Page 1

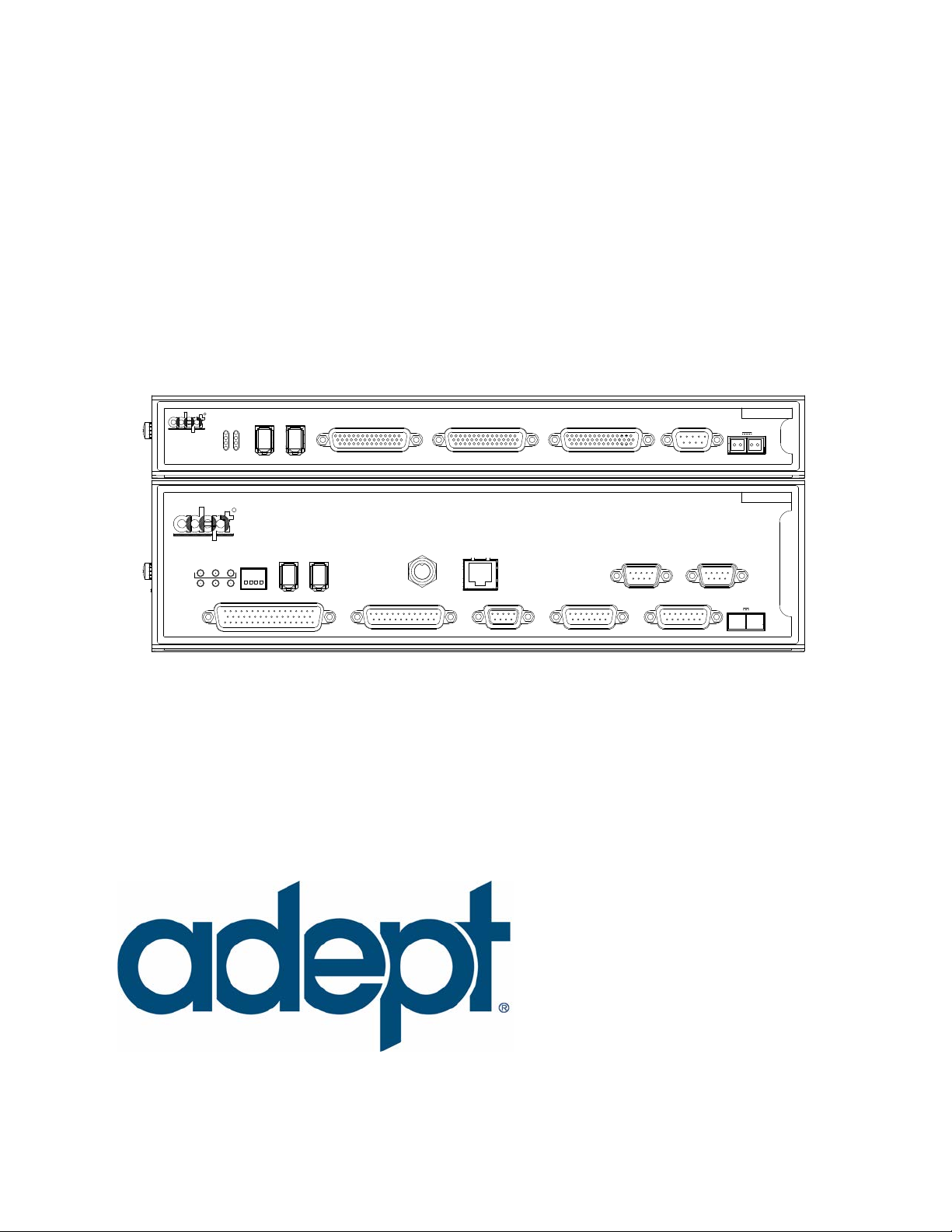

Adept SmartMotion

12 3

RS-422/485

XUSR

XSYS

SF

XMCP

1.1

SmartController CS

LANHPE

OFF

24V 5A

ON

RS-232/TERM

XFP

HDES

XDIO

Eth 10/100

*S/N 3561-XXXXX*

SW1

Device Net

SmartServo

XDC1 XDC2

-+ -+

1234

OK

R

1.2

Adept SmartController CS with sMI6 Motion Interface Module

24V

R

F2 DE2 F6 DE6

F1 DE1

ES HPE

STATUS

F5 DE5

F4 DE4

F3 DE3

-+ -+

s

XMACHINEXENCODER

MI6

*S/N 3564-XXXXX*

SmartServo

XSERVO

1.1 1.2

XANL

XDC1 XDC2

0.5A

Installation Guide

Page 2

Page 3

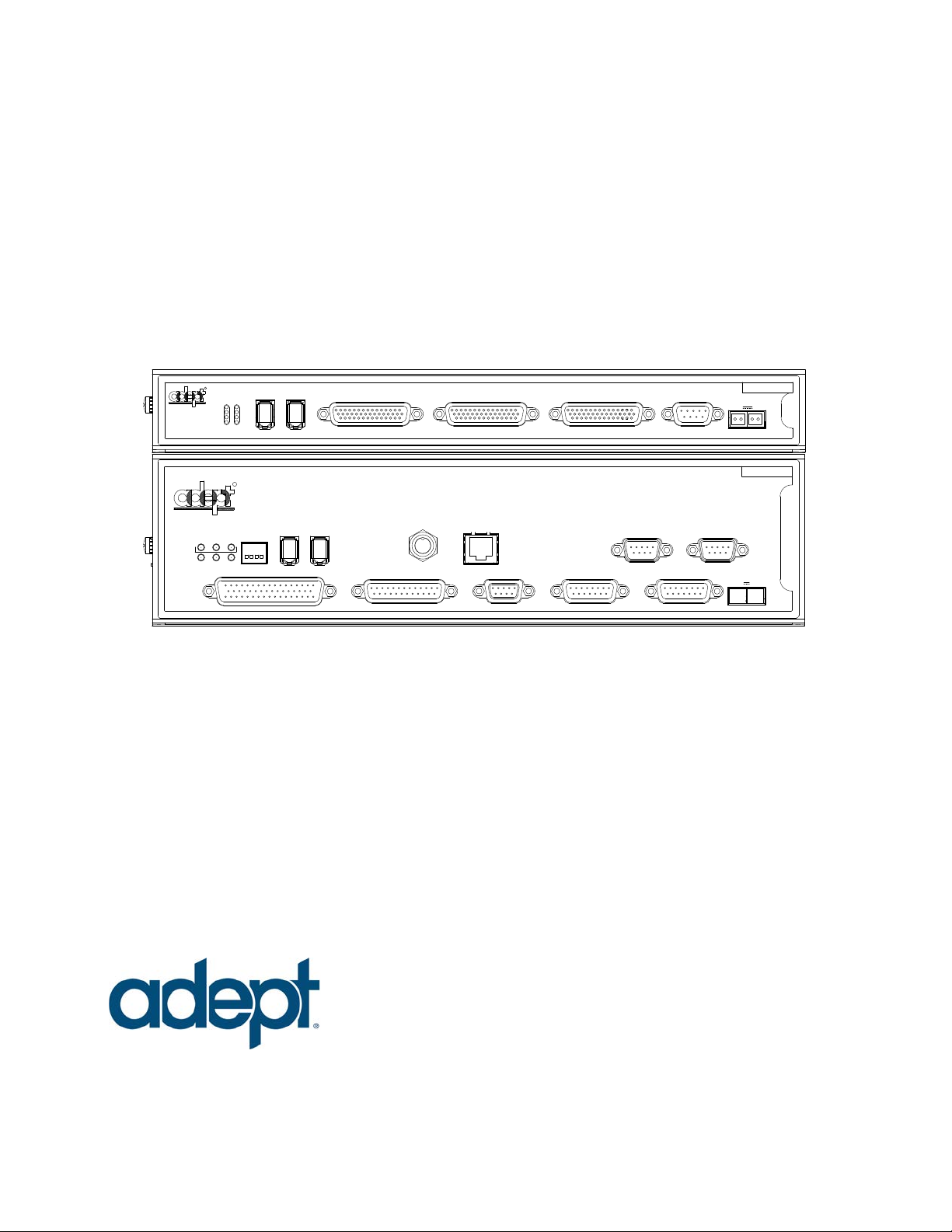

Adept SmartMotion

12 3

RS-422/485

XUSR

XSYS

SF

XMCP

1.1

SmartController CS

LANHPE

OFF

24V 5A

ON

RS-232/TERM

XFP

HDES

XDIO

Eth 10/100

*S/N 3561-XXXXX*

SW1

Device Net

SmartServo

XDC1 XDC2

-+ -+

1234

OK

R

1.2

Adept SmartController CS with sMI6 Motion Interface Module

24V

R

F2 DE2 F6 DE6

F1 DE1

ES HPE

STATUS

F5 DE5

F4 DE4

F3 DE3

-+ -+

s

XMACHINEXENCODER

MI6

*S/N 3564-XXXXX*

SmartServo

XSERVO

1.1 1.2

XANL

XDC1 XDC2

0.5A

5960 Inglewood Drive • Pleasanton, CA 94588 • USA • Phone 925.245.3400 • Fax 925.960.0452

Otto-Hahn-Strasse 23 • 44227 Dortmund • Germany • Phone 49.231.75.89.40 • Fax 49.231.75.89.450

Block 5000 Ang Mo Kio Avenue 5 • #05-12 Techplace II • Singapore 569870 • Phone +65.6755 2258 • Fax +65.6755 0598

Installation Guide

P/N: 02170-000, Rev. C

February, 2013

Page 4

The information contained herein is the property of Adept Technology, Inc., and shall not be reproduced in whole or in part without prior written approval of Adept Technology, Inc. The information herein is subject to change without notice and should not be construed as a commitment by

Adept Technology, Inc. This manual is periodically reviewed and revised.

Adept Technology, Inc., assumes no responsibility for any errors or omissions in this document.

Critical evaluation of this manual by the user is welcomed. Your comments assist us in preparation

of future documentation. Please email your comments to: techpubs@adept.com.

Copyright

Adept, the Adept logo, the Adept Technology logo, AdeptVision, AIM, Blox, Bloxview,

FireBlox, Fireview, HexSight, Meta Controls, MetaControls, Metawire, Soft Machines, and Visual

Brain on Board is a registered trademark of Adept Technology, Inc. in Germany.

Adept ACE, Adept sDIO, Adept SmartController CX, Adept SmartController EX,

Adept SmartMotion, Adept SmartVision EX, AdeptSight, eV+, and V+

2003, 2013, 2013 by Adept Technology, Inc. All rights reserved.

Machines are registered trademarks of Adept Technology, Inc.

are trademarks of Adept Technology, Inc.

Any trademarks from other companies used in this publication

are the property of those respective companies.

Printed in the United States of America

Page 5

Table of Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.1 Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Adept SmartMotion Hardware Overview . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Adept sMI6 Motion Interface Module . . . . . . . . . . . . . . . . . . . . . . . 12

Motion Interface Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Reading and Training for Users and Operators . . . . . . . . . . . . . . . . . . . . . . 12

System Safeguards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Safety Features on Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Computer Controlled Robots and Motion Devices . . . . . . . . . . . . 13

Manually Controlled Robots and Motion Devices . . . . . . . . . . . . . 13

Other Computer Controlled Devices . . . . . . . . . . . . . . . . . . . . . . . . 13

Program Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Overspeed Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Voltage Interruptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Inappropriate Uses of the Adept SmartController . . . . . . . . . . . . . . . . . . . . 14

1.3 Warnings, Cautions, and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.4 How Can I Get Help? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.5 Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2 System Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.1 Overview of Installation Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.2 Adept sMI6 Connectors and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Adept sMI6 LED Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Adept sMI6 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.3 System Cable Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.4 Adept sMI6 Hardware Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

sMI6 Digital Input Logic Voltage Configuration . . . . . . . . . . . . . . . . . . . . . . 21

2.5 Proper Wiring and Electrical Design Practices . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.6 Enclosure for SmartController and sMI6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.7 Installing the Adept SmartController . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.8 Installing the Adept sMI6 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.9 Installing MP6 Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Rail Mounting the MP6 Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Panel Mounting the MP6 Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Plug-In Opto Modules on the MP6-M . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Adept SmartMotion Installation Guide, Rev. C 5

Page 6

Table of Contents

2.10 MP6 Machine (MP6-M) Panel Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.11 MP6 Servo (MP6-S) Panel Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.12 MP6 Encoder (MP6-E) Panel Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Optical Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Input Current Requirements (OT, HM) . . . . . . . . . . . . . . . . . . . . . . . . 31

Input Voltage Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Output Current Requirements (MP6-M, HPE and BR, External). . . . 32

User-Supplied Logic Power (Internal). . . . . . . . . . . . . . . . . . . . . . . . . 32

Overtravel Limit Switches (Input). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Home Switch (Input) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Brake Release (Output) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

High Power Enable (Output) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Drive Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Optical Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

MP6-S Input Current Requirements (Drive Fault) . . . . . . . . . . . . . . . 35

MP6-S Output Current Requirements (Drive Enable) . . . . . . . . . . . . 35

Connecting the Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Drive Enable (Output) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Delay Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Drive Fault (Input) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Command Drive (Output) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Encoder Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Connecting Power to the Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Encoder Power Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Encoder Cable Length (User Supplied) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Connecting the Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Encoder Input Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Single-Ended Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3 Software Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.2 Phase 1 - Preparation for Software Configuration. . . . . . . . . . . . . . . . . . . . . . . . 44

3.3 Phase 2 - Load Device Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.4 Phase 3 - Configure SmartServo Network Map. . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.5 Phase 4 - Create Software Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.6 Phase 5 - Testing the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.7 Motion Control Application Development . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4 Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.1 Dimensions for sMI6 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.2 Dimensions for Mounting sMI6 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.3 MP6 to sMI6 Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6 Adept SmartMotion Installation Guide, Rev. C

Page 7

Table of Contents

4.4 Typical Input and Output Circuits in sMI6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Input Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Output Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.5 Emergency Stop Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Adept SmartMotion Installation Guide, Rev. C 7

Page 8

Page 9

List of Figures

Figure 1-1. Adept sMI6 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 2-1. Close-up of sMI6 LED Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 2-2. Adept sMI6 Module Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 2-3. Adept SmartMotion System Cable Diagram . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 2-4. Opening the sMI6 Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 2-5. Location of Jumpers on Main PCA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 2-6. MP6-S Panel – Layout and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 2-7. MP6-E Panel – Layout and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 2-8. MP6-M Panel – Layout and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 2-9. Typical System Wiring for One Axis of Motion . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 2-10. Encoder Input Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 2-11. Encoder Input Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 2-12. Single-Ended Encoder Wiring Using Inverted Outputs . . . . . . . . . . . . . . . . . 42

Figure 2-13. Single-Ended Encoder Wiring Using Non-Inverted Outputs . . . . . . . . . . . . . 42

Figure 3-1. SmartMotion System Installed to Control a User Mechanism . . . . . . . . . . . . 43

Figure 4-1. Dimensions for sMI6 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 4-2. Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 4-3. Panel Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 4-4. Table Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 4-5. Typical Input Circuit in sMI6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 4-6. Typical Output Circuit in sMI6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 4-7. Category 3 E-Stop Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 4-8. Category 1 E-Stop Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Adept SmartMotion Installation Guide, Rev. C 9

Page 10

Page 11

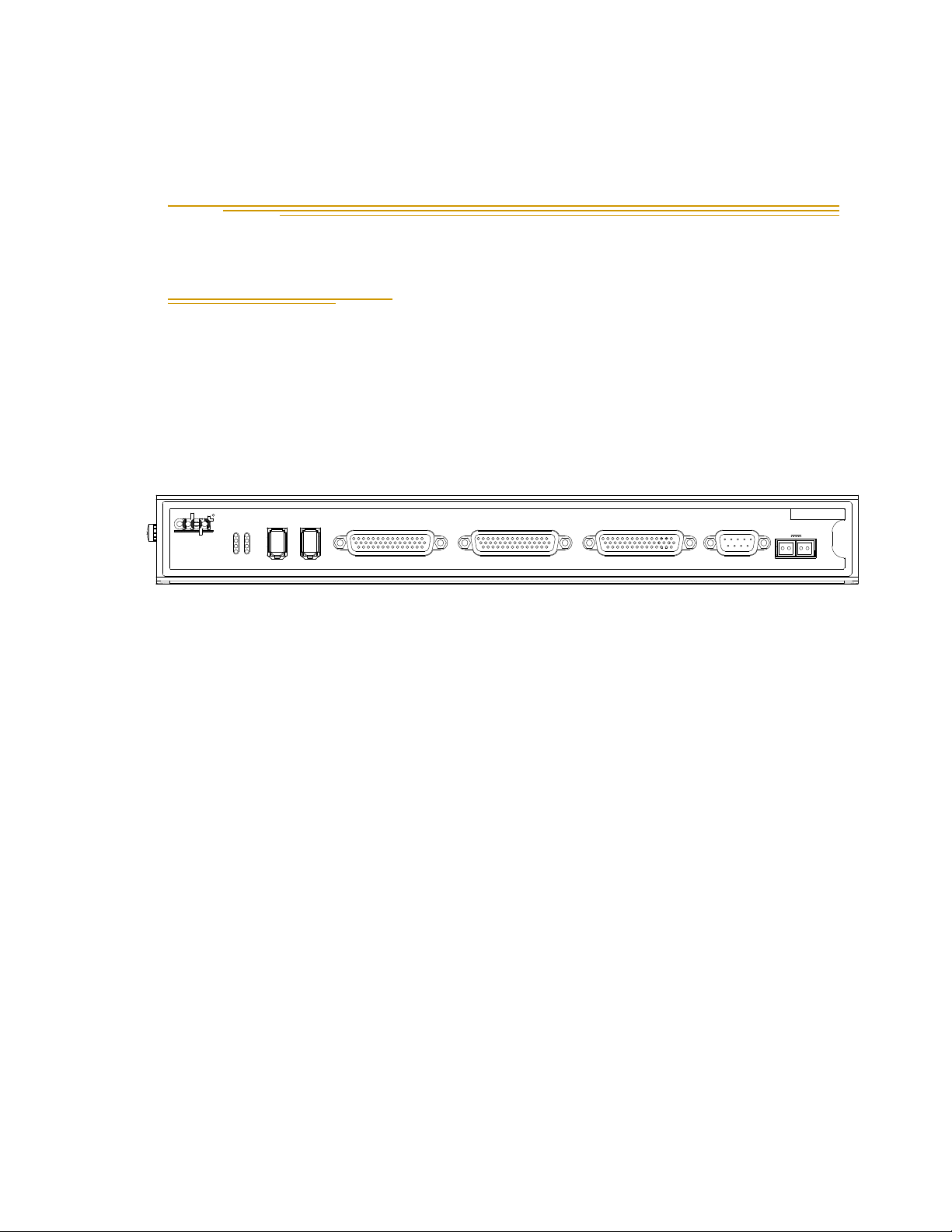

1.1 Product Description

24V

R

F2 DE2 F6 DE6

F1 DE1

ES HPE

STATUS

F5 DE5

F4 DE4

F3 DE3

-+ -+

s

XMACHINEXENCODER

MI6

*S/N 3564-XXXXX*

SmartServo

XSERVO

1.1 1.2

XANL

XDC1 XDC2

0.5A

The Adept SmartMotion product consists of a hardware and software package that

provides high-performance coordinated motion control for industrial automation devices.

Adept SmartMotion includes the sMI6 motion interface module and the Adept

SmartController, communicating via the SmartServo network, Adept’s distributed

controls network built on IEEE 1394. Completely integrated V+ software provides the

same high-level motion instructions that are used for Adept robots. The sMI6 supports up

to six axes of motion control per module.

Figure 1-1. Adept sMI6 Module

Introduction 1

System Overview

Adept SmartMotion has been designed to function as an integral part of Adept’s control

system. Typical components include an Adept SmartController (CS or CX model), one or

more sMI6 modules, MP6 panels, a manual control pendant, a desktop or laptop PC, and

a user-supplied mechanism with servomotors, encoders, and amplifiers. Additional

options such as Adept-supplied robots and vision systems are available.

Adept SmartMotion is intended to provide complete motion control of user-supplied

mechanisms. Users retain the flexibility of selecting the drive components that are best

suited for their applications. Adept SmartMotion can interface to industry standard drive

components including most servo amplifiers and optical encoders. Motion-related I/O

signals can utilize voltage levels chosen by the user.

Adept SmartMotion Hardware Overview

There are two major hardware components of the system, in addition to the

SmartController:

• Adept sMI6 Motion Interface Module

• Motion Interface Kit, includes MP6 panels and interface cables (this kit is optional)

Adept SmartMotion Installation Guide, Rev. C 11

Page 12

Chapter 1 - Introduction

Adept sMI6 Motion Interface Module

The Adept sMI6 Motion Interface module is a six-channel unit that runs the Adept

SmartMotion product. The sMI6 module is a stand-alone unit designed to control a total

of six motion axes or external encoders. Each sMI6 module has six servo drive outputs, six

incremental encoder inputs, and digital I/O for machine and amplifier control.

Motion Interface Kit

The Motion Interface Kit includes the three Motion-interface Panels (MP6-E, MP6-M, and

MP6-S) that serve as the interface between the sMI6 module and the user’s hardware. The

MP6 panels provide mounting sockets for I/O modules used in conjunction with the

dedicated discrete input/output signals. The MP6 panels also provide detachable

barrier-type screw terminal strips and 9-Pin D connectors for all field wiring terminations.

Interface cables (3 meter) for connecting the sMI6 to the MP6 panels are included in the

kit.

NOTE: The Motion Interface Kit is optional, but it is recommended for

typical installations. Customers who do not order this option must

provide similar functionality.

1.2 Safety

WARNI NG : See the Adept SmartController User’s Guide

for additional safety information.

Reading and Training for Users and Operators

Adept systems can include computer-controlled mechanisms that are capable of moving

at high speeds and exerting considerable force. Like all robot and motion systems, and

most industrial equipment, they must be treated with respect by the user and the operator.

This manual should be read by all personnel who operate or maintain Adept systems, or

who work within or near the workcell.

We recommend you read the American National Standard for Industrial Robot Systems -

Safety Requirements, published by the Robotic Industries Association (RIA), in conjunction

with the American National Standards Institute. The publication, ANSI/RIA R15.06 1992, contains guidelines for robot system installation, safeguarding, maintenance,

testing, start-up, and operator training.

We also recommend you read the European Standard EN 60204, Safety of Machinery –

Electrical Equipment of Machines, particularly if the country of use requires a CE-certified

installation. (See the Adept SmartController User’s Guide for ordering information for

national and international standards.)

This manual assumes that the user has attended an Adept training course, or at least has a

basic working knowledge of the system. The user should provide the necessary additional

training for all personnel who will be working with the system.

12 Adept SmartMotion Installation Guide, Rev. C

Page 13

There are several warnings in this manual that say only skilled or instructed persons

should attempt certain procedures. These are defined as:

• Skilled persons have technical knowledge or sufficient experience to enable them

to avoid the dangers which electricity may create (engineers and technicians).

• Instructed persons are adequately advised or supervised by skilled persons to

enable them to avoid the dangers which electricity may create (operating and

maintenance staff).

System Safeguards

Safeguards should be an integral part of robot or motion workcell design, installation,

operator training, and operating procedures.

Adept systems have various communication features to aid in constructing system

safeguards. These include the emergency stop circuitry and digital input and output lines.

Some of these features are described in the Adept SmartController User’s Guide.

Safety Features on Front Panel

Safety

The optional Front Panel has important safety features, including the

indicator, the

AUTO/MANUAL keyswitch, and the EMERGENCY STOP switch. If you

HIGH POWER

choose not to use the Front Panel, you should provide similar safety features by using the

connectors on the SmartController. Refer to the Adept SmartController User’s Guide for

more information.

WARNI NG : Entering the workcell when the

HIGH POWER

light is on can result in severe injury. This warning applies

to each of the next three sections.

Computer Controlled Robots and Motion Devices

Adept systems are computer controlled, and the program that is currently running the

robot or motion device may cause it to move at times or along paths you may not

anticipate. When the

HIGH POWER light is illuminated, do not enter the workcell because

the robot or motion device might move unexpectedly.

Manually Controlled Robots and Motion Devices

Adept robots and other motion devices can also be controlled manually when the

POWER

light on the Front Panel is illuminated. When this light is lit, motion can be

HIGH

initiated from the system keyboard or from the optional Manual Control Pendant (MCP).

If you have to enter the workcell when this light is lit, press the

MAN/HALT button on the

MCP. This will prevent anyone else from initiating unexpected motion from the system

keyboard.

Other Computer Controlled Devices

In addition, Adept systems can be programmed to control equipment or devices other

than the robot or main motion device. The program controlling these other devices may

cause them to operate unexpectedly. Make sure that safeguards are in place to prevent

personnel from entering the workcell when a program is running.

Adept SmartMotion Installation Guide, Rev . C 13

Page 14

Chapter 1 - Introduction

Adept Technology highly recommends the use of additional safety features such as light

curtains, safety gates, or safety floor mats to prevent entry to the workcell while

POWER

is enabled. These devices can be connected using the emergency stop circuitry.

Program Security

HIGH

Programs and data stored in memory can be changed by trained personnel using the V+

+

commands and instructions documented in the V

manuals. To prevent unauthorized

alteration of programs, you should restrict access to the keyboard. This can be done by

+

placing the keyboard in a locked cabinet. Alternatively, the V

+

be used in your programs to restrict access to the V

command prompt.

ATTACH instruction can

Overspeed Protection

Overspeed protection for a robot or motion system has to be taken into account during

system integration by the integrator or end-user. Overspeed protection is not guaranteed

+

by the controller hardware alone. The V

system software offers some overspeed

protection capabilities.

Voltage Interruptions

If the power supply to the controller is interrupted, the passive E-stop output will be

automatically turned on (opened). In addition, the High Power, Brake Release, and Drive

Enable signals will be turned off. You must ensure that these signals are used to prevent a

hazardous condition.

Inappropriate Uses of the Adept SmartController

The Adept SmartController is intended for use as a component sub-assembly of a

complete industrial automation system. The SmartController sub-assembly must be

installed inside a suitable enclosure. Installation and usage must comply with all safety

instructions and warnings in this manual. Installation and usage must also comply with

all applicable local or national statutory requirements and safety standards.The

SmartController sub-assembly is not intended for use in any of the following situations:

• In hazardous (explosive) atmospheres

• In mobile, portable, marine, or aircraft systems

• In residential installations

• In situations where the SmartController sub-assembly may come into contact with

liquids.

• In situations where the SmartController sub-assembly will be subject to extremes

of heat or humidity. See the specifications for allowable temperature and humidity

ranges.

See the Adept SmartController User’s Guide for any additional restrictions.

14 Adept SmartMotion Installation Guide, Rev. C

Page 15

1.3 Warnings, Cautions, and Notes

There are four levels of special alert notation used in this manual. In descending order of

importance, they are:

DANGER: This indicates an imminently hazardous

situation which, if not avoided, will result in death or

serious injury.

WARNI NG : This indicates a potentially hazardous

situation which, if not avoided, could result in serious

injury or major damage to the equipment.

Safety

CAUTION: This indicates a situation which, if not avoided,

could result in minor injury or damage to the equipment.

NOTE: This provides supplementary information, emphasizes a point or

procedure, or gives a tip for easier operation.

Adept SmartMotion Installation Guide, Rev . C 15

Page 16

Chapter 1 - Introduction

1.4 How Can I Get Help?

Refer to the How to Get Help Resource Guide (Adept P/N 00961-00700) for details on

getting assistance with your Adept software and hardware. This document is available on

the Adept Documentation Library CD-ROM that is shipped with all systems.

Additionally, you can access information sources on Adept’s corporate Web site:

http://www.adept.com

1.5 Related Manuals

This manual covers the installation of an Adept SmartMotion system. There are additional

manuals that cover software configuration, programming the system, reconfiguring

installed components, and adding other optional components. Refer to the following

manuals for additional information your Adept system.

NOTE: Al l of the manuals in Table 1-1 are available on the Adept

Documentation Library CD-ROM provided with each system.

(Previously this was known as the Knowledge Express CD-ROM.)

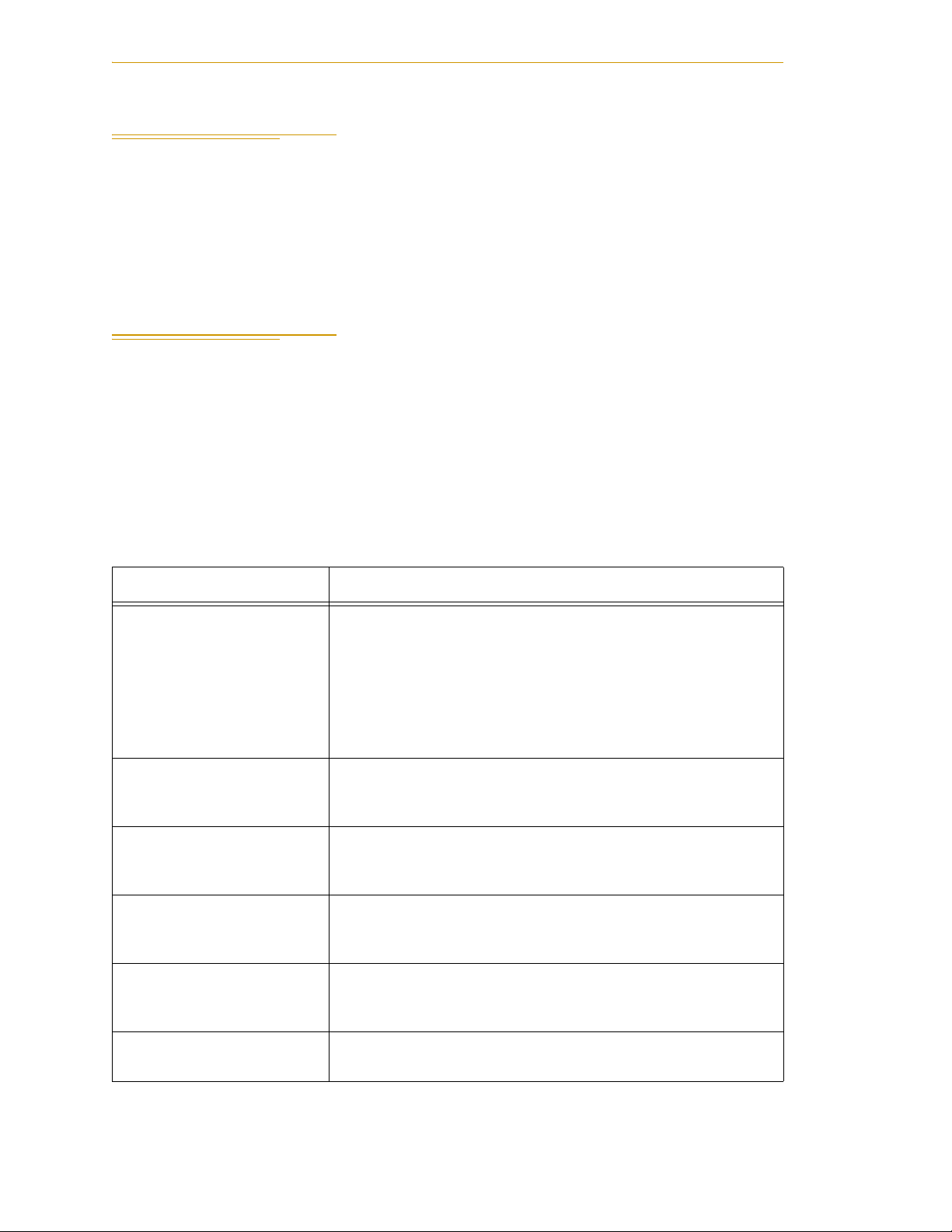

Table 1-1. Related Manuals

Manual Title Description

Adept SmartMotion

Developer’s Guide

Adept SmartController

User’s Guide

AdeptWindows Installation

Guide and AdeptWindows

Online Help

Instructions for Adept

Utility Programs

V+ Operating System User’s

Guide

V+ Language User’s Guide Describes the V

Describes the software configuration process for the Adept

SmartMotion product. See Chapter 3 for more information.

The Adept SmartMotion Developer’s Guide is provided as an

online HTML document with a Table of Contents, Search, and

Index features to navigate the document. If you do not see these

features when you are viewing a topic, click the SHOW TOC

icon that displays in the upper left corner of each page.

Contains complete information on the installation and

operation of the Adept SmartController and the optional sDIO

product.

Describes complex network installations, installation and use of

NFS server software, and the AdeptWindows DDE software.

Describes the utility programs used for advanced system

configurations, system upgrades, file copying, and other

system configuration procedures.

Describes the V

operations, monitor commands, and monitor command

programs.

control system.

+

operating system, including disk file

+

language and programming of an Adept

16 Adept SmartMotion Installation Guide, Rev. C

Page 17

System Installation 2

2.1 Overview of Installation Process

This section provides a summary of the major steps involved with installing a Adept

SmartMotion system.

1. Verify that the default hardware configuration for the sMI6 module is correct for

your application. The area to look at is:

• Digital Input Logic Voltage - see page 21.

If you need to change these settings, you will have to open the chassis and install

or move jumpers.

2. Review the proper field wiring practices. See Section 2.5 on page 23.

3. Select an enclosure for the SmartController and sMI6 chassis. See Section 2.6 on

page 24.

NOTE: Refer to the system cable diagram in Figure 2-3 on page 20 for the

remaining steps in this process.

4. Install the SmartController and peripherals. See Section 2.7 on page 25.

5. Install the sMI6 module. See Section 2.8 on page 25.

6. Install mounting rails for the three MP6 panels, then mount the three MP6 panels

on the rails. See Section 2.9 on page 26.

7. Connect cables from the sMI6 to the MP6-M, MP6-S, and MP6-E panels.

8. Install wiring to user equipment from the MP6-M and MP6-S panels. Also select

and install opto-modules. See Section 2.10 on page 31 and Section 2.11 on page

35.

9. Install wiring to user encoders from the MP6-E. See Section 2.12 on page 38.

When the above process is complete, the next step is to use the CONFIG_C and SPEC

utility programs to configure the software for your system. An overview for this process is

located in Chapter 3.

Adept SmartMotion Installation Guide, Rev. C 17

Page 18

Chapter 2 - System Installation

6

5

3

S

US

Note: early sMI6 Module LED labels

had DF instead of F for fault conditions,

and NET instead of STATUS. The

functionality is identical for both

versions.

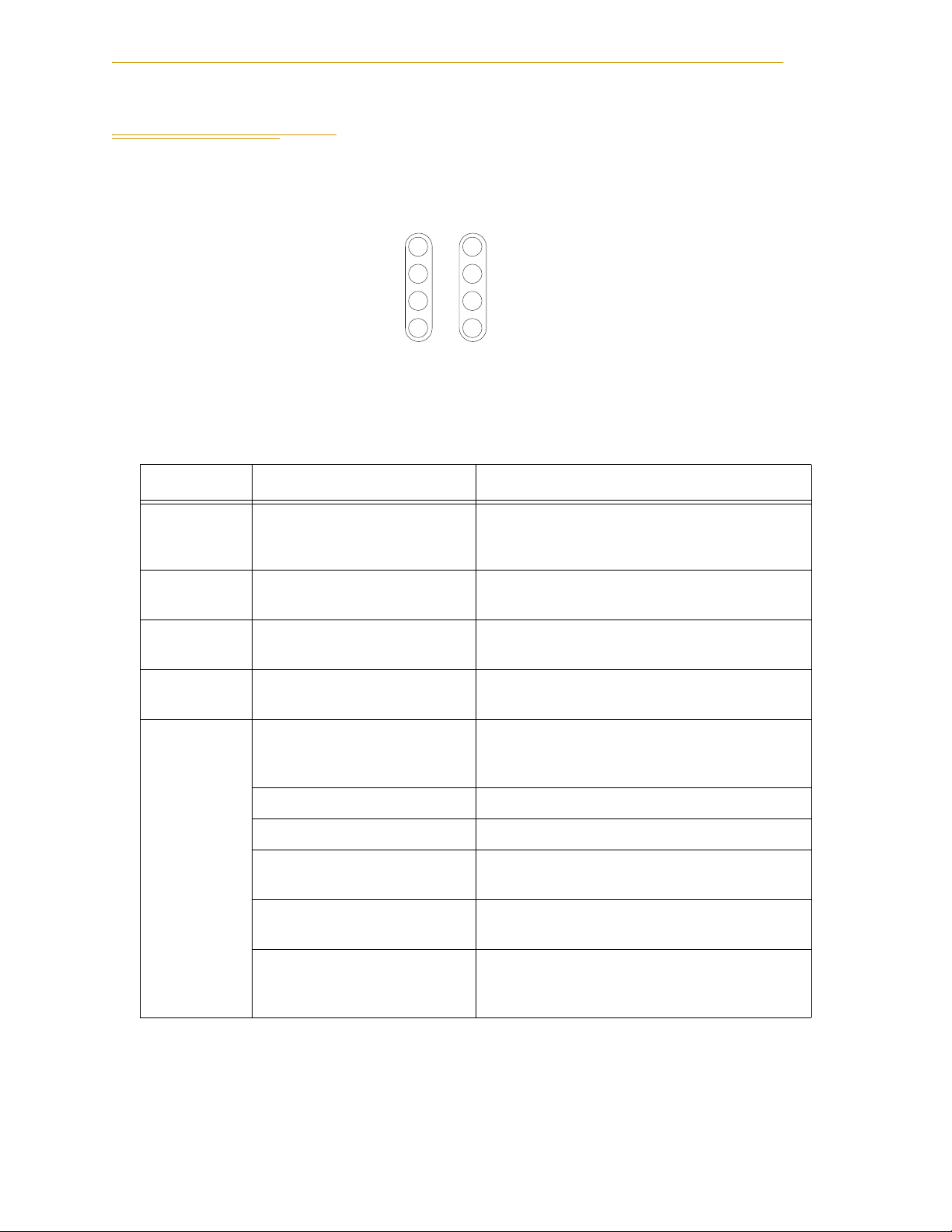

2.2 Adept sMI6 Connectors and Indicators

Adept sMI6 LED Descriptions

F6DE

F5DE

E

STAT

F3DE

Figure 2-1. Close-up of sMI6 LED Labels

The LEDs on the sMI6 are two-color devices - they can display either green or red.

Table 2-1. sMI6 LED Functions

LED Name Color Function Description

Fx (1-6) Solid Red Indicates a Fault condition exists on channel x

(1-6). Possible causes are Drive Fault,

Overtravel, quadrature error, or broken wire.

DEx (1-6) Solid Green Indicates a Drive Enable signal has been

asserted for channel x (1-6).

ES Solid Red Indicates an E-Stop signal has been asserted

from the sMI6.

HPE Solid Green Indicates the High Power Enable signal has

been asserted.

STATUS Solid Red Boot up or microprocessor problem (set by the

sMI6 hardware, other patterns are software

generated)

Slow Blinking Green Normal operation, high power OFF

Fast Blinking Green Normal operation, high power ON

Fast Blinking Red An error caused High Power to be disabled.

+

message for source of error.

See V

Fast Blinking Red/Green Triggered by utility for identifying a node on

the 1394 network

Short blink red, long blink

red, off, then repeat

If this pattern appears at boot-up, it means the

SDRAM has failed and the unit must be

returned to Adept.

18 Adept SmartMotion Installation Guide, Rev. C

Page 19

Adept sMI6 Connectors and Indicators

24V

R

F2 DE2 F6 DE6

F1 DE1

ES HPE

STATUS

F5 DE5

F4 DE4

F3 DE3

-+ -+

s

XMACHINEXENCODER

MI6

*S/N 3564-XXXXX*

SmartServo

XSERVO

1.1 1.2

XANL

XDC1 XDC2

0.5A

Figure 2-2. Adept sMI6 Module Front Panel

Adept sMI6 Connectors

1. SmartServo 1.1 and 1.2

These are SmartServo ports. Port 1.1 or 1.2 connects to the SmartController. The other port can

connect to an additional sMI6 module or an optional sDIO.

2. XENCODER connector

Connects to the MP6-E Panel to communicate signals to and from encoders.

3. XMACHINE connector

Connects to the MP6-M Panel to communicate machine signals, such as overtravel, home,

brake release, etc.

4. XSERVO connector

Connects to the MP6-S Panel to communicate servo signals, such as drive enable, drive fault,

etc.

5. XANL connector

Reserved for future use.

6. 24VDC connectors

Connects user-supplied 24VDC power from the SmartController to the sMI6 connector. The

XDC1 and XDC2 connectors are interchangeable - you can use either one.

Adept SmartMotion Installation Guide, Rev . C 19

Page 20

Chapter 2 - System Installation

STOP

R

1 2 3

RS-422/485

XUSR

XSYS

SF

XMCP

1.1

SmartController CS

LANHPE

OFF

24V 5A

ON

RS-232/TERM

XFP

HDES

XDIO

Eth 10/100

*S/N 3561-XXXXX*

SW1

Device Net

SmartServo

XDC1 XDC2

- + - +

1 2 3 4

OK

R

1.2

IEEE 1394

Cable

24VDC Power from

Controller (XDC2)

to sMI6 (XDC1)

sMI6 Module

24V

R

DF2 DE2 DF6 DE6

DF1 DE1

ES HPE

STATUS

DF5 DE5

DF4 DE4

DF3 DE3

-+ -+

s

XMACHINEXENCODER

MI6

*S/N 3564-XXXXX*

SmartServo

XSERVO

1.1 1.2

XANL

XDC1 XDC2

0.5A

MCP

24V 5V

SmartController

MP6-E MP6-M MP6-S

Front Panel

Ethernet (Eth 10/100) to PC

Controller (XMCP) to MCP

Controller (XFP) to

Front Panel (XFP)

User-Supplied

Ground Wires

MCP Adapter Cable

24VDC Power from

User-Supplied

Power Supply to

Controller (XDC1)

5VDC Power from User-Supplied

Power Supply to MP6-E and MP6-M

User-Supplied

Power Supply

Desktop or Laptop PC

Terminator

Installed

Motion-interface Panel - SERVO (MP6-S)

S

E

R

V

O

CHAN2

CHAN1

CHAN4

CHAN3

CHAN6

CHAN5

ANALOG

PWR

SPARE

P1

Motion-interface Panel - ENCODER (MP6-E)

E

N

C

O

D

E

R

CHAN2

CHAN1

CHAN4

CHAN3

CHAN6 RESVD

CHAN5

ENC PWR

P1

M

A

C

H

I

N

E

HPE

P1

CHAN1

CHAN2

CHAN3

CHAN4

SPARE

CHAN5

CHAN6

LOGIC

PWR

BRAKE-BR1

BRAKE-BR2

BRAKE-BR3

BRAKE-BR4

BRAKE-BR5

BRAKE-BR6

HIGH POWER ENABLE-HPE

HOME

OVERTRAVEL

HOME

OVERTRAVEL

HOME

OVERTRAVEL

HOME

OVERTRAVEL

HOME

OVERTRAVEL

HOME

OVERTRAVEL

2.3 System Cable Diagram

Figure 2-3. Adept SmartMotion System Cable Diagram

20 Adept SmartMotion Installation Guide, Rev. C

Page 21

2.4 Adept sMI6 Hardware Configuration

sMI6 Digital Input Logic Voltage Configuration

The sMI6 can be configured to operate with either a 5V (min 3.0V, max 5.7V) or a 12/24V

(min 8.75V, max 27.5V) logic interface. This affects the Home, Overtravel, and Drive Fault

signals. The sMI6 is normally shipped configured for 12V input, and must be

reconfigured if you decide to operate at 5V. After you configure the sMI6 voltage option,

then you must install the MP6 Machine and Servo panels accordingly.

NOTE: Refer to Figure 4-5 on page 53 for a typical input circuit in the

sMI6.

The input voltage is determined by jumpers on the main printed circuit assembly (PCA)

inside the chassis. To reconfigure the sMI6 for 5V logic operation, follow this procedure.

1. Verify that the sMI6 is disconnected from the 24VDC power source.

2. Remove the cover of the chassis by removing three screws at the back of the

chassis. See Figure 2-4.

Adept sMI6 Hardware Configuration

3. Install jumpers for each channel that you are using. See Figure 2-5 on page 22.

4. Reinstall the cover on the chassis.

Figure 2-4. Opening the sMI6 Chassis

Adept SmartMotion Installation Guide, Rev . C 21

Page 22

Chapter 2 - System Installation

Jumpers for Overtravel signals,

channels 1 to 6

Jumpers for Home signals,

channels 1 to 6

Jumpers for Drive Fault signals,

channels 1 to 6

No jumper = 12/24 V logic (factory default)

Jumper installed = 5 V logic

Digital Input Logic Voltage Configuration

Figure 2-5. Location of Jumpers on Main PCA

22 Adept SmartMotion Installation Guide, Rev. C

Page 23

Adept sMI6 Hardware Configuration

2.5 Proper Wiring and Electrical Design Practices

Designing a high-performance servo system requires attention to electrical design. Adept

SmartMotion is designed to respond to high-resolution encoder inputs, up to 32 MHz

count rate. Most drive amplifiers, DC power supplies, and brush-type motors are

potential sources of high-frequency electrical noise. Other equipment in the workcell can

also generate noise. Proper system wiring, and especially grounding, is very important to

a successful installation. The function of proper grounding is two-fold: first, to reduce the

risk of electrical shock from faults in your high-voltage equipment; and second, to help

shield from electro-magnetic and radio frequency interference (EMI and RFI).

All connections of Adept SmartMotion signals to user-supplied hardware are made via

connectors on the three MP6 panels. For proper operation, you must use good wiring

practices. Follow the general guidelines presented below. In addition, observe all

applicable local and national safety codes.

Be sure to:

• Verify that all equipment, including motor drives (amplifiers), the robot

mechanism, and the SmartController and sMI6 chassis, are properly grounded.

• Ensure that all three MP6 Ground terminals are connected to the user-supplied

ground point.

• Ensure that the MP6 DIN-mounting rail is connected to the user-supplied ground

point.

• Use only one ground point (star ground system) and keep all ground wires as

short as possible. For best results, use braided ground straps for ground

connections. (Braid has lower high-frequency impedance, for a given

cross-sectional area.)

• Use shielded twisted-pair cable for all encoder connections and analog drive

signals, and preferably for all signals.

• Use separate cables for every encoder and motor drive. Route digital signals,

motor power, and encoder signal cables separately from one another.

• Locate noise inducing devices away from the controller and other Adept

SmartMotion hardware.

• Provide noise-free regulated power for all Adept SmartMotion hardware.

• Maintain the integrity of optical isolation by using power sources other than the

Adept controller to power all signals from user-supplied equipment.

• Size all wire according to recognized electrical standards and applicable codes.

• Use proper arc suppression devices on all relay and solenoid coils.

• Adept recommends using power line filters to help prevent electrical noise from

the drive amplifiers “contaminating” the AC power lines, and vice-versa.

Adept SmartMotion Installation Guide, Rev . C 23

Page 24

Chapter 2 - System Installation

2.6 Enclosure for SmartController and sMI6

The Adept SmartController and the Adept sMI6 module should be installed in a suitable

enclosures. All of the equipment can be installed in one enclosure, or the sMI6 and

associated components can be placed in a separate enclosure near the user’s equipment;

see Note below. Enclosures can be very beneficial in helping protect the controller, sMI6

chassis, and associated peripherals and wiring from noise problems and other hazards

that are typical in many industrial settings.

NOTE: While the sMI6 and MP6 panels should be installed in an

enclosure for protection, they can be installed, along with the third-party

servo amplifiers, in a remote location closer to the user’s mechanism. The

interface between the SmartController system and the sMI6 module is via

the SmartServo network using an IEEE 1394 cable.

The enclosure must provide the internal environmental conditions (temperature,

humidity, etc.) required by the equipment. The enclosure must also meet all local and

national safety codes after the equipment is installed. The Emergency Stop circuitry must

be incorporated into the setup of the enclosure.

It is a good idea to select an enclosure that is large enough so the three MP6 panels can be

installed in the same enclosure as the other equipment. The enclosure is also a good place

to install additional user equipment such as power supplies, DIN mounting rails, wiring

terminal strips, etc.

Make sure to keep low-voltage control signal wiring away from high-voltage wiring to

avoid interference and noise problems.

24 Adept SmartMotion Installation Guide, Rev. C

Page 25

2.7 Installing the Adept SmartController

Refer to the System Cable Diagram in Figure 2-3 on page 20 and to the Adept

SmartController User’s Guide to install the SmartController and related peripherals. A

brief summary is presented here.

1. Mount the SmartController in the workcell according to the instructions in the

Adept SmartController User’s Guide.

2. Install the Compact Flash.

3. Install the user-supplied ground wire from the ground screw on the side of the

controller chassis to ground.

4. Install the user-supplied 24VDC power to the controller. Power must be turned

off.

5. Connect the optional Adept Front Panel.

6. Connect the MCP.

7. Connect the user-supplied PC and install the AdeptWindows user interface on

the PC.

Installing the Adept sMI6 Module

2.8 Installing the Adept sMI6 Module

Refer to the System Cable Diagram in Figure 2-3 on page 20.

1. Mount the sMI6 module in the workcell. The mounting options include rack

mounting, panel mounting, and table mounting. See Section 4.2 on page 48 for

dimension drawings of the different mounting brackets.

You can also stack-mount the sMI6 directly above the SmartController with

combining brackets. See the Stacking Components section in the Adept

SmartController User’s Guide. The sMI6 has the same dimensions as the sDIO

module that is shown there.

2. Connect an IEEE 1394 cable from the SmartController to the sMI6.

3. Connect a user-supplied ground wire from the ground screw on the side of the

sMI6 chassis to ground. The ground wire must be less than 3 meters long.

4. Connect a 24VDC cable from the SmartController to the sMI6. The DC power

cable must be less than 10 meters long.

Adept SmartMotion Installation Guide, Rev . C 25

Page 26

Chapter 2 - System Installation

2.9 Installing MP6 Panels

The three 6-channel Motion-interface Panels (MP6-M, MP6-S, and MP6-E) serve as the

interface between the sMI6 module and the user’s hardware. The MP6-M panel also

provides mounting sockets for up to seven Opto-22 output modules. Figure 2-6, Figure

2-7, and Figure 2-8 show the layout and dimensions of the MP6 panels. Figure 2-9 on page

30 shows a typical system wiring for one axis of motion. One set of MP6 panels is required

for every sMI6.

WARNI NG : The six removable connectors on the MP6-M

are purposely not keyed so they can be interchanged for

diagnostic purposes. It is important that these connectors

are not interchanged during normal operation. Doing so

can cause unstable operation which could result in serious

equipment damage and injury to personnel.

Rail Mounting the MP6 Panels

The MP6 panels are designed to be installed on DIN-style industrial mounting rails. The

MP6 panels will fit on these types of rails:

TS 35 Symmetrical 35mm x 7.5mm

TS 35 Symmetrical 35mm x 15mm

TS 32 Asymmetrical 32mm x 15mm

DIN rail hardware is available from many vendors, including:

•Weidmüller

• Allen-Bradley

•Phoenix

Install the mounting rails in the workcell in a location that is easily accessible and close

enough to the Adept SmartController so the motion interface cables can reach between the

controller and the MP6 panels. One of the best places to install the mounting rails is in the

same enclosure as the controller.

A variety of other DIN-rail mountable hardware is available from the vendors listed

above, including terminal blocks, end brackets, opto-isolation systems (for voltage-level

shifting and additional current drive) and power supplies.

26 Adept SmartMotion Installation Guide, Rev. C

Page 27

Installing the Adept sMI6 Module

Panel Mounting the MP6 Panels

If you do not want to use DIN-rail mounting, you can use panel (screw) mounting instead.

1. Remove and discard the MP6 mounting enclosures. This is done by removing two

screws on either end of each unit, then sliding out the printed circuit assembly

(PCA).

2. Use the four mounting holes provided on each MP6 panel to mount the PCA with

appropriate screws.

WARNI NG : Be sure to use suitable stand-offs or spacers

and comply with national and local electrical regulations

regarding spacing and insulation.

Plug-In Opto Modules on the MP6-M

The plug-in opto-isolator output modules are standard Opto-22 Generation-4 single-point

type, or equivalent. These modules have built-in indicator LEDs and are individually

fused. The mounting panels are supplied from Adept without I/O modules so you can

choose the type of modules (AC, DC, voltage range) which best suit your particular

application.

See Section 2.10 for more detailed information on the opto modules.

Adept SmartMotion Installation Guide, Rev . C 27

Page 28

Chapter 2 - System Installation

P1

33

50

17

Motion-interface Panel - SERVO (MP6-S)

P1

S

E

R

108mm

(4.25")

S

E

R

V

O

CHAN2

CHAN4

CHAN6

V

O

CHAN1

34

18

1

1

DE1

DF1

6

9

5

CHAN1 to 6

136.5mm

(5.375")

CD1

CHAN3

CHAN5

ANALOG PWR

Figure 2-6. MP6-S Panel – Layout and Dimensions

P1

33

50

17

Motion-interface Panel - ENCODER (MP6-E)

P1

E

N

C

O

108mm

(4.25")

D

E

N

C

O

D

E

R

CHAN2

CHAN4

CHAN6 RESVD

E

R

CHAN1

CHAN3

CHAN5

ENC PWR

SPARE

ANALOG

PWR

1 +12V

2 RTN

3 –12V

4 SHD/GND

34

18

1

1

5

6

9

112mm

(4.4")

ENC PWR

CHAN1 to 6

Figure 2-7. MP6-E Panel – Layout and Dimensions

28 Adept SmartMotion Installation Guide, Rev. C

1 PWR

2 RTN

3 SHD

4 GND

Page 29

3

LOGIC PWR

+

4 GND

3 SHD

2 5VRTN

1 5V

Installing the Adept sMI6 Module

M

A

C

H

I

N

34

18

1

LOGIC

PWR

CHAN1

E

108mm

(4.25")

BRAKE-BR1

MACHINE

OVERTRAVEL

50

33

17

P1

SPARE

206.4mm

(8.125")

CHAN4

CHAN1 to 3

9 SHD

8 BR–

7 BR+

6 HM–

5 HM+

4 OT–

3

1 OT

CHAN2

HAN

HOME

BRAKE-BR4

OVERTRAVEL

BRAKE-BR2

HOME

BRAKE-BR5

OVERTRAVEL

BRAKE-BR3

HOME

BRAKE-BR6

OVERTRAVEL

HOME

OVERTRAVEL

HOME

OVERTRAVEL

HOME

3 GND

2 HPE–

1 HPE+

CHAN5

CHAN6

HPE

HPE

4 SHD

Figure 2-8. MP6-M Panel – Layout and Dimensions

1 OT+

2

3

4 OT–

5 HM+

6 HM–

7 BR+

8 BR–

9 SHD

CHAN4 to 6

Adept SmartMotion Installation Guide, Rev . C 29

Page 30

Chapter 2 - System Installation

Customer's Hardware

Adept SmartMotion Hardware

Drive Amplifier

(Typical)

1

Drive

Enable

DE+

DE–

2

+FD4

DF–

5

Drive

Fault

+

+

Drive

Enable

Drive

Fault

1

High Power

Enable

HPE+

HPE–

2

MP6-S

MP6-M

Output

Input

1

Brake

Release

OT+

2

3

Positive

Overtravel

OT–

4

5

Negative

Overtravel

HM+

HM–

6

7

Home

BR+

BR–

8

Output

1

2

3

4

PWR

RTN

SHD

GND

9

SHD

Input

Input

Output

+

–

Typical

wiring for

one of six

axes

L1

L2

+

–

User I/O

Power Supply

User Power Supply

MP6-E

A–

A+

B+

B–

I+

I–

Encoder

+

–

Pin numbers

typical for encoder

channels 1 to 6

3

1

2

4

5

6

7

8

9

SHD

1

2

3

4

PWR

RTN

SHD

GND

+

–

User

Power

Supply

for Encoders

+

–

Brake Solenoid

PWR

RTN

Note: Opto-modules shown

as simplified equivalent

circuit only.

Line Filter

(recommended)

*

*

Commutating diode must be

used on all inductive loads.

(typical 1N4005)

Command

Signal

CD+

CD–

SHD

Analog Command

7

8

3

M

Motor

Output

Typical

wiring for

one of six

axes

User Logic

Power Supply

User-Supplied

Jumper

Emergency-Stop Power Cutoff

To SmartController

XUSR Connector

See pages 54 and 55 for e xamples of

this circuitry for various categories of

application safety requirements.

30 Adept SmartMotion Installation Guide, Rev. C

Figure 2-9. Typical System Wiring for One Axis of Motion

Page 31

MP6 Machine (MP6-M) Panel Wiring

2.10 MP6 Machine (MP6-M) Panel Wiring

The MP6-M is used to interface to the machine (robot or motion mechanism). It provides

two digital inputs and one digital output for each of six channels (Channels 1 to 6). See

Figure 2-8 on page 29 for the location of the various connectors.

• digital input for Overtravel (OT)

• digital input for Home Switch (HM)

• digital output for Brake Release (BR)

The MP6-M also has one independent output for high power enable (HPE).

The function of the MP6-M is to provide convenient interconnect points and to perform

voltage level-shifting of some signals, for example, to interface 120VAC or 230VAC user

circuits to the HPE output.

Optical Isolation

All signals (input and output) are isolated inside the sMI6 module. Additional isolation

for the output channels (6 for Brake Release (BR), one for High Power Enable) is provided

on the MP6-M using Opto-22 modules. The main functions of the Opto-22 modules on the

output channels of the MP6-M are to give enhanced current drive capability, and allow

flexibility in connecting to a variety of voltage levels.

Input Current Requirements (OT, HM)

The inputs on the MP6-M are connected directly to the sMI6. Therefore, the input

specifications for the MP6-M are the same as for the MP6-S. See Table 2-2.

Table 2-2. Digital Input Specifications (sMI6 module)

Operational voltage range 0 to 24 VDC

“Off” state voltage range 0 to 3 VDC

“On” state voltage range 10 to 24 VDC

Operational current range

“Off” state current range

“On” state current range

Typical threshold current, per channel

Impedance (V

Current at V

in/Iin

= +24 VDC Iin 20 mA

in

Turn on response time (hardware

Turn off response time (hardware

a

The input current specifications are provided for reference; voltage sources are typically used

a

a

a

a

) 1.3 K minimum

b

)

b

)5 µsec maximum

0 to 20 mA

0 to 1.2 mA

7 to 20 mA

10 mA

5 µsec maximum

to drive the inputs.

b

The software scan rate depends on Servo software, and is currently 1 ms.

Adept SmartMotion Installation Guide, Rev . C 31

Page 32

Chapter 2 - System Installation

Input Voltage Configuration

See “sMI6 Digital Input Logic Voltage Configuration” on page 21.

Output Current Requirements (MP6-M, HPE and BR, External)

The digital outputs (HPE and BR) on the MP6-M are optically-isolated via Opto-22

modules. (Therefore, the output specifications for the MP6-M are different than the

MP6-S.) Select an appropriate plug-in single-channel module from the “Generation 4”

(G4) range manufactured by Opto-22. (Compatible modules are also made by other

manufacturers.)

Modules are available for various external voltages to suit the user’s equipment, including

12V DC and 24V DC, and 110VAC and 230VAC. See Table 2-3 for specifications of some

commonly-used modules. (See the manufacturer’s documentation for any parameters or

module types not listed.) You must provide logic-power to connect to and from the

Opto-22 modules. The logic input current required depends on the number, voltage, and

type of Opto-22 modules.

The Opto-22 DC output modules can each supply from 0.5 to 3 Amps to the user’s

external equipment. The total current actually required for outputs will depend on the

user-supplied external equipment (relays, solenoids, limit switches, etc.).

Table 2-3. Digital Output Specifications for HPE and BR (Opto-22 module, typical)

Opto-22 module type G4ODC5 G4ODC5A G4OAC5 G4OAC5A

Operating voltage range 5 - 60 VDC 5 - 200

VDC

Current rating @45°C ambient

@70°C ambient

3 A

2 A

1 A

0.55 A

12 - 140

VAC

—

1.5 A

24 - 280

VAC

—

1.5 A

Output voltage drop maximum 1.6 V 1.6 V 1.6 V peak 1.6 V peak

a

Off-state leakage @max voltage 1 mA 1 mA 5 mA rms

Turn-on time (hardware), max

Turn-off time (hardware), max

Logic voltage range (V

) 2.4-8 VDC 2.4-8 VDC 4-8 VDC 4-8 VDC

cc

c

c

50 µs 100 µs 1/2 cycle 1/2 cycle

50 µs 750 µs 1/2 cycle 1/2 cycle

5 mA rms

Logic input current 12mA@5V 12mA@5V 12mA@5V 12mA@5V

a

At 60 Hz, 140VAC

b

At 60 Hz, 280VAC (2.5 mA rms at 60 Hz, 120VAC)

c

The software scan rate depends on Servo software, and is currently 1 ms.

User-Supplied Logic Power (Internal)

b

The Opto-22 opto-isolator modules also require logic voltage to interface with the Adept

sMI6 module. This voltage must be provided by the user at the PWR terminals. The power

supply voltage should be the same as the logic voltage rating of the Opto 22 output

module. For example: 5V logic voltage Opto 22 requires a 5V logic user-supplied power

supply. Use of shielded, twisted-pair cable is recommended. Allow 12mA per output

channel (a total 0.1A for 7 modules) for each MP6-M.

32 Adept SmartMotion Installation Guide, Rev. C

Page 33

MP6 Machine (MP6-M) Panel Wiring

Overtravel Limit Switches (Input)

One Overtravel Limit switch input is provided for each axis. (Two normally-closed

switches must be wired in series or normally-open switches in parallel for one input.)

These inputs can be used to help protect the mechanical hardware when the end of axis

travel is reached. Each switch should be normally closed, and open only when an

overtravel condition is reached. If any of the overtravel switches is opened on an active

channel, the controller will disable High Power.

The input polarity for the overtravel inputs is configurable using the SPEC program.

The presence of an Overtravel signal will prevent the successful completion of the Drive

Enable sequence. Any unused Overtravel inputs on active channels must be configured to

provide a “no fault” condition. In most industrial situations there will be considerable

electrical noise in the operating environment. An unterminated input may not function as

anticipated. Adept recommends that you install a shorting wire between the MP6-M

terminals of any unused overtravel inputs.

NOTE: Refer to Figure 4-5 on page 53 for a typical input circuit in the

sMI6.

Home Switch (Input)

The Home Switch inputs are used during the calibration sequence of each axis. These

inputs can be activated anywhere within the travel of the axis, however, it is

advantageous to locate the home switch just inside one of the overtravel limit switches.

The input polarity of the Home input is configurable using the SPEC program. You

should design the home switch so that it remains active all the way through one of the

overtravel limits, then Adept SmartMotion will always be able to calibrate the axis.

Brake Release (Output)

The Brake Release (BR) signals are provided to control external safety brakes. These

signals are asserted to release the brakes after the drive has been successfully enabled. The

output modules are on (conduct) when in the “Brake Released” condition.

NOTE: Refer to Figure 4-6 on page 53 for a typical output circuit in the

sMI6.

High Power Enable (Output)

One High Power Enable (HPE) signal is provided for the entire system. (If you have more

than one sMI6 module, the signal is internally connected in parallel to every sMI6.) The

HPE signal drives the user-supplied power contactor for the motor drive-amplifiers. The

output is controlled via the Emergency Stop circuitry in the controller. The High Power

Enable signal is accessible on the HPE terminal block of the MP6-M.

Adept SmartMotion Installation Guide, Rev . C 33

Page 34

Chapter 2 - System Installation

Table 2-4. MP6-M Connector Terminal Assignments (Typical, 1 of 6)

Pin

Signal

Abbrev. Description

Signal

Typ e

Default Mode of

Operation

1 OT+ Overtravel(+) input Open on overtravel

2 — (Connected to terminal 3)

3 — (Connected to terminal 2)

a

a

—

—

(configurable using

SPEC program)

4 OT– Overtravel (return) return

5 HM+ Home Switch(+) input Closed at home

6 HM– Home Switch (return) return

(configurable using

SPEC program)

7 BR+ Brake Release (+) output Closed in brake

8 BR– Brake Release (return) return

released condition (not

configurable)

9 SHD Shield shield ——

a

Pins 2 and 3 are connected to each other to help you connect a normally-closed switch in

series, if you have separate OT signals from the limit switches at each end of the axis. Use

them if you need, otherwise make no connection.

Table 2-5. MP6-M Opto Power (Logic) Connectors (one per MP6-M)

Signal

Pin

Abbrev. Description

1 +PWR If using Opto-22 G4ODC5 or G4OAC5 series modules: 5V.

2 RTN Common (return) for the above voltage

3 SHD Shield for power cable

4 GND Ground for all MP6-M shield connections. Connect this to

your ground point.

34 Adept SmartMotion Installation Guide, Rev. C

Page 35

2.11 MP6 Servo (MP6-S) Panel Wiring

The MP6-S is used to interface to the Servo Drive amplifiers. It provides one digital input

(drive fault, DF) and one digital output (drive enable, DE) for each of six channels

(channels 1 to 6). It also provides one analog output (command drive, CD) for each of six

channels. The function of the MP6-S is to interconnect the signals from user circuits to the

sMI6 module.

Drive Compatibility

The Adept SmartMotion control system is compatible with most industry-standard motor

drives that accept a ±10 Volt analog input signal for current (torque) or velocity

commands. In addition, Adept SmartMotion provides two discrete I/O signals that are

dedicated to specific functions supported by most commercially available motor drives. In

summary, each motion channel supports the following drive signals:

• analog output (±10V) for Command Drive (CD)

• digital output (to the drive) for Drive Enable (DE)

• digital input (from the drive) to monitor for a Drive Fault (DF)

MP6 Servo (MP6-S) Panel Wiring

Optical Isolation

The digital signals, Drive Enable and Drive Fault, are optically isolated. No additional

isolation is required on the MP6-S. The MP6-S does not use Opto-22 modules. Note that

the Analog Output is not optically isolated in the sMI6 module, unlike in previous

versions of the Adept Motion Interface products.

MP6-S Input Current Requirements (Drive Fault)

The digital inputs on the MP6-S are connected directly to the sMI6. Therefore, the input

specifications for the MP6-S are the same as for the MP6-M. See Table 2-2 on page 31.

MP6-S Output Current Requirements (Drive Enable)

The digital outputs on the MP6-S are connected directly to the sMI6. Therefore, the output

specifications for the MP6-S are different than the MP6-M. See Table 2-6.

Table 2-6. Digital Output Specifications for Drive Enable Signal

Operating voltage range 5 to 24 VDC

Operational current range, per channel I

V

across output in ON condition V

drop

100 mA

out

0.85 V at 100 mA

drop

0.80 V at 10 mA

V

drop

Output-off leakage current I

Turn-on response time (hardware

Turn-off response time (hardware

a

The software scan rate depends on Servo software, and is currently 1 ms.

a

)

a

) 200 µsec maximum

600 µA

out

3 µsec maximum

Adept SmartMotion Installation Guide, Rev . C 35

Page 36

Chapter 2 - System Installation

Connecting the Drives

Each channel (1 to 6) has a 9-pin female D-connector that connects to the user’s

equipment. All six connectors have the same pin assignments (see Table 2-4 on page 34).

Refer to Figure 2-6 for the physical location of each connector. All signal nomenclature is

defined as viewed from the controller. Thus, an output is controlled by the Adept

controller and an input is monitored by the Adept controller.

Table 2-7. MP6-S Connector Pin Assignments (Typical, 1 of 6)

Pin

Signal

Abbrev. Description

Signal

Type Mode of Operation

1 DE+ Drive Enable (+) output Not configurable –

2 DE– Drive Enable (return) return

On to enable drive

4 DF+ Drive Fault (+) input Configurable using

5 DF– Drive Fault (return) return

SPEC program

7 CD+ DAC Command (+) output ±10V, configurable

using SPEC program

8 CD– DAC Command (return) return

3SHD Shield

a

shield ——

6 Not connected

9 Not connected

a

If two separate cables are used for Command signals and Drive signals, then their shields

should be tied together at Pin 3 SHD.

36 Adept SmartMotion Installation Guide, Rev. C

Page 37

MP6 Servo (MP6-S) Panel Wiring

Drive Enable (Output)

The Drive Enable signals (DE+, DE–) are outputs to the drives which command the drives

to enable motor power. These signals are activated as part of the power enable sequence,

after the High Power Enable signal has been activated. Refer to the SPEC program for

complete details on the power enable sequence and software-timing parameters.

The Drive Enable output logic is set to normally open (closed/on to enable drive). The

signal polarity is not user configurable. However, the user can provide an external circuit,

such as a relay, to change the polarity if required.

Delay Time

Refer to the SPEC program for information on setting the delay time for ignoring an

amplifier fault immediately after the amplifier has been enabled with a Drive Enable

signal.

Drive Fault (Input)

The Drive Fault input (DF+, DF–) is used to indicate a drive fault, such as

over-temperature, over-current, etc., and causes all drives to power down via the Drive

Enable signals. This input is configurable via software (SPEC program) so that a fault is

declared in either a voltage-present or voltage-absent condition. Thus, this input can also

be used to monitor a “drive ready” signal. Drive Fault inputs are only monitored while

Drive Enable is on, therefore, drive faults on unused channels are not monitored.

The presence of a drive fault will prevent the successful completion of the Drive Enable

sequence. Any unused Drive Fault inputs on active channels must be configured to

provide a “no fault” condition. In many industrial situations there will be considerable

electrical noise in the operating environment. An unterminated input may not function as

anticipated. Adept recommends that you install a shorting wire between the MP6-S pins

of any unused Drive Fault inputs.

Command Drive (Output)

The Command Drive outputs (CD+, CD–) provide a command signal to each of the

drives. Maximum output is ± 10 Volts into a 10K ohm input resistance. These analog

outputs are rated at 100 mA (max) per channel. Short-circuit protection is provided by a

100 ohm internal current limiting resistor. Refer to the SPEC program for complete details

on configuring this signal.

A separate tie point for the cable shield is provided to help minimize electrical noise. The

shield should normally be left floating at the amplifier end. For the shield to be effective,

you must connect the GND terminal of the MP6-M Opto Pwr connector to a suitable

ground point.

Separate + and – outputs are provided for each of the six CD (Command Drive) outputs.

You should use a separate twisted-pair wire for each CD pair. Do not use a “common”

wire to connect the negative outputs as this will seriously reduce the noise-immunity of

the system.

Adept SmartMotion Installation Guide, Rev . C 37

Page 38

Chapter 2 - System Installation

2.12 MP6 Encoder (MP6-E) Panel Wiring

Encoder Compatibility

The MP6-E is used to interface to the encoders. It supports up to six encoder channels,

with differential input (A, B and Index) for each encoder. Each channel is designed to

interface directly to encoders which use industry standard AB quadrature outputs and an

optional zero-index channel. The encoder input circuitry is compatible with encoders

using differential line driver outputs (RS-422 signal, +5VDC). (Alternatively, 5V

single-ended outputs may be used, but they will be much more sensitive to external

electrical noise. For information on compatibility with other types of encoders, please

consult Adept Customer Service.) Adept strongly recommends using differential

encoders, with index pulse.

Each of the six encoder channels has its own 9-pin female D-connector located on the

MP6-E. Refer to Figure 2-7 on page 28 for the physical location of each connector.

Connecting Power to the Encoders

All encoder inputs for the sMI6 use a scheme similar to an RS-422 differential receiver

based on industry standard 75175 integrated circuits. The difference is that a custom

resistor network and two differential receivers are used on each of the A and B inputs.

This scheme allows for the detection of broken or shorted encoder wiring. See Figure 2-11

on page 41 for a schematic.

The encoder inputs for the previous Adept MI6 product are optically isolated at the MI6

module. This provided the ability to use different power supplies for different channels

with no common ground. Although this provided some noise immunity, it was at the

expense of a slower input pulse rate due to the slow switching speed of the optical inputs.

To provide higher encoder pulse rates, the sMI6 was designed with standard RS-422

receivers to replace these optical isolation components.

In order to maintain compatibility with the Adept MI6, all encoder power must be

supplied by an external source. Power for each encoder can be supplied from

independent power supplies or from one common power supply. However, all encoder

power supply commons must be connected together and must be connected to the sMI6's

24V power input common. Encoder power should be supplied from a source that remains

on when High Power and/or Drive Enable is off. This eliminates the need to re-calibrate

the mechanism after High Power has been cycled off.

Adept strongly recommends using shielded, twisted-pair cable for all encoder and power

connections. The MP6-E can be used to distribute power to the encoders. The power,

voltage, and current required depend upon the encoders chosen by the user. If one

common power supply is being used for all encoder channels, the power source is

connected to the “Encoder Pwr” terminal on the lower section of the MP6-E. The encoder

power supply should not be used to power other equipment, because this may cause

electrical interference to the encoder signals.

If separate power is desired for any of the encoder channels (for example, if any of your

encoders require different supply voltages), power connections must be made directly to

that encoder. The encoder input circuitry on the MP6-E does not require power from an

external supply.

38 Adept SmartMotion Installation Guide, Rev. C

Page 39

MP6 Encoder (MP6-E) Panel Wiring

Adept recommends using a linear power supply instead of a switching power supply. If a

switching power supply is used, make sure to meet the minimum current requirements.

Encoder Power Grounding

Because the 75175 input circuits on the sMI6 have a common-mode input range of +/-12V,

the nominal differential signal swing of 0 to 5V must remain within common-mode input

range. Since a separate power supply is used to power the encoder RS-422 (or

single-ended) drivers, the common of the separate supplies must share a common ground

reference with the voltage supply into the sMI6. Thus, it is very important that the

common signals for these separate supplies be connected to the common of the 24V

plug-in terminal on the front of the sMI6.

If an older MI6-based system is being retrofitted with the sMI6, a modification to the

encoder power supply circuit may need to be made to provide this common power

supply connection. In some cases, new wiring must be provided. For example, the

Yaskawa Sigma amplifiers provide an “SG” or signal ground wire in the “CN” connector

that may not have been needed on the MI6. Since this SG ground must now be connected

to the sMI6 common for differential-signal common-mode reference, a new connection

might have to be made.

The DC power supply common for the internal voltages, including the 5V for the

differential receivers, is connected to the frame ground of the sMI6 internally. The shield

for the sMI6/MP6E cable is also connected to frame ground at the sMI6 XENCODER

connector. Thus, one can sometimes provide the common ground reference at the MP6E

Encoder Power terminal block by connecting pin 2, User's Encoder Power Supply Return

“RTN”, to pin 3 Cable Shield “SHD”. See Table 2-8 and Figure 2-10 on page 41. This

Terminal can thus serve as the common ground wiring point on an encoder power system

of separate encoder voltage sources.

Table 2-8. MP6-E Power Connectors (one per MP6-E)

Signal

Pin

1 PWR Encoder voltage supply

2 RTN Common (return) for the above voltage

3 SHD Shield for power cable

4 GND Ground for all MP6-E shield connections. Connect this to your

Abbrev. Description

ground point.

Encoder Cable Length (User Supplied)

Because encoders are not supplied with the system and output circuitry varies between

different encoders, it is not possible for Adept to specify a maximum cable length.

However, it is good practice to keep the encoder cable length to a minimum. This practice

helps to improve noise immunity and reduces the risk of encoder signal problems.

Adept SmartMotion Installation Guide, Rev . C 39

Page 40

Chapter 2 - System Installation

Connecting the Encoders

Each encoder channel has its own 9-pin D-connector. The connectors are intentionally not

keyed and can be interchanged for diagnostic purposes, provided that no attempt is made

to enable the associated axis. The pin assignment for each connector is detailed in Ta bl e

2-9. For best protection against noise, use shielded twisted-pair cable. The shield should

encase only those signals associated with that particular encoder channel. A separate

terminal is provided for connection of the shield. To avoid creating a “ground loop,” the

shield should normally be left floating (not connected) at the encoder end, unless the

encoder body is electrically isolated from the equipment it is mounted to.

Table 2-9. Encoder Channel Pin Assignments (Channel 1 to 6)

Pin Number Encoder Signal Pin Number Encoder Signal

1A +6Index +

2A –7Index –

3 Cable Shield 8 +Power

4B +9Power Com

5B –

Encoder Input Circuitry

All incremental-encoder input circuits are identical. Standard hardware configurations of

the sMI6 support RS-422 +5VDC signal levels in a differential mode. Adept strongly

recommends using differential encoders for maximum noise immunity. Using differential

encoders also enables the Encoder failure detection system to function. However, Adept

SmartMotion hardware is compatible with single-ended and open-collector outputs.

Schematics to connect these types of encoders are located in Figure 2-12 and Figure 2-13.

NOTE: If you use single-ended inputs, say by connecting the encoder's A

signal to the sMI6's “A-” input as in earlier MI6 systems, then you must

now connect the opposite polarity signal, “A+” in this example, to the

encoder and sMI6 power supply common.

If an older MI6-based system is being retrofitted with the sMI6, the connections of any

single-ended encoder signals must be modified in the customer wiring. The unused

differential signal input on A, B or Index, must be connected to the encoder power

common. For example, the standard wiring scheme was to connect the encoder

single-ended A to Adept's A-, the encoder B to B- and encoder Index to Index-. For this

example, the Adept A+, B+, and Index+ signals must be connected to Power Com in the

user wiring, say at the 9-pin connector, for the single-ended encoder to work on the sMI6.

See Table 2-9.

The encoder signals pass directly through the MP6-E to the sMI6 module. All encoder

inputs use RS-422 receivers on the differential inputs. Figure 2-10 and Figure 2-11

illustrate the input circuit for each encoder channel. The A, B, and Index signals are then

digitally filtered to improve noise immunity.

40 Adept SmartMotion Installation Guide, Rev. C

Page 41

MP6 Encoder (MP6-E) Panel Wiring

sMI6

5V

A

A

5V

B

B

I

I

A+

A–

B+

B–

5V

I+

I–

+PWR

SHLD

Adept sMI6/

MP6-E Cable

SHLD

MP6-E

A+

A–

B+

B–

I+

I–

PWR

RTN

SHD

PWR

RTN

SHD

GND