Page 1

User’s Manual

9640

Enhanced Scan Tool

Professional

Page 2

Scan Tool Information

Complete the following list using the

function “Tool Information”. Provide

this information when contacting

customer support.

Serial No:

SW ID:

HW Ver:

Boot Ver:

Prod ID:

Board ID:

Burn Date:

Burn Loc:

Copyright Information

Copyright © 2005 SPX Corporation.

All rights reserved.

The information, specifications and illustrations in this

manual are based on the latest information available at the

time of printing. SPX Corporation reserves the right to

make changes at any time without notice.

Page 3

Safety Precautions

For your safety, read this manual thoroughly before operating your Professional

Enhanced Scan Tool. Always refer to and follow safety messages and test

procedures provided by the manufacturer of the vehicle or equipment being

tested.

Your scan tool is intended for use by properly trained, skilled professional

automotive technicians. The safety messages presented below and throughout

this user’s manual are reminders to the operator to exercise extreme care when

using this test instrument.

Read All Instructions

Read, understand and follow all safety messages and instructions in this

manual and on the test equipment. Safety messages in this section of the

manual contain a signal word with a three-part message and, in some

instances, an icon. The signal word indicates the level of the hazard in a

situation.

Safety Messages

Safety messages are provided to help prevent personal injury and equipment

damage. All safety messages are introduced by a signal word indicating the

hazard level. The types of safety messages are:

DANGER

!

WARNING

!

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury to the operator

or to bystanders.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury to the

operator or to bystanders.

!

Indicates a potentially hazardous situation which, if not

!

CAUTION

IMPORTANT

Safety messages contain three different type styles.

• Normal type states the hazard.

• Bold type states how to avoid the hazard.

• Italic type states the possible consequences of not avoiding the hazard.

An icon, when present, gives a graphical description of the potential hazard.

Example:

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • Safety – i

avoided, may result in moderate or minor injury to the

operator or to bystanders.

Indicates a situation which, if not avoided, may result in

damage to the test equipment or vehicle.

Engine systems can malfunction expelling fuel, oil vapors, hot

steam, hot toxic exhaust gases, acid, refrigerant and other

debris.

Wear safety goggles and protective gloves, user and

bystander. Everyday eyeglasses only have impact resistant

lenses, they are NOT safety glasses.

Engine systems that malfunction can cause injury.

Page 4

Safety Precautions

Important Safety Instructions

!

Risk of electric shock.

• Do not exceed voltage limits between inputs as indicated

in the “Specifications”.

• Use extreme caution when working with circuits that have

greater than 60 volts DC or 24 volts AC.

Electric shock can cause injury.

Risk of explosion.

• Wear safety goggles and protective clothing, user and

bystander. Everyday eyeglasses only have impact

resistant lenses, they are NOT safety glasses.

!

WARNING

WAR NI N G

!

!

WARNING

• Do not use this system in environments where explosive

vapor may collect, such as in below-ground pits, confined

areas, or areas that are less than 18 inches above the floor.

• Use this equipment in locations with mechanical

ventilation providing at least four air changes per hour.

• Flammable fuel and vapors can ignite.

• Do not smoke, strike a match, or cause a spark in the

vicinity of the battery. Battery gases can ignite.

• Avoid making accidental connection between battery

terminals. Do not place uninsulated metal tools on the

battery.

• When removing battery cables, remove ground cable first.

• Avoid sparks when connecting or disconnecting power

leads to battery.

• Be sure ignition is OFF, headlights and other accessories

are OFF and vehicle doors are closed before

disconnecting battery cables. This also helps prevent

damage to on-board computer systems.

• Always disconnect battery ground connections before

servicing electrical system components.

Explosion can cause injury.

Risk of poisoning.

• Use this equipment in locations with mechanical

ventilation providing at least four air changes per hour.

Engine exhaust contains odorless lethal gas.

• Route exhaust outside while testing with engine running.

Poisoning can result in death or serious injury.

Battery acid is a highly corrosive sulfuric acid.

• Wear safety goggles and protective gloves, user and

bystander. Everyday eyeglasses only have impact

resistant lenses, they are NOT safety glasses.

• Make sure someone can hear you or is close enough to

provide aid when working near a battery.

• Have plenty of fresh water and soap nearby. If battery acid

contacts skin, clothing, or eyes, flush exposed area with

soap and water for 10 minutes.

• Seek medical help.

• Do not touch eyes while working near battery.

Battery acid can burn eyes and skin.

Risk of fire.

• Wear safety goggles and protective clothing, user and

bystander. Everyday eyeglasses only have impact

resistant lenses, they are NOT safety glasses.

Safety – ii • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Page 5

Safety Precautions

• Do not position head directly over or in front of throttle

body. Do not pour gasoline down throttle body when

cranking or running engine, when working with fuel

delivery systems or any open fuel line. Engine backfire

can occur when air cleaner is out of position.

• Do not use fuel injector cleaning solvents when

performing diagnostic testing.

• Keep cigarettes, sparks, open flame and other sources of

ignition away from vehicle.

• Keep a dry chemical (Class B) fire extinguisher rated for

gasoline, chemical and electrical fires in work area.

Fire can cause death or serious injury.

Risk of flying particles.

Wear safety goggles while using electrical equipment.

Electrical equipment or rotating engine parts can cause

flying particles.

Flying particles can cause eye injury.

Risk of burns.

Batteries can produce a short-circuit current high enough

to weld jewelry to metal. Remove jewelry such as rings,

bracelets and watches before working near batteries.

Short circuits can cause injury.

WARNING

!

Risk of burns.

• Do not remove radiator cap unless engine is cold.

Pressurized engine coolant may be hot.

• Do not touch hot exhaust systems, manifolds, engines,

radiators, sample probe, etc.

• Wear insulated gloves when handling hot engine

components.

• Tester leads can become hot after extended testing in

close proximity to manifolds etc.

Hot components can cause injury.

Risk of expelling fuel, oil vapors, hot steam, hot toxic exhaust

gases, acid, refrigerant and other debris.

• Wear safety goggles and protective clothing, user and

bystander. Everyday eyeglasses only have impact

resistant lenses, they are NOT safety glasses.

• Engine systems can malfunction expelling fuel, oil

vapors, hot steam, hot toxic exhaust gases, acid,

refrigerant and other debris.

Fuel, oil vapors, hot steam, hot toxic exhaust gases, acid,

refrigerant and other debris can cause serious injury.

The engine compartment contains electrical connections and

hot or moving parts.

• Keep yourself, test leads, clothing and other objects clear

of electrical connections and hot or moving engine parts.

• Do not wear watches, rings, or loose fitting clothing when

working in an engine compartment.

• Do not place test equipment or tools on fenders or other

places in the engine compartment.

• Barriers are recommended to help identify danger zones

in test area.

• Prevent personnel from walking through immediate test

area.

Contact with electrical connections and hot or moving parts

can cause injury.

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • Safety – iii

!

Page 6

Safety Precautions

!

WARNING

!

PR ND L2

!

CAUTION

!

CAUTION

DANGER

!

Risk of injury.

• This equipment should be operated by qualified

personnel only.

• Use this equipment only as described in this manual. Use

only the manufacturer’s recommended attachments.

• Do not operate equipment with a damaged cord or if the

equipment has been dropped or damaged, until it has

been examined by a qualified service representative.

Operation of this equipment by anyone other than qualified

personnel may result in injury.

Risk of unexpected vehicle movement.

• Block drive wheels before performing a test with engine

running.

• Unless instructed otherwise, set parking brake and put

gear selector in neutral for standard transmissions or park

for automatic transmissions.

• If vehicle has an automatic parking brake release,

disconnect release mechanism for testing and reconnect

when testing is completed.

• Do not leave a running engine unattended.

A moving vehicle can cause injury.

Risk of equipment or circuit damage.

• Unless specifically directed by the manufacturer, make

sure the ignition is OFF before connecting or

disconnecting connectors or any vehicle electrical

terminals.

• Do not create a short between battery terminals with a

jumper wire or tools.

Improper equipment use can cause equipment or circuit

damage.

Misdiagnosis may lead to incorrect or improper repair and/or

adjustment.

Do not rely on erratic, questionable, or obviously erroneous

test information or results. If test information or results are

erratic, questionable, or obviously erroneous, make sure

that all connections and data entry information are correct

and that the test procedure was performed correctly. If test

information or results are still suspicious, do not use them

for diagnosis.

Improper repair and/or adjustment may cause vehicle or

equipment damage or unsafe operation.

Some vehicles are equipped with air bags. You must follow

vehicle service manual’s warnings when working around the

air bag components or wiring. If the service manual’s instructions are not followed, the air bag may open up unexpectedly,

resulting in personal injury. Note that the air bag can still open

up several minutes after the ignition key is off (or even if the

vehicle battery is disconnected) because of a special energy

reserve module.

Safety – iv • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Page 7

Safety

!

Table of Contents

Section 1 –––––––––– Using this Manual

Section 2 –––––––––––– Getting Started

Section 3 ––––––––Using The Scan Tool

Section 4 ––– Global OBD II Diagnostics

Section 5 –––––––––––– GM Diagnostics

Section 6 ––––––––––– Ford Diagnostics

1

2

3

4

5

6

ToC

Section 7 ––––––––Chrysler Diagnostics

Section 8 ––––––––– Import Diagnostics

Section 9 ––––––– Help & Troubleshooting

Appendix A ––––– Data Link Connectors

Appendix B –––––––––––––––– Glossary

7

8

9

A

B

Page 8

Page 9

Section 1 – Using This Manual

This manual contains instructions for use and setup of your scan tool. A table

of contents and glossary are provided to make this manual easy to use.

Some of the information shown in text or illustrations is obtained using optional

equipment. A Sales Representative can determine option availability.

This section contains a list of conventions used.

Safety Messages

Refer to “Safety Precautions” on page i.

Check Note

A check note provides additional information about the subject in the preceding

paragraph.

Example:

✓ Make sure the printer is turned on, on-line and connected.

Equipment Tips and Lists

Equipment tips and lists provide information that applies to specific equipment.

Each tip is introduced by this icon

Example:

❒ Observe all vehicle and/or equipment manufacturer’s cautions and

warnings when testing with the scan tool.

❒ for easy identification.

1

Equipment Damage

Situations arise during testing that could damage the vehicle or the test

equipment. The word IMPORTANT signals these situations.

Example:

IMPORTANT

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 1 – 1

Failure to follow these instructions could damage the scan tool.

Page 10

Using This Manual

Functions and Selections

Diagnostic and tool functions performed by the scan tool are highlighted in bold.

Example:

The View Data function allows you to view the vehicle’s Parameter

Identification (PID) data in real time.

1

Menus

The menus on the scan tool display are referenced in the procedures and are

highlighted in bold-italic text.

Example:

When the OBDII Function List menu displays, the scan tool is ready for use.

Questions and Responses

Messages and user responses are CAPITALIZED.

Example:

The Scan Tool displays the Pending DTCs or a message stating SYSTEM

PASS: NO FAULT DETECTED.

Manual References

Used to reference other sections of the manual. References include the “Title”

and page number (section-page).

Example:

For more information on DTCs, refer to “Diagnostic Link Connectors (DLC)”

on page 2-5.

Screens

Certain Help messages, information, and data that are displayed on the scan

tool are also shown in graphical text boxes. The screens are presented as

examples and may change as the software is updated.

Example:

Main Menu ?

` Vehicle Diagnosis

Tool Setup [

Tool Self-Tests ~

1 – 2 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Page 11

Table of Contents

Safety Precautions

Section 1 – Using This Manual

Section 2 – Getting Started

Vehicle Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Introduction to On-Board Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Diagnostic Link Connectors (DLC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

OBD II (J1962) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Ford Historic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

GM Historic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Chrysler Historic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Diagnostic Trouble Codes (DTCs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Section 3 – Using The Scan Tool

The Scan Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Scan Tool Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Connecting The Scan Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Vehicle Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Keep Current Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Changing the Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

User Responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Viewing Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

ToC

Page 12

Section 4 – Global OBD II Diagnostics

Manual Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

I/M Readiness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Read Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Pending Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

ToC

Erase Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

View Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

View Freeze Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

O2 Monitor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Diagnostic Monitor Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

On-Board Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Record Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Vehicle Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Modules Present . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Review Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Playback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Print Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Printing Data (except Playback) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Printing Playback Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Code Lookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Section 5 – GM Diagnostics

GM Historic (OBD I) Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Manual Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Read Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Erase Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

View Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Record Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Review Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Field Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Code Lookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Print Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

GM Enhanced (OBD II) Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Manual Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

I/M Readiness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Read Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Pending Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Erase Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

View Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

View Freeze Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

O2 Monitor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Diagnostic Monitor Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Record Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Vehicle Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Review Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Playback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Print Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Code Lookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

ii

Page 13

Section 6 – Ford Diagnostics

Ford Historic Self-Test Routines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Manual Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-1

Read KOEO Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-1

Read KOER Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-3

Review Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-6

Erase Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-7

Wiggle Test (EEC-IV Vehicles) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Output Switch Test (EEC-IV Vehicles) . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Cylinder (Cyl) Balance Test (EEC-IV Vehicles) . . . . . . . . . . . . . . . . . .. 6-11

IVSC-Speed Ctrl (EEC-IV Vehicles) . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-13

STAR Test Mode (EEC-IV, MECS and MCU Vehicles) . . . . . . . . . . . . 6-15

Code Lookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Print Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-17

DCL Data Functions (EEC-IV Vehicles) . . . . . . . . . . . . . . . . . . . . . . .. 6-17

Ford Enhanced (OBD II) Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Manual Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-21

I/M Readiness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-21

Read MIL DTC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-21

Read All DTC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-22

Pending Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-22

Erase Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-23

View Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-23

View Freeze Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-24

Quick Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-24

Quick Tests (7.3L Powerstroke Diesel Only) . . . . . . . . . . . . . . . . . . . . . 6-28

O2 Monitor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-32

Diagnostic Monitor Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

On-Board Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-32

Record Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

Vehicle Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-32

Review Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-32

Print Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6-32

Code Lookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

ToC

iii

Page 14

Section 7 – Chrysler Diagnostics

Manual Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Read Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Read Temporary Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Erase Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

ToC

View Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Freeze Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Record Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Switch Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Actuator Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Idle Speed Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Sensor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Controller Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 710

Reset EMR Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Set Basic Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

Review DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Print Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

Code Lookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

Section 8 – Import Diagnostics

Import Enhanced (OBD II) Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Manual Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

I/M Readiness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Read Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Pending Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Erase Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

View Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

View Freeze Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

O2 Monitor Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Diagnostic Monitor Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Record Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Vehicle Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Playback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Print Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Code Lookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

iv

Page 15

Section 9 – Help & Troubleshooting

How to Use On-Line Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Scan Tool Does Not Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Using Non-OBD II Adapter Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Using J1962 (OBD II) or Chrysler LH Adapter Cable . . . . . . . . . . . . . .. 9-1

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Vehicle Communication Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 9-2

Operating Error or Erroneous Data . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 9-2

Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Tool Self-Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Display Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 9-4

Keyboard Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 9-4

Memory Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 9-5

Printer Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 9-5

Program Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Appendix A – Data Link Connectors

Appendix B – Glossary

ToC

v

Page 16

ToC

vi

Page 17

Section 2 – Getting Started

The Professional Enhanced Scan Tool was developed by experts in the

automotive service industry to help diagnose vehicles and assist in

troubleshooting procedures. The tool monitors vehicle events and retrieves

codes from the vehicle computer’s memory to pinpoint problem areas.

All information, illustrations and specifications contained in this manual are

based on the latest information available from industry sources at the time of

publication. No warranty (expressed or implied) can be made for its accuracy

or completeness, nor is any responsibility assumed by the manufacturer or

anyone connected with it for loss or damages suffered through reliance on any

information contained in this manual or misuse of accompanying product. The

manufacturer reserves the right to make changes at any time to this manual or

accompanying product without obligation to notify any person or organization

of such changes.

VEHICLE SERVICE INFORMATION

The following is a list of web sites and phone numbers where electronic

engine control diagnostic information is available.

✓ Some manuals may be available at your local dealer, auto parts

stores or local public libraries.

Domestic Vehicles Web Site Phone Number

General Motors

Chevrolet www.chevrolet.com 1-800-551-4123

Pontiac www.pontiac.com 1-800-551-4123

Oldsmobile www.oldsmobile.com 1-800-551-4123

Buick www.buick.com 1-800-551-4123

Cadillac www.cadillac.com 1-800-333-4CAD

Saturn www.saturn.com 1-800-553-6000

Ford

Ford www.ford.com 1-800-392-3673

Lincoln www.lincoln.com 1-800-392-3673

Mercury www.mercury.com 1-800-392-3673

Chrysler

Chrysler www.chrysler.com 1-800-348-4696

Dodge www.dodge.com 1-800-348-4696

Plymouth Not Available 1-800-348-4696

Eagle Not Available 1-800-348-4696

2

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 2 – 1

Page 18

Getting Started

European Vehicles

Audi www.audi.com 1-800-544-8021

Volkswagon www.vw.com 1-800-544-8021

BMW www.bmw.com 1-201-307-4000

MINI www.mini.com 1-201-307-4000

Jaguar www.jaguar.com 1-800-4-JAGUAR

Volvo www.volvo.com 1-800-458-1552

Mercedes www.mercedes-benz.com 1-800-367-6372

Land Rover www.landrover.com 1-800-637-6837

Porsche www.porsche.com 1-800-PORSCHE

Saab www.saab.com 1-800-955-9007

Asian Vehicles Web Site Phone Number

Acura www.acura.com 1-800-999-1009

2

Honda www.honda.com 1-800-999-1009

Lexus www.lexus.com 1-800-255-3987

Scion www.scion.com 1.866.70.SCION

Toyota www.toyota.com 1-800-GO-TOYOTA

Hyundai www.hyundai.com 1-800-633-5151

Infiniti www.infiniti.com 1-800-662-6200

Nissian www.nissianusa.com 1-800-nissian1

Kia www.kia.com 1-800-333-4542

Mazda www.mazda.com 1-800-222-5500

Daewoo www.daewoo.com 1-822-759-2114

Subaru www.subaru.com 1-800-SUBARU3

Isuzu www.isuzu.com 1-800-255-6727

Geo Not Available Not Available

Mitsubishi www.mitsubishi.com 1-888-MITSU2004

Suzuki www.suzukiauto.com 1-800-934-0934

Other Manuals

Chilton Book Company www.chiltonsonline.com 1-800-347-7707

Haynes Publications www.haynes.com 1-800-242-4637

Bentley Publishers ‘ www.bentleypublishers.com 1-800-423-4595

Repair Information Programs

Mitchell www.mitchell1.com 1-888-724-6742

Alldata www.alldata.com 1-800-697-2533

Suitable Manual Titles

“Diagnostic Service Manuals”

“PowerTrain Codes and Oxygen Sensors”

“Automotive Emission Control Manual”

“Fuel Injection”

“Automotive Electrics and Electronics”

“Automotive Sensors”

“Electronic Transmission Control”

“Emission Control Technology

“Engine Management”

or similar titles...

2 – 2 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Page 19

Getting Started

INTRODUCTION TO ON-BOARD DIAGNOSTICS

The original on-board diagnostics (OBD I) lacked consistency in

communication and interface while allowing different interpretations amongst

vehicle manufacturers. Ford and Chrysler used different types of engine control

computers and data link connectors, and GM varied the trouble codes and

communication protocols from year-to-year.

The tables below highlight changes for GM, Ford, and Chrysler. If this seems

confusing; don’t worry. Your tool makes it easy. Based on the VIN information

selected during Scan Tool setup, the processor is automatically recognized. All

you have to do is choose the correct adapter cable and jumper wires (if

necessary). Details on adapter cables and jumper wires may be found in

“Diagnostic Link Connectors (DLC)” on page 2-5

.

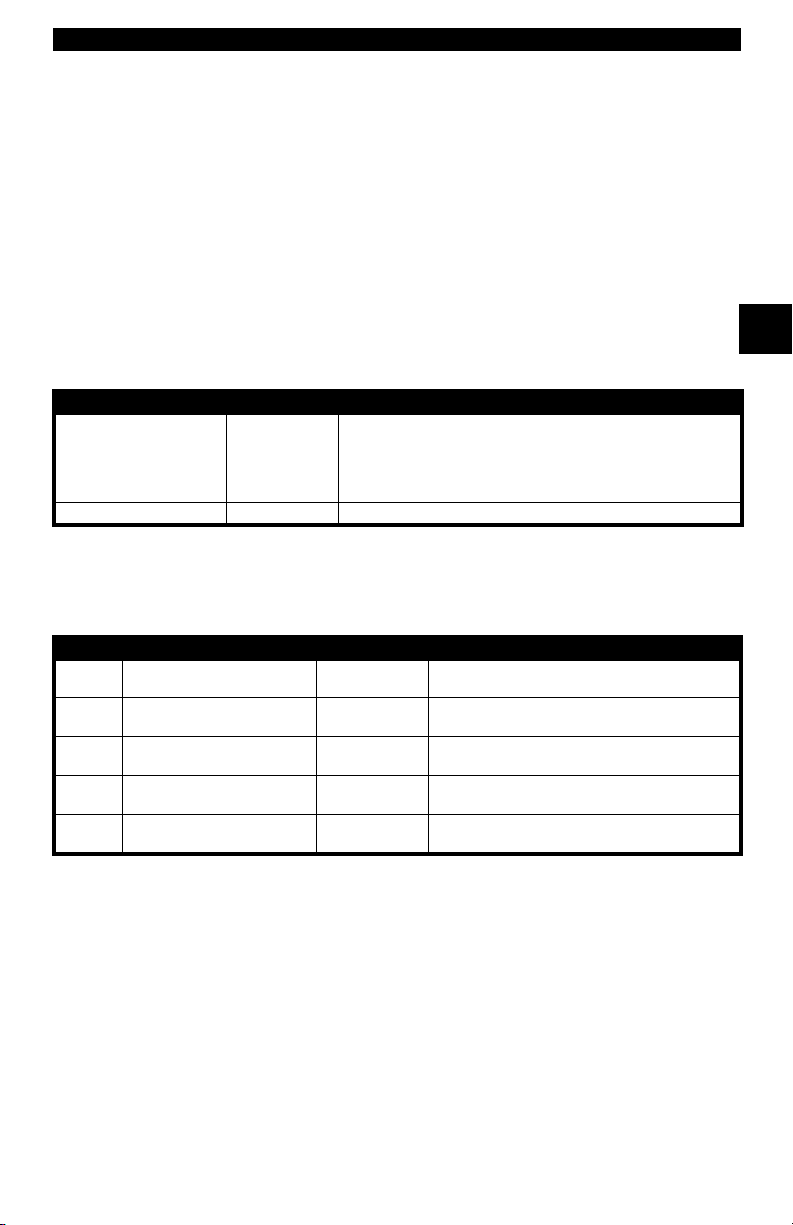

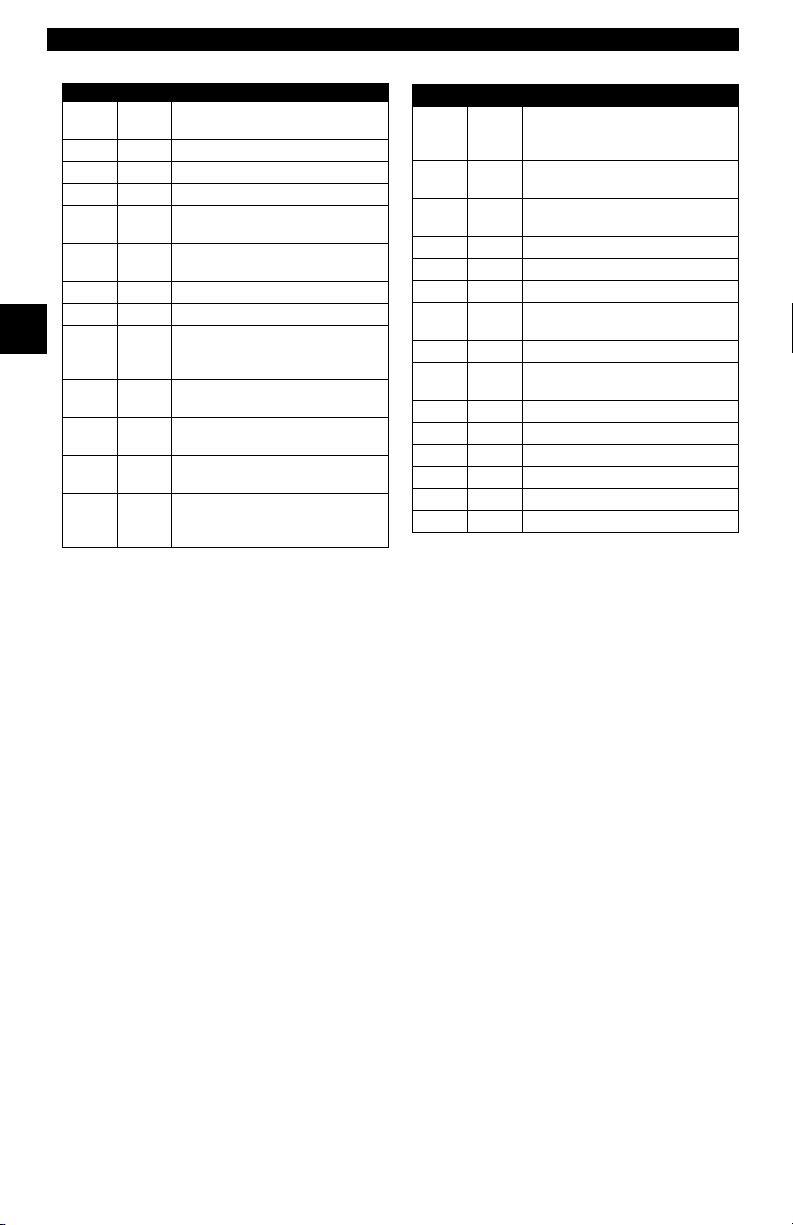

GM On-Board Diagnostics

System Years Description

Most vehicles used the 12-pin ALDL (Assembly Line Data Link)

OBD I Control Module

OBD II Control Module

*

OBD II system is used on certain 1994-1995 vehicles equipped with a 2.2L, 2.3L, 3.8L, 4.3L or 5.7L

engines.

1981–1995

1994*-Present Complies with OBD II regulations and uses the J1962 DLC.

located under the dash on the driver side. Some 94-95 vehicles

used the 16-pin OBD II (J1962) data link connector (DLC), but

use the Historical application software. Refer to the vehicle’s

Vehicle Emission Control Information label.

2

Ford On-Board Diagnostics

System Long Name Years Description

MCU

Microprocessor Control Unit 1980 –1991

EEC-IV

* EEC-V OBD II system used in 1994-1995 vehicles equipped with a 3.8L or 4.6L engine.

Electronic Engine Control,

Fourth generation

Mazda Electronic Control

MECS

System

Electronic Engine Control,

EEC-V

Fifth generation

Powertrain Electronic

PTEC

Controller

1984 –1995

1988 –1995

1994* – present

2000 – present

Used in police vehicles, containing carbureted

engines. Uses the MCU DLC.

Most Ford vehicles equipped with North

American engines. Uses the EEC-IV DLC.

Vehicles equipped with Mazda-sourced engines.

Uses MECS 6-pin and 17-pin DLCs.

Complies with OBD II regulations and uses the

OBD II J1962 DLC.

Complies with OBD II regulations and uses the

OBD II J1962 DLC.

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 2 – 3

Page 20

Getting Started

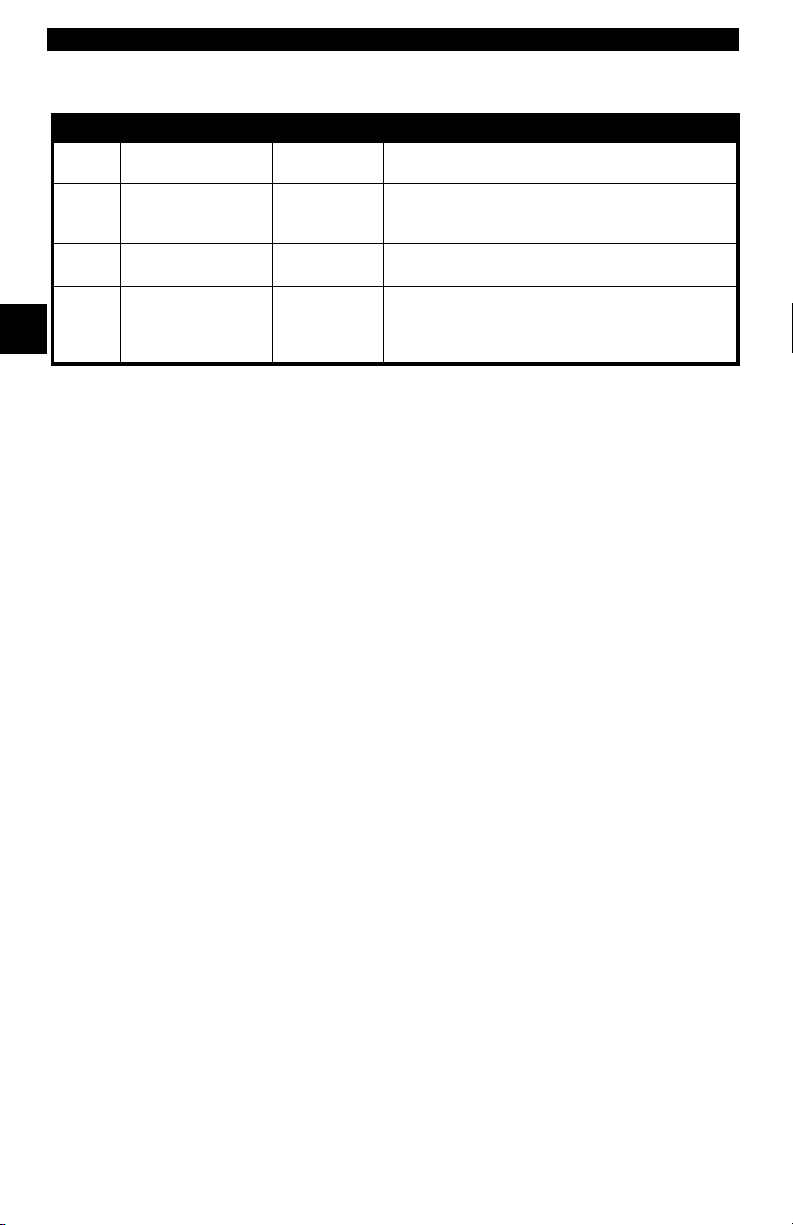

Chrysler On-Board Diagnostics

System Long Name Years Description

Single Module Engine

SMEC

Controller

Single Board Engine

SBEC

Controller

OBD II

OBD II Powertrain

PCM

Control Module

Jeep/Truck Engine

JTEC

2

* In 1989, the SBEC system was installed in selected vehicles with 3.0L V6 engines.

** Some vehicles in 1995 were equipped with the OBD II PCM.

Controller

1989–1990

1989*–1995

1995**– present

1996– present

Used a 6-pin Serial Communication Interface (SCI)

DLC and has bidirectional capability.

Used two types of DLCs: a 6-pin SCI and a 6-pin LH

series.

The first to allow a tool to reset the EMR light on trucks.

Complies with OBD II regulations and uses the OBD II

J1962 DLC.

Complies with OBD II regulations and uses the OBD II

J1962 DLC.

The JTEC system is used on light-duty trucks and

Jeeps

OBD II stands for On-Board Diagnostics version II. OBD II is a system that the

Society of Automotive Engineers (SAE) developed to standardize automotive

electronic diagnosis. Technicians now can use the same tool to test any OBD

II compliant vehicles without special adapters. The SAE established guidelines

that provide:

• a universal diagnostic test connector, called the data link connector (DLC),

with dedicated pin assignments.

• a standardized location for the DLC, visible under the dash on the driver’s

side.

• a standardized list of diagnostic trouble codes (DTCs) used by all

manufacturers.

• a standardized list of parameter identification (PID) data used by all

manufacturers.

• the ability of the vehicle system to record a freeze frame of the operating

conditions when a fault occurs.

• expanded diagnostic capabilities that records a code whenever a condition

occurs that effects vehicle emissions.

• the ability to clear stored codes from vehicle memory with the scan tool.

2 – 4 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Page 21

Getting Started

In addition, SAE has published hundreds of pages of text defining a standard

communications protocol that establishes the hardware, software, and circuit

parameters of OBD II systems. Unfortunately, vehicle manufacturers have

different interpretations of this standard communications protocol. As a result,

the generic OBD II communications scheme used will vary, depending on the

vehicle.

SAE publishes recommendations, not laws, but the Environmental Protection

Agency (EPA) and California Air Resources Board (CARB) made many of

SAE’s recommendations legal requirements that vehicle manufacturers were

required to phase in over a three-year period. Beginning in 1994, vehicles with

a new engine management computer – about 10% of each manufacturers fleet

– were supposed to comply with OBD II standards. For 1995, OBD II systems

were to appear on about 40% of the new vehicles sold in the USA. Some of the

1994-1995 OBD II systems were not fully compliant, so the Government

granted waivers to give manufacturers time to fine-tune their systems.

Beginning in 1996, most of the new vehicles sold in the USA were fully OBD II

compliant.

DIAGNOSTIC LINK CONNECTORS (DLC)

The Data Link Connector (DLC) allows the scan tool to communicate with the

vehicle’s computer(s). Before OBD II, manufacturers used different data link

connectors to communicate with the vehicle. The proper DLC adapter cable

must be used to connect the tool to the vehicle. Also, the vehicle’s DLC may be

found in several different places and have many different configurations. The

following describes the DLCs used by Ford, GM and Chrysler. The DLC location

and types for domestic vehicles can be looked up in the charts in “Appendix

A - Data Link Connectors".

2

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 2 – 5

Page 22

Getting Started

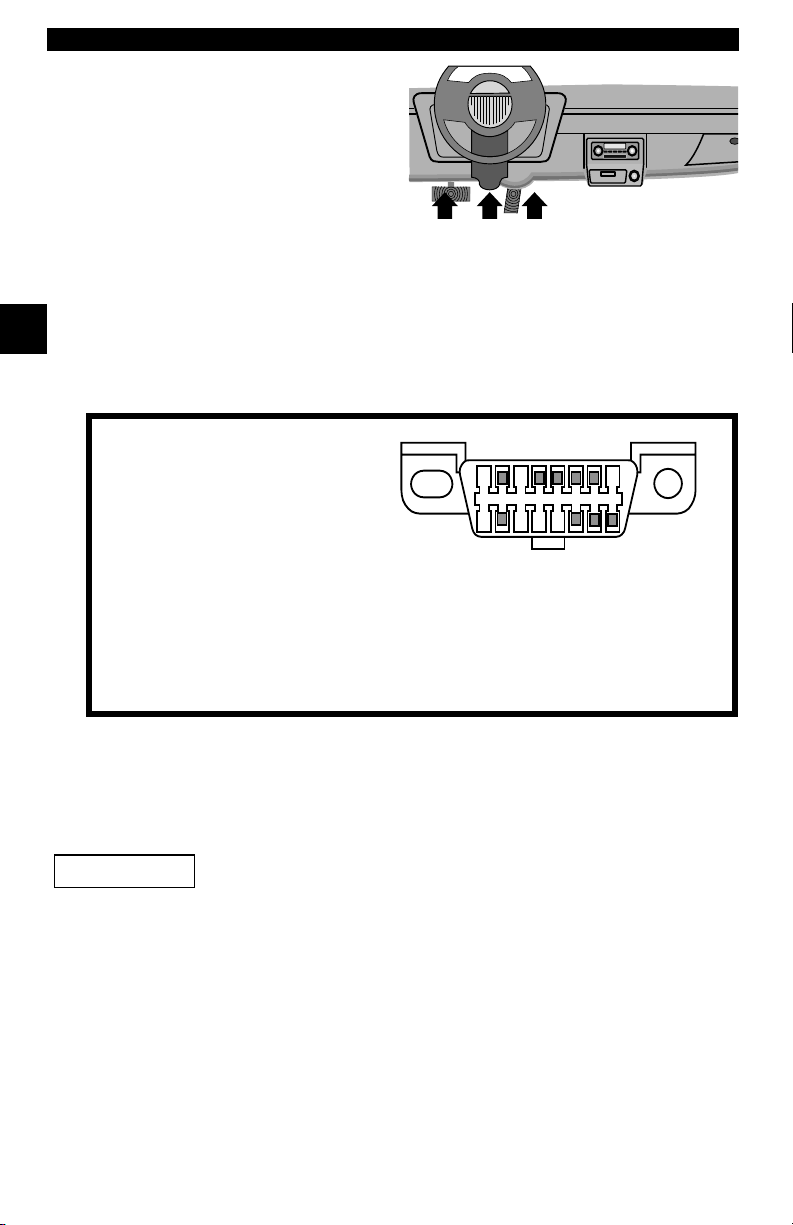

OBD II (J1962)

2

Beginning in 1996, vehicles sold in

the United States use the J1962

(OBD II) DLC, a term taken from a

physical and electrical specification

number assigned by SAE (J1962).

The DLC should be located under

the dashboard on the driver side of

the vehicle. If the DLC is not located under the dashboard as stated, a decal

describing its location should be attached to the dashboard in the area the DLC

should have been located.

Because the OBD II J1962 connector has power and ground, you only need a

single cable connection to the tool for both power and tool communications.

Attach the OBD II adapter cable to the extender cable, both supplied with the

tool, to connect the tool. Certain pins in the connector are reserved

.

1 - Manufacturer Reserved

2 - J1850 Bus+

3 - Manufacturer Reserved

4 - Chassis Ground

5 - Signal Ground

6 - CAN High, J-2284

7 - K Line, ISO 9141-2 & ISO/DIS 14230-4

8 - Manufacturer Reserved

9 - Manufacturer Reserved

10 - J1850 Bus

11 - Manufacturer Reserved

12 - Manufacturer Reserved

Ford Historic

Ford used three types of DLCs with their historic (OBD I) systems. Refer to

“Appendix A - Data Link Connectors" for the adapter cable needed for your

vehicle.

IMPORTANT

Use the Battery Power cable to provide power to the scan tool

for all systems.

1

9

13 - Manufacturer Reserved

14 - CAN Low, J-2284

15 - L Line, ISO 9141-2 & ISO/DIS 14230-4

16 - Battery Power

8

16

2 – 6 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Page 23

Getting Started

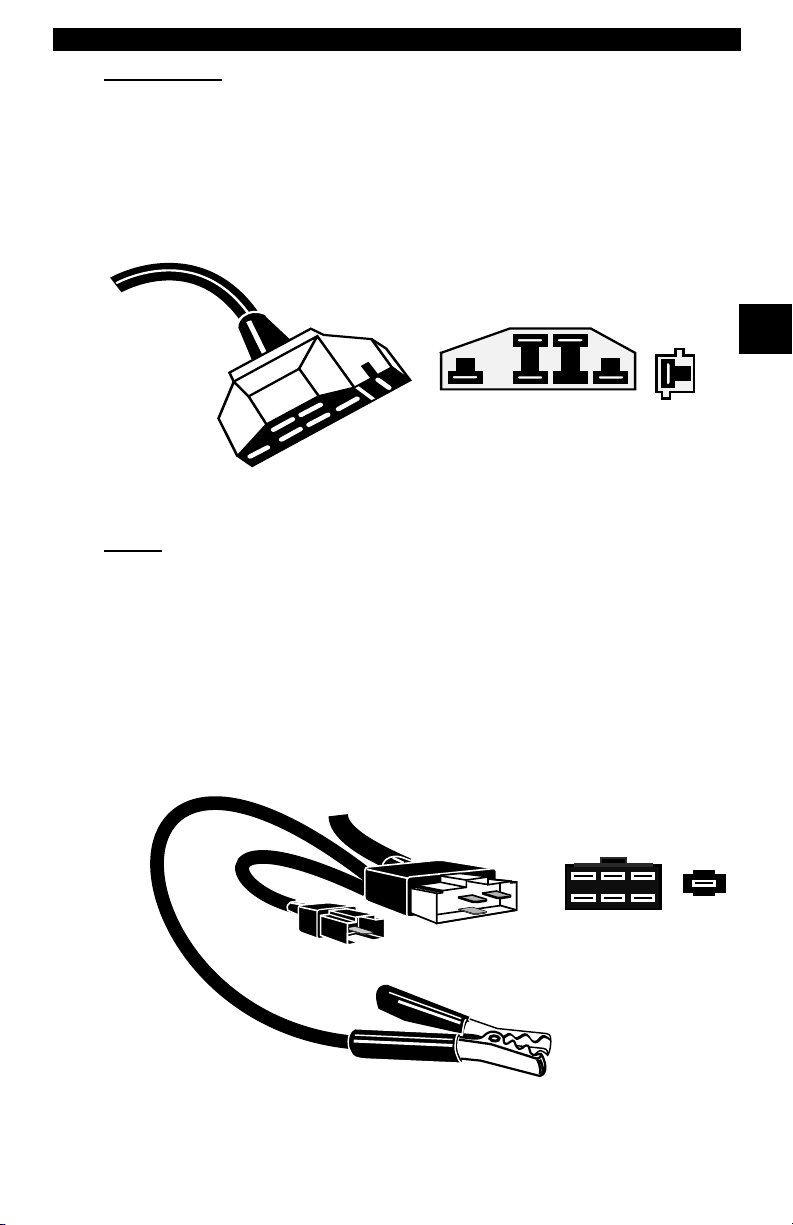

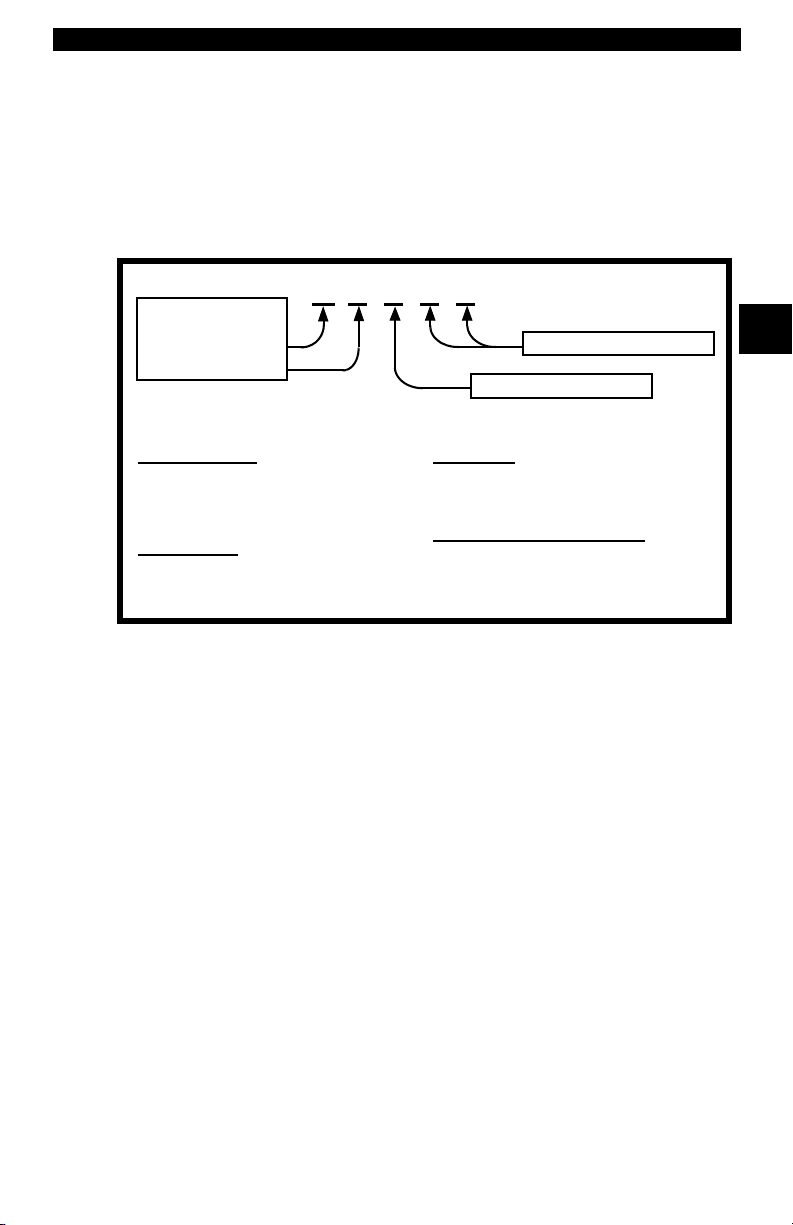

EEC-IV/MCU

The EEC-IV/MCU DLC is a large six-sided connector with a pigtail connector.

The pigtail connector is not used on MCU vehicles – leave the pigtail

unattached. The EEC-IV/MCU cable adapter is included with the scan tool.

Cable Adapter

EEC-IV/MCU

To Scan

Tool

Vehicle DLC

EEC-IV/MCU

STI Pigtail

EEC-IV

MECS

MECS vehicles (1988 –1995) use either a 6-pin (with pigtail) or a 17-pin DLC.

Use the MECS 6-pin adapter cable kit (P/N 9603) for both configurations. The

MECS adapter cable kit includes jumper wires to connect to the MECS 17-pin

DLC. The MECS adapter cable kit is not included with this tool. It is available

through your dealer. Use the following diagrams to connect the adapter cable.

6-Pin MECS

Cable Adapter

6-Pin MECS

P/N 9603

Vehicle DLC

6-Pin MECS

only

2

To Scan

Too l

Pigtail

6

5

4

3

2

1

STI Pigtail

Clip to good

Vehicle ground

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 2 – 7

Page 24

Getting Started

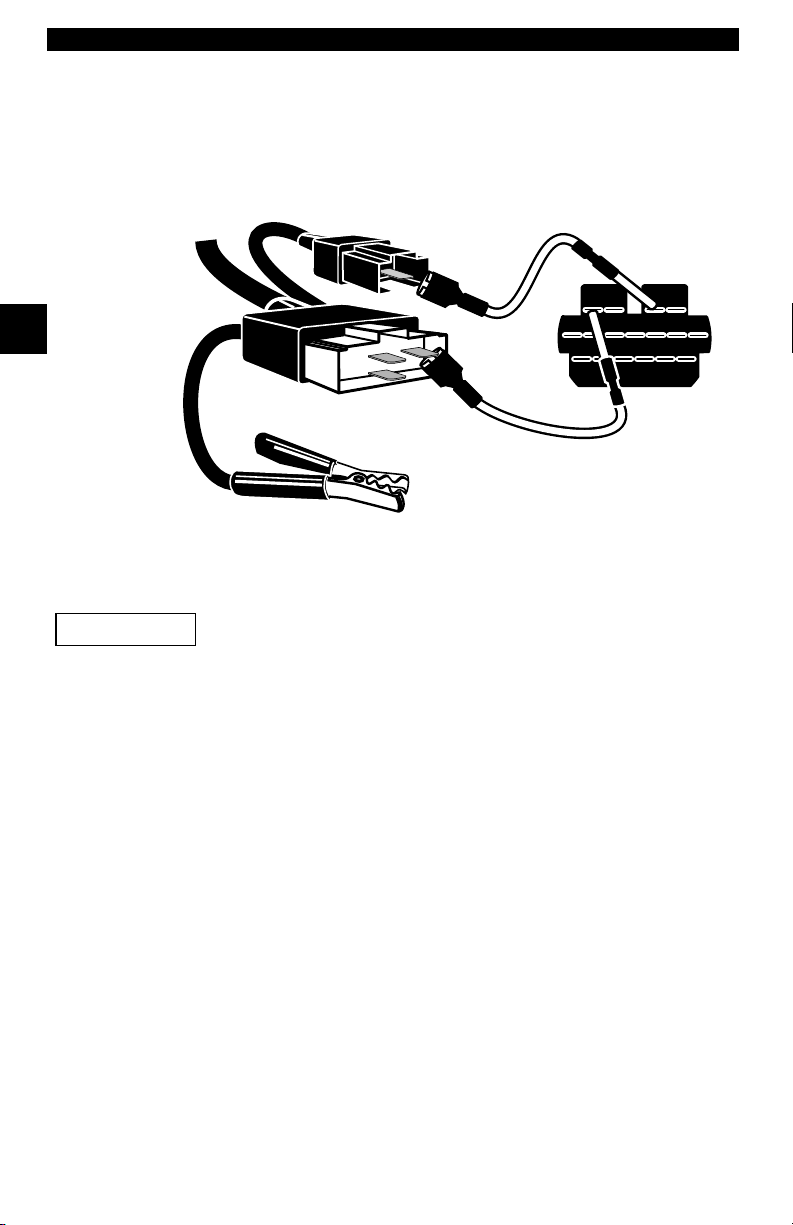

17-Pin MECS

2

IMPORTANT

Adapter Cable

To

Scan Tool

MECS Ford Probe

Certain Ford Probes have a WHITE TACH CONNECTOR

located very close to the 6-pin Self-Test connector and

bundled in the same wiring harness. This is NOT the STI

(Self Test Input) Pigtail.

6-Pin MECS

P/N 9603

4

1

STI Pigtail

6

5

3

2

Clip to good

vehicle ground

Vehicle DLC

17-Pin MECS

STO

Connect the pigtail to the BLACK STI connector located farther back on the wire

harness. If the tool is connected to the WHITE Tach connector, serious damage

may result and may void warranty. Refer to the illustration.

2 – 8 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Page 25

Getting Started

Cable Adapter

To

Scan

Tool

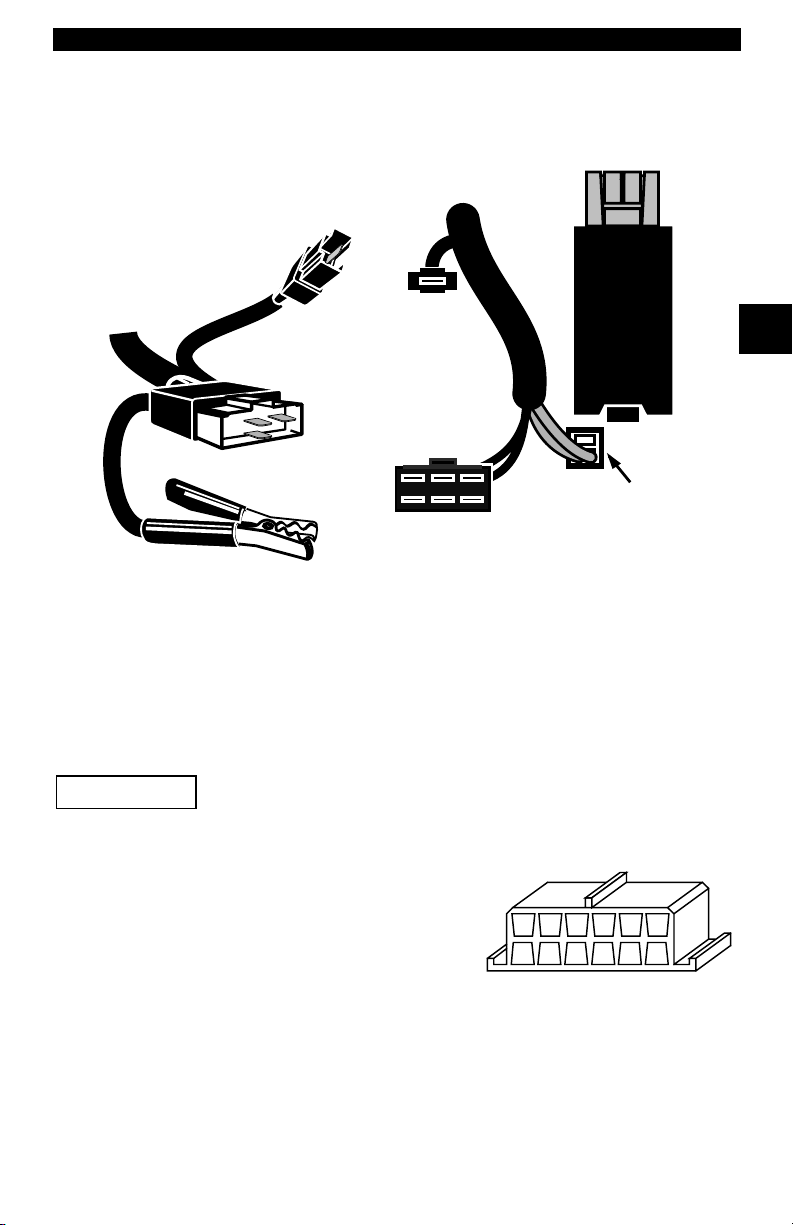

GM Historic

Prior to1996, most GM vehicles used the 12-pin Assembly Line Diagnostic Link

(ALDL) DLC. The GM ALDL cable kit includes the ALDL adapter and cigarette

lighter power cable. This adapter cable is included with the scan tool. In 1994

and 1995, certain GM vehicles use the J1962 (OBD II) DLC, but are not OBD

II compliant. Refer to “Appendix A - Data Link Connectors".

IMPORTANT

Vehicle DLC

6-Pin MECS

P/N 9603

STI

Pigtail

BLACK STI

Connector

6

5

4

3

2

1

6-Pin MECS

6-Pin MECS

Clip to good

vehicle ground

Use the Battery Power cable to provide 12V to the tool.

6-Pin MECS

Windshield

Wiper

Motor

WHITE

Tach

Connector

DO NOT USE!

2

The ALDL DLCs are usually located under

the dashboard on the driver’s side.

ALDL

On Corvettes & Fieros, the DLC may be

located in the center console behind the

ashtray. Refer to vehicle service manual for

exact location. It may be in full view, or it

FGEHDJCKBLA

M

may be recessed behind a panel. An

opening in the panel should allow access to the recessed connector.

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 2 – 9

Page 26

Getting Started

Chrysler Historic

Prior to 1996, most Chrysler vehicles used either the SCI or LH DLC. Refer to

“Appendix A - Data Link Connectors" for DLC type and location. The SCI

adapter cable is included with the scan tool. The LH adapter cable (P/N 9605)

can be purchased from your dealer.

IMPORTANT

SCI

2

LH

Use the Battery Power cable to provide 12V to the tool when

using the SCI adapter cable.

SCI

The SCI (serial communications interface) DLC is a

6-pin connector located in the engine compartment.

The adapter cable to be used on these vehicles is

supplied with the tool. This cable is labeled CHRY on

the 15 pin DB style connector and SCI on the vehicle

end.

LH (P/N 9605)

The DLC is used on LH platform vehicles. The LH

style DLC is a small, blue, rectangular 6-pin

connector located in the passenger compartment

below the dashboard to the right of the steering

column.

The LH Adapter Cable (P/N 9605) is optional and

must be purchased separately.

2 – 10 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Page 27

Getting Started

Diagnostic Trouble Codes (DTCs)

✓ Diagnostic Trouble Codes are used to help determine the cause of

a problem or problems with a vehicle.

❒ Diagnostic Trouble Codes (DTCs) consist of a five-digit

alphanumeric code.

The Diagnostic Trouble Codes format and general code types are shown below.

Bx - Body

Cx - Chassis

Px - Powertrain

Ux - Network Comm.

x = 0, 1, 2 or 3

Example:

P0101 - Mass or Volume Air Flow Circuit Range/Performance Problem

Powertrain Codes

P0xxx - Generic (SAE)

P1xxx - Manufacturer Specific

P2xxx - Generic (SAE)

P30xx-P33xx - Manufacturer Specific

P34xx-P39xx - Generic (SAE)

Chassis Codes

C0xxx - Generic (SAE)

C1xxx - Manufacturer Specific

C2xxx - Manufacturer Specific

C3xxx - Generic (SAE)

P 0 1 0 1

Body Codes

B0xxx - Generic (SAE)

B1xxx - Manufacturer Specific

B2xxx - Manufacturer Specific

B3xxx - Generic (SAE)

Network Communication Codes

U0xxx - Generic (SAE)

U1xxx - Manufacturer Specific

U2xxx - Manufacturer Specific

U3xxx - Generic (SAE)

Specific Fault Designation

Vehicle Specific System

Within each general category, the DTCs are assigned to specific ranges that

cover certain vehicle systems.

2

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 2 – 11

Page 28

Getting Started

L

Assi

d DTC Syst

owerUpper

P0000 P00FF

P0100 P02FF

P0300 P03FF

P0400 P04FF

P0500 P05FF

P0600 P06FF

P0700 P09FF

P0A00 P0AFF

2

P1000 P10FF

P1100 P12FF

P1300 P13FF

P1400 P14FF

P1500 P15FF

gne

Fuel Air Metering Auxiliary

Emission Controls

Fuel Air Metering

Ignition System or Misfire

Auxiliary Emission Controls

Vehicle Speed Idle Control

Auxiliary Inputs

Computer and Auxiliary

Outputs

Transmission

Hybrid Propulsion

Manufacturer Control Fuel &

Air Metering, Auxiliary

Emission Controls

Manufacturer Control Fuel &

Air Metering

Manufacturer Control Ignition

System or Misfire

Manufacturer Control

Auxiliary emission Controls

Manufacturer Cntrl Veh.Spd.

Idle Speed Control Auxiliary

Inputs

em

Lower Upper Assigned DTC System

P1600 P16FF

P1700 P19FF

P2000 P22FF

P2300 P23FF

P2400 P24FF

P2500 P25FF

P2600 P26FF

P2700 P27FF

P2900 P32FF

P3300 P33FF

P3400 P34FF

U0000 U00FF

U0100 U02FF

U0300 U03FF

U0400 U04FF

Manufacturer Control

Auxiliary Inputs Auxiliary

Outputs

Manufacturer Control

Transmission

Fuel Air Metering Auxiliary

emission Controls

Ignition System or Misfire

Auxiliary Emission Controls

Auxiliary Inputs

Computer and Auxiliary

Outputs

Transmission

Fuel Air Metering Auxiliary

Emission Controls

Ignition System

Cylinder Deactivation

Network Electrical

Network Communication

Network Software

Network Data

✓ J2012 and ISO 15031-6 are standards for all Diagnostic Trouble

Codes, established by the SAE, International Organization for

Standardization (ISO) and other governing bodies.

❒ Codes and definitions assigned by this specification are known as

Generic OBDII codes.

❒ OBDII requires compliance to this standard, for all cars, light

trucks, APVs, MPVs, and SUVs sold in the U.S.

Codes not reserved by the SAE are reserved for manufacturer and

referred to as Manufacturer Specific Codes.

2 – 12 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Page 29

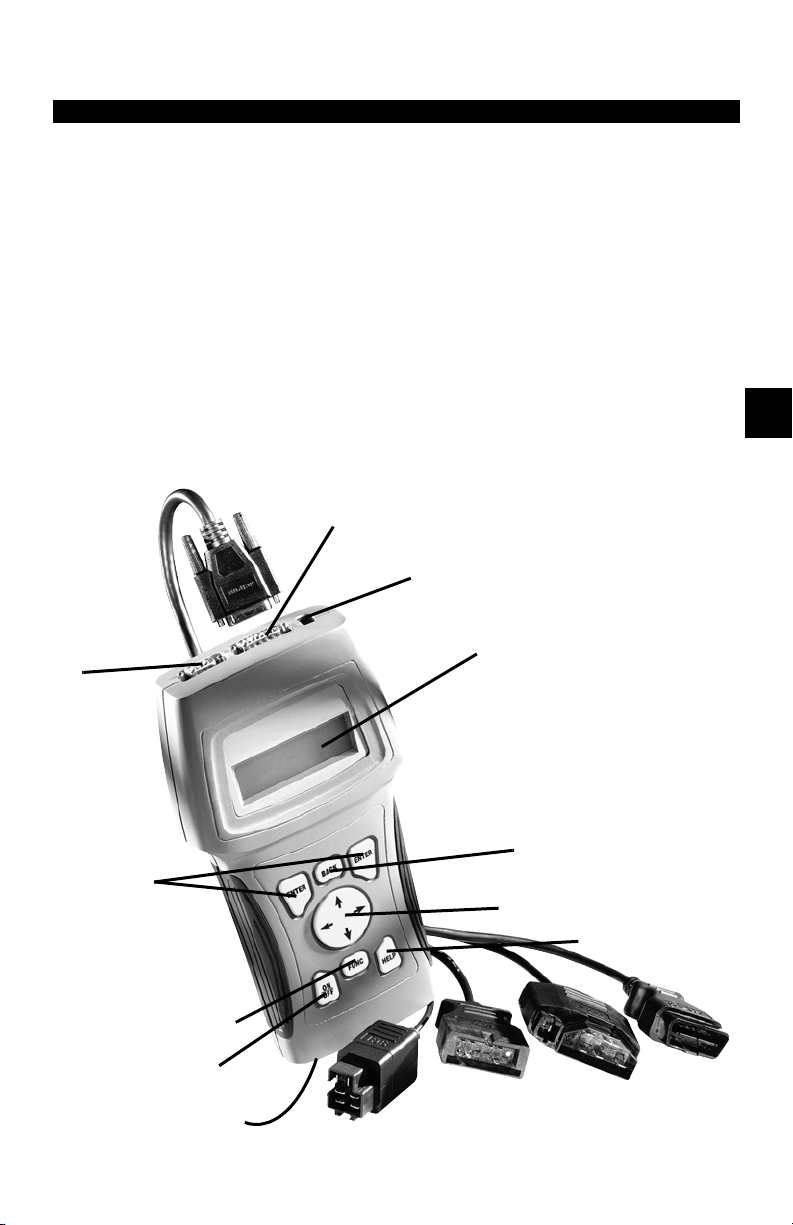

Section 3 – Using The Scan Tool

THE SCAN TOOL

B Serial Port (DB9 Male Connector) – provides a serial RS232 connection for a printer

and for updating the software.

C DLC Port (DB15 Male Connector) – provides connection for vehicle interface.

D 12V Power Jack

E LCD Display – backlit, 4 line x 20 character with contrast adjustment.

F

BACK

key – goes to the previous screen or level.

G

UP/DOWN

LEFT/RIGHT

H

HELP

I

ENTER

J

FUNC

a

ON/OFF

b Battery compartment cover.

B

arrows – scrolls UP or DOWN and moves the selection pointer (`).

arrows – selects responses and moves cursor (^) in code lookup.

key – accesses the Help Function.

key – selects displayed items.

key – returns back to a function list or menu.

key – turns power ON/OFF when not connected to vehicle.

C

D

E

3

F

I

G

H

j

a

b

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 3 – 1

Page 30

Using The Scan Tool

Specifications

Display: Backlit LCD, 4 line, 20 column, contrast adjust

Operating Temperature: 0 to 50°C (32 to 122°F)

Storage Temperature: -20 to 70°C (-4 to 158°F)

Internal Power: 6-AAA cells

External Power: 7 to 16 Volts

✓ Most vehicle control modules require at least 8.0 V to operate properly.

Power Dissipation: 3.5 Watts maximum

Dimensions: Height

Weight: 3.16 lbs (1432 g)

Accessories

3

Standard 8 ft Extender Cable

Battery Power Cable (includes cigarette lighter adapter)

Adapter Cables: Standard OBD II (J1962) cable — Included

Optional / Replacement Parts are available from the:

• dealer where you originally purchased your tool.

• manufacturer contact customer service at 1-800-228-7667 (8:00 – 6:00 EST

Monday – Friday) .

Width Length

1.625" 5.25" 9.75"

41 mm 133 mm 248 mm

– Battery Clip Adapter — Optional

GM ALDL cable kit — Included

Ford EEC-IV/MCU cable kit — Included

Chrysler SCI cable kit — Included

9605 Chrysler LH cable kit — Optional

9603 Ford Probe/MECS cable kit — Optional

3 – 2 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Page 31

Using The Scan Tool

Display

The scan tool uses a 4 line by 20 character, back-lit Liquid Crystal Display

(LCD). The large viewing area displays messages, instructions, and diagnostic

information. The contrast can be adjusted.

Seven characters help you navigate

and operate the scan tool:

? appears in upper right corner of

display to indicate Help is available.

` identifies the selection.

[ indicates additional information is

available on the next screen.

] indicates additional information is available on the previous screen.

« identifies selected items in data lists.

~ Bell in lower right corner means the sound alert is on or active.

Low battery symbol will appear in bottom right-hand corner of the screen

at power-up if the internal batteries need replacement or are not installed.

Keyboard

The scan tool’s software is designed for ease in operating and navigating

through menus. Do not use solvents such as alcohol to clean the keypad or

display. Use a mild nonabrasive detergent and a soft cotton cloth. Do not soak

the keypad as water might find its way inside the scan tool.

Function List ?

` 2)Read DTC(Codes) ]

3)Erase DTC(Codes) [

4)View Data ~

3

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 3 – 3

Page 32

Using The Scan Tool

Power

✓ Refer to “Scan Tool Does Not Power Up” on page 9-1 if you encounter

problems.

Internal Batteries

When the scan tool is not connected to the vehicle, the

the scan tool. Press and hold down the

turn ON the scan tool.

To conserve battery power, the scan tool disables the display’s back-lighting

and turns OFF after a period of inactivity.

Each time the scan tool is powered up, the voltage of the batteries is checked.

If the voltage is low, the Low Battery Symbol () displays on the screen. Replace

batteries using the instructions provided in “Battery Replacement” on

page 9-3.

✓ If the scan tool will not be used for an extended period of time, remove the

3

batteries to prevent electrolyte leakage from damaging the battery

compartment.

Vehicle Power

When using the OBD II J1962 or Chrysler LH adapter cables, the power to the

tool comes from vehicle Data Link Connector (DLC). All other vehicles will

require power connection to the cigarette lighter, accessory plug, or the vehicle

battery using battery clip adapters. If you are unsure of what DLC adapter to

use, then refer to “Appendix A - Data Link Connectors".

Some vehicle cigarette lighters are not powered when the ignition is in the OFF

position. Therefore, you may wish to use battery clip adapters.

ON/OFF

Battery Clip Adapter (optional)

ON/OFF

key for at least one second to

key turns ON

Cigarette Lighter Adapter

AC Power Adapter

An AC power adapter (not included) can be used to power the tool when

reprogramming from a personal computer or off-vehicle reviewing of codes and

printing. 12V AC-DC converters are available at most PC and electronic stores.

The tool is equipped to accept any 110 Vac - 12

Vdc wall adapter with the following specifications:

• 300 mA minimum current unregulated wall

power adapter.

• Adapter Dimensions: 5.5 mm Outside Diameter

• 2.5 mm Inside Diameter

• The Inside Tip is positive (+).

3 – 4 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

12 VGND

Page 33

Using The Scan Tool

Scan Tool Setup

Tool Setup allows you to change the

measurement units and LCD contrast,

turn beeper On/Off and display tool

information. The settings remain until

the internal batteries become

discharged.

Main Menu ?

` Vehicle Diagnosis

Tool Setup [

Tool Self-Tests ~

Measurement Units

To change the measurement units, use

the

UP/DOWN

English/Metric and press

In the Measurement Units menu,

select English or Metric and then press

ENTER

ENTER

Press

arrow keys to select

ENTER

. English is the default.

again to return to the Setup Tool menu.

Setup Tool

` 1)English/Metric

.

2)Display Contrast [

3)Beeper ~

Changing Display Contrast

The display contrast can be adjusted

from the Tool Setup menu. Select

Display Contrast and press

Use the

increase and decrease the contrast.

Press

return to the Setup Tool menu.

UP/DOWN

ENTER

arrow keys to

to save the setting and to

ENTER

] Increase Contrast

[ Decrease Contrast

.

Press ENTER To Save ~

Beeper

Beeper selection allows the user to turn Off the tool’s beeper. The bell symbol

~

will not appear in the lower right hand corner of the display when the beeper

is off.

Tool Information

This function allows you to view specific

tool information that may be needed when

contacting customer service.

Select Tool Information with the

UP/DOWN

The information shown to the right displays

on the screen. Use the

keys to view all the lines.

Press the

the Setup Tool menu.

arrow keys and press

UP/DOWN

BACK

or

ENTER

key to return to

ENTER

arrow

Tool Information:

` Serial No:10000085

SW ID: 945BH

HW Ver: 0

Boot Ver: 0

.

Prod ID:3

Board ID: 10

Burn Date:03/07/02

✓ Write this information in the space provided on the inside of the front cover.

3

Printer Interface

The scan tool is designed as a Data Terminal Equipment (DTE) device with a

DB9M (9-pin D-shape male) connector to interface with a compatible serial

printer.

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 3 – 5

Page 34

Using The Scan Tool

Compatible Printers

The printer must have a serial RS-232 interface circuit and be compatible with

the Epson FX format. The following printers are recommended:

❒ Seiko DPU-414

❒ Kodak DICONIX 180si (serial printer model)

❒ Lexmark Model 2480 with optional serial interface (p/n 12T0154)

❒ Panasonic KX-P1131 printer

Cabling

❒ Type: A standard RS-232 type cable.

❒ Scan Tool end: DB9F (female) connector.

❒ Printer end:

• Use a DB9M (male) connector for the Seiko and

Kodak printers.

• Use a DB25 male connector for the Lexmark and

Panasonic printers.

3

• If the printer uses a different connector, then an

adapter or different RS-232 cable is required. Adapters are available at most local PC stores or electronics outlets.

Serial Port Settings

❒ Default settings for the scan tool are: 9600 Baud, 8 Data Bits, No Parity

❒ Ensure the settings on the scan tool and printer match.

❒ For the Lexmark and Panasonic printers, ensure the printer’s interface

The printer and scan tool must have the same communication settings. You can

change the scan tool’s settings if necessary.

DB9

DB25

and 1 Stop Bit.

selection is set to either “auto” or “serial”.

Changing the Printer Settings

Select either Print Codes from the Main

Menu or Print Data from of the

Function List and press

ENTER

.

Main Menu ?

Vehicle Diagnosis

` Print Codes [

Tool Setup

Next, the tool will inform you of the

printer settings (Custom or Default),

then ask if you wish to change them.

Select YES and press

default values are designated on the

display with the word (Default) next to

the option.

3 – 6 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

ENTER

.The

Tool Set To Default ?

Printer Settings.

Change Settings?

Yes <No>

Page 35

Using The Scan Tool

Refer to the printer manual for the settings. The changes made reside in the tool

even when the tool is turned off.

Tool settings are as follows. Defaults are in [ . . . ]

❒ Baud Rate: [9,600], 1200, 2400

❒ Stop Bits: [1 Bit], 2 bits

❒ Parity: [None], Odd, Even

❒ Printer Speed: [Fast], Slow

Press

ENTER

the screens. For the printer to work properly, the tool and the printer must be set

to the same configuration. Change the settings accordingly.

To change the settings,

press the

and then

Use the

return to the previous

menu.

BACK

after selecting each setting. Follow the instructions displayed on

LEFT

ENTER

key to

arrow

.

Select Baud Rate

` 9600(Defalut)

1200 [

2400

Select Data Bits

` 8 (Default)

3

The new printer settings

are tested by printing the

ASCII character set.

Press to continue.

Select Stop Bits

1 Bit(Default)

`2 Bits

Select Parity

` None (Default)

Make sure printer is

turned ON, ONLINE and

connected to the tool.

Press the

begin printing.

If the printout is not OK, then retry or

change settings. If it is, press

and the data transmits and prints.

ENTER

key to

ENTER

Odd

Even

Printer

` Fast (Default)

Slow

The ASCII Character

Set Will Be Printed

Once.

Press ENTER to Cont.

Test Ends By Itself

In Approximately 10

Seconds.

Press ENTER to Cont.

Make Sure Device

Is Turned On, Online

& Connected To Tool.

ENTER To Print

A printout of the test looks similar to the

example shown.

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 3 – 7

-[ Print Test ]-

!"#$%&'()*+,-./01234

56789:;<=>?@ABCDEFGH

IJKLMNOPQRSTUVWXYZ[\

]^_`abcdefghijklmnop

qrstuvwxyz{|}~

Page 36

Using The Scan Tool

Diagnostic

Connector

CONNECTING THE SCAN TOOL

To diagnose a vehicle, connect the DLC and

power adapter (if applicable) to the scan tool.

Refer to “Diagnostic Link Connectors (DLC)”

on page 2-5 of Getting Started.

If you just want to power up the tool to do its

self-tests, code lookup, review or printing data

from the last vehicle tested, then you do not need

to attach the cable to the Data Link Connector. The internal battery provides

power for this.

When the scan tool powers up, a series

of messages display on the screen

beginning with a “Welcome” screen and

ending with a “Key Button Help” screen.

If you wish to review the key button

3

definitions, push the

otherwise, press

Vehicle Selection

When the tool powers up, the “Key Button Help” screen is followed by a Main

Menu screen.

Pick Vehicle Diagnosis to begin

Vehicle Selection. If there is a previous

vehicle present, the tool displays that

vehicle. You can choose the last vehicle

selected or setup for a new vehicle. The

tool retains all data retrieved from the

last vehicle selected until any of the

following occurs:

❒ A new vehicle is selected

❒ Internal AAA batteries are depleted or disconnected

❒ Tool is flash programmed to update software

❒ The last vehicle selected is kept but you choose Erase Data

You can either keep the previously

selected vehicle or change it. If

changing the vehicle, press the

arrow key and press

Otherwise, press

current one.

HELP

ENTER

ENTER

ENTER

key;

to continue.

RIGHT

.

to keep the

Welcome To The

Professional

Enhanced Scan Tool

SW ID: XXXX

Main Menu ?

` Vehicle Diagnosis

Tool Setup [

Tool Self-Tests ~

1995 Neon

C=2.0L SFI SOHC

<KEEP> CHANGE

Keep Current Vehicle

The next screen asks if you want to

erase the stored data. The default is NO.

After pressing

displays.

3 – 8 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

ENTER

, the function list

Erase All Stored

Data For Selected

Vehicle?

YES <NO>

Page 37

Using The Scan Tool

Changing the Vehicle

Changing vehicles erases all data

stored in the tool. The default is YES.

Press

ENTER

to continue.

Four Vehicle Options are available: Global OBD II, Domestic Vehicles,

European Vehicles, Asian Vehicles. Global OBD II does not require additional

information and takes you directly to the function list. The other three require

additional information so that the tool can communicate with the vehicle. For

example, select GENERAL MOTORS.

Picking New Vehicle

Erases All Stored

Data. Continue?

<YES> NO

✓ On GM vehicles the tool may require you to look at the VIN to determine the

Series Model, Engine Size, etc.

3

GM Typical VIN

VIN Position

Description of Number

1234567891011121314151617

Line Chassis

Series

Chassis Type

Engine Type

Model Year

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 3 – 9

Page 38

Using The Scan Tool

The menus provide a list

of choices and reference

the vehicle’s VIN where

applicable. The VIN is

visible from outside the

vehicle by looking

through the base of the

front windshield at the top

of the dashboard on the

driver’s side. Because

manufacturers use

different VIN schemes,

the tool will indicate which

digit of the VIN to locate

for information such as

Year, Make and Engine.

3

Use

keys to move through the

list.

If you make a mistake,

press the

return to the previous

menu.

At the last screen, press

ENTER

UP/DOWN

BACK

.

arrow

key to

Select Vehicle

Global OBDII

` Domestic Vehicle [

Select Manufacturer

` General Motors

Ford [

Select Vehicle Type

Chrysler

` Car

Truck

Select Year VIN 10

T=1996 ]

` S=1995 [

R=1994

Select Make VIN 3

3=Oldsmobile ]

` 4=Buick [

6=Cadillac

Select Model

Park Avenue ]

` Regal [

Reviera

Select Engine VIN 8

` L=3.8L SFI

M=3.1L SFI 4T60E

M=3.1L SFI AUTO-3S

1995 Regal

L=3.8L SFI

<KEEP> CHANGE

If a message displays, follow the

instructions then press

ENTER

.

Turn Key Off

For 10 Seconds

Then Turn Key On

Then Press ENTER

3 – 10 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Page 39

Using The Scan Tool

User Interface

The scan tool is designed to be as intuitive as possible. All menu and lists

operate the same way. Use the

through the display or move the cursor (

ENTER

the

HELP

If a list or message contains more than four lines, an arrow icon displays on the

last column of the display to indicate the scrolling direction available: up (

down (

display. When the bottom of the list is reached, then only the

top of the list, only the

key to select the function or item. To return to previous screens, press

BACK

key after powering up the scan tool.

[). Use the

UP/DOWN

arrow keys to move

UP/DOWN

`) to a selectable item. Press the

key. This information can be viewed on the scan tool by pressing the

]) or

UP/DOWN

arrow keys to move line-by-line through the

] displays. At the

[ displays.

For example: to read DTCs stored in the

vehicle, move the cursor to Read

Codes with the

and press

choice, such as viewing data, use the

UP/DOWN

cursor down to View Data and press

ENTER

.

UP/DOWN

ENTER

arrow keys to move the

. To make a different

arrow keys

Function List ?

` 3)Erase DTC(Codes) ]

4)View Data [

5)View Freeze Data ~

User Responses

The scan tool may ask a question which

requires a YES or NO response —

brackets (<>) enclose the default one.

To accept the default choice, press the

ENTER

press the

move the brackets to another response and press

key. To change the answer,

LEFT/RIGHT

arrow keys to

View Instructions

For Creating Custom

Data List?

Yes <No> ~

ENTER

Viewing Data

Viewing data allows you to observe

sensor data and the operation of

switches, solenoids, and relays. As the

computer monitors the vehicle, the

parameter Identification (PID) data is

transmitted to the scan tool.

For viewing options, select View Data from the Function List and press

ENTER

.

Function List ?

3)Erase DTC(Codes) ]

` 4)View Data [

5)View Freeze Data ~

3

.

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 3 – 11

Page 40

Using The Scan Tool

Entire Data List

The Entire Data List shows all

supported parameter identification

(PID) data for the vehicle being tested.

When the scan tool makes a recording,

the data from all supported PIDs are

stored in the scan tool.

Select Data To View

` Entire Data List

Custom Data List

View Data Setup ~

Custom Data List

The Custom Data List allows you to

select certain PIDs from the Entire Data

List, such as those PIDs that pertain to

a specific driveability symptom or

system. The scan tool asks if you want

to view the instructions.

View Instructions

For Creating Custom

Data List?

YES <NO> ~

3

Once in the Custom Data List menu,

follow the instructions described below.

A

« symbol will be displayed next to all

selected PIDs. Use the

arrow keys to scroll through the list.

•Use the

•

UP

•

DOWN

RIGHT

•

values are marked with

•

LEFT

ENTER

•

data parameters.

UP/DOWN

arrow: Moves the cursor up the data list.

arrow: Moves the cursor down the data list.

arrow: Selects or deselects a data parameter. All selected data

arrow: Deselects all marked data parameters.

key: Starts playing back data, recording data, or displaying selected

UP/DOWN

arrow keys to move up and down through the list.

« symbol.

Select Custom List

« MIL STATUS

ABSLT TPS(%) [

` ENGINE(RPM) ~

Once in the Custom Data List selection screens, follow the instructions

described above to build a Custom Data List. Data parameters or Parameter

Identification Data (PID) will follow in alphabetical order.

When you are done selecting the PIDs, press the

PID values. Press the

menu.

BACK

key twice to return to the Select Data To View

View Data Setup

View Data Setup changes the number

of lines shown on the screen. Selecting

fewer lines provides faster update

speeds. The default is four-line display.

3 – 12 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

ENTER

Select Data To View

Entire Data List

Custom Data List

` View Data Setup ~

key to view selected

Page 41

Section 4 – Global OBDII Diagnostics

The first time scan tool links to the vehicle, communication is automatically

detected, and is used until scan tool is turned OFF or another vehicle is

diagnosed.

✓ If an Error Message displays, make sure OBDII connector is attached,

and ignition key is ON. Cycle ignition key to OFF for 10 seconds, then ON.

This may be required to reset computer. If required, select YES to try

again. If problem still exists, refer to “Error Messages” on page 9-2.

✓ On initial link to vehicle, Scan Tool checks status of I/M Monitors no

matter which function is selected.

MANUAL INFO

The Manual Info function, tells user what section of manual to use. This section

covers Global OBDII Diagnostics.

I/M READINESS

The I/M Readiness (Inspection and Maintenance) function displays state of

vehicle’s OBD II Monitors. Monitors are tests to verify operation of emission

related systems or components and detect out-of-range values. Vehicle may

have to be operated under certain driving conditions to initiate a monitor. If

vehicle loses electrical power or codes are erased, monitors may be cleared.