Page 1

Adept Python

Modules

User’s Guide

Page 2

Page 3

Adept Python

Modules

User’s Guide

P/N:05850-000, Rev. E

August, 2009

5960 Inglewood Drive • Pleasanton, CA 94588 • USA • Phone 925.245.3400 • Fax 925.960.0452

Otto-Hahn-Strasse 23 • 44227 Dortmund • Germany • Phone +49.231.75.89.40 • Fax +49.231.75.89.450

Block 5000 Ang Mo Kio Avenue 5 • #05-12 Techplace II • Singapore 569870 • Phone +65.6755 2258 • Fax +65.6755 0598

Page 4

The information contained herein is the property of Adept Technology, Inc., and shall not be reproduced in whole or in part without prior written approval of Adept Technology, Inc. The information herein is subject to change without notice and should not be construed as a commitment by

Adept Technology, Inc. This manual is periodically reviewed and revised.

Adept Technology, Inc., assumes no responsibility for any errors or omissions in this document.

Critical evaluation of this manual by the user is welcomed. Your comments assist us in preparation

of future documentation. Please e-mail your comments to: techpubs@adept.com.

Copyright

Adept, the Adept logo, the Adept Technology logo, AdeptVision, AIM, Blox, Bloxview, FireBlox,

Fireview, HexSight, Meta Controls, MetaControls, Metawire, Soft Machines, and Visual Machines

Brain on Board is a registered trademark of Adept Technology, Inc. in Germany.

ACE, Adept 1060 / 1060+, Adept 1850 / 1850 XP, Adept 540 Adept 560, Adept AnyFeeder,

Adept Award, Adept C40, Adept C60, Adept CC, Adept Cobra 350, Adept Cobra 350 CR/ESD,

Adept Cobra 550, Adept 550 CleanRoom, Adept Cobra 600, Adept Cobra 800, Adept Cobra i600,

Adept Cobra i800, Adept Cobra PLC server, Adept Cobra PLC800, Adept Cobra s600, Adept Cobra

s800, Adept Cobra s800 Inverted, Adept Cobra Smart600, Adept Cobra Smart800, Adept DeskTop,

Adept FFE, Adept FlexFeeder 250, Adept IC, Adept iSight, Adept Impulse Feeder,

Adept LineVision, Adept MB-10 ServoKit, Adept MC, Adept MotionBlox-10,

Adept MotionBlox-40L, Adept MotionBlox-40R, Adept MV Adept MV-10, Adept MV-19,

Adept MV4, Adept MV-5, Adept MV-8, Adept OC, Adept Python, Adept Quattro s650,

Adept Quattro s650H, Adept sDIO, Adept SmartAmp, Adept SmartAxis, Adept SmartController

CS, Adept SmartController CX, Adept SmartModule, Adept SmartMotion, Adept SmartServo,

Adept sMI6, Adept sSight, Adept Viper s650, Adept Viper s850, Adept Viper s1300, Adept Viper

s1700, Adept Viper s2000, AdeptCartesian, AdeptCast, AdeptForce, AdeptFTP, AdeptGEM,

AdeptModules, AdeptMotion, AdeptMotion Servo, AdeptMotion VME, AdeptNet, AdeptNFS,

AdeptOne, AdeptOne-MV, AdeptOne-XL, AdeptRAPID, AdeptSight, AdeptSix, AdeptSix 300,

AdeptSix 300 CL, AdeptSix 300 CR, AdeptSix 600, AdeptTCP/IP, AdeptThree, AdeptThree-MV,

AdeptThree-XL, AdeptTwo, AdeptVision, AVI AdeptVision, AGS AdeptVision GV, AdeptVision

I, AdeptVision II, AdeptVision VME, AdeptVision VXL, AdeptVision XGS, AdeptVision XGS II,

AdeptWindows, AdeptWindows Controller, AdeptWindows DDE, AdeptWindows Offline

Editor, AdeptWindows PC, AIM Command Server, AIM Dispense, AIM PCB, AIM VisionWare,

A-Series, FlexFeedWare, HyperDrive, IO Blox, MicroV+, MotionBlox, MotionWare, ObjectFinder,

ObjectFinder 2000, PackOne, PalletWare, sAVI, S-Series, UltraOne, V, V+ and VisionTeach are

©2006-2009 by Adept Technology, Inc. All rights reserved.

are registered trademarks of Adept Technology, Inc.

trademarks of Adept Technology, Inc.

Any trademarks from other companies used in this publication

are the property of those respective companies.

Printed in the United States of America

Page 5

Table of Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.1 Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Adept Python Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

MotionBlox-10 Servo Controller and Amplifier . . . . . . . . . . . . . . . . . . . . . . . 15

Special and Custom Orders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Adept SmartController CX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Power Distribution Unit (PDU3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.2 Overview of Typical System Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installing Adept Python Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installing the SmartController . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installing Peripherals and Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Turning On the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.3 Manufacturer’s Declaration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.4 How Can I Get Help? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.5 Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Adept Document Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.1 Dangers, Warnings, Cautions, and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.2 Intended Use of the Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.3 Risk Assessment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Exposure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Severity of Injury . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Avoidance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Control System Behavior Category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.4 Precautions and Required Safeguards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Maximum Thrust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Safety Barriers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Impact and Trapping Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Hazards From Expelling a Part or Attached Tooling . . . . . . . . . . . . 28

Additional Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.5 Equipment Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Acceptable Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Unacceptable Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.6 Transport. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Encoder Battery Life. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.7 Safety Requirements for Additional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . 31

Adept Python Modules User’s Guide, Rev. E 5

Page 6

Table of Contents

2.8 Sound Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.9 Thermal Hazard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.10 Working Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.11 Qualification of Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.12 Safety Equipment for Operators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.13 Protection Against Unauthorized Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.14 Safety Aspects While Performing Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 34

2.15 Risks That Cannot Be Avoided . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.16 Risks Due to Incorrect Installation or Operation . . . . . . . . . . . . . . . . . . . . . . . . 34

2.17 What to Do in an Emergency Situation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3 Python Linear Module Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.1 Adept Python Linear Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Single-Axis and Multiple-Axis Configurations . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.2 Linear Module Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

L-Series Module Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Payloads and Moments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Stroke Length. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Ball Screw Lead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Acceleration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Resolution and Repeatability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Thrust. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Motor Mount Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Harness Exit Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Module Preparation (Assembly) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Cleanroom Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Module Descriptor Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

L18 Module Descriptor Number Example and Key . . . . . . . . . . . . . 52

L12 Module Options and Descriptor Number Key . . . . . . . . . . . . . 55

L08 Module Options and Descriptor Number Key . . . . . . . . . . . . . . 57

3.3 Gantry Support Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Gantry Support Module Descriptor Numbers . . . . . . . . . . . . . . . . . . . . . . . . 59

4 Python Theta Module Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4.1 Adept Python Theta Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Single-Axis and Multiple-Axis Configurations . . . . . . . . . . . . . . . . . . . . . . . . . 61

6 Adept Python Modules User’s Guide, Rev. E

Page 7

Table of Contents

4.2 Theta Module Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

L-Series Module Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Gear Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Module Preparation (Assembly). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Cleanroom Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Module Descriptor Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

LT1 Module Descriptor Number Example and Key . . . . . . . . . . . . . 64

5 Module System Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5.1 System Configuration Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5.2 Module System Descriptor Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Module System Descriptor Number Example and Key . . . . . . . . . . . . . . . . 68

Control Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

5.3 System Configuration and Module Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Module Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Single-Axis Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

System Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Single-Axis Theta Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Two-Axis Configuration Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

D Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

G Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

K Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

X Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Z Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Three-Axis Configuration Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

P Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Q Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Four-Axis Configuration Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

P Configuration with Theta . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Q Configuration with Theta . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

5.4 System Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Single-Axis Orientations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Typical Two-Axis Orientations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

5.5 Mounting Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Mounting Feet Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Toe Clamp Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Mounting Feet Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Toe Clamp Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

5.6 Cable Kits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Adept Python Modules User’s Guide, Rev. E 7

Page 8

Table of Contents

5.7 Gantry Mounting Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Gantry Support Module Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Parallel Alignment Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Gantry Over-Travel Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 101

5.8 IO Blox. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

5.9 Cabling/Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

6 Module Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

6.1 Lifting and Transporting Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

6.2 Mounting Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Mounting Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

6.3 Installing a Python Module System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

General Installation Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

6.4 Cleanroom System Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

7 Controller System Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

7.1 Installing the SmartController . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Space Around the Chassis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Mounting the Controller Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Connect 24 VDC Power and Ground to the SmartController . . . . . . . . . 117

7.2 System Cable Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

7.3 Installing the PDU3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

7.4 Installing the Adept Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

7.5 Connecting the Optional T2 Pendant to the Controller . . . . . . . . . . . . . . . . . . 119

7.6 Installing the User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Using AdeptWindows PC Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Graphical Interface Using Adept DeskTop . . . . . . . . . . . . . . . . . . . . . . . . . 120

7.7 Installing Optional IO Blox Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

8 Power Distribution Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

8.1 Introduction to the PDU3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

8.2 Installing the PDU3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

8.3 Typical AC Power Connection Diagrams for PDU3 . . . . . . . . . . . . . . . . . . . . . 123

8.4 PDU3 Connectors and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

8.5 PDU3 Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Procedure to Remove Fuse Holder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

8.6 PDU3 Mounting Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

8.7 PDU3 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

8.8 PDU3 Mounting Bracket Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

8 Adept Python Modules User’s Guide, Rev. E

Page 9

Table of Contents

8.9 PDU3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

8.10 PDU3 E-Stop Circuit Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

8.11 PDU3 Connector Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

XDCS Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

XSLV1/2 Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

9 Adept MB-10 Amps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

9.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

9.2 MB-10 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Status Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Indicator LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Brake Release Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

MB-10 Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

IO Blox Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

EEPROM on MB-10 T-Bracket. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

9.3 MB-10 Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

9.4 MB-10 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

9.5 MB-10 Connector Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

10 System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

10.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

10.2 Verifying Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Mechanical Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Power Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Cable Installation Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

User-Supplied Safety Equipment Checks . . . . . . . . . . . . . . . . . . . . . . . . . . 144

10.3 Turning On Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

10.4 Software Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Load and Run DC_SETUP.V2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Run Module Calibration Setup Program . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Adaptive Feed-Forward Compensation . . . . . . . . . . . . . . . . . . . . 150

10.5 Enable High Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

10.6 Run-Time Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

10.7 Turning Off Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

10.8 Operating and Programming an Adept Python Modules System . . . . . . . . 151

11 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

11.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

11.2 Checking Safety Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Every Six Months . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Adept Python Modules User’s Guide, Rev. E 9

Page 10

Table of Contents

11.3 Replacing the MB-10 Internal Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Battery Replacement Time Periods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Battery Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

11.4 Replacing the Module Encoder Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Battery Replacement Time Periods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Battery Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Battery Accessible via End Cap Removal . . . . . . . . . . . . . . . . . . . 157

Battery Not Easily Accessible, MB-10 Removal Required . . . . . . . 158

11.5 Python Module Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

11.6 Additional Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

11.7 MB-10 Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

12 Advanced System Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . 161

12.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

10 Adept Python Modules User’s Guide, Rev. E

Page 11

List of Figures

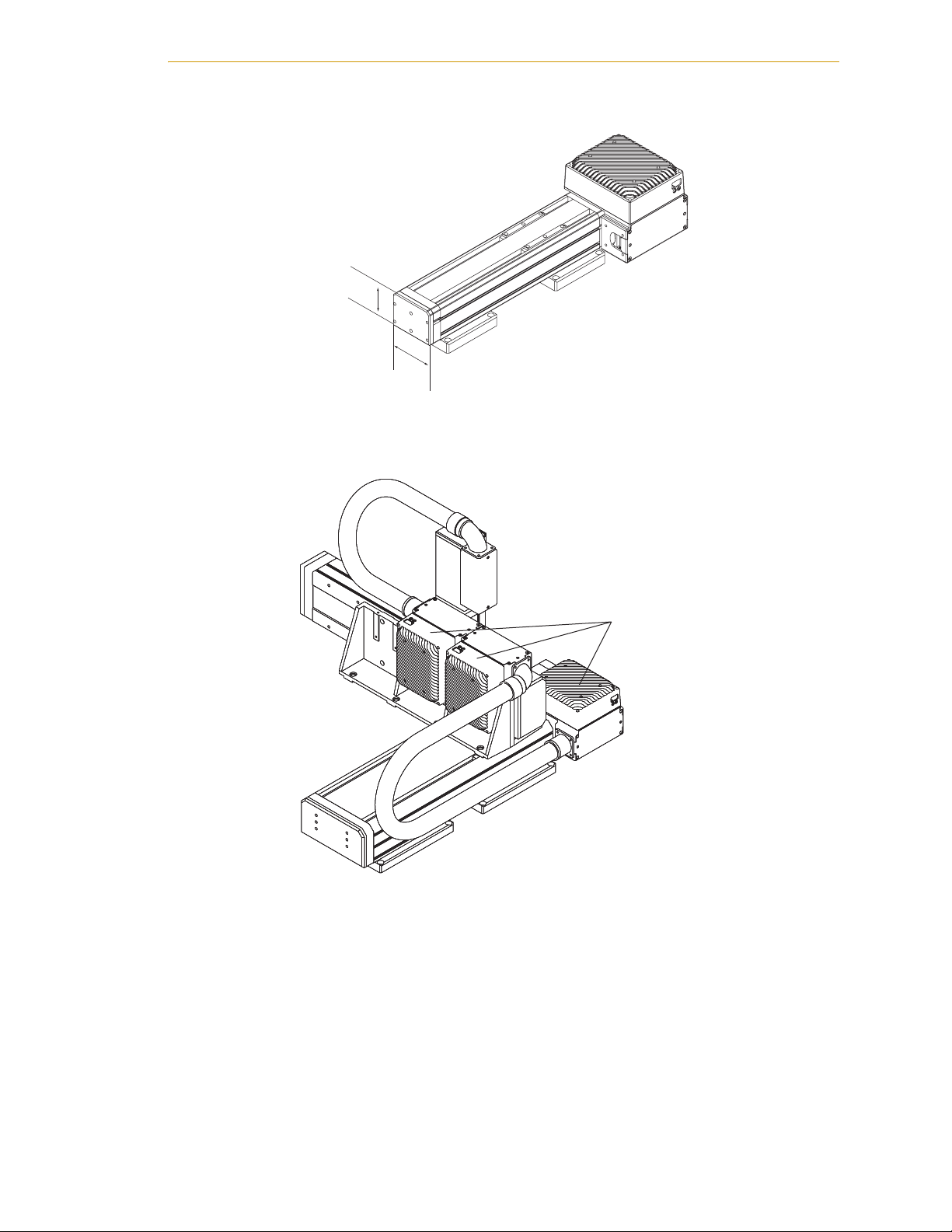

Figure 1-1. L18 Linear Module with MB-10 Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 1-2. L12 Linear Module with MB-10 Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 1-3. L08 Linear Module with MB-10 Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 1-4. Three-Axis System with L18, L12, and L08 Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

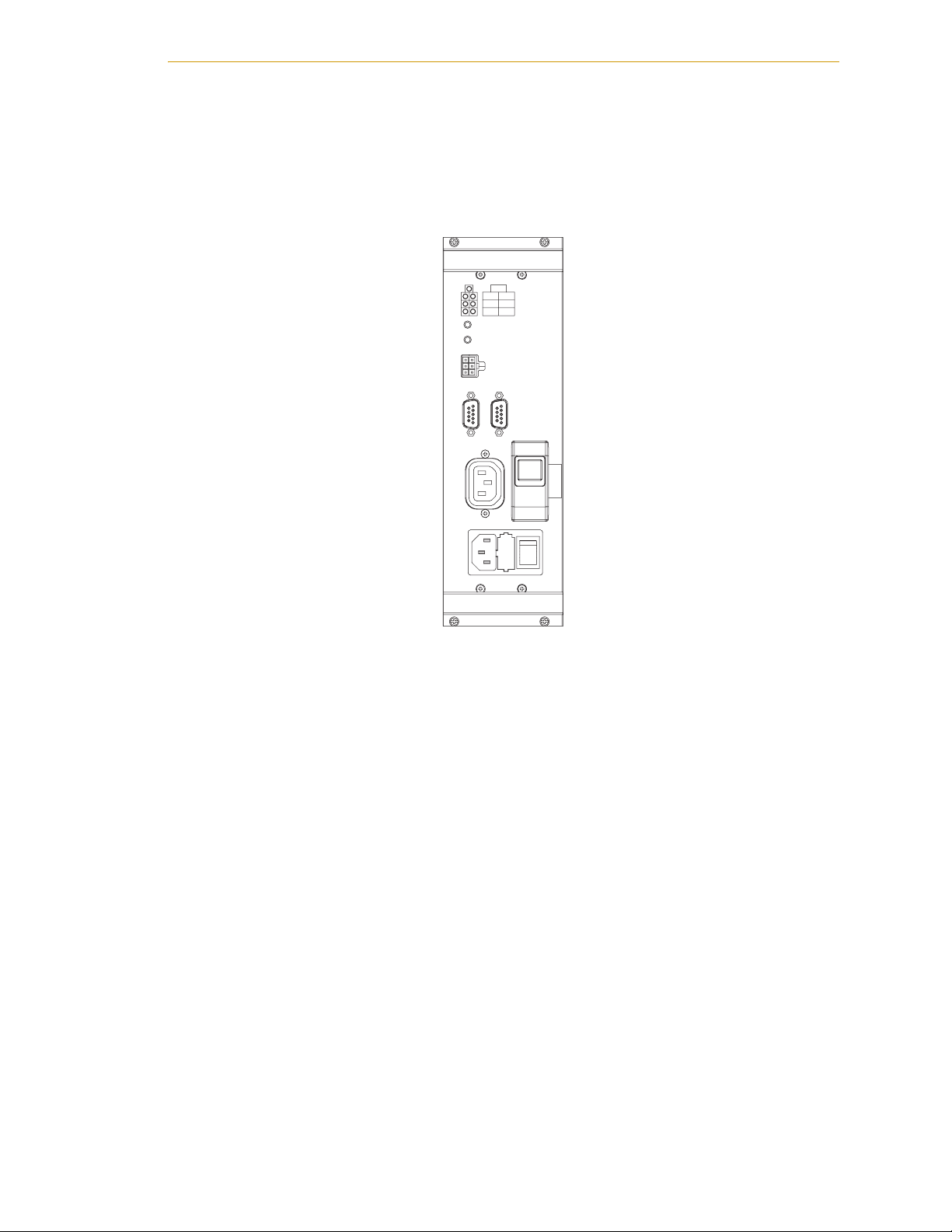

Figure 1-5. Adept SmartController CX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

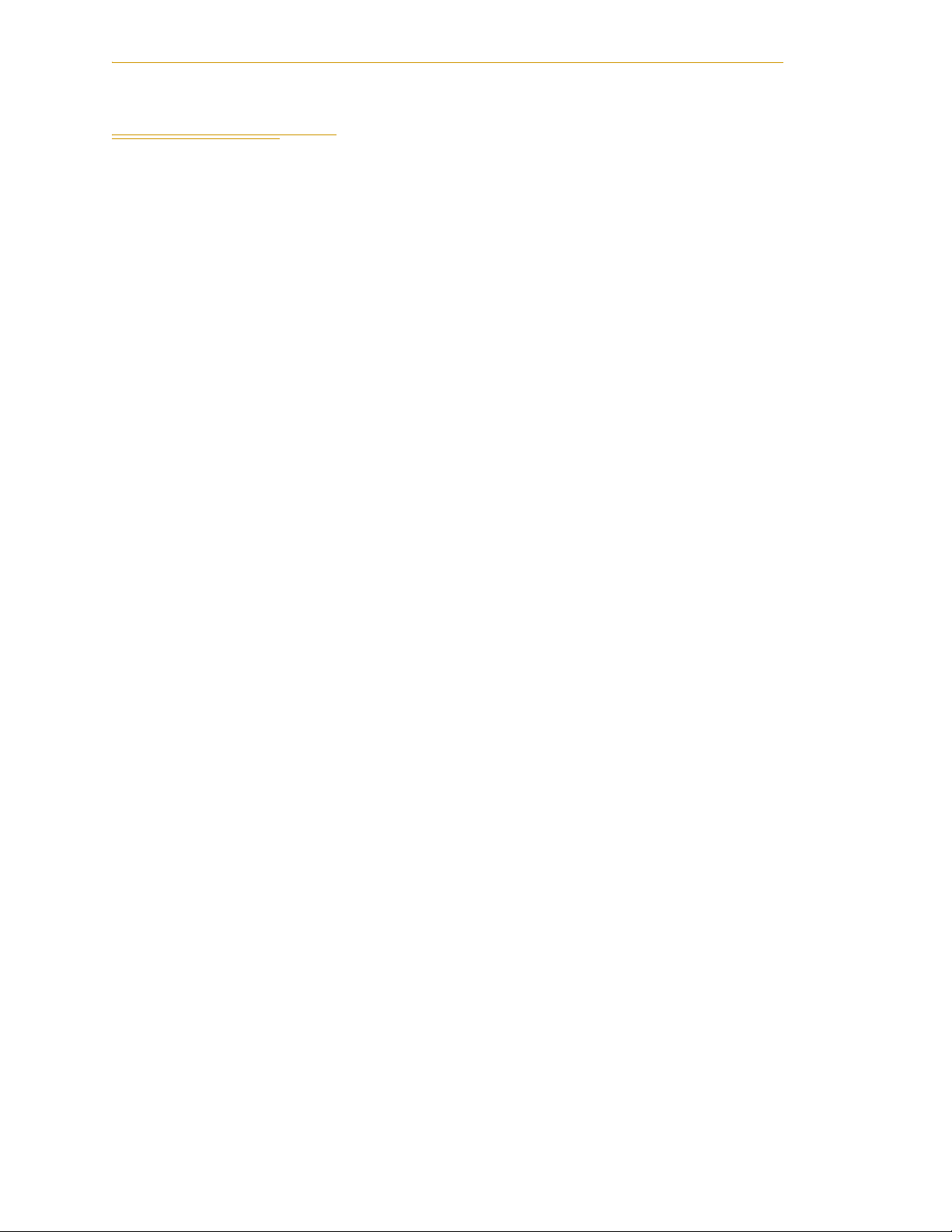

Figure 1-6. PDU3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 3-1. L18 Module without Brake, Shown at End of Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 3-2. L18 Module with Brake, Shown at End of Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 3-3. L12 Module without Brake, Shown at End of Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 3-4. L12 Module with Brake, Shown at End of Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 3-5. L08 Module with Brake (Left) and without Brake (Right) . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 3-6. Left- and Right-Hand Orientation Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 3-7. L18 Module with In-line Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 3-8. L18 Module with Left-Side Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 3-9. L18 Module with Right-Side Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 3-10. L18 Module with Bottom-Mount Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 3-11. In-Line Motor, Left Harness Exit Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 3-12. In-Line Motor, Right Harness Exit Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 3-13. Left-Side Motor Mount, Harness Exit Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 3-14. Right-Side Motor Mount, Harness Exit Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 3-15. L18 Descriptor Number Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 3-16. L18 Module Descriptor Key, Part 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 3-17. L18 Module Descriptor Key, Part 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 3-18. L12 Descriptor Number Key, Part 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 3-19. L12 Descriptor Number Key, Part 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 3-20. L08 Descriptor Number Key, Part 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 3-21. L08 Module Descriptor Key, Part 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 3-22. Gantry (LG6) Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 3-23. LG6 (Gantry) Descriptor Number Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 3-24. LG6 (Gantry) Descriptor Number Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 4-1. LT1 (Theta) Module with User Flange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 4-2. LT1 (Theta) Module with Standard Shaft/Range of Motion . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 4-3. LT1 (Theta) Module Descriptor Number Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 4-4. LT1 (Theta) Module Descriptor Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 5-1. Module System Descriptor Number Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 5-2. Module System Descriptor Number Key, Part 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Figure 5-3. Module System Descriptor Number Key, Part 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Figure 5-4. IO Blox Options in Module System Descriptor Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Figure 5-5. Three-Axis System with MB-10 Amplifiers Identified . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Figure 5-6. Configuration Options in Module System Descriptor Number . . . . . . . . . . . . . . . . . . . . . . 72

Figure 5-7. S2000 System with Mounting Feet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Figure 5-8. S2000 System (with Brake) Mounted Vertically . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Adept Python Modules User’s Guide, Rev. E 11

Page 12

List of Figures

Figure 5-9. LT1 (Theta) Module Envelope/Mounting Hole Dimensions (Top View) . . . . . . . . . . . . . . . 75

Figure 5-10. LT1 (Theta) Module Envelope/Mounting Hole Dimensions (Side View) . . . . . . . . . . . . . 76

Figure 5-11. LT1 (Theta) Module Envelope/Mounting Hole Dimensions (Bottom View) . . . . . . . . . . . 76

Figure 5-12. LT1 (Theta) Module User Flange Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Figure 5-13. D1200 System with Optional Mounting Feet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Figure 5-14. G1200 System with Optional Mounting Feet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Figure 5-15. K1200 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Figure 5-16. X1100 System with Optional Mounting Feet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Figure 5-17. Z1200 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Figure 5-18. P Configuration (P1230 System) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Figure 5-19. Q Configuration (Q1230 System) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Figure 5-20. P Configuration with Theta . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Figure 5-21. Q Configuration with Theta . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Figure 5-22. Single-Axis Orientation Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Figure 5-23. Standard/Standard Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Figure 5-24. Flipped/Standard Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Figure 5-25. Standard/Rolled Orientation (Rear View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Figure 5-26. Flipped/Rolled Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Figure 5-27. Mounting Options in Module System Descriptor Number . . . . . . . . . . . . . . . . . . . . . . . . 90

Figure 5-28. S1000SS13 - Single L18 System with Three Mounting Feet . . . . . . . . . . . . . . . . . . . . . . . . . 91

Figure 5-29. S1000SS00 - Single L18 System without Mounting Feet . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Figure 5-30. L08 Module with Toe Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Figure 5-31. L12 Module with Toe Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Figure 5-32. L18 Module with Toe Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Figure 5-33. L18 Module with Mounting Feet Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Figure 5-34. L12 Module with Mounting Feet Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Figure 5-35. L08 Module with Mounting Feet Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Figure 5-36. LG6 Module with Mounting Feet Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Figure 5-37. L08 Module with Toe Clamp Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Figure 5-38. L12 Module with Toe Clamp Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Figure 5-39. L18 Module with Toe Clamp Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Figure 5-40. Cable Kit Descriptors for a Typical 3-Axis P or Q System . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Figure 5-41. Gantry (LG6) Module Shown with Gantry Mounting Kit . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Figure 5-42. Gantry Key Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Figure 5-43. L12 Gantry Mounting Methods, End and Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Figure 5-44. Gantry Installation: Parallel Alignment Specs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Figure 5-45. Gantry Installation: Lip Seal to Support Bracket Gap Dimensions . . . . . . . . . . . . . . . . . 101

Figure 5-46. Gantry Over-Travel Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Figure 5-47. IO Blox Options in Module System Descriptor Number . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Figure 5-48. Mounting onto an MB-10 Amp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Figure 5-49. Mounting onto an L18 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Figure 5-50. Mounting onto a Module T-Slot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Figure 5-51. Mounting onto a Two-Axis System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Figure 5-52. Mounting onto a Three-Axis System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Figure 5-53. Cabling/Plumbing Options in Module System Descriptor Number . . . . . . . . . . . . . . . . 107

Figure 6-1. Recommended Lifting Technique for Python System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

12 Adept Python Modules User’s Guide, Rev. E

Page 13

List of Figures

Figure 6-2. Typical Three-Axis System on Shipping Pallet with Contents Labelled . . . . . . . . . . . . . . 111

Figure 6-3. Removing Shipping Screws from Axis 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Figure 6-4. Installing Axis 3 on Axis 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Figure 6-5. Removing Shipping Screws from Axis 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Figure 6-6. Removing Shipping Screws from Axis 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Figure 6-7. Lifting a Python System Using a Hoist and Slings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Figure 6-8. Example Cleanroom Module System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Figure 7-1. System Cable Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Figure 8-1. Adept PDU3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Figure 8-2. Typical Single-Phase 200-240 VAC Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Figure 8-3. Typical Three-Phase 200-240 VAC Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Figure 8-4. Typical Three-Phase 380-415 VAC Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Figure 8-5. PDU3 with Mounting Brackets Installed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Figure 8-6. PDU3 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Figure 8-7. Mounting Bracket Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Figure 8-8. E-Stop Circuit Diagram for PDU3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Figure 9-1. Adept MB-10 Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Figure 9-2. Connector Locations on MB-10 Amp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Figure 9-3. Attaching the AC Power and Ground Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Figure 9-4. EEPROM Device on T-Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Figure 10-1. DC_SETUP Program Main Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Figure 10-2. DC_SETUP Program Setup Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Figure 10-3. DC_SETUP Program Node to Robot/Motor Map Screen . . . . . . . . . . . . . . . . . . . . . . . . 147

Figure 10-4. DC_SETUP Program Current Configuration Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Figure 10-5. Calibration Setup Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Figure 11-1. MB-10 Internal Battery and Retaining Clip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Figure 11-2. MB-10 Internal Battery Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Figure 11-3. Encoder Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Figure 11-4. Replacement Cable Assembly Installed in Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Figure 12-1. System Installation with Two Linear Module Robots Daisy-Chained . . . . . . . . . . . . . . . 162

Figure 12-2. System Installation with Three Linear Module Robots and Two PDUs . . . . . . . . . . . . . . 163

Figure 12-3. Three Linear Module Robots, Two PDUs, and a Cobra s600 with Vision . . . . . . . . . . . . 164

Adept Python Modules User’s Guide, Rev. E 13

Page 14

Page 15

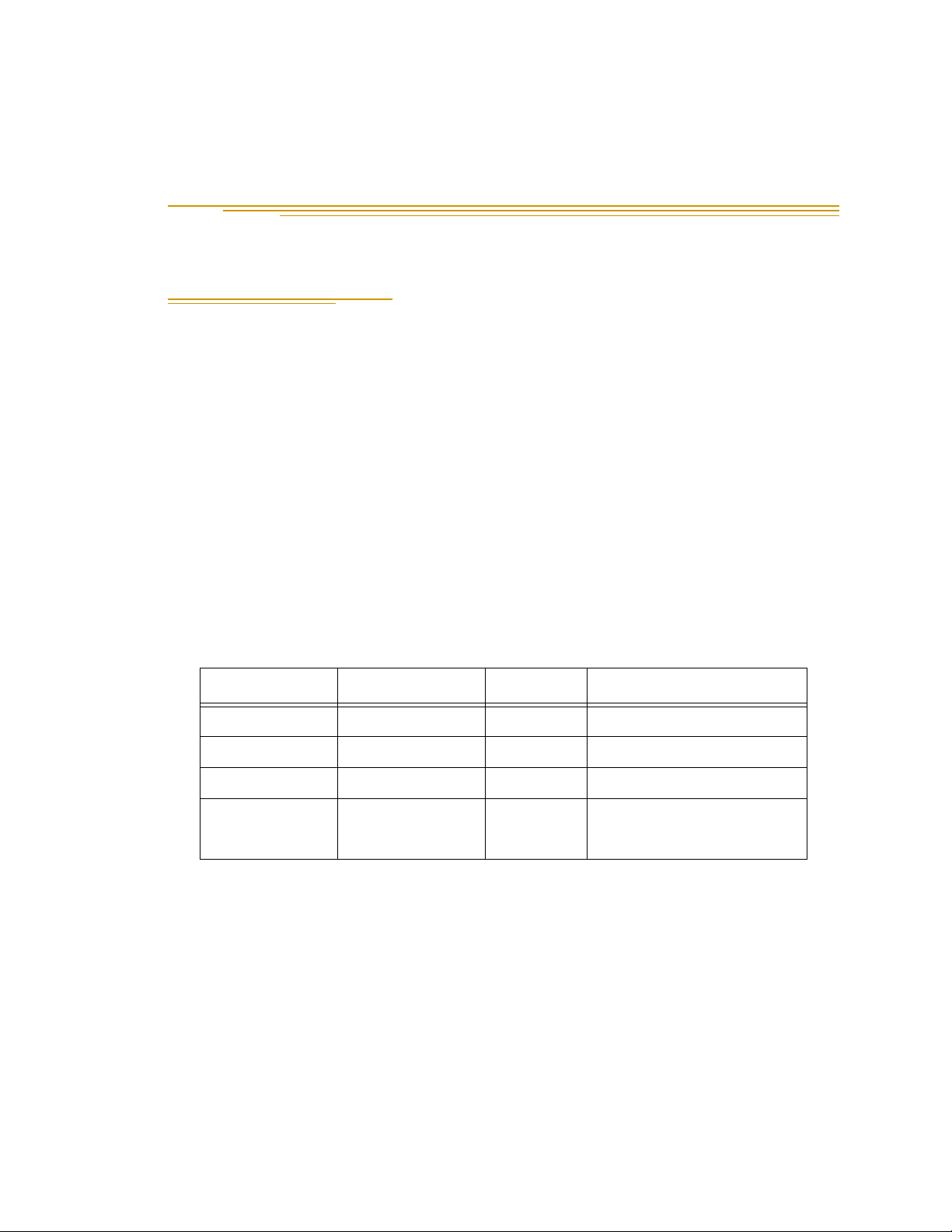

1.1 Product Description

Adept Python Modules

The Adept Python Linear Modules product line consists of precision ball-screw driven

modules that function as single-axis mechanisms, and can also be combined into

numerous two-, three-, and four-axis configurations. Each linear module is available in

different lengths (see Table 1-1) and motor mounting configurations. The Theta module

adds a rotational axis to a Python system, providing additional handling options. You can

find drawings for the multiple axis configurations in Chapter 5.

Most module configurations are shipped fully assembled, so the user only needs to

connect the controller and any peripherals. This manual describes the different module

and system types, and covers the basic steps of installing a typical system. Refer to

Table 1-2 on page 22 for a list of manuals that provide additional information on your

Adept system.

Introduction 1

Table 1-1. Adept Python Modules

Module Type Width Height Available Lengths

L18 185 mm 93 mm 300 to 2000 mm

L12 125 mm 83 mm 200 to 1500 mm

L08 85 mm 68 mm 100 to 800 mm

LT1 90 mm 65 mm With User Flange = 240 mm

Without Flange = 230 mm

MotionBlox-10 Servo Controller and Amplifier

Each module axis is controlled and powered by its own on-board servo controller and

amplifier, called a MotionBlox-10 (MB-10). Each MB-10 is linked via the IEEE 1394

high-speed serial communication protocol to the Adept SmartController.

Adept Python Modules User’s Guide, Rev. E 15

Page 16

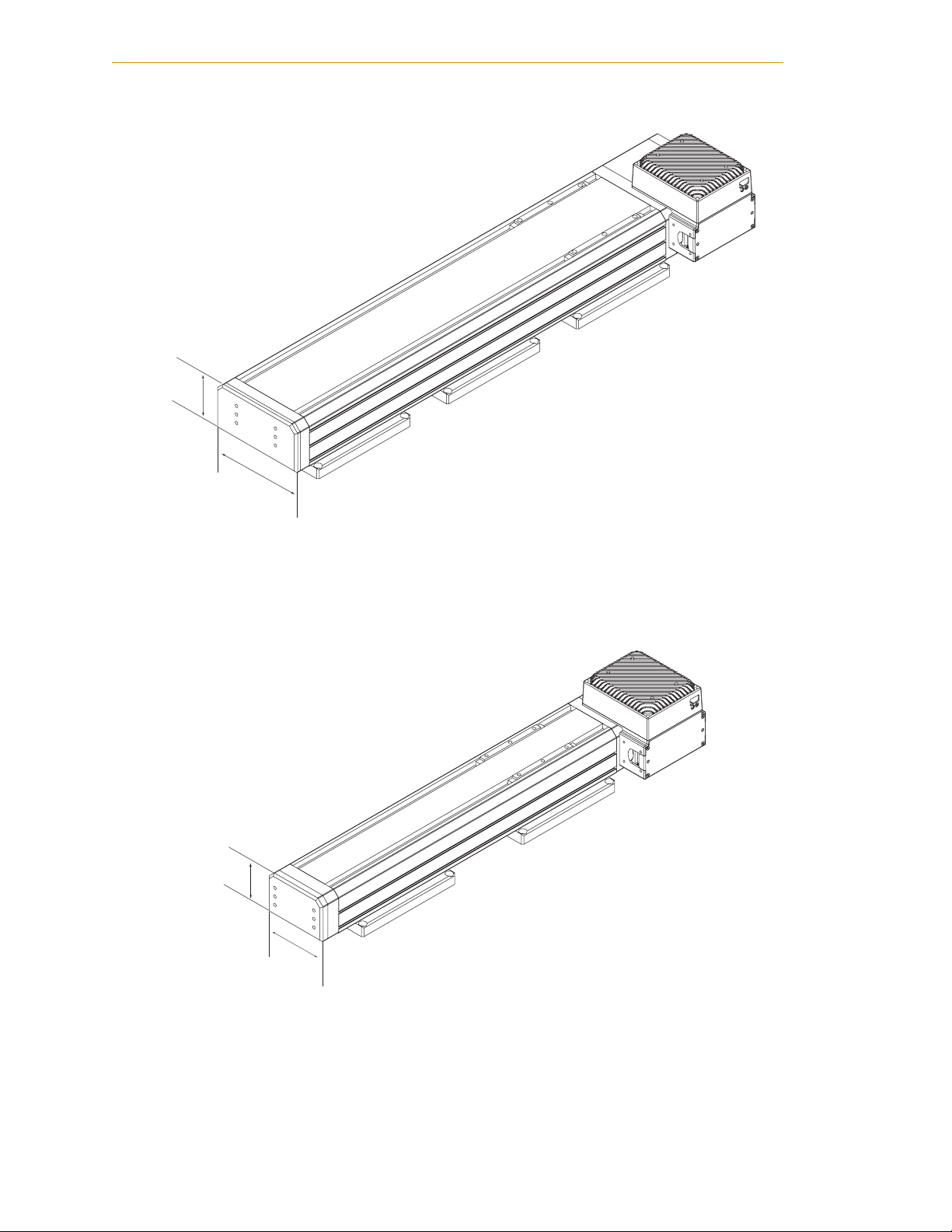

Chapter 1 - Introduction

93 mm

L18 Module with

MotionBlox-10 Amp

83 mm

185 mm

Figure 1-1. L18 Linear Module with MB-10 Amplifier

L12 Module with

MotionBlox-10 Amp

125 mm

Figure 1-2. L12 Linear Module with MB-10 Amplifier

16 Adept Python Modules User’s Guide, Rev. E

Page 17

L08 Module with

MotionBlox-10 Amp

68 mm

85 mm

Figure 1-3. L08 Linear Module with MB-10 Amplifier

Product Description

Daisy-chained set of

MB-10 amplifiers, one

for each module

Figure 1-4. Three-Axis System with L18, L12, and L08 Modules

Adept Python Modules User’s Guide, Rev. E 17

Page 18

Chapter 1 - Introduction

Special and Custom Orders

Special orders consist of any unique module or system configuration not outlined in this

manual, or supported by the Adept 3D Modules configuration tool on our website.

Custom orders consist of any order containing a custom module or module system. These

orders may not be fully assembled at the factory.

Adept SmartController CX

The SmartController CX is the foundation of Adept’s family of high-performance

distributed motion and vision controllers. The SmartController CX is designed for use

with:

• Adept Cobra s-series robots

• Adept Viper s-series robots

•Adept Python Modules

• Adept Servo Kit Systems

•Adept sMI6 (SmartMotion)

• Adept Quattro robots

The SmartController CX supports an integrated vision option and a conveyor tracking

option. It offers scalability and support for IEEE 1394-based digital I/O and general

motion expansion modules. The IEEE 1394 interface is the backbone of Adept SmartServo,

Adept's distributed controls architecture supporting Adept products. The controller also

includes Fast Ethernet and DeviceNet.

RS-422/485

RS-232-2

*S/N 3562-XXXXX*

XDC1 XDC2

24V 5A

-+ -+

SmartController CX

OK

SF ES HD

123

R

LANHPE

1234

SmartServo IEEE-1394

1.1 1.2 2.1 2.2

SW1

ON

OFF

XDIO

XUSR

Device Net

Eth 10/100

XSYS

CAMERA

BELT ENCODER

RS-232/TERM

RS-232-1

XFP

XMCP

Figure 1-5. Adept SmartController CX

18 Adept Python Modules User’s Guide, Rev. E

Page 19

Product Description

Power Distribution Unit (PDU3)

The Power Distribution Unit (PDU3) is a safety device that provides Category-3 E-Stop

functionality, per EN 954. The PDU3 also provides surge protection, power filtering, and

DC power for the MB-10 and optional IO Blox devices.

PDU3

24V

AMP

AUX

CH1 CH2

ES2

ES1

AMP DC RESET

AUX DC RESET

XDCS

1

AC

PWR

AMP

AC

PWR

IN

2

XSLV1/

XSLV2

Figure 1-6. PDU3

B

C

R

I

E

R

A

C

K

U

E

I

R

T

Adept Python Modules User’s Guide, Rev. E 19

Page 20

Chapter 1 - Introduction

1.2 Overview of Typical System Installation

This section provides an overview of the installation process for a typical Adept Python

modules system using an Adept SmartController.

Installing Adept Python Modules

1. Unpack your system and verify that you have everything required.

2. Install the modules onto your work surface (see Chapter 6 for information).

3. Connect these cables:

a. IEEE 1394 cable from MB-10 #1 to SmartController

b. Switched AC power cable from MB-10 #1 to PDU3

c. 24 VDC cable from MB-10 #1 to PDU3

4. To install an optional IO Blox device, see the Adept IO Blox User’s Guide.

Installing the SmartController

NOTE: Refer to the Adept SmartController User’s Guide for detailed

instructions on installing the controller.

1. Mount the controller chassis in the workcell. There are several different mounting

choices. See page 117.

2. Connect 24 VDC power to the SmartController.

3. Connect a ground wire to the SmartController.

Installing Peripherals and Options

1. Install the PDU3 in the workcell. See Section 8.2 on page 122.

2. Connect AC power to the PDU3. See Section 8.3 on page 123.

3. Mount the Adept Front Panel.

It must be outside of the workcell. See the Adept SmartController User’s Guide

for information on using the Front Panel.

4. Connect the Front Panel to the SmartController. See Section 7.4 on page 119.

5. Connect the optional T2 pendant to the SmartController. See Section 7.5 on page

119.

6. Install the User Interface. See Section 7.6 on page 120. There are two choices:

• AdeptWindows PC software, running on the user-supplied PC

• Optional Adept DeskTop software, running on the user-supplied PC

20 Adept Python Modules User’s Guide, Rev. E

Page 21

7. Refer to the Operation chapter in the Adept SmartController User’s Guide for

information on installing customer-supplied equipment and safety circuits,

including:

• Emergency Stop circuits

• Remote Manual Mode control

• Remote High Power control

• Connecting user-supplied serial and digital I/O equipment

Turning On the System

1. Refer to Chapter 10 to perform system installation verification.

2. After the installation has been verified for all safety regulations, turn on DC

power to the controller and AC power to the PDU.

3. See Section 10.4 on page 145 for the software configuration process.

Manufacturer’s Declaration

1.3 Manufacturer’s Declaration

The Manufacturer’s Declaration of Incorporation and Conformity for Adept Python

modules systems can be found on the Adept website, in the Download Center of the

Support section.

http://www.adept.com/support/downloads_disclaimer.asp

In the Download Types search box, select Regulatory Certificates to find the document,

which you can then download.

1.4 How Can I Get Help?

Refer to the How to Get Help Resource Guide (Adept P/N 00961-00700) for details on

getting assistance with your Adept software and hardware.

Additionally, you can access information sources on Adept’s corporate website:

http://www.adept.com

Adept Python Modules User’s Guide, Rev. E 21

Page 22

Chapter 1 - Introduction

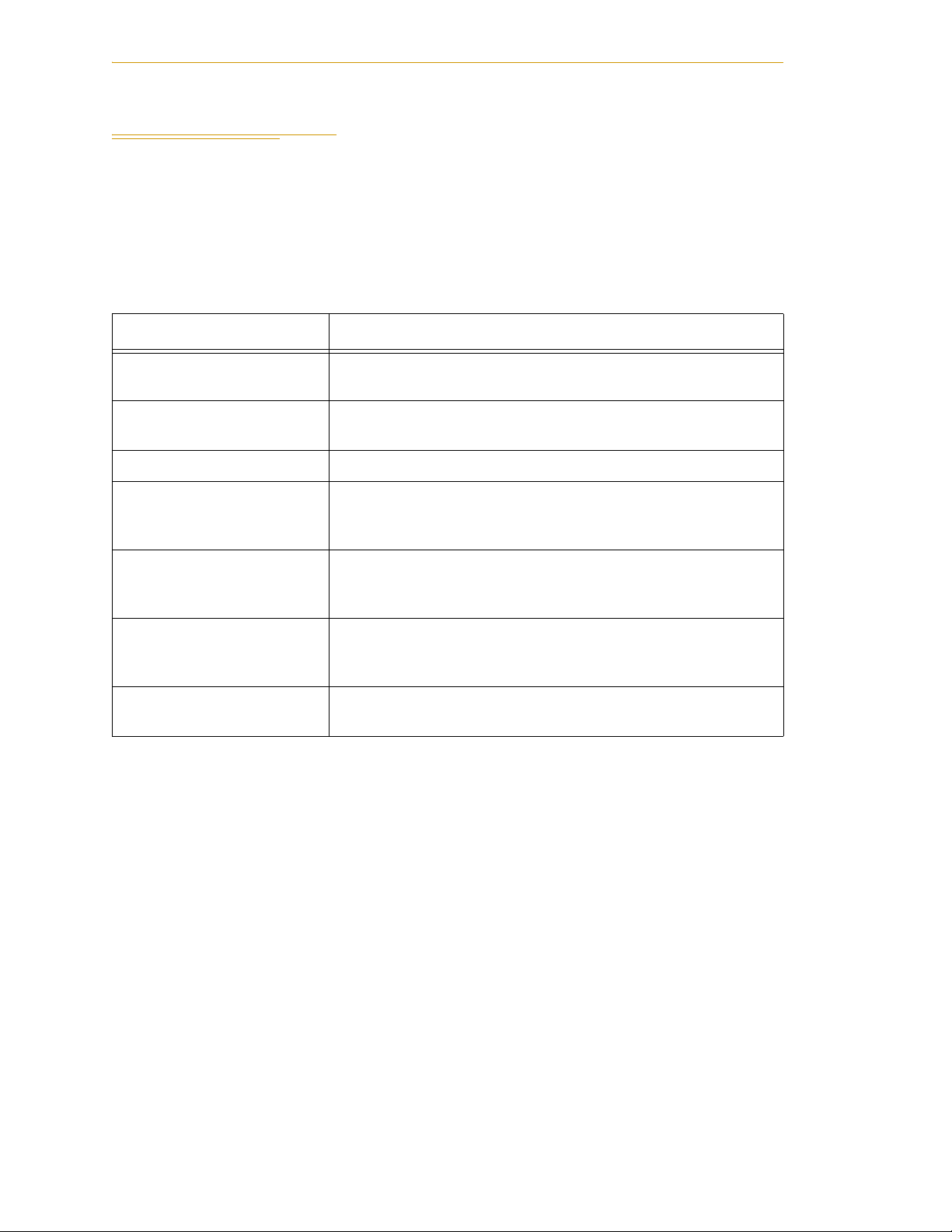

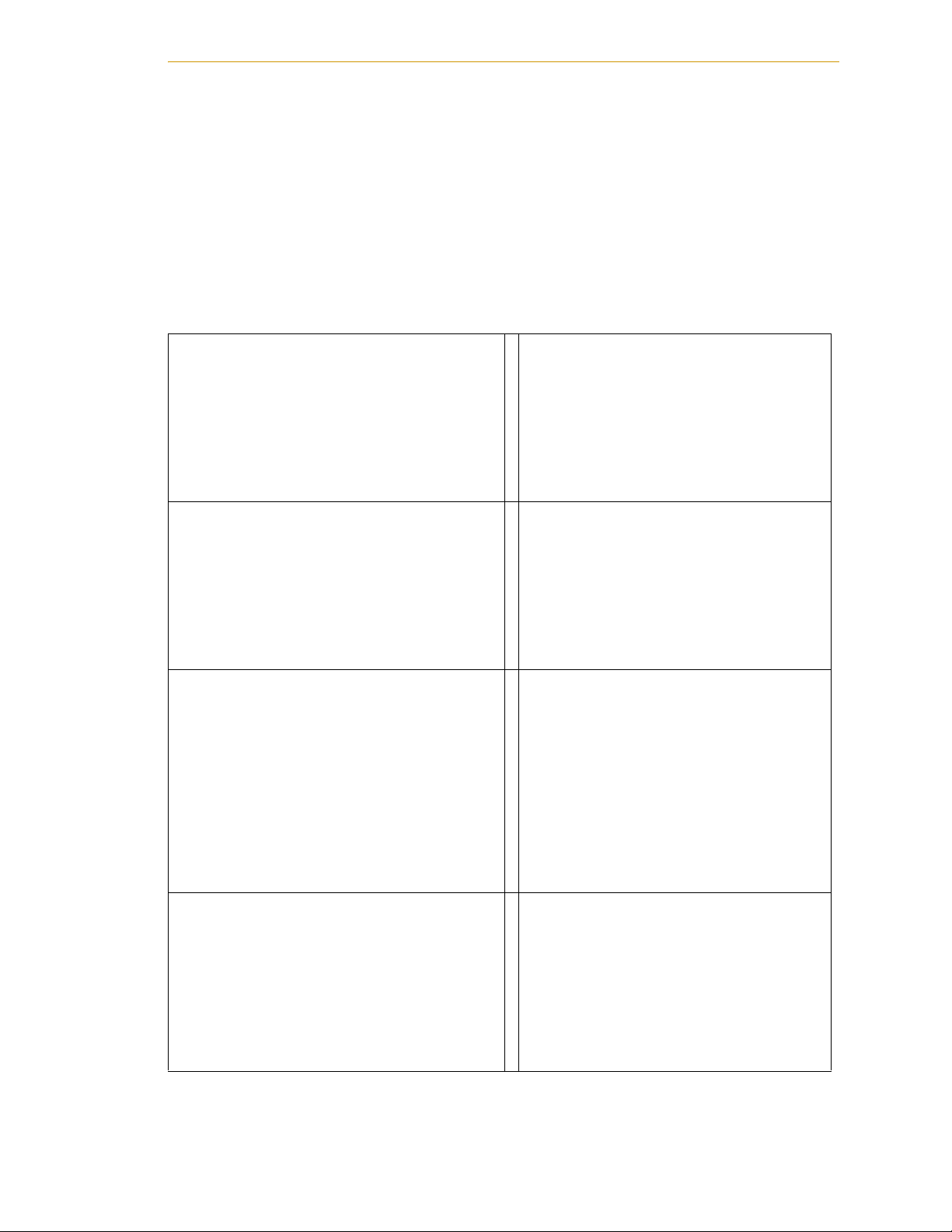

1.5 Related Manuals

This manual covers the installation of a SmartContoller-based Adept Python Modules

system. There are additional manuals that cover programming the system, reconfiguring

installed components, and adding other optional components. See Table 1-2. These

manuals are available on the Adept Document Library on CD-ROM provided with each

system.

Manual Title Description

Table 1-2. Related Manuals

Adept SmartController

User’s Guide

Adept T2 Pendant User’s

Guide

Adept IO Blox User’s Guide Describes the IO Blox product.

AdeptWindows Installation

Guide and AdeptWindows

Online Help

Instructions for Adept

Utility Programs

V+ Operating System User’s

Guide

V+ Language User’s Guide Describes the V

Contains complete information on the installation and operation

of the Adept SmartController and the optional sDIO products.

Describes the T2 Pendant product.

Describes complex network installations, installation and use of

NFS server software, the AdeptWindows Offline Editor, and the

AdeptWindows DDE software.

Describes the utility programs used for advanced system

configurations, system upgrades, file copying, and other system

configuration procedures.

Describes the V

operations, monitor commands, and monitor command

programs.

control system.

+

operating system, including disk file

+

language and programming of an Adept

Adept Document Library

In addition to the Adept Document Library on CD-ROM, you can find Adept product

documentation on the Adept website in the Document Library area. The Document

Library search engine allows you to locate information on a specific topic. Additionally,

the Document Menu provides a list of available product documentation.

To access the Adept Document Library, type the following URL into your browser:

http://www.adept.com/Main/KE/DATA/adept_search.htm

or, select the Document Library link on the Home page of the Adept website.

22 Adept Python Modules User’s Guide, Rev. E

Page 23

Safety 2

2.1 Dangers, Warnings, Cautions, and Notes

There are six levels of special alert notation used in this manual. In descending order of

importance, they are:

DANGER: This indicates an imminently hazardous

electrical situation which, if not avoided, will result in

death or serious injury.

DANGER: This indicates an imminently hazardous

situation which, if not avoided, will result in death or

serious injury.

WARN IN G: This indicates a potentially hazardous

electrical situation which, if not avoided, could result in

injury or major damage to the equipment.

WARN IN G: This indicates a potentially hazardous

situation which, if not avoided, could result in injury or

major damage to the equipment.

CAUTION: This indicates a situation which, if not avoided,

could result in damage to the equipment.

NOTE: This provides supplementary information, emphasizes a point or

procedure, or gives a tip for easier operation.

Adept Python Modules User’s Guide, Rev. E 23

Page 24

Chapter 2 - Safety

2.2 Intended Use of the Modules

The installation and use of Adept products must comply with all safety instructions and

warnings in this manual. Installation and use must also comply with all applicable local

and national requirements and safety standards (see Section 2.7 on page 31).

Adept Python Modules are intended for use in parts assembly and material handling for a

variety of payloads, depending on the specific configuration.

WARN IN G: For safety reasons, it is prohibited to make

certain modifications to Adept robots (see Section 2.5 on

page 30).

The SmartController is a component subassembly of a complete industrial automation

system. The SmartController must be installed inside a suitable enclosure. The

SmartController and modules must not come into contact with liquids.

The Adept equipment is not intended for use in any of the following situations:

• In hazardous (explosive) atmospheres

• In mobile, portable, marine, or aircraft systems

• In life-support systems

• In residential installations

• In situations where the Adept equipment will be washed down or subject to

extremes of heat or humidity.

Non-intended use of an Adept Python Modules system can:

• Cause injury to personnel

• Damage the robot or other equipment

• Reduce system reliability and performance

All persons that install, commission, operate, or maintain the robot must:

• Have the necessary qualifications

• Read and follow exactly the instructions in the documentation

WARN IN G: The instructions for operation, installation,

and maintenance given in the documentation must be

strictly observed.

If there is any doubt concerning the application, ask Adept to determine if it is an

intended use or not.

24 Adept Python Modules User’s Guide, Rev. E

Page 25

Risk Assessment

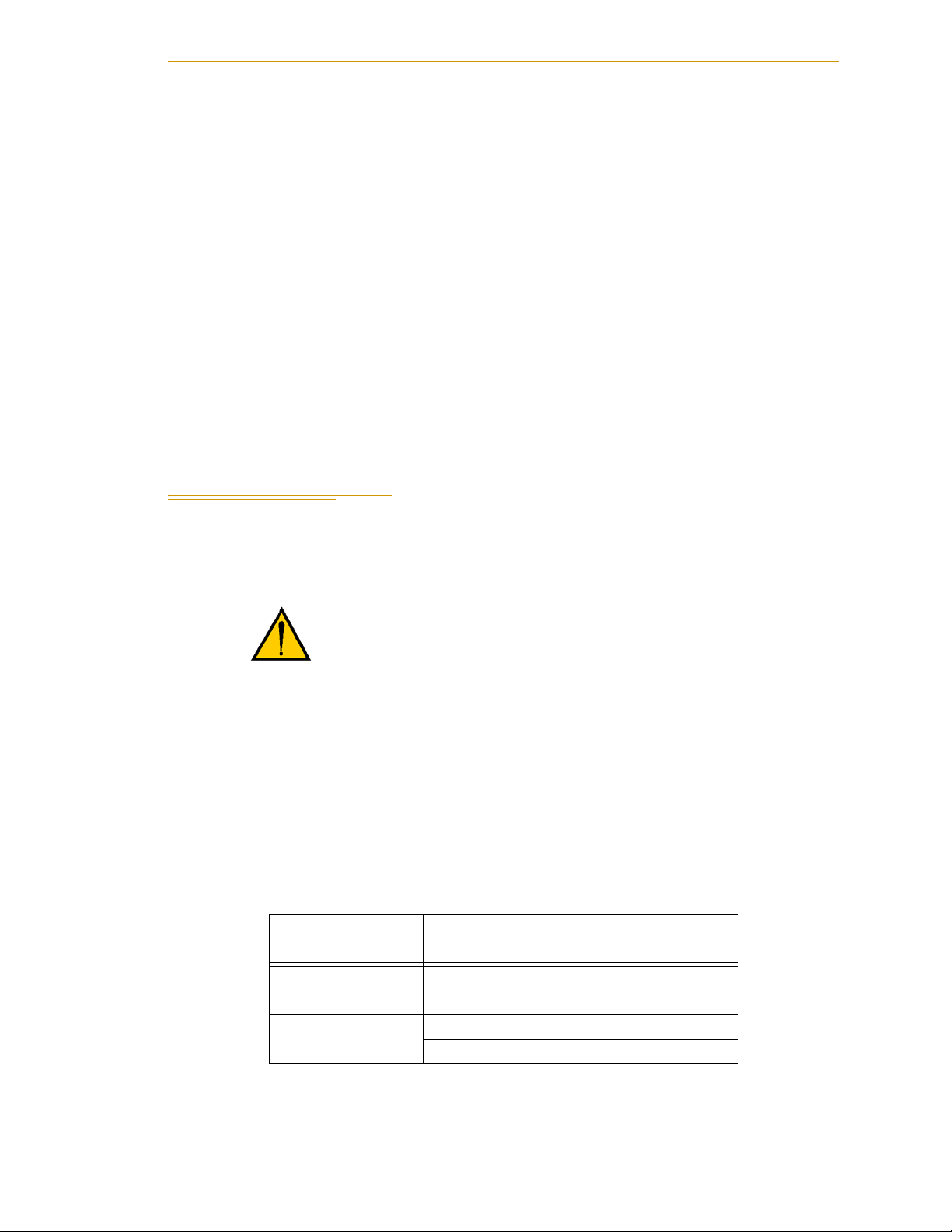

2.3 Risk Assessment

Without special safeguards in its control system, Adept Python Modules could inflict

serious injury on an Operator working within its work envelope. Safety standards in

many countries require appropriate safety equipment to be installed as part of the system.

Table 2-1 lists some of the safety standards that affect industrial robots. It is not a

complete list. You must comply with all applicable local and national standards for the

location where the robot will be installed.

Table 2-1. Partial List of Robot and Machinery Safety Standards

International USA Canada Europe Title of Standard

ISO 10218 EN 775 Manipulating Industrial Robots -

Safety

ANSI/RIA

R15.06

Adept has performed a Risk Assessment for this product, based on the intended

applications of the robot. The conclusions are summarized in the following sections.

CAN/CSAZ434-94

Industrial Robots and Robot Systems

- Safety Requirements

EN 292-2 Safety of Machinery - Basic

Concepts, General Principles for

Design

EN 954-1 Safety Related Parts of Control

Systems - General Principles for

Design

EN 1050 Safety of Machinery - Risk

Assessment

Exposure

When High Power is on, all personnel must be kept out of the robot work envelope by

interlocked perimeter barriers. The only permitted exception is for teaching the robot in

Manual Mode by a skilled programmer (see Section 2.11 on page 33), who must wear

safety equipment (see Section 2.12 on page 33) and carry the T2 pendant. Therefore,

exposure of personnel to hazards related to the robot is limited (seldom and/or short

exposure time).

Severity of Injury

Provided that skilled personnel who enter the modules robot work envelope are wearing

protective headgear, eyeglasses, and safety shoes, it is likely that any injuries caused by

the robot would be slight (normally reversible).

Adept Python Modules User’s Guide, Rev. E 25

Page 26

Chapter 2 - Safety

Avoidance

Due to the module’s size and speed capability, it is likely that such personnel could avoid

being hit by the robot even in a high-acceleration, runaway failure condition. The

programmer must carry the T2 pendant when inside the work envelope, as the T2

pendant provides both E-Stop and Enabling switch functions.

For normal operation, AUTO mode, user-supplied interlocked guarding must be installed

to prevent any person entering the workcell while High Power is on.

DANGER: The Adept-supplied system components

provide Category 3 Emergency Stop functionality and

Category 1 protection during TeachMode operation, as

defined by EN 954. The robot system must be installed

with user-supplied interlock barriers. The interlocked

barrier should interrupt the AC supply to the system in

the event of personnel attempting to enter the workcell

when High Power is enabled, except for Teaching in

Manual mode. Failure to install suitable guarding could

result in injury or death.

The E-stop CIRCUIT is "category 3" as defined by EN 954 (dual channel: redundant,

diverse, and control-reliable).

Activating the E-stop system causes a Category 0, Uncontrolled stop, as defined by

NFPA79.

The E-stop circuit is Dual Channel (redundant, diverse, and control reliable).

The Risk Assessment for teaching this product depends on the application. In many

applications, the programmer will need to enter the robot workcell while High Power is

enabled to teach the robot. Other applications can be designed so that the programmer

does not have to enter the work envelope while High Power is on. Examples of alternative

methods of programming include:

1. Programming from outside the safety barrier.

2. Programming with High Power off (using the brake release button when

required).

3. Copying a program from another (master) robot.

4. Off-line or CAD programming.

Control System Behavior Category

The following paragraphs relate to the requirements of European (EU/EEA) directives for

Machinery, Electric Safety, and Electromagnetic Compatibility (EMC).

26 Adept Python Modules User’s Guide, Rev. E

Page 27

Precautions and Required Safeguards

In situations with low exposure consideration factors, European Standard EN 1050

specifies use of a Category 1 Control System per EN 954. EN 954 defines a Category 1

Control System as one that employs Category B components designed to withstand

environmental influences, such as voltage, current, temperature, EMI, and well-tried

safety principles. The standard SmartController control system described in this user’s

guide employs hardware components in its safety system that meet or exceed the

requirements of the EU Machinery Directive and Low Voltage Directive.

Furthermore, the standard control system is fully hardened to all EMI influences per the

EU EMC Directive and meets all functional requirements of ISO 10218 (EN 775)

Manipulating Robots Safety. In addition, a software-based reduced speed and maximum

current limit provided to the motor by the amplifier have been incorporated to limit speed

and impact forces on the Operator and production tooling when the robot is operated in

Manual mode.

In consideration of the above, the standard Adept SmartController Control System meets

or exceeds the requirements imposed by the EN 954 specified Category 1 level of safety.

2.4 Precautions and Required Safeguards

This manual must be read by all personnel who install, operate, or maintain Adept

systems, or who work within or near the workcell.

WARN IN G: Adept Technology strictly prohibits

installation, commissioning, or operation of an Adept

robot without adequate safeguards according to

applicable local and national standards. Installations in EU

and EEA countries must comply with EN 775/ISO 10218,

especially sections 5, 6, EN 292-2, EN 954-1, and

EN 60204-1, especially section 13.

Maximum Thrust

Adept Python Modules systems include computer-controlled mechanisms that are

capable of exerting considerable force. Like all robot and motion systems, and most

industrial equipment, they must be treated with respect by the user and the operator (see

Table 2-2 and Table 2-3).

Table 2-2. Maximum Thrust (at slider)

Module Type

Lead type,

mm/rev

[N], Instantaneous

a

Maximum thrust

L18 and L12 10 2280

20 1140

L08 10 850

20 430

Adept Python Modules User’s Guide, Rev. E 27

Page 28

Chapter 2 - Safety

a

Safety Barriers

Safety barriers must be an integral part of robot workcell design. Adept systems are

computer-controlled and may activate remote devices under program control at times or

along paths not anticipated by personnel. It is critical that safeguards be in place to

prevent personnel from entering the workcell whenever equipment power is present.

The robot system integrator, or end user, must ensure that adequate safeguards, safety

barriers, light curtains, safety gates, safety floor mats, etc., will be installed. The robot

workcell must be designed according to the applicable local and national standards (see

Section 2.7 on page 31).

The safe distance to the robot depends on the height of the safety fence. The height and

the distance of the safety fence from the robot must ensure that personnel cannot reach the

danger zone of the robot (see Section 2.7 on page 31).

The Adept control system has features that aid the user in constructing system

safeguards, including customer emergency stop circuitry and digital input and output

lines. The emergency power-off circuitry is capable of switching external power systems,

and can be interfaced to the appropriate user-supplied safeguards.

See module product specifications for maximum rated thrust

that can be applied repeatedly in an application. The values

listed in the table above are for safety considerations.

Impact and Trapping Points

The modules are capable of moving at high speeds. If a person is struck by a robot

(impacted) or trapped (pinched), death or serious injury could occur. System

configuration, joint speed, joint orientation, and attached payload all contribute to the

total amount of energy available to cause injury.

Hazards From Expelling a Part or Attached Tooling

The maximum joint tip speeds that can be achieved by Adept Python Modules in a

runaway situation are listed in Table 2-3. Any tooling, fixtures, end-effectors, etc.,

mounted to the module must be attached by sufficient means to resist being expelled from

the module. Additionally, any payload must be held by the end-effector in a manner that

prevents the payload from being expelled accidentally.

Table 2-3. Maximum Linear Modules Joint Velocities in Runaway Situations

Module Type

Lead type,

mm/rev

Max linear speed

(mm/s)

a

L18 10 979

20 1940

L12 10 979

20 1940

L08 10 1170

20 2340

a

These velocities can occur only in a runaway or mechanical

failure situation. These are not performance specifications.

28 Adept Python Modules User’s Guide, Rev. E

Page 29

Precautions and Required Safeguards

The safety fence or barrier constructed around the robot must be designed to withstand

the impact of any item expelled accidentally from the robot. Projectile energy can be

calculated using the formula E = 1/2mv

2

.

Additional Safety Information

The standards and regulations listed in this manual contain additional guidelines for

robot system installation, safeguarding, maintenance, testing, start-up, and operator

training. Table 2-4 on page 29 lists some sources for the various standards.

.

Table 2-4. Sources for International Standards and Directives

SEMI International Standards

3081 Zanker Road

San Jose, CA 95134

USA

Phone: 1.408.943.6900

Fax: 1.408.428.9600

http://www.semi.org/

BSI Group (British Standards)

389 Chiswick High Road

London W4 4AL

United Kingdom

Phone +44 (0)20 8996 9000

Fax +44 (0)20 8996 7400

http://www.bsi-global.com

DIN, Deutsches Institut für Normung e.V.

German Institute for Standardization

Burggrafenstrasse 6

10787 Berlin

Germany

Phone.: +49 30 2601-0

Fax: +49 30 2601-1231

American National Standards Institute (ANSI)

11 West 42nd Street, 13th Floor

New York, NY 10036

USA

Phone 212-642-4900

Fax 212-398-0023

http://www.ansi.org

Document Center, Inc.

1504 Industrial Way, Unit 9

Belmont, CA 94002

USA

Phone 415-591-7600

Fax 415-591-7617

http://www.document-center.com

Global Engineering Documents

15 Inverness Way East

Englewood, CO 80112

USA

Phone 800-854-7179

Fax 303-397-2740

http://global.ihs.com

http://www.din.de

http://www2.beuth.de/ (publishing)

IEC, International Electrotechnical Commission

Rue de Varembe 3

PO Box 131

CH-1211 Geneva 20

Switzerland

Phone 41 22 919-0211

Fax 41 22 919-0300

http://www.iec.ch

Adept Python Modules User’s Guide, Rev. E 29

Robotic Industries Association (RIA)

900 Victors Way

PO Box 3724

Ann Arbor, MI 48106

USA

Phone 313-994-6088

Fax 313-994-3338

http://www.robotics.org

Page 30

Chapter 2 - Safety

Table 2-4. Sources for International Standards and Directives (Continued)

Underwriters Laboratories Inc.

333 Pfingsten Road

Northbrook, IL 60062-2096 USA

Phone: +1-847-272-8800

Fax: +1-847-272-8129

http://www.ul.com/info/

2.5 Equipment Modifications

It is sometimes necessary to modify the robot in order to successfully integrate it into a

workcell. Unfortunately, many seemingly simple modifications can either cause a robot

failure or reduce the robot’s performance, reliability, or lifetime. The following

information is provided as a guideline to modifications.

Acceptable Modifications

In general, the following modifications will not cause problems, but may affect

performance:

• Attaching tooling, utility boxes, solenoid packs, vacuum pumps, screwdrivers,

cameras, lighting, etc., to a module.

• Attaching hoses, pneumatic lines, or cables to a module. These should be designed

so they do not restrict robot motion or cause robot motion errors. T-slots and

threaded holes are provided on each module for the purpose of mounting user

equipment. T-slots accept a standard M4 square nut (DIN 562).

Unacceptable Modifications

The following modifications may damage the module, reduce system safety and

reliability, or shorten the life of the module.

CAUTION: Making any of the modifications outlined

below will void the warranty of any components that

Adept determines were damaged due to the modification.

You must contact Adept Customer Service if you are

considering any of the following modifications.

• Modifying any of the module harnesses or module-to-controller cables.

• Modifying any module access covers or drive system components.

• Modifying, including drilling or cutting, any module extrusion.

• Modifying any module or MB-10 electrical component or printed-circuit board.

• Routing additional hoses, air lines, or wires through the module.

• Modifications that compromise EMC performance, including shielding.

30 Adept Python Modules User’s Guide, Rev. E

Page 31

2.6 Transport

Always use adequate equipment to transport and lift Adept products.

Encoder Battery Life

The servo motors in Adept Python modules with MB-10 amplifiers have a serial absolute

encoder. Each module is calibrated before shipment. An external encoder backup battery

is shipped with each module, and is located inside the motor cover. The battery allows the

encoder to retain the calibration data for 10 years of use in this application. The MB-10

amplifier has its own internal battery, which is also rated for 10 years. The encoder does

not receive any power from the MB-10 amplifier’s battery. Therefore, leaving the encoder

connected to the MB-10 during transport or power-off periods will not drain the MB-10

battery. Likewise, disconnecting the module from the MB-10 will not affect the absolute

encoder.

Transport

WARN IN G: Never stand under the module while it is

lifted or transported.

CAUTION: Do not disconnect the encoder backup battery

from the motor encoder cable. Doing so may cause loss of

encoder multi-turn data and the user will be required to

recalibrate the system. See Section 11.4 on page 156 for the

procedure to replace the encoder battery.

2.7 Safety Requirements for Additional Equipment

Additional equipment used with modules (grippers, conveyor belts, etc.) must not reduce

the workcell safeguards.

All emergency stop switches must always be accessible.

If the system is to be used in an EU or EEA member country, all components in the system

workcell must comply with the safety requirements in the European Machine Directive

89/392/EEC (and subsequent amendments) and related harmonized European,

international, and national standards. For robot systems, these include: EN 775/ISO

10218, sections 5,6, EN 292-2, EN 954-1, and EN 60204. For safety fences, see EN 294.

In other countries, Adept strongly recommends, in addition to complying with the

applicable local and national regulations, that a similar level of safety be obtained.

In the USA, applicable standards include ANSI/RIA R15.06 and ANSI/UL 1740.

In Canada, applicable standards include CAN/CSA Z434.

Adept Python Modules User’s Guide, Rev. E 31

Page 32

Chapter 2 - Safety

2.8 Sound Emissions

The sound emission level of a module system depends on the commanded speed and

payload. The maximum value is 85 dB, when measured at 1 meter. (This is at maximum

AUTO-mode speed.)

CAUTION: Acoustic emission from this system may be up

to 85 dB (A) under worst-case conditions. Typical values

will be lower, depending on payload, speed, acceleration,

and mounting. Appropriate safety measures should be

taken, such as ear protection and display of a warning

sign.

2.9 Thermal Hazard

WARN IN G: Thermal Hazard!

You can burn yourself. Do not touch the MB-10 cooling

fins shortly after the system has been running at high

ambient temperatures (40°C/104°F) or at fast cycle times

(over 60 cycles per minute). The MB-10 skin/surface

temperature can reach 85°C (185°F).

2.10 Working Areas

Adept Python Modules have a Manual and an Automatic (AUTO) operating mode. While

in Automatic Mode, personnel are not allowed in the workcell.

In Manual mode, operators with additional safety equipment (see Section 2.12 on page

33) are allowed to work in the workcell. For safety reasons the operator should, whenever

possible, stay outside of the work envelope to prevent injury. The maximum speed and

power of the robot is reduced, but it could still cause injury to the operator.

Before performing maintenance in the working envelope of the robot, High Power must

be switched off and the power supply of the robot must be disconnected. After these

precautions, a skilled person is allowed to maintain the robot. See Section 2.11 for the

specifications.

WARN IN G:

Electrical Hazard!

Impact Hazard!

Never remove any safeguarding and never make changes

in the system that will decommission a safeguard.

32 Adept Python Modules User’s Guide, Rev. E

Page 33

2.11 Qualification of Personnel

This manual assumes that all personnel have attended an Adept training course and have

a working knowledge of the system. The user must provide the necessary additional

training for all personnel who will be working with the system.

As noted in this manual, certain procedures should be performed only by skilled or

instructed persons. For a description of the level of qualification, Adept uses the standard

terms:

• Skilled persons have technical knowledge or sufficient experience to enable them

to avoid the dangers, electrical and/or mechanical.

• Instructed persons are adequately advised or supervised by skilled persons to

enable them to avoid the dangers, electrical and/or mechanical.

All personnel must observe sound safety practices during the installation, operation, and

testing of all electrically powered equipment. To avoid injury or damage to equipment,

always remove power by disconnecting the AC power from the source before attempting

any repair or upgrade activity. Use appropriate lockout procedures to reduce the risk of

power being restored by another person while you are working on the system.

Qualification of Personnel

WARN IN G: The user must get confirmation from every

entrusted person before they start working with the robot

that the person:

• Has received the manual

• Has read the manual

• Understands the manual

• Will work in the manner specified by the manual

For vertically oriented modules, always lower the payload to the bottom hardstop before

attempting any repair or upgrade activity.

2.12 Safety Equipment for Operators

Adept advises operators to wear extra safety equipment in the workcell. For safety

reasons, operators must wear the following when they are in the robot workcell:

• Safety glasses

• Protective headgear (hard hats)

•Safety shoes

Install warning signs around the workcell to ensure that anyone working around the

robot system knows they must wear safety equipment.

Adept Python Modules User’s Guide, Rev. E 33

Page 34

Chapter 2 - Safety

2.13 Protection Against Unauthorized Operation

The system must be protected against unauthorized use. Restrict access to the keyboard

and the pendant by locking them in a cabinet or use another adequate method to prevent

access to them.

2.14 Safety Aspects While Performing Maintenance

Only skilled persons with the necessary knowledge about the safety and operating

equipment are allowed to maintain the robot and controller.

WARN IN G: During maintenance and repair, the power to

the SmartController and PDU3 must be turned off.

Unauthorized third parties must be prevented from

turning on power through the use of lockout measures.

2.15 Risks That Cannot Be Avoided

The Adept Python Modules control system implementation has devices that disable High

Power if a system failure occurs. However, certain residual risks or improper situations

could cause hazards. The following situations may result in risks that cannot be avoided:

• Failure of software or electronics that may cause high-speed robot motion in

Manual mode

• Failure of hardware associated with enabling a device or an E-Stop system

2.16 Risks Due to Incorrect Installation or Operation

Certain risks will be present if installation or operation is not performed properly.

• Purposely defeating any aspect of the safety E-Stop system

• Improper installation or programming of the robot system

• Unauthorized use of cables other than those supplied or use of modified

components in the system