Page 1

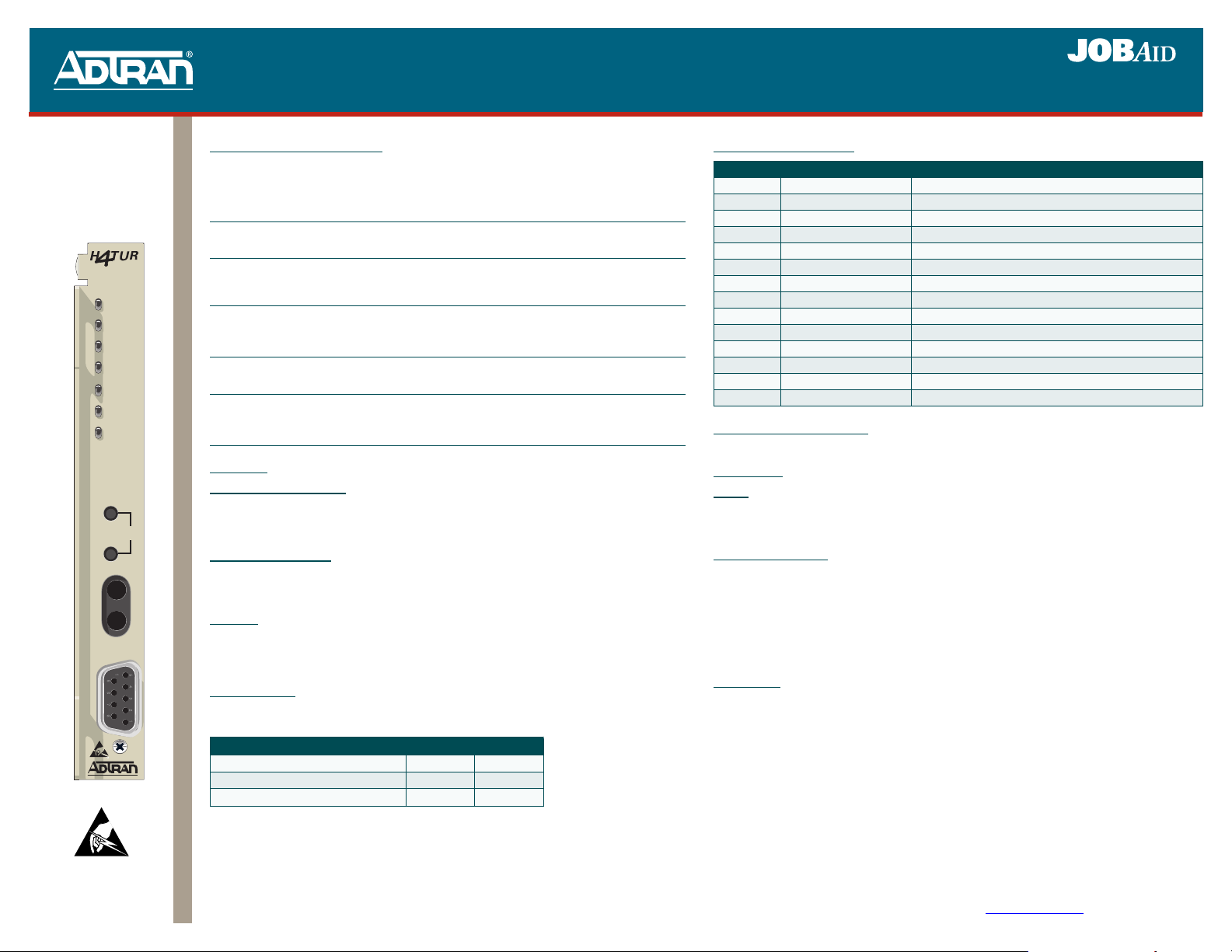

T200 HDSL4 Transceiver Unit, Remote-Local Powered

61223424L2-22B

0505

HDSL4

T200 H4TU-R

P/N 1223424L2

CLEI: T1L83Z3C_ _

1223424L2

LOCAL

DSL 1

DSL 2

DS1

ALM

ESF/SF

(YEL)

(GRN)

B8ZS/AMI

(GRN)

(YEL)

LLB/RLB

(GRN)

(YEL)

LOC

LBK

REM

TX

M

O

N

RX

R

S

2

3

2

*61223424L2-22B*

C A U T I O N !

SUBJECT TO ELECTROSTATIC DAMAGE

OR DECREASE IN RELIABILITY.

HANDLING PRECAUTIONS REQUIRED.

FRONT PANEL LED STATUS

DSL1/DSL2

DS1

ALM

ESF/SF

B8ZS/AMI

LLB/RLB

!!Green

Red

!!Green

Red

"

Off

!

Yellow

!

Red

"

Off

!

Green

!

Yellow

!!Green

Yellow

"

Off

!

Yellow

!

Green

Loop 1/Loop 2 synchronization achieved and signal is present

No errors currently detected, and SNR margin ≥ 3 dB

Loop 1/Loop 2 synchronization not achieved, in sync with

errors, or SNR margin < 3 dB

DS1 signal present and no errors currently detected

No DS1 signal, or signal present with errors

No active alarm present

Loss of DSX-1 signal from the network

Loss of DS1 signal from the customer (CPE)

Unit is provisioned for UNFRAMED data

Unit is provisioned for SF data

Unit is provisioned for ESF data

Unit is provisioned for AMI line code

Unit is provisioned for B8ZS line code

No local loopbacks active

Local loopback active

Active loopback at the H4TU-C toward the customer

OPTIONS

Front Panel Pushbuttons

LOC Initiates a bidirectional loopback of the T200 H4TU-R toward the network and customer

REM Initiates a loopback at the H4TU-C toward the customer

DS1 MONITOR JACKS

TX DS1 signal from the DCP toward network (nonintrusive)

RX DS1 receive from the local loop (nonintrusive)

POWER

This specific unit is intended for Local Power Only. If a Span Powered unit is required, refer to

P/N 1223426L2.

A local power supply is available from ADTRAN by ordering P/N 1353.DSK48V04.

COMPLIANCE

This product is intended to be installed in Restricted Access Areas only and in equipment with

a Type “B” or “E” enclosure.

Code Input Output

Power Code C C

Telecommunication Code (TC) X X

Installation Code (IC) A –

This product meets all requirements of Bellcore GR-1089-CORE (Class A2), ANSI T1.418-

2002. This product is NRTL listed to the applicable UL standards.

WARNING: Up to –200 VDC may be present on telecommunications wiring. Ensure

Chassis ground is properly connected.

For more information, refer to the Installation and Maintenance Practice (P/N 61223HDSL4L2-5) available online at www.adtran.com.

CARD EDGE PINOUTS

Pin Designation Description

1 CH GND Chassis ground

5 DS1-T1 DS1 receive out tip (to customer interface)

7 H1-T HDSL4 Loop tip (facility)

11 CH GND Chassis ground

13 H1-R HDSL4 Loop ring (facility)

15 DS1-R1 DS1 receive out ring (to customer interface)

17 48 VR 48 VDC Return

20 VCC +5 VDC for protection switching

27 CH GND Chassis ground

35 48 V 48 VDC; range ±24 to ± 56 VDC (48 VDC nominal)

41 H2-T HDSL4 Tip (Loop 2)

47 H2-R HDSL4 Ring (Loop 2)

49 DS1-R DS1 transmit in ring (from customer interface)

55 DS1-T DS1 transmit in tip (from customer interface

PROVISIONING OPTIONS

Provisioning options are assumed from settings made at the H4TU-C.

FEATURES

TScan

The ADTRAN® T200 H4TU-R incorporates the TScan™ feature. TScan allows for remote

retrieval of circuit diagnostics and performs advanced fault location. For more information about

TScan refer to the Installation and Maintenance practice.

Bad Splice Detection

The Runtime TScan bad splice detection feature is an ADTRAN proprietary non-intrusive method

for detection of anomalies (bad splices) in the copper plant. This feature non-intrusively monitors

the cable pair during runtime for the presence of bad splices, which may potentially impact service.

Poor splices in the cable are often undetected by normal testing methods. Often, these splices

present no problem for the data transmission equipment until the point at which oxidation with the

splice itself causes a rapid impedance change. Such a change in impedance may cause errors,

signal margin fluctuation, and/or a retrain of the DSL transceivers. The splice detection feature is

accessed from the Troubleshooting Screen via the craft access port.

Fast Retrain

Fast Retrain is an ADTRAN proprietary feature that minimizes downtime due to an intermittent

impairment which due to its duration cannot be bridged. When such impairments occur, the fast

retrain feature will be invoked to restore service within 5 to 7 seconds, instead of the traditional 25

to 30 second retrain duration.

NOTE: Fast-Retrain capable units must be installed on both ends of the circuit for this feature

to function properly. Also, if there is a failure, for any reason, of a fast retrain attempt

then the traditional (25-30 second) retrain will be initiated.

Page 2

T200 HDSL4 Transceiver Unit, Remote-Local Powered

PRICING AND AVAILABILITY 800.827.0807

TECH SUPPORT 800.726.8663

RETURN FOR REPAIR 256.963.8722

www.adtran.com

61223424L2-22B

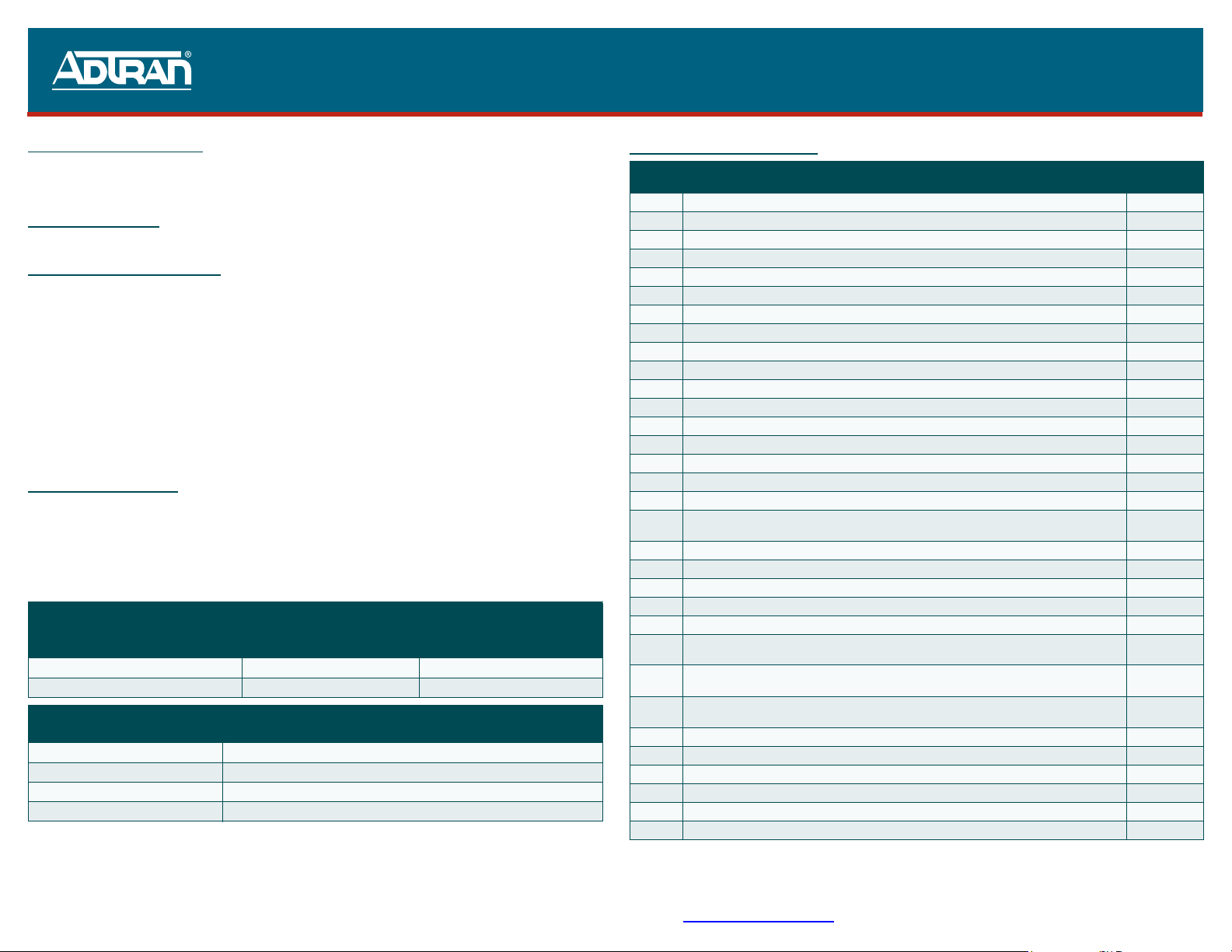

TROUBLESHOOTING HDSL4

This ADTRAN HDSL4 unit is equipped with troubleshooting-at-a-glance LEDs (identified on the reverse side of

this document) that provide customers with a simple means of identifying the location of certain faults.

Additionally, screens available via the craft interface simplify the trouble isolation process. These screens and their

associated benefits are described below.

Troubleshooting Screen

Available via the Main Menu: provides ADTRAN contact information and access to the Troubleshooting Guidance

and General Information screens.

Troubleshooting Guidance Screens

Available via the Troubleshooting screen: detects and displays errors and/or alarms at any of the monitored inputs

(DSX1, DS1 and HDSL). Guidance on the fault(s) detected includes possible cause(s) and suggested actions,

including those shown below:

DSX-1/DS1:

LOS Loss of signal (Red Alarm) at the DSX-1/DS1

receiver

CLK T1 receive clock is out of range

RAI Remote Alarm Indication (Yellow Alarm)

detected at DSX-1/DS1 receiver

AIS Alarm Indication Signal (Blue Alarm) detected

at DSX-1/DS1 receiver

ERR Errors recorded at DSX-1/DS1 receiver

General Information Screen

Available via the Troubleshooting screen: a reference page which displays the minimum acceptable signal margin,

maximum attenuation, and other deployment parameters for this HDSL4 circuit.

NOTE: Along with the Troubleshooting screens, the Detailed Status screen and Performance History screen,

available via the craft access terminal, provide both real-time and historical view of this circuit.

For complete deployment guidelines on the HDSL4 circuit, refer to the Installation and Maintenance

Practice referenced on the front page.

ATTENUATION LIMITS

Segment Upstream Downstream

1st segment

2nd and 3rd segment

RANGE LIMITS, PIC Cable, 70°F

Gauge/Segment Recommended Maximum

26 Gauge, 1st segment

26 Gauge, 2nd and 3rd segment 9,865 ft.

24 Gauge, 1st segment

24 Gauge, 2nd and 3rd segment 14,050 ft.

1

In three segment circuits (two H4Rs), individual segment resistance values must be verified. Refer to the Installa-

tion and Maintenance Practice for details and calculations.

2

When designing a dual H4R loop (three segment), the first segment should have lower DC resistance than the

second segment.

Warranty: ADTRAN will replace or repair this product within the warranty period if it does not meet its published specifications or fails while in service.

Facility:

GROUND Ground Fault on span (facility pair grounded)

SHORT Short circuit (or low impedance) between pairs

OPEN Open circuit between facility pairs

DSL:

LOS Loss of HDSL sync

MARG Margin has exceeded the alarm threshold

ATTEN Attenuation has exceeded the alarm threshold

ERR Errors recorded at the HDSL receiver

HIST Performance History of the DSL units

Recommended Maximum

30 dB 32 dB

28 dB 28 dB

10,470 ft.

1,2

14,770 ft.

1,2

Warranty information can be found at www.adtran.com/warranty

LOOPBACK CONTROL CODES

Pattern Description

1in3 Loop down all units and disarm. No

2in5 Arming Pattern, H4TU-R will loop up if Smartjack LB is enabled. No

3in5 Disarm and loop down all units. Restores LB TMO after D5D6. No

2in6 H4R1 LB to Network. No

3in6 H4R2 LB to Network. No

4in6 H4R1 LB to Customer. No

5in6 H4R2 LB to Customer. No

3in7 H4TU-R LB to Network. No

4in7 H4TU-C LB to Network. No

5in7 H4TU-R LB to Customer. No

6in7 H4TU-C LB to Customer. No

3F1E H4TU-C LB to Customer. No

3F02 H4TU-R LB to Customer. No

3F04 H4R1 LB to Customer. No

3F06 H4R2 LB to Customer. No

3F08 H4R3 LB to Customer No

6767 Disable span powering while present. Ye s

9393 Loop down H4TU-C, Repeaters – all loopbacks. Loop down H4TU-R – Cust LB always. Will only

loop down H4TU-R Network LB if NIU is disabled. Does not disarm units if they are armed.

C741 H4R1 loopback pattern. 10 bit error injection. Ye s

C742 H4TU-R loopback pattern. 20 bit error injection. Ye s

C754 H4R2 loopback pattern. 200 bit error injection. Ye s

C743 H4R3 loopback pattern. 30 bit error injection. Ye s

D3D3 H4TU-C loop up pattern. 231 bit error injection. Ye s

D5D5 Query Loopback Pattern (error injection) - H4TU-C: 231 Errors, H4R1: 10 Errors,

H4R2: 200 Errors, H4R3: 30 errors, H4TU-R: 20 Errors

D5D6 Loopback Timeout Override: Disables LB timeout. Restores original LB timeout when unit is dis-

armed.

FF48 FDL Arming Pattern (ESF only). Arms all units, H4TU-R will LB to Network if NIU Enabled (if

pattern sources at network).

FF24 FDL Disarm Pattern (ESF only). Loop down and disarm all units No

FF1E H4TU-C LB to Network. Will not loop up H4TU-C if H4TU-C already in LB to Customer. No

FF02 H4TU-R LB to Network. Will not loop up H4TU-R if any unit already in LB to Customer. No

FF04 H4R1 LB to Network. No

FF06 H4R2 LB to Network. No

FF08 H4R3 LB to Network No

.

Requires

Arming?

No

No

Ye s

No

Loading...

Loading...