Page 1

Technical data

Transformer terminology and FAQs

Transformers

What is a transformer?

A transformer is a passive electrical device which is designed to change one

voltage to another by magnetic induction.

What is an isolation transformer?

An isolation transformer, also referred to as an insulating transformer, is one

where the primary and secondary windings are separate, as opposed to an

autotransformer where the primary and secondary share a common winding.

What is a control transformer?

A control transformer is an isolation transformer designed to provide a high

degree of secondary voltage stability (regulation) during a short period overload

condition typically referred to as inrush. Control transformers are also referred to

as Industrial Control Transformers, Machine Tool Transformers or Control Power

Transformers (CPTs).

Can a control transformer be reversed connected?

A control transformer can be reverse connected. However, the output voltage

will be less than nameplate due to the compensation factor of the windings.

Can a single phase transformer be used with a three

phase source?

A single phase transformer can be used with a three phase source by

connecting the primary leads to any two wires of the three phase system. The

transformer output will be single phase.

Can a transformer be used at higher frequencies?

A transformer designed for 50/60HZ operation can be utilized at frequencies up

to 400 HZ. However, at 400 HZ, the inrush capability will be reduced.

What is regulation?

Regulation is the change in output voltage when the load is reduced from rated

value (full load) to zero (no load) with input voltage remaining constant.

Can transformers be used at ambients other than 40°C?

Transformers may be used at ambients less than 40°C at full nameplate

capacity. For ambients above 40°C, they must be derated as follows:

Max. ambient temperature Max. percent of load

180°C Units 105°C Units

40°C 100% 100%

50°C 90% 78%

60°C 79% 50%

What is the effect of altitude on a transformer?

A transformer may be used at full nameplate capacity up to 3300 feet (1000

meters). Above that altitude, the capacity of the transformer should be derated

by 0.3% for each 300 feet of elevation above 3300 feet.

What is the effect of load on a control transformer?

A control transformer is designed to provide rated output voltage at full VA. As

the load decreases, the output voltage will go up. Conversely, increases in load

will result in lower output voltages. Typically, the smaller the VA size of the unit,

the greater difference there is between no-load and full-load voltage.

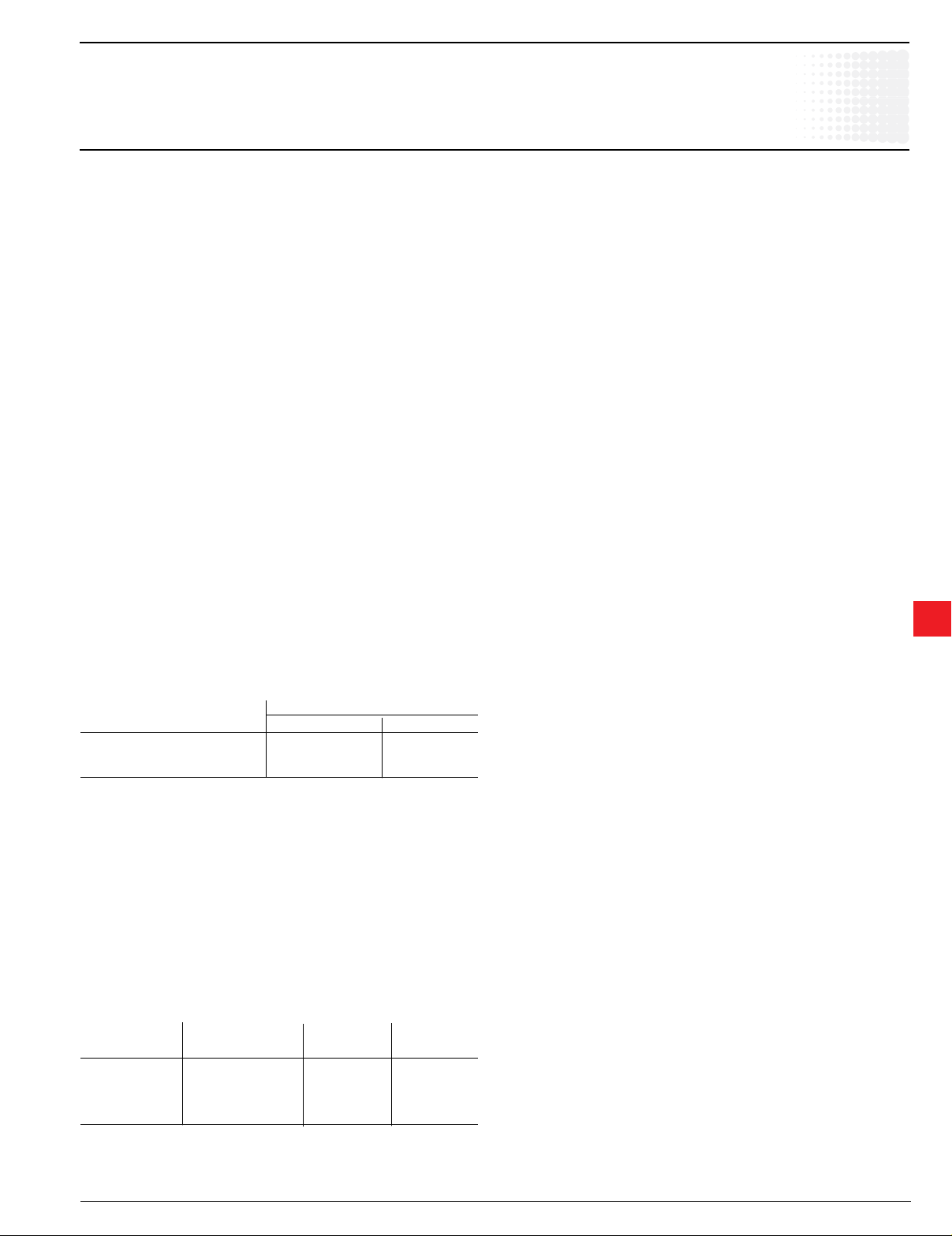

What is temperature class?

Temperature class is the rating of the transformer insulation system. It is

determined by adding the ambient temperature, temperature rise and hottest

spot temperature. The standard insulation system classication per UL506, are

as follows:

Ambient Average winding Hot spot Temperature

temperature temperature rise* temperature class

What is temperature rise?

Temperature rise is the difference between the average temperature of the

transformer windings and the ambient temperature.

What is hot spot?

The hot spot is an allowance selected to approximate the difference between the

highest temperature inside the transformer coil and the average temperature of the

transformer coil.

Is one insulation system better than another?

One insulation system is not necessarily better than another. Each will typically

provide a comparable life expectancy. The choice of an insulation system depends

upon application, performance and cost considerations.

Why is a control transformer needed?

A control transformer is required to supply voltage to a load which requires

signicantly more current when initially energized than under normal steady state

operating conditions. A control transformer is designed to provide secondary

voltage stability under a short period of specic overload referred to as inrush.

Are control transformers current limiting?

A control transformer is not current limiting and will allow as much current to pass

through as is demanded by the load. As such, a secondary overcurrent device

should be utilized.

Will a control transformer regulate output voltage?

Control transformers are not voltage regulating. Because voltage changes are

a function of the transformer’s turns ratio, variations in input voltage will be

proportionally reected to the output.

What is duty cycle?

Duty cycle is the period and duration when a transformer will be loaded. The

transformer is designed to run continuously at full load without exceeding the

temperature limits. Transformers may also be operated for short time duty.

Depending upon the time and cycle of the maximum load, the transformer VA size

may be smaller than for continuous duty.

What is the value of encapsulation in control transformers?

Encapsulating the coils of a control transformer will help to protect the unit from

moisture, dust, dirt and industrial contaminants. Encapsulation helps provide

maximum protection in hostile environments while allowing the unit to run cooler

than a non-encapsulated unit.

What effect does a control transformer have on electrical

disturbances found on the line?

Because a control transformer has isolated primary and secondary windings, it will

provide some degree of “clean-up” with regard to electrical noise, spikes, surges

and transients. It will not, however, provide the same degree of power conditioning

found in products designed for that purpose.

12

40°c 55°C 10°C 105°C

40°c 80°C 10°C 130°C

40°c 100°C 15°C 155°C

40°c 120°C 20°C 180°C

*Measured by change-in-resistance method

Low Voltage Products & Systems 12.7

ABB Inc. • 888-385-1221 • www.abb-control.com 1SXU000023C0201

Page 2

Technical data

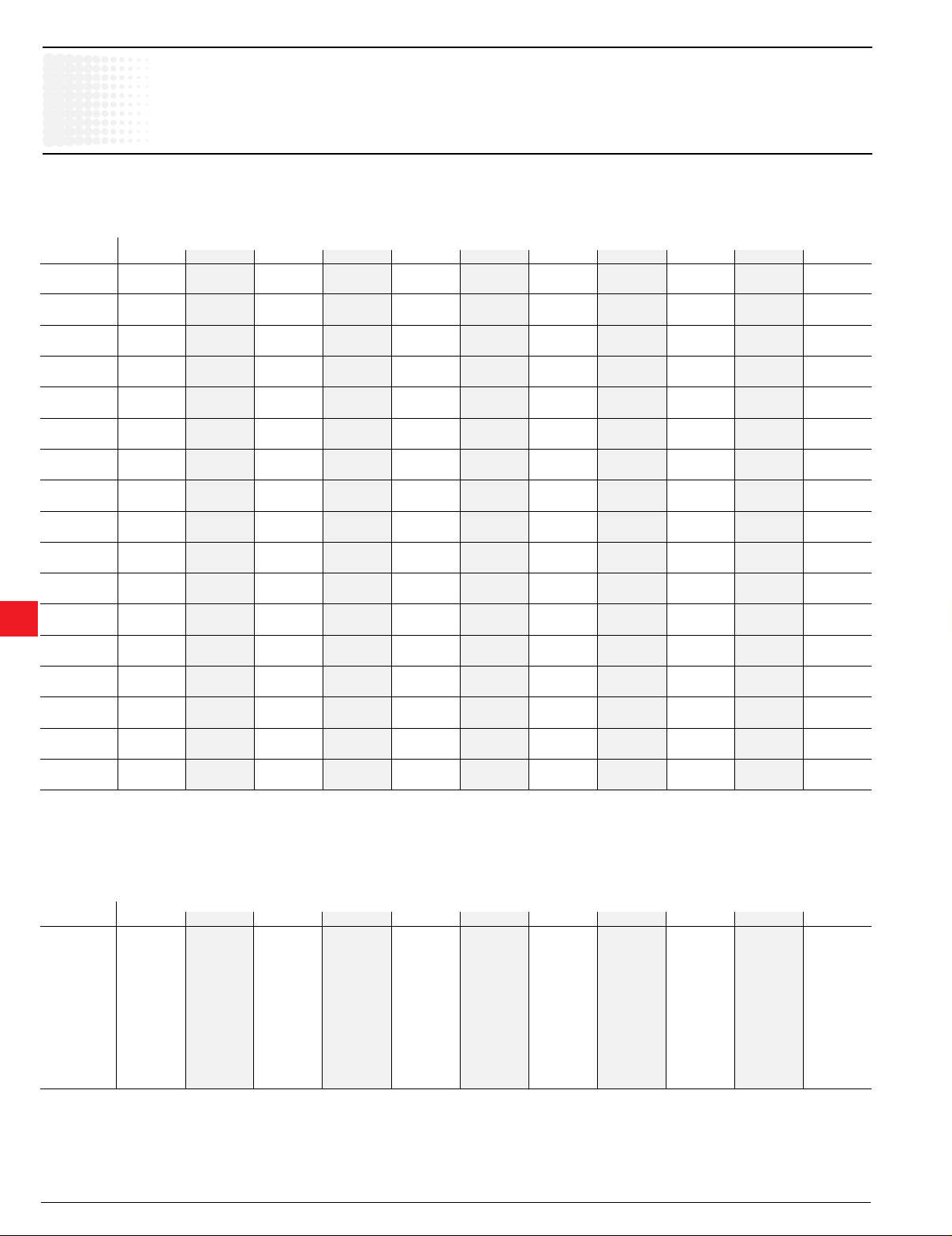

UL Overcurrent protection

Transformers

Overcurrent protection on both the primary and secondary sides of transformers are specied in UL508 and the National Electrical Code. The maximum acceptable

ratings are shown below. Due to the high inrush currents present when a transformer is initially energized, it is recommended that the primary fuse be time delay, to

prevent nuisance trips during startup.

Maximum acceptable rating of primary overcurrent protection

Primary VA Rating

voltage 25 50 75 100 150 200 250 300 350 500 750

6/10 1-1/4 1-8/10 2-1/2 3-1/2 5 5 6-1/4 7-1/2 10 15

115

(1) (2) (3-2/10) (4) (6-1/4) (8)

6/10 1-1/4 1-8/10 2-1/4 3-1/2 5 5 6-1/4 7 10 15

120

(1) (2) (3) (4) (6-1/4) (8)

3/10 3/4 1-1/8 1-1/2 2-1/4 3 3-1/2 4-1/2 5 6-1/4 9

200

(6/10) (1-1/4) (1-8/10) (2-1/2) (3-1/2) (5) (6-1/4) (7-1/2) (8)

3/10 6/10 1 1-4/10 2 2-8/10 3-1/2 4 5 6 9

208

(6/10) (1-1/8) (1-8/10) (2-1/4) (3-1/2) (4-1/2) (6) (7) (8)

3/10 6/10 1 1-1/4 2 2-1/2 3-2/10 4 4-1/2 5-6/10 8

220

(1/2) (1-1/8) (1-6/10) (2-1/4) (3-2/10) (4-1/2) (5-6/10) (6-1/4) (7-1/2)

3/10 6/10 8/10 1-1/4 1-8/10 2-1/2 3-2/10 3-1/2 4-1/2 5 8

230

(1/2) (1) (1-6/10) (2) (3-2/10) (4) (5) (6-1/4) (7-1/2)

3/10 6/10 8/10 1-1/4 1-8/10 2-1/4 3 3-1/2 4 5 7-1/2

240

(1/2) (1) (1-1/2) (2) (3) (4) (5) (6-1/4) (7)

1/4 1/2 8/10 1 1-6/10 2 2-1/2 3-2/10 3-1/2 5 6-1/4

277

(4/10) (8/10) (1-1/4) (1-8/10) (2-1/2) (3-1/2) (4-1/2) (5) (6-1/4) (9)

3/16 3/10 1/2 3/4 1-1/8 1-1/2 1-8/10 2-1/4 2-1/2 3-1/2 5-6/10

380

(3/10) (6/10) (8/10) (1-1/4) (1-8/10) (2-1/2) (3-2/10) (3-1/2) (4-1/2) (6-1/4) (9)

3/16 3/10 1/2 3/4 1-1/8 1-1/2 1-8/10 2-1/4 2-1/2 3-1/2 5-6/10

400

(3/10) (6/10) (8/10) (1-1/4) (1-8/10) (2-1/2) (3) (3-1/2) (4) (6-1/4) (9)

15/100 3/10 1/2 6/10 1 1-4/10 1-8/10 2 2-1/2 3-1/2 5

415

(3/10) (6/10) (8/10) (1-1/8) (1-8/10) (2-1/4) (3) (3-1/2) (4) (6) (9)

12

15/100 3/10 1/2 6/10 1 1-1/4 1-6/10 2 2-1/4 3-2/10 5

440

(1/4) (1/2) (8/10) (1-1/8) (1-6/10) (2-1/4) (2-8/10) (3-2/10) (3-1/2) (5-6/10) (8)

15/100 3/10 4/10 6/10 8/10 1-1/4 1-6/10 1-8/10 2-1/4 3-2/10 4-1/2

460

(1/4) (1/2) (8/10) (1) (1-6/10) (2) (2-1/2) (3-2/10) (3-1/2) (5) (8)

15/100 3/10 4/10 6/10 8/10 1-1/4 1-1/2 1-8/10 2 3 4-1/2

480

(1/4) (1/2) (3/4) (1) (1-1/2) (2) (2-1/2) (3) (3-1/2) (5) (7-1/2)

1/8 1/4 4/10 1/2 8/10 1 1-1/4 1-6/10 1-8/10 2-1/2 4

550

(2/10) (4/10) (6/10) (8/10) (1-1/4) (1-8/10) (2-1/4) (2-1/2) (3) (4-1/2) (6-1/4)

1/8 1/4 3/10 1/2 3/4 1 1-1/4 1-1/2 1-8/10 2-1/2 3-1/2

575

(2/10) (4/10) (6/10) (8/10) (1-1/4) (1-6/10) (2) (2-1/2) (3) (4) (6-1/4)

1/8 2/10 3/10 1/2 3/4 8/10 1-1/4 1-1/2 1-6/10 2-1/4 3-1/2

600

(2/10) (4/10) (6/10) (8/10) (1-1/4) (1-6/10) (2) (2-1/2) (2-8/10) (4) (6-1/4)

If the rated primary current is less than 2 amps, the maximum rating of the overcurrent device is 300% for power circuits, shown above, or 500% for control circuits,

shown above in (brackets). If the rated primary current is 2 amps or more, the maximum rating of the overcurrent device is 250%.

All gures assume secondary overcurrent protection per UL/NEC.

Reference: NEC 430 - 72(c) exception #2, 450-3(b) 1 & 2, UL508 32.7, UL845 11.16 & 11.17.

Primary & secondary

Maximum acceptable rating of secondary overcurrent protection

Secondary VA Rating

voltage 25 50 75 100 150 200 250 300 350 500 750

23 1-8/10 3-1/2 5 7 10 12 15 20 20 30 45

24 1-6/10 3-2/10 5 6-1/4 10 12 15 20 20 30 40

25 1-6/10 3-2/10 5 6-1/4 10 12 15 15 20 25 40

90 4/10 8/10 1-1/4 1-8/10 2-1/2 3-1/2 4-1/2 5 6-1/4 9 12

95 4/10 8/10 1-1/4 1-6/10 2-1/2 3-1/2 4 5 6 8 12

100 4/10 8/10 1-1/4 1-6/10 2-1/2 3-2/10 4 5 5-6/10 8 12

110 3/10 3/4 1-1/8 1-1/2 2-1/4 3 3-1/2 4-1/2 5 7-1/2 10

115 3/10 6/10 1 1-4/10 2 2-8/10 3-1/2 4 5 7 10

120 3/10 6/10 1 1-1/4 2 2-1/2 3-2/10 4 4-1/2 6-1/4 10

220 15/100 3/10 1/2 3/4 1-1/8 1-1/2 1-8/10 2-1/4 2-1/2 3-1/2 5-6/10

230 15/100 3/10 1/2 6/10 1 1-4/10 1-8/10 2 2-1/2 3-1/2 5

240 15/100 3/10 1/2 6/10 1 1-1/4 1-6/10 2 2-1/4 3-2/10 5

If the rated secondary current is less than 9 amps, the maximum rating of the overcurrent device is 167%; 9 amps or more, the maximum rating of the overcurrent

device is 125%. If 125% does not correspond to a standard fuse rating, the next highest standard rating may be used.

Reference: NEC 430 - 72(c) exception #2, 450-3(b) 1 & 2, UL508 32.7, UL845 11.16 & 11.17.

12.8 Low Voltage Products & Systems

1SXU000023C0201 ABB Inc. • 888-385-1221 • www.abb-control.com

Loading...

Loading...