ABB ACS800 Brochure

ABB industrial drives

ACS800, regenerative drives, 5.5 to 5200 kW

Complete regenerative drives

The ACS800 regenerative drives

are equipped with an active supply

unit. It allows full power flow both in

motoring and generating modes at

a voltage range from 208 to 690 V

(ACS800-17LC: 380 - 690 V). This

complete regenerative solution includes

everything that is needed, including the

line filter, in one compact package.

Wall-mounted regenerative drive

ACS800-11, 5.5 to 110 kW

With the wall-mounted ACS800-11 the

user gets everything in a single and

complete IP21 package. All important

features and options such as LCL filter

and EMC filter are built inside the drive.

Cabinet-built regenerative drive

ACS800-17, 45 to 2500 kW

The ACS800-17 is a cabinet-built

solution for drive applications where

regenerative operation is required. It

covers a wide power range and, like

other cabinet-built drives, it has a wide

range of built-in features and options. It

is available with IP21, IP22, IP42, IP54,

IP54R protection classes and module

package.

Liquid-cooled regenerative drive

ACS800-17LC, 75 to 5200 kW

The ACS800-17LC is a cabinet-built

drive that is equipped with both liquid

cooling and regenerative capabilities.

Liquid cooling eliminates the need for

air cooling in equipment rooms and

delivers effective heat transfer for high

overall efficiency. Direct liquid cooling

also allows to make the drive extremely

compact and silent. This drive can be

provided with DNV, LR and ABS marine

certifications and comes in IP42 as

standard, with optional IP54.

High performance

The ACS800 regenerative drives are

especially suitable for demanding

applications. Transition between

motoring and generating is fast due to

the DTC control method.

The active supply unit is able to boost

output voltage, which guarantees full

motor voltage even when the supply

voltage is below nominal. The active

supply unit combined with DTC control

can even compensate for fast variations

in line voltage. There is no risk of fuse

blow or component damage due to

voltage drops in the network.

Energy savings

The regenerative drive offers significant

energy savings compared with other

braking methods such as mechanical

and resistor braking, as energy is

fed back to the supply network. No

external brake resistor is needed, which

translates into simplified installation and

no wasted heat.

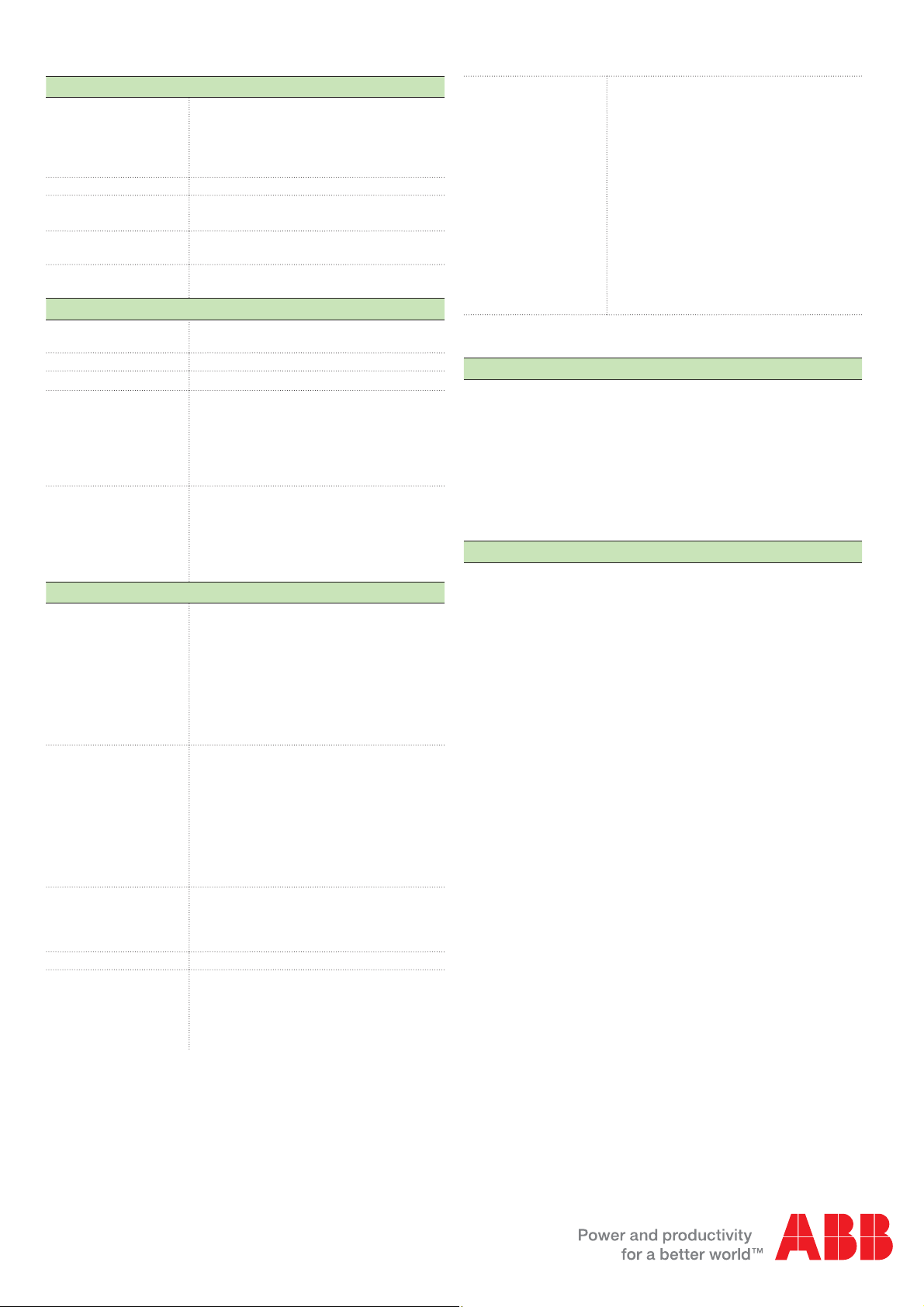

Technical data

Mains connection

Voltage and

power range

Frequency

Power factor

TDHI (total harmonic

distortion of current)

Efficiency (at nominal

power)

Motors connection

Frequency

Field weakening point

Motor control software

Torque control

Open loop

Closed loop

Open loop

Closed loop

Speed control

Open loop

Closed loop

Open loop

Closed loop

Environmental limits

Ambient temperature

Transport

Storage

Operation

ACS800-17LC

Cooling method

Cooling liquid:

Altitude

0 to 1000 m

1000 to 4000 m

Relative humidity

Degree of protection

ACS800-11 / -17

As option for ACS800-17

ACS800-17LC

As option

3-phase, U

3-phase, U

3-phase, U

3-phase, U

(600 V UL, CSA)

= 208 to 240 V, ± 10%

2IN

= 380 to 415 V, ± 10%

3IN

= 380 to 500 V, ± 10%

5IN

= 525 to 690 V, ± 10%

7IN

48 to 63 Hz

cosϕ

= 1 (fundamental)

1

cosϕ

= 0.99 (total)

1

< 5%

97%

0 to ± 300 Hz

0 to ± 120 Hz with external du/dt filters

8 to 300 Hz

ABB’s direct torque control (DTC)

Torque step rise time:

<5 ms with nominal torque

<5 ms with nominal torque

Non-linearity:

± 4% with nominal torque

± 3% with nominal torque

Static accuracy:

10% of motor slip

0.01% of nominal speed

Dynamic accuracy:

0.3 to 0.4%sec. with 100% torque step

0.1 to 0.2%sec. with 100% torque step

-40 to +70 °C

-40 to +70 °C

0 to +50 °C, no frost allowed

40 to 50 °C at reduced output current

(1% / 1 °C)

0 to 45 °C, no frost allowed

45 to 55 °C at reduced output current

(0.5% / 1 °C)

Dry clean air

Direct liquid-cooling

+45 °C max. customer circuit, fresh water or

sea water (optional liquid-cooling unit)

+38 to +45 °C at reduced output current

1% / 1 °C

+48 °C max converter circuit, fresh water

+42 to +48 °C at reduced output current

1% / 1 °C

without derating

with derating ~ (1% / 100 m)

(690 V units 1000 to 2000 m with derating)

5 to 95%, no condensation allowed

IP21

IP22, IP22R, IP42, IP42R, IP54 and IP54R

IP42

IP54

Paint colour

ACS800-11: NCS 1502-Y

ACS800-17/ -17LC: RAL 7035

Contamination levels

Storage

No conductive dust allowed

IEC 60721-3-1, Class 1C2 (chemical gases),

Class 1S2 (solid particles)

Transportation

IEC 60721-3-2, Class 2C2 (chemical gases),

Class 2S2 (solid particles)

Operation

IEC 60721-3-3, Class 3C2 (chemical gases),

Class 3S2 (solid particles without air inlet

filters)

Vibration

IEC 60068-2-6, 10 to 58 Hz 0.075 mm

displacement amplitude 58 to150 Hz 10m/s

(1 g)

Vibration marine

classification

2 to 13.2 Hz: ± 1.0 mm amplitude (peak)

13.2 to 100 Hz: 0.7g acceleration

C = chemically active substances

S = mechanically active substances

Product compliance

CE

Low Voltage Directive 2006/95/EC

Machinery Directive 2006/42/EC

EMC Directive 2006/108/EC

Quality assurance system ISO 9001 and

Environmental system ISO 14001

ACS800-11 / -17: UL, cUL 508A or 508C and CSA

C22.2 NO.14-95, C-Tick, GOST R

ACS800-17LC: UL, CSA

Marine type approvals for ACS800-17LC: ABS, DNV, Lloyd´s Register

EMC according to EN 61800-3

2nd environment, unrestricted distribution category C3 as option

st

1

environment, restricted distribution category C2 as option up to

1000 A input current

For more information please contact:

www.abb.com/drives

www.abb.com/drivespartners

© Copyright 2010 ABB. All rights reserved. Specifications subject to change

without notice.

2

3AFE68443105 REV C EN 30.6.2010 #14978

Loading...

Loading...