Page 1

X

HDSL4 T200 H4TU-R

Installation and Maintenance Practice

CONTENTS

1. General...................................................................................... 1

2. Installation ................................................................................ 2

3. Connections .............................................................................. 5

4. HDSL4 System Testing ............................................................ 5

5. Front Panel Operation ............................................................... 7

6. Control Port Operation.............................................................. 7

7. HDSL4 Deployment Guidelines ............................................. 18

8. Maintenance............................................................................ 23

9. Specifications.......................................................................... 23

10. Warranty and Customer Service ............................................. 23

Appendix A. HDSL4 Loopbacks.............................................. A-1

TABLES

Table 1. ADTRAN Unit Compatability........................................ 1

Table 2. H2TU-R Enclosure Compatibility .................................. 2

Table 3. Compliance Codes .......................................................... 2

Table 4. Front Panel Indicators ..................................................... 3

Table 5. Provisioning Options ...................................................... 4

Table 6. Attenuation limits ......................................................... 18

Table 7. Range Limits: 26 Gauge / 70°F / PIC .......................... 18

Table 8. Range Limits: 24 Gauge / 70°F / PIC .......................... 18

Table 9. Single Pair DC Resistance Value.................................. 19

Table 10. HDSL4 Insertion Loss Values ...................................... 22

Table 11. Single Span and First Segment of Repeatered Loop .... 22

Table 12. Second or Third Segment of Repeatered Loop............. 22

Table 13. Troubleshooting Guide ................................................. 23

Table 14. HDSL4 T200 H4TU-R Specifications.......................... 24

Table A-1. HDSL4 Loopback Control Codes............................ A-2

Table A-2. Loopback Control Codes......................................... A-3

Section 61223424L2-5A

Issue 1, December 2003

CLEI Code: T1L497PC_ _

1223424L2

LOCAL

DSL 1

DSL 2

DS1

ALM

SF

ESF/

(YEL)

(GRN)

B8ZS

/

AMI

(GRN)

(YEL)

LLB

/

RLB

(GRN)

(YEL)

LOC

LBK

REM

TX

TX

M

O

N

RX

R

R

S

2

3

2

1. GENERAL

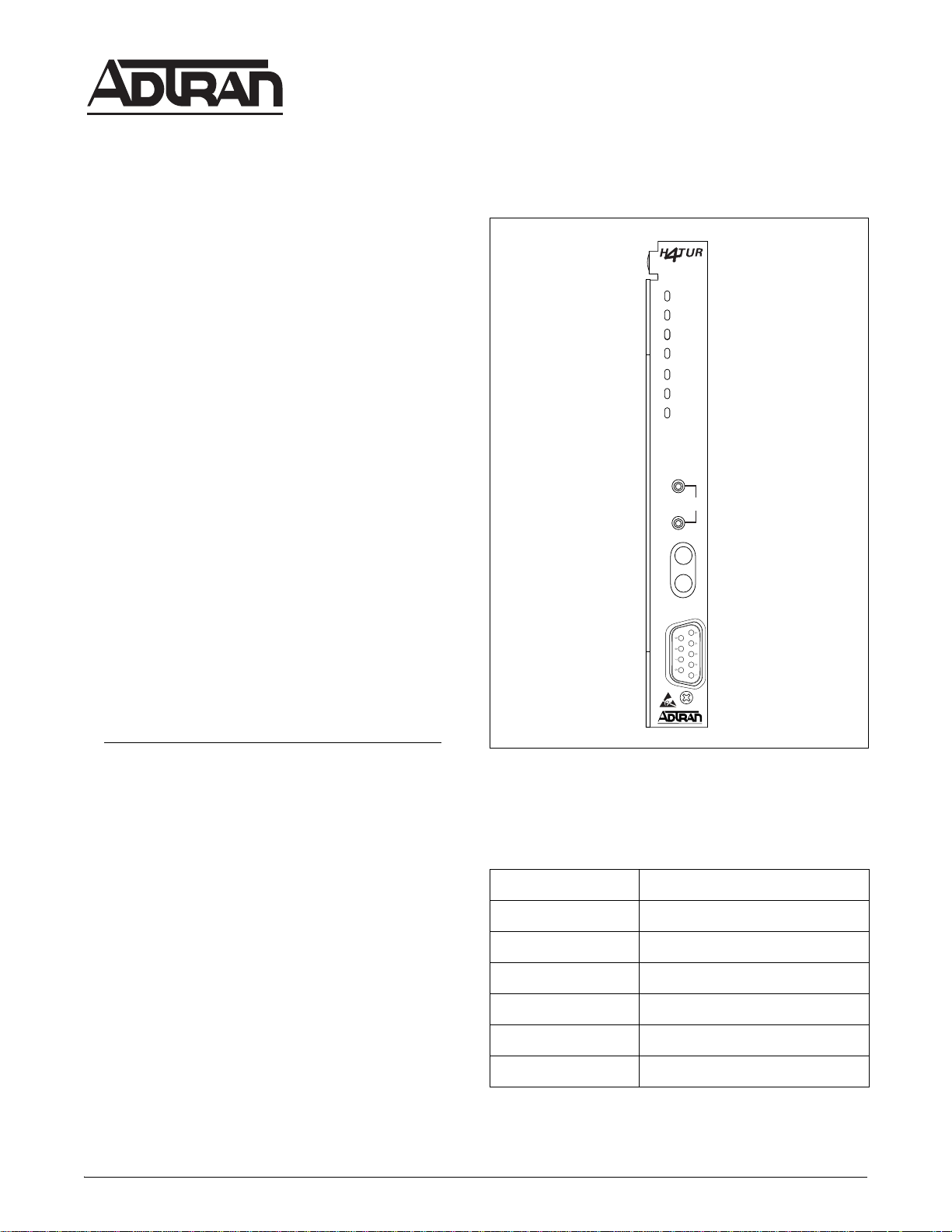

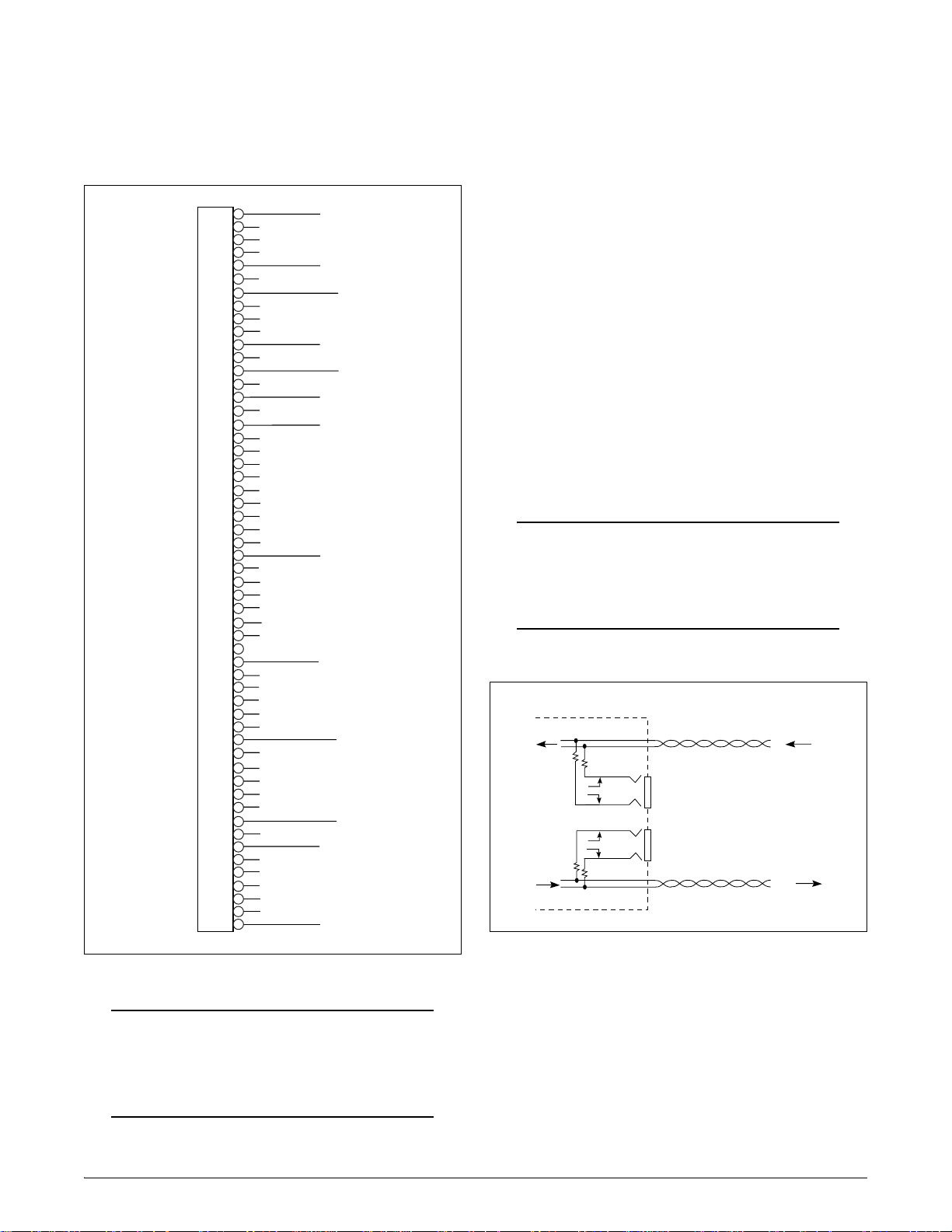

Figure 1. ADTRAN HDSL4 T200 H4TU-R

The ADTRAN 4-wire T200 HDSL4 transceiver unit for

the remote end (H4TU-R), P/N 1223424L2, is a

network terminating unit used to deploy an HDSL4 T1

circuit using 4-wire metallic facilities. See Figure 1.

This version of the H4TU-R works with multiple list

versions of the HDSL4 transceiver unit for the central

Table 1. ADTRAN Unit Compatability

Unit Number Description

122x401L1 or L2 220 H4TU-C

office (H4TU-C) and repeater (H4R) as listed in

Tab l e 1 .

122x403L1 or L2 DDM+ H4TU-C

122x404L1 or L2 3192 H4TU-R

Revision History

This is the initial release of this document. Future

revisions to this document will be explained in this

subsection.

61223424L2-5A 1

Trademarks: Any brand names and product names included in this document are

trademarks, registered trademarks, or trade names of their respective holders.

118141xL1 Total Access H4TU-C

122x441L1 T200 H4R

122x445L1 239 H4R

NOTE: x = any generic release number

Page 2

Description

The T200 H4TU-R can be deployed in circuits using

one H4TU-C, one H4TU-R, and up to two H4Rs.

The T200 H4TU-R terminates local loop HDSL4

signals originating from the Central Office (CO) unit

and transforms the HDSL4 signal into traditional DS1

signals to be delivered to the customer.

Compliance

Tab l e 3 shows the compliance codes for the T200

H4TU-R. This product is intended for installation in

equipment with a Type “B” or “E” enclosure.

This product meets all requirements of Bellcore GR1089-CORE (Class A2), ANSI T1.418-2002 and is

NRTL listed to the applicable UL standards.

The T200 H4TU-R can be used with any H4TU-C to

complete an HDSL4 circuit with up to two H4Rs. Local

power is provided through the enclosure.

NOTE

This unit is intended for Local Power Only. If

a span powered unit is needed, refer to P/N

122x426L2.

The H4TU-R is a T200 mechanics card which will fit

Type 200 or Type 400 mechanics enclosures, as listed

in Tab l e 2 . This table also provides reference information on the ADTRAN enclosures.

Table 2. H4TU-R Enclosure Compatibility

Part

Number

1242007Lx HR12 Metal

1242008L1 HR4 Installation/

1242034L2 T400 Single Mount

1242034L3 T400 Single-Mount

1245034L1

Description

Enclosure Remote

Shelf

Maintenance

(removable RJ-48

jacks)

High Voltage

Enclosure

2

T200 Dual-Mount

Installation/

Maintenance

1

Document

Number

61242007LX-5x

61242008L1-5

61242034L2-5

61242034L3-5

61245034L1-5

Table 3. Compliance Codes

Code Input Output

Power Code (PC) C C

Telecommunication Code (TC) X X

Installation Code (IC) A –

2. INSTALLATION

After unpacking the unit, inspect it for damage. If

damage is discovered, file a claim with the carrier, then

contact ADTRAN. Refer to the Warranty and Customer

Service section in this practice. The settings on the

H4TU-C are encoded and transmitted to the T200

H4TU-R once the circuit has achieved synchronization.

There are no switch settings on the T200 H4TU-R.

To install the T200 H4TU-R, perform the following

steps:

1. If present, remove the Access Module Blank from

the appropriate access module slot of the

enclosure.

2. Hold the T200 H4TU-R by the front panel while

supporting the bottom edge of the module.

3. Align the module edges to fit in the lower and

upper guide grooves for the module slot.

4. Slide the module into the slot. Simultaneous thumb

pressure at the top and at the bottom of the module

will ensure that the module is firmly seated against

the backplane of the enclosure.

WARNING

1 In all applications the H4TU-R must be installed in NEBS

compliant and UL listed enclosures to insure full compliance with this unit.

2 ADTRAN’s T200 Dual-Mount housing (P/N 1245034L1)

is required when using the T200 H4TU-R for HDSL Loop

Support System (H-LSS

2 Issue 1, December 2003 61223424L2-5A

TM

) protection circuits.

Up to –200 VDC may be present on telecommunications wiring. Ensure chassis ground is

properly connected.

Page 3

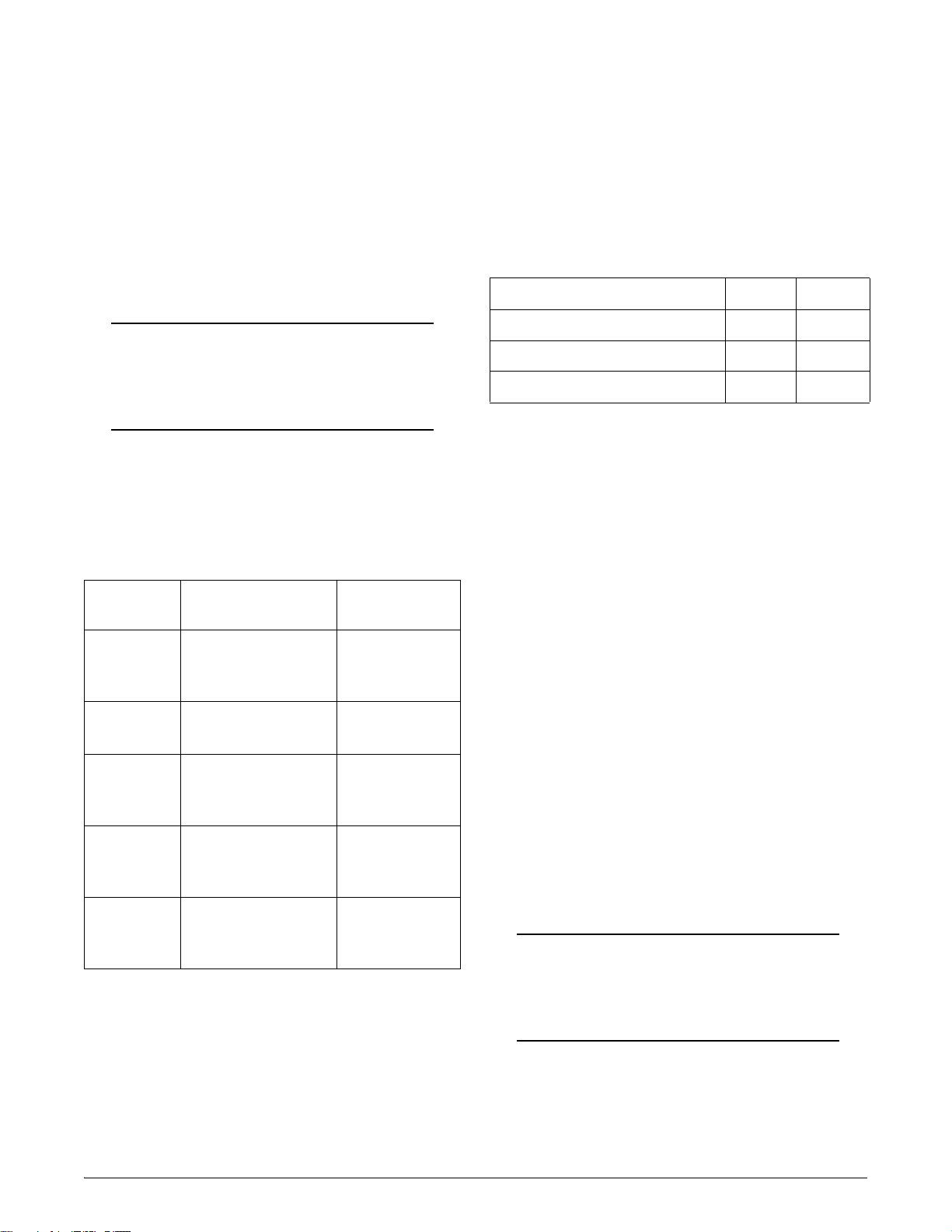

Front Panel LED Indicators

X

There are seven front panel mounted status LED

indicators. Each indicator is described in Tab l e 4 .

Table 4. Front Panel LED Indicators

Front Panel Name Indication Description

1223424L2

LOCAL

DSL 1

DSL 2

DS1

ALM

ESF/

(YEL)

B8ZS

(YEL)

LLB

(YEL)

LOC

REM

TX

M

O

N

RX

R

S

2

3

2

SF

(GRN)

/

(GRN)

/

(GRN)

LBK

AMI

RLB

TX

R

DSL 1

DSL 2

DS1

ALM

ESF/SF

B8ZS/AMI

LLB/RLB

Green

DSL Loop 1 sync, no errors currently detected, and signal margin ≥3dB

Red No DSL Loop 1 sync, errors being detected, or signal margin <3dB

Green

DSL Loop 2 sync, no errors currently detected, and signal margin ≥3dB

Red No DSL Loop 2 sync, errors being detected, or signal margin <3dB

Green DS1 signal is present and no errors currently being detected

Red No DS1 signal or signal is present with errors

OFF No active alarm present

Red Loss of DS1 signal to the unit

Yellow Loss of DSX-1 signal to the H4TU-C

OFF Unit is provisioned for UNFRAMED data

Yellow Unit is provisioned for ESF data

Green Unit is provisioned for SF data

Yellow Unit is provisioned for B8ZS coded data

Green Unit is provisioned for AMI data

OFF Unit is NOT in loopback

Yellow Unit is in loopback (network and/or customer)

Green H4TU-C is in loopback toward this unit

61223424L2-5A Issue 1, December 2003 3

Page 4

Remote Provisioning

There are no configuration switches for the T200

H4TU-R. Configuration is performed via software

discussed in the Control Port Operation section of this

The provisioning settings can be viewed and manipulated through management access via the front panel

RS-232 port. Tab l e 5 lists the available provisioning

options and their factory default settings.

practice.

Table 5. Provisioning Options

Provisioning Option Option Settings Default Settings

1. DSX-1 Line Build Out 0-133 ft., 133-266 ft., 266-399 ft.,

0 to 133 ft.

399-533 ft., 533-655 ft.

2. DSX-1/DS1 Line Code B8ZS, AMI B8ZS

3. DSX-1/DS1 Framing SF, ESF, Unframed, Auto ESF

4. Force Frame Conversion

1

Disabled, Enabled Disabled

5. Smartjack Loopback Disabled, Enabled Enabled

6. Loopback Time Out None, 120 Min 120 Minutes

7. Latching Loopback Mode

2

T1 (Disabled), FT1 (Enabled) T1 (Disabled)

8. DS1 Tx Level 0 dB, -7.5 dB, -15 dB 0 dB

9. Customer Loss Indicator

3

AIS, Loopback, AIS/CI AIS/CI

11. Performance Reporting Messages None, SPRM, NPRM, AUTO (both) AUTO

12. Loop Attenuation Alarm Threshold 0 (Disabled), 1-99 dB 34 dB

13. SNR Margin Alarm Threshold 0 (Disabled), 1-15 dB 04 dB

14. Remote Provisioning Disabled, Enabled Enabled

1

The forced frame format conversion (FFFC) mode sets the H2TU-C to ESF and the H2TU-R to SF. This mode should be used to force

SF (DS1 from customer) to ESF (DSX-1 to network) conversion in the absence of network-provided ESF framing.

2

Latching Loopback Mode

• T1 — When optioned for T1 mode, the unit does not respond to DDS Latching Loopback codes.

• FT1 — DDS Latching Loopback operation is supported. The H4TU-C and any H4R units which are in the HDSL circuit are treated

as identical Tandem Data ports and the HTU-R is treated as a different Tandem Data port.

NOTE: When operating in FT1 mode and during periods of T1 loss of signal, LOS, or T1 AIS from the customer CI, the HDSL

system will send in the network direction from the HTU-C a Fractional DS1 idle signal consisting of a repeating 7E (HEX) byte

payload within a framed/unframed T1 signal. In addition, when optioned for FT1 mode, the setting for Customer Loss Response is

ignored.

3

Customer Loss Indicator

• AIS — Send AIS to network upon T1 loss of signal or T1 AIS from customer.

• LPBK — HTU-R initiates a network loopback upon T1 loss of signal or T1 AIS from customer.

• AIS/CI — HTU-R sends customer disconnect indication upon loss of signal, loss of synchronization, or receipt of T1 AIS from

customer.

NOTE: The CI is generated by transmitting the framing received from the network while overwriting the payload with a repeating

pattern. For applications where the DS1 is Extended Superframe, the data link is overwritten with a Yellow Alarm that is interrupted

once every second by a 100 milli-second code burst of 7E (HEX).

4 Issue 1, December 2003 61223424L2-5A

Page 5

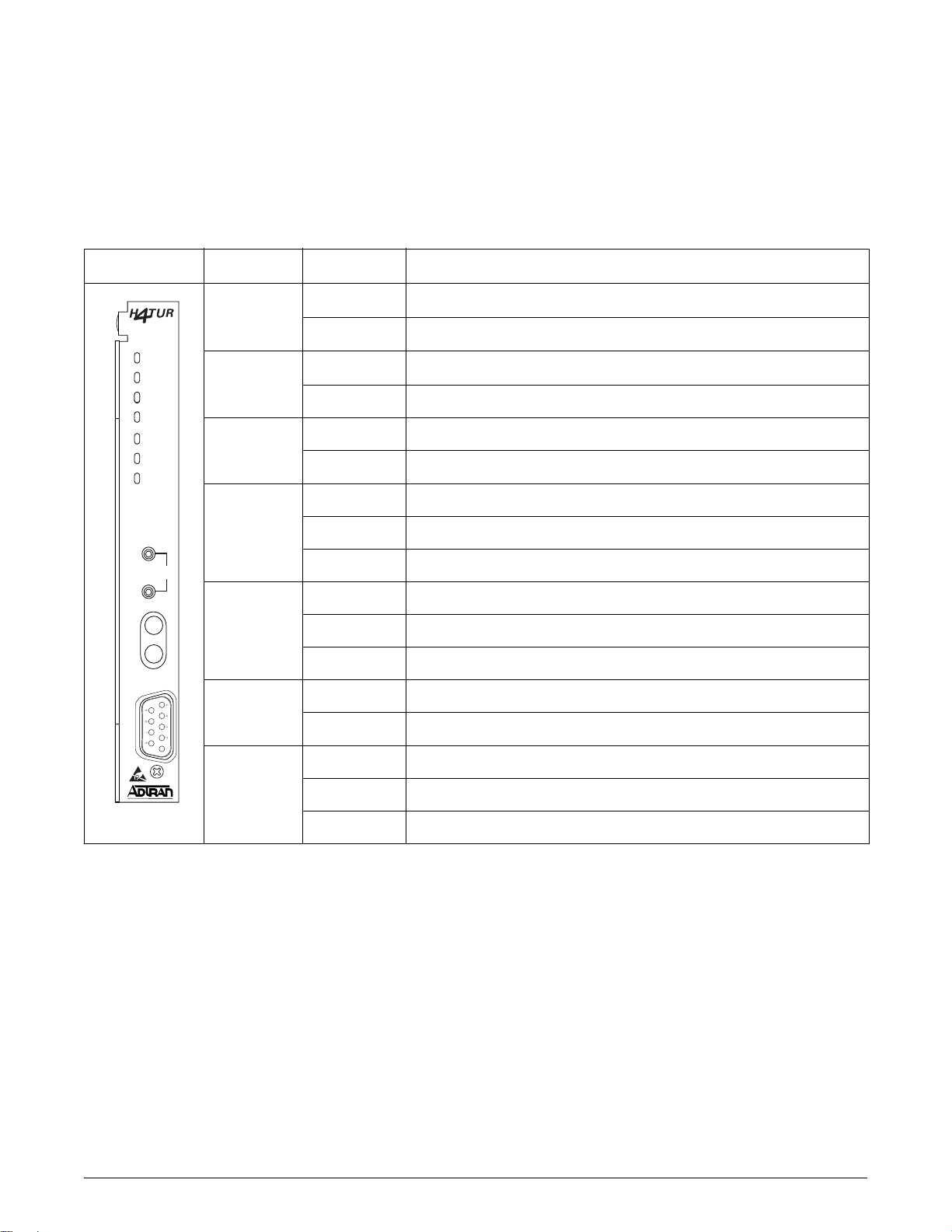

3. CONNECTIONS

Chassis Ground

All connections of the T200 H4TU-R are made through

card edge connectors. Figure 2 gives the card edge pin

assignments for the T200 H4TU-R circuit pack.

1

2

3

4

DS1 TX Tip

5

6

HDSL4 Tip Loop 1

7

8

9

10

Chassis Ground

11

12

HDSL4 Ring Loop 1

13

14

DS1 TX Ring

15

16

–24 V/-48 V Return

17

18

19

20

21

22

23

24

25

26

Chassis Ground

27

28

29

30

31

32

33

34

–24 VDC/-48 VDC

35

36

37

38

39

40

HDSL4 Tip Loop 2

41

42

43

44

45

46

HDSL4 Ring Loop 2

47

48

DS1 RX Ring

49

50

51

52

53

54

DS1 RX Tip

55

4. HDSL4 SYSTEM TESTING

The T200 H4TU-R provides diagnostic, loopback, and

signal monitoring capabilities.

The seven front panel LEDs provide diagnostics for

HDSL4 loops, DS1 signals, alarms, provisioning, and

loopbacks. Refer to the Installation section for details.

The H4TU-R provides a bidirectional loopback via the

loopback button on the front panel. Refer to the

H4TU-R Network Loopbacks and Customer Loopbacks

sections for more details.

DS1 MON Bantam Jacks

The MON jack provides a non intrusive access point for

monitoring the characteristics of the transmit and

receive signals at the DS1 interface point.

For example, the DS1 MON jack on the H4TU-R could

be used to connect to a bit error rate tester to monitor for

synchronization, test patterns, etc.

Figure 3 is an illustration of specific jack detail.

NOTE

For the MON jacks, the TX and RX indications

relate to the direction of the signal to/from the

CPE.

H4TU-R

T

R

TX

RX

DS1

MON

CPE

DS1

INTERFACE

T1

R1

Figure 3. H4TU-R MON Diagram

Figure 2. H4TU-R Edge Connector Wiring

CAUTION

Ensure chassis ground is properly connected

for either standalone or shelf-mounted applications.

61223424L2-5A Issue 1, December 2003 5

Page 6

H4TU-R Network Loopbacks

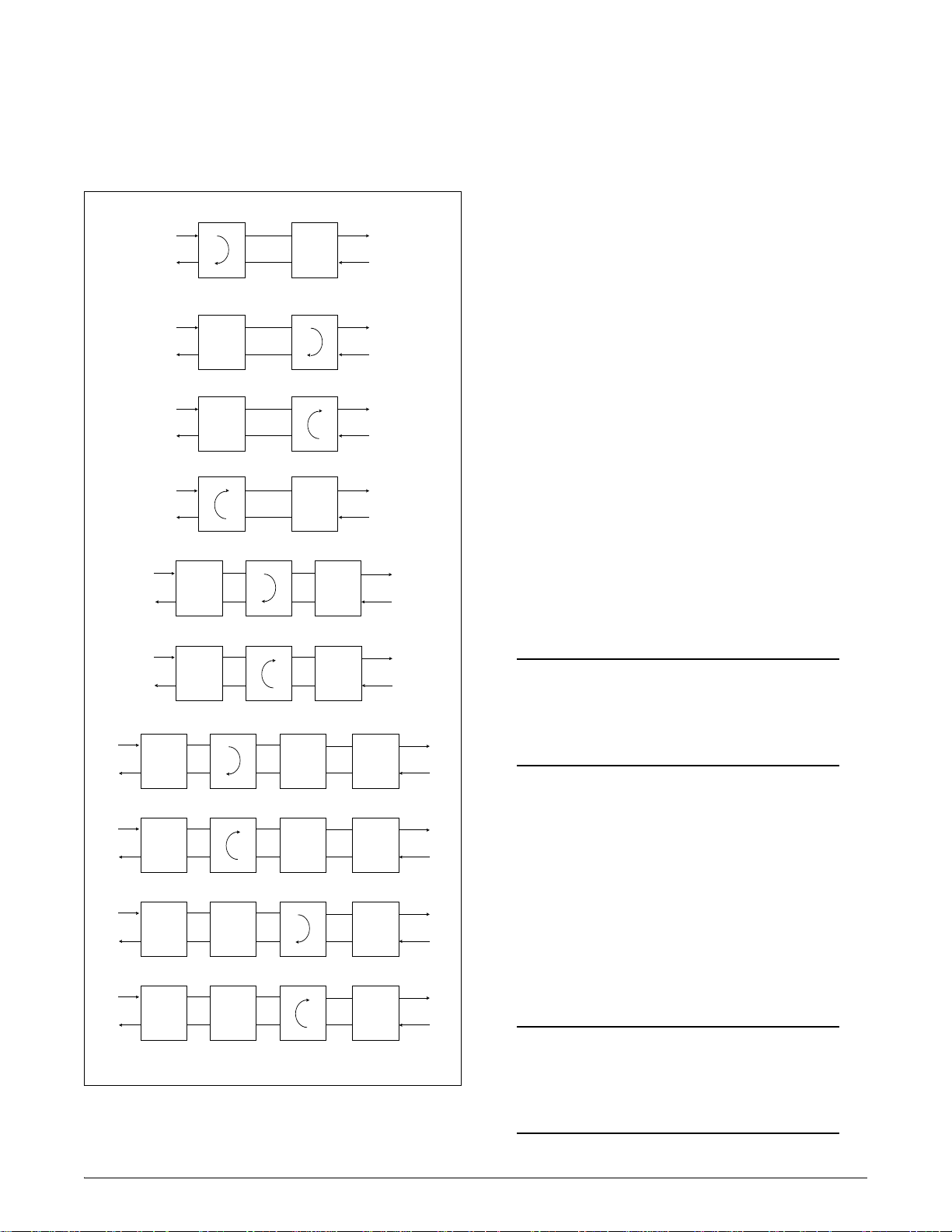

D

D

D

D

The loopback position is a logic loopback located

within the H4TU-R internal HDSL4 transceiver. See

Figure 4.

The H4TU-R responds to multiple loopback activation

processes:

• First, manual loopback on the H4TU-R and/or the

H4TU-C unit may be controlled from the front

panel. Refer to the Front Panel Operation section

of this practice for more detail.

H4TU-C Network-Side Loopback

DSX-1

H4TU-C

H4TU-R Network-Side Loopback and/or

H4TU-R NIU Loopback

DSX-1

H4TU-C

LOCAL

LOOP

LOCAL

LOOP

H4TU-R

H4TU-R

AIS

DS1

X

AIS

DS1

X

• Second, loopback activation may be accomplished

using the control port of the H4TU-R.

• Third, the H4TU-R will respond to the industry

standard HDSL loopback codes as designated in the

ANSI document T1E1.4/92. These are described in

Appendix A, HDSL4 Loopbacks.

• Fourth, the H4TU-R responds to T1 Network Interface Unit (NIU) loopback codes as described in

H4TU-R Customer-Side Loopback

X

DSX-1

AIS

H4TU-C

H4TU-C Customer-Side Loopback

X

DSX-1

AIS

H4TU-C

LOCAL

LOOP

LOCAL

LOOP

DS1

H4TU-R

DS1

H4TU-R

Bellcore TR-TSY-000312, as follows:

In-Band Codes

Loop up 11000 (2 in 5)

Loop down 11100 (3 in 5)

ESF Codes

Loop up 1111 1111 0100 1000 (FF 48)

Loop down 1111 1111 0010 0100 (FF 24)

H4R Network-Side Loopback

H4TU-C

H4R Customer-Side Loopback

X

DSX-1

H4TU-C H4TU-RH4R

AIS

H4R

H4TU-R

AIS

DS1DSX-1

X

DS1

Receiving the in-band codes for more than five seconds

or the ESF codes four consecutive times will cause the

appropriate loopback action. The ESF codes must be

transmitted in the Facility Data Link (FDL).

NOTE

The NIU loopback option must be enabled

H4R1 Network-Side Loopback

SX-1

H4TU-C H4TU-RH4R1 H4R2

H4R1 Customer-Side Loopback

X

SX-1

H4TU-C H4TU-RH4R1 H4R2

AIS

AIS

DS1

X

DS1

before the H4TU-R can respond to the NIU

loopback.

The H4TU-R will respond to the loopback codes by

activating the NIU loopback from either the disarmed or

armed state. The loop down codes will return the

H4TU-R to the disarmed or de-activated state

depending upon the code utilized.

H4R2 Network-Side Loopback

SX-1

H4TU-C H4TU-RH4R1 H4R2

H4R2 Customer-Side Loopback

X

SX-1

H4TU-C H4TU-RH4R1 H4R2

AIS

X = Signal Inactive

AIS

DS1

X

Customer Loopbacks

In addition to the loopbacks in the direction of the

network, the H4TU-R may also be looped back in the

direction of the customer. The H4TU-C and H4TU-R

DS1

Customer Side Loopbacks are illustrated in Figure 4.

NOTE

Network and customer loopbacks are governed

Figure 4. HDSL4 Loopbacks

by the loopback time out option (Default=120

minutes).

6 Issue 1, December 2003 61223424L2-5A

Page 7

5. FRONT PANEL OPERATION

)

)

d)

The front panel contains two pushbuttons. These are

labeled

The

LOC and REM.

LOC pushbutton controls a bidirectional loopback

at the H4TU-R. Pressing the button causes a bidirectional loopback to occur. If the bidirectional loopback is

active, pressing the button a second time will disable the

loopback.

REM pushbutton controls a bidirectional loopback

The

at the H4TU-C. Pressing the button causes a loopback

toward the H4TU-R and network to occur. If the

loopback is active, pressing the button a second time

will disable the loopback.

6. CONTROL PORT OPERATION

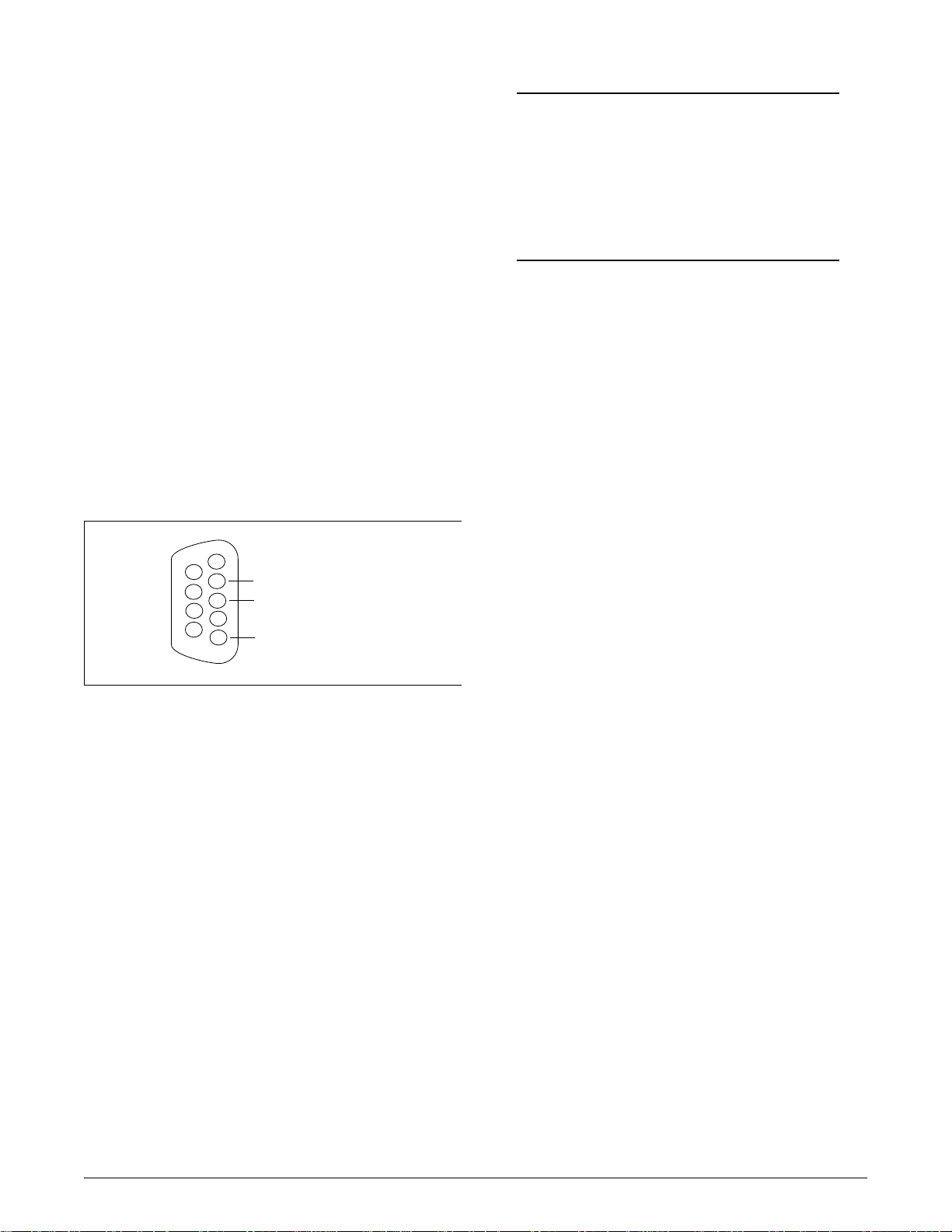

The H4TU-R provides a front panel-mounted DB-9

connector that supplies an RS-232 interface for

connection to a controlling terminal. The pinout of the

DB-9 is illustrated in Figure 5.

1

6

7

8

9

TXD (Transmit Data

2

3

RXD (Receive Data

4

5

SGN (Signal Groun

NOTE

If a personal computer with terminal emulation

capability is being used, be sure to disable any

power-saving programs. Otherwise, communication between the PC and the HDSL4 unit

may be disrupted, resulting in misplaced

characters or screen time outs.

Operation

The screens illustrated in the following section apply to

an HDSL4 circuit deployed with the ADTRAN HDSL4

technology. The circuit includes an H4TU-C, up to two

H4Rs and an H4TU-R. Other configurations are

possible (such as use of another vendor's equipment)

and their displays will vary slightly from those shown in

this section.

A terminal session is initiated by entering multiple

spacebar characters which are used by the H4TU-R to

determine the speed of the terminal. Once the speed has

been determined, an HDSL4

Main Menu is presented as

illustrated in Figure 6.

Figure 5. RS-232 (DB-9) Connector Pinout

The terminal interface operates at data rates from 1.2,

2.4, 4.8, 9.6, and 19.2 kbps. The asynchronous data

format is fixed at 8 data bits, no parity, and 1 stop bit.

61223424L2-5A Issue 1, December 2003 7

Page 8

This ADTRAN HDSL4 Main Menu provides access to

detailed performance and configuration information.

The OAM&P (Operation, Administration, Maintenance, and Provisioning) screens are available as listed

on the

Main Menu (Figure 6). To access a particular

menu item, press the number associated with that item,

and press

ENTER.

Circuit ID: 10/01/03 09:29:45

Adtran HDSL4 Main Menu

1. HDSL4 Unit Information

2. Provisioning

3. Span Status

4. Loopbacks and Test

5. Performance History

6. Scratch Pad, Ckt ID, Time/Date

7. Terminal Modes

8. Alarm History

9. Event History

10. System PM/Screen Report

11. Clear PM and Alarm Histories

12. Troubleshooting

13. Virtual Terminal Control

The HDSL4

Unit Information Screen (Figure 7)

provides detailed product information on each

component in the HDSL4 circuit. This screen also

displays contact information for ADTRAN Technical

Support, Internet site, and address.

Selection:

Figure 6. HDSL4 Main Menu

Circuit ID: 10/01/03 09:29:45

Press ESC to return to previous menu

ADTRAN

901 Explorer Boulevard

Huntsville, Alabama 35806-2807

--------------------- For Information or Technical Support -------------------- Support Hours ( Normal 7am - 7pm CST, Emergency 7 days x 24 hours )

Phone: 800.726.8663 / 888.873.HDSL Fax: 256.963.6217 Internet: www.adtran.com

--------------------------------------------------------------------------------

ADTN H4TU-C ADTN H4TU-R

P/N: 1223403L2 P/N: 1223424L2

S/N: 123456789 S/N: 123456789

CLEI: T1L7PODAAA CLEI: T1L497PCAA

Manf: 01/01/2000 Manf: 01/01/2000

Ver: A00 Ver: A01

ADTN H4R1 ADTN H4R2

P/N: 1221445L1 P/N: 1221445L1

S/N: BB50A8343 S/N: BB50A8353

CLEI: T1R5YP3DAA CLEI: T1R5YP3DAA

Manf: 02/12/2002 Manf: 02/12/2002

Ver: A01 Ver: A01

Figure 7. Unit Information Screen

8 Issue 1, December 2003 61223424L2-5A

Page 9

The Provisioning menu (Figure 8) displays current

provisioning settings for the HDSL4 circuit. Options

that can be changed from this screen are labeled with a

number (for example, “1” for DSX-1 Line Build Out).

To change a particular option setting, select the appropriate number, and a new menu will appear with a list of

the available settings.

Circuit ID: 10/01/03 09:29:45

Press ESC to return to previous menu

Provisioning

1. DSX-1 Line Buildout = 0-133 ft

2. DSX-1/DS1 Line Code = B8ZS

3. DSX-1/DS1 Framing = ESF

4. Forced Frame Conversion = Disabled

5. Smartjack Loopback = Enabled

6. Loopback Timeout = 120 Min

7. Latching Loopback Mode = T1 (Disabled)

8. DS1 TX Level = 0 dB

9. Span Power = Enabled

10. Customer Loss Indicator = AIS/CI

11. PRM Setting = AUTO

12. Loop Atten Alarm Thres = 34dB

13. SNR Margin Alarm Thres = 04dB

14. Remote Provisioning = Enabled

D. Restore Factory Defaults

The options shown in Table 5 are available with the

T200 H4TU-R (P/N 1223426L2). Some settings may

differ when using different H4TU-Rs.

The

Span Status Screen (Figure 9) provides quick

access to status information for each HDSL4 receiver in

the circuit.

Selection:

Figure 8. Provisioning Menu

Circuit ID: 10/01/03 09:29:45

Press ESC to return to previous menu

Span Status Screen

______ ______ ______ ______

NET | | | | | | | | CUST

| | | | | | | |

----->| |-------| |-------| |----------------------| |----->

| | | | | | | |

| | | | | | | |

<-----| |-------| |-------| |----------------------| |<---- | | | | | | | |

DSX-1 |______| |______| |______| |______| DS1

H4TUC H4R 1 H4R 2 H4TUR

1. View Detailed Status

Selection:

Figure 9. Span Status Screen

61223424L2-5A Issue 1, December 2003 9

Page 10

The Detailed Status Screen from the Span Status menu

(Figure 10), displays the HDSL4 status for each

receiver point.

The

Loopbacks and Test Commands menu (Figure 11)

provides the ability to invoke or terminate all available

HDSL4 loopbacks.

Circuit ID: 10/01/03 09:29:45

Press ESC to return to previous menu

Detailed Status Screen

LOOP 1 LOOP 2

MARGIN ATTEN MARGIN ATTEN

Interface (CUR/MIN/MAX) (CUR/MAX) (CUR/MIN/MAX) (CUR/MAX)

--------- ------------- --------- ------------- --------H4TUC 17/00/17 00/00 17/00/17 00/00

H4R1 NETW 17/00/17 00/00 17/13/17 00/00

H4R1 CUST 17/17/17 00/00 17/00/17 00/00

H4R2 NETW 17/00/17 00/00 17/13/17 00/00

H4R2 CUST 17/17/17 00/00 17/00/17 00/00

H4TUR 17/00/17 00/00 17/00/17 00/00

Each HDSL4 circuit component can be looped toward

the network or customer from this screen. Unit self tests

can also be initiated from this screen.

1. Reset Min/Max

2. View Performance History

Selection:

Figure 10. Detailed Status Screen

Circuit ID: 10/01/03 09:29:45

Press ESC to return to previous menu

Loopbacks and Test Commands

______ ______ ______ ______

NET | | | | | | | | CUST

| | | | | | | |

----->| |-------| |-------| |----------------------| |----->

| | | | | | | |

| | | | | | | |

<-----| |-------| |-------| |----------------------| |<---- | | | | | | | |

DSX-1 |______| |______| |______| |______| DS1

H4TUC H4R 1 H4R 2 H4TUR

1. Run Self Tests 7. H4R1 Loopup Cust

2. H4TU-C Loopup Net 8. H4R1 Loopup Net

3. H4TU-C Loopup Cust 9. H4R2 Loopup Cust

4. H4TU-R Loopup Net

5. H4TU-R Loopup Cust

6. H4R1 Loopup Net

Selection:

Figure 11. Loopbacks and Test Commands Menu

10 Issue 1, December 2003 61223424L2-5A

Page 11

The Performance History screens (Figure 12 and

Figure 13) are used to select and display the historical

HDSL4 and T1 performance data in several different

registers. At each 15-minute interval, the performance

information is transferred to the 15-minute performance

data register. This unit stores performance data in 15-

Circuit ID: 10/01/03 09:29:45

Press ESC to return to previous menu

Menu 15 Minute H4TUC DSX-1 Performance Data

1. Definitions ES-L SES-L LOSS-L CV-L

2. Reset Data 000 000 000 00000

3. 15 Min Data 14:15 000 000 000 00000

4. 60 Min Data 14:00 000 000 000 00000

5. 24 Hr Data 13:45 000 000 000 00000

6. Line Data 13:30 000 000 000 00000

7. Path Data 13:15 000 000 000 00000

8. H4TUC DSX-1 13:00 000 000 000 00000

9. H4TUR LOOP 12:45 000 000 000 00000

10. H4TUR LOOP 12:30 000 000 000 00000

11. H4TUR DS1

12. H4R #1 NETW

13. H4R #1 CUST

14. H4R #2 NETW ___ ___ ___ ___

15. H4R #2 CUST | C | |#1 | |#2 | | R |

-8->| |-----| |-----| |---------------| |--->

| |9 12| |13 14| |15 10| |

<---| |-----| |-----| |---------------| |<-11

|___| |___| |___| |___|

Selection:

minute increments for the previous 24-hour period. At

each 24-hour interval, the performance data is transferred into the 24-hour performance data registers. This

unit stores up to 31 days of 24-hour interval data. Line

Data or Path Data results are available by selecting the

appropriate menu item.

Figure 12. 15-Minute Performance Data Screen

Circuit ID: 10/01/03 09:29:45

Press ESC to return to previous menu

Menu 24 Hour H4TUC LOOP Performance Data

LOOP 1 LOOP 2

1. Definitions ES-L SES-L UAS-L ES-L SES-L UAS-L

2. Reset Data 00000 00000 00000 00000 00000 00000

3. 15 Min Data 10/17 ----- ----- ----- ----- ----- -----

4. 60 Min Data 10/16 ----- ----- ----- ----- ----- -----

5. 24 Hr Data 10/15 ----- ----- ----- ----- ----- -----

6. Line Data 10/14 ----- ----- ----- ----- ----- -----

7. Path Data 10/13 ----- ----- ----- ----- ----- -----

8. H4TUC DSX-1 10/12 ----- ----- ----- ----- ----- -----

9. H4TUC LOOP 10/11 ----- ----- ----- ----- ----- -----

10. H4TUR LOOP

11. H4TUR DS1

12. H4R #1 CUST

13. H4R #1 CUS

14. H4R #2 NETW ___ ___ ___ ___

15. H4R #2 CUST | C | |#1 | |#2 | | R |

-8->| |-----| |-----| |---------------| |--->

| |9 12| |13 14| |15 10| |

<---| |-----| |-----| |---------------| |<-11

|___| |___| |___| |___|

Selection:

Figure 13. 24-Hour Performance Data Screen

61223424L2-5A Issue 1, December 2003 11

Page 12

Abbreviations used in the Performance History screens

are defined in

Performance Data Definitions screens

(Figure 14 and Figure 15).

Circuit ID: 10/01/03 09:29:45

Performance Data Definitions

H4TUC, H4TUR, and H4R LOOP Related: HDSL4 Framing

ES-L Errored Seconds CRC>=1 or LOSW>=1

SES-L Severely Errored Seconds CRC>=50 or LOSW>=1

UAS-L Unavailable Seconds >10 cont. SES-Ls

DS1 and DSX-1 Line Related: Superframe and Extended Superframe

ES-L Errored Seconds (BPV+EXZ)>=1 or LOS>= 1

SES-L Severely Errored Seconds (BPV+EXZ)>=1544 or LOS>=1

LOSS-L Loss of Signal Seconds LOS>= 1

PDVS-L Pulse Density Violation Secs EXZ>=1; >7 zeros if B8ZS, >15 if AMI

B8ZS-L B8ZS Seconds B8ZS coded signal received

CV-L Code Violation Count (BPV+EXZ) count

NOTE: Reverse video indicates invalid data due to a terminal restart (or power

cycle), a data register reset, or a system date or time change.

N. Next

P. Previous Selection:

Line related definitions are shown in Figure 14 while

Path related definitions are provided in Figure 15.

Figure 14. Performance Data Definitions

Circuit ID: 10/01/03 09:29:45

Performance Data Definitions

DS1 and DSX-1 Path Related: Superframe Extended Superframe

ES-P Errored Seconds FE>=1 or CRC>=1 or

SEF>=1 or AIS>=1 SEF>=1 or AIS>=1

SES-P Severely Errored Seconds FE>=8 or CRC>=320 or

SEF>=1 or AIS>=1 SEF>=1 or AIS>=1

UAS-P Unavailable Seconds >10 cont. SES-Ps >10 cont. SES-Ps

SAS-P SEF/AIS Seconds SEF>=1 or AIS>=1 SEF>=1 or AIS>=1

ES-PFE Far End Errored Seconds n/a PRM bits G1-G6,SE,

or SL=1, or RAI

CV-P Code Violation Count FE count CRC error count

NOTE: Under a UAS-P condition, ES-P and SES-P counts are inhibited.

Under a SES-L or SES-P condition, the respective CV-L or CV-P count is

inhibited.

P. Previous Selection:

Figure 15. Performance Data Definitions (Continued)

12 Issue 1, December 2003 61223424L2-5A

Page 13

The Scratch Pad, Circuit ID, and Time/Date Screen

(Figure 16) provides a Scratch Pad for user-defined

information and can be any alphanumeric string up to

50 characters in length. The Circuit ID can be any

alphanumeric string up to 25 characters in length. The

time should be entered using military time. (For

example, enter 3:15 p.m. as “151500”.) The date should

be entered in the MMDDYY format. (For example,

enter January 02, 2003, as “010203”.)

Circuit ID: 10/01/03 09:29:45

Current Scratch Pad:

New Scratch Pad =

New Circuit ID =

The

T1 Alarm History menu (Figure 17) and HDSL4

Span History

menu (Figure 18) provide a detailed alarm

history and events log for the HDSL4 and T1 spans.

These screens include a time, date, first and last occurrence, and count for each type of HDSL4 or T1 alarm.

A historical alarm log is also available in the

Alarm

menu.

System

New Date = / / (MM/DD/YY)

New Time = : : (HH:MM:SS)

Press TAB to skip to next entry field.

Figure 16. Scratch Pad, Circuit ID, and Time/Date Screen

Circuit ID: 10/01/03 09:29:45

Press ESC to return to previous menu

T1 Alarm History

LOCATION ALARM FIRST LAST CURRENT COUNT

------------------------------------------------------------------------------

H4TU-C RED(LOS/LOF) 01/01/00 00:00:05 01/01/00 00:00:05 Alarm 001

(DSX-1) YELLOW(RAI) OK 000

BLUE(AIS) OK 000

H4TU-R RED(LOS/LOF) 06/01/03 23:46:22 06/01/03 23:46:22 Alarm 001

(DS1) YELLOW(RAI) OK 000

BLUE(AIS) OK 000

------------------------------------------------------------------------------

1. T1 Alarm 4. Span H4R1 to H4R2

2. Facility Alarm 5. Span H4R2 to H4TU-R

3. Span H4TUC to H4R1 C. Clear T1 Alarms

Figure 17. T1 Alarm History Menu

61223424L2-5A Issue 1, December 2003 13

Page 14

The Event History screen (Figure 19) provides a log

history of HDSL4 circuit events.

Circuit ID: 10/01/03 09:29:45

Press ESC to return to previous menu

HDSL4 Span History

LOCATION ALARM FIRST LAST CURRENT COUNT

----------------------------------------------------------------------------SPAN C-H1 L1 LOS OK 000

L2 LOS OK 000

H4TU-C L1 MRGN OK 000

L2 MRGN OK 000

H4R1 NET L1 MRGN OK 000

L2 MRGN OK 000

H4TU-C L1 ATTEN OK 000

L2 ATTEN OK 000

H4R1 NET L1 ATTEN OK 000

L2 ATTEN OK 000

--------------------------------------------------------------------------------

1. T1 Alarm 4. Span H4R1 to H4R2

2. Facility Alarm 5. Span H4R2 to H4TU-R

3. Span H4TUC to H4R1 C. Clear Span Alarms

Selection:

Figure 18. HDSL4 Span History Screen

Circuit ID: 10/01/03 09:29:45

Press ESC to return to previous menu

Num Description of Event Date Time

-----------------------------------------------------------------

1. H4TU-C Powered Up 01/25/02 11:52:00

Page Number: 1/ 1 Number of Events: 1

---------------------------------------------------------------- 'P' - Previous Page 'H' - Home 'R' - Reset Events

'N' - Next Page 'E' - End

Selection:

Figure 19. Event History Screen

14 Issue 1, December 2003 61223424L2-5A

Page 15

The System PM/Screen Report option (Figure 20)

offers four types of reports on performance monitoring.

Selecting a report type will then display all the reports

for that category on the screen at once, which is more

efficient than stepping through the menus individually.

1. HDSL4 Unit Information

2. Provisioning

3. Span Status

4. Loopbacks and Test

5. Performance History

6. Scratch Pad, Ckt ID, Time/Date

7. Terminal Modes

8. Alarm History

9. Event History

10. System PM/Screen Report

11. Virtual Terminal Control

Selection: 10

Enable data logging now.

Select Report Type or Press Escape to cancel:

1) Full System/History Report

2) Current Status Report

3) System Configuration Report

4) Alarm/Event History

The Clear PM and Alarm Histories screen (Figure 21)

initializes data from performance monitoring and alarm

histories. Selecting this option from the Main Menu

displays the prompt, “This will clear the history data for

all elements in the circuit. Are you sure (Y/N)?”

Figure 20. System PM/Screen Report Option

Circuit ID: 10/01/03 09:29:45

Adtran HDSL4 Main Menu

1. HDSL4 Unit Information

2. Provisioning

3. Span Status

4. Loopbacks and Test

5. Performance History

6. Scratch Pad, Ckt ID, Time/Date

7. Terminal Modes

8. Alarm History

9. Event History

10. System PM/Screen Report

11. Clear PM and Alarm Histories

12. Troubleshooting

13. Virtual Terminal Control

This will clear the PM, Alarm, Span Status, and

Troubleshooting Histories for all circuit elements.

Are you sure (Y/N)?

Selection: 11

Figure 21. Clear PM and Alarm Histories

61223424L2-5A Issue 1, December 2003 15

Page 16

Item 12 on the Main Menu displays the Troubleshooting

screen (Figure 22). Helpful ADTRAN contact information along with two menu items appear on the bottom

of this screen.

Circuit ID: 10/01/03 09:29:45

Press ESC to return to previous menu

Troubleshooting

For HELP based on detected problems, select Troubleshooting Guidance from the

list below. If further assistance is needed, contact ADTRAN Tech Support.

Hours: Normal 7am - 7pm CST 1. Troubleshooting Guidance

Emergency 7 days x 24 hours 2. General Information

Phone: 800.726.8663 / 888.873.HDSL

Fax: 256.963.6217

Selecting option 1 from the Troubleshooting screen

causes the H2TU-C to read the operational status of the

card and return

Troubleshooting Guidance, or hints, as

to the probable cause of the trouble, as shown in Figure

23.

Selection:

Figure 22. Troubleshooting Screen

Circuit ID: 10/01/03 09:29:45

Press ESC to return to previous menu

DSX-1 Loss of Signal (Red Alarm)

- Patch test set REC jack into H4TUC MON TX jack to verify integrity of

signal to the H4TUC from the network (verify test set in MON mode).

- If signal to H4TUC is missing, insert test set at DSX panel IN Jack connecting

toward H4TUC (to verify wiring between DSX and H4TUC shelf). Check H4TUC to

verify DSX-1 LOS alarm is cleared. This verifies TX(out) and RX(in) pairs are

not swapped.

- If signal from DSX OK, verify cross-connect wiring at DSX panel is turned over

(OUT to IN) and (IN to OUT).

-If DSX wiring OK, connect test set REC to the DSX MON, network side equipment,

to verify signal from network (verify test set to MON). If no signal,

troubleshoot office problems.

For Total Access cards verify the following:

- Provisioning>Network Source is configured correctly for Mux or DSX operation.

- Provisioning>Service State is not configured for OOS-Unassigned.

- Mux card is mapped correctly.

- Mux card is functioning correctly.

Figure 23. Troubleshooting Guidance

16 Issue 1, December 2003 61223424L2-5A

Page 17

Selecting option 2 from the Troubleshooting screen

accesses the

General Information Screen (Figure 24)

that summarizes the deployment guidelines necessary

to provision this HDSL4 circuit.

Circuit ID: 10/01/03 09:29:45

Press ESC to return to previous menu

HDSL4 Loop Guidelines for optimum operation

------------------------------------------ Non-loaded cable pair

Single bridge tap < 2 Kft

Total bridge taps < 2.5 Kft

Power influence <= 80 dBrnC

Longitudinal Balance >= 60 dB (If using Wideband test at 196 kHz >= 40 dB)

Foreign DC Voltage (t-r, t-g, r-g) < 3 VDC

Loop Resistance <= 1000 ohms 1st segment

Loop Resistance <= 920 ohms 2nd segment

The following guidelines are provided as a recommendation and may be superseded

by internal deployment guidelines

Margin >= 6 dB

Attenuation (1st Segment) H4TUC <= 30 dB, H4TUR/H4R <= 32 dB

Attenuation (2nd or 3rd Segment) H4TUR/H4R <= 28 dB

Virtual Terminal Session Screen (Figure 25) allows

The

control of the Remote card provisioning from the

H4TU-C. Press 1 from this screen to begin a userinitiated session with the Remote card. When the

remote session is completed, Press

CTRL+X to terminate

the session.

Figure 24. General Information Screen

Circuit ID: 10/01/03 09:29:45

Press ESC to return to previous menu

Virtual Terminal Session: Inactive

Virtual Host: no

Virtual Terminal Control

1. Log into H4TU-C

Selection:

Figure 25. Virtual Terminal Session Screen

61223424L2-5A Issue 1, December 2003 17

Page 18

7. HDSL4 DEPLOYMENT GUIDELINES

The different segments of an HDSL4 circuit are defined

in Figure 26.

Figure 26. HDSL4 Circuit Segments

The guidelines reflected herein are for worst-case

scenarios, that is, for loops that contain a maximum

amount of disturbers, noise, etc. Actual deployment

guidelines may vary based on local policy. Please refer

to those guidelines on an as-necessary basis to ensure

optimum performance.

Designing a circuit with loop attenuation greater than

the recommended maximum loss may result in compromised reliability of that loop. Follow the guidelines in

in this section to ensure that the circuit meets basic

requirements:

The ADTRAN HDSL4 system provides DS1-based

services over loops designed to comply with the guidelines given below. These guidelines apply to the

following circuit configurations:

• a single segment or an HDSL4 circuit with no

H4Rs,

• a circuit having two segments (with one H4R), or

• a circuit having three segments (with two H4Rs).

Table 6. Attenuation limits

Upstream Downstream

st

1

segment

nd

and 3rd segment

2

30 dB 32 dB

28 dB 28 dB

Table 7. Range Limits: 26 Gauge / 70°F / PIC

26 Gauge Recommended Maximum

1. All loops are nonloaded only.

2. Any single bridged tap is limited to 2 kft.

3. Total bridged tap length is limited to 2.5 kft.

4. Bridge tap within 1000 feet of units may affect

performance of the circuit.

5. Loop Attenuation Limits. See Tabl e 6.

6. DSL-Recommended Range Limits. See Tabl e 7

and Tabl e 8.

Recommended Maximum

st

1

segment

nd

segment

2

rd

segment

3

10,470 ft.

9,865 ft.

9,865 ft.

Table 8. Range Limits: 24 Gauge / 70°F / PIC

26 Gauge Recommended Maximum

st

segment

1

nd

2

segment

rd

segment

3

18 Issue 1, December 2003 61223424L2-5A

14,770 ft.

14,050 ft.

14,050 ft.

Page 19

8. MAINTENANCE

The T200 H4TU-R requires no routine maintenance for

normal operation. In case of equipment malfunction,

use the front panel bantam jack connectors to help

locate the source of the problem. Verification of

possible trouble indications may be accomplished using

the Troubleshooting Guide in Tabl e 9.

ADTRAN does not recommend that repairs be

attempted in the field. Repair services may be obtained

by returning the defective unit to ADTRAN. Refer to

the Warranty and Customer Service section for further

information.

9. SPECIFICATIONS

Specifications for the T200 H4TU-R are detailed in

Tab l e 1 0 .

10. WARRANTY AND CUSTOMER SERVICE

ADTRAN will replace or repair this product within the

warranty period if it does not meet its published specifications or fails while in service. Warranty information

can be found at www.adtran.com/warranty

.

U.S. and Canada customers can also receive a copy of

the warranty via ADTRAN’s toll-free faxback server at

877-457-5007.

• Request document 414 for the U.S. and Canada

Carrier Networks Equipment Warranty.

• Request document 901 for the U.S. and Canada

Enterprise Networks Equipment Warranty.

Refer to the following subsections for sales, support,

CAPS requests, or further information.

ADTRAN Sales

Pricing/Availability:

800-827-0807

ADTRAN Technical Support

Pre-Sales Applications/Post-Sales Technical

Assistance:

800-726-8663

Standard hours: Monday - Friday, 7 a.m. - 7 p.m. CST

Emergency hours: 7 days/week, 24 hours/day

ADTRAN Repair/CAPS

Return for Repair/Upgrade:

(256) 963-8722

Repair and Return Address

Contact Customer and Product Service (CAPS) prior to

returning equipment to ADTRAN.

ADTRAN, Inc.

CAPS Department

901 Explorer Boulevard

Huntsville, Alabama 35806-2807

Table 9. Troubleshooting Guide

Condition: All front panel indicators are off.

Solutions:

1. Make sure the H4TU-R is properly seated in the housing.

2. Verify that the enclosure is delivering sufficient voltage to the unit.

If steps 1 and 2 pass and front panel indicators remain off, replace the H4TU-R.

Condition: DSL 1/DSL 2 LED is red.

Solutions:

1. Verify that loss (attenuation) on Detailed System Status screen is < 32 dB on the first segment of the circuit and

< 28 dB on the second and third segments of the circuit.

2. Verify that the loop meets requirement stated in the HDSL4 Deployment Guidelines section of this practice.

3. Verify that noise on the HDSL4 loops is within acceptable limits.

If steps 1-3 pass and LED is red, replace the H4TU-R.

61223424L2-5A Issue 1, December 2003 19

Page 20

Specification Description

H4TU-C Transmit Power (Data) Level

H4TU-C Transmit Power (Activation) Level

Maximum Loop Resistance

Tested with the ADTRAN H4TU-C (P/N 1223401L2) and H4R (P/N 1223445L1)

H4TU-R Power Dissipation

T200 Office Repeater Shelf-Mounted

Operating Temperature (Standard)

Storage Temperature

UL 60950; GR-1089-CORE; GR-63-CORE; ANSI T1.418-2001, Issue 2; ANSI T1.102 (DS1 Interface)

Table 10. HDSL4 T200 H4TU-R Specifications

Loop Interface

Modulation Type

Number of Pairs

Line Rate

Baud Rate

Loop Loss

Bridged Taps

Performance

Input Impedance

Return Loss

Network Interface

DS1 Transmit Level

DSX-1 Line Buildout

DSX-1 Line Code

Local Power

Fusing

Clock Sources

Internal Clock Accuracy

Diagnostics Self-Test, Local Loopback (H4TU-C), Remote Loopback

Dimensions

Weight

T200 H4TU-R 1223424L2

16 TC PAM

Full Duplex, partially overlapped echo canceling

Mode

2

1.552 Mbps

261.333 k baud

Refer to the HDSL4 Deployment Guidelines section.

Single Taps < 2000 ft., Total Taps < 2500 ft.

Compliant with T1.418-2000 (HDSL4 Standard, issue 2)

14.1 ±0.5 dBm (0 to 400 kHz)

14.1 ±0.5 dBm (0 to 307 kHz)

135 ohms

1150 ohms (nonrepeatered circuit)

12 dB (50 kHz to 200 kHz)

0 dB (default), –7.5 dB, –15 dB

0-133 ft. ABAM (default)

133-266 ft. ABAM

266-399 ft. ABAM

399-533 ft. ABAM

533-655 ft. ABAM

B8ZS (default), AMI

Power

3.8 watts

–48 VDC ± 24 VDC

1.00 A (not field-replaceable)

Clock

DSX-1 Derived (with HDSL4 frame bit stuffing)

±25 ppm (Exceeds Stratum 4), meets T1.101 Timing

Requirements

Test s

(H4TU-R)

Physical

5.5 in. High, x 0.7 in. Wide, x 6.0 in. Deep

< 1 lb.

Environment

–40°C to + 70°C

–40°C to + 85°C

Compliance

Part Number

20 Issue 1, December 2003 61223424L2-5A

Page 21

Appendix A

HDSL4 Loopbacks

HDSL4 MAINTENANCE MODES

This appendix describes operation of the HDSL4

system with regard to detection of inband and ESF

facility data link loopback codes.

Upon deactivation of a loopback, the HDSL4 system

will synchronize automatically.

Loopback Process Description

In general, the loopback process for the HDSL4 system

elements is modeled on the corresponding DS1 system

process. Specifically, the H4TU-C loopback is similar

to an Intelligent Office Repeater loopback, and the

H4TU-R loopbacks are similar to an in-line T1 Repeater

loopback.

In-band control code sequences are transmitted over the

DS1 link by either the insert or overwrite method. The

HDSL4 elements respond to either method. The insert

method produces periodic control sequences that are not

overwritten by the DS1 framing bits.

The overwrite method produces periodic control

sequences. However, once per frame, the framing bit

overwrites one of the bits in the control sequence.

The unit can detect the loopback activation or deactivation code sequence only if an error rate of 1E-03 or

greater is present.

Loopback Control Codes

A summary of control sequences is given in Tabl e A -1

and Tab l e A - 2.

NOTE

In all control code sequences presented, the inband codes are shown left-most bit transmitted

first, and the esf data link codes with rightmost bit transmitted first.

61223424L2-5A A-1

Page 22

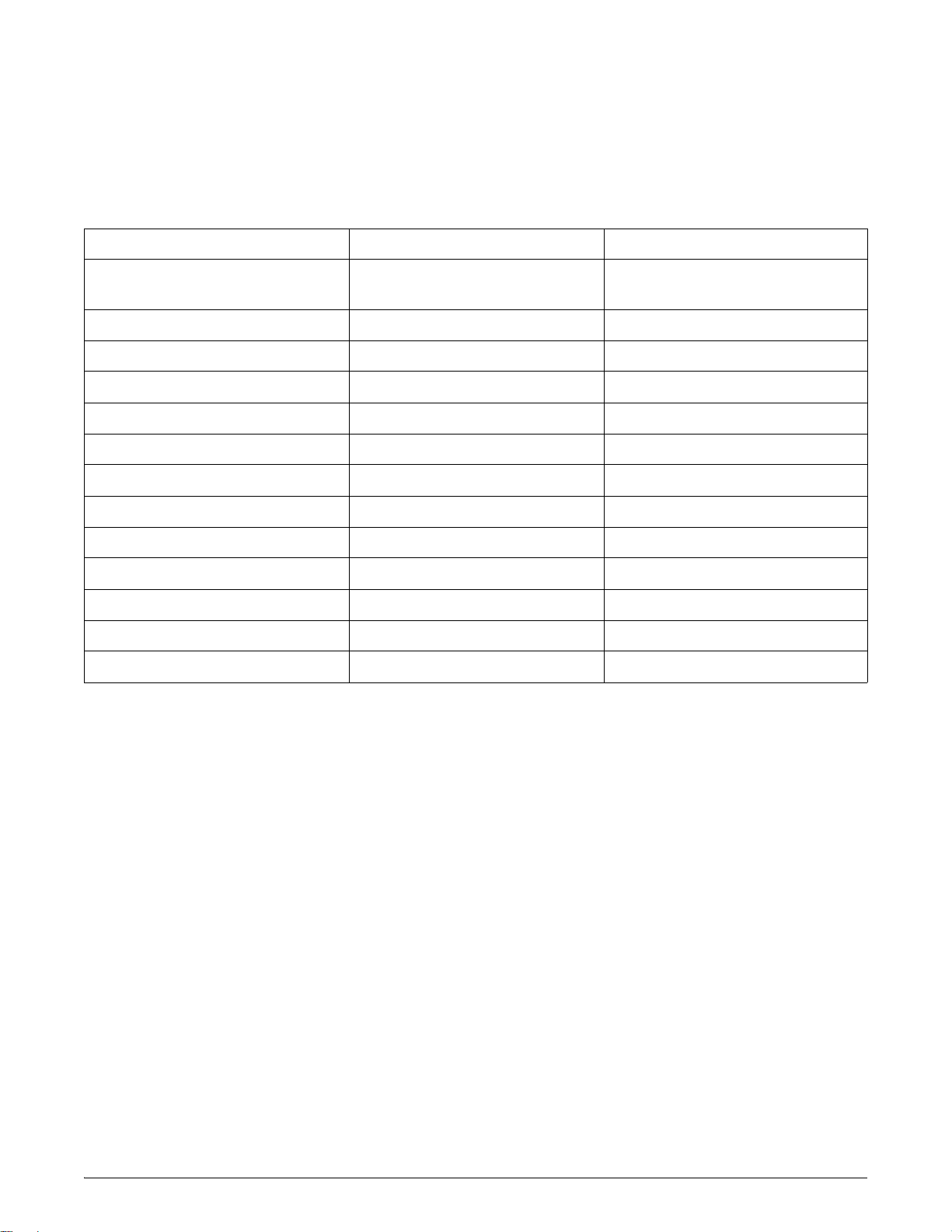

Table A-1. HDSL4 Loopback Control Codes

Type

Source

Abbreviated (N)

(N)

(N)

(N)

(C)

(C)

(C)

(C)

Wescom (N)

(C)

(N)

(N)

(C)

(C)

(N)

(C)

(C)

(N)

(N/C)

(N/C)

1

Code

2,3

3in7 (1110000)

4in7 (1111000)

2in6 (110000)

3in6 (111000)

6in7 (1111110)

5in7 (1111100)

4in6 (111100)

5in6 (111110)

FF1E (1111 1111 0001 1110)

3F1E (0011 1111 0001 1110)

FF04 (1111 1111 0000 0100)

FF06 (1111 1111 0000 0110)

3F04 (0011 1111 0000 0100)

3F06 (0011 1111 0000 0110)

FF02 (1111 1111 0000 0010)

3F02 (0011 1111 0000 0010)

FF48 (1111 1111 0100 1000)

FF48 (1111 1111 0100 1000)

1 in 3 (100)

FF24 (1111 1111 0010 0100)

Name

Loopback data from network toward network in the HTU-R.

Loopback data from network toward network in the HTU-C.

Loopback data from network toward network in first HRE.

Loopback data from network toward network in second HRE.

Loopback data from customer toward customer in HTU-C.

Loopback data from customer toward customer in HTU-R.

Loopback data from customer toward customer in first HRE.

Loopback data from customer toward customer in second HRE.

Loopback data from network toward network at HTU-C.

Loopback data from customer toward customer at HTU-C.

Loopback data from network toward network at HRE1.

Loopback data from network toward network at HRE2.

Loopback data from customer toward customer at HRE1.

Loopback data from customer toward customer at HRE2.

Loopback data from network toward network at HTU-R.

Loopback data from customer toward customer at HTU-R.

Loopback data from customer toward customer at HTU-R.(FDL)

Loopback data from network toward network at HTU-R. (FDL)

Loopdown everything.

Loopdown everything. (ESF-DL)

1. The Source column indicates from which side of the interface the control codes are sent. For example, an (N) indicates a network sourced code while a (C) indicates a customer sourced code.

2. All codes are in-band unless labeled ESF-DL.

3. All codes listed above must be sent for a minimum of 5 seconds to be detected and acted upon.

A-2 Issue 1, December 2003 61223424L2-5A

Page 23

Table A-2. Loopback Control Codes

Function Code (Hex / Binary) Response

ARM (in-band) - also

11000 (binary) If the pattern is sent from the network, the units will arm, and

known as 2-in-5 pattern

ARM (ESF Data Link) FF48 or

1111 1111 0100 1000

sent in the Facility Data Link

Disarm (in-band) - also

11100 (binary) When sent from the network or customer, all units are

known as 3-in-5 pattern

Disarm (ESF Data Link) FF24 or

1111 1111 0010 0100

sent in the Facility Data Link

H4TU-C Loop Up

1,2

D3D3 or

1101 0011 1101 0011

Loop Down w/o Disarm 9393 or

1001 0011 1001 0011

the H4TU-R will loop up if NIU Loopback is enabled.

If the pattern is sent from the network, the units will arm, and

the H4TU-R will loop up if NIU Loopback is enabled. When

sent from the customer, the units will arm.

removed from the armed state, and loopbacks will be released.

When sent from the network or customer, all units are

removed from the armed state, and loopbacks will be released.

If armed, the H4TU-C will loop up, 2 seconds of AIS (all

ones) will be transmitted, the looped data will be sent for 5

seconds, and then a burst of 231 logic errors will be injected.

The burst of 231 logic errors will continue every 20 seconds as

long as the D3D3 pattern is detected. When the pattern is

removed, the unit will remain in loopback. If the pattern is

reinstated, the injection of 231 logic errors will continue every

20 seconds.

When sent from the network, all units currently in loopback

will loop down. Armed units will not disarm. In order to

behave like a smartjack, the H4TU-R will not loop down from

a network loopback in response to the 9393 pattern if NIU

Loopback is enabled.

Loopback Query

1

Loopback Time Out

Override

1

D5D5 or

1101 0101 1101 0101)

D5D6 or

1101 0101 1101 0110

When the pattern is sent from the network, logic errors will be

injected toward the network to indicate a loopback is present

toward the network. The number of errors injected is

determined by the nearest unit that is in loopback. As long as

the pattern continues to be sent, errors are injected again every

20 seconds:

H4TU-C 231 errors

H4R1 10 errors

H4R2 200 errors

H4TU-R 20 errors

If the units are armed or a unit is currently in loopback when

this pattern is sent from the network, the loopback time out

will be disabled. As long as the units remain armed, the time

out will remain disabled. When the units are disarmed, the

loopback time out will revert to the previous loopback time

out setting.

If any element is in network loopback a bit error confirmation

will be sent.

H4TU-C 231 errors

H4R1 10 errors

H4R2 200 errors

H4TU-R 20 errors

61223424L2-5A Issue 1, December 2003 A-3

Page 24

Table A-2. Loopback Control Codes (Continued)

Function Code (Hex / Binary) Response

Span Power Disable

First H4R Loop Up

1

1,2

Second H4R Loop Up

6767 or

0110 0111 0110 0111

C741

1100 0111 0100 0001

1,2

C754

1100 0111 0101 0100

If the units are armed and 6767 is sent from the network, the

H4TU-C will disable span power. If the pattern is sent from

the network, the span power will be disabled as long as 6767

pattern is detected. Once the pattern is no longer received, the

H4TU-C will reactivate span power. All units will then retrain

and return to the disarmed and unlooped state.

If one or more H4Rs are present, the H4R closest to the

H4TU-C will loop up toward the network, 2 seconds of AIS

(all ones) will be transmitted, the looped data will be sent for 5

seconds, and then a burst of 10 logic errors will be injected.

The burst of 10 logic errors will continue every 20 seconds as

long as the C741 pattern is detected. When the pattern is

removed, the unit will remain in loopback. If the pattern is

reinstated, the injection of 10 logic errors will continue every

20 seconds.

If two H4Rs are present, the second H4R from the H4TU-C

will loop up toward the network, 2 seconds of AIS (all ones)

will be transmitted, the looped data will be sent for 5 seconds,

and then a burst of 200 logic errors will be injected. The burst

of 200 logic errors will continue every 20 seconds as long as

the C754 pattern is detected. When the pattern is removed, the

unit will remain in loopback. If the pattern is reinstated, the

injection of 200 logic errors will continue every 20 seconds.

H4TU-R Address 20 for

Extended Demarc

1,2

C742

1100 0111 0100 0010

If armed, the H4TU-R will loop up toward the network, 2

seconds of AIS (all ones) will be transmitted, the looped data

will be sent for 5 seconds, and then a burst of 20 logic errors

will be injected. The burst of 20 logic errors will continue

every 10 seconds as long as the C742 pattern is detected.

When the pattern is removed, the unit will remain in loopback.

If the pattern is reinstated, the injection of 20 logic errors will

continue every 10 seconds.

1. Units must be armed with 11000b or FF48h before this code will work.

2. Loopback and error injection will only occur if the in-band code is received by the unit that is to go into loopback. In

other words, if another loopback blocks the in-band code from being transmitted to the unit that is to go into loopback, loopback and error injection will not occur.

Note: All codes listed above must be sent for a minimum of 5 seconds to be detected and acted upon

A-4 Issue 1, December 2003 61223424L2-5A

Page 25

This page is intentionally blank.

61223424L2-5A Issue 1, December 2003 A-5

Page 26

A-6 Issue 1, December 2003 61223424L2-5A

Loading...

Loading...