Page 1

User’s Guide

Agilent 16440A SMU/Pulse Generator Selector

Agilent Part No. 16440-90000

Printed in Japan January 2000

Edition 4

Page 2

Legal Notice

The information contained in this document is subject to change without notice.

Copyright © 1994 - 2000 Agilent Technologies

This document contains information which is protected by copyright. All rights are

reserved. Reproduction, adaptation, or translation without prior written permission

is prohibited, except as allowed under the copyright laws.

• Product Warranty

Agilent Technologies warrant Agilent Technologies hardware, accessories and

supplies against defects in materials and workmanship for the period of one year

from the warranty start date specified below. If Agilent Technologies receive

notice of such defects during the warranty period, Agilent Technologies will, at

its option, either repair or replace products which prove to be defective.

Replacement products may be either new or like-new.

Warranty service of this product will be performed at Agilent Technologies.

Buyer shall prepay shipping charges to Agilent Technologies and Agilent

Technologies shall pay shipping charges to return the product to Buyer.

However, Buyer shall pay all shipping charges, duties, and taxes for products

returned to Agilent Technologies from another country.

Agilent Technologies do not warrant that the operation of Agilent Technologies

products will be uninterrupted or error free. If Agilent is unable, within a

reasonable time, to repair or replace any product to a condition as warranted,

customer will be entitled to a refund of the purchase price upon prompt return of

the product.

The Agilent Technologies products may contain remanufactured parts

equivalent to new in performance or may have been subject to incidental use.

The warranty period begins on the date of delivery or on the date of installation

if installed by Agilent Technologies. If customer schedules or delays Agilent

Technologies installation more than 30 days after delivery, warranty begins on

the 31st day from delivery.

Warranty does not apply to defects resulting from (a) improper or inadequate

maintenance or calibration, (b) software, interfacing, parts or supplies not

supplied by Agilent Technologies, (c) unauthorized modification or misuse, (d)

operation outside of the published environmental specifications for the product,

or (e) improper site preparation or maintenance.

2 Agilent 16440A User’s Guide, Edition 4

Page 3

To the extent allowed by local law, the above warranties are exclusive and no

other warranty or condition, whether written or oral, is expressed or implied and

Agilent Technologies specifically disclaim any implied warranties or conditions

of merchantability, satisfactory quality, and fitness for a particular purpose.

Agilent Technologies will be liable for damage to tangible property per incident

up to the greater of $300,000 or the actual amount paid for the product that is the

subject of the claim, and for damages for bodily injury or death, to the extent

that all such damages are determined by a court of competent jurisdiction to

have been directly caused by a defective Agilent Technologies product.

To the extent allowed by local law, the remedies in this warranty statement are

customer’s sole and exclusive remedies. Expect as indicated above, in no event

will Agilent Technologies or its suppliers be liable for loss of date or for direct,

special, incidental, consequential (including lost profit or date), or other damage,

whether based in contract, tort, or otherwise.

For consumer transactions in Australia and New Zealand: the warranty terms

contained in this statement, except to the extent lawfully permitted, do not

exclude, restrict or modify and are in addition to the mandatory statutory rights

applicable to the sale of this product to you.

• Assistance

Product maintenance agreements and other customer assistance agreements are

available for Agilent Technologies products.

For any assistance, contact your nearest Agilent Technologies Sales Office.

• Certification

Agilent Technologies Inc certifies that this product met its published

specifications at the time of shipment from the factory. Agilent further certifies

that its calibration measurements are traceable to the National Institute of

Standards and Technology (NIST), to the extent allowed by the Institute’s

calibration facility, and to the calibration facilities of other International

Standards Organization members.

• Safety Summary

The following general safety precautions must be observed during all phases of

operation, service, and repair of this instrument. Failure to comply with these

precautions or with specific warnings elsewhere in this manual may impair the

protections provided by the equipment. In addition, it violates safety standards

of design, manufacture, and intended use of the instrument. Agilent

Technologies Inc. assumes no liability for customer’s failure to comply with

these requirements.

Agilent 16440A User’s Guide, Edition 4 3

Page 4

• GROUND THE INSTRUMENT

This is Safety Class I instrument. To minimize shock hazard, the instrument

chassis and cabinet must be connected to an electrical ground. The power

terminal and the power cable must meet International Electrotechnical

Commission (IEC) safety standards.

• DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of flammable gases or fumes.

Operation of any electrical instrument in such an environment constitutes a

definite safety hazard.

• KEEP AWAY FROM LIVE CIRCUITS

Operation personnel must not remove instrument covers. Component

replacement and internal adjustments must be made by qualified

maintenance personnel. Do not replace components with power cable

connected. Under certain conditions, dangerous voltages may exist even

with the power cable removed. To avoid injuries, always disconnect power

and discharge circuits before touching them.

• DO NOT SERVICE OR ADJUST ALONE

Do not attempt internal service or adjustment unless another person, capable

of rendering first aid and resuscitation, is present.

• DO NOT SUBSTITUTE PARTS OR MODIFY INSTRUMENT

Because of the danger of introducing additional hazards, do not install

substitute parts or perform any unauthorized modification to the instrument.

Return the instrument to a Agilent Technologies Sales and Service Office for

services and repair to ensure that safety features are maintained.

• DANGEROUS PROCEDURE WARNINGS

Warnings, such as example below, precede potentially dangerous procedures

throughout this manual. Instructions contained in the warnings must be

followed.

WARNING Dangerous Voltage, capable of causing death, are present in this instrument.

Use extreme caution when handling, testing, and adjusting.

4 Agilent 16440A User’s Guide, Edition 4

Page 5

• Safety Symbols

The general definitions of safety symbols used on equipment or in manuals are

listed below.

Instruction manual symbol: the product will be marked with this symbol when it

is necessary for the user to refer to the instruction manual in order to protect

against damage to the instrument.

Indicates dangerous voltage and potential for electrical shock. Do not touch

terminals that have this symbol when instrument is on.

Protective conductor terminal. For protection against electrical shock in case of

a fault. Used with field wiring terminals to indicate the terminal which must be

connected to ground before operating equipment.

Frame or chassis terminal. A connection to the frame (chassis) of the equipment

which normally includes all exposed metal structures.

Indicates earth (ground) terminal.

Alternating current.

Direct current.

ON (Supply).

OFF (Supply).

STANDBY (Supply).

CAT 1

Means INSTALLATION CATEGORY I. Measurement terminals on the rear

panel comply with INSTALLATION CATEGORY I.

WARNING The warning sign denotes a hazard. It calls attention to a procedure, practice,

condition or the like, which, if not correctly performed or adhered to, could result in

injury or death to personal.

CAUTION The caution sign denotes a hazard. It calls attention to an operating procedure,

practice, condition or the like, which, if not correctly performed or adhered to, could

result in damage to or destruction of part or all of the product.

Agilent 16440A User’s Guide, Edition 4 5

Page 6

• Herstellerbescheinigung

GEÄUSCHEMISSION

Lpa < 70 dB

am Arbeitsplatz

normaler Betrieb

nach DIN 45635 T. 19

• Manufacturer’s Declaration

ACOUSTIC NOISE EMISSION

Lpa < 70dB

operator position

normal operation

per ISO 7779

Printing History

Edition 1: February 1994

Edition 2: April 1995

Edition 3: August 1997

Edition 4: January 2000

6 Agilent 16440A User’s Guide, Edition 4

Page 7

User's Guide

Agilent 16440A User’s Guide, Edition 4

Page 8

User's Guide

Agilent 16440A SMU/Pulse Generator Selector is one of the accessories available

for Agilent 4155/4156 Semiconductor Parameter Analyzers. The selector is for

automatically switching the unit (SMU or PGU) that is connected to a DUT pin

according to the state (stress force state or measurement state).

NOTE To use the selector, the 4155/4156 must be equipped with Agilent 41501 SMU/pulse

generator expander that contains two PGUs.

This manual consists of the following sections.

• Introduction

• Operation

• Installation

• Maintenance

• Specifications

2 Agilent 16440A User’s Guide, Edition 4

Page 9

Introduction

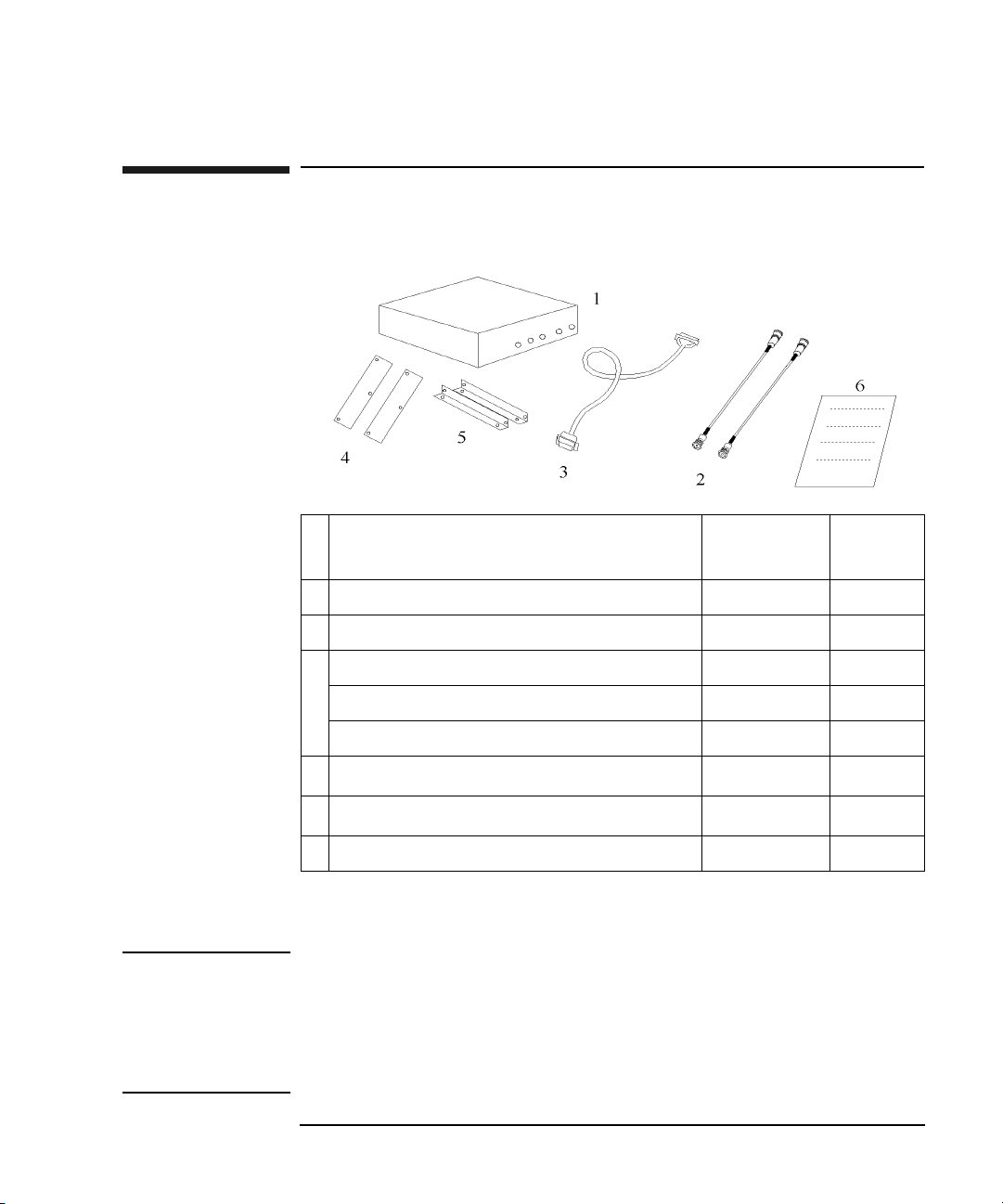

The 16440A selector contains the following accessories:

User's Guide

Introduction

Description

1 SMU/Pulse Generator Selector 16440A 1

2 40 cm triaxial cable 04155-61605 2

3 (option 001) 1.5 m control cable 04155-61612 1

(option 002) 3 m control cable 04155-61611 1

(option 003) 40 cm control cable 04155-61608 1

4

5

6 (option 001/002) User's Guide (this document) 16440-90000 1

NOTE Inspecting the 16440A upon Receiving

When the 16440A arrives at your site, make sure that nothing is missing or

damaged. Unpack the carton, then check the contents against figure and table above.

If anything is missing or damaged, contact your nearest Agilent Technologies sales

office.

a

plate

(option 001/002) angle

a. Three screws are furnished for each plate.

b. Two screws are furnished for each angle.

b

Agilent

Part Number

16440-60001 2

16440-60002 2

Quantity

Agilent 16440A User’s Guide, Edition 4 3

Page 10

User's Guide

Operation

Operation

This section describes the operating theory of the selector.

Agilent 4155/4156 can control the selector to automatically switch the unit (SMU or

PGU) that is connected to a DUT pin according to the state (stress force state or

measurement state).

This is useful for performing reliability testing (stress testing) of DUTs. For

example, the selector can connect a PGU to the DUT for forcing ac stress, then can

switch and connect an SMU for measuring dc characteristics.

You define the selector connections in SMU/PG SELECTOR table on the STRESS:

CHANNEL DEFINITION page. The switching state specified in the STRESS

column is automatically performed during stressing. The switching state specified in

the MEASURE column is automatically performed during measurement. See

"STRESS: CHANNEL DEFINITION screen" in the 4155/4156 User's Guide.

For example, you can specify to connect the PGU to the DUT during stress, and

connect the SMU to the DUT during measurement. So, when you press the

key, the PGU is automatically connected to the DUT. And when you press a

measurement key, the SMU is automatically connected to the DUT.

Stre s s

The 4155/4156 controls the switching of the selector.

Each selector has two channels. If you want to add two more channels for a total of

four, you can order 16440A option 003, which is called the "selector expander".

The selector and selector expander have identical circuits. The only difference is the

channel naming. The selector has CH 1 and CH 2, and the selector expander has CH

3 and CH 4.

4 Agilent 16440A User’s Guide, Edition 4

Page 11

User's Guide

Operation

The following figure shows a simple circuit diagram of the selector (selector

expander).

The CH 1 and CH 3 circuits are different from the CH 2 and CH 4 circuits. Each

channel has one mechanical relay for SMU and one mechanical relay for PGU, but

the CH 1 and CH 3 circuits also have a semiconductor relay for PGU. The relays are

controlled by the 4155/4156 via the control circuit.

The semiconductor relay is useful when you need to perform a lot of switching (for

example, read/write tests of flash ROM) because the semiconductor relay is more

durable than mechanical relays.

CH 1 and CH 3 can have four switching states: all open, SMU on, PGU on, and

PGU open. CH 2 and CH 4 can have three switching states: all open, SMU on, and

PGU on.

Agilent 16440A User’s Guide, Edition 4 5

Page 12

User's Guide

Operation

The switching state of a channel is indicated by the green LEDs on the selector front

panel. The following table shows the relation of the relays and the LEDs for each

switching state.

States CH 1 and CH 3 CH 2 and CH 4

All open

SMU on

PGU on

PGU open

The "PGU open" state is useful if a lot of switching needs to be performed. When

the switching state changes from "PGU on" to "PGU open", only the semiconductor

relay switches. This reduces the amount of times the mechanical relay is switched.

The semiconductor relay has a much longer switching life than the mechanical relay.

6 Agilent 16440A User’s Guide, Edition 4

Page 13

User's Guide

Installation

Installation

This section describes how to attach the selector to Agilent 16442A test fixture or to

a shielding box, and how to connect it to Agilent 4155/4156.

To Attach the Selector to Test Fixture

You can attach your selector to the 16442A test fixture. You need a standard

screwdriver.

1. Place the selector on your workbench. 2. Place the test fixture on top of the selector.

3. Position a plate on both sides. 4. Attach each plate using the three flathead

screws supplied with the instrument.

Agilent 16440A User’s Guide, Edition 4 7

Page 14

User's Guide

Installation

The following steps apply when using two selectors:

5. Place the second selector on your

workbench. Place the selector and the test

fixture on top of the second selector.

6. Position a plate on both sides. 7. Attach each plate using the three flathead

screws supplied with the instrument.

8 Agilent 16440A User’s Guide, Edition 4

Page 15

User's Guide

Installation

If you use the 16441A R-box, attach the R-Box to the selector as shown below:

Agilent 16440A User’s Guide, Edition 4 9

Page 16

User's Guide

Installation

To Attach the Selector to Shielding Box

You can attach your selector to a shielding box. You need a standard screwdriver.

The following figure shows the spacing of the 16440A screw holes. You need to

prepare four screws and nuts to match the screw holes.

10 Agilent 16440A User’s Guide, Edition 4

Page 17

User's Guide

Installation

If you use two selectors, connect selectors before attaching to the shielding box, as

shown below:

1. Place the selector on your workbench. 2. Place the second selector on top of the

selector.

3. Position a plate on both sides. 4. Attach each plate using the three flathead

screws supplied with the instrument.

Agilent 16440A User’s Guide, Edition 4 11

Page 18

User's Guide

Installation

Attach the selector to the shielding box as shown below:

1. Attach an angle bracket to each side of the selector, using the screws supplied.

2. Place the selector(s) on the side panel of

the shielding box.

3. Position four nuts on the inside panel of

the shielding box.

4. Attach the angle bracket to the shielding

box using four flathead screws.

12 Agilent 16440A User’s Guide, Edition 4

Page 19

User's Guide

Installation

If you use the 16441A R-box, attach the R-Box to the selector on the shielding box

as shown below:

Agilent 16440A User’s Guide, Edition 4 13

Page 20

User's Guide

Installation

Connecting the Selector to the 4155/4156

• Connecting two selectors

If you use two selectors, connect the Control Output terminal of the selector to

the Control Input terminal of the second selector using a 40 cm control cable as

shown below.

14 Agilent 16440A User’s Guide, Edition 4

Page 21

User's Guide

• Connecting the selector to the 4155/4156

Turn off the 4155/4156 and 41501 before connecting the instruments. Then

connect as shown below.

4155/4156

16442A Test Fixture

4

2

41501

16440A Selector

3

1

Installation

Instrument Terminal

41501 To SMU/Pulse

16440A

Te rm i na l

Cable

CONTROL Input 3.0 m or 1.5 m Control Cable

Generator Selector

Interface

PGU

Input PGU

a

3.0 m or 1.5 m Coaxial Cable

MPSMU or HPSMU Input SMU 3.0 m or 1.5 m Triaxial Cable

4155 MPSMU

4156 HRSMU

b

16442A SMU

Output Selected

40 cm Triaxial Cable

Connector Plate SMU

a. You can use two inputs for one selector, and four inputs for two selectors.

b. You can use two outputs for one selector and four outputs for two selectors. Selector

output is either one of the PGU outputs or the SMU output.

Agilent 16440A User’s Guide, Edition 4 15

Page 22

User's Guide

Maintenance

Maintenance

This section provides the following maintenance information:

• Cleaning

• Servicing

Cleaning the Selector

To maintain high performance, the selector must be kept clean. Oil, perspiration,

hair, dust, and dirt will degrade the board insulation, which increases leakage

current and decreases measurement accuracy.

Agilent Technologies recommend the following cleaning procedure:

1. Make sure that voltage or current is not present at any channel.

2. Disconnect all cables from the selector.

3. Using lint-free paper, gently wipe the chassis. For any area that will not come

clean, dip the lint-free paper into alcohol and wipe the area gently.

Servicing the Selector

This section provides information for trained service personnel to repair the selector.

When a replaceable part, which is shown with the Agilent part number in this

section, needs to be replaced, order the parts from the nearest Agilent Technologies

Sales and Service Office.

WARNING High voltages may be present in the selector when voltage or current is applied.

Be careful to avoid electric shock.

Before you repair the selector, make sure that terminals are not connected to any

instrument.

16 Agilent 16440A User’s Guide, Edition 4

Page 23

Circuit Block Diagram

User's Guide

Maintenance

Agilent 16440A User’s Guide, Edition 4 17

Page 24

User's Guide

Maintenance

Replaceable Parts

When soldering, use low hydrochloric acid solder (Agilent part number: 8090-0433)

to prevent the flux in the solder from spreading unnecessarily, and make sure that

adjacent terminals are not bridged. After soldering, make sure that there are no lint

bridges, which would increase the leakage current.

Reference

Designation

R1 0757-0442 Resistor 10 kW, 1%, 0.125 W

R6 0698-3440 Resistor 196 W, 1%, 0.125 W

R7 0757-0402 Resistor 110 W, 1%, 0.125 W

R8 0698-3440 Resistor 196 W, 1%, 0.125 W

R9 0698-3440 Resistor 196 W, 1%, 0.125 W

R12 0698-0085 Resistor 2.61 kW, 1%

18 Agilent 16440A User’s Guide, Edition 4

Agilent

Part Number

Description

Page 25

User's Guide

Maintenance

Reference

Designation

R13 0698-0085 Resistor 2.61 kW, 1%

R15 0757-0279 Resistor 3.16 kW, 1%

CR1 1901-0050 Diode

CR2 1901-0050 Diode

CR3 1901-0050 Diode

CR4 1901-0050 Diode

L1 9140-0210 Inductor 100 mH ±5%

C1 0180-3468 Capacitor 47 mF 50 V

CP1 1990-1625 Opto-isolator

CP2 1990-1625 Opto-isolator

K1 0490-1791 Reed Relay

K2 0490-1791 Reed Relay

K3 0490-1791 Reed Relay

K4 0490-1791 Reed Relay

DS8 1990-0967 LED Green

DS9 1990-0967 LED Green

DS10 1990-0967 LED Green

DS11 1990-0967 LED Green

DS12 1990-0967 LED Green

J1 1252-1481 Connector

J2 1250-1842 Connector BNC

J3 1250-1842 Connector BNC

J4 1252-1481 Connector

SW1 3101-2885 Switch - DIP

I1 0360-1641 Terminal

I2 0340-0060 Terminal

I3 0360-1641 Terminal

I4 0340-0060 Terminal

Agilent

Part Number

Description

Agilent 16440A User’s Guide, Edition 4 19

Page 26

User's Guide

Specifications

Specifications

The "supplemental information" and "typical" entries, in the following

specifications are not warranted, but provide useful information about the functions

and performance of the instruments.

The following specifications data is specified at 23 ± 5 °C and 50 % relative

humidity.

• Function

Agilent 16440A switches either a SMU or PGU to the associated output port.

You can expand to 4 channels by adding an additional 16440A. The channel 1

PGU port provides "PGU OPEN" function, which can disconnect the PGU by

opening a semiconductor relay. The 16440A can not work without two pulse

generator units of Agilent 41501 SMU and Pulse Generator Expander.

• Channel configuration: 2 channels (CH1 and CH2). Can add additional 2

channels (CH3 and CH4) by adding another 16440A (selector expander).

Input Output

Channel 1 (CH 1) 2 (SMU and PGU) 1

Channel 2 (CH 2) 2 (SMU and PGU) 1

Channel 3 (CH 3)

Channel 4 (CH 4)

a

a

2 (SMU and PGU) 1

2 (SMU and PGU) 1

a. These channels are available when an 16440A SMU/PG selector

expander is installed.

• Voltage and current range

Input port Maximum Voltage Maximum Current

SMU 200 V 1.0 A

PGU 40 V

0.2 A

a

a. This is peak-to-peak ac current.

20 Agilent 16440A User’s Guide, Edition 4

Page 27

• Accessories (furnished). See Section 1 for details.

• Option 001

• 1.5 m control cable (Agilent part number 04155-61612)

• 40 cm triaxial cable (Agilent part number 04155-61605)

• Option 002

• 3.0 m control cable (Agilent part number 04155-61611)

• 40 cm triaxial cable (Agilent part number 04155-61605)

• Option 003

• 40 cm control cable (Agilent part number 04155-61608) for connecting

selector to selector expander

• 40 cm triaxial cable (Agilent part number 04155-61605)

• General specifications

• Environment

Operating temperature 5 °C to 40 °C

User's Guide

Specifications

Storage temperature -40 °C to 70 °C

Operating Humidity 5 % to 80 % relative humidity

(at no condensation)

Storage Humidity 5 % to 90 % relative humidity at 65 °C

• Weight

Approximately 1.1 kg (2.43 lb)

Agilent 16440A User’s Guide, Edition 4 21

Page 28

User's Guide

Specifications

Supplemental Information

The following reference data is specified at 23 ± 5 °C (73 ± 9 °F) and 50 % relative

humidity.

• SMU channel

Leakage current less than 100 fA at 100 V

Residual resistance 0.2 W typical

Stray capacitance

(force common) 0.3 pF typical at 1 MHz

Stray capacitance

(force guard) 15 pF typical at 1 MHz

Stray capacitance

(guard common) 130 pF typical at 1 MHz

• PGU channel

Residual resistance 3.4 W

Stray capacitance

(relay off) 5 pF typical

Stray capacitance

(open) 700 pF typical (at 1 MHz Vin - Vou t = 0 V)

Signal transfer

characteristics Overshoot < 5 % of pulse amplitude (at 20 ns leading

and trailing time, 50 W pulse generator source

impedance, 50 pF 1 MW in parallel load)

22 Agilent 16440A User’s Guide, Edition 4

Loading...

Loading...