Page 1

Adept AnyFeeder

User’s Guide

Page 2

Page 3

Adept AnyFeeder

5960 Inglewood Drive • Pleasanton, CA 94588 • USA • Phone 925.245.3400 • Fax 925.960.0452

Otto-Hahn-Strasse 23 • 44227 Dortmund • Germany • Phone +49.231.75.89.40 • Fax +49.231.75.89.450

Block 5000 Ang Mo Kio Avenue 5 • #05-12 Techplace II • Singapore 569870 • Phone +65.6755 2258 • Fax +65.6755 0598

User’s Guide

P/N: 05284-002, Rev. B

January 2011

Page 4

The information contained herein is the property of Adept Technology, Inc., and shall not be reproduced

in whole or in part without prior written approval of Adept Technology, Inc. The information herein is subject to change without notice and should not be construed as a commitment by Adept Technology, Inc. This

manual is periodically reviewed and revised.

Adept Technology, Inc., assumes no responsibility for any errors or omissions in this document. Critical

evaluation of this manual by the user is welcomed. Your comments assist us in preparation of future documentation. Please email your comments to: techpubs@adept.com.

Copyright

Adept, the Adept logo, the Adept Technology logo, AdeptVision, AIM, Blox, Bloxview, FireBlox, Fireview,

HexSight, Meta Controls, MetaControls, Metawire, Motivity, Motivity by MobileRobots, Soft Machines,

and Visual Machines are registered trademarks of Adept Technology, Inc.

Brain on Board is a registered trademark of Adept Technology, Inc. in Germany.

ACE, Adept 1060 / 1060+, Adept 1850 / 1850 XP, Adept 540 Adept 560, Adept AnyFeeder,

Adept Award, Adept C40, Adept C60, Adept CC, Adept Cobra 350, Adept Cobra 350 CR/ESD, Adept

Cobra 550, Adept 550 CleanRoom, Adept Cobra 600, Adept Cobra 800, Adept Cobra i600, Adept Cobra i800,

Adept Cobra PLC server, Adept Cobra PLC800, Adept Cobra s600, Adept Cobra s800, Adept Cobra s800

Inverted, Adept Cobra Smart600, Adept Cobra Smart800, Adept DeskTop, Adept FFE, Adept FlexFeeder

Adept LineVision, Adept MB-10 ServoKit, Adept MC, Adept MotionBlox-10,

Adept MotionBlox-40L, Adept MotionBlox-40R, Adept MV, Adept MV-10, Adept MV-19,

Adept MV4, Adept MV-5, Adept MV-8, Adept OC, Adept PAC, Adept Python, Adept Quattro s650,

Adept Quattro s650H, Adept Quattro s650HS, Adept Quattro s800H, Adept Quattro s800HS, Adept sDIO,

Adept SmartAmp, Adept SmartAxis, Adept SmartController CS, Adept SmartController CX, Adept

SmartModule, Adept SmartMotion, Adept SmartServo, Adept sMI6, Adept sSight, Adept Viper s650,

Adept Viper s850, Adept Viper s1300, Adept Viper s1700, Adept Viper s2000, AdeptCartesian, AdeptCast,

AdeptForce, AdeptFTP, AdeptGEM, AdeptModules, AdeptMotion, AdeptMotion Servo, AdeptMotion

VME, AdeptNet, AdeptNFS, AdeptOne, AdeptOne-MV, AdeptOne-XL, AdeptRAPID, AdeptSight,

AdeptSix, AdeptSix 300, AdeptSix 300 CL, AdeptSix 300 CR, AdeptSix 600, AdeptTCP/IP, AdeptThree,

AdeptThree-MV, AdeptThree-XL, AdeptTwo, AdeptVision, AVI AdeptVision, AGS AdeptVision GV,

AdeptVision I, AdeptVision II, AdeptVision VME, AdeptVision VXL, AdeptVision XGS, AdeptVision XGS

II, AdeptWindows, AdeptWindows Controller, AdeptWindows DDE, AdeptWindows Offline Editor,

AdeptWindows PC, AIM Command Server, AIM Dispense, AIM PCB, AIM VisionWare, A-Series,

FlexFeedWare, HyperDrive, IO Blox, MicroV+, MotionBlox, MotionWare, ObjectFinder, ObjectFinder 2000,

PackOne, PalletWare, sAVI, S-Series, UltraOne, V, V+ and VisionTeach are trademarks of Adept

2007-2011 by Adept Technology, Inc. All rights reserved.

250, Adept IC, Adept iSight, Adept Impulse Feeder,

Technology, Inc.

Any trademarks from other companies used in this publication

are the property of those respective companies.

Printed in the United States of America

Page 5

Table of Contents

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.2 About Your Adept AnyFeeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3 Other Items You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.4 Warnings, Cautions, and Notes in Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.5 Sound Emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.6 Workcell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.7 Qualification of Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.8 Safety Equipment for Operators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.9 Protection Against Unauthorized Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.10 Safety Aspects While Performing Maintenance . . . . . . . . . . . . . . . . . . . . . . . 15

1.11 Risks That Cannot Be Avoided . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.12 Risks Due to Incorrect Installation or Operation. . . . . . . . . . . . . . . . . . . . . . . . 16

1.13 What to Do in an Emergency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.14 How Can I Get Help? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Adept Document Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.2 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.3 Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Preparing a Mounting Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Moving the Adept AnyFeeder to the Mounting Location . . . . . . . . . . . . . 23

2.4 Installing the Pneumatic Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.5 Installing Cables and Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

System Cable Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Serial Cable Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Serial Cable Wiring Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Digital I/O Cable Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Digital I/O Cable Wiring Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Connecting the Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Setting the Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.6 Verifying the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Adept AnyFeeder User’s Guide, Rev. B 5

Page 6

Table of Contents

3 Using the AnyFeeder with Serial Communications . . . . . . . . . . . . . . . . 31

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.2 System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.3 Program Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.4 Programming/Using the AnyFeeder with Adept ACE. . . . . . . . . . . . . . . . . . . . . 32

3.5 Serial Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Setting the Serial Port Communication Parameters . . . . . . . . . . . . . . . . . . . 32

3.6 Serial Command Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Sending Commands to the Adept AnyFeeder . . . . . . . . . . . . . . . . . . . . . . . 33

Adept AnyFeeder Responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Standard Responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

AnyFeeder Command Parameters Default Values . . . . . . . . . . . . . . . . . . . 38

Serial Dialog Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Initializing the AnyFeeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Feeding Parts Forward. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Changing the Feed Forward Repetitions and Execute. . . . . . . . . . 40

Set Feed/Flip Forward Turns and Execute . . . . . . . . . . . . . . . . . . . . . 40

AnyFeeder not Initialized. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Flip Drive has a Servo Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Unknown Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4 Using the AnyFeeder with Digital I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.1 Digital I/O Wiring Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.2 Digital I/O Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Signal Handshake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.3 Commands and Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.2 Periodic Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.3 Removing and Installing the Feed Surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6 Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.2 Backlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7 Dimension Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.1 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6 Adept AnyFeeder User’s Guide, Rev. B

Page 7

Table of Contents

A Controlling the AnyFeeder from V+ . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

A.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

A.2 V+ Keywords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

VPARAMETER program instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

VRUN program instruction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

VWAITI program instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

VSTATE real-valued function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Example V+ Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Adept AnyFeeder User’s Guide, Rev. B 7

Page 8

Page 9

List of Figures

Figure 1-1. Adept AnyFeeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 2-1. AnyFeeder Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 2-2. Shipping Screws on Mounting Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 2-3. Preparing the Mounting Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 2-4. Handles for Lifting/Moving the Adept AnyFeeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 2-5. Pneumatic Connector Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 2-6. Air Line Attached to Pneumatic Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 2-7. System Cable Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 2-8. Serial Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 2-9. DIO Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 2-10. DC Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 2-11. 24 VDC In Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 2-12. Com Mode Selection Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 2-13. I/O Power and Motor Power LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 2-14. Serial Mode Indicator LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 4-1. Digital Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 5-1. Feed Deck and Drive Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 6-1. Removing the Feed Platform Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 6-2. Backlight Power Plug Installed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 6-3. Connection to Backlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 6-4. Securing Backlight to AnyFeeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 7-1. Adept AnyFeeder Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Adept AnyFeeder User’s Guide, Rev. B 9

Page 10

Page 11

1.1 Introduction

This manual describes the key points for getting your Adept AnyFeeder operational.

Before getting started, make sure you have all the components necessary to set up your

Adept AnyFeeder. In addition to the Adept AnyFeeder (shown in Figure 1-1 below), it is

assumed that you have the appropriately configured Adept-controlled robot with vision

guidance. (See Section 1.3 and Section 2.1 for details.)

Overview 1

Figure 1-1. Adept AnyFeeder

1.2 About Your Adept AnyFeeder

Your Adept AnyFeeder provides flexible parts feeding without the limitations of a

hard-tooled feed system (such as a bowl-feeder or tray-feeding system). The Adept

AnyFeeder is designed for feeding a wide variety of parts with rapid change-over times.

Your Adept AnyFeeder package includes:

• Adept AnyFeeder SX240 (P/N 05284-001)

• White Flat Feed Surface (P/N 05284-101)

• 24 VDC Power Cable, 5 m (P/N 05284-301)

• Parallel DIO (Digital I/O) cable, 5 m (P/N 05284-302)

• RS232 Cable, 4.5 m (P/N 05284-303)

• RS232 Loopback Connector (not used for Serial installations) (P/N 05284-304)

Adept AnyFeed er User’ s Guide, Re v. B 11

Page 12

Chapter 1 - Overview

To increase the flexibility of your Adept AnyFeeder, you may have ordered one or more

of the following options:

• Black Flat Feed Surface (P/N 05284-102)

• Red LED (590 nm wavelength) backlighting package (P/N 05284-201)

• Infrared LED (875 nm wavelength) backlighting package (P/N 05284-202)

1.3 Other Items You Need

• Adept robot (Adept Cobra s600/s800, Adept Cobra i600/i800, Adept Viper

s650/s850, etc.)

• Adept SmartController CX with Adept vision option installed

• Adept vision-guidance system

• Sturdy mounting table(s) for the Adept robot and Adept AnyFeeder

• Camera-mounting structure

• High-resolution camera with lens

• Camera interface cables

• Personal computer (for interfacing with and programming the robot and vision

system)

1.4 Warnings, Cautions, and Notes in Manual

There are six levels of special alert notation used in this manual. In descending order of

importance, they are:

DANGER: This indicates an imminently hazardous

electrical situation which, if not avoided, will result in

death or serious injury.

DANGER: This indicates an imminently hazardous

situation which, if not avoided, will result in death or

serious injury.

WARN IN G: This indicates a potentially hazardous

electrical situation which, if not avoided, could result in

injury or major damage to the equipment.

12 Adept AnyFeeder User ’ s Guide, Re v. B

Page 13

WARN IN G: This indicates a potentially hazardous

situation which, if not avoided, could result in injury or

major damage to the equipment.

CAUTION: This indicates a situation which, if not avoided,

could result in damage to the equipment.

NOTE: Notes provide supplementary information, emphasize a point or

procedure, or give a tip for easier operation.

1.5 Sound Emissions

The sound emission level of the Adept AnyFeeder depends on the type of parts being fed,

speed, and payload. The maximum value is 85 dB.

Sound Emissions

1.6 Workcell

The Adept robot systems used with the Adept AnyFeeder have a Manual and an

Automatic (

in the workcell.

In Manual mode, operators with additional safety equipment (see Section 1.8 on page 15)

are allowed to work in the workcell. For safety reasons the operator should, whenever

possible, stay outside of the workcell to prevent injury. The maximum speed and power

of the robot is reduced, but it could still cause injury to the operator.

Before performing maintenance in the workcell of the robot, High Power must be

switched off and the power supply of the robot must be disconnected. After these

precautions, a skilled person is allowed to maintain the robot. See Section 1.7 for the

specifications.

WARN IN G: Acoustic emission from the Adept AnyFeeder

may be up to 85 dB (A) under worst-case conditions.

Typical values will be lower, depending on the type of

parts being fed, speed, and payload. Appropriate safety

measures should be taken against excessive acoustic

emission, such as using ear protection and displaying a

warning sign.

AUTO) operating mode. While in Automatic Mode, personnel are not allowed

Adept AnyFeed er User’ s Guide, Re v. B 13

Page 14

Chapter 1 - Overview

WARN IN G:

Electrical Hazard!

Impact Hazard!

Never remove any safeguarding and never make changes

in the system that will decommission a safeguard.

1.7 Qualification of Personnel

This manual assumes that all personnel have attended an Adept training course and have

a working knowledge of the system. The user must provide the necessary additional

training for all personnel who will be working with the system.

As noted in this manual, certain procedures should be performed only by skilled or

instructed persons. For a description of the level of qualification, Adept uses the standard

terms:

• Skilled persons have technical knowledge or sufficient experience to enable them

to avoid the dangers, electrical and/or mechanical.

• Instructed persons are adequately advised or supervised by skilled persons to

enable them to avoid the dangers, electrical and/or mechanical.

All personnel must observe sound safety practices during the installation, operation, and

testing of all electrically powered equipment. To avoid injury or damage to equipment,

always remove power by disconnecting the AC power from the source before attempting

any repair or upgrade activity. Use appropriate lockout procedures to reduce the risk of

power being restored by another person while you are working on the system.

WARN IN G: The user must get confirmation from every

entrusted person, before the person starts working with

the robot, that the person:

• Has received the manual

• Has read the manual

• Understands the manual

• Will work in the manner specified by the manual

14 Adept AnyFeeder User ’ s Guide, Re v. B

Page 15

Safety Equipment for Operators

1.8 Safety Equipment for Operators

Adept advises operators to wear extra safety equipment in the workcell. For safety

reasons, operators must wear the following when they are in the robot workcell:

• Safety glasses

• Protective headgear (hard hats)

•Safety shoes

Install warning signs around the workcell to ensure that anyone working around the

robot system knows they must wear safety equipment.

1.9 Protection Against Unauthorized Operation

The system must be protected against unauthorized use. Restrict access to the keyboard

and the pendant by locking them in a cabinet or use another adequate method to prevent

access to them.

1.10 Safety Aspects While Performing Maintenance

Only skilled persons with the necessary knowledge about the safety and operation of the

equipment are allowed to maintain the robot and controller.

WARN IN G: During maintenance and repair, the power to

the SmartController and robot must be turned off. Use

lockout measures to prevent unauthorized users from

turning on power.

1.11 Risks That Cannot Be Avoided

Adept robot control system implementation has devices that disable High Power if a

system failure occurs. However, certain residual risks or improper situations could cause

hazards. The following situations may result in risks that cannot be avoided:

• Failure of software or electronics that may cause high-speed robot motion in

Manual mode

• Failure of hardware associated with enabling a device or an E-Stop system

Adept AnyFeed er User’ s Guide, Re v. B 15

Page 16

Chapter 1 - Overview

1.12 Risks Due to Incorrect Installation or Operation

Certain risks will be present if installation or operation is not performed properly:

• Purposely defeating any aspect of the safety E-Stop system

• Improper installation or programming of the robot system

• Unauthorized use of cables other than those supplied or use of modified

components in the system

• Defeating an interlock so that an operator can enter a workcell with High Power

ON

Take precautions to ensure that these situations do not occur.

1.13 What to Do in an Emergency

Press any E-Stop button (a red push-button on a yellow background/field) and then

follow the internal procedures of your company or organization for an emergency. If a fire

occurs, use CO

to extinguish the fire.

2

1.14 How Can I Get Help?

For details on getting assistance with your Adept software or hardware, you can access

the following information sources on the Adept corporate website:

• For contact information: http://www.adept.com/contact/americas

• For product support information:

http://www.adept.com/support/service-and-support/main

• For user discussions, support, and programming examples:

http://www.adept.com/forum/

• For further information about Adept Technology, Inc.: http://www.adept.com

Refer to the How to Get Help Resource Guide (Adept P/N 00961-00700) for additional

information on getting assistance with your Adept software and hardware.

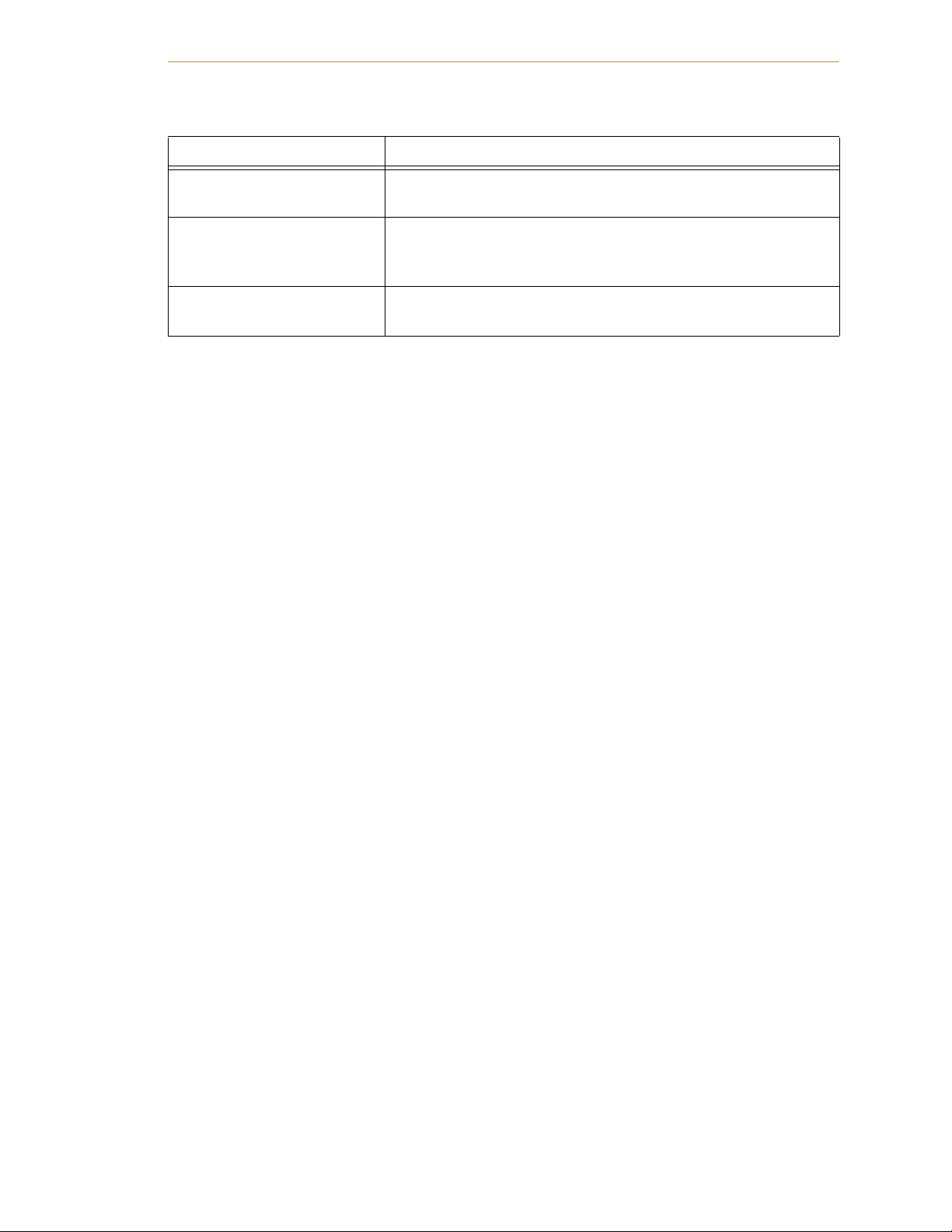

Related Manuals

This manual covers the installation, operation, and maintenance of the Adept AnyFeeder

product. There are additional manuals that cover programming the system, reconfiguring

installed components, and adding optional components. See the following table. These

manuals are available on the Adept Document Library CD-ROM shipped with each

system.

16 Adept AnyFeeder User ’ s Guide, Re v. B

Page 17

Manual Title Description

How Can I Get Help?

Adept SmartController

User’s Guide

Adept ACE User’s Guide Describes the installation and use of Adept ACE. This guide

AdeptSight Reference Guide Describes V+ and microV+ keywords and prope rties. Also

Contains complete information on the installation and oper ation

of the Adept SmartController and the optional sDIO product.

also provides information on ACE PackXpert packaging

applications.

describes framework and tool properties.

Adept Document Library

The Adept Document Library (ADL) contains documentation for Adept products. You

can access the ADL from:

• the Adept Software CD shipped with your system

• the Adept website. Select Support > Document Library from the Adept home

page. To go directly to the Adept Document Library, type the following URL into

your browser:

http://www.adept.com/Main/KE/DATA/adept_search.htm

To locate information on a specific topic, use the Document Library search engine on the

ADL main page, or select one of the available menu options.

Adept AnyFeed er User’ s Guide, Re v. B 17

Page 18

Page 19

2.1 Introduction

This chapter describes the installation procedure for the Adept AnyFeeder.

In addition to installing the Adept AnyFeeder, you will need to install the following items

in the workcell:

• Robot: one of the following:

• Adept robot that interfaces with an Adept SmartController CX, running V+

version 16.x or later

OR

• Adept i-Series robot (Adept Cobra i600 or Adept Cobra i800 robot)

• Vision: an Adept SmartController CX

• Licenses: V+ Extension, Guided Vision

• An available serial port

Installation 2

• Camera: a user-supplied camera (with lens) and a vision system

• Camera interface cables

• User-supplied personal computer (for interfacing with and programming the

robot and vision system)

• All required safety devices (light curtains, guarding, etc.) for the workcell

Adept AnyFeed er User’ s Guide, Re v. B 19

Page 20

Chapter 2 - Installation

Feed platform

Interface panel

Feed platform

front panel

Bulk container

Mounting rail

Pneumatic connector

2.2 Unpacking

This section describes the procedure for unpacking the Adept AnyFeeder.

Figure 2-1. AnyFeeder Parts

The Adept AnyFeeder is shipped in a carton that is banded onto a wooden pallet. The

shipping carton with pallet is approximately 1219 mm (48 in) x 762 mm (30 in) x 431.8 mm

(17 in) (L x W x H). The shipping carton with pallet weighs approximately 80 kg.

To unpack the Adept AnyFeeder:

1. Use a forklift or hand truck to move the shipping carton with pallet to the

installation area.

2. Cut the banding with a utility knife or scissors.

3. Raise the shipping carton cover straight up until it clears the contents, and then

remove it.

4. Detach the Adept AnyFeeder from the shipping pallet by using a 4 mm Allen

wrench and 10 mm wrench or socket to remove the four (4) screws from the

mounting rails of the Adept AnyFeeder, as shown in Figure 2-2.

20 Adept AnyFeeder User ’ s Guide, Re v. B

Page 21

Figure 2-2. Shipping Screws on Mounting Rail

Unpacking

Adept AnyFeed er User’ s Guide, Re v. B 21

Page 22

Chapter 2 - Installation

WARN IN G: The Adept AnyFeeder must be bolted or clamped down

to the base plate at any time it is in operation. Due to its working

principle the Adept AnyFeeder may “walk off” the base plate during

operation if it is not properly secured to the base plate.

WARN IN G: Do not connect the Adept AnyFeeder to electrical power

or compressed air before it is securely bolted or clamped down to the

base plate.

2.3 Mechanical Installation

This section describes the mechanical installation procedure for the Adept AnyFeeder.

Preparing a Mounting Location

Before the Adept AnyFeeder can be used, it must be securely mounted in a prepared

location within the robot’s workcell.

Prepare the mounting hole pattern as shown in Figure 2-3. Locate the mounting hole

pattern on the base plate so that at least 650 mm of the AnyFeeder’s base housing rests on

the base plate, as shown in Figure 2-3.

250

650

1125

Minimum Base Plate Contact

800

250

197

244.50

236250

38

284

237.50

309

Figure 2-3. Preparing the Mounting Location

22 Adept AnyFeeder User ’ s Guide, Re v. B

Page 23

Moving the Adept AnyFeeder to the Mounting Location

WARN IN G: Two people must lift and move the Adept AnyFeeder to

the prepared location. Lift the Adept AnyFeeder only by holding it at

the base housing at the handles indicated below.

1. Find a co-worker to help you move the Adept AnyFeeder.

2. Lift the Adept AnyFeeder by the handles shown in Figure 2-4.

Mechanical Installation

Figure 2-4. Handles for Lifting/Moving the Adept AnyFeeder

3. Move the Adept AnyFeeder to the prepared mounting location.

4. Bolt the Adept AnyFeeder to the mounting location by inserting at least four (4)

M6 x 16 mm Allen screws with washers and lock washers through the holes in the

feeder’s mounting rails (use at least two screws in each mounting rail).

Adept AnyFeed er User’ s Guide, Re v. B 23

Page 24

Chapter 2 - Installation

2.4 Installing the Pneumatic Line

This section describes the pneumatic installation procedure for the Adept AnyFeeder.

1. Locate the pneumatic connector below the side handle on the Adept AnyFeeder

(see Figure 2-5).

Figure 2-5. Pneumatic Connector Location

2. Prepare an 8 mm OD air line.

3. Attach the air line to the pneumatic connector (see Figure 2-6). Do not overtighten

the connection.

Figure 2-6. Air Line Attached to Pneumatic Connector

24 Adept AnyFeeder User ’ s Guide, Re v. B

Page 25

2.5 Installing Cables and Power

This section describes the electrical installation procedure for the Adept AnyFeeder. The

Adept AnyFeeder requires the following cable connections:

• the 24 VDC power cable (supplied)

• the RS232 serial communications cable (supplied)

• the DIO (Digital I/O) cable (supplied)

System Cable Diagram

DIO Cable

Pins 13, 25: +24 VDC

Pins 12, 24: Ground

Installing Cables and Power

AnyFeeder Interface Panel

Black: Shield

Ground to

Power Supply

Case

NOTE: Refer to your robot user’s guide for additional system cable

information.

NOTE: The Adept AnyFeeder is equipped with fuses to protect the

internal components. The motor power 24 VDC input is protected with a

10 Amp fuse, and the parallel I/O 24 VDC lines are protected with a 3

Amp fuse. These fuses can be replaced in the field. If you suspect a

problem with one or both of these fuses, contact Adept Customer Service

(see Section 1.14 on page 16) for part information and instructions.

Red: +24 VDC

Blue: Ground

Black: Shield

User-supplied

24 VDC

power supply

Figure 2-7. System Cable Diagram

Note: To serial port on Adept

SmartController (for V+/AIM

applications) or to user-supplied

PC (for ACE/iSight applications)

Adept AnyFeed er User’ s Guide, Re v. B 25

Page 26

Chapter 2 - Installation

Connects to serial

port on AnyFeeder

Connects to serial

port on robot controller

or PC

Serial Cable Installation

A serial communications cable is supplied with the Adept AnyFeeder (see Figure 2-8).

Connect the male end of the cable to the RS232 (J2) port on the Adept AnyFeeder. Connect

the female end of the cable to the serial port on the robot controller or PC.

Figure 2-8. Serial Cable

Serial Cable Wiring Assignments

Table 2-1 shows the wiring assignments for the supplied cable.

Table 2-1: Serial Cable Wiring Assignments

Pin #

DSUB 9 male

(to AnyFeeder)

2RX2

3TX3

5 GROUND 5

Function

Pin #

DSUB 9 female

(to controller)

26 Adept AnyFeeder User ’ s Guide, Re v. B

Page 27

Installing Cables and Power

Digital I/O Cable Installation

A digital I/O cable is supplied with the Adept AnyFeeder (see Figure 2-9). Connect the

female end of the cable to the parallel I/O +24 VDC in I/O Pwr (J3) port on the Adept

AnyFeeder.

Figure 2-9. DIO Cable

Digital I/O Cable Wiring Assignments

The supplied digital I/O cable must be wired as shown in Table 2-2.

NOTE: If you want to communicate with your Adept AnyFeeder using

digital I/O rather than serial communications, refer to Chapter 4 for the

cable pin/wire assignments.

NOTE: Regardless of your method of communicating with the Adept

AnyFeeder (DIO or RS232 Serial), you must supply power to the logic

board through this cable on the pins specified in Table 2-2.

Table 2-2: Digital I/O Wiring Assignments

Function

+24 VD V 25 WH / BK +24 VDC

+24 VDC 13 WH / GN +24 VDC

0 VDC 24 BN / RD 0 VDC

0 VDC 12 RD / BU 0 VDC

Pin #

DSUB 25

Wire Color

Power Supply

Robot

Controller

Shield N/A BK Ground to Case

Adept AnyFeed er User’ s Guide, Re v. B 27

Page 28

Chapter 2 - Installation

Connecting the Power Cable

1. Locate the DC power cable with connector that was supplied with the Adept

AnyFeeder (see Figure 2-10).

Figure 2-10. DC Power Cable

2. Connect the wire end of the cable to the user-supplied 24 VDC / 10 A regulated

power supply.

3. Attach the connector end of the cable to the Motor Power 24 VDC In (J1)

connector on the front of the Adept AnyFeeder (see Figure 2-11).

Figure 2-11. 24 VDC In Connector

28 Adept AnyFeeder User ’ s Guide, Re v. B

Page 29

Installing Cables and Power

Setting the Switches

The Adept AnyFeeder will be set for serial communications. The Com Mode Selection

switches (see Figure 2-12) must be set as follows:

1. Move the A switch (selects Parallel I/O or RS232) to the down position, to select

Serial.

Figure 2-12. Com Mode Selection Switches

After changing the switch settings, you must cycle power to the Adept AnyFeeder.

• If the Adept AnyFeeder and connected equipment are powered from a common

source, you can turn that source off and then back on.

• If the Adept AnyFeeder and connected equipment are powered from different

sources, then you must disconnect and then reconnect the following cables:

• 24 VDC power cable. See “Connecting the Power Cable” on page 28 for

details

• Digital I/O interface cable. See “Digital I/O Cable Installation” on page 27

for details

Adept AnyFeed er User’ s Guide, Re v. B 29

Page 30

Chapter 2 - Installation

2.6 Verifying the Installation

This section describes the procedure for verifying the Adept AnyFeeder after installation.

After wiring the system, turn on the 24 VDC power supply and verify that the two (2)

Status LEDs are on (see Figure 2-13).

Figure 2-13. I/O Power and Motor Power LEDs

Additionally, the LED shown in Figure 2-14 will blink to indicate Serial mode.

Figure 2-14. Serial Mode Indicator LED

30 Adept AnyFeeder User ’ s Guide, Re v. B

Page 31

Using the AnyFeeder with

Serial Communications 3

3.1 Introduction

This chapter describes the requirements for using the Adept AnyFeeder with a

robot/vision system and serial communications.

3.2 System Requirements

To use the Adept AnyFeeder with a robot/vision system, your workcell must contain the

equipment described in Section 2.1 on page 19.

3.3 Program Flow

The steps below briefly describe a simple program flow for using the Adept AnyFeeder in

the workcell:

1. Initialize the Adept AnyFeeder.

2. Send “dispense” command to Adept AnyFeeder to feed parts.

3. Acquire vision image and locate “usable” parts; store part count.

4. Command robot to pick-place the usable parts; decrement part count for each

pick.

5. When part count reaches 0, send combinations of “feed forward,” “feed

backward,” “flip,” “feed/flip forward,” and “feed/flip backward” commands,

along with acquiring vision images, to locate more usable parts.

a. If usable parts are found, store part count and loop back to step 4.

b. If no usable parts are found, and feed area is not empty, repeat step 5.

c. If no usable parts are found, and feed area is empty, go to step 2.

Adept AnyFeed er User’ s Guide, Re v. B 31

Page 32

Chapter 3 - Using the AnyFeeder with Serial Communications

3.4 Programming/Using the AnyFeeder with Adept ACE

You can use an AnyFeeder object (control panel) in Adept ACE to configure the

AnyFeeder for your application (in this case, you would likely use the Process Manager in

Adept ACE to create the application; the Process Manager allows you to include the

AnyFeeder object in your process). See the Adept ACE User’s Guide for information. See

Appendix A on page 57 for information on V+ programming.

3.5 Serial Communications

This section describes how to set up serial communications with the Adept AnyFeeder.

NOTE: If you want to communicate with your Adept AnyFeeder using

digital I/O rather than serial communications, refer to Chapter 4 for the

cable pin/wire assignments.

Setting the Serial Port Communication Parameters

In order for the SmartController CX to communicate properly with the Adept AnyFeeder,

you must configure the serial port as follows:

Table 3-1: Serial Port Settings

Item Setting

Baud rate 9600

Data bits 8

Stop bit 1

Parity none

Flow control none

In addition to the above:

- Disable local echo

- Append “line feed” to each line sent

- Append “line feed” to each line received

NOTE: The Adept AnyFeeder will not receive or send any serial data if

the baud rate is not set correctly.

32 Adept AnyFeeder User ’ s Guide, Re v. B

Page 33

3.6 Serial Command Codes

The following sections describe:

• The serial commands that can be sent to the Adept AnyFeeder

• The default values for the Adept AnyFeeder command parameters

• How the Adept AnyFeeder responds to received commands

• Sample serial communications dialogs

Sending Commands to the Adept AnyFeeder

Table 3-3 provides a list of all available Adept AnyFeeder serial commands. With each

command there is a maximum of two associated parameters which influence that

command. Note that some commands do not need any parameters.

During startup, the Adept AnyFeeder firmware assigns default values to all parameters.

For example, if you send the Adept AnyFeeder a “feed forward” command without first

changing any of its parameters, the Adept AnyFeeder control system will apply the

default parameters (see Table 3-7 for details).

Serial Command Codes

Table 3-2: Description of Symbols used in Tables

Symbol Description

> Represents the prompt of a text terminal window

<cr> Carriage return, ASCII code 13 (decimal)

[speed] Integer in the range 1…10

[turns] Integer in the range 1…10, except for purge

(range is 1…127)

_ Explicit space (not an underscore)

Note that all text in the Syntax column is case sensitive

See Table 3-6, “Standard Responses,” on page 38 for a list of standard responses.

Table 3-3: AnyFeeder Serial Commands

Command Description Syntax Explanation Response

Feed Forward [ffwd] Feed parts forward > x=1<cr> Executes a feed

forward

Feed Backward [fbwd] Feed parts backward > x=2<cr> Executes a feed

backward

Standard response

Standard response

Feed + Flip Forward

[flipfwd]

Feed + Flip Backward

[flipbwd]

Flip parts forward > x=3<cr> Executes a flip

forward

Flip parts backward > x=4<cr> Executes a flip

backward

Adept AnyFeed er User’ s Guide, Re v. B 33

Standard response

Standard response

Page 34

Chapter 3 - Using the AnyFeeder with Serial Communications

Table 3-3: AnyFeeder Serial Commands

Command Description Syntax Explanation Response

Flip [flip] Flip parts without moving

forward or backward

Dispense [dispense] Move parts from the bulk

container onto the feed

surface

Purge [purge] Feed parts out backwards,

purge gate must be opened

manually

Heavy Dispense

[hdisp]

Initialize [init] Move the An yFeeder into its

Stop [stop] Stop current action and move

Startup AnyFeeder

firmware

Aggressively mov e parts from

bulk container onto feed

surface

home position; required

before any other action can

take place

AnyFeeder to home position

Start AnyFeeder firmware

(also stops active motions)

> x=5<cr> Executes a flip Standard response

> x=6<cr> Executes a

dispense

> x=7<cr> Executes a purge Standard response

> x=8<cr> Executes a heavy

dispense

> x=16<cr> Initializes the

AnyFeeder

> x=15<cr> Executes a stop Standard response

> S_RUN<cr> Restarts AnyFeeder

firmware

Standard response

Standard response

Standard response

AnyFeeder will

respond:

m10<cr>

m20<cr>

to indicate

AnyFeeder is online

Reset Error Reset error status and moves

AnyFeeder to home position

Restart Firmware Restart AnyFeeder firmware;

resets all parameters to

default values

> x=30<cr> Resets error status Standard response

> x=31<cr> Restarts AnyFeeder

firmware and resets

defaults

Standard

Table 3-4: Setting Parameters

Command Description Syntax Explanation Response

Setting the Number of Repetitions

Set Feed Forward

repetitions

Set Feed Forward

repetitions and

execute feed

forward

Set number of

repetitions for feed

forward

Set number of

repetitions for feed

forward and

exec ut e mo tion

> ab[1]=[turns]<cr> Sets repetitions No response

> ab[1]=[turns]_x=1<cr> Sets repetitions and

executes motion

Standard

response

response

34 Adept AnyFeeder User ’ s Guide, Re v. B

Page 35

Serial Command Codes

Table 3-4: Setting Parameters

Command Description Syntax Explanation Response

Set Feed Backward

repetitions

Set Feed Backward

repetitions and

execute feed

backward

Set Feed + Flip

Forward repetitions

Set Feed + Flip

Forward repetitions

and execute flip

forward

Set Feed + Flip

Backward

repetitions

Set Feed + Flip

Backward

repetitions and

execute flip

backward

Set number of

repetitions for feed

backward

Set number of

repetitions for feed

backward and

exec ute motion

Set number of

repetitions for feed

flip forward

Set number of

repetitions for feed

flip forward and

exec ute motion

Set number of

repetitions for feed

flip backward

Set number of

repetitions for feed

flip backward and

exec ute motion

> ab[2]=[turns]<cr> Sets repetitions No response

> ab[2]=[turns]_x=2<cr> Sets repetitions and

executes motion

> ab[3]=[turns]<cr> Sets repetitions No response

> ab[3]=[turns]_x=3<cr> Sets repetitions and

executes motion

> ab[4]=[turns]<cr> Sets repetitions No response

> ab[4]=[turns]_x=4<cr> Sets repetitions and

executes motion

Standard

response

Standard

response

Standard

response

Set Flip Repetitions Set number of

repetitions for flip

Set Flip Repetitions

and execute flip

Set Dispense

Repetitions

Set Dispense

Repetitions and

execute disp

Set Purge

Repetitions

Set Purge

Repetitions and

execute purge

Set Heavy

Dispense

Repetitions

Set number of

repetitions for flip

and execute motion

Set number of

repetitions for

dispense

Set number of

repetitions for

dispense and

exec ute motion

Set number of

repetitions for purge

Set number of

repetitions for purge

and execute motion

Set number of

repetitions for heavy

dispense

> ab[5]=[turns]<cr> Sets repetitions No response

> ab[5]=[turns]_x=5<cr> Sets repetitions and

executes motion

> ab[6]=[turns]<cr> Sets repetitions No response

> ab[6]=[turns]_x=6<cr> Sets repetitions and

executes motion

> ab[7]=[turns]<cr> Sets repetitions No response

> ab[7]=[turns]_x=7<cr> Sets repetitions and

executes motion

> ab[8]=[turns]<cr> Sets repetitions No response

Standard

response

Standard

response

Standard

response

Adept AnyFeed er User’ s Guide, Re v. B 35

Page 36

Chapter 3 - Using the AnyFeeder with Serial Communications

Table 3-4: Setting Parameters

Command Description Syntax Explanation Response

Set Heavy

Dispense

Repetitions and

exec ute heavy

dispense

Set number of

repetitions for heavy

dispense and

exec ut e mo tion

Setting the Speed of Operation

Set Feed Forward

speed

Set Feed Backward

speed

Set Feed + Flip

Forward speed

Set Feed + Flip

Backward speed

Set Flip speed Set speed of flip

Set Dispense speed Set speed of

Set Purge speed Set speed of purge

Set speed of feed

forward op e ration

Set speed of feed

backward operation

Set speed of feed

flip forward

operation

Set speed of feed

flip backward

operation

operation

dispense operation

operation

> ab[8]=[turns]_x=8<cr> Sets repetitions and

executes motion

> ab[17]=[speed]_x=17<cr> Sets speed Standard

> ab[18]=[speed]_x=18<cr> Sets speed Standard

> ab[19]=[speed]_x=19<cr> Sets speed Standard

> ab[20]=[speed]_x=20<cr> Sets speed Standard

> ab[21]=[speed]_x=21<cr> Sets speed Standard

> ab[22]=[speed]_x=22<cr> Sets speed Standard

> ab[23]=[speed]_x=23<cr> Sets speed Standard

Standard

response

response

response

response

response

response

response

response

Set Heavy

Dispense speed

Backlight/Strobe

mode

Vision trigger

interval

Vision trigger delay Sets the vision

Set speed of heavy

dispense operation

Set the state of the

optional Backlight (if

installed)

Sets the vision

trigger interval in

multiples of 20 ms

trigger delay in

multiples of 20 ms.

The trigger delay

starts after a

AnyFeeder action

has completed.

> ab[24]=[speed]_x=24<cr> Sets speed Standard

response

Other Settings

> ab[12]=[mode] Mode:

0: Backlight is OFF

1: Backlight is ON

(default)

2: Backlight is strobed

(controlled by settings

“trigger interval” and

“trigger delay”)

> ab[25]=[value]_x=25<cr> Range for value is

1…63

Default is 240 ms

(value=12)

> ab[26]=[value]_x=26<cr> Range for value is

1…63

Default is 500 ms

(value=25)

No response

No response

No response

36 Adept AnyFeeder User ’ s Guide, Re v. B

Page 37

Serial Command Codes

Table 3-4: Setting Parameters

Command Description Syntax Explanation Response

Set digital output Set the state of the

AnyFeeder's

internal digital

outputs. It is not

recommended to

set these during

normal operation,

only for debugging

purposes.

Adept AnyFeeder Responses

After receiving a command, the Adept AnyFeeder will respond with specific characters to

indicate the status of each motor in the mechanism.

Motor 1: The “flip” drive, located to the front of the AnyFeeder, under the feed surface

Motor 2: The “dispense” drive, located to the rear of the AnyFeeder, under the bulk

container

Responses

mix

> ab[27]=[mode]_x=27<cr> Mode:

0: Engage the

dispense clutch

1: Engage the flip

clutch

2:Turn backlight OFF

3:Turn backlight ON

4: Move retainer gate

UP

5: Move retainer gate

DOWN

Standard

response

Where:

i = the drive number (1 or 2) that is reporting

x = the status of the drive

Table 3-5: AnyFeeder Responses

Response Meaning Details

m10 Motor 1 completed action successfully

m11 Motor 1 received command and is busy

m12 Invalid command Command or command syntax incorrect

m13 Motor 1 servo error Possibly overloaded. Check for obstructions or

hardware problems. Error must be reset before

operation can continue.

m16 Motor 1 not initialized AnyFeeder must be initialized before

commands can be sent

m17 Motor 1 error state Motor 1 reporting an error. Error must be reset

before operation can continue.

m20 Motor 2 completed action successfully

Adept AnyFeed er User’ s Guide, Re v. B 37

Page 38

Chapter 3 - Using the AnyFeeder with Serial Communications

Table 3-5: AnyFeeder Responses

Response Meaning Details

m21 Motor 2 received command and is busy

m22 Invalid command Command or command syntax incorrect

m23 Motor 2 servo error Possibly overloaded. Check for obstructions or

hardware problems. Error must be reset before

operation can continue.

m26 Motor 2 not initialized AnyFeeder must be initialized before

commands can be sent.

m27 Motor 2 error state Motor 2 reporting an error. Error must be reset

before operation can continue.

m28 Timeout- no sync-signal received The sync-signal was not received f rom Motor 1.

Therefore, Motor 2 cannot start its action.

Standard Responses

During normal operation, the responses you should expect to see from the AnyFeeder are

as follows.

Table 3-6: Standard Responses

a

Response Meaning

m21<cr> Motor 2 understood command and is busy

m11<cr> Motor 1 understood command and is busy

m20<cr> Motor 2 completed action successfully and is OK

m10<cr> Motor 1 completed action successfully and is OK

a

Motors 1 and 2 may report back in different orders,

meaning sometimes motor 1 will report back first and

sometimes motor 2 will report back first.

Because the two motors perform different motions during

the same operation, there will be some time between the

responses.

AnyFeeder Command Parameters Default Values

Table 3-7 shows the default values for the AnyFeeder command parameters. Note that

whenever the AnyFeeder’s firmware is reset, the parameters return to these default

values.

Table 3-7: Parameter Default Values

Parameter Default Value

ab[1]=3 default feed forward repetitions

ab[2]=3 default feed backward repetitions

38 Adept AnyFeeder User ’ s Guide, Re v. B

Page 39

Table 3-7: Parameter Default Values

Parameter Default Value

ab[3]=3 default feed and flip forward repetitions

ab[4]=3 default feed and flip backward repetitions

ab[5]=3 default flip repetitions

ab[6]=3 default dispense repetitions

ab[7]=64 default purge repetitions

ab[8]=3 default heavy dispense repetitions

ab[17]=1 feed forward speed

ab[18]=1 fe ed ba ckward speed

ab[19]=1 feed/flip forward speed

ab[20]=1 feed/flip backward speed

ab[21]=1 flip speed

ab[22]=1 dispense speed

ab[23]=1 purge speed

Serial Command Codes

Serial Dialog Examples

This section provides some examples of serial communication streams for basic Adept

AnyFeeder operations.

Initializing the AnyFeeder

Table 3-8 shows responses to the

Table 3-8: Initializing the AnyFeeder

Terminal

Window

m21<cr> Motor/Drive 2 understood command and is now busy, indicated by the

'1'

m11<cr> Motor/Drive 1 understood command and is now busy, indicated by the

second '1'

m10<cr> Motor/Drive 1 completed action successfully, indicated by '0'

m20<cr> Motor/Drive 2 completed action successfully

Feeding Parts Forward

Table 3-9 shows responses to the

Table 3-9: Feeding Parts Forward

Init command (x=16<cr>).

Explanation

Feed Forward command (x=1<cr>).

Terminal

Window

m21<cr> Motor/Drive 2 understood command and is now busy, indicated by the

'1'

Explanation

Adept AnyFeed er User’ s Guide, Re v. B 39

Page 40

Chapter 3 - Using the AnyFeeder with Serial Communications

Table 3-9: Feeding Parts Forward

Terminal

Window

m11<cr> Motor/Drive 1 understood command and is now busy, indicated by the

second '1'

m20<cr> Motor/Drive 2 completed action successfully, indicated by '0'; in feed

commands the 'dispense drive' does not execute a motion, but still

confirms that it accepted the command and is 'alive'. A consistent

drive reporting scheme is easier to handle by the receiving host

computer and the additional communication overhead is minimal.

m10<cr> Motor/Drive 1 completed action successfully

Explanation

Changing the Feed Forward Repetitions and Execute

Table 3-10 shows responses to the Feed Forward Repetitions and Execute command

ab[1]=10 x=1<cr>).

(

Table 3-10: Changing the Flip Speed/Intensity

Terminal

Window

m21<cr> Drive 2 command understood

m11<cr> Drive 1 command understood

m10<cr> Drive 1 finished

m20<cr> Drive 2 finished

Explanation

Set Feed/Flip Forward Turns and Execute

Table 3-11 shows responses to the Feed/Flip Forward Turns and Execute command

ab[3]=6 x=3<cr>).

(

Table 3-11: Set Feed/Flip Forward Turns and Execute

Terminal

Window

m21<cr> Drive 2 command understood

m11<cr> Drive 1 command understood

m10<cr> Drive 1 finished

m20<cr> Drive 2 finished

Explanation

AnyFeeder not Initialized

Table 3-12 shows responses to the

initialized

(x=1<cr>).

Feed Forward command before the AnyFeeder has been

Table 3-12: AnyFeeder not Initialized

Terminal

Window

m26<cr> Drive 2 reports that it is not initialized

Explanation

40 Adept AnyFeeder User ’ s Guide, Re v. B

Page 41

Table 3-12: AnyFeeder not Initialized

Serial Command Codes

Terminal

Window

m16<cr> Drive 1 reports that it is not initialized

Explanation

Flip Drive has a Servo Problem

Table 3-13 shows responses to the

Flip command when the flip drive has a servo problem

(x=5<cr>).

Table 3-13: Flip Drive has a Servo Problem

Terminal

Window

m21<cr> Drive 2 reports that it is not initialized

m11<cr> Drive 1 reports that it is not initialized

m20<cr> Drive 2 reports end of motion

m13<cr> Drive 1 reports a servo error

Explanation

Unknown Command

Table 3-14 shows responses to an unknown

command (x=9<cr>).

Table 3-14: Unknown Command

Terminal

Window

m22<cr> Drive 2 reports that this is an unknown command

m12<cr> Drive 1 reports that this is an unknown command

Explanation

Adept AnyFeed er User’ s Guide, Re v. B 41

Page 42

Page 43

Using the AnyFeeder with

4.1 Digital I/O Wiring Assignments

To use the Adept AnyFeeder system with digital I/O communications, refer to Table 4-1

for the cable pin/wire assignments.

Table 4-1. Digital I/O Wiring Assignments

Digital I/O 4

AnyFeeder Function

+24 VDV 25 WH / BK +24 VDC

+24 VDC 13 WH / GN +24 VDC

0 VDC 24 BN / RD 0 VDC

0 VDC 12 RD / BU 0 VDC

OUT 1 14 BN / GN IN 1

OUT 2 1 WH IN 2

OUT 3 15 WH / YE IN 3

OUT 4 2 BN IN 4

OUT 5 16 YE / BN IN 5

OUT 6 3 GN IN 6

OUT 7 17 WH / GY IN 7

OUT 8 4 YE IN 8

IN 1 18 GY / BN OUT 1

AnyFeeder Pin #

DSUB 25

Wire Color

Pow er Supply/

SmartController

Function

IN 2 5 GY OUT 2

IN 3 19 WH / PK OUT 3

IN 4 6 PK OUT 4

IN 5 20 PK / BN OUT 5

IN 6 7 BU OUT 6

IN 7 21 WH / BU OUT 7

Adept AnyFeed er User’ s Guide, Re v. B 43

Page 44

Chapter 4 - Using the AnyFeeder with Digital I/O

Table 4-1. Digital I/O Wiring Assignments

AnyFeeder Function

IN 8 8 RD OUT 8

IN 9 22 BN / BU OUT 9

IN 10 9 BK OUT 10

IN 11 23 WH / RD OUT 11

IN 12 10 VT OUT 12

not used 11 GY / PK not used

Shield, ground to case N/A BK

AnyFeeder Pin #

DSUB 25

4.2 Digital I/O Communications

This section describes the Adept AnyFeeder system digital I/O communications.

Signal Handshake

Wire Color

Pow er Supply/

SmartController

Function

Communication works on the basis of a master/slave relationship. For a given situation,

the master sends the Adept AnyFeeder a command, the Adept AnyFeeder confirms

reception of the command, executes it, and reports the status back to the master (whether

the command completed successfully or not).

As viewed from the robot/controller (master) side, the digital I/O interface consists of 12

digital outputs and 8 digital inputs (see Figure 4-1).

• The 12 outputs are used by the master controller to send the Adept AnyFeeder an

action command or set a parameter.

• The 8 inputs return information about the Adept AnyFeeder status and report if an

action has been completed.

44 Adept AnyFeeder User ’ s Guide, Re v. B

Page 45

Digital I/O Communications

Outputs

(12)

Inputs

(8)

Inputs

Outputs

Figure 4-1. Digital Inputs and Outputs

The handshake for the command cycle works as follows:

1. Master outputs the binary representation of a command’s decimal value to cmd

bits 0 thru 4.

2. Master outputs the binary representation of a parameter’s decimal value to data

bit 0 through 5.

3. Master sets the STROBE signal to HIGH, to tell the Adept AnyFeeder that a valid

command and parameter can be fetched from the corresponding Adept

AnyFeeder input sets.

4. When the Adept AnyFeeder sees the STROBE go HIGH, it sets ACKNOWLEDGE

and BUSY to HIGH and reads in the command and the parameter.

5. When the master sees ACKN go HIGH, it sets STROBE to LOW.

6. Upon completion of the command, the Adept AnyFeeder sets BUSY to LOW. If

the command could not be completed successfully, the Adept AnyFeeder sets

ERROR to HIGH and outputs an error code to data bits 0 through 4.

Adept AnyFeed er User’ s Guide, Re v. B 45

Page 46

Chapter 4 - Using the AnyFeeder with Digital I/O

4.3 Commands and Parameters

Table 4-2. Commands and Parameters

cmd

(Decimal

Value)

Action Commands

1 feed-forward 1...64 feed-forward

2 feed-backward 1...64 feed-backward

3 feed-/flip-forward 1...64 feed-/flip-forward

4 feed-/flip-backward 1...64 feed-/flip-backward

cmd Description

param

(Decimal

Value)

param Description Details

repetitions

repetitions

repetitions

repetitions

Moves parts on

feed plate

forward.

Moves parts on

feed plate

backward.

Moves parts on

feed plate

forward and flips

them at the same

time.

Moves parts on

feed plate

backward and

flips them at the

same time.

5 flip 1...64 flip repetitions Flips parts on the

feed plate.

6 dispense 1...64 dispense

repetitions

7 purge 1...64 purge repetitions Feeds parts on

14 turn off servo

motors

16 initialize - - Must be sent

- - Turns off both

Dispenses parts

from the bulk

container onto

the feed plate.

the feed plate

and in the bulk

container

backward.

servo motors.

prior to any other

action command.

46 Adept AnyFeeder User ’ s Guide, Re v. B

Page 47

Commands and Parameters

Table 4-2. Commands and Parameters

cmd

(Decimal

Value)

30 reset error

31 restart feed

Commands to Set Parameters

17 set feed-forward

18 set feed-backward

19 set

cmd Description

condition

firmware

speed

speed

feed-/flip-forward

speed

param

(Decimal

Value)

- - Must be

- - Performs a ‘soft’

1...10 feed-forward speed default = 1;

1...10 feed-backward

1...10 feed-/flip-forward

param Description Details

executed after

feeder reports an

error; feed plate

and bulk

container are

moved to the

home position.

restart of feeder

firmware.

10 max.

default = 1;

speed

intensity

10 max.

default = 1;

10 max.

20 set

feed-/flip-backward

intensity

21 set flip intensity 1...10 flip intensity default = 1;

22 set dispense feed 1...10 dispense feed default = 1;

23 set purge speed 1...10 purge speed default = 1;

1...10 feed-/flip-backward

intensity

default = 1;

10 max.

10 max.

10 max.

10 max.

Adept AnyFeed er User’ s Guide, Re v. B 47

Page 48

Page 49

5.1 Introduction

This chapter describes:

• The periodic maintenance required for the Adept AnyFeeder

• The replacement procedure for the feed surface

• The adjustment procedure for the feed-deck height

5.2 Periodic Maintenance

Table 1 shows the periodic (routine) maintenance tasks required for the Adept

AnyFeeder.

Table 1: Periodic Maintenance Tasks

Item Description Interval

Maintenance 5

Feed surface Clean upper side of feed surface and

frame with a non-abrasiv e, no-residue

cleaner, such as rubbing alcohol or

window cleaner. Failure to do this may

degrade vision performance.

Feed surface and

support

Backlight Remove side panel and clean upper

Servo valve Check the two plastic silencers that

Remove feed surface and clean

bottom side with a non-abrasive,

no-residue cleaner, such as rubbing

alcohol or window cleaner.

Clean support surface and glass

window with alcohol.

Failure to do this may degrade vision

performance.

side of backlight.

Failure to do this may degrade vision

performance.

are screwed into the servo valve to

see if they are blocked with oil. If

needed, replace the silencers.

Failure to do this may degrade

AnyFeeder performance.

Weekly

Monthly

Quarterly

Annually

Adept AnyFeed er User’ s Guide, Re v. B 49

Page 50

Chapter 5 - Maintenance

WARN IN G: Follow proper lockout procedures before performing this

service procedure. Failure to do so could result in injury.

NOTE: Maintenance intervals may require adjustment based on

environment and/or application conditions. If you are feeding dirty parts

or if bulk parts contain debris, you may need to shorten the maintenance

interval in order to maintain optimum performance of the equipment.

5.3 Removing and Installing the Feed Surface

The feed surface is subject to wear during normal system use and will need to be replaced

periodically. To replace the feed surface:

1. Purge all parts from the Adept AnyFeeder.

2. Turn off the power and air supply to the Adept AnyFeeder.

3. Disconnect the I/O cable from the front of the Adept AnyFeeder.

4. Loosen the screws on the side rails.

5. Remove the feed surface by sliding it out of the rear end of the Adept AnyFeeder.

6. After the existing feed surface has been removed, clean all residue from the

exposed feed deck. (See Figure 5-1.)

Figure 5-1. Feed Deck and Drive Block

50 Adept AnyFeeder User ’ s Guide, Re v. B

Page 51

Removing and Installing the Feed Surface

CAUTION: Use only a non-abrasive, no-residue cleaner, such as

rubbing alcohol or window cleaner applied to a clean shop towel. Do

not spray cleaner directly onto the feed deck.

a. Spray the cleaning product onto a clean shop towel.

b. Wipe the feed deck with the shop towel to remove any dirt or debris.

7. Unpackage the new feed surface. The feed surface is self-lubricating. Therefore,

no lubricants should be applied to the feed surface.

8. Slide the new feed surface into the feed deck.

9. Re-tighten the screws on the side rails.

10. Turn on the power and air supply to the Adept AnyFeeder.

Adept AnyFeed er User’ s Guide, Re v. B 51

Page 52

Page 53

6.1 Introduction

This chapter describes optional equipment that is available for the Adept AnyFeeder.

6.2 Backlight

This section describes the procedure for installing the backlight option on the Adept

AnyFeeder. A red (P/N 05284-201) and an infrared (P/N 05284-202) backlight are

available.

1. Slide out the feed surface from the back of the Adept AnyFeeder.

2. Use a 2.5 mm Allen wrench and 7 mm wrench or socket to remove the two screws

from the feed platform front cover.

Optional Equipment 6

Figure 6-1. Removing the Feed Platform Front Cover

3. Insert the backlight power plug into the 4-pin connector in the Adept

AnyFeeder’s base housing. Screw in the plug to secure it in place. Make sure the

plug is oriented toward the back of the Adept AnyFeeder, as shown in the

following illustration.

Adept AnyFeed er User’ s Guide, Re v. B 53

Page 54

Chapter 6 - Optional Equipment

Figure 6-2. Backlight Power Plug Installed

4. Route the two small plugs of the backlight power cable through the front of the

feed platform and connect them to two connectors on the back of the backlight.

Figure 6-3. Connection to Backlight

5. Slide the backlight through the front of the feed platform.

6. Use a 3 mm Allen wrench to install four screws at the corners of the backlight to

secure it to the Adept AnyFeeder.

Figure 6-4. Securing Backlight to AnyFeeder

7. Reinsert the feed surface from the back of the Adept AnyFeeder and reinstall the

feed platform front cover using two screws.

54 Adept AnyFeeder User ’ s Guide, Re v. B

Page 55

Dimension Drawings 7

7.1 Dimensions

This section provides the critical dimensions for the Adept AnyFeeder.

2.50

332

268

434

125 125 125 125 125 125

800

1125

320

236

197

244.50

38

240

284

309

237.50

Figure 7-1. Adept AnyFeeder Dimensions

Adept AnyFeed er User’ s Guide, Re v. B 55

Page 56

Page 57

The Adept AnyFeeder can be controlled from a V+ program. This appendix provides an overview

of that process. This feature requires AdeptSight version 3.1 or later.

NOTE: Although the Adept AnyFeeder can be controlled from a V+ program,

Adept recommends that you use the graphical interface provided in the Adept

ACE software. For details, see the Adept ACE User’s Guide.

A.1 Overview

When a V+ vision (AdeptSight) keyword is used in a V+ program, the corresponding function on

the PC side checks the specified index:

• If the index corresponds to an AdeptSight vision sequence, it executes that sequence.

• If it corresponds to an Adept AnyFeeder, it executes control for the Adept AnyFeeder.

Controlling the

AnyFeeder from V+ A

NOTE: The Adept AnyFeeder index can be set using the Adept AnyFeeder object

editor in the Adept ACE software. For details on the AnyFeeder object editor, see

the Adept ACE User’s Guide.

CAUTION: If an AdeptSight vision sequence and an Adept AnyFeeder

have the same index value, only the AdeptSight vision sequence will be

executed. This prevents any conflict with an existing AdeptSight vision

system when adding an Adept AnyFeeder.

A.2 V+ Keywords

The following pages describe the V+ keywords in the AdeptSight software that can be used to

control the Adept AnyFeeder. Each page provides the syntax and details for controlling the Adept

AnyFeeder. For details on the AdeptSight software vision functionality of the keyword, see that

keyword description in the AdeptSight Reference Guide.

NOTE: This feature requires AdeptSight version 3.1 or later.

Adept AnyFeeder User’s Guide, Rev B 57

Page 58

Controlling the AnyFeeder from V+

VPARAMETER program instruction

Description

Writes an Adept AnyFeeder parameter.

Syntax

VPARAMETER(anyfeeder.id, -1, parameter.id, -1, -1) $ip = parameter.value

Parameters

anyfeeder.id The AnyFeeder index specified in the Adept AnyFeeder object editor.

parameter.id The code corresponding to the parameter to read or write. as shown in

the following table.

$ip IP address of the PC to which the Adept AnyFeeder is connected.

parmeter.value The value of the parameter. If the specified value is outside of the

allowed range, as specified in the following table, the command is

ignored.

Table A-1. VPARAMETER Parameter Indexes

Parameter Code

AnyFeederVRunCommand 6000 Value

Value

(Range)

shown in

Table A-2

Description

Sets the AnyFeeder command that

will be called on a VRUN. For more

details, see Table A-2.

AnyFeederFeedForwardSpeed 6001 0 to 10 Sets the speed for the feed-forward

operation.

AnyFeederDispenseSpeed 6002 0 to 10 Sets the speed for the dispense

operation.

AnyFeederFlipSpee d 6003 0 to 10

AnyFeederPurgeSp eed 6004 0 to 10

AnyFeederFeedBackwardSpeed 6005 0 to 10

AnyFeederHeavyDispenseSpeed 6006 0 to 10

AnyFeederFeedFlipForwardSpeed 6007 0 to 10

Sets the

Sets the

Sets the speed of the feed-backward

operation.

Sets the speed of the heavy-dispense

operation.

Sets the speed of the feed flip-forward

operation.

speed of the flip operation.

speed of the purge operation.

AnyFeederFeedFlipBackwardSpeed 6008 0 to 10

AnyFeederFeedForwardIterations 6011 1 to 63

Sets the speed of the feed flip-backward

operation.

Sets the number of iterations for feed

forward.

58 Adept AnyFeeder User’s Guide, Rev B

Page 59

Table A-1. VPARAMETER Parameter Indexes

V+ Keywords

Parameter Code

AnyFeederDispenseIterations 6012 1 to 63

AnyFeederFlipIterations 6013 1 to 63

AnyFeederPurgeIterations 6014 1 to 63

AnyFeederFeedBackwardIterations 6015 1 to 63

Value

(Range)

Description

Sets the number of iterations for

dispense.

Sets the number of iterations for flip.

Sets the number of iterations for purge.

Sets the number of iterations for feed

backward.

AnyFeederHeavyDispenseIterations 6016 1 to 63 Sets the number of iterations for

heavy dispense.

AnyFeederFeedFlipForwardIterations 6017 1 to 63

AnyFeederFeedFlipBackwardIterations 6018 1 to 63

Sets the number of iterations for feed flip

forward.

Sets the number of iterations for feed flip

backward.

Adept AnyFeeder Use r’ s Guide, Rev B 59

Page 60

Controlling the AnyFeeder from V+

VRUN program instruction

Description

Initiates the specified operation of the Adept AnyFeeder.

Syntax

VRUN $ip, anyfeeder.id

Parameters

$ip IP address of the PC to which the Adept AnyFeeder is connected.

anyfeeder.id The AnyFeeder index specified in the Adept AnyFeeder object editor.

Operation and Values

The command codes correspond to the Adept AnyFeeder device command codes, with the

exceptions of “100” and “101”, which do not follow this format.

Table A-2. AnyFeeder VRUN Command Operation and Values

Operation Value

FeedForward 1

FeedBackward 2

FeedFlipForward 3

Flip 5

Dispense 6

Purge 7

HeavyDispense 8

Stop 15

Init 16

SetOutput 27

ErrorReset 30

FirmwareRestart 31

SwitchBacklightON 100

SwitchBacklightOFF 101

Details

The Adept AnyFeeder runs the command that was selected by the AnyFeederVRunCommand

(6000) parameter (see Table A-1). VRUN returns after the Adept AnyFeeder operation starts or,

eventually, on an Adept AnyFeeder error.

60 Adept AnyFeeder User’s Guide, Rev B

Page 61

VWAITI program instruction

Description

Pauses program execution until the current Adept AnyFeeder operation has completed.

Syntax

VWAITI (anyfeeder.id) $ip, type

Parameters

anyfeeder.id The AnyFeeder index specified in the Adept AnyFeeder object editor.

$ip IP address of the PC to which the Adept AnyFeeder is connected.

type 0 Wait for full completion (default).

Details

Use VWAITI call after VRUN.

V+ Keywords

Contrary to vision sequences, when VWAITI is used with the Adept AnyFeeder, it always waits

for full completion of the current Adept AnyFeeder operation. Therefore, the type parameter can

be omitted.

Adept AnyFeeder Use r’ s Guide, Rev B 61

Page 62

VSTATE real-valued function

Description

Returns the Adept AnyFeeder status.

Syntax

VSTATE($ip, anyfeeder.id)

Parameters

$ip IP address of the PC to which the Adept AnyFeeder is connected.

anyfeeder.id The AnyFeeder index specified in the Adept AnyFeeder object editor.

Details

The following table shows the possible returned values and corresponding Adept AnyFeeder

status.

Table A-3. AnyFeeder Status and Returned Values

Status Value

Idle 0

Running 1

Error 4

Page 63

V+ Keywords

Example V+ Code

The following V+ code provides an example of implementing Adept AnyFeeder control through a

V+ program. For proper functionality, this code would be used along with robot-control code and

error-checking code to create a complete V+ application.

; Set parameter values

$ip = "172.21.12.91"

prm.ffwd.speed = 6001

prm.ffwd.iter = 6011

prm.run.action = 6000

operation = 1

anyfeeder.id = 3

; Set FeedForward speed

VPARAMETER(anyfeeder.id, -1, prm.ffwd.speed, -1, -1) $ip = 1

; Set FeedForward iterations