Page 1

16700 Series

Logic Analysis System

Product Overview

Debugging today's digital systems

is tougher than ever. Increased

product requirements, complex

software, and innovative hardware

technologies make it difficult to

meet your time-to-market goals.

The Agilent Technologies

16700 Series logic analysis systems

provide the simplicity and power you

need to conquer complex systems

by combining state/timing analysis,

oscilloscopes, pattern generators,

post-processing tool sets, and

emulation in one integrated system.

Page 2

2

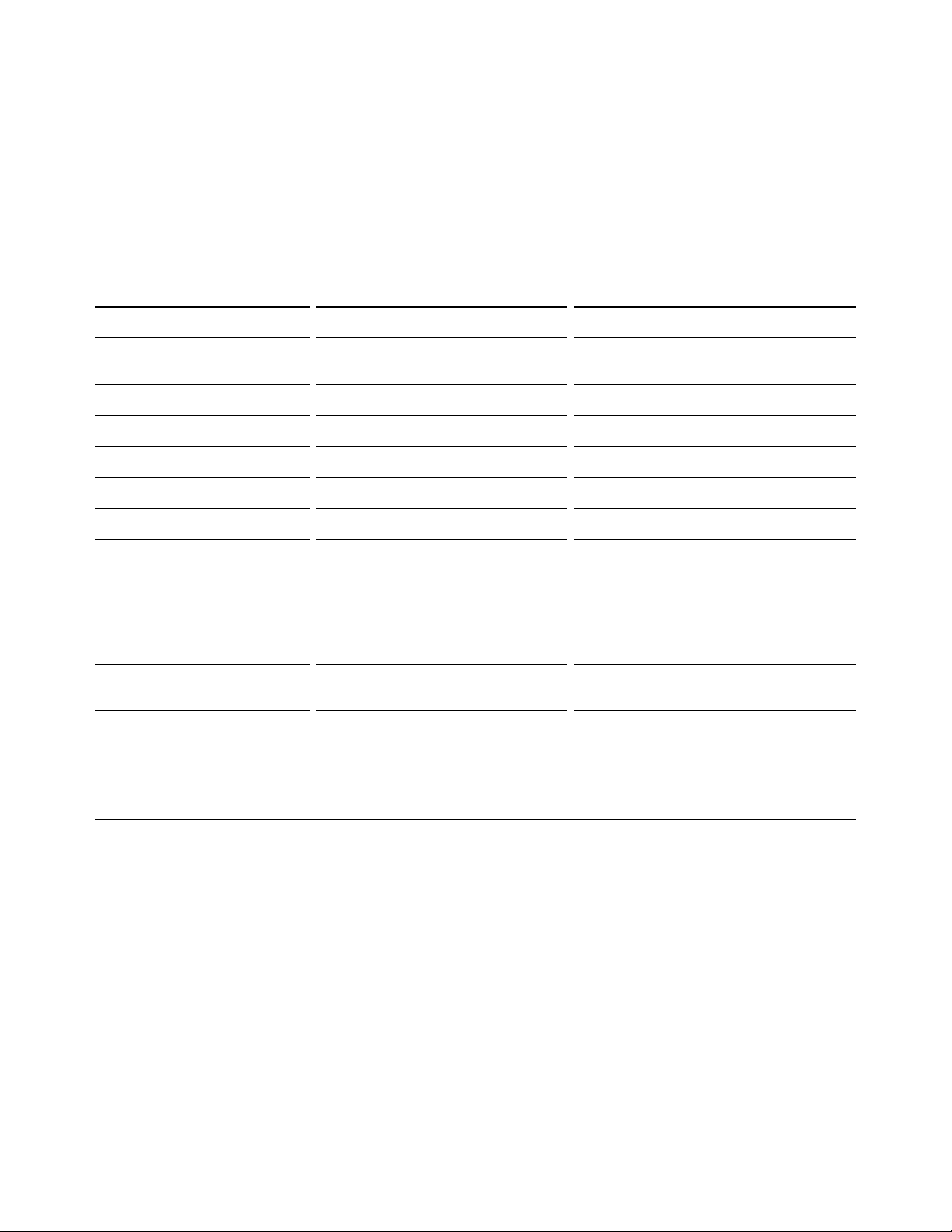

Table of Contents

System Overview

Modular Design page 3

Features and Benefits page 4

Selecting the Right System page 6

Mainframes

Display page 7

Back Panel page 8

System Screens page 9

IntuiLink page 12

Probing Solutions

Criteria for Selection page 13

Technologies page 14

Data Acquisition and Stimulus

State/Timing Modules page 17

Oscilloscope Modules page 30

Pattern Generation Modules page 33

Emulation Modules page 37

Post-Processing and Analysis Tool Sets

Software Tool Sets page 39

Source Correlation page 41

Data Communications page 45

System Performance Analysis page 54

Serial Analysis page 61

Tool Development Kit page 67

Licensing Information page 73

Time Correlation with Agilent Infiniium Oscilloscopes

E5850A Logic Analyzer - Oscilloscope Time Correlation Fixture page 74

Technical Specifications and Characteristics

Mainframe page 75

Probing Solutions page 83

State/Timing Modules page 85

Oscilloscope Modules page 101

Pattern Generation Modules page 104

Trade-In, Trade-Up page 115

Ordering Information page 116

Third-Party Solutions page 123

Support, Warranty and Related Literature page 124

Sales Offices Information page 125

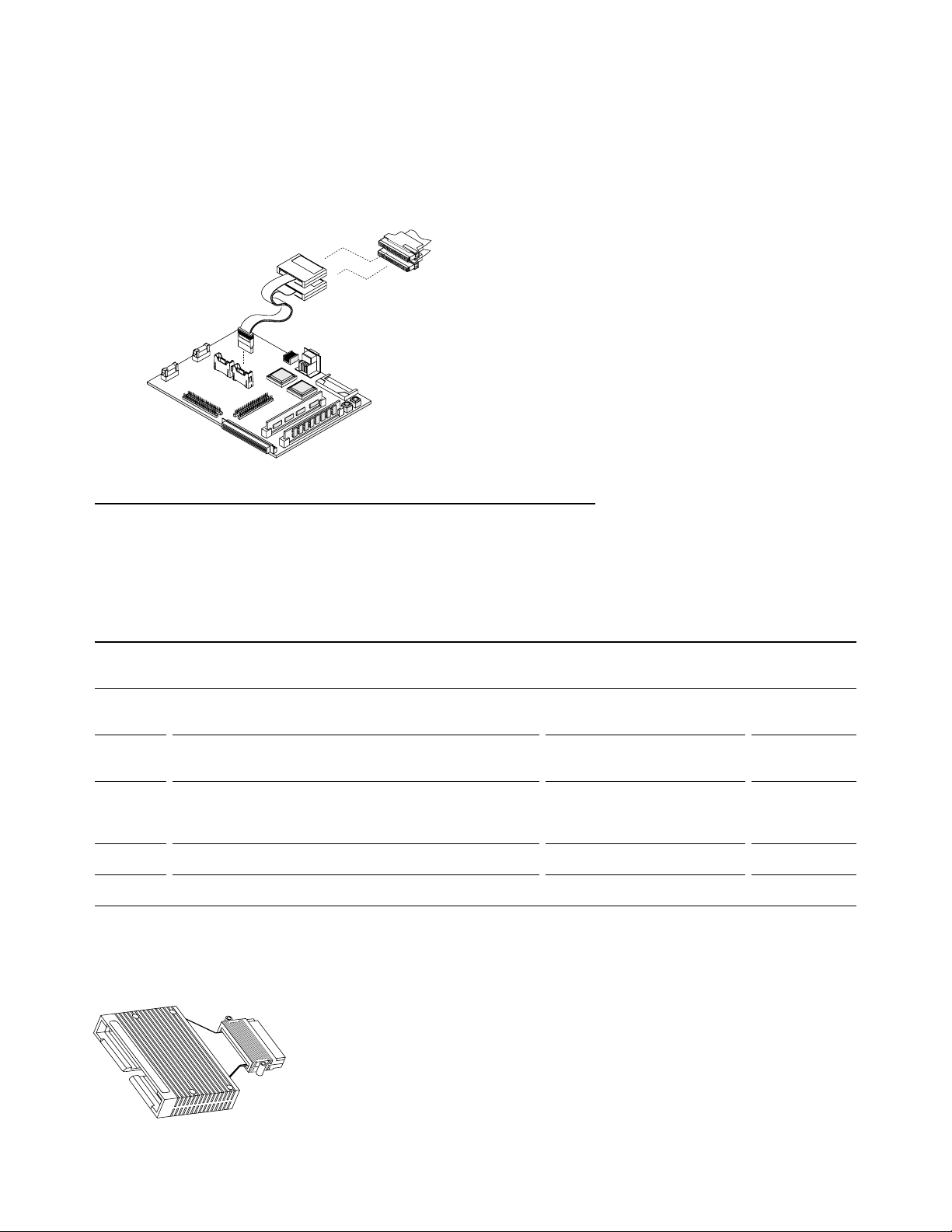

Page 3

3

Modular Design Protects Your

Long-Term Investment

Modularity is the key to the Agilent

16700 Series logic analysis systems'

long term value. You purchase only

the capability you need now, then

expand as your needs evolve. All

modules are tightly integrated to

provide time-correlated, cross

domain measurements.

Module Choices User Benefits

State/Timing Agilent offers a wide variety of state/timing modules for a range

of applications, from high-speed glitch capture to multi-channel

bus analysis.

High-Speed Timing Precisely characterize setup/hold times over a wide channel

count. Capture data over many clock cycles while retaining the

highest multi-channel accuracy.

Oscilloscopes Identify signal integrity issues and characterize signals quickly

with automatic measurements of rise time, voltage, pulse width,

and frequency.

Pattern Generation Use stimulus to substitute for missing system components or to

provide a stimulus-response test environment.

Emulation An emulation module connects to the debug port (BDM or JTAG)

on your target. You have full access to processor execution

control features of the module through the built-in emulation

control interface or a third-party debugger.

External Ports

Target Control Port Use the target control port to force a reset of your target or

activate a target interrupt.

Port-in/Port-out A BNC connector allows you to trigger or arm external devices

or to receive signals that can be used to arm acquisition

modules within your logic analyzer.

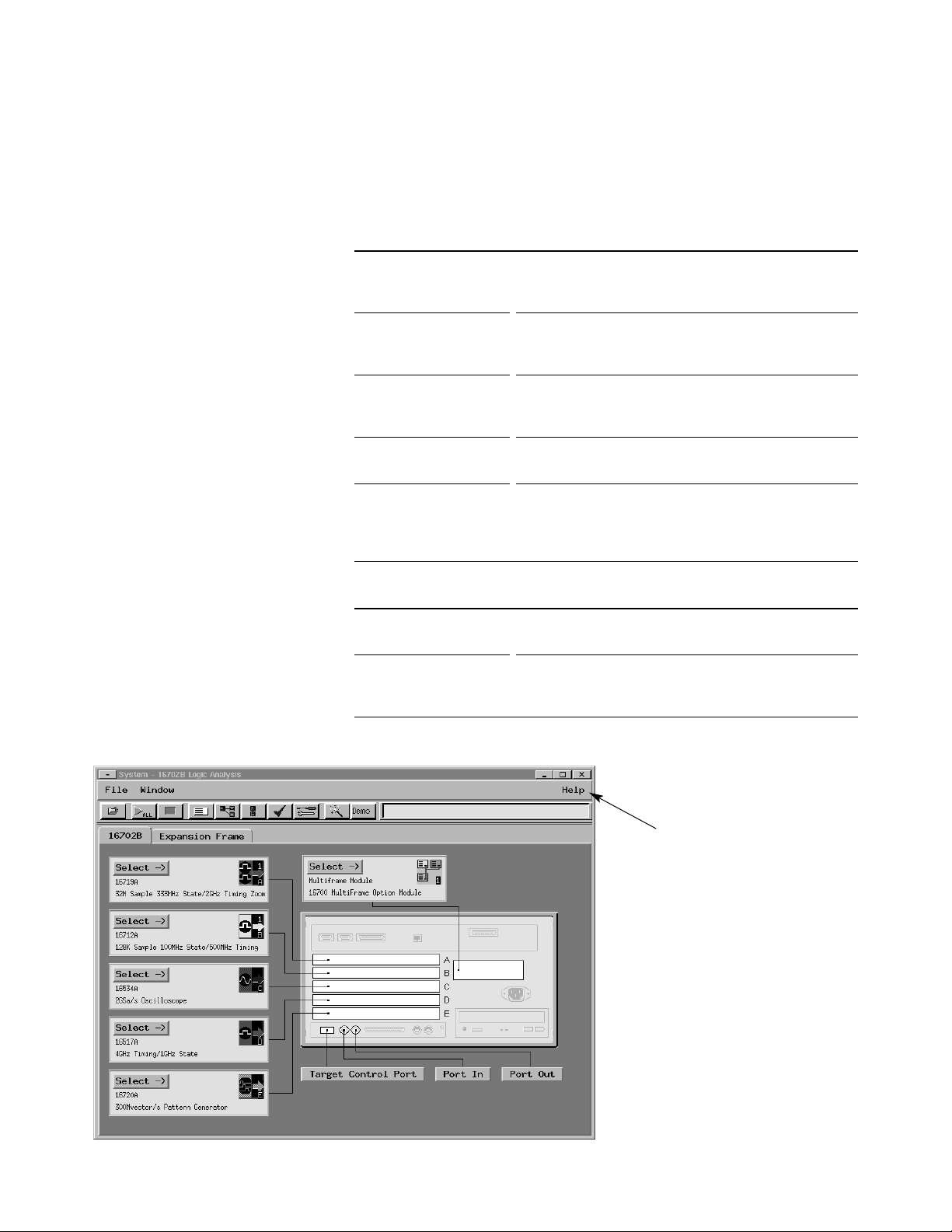

System Overview

Modular Design

Figure 1.1. The system boot up screen shows you

what modules are configured into your logic

analysis system.

Help

enables you to

access the online

user’s guide and

measurement

examples.

Page 4

4

System Overview

Features and Benefits

System Capability

NEW Touch Screen Interface The Agilent 16702B mainframe supports a large, 12.1 inch LCD touch screen and redesigned front panel

controls for an easy-to-operate, self-contained unit requiring minimal bench space and offering simple

portability.

NEW Multiframe Configuration By connecting up to eight mainframes and expanders you can simultaneously view time-correlated traces for

all buses in a large channel count, multibus system.

NEW Enhanced Mainframe Hardware Mainframe now includes a 40X CD-ROM drive, a 9 GB hard disk drive, 100BaseT-X LAN, and 128 MB of

internal system RAM (optional 256 MB total).

Scalable System

• State/timing analyzers • Select the optimum combination of performance, features, and price that you need for your specific

• High-speed timing application today, with the flexibility to add to your system as your measurement needs change.

• Oscilloscopes • View system activity from signals to source code.

• Pattern generators

• Emulation modules

Measurement Modules/Interfaces

The Agilent 16760A With up to 1.5 Gb/s state speed, the 16760A lets you debug today’s and tomorrow’s ultra-high-speed

State/Timing Module digital buses. NEW Eye scan gives a rapid comprehensive overview of signal integrity on hundreds of

channels simultaneously

The Agilent 16750A, 16751A, With up to 400 MHz state speed and up to 32 MBytes of trace depth these modules help you address today’s

and 16752A State/Timing Modules high-performance measurement requirements. (See page 19)

The Agilent 16720A With up to 16 MVectors depth and 300 MVectors/sec operation and up to 240 channels[1] of stimulus, the

Pattern Generator 16720A provides a new level of capability that makes complex device substitution a reality. Supports TTL,

CMOS, 3.3V, 1.8V, LVDS, 3-state, ECL, PECL, and LVPECL.

High-Speed Bus Measurements Agilent’s eye finder technology automatically adjusts the setup and hold on every channel, eliminating the

Made Simple with Eye Finder need for manual adjustment and ensuring accurate state measurements on high-speed buses.

Technology

Timing Zoom Technology Simultaneously acquire data at up to 2 GHz timing and 400 MHz state through the same connection. Timing

Zoom is available across all channels, all the time. (See page 23)

VisiTrigger Technology • Use graphical views and sentence-like structure to help you define a trace event.

• Select trigger functions as individual trigger conditions or as building blocks to easily customize a trigger

for your specific task.

Processor and Bus Support • Get control over your microprocessor’s internal and external data.

• Quickly and reliably connect to the device under test. (See page 36)

Direct Links to Industry Standard • Debuggers provide visibility into software execution for systems running software written in C and C++ as

Debuggers and High-Level well as active microprocessor execution control (run control).

Language Tools • Import symbol files created by your language tool. Symbols allow you to set up trigger conditions and review

waveform and state listings in easily recognized terms that relate directly to the names used for signals on

your target and the functions and variables in your code.

Direct Links to EDA Tools • Use captured logic analysis waveforms to generate simulation test vectors.

• Easily find problems by comparing captured waveforms with simulated waveforms.

[1] 240 channel system consists of five 16720A pattern generator modules with 48 channels per module. Full channel mode runs at 180 MVectors/s and 8 MVectors depth.

300 MVectors/s and 16 MVectors depth are offered in half channel mode.

Page 5

5

System Overview

Features and Benefits

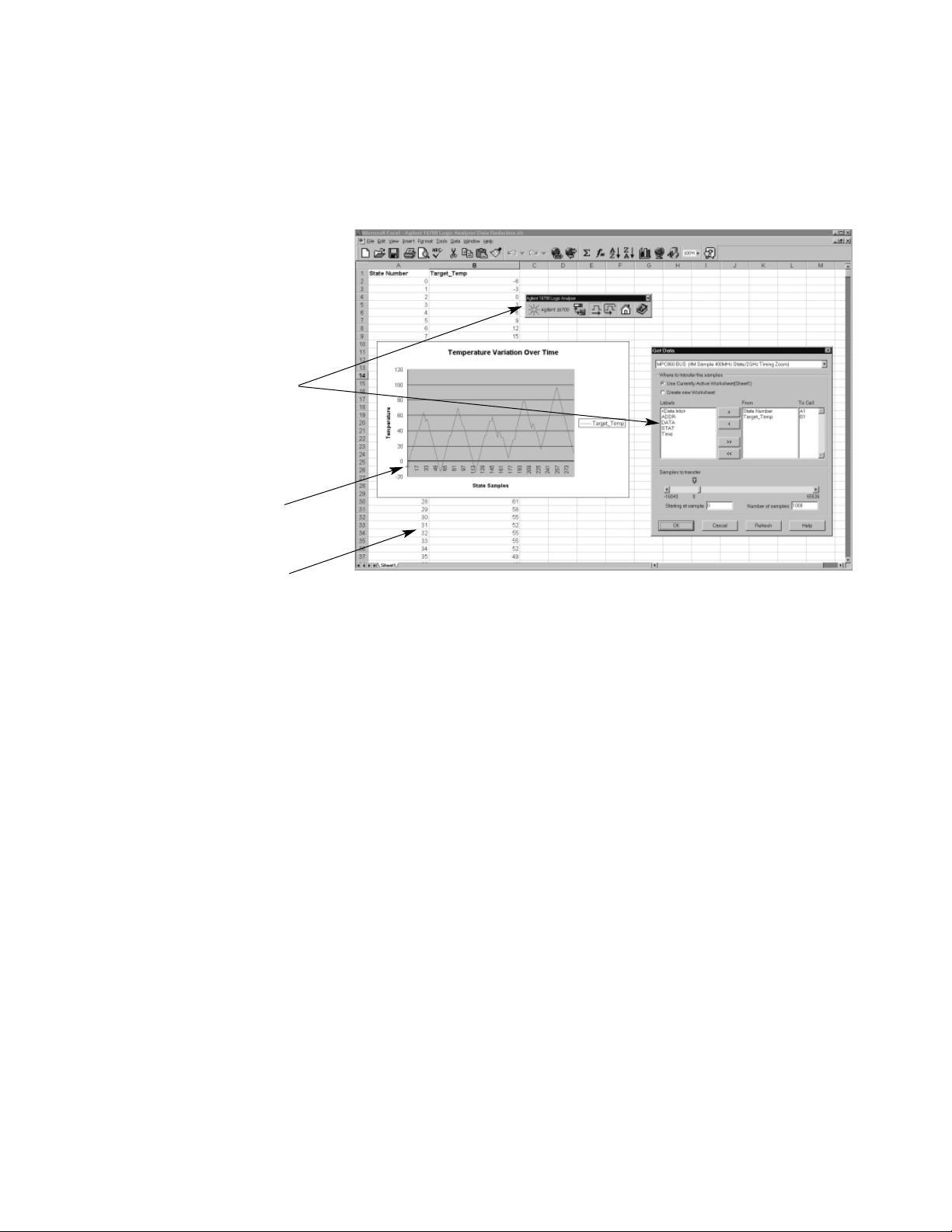

Data Transfer, Documentation, and Remote Programming

Direct Link to Microsoft®Excel via • Automatically move your data from the logic analyzer into Microsoft Excel with just a click of the mouse.

Agilent IntuiLink (See page 12)

• Use Microsoft Excel’s powerful functions to post-process captured trace data to get the insight you need.

Transfer Data for Offline Analysis - • Fast binary (compressed binary) from the FileOut tool provides highest performance transfer rate.

Data Export • ASCII format provides same format as listing display, including inverse-assembled data.

Transparent File System Access • Access, transfer, and archive files.

• Stay synchronized with your source code by mapping shared directories and file systems from your

Windows 95/98/NT-based PC directly onto the logic analyzer and vice versa.

• Move data files to and from the logic analyzer for archiving or use elsewhere.

Documentation Capability • Save graphics in standard TIFF, PCX, and EPS formats.

• Print screen shots and trace listings to a local or networked printer.

• Save your lab notes and trace data in the same file by entering relevant information in the Comments tab of

the display.

Remote Programming with • Perform pass/fail analysis, stimulus response tests, data acquisition for offline analysis, and system

Microsoft’s COM Using verification and characterization tests.

Microsoft Visual Basic or • Powerful-yet-efficient command set focuses on your programming tasks, resulting in a shorter learning

Visual C++ curve while maintaining necessary functionality.

System Software Features

Post-Processing Analysis Tools Rapidly consolidate large amounts of data into displays that provide insight into your system’s behavior.

(See page 38)

Setup Assistant Quickly configure the logic analysis system for your target microprocessor. (See page 9)

Tabbed Interface • Groups like tasks together so you can quickly find and complete the task you want to perform.

• Spend your time solving problems, not setting up a measurement.

Multi-Windowed View of • View your cross-domain measurements, time-corrected on the same screen. (See page 10)

Target System Activity • Debug faster because you can view system activity at a glance.

Global Markers Track a symptom in one domain (e.g., timing) to its cause in another domain (e.g., analog).

Resizable Windows and Data Views • Magnify your view or zoom in on a boxed area of interest.

• Resize waveforms and data or quickly change colors to highlight areas of interest.

Web-Enabled System • Directly access the instrument’s web page from your web browser. (See page 11)

• Remotely check the instrument’s measurement status without disturbing the acquisition.

• Remotely access, monitor and control your logic analysis system.

Network Security • Protect your networked assets and comply with your company’s security requirements with individual user

logins that provide system integrity.

NEW Time Correlation with • Make time-correlated measurements using an Agilent 16700 Series logic analyzer and an

Infiniium 54800 Series Oscilloscopes Agilent Infiniium 54800 Series oscilloscope.

• View Infiniium oscilloscope waveforms in the 16700 logic analyzer’s waveform display.

• Use the 16700 logic analyzer’s global markers to measure time between any domain in the 16700 and voltage

waveforms acquired by the Infiniium oscilloscope.

Page 6

6

System Overview

Selecting the Right System

Select a mainframe (page 7)

Choose a system based on your needs:

• Self-contained unit or a unit with

external mouse, keyboard, and monitor

• Expander frame for large channel count

requirements

Selecting a system for your application

Determine your probing requirements (page 13)

• Are you analyzing a microprocessor?

• Do you need to probe a specific package type?

Select the measurement modules to meet your

application needs

• State/Timing Logic Analyzers (page 17)

• Oscilloscopes (page 29)

• Pattern Generation (page 32)

• Emulation (page 36)

Add post-processing tool sets for analysis and

insight (page 38)

• Source correlation

• Data communications

• System performance analysis

• Serial analysis

• Tool development kit

Support, services, and assistance (page 123)

• Training classes

• Consulting

• On-line support

• Warranty extension

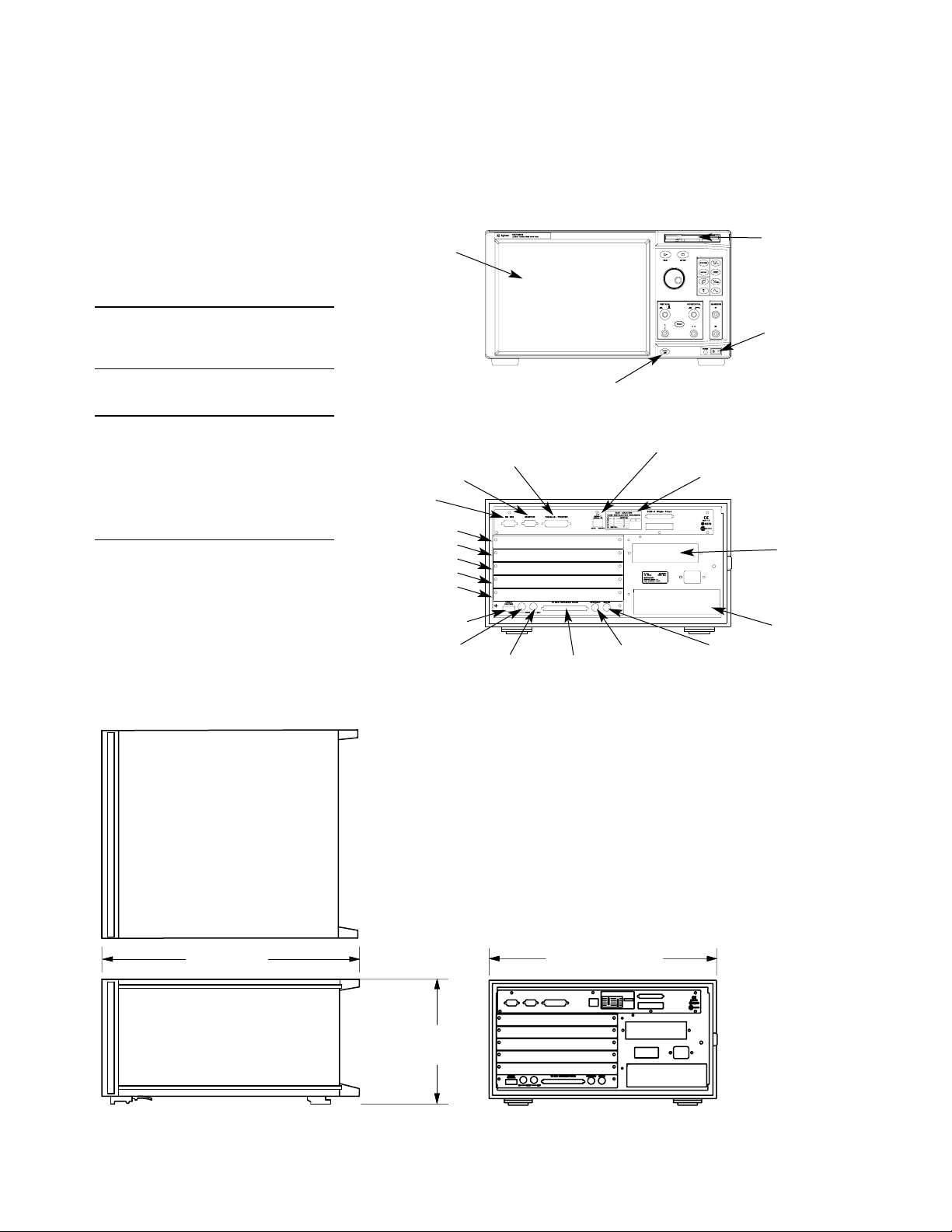

Page 7

7

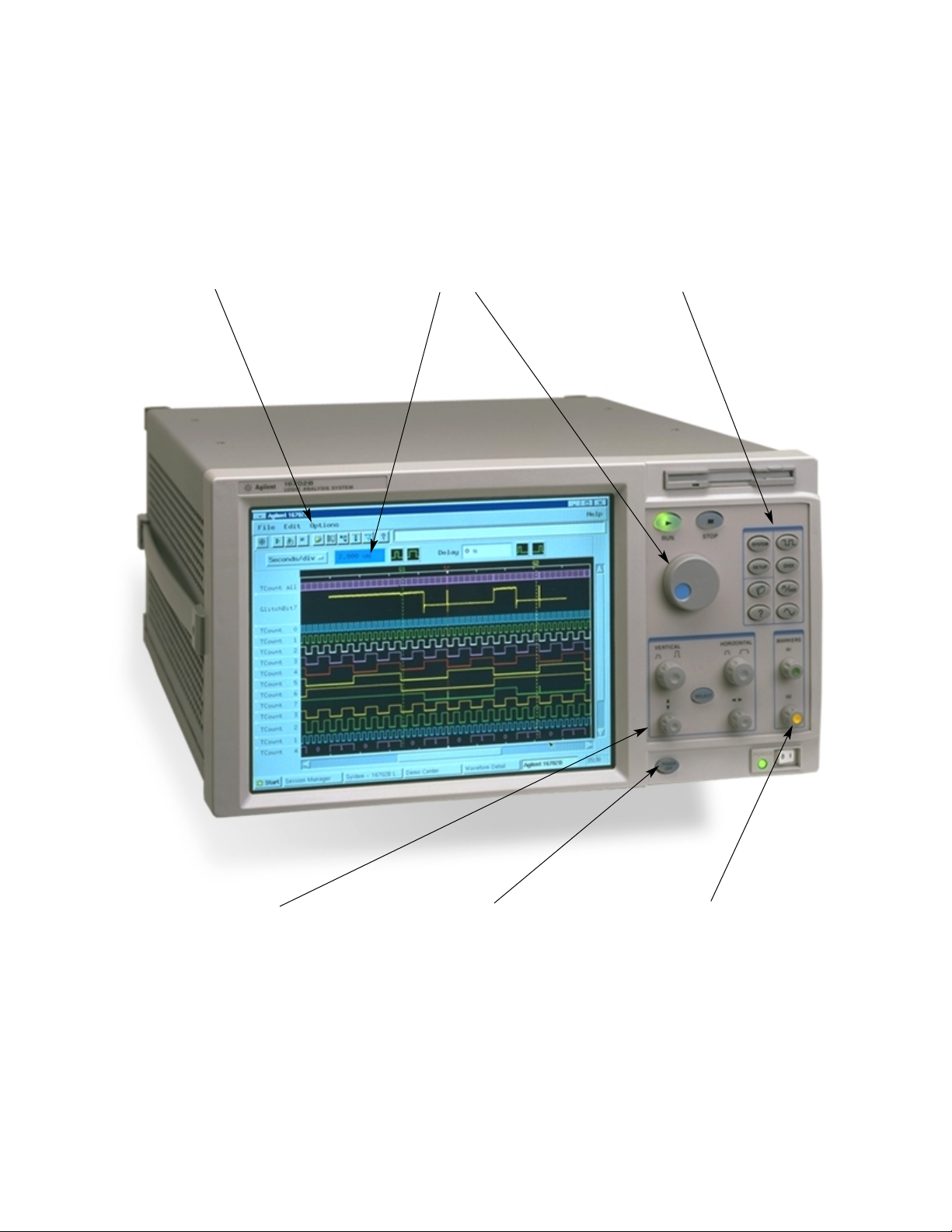

12.1" LCD display with touch screen on

the 16702B makes it easy to view a large

number of waveforms or states.

Dedicated hot keys give instant access to

the most frequently used menus, displays,

and on-line help.

"Touch Off" button disables the touch

screen and allows you to point out a

nomalies to a colleague without altering

the display settings.

Dedicated knobs for horizontal and vertical

scaling and scrolling. Adjust the display to

get just the information you need to solve

your problem.

Mainframes

Display

Select a modifiable variable by touching

it, then turn the knob to quickly step

through values for the variable.

Figure 2.1. The Agilent 16702B quickly tracks down problems in your design while saving precious bench space.

Dedicated knobs for global markers help

track down tough problems. A symptom

seen in one domain (e.g., timing) can be

tied to its cause in another domain

(e.g., analog).

Page 8

8

Connection for optional monitor.

(Up to 1600x1200 video

resolution with option 003)

10/100BaseT LAN - autosensing

Parallel printer port SCSI-II connection for an

external 18 GByte data drive or

external removable hard drive

Expander frame connection provides an

additional five slots for measurement

modules.

Built-in 40x CD-ROM drive makes it easy

to install or update system software,

processor support, or tool sets.

Option slot for an emulation module or

for a multiframe module. Multiframe

option allows up to eight mainframes

and expanders to be combined so that

you can see all the buses in a complex

target system.

Mainframes

Back Panel

Figure 2.2. The mainframe and expander frame provide advanced capabilities for debugging complex target systems.

Five slots for

measurement

modules

Page 9

9

Mainframes

System Screens

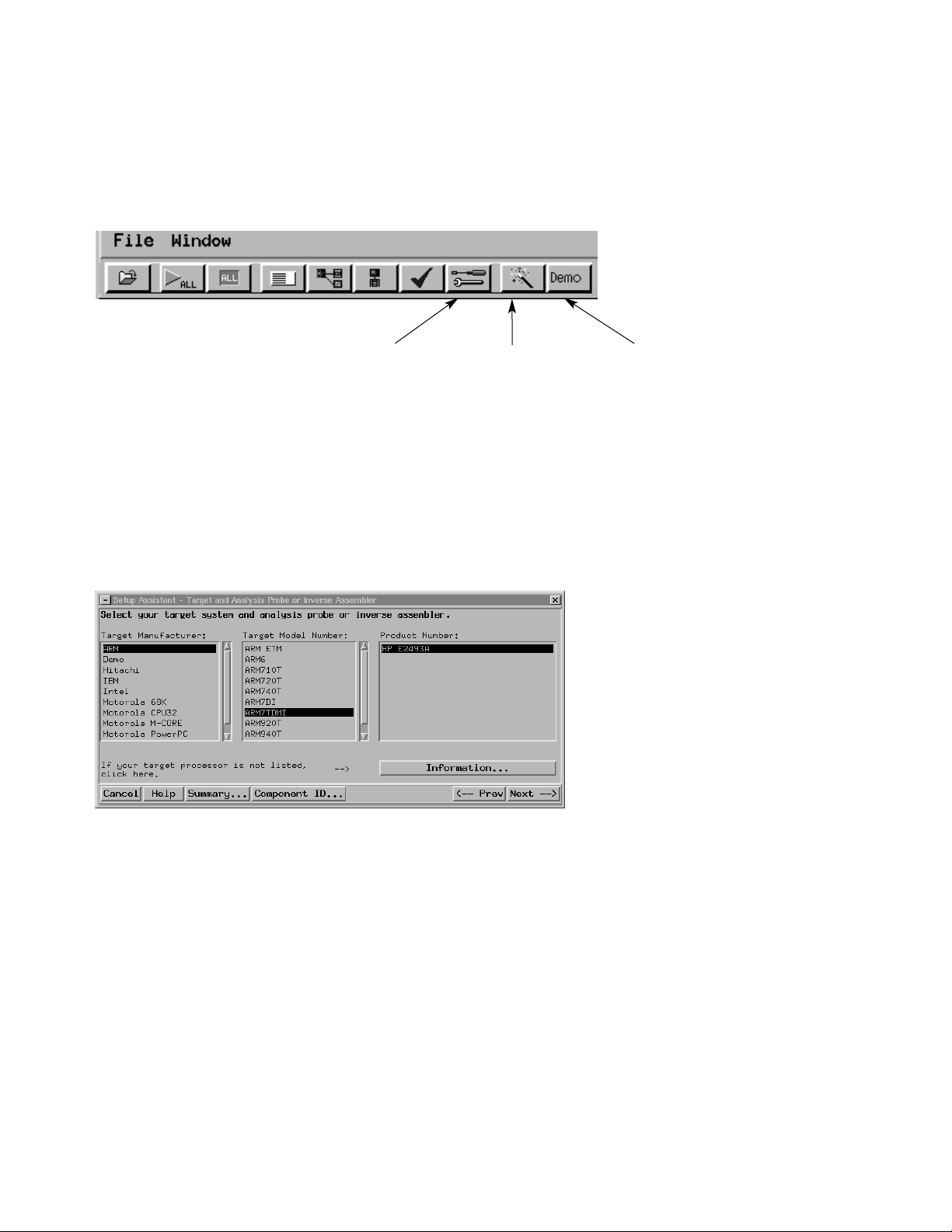

Figure 2.4. Setup Assistant gets you up and

running quickly.

System Admin

allows you to quickly set up the instrument on your network, configure

print servers, set up

user accounts for

security or install

software updates.

Demo Center

provides simple

demos of the most

commonly used

features.

Setup Assistant

is a guided menu

system that helps

you configure the

logic analysis system for your target

microprocessor or

bus. Online information guides you

through the setup.

(See figure 2.4)

Figure 2.3. Icons in the power-up screen give you

quick access to common tasks.

Page 10

10

Mainframes

System Screens

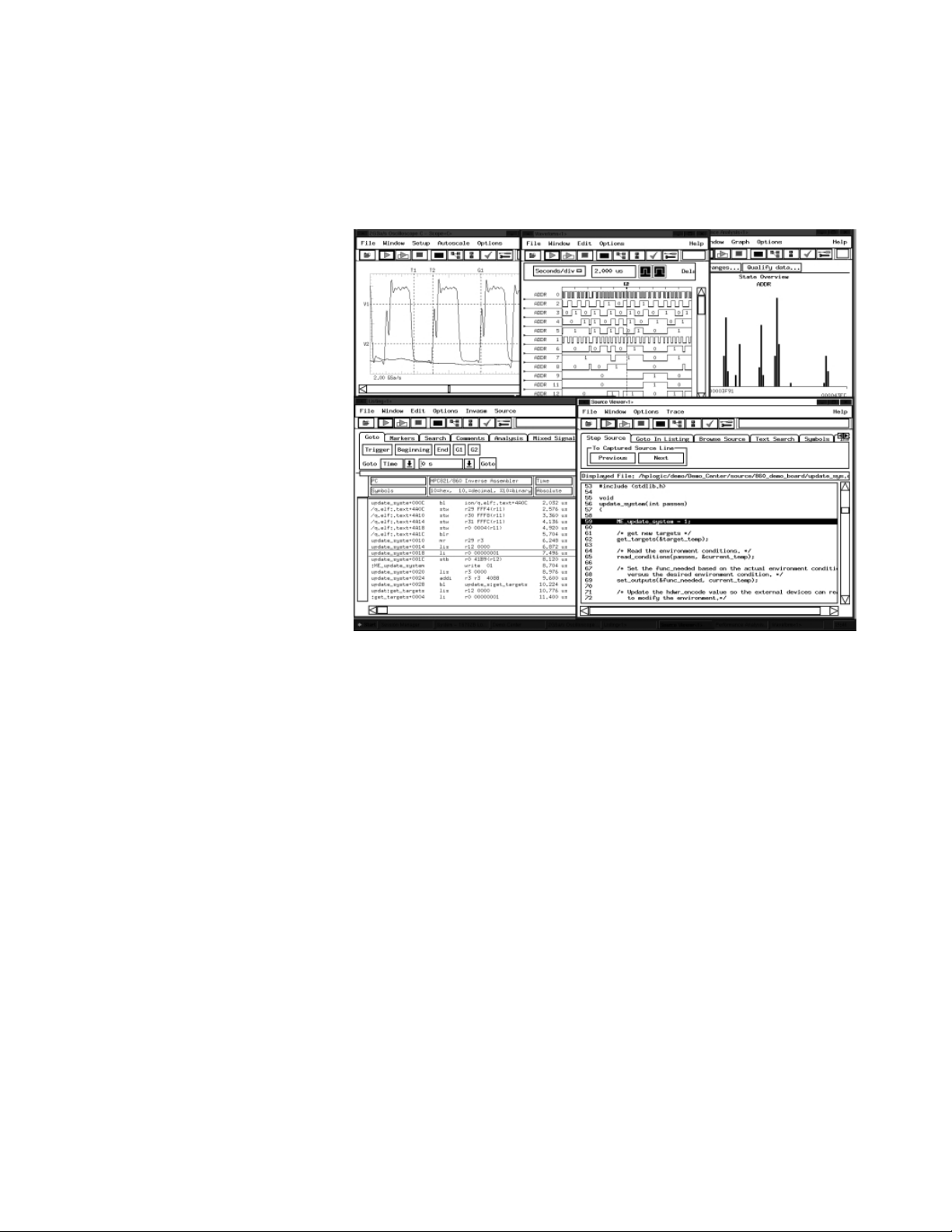

See the Big Picture of Your

Prototype System's Behavior

A large external display (option 001)

with multiple, resizable windows

allows you to see at a glance more of

your target system's operation. A

built-in, flat-panel display in the

16702B fits in environments with

limited space. Color lets you highlight

critical information so you can find

it quickly.

Use one system to examine target

operation from different perspectives. Multiple time-correlated views

of data let you confirm both signal

integrity and software execution

flow. These views are invaluable in

solving cross-domain problems.

Figure 2.5. You can quickly isolate the root cause of system problems by examining target operation across a wide

analysis domain, from signals to source code.

Page 11

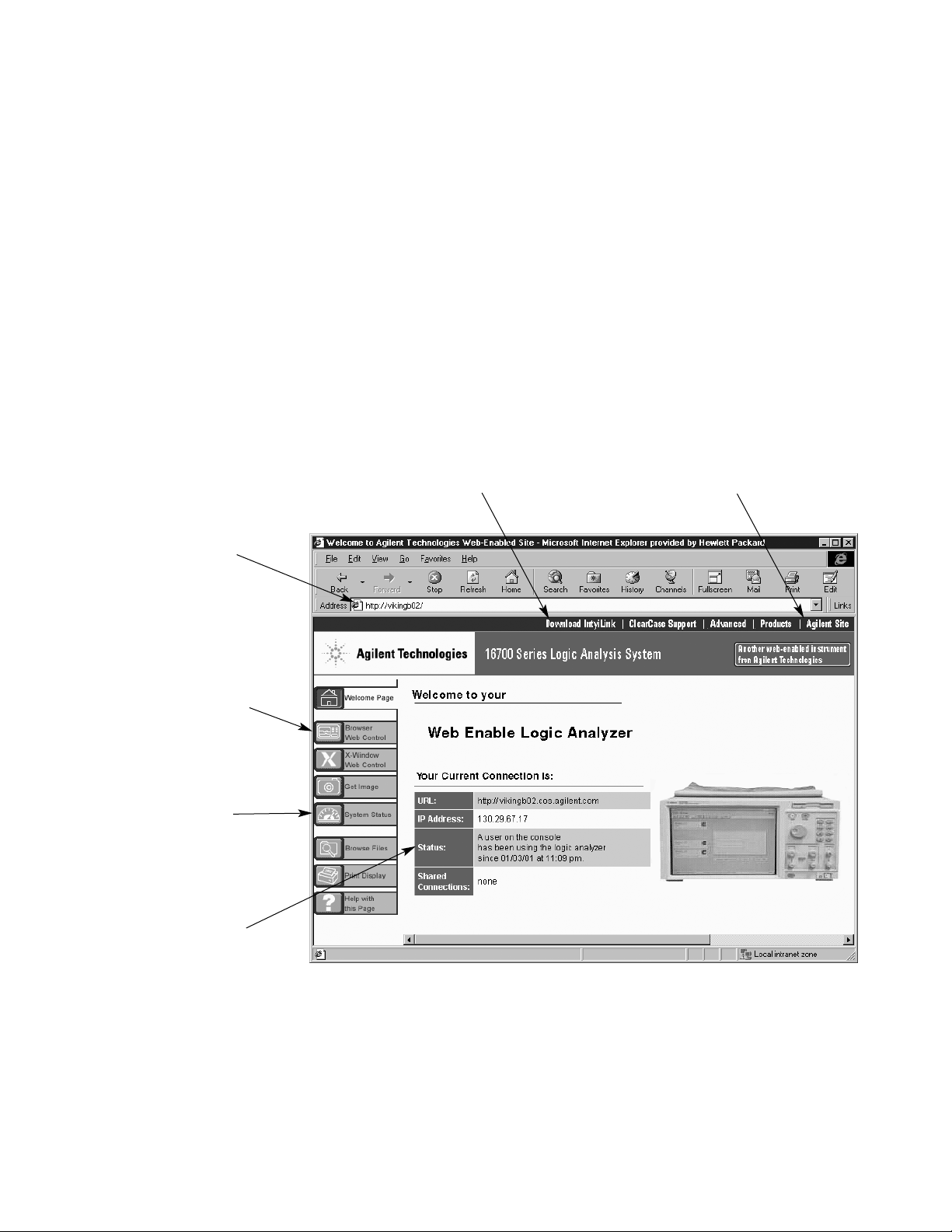

...access Agilent's Web site for the latest

online manuals and technical information

...install Agilent IntuiLink to seamlessly

transfer data from the system to a PC

11

Mainframes

System Screens

Expanding Possibilities with

Network Connectivity

Web-enabled instrumentation gives

you the freedom to access the

system—anywhere, anytime. Have

you ever needed to check on a

measurement's status while you were

in a remote location? Now you can.

Figure 2.6. Your logic analyzer is its own web site. From the Home Page, you can perform multiple remote functions.

With a Web Enabled Logic

Analysis System You Can...

...access the logic analysis

system's Web page from

your browser by using the

instrument's hostname as

a URL

...access the system’s user

interface directly from within your browser, giving you

full control of all analysis

functions

...remotely check current

measurement status to find

out if the system has

triggered

...quickly check instrument

status to determine if the

system is available for use

Page 12

12

Programming

IntuiLink also includes an Active-X

automation server to provide

programmatic control of the logic

analysis system from an external

environment, such as LabVIEW or the

Microsoft VisualStudio environment

of Visual Basic and Visual C++ tools.

The instrument's Remote

Programming Interface (or RPI) also

allows you to write Perl or other

scripts to control the logic analyzer.

Use the sample programs provided

to assist you in creating your own

custom programs.

Mainframes

IntuiLink

Figure 2.7. Transfer data into Microsoft Excel with just a click of the mouse.

Agilent IntuiLink Moves Your

Data Automatically into

Microsoft

®

Excel for

Advanced Offline Analysis

IntuiLink is shipped with each logic

analysis system and can be downloaded to your PC from the system’s

own web page. Use the Agilent

IntuiLink tool bar to connect to a

logic analysis system. Select from

the available labels and specify

the destination cell location in

Microsoft Excel.

Use Microsoft Excel's powerful

functions to post-process captured

trace data for the insight you need.

Import data from a current

acquisition or data previously saved

to a file via the File Out tool.

Page 13

13

Probing Solutions

Criteria for Selection

Why is Probing Important?

Your debugging tools perform three

important tasks: probing your target

system, acquiring data, and analyzing

data. Data acquisition and analysis

tools are only as effective as the

physical interface to your target

system. Use the following criteria to

see how your probing measures up.

How to Determine Your

Requirements

To determine what probing method

is best to use you need to take the

following into consideration:

• The number of signals to be

probed

• The ability to design probing

connectors on the target PC board

itself

• Mechanical probing clearance

requirements

• Signal loading effects

• Ease of attachment

• Package type to be probed

DIP Dual In-line Package

PGA Pin Grid Array

BGA Ball Grid Array

PLCC Plastic Leaded Chip

Carrier

PQFP Plastic Quad Flat Pack

TQFP Thin Quad Flat Pack

SOP Small Outline Package

TSOP Thin Small Outline

Package

• Package Pin Pitch (distance

between pin centers)

Immunity to Noise EMF noise is everywhere and can corrupt your data. Active

attenuator probing can be particularly susceptible to noise effects.

Agilent Technologies designs probing solutions with high immunity to

transient noise.

Impedance High input impedance will minimize the effect of probing on your

circuit. Although many probes are acceptable for lower frequencies,

capacitive loading dominates at higher frequencies.

Ruggedness A flimsy probe will give you unintended open circuits. Agilent

Technologies' probes are mechanically designed to relieve strain and

ensure a rugged and reliable connection.

Connectivity A multitude of device packages exist in the digital electronics industry.

Check our large selection of probing solutions designed for specific

chip packages or buses. As an alternative, we offer reliable

termination adapters that work with standard on-target connectors.

Figure 3.1. A rugged connection lets you focus on debugging your target, not your probe.

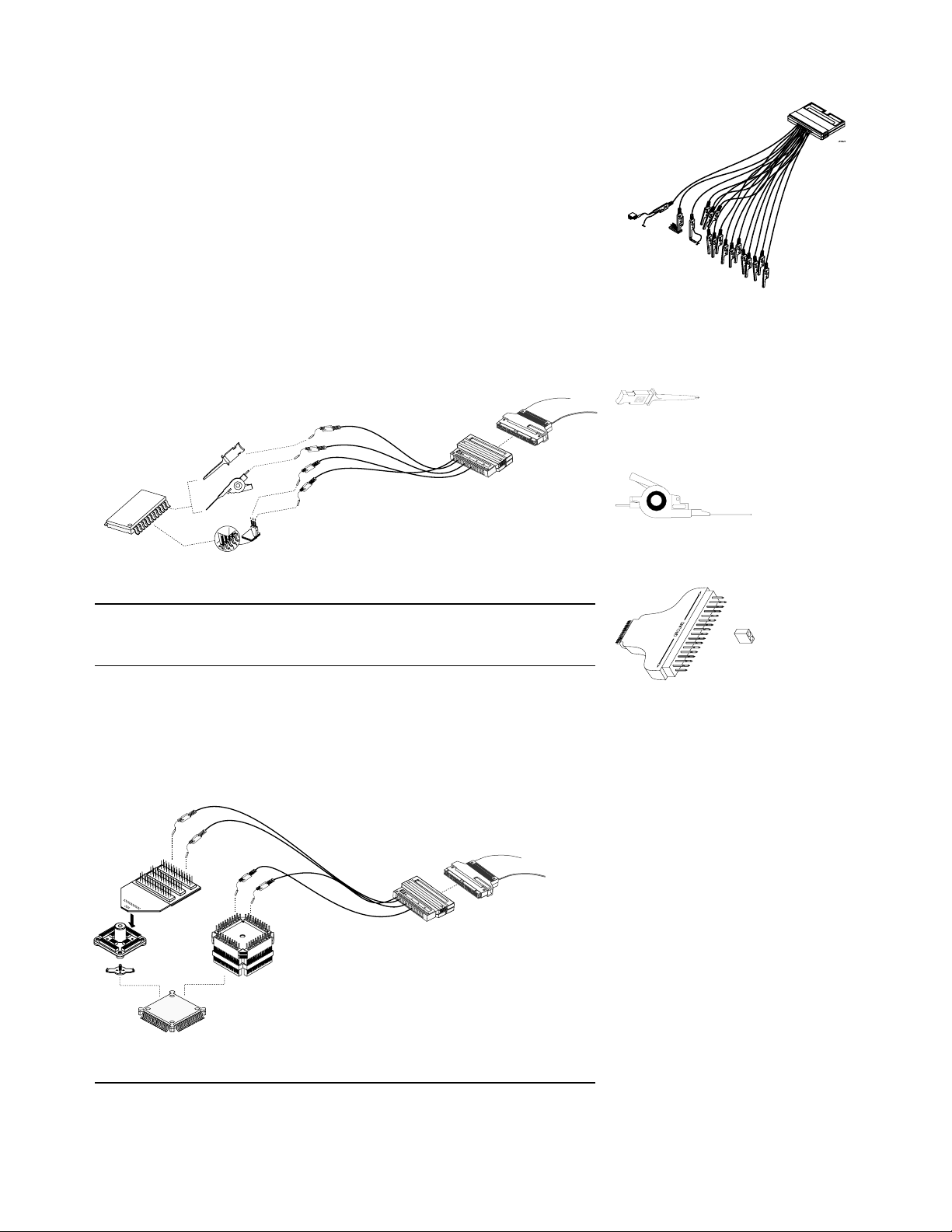

Page 14

14

Probing Solutions

Technologies

Choose the Optimum Probing

Strategy for Your Application

Advantages Limitations

Most flexible method. Can be time-consuming to connect a large

Flying-lead probes are included with logic number of channels. Least space-efficient

analyzer module (except 16760A). method.

Figure 3.2.

Figure 3.4. Surface mount IC clip.

5090-4356 (20 clips).

Figure 3.5. 0.5 mm IC clip.

10467-68701 (4 clips).

Figure 3.6. Wedge adapters connect to multiple

pins of 0.5 mm or 0.65 mm QFP ICs. Refer to

“Probing Solutions for Agilent Technologies

Logic Analysis Systems,” publication number

5968-4632E, for specific part numbers.

Connecting to individual test

points with flying leads

Advantages Limitations

Rapid access to all pins of fine-pitch Requires minimal keepout area.

QFP package.

Very reliable connections.

Figure 3.7.

Refer to “Probing Solutions for

Agilent Technologies Logic Analysis

Systems,” publication number

5968-4632E, for specific solutions.

Connecting to all the pins of a

quad flat pack (QFP) package

NEW Figure 3.3. The E5382A single-ended flying lead

probe set provides connections for 17 channels of

the 16760A logic analyzer.

Page 15

15

Probing Solutions

Technologies

Advantages Limitations

Very reliable connections. Requires advance planning in the design stage.

Saves time in making multiple connections. Requires some dedicated board space.

Moderate incremental cost.

Figure 3.8.

High-density probing solutions

Model Description Requires kit of 5 connectors Usable with

number and 5 shrouds logic analyzers

E5385A 100-pin probe with built-in isolation networks for the logic analyzer 16760-68701 All except 16517A,

16518A,16760A

E5346A 34-channel, 38-pin probe with built-in E5346-68701 All except 16517A,

isolation networks for the logic analyzer. 16518A, 16760A

E5351A 34-channel 38-pin adapter cable, requires logic analyzer E5346-68701 All except 16517A,

isolation networks on the target. 16518A, 16760A

E5339A 34-channel 38-pin low-voltage probe with E5346-68701 All except 16517A,

built-in isolation networks for the logic analyzer. Designed for signals 16518A, 16760A

with peak-to-peak amplitude as small as 250 mV.

E5378A 34-channel 100-pin single-ended probe for 16760A 16760-68701 16760A only

E5379A 17-channel 100-pin differential probe for 16760A 16760-68701 16760A only

E5380A 34-channel 38-pin single-ended probe for 16760A E5346-68701 16760A only

Designing connectors into

the target system

Moderate-density probing solutions

The Agilent 01650-63203 isolation

adapter contains the termination

networks for the logic analyzer. The

01650-63203 connects to a 3M 20-pin

connector on the target PC board.

Refer to "Probing Solutions for

Agilent Technologies Logic Analysis

Systems," publication number

5968-4632E, for design guidelines

and part numbers for mating

connectors.

You may also add the isolation

networks to the target PC board and

connect the logic analyzer cable

directly to a 40-pin 3M connector on

the PC board. Refer to "Probing

Solutions for Agilent Technologies

Logic Analysis Systems," publication

number 5968-4632E, for design

guidelines in addition to part numbers for mating connectors and

isolation networks.

Figure 3.9. 01650-63203 termination adapter.

Page 16

16

Probing Solutions

Technologies

Advantages Limitations

Easiest and fastest connection to supported Moderate to significant incremental cost.

processors and buses. Only useable for the specific processor or bus.

May require moderate clearance around

processor or bus.

Figure 3.10.

Refer to “Processor and Bus Support

for Agilent Technologies Logic

Analyzers,” publication number

5966-4365E, for specific solutions.

Using a processor- or bus-specific

analysis probe

Page 17

17

Data Acquisition and Stimulus

State/Timing Modules

Selecting the Correct Modules

to Meet Your Needs

Selecting the proper logic analyzer

modules for your needs requires a

series of choices concerning

performance, cost, and the amount of

data you will be able to capture. The

following table explains these factors

in greater detail.

Considerations for Choosing Modules

Microprocessor/ Will you be using an analysis probe for a particular processor or bus? If so, a good starting point is the document Processor

Bus Support and Bus Support for Agilent Technologies Logic Analyzers, publication number 5966-4365E, available on the worldwide web

at www.agilent.com/find/logicanalyzer. This document provides the number of channels and state speed required for any

particular analysis probe. It also indicates which analysis modules are supported and how many are required.

State Speed • State analysis uses a clock or strobe signal from your system under test to determine when to sample. Because state

analysis samples are synchronous with the system under test, they provide a view of how your system is executing. You can

use state analysis to capture bus cycles from a microprocessor or I/0 bus and convert the data into processor mnemonics

or bus transactions using an Agilent Technologies inverse assembler.

• Select a state acquisition system that provides the speed and headroom you need without breaking your budget. Remember

that a microprocessor will have an internal core frequency that is normally 2X-5X the speed of the external bus.

Headroom You may realize a better return on your investment if you consider possible future needs when purchasing analysis modules.

The things to consider are primarily state speed and memory depth.

Setup/Hold • Logic analyzers require time for the data at the inputs to become valid (setup time), and time to capture the data (hold time).

A lengthy setup and hold can make the difference between capturing valid data or data in transition.

• Your device under test will ensure that data is valid on the bus for a defined length of time. This is known as the data valid

window. Your target's data valid window must be large enough to meet the setup/hold specifications of the logic analyzer.

The data valid window of most devices is generally less than half of the clock period. Don't be fooled by "typical" setup and

hold specifications for logic analyzers.

• As bus speeds increase, the time window during which data is stable decreases. Jitter, skew, and pattern-dependent ISI

add more uncertainty and consume a greater portion of the data-valid window at high speeds. A logic analyzer with

adjustable setup/hold with fine position resolution provides unparalleled measurement accuracy at high frequencies.

Timing Resolution Timing analysis uses the logic analyzer's internal clock to determine when to sample. Since timing analysis samples

asynchronously to the system under test, you should consider what accuracy you will need to verify your system.

Accuracy is made up of two elements: sample speed and channel-to-channel skew. Remember to evaluate both of these

elements and be careful of logic analyzers that have a fast sample speed with a large channel-to-channel skew.

Transitional Timing If your system has bursts of activity followed by times with little activity, you can use transitional timing to capture a longer

trace. In transitional timing, the analyzer samples data at regular intervals, but only stores the data when there is a transition

on one of the signals.

Page 18

18

Data Acquisition and Stimulus

State/Timing Modules

Considerations for Choosing Modules (continued)

Channel Count Determine the number of signals you want to analyze on your system under test. You will need this number of channels in

your logic analyzer. Even if you have enough channels to view all the signals in your system today, you should consider logic

analysis systems that allow you to add more channels for your future application needs.

Memory Depth • Complex architectures and bus protocols make your debugging job increasingly challenging. Split transactions, multiple

outstanding transactions, pipelining, out-of-order execution, and deep FIFOs, all mean that the flow of data related to a

problem can be distributed over thousands or millions of bus cycles.

• The keys to useful insight are the combination of deep memory with responsive display refresh, search, rescaling, and

scrolling to help you find information and answers quickly. Hardware-assisted memory management in the Agilent

16740A, 16741A, 16742A, 16750A, 16751A, 16752A, and 16760A state and timing analysis modules makes quick work of

refreshing the display, rescaling, scrolling, and searching. It takes only a few seconds to refresh, rescale, or scroll a 32M

sample record. Agilent Technologies offers a range of state and timing analyzer modules with memory depths up to 128M

samples, at prices to meet your budget.

Triggering • The logic analyzer memory system is similar to a circular buffer. When the acquisition is started, the analyzer continuously

gathers data samples and stores them in memory. When memory becomes full, it simply wraps around and stores each new

sample in the place of the sample that has been in memory the longest. This process will continue until the logic analyzer

finds the trigger point. The logic analyzer trigger stops the acquisition at the point you specify and provides a view into the

system under test. The primary responsibility of the trigger is to stop the acquisition, but it can also be used to control the

selective storage of data. Consider a logic analyzer with the trigger resources you need to quickly set up your

measurements.

• After memory depth, triggering is the most important aspect of a logic analyzer to consider. On the one hand, powerful

triggering resources and algorithms will allow you to focus on potential problem sources without using up valuable memory.

On the other hand, to be useful, the trigger must be easy to set up.

Other In addition to the measurements made with an analysis probe, consider whether you need to monitor other signals. Be sure to

Measurements allow enough channels to make those measurements. For state measurements, the state speed of the analyzer must be at least

as high as the clock speed of your circuit. You may want to test the margin in your circuit by operating it at higher than the

nominal clock speed to determine if the analyzer has sufficient clock speed. For timing measurements, the timing analyzer rate

should be from 2-10X the clock speed of your target.

Page 19

19

Data Acquisition and Stimulus

State/Timing Modules

Key Features of Agilent’s

State/Timing Modules

• Memory depth up to 128M

samples at a price to meet your

budget

• State analysis up to 1.5 Gb/s

• Timing analysis up to 2 GHz

• VisiTrigger combines powerful

functionality with an intuitive

user interface

• Timing Zoom 2-GHz timing on

all channels

• Eye finder for automatic setup

and hold on all channels

Multichannel Eye scan allows you to make eye diagram measurements, quickly and easily,

Eye measurements on hundreds of channels simultaneously (16760A only)

Triggering for the VisiTrigger combines powerful trigger functionality with a user interface

most elusive that is easy to understand and use. Capturing complex sequences of

problems events is as simple as pointing to the function you want to use and filling in

the blanks to customize it to your specific situation.

Reliable Eye finder automatically adjusts the setup and hold on every channel,

measurements eliminating the need for manual adjustment and ensuring the highest

on high-speed confidence in accurate state measurements on high-speed buses.

buses

High-speed Timing Zoom provides the data acquisition speed you need for high-speed

timing on microprocessors and buses.

all channels

Choose the Logic Analyzer and Measurement Modules that Best Fit Your Application

State/Timing General- 8/16 Bit 32/64 Bit High- Timing Deep trace High- Analysis of

Modules purpose processor processor speed margin capture speed data intensive

hardware debug debug or bus analysis or with timing computer systems and

debug channel analysis characterize or state debug performance

intensive setup/hold analysis

systems

16710A √√

16711A √√

16712A √√

16715A √√√

16716A √√√√√

16717A √√√√√

16740A √√√√√√

16741A √√√√√√

16742A √√√√√√

16750A √√√√√√

16751A √√√√√√

16752A √√√√√√

16760A √√√

A variety of measurement modules allow you to select the optimum combination of performance, features, and price to meet your specific needs now and in the future.

Page 20

20

Data Acquisition and Stimulus

State/Timing Modules

Improve Your Productivity with an

Intuitive User Interface

Agilent Technologies has made the

user interface easy to understand

and use. Now you can spend more

time making measurements and less

time setting up the logic analyzer.

Measurement configuration and

data files can be loaded directly into

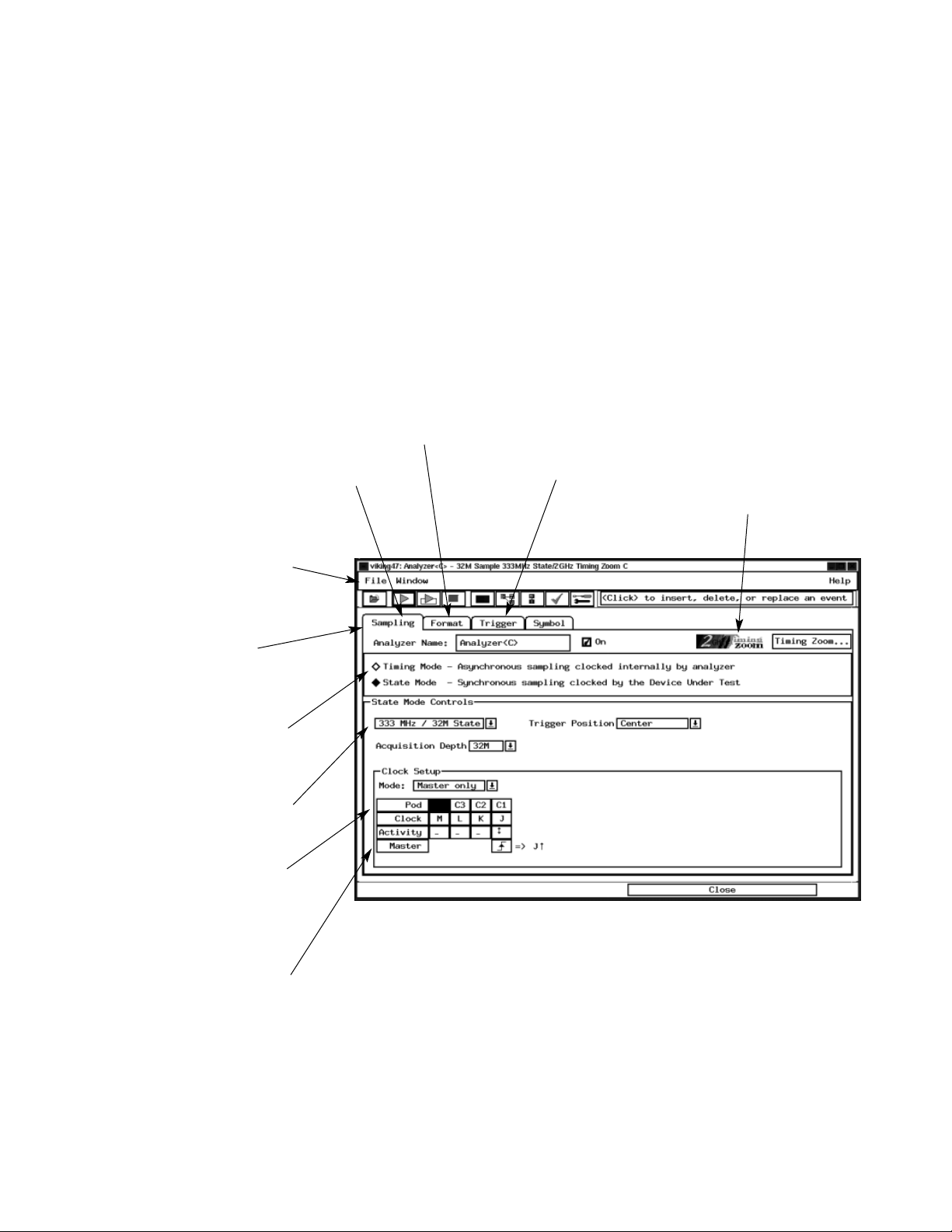

the logic analyzer

Menu tabs provide a logical

progression through the setup of

your measurement.

State and timing mode selections

specify how data is sampled.

Single location for access to all state

acquisition options.

Convenient color coding helps you

identify the signals in the interface

with the physical connection to your

device under test.

Clocking for state measurements

can be quickly defined using the

clock setup menu.

Sampling defines how the logic

analyzer will acquire the data.

Format allows you to

group signals into buses.

Trigger defines what

data is acquired.

Timing Zoom provides 2 GSa/s timing

analysis simultaneous with state or

conventional timing analysis on all

channels. Sampling rate and position

relative to trigger are adjustable

(16716A, 16717A, 16740A, 16741A

16742A, 16750A, 16751A, and

16752A only).

Figure 4.1. Setting up your logic analyzer has never been this easy.

Page 21

21

Data Acquisition and Stimulus

State/Timing Modules

VisiTrigger Quickly Locates

Your Most Elusive Problems

VisiTrigger technology is a breakthrough in logic analysis usability. It

combines increased trigger functionality with a user interface that is easy

to understand and use. Now with

VisiTrigger, capturing complex events

is as simple as pointing to the trigger

function and filling-in-the-blanks.

Features and Applications

VisiTrigger • Use graphical views and sentence-like structures to help you

(available in the 16715A, define a trace event.

16716A, 16717A, 16740A, • Select trigger functions as individual trigger conditions or as

16741A, 16742A, 16750A building blocks to easily customize a trigger for your specific task.

16751A, 16752A, and • Set global counters to count events such as the number of times a

16760A state/timing function executes, or the number of accesses to an l/O port.

modules) • Set, clear or evaluate flags by any module in the frame. Flags allow

you to set up a trigger that is dependent on activity from more than

one bus in the system.

• Specify four-way arbitrary IF/THEN/ELSE branching.

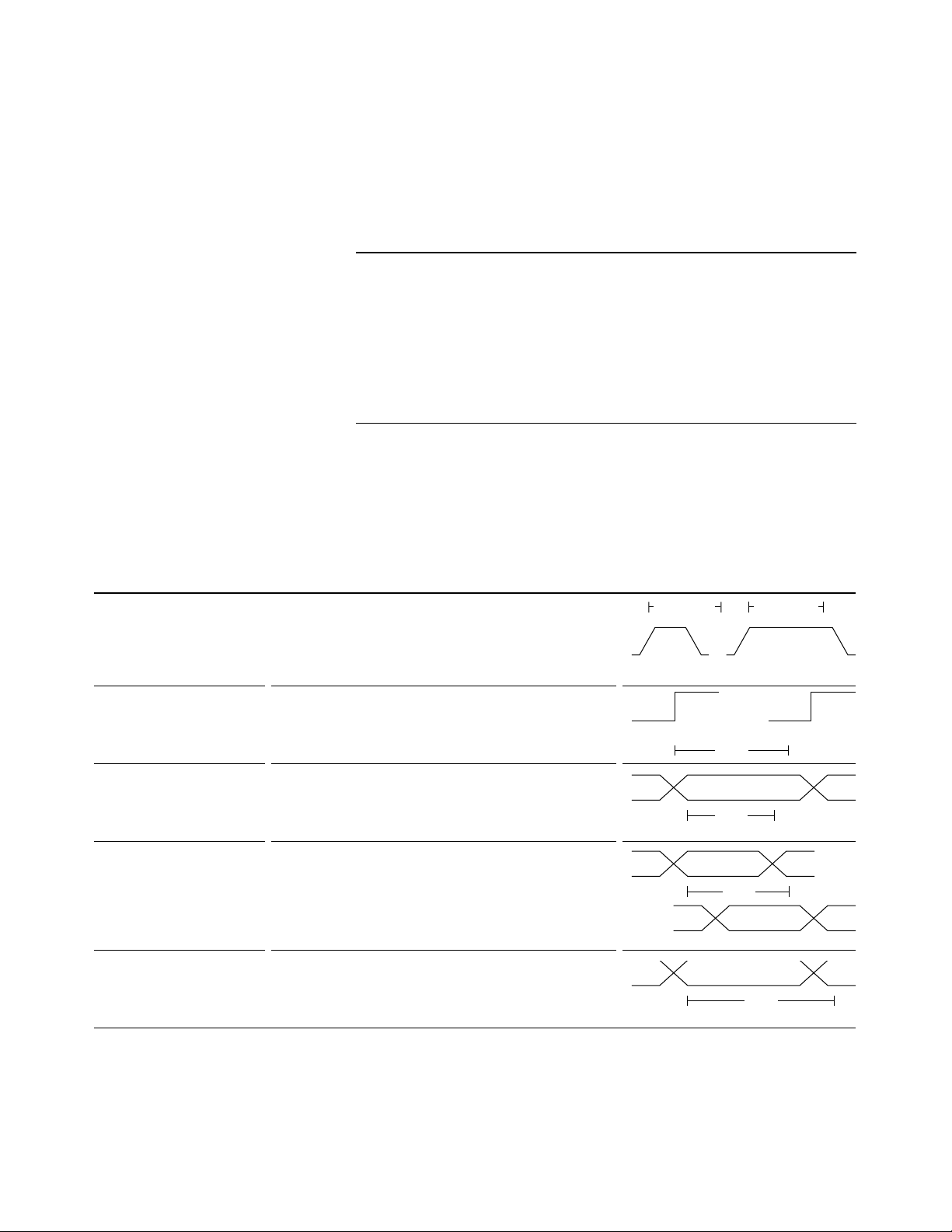

Examples of Problems that Can be Captured Easily with VisiTrigger

Description Typical Applications Graphic

Pulse too narrow or too wide • Line hangs at wrong level (high or low).

• Asynchronous input (for example, an interrupt) persists too long.

• Strobe width is too narrow or too wide.

Time between two edges is • Excessive delay in responding to a bus grant request.

longer than specified • Excessive delay in responding to a data valid with a data

acknowledged.

Pattern lasts longer than a • A bus hangs up at a given value.

specified time

Pattern two exists within a • An incorrect response to a read or write.

specified time after pattern • An incorrect output from a FIFO or bridge.

one is detected

A pattern exists for less • A driver is not holding a bus value long enough for a receiver to

than a specified time respond.

Pulse too narrow

Pulse too wide

Min width

Max width

OR

time

edge 1 edge 2

pattern

time

pattern 1

pattern 2

time

pattern

time

Page 22

22

Data Acquisition and Stimulus

State/Timing Modules

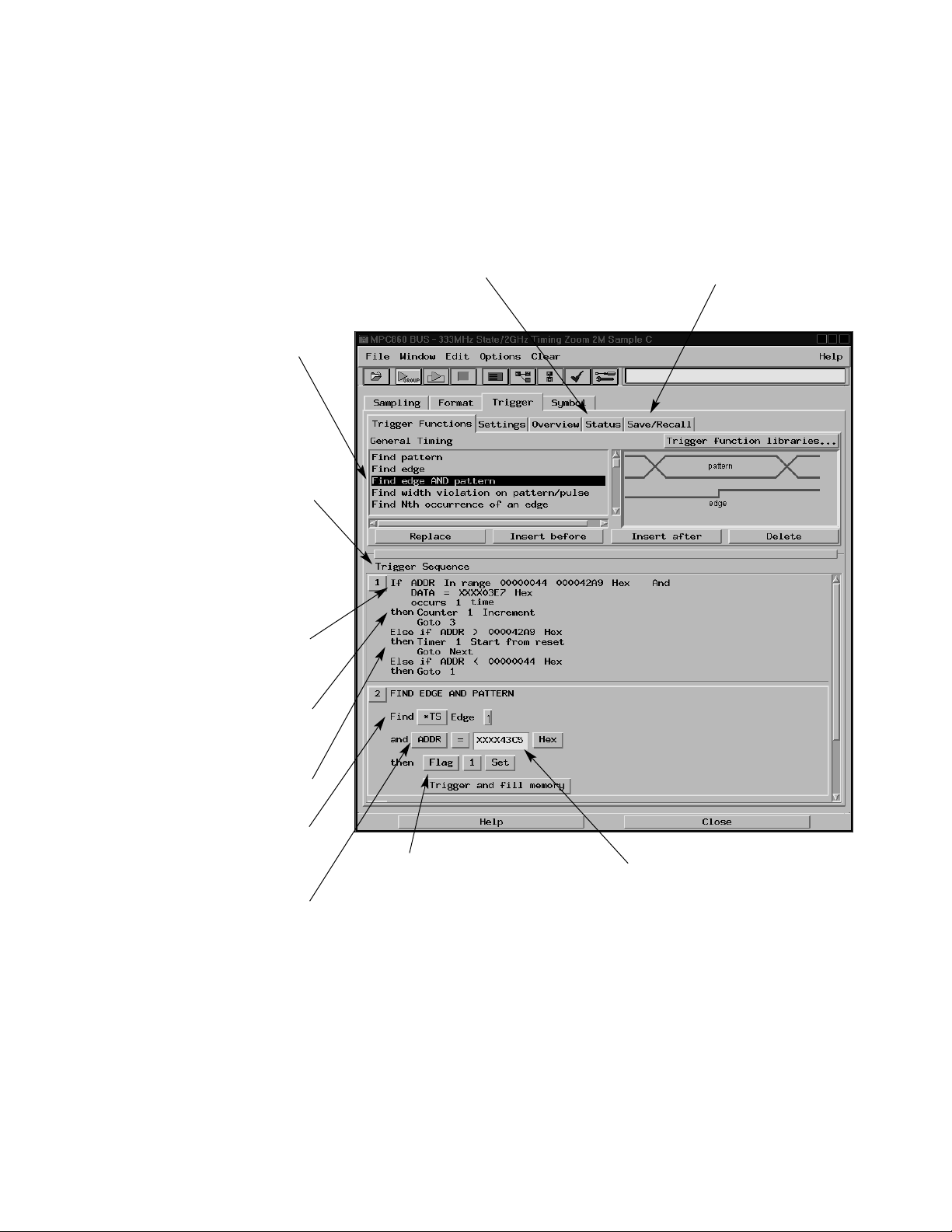

Save and recall up to ten of your

custom trigger setups without loading

a new configuration file.

View current information on the state of

the timers, counters, flags, and the trigger

sequence level.

VisiTrigger

Your most commonly used triggers are

just a mouse click away with the built-in

trigger functions. VisiTrigger’s graphical

representation shows you how the

trigger condition will be defined. You can

use trigger functions as building blocks

to easily customize a trigger for your

specific task.

Sequence levels allow you to develop a

sequence of analyzer instructions to

specify a trigger point or to qualify data

and store only the information that

interests you. Each step in the sequence

contains an "IF/THEN/ELSE" structure

that can evaluate up to four logic

events. Each event can specify a

combination of actions such as: store

sample, increment counters, reset

timers, trigger, or go to another step

in the sequence level.

Ranges provide a way to monitor

program and data accesses within a

specified area in memory.

Global counters can count events such

as the number of times a function

executes or accesses an I/O port.

Timers can be set up to evaluate when

one event happens too late or too soon

with respect to another event.

In timing mode, edge terms let you

trigger on a rising edge, falling edge,

either edge, or a glitch.

Patterns and their logical combinations

let you identify which states to store,

when to branch and when to trigger.

Flags can be set, cleared and evaluated by

any 16715A/16A/17A/40A/41A/42A/50A/

51A/52A/60A module in the frame. This

allows you to set up a trigger that is dependent on activity from more than one bus in the

system.

Values can be easily entered directly into

the trigger description.

Figure 4.2. Set up your trigger in terms of the measurements you want to make.

Page 23

23

Data Acquisition and Stimulus

State/Timing Modules

2 GHz Timing Zoom Provides HighSpeed Timing Analysis Across All

Channels, All the Time

When you're pushing the speed

envelope, you may run into elusive

hardware problems. Capturing

glitches and verifying that your

design meets critical setup/hold

times can be difficult without the

proper tools. With Timing Zoom you

have access to the industry's most

powerful tool for high-speed

digital debug.

Features and Applications

Timing Zoom • Simultaneously acquire up to 16K of data at 2 GHz timing and

(available in the 16716A, 400 MHz state across all channels, all the time, through the same

16717A, 16740A, 16741A, connection

16742A, 16750A, 16751A • Vary the Timing Zoom sample rate from 250 MHz to 2 GHz

and 16752A state/timing • Vary the placement of Timing Zoom data around the trigger point

modules) • Efficiently characterize hardware with 500 ps resolution

Now it’s easy to capture simultaneous

2 GHz timing and high-speed state

information through a single connection.

Use the global

markers to

time-correlate

events across

multiple displays.

Timing Zoom labels are automatically

created and marked with an _TZ extension.

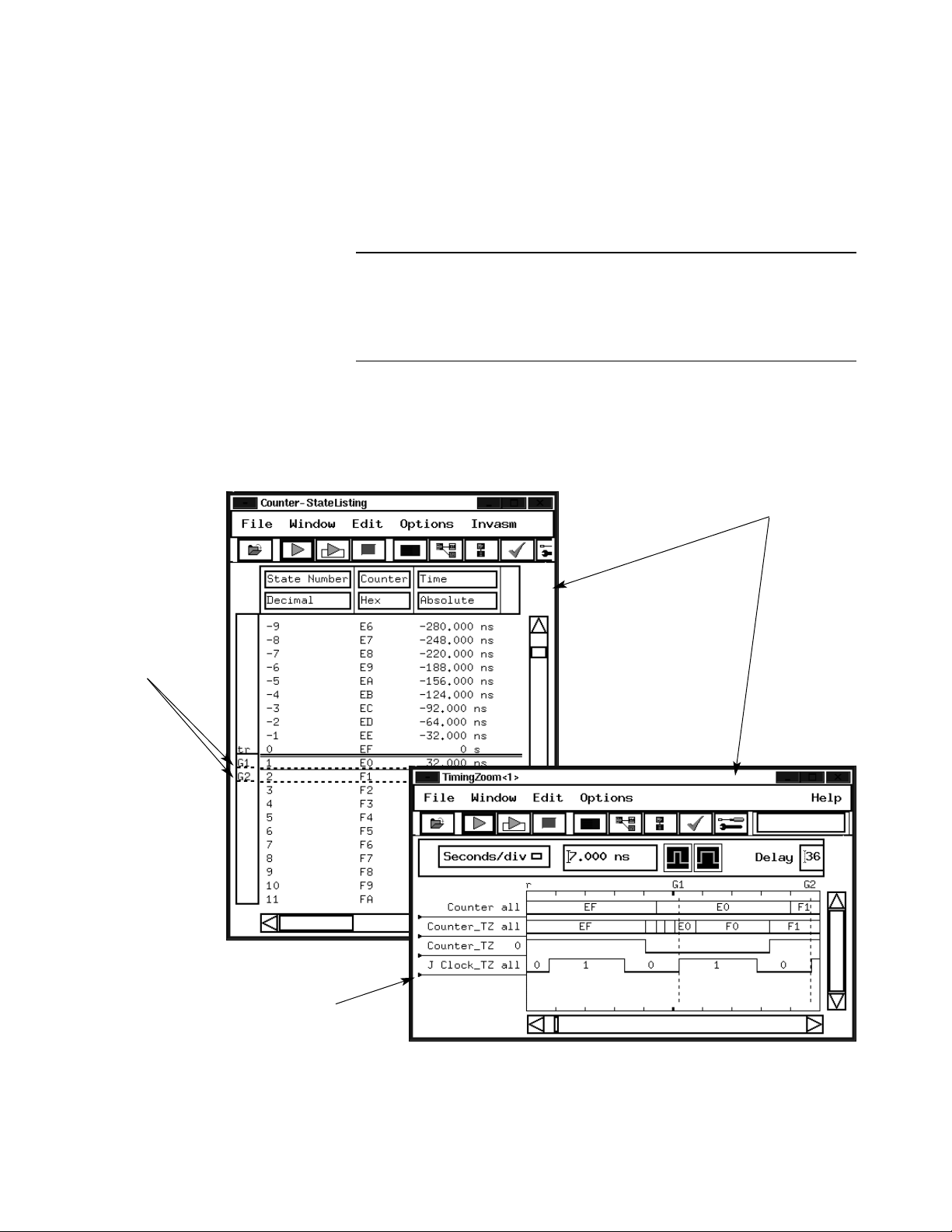

Figure 4.3. Verifying critical edge timing in your system is easy with Agilent Technologies' 2 GHz Timing Zoom technology.

Page 24

24

Data Acquisition and Stimulus

State/Timing Modules

Eye Finder

Agilent’s eye finder examines the

signals coming from the circuit under

test and automatically adjusts the

logic analyzer’s setup and hold

window on each channel. Eye finder,

combined with 100 ps adjustment

resolution (10 ps on 16760A) on

Agilent’s logic analyzer modules,

yields the highest confidence in

accurate state measurements on

high-speed buses.

It takes less than a minute to run

eye finder. No special setup or

additional equipment is required.

You only need to run eye finder

once, when the logic analyzer is set

up and connected to the target.

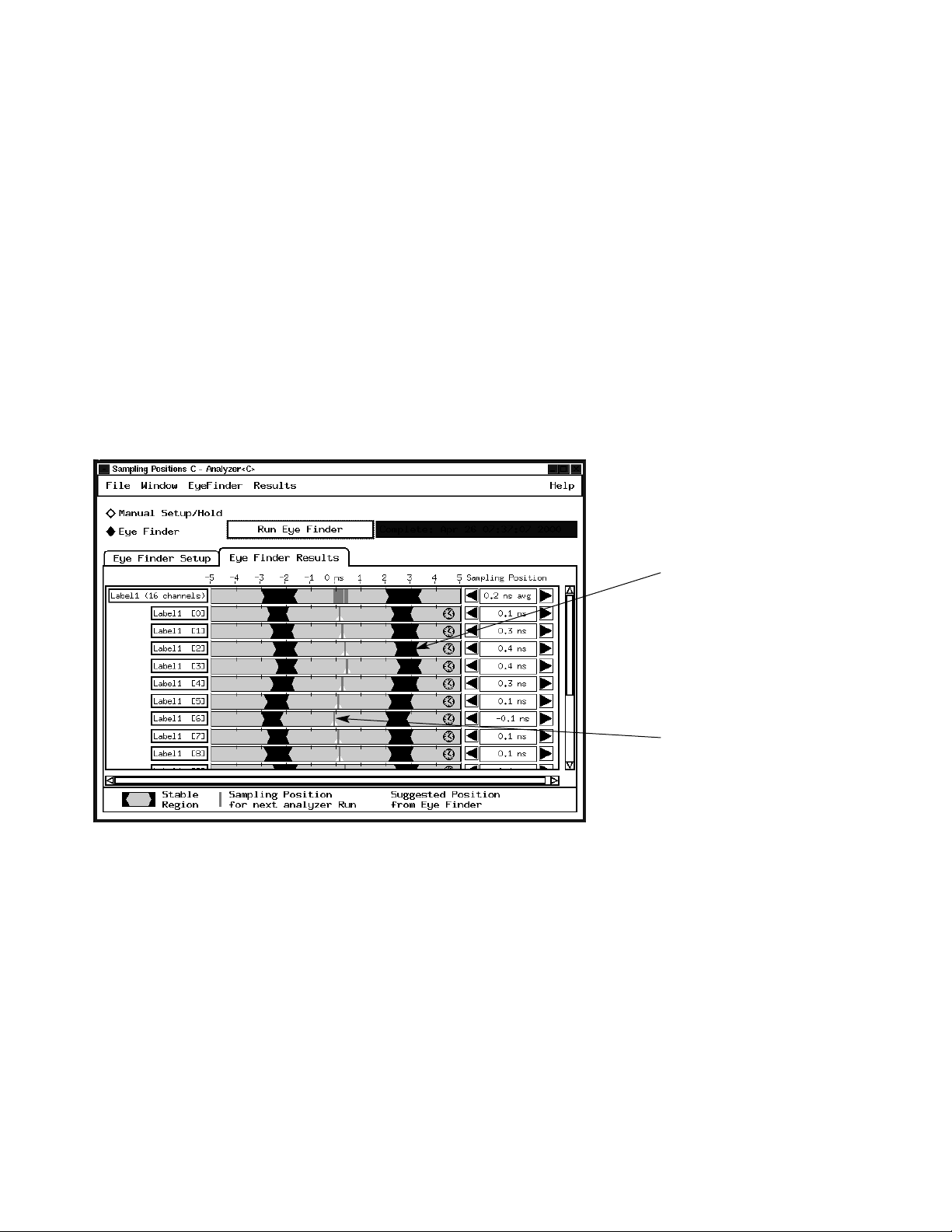

Figure 4.4. The eye finder display.

Gray shading indicates

regions where

transitions are detected.

Blue bars indicate

the sampling point

selected by eye finder.

The eye finder display shows:

• Regions of transitions that were

discovered on all channels

selected

• The sampling point selected by eye

finder

If you want to select a different

sample point on any individual

channel, just drag and drop the blue

"sample" bar at the desired point.

Times in the eye finder display are

referenced to the incoming clock

transitions. The center of the display

(labeled "0 ns") corresponds to the

clock transitions.

Page 25

25

Data Acquisition and Stimulus

State/Timing Modules

Eye Finder as an Analytical Tool

Eye finder is very useful as a firstpass screening test for data valid

windows. Because eye finder quickly

examines all channels, it is

considerably faster than examining

each channel with an oscilloscope.

After running eye finder, you may

want to use an oscilloscope to

examine only those signals that are

close to your desired specifications

for setup and hold.

Eye finder also can quickly provide

useful diagnostic or troubleshooting

information. If a channel has an

unexpectedly small data valid

window, or an anomalous offset

relative to clock, this could be an

indication of a problem, or could be

used to validate the cause of an

intermittent timing problem.

Differences in the position of the

stable region from one signal to

another on a bus indicate skew. An

indication of excessive skew on eye

finder can help isolate which

channels you want to check with an

oscilloscope, or with the Timing

Zoom 2 GHz timing analysis mode

in your logic analyzer.

When Do You Need Eye Finder?

Eye finder becomes critical when

the data valid window is <2.5 ns. If

you’re unsure where your clock edge

is relative to the data valid window,

you can run eye finder for maximum

confidence. If the clock in your

system runs at 100 MHz or slower,

and the clock transitions are approximately centered in the data valid

window, you may not see any transition zones indicated in the eye finder

display. This is because eye finder

only examines a time span of 10 ns

(16760A: 6 ns) centered about the

clock.

Examples of When to Run Eye Finder

You should use eye finder in the

following situations:

Probing a new target, or probing

different signals in the same target

• Because eye finder examines the

actual signals in the circuit under

test, you should run it whenever

you probe a different bus or a

different target.

Significant change of target

temperature

• The propagation delays and signal

levels in your target system may

vary with temperature. If, for

example, you place your target

system in a controlled temperature chamber to evaluate its operation over a range of temperatures

or to trouble-shoot a problem that

only occurs at high or low temperatures, you should run eye finder

after the target system stabilizes

at the new ambient temperature.

Page 26

26

Data Acquisition and Stimulus

State/Timing Modules

Features Supported in Agilent State and Timing Analysis Modules

Agilent Module Number 16710A, 16711A, 16715A 16716A, 16717A, 16760A

16712A 16740A, 16741A,

16742A, 16750A

16751A, 16752A

Eye finder √√√

Visitrigger √√√

Timing Zoom √

Transitional timing √√√√

Context Store √

Eye Scan √

Page 27

27

Data Acquisition and Stimulus

State/Timing Modules

Agilent 16760A: Extending Logic

Analysis to New Realms

• Differential inputs (single-ended

probes also available).

• State analysis up to 1.5 Gb/s.

• Setup-and-hold time of 500 ps.

• Input signal amplitude as low as

200 mV p-p.

Logic analysis at state speeds up to

1.5 Gb/s imposes a stringent set of

criteria for a logic analyzer.

• Probing

Agilent’s 16760A uses an innovative

probing system with only 1.5 pF of

probe tip capacitance, including the

connector. The connector is a joint

design between Agilent and Samtec,

optimized especially for logic analysis

measurements.

Ground pins located between every

pair of signal pins provide excellent

channel-to-channel isolation at high

speeds.

• Setup and hold

As state speeds go up, the data valid

window shrinks. To make reliable

measurements, a logic analyzer’s

combined setup and hold window

must be smaller than the data valid

window of the signals it is acquiring.

Agilent’s 16760A has a combined

setup and hold time of 500 ps to

match the data valid window of

very high-speed buses.

To position the analyzer’s setup-andhold window inside the data valid

window requires very fine adjustment resolution. The 16760A gives

you the ability to position the setupand-hold window with 10 ps resolution.

• Small-amplitude signals

Many high-speed designs use small

signal amplitudes to limit slew rates

and reduce power. Agilent’s 16760A

can make reliable measurements on

signals as small as 200 mV p-p.

• Differential signals

Many high-speed designs use differential signaling to minimize simultaneous switching noise and to provide

immunity to crosstalk and noise. The

Agilent 16760A has differential inputs

to allow you to acquire differential

signals with complete confidence.

Single-ended probes are also available.

Agilent helps you get started in the

design stage.

To probe high-speed signals with a

logic analyzer, you need to design the

probe in when you are designing your

PC board. The following document

from Agilent will help you design your

system to take maximum advantage

of the capabilities of the 16760A logic

analyzer:

• Logic signal standards supported

TTL LVTTL

HSTL Class I & II HSTL CLass III & IV

SSTL2 SSTL3

AGP-2X LVCMOS 1.5V

LVCMOS 1.8V LVCMOS 2.5V

LVCMOS3.3V CMOS 5V

ECL LVPECL

PECL

User defined from -3V to +5V in 10mV

increments

Publication Title Description Publication Number

User’s Guide, Agilent Technologies E5378A, E5379A, and Mechanical drawings, electrical models, 16760-97007

E5380A Probes for the 16760A Logic Analyzer general information on probes for the 16760A

Designing High-Speed Digital Systems for Guidelines and design examples for designing 5988-2989EN

Logic Analyzer Probing logic analyzers probing into your target system

Page 28

28

Data Acquisition and Stimulus

State/Timing Modules

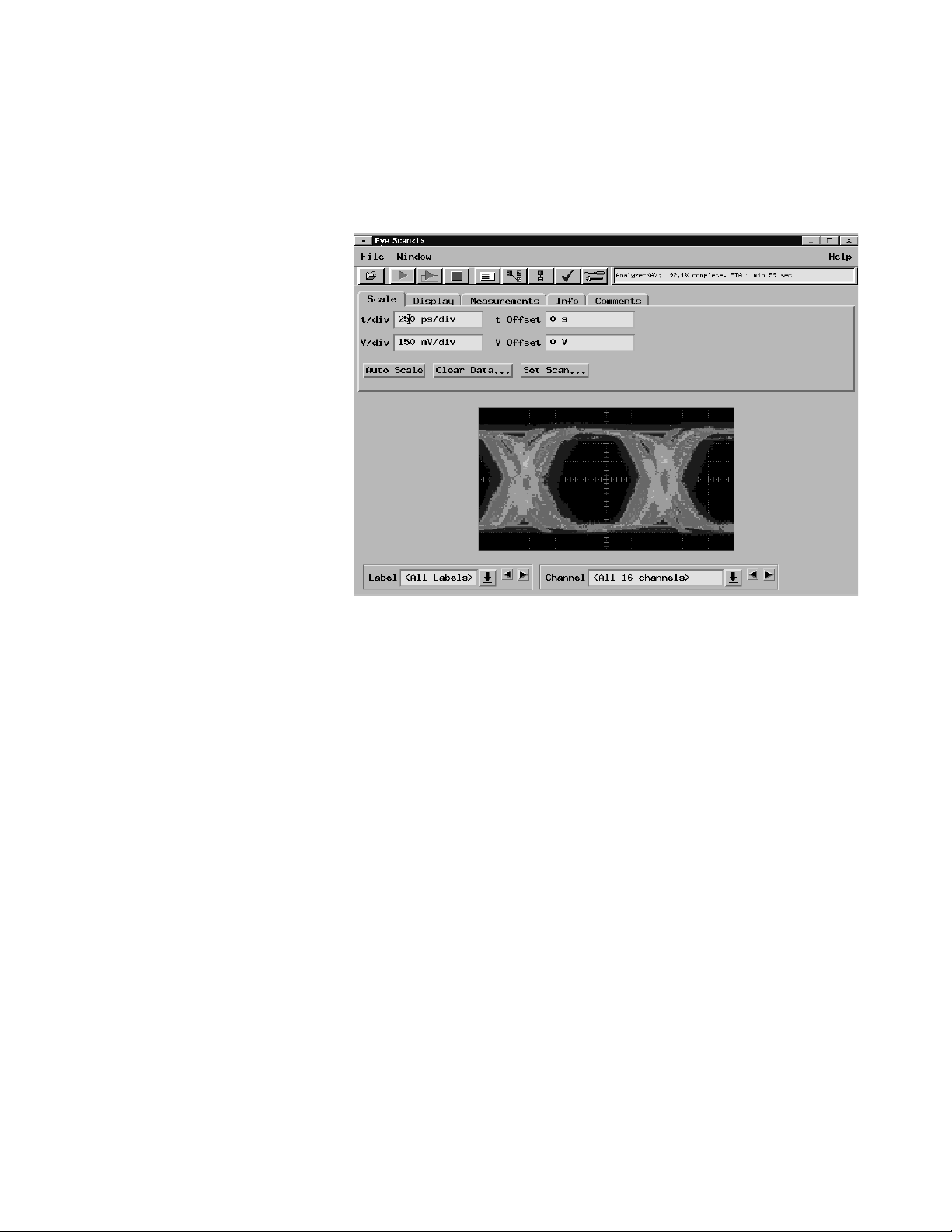

Eye scan

In the eye scan mode, the Agilent

16760A scans all incoming signals for

activity in a time range centered on

the clock and over the entire voltage

range of the signal. The results are

displayed in a graph similar to an eye

diagram as seen on an oscilloscope.

As timing and voltage margins

continue to shrink, confidence in

signal integrity becomes an

increasingly vital requirement of the

design verification process. Eye scan

lets you acquire comprehensive signal

integrity information on all the buses

in your design, under a wide variety

of operating conditions, in minimum

time.

Qualified eye scan

In the qualified eye scan mode, a

single qualifier input defines what

clock cycles are to be acquired and

what cycles are to be ignored in the

eye scan acquisition. For example,

you may wish to examine the eye

diagram for read cycles only,

ignoring write cycles.

Cursors

Two manually positioned cursors are

available. The readout indicates the

time and voltage coordinates of each

cursor.

Eye limit

The eye limit tool is a single point

cursor that can be positioned manually. The readout indicates the inner

eye limits detected at the time and

voltage coordinates of the cursor.

Histogram

The histogram tool indicates the relative number of transitions along a

selected line. The time range and

voltage levels of the histogram are

selected by manually positioning a

pair of cursors. The cursors indicate

the voltage level and the beginning

and end times of the histogram.

Polygon

A 4-point or 6-point polygon can be

defined manually.

Slope

The slope tool indicates DV/DT

between two manually - positions

cursors.

Eye scan allows the user to set the

following variables:

• The number of clock cycles to be

evaluated at each time and voltage

region

• The display mode

• Color graded

• Intensity shaded

• Solid color

• Aspect ratio of the display

• Time/division

• Time offset

• Volts/division

• Voltage offset

• Time resolution of measurement

• Voltage resolution of

measurement

Results can be viewed for each

individual channel. A composite

display of multiple channels and/or

multiple labels is also available.

Individual channels can be highlighted in the composite view

Eye scan data can be stored and

recalled for later comparison or

analysis.

Page 29

29

Probing solutions to match the

measurement capabilities

Three probing options are available

for the Agilent 16760A. Each probe

can be ordered by its individual

model number or as an option to the

16760A. The following table indicates

both the model number and the

option number.

Probes are not supplied as part of the

standard 16760A. Probes must be

ordered separately, either as options

to the 16760A or individually by their

respective model numbers.

Data Acquisition and Stimulus

State/Timing Modules

Agilent Model Number 16760A Option Number Description Notes

E5378A 010 100-pin single-ended probe Requires a kit of mating connectors and shrouds

(see the next table) to connect to target system.

E5379A 011 100-pin differential probe Two E5379A (or two option 011 on the 16760A) are

required to support all 34 channels on a 16760A.

Requires a kit of mating connectors and shrouds

(see the next table) to connect to target system.

E5380A 012 38-pin single-ended probe, compatible Maximum state analysis speed is 600 Mb/s.

with target systems designed for the Minimum input amplitude is 300 mV p-p.

Agilent E5346A Mictor adapter cable Requires a kit of mating connectors and shrouds

(see the next table) to connect to target system.

E5382A 013 17-channel, single-ended flying lead Two E5382A are required to support all the channels

probe set for the 16760A of a 16760A.

Connector and shroud kits for probes for the 16760A logic analyzer

For probe model number For PC board thickness Probing connector kit part number

(each contains 5 mating connectors and 5 support shrouds)

E5378A Up to 1.57 mm (0.062") 16760-68702

Up to 3.05 mm (0.120") 16760-68703

E5379A Up to 1.57 mm (0.062") 16760-68702

Up to 3.05 mm (0.120") 16760-68703

E5380A Up to 1.57 mm (0.062") E5346-68701

Up to 3.18 mm (0.125") E5346-68700

Page 30

30

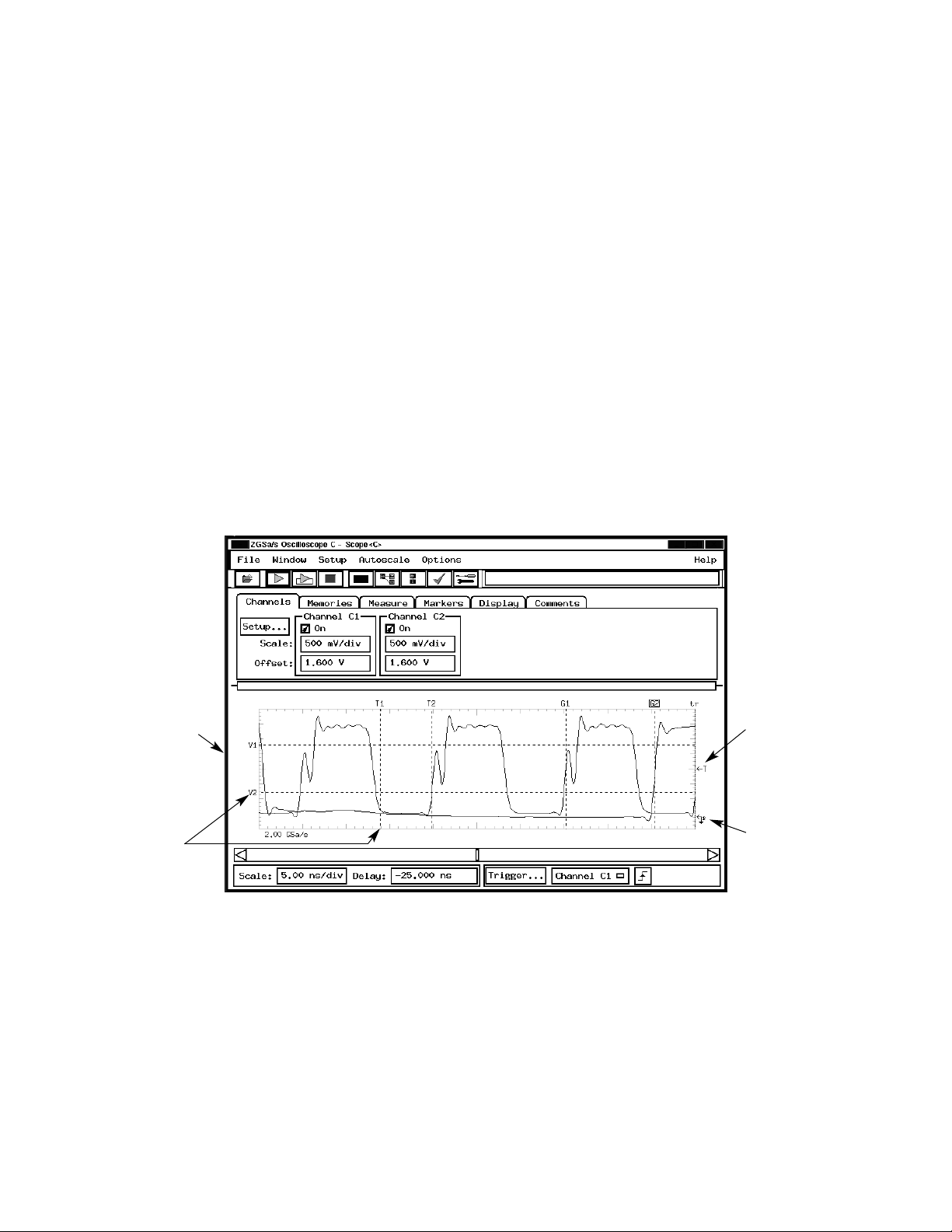

Data Acquisition and Stimulus

Oscilloscope Modules

When integrated into the 16700

Series logic analysis systems, the

oscilloscope modules make powerful

measurement and analysis more

accessible, so you can find the

answers to tough debugging problems

in less time. Oscilloscope controls are

easy to find and use.

Scope controls

and waveform

display are integrated into a

single window,

making interactive adjustment

easy.

Time and voltage

markers allow you

to measure signal

details precisely.

Multiple Views of Target Behavior

Isolate Problems Quicker

Frequently a problem is detected in

one measurement domain, while the

clues to the cause of the problem are

found in another. That’s why the ability to view your prototype's behavior

from all angles simultaneously—from

software execution to analog signals—

is essential for quickly gaining insight

into problems.

For example, using a state analyzer

you may observe a failed bus cycle. A

timing problem caused by a reflection

on an incorrectly terminated line

may be causing the bus cycle to fail.

By triggering an oscilloscope from the

state analyzer, you can quickly identify the cause. The ability to cross-trigger and time-correlate state, timing,

and analog measurements can help

you in solving these tough problems.

Figure 4.5. All primary oscilloscope control settings, including scale factors and trigger settings, are visible

simultaneously.

Trigger icon

indicates trigger

level, making it

easy for you to

adjust trigger

level.

Ground icon

always shows

you where ground

is relative

to signal.

Page 31

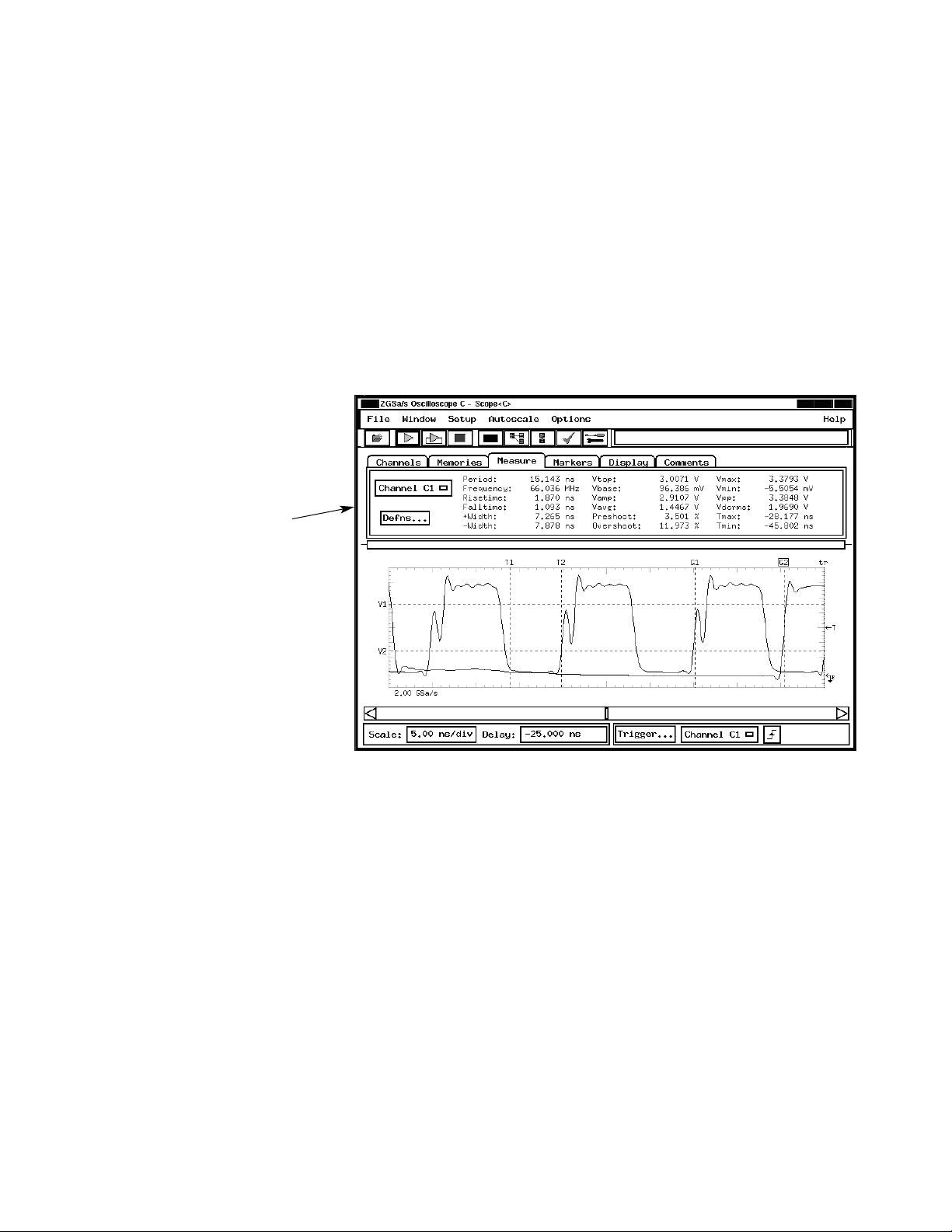

31

Data Acquisition and Stimulus

Oscilloscope Modules

Automatic Measurements Quickly

Characterize Signals

The Agilent Technologies 16534A

oscilloscope modules quickly characterize signals with automatic measurements of rise time, voltage, pulse

width, and frequency.

Markers Easily Set Up Timing and

Voltage Margin Measurements

Four independent voltage markers

and two local time markers are available to quickly set up measurements

of voltage and timing margins.

The global time markers of the 16700

Series logic analysis systems let you

correlate state, timing, and oscilloscope measurements to track problems across multiple measurement

domains.

Automatic measurements

save time in characterizing

signal parameters.

Figure 4.6. Automatic measurements and markers let you make faster analysis.

Page 32

32

Data Acquisition and Stimulus

Oscilloscope Modules

More Channels When You Need Them

You can combine up to four 16534A

oscilloscope modules to provide up

to eight channels on a single time

base. When you operate in this

mode, you can use the master module

for triggering.

Channel 1 input

Figure 4.7. Connector panel of the 16534A oscilloscope module.

Calibrator output used

for operational accuracy

calibration

Probe power output provides power

for 1145A dual active probe or two

1141A active probes

Channel 2 input

External trigger input and output are

used to connect up to four oscilloscope

modules, providing up to eight channels

on a single time base.

!

CHAN 1 & 2

1MW = 7pF

250V MAX OR

50W 5Vrms MAX

CHAN

1

IN OUTECL EXT

AC/DC CAL

TRIG

!

!

! PROBE POWER

CHAN

SN US35021924

16534A

MADE IN THE USA

16534A

2

2 GSa / s

OSCILLOSCOPE

Page 33

33

Data Acquisition and Stimulus

Pattern Generation Modules

Digital Stimulus and Response in a

Single Instrument

Configure the logic analysis system to

provide both stimulus and response

in a single instrument. For example,

the pattern generator can simulate a

circuit initialization sequence and

then signal the state or timing analyzer to begin measurements. Use the

compare mode on the state analyzer

to determine if the circuit or subsystem is functioning as expected. An

oscilloscope module can help locate

the source of timing problems or

troubleshoot signal problems due to

noise, ringing, overshoot, crosstalk,

or simultaneous switching.

Key Characteristics

Agilent Model 16720A

Maximum clock (full/half channel) 180/300 MHz

Number of data channels (full/half channel) 48/24 Channels

Memory depth (full/half channels) 8/16 MVectors

Maximum vector width 240/120 Bits

(5 module system, full/half channel)

Logic levels supported TTL, 3-state TTL, 3.3V, 1.8V, 3-state CMOS, ECL,

5V PECL, 3.3V LVPECL, LVDS

Maximum binary vector set size 16 MVectors (24 channels)

Editable ASCII vector set size 1 MVectors

Parallel Testing of Subsystems

Reduces Time to Market

By testing system subcomponents

before they are complete, you can fix

problems earlier in the development

process. Use the Agilent 16720A as a

substitute for missing boards,

integrated circuits (ICs), or buses

instead of waiting for the missing

pieces. Software engineers can create

infrequently encountered test

conditions and verify that their code

works—before complete hardware is

available. Hardware engineers can

generate the patterns necessary to

put their circuit in the desired state,

operate the circuit at full speed or

step the circuit through a series

of states.

Page 34

34

Data Acquisition and Stimulus

Pattern Generation Modules

Vectors Up To 240 Bits Wide

Vectors are defined as a "row" of

labeled data values, with each data

value from one to 32 bits wide. Each

vector is output on the rising edge of

the clock.

Up to five, 48-channel 16720A modules can be interconnected within a

16700 Series mainframe or expansion

frame. This configuration supports

vectors of any width up to 240 bits

with excellent channel-to-channel

skew characteristics (see specific

data pod characteristics in Pattern

Generation Modules Specifications

starting on page 105). The modules

operate as one time-base with one

master clock pod. Multiple modules

also can be configured to operate

independently with individual clocks

controlling each module.

Depth Up to 16 MVectors

With the 16720A pattern generator,

you can load and run up to

16 MVectors of stimulus. Depth on

this scale is most useful when coupled with powerful stimulus

generated by electronic design

automation tools, such as

SynaptiCAD's WaveFormer and

VeriLogger. These tools create

stimulus using a combination of

graphically drawn signals, timing

parameters that constrain edges,

clock signals, and temporal and

Boolean equations for describing

complex signal behavior. The

stimulus also can be created from

design simulation waveforms. To take

advantage of the full depth of the

16720A pattern generator, data must

be loaded into the module in the

Pattern Generator Binary (.PGB) format. The SynaptiCAD tools allow you

to convert .VCD files into .PGB files

directly, offering you an integrated

solution that saves you time.

Synchronized Clock Output

You can output data synchronized to

either an internal or external clock.

The external clock is input via a clock

pod, and has no minimum frequency

(other than a 2 ns minimum high

time).

The internal clock is selectable

between 1 MHz and 300 MHz in

1 MHz steps. A Clock Out signal is

available from the clock pod and can

be used as an edge strobe with a

variable delay of up to 8 ns.

Initialize (INIT) Block for

Repetitive Runs

When running repetitively, the vectors in the initialize (init) sequence

are output only once, while the main

sequence is output as a continually

repeating sequence. This "init"

sequence is very useful when the

circuit or subsystem needs to be

initialized. The repetitive run capability is especially helpful when operating the stimulus module independent

of the other modules in the logic

analysis system.

"Signal IMB" Coordinates System

Module Activity

A "Signal IMB" (intermodule bus)

instruction acts as a trigger arming

event for other logic analysis modules

to begin measurements. IMB setup

and trigger setup of the other logic

analysis modules determine the

action initiated by "Signal IMB".

"Wait" for Input Pattern

The clock pod also accepts a 3-bit

input pattern. These inputs are levelsensed so that any number of "Wait"

instructions can be inserted into a

stimulus program. Up to four pattern

conditions can be defined from the

OR-ing of the eight possible 3-bit

input patterns. A "Wait" also can be

defined to wait for an intermodule

bus event. This intermodule bus

event signal can come from any other

module in the logic analysis system.

Page 35

35

Data Acquisition and Stimulus

Pattern Generation Modules

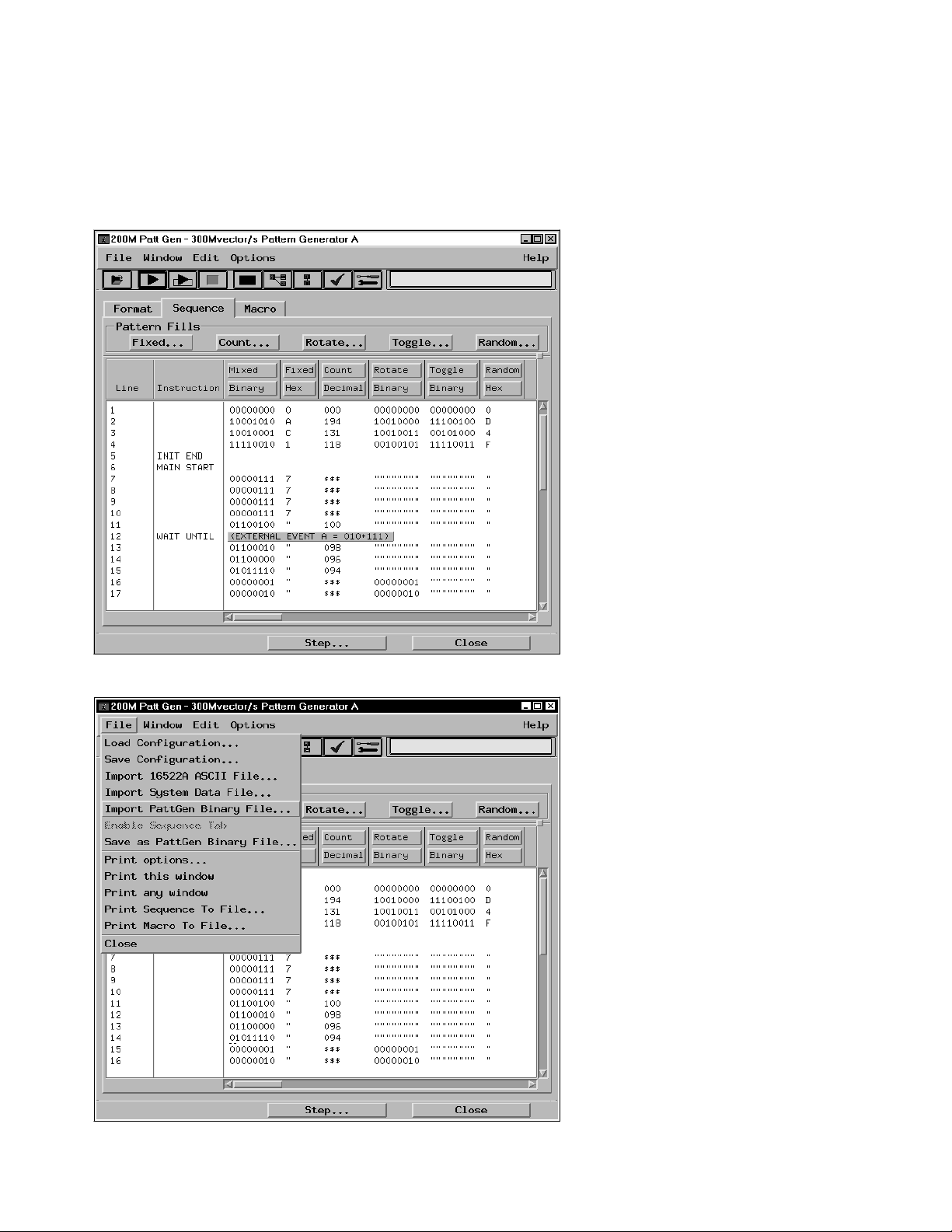

Figure 4.8. Stimulus vectors are defined in the

Sequence menu tab. In this example, vector output

halts until the WAIT UNTIL condition is satisfied.

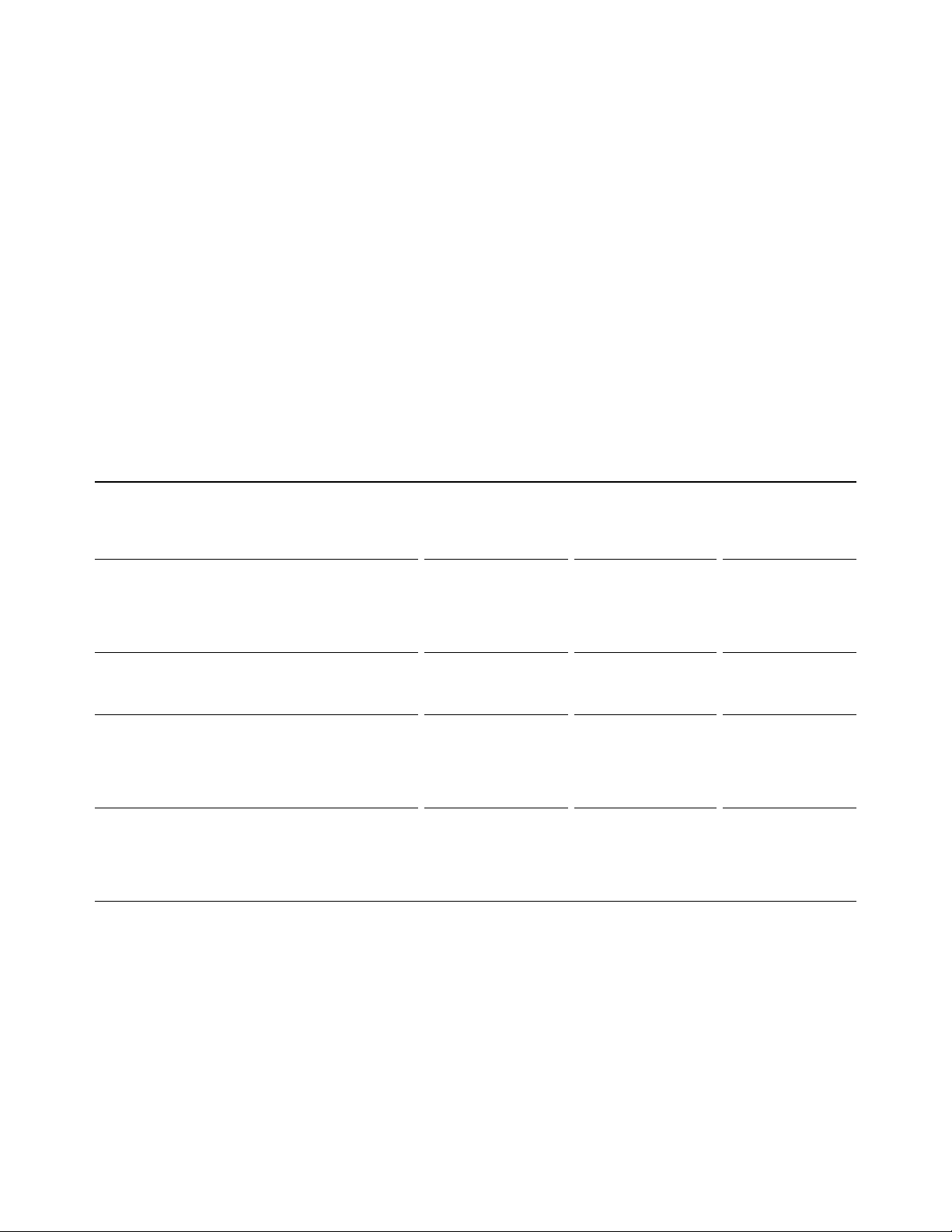

Figure 4.9. To fill the 16720A pattern generator's 8 MVector

deep memory (16 MVector in half channel mode) with data,

the stimulus must be in 'pattern generator binary' format.

Stimulus files in .PGB format can be loaded directly from

the user interface.

Page 36

36

Data Acquisition and Stimulus

Pattern Generation Modules

"User Macro" and "Loop" Simplify

Creation of Stimulus Programs

User macros permit you to define a

pattern sequence once, then insert

the macro by name wherever it is

needed. Passing parameters to the

macro will allow you to create a more

generic macro. For each call to the

macro you can specify unique values

for the parameters. Each macro can

have up to 10 parameters. Up to 100

different macros can be defined for

use in a single stimulus program.

Loops enable you to repeat a defined

block of vectors for a specified

number of times. The repeat counter

can be any value from 1 to 20,000.

Loops and macros can be nested,

except that a macro can not be nested

within another macro. When nested,

each invocation of a loop or a macro

is counted towards the 1,000 invocation limit. At compile time, loops and

macros are expanded in memory to a

linear sequence.

Convenient Data Entry and Editing

Feature

You can conveniently enter patterns

in hex, octal, binary, decimal, and

two's complement bases. The data

associated with an individual label

can be viewed with multiple radixes

to simplify data entry. Delete, Insert,

Copy, and Merge commands are

provided for easy editing. Fast and

convenient Pattern Fills give the

programmer useful test patterns with

a few key strokes. Fixed, Count,

Rotate, Toggle, and Random are

available to quickly create a test

pattern, such as "walking ones".

Pattern parameters, such as Step

Size and Repeat Frequency, can be

specified in the pattern setup.

ASCII Input File Format: Your Design

Tool Connection

The 16720A supports an ASCII file

format to facilitate connectivity to

other tools in your design environment. Because the ASCII format does

not support the instructions listed

earlier, they cannot be edited into the

ASCII file. User macros and loops

also are not supported, so the vectors

need to be fully expanded in the

ASCII file. Many design tools will

generate ASCII files and output the

vectors in this linear sequence. Data

must be in Hex format, and each label

must represent a set of contiguous

output channels. Data in this ASCII

format is limited to 1 MVectors in

the 16720A.

Configuration

The 16720A pattern generators

require a single slot in a logic

analysis system frame. The pattern

generator operates with the clock

pods, data pods, and lead sets

described later in this section. At

least one clock pod and one data pod

must be selected to configure a functional system. Users can select from a

variety of pods to provide the signal

source needed for their logic devices.

The data pods, clock pods and data

cables use standard connectors. The

electrical characteristics of the data

cables also are described for users

with specialized applications who

want to avoid the use of a data pod.

The 16720A can be configured in

systems with up to five cards for a

total of 240 channels of stimulus.

Direct Connection to Your Target

System

The pattern generator pods can be

directly connected to a standard

connector on your target system. Use

a 3M brand #2520 Series, or similar

connector. The 16720A clock or data

pods will plug right in. Short, flat

cable jumpers can be used if the

clearance around the connector is

limited. Use a 3M #3365/20, or equivalent, ribbon cable; a 3M #4620

Series, or equivalent, connector on

the 16720A pod end of the cable; and

a 3M #3421 Series, or equivalent,

connector at your target system end

of the cable.

Probing Accessories

The probe tips of the Agilent 10474A,

10347A, and 10498A lead sets plug

directly into any 0.1 inch grid with

0.026 inch to 0.033 inch diameter

round pins or 0.025 inch square pins.

These probe tips work with the

Agilent 5090-4356 surface mount

grabbers and with the Agilent

5959-0288 through-hole grabbers.

Other compatible probing accessories

are listed in ordering information on

page 121.

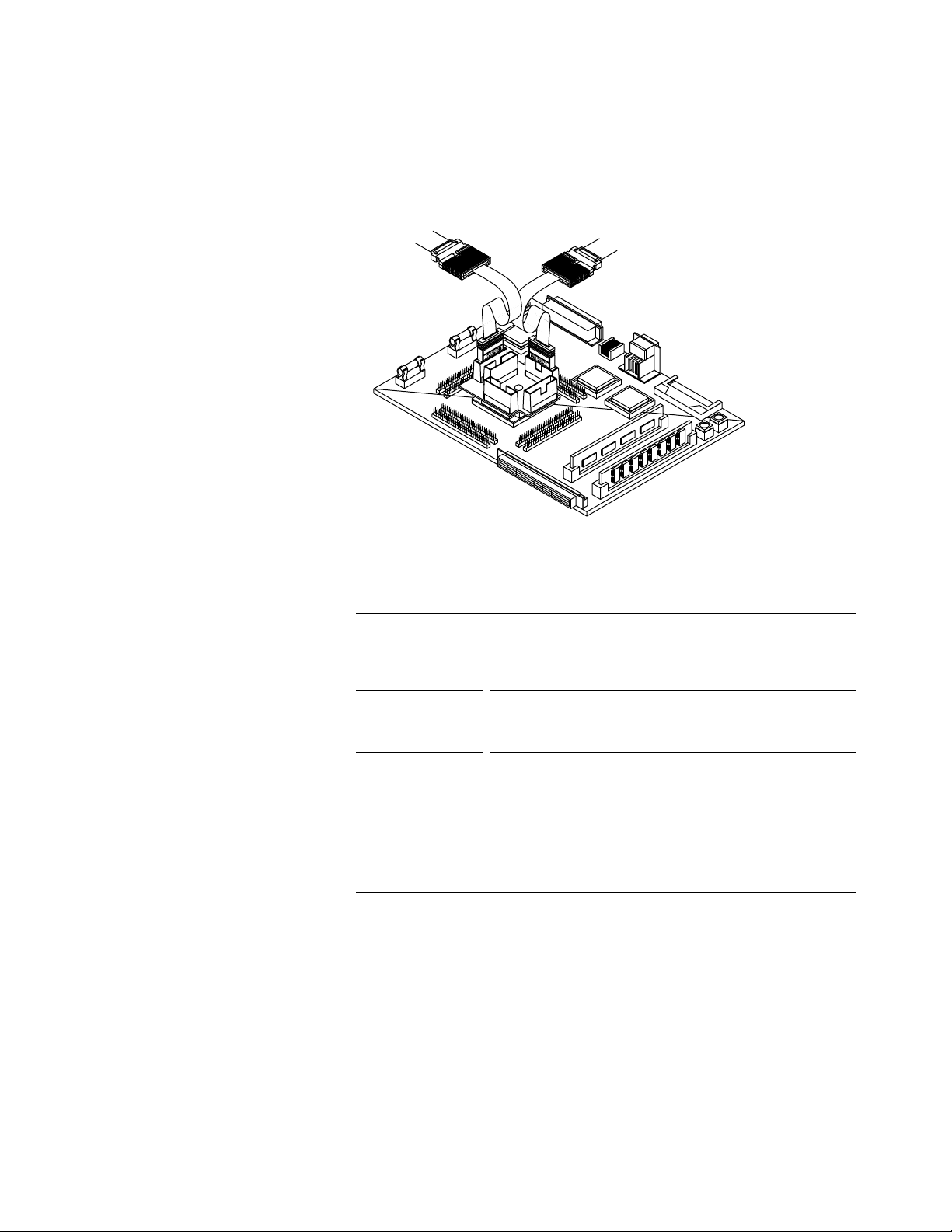

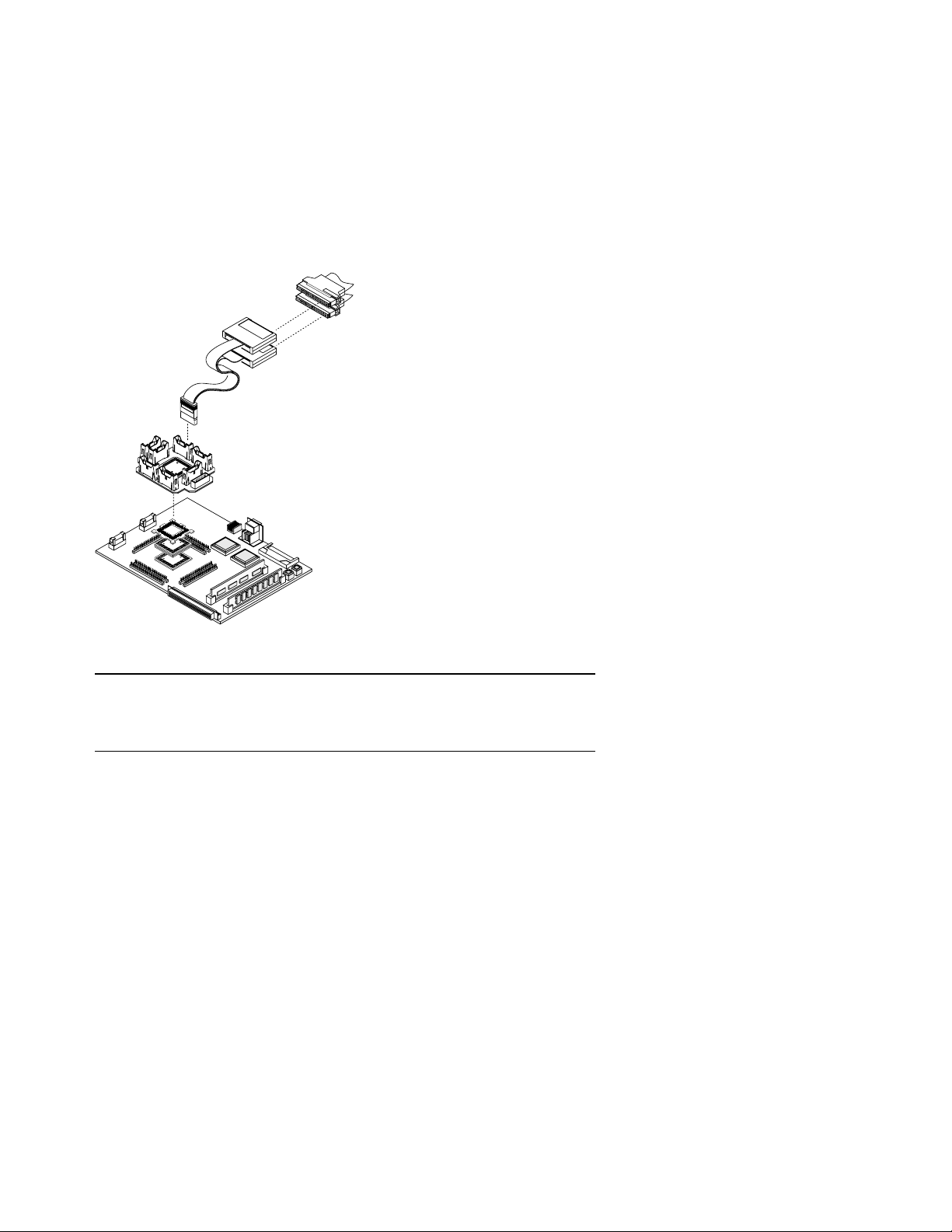

Page 37

37

Speed Problem Solving With

Off-the-Shelf Solutions for Many

Common Microprocessors

To help you design and debug your

microprocessor-based target systems,

Agilent offers different microprocessor specific products that let you get

control and visibility over your

microprocessor’s internal and

external data.

An analysis probe allows you to

quickly connect an Agilent logic

analyzer to your target system. The

analysis probe provides non-intrusive

capture and disassembly of microprocessor and bus activity

Analysis probes are available for over

200 microprocessors and microcontrollers. Bus probes allow probing of

popular bus architectures such as

PCI, AGP, USB, VXI, SCSI, and many

others.

Flexible physical probing schemes

give quick and reliable connections to

almost any device on your prototype.

On-Chip Emulation Tools Make Fixing

Bugs Easier

For specific microprocessor families

that feature on-chip emulation, you

can add a processor emulation

module to your system to connect

the on-board debugging resources

of the microprocessor to the logic

analysis system.

The microprocessor’s BDM or JTAG

technology provides control over

processor operation even if there is

no software monitor on the target

system. This feature is particularly

helpful during the development of

your target system’s boot code.

Data Acquisition and Stimulus

Emulation Modules

Figure 4.10. Agilent analysis probes make it easy to connect a logic analyzer to your target system.

Page 38

38

Data Acquisition and Stimulus

Emulation Modules

Emulation Control Interface

The emulation control interface is

accessed from the power up screen of

the Agilent 16700 Series system. The

interface is included with the Agilent

E5901A/B emulation modules.

Designed for hardware engineers,

this graphical user interface provides

the following features:

• Control over processor execution:

run/break/reset/step.

• Register display/modification.

• Memory display/modification in

various formats including disassembly for code visualization.

Memory modification or memory

block fill can be done to check

processor memory access or to

reinitialize memory areas.

• Multiple breakpoint configuration:

hardware, software, and processor

internal breakpoint registers.

• Code download to the target.

• Command scripts to reproduce

test sequences.

• The ability to trigger a measurement module on a processor break

or to receive a trigger from the

logic analysis system’s measurement modules.

Integrated Debugger Support

When the hardware turn-on phase is

completed, the same Agilent emulation module can be connected to

high-level debuggers for C or C++

software development.

You can achieve the functionality of

a full-featured emulator by using a

third-party debugger to drive the

installed Agilent emulation module.

This gives you complete microprocessor execution control (run control).

Figure 4.11. Emulation control interface.

Page 39

39

Post-Processing and Analysis Tool Sets

Software Tool Sets

Once the data is acquired, you can

rely on the post-processing tools to

rapidly consolidate data into displays

that provide insight into your system's behavior. The tool sets

described in the following pages are

optional, post-processing software

packages for the 16700 Series logic

analysis systems.

Selecting the Right Tool Set

Take a look at the tool set descriptions below to see if they meet your

needs. If you don't immediately see

what you need there is also the

option of writing your own analysis

application using the tool development kit. Best of all, you can try out

any one of these tool sets with no

obligation to buy.

Application Product Name Model Number Detailed Information

Debug your real-time code at the source level Source Correlation B4620B Page 40

Correlate a logic analyzer trace with the high-level source Tool Set

code that produced it. Set up the logic analyzer trace by

simply pointing and clicking on a line of source code.

Debug your parallel data communication buses Data Communications B4640B Page 44

Display logic analyzer trace information at a protocol level. Tool Set

Powerful trigger macros allow triggering on standard or

custom protocol fields. Data bus width is limited only by

the number of available channels.

Optimize your target system's performance System Performance B4600B Page 53

Profile your target system's performance to identify system Analysis Tool Set

bottlenecks and to identify areas needing optimization.

Solve your serial communication problems Serial Analysis B4601B Page 60

Convert serial bit streams to parallel format for easy viewing Tool Set

and analysis. Supports serial data with or without an external

clock reference and protocols that use bit stuffing to maintain

clock synchronization. Works at speeds up to 1 GHz.

Customize your trace for greater insight Tool Development B4605B Page 66

Create custom tools using the C programming language. Kit

Custom tools can analyze captured data and present it in

a form that makes sense to you. Analysis systems do not

require the tool development kit to run generated tools.

Page 40

40

Post-Processing and Analysis Tool Sets

Software Tool Sets

Figure 5.1. For a free, one-time, 21-day trial of any tool set, simply type “demo” in the password field for the product

you want to evaluate.

Free Tool Set Evaluation

To see which tool sets best fit your

needs, Agilent Technologies offers a

free 21-day trial period that lets you

evaluate any tool set as your work

schedule permits. Once you receive

your tool, you obtain a password that

temporarily enables the tool.

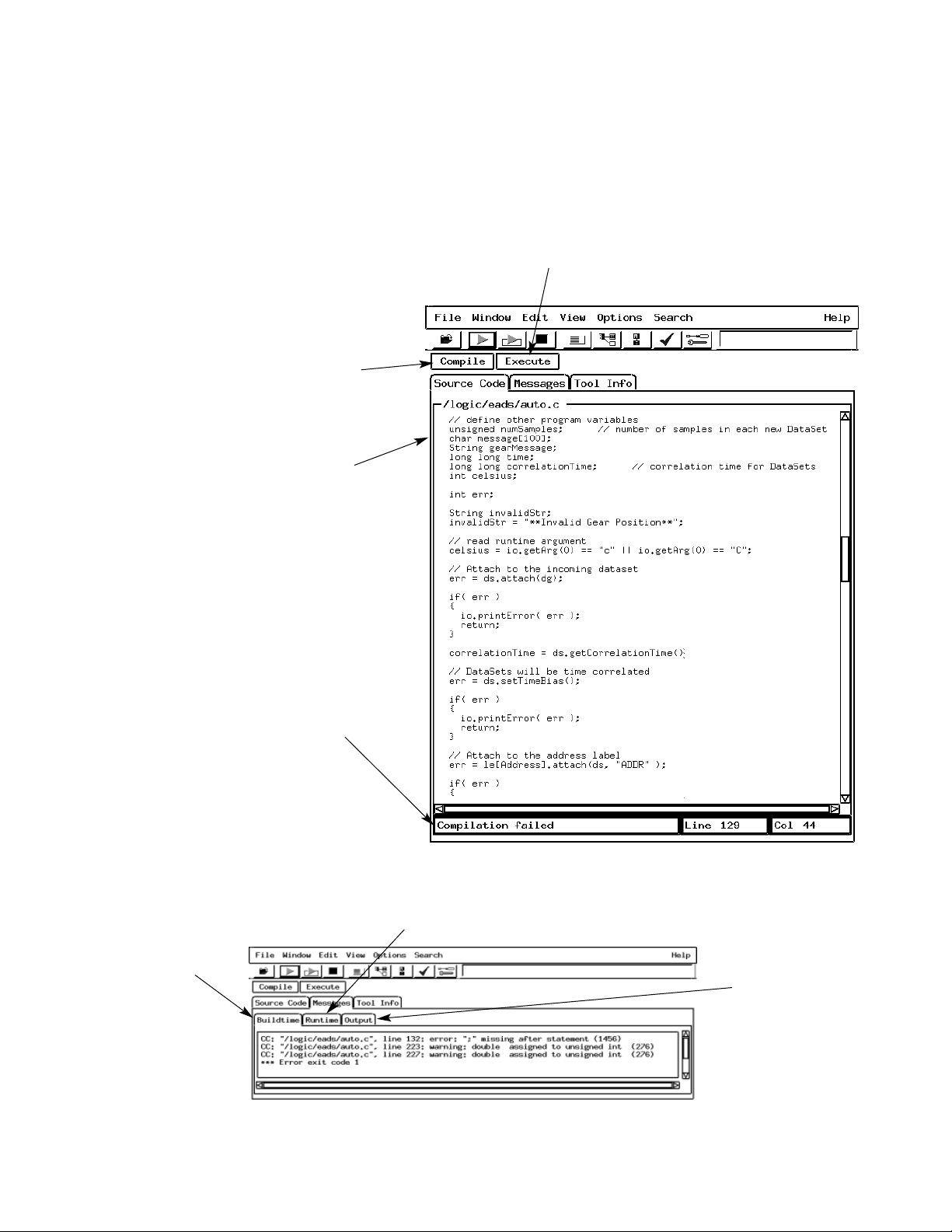

Page 41

41

Post-Processing and Analysis Tool Sets

Source Correlation

Debug Your Source Code

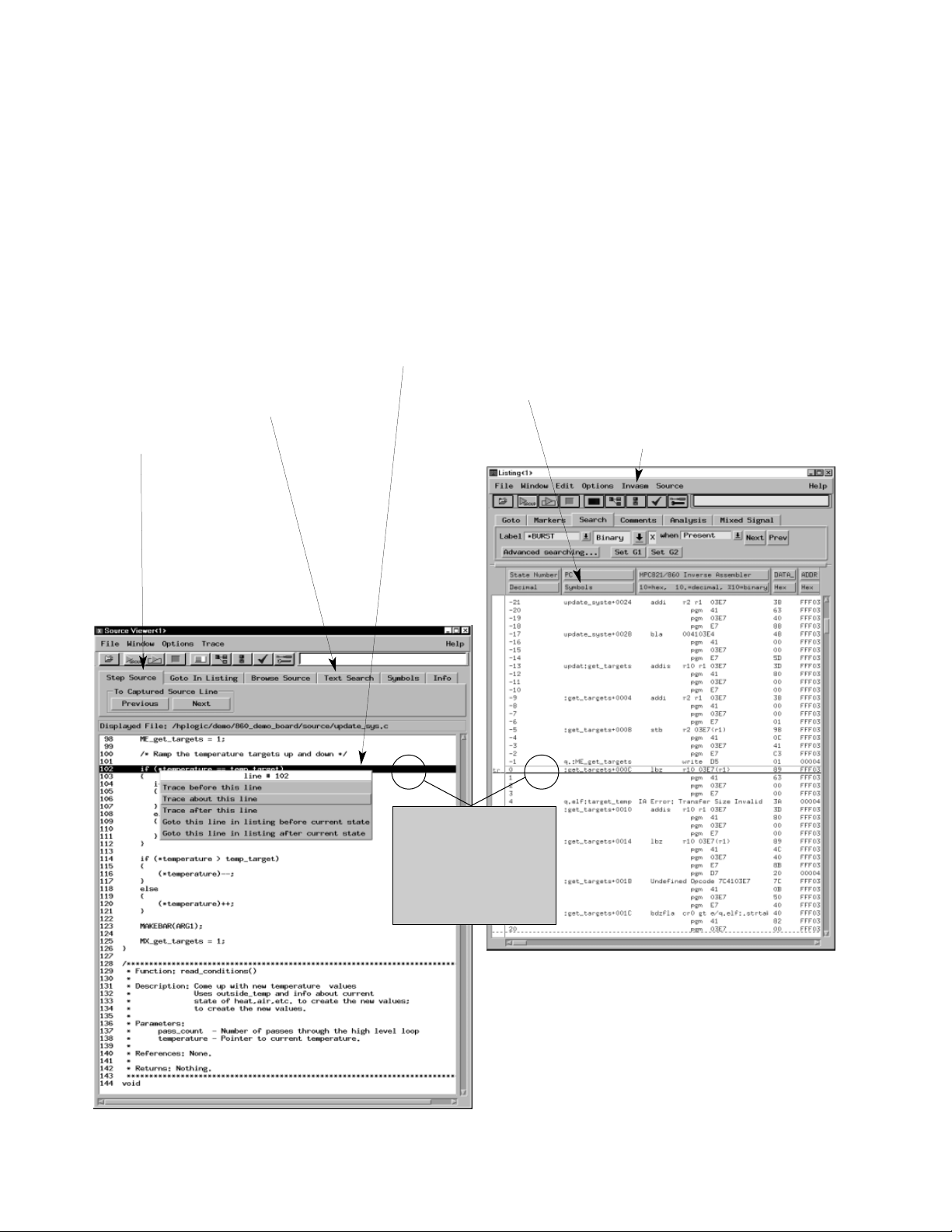

The Agilent B4620B source correlation tool set correlates a microprocessor execution trace window with a

corresponding high-level source code

window. The source correlation tool

set enhances your software development environment by providing multiple views of code execution and

variable content under severe realtime constraints.

Using the B4620B you can obtain

answers to many of your questions

concerning software code execution,

data tracking, and software-hardware

integration.

Obtain Answers to the Following

Questions:

Software Code Execution

• What happened just before the

target system crashed?

• What source code was executed at

a specific point in time?

• What is the exact time between

two user-defined system events?

• What is the execution history

leading up to or occurring after an

area of interest?

Data Tracking

• What is the exact history of a

variable's value over time?

• Which routine(s) corrupted the

data?

Software-Hardware Integration

• What is the root cause of a system

failure—hardware or software?

• Are timing anomalies found by the

hardware engineer the cause of

software problems?

• Is the software engineer working

on the same problem as the hardware engineer?

• What portion of the source code

correlates to the problem the

hardware engineer reported?

Product Description

The tool set's main advantage is its

ability to allow you to observe software execution without halting the

system or adding instructions to the

code. The tool set uses information

provided in your compiler's object file

to build a database of source files,

line numbers and symbol information

to reference to logic analyzer traces.

The tool set can also be used to set up

the logic analyzer trace by simply

pointing and clicking on a source

line.

Once the tool set is enabled on your

16700 Series system, you can support

new processors by changing analysis

probes and verifying object file compatibility. Multiple-processor systems

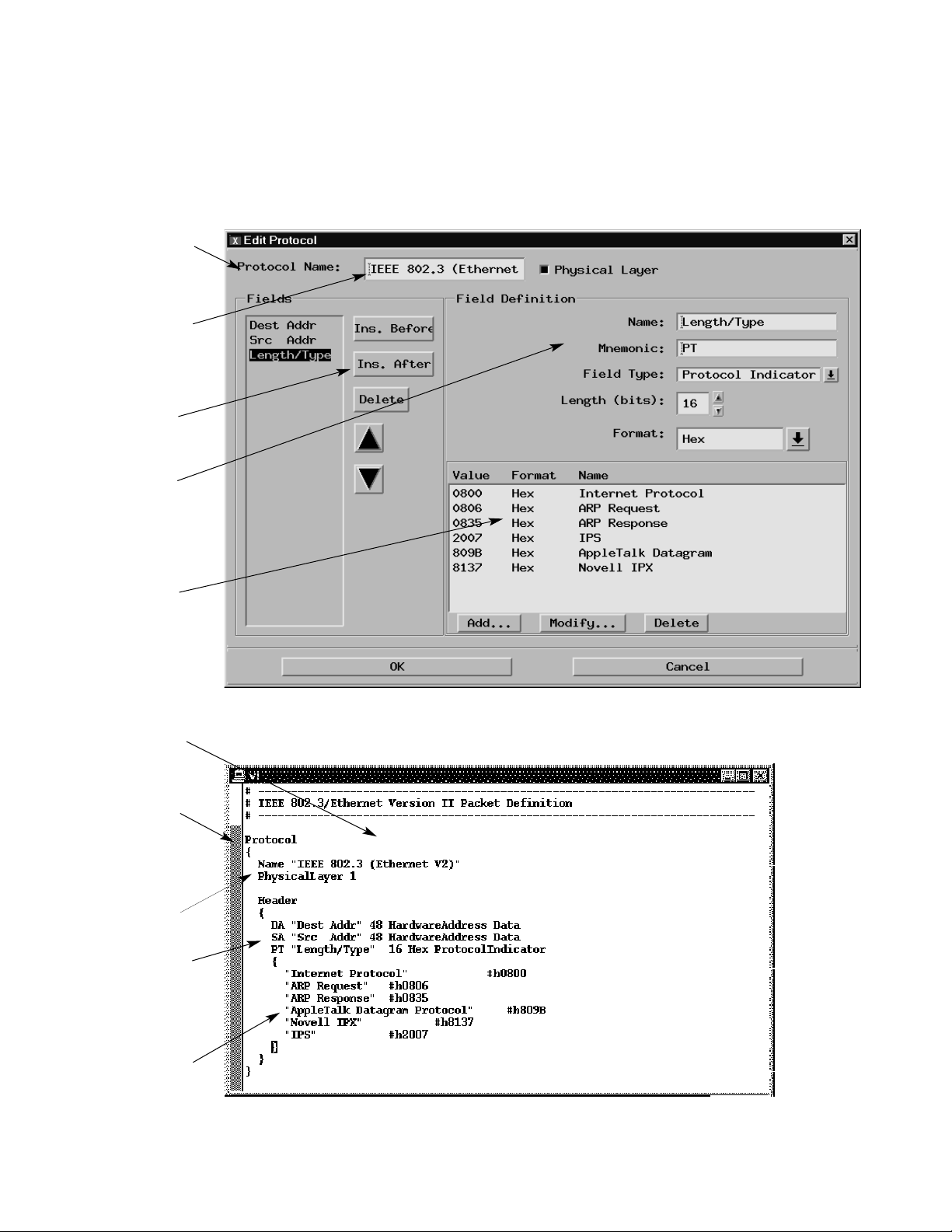

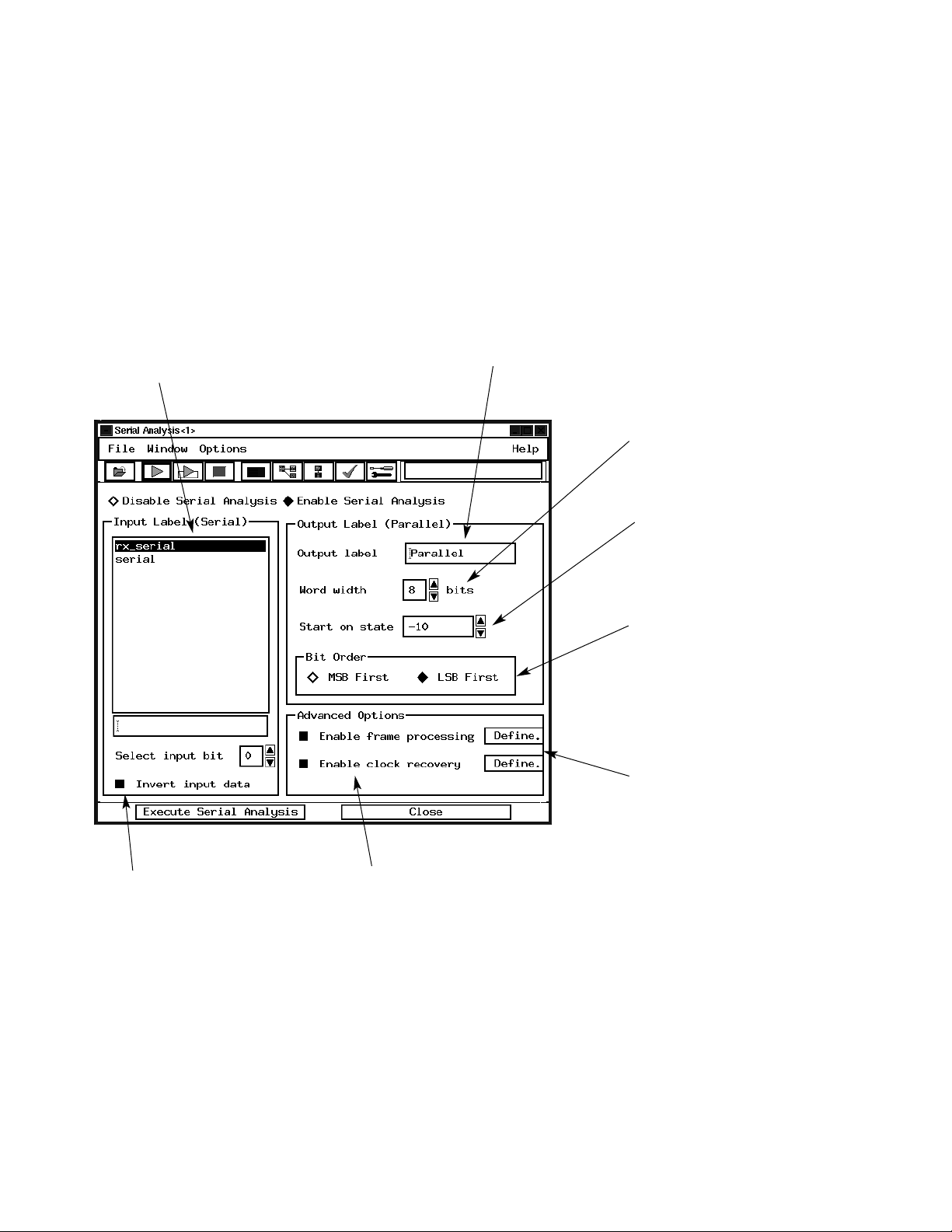

are also supported.