Smart 16e Shelf

with embedded SNMP

USER MANUAL

4200023L5 AC Version

4200023L6 DC Version

61200.162L1-1A

January 1997

901 Explorer Boulevard

P.O. Box 140000

Huntsville, AL 35814-4000

Phone: (205) 963-8000

© 1997 ADTRAN, Inc.

All rights reserved.

Printed in USA.

FCC regulations require that the following information be provided in this manual:

1. This equipment complies with Part 68 of the FCC rules. On the bottom of the

equipment housing is a label that shows the FCC registration number and Ringer

Equivalence Number (REN) for this equipment. If requested, provide this

information to the telephone company (REN is not required for some types of

analog or digital facilities).

2. If this equipment causes harm to the telephone network, the telephone company may

temporarily discontinue service. If possible, advance notification is given;

otherwise, notification is given as soon as possible. The telephone company will

advise the customer of the right to file a complaint with the FCC.

3. The telephone company may make changes in its facilities, equipment, operations,

or procedures that could affect the proper operation of this equipment; advance

notification and the opportunity to maintain uninterrupted service are given.

4. If experiencing difficulty with this equipment, please contact ADTRAN for repair

and warranty information. The telephone company may require this equipment to

be disconnected from the network until the problem is corrected or it is certain the

equipment is not malfunctioning.

5. This unit contains no user serviceable parts.

6. An FCC compliant telephone cord with a modular plug is provided with this

equipment. In addition, an FCC compliant cable appropriate for the dial backup

option ordered is provided with this equipment. This equipment is designed to be

connected to the telephone network or premises wiring using an FCC compatible

modular jack, which is Part 68 compliant.

7. The following information may be required when applying to the local telephone

company for leased line facilities:

Service Digital Facility Service Order Network

Type Interface Code Code Jacks

2.4 kbps Digital Interface 04DU5-24 6.0F RJ-48S

4.8 kbps Digital Interface 04DU5-48 6.0F RJ-48S

9.6 kbps Digital Interface 04DU5-96 6.0F RJ-48S

19.2 kbps Digital Interface 04DU5-19 6.0F RJ-48S

38.4 kbps Digital Interface 04DU5-38 6.0F RJ-48S

56 kbps Digital Interface 04DU5-56 6.0F RJ-48S

64 kbps Digital Interface 04DU5-64 6.0F RJ-48S

8. In the event of equipment malfunction, all repairs should be performed by

ADTRAN. It is the responsibility of users requiring service to report the need for

service to their distributor or ADTRAN. See the last page of this manual for

information on contacting ADTRAN for service.

Federal Canadian Emissions Requirements

Radio Frequency Interference Statement

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful interference to radio frequencies.

Operation of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense.

Shielded cables must be used with this unit to ensure compliance with Class A FCC limits.

Change or modifications to this unit not expressly approved

by the party responsible for compliance could void the user's

authority to operate the equipment.

CANADIAN EMISSIONS REQUIREMENTS

This digital apparatus does not exceed the Class A limits for radio noise

emissions from digital apparatus as set out in the interference-causing

equipment standard entitled "Digital Apparatus," ICES-003 of the Department of Communications.

Cet appareil nuerique respecte les limites de bruits radioelectriques

applicables aux appareils numeriques de Class A prescrites dans la norme

sur le materiel brouilleur: "Appareils Numeriques," NMB-003 edictee par le

ministre des Communications.

CANADIAN EQUIPMENT LIMITATIONS

Notice: The Canadian Industry and Science Canada label identifies certified

equipment. This certification means that the equipment meets certain telecommunications network protective, operational, and safety requirements.

The Department does not guarantee the equipment will operate to the user's

satisfaction.

Before installing this equipment, users should ensure that it is permissible to

be connected to the facilities of the local telecommunications company. The

equipment must also be installed using an acceptable method of connection.

In some cases, the company's inside wiring associated with a single line

individual service may be extended by means of a certified connector assembly (telephone extension cord). The customer should be aware that compliance with the above conditions may not prevent degradation of service in

some situations.

Repairs to certified equipment should be made by an authorized Canadian

maintenance facility designated by the supplier. Any repairs or alterations

made by the user to this equipment, or equipment malfunctions, may give the

telecommunications company cause to request the user to disconnect the

equipment.

Users should ensure for their own protection that the electrical ground

connections of the power utility, telephone lines and internal metallic water

pipe system, if present, are connected together. This precaution may be

particularly important in rural areas.

Users should not attempt to make such connections themselves, but should contact the appropriate electric inspection

authority, or an electrician, as appropriate.

The Load Number (LN) assigned to each terminal device denotes the percentage of the total load to be connected to a telephone loop which is used by the

device, to prevent overloading. The termination on a loop may consist of any

combination of devices subject only to the requirement that the total of the

Load Numbers of all devices does not exceed 100.

Table of Contents

Table of Contents

Table of Contents

Chapter 1. Introduction

About This Manual............................................................................................1

Product Overview .............................................................................................1

Warranty and Customer Service......................................................................3

Chapter 2. Installation

Unpack, Inspect, Power Up..............................................................................5

Receiving Inspection .................................................................................. 5

Equipment Included .................................................................................. 5

Customer Provides..................................................................................... 6

Power Up ..................................................................................................... 6

Installation into Cabinet or Rack .....................................................................7

Installation of Power Supplies .........................................................................7

Installation of Controller Card.........................................................................8

Connecting Input Devices to the Controller Card................................. 9

DATAMATE Connection................................................................. 10

Ethernet Connection ......................................................................... 10

VT 100, Modem, SLIP, or Async PPP Connection........................ 10

Multi-Shelf Connection (Daisy Chaining) ..................................... 11

Alarm Connections ........................................................................... 11

Fuses.................................................................................................... 11

AC/DC Power ................................................................................... 12

Chapter 3. Operation

Local Operation................................................................................................17

VT 100 Terminal ....................................................................................... 17

Operation............................................................................................ 17

Connection ......................................................................................... 17

Jumper and Switch Settings............................................................. 19

Main Menu ......................................................................................... 20

Select Unit Menu ............................................................................... 22

Alarm Menu ....................................................................................... 24

Utilities Menu .................................................................................... 25

Factory Reset Menu .......................................................................... 27

DATAMATE ............................................................................................. 27

Manual Operation and Button Functions...................................... 29

Remote Operation............................................................................................32

61200.162L1-1 Smart 16e Shelf User Manual i

Table of Contents

Operation with a Network Manager

Using the SLIP, Async PPP, or Ethernet Interface .......................................34

Configure Network Interface Using a VT 100 Terminal ............................34

Using Telnet ......................................................................................................35

Multi-Shelf Operation (Daisy Chaining) ......................................................36

Interpreting Alarms and Error Messages ............................................. 39

Clearing DBU Alarms .............................................................................. 41

Appendix A. Specifications ......................................................................... 43

Index.................................................................................................................. 47

List of Tables

Table 2-A Input Device Type Switch Settings ............................................9

Table 2-B Baud Rate Switch Settings .......................................................... 9

Table 2-C Pin Assignments for EIA-232 Connector ................................13

Table 2-D Pin Assignments for CTRL IN and CTRL OUT Connectors 13

Table 3-A Switch 1 Shelf Numbering Settings .........................................38

Table 3-B Controller Card Error Messages ..............................................39

Table 3-C LED Alarm Messages ................................................................ 41

List of Figures

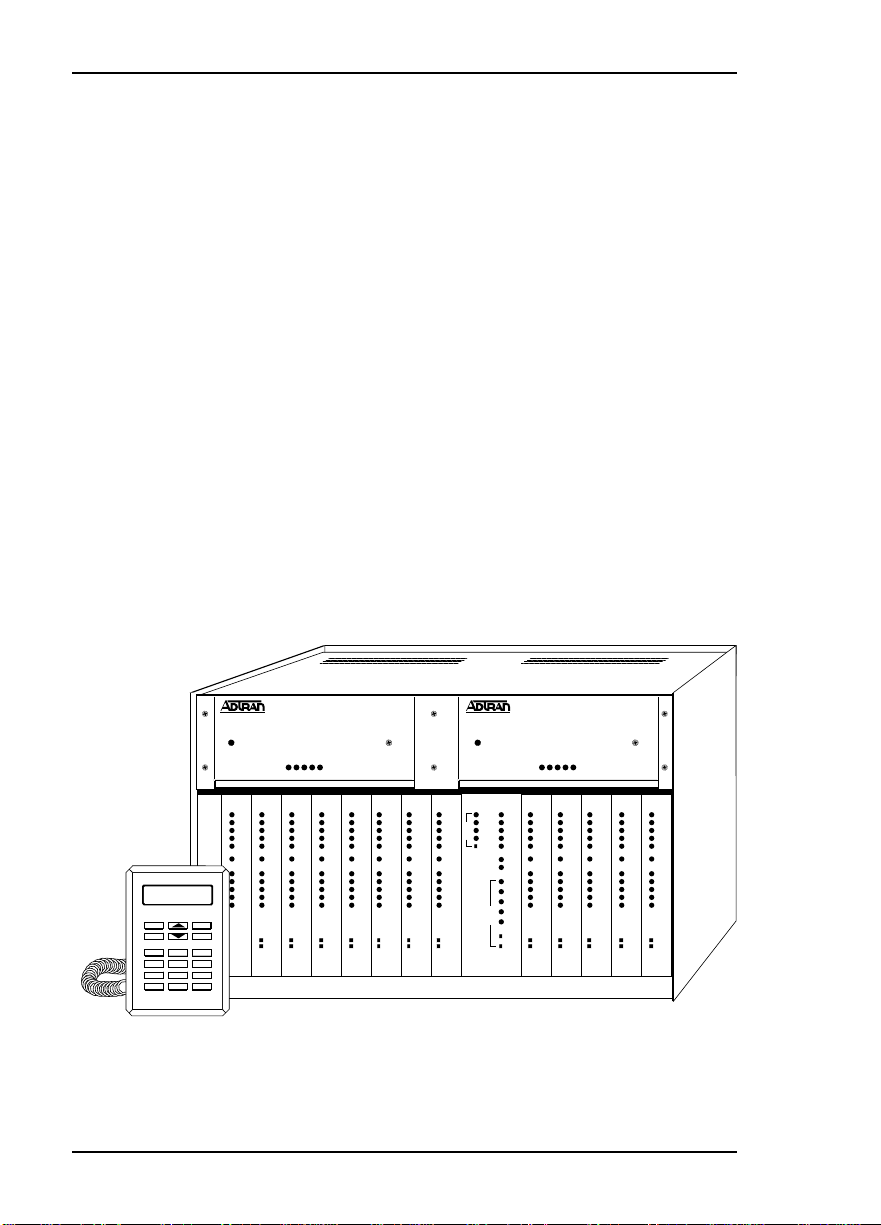

Figure 1-1 Smart 16e Shelf ............................................................................. 2

Figure 2-1 Rear AC Power/Control Segment...........................................14

Figure 2-2 Rear DC Power/Control Segment...........................................15

Figure 3-1 Local Configuration ...................................................................18

Figure 3-2 Jumper and Switch Locations ..................................................19

Figure 3-3 Main Menu.................................................................................. 21

Figure 3-4 Select Unit Menu with Enhanced Select Disabled ................22

Figure 3-5 Select Unit Menu with Enhanced Select Enabled..................23

Figure 3-6 Alarm Menu................................................................................ 24

Figure 3-7 Utilities Menu .............................................................................25

Figure 3-8 Factory Reset Menu ................................................................... 27

Figure 3-9 DATAMATE................................................................................ 29

Figure 3-10 DATAMATE Utility Menu ........................................................ 31

Figure 3-11 Remote Configuration ...............................................................33

Figure 3-12 Controller Configuration Switch Positions ............................36

Figure 3-13 Multi-Shelf Application.............................................................37

Figure 3-14 Controller Card Front Panel ..................................................... 40

ii Smart 16e Shelf User Manual 61200.162L1-1

ABOUT THIS MANUAL

This manual provides the information needed for the

installation and operation of the Smart 16e Shelf (see

Figure 1-1). Operation instructions for the data communication devices used with the shelf are provided

in the manuals furnished with those products.

PRODUCT OVERVIEW

The ADTRAN Smart 16e Shelf provides convenient

mounting for up to 16 data communication devices for

large host-type applications. The shelf can be mounted

in either 19" or 23" racks and cabinets by using a set of

brackets mounted alongside the shelf.

Chapter 1. Introduction

Chapter 1

Introduction

The Smart 16e Shelf has an intelligent Controller card

designed to configure and control all devices in the

local shelf. SNMP management is available for all

Smart 16e devices via the embedded SNMP agent. For

larger applications, the Controller can access up to 15

additional shelves by daisy-chaining the control ports.

There are five choices of input devices for the Controller card:

• A VT 100 compatible terminal which can be connected to the EIA-232 interface, located on the rear

panel of the Controller card. For remote applications, a modem can be used.

61200.162L1-1 Smart 16e Shelf User Manual 1

Chapter 1. Introduction

• The optional DATAMATE, a hand-held keypad with

a 2 x 16 LCD display. This unit plugs into the RJ-11

jack on the front of the Controller card.

• A device running SLIP protocol. A SLIP interface

(the EIA-232 interface) is located on the rear panel of

the Controller card. For remote applications, a

modem can be used.

• A device running async PPP protocol. An async PPP

interface (the EIA-232 interface) is located on the

rear panel of the Controller card. For remote

applications, a modem can be used.

• A LAN running ethernet protocol. An ethernet

10baseT interface is located on the rear panel of the

Controller card.

The shelf and all installed units are internally powered

by an AC or DC supply. An optional second power

supply can be used for backup protection.

POWER SUPPLY POWER SUPPLY

+5V

+12V

-12V

-5V

CHECK

DSU III AR DSU III AR DSU III AR DSU III AR DSU III S4W DSU III S4W DSU III S4W DSU III S4W DSU III DBU

SHELF

CONTROLLER

DATAMATE

ENTER

CANCEL

ABC

123

DEF

456

7*89

QUICKSHIFT

#

0

1 1623456789101112131415

RS

RS

CS

TD

RD

CD

ALM

DTE

LOOP

RDL

PTRN

ERROR

SELECT

TEST

RS

RS

RS

RS

CS

CS

TD

TD

RD

RD

CD

CD

ALM

ALM

DTE

DTE

LOOP

LOOP

RDL

RDL

PTRN

PTRN

ERROR

ERROR

SELECT

SELECT

TEST

TEST

RS

CS

CS

CS

CS

TD

TD

TD

TD

RD

RD

RD

RD

CD

CD

CD

CD

ALM

ALM

ALM

ALM

DTE

DTE

DTE

DTE

LOOP

LOOP

LOOP

LOOP

RDL

RDL

RDL

RDL

PTRN

PTRN

PTRN

PTRN

ERROR

ERROR

ERROR

ERROR

SELECT

SELECT

SELECT

SELECT

TEST

TEST

TEST

TEST

DSU III TDM

RS

1

CS

2

P

O

TD

3

R

T

RD

4

SELECT

CD

ALM

DTE

LOOP

RDL

PTRN

ERROR

SELECT

TEST

+5V

+12V

-12V

-5V

CHECK

DSU III DBU DSU S2W DSU S2W DSU S2W

RS

RS

RS

CS

CS

CS

TD

TD

TD

RD

RD

RD

CD

CD

CD

ALM

ALM

ALM

DBU

DTE

DTE

LOOP

LOOP

DTE

RDL

RDL

LOOP

PTRN

PTRN

RDL

ERROR

T

E

S

T

ERROR

PTRN

ERROR

SELECT

SELECT

SELECT

TEST

TEST

TEST

RS

RS

CS

TD

RD

CD

ALM

DTE

LOOP

RDL

PTRN

ERROR

SELECT

TEST

RS

CS

CS

TD

TD

RD

RD

CD

CD

ALM

ALM

DTE

DTE

LOOP

LOOP

RDL

RDL

PTRN

PTRN

ERROR

ERROR

SELECT

SELECT

TEST

TEST

Figure 1-1

Smart 16e Shelf

2 Smart 16e Shelf User Manual 61200.162L1-1

WARRANTY AND CUSTOMER SERVICE

ADTRAN will replace or repair this product within

five years from the date of shipment if it does not meet

its published specifications or fails while in service.

For detailed warranty, repair, and return information

refer to the ADTRAN Equipment Warranty and Repair

and Return Policy Procedure.

Return Material Authorization (RMA) is required

prior to returning equipment to ADTRAN.

For service, RMA requests, or further information,

contact one of the numbers listed on the last page of

this manual.

Chapter 1. Introduction

61200.162L1-1 Smart 16e Shelf User Manual 3

Chapter 1. Introduction

4 Smart 16e Shelf User Manual 61200.162L1-1

UNPACK, INSPECT, POWER UP

Receiving Inspection

Carefully inspect the Smart 16e Shelf for shipping

damage. If damage is suspected, file a claim immediately with the carrier and contact ADTRAN Customer

Service. If possible, keep the original shipping container to ship the shelf for repair or verify damage

during shipment.

Chapter 2. Installation

Chapter 2

Installation

Equipment Included

The following items are included in ADTRAN shipments of the Smart 16e Shelf:

• Smart 16e chassis

• Controller card

• Power supply (AC or DC)

• Blank power faceplate

• Rear panel segment for power input and Controller

operation

• Mounting brackets

• User manual

61200.162L1-1 Smart 16e Shelf User Manual 5

Chapter 2. Installation

Customer Provides

The customer must supply the following items:

• A PC capable of emulating VT 100 for configuring

• An EIA-232 cable for connection to the VT 100

• Optionally, a DATAMATE (part number 1200045L1)

• For SNMP access, a cable for connection to either the

The VT 100 interface is required for setting up the initial

network settings for SLIP, async PPP, or ethernet communications.

Power Up

devices installed in the Smart 16e Shelf.

interface.

which can be used for most shelf configuration.

Controller card's EIA-232 connector (for SLIP or PPP

async protocol) or the card's 10baseT interface (for

ethernet protocol).

The shelf and installed units are internally powered by

an AC or DC supply. An optional second power

supply can be used for redundant protection.

6 Smart 16e Shelf User Manual 61200.162L1-1

INSTALLATION INTO CABINET OR RACK

The set of brackets supplied with the Smart 16e Shelf

can be used for either 19" or 23" applications. For 19"

applications, the longer side of the bracket should be

flush with the side of the chassis. For 23" applications,

the short side of the bracket should be flush with the

side of the chassis.

There are two sets of mounting holes for the brackets

on the left and right sides of the Smart 16e Shelf. One

set positions the front of the Smart 16e Shelf in line

with the front of the rack. The other set extends the

front of the Smart 16e Shelf beyond the front of the

rack.

INSTALLATION OF POWER SUPPLIES

The power supply can be installed in either of the two

slots at the top of the Smart 16e Shelf. If only one

power supply is used, the blank power supply faceplate furnished with the rack should be installed over

the unused slot.

Chapter 2. Installation

The Smart 16e Shelf is fully operational with one

power supply; however, a second supply can be

added to provide backup for the power supply

subsystem. With the two-supply configuration, one of

the supplies will operate in a hot-standby mode (the

corresponding output on the standby supply will

automatically provide the power required if any one

of the four outputs from a supply fails or begins to

operate out of specifications).

The power supplies can be "hot swapped".

Slide the power supply along the card guides of one of

the top slots until it is fully seated in the connector and

the faceplate is flush with the chassis. Tighten the

screws on the front of the power supply panel.

61200.162L1-1 Smart 16e Shelf User Manual 7

Chapter 2. Installation

Each power supply has a green indicator for each of

the output voltages (+5V, -5V, +12V, and -12V) as well

as a red indicator to indicate an alarm condition.

Illumination of a green LED indicates that the corresponding voltage is operating properly. When operation of any one of the four voltages drops out of

specifications, the green LED for that voltage will go

out and the red LED will come on.

Only personnel familiar with installation and maintenance

of the Smart 16 Shelf should install or replace the power

supplies. A shock hazard could be present if an empty

power supply slot is left uncovered.

INSTALLATION OF CONTROLLER CARD

The Smart 16e Shelf has 17 vertical slots in the front

and rear of the chassis. The left-most front position is

reserved for the Smart 16e Shelf Controller card. All

other front slots can be used in any order for

rackmount cards. The PWR/CTRL rear segment

occupies the slot behind the Smart 16e Controller card.

All other rear slots are for DTE/Network Interface

Cards.

The rear segment is already installed. The Controller

card slides into the corresponding front slot until

contact is made with both the backplane connector

and the rear segment connector and the panel is flush

with the front of the chassis. The Controller card may

be inserted and removed while the Smart 16e Shelf is

receiving power.

The card can appear to be operational (i.e., receiving power)

and yet may not be completely connected. The rear segment

must be fully seated and the screws must be tight for proper

operation.

8 Smart 16e Shelf User Manual 61200.162L1-1

Chapter 2. Installation

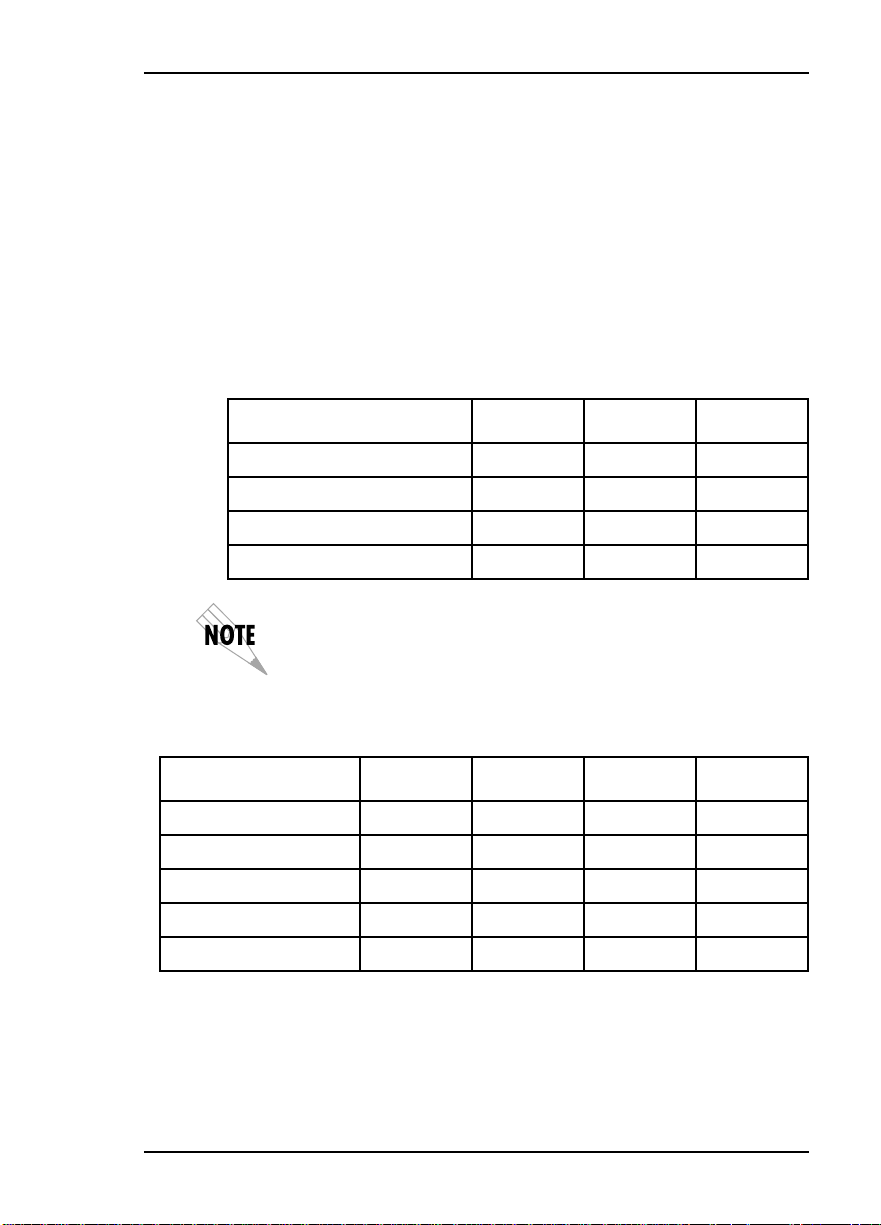

Connecting Input Devices to the Controller Card

There are five choices of input devices for the Smart

16e Controller card: a VT 100 terminal, the optional

DATAMATE (part number 1200045L1), SLIP, async

PPP, and ethernet 10baseT . See Table 2-A for input

device selections using SW1 and Table 2-B for baud

rate settings using SW2. See Figure 3-1 in the chapter

Operation for the location of these switches.

Input Device Type Switch Settings

Table 2-A

Input Device Type

VT 100 ON ON ON

SLIP OFF ON ON

PPP Async ON ON OFF

Ethernet ON OFF ON

SW1-5 SW1-6 SW1-7

After changing a switch setting or the IP address information, pull the Controller card out and reinsert it to activate

the changes.

Baud Rate Switch Settings

Baud Rate (bps)

9600 ON ON ON ON

19200 OFF ON ON ON

38400 ON OFF ON ON

57600 OFF OFF ON ON

115200 ON ON OFF ON

SW2-1 SW2-2 SW2-3 SW2-4

Table 2-B

61200.162L1-1 Smart 16e Shelf User Manual 9

Chapter 2. Installation

DATAMATE Connection

The optional DATAMATE is a hand-held device that

plugs into the RJ-11 jack on the front of the Controller

card.

Ethernet Connection

The 10baseT ethernet connector on the rear of the

Controller card labelled LAN 10baseT provides a LAN

interface used for both local and remote configuration

using SNMP and telnet. Refer to Table 2-A for input

device selections.

VT 100, Modem, SLIP, or Async PPP Connection

The 25-pin EIA-232 connector on the rear of the

Controller card (labelled DTE/DCE EIA 232) provides

an interface for an asynchronous ASCII VT 100

terminal, used for both local and remote configuration.

The terminal must be set to line wrap off, flow control

off, 8-bit character size, no parity, one stop bit, and VT

100 mode.

The Smart 16e Shelf and any rackmount units in the

shelf can be configured remotely using a modem

connected to the EIA-232 connector. See the chapter

Operation for more detailed information on remote

operation.

This connector also provides an interface for SLIP or

async PPP. This interface is used for both local and

remote configuration using SNMP and telnet. See

Table 2-A for input device selections using SW1 and

Table 2-B for baud rate settings using SW2.

The pin assignments for the EIA-232 connector are

listed in Table 2-C.

10 Smart 16e Shelf User Manual 61200.162L1-1

Multi-Shelf Connection (Daisy Chaining)

For multi-shelf applications, the control port is daisychained through the two 6-pin modular jacks labelled

CTRL LINK. Cabling of a multi-shelf system is detailed in the chapter Operation. This application

requires a straight through cable. If problems arise

with the operation of one of the shelves in the chain,

the malfunctioning shelf will be bypassed so that the

chain will not be broken. See Table 2-D for the pin

assignments for the CTRL IN and CTRL OUT connectors.

Alarm Connections

The terminal strips located on the back of the Smart

16e Controller card are labeled ALARM. They are

used for audio or visual alarm indicators provided by

the user. The top two terminals are a set and the

bottom two are a set. The terminals are activated

when the cards inserted in the designated slots have

encountered some type of alarm, such as going into

dial backup (DBU).

Chapter 2. Installation

To verify proper operation of the terminal strip,

measure the impedance (approximately 0.6 ohm)

across each set. The two sets operate identically and

should have the same impedance when cards are in

alarm. The power specifications for any alarms used

are NEC Class 2 and 48 VDC @ 500 mA maximum.

Fuses

There are two fuses located on the rear panel. Fuse

one (F1) corresponds to the left power supply, and

Fuse two (F2) corresponds to the right power supply.

See the appendix Specifications for fuse ratings.

61200.162L1-1 Smart 16e Shelf User Manual 11

Chapter 2. Installation

AC/DC Power

The AC version, illustrated in Figure 2-1, has a captive

8-foot power cord. The power cord is terminated by a

three-prong plug which connects to a grounded power

receptacle. The grounded power receptacle should be

installed near the shelf and be easily accessible. The

power receptacle should also have suitable disconnect

devices that are provided as part of the building

wiring. The power receptacle should be properly

grounded. The protection of the telecommunications

network relies on the protective grounding of the

Smart 16e Shelf.

The DC version, illustrated in Figure 2-2, provides a

two-position screw terminal block for connection to a

-48 V source.

12 Smart 16e Shelf User Manual 61200.162L1-1

Chapter 2. Installation

g

)

Pin Assignments for EIA-232 Connector

Pin EIA Description

1 AA Protective Ground (PG)

2 BA Transmit Data (TD)

3 BB Receive Data (RD)

4 CA Request to Send (RS)

5 CB Clear to Send (CS)

6 C C Data Set Ready (SR)

7 AB Signal Ground (SG)

8 CF Received Line Si

9 - +12 Test Point

10 - -12 Test Point

15 D B Transmit Clock (TC)

17 D D Receive Clock (RC)

18 - Local Loopback (LL)

20 CD Data Terminal Ready (TR)

21 - Remote Loopback (RL)

22 CE Ring Indicator (RI)

24 DA External TX Clock (ETC)

25 - Test Indicator (TI)

nal Detector (CD

Table 2-C

Table 2-D

Pin Assignments for CTRL IN and CTRL OUT Connectors

CTRL IN CTRL OUT

1 GND 1 GND

2 RX CTL IN - 2 TX CTL OUT 3 RX CTL IN + 3 TX CTL OUT +

4 TX CTL IN - 4 RX CTL OUT 5 TX CTL IN + 5 RX CTL OUT +

6 GND 6 GND

61200.162L1-1 Smart 16e Shelf User Manual 13

Chapter 2. Installation

8-pin modular jack

used for Ethernet

10 base T connection

SMART 16e

SHELF

CONTROLLER

L

A

N

10 BASE T

D

T

E

/

D

C

E

E

I

A

2

3

2

25-pin EIA-232 connector

interface for connection to an

asynchronous ASCII VT 100

terminal, a modem, or a device

running SLIP or async PPP protocol

6-pin modular jacks

for daisy-chaining

shelves together (use

straight through cable)

Fuse for left power supply

Captive 8-foot power cord

I

C

T

R

L

L

I

N

K

A

L

A

R

M

F1

N

O

U

T

N

E

Terminal strip for external

C

C

L

alarm circuits or other devices

A

S

S

2

I

N

P

U

T

3A

3AG

Fuse for right power supply

115V AC

60 HZ

2 AMPS

3AG

3A

F2

Figure 2-1

Rear AC Power/Control Segment

14 Smart 16e Shelf User Manual 61200.162L1-1

Chapter 2. Installation

8-pin modular jack

used for Ethernet

10 base T connection

6-pin modular jacks

for daisy-chaining

shelves together (use

straight through cable)

Fuse for left power supply

Two-position screw

terminal block for

connection to a

-48 V source

SMART 16e

SHELF

CONTROLLER

L

A

N

10 BASE T

D

T

E

/

D

C

E

E

I

A

2

3

2

C

T

R

L

L

I

N

K

A

L

A

R

M

F1

F2

-48V

-48V

RET

-48VDC

NEC CLASS 2

INPUT

25-pin EIA-232 connector

interface for connection to an

asynchronous ASCII VT 100

terminal, a modem, or a device

running SLIP or async PPP protocol

I

N

O

U

T

N

Terminal strip for external

E

C

alarm circuits or other devices

C

L

A

S

S

2

I

N

P

U

T

5A

3AG

Fuse for right power supply

5A

3AG

(+)

(-)

External Power Supply Specs:

Input=120 VAC @60 Hz

Output=48 VDC, 6 mA

Figure 2-2

Rear DC Power/Control Segment

61200.162L1-1 Smart 16e Shelf User Manual 15

Chapter 2. Installation

16 Smart 16e Shelf User Manual 61200.162L1-1

LOCAL OPERATION

There are five methods of local configuration for the

Smart 16e Shelf: a VT 100 terminal, DATAMATE (part

number 1200045L1), SLIP, async PPP, and ethernet

10baseT.

If enabled, the password parameter protects the

terminal interface from unauthorized configuration.

VT 100 Terminal

Chapter 3. Operation

Chapter 3

Operation

Operation

The Smart 16e Shelf may be configured by attaching a

VT 100 compatible terminal or equivalent to the

control port on the rear of the Smart 16e Shelf Controller card. The terminal must be set to line wrap off,

flow control off, and VT 100 mode. The Controller

card settings are as follows: 9600 to 115.2k bps baud

rate, 8-bit character size, no parity, and one stop bit.

Connection

The connection to a terminal is made through the EIA232 25-pin connector on the rear PWR/CTRL segment

(see Figure 3-1). This connection is used for both local

and remote configuration.

61200.162L1-1 Smart 16e Shelf User Manual 17

Chapter 3. Operation

SMART 16e

SHELF

CONTROLLER

L

A

N

10 BASE T

D

T

E

/

D

C

E

E

I

A

2

3

2

C

T

R

L

L

I

N

K

A

L

A

R

M

F1

I

N

O

U

T

N

E

C

C

L

A

S

S

2

I

N

P

U

T

3A

3AG

3A

F2

3AG

115V AC

60 HZ

2 AMPS

Figure 3-1

Local Configuration

18 Smart 16e Shelf User Manual 61200.162L1-1

Jumper and Switch Settings

For local configuration, place the jumper on the

header of JP5 labeled DCE. If only one shelf is being

used, the shelf must be configured as the master (SW18 on). See Figure 3-2 for jumper and switch locations.

See the section Multi-Shelf Operation in this chapter for

information on switch settings in a multiple shelf

configuration.

If only one shelf is being used, the shelf must be configured

as the master (SW1-8 on).

After changing a switch setting or the IP address information, pull the Controller card out and reinsert it to activate

the changes.

Chapter 3. Operation

Fuses

O

1

2 3 4 5 6 7 8

N

SW1

SW2

O

N

1

2 3 4

Switch 1 sets shelf number,

master/slave operation, and

input device selection. See

Table 2-A and Figure 3-12.

Switch 2 sets the baud rate.

See Table 2-B.

F1

F2F3

JP5

DCE

JP1

DTE

Jumpers configure the

card for local (direct)

or remote (modem)

operation.

Figure 3-2

Jumper and Switch Locations

61200.162L1-1 Smart 16e Shelf User Manual 19

Chapter 3. Operation

Main Menu

After initiating terminal mode by pressing the Return

key until the Main menu appears, the display will

divide into three sections (see Figure 3-3):

1. The main window which displays all options of a

menu level.

2. The information window which lists all possible

choices for a selected option.

3. The command line which displays the current

setting for a selected option. The setting can be

updated by entering the number corresponding to

the desired selection, followed by a carriage

return. The new setting will be updated in the

main window.

From the Main menu, select a unit, view alarms of

individual units, access a utility menu, or reset the

shelf to the following factory default settings:

TIME= 00:00:00

DATE= 00-00-00

TIMEOUT LIMIT=0

SNMP PHONE NUMBERS=(blank)

PASSWORD=PASSWORD

IP ADDRESS=0.0.0.0

SUBNET MASK=255.255.255.0

GW IP ADDRESS=0.0.0.0

TRAP HOST IP=0.0.0.0

The following settings are only available with the VT

100 interface:

SNMP GET COMMUNITY=public

SNMP SET COMMUNITY=private

SNMP TRAP COMMUNITY=SNMP_trap

20 Smart 16e Shelf User Manual 61200.162L1-1

Chapter 3. Operation

Figure 3-3

Main Menu

61200.162L1-1 Smart 16e Shelf User Manual 21

Chapter 3. Operation

Select Unit Menu

The Select Unit menu, illustrated in Figure 3-4, appears after selecting 1 SELECT UNIT from the Main

menu with ENHANCED SELECT in the Utilities

menu disabled.

Press 1 to select the shelf number (displayed on the

front of the shelf Controller card).

Press 2 to select the slot number.

Press 3 to execute the choices and begin configuring

the rackmount unit.

Figure 3-4

Select Unit Menu with Enhanced Select Disabled

22 Smart 16e Shelf User Manual 61200.162L1-1

Chapter 3. Operation

If ENHANCED SELECT is enabled, the menu in

Figure 3-5 will appear.

Figure 3-5

Select Unit Menu with Enhanced Select Enabled

61200.162L1-1 Smart 16e Shelf User Manual 23

Chapter 3. Operation

Alarm View Menu

The Alarm menu (Figure 3-6) appears after selecting 2

ALARM VIEW from the Main menu. This menu

displays the current system status. Select any active

shelf and slot number to view its status.

Figure 3-6

Alarm Menu

24 Smart 16e Shelf User Manual 61200.162L1-1

Utilities Menu

Chapter 3. Operation

The Utilities menu (Figure 3-7) appears after selecting

3 UTILITIES from the Main menu.

Figure 3-7

Utilities Menu

From the Utilities menu, perform the following

functions:

TERMINAL TIMEOUT (min) = nn

Set how many minutes of keyboard inactivity can take

place before the screen goes blank.

CHANGE PASSWORD

Set private password which will prevent unauthorized

users from configuring or testing individual DSU

cards. The default password for the controller card is

PASSWORD.

PASSWORD

Enable or disable password function.

61200.162L1-1 Smart 16e Shelf User Manual 25

Chapter 3. Operation

SET TIME

Set time of day.

SET DATE

Set the date.

EDIT SHELF/SLOT DESCRIPTIONS

Assign names to the shelves and slots.

TERMINAL ALARM

Enable or disable terminal alarm function.

ENHANCED SELECT

If enabled, the Select Unit menu shown in Figure 3-4

will be replaced with the menu in Figure 3-5.

EDIT SNMP PHONE NUMBER

For SNMP dial up operation, enter the phone number

that the Controller calls to send an SNMP trap.

EDIT SNMP GET COMMUNITY

For SNMP operation, view and edit the SNMP GET

community string.

EDIT SNMP SET COMMUNITY

For SNMP operation, view and edit the SNMP SET

community string.

EDIT SNMP TRAP COMMUNITY

For SNMP operation, view and edit the SNMP trap

community string.

EDIT IP ADDRESS

For SNMP and telnet operation, view and edit the

Smart 16e Controller IP address.

EDIT SUBNET MASK

For SNMP and telnet operation, view and edit the

Smart 16e Controller subnet mask.

EDIT GATEWAY ADDRESS

For SNMP and telnet operation, view and edit the

Smart 16e Controller gateway address.

26 Smart 16e Shelf User Manual 61200.162L1-1

EDIT TRAP HOST

For SNMP operation, view and edit the address to

which the Smart 16e Controller sends traps.

READ MAC ADDRESS

For SNMP operation, view the Smart 16e Controller

ethernet hardware address.

Factory Reset Menu

The Factory Reset menu (Figure 3-8) appears after

selecting 4 FACTORY RESET from the Main menu.

Chapter 3. Operation

Figure 3-8

Factory Reset Menu

DATAMATE

The DATAMATE, illustrated in Figure 3-9, is a handheld keypad with a 2x16 LCD display. The

DATAMATE connects to the 6-pin modular jack on the

front of the Controller card (see Figure 3-14 for jack

location).

While all controller input devices (DATAMATE, VT 100

terminal, SLIP, async PPP, and ethernet) can be installed at

the same time, only one can be active at a time.

61200.162L1-1 Smart 16e Shelf User Manual 27

Chapter 3. Operation

When both the DATAMATE and the VT 100 interfaces

are installed, the DATAMATE is active until the

terminal mode is selected. To enter terminal mode

while the DATAMATE is installed, the DATAMATE

must be in the top level of its menu tree (press Cancel

until the desired menu level is reached). The terminal

mode cannot be activated while communication

between the DATAMATE and the data communication

product is in progress. The terminal mode is initiated

by pressing the carriage return key until the Main

menu is displayed. While in the terminal mode, the

DATAMATE goes into standby mode and displays the

following message:

HOLD CANCEL KEY

FOR SERVICE

Control can be returned to the DATAMATE by pressing Escape until the terminal mode is exited or by

holding the DATAMATE's Cancel key down. Once

communication with an individual rackmount unit

has been established, menus identical to those of the

stand alone version of the product are displayed on

the DATAMATE.

See Table 2-A for the switch setting used to select the

input device type .

28 Smart 16e Shelf User Manual 61200.162L1-1

Displays menu

items and messages

Chapter 3. Operation

Use arrows to scroll

through submenu

items

Press before

desired alpha

character selection

DATAMATE

ENTER

CANCEL

AB

12

DE

45

7

SHIFT QUICK

*

Press to return to the Main menu

C

3

F

6

89

0

#

Manual Operation and Button Functions

The following function descriptions apply to the

DATAMATE. The DATAMATE's Utility menu is

provided in Figure 3-10.

LCD Window

Displays menu items and messages in 2 lines by 16

characters.

Enter

Selects active menu items. To activate a menu item,

press the number of the item. When the menu item is

flashing, press Enter to select it. This action displays

a submenu item (if there is one) or sets the configuration parameter. The display of COMMAND ACCEPTED indicates a valid operation.

Press to select active

(flashing) menu items

Press to stop current

activity and return

to previous menu

Use numeric keypad

to activate menu items

and enter parameters

Figure 3-9

DATAMATE

Numeric Keypad

The numeric keypad contains the numbers 0 through 9

and alpha characters A through F, which are used to

activate menu items. Numbers 0 through 9 are also

used to enter parameters.

61200.162L1-1 Smart 16e Shelf User Manual 29

Chapter 3. Operation

When entering IP address information, use the pound key

(#) to insert decimal points.

Shift

Alpha characters are entered by pressing and releasing

Shift before each desired character. To activate a

menu item designated by an alpha character rather

than a number, display the menu item using the Up

and Down Arrows, press Shift and then the letter.

Press Enter to select the item.

If a key is pressed without using Shift, the numbered

item becomes active instead of the alpha item. If this

happens, repeat the correct procedure.

Quick

During most operations, the Quick key returns the

display to the Main menu. During a test, the Quick

key returns to the top of the Test menu.

Cancel

The Cancel key stops the current activity and returns

to the previous menu. Press Cancel until the desired

menu level is reached.

Up and Down Arrows

The Up and Down Arrows scroll through the submenu items available in the current menu. Submenu

items appear two at a time. When scrolled, they

continuously appear from beginning to end in a

forward (Down Arrow) or reverse (Up Arrow)

pattern.

30 Smart 16e Shelf User Manual 61200.162L1-1

Chapter 3. Operation

SHELF=x Yields individual

1=SELECT UNIT SLOT=x unit's menu

TIME 04:23:44

2=UTILITIES 1=SET TIME SHELF=x xx:xx:xx

DATE 08-15-97

2=SET DATE SHELF=x xx-xx-xx

3=TIMEOUT LIMIT TIME OUT TIMER

TIMER=0 MIN.

4=SOFTWARE REV. SOFTWARE REV=x

CHECKSUM=xxxx

5=SNMP PHONE NUMBER xxxxxxxx

6=SET PASSWORD xxxxxxxx

7=IP ADDRESS xxxxxxxx

8=SUBNET MASK xxxxxxxx

9=GW IP ADDRESS xxxxxxxx

A=TRAP HOST xxxxxxxx

B=MAC ADDRESS xxxxxxxx

3=FACTORY RESET ARE YOU SURE?

SHELF=x

4=ALARM CLEAR ARE YOU SURE?

SHELF=x

Figure 3-10

DATAMATE Utility Menu

61200.162L1-1 Smart 16e Shelf User Manual 31

Chapter 3. Operation

REMOTE OPERATION

The Smart 16e Shelf and any rackmount units in the

shelf can be configured remotely using a modem. See

Figure 3-11. Follow these steps to set up this application:

1. Configure modem as follows:

Display Result Code

Echo Off

Result Code Displayed as Words (verbose form)

Normal DTR

Normal DCD

Auto Answer On

2. At the remote site, pull the Controller card out of

the shelf and locate the Jumper JP1 labeled DTE.

Place the 18-pin jumper on the header. See Figure

3-1 for the jumper location.

3. Locate the EIA-232 interface on the back panel of

the Controller card. Connect the modem to this

interface.

4. Make sure the shelf baud rate is not configured

above 19.2 kbps.

5. Set the data format as follows: word length = 8

bits, parity = none, stop bit = 1.

32 Smart 16e Shelf User Manual 61200.162L1-1

SMART 16e

SHELF

CONTROLLER

L

A

N

10 BASE T

D

T

E

/

D

C

E

E

I

A

2

3

2

C

T

R

L

L

I

N

K

A

L

A

R

M

F1

Chapter 3. Operation

MODEM

PSTN

I

N

O

U

T

MODEM

N

E

C

C

L

A

S

S

2

I

N

P

U

T

3A

3AG

3A

F2

3AG

115V AC

60 HZ

2 AMPS

Figure 3-11

Remote Configuration

61200.162L1-1 Smart 16e Shelf User Manual 33

Chapter 3. Operation

OPERATION WITH A NETWORK MANAGER

USING THE SLIP, ASYNC PPP, OR ETHERNET INTERFACE

Before SLIP, async PPP, or ethernet communication can

be established with a network manager, some initial

network settings must be configured using a local VT

100 terminal attached to the EIA-232 port of the Smart

16e Controller card.

Obtain information such as the internet protocol (IP)

address, subnet mask, gateway IP address, and trap host IP

address from the network administrator.

The ethernet LAN interface in the Smart 16e Controller card has the network media access control address

as displayed in hexadecimal byte notation. The IP

address, subnet mask, gateway, and trap host systems

are entered using dotted decimal notation.

The subnet mask is the filter used for subnetwork

addressing. The default value is a typical Class C

subnet mask value (255.255.255.0).

The SNMP community names are used in SNMP GET,

SET, and trap messages for authentication.

The trap host IP address identifies where the network

manager system receives trap messages from the

Smart 16e Shelf.

Configure Network Interface Using a VT 100 Terminal

In order to set the Smart 16e Shelf up to accept SLIP,

async PPP, or ethernet communication from a network

manager, perform the following steps:

1. Connect the terminal to the Smart 16e Controller

EIA-232 port. The terminal settings should match

the Smart 16e Controller baud rate setting (i.e.,

9600 bps, 8 data bits, no parity, and 1 stop bit).

34 Smart 16e Shelf User Manual 61200.162L1-1

Chapter 3. Operation

2. Power the Smart 16e Controller card on. After

performing initial diagnostics, the Controller card

displays the shelf number in the 7-segment LED

display. Press Enter until the Main menu appears

on the terminal screen.

3. Go to the Utilities menu.

4. Configure the following Smart 16e network

interface settings: IP address, Subnet Mask,

Gateway IP address (if required), Trap Host IP

address, GET community name, SET community

name, and SNMP Trap community name.

5. Restart the Smart 16e (power off, then on) to begin

operating with new values for the Controller card

IP address, Subnet Mask, Gateway IP address, and

Trap Host IP address.

The DATAMATE cannot be used to configure the initial

network settings necessary for establishing network

manager operation. The VT 100 interface must be used for

this set up.

After changing a switch setting or the IP address information, pull the Controller card out and reinsert it to activate

the changes.

USING TELNET

The Smart 16e Shelf supports telnet access, allowing

remote access to the Smart 16e Shelf menu interface by

the network manager.

To access the Smart 16e Shelf menu interface, establish

a Telnet session using the Smart 16e Shelf IP address

to open the device session. The Smart 16e Shelf's Main

menu will display. Configure or monitor the Smart

16e Shelf devices as if they were locally connected to

the shelf with a VT 100 terminal. Close the Telnet

application according to the network manager's

instructions.

61200.162L1-1 Smart 16e Shelf User Manual 35

Chapter 3. Operation

MULTI-SHELF OPERATION (DAISY CHAINING)

For larger applications, the controller allows access to

15 additional Smart 16e Shelves. In these large applications, one shelf controller is configured as the master

and all other shelf controllers are configured as

subcontrollers (see Figures 3-12 and 3-13). This parameter is set through Switch 1 (SW1), the eight-position

rocker switch on the Controller card, as illustrated in

Figure 3-12. Select either master (SW1-8 on) or

subcontroller (SW1-8 off) by moving the switch to the

desired position. See Figure 3-1 for switch location.

This capability is also available through SNMP

management. With SNMP, 256 devices can be managed locally with only one IP address.

A Smart 16e Controller card configured as the master can

use SNMP to manage other Smart 16 shelves even if the

slave shelves do not have SNMP capabilities.

Using SW1-1 through SW1-4, set the shelf number

from 1 to 16. Switch settings are detailed in Table 3-A.

The indicator display on the front of the Controller

card shows the current shelf number.

Shelf Number

Selection

12345678O

N

Input Device

Selection

Controller Configuration Switch Positions

36 Smart 16e Shelf User Manual 61200.162L1-1

Master

Control

Sub

Control

Figure 3-12

SHELF 1

Master (SW1-8 on)

SHELF 2

Subcontoller (SW1-8 off)

SMART 16e

SHELF

CONTROLLER

L

A

N

10 BASE T

D

T

E

/

D

C

E

E

I

A

2

3

2

C

T

R

L

L

I

N

K

A

L

A

R

M

F1

F2

115V AC

60 Hz

2 Amps

SMART 16e

SHELF

CONTROLLER

L

A

N

10 BASE T

D

T

E

/

D

C

E

E

I

A

2

3

2

C

T

R

L

L

I

N

K

A

L

A

R

M

F1

F2

115V AC

60 Hz

2 Amps

Chapter 3. Operation

I

N

O

U

T

3A

3AG

3A

3AG

I

N

O

U

T

3A

3AG

3A

3AG

SMART 16e

SHELF

CONTROLLER

I

L

N

A

T

N

F

10 BASE T

D

T

E

/

D

C

E

E

I

A

2

3

2

C

I

T

N

R

SHELF 3

Subcontoller (SW1-8 off)

L

L

O

I

U

N

T

K

A

L

A

R

M

3A

3AG

F1

3A

3AG

F2

115V AC

60 Hz

2 Amps

Figure 3-13

Multi-Shelf Application

61200.162L1-1 Smart 16e Shelf User Manual 37

Chapter 3. Operation

Table 3-A

Switch 1 Shelf Numbering Settings

Shelf

Number

1 OnOnOnOn

2 Off On On On

3 On Off On On

4 Off Off On On

5 On On Off On

6 Off On Off On

7 On Off Off On

8 Off Off Off On

9 OnOnOnOff

10 Off On On Off

11 On Off On Off

12 Off Off On Off

13 On On Off Off

14 Off On Off Off

15 On Off Off Off

16 Off Off Off Off

SW1-1 SW1-2 SW1-3 SW1-4

38 Smart 16e Shelf User Manual 61200.162L1-1

Chapter 3. Operation

INTERPRETING ALARMS AND ERROR MESSAGES

The Alarm menu, illustrated in Figure 3-6, provides

the status information of 16 individual units.

Four indicators on the front panel of the Controller

card show alarm conditions in the rack, as shown in

Figure 3-14.

Additional error messages are displayed in the

numerical display of the Controller card. The conditions, along with the numbers that represent them, are

listed in Table 3-B. Table 3-C presents alarm conditions and solutions.

These alarms, with the exception of the E2 alarm,

cannot be resolved in the field and will require the

unit to be returned to ADTRAN for service (see the

last page of this manual for repair and return information).

Some error messages are caused by a blown fuse in

one of the shelf cards. To determine if a fuse is the

cause, begin taking one card out of the shelf at a time

until the E2 message clears. Replacing the problem

card's fuse should solve the problem. If the problem

continues, contact your ADTRAN customer service

representative (see last page of the manual).

Table 3-B

Controller Card Error Messages

Error

Number

E0 ROM error in the controller

E1 RAM error in the controller

E2 UART A1 failed in the controller

E3 UART B1 failed in the controller

E4 Ethernet chip failed in the controller

E5 Non-volatile RAM test

E6 UARTX A1 failed in the controller

E7 UARTX A2 failed in the controller

61200.162L1-1 Smart 16e Shelf User Manual 39

Condition

Chapter 3. Operation

6-pin modular jack used

for DATAMATE connection.

SMART 16e

SHELF

CONTROLLER

SHELF

NUMBER

1

2

ALARM

3

4

LOCAL

CONTROL

Displays assigned shelf number.

Also displays error messages

(see Table 3-B).

Alarm LEDs. See Table

3-C for conditions and

solutions.

Figure 3-14

Controller Card Front Panel

40 Smart 16e Shelf User Manual 61200.162L1-1

Chapter 3. Operation

Table 3-C

LED Alarm Messages

Alarm

Number

Failure in left power supply.

1

Failure in right power supply.

2

3 Latched alarm (DBU has been

activated).

4 No activity in last 6500 ms

(illuminates on subcontroller

shelf only). The subcontroller

shelf did not get a poll from

the master shelf.

Condition Solution

Clearing DBU Alarms

To clear DBU alarms from the Controller card's front

panel (indicated by ALARM LED 3) proceed with the

steps listed below.

DATAMATE Procedure

1. Clear the DBU alarm associated with the DSU

card.

2. Press 4=ALARM CLEAR from the Main menu.

Replace power supply.

Replace power supply.

Clear alarm by following the

steps in the section Clearing DBU

Alarms.

Check for the following

conditions:

1. Bad cable.

2. Backplane not seated

correctly.

3. Chain in/chain out scheme

incorrect (see Figure 3-13).

VT 100 Procedure

1. Clear DBU alarm associated with the DSU card.

2. Select 2= ALARM VIEW from the Main menu.

3. Select the shelf number.

4. View latched alarms.

5. Select the slot number.

6. Clear latched alarms.

61200.162L1-1 Smart 16e Shelf User Manual 41

Chapter 3. Operation

42 Smart 16e Shelf User Manual 61200.162L1-1

This section describes the standard specifications and

features incorporated in the Smart 16e Shelf.

Network Compatibility

DDS, 4-wire Switched 56, 2-wire Switched 56, T1, FT1,

ISDN

Indicators and Controls

Faceplate

4 LED alarm indicators

Numerical display (Shelf Address)

Appendix A. Specifications

Appendix A

Specifications

Rackmount Units

LED indicators (defined in each unit's user manual)

2 test push-buttons

Power Supplies

AC and DC: indicators for +5V, -5V, +12V, -12V

(green) and Check (red)

Rear Panel Connections

Control/SLIP/Async PPP/Modem Port

DB-25 (EIA-232)

Control In and Out

RJ-11

Ethernet Port

10BaseT

61200.162L1-1 Smart 16e Shelf User Manual 43

Appendix A. Specifications

Rackmount Units

Up to 32 V.35 and EIA-232 DTE connectors

Up to 32 RJ-XX network jacks for DSU network

connections

Captive Power Cord

AC version

2-screw Terminals

DC version

Alarm

4-screw terminals

Physical

Size

17.25" wide, 10.5" high, 14.875" deep

Weight

20 pounds (empty)

45 pounds (full)

Mounting

19" rack or cabinet

23" rack or cabinet

Power

Inputs

AC voltage: 120 VAC ±20%

Frequency: 47 - 63 Hz

DC voltage: 30 - 72 VDC

Fuse Ratings

AC version 3A, 3AG

DC version 5A, 3AG

Relay Contact Ratings

Noninductive load

Maximum switched power: 60 W or 125 VA

Maximum switched current: 2 amps

Maximum switched voltage: 150 VDC or 300 VAC

U.L. Rating: 2 A @ 30 VDC

1 A @ 120 VAC

44 Smart 16e Shelf User Manual 61200.162L1-1

Environmental

Appendix A. Specifications

Outputs

+5 VDC@ 14 amps

-5 VDC @ 1.5 amps

+12 VDC @ 2.0 amps

-12 VDC @ 2.0 amps

Temperature

Operating: 0 to 50 °C (32 to 122 °F)

Storage: -20 to +70 °C (-4 to +158 °F)

Relative Humidity

Up to 95% non-condensing

61200.162L1-1 Smart 16e Shelf User Manual 45

Appendix A. Specifications

46 Smart 16e Shelf User Manual 61200.162L1-1

Index

Index

A

AC version 12

AC/DC power 12

alarm connections 11

alarm menu 39

alarm view menu 24

alarms 39

arrows 30

async PPP 2, 6, 9, 10, 27, 34, 43

B

baud rate switch settings 9

C

cancel key 30

change password 25

configuration 17

connection 17

controller card error messages 39

controls 43

CTRL IN 11

CTRL IN /CTRL OUT connectors

pin assignments 13

CTRL OUT 11

customer service 3

D

daisy chaining 11, 36

SNMP 36

DATAMATE 2, 27, 29

arrow keys 30

cancel key 30

connection 10

enter key 29

LCD window 29

numeric keypad 29

quick key 30

shift key 30

DBU alarms

clearing 41

DC version 12

down arrow 30

E

edit gateway address 26

edit IP address 26

edit shelf/slot descriptions 26

edit SNMP GET community 26

edit SNMP phone number 26

edit SNMP SET community 26

edit SNMP trap community 26

edit subnet mask 26

61200.162L1-1 Smart 16e Shelf User Manual 47

Index

edit trap host 27

EIA-232 connector 10

pin assignments 13

enhanced select 23, 26

enter key 29

equipment included 5

equipment needed 6

error messages 39

ethernet 2, 27, 34

ethernet connection 10

F

factory reset menu 27

fuse ratings 44

fuses 11

G

gateway 34

gateway IP address 34, 35

GET community name 35

I

indicators 43

input device type switch settings

9

input devices 1

installation

cabinet/rack 7

controller card 8

power supplies 7

IP address 34, 35

LED alarm messages 41

local configuration 18, 19

local operation 17

M

main menu 20, 30

modem 32

modem connection 10

mounting 1

multi-shelf connection 11

multi-shelf operation 36

N

network compatibility 43

network interface

configure 34

network manager 34

numeric keypad 29

P

password 25

power 44

power supplies 43

power up 6

PPP. See also async PPP

PPP async. See also async PPP

Q

quick key 30

R

J

jumper locations 19

jumper settings 19

L

LAN 2, 34

LCD window 29

48 Smart 16e Shelf User Manual 61200.162L1-1

read MAC address 27

rear panel connections 43

receipt inspection 5

relay contact ratings 44

remote operation 32, 33

return material authorization

(RMA) 3

S

select unit menu 22

SET community name 35

set date 26

set time 26

shift key 30

SLIP 2, 27, 34

SNMP trap community name 35

subnet mask 34, 35

switch 1 shelf numbering 38

switch locations 19

switch positions 36

switch settings 19

T

telnet 35

terminal alarm 26

terminal timeout 25

trap host 34, 35

trap host IP address 34

Index

U

up arrow 30

utilities menu 25

SNMP version 25

V

VT 100 1, 17

VT 100 connection 10

W

warranty 3

61200.162L1-1 Smart 16e Shelf User Manual 49

Index

50 Smart 16e Shelf User Manual 61200.162L1-1

Product Support Information

Presales Inquiries and Applications Support

Please contact your local distributor, ADTRAN

Applications Engineering, or ADTRAN Sales:

Applications Engineering (800) 615-1176

Sales (800) 827-0807

Post-Sale Support

Please contact your local distributor first. If your local

distributor cannot help, please contact ADTRAN

Technical Support and have the unit serial number

available.

Technical Support (888) 4ADTRAN

Repair and Return

If ADTRAN Technical Support determines that a

repair is needed, Technical Support will coordinate

with the Return Material Authorization (RMA)

department to issue an RMA number. For information regarding equipment currently in house or

possible fees associated with repair, contact RMA

directly at the following number:

RMA Department (205) 963-8722

Identify the RMA number clearly on the package

(below address), and return to the following address:

ADTRAN, Inc.

RMA Department

901 Explorer Boulevard

Huntsville, Alabama 35806

RMA # _____________

Loading...

Loading...