Page 1

Adept Viper

s1300 Robot

User’s Guide

Page 2

Page 3

Adept Viper

5960 Inglewood Drive • Pleasanton, CA 94588 • USA • Phone 925.245.3400 • Fax 925.960.0452

Otto-Hahn-Strasse 23 • 44227 Dortmund • Germany • Phone +49.231.75.89.40 • Fax +49.231.75.89.450

Block 5000 Ang Mo Kio Avenue 5 • #05-12 Techplace II • Singapore 569870 • Phone +65.6755 2258 • Fax +65.6755 0598

s1300 Robot

User’s Guide

P/N: 06561-000, Rev B

December 2011

Page 4

The information contained herein is the property of Adept Technology, Inc., and shall not be reproduced

in whole or in part without prior written approval of Adept Technology, Inc. The information herein is subject to change without notice and should not be construed as a commitment by Adept Technology, Inc. This

manual is periodically reviewed and revised.

Adept Technology, Inc., assumes no responsibility for any errors or omissions in this document. Critical

evaluation of this manual by the user is welcomed. Your comments assist us in preparation of future documentation. Please email your comments to: techpubs@adept.com.

Copyright

The Adept logo, AdeptVision, AIM, HexSight, and HexaVision

Adept SmartController CX are trademarks of Adept Technology, Inc.

Any trademarks from other companies used in this publication

2006, 2011 by Adept Technology, Inc. All rights reserved.

are registered trademarks of Adept Technology, Inc.

Adept ACE, Adept Viper s1300, Adept PA-4, and

are the property of those respective companies.

Printed in the United States of America

Page 5

Table of Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Adept Viper s1300™ Robots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Adept SmartController CX™. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Adept PA-4™ CAT-3 Power Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.2 Dangers, Warnings, Cautions, and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.4 What to Do in an Emergency Situation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.5 Additional Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Manufacturer’s Declaration of Compliance (MDOC) . . . . . . . . . . . . . . . . 12

Adept Robot Safety Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.6 Intended Use of the Robots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.7 Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.8 Manufacturer’s Declaration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.9 How Can I Get Help? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Adept Document Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2 Robot Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.1 Unpacking and Inspecting the Adept Equipment. . . . . . . . . . . . . . . . . . . . . . . 17

2.2 Environmental and Facility Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.3 Transporting the Robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Precautions in Transporting Robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Transport Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.4 Mounting the Robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.5 Grounding the Robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.6 Description of Connectors on Robot Interface Panel . . . . . . . . . . . . . . . . . . . . 24

2.7 Air Lines and Signal Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Optional Solenoid Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Solenoid Valve Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

External Mounting Locations on Robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.8 Designing End-Effectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Mass of End-Effector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Center of Gravity Position of End-Effector . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Moment of Inertia Around J4, J5 and J6 . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Adept Viper s1300 Robot User’s Guide, Rev B 5

Page 6

Table of Contents

3 System Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.1 System Cable Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.2 Installing the SmartController . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.3 Installing the Adept ACE Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.4 Connecting the PC to the SmartController . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.5 Installing the PA-4 Power Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.6 Connecting 3-Phase AC Power to PA-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

PA-4 3-Phase Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Connecting the PA-4 3-Phase AC Power Cord to AC Supply . . . . . . . . . . 38

Typical 3-Phase AC Power Installation Diagrams . . . . . . . . . . . . . . . . . . . . . 39

4 System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.1 Commissioning the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Verifying Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Mechanical Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

System Cable Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

User-Supplied Safety Equipment Checks . . . . . . . . . . . . . . . . . . . . . 42

System Start-up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Running the Adept ACE Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Starting the Adept ACE Software . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Enabling High Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Verifying E-Stop Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Verifying Robot Motions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.2 Learning to Program the Robot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.3 Connecting Digital I/O to the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.4 Status Panel Codes on sDAI Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.5 Installing and Using the Brake Release Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.1 Replacing Encoder Backup Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.2 Installing User-Supplied Hardstops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6 Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.1 Robot Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.2 Robot Flange Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6 Adept Viper s1300 Robot User’s Guide, Re v B

Page 7

List of Figures

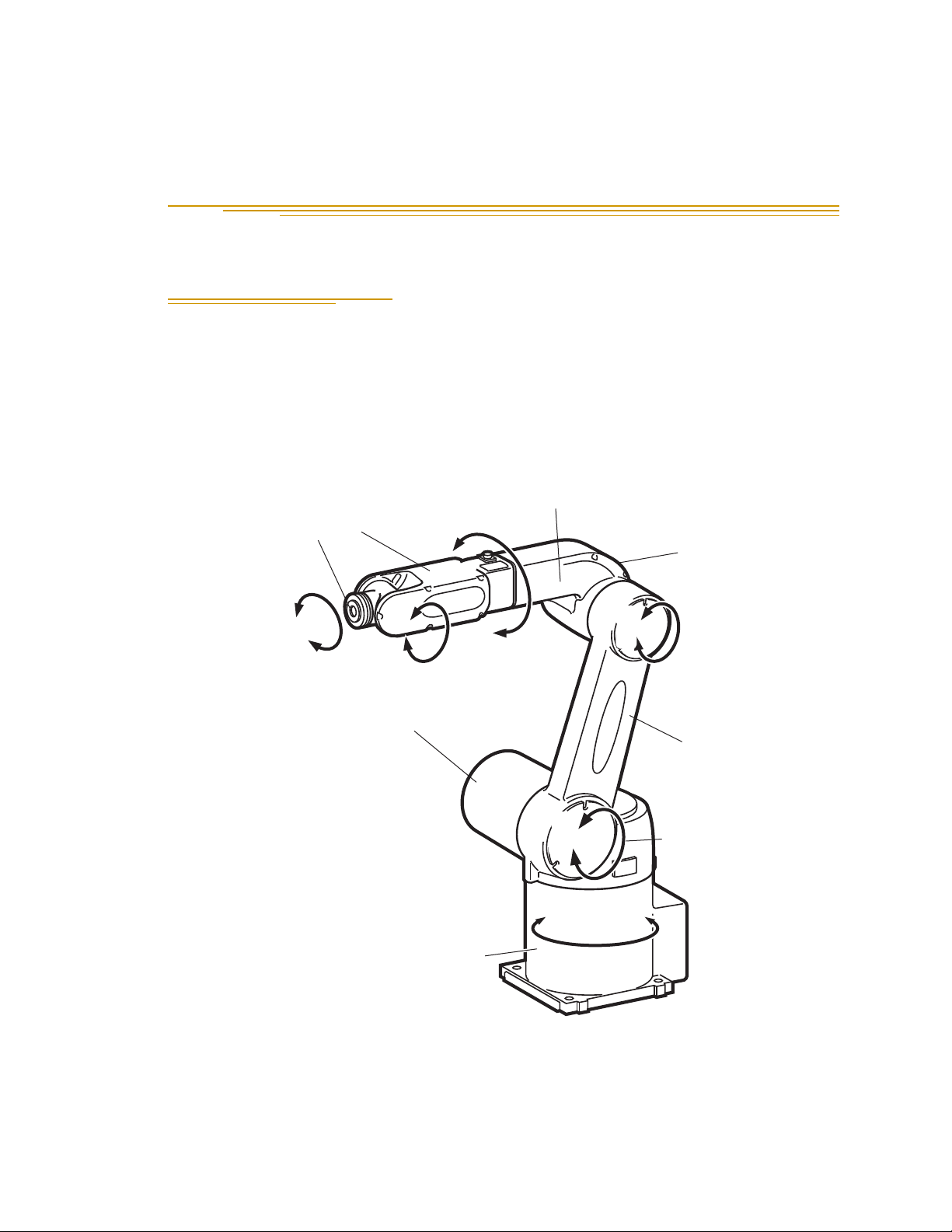

Figure 1-1. Robot Axis Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 1-2. Adept SmartController CX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 2-1. Robot in Hoisting Sling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 2-2. Mounting Hole Pattern for Robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 2-3. Ground Point on Robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 2-4. Robot Interface Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 2-5. External Mounting Holes on Robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 2-6. Allowable Range of Center of Gravity Position of End-effector . . . . . . . . . . . . . . . . . . . . 29

Figure 2-7. Moment of Inertia Calculation Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 3-1. System Cable Diagram for Adept Viper s1300 Robot . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 3-2. Adept PA-4 Power Chassis with sDAI Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 3-3. Typical 3-Phase 200-240 VAC Connection for PA-4 System . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 3-4. Typical 3-Phase 380-415 VAC Connection for PA-4 System . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 4-1. High Power Button on Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 4-2. Connecting Digital I/O to the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 4-3. Manual Brake Release Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 5-1. Removing Cover to Replace Encoder Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 5-2. Removing Battery Support Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 5-3. Removing Dummy Connector Cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 5-4. Connecting First New Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 5-5. Connecting Second New Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 5-6. Connecting Third New Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 5-7. Reconnecting Dummy Connector Cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 6-1. Adept Viper s1300 Side Dimensions and Work Envelope . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 6-2. Adept Viper s1300 Top Dimensions and Work Envelope . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 6-3. Robot Flange Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Adept Viper s1300 Robot User’s Guide, Rev B 7

Page 8

List of Figures

8 Adept Viper s1300 Robot User’s Guide, Re v B

Page 9

1.1 Product Description

Adept Viper s1300™ Robots

The Adept Viper s1300 is a high-performance, six-axis robot designed specifically for

assembly applications. The speed and precision of the Adept Viper robots also make them

ideal for material handling, packaging, machine tending, and many other operations

requiring fast and precise automation.

Tool mounting

flange

Second arm

Introduction 1

3rd-axis motor cover (rear side)

4th axis (J4)

(+)

4th-axis cover

6th axis (J6)

2nd-axis motor cover (rear side)

(+)

(-)

(+)

Base

(-)

(+)

(-)

(-)

1st axis (J1)

(-)

5th axis (J5)

Figure 1-1. Robot Axis Identification

(+)

(-)

(+)

3rd axis (J3)

First arm

2nd axis (J2)

Adept Viper s1300 Robot User’s Guide, Rev B 9

Page 10

Chapter 1 - Introduction

R

ON

SmartServo IEEE-1394

1234

SF ES HD

SW1

1.1 1.2 2.1 2.2

OK

123

XDIO

LANHPE

OFF

XSYS

CAMERA

Eth 10/100

XUSR

Device Net

XFP

RS-232/TERM

RS-232-1

XMCP

BELT ENCODER

SmartController CX

-+ -+

RS-422/485

XDC1 XDC2

24V 5A

*S/N 3562-XXXXX*

RS-232-2

Adept SmartController CX™

The SmartController CX is the foundation of Adept’s family of high-performance

distributed motion controllers. The SmartController CX is designed for use with Adept

Cobra s600 and s800 robots, Adept Python Modules, Adept Viper robots, Adept Quattro

robots, and the Adept sMI6 Module for the SmartMotion product.

The SmartController CX supports a conveyor tracking option. It offers scalability and

support for IEEE 1394-based digital I/O and general motion expansion modules. The

IEEE 1394 interface is the backbone of Adept SmartServo, Adept's distributed controls

architecture supporting Adept products. The controller also includes Fast Ethernet and

DeviceNet.

Figure 1-2. Adept SmartController CX

Adept PA-4™ CAT-3 Power Chassis

The PA-4 CAT-3 includes AC-DC power conversion electronics that support a range of

Adept power amplifiers and robot control modules. In addition, the PA-4 CAT-3 includes

dual (redundant) high-power AC contactors. The PA-4 is configured with J Amplifier

modules to support the Adept Viper s1300 robot systems.

The J and K amplifiers in the Adept Viper s1300 robot system are controlled by the sDAI

(100 W) distributed control module. The sDAI module resides in the PA-4 chassis and

contains a RISC microprocessor and interface circuitry that close the servo loops for highperformance robot motion. The sDAI is connected to a host Adept SmartController via the

SmartServo interface (based on IEEE 1394).

10 Adept Viper s1300 Robot User’s Guide, Rev B

Page 11

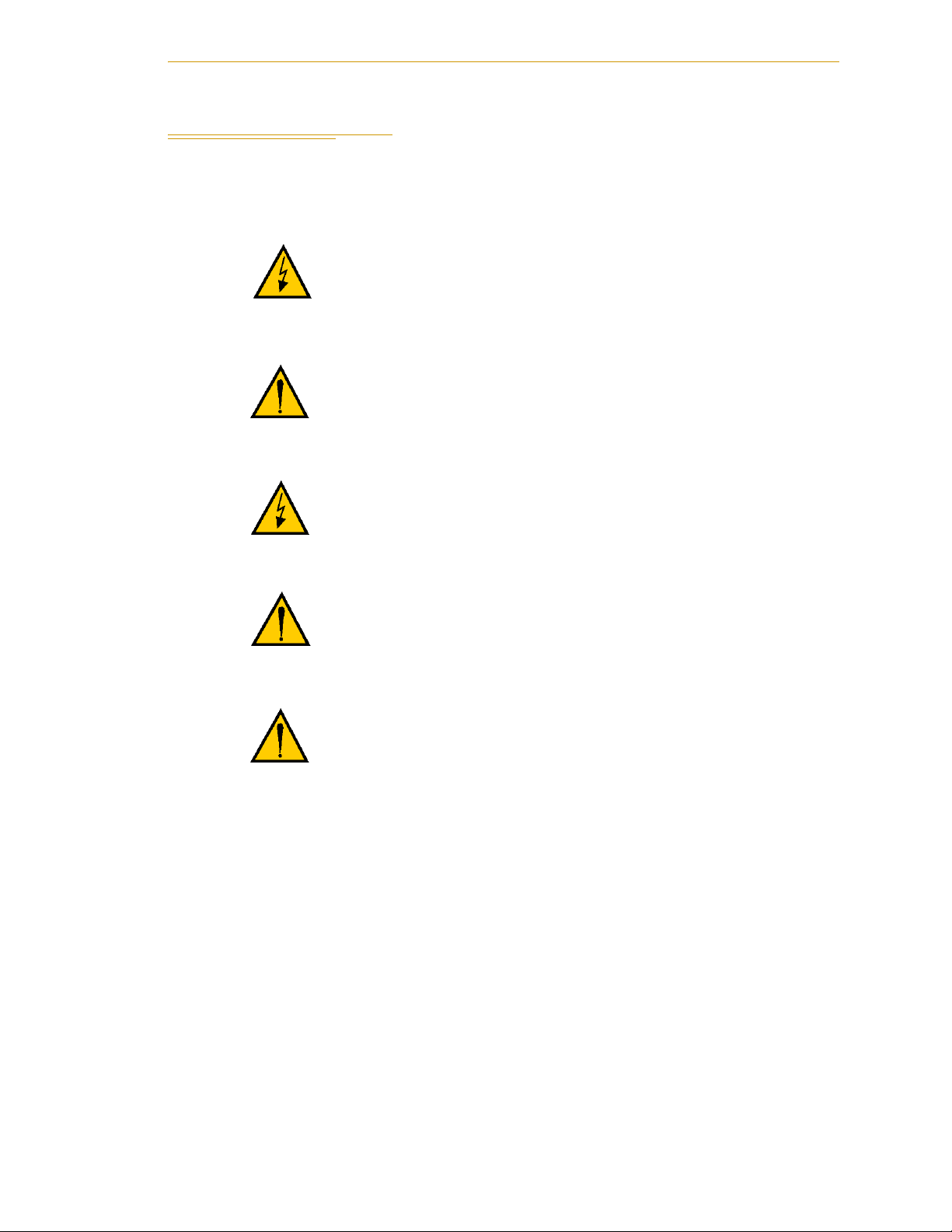

Dangers, Warnings, Cautions, and Notes

1.2 Dangers, Warnings, Cautions, and Notes

There are six levels of special alert notation used in Adept manuals. In descending order

of importance, they are:

DANGER: This indicates an imminently hazardous

electrical situation which, if not avoided, will result in

death or serious injury.

DANGER: This indicates an imminently hazardous

situation which, if not avoided, will result in death or

serious injury.

WAR NI NG : This indicates a potentially hazardous

electrical situation which, if not avoided, could result in

injury or major damage to the equipment.

WAR NI NG : This indicates a potentially hazardous

situation which, if not avoided, could result in injury or

major damage to the equipment.

CAUTION: This indicates a situation which, if not avoided,

could result in damage to the equipment.

NOTE: Notes provide supplementary information, emphasize a point or

procedure, or give a tip for easier operation.

Adept Viper s1300 Robot User’ s Gu ide, Re v B 11

Page 12

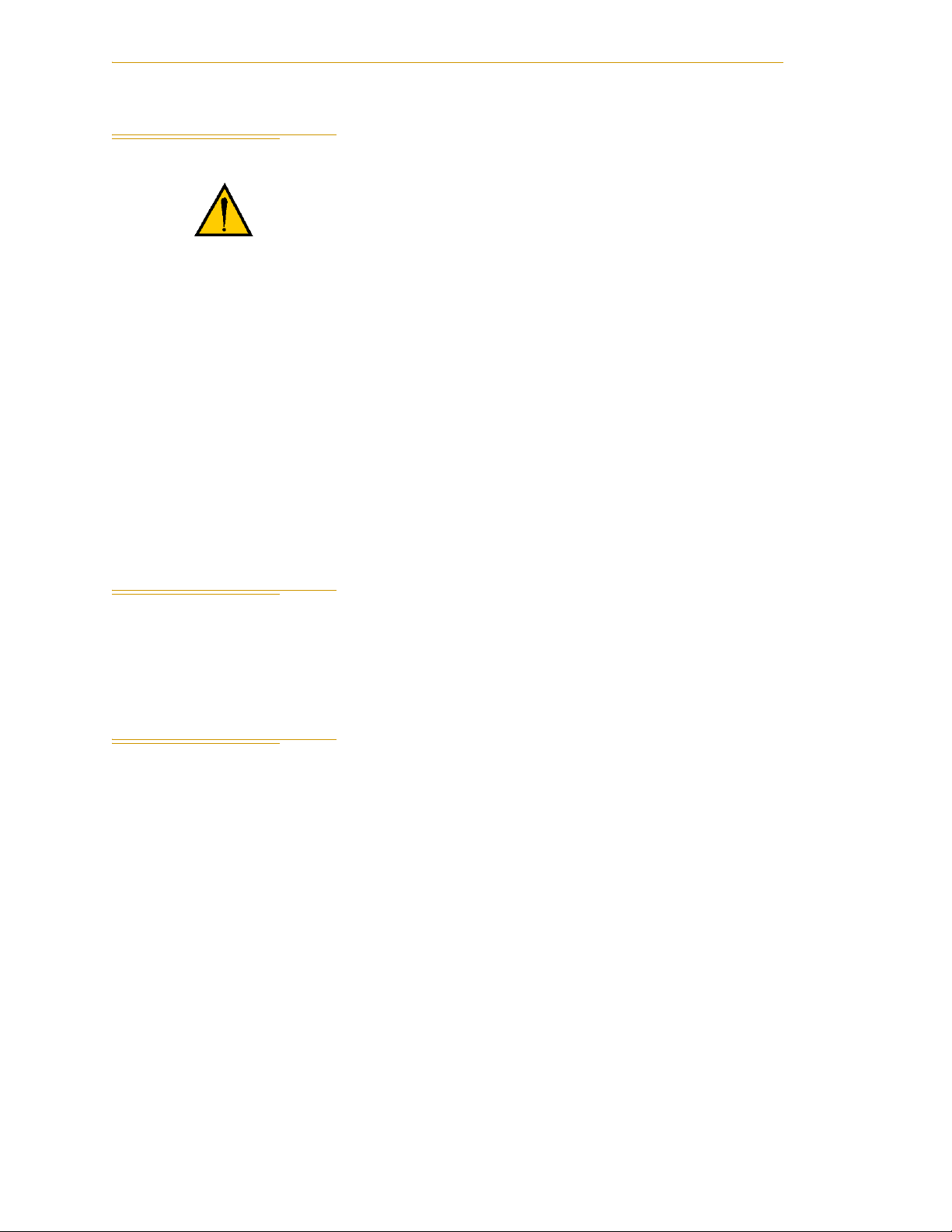

Chapter 1 - Introduction

1.3 Safety Precautions

DANGER: The Adept Viper s1300 robot can cause serious

injury or death, or damage to itself and other equipment, if

the following safety precautions are not observed:

• All personnel who install, operate, teach, program, or maintain the system must

read this guide, read the Adept Robot Safety Guide, and complete a training

course for their responsibilities in regard to the robot.

• All personnel who design the robot system must read this guide, read the Adept

Robot Safety Guide, and must comply with all local and national safety

regulations for the location in which the robot is installed.

• The robot system must not be used for purposes other than described in Section

1.6. Contact Adept if you are not sure of the suitability for your application.

• The user is responsible for providing safety barriers around the robot to prevent

anyone from accidentally coming into contact with the robot when it is in motion.

• Power to the robot and its power supply must be locked out and tagged out before

any maintenance is performed.

1.4 What to Do in an Emergency Situation

Press any E-Stop button (a red push-button on a yellow background/field) and then

follow the internal procedures of your company or organization for an emergency

situation. If a fire occurs, use CO

to extinguish the fire.

2

1.5 Additional Safety Information

Adept provides other sources for more safety information:

Manufacturer’s Declaration of Compliance (MDOC)

This lists all standards with which each robot complies. See “Manufacturer’s

Declaration” on page 13.

Adept Robot Safety Guide

The Adept Robot Safety Guide provides detailed information on safety for Adept robots.

It also gives resources for more information on relevant standards.

It ships with each robot manual, and is also available from the Adept Document Library.

See “Adept Document Library” on page 15.

12 Adept Viper s1300 Robot User’s Guide, Rev B

Page 13

1.6 Intended Use of the Robots

The Adept Viper robots are intended for use in parts assembly and material handling for

payloads less than 10 kg. See Chapter 2 for complete information on tooling and

payloads.

1.7 Installation Overview

The system installation process is summarized in the following table. Refer also to the

system cable diagram in Figure 3-1 on page 33.

NOTE: For dual-robot installations, see the Adept Viper Dual Robot

Configuration Procedure, which is available in the Adept Document

Library.

Table 1-1. Installation Overview

Task to be Performed Reference Location

1. Mount the robot on a flat, secure mounting surface. See Section 2.4 on page 22.

Intended Use of the Robots

2. Install the SmartController, Front Panel, and Adept

ACE™ software.

3. Install the PA-4 power chassis. See Section 3.5 on page 35.

4. Install the Arm Power/Signal cable between the

PA-4 and the robot.

5. Install the IEEE 1394 and XSYS cables between

the PA-4 and SmartController.

6. Connect AC power to PA-4 power chassis. See Section 3.6 on page 37.

7. Start the Adept ACE software, connect to the

controller, and turn on power to the system.

1.8 Manufacturer’s Declaration

The Manufacturer’s Declaration of Incorporation and Conformity lists all standards for

which the Adept Viper robot system complies. It can be found on the Adept Web site, in

the Download Center of the Support section.

ftp://ftp1.adept.com/Download-Library/Manufacturer-Declarations/

See Section 3.2 on page 34.

See Section 3.5 on page 35.

See Section 3.5 on page 35.

See Section 4.1 on page 41.

Each Manufacturer's Declaration is supplied in PDF format and stored on the website in a

ZIP archive. To access the PDF document:

1. Click on the appropriate .zip file. You are prompted to Open or Save the file.

2. Click Open to open the file and display the archive contents.

3. Double-click on a .pdf file to open it.

Adept Viper s1300 Robot User’ s Gu ide, Re v B 13

Page 14

Chapter 1 - Introduction

1.9 How Can I Get Help?

Refer to the How to Get Help Resource Guide (Adept P/N 00961-00700) for details on

getting assistance with your Adept software and hardware. Additionally, you can access

information sources on Adept’s corporate web site:

http://www.adept.com

• For Contact information:

http://www.adept.com/contact/americas

http://www.adept.com/contact/asiapacific-rim

http://www.adept.com/contact/europe

• For Product Support information:

http://www.adept.com/support/service-and-support/main

• For user discussions, support, and programming examples:

http://www.adept.com/forum/

• WEEE/RoHS, Policy:

ftp://ftp1.adept.com/Download-Library/Regulatory/

• WEEE Drop-off Sites:

http://www.adept.com/contact/americas

http://www.adept.com/contact/asiapacific-rim

http://www.adept.com/contact/europe

The Download Center (ID # 500080) provides Adept WEEE/RoHS Policy. The

Contact area of the web site gives locations of WEEE drop-off sites.

14 Adept Viper s1300 Robot User’s Guide, Rev B

Page 15

How Can I Get Help?

Related Manuals

This manual covers the installation, operation, and maintenance of an Adept Viper s1300

robot system. There are additional manuals that cover programming the system,

reconfiguring installed components, and adding other optional components. See Ta bl e

1-2. These manuals are available on the Adept Document Library CD-ROM shipped with

each system.

Table 1-2. Related Manuals

Manual Title Description

Adept Robot Safety Guide Contains general safety information for all Adept robots.

Adept SmartController

User’s Guide

Contains complete information on the installation and

operation of the Adept SmartController and the optional sDIO

product.

Adept PA-4 Power Chassis

User’s Guide

Contains complete information on the installation and

operation of the PA-4 Power Chassis.

Adept ACE User’s Guide Describes installation of Adept ACE software.

Adept Viper Dual Robot

Configuration Procedure

Instructions for Adept

Utility Programs

Contains cable diagrams and configuration procedures for a

dual-robot system.

Describes the utility programs used for advanced system

configurations, system upgrades, file copying, and other

system configuration procedures.

+

V+ Operating System User’s

Guide

Describes the V

operations, monitor commands, and monitor command

operating system, including disk file

programs.

+

V+ Language User’s Guide Describes the V

language and programming of an Adept

control system.

Adept Document Library

The Adept Document Library (ADL) contains documentation for Adept products. You

can access the ADL from:

• the Adept Software CD shipped with your system

• the Adept Web site. Select Document Library from the Adept home page. To go

directly to the Adept Document Library, type the following URL into your

browser:

http://www.adept.com/Main/KE/DATA/adept_search.htm

To locate information on a specific topic, use the Document Library search engine on the

ADL main page. To view a list of available product documentation, select the Document

Titles option.

Adept Viper s1300 Robot User’ s Gu ide, Re v B 15

Page 16

Chapter 1 - Introduction

16 Adept Viper s1300 Robot User’s Guide, Rev B

Page 17

Robot Installation 2

2.1 Unpacking and Inspecting the Adept Equipment

Before Unpacking

Carefully inspect all shipping crates for evidence of damage during transit. Pay special

attention to tilt and shock indication labels on the exteriors of the containers, if installed. If

any damage is indicated, request that the carrier’s agent be present at the time the

container is unpacked.

Upon Unpacking

Before signing the carrier’s delivery sheet, please compare the actual items received (not

just the packing slip) with your equipment purchase order and verify that all items are

present and that the shipment is correct and free of visible damage.

If the items received do not match the packing slip, or are damaged, do not sign the

receipt. Contact Adept as soon as possible.

If the items received do not match your order, please contact Adept immediately.

Inspect each item for external damage as it is removed from its container. If any damage is

evident, contact Adept (see Section 1.9 on page 14).

Retain all containers and packaging materials. These items may be necessary to settle

claims or, at a later date, to relocate equipment.

Adept Viper s1300 Robot User’s Guide, Rev B 17

Page 18

Chapter 2 - Robot Installation

2.2 Environmental and Facility Requirements

The Adept robot system installation must meet the operating environment requirements

shown in Table 2-1.

Table 2-1. Robot System Operating Environment Requirements

Item Condition

Flatness of the mounting

surface

Installation type Floor-mount or Overhead-mount

Ambient temperature During operation: 0 to 40°C

Humidity During operation: 90% or less (No dew condensation allowed.)

Vibration During operation: 4.9 m/s

Safe Installation

Environment

0.1/500 mm

During storage and transportation: -10 to 60°C

During storage and transportation: 75% or less (No dew

condensation allowed.)

2

(0.5G) or less

During storage and transportation: 29.4 m/s

The robot should not be installed in an environment where:

• there are flammable gases or liquids,

• there are any acidic, alkaline or other corrosive gases,

• there is sulfuric or other types of cutting or grinding oil

mist, or

• there are any large-sized inverters, high output/high

frequency transmitters, large contactors, welders, or other

sources of electrical noise.

• there are any shavings from metal processing or other

conductive material flying about,

• it may be directly exposed to water, oil, or cutting chips.

2

(3G) or less

Working space, etc. • Sufficient service space must be available for inspection and

disassembly.

• Keep wiring space (230 mm or more) behind the robot, and

fasten the wiring to the mounting face or beam so that the

weight of the cables will not be directly applied to the

connectors.

Installation conditions Grounding resistance: 100 milliohms or less

See Figure 2-3 on page 23.

18 Adept Viper s1300 Robot User’s Guide, Rev B

Page 19

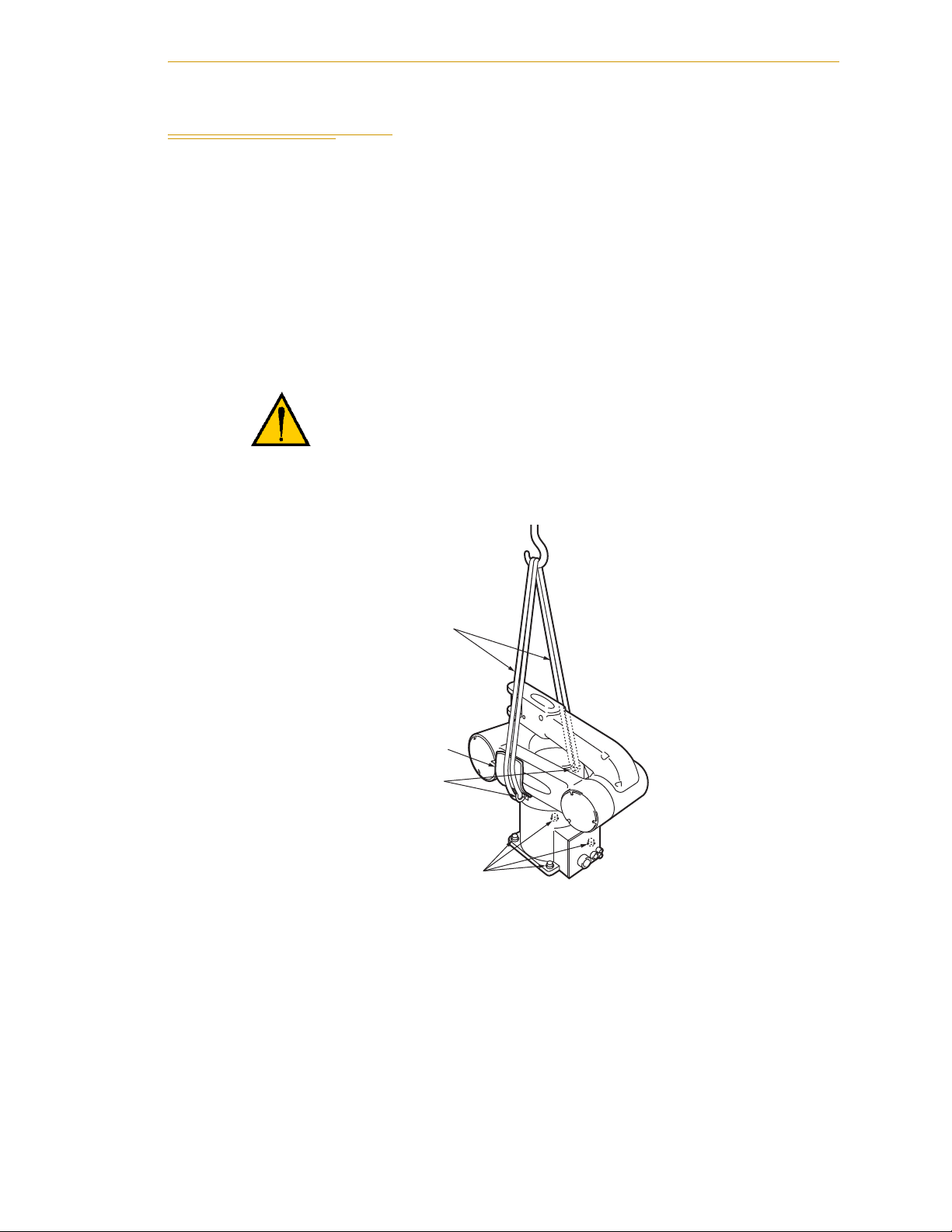

2.3 Transporting the Robot

Precautions in Transporting Robot

• The robot weighs approximately 78 kg. Use a crane suitable for the robot weight.

• Have at least two workers handle this job.

• Workers should wear helmets, safety shoes, and gloves during transport.

• Do not hold the first arm, elbow, either side of the 2nd arm, 2nd-axis cover, or

3rd-axis cover, or apply force to any of them. See Figure 1-1 on page 9.

CAUTION: Pass the hoisting wires through the specified

eyebolts as illustrated below. Passing them through other

sections may drop the robot unit, resulting in injuries to

personnel or damage to the robot.

Transporting the Robot

Wire

(Belt sling)

Waste Cloth

Eyebolts

Robot Mounting

Bolts

Figure 2-1. Robot in Hoisting Sling

Adept Viper s1300 Robot User’ s Gu ide, Re v B 19

Page 20

Chapter 2 - Robot Installation

Transport Procedure

Step Procedure Drawing

1 Before transportation, set the robot in

a transport position as shown at right

by manually moving the second, third

and fourth axes.

When unpacked first, the robot is in

the transport position, so this job is

not required.

Axis Angle

Transport Position

2 Disconnect the robot control cable, air

piping and user signal cables from the

robot unit.

When the robot unit is first unpacked,

this job is not required.

3 As shown at right, mount the

eyebolts.

When delivered, the robot unit is

packed with eyebolts attached, so this

job is not required

First axis (J1) +90°

Second axis (J2) -175°

Third axis (J3) +255°

Fourth axis (J4) -90°

Fifth axis (J5) -90°

20 Adept Viper s1300 Robot User’s Guide, Rev B

Eyebolts

Page 21

Step Procedure Drawing

4 As shown at right, place a waste cloth

on the second arm and pass the wire

through the two eyebolts.

Wire

Note: Before transporting the robot,

check that the path to the target

position is free of obstacles.

(Belt sling)

Waste Cloth

Eyebolts

Transporting the Robot

5Worker A: Remove the four bolts

while supporting the robot unit to

prevent it from getting overturned.

6 Worker B: Operate the crane and

move the robot unit to the target site.

7 Worker B: Put the robot unit down in

the target position.

Worker A: Temporarily secure the

robot unit with four bolts.

8 Secure the robot unit according to the

instructions in Section 2.4 on page 22.

9 Remove the eyebolts from the robot

unit.

Robot Mounting

Bolts

Caution: Before running the robot unit, be

sure to remove the eyebolts. Otherwise, the

robot arm will strike against those eyebolts.

Adept Viper s1300 Robot User’ s Gu ide, Re v B 21

Page 22

Chapter 2 - Robot Installation

2.4 Mounting the Robot

150

240

250

192

250

155 ± 0.1

Reference

plane

1. See Figure 2-2 for the dimensions of the mounting holes in the robot mounting

position where the robot unit is to be secured.

2. Drill four bolt holes (M12), 15 mm deep or more.

3. Secure keys or pins to the reference planes.

NOTE: Be sure to secure keys or pins. They can minimize positional

deviations that may be caused by the removal and installation of the

robot unit for maintenance.

4. Set the robot unit into place on the robot mount. When transporting the robot

unit, follow the instructions given in Section 2.3 on page 19.

5. Secure the robot unit to the mount with four bolts and plain washers.

25

190

155 ± 0.1 150

Figure 2-2. Mounting Hole Pattern for Robot

• Bolt: M12 x 40 mm (strength class: 12.9)

φ30

25

4-φ14.5 drill

(for M12 screw)

• Tightening torque: 110 +/- 22 Nm

• Plain washer: JIS B 1256 (polished round)

22 Adept Viper s1300 Robot User’s Guide, Rev B

Page 23

2.5 Grounding the Robot

AIR1

CN20

CN22

AIR2

Grounding

Terminal (M5)

User-Supplied

Ground Wire

5.5mm

2

or more

Ground the grounding terminal of the robot unit with a wire of 12 AWG or more. Ground

resistance must be less than 100 milliohms.

NOTE: Use a dedicated grounding wire and grounding electrode. Do not

share them with any other electric power or power equipment such as a

welder.

WAR NI NG : Wiring must be performed by authorized or

certified personnel. Failure to observe this caution may

result in fire or electric shock.

Grounding the Robot

Figure 2-3. Ground Point on Robot

Adept Viper s1300 Robot User’ s Gu ide, Re v B 23

Page 24

Chapter 2 - Robot Installation

2.6 Description of Connectors on Robot Interface Panel

CN22

CN20

AIR1

AIR2

AIR 1

AIR 2

Ground

Terminal (M5)

CN20

CN22 Power/Signal Cable,

to PA-4

Figure 2-4. Robot Interface Panel

CN22 - the Arm Power/Signal cable from the PA-4 is installed at this connector.

CN20 - Pins 1 to 10 are wired directly to corresponding pins 1 to 10 on CN21 on the upper

arm. Pins 12 to 18 are for solenoid control. See Section 2.7 on page 25.

AIR 1 - air piping connector (BSPT1/4) for three solenoids in robot. See Section 2.7 on

page 25.

AIR 2 - air piping connector (BSPT1/4), connects directly to AIR 2 on the second (upper)

arm.

Grounding Terminal - ground point on robot, see Section 2.5 on page 23.

24 Adept Viper s1300 Robot User’s Guide, Rev B

Page 25

2.7 Air Lines and Signal Wiring

CN20 pin No.

Used for:

12 0V

13 Solenoid 1A (solenoid valve 1)

14 Solenoid 1B (solenoid valve 1)

15 Solenoid 2A (solenoid valve 2)

16 Solenoid 2B (solenoid valve 2)

17 Solenoid 3A (solenoid valve 3)

18 Solenoid 3B (solenoid valve 3)

Note 1: Pin #1 to #10 on CN21 and those on CN20 are connected with each oth er. The allowable current per line is 1 A.

Note 2: Use the supplied connector sets for CN20 and CN21.

ecnaraeppAeman trap dna ledoM.oN trap tes rotcennoC

for CN20

for CN21

SRCN6A25-24S

(round type connector )

(Japan Aviation Electronics Industry Ltd)

05019-000

JMLP1610M

(L type plug connector)

DDK Electronics, Inc.

Air Piping

Joint (M5)

Valve Symbols and Air Intake and Exhaust States

(1A and 1B are piping joint symbols.)

Air piping joint Valve signal

Solenoid

Air

intake

Exhaust

Solenoid

valve

AB

1A 1B 1 ON OFF

1B 1A 1 OFF ON

2A 2B 2 ON OFF

2B 2A 2 OFF ON

3A 3B 3 ON OFF

AIR1

3B 3A

3OFFON

AIR2

Connector (CN20) for end-effector

signal/valve control wires

View (B)

AIR1 piping joint

(BSPT 1/4)

AIR2 piping joint

(BSPT 1/4)

CN20 pin layout

CN21 pin layout

View (A)

CN21 for end-effector

control signal wires

(B)

(A)

For controller I/O unit, PNP type

(sink IN, source OUT)

AIR1

CN20

CN22

AIR2

1A

2A

3A

1B

2B

3B

AIR2

CN21

● ● ●

● ● ●

● ● ●●

3 2 1

7 6 5 4

10 9 8

Air Lines and Signal Wiring

Adept Viper s1300 Robot User’ s Gu ide, Re v B 25

Page 26

Chapter 2 - Robot Installation

Optional Solenoid Cable

An optional 4 meter Solenoid cable is available that connects between the XDIO connector

on the SmartController and the CN20 connector on the robot. The part number is

05739-040.

Installing this cable allows you to control the three internal robot solenoids directly from

V+. See Table 2-2 for the details on activating the individual ports on each solenoid.

Table 2-2. Viper Solenoid Control from V+

Active Output Port V+ Signal States

a

Solenoid 1 A 0001 –0002

B –0001 0002

Solenoid 2 A 0003 –0004

B –0003 0004

Solenoid 3 A 0005 –0006

B –0005 0006

a

The two-position, double solenoids require both V+ signal states to be

activated. Invalid states will result in indeterminate outputs.

In addition to controlling the internal robot solenoids, the Solenoid cable brings a portion

of the other XDIO signals out to the CN21 connector at the top of the robot. See Table 2-3

for the details of which signals are available at CN21. See the Adept SmartController

User’s Guide for the electrical specifications for the signals from the XDIO connector.

Table 2-3. CN21 Signal List When Using Solenoid Cable

Signal from XDIO on

CN21 Pin #

SmartController CN21 Pin #

1 Input 1001

a

6 Not connected

Signal from XDIO on

SmartController

2 Input 1002

3 Input 1003

4 Input 1004

5 Input 1005

a

Inputs 1001 to 1005 are preconfigured as low-active (sinking) inputs.

b

Outputs 0007 and 0008 are preconfigured as high-side (sourcing) outputs.

c

Limited to a combined total of 1A of current.

a

a

a

a

7 Output 0007

8 Output 0008

924V Output

10 Ground

26 Adept Viper s1300 Robot User’s Guide, Rev B

b

b

c

Page 27

Air Lines and Signal Wiring

Solenoid Valve Specifications

Table 2-4. Solenoid Valve Specifications

Item Specifications

Valve Switching system 2-position double

Applicable fluid Air

Operating system Pilot type

Effective cross section

(Cv value)

Lubrication Oilless

Operating pressure range 0.1 to 0.7 Mpa

Response time 10 ms or less (at 0.5 Mpa)

Maximum operating frequency 10 Hz

Ambient temperature -5 to 50 degrees C (No dew condensation

Solenoid Operating voltage 24 V ±10%

Power consumption (current) 0.65 W (27 mA)

Surge voltage protection circuit Diode

0.27 (P-->A/B) 0.3 (A/B-->EA/EB)

allowed. When dry air is used)

Adept Viper s1300 Robot User’ s Gu ide, Re v B 27

Page 28

Chapter 2 - Robot Installation

External Mounting Locations on Robot

2 M4 12 deep 2 M6 18 deep

50

90

2 M6 18 deep

120

2 M12 34 deep

Figure 2-5. External Mounting Holes on Robot

30

28 Adept Viper s1300 Robot User’s Guide, Rev B

Page 29

2.8 Designing End-Effectors

100

90

80

Center of rotation of J5

Center of rotation of J4 and J6

Allowable range of center of

gravity position

190

Design an end-effector such that it is in compliance with items described in this section.

CAUTION: If the end-effector design precautions are not

observed, the clamped parts of the robot unit may become

loose, rattle or be out of position. In the worst case, the

mechanical parts of the robot and robot controller may

become damaged.

Mass of End-Effector

Design the end-effector so that the total mass of the end-effector (including workpiece)

will be lighter than the maximum payload capacity of the robot. The total mass includes

the wiring, piping, etc.

Maximum total mass of end-effector (including workpiece) must be less than or equal to

maximum payload capacity (10 kg).

Designing End-Effectors

Center of Gravity Position of End-Effector

Design an end-effector so that the center of gravity position of the end-effector (including

workpiece) is within the range shown in Figure 2-6.

Figure 2-6. Allowable Range of Center of Gravity Position of End-effector

Adept Viper s1300 Robot User’ s Gu ide, Re v B 29

Page 30

Chapter 2 - Robot Installation

1. Cylinder (1)

(Axis of rotation = Center axis)

4. Sphere

(Axis of rotation = Center axis)

2. Cylinder (2)

(The axis of rotation passes through the center of gravity.)

5. Center of gravity not on the axis of rotation

:

3. Rectangular parallelepiped

(The axis of rotation passes through the center of gravity.)

l: Moment of inertia ❲kgm

2

❳

m:Mass ❲kg❳

r: Radius ❲m❳

b, c, : Length ❲m❳

Inertia moment around center of gravity

Moment of Inertia Around J4, J5 and J6

Design an end-effector so that its moments of inertia around J4, J5, and J6 (including

workpiece) do not exceed the maximum allowable moment of inertia of the robot.

Moment of inertia around J4, J5, and J6 of end-effector (including mass of workpiece)

must be less than or equal to the maximum allowable moment of inertia

Maximum allowable moment of inertia around J4 and J5: 0.36 kgm

Maximum allowable moment of inertia around J6: 0.064 kgm

2

2

When calculating the moment of inertia around J4, J5, and J6 of the end-effector, use the

formulas given in Table 2-5, and see examples in Figure 2-7 on page 31.

Table 2-5. Moment of Inertia Formulas

30 Adept Viper s1300 Robot User’s Guide, Rev B

Page 31

Designing End-Effectors

Calculation example : When calculating the

moment of inertia of a complicated shape, divide it into

simple parts as much as possible for easier calculations.

As shown in the figure below, divide the end-effector into three parts (Q, R, S).

(1) Moment of inertia around J6

Unit: mm

Robot flange

center

Q

R

S

φ20φ

40

φ

40

Moment of inertia around J6 of Q: I1(from 3 and 5inTable 2-3)

Moment of inertia around J6 of R: I

2

(from 1 and 5inTable 2-3)

Moment of inertia around J6 of S: I

3

(from 1 and 5inTable 2-3)

Moment of inertia around J6 of entire end-effector: I

J6

(2) Moment of inertia around J4 and J5 For the end-effector shown below, the moment of

inertia around J4 and J5 can be calculated according

to the same formula.

80

80

((0.08 + 0.005)2+0.01)

1.03 × 10-3 [kgm2]

1.39 × 10-3 [kgm2]

2.30 × 10

-3

[kgm2]

2.54×10

-2

[kgm2]

((0.08 + 0.01 + 0.02)

2

+0.042)

((0.08 + 0.01 + 0.05)

2

+0.052)

Moment of inertia around J4 and J5 of Q: I1(from 3 and 5 in Table 2-3)

Moment of inertia around J4 and J5 of R: I

2

(from2 and 5 in Table 2-3)

Moment of inertia around J4 and J5 of S: I

3

(from2 and 5 in Table 2-3)

Moment of inertia around J4 and J5 of entire end-effector: I

J4

, I

J5

Center o

f

gravity of

Q

Center o

f

gravity of

S

Center o

f

gravity of

R

Around J6

Around J6

Table 3-5

Table 3-5

Table 3-5

Table 3-5

Table 3-5

Table 3-5

Figure 2-7. Moment of Inertia Calculation Examples

Adept Viper s1300 Robot User’ s Gu ide, Re v B 31

Page 32

Chapter 2 - Robot Installation

32 Adept Viper s1300 Robot User’s Guide, Rev B

Page 33

System Installation 3

3.1 System Cable Diagram

IEEE 1394 Cable

Adept

SmartController CX

R

SmartServo IEEE-1394

OK

LANHPE

1.1 1.2 2.1 2.2

SW1

SF ES HD

1 2 3 4

ON

OFF

123

XDIO

Terminator

Installed

XUSR

User-Supplied Ground Wire

CAMERA

Device Net

Eth 10/100

BELT ENCODER

XFP

XSYS

RS-232/TERM

*S/N 3562-XXXXX*

RS-422/485

RS-232-2

RS-232-1

XDC1 XDC2

XMCP

24V 5A

-+ -+

SmartController CX

K Amp

K AMP K AMP J AMP

DO NOT REMOVE OR INSTALL THIS

DO NOT REMOVE OR INSTALL THIS

MODULE UNLESS HIGH VOLTS LED

MODULE UNLESS HIGH VOLTS LED

IS COMPLETELY DISTINGUISHED

IS COMPLETELY DISTINGUISHED

HIGH VOLTS ON

HIGH VOLTS ON

PWM ON

PWM ON

LOW VOLTS ON

LOW VOLTS ON

OPEN CKT FAULT

OPEN CKT FAULT

HV SAG/OVER TEMP FAULT

HV SAG/OVER TEMP FAULT

SHORT FAULT

SHORT FAULT

CH1

CH2

CH1

CH2

A

A

M

M

P

P

L

L

I

I

F

F

I

I

E

E

R

R

C

C

O

O

N

N

T

T

R

R

O

O

L

L

CH2CH1

CH2CH1

M

M

O

O

T

T

O

O

R

R

P

P

O

O

W

W

E

E

R

R

O

O

U

U

T

T

P

P

U

U

T

T

adept

technology, inc.

K Amp

J Amp

B

R

A

DO NOT REMOVE OR INSTALL THIS

K

MODULE UNLESS HIGH VOLTS LED

IS COMPLETELY DISTINGUISHED

E

HIGH VOLTS ON

PWM ON

LOW VOLTS ON

1

OPEN CKT FAULT

HV SAG/OVER TEMP FAULT

SHORT FAULT

2

CH1

CH2

A

M

P

L

I

F

I

E

R

C

O

N

T

R

O

L

C

N

P

G

1

2

3

CH2CH1

M

O

T

O

R

P

O

W

E

R

O

U

T

P

U

T

sDAI Module

(100W)

s

DAI

CAUTION

HIGH

VOLTAGE

INSIDE

STATUS

R

S

2

SmartServo

3

2

E

X

P

I

O

X

S

L

V

C

N

P

G

4

5

6

C

N

2

5

C

N

2

9

100W

XSYS cable

Arm Power/

Signal Cable

Controller (XFP) to

Front Panel (XFP)

Ethernet to PC

R

Front Panel

User-supplied PC

running AdeptWindows

Figure 3-1. System Cable Diagram for Adept Viper s1300 Robot

STOP

24VDC Power from

User-Supplied

Power Supply to

Controller (XDC1)

T2 Pendant

(optional)

User-Supplied

Power Supply

Adept Viper s1300

Robot

Adept PA-4

Power Chassis

200-240 VA C 3-Phase

or

380-415 VA C 3-Phase

User-Supplied

Ground Wire

Grounding

Terminal

Adept Viper s1300 Robot User’s Guide, Rev B 33

Page 34

Chapter 3 - System Installation

3.2 Installing the SmartController

Refer to the Adept SmartController User’s Guide for complete information on installing

the Adept SmartController. This list summarizes the main steps.

1. Mount the SmartController and Front Panel.

2. Connect the Front Panel to the SmartController.

3. Connect the optional pendant to the SmartController, if included.

4. Connect user-supplied 24 VDC power to the controller.

5. Install a user-supplied ground wire between the SmartController and ground.

6. Install the Adept ACE PC software on the user-supplied PC. This includes

connecting the supplied Ethernet crossover cable between the user-supplied PC

and the Ethernet port on the SmartContoller.

3.3 Installing the Adept ACE Software

The Adept ACE software is installed from the Adept ACE software CD-ROM.

1. Insert the CD-ROM into the CD-ROM drive of your PC.

If Autoplay is enabled, the Adept software CD-ROM menu is displayed. If

Autoplay is disabled, you will need to manually start the CD-ROM.

2. Especially if you are upgrading your Adept ACE software installation: from the

Adept ACE software CD-ROM menu, click Read Important Information.

3. From the Adept ACE software CD-ROM menu, select:

Install the Adept ACE Software

The Adept ACE Setup wizard opens.

4. Follow the online instructions as you step through the installation process.

5. When the installation is complete, click Finish.

6. After closing the Adept ACE Setup wizard, click Exit on the CD-ROM menu to

close the menu.

NOTE: You will have to restart the PC after installing the Adept ACE

software.

3.4 Connecting the PC to the SmartController

The Adept SmartController motion controller must be connected to a user-supplied PC or

the Adept SmartVision EX processor for setup, control, and programming.

• Connect an Ethernet crossover cable between the PC and the SmartController

motion controller

or

34 Adept Viper s1300 Robot User’s Guide, Rev B

Page 35

• Use two standard Ethernet cables with a network hub or switch in place of the

Ethernet crossover cable.

NOTE: Do not use an Ethernet crossover cable with a network hub or

switch.

For more details, refer to the Adept ACE User’s Guide.

3.5 Installing the PA-4 Power Chassis

Refer to the Adept PA-4 Power Chassis User’s Guide for complete information on the

PA-4 chassis. This list summarizes the main steps.

1. Mount the PA-4 chassis.

NOTE: For the PA-4 in an Adept Viper system, only the panel-mounting

option is available.

2. Locate these cables, shipped in the cable/accessories box.

Installing the PA-4 Power Chassis

• IEEE 1394 cable (length 4.5M)

• XSYS cable (length 4.5M)

• Arm Power/Signal cable (length 4 M)

3. Install one end of the IEEE 1394 cable into the SmartServo port 1.1 connector on

the SmartController, and install the other end into the SmartServo port 1

connector on the sDAI module in the PA-4. See Figure 3-1 on page 33 and Figure

3-2 on page 36.

4. Install the XSYS cable between the XSYS connector on the SmartController, and

the XSLV connector on the sDAI module, and tighten the latching screws.

5. Install the Arm Power/Signal cable between the CN22 connector on the robot and

the Arm Power/Signal connector on the PA-4.

Adept Viper s1300 Robot User’ s Gu ide, Re v B 35

Page 36

Chapter 3 - System Installation

Latching Screws

Interface Box

Arm Power/Signal

Connector

K-Amp

K-Amp

K-AMP K-AMP J-AMP

DO NOT REMOVE OR INSTALL THIS

DO NOT REMOVE OR INSTALL THIS

MODULE UNLESS HIGH VOLTS LED

IS COMPLETELY DISTINGUISHED

HIGH VOLTS ON

PWM ON

LOW VOLTS ON

OPEN CKT FAULT

HV SAG/OVER TEMP FAULT

SHORT FAULT

CH1

CH2

A

M

P

L

I

F

I

E

R

C

O

N

T

R

O

L

M

O

T

O

R

P

O

W

E

R

O

U

T

P

U

T

CH2CH1

DO NOT REMOVE OR INSTALL THIS

MODULE UNLESS HIGH VOLTS LED

IS COMPLETELY DISTINGUISHED

CH1

CH2

M

O

T

O

R

P

O

W

E

R

O

U

T

P

U

T

MODULE UNLESS HIGH VOLTS LED

IS COMPLETELY DISTINGUISHED

HIGH VOLTS ON

PWM ON

LOW VOLTS ON

OPEN CKT FAULT

HV SAG/OVER TEMP FAULT

SHORT FAULT

CH1

CH2

A

M

P

L

I

F

I

E

R

C

O

N

T

R

O

L

M

O

T

O

R

P

O

W

E

R

O

U

T

P

U

T

adept

technology, inc.

CH2CH1

HIGH VOLTS ON

PWM ON

LOW VOLTS ON

OPEN CKT FAULT

HV SAG/OVER TEMP FAULT

SHORT FAULT

A

M

P

L

I

F

I

E

R

C

O

N

T

R

O

L

J-Amp

sDAI Module (100 W)

s

DAI

CAUTION

HIGH

VOLTAGE

INSIDE

B

R

A

K

STATUS

E

1

R

S

2

SmartServo

3

2

2

E

X

P

I

O

X

S

L

V

C

C

N

N

P

P

G

G

4

1

5

2

6

3

CH2CH1

C

N

2

5

C

N

2

9

Brake Release

Status Panel

RS-232

SmartServo 1 & 2

EXPIO

XSLV

External Brake

Connector

Figure 3-2. Adept PA-4 Power Chassis with sDAI Module

NOTE: In Adept Viper s1300 systems, the sDAI module must be a 100 W

version. A standard sDAI will not work.

36 Adept Viper s1300 Robot User’s Guide, Rev B

Page 37

Connecting 3-Phase AC Power to PA-4

3.6 Connecting 3-Phase AC Power to PA-4

PA-4 3-Phase Power Requirements

Table 3-1. Adept PA-4 Power Chassis 3-Phase Power Requirements

Nominal

Voltage

Range

Frequency/

Phasing

Minimum

Operating

Voltage

Maximum

Operating

Voltage

Recommended

External

Circuit Breaker

(user-supplied)

200 to 240

VAC

380 to 415

VAC

50-60 Hz,

3-phase

50-60 Hz,

3-phase with

180 VAC 245 VAC 20 amps

342 VAC 424 VAC 20 amps

neutral

a

Table 3-2. Typical Robot Power Consumption

Robot Move

No load - Adept cycle

Adept Viper

s1300

10.0 kg - Adept cycle

Average Power

(W)

c

c

3851871

319 1382

Peak Power

b

(W)

10.0 kg - all joints move 912 3674

a

Typical power data is with 220 VAC, 60 Hz, 3-phase nominal input.

b

For short durations (100 ms)

c

Adept cycle: the robot tool performs continuous path, straight-line motions 25 mm up, 305 mm

over , 25 mm down, and back along the same path. COARSE is enabled and BREAKs are used

at each end location. Not achievable over all paths.

The Adept PA-4 power chassis can be shipped from the factory configured for either

3-phase 200-240

VAC or 380-415 VAC operation, depending on your sales order.

A voltage setting label is located on the front of the chassis below the circuit breaker. The

voltage setting is also shown on the ID label on the side of the chassis. Verify that the

setting matches your facility power before installation.

If you need to change the AC voltage setting from 200-240

versa

, see the Adept PA-4 Power Chassis User’s Guide.

VAC to 380-415 VA C, or vi ce

WAR NI NG : Verify the voltage settings are correct before

turning on power. Operating the Adept PA-4 power

chassis with incorrect voltage settings can cause damage

or injury.

Adept Viper s1300 Robot User’ s Gu ide, Re v B 37

Page 38

Chapter 3 - System Installation

Connecting the PA-4 3-Phase AC Power Cord to AC Supply

The user end of the cord is unterminated. Connect each conductor of the power cord

securely to your AC power source, using the color code shown in Table 3-3. The

installation must meet all applicable European, international, and national standards and

regulations.

Table 3-3. 3-Phase AC Power Cord Specifications for PA-4

Cord length 3 meters ±0.1 m (9 ft 10 in ±4 in)

Cord rating 25 amps

Number and size of

5 x 2.5 mm

2

conductor size

Color code: 200 - 240 VAC

line 1

line 2

line 3

no connection

ground

black

black (or gray)

a

brown

blue (must be insulated)

green/yellow

Color code: 380 - 415 VAC

line 1

line 2

line 3

neutral

ground

a

Note: The two black wires can also be one black and one gray wire, but the

functionality is the same for either case.

black

black (or gray)

brown

blue

green/yellow

a

DANGER: Electrical hazard!

The installation of the power cord must be done by a

skilled person. The power supply can injure or kill the

person who installs the cord. An incorrect installation can

injure or kill anyone that touches the equipment in the

robot workcell.

The protective ground conductor (colored green/yellow) of the Adept PA-4 power

chassis is internally connected to the accessible metal parts of the power chassis. To

ensure electrical-shock protection, the ground conductor must be connected to a properly

grounded power source.

WAR NI NG : Ensure that a proper protective ground

connection exists before turning on the power.

38 Adept Viper s1300 Robot User’s Guide, Rev B

Page 39

Connecting 3-Phase AC Power to PA-4

Typical 3-Phase AC Power Installation Diagrams

L1

3Ø

200–240V~

20A

PE

PE

L3L3L2L2L1

Adept PA-4

3Ø 200–240V~

Figure 3-3. Typical 3-Phase 200-240 VAC Connection for PA-4 System

3Ø

380–415V~

20A

L1

PEPENNL3L3L2L2L1

Adept PA-4

3Ø 380–415V~

Figure 3-4. Typical 3-Phase 380-415 VAC Connection for PA-4 System

Adept Viper s1300 Robot User’ s Gu ide, Re v B 39

Page 40

Chapter 3 - System Installation

40 Adept Viper s1300 Robot User’s Guide, Rev B

Page 41

System Operation 4

4.1 Commissioning the System

Turning on the robot system for the first time is known as “commissioning the system.”

Follow the steps in this section to safely bring up your robot system. The steps include:

• Verifying installation, to confirm all tasks have been performed correctly

• Starting up the system by turning on power for the first time

• Verifying all E-Stops in the system function correctly

• Moving each axis of the robot to confirm it moves in the proper directions

Verifying Installation

Verifying that the system is correctly installed and that all safety equipment is working

correctly is an important process. Before using the robot, make the following checks to

ensure that the robot and controller have been properly installed.

DANGER: After installing the robot, you must test it before

you use it for the first time. Failure to do this could cause

death, serious injury, or equipment damage.

Mechanical Checks

• Verify that the robot is mounted level and all fasteners are installed and tightened.

• Verify that any end-of-arm tooling is properly installed.

• Verify that all other peripheral equipment is properly installed and in a state

where it is safe to turn on power to the robot system.

System Cable Checks

Verify the following connections:

• Front Panel to the SmartController.

• Pendant to the SmartController, via the pendant adapter cable.

• User-supplied 24 VDC power to the controller.

• User-supplied 200/240 VAC power to the PA-4.

• User-supplied ground wire between the SmartController and ground.

• XSYS cable between the robot interface panel XSLV safety interlock connector and

XSYS connector on the SmartController, and the latching screws tightened.

Adept Viper s1300 Robot User’s Guide, Rev B 41

Page 42

Chapter 4 - System Operation

• One end of the IEEE 1394 cable into the SmartServo port 1.1 connector on the

SmartController, and the other end into the SmartServo port 1 connector on the

robot interface panel.

• XSYS cable between the robot interface panel XSLV safety interlock connector and

XSYS connector on the SmartController, and the latching screws tightened.

User-Supplied Safety Equipment Checks

Verify that all user-supplied safety equipment and E-Stop circuits are installed correctly.

System Start-up Procedure

Once the system installation has been verified (see “Verifying Installation” on page 41),

you are ready to start up the system.

1. Switch on AC power to the PA-4.

2. Switch on the 24 VDC power to the SmartController.

3. Turn on power to the robot.

4. Follow the instructions, beginning with Starting the Adept ACE Software, in the

following section.

Running the Adept ACE Software

Starting the Adept ACE Software

The robot should be on, and the status panel should display OK before proceeding.

1. Turn on the PC and start the Adept ACE software.

• Double-click the Adept ACE icon on your Windows desktop

or, from the Windows Start menu bar,

•Select Start > Programs > Adept Technology > Adept ACE > Adept ACE.

2. On the Adept ACE Startup menu, click New SmartController Workspace.

3. Click-select the SmartController you want to use, and click OK.

Enabling High Power

After you have started the Adept ACE software and connected to the controller, enable

high power to the robot motors:

1. From the Adept ACE main menu, click the Enable High Power icon:

2. If the High Power button on the Front Panel is blinking, press and release it.

NOTE: The use of the blinking High Power button can be configured (or

eliminated) in software. Your system may not require this step.

The Front Panel, which is mounted just outside the workcell safety barrier, is

shown in the following figure. If enabled, the High Power button must be pressed

while blinking (default time-out is 10 seconds). If the button stops blinking, you

must enable power again.

42 Adept Viper s1300 Robot User’s Guide, Rev B

Page 43

Figure 4-1. High Power Button on Front Panel

Switch, in

Auto Mode

Press High Power button

when blinking

This step turns on high power to the robot motors and calibrates the robot.

• The amplifier status LED blinks green rapidly

(a slow green blink has a different meaning).

In addition, for Adept IP-65 Viper robots, the lamps on the robot glow solid

amber.

• The status panel on the robot or amplifier chassis displays ON.

Verifying E-Stop Functions

Learning to Program the Robot

Verify that all E-Stop devices are functional (pendant, Front Panel, and user-supplied).

Test each mushroom button, safety gate, light curtain, etc., by enabling high power and

then opening the safety device. The High Power push button/light on the Front Panel

should go out.

Verifying Robot Motions

Use the pendant to test the motion of each axis on the robot to confirm it moves in the

proper directions. Refer to the Adept SmartController User’s Guide and the T2 Pendant

User’s Guide for complete instructions on using the pendant.

NOTE: If the optional pendant is not installed in the system, you can

move the robot using the Robot Jog Control in the Adept ACE software.

For details, see the Adept ACE User's Guide.

4.2 Learning to Program the Robot

To learn how to use and program the robot, see the Adept ACE User’s Guide, which

provides information on robot configuration, control and programming through the

Adept ACE software "point and click" user interface.

For V+ programming information, refer to the following optional manuals:

• V+ Language User’s Guide

• V+ Language Reference Guide

• V+ Operating System Reference Guide

NOTE: When using an Adept pendant with an Adept Viper robot, the

Free Mode is disabled for safety reasons.

Adept Viper s1300 Robot User’ s Gu ide, Re v B 43

Page 44

Chapter 4 - System Operation

CAUTION

HIGH

VOLTAGE

INSIDE

B

R

A

K

E

STATUS

SmartServo

1

2

R

S

2

3

2

E

X

P

I

O

X

S

L

V

C

N

P

G

1

2

3

C

N

P

G

4

5

6

C

N

2

5

C

N

2

9

DAI

s

adept

technology, inc.

LOW VOLTS ON

HV SAG/OVER TEMP FAULT

DO NOT REMOVE OR INSTALL THIS

SHORT FAULT

OPEN CKT FAULT

MODULE UNLESS HIGH VOLTS LED

IS COMPLETELY DISTINGUISHED

PWM ON

CH1

HIGH VOLTS ON

CH2

A

M

P

L

I

F

I

E

R

C

O

N

T

R

O

L

CH2CH1

M

O

T

O

R

P

O

W

E

R

O

U

T

P

U

T

K AMP K AMP J AMP

LOW VOLTS ON

HV SAG/OVER TEMP FAULT

DO NOT REMOVE OR INSTALL THIS

SHORT FAULT

OPEN CKT FAULT

MODULE UNLESS HIGH VOLTS LED

IS COMPLETELY DISTINGUISHED

PWM ON

CH1

HIGH VOLTS ON

CH2

A

M

P

L

I

F

I

E

R

C

O

N

T

R

O

L

CH2CH1

M

O

T

O

R

P

O

W

E

R

O

U

T

P

U

T

LOW VOLTS ON

HV SAG/OVER TEMP FAULT

DO NOT REMOVE OR INSTALL THIS

SHORT FAULT

OPEN CKT FAULT

MODULE UNLESS HIGH VOLTS LED

IS COMPLETELY DISTINGUISHED

PWM ON

CH1

HIGH VOLTS ON

CH2

A

M

P

L

I

F

I

E

R

C

O

N

T

R

O

L

CH2CH1

M

O

T

O

R

P

O

W

E

R

O

U

T

P

U

T

SF

IEEE-1394

X2

SC-DIO

LINK

*S/N 3563-XXXXX*

X1

24V 0.5A

R

OK

X4

- + - +

1.1 1.2

XDC1 XDC2

X3

R

ON

SmartServo IEEE-1394

1 2 3 4

SF ES HD

SW1

1.1 1.2 2.1 2.2

OK

123

XDIO

LANHPE

OFF

XSYS

CAMERA

Eth 10/100

XUSR

Device Net

XFP

RS-232/TERM

RS-232-1

XMCP

BELT ENCODER

SmartController CX

-+ -+

RS-422/485

XDC1XDC2

24V 5A

*S/N 3562-XXXXX*

RS-232-2

Optional

sDIO #1

SmartController

Adept PA-4

Optional

IO Blox Device

To EXPIO

on sDAI

XDIO Connector

12 Input signals: 1001 to 1012

8 Output signals: 0001 to 0008

IO Blox #1

8 Input signals: 1113 to 1120

8 Output signals: 0105 to 0112

sDIO #1

32 Input signals: 1033 to 1064

32 Output signals: 0033 to 0064

CN20 Connector

For input signals to control

internal robot solenoids

and general user I/O.

Signals can come from

IO Blox device or XDIO

on SmartController.

Adept Viper s1300

Robot

4.3 Connecting Digital I/O to the System

You can connect digital I/O to the system in several different ways. See Table 4-1 and

Figure 4-2. Also refer to page 26 for information on the optional Solenoid cable.

Table 4-1. Digital I/O Connection Options

Product I/O Capacity For more details

XDIO Connector on

SmartController

Optional IO Blox Device,

connects to sDAI in PA-4

Optional sDIO Module,

connects to controller

12 inputs

8 outputs

8 inputs, 8 outputs per device; up

to four IO Blox devices per robot

32 inputs, 32 outputs per module;

up to four sDIO per system

see Adept SmartController

User’s Guide

see Adept IO Blox User’s

Guide

see Adept SmartController

User’s Guide

44 Adept Viper s1300 Robot User’s Guide, Rev B

Figure 4-2. Connecting Digital I/O to the System

Page 45

Connecting Digital I/O to the System

Table 4-2. Default Digital I/O Signal Configuration, Single Robot System

Location Type Signal Range

Controller XDIO connector Inputs 1001 - 1012

Outputs 0001 - 0008

sDIO Module 1 Inputs 1033 - 1064

Outputs 0033 - 0064

sDIO Module 2 Inputs 1065 - 1096

Outputs 0065 - 0096

sDIO Module 3

(recommended)

sDIO Module 4

(recommended)

IO Blox 1 Inputs 1113 - 1120

IO Blox 2 Inputs 1121 - 1128

Inputs 1201 - 1232

Outputs 0201 - 0232

Inputs 1233 - 1264

Outputs 0233 - 0264

Outputs 0105 - 0112

Outputs 0113 - 0120

IO Blox 3 Inputs 1129 - 1136

Outputs 0121 - 0128

IO Blox 4 Inputs 1137 - 1144

Outputs 0129 - 0136

Adept Viper s1300 Robot User’ s Gu ide, Re v B 45

Page 46

Chapter 4 - System Operation

4.4 Status Panel Codes on sDAI Module

The status panel display on the sDAI module in the PA-4 displays alpha-numeric codes

that indicate the operating status of the robot, including detailed fault codes. See Ta bl e

4-3 for definitions of the status codes. These codes provide details for quickly isolating

problems during troubleshooting. See the Adept PA-4 Power Chassis User’s Guide for

additional information on the sDAI module.

Table 4-3. Status Panel Codes

LED Status Code LED Status Code

OK No Fault h# High Temp Amp (Joint #)

ON High Power ON Status H# High Temp Encoder (Joint #)

MA Manual Mode hV High Voltage Bus Fault

24 24V Supply Fault I# Initialization Stage (Step #)

A# Amp Fault (Joint #) M# Motor Stalled (Joint #)

B# IO Blox Fault (Address #) NV Non-Volatile Memory

AC AC Power Fault P# Power System Fault (Code #)

D# Duty Cycle Exceeded (Joint #) PR Processor Overloaded

E# Encoder Fault (Joint #) RC RSC Fault

ES E-Stop SWWatchdog Timeout

F# External Sensor Stop S# Safety System Fault (Code #)

FM Firmware Mismatch T# Safety System Fault

(Code 10 + #)

FW 1394 Fault V# Hard Envelope Error (Joint #)

For more information on status codes, go to the Adept Document Library on the Adept

website, and in the Procedures, FAQs, and Troubleshooting section, look for the Adept

Status Code Summary document.

46 Adept Viper s1300 Robot User’s Guide, Rev B

Page 47

Installing and Using the Brake Release Box

4.5 Installing and Using the Brake Release Box

The manual brake release box can be used to release the brakes on a specific axis of the

robot. This procedure describes how to install and use this device. See Figure 4-3 on page

47.

WAR NI NG : Secure the robot prior to releasing the brakes

on axes 2 and 3, to prevent injury to personnel or equipment damage.

1. Make sure that high power is disabled (off).

2. Connect the 15-pin male D-sub connector into the 15-pin female D-sub connector

marked Brake on the sDAI board.

3. Press one of the E-Stops (Pendant, Front Panel, or external).

4. Using the axis selector switch, select the axis that you want to release the brake.

5. Depress the brake release push button, to release the brake.

6. Repeat steps 4 and 5 above for releasing the brakes on another axis.

NOTE: When the Status LED (Green) is on, it indicates that the circuit is

enabled, when the brake release push button is pressed.

3

Axis selector switch

2

4

1

5

6

OFF

BRAKE

RELEASE

Status LED

Brake Release

Pushbutton

15-pin male

D-Sub connector

Figure 4-3. Manual Brake Release Box

Adept Viper s1300 Robot User’ s Gu ide, Re v B 47

Page 48

Chapter 4 - System Operation

48 Adept Viper s1300 Robot User’s Guide, Rev B

Page 49

Maintenance 5

5.1 Replacing Encoder Backup Battery

The encoder backup batteries should be replaced every two years. Replace the batteries

according to the procedure below.

1. Prepare a new set of 3 backup batteries for replacement.

2. Turn off AC power to the PA-4 and DC power to the controller.

3. Remove the cover from the robot unit. See Figure 5-1.

Connector Plate

Battery Support

Plate

Figure 5-1. Removing Cover to Replace Encoder Batteries

4. Pull out the battery support plate. See Figure 5-2.

Adept Viper s1300 Robot User’s Guide, Rev B 49

Page 50

Chapter 5 - Maintenance

Battery support plate

Figure 5-2. Removing Battery Support Plate

5. Remove the dummy connector cap from the battery board. See Figure 5-3.

Dummy connector cap

Figure 5-3. Removing Dummy Connector Cap

6. Connect a new battery (1st one) to the pin from which you have disconnected the

dummy connector cap in Step 5. See Figure 5-4.

NOTE: Do not disconnect old backup batteries before connecting a new

one to the pin from which the dummy connector cap is removed. If you

do so, the encoder positional data may be lost.

50 Adept Viper s1300 Robot User’s Guide, Rev B

Page 51

Replacing Encoder Backup Battery

New battery (1st one)

Figure 5-4. Connecting First New Battery

7. Disconnect the old backup battery that is next to the new battery connected in

Step 6, and then connect a new battery (2nd one). See Figure 5-5.

Old battery New battery (2nd one)

Battery holder

New battery (1st one)

Figure 5-5. Connecting Second New Battery

NOTE: Be sure to replace all of three batteries with new ones at one time.

Otherwise, the battery service life will be reduced.

8. Disconnect the old backup battery that is next to the new battery connected in

Step 7, and then connect a new battery (3rd one). See Figure 5-6.

Adept Viper s1300 Robot User’ s Gu ide, Re v B 51

Page 52

Chapter 5 - Maintenance

Old battery

New battery (3rd one)

New battery (2nd one)

Battery holder

Figure 5-6. Connecting Third New Battery

9. Remove the last old battery and connect the dummy connector cap disconnected

in Step 5. See Figure 5-7.

Old battery

Dummy connector cap

Battery holder

New battery (3rd one)

Figure 5-7. Reconnecting Dummy Connector Cap

10. Secure the battery support plate to the connector plate.

Tightening torque: 1.6 +/- 0.3 Nm

52 Adept Viper s1300 Robot User’s Guide, Rev B

Page 53

5.2 Installing User-Supplied Hardstops

For the purpose of limiting the robot working envelope, the hardstops, or mechanical

ends, for Joints 1, 2, and 3 on the Adept Viper robots can be changed by installing

user-supplied hardstop devices. In addition, the default softstops, or software limits, must

be modified after the hardstops have been installed.

If you need information on modifying hardstops, please contact Adept.

CAUTION: Failures caused by user-supplied hardstops are

not covered by the warranty, even if the robot is under

warranty.

Installing User-Supplied Hardstops

Adept Viper s1300 Robot User’ s Gu ide, Re v B 53

Page 54

Chapter 5 - Maintenance

54 Adept Viper s1300 Robot User’s Guide, Rev B

Page 55

Technical Specifications 6

R1118.41

491.11

R795.38

R223.45

R598.41

R598

1593.41

475

520

R598

120.0°

120.0°

135.0°

90.0°

135.0°

180

84.53

27

1153

520

100

58

185

290

261

328

6

590

84

6.1 Robot Dimensions

Figure 6-1. Adept Viper s1300 Side Dimensions and Work Envelope

Adept Viper s1300 Robot User’s Guide, Rev B 55

Page 56

Chapter 6 - Technical Specifications

R1298

170.0°

170.0°

R403.45

150

188

130

Figure 6-2. Adept Viper s1300 Top Dimensions and Work Envelope

56 Adept Viper s1300 Robot User’s Guide, Rev B

Page 57

6.2 Robot Flange Dimensions

0.000

Ø50

-0.039

H8

Robot Flange Dimensions

4x 90°

45°

Ø25

+0.021

0.000

H7 9.5

Bolt circleØ40

Figure 6-3. Robot Flange Dimensions

4x M6 9

Ø6

+0.012

0.000

H7 9

Adept Viper s1300 Robot User’ s Gu ide, Re v B 57

Page 58

Chapter 6 - Technical Specifications

6.3 Specifications

Table 6-1. Robot Specifications

Specification s1300

Overall arm length 520 (first arm) + 590 (second arm) = 1100 mm

Arm offset J1 (swing): 180 mm, J3 (front arm): 100 mm

Maximum motion area R = 1388 mm (end-effector mounting face)

R = 1298 mm (Point P: J4, J5, J6 center)

Motion range J1: ±170°

J2: -180°, +45°

J3: +10°, +255°

J4: ±185°

J5: ±120°

J6: ±360°

Maximum composite speed

8300 mm/s

(at the center of an

end-effector mounting face)

Maximum payload 10 kg

Position repeatability (Note 1) In each of X, Y and Z directions: ±0.07 mm

(at the center of an end-effector mounting face)