Page 1

Programmer’s Guide

Publication number 01660-97033

Second edition, January 2000

For Safety information, Warranties, and Regulatory

information, see the pages behind the index

Copyright Agilent Technologies 1992-2000

All Rights Reserved

Agilent Technologies

1660A/AS-Series Logic

Analyzers

Page 2

ii

Page 3

In This Book

Introduction to Programming

1

This programmer’s guide contains general

information, mainframe level commands,

logic analyzer commands, oscilloscope

module commands, and programming

examples for programming the

1660-series logic analyzers. This guide

focuses on how to program the

instrument over the GPIB and the

RS-232C interfaces.

Instruments covered by the

1660-Series Programmer’s Guide

The 1660-series logic analyzers are

available with or without oscilloscope

measurement capabilities. The

1660A-series logic analyzers contain only

a logic analyzer. The 1660AS-series logic

analyzers contain both a logic analyzer

and a digitizing oscilloscope.

What is in the 1660-Series

Programmer’s Guide?

The 1660-Series Programmer’s Guide

is organized in five parts.

2

3

4

5

6

7

8

9

10

11

Programming Over GPIB

Programming Over RS-232C

Programming and

Documentation Conventions

Message Communication

and System Functions

Status Reporting

Error Message

Common Commands

Mainframe Commands

SYSTem Subsystem

MMEMory Subsystem

Part 1 Part 1 consists of chapters 1

through 7 and contains general

information about programming basics,

GPIB and RS-232C interface

requirements, documentation

conventions, status reporting , and error

messages.

12

13

14

INTermodule Subsystem

MACHine Subsystem

WLISt Subsystem

iii

Page 4

If you are already familiar with IEEE 488.2 programming and GPIB or

RS-232C, you may want to just scan these chapters. If you are new to

programmiung the system, you should read part 1.

Chapter 1 is divided into two sections. The first section, "Talking to the

Instrument," concentrates on program syntax, and the second section,

"Receiving Information from the Instrument," discusses how to send queries

and how to retrieve query results from the instrument.

Read either chapter 2, "Programming Over GPIB," or chapter 3,

"Programming Over RS-232C" for information concerning the physical

connection between the 1660-series logic analyzer and your controller.

Chapter 4, "Programming and Documentation Conventions," gives an

overview of all instructions and also explains the notation conventions used

in the syntax definitions and examples.

Chapter 5, "Message Communication and System Functions," provides an

overview of the operation of instruments that operate in compliance with the

IEEE 488.2 standard.

Chapter 6 explains status reporting and how it can be used to monitor the

flow of your programs and measurement process.

Chapter 7 contains error message descriptions.

Part 2 Part 2, chapters 8 through 12, explain each command in the

command set for the mainframe. These chapters are organized in

subsystems with each subsystem representing a front-panel menu.

The commands explained in this part give you access to common commands,

mainframe commands, system level commands, disk commands, and

intermodule measurement commands. This part is designed to provide a

concise description of each command.

Part 3 Part 3, chapters 13 through 25 explain each command in the

subsystem command set for the logic analyzer. Chapter 26 contains

information on the SYSTem:DATA and SYSTem:SETup commands for

the logic analyzer.

The commands explained in this part give you access to all the commands

used to operate the logic analyzer portion of the 1660-series system. This

part is designed to provide a concise description of each command.

Part 4 Part 4, chapters 27 through 35 explain each command in the

subsystem command set for the oscilloscope.

iv

Page 5

15

SFORmat Subsystem

The commands explained in this part give

you access to all the commands used to

operate the oscilloscope portion of the

1660-series system. This part is designed

to provide a concise description of each

command.

Part 5 Part 5, chapter 36 contains

program examples of actual tasks that

show you how to get started in

programming the 1660-series logic

analyzers. The complexity of your

programs and the tasks they accomplish

are limited only by your imagination.

These examples are written in HP BASIC

6.2; however, the program concepts can

be used in any other popular

programming language that allows

communications over GPIB or RS-232

buses.

STRigger (STRace) Subsystem

16

17

18

19

20

21

22

23

24

SLISt Subsystem

SWAVeform Subsystem

SCHart Subsystem

COMPare Subsystem

TFORmat Subsystem

TRIGger {TRACe} Subsystem

TWAVeform Subsystem

TLISt Subsystem

25

26

27

28

SYMbol Subsystem

DATA and SETup Commands

Oscilloscope Root Level

Commands

ACQuire Subsystem

v

Page 6

vi

Page 7

29

CHANnel Subsystem

30

31

32

33

34

35

36

DISPlay Subsystem

MARKer Subsystem

MEASure Subsystem

TIMebase Subsystem

TRIGger Subsystem

WAVeform Subsystem

Programming Examples

Index

vii

Page 8

viii

Page 9

Contents

Part 1 General Information

1 Introduction to Programming

Talking to the Instrument 1–3

Initialization 1–4

Instruction Syntax 1–5

Output Command 1–5

Device Address 1–6

Instructions 1–6

Instruction Terminator 1–7

Header Types 1–8

Duplicate Keywords 1–9

Query Usage 1–10

Program Header Options 1–11

Parameter Data Types 1–12

Selecting Multiple Subsystems 1–14

Receiving Information from the Instrument 1–15

Response Header Options 1–16

Response Data Formats 1–17

String Variables 1–18

Numeric Base 1–19

Numeric Variables 1–19

Definite-Length Block Response Data 1–20

Multiple Queries 1–21

Instrument Status 1–22

2 Programming Over GPIB

Interface Capabilities 2–3

Command and Data Concepts 2–3

Addressing 2–3

Communicating Over the GPIB Bus (HP 9000 Series 200/300 Controller) 2–4

Local, Remote, and Local Lockout 2–5

Bus Commands 2–6

Contents–1

Page 10

Contents

3 Programming Over RS-232C

Interface Operation 3–3

RS-232C Cables 3–3

Minimum Three-Wire Interface with Software Protocol 3–4

Extended Interface with Hardware Handshake 3–4

Cable Examples 3–6

Configuring the Logic Analzer Interface 3–8

Interface Capabilities 3–9

RS-232C Bus Addressing 3–10

Lockout Command 3–11

4 Programming and Documentation Conventions

Truncation Rule 4–3

Infinity Representation 4–4

Sequential and Overlapped Commands 4–4

Response Generation 4–4

Syntax Diagrams 4–4

Notation Conventions and Definitions 4–5

The Command Tree 4–5

Tree Traversal Rules 4–6

Command Set Organization 4–14

Subsystems 4–15

Program Examples 4–16

5 Message Communication and System Functions

Protocols 5–3

Syntax Diagrams 5–5

Syntax Overview 5–7

6 Status Reporting

Event Status Register 6–4

Service Request Enable Register 6–4

Bit Definitions 6–4

Key Features 6–6

Serial Poll 6–7

Contents–2

Page 11

7 Error Messages

Device Dependent Errors 7–3

Command Errors 7–3

Execution Errors 7–4

Internal Errors 7–4

Query Errors 7–5

Part 2 Mainframe Commands

8 Common Commands

*CLS (Clear Status) 8–5

*ESE (Event Status Enable) 8–6

*ESR (Event Status Register) 8–7

*IDN (Identification Number) 8–9

*IST (Individual Status) 8–9

*OPC (Operation Complete) 8–11

*OPT (Option Identification) 8–12

*PRE (Parallel Poll Enable Register Enable) 8–13

*RST (Reset) 8–14

*SRE (Service Request Enable) 8–15

*STB (Status Byte) 8–16

*TRG (Trigger) 8–17

*TST (Test) 8–18

*WAI (Wait) 8–19

Contents

9 Mainframe Commands

BEEPer 9–6

CAPability 9–7

CARDcage 9–8

CESE (Combined Event Status Enable) 9–9

CESR (Combined Event Status Register) 9–10

EOI (End Or Identify) 9–11

LER (LCL Event Register) 9–11

LOCKout 9–12

MENU 9–12

Contents–3

Page 12

Contents

MESE<N> (Module Event Status Enable) 9–14

MESR<N> (Module Event Status Register) 9–16

RMODe 9–18

RTC (Real-time Clock) 9–19

SELect 9–20

SETColor 9–22

STARt 9–23

STOP 9–24

10 SYSTem Subsystem

DATA 10–5

DSP (Display) 10–6

ERRor 10–7

HEADer 10–8

LONGform 10–9

PRINt 10–10

SETup 10–11

11 MMEMory Subsystem

AUToload 11–8

CATalog 11–9

COPY 11–10

DOWNload 11–11

INITialize 11–13

LOAD [:CONFig] 11–14

LOAD :IASSembler 11–15

MSI (Mass Storage Is) 11–16

PACK 11–17

PURGe 11–17

REName 11–18

STORe [:CONFig] 11–19

UPLoad 11–20

VOLume 11–21

Contents–4

Page 13

12 INTermodule Subsystem

:INTermodule 12–5

DELete 12–5

HTIMe 12–6

INPort 12–6

INSert 12–7

SKEW<N> 12–8

TREE 12–9

TTIMe 12–10

Part 3 Logic Analyzer Commands

13 MACHine Subsystem

MACHine 13–4

ARM 13–5

ASSign 13–5

LEVelarm 13–6

NAME 13–7

REName 13–8

RESource 13–9

TYPE 13–10

Contents

14 WLISt Subsystem

WLISt 14–4

DELay 14–5

INSert 14–6

LINE 14–7

OSTate 14–8

OTIMe 14–8

RANGe 14–9

REMove 14–10

XOTime 14–10

XSTate 14–11

XTIMe 14–11

Contents–5

Page 14

Contents

15 SFORmat Subsystem

SFORmat 15–6

CLOCk 15–6

LABel 15–7

MASTer 15–9

MODE 15–10

MOPQual 15–11

MQUal 15–12

REMove 15–13

SETHold 15–13

SLAVe 15–15

SOPQual 15–16

SQUal 15–17

THReshold 15–18

16 STRigger (STRace) Subsystem

Qualifier 16–7

STRigger (STRace) 16–9

ACQuisition 16–9

BRANch 16–10

CLEar 16–12

FIND 16–13

RANGe 16–14

SEQuence 16–16

STORe 16–17

TAG 16–18

TAKenbranch 16–19

TCONtrol 16–20

TERM 16–21

TIMER 16–22

TPOSition 16–23

17 SLISt Subsystem

SLISt 17–7

COLumn 17–7

Contents–6

Page 15

CLRPattern 17–8

DATA 17–9

LINE 17–9

MMODe 17–10

OPATtern 17–11

OSEarch 17–12

OSTate 17–13

OTAG 17–13

OVERlay 17–14

REMove 17–15

RUNTil 17–15

TAVerage 17–17

TMAXimum 17–17

TMINimum 17–18

VRUNs 17–18

XOTag 17–19

XOTime 17–19

XPATtern 17–20

XSEarch 17–21

XSTate 17–22

XTAG 17–22

Contents

18 SWAVeform Subsystem

SWAVeform 18–4

ACCumulate 18–5

ACQuisition 18–5

CENTer 18–6

CLRPattern 18–6

CLRStat 18–7

DELay 18–7

INSert 18–8

RANGe 18–8

REMove 18–9

TAKenbranch 18–9

TPOSition 18–10

Contents–7

Page 16

Contents

19 SCHart Subsystem

SCHart 19–4

ACCumulate 19–4

HAXis 19–5

VAXis 19–7

20 COMPare Subsystem

COMPare 20–4

CLEar 20–5

CMASk 20–5

COPY 20–6

DATA 20–7

FIND 20–9

LINE 20–10

MENU 20–10

RANGe 20–11

RUNTil 20–12

SET 20–13

21 TFORmat Subsystem

TFORmat 21–4

ACQMode 21–5

LABel 21–6

REMove 21–7

THReshold 21–8

22 TTRigger (TTRace) Subsystem

Qualifier 22–6

TTRigger (TTRace) 22–8

ACQuisition 22–9

BRANch 22–9

CLEar 22–12

FIND 22–13

GLEDge 22–14

RANGe 22–15

Contents–8

Page 17

SEQuence 22–17

SPERiod 22–18

TCONtrol 22–19

TERM 22–20

TIMER 22–21

TPOSition 22–22

23 TWAVeform Subsystem

TWAVeform 23–7

ACCumulate 23–7

ACQuisition 23–8

CENTer 23–8

CLRPattern 23–9

CLRStat 23–9

DELay 23–9

INSert 23–10

MMODe 23–11

OCONdition 23–12

OPATtern 23–13

OSEarch 23–14

OTIMe 23–15

RANGe 23–16

REMove 23–16

RUNTil 23–17

SPERiod 23–18

TAVerage 23–19

TMAXimum 23–19

TMINimum 23–20

TPOSition 23–20

VRUNs 23–21

XCONdition 23–22

XOTime 23–22

XPATtern 23–23

XSEarch 23–24

XTIMe 23–25

Contents

Contents–9

Page 18

Contents

24 TLISt Subsystem

TLISt 24–7

COLumn 24–7

CLRPattern 24–8

DATA 24–9

LINE 24–9

MMODe 24–10

OCONdition 24–11

OPATtern 24–11

OSEarch 24–12

OSTate 24–13

OTAG 24–14

REMove 24–14

RUNTil 24–15

TAVerage 24–16

TMAXimum 24–16

TMINimum 24–17

VRUNs 24–17

XCONdition 24–18

XOTag 24–18

XOTime 24–19

XPATtern 24–19

XSEarch 24–20

XSTate 24–21

XTAG 24–22

25 SYMBol Subsystem

SYMBol 25–4

BASE 25–5

PATTern 25–6

RANGe 25–6

REMove 25–7

WIDTh 25–8

Contents–10

Page 19

26 DATA and SETup Commands

Data Format 26–3

:SYSTem:DATA 26–4

Section Header Description 26–6

Section Data 26–6

Data Preamble Description 26–6

Acquisition Data Description 26–10

Time Tag Data Description 26–12

Glitch Data Description 26–14

SYSTem:SETup 26–15

RTC_INFO Section Description 26–17

Part 4 Oscilloscope Commands

Contents

27 Oscilloscope Root Level Commands

AUToscale 27–3

DIGitize 27–5

28 ACQuire Subsystem

COUNt 28–4

TYPE 28–4

29 CHANnel Subsystem

COUPling 29–4

ECL 29–5

OFFSet 29–6

PROBe 29–7

RANGe 29–8

TTL 29–9

30 DISPlay Subsystem

ACCumulate 30–4

CONNect 30–5

INSert 30–5

Contents–11

Page 20

Contents

LABel 30–7

MINus 30–8

OVERlay 30–8

PLUS 30–9

REMove 30–9

31 MARKer Subsystem

AVOLt 31–6

ABVolt? 31–7

BVOLt 31–7

CENTer 31–8

MSTats 31–8

OAUTo 31–9

OTIMe 31–10

RUNTil 31–11

SHOW 31–12

TAVerage? 31–12

TMAXimum? 31–13

TMINimum? 31–13

TMODe 31–14

VMODe 31–15

VOTime? 31–16

VRUNs? 31–16

VXTime? 31–17

XAUTo 31–18

XOTime? 31–19

XTIMe 31–19

32 MEASure Subsystem

ALL? 32–5

FALLtime? 32–6

FREQuency? 32–6

NWIDth? 32–7

OVERshoot? 32–7

PERiod? 32–8

PREShoot? 32–8

Contents–12

Page 21

PWIDth? 32–9

RISetime? 32–9

SOURce 32–10

VAMPlitude? 32–11

VBASe? 32–11

VMAX? 32–12

VMIN? 32–12

VPP? 32–13

VTOP? 32–13

33 TIMebase Subsystem

DELay 33–4

MODE 33–5

RANGe 33–6

Contents

34 TRIGger Subsystem

CONDition 34–5

DELay 34–7

LEVel 34–8

LOGic 34–10

MODE 34–11

PATH 34–12

SLOPe 34–12

SOURce 34–13

35 WAVeform Subsystem

Format for Data Transfer 35–4

Data Conversion 35–6

COUNt? 35–9

DATA? 35–9

FORMat 35–10

POINts? 35–10

PREamble? 35–11

RECord 35–12

SOURce 35–12

Contents–13

Page 22

Contents

SPERiod? 35–13

TYPE? 35–13

VALid? 35–14

XINCrement? 35–15

XORigin? 35–16

XREFerence? 35–16

YINCrement? 35–17

YORigin? 35–17

YREFerence? 35–18

Part 5 Programming Examples

36 Programming Examples

Making a Timing analyzer measurement 36–3

Making a State analyzer measurement 36–5

Making a State Compare measurement 36–9

Transferring the logic analyzer configuration 36–14

Transferring the logic analyzer acquired data 36–17

Checking for measurement completion 36–21

Sending queries to the logic analyzer 36–22

Getting ASCII Data with PRINt? ALL Query 36–24

Reading the disk with the CATalog? ALL query 36–25

Reading the Disk with the CATalog? Query 36–26

Printing to the disk 36–27

Transferring waveform data in Byte format 36–28

Transferring waveform data in Word format 36–30

Using AUToscale and the MEASure:ALL? Query 36–32

Using Sub-routines in a measurement program 36–33

Contents–14

Page 23

Part 1

General Information

Page 24

Page 25

1

Introduction to Programming

Page 26

Introduction

This chapter introduces you to the basics of remote programming and

is organized in two sections. The first section, "Talking to the

Instrument," concentrates on initializing the bus, program syntax and

the elements of a syntax instuction. The second section, "Receiving

Information from the Instrument," discusses how queries are sent and

how to retrieve query results from the mainframe instruments.

The programming instructions explained in this book conform to

IEEE Std 488.2-1987, "IEEE Standard Codes, Formats, Protocols, and

Common Commands." These programming instructions provide a

means of remotely controlling the 1660-series logic analyzers. There

are three general categories of use. You can:

• Set up the instrument and start measurements

• Retrieve setup information and measurement results

• Send measurement data to the instrument

The instructions listed in this manual give you access to the

measurements and front panel features of the 1660-series logic

analyzers. The complexity of your programs and the tasks they

accomplish are limited only by your imagination. This programming

reference is designed to provide a concise description of each

instruction.

1–2

Page 27

Talking to the Instrument

In general, computers acting as controllers communicate with the instrument

by sending and receiving messages over a remote interface, such as GPIB or

RS-232C. Instructions for programming the 1660-series logic analyzers will

normally appear as ASCII character strings embedded inside the output

statements of a "host" language available on your controller. The host

language’s input statements are used to read in responses from the

1660-series logic analyzers.

For example, HP 9000 Series 200/300 BASIC uses the OUTPUT statement for

sending commands and queries to the 1660-series logic analyzers. After a

query is sent, the response can be read in using the ENTER statement. All

programming examples in this manual are presented in HP BASIC.

Example This Basic statement sends a command that causes the logic analyzer’s

machine 1 to be a state analyzer:

OUTPUT XXX;":MACHINE1:TYPE STATE" <terminator>

Each part of the above statement is explained in this section.

1–3

Page 28

Introduction to Programming

Initialization

Initialization

To make sure the bus and all appropriate interfaces are in a known state,

begin every program with an initialization statement. BASIC provides a

CLEAR command that clears the interface buffer. If you are using GPIB,

CLEAR will also reset the parser in the logic analyzer. The parser is the

program resident in the logic analyzer that reads the instructions you send to

it from the controller.

After clearing the interface, you could preset the logic analyzer to a known

state by loading a predefined configuration file from the disk.

Refer to your controller manual and programming language reference manual

for information on initializing the interface.

Example This BASIC statement would load the configuration file "DEFAULT " (if it

exists) into the logic analyzer.

OUTPUT XXX;":MMEMORY:LOAD:CONFIG ’DEFAULT ’"

Refer to chapter 10, "MMEMory Subsystem" for more information on the

LOAD command.

Example Program This program demonstrates the basic command structure used to program

the 1660-series logic analyzers.

10 CLEAR XXX !Initialize instrument interface

20 OUTPUT XXX;":SYSTEM:HEADER ON"!Turn headers on

30 OUTPUT XXX;":SYSTEM:LONGFORM ON" !Turn longform on

40 OUTPUT XXX;":MMEM:LOAD:CONFIG ’TEST E’" !Load configuration file

50 OUTPUT XXX;":MENU FORMAT,1" !Select Format menu for machine 1

60 OUTPUT XXX;":RMODE SINGLE" !Select run mode

70 OUTPUT XXX;":START" !Run the measurement

1–4

Page 29

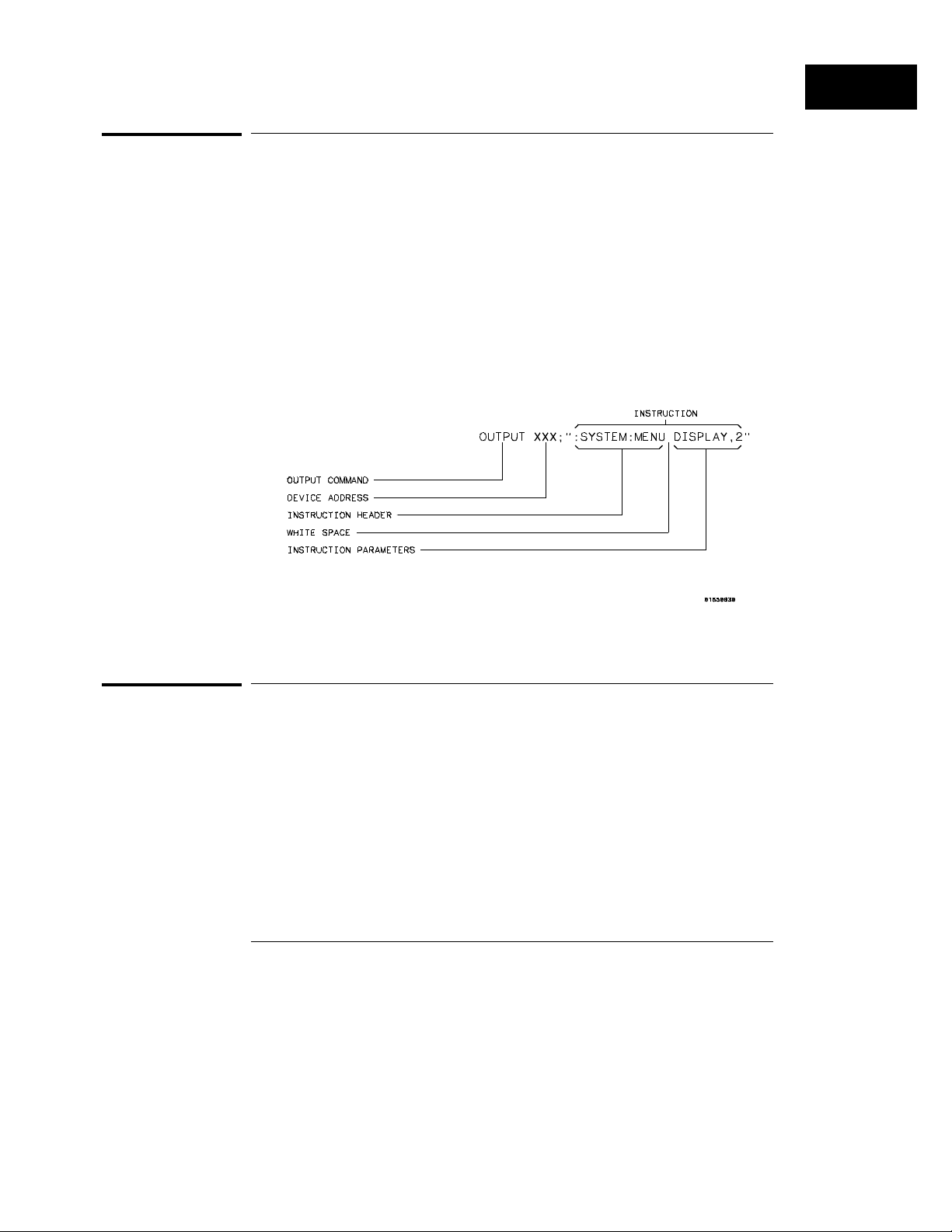

Figure 1-1

Introduction to Programming

Instruction Syntax

Instruction Syntax

To program the logic analyzer remotely, you must have an understanding of

the command format and structure. The IEEE 488.2 standard governs syntax

rules pertaining to how individual elements, such as headers, separators,

parameters and terminators, may be grouped together to form complete

instructions. Syntax definitions are also given to show how query responses

will be formatted. Figure 1-1 shows the three main syntactical parts of a

typical program statement: Output Command, Device Address, and

Instruction. The instruction is further broken down into three parts:

Instruction header, White space, and Instruction parameters.

Program Message Syntax

Output Command

The output command depends on the language you choose to use.

Throughout this guide, HP 9000 Series 200/300 BASIC 6.2 is used in the

programming examples. If you use another language, you will need to find

the equivalents of Basic Commands, like OUTPUT, ENTER and CLEAR in

order to convert the examples. The instructions are always shown between

the double quotes.

1–5

Page 30

Introduction to Programming

Device Address

Device Address

The location where the device address must be specified also depends on the

host language that you are using. In some languages, this could be specified

outside the output command. In BASIC, this is always specified after the

keyword OUTPUT. The examples in this manual use a generic address of

XXX. When writing programs, the number you use will depend on the cable

you use, in addition to the actual address. If you are using an GPIB, see

chapter 2, "Programming over GPIB." If you are using RS-232C, see

chapter 3, "Programming Over RS-232C."

Instructions

Instructions (both commands and queries) normally appear as a string

embedded in a statement of your host language, such as BASIC, Pascal or C.

The only time a parameter is not meant to be expressed as a string is when

the instruction’s syntax definition specifies block data. There are just a few

instructions which use block data.

Instructions are composed of two main parts: the header, which specifies the

command or query to be sent; and the parameters, which provide additional

data needed to clarify the meaning of the instruction. Many queries do not

use any parameters.

Instruction Header

The instruction header is one or more keywords separated by colons (:). The

command tree in figure 4-1 illustrates how all the keywords can be joined

together to form a complete header (see chapter 4, "Programming and

Documentation Conventions").

The example in figure 1-1 shows a command. Queries are indicated by

adding a question mark (?) to the end of the header. Many instructions can

be used as either commands or queries, depending on whether or not you

have included the question mark. The command and query forms of an

instruction usually have different parameters.

1–6

Page 31

Introduction to Programming

Instruction Terminator

When you look up a query in this programmer’s reference, you’ll find a

paragraph labeled "Returned Format" under the one labeled "Query." The

syntax definition by "Returned format" will always show the instruction

header in square brackets, like [:SYSTem:MENU], which means the text

between the brackets is optional. It is also a quick way to see what the

header looks like.

White Space

White space is used to separate the instruction header from the instruction

parameters. If the instruction does not use any parameters, white space

does not need to be included. White space is defined as one or more spaces.

ASCII defines a space to be a character, represented by a byte, that has a

decimal value of 32. Tabs can be used only if your controller first converts

them to space characters before sending the string to the instrument.

Instruction Parameters

Instruction parameters are used to clarify the meaning of the command or

query. They provide necessary data, such as: whether a function should be

on or off, which waveform is to be displayed, or which pattern is to be looked

for. Each instruction’s syntax definition shows the parameters, as well as the

range of acceptable values they accept. This chapter’s "Parameter Data

Types" section has all of the general rules about acceptable values.

When there is more than one parameter, they are separated by commas (,).

White space surrounding the commas is optional.

Instruction Terminator

An instruction is executed after the instruction terminator is received. The

terminator is the NL (New Line) character. The NL character is an ASCII

linefeed character (decimal 10).

The NL (New Line) terminator has the same function as an EOS (End Of

String) and EOT (End Of Text) terminator.

1–7

Page 32

Introduction to Programming

Header Types

Header Types

There are three types of headers: Simple Command, Compound Command,

and Common Command.

Simple Command Header

Simple command headers contain a single keyword. START and STOP are

examples of simple command headers typically used in this logic analyzer.

The syntax is: <function><terminator>

When parameters (indicated by <data>) must be included with the simple

command header, the syntax is: <function><white_space><data>

<terminator>

Example :RMODE SINGLE<terminator>

Compound Command Header

Compound command headers are a combination of two or more program

keywords. The first keyword selects the subsystem, and the last keyword

selects the function within that subsystem. Sometimes you may need to list

more than one subsystem before being allowed to specify the function. The

keywords within the compound header are separated by colons. For

example, to execute a single function within a subsystem, use the following:

:<subsystem>:<function><white_space><data><terminator>

Example :SYSTEM:LONGFORM ON

To traverse down one level of a subsystem to execute a subsystem within

that subsystem, use the following:

<subsystem>:<subsystem>:<function><white_space>

<data><terminator>

Example :MMEMORY:LOAD:CONFIG "FILE "

1–8

Page 33

Common Command Header

Common command headers control IEEE 488.2 functions within the logic

analyzer, such as, clear status. The syntax is:

*<command header><terminator>

No white space or separator is allowed between the asterisk and the

command header. *CLS is an example of a common command header.

Combined Commands in the Same Subsystem

To execute more than one function within the same subsystem, a semicolon

(;) is used to separate the functions:

:<subsystem>:<function><white

space><data>;<function><white space><data><terminator>

Example :SYSTEM:LONGFORM ON;HEADER ON

Introduction to Programming

Duplicate Keywords

Duplicate Keywords

Identical function keywords can be used for more than one subsystem. For

example, the function keyword MMODE may be used to specify the marker

mode in the subsystem for state listing or the timing waveforms:

• :SLIST:MMODE PATTERN - sets the marker mode to pattern in

the state listing.

• :TWAVEFORM:MMODE TIME - sets the marker mode to time in the

timing waveforms.

SLIST and TWAVEFORM are subsystem selectors, and they determine which

marker mode is being modified.

1–9

Page 34

Introduction to Programming

Query Usage

Query Usage

Logic analyzer instructions that are immediately followed by a question mark

(?) are queries. After receiving a query, the logic analyzer parser places the

response in the output buffer. The output message remains in the buffer

until it is read or until another logic analyzer instruction is issued. When

read, the message is transmitted across the bus to the designated listener

(typically a controller).

Query commands are used to find out how the logic analyzer is currently

configured. They are also used to get results of measurements made by the

logic analyzer.

Example This instruction places the current full-screen time for machine 1 in the

output buffer.

:MACHINE1:TWAVEFORM:RANGE?

In order to prevent the loss of data in the output buffer, the output buffer

must be read before the next program message is sent. Sending another

command before reading the result of the query will cause the output buffer

to be cleared and the current response to be lost. This will also generate a

"QUERY UNTERMINATED" error in the error queue. For example, when you

send the query :TWAVEFORM:RANGE? you must follow that with an input

statement. In Basic, this is usually done with an ENTER statement.

In Basic, the input statement, ENTER XXX; Range, passes the value across

the bus to the controller and places it in the variable Range.

Additional details on how to use queries is in the next section of this chapter,

"Receiving Information for the Instrument."

1–10

Page 35

Introduction to Programming

Program Header Options

Program Header Options

Program headers can be sent using any combination of uppercase or

lowercase ASCII characters. Logic analyzer responses, however, are always

returned in uppercase.

Both program command and query headers may be sent in either long form

(complete spelling), short form (abbreviated spelling), or any combination of

long form and short form.

Programs written in long form are easily read and are almost selfdocumenting. The short form syntax conserves the amount of controller

memory needed for program storage and reduces the amount of I/O activity.

The rules for short form syntax are discussed in chapter 4, "Programming and

Documentation Conventions."

Example Either of the following examples turns on the headers and long form.

Long form:

OUTPUT XXX;":SYSTEM:HEADER ON;LONGFORM ON"

Short form:

OUTPUT XXX;":SYST:HEAD ON;LONG ON"

1–11

Page 36

Introduction to Programming

Parameter Data Types

Parameter Data Types

There are three main types of data which are used in parameters. They are

numeric, string, and keyword. A fourth type, block data, is used only for a few

instructions: the DATA and SETup instructions in the SYSTem subsystem

(see chapter 10); the CATalog, UPLoad, and DOWNload instructions in the

MMEMory subsystem (see chapter 11). These syntax rules also show how

data may be formatted when sent back from the 1660-series logic analyzers

as a response.

The parameter list always follows the instruction header and is separated

from it by white space. When more than one parameter is used, they are

separated by commas. You are allowed to include one or more white spaces

around the commas, but it is not mandatory.

Numeric data

For numeric data, you have the option of using exponential notation or using

suffixes to indicate which unit is being used. However, exponential notation

is only applicable to the decimal number base. Tables 5-1 and 5-2 in chapter

5, "Message Communications and System Functions," list all available

suffixes. Do not combine an exponent with a unit.

Example The following numbers are all equal:

28 = 0.28E2 = 280E-1 = 28000m = 0.028K.

The base of a number is shown with a prefix. The available bases are binary

(#B), octal (#Q), hexadecimal (#H) and decimal (default).

Example The following numbers are all equal:

#B11100 = #Q34 = #H1C = 28

You may not specify a base in conjunction with either exponents or unit

suffixes. Additionally, negative numbers must be expressed in decimal.

1–12

Page 37

Introduction to Programming

Parameter Data Types

When a syntax definition specifies that a number is an integer, that means

that the number should be whole. Any fractional part would be ignored,

truncating the number. Numeric parameters that accept fractional values are

called real numbers.

All numbers are expected to be strings of ASCII characters. Thus, when

sending the number 9, you send a byte representing the ASCII code for the

character "9" (which is 57, or 0011 1001 in binary). A three-digit number,

like 102, will take up three bytes (ASCII codes 49, 48 and 50). This is taken

care of automatically when you include the entire instruction in a string.

String data

String data may be delimited with either single (’) or double (") quotes.

String parameters representing labels are case-sensitive. For instance, the

labels "Bus A" and "bus a" are unique and should not be used

indiscriminately. Also pay attention to the presence of spaces, because they

act as legal characters just like any other. So, the labels "In" and " In" are

also two different labels.

Keyword data

In many cases a parameter must be a keyword. The available keywords are

always included with the instruction’s syntax definition. When sending

commands, either the longform or shortform (if one exists) may be used.

Uppercase and lowercase letters may be mixed freely. When receiving

responses, upper-case letters will be used exclusively. The use of longform

or shortform in a response depends on the setting you last specified via the

SYSTem:LONGform command (see chapter 10).

1–13

Page 38

Introduction to Programming

Selecting Multiple Subsystems

Selecting Multiple Subsystems

You can send multiple program commands and program queries for different

subsystems on the same line by separating each command with a semicolon.

The colon following the semicolon enables you to enter a new subsystem.

<instruction header><data>;:<instruction header><data>

<terminator>

Multiple commands may be any combination of simple, compound and

common commands.

Example :MACHINE1:ASSIGN2;:SYSTEM:HEADERS ON

1–14

Page 39

Receiving Information from the Instrument

After receiving a query (logic analyzer instruction followed by a question

mark), the logic analyzer interrogates the requested function and places the

answer in its output queue. The answer remains in the output queue until it

is read, or, until another command is issued. When read, the message is

transmitted across the bus to the designated listener (typically a controller).

The input statement for receiving a response message from an logic

analyzer’s output queue usually has two parameters: the device address and

a format specification for handling the response message.

All results for queries sent in a program message must be read before another

program message is sent. For example, when you send the query

:MACHINE1:ASSIGN?, you must follow that query with an input statement.

In Basic, this is usually done with an ENTER statement.

The format for handling the response messages is dependent on both the

controller and the programming language.

Example To read the result of the query command :SYSTEM:LONGFORM? you can

execute this Basic statement to enter the current setting for the long form

command in the numeric variable Setting.

ENTER XXX; Setting

1–15

Page 40

Introduction to Programming

Response Header Options

Response Header Options

The format of the returned ASCII string depends on the current settings of

the SYSTEM HEADER and LONGFORM commands. The general format is

<instruction_header><space><data><terminator>

The header identifies the data that follows (the parameters) and is controlled

by issuing a :SYSTEM:HEADER ON/OFF command. If the state of the

header command is OFF, only the data is returned by the query.

The format of the header is controlled by the :SYSTEM:LONGFORM ON/OFF

command. If long form is OFF , the header will be in its short form and the

header will vary in length, depending on the particular query. The separator

between the header and the data always consists of one space.

A command or query may be sent in either long form or short form, or in any

combination of long form and short form. The HEADER and LONGFORM

commands only control the format of the returned data, and, they have no

affect on the way commands are sent.

Refer to chapter 10, "SYSTem Subsystem" for information on turning the

HEADER and LONGFORM commands on and off.

Examples The following examples show some possible responses for a

:MACHINE1:SFORMAT:THRESHOLD2? query:

with HEADER OFF:

<data><terminator>

with HEADER ON and LONGFORM OFF:

:MACH1:SFOR:THR2 <white_space><data><terminator>

with HEADER ON and LONGFORM ON:

:MACHINE1:SFORMAT:THRESHOLD2 <white_space><data><terminator>

1–16

Page 41

Introduction to Programming

Response Data Formats

Response Data Formats

Both numbers and strings are returned as a series of ASCII characters, as

described in the following sections. Keywords in the data are returned in the

same format as the header, as specified by the LONGform command. Like

the headers, the keywords will always be in uppercase.

Examples The following are possible responses to the MACHINE1: TFORMAT: LAB?

’ADDR’ query.

Header on; Longform on

MACHINE1:TFORMAT:LABEL "ADDR ",19,POSITIVE<terminator>

Header on;Longform off

MACH1:TFOR:LAB "ADDR ",19,POS<terminator>

Header off; Longform on

"ADDR ",19,POSITIVE<terminator>

Header off; Longform off

"ADDR ",19,POS<terminator>

Refer to the individual commands in Parts 2 through 4 of this guide for

information on the format (alpha or numeric) of the data returned from each

query.

1–17

Page 42

Introduction to Programming

String Variables

String Variables

Because there are so many ways to code numbers, the 1660-series logic

analyzers handle almost all data as ASCII strings. Depending on your host

language, you may be able to use other types when reading in responses.

Sometimes it is helpful to use string variables in place of constants to send

instructions to the 1660-series logic analyzers, such as, including the headers

with a query response.

Example This example combines variables and constants in order to make it easier to

switch from MACHINE1 to MACHINE2. In BASIC, the & operator is used for

string concatenation.

5 OUTPUT XXX;":SELECT 1" !Select the logic analyzer

10 LET Machine$ = ":MACHINE2" !Send all instructions to machine 2

20 OUTPUT XXX; Machine$ & ":TYPE STATE" !Make machine a state analyzer

30 ! Assign all labels to be positive

40 OUTPUT XXX; Machine$ & ":SFORMAT:LABEL ’CHAN 1’, POS"

50 OUTPUT XXX; Machine$ & ":SFORMAT:LABEL ’CHAN 2’, POS"

60 OUTPUT XXX; Machine$ & ":SFORMAT:LABEL ’OUT’, POS"

99 END

If you want to observe the headers for queries, you must bring the returned

data into a string variable. Reading queries into string variables requires little

attention to formatting.

Example This command line places the output of the query in the string variable

Result$.

ENTER XXX;Result$

In the language used for this book (HP BASIC 6.2), string variables are casesensitive and must be expressed exactly the same each time they are used.

The output of the logic analyzer may be numeric or character data depending

on what is queried. Refer to the specific commands, in Part 2 of this guide,

for the formats and types of data returned from queries.

1–18

Page 43

Introduction to Programming

Numeric Base

Example The following example shows logic analyzer data being returned to a string

variable with headers off:

10 OUTPUT XXX;":SYSTEM:HEADER OFF"

20 DIM Rang$[30]

30 OUTPUT XXX;":MACHINE1:TWAVEFORM:RANGE?"

40 ENTER XXX;Rang$

50 PRINT Rang$

60 END

After running this program, the controller displays: +1.00000E-05

Numeric Base

Most numeric data will be returned in the same base as shown onscreen.

When the prefix #B precedes the returned data, the value is in the binary

base. Likewise, #Q is the octal base and #H is the hexadecimal base. If no

prefix precedes the returned numeric data, then the value is in the decimal

base.

Numeric Variables

If your host language can convert from ASCII to a numeric format, then you

can use numeric variables. Turning off the response headers will help you

avoid accidently trying to convert the header into a number.

Example The following example shows logic analyzer data being returned to a numeric

variable.

10 OUTPUT XXX;":SYSTEM:HEADER OFF"

20 OUTPUT XXX;":MACHINE1:TWAVEFORM:RANGE?"

30 ENTER XXX;Rang

40 PRINT Rang

50 END

1–19

Page 44

Introduction to Programming

Definite-Length Block Response Data

This time the format of the number (such as, whether or not exponential

notation is used) is dependant upon your host language. In Basic, the output

will look like: 1.E-5

Definite-Length Block Response Data

Definite-length block response data, also refered to as block data, allows any

type of device-dependent data to be transmitted over the system interface as

a series of data bytes. Definite-length blick data is particularly useful for

sending large quantities of data, or, for sending 8-bit extended ASCII codes.

The syntax is a pound sign ( # ) followed by a non-zero digit representing the

number of digits in the decimal integer. Following the non zero digit is the

decimal integer that states the number of 8-bit data bytes to follow. This

number is followed by the actual data.

Indefinite-length block data is not supported on the 1660-series logic

analyzers.

For example, for transmitting 80 bytes of data, the syntax would be:

Figure 1-2

Definite-length Block Response Data

The "8" states the number of digits that follow, and "00000080" states the

number of bytes to be transmitted, which is 80.

1–20

Page 45

Introduction to Programming

Multiple Queries

Multiple Queries

You can send multiple queries to the logic analyzer within a single program

message, but you must also read them back within a single program message.

This can be accomplished by either reading them back into a string variable

or into multiple numeric variables.

Example You can read the result of the query :SYSTEM:HEADER?;LONGFORM? into

the string variable Results$ with the command:

ENTER XXX; Results$

When you read the result of multiple queries into string variables, each

response is separated by a semicolon.

Example The response of the query :SYSTEM:HEADER?:LONGFORM? with HEADER

and LONGFORM turned on is:

:SYSTEM:HEADER 1;:SYSTEM:LONGFORM 1

If you do not need to see the headers when the numeric values are returned,

then you could use numeric variables. When you are receiving numeric data

into numeric variables, the headers should be turned off. Otherwise the

headers may cause misinterpretation of returned data.

Example The following program message is used to read the query

:SYSTEM:HEADERS?;LONGFORM? into multiple numeric variables:

ENTER XXX; Result1, Result2

1–21

Page 46

Introduction to Programming

Instrument Status

Instrument Status

Status registers track the current status of the logic analyzer. By checking

the instrument status, you can find out whether an operation has been

completed, whether the instrument is receiving triggers, and more.

Chapter 6, "Status Reporting," explains how to check the status of the

instrument.

1–22

Page 47

2

Programming Over GPIB

Page 48

Introduction

This section describes the interface functions and some general

concepts of the GPIB. In general, these functions are defined by IEEE

488.1 (GPIB bus standard). They deal with general bus management

issues, as well as messages which can be sent over the bus as bus

commands.

2–2

Page 49

Programming Over GPIB

Interface Capabilities

Interface Capabilities

The interface capabilities of the 1660-series logic analyzers, as defined by

IEEE 488.1 are SH1, AH1, T5, TE0, L3, LE0, SR1, RL1, PP0, DC1, DT1, C0,

and E2.

Command and Data Concepts

The GPIB has two modes of operation: command mode and data mode. The

bus is in command mode when the ATN line is true. The command mode is

used to send talk and listen addresses and various bus commands, such as a

group execute trigger (GET). The bus is in the data mode when the ATN line

is false. The data mode is used to convey device-dependent messages across

the bus. These device-dependent messages include all of the instrument

commands and responses found in chapters 8 through 35 of this manual.

Addressing

By using the front-panel I/O and SELECT keys, the GPIB interface can be

placed in either talk only mode, "Printer connected to GPIB," or in addressed

talk/listen mode, "Controller connected to GPIB," (see chapter 16, "The

RS-232/GPIB Menu" in the Agilent Technologies 1660-Series Logic

Analyzer User’s Reference). Talk only mode must be used when you want

the logic analyzer to talk directly to a printer without the aid of a controller.

Addressed talk/listen mode is used when the logic analyzer will operate in

conjunction with a controller. When the logic analyzer is in the addressed

talk/listen mode, the following is true:

Each device on the GPIB resides at a particular address ranging from 0 to

•

30.

The active controller specifies which devices will talk and which will listen.

•

An instrument, therefore, may be talk-addressed, listen-addressed, or

•

unaddressed by the controller.

2–3

Page 50

Programming Over GPIB

Communicating Over the GPIB Bus (HP 9000 Series 200/300 Controller)

If the controller addresses the instrument to talk, it will remain configured to

talk until it receives:

an interface clear message (IFC)

•

another instrument’s talk address (OTA)

•

its own listen address (MLA)

•

a universal untalk (UNT) command.

•

If the controller addresses the instrument to listen, it will remain configured

to listen until it receives:

an interface clear message (IFC)

•

its own talk address (MTA)

•

a universal unlisten (UNL) command.

•

Communicating Over the GPIB Bus (HP 9000 Series

200/300 Controller)

Because GPIB can address multiple devices through the same interface card,

the device address passed with the program message must include not only

the correct instrument address, but also the correct interface code.

Interface Select Code (Selects the Interface)

Each interface card has its own interface select code. This code is used by

the controller to direct commands and communications to the proper

interface. The default is always "7" for GPIB controllers.

Instrument Address (Selects the Instrument)

Each instrument on the GPIB port must have a unique instrument address

between decimals 0 and 30. The device address passed with the program

message must include not only the correct instrument address, but also the

correct interface select code.

2–4

Page 51

Programming Over GPIB

Local, Remote, and Local Lockout

Example For example, if the instrument address is 4 and the interface select code is 7,

the instruction will cause an action in the instrument at device address 704.

DEVICE ADDRESS = (Interface Select Code) X 100 + (Instrument

Address)

Local, Remote, and Local Lockout

The local, remote, and remote with local lockout modes may be used for

various degrees of front-panel control while a program is running. The logic

analyzer will accept and execute bus commands while in local mode, and the

front panel will also be entirely active. If the 1660-series logic analyzer is in

remote mode, the logic analyzer will go from remote to local with any front

panel activity. In remote with local lockout mode, all controls (except the

power switch) are entirely locked out. Local control can only be restored by

the controller.

Hint Cycling the power will also restore local control, but this will also reset

certain GPIB states. It also resets the logic analyzer to the power-on defaults

and purges any acquired data in the acquisition memory.

The instrument is placed in remote mode by setting the REN (Remote

Enable) bus control line true, and then addressing the instrument to listen.

The instrument can be placed in local lockout mode by sending the local

lockout (LLO) command (see SYSTem:LOCKout in chapter 9, "Mainframe

Commands"). The instrument can be returned to local mode by either

setting the REN line false, or sending the instrument the go to local (GTL)

command.

2–5

Page 52

Programming Over GPIB

Bus Commands

Bus Commands

The following commands are IEEE 488.1 bus commands (ATN true). IEEE

488.2 defines many of the actions which are taken when these commands are

received by the logic analyzer.

Device Clear

The device clear (DCL) or selected device clear (SDC) commands clear the

input and output buffers, reset the parser, clear any pending commands, and

clear the Request-OPC flag.

Group Execute Trigger (GET)

The group execute trigger command will cause the same action as the

START command for Group Run: the instrument will acquire data for the

active waveform and listing displays.

Interface Clear (IFC)

This command halts all bus activity. This includes unaddressing all listeners

and the talker, disabling serial poll on all devices, and returning control to the

system controller.

2–6

Page 53

3

Programming Over RS-232C

Page 54

Introduction

This chapter describes the interface functions and some general

concepts of the RS-232C. The RS-232C interface on this instrument is

Agilent Technologies’ implementation of EIA Recommended Standard

RS-232C, "Interface Between Data Terminal Equipment and Data

Communications Equipment Employing Serial Binary Data

Interchange." With this interface, data is sent one bit at a time, and

characters are not synchronized with preceding or subsequent data

characters. Each character is sent as a complete entity without

relationship to other events.

3–2

Page 55

Programming Over RS-232C

Interface Operation

Interface Operation

The 1660-series logic analyzers can be programmed with a controller over

RS-232C using either a minimum three-wire or extended hardwire interface.

The operation and exact connections for these interfaces are described in

more detail in the following sections. When you are programming a

1660-series logic analyzer over RS-232C with a controller, you are normally

operating directly between two DTE (Data Terminal Equipment) devices as

compared to operating between a DTE device and a DCE (Data

Communications Equipment) device.

When operating directly between two DTE devices, certain considerations

must be taken into account. For a three-wire operation, XON/XOFF must be

used to handle protocol between the devices. For extended hardwire

operation, protocol may be handled either with XON/XOFF or by

manipulating the CTS and RTS lines of the RS-232C link. For both threewire and extended hardwire operation, the DCD and DSR inputs to the logic

analyzer must remain high for proper operation.

With extended hardwire operation, a high on the CTS input allows the logic

analyzer to send data, and a low disables the logic analyzer data transmission.

Likewise, a high on the RTS line allows the controller to send data, and a low

signals a request for the controller to disable data transmission. Because

three-wire operation has no control over the CTS input, internal pull-up

resistors in the logic analyzer assure that this line remains high for proper

three-wire operation.

RS-232C Cables

Selecting a cable for the RS-232C interface depends on your specific

application, and, whether you wish to use software or hardware handshake

protocol. The following paragraphs describe which lines of the 1660-series

logic analyzer are used to control the handshake operation of the RS-232C

relative to the system. To locate the proper cable for your application, refer

to the reference manual for your computer or controller. Your computer or

controller manual should describe the exact handshake protocol your

controller can use to operate over the RS-232C bus. Also in this chapter you

will find cable recommendations for hardware handshake.

3–3

Page 56

Programming Over RS-232C

Minimum Three-Wire Interface with Software Protocol

Minimum Three-Wire Interface with Software Protocol

With a three-wire interface, the software (as compared to interface

hardware) controls the data flow between the logic analyzer and the

controller. The three-wire interface provides no hardware means to control

data flow between the controller and the logic analyzer. Therefore,

XON/OFF protocol is the only means to control this data flow. The

three-wire interface provides a much simpler connection between devices

since you can ignore hardware handshake requirements.

The communications software you are using in your computer/controller must

be capable of using XON/XOFF exclusively in order to use three-wire interface

cables. For example, some communications software packages can use

XON/XOFF but are also dependent on the CTS, and DSR lines being true to

communicate.

The logic analyzer uses the following connections on its RS-232C interface for

three-wire communication:

Pin 7 SGND (Signal Ground)

•

Pin 2 TD (Transmit Data from logic analyzer)

•

Pin 3 RD (Receive Data into logic analyzer)

•

The TD (Transmit Data) line from the logic analyzer must connect to the RD

(Receive Data) line on the controller. Likewise, the RD line from the logic

analyzer must connect to the TD line on the controller. Internal pull-up

resistors in the logic analyzer assure the DCD, DSR, and CTS lines remain

high when you are using a three-wire interface.

Extended Interface with Hardware Handshake

With the extended interface, both the software and the hardware can control

the data flow between the logic analyzer and the controller. This allows you

to have more control of data flow between devices. The logic analyzer uses

the following connections on its RS-232C interface for extended interface

communication:

3–4

Page 57

Programming Over RS-232C

Extended Interface with Hardware Handshake

Pin 7 SGND (Signal Ground)

•

Pin 2 TD (Transmit Data from logic analyzer)

•

Pin 3 RD (Receive Data into logic analyzer)

•

The additional lines you use depends on your controller’s implementation of

the extended hardwire interface.

Pin 4 RTS (Request To Send) is an output from the logic analyzer which

•

can be used to control incoming data flow.

Pin 5 CTS (Clear To Send) is an input to the logic analyzer which

•

controls data flow from the logic analyzer.

Pin 6 DSR (Data Set Ready) is an input to the logic analyzer which

•

controls data flow from the logic analyzer within two bytes.

Pin 8 DCD (Data Carrier Detect) is an input to the logic analyzer which

•

controls data flow from the logic analyzer within two bytes.

Pin 20 DTR (Data Terminal Ready) is an output from the logic analyzer

•

which is enabled as long as the logic analyzer is turned on.

The TD (Transmit Data) line from the logic analyzer must connect to the RD

(Receive Data) line on the controller. Likewise, the RD line from the logic

analyzer must connect to the TD line on the controller.

The RTS (Request To Send), is an output from the logic analyzer which can

be used to control incoming data flow. A true on the RTS line allows the

controller to send data and a false signals a request for the controller to

disable data transmission.

The CTS (Clear To Send), DSR (Data Set Ready), and DCD (Data Carrier

Detect) lines are inputs to the logic analyzer, which control data flow from

the logic analyzer. Internal pull-up resistors in the logic analyzer assure the

DCD and DSR lines remain high when they are not connected. If DCD or

DSR are connected to the controller, the controller must keep these lines

along with the CTS line high to enable the logic analyzer to send data to the

controller. A low on any one of these lines will disable the logic analyzer data

transmission. Pulling the CTS line low during data transmission will stop

logic analyzer data transmission immediately. Pulling either the DSR or DCD

line low during data transmission will stop logic analyzer data transmission,

but as many as two additional bytes may be transmitted from the logic

analyzer.

3–5

Page 58

Figure 3-1

Programming Over RS-232C

Cable Examples

Cable Examples

HP 9000 Series 300

Figure 3-1 is an example of how to connect the 1660-series logic analyzer to

the HP 98628A Interface card of an HP 9000 series 300 controller. For more

information on cabling, refer to the reference manual for your specific

controller.

Because this example does not have the correct connections for hardware

handshake, you must use the XON/XOFF protocol when connecting the logic

analyzer.

Cable Example

HP Vectra Personal Computers and Compatibles

Figures 3-2 through 3-4 give examples of three cables that will work for the

extended interface with hardware handshake. Keep in mind that these

cables should work if your computer’s serial interface supports the four

common RS-232C handshake signals as defined by the RS-232C standard.

The four common handshake signals are Data Carrier Detect (DCD), Data

Terminal Ready (DTR), Clear to Send (CTS), and Ready to Send (RTS).

Figure 3-2 shows the schematic of a 25-pin female to 25-pin male cable. The

following cables support this configuration:

HP 17255D, DB-25(F) to DB-25(M), 1.2 meter

•

HP 17255F, DB-25(F) to DB-25(M), 1.2 meter, shielded.

•

In addition to the female-to-male cables with this configuration, a

male-to-male cable 1.2 meters in length is also available:

HP 17255M, DB-25(M) to DB-25(M), 1.2 meter

•

3–6

Page 59

Figure 3-2

Programming Over RS-232C

Cable Examples

25-pin (F) to 25-pin (M) Cable

Figure 3-3 shows the schematic of a 25-pin male to 25-pin male cable 5

meters in length. The following cable supports this configuration:

HP 13242G, DB-25(M) to DB-25(M), 5 meter

•

Figure 3-3

25-pin (M) to 25-pin (M) Cable

3–7

Page 60

Figure 3-4

Programming Over RS-232C

Configuring the Logic Analzer Interface

Figure 3-4 shows the schematic of a 9-pin female to 25-pin male cable. The

following cables support this configuration:

HP 24542G, DB-9(F) to DB-25(M), 3 meter

•

HP 24542H, DB-9(F) to DB-25(M), 3 meter, shielded

•

HP 45911-60009, DB-9(F) to DB-25(M), 1.5 meter

•

9-pin (F) to 25-pin (M) Cable

Configuring the Logic Analzer Interface

The RS-232C menu field in the System Configuration Menu allows you access

to the RS-232C Configuration menu where the RS-232C interface is

configured. If you are not familiar with how to configure the RS-232C

interface, refer to the Agilent Technologies 1660-Series Logic Analyzer

User’s Reference.

3–8

Page 61

Programming Over RS-232C

Interface Capabilities

Interface Capabilities

The baud rate, stopbits, parity, protocol, and databits must be configured

exactly the same for both the controller and the logic analyzer to properly

communicate over the RS-232C bus. The RS-232C interface capabilities of

the 1660-series logic analyzers are listed below:

Baud Rate: 110, 300, 600, 1200, 2400, 4800, 9600, or 19.2k

•

Stop Bits: 1, 1.5, or 2

•

Parity: None, Odd, or Even

•

Protocol: None or XON/XOFF

•

Data Bits: 8

•

Protocol

NONE With a three-wire interface, selecting NONE for the protocol

does not allow the sending or receiving device to control dataflow. No

control over the data flow increases the possibility of missing data or

transferring incomplete data.

With an extended hardwire interface, selecting NONE allows a hardware

handshake to occur. With hardware handshake, the hardware signals control

dataflow.

XON/XOFF XON/XOFF stands for Transmit On/Transmit Off. With this

mode, the receiver (controller or logic analyzer) controls dataflow, and,

can request that the sender (logic analyzer or controller) stop dataflow.

By sending XOFF (ASCII 19) over its transmit data line, the receiver

requests that the sender disables data transmission. A subsequent XON

(ASCII 17) allows the sending device to resume data transmission.

Data Bits

Data bits are the number of bits sent and received per character that

represent the binary code of that character. Characters consist of either 7 or

8 bits, depending on the application. The 1660-series logic analyzer supports

8 bit only.

8 Bit Mode Information is usually stored in bytes (8 bits at a time).

With 8-bit mode, you can send and receive data just as it is stored,

without the need to convert the data.

3–9

Page 62

Programming Over RS-232C

RS-232C Bus Addressing

The controller and the 1660-series logic analyzer must be in the same bit

mode to properly communicate over the RS-232C. This means that the

controller must have the capability to send and receive 8 bit data.

See Also For more information on the RS-232C interface, refer to the Agilent

Technologies 1660-Series Logic Analyzer User’s Reference. For

information on RS-232C voltage levels and connector pinouts, refer to the

Agilent Technologies 1660-Series Logic Analyzer Service Guide.

RS-232C Bus Addressing

The RS-232C address you must use is dependent on the computer or

controller you are using to communicate with the logic analyzer.

HP Vectra Personal Computers or compatibles

If you are using an HP Vectra Personal Computer or compatible, it must have

an unused serial port to which you connect the logic analyzer’s RS-232C port.

The proper address for the serial port is dependent on the hardware

configuration of your computer. Additionally, your communications software

must be configured to address the proper serial port. Refer to your computer

and communications software manuals for more information on setting up

your serial port address.

HP 9000 Series 300 Controllers

Each RS-232C interface card for the HP 9000 Series 300 Controller has its

own interface select code. This code is used by the controller for directing

commands and communications to the proper interface by specifying the

correct interface code for the device address.

Generally, the interface select code can be any decimal value between 0 and

31, except for those interface codes which are reserved by the controller for

internal peripherals and other internal interfaces. This value can be selected

through switches on the interface card. For example, if your RS-232C

interface select code is 9, the device address required to communicate over

the RS-232C bus is 9. For more information, refer to the reference manual

for your interface card or controller.

3–10

Page 63

Programming Over RS-232C

Lockout Command

Lockout Command

To lockout the front-panel controls, use the SYSTem command LOCKout.

When this function is on, all controls (except the power switch) are entirely

locked out. Local control can only be restored by sending the :LOCKout OFF

command.

Hint Cycling the power will also restore local control, but this will also reset

certain RS-232C states. It also resets the logic analyzer to the power-on

defaults and purges any acquired data in the acquisition memory of all the

installed modules.

See Also For more information on this command see chapter 10, "System Commands."

3–11

Page 64

3–12

Page 65

4

Programming and Documentation Conventions

Page 66

Introduction

This chapter covers the programming conventions used in

programming the instrument, as well as the documentation

conventions used in this manual. This chapter also contains a detailed

description of the command tree and command tree traversal.

4–2

Page 67

Programming and Documentation Conventions

Truncation Rule

Truncation Rule

The truncation rule for the keywords used in headers and parameters is:

If the longform has four or fewer characters, there is no change in the

•

shortform. When the longform has more than four characters the

shortform is just the first four characters, unless the fourth character is

a vowel. In that case only the first three characters are used.

There are some commands that do not conform to the truncation rule by design.

These will be noted in their respective description pages.

Some examples of how the truncation rule is applied to various commands

are shown in table 4-1.

Table 4-1

Truncation Examples

Long Form Short Form

OFF OFF

DATA DATA

START STAR

LONGFORM LONG

DELAY DEL

ACCUMULATE ACC

4–3

Page 68

Programming and Documentation Conventions

Infinity Representation

Infinity Representation

The representation of infinity is 9.9E+37 for real numbers and 32767 for

integers. This is also the value returned when a measurement cannot be

made.

Sequential and Overlapped Commands

IEEE 488.2 makes the distinction between sequential and overlapped

commands. Sequential commands finish their task before the execution of

the next command starts. Overlapped commands run concurrently; therefore,

the command following an overlapped command may be started before the

overlapped command is completed. The overlapped commands for the

1660-series logic analyzers are STARt and STOP.

Response Generation

IEEE 488.2 defines two times at which query responses may be buffered.

The first is when the query is parsed by the instrument and the second is

when the controller addresses the instrument to talk so that it may read the

response. The 1660-series logic analyzers will buffer responses to a query

when it is parsed.

Syntax Diagrams

At the beginning of each chapter in Parts 2 through 4, "Commands," is a

syntax diagram showing the proper syntax for each command. All characters

contained in a circle or oblong are literals, and must be entered exactly as

shown. Words and phrases contained in rectangles are names of items used

with the command and are described in the accompanying text of each

command. Each line can only be entered from one direction as indicated by

the arrow on the entry line. Any combination of commands and arguments

that can be generated by following the lines in the proper direction is

syntactically correct. An argument is optional if there is a path around it.

When there is a rectangle which contains the word "space," a white space

character must be entered. White space is optional in many other places.

4–4

Page 69

Programming and Documentation Conventions

Notation Conventions and Definitions

Notation Conventions and Definitions

The following conventions are used in this manual when describing

programming rules and example.

< > Angular brackets enclose words or characters that are used to symbolize a

program code parameter or a bus command

::= "is defined as." For example, A ::= B indicates that A can be replaced by B in

any statement containing A.

| "or." Indicates a choice of one element from a list. For example, A | B

indicates A or B, but not both.

... An ellipsis (trailing dots) is used to indicate that the preceding element may

be repeated one or more times.

[ ] Square brackets indicate that the enclosed items are optional.

{ } When several items are enclosed by braces and separated by vertical bars (|),

one, and only one of these elements must be selected.

XXX Three Xs after an ENTER or OUTPUT statement represent the device

address required by your controller.

<NL> Linefeed (ASCII decimal 10).

The Command Tree

The command tree (figure 4-1) shows all commands in the 1660-series logic

analyzers and the relationship of the commands to each other. Parameters

are not shown in this figure. The command tree allows you to see what the

1660-series logig analyzer parser expects to receive. All legal headers can be

created by traversing down the tree, adding keywords until the end of a

branch has been reached.

4–5

Page 70

Programming and Documentation Conventions

Tree Traversal Rules

Command Types

As shown in chapter 1, "Header Types," there are three types of headers.

Each header has a corresponding command type. This section shows how

they relate to the command tree.

System Commands The system commands reside at the top level of

the command tree. These commands are always parsable if they occur at

the beginning of a program message, or are preceded by a colon. START

and STOP are examples of system commands.

Subsystem Commands Subsystem commands are grouped together

under a common node of the tree, such as the MMEMORY commands.

Common Commands Common commands are independent of the tree,

and do not affect the position of the parser within the tree. *CLS and

*RST are examples of common commands.

Tree Traversal Rules

Command headers are created by traversing down the command tree. For

each group of keywords not separated by a branch, one keyword must be

selected. As shown on the tree, branches are always preceded by colons. Do

not add spaces around the colons. The following two rules apply to traversing

the tree:

A leading colon (the first character of a header) or a <terminator> places the

parser at the root of the command tree.

Executing a subsystem command places you in that subsystem until a leading

colon or a <terminator> is found. The parser will stay at the colon above the

keyword where the last header terminated. Any command below that point

can be sent within the current program message without sending the

keywords(s) which appear above them.

4–6

Page 71

Programming and Documentation Conventions

Tree Traversal Rules

The following examples are written using HP BASIC 6.2 on a HP 9000 Series

200/300 Controller. The quoted string is placed on the bus, followed by a

carriage return and linefeed (CRLF). The three Xs (XXX) shown in this

manual after an ENTER or OUTPUT statement represents the device address

required by your controller.

Example 1 In this example, the colon between SYSTEM and HEADER is necessary since

SYSTEM:HEADER is a compound command. The semicolon between the

HEADER command and the LONGFORM command is the required <program

message unit separator> . The LONGFORM command does not need

SYSTEM preceding it, since the SYSTEM:HEADER command sets the parser

to the SYSTEM node in the tree.

OUTPUT XXX;":SYSTEM:HEADER ON;LONGFORM ON"

Example 2 In the first line of this example, the subsystem selector is implied for the

STORE command in the compound command. The STORE command must

be in the same program message as the INITIALIZE command, since the

<program message terminator> will place the parser back at the root

of the command tree.

A second way to send these commands is by placing MMEMORY: before the

STORE command as shown in the fourth line of this example 2.

OUTPUT XXX;":MMEMORY:INITIALIZE;STORE ’FILE ’,’FILE

DESCRIPTION’"

or

OUTPUT XXX;":MMEMORY:INITIALIZE"

OUTPUT XXX;":MMEMORY:STORE ’FILE ’,’FILE DESCRIPTION’"

Example 3 In this example, the leading colon before SYSTEM tells the parser to go back

to the root of the command tree. The parser can then see the

SYSTEM:PRINT command.

OUTPUT XXX;":MMEM:CATALOG?;:SYSTEM:PRINT ALL"

4–7

Page 72

Figure 4-1

Programming and Documentation Conventions

Tree Traversal Rules

1660-Series Logic Analyzer Command Tree

4–8

Page 73

Figure 4-1 (continued)

Programming and Documentation Conventions

Tree Traversal Rules

1660-Series Logic Analyzer Command Tree (continued)

4–9

Page 74

Figure 4-1 (continued)

Programming and Documentation Conventions

Tree Traversal Rules

1660-Series Logic Analyzer Command Tree (continued)

4–10

Page 75

Table 4-2

Alphabetic Command Cross-Reference

Programming and Documentation Conventions

Tree Traversal Rules

Command Subsystem

ABVOLt MARKer

ACCumulate SCHart, SWAVeform, TWAVeform,

DISPlay

ACQMode TFORmat

ACQuisition STRigger, SWAVeform, TTRigger,

TWAVeform

ALL MEASure

ARM MACHine

ASSign MACHine

AUToload MMEMory

AUToscale MODULE LEVEL

AVOLt MARKer

BASE SYMBol

BEEPer Mainframe

BRANch STRigger, TTRigger

BVOLt MARKer

CAPability Mainframe

CARDcage Mainframe

CATalog MMEMory

CENTer SWAVeform, TWAVeform, MARKer

CESE Mainframe

CESR Mainframe

CLEar COMPare, STRigger, TTRigger

CLOCk SFORmat

CLRPattern SLISt, SWAVeform, TLISt, TWAVeform

CLRStat SWAVeform, TWAVeform

CMASk COMPare

COLumn SLISt, TLISt

CONDition TRIGger

CONNect DISPlay

COPY COMPare, MMEMory

COUNt ACQuire, WAVeforml

COUPling CHANNel

DATA COMPare, SLISt, SYSTem, TLISt,

WAVeform

DELay SWAVeform, TWAVeform, WLISt,

TIMebase. TRIGger

DELete INTermodule

DIGitize ROOT

DOWNload MMEMory

Command Subsystem

DSP SYSTem

ECL CHANnel

EOI Mainframe

ERRor SYSTem

FALLtime MEASure

FIND COMPare, STRigger, TTRigger

FORMat WAVeform

FREQuency MEASure

GLEDge TTRigger

HAXis SCHart

HEADer SYSTem

HTIMe INTermodule