Page 1

User’s Manual

9640A

Enhanced Scan T ool

Professional

Page 2

Scan Tool Information

Complete the following list using the

function “Tool Information” on

page 3-4. Provide this information

when contacting customer support.

Serial No:

SW ID:

HW Ver:

Boot Ver:

Prod ID:

Board ID:

Burn Date:

Burn Loc:

Copyr igh t In fo rm a tio n

Copyright © 2003 Actron Manufacturing, Inc.

All rights reserved.

The information, specifications and illustrations in this

manual are b ased o n the latest i nf orma tion ava i lable at the

time of printing.

to make changes at any time without notice.

Actron Manufacturing

reserves the right

Page 3

Safety

!

Table of Contents

Section 1 –––––––––– Using this Manual

Section 2 –––––––––––– Getting Started

Section 3 ––––––––Using The Scan Tool

Section 4 ––– Global OBD II Diagnostics

Section 5 –––––––––––– GM Diagnostics

Section 6 –––––––––––Ford Diagnostics

ToC

1

2

3

4

5

6

Section 7 ––––––––Chrysler Diagnostics

Section 8 ––––– Help & Troubleshooting

Appendix A ––––– Data Link Connectors

Appendix B –––––––––––––––– Glossary

7

8

A

B

Page 4

Page 5

Safety Precautions

For your safety , read this manual thoroughly before oper ating your Professional

Enhanced Scan Tool. Always r efer to and foll ow safety messag es and test procedures provided by the manufacturer of the vehi cle or equipment being tested .

Y our scan t ool is intend ed for us e by properl y trained, sk illed pr ofessiona l automotive techni cians. The safety mes sages presented b elow and throughou t this

user’s manual are reminders to the operator to exercise extreme care when

using this test instrument.

Read All Instructions

Read, understa nd and fol low al l safet y mes sages and i nstru ctions in thi s manual and on the test equipment. Safety messag es in this secti on of the manual

contain a signal word with a three-part message and, in some instances, an

icon. The signal word indicates the level of the hazard in a situation.

Safety Messages

Safety messages are provided t o help prevent personal injury and equipment

damage. All safety messages are introduced by a signal word indicating the

hazard level. The types of safety messages are:

DANGER

!

WARNING

!

Indicates an imminently hazardous situation which, if not

avoided, will r esult in deat h or serious i njury to the o perator

or to bystanders.

Indicates a potential ly hazardous situation which, if not

avoided, could resul t in deat h or serio us injur y to the operator or to bystanders.

!

Indicates a potential ly hazardous situation which, if not

!

CAUTION

IMPORTANT

Safety messages contain three different type styles.

• Normal type states the hazard.

• Bold type states how to avoid the hazard.

•

Italic

An icon, when present, gives a graphical description of the potential hazard.

Example

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • Safety – i

avoided, may resul t in mod erate or m inor inj ury to the operator or to bystanders.

Indicates a situation which, if not avoided, may result in

damage to the test equipment or vehi cle.

type states th e possible consequences of not avoidi ng the hazard.

:

Engine systems can malfunction expelling fuel, oil vapors, hot

steam, hot toxic exhaust gases, acid, refrigerant and other

debris.

Wear safety goggles and protective gloves, user and

bystander . Ever yday eyeglasses onl y have impact resistant

lenses, they are NOT safety glasses.

Engine systems that malfunction can cause injury.

Page 6

Safety Precautions

!

Important Safe ty Instru ct ion s

Risk of electric shoc k.

• Do not exceed volt age limits between inputs as indicated

in the “Specifi cations” on page 3-2.

• Use extre me caution when worki ng with circuit s that have

greater than 60 volts DC or 24 volts AC.

Electric shock can cause injury .

Risk of explosion.

• Wear safety goggles and protective clothing, user and

bystan der. Everyday eyeglasses only have impact resistant lenses, they are NOT safety glasses.

• Do not use this system in environments where explosive

vapor may collect, such as i n below-ground pits , confined

areas, or area s that are less than 18 inches above t he floor .

• Use this equipment in locations with mechanical ventilation providing at least four air changes per hour.

• Flammable fuel and vapors can ignite.

• Do not smoke, stri ke a match, or cause a spark in the vicinity of the battery. Battery gases can ignite.

• Avoid making accidental connection between battery terminals. Do not place uninsula ted m etal tools on the battery.

• When removing battery cabl es, remove ground cable firs t.

• Avoid sparks when connecting or disconnecting power

leads to battery.

• Be sure ignition is OFF, headlight s and other accessori es

are OFF and vehicle doors are closed before disconnecting battery cables. Thi s also helps prevent damage to

on-board computer systems.

• Always disconnect batt ery ground connections before

servicing electrical system components.

Explosion can cause injury.

WAR NI NG

!

Risk of poisoning.

• Use this equipment in locations with mechanical ventilation providing at least four air changes per hour. Engine

exhaust contains odorless lethal gas.

• Route exhaust outside while testing with engine running.

Poisoning can result in death or serious injury.

!

WARNING

Battery acid is a highl y corrosive sulfuric acid.

• Wear safety goggles and protective gloves, user and

bystan der. Everyday eyeglasses only have impact resistant lenses, they are NOT safety glasses.

• Make sure someone can hear you or is close enough to

provide aid when working near a battery.

• Have plenty of fresh wat er and soap nearby . If battery aci d

contacts skin, clothing, or eyes, flush exposed area with

soap and water for 10 minutes.

• Seek medical help.

• Do not touch eyes while working near battery.

Battery acid can burn eyes and skin.

Risk of fire.

• Wear safety goggles and protective clothing, user and

bystan der. Everyday eyeglasses only have impact resistant lenses, they are NOT safety glasses.

Safety – ii • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Page 7

Safety Precautions

• Do not position head directly over or in front of throttle

body. Do not pour gasoline down throttle body when

cranking or ru nning engi ne, when wor king wit h fuel delivery systems or any open fuel line. Engine backfire can

occur when air cleaner is out of positi on.

• Do not use fuel injector cleaning solvents when performing diagnostic testi ng.

• Keep cigarett es, sp a rks, op en f lame and o ther sources of

ignition away from vehicl e.

• Keep a dry chemical (Class B) fire extinguisher rated for

gasoline, chemical and electrical fires in work area.

Fire can cause death or serious injury .

Risk of flying particles.

Wear safety goggl es while using elect rical equipment . Electrical equipment or rotating engine parts can cause flying

particles.

Flying particles can cause eye injury.

Risk of burns.

Batteries can produce a short-circuit current high enough

to weld je w e lr y to me tal . Re move jew e lr y su ch a s ri n g s,

bracelets and watches before working near batteri es.

Short circuits can cause injury.

WARNING

!

Risk of burns.

• Do not remove radiator cap unless engine is cold. Pressurized engine cool ant may be hot.

• Do not touch hot exhaust systems, ma nifolds, engines,

radiators, sampl e probe, etc.

• Wear insulated gloves when handling hot engine components.

• Tester leads can become hot after extended testing in

close proximity to manifolds etc.

Hot components can cause injury.

Risk of expelling fue l, oil vapors, hot steam, hot toxic exhaus t

gases, acid, refri gerant and other debris.

• Wear safety goggles and protective clothing, user and

bystan der. Everyday eyeglasses only have impact resistant lenses, they are NOT safety glasses.

• Engine systems can malfunction expelling fuel, oil

vapors, hot st eam, hot toxi c exhaust gas es, aci d, ref rigerant and other debris.

Fuel, oil vapors, hot steam, hot toxic exhaust gases, acid,

refrigerant and other debris can cause serious injury.

The engine compartment contains electrical connections and

hot or moving parts.

• Keep yourself, test le ads, clothing and other obj ect s clear

of electrical connections and hot or moving engine parts.

• Do not wear watches, rings, or loo se fitting cl othing when

working in an engine compartment.

• Do not place test equipment or tools on fenders or other

places in the engine compartment.

• Barriers are recommended to help identify dan ger zones

in test area.

• Prevent personnel f rom walking through immediate test

area.

Contact with electrical connections and hot or moving parts

can cause injury.

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • Safety – iii

!

Page 8

Safety Precautions

!

WARNING

!

PR N DL 2

!

CAUTION

!

CAUTION

DANGER

!

Risk of injury.

• This equipment should be oper ated by qualified personnel only.

• Use this equipment onl y as described in this manual. Use

only the manufacturer’s recommended attachments.

• Do not operate equipment with a damaged cord or if the

equipment has been dropped or damaged, until it has

been examined by a qualified service representative.

Operation of this equipment by anyone other than qualified

personnel may result in injury.

Risk of unexpected vehicle movement.

• Block drive wheels before performing a test with engine

running.

• Unless instruct ed otherwise, set parking bra ke and pu t

gear selector in neut ral for standar d transmissions or park

for automatic transmissions.

• If vehicle has an aut omatic p ar king br ake r elease, disconnect release mech anism for testing and reconnect when

testing is completed.

• Do not leave a running engine unattended.

A moving vehicle can cause injury.

Risk of equipment or circ uit damage.

• Unless specific ally directed by the manufacturer, make

sure the ignition i s OFF before connect ing or disconnec ting connectors or any vehi cle electrical terminals.

• Do not create a short between bat tery terminals with a

jumper wire or tools.

Improper equipment use can cause equipment or circuit damage.

Misdiagnosis may lead to incorrect or improper repair and/or

adjustment.

Do not rely on errati c, questionable, or ob viously erroneous

test informati on or result s. If test in formation or re sults ar e

erratic, questionable, or obviously erroneous, make sure

that all connectio ns and da ta e ntr y infor mation are corr ect

and that the test proc edure was perform ed correctly . If test

information or resul ts ar e sti ll su spicious , do not use them

for diagnosis.

Improper repair and/or adjustment may cause vehicle or equipment damage or unsafe operation.

Some vehicles are equi pped wit h air bags. You must follow

vehicle service manual’s warnings when working around the

air bag components or wiring. If the service manual’s instructions are not follo wed, the air bag may open up unexpectedly,

resulting in perso nal injury. Note that the air bag can still open

up several minutes af ter the ignition key is off (or even if the

vehicle battery is disconnected) because of a speci al energy

reserve module.

Safety – iv • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Page 9

Table of Contents

Safety Precautions

Section 1 – Using This Manual

Section 2 – Getting Started

Vehicle Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Introduction to On-Board Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Diagnostic Link Connectors (DLC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

OBD II (J1962) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Ford Historic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

GM Historic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Chrysler Historic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Diagnostic Trouble Codes (DTCs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Section 3 – Using The Scan Tool

The Scan Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Scan Tool Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Connecting The Scan Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Vehicle Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Keep Current Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Changing the Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

User Responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Viewing Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

ToC

Page 10

Section 4 – Global OBD II Diagnostics

Manual Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

I/M Readiness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Read Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Pending Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

ToC

Erase Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

View Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

View Freeze Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

O2 Monitor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Non-Continuous Test s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

On-Board Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Record Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Vehicle Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Modules Present . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Review Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Playback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Print Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Printing Data (except Playback) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Printing Playback Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Code Lookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Section 5 – GM Diagnostics

GM Historic (OBD I) Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Manual Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Read Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Erase Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

View Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Record Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Review Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Field Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Code Lookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Print Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

GM Enhan c ed (O BD II) Diagn ostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Manual Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

I/M Readiness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Read Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Pending Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Erase Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

View Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

View Freeze Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

O2 Monitor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Non-Continuous Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

On-Board Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Record Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Vehicle Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Review Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Print Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Code Lookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

ii

Page 11

Section 6 – Ford Diagnostics

Ford Historic Self-Test Routines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Manual Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-1

Read KOEO Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-1

Read KOER Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-3

Review Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-5

Erase Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-6

Wiggle Test (EEC-IV Vehicles) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-7

Output Switch Test (EEC-IV Vehicles) . . . . . . . . . . . . . . . . . . . . . . . . .. 6-8

Cylinder (Cyl) Balance Test (EEC-IV Vehicles) . . . . . . . . . . . . . . . . . . .. 6-9

IVSC-Speed Ctrl (EEC-IV Vehicles) . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-11

STAR Test Mode (EEC-IV, MECS and MCU Vehicles) . . . . . . . . . . .. 6-12

Code Lookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-14

Print Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-14

DCL Data Functions (EEC-IV Vehicles) . . . . . . . . . . . . . . . . . . . . . . .. 6-15

Ford Enhanced (OBD II) Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Manual Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-18

I/M Readiness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-18

Read MIL DTC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-18

Read All DTC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-19

Pending Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-19

Erase Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-19

View Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-19

View Freeze Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-20

Quick Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-21

Quick Tests (7.3L Powerstroke Diesel Only) . . . . . . . . . . . . . . . . . . . .. 6-24

O2 Monitor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-26

Non-Continuous Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-26

On-Board Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-26

Record Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-27

Vehicle Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-27

Review Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-27

Print Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-27

Code Lookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-27

ToC

iii

Page 12

Section 7 – Chrysler Diagnostics

Manual Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Read Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Read Temporary Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Erase Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

ToC

View Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Record Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Switch Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Actuator Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Idle Speed Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Sensor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Controller Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Reset EMR Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Set Basic Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Review DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

Print Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Code Lookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Section 8 – Help & Troubleshooting

How to Use On-Line Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Scan Tool Does Not Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Using Non-OBD II Adapter Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Using J1962 (OBD II) or Chrysler LH Adapter Cable . . . . . . . . . . . . . . . 8-1

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Vehicle Communication Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Operating Error or Erroneous Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Tool Self-Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Display Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Keyboard Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Memory Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Printer Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Program Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Appendix A – Data Link Connectors

Appendix B – Glossary

iv

Page 13

Section 1 – Using This Manual

This manual cont ains in struct ions f or use and se tup of your sc an too l. A tabl e

of contents and gl ossary are provided to make this manual eas y to use.

Some of the inf ormation sh own in text or illust rations is obtaine d using optional

equipment. A

This section contains a list of conventions use d.

Safety Messages

Refer to “Safety Precautions” on page i.

Check Note

A check note provi des additional i nformation abou t the subject in t he preceding

paragraph.

Example

✓ Make sure the printer is turned on, on- line and connected.

Equipm ent Tips and Lists

Equipment tips and list s provide informat ion that applies to specifi c equipment.

Each tip is introduced by this icon

Example

❒ Observe all vehicle and/or equipment manufacturer’s cautions and warn-

ings when testing with the scan tool.

Equipment Damage

Situations aris e during t esti ng that coul d damag e the vehic le or the test equipment. The word IMPORTANT signals these situat ions.

Example

Sales Representa tive can determine option availabi li ty.

:

❒ for easy identification.

:

:

1

IMPORTANT

Failure to follow these instructions could damage the scan tool.

Functions and Selections

Diagnostic and tool functions performed by the scan too l ar e highlighted in

bold.

Example

The View Data function al lows you to view the vehicle’s Parameter Identification (PID) data in real time.

:

Menus

The menus on the scan tool display ar e refere nced in the pr ocedu res and are

highlighted in

Example

When the

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 1 – 1

bold-italic

text.

:

OBDII Function List

menu displays, the scan tool is ready for use.

Page 14

Using This Manual

Questions and Responses

Messages and user responses are CAPITALIZED.

The Scan Tool displays the Pending DTCs or a message stating SYSTEM

PASS: NO FAULT DETECTED.

Manual References

1

Used to reference other sections of the manual. Reference s include the “Title”

and page number (secti on-page).

For more information on DTCs, refer to “Diagnostic Link Connectors (DLC)”

on page 2-3.

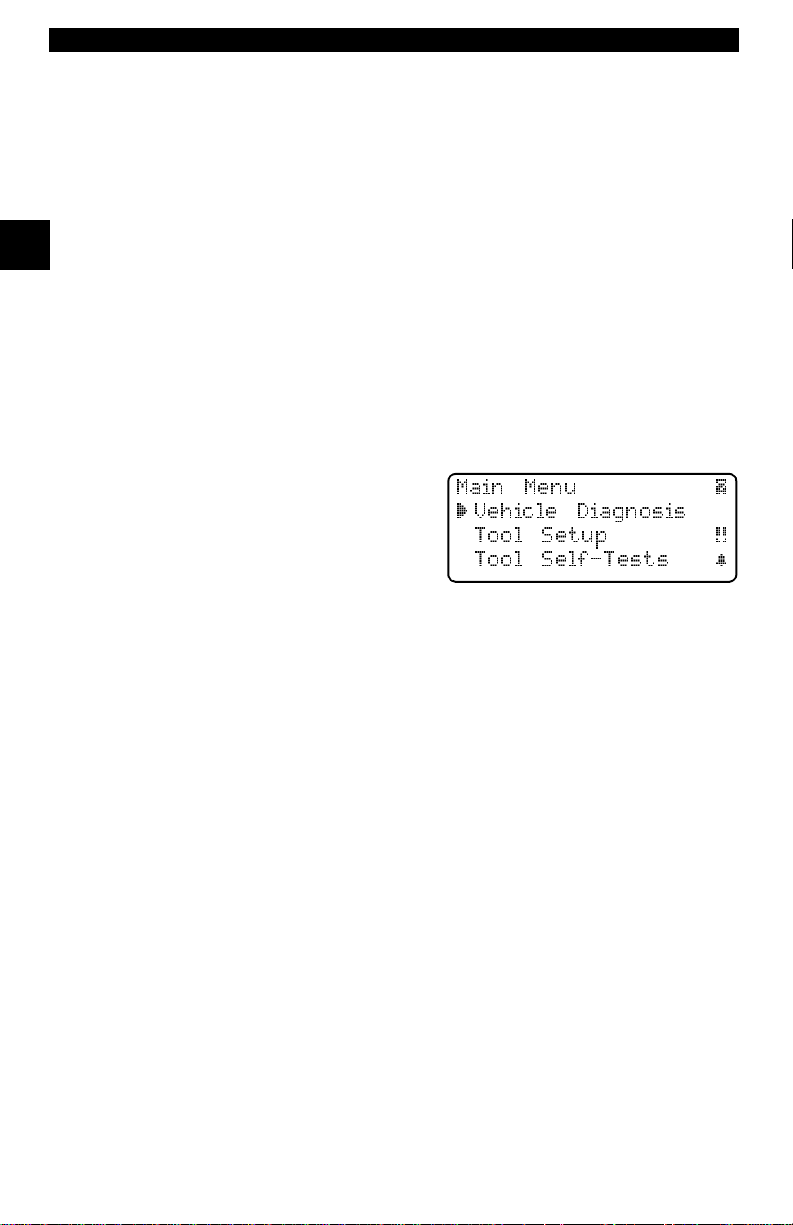

Screens

Certain Help mess ages, information, and dat a that are displayed on the scan

tool are also shown in graphical text boxes. The screens are presented as

examples and may change as the software is updated.

Example

Example

Example

:

:

:

Main Menu |

` Vehicle Diagnosis

Tool Setup [

Tool Self-Tests ~

1 – 2 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Page 15

Section 2 – Getting Started

The Professional Enhanced Scan Tool was developed by experts in the automotive servi ce industr y to help diagnose ve hicles and assist i n troubl eshooting

procedures. The tool monit ors vehicle e vents an d retrieves co des from t he vehicle computer’s memory to pinpoint problem areas.

All information, il lustrations and specifications contained in this manual are

based on the latest information available from indust ry sources at the time of

publication. No warranty (expressed or implied) can be made for its accur acy

or completeness , nor is any r esponsibilit y assumed by th e manufacturer or anyone connected with it for loss or damages suffered through reli ance on any

information conta ined i n t his manual o r misuse of acco mpan yin g produc t. The

manufacturer res erves the right to make changes at any time to this manual or

accompanyin g product without obligation to notify any person or organization

of such changes.

V EHICLE SERVICE INFORMATION

The following is a list of publi shers who have manuals containing el ectronic

engine control diagnost ic informat ion. Some m anuals may be availabl e at auto

parts stor es or your local public library. For others, you need to write for availability and pricing, specifying the make, model and year of your vehicle.

2

Chilton Book Company

Chilton Wa y

Radnor, PA 19089

Haynes Publications

861 Lawrence Drive

Newbury Park, CA 91320

Cordura Publications

Mitchell Manual s, Inc.

Post Office Box 26260

San Diego, CA 92126

Motor ís t Au to R ep a i r M a nu a l

Hearst Company

250 W. 55th Street

New York, NY 10019

General Motors Corporation:

Buick, Cadillac, Chevrolet, GEO, GMC,

Oldsmobile, & Pontiac

Helm Incorporated

Post Office Box 07130

Detroit, MI 48207

Saturn:

Adistra Corporation

c/o Saturn Publicat ions

101 Union St.

Post Office Box 100 0

Plymouth, MI 48170

Ford Motor Company:

Ford, Lincoln, & Mercury

Ford Publication Depar tment

Helm Incorporated

Post Office Box 07150

Detroit, MI 48207

Chrysler Corporation:

Chrysler, Plymouth, & Dodge

Chrysler Motors Service Training

26001 Lawrence Avenue

Center Line, MI 48015

INTRODUCTION TO ON-BOARD DIAGNOSTICS

Suitable manuals have titl es such as:

•“Electronic Engine Controls”

•“Fuel Injection and Feedback Carburetors”

•“Fuel Injection and Electronic Engine Controls”

•“Emissions Control Manual”

... or sim ila r titl es

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 2 – 1

Page 16

Getting Started

The original on-board diagnostics (OBD I) lacked consistency in communication and interfac e while allowin g different interpr etations am ongst vehicle m anufacturers. For d and Chr ysler used different types of engine cont rol comput ers

and data link conn ectors, and GM varied the tr ouble codes and communicat ion

protocols from year-to-year.

The tables belo w highl ight changes for GM, Ford, and Chrysl er. If this seems

confusing; d on’t worry. Your tool makes it easy. Based on the VI N information

selected during Scan Tool setup, the processor is aut omatically recogni zed. All

you have to do is choose the correct adapter cable and jumper wires (if necessary). Details on adapter cables and jumper wires may be found in “Diag-

nostic Link Connectors (DLC)” on page 2-3.

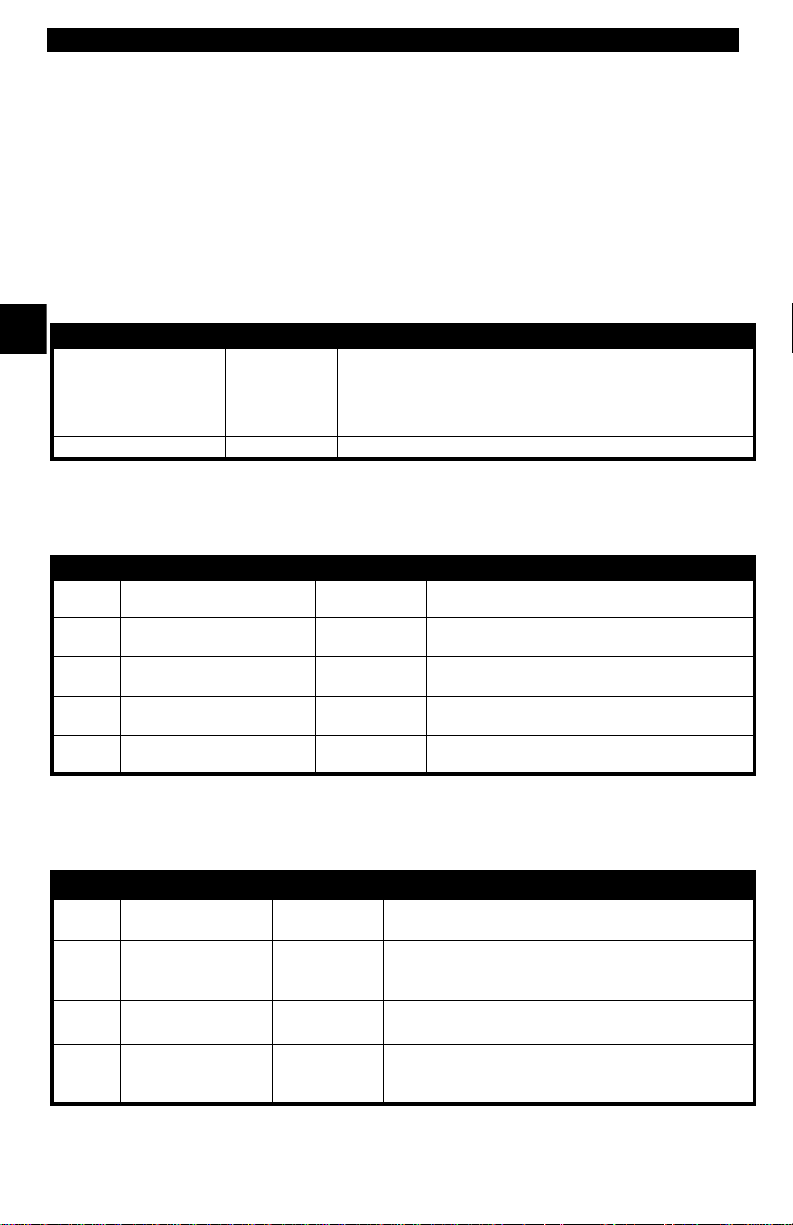

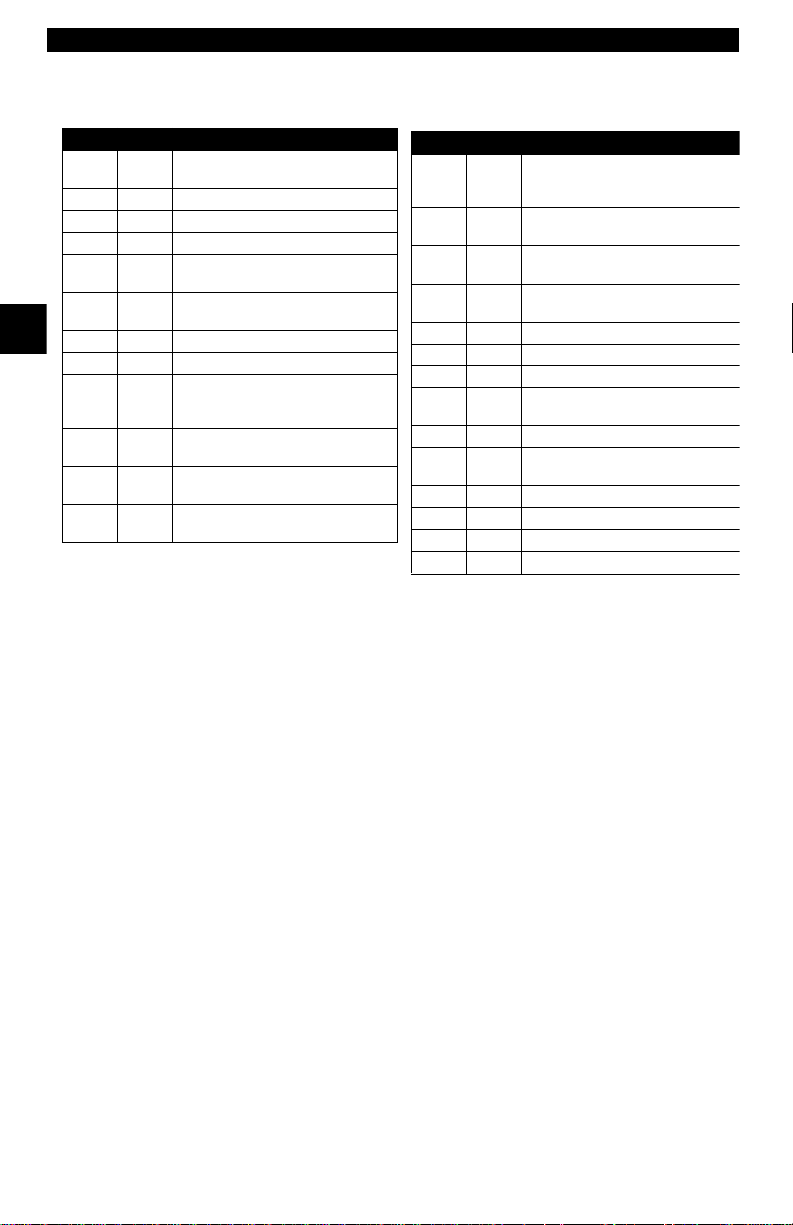

GM On-Board Diagnostics

2

System Years Description

Most vehicles u sed the 12 -pin AL DL (Asse m bly Li ne Data Li nk)

OBD I Control Module

OBD II Control Modul e

*

OBD II system used in certain 1994-1995 vehicles equipped with a 2.2L, 2.3L, 3.8L, 4.3L or 5.7L engines.

1981–199 5

1994*-Presen t Complies with OBD I I regulation s and us e s the J1 962 DLC.

located under the d ash on the driver side. S om e 94 -95 vehicles

used the 16-pin O B D II (J19 62) da ta link c onn ect or (DL C ), but

use the Historical application software. Refer to the vehicle’s

Vehicle Emission Control Information label.

Ford On-Board Diagnostics

System Long Na me Years Description

MCU

Microproc essor C o ntrol Unit 1980 –1991

EEC-IV

* EEC-V OBD II system used in 1994-1995 vehicles equipped with a 3.8L or 4.6L engine.

Elec tronic Engine Control,

Fourth gene ration

Mazda Electronic Control

MECS

System

Elec tronic Engine Control,

EEC-V

Fifth generation

Powertrain E lectron ic Co n-

PTEC

troller

1984 –1995

1988 –1995

1994* – present

2000 – presen t

Used in police vehicles, contai ning carbureted

engines. Uses the MCU DLC.

Most Ford ve hicles e quipped with North Am erican

engines. Uses the EEC- IV DLC.

Vehicles equ ipped with Mazda-sourced en gin es.

Uses MECS 6- pin and 17-pin DLCs.

Complies with O B D II regulations an d uses the

OBD II J1962 DLC.

Complies with O B D II regulations an d uses the

OBD II J1962 DLC.

Chrysler On-Board Diagnostics

System Long Na me Years Description

Single Module Engine

SMEC

Controller

Single Board Engine

SBEC

Controller

OBD II

OBD II Pow ert rain

PCM

Control Module

Jeep/T ruck Engi ne

JTEC

Controller

* In 1989, the SBEC system was installed in selected vehicles with 3.0L V6 engines.

** Some vehicles in 1995 were equipped with the OBD II PCM.

1989–199 0

1989*–19 95

1995**– present

1996– present

Used a 6-pin Serial Communication Interface (SCI) DLC

and has bidirectiona l cap ability.

Used two types of DLCs: a 6-pin SCI and a 6-pin LH

series.

The first to allow a tool to reset the EMR light on trucks.

Complies with O B D II regulations an d uses the O B D II

J1962 DLC .

Complies with O B D II regulations an d uses the O B D II

J1962 DLC .

The JTEC system is used on light-duty trucks and Jeeps

2 – 2 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Page 17

Getting Started

OBD II stands for O n-Boar d Diagnos tics ver sion I I. OBD I I is a syste m tha t the

Society of Autom otive Engineers (SAE) dev eloped to standardize automotive

electronic diagnosis. Technicians now can use the same tool to test any OBD

II compliant vehic les without special adapt ers. The SAE establish ed guidelines

that provide:

• a universal diagnostic test connector, c alled the data link connector (DLC),

with dedicated pin assi gnm ents.

• a standardized location for the DLC, visible under the dash on the driver’s

side.

• a standa rdi zed list of diagnostic trouble codes (DTCs) used by all manufacturers.

• a standardized list of parameter identification (PID) data used by all manufacturers.

• the ability of the vehicle system to recor d a freeze frame of the operati ng conditions when a fault occurs.

• expanded diagnostic capabilities that records a code whenever a condition

occurs that ef fects vehicle emissions.

• the ability to clear stored codes from vehicle memory with the scan tool.

In addition, SAE has published hundreds of pages of text defining a stan dard

communications protocol that establishes the hardware, software, and cir cuit

parameters of OBD II systems. Unfortunately , vehicle manufacturers have different interpr etations of this standard comm unications prot ocol. As a result, the

generic OBD II communic ations scheme us ed will vary, depending on t he vehicle.

SAE publishes r ecom m endations, not laws, bu t t he Environmental Protection

Agency (EPA) and California Air Resources Board (CARB) made many of

SAE’s recommenda ti ons legal requirements that vehicle manufacturers were

required to phase in over a three-year period. Beginni ng in 1994, vehicle s with

a new engine m anagement c omputer – about 1 0% of ea ch manufact urers fl eet

– were supposed to comply with O BD II standards. For 1995, OBD II systems

were to appear on about 40% of t he new vehic les sold in t he USA. Some of the

1994-1995 OBD II systems were not fully compliant, so the Government

granted waivers to give manufacturers time to fine-tune their systems. Beginning in 1996, m ost of the new vehicles sold in the USA were fully OBD II compliant.

2

DIAGNOSTIC LINK CONNECTORS (DLC)

The Data Link Connector (DLC) allows the scan to ol to communicate wit h the

vehicle’ s com puter(s). Before OBD II, manufactur ers used different data link

connectors to communicate with the vehicle. The proper DLC adapter cable

must be used to connect the tool to the ve hicle. Also , the vehi cle’s DLC may be

found in several different places and have many different configurations. The

following descri bes the DLCs used by Ford, GM and Chrysl er. The DLC lo cation

and types for domestic vehicles can be looked up in the charts in “Appendix

A - Data Link Connectors".

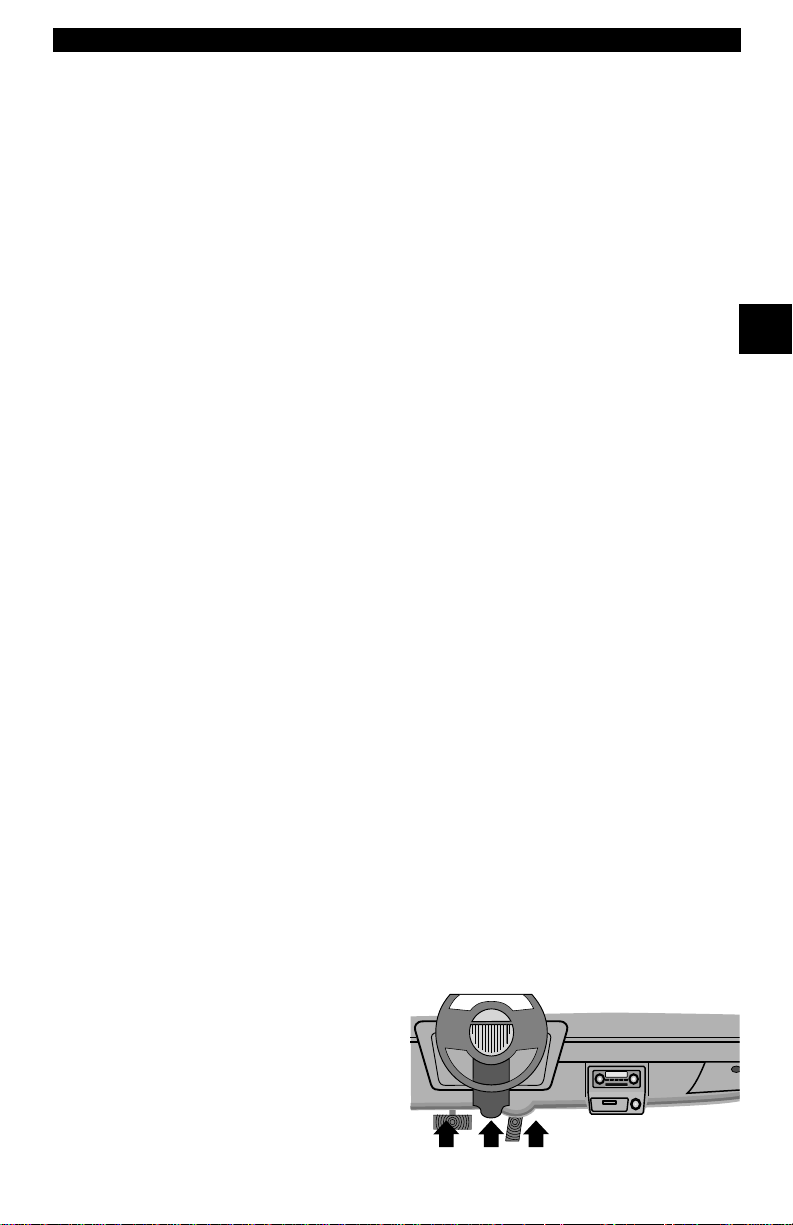

OBD II (J1962)

Beginning in 1996, vehicl es sold in

the United States use the J1962

(OBD II) DLC, a term taken from a

physical and el ectrical speci fication

number assigned by SAE (J1962).

The DLC should be located under

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 2 – 3

Page 18

Getting Started

the dashboard o n t he dri ver si de of the vehicl e. I f the DLC is n ot locat ed under

the dashboard as stated, a decal describing its location should be attached to

the dashboard in the area the DLC should have been located.

Because the OBD II J196 2 conn ector ha s power and ground , yo u only need a

single cable conn ection to the tool for both power and tool communi cations.

Attach the OBD II adapter cable to the extender cabl e, both supplied with the

tool, to connect the t ool. Certain pins in the connector are reserved.

2

Ford Historic

IMPORTANT

EEC-IV/MCU

1 - Manufacturer Reserved

2 - J1850 Bus+

3 - Manufacturer Reserved

4 - Chassis Ground

5 - Signal Groun d

6 - CAN High, J-2284

7 - K Line, I SO 914 1- 2 & IS O/ DIS 14 230- 4

8 - Manufacturer Reserved

9 - Manufacturer Reserved

10 - J1850 Bus

11 - Manufacturer Reserved

12 - Manufacturer Reserved

1

9

13 - Manufacturer Reserved

14 - CAN Low, J-2284

15 - L Line, I SO 91 41-2 & ISO /DIS 14 230- 4

16 - Battery Power

8

16

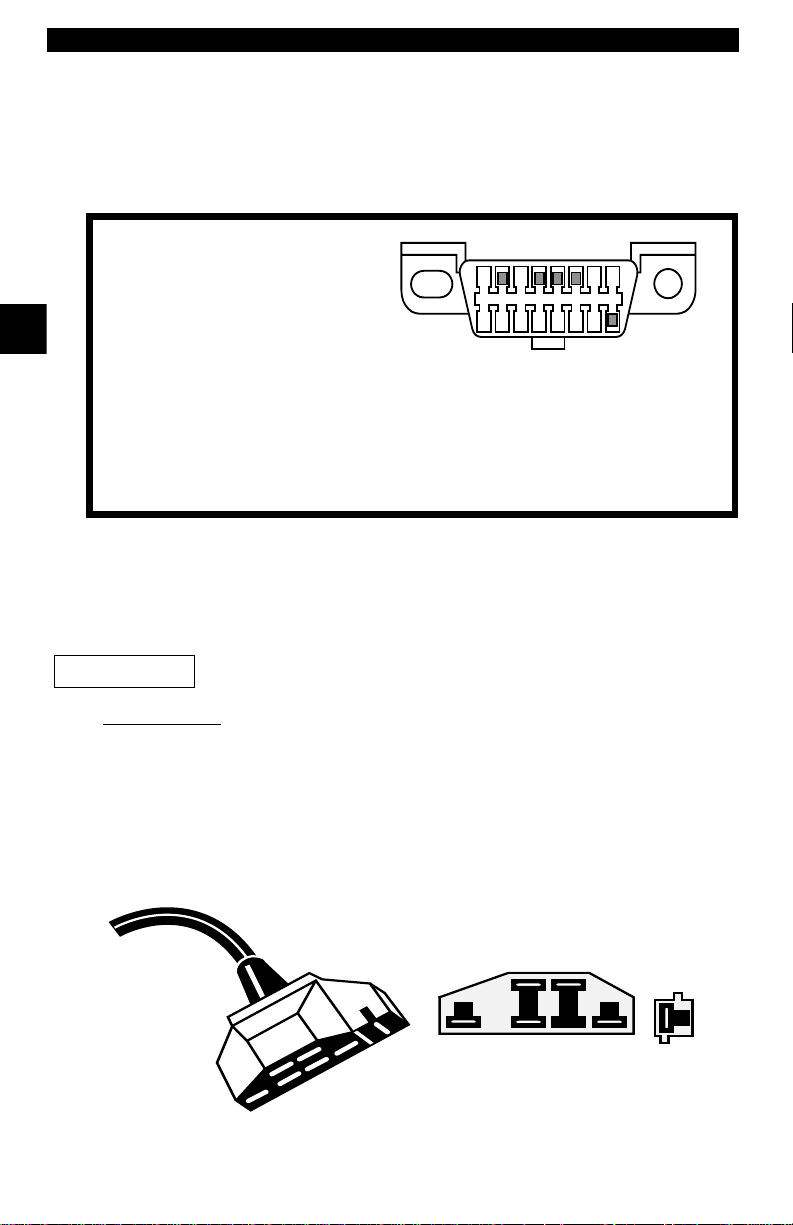

Ford used three types of DLCs with their historic (OBD I) systems. Refer to

“Appendix A - Data Link Connectors" for the adapte r cable neede d for your

vehicle.

Use the Battery Power cab le to provi de power to the sca n tool

for all systems.

The EEC-IV/MCU DLC is a large si x-side d conn ector wi th a pi gtai l conne cto r .

The pigtail connector is not used on MCU vehicles – leave the pigtail unattached. The EEC-IV/MCU cable adapter is included with the scan tool.

Cable Adapter

EEC-IV/MCU

To Scan

Tool

Vehicle DLC

EEC-IV/MCU

STI Pigtail

EEC-IV

only

2 – 4 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Page 19

Getting Started

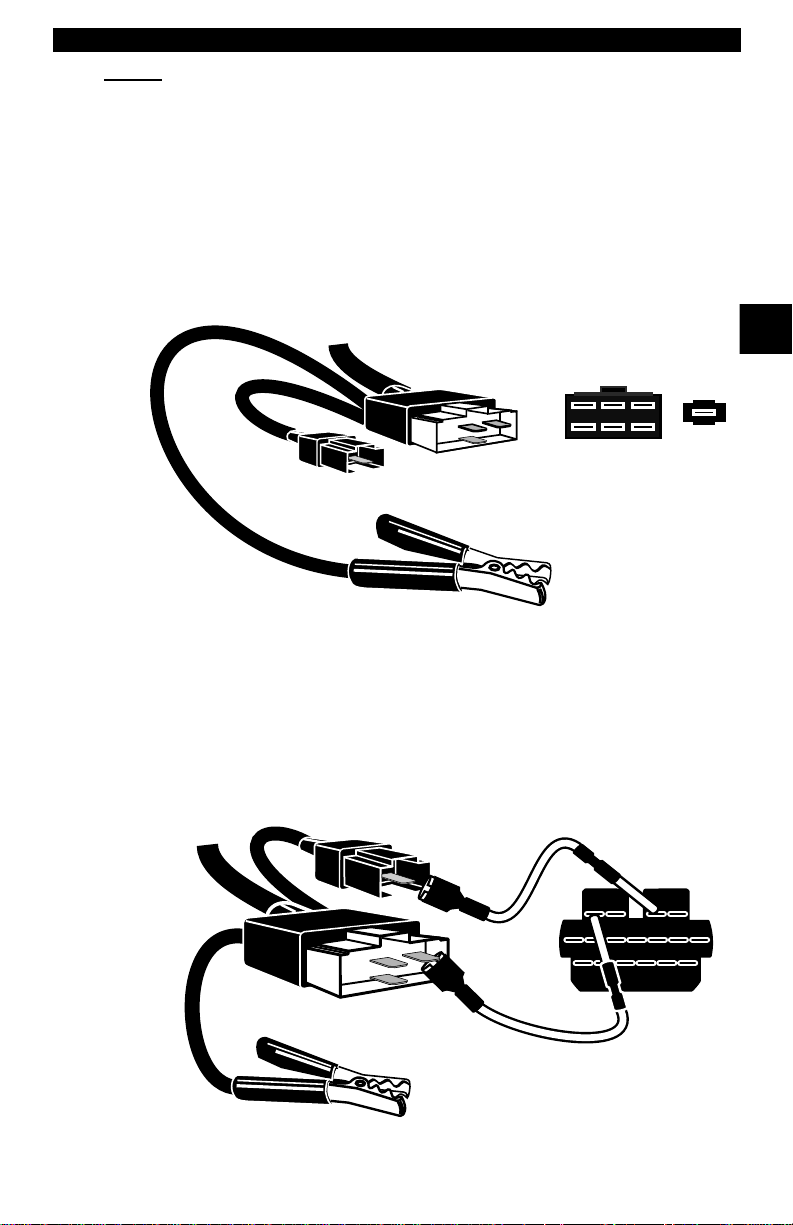

MECS

MECS vehicles (1988 –1995) use either a 6-pin (with pigtail) or a 17-pin DLC.

Use the MECS 6-pin adapte r cable k it (P/N 9603) fo r both con figur ation s. The

MECS adapter cable ki t includes jumpe r wires to connect to the MECS 17- pin

DLC. The MECS adapter cable kit is not included with this tool. It is available

through your dealer. Us e the following diagram s to connect the adapter cable.

6-Pin MECS

17-Pin MECS

To

Scan Tool

Cable Adapter

6-Pin MECS

P/N 9603

To Scan

To ol

STI Pigtail

Adapter Cable

6-Pin MECS

P/N 9603

STI Pigtail

Vehicle DLC

6-Pin MECS

2

Pigtail

6

5

4

3

2

1

Clip to good

Vehicle ground

Vehicle DLC

17-Pin MECS

4

1

3

2

6

5

STO

Clip to good

vehicle ground

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 2 – 5

Page 20

Getting Started

IMPORTANT

2

MECS Ford Probe

Certain Ford Probes have a WHITE TACH CONNECTOR

located very close to the 6-pi n Self-Test connec tor and

bundled in the same wiring harness. This is NOT the STI

(Self Test Input) Pigtail.

Connect the pigtail to the BLACK STI connector located fart her back on the wire

harness. If the tool is connec ted to the WHITE Tach co nnector , serious damage

will result and may void warranty. Refer to the illustration.

Cable Adapter

6-Pin MECS

P/N 9603

STI

Pigtail

Vehicle DLC

6-Pin MECS

To

Scan

Tool

GM Historic

Prior to1996, m ost GM vehicles us ed the 12-pin Assem bly Line Diagnosti c Link

(ALDL) DLC. The GM ALDL ca ble kit incl udes th e ALDL adapter and cigar ette

lighter power cable. This adapter cable is included with t he scan too. In 1994

and 1995, certain GM vehicles use the J1962 (OBD II) DLC, but are not OBD

II compliant. Refer to “Appendix A - Data Link Connectors".

IMPORTANT

The ALDL DLCs are usually located unde r

the dashboard on the driver’ s side.

On Corvettes & Fieros, the DLC may be

located in the center console behind the

ashtray . Refer to vehicle service manual for

exact locati on. I t may be in full view, or it

may be recessed behind a p anel. A n opening in the panel sho uld allow access to the recessed connect or.

Windshield

Wiper

Motor

WHITE

Tach

Connector

6

5

4

3

2

1

6-Pin MECS

BLACK STI

Connector

6-Pin MECS

DO NOT USE!

Clip to good

vehicle ground

Use the Battery Power cable to provide 12V to the tool.

ALDL

FGEHDJCKBLA

M

2 – 6 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Page 21

Getting Started

Chrysler Historic

Prior to 1996, most Chrys ler vehicl es use d either the SCI or LH DLC. Refer to

“Appendix A - Data Link Connectors" for DLC type and lo cation. The SCI

adapter cable is i ncluded with th e scan tool. The LH adapte r cab le (P/ N 9605)

can be purchased from your dealer.

IMPORTANT

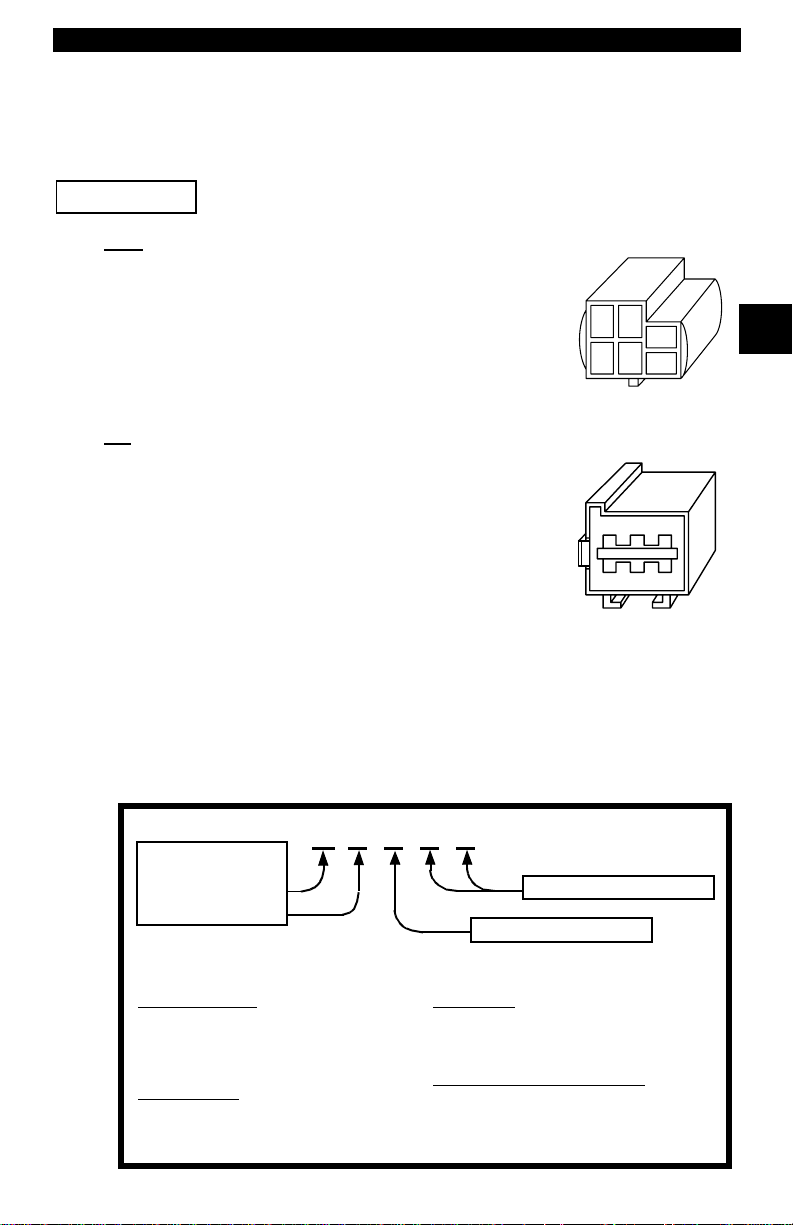

SCI

The SCI (serial communications interface) DLC is a

6-pin connector located in the engine compartment.

The adapter cable to be used on these vehicl es is supplied with the tool. This ca ble is labeled CHRY on the

15 pin DB styl e connec tor an d SCI on the veh icle end.

Use the Battery Power cable to provide 12V to the tool when

using the SCI adapter cable.

SCI

2

LH

The DLC is used on LH platform vehic les. The LH

style DLC is a small, blue, rectangular 6-pin connector located in the pas senger comp art ment belo w the

dashboard to the right of the steering column.

The LH Adapter Cable (P/N 9605) is optional and

must be purchased separately.

DIAGNOSTIC TROUBLE CODES (DTCS)

Diagnostic T rouble Codes (DTCs) consist of a five-digit alphanumeric code.

The DTC format and gener al code typ es are shown bel ow . When the on-b oard

computer recogni zes and identifi es a probl em, a DTC for t hat fault is stor ed in

memory. These codes are intended to help you determine the root cause of a

problem.

Bx - Body

Cx - Chassis

Px - Powert rain

Ux - Network Comm.

x = 0, 1, 2 or 3

Example:

P0101 - Mass or Volume Air Flow Circuit Range/Performance Problem

Powertrain Codes

P0xxx - Generic (SAE)

P1xxx - Manufacturer Specific

P2xxx - Generic (SAE)

P30xx-P33xx - Manufacturer Specific

P34xx-P39xx - Generic (SAE)

Chassis Codes

C0xxx - Generic (SAE)

C1xxx - Manufacturer Specific

C2xxx - Manufacturer Specific

C3xxx - Generic (SAE)

P 0 1 0 1

Body Codes

B0xxx - Generic (SAE)

B1xxx - Manufacturer Specific

B2xxx - Manufacturer Specific

B3xxx - Generic (SAE)

Network Communication Codes

U0xxx - Generic (SAE)

U1xxx - Manufacturer Specific

U2xxx - Manufacturer Specific

U3xxx - Generic (SAE)

Specific Fault Designation

Vehicle Specific System

LH (P/N 9605)

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 2 – 7

Page 22

Getting Started

y

Within each general category, th e DTCs are assi gned to specific ranges that

cover certain vehicle systems.

Lower Upper Assigned DTC Syste m

Fuel Air Metering Auxiliary

Emission Controls

Fuel Air Metering

Ignition System or Misfire

Auxiliary Em is sion Contr o ls

Vehicle Speed Idle Speed Con-

trol Auxiliary Inputs

Computer and Auxiliary Out-

puts

Transmission

Hybrid Propulsion

Manufacturer Control Fuel & Air

Meterin g, Auxil ia ry Emis sion

Controls

Manufacturer Control Fuel & Air

Metering

Manufacturer Control Ignition

System or Misfire

Manufacturer Control Auxiliary

emission Controls

2

P0000 P00FF

P0100 P02FF

P0300 P03FF

P0400 P04FF

P0500 P05FF

P0600 P06FF

P0700 P09FF

P0A00 P0AFF

P1000 P10FF

P1100 P12FF

P1300 P13FF

P1400 P14FF

J2012 and ISO 15031-6 are standards for all DTCs, established by the SAE,

International Organization for S tandardization (ISO) and other governing bodies. Codes and the definitions assigned by this specification are known as

Generic OBD II codes. OBD II requi res compliance of this standard, and has

made it a standard for all cars , light t rucks , APVs, MPVs, an d SUVs so ld in t he

U.S. Codes not reserved by the SAE are reserved for the manufacturer and

referred to as Manuf acturer Specific.

Lower Upper Assigned DTC Syste m

Manufacturer Cntrl Veh.Spd.

P1500 P15FF

P1600 P16FF

P1700 P19FF

P2000 P22FF

P2300 P23FF

P2400 P24FF

P2500 P25FF

P2600 P26FF

P2700 P27FF

P2900 P32FF

P3300 P33FF

P3400 P34FF

U0000 U00FF

U0100 U02FF

Idle Speed Cont rol Auxiliary

Inputs

Manufacturer Control Auxiliar

Inputs Auxiliar y Outputs

Manufacturer Control Transmission

Fuel Air Metering Auxiliary

emission Controls

Ignition System or Misfire

Auxiliary Emission Controls

Auxiliary Inputs

Computer and Aux iliary Out -

puts

Transmission

Fuel Air Metering Auxiliary

Emission Controls

Ignition System or

Cylinder Deactivation

Network Electrical

Network Communication

2 – 8 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Page 23

Section 3 – Using The Scan Tool

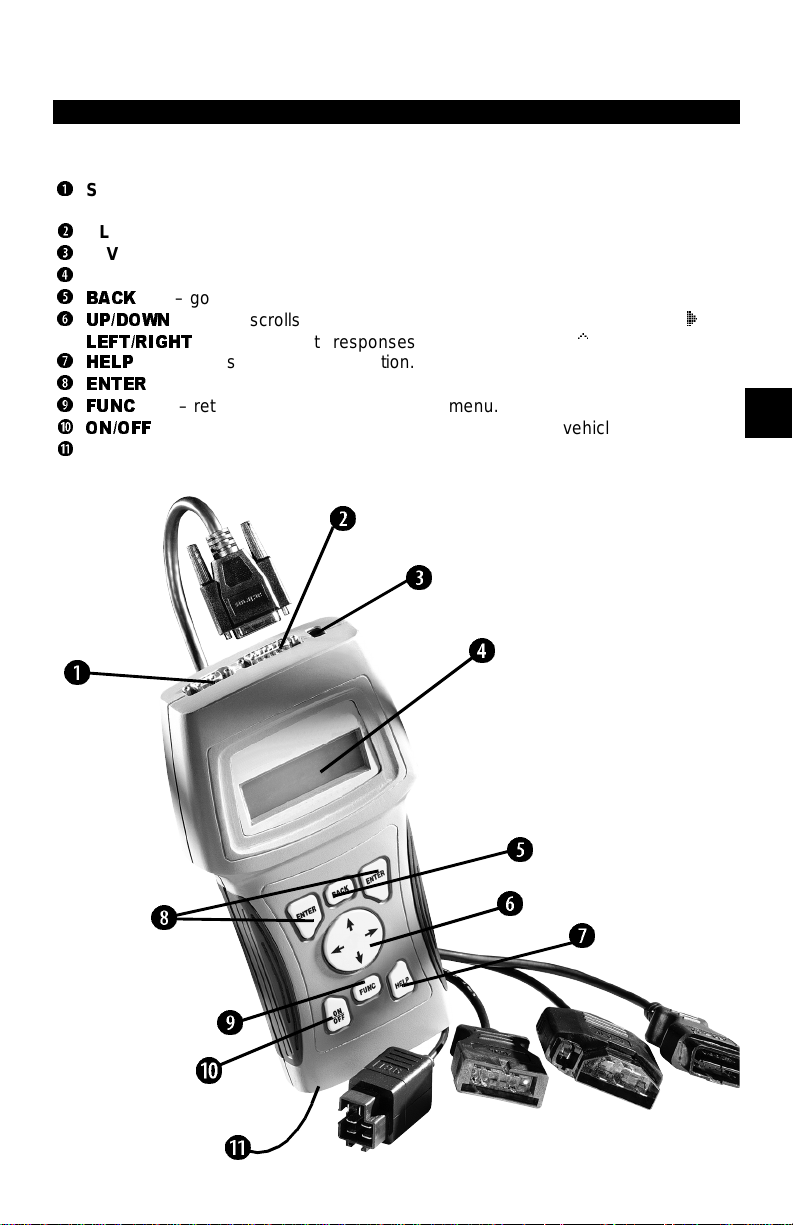

THE SCAN TOOL

B

Serial Port (DB9 Male Connector) – provides a serial RS232 connection for a prin ter

and for updating the soft ware.

C

DLC Port (DB15 Male Connector) – provides connection for vehicle interface.

D

12V Power Jack

E

LCD Display – backlit, 4 li ne x 20 character with contrast adjustment.

F

BACK

key – goes to the previous screen or level.

G

UP/DOWN

LEFT/RIGHT

H

HELP

I

ENTER

J

FUNC

a

ON/OFF

b

Battery compartment cover.

B

arrows – scrolls UP or DOWN and moves the selection pointer (`).

key – accesses the Help Functi on.

arrows – selects responses and moves cursor (^) in code lookup.

key – selects displa yed items.

key – returns back to a function li st or menu.

key – turns power ON/OFF when not connected to vehicle.

C

D

E

3

F

I

G

H

j

a

b

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 3 – 1

Page 24

Using The Scan Too l

Specifications

Display: Backlit LCD, 4 line, 20 column, contrast adjust

Operating Temperature: 0 to 50°C (32 to 122°F)

Storage Temperature: -20 to 70°C (-4 to 158°F)

Intern a l P o w e r: 6-AAA cells

External Power: 6.5 to 15 .5 Volts

✓ Most vehicle control modul es require at least 8.0 V to operate properly.

Power Dissipation: 3.5 Watts maximum

Dimensions: Height

1.625" 5.25" 9.75"

41 mm 133 mm 248 mm

Weight: 3.16 lb s (1432 g)

Accessories

3

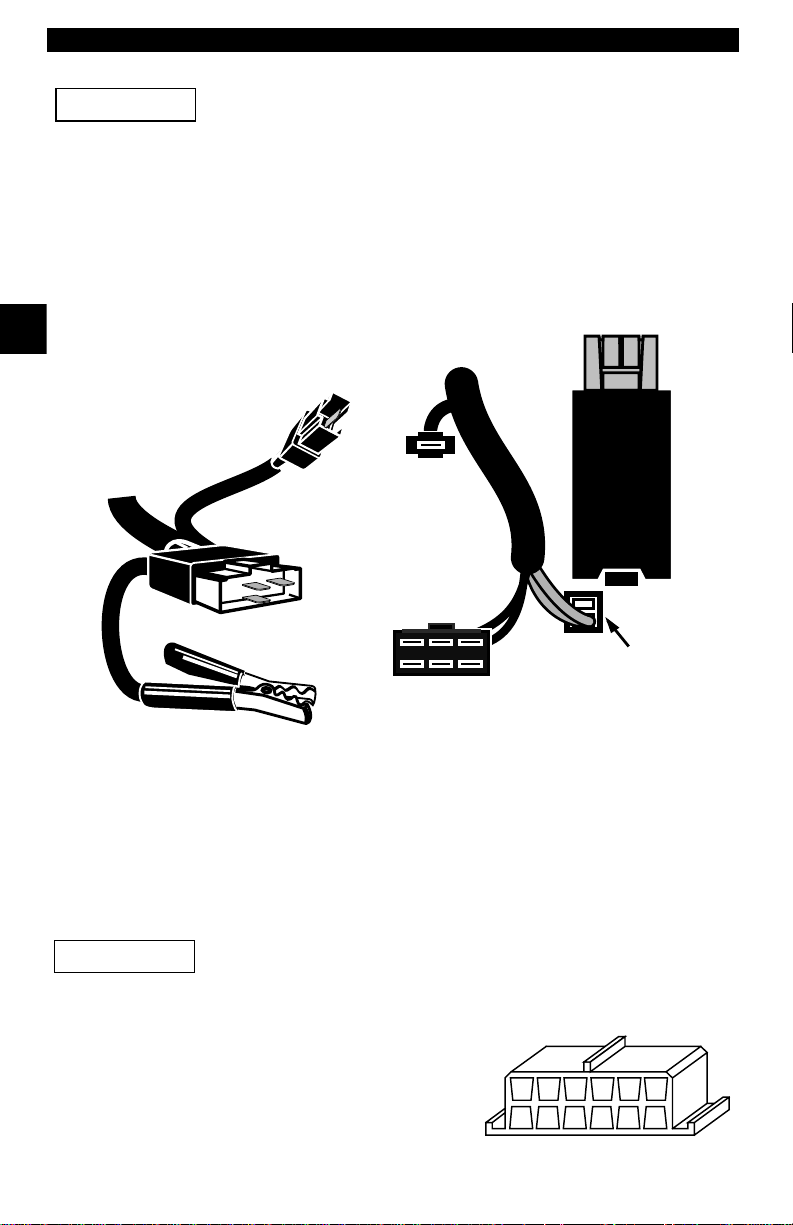

Stan dard 8 ft Extender Cable

Battery Power Cable (includes cigarette lighter adapter)

– included with adapter cable kits

– Battery Clip Adapter — Optional

Adapter Cables: Standard OBD II (J1962) cable — Included

GM ALDL cable kit — Included

Ford EEC-IV/MCU cable kit — Included

Chrysler SCI cable kit — Included

9605 Chrysler LH cable kit — Optional

9603 Ford Probe/MECS cable kit — Optional

Optional / Replacement Parts are available from the:

• dealer where you originally purchased your tool.

• manufactur er cont act cust omer se rvice at 1-800-228-7667 (8:00 – 6:00 EST

Monday – Friday) or send an email to tech_support@actron.com.

Display

The scan tool uses a 4 line by 20 character, back-li t Liquid Crystal Display

(LCD). The l arge viewing area di splays mess ages, ins tructio ns, and di agnostic

informatio n. The contrast can be adjusted.

Seven charact ers help you nav igate and

operate the scan too l:

|

appears in upper right corner o f display to indicate Hel p is available.

`

identifies the selection.

[

indicates additional information is

available on the ne xt screen.

]

indicates additional information is available on the previous screen.

«

identifies selected items in data lists.

~

Bell in lower right corner means the sound alert is on or active.

Low battery symbol will appear i n bottom rig ht-hand corner of the screen at

power-up if the inte rnal batteries need replacement or are not installed.

Keyboard

The scan tool’ s software is designed for ease in operat ing and navigating

through menus. Do not use s olvents such as alco hol to cl ean the keyp ad or display . Use a mi ld nonabrasive de tergent and a soft cot ton cloth. Do not soak th e

keypad as water might find its way inside the scan tool.

3 – 2 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Width Length

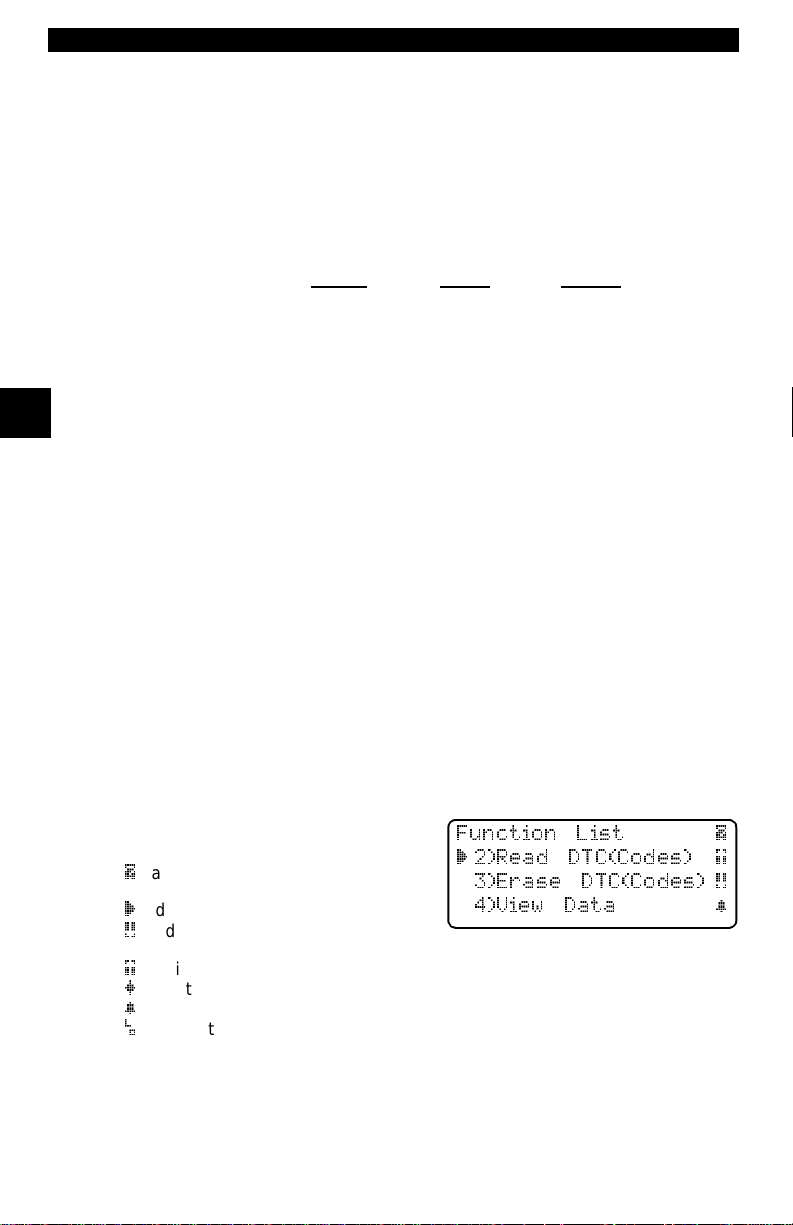

Function List |

` 2)Read DTC(Codes) ]

3)Erase DTC(Codes) [

4)View Data ~

Page 25

Using The Scan Tool

Power

✓ Refer to “Scan Tool Does Not Power Up” on page 8-1 if you encounter

problems.

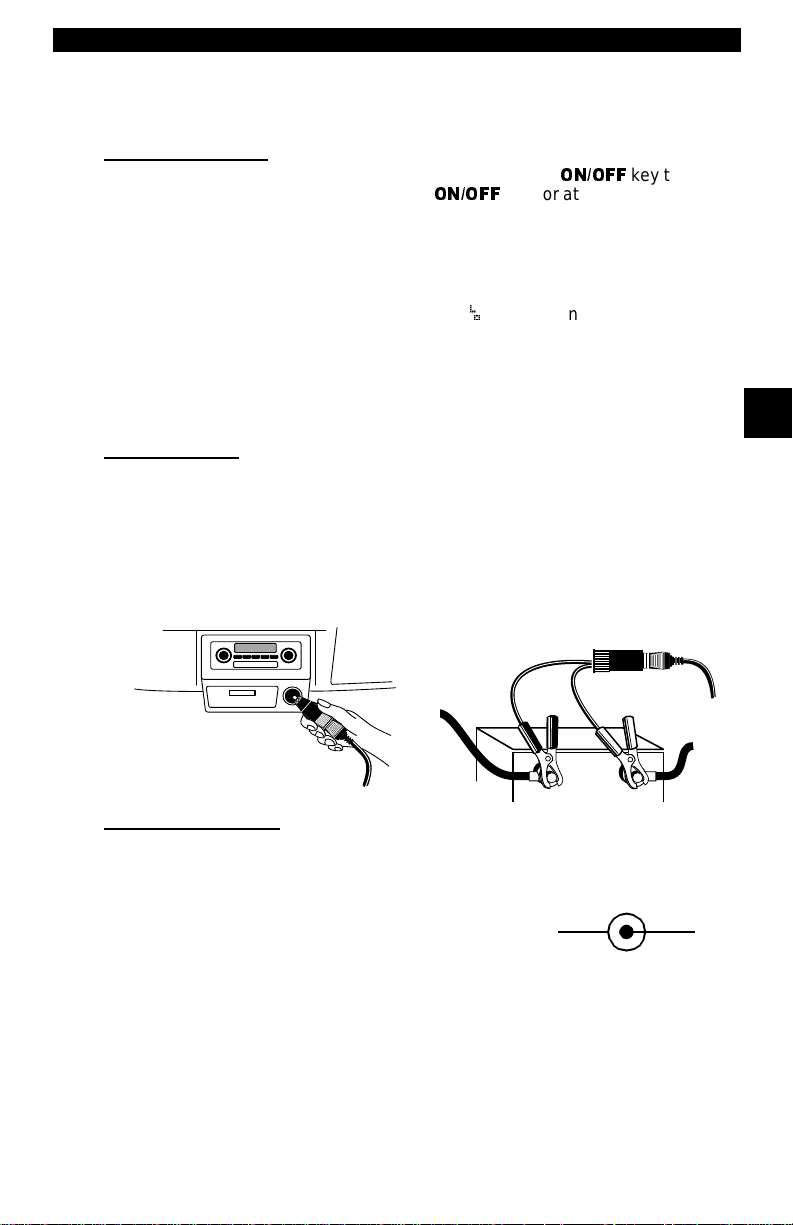

Internal Batteries

When the scan tool is no t connect ed to the ve hicle , the

the scan tool . Press and hold do wn th e

turn ON the scan tool.

To conserve battery power, the scan tool disab les the display’s back-lighting

and turns OFF after a period of inactivity.

Each time the s can tool is p owere d up, t he v olt age of t he b atter ies i s checke d.

If the voltag e is low, t he Low Battery Symbol (

batteries using the instructions provided in “Battery Replacement” on

page 4-3.

ON/OFF

) displays on the screen. Replace

ON/OFF

key for at l east o ne se cond to

✓ If the scan tool wi ll not be used for an extended period of time, rem ove the

batteries to prevent electrolyte leakage from damaging the battery compartment.

Vehicle Power

When using the OB D II J1962 or Chry sler LH adapte r cabl es, th e powe r to t he

tool comes from vehicle Dat a Link Connector (DLC). All other vehicles will

require power connec tion to the cigarette light er, acces sory plug, or the vehicl e

battery using battery clip adapters. If you are unsure of what DLC adapter to

use, then refer to “Appendix A - Data Link Connectors".

Some vehicle ci garette lighters are not po wered when the ignit ion is i n the OFF

position. Therefore, you may wish to use battery clip adapt ers.

Batter y Clip A da p ter (op t io na l)

key turns ON

3

Cigarette Lighter Adapter

AC Power Adapter

An AC power adapter (not incl uded) can be used to power the t ool when reprogramming from a per sonal comput er or off-vehi cle reviewing of codes and print ing. 12V AC-DC converters are available at most PC and electronic stores.

The tool is equipped to accept any 110 Vac - 12

Vdc wall adapter wit h the following specificat ions:

• 300 mA minimum current unregulated wall

power adapter.

• Adapter Dimensions: 5.5 mm Outside Diameter

• 2.5 mm Inside Diameter

• The Inside Tip is positive (+).

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 3 – 3

12 VGND

Page 26

Using The Scan Too l

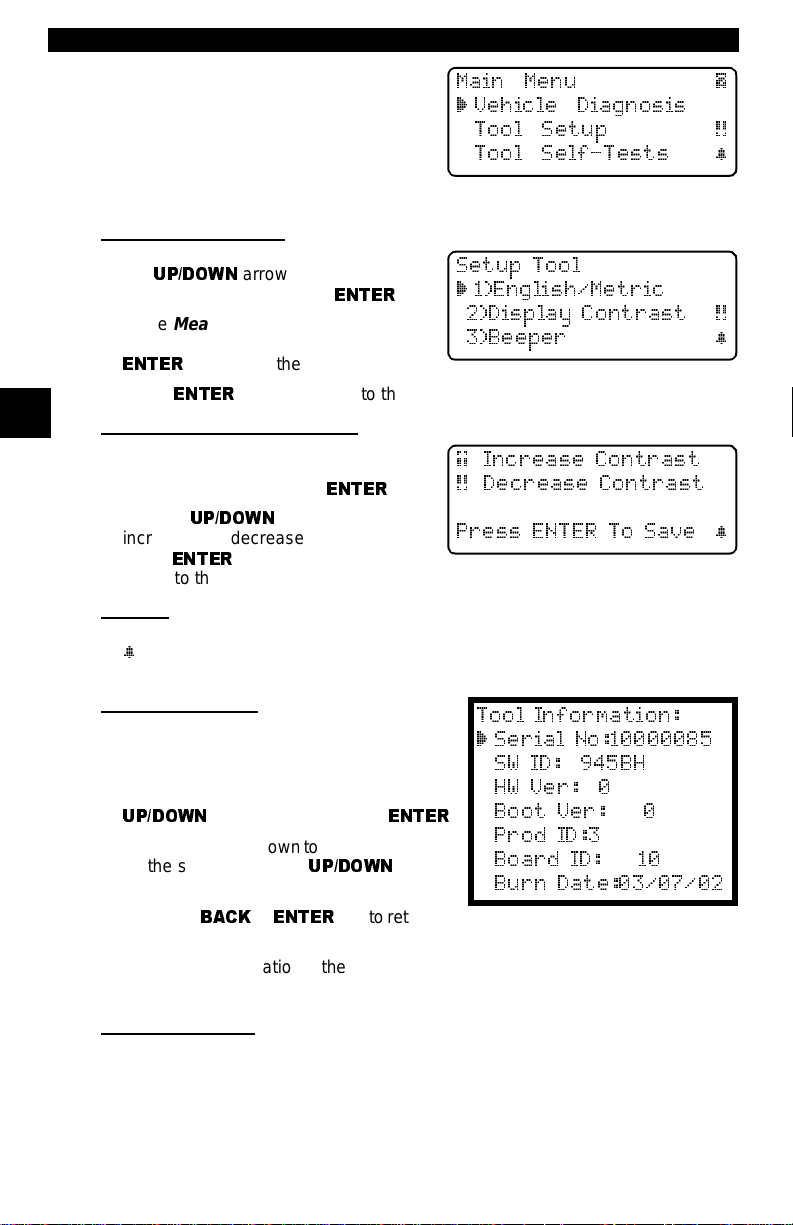

Scan Tool Setup

Tool Setup allows you to change the

measurement units and LCD contrast,

turn beeper On/Off and display tool

informatio n. The set tings remain until

the internal batteries become discharged.

Measurement Units

T o ch ange t he measur ement unit s, use

the

UP/DOWN

English/Metric and pre ss

In the

select English or Metric and then press

ENTER

Press

3

Changing Display Contrast

The display contr ast can be adjusted

from the

play Contrast and press

Use the

increase and decrease the contrast.

Press

return to the

Beeper

Beeper selection a llows the user to turn Off the tool ’s beeper. The bell symbol

~

will not appea r in t he lower right han d corner of th e displ ay wh en the be eper

is off.

Tool Information

This function allows you to view specific

tool informati on that may be needed when

contacting customer service.

Select Tool Information with th e

UP/DOWN

The information shown t o the right displays

on the screen. Use the

keys to view all the lines.

Press the

the

Setup Tool

✓ Write this inform ation in the space provi ded on the inside of the front cov er.

arrow keys to select

Measurement Units

. English is the default.

ENTER

ENTER

again to re tu rn to th e

Tool Setup

UP/DOWN

Setup Tool

arrow keys and press

BACK

menu. Sele ct Dis-

arrow keys to

to save the setting and to

or

menu.

menu.

UP/DOWN

ENTER

ENTER

ENTER

key to return to

.

menu,

Setup Tool

.

ENTER

arrow

Main Menu |

` Vehicle Diagnosis

Tool Setup [

Tool Self-Tests ~

Setup Tool

` 1)English/Metric

2)Display Contrast [

3)Beeper ~

menu.

] Increase Contrast

[ Decrease Contrast

Press ENTER To Save ~

Tool Information:

` Serial No:10000085

SW ID: 945BH

HW Ver: 0

Boot Ver: 0

.

Prod ID:3

Board ID: 10

Burn Date:03/07/02

Printer Interface

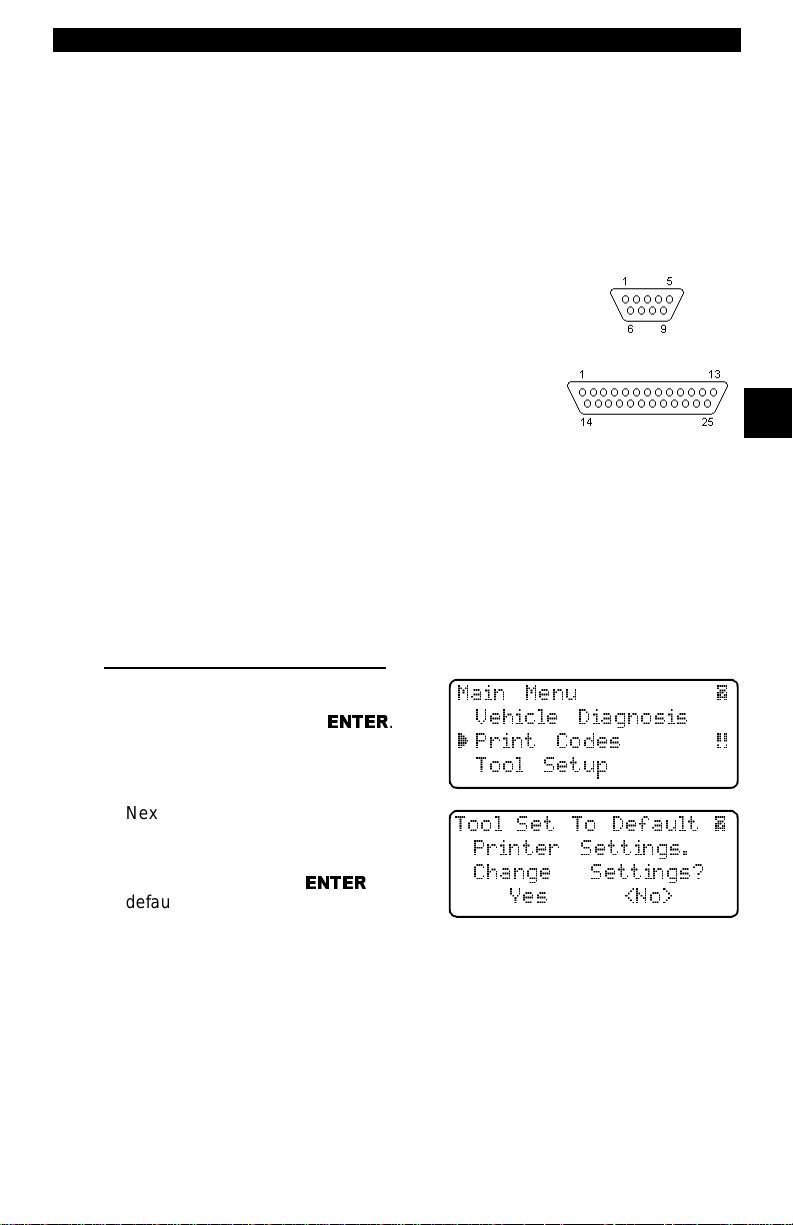

The scan tool is designed as a Data Terminal Equipment (DTE) dev ice with a

DB9M (9-pin D-shape male) connector to interface with a compatibl e serial

printer.

Compatible Printers

The printer must have a ser ial RS- 232 inte rface c ircui t and be comp at ible wit h

the Epson FX format. The following printers are recommended:

3 – 4 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Page 27

Using The Scan Tool

❒ Seiko DPU-414

❒ Kodak DICONIX 180si (seri al printer model)

❒ Lexmark Model 2480 with optional serial interface (p/n 12T0154)

❒ Panasonic KX-P1131 printer

Cabling

❒ Type: A standard RS-232 type cable.

❒ Scan Tool end: DB9F (female) connector.

❒ Printer end:

• Use a DB9M (male) connec-t or for the Seiko and

Kodak printers.

• Use a DB25 male connector f or the Lexmark and

Panasonic printers.

• If the printer uses a di fferent connector, then an

adapter or different RS-232 cable is required.

Adapters are available at most local PC stores or

electronics outlets.

Serial Port Settings

❒ Default settings for the scan tool are: 9600 Baud, 8 Data Bits, No Parity

and 1 Stop Bit.

❒ Ensure the settings on the scan tool and printer match .

❒ For the Lexmark and Panasonic printers, ensure the pri nter’s interface

selection is set to either “auto” or “serial”.

The printer and scan tool must have t he same comm unication sett ings. Y ou c an

change the scan tool’s settings if necessary.

Changing the Printer Settings

Select either Print Codes from the

Main Menu

Function List

or Print D ata from of the

and press

ENTER

DB9

DB25

3

Main Menu |

.

Vehicle Diagnosis

` Print Codes [

Tool Setup

Next, the tool will inform you of the

printer setti ngs (Custom or Default),

then ask if you wish to change them.

Select YES and press

default values are desi gnated on the display with the word (Default) next to the

option.

Refer to the printer manu al for the settings. The changes made res ide in the tool

even when the tool is turned of f.

Tool settings are as follows. Defaults are in [ . . . ]

ENTER

.The

Tool Set To Default |

Printer Settings.

Change Settings?

Yes <No>

❒ Baud Rate: [9,6 00], 1200, 2400

❒ Stop Bits: [1 Bit], 2 bits

❒ Parity: [None], Odd, Even

❒ Printer Speed: [Fast], Slow

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 3 – 5

Page 28

Using The Scan Too l

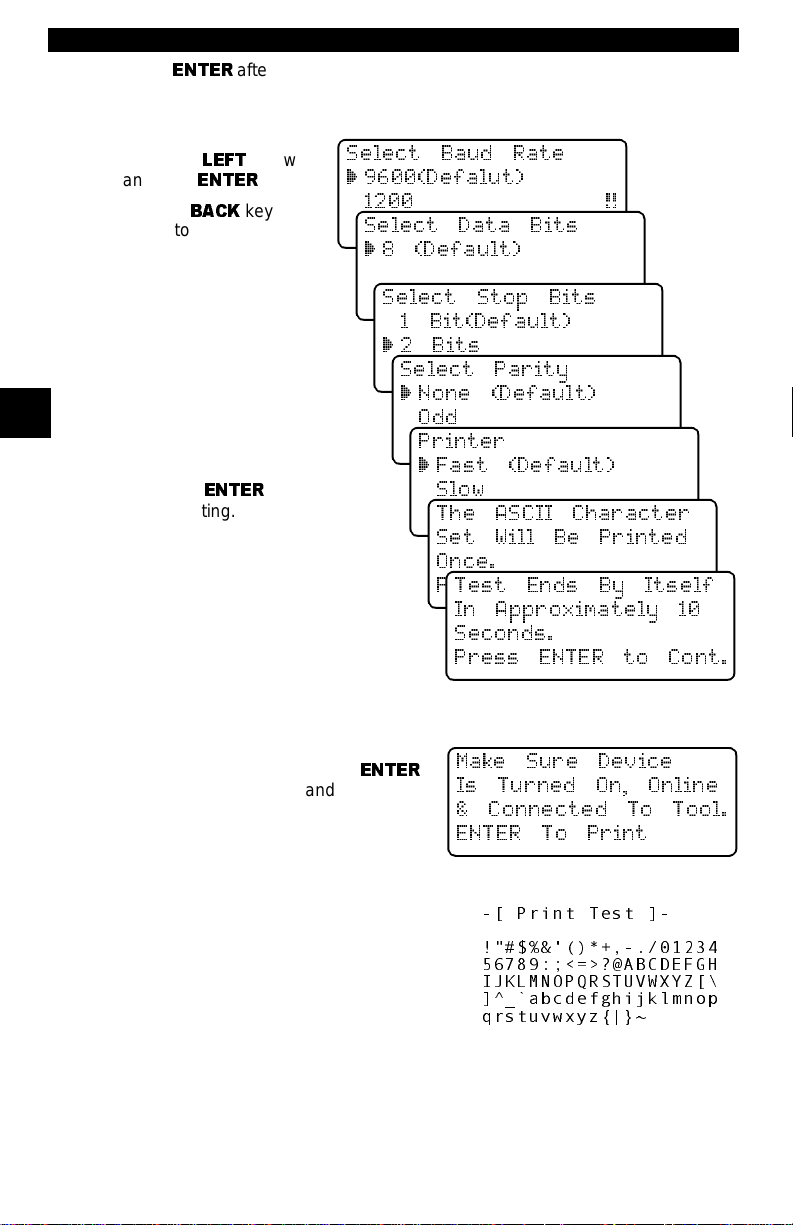

Press

ENTER

the screens. For the printer to work pro perly , the tool and the printer must be set

to the same configur ati on. Change the settings accordingly.

To change the settings,

press the

and then

Use the

return to the previous

menu.

LEFT

ENTER

BACK

after s electin g each sett ing. Fol low the i nstructions displaye d on

arrow

.

key to

Select Baud Rate

` 9600(Defalut)

1200 [

2400

Select Data Bits

` 8 (Default)

The new printer setti ngs

are tested by pr inting t he

ASCII character set.

Press to continue .

Select Stop Bits

1 Bit(Default)

`2 Bits

Select Parity

` None (Default)

3

Make sure print er is

turned ON, ONLINE and

connected to the too l.

Press the

begin printing.

ENTER

key to

Odd

Even

Printer

` Fast (Default)

Slow

The ASCII Characte r

Set Will Be Printed

Once.

Press ENTER to Cont.

Test Ends By Itself

In Approximately 10

Seconds.

Press ENT ER t o C ont .

If the printout is not OK, then retry or

change settings. If it is, press

and the data transmits and prints.

ENTER

Make Sure Device

Is Turned On, Online

& Connected To Tool.

ENTER To Print

A printout of the test looks similar to the

example shown.

3 – 6 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

-[ Print Test ]-

!"#$%&'()*+,-./01234

56789:;<=>?@ABCDEFGH

IJKLMNOPQRSTUVWXYZ[\

]^_`abcdefghijklmnop

qrstuvwxyz{|}~

Page 29

Using The Scan Tool

Diagnostic

Connector

CONNECTING THE SCAN TOOL

To diagnose a vehicle, connect the DLC and

power adapter (if applicable) to the scan tool.

Refer to “Diagnostic Link Connectors (DLC)”

on page 2-3 of Getting St arted.

If you just want to power up the tool to do its

self-tests, code lookup, review or printing data

from the last vehicle t ested, then you do not need

to attach the cable to the Data Link Connector . The internal battery provides

power fo r th is .

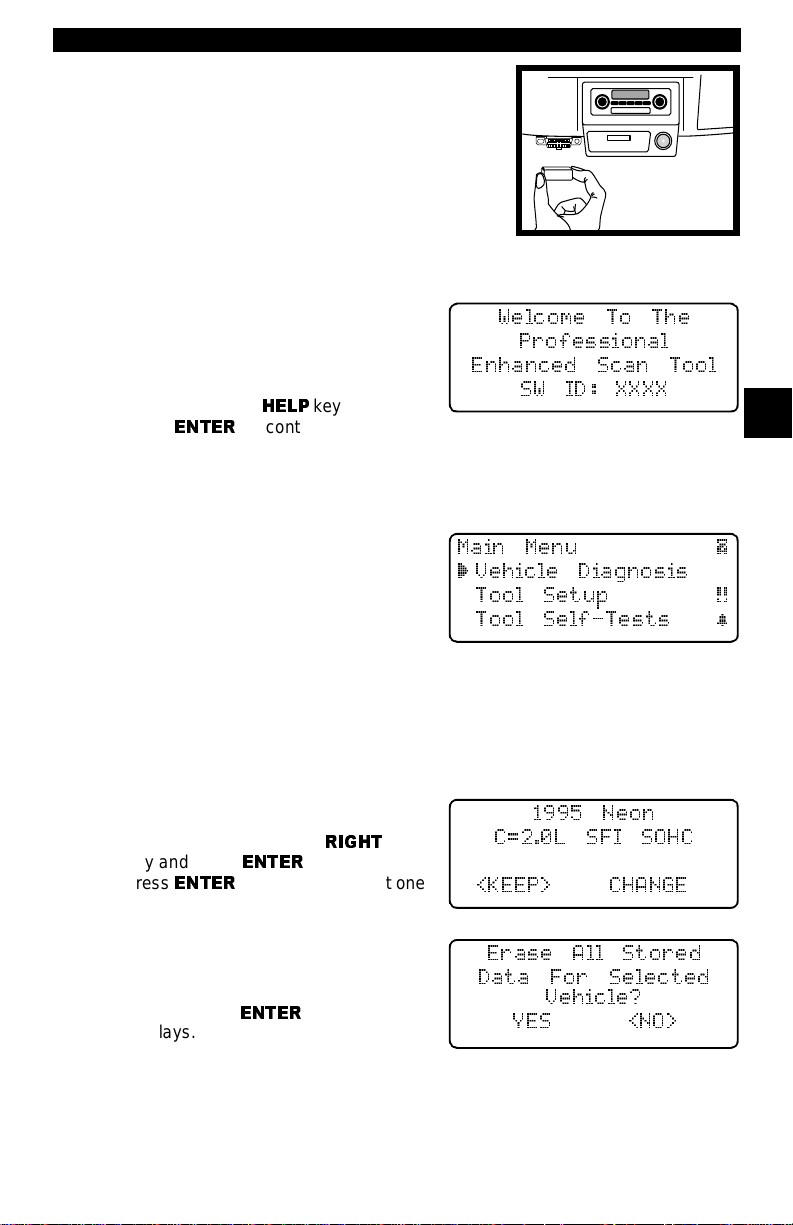

When the scan tool powers u p, a series

of messages display on the screen

beginning with a “Welcome” scr een and

ending with a “Key Bu tton Help” scr een.

If you wish to re vie w the key button def initions, pus h the

press

ENTER

Veh icle Sel ectio n

When the tool powers up, the “Key Butt on Help” screen is fol lowed by a

Menu

screen.

Pick Vehicle Di agnosis to begin Vehi-

cle Selection. I f there is a pr evious vehi cle present, the tool displays that

vehicle. Y o u can choose the l ast vehicle

selected or set up for a new vehicle. The

tool retains all data retrieved from the

last vehicle select ed until any of the fol lowing occurs:

❒ A new vehicle is selected

❒ Internal AAA batteries are depleted or disconnect ed

❒ Tool is flash pro grammed to update software

❒ The last vehicle selected is kept but you choose Erase Data

You can either keep the previously

selected vehicle or change it. If changing the vehi cle, press t he

key and press

press

ENTER

Keep Current Vehicle

The next screen asks if you want t o

erase the stored data. The default is

NO.

After pressing

displays.

HELP

key; othe rwise,

to continue.

RIGHT

arrow

ENTER

. Otherwise,

to keep the current one.

ENTER

, the functi on li st

Main Menu |

` Vehicle Diagnosis

<KEEP> CHANGE

Welcome To The

Professional

Enhanced Scan Tool

SW ID: XXXX

3

Main

Tool Setup [

Tool Self-Tests ~

1995 Neon

C=2.0L SFI SOHC

Erase All Stored

Data For Selected

Vehicle?

YES <NO>

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 3 – 7

Page 30

Using The Scan Too l

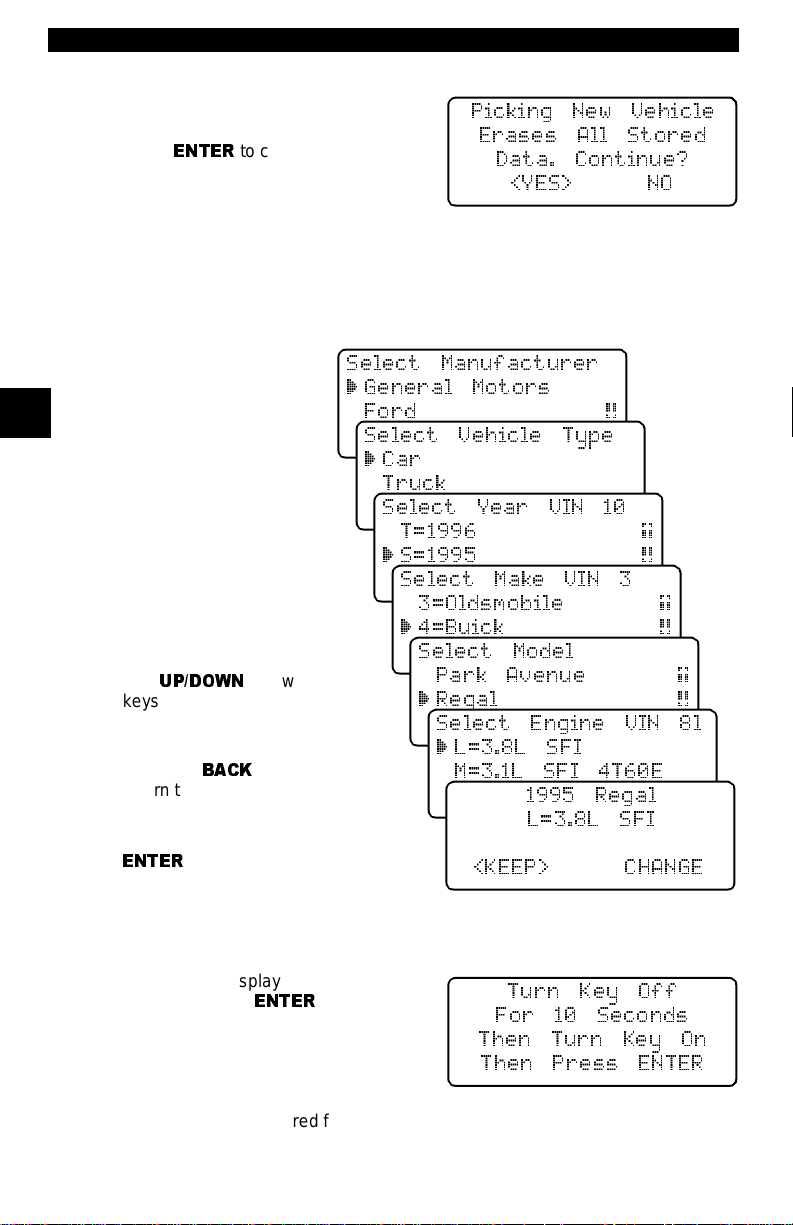

Chan ging the Vehicle

Changing vehicl es erases all data

stored in the tool. The default is YES.

Press

ENTER

Four V ehicle Op tions are avai lable: General Motor s, Ford, Ch rysler and Glo bal

OBD II. Global OBD II does not require additional information and takes you

directly to th e function list . The other three requ ire additional inf ormation so that

the tool can communicate with the vehicle. For example, selec t GENERAL

MOTORS.

The menus provide a list

of choices and reference

the vehicle’s VIN where

3

applicable. The VI N is visible fro m outsid e the vehi cle by looking thr ough the

base of the front windshield at the top of the

dashboard on the dr iver’s

side. Because manufacturers use diff erent VIN

schemes, the tool will

indicate which d igit of the

VIN to loca t e fo r info r m a tion such as Year, Make

and Engine.

Use

UP/DOWN

keys to move through the

list.

If you make a mistake,

press the

return to the previous

menu.

At the last screen, press

ENTER

BACK

.

to continue.

arrow

key to

Picking New Vehicle

Erases All Stored

Data. Continue?

<YES> NO

Select Manufacturer

` General Motors

Ford [

Chrysler

Select Vehicle Type

` Car

Truck

Select Year VIN 10

T=1996 ]

` S=1995 [

R=1994

Select Make VIN 3

3=Oldsmobile ]

` 4=Buick [

6=Cadillac

Select Model

Park Avenue ]

` Regal [

Reviera

Select Engine VIN 8l

` L=3.8L SFI

M=3.1L SFI 4T60E

M=3.1L SFI AUTO-3S

1995 Regal

L=3.8L SFI

<KEEP> CHANGE

If a message displays , follow the instructions then press

ENTER

.

Turn Key Off

For 10 Seconds

Then Turn Key On

Then Press ENTER

✓ Vehicles manufactured from 2000 to present automatically use G lobal OBD

II Diagnostics even if GM, Ford or Chrysler was selected.

3 – 8 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Page 31

Using The Scan Tool

User Interface

The scan tool i s designed t o be as intuit ive as possi ble. All m enu and list s operate the same way. Use the

the display or move t he cursor (

to select the functi on or item. To return to previous screens , pr ess the

key . This informat ion can be viewed on t he sca n tool by pressing the

after powering up the scan tool.

If a list or message c ontains more than f our lin es, an arr ow icon di splays on t he

last column o f the di splay to indi cate t he scr olli ng direct ion a vaila ble: up (

down (

[

play . When the bott om of the list i s reached , then on ly the

of the list, only the

For example: to read DTCs stored i n the

vehicle, move the cursor to Read

Codes with th e

and press

choice, such as viewing data, use the

UP/DOWN

sor down to View Data and press

ENTER

). Use the

.

User Responses

The scan tool may ask a questi on which

requires a YES or NO response —

brackets (

To accept the default choice, press the

ENTER

press the

ets to another re sponse and press

key. T o change the answer,

HELP

UP/DOWN

`

) to a selectable it em. Press t he

UP/DOWN

[

displays.

UP/DOWN

ENTER

<>

. To make a different

arrow keys to move the cur-

) enclose the defaul t one.

key to move the brack-

arrow keys to move line-by-line through the di s-

arrow keys

ENTER

arrow keys to m ove

UP/DOWN

ENTER

]

displays. At the top

Function List |

` 3)Erase DTC(Codes) ]

4)View Data [

5)View Freeze Data ~

View Instructions

For Creating Custom

Data List?

Yes <No> ~

.

through

BACK

HELP

]

key

key

) or

3

Viewing Data

Viewing dat a allows you to obs erve sensor data and the oper ation of switche s,

solenoids, a nd rel ays. As the compu ter

monitors the vehicle, the parameter

Identificati on (PID) data is transmitted to

the scan tool.

For viewing options, select View Data from the

ENTER

.

Entire Data List

The Entire Data List shows all sup-

ported parameter id entifica tion (PID)

data for the v ehi cle be ing t est ed. When

the scan tool makes a recording, the

data from al l support ed PIDs are stor ed

in the scan tool.

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 3 – 9

Function List |

3)Erase DTC(Codes) ]

` 4)View Data [

5)View Freeze Data ~

Function List

and press

Select Data To View

` Entire Data List

Custom Data List

View Data Setup ~

Page 32

Using The Scan Too l

Custom Data List

The Custom Data List allows you to

select certai n PIDs from the Entire Data

List, such as those PI Ds t hat pert ain to

a specific driveability symptom or system. The scan tool asks if you want to

view the instructions.

Once in the

follow the i nst ructions des cribed below.

A

«

symbol will be displ ayed next to all

selected PIDs. Use the

arrow keys to scroll through the list.

Custom Data List

UP/DOWN

menu,

View Instructions

For Creating Custom

Data List?

YES <NO> ~

Select Custom List

« MIL STATUS

ABSLT TPS(%) [

` ENGINE(RPM) ~

• Use the

•

UP

•

3

DOWN

•

RIGHT

ues are marked with

LEFT

•

•

ENTER

data pa r a m e ters .

Once in the Custom Data List selection screens, follow the instructions

described above to buil d a Custom Data List. Data parameter s or Parameter

Identificat ion Data (PID) will follow in alphabeti cal order . Refer t o “Appendix C

- PID Lis t " for a complete list ing of all PIDs.

When you are don e sele cting the PI Ds, pr ess the

PID values. Press the

menu.

UP/DOWN

arrow: Moves the cursor up the data list.

arrow: Moves the cursor down the data list.

arrow: Selects or deselects a data param eter. All select ed data val-

arrow: Desele cts all marked data parameters.

key: S tarts p laying back data , recording da ta, or displayi ng selected

View Da ta Se t up

View Data Setup changes the numbe r

of lines sh own on the scr een. Sel ecti ng

fewer lines provides faster update

speeds. The default is four-line display.

arrow keys to move up and down through the list.

«

symbol.

BACK

key twice to return to the

ENTER

key to view selected

Select Data To View

Select Data To View

Entire Data List

Custom Data List

` View Data Setup ~

3 – 10 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Page 33

Section 4 – Global OBD II Diagnostics

The first time the scan tool communi cates with the veh icle, th e communicatio n

type is automat ical ly det ected, and is u sed u ntil th e sca n tool is tur ned OF F or

another vehicle is diagnosed.

✓ If an Error Message displays, make sure the OBD II connector is

securely attached, and the ignition key is ON. Cycle the ignition key to

OFF for 10 sec onds, then ON. This may b e required t o reset the computer .

If required, select Y ES t o try again. I f the problem s till exist s, refer to “Error

Messages” on page 8-2.

✓ On the initial link to the vehicle, the scan tool checks the status of the

I/M Monitors and conveys it to the operator, no matter which function is

selected.

MANUAL INFO

The Manual Info function, the last one in the f unction list, inst ructs the user what

section of t he manu al to u se. Thi s se ction covers Global OBD II Diagnos tics .

I/M READINESS

The I/M Readiness (Inspe cti on and Maintenance) function displays the st ate

of the vehicle ’s OBD II Moni tors. Monitor s are test s designed t o verify t he operation of emis sion related systems o r components and detect out-of-range values. The vehicle may have to be operated under certain driving conditions to

initiate a moni t or . I f the vehi cle l ose s elect ric al power or code s ar e erase d, the

monitors may be cleared. This function can be performed with the key ON —

engine OFF (KOEO) or key ON — engine Running (KOER).

The abbreviation s and names fo r the OBD II Moni tors suppor ted by this tool are

shown in the following lis t. They are required by the U.S. Environmental Protection Agency (EPA). Not all monitors are supported by all vehicles.

Abbreviated Name

Misfire Monitor ..............................Misfire Monitor

Fuel System Mon .........................Fuel System Monitor

Com Component..........................Comprehensive Component s Monitor

Catalyst Mon ................................Catalyst Monitor

Htd Catalyst..................................Heated Catalyst Monitor

Evap System Mon.......... ..............Evaporative System Monitor

Sec Air System............... .............Secondary Air System Monit or

A/C Refrig Mon.............................Air Conditioning Refrigerant Monitor

Oxygen Sens Mon................. .. ....Oxygen Sensor Monitor

Oxygen Sens Htr.............. .. .........Oxygen Heater Sensor Monitor

EGR System Mon ................ .... ....Exhaust Gas Recirc ulati on Syst em Moni tor

The vehicle may support two types of I/M Readiness:

❒

SINCE DTCs CLEARED

DTCs were last erased.

❒

THIS DRIVING CYCLE

of the current drive cycle.

If the monitors ar e not supported for

only shows monitors for

Expanded Name

shows the status of the monitors since the

shows the status of the monitors since the start

THIS DRIVING CYCLE

SINCE DTCs CLEARED

with no header on line 1.

, then the scan tool

4

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 4 – 1

Page 34

Global OBD II Diagnos t ic s

Select I/M Readiness from the

Function List

The scan tool displays a message stating whether the I/M Readi ness monitors

are completed.

menu and press

OBDII

ENTER

OBDII Function List |

.

` 1)I/M Readiness

2)Read Codes [

3)Pending Codes ~

Use the

supported, t hen use the

types.

4

4

• A status of “OK” means that the re quired driv ing c onditi ons f or that monito r

• A status of “Inc” means tha t the required driving conditions for that monitor

• A status of “N/A” mean s the vehicle does not support that monitor.

When done, press the

READ CODES

The Read Codes function retrieves Diagnos tic Trou ble Codes (DTCs) from th e

vehicle’ s compute r modul e(s). Thi s funct ion can be per f ormed with the KOEO

or KOER.

These codes cause t he c omputer t o illuminate the Malfunction Indicator Lamp

(MIL) when an emissi on-related or driveability faul t occurs. The MIL is also

known as the “service engine soon” or “check engine” lamp.

Select Read Codes and press

The Scan Tool retrieves the DTCs

stored in the veh icl e’s computer module(s).

On-Board Readiness |

Tests Are Complete

Not All Supported

On-Board Readiness