Page 1

7509 D

Einbau-Flachschirm-Dunstabzugshaube

Built-In- Flat-Screen Fume Extractor Hood

Montage- und Gebrauchsanweisung

Installation and Operating Instructions

Page 2

Summary

Safety warnings Page

For the electrical installer 30

For the kitchen furniture installer 30/31

Before installation

General information 32

Appliance description 32

Technical data: 33

- Dimensions 33

- Electrical connection data 33

- Air outlet 34

- Accessories/installation material 35

Installation

Preparation of the cabinet 36

Installation of the cooker hood 37-40

Recycling installation 41/42

Evacuation installation 43/44

Electrical connection 45/46

Safety warnings

for the user 47

Appliance description/controls

- Controls 48/49

Maintenance

- Metal filters (cleaning) 50

- Charcoal filters (only in recycling version) 51

- Fluorescent strip light/Starter 52-54

- General cleaning instructions 54

Special accessories 55

After Sales Service 55

28

SYSTEM

OKO

MADE IN GERMANY

Printed on recycled paper.

AEG - putting words into action.

29

Page 3

Safety warnings

For the

electrical

installer

For the

kitchen

furniture

installer

30 31

The installation of a socket immediately above the cooker hood

or the cabinet has two advantages:

1. The socket is out of sight

2. If necessary, the cooker hood can be disconnected by

removing the plug.

Should it be necessary to connect the hood permanently, this

should be carried out only by a qualified electrician or a

competent person. Connect the hood to the mains supply via

a double pole switch which has 3mm minimum clearance

between the contacts.

Suitable double pole switch breakers are e.g. switches,

fuses (screw-in fuses must be taken out from their holder),

safety switches and protection switches having more than

3mm clearance between the contacts.

Electric connection

230 V through cable with plug

240 V through cable (England)

The permanent electrical connection should be carried out only

by a qualified electrician or a competent person.

CE This appliance complies with the requirements of the fol-

lowing CEE directives:

72/23/EWG of 19.02.1973, low tension directive (including

modification directive 93/68/EWG).

89/336/EWG of 03.05.1989 (including modification directive

92/31/EWG - EMV directive).

When used in the evacuation mode the cooker hood must

not be connected to a central heating flue, radiator or a

water heater.

If the room where the cooker hood is to be used contains

other non-electric appliances (such as gas appliances) do

not connect the appliance to the room ventilation ducting.

If the cooker hood is connected to chimneys no longer in

use, it is advisable to seek the consent to the competent

chimney-sweeper.

If the cooker hood is installed in the evacuation mode, the

requirements of the concerned authorities have to be

observed.

An adequate air inlet having the same size as the air outlet

is to be ensured.

If the room where the cooker hood is to be used contains

other non-electric appliances (such as gas or coke appliances), their use is subject to some restrictions.

When the cooker hood and appliances supplied with energy

other than electricity are simultaneously in operation, the

negative pressure in the room must not exceed 0,04 mbar

in order to avoid a return of the gas emissions.

The air inlet must have a 500-600 cm

2

surface.

Should you have any problem, it is advisable to seek the

advice and consent of the competent area chimney-sweeper

or the local building authorities.

Since in rooms without non-electric appliances the rule is

the following: “Air inlet must be as large as the air outlet,

the good working of the cooker hood could be reduced if

the air outlet is bigger than 500-600 cm

2

.

The functionning of the cooker hood in the recirculation

mode, in the same conditions, does not present any danger.

The following instructions should be observed to avoid

any risk in the use of the cooker hood in the evacuation

mode:

- short and straight ducting

- as few bends as possible

- no 90

° bends, but flat angles

- as large as possible duct diameters (basically 120mm Ø

minimum for two motors cooker hoods).

Should these instructions not be observed, a sensible loss

of performance can take place.

The following distances between the upper edge of the

cooktop and the lower edge of the cooker hood are to be

observed:

electric cooktops 465mm

gas cooker hoods 650mm

For the

kitchen

furniture

installer

Page 4

General

information

This cooker hood features a through flow retractable visor which

offers a large collection area for contaminated air once it is

extended into its working position.

The functions are selected through the sliders; the opening of

the visor can be used to switch the appliance on when the

controls have been pre-set.

The cooker hood can be used either in recirculation or

evacuation mode.

The installation work should be undertaken by a qualified and

competent person

Dimensions:

Height Width Depth (in mm)

420 900 260

Weight:

Net: 16 Kg

Technical

data

Appliance

description

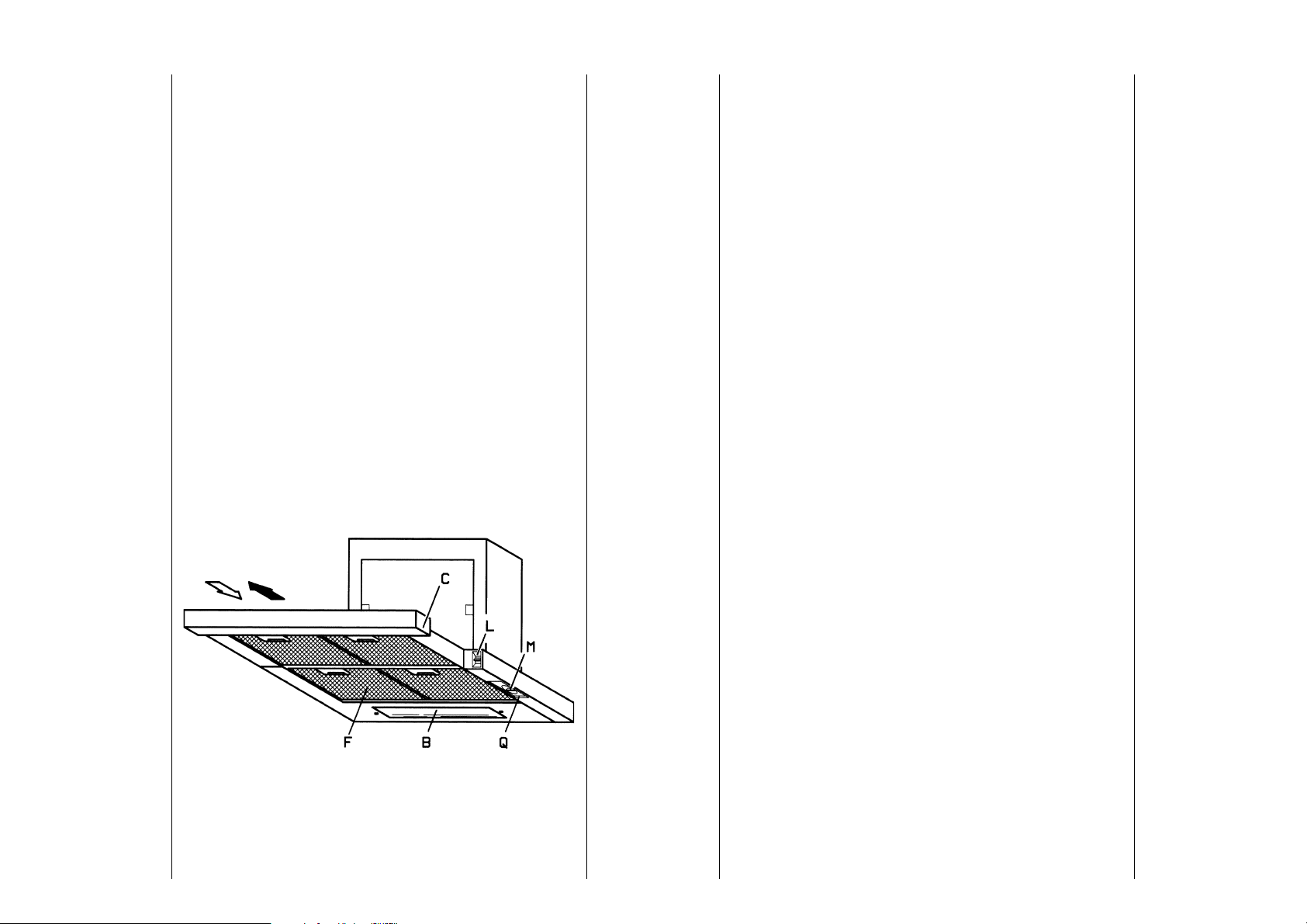

C = Visor

Q = Controls

M = Motor switch

L = Lighting switch

B = Lighting

F = Metal filter

Electrical connection:

Total absorbed power: 270 W

Motor: 2x126 W

Lighting: 1x18 W

Evacuation ducting 120/125/150 mm Ø.

32

33

Page 5

Accessories/installation material

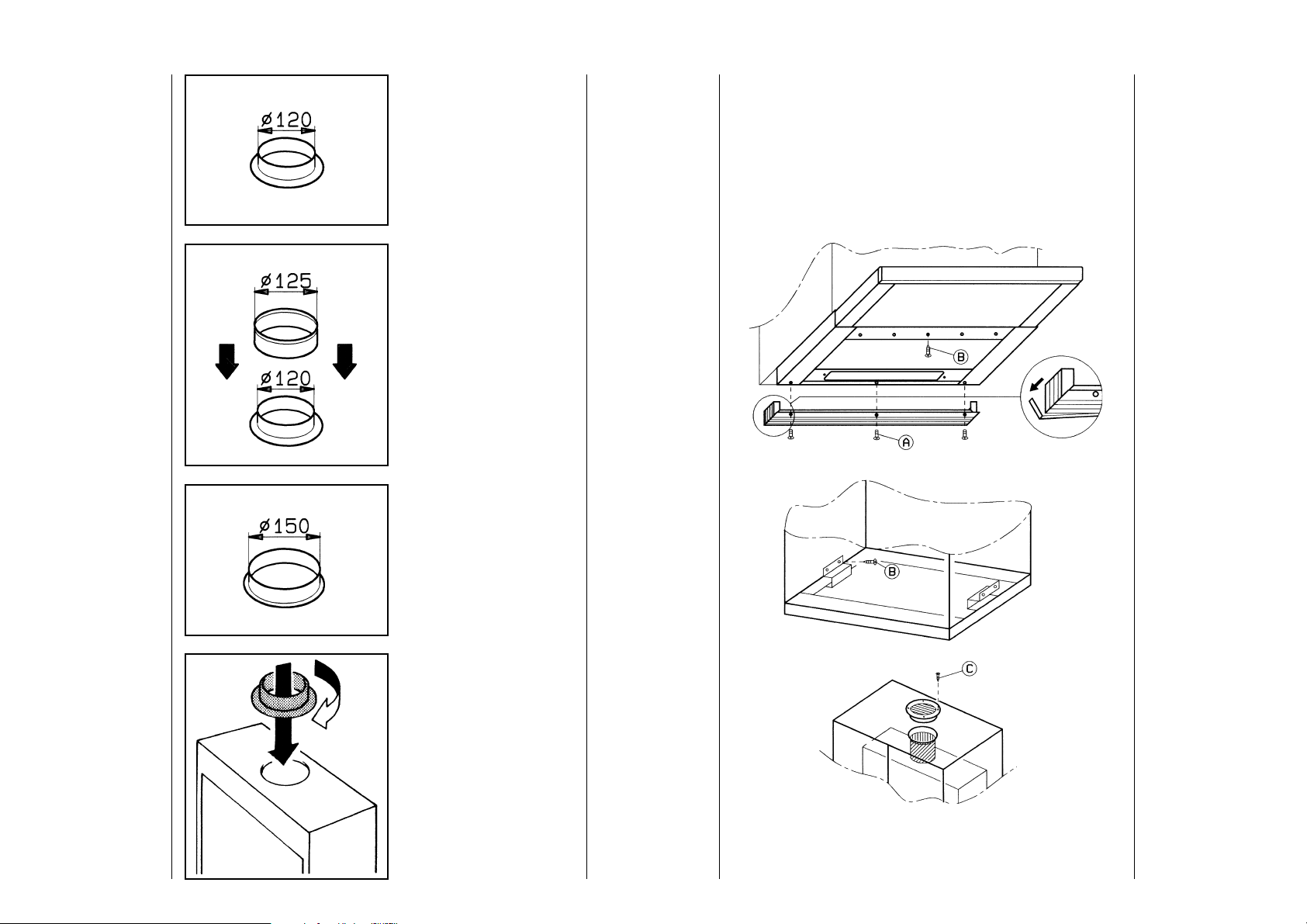

Air outlet

Air outlet 120 mm Ø

Air outlet 125 mm Ø

1 ducting spigot Ø 120mm

1 ring Ø 120-125mm

1 ducting spigot Ø 150mm

1 break-off wall infill spacer to be applied on the lower part of

the cooker hood to cover the hollow space up to the wall

1 venting grille Ø 120mm

2 brackets to fix the cooker hood

3 screws (A)

9 screws (B)

2 screws (C)

34

Air outlet 150 mm Ø

ATTENTION: The installer should ensure that the material

for the connection of the cooker hood to the evacuation

duct or to the upper part of the cabinet is available.

The venting grille can be fitted only on 120 mm Ø ducts.

35

Page 6

Installation

Preparing

the

cabinet

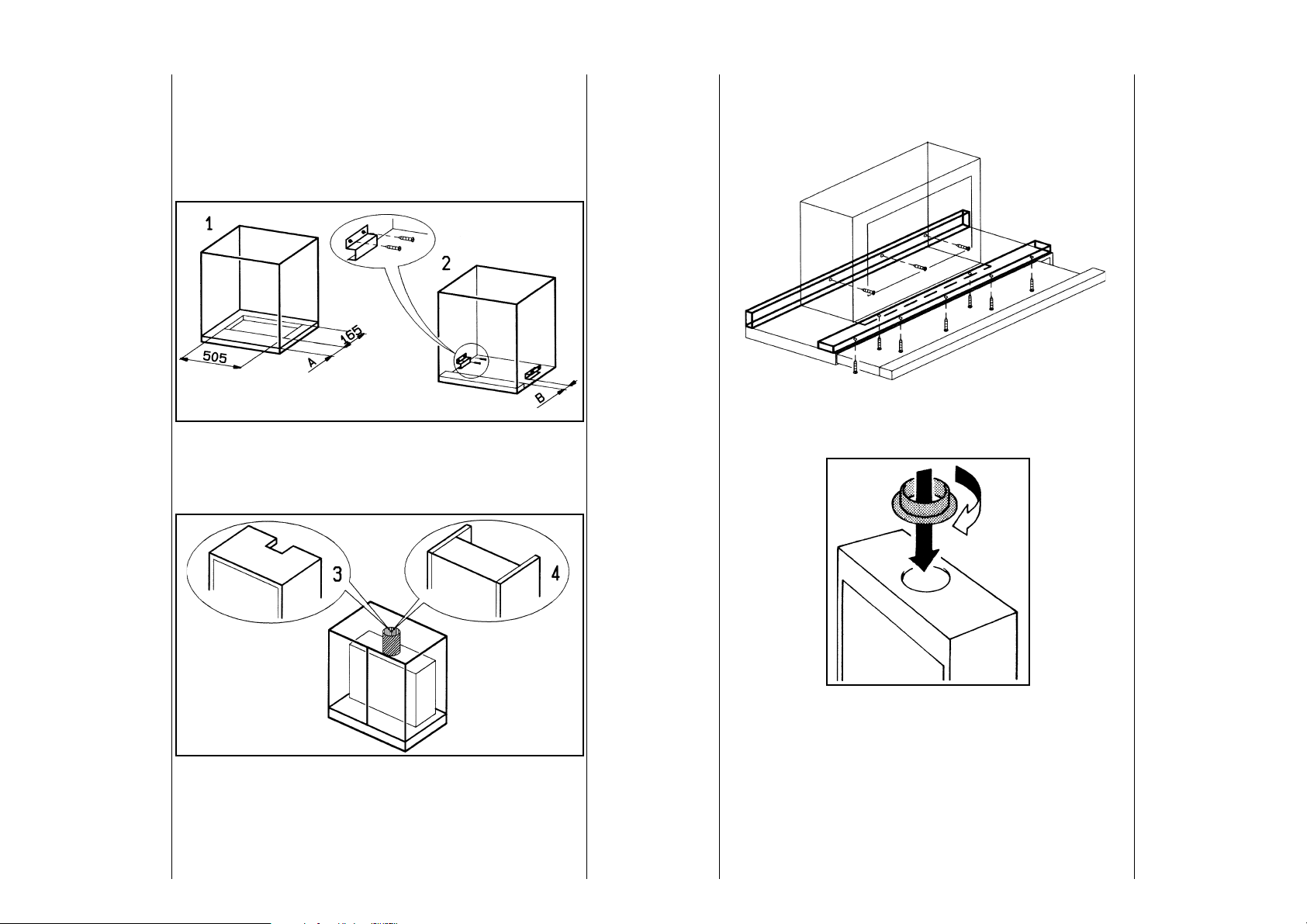

Make a 505 x 165mm hole on the bottom of the cabinet 1).

The measure A must be calculated by the installer according

to the requested alignment between the lower visible part of

the cooker hood and the cabinet. If the cabinet is without bottom

2), fix the two brackets at a distance B of minimum 30mm and

maximum 60mm.

Make a hole on the lower part of the cabinet for the duct outlet

or leave the cabinet open 4).

InstallationBefore carrying out the installation, the wooden transportation

protections screwed on the visor and on the canopy body must

be removed.

Fit the ducting spigot on the upper opening.

Remove the metal filters and ensure that the butterfly quick

fixing clamps are completely open.

If not, rotate the adjustment screws 2 completely.

36 37

Page 7

Installation

Fit the cooker hood in the cabinet until it is well fixed to the

butterfly quick fixing system placed on the lower part of the

cabinet or on the two brackets.

Connection to the evacuation duct may be realised through a

round or flat duct.

Partially tighten the adjustment screws 2 of the butterly quick

fixing system.

The lower visible part of the cooker hood can be adjusted

(max 20mm) for the horizontal alignment with the cabinet.

Partially loosen the four screws fixing the lower part of the

cooker hood to the upper part 1), adjust the lower part of the

cooker hood 2) in the desired position and tighten the screws

definitively.

Definitely fix the cooker hood to the cabinet by tightening the

adjusting screws 2.

Installation

38

Fix the lower part to the cabinet using five supplied screws.

39

Page 8

Front strip

If you wish to replace the factory fitted front strip with a wooden

one or with a front strip made with the same material as the

kitchen, remove the five screws. Remove the front strip.

Fix the new front strip with the central screw before and, later,

fasten the other four screws definitely.

If the cooker hood is to be installed in recirculation mode then

charcoal filters (on request) must be provided.

Fit the charcoal filters ensuring that they click into position correctly.

Recirculation

fitting

The cooker hood can be installed in two different ways:

RECIRCULATION FITTING:

using two charcoal filters to catch the odours and to recirculate

the air back into the kitchen.

EVACUATION FITTING:

(without charcoal filters) to pass contaminated air out through

ducting to the atmosphere.

40 41

Page 9

Recirculation

fitting

Connect a suitable length of ducting to the air outlet on the top

of the cooker hood inside the cabinet. The ducting should be

long enough to project through the hole in the top of the cabinet.

Fit the venting grille over the ducting and screw the grille to the

top using the screws provided. Ensure that the blades in the

grille are angled forwards.

Recycling installation is now completed.

If you wish to install the appliance in evacuation mode, the

charcoal filters are not required.

Ducting

fitting

To remove the charcoal filters, press in the two charcoal filters

catches.

4342

Page 10

Electrical connection

fitting

Replace the metal filters.Evacuation

It is now possible to install the ducting. Attention should be

taken when installing the ducting to choose the shortest possible

run with the minimum number of bends. The use of bends may

cause a loss of air capacity and should be avoided where

possible.

The internal diameter of the ducting should be the same as the

external diameter of the ducting spigot.

Now ducting installation is completed.

Your appliance must be connected to fixed wiring via the use

of a double pole switched fused spur outlet with or without pilot

lamp.

We strongly recommend the appliance is connected by a

qualified electrician who is a member of the NICEIC who will

comply with the IEE and any local regulations.

44

NOTE: The terminology "DOUBLE POLE" means that both the

live and neutral supplies are switched and disconnected at the

same time.

45

Page 11

Safety warnings

The terminations laballed SUPPLY are for connection for the

internal house wiring and the terminations labelled LOAD are

for the appliance.

IMPORTANT - The wires of the mains load supplied with this

appliance are coloured in accordance with the following code:

Blue - Neutral

Brown - Live

As the colours of the flexible cord of this appliance may not

correspond with the coloured markings identifying the terminals

in your plug, poceed as follows:

The wire which is coloured brown must be connected to the

terminal which is marked with the letter L or coloured red.

The wire which is coloured blue must be connected to the

terminal which is marked with the letter N or coloured black.

Never leave the burners of the hob uncovered while the

hood is in use: an excessive heat could damage the

appliance. Open-fire cooktops, such as oil-, gas- and coalfired cooktops, must be avoided.

Never leave frying pans unattended during use as

overheated fat and oils may catch fire.

Polluted oils increase fire hazard.

The overheating can cause fire hazard.

Never do flambé cooking under the cooker hood.

Before carrying out any kind of cleaning or maintenance,

even the replacement of the fluorescent strip light,

disconnect the appliance unplugging the cooker hood or

acting on the mains supply.

The metal filters or the charcoal filters should be cleaned

or replaced as recommended by the manufacturer.

There could be a possible fire hazard in the case of grease

accumulation on the filters.

For the

user

46 47

Page 12

Appliance description/controls

To switch on the cooker hood slide the switch marked M selecting the required fan speed.

The symbols and numbers have the following meaning:

Motor Lighting

M = Motor switch L = Lighting switch

0 = The motor is off 0 = Lighting is off

1 = Low speed 1 = Lighting is on

2 = Medium speed

3 = Top speed

The movement of the visor can be used to switch the appliance

on and off.

ControlsControls

To switch on the worktop lighting slide the switch L to position 1.

48 49

Page 13

Cleaning and maintenance

Metal filters

Before carrying out any kind of maintenance, disconnect the

hood form the mains supply or unplug the appliance.

The metal filters retain grease particles and are used both in

evacuation and recirculation mode.

The metal filters should be cleaned every 4 weeks in the

dishwasher or by hand.

The charcoal filter is to be used only in recirculation mode.

You should use only AEG original filters (see Special Accessories).

The charcoal filter cannot be cleaned or regenerated.

It should be replaced every 8 months if the hood is used normally.

To replace the charcoal filters push the metal retaining clips

inwardly.

To order the spare filters, you should state the reference, the

model and the product number of the cooker hood.

These data are shown on the rating plate inside the hood.

The charcoal filters can be ordered at AEG After Sales Service.

Charcoal

filters

Washing by

hand

Washing in the

dishwasher

50

Leave the metal filter in warm water with mild detergent for one

hour and then rinse with warm water. The operation should be

repeated if necessary. The filter can be refitted after having

ensured it is completely dry.

Put the filters in the dishwasher. Choose the strongest washing

programme, 65° at least. The operation should be repeated if

necessary. Refit the filter after having ensured it is completely

dry.

Use only warm detergent to clean the internal part of the cooker

hood (do not use abrasive cleaners, brushes or scouring

agents).

51

Page 14

Strip light

replacement

(Starter)

A 18W fluorescent strip light ensures the lighting of the worktop.Fluorescent

To replace the fluorescent strip light operate as follows:

Disconnect the hood from the mains supply.

Unplug the hood.

Remove the screw on the plastic terminal near the lighting

diffuser.

Move the glass strip until the opposite end is free.

Pull the glass strip slightly downward.

Move the strip glass toward one side and remove.

Replace the fluorescent strip light.

Fluorescent

strip light

replacement

(Starter)

To replace the starter, remove the inside cover of the lighting

area operating as follows:

Remove the metal filter.

Remove the two screws and turn the inside cover upward.

52 53

Page 15

Special accessories

strip light

(Starter)

General

warnings for

the cleaning

Turn the Starter as illustrated and replace.Fluorescent

Attention: To clean the cooker hood disconnect the appliance from the mains supply.

Do not insert any sharp object in the motor protection

grille.

Clean the outside parts of the cooker hood with mild detergent. Do not use abrasive cleaners, brushes or scouring

agents.

Control panel should be cleaned only with a damp cloth

and mild detergent.

Charcoal filter E. Nr. 610 899 435

KF 7509

Wall box E. Nr. 610 899 004

MKZ

Outside dimensions for the 250x220

hole on the wall 185x210

Evacuation duct E. Nr. 610 899 007

120 mm Ø Aluminium

Evacuation duct E. Nr. 610 899 008

125 mm Ø Aluminium

After Sales Service

There could be a possible fire hazard if the grease filters

are not cleaned or replaced when necessary and according

to these instructions.

54

In case of any enquiries or faults, please call our After Sales

Service (see list of After Sales Centres).

When you call, please state what follows:

1. The model reference

2. The appliance number (E. Nr.)

3. The production number (F. Nr.)

These data are shown on the rating plate inside the hood.

The rating plate is visible once the metal filters have been

removed.

In the interest of technical progress, the manufacturer reserves

the right to make design and colour alterations without prior

notice.

55

Page 16

56

57

Page 17

58

59

Page 18

616063

Page 19

62

Page 20

Bitte geben Sie unserem Kundendienst folgende Angaben bei einer

Störung an:

If your appliance has a fault, please contact our service engineer and

state the following numbers:

E-Nr. 610

F-Nr.

AEG Hausgeräte GmbH

Postfach 1036

D-90327 Nürnberg

© Copyright by AEG

H 259 214 700 - 1294/02 -

4324241 02- 020301

Loading...

Loading...