Page 1

Agilent 16192A

Parallel Electrode SMD Test Fixture

Operation and Service Manual

Page 2

Page 3

Agilent

16192A P

arallel

Electrode

SMD

T

est

Fixture

Operation and

Service

Manual

Agilent Part No. 16192-90030

Printed in JAPAN August 2001

Sixth Edition

Page 4

Notice

The

information

This

document

reserved.

language

contains

No

part

without

contained

proprietary

of

this

the

prior

in

this

document

written

document

information

may

be

consent

is

subject

that

is

photocopied,

of

the

Agilent

to

change

protected

reproduced,

T

echnologies.

without

by

copyright.

or

notice

.

All

translated

rights

to

another

are

Agilent

T

echnologies

Component

1-3-2,

Hyogo

Murotani,

,

651-2241

T

est

Japan,

PGU-Kobe

Nishi-ku,

Japan

Ltd.

Kobe-shi,

c

Copyright Agilent Technologies Japan, Ltd. 1993, 1996, 1999, 2000, 2001

Page 5

Manual Printing

The

manual

changes

at

reprint

technical

printing

when

do

not

changes

a

date

new

edition

cause

are

incorporated.

History

and part

is

the

date to

number indicate

printed. (Minor

change.)

The manual

its current

corrections and

part number

edition. The

updates that

changes when

printing date

are incorporated

extensive

December

June

1996

October

1996

December

September

A

ugust

2001

1993

:

:

:

1999

2000

:

:

:

::

::

:

:

::

::

::

::

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

::

::

::

::

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

::

::

::

::

:

:

:

:

:

:

:

:

:

First

Edition

::

::

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

::

::

::

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

::

::

::

:

:

:

:

:

:

:

:

:

:

:

:

Second

:

:

:

::

::

::

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

::

::

::

:

:

:

:

:

Third

::

Edition

:

:

:

:

::

::

::

::

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

::

::

::

:

F

ourth

Edition

::

::

::

::

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

::

::

::

::

:

:

:

:

Fifth

Edition

::

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

::

::

::

::

:

:

:

:

:

:

:

:

:

Sixth

Edition

(part

(part

(part

(part

number:

number:

number:

number:

Edition

16192-90010)

16192-90010)

16192-90020)

16192-90030)

iii

Page 6

Safety Summary

The

following

service

W

and

The

,

ARNINGS

intended

A

gilent

requirements

DO

NOT

Do

not

operate

electrical

K

eep

A

general

and

repair

given

T

of

elsewhere

use

of

the

echnologies assumes

.

Operate

the

instrument

instrument

way

From

in

safety

this

In

Live Circuits

precautions must

instrument. F

in

this

instrument.

An

Explosive

in

the

such

an

environment

be observed

ailure to

manual violates

no liability

for the

Atmosphere

presence

constitutes

comply with

safety standards

customer's failure

of

ammable

during all

these precautions

gasses

a

safety

hazard.

phases of

of design,

to

or

fumes

operation,

or with

manufacture,

comply

.

Operation

with

specic

these

of

any

Operating

adjustments

with

with

circuits

DO NOT

Do not

aid and

DO

Because

unauthorized

Sales

personnel

must

the

power

the power

be

cable

cable

must

made by

connected.

removed.

before touching

Service

attempt

resuscitation,

Or

internal

is

NOT Substitute

of the

danger

modications to

and Service

Oce for

them.

service

present.

P

of

introducing

Dangerous Procedure

Warning

this

Warning

s,

manual.

such as

Instructions

Dangerous

the

example

instrument.

this instrument.

not

remove

instrument covers

qualied maintenance

A

djust

arts

Under

T

o

or

Or

certain

avoid

Alone

adjustment

Modify

additional

the instrument.

service

and

repair

Warnings

below

,

precede

contained

voltages

Use

in

the

,

capable

extreme

conditions

injuries

,

always

unless

Instrument

hazards

Return

to

ensure

potentially

warnings

of

causing

caution when

. Component

personnel.

,

dangerous voltages

disconnect

another

,

do

not

the

instrument

the

dangerous

must

be

death,

handling,

Do

person,

substitute

safety

features

followed.

are

replacement and

not

replace

components

may

power

capable

parts

to

a

Agilent

and

discharge

of

or

are

maintained.

procedures

present in

testing,

and

internal

exist

rendering

perform

T

echnologies

throughout

this

adjusting

even

rst

The voltage levels found in this test xture

when used with the intended instruments do not

warrant more than normal safety precautions for operator safety

iv

.

Page 7

Operating Precaution

Do

not

exceed

appropriate

for

the

operating input

the

instrument

power,

being

used,

voltage,

refer to

and current

level and

your instrument's

signal type

operation manual.

Caution

Electrostatic discharge

your instrument.

being connected

grounding strap

ground yourself

outer

connectors.

Never touch

Use a

Certication

Agilent

of

measurements

T

echnology

facilities

T

echnologies

shipment

of

from

,

to

other

are

the

shell

of

work

station

certies

the

factory

traceable

extent

.

to

allowed

International

(

ESD damage

or disconnected.

that provides

to discharge

any

grounded

the

test

clip

equipped

that

this

product

Agilent

the

T

United

by

the

echnologies

Standards

esd

)can

is

a

high

any

instrument

contacts

with

met

States

Institution's

Organization

damage the

most

likely

Protect

them

resistance

static

charge

chassis

.

an

anti-static

its

published

further

National

Institute

calibration

members

highly sensitive

to

occur

as

from

ESD

path

to

built-up

before

work

by

touching

surface

specications

certies

that

of

Standards

facility

.

microcircuits

the

test

xtures

damage

ground.

Alternatively

touching

the

.

at

the

its calibration

and

,or

to the

in

are

by

wearing

the

test

port

time

calibration

a

,

W

arranty

This

Agilent

workmanship

certain

for

the

either

F

or

warranty service

Agilent T

T

echnologies

pay all shipping charges

another country

Agilent T

Technologies for use with an

T

echnologies

for

components

specied

repair

or replace

a

period.

instrument

period

listed

of

in

During

products which

or repair

echnologies.

shall

Buyer shall

pay

shipping

, duties

.

echnologies warrants that

product

one

year

Instrument

the

warranty

from

is

the date

Specications

period,

prove to

, this

product must

prepay shipping

charges

to

return

, and taxes for products returned to Agilent T

its software and rmware designated by Agilent

instrument will execute its programming instruction when

property installed on that instrument. Agilent T

of the instrument, or software

,or

rmware will be uninterrupted or error free

warranted

be

defective

be

returned

charges to

the

against

of shipment,

of

this

manual, the

Agilent

T

echnologies will,

.

to

Agilent T

product

to

defects

except that

a

service

echnologies

Buyer

. However

in material

in the

and

case

warranty shall

at its

option,

facility

designated

and

,

Buyer

of

be

by

Agilent

shall

echnologies from

echnologies does not warrant that the operation

.

v

Page 8

Limitation Of

The

foregoing

maintenance

misuse

,

operation

preparation

No

other

implied

warranty

by

Buyer

or

maintenance

warranty

warranties

outside

Warranty

shall

not apply

,

Buyer-supplied

of

the

.

is

expressed or

of

merchantability

to defects

software

resulting from

or interfacing,

environmental specications

implied. A

and

gilent T

tness

echnologies specically

for a

particular purpose

improper or

inadequate

unauthorized modication

for the

product, or

improper site

disclaims

.

or

the

Exclusive

The

remedies

shall

not

whether

be

liable for

based

provided

Assistance

Product

Agilent

F

or

A

ddresses

maintenance

T

echnologies

any

assistance

are

Remedies

herein

any direct,

on

contract, tort,

agreements

products

,

contact

provided

at

are

or any

.

your

nearest Agilent

the

back

buyer's

sole

and exclusive

indirect, special,

other legal

and

other

customer assistance

T

of

this

manual.

incidental, or

theory.

echnologies

remedies.

consequential

agreements are

Sales

and

Service

Agilent

Technologies

damages

available

Oce

,

for

.

vi

Page 9

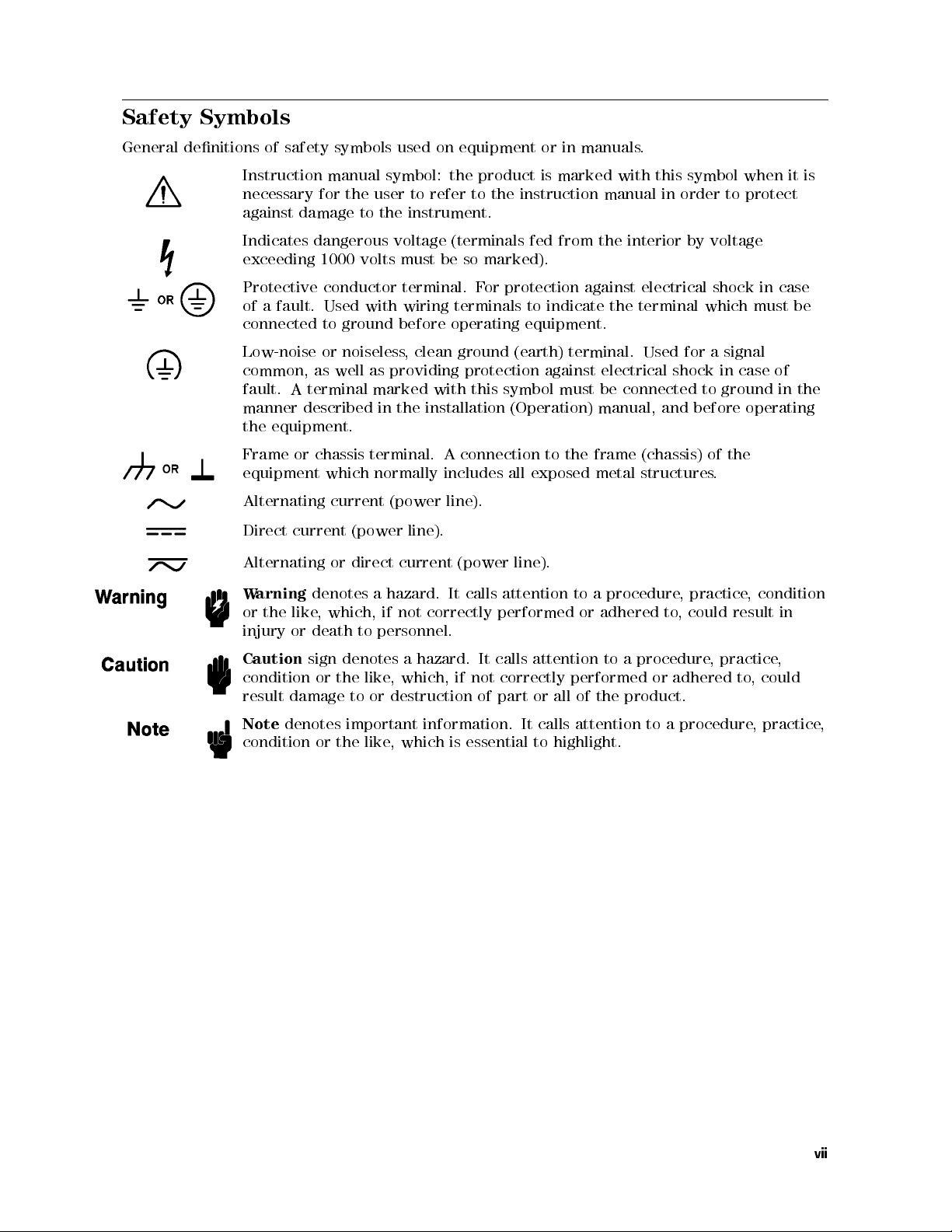

Safety Symbols

General

denitions

Instruction

necessary

against

Indicates

exceeding

Protective

of

connected

Low-noise

common,

fault.

manner

the equipment.

Frame

equipment

Alternating

Direct current

Alternating

W

or

injury

of

safety

a

fault.

A

or

arning

the

like

or

symbols used

manual

for

damage

dangerous

1000

the

user

to

the

volts

symbol:

voltage

conductor

Used

with

to

ground before

or

noiseless,

as

well as

providing protection

terminal marked

described

chassis

which

current

in the

terminal.

normally

(power

(power line).

or

direct

current

denotes

,

death

which,

to

a

hazard.

if

not

personnel.

on equipment

the

product

to

refer

to the

instruction manual

instrument.

must

be

terminal.

wiring

(terminals

so

F

terminals to

fed

marked).

or

protection

operating equipment.

clean ground

with this

(earth) terminal.

symbol must

installation (Operation)

A

connection

includes

all

line).

(power

It

calls

correctly

line).

attention

performed

or in

manuals.

is

marked with

from

the interior

against electrical

indicate the

against electrical

be connected

manual, and

to

the

frame

exposed

to

or

metal

a

adhered

procedure

this symbol

in order

to protect

by voltage

shock in

terminal which

Used for

a

signal

shock in

to

ground

before operating

(chassis)

structures

of

.

,

practice,

to

,

could result

the

when it

must

case

of

condition

case

be

in

in

is

the

Caution

condition

result

Note

sign

or

damage

denotes

condition or

denotes

the

like

to

or

important

the like

a

hazard.

,

which,

if not

destruction

information.

,

which

is

It

calls attention

correctly performed

of

part or

all of

It calls

essential

to

highlight.

to

a

procedure

the

product.

attention to

,

or

adhered

a procedure

practice

to

,

could

, practice

,

,

vii

Page 10

APC-7

viii

R

is a U.S. registered trademark of the Bunker Ramo Corporation.

Page 11

Contents

1.

General

Introduction

Manual Summary

Product Description

Applicable Instruments

Options A

A

ccessories

Specications

Supplemental

Residual

2.

Preparation

Introduction

Initial

Inspection

A

djusting

Connecting

Repackaging

Measurement

3.

Operation

Introduction

Operating

Overview

How

to

set

Setting

Setting

How

to

connect

Information

.

.

.

.

vailable

Supplied

Inductance

the

the

Flow

.

the

the

the

.

.

.

.

P

erformance

for

Use

.

.

.

.

.

.

Conguration

T

est

the

T

est

Error

Correcting

.

.

.

.

.

.

.

.

.

.

SHORT

SHORT

OPEN

the

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Characteristics

of

the

Shorting

.

.

.

.

.

.

Fixture

Fixture

.

.

.

.

.

.

.

..

condition,

condition

condition

DUT

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

to

SMD

for

Use

F

or

Function

.

.

..

..

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Bar

.

.

.

.

.

.

Size

.

Shipment

.

.

.

..

.

.

.

.

and

the OPEN

.

..

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

for

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

Each

..

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

..

..

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

.

.

.

.

.

.

.

..

..

.

.

..

.

.

.

.

.

.

.

.

.

.

Instrument

.

.

.

.

.

.

.

.

.

.

.

.

condition .

.

.

.

.

.

.

.

.

..

..

.

..

.

.

..

..

..

.

.

.

..

..

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

..

..

.

.

.

.

.

..

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

..

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 3-1

. 3-2

.

.

.

.

.

.

.

.

1-1

1-1

1-1

1-1

1-2

1-2

1-2

1-3

1-4

2-1

2-1

2-3

2-4

2-5

2-6

3-1

3-3

3-3

3-4

3-5

4.

Service

Introduction

General

Assembly Replacement . . . . . . . . . . . .

Disassembly and Assembly Procedure . . . . . . . . . . . . . . . . . . .

Length P

Width P

Replaceable

Troubleshooting

Open Impedance Check

Short Impedance Check

Short Impedance Repeatability Check . . . . . . . . . . . . . . . . . . . . 4-11

..

..

..

..

..

.

.

.

.

.

.

.

.

.

.

.

..

..

..

..

Information

ositioning Stage Assembly Removal:

ositioning Stage Assembly Removal: . . . . . . . . . . . . . . . .

Parts .......................

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

..

.

.

................

...... ...... ...

.........................

........

.........

..................

.................

.

.

......

......

..

.

.

..

.

4-1

.

4-1

4-3

. 4-3

4-3

4-3

4-4

4-10

4-10

4-11

Contents-1

Page 12

Figures

1-1. Applicable

1-2. Simulation

2-1. 16192A

2-2. Electrodes

2-3. Connecting

3-1.

16192A

4-1.

16192A

4-2.

Replaceable

4-3.

Replaceable

4-4. Replaceable

4-5.

Replaceable

4-6. Replaceable

4-7. Obsolete

4-8. Shorting

T

ables

1-1.

Furnished

1-2.

Supplied

1-3.

Option

2-1.

16192A

2-2.

Measurement

4-1.

16192A

4-2.

Replaceable

4-3.

Replaceable

4-4.

Replaceable

4-5.

Replaceable

4-6.

Replaceable

4-7. Open Impedance V

4-8. Short Impedance V

4-9. Short Impedance Repeatability Guideline

DUT

Size

.

Setup

Product

conguration and

the T

T

est

Fixture

Product

P

P

P

P

P

parts manufactured

Device

Accessories

Shorting

010

Shorting

Contents

Product

P

P

P

P

P

.

.

Overview

est

Fixture

Overview

Overview

arts

for

Main

arts

for

Length

arts

for

Insertion

arts

for

Width

arts

for

T

est

P

osition

Device

Device

.

.

Error

Correcting

Overview

arts

for

Main

arts

for

Length

arts

for

Insertion

arts

for

Width

arts

for

T

est

alue Guideline . . . . . . .

alue Guideline . . . . . . . . . . . . . . . .

.

.

.

.

.

Assembly

Stage

.

.

.

Residual

.

.

Assembly

Stage

.

.

.

.

.

SMD

with

.

.

P

ositioning

Clip

P

ositioning

earlier

.

.

.

.

Residual

.

.

Functions

.

.

P

ositioning

Clip

P

ositioning

.

.

.

.

.

.

.

.

.

.

.

.

Size

APC-7

.

.

.

.

.

.

.

.

.

Assembly

Assembly

than

.

.

.

.

.

.

.

.

Inductance

Inductance

.

.

.

.

.

.

.

.

.

Assembly

Assembly

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

R

Connector (4291B)

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

..

.

.

.

.

.

.

.

.

Stage

Assembly

.

.

.

.

.

Stage

Assembly

.

.

.

.

.

.

.

1996

.

.

.

for

.

.

Stage

Stage

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

(Typical)

(Typical)

.

.

.

.

.

..

Each

Instrument

.

.

.

.

.

.

.

.

.

..

..

..

Assembly

.

.

.

..

Assembly .

..

.

.

.

.

.

...... ...... ...

...... ...... ......

..

..

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

..

.

.

..

..

..

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

..

..

..

.

.

.

.

..

.

.

.

.

..

.

..

..

.

..

.

.

.

..

.

..

.

..

..

.

.

.

.

.

.

.

.

.

.

.

.

.

..

..

.

.

.

.

..

.

.

.

.

..

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

.

..

..

..

.

.

..

..

.

..

.

......

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

.

..

.

.

..

.

.

.

.

.

.

.

.

.

.

.

..

.

.

1-3

.

1-5

.

2-2

2-3

.

2-4

.

3-2

.

4-2

.

4-4

4-5

.

4-6

.

4-7

4-8

. 4-9

.

4-10

.

1-2

.

1-4

.

1-4

.

2-2

.

2-6

.

4-2

.

4-4

.

4-5

.

4-6

4-7

.

4-9

4-11

4-11

4-11

Contents-2

Page 13

1

General

Information

Introduction

The

purpose

Fixture

Manual

This

manual

The

specications

Installing

Operating

Ordering

Product

The 16192A

of

this manual

eciently

Summary

contains

the

16192A

the

16192A

replaceable

Description

is

used

repeatability.

and

condently.

the

of

the

parts

to

measure

is to

following:

16192A

(see

Chapter

(see

Chapter

for

enable you

(see

2).

3).

the

16192A

a

parallel

to

this

chapter).

(see

electrodes

use

Chapter

your

surface

16192A

4).

mount

P

arallel

device

Electrode

(SMD)

SMD

with

T

high

est

Applicable

The

16192A

Instruments

has

been

designed

to

operate

specically

with

the

following

LCR

meters

impedance analyzers:

Y

ou

can

directly

Y

ou

can

use

the

connect

16192A

the

with

16192A

43961A:

to:

4191A,

4395A

4291B

(option

,

E4991A

010),

4396A/B (option 010)

You can use the 16192A with 41951A:

You can use the 16192A with RF adapter 42942A:

You can use the

You can use the 16192A

1

The 4284A is a typical instrument. Other 4-terminal pair instruments that can be used with the 16085B are

16192A with RF adapter 16085B:

with RF adapter 16099A:

4195A

4294A

4284A

1

4194A with 41941A

23

also applicable.

2

The 4194A with 41941A is a typical instrument. Other instruments that can be used with the 16099A are also

applicable.

3

The 16192A is not adapted by some old type 16099A. For detail, please contact your Agilent Technologies sales

oce.

General Information 1-1

and

Page 14

Options A

The

following

vailable

option

is

supplied for

the 16192A:

Option

Option

A

The

001

010

Delete

A

dd

the

industry

ccessories Supplied

following

accessories

Description

Operation

Shorting

Case

Option

Magnifying

for

010

and

device

shorting

*1

lens

Tweezers

Insulator

magnifying

standard

are

supplied

T

able

Service

(4

types)

devices

lens

size short

with

1-1.

Manual

and tweezers

bar set

the

16192A:

Furnished

Part

P/N

P/N

P/N

P/N

P/N

P/N

P/N

P/N

P/N

P/N

P/N

P/N

P/N

A

ccessories

Number Quantity

16192-90030

16191-29001

16191-29002

16191-29003

16191-29004

1540-0692

16191-29005

16191-29006

16191-29007

16191-29008

16193-60002

8710-2081

16192-09002

1

1

1

1

1

1

1

1

1

1

1

1

1

*1

Option

set

2012(mm)/0805(inch),

has

has

the

010

the

same

sizes

following

size

as

are

the

same

as

industry

SMD

sizes

included

3216(mm)/1206(inch).

the

EIA/EIAJ

sizes

standard

:

1005(mm)/0402(inch),

Order

(EIA/EIAJ)

option

.

010

SMD

1608(mm)/0603(inch),

if

the

SMD

Specications

This

section lists the complete 16192A specications

standards and limits against which the 16192A is tested. When

. These specications are the performance

shipped from the factory

16192A meets the following specications:

Maximum DC Bias V

Operating T

emperature

Operating Humidity

:::::::::::::::::::::::

Non-operating Temperature

Non-operating Humidity

oltage

:::::: :

::::::::::

:::::: ::::::: ::::::: :::::

:::::::::::::::::::::::::

(@wet bulb temperature

:::::::::::::::::::::::::

:::::::::::::::::::::::::::::::::::::::::::::::::::::055 to +85C

(@wet bulb temperature<65C)

:::::::::::::::::::::::::

:::::::::::::::::::::::

C)

<

40

::::::: :::::: ::::::: :::::

:::::: ::::::: ::::::: :::::: ::::::: ::::::: :::::: ::::::: ::::::: :::::: ::::::: ::::::: :

Weight

Dimension

:::::: ::::::: ::::::: :::::: ::::::: ::::::: :::::: ::::::: ::::::: :::::: ::::::: ::::::: :::::

:::::: ::::::: :::::: ::::::: ::::::: :::::: ::::::: ::::::: :::

150(W)270(H)290(D) [mm]

sizes

.

This

short

that

is

to

be

0

:::::

15 % to 95 % RH

Up to 90 % RH

bar

measured

, the

::::::

55

to +85

6

40V

400 g

C

1-2 General Information

Page 15

Supplemental P

This

section

characteristics

information

lists

supplemental

are

not

for

the

operator

erformance Characteristics

performance characteristics

specications

.

Supplemental

,

but

are typical

performance characteristics

. Supplemental

characteristics included

performance

as additional

are not

guaranteed.

Frequency

Applicable

Supplied

P/N

P/N

P/N

P/N

Option

P/N

P/N

P/N

P/N

Electrical

A

dditional

Repeatability

(for

:

:

:

3

f:

frequency

Range

DUT

shorting

16191-29001

16191-29002

16191-29003

16191-29004

010

shorting device

16191-29005

16191-29006

16191-29007

16191-29008

length

Error

inductive

:

:

:

:

:

:

:

size

(when

3

3

component)

::

::

:

:

:

(GHz)

:

:

:

:

:

:

(see

device

:

:

:

:

::

:

:

:

:

::

:

:

:

:

::

::

::

::

::

::

::

::

::

::

::

::

::

:

:

::

::

:

:

:

:

:

:

:

:

:

:

:

::

::

::

::

Figure 1-1

size

::

::

:

:

::

::

:

:

::

::

:

:

::

:

:

:

:

size

::

:

:

:

:

::

:

:

:

:

::

:

:

:

:

:

:

:

:

:

:

the

length

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

)

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

between

:

:

:

:

:

:

:

:

:

:

:

::

:

:

:

:

:

:

:

:

:

:

:

:

::

::

::

::

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

::

::

::

::

:

:

DC

to

2

GHz

:

::

::

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

::

::

::

::

:

:

:

:

:

:

:

:

:

:

:

:

1

mm

to

20

mm

:

:

:

:

:

:

:

:

:

:

::

::

::

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

::

::

::

1

2

1

2

2.4

[mm]

:

:

:

:

:

:

:

:

:

:

::

::

::

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

::

::

1.6

2

2.4

2

2

[mm]

:

:

:

:

:

:

:

:

:

:

::

::

::

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

::

2.4

2

2.4

2

3.2

[mm]

:

:

:

:

:

:

::

::

::

::

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

::

::

::

2.4

2

2.4

2

4.5

[mm]

:

:

:

:

:

:

:

::

::

::

::

:

:

:

:

:

:

:

:

:

:

:

:

:

1.0(L)

:

:

:

:

:

:

:

::

::

::

::

:

:

:

:

:

:

:

:

:

:

:

:

:

1.6(L)

:

:

:

:

:

:

:

::

::

::

::

:

:

:

:

:

:

:

:

:

:

:

:

:

2.0(L)

:

:

:

:

:

:

:

:

:

::

::

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

3.2(L)

electrodes is

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

::

::

::

::

:

:

:

:

::

:

:

:

:

:

:

:

:

:

:

:

:

:

2

mm)

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

::

::

:

2

0.5(W)

2

0.8(W)

2

1.2(W)

2

1.6(W)

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

::

::

::

::

:

(impedance

:

:

:

:

:

:

:

:

:

:

(admittance

2

0.5(H) [mm]

2

0.8(H) [mm]

2

0.8(H) [mm]

2

0.8(H)

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

1.5

:

:

30

+

250

of

30

:

:

:

:

:

2

+

of

:

:

m,

30

2

[mm]

::

11

mm

2

[%]

2

f

2

f

[m]

40

pH)

2

f

[

S]

S,

5

fF)

Figure 1-1. Applicable DUT Size

General Information 1-3

Page 16

Residual Inductance

The

usual

method

In

this

method,

shorting

not

On

bar's

estimated.

the

other

measurement

inductance

a

reference

conditions

The

reference

relative

The

measurement

reproduce

as

of

dierence

the

value

to

compensate the

the

measurement

impedance

hand,

result

a

result

.

the

measurement

there is

is

the

of

This

method,

.

The

a denition

absolute

its

size and

inductance values

to a

disk-type 0

of these

short bars

reference inductance

Table

1-2. Supplied

of the

test xture's

result

short

bar's residual

value

shape is

is useful

system.

presented T

termination

under other

values.

Shorting

Shorting Bar

residual inductance

is the

relative value

inductance as

method to

of the

let SHORT

device's impedance

estimated under

for devices

able 1-2

with values

and T

on either

conditions than

Device

Residual

of the

a result

=

x

specic

able

1-3

the

7

mm

Inductance

is to

let SHORT

measured impedance

of its

size and

H.

In

this

method,

.The

short

bar's

which

were

or

shown

conditions

are

simulated

the

below

close

3.5

and

to

as

mm

cannot

(Typical)

=0H.

to the

shape is

the

residual

is

used

the

short

the

connector

as

.

Shorting

P/N

16191-29001

P/N

16191-29002

P/N

16191-29002

P/N

16191-29002

P/N

16191-29003

P/N

16191-29004

T

able

Shorting

P/N

16191-29005

P/N

16191-29006

P/N

16191-29007

P/N

16191-29008

Bar

1-3.

Bar

l

[mm]d[mm]h[mm]

Oset

[mm]

1 2.4 1 0.75 3.5

1.6 2.4 2 0.45 3.5

2 2.4 1.6 0.25 3.5

2.4 2 1.6 1.3 7

3.2 2.4 2.4 0.9 7

4.5 2.4 2.4 0 7

Option

010

Shorting

l

[mm]d[mm]h[mm]

Device

Oset

Residual

[mm]

1.0 0.5 0.5 0.75 3.5

1.6 0.8 0.8 0.45 3.5

2.0 1.2 0.8 1.5 7

3.2 1.6 0.8 0.9 7

Connector Inductance

(Typical)

mm

mm

mm

mm

mm

mm

Inductance

(Typical)

0.2

0.2

0.2

0.7

0.6

0.6

Connector Inductance

(Typical)

mm

mm

mm

mm

0.5

0.4

0.9

0.8

nH

nH

nH

nH

nH

nH

nH

nH

nH

nH

1-4 General Information

Page 17

Figure

1-2.

Simulation

Setup

General Information 1-5

Page 18

Page 19

2

Preparation

for Use

Introduction

This

chapter explains

Initial

Connecting

inspection.

the test

Repackaging

Measurement

the test

how to

xture for

xture for

error correcting

Initial Inspection

The

parallel

from

the

should

inspection

missing

Agilent

the

claim

electrode

factory

also

be

in

to

check

contents

T

echnologies

to

be

.

It

should

perfect

the

.

If

any

sales

settled.

SMD

parallel

install the

use.

shipment.

function

test

xture

be

in

perfect

electrical

electrode

discrepancy

oce

will

16192A.

for

has

been

physical

condition.

SMD

is

found,

arrange

each

V

erify

test

notify

for

repair

The

carefully

topics

instrument.

inspected

condition,

this

by

xture

the

carrier

and

include

no

the

scratches

carefully

set

for

signs

and

replacement

following:

before

,

dents

being

performing an

of physical

Agilent

Technologies

without

shipped

or

the

incoming

damage

waiting

like

.It

.

for

and

Y

our

Inspect

the

completed.

V

erify

that

T

able

2-1

.

Inspect the

shipping

the

exterior of

container

shipping container

the

for

16192A

damage

. Keep

the shipping

contains everything

for

any

signs

of

damage

shown in

.

materials

Figure 2-1

until

and

the

inspection

listed

is

in

Preparation for Use 2-1

Page 20

Figure

T

able

2-1.

16192A

2-1.

16192A

Product

Contents

Overview

1

T

est xture

2

Operation

3

Shorting device

4Case for shorting device

5Magnifying lens

6Tweezers

7Insulator P/N 16192-09002

1

Operation and Service Manual is not shown in Figure 2-1.

2

Depending on your order conguration.

3

The magnifying lens is packed separately from the 16192A body. Connect it as shown in

Figure 2-1.

4

Not contained if you ordered the 16192A option 001.

2-2 Preparation for Use

Description

and Service

2

34

4

Agilent

P

art

Number

16192A

1

2.4[mm]) P/N 16191-29001

(1

Manual

212

P/N

16192-90030

(1.622.422[mm]) P/N 16191-29002

(2.422.423.2[mm]) P/N 16191-29003

(2.422.424.5[mm]) P/N 16191-29004

P/N 1540-0692

P/N 16193-60002

P/N 8710-2081

Quantity

1

1

1

1

1

1

1

1

1

1

Page 21

Adjusting

The

16192A's

follows

.

the Conguration

applicable

SMD

size is

1mm

to SMD

to 20

mm, changing

Size

the electrodes

conguration as

Figure 2-2. Electrodes conguration and SMD Size

Preparation for Use 2-3

Page 22

Connecting the

Note

Some

\Applicable

1.

Calibrate

T

able

standards

2.

Place

3.

Tighten

your

analyzer

2-2

for

the

applicable

from

the

the

xture

on

(turn counterclockwise)

Test

Fixture for

instruments

Instruments"

at

the

error correcting

R

APC-7

the

connector

APC-7

require

R

APC-7

.

R

connector

the coupling

Use

an

adapter

in

Chapter

connector

function. After

.

nut of

to be

1).

plane

before

the APC-7

connected to

the 16192A

connecting

calibration, disconnect

R

connector

test

.

(see

xture

any

.See

Figure 2-3. Connecting the T

2-4 Preparation for Use

est Fixture with APC-7

R

Connector (4291B)

Page 23

Repackaging the

If

shipment

repackaged

If

this

electrode

sucient

and

to

to

using

material

SMD

shock

prevent

an

Agilent T

the

original

is

not

available

test

xture

absorbing

movement.

Test

Fixture F

echnologies service

factory

packaging

, comparable

in

heavy

material

Seal

paper

on all

sides of

the

shipping container

or Shipment

center is

required, each

materials.

packaging materials

and

pack in

anti-static plastic

the 16192A

securely and

may be

to provide

mark it

test xture

used. Wrap

should be

the parallel

packing material.

a

thick,

FRA

rm

GILE

Use

cushion

.

Preparation for Use 2-5

Page 24

Measurement Error

Each

LCR

meter

functions

of

Open/Short/Load

T

able

or

analyzer has

the

instrument

compensation.

2-2.

Measurement

Correcting Function

measurement error

that

can

be used

Error Correcting

for calibration,

correcting functions

Functions for

for Each

setting the

Each Instrument

Instrument

.T

able 2-2

shows the

electrical length,

and

Instrument Calibration Electrical

4291A Calibration

OPEN

Selecting

P

ort Extension

SHORT

LO

AD

LOW-LOSS

Capacitor

4191A Calibration

0

S

0

50

4194A

with

No

capability

1

Electrical Length No capability No capability No capability

No

16085B

4195A

with

41951A

4194A

with

41941A/B

16099A

4194A

with

16085B

1

A

ccording

,

to

Calibration

demand

SHORT

LO

AD

Calibration

0

S

0

50

Calibration

0

S

0

50

for

precise

OPEN

measurement

P

ort

(Port

No

No

length

T

est

Fixture

capability

Extension

1

or

P

ort

capability

capability

OPEN

Compensation

OPEN

Compensation

OPEN

Correction

0

S

OFFSET

SHORT

Compensation

SHORT

Compensation

SHORT

CorrectionLOAD

0

OFFSET

LO

AD

Compensation

LO

AD

Compensation

Correction

No

capability

1

1

2)

Compensation

ZERO

OPEN

Compensation

ZERO

OPEN

Compensation

ZERO

SHORT

Compensation

ZERO

SHORT

No

capability

No

capability

2-6 Preparation for Use

Page 25

Operation

Introduction

This

chapter describes

techniques

for the

how to

test xture

use the

.

test

xture

and

the

measurement

error

3

correcting

Operating

Before

xture

measuring

performing a

by using

the

The

16192A

measurement.

measurement

Flow

the

measurement

DUT:

has

inherent

To

compensate for

instrument's

measurement, you

stray

capacitance

these

residuals

OPEN

and

SHORT

Described

The

16192A's

T

o

set

the

T

oset

the xture

7

\How

to

have

correcting

,

residual

and

compensation

(

7

indicates

in

Chapter

electrical

electrical

set

the

to

compensate

functions

inductance

thus

minimize

capabilities

procedures

2.

length

length,

and

devices

SHORT

for

.

P

,

and

residual

their

must

is

11

see

your

for

xture

condition,

the

erform

resistance

eect

on

be used.

in

the

mm

analyzer's

and

residual

the

error

following

that

aect

measurement

following

(typical

pages

value).

Operation

compensation,

the

OPEN

of

the

steps

the

accuracy

.)

Manual.

see:

condition

test

when

,

the

"

These

OPEN/SHORT/LOAD compensation procedure

For how to

supplied with your analyzer

To connect the DUT

3

The compensating functions are dierent for each instrument. See Table 2-2 and perform the listed functions.

procedures

show

how

measure OPEN/SHORT/LO

, see:

7

\How to connect the DUT"

to

set

the

AD, see the Operation Manual

.(Y

ou can omit LO

test

xture

for

the

.

AD compensation.)

Operation 3-1

Page 26

Overview

Figure

Length

Length

Device

Device

Width

Width

Device

positioning

locking

stage

knob

stage

holder

locking

positioning

knob

stage

holder adjustment

Electrodes

Device scale

Insertion clip

Shorting device

Four types of shorting devices are supplied with

When making a shorting device of same dimensions as your DUT

3-1.

16192A

Slides

to

Fixes

the

T

eon

sheet

Fixes

a

device

Fixes

the

Fixes

the

Moves the

These are

x

length

width

device

connected to

T

est

Fixture

an

electrode

positioning

to

place

the device

.

positioning

holder

device holder

.

and the

.

the device

Used for rough adjustment of the length positioning stage

Tightens or loosens an electrode

(

Not shown in Figure 3-1

) Used for short compensation.

the 16192A. Use one that has dimensions similar to the DUT

, very low residual

conductivity metal (that is not easily corroded) must be used to construct the

clean.)

Magnifying lens

(

Not shown in Figure 3-1

) Used when placing a small device

within the electrodes.

Overview

stage

.

.

stage.

device stage

.

.

impedance and a high

shorting device

.

.

.

. (It must also be

Warning

3-2 Operation

DO NOT look at the sun through the magnifying glass.

DO NOT operate or leave the magnifying glass under direct sunlight.

Page 27

How to

set the

SHORT condition,

and the

OPEN condition

Setting

The

the

names

SHORT

of

each

part

are

condition

listed

above

.

1.

Loosen

the

three

knobs

.

2.

Move stage

outside

Aand

the

two

device

holders

to

the

.

4. Place the shorting device so that it contacts the

electrode.

3.

Adjust

stage C

so

that

the

on

position

s

shorting

.

device

is

placed

5. Adjust the two B stages and the two device holders

to hold the shorting device.

Operation 3-3

Page 28

6.

Tighten

the

device holders

8.

Tighten

knob

two

.

A

B

knobs

while

to

x the

pushing the

B stages

lever.

and the

7.

1

Push

the lever

contacts

9.

Release

the

until the

the

shorting

the

lever

.

electrode on

lever

to

2

Slide stage

device

hold

.

the

A while

the stage

shorting

pushing

A

slightly

device

.

Setting the

OPEN

condition

1. Set the DUT on the test xture just as you set the

shorting device in the SHORT compensation.

3-4 Operation

2. Push the black lever and remove the DUT.

Page 29

How to

1.

Push

connect the

the

lever

and

place

the

DUT

DUT

on

the

electrode

.

2.

Release

the

lever

to

hold

the

DUT.

Operation 3-5

Page 30

Page 31

Service

Introduction

This

chapter

covers

the following

4

subjects:

General

Assembly

Information

Replacement

Disassembly

Replaceable

Procedure for

Parts

Troubleshooting

W

arning

Caution

These

NOT

section)

When

inner

(Agilent

servicing

perform

unless

you

repair

parts

of

part

General Information

T

able

4-1

shows

all

items

included

main assembly

instructions

any

servicing

you

are

the

16192A,

the

16192A.

number

9300-0163).

with

the

are for

(other

qualied

put

Agilent T

16192A

use by

than

to

do

so

on

lint-free

echnologies

P

arallel

qualied personnel

that

contained

.

groves

Electrode

to

supplies

SMD

avoid

lint-free

only

in

the

operating

contaminating

groves

T

est

Fixture

.

Do

.

Service 4-1

Page 32

Figure

T

able

4-1.

4-1.

16192A

16192A

Product

Product

Overview

Overview

Reference

Agilent

Designator

1 (not assigned) 1 Main Assembly

2 16193-60002 1 Magnifying

3 16192-09002 1 Insulator

4 8710-2081 1 Tweezers

5 16191-29001 1 Shorting Device (1

6 16191-29002 1 Shorting Device (1.6

7 16191-29003 1 Shorting Device (2.4

8 16191-29004 1 Shorting Device (2.4

9 1540-0692 1 Case for shorting devices

- 16191-29021 1 Styrofoam Holder

- 16192-90030 1 Operation and Service Manual

1 Not shown in the gure.

4-2 Service

P

art

Number Qty

.

Description

Glass

2

122.4 mm)

2

2.422mm)

2

2.423.2 mm)

2

2.424.5

mm)

1

1

Page 33

Assembly Replacement

This

Main

section

Assembly

includes

.

Disassembly

and Assembly

Procedures and

Replacement P

arts for

the

Disassembly

This

section contains

Length

1.

2.

Width

1.

2.

3.

P

Loosen

Remove

P

ositioning

Loosen

Remove

Remove

ositioning

the

the

each

each

the

and Assembly

the

information

Stage

Length

Length

Locking

P

ositioning

Stage

Width

Device

Width

P

ositioning

P

ositioning

Stage

Procedure

required

Assembly

Knob

(\1"

Stage

Assembly

Knob

Stage

(\2"

in

T

able

to

Removal:

in

T

able

Assembly

Removal:

(\1"

in

T

able

Assembly

4-2

).

disassemble

4-3

).

(\1"

in

T

able

4-5

).

(\3"

and

and

\4"

assemble

4-2

).

in

T

able

4-2

the

).

Main

Assembly

.

Service 4-3

Page 34

Replaceable

T

able

4-2

through

can

be

ordered

include

the

Agilent

P

arts

T

from

able

your

part

4-5

show

nearest

number

and

Agilent

and

list

the replaceable

T

echnologies Oce

the

quantity

parts for

required.

the 16192A

. Ordering

.The

parts listed

information must

Reference

Designator

1 (not assigned) 1 Length P

2 16192-09001 1 Device Stage

3 (not assigned) 1 Width Positioning Stage Assembly

4 (not assigned) 1 Width Positioning Stage Assembly

5 (not assigned) 1 Test Stage Assembly

4-4 Service

Figure 4-2. Replaceable P

Table

4-2. Replaceable P

Agilent P

art

arts for Main Assembly

arts for Main Assembly

Number Qty. Description

ositioning Stage Assembly

Page 35

Figure

Table

4-3.

Replaceable

4-3. Replaceable

P

P

arts

arts

for

for

Length

Length

P

ositioning

P

ositioning

Stage

Stage

Assembly

Assembly

Reference

Designator

1 16192-24006 1 Length

2 16192-20002 1 Length P

Agilent

P

art

Number Qty

.

Locking

ositioning Stage Block

3 16192-23001 2 Nut

4 16192-01202 1 Contact

5 0515-2421 2 Screw M1.4L3

6 (not

assigned)

1 Insertion

Clip Assembly

7 3050-1066 2 Washer

8 2190-0654 2 Washer

9 0515-0976 2 Screw Pan Head M2L6

10 16192-25004 1 Rod

Description

Knob

Service 4-5

Page 36

Figure

Table

4-4.

Replaceable

4-4.

Replaceable

P

P

arts

arts

for

for

Insertion

Insertion

Clip

Clip

Assembly

Assembly

Reference

Designator

1 0520-0133 1 Screw

2 2190-0014 1 W

3 16092-40010 1 Holder

4 16092-40016 1 Holder

5 16092-40011 1 Lever

6 16092-23010 1 Shaft

7 1460-0352 1 Spring

4-6 Service

Agilent

P

art

Number Qty

.

Description

asher

Page 37

Figure

4-5.

Replaceable

P

arts

for

Width

P

ositioning

Stage

Assembly

Table

Reference

Designator

1 16192-24006 2 Width

2 16192-24005 2 Device

4-5.

Replaceable

AgilentP

art

P

Number Qty

arts

for

.

Width

P

ositioning

P

ositioning

Holder A

3 16192-24004 2 Holder

4 16192-25002 1 Device

Holder L

5 16192-25003 1 Device Holder R

6 0515-0994 2 Screw Flat Head M2L6

Stage

Assembly

Description

Knob

djustment Knob

Service 4-7

Page 38

4-8 Service

Figure 4-6. Replaceable Parts for Test Stage Assembly

Page 39

T

able 4-6.

Replaceable P

arts for

T

est

Stage

Assembly

Reference

Designator

1 0515-0914 4 Screw

2 16192-00201 1 Table

3 16192-00603 1 Plate

4 16192-01201 2 Angle

5 16192-60001 1 Contact

6 16192-24013 3 Nut

7 0515-0952 3 Screw

8 1250-0907 1 Contact-RF

Caution

Agilent P

art

Number Qty. Description

Flat

Head

M3L6

Assembly

Flat

Head

M2L4

Connector

If

your

to

replace

5),

it

and

(

Figure

will

5)

16192A

since

4-6

either

be

necessary

they

:

3

and

test

the

xture

plate

were

5)

was

manufactured

(

Figure 4-7

to

buy replacements

modied

can

be

at

tted

the

to

:3)

the

earlier

or the

for both

same time

other

obsolete

contact assembly

. Neither

5).

than

parts (

parts (

1996

and you

(

Figure 4-6

of

the

new

Figure

Figure

:

3

parts

4-7

need

4-7

:

3

:

and

Figure 4-7. Obsolete parts manufactured earlier than 1996

Service 4-9

Page 40

Troubleshooting

This

section

Electrode

includes

SMD

T

est

the

Fixture

functional check

.

procedure used

to troubleshoot

the 16192A

Parallel

Open Impedance

1.

A

djust

the

electrode

16191-29001).

(Refer

to

Figure

Check

4-8

.)

distance

for

connecting

the

1

2

1

2

2.4

mm Shorting

Device

(PN

2. Place the xture

Figure

on the calibrated APC-7

4-8.

Shorting

R

Device

terminal of the 4291B

Analyzer.

3. Set the 4291B RF Impedance/Material Analyzer as follows:

Measurement P

Start Frequency

Stop Frequency

arameter Cp (parallel capacitance)

100 MHz

1GHz

OSC Level 0.12 V

Number of Point 2

Point Averaging Factor 16

Point Averaging ON

4. Perform a single sweep measurement.

5. Read Cp value at 100 MHz and 1 GHz.

The guideline for the open impedance value is as follows:

4-10 Service

P

osition

RF Impedance/Material

Page 41

T

able 4-7.

Open Impedance

Value

Guideline

Short

1.

Impedance

After the

16191-29001)

2.

Set the

Measurement

Start

Frequency 100

Stop

Frequency 1

OSC

Level 0.12

Number

P

oint

A

P

oint

A

3.

Make

4.

Read

Ls

The

guideline

Parameter Frequency Guideline (absolute

Cp 100

Cp 1

Open Impedance

between the

4291B RF

Parameter

of P

oint

veraging

F

veraging

a

single

value

of

sweep

at

the

GHz

Check

Check is

electrodes (refer

Impedance Analyzer

actor 16

measurement.

100

MHz

and

1GHz.

short

impedance

T

able

4-8. Short

value

MHz

completed,

as follows:

Ls (series

MHz

GHz

V

2

ON

is

as follows:

Impedance

put

the

to Figure

inductance)

V

750

750

1

4-8

alue

fF

6

fF

6

2

1

2

2.4

).

Guideline

300

300

mm

value)

fF

fF

Shorting

Device

(PN

P

arameter

Ls 100

Ls 1

Short

1.

2.

3. Read

Impedance

After

the

on

the

Make

a

Lp value

V

alue

Guideline

Short

same

single

Impedance

place

sweep

at

100

described

Repeatability

again

measurement

MHz

4. Calculate the dierence between the rst Ls measurement

measurement value at each frequency

Frequency Guideline

MHz

GHz

Check

Check

(refer

and

in

to

Figure

1

GHz

T

able 4-8

is

completed,

4-8

with

the

and

.

).

same

check

.

4.5

4.5

remove

the

measurement

the

value

(absolute value)

nH

nH

Shorting

is

value and second Ls

The guideline for the short impedance repeatability is as follows:

Table 4-9. Short Impedance Repeatability Guideline

Parameter Frequency Guideline (dierence)

Ls 100 MHz

Ls 1GHz

6

6

6

1.5

nH

6

1.5

nH

Device

conditions

within the

45 pH

20 pH

and

put

it

.

Short Impedance

back

Service 4-11

Page 42

Page 43

REGIONAL SALES AND SUPPORT OFFICES

For more information about Agilent Technologies test and measurement products, applications, services, and

for a current sales office listing, visit our web site: http://www.agilent.com/find/tmdir. You can also contact one

of the following centers and ask for a test and measurement sales representative. 11/29/99

United States:

Agilent Technologies

Test and Measurement Call Center

P.O.Box 4026

Englewood, CO 80155-4026

(tel) 1 800 452 4844

Canada:

Agilent Technologies Canada Inc.

5150 Spectrum Way

Mississauga, Ontario

L4W 5G1

(tel) 1 877 894 4414

Europe:

Agilent Technologies

Test & Measurement

European Marketing Organization

P.O.Box 999

1180 AZ Amstelveen

The Netherlands

(tel) (31 20) 547 9999

(fax) (61 3) 9272 0749

(tel) 0 800 738 378 (New Zealand)

(fax) (64 4) 802 6881

Asia Pacific:

Agilent Technologies

24/F, Cityplaza One, 1111 King’s Road,

Taikoo Shing, Hong Kong

(tel) (852)-3197-7777

(fax) (852)-2506-9284

Japan:

Agilent Technologies Japan Ltd.

Call Center

9-1, Takakura-Cho, Hachioji-Shi,

Tokyo 192-8510, Japan

(tel) (81) 426 56 7832

(fax) (81) 426 56 7840

Latin America:

Agilent Technologies

Latin American Region Headquarters

5200 Blue Lagoon Drive, Suite #950

Miami, Florida 33126

U.S.A.

(tel) (305) 267 4245

(fax) (305) 267 4286

Australia/New Zealand:

Agilent Technologies Australia Pty Ltd

347 Burwood Highway

Forest Hill, Victoria 3131

(tel) 1-800 629 485 (Australia)

Page 44

Page 45

16192-90030

Copyright Agilent Technologies, Inc.

©

1993, 1996, 1999, 2000, 2001

Printed in Japan 8/2001

Reorder No. 16192-90030

Loading...

Loading...