Page 1

Operation Manual

TPS 57D01

ABB Turbo Systems Ltd

CH 5401 Baden

Type TPS 57D01 HT843552

n

Mmax

n

Bmax

SGAK02 00410 12 50 50

Year 2017

HZTL2410 English

Original Operation Manual

709 t

678 t

Mmax

1/s °C

Bmax

kg

made in Switzerland

650

620

Application according to

the Operation Manual

ABB Turbocharging

Page 2

Operating condition and replacement intervals

The operational limits for the turbocharger nBmax, tBmax, nMmax, tMmax, inspection- and replacement intervals for the components concerned on the rating plate are valid for the operational mode and compressor inlet condition, which has been agreed upon

between the engine builder and ABB.

Note: Replacement intervals of components depends on the load profi le, turbine inlet temperature, suction air temperature and

Unless otherwise agreed, the application limits nMmax, tMmax are valid for the test operation for a limited time.

turbocharger speed. In case the operation conditions differs signifi cantly from what is considered to be normal for the current application, it is recommended to contact ABB for a re-calculation of replacement intervals. Frequent load alterations,

high temperatures and high speed lower the life of components.

Page 3

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Table of contents

© Copyright 2016 ABB. All rights reserved.

Table of contents

1

Preliminary remarks

1.1

Purpose of this manual

1.2

Layout and function

1.3

Intended use of the turbocharger

1.4

Storage of new turbochargers and spare parts

1.5

Essential information

1.6

Symbols and definitions

1.7

Turbocharger rating plate

1.8

Contact information

2

Safety

2.1

Introduction

2.2

CE conformity

2.3

Definition of mandatory signs

2.4

Definition of Safety instructions

2.5

Warning plates on the turbocharger

2.6

Safe operation and maintenance

2.7

Hazards during operation and maintenance

2.8

Deflagration on gas engines

2.9

Periodic checking of the pressure vessel

2.10

Lifting loads

3

Commissioning

3.1

Oil supply

3.2

Inspection work

3.3

Commissioning after taking out of operation

4

Operation

4.1

Noise emissions

4.2

Servicing work

4.3

Expected exchange intervals

4.4

Speed measurement

4.5

Stopping the engine

Page 1

September 2016 HZTL2410_EN Revision E

Page 4

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Table of contents

© Copyright 2016 A

5

Maintenance

5.1

Foreword to Maintenance

5.2

Cleaning the compressor during operation

5.3

Turbine cleaning during operation

5.4

Cleaning components mechanically

6

Troubleshooting

6.1

Malfunctions when starting

6.2

Surging of the turbocharger

6.3

Malfunctions during operation

6.4

Malfunctions when stopping

6.5

Speed measurement system

7

Removal and installation

7.1

Transport

7.2

Turbocharger weights

7.3

Remove the turbocharger

7.4

Installing the turbocharger

8

Disassembly and assembly

8.1

Introduction

8.2

Module weights

8.3

Disassembling and assembling turbocharger

8.4

Axial clearance A and radial clearance B

8.5

Radial clearances N and R

8.6

Table of tightening torques

9

Taking out of operation

9.1

Shutting down the turbocharger

10

Mothballing the turbocharger

10.1

Taking the engine out of operation for up to 12 months

10.2

Taking the engine out of operation for more than 12 months

11

Disposing of turbocharger components

12

Spare parts

12.1

Ordering spare parts

12.2

View of turbocharger showing part numbers

12.3

View of cartridge group showing part numbers

Page 2

September 2016 HZTL2410_EN Revision E

BB. All rights reserved.

Page 5

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Preliminary remarks

1

Purpose of this manual

1.1

© Copyright 2016 ABB. All rights reserved.

Preliminary remarks

Purpose of this manual

Operation Manual

Target group

Availability of operation manual

1

1.1

Page 3

1.1

September 2016 HZTL2410_EN Revision E

This operation manual belongs to the turbocharger with the identical HT

number (01), see the cover sheet of the operation manual and the turbocharger rating plate.

This Operation Manual enables you to familiarize yourself with the turbocharger supplied by ABB Turbo Systems and to use it as intended.

It provides important information in order that the turbocharger can be operated safely, correctly and efficiently.

This Operation Manual complements and expands existing national regulations concerning work safety and accident prevention.

This Operation Manual is intended for engineers and qualified mechanics

who are responsible for operating the engine and the turbocharger installed on it.

An operation manual must be available at all times at the place where the

turbocharger is used.

Everyone who operates or works on the turbocharger must have first read

and understood the operation manual.

Page 6

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Preliminary remarks

1

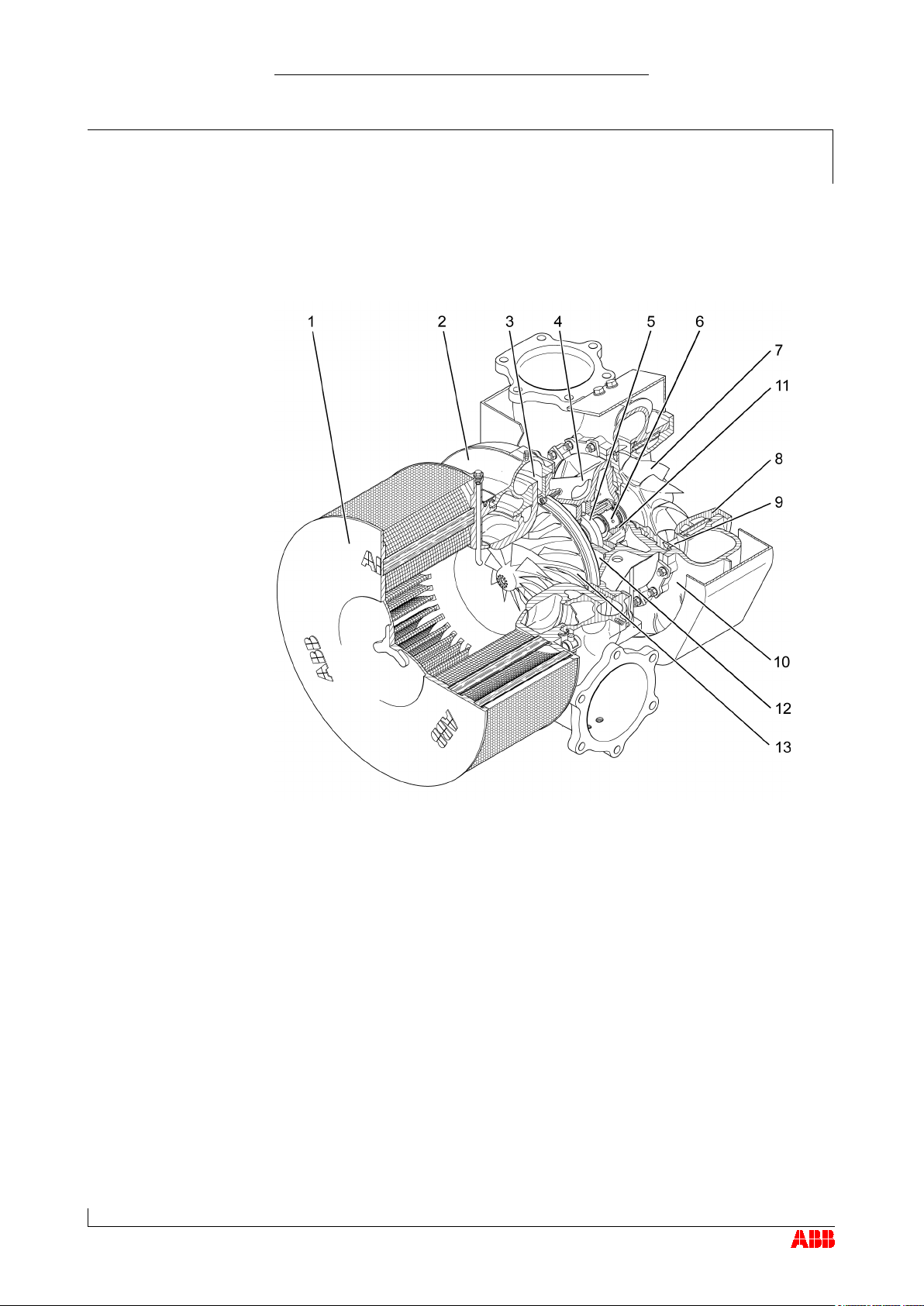

Layout and function

1.2

© Copyright 2016 ABB. All righ

Layout and function

1.2

1.2

Page 4

September 2016 HZTL2410_EN Revision E

1 Suction branch / filter silencer 8 Gas outlet flange

2

Compressor casing 9 Nozzle ring

3

Diffuser 10 Turbine casing

4

Bearing casing 11 Turbine-end bearing flange

5

Axial thrust bearing 12 Compressor-end bearing flange

6

Radial plain bearing (visible

13 Compressor wheel

only at turbine end)

7

Turbine

ts reserved.

Page 7

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Preliminary remarks

1

Layout and function

1.2

© Copyright 2016 ABB. All rights reserved.

Mode of operation

Page 5

The turbocharger is a turbomachine consisting of the following main components:

Turbine

September 2016 HZTL2410_EN Revision E

Compressor

These are mounted on a common shaft.

Exhaust gases from the diesel or gas engine flow through the turbine casing (10) and the nozzle ring (9) to impinge on the turbine (7).

The turbine (7) uses the energy contained in the exhaust gas to drive the

compressor wheel (13). The compressor draws in fresh air, compresses it

and then forces it into the engine's cylinders.

The exhaust gases escape into the ambient air through the exhaust gas

pipe, which is connected to the gas outlet flange (8).

The air, which is necessary for operation of the diesel or gas engine and

is compressed in the turbocharger, is drawn into the compressor wheel

(13) through the suction branch or filter silencer (1). It then passes

through the diffuser (3) and leaves the turbocharger through the outlet on

the compressor casing (2).

The rotor runs in two radial plain bearings (6), which are located in the

bearing flanges (11/12) between the compressor and the turbine. The axial thrust bearing (5) is located between the two radial plain bearings.

The bearings are connected to a central lubricating oil duct which is supplied by the engine's lubricating oil circuit. The oil outlet is always at the

lowest point of the bearing casing (4).

Page 8

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Preliminary remarks

1

Intended use of the turbocharger

1.3

© Copyright 2016 ABB. All righ

Intended use of the turbocharger

NOTICE

This turbocharger supplied by ABB Turbo Systems has been developed

used

with a gas engine

not

explosive environment

not potentially explosive

WARNING

Improper operation and maintenance of the turbocharger can result in

1.3

State of the art

Perfect condition

1.3

Page 6

for use on diesel engines to generate the volume of air and the charging pressure required to operate the engine.

The engine builder has provided ABB Turbo Systems with information

regarding the intended use of the engine, from which the operating limits specific to the turbocharger shown on the rating plate (such as operating speeds, temperatures, exchange intervals / replacement intervals)

have been derived.

If it is

stalled in a potentially

in conjunction

, the engine must

, and precautionary

be in-

measures must be taken to ensure that the machine room as a whole is

classified as

.

Any other use will be regarded as a special application which must first

be discussed with ABB Turbo Systems. The manufacturer accepts no

liability for other applications. If it is used otherwise, ABB Turbo Systems reserves the right to reject all warranty claims.

September 2016 HZTL2410_EN Revision E

This turbocharger was built according to state-of-the-art technology and is

operationally safe according to recognised safety regulations.

danger to life and limb of the user or third parties. In addition, improper

use may cause damage to the machine.

The machine may be operated only by trained personnel.

Use of the turbocharger as intended also includes observance of the installation / fitting, disassembly / removal, operating, maintenance / servicing and repair conditions specified by the manufacturer. Disposal regulations set down by local authorities must be observed.

The turbocharger may be installed only when in technically perfect condition while observing the instructions given in the engine builder's manual.

It may be used only for the intended purpose and operated in compliance

with the operation manual.

Malfunctions which could affect safety must be eliminated immediately.

The manufacturer accepts no liability for any damage resulting from unauthorised alterations to the turbocharger.

ts reserved.

Page 9

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Preliminary remarks

1

Storage of new turbochargers and

spare parts

1.4

© Copyright 2016 ABB. All rights reserved.

Storage of new turbochargers and spare

parts

Storage of new turbochargers and spare parts up to 6 months

V

Storage of new turbochargers and spare parts for more than 6 months (VCI)

WARNING

Protection of health when handling VCIs

1.4

Page 7

1.4

September 2016 HZTL2410_EN Revision E

New turbochargers and spare parts from ABB Turbo Systems can be stored

in sealed packaging without additional mothballing measures for up to 6

months from the date of delivery (marked by the VCI label on the package).

olatile Corrosion Inhibitor (VCI)

Only dry rooms in which the relative humidity is between 40…70 % and

no condensation can form are suitable for storage.

VCI products are not hazardous in the sense of the Hazardous Substances Ordinance. Nevertheless, the following points are to be observed when handling VCIs:

Ensure good room ventilation.

Do not eat, drink or keep food at the workplace while working with

VCIs.

Wear safety gloves.

Clean hands and face after working with VCIs.

For further information refer to www.branopac.com.

Wear safety gloves to protect against chemical hazards.

The following mothballing measures are required every 6 months:

Open the package.

Remove the VCI corrosion protection emitter from the package and

Dispose of the old VCI corrosion protection emitter in an environmen-

Seal the package. The better the external seal is designed, the more

replace it with a new, identical VCI corrosion protection emitter. New

VCI corrosion protection emitters can be obtained at

www.branopac.com.

tally compatible manner, professionally and in accordance with local

regulations.

permanent the protection.

Page 10

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Preliminary remarks

1

Storage of new turbochargers and

spare parts

1.4

© Copyright 2016 ABB. All righ

Long-term storage of replacement turbochargers or spare parts

NOTICE

Replacement components ready for operation

Unpacking replacement turbochargers or spare parts

Page 8

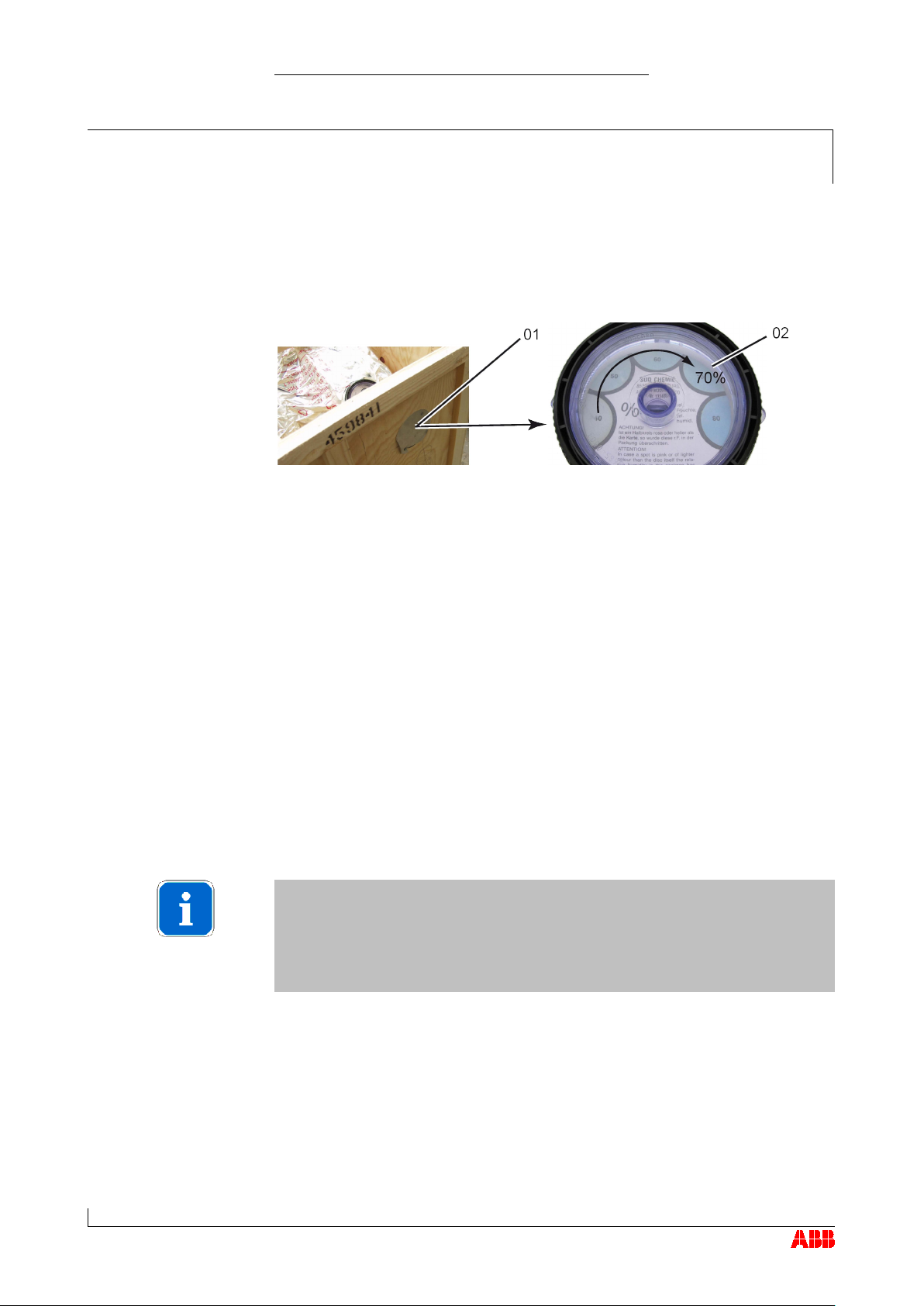

Per order, turbochargers or cartridge groups will be prepared by ABB Turbo Systems for prolonged storage. The package is equipped with a hygrometer (see illustration).

September 2016 HZTL2410_EN Revision E

The following measures are required every 6 months:

Check the hygrometer (02) in the sight-glass. There is an opening (01)

in the wooden crate which allows this check to be carried out. When

the display field has changed colour at the 70% level, the maximum

permissible humidity has been exceeded. In this case the turbocharger

or rotor must be inspected by an ABB Turbocharging Service Station

and repacked.

Inspect the package for damage. If the package is damaged, the tur-

bocharger or cartridge group must be inspected by an ABB Turbocharging Service Station and repacked.

After every 3 years the following work steps must be performed by an

ABB Turbocharging Service Station:

Inspect the components

Exchange the desiccant agent

Repackage the components.

If the 70% display field of the hygrometer (02) has not changed colour

and the package is undamaged, the replacement turbocharger or replacement cartridge group can be placed into operation without any prior testing by an ABB Turbocharging Service Station.

The corrosion protection effect ends after the material is unpacked from

the VCI package.

To avoid the formation of condensation, the surroundings and the content

of the package must have the same temperature during unpacking.

ts reserved.

Page 11

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Preliminary remarks

1

Essential information

1.5

© Copyright 2016 ABB. All rights reserved.

Essential information

Organisational measures

NOTICE

The manner in which personnel work on and with the turbocharger with

NOTICE

Any modifications, additions or conversions made to the turbocharger,

1.5

1.5

Page 9

In addition to the Operation Manual, the general statutory regulations for

September 2016 HZTL2410_EN Revision E

the prevention of accidents and for environmental protection in the country

of use must also be observed.

This also applies to the provision and wearing of personal protective

equipment.

regard to safety and risks is to be checked on a regular basis in accordance with the Operation Manual.

The turbocharger must be shut down immediately in the event of modi-

fications affecting safety or of corresponding operating behaviour by

stopping the engine. The fault should be reported to the person or department responsible.

which could impair safety, require the prior approval of ABB Turbo Systems.

Page 12

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Preliminary remarks

1

Essential information

1.5

© Copyright 2016 ABB. All righ

Original parts and safety

WARNING

Use original parts

Competence of personnel

Page 10

Original parts and accessories are specially designed for the turbocharger

supplied by ABB Turbo Systems.

September 2016 HZTL2410_EN Revision E

Operation of the turbocharger with non-original parts can impair the

safety of the turbocharger and can cause serious damage to property

and injury to personnel.

Only use original parts from ABB Turbo Systems.

ABB Turbo Systems accepts no liability for any damage resulting from the

use of non-original parts and corresponding accessories.

The turbocharger must only be operated and serviced by trained and authorised personnel. Basic mechanical training is a prerequisite.

ts reserved.

Page 13

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Preliminary remarks

1

Essential information

1.5

© Copyright 2016 ABB. All rights reserved.

Design variants

Accuracy of illustrations

Registered Trademarks

Page 11

This document is valid for different design variants of turbochargers.

There may be sections and descriptions of components that are not relevant for a specific turbocharger variant.

September 2016 HZTL2410_EN Revision E

ABB Turbocharging Service Stations will be happy to provide information

on questions regarding a design variant (see Contact information at

www.abb.com/turbocharging).

The illustrations in this document are general in nature and intended for

ease of understanding. Differences in detail are therefore possible.

Registered trademarks of external companies are used in this document.

The trademarks are marked with ®.

Page 14

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Preliminary remarks

1

Symbols and definitions

1.6

© Copyright 2016 ABB. All righ

Symbols and definitions

Definition of notes

NOTICE

Note

Definition of mandatory signs

Definition of caution / warning

ABB Turbo Systems

Official ABB Turbo Systems Service Stations

1.6

1.6

Page 12

The following symbols are used in the documents:

Prerequisite

Step of a procedure

List, first level

- List, second level

[➙ ] Refers to a page number

September 2016 HZTL2410_EN Revision E

A note provides suggestions which facilitate the work on the product.

Mandatory signs show the protective equipment to be worn for a task. The

mandatory signs are described in chapter Safety and must be complied with.

The caution and warning signs are described in the chapter Safety.

In this document, ABB Turbo Systems Ltd is abbreviated to ABB Turbo

Systems.

In this document, official service stations are referred to as ABB Turbocharging Service Stations. They are inspected and certified regularly by

ABB Turbo Systems. See also chapter Contact information [➙ 15].

ts reserved.

Page 15

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Preliminary remarks

1

Turbocharger rating plate

1.7

© Copyright 2016 ABB. All rights reserved.

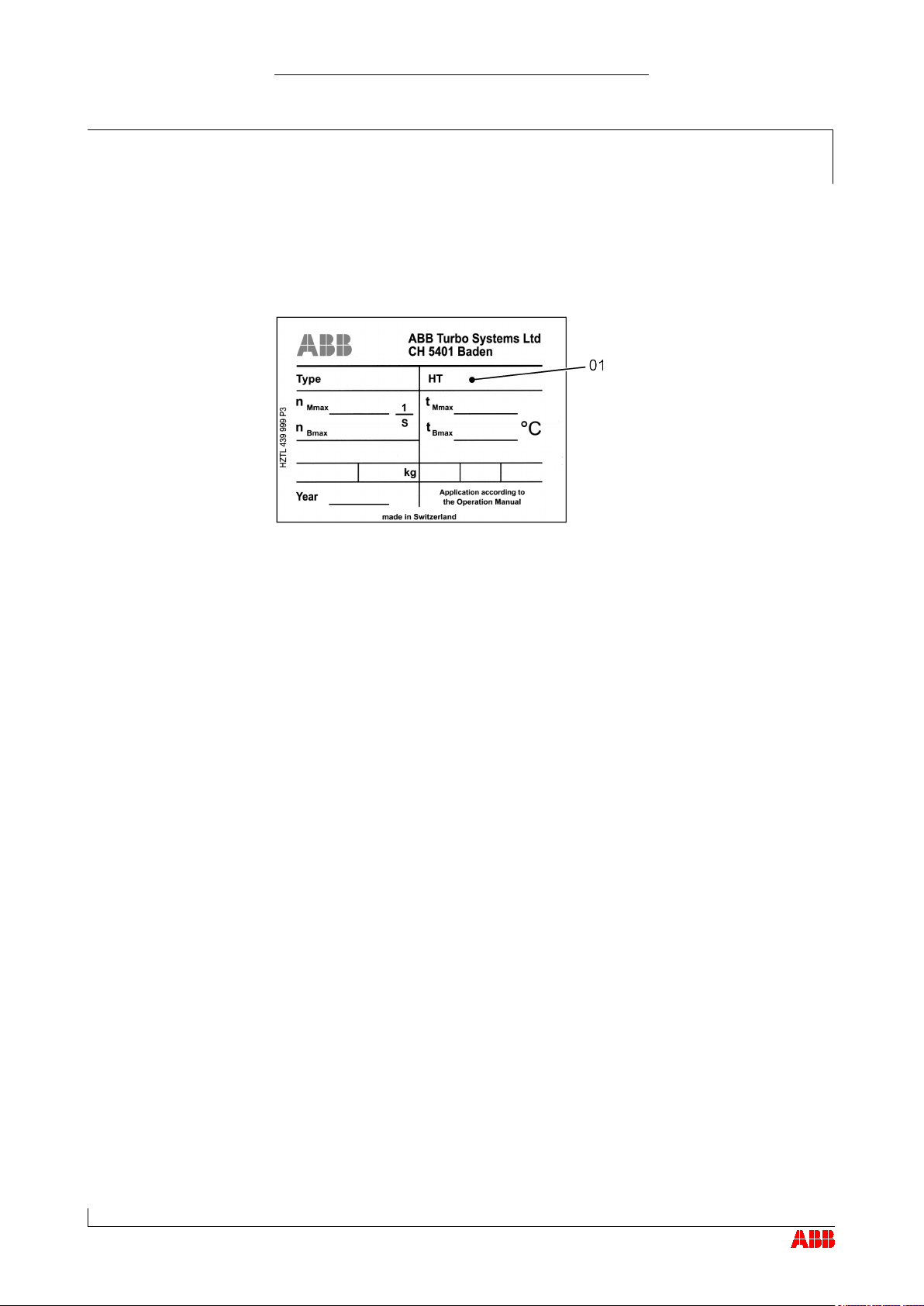

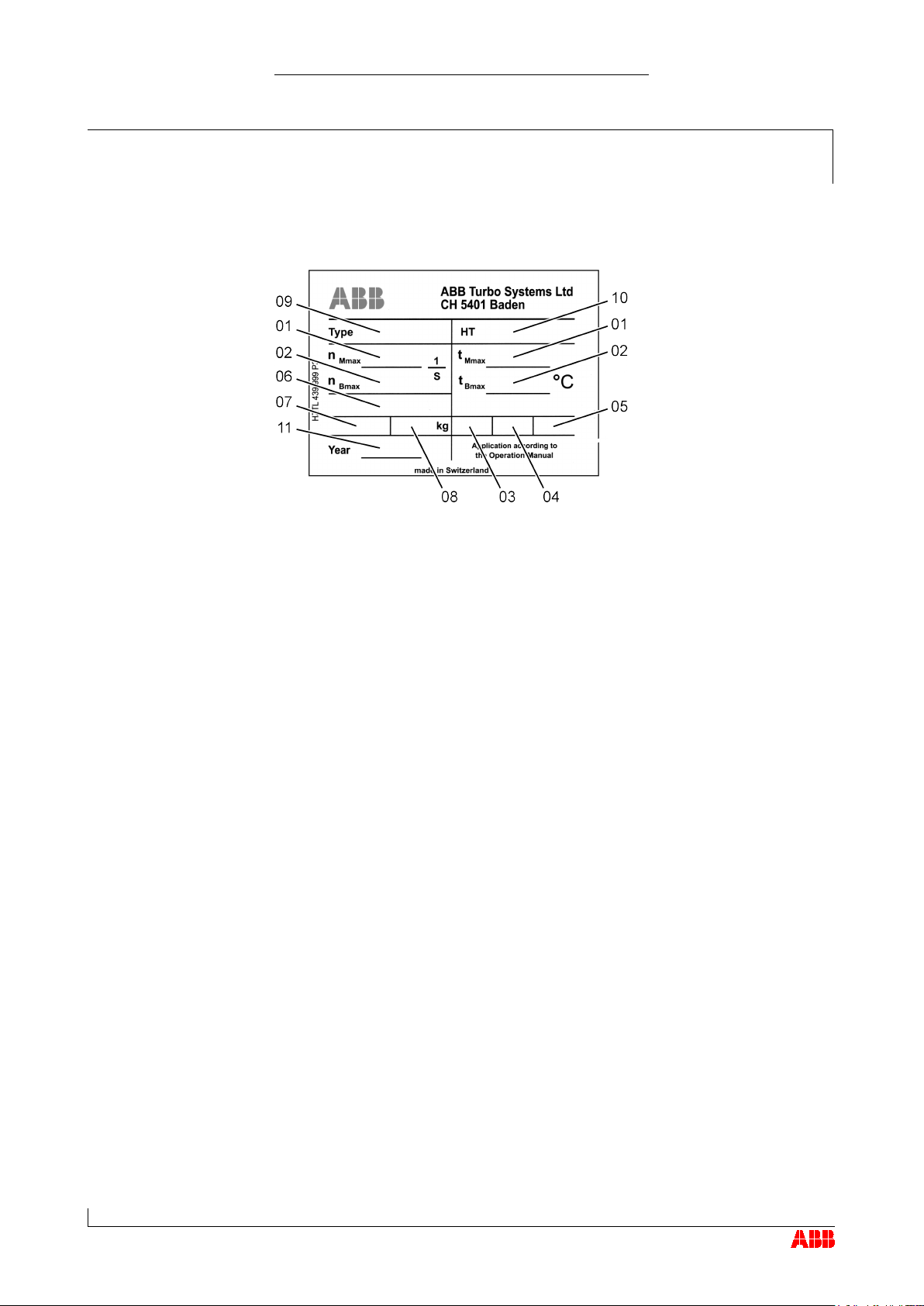

Turbocharger rating plate

06 Customer part number

07 Designation of the special design

08 Weight of turbocharger in kg

09 Turbocharger type

11 Year of construction of turbocharger

1.7

Operating limits

Recommended inspection

and replacement intervals

of turbocharger components

Further data

1.7

September 2016 HZTL2410_EN Revision E

Page 13

01 Turbocharger operating limits at engine overload (110%).

Only when operating in the test rig unless otherwise agreed with the

enginebuilder.

02

Turbocharger operating limits during operation

03 Inspection interval of plain bearings in 1000 h

04

Replacement interval of compressor in 1000 h

05

Replacement interval of turbine in 1000 h

10 Serial number

Page 16

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Preliminary remarks

1

Turbocharger rating plate

1.7

© Copyright 2016 ABB. All righ

Explanation of the rating plate

Positions of the rating plates

1.7.1

1.7.2

Page 14

The recommended replacement intervals and the corresponding operational limits are jointly defined with the engine manufacturer. This information is specific to the system.

Operation above the indicated values n

Bmax

, t

can considerably shorten the

Bmax

recommended replacement intervals. In such cases, we recommend that you

contact the nearest official ABB Turbocharging service station.

n

Mmax

and t

normally apply only when running at overload (110%) during tri-

Mmax

als on the engine test bed. These limits can also be permitted during operation

for special applications. Operation above n

Mmax

and t

is not permitted.

Mmax

Non-observance of the recommended replacement intervals can increase the

risk of unpredictable component failures.

September 2016 HZTL2410_EN Revision E

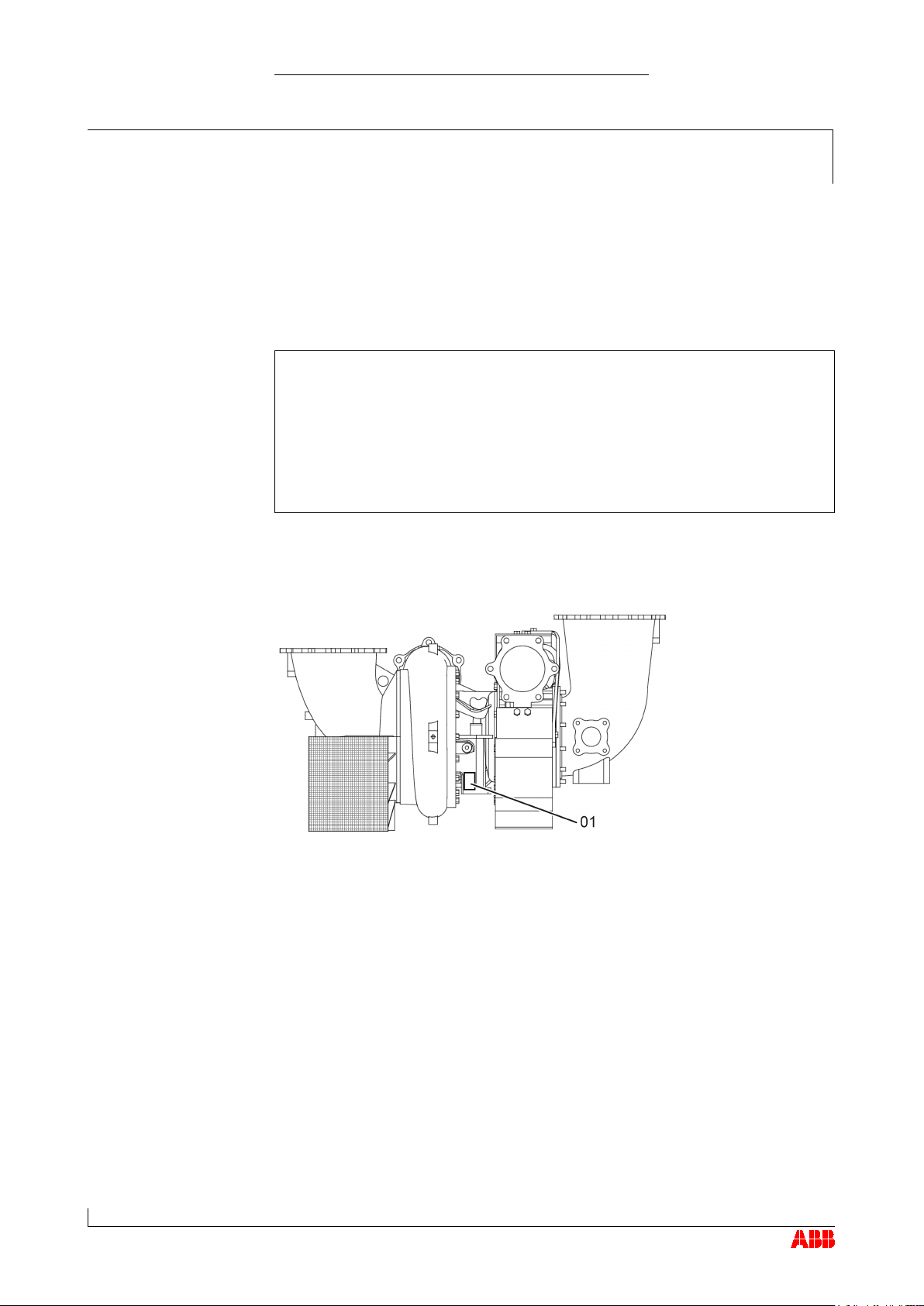

One rating plate (01) each is attached on the left and the right side of the

turbocharger bearing casing.

ts reserved.

Page 17

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Preliminary remarks

1

Contact information

1.8

© Copyright 2016 ABB. All rights reserved.

Contact information

Contact information

1.8

1.8

Page 15

Contact information for the official service stations of ABB Turbo Systems

September 2016 HZTL2410_EN Revision E

is available online.

Scan the QR code to access our website.

ABB Turbo Systems Ltd

Bruggerstrasse 71a

CH-5401 Baden

Switzerland

www.abb.com/turbocharging

Page 18

Page 19

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Safety

2

Introduction

2.1

© Copyright 2016 ABB. All rights reserved.

Safety

Introduction

2

2.1

Page 17

2.1

September 2016 HZTL2410_EN Revision E

Turbochargers manufactured by ABB Turbo Systems are state of the art

and comply with the pertinent safety and health-protection requirements

that applied when the turbocharger was manufactured. Consequently, the

turbocharger is safe to operate. Nevertheless, during turbocharger operation and when working on the turbocharger, residual risks can exist which:

originate from the turbocharger itself and its accessories

originate from the operating and auxiliary materials used

are the consequence of insufficient observance of the safety instruc-

tions

are the consequence of unsatisfactory and improper execution of

maintenance and inspection work

The operator is responsible for access to the turbocharger as well as the

organisational measures which regulate the safe handling of the turbocharger by his personnel.

All instructions in this chapter must be observed to ensure safe and trouble-free turbocharger operation and during work on the turbocharger.

In the same vein, all other specially marked safety instructions in every

chapter of this manual must be observed (see the section entitled Definition of safety instructions).

Page 20

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Safety

2

CE conformity

2.2

© Copyright 2016 ABB. All rights reserved.

CE conformity

Information

2.2

2.2

Page 18

ABB turbochargers fulfil Directive 2006/42/EC on machinery and are considered partly completed machinery in the sense of Article 2 g.

September 2016 HZTL2410_EN Revision E

Page 21

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Safety

2

Definition of mandatory signs

2.3

© Copyright 2016 ABB. All rights reserved.

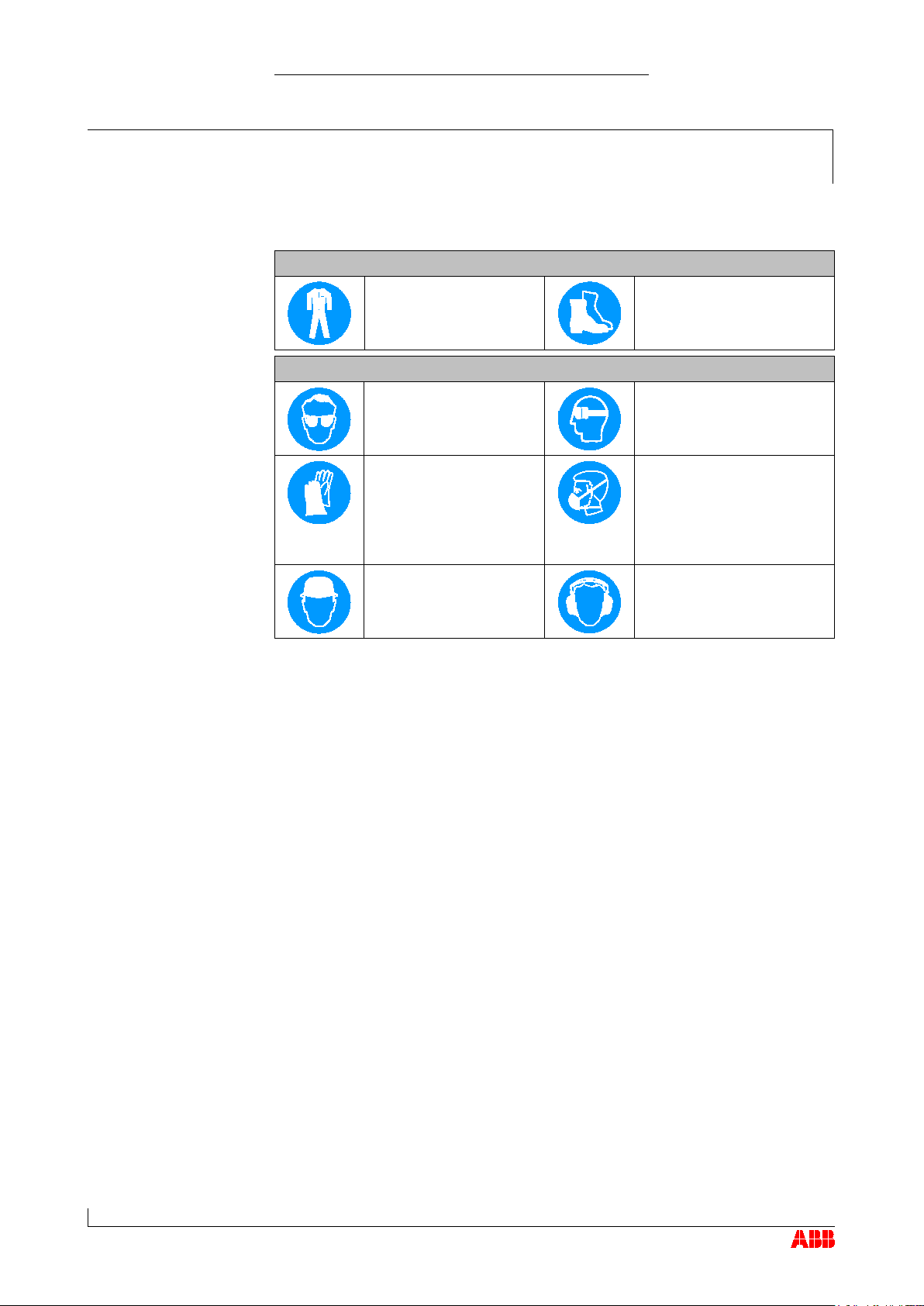

Definition of mandatory signs

To be worn at all times

Protective clothing

Safety footwear

To be worn according to the specific work

Safety glasses

Safety goggles

Safety gloves to protect

Respiratory mask to protect

Safety helmet

Ear protection

2.3

2.3

Page 19

to protect

against mechanical hazard

and risk of falling

September 2016 HZTL2410_EN Revision E

against

- Mechanical hazard

- Chemical hazard

against

- Dusts

- Gases

- Thermal hazard

Page 22

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Safety

2

Definition of Safety instructions

2.4

© Copyright 2016 ABB. All rights reserved.

Definition of Safety instructions

WARNING

Definition of warning

WARNING

Warning signs must be observed at all times.

CAUTION

Definition of caution

CAUTION

Caution signs must be observed at all times

2.4

2.4

Page 20

The following symbols and terms used in this manual concern safety or

refer to possible hazards:

Serious personal injuries and even accidents with fatal consequences

may occur if work and operating instructions marked with this symbol

and the word

are either not followed or not followed precisely.

Serious machine or property damage may occur if work and operating

instructions marked with this symbol and the word

are either

not followed or not followed precisely.

.

September 2016 HZTL2410_EN Revision E

Page 23

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Safety

2

Warning plates on the turbocharger

2.5

© Copyright 2016 ABB. All rights reserved.

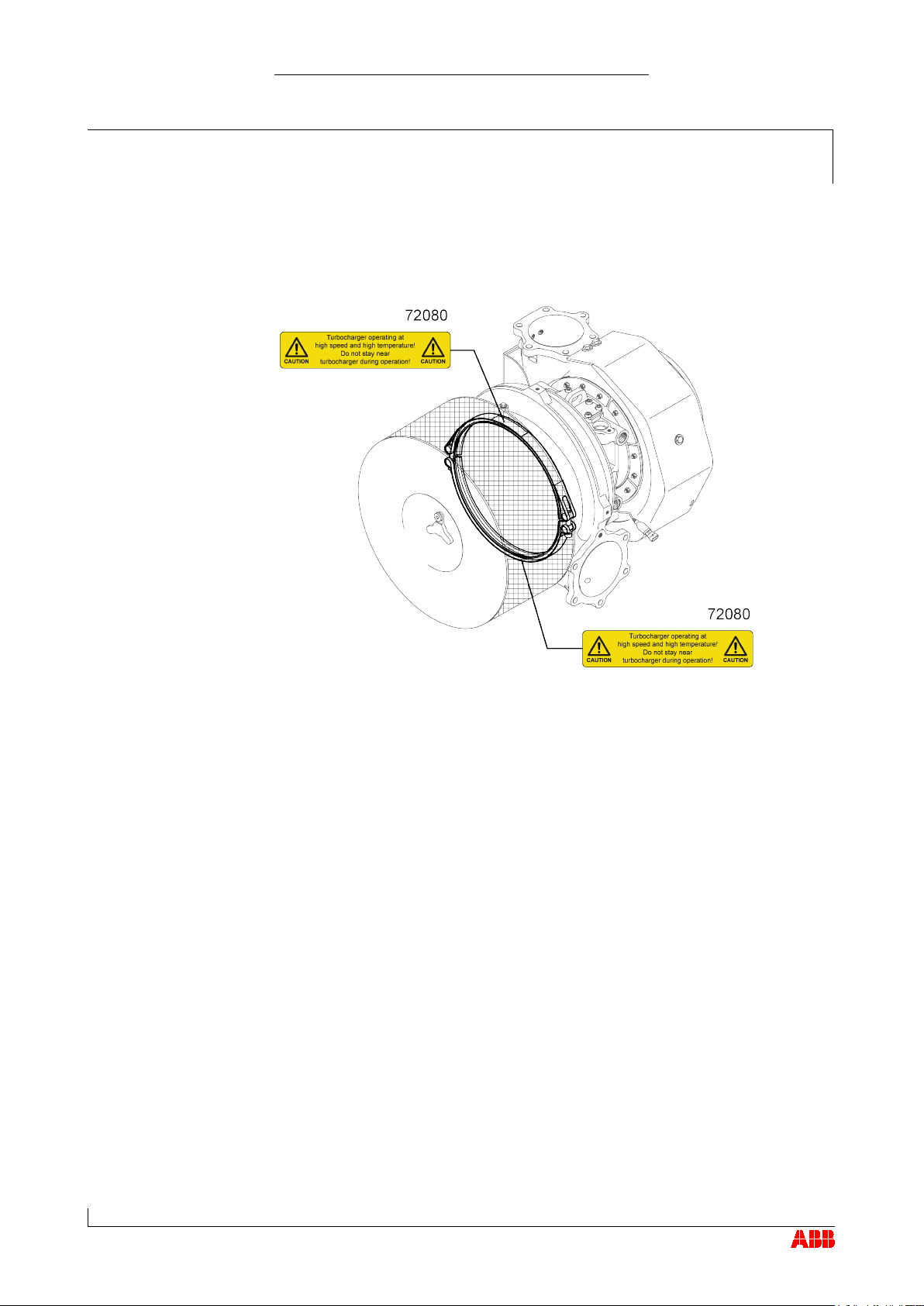

Warning plates on the turbocharger

Uninsulated turbochargers

2.5

2.5

Page 21

Warning plates are attached to the turbocharger at the following places:

September 2016 HZTL2410_EN Revision E

If warning plates are not present at the intended places or are not legible,

then proceed as follows:

Order new warning plates from ABB Turbocharging Service Stations.

Remove unreadable warning plates.

Clean and degrease surfaces provided for warning plates.

Attach new warning plates.

When uninsulated turbochargers are delivered to the engine builder, the

warning plates must be subsequently attached to the insulation. This is

the responsibility of the engine builder.

Page 24

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Safety

2

Safe operation and maintenance

2.6

© Copyright 2016 ABB. All rights reserved.

Safe operation and maintenance

Work safety and work area safety

WARNING

Risk of falling

Welding work in the vicinity of the turbocharger

2.6

2.6

Page 22

The instructions specified in this section are for the safety of personnel.

Together with the instructions in the Hazards during operation and

maintenance section, they allow the user to safely use the turbocharger.

September 2016 HZTL2410_EN Revision E

There is the risk that someone can fall when working on the turbocharger.

Do not climb on the turbocharger or on parts attached to it or use

these as climbing aids.

When working at levels above the head, use climbing aids and work

platforms suitable for this purpose.

Observe all general regulations for the prevention of accidents.

Do not work on the turbocharger if you are under physical or mental

stress.

Work only with suitable tools as well as equipment and working mate-

rials that are in perfect condition.

Electric tools must be solidly earthed, and connecting cables may not

be damaged.

Keep the workplace clean, clear away loose objects and remove ob-

stacles on the floor.

Keep the floor, equipment and the turbocharger clean.

Have oil binding materials ready at hand and keep oil catch pans

ready or in position

Eliminate leaks.

Keep fire-protection materials and fire-extinguishing equipment ready.

When performing welding work in the vicinity of the turbocharger, al-

ways cover the filter silencer to prevent the filter mat from being damaged.

Keep flammable objects and substances out of the range of flying

sparks.

Cover all connections on the turbocharger so that no foreign objects

can enter the turbocharger.

Wear personal protective equipment (PPE) for welding operations.

Page 25

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Safety

2

Safe operation and maintenance

2.6

© Copyright 2016 ABB. All rights reserved.

Safety during start-up / commissioning and operation

Safety during cleaning

Page 23

Before starting work, carry out visual inspection of working area.

Remove any obstacles and objects lying around.

Before start-up / commissioning, check all pipes from and to turbo-

September 2016 HZTL2410_EN Revision E

charger for damage and leaks.

Don't work in any way that could impair safety when working on turbo-

charger.

After about every 12 hours of operation or at least once a day, inspect

turbocharger for visible damage and defects.

Immediately report any damage or changes in operational perfor-

mance to person responsible.

If damage is discovered, immediately shut down turbocharger and se-

cure it against inadvertent or unauthorized use.

When switching on auxiliary power sources (hydraulics, pneumatics,

electricity, water), keep an eye open for any hazards resulting from

supplying these power sources.

If cleaning agents or solvents are used for cleaning, the corresponding

material safety data sheet and the safety instructions in section "Hazards

due to operating and auxiliary materials" must be observed.

Observe the material safety data sheet for the cleaning agent or sol-

vent.

Wear personal protective equipment (PPE) according to the material

safety data sheet.

Inspect the electric cables for abrasion and damage before and after

your cleaning work.

Page 26

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Safety

2

Safe operation and maintenance

2.6

© Copyright 2016 ABB. All rights reserved.

Safety during disassembly, assembly, maintenance and troubleshooting

CAUTION

Mechanical work on the turbocharger

Safety when taking out of operation or preparing for mothballing

Page 24

Always perform the specified adjustments, servicing as well as inspec-

tion work and observe inspection intervals.

Inform operating personnel about all service and repair work before

beginning.

September 2016 HZTL2410_EN Revision E

Before opening a cover or removing a protective device on a turbo-

charger, the engine must be switched off and the turbocharger must

have come to a standstill.

Ensure that the supply of oil is interrupted, especially with an external

oil supply.

Put the engine into operation only after all parts have been refitted

properly.

Possible damage to or destruction of components on the turbocharger.

Perform only those tasks that are described in this manual.

Perform work only for which training has been carried out.

Secure the rotor so it cannot turn. The rotor can turn on its own from

the force of the stack draught.

Clean the turbocharger before mothballing it.

Observe the material safety data sheet for the cleaning and mothball-

ing agents.

Wear personal protective equipment (PPE) according to the material

safety data sheet.

Page 27

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Safety

2

Hazards during operation and

maintenance

2.7

© Copyright 2016 ABB. All rights reserved.

Hazards during operation and maintenance

Mechanical hazards during operation

WARNING

Risk of injury

Mechanical hazards when working on the turbocharger

WARNING

Mechanical hazards

2.7

2.7

Page 25

September 2016 HZTL2410_EN Revision E

charger if it has been installed properly.

During normal operation, no mechanical hazards emanate from the turbo-

Contact with rotating parts can lead to serious injuries. The turbocharger must never be operated without a filter silencer or an air suction

branch. When the engine is at a standstill, the rotor can turn on its own

because of stack draught.

Operate the turbocharger in accordance with instructions.

During maintenance work, secure the rotor against unintentional ro-

tation.

During maintenance work, various risks can occur through the improper

handling of components, through the non-observance of work instructions,

due to inadequate care or as a consequence of insufficient training.

Severe injuries to personnel or fatal accidents can be caused by mechanical influences as a consequence of hazardous and inadequate

operational procedures.

Observe the general rules for occupational safety and prevention of

accidents.

Ensure workplace safety.

Only perform operations that are described in this document.

Only perform operations for which you have previously received in-

struction or training.

Page 28

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Safety

2

Hazards during operation and

maintenance

2.7

© Copyright 2016 ABB. All rights reserved.

Hazards due to noise

WARNING

Hazards due to noise

Hazards due to hot surfaces and substances

WARNING

Risk of burning

Page 26

The development of noise during operation is influenced by the installation

and operating conditions. Noise with a sound pressure level exceeding

85 dB(A) is harmful.

Noise can cause impaired hearing, damage to health, mental disturb-

September 2016 HZTL2410_EN Revision E

ances, diminished attention and irritation.

Always wear ear protection when the engine is running.

When the sound pressure level is above 85 dB(A), always wear ear

protection.

Wear ear protection.

During operation, turbocharger surfaces and attached parts as well as operating materials (lubricating oil) become hot. The surface temperature is

dependent on the effectiveness of the insulation being used. The temperature can become high enough so that it falls into ranges where burns

are possible.

Touching hot surfaces or contact with hot operating materials can lead

to serious burns.

Do not touch hot surfaces and heed the warning plate on the turbo-

charger.

Wear heat-resistant safety gloves and protective clothing.

Allow the turbocharger to cool down before carrying out any work.

Wear safety gloves to protect against thermal hazards.

Page 29

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Safety

2

Hazards during operation and

mainten

2.7

© Copyright 2016 ABB. All rights reserved.

WARNING

Hot surfaces on the non-insulated turbocharger

Hazards due to operating and auxiliary materials

WARNING

Handling operating and auxiliary materials

Page 27

ance

Non-insulated turbochargers can cause serious injuries to personnel

(burns).

The turbocharger is supplied by ABB Turbo Systems without insulation

depending on the order from the enginebuilder. If supply is without insu-

September 2016 HZTL2410_EN Revision E

lation, the enginebuilder is responsible for providing the turbocharger

with proper insulation and for providing protection against contact with

hot surfaces.

Compliance with the instructions and specifications given by the en-

ginebuilder to protect against hot turbocharger surfaces is compulsory.

Wear safety gloves to protect against thermal hazards.

Operating and auxiliary materials are substances used for operation or the

execution of maintenance work. Oils, greases, coolants, cleaning agents

and solvents, acids, etc. can be regarded as hazardous materials. Operating and auxiliary materials can be combustible and easily ignited.

Ingestion or inhalation of vapours of operating and auxiliary materials or

contact with such can cause damage to health.

Avoid inhalation and contact with the skin.

Ensure good ventilation.

Observe details in the safety data sheets of the operating and auxil-

iary materials.

Observe local laws.

Wear safety goggles.

Wear safety gloves to protect against chemical hazards.

Wear a respiratory mask to protect against gases.

Page 30

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Safety

2

Hazards during operation and

maintenance

2.7

© Copyright 2016 ABB. All rights reserved.

WARNING

Risk of fire, explosion

CAUTION

Risk of environmental damage

Page 28

Flammable and combustible operating materials and supplies can catch

fire or resulting vapours can lead to an explosion.

Observe the details in the material safety data sheets of the operat-

ing and auxiliary materials.

Comply with local legislation.

Do not allow any exposed flame or ignition source during cleaning

September 2016 HZTL2410_EN Revision E

work.

Carry out cleaning in the open or provide sufficient aeration and ven-

tilation.

The escape of operating and auxiliary materials into the atmosphere or

contamination of the ground and water due to improper disposal can

lead to environmental damage.

Handle operating and auxiliary materials carefully.

Heed the instructions for use, safety data sheets and hazard notices

on the containers of the operating and auxiliary materials.

Wear appropriate protective clothing.

Avoid inhalation and contact with the skin.

Ensure that the work space is adequately ventilated.

Seal containers tightly immediately after use and put them away.

Collect used working and auxiliary materials safely, store them sepa-

rately in suitable containers and dispose of them properly and in an

environmentally compatible manner in accordance with statutory regulations.

In the event of leaks or after spilling, immediately spread a suitable

binding agent and dispose of it properly and in an environmentally

compatible manner in accordance with statutory regulations.

Page 31

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Safety

2

Hazards during operation and

maintenance

2.7

© Copyright 2016 ABB. All rights reserved.

Hazards when handling insulating materials

WARNING

Hazards due to insulating materials

Page 29

September 2016 HZTL2410_EN Revision E

Dust and fibres from insulating materials can cause damage to health

or irritations. Unsuitable, combustible insulating materials signify a fire

hazard.

Use only suitable, non-combustible insulating materials.

Ensure that the work area is well ventilated.

Avoid stirring up dust.

Use tools and processes which keep dust to a minimum.

Remove packing materials only in the work area.

Take particular care when removing old insulating materials.

Dispose of insulating materials properly and in an environmentally

compatible way in accordance with applicable local regulations.

Wear safety goggles.

Wear a respiratory mask to protect against dusts.

Wear safety gloves to protect against chemical hazards.

Use only suitable, non-combustible insulating materials.

Ensure that the work area is well ventilated.

Wear suitable work clothing (safety glasses, respiratory mask).

Avoid stirring up dust.

Use tools and processes which keep dust to a minimum.

Remove packing materials only in the work area.

Take particular care when removing old insulating materials.

Dispose of insulating materials properly and in an environmentally

compatible way in accordance with applicable local regulations.

Page 32

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Safety

2

Hazards during operati

maintenance

2.7

© Copyright 2016 ABB. All rights reserved.

Hazards due to electrical components

WARNING

Hazards due to electrical components

on and

Page 30

Electrical components operate with voltages which can present hazards

to humans.

All work on or with electrical components may only be performed by

trained specialists.

Heed any country-specific regulations.

September 2016 HZTL2410_EN Revision E

Page 33

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Safety

2

Deflagration on gas engines

2.8

© Copyright 2016 ABB. All rights reserved.

Deflagration on gas engines

2.8

2.8

Page 31

ABB turbochargers can tolerate a deflagration with a transient pressure

increase of 12 bar.

After a deflagration event ABB Turbo Systems recommends verifying the

September 2016 HZTL2410_EN Revision E

following points on the turbocharger:

Position of the turbine and compressor casings to the bearing casing

Shifting of the bearing casing in relation to the bracket

Cracks in casings

If during external inspection anomalies are found or if a particularly strong

deflagration event has taken place, it is also recommended to check the

bearings of the turbochargers before the next start. This inspection and

evaluation must be carried out by an ABB Turbocharging Service Station.

Page 34

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Safety

2

Periodic checking of the pressure

vessel

2.9

© Copyright 2016 ABB. All rights reserved.

Periodic checking of the pressure vessel

WARNING

Hazards from pressure vessels

2.9

2.9

Page 32

The pressure vessels used by ABB Turbo Systems, such as those for wet

or dry cleaning, are so-called "simple pressure vessels".

The local, statutory regulations covering periodic checks of pressure

vessels must be observed.

September 2016 HZTL2410_EN Revision E

The operator is responsible for the safe operation of the pressure vessel.

The operator must keep the pressure vessel in a proper condition and

monitor it. Necessary repair or maintenance work must be carried out

without delay and the required safety precautions must be taken.

Pressure equipment must not be operated if it has defects.

Page 35

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Safety

2

Lifting loads

2.10

© Copyright 2016 ABB. All rights reserved.

Lifting loads

WARNING

Suspended loads

2.10

2.10

Page 33

September 2016 HZTL2410_EN Revision E

Loads not suspended in compliance with regulations may lead to personal injury or accidents with fatal consequences.

Loads must always be fastened to technically perfect lifting gear with

sufficient loading capacity.

Make sure the load is suspended properly on the crane hook.

Do not let anyone stand beneath a suspended load.

Wear safety gloves to protect against mechanical hazards.

Wear safety helmet.

In the case of two or more suspension points, the slinging angle must not

exceed 45°. This avoids excessive loading due to inclined tensile loading.

Fasten turbocharger assemblies / components as described in respec-

tive handling steps.

Before attaching slings, allow turbocharger components to cool down

(maximum 80°C).

Use suitable protection at sharp edges.

Completely screw in assembly / fitting devices without fail so that they

cannot work loose during use.

Use assembly / fitting devices only for applications described.

Make sure removed turbocharger components stand safely and se-

curely.

Page 36

Page 37

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Commissioning

3

Oil supply

3.1

© Copyright 2

Commissioning

Oil supply

Oil filtration

CAUTION

Depending on the turbine specifications and bearings used, varying

NOTICE

Also follow the enginebuilder's instructions regarding filter mesh and

3

3.1

Page 35

3.1

September 2016 HZTL2410_EN Revision E

A carefully designed and installed oil supply, which functions in all possible operational conditions, is an important prerequisite for trouble-free turbocharger operation.

The turbocharger is normally lubricated with oil from the engine oil circuit.

If a separate lubricating system is used, then emergency lubrication is also to be provided.

Heed the instructions of the engine builder when selecting the lubricat-

ing oil and oil-change intervals.

amounts of contaminants have to be filtered out of the lubricating oil to

avoid dangerous wear of the bearing parts.

The standard oil filter specification for the turbocharger is 34 µm. This

means that contaminants larger than 0.034 mm must be filtered out of the

oil with a separation efficiency > 99%.

Fit an accessory filter if engine oil filter is not efficient enough.

If the engine is started cold and the flow resistance rises to above 0.5

bar due to deposits of dirt in the accessory filter, a bypass must open

which ensures that oil flows to the turbocharger by circumventing the

filter.

Check that oil filters are clean before commissioning.

separation efficiency.

016 ABB. All rights reserved.

Page 38

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Commissioning

3

Oil supply

3.1

© Copyright 2016 ABB. All rights reserved.

Lubricant

NOTICE

All lubricating oils used for engines are admissible.

Oil inlet viscosity and temperature

CAUTION

Falling below the minimum oil inlet temperature

Page 36

September 2016 HZTL2410_EN Revision E

The oil-inlet temperature must not exceed 105°C. Permissible oil-inlet viscosities and oil-inlet temperatures are shown in the following chart.

1) Kinematic viscosity (mm2/s = cSt)

2) Oil-inlet temperature (°C)

A Permissible range

Serious machine or property damage can be caused by excessively

high oil viscosity and the resulting lack of oil in the bearings.

Do not allow the oil inlet temperature to fall below the minimum 30 ºC

when starting the engine.

The oil inlet temperature must never be less than 10 °C.

Page 39

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Commissioning

3

Oil supply

3.1

© Copyright 2

Oil pressure

Status for operation

Oil pressure in front of

turbocharger

[bar]

CAUTION

Prelubrication

Page 37

The oil pressure in front of the turbocharger must be maintained precisely

to ensure trouble-free operation.

September 2016 HZTL2410_EN Revision E

Normal operation 2.0 … 4.5

Engine start: cold oil, permissible for maximum

≤ 8.0

15 minutes

Engine idling ≥ 0.2

Pre- and post-lubrication (engine stopped) ≤ 1.0

Serious machine or property damage might result if the turbocharger is

not supplied with oil when the engine is starting.

Activate prelubrication device before starting engine.

016 ABB. All rights reserved.

Page 40

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Commissioning

3

Oil supply

3.1

© Copyright 2016 ABB. All rights reserved.

Lubricating oil temperature at the inlet

CAUTION

Machine damage

Status for operation

Oil temperature at inlet

T

oil,inlet

Permissible

30 … 105 °C

Not permissible → stop engine

> 110 °C

Lubricating oil temperature at the outlet

Status for operation

Oil temperature at outlet

T

oil,outlet

Page 38

Machine damage may result if the oil temperature at the oil inlet exceeds the permissible range.

Keep the oil temperature at the oil inlet as specified in the following

table.

Temporarily permissible (< 1 h) → alarm > 105 °C

Not permissible → do not start engine (before

starting: preheat oil)

< 30 °C

September 2016 HZTL2410_EN Revision E

The oil temperature at the outlet depends mainly on:

lubricating oil temperature and pressure at the oil inlet

engine load and turbocharger speed

exhaust gas temperature

The maximum permissible oil temperature at the outlet is listed in the following table. The specified oil outlet temperature must be regarded as an

alarm value for turbocharger operation and be monitored in accordance

with standard regulations.

Permissible ≤ 160 °C

Temporarily permissible → alarm > 160 °C

Not permissible → stop engine > 180 °C

Permissible ≤ T

Temporarily permissible → alarm > T

oil,inlet

oil,inlet

+ 55 K

+ 55 K

If the turbocharger has been operated outside the permissible range for a

prolonged period of time, ABB Turbo Systems recommends having the

turbocharger inspected by an ABB Turbocharging Service Station.

Page 41

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Commissioning

3

Inspection work

3.2

© Copyright 2

Inspection work

Inspection before commissioning

CAUTION

Contaminated oil

CAUTION

Prelubrication

3.2

3.2.1

Monitoring devices

Filter mat

Lubricating system

Warning plates on turbocharger

3.2

Page 39

Inspection work includes preventive visual controls plus monitoring and

measuring work before and during commissioning. Inspections help detect

changes to the turbocharger. Machine damage can be avoided.

September 2016 HZTL2410_EN Revision E

Check for correct functioning.

Inspect for damage.

Check oil filter for cleanliness before commissioning.

Particles of dirt and solid matter in the oil can cause serious damage to

the machine or property.

During initial commissioning and after all service work, the complete

lubricating system must be flushed thoroughly with warm oil.

When running in the engine and after all service work on the lubricat-

ing system, special running-in filters must be used.

Check oil pressure in oil supply lines.

Serious machine or property damage might result if the turbocharger is

not supplied with oil when the engine is starting.

Activate prelubrication device before starting engine.

Check whether the warning plates are present and legible.

Check whether the protective sheets have been removed.

016 ABB. All rights reserved.

Page 42

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Commissioning

3

Inspection work

3.2

© Copyright 2016 ABB. All rights reserved.

Check after start-up (engine at idling speed)

Lubricating system

Gas, air and oil lines

Check when running up engine

NOTICE

Lubricants and pastes used during assembly of the turbocharger liquefy

Inspection after 100 service hours

3.2.2

3.2.3

3.2.4

Page 40

Check oil pressure in oil supply lines.

Check oil inlet temperature.

September 2016 HZTL2410_EN Revision E

The permissible values are listed in the section Oil supply.

Check all gas, air and oil lines for leaks after starting the engine.

Measure speed, oil pressure and charging pressure at various engine

performance levels.

Measure exhaust gas temperature in front of and behind turbine.

Measure air temperature in front of and behind compressor.

The measured values must be compared with the values in the acceptance

test report, while taking different operating conditions into account.

or vaporise and might escape as an oily liquid in the first few hours after

commissioning. If oily liquid continues to escape after this period, an oil

leak must be suspected. The first step is to check for leakage of the oil

supply to the turbocharger. If this is leaky, contact an official ABB Turbocharging service station.

Clean or replace lubricating oil filters after the first 100 service hours.

Page 43

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Commissioning

3

Commissioni

operation

3.3

© Copyright 2

Commissioning after taking out of operation

3.3

If provided

ng after taking out of

Page 41

3.3

Remove cover plates (blind flanges) between compressor casing out-

let and charge air duct, before gas inlet and after gas outlet.

September 2016 HZTL2410_EN Revision E

Inspect exhaust gas duct / line in front of and after turbine for any

combustion deposits, foreign matter or residual water. Clean and remove.

Inspect air supply line or filter silencer for any foreign matter. Clean

and remove.

Start up turbocharger oil circulation system at engine end.

Prepare turbocharger for operation as instructed in section "Inspection

work before start-up / commissioning" of chapter headed "Start-up /

commissioning".

Start up turbocharger.

016 ABB. All rights reserved.

Page 44

Page 45

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Operation

4

Noise emissions

4.1

© Copyright 2016 ABB. All rights reserved.

Operation

Noise emissions

WARNING

Hazards due to noise

1)

Directive 2006/42/EC, 1.7.4.2 / u / Paragraphs 5 + 7 :

2)

In the event of divergent insulation designs, the engine builder must en-

4

4.1

Page 43

4.1

September 2016 HZTL2410_EN Revision E

Noise can cause impaired hearing, damage to health, mental disturbances, diminished attention and irritation.

Always wear ear protection when the engine is running.

When the sound pressure level is above 85 dB(A), always wear ear

protection.

Wear ear protection.

The sound pressure level (A-weighted) of emissions is measured at a distance of 1 metre from the turbocharger.

1)

The highest sound pressure level of emissions

reaches a maximum of

105 dB(A) near the filter silencer and over the entire speed range.

The following prerequisites must be fulfilled on the turbocharger in order

to observe this limit value:

Fitted air-inlet system

All standard, noise-reducing measures have been taken

2)

.

The bellows at the air outlet have been perfectly insulated acoustically

by the engine builder. He is also responsible for insulating the charge

air / scavenging air line and the charge air cooler.

A-weighted emission sound pressure level

sure that equivalent acoustic insulating measures are taken.

Page 46

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Operation

4

Noise emissions

4.1

© Copyright 2016 ABB. All rights reserved.

Suggestion for noise insulation of the bellows

02

Bellows

05

Insulation mat (at least 15 mm)

Page 44

September 2016 HZTL2410_EN Revision E

01 Compressor casing 04 Insulation pads

03 Charge air duct / scavenging

air line

06 Sheet metal cover

Page 47

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Operation

4

Servicing work

4.2

© Copyright 2016 ABB. All rights reserved.

Servicing work

CAUTION

Service intervals

CAUTION

Shortened service intervals

NOTICE

Service inspection after 5 years

4.2

4.2

Page 45

Service work to be carried out during operation involves visual checks,

monitoring, measuring, inspection work and functional checks. It is then

possible for changes to the turbocharger to be identified and rectified. In

this way, it can be ensured that the turbocharger remains in full working

September 2016 HZTL2410_EN Revision E

order.

Service work on the turbocharger that is neglected or carried out too

late can lead to excessive contamination and wear as well as operating

failures.

Carry out service work at specified time intervals.

Despite observance of the service intervals, unusual loads, such as

several start-stops a day, harsh environmental factors, poor fuel quality

or heavy installation vibration can lead to premature machine damage.

A shortened service interval must be arranged with ABB Turbo Sys-

tems.

To prevent age- and stoppage-related machine damage, an inspection

by an ABB Turbocharging Service Station is recommended at the latest

5 years after the last service.

Page 48

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Operation

4

Servicing work

4.2

© Copyright 2016 ABB. All rights reserved.

Service work every 25 … 50 hours

CAUTION

Unknown changes during operation

Servicing work according to the engine manufacturer's instructions

Service work in accordance with instructions on rating plate

4.2.1

4.2.2

Oil filter

4.2.3

Page 46

Visual inspection for air, exhaust gas, water and oil leaks.

Record operating data and enter it in the engine logbook.

Clarify the cause of any variances.

September 2016 HZTL2410_EN Revision E

The consequences can range from an impairment to a breakdown.

Have unknown causes clarified by an ABB Turbocharging service

station.

Clean or replace oil filter in supply line to turbocharger when engine is

not running.

(In general, after 8000 - 12000 hours of operation)

Rotor and bearing parts must be inspected and assessed by an ABB Turbocharging Service Station. The following work can be carried in preparation.

Remove cartridge group as described in chapter Disassembly and as-

sembly.

Measure clearances.

Clean turbine and compressor casings and check them for cracks and

erosion / corrosion.

Clean bearing casing and blow air through oil ports / holes.

Clean nozzle ring and check for cracks and erosion.

Page 49

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Operation

4

Servicing work

4.2

© Copyright 2016 ABB. All rights reserved.

Entries in engine logbook

4.2.4

If provided

Page 47

By monitoring the engine, conclusions can be drawn about the turbocharger performance.

September 2016 HZTL2410_EN Revision E

The following operating data and measured values must be entered regularly in the engine manufacturer's engine logbook:

Engine performance and speed

Air intake temperature

Exhaust gas temperature in front of and behind the turbine

Pressure of charge air

Pressure drop in charge air cooler

Lubricating oil pressure and lubricating oil temperature

Air temperature behind compressor and charge air cooler

Turbocharger speed

Pressure loss in air filter

Page 50

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Operation

4

Expected exchange intervals

4.3

© Copyright 2016 ABB. All rights reserved.

Expected exchange intervals

Rotating components

Non-rotating components

Expected replacement intervals [h]

GAS / MDO

HFO

Nozzle ring

50000

10000 … 25000

Partition wall

50000

35000 … 50000

Bearing parts

12000 … 24000

12000 … 24000

4.3

4.3

Page 48

The recommended replacement intervals for compressor wheels and turbine wheels are defined depending on the operating conditions and based

on the safety concept (SiKo) for rotating parts. These intervals can be

found on the turbocharger rating plate.

Depending on the system-specific operating conditions, a distinction is

made between:

the replacement interval for the bearing parts and

the replacement interval for those non-rotating components that are

exposed to hot gases.

September 2016 HZTL2410_EN Revision E

Decisive in this respect are various influencing parameters, which can

drastically shorten the replacement intervals of these parts in extreme

cases.

During the specified periodic service work, the individual components are

inspected for wear and, if necessary, replaced.

Turbine casing 25000 … 50000 25000 … 50000

Gas outlet flange 50000 35000 … 50000

Rotor components See the data on the rating plate

Other casings 50000 50000

GAS = Natural gas MDO = Marine diesel oil HFO = Heavy fuel oil

The specified values are a guide only and not guaranteed (see following

section Influencing parameters).

Page 51

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Operation

4

Expected exchange intervals

4.3

© Copyright 2016 ABB. All rights reserved.

Influencing parameters

Page 49

The specified values are only guide values and not guaranteed. The actual values can deviate considerably from the guide values due, for example, to the following influences:

September 2016 HZTL2410_EN Revision E

Fuel quality and preparation

Load profile (thermal load cycles, also starts / stops, emergency shut-

downs)

Gas inlet temperature

Frequency and execution of turbine and compressor cleaning

Turbocharger specification

System-specific operating conditions (operating point, combustion

quality, composition of exhaust gas)

For bearing parts

Lubricating oil quality (oil filtration, condition of lubricating oil, oil moni-

toring)

Load profile (rpm / speed, pressure conditions, temperature)

State of rotor unbalance (degree of contamination)

Page 52

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Operation

4

Speed measurement

4.4

© Copyright 2016 ABB. All rights reserved.

Speed measurement

CAUTION

Do not use cables as a climbing aid

4.4

4.4

Page 50

A speed measuring system permits continuous monitoring of the turbocharger speed.

If you pull the speed measurement cables too hard, contacts can be

pulled out.

Do not tension the speed measurement cables.

September 2016 HZTL2410_EN Revision E

86505(A) Speed sensor (cable not integrated) 86526 F/I converter

86505(B)

86515(A)

86515(B)

Speed sensor (cable integrated) 86528 Tachometer

Cable connector to 86505(A) 01 Screw plug

Cable connector to 86505(B) 02 Gasket

Page 53

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Operation

4

Speed measurement

4.4

© Copyright 2016 ABB. All rights reserved.

Speed differences with multiple turbochargers per engine

4.4.1

Page 51

The speeds of all turbochargers on one engine differ only slightly from

each other in normal operation.

September 2016 HZTL2410_EN Revision E

The difference between the highest and the lowest turbocharger speed

must not be more than 3 % relative to the speed limit n

Bmax

.

If this permissible range of difference is exceeded, the following steps

must be carried out:

Reduce engine performance immediately until the highest turbo-

charger speed no longer exceeds 70% of n

Bmax

.

If the engine cannot be stopped, continue to run at this reduced engine

performance or turbocharger speed.

If the turbocharger surges continuously, engine performance must be

reduced further.

Measure the temperatures in the air and gas lines to and from the tur-

bochargers and compare them with standard values.

If the engine can be stopped for a short time:

Inspect the air and gas lines as well as the turbocharger and eliminate

any problems.

In any event, it is recommended that you contact the nearest ABB

Turbocharging Service Station.

Page 54

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Operation

4

Speed measurement

4.4

© Copyright 2016 ABB. All rights reserved.

Replacing the speed sensor

WARNING

Hot cable connector and hot speed sensor

Part number

TPS48

TPS52

TPS57

TPS61

4.4.2

Page 52

Risk of burning. During operation, the cable connector and the speed

sensor can reach temperatures exceeding 100 °C.

Wear safety gloves when removing the cable connector and speed

sensor.

Wear safety gloves to protect against thermal hazards.

September 2016 HZTL2410_EN Revision E

Reduce engine performance to the idling speed, then stop the engine.

Switch off the lubricating oil supply to the turbocharger.

Disconnect the cable connector from the speed sensor.

Screw out defective speed sensor.

Screw in a new speed sensor up to the limit block.

Adhere to tightening torque.

86505 15 Nm 15 Nm 15 Nm 15 Nm

Page 55

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Operation

4

Speed measurement

4.4

© Copyright 2016 ABB. All rights reserved.

NOTICE

Sealing the speed sensor

Failure of speed measuring system

4.4.3

Page 53

September 2016 HZTL2410_EN Revision E

The speed sensor is designed with a sealing lip and does not require an

additional gasket when fitted.

Connect cable connector to speed sensor.

Switch on lubricating oil supply to turbocharger.

Possible reasons for failure of the speed measuring system are described

in the chapter Troubleshooting.

Page 56

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Operation

4

Stopping the engine

4.5

© Copyright 2016 ABB. All rights reserved.

Stopping the engine

CAUTION

Stopping the engine of oil-cooled turbocharger version

CAUTION

Stopping the engine of water-cooled turbocharger version

4.5

4.5

Page 54

Heat in the turbocharger must be dissipated by the further circulating

lubricating oil.

Post-lubricate for 15 … 20 minutes.

Maintain oil pressure of 0.5 … 1.0 bar for post-lubrication.

Heat in the turbocharger must be dissipated.

Allow turbocharger cooling water to run for 15 … 20 minutes after

stopping engine.

Allow oil lubrication to continue running until rotor comes to a stop.

Further post-lubrication is not required and not recommended.

September 2016 HZTL2410_EN Revision E

Page 57

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Maintenance

5

Foreword to Maintenance

5.1

© Copyright 2016 ABB. All rights reserved.

Maintenance

Foreword to Maintenance

CAUTION

Risk of damage during mechanical cleaning

NOTICE

Cleaning method

5

5.1

Page 55

5.1

September 2016 HZTL2410_EN Revision E

General maintenance work involves regular visual checks and cleaning

tasks which are intended to ensure the trouble-free functioning of the turbocharger.

The maintenance points described here are differentiated as follows:

Cleaning during operation:

– Compressor

– Turbine and nozzle ring.

Mechanical cleaning of individual components:

– Filter silencer

– Casings, diffuser, nozzle ring

– Cartridge group: Compressor, turbine

If mechanical cleaning is carried out too often, this can lead to damage

and corrosion on the components.

If cleaning during operation is not sufficient to achieve acceptable

values regarding thermal load and engine performance, mechanical

cleaning of certain spots can be carried out.

Perform mechanical cleaning, especially of the cartridge group, only

once within the service interval.

To allow you to observe the standard service intervals and to maintain a

high turbocharger efficiency, ABB Turbo Systems recommends that the

cleaning procedure be carried out during operation. This allows the

thermal load of the engine to be kept low while ensuring maximum fuel

efficiency.

Dispose of dirty water and cleaning agents in an environmentally com-

patible manner, professionally and in accordance with valid local regulations.

Page 58

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Maintenance

5

Cleaning the compressor during

operation

5.2

© Copyright 2016 ABB. All rights reserved.

Cleaning the compressor during operation

NOTICE

If the coating of dirt is very thick and hard, the compressor can only be

5.2

General

Cleaning interval

5.2

Page 56

The contamination of the compressor stage (compressor wheel, wall insert and diffuser) depends on the degree of purity of the taken-in air.

Deposits can form in the flow channels if salt, oil mist, exhaust gas or dust

are sucked in with the air.

September 2016 HZTL2410_EN Revision E

Consequences of contamination:

Impaired compressor efficiency

Higher exhaust gas temperatures

Increased fuel consumption

Increased rotor unbalance

Periodic cleaning of the compressor during operation prevents or delays

any major increase in contamination. But it never replaces the regular

service work where the turbocharger is completely dismantled and the

compressor is mechanically cleaned.

cleaned manually when disassembled. This cleaning must be carried

out by an ABB Turbocharging Service Station.

The interval between periodic cleaning is very dependent on the operating

conditions. In general, cleaning should be carried out every 25 ... 100 operating hours.

Should the specified cleaning intervals prove incompatible with engine

operation, please contact ABB Turbo Systems.

Page 59

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Maintenance

5

Cleaning the compressor during

operation

5.2

© Copyright 2016 ABB. All rights reserved.

Cleaning method

CAUTION

Corrosion and deposits when cleaning

CAUTION

The injection pipe must on no account be connected directly via a cock

Principle of wet cleaning

V-engines

Sequential charging

Page 57

Cleaning the compressor while in operation is carried out as wet cleaning.

This cleaning method has been tested and approved by ABB Turbo Systems.

September 2016 HZTL2410_EN Revision E

To clean the compressor stage during operation, water is injected in front

of the compressor wheel through an injection pipe fitted in the filter silencer or the suction branch.

The water does not act as a solvent, but the dirt deposit is removed by the

mechanical impact of the droplets. This is a very suitable process, provided that the degree of contamination is not too high.

Damage and impairment of turbocharger parts due to salt water and

cooling water additives

Don't use salt water for cleaning, but only clean fresh water.

to a water pipe or a dosing vessel larger than the one supplied. This

prevents uncontrolled volumes of water entering the turbocharger and

engine, which can lead to serious damage.

In the case of V-engines with several turbochargers on each engine, we

recommend parallel cleaning of the compressors. This cleaning process is

faster and the risk of turbocharger surging is reduced.

In the case of sequential charging, care must be taken to ensure that turbocharger compressors are cleaned regularly, especially after periods of

operation in the lower performance range.

Page 60

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Maintenance

5

Cleaning the compressor during

operation

5.2

© Copyright 2016 ABB. All rights reserved.

Wet cleaning compressor using external water pressure vessel (XC1)

NOTICE

Supplying water from the externally mounted water vessel is suitable

Operating state prerequisites for cleaning compressor with XC1

NOTICE

To be able to carry out a satisfactory cleaning process that has been

5.2.1

Approval by enginebuilder

Page 58

These instructions for wet cleaning only apply when cleaning is carried out

with clean water and under the precondition that the enginebuilder approves the process.

September 2016 HZTL2410_EN Revision E

only for those applications where a negative pressure exists in front of

the compressor wheel (not used for: blowers connected in front of the

compressor or high-pressure compressor stages with two-stage charging).

tested and is recommended by ABB Turbo Systems, the following prerequisites must be fulfilled:

Run engine at load from 50 … 85 %.

Start cleaning cycle according to following description Wet cleaning

operation with XC1.

Page 61

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Maintenance

5

Cleaning the compressor during

operation

5.2

© Copyright 2016 ABB. All rights reserved.

Procedure for wet cleaning the compressor with XC1

NOTICE

Whether or not cleaning has been successful can be seen from the

Product

Engine load

Contents

of cleaning medium vessel

[dm3]

Water

injection time

t1 [s]

TPS

50 … 85 %

0.4

10

Operating the water pressure vessel

Cleaning parameters per

turbocharger compressor

Page 59

September 2016 HZTL2410_EN Revision E

X Sealing plug D Compressed air

Y

Valve activator W Water

Z

Vessel

Remove sealing plug (X).

Fill the vessel (Z) with clean water.

Screw in the sealing plug.

Push the valve activator (Y) against the spring and hold for 10 to

15 seconds until the entire volume of water has been injected.

Do not repeat the cleaning cycle until a stabilisation period of at least

10 minutes has elapsed.

charging or flushing pressure and also from the exhaust gas temperatures. If the cleaning process is unsatisfactory, it can be repeated up to

2 times.

If the cleaning result is still not satisfactory after three attempts and the

engine values are also unsatisfactory, we recommend that you have the

turbocharger inspected and cleaned by an official ABB Turbocharging

Service Station.

Page 62

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Maintenance

5

Turbine cleaning during operation

5.3

© Copyright 2016 ABB. All rights reserved.

Turbine cleaning during operation

NOTICE

Regular cleaning

5.3

5.3

Page 60

The combustion of fuels such as heavy fuel oil (HFO) in diesel engines

produces contamination of the turbocharger's turbine components. In

combination with a high exhaust gas temperature, poor quality fuel can

lead to particularly hard deposits on the nozzle ring and especially on the

gas outlet flange.

ABB Turbo Systems recommends using fuels with a low ash, sulphur, sodium and vanadium content.

Consequences of contamination:

Poor turbine efficiency

elevated exhaust gas temperatures

higher charging and ignition pressures as turbocharger speed rises

lower engine performance.

After stopping the engine, the rotor can become stuck in contamination

deposits.

September 2016 HZTL2410_EN Revision E

Experience with turbocharger operation shows that the intervals between

overhauls can be extended if cleaning while in operation is carried out periodically. Wet cleaning the turbine, as described below, should be used

for 4-stroke applications when there are heavy deposits from, for example,

HFO.

Under no circumstances is periodic cleaning of the turbine during operation a substitute for the service work carried out when the turbocharger is

completely dismantled and cleaned mechanically.

Turbines which are very heavily contaminated cannot be cleaned this way

any longer. In this case, the contaminated components must be mechanically cleaned by an ABB Turbocharging Service Station.

Regular turbine cleaning during operation prevents or delays excessive

build-up of contamination.

Page 63

Operation Manual / TPS48-D/E.. - TPS61-D/E..

Maintenance

5

Turbine cleaning during operation

5.3

© Copyright 2016 ABB. All rights reserved.

Cleaning intervals

NOTICE

Cleaning intervals

Cleaning method

NOTICE

Approval by engine manufacturer

Page 61