Page 1

AIR / FUEL RATIO GAUGE

INSTALLATION INSTRUCTIONS

This gauge was designed for 12-Volt, negative

ground electrical systems.It works with 1-wire,

2-wire, 3-wire, and 4-wire oxygen sensors. If your

vehicle is not equipped with an oxygen sensor, an

oxygen sensor kit can be purchased and installed.

Install the sensor in a location where the exhaust

streams from all cylinders meet and as close as

possible to the cylinder head.

PRECAUTIONS

1. Read the entire instructions before proceeding.

2. Route all wiring away from linkages, engine

parts that become hot, or moving parts.

3. Never smoke while working on your vehicle and

always keep a re extinguisher nearby. It should

be rated for gas/chemical/electrical res.

4. Never lay tools on top of the battery or wear

jewelry during electrical work to avoid severe

shorts.

5. Do not touch the wire(s) coming from the

oxygen sensor to power or ground. Do not

use ohmmeter on these wires. Either of these

actions will damage the sensor.

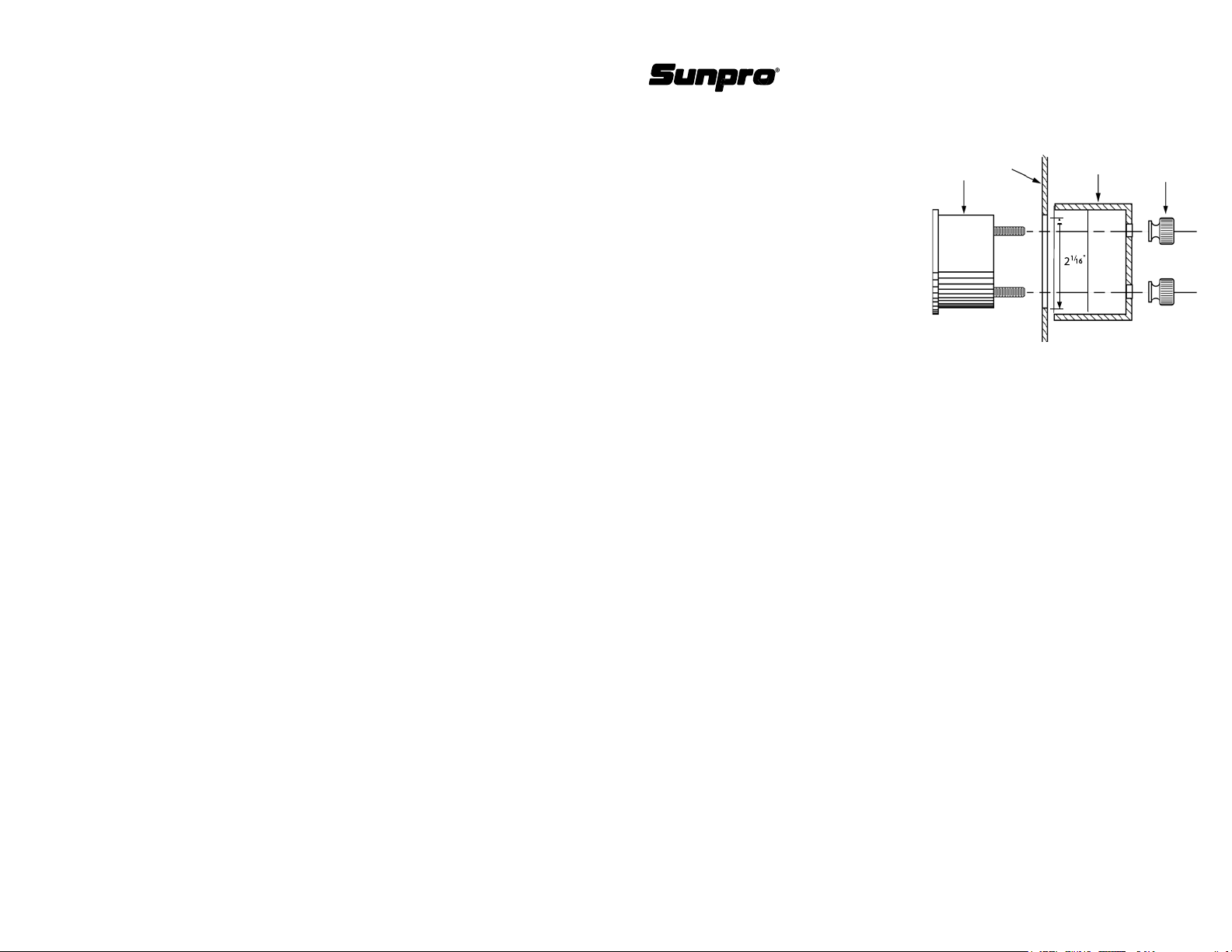

INSTALLING GAUGE

This gauge can be mounted into a surface of your

choice or into a gauge pod.

1. It is recommended that the battery ground cable

be disconnected before any electrical work is

performed.

2. Choose a location to mount the gauge where it

will be viewable from a normal driving position.

3. If you are installing the gauge into a surface (for

example the dashboard) make a 2-1/16” hole

for the gauge. Be sure to check for wires behind

dash. Do not accidentally cut any wires or hoses.

Be sure there is clearance around the hole for

the gauge mounting bracket.

4. Plug the wire harness connector into the

receptacle on the back of the gauge.

5. Insert the wires and the gauge into the mounting

panel or hole.

6. Install the mounting bracket and tighten the

knurled nuts lightly.

7. Position the gauge for best visibility and tighten

the knurled nuts with moderate pressure.

Figure 1

Gauge Mounting

GAUGE

DASHBOARD

BRACKET

NUTS

(KNURLED)

HOOKING UP WIRES

1. Verify that the battery grou nd ca ble is

disconnected before any electrical work is

performed.

2. Connect the red wire to a fuse protected source

of +12 Volts turned on and off with the ignition

key. The fuse box is usually a good place to

start.

3. Connect the white wire to a circuit which is

energized by the headlamp switch or to the tail

light circuit.

4. If desired, drill a 3/8” hole in the rewall, install a

rubber grommet (provided), and feed the black

and green wires through the grommet into the

engine compartment.

5. CONNECT THE BLACK WIRE TO A GOOD

ENGINE GROUND SOURCE. DO NOT

CO NN EC T BL AC K WIRE TO GR OU ND

POINTS UNDERNEATH THE DASH OR

ON THE BODY. FIND A LOCATION ON

THE ENGINE BLOCK. CLEAN RUST AND

PAINT IF NEEDED BEFORE MAKING THE

CONNECTION. USE THE RING TERMINAL

(PROVIDED).

6. Connect the green wire to the signal wire

between the oxygen sensor connector and

the car computer. Do not connect to the wire

between the oxygen sensor and the connector,

as this wire is often shielded. Refer to diagrams

below for selecting the correct connection

point. If the oxygen sensor has 2, 3, or 4 wires,

consult wiring diagram for your vehicle or

contact vehicle manufacturer to identify the

signal wire.

®

Sunpro

15825 Industrial Parkway,

Cleveland, OH 44135, U.S.A.

For warranty information

contact us at:

1-800 228-7667 or www.sunpro.com

Sunpro® is a registered trademark of Snap-On®

Corporation used under license to

SPX® Corporation

©2006 SPX Corporation

0002-000-2910

Page 2

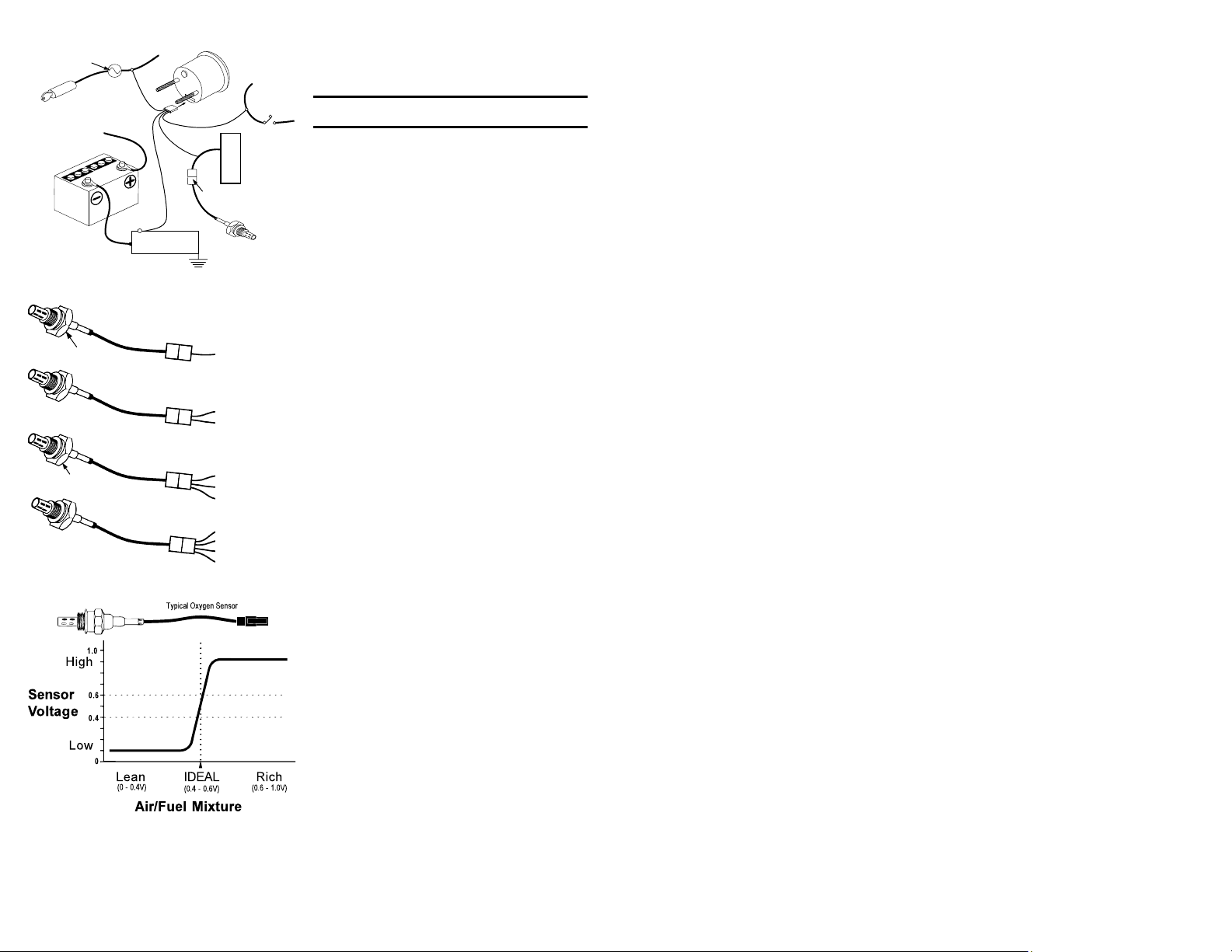

Figure 2

General Hookup

FUSE

BOX

+12V

POWER

RED

TO ENGINE

BLOCK GROUND

Figure 3 -

1, 2, 3 & 4 - Wire Sensors

1-WIRE

OXYGEN SENSOR

GROUND

2-WIRE

OXYGEN SENSOR

3-WIRE

OXYGEN SENSOR

GROUND

4-WIRE

OXYGEN SENSOR

Figure 4

Oxygen Sensor Operation

WHITE

GREEN

BLACK

AIR/FUEL GAUGE

TO HEAD LAMPS

OR TAIL LIGHTS

CAR

COMPUTER

CONNECTOR

CONNECT GREN WIRE

ON AIR/FUEL GAUGE TO

SENSOR SIGNAL WIRE

SENSOR SIGNAL

SENSOR SIGNAL

SENSOR GROUND

SENSOR SIGNAL

HEATER POWER

HEATER GROUND

SENSOR SIGNAL

SENSOR GROUND

HEATER POWER

HEATER GROUND

HEADLAMP

SWITCH

OXYGEN

SENSOR

for fuel delivery attempting to maintain an ideal

air/fuel mixture for low emissions and good fuel

economy.

GAUGE OPERATION

NOTE: Typical Air/Fuel Ratio Gauge operation is described

below. The operation may vary from vehicle to vehicle.

The gauge measures the voltage produced by

the oxygen sensor and displays it in real time on

a radial, LED (Light Emitting Diode) bar graph.

The LEDs are color coded for ease of viewing and

interpreting the gauge reading.

When the headlights are turned on, the gauge

background illuminates and the LEDs are dimmed

for easy night viewing.

When the key is in the ON position and the engine

is cold and not running, all segments of the gauge

are off.

When the engine rst starts, all segments of the

gauge are off since the sensor needs to warm up to

its operating temperature. The exact time depends

on whether the oxygen sensor is heated (less than

a minute) or non-heated (several minutes) and the

vehicle. On some vehicles the gauge may read

lean right away.

When the sensor reaches its operating temperature,

but the engine still has not reached the operating

temperature when the car computer takes over

(open loop), the gauge will most likely read rich.

When the engine is controlled by the car computer

(closed loop) and the car is cruising, the gauge

segments will swing between rich and lean. On

vehicles with an added oxygen sensor that do not

have a computer the gauge reading will change

depending on the engine condition, but will not

constantly swing like on the computer-controlled

vehicles.

When the throttle is open during heavy load, the

readings will move toward rich.

During deceleration, the readings will be in the lean

zone. During a hard deceleration, the computer

might lean out the mixture to the point where no

LED segments will be lit.

This sensor produces a voltage signal based on

OXYGEN SENSOR

the amount of oxygen it detects in the exhaust

stream. A low voltage (less than 0.4V) indicates a

lean exhaust (too much oxygen). A higher voltage

(0.6 - 1.0V) signals a rich exhaust (not enough

oxygen). The car computer uses the oxygen sensor

A sluggish response of the Air/Fuel Ratio Gauge

TROUBLESHOOTING

may indicate a partially fouled oxygen sensor. If

the sensor degradation is conrmed, the sensor

should be replaced. A lean operation under load

is a sign of improperly functioning fuel delivery

system. This can lead to engine damage.Persistent

rich operation (not under heavy load) can lead to

poor fuel economy, fouled spark plugs, and poor

performance.

2

Page 3

Schéma 2

Branchement Général

VERS BOÎTE

À FUSIBLES

+12V

ROUGE

VERS MASSE DU

BLOC MOTEUR

VERT

NOIR

BLANC

JAUGE

DE BORD

ORDINATEUR

CONNECTEUR

VERS PHARES

COMMUTATEUR

DE PHARES

DÉTECTEUR

D’OXYGÈNE

Schéma 3

Détecteur d’oxygèneà 1 l, à 2 ls, à 3 ls, à 4 ls

CONNEXION DE FIL VERT

SIGNAL DU DÉTECTEUR

D’OXYGÉNE

SIGNAL DU DÉTECTEUR

SIGNAL DU DÉTECTEUR

MASSE DU DÉTECTEUR

SIGNAL DU DÉTECTEUR

ALIMENTATION DE CHAUFFAGE

MASSE DE CHAUFFAGE

SIGNAL DU DÉTECTEUR

MASSE DU DÉTECTEUR

ALIMENTATION DE CHAUFFAGE

MASSE DE CHAUFFAGE

MASSE

MASSE

DÉTECTEUR

À 1 FIL

DÉTECTEUR

À 2 FIL

DÉTECTEUR

À 3 FIL

DÉTECTEUR

À 4 FIL

Schéma 4

Fonctionnement du détecteur d’oxygène

DÉTECTEUR D’OXYGÈNE

Ce détecteur génère un signal en tension basé

sur le taux d’oxygène qu’il trouve dans le gaz

d’échappement. Une tension faible (moins de

0,4 V) indique un échappement pauvre (trop

d’oxygène). Une tension plus élevée (0,6 - 1,0

V) signale un échappement riche (pas assez

d’oxygène). L’ordinateur de bord utilise le détecteur

d’oxygène pour l’alimentation en carburant, en

essayant de maintenir un mélange air/carburant

idéal an de minimiser les émissions nocives et

d’économiser le carburant.

FONCTIONNEMENT DE LA JAUGE

REMARQUE: Le fonctionnement habituel de la jauge

de rapport air/carburant est décrit plus loin. Son fonctionnement peut varier d’un véhicule à l’autre.

La jauge interprète la tension produite par le

détecteur d’oxygène et l’afche en temps réel par

un graphique radial à bâtons constitué de DEL

(diodes électroluminescentes). Ces DEL sont

codées en couleurs pour faciliter la visualisation et

l’interprétation de l’afchage de la jauge.

Quand les phares sont allumés, le fond de la jauge

s’allume et les DEL ont un éclairage atténué pour

faciliter la visualisation nocturne.

Quand la clé de contact est en position de marche

(ON) et que le moteur est froid et à l’arrêt, tous les

segments de la jauge sont éteints.

Quand le moteur commence à démarrer, tous les

segments de la jauge sont encore éteints car le

détecteur a besoin de chauffer à sa température

de fonctionnement. Le temps que cela prend

varie suivant que le détecteur est chauffé (moins

d’une minute) ou non chauffé (plusieurs minutes),

et suivant le véhicule. Sur certains véhicules la

jauge dans cette phase peut indiquer un mélange

pauvre.

Quand le détecteur atteint sa température de

fonctionnement, mais que le moteur n’est pas

encore chaud avant que l’ordinateur de bord ne

prenne le contrôle ((boucle ouverte), la jauge

indiquera probablement que l’échappement est

riche.

Quand le moteur est contrôlé par l’ordinateur de

bord (boucle fermée) et que la voiture roule, les

segments de la jauge vont osciller entre riche et

pauvre. Sur les véhicules comportant un détecteur

d’oxygène mais pas d’ordinateur de bord, la lecture

de la jauge va évoluer en fonction des conditions

du moteur, mais ne va pas osciller en permanence

comme sur les véhicules contrôlés par ordinateur.

Quand le papillon des gaz est ouvert pendant une

charge forte, les lectures bougeront vers la zone

riche.

Pendant une décélération, les lectures seront

dans la zone pauvre. Si la décélération est très

brutale, l’ordinateur peut appauvrir le mélange au

point qu’aucun segment LED ne sera plus allumé

sur la jauge.

TROUBLESHOOTING

Une réponse lente de la jauge de rapport air/

carburant peut indiquer un détecteur d’oxygène

partiellement encrassé. Si la dégradation du

détecteur est confirmée, il doit être remplacé.

Un fonctionnement paresseux sous forte charge

peut être le signe d’un système d’acheminement

de carburant défectueux. Cela peut entraîner des

dommages au moteur. Un fonctionnement restant

toujours en zone riche (même en charge normale)

peut provoquer une surconsommation de carburant,

un encrassement des bougies, et une performance

médiocre.

6

INDICADOR DE RELACION AIRE /

COMBUSTIBLE INSTRUCCIONES

DE INSTALACION

Este indicador ha sido diseñado para sistemas

eléctricos de 12 voltios, con negativo a tierra.

Puede trabajar con sensores de oxígeno de 1, 2,

3 y 4 cables. Si su vehículo no está equipado con

un sensor de oxígeno, puede comprar e instalar

un juego de sensor de oxígeno y accesorios.

Instale el sensor en una ubicación en donde se

concentren los flujos de escape de todos los

cilindros, y tan cerca de la cabeza de cilindros

como sea posible.

1. Lea completamente las instrucciones antes de

proceder a la instalación.

2. Encamine todos los cables lejos de articulaciones,

partes del motor que se calienten, o partes

móviles.

3. Nunca fume mientras trabaja en su vehículo,

y tenga siempre cerca un extinguidor de

incendios. El extinguidor debe ser de una

clase adecuada para fuegos de gas, químicos

y eléctricos.

4. Nunca deje herramientas sobre la batería ni use

ningún tipo de alhaja cuando realice trabajos

eléctricos, para evitar la posibilidad de severos

cortocircuitos.

5. No toque el cable o cables que conectan el

sensor de oxígeno con el voltaje positivo o con

tierra. Tampoco use el óhmetro con esos cables.

Cualquiera de estas dos acciones dañará al

sensor.

Este indicador puede montarse en cualquier su-

percie o en un soporte (pod).

1. Se recomienda desconectar el cable de tierra

de la batería antes de realizar cualquier trabajo

eléctrico.

2. Elija para el montaje del indicador un lugar tal

que pueda verlo desde la posición normal de

manejo.

3. Si está instalando el indicador en una supercie

(por ejemplo en el tablero), haga una agujero de

5.24 cm (2-1/16”) para el indicador. Asegúrese

de inspeccionar los cables tras el tablero. Cuide

de no cortar accidentalmente ningún cable ni

manguera. Asegúrese de que exista alrededor

del agujero un espacio libre para el soporte de

montaje del indicador.

4. Inserte el conector del arnés de cables en el

conector hembra ubicado en la parte de atrás

del indicador.

5. Inserte los cables y el indicador en el panel de

montaje o agujero.

6. Instale el sopo rte de mon taje y aju ste

suavemente las tuercas estriadas.

7. Posicione el indicador para tener una visibilidad

óptima, y ajuste las tuercas estriadas con una

presión moderada.

Importador: Ver Producto. Hecho en China.

PRECAUCIONES

INSTALANDO EL INDICADOR

Figura 1

Montaje del Indicador

INDICADOR

TABLERO

SUPORTE

TUERCAS

ESTRIADAS

CONECTANDO LOS CABLES

1. Verique que el cable de tierra de la batería esté

desconectado antes de realizar cualquier trabajo

eléctrico.

2. Conecte el cable rojo a una alimentación de

+12 voltios protegida por un fusible, que se

conecte y desconecte mediante la llave de

contacto del auto. Un buen lugar para comenzar

es normalmente la caja de fusibles.

3. Conecte el cable blanco a un circuito que

esté energizado por el interruptor de los faros

delanteros, o al circuito de la luz de posición

trasera.

4. Si lo desea, perfore un agujero de 10 mm

(3/8”) en la mampara cortafuegos, instale una

arandela de goma (provista), y lleve los cables

blanco y verde dentro del compartimiento del

motor, pasándolos a través de la arandela.

5. CONECTE EL CABLE NEGRO A UN BUEN

PUNTO DE TIERRA (CHASSIS) DEL MOTOR.

NO CONECTE EL CABLE NEGRO A PUNTOS

DE TIERRA QUE SE ENCUENTREN DEBAJO

DEL TABLERO O EN LA CARROCERÍA.

ELIJA UN LUGAR EN EL BLOQUE DEL

MOTOR. SI FUERA NECESARIO, LIMPIE LA

HERRUMBRE Y PINTURA ANTES DE HACER

LA CONEXIÓN. USE EL TERMINAL ANILLO

(PROVISTO).

6. Conecte el cable verde al cable de señal,

entre el conector del sensor de oxígeno y

la computadora del auto. No lo conecte al

cable de señal entre el sensor de oxígeno y el

conector, porque ese cable comúnmente lleva

blindaje. Vea los diagramas que siguen para

seleccionar el punto correcto para la conexión.

Si el sensor de oxígeno tiene 2, 3 o 4 cables,

consulte el diagrama de conexionado para su

vehículo, o consulte al fabricante del vehículo

para identicar el cable de señal.

3

Importador: Ver Producto. Hecho en China.

Page 4

Figura 2

Conexionado General

A LA CAJA

DE FUSIBLES

+12V

ROJO

A PUNTO DE TIERRA

EN EL BLOQUE DEL MOTOR

VERDE

NERGRO

INDICADOR

BLANCO

DEL AUUTO

COMPUTADORS

CONNECTOR

AL FARO

DELANTERO

INTERRUPTOR DEL

FARO DELANTERO

SENSOR

DE

OXĺGENO

Figura 3

Sensor Unilar (de 1 cable), Sensor Bilar

(de 2 cables), Sensor Trilar (de 3 cables) ,

Sensor Tetralar (de 4 cables)

SENSOR UNIFILAR

(DE 1 CABEL)

TIERRA

SENSOR BIFILAR

(DE 2 CABEL)

SENSOR TRIFILAR

(DE 3 CABEL)

TIERRA

SENSOR TETRAFILAR

(DE 4 CABEL)

Figura 4

Operación del Sensor de Oxígeno

CONECTE EL CABLE

VERDE AL CABLE DE

SEÑAL

SENSOR DE OXIGENO - SEÑAL

SENSOR DE OXIGENO - SEÑAL

SENSOR DE OXIGENO - TIERRA

SENSOR DE OXIGENO - SEÑAL

CALEFACTOR - ALIMENTATION

CALEFACTOR - TIERRA

SENSOR DE OXIGENO - SEÑAL

SENSOR DE OXIGENO - TIERRA

CALEFACTOR - ALIMENTATION

CALEFACTOR - TIERRA

SENSOR DE OXÍGENO

Este sensor produce una señal de voltaje basada

en la cantidad de oxígeno que detecta en el ujo

de escape. Un voltaje bajo (menor de 0.4 Voltio)

indica un escape con mezcla pobre (demasiado

oxígeno). Un voltaje mayor (0.6 Voltio - 1.0 Voltio)

señaliza un escape con mezcla rica (oxígeno insu-

ciente). La computadora del auto utiliza la señal

del sensor de oxígeno para controlar el suministro

de combustible, tratando de mantener una mezcla

aire/combustible ideal para obtener bajas emisiones y buena economía de combustible.

OPERACIÓN DEL INDICADOR

NOTA: A continuación se describe la operación típica

del Indicador de Relación Aire/Combustible. La operación

puede variar de un vehículo a otro.

El indicador mide el voltaje producido por el sensor

de oxígeno, y lo muestra en tiempo real sobre un

gráco de barras radial de LEDs (Diodos Emisores

de Luz). Los LEDs están codicados en colores,

para facilitar la visión y la interpretación de la lectura

del indicador.

Cuando se encienden los faros delanteros, el fondo

del indicador se ilumina y los LEDs disminuyen su

brillo, para una buena visión nocturna.

Cuando la llave de contacto está en posición ON y

el motor está frío y detenido, todos los segmentos

del indicador están apagados.

Cuando el motor arranca por primera vez, todos los

segmentos del indicador permanecen apagados

porque el sensor necesita calentarse hasta alcanzar su temperatura de operación. El tiempo exacto

depende de si el sensor de oxígeno está calefaccionado (menos de un minuto) o no (varios minutos),

y del vehículo. En algunos vehículos, el indicador

puede dar una indicación de mezcla pobre.

Cuando el sensor alcanza su temperatura de

operación, pero el motor no ha alcanzado aún la

temperatura de operación necesaria para que la

computadora del auto tome el control (operación a

lazo abierto), el indicador dará muy probablemente

una indicación de mezcla rica.

Cuando el motor está controlado por la computadora del auto (operación a lazo cerrado) y el auto

está circulando a velocidad de crucero, los segmentos del indicador oscilarán entre las indicaciones

de mezcla rica y mezcla pobre. En los vehículos

en que se agrega un sensor de oxígeno pero no

tienen computadora, la lectura del indicador cambiará dependiendo de la condición del motor, pero

no oscilará constantemente como en los vehículos

controlados por computadora.

Cuando en condiciones de servicio pesado se abre

el acelerador, las lecturas del indicador se mueven

hacia la zona de mezcla rica.

Durante una deceleración, las lecturas se ubicarán

en la zona de mezcla pobre. Durante una decel

eración brusca, podría ocurrir que la computadora

haga empobrecer la mezcla hasta tal punto que

todos los segmentos de LEDs del indicador se

apaguen.

LOCALIZACION DE FALLAS

Una respuesta lenta del Indicador de Relación

Aire/Combustible puede estar indicando que el

sensor de oxígeno está parcialmente obstruído.

Si la degradación del sensor se conrma, debe

reemplazarse. Una operación con mezcla pobre, con

el motor bajo carga, es un signo de funcionamiento

incorrecto del sistema de suministro de combustible.

Cette jauge est prévue pour des alimentations en

12 volts avec négatif à la masse. Elle fonctionne

avec des détecteurs d’oxygène à 1, 2, 3 et 4 ls.

Si votre véhicule n’est pas équipé d’un détecteur

d’oxygène, un ensemble peut être acheté et

installé pour cette fonction. Installez le détecteur

à un endroit où les gaz d’échappement de tous

les cylindres se rejoignent, et le plus près possible

de la culasse.

PRÉCAUTIONS

1. Lisez complètement ces instructions avant de

commencer l’installation.

2. Faites passer tout le câblage à l’écart des

transmissions et des piè ces moteur qu i

chauffent ou qui bougent.

3. Ne fumez jamais en travaillant sur votre

véhicule, et gardez toujours un extincteur à

proximité. Il faut qu’il soit adapté aux feux de

types électrique/chimique/gazeux.

4. Ne posez jamais d’outils sur le dessus de la

batterie, et ne portez pas de bijoux pendant

les travaux électriques, an d’éviter des courts-

circuits dangereux.

5. Ne faites pas toucher de fil(s) venant du

détecteur d’oxygène à la tension ou à la masse.

N’utilisez pas d’ohmètre sur ces ls. Ces deux

types d’action endommageraient le détecteur.

INSTALLATION DE LA JAUGE

Cette jauge peut être montée sur toute surface, ou

sur une console de jauges.

1. Il est recommandé que le câble de mise à

la masse de la batterie soit débranché avant

d’effectuer tout travail sur un circuit électrique.

2. Choisissez un emplacement pour monter la

jauge d’où elle sera lisible à partir d’une position

de conduite normale.

3. Si vous installez la jauge sur une surface

(comme la planche de bord), percez-y un trou de

5,24 cm (2-1/16”) pour passer la jauge. Vériez

bien l’éventuelle présence de ls derrière la

-

surface, ne blessez pas accidentellement des

ls ou conduites. Assurez-vous qu’il y aura

assez d’espacement autour du trou pour le

support de montage de la jauge.

4. Branchez le connecteur du toron de ls dans le

connecteur à l’arrière de la jauge.

5. Insérez ces ls et l’arrière de la jauge dans le

tableau de montage ou dans le trou.

6. Installez le support de montage et serrez les

écrous moletés légèrement.

7. Positionnez la jauge pour optimiser la visibilité

et serrez les écrous moletés avec une force

modérée.

INSTRUCTIONS D’INSTALLATION DE LA

JAUGE DE RAPPORT AIR / CARBURANT

Esto puede llevar a producir daños en el motor.

Una operación persistente con mezcla rica (no

estando el motor bajo carga pesada) puede

ocasionar un gasto excesivo de combustible, bujías

empastadas, y bajo desempeño.

4 5

Schéma 1

Montage de jauge

TABLEAU

DE BORD

ÉTRIER

SUPPORT

ÉCROUS

MOLETÉS

RACCORDEMENT DES FILS

1. Vériez que le câble de mise à la masse de la

batterie est bien débranché avant d’effectuer

tous travaux électriques.

2. Branchez le l rouge sur une source de +12 volts

protégée par fusible qui est alimentée et coupée

par la clé de contact. Le boîtier à fusibles est

généralement un bon point de raccordement.

3. Branchez le l blanc sur un circuit électrique qui

est alimenté par le commutateur de phares ou

de feux arrière.

4. Si vous le souhaitez, percez un trou de 10 mm

(3/8”) dans la paroi pare-feu, installez un œillet

en caoutchouc (fourni), et enlez les ls noir et

vert au travers de l’œillet vers le compartiment

du moteur.

5. BRANCHEZ LE FIL NOIR SUR UNE BONNE

MA SSE DU MOTE UR. NE BRANCH EZ

PAS CE FIL NOIR SUR DES POINTS DE

MASSE SITUÉS SOUS LE TABLEAU DE

BORD OU SUR LE CHÂSSIS. TROUVEZ

UN ENDR OIT SUR LE BLO C MOTEU R.

NETTOYEZ LA ROUILLE OU LA PEINTURE

SI NÉCESSAIRE AVANT DE RÉALISER

LA CONNEXION; UTILISEZ LA COSSE À

ANNEAU (FOURNIE).

6. Branchez le l vert sur le l de signal entre

le co nnecteur du détecteur d’oxygène et

l’ordinateur de bord. Ne branchez pas ce l entre

le détecteur d’oxygène et le connecteur, car ce l

est souvent blindé. Reportez-vous aux schémas

ci-dessous pour sélectionner le point de

raccordement correct. Si le détecteur d’oxygène

a 2, 3 ou 4 fils, consultez le diagramme

de câblage du véhicule ou contactez son

constructeur pour identier le l transportant le

signal.

Loading...

Loading...