ABB ACS800 Technical Catalog

Catalog

ABB industrial drives

ACS800, single drives, 0.75 to 6000 hp

Contents

ABB industrial drives

1

2

Product series ABB industrial drives ........................................................................................................................4

Direct Torque Technology ................................................................................................................5

Single drive main features ...............................................................................................................6

Technicalspecication .....................................................................................................................8

ACS800 Product Description ...........................................................................................................9

Wall-mounted drive, ACS800-U1 ..................................................................................................10

Single Drives Cabinet-built drive, ACS800-PC..................................................................................................... 12

Free-standing drive, ACS800-U2 ..................................................................................................14

Cabinet-built drive, ACS800-U7 .....................................................................................................16

Cabinet-built drive, ACS800-07...................................................................................................... 18

Wall-mounted regenerative drive, ACS800-U11 ............................................................................22

Cabinet-built regenerative drive, ACS800-17.................................................................................24

Wall-mounted ultra low harmonic drive, ACS800-U31 ................................................................... 26

Cabinet-built ultra low harmonic drive, ACS800-37 .......................................................................28

3

4

5

6

Brake options ................................................................................................................................. 30

Hardware options EMClters .....................................................................................................................................34

du/dtlters ....................................................................................................................................36

Sinelteroptions ...........................................................................................................................38

Standard user interface

Control connections and communications Control panel..............................................................................................................................39

Standard I/O...............................................................................................................................40

Options

Optional I/O ................................................................................................................................41

Fieldbus control ..........................................................................................................................42

Remote monitoring and diagnostics tool ...................................................................................43

Standard application software .......................................................................................................44

Application software and programming Optional application software

Control solutions for different applications .................................................................................45

DriveSize........................................................................................................................................48

PC Tools DriveAP ..........................................................................................................................................49

DriveWindow 2 ...............................................................................................................................50

DriveWindow Light 2 ......................................................................................................................51

7

Summary of features and options Table ..............................................................................................................................................52

8

Services and support Service and Support ......................................................................................................................54

9

2

Contact and web information www.abb-drives.com .....................................................................................................................59

Liquid-cooled drive, ACS800-07LC.................................................................................................20

1

2

3

4

5

6

7

8

9

3

ABB industrial drives

ACS800 - U1 - XXXX - X + XXXX

PC

U2

U7/07

U11/17

U31/37

ABB industrial drives

IndustrialIT enabled

ABB industrial drives are designed for industrial applications,

and especially for applications in process industries such as

the converting, pulp & paper, metals, mining, cement, power,

chemical, and oil & gas industries. ABB industrial drives are

highly exible AC drives that can be congured to meet the

precise needs of industrial applications, and therefore order-

based conguration is an integral part of the offering. These

drives cover a wide range of powers and voltages, including

industrial voltages up to 690 V. ABB industrial drives come

with a wide range of built in options. A key feature of these

drives is programmability, which makes adaptation to differ-

ent applications easy.

Industrial design

ABB industrial drives are designed with current ratings to

be used in industrial environments for applications requiring

high overloadability. The heart of the drive is DTC, Direct

Torque Control, that provides high performance and signicant benets: e.g. accurate static and dynamic speed and

torque control, high starting torque and use of long motor

cables. Built in drive options make the installation work fast

and easy. The robust enclosures and cabinets, with a wide

range of enclosure classes, as well as power terminals, are

designed for harsh environments.

ABB industrial drives are IndustrialIT enabled. This guar-

antees the user that ABB industrial drives can be easily

integrated into ABB Industrial IT systems.

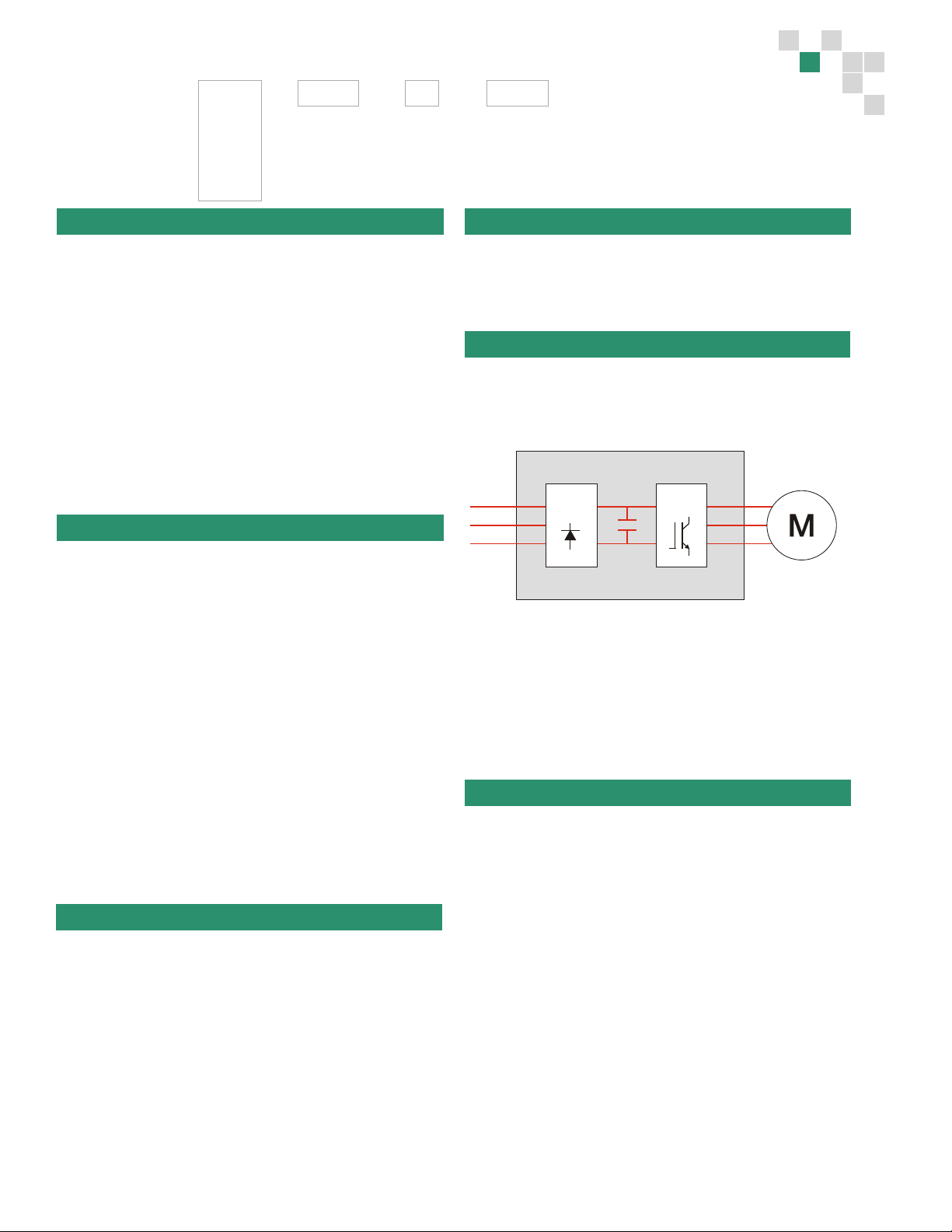

Single drives

The single drive conguration contains a rectier, DC link

and an inverter in one single AC drive unit.

Single drive

Rectier InverterDC link

The single drives are complete AC drives that can be installed

without any additional cabinet or enclosure. The single drives

are available as wall-mounted, free-standing and cabinet-built

constructions. The standard protection class of the single

drives is UL Type 1 and higher protection classes are available

as an option.

One of the most signicant design criteria of ABB industrial

drives has been long lifetime. Wearing parts such as fans and

capacitors have been selected accordingly. This means together with extensive protection features - excellent reliabil-

ity in demanding industrial applications.

DTC Motor Control

Direct Torque Control (DTC) developed by ABB has improved motor control accuracy without the requirement of

speed feedback device. Accurate speed and torque control

of the manufacturing process optimizes the quality of the

end product. Many applications no longer require additional

speed feedback when the ACS800 with DTC is used.

4

Type Code

This is the unique reference number that clearly identies

your drive by construction, power rating voltage and selected

options. By type code you can specify your drives from the

wide range of available options, customer specic ones are

added to the type code using the corresponding + code.

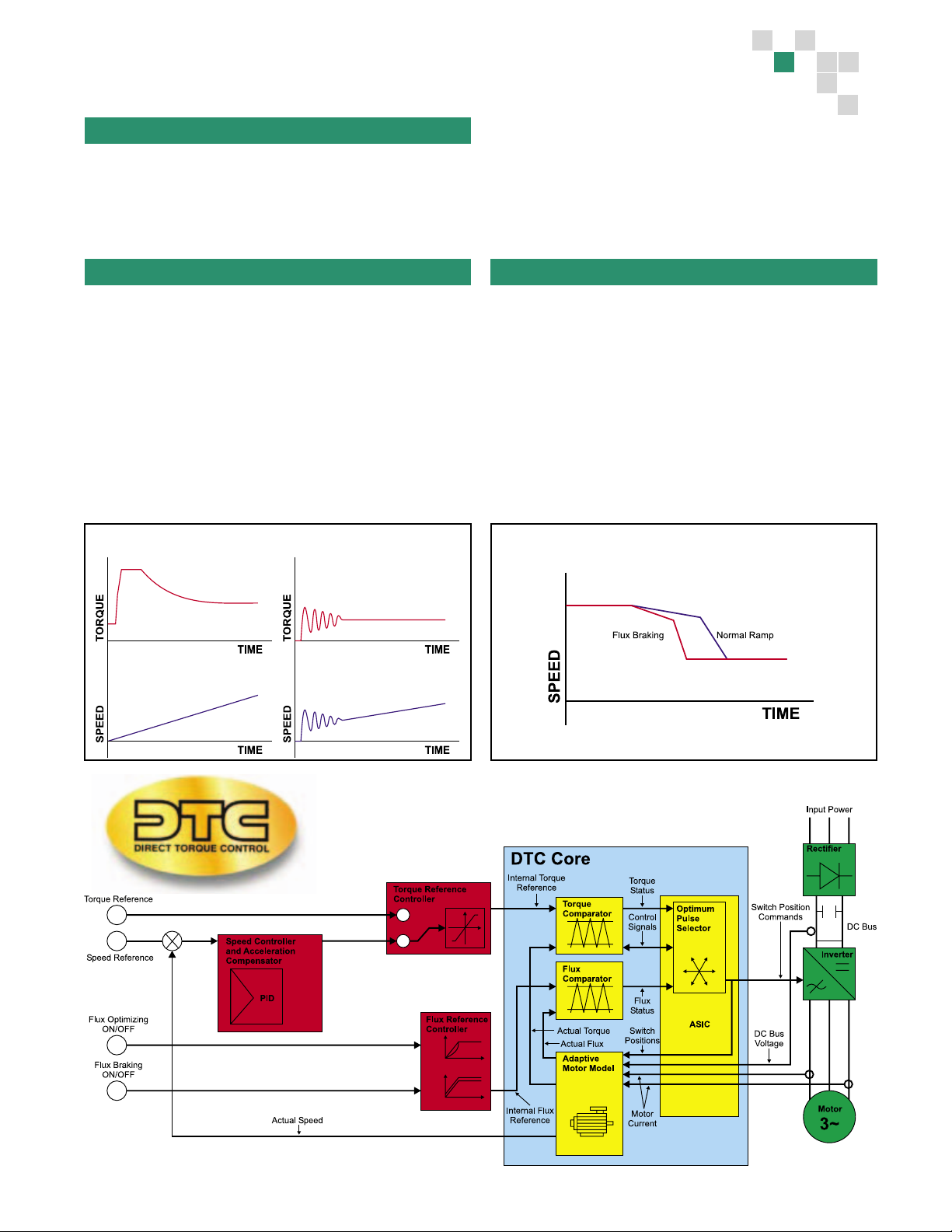

Direct Torque Control Technology

DTC Technology - key in the ACS800 family

Direct Torque Control is an optimized motor control method

for AC drives that allows direct control of all the core motor

variables. This opens up AC drive capabilities never before

realized and offers benets for all applications.

What is Direct Torque Control?

Direct Torque Control, DTC, is a revolutionary motor control method for AC drives which allows accurate

control of both motor speed and torque without pulse

encoder feedback from the motor shaft, down to zero

speed. In DTC, stator ux and torque are used as primary

control variables. The motor state calculations are updated

by the high speed digital signal processor at 40,000 times a

second in the advanced motor software model. Due to the

continuous updating of the motor state and the comparison of the actual values to the reference values, every

DTC PWM

single switching in the drive is determined separately. This

feature will always produce the optimal switching combi-

nation and can instantly react to dynamic changes such as

load shocks or power interruptions. In DTC, there is no

need for a separate voltage and frequency controlled pulse

width modulator.

Unequalled motor speed & torque control

Open loop dynamic speed control accuracy matches that of

AC drives using closed loop ux vector control. The ACS800

delivers static speed control accuracy of 0.1% to 0.5% of

nominal speed - more than adequate for most industrial applications. In applications requiring even more precise speed

regulation, an optional pulse encoder can be used. With an

open loop torque step rise time of less than 5 milliseconds

- compared to over 100 ms in AC drives using sensorless ux

vector control - the ACS800 AC dive is unbeatable.

5

Single drive main features

Features

Compact and complete

Compact size, everything

integrated

Built in harmonic lter in all

ACS800 drives

Wide range of options

available

Versatile braking options

User interface

User friendly customer

interface

Versatile connections and

communications

Benets

Less space and installation work required.

Low harmonics, meaning less interference and

less heating in cables and transformers.

Filter also protects the drive from line side

transients.

Standard solutions available from ABB to meet

most customers application needs.

Optimal braking options are always available.

No need for an external braking chopper

thus reducing size and installation cost.

Easy and fast commissioning and operation.

Standard I/O covers most requirements.

Connectable to commonly used

eldbuses.

Notes

No need to install extra components such as input

chokesorEMClter.

For the lowest harmonic level, ACS800-37 offers

almost a harmonic free solution.

Custom made solutions are available in the

ACS800-U7/07/17/37

Brake chopper built inside all frame sizes

(standard/optional).

Regenerative braking with ACS800-U11 and

ACS800-17.

Clear, alphanumeric display with start-up assistant

that guides through the start-up procedure.

Easy to use PC tools available for commissioning,

maintenance, monitoring and programming.

Extensive standard and optional I/O.

Extensive programmability

Industrial design

Wide power and voltage

range

Wide range of robust

enclosures available

Robust main circuit design

Flexibility. Possible to replace relays or even a PLC

in some applications.

One product series can be used to meet all

application needs, meaning less training and spare

parts and standardized interface to drives.

Industrial suitable solutions available for different

environments.

Suitable for heavy industrial use.

Reliable.

Long motor cables can be used without extra

outputlters.

Two levels of programmability:

1. Parameter programming (standard)

2. Adaptive programming (free block

programming)

- standard feature

- more blocks available as options

- all I/Os are programmable

0.75 to 3000 Hp

208 to 690 Vac

ULType1,ULType1ltered,ULType12

Components dimensioned for heavy duty and long

lifetime.

Advanced thermal model allows high

overloadability.

6

Product series

Single drive main features

Industrial design

NotesFeatures Benets

Extensive protection features

Galvanic isolation of I/O

All terminals designed for

industrial use

Worldwide approvals: CE, UL,

cUL, CSA, C-Tick, GOST R

Right performance for every

application

DTC, accurate dynamic and

static speed and torque control

DTC - allows high

overloadability and gives high

starting torque

DTC, fast control

Enhanced reliability, fewer process interruptions.

Possibility to also protect motors and process.

Safe and reliable operation without separate

isolators and relays.

Sufcientsizeevenforlargealuminumcables.

No need for special tools in I/O cabling.

Products that can be used everywhere in the

world.

Excellent process control even without speed

feedback device - improved product quality,

productivity, reliability and lower investment cost.

Reliable, smooth start without overdimensioning

the drive.

No unnecessary trips or process interruptions.

Several adjustable limits to protect other equipment

included.

Isolated input signals and relay outputs as

standard.

Fast reaction to load or voltage variations prevents

tripping.

Rides through power interruptions by using kinetic

energy of the load.

DTC, ux optimization and

sophisticated motor model

DTC, mechanics friendly

DTC, line supply control

Made by ABB

Global market leader in

AC drives.

Long experience.

World wide service and

support network

Excellentmotoranddriveefciency-costsavings

for non-dynamic applications like pumps or fans.

Less stress for mechanics improves reliability.

High performance and robust control in active

supply unit with programmable power factor.

Well proven, safe and reliable solutions.

Application know-how.

Professional support available around the world.

Optimaluxinthemotorreduceslosses

on applications where Dynamic Response

requirements are minimal.

No shock torques.

No torque ripple - minimized risk for torsional

vibration.

Active oscillation damping.

Applies for ACS800-U11, ACS800-17,

ACS800-U31, and ACS800-37

Product series

7

Technical specication

Mains connection

Voltage and 3-phase, U

power range except -U2,-U7,-07,-17,-37

3-phase, U

3-phase, U

(600 V UL, CSA)

Short Circuit Current

Rating (SCCR) ACS800-U1,-U11,-U31 = 65ka

ACS800-PC,-U2,-U7/07,-17,-37 = 100ka

Frequency 48 to 63 Hz

Nominal Impedance 3% Nominal Impedance

R2-R3, DC Bus Choke

R4 and greater, AC Reactor

Power factor

ACS800-U1,-PC,-U2,-U7/07 cosϕ

cosϕ = 0.93...0.95 (total)

ACS800-U11,-17,-U31,-37 cosϕ1 = 1 (fundamental)

cosϕ = 0.99 (total)

Efciency(atnominalpower)

ACS800-U1,-PC,-U2,-U7/07, 07LC 98%

ACS800-U11,-17,-U31,-37 97%

= 208 to 240 V, ± 10%,

2IN

= 380 to 500 V, ± 10%

5IN

= 525 to 690 V, ± 10%

7IN

= 0.98 (fundamental)

1

Motor connection

Voltage 3-phase output voltage 0...U

for > 500 V units please see “Filter selection table for

ACS800”underthedu/dtltersonpage33

Frequency 0...±300 Hz

(0...±120 Hz for -U7/-07 frames R6-R8 with

du/dt du/dtltersandexternaldu/dtlters)

Field weakening point 8...300 Hz

Motor control ABB’s exclusive Direct Torque Control (DTC)

Torque control Torque step rise time

Open loop <5 ms with nominal torque

Closed loop <5 ms with nominal torque

Non-linearity:

Open loop ±4% with nominal torque

Closed loop ±1% with nominal torque

Speed control Static accuracy

Open loop 10% of motor slip

Closed loop 0.01% of nominal speed

Dynamic accuracy

Open loop 0.3...0.4% sec. with 100% torque step

Closed loop 0.1...0.2% sec. with 100% torque step

2IN//U5IN//U7IN

Environmental

Ambient temperature

Transport -40...+70°C

Storage -40...+70°C

Operation -15...+50°C, no frost allowed

40...50°C at reduced output current

(1% / 1°C)

Operation 0 to +55°C, no frost allowed

(ACS800-07LC) +45 to 55°C, at reduced output current

(1% / 1°C)

Cooling method Dry clean air

Altitude

0...1000 m without derating

1000...4000 m with derating ~ (1% / 100 m)

(690 V units 1000...2000 m with derating)

Relative humidity 5 to 95%, no condensation allowed

Protection class

UL T ype 1 standard for -U1,-PC,-U2,-U7/07,07LC,

-U11, -17,-U31,-37

ULType1ltered optionfor-U7/07,-17,-37

UL T ype 12 option for -U1,-PC,-U7/07,07LC, -17,-37

Paint color -PC,-U7/07,07LC, -17,-37: RAL 7035

-U1,-U11,-U2,-U31: NCS 1502-Y

(RAL 90021, PMS 420 C)

Contamination levels No conductive dust allowed

Storage IEC60721-3-1, Class 1C2 (chemical

gases),

Class 1S2 (solid particles)

Transportation IEC60721-3-2, Class 2C2 (chemical

gases), Class 2S2 (solid particles)

Operation IEC60721-3-3, Class 3C1/3C2* (chemical

gases), Class 3S2 (solid particles)

C = chemically active substances

S = mechanically active substances

Product compliance

UL & cUL (508A or 508C) and CSA C22.2 NO.14-95, C-Tick, GOST R

NEC 430.126(A)(2) Motor Overtemperature Protection

Quality assurance system ISO 9001 and

Environmental system ISO 14001

CE (Available)

Low Voltage Directive 73/23/EEC with amendment 93/68/EEC

Machinery Directive 98/37/EC

EMC Directive 89/336/EEC with amendment 93/68/EEC

EMC (according to EN 61800-3)

nd

2

environment, unrestricted distribution category C3 as standard in

-07 (frame size nxR8i), 07LC, -17 and -37 (frame sizes R7i-nxR8i),

option in the others

st

1

environment, restricted distribution category C2 as option up to

1000 A input current

NOTE: Available options are shown in the Summary of features

options table. Please see pages 48-49.

8

Product series

ACS800 Product Description

Wall-mounted drive,

ACS800-U1

The wall-mounted drive, ACS800-U1 offers all that you need

up to 200 Hp. All important features and options are built inside the drive: line choke, EMC lter, brake chopper etc. The

user gets everything in a single and complete UL Type 1 or

UL Type 12 package. Still the drive is also extremely small. A

wide range of software alternatives makes this drive suitable

for almost any application.

Cabinet-built drive,

ACS800-PC

The cabinet built ACS800-PC is a US only construction using

the industrial Rittal

125 to 600Hp at 480Vac. The ACS800-PC is a standardized

package product that includes an input disconnect switch (circuit breaker) and class T input fuses. The drive is available in

UL Type 1 enclosure up to 400Hp and optional in UL Type

12 enclosure up to 600Hp. The ACS800-PC offers a variety

of options for factory installation including; I/O expansion,

line contactor with E-Stop, and aux motor starter for motor

cooling fan.

TM

standard enclosure and is available from

Free-standing drive,

ACS800-U2

The free-standing drive, ACS800-U2, with power ratings

from 125 to 600Hp, is available in an extremely compact UL

Type 1 enclosure and uniquely offers two mounting directions. It also offers a wide range of built in options including,

EMC lters, brake choppers, line apparatus such as fuse

disconnect switch and contactor.

Cabinet-built drive,

ACS800-U7/07

The cabinet-built drive, ACS800-U7/07 offers standardized

congurations that can be adapted to any application. It

covers a wide power range up to 3000 Hp and is very com-

pact, the largest drive is only 10.5 feet wide. It is available

with UL Type 1, UL Type 1 ltered and UL Type 12 protection classes. A wide range of built in options is available and

application engineering services can be offered when custom-

ization is needed.

Regenerative drive,

ACS800-U11/17

The ACS800 regenerative drive is equipped with an active

supply unit. It offers a full performance regenerative drive

in a single compact package. It is intended to drive

applications where regenerative operation is required. All

important features and options including an LCL line lter

and EMC lter are built inside the drive.

The power ratings of the wall-mounted drive, ACS800-U11

start from 7.5 Hp and go up to 125 Hp. It is available in UL

Type 1 protection class enclosure.

The power ratings of the cabinet-built drive, ACS800-17

start from 60 Hp and go up to 2,600 Hp. It is available with

UL Type 1, UL Type 1 ltered and UL Type 12 protection

classes. Tthe cabinet-built drive has an extensive range of

standardized congurations that can be adapted to any

application.

Ultra low harmonic drive,

ACS800-U31/37

The ultra low harmonic drive provides a unique ultra-low

harmonic solution fully incorporated inside the drive. This

design provides unmatched harmonic mitigation fullling

IEEE519-1992 requirements at the drive input terminals

without any additional external hardware. The active supply

unit also allows the drive to operate at unity power factor

and the harmonic mitigation is not effected by input line

imbalances up to and exceeding 3% voltage imbalance.

The wall-mounted drive, ACS800-31 is available from 7.5 to

125 Hp in a UL Type 1 enclosure. The cabinet-built drive,

ACS800-37 is available from 60 to 2,800 Hp with UL Type

1, UL Type 1 ltered and UL Type 12 protection classes.

Liquid-cooled drive, ACS800-07LC

ACS800 liquid-cooled frequency converter offers robust

design for medium and high power applications. The

compact size with a totally enclosed cabinet is optimized

for harsh environmental conditions. The ACS800 liquidcooled product series provides advanced reliability for both

industrial and marine sector. Liquid cooling minimizes the

noise level and improves heat transfer without a need for

air conditioning equipment.

Product series

9

Wall-mounted drive

ACS800-U1, 1 to 200 Hp

Compact and complete drive

The ACS800-U1 offers all that you need in a single, extremely

small, wall-mounted package making it a compact and complete drive. The standard degree of protection is UL Type 1.

Optional UL Type 12 allows full performance without derating. Power ratings start from 1 Hp heavy-duty rating and go

up to 200 Hp continuous load rating. There are ve different

mechanical frame sizes covering the power range. Each frame

size is optimized for performance, size and weight.

Everything inside

From the smallest to the largest ACS800-U1 there is an

extensive range of built in features and options. Standard

features include an AC Line Choke for harmonic ltering

and drive protection, extensive and exible I/O, user-friendly

control panel with Start-up Assistant feature and a silent,

long lifetime cooling fan. Brake chopper is included as stan-

dard in the two smallest frame sizes R2 and R3 as well as in

the 690V R4 frame. In other frames the chopper is a built in

option. Other built in options include EMC lters and extension modules for additional I/O, eldbus and pulse encoder

interface modules.

Main standard hardware features

n Wall mounting

n UL Type 1 protection class

n Compact design

n Harmonic ltering AC choke inside

n Input rectier protection

n Brake chopper (in frame sizes R2-R3; R4 only 690 V)

n Long lifetime cooling fan and capacitors

n Extensive, programmable I/O with galvanically

isolated inputs

n Three I/O and eldbus extension slots inside

n Alphanumeric, multilingual control panel with

start-up assistant feature

n Large power terminals allowing use of a wide range

of cable sizes

Options for ACS800-U1

Built in options:

n UL Type 12 protection class

n Brake chopper (in frame sizes R4-R6)

n EMC lter for 1

cording to EN 61800-3

n EMC lter for 2

according to EN 61800-3

n Analog and digital I/O extension modules

n Fieldbus modules (Communication)

n Pulse encoder interface module

n Resolver interface (Limited SW Support)

st

environment, restricted distribution ac-

nd

environment, unrestricted distribution

10

External options:

n Brake resistor

n Output du/dt lters

NEMA 12 Enclosure

Single Drives

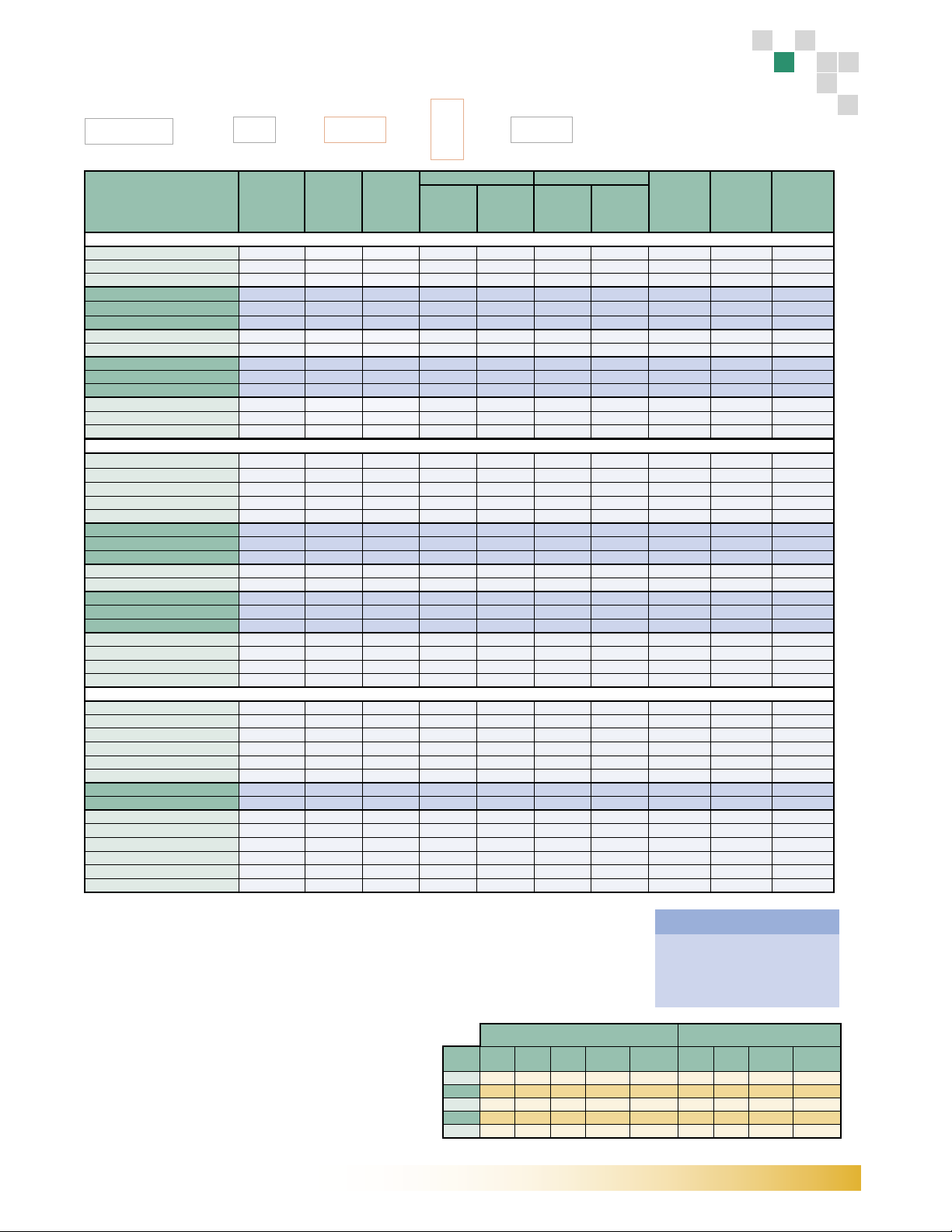

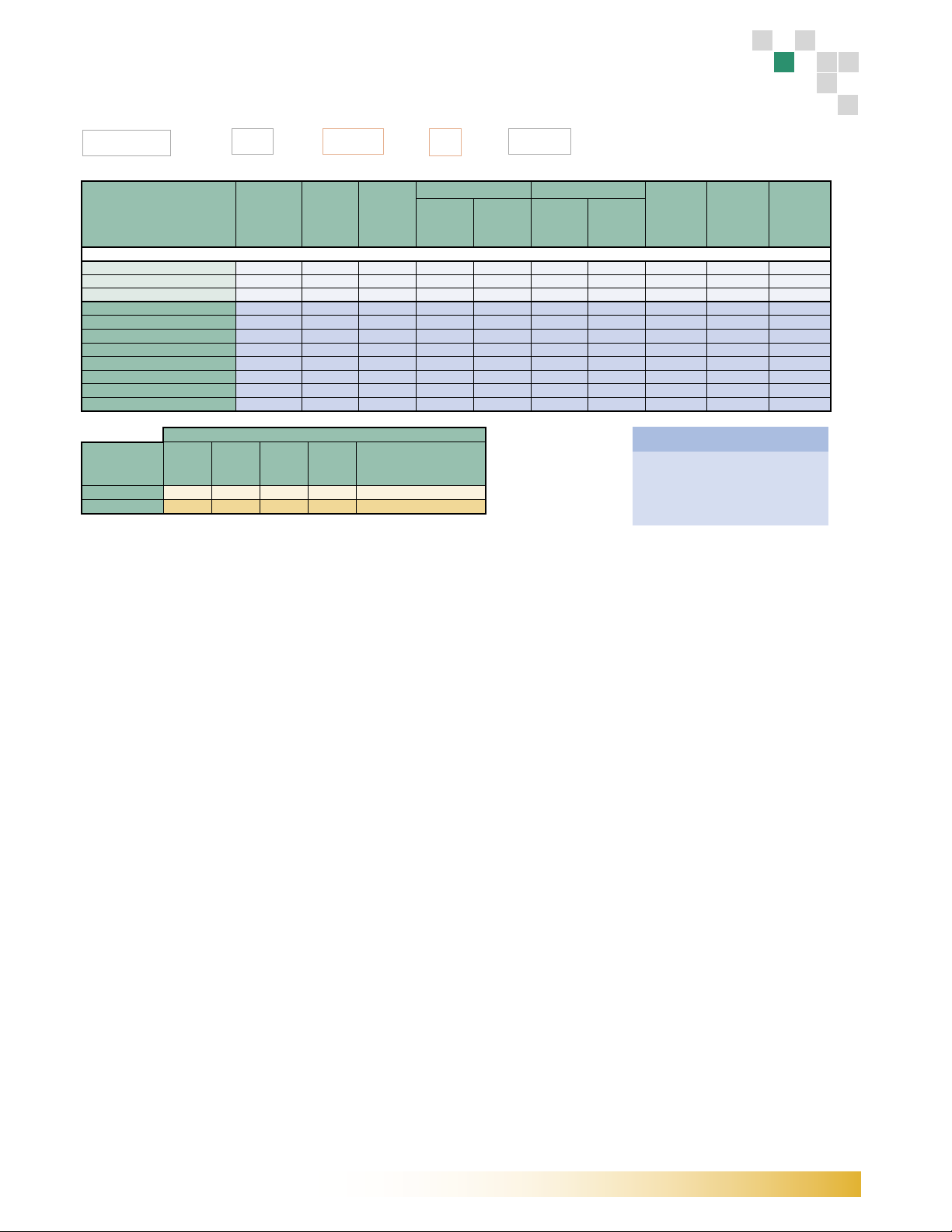

Ratings and dimensions

ACS800-U1

2

ACS800 - U1 - XXXX - 5 + XXXX

7

Type code Frame

size

Input

A

Normal Duty Heavy-duty use Noise

I

max

A

I

2N

A

PN

Hp

I

2HD

A

PHD

Hp

Level

dBA

Airow

ft3/min

Heat

dissipa-

tion

BTU/hr

3-phase supply voltage 208, 220, 230, 240. The power ratings are valid at nominal voltage, 240Vac (50 & 60Hz)

ACS800-U1-0002-2 R2 5.2 8.2 6.6 1.5 4.6 1 62 21 350

ACS800-U1-0003-2 R2 6.5 10.8 8.1 2 6.6 1.5 62 21 350

ACS800-U1-0004-2 R2 9.2 13.8 11 3 7.5 2 62 21 410

ACS800-U1-0006-2 R3 18 24 21 5 13 3 62 41 550

ACS800-U1-0009-2 R3 24 32 27 7.5 17 5 62 41 680

ACS800-U1-0011-2 R3 31 46 34 10 25 7.5 62 41 850

ACS800-U1-0016-2 R4 38 62 42 15 31 10 62 61 1150

ACS800-U1-0020-2 R4 49 72 54 20

ACS800-U1-0025-2 R5 64 86 69 25 54 20

ACS800-U1-0030-2 R5 75 112 80 30 68 25

ACS800-U1-0040-2 R5 102 138 104 40

ACS800-U1-0050-2 R6 126 164 132 50 104 40 65 238 3370

ACS800-U1-0060-2 R6 153 202 157 60 130 50

ACS800-U1-0070-2 R6 190 282 192 75 154 60

(1)

(1)

42 15

80 30

(2)

(2)

(2)

(2)

(2)

(2)

62 61 1490

65 99 1790

65 99 2090

65 99 2770

65 238 4050

65 238 4910

3-phase supply voltage 380, 400, 415, 460, 480, 500. The power ratings are valid at nominal voltage, 480Vac 60Hz

ACS800-U1-0004-5 R2 4.1 6.5 4.9 3 3.4 2 62 21 410

ACS800-U1-0005-5 R2 5.4 8.2 6.2 3 4.2 2 62 21 480

ACS800-U1-0006-5 R2 6.9 10.8 8.1 5 5.6 3 62 21 550

ACS800-U1-0009-5 R2 9.8 13.8 11 7.5 8.1 5 62 21 690

ACS800-U1-0011-5 R2 13 17.6 14 10 11 7.5 62 21 860

ACS800-U1-0016-5 R3 18 24 21 15 15 10 62 41 1150

ACS800-U1-0020-5 R3 24 32 27 20 21 15 62 41 1490

ACS800-U1-0025-5 R3 31 46 34 25 27 20 62 41 1790

ACS800-U1-0030-5 R4 40 62 42 30 34 25 62 61 2090

ACS800-U1-0040-5 R4 52 72 52 40 37 30

(3)

62 61 2770

ACS800-U1-0050-5 R5 63 86 65 50 52 40 65 99 3370

ACS800-U1-0060-5 R5 77 112 79 60 65 50 65 99 4050

ACS800-U1-0070-5 R5 94 138 96 75 77 60 65 99 4910

ACS800-U1-0100-5 R6 121 164 124 100 96 75 65 238 6610

ACS800-U1-0120-5 R6 155 202 157 125 124 100 65 238 7890

ACS800-U1-0140-5 R6 179 282 180 150 156 125 65 238 9600

ACS800-U1-0205-5 R6 252 326 254 200 215 150 65 238 13670

3-phase supply voltage 525, 550, 575, 600, 690. The power ratings are valid at nominal voltage, 575Vac 60Hz

ACS800-U1-0011-7 R4 10 14 11.5 10 8.5 5 62 61 1050

ACS800-U1-0016-7 R4 13 19 15 10 11 10 62 61 1200

ACS800-U1-0020-7 R4 19 28 20 15 15 10 62 61 1550

ACS800-U1-0025-7 R4 21 38 23 20 19 15 62 61 1850

ACS800-U1-0030-7 R4 29 44 30 25 22 20 62 61 2100

ACS800-U1-0040-7 R4 32 54 34 30 27 25 62 61 2400

ACS800-U1-0050-7 R5 45 68 46 40 34 30 65 99 2900

ACS800-U1-0060-7 R5 51 84 52 50 42 40 65 99 3450

ACS800-U1-0070-7 R6 70 104 73 60 54 50 65 238 4200

ACS800-U1-0100-7 R6 82 124 86 75 62 60 65 238 5650

ACS800-U1-0120-7 R6 103 172 108 100 86 75 65 238 6700

ACS800-U1-0145-7 R6 121 245 125 125 99 100 65 238 9084

ACS800-U1-0175-7 R6 150 245 155 150 131 125 65 238 11851

ACS800-U1-0205-7 R6 192 245 192 200 147 150 65 238 14275

NOTES:

(1)

Overload may be limited to 5% at higher motor speeds (speed >90% motor base speed) by the internal power limit of the drive

(2)

Overload may be limited to 40% at higher motor speeds (speed >90% motor base speed) by the internal power limit of the drive

(3)

Rating not applicable for all motors. Available for some 4-pole 460V high efciency NEMA motors.

I

current available for 10 seconds at start.

max

I2N continuous base current at 40°C (104°F). Overload cycle 110%

I2N for 1 minute / 5 minutes allowed.

I

continuous base current at 40°C (104°F). Overload cycle 150%

2hd

I

for 1 minute / 5 minutes allowed.

2hd

- Current ratings do not change with different supply voltages.

- Horsepower ratings are based on NEMA motor ratings for typical

4-pole motors (1800 rpm). Check motor nameplate current for

compatibility.

- All ACS800-U1 models come with a US conduit box (conduit plate

in NEMA 12) as standard.

Frame

H1

size

(in)

R2 15.9 14.6 6.5 8.9 20 20.8 10.4 9.5 34

R3 18.5 16.5 6.8 10.4 31 20.8 10.4 10.7 41

R4 23.9 19.3 9.4 10.8 57 30.5 14.8 10.9 73

R5 29.1 23.7 10.4 11.3 75 30.5 14.8 12.1 112

R6 34.6 27.6 11.8 15.7 148 36.3 16.5 16.5 170

H1 = Height with cable connection box H2=Height without cable connection box

W1 = Width of the standard unit

UL Type 1 UL Type 12

H2

(in)W1(in)

Depth

(in

Enclosure

Degree of Protection:

UL Type 1 (Standard)

UL Type 12 (Optional)

Paint color:

NCS 1502-Y (RAL 90021/PMS 420C)

Weight

(lbs)H1(in)W1(in)

Depth

Weight

(in)

(lbs)

Single Drives

11

Cabinet-built drive

ACS800-PC 125 up to 600 Hp

Customized solutions

The ACS800-PC is built in a robust cabinet designed for

heavy-duty industrial applications with power ratings from

125 to 600 Hp. It is available in UL Type 1 and UL Type 12

enclosures.

Note: 450Hp and greater is only available in UL Type 12.

The ACS800-PC is a standardized packaged cabinet drive

specically designed for the US. This drive comes standard

with a door interlock disconnect switch (circuit breaker) and

current limiting fast acting Class T fuses. The disconnect

switch is lockable in the off position. The ACS800-PC also

offers a wide variety of options such as I/O expansion, Line

Contactor with E-Stop and Aux Motor Starter.

Extensive range of features

The ACS800-PC has an extensive range of built in features

and options. Typical option choices include extended I/O

and eldbus options, line contactor, EMC ltering, Aux Motor Starter, all mountable within the single cabinet.

Options for ACS800-PC

n Analog and digital I/O extension modules

n Brake chopper and resistor (resistor external)

n Customer terminal block

n EMC lter for 2

according to EN 61800-3 (standard in frame R8)

n Fieldbus modules

n UL Type 12 enclosure class

n Line contactor with emergency stop push button

n Output for fan motor (Aux Motor Starter)

n Pulse encoder interface module

n 1 or 2 thermistor relays

n 3 PT100 relays

n Resolver Interface (Limited SW Support)

nd

environment, unrestricted distribution

Main standard features

n Compact design

n UL Type 1 protection class (0170-5 to 0400-5)

n UL Type 12 protection class (0440-5 to 0610-5)

n Built in harmonic ltering AC choke

n Common mode lters for motor protection

n Line disconnect switch (Circuit Breaker)

n Current Limiting Fast Acting Class T Fuses

n Extensive, programmable I/O

n Inputs galvanically isolated

n Long lifetime cooling fan and capacitors

n I/O and eldbus extension slots inside

n Alphanumeric multilingual control panel with

start-up assistant feature

n Top entry and exit of cables

n Coated Boards

12

Single Drives

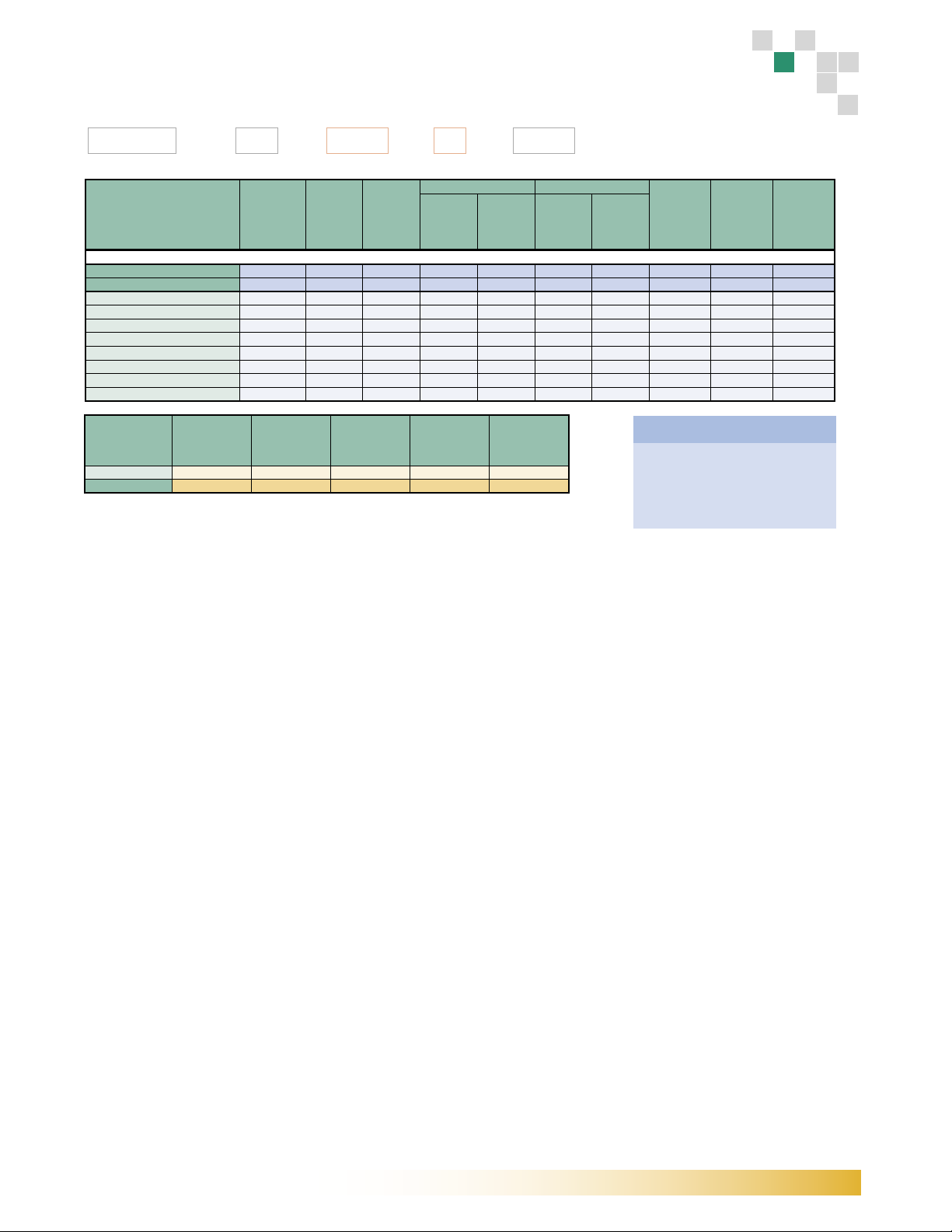

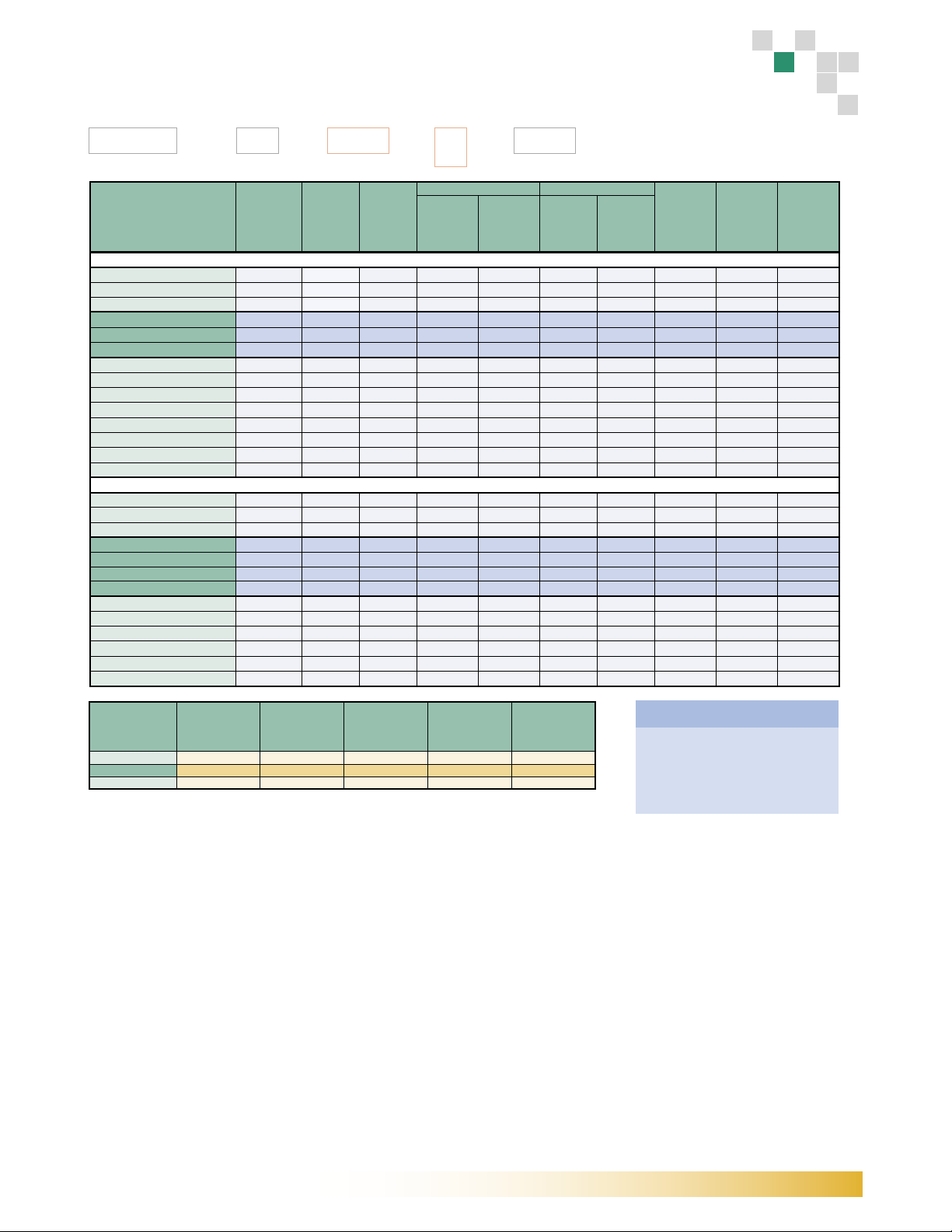

Ratings and dimensions

ACS800-PC

ACS800 - PC - XXXX - 5 + XXXX

Type code Frame

size

Input

A

Normal Duty Heavy-duty use Noise

I

max

A

I

2N

A

PN

Hp

I

2HD

A

PHD

Hp

Level

dBA

Airow

ft3/min

Heat

Dissipa-

tion

BTU/hr

3-phase supply voltage 380, 400, 415, 460, 480, 500. The power ratings are valid at nominal voltage, 480Vac 60Hz

ACS800-PC-0170-5 R7 191 326 192 150 162 125 71 318 10100

ACS800-PC-0210-5 R7 243 384 240 200 192 150 71 318 12900

ACS800-PC-0270-5 R8 299 480 316 250 240 200 72 718 15350

ACS800-PC-0300-5 R8 336 568 361 300 302 250 72 718 18050

ACS800-PC-0320-5 R8 424 588 435 350 340 250 72 718 23250

ACS800-PC-0400-5 R8 498 588 510 400 370 300 72 718 26650

ACS800-PC-0440-5+B055 R8 543 840 545 450 490 400 72 718 25950

ACS800-PC-0490-5+B055 R8 590 840 590 500 515

ACS800-PC-0550-5+B055 R8 669 1017 670 550 590

ACS800-PC-0610-5+B055 R8 702 1017 704 600 590

Frame size Width

in

Height

UL T ype 1

in

Height

UL T ype 12

in

Depth

in

Weight

R7 31.7 83.7 93.6 24.4 730

R8 31.7 83.7 93.6 24.4 990

(1)

450 72 718 27600

(1)

500 72 718 31100

(1)

500 72 718 33000

lb

Enclosure

Degree of Protection:

UL T ype 1

UL T ype 12

Paint color:

Light beige RAL 7035 semi-gloss

NOTES:

(1)

50% overload is allowed if ambient temperature is 30°C or less, Overload is limited to 40% at 40°C

I

current available for 10 seconds at start.

max

I2N continuous base current at 40°C (104°F). Overload cycle 110% I2N for 1 minute / 5 minutes allowed.

I

continuous base current at 40°C (104°F). Overload cycle 150% I

2hd

for 1 minute / 5 minutes allowed.

2hd

- Current ratings do not change with different supply voltages.

- Horsepower ratings are based on NEMA motor ratings for typical 4-pole motors (1800 rpm). Check motor nameplate current for compatibility.

Single Drives

13

Free-standing drive

ACS800-U2, 125 to 600 Hp

Compact and complete drive

The ACS800-U2 single drive is a unique, extremely compact

bookshelf-style unit with a new innovative free-standing

enclosure. The power ratings start from 125 Hp and go up to

600 Hp continuous load rating. It is available only in UL Type

1 protection class.

Fits anywhere

The ACS800-U2 drive is extremely compact without sacricing user-friendliness. When using bookshelf mounting, even

side-by-side installation is possible. In addition to bookshelf

mounting, the ACS800-U2 offers the possibility for at type

(sideways) mounting, making it possible to optimize depth

instead of width.

Everything inside

The ACS800-U2 has an extensive selection of built in features and options. Standard features include an AC choke for

harmonic ltering and drive protection, extensive and exible

I/O, user-friendly control panel with Start-up Assistant fea-

ture and a silent, long lifetime cooling fan.

Built in options include EMC lters, brake chopper, common

mode lter for motor protection and extension modules for

additional I/O, eldbus and pulse

encoder interface modules.

Main standard hardware features

n Free-standing

n UL Type 1 protection class

n Line fuse disconnect switch

n Harmonic ltering AC choke inside

n Input rectier protection

n Long lifetime cooling fan and capacitors

n Extensive, programmable I/O with galvanically

isolated inputs

n Three I/O and eldbus extension slots inside

n Alphanumeric, multilingual control panel with

start-up assistant feature

n Large power terminals allowing the use of a wide range of

cable sizes

n The ACS800-U2 includes the extension enclosure as

standard

Options for ACS800-U2

Built in options:

n Brake chopper

n EMC lter for 1

cording to EN 61800-3

n EMC lter for 2

according to EN 61800-3

n Analog and digital I/O extension modules

n Fieldbus modules

n Pulse encoder interface module

n Resolver Interface (Limited SW Support)

n Common mode lters for motor protection

st

environment, restricted distribution ac-

nd

environment, unrestricted distribution

14

Options available with standard enclosure extension:

n Contactor with emergency stop push button

n 1 or 2 thermistor relays

n 3 PT100 relays

n Cable bottom entry and exit

n Customer terminal block

External options:

n Brake resistor

n Output du/dt lters

Single Drives

Ratings and dimensions

ACS800-U2

ACS800 - U2 - XXXX - 5 + XXXX

Type code Frame

size

Input

A

I

max

A

I

2N

A

PN

Hp

I

2HD

A

PHD

Hp

Level

dBA

Normal Duty Heavy-duty use Noise

Airow

ft3/min

Heat

Dissipa-

tion

BTU/hr

3-phase supply voltage 380, 400, 415, 460, 480, 500. The power ratings are valid at nominal voltage, 480Vac 60Hz

ACS800-U2-0170-5 R7 191 326 192 150 162 125 71 318 10100

ACS800-U2-0210-5 R7 243 384 240 200 192 150 71 318 12900

ACS800-U2-0260-5 R7 291 432 286 200 224 150 71 318 15300

ACS800-U2-0270-5 R8 299 480 316 250 240 200 72 718 15350

ACS800-U2-0300-5 R8 336 568 361 300 302 152 72 718 18050

ACS800-U2-0320-5 R8 424 588 435 350 340 152 72 718 23250

ACS800-U2-0400-5 R8 498 588 510 400 370 300 72 718 25950

ACS800-U2-0440-5 R8 543 840 545 450 490 400 72 718 26650

ACS800-U2-0490-5 R8 590 840 590 500 515

ACS800-U2-0550-5 R8 669 1017 670 550 590

ACS800-U2-0610-5 R8 702 1017 704 600 590

UL T ype 1

Frame size Height

(in)

Width

(in)

Depth

(in)

Weight

(lbs)

Weight without

enclosure extension*

(lbs)

R7 59.3 23.7 20.6 516 243

R8 79.7 31.5 24.5 992 529

*

Weights are for the basic conguration with switch fuse, but without contactor and other options.

NOTES:

(1)

50% overload is allowed if ambient temperature is 30°C or less, Overload is limited to 40% at 40°C

current available for 10 seconds at start.

I

max

continuous base current at 40°C (104°F). Overload cycle 110% I2N for 1 minute / 5 minutes allowed.

I

2N

continuous base current at 40°C (104°F). Overload cycle 150% I

I

2hd

- Current ratings do not change with different supply voltages.

- Horsepower ratings are based on NEMA motor ratings for typical 4-pole motors (1800 rpm). Check motor nameplate current for compatibility.

- ACS800-02 product is no longer available. If the -02 type product is required, select ACS800-U2-xxxx-x+0C111 This will delete the extension

enclosure and force Bottom Entry/Exit. Adding +H350+H352 is not required.

for 1 minute / 5 minutes allowed.

2hd

(1)

450 72 718 27600

(1)

500 72 718 31100

(1)

500 72 718 33000

Enclosure

Degree of Protection:

UL Type 1(Standard)

Paint color:

NCS 1502-Y (RAL 90021/PMS 420C)

Single Drives

15

Cabinet-built drive

ACS800-U7 75 to 600 Hp

Customized solutions

The ACS800-U7 is built in a robust cabinet designed for

heavy-duty industrial applications with power ratings from 75

to 600 Hp.

The ACS800-U7 offers a wide variety of standardized congurations to adapt to different application requirements,

from line contactor to prevention of unexpected motor start.

If your application requires more, ABB’s application en-

gineering services can add special features to the standard

product such as an additional cabinet for customer specic

devices to ensure exact suitability

for the application.

Extensive range of features

The ACS800-U7 has an extensive range of built in features

and options. Typical option choices include extended I/O

and eldbus options, line contactor, EMC ltering, common

mode ltering and du/dt (voltage rise) ltering, all mountable

within the single cabinet.

Options for ACS800-U7

n Analog and digital I/O extension modules

n Brake chopper and resistor

n Cabinet heater

n Customer terminal block

n Ground fault monitoring for ungrounded network

n EMC lter for 1

cording to EN 61800-3

n EMC lter for 2

according to EN 61800-3

n Fieldbus modules

n UL Type 1 Filtered and UL Type 12 enclosure classes

n Line contactor with emergency stop push button

n Output for aux fan motor

n Pulse encoder interface module

n Prevention of unexpected start up of motor

n 1 or 2 thermistor relays

n 3, 5 or 8 PT100 relays

n Resolver Interface (Limited SW Support)

Plus tailor made options through ABB’s application engineering.

st

environment, restricted distribution ac-

nd

environment, unrestricted distribution

Main standard features

n Compact design

n UL Type 1 protection class

n Built in harmonic ltering AC choke

n Common mode lters for motor protection

n Line fuse disconnect switch

n Extensive, programmable I/O

n Inputs galvanically isolated

n Long lifetime cooling fan and capacitors

n 3 I/O and eldbus extension slots inside

n Alphanumeric multilingual control panel with

start-up assistant feature

n Top entry and exit of cables

16

Single Drives

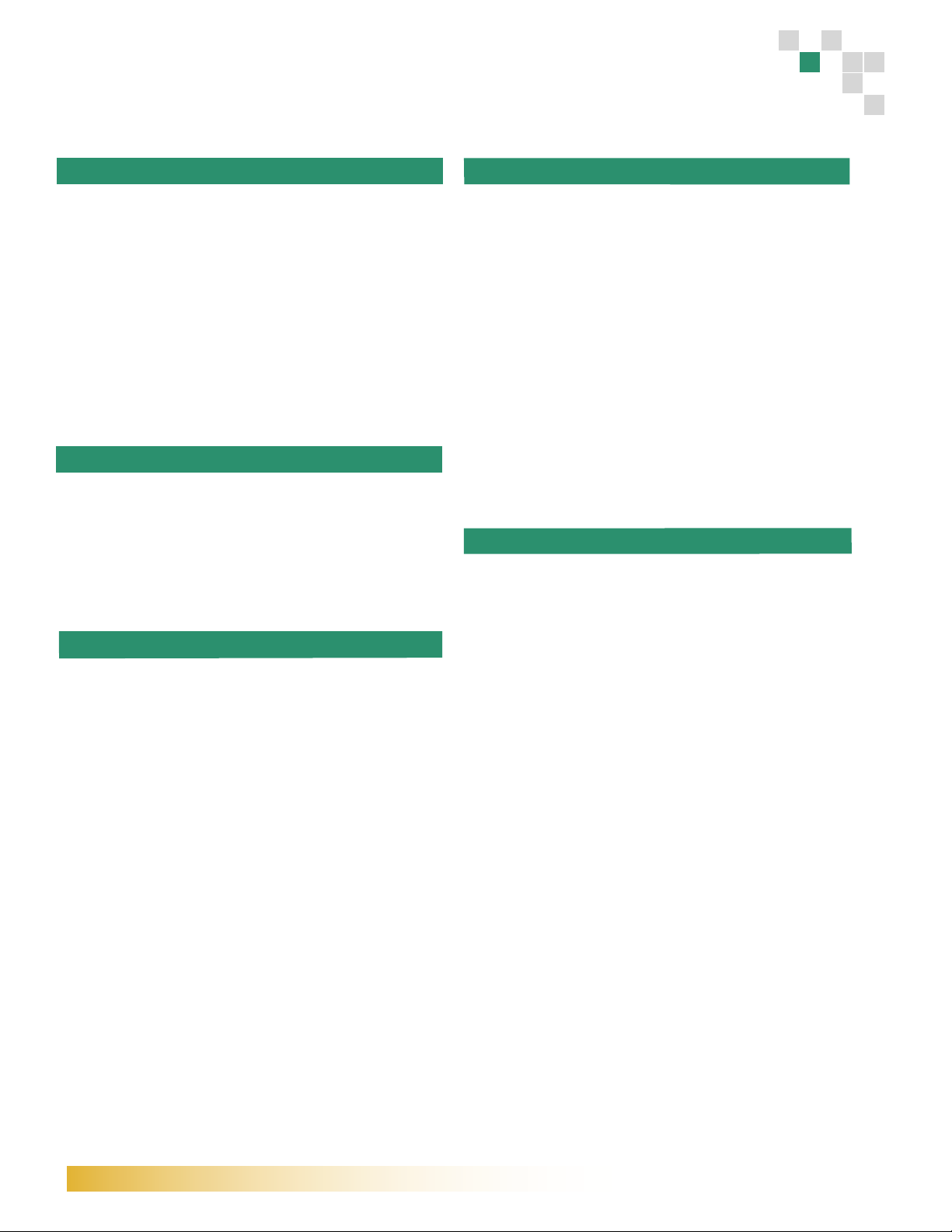

Ratings and dimensions

ACS800-U7

ACS800 - U7 - XXXX - 5 + XXXX

7

Type code Frame

size

Input

A

Normal Duty Heavy-duty use Noise

I

max

A

I 2N

A

PN

Hp

I

2HD

A

PHD

Hp

Level

dBA

Airow

ft3/min

Heat

Dissipa-

tion

BTU/hr

3-phase supply voltage 380, 400, 415, 460, 480, 500. The power ratings are valid at nominal voltage, 480Vac 60Hz

ACS800-U7-0100-5 R6 121 164 124 100 96 75 63 238 6610

ACS800-U7-0120-5 R6 155 202 157 125 124 100 63 238 7890

ACS800-U7-0140-5 R6 180 282 180 150 156 125 63 238 9600

ACS800-U7-0170-5 R7 191 326 192 150 162 125 71 318 10100

ACS800-U7-0210-5 R7 243 384 240 200 192 150 71 318 12900

ACS800-U7-0260-5 R7 291 432 286 200 224 150 71 718 15300

ACS800-U7-0270-5 R8 299 480 316 250 240 200 72 718 15350

ACS800-U7-0300-5 R8 336 568 361 300 302 250 72 718 18050

ACS800-U7-0320-5 R8 424 588 435 350 340 250 72 718 23250

ACS800-U7-0400-5 R8 498 588 510 400 370 300 72 718 26650

ACS800-U7-0440-5 R8 543 840 545 450 490 400 72 718 25950

ACS800-U7-0490-5 R8 590 840 590 500 515

ACS800-U7-0550-5 R8 669 1017 670 550 590

ACS800-U7-0610-5 R8 702 1017 704 600 590

(1)

450 72 718 27600

(1)

500 72 718 31100

(1)

500 72 718 33000

3-phase supply voltage 525, 575, 600 V. he power ratings are valid at nominal voltage, 575Vac 60Hz

ACS800-U7-0070-7 R6 95 104 73 60 54 50 65 238 4200

ACS800-U7-0100-7 R6 121 124 86 75 62 60 65 238 5650

ACS800-U7-0120-7 R6 155 172 108 100 86 75 65 238 6700

ACS800-U7-0140-7 R7 126 190 125 125 95 100

ACS800-U7-0170-7 R7 156 263 155 150 131 125 71 318 12150

ACS800-U7-0210-7 R7 191 294 165/195

ACS800-U7-0260-7 R7 217 326 175/212

(2)

(2)

150/200

150/200

(2)

147 150 71 318 14550

(2)

163 150 71 318 16400

71 318 9600

ACS800-U7-0320-7 R8 298 433 290 300 216 200 72 718 21050

ACS800-U7-0400-7 R8 333 548 344 350 274 250 72 718 22750

ACS800-U7-0440-7 R8 377 656 387 400 328 350 72 718 25300

ACS800-U7-0490-7 R8 423 775 426 450 387 400 72 718 28900

ACS800-U7-0550-7 R8 468 853 482 500 426 450 72 718 28350

ACS800-U7-0610-7 R8 533 964 537 500 482 500 72 718 33300

Frame size

R6 16.9 83.9 91.1 25.4 661.4

R7 32.7 83.9 91.1 25.4 881.8

R8 32.7 83.9 91.1 25.4 1102.31

Width

in

Height

UL Type 1

in

Height

UL Type 12

in

Depth

in

Weight

lb

Enclosure

Degree of Protection:

UL Type 1

UL Type 1 Filtered, UL Type 12

Paint color:

Light beige RAL 7035 semi-gloss

NOTES:

(1)

50% overload is allowed if ambient temperature is 30°C or less, Overload is limited to 40% at 40°C

(2)

The higher rating is available when output frequency is above 41 Hz.

I

current available for 10 seconds at start.

max

I2N continuous base current at 40°C (104°F). Overload cycle 110% I2N for 1 minute / 5 minutes allowed.

I

continuous base current at 40°C (104°F). Overload cycle 150% I

2hd

for 1 minute / 5 minutes allowed.

2hd

- Current ratings do not change with different supply voltages.

- Horsepower ratings are based on NEMA motor ratings for typical 4-pole motors (1800 rpm). Check motor nameplate current for compatibility.

Single Drives

17

Cabinet-built drive

ACS800-07, 500 to 3000 Hp

Customized solutions

The ACS800-07 is built in a robust cabinet designed for

heavy industrial applications.

The ACS800-07 offers a wide variety of standardized congurations to adapt to different application requirements, from

line contactor to prevention of unexpected motor start.

If your application requires more, ABB’s application en-

gineering services can add special features to the standard

product such as an additional cabinet for customer specic

devices to ensure exact suitabilityfor the application.

Smart module concept

ACS800-07 drives consist of separate rectier and inverter

modules, which have plug-in power connectors providing

easy maintenance and redundancy with parallel connected

units. If one module becomes defective, the drive can continue running with reduced power after disconnecting the

faulty module.

Extensive range of features

The ACS800-07 has an extensive range of built in features

and options. Typical option choices include extended I/O

and eldbus options, line contactor, EMC ltering, common

mode ltering and du/dt (voltage rise) output ltering, all

mountable within the single cabinet.

Main standard features

n Compact design

n UL Type 1 protection class

n Built in harmonic ltering choke

n du/dt output lters

n Common mode lters for motor protection

n Line fuse disconnect switch

n Extensive, programmable I/O

n Inputs galvanically isolated

n Long lifetime cooling fan and capacitors

n 3 I/O and eldbus extension slots inside

n Alphanumeric multilingual control panel with

start-up assistant feature

n EMC lter for 2

nd

environment, unrestricted distribution

according to EN 61800-3

n Top entry and exit of cables

Options for ACS800-07

n 6- or 12-pulse operation

n Analog and digital I/O extension modules

n Brake chopper and resistor

n Cabinet heater

n Customer terminal block

n Ground fault monitoring for ungrounded network

n EMC lter for 1

cording to EN 61800-3

n Fieldbus modules

n UL Type 1 Filtered and UL Type 12 enclosure classes

n Line contactor with emergency stop push button

n Output for aux fan motor

n Pulse encoder interface module

n Prevention of unexpected start up of motor

n 1 or 2 thermistor relays

n 3, 5 or 8 Pt100 relays

n Resolver Interface (Limited SW Support)

st

environment, restricted distribution ac-

18

Plus tailor made options through ABB’s application engineering group.

Single Drives

Loading...

Loading...