Page 1

—

ABB MEASUREMENT & ANALYTICS | OPERATING INSTRUCTION | OI/AV12 REV. E

AV1 and AV2

Characterizable pneumatic and

electro-pneumatic positioners

Pneumatic and electro-pneumatic

positioners built on proven

performance for demanding process

conditions

Measurement made easy

—

Characterizable

analog positioners

Introduction

AV characterizable pneumatic positioners are control

devices that satisfy a wide range of applications. They

provide fast, sensitive and accurate positioning of

pneumatic single- or double-acting, linear or rotary

motion actuators. A mechanical connection from the

actuator to a position feedback cam in the positioner

establishes actual position. Three characterized

segments on one cam provide application flexibility

by establishing various relationships between input

signal and actuator position. The relationships

provided by the segments are square root, linear and

square.

Page 2

Trademarks and Registrations

Registrations and trademarks used in this document include:

® Delrin Registered trademark of E.I. DuPont de Nemours Company, Incorporated

® Dow Corning Registered trademark of Dow Corning Corporation

® Lexan Registered trademark of General Electric Company, GE Plastics Division

® Monel Registered trademark of International Nickel Company

® Noryl Registered trademark of General Electric Company, GE Plastics Division

® PowerRac Registered trademark of DeZurik, a Unit of General Signal

® Rynite Registered trademark of E.I. DuPont de Nemours Company, Incorporated

® Teflon Registered trademark of E.I. DuPont de Nemours Company, Incorporated

® Valox Registered trademark of General Electric Company, GE Plastics Division

® Viton Registered trademark of E.I. DuPont de Nemours Company, Incorporated

WARNING notices as used in this manual apply to hazards or unsafe practices which could result in personal

injury or death.

CAUTION notices apply to hazards or unsafe practices which could result in property damage.

NOTES highlight procedures and contain information which assist the operator in understanding the informa-

tion contained in this manual.

All software, including design, appearance, algorithms and source codes, is copyrighted by ABB Inc. and is

owned by ABB Inc. or its suppliers.

WARNING

POSSIBLE PROCESS UPSETS. Maintenance must be performed only by qualified personnel and only after

securing equipment controlled by this product. Adjusting or removing this product while it is in the system may

upset the process being controlled. Some process upsets may cause injury or damage.

The information contained in this document is subject to change without notice.

ABB Inc., its affiliates, employees, and agents, and the authors of and contributors to this publication specifi-

cally disclaim all liabilities and warranties, express and implied (including warranties of merchantability and fitness for a particular purpose), for the accuracy, currency, completeness, and/or reliability of the information

contained herein and/or for the fitness for any particular use and/or for the performance of any material and/or

equipment selected in whole or part with the user of/or in reliance upon information contained herein. Selection

of materials and/or equipment is at the sole risk of the user of this publication.

NOTICE

This document contains proprietary information of ABB Inc., and is issued in strict confidence. Its use, or reproduction for use, for the reverse engineering, development or manufacture of hardware or software described

herein is prohibited. No part of this document may be photocopied or reproduced without the prior written consent of ABB Inc..

Copyright 2019 ABB Inc. [May, 2019]

Page 3

Table of Contents

Page

SECTION 1 - INTRODUCTION................................................................................................... 1-1

OVERVIEW.....................................................................................................................................1-1

INTENDED USER...........................................................................................................................1-1

DESCRIPTION................................................................................................................................1-1

Performance Series Option......................................................................................................1-2

Explosionproof I/P Option.........................................................................................................1-3

NEMA 4X Option......................................................................................................................1-3

APPLICATION.................................................................................................................................1-3

FEATURES .....................................................................................................................................1-3

INSTRUCTION CONTENT..............................................................................................................1-5

REFERENCE DOCUMENTS..........................................................................................................1-6

NOMENCLATURE ..........................................................................................................................1-6

SPECIFICATIONS...........................................................................................................................1-7

SECTION 2 - DESCRIPTION AND OPERATION....................................................................... 2-1

INTRODUCTION.............................................................................................................................2-1

FUNCTIONAL OPERATION ...........................................................................................................2-2

SECTION 3 - INSTALLATION.................................................................................................... 3-1

INTRODUCTION.............................................................................................................................3-1

UNPACKING AND INSPECTION....................................................................................................3-1

ENCLOSURE CLASSIFICATION....................................................................................................3-2

MOUNTING CONSIDERATIONS....................................................................................................3-2

MOUNTING TYPE AV POSITIONERS...........................................................................................3-4

TUBING CONNECTIONS ...............................................................................................................3-8

Air Supply Pressure..................................................................................................................3-8

Air Supply Filtering...................................................................................................................3-8

Air Supply Quality (Recommended).........................................................................................3-9

Tubing Connections .................................................................................................................3-9

WIRING TYPE AV2 POSITIONER................................................................................................3-10

WIRING TYPE AV1 POSITIONER................................................................................................3-13

RADIO FREQUENCY INTERFERENCE.......................................................................................3-15

WIRING REQUIREMENTS...........................................................................................................3-15

SECTION 4 - CALIBRATION...................................................................................................... 4-1

INTRODUCTION.............................................................................................................................4-1

CALIBRATION.................................................................................................................................4-1

Zero Adjustment.......................................................................................................................4-1

Span Adjustment......................................................................................................................4-3

CALIBRATION FOR PARTICULAR APPLICATION .......................................................................4-3

Zero Adjustment.......................................................................................................................4-4

Span Adjustment......................................................................................................................4-4

GAIN AND SPEED ADJUSTMENTS ..............................................................................................4-5

Gain Adjustment.......................................................................................................................4-5

Speed Adjustment....................................................................................................................4-6

ORIFICE............................................................................................................................4-6

PILOT VALVE STROKE ADJUSTMENT..........................................................................4-6

TROUBLESHOOTING CALIBRATION ADJUSTMENTS................................................................4-8

SECTION 5 - OPERATING PROCEDURES............................................................................... 5-1

INTRODUCTION.............................................................................................................................5-1

i

Page 4

Table of Contents (continued)

EQUALIZING AND AIR SUPPLY SHUTOFF VALVE..................................................................... 5-1

Transfer from Automatic to Manual Operation ........................................................................ 5-1

Transfer from Manual to Automatic Operation ........................................................................ 5-1

SECTION 6 - TROUBLESHOOTING...........................................................................................6-1

INTRODUCTION............................................................................................................................ 6-1

SECTION 7 - MAINTENANCE.....................................................................................................7-1

INTRODUCTION............................................................................................................................ 7-1

PREVENTIVE MAINTENANCE SCHEDULE................................................................................. 7-1

PREVENTIVE MAINTENANCE PROCEDURES ........................................................................... 7-2

MANIFOLD FILTERS ..................................................................................................................... 7-2

SECTION 8 - REPAIR AND REPLACEMENT.............................................................................8-1

INTRODUCTION............................................................................................................................ 8-1

REPLACEMENT PROCEDURES .................................................................................................. 8-1

Manifold................................................................................................................................... 8-1

Gain Hinge Spring................................................................................................................... 8-2

Pilot Valve Assembly............................................................................................................... 8-3

I/P Converter ........................................................................................................................... 8-4

Cam......................................................................................................................................... 8-5

Diaphragm Assembly .............................................................................................................. 8-5

DIAPHRAGM ASSEMBLY REMOVAL............................................................................. 8-6

DIAPHRAGM ASSEMBLY REPLACEMENT................................................................... 8-6

PILOT VALVE STROKE ADJUSTMENT........................................................................................ 8-7

Page

SECTION 9 - SUPPORT SERVICES...........................................................................................9-1

INTRODUCTION............................................................................................................................ 9-1

RECOMMENDED SPARE PARTS................................................................................................. 9-1

ADDITIONAL SPARE PARTS........................................................................................................ 9-3

APPENDIX A - POSITION TRANSMITTERS............................................................................. A-1

INTRODUCTION............................................................................................................................A-1

DESCRIPTION AND OPERATION ................................................................................................A-1

CALIBRATION................................................................................................................................A-2

Calibrating the Potentiometric Position Transmitter ................................................................A-2

POTENTIOMETRIC APPLICATION EXAMPLE ..............................................................A-3

CALIBRATING THE POTENTIOMETRIC EXAMPLE......................................................A-4

Calibrating the 4 to 20-mA Position Transmitter......................................................................A-6

APPENDIX B - QUICK START...................................................................................................B-1

INTRODUCTION............................................................................................................................B-1

PRODUCT IDENTIFICATION (NOMENCLATURE).......................................................................B-1

MOUNTING THE POSITIONER..................................................................................................... B-2

TUBING CONNECTIONS...............................................................................................................B-5

TYPE AV2 POSITIONER WIRING.................................................................................................B-8

TYPE AV1 POSITIONER WIRING...............................................................................................B-10

CALIBRATION..............................................................................................................................B-11

ii

Page 5

Table of Contents (continued)

Page

APPENDIX C - CAM CHARACTERIZATION.............................................................................C-1

INTRODUCTION............................................................................................................................C-1

CAM CHARACTERIZATION..........................................................................................................C-1

CAM SELECTION..........................................................................................................................C-3

CAM SHAPING ..............................................................................................................................C-5

APPENDIX D - TYPE AV1 PNEUMATIC POSITION TRANSMITTER.......................................D-1

INTRODUCTION............................................................................................................................D-1

DESCRIPTION...............................................................................................................................D-1

INSTALLATION..............................................................................................................................D-2

CALIBRATION................................................................................................................................D-3

List of Figures

No. Title Page

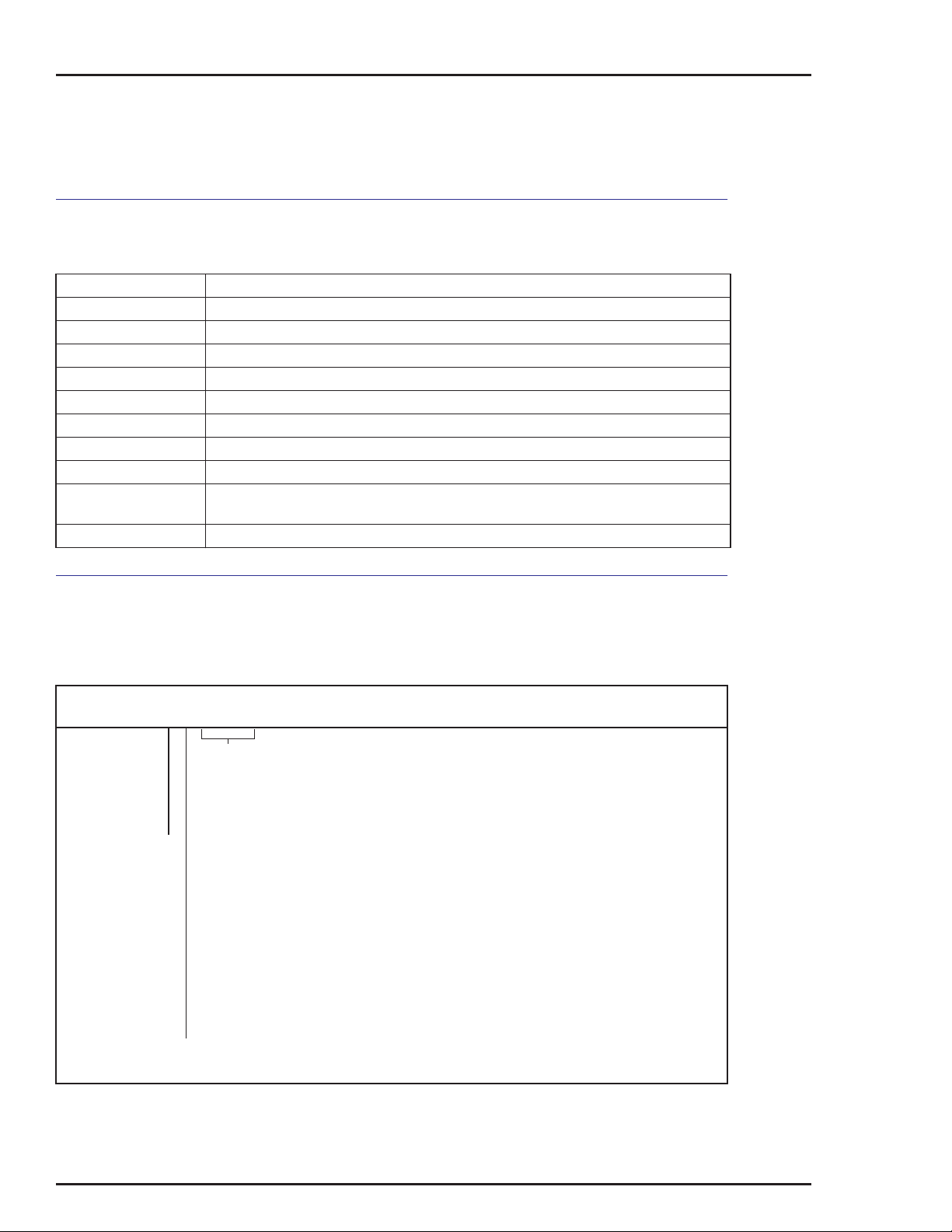

1-1. Capacity (Exhaust to Atmosphere)...........................................................................................1-9

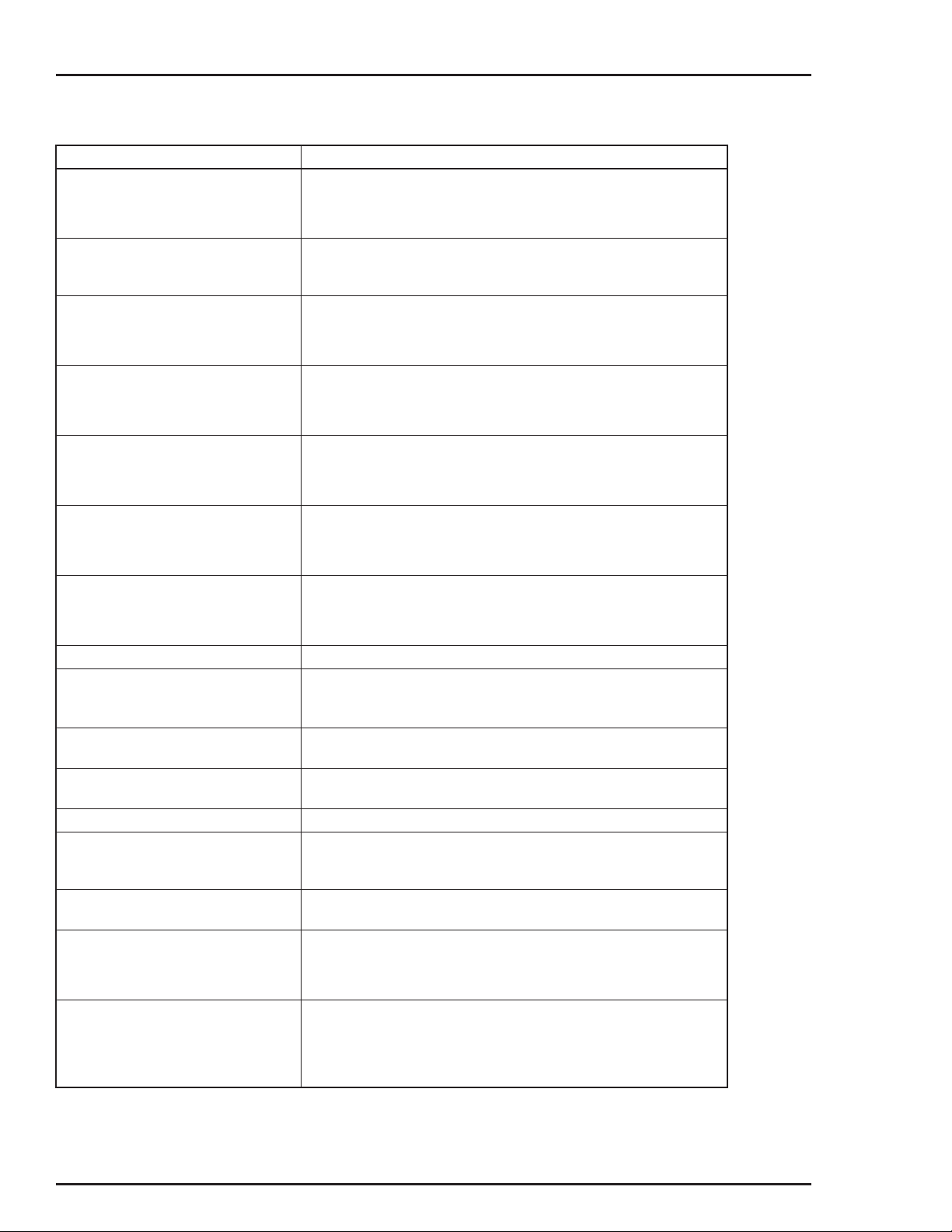

1-2. Air Consumption.....................................................................................................................1-10

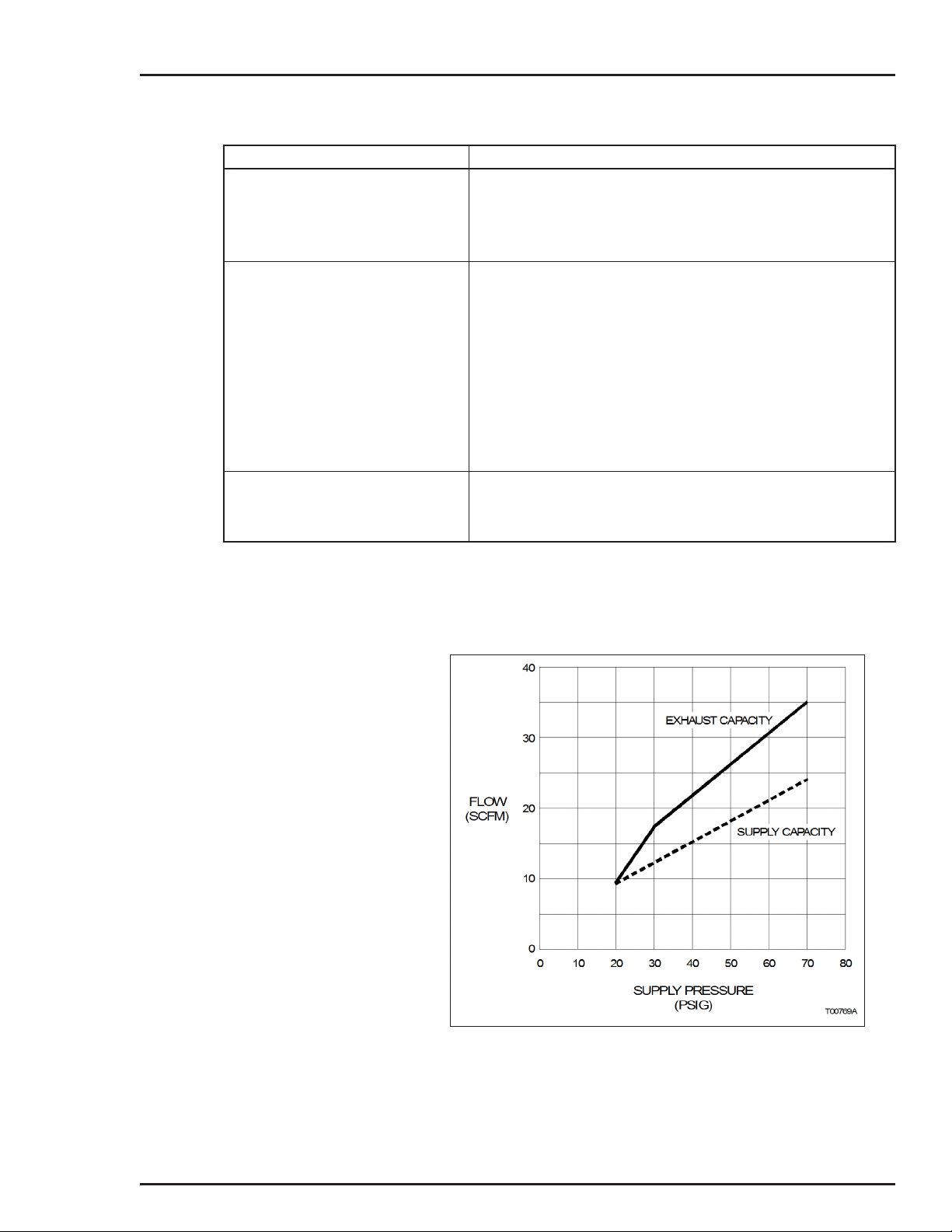

1-3. Output Air Flow vs. Error Signal — Standard and Performance Series.................................1-10

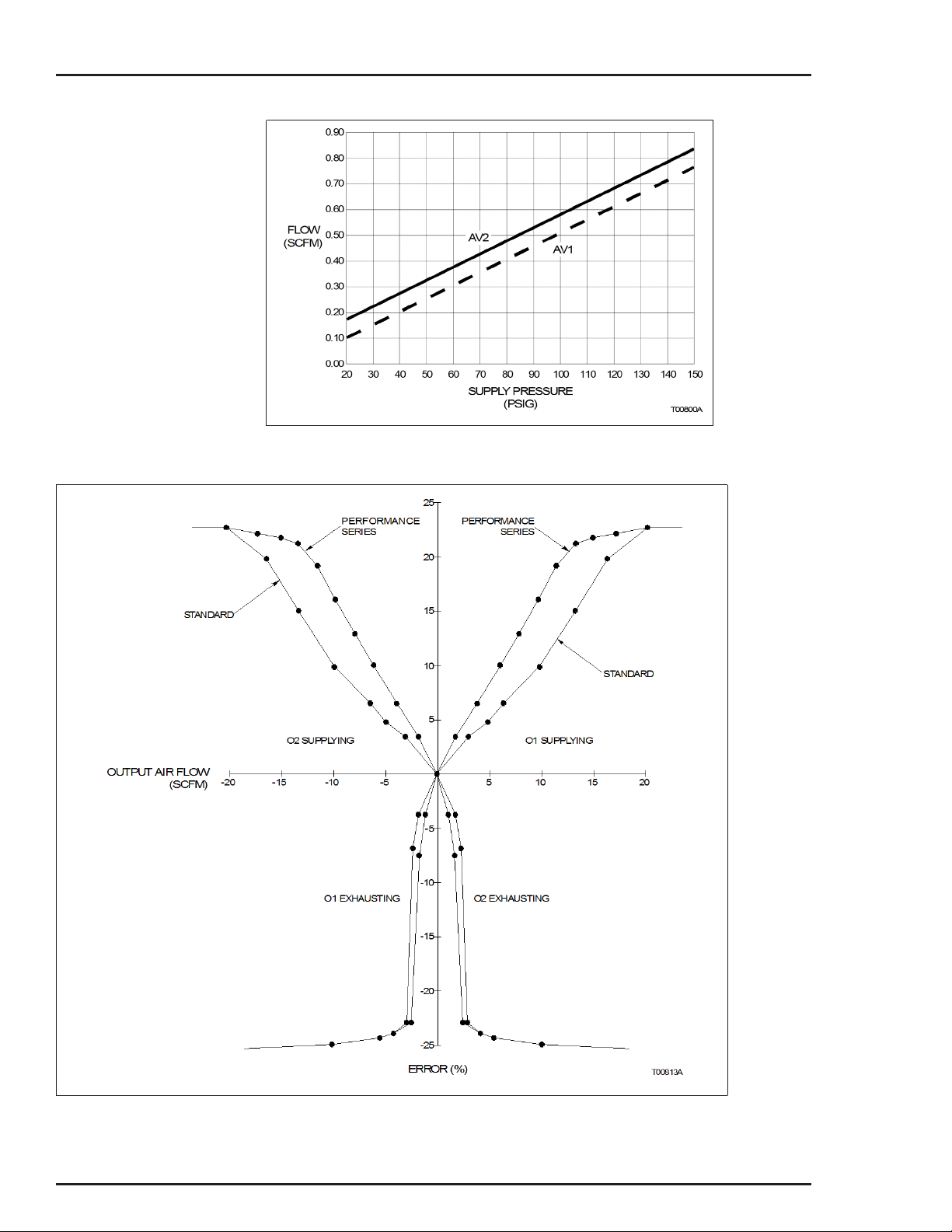

1-4. Expanded First Quadrant View ..............................................................................................1-11

2-1. Operation Diagram...................................................................................................................2-1

2-2. Block Diagram..........................................................................................................................2-1

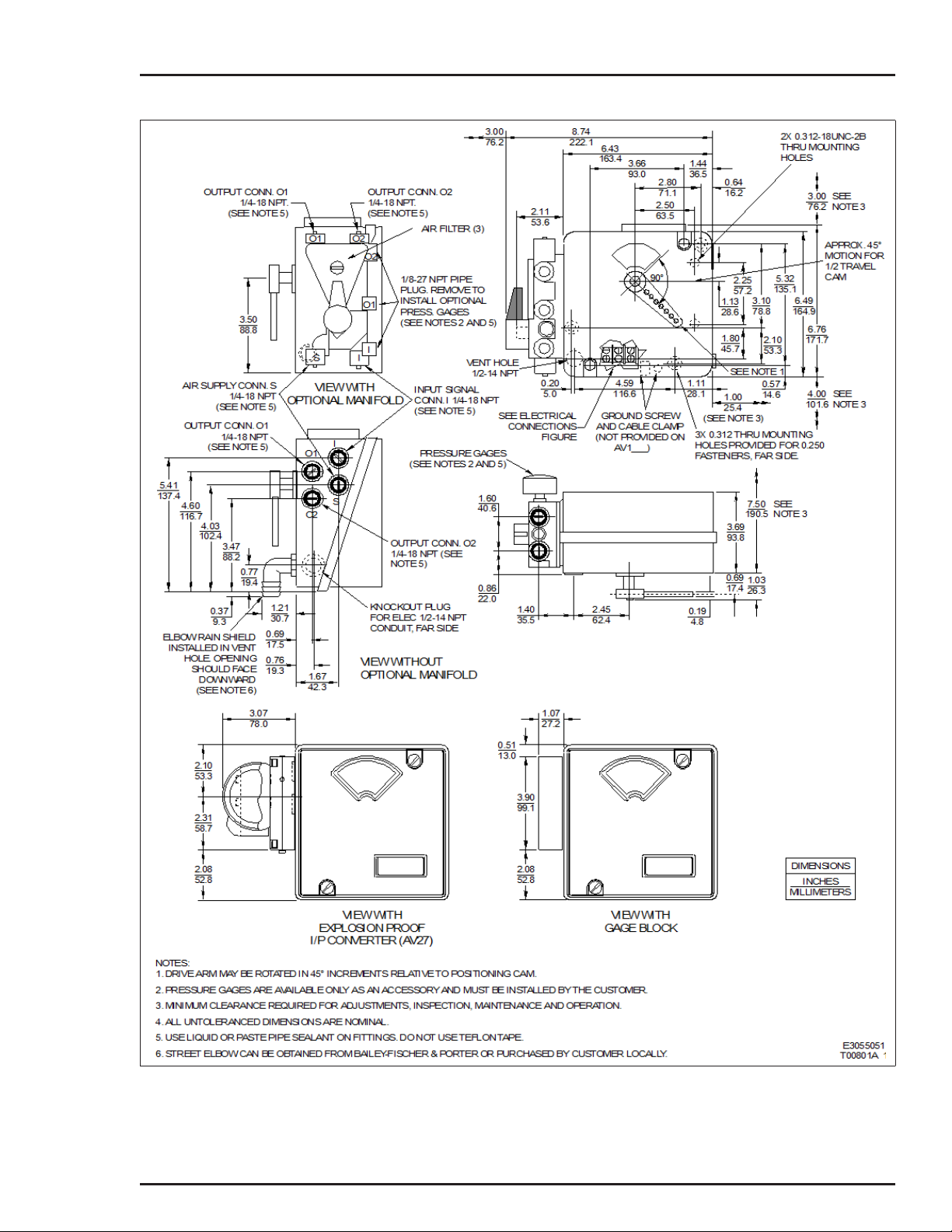

3-1. External and Mounting Dimensions..........................................................................................3-3

3-2. Electrical Connections..............................................................................................................3-4

3-3. Drive Arm Connections.............................................................................................................3-4

3-4. Drive Shaft Variations...............................................................................................................3-5

3-5. Mounting Using Linkage (Typical)............................................................................................3-5

3-6. Mounting Using Direct Coupling (Typical)................................................................................3-6

3-7. Cam..........................................................................................................................................3-7

3-8. Cam Roller Alignment...............................................................................................................3-8

3-9. Port Locations ..........................................................................................................................3-9

3-10. Direct Acting, Top Loaded, Single Acting Tubing Example.....................................................3-11

3-11. Reverse Acting, Top Loaded, Single Acting Tubing Example.................................................3-12

3-12. Direct Acting, Bottom Loaded, Single Acting Tubing Example...............................................3-12

3-13. Reverse Acting, Bottom Loaded, Single Acting Tubing Example...........................................3-13

3-14. Double Acting Tubing Example ..............................................................................................3-14

3-15. Wiring Connections................................................................................................................3-14

4-1. Calibration Adjustments............................................................................................................4-2

4-2. Cam Roller Alignment...............................................................................................................4-3

4-3. Zero Adjustment Graph ............................................................................................................4-4

4-4. Span Adjustment Graph ...........................................................................................................4-5

4-5. Pilot Valve Adjustment..............................................................................................................4-7

4-6. Speed Adjustment Screws .......................................................................................................4-7

4-7. I/P Adjustment..........................................................................................................................4-9

7-1. Positioner with Manifold ...........................................................................................................7-3

7-2. Manifold with Filter Cover Removed ........................................................................................7-3

8-1. Positioner with Manifold ...........................................................................................................8-2

8-2. Manifold O-Rings......................................................................................................................8-3

iii

Page 6

List of Figures (continued)

No. Title Page

8-3. Pilot Valve Measurement for Maximum Speed........................................................................ 8-8

8-4. Stroke Adjustment Screws....................................................................................................... 8-8

9-1. Mounting Kits........................................................................................................................... 9-6

9-2. Bypass Valve Assembly........................................................................................................... 9-8

9-3. Type AV1 Positioner ...............................................................................................................9-11

9-4. Type AV2 Positioner (Page 1 of 2)......................................................................................... 9-16

9-4. Type AV2 Positioner (Page 2 of 2)......................................................................................... 9-17

A-1. Terminal Block Connections....................................................................................................A-2

A-2. Schematic Diagram.................................................................................................................A-4

A-3. Potentiometric Position Transmitter (Exploded View)..............................................................A-5

A-4. Calibration Features for 4 to 20-mA Position Transmitter........................................................A-6

A-5. 4 to 20-mA Position Transmitter (Exploded View)...................................................................A-7

B-1. Mounting Using Linkage (Typical) ...........................................................................................B-3

B-2. Mounting Using Direct Coupling (Typical) ...............................................................................B-3

B-3. Drive Arm Connections............................................................................................................B-4

B-4. Cam Roller Alignment..............................................................................................................B-4

B-5. Port Locations..........................................................................................................................B-5

B-6. Direct Acting, Top Loaded, Single Acting Tubing Example......................................................B-6

B-7. Reverse Acting, Top Loaded, Single Acting Tubing Example..................................................B-6

B-8. Direct Acting, Bottom Loaded, Single Acting Tubing Example ................................................B-7

B-9. Reverse Acting, Bottom Loaded, Single Acting Tubing Example ............................................B-7

B-10. Double Acting Tubing Example................................................................................................B-8

B-11. Wiring Connections .................................................................................................................B-9

B-12. Calibration Adjustments...........................................................................................................B-9

C-1. Cam A, Square Root Relationship...........................................................................................C-1

C-2. Cam B, Linear Relationship.....................................................................................................C-2

C-3. Cam C, Square Relationship...................................................................................................C-2

C-4. Regulated Device Characteristics ...........................................................................................C-4

C-5. Desired Control........................................................................................................................C-4

C-6. Cam Characteristics................................................................................................................C-5

C-7. Graph to Cam Data Transfer...................................................................................................C-7

D-1. Pneumatic Position Transmitter Kit..........................................................................................D-2

List of Tables

No. Title Page

1-1. Reference Documents............................................................................................................. 1-6

1-2. Nomenclature.......................................................................................................................... 1-6

1-3. Type AV1/2 Positioner Specifications...................................................................................... 1-7

1-4. Type AV ____1__ Potentiometric Position Transmitter Specifications.................................. 1-11

1-5. Type AV ____2 __ 4 to 20-mA Position Transmitter Specifications ....................................... 1-11

1-6. Agency Approvals.................................................................................................................. 1-12

1-7. Accessories........................................................................................................................... 1-12

1-8. Rotary Actuator Retrofit Mounting Kits.................................................................................. 1-13

1-9. Speed Control Orifices .......................................................................................................... 1-13

1-10. Pressure Gages..................................................................................................................... 1-13

1-11. Supply Air Regulators with Gages......................................................................................... 1-13

iv

Page 7

List of Tables (continued)

No. Title Page

1-12. Supply Air Filters....................................................................................................................1-14

1-13. Component Material List ........................................................................................................1-14

3-1. Cam Characteristics.................................................................................................................3-7

4-1. Gain Hinge Springs..................................................................................................................4-5

6-1. Positioner Errors.......................................................................................................................6-1

7-1. Preventive Maintenance Schedule...........................................................................................7-1

9-1. Shutoff Valve Kit No. 258270_1...............................................................................................9-1

9-2. AV Diaphragm Assembly Kit No. 258486_1.............................................................................9-1

9-3. AV Diaphragm Assembly Kit No. 258486_ 2 ............................................................................9-2

9-4. Filter Replacement Kit No. 258487_1 ......................................................................................9-2

9-5. Pilot Valve Assembly Kit No. 258488_1...................................................................................9-2

9-6. Pilot Valve Assembly Kit No. 258488_ 2...................................................................................9-2

9-7. Pilot Valve Assembly Kit No. 258488_3...................................................................................9-2

9-8. Pilot Valve Assembly Kit No. 258488 _4...................................................................................9-3

9-9. Cam..........................................................................................................................................9-3

9-10. I/P Assembly Kit No. 258477_1................................................................................................9-3

9-11. Gain Hinge Springs..................................................................................................................9-3

9-12. Manifold Assembly Kit No. 258491_1 ......................................................................................9-3

9-13. Cam Follower Arm Kit No. 258544 _1 ......................................................................................9-4

9-14. Cover Assembly Kit No. 258545_1 ..........................................................................................9-4

9-15. Cover Assembly Kit No. 258545_1 ..........................................................................................9-4

9-16. Gage Block Assembly Kit No. 258569 _1.................................................................................9-4

9-17. Gage Block Assembly Kit No. 258569_3 .................................................................................9-4

9-18. Potentiometer...........................................................................................................................9-4

9-19. 4 to 20-mA Position Transmitter Circuit Board.........................................................................9-5

9-20. Positioner Mounting Kit Number 5327321_121........................................................................9-5

9-21. Positioner Mounting Kit Number 5327321_131........................................................................9-5

9-22. Positioner Mounting Kit Number 5327321_141 (for use on Fisher Actuators).........................9-6

9-23. Rotary Actuator Retrofit Mounting Kits.....................................................................................9-7

9-24. Bypass Valve Assembly (Optional)..........................................................................................9-7

9-25. Type AV1 Positioner Parts List.................................................................................................9-9

9-26. Input Signal Parts Reference for Type AV1 Positioners.........................................................9-10

9-27. Cam Selection and Manifold/Gage Block Parts Reference

for Type AV1 Positioners........................................................................................................9-10

9-28. Shaft Position Transmitter Parts Reference for Type AV1 Positioners..................................9-12

9-29. Drive Shaft Parts Reference for Type AV1 Positioners..........................................................9-12

9-30. Type AV2 Positioner Parts List ..............................................................................................9-12

9-31. Cam and Drive Shaft Parts Reference for Type AV2 Positioners..........................................9-13

9-32. Manifold/Gage Block Parts Reference for Type AV2 Positioners ..........................................9-15

9-33. Shaft Position Transmitter Parts Reference for Type AV2 Positioners..................................9-15

9-34. Conversion Kits......................................................................................................................9-17

A-1. Potentiometric Position Transmitter Parts List ........................................................................ A-5

A-2. 4 to 20-mA Position Transmitter Parts List.............................................................................. A-7

B-1. Nomenclature..........................................................................................................................B-1

B-2. Calibration Procedures..........................................................................................................B-11

C-1. Control Signal Pressure Conversions (AV1)...........................................................................C-3

C-2. Input to Output I/P Converter Relationships (AV2)..................................................................C-3

D-1. Pneumatic Position Transmitter Kit (258492_1)......................................................................D-2

v

Page 8

Read First

Do not install, maintain or operate this equipment without reading,

understanding and following the proper factory-supplied instructions and

All equipment being returned to the factory for repair must be free of any

hazardous materials (acids, alkalis, solvents, etc.). A Material Safety Data

Sheet (MSDS) for all process liquids must accompany returned equipment.

Contact the factory for authorization prior to returning equipment.

WARNING

INSTRUCTION MANUALS

manuals, otherwise injury or damage may result.

RETURN OF EQUIPMENT

Read these instructions before starting installation;

save these instructions for future reference.

Contacting the Factory . . .

Should assistance be required with any of the company’s products, contact the following:

Telephone:

24-Hour Call Center

1-800-HELP-365

E-Mail:

ins.techsupport@us.abb.com

Read First I

Page 9

Read First II

Page 10

OVERVIEW

SECTION 1 - INTRODUCTION

This section covers the following topics:

• Positioner description.

• Positioner application.

• Features of positioners.

• Instruction content.

• How to use this instruction.

• Positioner nomenclature.

• Positioner specifications.

• Position transmitter specifications.

• Agency approvals.

• Accessories.

• Mounting kits.

NOTE: Appendix B provides a quick start guide for the Type

AV positioner. It is intended for control engineers having

experience in the use and application of pneumatic positioners. The quick start guide highlights the major points of installation and calibration. Detailed installation and calibration

information is contained in Section 3 and Section 4 respectively.

INTENDED USER

DESCRIPTION

The information in this instruction is a guide for technical personnel responsible for installation, calibration, operation, maintenance

and repair of the positioner.

The Type AV1 and Type AV2 positioners are control devices that

satisfy a wide range of applications. They provide fast, sensitive

and accurate positioning of pneumatic single or double acting

actuators.

The Type AV1 positioner receives an external pneumatic signal

and converts it to a pneumatic output. The Type AV2 positioner

accepts a four to 20-milliamp current that is applied to an I/P (current to pneumatic) converter, located inside the housing, to generate an internal signal pressure.

If a loss of signal occurs, the Type AV2 positioner goes to the

four-milliamp position. The Type AV1 positioner goes to the 3 psi

position.

OVERVIEW

1 - 1

Page 11

INTRODUCTION

A mechanical connection from the actuator (i.e., cylinder, valve,

etc.) to the position feedback cam in the positioner establishes

actual position. Three characterized segments on the cam provide

application flexibility by establishing various relationships between

the input signal and the actuator position. The characterized

curves on the cam provide:

• Square root relationship.

• Linear relationship.

• Square characteristic.

Using the zero, span and gain adjustments and the cam, the actuator can respond with characteristics specific to an application.

An optional manifold assembly provides an integral shutoff and

equalizing valve that can be used to isolate the positioner from an

actuator, allowing manual override without removing the positioner

from the process (required on double acting actuators with manual

override). The manifold also provides gage ports and disposable

filter cartridges that insure fast servicing and minimum downtime.

An optional gage block provides gage ports for mounting pressure

gages. There are three gage ports on the block: One for instrument indication (internal input signal) and two for output indication.

The gage block does not provide filters or means of isolating the

positioner from the actuator. Installation of a supply gage is possible in the supply line (piping by customer).

Both positioners can be equipped with either an optional potentiometric or a four to 20-milliamp position transmitter that provides

additional control features.

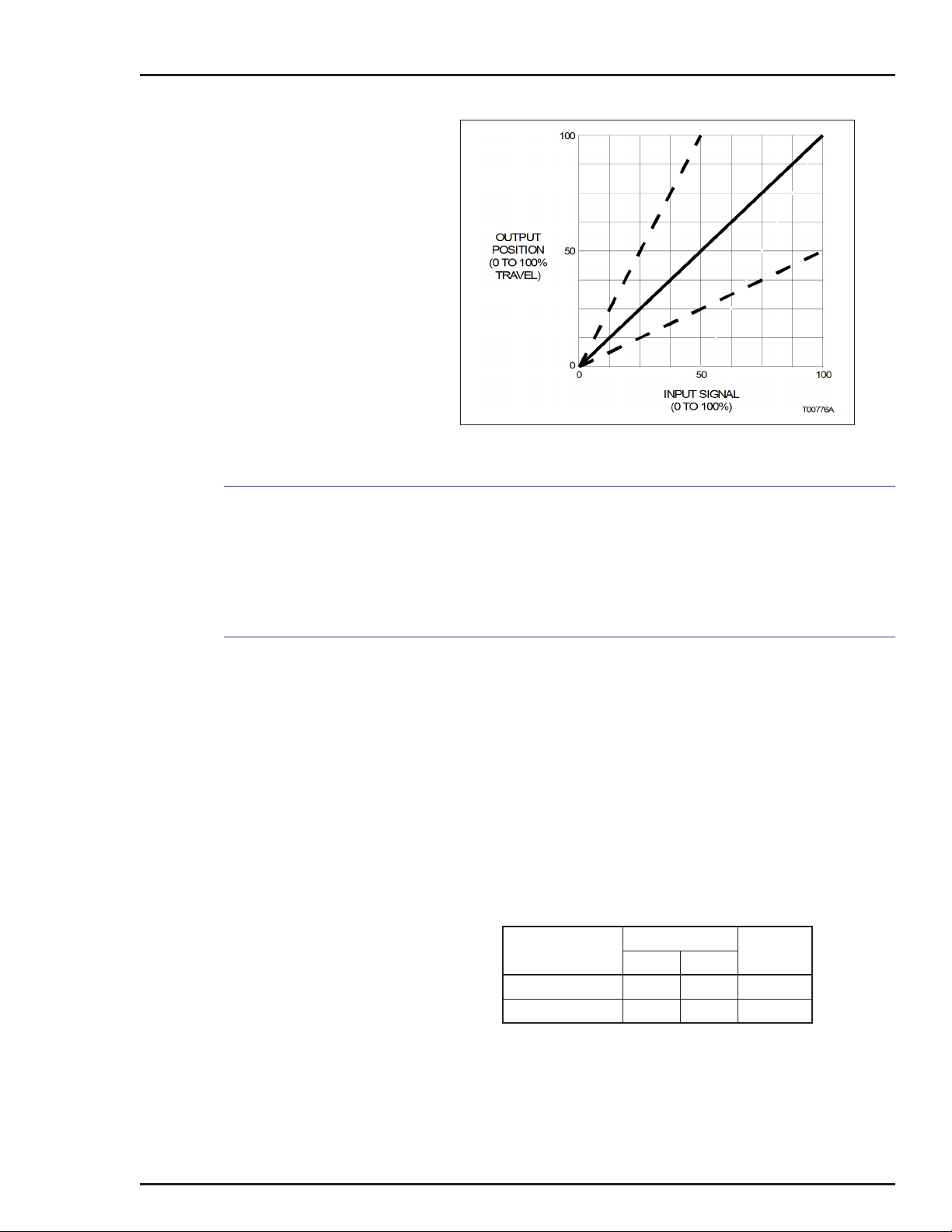

Performance Series Option

The Type AV positioner performance series provides a high flow

gain pilot valve body by adding a P in the ninth nomenclature position. This high gain pilot valve body has square ports that provide

a maximized air flow for a small motion of the pilot valve stem. A

relatively small error signal can therefore cause a relatively large

change in output air flow to the actuator. This feature is useful

when driving larger actuators that might otherwise be insensitive

or slow to respond to small signal changes.

Compared to other positioners on the market, the standard Type

AV positioners have a high delivery capacity. The performance

series increases this delivery capacity even more. The flow gain

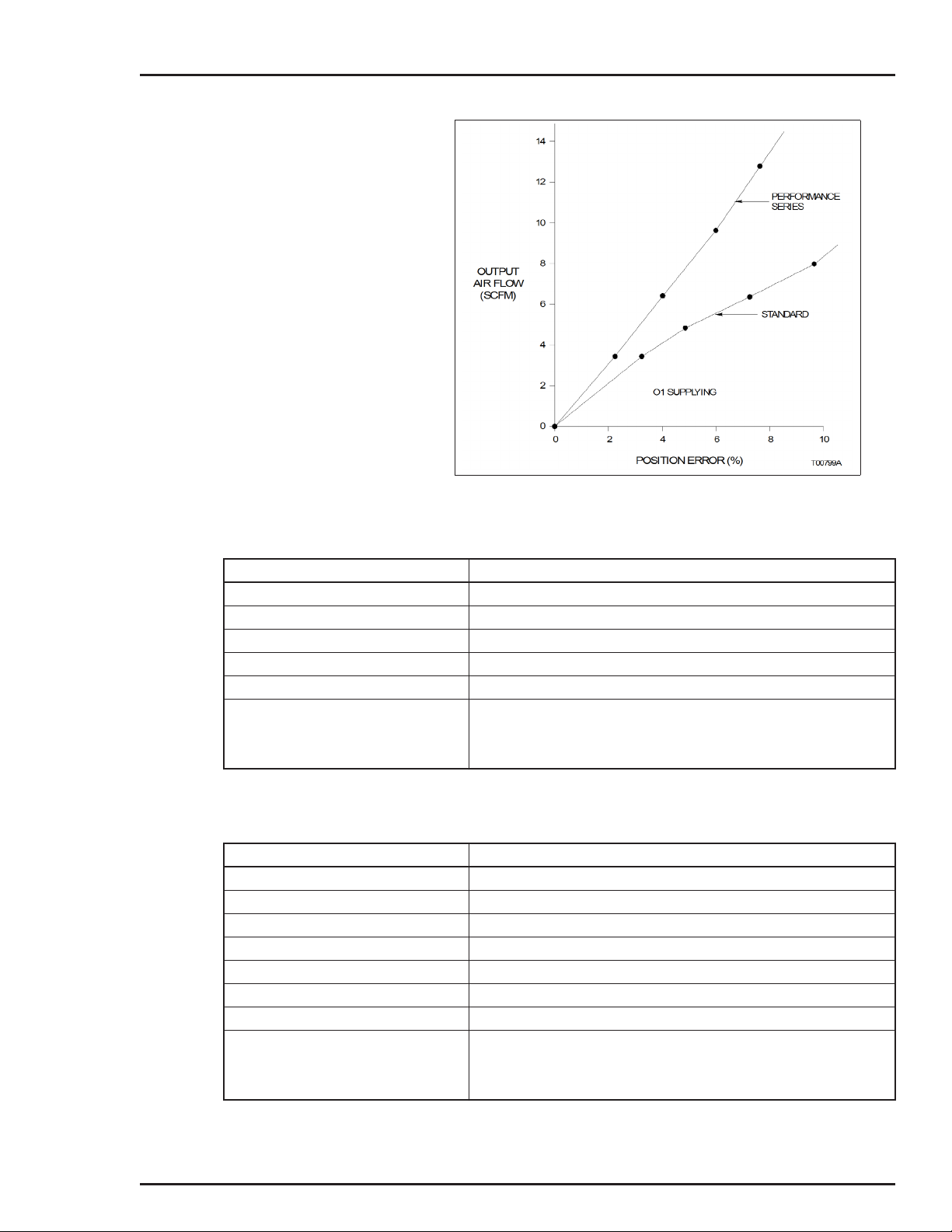

curves shown in Figures 1-3 and 1-4 show output air flow versus

input error signal for the standard and high gain performance

series positioners.

DESCRIPTION

1 - 2

Page 12

Explosionproof I/P Option

INTRODUCTION

Figures 1-3 and 1-4 show that the large signal maximum air flow

for both the standard and performance series positioners is about

the same. The performance series positioners achieve maximum

flow capacity at a much smaller error signal.

NOTE: ABB does not recommend using a performance

series positioner on a small actuator, as it could cause

instability.

The Type AV27 positioner employs an explosionproof I/P converter that is mounted to an adapter block manifold. The adapter

block manifold is bolted to the outside of the main positioner housing. The unit is a Type AV12 positioner with the electric to pneumatic (four to 20-milliamp to 20.7 to 103.4-kilopascal (3.0 to

15.0-pounds per square inch gage)) conversion occurring within

the externally mounted I/P converter.

The four to 20-milliamp input signal wires shall be connected

through an explosionproof conduit entrance on the I/P converter. If

no electrical connections are made within the main housing, the

entire positioner can be considered suitable for application in the

hazardous locations shown on the I/P label.

NEMA 4X Option

APPLICATION

FEATURES

Refer to Figure 3-1 for the external and mounting dimensions of

the Type A V27 positioner.

The Type A V

To maintain the NEMA 4X classification, the positioner shall be

installed per drawing C258567 and suitable piping shall be

attached to the vent opening and vented in a manner to preclude

the entrance of water under pressure, as from a hose. Additionally, the conduit connections shall be suitable for a NEMA 4X rating.

The Type A V1 and Type A V2 Characterizable Pneumatic Positioners control the position of a pneumatic actuator.

• Trouble-Free Operation. Proven pilot valve that is quickly

removable, provides less downtime, lower maintenance costs,

increased reliability and extended performance.

______N positioner comes with a NEMA 4X housing.

• Compact Rugged Design. Die cast aluminum housing,

beam, spring arm, follower arm and 303 stainless steel pilot

APPLICATION

1 - 3

Page 13

INTRODUCTION

valve provide long life and maximum environmental protection. The compact housing increases mounting flexibility.

• Characterizable Output. Large positioning cam can be

shaped to provide desired relationship between the input signal and the actuator position.

• Accurate Calibration. Independent zero and span adjust-

ments eliminate interaction and provide fast and accurate calibration.

• Simplified Reverse Operation. Action can be changed in the

field by changing cams and reversing 01 and 02 connections.

The reverse acting cam is conveniently located on the inside

of the front cover.

• Highly Visible Position Status Indicator. A fluorescent

orange position indicator is visible through a polycarbonate

window, providing fast indication of actuator position.

• Vent Design Allows Natural Gas Operation. Vent pipe

arrangement permits operation using natural gas.

• Split Range Service. Split range capability allows sequencing

of multiple actuators using a single control signal.

• Adjustable Gain. Two levels of gain are possible by changing

the hinge springs supplied with the positioner.

• Adaptable Usage. The positioner can control both single and

double acting, linear and rotary type actuators.

• High Capacity. More than 0.65 cubic meters per minute (23

standard cubic feet per minute) can be supplied or exhausted

at 482.6 kilopascals (70.0 pounds per square inch gage) supply pressure (Fig. 1-1).

• Continuously Adjustable Span and Zero for Each Stroke

Level. Capable of 100-percent stroke for 50-percent signal

span or 50-percent stroke for 100-percent signal span.

• Low Air Consumption. Enhanced pilot valve design and

manufacturing technique allows the Type AV positioner maximum performance with minimum air consumption (Fig. 1-2).

• Adjustable Speed Control without Additional Hardware.

Speed of actuator can be reduced to desired speed using the

pilot valve stroke adjustment screws.

FEATURES

1 - 4

Page 14

INSTRUCTION CONTENT

INTRODUCTION

This instruction includes the following sections:

Introduction

Description and

Operation

Installation

Calibration

Operating Procedures

Troubleshooting

Maintenance

Provides a description of this instruction; its sections and uses,

along with a brief description of the Type AV1 and Type AV2 positioners. This section also provides reference documents (Table

1-2), product nomenclature (Table 1-2), specifications (Tables 1-3,

1-4 and 1-5), agency approvals (Table 1-6) and positioner acces-

sories (Table 1-7). Table 1-8 lists retrofit mounting kits, Table 1-9

lists available speed control orifices, and Table 1-10 lists the available pressure gages. Table 1-11 lists pressure regulators, Table

1-12 lists supply air filters available from ABB and Table 1-13 lists

the materials used in the positioner components.

Describes the functional operation of the positioners.

Provides information about installing a Type AV positioner.

Provides calibration and adjustment procedures.

Presents information and procedures for various applications.

Provides a table containing errors, causes and corrective action.

Includes preventive maintenance information and procedures.

Repair and

Replacement

Support Services

Appendix A

Appendix B

Appendix C

Appendix D

Procedures in this section give step-by-step instructions for

removing and replacing components.

Provides recommended spare and replacement parts lists. Illustrations of both positioners provide part numbers for all major

components.

Provides calibration information about the four to 20-milliamp position transmitter and the potentiometric position transmitter.

Quick start section for control engineers that are knowledgeable

about positioners and the overall process in which the positioner is

to be used.

Details cam shaping information.

Covers the pneumatic position transmitter option.

HOW TO USE THIS INSTRUCTION

For safety reasons, read and completely understand this instruc-

tion before completing any tasks or procedures associated with

installation, calibration, operation, maintenance or repair.

INSTRUCTION CONTENT

1 - 5

Page 15

INTRODUCTION

The section arrangement of this instruction is sequential. After initial start-up and calibration, store this instruction in a safe place for

future reference.

REFERENCE DOCUMENTS

Table 1-1. Reference Documents

Number Title

ANSI/NFPA 70 National Electrical Code

CEC Canadian Electrical Code

D-AAP-UP Universal Pneumatic Rotary Actuator, Type UP (specification)

D-APE-AV1234 Characterizable Positioners, Type AV1, AV2, AV3 & AV4 (specification)

CSA c22.1 Process Control Equipment

I-E96-500 Site Planning and Preparation

I-P81-20 Universal Pneumatic Rotary Actuator, Type UP (instruction)

ANSI/ISA-7.0.01-1996 Quality Standards for Instrument Air

ISA S75.13-1989 Method of Evaluating the Performance of Positioners with Analog Input Signals and

Pneumatic Output (Instrument Society of America)

P-P88-001 Product Application Guide, Installing a Type AV Positioner in a Hazardous Location

NOMENCLATURE

Position 1 23456789

Type A V

_______

1

2

Next Page

1 20.7 to 103.4 kPa (3.0 to 15.0 psig) (Type AV1)

2 20.7 to 186.2 kPa (3.0 to 27.0 psig) (Type AV1)

3 4 to 20 mA (standard intrinsically safe Type AV2)

5 20.7 to 103.4 kPa (3.0 to 15.0 psig), high temperature applications

6 20.7 to 186.2 kPa (3.0 to 27.0 psig), high temperature applications

7 4 to 20 mA with explosionproof I/P converter (NEMA 7) (Type AV2)

1 12.7 to 50.8 mm (0.5 to 2.0 in.) or 45° rotary motion

2 25.4 to 101.6 mm (1.0 to 4.0 in.) or 90° rotary motion

Table 1-2. Nomenclature

Characterizable Positioners

Characterizable Pneumatic Positioner

Characterizable 4 to 20-mA Input Positioner (actuator moves to 0%

or 100% upon loss of signal)

Input Signal

(Type AV1)

(Type AV1)

Stroke/Rotary Motion (cam selection)

1

1

2

REFERENCE DOCUMENTS

1 - 6

Page 16

Position 1 23456789

Type A V

_______

INTRODUCTION

Table 1-2. Nomenclature (continued)

Characterizable Positioners

Prev

0 No manifold

1 Manifold with equalizing valve, filters and gage ports (required for dou-

2 Manifold with equalizing valve inoperable (includes filters and gage

3 Gage block (gage port only)

0 None (must be 0 for Types AV15, AV16 and AV27)

1 Potentiometric resistive output

2 4 to 20-mA output

0 Standard with feedback arm for linear motion

1 0.500-in. square end

2 0.342-in. square end for older DeZurik actuators

3 0.250 in. across flats (UP1 and UP2 after August, 1995)

4 0.375 in. square for DeZurik PowerRac

5 0.156 in. across flats for NAMUR rotary actuators

NOTES:

1. High temperature Type AV1 positioners are only available without manifolds or position transmitters; however, gage blocks are permitted.

2. Explosionproof Type AV2 positioners are not available with position transmitters or manifolds

3. No longer available as of October 2003..

Manifold (includes filters)/Gage Block

ble acting actuators with manual override)

3

ports)

1

Position Transmitter

Drive Shaft

®

actuators

Other Options

0 Standard (no other options)

N NEMA 4X enclosure rating (when installed per drawing C258567)

P Performance Series — high pneumatic gain for large actuators

SPECIFICATIONS

Table 1-3 provides performance specifications of the Type AV1

and Type AV2 positioners. Tables 1-4 and 1-5 provide performance specifications for the position transmitters.

Table 1-3. Type AV1/2 Positioner Specifications1

Property Characteristic/Value

Input range

AV11 and AV15 20.7 to 103.4 kPa (3.0 to 15.0 psig)

AV12 and AV16 20.7 to 186.2 kPa (3.0 to 27.0 psig)

AV23 and AV27 4 to 20 mA

Input impedance (Type AV2 only)

Nominal 215 at 22°C (72°F)

Maximum 245 at 60°C (140°F)

SPECIFICATIONS

1 - 7

Page 17

INTRODUCTION

Table 1-3. Type AV1/2 Positioner Specifications1 (continued)

Property Characteristic/Value

Standard stroke range (cam selection)

AV__1____ 12.7 to 50.8 mm (0.5 to 2.0 in.) linear, rotary input 45°

AV__2____ 25.4 to 101.6 mm (1.0 to 4.0 in.) linear, rotary input 90°

Gain 2 adjustment levels by changing gain hinge spring. Refer to the flow

gain curves as shown in Figures 1-3 and 1-4 for standard and high

gain units.

Accuracy

Resolution

Hysteresis

Repeatability

Deadband

Linearity

Supply pressure 172 to 1034 kPa (25 to 150 psig)

Supply pressure effect 0.05% per 6.9 kPa for ±69 kPa change

Capacity (maximum capacity exhausting to atmosphere)

Air consumption Refer to Figure 1-2.

Vibration effect

Pneumatic connections ¼-NPT on supply, signal and output connections

Materials of construction

Enclosure classification

2

AV1 0.80% of span maximum

AV2 0.90% of span maximum

AV1 0.09% of span maximum

AV2 0.30% of span maximum

2

AV1 0.45% of span maximum

AV2 0.70% of span maximum

2

AV1 0.12% of span maximum

AV2 0.50% of span maximum

2

AV1 0.12% of span maximum

AV2 0.30% of span maximum

2

0.70% of span maximum

NOTE: Minimum supply pressure should be 34.4 kPa (5.0 psig) above operating pressure required by actuator.

(0.05% per 1.0 psi for ±10 psig change)

Refer to Figure 1-1.

2

Enclosure Aluminum and <0.5% magnesium

Pilot valve 303 stainless steel

Standard NEMA 3R classification when vent hole is protected from rain using

AV______N NEMA 4X when installed per drawing C258567.

<2.0% error for:

5 to 15 Hz at peak-to-peak constant displacement of 4 mm (0.16 in.)

15 to 120 Hz at accelerations to 2 Gs

1

-NPT on pressure gages

8

rain elbow (½-NPT street elbow, refer to Figure 3-1).

SPECIFICATIONS

1 - 8

Page 18

INTRODUCTION

Table 1-3. Type AV1/2 Positioner Specifications1 (continued)

Property Characteristic/Value

Weight

AV1 1.84 kg (4.06 lbs)

AV2 (standard) 2.32 kg (5.11 lbs)

AV2 (explosionproof) 2.95 kg (6.51 lbs)

Temperature limits

Operating

AV11/2 -40°C to 82°C (-40°F to 180°F)

AV15/6 -20°C to 127°C (-4°F to 250°F)

AV2 -20°C to 82°C (-4°F to 180°F)

Storage

AV11/2 -40°C to 93°C (-40°F to 200°F)

AV15/6 -20°C to 127°C (-4°F to 250°F)

AV2 -20°C to 82°C (-4°F to 180°F)

Humidity limits

Operating 0% to 95% noncondensing

Storage 0% to 95% noncondensing

NOTES:

1. Performance testing performed on a ABB Type UP10 actuator.

2. Tested according to ISA-S75.13-1989

3. For operation below 4.4°C (40°F), dew point of the supply air must be 10°C (18°F) lower than the lowest expected operating temperature.

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE.

3

3

3

Figure 1-1. Capacity (Exhaust to Atmosphere)

SPECIFICATIONS

1 - 9

Page 19

INTRODUCTION

Figure 1-2. Air Consumption

Figure 1-3. Output Air Flow vs. Error Signal — Standard and Performance Series

SPECIFICATIONS

1 - 10

Page 20

INTRODUCTION

Figure 1-4. Expanded First Quadrant View of Figure 1-3

Table 1-4. Type AV ____1__ Potentiometric Position Transmitter Specifications

Property Characteristic/Value

Total resistance 2000

Power rating 1 W up to 70°C (158°F), 0 W at or above 125°C (257°F)

Wiper rate of change 9.9 nominal per degree of cam rotation

Temperature effect 0.05% (500 ppm) per °C (0.03% (278 ppm) per °F) maximum

Maximum voltage 35 VDC or 30 VAC across the potentiometer ends

Temperature limits

Operating -40°C to 82°C (-40°F to 180°F)

Storage -40°C to 93°C (-40°F to 200°F)

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE.

Table 1-5. Type AV____2 __ 4 to 20-mA Position Transmitter Specifications

Property Characteristic/Value

Supply voltage 16 to 34 VDC

Output signal 4 to 20 mA

Output loading 500 at 24 VDC, 1000 at 34 VDC

Accuracy <0.6% of span (maximum)

Hysteresis <0.5% of span (maximum)

Ambient temperature effect <0.063% per °C (<0.035% per °F)

EMI/RFI effect <1.5% maximum at 10 V/m field strength, 20 to 450 MHz

Temperature limits

Operating -40°C to 82°C (-40F° to 180°F)

Storage -40°C to 93°C (-40F° to 200°F)

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE.

SPECIFICATIONS

1 - 11

Page 21

INTRODUCTION

Table 1-6. Agency Approvals1

Nomenclature Approval/Certification

AV1 and AV23 Factory Mutual Research (FM):

Approved as nonincendive for:

Class I, Division 2, Groups A, B, C and D

Class II, Division 2, Groups F and G

Class III, Division 2

Approved as intrinsically safe for:

Class I, Division 1, Groups A, B, C and D

Class II, Division 1, Groups E, F and G

Class III, Division 1

AV27__0__ Factory Mutual Research (FM):

Canadian Standards Association (CSA):

Certified as:

Class 1, Division 2, Groups A, B, C and D

Class II, Division 2, Groups E, F and G

Class III, Division 2

Certified as intrinsically safe for:

Class I, Division 1, Groups A, B, C and D

Class II, Division 1, Groups E, F and G

Class III, Division 1

Canadian Standards Association (CSA):

2

Approved as explosionproof for:

Classes I, II; Division 1, Groups B, C, D,

E, F and G

All This product complies with all applicable European Community product require-

ments, and specifically with those required to display the CE marking on the product

nameplate.

NOTES:

1. Hazardous locations approvals for use in flammable atmospheres are for ambient conditions of -25°C to 40°C (-13°F to 104°F), 86 to

106 kPa (12.5 to 15.7 psig) with a maximum oxygen concentration of 21%.

2. For installing the positioner in a hazardous location, refer to Product Application Guide, Installing a Type AV Positioner in a Hazard-

ous Location.

Certified as explosionproof for:

Classes I, II; Division 1, Groups B, C, D,

E, F and G

Table 1-7. Accessories1

Accessory Description

Mounting kits Dependent on valve stem size (Figure 9-1, kit number 5327321__). For ABB retrofit

kits, refer to Table 1-8.

Speed control

orifices

Pressure gages For reading signal, supply and output pressures (refer to Table 1-10).

Blank cam Used to characterize the positioner if the standard cams (square, linear, square root)

Supply air regulator Refer to Table 1-11.

Pneumatic position

transmitter

Air filters ABB recommends installing an air filter in the supply air line to prevent particles from

Manifold Filters For addition or replacement of secondary air filters on manifold-equipped positioners.

Bypass valve

assembly

NOTE:

1. For recommended spare parts and additional spare parts, refer to Section 9.

Regulate time constant of positioner and final control device. Orifices are installed

directly into positioner output ports (refer to Table 1-9). Speed adjustment can also be

controlled by using the internal stroke adjustment screws (refer to PILOT VALVE

STROKE ADJUSTMENT in Section 4).

will not produce the desired relationship. Blank cam must be profiled (part number

5400277_1.

Refer to Appendix D (Type AV1__0___ positioner only).

entering the positioner that can lead to malfunctions. Refer to Table 1-12 for filter part

numbers.

Kit number 258487 _1.

Part number 5326945_1. Refer to Table 9-24 and Figure 9-2.

SPECIFICATIONS

1 - 12

Page 22

INTRODUCTION

Table 1-8. Rotary Actuator Retrofit Mounting Kits

Kit Number Drive Nomenclature Retrofit Mounting Kit

5400309_1 UP1, UP2 Type AP positioner to

258493_1 UP3, UP4

258494_1 UP5, UP6

258527_1 AC0404

258528 _1 AC0608

258529 _1 AC0816

258530 _2 AC1016

258527_1 AC0404 ABB part number pilot

258528_1 AC0608

258529 _1 AC0816

258530_1 AC1016

Type AV positioner

valve positioner to Type

AV positioner

Table 1-9. Speed Control Orifices

Part Number

5327327 _1 1.02 0.04

5327327_2 Blank (drill to suit) Blank (drill to suit)

NOTE:

1. Speed control can also be obtained by internal positioner adjustment. Refer to PILOT VALVE

STROKE ADJUSTMENT in Section 4.

mm in.

Size

1

Table 1-10. Pressure Gages

Part Number Legend

5326605 _4 Instrument 0 to 200 0 to 30

5326605 _5 Supply

5326605_6 Output 0 to 1,000 0 to 160

NOTE:

1. The optional manifold provides gage ports, one for instrument (internal input signal), and two output gages. A supply gage can be installed in the supply line (piping by customer).

kPa psig

1

0 to 1,000 0 to 160

Range

Table 1-11. Supply Air Regulators with Gages

Part Number

1951029 _5 125 250 ¼ NPT

Max. Outlet

Pressure (psig)

Max. Inlet

Pressure (psig)

Inlet/Outlet

Connections

Table 1-12. Supply Air Filters

Max. Inlet

Part Number

5328563 _2 250 121.0 125.0 ¼ NPT

NOTE:

1. In-line coalescing filter for removal of solid and liquid contaminants in compressed air. Filter

comes with universal mounting bracket and grade 6 filter that is 99.97% efficient at 0.3 micron. Part

number 5328563 _2 has a zinc bowl.

Pressure

(psig)

Max. Temperature Inlet/Outlet

°C °F

1

Connection

Size

SPECIFICATIONS

1 - 13

Page 23

INTRODUCTION

Table 1-13. Component Material List

Component Material

Housing Aluminum

Cover Aluminum

Inserts Lamond (thermoplastic elstomer)

®

Window Lexan

Screws Stainless steel

Range spring 302 stainless steel

Pilot valve (stem and body) 303 stainless steel

Gain hinge spring 302 stainless steel

Cam 302 stainless steel

Cam shaft 303 stainless steel

Bearings Bronze

Cam follower arm Aluminum

Bearing Stainless steel

Shaft 303 stainless steel

Spring arm Aluminum

Zero adjustment nut Aluminum

Indicator Valox

terphthalate)

Tubing Silicone

Drive arm Aluminum

®

washers Teflon

Teflon

Fasteners Steel/stainless steel

Signal connector Nylon

Diaphragms

All except Types AV15 and AV16 Buna-N with Dacron fabric

Types AV15 and AV16 Fluorosilicone with Dacron fabric

Diaphragm plastic parts Rynite

Gage block (optional) Aluminum

O-rings

All except Types AV15 and AV16 Buna-N

Types AV15 and AV16 Viton

Manifold (optional) Aluminum

Adhesive Epoxy

Handle Rynite

Plate Aluminum

Plug Stainless steel

Valve Aluminum

Valve handle Rynite

phthalate

(polycarbonate)

®

— unreinforced (polybutylene

®

(FR-530) polyethylene ter-

®

SPECIFICATIONS

1 - 14

Page 24

Table 1-13. Component Material List

Component Material

Position transmitter (optional)

(AV____1/2 __)

Gears Delrin

Gear hub Brass

Additional Type AV2 components

1

Regulator

Regulator bracket

Tubing Nylon

I/P converter Copper

1

Polysulfone

304 stainless steel

Copper clad glass laminate

Monel

Nickel-iron

Noryl

Polyethylene

Polyester magnet wire

Rare earth magnet

Zinc

INTRODUCTION

®

(coolymer acetal)

1

1

®

405

®

(phenylene ether/phenylene)

NOTE:

1. Regulator not applicable for AV2s after July, 2001.

SPECIFICATIONS

1 - 15

Page 25

Page 26

INTRODUCTION

SECTION 2 - DESCRIPTION AND OPERATION

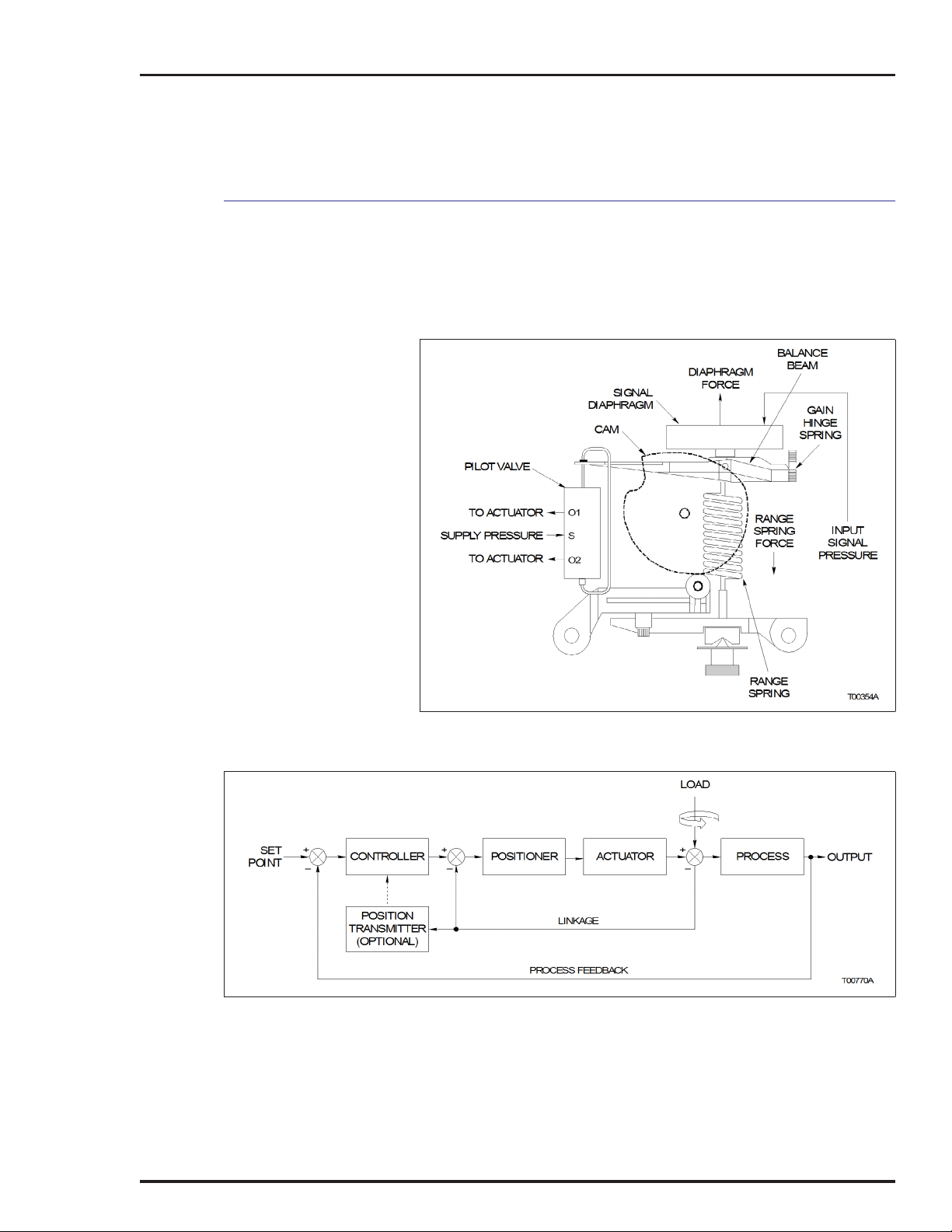

This section describes and explains the functional and physical

operation of Type AV1 and AV2 positioners. Figure 2-1 diagrams

the operating principles of the positioners. Figure 2-2 shows the

placement of a positioner in a typical control system.

Figure 2-1. Operation Diagram

Figure 2-2. Block Diagram

INTRODUCTION

2 - 1

Page 27

DESCRIPTION AND OPERATION

FUNCTIONAL OPERATION

Type AV positioners operate by balancing opposing forces. Figure

2-1 shows a diagram of the Type AV positioner. A balance beam,

hinged at one end and connected to the pilot valve at the other, is

acted upon by two forces:

• Upward force of the signal diaphragm assembly.

• Downward force from the range spring.

The input signal pressure determines the diaphragm force. The

Type AV1 positioner uses an external input pressure (either 20.7

to 103.4 kilopascals (3.0 to 15.0 pounds per square inch gage) or

20.7 to 186.2 kilopascals (3.0 to 27.0 pounds per square inch

gage)). The Type AV2 positioner uses a current to pneumatic converter to generate the input signal pressure.

The range spring force is a function of the shape and position of

the cam. The cam is coupled to the cam shaft that is connected

through linkage (or coupling) to the actuator. Therefore, range

spring tension is a function of the actuator position.

A change in input signal changes the force exerted by the signal

diaphragm, moving the balance beam, in turn moving the pilot

valve. The pilot valve supplies and/or exhausts air to the actuator

that ultimately changes its position. The change in actuator position is fed back to the positioning cam. The positioning cam

moves, changing the tension of the range spring until a balanced

condition once again exists.

The positioner is normally located in a control loop (Fig. 2-2)

between the controller and the actuator.

Actuator position is fed back to the positioner for comparison with

the position commanded by the input control signal (direct signal

pressure or a current value). For linear motion actuators, the feedback mechanism consists of:

• A drive rod that follows the motion of the actuator.

• An adjustable-length, swivel-ended connecting link that trans-

mits the motion of the drive rod to an adjustable drive arm on

the positioner.

• A camshaft and cam that are rotated through an angle by the

drive arm. A function of the cam is to permit characterization of

actuator position versus input signal.

FUNCTIONAL OPERATION

2 - 2

Page 28

INTRODUCTION

SECTION 3 - INSTALLATION

Several applications are possible using a Type AV positioner. The

steps for installing a Type AV positioner are in sequence in this

section. After installation is complete, refer to Section 4 for calibration information.

• Unpack and inspect the equipment.

• Mount the positioner.

• Connect tubing to the positioner.

• Connect wiring to the positioner.

NOTES:

1. For application in a hazardous location, refer to ABB Product Application Guide, Installing a Type AV Positioner in a

Hazardous Location.

2. Appendix B provides a quick start guide for the Type AV

positioner. It is intended for control engineers having extensive

experience in the use and application of pneumatic positioners.

The quick start guide highlights the major points of installation

and calibration. Detailed installation and calibration information

is contained in this section and in Section 4.

Select an installation method that provides a fail safe mode

upon loss of controller signal. Certain installation methods

WARNING

UNP ACKING AND INSPECTION

do not stroke the equipment to a fail safe condition upon

loss of controller signal. Failure to select a fail safe installation method could cause injury to personnel and damage to

equipment.

1. Check for obvious damage to the shipping carton.

2. Open the carton and remove all loose packing.

3. Carefully remove the positioner from the carton and inspect for

any physical damage that may have occurred during shipping.

4. Remove the two cover screws and the positioner cover and

examine the interior for any loose components such as nuts,

screws, springs, etc. Check the data on the nameplate to be certain the positioner type ordered for the application was received.

INTRODUCTION

3 - 1

Page 29

INSTALLATION

5. If the positioner is suitable for the application and appears

undamaged, install the cover and proceed with the installation

instructions.

6. If storing the positioner prior to installation, leave it in the original carton, if possible. Store in an area free from corrosive vapors

and extremes in temperature and humidity.

7. Do not store the positioner in an area that would take it out of

the specifications listed in Tables 1-3, 1-4 and 1-5.

ENCLOSURE CLASSIFICATION

The standard enclosure for the Type AV1 and Type AV2 positioners conform to NEMA 3R when a ½-14 NPT street elbow (Fig. 3-1)

is installed into the vent hole on the housing. The elbow prevents

water or other liquid from entering the enclosure. The position of

the elbow is related to the mounting plane of the positioner in its

service location. The elbow must be positioned to face downward.

The NEMA 3R version meets the extended corrosion resistance

requirements of NEMA 250.

A NEMA 4X version is available as an option (Type AV______N

positioners). To maintain the NEMA 4X classification, the positioner shall be installed per drawing C258567 and suitable piping

shall be attached to the vent opening and vented in a manner to

preclude the entrance of water under pressure, as from a hose.

Additionally, the conduit connections shall be suitable for a NEMA

4X rating.

MOUNTING CONSIDERATIONS

Choose a location for the positioner based on the following factors:

• Access to the internal positioner adjustments — the mounting

location should provide enough room to remove the cover in

order to perform calibration and repair and replacement procedures inside the positioner. Refer to Figure 3-1 for positioner

dimensions. Figure 3-2 shows the electrical connections, Figure 3-3 shows the dimensions of the drive arm connections

and Figure 3-4 shows the drive shaft variations.

• Allow room for linkage to the actuator — the mounting position

should be such that a practical linkage arrangement can be

made between the positioner and the actuator for full range

travel.

ENCLOSURE CLASSIFICATION

3 - 2

Page 30

INSTALLATION

Figure 3-1. External and Mounting Dimensions

MOUNTING CONSIDERATIONS

3 - 3

Page 31

INSTALLATION

Figure 3-2. Electrical Connections

NOTE: For Type AV27, the 4-20 mA input signal wires shall be

connected through an explosion-proof conduit entrance directly

to the I/P converter.

MOUNTING TYPE AV POSITIONERS

The Type AV positioner can be used with double acting or single acting

actuators. Mounting and external dimensions are shown in Figure 3-1.

Figure 3-5 shows a typical mounting arrangement using a ABB mounting

kit. Refer to Figure 9-23 for an exploded view and complete parts list of

Figure 3-3. Drive Arm Connections

MOUNTING TYPE AV POSITIONERS

3 - 4

Page 32

INSTALLATION

the kit. If using the positioner with a rotary actuator, the positioner can be

directly connected to the actuator, as shown in Figure 3-6.

NOTE: If the actuator is equipped with a Type AV positioner as

ordered, verify that all the connections are secure and make any

adjustments as required.

Figure 3-4. Drive Shaft Variations

Figure 3-5. Mounting Using Linkage (Typical)

MOUNTING TYPE AV POSITIONERS

3 - 5

Page 33

INSTALLATION

WARNING

Figure 3-6. Mounting Using Direct Coupling (Typical)

Due to the wide range of applications that the Type AV positioner

is suited for, we can only provide general information about

mounting. Use the following procedure to mount the positioner.

Before mounting or installing positioner, check nameplate

data to make certain positioner is suitable for application

desired. DO NOT AT ANY TIME EXCEED THE RATINGS

LISTED ON THE NAMEPLATE.

1. Set the actuator at the zero position. Connect the adjustable

linkage to the drive arm. The drive arm holes correspond to stroke

length of the actuator. Refer to Figure 3-3 for the stroke length for

each drive arm hole.

2. Install the cam (black, direct acting; or red, reverse acting) that

will provide the required direction of rotation.

A direct acting (black) positioning cam with segments A, B and C

(Fig. 3-7) and a reverse acting cam are furnished with each positioner. The reverse acting cam has red radial lines and arcs and

is stored on the inside of the positioner cover. Cam A is for a

square root function, cam B is for linear motion and cam C is for a

MOUNTING TYPE AV POSITIONERS

3 - 6

Page 34

INSTALLATION

square function (Table 3-1). Cam B is in place when the positioner

is shipped from the factory. The cams may be shaped to conform

to special applications. Refer to Appendix C for information about

cam shaping.

NOTE: If the application is reverse acting, the reverse acting

cam (red radial lines) must be installed and the connections to

ports 01 and 02 must be reversed.

Figure 3-7. Cam

Table 3-1. Cam Characteristics

Positioning

Cam

Any Stroke

A

B

C

The cam, camshaft and drive arm rotate as an assembly. Cam

motion is 90 degrees (Type AV__2____) or 45 degrees (Type

AV__1____) depending on the positioner type specified by

nomenclature (Figure 3-7).

Each cam shape (A, B or C) has its own eight-point center hole for

mounting on the camshaft (Fig. 3-7). Place the cam in one of the

eight 45-degree positions so that the midpoint of the cam corresponds to the mid stroke of the actuator. The drive arm should be

perpendicular to the motion of the actuator with the actuator at mid

stroke.

3. Adjust the connecting linkage so that the zero radial line on

the cam intersects the center of the cam roller when the actuator

is at its zero position (Fig. 3-8).

Piston or Valve Position (P)

vs

Control Signal (I)

Square root

Linear

Square

IP=

IP=

2

IP

=

Figure

Number

C-1

C-2

C-3

MOUNTING TYPE AV POSITIONERS

3 - 7

Page 35

INSTALLATION

4. Lock all linkage components in place.

TUBING CONNECTIONS

Air Supply Pressure

CAUTION

Air Supply Filtering

Figure 3-8. Cam Roller Alignment

Type AV positioners are available with (Type AV___1___ and

A V___2___) or without (AV___0 ___) manifolds. The following outlines supply air information and describes the piping connections.

Do not exceed the maximum supply pressure of 1034 kilopascals (150 pounds per square inch gage). Exceeding this

pressure could cause equipment damage.

The air supply pressure range is 172 to1034 kilopascals (25 to

150 pounds per square inch gage).

NOTE: The minimum supply pressure should be 34.4 kilopascals (5 pounds per square inch gage) above the operating pressure required by the actuator.

An external filter is recommended for Type AV positioners for primary filtration of the supply air. ABB provides supply air filters as

accessories. Refer to Table 1-12 for part numbers.

NOTE: Primary air supply filters are recommended for positioners with a manifold (AV___1/2___), without a manifold

(AV___0___) or with a gage block (AV___3___).

TUBING CONNECTIONS

3 - 8

Page 36

Positioners equipped with manifolds have three secondary filters

as part of the unit. If the filters become clogged, they can be

cleaned (by removing and reverse flushing with air or liquid) or

replaced (refer to Table 1-7 for kit number). Refer to Section 7 for

manifold filter replacement procedures.

Air Supply Quality (Recommended)

For long-term, trouble free operation, it is recommended that the

supply air be of instrument quality and conform to the ANSI/

ISA-7.0.01-1996 standard that includes the following:

INSTALLATION

Tubing Connections

• The pressure dew point as measured at the dryer outlet shall

be at least 10

which any part of the instrument air system is exposed. The

pressure dew point shall not exceed 4

sure.

• The oil content should be as close to zero as possible and,

under no circumstances, shall it exceed one (1) ppm w/w or

v/v.

• Instrument air should be free of corrosive contaminants and

hazardous gases, which could be drawn into the instrument air

supply.

In addition, the particle size in the supply line should not be

greater that 3.0 microns.

o

C (18oF) below the minimum temperature to

o

C (39oF) at line pres-

1. Connect the required air supply to connection S (Fig. 3-9).

NOTE: Use liquid or paste pipe sealant to seal the connection.

Maximum torque for ¼-NPT fittings is 13.6 Nm (10 ft-lbs).

Figure 3-9. Port Locations

TUBING CONNECTIONS

3 - 9

Page 37

INSTALLATION

2. Based on the positioner type, perform one of the following

steps (Fig. 3-9):

AV11 or AV15: Connect 20.7 to 103.4-kPa (3.0 to 15.0-psig)

instrument signal to connection I.

AV12 or AV16: Connect 20.7 to 186.2-kPa (3.0 to 27.0-psig)

instrument signal to connection I.

AV2: Connection I is not used and should be plugged. If it is

not plugged, do so at this time.

3. Connect the output ports 01 and 02 as required to provide the

desired direction of rotation. Figures 3-10, 3-11, 3-12 and 3-13

show single acting tubing examples, and Figure 3-14 shows a

double acting tubing example. Air pressure to the 01 port

increases from zero toward full supply as the control signal (error)

increases. Air pressure to the 02 port decreases from full supply

toward zero as the control signal increases.

NOTE: The tubing arrangements shown in Figures 3-10, 3-11,

3-12, 3-13 and 3-14 are typical examples and may not reflect the

arrangement required for the application.

1

4. -NPT permanent instrument gages can be installed into the

8

gage ports for calibration requirements.

WIRING TYPE AV2 POSITIONER

Use the following procedure to wire the Type AV2 positioner:

1. Connect the four to 20-mA position demand signal wires to

terminals TB1-4 (+) and TB1-5 (-) of the terminal block (Figs. 3-2

and 3-15). For Type AV27 positioners, unscrew the I/P cover and

make the four to 20-mA connections to the positive (+) and negative (-) terminals. If installing a Type AV2 ___0__ positioner, go to

Step 4.

NOTE: If using a twisted shielded pair for signal wiring, ground

one end of the shielded pair at the source. Trim the other end of

the pair, located inside the enclosure, so that bare wires are not

exposed.

2. If equipped with an optional 4 to 20-mA position transmitter

(AV2 ___2__), connect a 24-VDC power supply in series with the