ABB Tmax T8 Installation Manual

Installation and service

instructions

Installation, service and maintenance instructions

for low voltage moulded case circuit-breakers

1SDH000682R0002 L3885

Tmax T8

Dwg.

App.

Model

L3692

L3885

Resp. Off. LB-DTAT

Take over Off.

ABB SACE Division

Title

Installation, service and maintenance

instructions for low voltage moulded

case circuit-breakers

Apparatus

Doc.No.

Tmax T8

1SDH000682R0002

Language

en

Scale

Index

1. Description................................................................ pag. 3

1.1 General characteristics................................................... « 3

1.2 External front view of the circuit-breaker ....................... « 3

1.3.1 IEC Circuit-breaker rating plate data ............................ « 3

1.3.2 UL Circuit-breaker rating plate data ............................. « 3

2. Checking on receipt ....................................................... « 3

3. Storage, lifting and weights ........................................... « 3

4. Installation ....................................................................... « 4

4.1 Installation room .............................................................. « 4

4.2 Installation of the flange on the compartment door ....... « 4

5. Electrical connections ..................................................... « 5

5.1 Connections to the power circuit ................................... « 5

5.1.1 Shapes of the terminals ..................................................« 5

5.1.2 Examples of positioning the connection busbars

according to the types of terminals ............................. « 5

5.1.3 Assembly procedure for the connection busbars ........ « 6

5.2 Wiring the circuit-breaker auxiliary circuits .................... « 6

6. Putting into service ......................................................... « 7

6.1 General procedures ....................................................... « 7

7. Instructions for use ......................................................... « 8

7.1 Operating and signalling parts ...................................... « 8

7.2 Circuit-breaker closing and opening procedures ........ « 8

8. Maintenance ................................................................... « 10

8.1 Warning ..........................................................................« 10

8.2 Maintenance program .................................................... « 10

8.3 Maintenance operations ................................................. « 11

8.3.1 Preliminary operations .................................................... « 11

8.3.2 General inspection of the circuit-breaker ...................... « 11

8.3.3 Operating mechanism maintenance ............................. « 11

9. Measures to be taken for any operating

anomalies ...................................................................... « 12

10. Accessories ..................................................................... « 13

10.1 Electrical accessories .................................................... «13

10.2 Mechanical locks ...........................................................«15

10.3 Spare parts .................................................................... «15

11. Protection releases - References ................................... « 16

11.1 Safety notes .................................................................... « 16

11.1.1 Notes for dielectric stiffness tests ................................... « 16

11.2 General notes.................................................................. « 16

12. Overall dimensions ......................................................... « 17

13. Circuit diagrams ............................................................. « 23

Model

L3692

L3885

Apparatus

Doc. No.

Tmax T8

1SDH000682R0002

Scale

Page No.

1/29

Model

L3692

L3885

Apparatus

Doc.No.

Tmax T8

1SDH000682R0002

Scale

Page No.

2/29

1. Description

1.1 General characteristics

Tmax T8 serie of circuit-breakers and disconnectors consist of a plastic structure which houses the operating mechanism, the poles

and the auxiliary parts. Each pole, insulated from the others, contains the circuit-breaking parts and the current sensor of the corresponding

phase. The fixed version circuit-breaker has its own terminals for connection to the power circuit.

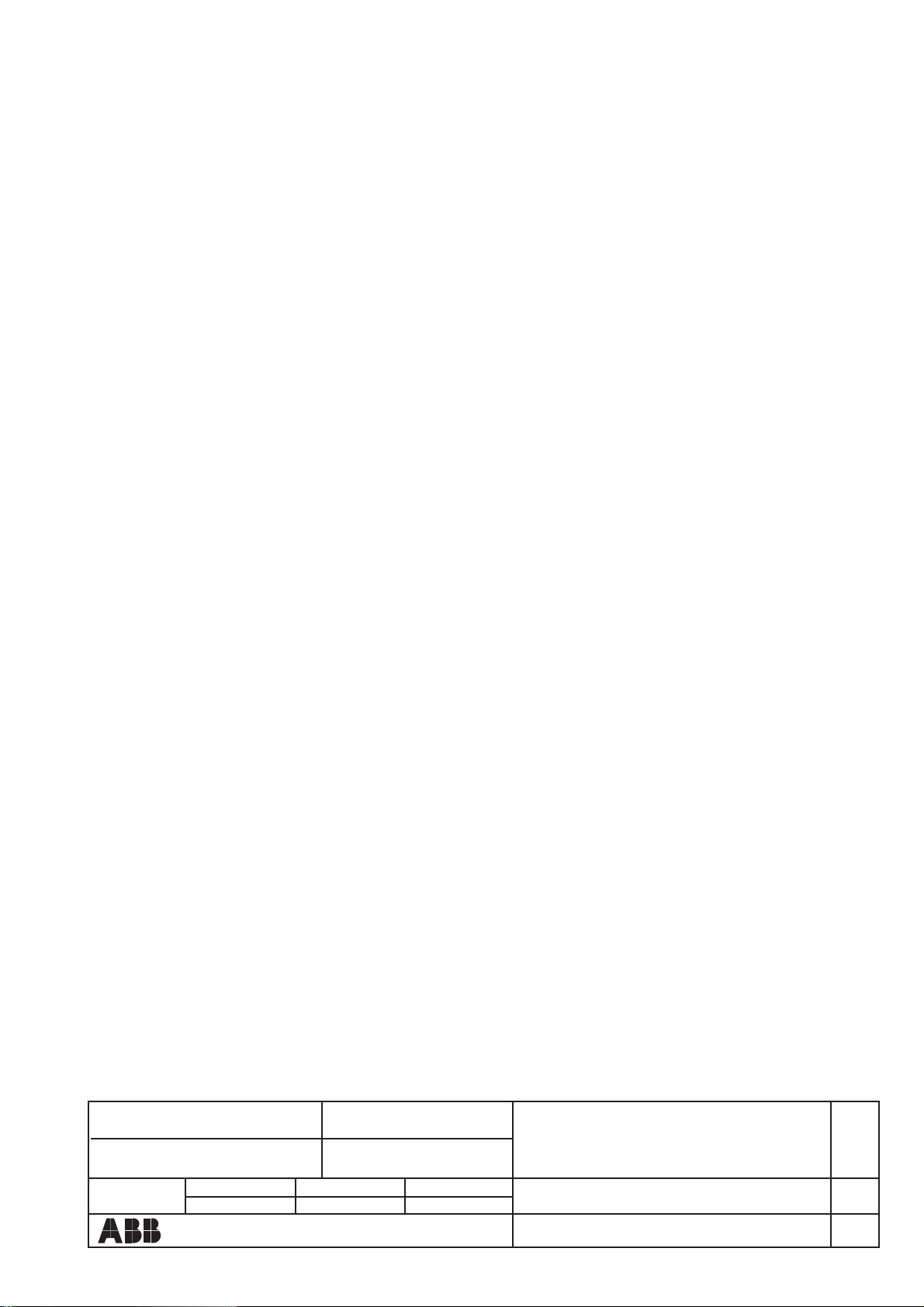

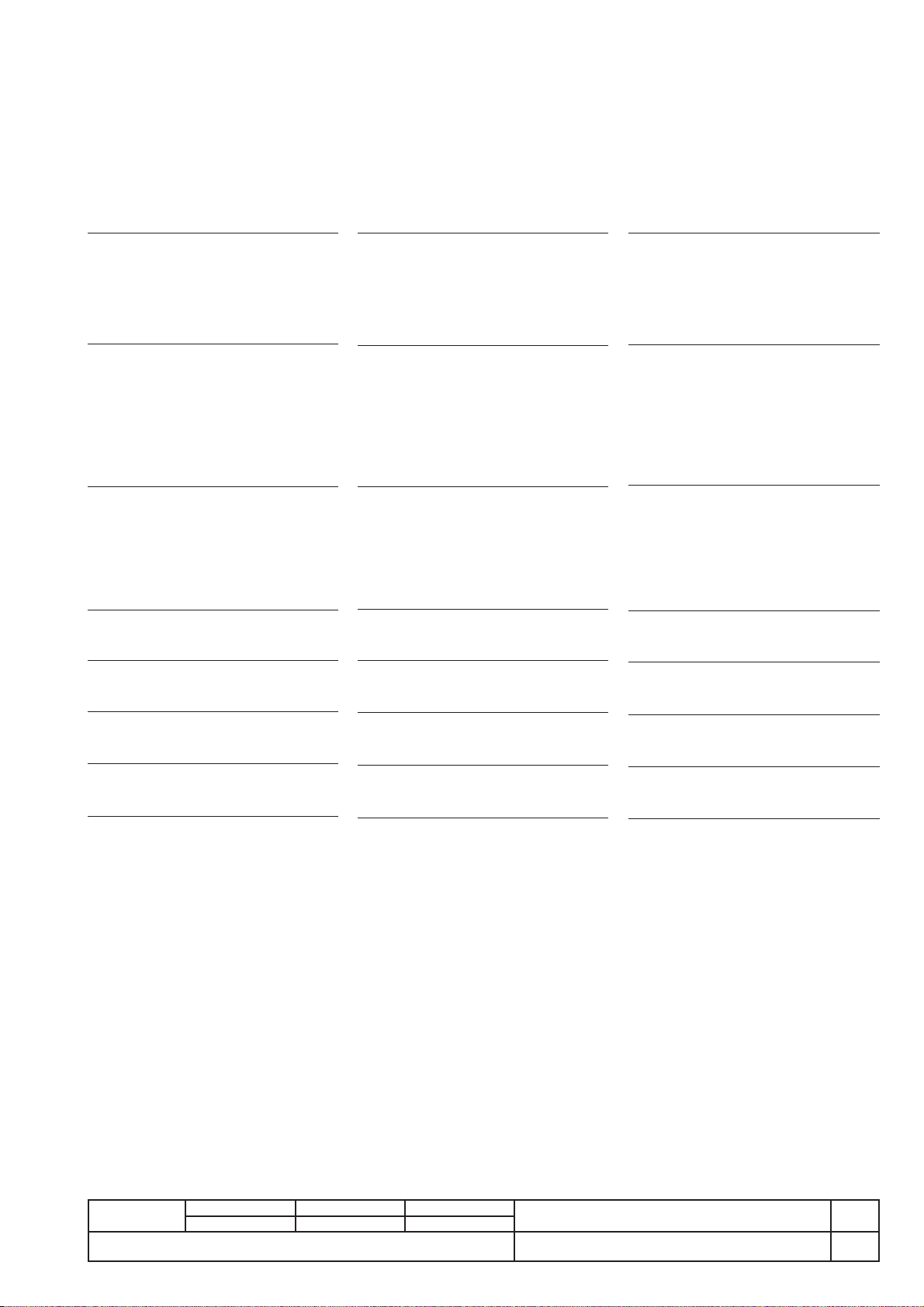

1.2 External front view of the circuit-breaker

1

2

Fig. 1

1 PR232/P-T8, PR331 o PR332 electronic microprocessor-based release

2 Operating and control parts of the operating mechanism and release tripped signals

3 Rating plate

3

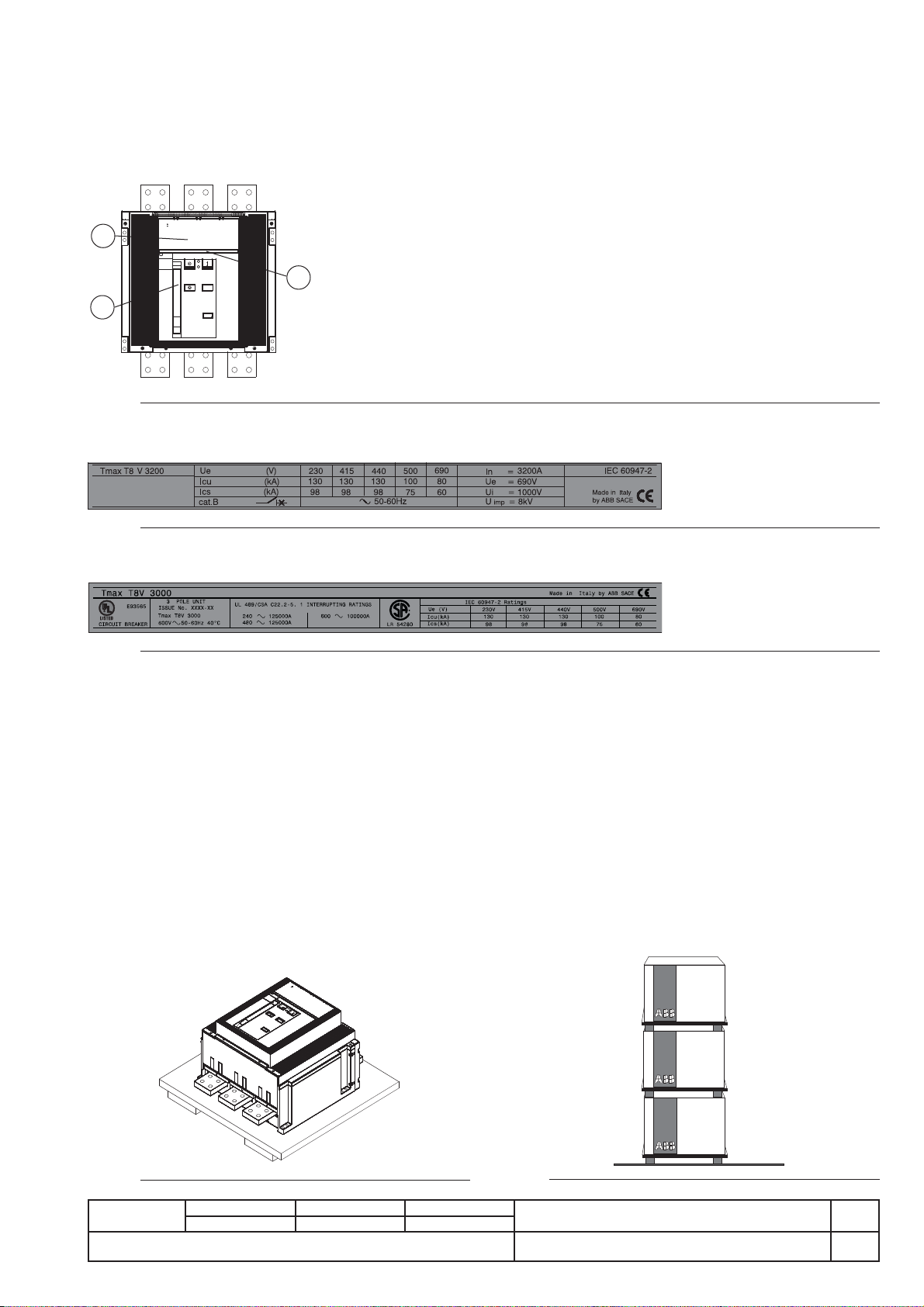

1.3.1 IEC Circuit-breaker rating plate data

Fig. 2

1.3.2 UL Circuit-breaker rating plate data

Fig. 3

2. Checking on receipt

Fixed circuit-breaker

Examine the state of the material received and its consistency with the content of the order. Should any damage or errors be found on unpacking,

which must be carried out carefully, make the relative notification within and not over 5 days from the receipt of the material.

The notification must indicate the number of the shipping note.

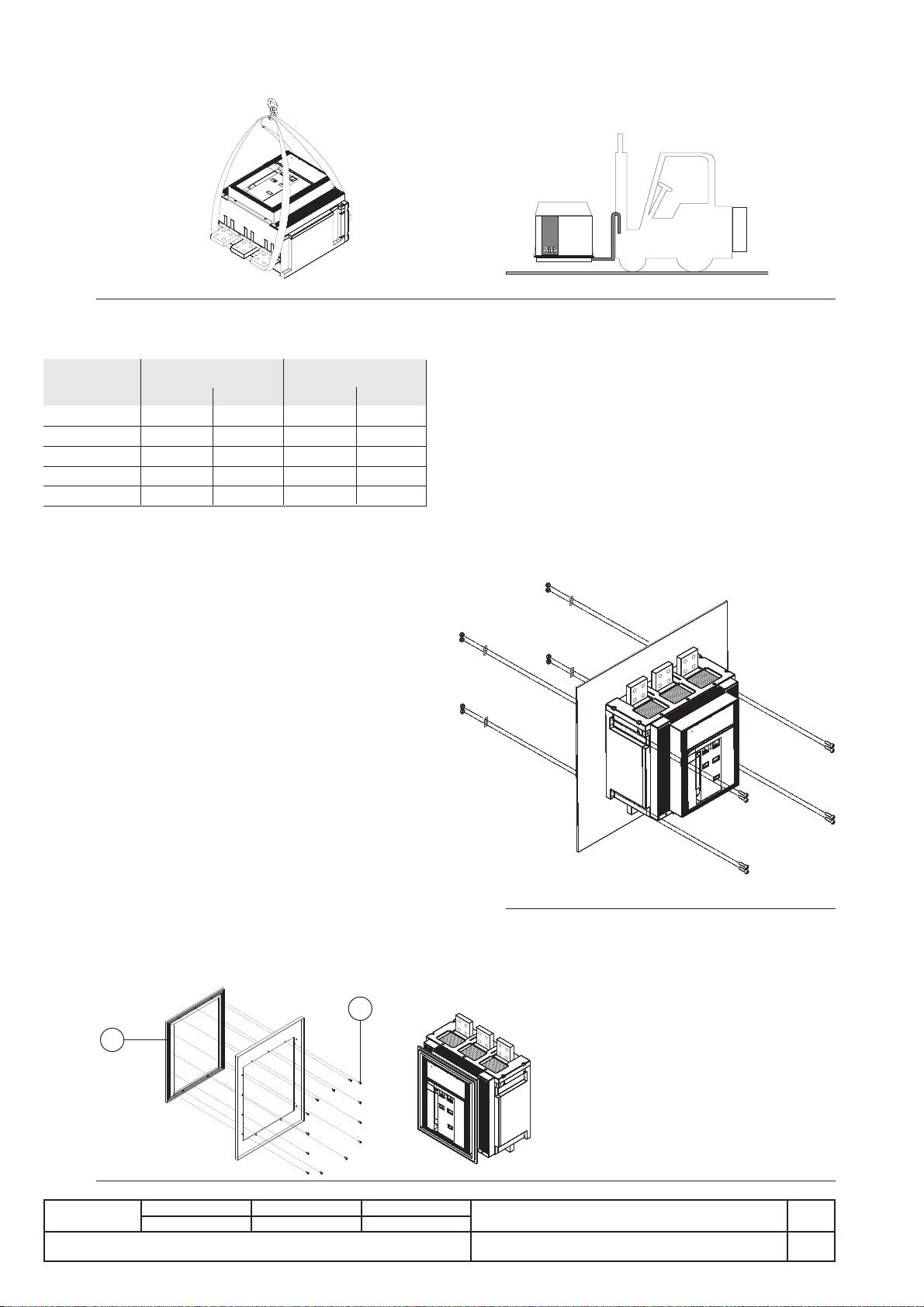

3. Storage, lifting and weights

The circuit-breaker, protected by an external wooden crate, is fixed by means of screws to the transport pallet or to the bottom of the packing

case. If the circuit-breaker has to remain in the warehouse even for a short time before being put into service, after checking it on receipt,

it must be put back in its container and covered with a waterproof sheet.

Caution

– Use a dry, dust-free room free of aggressive chemical agents as a storage room

– Position the circuit-breaker and any fixed part on a horizontal surface, not in direct contact with the floor, but on a suitable support surface

(Fig. 4)

– The maximum number of stackable circuit-breakers is indicated in figure 5

– Keep the circuit-breaker in the open position and with the closing springs discharged to avoid unnecessary stresses and the risk of accidents

to the personnel.

Fig. 4 Fig. 5

Model

L3692

L3885

Apparatus

Doc. No.

Tmax T8

1SDH000682R0002

Scale

Page No.

3/29

For lifting, refer to the following instructions: the circuit-breakers must be placed on a sturdy supporting surface and lifted, preferably, by means

of a special fork-lift truck. However, the use of ropes is allowed. In this case, the lifting ropes must be hooked up as shown in the figures

Fig. 6

Table of the circuit-breaker weights (Kg.)

Circuit-breaker 3 poles 4 poles

Kg Lbs Kg Lbs

T8 1600 (UL) 73 161 95 209

T8 2000 73 161 95 209

T8 2500 73 161 95 209

T8 3000 (UL) 107 236 140 308

T8 3200 (IEC) 107 236 140 308

Notes

The weights indicated in the table are intended for circuit-breakers complete with PR232/P-T8, PR331 or PR332 releases and relative current sensors, excluding the accessories.

4. Installation

4.1 Installation room

Install the circuit-breaker in a dry, dust-free, non-corrosive room,

and in such a way that it is not subject to shocks or vibrations.

Where this is not possible, install it inside a switchboard with a

suitable degree of protection.

For the preparation of the installation room, please refer to the

“Overall dimensions” paragraph, which gives information on the

following points:

– minimum installation volumes of the circuit-breakers and derived

versions

– distances to be respected for circuit-breakers in compartments

– overall dimensions of the circuit-breakers

– fixing drillings

– compartment door drillings.

The installation, commissioning and any ordinary and

extraordinary maintenance have to be done by skilled personnel,

with a detailed knowledge of the apparatus.

To install a circuit-breaker in the switchboard is enough to fix the circuitbreaker to a vertical surface with M8 screws (fig. 7).

4.2 Installation of the flange on the compartment door (Fig. 8)

– Make the compartment door drillings specified in the “Overall dimensions” paragraph.

– Attach the flange (1) on the front of the compartment door, fixing it from the inside by means of the self-tapping screws (2).

Fig.7

Fig. 8

Model

2

1

L3692

L3885

Apparatus

Doc.No.

Tmax T8

1SDH000682R0002

Scale

Page No.

4/29

5. Electrical connections

5.1 Connections to the power circuit

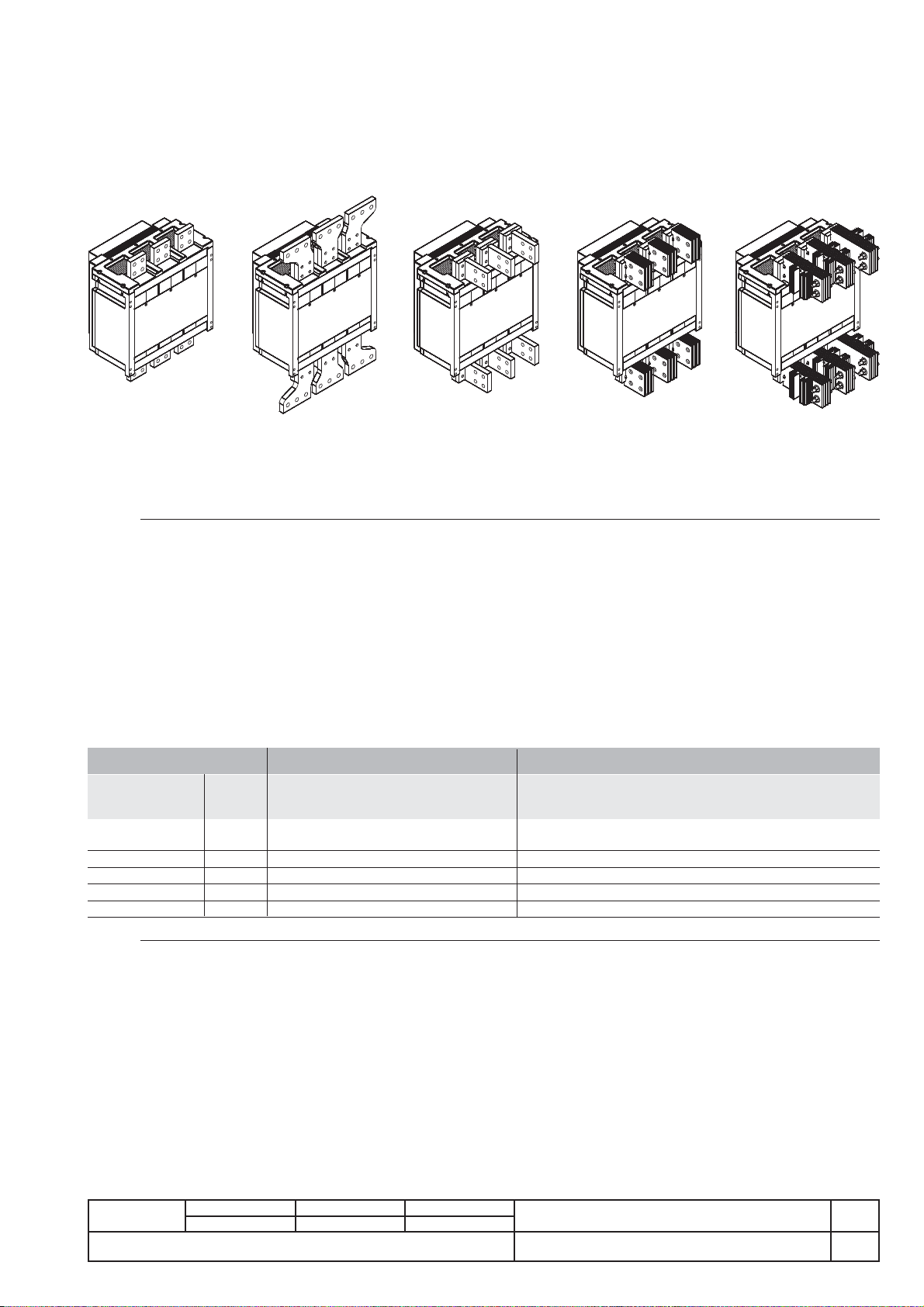

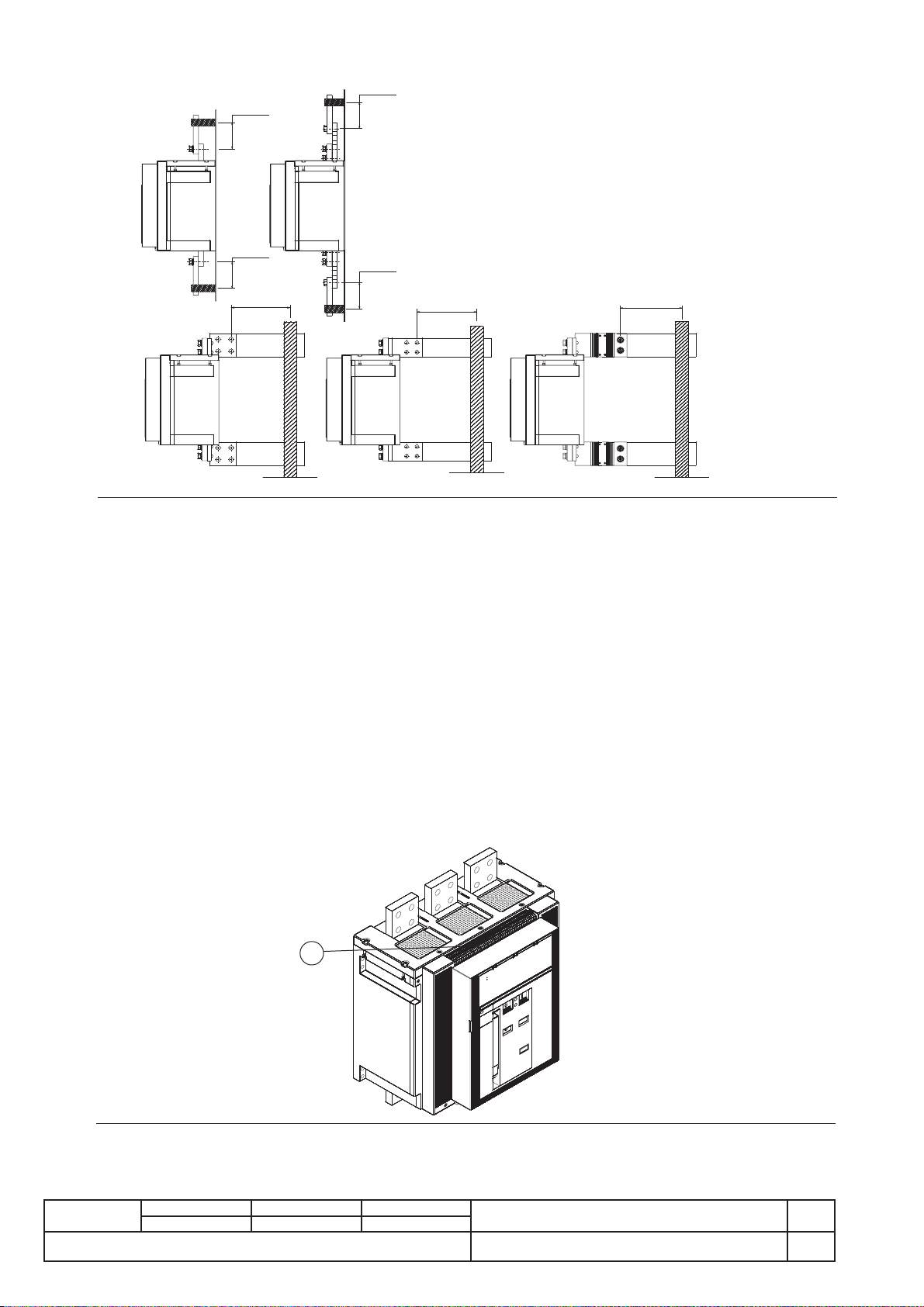

5.1.1 Shapes of the terminals

FES

Front terminals

(IEC/UL)

Fig. 9

Note

The drawings are provided to show the type of terminal in graphic form. The exact shape of the terminals is given in the “Overall dimensions”

chapter. Different terminals can be installed between the top and bottom parts (inlet and outlet).

5.1.2 Examples of positioning the connection busbars according to the types of terminals

Front terminals

extended (IEC)

VR/HR VR

Adjustable rear

terminals ( VR for

IEC/UL; HR for

IEC)

Vertical rear

terminals (IEC)

VR

Vertical rear

terminals (UL)

The connection busbars enable the connection between the terminals of the circuit-breakers and the busbars of the switchgear. Their sizing

must be carefully studied by the switchgear designer. Some examples of possible constructions in relation to the shape and size of the circuitbreaker terminals are given in this paragraph. It is normally advisable to exploit the whole contact surface of the terminal, so the width of the

connection busbars should be the same as that of the terminal. Different connection capacities can be obtained by adjusting the thickness

and number of busbars in parallel. In some cases, reductions in the width of the connection in relation to that of the terminal are allowable as

shown in the following examples.

Front terminals Vertical rear terminals

Circuit-breaker Iu [A] Busbar cross-section Busbar cross-section

[mm2]/[in2] [mm2]/[in2]

T8 V 1600 3x(100x5) / 3x(3.94x0.2) 3x(100x5) / 3x(3.94x0.2)

T8 L-V 2000 3x(100x5) / 3x(3.94x0.2) 3x(100x5) / 3x(3.94x0.2)

T8 L-V 2500 4x(100x5) / 4x(3.94x0.2) 4x(100x5) / 4x(3.94x0.2)

T8 V 3000 - 6x(100x5) / 6x(3.94x0.2)

T8 L-V 3200 - 6x(100x5) / 6x(3.94x0.2)

Fig. 10

Model

L3692

L3885

Apparatus

Doc. No.

Tmax T8

1SDH000682R0002

Scale

Page No.

5/29

Positioning the first anchoring baffle of the busbars

Anchoring to the switchgear

190

7.48"

190

7.48"

190

7.48"

190

7.48"

190

7.48"

190

7.48"

190

7.48"

Fig. 11

5.1.3 Assembly procedure for the connection busbars

Check the state of the contact surfaces of the connections very carefully: they must be very clean with no burrs, dents or traces of rust which

must be eliminated using a fine file or an emery cloth to prevent localized increases in temperature. On completion of the operation, remove

all traces of grease or dust with a cloth soaked in a suitable solvent.

When aluminium connections are used, it is necessary to tin-plate the contact surfaces.

The connections must not exert any strain on the terminals in any direction.

Always insert a large-diameter flat washer and a spring washer between them (to spread the tightening pressure over a greater area).

Make the contact between connection and terminal and tighten the fixing screws completely.

Always use two wrenches (so as not to strain the insulating parts excessively), applying the tightening torque

of the main terminals =70 Nm/615 lb in for M12 high strength screws. Check tightness after 24 hours.

5.2 Wiring the circuit-breaker auxiliary circuits

A special terminal box is provided, fitted with screw terminals for connecting the auxiliary circuits.

The terminals are marked with alphanumerical identification codes as for the electrical circuit diagram.

The terminal box is identified by code XV on the electrical circuit diagram.

The terminal box is immediately accessible when the compartment door is open.

XV

Fig. 12

Model

L3692

L3885

Apparatus

Doc.No.

Tmax T8

1SDH000682R0002

Scale

Page No.

6/29

6. Putting into service

6.1 General procedures

– Check tightness of the power connections at the circuit-breaker terminals

– Carry out all the preparatory operations on the release

– Make sure that the value of the auxiliary circuit power supply voltage is between 85 and 110% of the rated voltage of the electrical applications

– Make sure that there is an adequate air circulation in the place of installation to avoid overheating

– Also carry out the checks specified in the following table.

Item inspected

1 Manual operating mechanism

2 Geared motor (if provided)

3 Undervoltage release (if provided)

4 Shunt opening release (if provided)

5 Shunt closing release (if provided)

6 Circuit-breaker lock in the open position

(with key or padlocks)

7 Auxiliary contacts of the circuit-breaker

Procedure

Carry out some opening and closing

operations (see chapter 7.2).

CAUTION

When there is an undervoltage release, the

circuit-breaker can only be closed after the

release has been electrically energized.

Supply the spring loading geared motor at

the corresponding rated voltage.

Carry out some closing and opening

operations.

Note. Supply the undervoltage release at the

corresponding rated voltage (if any).

Supply the undervoltage release at the

corresponding rated voltage and carry out

the circuit-breaker closing operation.

Disconnect voltage to the release.

Supply the undervoltage release at the

corresponding rated voltage and carry out

the circuit-breaker closing operation.

Close the circuit-breaker.

Supply the shunt opening release at the

corresponding rated voltage.

Open the circuit-breaker.

Supply the shunt closing release at its rated

voltage.

Open the circuit-breaker, turn the key and

remove it from its seat. Attempt circuit-breaker

closing operation.

Insert the auxiliary contacts in suitable

signalling circuits. Carry out some circuit-

breaker closing and opening operations.

Positive check

The spring loading lever moves correctly.

The springs are loaded correctly.

The signals are correct.

The geared motor stops with the springs

loaded.

The geared motor reloads the springs after

each closing operation.

The circuit-breaker closes correctly. The

signals are correct.

The circuit-breaker opens. The signal changes

over.

The circuit-breaker opens correctly. The

signals are correct.

The circuit-breaker closes correctly. The

signalsare correct.

Both manual and electrical closing are

prevented.

The signals are given correctly.

Model

L3692

L3885

Apparatus

Doc. No.

Tmax T8

1SDH000682R0002

Scale

Page No.

7/29

7. Instructions for use

7.1 Operating and signalling parts

1 Pushbutton for the manual opening operation

2 Lever for manual loading of the closing springs

3 Mechanical indicator for circuit-breaker open “O” and closed “I”

4 Mechanical indicator for protection release tripped

5 Pushbutton for the manual closing operation

6 Signalling device for springs loaded - unloaded

7 Operation counter (on request)

8 Key lock on the closing operation (on request)

Fig.13

Note

On request, a transparent cover can be installed on the front of the circuit-breaker to increase the degree of protection to IP54. The cover has

a locking key.

As an alternative to the transparent cover, a protection can be mounted on the manual closing and opening controls, which only allows operation

of the pushbuttons by means of a special tool.

4

8

1

2

3

5

6

7

Fig. 14

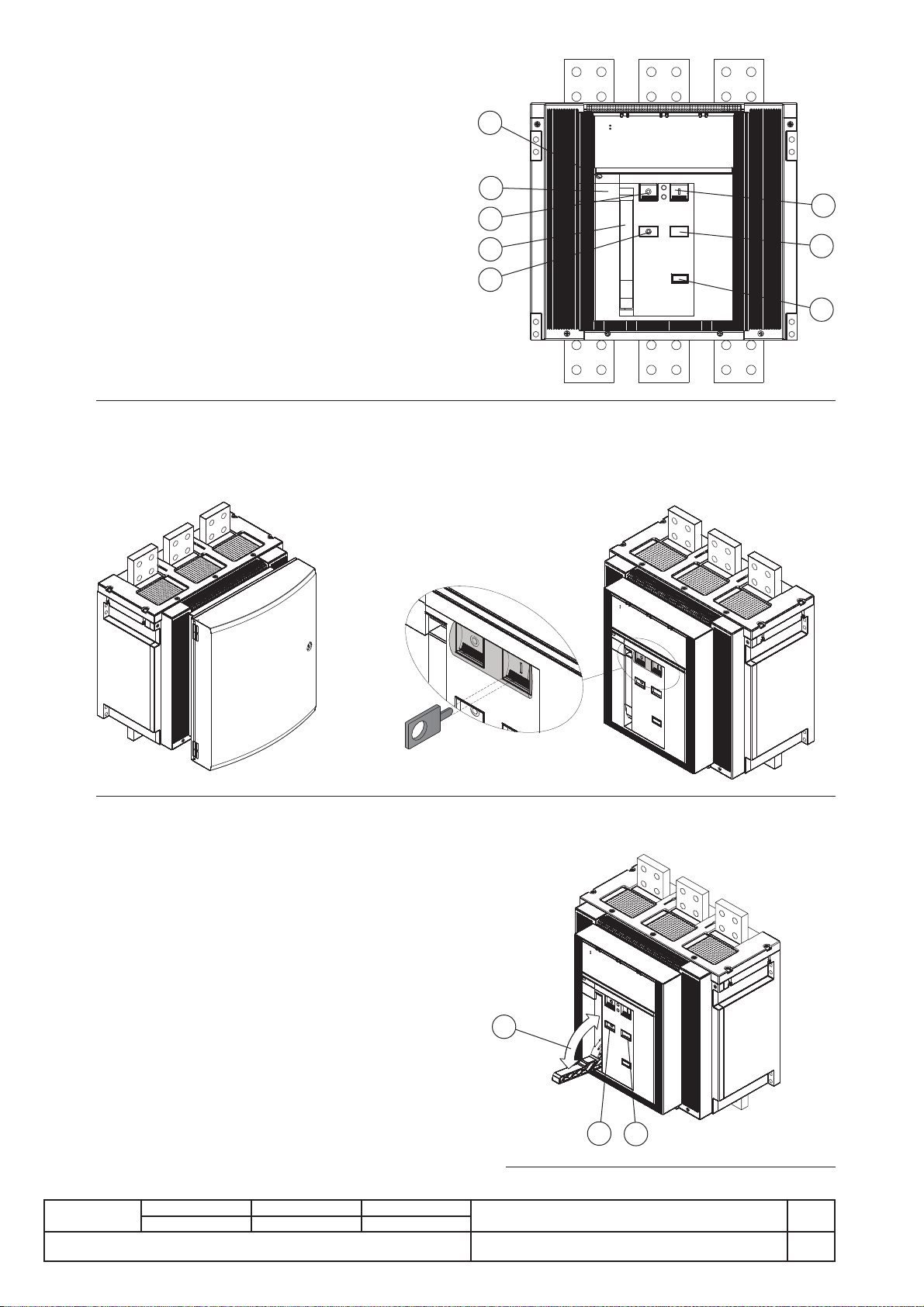

7.2 Circuit-breaker closing and opening procedures

The operation of the circuit-breaker can be either manual or electrical.

a) Manual loading of the closing springs

– Make sure that the indicator (3) shows “O” (circuit-breaker open)

– Make sure that the indicator (6) is WHITE (springs discharged)

– Repeatedly activate the lever (2) until the indicator (6) changes its

color to YELLOW

b) Electrical loading of the closing springs

The electrical loading of the circuit-breaker is possible when the

following accessories (supplied on request) are present:

– geared motor for automatic loading of the closing springs

– shunt closing release

– shunt opening release.

The geared motor automatically reloads the springs after each closing

operation until the yellow indicator appears (6, Fig. 15). When the

power is cut off during loading, the geared motor stops and

automatically starts reloading the springs again when the power

returns. It is, in any case, always possible to complete the reloading

operation manually.

Model

L3692

L3885

Fig. 15

Apparatus

Doc.No.

2

3 6

Tmax T8

1SDH000682R0002

Scale

Page No.

8/29

Loading...

Loading...