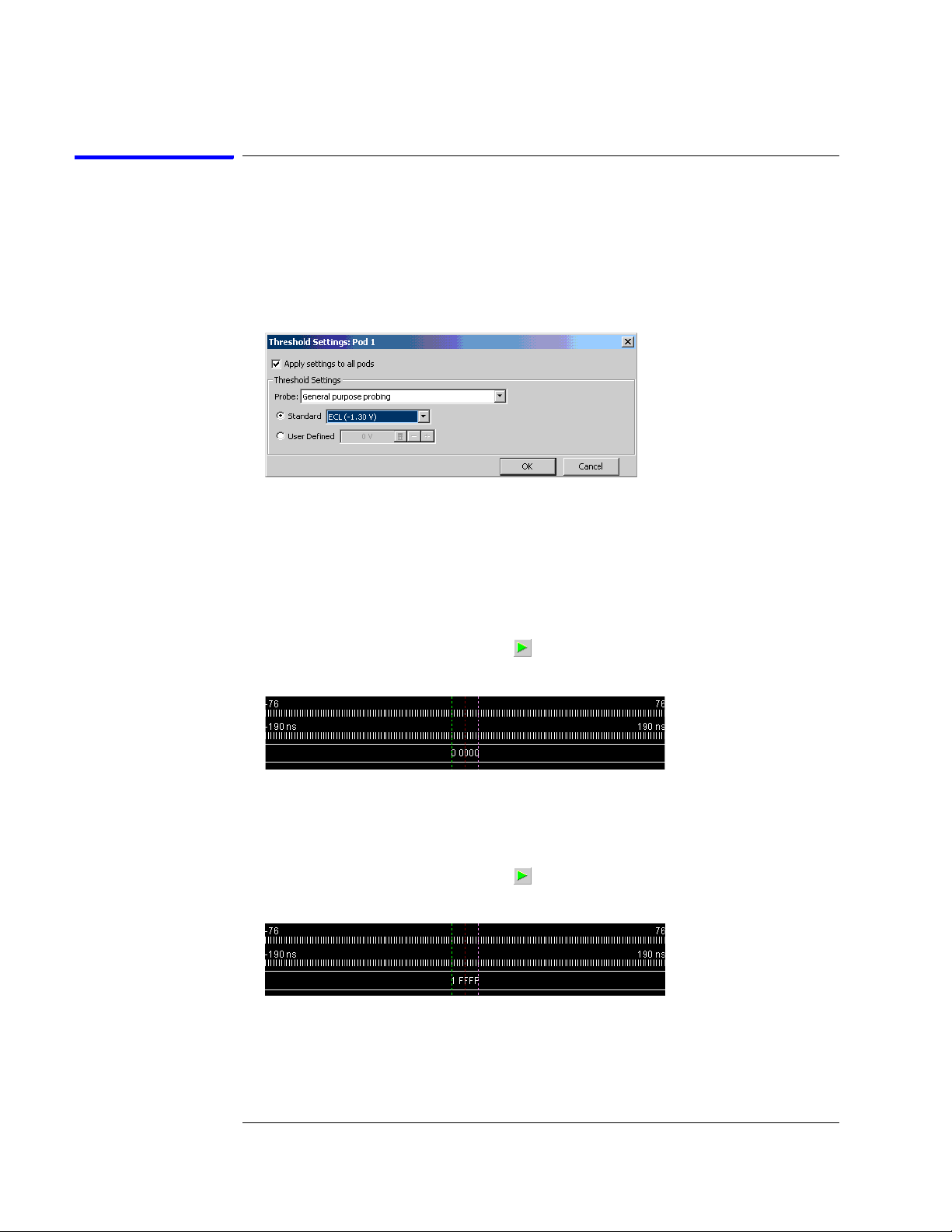

Test the ECL Threshold

1 Set up the logic analyzer:

a In the Analyzer Setup dialog, click the threshold field for Pod 1. The

Threshold Settings dialog appears.

b In the Threshold Settings dialog, select Standard and ECL (–1.30 V).

c Click OK to close the Threshold Settings dialog.

d Click OK to close the Analyzer Setup dialog.

2 Test the high-to-low transition:

a On the DC source, enter a voltage setting of –1.384 V.

b On the logic analyzer, click the Run icon. The display should show all

channels at a logic "0".

3 Test the low-to-high transition:

a On the DC source, enter a voltage setting of –1.216 V.

b On the logic analyzer, click the Run icon. The display should show all

channels at a logic "1" (0x1FFFF).

4 Record a PASS/FAIL in the performance test record for Threshold

Accuracy Pod 1 - ECL.

30

Page 31

Chapter 3: Testing Performance

To test the threshold accuracy

Test the 0 V User Threshold

1 Set up the logic analyzer:

a On the logic analyzer, click the Bus/Signal Setup icon. The Analyzer

Setup dialog opens.

b In the Analyzer Setup dialog, click the threshold field for Pod 1. The

Threshold Settings dialog appears.

c In the Threshold Settings dialog, select User Defined and enter 0 V in

the associated field.

d Click OK to close the Threshold Settings dialog.

e Click OK to close the Analyzer Setup dialog.

2 Test the high-to-low transition:

a On the DC source, enter a voltage setting of –0.064 V.

b On the logic analyzer, click the Run icon. The display should show all

channels at a logic "0".

3 Test the low-to-high transition:

a On the DC source, enter a voltage setting of 0.064 V.

b On the logic analyzer, click the Run icon. The display should show all

channels at a logic "1" (0x1FFFF).

4 Record a PASS/FAIL in the performance test record for Threshold

Accuracy Pod 1 - User 0 V.

31

Page 32

Chapter 3: Testing Performance

To test the threshold accuracy

Test the next pod

1 Using the 17-by-2 test connector and probe tip assembly, connect the data

and clock channels of the next pod to the output of the function generator

until all pods have been tested.

2 Start with “Connect and configure the logic analyzer” on page 29

substituting the next pod to be tested for pod 1.

32

Page 33

Chapter 3: Testing Performance

To set up the logic analyzer for the state mode tests

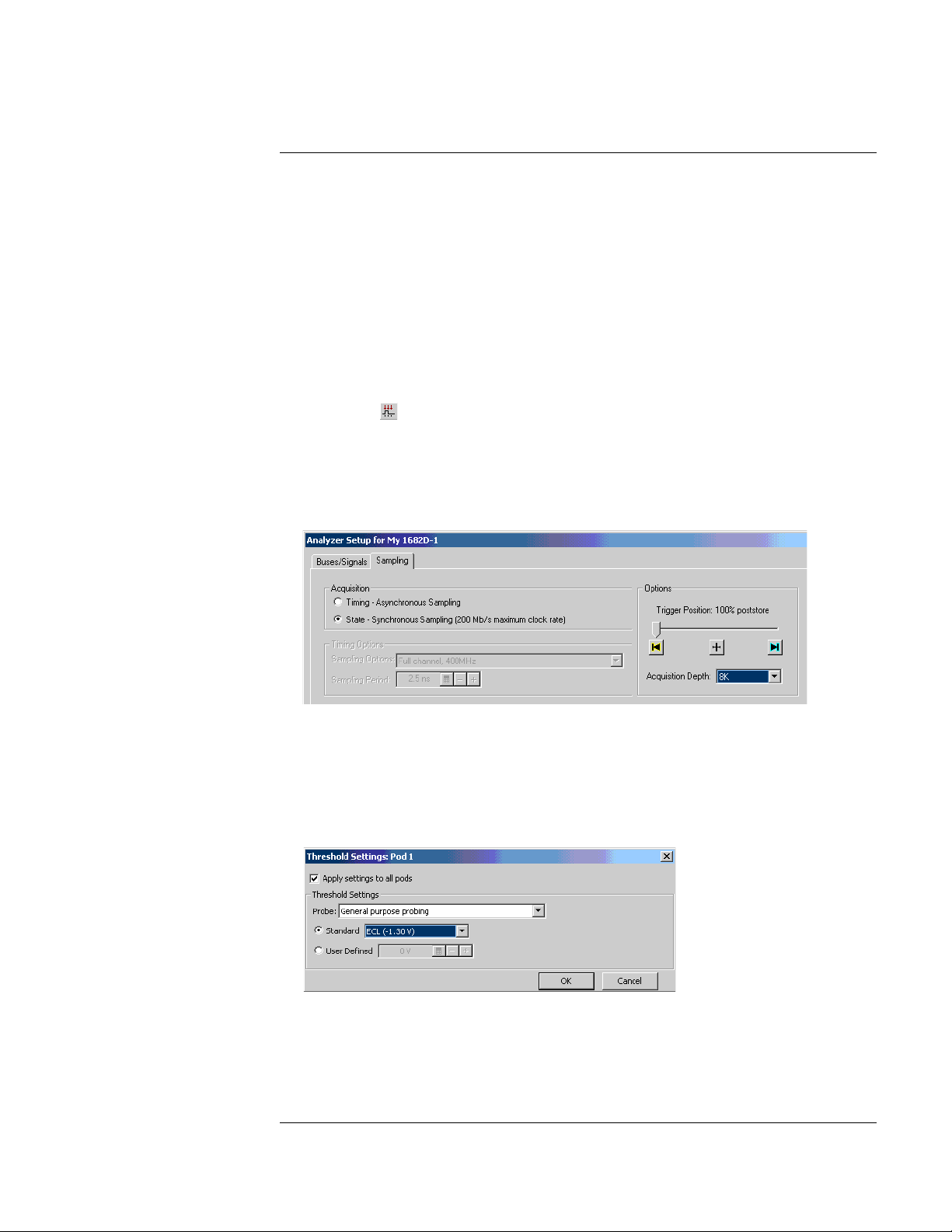

To set up the logic analyzer for the state mode tests

1 Set up the logic analyzer:

a If you have not already done so, do the procedure “To set up the test

equipment and the logic analyzer” on page 23.

b Exit and restart the Agilent Logic Analyzer application to reinitialize

the logic analyzer.

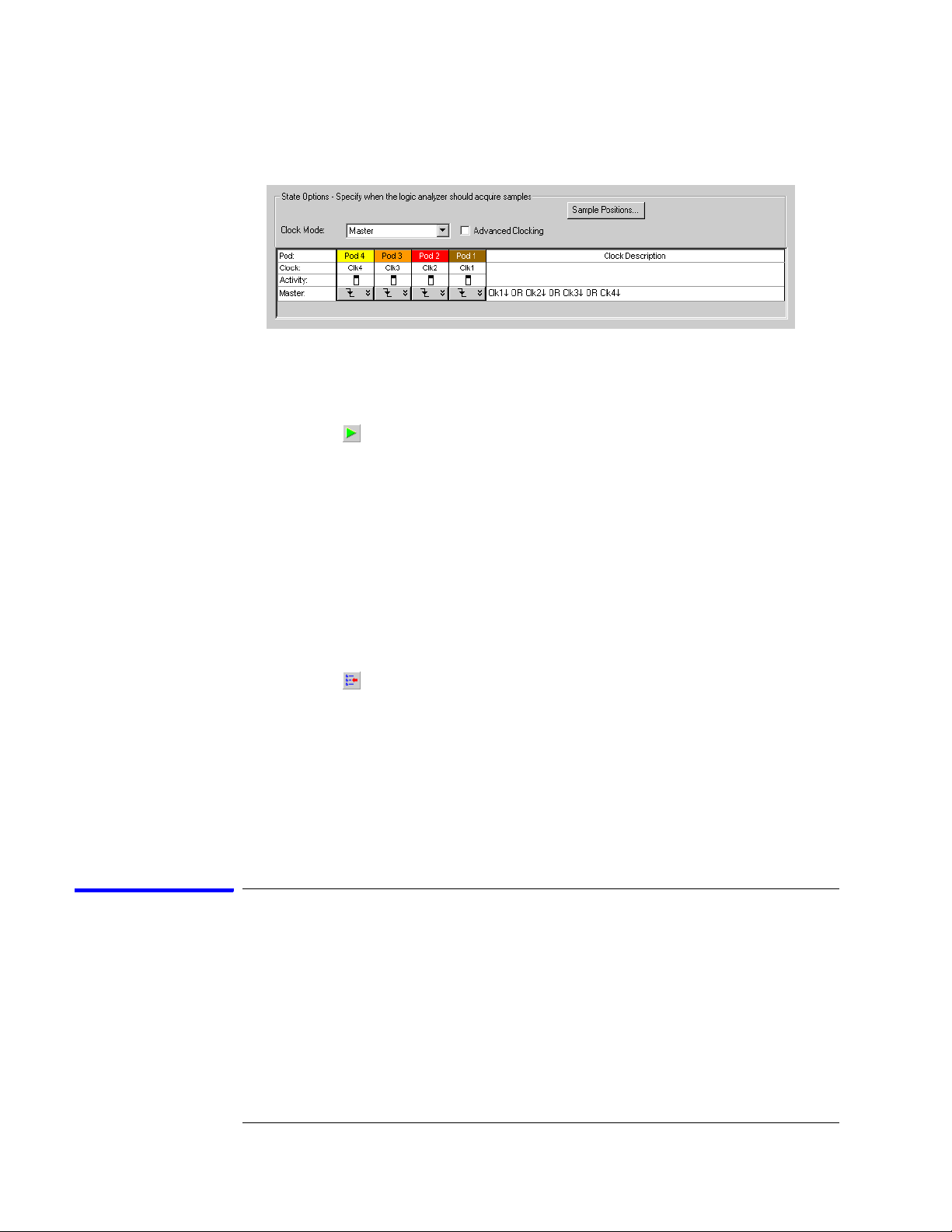

2 Configure the Analyzer Setup dialog:

a Click the Sampling Setup icon.

b Select State - Synchronous Sampling.

c Configure Trigger Position - 100% poststore.

d Select an Acquisition Depth of 8K.

e Click the Buses/Signals tab.

f Click the threshold field of one of the pods. The Threshold Settings

dialog appears.

g In the Threshold Settings dialog, select Standard and ECL (–1.30 V).

h Click OK to close the Threshold Settings dialog.

i Click OK to close the the Analyzer Setup dialog.

33

Page 34

Chapter 3: Testing Performance

To set up the logic analyzer for the state mode tests

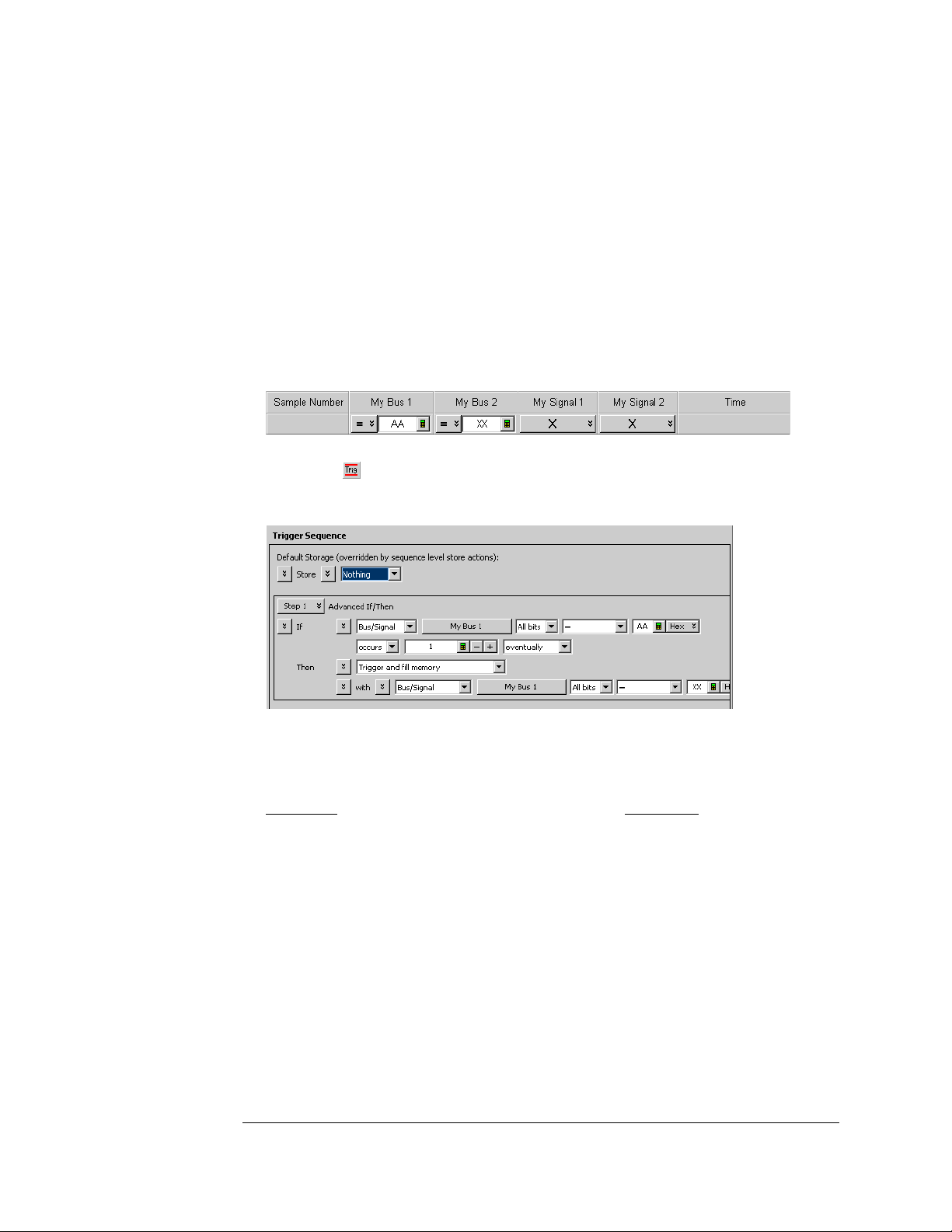

3 Configure the trigger according to your logic analyzer:

a In the Listing window, click on the trigger pattern field for My Bus 1 to

select.

b Enter the following pattern for your logic analyzer.

1680A,AD, 1690A,AD - "AA"

1681A,AD, 1691A,AD - "2A"

1682A,AD, 1692A,AD - "AA"

1683A,AD, 1693A,AD - "A"

c Click the Trigger Setup icon.

d For the Default Storage, select Store Nothing.

e Click OK to close the Advanced Trigger dialog.

4 Activate the pulse generator data and clock outputs:

a On the pulse generator, enable the channel 1 OUTPUT, channel 1

OUTPUT

, channel 2 OUTPUT and channel 2 OUTPUT (LEDs off)

b On the pulse generator, enable the trigger OUTPUT. (LED off)

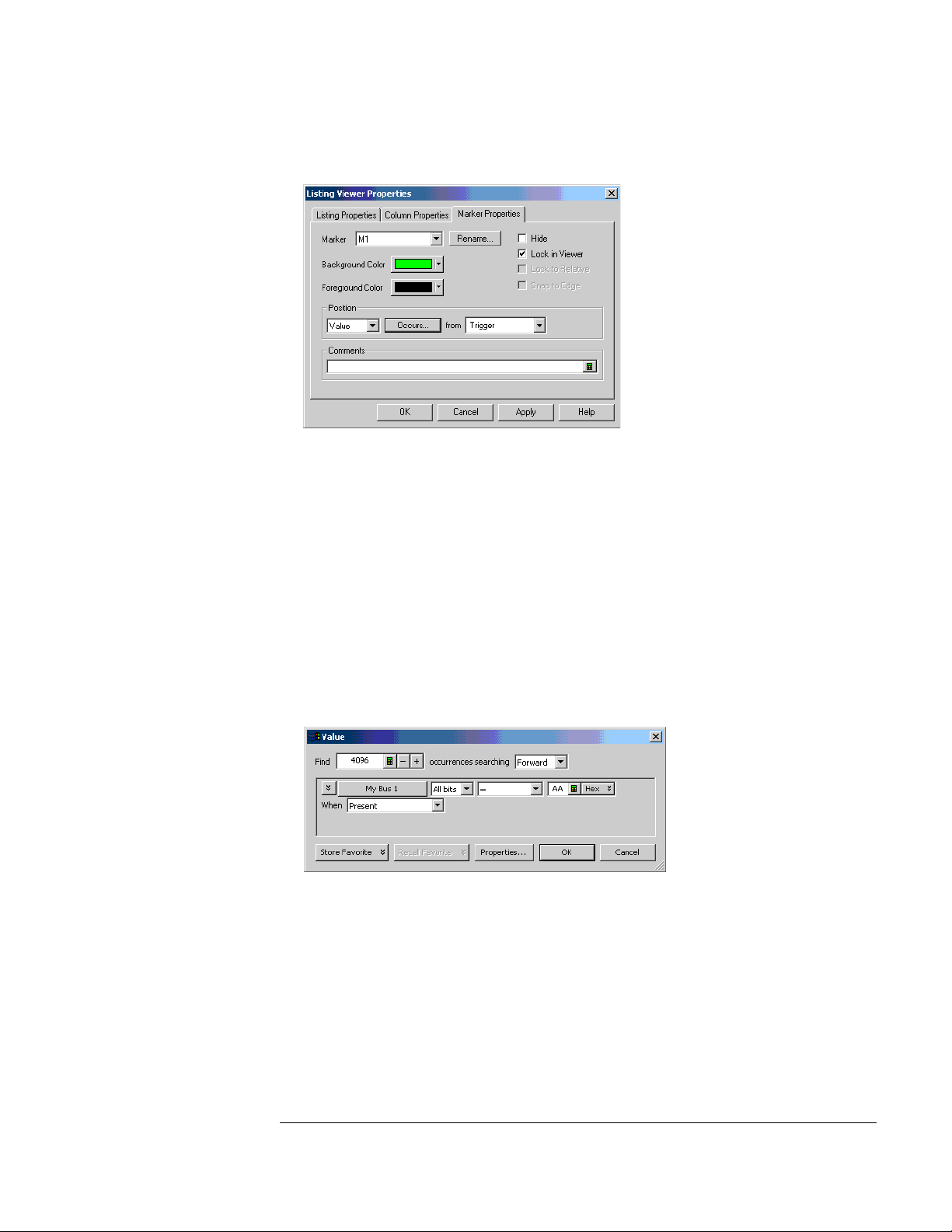

5 Set up the Markers:

The following procedure is done after the first run of test data is acquired (during

one of the state clock mode tests).

a From the main menu, choose Markers>Properties....

b In the Marker Properties tab of the Listing Viewer Properties dialog,

34

Page 35

Chapter 3: Testing Performance

To set up the logic analyzer for the state mode tests

select the M1 marker.

c In the Position box, select Value.

d Click on the Occurs... button and the Value dialog appears.

e Click on the Find occurrences field, and enter 4096.

f Click on the pattern field, then enter the following pattern according to

the logic analyzer being tested:

1680A,AD, 1690A,AD - "AA"

1681A,AD, 1691A,AD - "2A"

1682A,AD, 1692A,AD - "AA"

1683A,AD, 1693A,AD - "A"

g Click OK to close the Value dialog.

35

Page 36

Chapter 3: Testing Performance

To set up the logic analyzer for the state mode tests

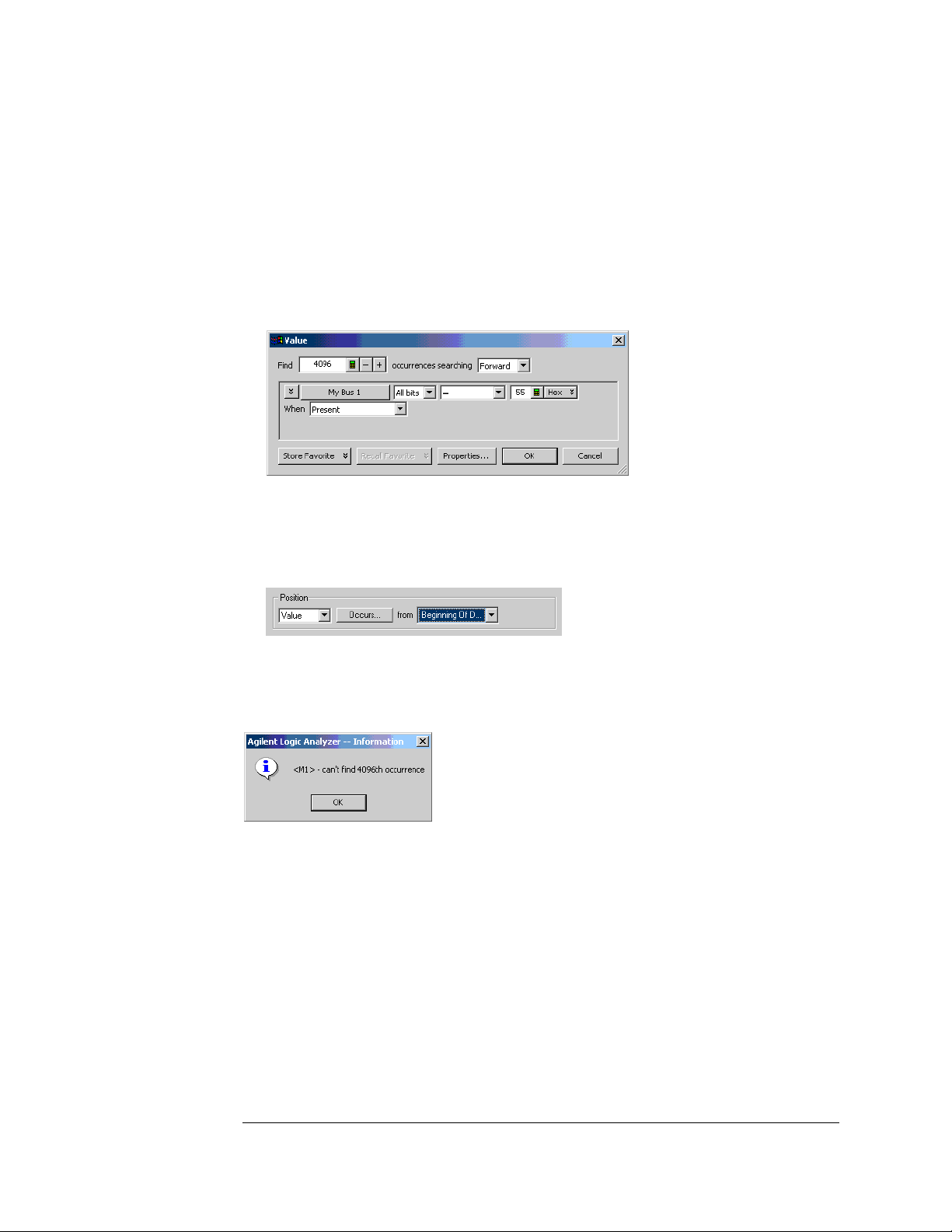

h Repeat steps b through f to configure marker M2 using the following

pattern according to the logic analyzer being tested.

1680A,AD, 1690A,AD - "55"

1681A,AD, 1691A,AD - "15"

1682A,AD, 1692A,AD - "55"

1683A,AD, 1693A,AD - "5"

i Click OK to close the Value dialog.

j In the Listing Viewer Properties dialog, select Beginning Of Data in the

“from” field.

The logic analyzer markers are now configured to verify the test data. If the error

message "can't find 4096 occurence(s)" does not appear, the test passes. Click

OK to close the Listing ViewerProperties dialog

When the above error message appears, one or more samples of test data is

incorrect. When this happens, check the following and attempt the test again:

• All cables are properly connected.

• Configuration of each test equipment is correct.

• Logic analyzer is properly set up according to the test procedure.

36

Page 37

Chapter 3: Testing Performance

To test the single-clock, single-edge, state acquisition

To test the single-clock, single-edge, state acquisition

Testing the single-clock, single-edge, state acquisition verifies the performance of

the following specifications:

• Minimum master-to-master clock time.

• Maximum state acquisition speed.

• Setup/Hold time for single-clock, single-edge, state acquisition.

This test checks two combinations of data channels using a single-edge clock at

two selected setup/hold times.

Equipment Required

Equipment Critical Specifications Recommended Model/Part

Pulse Generator 200 MHz 2.5 ns pulse width, <600 ps rise time 8133A option 003

Digitizing Oscilloscope ≥6 GHz bandwidth, <58 ps rise time 54750A w/ 54751A

Adapter SMA(m)-BNC(f) 1250-1200

SMA Coax Cable (Qty 3) 18 GHz bandwidth 8120-4948

Coupler BNC(m)(m) 1250-0216

BNC Test Connector,

6x2 (Qty 4)

Set up the equipment

If you have not already done so, do the following procedures:

“To set up the test equipment and the logic analyzer” on page 23.

“To set up the logic analyzer for the state mode tests” on page 33.

Connect and configure the logic analyzer

1 Using the 6-by-2 test connectors, connect the first combination of logic

analyzer clock and data channels listed in one of the following tables to the

pulse generator.

If you are testing a 1680/81/90/91A,AD, you will repeat this test for the second

combination.

37

Page 38

Chapter 3: Testing Performance

To test the single-clock, single-edge, state acquisition

2 Using SMA cables, connect the oscilloscope to the pulse generator channel

1 Output, channel 2 Output, and Trigger Output.

Connect the 1680/81/90/91A,AD Logic Analyzer to the Pulse Generator

Te s t i n g

Combinations

1 Pod 1, channel 3

2 Pod 1, channel 11

*1680A,AD or 1690A,AD only

Connect to 8133A

Channel 2 Output

Pod 3, channel 3

Pod 5, channel 3

Pod 7, channel 3

Pod 3, channel 11

Pod 5, channel 11

Pod 7, channel 11

Connect to 8133A

Channel 2 Output

Pod 2, channel 3

Pod 4, channel 3

Pod 6, channel 3

Pod 8, channel 3 *

Pod 2, channel 11

Pod 4, channel 11

Pod 6, channel 11

Pod 8, channel 11*

Connect to 8133A

Channel 1 Output

Pod 1 clock/data channel (Clk 1)

Pod 1 clock/data channel (Clk 1)

38

Page 39

Chapter 3: Testing Performance

To test the single-clock, single-edge, state acquisition

Connect the 1682/83/92/93A,AD Logic Analyzer to the Pulse Generator

Tes ti ng

Combination

1 Pod 1, channel 3

*1682A,AD or 1692A,AD only.

Connect to 8133A

Channel 2 Output

Pod 2, channel 3

Pod 3, channel 3

Pod 4, channel 3

Connect to 8133A

Channel 2 Output

Pod 1, channel 11

Pod 2, channel 11

Pod 3, channel 11*

Pod 4, channel 11*

Connect to 8133A

Channel 1 Output

Pod 1 clock/data channel (Clk 1)

3 Activate the data channels that are connected according to one of the

previous tables:

a Click on the Bus/Signal Setup icon. The Analyzer Setup dialog opens.

b In the Buses/Signals tab, click Delete All at the bottom of the dialog.

c Using the mouse, activate the data channels being tested. Assign

channels to bus/signal name My Bus 1.

d Click OK to close the Analyzer Setup dialog.

39

Page 40

Chapter 3: Testing Performance

To test the single-clock, single-edge, state acquisition

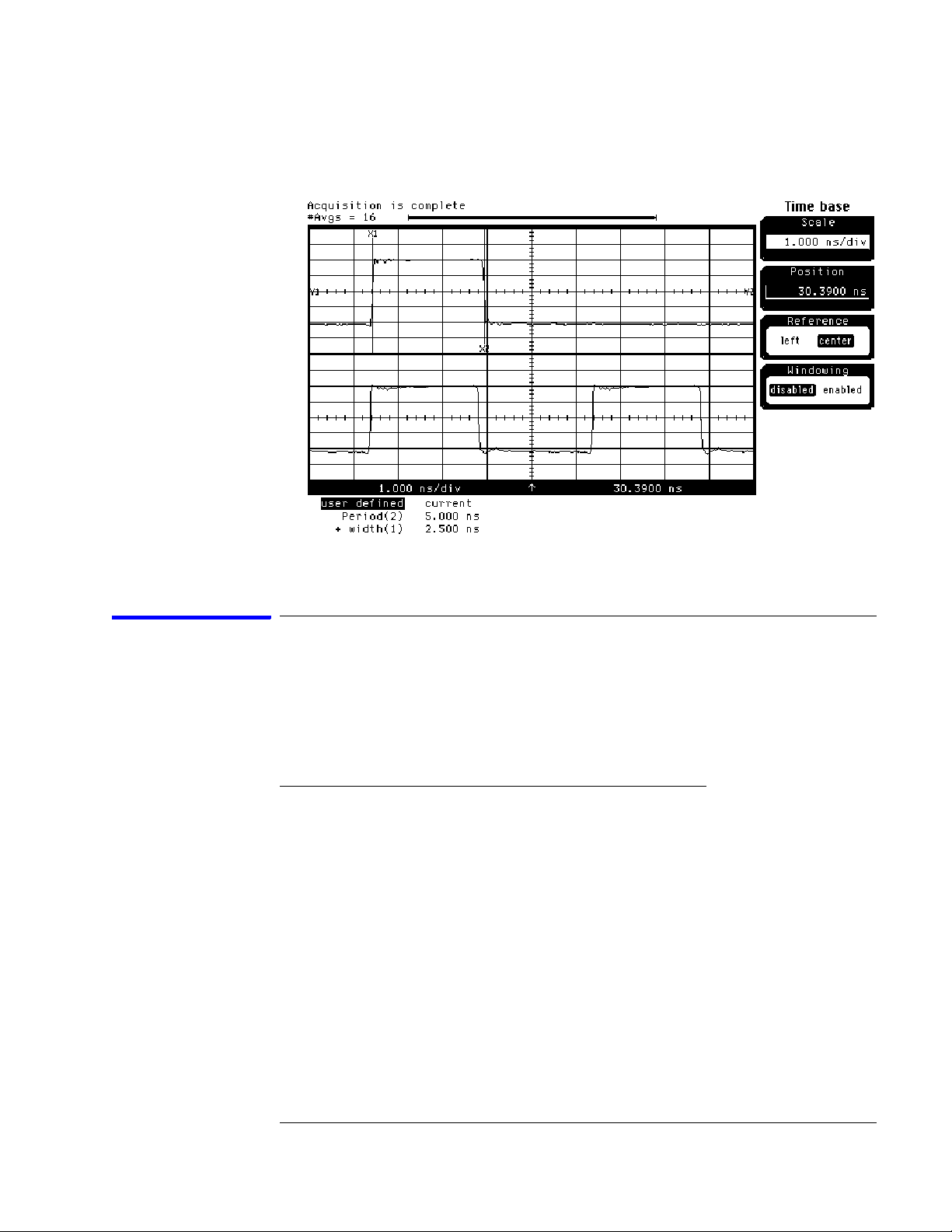

Verify the test signal

1 Check the clock period. Using the oscilloscope, verify that the master-to-

master clock time is 5.000 ns, +0 ps or −100 ps:

a In the oscilloscope Timebase menu, select Scale: 1.000 ns/div.

b In the oscilloscope Timebase menu, select Position. Using the

oscilloscope knob, position the clock waveform so that a rising edge

appears at the left of the display.

c On the oscilloscope, select [Shift] Period: channel 2, then select [Enter]

to display the clock period (Period(2)). If the period is not less than

5.000 ns, go to step d. If the period is less than 5.000 ns, go to step 2.

d In the oscilloscope Timebase menu, increase Position 5.000 ns. If the

period is not less than 5.000 ns, decrease the pulse generator Period in

until one of the two periods measured is less than 5.000 ns.

2 Check the data pulse width. Using the oscilloscope, verify that the data

pulse width is 2.500 ns, +0 ps or −100 ps.

a In the oscilloscope Timebase menu, select Position. Using the

oscilloscope knob, position the data waveform so that the waveform is

centered on the screen.

b On the oscilloscope, select [Shift] + width: channel 1, then select

[Enter] to display the data signal pulse width (+ width(1)).

40

Page 41

Chapter 3: Testing Performance

To test the single-clock, single-edge, state acquisition

c If the pulse width is outside the limits, adjust the pulse generator

channel 2 width until the pulse width is within limits.

Check the setup/hold combination

The following setup/hold combinations will be tested:

Setup/Hold Combinations

Te s t

Combination

1 4.50/-2.0 ns 2.5 ns -3.25 ns

2 -2.0/4.50 ns 2.5 ns +3.25 ns

1 Disable the pulse generator channel 1 COMP (with the LED off).

2 Using the Delay mode of the pulse generator channel 1, position the pulses

according to the setup time of the setup/hold combination selected,

+0.0 ps or −100 ps as measured on the oscilloscope:

a On the Oscilloscope, select [Define meas] Define ∆ Time - Stop edge:

rising, Edge number 2.

b In the oscilloscope timebase menu, select Position. Using the

oscilloscope knob, position the data waveform so the falling edge is near

the center of the display.

Setup/Hold

Times

Setup/Hold

Window

Sample Position

(in middle of Window)

41

Page 42

Chapter 3: Testing Performance

To test the single-clock, single-edge, state acquisition

c On the oscilloscope, select [Shift] ∆ Time, then select [Enter] to display

the setup time (∆ Time(1)-(2)).

d Adjust the pulse generator channel 1 Delay until the pulses are aligned

according to the setup time of the setup/hold combination selected,

+0.0 ps or –100 ps.

3 Select the logic analyzer sample positions:

a Click the Sampling Setup icon. The Analyzer Setup dialog opens with

the Sampling tab displayed.

b Click Sample Positions....

c In the Sample Positions dialog, drag the blue bar for My Bus 1 to the

sample position of the first setup/hold combination to be tested (or

enter the value in the signal fields).

42

Page 43

Chapter 3: Testing Performance

To test the single-clock, single-edge, state acquisition

d Click OK to close the Sample Positions dialog.

4 Select the clock to be tested:

The following clock configurations will be used in steps 4, 5, and 6.

a In the Analyzer Setup dialog, click on the Sampling tab.

b In the Sampling tab, click the Master button for the first clock to be

tested (Clk 1) and select Rising Edge.

43

Page 44

Chapter 3: Testing Performance

To test the single-clock, single-edge, state acquisition

c Click the Master buttons for the remaining clocks and select Don't Care

to turn off the other clocks.

d Connect the clock to be tested to the pulse generator channel 1 output.

e Click OK to close the Analyzer Setup dialog.

5 Verify the test data:

a Click the Run icon.

b If you have not already done so, do “Set up the Markers:” on page 34.

c If the "can't find 4096 occurence(s)" message does not appear, the test

passes.

The test passes when the logic analyzer finds all occurances of the patterns

programmed into the Markers. If the test passes, record a "Pass" in the

performance test record under single-clock single-edge next to the clock and

edge being tested.

6 Test the next clock:

a Click on the Sampling Setup icon.

b Disconnect the clock just tested from the pulse generator.

c Repeat steps 4, 5, and 6 for the next clock configuration listed in step 4

until all listed clock combinations have been tested.

7 Enable the pulse generator channel 1 COMP (with the LED on).

8 Using the Delay mode of the pulse generator channel 1, position the pulses

according to the setup/hold combination selected, +0.0 ps or –100 ps as

measured on the oscilloscope:

a On the Oscilloscope, select [Define meas] Define ∆ Time - Stop edge:

falling.

b On the oscilloscope, select [Shift] ∆ Time. Select Start src: channel 1,

44

Page 45

Chapter 3: Testing Performance

To test the single-clock, single-edge, state acquisition

then select [Enter] to display the setup time (∆ Time(1)-(2)).

c Adjust the pulse generator channel 1 Delay until the pulses are aligned

according to the setup time of the setup/hold combination selected,

+0.0 ps or –100 ps.

9 Select the clock to be tested:

The following clock configurations will be used in steps 9, 10 and 11.

a In the Analyzer Setup dialog, click the Sampling tab.

b In the Sampling tab, click the Master button for the first clock to be

tested (Clk 1) and select Falling Edge.

45

Page 46

Chapter 3: Testing Performance

To test the single-clock, single-edge, state acquisition

c Click the Master buttons for the remaining clocks and select Don't Care

to turn off the other clocks.

d Connect the clock to be tested to the pulse generator channel 1 output.

e Click OK to close the Analyzer Setup dialog.

10 Verify the test data:

a Click the Run icon.

b If you have not already done so, do “Set up the Markers:” on page 34.

c If the "can't find 4096 occurence(s)" message does not appear, the test

passes.

The test passes when the logic analyzer finds all occurances of the patterns

programmed into the Markers. If the test passes, record a "Pass" in the

performance test record under single-clock single-edge next to the clock and

edge being tested.

11 Test the next clock:

a Click the Sampling Setup icon.

b Disconnect the clock just tested from the pulse generator.

c Repeat steps 9, 10, and 11 for the next clock configuration listed in step

9 until all listed clock combinations have been tested.

12 Test the next setup/hold combination:

a Click the Bus/Signal Setup icon.

b Disconnect the clock just tested from the pulse generator.

c Repeat steps 1 through 12 for the next setup/hold combination listed on

page 41.

46

Page 47

Chapter 3: Testing Performance

To test the single-clock, single-edge, state acquisition

Test the next channels (1680/81A,AD and 1690/91A,AD)

Connect the next combination of data channels and clock channels; then, test

them.

Start with “Connect and configure the logic analyzer” on page 37, connect the

next combination; then, continue through the complete test.

47

Page 48

Chapter 3: Testing Performance

To test the multiple-clock state acquisition

To test the multiple-clock state acquisition

Testing the multiple-clock, state acquisition verifies the performance of the

following specifications:

• Minimum master-to-master clock time.

• Maximum state acquisition speed.

• Setup/Hold time for multiple-clock, state acquisition.

This test checks two combinations of data using multiple clocks at two selected

setup/hold times.

Equipment Required

Equipment Critical Specifications Recommended Model/Part

Pulse Generator 200 MHz 3.0 ns pulse width,

< 600 ps rise time

Digitizing Oscilloscope ≥ 6 GHz bandwidth, < 58 ps rise time 54750A w/ 54751A

Adapter SMA(m)-BNC(f) 1250-1200

SMA Coax Cable (Qty 3) 18 GHz bandwidth 8120-4948

Coupler BNC(m)(m) 1250-0216

BNC Test Connector,

6x2 (Qty 4)

8133A option 003

Set up the equipment

1 If you have not already done so, do the following procedures:

“To set up the test equipment and the logic analyzer” on page 23.

“To set up the logic analyzer for the state mode tests” on page 33.

2 Increase the pulse generator channel 2 width to 3.000 ns.

48

Page 49

Chapter 3: Testing Performance

To test the multiple-clock state acquisition

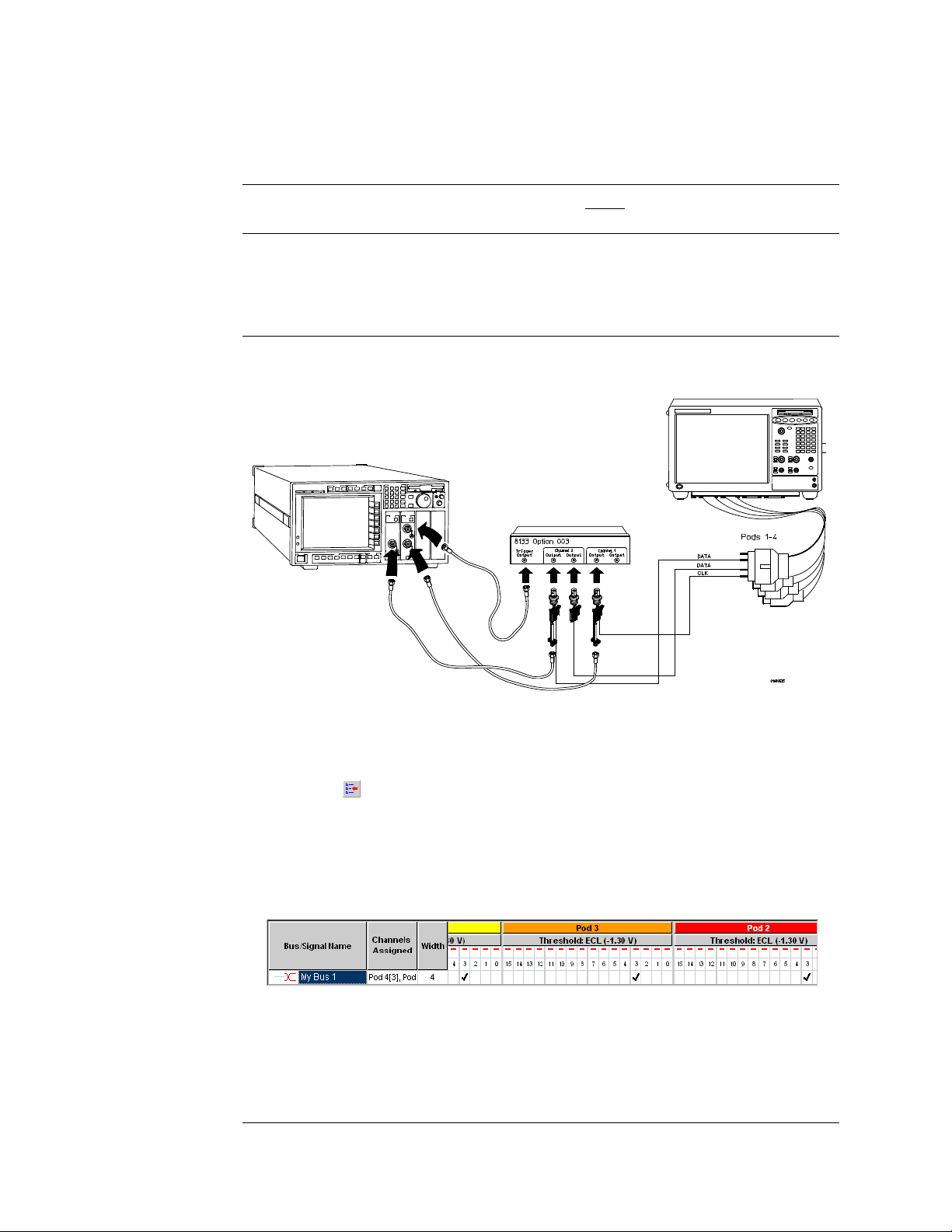

Connect and configure the logic analyzer

1 Using the 6-by-2 test connectors, connect the first combination of logic

analyzer clock and data channels listed in one of the following tables to the

pulse generator.

If you are testing a 1680/81/90/91A,AD, you will repeat this test for the second

combination.

2 Using SMA cables, connect channel 1, channel 2, and trigger of the

oscilloscope to the pulse generator.

Connect the 1680/81/90/91A,AD Logic Analyzer to the Pulse Generator

Tes ti ng

Combinations

1 Pod 1, channel 3

2 Pod 1, channel 11

*1680A, AD or 1690A, AD only.

Connect to 8133A

Channel 2 Output

Pod 3, channel 3

Pod 5, channel 3

Pod 7, channel 3

Pod 3, channel 11

Pod 5, channel 11

Pod 7, channel 11

Connect to 8133A

Channel 2 Output

Pod 2, channel 3

Pod 4, channel 3

Pod 6, channel 3

Pod 8, channel 3 *

Pod 2, channel 11

Pod 4, channel 11

Pod 6, channel 11

Pod 8, channel 11 *

Connect to 8133A

Channel 1 Output

Clock/data channel for

Pod 1, 2, 3, and 4

(Clk 1, Clk 2, Clk 3,

Clk 4)

Clock/data channel for

Pod 1, 2, 3, and 4

(Clk 1, Clk 2, Clk 3,

Clk 4)

49

Page 50

Chapter 3: Testing Performance

To test the multiple-clock state acquisition

Connect the 1682/83/92/93A,AD Logic Analyzer to the Pulse Generator

Tes ti ng

Combination

1 Pod 1, channel 3

*1682A, AD or 1692A, AD only.

Connect to 8133A

Channel 2 Output

Pod 2, channel 3

Pod 3, channel 3

Pod 4, channel 3

Connect to 8133A

Channel 2 Output

Pod 1, channel 11

Pod 2, channel 11

Pod 3, channel 11 *

Pod 4, channel 11 *

Connect to 8133A

Channel 1 Output

Clock/data channel for Pod 1,

2, 3, and 4 (Clk 1, Clk 2, Clk 3,

Clk 4)

3 Activate the data channels that are connected according to one of the

previous tables:

a Click the Bus/Signal Setup icon. The Analyzer Setup dialog opens.

b Under the Buses/Signals tab, click Delete All at the bottom of the

dialog.

c Using the mouse, activate the data channels being tested. Assign

channels to bus/signal name My Bus 1.

d Click OK to close the Analyzer Setup dialog.

50

Page 51

Chapter 3: Testing Performance

To test the multiple-clock state acquisition

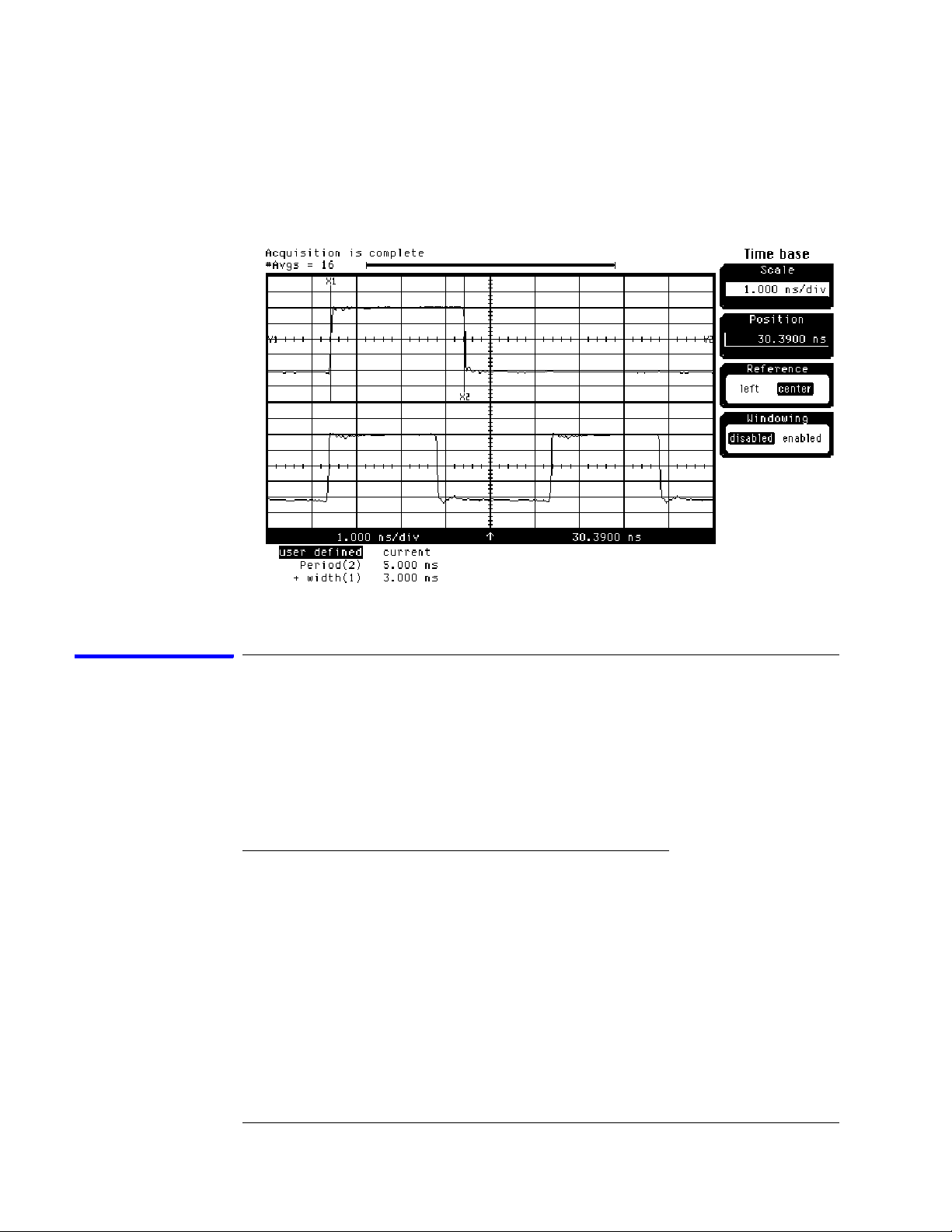

Verify the test signal

1 Check the clock period. Using the oscilloscope, verify that the master-to-

master clock time is 5.000 ns, +0 ps or –100 ps:

a In the oscilloscope Timebase menu, select Scale: 1.000 ns/div.

b In the oscilloscope Timebase menu, select Position. Using the

oscilloscope knob, position the clock waveform so that a rising edge

appears at the left of the display.

c On the oscilloscope, select [Shift] Period: channel 2, then select [Enter]

to display the clock period (Period(2)). If the period is not less than

5.000 ns, go to step d. If the period is less than 5.000 ns, go to step 2.

d In the oscilloscope Timebase menu, increase Position 5.000 ns. If the

period is not less than 5.000 ns, decrease the pulse generator Period in

10 ps increments until one of the two periods measured is less than

5.000 ns.

2 Check the data pulse width. Using the oscilloscope verify that the data

pulse width is 3.000 ns, +0 ps or −100 ps:

a In the oscilloscope Timebase menu, select Position. Using the

oscilloscope knob, position the data waveform so that the waveform is

centered on the screen.

51

Page 52

Chapter 3: Testing Performance

To test the multiple-clock state acquisition

b On the oscilloscope, select [Shift] + width: channel 1, then select

[Enter] to display the data signal pulse width (+ width (1)).

c If the pulse width is outside the limits, adjust the pulse generator

channel 2 width until the pulse width is within limits.

Check the setup/hold with single clock edges, multiple clocks

The following setup/hold combinations will be tested.

Setup/Hold Combinations

Te s t

Combination

1 5.0/-2.0 ns 3.0 ns -3.5 ns

2 -1.5/4.50 ns 3.0 ns +3.0 ns

1 Disable the pulse generator channel 1 COMP (LED off).

2 Using the Delay mode of the pulse generator channel 1, position the pulses

according to the setup time of the setup/hold combination selected,

+0.0 ps or −100 ps as measured on the oscilloscope:

a On the Oscilloscope, select [Define meas] Define ∆ Time - Stop edge:

rising, Edge number 2.

Setup/Hold

Times

Setup/Hold

Window

Sample Position

(in middle of Window)

52

Page 53

Chapter 3: Testing Performance

To test the multiple-clock state acquisition

b In the oscilloscope timebase menu, select Position. Using the

oscilloscope knob, position the data waveform so the falling edge is near

the center of the display.

c On the oscilloscope, select [Shift] ∆ Time, then select [Enter] to display

the setup time (∆ Time(1)-(2)).

d Adjust the pulse generator channel 1 Delay until the pulses are aligned

according to the setup time of the setup/hold combination selected,

+0.0 ps or –100 ps.

3 Select the clocks to be tested:

a Click the Sampling Setup icon. The Analyzer Setup dialog opens.

b In the Sampling tab, click the Master button for one of the clocks and

select Rising Edge.

c Repeat the above steps for each of the remaining clocks until all clocks

have been configured with Rising Edge.

53

Page 54

Chapter 3: Testing Performance

To test the multiple-clock state acquisition

d Connect all clock channels to the pulse generator channel 1 output.

e Click OK to close the Analyzer Setup dialog.

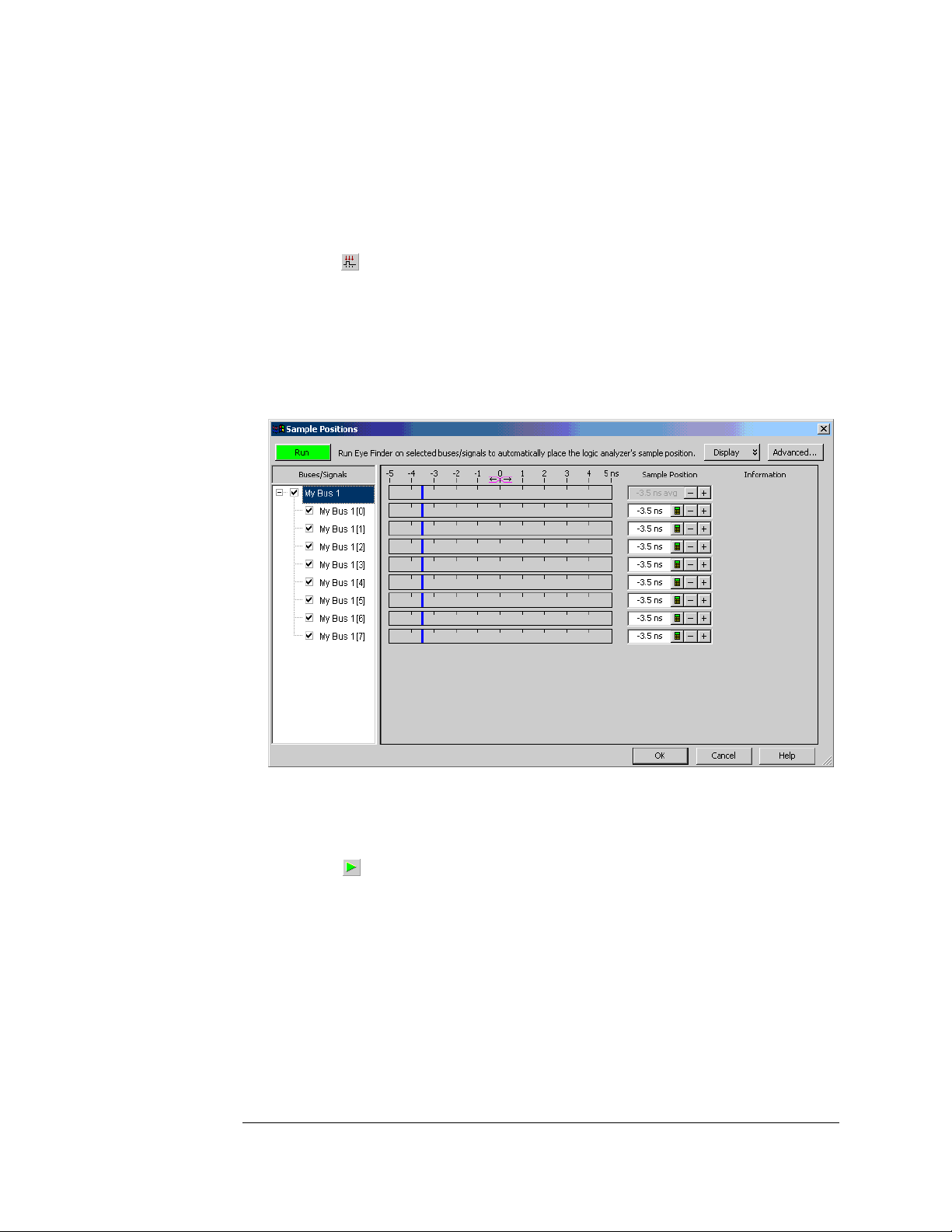

4 Select the logic analyzer sample positions:

a Click the Sampling Setup icon. The Analyzer Setup dialog opens with

the Sampling tab displayed.

b Click Sample Positions....

c In the Sample Positions dialog, drag the blue bar for My Bus 1 to the

sample position of the first setup/hold combination to be tested (or

enter the value in the signal fields).

d Click OK to close the Sample Positions dialog.

5 Verify the test data:

a Click the Run icon.

b If you have not already done so, do “Set up the Markers:” on page 34.

c If the "can't find 4096 occurence(s)" message does not appear, then the

test passes.

The test passes when the logic analyzer finds all occurances of the patterns

programmed into the Markers. If the test passes, record a "Pass" in the

performance test record under single-clock single-edge next to the clock and

edge being tested.

54

Page 55

Chapter 3: Testing Performance

To test the multiple-clock state acquisition

6 Enable the pulse generator channel 1 COMP (with the LED on).

7 Using the Delay mode of the pulse generator channel 1, position the pulses

according to the setup/hold combination selected, +0.0 ps or –100 ps:

a On the Oscilloscope, select [Define meas] Define ∆ Time - Stop edge:

falling.

b On the oscilloscope, select [Shift] ∆ Time. Select Start src: channel 1,

then select [Enter] to display the setup time (∆ Time(1)-(2)).

c Adjust the pulse generator channel 1 Delay until the pulses are aligned

according to the setup time of the setup/hold combination selected,

+0.0 ps or –100 ps.

8 Select the clocks to be tested:

a Click the Sampling Setup icon. The Analyzer Setup dialog opens.

b In the Sampling tab, click the Master button for one of the clocks and

select Falling Edge.

c Repeat the above steps for each of the remaining clocks until all clocks

55

Page 56

Chapter 3: Testing Performance

To test the multiple-clock state acquisition

have been configured with Falling Edge.

d Click OK to close the Analyzer Setup dialog.

9 Verify the test data:

a Click the Run icon.

b If you have not already done so, do “Set up the Markers:” on page 34.

c If the "can't find 4096 occurence(s)" message does not appear, the test

passes.

The test passes when the logic analyzer finds all occurances of the patterns

programmed into the Markers. If the test passes, record a "Pass" in the

performance test record under single-clock single-edge next to the clock and

edge being tested.

10 Test the next setup/hold combination:

a Click the Bus/Signal Setup icon.

b Disconnect the clock just tested from the pulse generator.

c Repeat steps 1 through 10 for the next setup/hold combination listed in

step 1 in page 52.

When aligning the data and clock waveforms using the oscilloscope, align the

waveforms according to the setup time of the setup/hold combination being

tested, +0.0 ps or −100 ps.

Test the next channels (1680/81A, AD and 1690/91A, AD)

Connect the next combination of data channels and clock channels, then repeat

the previous test.

Start with “Connect and configure the logic analyzer” on page 49, connect the

next combination, then continue through the complete test.

56

Page 57

Chapter 3: Testing Performance

To test the single-clock, multiple-edge, state acquisition

To test the single-clock, multiple-edge, state acquisition

Testing the single-clock, multiple-edge, state acquisition verifies the performance

of the following specifications:

• Minimum master-to-master clock time.

• Maximum state acquisition speed.

• Setup/Hold time for single-clock, multiple-edge, state acquisition.

This test checks two combinations of data using a multiple-edge single clock at

two selected setup/hold times.

Equipment Required

Equipment Critical Specifications Recommended Model/Part

Pulse Generator 200 MHz 3.0 ns pulse width, < 600 ps rise time 8133A option 003

Digitizing Oscilloscope ≥ 6 GHz bandwidth, < 58 ps rise time 54750A w/ 54751A

Adapter SMA(m)-BNC(f) 1250-1200

SMA Coax Cable (Qty 3) 18 GHz bandwidth 8120-4948

Coupler BNC(m)(m) 1250-0216

BNC Test Connector,

6x2 (Qty 4)

Set up the equipment

1 If you have not already done so, do the following procedures:

“To set up the test equipment and the logic analyzer” on page 23

“To set up the logic analyzer for the state mode tests” on page 33

2 Modify the following pulse generator settings:

Period: 10.000 ns

Channel 2: Width 3.000 ns

Channel 2: Pulse ÷1

Channel 1: Pulse

Channel 1: Width 5.000 ns

57

Page 58

Chapter 3: Testing Performance

To test the single-clock, multiple-edge, state acquisition

Connect and configure the logic analyzer

1 Using the 6-by-2 test connectors, connect the first combination of logic

analyzer clock and data channels listed in one of the following tables to the

pulse generator.

If you are testing a 1680/81/90/91A,AD, you will repeat this test for the second

combination.

2 Using the SMA cables, connect channel 1, channel 2, and trigger from the

oscilloscope to the pulse generator.

Connect the 1680/81/90/91A,AD Logic Analyzer to the Pulse Generator

Tes ti ng

Combinations

1 Pod 1, channel 3

2 Pod 1, channel 11

*1680A,AD or 1690A,AD only.

Connect to 8133A

Channel 2 Output

Pod 3, channel 3

Pod 5, channel 3

Pod 7, channel 3

Pod 3, channel 11

Pod 5, channel 11

Pod 7, channel 11

Connect to 8133A Channel

2 Output

Pod 2, channel 3

Pod 4, channel 3

Pod 6, channel 3

Pod 8, channel 3 *

Pod 2, channel 11

Pod 4, channel 11

Pod 6, channel 11

Pod 8, channel 11 *

Connect to 8133A

Channel 1 Output

Pod 1 clock/data channel

(Clk1)

Pod 1 clock/data channel

(Clk1)

58

Page 59

Chapter 3: Testing Performance

To test the single-clock, multiple-edge, state acquisition

Connect the 1682/83/92/93A,AD Logic Analyzer to the Pulse Generator

Tes ti ng

Combination

1 Pod 1, channel 3

*1682A,AD or 1692A,AD only.

Connect to 8133A

Channel 2 Output

Pod 2, channel 3

Pod 3, channel 3

Pod 4, channel 3

Connect to 8133A Channel

2 Output

Pod 1, channel 3

Pod 2, channel 3

Pod 3, channel 3 *

Pod 4, channel 3 *

Connect to 8133A

Channel 1 Output

Pod 1 clock/data channel

(Clk1)

3 Activate the data channels that are connected according to one of the

previous tables:

a Click the Bus/Signal Setup icon. The Analyzer Setup dialog opens.

b In the Buses/Signals tab, click Delete All at the bottom of the dialog.

c Using the mouse, activate the data channels being tested. Assign

channels to bus/signal name My Bus 1.

d Click OK to close the Analyzer Setup dialog.

59

Page 60

Chapter 3: Testing Performance

To test the single-clock, multiple-edge, state acquisition

Verify the test signal

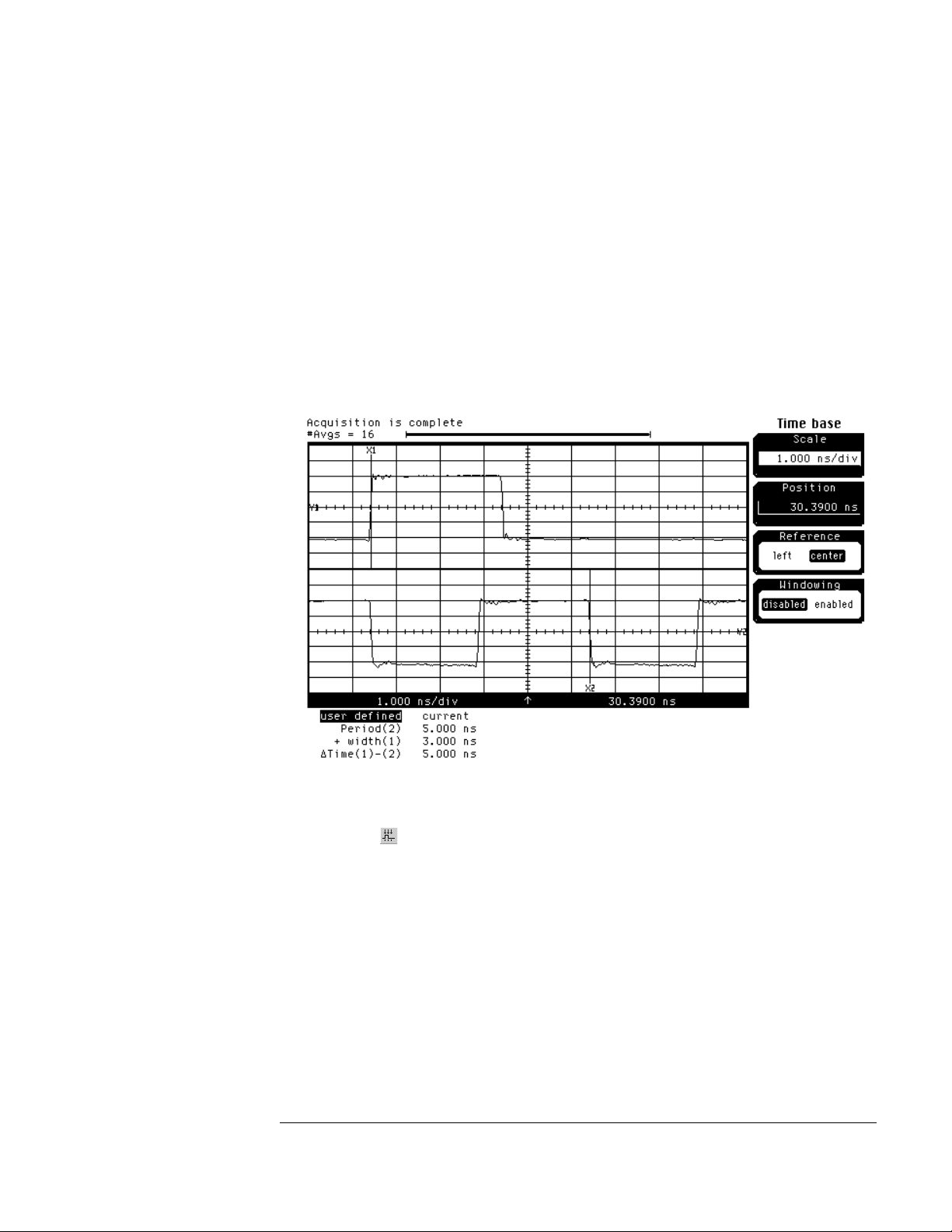

1 Check the clock period. Using the oscilloscope, verify that the master-to-

master clock time is 5.000 ns, +0 ps or –100 ps:

a Enable the pulse generator channel 1, channel 2, and trigger outputs

(LED off).

b In the oscilloscope Timebase menu, select Scale: 2.000 ns/div.

c In the oscilloscope Timebase menu, select Position. Using the

oscilloscope knob, position the clock waveform so that a rising edge

appears at the left of the display.

d On the oscilloscope, select [Shift] + width: channel 2, then select

[Enter] to display the master-to-master clock time (+ width(2)). If the

positive-going pulse width is more than 5.000 ns, go to step e. If the

positive-going pulse width is less than or equal to 5.000 ns but greater

than 4.900 ns, go to step 2.

e On the oscilloscope, select [Shift] - width: channel 2, then select [Enter]

(- width(2)). If the negative pulse width is less than or equal to 5.000 ns

but greater than 4.900 ns, go to step 2.

f Adjust the pulse generator Period and Channel 1 width until the

oscilloscope + width (2) or - width (2) reads less than or equal to

5.000 ns, but greater than 4.900 ns.

60

Page 61

Chapter 3: Testing Performance

To test the single-clock, multiple-edge, state acquisition

2 Check the data pulse width. Using the oscilloscope, verify that the data

pulse width is 3.000 ns, +0 ps or −100 ps:

a In the oscilloscope Timebase menu, select Scale: 1.000 ns/div.

b In the oscilloscope Timebase menu, select Position. Using the

oscilloscope knob, position the data waveform so that the waveform is

centered on the screen.

c On the oscilloscope, select [Shift] + width: channel 1, then select

[Enter] to display the data signal pulse width (+ width(1)).

d If the pulse width is outside the limits, adjust the pulse generator

channel 2 width until the pulse width is within limits.

Check the setup/hold with single clock, multiple clock edges

The following setup/hold combinations will be tested.

Setup/Hold Combinations

Te s t

Combination

1 5.0/-2.0 ns 3.0 ns -3.5 ns

2 -1.5/4.50 ns 3.0 ns +3.0 ns

61

Setup/Hold

Times

Setup/Hold

Window

Sample Position

(in middle of Window)

Page 62

Chapter 3: Testing Performance

To test the single-clock, multiple-edge, state acquisition

1 Using the Delay mode of the pulse generator channel 2, position the pulses

according to the setup time of the setup/hold combination selected,

+0.0 ps or –100 ps:

a On the Oscilloscope, select [Define meas] Define ∆ Time - Stop edge:

rising.

b In the oscilloscope timebase menu, select Position. Using the

oscilloscope knob, position the falling edge of the data waveform so that

it is near the center of the display.

c On the oscilloscope, select [Shift] ∆ Time. Select Start src: channel 1,

then select [Enter] to display the setup time (∆ Time(1)-(2)).

d Adjust the pulse generator channel 2 Delay until the pulses are aligned

according to the setup time of the setup/hold combination selected,

+0.0 ps or –100 ps.

2 Select the logic analyzer sample positions:

a Click the Sampling Setup icon. The Analyzer Setup dialog opens with

the Sampling tab displayed.

b Click Sample Positions....

c In the Sample Positions dialog, drag the blue bar for My Bus 1 to the

sample position of the first setup/hold combination to be tested (or

enter the value in the signal fields).

62

Page 63

Chapter 3: Testing Performance

To test the single-clock, multiple-edge, state acquisition

d Click OK to close the Sample Positions dialog.

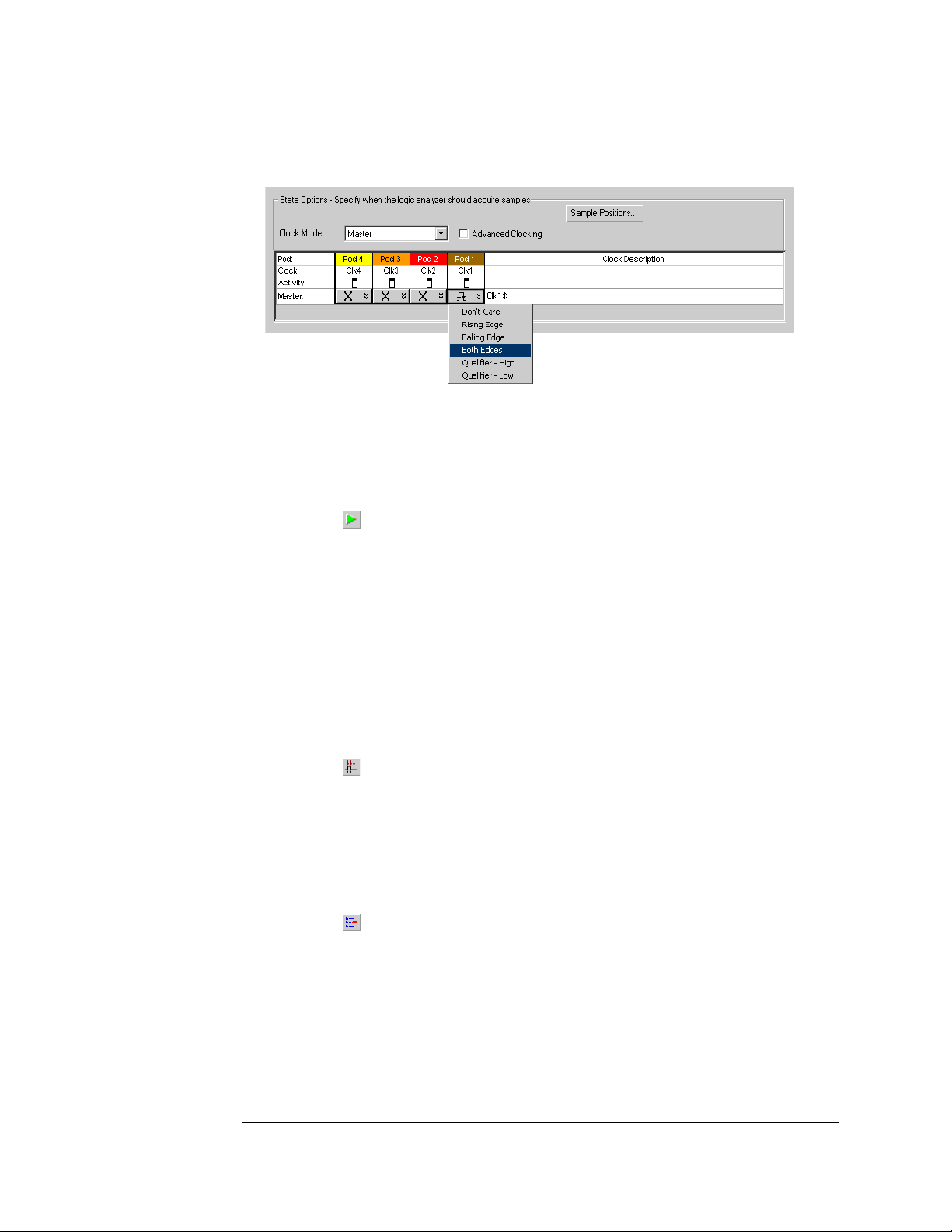

3 Select the clock to be tested:

The following clock configurations will be used in steps 3, 4, and 5.

a In the Analyzer Setup dialog, click the Sampling tab.

b In the Sampling tab, click the Master button for the first clock to be

tested (Clk 1) and select Both Edges.

c Click the Master buttons for the remaining clocks and select Don't Care

63

Page 64

Chapter 3: Testing Performance

To test the single-clock, multiple-edge, state acquisition

to turn off the other clocks.

d Connect the clock to be tested to the pulse generator channel 1 output.

e Click OK to close the Analyzer Setup dialog.

4 Verify the test data:

a Click the Run icon.

b If you have not already done so, do “Set up the Markers:” on page 34.

c If the "can't find 4096 occurence(s)" does not appear, then the test

passes.

The test passes when the logic analyzer finds all occurrences of the patterns

programmed into the Markers. If the test passes, record a "Pass" in the

performance test record under single-clock single-edge next to the clock and

edge being tested.

5 Test the next clock:

a Click the Sampling Setup icon.

b Disconnect the clock just tested from the pulse generator.

c Repeat steps 3, 4, and 5 for the next clock configuration listed in step 4

until all listed clock combinations have been tested.

6 Test the next setup/hold combination:

a Click the Bus/Signal Setup icon.

b Disconnect the clock just tested from the pulse generator.

c Repeat steps 1 through 6 for the next setup/hold combination listed in

step 1 in page 61.

64

Page 65

Chapter 3: Testing Performance

To test the single-clock, multiple-edge, state acquisition

Test the next channels (1680/81A,AD and 1690/91A,AD)

Connect the next combination of data channels and clock channels, then repeat

the previous test.

Start with “Connect and configure the logic analyzer” on page 58, connect the

next combination, then continue through the complete test.

65

Page 66

Chapter 3: Testing Performance

To test the time interval accuracy

To test the time interval accuracy

Testing the time interval accuracy does not check a specification, but does check

the following:

• 125 MHz oscillator

This test verifies that the 125 MHz timing acquisition synchronizing oscillator is

operating within limits.

Equipment Required

Equipment Critical Specifications Recommended Model/Part

Pulse Generator 200 MHz 2.5 ns pulse width, < 600 ps rise time 8133A option 003

Function Generator

SMA Cable 8120-4948

Adapter BNC(m)-SMA(f) 1250-2015

BNC Test Connector, 6x2

Accuracy≤ (5)(10

-6)

x frequency

33250A

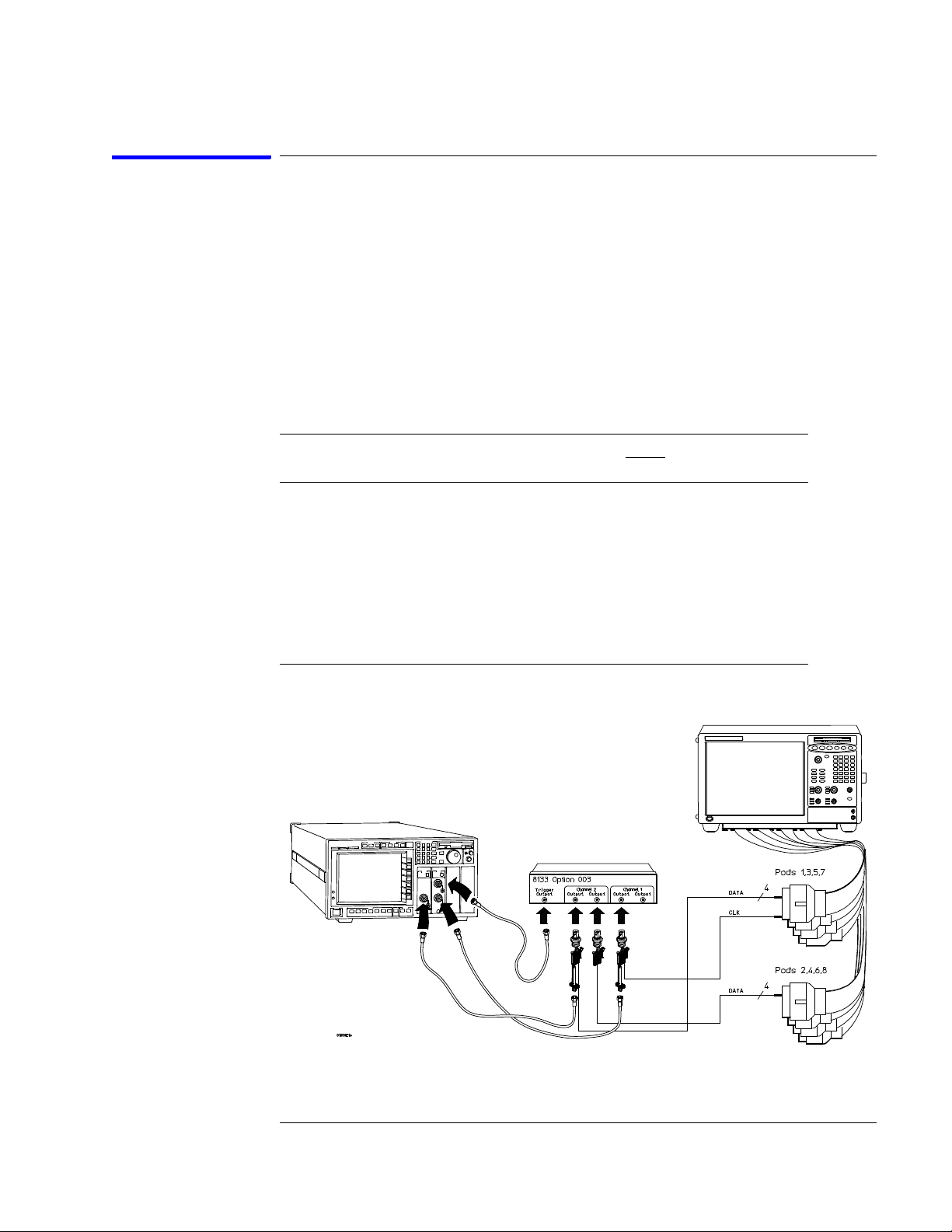

Set up the equipment

1 Set up the logic analyzer:

a If you have not already done so, do the procedure “To set up the test

equipment and the logic analyzer” on page 23.

b Exit and restart the Agilent Logic Analyzer applications to reinitialize

the logic analyzer.

2 Set up the pulse generator according to the following table.

Pulse Generator Setup

Timebase Channel 1 Trigger

Mode: Ext Mode: Square Divide: Divide ÷ 1

Delay: 0.000 ns Ampl: 0.50 V

High: -0.90 V Ampl: 0.50 V

Low: -1.70 V Offs: 0.00V

COMP: Disabled (LED off)

66

Page 67

Chapter 3: Testing Performance

To test the time interval accuracy

3 Set up the function generator according to the following table.

Function Generator Setup

Freq: 40.000 MHz

Ampl: 1.00 Vpp

Offset: 0.0 mV

Modulation Off

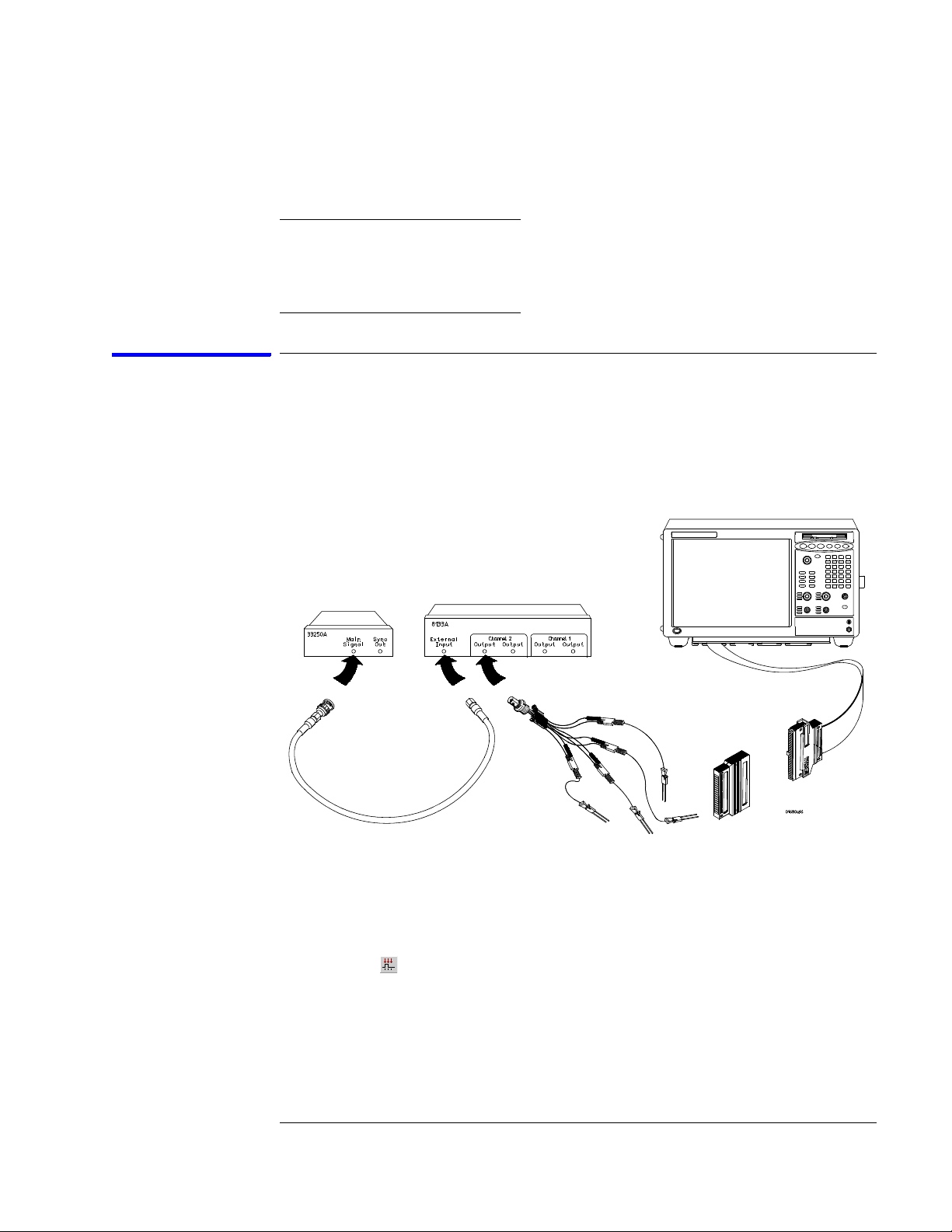

Connect and configure the logic analyzer

1 Using a 6-by-2 test connector, connect channel 0 of Pod 1 to the pulse

generator channel 1 output.

2 Using the SMA cable and the BNC adapter, connect the External Input of

the pulse generator to the Main Signal of the function generator.

3 Enable the function generator output and the pulse generator Channel 1

output.

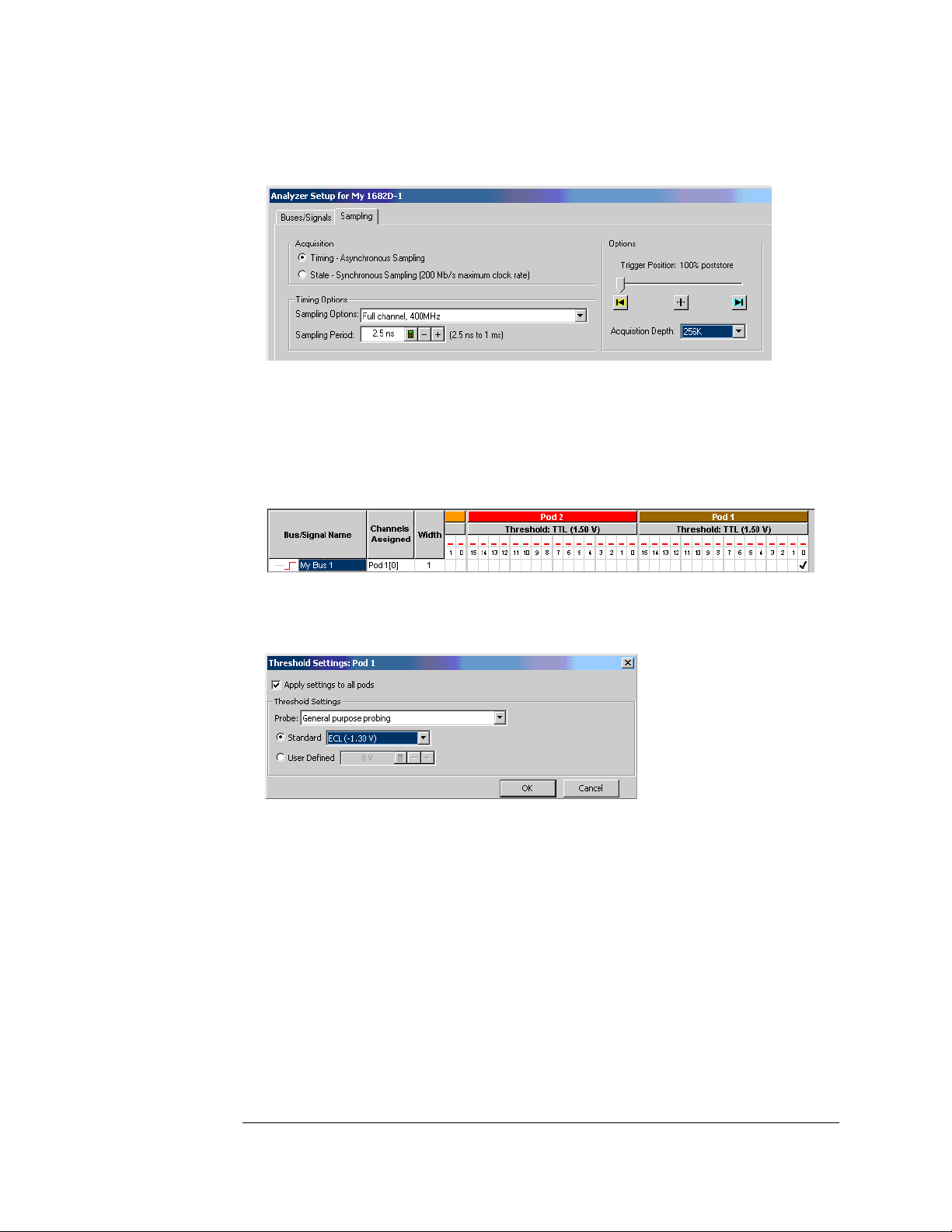

4 Configure the Analyzer Setup dialog:

a Click the Sampling Setup icon.

b In the Analyzer Setup dialog, select Timing - Asynchronous Sampling.

c Configure Trigger Position - 100% poststore.

67

Page 68

Chapter 3: Testing Performance

To test the time interval accuracy

d Select an Acquisition Depth of 256K.

5 Configure the logic analyzer channels:

a Click the Buses/Signals tab. In the Buses/Signals tab, click Delete All at

the bottom of the dialog.

b Using the mouse, select Pod 1 channel 0 to activate the channel.

c Click the threshold field for Pod 1. In the Threshold Settings dialog,

select Standard and ECL (–1.30).

d Click OK to close the Threshold Settings dialog.

e Click OK to close the Analyzer Setup dialog.

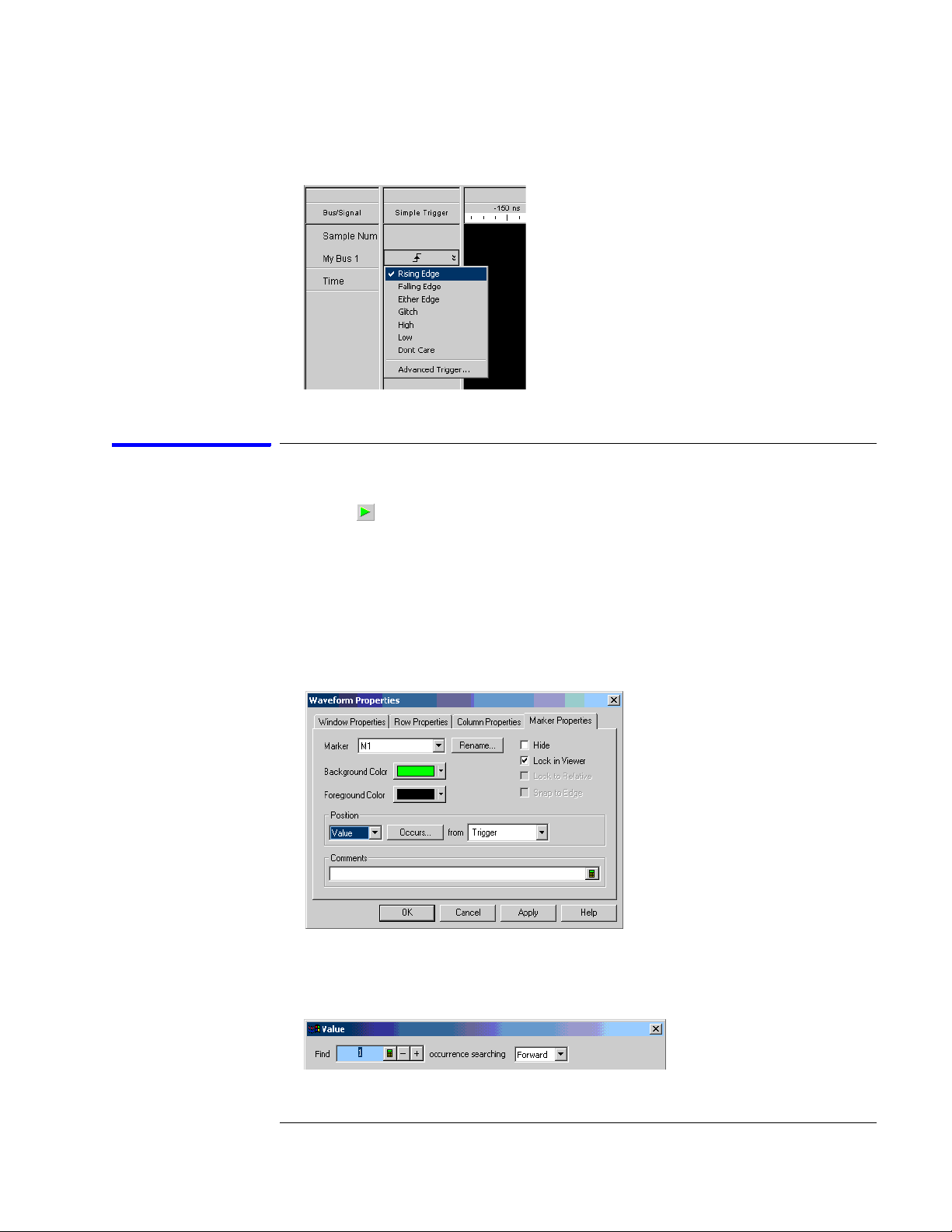

6 Set up the trigger in the Waveform window:

a Select the Simple Trigger field next to bus/signal name My Bus 1.

68

Page 69

b In the pop-up menu, select Rising Edge.

Acquire and verify the test data

Chapter 3: Testing Performance

To test the time interval accuracy

1 Click the Run icon to fill acquisition memory.

2 Set up the M1 marker for time interval measurement:

a From the main menu, choose Markers>Properties....

b In the Marker Properties tab of the Waveform Properties dialog, select

the M1 marker.

c In the Position box, select Value.

d Click Occurs....

e In the Value dialog, enter “1” in the Find occurrences field.

69

Page 70

Chapter 3: Testing Performance

To test the time interval accuracy

f Click OK to close the Value dialog.

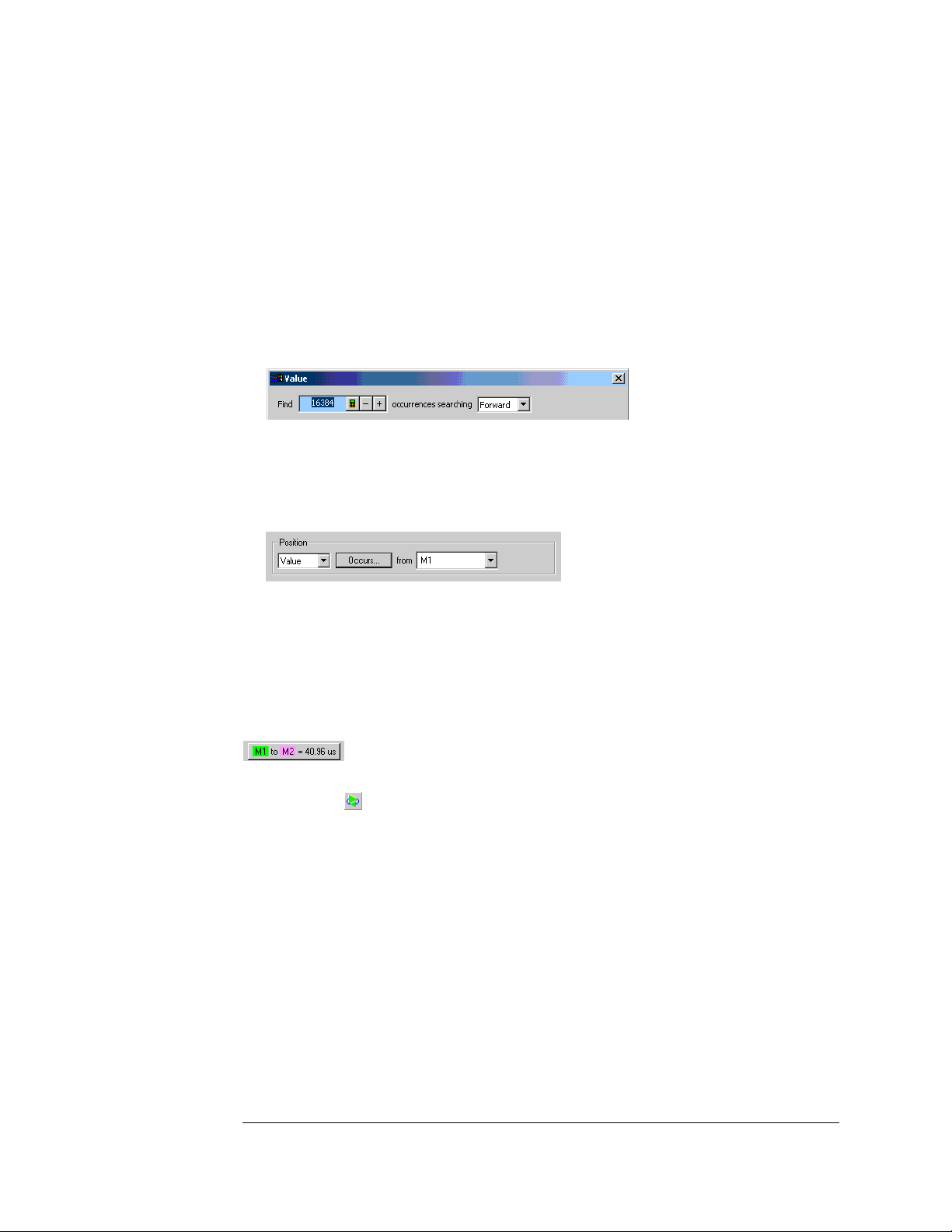

3 Set up the M2 marker for time interval measurement:

a In the Marker Properties tab of the Waveform Properties dialog, select

the M2 marker.

b In the Position box, select Value.

c Click Occurs....

d In the Value dialog, enter “16384” in the Find occurrences field.

e Click OK to close the Value dialog.

f In the Position box, select M1 in the “from” field. The Position should

now read Value Occurs from M1.

g Click Apply; then, click OK to close the Waveform Properties dialog.

4 An Interval Measurement should already be visible in the Markers Toolbar.

If not, choose Markers>New Time Interval Measurement from the main

menu; in the Time Interval dialog, select from M1 to M2, and click OK. An

M1 to M2 time interval field should now be visible in the Markers Toolbar.

5 Click on the Run-Repetitive icon. Allow the logic analyzer to acquire

data for at least 100 runs, as reported at the bottom of the window.

Observe the M1 to M2 time interval field in the Markers Toolbar and

ensure the time interval field is between 40.95571 and 40.96429 µs during

the test.

70

Page 71

Chapter 3: Testing Performance

Performance Test Record

Performance Test Record

Agilent 1680/90-Series Logic Analyzer_______

Serial No.______________________ Work Order No.___________________

Recommended Test Interval - 2 Years/4000 hours Date___________________

Recommended next testing___________________ Temperature___________________

Test Settings Results

Self-Tests

Threshold

Accuracy

Pass/Fail

± (65 mV + 1.5% of threshold setting)

________

Pod 1 ECL, ±84 mV

0 V, ±65 mV

Pod 2 ECL, ±84mV

0 V, ± 65mV

Pod 3 ECL, ±84 mV

0 V, ±65 mV

Pod 4 ECL, ±84 mV

0 V, ±65 mV

Pod 5 ECL, ±84 mV

0 V, ±65 mV

Pod 6 ECL, ±84 mV

0 V, ±65 mV

Pod 7 ECL, ±84 mV

0 V, ±65 mV

Pod 8 ECL, ±84 mV

0 V, ±65 mV

Pass/Fail

Pass/Fail

Pass/Fail

Pass/Fail

Pass/Fail

Pass/Fail

Pass/Fail

Pass/Fail

Pass/Fail

Pass/Fail

Pass/Fail

Pass/Fail

Pass/Fail

Pass/Fail

Pass/Fail

Pass/Fail

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

71

Page 72

Chapter 3: Testing Performance

Performance Test Record

Performance Test Record (continued)

Test Settings Results

Single-Clock, SingleEdge Acquisition

All Pods, Channel 3 Setup/Hold Time 4.5/-2.0 ns Clk 1↑

Clk 2↑

Clk 3↑

Clk 4↑

Setup/Hold Time -2.0/4.5 ns Clk 1↑

Clk 2↑

Clk 3↑

Clk 4↑

All Pods, Channel 11 Setup/Hold Time 4.5/-2.0 ns Clk 1↑

Clk 2↑

Clk 3↑

Clk 4↑

Setup/Hold Time -2.0/4.5 ns Clk 1↑

Clk 2↑

Clk 3↑

Clk 4↑

Multiple-Clock,

Multiple-Edge

Acquisition

Pass/Fail Pass/Fail

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

Clk 1↓

Clk 2↓

Clk 3↓

Clk 4↓

Clk 1↓

Clk 2↓

Clk 3↓

Clk 4↓

Clk 1↓

Clk 2↓

Clk 3↓

Clk 4↓

Clk 1↓

Clk 2↓

Clk 3↓

Clk 4↓

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

________

All Pods, Channel 3 Setup/Hold Time 5.0/-2.0 ns Clk 1↑ + Clk 2↑ +

Clk 3↑ + Clk 4↑

Setup/Hold Time -1.5/4.5 ns Clk 1↑+ Clk 2↑ +

Clk 3↑ + Clk 4↑

All Pods, Channel 11 Setup/Hold Time 5.0/-2.0 ns Clk 1↑ + Clk 2↑ +

Clk 3↑ + Clk 4↑

Setup/Hold Time -1.5/4.5 ns Clk 1↑ + Clk 2↑ +

Clk 3↑ + Clk 4↑

72

Pass/Fail Pass/Fail

________ Clk 1↓ + Clk 2↓ +

Clk 3↓ + Clk 4↓

________ Clk 1↓ + Clk 2↓ +

Clk 3↓ + Clk 4↓

________ Clk 1↓+ Clk 2↓ +

Clk 3↓ + Clk 4↓

________ Clk 1↓ + Clk 2↓ +

Clk 3↓ + Clk 4↓

________

________

________

________

Page 73

Performance Test Record (continued)

Test Settings Results

Single-Clock,

Multiple-Edge

Acquisition

All Pods, Channel 3 Setup/Hold Time 5.0/-2.0 ns Clk 1 ↑↓

Setup/Hold Time -1.5/4.5 ns Clk 1 ↑↓

All Pods, Channel 11 Setup/Hold Time 5.0/-2.0 ns Clk 1 ↑↓