Page 1

OPERATING MANUAL

(Original operating manual)

Automatic Pallet Loader APL-106

Agfa NV

Septestraat 27

B-2640 Mortsel

Telephone +32 3 444 2111

Internet www.agfagraphics.com

Please keep this manual for future use!

Page 2

Machine / machine line: Automatic Pallet Loader APL 106A / Agfa Expert Loader

Year of construction:

Manufacturer:

2018 following

Krause-Biagosch GmbH, Paul-Schwarze-Str.5, D-33649

Bielefeld

Version 06

Revision: March 2019

Document history

Version Date Reason for Change Editor Status

3 July 2017 First edition Richter released

4

November 2018

Cassette Loader and Extension

Modul added

Richter released

Agfa name change to Agfa NV

Chapter 5, Installation and Setup

changed,maintanance extended

to the cassette loader,

maintenance materials silicon

spray, cleaning agent and

grease

5

February 2019

Pallet and plate data more

detiled.Cassette safety (5,12),

Richter released

extension module and cassette

operation (44,46ff)

6

r1

March 2019

April 2019

Corrected version numbers.

Maintenance instructions for

cassettes, note for safety

stickers added.

Maintenance intervals changed

Ahlemeyer released

© Agfa NV

This operating manual and all illustrations contained herein are protected by copyright. Any

use beyond the constraints of copyright law without the prior written consent of the publisher

is illegal and punishable by law. This particularly applies to copying, translation, transfer to

microfilm, and saving and processing in electronic systems.

Page 3

Table of Contents

1 Introduction ............................................................................................................ 1

1.1 Means of representation .......................................................................................... 2

1.2 Warranty and liability ............................................................................................... 3

1.3 Copyright ................................................................................................................. 4

1.4 Terms of guarantee ................................................................................................. 4

1.5 Service / customer service ....................................................................................... 4

2 Safety ...................................................................................................................... 5

2.1 Intended use ............................................................................................................ 5

2.1.1 Constructional modifications to the machine ............................................................ 6

2.1.2 Foreseeable misuse ................................................................................................ 7

2.2 Personnel requirements ........................................................................................... 8

2.2.1 Obligations of the personnel .................................................................................... 9

2.2.2 Unauthorised persons .............................................................................................. 9

2.2.3 Instruction ................................................................................................................ 9

2.3 General safety information ..................................................................................... 10

2.4 Safety measures for environmental protection ....................................................... 10

2.5 Special hazard warnings ........................................................................................ 11

2.5.1 Symbols used on the machine ............................................................................... 11

2.5.2 Safty sticker on the machine .................................................................................. 12

2.5.3 Hazards due to electrical energy ............................................................................ 13

2.5.4 Hazards due to pneumatic energy ......................................................................... 13

2.6 Personal protective equipment .............................................................................. 14

2.7 Information for emergencies .................................................................................. 15

3 Machine description ............................................................................................ 17

3.1 Machine overview .................................................................................................. 17

3.2 Function and operating elements ........................................................................... 18

3.3 Operating panel ..................................................................................................... 19

3.4 Function description ............................................................................................... 20

3.5 Safety device ......................................................................................................... 22

3.5.1 MAIN SWITCH and EMERGENCY STOP. ............................................................ 22

3.5.2 Contact switches on the doors and hoods ............................................................. 22

3.6 Type plate .............................................................................................................. 23

4 Transport and installation site ............................................................................ 25

4.1 Transport ............................................................................................................... 25

4.1.1 Inspection on handover to the customer ................................................................ 25

4.1.2 Scope of delivery ................................................................................................... 25

4.1.3 Information regarding hazards during transport ..................................................... 26

Permissible auxiliary equipment for transport ......................................................... 27

4.1.4

Automatic Pallet Loader APL /Expert Loader I

Page 4

Table of Contents

4.1.5 Dimensions and weights of the packages .............................................................. 27

4.1.6 Recommended transport equipment ...................................................................... 28

4.1.7 Intermediate storage .............................................................................................. 28

4.1.8 Transport packing .................................................................................................. 28

4.2 Installation site ....................................................................................................... 29

4.2.1 Load-bearing capacity of the installation surface .................................................... 29

4.2.2 Flatness of the installation surface ......................................................................... 29

4.2.3 Safety lighting ........................................................................................................ 29

4.2.4 Air conditioning ...................................................................................................... 29

4.2.5 Regulation of the humidity ..................................................................................... 30

5 Installation and commissioning/first start-up .................................................... 31

6 Operation .............................................................................................................. 33

6.1 Switching on the machine ...................................................................................... 33

6.2 Emptying the paper bin .......................................................................................... 34

6.3 Loading a pallet ..................................................................................................... 37

6.4 Loading a machine with 2nd pallet space............................................................... 44

6.5 Removing a pallet .................................................................................................. 45

6.6 Loading plates to the cassettes (optional) .............................................................. 46

6.7 Removing faulty printing plates .............................................................................. 47

6.8 Switching off the machine ...................................................................................... 48

7 Malfunctions......................................................................................................... 49

7.1 Display of malfunction messages ........................................................................... 49

7.1.1 System error .......................................................................................................... 50

7.1.2 Warnings ............................................................................................................... 50

7.1.3 Sequence error ...................................................................................................... 52

8 Maintenance and cleaning .................................................................................. 53

8.1 Maintenance intervals and maintenance work........................................................ 54

8.2 Cleaning agents and lubricants .............................................................................. 56

9 De-commissioning ............................................................................................... 57

10 Dismantling .......................................................................................................... 59

10.1 Information regarding hazards during dismantling .................................................. 59

10.2 Preparatory measures ........................................................................................... 60

10.3 Dismantling the machine and securing it for transport ............................................ 60

10.3.1 Preparing and securing the machine for transport .................................................. 61

10.3.2 Supply lines ........................................................................................................... 65

10.3.3 Paper bin ............................................................................................................... 66

11 Disposal ................................................................................................................ 67

11.1 Terminology ........................................................................................................... 67

II

Page 5

Table of Contents

11.2

Overview of the assembly groups .......................................................................... 68

12 Appendix .............................................................................................................. 71

12.1 Technical data ....................................................................................................... 71

12.1.1 Dimensions ............................................................................................................ 71

12.1.2 Weights ................................................................................................................. 72

12.1.3 Electrical connected loads/rating ........................................................................... 72

12.1.4 Compressed air connected values/capacity ........................................................... 72

12.1.5 Ambient conditions ................................................................................................ 73

12.1.6 Airborne noise emitted ........................................................................................... 73

12.1.7 Heat emission ........................................................................................................ 73

12.1.8 Printing plate and pallet sizes ................................................................................ 74

12.2 Other applicable documents .................................................................................. 75

12.3 EC Declaration of Conformity ................................................................................ 75

Automatic Pallet Loader APL / Expert Loader III

Page 6

Page 7

1 Introduction

This operating manual provides you with all the information required for problemfree operation of the Automatic Pallet Loader APL-106 /Expert Loader (referred to

as "machine" hereinafter).

The function of the machine is to separate, align and convey printing plates to the

downstream machine line module "Recorder".

This operating manual must be read, understood and applied by all persons

instructed to carry out the

–

transport,

–

installation and assembly,

–

first start-up/commissioning,

–

operation,

–

maintenance and cleaning,

–

malfunction remedy,

–

de-commissioning and dismantling

–

and disposal

of the machine. This applies in particular to the specified safety instructions.

Studying the operating manual will enable you to correctly

–

install,

–

connect,

–

operate,

–

maintain

–

and dispose of the machine.

Observe the regulations generally valid by law and other binding regulations

regarding accident prevention and environmental protection of the country of use

in addition to this operating manual.

Automatic Pallet Loader APL / Expert Loader 1

Page 8

1.1 Means of representation

Statements in this installation manual intended as information on and direct

warning of hazards are identified as follows:

DANGER

This warning describes a hazard with a high degree of risk, which if

WARNING

not avoided, will lead to death or serious injury.

This warning describes a hazard with a medium degree of risk,

which if not avoided, may lead to death or serious injury.

1 Int roduction

CAUTION

This warning describes a hazard with a low degree of risk, which if

not avoided, may lead to minor or moderate injury.

NO TE

This warning describes a hazard with a low degree of risk, which if

Furthermore, the following text features are used:

– Dashes precede list items.

•

Bullets precede instructions describing actions that are to be carried out in

the specified order.

Text in inverted commas refers to other chapters or sections.

" "

Text in square brackets describes touch buttons to be pressed on the

[ ]

operating panel.

not avoided, may lead to damage to assets.

The information symbol marks useful information.

2

Page 9

1.2 Warranty and liability

Danger to life due to electric shock

Warning: suspended load

Symbols used in this manual

Particular hazards are additionally marked in warnings as follows:

This symbol warns of the life-threatening hazard of electrical current.

Contact with live components causes imminent danger to life.

This symbol warns of the hazards of standing/working under

suspended loads.

1.2 Warranty and liability

The obligations agreed to in the delivery contract, the General Terms and

Conditions, as well as the machine delivery terms and the legal regulations valid

at the time of the conclusion of the contract apply.

All the information and instructions in this operating manual were compiled taking

the valid standards and regulations, state of the art and our many years of

experience and expertise into consideration.

Warranty and liability claims on the basis of personal injury and damage to assets

are excluded if they can be traced back to one or several of the following causes:

–

Improper use or use other than that intended of the machine;

–

incorrect installation, assembly, operation, maintenance, cleaning,

disassembly;

–

non-observance of the operating manual and information in the operating

manual regarding installation, assembly, operation, maintenance, cleaning,

disassembly, disposal;

–

use of insufficiently qualified or insufficiently instructed/trained personnel;

–

structural changes to the machine (no conversions or any other changes to

the machine may be performed without the prior written consent of Agfa

NV. Any infringement will result in loss of the machine's EC conformity);

–

incorrectly carried out repairs;

–

use of non-approved spare parts and/or use of spare parts that do not meet

the technical requirements;

–

events of catastrophe caused by foreign objects and force majeure.

We reserve all rights to make technical changes within the framework of

improvement of the performance characteristics and further development.

Automatic Pallet Loader APL / Expert Loader 3

Page 10

1.3 Copyright

This operating manual is protected by copyright and is exclusively intended for

internal purposes.

1 Int roduction

Handing over the operating manual to third parties, making copies of any kind

including excerpts – as well as using and/or disclosing the contents are prohibited

unless expressly consented to in writing by Agfa NV, except for internal

purposes.

Any infringement will result in liability for damages. We reserve the right to assert

further claims.

1.4 Terms of guarantee

The terms of guarantee are contained in the General Business Terms of

Agfa NV.

1.5 Service / customer service

In the event of problems please contact the representative in charge.

–

4

Page 11

Non

-

observance of the fo

llowing safety information may have

ion to the instructions contained in this operating manual, the

user/owner must adhere to the existing national work, operating and

2 Safety

WARNING

serious consequences:

– Danger to persons resulting from electrical, pneumatic or

mechanical influences;

– failure of important machine functions.

Thoroughly read all the safety and warning information in this

section before commencing with the transport, installation,

connection and commissioning/start-up of this machine.

In addition to the instructions contained in this operating manual,

also observe the universally valid safety and accident prevention

regulations.

In addit

safety regulations. Also adhere to the existing internal works

regulations.

2.1 Intended use

The operational safety of the machine is only guaranteed if it is used in

accordance with its intended use.

The machine is exclusively intended for automatically loading printing plates into

the downstream machine line module "Recorder".

The machine is not intended for any use other than that specified here, any other

use is deemed as non-intended use. The following is forbidden in particular:

–

To transport persons with the machine;

–

to convey products other than those specified;

–

to convey products with different weights than those specified.

The intended use also includes:

–

Using energy supplies in accordance with the valid safety regulations;

–

adhering to the specified operating conditions.

–

adhering to the inspection and maintenance intervals;

Automatic Pallet Loader APL / Expert Loader 5

Page 12

–

using consumables and auxiliary substances in accordance with the valid

safety regulations;

–

adhering to the specified operating conditions.

The technical specifications specified in the technical data must be adhered to

without exception.

Only use the machine in accordance with its intended use, otherwise safe

operation will not be guaranteed.

The manufacturer declines any responsibility for injuries and damage to

assets resulting from any use other than that intended. The user/owner of

the machine line alone is fully liable in this respect!

2.1.1 Constructional modifications to the machine

2 Saf ety

The design and manufacturer's acceptance are based on the Product Safety Act

(ProdSG). No modifications, attachments to or conversions of the machine may

be carried out without the prior written permission of

Agfa NV.

Non-compliance will result in loss of the machine's EC conformity. The

manufacturer's warranty will become null and void. This also applies to welding

work on load-bearing parts.

Immediately replace components that are not in perfect condition.

Only use original spare parts/wear parts/accessory parts. These parts are

specifically designed for the machine. If non-original parts/parts procured from

other sources are used, it cannot be guaranteed that they are properly designed

and manufactured with regard to stress and safety.

Parts and special equipment not supplied by Agfa NV are not approved for use

on the machine.

6

Page 13

2.1 Intended use

Any addi

tional use and/or type of use of the machine other than

2.1.2 Foreseeable misuse

WARNING

the intended use can lead to serious injuries!

– Only use the machine in accordance with its intended use.

– Only load the machine with the designated printing plates.

Automatic Pallet Loader APL / Expert Loader 7

Page 14

Risk of injury in the event of insufficient qualifications!

2.2 Personnel requirements

WARNING

Incorrect handling can cause serious injuries to persons and

Ensure that the machine is only transported, installed, set up and operated by

personnel specifically qualified and/or instructed to do so. These persons must

be familiar with the operating manual and act accordingly. The respective duties

and responsibilities of the personnel must be clearly defined.

damage to assets.

– Therefore restrict all work to suitably qualified personnel.

2 Saf ety

The following qualifications are specified in the operating manual for various

areas of activity:

Instructed personnel

Instructed personnel have been instructed by the user/owner or by qualified

personnel regarding the tasks to be performed and the possible hazards caused

by incorrect behaviour.

Qualified personnel

Qualified personnel, due to their specialist training, knowledge and experience,

and knowledge of the pertinent regulations, are able to perform the work they are

commissioned with and independently recognize and avoid potential hazards.

Electricians

Electricians, due to their specialist training, knowledge and experience, as well as

knowledge of the pertinent standards and regulations, are able to carry out work

on the electrical equipment and independently recognise and avoid potential

hazards.

Qualified electricians are trained for the specific operating site at which they work,

and are familiar with the relevant standards and regulations pertaining to this site.

8

Page 15

2.2 Personnel requirements

Danger for unauthorised persons!

If in doubt, speak to the unauthorised persons and show them out

Specialist pneumatic personnel

Specialist pneumatic personnel, due to their specialist training, knowledge and

experience are able to monitor and maintain pneumatic equipment and systems.

They can independently recognise and avoid potential hazards.

Specialist pneumatic personnel are trained for the specific operating site at which

they work, and are familiar with the relevant standards and regulations pertaining

to this site.

2.2.1 Obligations of the personnel

Personnel may only include persons who can be expected to carry out their work

reliably. Do not allow persons whose reactions are negatively affected by drugs,

alcohol, medication or similar to work on the machine.

All persons instructed to work on the machine undertake, prior to commencing

work,

–

to observe the basic directives concerning health and safety at work and

accident prevention,

–

to read the safety instructions and the warnings contained in this operating

manual and confirm this with their signature, acknowledging that they have

understood the information.

2.2.2 Unauthorised persons

WARNING

Unauthorised persons who do not meet the requirements described

here with respect to the qualifications are not familiar with the

hazards in the work area.

– Keep unauthorised persons away from the work area.

–

of the work area.

– Interrupt the work while unauthorised persons are in the work

area.

2.2.3 Instruction

The personnel require regular instruction and training by the owner/user. This

instruction and training must be recorded in writing for monitoring purposes.

Automatic Pallet Loader APL / Expert Loader 9

Page 16

2.3 General safety information

–

The machine may only be transported, installed, set up and

commissioned/started up after the personnel have familiarised themselves

with this operating manual.

–

Only use the machine in accordance with its intended use (see section

"2.1 Intended use").

–

Keep the work area of the machine clean and tidy at all times to avoid

hazards caused by dirt and parts lying around.

–

Keep all safety and hazard information/signs on the machine in legible

condition and replace them when necessary.

–

Restrict all work on the machine to qualified or instructed personnel (see

Section "2.2 Personnel requirements").

2 Saf ety

2.4 Safety measures for environmental protection

Adhere to the regulations for waste avoidance and for correct waste recycling

and disposal.

In particular during installation work as well as during decommissioning,

disassembly and disposal ensure that substances hazardous to groundwater

such as grease, oil, solvent-containing cleaning agents or similar do not

contaminate the ground or enter the sewage system. Collect, transport, store and

dispose of these substances in suitable containers in accordance with the

national regulations.

10

Page 17

2.5 Special h azard war nings

Danger to life due to electric shock

Warning: danger of hand injury / crushing hazard

This symbol warns of the danger of eye damage from laser radiation.

2.5 Special hazard warnings

2.5.1 Symbols used on the machine

This symbol warns of the life-threatening hazard of electrical current.

Contact with live components causes imminent danger to life.

This symbol warns of the danger of hand injuries.

Your hands could be crushed, pulled in or otherwise injured.

Warning: danger of eye damage / laser radiation

Laser radiation entering the eye can lead to irreparable damage to

the eye.

Warnung: Maloperation

This symbol warns of danger due to maloperation for example when

loading the cassettes.

Keep all safety and hazard information/signs on the machine in legible

condition and replace them when necessary.

Automatic Pallet Loader APL / Expert Loader 11

Page 18

2.5.2 Safty sticker on the machine

2 Saf ety

Overview

There are safety stickers on the covers of the machine:

A

B

Fig. 2: Safety sticker on the machine

Position Safety Labels meaning

A

Danger to life due to electric

shock.

B

12

Class 1 laser product. No

dangerous laser radiation outside

the machine when all doors and

hatches are shut.

Page 19

2.5 Special h azard war nings

Contact with live parts causes electric shock.

2.5.3 Hazards due to electrical energy

DANGER

– Always keep electrical components enclosed.

– Only allow an electrician who is specifically trained to carry out

work on electrical equipment and who is able to detect and avoid

the hazards involved to perform work on the electrical equipment.

–

Restrict work on the electrical equipment to a designated qualified

electrician, e.g. company electrician.

–

Have the electrical equipment inspected/tested by an electrician before

installation and set-up of the machine.

–

Any changes made following this inspection must comply with

DIN EN 60204-1.

–

Damaged housings/casings and cables must be immediately repaired or

replaced before installation and set-up of the machine.

2.5.4 Hazards due to pneumatic energy

Air escaping at high pressure can penetrate the skin and cause serious injuries!

–

Only allow expert personnel specially trained and experienced in pneumatic

engineering to work on the pneumatic installations. Ensure that the

machine is switched off and secured against reactivation before

commencing work on the pneumatic installations.

–

Inspect all pneumatic lines, hoses and connections for externally visible

damage prior to installation and set-up of the machine.

–

Always keep pneumatic hoses away from your body.

–

Protect open air connections against the ingress of dirt.

–

Never interchange connections, connectors/plugs or switches. This will

inevitably result in malfunctions.

Automatic Pallet Loader APL / Expert Loader 13

Page 20

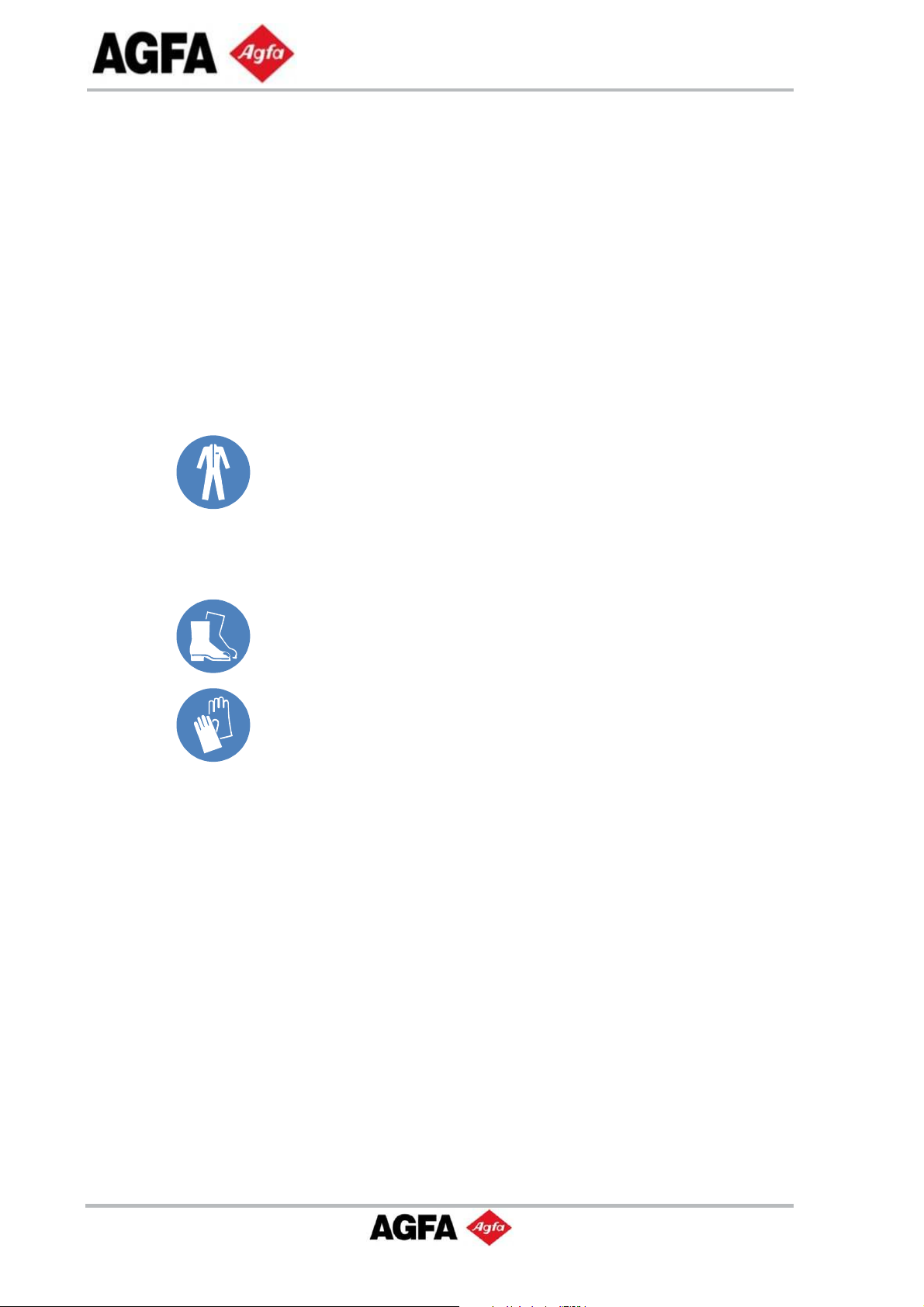

Protective clothing

fitting sleeves and without protruding parts.

Safety footwear

Protective gloves

2.6 Personal protective equipment

It is necessary to wear personal protective equipment during work on the

machine to minimise hazards to health.

–

Always wear the personal protective equipment required for each type of

work.

–

Always follow the instructions regarding personal protective equipment

affixed in the work area.

These symbols have the following meaning:

Protective clothing consists of tight-fitting work clothing with low

tensile strength, with tightThis mainly serves as protection against being caught by moving

machine parts.

2 Saf ety

Do not wear any rings, necklaces, chains or other jewellery.

Wear slip resistant safety shoes to protect against heavy falling parts

and to prevent slipping on smooth surfaces.

Wear protective gloves to protect your hands from friction, abrasion

or deeper injuries.

Personal protective equipment is to be provided by the owner/user and must

meet the pertinent requirements.

In addition, observe the national regulations and any internal instructions laid

down by the owner/user.

14

Page 21

2.7 Information for emergencies

2.7 Information for emergencies

Preventive measures

–

Be prepared for accidents at any time.

–

Keep the first-aid equipment (first-aid boxes, blankets etc.) ready to hand.

–

Train personnel so that they are familiar with accident reporting and the

first-aid equipment.

–

Keep accesses clear for emergency vehicles.

Measures in the event of accidents

–

Rescue persons from the hazardous area.

–

Immediately administer first aid in the event of cardiac arrest and/or

breathing arrest.

–

In the event of injury/damage to health immediately notify the first-aid

supervisor and an emergency doctor and the emergency rescue service.

–

Clear the accesses for emergency vehicles. Delegate someone to direct

the emergency personnel to the site of the accident if necessary.

Automatic Pallet Loader APL / Expert Loader 15

Page 22

Page 23

5

3 Machine description

3.1 Machine overview

1 Pallet compartment Printing plate intake

2 Paper bin Paper removal and double sheet detector

3 Operating panel Operation and status display

4 Transfer table Transfer to CTP exposure unit

5 Extension module Printing plate intake

Model right

Model left

Automatic Pallet Loader APL / Expert Loader 17

Page 24

6

3.2 Function and operating elements

3 Machine description

1 Door element Access to the pallet compartment and air servicing unit

2 Door element Acess to the paper bin

3 Operating panel Touch panel for operating the machine

4 Main switch ON/OFF switch

5 Folding table Transfer table, can be folded up

6 Cassette compartment

18

Page 25

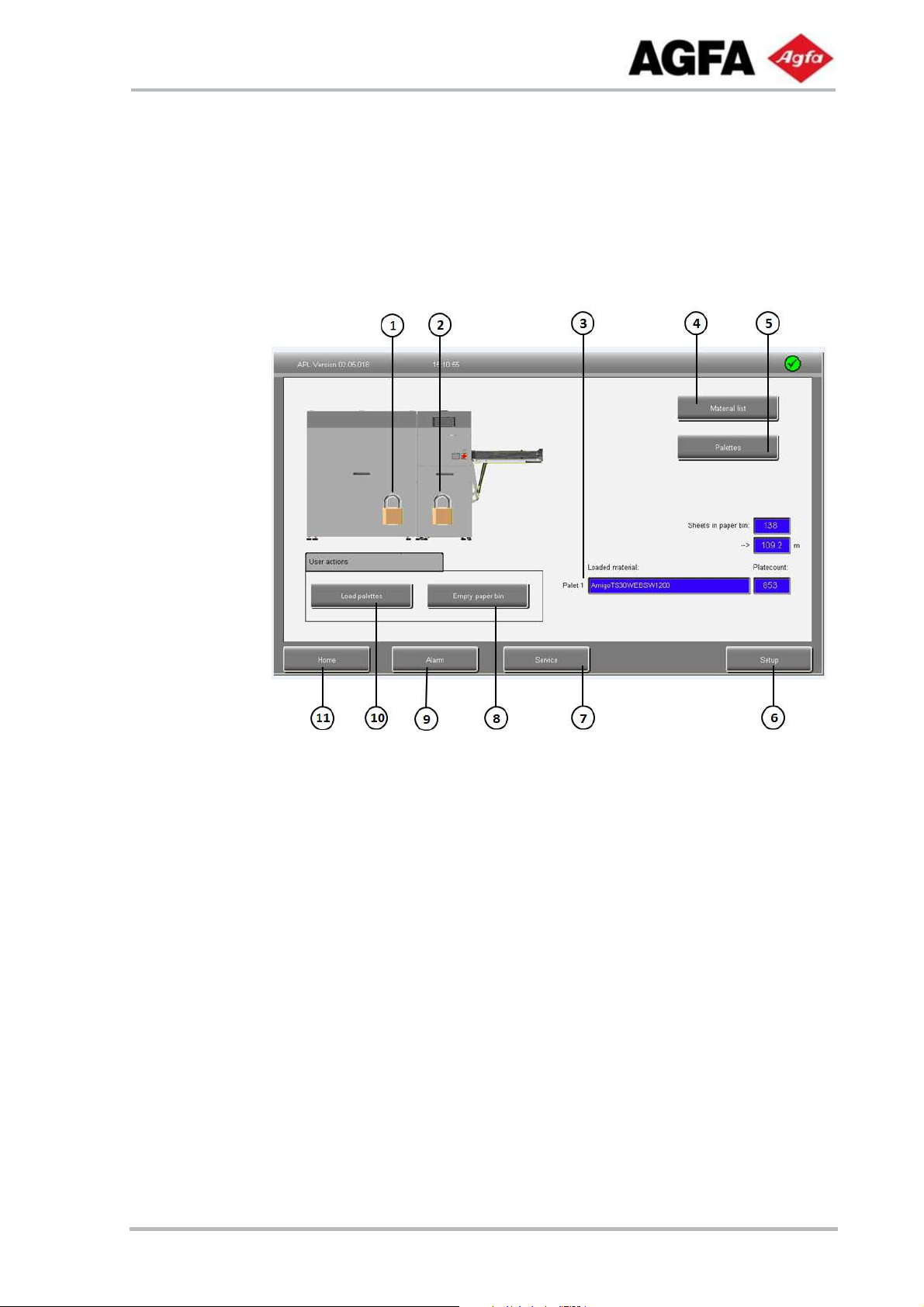

3.3 Operating panel

Display of the alarm list with the malfunctions that

3.3 Operating panel

Main menu

1 Display Locking status (pallet compartment hood)

2 Display Locking status (paper bin door)

3 Display Display of the currently loaded material with the

number of plates remaining

4 [Material list] Display of the material list (material database)

6 [Pallets] Display/change the loaded pallets/materials

6 [Setup] System settings

7 [Service] Settings

8 [Empty paper bin] User prompting for emptying the paper bin

(see section "6.2 Emptying the paper bin")

9 [Alarm]

have occurred

10 [Load pallets] User prompting for loading the pallets

(see section "6.3 Loading a pallet")

11 [Home] Return to main menu

Automatic Pallet Loader APL / Expert Loader 19

Page 26

3.4 Function description

The printing plates are delivered on a pallet which is equipped with a chipboard in

the respective format of the printing plate.

Loading the machine with pallets

One pallet each with printing plates can be placed in the receiving area of the

pallet compartment.

Fixing brackets are fitted to 2 corners of each pallet to prevent the printing plates

from slipping during transport to the receiving area.

A safety belt is supplied for transporting the unpacked printing plates with a lift

truck to prevent sliding of the up to 540 mm high plate stack during the

movement.

Loading the optional cassettes

3 Machine description

The cassettes are an option. The machine can be equipped with one or two

cassettes. Each cassette can carry up to maximum 100 plates of 0,3mm

thickness. The cassettes have movable stoppers adjusted to the required plate

format.

To lode a requested cassette it will be moved downwards by a machine to a

comfortable height before it can be pulled out for loading.

Alignment in the machine

The pallet is deposited with the aid of a lifting device into the receiving area of the

extension module or end module. A marking is located on the floor of the

respective receiving area along which the front edge of the respective pallet must

be aligned.

The position of the printing plate stack (in the transport direction) is indicated with

the aid of a laser marker. The longitudinal edge of the printing plate stack must

be aligned with the laser marking.

Referencing the printing plates

Once the the pallet with the printing plates has been placed in position and

aligned, the respective cover hood is closed.

The feeder – initiated by the downstream machine line module "Recorder"

–

performs a reference run. The position and format of the printing plates are

checked. If they correspond to the set point values, the machine is ready for

operation and the printing plates can be fed to the recorder.

20

Page 27

3.4 Funct ion description

Recorder feeding

The signal for feeding is given by the recorder control system.

The feeder moves over and is lowered onto the respective printing plate stack.

The separating sheet is gripped by the gripping device, pulled back slightly and then

lifted.

The suction device for the printing plate swivels into the suction position and moves

vertically onto the printing plate. The printing plate is lifted with the aid of suction

cups. The support rollers for the transport of the printing plate are extended and the

feeder moves with the printing plate and the gripped separating sheet into the transfer

position.

On reaching the transfer position, the separating sheet is pressed between 2 rubber

rollers with the aid of a pressure roller. The rubber rollers pull in the separating sheet

and convey it into the paper bin. The printing plate is conveyed up to the transfer

position of the loader and taken over by the loader of the recorder.

The loading process is completed. The feeder moves back to the printing plate stack

and picks up the next printing plate.

Automatic Pallet Loader APL / Expert Loader 21

Page 28

3.5 Safety device

The APL-106 is an independent machine. It is switched on using the red and

yellow main switch. The main switch also serves as an EMERGENCY STOP

switch

3.5.1 MAIN SWITCH and EMERGENCY STOP.

Turn the main switch to its horizontal position to disconnect the machine from all

voltage and trigger an EMERGENCY STOP.

To restart the machine, turn the MAIN SWITCH to position 1.

3.5.2 Contact switches on the doors and hoods

3 Machine description

The door to the set-up area of the paper bin in the basic module is equipped with

a door contact switch with guard control.

The cover hoods of the pallet compartment are equipped with contact switches

with guard control.

The door and cover hoods can be released on the operating panel.

1 Contact switch (Cover hood, pallet compartment)

2 Door contact switch (access to paper bin, basic module)

22

Page 29

3.6 T ype plat e

3.6 Type plate

The type plate is located on the rear of the paper bin or on the left-hand side of

the main switch

Automatic Pallet Loader APL / Expert Loader 23

Page 30

Page 31

4 Transport and installation site

4.1 Transport

The machine is delivered to the customer by a transport company authorised by

Agfa NV.

NO TE

It is important that the personnel provided by the owner/user follow

the instructions of the person in charge in order to ensure correct

transport and thus the functional reliability and precision of the

machine.

The persons in charge are named in the order confirmation.

4.1.1 Inspection on handover to the customer

When the component parts of the machine arrive, the customer must inspect

them for visible transport damage and completeness.

–

Document any transport damage before releasing the transport units

(packages).

–

Immediately report any transport damage to Agfa NV.

4.1.2 Scope of delivery

The machine delivery scope comprises the following components:

–

APL 106 with pressure plate transfer module

–

One optional extension module

–

Transfer tables, folded up for transport

–

Paper bin, interior

–

Assembly materials

Automatic Pallet Loader APL / Expert Loader 25

Page 32

Risk of injury due to incorrect handling of the packages!

When transporting the packages, take the following specific hazards

4 Transport and installation site

4.1.3 Information regarding hazards during transport

WARNING

into consideration:

– Protruding edges can cause crushing injuries or cuts.

– Use of load suspension devices other than those specified here

may lead to serious injuries.

NO TE

Handle the packages carefully and take care not to damage the

equipment:

– Lift the packages carefully during transport.

– Do not tilt or twist/distort the packages.

– Ensure that the packages are not subjected to moisture or

extreme temperatures (see section"12.1.5 Ambient conditions").

–

Also read the Chapter "2 Safety".

–

The machine and components may only be unloaded from the freight

forwarder's vehicle by suitably qualified and instructed personnel (forklift

truck operator with certificate of qualification) and in accordance with all

safety regulations.

–

The machine and components may only be transported with a load

suspension device by suitably instructed personnel in accordance with all

safety regulations.

–

Always wear protective clothing, safety footwear and protective gloves

during the work.

–

Ensure that the transport path is secured by an additional person.

–

Ensure that there are no persons on the transport path.

–

Always lift the machine slowly and carefully in order to ensure stability and

safety.

–

Do not remove the transport securing devices (marked red) until the

components have been installed at the installation site.

26

Page 33

4.1 T rans port

Length

4.1.4 Permissible auxiliary equipment for transport

The APL 106 is supplied on a pallet with a crate or in a box (package). These can

be moved using a forklift truck or lift truck.

Ensure that

–

the door widths and load-bearing capacity of the transport paths to the

installation site are sufficient (see section "4.1.5 Dimensions and weights ");

–

the load-bearing capacity of the forklift truck or lift truck is designed for the

weights of the packages (see section "4.1.5 Dimensions and weights ") and

–

the length of the load suspension fork of the forklift truck or lift truck is

sufficiently dimensioned for the packages (see section "4.1.5 Dimensions

and weights “).

The attachment points for secure transport to the installation site are

marked red on the respective packages.

4.1.5 Dimensions and weights of the packages

Package Table of contents

1

APL 106 incl. transfer

table and paper bin

(mm)

2400 2200 2200 685

Width

(mm)

APL 106 with extension

2

modul incl. transfer

3800 2300 2200 910

table and paper bin

* Weight incl. pallet weight (approx. 270 kg)

Interior dimensions of the packaging: 2100 x 2300 x 1900 mm

Height

(mm)

Weight

(kg)

Type

Crate

Crate

Automatic Pallet Loader APL / Expert Loader 27

Page 34

4 Transport and installation site

4.1.6 Recommended transport equipment

Transport equipment

Transport equipment 1

(for unloading the lorry and

lifting the machine off the

pallet)

Transport equipment 2

(for transport of the packages

on the ground)

Transport equipment 3

(for transport of the modules

to the installation site)

4.1.7 Intermediate storage

It the machine is not installed immediately after delivery, the components must be

carefully stored in a protected location. The components must be temporarily

stored such that they are protected from cold temperatures, humidity, dirt and

mechanical influences.

Type

(quantity)

Fork length

(mm)

Perm. loadbearing

capacity (kg)

Forklift truck 2000 3000

2 lift trucks 2000 2000

4 dollies

For the recommended storage conditions for the components please refer to the

section "12.1.5 Ambient conditions".

The manufacturer shall not assume any liability for damage resulting from

incorrect storage.

4.1.8 Transport packing

The machine components are to be unpacked under the supervision of

authorised personnel from Agfa NV.

The packing used for transport and protection of the machine

predominantly consists of recyclable materials.

– Dispose of the packing material in an environmentally friendly manner

in accordance with the applicable country-specific regulations.

28

Page 35

4.2 Installation site

4.2 Installation site

4.2.1 Load-bearing capacity of the installation surface

The load-bearing capacity of the installation surface must be sufficiently

dimensioned such that it can withstand the loads during installation and

production. Also take into consideration short-term point loads during transport by

lift truck and during installation.

Use the weight specifications in the section "4.1.5 Dimensions and weights " as a

basis for calculation.

4.2.2 Flatness of the installation surface

The flatness of the installation surface must meet the following specifications:

Height difference

(mm)

0.5 0.1

4 1

10 4

12 10

4.2.3 Safety lighting

The CTP room should be equipped with safety lighting as defined by the plate

manufacturer.

4.2.4 Air conditioning

over a length of (m)

Agfa NV recommends installing the machine in an air-conditioned room so that

the ambient conditions for the equipment and the materials to be processed can

be kept constant throughout the year

(see section "12.1.5 Ambient conditions").

For the design of the air conditioning system please take into consideration the

thermal output values of the installed devices as defined for the recorder.

Automatic Pallet Loader APL / Expert Loader 29

Page 36

4.2.5 Regulation of the humidity

The relative humidity should remain within defined tolerances. Too high or too

low humidity can have a negative influence on the exposure quality and on the

production stability of the system.

4 Transport and installation site

30

Page 37

The commissioning and first start up is not part of this manual. It shall only

5 Installation and commissioning/first start-up

be done by the quallifed service of Agfa NV.

Please note the restriction to warranty if the installation and setup is not

conducted by the Agfa NV.

Automatic Pallet Loader APL / Expert Loader 31

Page 38

Page 39

Risk of injury in the event of insufficient qualifications!

6 Operation

WARNING

Incorrect operation of the machine can cause serious injuries to

persons and damage to assets.

– Therefore restrict all activities for operating the machine to

suitably qualified personnel.

6.1 Switching on the machine

•

Switch on the higher-ranking machine line module if applicable

(see the "Recorder" operating manual).

•

Switch the machine on at the main

switch (1).

The system controls start up.

Automatic Pallet Loader APL / Expert Loader 33

Page 40

user mask is displayed

The machine carries

6 Ope ration

out a reference run.

The machine is ready

for operation when the

and the green dot at

the top right is visible.

The reference run is started automatically by the Suprasetter. The

APL106 itself starts a reference run after the actions pallet loading and

emptying the paper bin have been completed.

6.2 Emptying the paper bin

•

Touch [Empty paper bin]

(1).

The machine moves into the

safe position (park position).

34

Page 41

6.2 Emptying the paper bin

The door to the set-up area

of the paper bin is unlocked.

•

Open the door to the setup area of the paper bin.

Note: The process can be

aborted by pressing the

button [Cancel].

Display after opening the

door to the set-up area of

the paper bin

Note: If the door is

opened for longer than 10

seconds, the internal

paper counter will be set

to 0.0 m.

• Pull the paper bin (1) out

of the set-up area.

•

Empty the paper bin.

•

Push the paper bin back into the set-up area and close the door. The door is

automatically locked.

The machine has to carry out a reference run.

Automatic Pallet Loader APL / Expert Loader 35

Page 42

the reference run with

Note: If no reference run

seconds, the door will be

The machine carries out a

•

Confirm the start of

6 Ope ration

[OK].

is carried out after 10

unlocked again.

reference run.

•

Confirm the message

with [OK] when the

reference run has

been carried out.

Note: The message

disappears

automatically after 10

seconds.

The machine is then

ready for operation

again.

36

Page 43

6.3 Loading a pallet

6.3 Loading a pallet

A pallet with printing plates can be set up in the set-up area.

Pallet positions

The pallet has to be positioned accurately in the set-up area so that the printing

plate stacks can be detected by the stack detection system. The following figure

shows the area in which the pallet has to be set up.

min:195mm, max:215mm

Ensure that the

spacing between

the pallet stack

and the machine

frame is between

195 and 215 mm.

Left side U- profile

pallet

The laser lines (1)

serve as an

orientation aid for

correct positioning

of the pallet

Automatic Pallet Loader APL / Expert Loader 37

Page 44

6 Ope ration

Loading

The loading of a pallet is described in the following operating steps

•

Touch [Load

pallets] (1).

•

The machine

moves into the

safe position

(home position).

The hoods and the

door are unlocked.

The set-up area of

the machine can

be loaded.

•

Open the hoods.

•

Note: If the hoods are not opened after 30 seconds, they are automatically

locked again and the machine is ready for operation again.

38

Page 45

6.3 Loading a pallet

The pallet is in position

•

Move the pallet with the printing plates into the set-up area with the aid of a lift

truck.

The open and closed

hoods/door are

displayed in the user

mask.

•

Align the pallets such that

–

the front edge of the pallet is flush with the laser marking,

–

the longitudinal edge of the printing plate stack is flush with the second

laser marking.

Result:

The LH securing

brackets (1) remain on

the pallet

Automatic Pallet Loader APL / Expert Loader 39

Page 46

Confirm with [OK] to

6 Ope ration

We recommend that you also empty the paper bin during loading.

The paper bin door is therefore unlocked during loading.

•

Close the hoods and the paper bin door.

For safety reasons it is necessary to acknowledge the locking of the

hoods; the hoods are locked by confirming with [OK].

•

lock the hoods.

The machine has to carry out a reference run and pallet detection.

If no changes to the loading have been made (e.g. if you only

checked the storage compartment) and the set pallet(s)

hasn't(haven't) been moved, pallet detection can be skipped.

40

Page 47

6.3 Loading a pallet

First a reference run is carried

•

If pallets have been

loaded, removed or

moved, start the

detection with [Start

detection] (1).

•

Otherwise detection can

be skipped with [Skip

detection] (2).

out, then it is followed by the

pallet detection if applicable.

Automatic Pallet Loader APL / Expert Loader 41

Page 48

After completion of the

Following the reference

6 Ope ration

run, the stack detection is

active and the position of

the pallets with the printing

plate stacks is detected.

reference run and stack

detection, the allocation

of the pallet(s) in the setup area has to be

checked .

•

Touch [OK] to display

the operating mask

with the printing plate

parameters.

• Check the

allocation and

number of

loaded printing

plates in the

set-up area.

•

If you have

made any

changes, touch

[Apply

changes] after

completion of

the inspection.

42

Page 49

6.3 Loading a pallet

• To complete the

loading process

touch [OK].

Note: The

message

disappears

automatically after

10 seconds.

The machine is

then ready for

operation again.

The machine is ready for production. The machine receives the control

commands from the higher ranking machine line module "Recorder".

Automatic Pallet Loader APL / Expert Loader 43

Page 50

ed in

position another laser line

.

6.4 Loading a machine with 2nd pallet space

•

The machine with 2

pallets spaces (extension

module, EXT) is load

the same way as

described in chapter

Kapitel 6.3.

•

Start from the main

window with “Load pallet”

6 Ope ration

•

For the second pallet

mounted optionally.

•

The machine measures

both positions in any

case and displays the

found pallets and plates.

44

NO TE

The machine is stopped bevor loading and moves to a safe position

The second pallet cannot be loaded during production.

Page 51

6.5 R emoving a pallet

6.5 Removing a pallet

Once the last printing plate has been removed from the feeder, a message

appears on the operating panel Pallet Loader.

•

Start a loading sequence as described in section "6.3 Loading a pallet".

•

First remove the empty pallet and then load a new pallet with printing plates

into the set-up area (see section "6.3 Loading a pallet").

Also unscrew the holder for the

securing bracket (1) from the

empty pallet before disposing of

the pallet!

Also unscrew the rear retaining

brackets from the empty pallet

and fit them to the new pallet!

Automatic Pallet Loader APL / Expert Loader 45

Page 52

Caution

Make sure

is locked !

6.6 Loading plates to the cassettes (optional)

•

If the machine is equipped with

one or two cassettes these are

loaded in a similar procedure as

the pallet loading

•

In the main window press „load

cassettes)

6 Ope ration

•

Follow the instructions on the

screen step by step

•

The cassette moves downwards

to the loading position.

•

Unlock the cassette with the pushbutton at the handle and pull it out

for loading the plates.

•

The maximal loading of one

cassette is 100 plates of 0,3mm

thickness.

•

Make sure the cassette is locked

correctly after loading and

inserting.

that

the cassette

46

Page 53

6.7 R emoving fault y printing plates

6.7 Removing faulty printing plates

Faulty printing plates or printing plates with paper or cardboard are transported to

the transfer table. Then the machine stops with the prompt to remove the plate

from the transfer table.

Afterwards, restart the machine with Start.

Automatic Pallet Loader APL / Expert Loader 47

Page 54

6.8 Switching off the machine

•

6 Ope ration

Switch the machine off at the main

switch (1).

48

Page 55

Danger to life due to electrical voltage!

Risk of injury due to stored p

neumatic energy

Unexpected movements of the machine due to the release of stored

7 Malfunctions

DANGER

Contact with live parts causes electric shock, which can lead to

serious injuries or even death.

– Always turn off the main switch and secure it against being

switched on again prior to accessing the inside of the

machine/reaching into the machine.

CAUTION

energy can lead to moderately severe injuries.

– Always depressurise the machine prior to carrying out any work

on the pneumatics when there is a malfunction in the pneumatic

system.

Always adhere to the local safety regulations when remedying

malfunctions.

This chapter explains how to localise and remedy malfunctions and faults/errors.

Troubleshooting is assisted by the display of error numbers and error

descriptions in the operating mask.

7.1 Display of malfunction messages

If a malfunction message occurs, an alarm message window appears on the

operating panel with the following information regarding the occurred malfunction:

–

Type of malfunction:

–

System error

–

Warning

–

Sequence error

–

Error number

–

Error message

Automatic Pallet Loader APL / Expert Loader 49

Page 56

7.1.1 System error

Error number Error message

8200 No compressed air

8201 Motor 1 (X axis): no communication

8202 Motor 2 (Z axis): No communication

8203 Motor 3 (roller 2):no communication

8204 Motor 4 (roller 4):no communication

8205 Motor 5 (roller rotation):no communication

8206 Suction cup adjustment (Y axis): no pulse

8207 Suction cup adjustment (Y axis): Positioning time-out

8208 Suction cup adjustment (Y axis): Reference time-out

7 Malfunction s

8209 Flaps not closed

8210 Flaps not locked

8211 Flap locking error

8212 Paper bin door not closed

8213 Paper bin door not locked

8214 Motor voltage switched off

7.1.2 Warnings

Error number Error message

8301 Motor 1 (X axis): No reference

8302 Motor 2 (Z axis): No reference

8303 Motor 3 (roller 2): No reference

8304 Motor 4 (roller 4): No reference

8305 Motor 5 (roller rotation): No reference

8306 Suction cup adjustment (Y axis): No reference

8307 Paper bin door open

8308 Segment 1 door open

8309 Paper bin not in position

8310 Stack height cannot be calculated

50

Page 57

7.1 Displ ay of malfunction messages

Error number Error message

8311 No paper before gripping

8312 Paper detected during suction

8313 Motor 1 (X axis): Excessive temperature

8314 Motor 1 (X axis): Overcurrent

8315 Motor 1 (X axis): Undervoltage

8316 Motor 1 (X axis): Overvoltage

8317 Motor 2 (Z axis): Excessive temperature

8318 Motor 2 (Z axis): Overcurrent

8319 Motor 2 (Z axis): Undervoltage

8320 Motor 2 (Z axis): Overvoltage

8321 Motor 3 (roller 2): Excessive temperature

8322 Motor 3 (roller 2): Overcurrent

8323 Motor 3 (roller 2): Undervoltage

8324 Motor 3 (roller 2): Overvoltage

8325 Motor 4 (roller 4): Excessive temperature

8326 Motor 4 (roller 4): Overcurrent

8327 Motor 4 (roller 4): Undervoltage

8328 Motor 4 (roller 4): Overvoltage

8329 Motor 5 (roller rotation): Excessive temperature

8330 Motor 5 (roller rotation): Overcurrent

8331 Motor 5 (roller rotation): Undervoltage

8332 Motor 5 (roller rotation): Overvoltage

Automatic Pallet Loader APL / Expert Loader 51

Page 58

7.1.3 Sequence error

Error number Error message

8230 Double plate or paper detected 3 times

8231 Outfeed: no plate detected

8232 Paper jam in the paper pull-in

8233 Plate in the outfeed during initialisation

8234 Double plate or paper in the outfeed during initialisation

8235 Paper removal failed 3 times

8236 Double plate/paper during transfer

8237 Vacuum fault during plate pick-up

8238 Vacuum lost during plate pick-up

7 Malfunction s

8239 Plate not pulled in by Recorder

8240 Cardboard detected 3 times in a row

8241 Plate on the rollers during initialisation

52

Page 59

Danger to life due to electrical voltage!

Risk of injury due to stored pneumatic energy

tored

Risk of injury due to bursting pneumatic hoses

8 Maintenance and cleaning

DANGER

Contact with live parts causes electric shock, which can lead to

serious injuries or even death.

– Always turn off the main switch and secure it against being

switched on again prior to accessing the inside of the

machine/reaching into the machine.

– Restrict maintenance work on the machine to suitably qualified

personnel.

CAUTION

Unexpected movements of the machine due to the release of s

energy can lead to moderately severe injuries.

– Always depressurise the machine prior to carrying out any

maintenance work on the pneumatics.

CAUTION

Pneumatic hoses with an expired service life may burst and cause

slight or moderately severe injuries.

Proper maintenance and cleaning are crucial for the operational safety and long

service life of the machine. For this reason it is particularly important

– Check the condition of the pneumatic hoses at regular intervals

and replace them if visible wear is detected.

– Do not reuse old pneumatic hoses.

– Only use original spare parts.

–

to precisely adhere to the maintenance intervals;

–

to observe the maintenance chapters of the supplier's documentation.

Complying with the intended use includes adhering to the maintenance intervals

specified in the following.

Automatic Pallet Loader APL / Expert Loader 53

Page 60

8 Maintenance and cleaning

8.1 Maintenance intervals and maintenance work

Duties and

responsibilities

Custom

er

Assembly group

Maintenance

interval

Maintenance work

Service

Entire machine Every 6 months

Guide rails:

Every 6 months

– Feeder

– Extension and

end module

Guide rails:

Every 6 months

– Feeder / support

rollers

Optical sensors on

the feeder (paper

Every 6 months or

as required

detection, plate

edge):

– 4 light barrier

sensors

– Laser sensor

Ultrasonic sensors

at the outfeed slot

Every 6 months or

as required

to the Recorder.

– Clean the work area

– Clean and oil the slide rails.

– Spray the slide rails, in which

the support rollers run, with

silicone spray.

– Clean sensors with a soft lint-

free cloth.

– Clean sensors with a soft lint-

free cloth.

X

X

X

X

X

Feeder drive belts Every 6 months

– Check the drive belts for

X

damage.

Suction cups,

feeder

Every 6 months

– Check the suction cups for

damage (tears and

X

deformation).

Rubber rollers,

basic module

Pneumatic system

of the entire

machine

Every 6 months

Every 6 months

– Check the rubber rollers for

damage.

– Check the pneumatic system

for leaks.

– Check the pneumatic hoses

X

X

for damage.

– Check the condensate level

in the air servicing unit.

54

Page 61

8.1 M aintenan ce interv als and maintenance w ork

Assembly group

Maintenance

interval

Maintenance work

Duties and

responsibilities

Custom

Service

er

Cassette system

Chains

Cassette system,

Guiding rails and

carriages

Every 6 month

Every 12 months

Carefully clean the chain with

an greased tissue. Make sure

that now grease or oil can

sparkle around and damage

the printing plates

The carriages have grease

inside.

Grease the rails carefully

x

X

Automatic Pallet Loader APL / Expert Loader 55

Page 62

8.2 Cleaning agents and lubricants

NO TE

Risk of damage to the machine!

The machine can be damaged by the use of incorrect cleaning

Agfa NV recommends the following cleaning agents and lubricants:

Use Application Product

agents and lubricants.

Only use the recommended cleaning agents and lubricants.

8 Maintenance and cleaning

Cleaning agent Entire machine

Water/soapy water together with a

micro fiber cloth

Lubricant Guide rails Silicone spray

For example Caramba 619902

Silicon spray

Lubricating grease Cassette chain,

x-axis rails

Grease, for example Klüber

CentroPlex 2EP

56

Page 63

Danger to life due to electr

ic shock!

Risk of injury during work on the pneumatic system if it is

9 De-commissioning

DANGER

Danger to life when working on the electrical installation.

– Work on the electrical installation must be restricted to a qualified

electrician.

CAUTION

carried out by insufficiently qualified personnel!

There is a risk of injury during de-commissioning and dismantling

work on the pneumatic system for insufficiently qualified personnel.

– Only allow qualified expert personnel to carry out work on the

pneumatics.

•

Switch off the machine

(see figure in section "3.2 Function and operating elements ").

•

Switch off the downstream machine line module (see operating manual of the

higher ranking machine).

•

Have the supply energies (electricity, compressed air) disconnected by the

respective expert personnel.

•

Disconnect all supply lines from the machine.

Automatic Pallet Loader APL / Expert Loader 57

Page 64

Page 65

When dismantling the machine co

mponent parts, take the

Lifting of the component parts using attachment points not designed

for this purpose can lead to the component parts falling and causing

10 Dismantling

10.1 Information regarding hazards during dismantling

WARNING

following specific hazards into consideration:

injury.

– Only lift the component parts at the specified attachment points

marked red.

NO TE

If the transport securing devices and stabilising elements are not

attached, this can lead to the component parts falling and causing

injury.

– Fit the transport securing devices and stabilising elements before

dismantling the component parts.

Incorrectly dismantled lines/cables can be damaged and cause

smouldering fires and cable fires when reused.

– Restrict all work on the electrical installation to a qualified

electrician.

Incorrectly dismantled pressure lines and connections can be

damaged, causing injuries when reused.

– Restrict all work on the pneumatics to specialist pneumatic

personnel.

As a general rule:

– Wear your personal protective equipment for all work.

Unsuitable dismantling tools can cause damage to the component

parts.

– Use suitable tools only.

– Restrict all work to suitably trained and instructed personnel and

respective expert personnel.

Automatic Pallet Loader APL / Expert Loader 59

Page 66

10.2 Preparatory measures

Prior to dismantling the machine ensure that

–

the machine has been de-commissioned (properly shut down and

disconnected)

(see section "9 De-commissioning");

–

the necessary tools for dismantling are provided;

–

the necessary transport securing devices are provided;

–

the transport equipment is provided

(see section "4.1.6 Recommended transport equipment");

–

additional light sources (hand lamps) are provided for dismantling;

–

the floor area at the site is clean and dust-free to ensure problem-free

transport of the component parts.

10 Di smantling

10.3 Dismantling the machine and securing it for

transport

To prepare the machine for transport, proceed in the following order.

1. Preparing and securing the machine for transport

2. Supply lines

3. Paper bin

4. Package

60

Page 67

10.3 Dismantling the machine and securing it for transport

Moving the machine to its

unit is approximately below the

Movi

ng the transfer table down

10.3.1 Preparing and securing the machine for transport

transport position

• Lifting unit down (1)

• Z axis up to just before the

stop (2)

• x axis right until the extraction

line lasers (3)

• Move the transfer table down

Automatic Pallet Loader APL / Expert Loader 61

Page 68

Moving the transfer table down

Securing the z axis, part 1

10 Di smantling

•

Turn out the screws marked in

green

•

Have two persons hold the

table

•

Turn out the screws marked in

red,

•

Move the table and fasten on

both sides

•

using the screws marked in

green

Moving down and securing the

suction gripping unit

•

Use cable ties to secure the

lifting unit against turning and

moving up on both sides

•

Undo the framework pate on

the z axis (4 screws) (1)

•

Push the framework plate up to

the stop (2)

•

Tighten the screws on the

framework plate (3)

•

The hook of the feeder then

makes contact with the

framework plate (4)

62

Page 69

10.3 Dismantling the machine and securing it for transport

Securing the z axis, part 2

Place a foam plate between the

•

feeder and the cladding (1)

•

In addition, use a belt to

secure the feeder.

Guide the belt through two

openings in the cladding

crossbar (2).

Automatic Pallet Loader APL / Expert Loader 63

Page 70

Securing the z axis cylinder

Securing the x axis

10 Di smantling

•

Prevent the large z cylinder

from extending by securing it

with cable ties.

•

If the cylinder extends during

transport while the

feeder is secured in the top

position, the white timing belt

will come loose and lose its

position.

•

Use a bracket to secure the xz

unit (1).

•

The bracket is screwed to the

cladding and to the

perpendicular aluminium profile

of the x-z unit. The screw on

the cladding is used for this

purpose.

64

Page 71

10.3 Dismantling the machine and securing it for transport

Attaching transport bars

Two transport bars are used for

Cassette securing

•

transport with a lift truck. (1)

and (2)

The cassettes are secured

vertically with a wooden bar

between the cassette and the

paper trolley.

10.3.2 Supply lines

The cables for the voltage supply and the signal cables are routed in cable ducts

and in an energy chain.

•

•

•

Automatic Pallet Loader APL / Expert Loader 65

Disconnect the cables from the connections and pull them out of the cable

ducts.

Remove the energy chain.

Remove the compressed air hoses.

Page 72

Paper bin

Securing the hood

10.3.3 Paper bin

10 Di smantling

•

Open the door to the basic

module and pull the paper bin

out of the basic module.

•

Remove the paper bin

•

and screw it to the plywood

board (1)

(2).

•

Use one flat bar (1) each to

secure the hood on the feet.

66

Securing the paper bin door

•

Once everything is screwed to

the pallet, wrap the machine in

stretch film.

•

This also secures the paper bin

door (1)

.

Page 73

Hazards to health due to incorrect disposal of the machine!

e assembly groups and machine components

11 Disposal

CAUTION

The machine contains pollutants.

– Hand the assembly groups and machine components over to a

– Do not dispose of th

– Adhere to the national regulations.

recognised disposal company.

via the domestic waste system.

Addresses of recognised disposal companies can be obtained from the

environmental agency or responsible authorities.

The information is based on our current knowledge and experience. It

does not release the disposal company from the obligation of adhering to

the national regulations and laws valid at the time of disposal.

11.1 Terminology

Recyclable material

Assembly groups and/or components that contain no pollutants and can be

recycled in an environmentally safe manner.

Pollutants

Assembly groups and/or components that have to be disposed of or recycled

separately.

Automatic Pallet Loader APL / Expert Loader 67

Page 74

11.2 Overview of the assembly groups

The following figure shows the assembly groups and components that contain

recyclable material and pollutants.

11 Di sposal

Recyclable material/pollutants

Pos. Assembly group

Recyclable

material

Metal

Recyclable

material

Plastic

Pollutants

Timing belt,

vacuum suction

cups, pneumatic

hoses, plastic

Electronics and

pneumatics

10 Feeder

Steel and

aluminium

moulded parts

20 Paper removal Metal, steel Rubber rollers Electric motor

Electronic

30

Electrical

installation

Mounting plate

Terminals, cable

ducts

components,

power pack,

PCBs, cables

Air servicing unit,

40 Pneumatics

valves,

pneumatic hoses

50

68

Transport

equipment

Steel - -

Page 75

11.2 Overview of the assembly groups

Recyclable

Pos. Assembly group

material

Metal

60

Plate securing

device

Sheet steel

70 Transfer table Steel

Recyclable

material

Plastic

Belts, 3D printed

components

80 Collision guard Sheet steel

Metal, sheet

90 Cladding

steel, doors

made of

aluminium

100 XZ axle Metal, steel

Timing belt,

electric motor

Screws, nuts, bolts Steel

Dismantling information

Pollutants

Electric motor

Item Assembly group Dismantling information

10 Feeder

Screw-fitted to vertical guide

(relieve before dismantling)

20 Paper removal Screw-fitted

30

Electrical

installation

Mounting plate and operating panel screw-fitted,

cables plug-connected

40 Pneumatics Plug-connected, screw-fitted

50

60

Transport

equipment

Plate securing

device

Screw fitted (removed from the machine after

installation)

Screw-fitted, individual parts

70 Transfer table Screw-fitted

80 Collision guard Screw-fitted

90 Cladding Main elements screw-fitted,

100 XZ axle Screw-fitted

Automatic Pallet Loader APL / Expert Loader 69

Page 76

Page 77

12 Appendix

12.1 Technical data

12.1.1 Dimensions

Hoods and doors closed (in mm)

Module Length Width Height

Overall dimension including

all modules without optional

extensions

2930 1850 1550

Machine 1980 1850 1550

Transfer table 950 1200 840

Open hood 2395

Optional extension modules 1320 1850 1550

Hoods open, paper bin in front of basic module (in mm)

Module Length Width Height

Open hood 2700 2395

Open paper bin door - 1450 .

Automatic Pallet Loader APL / Expert Loader 71

Page 78

12.1.2 Weights

Weights without printing plates with empty paper bin (in kg)

12 Appendix

Module Weight

Machine 750 200

Max. floor load

per foot

12.1.3 Electrical connected loads/rating

Connection Value

Voltage 205-230V 50/60Hz 2~ + PE

Current 3.46 A

Connected load 0.79 kW

Customer-supplied fuse 10 A or 16A

Fuse in the Recorder -

12.1.4 Compressed air connected values/capacity

Max. surface

load

Connection Value

Pressure 7 bar

Quality

Consumption 170 l/min

Connection ½“