Page 1

High Capacity T200/T400 Cabinet

Installation and Maintenance

CONTENTS

1. GENERAL ..................................................................... 1

2. INSTALLATION............................................................ 4

3. TESTING ..................................................................... 15

4. MAINTENANCE......................................................... 18

5. WARRANTY AND CUSTOMER SERVICE .............. 20

FIGURES

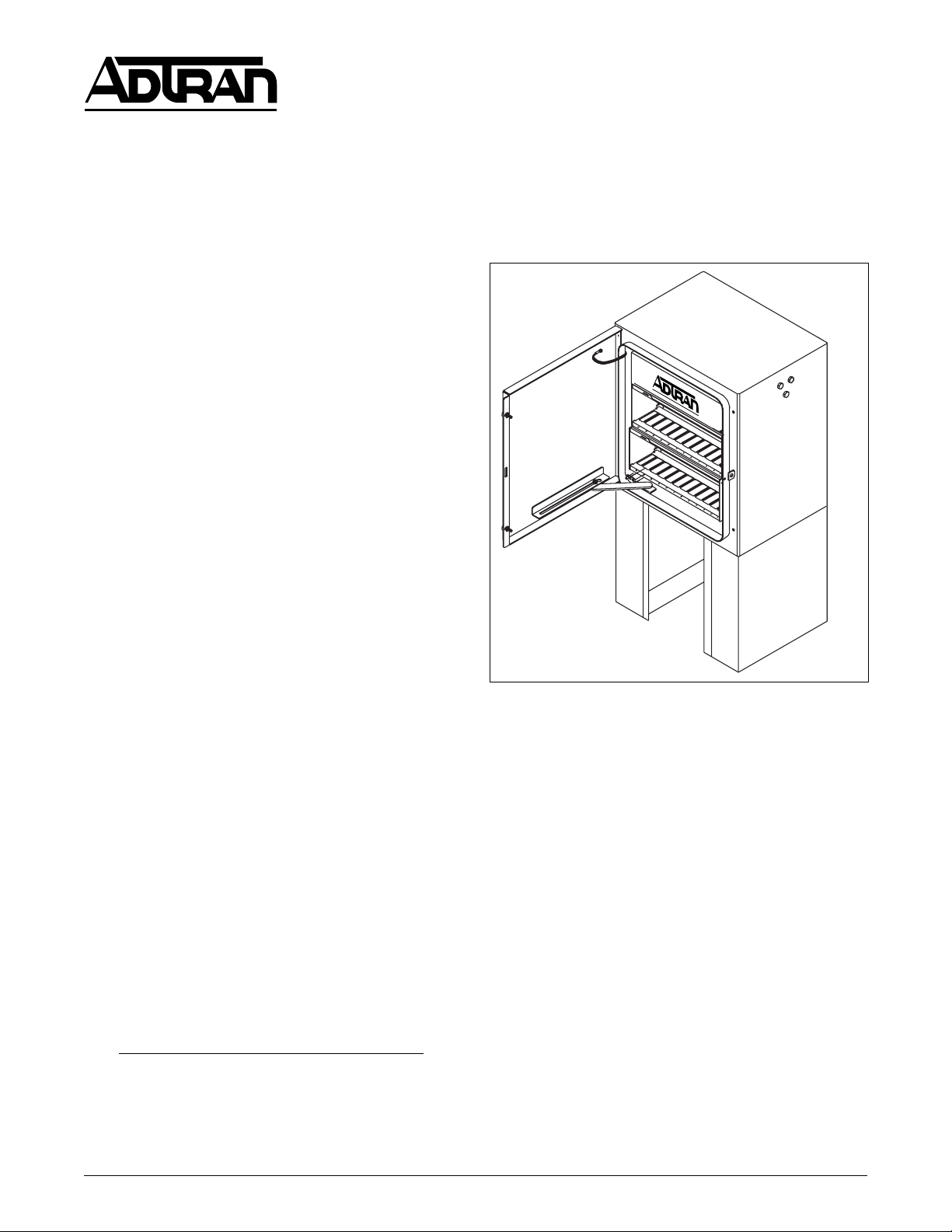

Figure 1. High-Capacity T200/T400 Cabinet

(Pad Mount Model) ........................................... 1

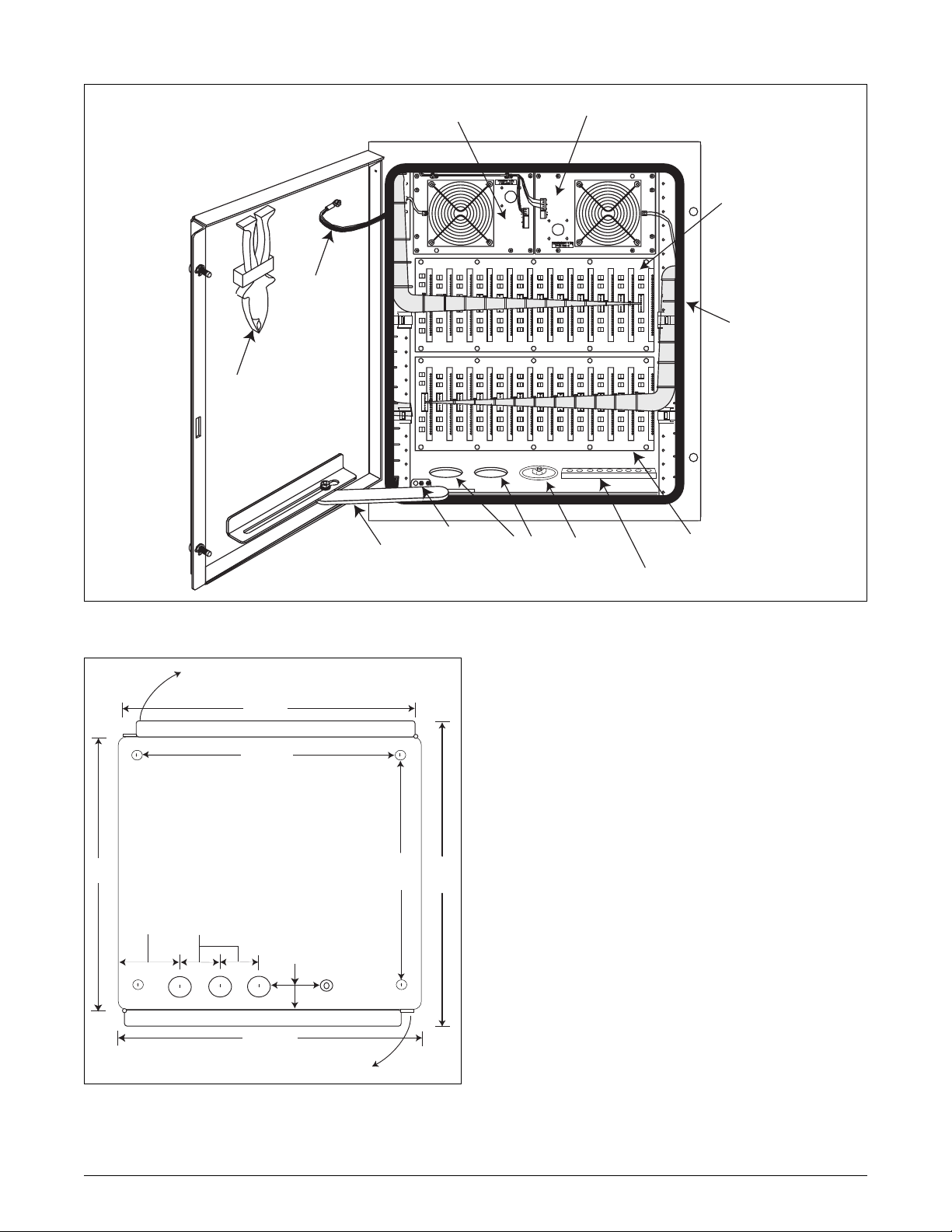

Figure 2. Cabinet Assembly, Rear View............................ 3

Figure 3. Top View Cutaway With Installation

Measurements.................................................... 3

Figure 4. Pad Mount Dimensions ...................................... 5

Figure 5. Lifting Detail Assembly..................................... 5

Figure 6. Pad Mounting Bracket Installation .................... 6

Figure 7. Pole Mount Dimensions..................................... 6

Figure 8. Mounting Bracket Assembly.............................. 7

Figure 9. Bottom Support Bracket Assembly.................... 8

Figure 10. Guide for Pole Mounting .................................. 8

Figure 11. Sealing Grommet Assembly .............................. 9

Figure 12. Shield Connector Assembly............................ 10

Figure 13. Primary & Secondary Fan Boards .................. 15

Figure 14. Surge Arrestor Board....................................... 18

Figure 15. Surge Arrestor Gas Tube Replacement .......... 18

Figure 16. Door Switch .................................................... 20

TABLES

Table 1. T200/T400 Cabinet Basic Features ..................... 2

Table 2. Pad Mounting Hardware ..................................... 5

Table 3. Pole Mount Hardware ......................................... 7

Table 4. Seal Grommet Kit................................................ 9

Table 5A.Splice Module 1 ................................................ 12

Table 5B.Splice Module 2 ................................................ 12

Table 6A.Circuit Technology Configuration

Chart (Part 1) ..................................................... 13

Table 6B.Circuit Technology Configuration

Chart (Part 2) ..................................................... 14

Table 7. Replacement Item Part Numbers....................... 18

Table 8. Customer & Circuit Information ....................... 21

1. GENERAL

This practice provides installation and maintenance

procedures for the ADTRAN High-Capacity

Section 61150090L1-5

Issue 1, April 1999

List 1: CLEI CODE # T1MJ4U0MRA

List 2: CLEI CODE # T1MJ5U0MRA

List 3: CLEI CODE # T1MJ4V0MRA

List 4: CLEI CODE # T1MJ5V0MRA

Figure 1. High-Capacity T200/T400 Cabinet

(Pad Mount Model)

T200/T400 Cabinet. Figure 1 is an illustration of the

unit. Four models are available.

The part numbers and basic features of each cabinet

model are provided in Table 1. The cabinet is a highcapacity T200/T400 enclosure which supports the

demand for numerous circuits spread over small areas.

Revision History

This is the first issue of this document. Future

revisions will be described in this paragraph.

Practice Review

This Practice contains important pre-installation

information. Craft personnel should review Sections 1

and 2 of this Practice as part of installation planning.

Description

The ADTRAN T200/T400 High Capacity Cabinet is

an outdoor, above-ground enclosure. Up to 24

61150090L1-5A Section 61150090L1-5A, Issue 1 1

Trademarks: Any brand names and product names included in this document are

trademarks, registered trademarks, or trade names of their respective holders.

Page 2

ADTRAN Line Powered T200 or T400 Circuit Packs

can be installed per cabinet. The cabinet system is prewired with surge arrestor boards to reduce installation

and turn-up time. Wiring consists of either pre-wired

cable stubs or pre-wired internal splice module

connections depending on the model.

The cabinet body is constructed of aluminum with a

powder coated gray finish. Earth ground connects to

the ground lug on the bottom of the cabinet. The nonvented enclosure protects the internal electronic

circuitry from the surrounding environmental

conditions.

For the pad mount model, the cabinet sits on two

bolt-on mounting brackets. The brackets are in-turn

bolted to the craft designated pad. The front and back

security access panels are then bolted to the brackets

to provide a secure enclosure for the wire runs exiting

the bottom of the cabinet.

All models incorporate tamper resistant access with

lockable front and rear cabinet doors, replaceable

surge arrestor gas tubes, and replaceable fan modules.

Features

The T200/T400 High Capacity Cabinet includes the

following features and components:

• Two 19 inch T200/T400 chassis with 24 slots

(2x12) for line powered T400 or T200 Circuit

Packs.

• Line powered internal cooling fans.

• Pre-wired 50 foot cable stubs, or internal splice

module connections, depending on the model.

• Pre-installed splicing modules on cable stub

ends or wiring harness for fast, simple

connections at the customer’s site or splice case.

• Surge arrestors are provided for each slot with

replaceable gas tubes.

• Gas tube extraction pliers.

• Moisture absorbing desiccant.

• Spare cable hole entrance with removable seal.

• Mounting template for craft planning.

Cabinet Access

The front and rear cabinet doors and support bracket

access panels include tamper resistant security

fasteners. The cabinet doors allow for a customer

supplied lock for added security. The front door

provides access to insert and remove the circuit packs

and desiccant bags. The rear door provides access to

the chassis backplane, cable and wire connections, fan

boards, and surge arrestor boards. All cable

penetrations are through the bottom panel.

When opened, the front and rear door switches

provide intrusion detection at the Central Office FPU

(Fan Power Unit). The door switch can then be

manually positioned to disable intrusion detection.

The door switch automatically resets when the door

closes. Retainers hold the door open until they are

manually released. Front and rear door features are

identical. Refer to Figure 2 for cabinet details, rear

view.

Mounting

The Cabinet is pad or pole mountable depending on

the model. The cabinet is for above ground use only.

The pad mounted model includes two interchangeable

boxlike brackets that raise the cabinet 18 inches above

the pad to allow easier access, provide additional

clearance for manipulating cables, and protection from

a high water condition. Pole mounting is

recommended where water conditions could reach a

pad mounted cabinet.

Mounting Template

The pad mounting footprint dimensions are provided

as a full size template on the unit’s packaging, and

complete installation measurements are shown in

Figure 3.

Table 1. T200/T400 Cabinet Basic Features

rebmuNtPIELCserutaeF

1L0900511ARM0U4JM1T

2L0900511ARM0U5JM1T

3L0900511ARM0V4JM1T

4L0900511ARM0V5JM1T

2 Section 61150090L1-5A, Issue 1 61150090L1-5A

.elbacdeilppusremotsucotnoitcennocrofseludom

.elbacdeilppusremotsucotnoitcennocrofseludom

.sbutselbaclanretxehtiwdetnuomdaP.skcaptiucric004T/002Tderewopenil42sesuoH

ecilpslanretnihtiwdetnuomdaP.skcaptiucric004T/002Tderewopenil42sesuoH

ecilpslanretnihtiwdetnuomeloP.skcaptiucric004T/002Tderewopenil42sesuoH

.sbutselbaclanretxehtiwdetnuomeloP.skcaptiucric004T/002Tderewopenil42sesuoH

Page 3

Gas T ube

Extractor

Pliers

Door

Ground

Braid

Pimary

Fan Board

to Cable A

Secondary

Fan Board

to Cable A

Surge Arrestor

Board for top Shelf

Door Gasket

Rear Door

Rear Door

Retainer

Switch

Figure 2. Cabinet Assembly, Rear View

OPEN

23"

Front door

20 7/16"

View is looking down with top cut away.

Mounting bolt hole center lines are 1 5/8" in from each edge.

Ground stud is 1 5/8" from rear edge.

Measurements shown are center to center (C/C).

Door width includes locking flange.

Cable penetrations are 1 7/8" in diameter.

Cabinet is 27" high not including cable stubs.

Pad mount brackets are 18" high.

17"

Dimensions are tape rule derived and measured from

outside the cabinet.

5 3/4"

3 1/4"

C/C

cable dimensions +/- 1/8"

13 3/4"

C/C

20"

overall

2 1/2" C/L

Ground

spare

B

A

Rear door

23 5/8"

overall

Lug

OPEN

Figure 3. Top View Cutaway With Installation

Measurements

A, B, and Spare

Cable Penetrations

Surge Arrestor Board

for bottom Shelf

Ground

Connecting lug on

()

Buss

cabinet bottom

Fan Operation and Indication

Two thermostatically controlled line powered cooling

fans limit heat buildup. The primary fan energizes at

about 110° F. The secondary fan energizes at about

150° F.

Primary and secondary fan board operation is

monitored by the FPU. The following conditions

cause an alarm at the FPU:

• Any fan or fan board not receiving power.

• Secondary fan turning On.

• Open cabinet door.

The single FPU at the CO has a separate power supply

for each fan board. The FPU fits into one slot of the

E220 HTU-C shelf (for HDSL applications).

The FPU is purchased separately. Information on fan

board operation and testing is in Section 3. For

additional details on the FPU refer to I&M Practice:

61150091L1-5. The FPU Practice should be on-hand

at the CO for reference during cabinet testing.

61150090L1-5A Section 61150090L1-5A, Issue 1 3

Page 4

NOTE

Because heat dissipates across the cabinet

surfaces, the cabinet should not be installed

within another enclosure or hut unless such

enclosure has positive ventilation.

Status Indicator LEDs

Each fan board has two status indicator LEDs:

• DOOR LED (Red), verifies that FPU power is

present on the associated fan board.

• FAN LED (Green), verifies the open or closed

position of the fan’s associated thermostat.

The LEDs give positive indication that power is

present to operate the fans and thermostats.

DOOR (Power) LED

Power is present at the corresponding fan board if the

red Door LED turns On when the door is opened as

explained here:

• When the front door is opened, the secondary

fan board red Door LED turns On until the front

door switch is manually disabled or the front

door is closed.

• When the rear door is opened, the primary fan

board red Door LED turns On until the rear door

switch is manually disabled or the rear door is

closed.

2. INSTALLATION

C A U T I O N !

SUBJECT TO ELECTROSTATIC DAMAGE

OR DECREASE IN RELIABILITY.

HANDLING PRECAUTIONS REQUIRED.

The cabinet assembly weighs about 200 pounds. This

Practice assumes that proper lifting devices are on

hand for maneuvering and holding the cabinet in

position until securely mounted.

After unpacking the T200/T400 High Capacity

Cabinet inspect it for damage. If damage is noted file

a claim with the carrier, then contact ADTRAN

Customer Service (refer to Section 5).

WARNING

Never install telephone wiring during a

lightning storm.

If equipment is to be stored for any period of time,

ADTRAN recommends that the equipment be kept in

the original shipping container until arriving at the

installation site.

CAUTION

Although sealed from the elements the cabinet

is not designed to be waterproof and must not

be located where any type of immersion could

occur.

NOTE

The door switch also controls intrusion

detection on the FPU at the CO.

Cabinet location should be selected with the following

in mind:

• Personnel and equipment safety

FAN (Thermostat) LED

The green LEDs indicate that power is present at the

thermostat by being On when the fans are Off.

When the thermostat is Open, the green FAN LED

should be On and the fan should be Off. When the

thermostat is Closed, the FAN LED should be Off and

the fan should be On. FAN LED operation is

independent of door switch status.

• Personnel access

• For cable stubbed versions, the proposed cable

routes should not exceed the 50-foot cable stub

lengths.

• Clearances between the cabinet and adjacent

structures must be adequate for access during

maintenance (refer to pad and pole mount

subsections).

Pad Mount Installation

Pad configuration is designated by the installing

activity. The cabinet shipping box has a printed

template for support bracket bolt hole location. Craft

planning will ensure the pad four bolt pattern matches

4 Section 61150090L1-5A, Issue 1 61150090L1-5A

Page 5

the bracket pattern. Refer to Figure 4 for pad mount

tP.tiKerawdraHtnuoMdaP

#

8-0900512

noitpircseDytitnauQ

sliatedgnitfiL*2

tekcarbgnitnuomdaP2

revoctekcarbgnitnuomdaP2

stloB"1x61-8/34

rehsawtalF8/34

rehsawtilpS8/34

rehsawgnilaeS8/34

swercsytiruceS8

deppihserasliatedgnitfilhcattaotdesusrenetsaF*

.snoitacoltenibacdetangisedriehtotnidetresni-erp

access dimensions.

1. At the installation site remove all packaging

material enclosing the cabinet.

2. Remove and set aside the mounting hardware

kit. Verify contents per Table 2.

3. The cabinet is bolted to two boards running

across the box frame. Remove the screws

securing the two boards to the wood box frame.

4. Attach lifting details. Screwed into each side of

the cabinet is a group of three bolts and washers.

Remove these for reuse.

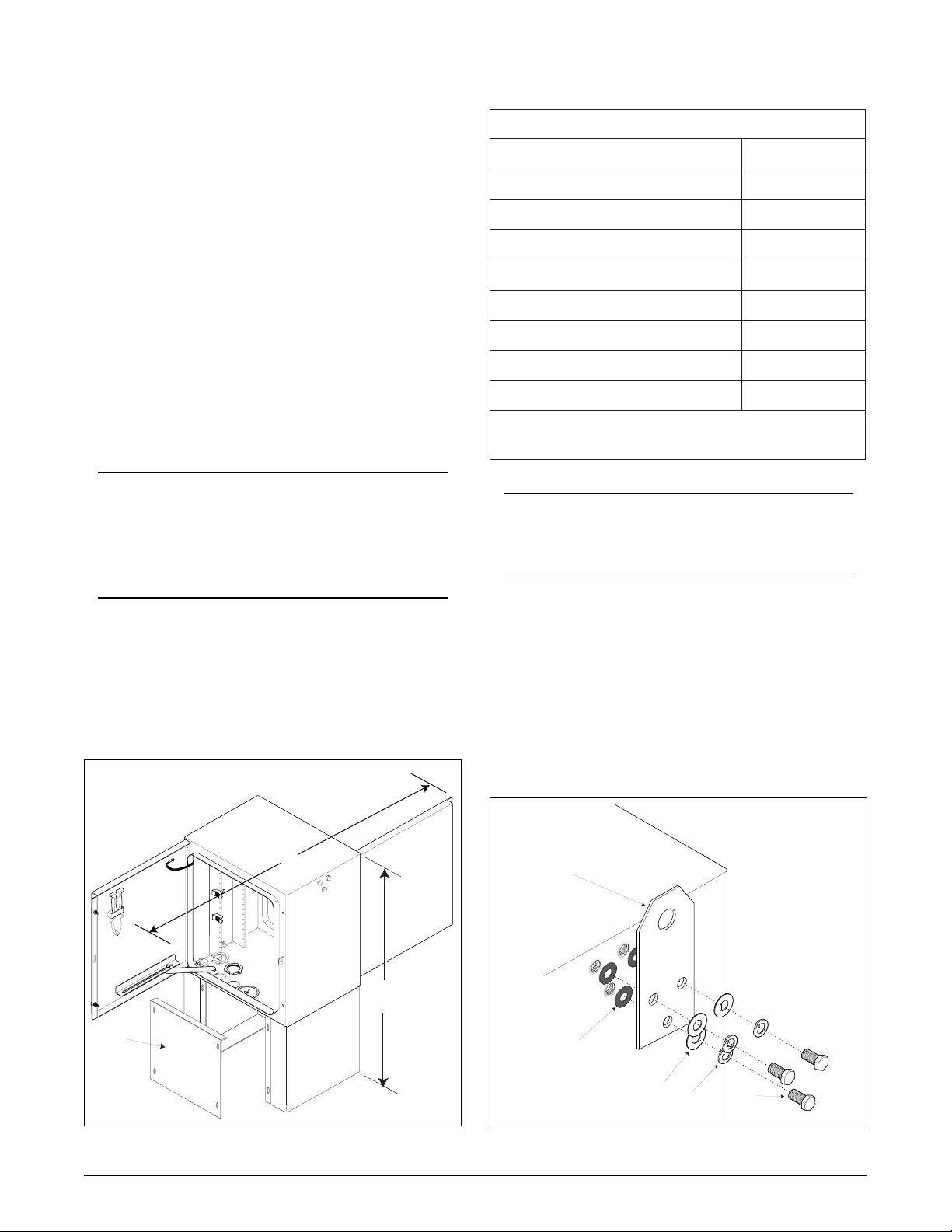

5. Following the illustration in Figure 5, attach the

lifting details to each side of the cabinet using

the bolt and washer groups. Ensure the sealing

washers are placed between the cabinet and the

lifting details. Tighten bolts to 110-130 in-lbs.

WARNING

When lifting the cabinet out of the shipping

package and during installation, be sure to

exercise caution and observe all safety

measures.

Table 2. Pad Mounting Hardware

CAUTION

Do not reuse shipping hardware. It is not

designed for cabinet mounting.

6. Using appropriately sized and tested hoisting

gear, attach a hoist cable between the two lifting

details. Hoist the cabinet from the package and

lower the cabinet onto its side.

7. Remove all hardware securing the wood

shipping frame to the bottom of the cabinet.

63"

overall with

doors open

45"

total

Security

Access

Cover

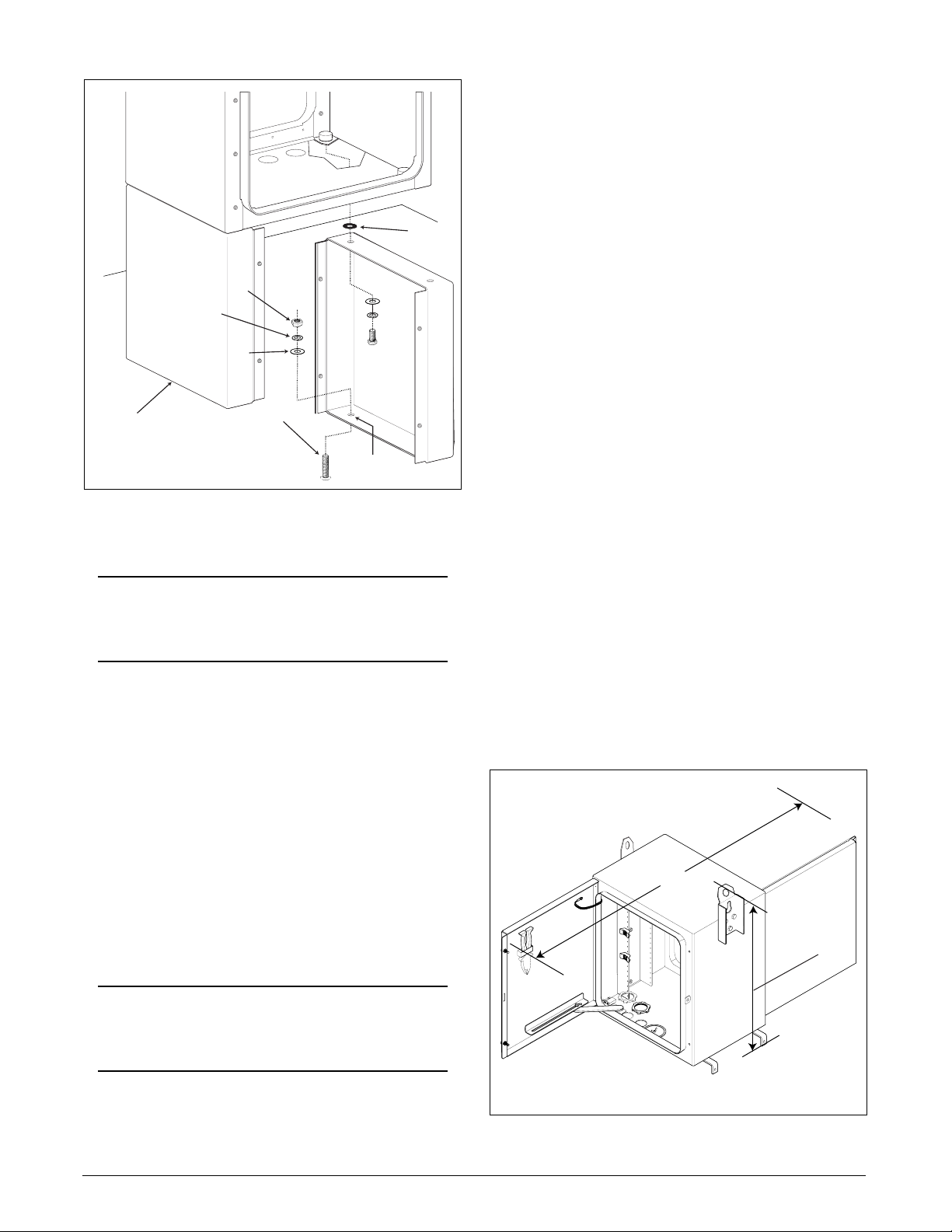

8. Following the illustration in Figure 6 and using

the parts supplied in the pad mounting kit, fasten

the two pad mounting brackets to both sides of

the bottom of the cabinet. Ensure the sealing

washers are placed between the cabinet and the

pad mounting brackets. Tighten to

100-110 in-lbs.

One side shown, other

side identical.

lifting detail

Bolt torque:

110-130 in-lbs

sealing washer

flat washer

split washer

bolt

Figure 4. Pad Mount Dimensions

Figure 5. Lifting Detail Assembly

61150090L1-5A Section 61150090L1-5A, Issue 1 5

Page 6

sealing washer

on the pad mounting brackets using the included

fasteners. Tighten to 10-15 in-lbs. Install with

the access cover lip facing in and against the

cabinet’s bottom panel. See Figure 4.

13.If lifting details are to be removed, replace the

fasteners removed in step 4 ensuring the sealing

washers are installed next to the cabinet side

panels.

nut*

split

washer*

flat

washer*

Mounting

Bracket

*Customer supplied

Pad arrangement is representative

Pad mounted stud*

(4 places)

bolt torque:

100-110 in-lbs

5/8" dia

Figure 6. Pad Mounting Bracket Installation

9. Hoist the cabinet to an upright position and

center it over the pad.

CAUTION

The minimum internal bend radius for cable

stubs is nine inches.

10.At this time, on the cable stub model, the cable

stubs should be fed through their designated

conduit or other route per craft plan.

11.Lower the cabinet with attached brackets onto

the pad ensuring the four bottom bracket

5/8 inch bolt holes align with the pad fastener

arrangement. Secure with customer supplied

fasteners. Continue feeding the cable stubs as the

cabinet is lowered.

12.On the ground lug on the cabinet bottom next to

the spare cable penetration attach an

appropriately sized (6 AWG) ground cable to the

most direct path to ground. Ground cable and

connectors are customer supplied.

Pole Mount Installation

Pole mounting has two configurations:

• Mounted to a single pole on either the left or

right side panel.

• H-frame where the cabinet is supported by a

frame arrangement at either the left or right side

panel.

The pole-mount or H-frame support structure must

bear the weight of a fully equipped cabinet (200 Lbs).

The weight and the distance the cabinet will be

installed above the ground determines the type of pole

configuration to be selected. Refer to Figure 7 for

pole mount access clearances.

1. At the installation site remove all packaging

material enclosing the cabinet.

2. Remove and set aside the Mounting Hardware

Kit. Verify kit contents per Table 3.

3. The cabinet is bolted to two boards running

across the wood box frame. Remove the screws

securing the two boards to the wood box frame.

63"

overall with

doors open

33"

top to bottom

brackets included

CAUTION

Without positive ground surge protection is

lost.

13.After the cabinet is secured to the pad the front

and back security access covers can be installed

6 Section 61150090L1-5A, Issue 1 61150090L1-5A

Figure 7. Pole Mount Dimensions

Page 7

Table 3. Pole Mount Hardware

9-0900512#tPtiktnuomeloP

noitpircseDytitnauQ

liatedgnitfiL*1

)liatedgnitfil(tekcarbtnuomeloP**1

tekcarbtroppusgnitnuomeloP2

stloB"1x61-8/34

rehsawtalF8/36

Mounting Bracket shown,

Lifting Detail similar.

rehsawtilpS8/34

rehsawgnilaeS8/34

deppihserasliatedgnitfilhcattaotdesusrenetsaF*

.snoitacoltenibacdetangisedriehtotnidetresni-erp

gnitfilasasevrestekcarbgnitnuomelopehT**

.noitallatsnignirudliated

4. Attach lifting details. Screwed into each side of

the cabinet is a group of three bolts and washers.

Remove these for reuse.

NOTE

Observe that one of the lifting details is also

the mounting bracket. Ensure the mounting

bracket is attached to the side of the cabinet

designated to be against the pole.

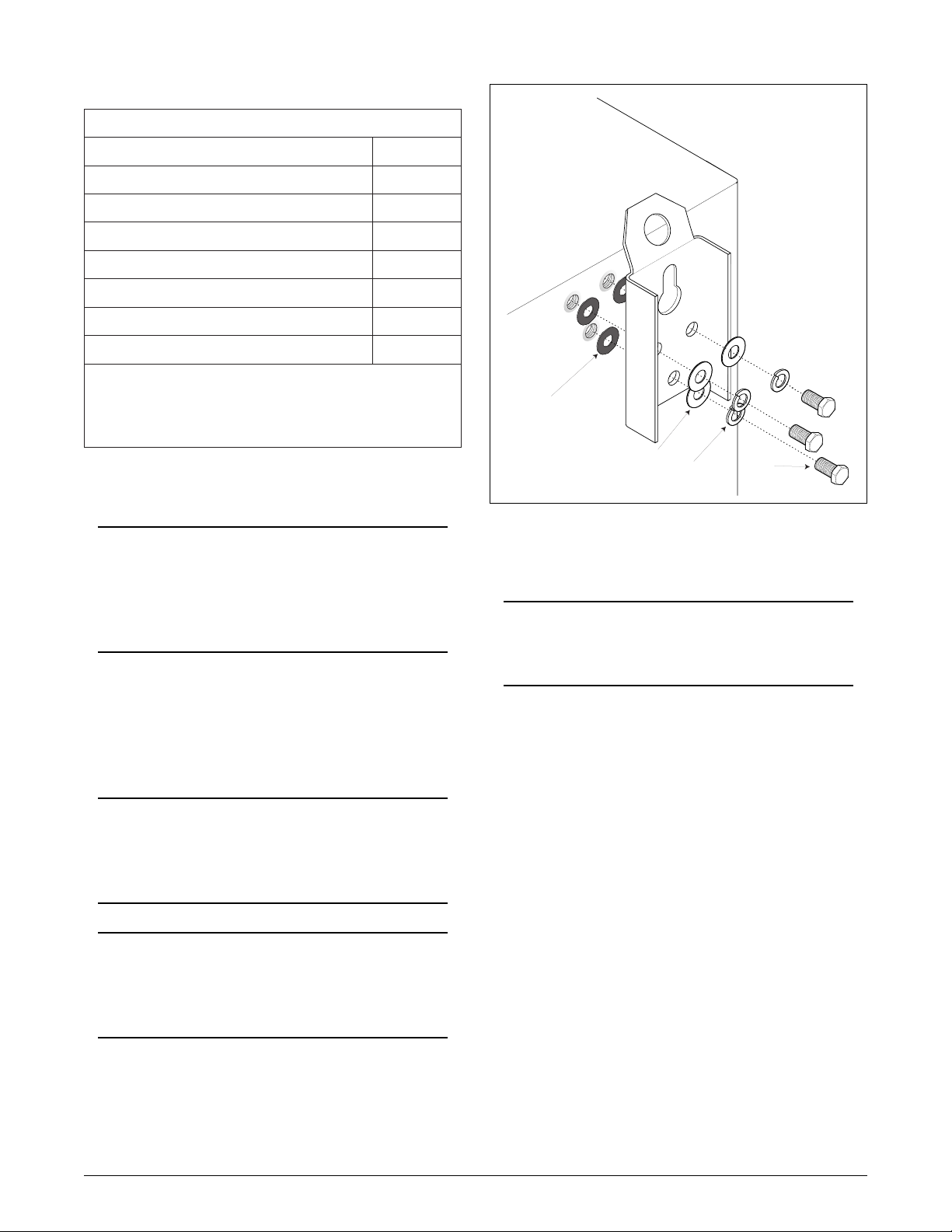

5. Following the illustration in Figure 8, attach the

lifting details to each side of the cabinet using

the bolt and washer groups. Ensure the sealing

washers are placed between the cabinet and the

lifting details. Tighten bolts to 110-130 in-lbs.

WARNING

Exercise caution and observe all safety

measures when lifting the cabinet out of the

shipping package and during installation.

WARNING

Do not disconnect lifting cable until the cabinet

is fully secured and all mounting bracket and

support fasteners are tightened.

6. Using appropriately sized and tested hoisting

gear, attach a hoist cable between the lifting

details. Hoist the cabinet from the package and

lower the cabinet onto its side.

Bolt torque:

110-130 in-lbs

sealing washer

flat washer

split washer

bolt

Figure 8. Mounting Bracket Assembly

7. Remove hardware securing the wooden boards

to the bottom of the cabinet.

CAUTION

Do not reuse shipping hardware. It is not

designed for cabinet mounting.

8. Identify which side of the cabinet will be

mounted to the pole and on that side attach

(finger tight) the slotted end of the two bottom

support brackets. Ensure the short end will point

down after the cabinet is upright and that the

sealing washers are against the bottom of the

cabinet. Refer to Figure 9. Ensure a flat washer

is on both sides of the support bracket.

9. After determining the appropriate upper

mounting height of the cabinet, drill a 5/8” hole

through the pole for the top pole mounting

bracket. The 1/2 inch diameter through-bolt, nut,

and washers are customer supplied. Install the

bolt through the pole and tighten to leave the

bolt head approximately 1 3/4 inches from the

pole to allow the upper pole mounting bracket to

slide over and down, catching the bolt head.

Refer to Figure 10.

10.Maneuver the cabinet so as to fit the through bolt

head through the slot key opening on the

mounting bracket. When the cabinet is hanging

61150090L1-5A Section 61150090L1-5A, Issue 1 7

Page 8

sealing washer

flat washer

split washer

Bolt torque: 100-110 in-lbs

Insert all unused fasteners

bolt

*1/2" Thru-bolt

*3/8" x 2-1/2" Lag Screws (2)

*Customer furnished hardware

Figure 10. Guide for Pole Mounting

*1/2" Nut

*1/2" Washer

Pole Mount

Bracket

Pole Support

Brackets (2)

Figure 9. Bottom Support Bracket Assembly

on the through bolt, the nut on the other end can

be tightened to snug the bolt head to the

mounting bracket. Do not torque at this time.

11.Ensuring the cabinet is secure to the pole, relieve

tension on the hoist device but do not remove.

This allows positioning of the cabinet.

12.At the bottom of the cabinet insert a temporary

spacer between the cabinet and the pole so the

cabinet hangs plumb. The space between the

pole and the cabinet should be the same from top

to bottom.

13.At the bottom of the cabinet, position and angle

the support brackets so the short ends are flush

against the pole. Using a level, ensure the

cabinet is plumb then tighten the bolts (100-110

in-lbs) securing the brackets to the cabinet.

14.Using two 3/8 inch x 2 1/2 inch lag screws

attach the bottom support brackets to the pole.

CAUTION

If bottom bracket adjustment is required,

loosen the bottom support bracket bolts before

adjusting cabinet. Failure to loosen bolts will

cause damage to the sealing washers.

15 Tighten all fasteners to the proper torque.

Remove the lifting gear from the cabinet.

16.If the unused lifting detail is to be removed,

replace the fasteners removed in step 4 ensuring

the sealing washer is installed next to the

cabinet.

NOTE

All unused threaded openings in the cabinet

must have their designated fasteners inserted

and tightened to ensure a proper seal.

H-Frame Mount

For mounting the cabinet to an H-Frame, follow the

same procedure as for Pole Mounting except

substitute acceptable 3/8 inch bolts, nuts, and washers

(customer supplied) instead of lag screws for attaching

the bottom pole mount support brackets to the

H-frame. ADTRAN recommends the use of steel cross

bars between the two poles to ensure adequate

strength. The H-frame facility must be able to bear the

weight of a fully-equipped cabinet (200 Lbs).

Splice Wires (Pre-Stubbed Version or Internal

Splice Module Version)

A T200/T400 Test Access Card (part number

1244065L1, purchased separately) can be inserted into

a slot to assist in circuit or continuity tests. Refer to

ADTRAN Test Access Card Practice, Section

61244065L1-5, for more information.

8 Section 61150090L1-5A, Issue 1 61150090L1-5A

Page 9

CAUTION

Ensure all grounds are securely connected to

the cabinet ground buss and the ground lug

connected to the most direct path to ground.

The following procedures describe wiring connections

for both the stubbed and module connection models:

1. Unscrew the security screws on the front and

rear doors using a 7/16 inch nut driver or

equivalent tool. While loosening the security

screws, alternate between the top and bottom

screws to allow even pressure release.

2. Open the door and allow the door retainer to

engage. The door retainer can be disengaged by

pulling up slightly on the door retainer arm.

3. Manually disable both door alarm switches by

centering the rod and pulling outward.

4. For pre-stubbed cabinets, the top T200/T400

shelf, top surge arrestor board, and the primary

and secondary fan boards are on cable A. The

bottom T200/T400 shelf and bottom surge

arrestor board are on cable B.

diameter range from 0.86 to 1.26 inches. Use care to

ensure correct sequence of assembly.

b. Insert the O-ring evenly in the groove

provided on the sealing grommet.

c. Insert the sealing grommet up through the

designated cable opening until the O-ring is

flush with the bottom of the cabinet.

d. Screw the 1 1/2 inch hex nut onto the sealing

grommet until the O-ring is snug to the bottom

of the cabinet.

e. Using a wrench to hold the sealing grommet

steady, use a second wrench to tighten down

on the hex nut.

f. Screw the compression nut onto the

compression skirt threads, leave the nut loose.

g. Place the shrink-wrap over the cable, let it

slide down out of the way.

h. Insert the cable up through the sealing

grommet providing the correct length of cable

on the inside of the cabinet for splicing.

NOTE

For non-stubbed cables, complete the

following three assembly procedures prior to

completing Step 5.

I. CABLE STUB ENTRY

a. Verify contents of the Cable Stub Entry Kit

per Table 4. The kit is located inside the

mounting kit.

The cable sealing grommet assembly is installed in the

cable opening as shown in Figure 11. The sealing

grommet can accommodate cables with an outside

Table 4. Seal Grommet Kit

51-0900512#tPtiKyrtnEbutSelbaC

noitpircseDytitnauQ

tunnoisserpmoc/wtemmorggnilaeS2

Cabinet

Bottom

Compression

Nut

1 1/2" NPT Hex Nut

O-Ring

Cable

Sealing

Grommet

Compression

Skirt

Cable A or B

(0.86" to 1.26" OD)

Shrink

Wrap 6"

gnir-OtemmorG2

tunxehTPN"2/112

denil-evisehda,knirhs-taeHae"6@2

61150090L1-5A Section 61150090L1-5A, Issue 1 9

Figure 11. Sealing Grommet Assembly

Page 10

NOTE

Refer to Splice Module installation

instructions for the length required inside the

cabinet. Ensure sufficient sheathed cable

exists at the top of the sealing grommet to

install shield connectors.

first nut and tighten until the connector securely

grips the shield and insulator. See view D.

f. Install the ground braid over the stud followed

by the second nut and tighten securely. See view

E. Repeat this process for the remaining cable.

g. Ensure the trailing end of the ground braid is

securely connected to the ground buss.

i. Using a wrench to hold the sealing grommet

steady, use a second wrench to tighten the

compression nut until the compression skirt

creates a weathertight seal around the cable.

II. SHIELDING

On non-stubbed cabinet installations the shield and

braid must be connected to the ground buss as

described in this procedure. Refer to Figure 12 for

views of the connector components, cable, and

assembly sequence. Entry cables have an outer

insulator, a shield sheath, and a core wrap protecting

the inner wire bundle, see View A. The shield sheath

must connect to ground with the supplied connectors

and ground braid.

The connectors and ground braid are temporarily

attached at the factory for cabinet shipment, remove

the connectors from the braid for this procedure.

CAUTION

Ensure wire insulation is not damaged during

shield connection.

Connector

Bottom

A

B

Wire

Bundle

Core

Wrap

Connector Top

Securing Nuts (2)

Shield

Insulator

Shield &

Insulator

C

a. From where the wire bundle exits the cable,

remove about 3/4 inch of insulation and shield

but leaving the protective core wrap intact. See

view B for steps a and b.

b. On the side opposite from where the shield

connector will be placed, make a one inch slice

D

through the insulator and the shield but not the

core wrap. This eases the insertion of the

connector.

c. Opposite the slice, insert the connector bottom

into the cable between the shield and the core

wrap until it reaches the small stop tabs. See

view C for steps c and d.

d. Tap the cable in the area of the leading edge of

the connector to set the contact teeth into the

E

shield

e. Slide the connector top over the stud so it

sandwiches the shield and insulator. Install the

1 0 Section 61150090L1-5A, Issue 1 61150090L1-5A

Figure 12. Shield Connector Assembly

Page 11

III. SHRINK-WRAP

After all other connections are completed, or correct

wire lengths verified, complete the shrink-wrap

process as follows:

a. Position the shrink-wrap up against the bottom

of the cabinet enclosing the entire sealing

grommet assembly.

b. Heat treat the shrink-wrap until properly

constricted around the assembly.

NOTE

On pole mounts, secure the cable exiting the

cabinet to the pole using standard practices

and customer-supplied hardware.

Proceed with Step 5 of the Splice Wires sub section.

5. Insert the circuit pack into the desired slot. The

card’s edge connector is offset and must be

properly aligned to ensure connectivity.

CAUTION

Without positive ground the cabinet does not

provide surge protection.

9. Inspect and clean the door gasket and gasket

sealing area prior to closing the front or rear

doors. If there is visible damage, replace the

door gasket.

10.Tighten the tamper resistant security screws on

the front and rear doors using a 7/16 inch nut

driver or an equivalent tool. While loosening or

tightening the security screws, alternate between

the top and bottom screws to allow even

pressure. Tighten to 10-15 in-lbs. maximum.

CAUTION

The FPU at the CO must be online for fan

operation. For the best cooling results, fully

load the top shelf with circuit cards before

loading the bottom shelf.

6. Connect the wiring in cable stubs based on the

appropriate matching slot used.

7. Refer to Table 5A and 5B for splice module

connections and Table 6A and 6B for Circuit

Technology Configuration charts. Table 5 also

provides circuit and pair identification to

configure the cards listed in the table.

NOTE

2

Refer to the 3M MS

™ Modular Splicing

System Instructions Booklet for splicing and

connecting to 4005-DPM Super Mate

Pluggable Modules.

8. Connect the ground lug on the bottom of the

cabinet to an appropriate 6 AWG ground cable

and earth ground.

61150090L1-5A Section 61150090L1-5A, Issue 1 11

Page 12

Table 5A. Splice Module 1 Table 5B. Splice Module 2

Splice Module #1

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Blue Binder

Group

piTgniR

etihW

eulB

etihW

egnarO

etihW

neerG

etihW

nworB

etihW

etalS

deR

eulB

deR

egnarO

deR

neerG

deR

nworB

deR

etalS

kcalB

eulB

kcalB

egnarO

kcalB

neerG

kcalB

nworB

kcalB

etalS

wolleY

eulB

wolleY

egnarO

wolleY

neerG

wolleY

nworB

wolleY

etalS

teloiV

eulB

teloiV

egnarO

teloiV

neerG

teloiV

nworB

teloiV

etalS

Surge Arrestor

Header Connection

1.1P

1.2P

1.3P

1.4P

1.5P

1.6P

1.7P

1.8P

1.9P

1.01P

1.11P

1.21P

3.1P

3.2P

3.3P

3.4P

3.5P

3.6P

3.7P

3.8P

3.9P

3.01P

3.11P

3.21P

1.1PJ

Ckt Bd Slot

5-1PC

2.1P

5-2PC

2.2P

5-3PC

2.3P

5-4PC

2.4P

5-5PC

2.5P

5-6PC

2.6P

5-7PC

2.7P

5-8PC

2.8P

5-9PC

2.9P

2.01P

2.11P

2.21P

7-1PC

4.1P

7-2PC

4.2P

7-3PC

4.3P

7-4PC

4.4P

7-5PC

4.5P

7-6PC

4.6P

7-7PC

4.7P

7-8PC

4.8P

7-9PC

4.9P

4.01P

4.11P

4.21P

3.1PJ

Connections

51-1PC

51-2PC

51-3PC

51-4PC

51-5PC

51-6PC

51-7PC

51-8PC

51-9PC

5-01PC

51-01PC

5-11PC

51-11PC

5-21PC

51-21PC

31-1PC

31-2PC

31-3PC

31-4PC

31-5PC

31-6PC

31-7PC

31-8PC

31-9PC

7-01PC

31-01PC

7-11PC

31-11PC

7-21PC

31-21PC

+NAFIRP

Used on Cable A only

–NAFIRP

Splice Module #2

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Orange Binder

Group

piTgniR

etihW

eulB

etihW

egnarO

etihW

neerG

etihW

nworB

etihW

etalS

deR

eulB

deR

egnarO

deR

neerG

deR

nworB

deR

etalS

kcalB

eulB

kcalB

egnarO

kcalB

neerG

kcalB

nworB

kcalB

etalS

wolleY

eulB

wolleY

egnarO

wolleY

neerG

wolleY

nworB

wolleY

etalS

teloiV

eulB

teloiV

egnarO

teloiV

neerG

teloiV

nworB

teloiV

etalS

Surge Arrestor

Header Connection

5.1P

5.2P

5.3P

5.4P

5.5P

5.6P

5.7P

5.8P

5.9P

5.01P

5.11P

5.21P

7.1P

7.2P

7.3P

7.4P

7.5P

7.6P

7.7P

7.8P

7.9P

7.01P

7.11P

7.21P

1.4PJ

Ckt Bd Slot

6.1P

6.2P

6.3P

6.4P

6.5P

6.6P

6.7P

6.8P

6.9P

6.01P

6.11P

6.21P

8.1P

8.2P

8.3P

8.4P

8.5P

8.6P

8.7P

8.8P

8.9P

8.01P

8.11P

8.21P

5.4PJ

Connections

14-1PC

74-1PC

14-2PC

74-2PC

14-3PC

74-3PC

14-4PC

74-4PC

14-5PC

74-5PC

14-6PC

74-6PC

14-7PC

74-7PC

14-8PC

74-8PC

14-9PC

74-9PC

14-01PC

74-01PC

14-11PC

74-11PC

14-21PC

74-21PC

55-1PC

94-1PC

55-2PC

94-2PC

55-3PC

94-3PC

55-4PC

94-4PC

55-5PC

94-5PC

55-6PC

94-6PC

55-7PC

94-7PC

55-8PC

94-8PC

55-9PC

94-9PC

55-01PC

94-01PC

55-11PC

94-11PC

55-21PC

94-21PC

+NAFCES

Used on Cable A only

–NAFCES

1 2 Section 61150090L1-5A, Issue 1 61150090L1-5A

Page 13

tkC

#kcaP#kcaP

#kcaP

#kcaP#kcaP

#niP&#niP&

#niP&

#niP&#niP&

daeLelbaC

redniBredniB

redniB

redniBredniB

roloCroloC

roloC

roloCroloC

riaP

##

#

##

piT

eriWeriW

eriW

eriWeriW

roloCroloC

roloC

roloCroloC

gniR

eriWeriW

eriW

eriWeriW

roloCroloC

roloC

roloCroloC

LSDH

ERHERH

ERH

ERHERH

LSDH

R-UTHR-UTH

R-UTH

R-UTHR-UTH

NDSI

R-RTR-RT

R-RT

R-RTR-RT

SDD

R-SDDRTR-SDDRT

R-SDDRT

R-SDDRTR-SDDRT

NDSI

R-eldirBR-eldirB

R-eldirB

R-eldirBR-eldirB

LSDH

DINFDINF

DINF

DINFDINF

51-5,1PC

31-7

74-14

94-55

1R-1T

1R-1T

R-T

R-T

eulB

eulB

egnarO

egnarO

1311

31

etihW

kcalB

etihW

kcalB

eulB

neerG

eulB

neerG

1pooL,tsuC

1pooL,kwtN

2pooL,kwtN

2pooL,tsuC

tsuCoT

1pooL,kwtN

2pooL,kwtN

tsuCmF

CN

CN

kwtN

1TN-tsuC

)XR(tsuCoT

CN

kwtNmF/oT

)XT(tsuCmF

tsuC

1pooL,kwtN

2pooL,kwtN

CN

tsuCoT

kwtN

CN

tsuCmF

51-5,2PC

31-7

74-14

94-55

1R-1T

1R-1T

R-T

R-T

eulB

eulB

egnarO

egnarO

2412

41

etihW

kcalB

etihW

kcalB

egnarO

nworB

egnarO

nworB

1pooL,tsuC

1pooL,kwtN

2pooL,kwtN

2pooL,tsuC

tsuCoT

1pooL,kwtN

2pooL,kwtN

tsuCmF

CN

CN

kwtN

1TN-tsuC

)XR(tsuCoT

CN

kwtNmF/oT

)XT(tsuCmF

tsuC

1pooL,kwtN

2pooL,kwtN

CN

tsuCoT

kwtN

CN

tsuCmF

51-5,3PC

31-7

74-14

94-55

1R-1T

1R-1T

R-T

R-T

eulB

eulB

egnarO

egnarO

3513

51

etihW

kcalB

etihW

kcalB

neerG

etalS

neerG

etalS

1pooL,tsuC

1pooL,kwtN

2pooL,kwtN

2pooL,tsuC

tsuCoT

1pooL,kwtN

2pooL,kwtN

tsuCmF

CN

CN

kwtN

1TN-tsuC

)XR(tsuCoT

CN

kwtNmF/oT

)XT(tsuCmF

tsuC

1pooL,kwtN

2pooL,kwtN

CN

tsuCoT

kwtN

CN

tsuCmF

51-5,4PC

31-7

74-14

94-55

1R-1T

1R-1T

R-T

R-T

eulB

eulB

egnarO

egnarO

4614

61

etihW

wolleY

etihW

wolleY

nworB

eulB

nworB

eulB

1pooL,tsuC

1pooL,kwtN

2pooL,kwtN

2pooL,tsuC

tsuCoT

1pooL,kwtN

2pooL,kwtN

tsuCmF

CN

CN

kwtN

1TN-tsuC

)XR(tsuCoT

CN

kwtNmF/oT

)XT(tsuCmF

tsuC

1pooL,kwtN

2pooL,kwtN

CN

tsuCoT

kwtN

CN

tsuCmF

51-5,5PC

31-7

74-14

94-55

1R-1T

1R-1T

R-T

R-T

eulB

eulB

egnarO

egnarO

5715

71

etihW

wolleY

etihW

wolleY

etalS

egnarO

etalS

egnarO

1pooL,tsuC

1pooL,kwtN

2pooL,kwtN

2pooL,tsuC

tsuCoT

1pooL,kwtN

2pooL,kwtN

tsuCmF

CN

CN

kwtN

1TN-tsuC

)XR(tsuCoT

CN

kwtNmF/oT

)XT(tsuCmF

tsuC

1pooL,kwtN

2pooL,kwtN

CN

tsuCoT

kwtN

CN

tsuCmF

51-5,6PC

31-7

74-14

94-55

1R-1T

1R-1T

R-T

R-T

eulB

eulB

egnarO

egnarO

6816

81

deR

wolleY

deR

wolleY

eulB

neerG

eulB

neerG

1pooL,tsuC

1pooL,kwtN

2pooL,kwtN

2pooL,tsuC

tsuCoT

1pooL,kwtN

2pooL,kwtN

tsuCmF

CN

CN

kwtN

1TN-tsuC

)XR(tsuCoT

CN

kwtNmF/oT

)XT(tsuCmF

tsuC

1pooL,kwtN

2pooL,kwtN

CN

tsuCoT

kwtN

CN

tsuCmF

51-5,7PC

31-7

74-14

94-55

1R-1T

1R-1T

R-T

R-T

eulB

eulB

egnarO

egnarO

7917

91

deR

wolleY

deR

wolleY

egnarO

nworB

egnarO

nworB

1pooL,tsuC

1pooL,kwtN

2pooL,kwtN

2pooL,tsuC

tsuCoT

1pooL,kwtN

2pooL,kwtN

tsuCmF

CN

CN

kwtN

1TN-tsuC

)XR(tsuCoT

CN

kwtNmF/oT

)XT(tsuCmF

tsuC

1pooL,kwtN

2pooL,kwtN

CN

tsuCoT

kwtN

CN

tsuCmF

Table 6A. Circuit Technology Configuration Chart (Part 1)

61150090L1-5A Section 61150090L1-5A, Issue 1 13

Page 14

#kcaP

#niPdna#niPdna

#niPdna

#niPdna#niPdna

daeLelbaC

redniBredniB

redniB

redniBredniB

roloCroloC

roloC

roloCroloC

riaP

##

#

##

piT

eriWeriW

eriW

eriWeriW

roloCroloC

roloC

roloCroloC

gniR

eriWeriW

eriW

eriWeriW

roloCroloC

roloC

roloCroloC

LSDH

ERHERH

ERH

ERHERH

LSDH

R-UTHR-UTH

R-UTH

R-UTHR-UTH

NDSI

R-RTR-RT

R-RT

R-RTR-RT

SDD

R-SDDRTR-SDDRT

R-SDDRT

R-SDDRTR-SDDRT

NDSI

R-eldirBR-eldirB

R-eldirB

R-eldirBR-eldirB

LSDH

DINFDINF

DINF

DINFDINF

51-5,8PC

31-7

74-14

94-55

1R-1T

1R-1T

R-T

R-T

eulB

eulB

egnarO

egnarO

8028

02

deR

wolleY

deR

wolleY

neerG

etalS

neerG

etalS

1pooL,tsuC

1pooL,kwtN

2pooL,kwtN

2pooL,tsuC

tsuCoT

1pooL,kwtN

2pooL,kwtN

tsuCmF

CN

CN

kwtN

1TN-tsuC

)XR(tsuCoT

CN

kwtNmF/oT

)XT(tsuCmF

tsuC

1pooL,kwtN

2pooL,kwtN

CN

tsuCoT

kwtN

CN

tsuCmF

51-5,9PC

31-7

74-14

94-55

1R-1T

1R-1T

R-T

R-T

eulB

eulB

egnarO

egnarO

9129

12

deR

teloiV

deR

teloiV

nworB

eulB

nworB

eulB

1pooL,tsuC

1pooL,kwtN

2pooL,kwtN

2pooL,tsuC

tsuCoT

1pooL,kwtN

2pooL,kwtN

tsuCmF

CN

CN

kwtN

1TN-tsuC

)XR(tsuCoT

CN

kwtNmF/oT

)XT(tsuCmF

tsuC

1pooL,kwtN

2pooL,kwtN

CN

tsuCoT

kwtN

CN

tsuCmF

51-5,01PC

31-7

74-14

94-55

1R-1T

1R-1T

R-T

R-T

eulB

eulB

egnarO

egnarO

012201

22

deR

teloiV

deR

teloiV

etalS

egnarO

etalS

egnarO

1pooL,tsuC

1pooL,kwtN

2pooL,kwtN

2pooL,tsuC

tsuCoT

1pooL,kwtN

2pooL,kwtN

tsuCmF

CN

CN

kwtN

1TN-tsuC

)XR(tsuCoT

CN

kwtNmF/oT

)XT(tsuCmF

tsuC

1pooL,kwtN

2pooL,kwtN

CN

tsuCoT

kwtN

CN

tsuCmF

51-5,11PC

31-7

74-14

94-55

1R-1T

1R-1T

R-T

R-T

eulB

eulB

egnarO

egnarO

113211

32

kcalB

teloiV

kcalB

teloiV

eulB

neerg

eulB

neerG

1pooL,tsuC

1pooL,kwtN

2pooL,kwtN

2pooL,tsuC

tsuCoT

1pooL,kwtN

2pooL,kwtN

tsuCmF

CN

CN

kwtN

1TN-tsuC

)XR(tsuCoT

CN

kwtNmF/oT

)XT(tsuCmF

tsuC

1pooL,kwtN

2pooL,kwtN

CN

tsuCoT

kwtN

CN

tsuCmF

51-5,21PC

31-7

74-14

94-55

1R-1T

1R-1T

R-T

R-T

eulB

eulB

egnarO

egnarO

214221

42

kcalB

teloiV

kcalB

teloiV

egnarO

nworB

egnarO

nworB

1pooL,tsuC

1pooL,kwtN

2pooL,kwtN

2pooL,tsuC

tsuCoT

1pooL,kwtN

2pooL,kwtN

tsuCmF

CN

CN

kwtN

1TN-tsuC

)XR(tsuCoT

CN

kwtNmF/oT

)XT(tsuCmF

tsuC

1pooL,kwtN

2pooL,kwtN

CN

tsuCoT

kwtN

CN

tsuCmF

noitcnuFdaeL

elbaC

redniBredniB

redniB

redniBredniB

roloCroloC

roloC

roloCroloC

riaP

##

#

##

piT

eriWeriW

eriW

eriWeriW

roloCroloC

roloC

roloCroloC

gniR

eriWeriW

eriW

eriWeriW

roloCroloC

roloC

roloCroloC

:SETON

.flehsehtedisnirebmunkcaptiucricehtsi#PC.1

.detcennoCtoN=CN.2

.dnuorGsirotcennocegdedrachcaefo11niP.3

.pudliubtaehtneverpotlanoitcnufebtsumsnaF.4

.metsysgniloocnafrotinomdnarewopotderiuqersiUPFdellatsniOCehT.5

.yletarapesdesahcrupsitinUgnirewoPnaFehT.6

.sdraobnafhtobdnaflehs004Tpotehtotstcennoc"A"elbaC.7

.flehs004Tmottobehtotstcennoc"B"elbaC.8

.hcaestols21evahsevlehs004TowtehT.9

.draobrotserraegrusnwostisahflehshcaE.01

.noitamrofniremotsucdrocerottnemucodsihtfodneehtta8elbaTesU.11

naFyramirP

/soP

geN

eulB52teloiVetalS

"A"elbaC

ylnO

yradnoceS

naF

/soP

geN

egnarO52teloiVetalS

"A"elbaC

ylnO

sriaPerapS

eulB

eulB

egnarO

egnarO

1#PS

2#PS

1#PS

2#PS

etihW

etihW

etihW

etihW

deR

kcalB

deR

kcalB

1 4 Section 61150090L1-5A, Issue 1 61150090L1-5A

Table 6B. Circuit Technology Configuration Chart (Part 2)

Page 15

3. TESTING General

Each test identifies a particular malfunction. For that

reason associated components used to isolate a

malfunction are assumed to be functioning correctly.

Certain troubleshooting requires personnel at both the

Central Office to monitor the FPU, and field personnel

at the cabinet to determine if a fault condition exists.

Refer to Figure 13 to identify fan board component

locations.

Fan Board Indication

Each fan board has two status indicator lights:

• DOOR (Red) LED (Power and Door Alarm

indication)

• FAN (Green) LED (Thermostat position)

Door Switch

Front and rear door switches are identical. The

following description applies to both. The door switch

responds to three conditions:

• Door closed

• Door open

• Manual override

When the door is closed the switch contacts are closed

allowing power to the fan.

When the door is opened the switch contacts open

securing power to the fan. Board circuitry recognizes

the condition and sends a door open “intrusion

notification” alarm to the FPU at the CO, and also

turns the door LED On at the corresponding fan

board.

Manual override is electrically identical to the door

closed condition.

During cabinet maintenance the manual override (or

closing the door) resets the alarm at the FPU.

Indication that the alarm has reset is by the

corresponding door LED turning Off.

Verify Power at the Fan Boards

Power is present at the corresponding fan board if the

red Door LED comes On when the door is opened.

Verify that the primary fan board is receiving power:

1. Push-in and release the rear door switch.

2. If the primary fan board Door LED goes On, the

primary fan board has power. At the CO the

FPU Door Alarm LED will turn red.

3. Disable the rear door switch by centering the rod

and pulling outward. The primary fan board

Door LED should go Off and the Door Alarm

LED at the FPU will turn green.

Verify that the secondary fan board is receiving

power:

1. Push-in and release the front door switch.

2. If the secondary fan board Door LED turns On,

the secondary fan board has power. At the CO

the FPU Door Alarm LED will turn red.

To Rear

Door Switch

JP2

Pimary

Fan Board

to Cable A

Rear

Door LED

Fan LED

(thermostat)

Thermostat

JP4

JP1

Thermostat

Secondary

Fan Board

to Cable A

Fan LED

(thermostat)

Front

Door LED

JP2

To Front

Door Switch

Figure 13. Primary & Secondary Fan Boards

61150090L1-5A Section 61150090L1-5A, Issue 1 15

Page 16

3. Disable the front door switch by centering the

rod and pulling outward. The secondary fan

board Door LED should go Off and the Door

Alarm LED at the FPU will turn green.

Fan Operation

When the cabinet is initially installed without heat

generating circuit packs, the primary and secondary

fans will not automatically turn On. Fan board

thermostats control the On/Off fan cycle when the

interior temperature reaches the thermostat’s set

points.

• The primary thermostat Closes at about 110° F

increasing and Opens at about 80° F decreasing.

• The secondary thermostat Closes at about 150° F

increasing and Opens at about 120° F

decreasing.

• Thermostat set points may vary slightly from

stated temperatures.

When the primary and secondary fan boards are

initially wired and connected to the Central Office

FPU, both the primary and secondary fan board

thermostat (Green) LEDs should be On and the fans

should be Off. This indicates that both of the fan

board thermostats are Open.

If the thermostat was Closed, the thermostat LED

would be Off and the fans would be On (if the

temperature was within the thermostat’s Closed

operating range). The thermostat LED’s operation is

independent of the door switch status.

Verify Proper Connections

Test to ensure that changes to the primary fan board

will cause changes to the associated LEDs at the

Central Office FPU:

NOTE

This test specifies the rear door/primary fan

board. Test the front door/secondary fan

board by conducting a similar process.

1. Disable the rear door switch by centering the rod

and pulling outward. The primary fan board

Door LED should go Off.

WARNING

High voltages are present on exposed pins.

DO NOT contact exposed surfaces.

2. On the primary fan board, disconnect the JP1

connector by pulling the connector out of the

header. DO NOT PULL ON WIRES.

- At the Central Office FPU, the PRI FAN LED

will turn red (alarm condition). This verifies

the primary fan board connections are correct.

- If the PRI FAN LED at the FPU does not turn

red, the connections are incorrect.

- If the secondary FPU SEC FAN LED turns on

red, the circuits are crossed between the

cabinet and the FPU.

3. Align and reconnect the JP1 connector.

NOTE

If the primary and secondary fan powering

cable pairs are reversed at either the Central

Office or at the cabinet, the primary fan will

still go On at 110

° F but the Central Office

FPU will indicate that the SEC FAN is

running. This is an ALARM condition at the

FPU.

Abnormal Condition Turning the Secondary

Fan On

Any condition that causes the secondary fan to turn

On is considered abnormal. The following conditions

will allow heat buildup causing the secondary fan

thermostat to eventually Close:

• The primary fan cannot keep up with heat load.

• The primary fan or fan board is not functioning.

• The circuitry between the FPU and the primary

fan board has opened, shorted, or otherwise

malfunctioned.

• The FPU at the CO is not providing power to the

primary fan board.

• Additionally, the secondary fan thermostat may

not be operating properly.

Fan Board Troubleshooting

If troubleshooting a fan board malfunction, fan board

operation should be examined during the hottest time

of the day before the outside temperature drops.

The cabinet internal temperature may stabilize slowly

or quickly depending on the outside air temperature,

wind conditions, exposure to the sun, shading during a

particular time of day, and also the number of circuits

installed inside the cabinet.

1 6 Section 61150090L1-5A, Issue 1 61150090L1-5A

Page 17

If the cabinet has been opened during the day allowing

the heat to escape before proper troubleshooting tests

could be conducted, close the cabinet doors and allow

the cabinet internal temperature to restabilize.

Recheck during the hottest time of the following day

before the outside temperature has a chance to drop.

PRIMARY FAN BOARD

If the primary fan board is believed to be damaged,

check the following in the listed order immediately

upon opening the rear door:

• Power is present at the fan board. (Door LED

turns On as soon as the rear door is opened.) If

the door LED does not turn On, troubleshoot for

lack of power.

• Manually disable the rear door switch and check

the fan LED status:

- If the primary fan LED is Off, the primary fan

should be On.

- If the primary fan LED is On, the primary fan

should be Off.

• If either condition does not exist the primary fan

board is suspect and should be replaced.

SECONDARY FAN BOARD

If the secondary fan board is believed to be damaged,

check the following in the listed order immediately

upon opening the rear door:

• Power is present at the fan board. (Door LED

turns On as soon as the front door is opened.) If

the door LED does not turn On, troubleshoot for

lack of power.

• Manually disable the front door switch and

check the fan LED status:

- If the secondary fan LED is Off, the secondary

fan should be On.

- If the secondary fan LED is On, the secondary

fan should be Off.

• If either condition does not exist the secondary

fan board is suspect and should be replaced.

Open Loop/No Continuity

The primary or secondary Door LEDs will remain Off

when the rear or front door is opened if the respective

primary or secondary power loop has no continuity

(Open) between the cabinet and the FPU.

1. Verify the Central Office FPU is online.

2. Check the LED indication on the FPU.

3. If the FPU is sending power but the cabinet is

not receiving it, check the wiring connections at

both the cabinet and the FPU.

Shorted Loop

The primary or secondary Door LEDs will remain Off

when the rear or front doors are opened if the

respective primary or secondary fan powering loop

has a short across the tip/ring cable pair between the

cabinet and the Central Office FPU.

1. Verify the Central Office FPU is online.

2. Check the LED indication on the FPU.

3. If the FPU is sending power but the cabinet is

not receiving it, check the wiring connections at

both the cabinet and the FPU.

Door Switch Troubleshooting

Door switches can fail in either the Closed or Open

position. The next two procedures will identify the

particular failure. The procedure applies to both front

and rear door switches.

WARNING

High Voltages are present on exposed pins.

Do not contact exposed surfaces.

Door Switch Failure-Closed

1. Verify with the CO that the FPU is online.

2. Push in and release the door switch.

3. If the Door LED is On, the door switch is not

defective.

4. If the Door LED stays Off, regardless of the

door switch position, proceed with Step 5.

5. Disconnect the JP2 door switch connector on the

fan board by carefully pulling the connector off

the header. DO NOT PULL ON WIRES.

6 If the Door LED turns On, the corresponding

door switch is defective.

7. Follow the door switch replacement instructions

to replace the defective door switch.

Door Switch Failure-Open

1. Verify with the CO that the FPU is online.

2. Push in and release the door switch. The Door

LED should go On.

3. Manually disable the door switch by centering

the rod and pulling outward.

4. The Door LED should go Off.

5. If the Door LED stays On regardless of switch

position, proceed with Step 6.

61150090L1-5A Section 61150090L1-5A, Issue 1 17

Page 18

6. Disconnect the door switch JP2 connector on the

Typical removal

or replacement

shown.

fan board by carefully pulling the connector off

the header. DO NOT PULL ON WIRES.

7. Take an insulated ball-clip or alligator-clip and

short across the two exposed door switch JP2

connector pins at the fan board.

8. If the Door LED goes Off, the door switch is

defective.

9. Follow the door switch replacement Instructions

to replace the defective door switch.

NOTE

Refer to the Fan Powering Unit I&M Practice:

61150091L1-5, for additional details on the

FPU.

4. MAINTENANCE

Maintenance consists of replacement of surge arrester

gas tubes, door gaskets, or other replaceable items.

Fan board repairs should not be attempted in the field.

Repair services are obtained by returning the defective

unit to ADTRAN Customer Service.

Surge Arrester Replacement

Each slot in the T200/T400 shelf has four associated

surge arrestor gas tubes (Figure 14) for surge

protection. Surge protection is provided by

replaceable gas surge arrestor tubes. Perform the

following procedure to replace gas tubes:

WARNING

Prevent electrical shock during maintenance

by removing the appropriate slot powering

modules and tagging out to prevent

inadvertent insertion.

1. At the CO, remove the appropriate power

module to deenergize the associated slot at the

cabinet.

2. Grasp one gas tube and remove it using the gas

tube pliers supplied with the cabinet, see

Figure 15.

3. Insert a replacement gas tube in the same

position.

Refer to Table 7 for a list of replacement item part

numbers.

Table 7. Replacement Item Part Numbers

noitpircseDrebmuNtraP

gaB.zO8,tnacciseD1008613

sebuTsaG1006813

looTtcartxE/tresnIebuTsaG2409623

draoBnaFyramirP5-0900512

draoBnaFyradnoceS6-0900512

tiKtnuoMdaP8-0900512

tiKtnuoMeloP9-0900512

)"62.1-68.0(tiKtnuoMbutSelbaC51-0900512

tiKriapeRteksaGrooD61-0900512

tiKriapeRhctiwSrooD71-0900512

Desiccant Renewal

Each cabinet is shipped with two moisture absorbing

desiccant bags inside the cabinet. To ensure continued

moisture absorption the desiccant must be renewed

periodically, depending on the environment.

P12

P11

Slot 12,

Gas T ubes

Slot 12,

Connection

to Cable

P10

P9

P7

P8

P6

Slot 1,

Connection

to Cable

P5

P4

Figure 14. Surge Arrestor Board

Figure 15. Surge Arrestor Gas Tube

Replacement

P3

P2

P1

Slot 1,

Gas T ubes

1 8 Section 61150090L1-5A, Issue 1 61150090L1-5A

Page 19

4. Replace the remaining gas tubes in the same

manner. Each slot has four gas tubes.

5. Untag and reinsert the associated slot power

module at the CO.

6. Perform circuit tests to verify proper circuit

operation.

WARNING

Provide adequate ventilation when using

sealant. Do not inhale vapors. Avoid contact

with the skin. Follow all sealant

manufacturers instructions.

NOTE

If lightning is the suspected cause of circuit

pack failure, ADTRAN recommends

replacing all the surge arrestor gas tubes.

Door Gasket Replacement

The door gasket provides a weathertight seal. Routine

preventive maintenance includes cleaning the seal and

seal area when the cabinet door is opened. A

deteriorated or damaged gasket should be replaced

using the following procedure:

WARNING

Follow all manufacturers safety precautions,

directions, and other label warnings or

information when using gasket sealing

compound. Follow all application directions

to ensure a proper seal.

1. Remove damaged door gasket.

2. Thoroughly clean the gasket sealing area on the

door and the gasket flange using a soap solution.

Rinse and dry. Do not use solvents or chemical

agents that could damage the surface finish.

3. Install the replacement gasket to the gasket

flange with the joining ends at the bottom center

of the flange. Note that the replacement gasket

has vent holes. Install the gasket such that the

vent holes are on the cabinet interior side of the

gasket mounting flange.

4. Totally install the gasket to determine proper

circumference fit. If a small gap appears at the

joining ends the gasket can be slightly stretched

starting at the top and working towards the

bottom. Reverse this process if an overlap exists.

Continue this manipulation until the gasket ends

fit flush.

5. Where the gasket joins, on each side pull about 6

inches of gasket away from the flange.

6. An insert gasket “rope” provides a bonding

medium, gasket support, and end alignment.

CAUTION

The alignment rope is sized to fit equally

between the two ends of the gasket without

blocking the vent holes. During assembly keep

the rope equally positioned between the two

gasket ends.

Apply a small amount of sealant around one end

of the rope and slide it halfway into the gasket

core (either end).

CAUTION

Excessive sealant will decrease adhesion and

cause longer cure time. Inadequate sealant

will cause gaps allowing moisture penetration.

7. Apply a thin bead of sealant on the gasket

mating end. A proper seal requires a complete

sealant bead without breaks.

8. Carefully mate the two ends allowing the

alignment rope to slide into the gasket core on

the adjoining end until the two gasket ends meet

as seamless as possible. A small amount of

sealant should extrude around the mating edges.

9. Immediately install the gasket onto the flange to

maintain alignment and positive end contact.

Hold the gasket in this position for 2 minutes (or

manufacturer’s directions).

10.Inspect the gasket joint. If any sealant gaps are

visible a thin coat of sealant can be applied to fill

the gap.

11.Follow the sealant manufacture’s directions for

cure time (about 6 to 8 hours or until surface is

not tacky).

12.Do not close the door until the joint is totally

cured. This prevents the door from sticking to

the gasket on the next opening.

To ensure cabinet integrity it is important that the

joined surface that contacts the door when it is shut be

free of irregularities.

61150090L1-5A Section 61150090L1-5A, Issue 1 19

Page 20

Door Switch Replacement

The door switch can be replaced in the field if it is

damaged or becomes defective.

WARNING

High Voltages are present on exposed pins.

Do not contact exposed surfaces.

The following procedure applies to either the front or

rear door switch (Figure 16):

1. On the affected switch trace the wires to the fan

board JP2 connector. Disconnect by pulling the

connector out of the header. DO NOT PULL ON

WIRES.

2. Remove the two slide-on terminal connectors on

the switch by grasping the heat-shrink insulation

and sliding away from the switch. DO NOT

PULL ON WIRES.

3. Remove the two Phillips head screws that secure

the switch to the cabinet flange and remove the

switch.

4. On the replacement switch, identify the COM

(common) and NO (normally open) terminals.

5. Position and correctly orient the replacement

switch then insert and tighten the two Phillips

head screws.

6. Note that one slide-on connector has notched

insulation. Slide that connector onto the COM

terminal such that the notched side is against the

switch.

Phillips head screws

COM

7. Slide the remaining connector onto the NO

terminal.

8. At the other end insert the connector into the fan

board JP2 header.

9. Conduct a functional test to verify proper door

switch operation.

Customer Identification

To easily identify the customer and record circuit

information, Table 8 is provided for placement in the

plastic holder inside the front door of the cabinet. The

Table can be updated when circuits are connected or

changed.

5. WARRANTY AND CUSTOMER SERVICE

ADTRAN will replace or repair this product within

five years from the date of shipment if it does not

meet its published specifications or fails while in

service (see: ADTRAN Carrier Network Equipment

Warranty, Repair, and Return Policy and Procedure,

document: 60000087-10A).

Contact Customer And Product Service (CAPS) prior

to returning equipment to ADTRAN.

For service, CAPS requests, or further information,

contact one of the following numbers:

ADTRAN Technical Support

(800) 726-8663

Standard hours: Monday-Friday, 7 a.m.-7 p.m. CST

Emergency hours: 7 days/week, 24 hours/day

ADTRAN Sales

(800) 827-0807

ADTRAN Repair/CAPS

(256) 963-8722

Repair and Return Address

ADTRAN, Inc.

CAPS Department

901 Explorer Boulevard

Huntsville, Alabama 35806-2807.

NO

View from inside cabinet

Figure 16. Door Switch

2 0 Section 61150090L1-5A, Issue 1 61150090L1-5A

Page 21

Table 8. Customer & Circuit Information

flehSpoT

#tolS#tolS

#tolS#tolS

#tolS

emaNremotsuC.D.ItiucriCetuoRmetsyS#metsySepyTtiucriC

1

2

3

4

5

6

7

8

9

01

11

21

flehSmottoB

#tolS#tolS

#tolS#tolS

#tolS

emaNremotsuC.D.ItiucriCetuoRmetsyS#metsySepyTtiucriC

1

2

3

4

5

6

7

8

9

01

11

21

:SETON

61150090L1-5A Section 61150090L1-5A, Issue 1 21

Loading...

Loading...