Page 1

Operation Manual

TPS61-R

HT591545 English

Original Operation Manual

Chapter Document-ID

1 Introduction

2 Safety

3 Safety data sheet

4 Product description

HZTL4005_EN_F

HZTL4027_EN_A

HT591545

HZTL4042_EN_B

ABB Turbocharging

Page 2

Operating limits and replacement intervals

The recommended replacement intervals and the corresponding operating limits in chapter 3 are jointly defined

with the enginebuilder. This information is specific to the product.

Non-observance of the recommended replacement intervals and the operating limits increases the risk of unpredictable component failures.

Page 3

Operation Manual / 1 Introduction

Table of contents

Introduction

1 Introduction............................................................................................................ 2

1.1 Purpose of the manual.................................................................................................. 2

1.2 Symbols, definitions...................................................................................................... 3

1.3 Storage of new turbochargers and spare parts...................................................... 5

1.4 Contact information...................................................................................................... 7

© Copyright 2017 ABB. All rights reserved. HZTL4005_EN Revision F May 2017

Page 4

Operation Manual / 1 Introduction

1 Introduction / 1.1 Purpose of the manual

1 Introduction

1.1 Purpose of the manual

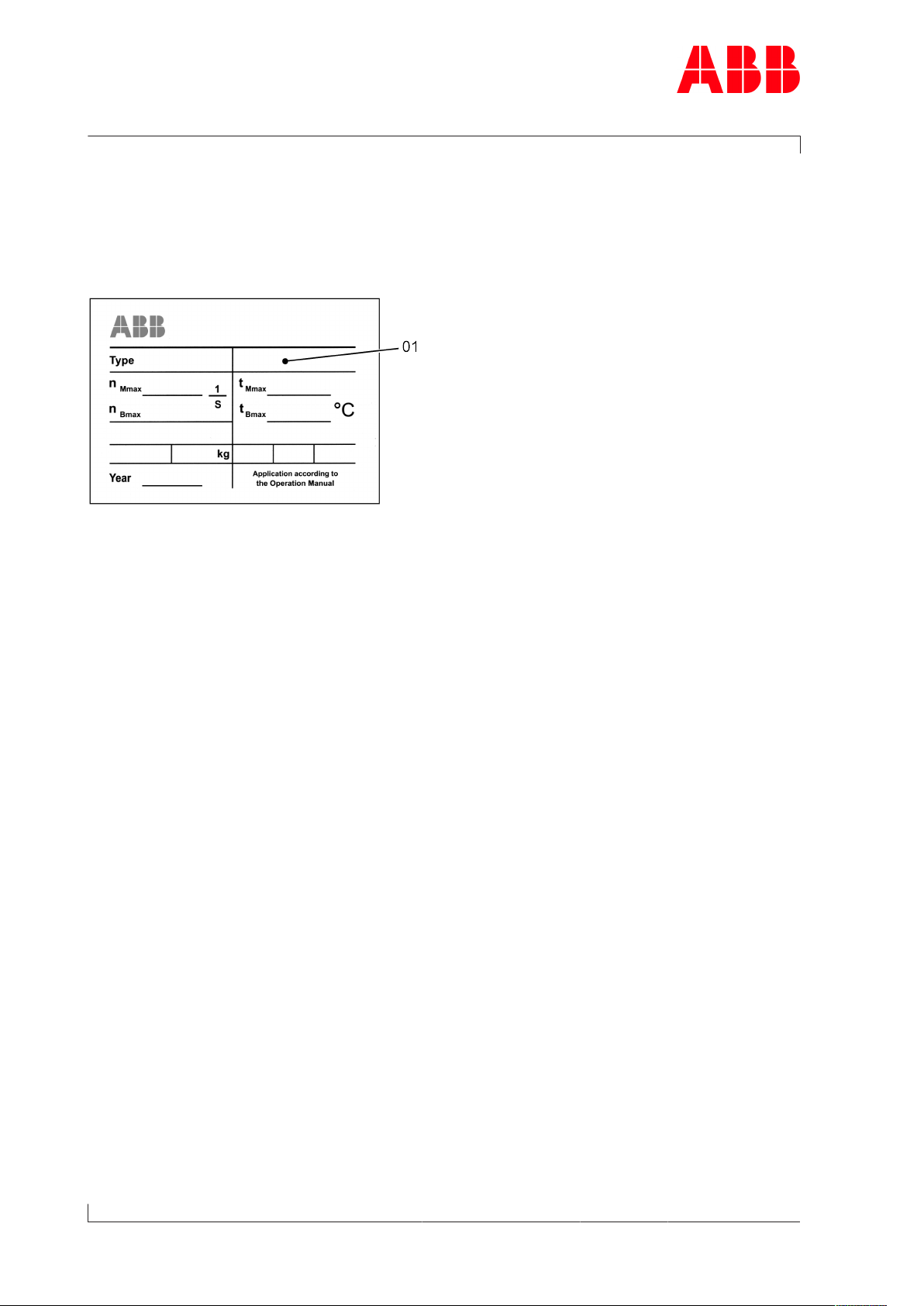

Fig.1: Serial number (01) on the rating plate

This Operation Manual belongs to the turbocharger with the identical serial number (01), see

chapter 3 (Safety data sheet) and the rating plate on the turbocharger.

Operation Manual

The Operation Manual explains the turbocharger and contains instructions for safe opera-

Page 2 / 7

tion.

The Operation Manual is a complement to and expansion of existing national regulations for

occupational safety, accident prevention and environmental protection.

Target group

The Operation Manual is aimed at engineers and trained mechanics responsible for the

proper operation of the engine and for the turbocharger connected to it.

Availability of the Operation Manual

The Operation Manual must be available where the turbocharger is used.

All persons operating or working on the turbocharger must have read and fully understood

the Operation Manual.

© Copyright 2017 ABB. All rights reserved. HZTL4005_EN Revision F May 2017

Page 5

Operation Manual / 1 Introduction

1 Introduction / 1.2 Symbols, definitions

1.2 Symbols, definitions

Symbols

The following symbols are used in this document:

u Indicates an action step.

1. Indicates a numbered action step.

→ Refers to a page number.

Definition of Note

NOTICE

Note

The note provides advice which facilitates the work.

Definition of mandatory signs

Mandatory signs show the protective equipment to be worn for a task. The mandatory signs

are described in chapter Safety and must be complied with.

Definition of Caution / Warning

Caution and warning signs are described in chapter Safety.

ABB Turbo Systems

ABB Turbo Systems Ltd is identified as ABB Turbo Systems in this document.

Official service stations of ABB Turbo Systems

Official service stations are identified in this document as ABB Turbocharging Service Stations. They are regularly audited and certified by ABB Turbo Systems. Also see chapter Con-

tact information →7.

Page 3 / 7

© Copyright 2017 ABB. All rights reserved. HZTL4005_EN Revision F May 2017

Page 6

Operation Manual / 1 Introduction

1 Introduction / 1.2 Symbols, definitions

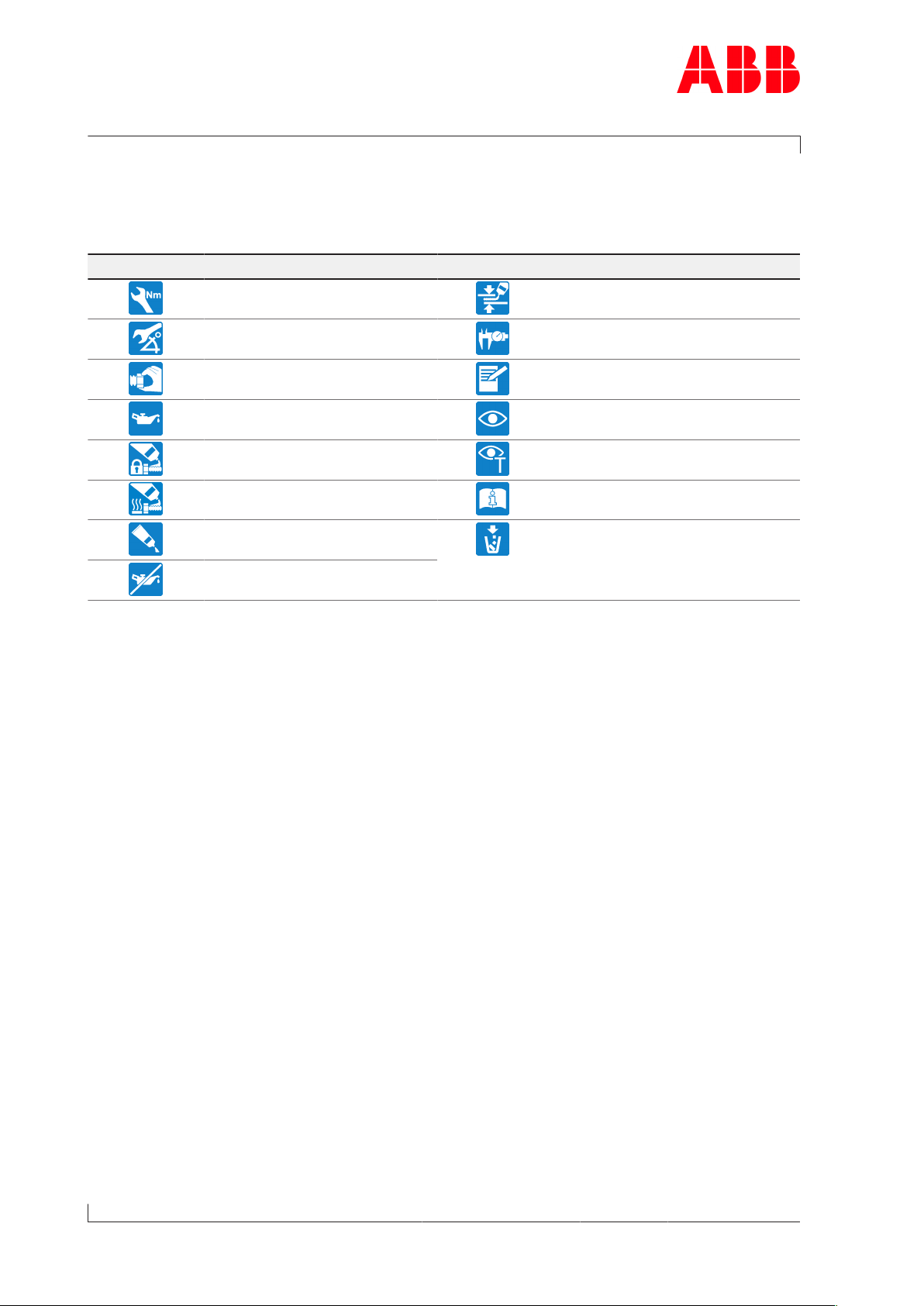

Definition of pictograms

The following pictograms can occur in this document. These point out actions that must be

taken in accordance with the meaning of the relevant pictogram.

Pictogram Meaning Pictogram Meaning

Tighten with specified torque Affix

Tighten over specified tightening angle

Hand-tight, tighten without

tools

Oil Visually inspect

Apply screw locking paste (e.g.

Loctite)

Apply high-temperature grease See document

Apply other paste in accordance with specifications

Oil free, grease free and dry

Table1: Definition of pictograms

Measure

Note

Please note text for numbered

work step

Dispose of in an environmentally

compatible, professional way and

in compliance with locally applicable regulations

Page 4 / 7

© Copyright 2017 ABB. All rights reserved. HZTL4005_EN Revision F May 2017

Page 7

Operation Manual / 1 Introduction

1 Introduction / 1.3 Storage of new turbochargers and spare parts

1.3 Storage of new turbochargers and spare parts

Storage of new turbochargers and spare parts for up to 6 months

New turbochargers and spare parts can be stored in their closed packages for 6 months

from the date of delivery without additional mothballing measures, indicated by the VCI label on the package.

Fig.2: Volatile Corrosion Inhibitor (VCI)

Only dry rooms with 40...70 % atmospheric humidity, in which no water condensation can

form, are suitable as storage locations.

Storage of new turbochargers and spare parts for more than 6 months

WARNING

Health protection when handling VCI

VCI products are not hazardous in terms of the Ordinance on Hazardous

Substances. Nevertheless, the following points must be observed when

handling VCI:

u Observe information in material safety data sheet

u Ensure proper space ventilation.

u Do not eat, drink or store food at the workplace while working with VCI.

u Clean hands and face after working with VCI.

u For more information, see www.branopac.com.

Wear safety gloves to protect against mechanical hazards.

Every 6 months, the following mothballing measures are required:

u Open package.

u Remove VCI corrosion protection emitter from package and replace with a new VCI corro-

sion protection emitter of the same kind. New VCI corrosion protection emitters can be

obtained from www.branopac.com.

u Old VCI corrosion protection emitters must be disposed of in an environmentally compat-

ible, professional way and in compliance with locally applicable regulations.

Page 5 / 7

u Close package. The more tightly the package is sealed, the longer the protection dura-

tion.

© Copyright 2017 ABB. All rights reserved. HZTL4005_EN Revision F May 2017

Page 8

Operation Manual / 1 Introduction

1 Introduction / 1.3 Storage of new turbochargers and spare parts

Long-term storage of replacement turbochargers or spare parts

The turbochargers or cartridge groups will be prepared for long-term storage if requested in

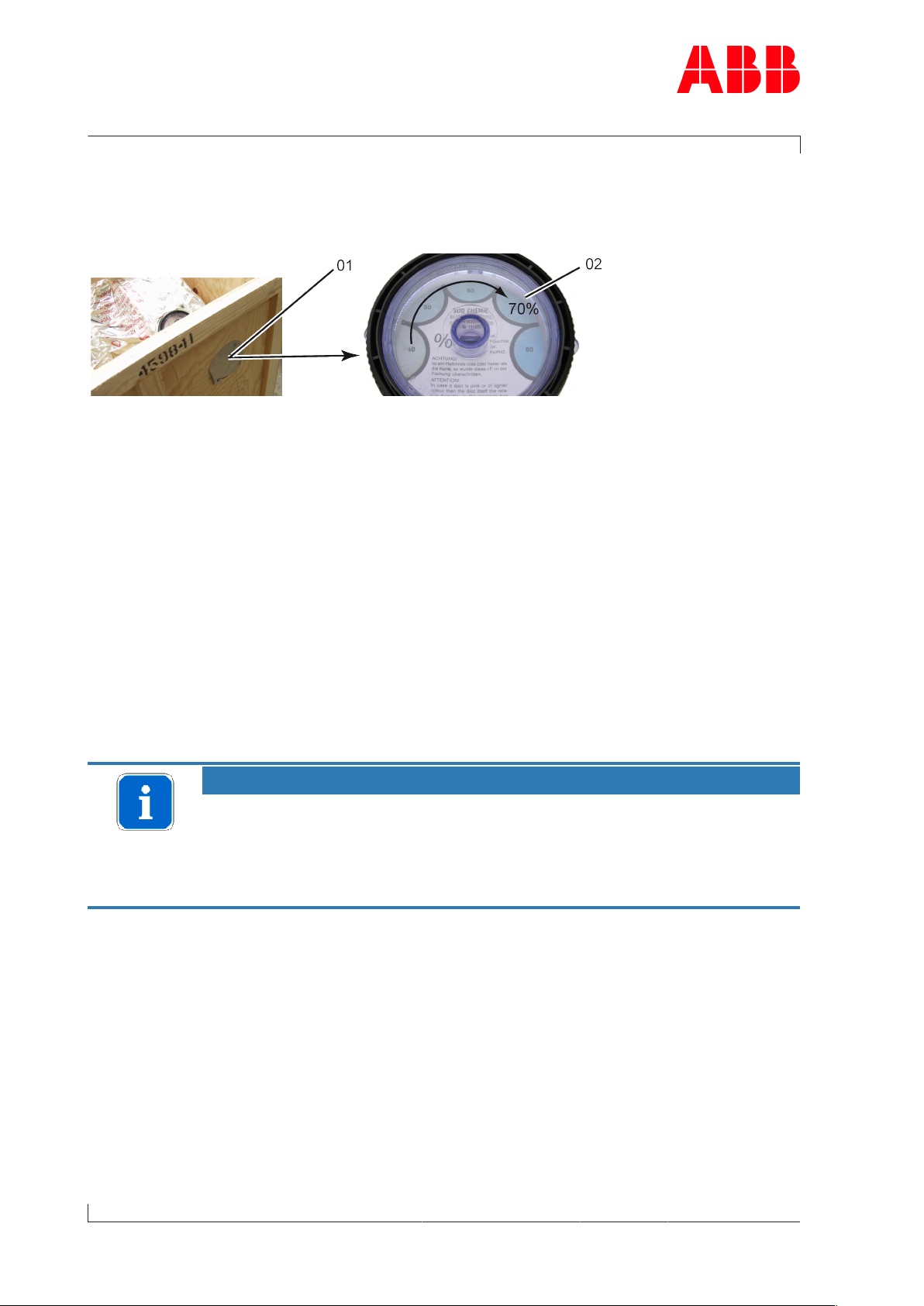

the purchase order. The package is equipped with a hygrometer (see illustration).

Fig.3: Package with hygrometer

Every 6 months, the following measures are required:

u Check the hygrometer(02) in the sight-glass. There is an opening(01) in the wooden

crate to enable you to perform this check. If the 70% indicator field has changed colour,

the maximum admissible atmospheric humidity has been exceeded. In this case, the turbocharger or cartridge group must be checked and repackaged by an ABB Turbocharging

Service Station.

u Check the package for damage. If the package is damaged, the turbocharger or cartridge

group must be checked and repackaged by an ABB Turbocharging Service Station.

After every 3 years, the following steps must be carried out by an ABB Turbocharging Service

Station:

Page 6 / 7

¡ Checking the component

¡ Replacing the desiccant

¡ Repackaging the component.

NOTICE

Replacement components which are ready for operation

If the 70% field of the hygrometer(02) has not changed colour and the package is not damaged, the replacement turbocharger or replacement cartridge

group can be put into operation without previously having been checked by

an ABB Turbocharging Service Station.

Unpackaging replacement turbochargers or spare parts

Once the material has been unpackaged from the VCI package, the corrosion protection is

no longer effective.

To prevent condensation, the temperature of the package contents must be the same as the

ambient temperature.

© Copyright 2017 ABB. All rights reserved. HZTL4005_EN Revision F May 2017

Page 9

Operation Manual / 1 Introduction

1 Introduction / 1.4 Contact information

1.4 Contact information

Contact information for the ABB Turbocharging Service Stations is available online.

u Scan the QR code to access our website.

ABB Turbo Systems Ltd

Bruggerstrasse 71a

CH-5401 Baden

Switzerland

www.abb.com/turbocharging

Page 7 / 7

© Copyright 2017 ABB. All rights reserved. HZTL4005_EN Revision F May 2017

Page 10

Page 11

Operation Manual / 2 Safety / TPS-R

Table of contents

Safety

1 Safety ...................................................................................................................... 2

1.1 Introduction .................................................................................................................... 2

1.2 CE conformity................................................................................................................. 2

1.3 Definition of mandatory signs .................................................................................... 3

1.4 Definition of safety instructions ................................................................................ 3

1.5 Intended use .................................................................................................................. 4

1.6 Warning plates on the turbocharger.......................................................................... 5

1.7 Turbocharger rating plate........................................................................................... 6

1.8 Lifting of loads .............................................................................................................. 8

1.9 Prerequisites for operation and maintenance........................................................ 9

1.10 Hazards during operation and maintenance ......................................................... 10

1.11 Safe operation .............................................................................................................. 12

1.12 Safe maintenance ........................................................................................................ 13

© Copyright 2018 ABB. All rights reserved. HZTL4027_EN Revision A April 2018

Page 12

Operation Manual / 2 Safety / TPS-R

1 Safety / 1.1 Introduction

1 Safety

1.1 Introduction

Turbochargers manufactured by ABB reflect the state of the art. The respective safety and

health protection requirements are met. This ensures safe operation of the turbocharger.

Nevertheless, there may be some residual risks during operation of and work on the turbocharger which:

¡ Are caused by the turbocharger itself or its accessories.

¡ Are caused by the operating equipment used or supplies and materials.

¡ Are a consequence of insufficient compliance with safety instructions.

¡ Are a consequence of insufficient or inappropriate performance of maintenance and in-

spection work.

The operating company is responsible for defining measures that regulate safe access to

and safe handling of the turbocharger.

Page 2 / 16

All instructions contained in this chapter must be observed for safe and trouble-free operation of the turbocharger and during all work on the turbocharger.

All further safety instructions contained and specifically identified in every chapter of this

manual (Definition of safety instructions →3) must also be observed.

1.2 CE conformity

Information

ABB turbochargers comply with the Machinery Directive 2006/42/EC and are partly completed machinery as defined by Article 2 g in this directive.

© Copyright 2018 ABB. All rights reserved. HZTL4027_EN Revision A April 2018

Page 13

Operation Manual / 2 Safety / TPS-R

1 Safety / 1.3 Definition of mandatory signs

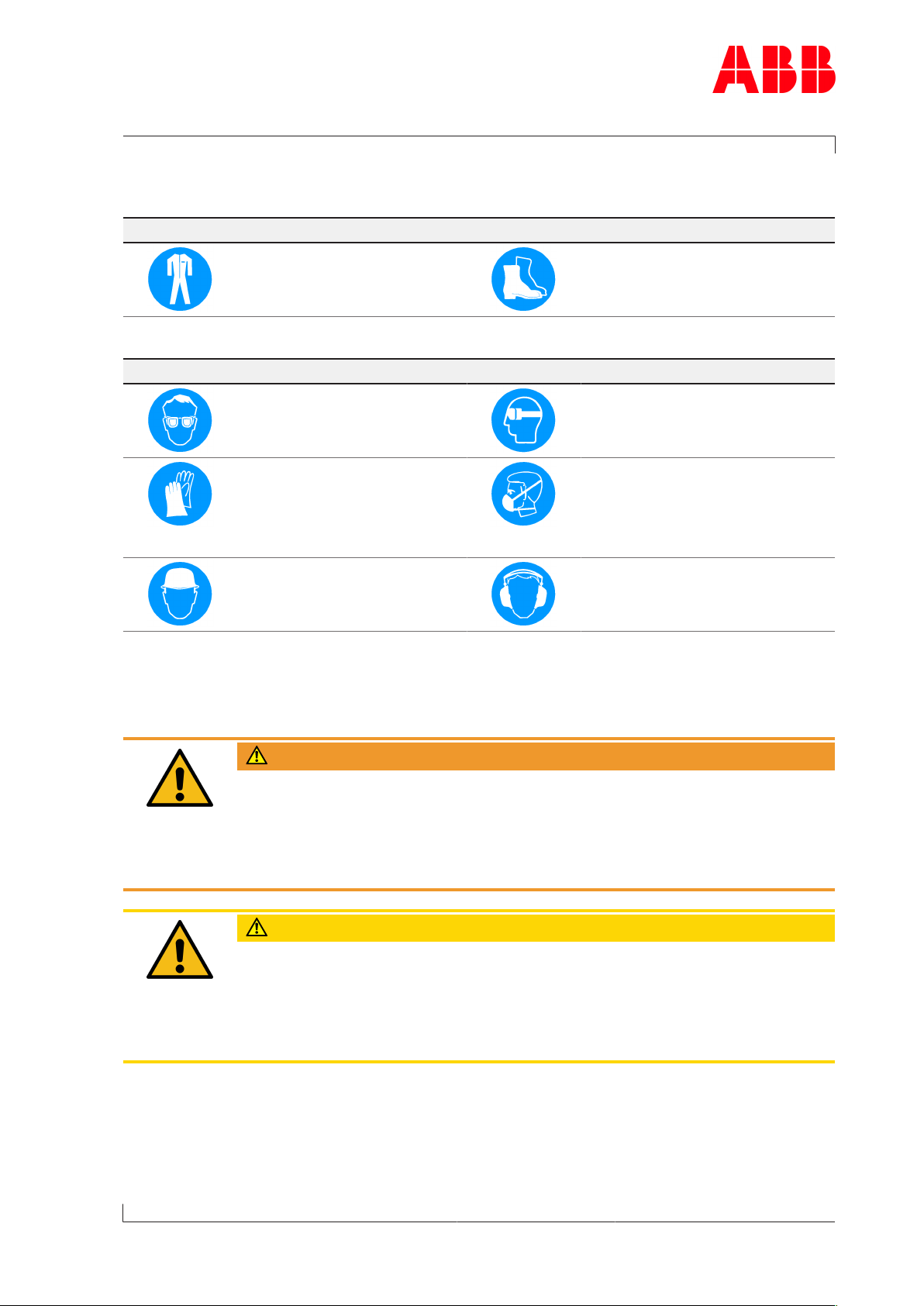

1.3 Definition of mandatory signs

To be worn at all times

Protective clothing Safety footwear to protect

against mechanical hazard and

risk of falling

Table1: Personal protective equipment to be worn at all times

To be worn specific to the respective task

Safety glasses Safety goggles

Safety gloves to protect

against

- Mechanical hazard

- Chemical hazard

- Thermal hazard

- Electrical hazard

Safety helmet Ear protection

Table2: Personal protective equipment to be worn specific to the respective task

Respiratory mask to protect

against

- Dusts

- Gases

1.4 Definition of safety instructions

WARNING

Definition of Warning

Non-compliance or inaccurate compliance with working or operating instructions indicated by this symbol and the word WARNING can lead to serious injuries to personnel and even to fatal accidents.

u Warning signs must always be observed.

Page 3 / 16

CAUTION

Definition of Caution

Non-compliance or inaccurate compliance with working or operating instructions indicated by this symbol and the word CAUTION can lead to serious damage to engine or property with grave consequences.

u Caution signs must always be observed.

© Copyright 2018 ABB. All rights reserved. HZTL4027_EN Revision A April 2018

Page 14

Operation Manual / 2 Safety / TPS-R

1 Safety / 1.5 Intended use

1.5 Intended use

Use on internal combustion engines in general

ABB turbochargers are intended for charging internal combustion engines.

The turbocharger supplies the engine with the air volume or air/gas mixture and the associated charging pressure required for operation.

The turbocharger is solely intended to be operated with a clockwise direction of rotation as

viewed from the turbine end.

The specific operating limits of the turbocharger were determined on the basis of information from the enginebuilder about the intended use. These data are given on the rating

plate.

ABB accepts no liability and rejects all warranty claims for any non-intended uses.

WARNING

Unapproved operation

Any operation of the turbocharger outside of its operating limits can be hazardous to personnel.

u Only operate the turbocharger within the operating limits.

u Only trained personnel must operate the turbocharger.

Page 4 / 16

The intended use of the turbocharger includes compliance with all regulations and conditions. In particular, the following must be observed:

¡ Operation Manual

¡ Instructions of the enginebuilder

State of the art

The turbocharger is designed and manufactured according to the state of the art and is safe

to operate.

Perfect condition

The turbocharger must only be used when it is in a technically flawless condition and operated in compliance with its intended use.

ABB excludes any liability for damage resulting from unauthorized modifications to the turbocharger or improper operation.

© Copyright 2018 ABB. All rights reserved. HZTL4027_EN Revision A April 2018

Page 15

Operation Manual / 2 Safety / TPS-R

1 Safety / 1.6 Warning plates on the turbocharger

1.6 Warning plates on the turbocharger

Warning plates are attached to the turbocharger, which must be observed. The warning

plates must always be present in the intended locations and must be legible.

Fig.1: Warning plate

If warning plates are not present in the intended locations or are not legible, they must be

replaced with new warning plates. The necessary information can be found in the Operation

Manual, Chapter 4 Product description.

Turbochargers supplied to the enginebuilder without insulation must be equipped later with

warning plates on the insulation. This is the responsibility of the enginebuilder.

Page 5 / 16

© Copyright 2018 ABB. All rights reserved. HZTL4027_EN Revision A April 2018

Page 16

Operation Manual / 2 Safety / TPS-R

1 Safety / 1.7 Turbocharger rating plate

1.7 Turbocharger rating plate

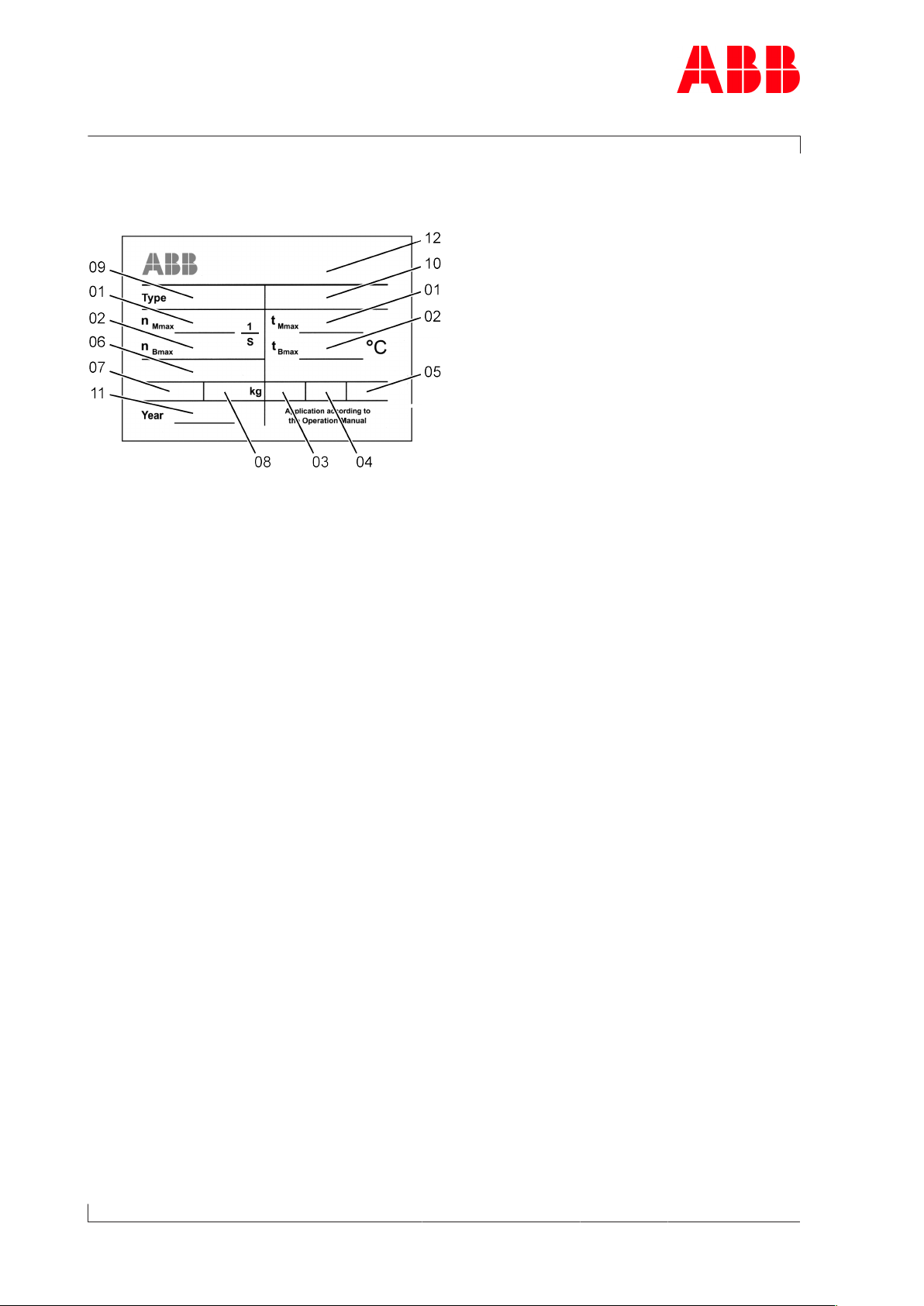

Fig.2: Rating plate

Page 6 / 16

Operating limits

01 Turbocharger operating limits at engine overload (110%).

In test rig operation only, unless otherwise agreed with the enginebuilder.

02 Turbocharger operating limits during operation

Recommended inspection and replacement intervals of turbocharger components

03 Inspection interval of plain bearings in 1000h

04 Replacement interval of compressor in 1000h

05 Replacement interval of turbine in 1000h

Further data

06 Customer part number

07 Designation for special design

08 Weight of turbocharger in kg

09 Turbocharger type

10 Serial number

11 Year of construction of turbocharger

12 Manufacturing plant

© Copyright 2018 ABB. All rights reserved. HZTL4027_EN Revision A April 2018

Page 17

Operation Manual / 2 Safety / TPS-R

1 Safety / 1.7 Turbocharger rating plate

Explanations regarding the rating plate

The recommended inspection and replacement intervals and the corresponding operating

limits are jointly defined with the enginebuilder. This information is specific to the system.

Operation above the indicated values n

Bmax

, t

can considerably shorten the recommended

Bmax

replacement intervals. In such a case, we recommend that you contact the nearest official

service station of ABB Turbo Systems.

n

, t

Mmax

normally apply only when running at overload (110%) during trials on the engine

Mmax

test bed. These limit values can also be permitted during operation for special applications.

Operation above n

Mmax

and t

is not permitted.

Mmax

Non-observance of the recommended inspection and replacement intervals increases the

risk of unpredictable component failures.

Locations of the rating plates

The locations of the rating plates are defined in the Operation Manual, Chapter 4 Product

description.

Page 7 / 16

© Copyright 2018 ABB. All rights reserved. HZTL4027_EN Revision A April 2018

Page 18

Operation Manual / 2 Safety / TPS-R

1 Safety / 1.8 Lifting of loads

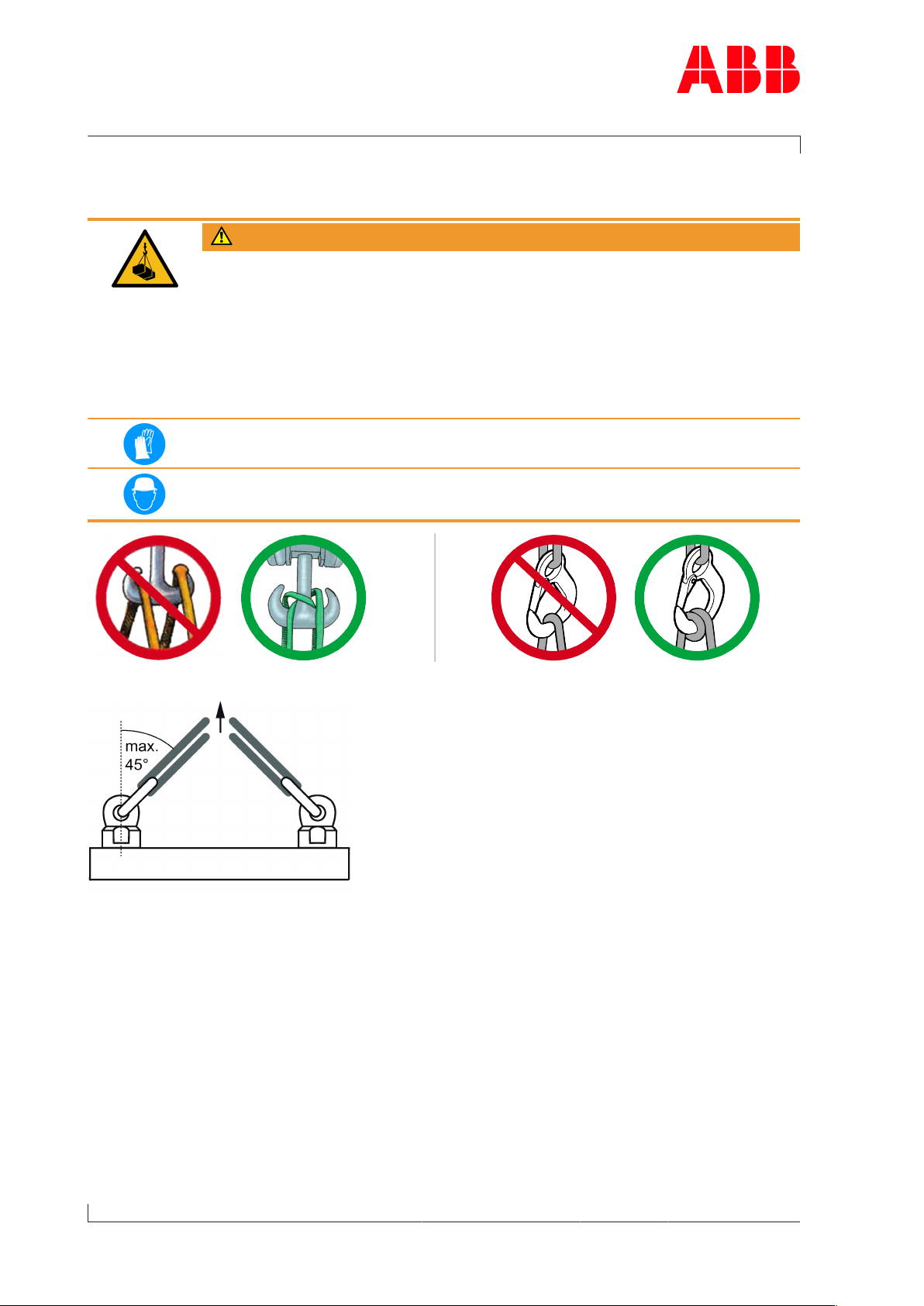

1.8 Lifting of loads

WARNING

Suspended loads

Loads that are not attached according to regulations can cause injury to

personnel or fatal accidents.

u Loads must always be fastened to properly functional lifting gear with a

sufficient load limit.

u Pay attention to the correct attachment of loads on the crane hook.

u People must not stand beneath suspended loads.

Wear safety gloves to protect against mechanical hazards.

Wear safety helmet.

Page 8 / 16

Fig.3: Attachment of loads on the crane hook

Fig.4: Attachment angle

If there are two or more suspension points, the attachment angle of 45° must not be exceeded. This prevents excessive loading due to diagonal pull.

u Before looping around the components of the turbocharger, let them cool down (max-

imum 80°C).

u Attach components of the turbocharger as described in the respective action steps.

u Use a suitable edge guard if there are sharp edges.

u The assembly devices must be completely screwed in and must not unscrew during use.

u Use assembly devices only for the described applications.

u Put down dismantled components of the turbocharger in such a way that they cannot tip

over.

© Copyright 2018 ABB. All rights reserved. HZTL4027_EN Revision A April 2018

Page 19

Operation Manual / 2 Safety / TPS-R

1 Safety / 1.9 Prerequisites for operation and maintenance

1.9 Prerequisites for operation and maintenance

Responsibility of the operating company

In awareness of its responsibility, the operating company must ensure that only authorised

personnel work on the turbocharger, who:

¡ Are versed in the general and locally applicable regulations for occupational safety and

accident prevention

¡ Are equipped with the prescribed personal protective equipment

¡ Have read and understood the Operation Manual

¡ Have been instructed in the use of the turbocharger.

The safety-conscious work of the personnel and adherence to the Operation Manual must be

checked periodically.

Suitable working materials and personal protective equipment must be kept in a perfect

condition.

Only authorised personnel may remain in the vicinity of the turbocharger when the engine is

running.

Competence of personnel

The turbocharger must only be operated and serviced by trained and authorised personnel.

Basic mechanical training is a prerequisite.

Modifications to the turbocharger

Modifications to the turbocharger must be approved by ABB Turbo Systems.

WARNING

Use original parts

Operation of the turbocharger with non-original parts can impair the safety

of the turbocharger and can cause serious damage to property and injury to

personnel.

u Only use original parts from ABB.

Original parts and accessories are specially designed for ABB turbochargers.

ABB accepts no liability for any damage resulting from the use of non-original parts and corresponding accessories.

Page 9 / 16

© Copyright 2018 ABB. All rights reserved. HZTL4027_EN Revision A April 2018

Page 20

Operation Manual / 2 Safety / TPS-R

1 Safety / 1.10 Hazards during operation and maintenance

1.10 Hazards during operation and maintenance

Noise hazards

The turbocharger's noise emission is influenced by its installation and operating conditions.

A noise level exceeding 85 dB(A) is harmful.

WARNING

Danger due to noise

Exposure to noise can harm the hearing system, impair health and the psychological state and may lead to lack of attention and irritation.

u When the engine is running, always wear ear protection.

u Always wear ear protection if the sound pressure level exceeds 85 dB(A).

Wear ear protection.

Page 10 / 16

Hazards due to hot surfaces

Surfaces of the turbocharger, attached parts and operating fluids (lubricating oil) get hot

during operation. The surface temperature depends on the efficacy of the existing insulation. The temperature may rise to a level that can cause burns.

WARNING

Danger of burns

Touching hot surfaces or contact with hot operating fluids can cause burns.

u Do not touch hot surfaces. Observe the warning plate on the turbochar-

ger.

u Wear heat-resistant safety gloves and protective clothing.

u Wait for the turbocharger to cool down before carrying out any work.

Wear safety gloves to protect against thermal hazards.

© Copyright 2018 ABB. All rights reserved. HZTL4027_EN Revision A April 2018

Page 21

Operation Manual / 2 Safety / TPS-R

1 Safety / 1.10 Hazards during operation and maintenance

WARNING

Hot surfaces on a non-insulated turbocharger

Non-insulated turbochargers can cause serious injuries to personnel (burns).

The turbocharger is supplied with or without insulation in accordance with

the purchase order received from the enginebuilder. If supply is without insulation, the enginebuilder is responsible for providing the turbocharger

with proper insulation and for providing protection against contact with hot

surfaces.

u Compliance with the instructions and specifications given by the en-

ginebuilder to protect against hot turbocharger surfaces is compulsory.

Wear safety gloves to protect against thermal hazards.

Hazards due to rotating parts

WARNING

Physical hazards

Contact with rotating parts can cause severe injury. The turbocharger must

never be used without the filter silencer or the air suction branch. With the

engine stopped, the rotor can rotate due to the stack draught alone.

u Operate the turbocharger in compliance with the specifications.

u Secure the rotor against unintentional rotation during maintenance.

Wear safety gloves to protect against mechanical hazards.

Page 11 / 16

© Copyright 2018 ABB. All rights reserved. HZTL4027_EN Revision A April 2018

Page 22

Operation Manual / 2 Safety / TPS-R

1 Safety / 1.11 Safe operation

1.11 Safe operation

Mechanical hazards during operation

During standard operation, no mechanical hazards are caused by the turbocharger itself if it

has been properly installed.

Safety during commissioning and operation

u Visually inspect your working environment before starting work.

u Remove any obstacles and objects littering the workplace.

u Check all pipes to and from the turbocharger for damage and leaks before commission-

ing.

u Check turbocharger for recognisable damage or defects every 12 hours of operation or at

least once a day.

u Report any damage and any alterations of operational characteristics to the responsible

department immediately.

Page 12 / 16

u In case of damage, take the turbocharger out of operation immediately and safeguard

against accidental/unauthorised use.

u When switching on operating energy supplies (hydraulics, pneumatics, electricity), pay at-

tention to the risks that may occur as a consequence of this energy input.

© Copyright 2018 ABB. All rights reserved. HZTL4027_EN Revision A April 2018

Page 23

Operation Manual / 2 Safety / TPS-R

1 Safety / 1.12 Safe maintenance

1.12 Safe maintenance

Occupational safety

WARNING

Injuries to persons

Severe injuries to personnel or fatal accidents can be caused by mechanical

influences as a consequence of hazardous and inadequate operational procedures or non-compliance with safety and health standards.

u When working on the turbocharger always wear safety footwear and pro-

tective clothing to protect against mechanical hazards.

u Keep personal protective equipment in perfect condition.

u Obey mandatory signs.

u Observe the general rules for occupational safety and prevention of acci-

dents.

u Only perform operations that are described in this manual.

u Only perform operations for which you have received instruction or train-

ing.

Wear safety footwear to protect against mechanical hazard and risk of falling.

Wear protective clothing.

WARNING

Risk of falling

When working on the turbocharger, there is a risk of falling.

u Do not climb onto the turbocharger or onto attached parts and do not

use them as climbing aids.

u Use suitable climbing aids and working platforms for work above body

height.

u Comply with the general accident prevention regulations.

u Only perform work on the turbocharger when you are in a physically and psychologically

stable condition.

u Only work with suitable tools, equipment and appliances that function properly.

u Power tools must be grounded and cables must be undamaged.

u Keep the workplace clean; clear away any loose objects and obstacles on the floor.

Page 13 / 16

u Keep the floor, equipment, and turbocharger clean.

u Have oil binding agents ready and provide or keep oil pans at hand.

u Clean up any spills.

u Have fire protection means and extinguishing agents available.

© Copyright 2018 ABB. All rights reserved. HZTL4027_EN Revision A April 2018

Page 24

Operation Manual / 2 Safety / TPS-R

1 Safety / 1.12 Safe maintenance

Use of assembly devices

Assembly devices are specially constructed and designed for the defined use; they are not

commercially available products.

u Use assembly devices only for the described applications.

Welding work in the vicinity of the turbocharger

u When performing welding work in the vicinity of the turbocharger, always cover the filter

silencer to prevent the filter mat from being damaged.

u Keep flammable objects and substances out of the vicinity of flying sparks.

u Cover all connections on the turbocharger so that no foreign objects can enter the tur-

bocharger.

u Wear personal protective equipment (PPE) for welding operations.

Safety during cleaning

Page 14 / 16

If cleaning agents or solvents are used for cleaning, the corresponding material safety data

sheet and the safety instructions in section Hazards due to operating materials and supplies

must be observed.

u Observe the material safety data sheet for the cleaning agent or solvent.

u Wear personal protective equipment (PPE) according to the material safety data sheet.

u Inspect the electric cables for abrasion and damage before and after your cleaning work.

Safety during disassembly, assembly, maintenance and repair

u Observe the procedures for set-up, service and inspection work and the inspection inter-

vals.

u Inform the operating staff before starting any service or repair work. Make sure the en-

gine is not started while work is being conducted on the turbocharger.

u Before taking off any cover or removing any guard from the turbocharger, switch off the

engine and wait until the turbocharger has come to a standstill.

u Make sure that the oil supply is interrupted, especially with an external oil supply.

u Only restart the engine after all parts have been properly fitted again and oil supply is en-

sured.

CAUTION

Mechanical operations on the turbocharger

Components of the turbocharger can be damaged or destroyed as a result

of improper procedures.

u Only perform operations that are described in this chapter.

u Only perform operations for which you have received instruction or train-

ing.

© Copyright 2018 ABB. All rights reserved. HZTL4027_EN Revision A April 2018

Page 25

Operation Manual / 2 Safety / TPS-R

1 Safety / 1.12 Safe maintenance

Safety when taking out of operation or preparing for mothballing

u Secure rotor against turning. The rotor can rotate due to the stack draught alone.

u Observe the material safety data sheet for the cleaning and mothballing agents.

u Wear personal protective equipment (PPE) according to the material safety data sheet.

Mechanical hazards when working on the turbocharger

WARNING

Physical hazards due to rotating parts

The rotor can rotate due to the stack draught alone. Contact with rotating

parts can cause severe injury.

u Secure rotor against turning.

WARNING

Mechanical hazard

Severe injuries to personnel or fatal accidents can be caused by mechanical

influences as a consequence of hazardous and inadequate operational procedures.

u Observe the general rules for occupational safety and prevention of acci-

dents.

u Ensure workplace safety.

u Only perform operations that are described in this chapter.

u Only perform operations for which you have previously received instruc-

tion or training.

Page 15 / 16

© Copyright 2018 ABB. All rights reserved. HZTL4027_EN Revision A April 2018

Page 26

Operation Manual / 2 Safety / TPS-R

1 Safety / 1.12 Safe maintenance

Hazards due to operating materials and supplies

Operating materials and supplies are substances required for the operation of the turbocharger or for the performance of maintenance work. Oils, greases, coolants, detergents

and solvents, acids and similar substances can be classified as hazardous substances.

WARNING

Handling operating materials and supplies

Swallowing or inhaling vapours of operating materials and supplies or contact with them may be harmful to health.

u Do not breathe in these substances and avoid contact with the skin.

u Ensure proper ventilation.

u Observe the information in the material safety data sheet for the operat-

ing materials and supplies.

u Wear personal protective equipment (PPE) according to the material

safety data sheet.

u Comply with local legislation.

Page 16 / 16

Wear safety goggles.

Wear safety gloves to protect against chemical hazards.

Wear a respiratory mask to protect against gases.

WARNING

Danger of fire or explosion

Flammable and combustible operating materials and supplies can catch fire

or resulting vapours can lead to an explosion.

u Observe the information in the material safety data sheet for the operat-

ing materials and supplies.

u Comply with local legislation.

u Do not allow any exposed flame or ignition source during cleaning work.

u Carry out cleaning in the open or provide sufficient ventilation.

CAUTION

Environmental hazard

Improper handling of operating materials and supplies can lead to environmental damage.

u Observe the information in the material safety data sheet for the operat-

ing materials and supplies.

u Comply with local legislation.

© Copyright 2018 ABB. All rights reserved. HZTL4027_EN Revision A April 2018

Page 27

Operation Manual / TPS61-R / Safety data sheet

Safety data sheet

TPS61-R HT591545

TPS61-R HT591545

Page 1 / 1

511 650

511 620

TPS61R35-162850A

720 12 50 50

2019

© Copyright 2019 ABB. All rights reserved. HT591545 October 2019

Page 28

Page 29

Operation Manual / 4 Product description / TPS61-R

Table of contents

Product description

1 Introduction............................................................................................................ 3

1.1 Essential information.................................................................................................... 3

1.2 Registered trademarks................................................................................................. 3

1.3 Related documents........................................................................................................ 3

1.4 Layout and function of the turbocharger ................................................................ 4

1.5 Locations of the rating plates..................................................................................... 5

1.6 Warning plates on the turbocharger......................................................................... 6

2 Removing and Installing........................................................................................ 7

2.1 Turbocharger weight and transportation ................................................................ 7

2.2 Removing the turbocharger........................................................................................ 8

2.3 Installing the turbocharger......................................................................................... 9

3 Commissioning ..................................................................................................... 11

3.1 Oil supply ....................................................................................................................... 11

3.2 Inspection procedures................................................................................................ 12

3.3 Commissioning after taking out of operation....................................................... 14

4 Monitoring operation .......................................................................................... 15

4.1 Oil pressure, oil temperature..................................................................................... 15

4.2 Exhaust gas temperature before turbine ............................................................... 18

4.3 Turbocharger speed.................................................................................................... 18

5 Operation and service ......................................................................................... 21

5.1 Noise emission ............................................................................................................. 21

5.2 Service work .................................................................................................................. 23

5.3 Expected replacement intervals .............................................................................. 26

6 Stopping the engine ............................................................................................ 27

7 Eliminating malfunctions.................................................................................... 28

7.1 Malfunctions when starting...................................................................................... 28

7.2 Malfunctions during operation ................................................................................ 28

7.3 Turbocharger is surging ............................................................................................. 32

7.4 Malfunctions when stopping.................................................................................... 33

7.5 Speed measurement system .................................................................................... 33

8 Mothballing the turbocharger............................................................................ 35

8.1 Taking the engine out of operation for up to 12months ................................... 35

8.2 Taking the engine out of operation for more than 12months .......................... 36

9 Disposing of turbocharger components .......................................................... 37

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Page 30

Operation Manual / 4 Product description / TPS61-R

Table of contents

10 Spare parts ........................................................................................................... 38

10.1 Ordering spare parts.................................................................................................. 38

10.2 Spare parts of the speed measurement system .................................................. 38

Figures................................................................................................................... 39

Tables .................................................................................................................... 40

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Page 31

Operation Manual / 4 Product description / TPS61-R

1 Introduction / 1.1 Essential information

1 Introduction

1.1 Essential information

Design variants

This document is valid for different design variants of turbochargers. There may be sections

and descriptions of components that are not relevant for a specific turbocharger variant.

Please contact an ABB Turbocharging Service Station if you have any questions regarding a

design variant (see Contact information at www.abb.com/turbocharging).

Accuracy of illustrations

The illustrations in this document are general in nature and intended for ease of understanding. Differences in detail are therefore possible.

1.2 Registered trademarks

The trademarks of outside companies are used in this document. These are marked with the

® symbol.

1.3 Related documents

Chapter Document number

Operation Manual / 1 Introduction HZTL4005

Operation Manual / 2 Safety HZTL4027

Operation Manual / 3 Safety data sheet *) Serial number of the turbocharger

Table1: Related documents

*) This chapter is only present in serialised operation manuals.

Page 3 / 40

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Page 32

Operation Manual / 4 Product description / TPS61-R

1 Introduction / 1.4 Layout and function of the turbocharger

1.4 Layout and function of the turbocharger

Page 4 / 40

Fig.1: Layout and function of TPS61-R

01 Air suction branch 06 Plain bearing bush

02 Compressor casing 07 Turbine

03 Diffuser 08 Turbine casing

04 Bearing casing 09 Nozzle ring

05 Axial thrust bearing 10 Compressor wheel

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Page 33

Operation Manual / 4 Product description / TPS61-R

1 Introduction / 1.5 Locations of the rating plates

Mode of operation

The turbocharger is a turbomachine and consists of the following main components:

¡ Turbine

¡ Compressor.

These components are installed on a common shaft and form the rotor (see Fig.1: Layout

and function of TPS61-R →4).

The exhaust gases of the internal combustion engine flow through the turbine casing(08)

and the nozzle ring(09) onto the turbine(07). The turbine(07) uses the energy contained in

the exhaust gas to drive the rotor and thus the compressor wheel(10). The exhaust gases

then reach the atmosphere through the exhaust gas pipe connected to the turbine casing.

The compressor wheel(10) sucks in air through the air suction branch(01). In the compressor wheel(10), the energy required for building up the pressure is transferred to the air.

By flowing through the diffuser(03) and the compressor casing(02), the air is compressed

further and is then directed to the engine cylinders.

The rotor runs in two radial plain bearing bushes(06) which are located in the bearing casing(04) between the compressor and turbine. The axial thrust bearing(05) is located in

front of the two radial plain bearing bushes.

The bearings are connected to a central lubricating oil duct which is normally supplied by the

lubricating oil circuit of the engine. The oil outlet lies at the deepest point of the bearing casing(04).

1.5 Locations of the rating plates

Page 5 / 40

Fig.2: Locations of the rating plates

One rating plate (01) each is attached on the left and the right side of the turbocharger bearing casing.

Explanations regarding the rating plate can be found in the chapter dealing with safety.

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Page 34

Operation Manual / 4 Product description / TPS61-R

1 Introduction / 1.6 Warning plates on the turbocharger

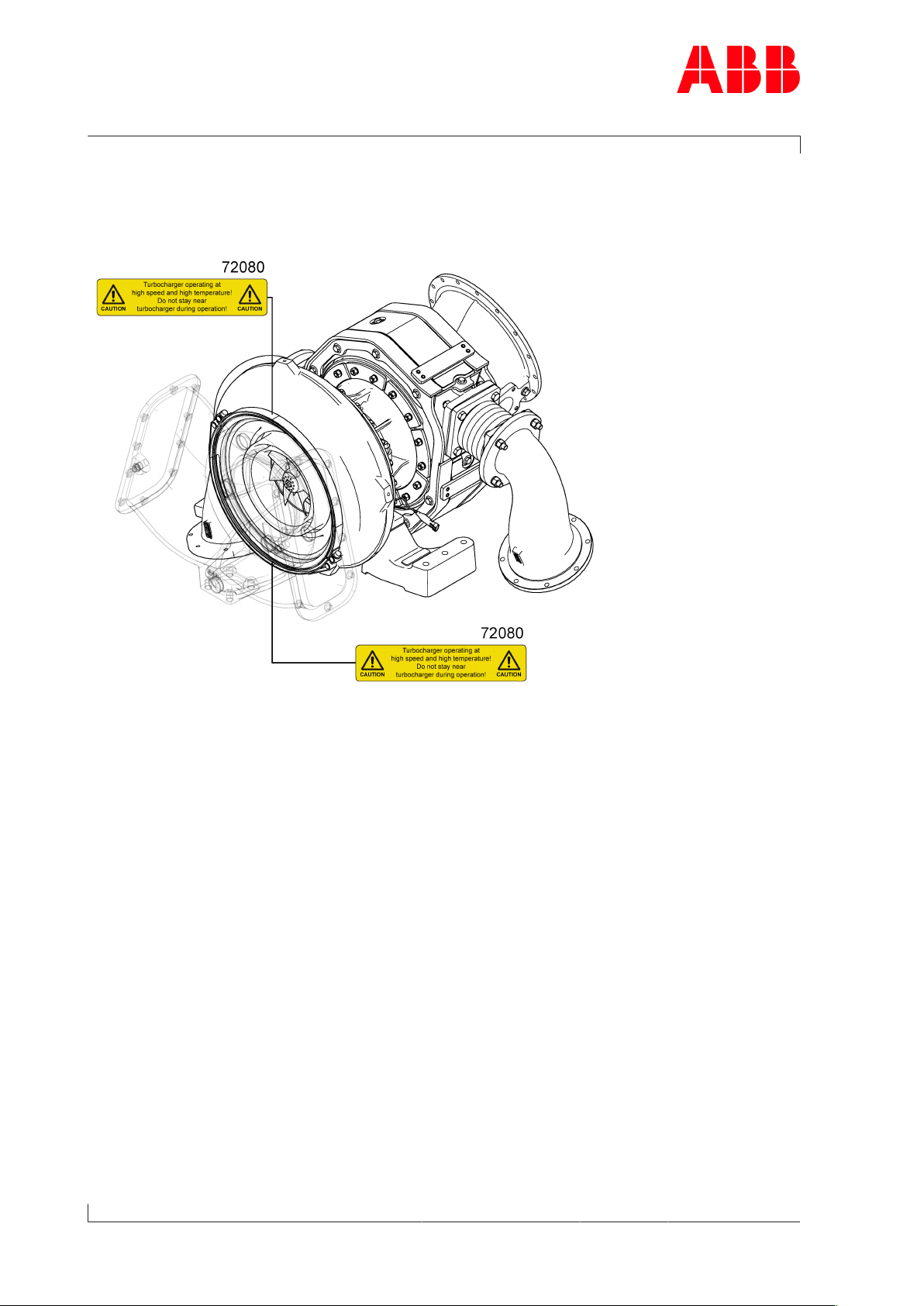

1.6 Warning plates on the turbocharger

Warning plates are affixed at the following locations:

Page 6 / 40

Fig.3: Warning plates on the turbocharger

ABB does not supply insulation for this turbocharger. If the turbocharger is insulated at a

later date and warning plates are covered, the warning signs must be attached to the insulation. This is the responsibility of the enginebuilder.

If warning plates are not present in the designated locations or not readable, proceed as follows:

u Order new warning plates (72080) from ABB Turbocharging Service Stations (see chapter

Ordering spare parts →38).

u Remove any warning plates that have become unreadable.

u Clean and degrease the areas designated for the warning plates.

u Fit new warning plates and remove protective sheets.

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Page 35

Operation Manual / 4 Product description / TPS61-R

2 Removing and Installing / 2.1 Turbocharger weight and transportation

2 Removing and Installing

2.1 Turbocharger weight and transportation

Lifting gear with a sufficient load limit must be used for removing and installing the turbocharger. The following weight specification applies to the heaviest variant possible. Depending on the specification, the weight specified on the rating plate may be lower than the

standard value specified here.

CAUTION

Damage to bellows

The turbochargers are supplied without fitted pipe sections and bellows.

The parts are delivered separately, because they can be damaged or destroyed during turbocharger transport if they are fitted.

u Never transport turbocharger with bellows fitted.

Fig.4: Turbocharger transport

Product Weights [kg]

TPS61-R 720

Table2: Weight of the turbocharger

Page 7 / 40

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Page 36

Operation Manual / 4 Product description / TPS61-R

2 Removing and Installing / 2.2 Removing the turbocharger

2.2 Removing the turbocharger

WARNING

Danger of burns

Touching hot surfaces or contact with hot operating fluids can cause burns.

u Do not touch hot surfaces. Observe the warning plate on the turbochar-

ger.

u Wear heat-resistant safety gloves and protective clothing.

u Wait for the turbocharger to cool down before carrying out any work.

Wear safety gloves to protect against thermal hazards.

CAUTION

Do not strain cables

If you pull the speed measurement cables too hard, contacts can be pulled

out.

u Do not strain the speed measurement cables by pulling.

Page 8 / 40

u Disconnect all pipes according to the instructions of the enginebuilder.

u Unplug the cable connector at the speed sensor (86505).

Fig.5: Removing the turbocharger

1. Ensure that the oil connections have been dismantled.

2. Remove the bellows.

3. Attach lifting gear to the turbocharger.

4. Loosen and remove screws.

5. Lift turbocharger from engine support vertically upwards.

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Page 37

Operation Manual / 4 Product description / TPS61-R

2 Removing and Installing / 2.3 Installing the turbocharger

The compressor casing(72000) can be lower than the turbocharger support depending on

the casing position.

Fig.6: Putting down the turbocharger

u Put the turbocharger down onto a solid surface so that the turbocharger cannot tip over.

Support the turbocharger if necessary.

2.3 Installing the turbocharger

Requirements for the fixing screws(01)

The fixing screws(01) that are required for attaching the turbocharger bracket(02) to the

engine support(03) are not included in the ABB Turbo Systems scope of delivery. These

parts depend on the version of the engine-side bracket.

Fig.7: Requirements for fixing screws

Product Diameter

Hole in

bracket

[mm]

TPS61R

Table3: Requirements for fixing screws

Ø18 / M16 M16 ≥ 30 120 10.9 300Nm

Screw size Length

L1 [mm]

Length

L2 [mm]

Material

DIN / ISO 898

(Part 1)

Tightening

torque

Page 9 / 40

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Page 38

Operation Manual / 4 Product description / TPS61-R

2 Removing and Installing / 2.3 Installing the turbocharger

2.3.1 Attaching the turbocharger to the bracket

CAUTION

Damage to bellows

If the axes of the flanges of the turbine casing do not align with the piping,

the bellows can be damaged or destroyed.

u During installation of the bellows, ensure that the axes of the flanges of

the turbine casing align with the piping. If necessary, correct alignment of

the turbocharger on the engine support.

Page 10 / 40

Fig.8: Placing the turbocharger on the bracket

Product Screw position Tightening torque

(assumed friction coefficient

µ

=0.12)

TPS61-R 01 M16

300Nm

TPS61-R 02 M16

325Nm

Table4: Tightening torque for turbocharger fixing screws

1. Attach lifting gear to turbocharger and place turbocharger onto bracket.

2. Fit hexagon head screws(01) but do not tighten them yet.

3. Coat thread of hexagon-head screws(02) with high-temperature grease such as Loctite®

8009. Fit bellows with hexagon-head screws(02), Verbus Ripp® washers and nuts. Observe the tightening torque.

4. Tighten hexagon-head screws(01). Observe the tightening torque.

5. Connect the oil supply. Ensure that the connection is tight.

6. Connect cable to speed sensor(86505).

7. Remove the lifting gear.

u Connect all the gas pipes and air lines according to the enginebuilder's instructions.

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Page 39

Operation Manual / 4 Product description / TPS61-R

3 Commissioning / 3.1 Oil supply

3 Commissioning

3.1 Oil supply

3.1.1 Introduction

In all operating states, a functioning and carefully executed oil supply is an important prerequisite for trouble-free operation of the turbocharger.

The lubrication of the turbocharger is usually carried out with oil from the engine oil circulation.

u Comply with the enginebuilder's specifications regarding the selection of lubricating oil

and the oil change intervals.

3.1.2 Pre-lubrication

Pre-lubrication must be carried out as follows:

u Switch on the oil pump.

u Build up oil pressure &.

u Do not exceed a pre-lubrication time of 2 minutes.

u Start the engine.

u Let the oil pump run until the pump driven by the engine generates sufficient pressure.

3.1.3 Oil filtering

Filtering the lubricating oil with a filter mesh width of ≤0.034mm is sufficient for this turbocharger.

3.1.4 Oil pressure

Comply precisely with the oil pressure before the turbocharger for trouble-free operation.

The admissible values are specified in chapter Monitoring operation →15.

Page 11 / 40

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Page 40

Operation Manual / 4 Product description / TPS61-R

3 Commissioning / 3.2 Inspection procedures

3.2 Inspection procedures

3.2.1 Introduction

Inspection procedures include preventative visual controls, monitoring and measuring work

before and during commissioning. Inspection procedures enable changes to the turbocharger to be detected. Machine damage can be prevented.

3.2.2 Checks before commissioning

Lubricating system

CAUTION

Contaminated oil

Serious damage to engine or property can be caused by dirt and solid material particles in the oil.

u For the initial commissioning phase and after all service work, flush the

complete lubricating system with warm oil.

u Use special running-in filters when running in the engine and after all ser-

vice work on the lubricating system.

Page 12 / 40

u Check that the oil filter is clean before commissioning.

u Adhere to lubricating oil pressure at the inlet.

u Adhere to lubricating oil temperature at the inlet.

u For permissible values, see chapter Monitoring operation →15.

Warning plates

u Check whether warning plates are present and legible.

u Check whether the protective sheets have been removed.

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Page 41

Operation Manual / 4 Product description / TPS61-R

3 Commissioning / 3.2 Inspection procedures

3.2.3 Checks after commissioning (engine in idle mode)

Lubricating system

u Keep to the lubricating oil pressure at the inlet.

u Keep to the lubricating oil temperature at the inlet.

u Refer to chapter Monitoring operation →15 for admissible values.

Leaktightness of pipes

WARNING

Risk of burning from hot gas

Escaping gases are hot and will lead to serious burns in the event of contact.

u Check all pipes for leaks in accordance with the enginebuilder’s instruc-

tions.

3.2.4 Checks when starting up the engine

If present:

u Measure speed, oil pressure and charging pressure at various engine performances.

u Measure the exhaust gas temperature before and after the turbine.

u Measure the air temperature before and after the compressor.

u Compare the measured values with the values of the acceptance report. Different operat-

ing conditions indicate a malfunction (see chapter Eliminating malfunctions →28).

Lubricants and pastes used during assembly can liquefy or vaporise and escape as oily fluids

during the initial hours of operation. Continual escape of an oily fluid indicates an oil leak. If

there is a leak, contact an ABB Turbocharging Service Station.

Page 13 / 40

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Page 42

Operation Manual / 4 Product description / TPS61-R

3 Commissioning / 3.3 Commissioning after taking out of operation

3.3 Commissioning after taking out of operation

If present

u Remove cover plates (blind flanges) from the compressor casing, the gas inlet and the

gas outlet.

General

u Check the exhaust gas pipe before and after the turbine for combustion residues or wa-

ter residues and clean it. Remove any foreign objects that may be present.

u Check and clean the air supply system, and remove any foreign objects that may be

present.

u Put engine-side oil circulation to the turbocharger into operation.

u Prepare the turbocharger for operation according to section "Checks before commission-

ing".

Page 14 / 40

u The turbocharger is now ready for operation.

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Page 43

Operation Manual / 4 Product description / TPS61-R

4 Monitoring operation / 4.1 Oil pressure, oil temperature

4 Monitoring operation

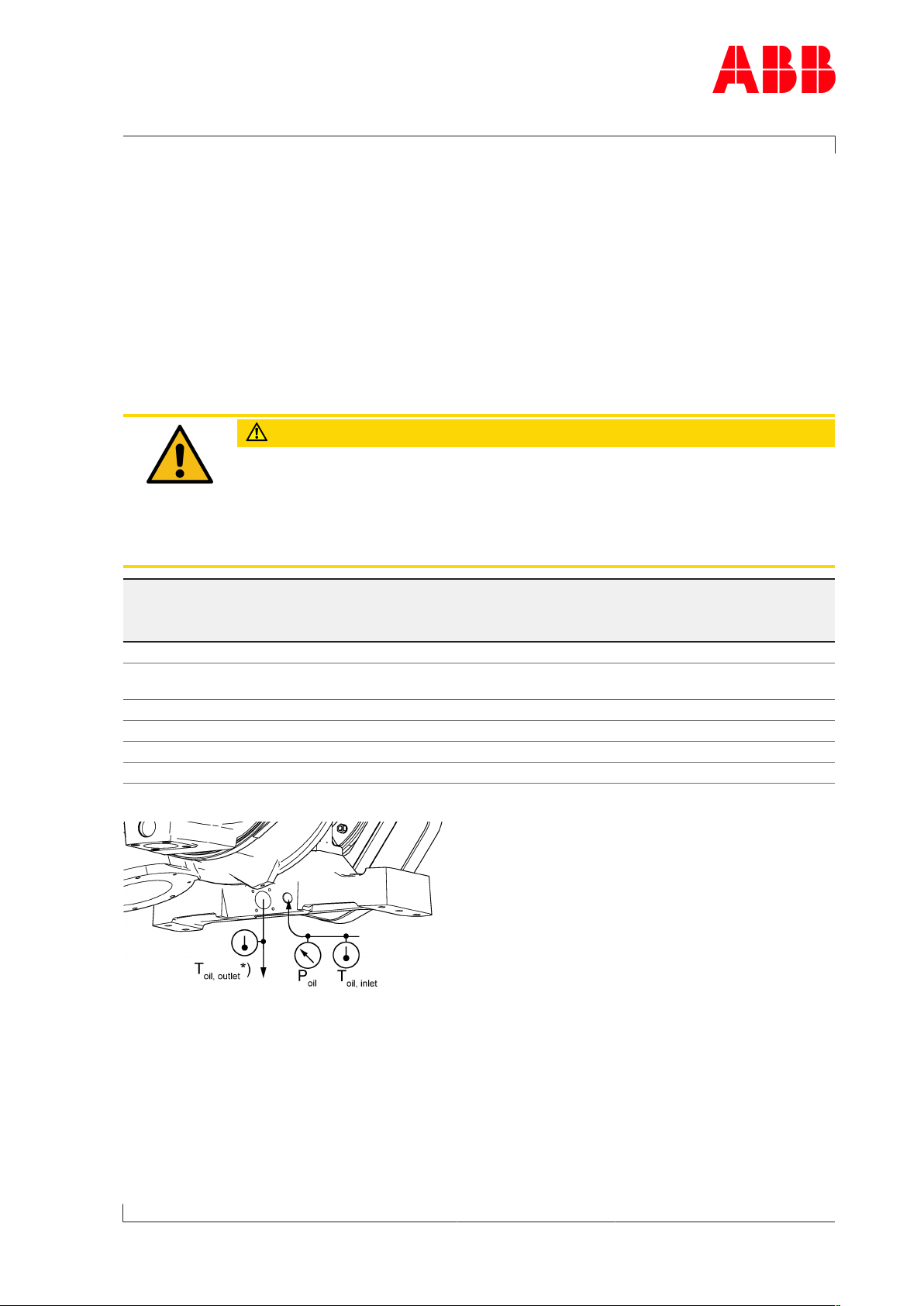

4.1 Oil pressure, oil temperature

Lubricating oil pressure, oil inlet

To limit the oil flow rate through the turbocharger to the admissible values with the engine

at full load, an oil orifice is mandatory or already fitted at the turbocharger oil inlet if the oil

inlet pressure is > 3bar.

CAUTION

Assuring lubricating oil pressure

Serious damage to the engine or property can result from a missing or insufficient lubricating oil supply.

u The lubricating oil pressure must be monitored during operation and the

necessary pressure assured at the oil inlet.

Status for operation Pressure at oil inlet upstream of

the turbocharger

[bar] Overpressure

Normal operation 2.0< p

Engine start: Cold oil, admissible for a maximum of 15

minutes

Engine idling, admissible for a maximum of 1 hour 0.2< p

Pre-lubrication and post-lubrication (engine stopped) 0.2< p

Warning signal: (n ≥ 0.5 x n

Alarm signal: Not admissible. Stop the engine immediately. <0.2

Table5: Lubricating oil pressure at oil inlet before turbocharger

Fig.9: Arrangement of oil temperature and oil pressure measuring points

P Oil pressure measuring point

T Oil temperature measuring point

) <1.25

Bmax

oil

<8.0

oil

oil

≤4.5

≤2.5

≤1.0

Page 15 / 40

For monitoring the lubricating oil pressure, ABB Turbo Systems recommends installing a "P"

manometer immediately upstream of the turbocharger oil inlet before the orifice. If the

pressure is controlled electronically, the relevant signals should be triggered at the warning

and alarm values.

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Page 44

Operation Manual / 4 Product description / TPS61-R

4 Monitoring operation / 4.1 Oil pressure, oil temperature

*) If the drain pipe is vented, the lubricating oil temperature measuring point can be installed

at the outlet in the vent tank. Otherwise the measurement should be taken in the drain pipe

as close to the turbocharger as possible.

The measuring points for temperature(T) and pressure (M) in the oil supply pipe should be

attached as closely to the turbocharger as possible. No reducing installations such as orifices or valves may be attached at the engine side between the measuring point and the turbocharger oil inlet. The temperature and pressure are measured to monitor the lubrication.

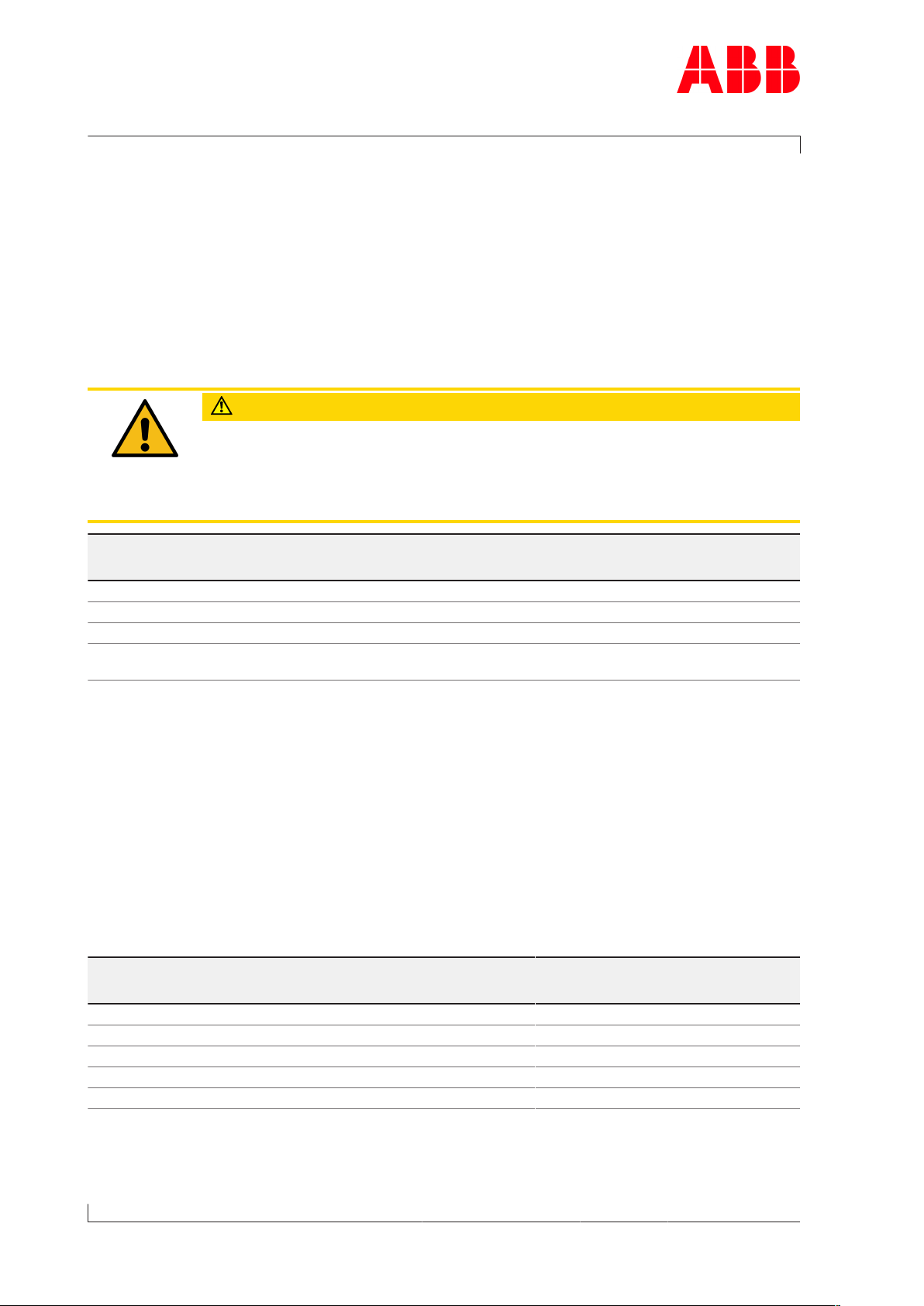

Lubricating oil temperature at the inlet

CAUTION

Machine damage

If the oil temperature at the oil inlet exceeds the admissible range, this may

lead to engine damage.

u Observe oil temperature at the oil inlet according to the following table.

Page 16 / 40

Status for operation Oil temperature at the inlet

T

oil,inlet

Admissible 8…105°C

Temporarily admissible (<1h) → Alarm >105°C

Not admissible → stop engine >110°C

Not admissible → do not start engine (before start: preheat

<8°C

oil)

Table6: Lubricating oil temperature at the inlet

Lubricating oil temperature at the outlet

The oil temperature at the outlet is mainly dependant on:

¡ Lubricating oil temperature and pressure at the oil inlet

¡ Engine load and turbocharger speed

¡ Exhaust gas temperature

The maximum admissible oil temperature at the outlet is listed in the following table. The

specified oil outlet temperature is to be considered as alarm value for the turbocharger operation and must be monitored according to the current regulations.

Status for operation Oil temperature at the outlet

T

oil,outlet

Admissible ≤160°C

Temporarily admissible → alarm >160°C

Not admissible → stop engine >180°C

Admissible ≤ T

Temporarily admissible → alarm > T

Table7: Lubricating oil temperature at the outlet

oil,inlet

oil,inlet

+ 55K

+ 55K

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Page 45

Operation Manual / 4 Product description / TPS61-R

4 Monitoring operation / 4.1 Oil pressure, oil temperature

If the turbocharger was operated for a longer period of time outside of the admissible

range, ABB Turbo Systems recommends to have the turbocharger inspected by an ABB Turbocharging Service Station.

Page 17 / 40

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Page 46

Operation Manual / 4 Product description / TPS61-R

4 Monitoring operation / 4.2 Exhaust gas temperature before turbine

4.2 Exhaust gas temperature before turbine

CAUTION

Factors influencing replacement intervals

Operation above the operating limits defined on the rating plate can

shorten the recommended replacement intervals considerably.

u Measure exhaust gas temperature upstream of turbine.

u Comply with operating limits on rating plate.

u Definition and explanations concerning rating plate: refer to chapter 2 of Operation

Manual / Safety.

u Operating limits: refer to chapter 3 of Operation Manual / Safety data sheet or examine

rating plate.

4.3 Turbocharger speed

Page 18 / 40

4.3.1 Introduction

A speed measuring system enables the constant monitoring of the turbocharger speed.

CAUTION

Do not strain cables

If you pull the speed measurement cables too hard, contacts can be pulled

out.

u Do not strain the speed measurement cables by pulling.

CAUTION

Machine damage

Operation above the operating limits defined on the rating plate can

shorten the recommended replacement intervals considerably and cause

machine damage.

u Measure turbocharger speed.

u Comply with operating limits on rating plate.

u Definition and explanations concerning rating plate: refer to chapter 2 of Operation

Manual / Safety.

u Operating limits: refer to chapter 3 of Operation Manual / Safety data sheet or examine

rating plate.

If no speed measurement system is present, the system below can be ordered from an ABB

Turbocharging Service Station (see chapter Ordering spare parts →38).

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Page 47

Operation Manual / 4 Product description / TPS61-R

4 Monitoring operation / 4.3 Turbocharger speed

4.3.2 Layout and overview

Fig.10: Speed measurement system

86505 Speed sensor (cable not integrated)

86515 Cable connector to 86505

32109 Sealing disc

01 Screw plug

02 Gasket

4.3.3 Malfunctions on the speed measurement system

In the case of malfunctions of the speed measurement system, refer to the chapter entitled

Troubleshooting/Speed measurement system →33.

Page 19 / 40

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Page 48

Operation Manual / 4 Product description / TPS61-R

4 Monitoring operation / 4.3 Turbocharger speed

4.3.4 Replacing the speed sensor

WARNING

Hot speed sensor

Danger of burns. The speed sensor can reach temperatures of more than

100°C during operation.

u Wear safety gloves when disassembling the speed sensor.

Wear safety gloves to protect against thermal hazards.

The speed sensor supplied by ABB is equipped with a sealing lip and an O-ring. No additional

gasket is required during assembly.

Page 20 / 40

Fig.11: Fitting the speed sensor

Part number Tightening torque

86505 15Nm

Table8: Tightening torque(86505)

u Reduce the engine performance to idling and then stop the engine. Pay attention to post-

lubrication (Stopping the engine →27).

u Switch off the lubricating oil supply to the turbocharger.

u Disconnect cable connector (86515) from speed sensor (86505).

u Unscrew and remove defective speed sensor (86505).

u Screw in new speed sensor(86505) as far as it will go and tighten.

u Connect cable connector (86515) to speed sensor (86505).

u Switch on lubricating oil supply to the turbocharger.

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Page 49

Operation Manual / 4 Product description / TPS61-R

5 Operation and service / 5.1 Noise emission

5 Operation and service

5.1 Noise emission

WARNING

Danger due to noise

Exposure to noise can harm the hearing system, impair health and the psychological state and may lead to lack of attention and irritation.

u When the engine is running, always wear ear protection.

u Always wear ear protection if the sound pressure level exceeds 85 dB(A).

Wear ear protection.

The emission sound pressure level (A-weighted) is measured at a distance of 1 meter from

the turbocharger.

The highest value of the emission sound pressure level1) reaches a maximum of 105 dB(A)

near the filter silencer. The following prerequisites must be fulfilled with regard to the turbocharger to observe this limit value:

¡ Air-inlet system has been fitted

¡ All standard, noise-reducing measures2) have been fitted

¡ Bellows at the air-outlet has been acoustically insulated by the enginebuilder (see Fig.12:

Noise insulation, bellows →22).

The enginebuilder is responsible for insulating the charge air/scavenging air line and the

charge air cooler.

1) Directive 2006/42/EC, 1.7.4.2 / u / Paragraphs 5 + 7:

A-weighted emission sound pressure level

2) The enginebuilder must provide acoustically equivalent measures in case of deviating insulation versions

Page 21 / 40

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Page 50

Operation Manual / 4 Product description / TPS61-R

5 Operation and service / 5.1 Noise emission

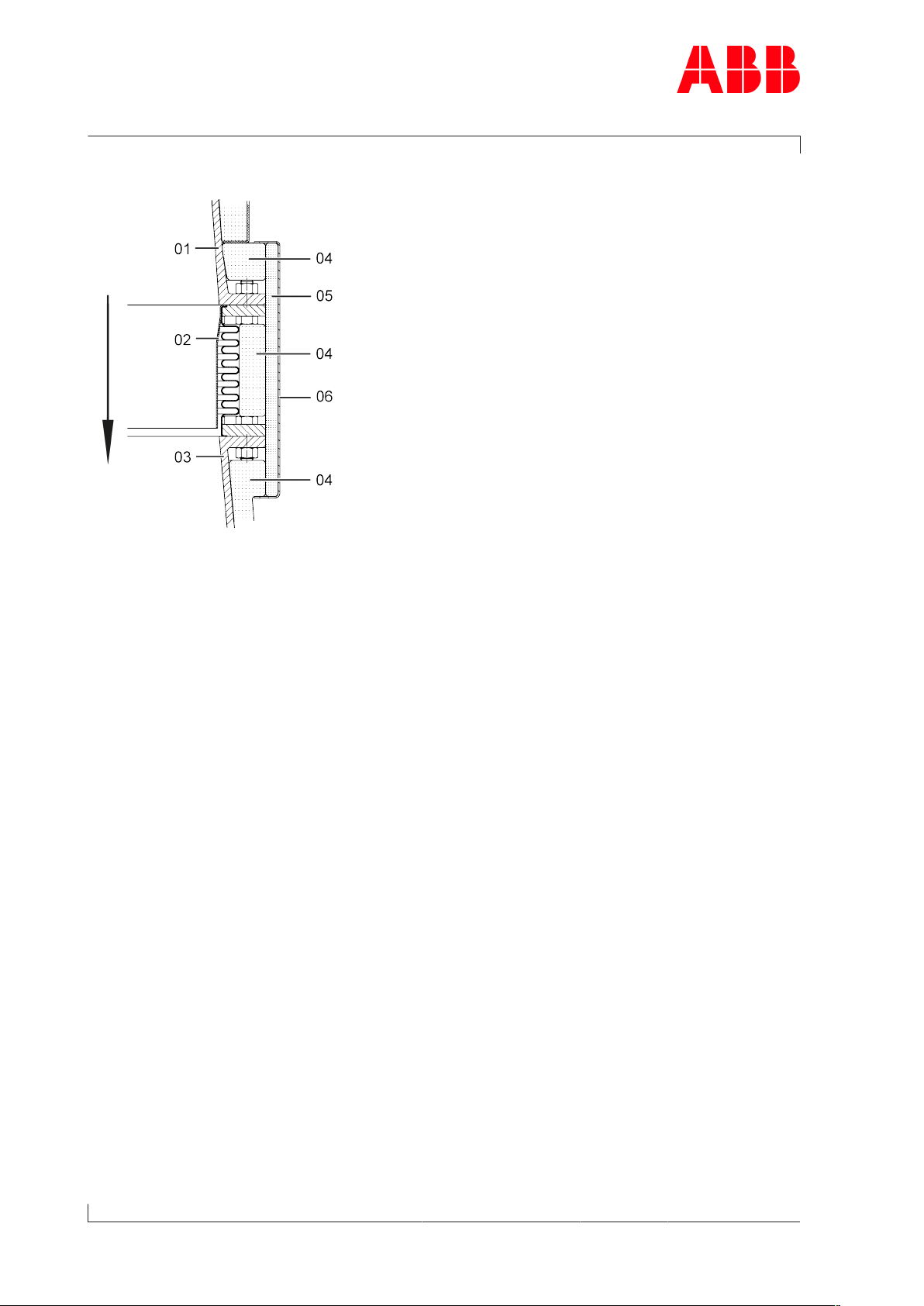

Suggestion for noise insulation, bellows

Page 22 / 40

Fig.12: Noise insulation, bellows

01 Compressor casing

02 Bellows

03 Charge air duct / scavenging air duct

04 Insulation cushion

05 Insulation mat (at least 15 mm)

06 Sheet metal cover

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Page 51

Operation Manual / 4 Product description / TPS61-R

5 Operation and service / 5.2 Service work

5.2 Service work

Service work includes visual controls, monitoring, measuring and inspection as well as functional checks. Service work enables the detection and rectification of changes to the turbocharger and ensures full operability of the turbocharger.

CAUTION

Service intervals

Any service work on the turbocharger that is omitted or performed too late

can cause excessive contamination, wear and operating failures.

u Carry out the service work at the specified time intervals.

CAUTION

Shortened service intervals

Exceptional stresses such as several starts/stops per day, harsh environmental conditions, poor fuel quality or high system vibrations can lead to

untimely machine damage even if the prescribed service intervals are observed.

u Agree on a shortened service interval with ABB Turbo Systems.

To prevent machine damage caused by ageing and downtime, we recommend having an inspection carried out by an ABB Turbocharging Service Station no later than 5 years after the

last service.

Page 23 / 40

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Page 52

Operation Manual / 4 Product description / TPS61-R

5 Operation and service / 5.2 Service work

5.2.1 Service work every 24 … 48 hours

Pipes

u Check all the inlet and outlet pipes of the turbocharger for leaks.

Operating data

CAUTION

Unknown operational changes

Impairment to the degree of a possible operating failure can be the consequence.

u Have any unknown causes clarified by an ABB Turbocharging Service Sta-

tion.

Page 24 / 40

Monitoring the engine's operating data makes it possible to draw conclusions about the operating behaviour of the turbocharger.

u The following operating data and measured values must be entered every 24 … 48 hours

in the engine logbook of the enginebuilder.

¡ Performance and speed of the engine

¡ Air intake temperature

¡ Charging pressure

¡ Pressure loss in the charge air cooler

¡ Lubricating oil pressure and lubricating oil temperature.

If present:

¡ Speed of the turbocharger

¡ Pressure in air inlet system

u In case of different values, determine the cause.

5.2.2 Service work at 100 hours after commissioning

u Clean or replace the oil filter located in the supply pipe to the turbocharger while the en-

gine is stopped.

5.2.3 Service work according to instructions of enginebuilder

u Clean or replace the oil filter located in the supply pipe to the turbocharger while the en-

gine is stopped.

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Page 53

Operation Manual / 4 Product description / TPS61-R

5 Operation and service / 5.2 Service work

5.2.4 Service work according to data on the rating plate

WARNING

Incorrect handling of a cartridge group

The disassembly and assembly of the cartridge group, as well as the assessment of the rotor and bearing parts, requires the expertise of an ABB Turbocharging Service Station. The rotor parts rotate extremely quickly and are

sensitive to unbalance. Incorrect handling of a cartridge group can damage

the turbocharger and cause injuries to persons.

u Ensure that the disassembly and assembly of the cartridge group is only

carried out by an ABB Turbocharging Service Station.

The following service work must be carried out by an ABB Turbocharging Service Station.

¡ Dismantle turbocharger and measure clearances.

¡ Clean nozzle ring, turbine casing and compressor casing mechanically.

¡ Check nozzle ring, turbine casing and compressor casing for cracks and erosion/corro-

sion.

¡ Check and assess rotor and bearing parts.

The following work can be carried out as preparation.

u Remove the turbocharger from the engine (see chapter Removing and Installing →7).

Page 25 / 40

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Page 54

Operation Manual / 4 Product description / TPS61-R

5 Operation and service / 5.3 Expected replacement intervals

5.3 Expected replacement intervals

Component Operating hours

Turbine casing 25000…50000

Nozzle ring 50000

Gas outlet flange 50000

Partition wall 50000

Rotating components See rating plate information

Bearing parts 12000…24000

Other casings 50000

Table9: Expected replacement intervals [h]

1)

Page 26 / 40

1)

The recommended replacement intervals of the compressor and turbine wheels are specified with the aid of the safety concept for rotating parts (SIKO) and dependent on the

operating conditions.

Influencing parameters

The specified values are guideline values and are not guaranteed. The actual values can deviate considerably from the guideline values, for example, due to the following influences:

¡ Fuel quality and fuel treatment

¡ Load profile (thermal cycling, also number of starts/stops, emergency shutdowns, oper-

ating point)

¡ Gas inlet temperature

¡ Turbocharger specification.

¡ System-specific operating conditions (combustion quality, exhaust gas composition)

For bearing parts

¡ Lubricating oil quality (oil filtering, oil condition, oil monitoring)

¡ Load profile (speed, pressure conditions, temperature)

¡ Number of starts/stops

¡ Unbalance of the rotor (degree of contamination).

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Page 55

Operation Manual / 4 Product description / TPS61-R

6 Stopping the engine /

6 Stopping the engine

CAUTION

Post-lubrication

If the heat in the turbocharger is not dissipated after the engine stops, damage may result.

u Perform post-lubrication 15…20minutes after stopping the engine.

Page 27 / 40

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Page 56

Operation Manual / 4 Product description / TPS61-R

7 Eliminating malfunctions / 7.1 Malfunctions when starting

7 Eliminating malfunctions

7.1 Malfunctions when starting

Delayed start-up

Possible causes Remedy

Turbocharger

Table10: Malfunctions when starting – Delayed start-up

Vibrations

Turbocharger contaminated Have cleaning carried out by an ABB

Turbocharging Service Station.

Bearing damaged Contact ABB Turbocharging Service Sta-

Rotor rubbing

Foreign object in the turbocharger

tion

Page 28 / 40

Possible causes Remedy

Turbocharger

Engine Vibrations from engine Contact enginebuilder

Table11: Malfunctions when starting – Vibrations

Rotor unbalance Contact ABB Turbocharging Service

Turbine or compressor damaged

Bearing damaged

Station

Rotating parts rubbing

Normal behaviour, not a malfunction

Turbocharger

Table12: Malfunctions when starting - Rotating parts rubbing

A minimal and uniform wear on the circumference of the rotor components is

permitted. This wear can be caused by slight local rubbing against adjacent components. This causes the compressor or turbine blades to be somewhat

shortened. To prevent significant loss of efficiency, specific tolerances must be

fulfilled.

¡ If there is any doubt about the extent of the rubbing, contact an ABB Tur-

bocharging Service Station.

¡ Have a dimension check carried out by an ABB Turbocharging Service Sta-

tion.

7.2 Malfunctions during operation

Lubricating oil pressure too low

Possible causes Remedy

Turbocharger

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Axial clearance of the rotor excessive Contact ABB Turbocharging Service

Station

Page 57

Operation Manual / 4 Product description / TPS61-R

7 Eliminating malfunctions / 7.2 Malfunctions during operation

Possible causes Remedy

Engine Oil filter heavily contaminated Clean

Oil pump in lubricating system defective

Manometer displays incorrectly Replace manometer

Table13: Malfunctions during operation – Lubricating oil pressure too low

Check/replace

Speed reduces

Possible causes Remedy

Turbocharger

Engine Defects on the connected cylinders in

Pipes Defects, such as leaks, in the exhaust gas

Table14: Malfunctions during operation – Speed reduces

Turbine and/or nozzle ring severely contaminated

Rotor components or bearing damaged Contact ABB Turbocharging Service Sta-

pulse charging

pipes or charge air ducts

Have cleaning carried out by an ABB

Turbocharging Service Station.

tion

Contact enginebuilder

Repair

Speed increasing

Possible causes Remedy

Turbocharger

Table15: Malfunctions during operation – Speed increases

Light to medium contamination of the

turbine and/or nozzle ring

Have cleaning carried out by an ABB

Turbocharging Service Station.

Page 29 / 40

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Page 58

Operation Manual / 4 Product description / TPS61-R

7 Eliminating malfunctions / 7.2 Malfunctions during operation

Exhaust gas temperature too high

Engine performance and engine speed unchanged

Possible causes Remedy

Turbocharger Compressor/turbine contaminated Have cleaning carried out by an ABB

Turbocharging Service Station.

Exhaust gas back pressure too high Check the exhaust gas system.

Turbine damaged or eroded Contact ABB Turbocharging Service

Station

Air inlet system Insufficient air, for example, if the air

filter is blocked

Engine Malfunction in the injection system Repair or contact manufacturer

Charge air

cooler

Table16: Malfunctions during operation – Exhaust gas temperature too high

Cooler contaminated Clean

Cooling water volume too low Fill

Inlet temperature of cooling water too

high

Insufficient ventilation Improve ventilation

Clean or replace the air filter.

Check/clean cooling system

Page 30 / 40

Charge air pressure too low

Engine performance and engine speed unchanged, suction condition normal

Possible causes Remedy

Turbocharger

Air inlet system

Engine Air receiver not sealed Repair

Pipes Pipes downstream to the compressor

Table17: Malfunctions during operation – Charge air pressure too low

Compressor end and/or turbine end

contaminated

Compressor/turbine damaged Contact ABB Turbocharging Service Sta-

Insufficient air, for example, if the air filter is blocked

Gas piping between engine and turbine

leaking

Injection mistimed Set correctly

Valve control misadjusted

outlet not sealed.

Exhaust gas back pressure too high Check the exhaust gas system.

Have cleaning carried out by an ABB

Turbocharging Service Station.

tion

Clean or replace the air filter.

Repair.

© Copyright 2019 ABB. All rights reserved. HZTL4042_EN Rev.B June 2019

Page 59

Operation Manual / 4 Product description / TPS61-R

7 Eliminating malfunctions / 7.2 Malfunctions during operation

Charge air pressure too high

Engine performance and engine speed unchanged, suction condition normal

Possible causes Remedy

Engine Malfunction in the injection system Repair or contact manufacturer

Injection mistimed Set correctly

Engine performance higher than indicated

Table18: Malfunctions during operation – Charge air pressure too high

Check engine performance

Reduced compressor performance/efficiency and therefore engine performance

losses

CAUTION

Compressor damage

A severely contaminated or corroded compressor wheel can reduce the compressor wheel’s fatigue endurance limit and result in the turbocharger being

damaged.

u Rectify malfunction in accordance with the following table.

Possible causes Remedy

Turbocharger

Table19: Malfunctions during operation – Engine performance losses

Compressor components severely contaminated by the ventilation gases that

have been fed in

Increased blade vibration, compressor

blade damage due to the ventilation

gases that have been fed in

Material of the compressor wheel corroded due to the feeding in of ventilation

gases containing corrosive components

Material of the compressor wheel corroded due to intake air containing exhaust gases or salt

Have cleaning carried out by an ABB

Turbocharging Service Station.

Optimize oil separation