Page 1

Installation Guide

Publication number 16700-97023

November 2002

For Safety information and Regulatory information, see the pages behind the

index.

© Copyright Agilent Technologies 2000-2002

All Rights Reserved

Agilent Technologies

16700B-Series Logic Analysis

Systems

Page 2

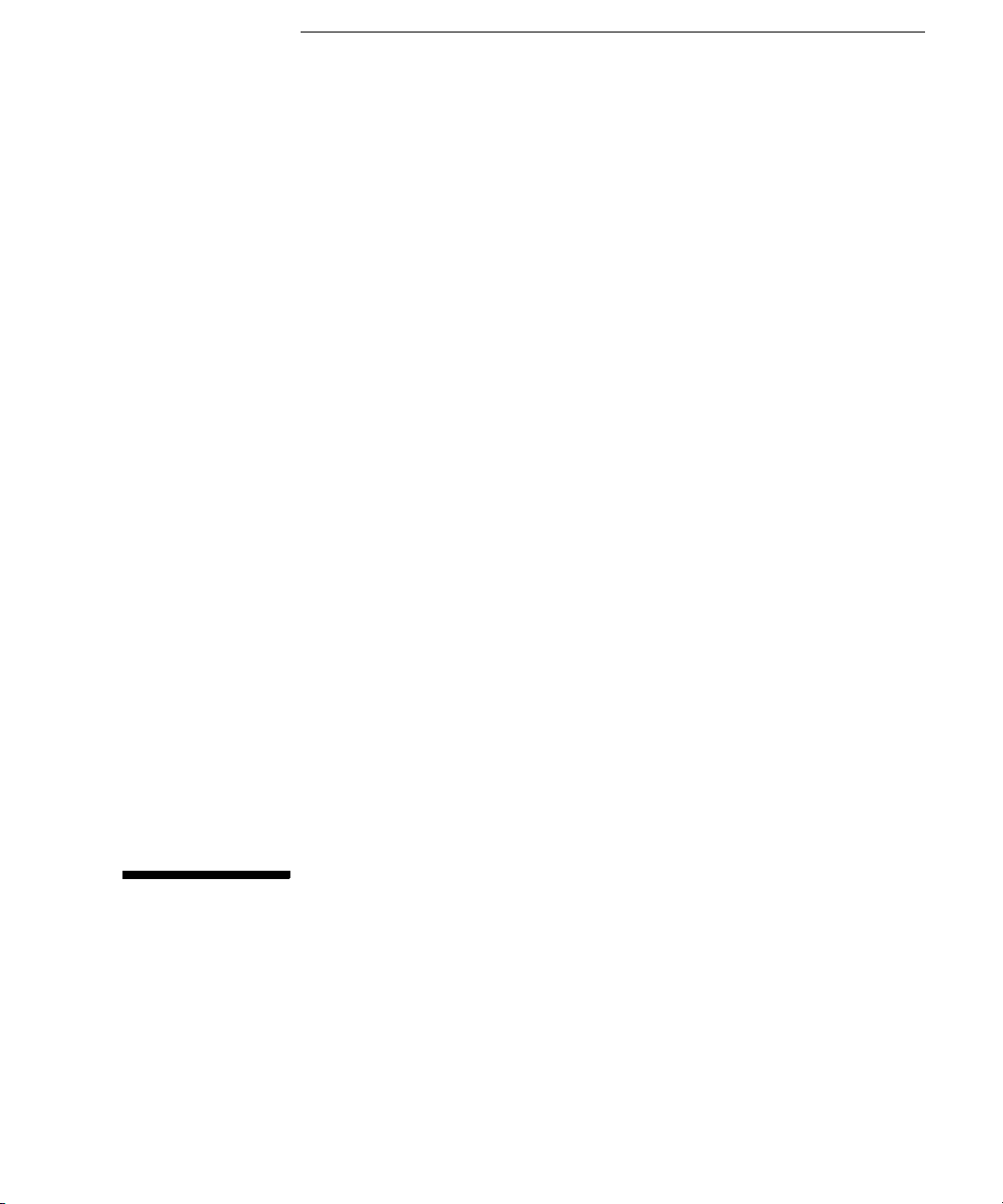

Installation at a Glance

16700B Overview

16700B Mainframe

Power Cable

Training Board & Kit

If ordered:

Monitor

Monitor Cable

Monitor Power Cable

Keyboard

& Mouse

Additional Connections

External Disk Drive & Cable

(Data Drive - Option 008)

(Boot Drive - Option 009)

2

16701A/B

Expander

Frame

Printer &

Cable

Page 3

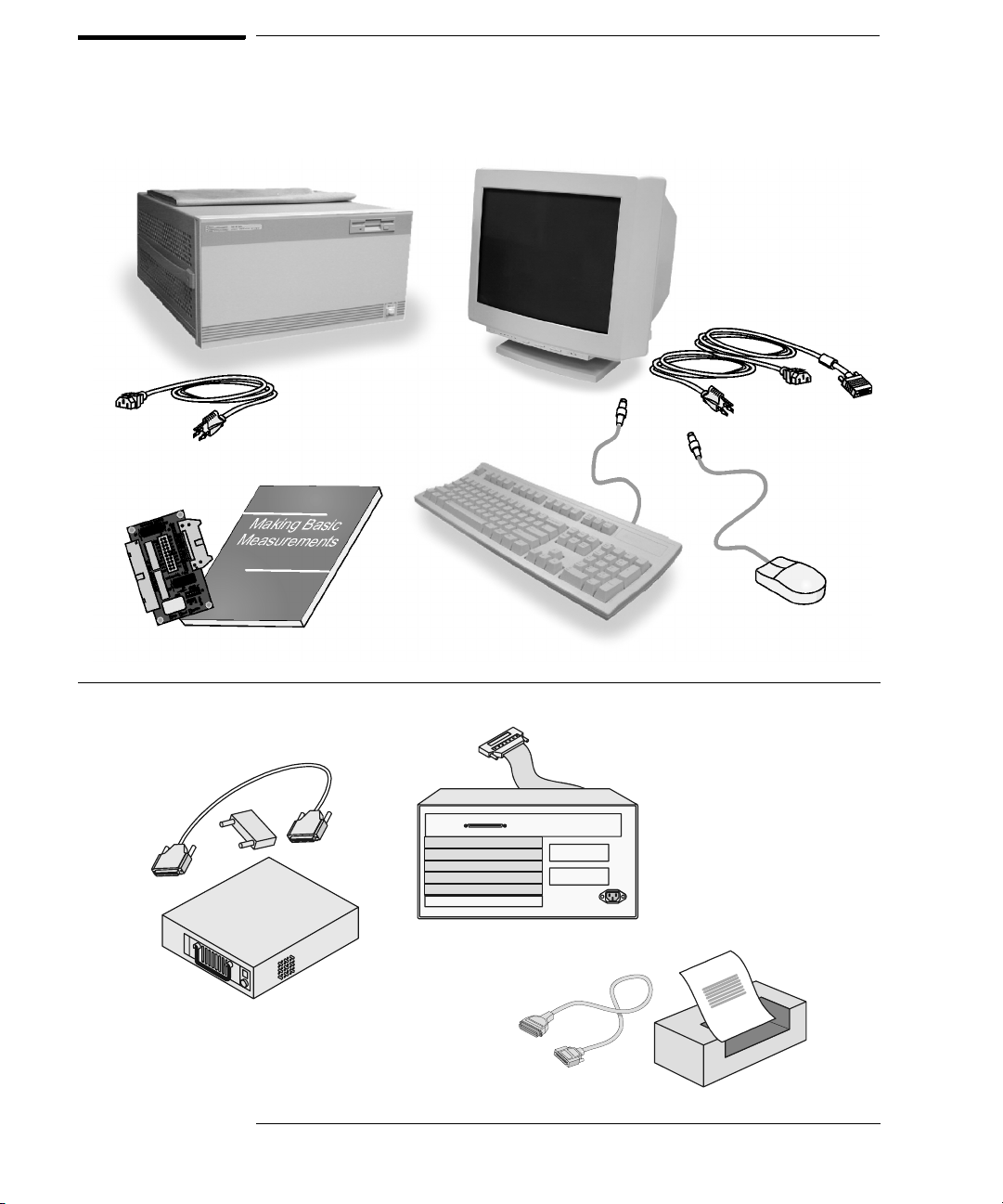

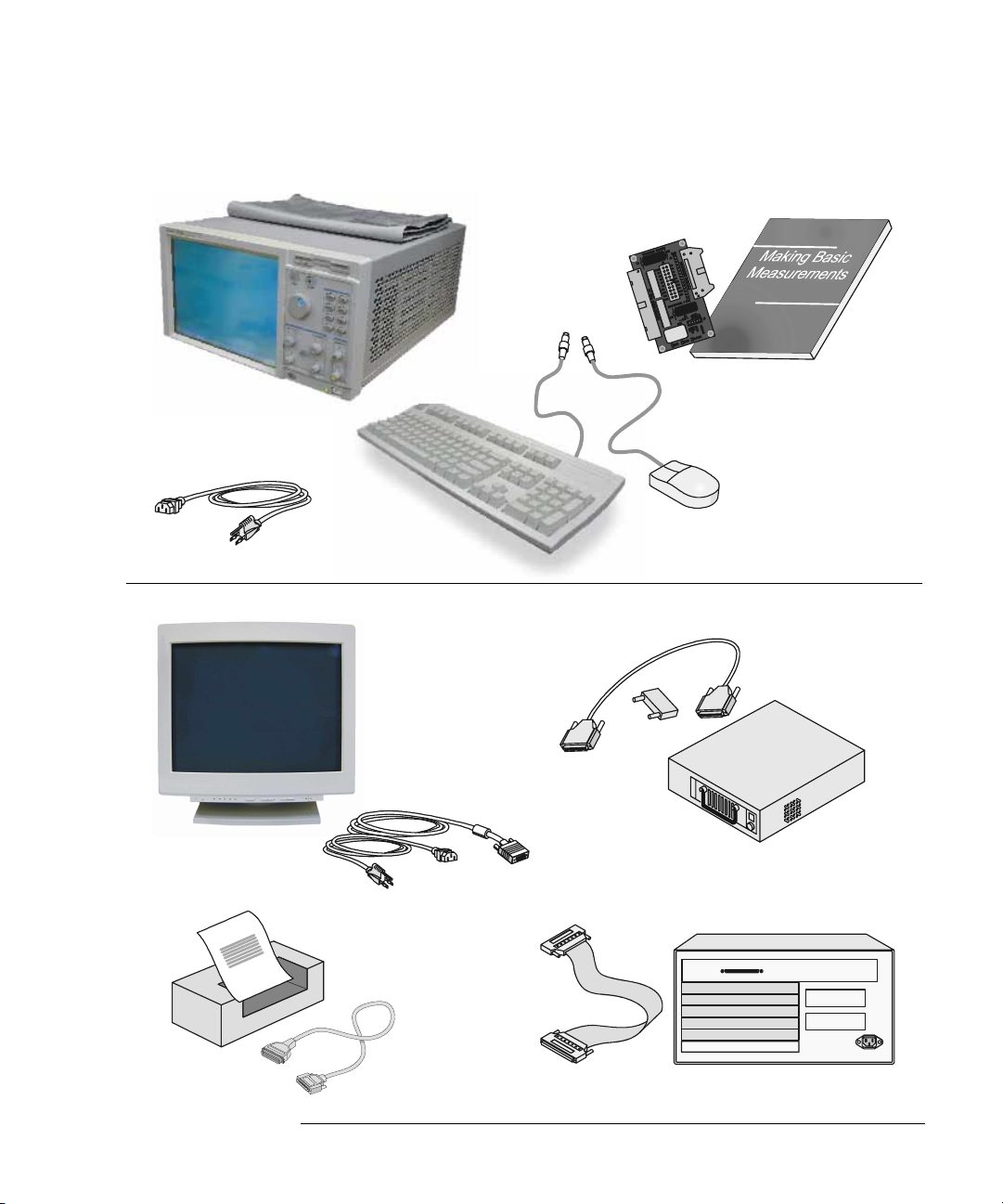

16702B Overview

16702B

Mainframe

Power Cable

Additional Connections

Orderable:

Monitor

Monitor Cable

Monitor Power Cable

Training Board

& Kit

Keyboard

& Mouse

External Disk Drive & Cable

(Data Drive - Option 008)

(Boot Drive - Option 009)

Printer &

Cable

16701A/B Expander Frame

3

Page 4

4

Page 5

Contents

Installation at a Glance

1 General Information 9

To locate information on using the logic analyzer 10

To locate specifications and characteristics 11

To create a backup file of your system settings and license passwords 13

To reload system settings and license passwords 15

2 Connecting and Configuring Hardware 17

To connect the mouse, keyboard, and monitor 18

To configure a monitor for the 16700B 19

To configure an optional monitor for the 16702B 21

To change monitors (16700B or 16702B) 22

To connect to LAN 22

To connect a printer 24

To connect an external data drive (option 008) 26

To disconnect an external data drive (option 008) 30

To connect a removable boot drive (option 009) 31

To disconnect a removable boot drive (option 009) 34

To install software 34

To connect a 16701B expander frame 37

To connect multiple frames 38

To install, remove, or replace measurement modules 42

3 Installing Logic Analyzer

Measurement Modules

45

5

Page 6

Contents

Software Requirements 46

16517/18A Logic Analyzer (2-card module) 47

16517/18A Logic Analyzer (3-card module) 48

16517/18A Logic Analyzer (4-card module) 49

16517/18A Logic Analyzer (5-card module) 50

16557D Logic Analyzer (1-card module) 50

16557D Logic Analyzer (2-card module) 51

16557D Logic Analyzer (3-card module) 52

16557D Logic Analyzer (3-card module) 53

16557D Logic Analyzer (5-card module) 54

16710/11/12A Logic Analyzer (1-card module) 55

16710/11/12A Logic Analyzer (2-card module) 56

16715/16/17A, 16718/19A, 16740/41/42A, 16750/51/52A/B Logic Analyzer (1card module) 57

16715/16/17A, 16718/19A, 16740/41/42A, 16750/51/52A/B Logic Analyzer (2card module) 58

16715/16/17A, 16718/19A, 16740/41/42A, 16750/51/52A/B Logic Analyzer (3card module) 59

16715/16/17A, 16718/19A, 16740/41/42A, 16750/51/52A/B Logic Analyzer (4card module) 60

16715/16/17A, 16718/19A, 16740/41/42A, 16750/51/52A/B Logic Analyzer (5card module) 61

16753/54/55/56A Logic Analyzer (1-card module) 62

16753/54/55/56A Logic Analyzer (2-card module) 63

16753/54/55/56A Logic Analyzer (3-card module) 64

16753/54/55/56A Logic Analyzer (4-card module) 65

16753/54/55/56A Logic Analyzer (5-card module) 66

16760A Logic Analyzer (1-card module) 67

16760A Logic Analyzer (2-card module) 67

16760A Logic Analyzer (3-card module) 68

16760A Logic Analyzer (4-card module) 69

16760A Logic Analyzer (5-card module) 70

4 Installing Oscilloscope

6

Page 7

Contents

Measurement Modules 71

16533/34A Oscilloscope Module (single or multi-card modules) 72

5 Installing Pattern Generator

Measurement Modules

Software Requirements 88

16522A Pattern Generator (1-card module) 88

16522A Pattern Generator (2-card module) 89

16522A Pattern Generator (3-card module) 89

16522A Pattern Generator (4-card module) 90

16522A Pattern Generator (5-card module) 91

16720A Pattern Generator (1-card module) 92

16720A Pattern Generator (2-card module) 92

16720A Pattern Generator (3-card module) 93

16720A Pattern Generator (4-card module) 94

16720A Pattern Generator (5-card module) 95

87

6 Connecting Accessories 97

For More Information

General-purpose probing 99

Isolation adapter (Part number 01650-63203) 101

Direct connection 102

38-pin Low-voltage Probe (E5339A with tip isolation network) 103

38-pin Single-ended Probe (E5346A for analyzers with 40-pin pod

connectors) 104

38-pin Adapter Cable (E5351A no tip network) 105

100-pin Single-ended Probe (E5378A for analyzers with 90-pin pod

connectors) 106

7

Page 8

Contents

100-pin Differential Probe (E5379A for analyzers with 90-pin pod

connectors) 107

38-pin Single-ended Probe (E5380A for analyzers with 90-pin pod

connectors) 108

Half-channel Adapter (E5386A) 109

Single-ended Flying Lead Probe Set (E5382A) 110

Soft Touch Probes (E5387A and E5390A for analyzers with 90-pin pod

connectors) 111

7 Troubleshooting 113

To run self-tests 114

To execute disaster recovery procedures 115

8

Page 9

1

General Information

9

Page 10

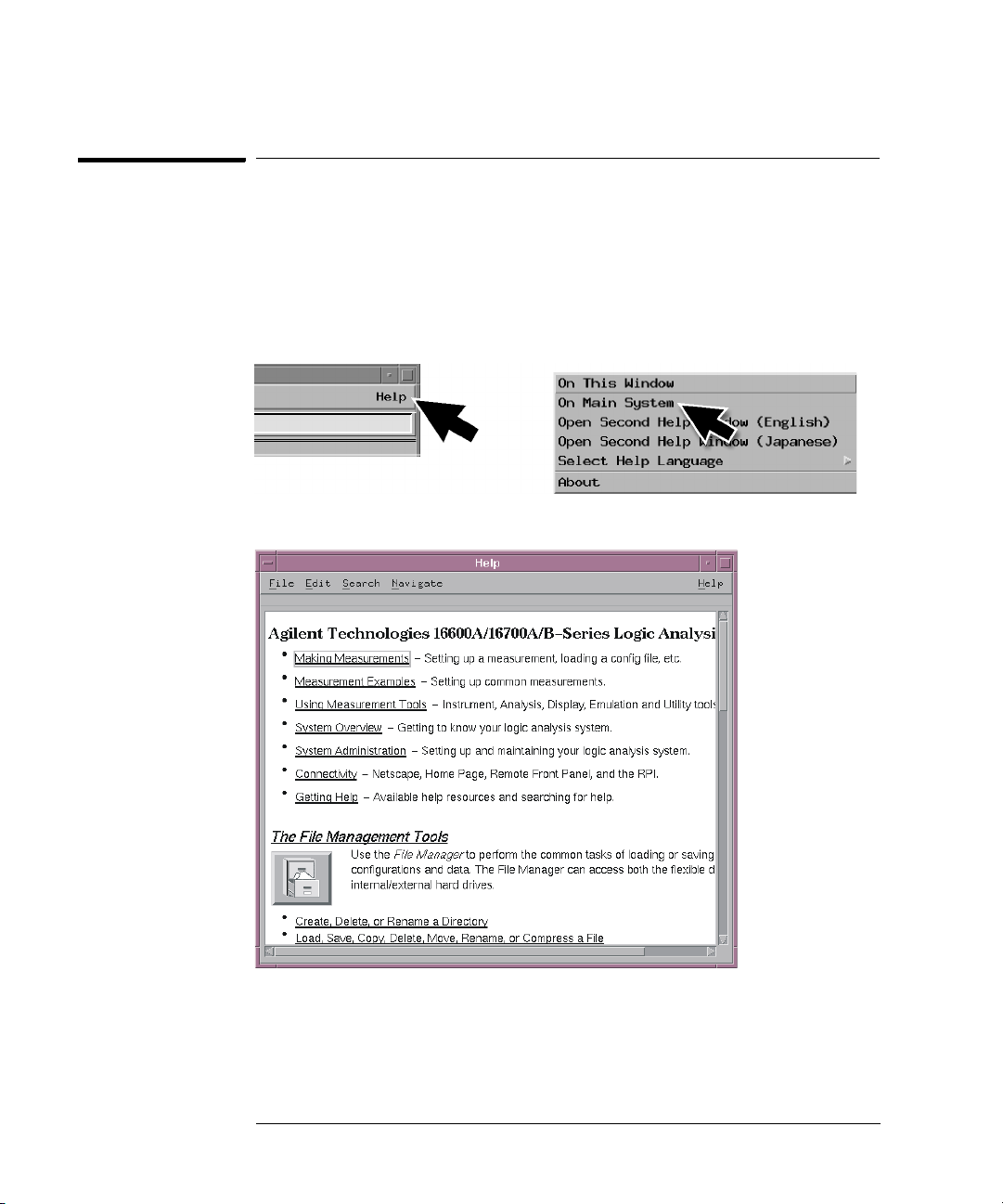

Chapter 1: General Information

To locate information on using the logic analyzer

To locate information on using the logic analyzer

Go to on-line help for information on using your logic analyzer. A pdf file of the

on-line help is on the CD that came with your system if you want to print it

out.

1 Select Help in the upper right corner of the screen and then select On

Main System.

2 Select the task you need information about. .

10

Page 11

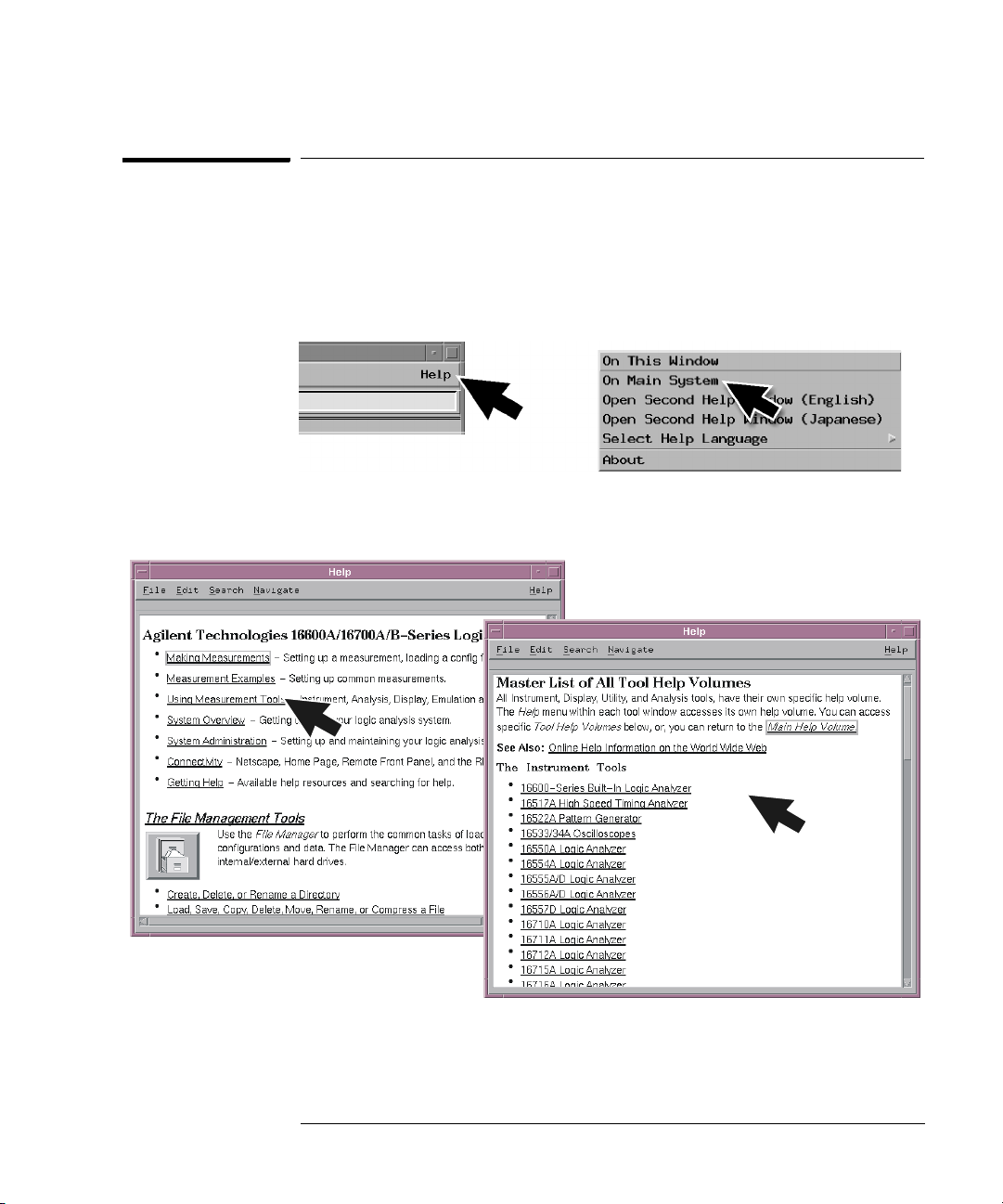

Chapter 1: General Information

To locate specifications and characteristics

To locate specifications and characteristics

The specifications and characteristics for your instrument and measurement

module are in the on-line Help.

1 Select Help in the upper right corner of the screen and then select On

Main System.

2 Select Using Measurement Tools and then select your instrument or

measurement module from the list.

11

Page 12

Chapter 1: General Information

To locate specifications and characteristics

3 Under Interface Reference, select Specifications and Characteristics.

12

Page 13

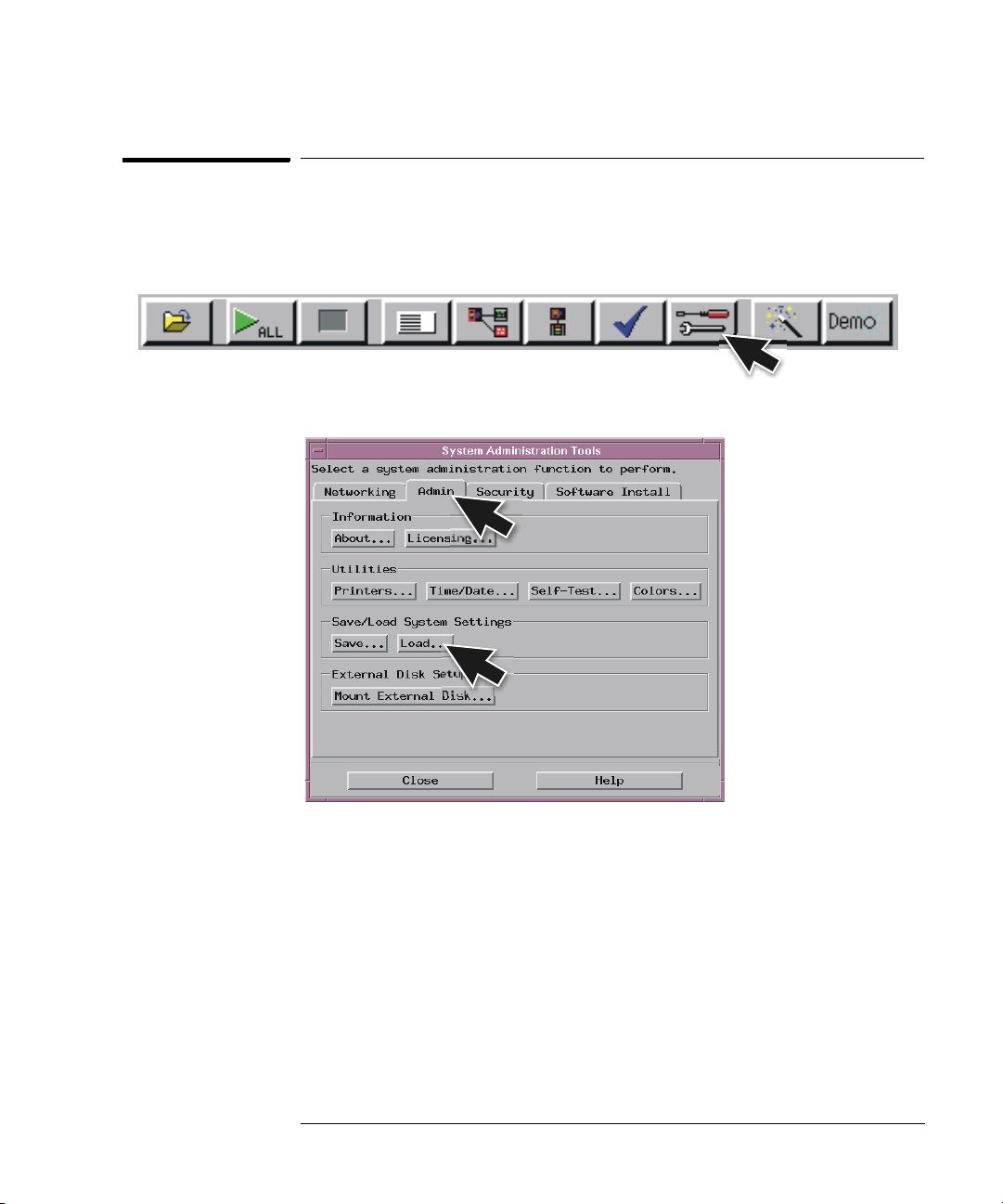

Chapter 1: General Information

To create a backup file of your system settings and license passwords

To create a backup file of your system settings and

license passwords

By saving your system settings to a flexible disk or a mounted directory, you

create a backup file that can be used to quickly setup systems or to restore

current system settings in case of problems.

1 Insert a flexible disk or set up a mounted directory.

2 Select the Tools icon from the menu bar.

3 Select the Admin tab and select Save, then select Licenses and Save to

File.

13

Page 14

Chapter 1: General Information

To create a backup file of your system settings and license passwords

4 Select Flexible Disk or a Mounted Directory and then select OK.

14

Page 15

Chapter 1: General Information

To reload system settings and license passwords

To reload system settings and license passwords

1 Insert the flexible disk or set up a mounted directory.

2 Select the Tools icon from the menu bar.

3 Go to the Admin tab and select Load.

15

Page 16

Chapter 1: General Information

To reload system settings and license passwords

4 Select Flexible Disk or Mounted Directory and select OK.

If an item is not valid, or was not initially saved to the file, the selection will be

grayed out in the interface. Also, if no file extension is added, a ‘.set’ extension

is automatically added for you.

16

Page 17

2

Connecting and Configuring Hardware

17

Page 18

Chapter 2: Connecting and Configuring Hardware

To connect the mouse, keyboard, and monitor

To connect the mouse, keyboard, and monitor

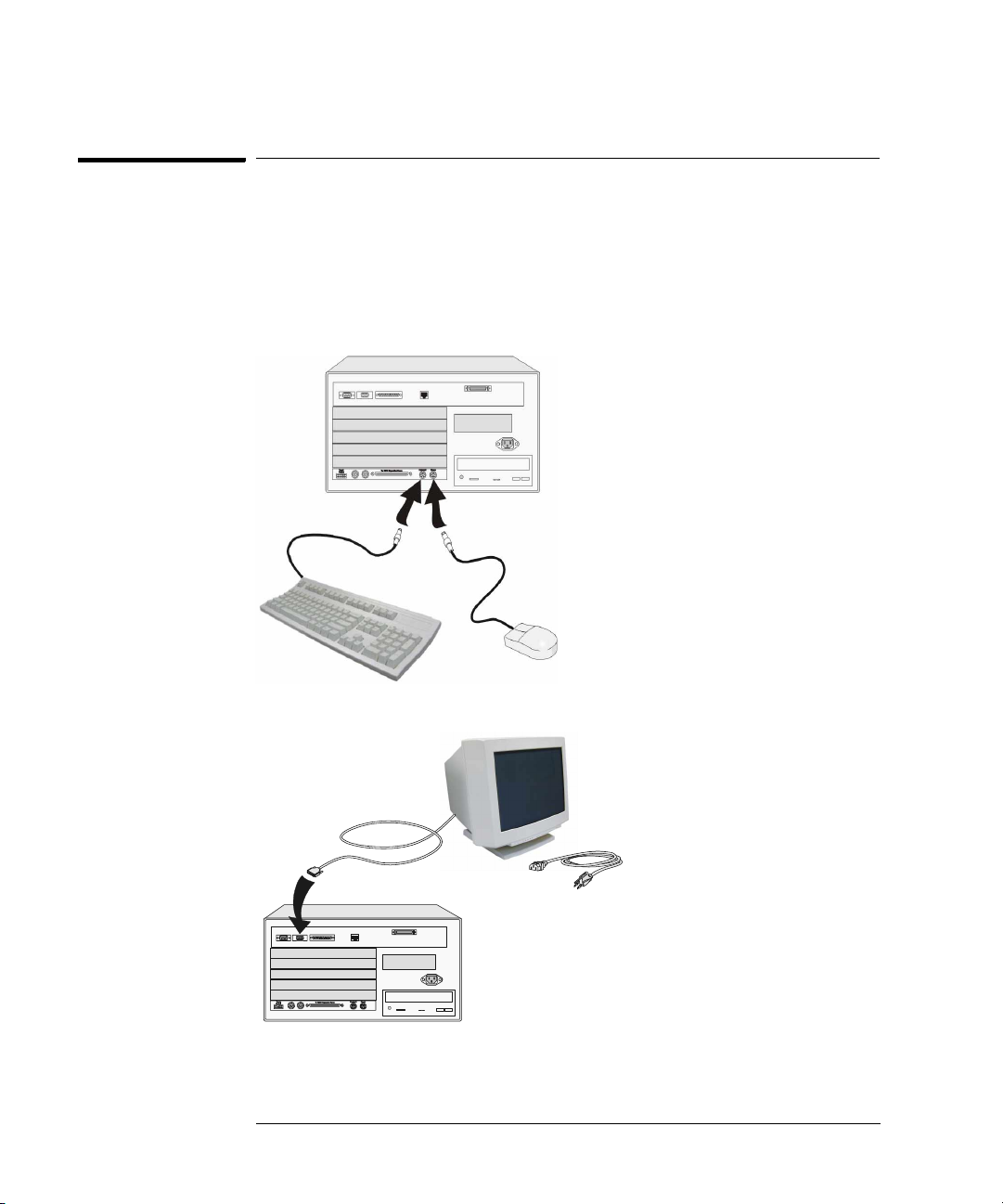

The 16700B must have the system mouse and keyboard connected for the

system to boot up properly. Once enabled on the LAN, the system can be

operated remotely without a keyboard or mouse. Use of a monitor is optional

for the 16700B and 16702B.

1 Connect the mouse and keyboard to the back of the 16700B or 16702B.

2 Connect the optional monitor to the back of the 16700B or 16702B.

3 Connect the monitor power cable. International versions of the power

cables can be found in the accessories box.

18

Page 19

Chapter 2: Connecting and Configuring Hardware

To configure a monitor for the 16700B

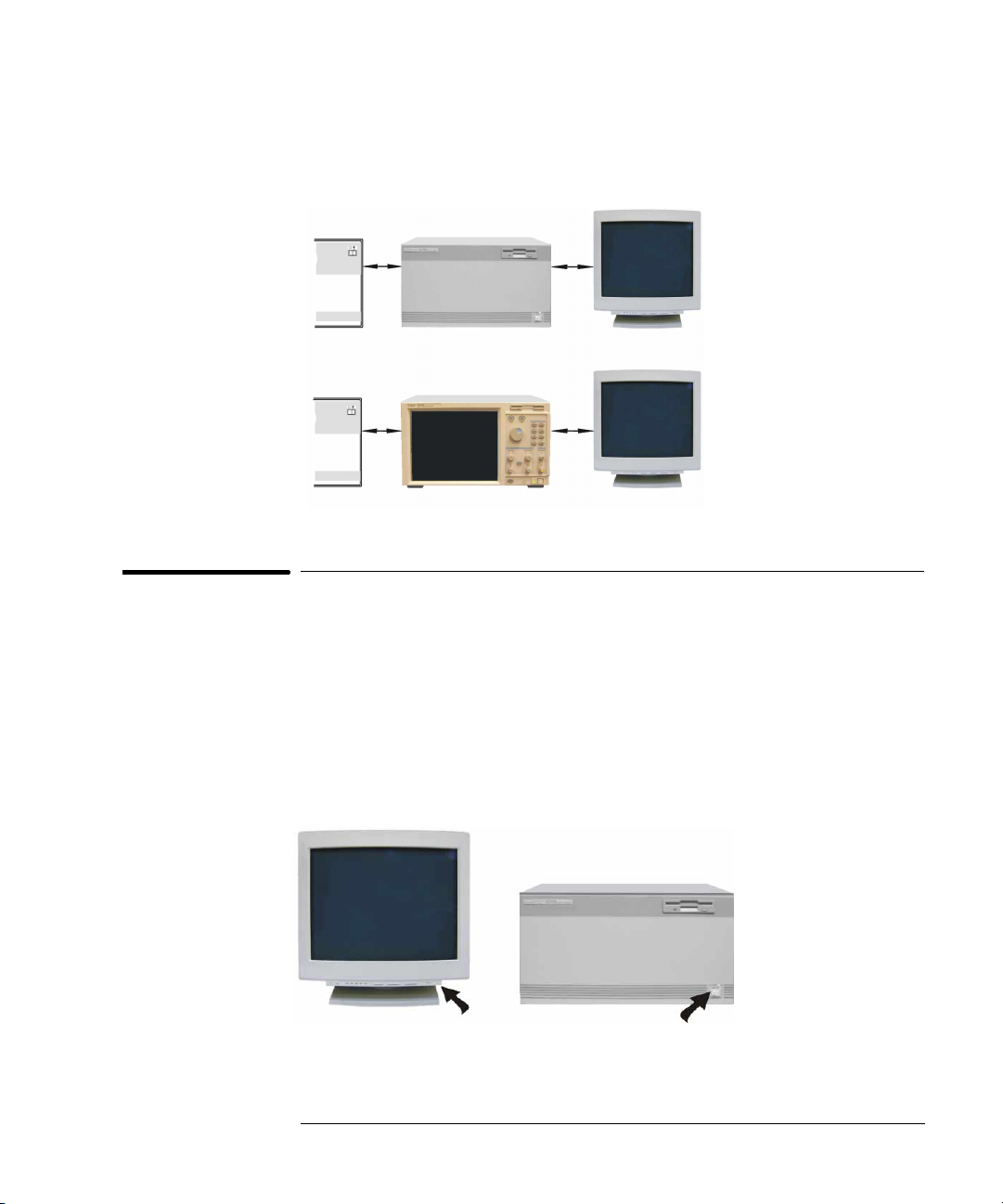

4 Allow a minimum of 5 cm spacing between instruments for proper

cooling.

5cm

16700B

5cm

16702B

5cm

5cm

To configure a monitor for the 16700B

If you ordered the optional monitor with your logic analyzer, the monitor

resolution setting is pre-configured for 1280 x 1024 at the factory. Use this

procedure if you wish to configure an external monitor other than the optional

monitor orderable with the 16700B.

1 Connect your monitor to the logic analysis system as shown on page 18.

2 Turn on power to the monitor and then to the logic analysis system.

1

19

2

Page 20

Chapter 2: Connecting and Configuring Hardware

To configure a monitor for the 16700B

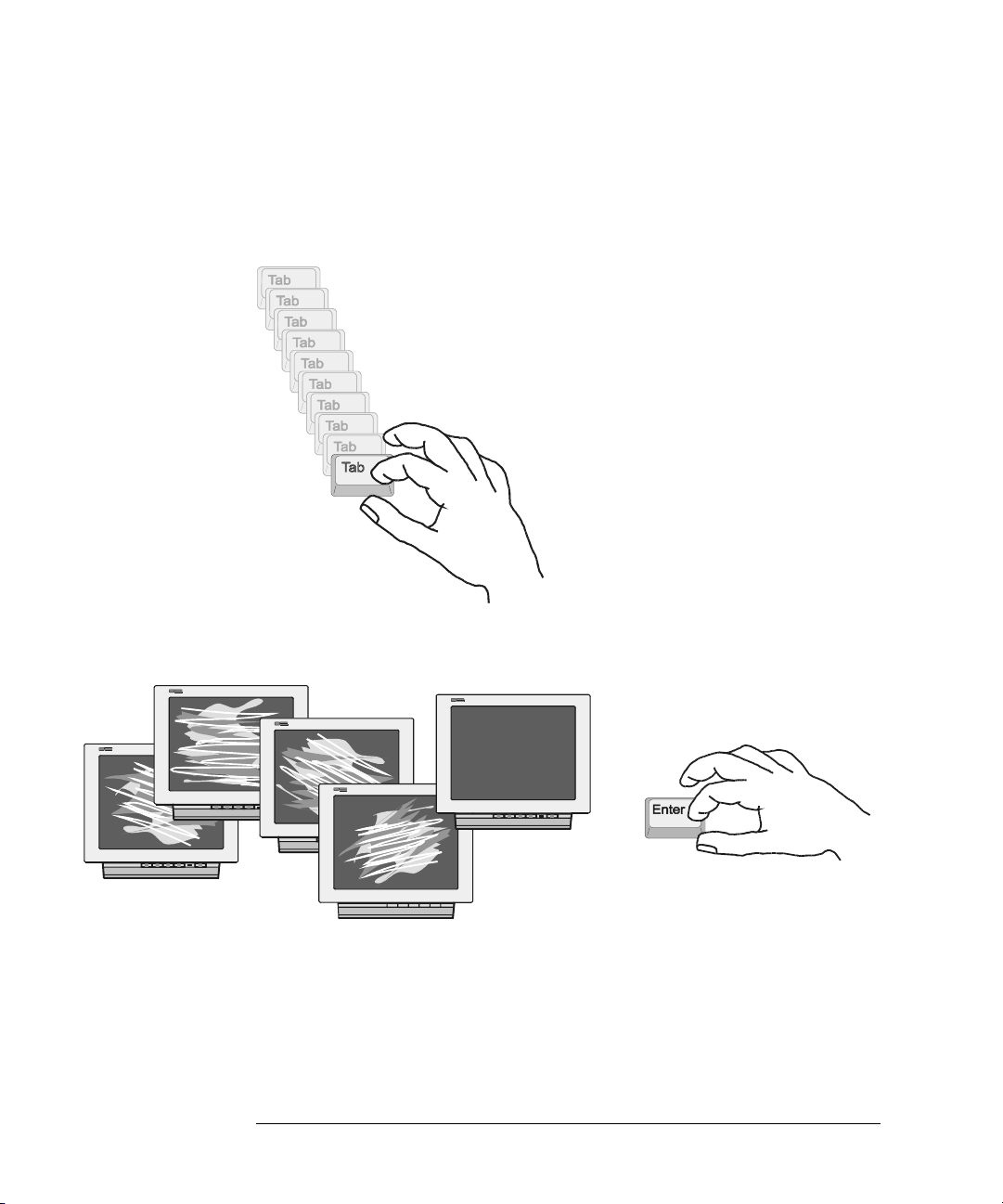

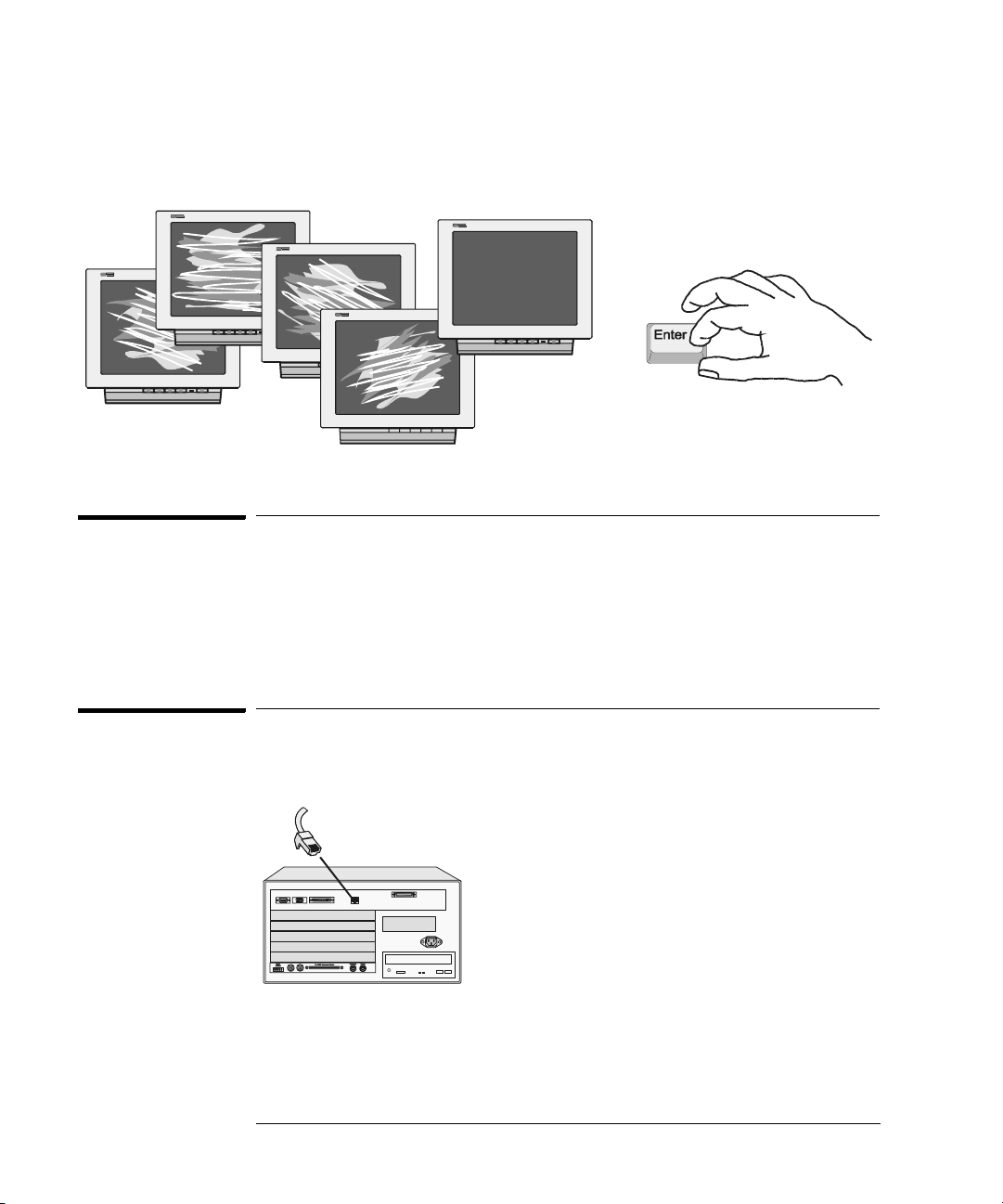

3 Immediately press the TAB key. Press once per second for

approximately 30 seconds.

every few seconds as the system cycles through the monitor resolution

choices.

The monitor display will change on the screen

4 Press ENTER when you see a clear image to select your monitor choice

and type ‘Y” to confirm.

Clear

Images

20

Page 21

Chapter 2: Connecting and Configuring Hardware

To configure an optional monitor for the 16702B

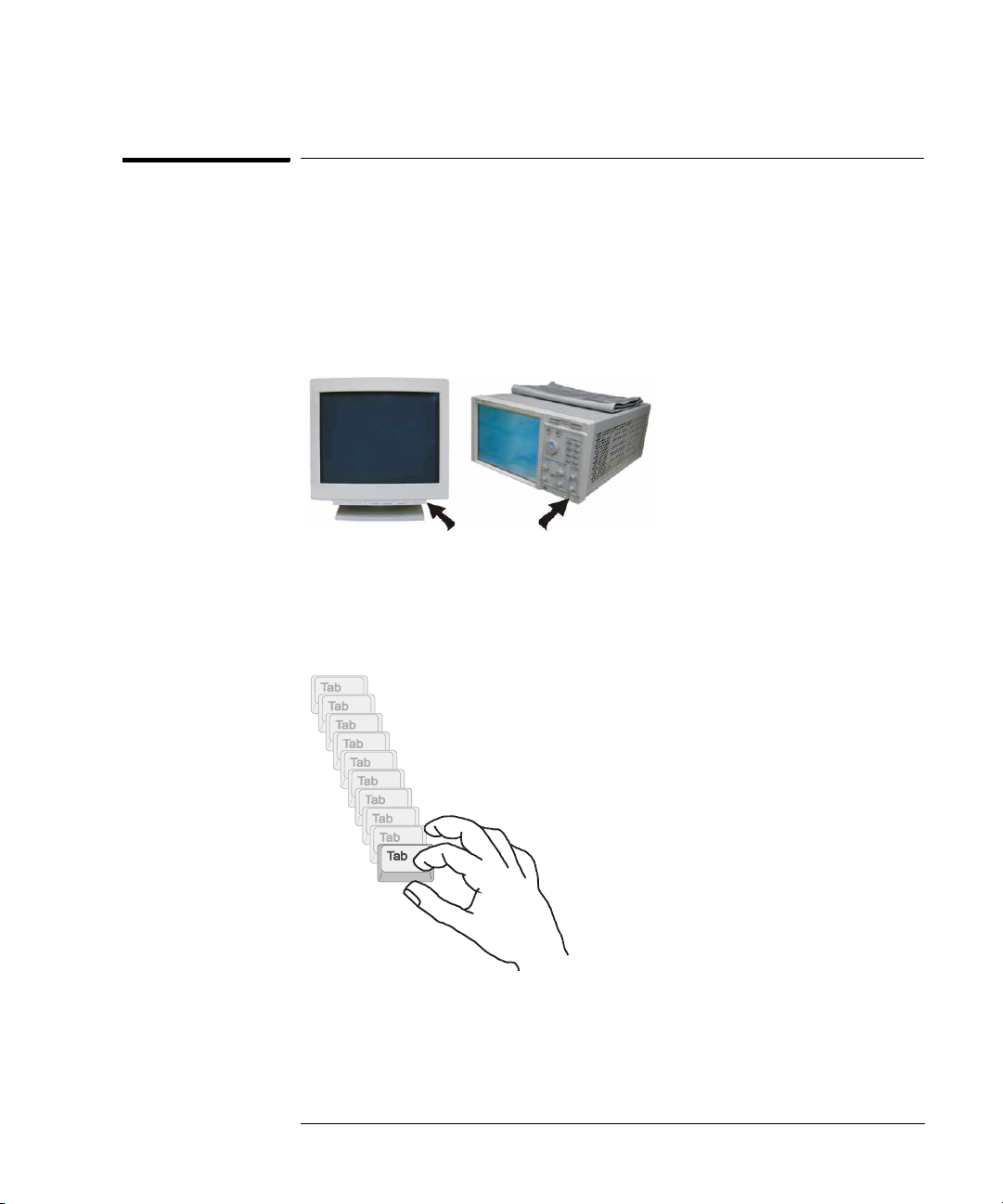

To configure an optional monitor for the 16702B

The internal LCD display is pre-configured for 800 x 600 at the factory. Use

this procedure if you wish to configure an external monitor or change the

monitor setting to a different resolution.

1 Connect your monitor to the logic analysis system as shown on page 18.

2 Turn on power to the monitor and then to the logic analysis system.

1

2

3 Immediately press the TAB key. Press once per second for

approximately 30 seconds. The display will change on the screen every

few seconds as the system cycles through the monitor resolution

choices.

21

Page 22

Chapter 2: Connecting and Configuring Hardware

To change monitors (16700B or 16702B)

4 Press ENTER when you see a clear image to select your monitor choice

and type ‘Y” to confirm.

Clear

Images

To change monitors (16700B or 16702B)

Any time you change monitors you will need to re-configure the new monitor.

Follow the instructions beginning with step one on page 19 if you have a

16700B or page 21 if you have a 16702B.

To connect to LAN

1 Connect the LAN cable to the back of the16700B or 16702B.

10Base-T/100Base-TX

22

Page 23

Chapter 2: Connecting and Configuring Hardware

To connect to LAN

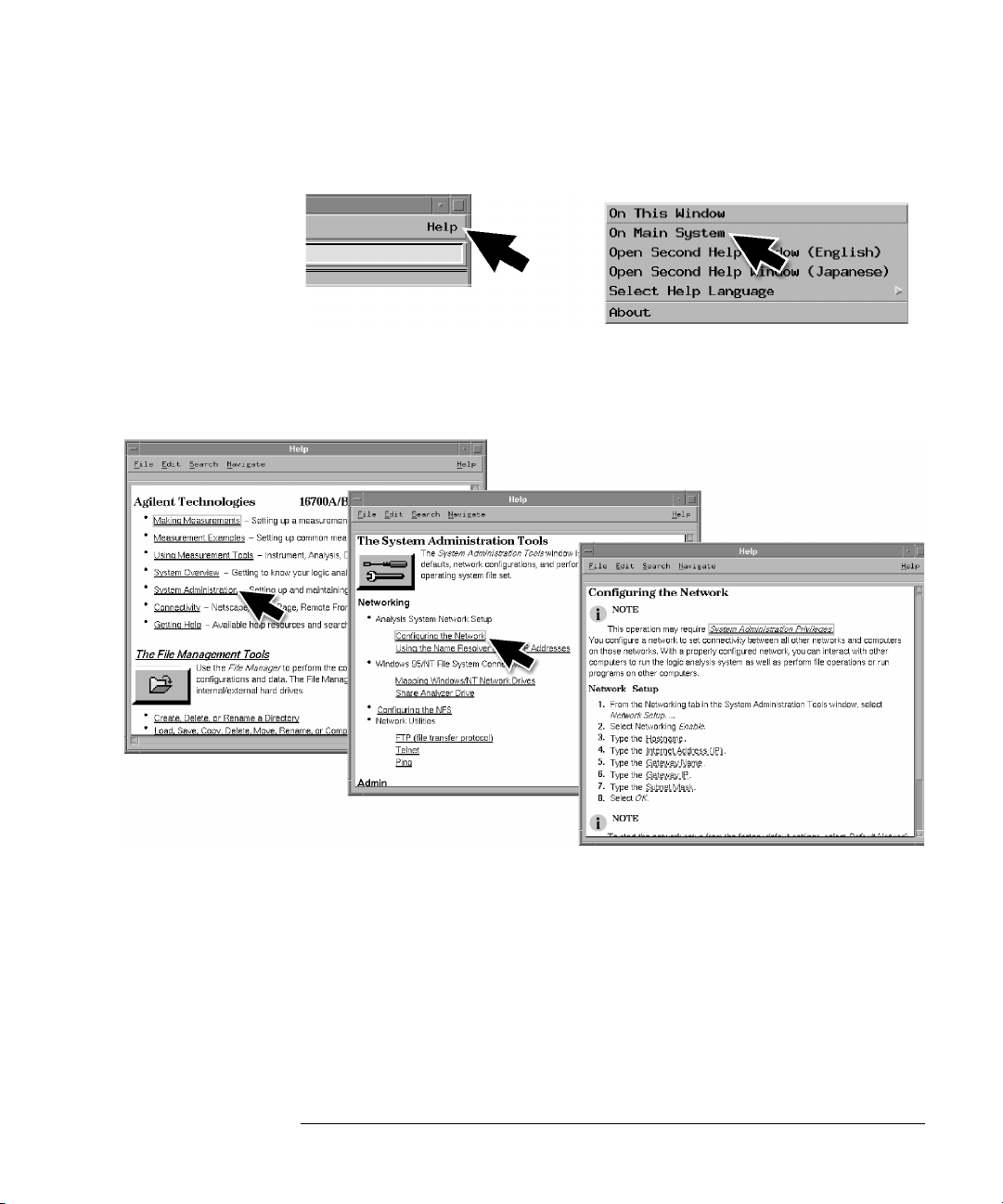

2 Go to the Help menu and select On Main System.

3 In the Help window select System Administration and then select

Configuring the Network. Follow the instructions on configuring the

network.

23

Page 24

Chapter 2: Connecting and Configuring Hardware

To connect a printer

To connect a printer

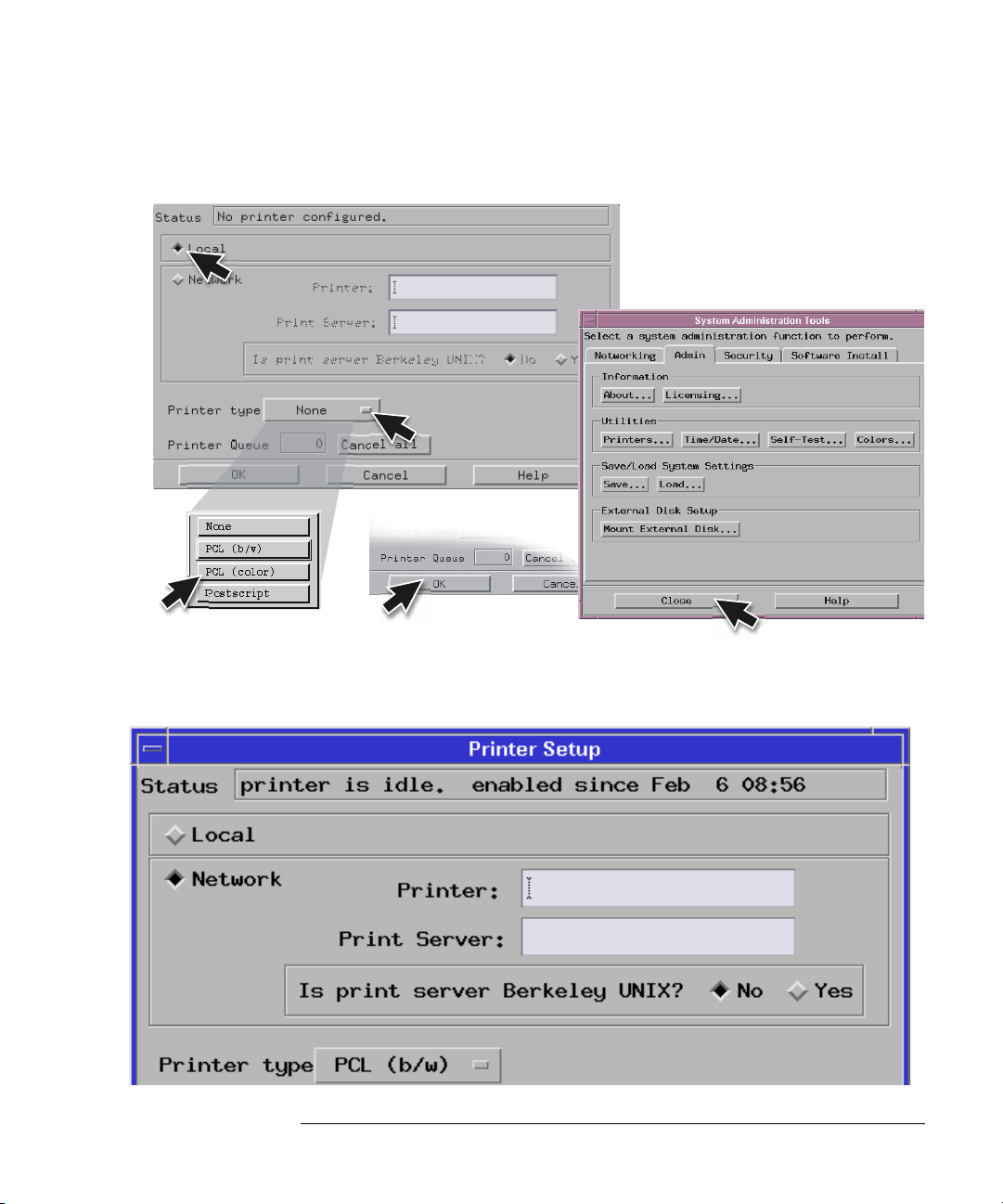

1 Connect the printer cable to the back of your 16700B or 16702B.

2 Select the Tools icon from the menu bar.

3 Go to the Admin. tab and select Printers.

24

Page 25

(Your

printer)

Chapter 2: Connecting and Configuring Hardware

To connect a printer

4 If you are connecting a local printer, select Local, select your printer

type, select OK, and then Close.

5 If you are connecting a network printer, select Network, enter the

printer name, server address, select type, select OK, and then Close.

25

Page 26

Chapter 2: Connecting and Configuring Hardware

To connect an external data drive (option 008)

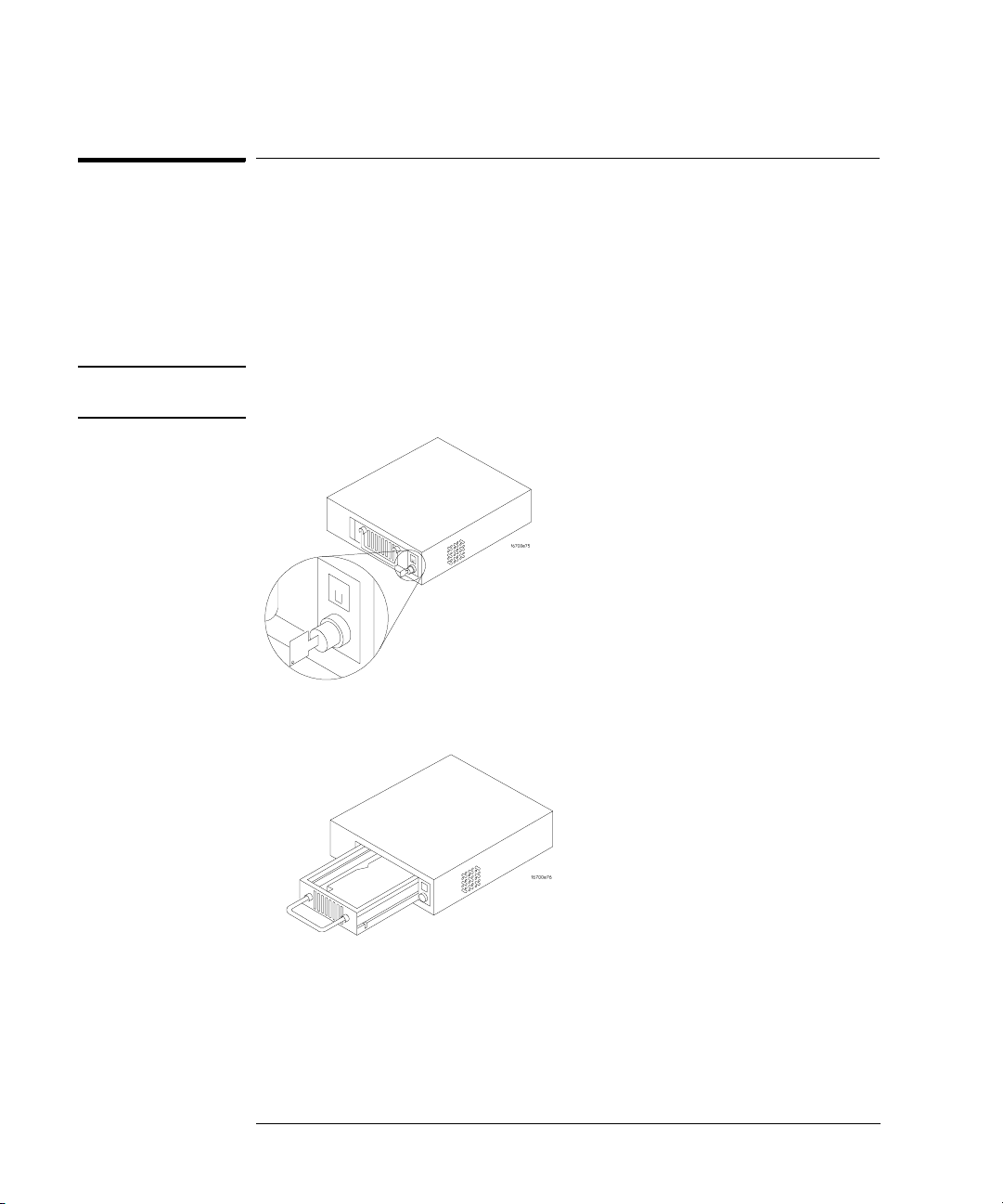

To connect an external data drive (option 008)

1 Power up the data drive.

2 Set the address.

a Unlock the data drive carrier. Wait until the drive stops spinning and

a “u” is displayed as shown.

CAUTION: Damage could result to the data drive if it is removed from the carrier while

the number is flashing.

b Remove the data drive from the carrier.

26

Page 27

Chapter 2: Connecting and Configuring Hardware

To connect an external data drive (option 008)

c Set the external data drive address to 3 or 4 using the alignment

tool supplied with the drive. The rotating switch is located inside

the carrier.

d Insert the disk drive into the carrier and lock it into place.

3 Power down the data drive.

27

Page 28

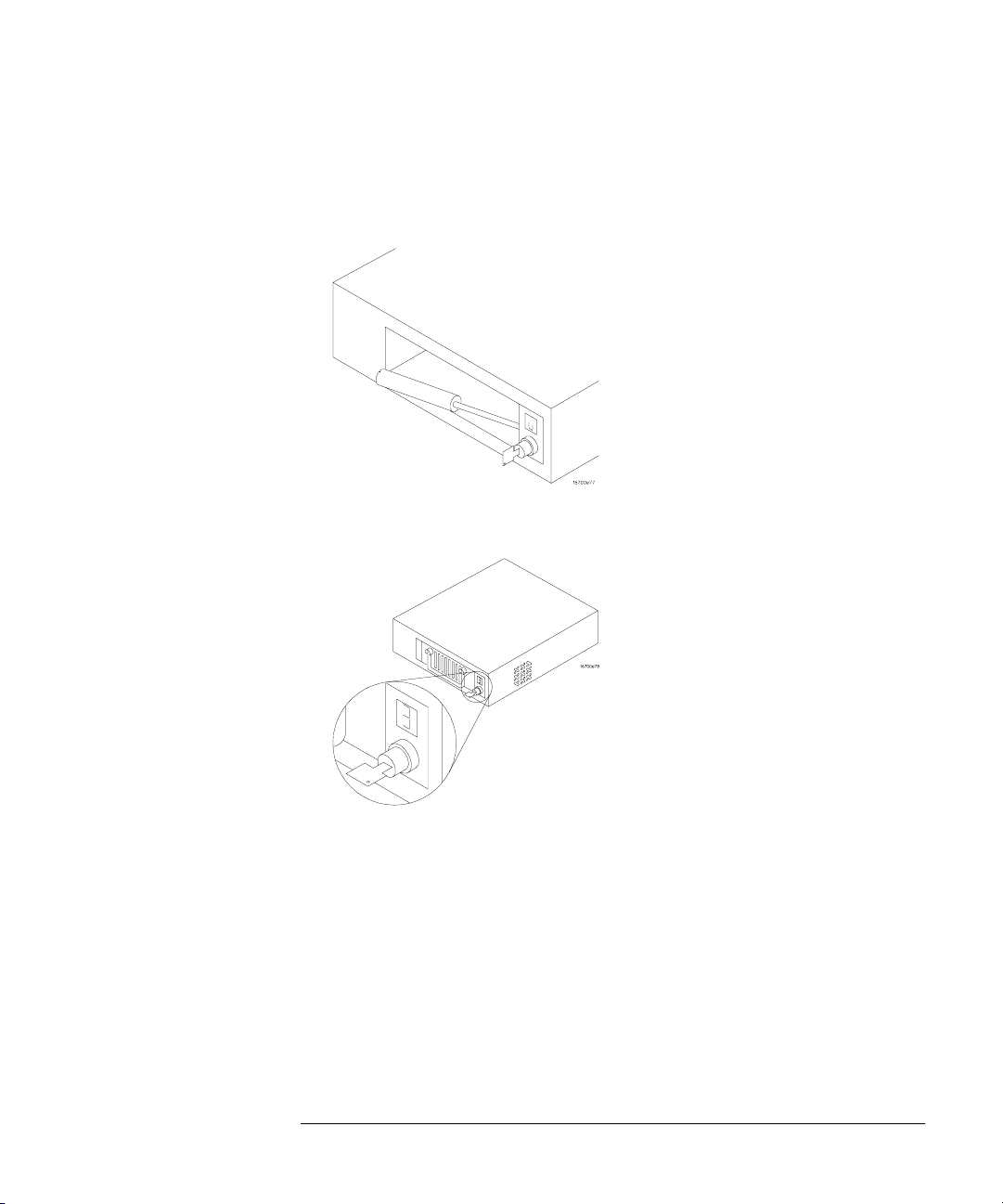

4 Connect the data drive to the SCSI-II port.

Termination Plug

(68 pin)

5 Power up the data drive, then the monitor, and then the system

Chapter 2: Connecting and Configuring Hardware

To connect an external data drive (option 008)

16700B or 16702B

(68 pin)

(50 pin)

External Disk Drive

Cable

(16700B or 16702B).

16700A

16700B or 16702B

6 Mount the disk.

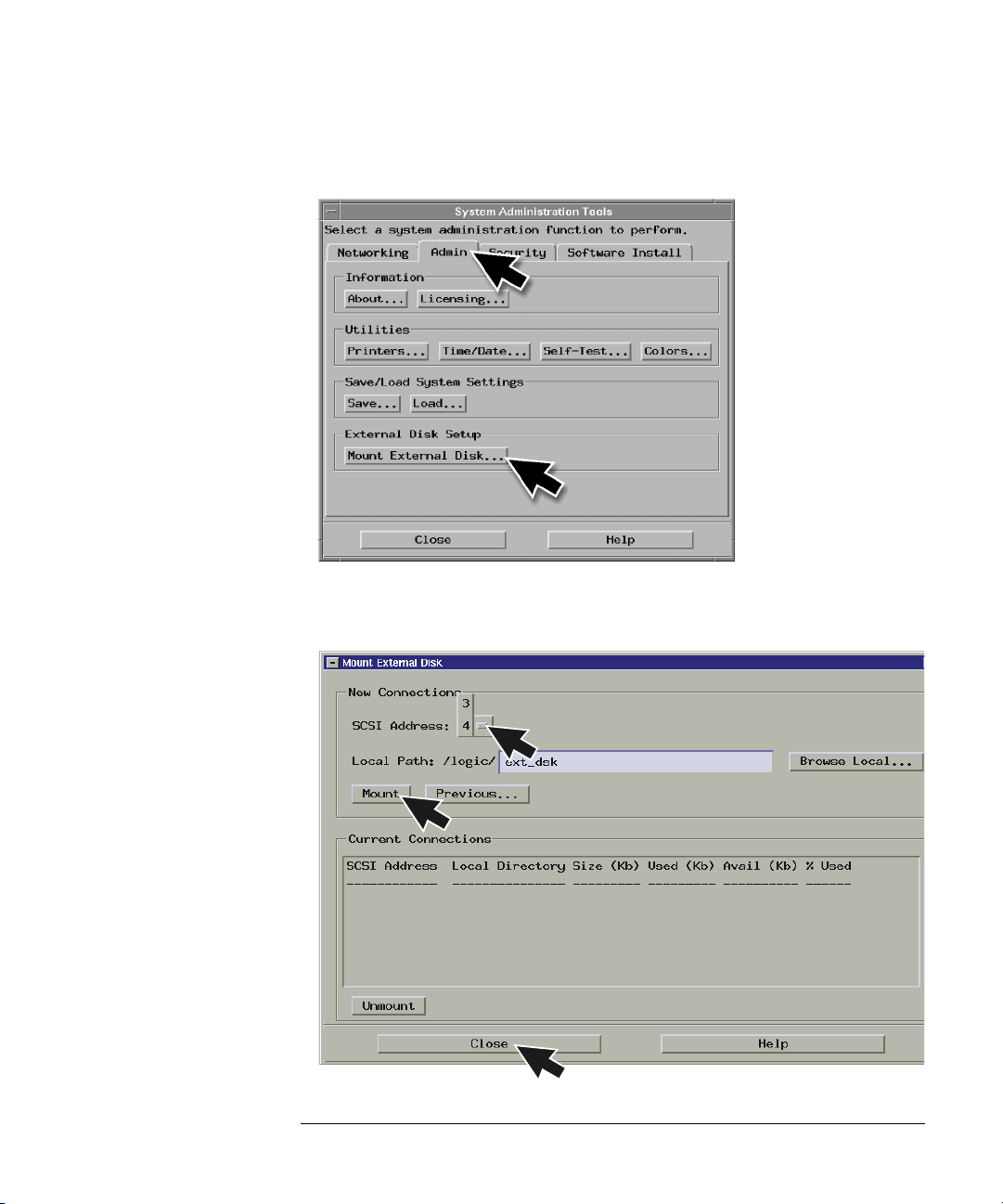

a Select the Tools icon from the menu bar

28

Power

Busy

Page 29

Chapter 2: Connecting and Configuring Hardware

To connect an external data drive (option 008)

b Go to the Admin. tab and select Mount External Disk.

c Select SCSI Address to the same number set in step 2, then Mount,

and Close.

29

Page 30

Chapter 2: Connecting and Configuring Hardware

To disconnect an external data drive (option 008)

To disconnect an external data drive (option 008)

It is important that you unmount the disk before turning the system off.

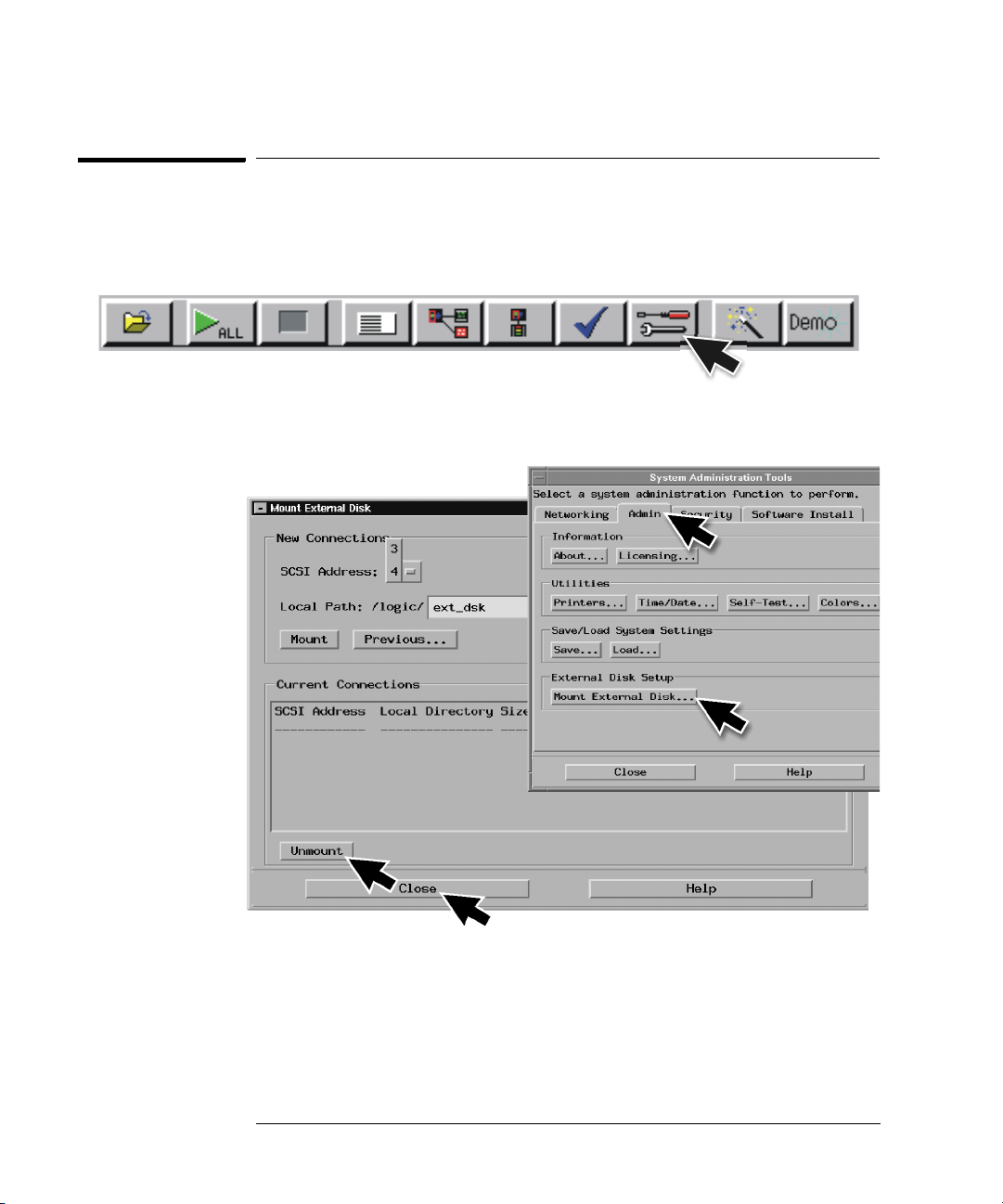

1 Select the Tools icon from the menu bar.

2 Select the Admin. tab, select Mount External Disk, select Unmount,

and then Close.

30

Page 31

16700A

16700B or 16702B

Chapter 2: Connecting and Configuring Hardware

To connect a removable boot drive (option 009)

3 Turn the power off on the system, then the monitor, and then the data

drive.

Power

Busy

To connect a removable boot drive (option 009)

1 Power up the boot drive.

2 Set the address.

a Unlock the boot drive carrier. Wait until the drive stops spinning and

a “u” is displayed as shown.

CAUTION: Damage could result to the data drive if it is removed from the carrier while

the number is flashing.

31

Page 32

Chapter 2: Connecting and Configuring Hardware

To connect a removable boot drive (option 009)

b Remove the boot drive from the carrier.

c Set the external boot drive address to 6 using the alignment tool

supplied with the drive. The rotating switch is located inside the

carrier.

d Insert the disk into the carrier drive and lock it into place.

32

Page 33

3 Power down the boot drive.

4 Connect the boot drive to the SCSI-II port.

Termination Plug

(68 pin)

Chapter 2: Connecting and Configuring Hardware

To connect a removable boot drive (option 009)

16700B or 16702B

(68 pin)

(50 pin)

External Disk Drive

Cable

5 Power up the boot drive, then the monitor, and then the system.

16700A

16700B or 16702B

33

Power

Busy

Page 34

16700A

16700B or 16702B

Chapter 2: Connecting and Configuring Hardware

To disconnect a removable boot drive (option 009)

To disconnect a removable boot drive (option 009)

Turn the power off on the system, then the monitor, and then the boot drive.

Power

Busy

To install software

When a system is shipped, the factory installs the current operating system

and ordered processor support packages and tools. The latest software update

is available at www.software.cos.agilent.com/16700

1 Select the Tools icon from the menu bar.

34

.

Page 35

Chapter 2: Connecting and Configuring Hardware

2 Select the Software Install tab and then select Install.

To install software

3 Select the media type and select Apply. The resulting window will

display software that can be loaded.

35

Page 36

Chapter 2: Connecting and Configuring Hardware

To install software

4 To load System Software, highlight it and select Install.

5 To load Additional Tools or Processor Support Software:

a Double click to display the available packages.

b Select one or more desired packages. A second click on a

highlighted item will deselect it.

c Select Install and the system will automatically reboot if it is

required by the newly installed package.

36

Page 37

Chapter 2: Connecting and Configuring Hardware

16701B Expander Frame

To connect a 16701B expander frame

To connect a 16701B expander frame

1 Install your measurement modules in the 16701B expander frame.

Module installation instructions are on page 42. For information on

specific measurement modules go to:

Module Type Page

Logic Analyzer 45

Oscilloscope 71

Pattern Generator 87

2 Connect either a 30 cm (12 inch) or 90 cm (36 inch) interconnect cable

to the expander and system frames.

3 Tighten the connector screws with the screwdriver provided.

4 Connect the power cable to the 16701B.

5 Power up the 16700B or 16702B system.

16700B or 16702B

Screwdriver

16701B

Interconnect

Cable

37

Page 38

Chapter 2: Connecting and Configuring Hardware

To connect multiple frames

To connect multiple frames

As many as eight 16700B’s and/or 16702B’s with expander frames may be

connected together. To connect multiple frames you need to order 16700B

option #012 and/or 16702B option #012.

NOTE: The multiframe module requires software Rev. A.02.00.00 or higher. Agilent

16700B and 16702B logic analysis systems ordered with the multiframe option

installed will have the current operating system software installed.

1 If the multiframe module is already installed, skip to step 11.

2 End your logic analysis session.

a Exit all logic analysis sessions. In the session manager, select

Shutdown.

b At the query, select Powerdown.

c When the “OK to turn off power or reset system” message appears,

turn the instrument off.

d Remove power from the instrument.

3 Disconnect the power cable and all data and peripheral cables from the

rear panel.

4 Move the instrument to a static-safe work area.

5 Lay the instrument on its side so the handle side is up.

6 Using a Torx T10 screwdriver, remove two feet and one screw at the

center rear of the cover that secures the bottom cover to the frame.

38

Page 39

Chapter 2: Connecting and Configuring Hardware

To connect multiple frames

7 Slide the bottom cover toward the rear of the instrument and away..

8 Remove the cover plate.

39

Page 40

Chapter 2: Connecting and Configuring Hardware

To connect multiple frames

9 Insert the Multiframe Module with the cable attached.

16700e24.cdr

40

Page 41

Chapter 2: Connecting and Configuring Hardware

To connect multiple frames

10 Connect the Multiframe Module cable to the connector on the bottom

side of the Interface Board, insert the screws and reassemble the

frame.

16700e25.cdr

11 Connect mainframe and expander frames together.The frame at the

beginning of the series must have its INPUT port open and the last

frame in the series must have its OUTPUT port open.

Input port open on first frame

Output port open on last frame

41

Page 42

Chapter 2: Connecting and Configuring Hardware

To install, remove, or replace measurement modules

To install, remove, or replace measurement modules

CAUTION: Electrostatic discharge can damage electronic components. Use grounded

wrist straps and mats when performing any service to measurement modules.

NOTE: Measurement modules with different model numbers may not be connected

together in multi-card (Master/Expander) modules unless stated otherwise.

For information on specific measurement modules go to:

Module Type Page

Logic Analyzer 45

Oscilloscope 71

Pattern Generator 87

1 Power down the system and disconnect the power cable before

installing, removing or replacing measurement modules.

Power

Busy

2 Remove filler panels and carefully slide the module into the frame.

3 Gently apply pressure to the center of the module while tightening the

thumb screws.

42

Page 43

Chapter 2: Connecting and Configuring Hardware

Insert

or filler panels.

s

filler panels.)

To install, remove, or replace measurement modules

4 If you are inserting more than one module, the tightening order is

bottom module to top module. A single-module configuration can be

installed in any available slot.

module

Remove filler panels.

(Other or

modules

(Other or

modules

filler panels.)

5 Some modules require calibration if they are moved to a different slot.

For calibration information, refer to the on-line help for the individual

modules.

WARNING: For correct air circulation, filler panels must be installed in all unused card

slots. Correct air circulation keeps the instrument from overheating. Keep

any extra filler panels for future use.

43

Page 44

Chapter 2: Connecting and Configuring Hardware

To install, remove, or replace measurement modules

44

Page 45

3

Installing Logic Analyzer Measurement Modules

45

Page 46

Chapter 3: Installing Logic Analyzer Measurement Modules

Software Requirements

Software Requirements

The following table gives you the software version required in your 16700A/B

or 16702A/B mainframe for use with logic analyzer measurement modules. For

software installation instructions go to page page 34

Model Number Software Version

16517/18A All versions

16557D All versions

16710/11/12A A.01.20.00 or higher

16715/16/17A A.01.40.00 or higher

16718/19A A.01.50.00 or higher

16740/41/42A A.02.50.00 or higher

16750/51/52A A.02.00.00 or higher

16750/51/52B A.02.50.00 or higher

16753/54/55/56A A.02.70.00 or higher

16760A A.02.20.00 or higher

.

46

Page 47

Chapter 3: Installing Logic Analyzer Measurement Modules

16517/18A Logic Analyzer (2-card module)

16517/18A Logic Analyzer (2-card module)

The 16517A is the master card and the 16518A is the expander card. Connect

the cards together in one of the two ways shown below.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

2 Connector

Cable

Expander

Expander (16518A)

Master (16517A)

Master (16517A)

Expander (16518A)

Master

Expander

Master

2 Connector

Cable

47

Page 48

Chapter 3: Installing Logic Analyzer Measurement Modules

16517/18A Logic Analyzer (3-card module)

16517/18A Logic Analyzer (3-card module)

The 16517A is the master card and the 16518A cards are expander cards.

Connect the cards together in one of the three ways shown below.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

3 Connector

Master

Cable

2 Connector

Cable

Master (16517A)

Expander (16518A)

Expander (16518A)

Expander (16518A)

Master (16517A)

Expander (16518A)

Master

Expander

Expander

2 Connector

Cable

Expander

Expander

3 Connector

Cable

Expander (16518A)

Expander (16518A)

Master (16517A)

Expander

Expander

Master

48

Page 49

Chapter 3: Installing Logic Analyzer Measurement Modules

C

3 Connector

16517/18A Logic Analyzer (4-card module)

16517/18A Logic Analyzer (4-card module)

The 16517A is the master card and the 16518A cards are expander cards.

Connect the cards together in one of the two ways shown below.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

2

onnector

Cable

Expander (16518A)

Master (16517A)

Expander (16518A)

Expander (16518A)

Expander

Master

Expander

Expander

3 Connector

Cable

Expander (16518A)

Expander (16518A)

Master (16517A)

Expander (16518A)

Cable

Expander

Expander

Master

Expander

2 Connector

Cable

49

Page 50

Chapter 3: Installing Logic Analyzer Measurement Modules

3 Connector

16517/18A Logic Analyzer (5-card module)

16517/18A Logic Analyzer (5-card module)

The 16517A is the master card and the 16518A cards are expander cards.

Connect the cards together as shown below.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

Cable

Expander (16518A)

Expander (16518A)

Master (16517A)

Expander (16518A)

Expander (16518A)

Expander

Expander

Master

Expander

Expander

3 Connector

Cable

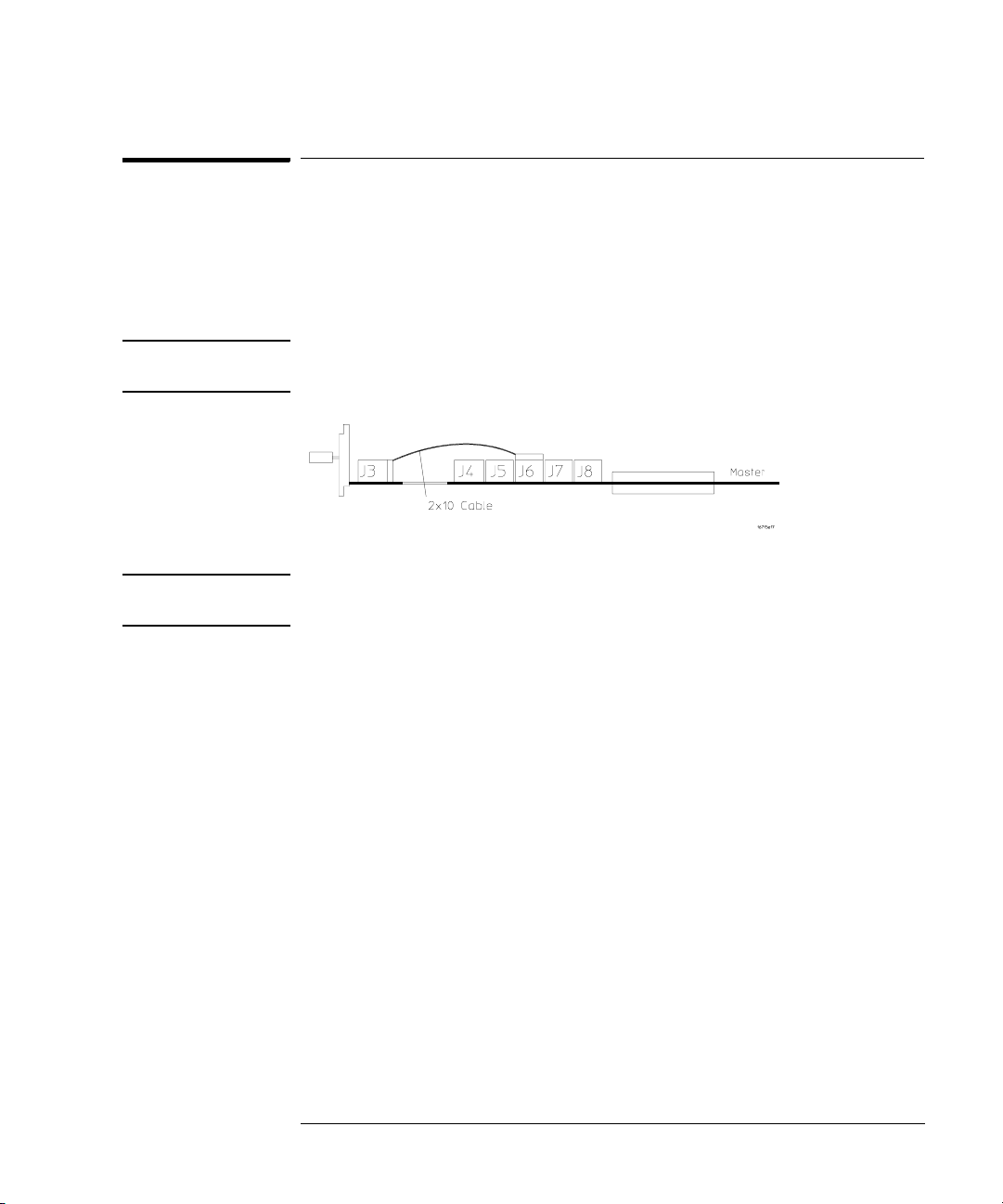

16557D Logic Analyzer (1-card module)

When ordered as a single card, the 16557D is shipped with a 2 x 10 cable

factory configured as a single-card module.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

2x10 Cable

Master

50

Page 51

Chapter 3: Installing Logic Analyzer Measurement Modules

2x10 Cables

16557D Logic Analyzer (2-card module)

16557D Logic Analyzer (2-card module)

Use two 2 x 25 cables and two 2 x 10 cables to connect the cards as shown.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

Expander

Master

2x25 Cables

Expander

Master

(Need 2)

51

Page 52

Chapter 3: Installing Logic Analyzer Measurement Modules

2x25 Cables

2x10 Cables

16557D Logic Analyzer (3-card module)

16557D Logic Analyzer (3-card module)

Use two 2 x 25 cables and three 2 x 10 cables to connect the cards as shown.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

(Need 2)

Expander

Master

Expander

Expander

Master

Expander

52

Page 53

Chapter 3: Installing Logic Analyzer Measurement Modules

2x25 Cables

16557D Logic Analyzer (3-card module)

16557D Logic Analyzer (3-card module)

Use two 2 x 25 cables and four 2 x 10 cables to connect the cards as shown.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

(Need 2)

Expander

Expander

Master

Expander

2x10 Cables

Expander

Expander

Master

Expander

53

Page 54

Chapter 3: Installing Logic Analyzer Measurement Modules

2x25 Cables

16557D Logic Analyzer (5-card module)

16557D Logic Analyzer (5-card module)

Use two 2 x 25 cables and five 2 x 10 cables to connect the cards as shown.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

(Need 2)

Expander

Expander

Master

Expander

Expander

Master

Expander

Expander

Expander

Expander

2x10 Cables

54

Page 55

Chapter 3: Installing Logic Analyzer Measurement Modules

16710/11/12A Logic Analyzer (1-card module)

16710/11/12A Logic Analyzer (1-card module)

A single 16710/11/12A logic analyzer module will have the 2 x 40 cable

connected in the single-card configuration.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

J9

J7

Master

J8

2x40 Cable

NOTE: Measurement modules with different model numbers may not be connected

together in multi-card (Master/Expander) modules.

55

Page 56

Chapter 3: Installing Logic Analyzer Measurement Modules

16710/11/12A Logic Analyzer (2-card module)

16710/11/12A Logic Analyzer (2-card module)

Connect two modules as shown using two 2 x 25 cables and two 2 x 40 cables.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

2x40

Cable

J6

2x25

Cable

J5

Master

J5

Expander

J7

2x25

Cable

J6

J7

2x40

Cable

J9

J8

J9

J8

NOTE: Measurement modules with different model numbers may not be connected

together in multi-card (Master/Expander) modules.

56

Page 57

Chapter 3: Installing Logic Analyzer Measurement Modules

16715/16/17A, 16718/19A, 16740/41/42A, 16750/51/52A/B Logic Analyzer (1-card module)

16715/16/17A, 16718/19A, 16740/41/42A, 16750/51/52A/B

Logic Analyzer (1-card module)

Each card shipped stand-alone has the 2 x 10 cable connected in the singlecard module configuration. A single-card module can be installed in any

available slot.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

NOTE: Measurement modules with different model numbers may not be connected

together in multi-card (Master/Expander) modules.

57

Page 58

Chapter 3: Installing Logic Analyzer Measurement Modules

16715/16/17A, 16718/19A, 16740/41/42A, 16750/51/52A/B Logic Analyzer (2-card module)

16715/16/17A, 16718/19A, 16740/41/42A, 16750/51/52A/B

Logic Analyzer (2-card module)

Use two 2 x 10 cables and two 2 x 40 cables (in the accessory pouch) to

connect the modules.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

NOTE: Measurement modules with different model numbers may not be connected

together in multi-card modules. However, the 16750A works with the 16750B;

the 16751A works with the 16751B; the 16752A works with the 16752B.

58

Page 59

Chapter 3: Installing Logic Analyzer Measurement Modules

16715/16/17A, 16718/19A, 16740/41/42A, 16750/51/52A/B Logic Analyzer (3-card module)

16715/16/17A, 16718/19A, 16740/41/42A, 16750/51/52A/B

Logic Analyzer (3-card module)

Use three 2 x 10 cables and four 2 x 40 cables (in the accessory pouch) to

connect the modules.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

NOTE: Measurement modules with different model numbers may not be connected

together in multi-card modules. However, the 16750A works with the 16750B;

the 16751A works with the 16751B; the 16752A works with the 16752B.

59

Page 60

Chapter 3: Installing Logic Analyzer Measurement Modules

16715/16/17A, 16718/19A, 16740/41/42A, 16750/51/52A/B Logic Analyzer (4-card module)

16715/16/17A, 16718/19A, 16740/41/42A, 16750/51/52A/B

Logic Analyzer (4-card module)

Use four 2 x 10 cables and six 2 x 40 cables (in the accessory pouch) to

connect the modules.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42

NOTE: Measurement modules with different model numbers may not be connected

together in multi-card modules. However, the 16750A works with the 16750B;

the 16751A works with the 16751B; the 16752A works with the 16752B.

60

Page 61

Chapter 3: Installing Logic Analyzer Measurement Modules

16715/16/17A, 16718/19A, 16740/41/42A, 16750/51/52A/B Logic Analyzer (5-card module)

16715/16/17A, 16718/19A, 16740/41/42A, 16750/51/52A/B

Logic Analyzer (5-card module)

Use five 2 x 10 cables and eight 2 x 40 cables (in the accessory pouch) to

connect the modules

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

NOTE: Measurement modules with different model numbers may not be connected

together in multi-card modules. However, the 16750A works with the 16750B;

the 16751A works with the 16751B; the 16752A works with the 16752B.

61

Page 62

Chapter 3: Installing Logic Analyzer Measurement Modules

16753/54/55/56A Logic Analyzer (1-card module)

16753/54/55/56A Logic Analyzer (1-card module)

Each card shipped stand-alone has the 2 x 15 cable connected in the singlecard module configuration. The 2 x 50 cables in the accessory pouch are not

used. A single-card module can be installed in any available slot.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

62

Page 63

Chapter 3: Installing Logic Analyzer Measurement Modules

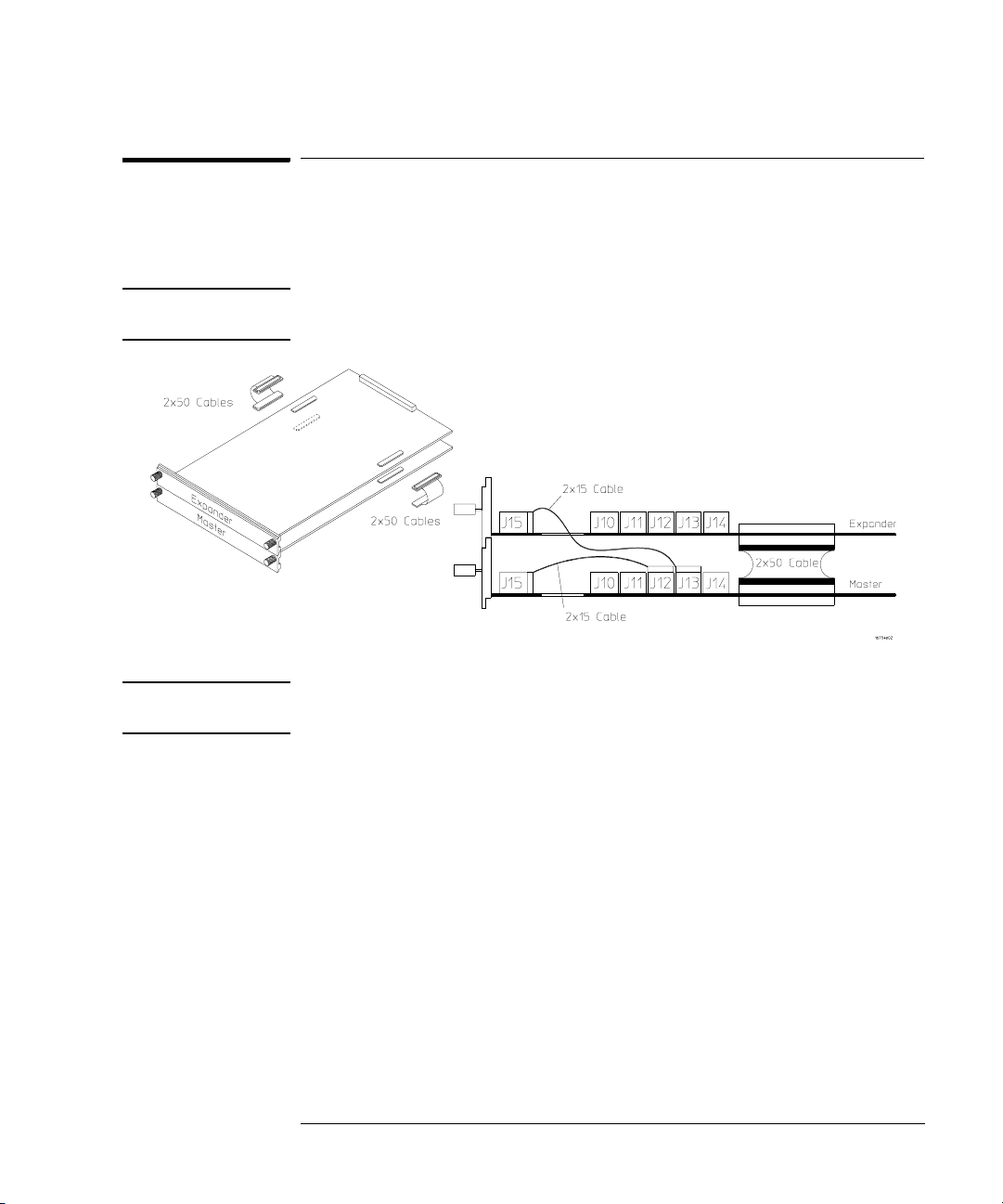

16753/54/55/56A Logic Analyzer (2-card module)

16753/54/55/56A Logic Analyzer (2-card module)

Use two 2 x 15 cables and two 2 x 50 cables (in the accessory pouch) to

connect the modules.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

NOTE: Measurement modules with different model numbers can be mixed in multi-

card modules.

63

Page 64

Chapter 3: Installing Logic Analyzer Measurement Modules

16753/54/55/56A Logic Analyzer (3-card module)

16753/54/55/56A Logic Analyzer (3-card module)

Use three 2 x 15 cables and four 2 x 50 cables (in the accessory pouch) to

connect the modules.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

NOTE: Measurement modules with different model numbers can be mixed in multi-

card modules.

64

Page 65

Chapter 3: Installing Logic Analyzer Measurement Modules

16753/54/55/56A Logic Analyzer (4-card module)

16753/54/55/56A Logic Analyzer (4-card module)

Use four 2 x 15 cables and six 2 x 50 cables (in the accessory pouch) to

connect the modules.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42

NOTE: Measurement modules with different model numbers can be mixed in multi-

card modules.

65

Page 66

Chapter 3: Installing Logic Analyzer Measurement Modules

16753/54/55/56A Logic Analyzer (5-card module)

16753/54/55/56A Logic Analyzer (5-card module)

Use five 2 x 15 cables and eight 2 x 50 cables (in the accessory pouch) to

connect the modules

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

NOTE: Measurement modules with different model numbers can be mixed in multi-

card modules.

66

Page 67

Chapter 3: Installing Logic Analyzer Measurement Modules

16760A Logic Analyzer (1-card module)

16760A Logic Analyzer (1-card module)

A single 16760A logic analyzer module will have the 2 x 10 cable connected in

the single-card configuration.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

16760A Logic Analyzer (2-card module)

Use two 2 x 10 cables and two 2 x 40 cables (in the accessory pouch) to

connect the modules.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

67

Page 68

Chapter 3: Installing Logic Analyzer Measurement Modules

16760A Logic Analyzer (3-card module)

16760A Logic Analyzer (3-card module)

Use three 2 x 10 cables and four 2 x 40 cables (in the accessory pouch) to

connect the modules.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

68

Page 69

Chapter 3: Installing Logic Analyzer Measurement Modules

16760A Logic Analyzer (4-card module)

16760A Logic Analyzer (4-card module)

Use four 2 x 10 cables and six 2 x 40 cables (in the accessory pouch) to

connect the modules.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

69

Page 70

Chapter 3: Installing Logic Analyzer Measurement Modules

16760A Logic Analyzer (5-card module)

16760A Logic Analyzer (5-card module)

Use five 2 x 10 cables and eight 2 x 40 cables (in the accessory pouch) to

connect the modules.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

70

Page 71

4

Installing Oscilloscope Measurement Modules

71

Page 72

Chapter 4: Installing Oscilloscope Measurement Modules

16700A

Power

Busy

16700B or 16702B

16533/34A Oscilloscope Module (single or multi-card modules)

16533/34A Oscilloscope Module (single or multi-card

modules)

The Agilent Technologies 16533A/34A oscilloscope module functions as either

a master card or expander card. It is compatible with all versions of software

in your 16700A/B or 16702A/B mainframe. The circuitry in the module

requires an operational accuracy calibration to optimize measurement

accuracy.

A multicard module should contain either all 16533A or 16534A cards.

NOTE: Each of the individual cards of a multicard 16533A or a multicard 16534A

module must first be calibrated as a single card. After reconfiguring into a

multicard module, the channel skew calibration needs to be done.

Step 1 Prepare a single 16533/34A card for calibration

CAUTION: The effects of ELECTROSTATIC DISCHARGE can damage components. Use

grounded wrist straps and mats when you are performing any kind of service

on this module.

1 Power down your 16700A/B or 16702A/B mainframe.

2 Remove all modules and filler panels from the mainframe and set the

PROTECTED/UNPROTECTED switch to UNPROTECTED.

72

Page 73

Chapter 4: Installing Oscilloscope Measurement Modules

D

16533/34A Oscilloscope Module (single or multi-card modules)

NOTE: If you calibrate a module without unprotecting the memory, the new

calibration settings will not be saved when the system is shut down. The

system will default to the previous settings. The new calibration settings

would be effective for the current active session only.

UNPROTECTE

PROTECTED

3 Reinstall the 16533/34A modules and filler panels into the mainframe.

73

Page 74

Chapter 4: Installing Oscilloscope Measurement Modules

Power

16533/34A Oscilloscope Module (single or multi-card modules)

4 Power up the monitor (if applicable) and then the system.

16700A

16700B or 16702B

Busy

5 For more accurate calibration, allow the system 30 minutes to warm

up.

0

15

30

74

Page 75

Chapter 4: Installing Oscilloscope Measurement Modules

16533/34A Oscilloscope Module (single or multi-card modules)

Step 2 Perform operational accuracy calibration

1 Connect the BNC Tee and the (equal length) 50-ohm BNC cables to the

module.

AC/DC Cal

Channel 1

Channel 2

2 In the Logic Analysis System window, select the module icon for the

16533A/34A to be calibrated, then select Calibration.

$

75

Page 76

Chapter 4: Installing Oscilloscope Measurement Modules

16533/34A Oscilloscope Module (single or multi-card modules)

3 In the Calibration window, select Default Factors. At the confirmation,

select OK to load the default factors.

4 Select the Run icon and the instrument will remind you to connect the

cables to the appropriate locations on the rear panel of the module.

Select OK and wait until the operational accuracy calibration is

complete.

RUN

76

Page 77

Chapter 4: Installing Oscilloscope Measurement Modules

16533/34A Oscilloscope Module (single or multi-card modules)

As operational accuracy calibration runs, messages appear in the message box

on screen.

The Calibration Status window indicates pass or fail as each operational

accuracy calibration routine is completed. The resulting calibration factors are

automatically stored to non-volatile RAM at the conclusion of each calibration

routine.

77

Page 78

Chapter 4: Installing Oscilloscope Measurement Modules

16533/34A Oscilloscope Module (single or multi-card modules)

Step 3 Calibrate a single card for external trigger skew

1 Connect a 9-inch 50-ohm BNC cable to one side of the BNC tee

adapter. On the other side of the BNC tee adapter connect a 9-inch 50ohm BNC and a BNC(f)/SMB(m) adapter.

AC/DC Cal

Channel 1

ECL

External

Tri gge r I n

BNC/SMB

Adapter

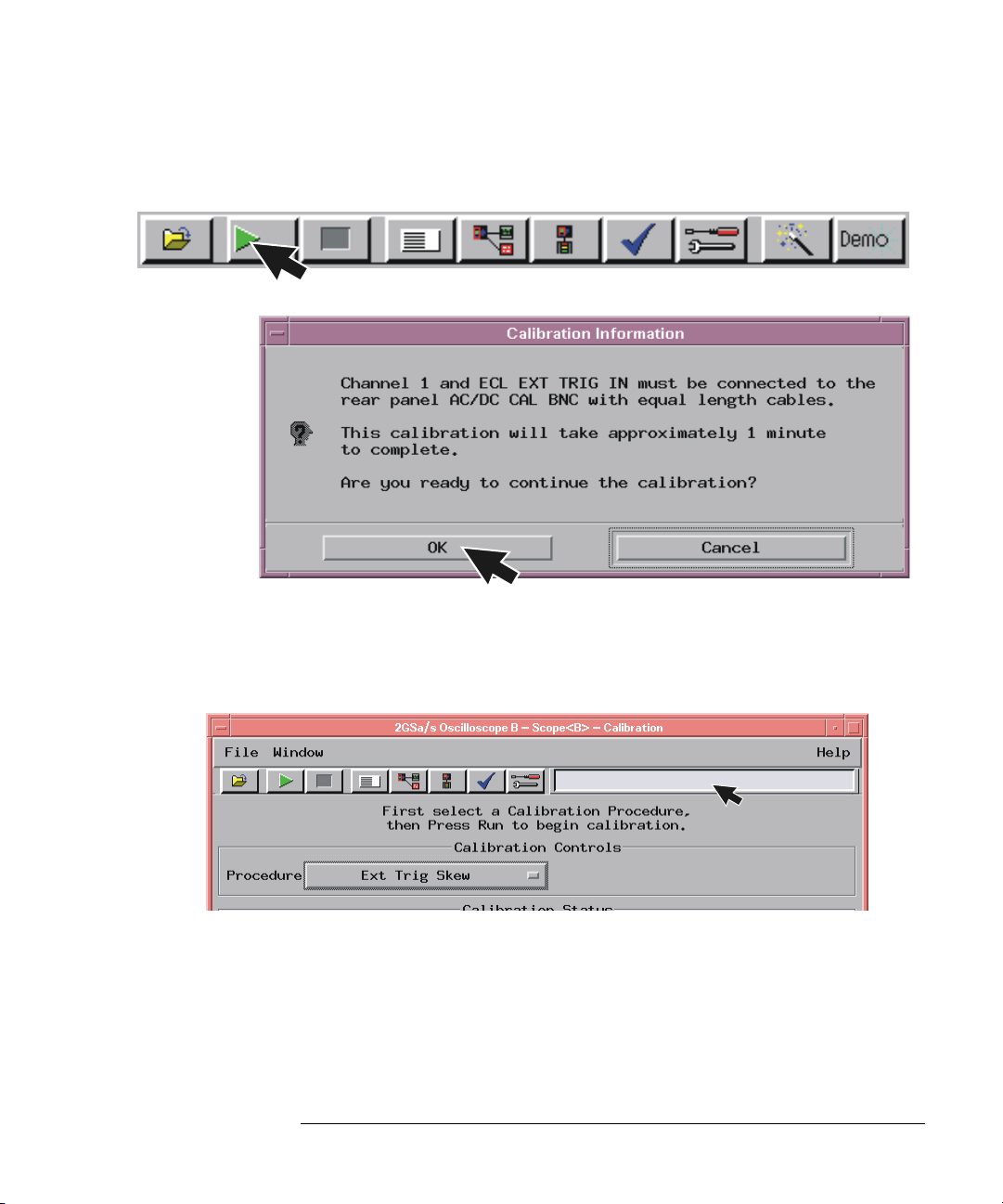

2 Select the Procedure field and then select Ext Trig Skew.

78

Page 79

Chapter 4: Installing Oscilloscope Measurement Modules

16533/34A Oscilloscope Module (single or multi-card modules)

3 Select the Run icon and the instrument will remind you to connect the

cables. Select OK and wait for the trigger skew calibration to complete.

RUN

As trigger skew calibration runs, messages appear in the message box on

screen. When the Ext Trig Skew calibration is complete, the resulting

calibration factors are stored in non-volatile RAM.

4 If a multi-card module is being calibrated, repeat the procedures

beginning with Step 1 on page 72 for each card until all cards have been

calibrated.

5 If all cards have been calibrated, remove the BNC cables from the

instrument.

6 Select Close in the Calibration window.

79

Page 80

Chapter 4: Installing Oscilloscope Measurement Modules

16533/34A Oscilloscope Module (single or multi-card modules)

7 In the Logic Analysis System window select File, then select Exit and

OK to close the session.

8 In the Session Manager window select Shutdown.

9 When the “OK to powerdown” message appears, turn off the power

switch.

80

Page 81

Chapter 4: Installing Oscilloscope Measurement Modules

16533/34A Oscilloscope Module (single or multi-card modules)

10 If you are only calibrating one card set the PROTECTED/

UNPROTECTED switch back to PROTECTED.

If only calibrating one

card set protect.

UNPROTECTED

PROTECTED

11 For multi-card modules, leave the switch set to UNPROTECTED and

continue to Step 4 to perform reconfiguration.

Step 4 Reconfigure multi-card modules

A multicard module should contain either all 16533A or 16534A cards.

1 After calibrating each card individually (following the procedures

beginning on page 72) and before applying power to the mainframe,

connect the module cables.

a Beginning with the top-most card, connect the ECL EXT TRIG OUT

to the ECL EXT TRIG IN of the card immediately below. Use the

master/expander trigger cable included with the accessory kit of

each card.

Master/expander

trigger cables

81

Page 82

Chapter 4: Installing Oscilloscope Measurement Modules

16533/34A Oscilloscope Module (single or multi-card modules)

b Repeat for all cards in the module. Up to 4 cards may be configured

on a single time base and trigger in a 16700A, 16700B, 16702A, or

16702B mainframe

2 Reapply power to the 16700-series mainframe.

3 In the Logic Analysis System window select the icon for the master

card of the multi-card module then select Calibration.

$

4 Perform channel skew calibration on the multi-card module.

a Connect two 9-inch 50-ohm BNC cables and a BNC tee adapter

between channel 1, AC/DC cal, of the first card and channel 1 of the

second card.

Chan. 1

Chan. 1

Chan. 2

Chan. 2

82

Channel 1

Upper Card

AC/CD Cal

Upper Card

Channel 1

Lower Card

Page 83

Chapter 4: Installing Oscilloscope Measurement Modules

16533/34A Oscilloscope Module (single or multi-card modules)

b Select the Procedure field and then select Ext Trig Skew.

c Select Run and the instrument will remind you to connect the

cables. Select OK and the Calibration window opens.

RUN

83

Page 84

Chapter 4: Installing Oscilloscope Measurement Modules

16533/34A Oscilloscope Module (single or multi-card modules)

d Select the Channels field, select two channels to deskew, select

Run, and follow the instructions on the display.

RUN

e Repeat the channel skew procedure until all channel combinations

have been deskewed.

5 Remove the BNC cables from the instrument.

6 Select Close in the Calibration window.

84

Page 85

Chapter 4: Installing Oscilloscope Measurement Modules

D

16533/34A Oscilloscope Module (single or multi-card modules)

7 In the Logic Analysis System window select File, then select Exit and

OK to close the session.

8 In the Session Manager window select Shutdown.

9 When the “OK to powerdown” message appears, turn off the power

switch.

10 Set the PROTECTED/UNPROTECTED switch back to PROTECTED.

UNPROTECTE

PROTECTED

85

Page 86

86

Page 87

5

Installing Pattern Generator Measurement Modules

87

Page 88

Chapter 5: Installing Pattern Generator Measurement Modules

Software Requirements

Software Requirements

The following table gives you the software version required in your 16700A/B

or 16702A/B mainframe for use with pattern generator measurement modules.

For software installation instructions go to page page 34

Model Number Software Version

16522A All versions

16720A A.02.00.00 or higher

.

16522A Pattern Generator (1-card module)

Each 16522A shipped stand-alone has the 2 x 10 cable connected in the

single-card module configuration. A single-card module can be installed in any

available slot.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

2x10 cable

Master

88

Page 89

Chapter 5: Installing Pattern Generator Measurement Modules

16522A Pattern Generator (2-card module)

16522A Pattern Generator (2-card module)

Use two 2 x 10 cables to connect the modules as shown.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

2x10 Cable

Expander

Master

16522A Pattern Generator (3-card module)

Use three 2 x 10 cables to connect the modules.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

2x10 Cable

Expander

Master

Expander

89

Page 90

Chapter 5: Installing Pattern Generator Measurement Modules

16522A Pattern Generator (4-card module)

16522A Pattern Generator (4-card module)

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

1 Carefully slide the 4 cards half way into the mainframe slots.

2 Use four 2 x 10 cables to connect the modules. Cable the bottom

Expander Card to the Master Card first. Then cable the upper two

Expander Cards to the Master Card.

2x10 Cable

Expander

Expander

Master

Expander

3 Gently slide the cabled assembly fully into the frame and tighten the

thumb screws.

90

Page 91

Chapter 5: Installing Pattern Generator Measurement Modules

16522A Pattern Generator (5-card module)

16522A Pattern Generator (5-card module)

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

1 Carefully slide the 4 cards half way into the mainframe slots.

2 Use five 2 x 10 cables to connect the modules. Cable the bottom

Expander Card to the Master Card first. Then cable the upper two

Expander Cards to the Master Card.

2x10 Cable

Expander

Expander

Master

Expander

Expander

3 Gently slide the cabled assembly fully into the frame and tighten the

thumb screws.

91

Page 92

Chapter 5: Installing Pattern Generator Measurement Modules

16720A Pattern Generator (1-card module)

16720A Pattern Generator (1-card module)

Each card shipped stand-alone has the 2 x 10 cable connected in the singlecard module configuration. A single-card module can be installed in any

available slot.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

2x10 cable

for a single-card

connection

2x10 cable

Master

16720A Pattern Generator (2-card module)

Use two 2 x 10 cables to connect the modules.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

2x10 Cable

Expander

Master

92

Page 93

Chapter 5: Installing Pattern Generator Measurement Modules

16720A Pattern Generator (3-card module)

16720A Pattern Generator (3-card module)

Use three 2 x 10 cables to connect the modules.

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

Expander

Master

Expander

2x10 Cable

93

Page 94

Chapter 5: Installing Pattern Generator Measurement Modules

16720A Pattern Generator (4-card module)

16720A Pattern Generator (4-card module)

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

1 Carefully slide the 4 cards half way into the mainframe slots.

2 Use four 2 x 10 cables to connect the modules. Cable the bottom

Expander Card to the Master Card first. Then cable the upper two

Expander Cards to the Master Card.

2x10 Cable

Expander

Expander

Master

Expander

3 Gently slide the cabled assembly fully into the frame and tighten the

thumb screws.

94

Page 95

Chapter 5: Installing Pattern Generator Measurement Modules

16720A Pattern Generator (5-card module)

16720A Pattern Generator (5-card module)

NOTE: Turn off the mainframe power before removing, replacing, or installing

modules following the procedures on page 42.

1 Carefully slide the 4 cards half way into the mainframe slots.

2 Use six 2 x 10 cables to connect the modules. Cable the bottom two

Expander Cards to the Master Card first. Then cable the upper two

Expanders to the Master Card.

2x10 Cable

Expander

Expander

Master

Expander

Expander

3 Gently slide the cabled assembly fully into the frame and tighten the

thumb screws.

95

Page 96

96

Page 97

6

Connecting Accessories

97

Page 98

Chapter 6: Connecting Accessories

For More Information

The following sections give you an overview of Agilent Technologies probes

and time correlation fixture.

More information on probing options can be found in a document titled

Probing Solutions for Logic Analysis Systems which you can download from

www.agilent.com

Systems’ and select go. Scroll down to Datasheets, Demonstrations, &

Catalogs to find the document.

Detailed information on specific probes or the time correlation fixture can be

found in the documentation that comes with the product. Product

documentation can also be downloaded from http://www.tm.agilent.com/

classes/ProdSearch. Type in the model number or product name and select go.

Scroll down to Manuals, Guides & Service Notes to find these documents.

. In the search box type ‘Probing Solutions for Logic Analysis

98

Page 99

Chapter 6: Connecting Accessories

Ground Lead

General-purpose probing

General-purpose probing

NOTE: For all Agilent logic analyzers except 16517A, 16518A, 16760A, and

16753/54/55/56A.

General-purpose probing requires connecting probe leads to individual signal

lines. It is generally the most cumbersome method but it is also the most

flexible. There are no active circuits at the outer end of the cable due to the

passive design of the probe.

Probe Tip

Assembly

01650-61608

Probe

Housing

Logic Analyzer

Pod

Probe Lead

Ground Lead

(Short)

Probe Tip

(Long)

The advantages of general-purpose probing are:

• High-input impedance as shown in the equivalent load model below.

• Signal ground at the probe tip for high-speed signals.

• Inexpensive, removable probe tip assemblies.

Equivalent Load

370

Signal

Ground

ohm

7.4pF1.5pF

100k

ohm

Includes logic analyzer

99

Page 100

Chapter 6: Connecting Accessories

General-purpose probing

Connecting probe leads to the target. The signal and ground leads

can be connected directly to the target system. This requires installing 0.63

mm (0.025 inch) square pins, or round pins with a diameter between 0.66 and

0.84 mm (0.026 and 0.033 inch) directly on the board. You can also use an IC

test clip with pins with those dimensions.

You can also connect the leads using through-hole grabbers that have small

enough hooks to fit around adjacent IC pins, or by using surface-mount

grabbers designed for fine surface-mount component leads.

Grounding. Proper grounding will improve the signal quality and is essential

for high speed measurements. Each pod has a pod ground lead, which must be

used. If you use this ground only, signal quality for high speed signals will be

poor.

For better results, ground not only the pod, but every third or fourth lead.

For best results, and when probing signals with rise and fall times of 1 ns or

less, ground each probe lead with no more than a 2-inch ground lead as well as

grounding the pod with the pod ground lead.

Replacing damaged leads. You can replace damaged leads. Disconnect

individual probe leads by pushing on the latch at the lead base with a ballpoint pen.

Connecting grabbers to the leads. Connect grabbers to the leads by

slipping the end of the lead over the recessed pin located in the side of the

grabber.

100

Loading...

Loading...