Page 1

Help Volume

© 1992-2002 Agilent Technologies. All rights reserved.

Agilent Technologies 16760A

Logic Analyzer

Page 2

Agilent Technologies 16760A Logic Analyzer

The Agilent Technologies 16760A 1500 Mb/s State/800 MHz Timing

logic analyzer offers 64M deep memory with up to 170 channels on a

single time base (5 cards, 34 channels per card). Differential probing

captures input signals as low as 200 mV p-p.

“Getting Started” on

page 13

“Probing and

Selecting the

Sampling Mode” on

page 33

• “Probing and Sampling Mode Selection Steps” on page 15

• “Timing Mode or State Mode Steps” on page 22

• “Eye Scan Mode Steps” on page 26

• “Probing the Device Under Test” on page 35

• “Using the E5378A Single-Ended Probe” on page 35

• “Using the E5379A Differential Probe” on page 37

• “Using the E5380A Mictor-Compatible Probe” on page 39

• “Using the E5382A Single-ended Flying Lead Probe Set” on page 40

• “Using an Analysis Probe” on page 41

• “Choosing the Sampling Mode” on page 43

• “Selecting the Timing Mode (Asynchronous Sampling)” on page 43

• “Selecting the State Mode (Synchronous Sampling)” on page 46

• “In Either Timing Mode or State Mode” on page 53

• “Selecting the Eye Scan Mode” on page 55

• “Formatting Labels for Logic Analyzer Probes” on page 57

“Using the Logic

Analyzer in Timing or

State Mode” on

page 67

• “Setting Up Triggers and Running Measurements” on page 69

• “Using Trigger Functions” on page 70

• “Using Other Trigger Features” on page 75

2

Page 3

Agilent Technologies 16760A Logic Analyzer

• “Editing the Trigger Sequence (Timing or 200, 400 Mb/s State Only)”

on page 78

• “Editing Advanced Trigger Functions (Timing or 200 Mb/s State Only)”

on page 83

• “Saving/Recalling Trigger Setups” on page 90

• “Running Measurements” on page 91

• “Displaying Captured Data” on page 94

• “Using Symbols” on page 101

• “Printing/Exporting Captured Data” on page 110

• “Cross-Triggering” on page 112

• “Solving Logic Analysis Problems” on page 114

• “Saving and Loading Logic Analyzer Configurations” on page 116

“Using the Logic

Analyzer in Eye Scan

Mode” on page 117

“Reference” on

page 153

“Concepts” on

page 239

• “Setting Up and Running Eye Scan Measurements” on page 119

• “Displaying Captured Eye Scan Data” on page 133

• “Saving and Loading Captured Eye Scan Data” on page 152

• “The Sampling Tab” on page 155

• “The Format Tab” on page 174

• “The Trigger Tab” on page 176

• “The Symbols Tab” on page 193

• “The Eye Scan Tab” on page 204

• “The Calibration Tab” on page 210

• “Error Messages” on page 211

• “Specifications and Characteristics” on page 227

• “Understanding Logic Analyzer Triggering” on page 240

• “Understanding State Mode Sampling Positions” on page 256

• “Understanding Eye Scan Measurements” on page 259

3

Page 4

Agilent Technologies 16760A Logic Analyzer

See Also Main System Help (see the Agilent Technologies 16700A/B-Series Logic

Analysis System help volume)

Glossary (see page 263)

4

Page 5

Contents

Agilent Technologies 16760A Logic Analyzer

1 Getting Started

Probing and Sampling Mode Selection Steps 15

Step 1. Connect logic analyzer to the device under test 15

Step 2. Choose the sampling mode 16

Step 3. Format labels for the probed signals 19

Timing Mode or State Mode Steps 22

Step 4. Define the trigger condition 22

Step 5. Run the measurement 23

Step 6. Display the captured data 24

Eye Scan Mode Steps 26

Step 4. Select channels for the eye scan measurement 26

Step 5. Set the eye scan range and resolution 27

Step 6. Run the eye scan measurement 28

Step 7. Display the captured eye scan data 29

For More Information... 31

2 Probing and Selecting the Sampling Mode

Probing the Device Under Test 35

Using the E5378A Single-Ended Probe 35

Using the E5379A Differential Probe 37

Using the E5380A Mictor-Compatible Probe 39

Using the E5382A Single-ended Flying Lead Probe Set 40

Using an Analysis Probe 41

5

Page 6

Contents

Choosing the Sampling Mode 43

Selecting the Timing Mode (Asynchronous Sampling) 43

Selecting the State Mode (Synchronous Sampling) 46

In Either Timing Mode or State Mode 53

Selecting the Eye Scan Mode 55

Formatting Labels for Logic Analyzer Probes 57

To assign pods to the analyzer 57

To set pod threshold voltages 58

To set clock threshold voltages 59

To assign probe channels to labels 60

To import label names and assignments from a netlist 62

To import label definitions from an ASCII file 63

To export label definitions to an ASCII file 64

To change the label polarity 64

To reorder bits in a label 65

To turn labels off or on 66

3 Using the Logic Analyzer in Timing or State Mode

Setting Up Triggers and Running Measurements 69

Using Trigger Functions 70

Using Other Trigger Features 75

Editing the Trigger Sequence (Timing or 200, 400 Mb/s State Only) 78

Editing Advanced Trigger Functions (Timing or 200 Mb/s State Only) 83

Saving/Recalling Trigger Setups 90

Running Measurements 91

Displaying Captured Data 94

To open Waveform or Listing displays 94

To use other display tools 95

If the captured data doesn't look correct 97

If there are filtered data holes in display memory 98

To display symbols for data values 99

To cancel the display processing of captured data 100

6

Page 7

Contents

Using Symbols 101

To load object file symbols 102

To adjust symbol values for relocated code 103

To create user-defined symbols 104

To enter symbolic label values 105

To create an ASCII symbol file 106

To create a readers.ini file 107

Printing/Exporting Captured Data 110

Cross-Triggering 112

To cross-trigger with another instrument 112

Solving Logic Analysis Problems 114

To test the logic analyzer hardware 114

Saving and Loading Logic Analyzer Configurations 116

4 Using the Logic Analyzer in Eye Scan Mode

Setting Up and Running Eye Scan Measurements 119

To select channels for the eye scan 119

To set the eye scan range and resolution 120

To run an eye scan measurement 121

To set advanced eye scan options 121

To set up qualified eye scan measurements 122

To comment on the eye scan settings 132

7

Page 8

Contents

Displaying Captured Eye Scan Data 133

To open the Eye Scan display 133

To select the channels displayed 134

To scale the Eye Scan display 135

To set Eye Scan display options 136

To make measurements on the eye scan data 142

To display information about the eye scan data 149

To comment on the eye scan data 151

Saving and Loading Captured Eye Scan Data 152

5 Reference

The Sampling Tab 155

Timing Mode 156

State Mode 158

Sampling Positions Dialog 159

Eye Scan Mode 172

The Format Tab 174

Pod Assignment Dialog 175

The Trigger Tab 176

Trigger Functions Subtab 177

Settings Subtab 188

Overview Subtab 189

Default Storing Subtab 190

Status Subtab 191

Save/Recall Subtab 191

The Symbols Tab 193

Symbols Selector Dialog 195

Symbol File Formats 197

General-Purpose ASCII (GPA) Symbol File Format 198

8

Page 9

Contents

The Eye Scan Tab 204

Labels Subtab 204

Scan Settings Subtab 205

Advanced Subtab 206

Qualifier Subtab 208

Comments Subtab 209

The Calibration Tab 210

Error Messages 211

Analyzer armed from another module contains no "Arm in from IMB"

event 212

Branch expression is too complex 212

Cannot specify range on label with clock bits that span pod pairs 217

Counter value checked as an event, but no increment action specified 218

Goto action specifies an undefined level 218

Hardware Initialization Failed 218

Maximum of 32 Channels Per Label 219

Must assign another pod pair to specify actions for flags 219

Must assign Pod 1 on the master card to specify actions for flags 219

No more Edge/Glitch resources available for this pod pair 219

No more Pattern resources available for this pod pair 220

No Trigger action found in the trace specification 221

Slow or Missing Clock 221

Timer value checked as an event, but no start action specified 222

Trigger function initialization failure 222

Trigger inhibited during timing prestore 223

Trigger Specification is too complex 223

Waiting for Trigger 225

9

Page 10

Contents

Specifications and Characteristics 227

E5378A Single-Ended Probe Specifications and Characteristics 228

E5379A Differential Probe Specifications and Characteristics 228

E5380A MICTOR-Compatible Probe Specifications and Characteristics 229

1500 Mb/s Sampling Mode Specifications and Characteristics 230

1250 Mb/s Sampling Mode Specifications and Characteristics 231

800 Mb/s Sampling Mode Specifications and Characteristics 232

400 Mb/s Sampling Mode Specifications and Characteristics 233

200 Mb/s Sampling Mode Specifications and Characteristics 234

Conventional Timing Mode Specifications and Characteristics 235

Transitional Timing Mode Specifications and Characteristics 235

What is a Specification? 236

What is a Characteristic? 237

6 Concepts

Understanding Logic Analyzer Triggering 240

The Conveyor Belt Analogy 240

Summary of Triggering Capabilities 242

Sequence Levels 242

Boolean Expressions 245

Branches 246

Edges 246

Ranges 246

Flags 247

Occurrence Counters and Global Counters 247

Timers 248

Storage Qualification 249

Strategies for Setting Up Triggers 251

Conclusions 255

Understanding State Mode Sampling Positions 256

Understanding Eye Scan Measurements 259

10

Page 11

Contents

Glossary

Index

11

Page 12

Contents

12

Page 13

1

Getting Started

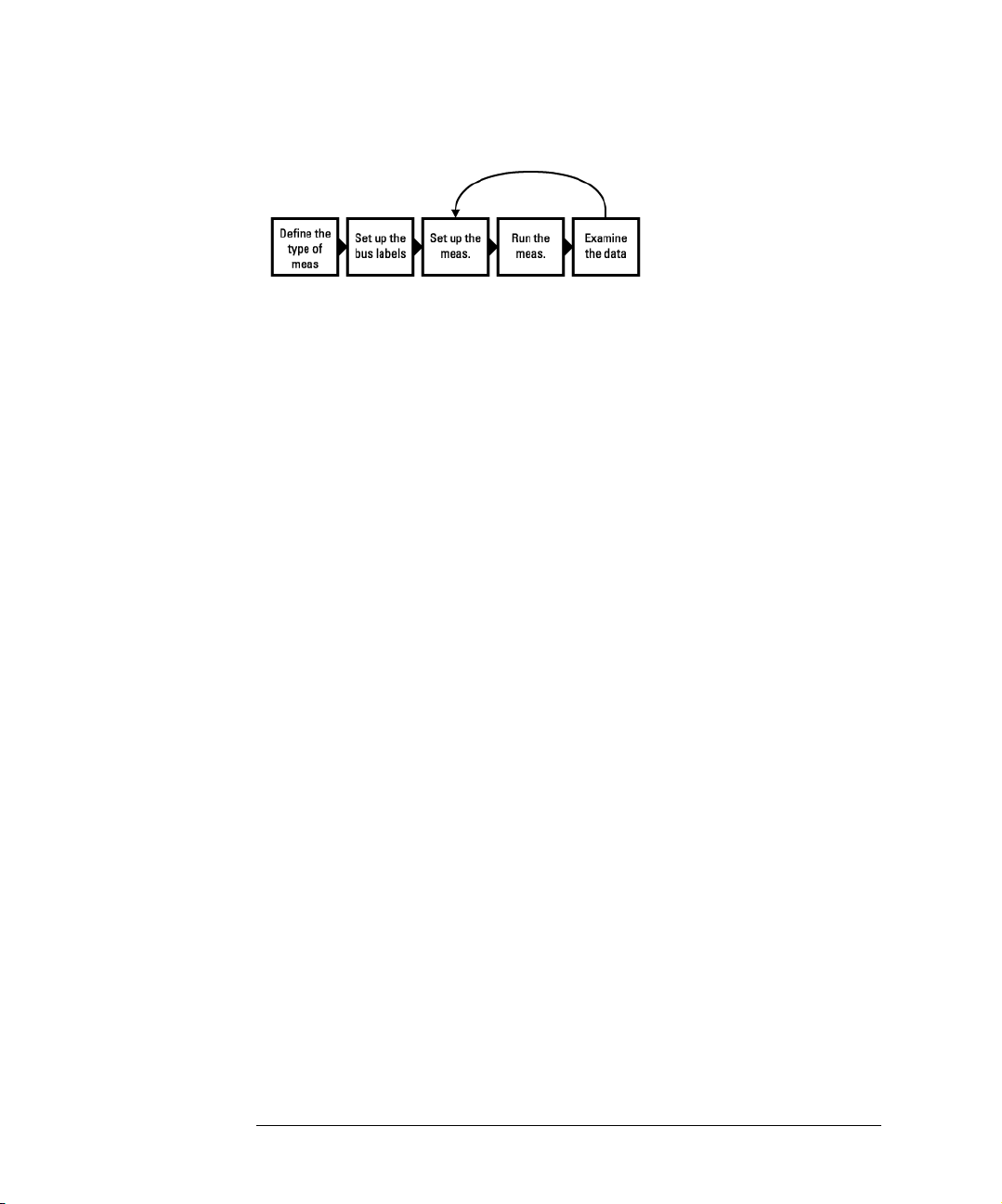

After you have connected the logic analyzer probes to your device

under test (see “Step 1. Connect logic analyzer to the device under

test” on page 15), all measurements will have the following initial steps:

13

Page 14

Chapter 1: Getting Started

• “Step 2. Choose the sampling mode” on page 16

• “Step 3. Format labels for the probed signals” on page 19

In the timing (asynchronous) or state (synchronous) sampling modes,

measurements will have these steps:

• “Step 4. Define the trigger condition” on page 22

• “Step 5. Run the measurement” on page 23

• “Step 6. Display the captured data” on page 24

In the eye scan sampling mode, measurements will have these steps:

• “Step 4. Select channels for the eye scan measurement” on page 26

• “Step 5. Set the eye scan range and resolution” on page 27

• “Step 6. Run the eye scan measurement” on page 28

• “Step 7. Display the captured eye scan data” on page 29

If you have previously saved a logic analyzer setup to a configuration

file, or if configuration files are included with an analysis probe, you

can load the configuration file to set up the logic analyzer and the

measurement.

Once you have made a logic analyzer measurement, the measurement

can be refined by repeating the measurement set up, run, and display

steps.

Next: “Step 1. Connect logic analyzer to the device under test” on

page 15

14

Page 15

Chapter 1: Getting Started

Probing and Sampling Mode Selection Steps

Probing and Sampling Mode Selection Steps

You will always take the following steps regardless of the sampling

mode you plan to use.

• “Step 1. Connect logic analyzer to the device under test” on page 15

• “Step 2. Choose the sampling mode” on page 16

• “Step 3. Format labels for the probed signals” on page 19

Step 1. Connect logic analyzer to the device under test

Before you begin setting up the logic analyzer for a measurement, you

need to physically connect the logic analyzer to your device under test.

There are four probing options available to connect your logic analyzer

to the device under test:

• Single-ended probes with Samtec connectors (see page 35).

• Differential probes with Samtec connectors (see page 37).

• Single-ended probes with MICTOR connectors (see page 39).

•Use an analysis probe to connect to microprocessors and standard buses.

When using an analysis probe, the Setup Assistant guides you through the

connection and setup process for your particular logic analyzer and

analysis probe.

Next: “Step 2. Choose the sampling mode” on page 16

15

Page 16

Chapter 1: Getting Started

Probing and Sampling Mode Selection Steps

Step 2. Choose the sampling mode

There are three logic analyzer sampling modes to choose from: timing

mode, state mode, and eye scan mode.

In timing mode, the logic analyzer samples asynchronously, based on

an internally-generated sampling clock.

In state mode, the logic analyzer samples synchronously, based on a

sampling clock signal from the device under test. Typically, the signal

used for sampling in state mode is a state machine or microprocessor

clock signal.

In eye scan mode, the logic analyzer samples small windows of time

and voltage on data channels around a clock signal from the device

under test. The resulting eye diagrams let you validate and

characterize the data valid windows of signals latched on the clock.

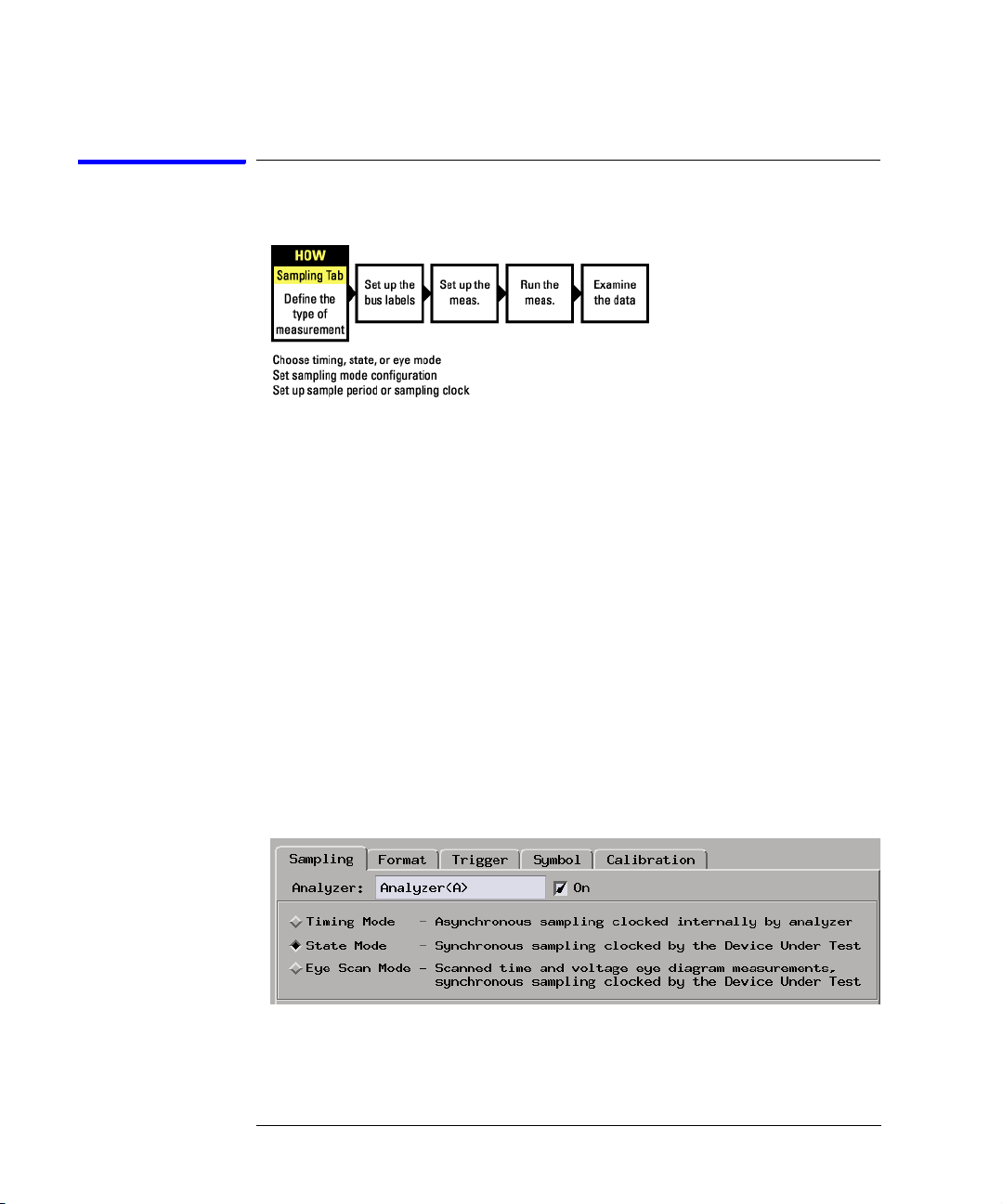

To choose the sampling mode

1. In the Sampling tab, choose Timing Mode, State Mode, or Eye Scan

Mode.

16

Page 17

Chapter 1: Getting Started

Probing and Sampling Mode Selection Steps

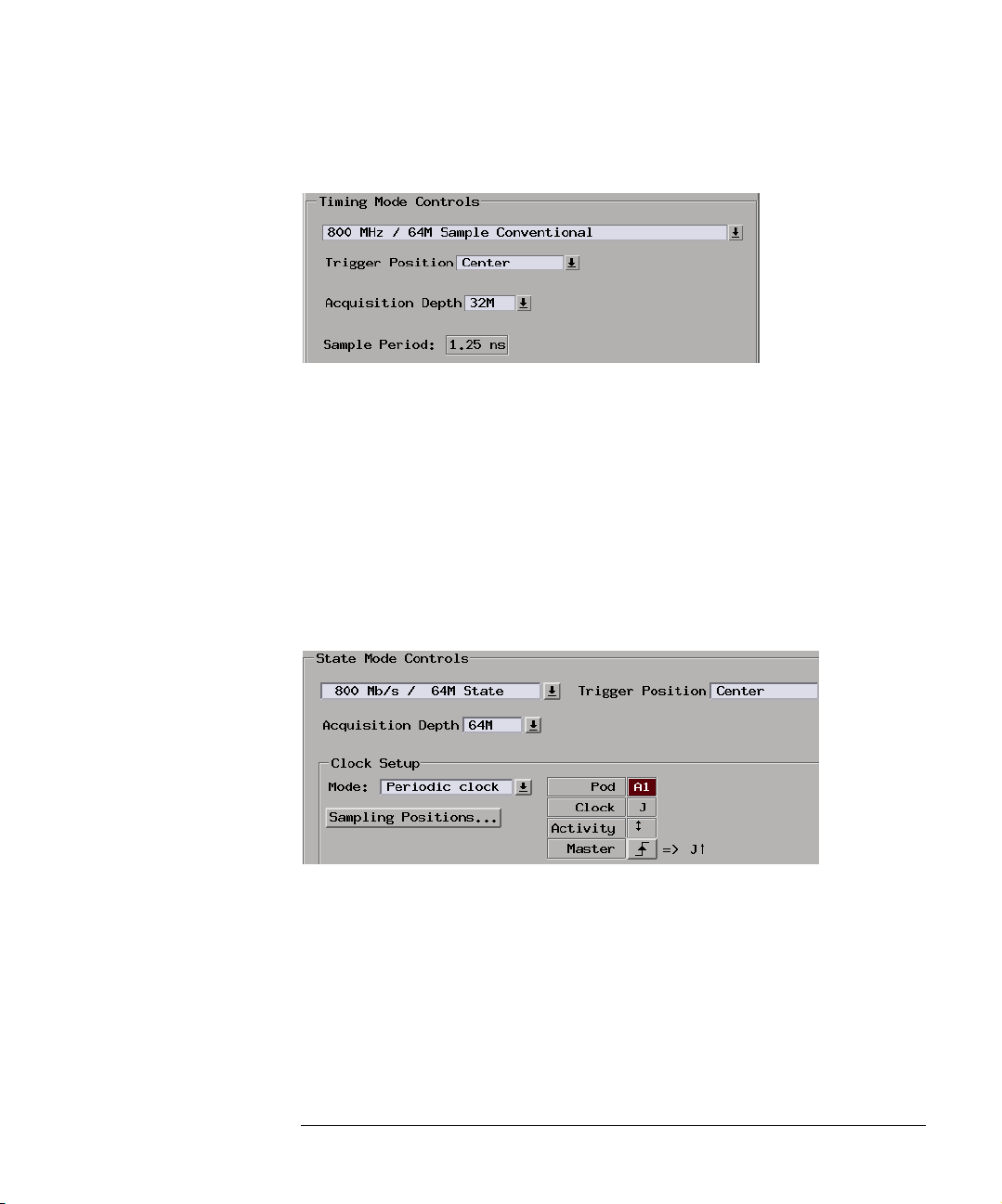

If you chose Timing Mode

1. Select the timing analyzer conventional/transitional configuration.

In the transitional timing configuration, the logic analyzer can capture a

greater period of execution because only transitions are stored in memory.

2. If you chose the transitional timing configuration, set the sample period.

To capture signal level changes reliably, the sample period should be less

than half (many engineers prefer one-fourth) of the period of the fastest

signal you want to measure.

If you chose State Mode

1. Select the state analyzer speed configuration.

There are trade-offs between high-speed sampling, the number of available

channels, triggering capabilities, and other logic analyzer characteristics.

For example, in the 1250 Mb/s configuration, a periodic clock input signal

is required.

2. In the Clock Setup, specify which clock signal edges from the device under

test will be used as the sampling clock.

17

Page 18

Chapter 1: Getting Started

Probing and Sampling Mode Selection Steps

3. Specify the sampling position. Select the Sampling Positions... button,

then select the Run Eye Finder button to locate the data valid window in

relation to the sampling clock, and automatically set the sampling position

of the logic analyzer.

See Also “To automatically adjust sampling positions” on page 49

In either Timing Mode or State Mode

1. Specify the trigger position.

The trigger is the event in the device under test that you want to capture

data around.

Specify whether you want to look at data after the trigger (Start), before

and after the trigger (Center), before the trigger (End), or use a

percentage of the logic analyzer's memory for data after the trigger (User

Defined).

2. Set the acquisition memory depth.

If you need less data and want measurements to run faster, you can limit

the amount of trace memory that is filled with samples.

If you chose Eye Scan Mode

1. Select the eye scan mode speed configuration.

There are trade-offs between high-speed sampling, the number of available

channels, and other logic analyzer characteristics.

2. In the Clock Setup, specify which clock signal edges from the device under

test will be used as the reference clock for the eye scan measurement.

Next: “Step 3. Format labels for the probed signals” on page 19

18

Page 19

Chapter 1: Getting Started

Probing and Sampling Mode Selection Steps

Step 3. Format labels for the probed signals

When a logic analyzer probes hundreds of signals in a device under

test, you need to be able to give those channels more meaningful

names than "pod 1, channel 1".

The Format tab is mainly used for assigning bus and signal names

(from the device under test) to logic analyzer channels. These names

are called labels. Labels are also used when setting up triggers and

displaying captured data.

The Format tab also lets you do things like assign pods to the logic

analyzer and specify the logic analyzer threshold voltage.

The Format tab has activity indicators that show whether the signal a

channel is probing is above the threshold voltage (high), below the

threshold voltage (low), or transitioning.

19

Page 20

Chapter 1: Getting Started

Probing and Sampling Mode Selection Steps

To assign pods to the logic analyzer

1. In the Format tab, select the Pod Assignment button.

2. In the Pod Assignment dialog, drag a pod to the appropriate logic analyzer.

3. Select the Close button.

To specify threshold voltages

The threshold voltage is the voltage level that a signal must cross

before the logic analyzer recognizes a change in logic levels.

1. In the Format tab, select the button under the pod name.

2. In the Pod threshold dialog, select a Standard, External Ref, Differential,

or a User Defined threshold voltage.

3. Select the Close button.

4. Select the Clk Thresh button.

5. In the Clock Thresholds dialog, select the button of the clock whose

threshold you wish to set.

6. In the J, K, etc., threshold dialog, select a Standard, Differential, or a User

20

Page 21

Chapter 1: Getting Started

Probing and Sampling Mode Selection Steps

Defined threshold voltage.

7. Select the Close button.

8. Select the Close button.

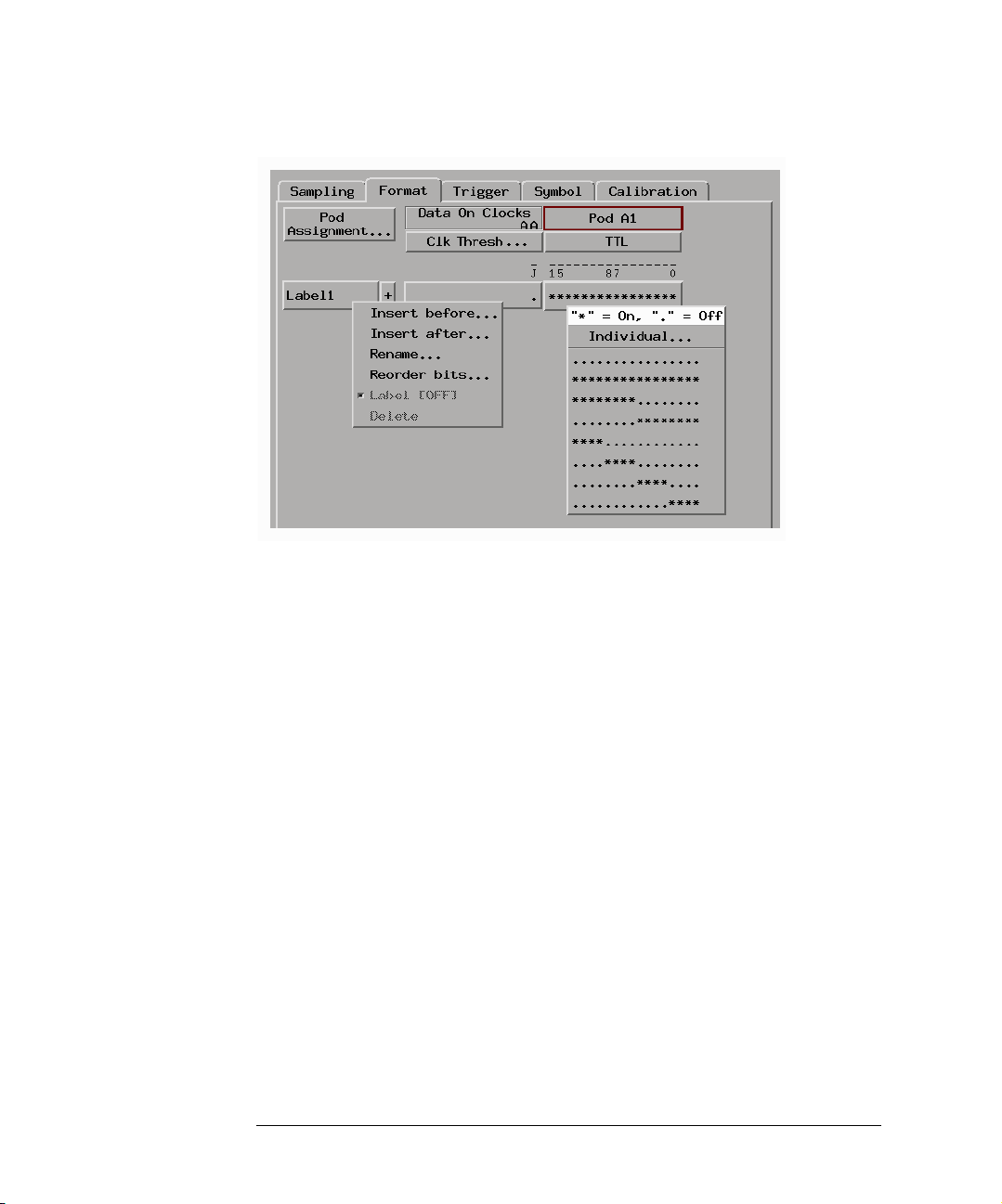

To assign names to logic analyzer channels

1. Select a label button, and either:

• Choose the Rename command, enter the label name, and select the OK

button.

• Or, choose the Insert before or Insert after command, enter the label

name, and select the OK button.

2. In the label row, select the button of the pod that contains the channels

you want to assign.

3. Either choose one of the standard channel assignments--dots (.) mean the

channel is unassigned, asterisks (*) mean the channel is assigned--or

choose Individual.

If you chose Individual:

a. In the "label - pod" dialog, select the channels you want to assign/

unassign.

b. Select the OK button.

Next:

• If you are using the logic analyzer in timing mode or in state mode, go to

“Step 4. Define the trigger condition” on page 22.

• If you are using the logic analyzer in eye scan mode, go to “Step 4. Select

channels for the eye scan measurement” on page 26.

21

Page 22

Chapter 1: Getting Started

Timing Mode or State Mode Steps

Timing Mode or State Mode Steps

When you have selected the timing or state sampling modes, you need

to perform the following steps.

• “Step 4. Define the trigger condition” on page 22

• “Step 5. Run the measurement” on page 23

• “Step 6. Display the captured data” on page 24

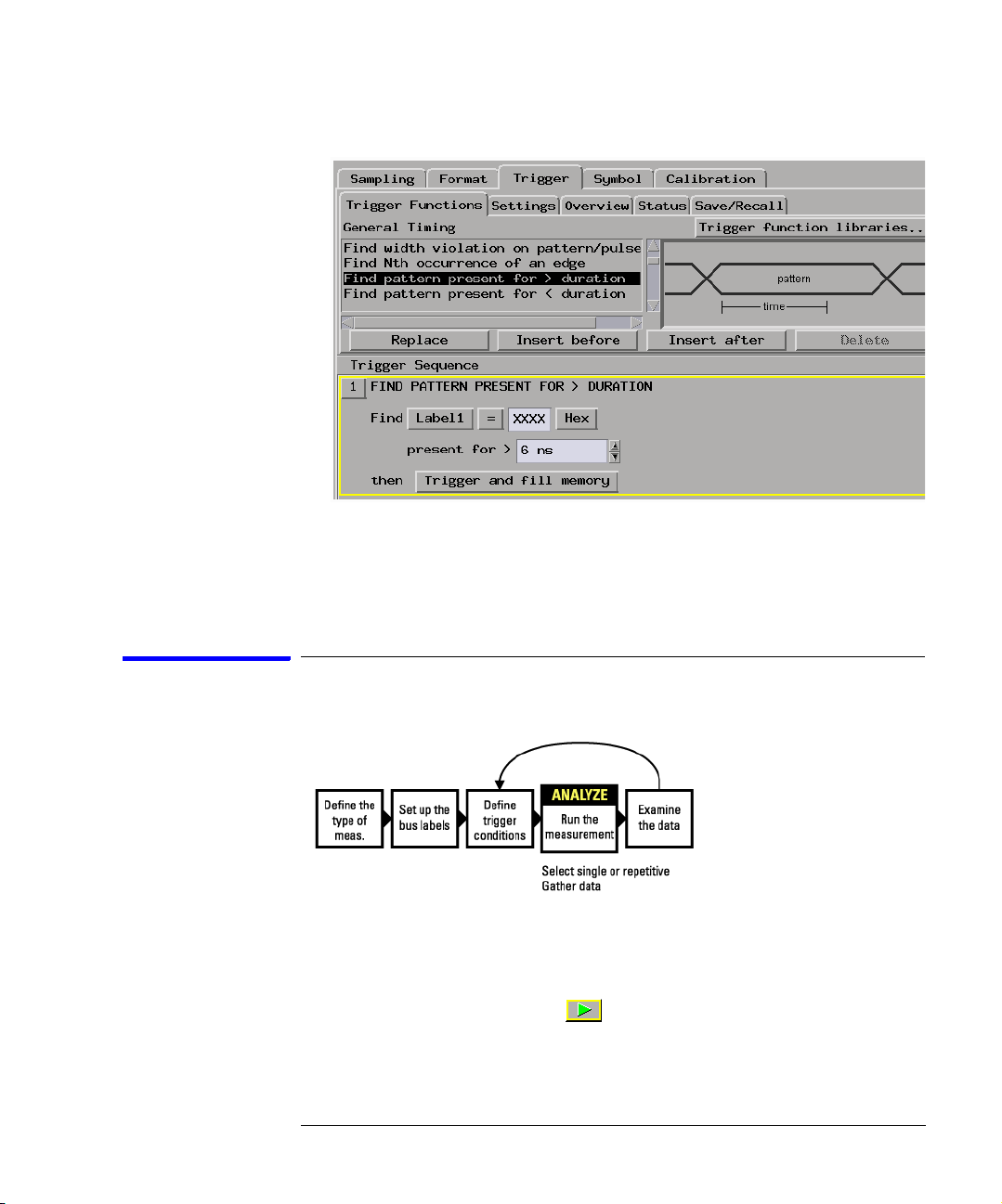

Step 4. Define the trigger condition

The trigger is the event in the device under test that you want to

capture data around.

1. In the Trigger tab, and in the Trigger Functions subtab, choose the type of

trigger you want to specify, and select the Replace button.

22

Page 23

Chapter 1: Getting Started

Timing Mode or State Mode Steps

2. In the Trigger Sequence portion of the Trigger tab, select the buttons to

define the label values and/or other conditions you want to trigger on.

Next: “Step 5. Run the measurement” on page 23

Step 5. Run the measurement

Once the trigger condition has been defined, you can run the

measurement.

1. Select the Run Single button .

When you run a measurement, the Stop button becomes available while

the logic analyzer looks for the trigger condition.

23

Page 24

Chapter 1: Getting Started

Timing Mode or State Mode Steps

Logic analyzers with deep acquisition memory take a noticeable amount of

time to complete a run; however, messages like "Waiting in level 1" may

indicate you need to stop the measurement and refine the trigger

condition.

When the trigger condition is found, logic analyzer acquisition memory is

filled, the captured data is processed to the display tools, and the Run

Single button becomes available again.

Next: “Step 6. Display the captured data” on page 24

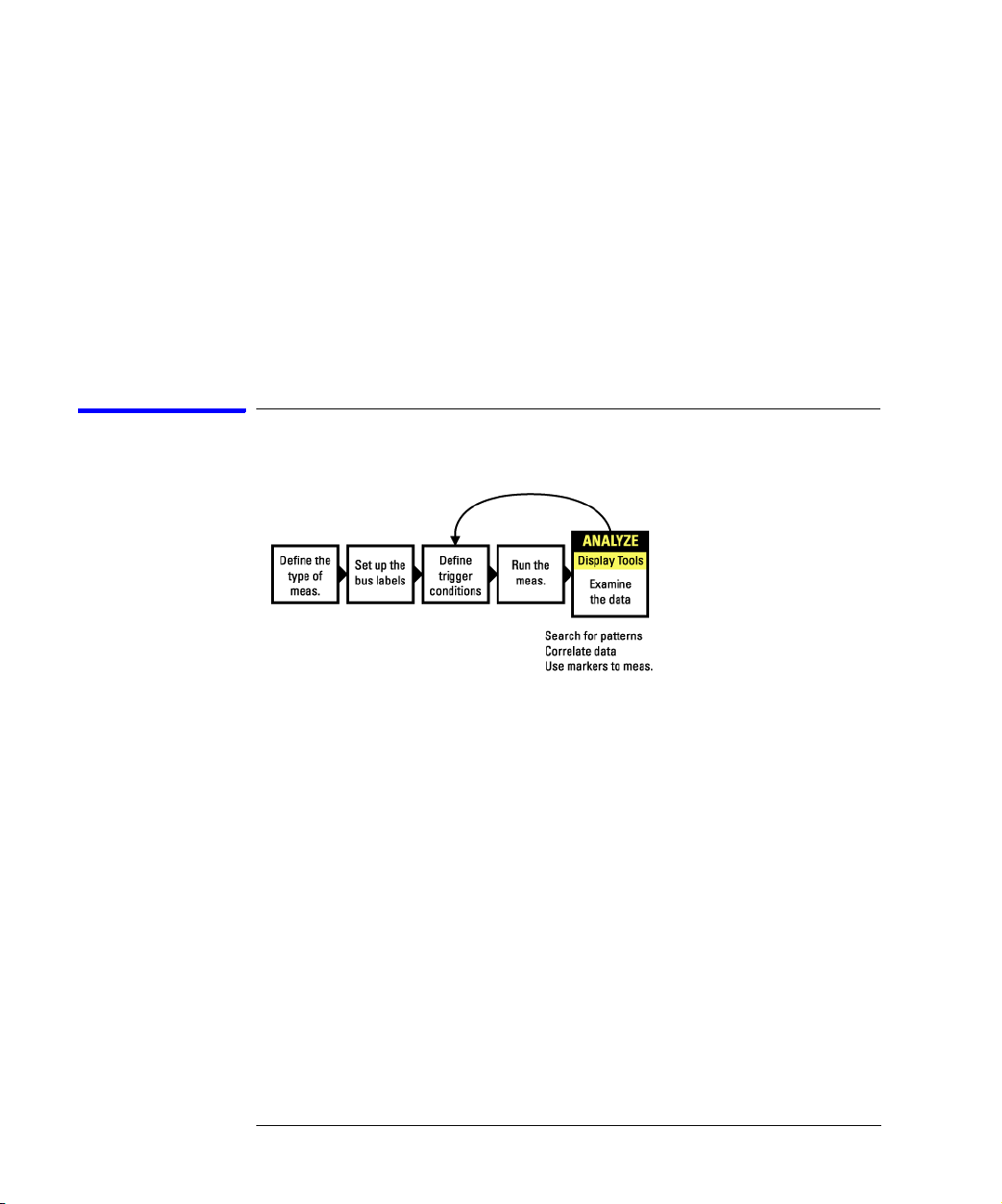

Step 6. Display the captured data

Once you have run a measurement and filled the logic analyzer's

acquisition memory with captured data, you can display it with one of

the display tools.

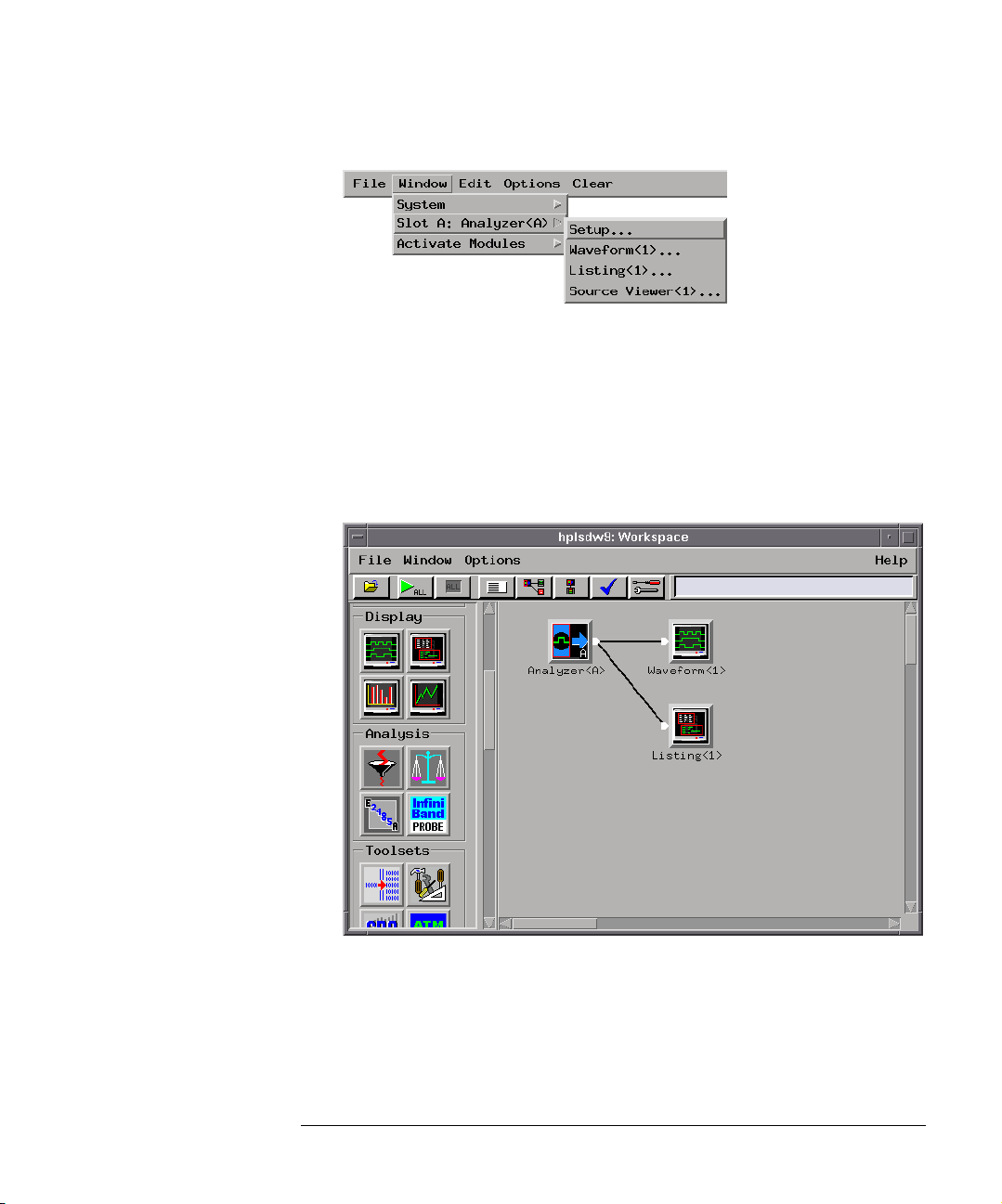

To open Waveform or Listing displays

Waveform displays are typically used when data is captured with the

timing sampling mode, and Listing displays are used when data is

captured with the state sampling mode.

1. From the Window menu, select your logic analyzer and choose the

Waveform or Listing command.

24

Page 25

Chapter 1: Getting Started

Timing Mode or State Mode Steps

To add display tools via the Workspace window

1. Select the Workspace button (or from the Window menu, select System

and Workspace).

2. In the Workspace window, scroll down to the Display portion of the tool

icon list.

3. Drag the display tool icon and drop it on the analyzer icon.

4. To open the display tool, select its icon and choose the Display command.

Next: “For More Information...” on page 31

25

Page 26

Chapter 1: Getting Started

Eye Scan Mode Steps

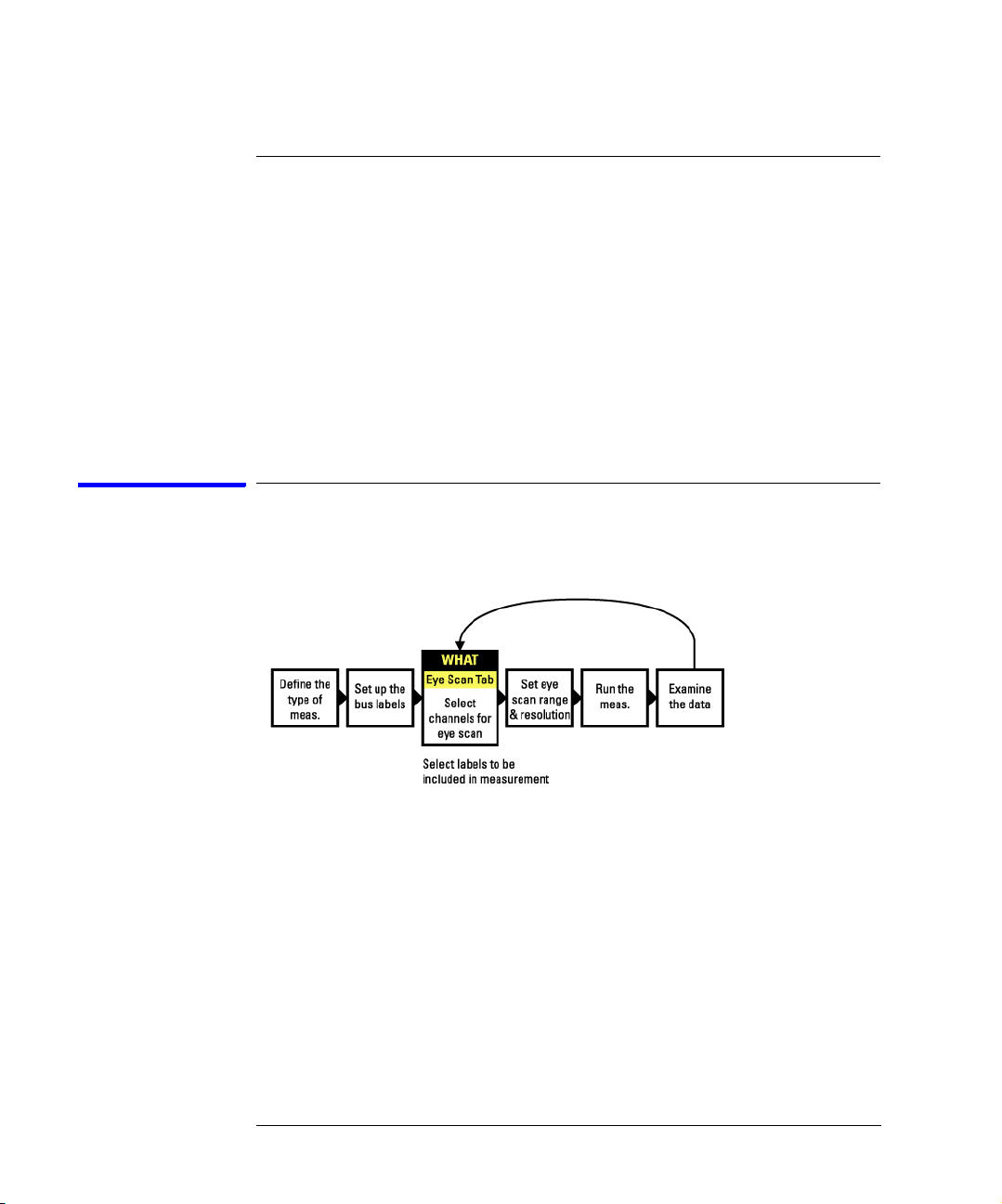

Eye Scan Mode Steps

When you have selected the eye scan sampling mode, you need to

perform the following steps.

• “Step 4. Select channels for the eye scan measurement” on page 26

• “Step 5. Set the eye scan range and resolution” on page 27

• “Step 6. Run the eye scan measurement” on page 28

• “Step 7. Display the captured eye scan data” on page 29

Step 4. Select channels for the eye scan measurement

1. In the Eye Scan tab, Labels subtab, select the channels you want in the eye

scan measurement.

26

Page 27

Chapter 1: Getting Started

Eye Scan Mode Steps

Next: “Step 5. Set the eye scan range and resolution” on page 27

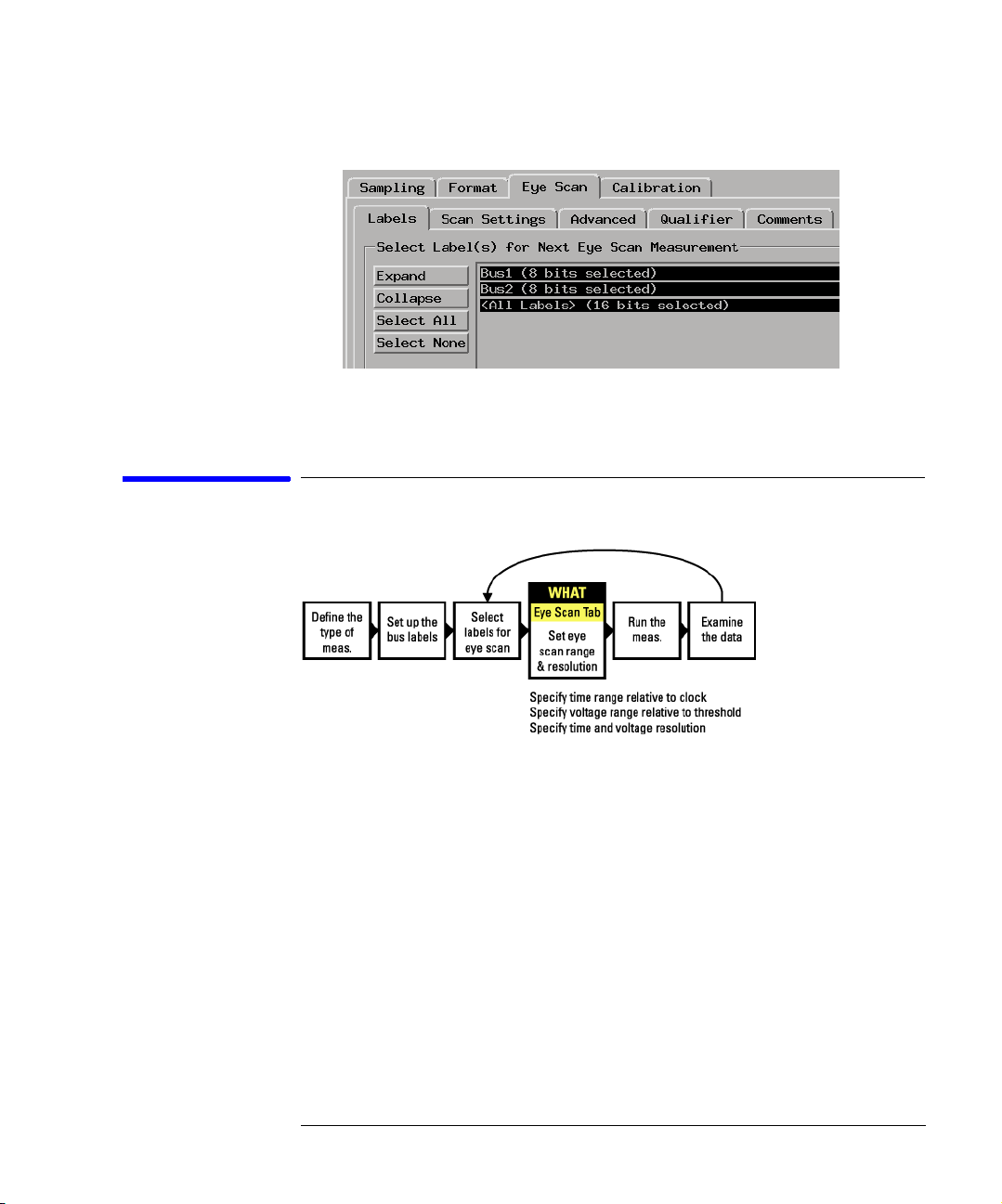

Step 5. Set the eye scan range and resolution

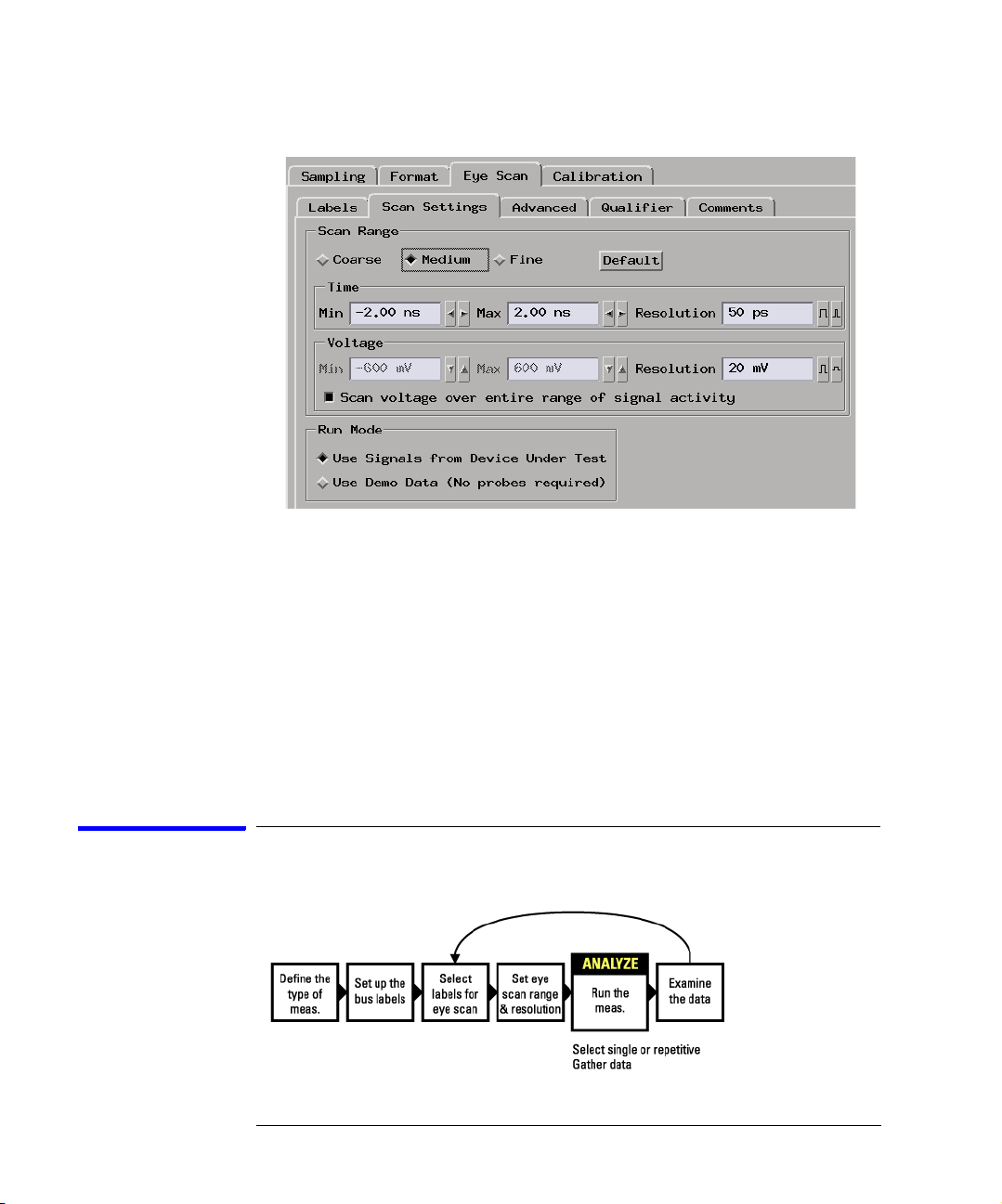

1. In the Eye Scan tab, Scan Settings subtab, select the settings for the eye

scan measurement.

27

Page 28

Chapter 1: Getting Started

Eye Scan Mode Steps

These settings define the number and size of the time and voltage windows

used in the eye scan.

Measurements using the coarse settings run faster because there are fewer

time and voltage windows to scan, but the resulting eye diagrams have less

resolution.

Measurements using the fine settings result in eye diagrams with better

resolution, but the measurements take longer to run because there are

more time and voltage windows to scan.

Next: “Step 6. Run the eye scan measurement” on page 28

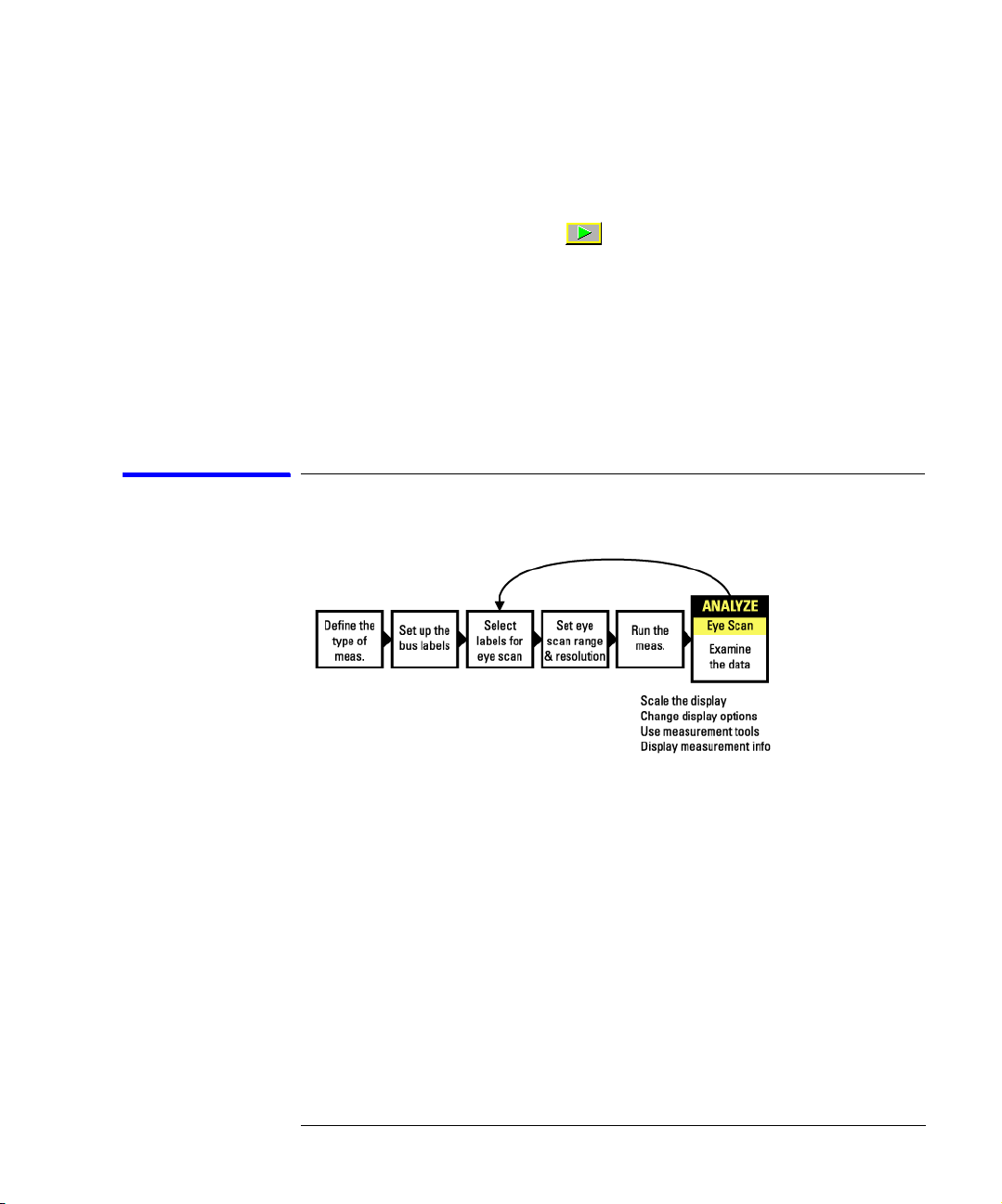

Step 6. Run the eye scan measurement

28

Page 29

Chapter 1: Getting Started

Eye Scan Mode Steps

Once the eye scan settings have been selected, you can run the

measurement.

1. Select the Run Single button .

The Eye Scan display window opens, and the captured measurement data

begins to appear.

While the eye scan measurement runs, the Stop button becomes available.

The estimated time of the measurement is shown in the status field.

Next: “Step 7. Display the captured eye scan data” on page 29

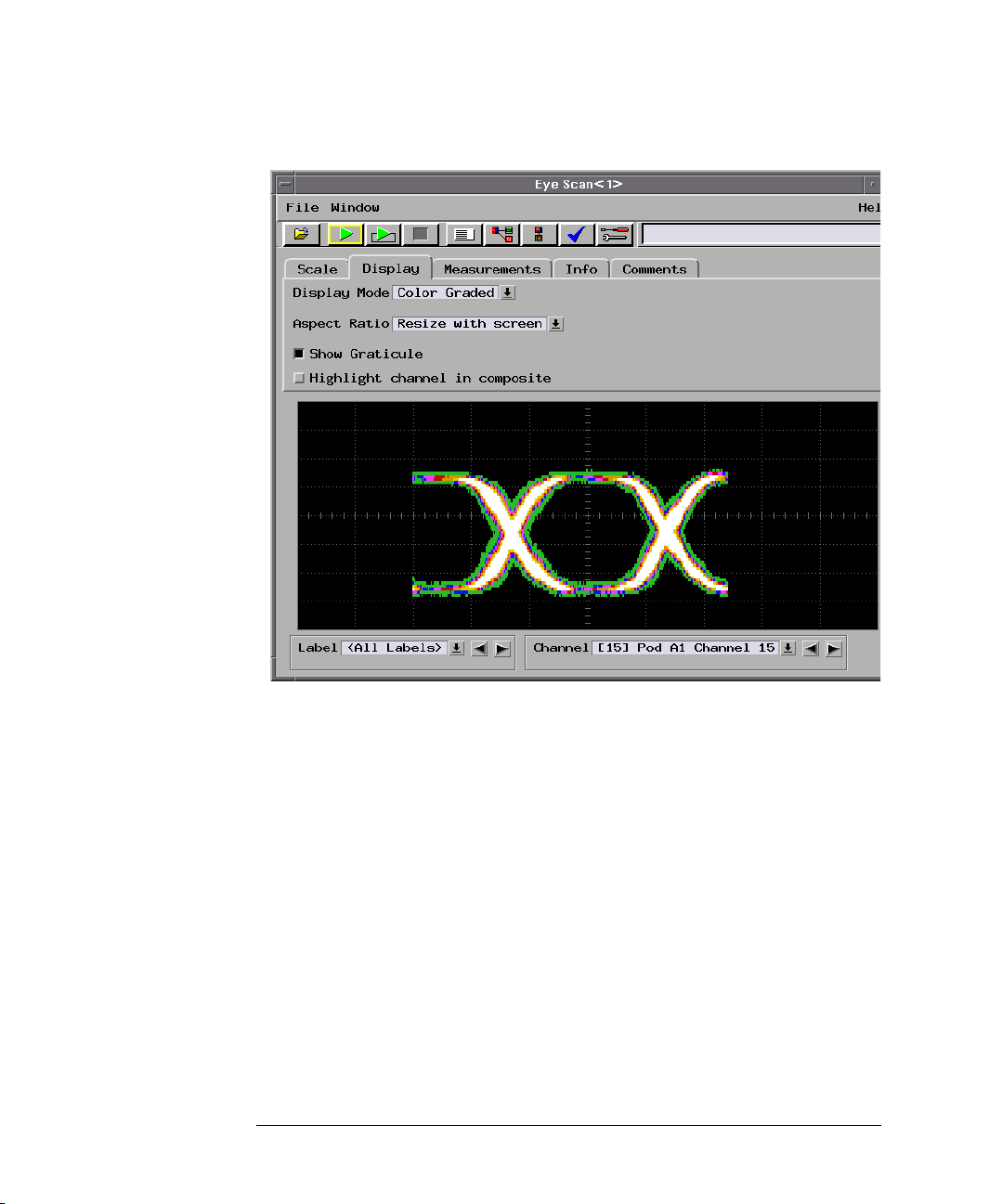

Step 7. Display the captured eye scan data

29

Page 30

Chapter 1: Getting Started

Eye Scan Mode Steps

In the Eye Scan display window, use the following subtabs:

• Scale to zoom in or out on the captured data.

• Display to change the display options.

• Measurements to use tools for displaying useful information about the

data.

• Info to display textual information about the captured measurement data.

• Comments to save your comments with the data.

Next: “For More Information...” on page 31

30

Page 31

For More Information...

Chapter 1: Getting Started

For More Information...

On connecting the

logic analyzer:

On choosing the

sampling mode:

On formatting labels

for probed signals:

On setting up

measurements:

• “Probing the Device Under Test” on page 35

• Setup Assistant (see the Setup Assistant help volume) (when using

analysis probes).

• Logic Analysis System and Measurement Modules Installation Guide

for probe pinout and circuit diagrams.

• “Choosing the Sampling Mode” on page 43

• “The Sampling Tab” on page 155

• “Formatting Labels for Logic Analyzer Probes” on page 57

• “The Format Tab” on page 174

• “Understanding Logic Analyzer Triggering” on page 240

• “Understanding Eye Scan Measurements” on page 259

• “Setting Up Triggers and Running Measurements” on page 69

• “Setting Up and Running Eye Scan Measurements” on page 119

• “The Trigger Tab” on page 176

• “The Eye Scan Tab” on page 204

On running

measurements:

On displaying

captured data:

• “Running Measurements” on page 91

• “To run an eye scan measurement” on page 121

• “Displaying Captured Data” on page 94

• “Displaying Captured Eye Scan Data” on page 133

• Using the Waveform Display Tool (see the Waveform Display Tool help

volume)

• Using the Listing Display Tool (see the Listing Display Tool help volume)

• Working with Markers (see the Markers help volume)

31

Page 32

Chapter 1: Getting Started

For More Information...

• Using the Chart Display Tool (see the Chart Display Tool help volume)

• Using the Distribution Display Tool (see the Distribution Display Tool

help volume)

• Using the Compare Analysis Tool (see the Compare Tool help volume)

32

Page 33

2

Probing and Selecting the Sampling Mode

• “Probing the Device Under Test” on page 35

33

Page 34

Chapter 2: Probing and Selecting the Sampling Mode

• “Choosing the Sampling Mode” on page 43

• “Selecting the Timing Mode (Asynchronous Sampling)” on page 43

• “Selecting the State Mode (Synchronous Sampling)” on page 46

• “In Either Timing Mode or State Mode” on page 53

• “Selecting the Eye Scan Mode” on page 55

• “Formatting Labels for Logic Analyzer Probes” on page 57

34

Page 35

Chapter 2: Probing and Selecting the Sampling Mode

Probing the Device Under Test

Probing the Device Under Test

When using the 16760A logic analyzer, there are four probing options

available:

• “Using the E5378A Single-Ended Probe” on page 35

• “Using the E5379A Differential Probe” on page 37

• “Using the E5380A Mictor-Compatible Probe” on page 39

• “Using the E5382A Single-ended Flying Lead Probe Set” on page 40

• “Using an Analysis Probe” on page 41

Using the E5378A Single-Ended Probe

Mechanical

Considerations

The E5378A single-ended probe has 34-channels and is capable of

capturing data at rates up to 1500 Mb/s. The probe has the following

inputs:

• 32 single-ended data inputs, in two groups (pods) of 16.

• Two differential clock inputs. Either or both clock inputs can be acquired

as data inputs if not used as a clock.

• Two data threshold reference inputs, one for each pod (group of 16 data

inputs).

This probe matches two 17-channel probe cables to a single-ended

100-pin Samtec connector.

Each E5379A probe requires a mating connector and support shroud

built into the device under test.

You can order a probing connector kit, which contains five mating

connectors and five support shrouds, using the Agilent part numbers:

• 16760-68702 for PC board thicknesses up to 0.062 in.

• 16760-68703 for PC board thicknesses up to 0.120 in.

35

Page 36

Chapter 2: Probing and Selecting the Sampling Mode

Probing the Device Under Test

You can order mating connectors separately using the Agilent part

number:

• 1253-3620 (or Samtec #ASP-65067-01)

You can order support shrouds separately using the Agilent part

numbers:

• 16760-02302 for PC board thicknesses up to 0.062 in.

• 16760-02303 for PC board thicknesses up to 0.120 in.

Electrical

Considerations

Data threshold reference inputs

The E5378A single-ended probe has two inputs for threshold reference

voltages for the data inputs. One input is for the even pod and the

other is for the odd pod. The threshold inputs (pins 87 and 88) may be

either:

Connected to a DC threshold reference voltage. In this case, the logic

analyzer will use the threshold reference voltage to determine when the

signal is high or low.

Or:

Grounded or left unconnected. In this case, you need to set the logic

threshold voltage in the user interface.

The advantages of supplying a threshold voltage via the threshold input

on the probe are:

• A threshold voltage supplied from the device under test will typically track

changes in supply voltage, temperature, etc.

• A threshold voltage supplied from the device under test is typically the

same threshold that the device's logic uses to evaluate the signals.

Therefore, the data captured by the logic analyzer will be the same as the

data interpreted by the device under test.

Clock Input

The clock input on the E5378A probe can be a differential signal or a

single-ended signal.

If the clock input is a differential signal, select the "differential" option

in the clock threshold user interface.

36

Page 37

Chapter 2: Probing and Selecting the Sampling Mode

If the clock input is a single-ended signal, either ground the negative

clock input and adjust the clock threshold voltage in the user interface,

or connect the negative clock input to the DC clock threshold

reference voltage.

In the user interface, the clock input threshold voltage adjustment is

separate from the data input threshold voltage adjustments.

See Also “To set pod threshold voltages” on page 58

“To set clock threshold voltages” on page 59

For complete information, including mechanical considerations such as

pin-out and footprint and electrical considerations such as circuit board

design best practices, refer to the Agilent Technologies E5378A, E5379A,

and E5380A Probes for the 16760A Logic Analyzer user's guide that

comes with the probes.

Probing the Device Under Test

Mechanical

Considerations

Using the E5379A Differential Probe

The E5379A differential probe has 17 channels and is capable of

capturing data at rates up to 1500 Mb/s. The probe has the following

inputs:

• 16 differential data inputs.

• One differential clock input. The clock input can also be used as a data

input.

This probe matches one 17-channel probe cable to a differential 100pin Samtec connector. Two E5379A probes are required to support the

inputs on one 16760A logic analyzer card.

Each E5379A probe requires a mating connector and support shroud

built into the device under test.

You can order a probing connector kit, which contains five mating

connectors and five support shrouds, using the Agilent part numbers:

• 16760-68702 for PC board thicknesses up to 0.062 in.

• 16760-68703 for PC board thicknesses up to 0.120 in.

37

Page 38

Chapter 2: Probing and Selecting the Sampling Mode

Probing the Device Under Test

You can order mating connectors separately using the Agilent part

number:

• 1253-3620 (or Samtec #ASP-65067-01)

You can order support shrouds separately using the Agilent part

numbers:

• 16760-02302 for PC board thicknesses up to 0.062 in.

• 16760-02303 for PC board thicknesses up to 0.120 in.

Electrical

Considerations

Data inputs

The E5379A differential probe can capture data on differential signals

or single-ended signals.

When capturing data on differential signals, the logic analyzer will

determine high and low states based on the crossover of the data and

negative data inputs.

When capturing data on single-ended signals, either ground the

negative data inputs and adjust the threshold voltage in the user

interface, or connect the negative data inputs to the DC threshold

reference voltage.

Clock input

The clock input on the E5379A differential probe can also be a

differential signal or a single-ended signal, in the same way as

described for the data inputs above. The clock input has a separate,

independent threshold adjustment.

See Also “To set pod threshold voltages” on page 58

“To set clock threshold voltages” on page 59

For complete information, including mechanical considerations such as

pin-out and footprint and electrical considerations such as circuit board

design best practices, refer to the Agilent Technologies E5378A, E5379A,

and E5380A Probes for the 16760A Logic Analyzer user's guide that

comes with the probes.

38

Page 39

Chapter 2: Probing and Selecting the Sampling Mode

Probing the Device Under Test

Using the E5380A Mictor-Compatible Probe

The E5380A MICTOR-compatible probe has a MICTOR connector end.

If you have a device under test with connectors designed for the

Agilent E5346A high-density probe adapter, you can also use the

E5380A probe.

However, the lower bandwidth of the E5380A probe limits the

maximum state speed of the logic analyzer to 600 Mbits/second.

The minimum input signal amplitude required by the E5380A probe is

300 mV.

The probe matches two 17-channel probe cables to a single-ended 38

pin MICTOR connector.

Mechanical

Considerations

Electrical

Considerations

Each E5380A probe requires a MICTOR connector and support shroud

built into the device under test.

You can order a probing connector kit, which contains five MICTOR

connectors and five support shrouds, using the Agilent part numbers:

• E5346-68701 for PC board thicknesses up to 0.062 in.

• E5346-68702 for PC board thicknesses from 0.062 to 0.125 in.

You can order MICTOR connectors separately using the Agilent part

number:

• 1252-7431 (or AMP part #2-767004-2)

You can order support shrouds separately using the Agilent part

numbers:

• E5346-44701 for PC board thicknesses up to 0.062 in.

• E5346-44704 for PC board thicknesses from 0.062 to 0.125 in.

• E5346-44703 for PC board thicknesses from 0.125 to 0.70 in.

All inputs on the E5380A MICTOR-compatible probe are single-ended.

The E5380A probe does not have a threshold reference voltage input.

When using the E5380A probe, the logic threshold voltage is adjusted

in the user interface.

39

Page 40

Chapter 2: Probing and Selecting the Sampling Mode

Probing the Device Under Test

The clock input on the E5380A probe is single-ended. The clock

threshold voltage may be adjusted independently of the data threshold

voltages.

See Also “To set pod threshold voltages” on page 58

“To set clock threshold voltages” on page 59

For complete information, including mechanical considerations such as

pin-out and footprint and electrical considerations such as circuit board

design best practices, refer to the Agilent Technologies E5378A, E5379A,

and E5380A Probes for the 16760A Logic Analyzer user's guide that

comes with the probes.

Using the E5382A Single-ended Flying Lead Probe Set

Mechanical

Considerations

Electrical

Considerations

Clock Input

The E5382A is a 17-channel single-ended flying lead probe set. The

E5382A lets you acquire signals from randomly located points in your

target system. Two E5382As are required to support 34 channel logic

analyzer cards. Four are required to support 68-channel logic analyzer

cards.

The Agilent E5382A single-ended flying lead probe set comes with

accessories that trade off flexibility, ease of use, and performance.

Discussion and comparisons between four of the most common

intended uses of the accessories are included in the E5382A Single-

ended Flying Lead Probe Set User's Guide (supplied with the

probe). A list of replacable parts and additional accessories is given

below.

Data inputs on the E5382A flying lead probe are single-ended. The

E5382A probe does not have a threshold reference voltage input. When

using the E5382A probe, the logic threshold voltage is adjusted in the

user interface.

The maximum nondestructive input voltage is +/- 40 Vdc.

The clock input on the E5382A probe can be a differential signal or a

40

Page 41

Chapter 2: Probing and Selecting the Sampling Mode

Probing the Device Under Test

single-ended signal. If the clock input is a differential signal, select the

"differential" option in the clock threshold user interface.

If the clock input is a single-ended signal, ground the negative clock

input and adjust the clock threshold voltage in the user interface. The

minimum voltage swing for single-ended clock operation is 250 mV p-p.

In the user interface, the clock input threshold voltage adjustment is

separate from the data input threshold voltage adjustments.

Replacable Parts and

Additional

Accessories

A variety of accessories are supplied with the E5382A to allow you to

access signals on various types of components on your PC board. The

following table shows the part numbers for ordering replacement parts

and additional accessories.

Description Qty Agilent Part Number

-------------- --- -------------------

Probe Pin Kit 4 16517-82107

High Frequency Probing Kit 8 16517-82104

(4 resistive signal pins & 4 solder-down grounds)

Ground Extender 20 16517-82105

Grabber Clip Kit 20 16517-92109

Right-angle Ground Lead 20 16517-82106

Cable - Main 1 E5382-61601

Probe Tip to BNC Adapter 1 E9638A

Using an Analysis Probe

Analysis probes, formerly called preprocessors, are products that make

it easier to probe a specific microprocessor or bus.

Generally, analysis probes consist of hardware that probes a

microprocessor or bus and routes the probed signals to connectors for

the logic analyzer probe cables.

Analysis probes include configuration files that properly set up the

logic analyzer. Also included, typically, are inverse assemblers or other

tools for decoding the captured data.

The Setup Assistant (see the Setup Assistant help volume) in the logic

41

Page 42

Chapter 2: Probing and Selecting the Sampling Mode

Probing the Device Under Test

analysis system helps you to properly configure the logic analyzer.

42

Page 43

Chapter 2: Probing and Selecting the Sampling Mode

Choosing the Sampling Mode

Choosing the Sampling Mode

There are three logic analyzer sampling modes to choose from: timing

mode, state mode, or eye scan mode.

In timing mode, the logic analyzer samples asynchronously, based on

an internally-generated sampling clock.

In state mode, the logic analyzer samples synchronously, based on a

sampling clock signal (or signals) from the device under test. Typically,

the signal used for sampling in state mode is a state machine or

microprocessor clock signal.

In eye scan mode, the logic analyzer samples small windows of time

and voltage on data channels around a clock signal from the device

under test. The resulting eye diagrams let you validate and

characterize the data valid windows of the signals on a bus.

• “Selecting the Timing Mode (Asynchronous Sampling)” on page 43

• “Selecting the State Mode (Synchronous Sampling)” on page 46

• “In Either Timing Mode or State Mode” on page 53

• “Selecting the Eye Scan Mode” on page 55

Selecting the Timing Mode (Asynchronous Sampling)

In timing mode, the logic analyzer samples asynchronously, based on

an internally-generated sampling clock.

• “To select the timing mode” on page 44

• “To select the conventional/transitional configuration” on page 44

• “To specify the sample period” on page 45

43

Page 44

Chapter 2: Probing and Selecting the Sampling Mode

Choosing the Sampling Mode

To select the timing mode

1. Open the logic analyzer Setup window.

2. Select the Sampling tab.

3. Choose the Timing Mode option.

You can also select the timing sampling mode in the “Pod Assignment

Dialog” on page 175.

To select the conventional/transitional configuration

1. In the Sampling tab with Timing Mode selected, select the timing analyzer

configuration. You can choose between:

• 800 MHz / 64M Sample Conventional

In this configuration, the analyzer samples and stores measurement

data at each sampling interval, as often as every 1.25 ns.

NOTE: With the Sample Period at 1.25 ns, data is acquired at four times the trigger

sequencer rate. This means that data must be present for at least four samples

before the trigger sequencer can reliably detect it. The trigger sequencer

could miss data present for less than four sample periods.

The trigger sequencer treats the data as a group of four samples for each

sequencer clock. This means that the trigger point indication could be off by

three samples.

Although the trigger sequencer cannot detect all data, the analyzer will

correctly capture all data present for at least one sample period.

• 400 MHz / 32M Sample Transitional or Store Qualified

In this configuration, the analyzer samples data at regular intervals, as

often as every 2.5 ns, but only stores the data if it's different than the

previously stored data.

You can further qualify storage of transitions by ignoring data changes

on particular labels.

A time tag is stored with each stored data sample so that all sampled

values can be reconstructed and displayed later.

44

Page 45

Chapter 2: Probing and Selecting the Sampling Mode

Choosing the Sampling Mode

NOTE: If all pods are used, memory depth is reduced by half in order to store the

required time tags.

NOTE: With the Sample Period at 2.5 ns, data is acquired at two times the trigger

sequencer rate. This means that data must be present for at least two samples

before the trigger sequencer can reliably detect it. The trigger sequencer

could miss data present for less than two sample periods.

The trigger sequencer treats the data as a group of two samples for each

sequencer clock. This means that the trigger point indication could be off by

one sample.

Although the trigger sequencer cannot detect all data, the analyzer will

correctly capture all data present for at least one sample period.

See Also “To specify default storing” on page 76

“How Samples are Stored in Transitional Timing” on page 157

“Default Storing Subtab” on page 190

To specify the sample period

When the logic analyzer is in timing (asynchronous sampling) mode,

the Sample Period setting specifies how often the logic analyzer

samples the signals from the device under test.

1. In the Sampling tab, with Timing Mode selected, enter the desired time

between logic analyzer samples.

To capture signal level changes reliably, the sample period should be less

than half (many engineers prefer one-fourth) of the period of the fastest

signal you want to measure.

The sample rate is the inverse of the sample period.

NOTE: In the conventional timing configuration, the sample rate is fixed at 1.25 ns.

45

Page 46

Chapter 2: Probing and Selecting the Sampling Mode

Choosing the Sampling Mode

Selecting the State Mode (Synchronous Sampling)

In state mode, the logic analyzer samples synchronously, based on a

sampling clock signal from the device under test. Typically, the signal

used for sampling in state mode is a state machine or microprocessor

clock signal.

The clock signal can be either Periodic (synchronous all the time), or

Aperiodic (bursted or varying in frequency).

• “To select the state mode” on page 47

• “To select the state speed configuration” on page 47

• “To set up the sampling clock” on page 48

State Mode Sampling

Position

In order for a state mode logic analyzer to accurately capture data from

a device under test, the logic analyzer's setup/hold time (window) must

fit within the device under test's data valid window.

Because the location of the data valid window relative to the bus clock

is different for different types of buses, the logic analyzer lets you

adjust the sampling position in order to accurately capture data on

high-speed buses (see “Understanding State Mode Sampling Positions”

on page 256).

When the device under test's data valid window is less than 2.5 ns

(roughly, for clock speeds >= 200 MHz), it's easiest to use eye finder

to locate the stable and transitioning regions of signals and to

automatically adjust sampling positions.

• “To automatically adjust sampling positions” on page 49

When the device under test's data valid window is greater than 2.5 ns

(roughly, for clock speeds < 200 MHz), it's easiest to adjust the

sampling position manually, without using the logic analyzer to locate

the stable and transitioning regions of signals.

• “To manually adjust sampling positions” on page 52

46

Page 47

Chapter 2: Probing and Selecting the Sampling Mode

Choosing the Sampling Mode

To select the state mode

1. Open the logic analyzer Setup window.

2. Select the Sampling tab.

3. Choose the State Mode option.

You can also select the state sampling mode in the “Pod Assignment

Dialog” on page 175.

To select the state speed configuration

1. In the Sampling tab, with State Mode selected, select one of the state

analyzer configurations.

The selected configuration specifies the speed up to which the state mode

sampling clock will match input clock edges from the device under test.

For example, in the 800 Mb/s / 64M State configuration, the state mode

sampling clock will match input clock edges up to 800 MHz.

The selected configuration also specifies the memory depth for samples

and whether only half of the logic analyzer channels are available.

You can choose from:

• 1500 Mb/s / 128M Half Channel

In this configuration: The input clock signal must be periodic, and both

edges indicate valid data. The clock input can only be used as a clock

and not as an extra data channel. The logic analyzer setup/hold window

is 500 ps, and eye finder must be used to automatically adjust

sampling positions. The limited set of 16760 Half Channel State

trigger functions are available. In half-channel mode the analyzer

accesses only the even channels (0, 2, 4, etc.).

• 1250 Mb/s / 128M Half Channel

In this configuration: The input clock signal must be periodic, and both

edges indicate valid data. The clock input can only be used as a clock

and not as an extra data channel. The logic analyzer setup/hold window

is 1 ns, and sampling positions may be adjusted automatically or

manually. The limited set of 16760 Half Channel State trigger

functions are available. In half-channel mode the analyzer accesses

only the even channels (0, 2, 4, etc.).

47

Page 48

Chapter 2: Probing and Selecting the Sampling Mode

Choosing the Sampling Mode

• 800 Mb/s / 64M State

In this configuration: The input clock signal can be periodic or

aperiodic, and either rising, falling, or both edges can indicate valid

data. The logic analyzer setup/hold window is 1 ns, and sampling

positions may be adjusted automatically or manually. The limited set of

16760 State trigger functions are available.

• 400 Mb/s / 32M State

In this configuration: Either rising, falling, or both edges can indicate

valid data. The logic analyzer setup/hold window is 2.5 ns, and sampling

positions may be adjusted automatically or manually. The limited set of

Turbo State trigger functions are available.

• 200 Mb/s / 32M State

In this configuration: Rising, falling, or both edges can indicate valid

data. The logic analyzer setup/hold window is 3.0 ns, and sampling

positions may be adjusted automatically or manually. The General

State trigger functions are available.

In all configurations but the 200 Mb/s / 32M State configuration, if time is

counted (that is time tags are being stored), one pod must be left

unassigned in order to store the time tags. In the 200 Mb/s / 32M State

configuration, memory depth is reduced by half if all pods are used and

time or state counts are being stored.

See Also “To set up the sampling clock” on page 48

“To manually adjust sampling positions” on page 52

“To automatically adjust sampling positions” on page 49

“Trigger Functions Subtab” on page 177

To set up the sampling clock

For the clock input signal that will be used:

1. In the Clock Setup, select the desired Mode. Your choices are Periodic or

Aperiodic. If the State Mode is set to 1250 or 1500 Mb/s configuration, the

input clock must be Periodic.

2. Select the pod's Master button (under the activity indicator).

48

Page 49

Chapter 2: Probing and Selecting the Sampling Mode

Choosing the Sampling Mode

3. Specify when to sample. Your choices are Rising Edge, Falling Edge, or

Both Edges. Only Both Edges is available in the 1250 and 1500 Mb/s

configurations.

See Also “To select the state speed configuration” on page 47

To automatically adjust sampling positions

When adjusting the state mode sampling position with eye finder, the

logic analyzer looks at signals from the device under test, figures out

the location of the data valid window in relation to the sampling clock,

and automatically sets the sampling position.

Because eye finder automatically runs on individual channels, it can

correct for the small delay effects caused by probe cables and circuit

board traces. This makes the logic analyzer's setup/hold window

smaller and lets you accurately capture data at higher clock speeds.

Eye finder requires:

• At least 500 transitions on each signal during its run. (You can use the

advanced eye finder settings to cause longer or shorter runs.)

• All devices which can drive each signal should contribute to the stimulus.

• All device under test operating modes relevant to the eventual logic

analysis measurement should contribute to the stimulus as well.

NOTE: Eye finder measurements and normal logic analyzer measurements cannot

run simultaneously.

To run eye finder

1. Probe the device under test by connecting the logic analyzer channels.

2. Select the state (synchronous sampling) mode (see “To select the state

mode” on page 47).

3. Format labels for those logic analyzer channels.

4. Make sure that the device under test and the logic analyzer have warmed

up to their normal operating temperatures.

5. In the Format tab, select the Setup/Hold button.

49

Page 50

Chapter 2: Probing and Selecting the Sampling Mode

Choosing the Sampling Mode

6. In the Sampling Positions dialog, select the Eye Finder option.

7. In the Eye Finder Setup tab, select the Use signals from Device Under

Test option.

The Use demo data (no probes required) option is for demonstration

purposes only.

8. Choose the labels that you wish to run eye finder on.

You may want to run eye finder on channel subsets, for example, when

certain bus signals transition in one operating mode (of the device under

test) and other bus signals transition in a different operating mode.

9. Select the Run Eye Finder button.

For more information on run messages, see “Eye Finder Run Messages” on

page 162.

When eye finder finds more than one stable region on a channel, it uses

the current sampling position as a hint about which stable region it should

suggest a position for.

If eye finder picks the wrong stable region, you can expand the label and

drag the blue Sampling Position line into the correct stable region. The

suggested sampling position for that region will be shown (see “How

Selected/Suggested Positions Behave” on page 161).

10. If you have moved the sampling position and wish to return to the

suggested positions, go to the Eye Finder Results tab, select a label button

or the Results menu, and choose the "set to suggested" command.

For more information on informational messages in the Eye Finder Results

tab, see “Eye Finder Info Messages” on page 165.

Eye finder finds optimal sampling positions for the actual specific

conditions -- amplitude, offset, slew rates, and ambient temperature.

Therefore, you will get the best results by running eye finder under

the same conditions that will be present when logic analysis

measurements are made.

To run eye finder repetitively

1. Select the Repetitive Run option in the Eye Finder Setup tab.

2. Select the Run Eye Finder (r) button.

50

Page 51

Chapter 2: Probing and Selecting the Sampling Mode

Choosing the Sampling Mode

In the Eye Finder Results tab, you can see how the stable and transitioning

areas vary over time.

3. Select the Stop Eye Finder button.

To view eye finder data as a bus composite

When you want a compressed, high-level view of the eye finder data:

1. In the Eye Finder Results tab, select the label button and choose the View

as Bus Composite command.

Average sampling positions as well as stable and transitioning areas are

displayed for the whole label. This is the default. Stable areas show

positions where every channel in the label is stable.

To view eye finder data as a stack of channels

When you want more resolution in your view of the eye finder data:

1. In the Eye Finder Results tab, select the label button and choose the View

as Stack of Channels command.

Individual sampling positions and stable and transitioning areas for all the

channels in a label are shown.

To save/load eye finder data

While the eye finder sampling positions are saved with the logic

analyzer configuration, eye finder measurement data is not; therefore,

51

Page 52

Chapter 2: Probing and Selecting the Sampling Mode

Choosing the Sampling Mode

eye finder data must be saved and loaded separately.

1. In the File Info tab, select the Save As... or Load... buttons.

You can also choose the Save Eye Finder or Load Eye Finder command

from the File menu.

2. In the file browser dialog, name the file to be saved or select the file to be

loaded.

For more information on save/load messages, see “Eye Finder Load/Save

Messages” on page 167.

See Also “Understanding State Mode Sampling Positions” on page 256

“Eye Finder Advanced Settings Dialog” on page 170

“To manually adjust sampling positions” on page 52

To manually adjust sampling positions

Although the Eye Finder option was intended for automatically

adjusting state mode sampling positions, you can also use it to

manually adjust sampling positions. You don't have to Run Eye Finder

to locate stable and transitioning regions on signals, just go directly to

the Eye Finder Results tab, and drag the sampling positions to the

proper locations.

1. Select the state (synchronous sampling) mode (see “To select the state

mode” on page 47).

2. In the Format tab, select the Setup/Hold button.

3. In the Sampling Positions dialog, select the Eye Finder option.

4. In the Eye Finder Results tab, drag the sampling positions to the proper

locations.

You can select bus labels to expand or collapse the channels in the label.

When using the Eye Finder option to manually adjust state mode

sampling positions, the sampling positions are saved with the logic

analyzer configuration (see “Saving and Loading Logic Analyzer

Configurations” on page 116).

52

Page 53

Chapter 2: Probing and Selecting the Sampling Mode

Choosing the Sampling Mode

See Also “Understanding State Mode Sampling Positions” on page 256

“To automatically adjust sampling positions” on page 49

In Either Timing Mode or State Mode

• “To specify the trigger position” on page 53

• “To set acquisition memory depth” on page 53

• “To name an analyzer” on page 54

• “To turn an analyzer off or on” on page 54

To specify the trigger position

1. In the Sampling tab (or in the Settings subtab of the Trigger tab), select

the trigger position.

Specify whether you want to look at data after the trigger (Start), before

and after the trigger (Center), before the trigger (End), or use a

percentage of the logic analyzer's memory for data after the trigger (User

Defined).

In the timing sampling mode's 800 MHz / 64M Sample Conventional

configuration, when a Run is started, the analyzer will not look for a

trigger until the specified percentage of pretrigger data has been

stored. After a trigger has been detected, the specified percentage of

posttrigger data is stored before the analyzer halts. This ensures that

both pretrigger and posttrigger storage are complete.

In the state sampling mode, or in the timing sampling mode's 400 MHz

/ 32M Sample Transitional or Store Qualified configuration, when a

Run is started, the analyzer immediately looks for the trigger condition.

In other words, the trigger position setting specifies the maximum

amount of data that should be stored before the trigger.

To set acquisition memory depth

If you need less data and want measurements to run faster, you can

limit the number of samples that are stored in logic analyzer acquisition

memory.

53

Page 54

Chapter 2: Probing and Selecting the Sampling Mode

Choosing the Sampling Mode

1. In the Sampling tab (or in the Settings subtab of the Trigger tab), select

the acquisition depth.

The number of samples that can be chosen for the Acquisition Depth are

approximations. The combination of count tags, pod assignments, and

configuration modes affect what choices are available.

To name an analyzer

You can give more descriptive names to a logic analyzer.

1. In the Sampling tab, select the Analyzer Name field.

2. Enter the new name.

The name now appears below the instrument tool icon in the workspace.

You can also name analyzers in the “Pod Assignment Dialog” on

page 175.

To turn an analyzer off or on

You may want to turn an analyzer off if you don't want it to be included

in further measurements.

To turn an analyzer off

1. In the Sampling tab, select the On box that is checked.

2. In the Analyzer Shutdown Options dialog, choose either:

• Soft -- This will leave the logic analyzer window but turn off most

options.

• Hard -- This will remove the logic analyzer and its display tools from

the Workspace.

You can also turn an analyzer off in the “Pod Assignment Dialog” on

page 175.

To turn an analyzer back on

1. If you used the Soft option when turning the logic analyzer off, you can

turn it on again by selecting the Off check box.

2. If you used the Hard option when turning the logic analyzer off, you can

54

Page 55

Chapter 2: Probing and Selecting the Sampling Mode

Choosing the Sampling Mode

turn it on again by selecting the Setup button in the System window or by

dragging the analyzer's instrument tool icon to the workspace in the

Workspace window.

Selecting the Eye Scan Mode

In eye scan mode, the logic analyzer becomes a tool for validating and

characterizing the data valid windows of signals latched by a clock. The

Eye Scan display shows eye diagrams for each channel, like an

oscilloscope, but with less accuracy and resolution. The Eye Scan

display can help you quickly identify setup/hold or other signal

integrity anomalies which can then be examined in greater detail with a

high-speed or high-bandwidth oscilloscope.

• “To select the eye scan mode” on page 55

• “To select the eye scan mode speed configuration” on page 55

• “To set up the eye scan mode reference clock” on page 56

See Also “Setting Up and Running Eye Scan Measurements” on page 119

“Displaying Captured Eye Scan Data” on page 133

“Saving and Loading Captured Eye Scan Data” on page 152

“Understanding Eye Scan Measurements” on page 259

To select the eye scan mode

1. Open the logic analyzer Setup window.

2. Select the Sampling tab.

3. Choose the Eye Scan Mode option.

To select the eye scan mode speed configuration

1. In the Sampling tab, with Eye Scan Mode selected, select one of the eye

scan mode speed configurations.

The selected configuration specifies the speed that the input reference

clock may be as fast as. For example, in the 800 Mb/s / Eye Scan

55

Page 56

Chapter 2: Probing and Selecting the Sampling Mode

Choosing the Sampling Mode

configuration, the input reference clock edges can occur at rates up to 800

MHz.

You can choose from:

• 800 Mb/s / Eye Scan

In this configuration: Either rising, falling, or both edges of the input

reference clock can indicate valid data. All of the logic analyzer

channels are available. The maximum number of clocks that can be

processed at each scan point is 60,000,000.

• 1500 Mb/s / Eye Scan

In this configuration: Both edges of the input reference clock indicate

valid data. Only half of the logic analyzer channels are available. The

maximum number of clocks that can be processed at each scan point is

120,000,000.

To set up the eye scan mode reference clock

For the clock input signal that will be used:

1. Select the pod's Master button (under the activity indicator).

2. Select whether data is valid on the Rising Edge, Falling Edge, or Both

Edges.

In the 1500 Mb/s / Eye Scan speed configuration, data must be valid on

Both Edges.

See Also “To select the eye scan mode speed configuration” on page 55

56

Page 57

Chapter 2: Probing and Selecting the Sampling Mode

Formatting Labels for Logic Analyzer Probes

Formatting Labels for Logic Analyzer Probes

The Format tab is mainly for assigning bus and signal names (from the

device under test), to logic analyzer channels. These names are called

labels. Labels are used when setting up triggers and displaying

captured data.

The Format tab also lets you do things like assign pods to the logic

analyzer, specify the logic analyzer threshold voltage, change the label

polarity, reorder bits in a label, and turn labels off or on.

The Format tab has activity indicators that show signal levels.

• “To assign pods to the analyzer” on page 57

• “To set pod threshold voltages” on page 58

• “To set clock threshold voltages” on page 59

• “To assign probe channels to labels” on page 60

• “To import label names and assignments from a netlist” on page 62

• “To import label definitions from an ASCII file” on page 63

• “To export label definitions to an ASCII file” on page 64

• “To change the label polarity” on page 64

• “To reorder bits in a label” on page 65

• “To turn labels off or on” on page 66

To assign pods to the analyzer

The logic analyzer pods can be assigned to the logic analyzer, or, they

can be left unassigned.

1. In the Format tab, select the Pod Assignment button.

2. In the Pod Assignment dialog, drag a pod to the logic analyzer.

3. Select the Close button.

57

Page 58

Chapter 2: Probing and Selecting the Sampling Mode

Formatting Labels for Logic Analyzer Probes

Capturing Data on 17

Channels in State

Mode

On a single-card 16760A logic analyzer in the state (synchronous)

sampling mode, you can assign pod 2 to the logic analyzer and unassign

pod 1. (One pod must be unassigned in order to store time tags.) Even

though pod 1 is unassigned, its J clock input is still used as the

sampling clock input. This allows the 16 channels and the K clock input

on pod 2 to be used as data sampling channels. This lets you capture

data on high-speed buses that have 17 data bits, and a clock.

When you assign pods this way, the logic analyzer loses its ability to

detect, to prevent triggering or sequencing on, and to remove an initial

spurious sample in the acquisition (which can occur if the logic

analyzer measurement is started before the state clock input signal

starts toggling). However, because most high-speed devices have

continuously running periodic clocks, the appearance of an initial

spurious sample is unlikely.

When the K clock input is used as a data channel like this, it cannot be

used as a qualifier signal for eye scan measurements (unless the data

signal also happens to be the necessary clock qualification input for eye

scan).

See Also “To set up qualified eye scan measurements” on page 122

“Selecting the State Mode (Synchronous Sampling)” on page 46

To set pod threshold voltages

The threshold voltage is the voltage level that a signal must cross

before the logic analyzer recognizes a change in logic levels.

1. In the Format tab, select the threshold button located just below the pod

name.

2. In the Pod threshold dialog, either:

• Select the Standard option; then, select one of the predefined

threshold voltages from the drop-down list.

• Select the External Ref option. This option appears when the E5378A

single-ended probe is used. It should be selected when the probe's

threshold voltage reference inputs are used and are connected to the

58

Page 59

Chapter 2: Probing and Selecting the Sampling Mode

Formatting Labels for Logic Analyzer Probes

appropriate threshold voltage reference level.

• Select the Differential option. This option appears when the E5379A

differential probe is used. It should be selected when differential

signals are probed. The difference voltage (Vin+ - Vin-) must be greater

than or equal to 200 mV p-p.

• Select the User Defined option and enter the desired threshold voltage

value. The threshold level is selectable from -6.0 volts to +6.0 volts.

3. If you don't want the change to apply to all pods and clock input

thresholds, deselect the checked box next to Apply threshold setting to

all pods.

4. Select the Close button.

NOTE: The logic analyzer requires a minimum voltage swing of 250 mV for the

E5378A single-ended probe or 300 mV for the E5380A MICTOR-compatible

probe to recognize changes in logic levels. If you are using the E5379A

differential probe, 200 mV differential is required.

NOTE: The specified pod threshold voltage is also applied to the pod's clock

threshold if Apply settings to all pods is selected. However, the pod's clock

threshold can also be changed independently.

See Also “To set clock threshold voltages” on page 59

“Using the E5378A Single-Ended Probe” on page 35

“Using the E5379A Differential Probe” on page 37

“Using the E5380A Mictor-Compatible Probe” on page 39

“Using the E5382A Single-ended Flying Lead Probe Set” on page 40

To set clock threshold voltages

The threshold voltage is the voltage level that a signal must cross

before the logic analyzer recognizes a change in logic levels.

1. In the Format tab, select the Clk Thresh... button located just below Data

On Clocks.

59

Page 60

Chapter 2: Probing and Selecting the Sampling Mode

Formatting Labels for Logic Analyzer Probes

2. In the Clock Thresholds dialog, select the button of the clock whose

threshold voltage you wish to set.

3. In the J, K, etc., threshold dialog, either:

• Select the Standard option; then, select one of the predefined

threshold voltages from the drop-down list.

• Select the Differential option. This option appears when the E5378A

single-ended probe or the E5379A differential probe is used. It should

be selected when the clock input is a differential signal. The difference

voltage (Vin+ - Vin-) must be greater than or equal to 200 mV p-p.

• Select the User Defined option and enter the desired threshold voltage

value. The threshold level is selectable from -3.0 volts to +5.0 volts.

4. Select Close to close the J, K, etc., threshold dialog.

5. Select Close to close the Clock Thresholds dialog.

See Also “To set pod threshold voltages” on page 58

“Using the E5378A Single-Ended Probe” on page 35

“Using the E5379A Differential Probe” on page 37

“Using the E5380A Mictor-Compatible Probe” on page 39

“Using the E5382A Single-ended Flying Lead Probe Set” on page 40

To assign probe channels to labels

The logic analyzer lets you assign names (labels) to logic analyzer

channels so that it's easier to set up triggers and interpret the captured

data when displayed.

Typically, you give labels the names of the buses and signals in the

device under test that are are being probed.

1. In the Format tab, select a label button, and either:

• Choose the Rename command, enter the label name, and select the OK

button.

60

Page 61

Chapter 2: Probing and Selecting the Sampling Mode

Formatting Labels for Logic Analyzer Probes

• Or, choose the Insert before or Insert after command, enter the label

name, and select the OK button.

2. In the label row, select the button of the pod that contains the channels

you want to assign.

3. Either choose one of the standard label assignments or choose

Individual.

( * ) (asterisk) indicates an assigned bit.

( . ) (period) indicates an unassigned bit.

( R ) indicates an assigned bit in a reordered label.

If you chose Individual:

a. In the "label - pod" dialog, select the channels you want to assign/

unassign.

b. Select the OK button.

A maximum of 32 channels can be assigned to a label.

In the Format tab, least significant pod channels (bit 0) are on the right

and most significant pod channels (bit 15) are on the left. (The bit

numbers are shown just below the activity indicators.)

Labels can contain bits that are not consecutive; however, bits are

always numbered consecutively within a label.

To delete labels

1. Select the label name that you want to delete.

2. Choose Delete.

If only one label is defined, it cannot be deleted.

When you delete labels, their bit assignments are not saved. However,

you can make a label inactive and save its bit assignments by turning

the label off.

See Also “To reorder bits in a label” on page 65

“To turn labels off or on” on page 66

61

Page 62

Chapter 2: Probing and Selecting the Sampling Mode

Formatting Labels for Logic Analyzer Probes

“To change the label polarity” on page 64

To import label names and assignments from a netlist

You can create label names and assign logic analyzer probe channels by

importing netlists. These netlists come from the Electronic Design

Automation (EDA) tools used to design the device under test, and they

contain information about the signals on the connectors built into the

device under test for the E5378A, E5379A, or E5380A probes for the

16760A logic analyzer.

1. In the Format tab, select File from the menu; then, select the Import

Netlist... menu item.

2. Read the information and follow the instructions in the Import Netlist

wizard's dialogs.

Select Next --> to go to the next dialog, <-- Prev to go to the previous

dialog, Cancel to exit the wizard, or Done to complete the netlist import.

The E5378A and E5380A probes require two logic analyzer pods, and

the E5379A probe requires one logic analyzer pod. When mapping

connector names to logic analyzer pods in the Import Netlist wizard,

two pods must be assigned to the logic analyzer in order for the

E5378A and E5380A probe types to be selectable.

The E5379A probe is for differential signals where there are two

connector pins (negative and positive) for each signal. The Import

Netlist wizard will either merge the two net names or append "-/+"

when creating label names to indicate that the labels are for differential

signals.

Multiple labels are automatically created for buses wider than 32-bits

because 32 is the maximum number of channels that can be assigned to

a label.

See Also “Probing the Device Under Test” on page 35

“To assign pods to the analyzer” on page 57

62

Page 63

Chapter 2: Probing and Selecting the Sampling Mode

Formatting Labels for Logic Analyzer Probes

“To assign probe channels to labels” on page 60

“To import label definitions from an ASCII file” on page 63

To import label definitions from an ASCII file

You can create label names and assign logic analyzer probe channels by

importing label definitions from an ASCII file.

1. In the Format tab, select File from the menu; then, select the Import

Labels... menu item.

2. In the File Selection dialog, select the name of the file that contains the

label definitions.

3. Select OK.

Up to 126 labels can be defined. Label names can be up to 20

characters long (additional characters are truncated). A maximum of

32 channels can be assigned to a label.

Label Definition File

Format

Examples

When updating labels by importing label definitions, make sure that the

labels are turned ON. Labels that are not active will not be updated.

Label definition files have one definition per line, where each line has

the format:

label_name;pod_name[channel_list];pod_name[channel_list] ...

In a channel list, individual channels are separated by commas (","),

and a range of channels is separated by a colon (":").

To assign label name "Blue" to channel 5 on pod A2:

Blue;A2[5]

To assign label name "Green" to channels 5 through 2 and channel 0 on

pod A2:

Green;A2[5:2,0]

To assign label name "Yellow" to channel 1 on pod A2 and channel 0 on

pod A1:

Yellow;A2[1];A1[0]

63

Page 64

Chapter 2: Probing and Selecting the Sampling Mode

Formatting Labels for Logic Analyzer Probes