Page 1

ACS800

Firmware Manual

ACS800 Standard Control Program 7.x

Page 2

Page 3

ACS800 Standard Control Program 7.x

Firmware Manual

© 2009 ABB Oy. All Rights Reserved.

3AFE64527592 REV K

EN

EFFECTIVE: 14.12.2009

Page 4

Page 5

Table of contents

Table of contents

Introduction to the manual

Chapter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Product and service inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Product training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Providing feedback on ABB Drives manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Start-up and control through the I/O

5

Chapter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

How to start-up the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

How to perform the guided start-up (covers all essential settings) . . . . . . . . . . . . . . . . . . . . . . . 15

How to perform the limited start-up (covers only the basic settings) . . . . . . . . . . . . . . . . . . . . . 17

How to control the drive through the I/O interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

How to perform the ID Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

ID Run Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Control panel

Chapter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Overview of the panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Panel operation mode keys and displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Status row . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Drive control with the panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

How to start, stop and change direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

How to set speed reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Actual signal display mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

How to select actual signals to the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

How to display the full name of the actual signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

How to view and reset the fault history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

How to display and reset an active fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

About the fault history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Parameter mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

How to select a parameter and change the value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

How to adjust a source selection (pointer) parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Function mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

How to enter an assistant, browse and exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

How to upload data from a drive to the panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table of contents

Page 6

6

How to download data from the panel to a drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

How to set the contrast of the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Drive selection mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

How to select a drive and change its panel link ID number . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Reading and entering packed boolean values on the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Program features

Chapter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Start-up Assistant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

The default order of the tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

List of tasks and the relevant drive parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Contents of the assistant displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Local control vs. external control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Local control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

External control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Block diagram: start, stop, direction source for EXT1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Block diagram: reference source for EXT1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Reference types and processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Reference trimming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Programmable analogue inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Update cycles in the Standard Control Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Programmable analogue outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Update cycles in the Standard Control Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Programmable digital inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Update cycles in the Standard Control Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Programmable relay outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Update cycles in the Standard Control Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Actual signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Motor identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Power loss ride-through . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Automatic Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table of contents

Page 7

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

DC Magnetising . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

DC Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Flux Braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Flux Optimisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Acceleration and deceleration ramps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Critical speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Constant speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Speed controller tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Speed control performance figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Torque control performance figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Scalar control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

IR compensation for a scalar controlled drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Hexagonal motor flux . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Programmable protection functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

AI<Min . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Panel Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

External Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Motor Thermal Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Motor temperature thermal model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Use of the motor thermistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Stall Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Underload Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Motor Phase Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Earth Fault Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Communication Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Supervision of optional IO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Preprogrammed faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

7

Table of contents

Page 8

8

Overcurrent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

DC overvoltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

DC undervoltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Drive temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Enhanced drive temperature monitoring for ACS800, frame sizes R7 and R8 . . . . . . . . . . . . . 65

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Short circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Input phase loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Control board temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Overfrequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Internal fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Operation limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Power limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Automatic resets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Supervisions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Parameter lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Process PID control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Block diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Sleep function for the process PID control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Motor temperature measurement through the standard I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Motor temperature measurement through an analogue I/O extension . . . . . . . . . . . . . . . . . . . . . . 73

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Adaptive Programming using the function blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

DriveAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Control of a mechanical brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Operation time scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

State shifts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Master/Follower use of several drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Settings and diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Jogging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Reduced Run function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Table of contents

Page 9

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

User load curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Overload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Application macros

Chapter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Overview of macros . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Note on external power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Parameter settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Factory macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Default control connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Hand/Auto macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Default control connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

PID Control macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Connection example, 24 VDC / 4…20 mA two-wire sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Default control connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Torque Control macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Default control connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Sequential Control macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Operation diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Default control connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

User macros . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

9

Actual signals and parameters

Chapter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

01 ACTUAL SIGNALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

02 ACTUAL SIGNALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

03 ACTUAL SIGNALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

04 ACTUAL SIGNALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

09 ACTUAL SIGNALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

10 START/STOP/DIR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

11 REFERENCE SELECT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

12 CONSTANT SPEEDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

13 ANALOGUE INPUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

14 RELAY OUTPUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

15 ANALOGUE OUTPUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

16 SYST CTRL INPUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

20 LIMITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

21 START/STOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

22 ACCEL/DECEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

23 SPEED CTRL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

24 TORQUE CTRL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

25 CRITICAL SPEEDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

26 MOTOR CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

27 BRAKE CHOPPER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Table of contents

Page 10

10

30 FAULT FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

31 AUTOMATIC RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

32 SUPERVISION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

33 INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

34 PROCESS VARIABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

35 MOT TEMP MEAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

40 PID CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

42 BRAKE CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

45 ENERGY OPT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

50 ENCODER MODULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

51 COMM MODULE DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

52 STANDARD MODBUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

60 MASTER/FOLLOWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

70 DDCS CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

72 USER LOAD CURVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

83 ADAPT PROG CTRL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

84 ADAPTIVE PROGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

85 USER CONSTANTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

90 D SET REC ADDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

92 D SET TR ADDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

95 HARDWARE SPECIF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

96 EXTERNAL AO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

98 OPTION MODULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

99 START-UP DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Fieldbus control

Chapter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Redundant fieldbus control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Setting up communication through a fieldbus adapter module . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Setting up communication through the Standard Modbus Link . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Modbus addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Setting up communication through Advant controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Drive control parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

The fieldbus control interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

The Control Word and the Status Word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Fieldbus reference selection and correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Reference handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Actual Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Block diagram: Control data input from fieldbus when a type Rxxx fieldbus adapter is used . 202

Block diagram: Actual value selection for fieldbus when a type Rxxx fieldbus adapter is used 203

Block diagram: Control data input from fieldbus when a type Nxxx fieldbus adapter is used . 204

Block Diagram: Actual value selection for fieldbus when a type Nxxx fieldbus adapter is used 205

Communication profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

ABB Drives communication profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

03.01 MAIN CONTROL WORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

03.02 MAIN STATUS WORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Fieldbus reference scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Table of contents

Page 11

11

Generic Drive communication profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Drive commands supported by the Generic Drive communication profile . . . . . . . . . . . . . . 212

Fieldbus reference scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

CSA 2.8/3.0 communication profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

CONTROL WORD for the CSA 2.8/3.0 communication profile . . . . . . . . . . . . . . . . . . . . . . 214

STATUS WORD for the CSA 2.8/3.0 communication profile . . . . . . . . . . . . . . . . . . . . . . . . 214

Diverse status, fault, alarm and limit words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

03.03 AUXILIARY STATUS WORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

03.04 LIMIT WORD 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

03.05 FAULT WORD 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

03.06 FAULT WORD 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

03.07 SYSTEM FAULT WORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

03.08 ALARM WORD 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

03.09 ALARM WORD 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

03.13 AUXILIARY STATUS WORD 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

03.14 AUXILIARY STATUS WORD 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

03.15 FAULT WORD 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

03.16 ALARM WORD 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

03.17 FAULT WORD 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

03.18 ALARM WORD 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

03.19 INT INIT FAULT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

03.30 LIMIT WORD INV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

03.31 ALARM WORD 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

03.32 EXT IO STATUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

03.33 FAULT WORD 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

04.01 FAULTED INT INFO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

04.02 INT SC INFO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Fault tracing

Chapter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Warning and fault indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

How to reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Fault history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Warning messages generated by the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Warning messages generated by the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Fault messages generated by the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Analogue Extension Module

Chapter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Speed control through the analogue extension module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Basic checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Settings of the analogue extension module and the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Parameter settings: bipolar input in basic speed control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

Parameter settings: bipolar input in joystick mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Table of contents

Page 12

12

Additional data: actual signals and parameters

Chapter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Fieldbus addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Rxxx adapter modules (such as RPBA-01, RDNA-01, etc.) . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Nxxx adapter modules (such as NPBA-12, NDNA-02, etc.) . . . . . . . . . . . . . . . . . . . . . . . . . . 249

NPBA-12 Profibus Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

NIBA-01 InterBus-S Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

NMBP-01 ModbusPlus® Adapter and NMBA-01 Modbus Adapter . . . . . . . . . . . . . . . . . . . 250

Actual signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Control block diagrams

Chapter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Reference control chain, sheet 1: FACTORY, HAND/AUTO, SEQ CTRL and T CTRL macros

(continued on the next page …) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Reference control chain sheet 1: PID CTRL macro (continued on the next page …) . . . . . . . . . 266

Reference control chain sheet 2: All macros (continued on the next page …) . . . . . . . . . . . . . . 268

Handling of Start, Stop, Run Enable and Start Interlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Handling of Reset and On/Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Index

Table of contents

Page 13

Introduction to the manual

Chapter overview

The chapter includes a description of the contents of the manual. In addition it

contains information about the compatibility, safety and intended audience.

Compatibility

The manual is compatible with Standard Control Program version ASXR7360. See

parameter 33.01 SOFTWARE VERSION.

Safety instructions

Follow all safety instructions delivered with the drive.

• Read the complete safety instructions before you install, commission, or use

the drive. The complete safety instructions are given at the beginning of the

Hardware Manual.

13

Reader

Contents

• Read the software function specific warnings and notes before changing the

default settings of the function. For each function, the warnings and notes are

given in this manual in the section describing the related user-adjustable

parameters.

The reader of the manual is expected to know the standard electrical wiring

practices, electronic components, and electrical schematic symbols.

The manual consists of the following chapters:

• Start-up and control through the I/O instructs in setting up the application

program, and how to start, stop and regulate the speed of the drive.

• Control panel gives instructions for using the panel.

• Program features contains the feature descriptions and the reference lists of the

user settings and diagnostic signals.

• Application macros contains a short description of each macro together with a

connection diagram.

• Actual signals and parameters describes the actual signals and parameters of the

drive.

• Fieldbus control describes the communication through the serial communication

links.

Introduction to the manual

Page 14

14

• Fault tracing lists the warning and fault messages with the possible causes and

remedies.

• Analogue Extension Module, describes the communication between the drive and

the analogue I/O extension (optional).

• Additional data: actual signals and parameters contains more information on the

actual signals and parameters.

• Control block diagrams contains block diagrams concerning reference control

chains and handling of Start, Stop, Run Enable and Start Interlock.

Product and service inquiries

Address any inquiries about the product to your local ABB representative, quoting

the type code and serial number of the unit in question. A listing of ABB sales,

support and service contacts can be found by navigating to www.abb.com/drives

selecting Sales, Support and Service network.

Product training

For information on ABB product training, navigate to www.abb.com/drives and select

Training courses.

and

Providing feedback on ABB Drives manuals

Your comments on our manuals are welcome. Go to www.abb.com/drives and select

Document Library – Manuals feedback form (LV AC drives).

Introduction to the manual

Page 15

Start-up and control through the I/O

Chapter overview

The chapter instructs how to:

• do the start-up

• start, stop, change the direction of rotation, and adjust the speed of the motor

through the I/O interface

• perform an Identification Run for the drive.

How to start-up the drive

There are two start-up methods between which the user can select: Run the Start-up

Assistant, or perform a limited start-up. The Assistant guides the user through all

essential settings to be done. In the limited start-up, the drive gives no guidance:

The user goes through the very basic settings by following the instructions given in

the manual.

15

• If you want to run the Assistant, follow the instructions given in section How to

perform the guided start-up (covers all essential settings) on page 15.

• If you want to perform the limited start-up, follow the instructions given in

section How to perform the limited start-up (covers only the basic settings) on

page 17.

How to perform the guided start-up (covers all essential settings)

Before you start, ensure you have the motor nameplate data on hand.

SAFETY

The start-up may only be carried out by a qualified electrician.

The safety instructions must be followed during the start-up procedure. See the

appropriate hardware manual for safety instructions.

Check the installation. See the installation checklist in the appropriate hardware/installation

manual.

Check that the starting of the motor does not cause any danger.

De-couple the driven machine if:

- there is a risk of damage in case of incorrect direction of rotation, or

- a Standard ID Run needs to be performed during the drive start-up. (ID Run is essential only

in applications which require the ultimate in motor control accuracy.)

Start-up and control through the I/O

Page 16

16

POWER-UP

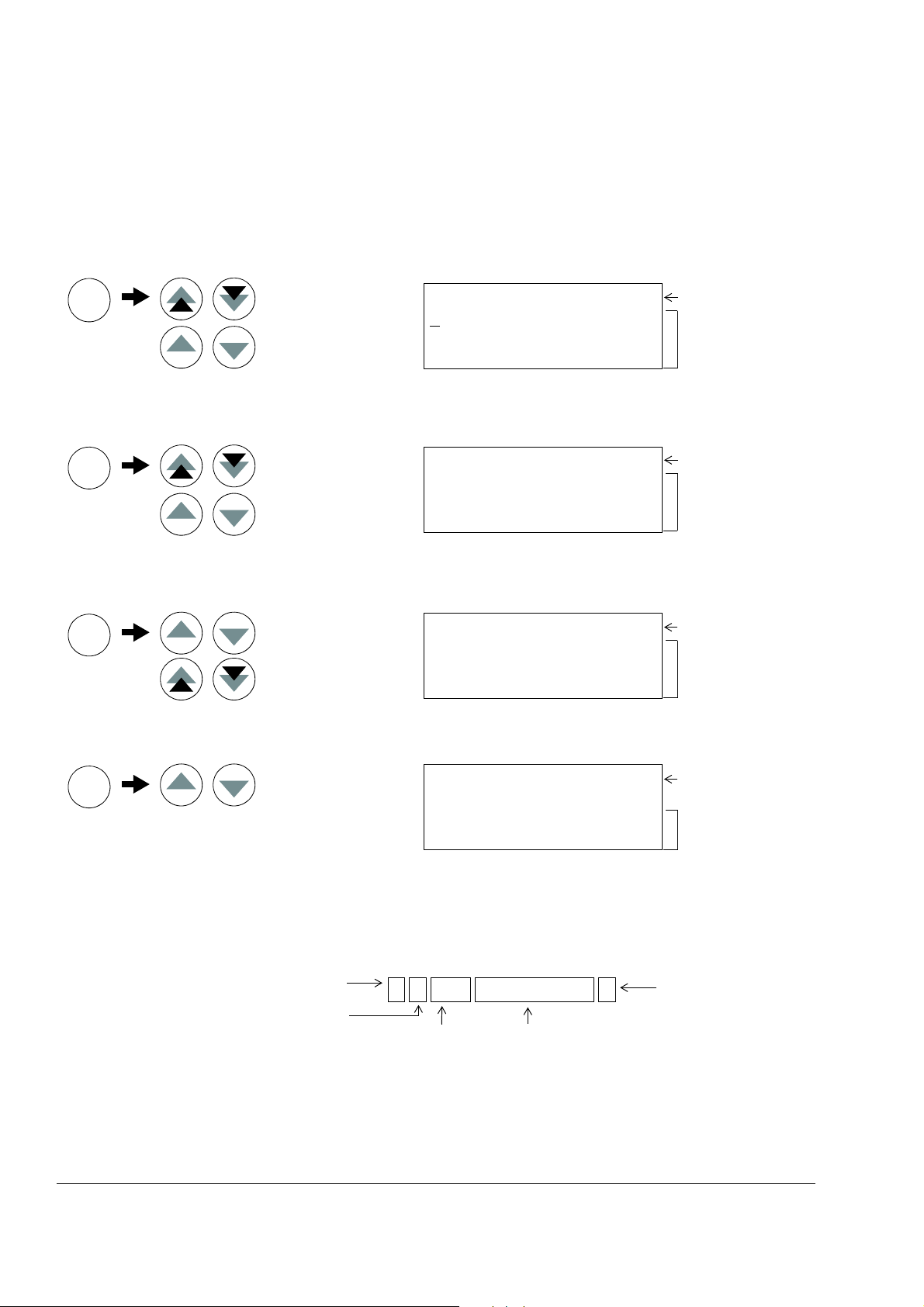

Apply the main power. The control panel first shows the panel

identification data …

… then the Identification Display of the drive …

… then the Actual Signal Display …

…after which the display suggests starting the Language Selection.

(If no key is pressed for a few seconds, the display starts to alternate between the

Actual Signal Display and the suggestion on selecting the language.)

The drive is now ready for the start-up.

SELECTING THE LANGUAGE

Press the FUNC key.

Scroll to the desired language by the arrow keys ( or ) and

press ENTER to accept.

(The drive loads the selected language into use, shifts back to the Actual Signal

Display and starts to alternate between the Actual Signal Display and the

suggestion on starting the guided motor set-up.)

CDP312 PANEL Vx.xx

.......

ACS800

ID NUMBER 1

1 -> 0.0 rpm O

FREQ 0.00 Hz

CURRENT 0.00 A

POWER 0.00 %

1 -> 0.0 rpm O

*** INFORMATION ***

Press FUNC to start

Language Selection

Language Selection 1/1

LANGUAGE ?

[ENGLISH]

ENTER:OK ACT:EXIT

1 -> 0.0 rpm O

*** INFORMATION ***

Press FUNC to start

guided Motor Setup

STARTING THE GUIDED MOTOR SET-UP

Press FUNC to start the guided motor set-up.

(The display shows which general command keys to use when stepping through

the assistant.)

Press ENTER to step forward.

Follow the instructions given on the display.

Motor Setup 1/10

ENTER: Ok/Continue

ACT: Exit

FUNC: More Info

Motor Setup 2/10

MOTOR NAMEPLATE DATA

AVAILABLE?

ENTER:Yes FUNC:Info

Start-up and control through the I/O

Page 17

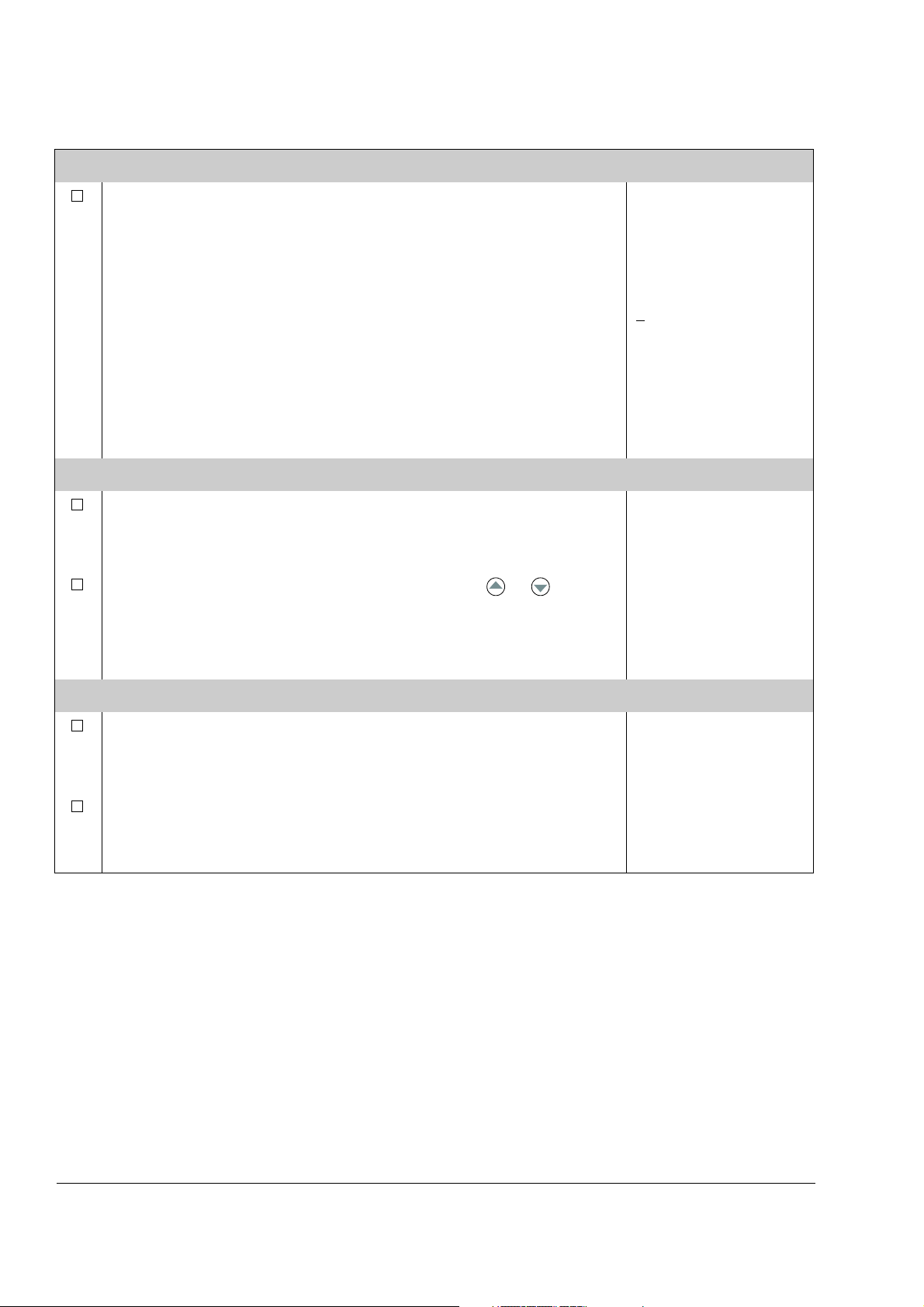

How to perform the limited start-up (covers only the basic settings)

Before you start, ensure you have the motor nameplate data at your hand.

SAFETY

The start-up may only be carried out by a qualified electrician.

The safety instructions must be followed during the start-up procedure. See the

appropriate hardware manual for safety instructions.

Check the installation. See the installation checklist in the appropriate hardware/installation

manual.

Check that the starting of the motor does not cause any danger.

De-couple the driven machine if:

- there is a risk of damage in case of incorrect direction of rotation, or

- a Standard ID Run needs to be performed during the drive start-up. (ID Run is essential

only in applications which require the ultimate in motor control accuracy.)

POWER-UP

17

Apply the main power. The control panel first shows the panel

identification data …

… then the Identification Display of the drive …

… then the Actual Signal Display …

…after which the display suggests starting the Language Selection.

(If no key is pressed for a few seconds, the display starts to alternate between the

Actual Signal Display and the suggestion on starting the Language Selection.)

Press ACT to remove the suggestion on starting the language

selection.

The drive is now ready for the limited start-up.

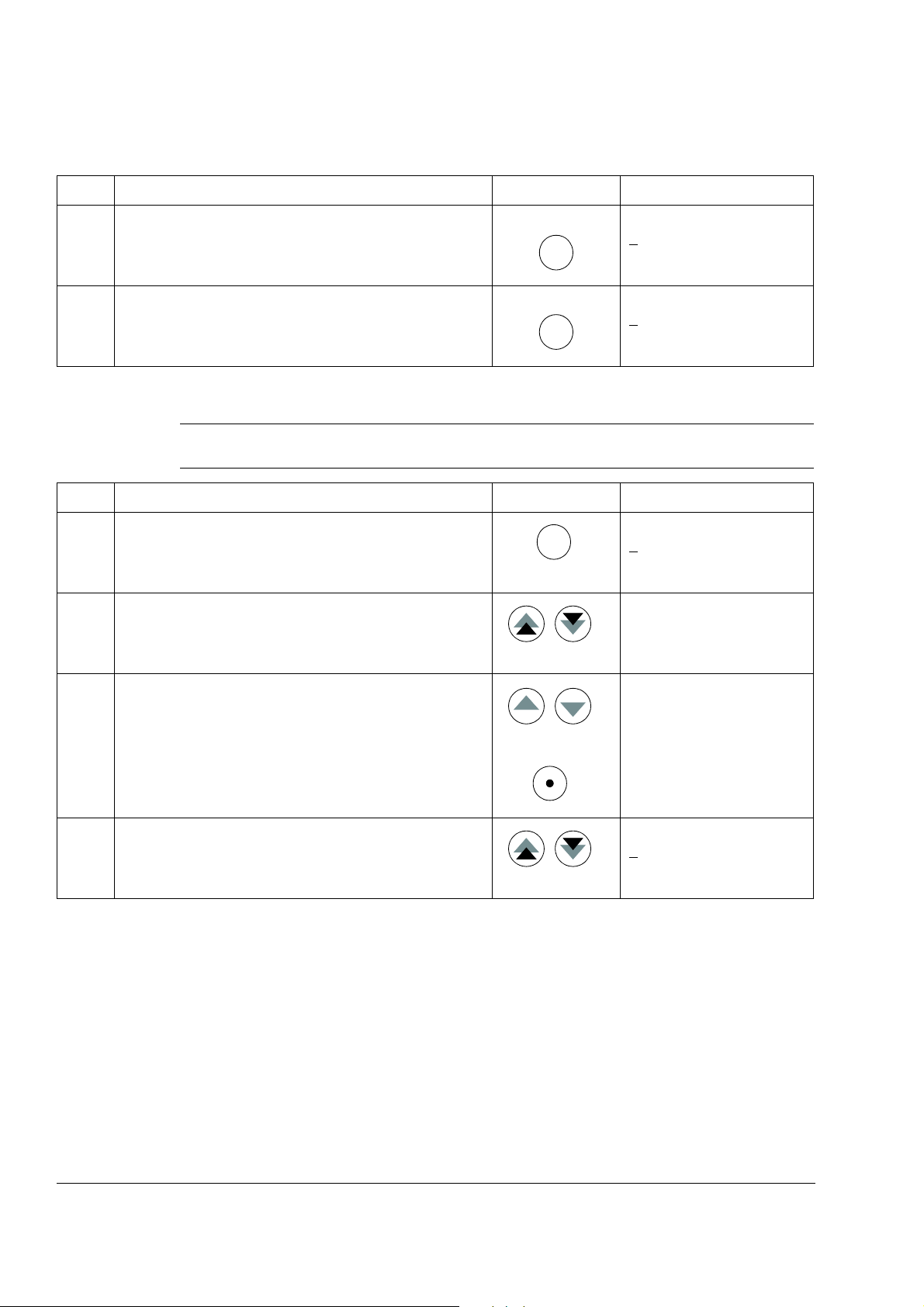

MANUAL START-UP DATA ENTERING (parameter group 99)

Select the language. The general parameter setting procedure is

described below.

The general parameter setting procedure:

- Press PAR to select the Parameter Mode of the panel.

- Press the double-arrow keys ( or ) to scroll the parameter groups.

- Press the arrow keys ( or ) to scroll parameters within a group.

- Activate the setting of a new value by ENTER.

- Change the value by the arrow keys ( or ), fast change by the doublearrow keys ( or ).

- Press ENTER to accept the new value (brackets disappear).

CDP312 PANEL Vx.xx

.......

ACS800

ID NUMBER 1

1 -> 0.0 rpm O

REQ 0.00 Hz

F

CURRENT 0.00 A

POWER 0.00 %

1 -> 0.0 rpm O

*** INFORMATION ***

Press FUNC to start

Language Selection

1 -> 0.0 rpm O

FREQ 0.00 Hz

CURRENT 0.00 A

POWER 0.00 %

1 -> 0.0 rpm O

99 START-UP DATA

01 LANGUAGE

ENGLISH

1 -> 0.0 rpm O

99 START-UP DATA

01 LANGUAGE

[ENGLISH]

Start-up and control through the I/O

Page 18

18

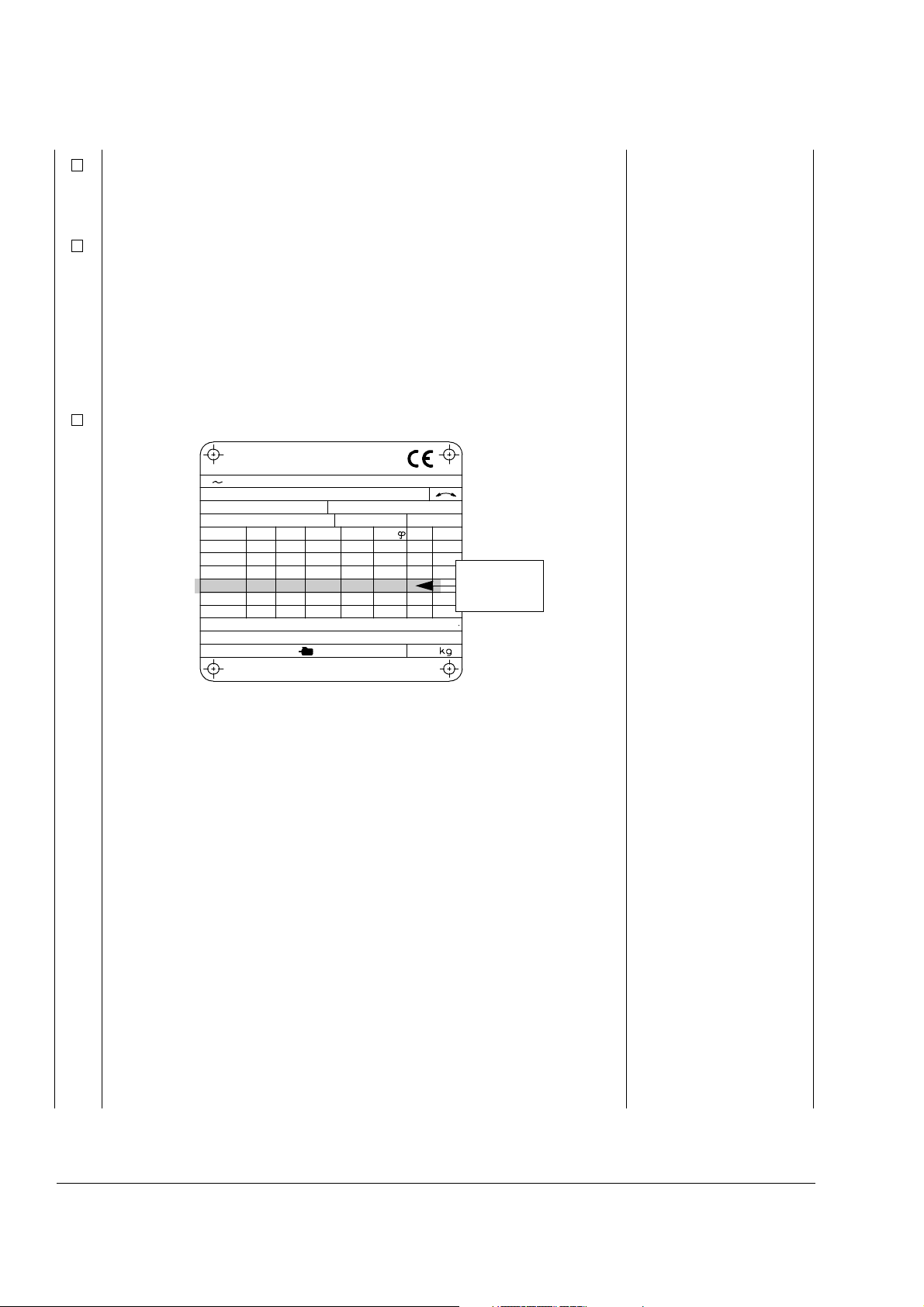

M2AA 200 MLA 4

1475

1475

1470

1470

1475

1770

32.5

56

34

59

54

59

0.83

0.83

0.83

0.83

0.83

0.83

3GAA 202 001 - ADA

180

IEC 34-1

6210/C36312/C3

Cat. no

35

30

30

30

30

30

50

50

50

50

50

60

690 Y

400 D

660 Y

380 D

415 D

440 D

V

Hz kW

r/min A

cos

IA/IN

t

E/s

Ins.cl. F

IP 55

No

IEC 200 M/L 55

3

motor

ABB Motors

380 V

input

voltage

Select the Application Macro. The general parameter setting

procedure is given above.

The default value FACTORY is suitable in most cases.

Select the motor control mode. The general parameter setting

procedure is given above.

DTC is suitable in most cases. The SCALAR control mode is recommended

- for multimotor drives when the number of the motors connected to the drive is

variable

- when the nominal current of the motor is less than 1/6 of the nominal current of

the inverter

- when the inverter is used for test purposes with no motor connected.

Enter the motor data from the motor nameplate:

1 -> 0.0 rpm O

99 START-UP DATA

02 APPLICATION MACRO

[ ]

1 -> 0.0 rpm O

99 START-UP DATA

04 MOTOR CTRL MODE

[DTC]

Note: Set the motor data to

exactly the same value as

on the motor nameplate.

For example, if the motor

nominal speed is 1440 rpm

on the nameplate, setting

the value of parameter

99.08 MOTOR NOM

SPEED to 1500 rpm

results in the wrong

operation of the drive.

- motor nominal voltage

Allowed range: 1/2 · U

each of the nominal voltage ranges: 415 VAC for 400 VAC units, 500 VAC for 500

VAC units and 690 VAC for 600 VAC units.)

- motor nominal current

Allowed range: approx. 1/6 · I

99.04 = SCALAR))

- motor nominal frequency

Range: 8 … 300 Hz

- motor nominal speed

Range: 1 …18000 rpm

-motor nominal power

Range: 0 …9000 kW

Start-up and control through the I/O

N

… 2 · U

2hd

of ACS800. (UN refers to the highest voltage in

N

… 2 · I

of ACS800 (0 … 2 · I

2hd

if parameter

2hd

1 -> 0.0 rpm O

99 START-UP DATA

05 MOTOR NOM VOLTAGE

[ ]

1 -> 0.0 rpm O

99 START-UP DATA

06 MOTOR NOM CURRENT

[ ]

1 -> 0.0 rpm O

99 START-UP DATA

07 MOTOR NOM FREQ

[ ]

1 -> 0.0 rpm O

99 START-UP DATA

08 MOTOR NOM SPEED

[ ]

1 -> 0.0 rpm O

99 START-UP DATA

09 MOTOR NOM POWER

[ ]

Page 19

19

When the motor data has been entered, two displays (warning and

information) start to alternate. Move to next step without pressing

any key.

1 -> 0.0 rpm O

ACS800

** WARNING **

ID MAGN REQ

Note: If you select STANDARD ID Run, the brake is opened when

the Start command is given from the control panel and the brake

remains open until the STANDARD ID Run is completed. If you

select ID MAGN, the brake is kept closed during the ID Run

sequence.

1 -> 0.0 rpm I

*** Information ***

Press green button

to start ID MAGN

Select the motor identification method.

The default value ID MAGN (ID Magnetisation) is suitable for most applications. It is applied

in this basic start-up procedure. If your selection is ID Magnetisation, move to next step

without pressing any key.

The ID Run (STANDARD or REDUCED) should be selected if:

- The operation point is near zero speed constantly, and/or

- Operation at torque range above the motor nominal torque within a wide speed range and

without any measured speed feedback is required.

If your selection is ID Run, continue by following the separate instructions given a few pages

ahead in section How to perform the ID Run on page 22.

IDENTIFICATION MAGNETISATION (with Motor ID Run selection ID MAGN)

Press the LOC/REM key to change to local control (L shown on the

first row).

Press to start the Identification Magnetisation. The motor is

magnetised at zero speed for 20 to 60 s. Three warnings are

displayed:

The first warning is displayed when the magnetisation starts.

The second warning is displayed while the magnetisation is on.

The third warning is displayed after the magnetisation is completed.

1 L -> 1242.0 rpm I

** WARNING **

MOTOR STARTS

1 L-> 0.0 rpm I

** WARNING **

ID MAGN

1 L-> 0.0 rpm O

** WARNING **

ID DONE

Start-up and control through the I/O

Page 20

20

forward

direction

reverse

direction

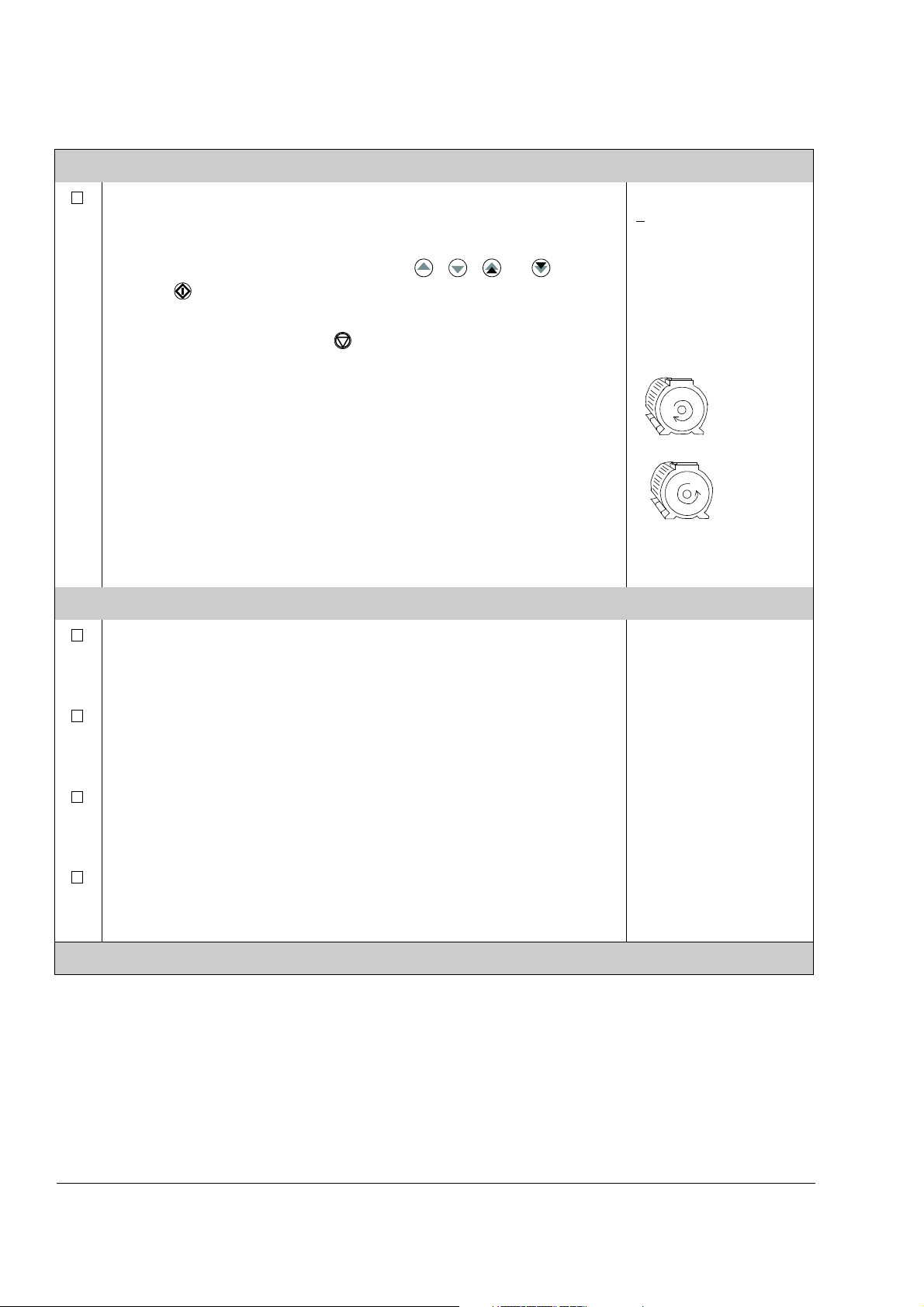

DIRECTION OF ROTATION OF THE MOTOR

Check the direction of rotation of the motor.

- Press ACT to get the status row visible.

- Increase the speed reference from zero to a small value by

pressing REF and then the arrow keys ( , , or ).

- Press to start the motor.

- Check that the motor is running in the desired direction.

- Stop the motor by pressing .

To change the direction of rotation of the motor:

- Disconnect the main power from the drive, and wait 5 minutes for

the intermediate circuit capacitors to discharge. Measure the

voltage between each input terminal (U1, V1 and W1) and earth

with a multimeter to ensure that the frequency converter is

discharged.

- Exchange the position of two motor cable phase conductors at the

motor terminals or at the motor connection box.

- Verify your work by applying the main power and repeating the

check as described above.

SPEED LIMITS AND ACCELERATION/DECELERATION TIMES

Set the minimum speed.

1 L->[xxx] rpm I

FREQ xxx Hz

CURRENT xx A

POWER xx %

1 L-> 0.0 rpm O

20 LIMITS

01 MINIMUM SPEED

[ ]

Set the maximum speed.

Set the acceleration time 1.

Note: Check also acceleration time 2, if two acceleration times will

be used in the application.

Set the deceleration time 1.

Note: Set also deceleration time 2, if two deceleration times will be

used in the application.

The drive is now ready for use.

1 L-> 0.0 rpm O

20 LIMITS

02 MAXIMUM SPEED

[ ]

1 L-> 0.0 rpm O

22 ACCEL/DECEL

02 ACCELER TIME 1

[ ]

1 L-> 0.0 rpm O

22 ACCEL/DECEL

03 DECELER TIME 1

[ ]

Start-up and control through the I/O

Page 21

How to control the drive through the I/O interface

The table below instructs how to operate the drive through the digital and analogue

inputs, when:

• the motor start-up is performed, and

• the default (factory) parameter settings are valid.

PRELIMINARY SETTINGS

21

Ensure the Factory macro is active.

If you need to change the direction of rotation, change the setting of

parameter 10.03 to REQUEST.

Ensure the control connections are wired according to the connection

diagram given for the Factory macro.

Ensure the drive is in external control mode. Press the LOC/REM key to

change between external and local control.

STARTING AND CONTROLLING THE SPEED OF THE MOTOR

Start by switching digital input DI1 on.

Regulate the speed by adjusting the voltage of analogue input AI1.

CHANGING THE DIRECTION OF ROTATION OF THE MOTOR

Forward direction: Switch digital input DI2 off.

See parameter 99.02.

See chapter Application

macros.

In External control, there is

no L visible on the first row

of the panel display.

1 -> 0.0 rpm I

REQ 0.00 Hz

F

CURRENT 0.00 A

POWER 0.00 %

1 -> 500.0 rpm I

FREQ 16.66 Hz

CURRENT 12.66 A

POWER 8.33 %

1 -> 500.0 rpm I

FREQ 16.66 Hz

CURRENT 12.66 A

POWER 8.33 %

Reverse direction: Switch digital input DI2 on.

STOPPING THE MOTOR

Switch off digital input DI1.

1 <- 500.0 rpm I

REQ 16.66 Hz

F

CURRENT 12.66 A

POWER 8.33 %

1 -> 500.0 rpm O

REQ 0.00 Hz

F

CURRENT 0.00 A

POWER 0.00 %

Start-up and control through the I/O

Page 22

22

99 START-UP DATA

10 MOTOR ID RUN

[STANDARD]

1 L ->1242.0 rpm O

1 L ->1242.0 rpm O

ACS800

**WARNING**

ID RUN SEL

How to perform the ID Run

The drive performs the ID Magnetisation automatically at the first start. In most

applications there is no need to perform a separate ID Run. The ID Run (Standard or

Reduced) should be selected if:

• The operation point is near zero speed, and/or

• Operation at torque range above the motor nominal torque within a wide speed

range and without any measured speed feedback is required.

The Reduced ID Run is to be performed instead of the Standard if it is not possible to

disengage the driven machine from the motor.

Note: If you select STANDARD ID Run, the brake is opened when the Start

command is given from the control panel and the brake remains open until the

STANDARD ID Run is completed. If you select ID MAGN, the brake is kept closed

during the ID Run sequence.

ID Run Procedure

Note: If parameter values (Group 10 to 98) are changed before the ID Run, check

that the new settings meet the following conditions:

• 20.01 MINIMUM SPEED <

0 rpm

• 20.02 MAXIMUM SPEED > 80% of motor rated speed

• 20.03 MAXIMUM CURRENT >

100% · I

hd

• 20.04 MAXIMUM TORQUE > 50%

• Ensure that the panel is in the local control mode (L displayed on the status row).

Press the LOC/REM key to switch between modes.

• Change the ID Run selection to STANDARD or REDUCED.

•Press ENTER to verify selection. The following message will be displayed:

Start-up and control through the I/O

Page 23

23

• To start the ID Run, press the key. The Start Interlock (digital input DI_IL) and

Run Enable signals (parameter 16.01 RUN ENABLE) must be active.

Warning when the ID Run is

started

1 L -> 1242.0 rpm I

ACS800

**WARNING**

MOTOR STARTS

In general it is recommended not to press any control panel keys during the ID run.

However:

• The Motor ID Run can be stopped at any time by pressing the control panel stop

key ( ).

• After the ID Run is started with the start key ( ), it is possible to monitor the

actual values by first pressing the ACT key and then a double-arrow key ( ).

Warning during the ID Run Warning after a successfully

completed ID Run

1 L -> 1242.0 rpm I

ACS800

**WARNING**

ID RUN

1 L -> 1242.0 rpm I

ACS800

**WARNING**

ID DONE

Start-up and control through the I/O

Page 24

24

Start-up and control through the I/O

Page 25

Control panel

1 L -> 1242.0 rpm I

F

REQ 45.00 Hz

CURRENT 80.00 A

POWER 75.00 %

ACT PA R FU NC DR IV E

ENTER

LOC RESET REF

REM

I0

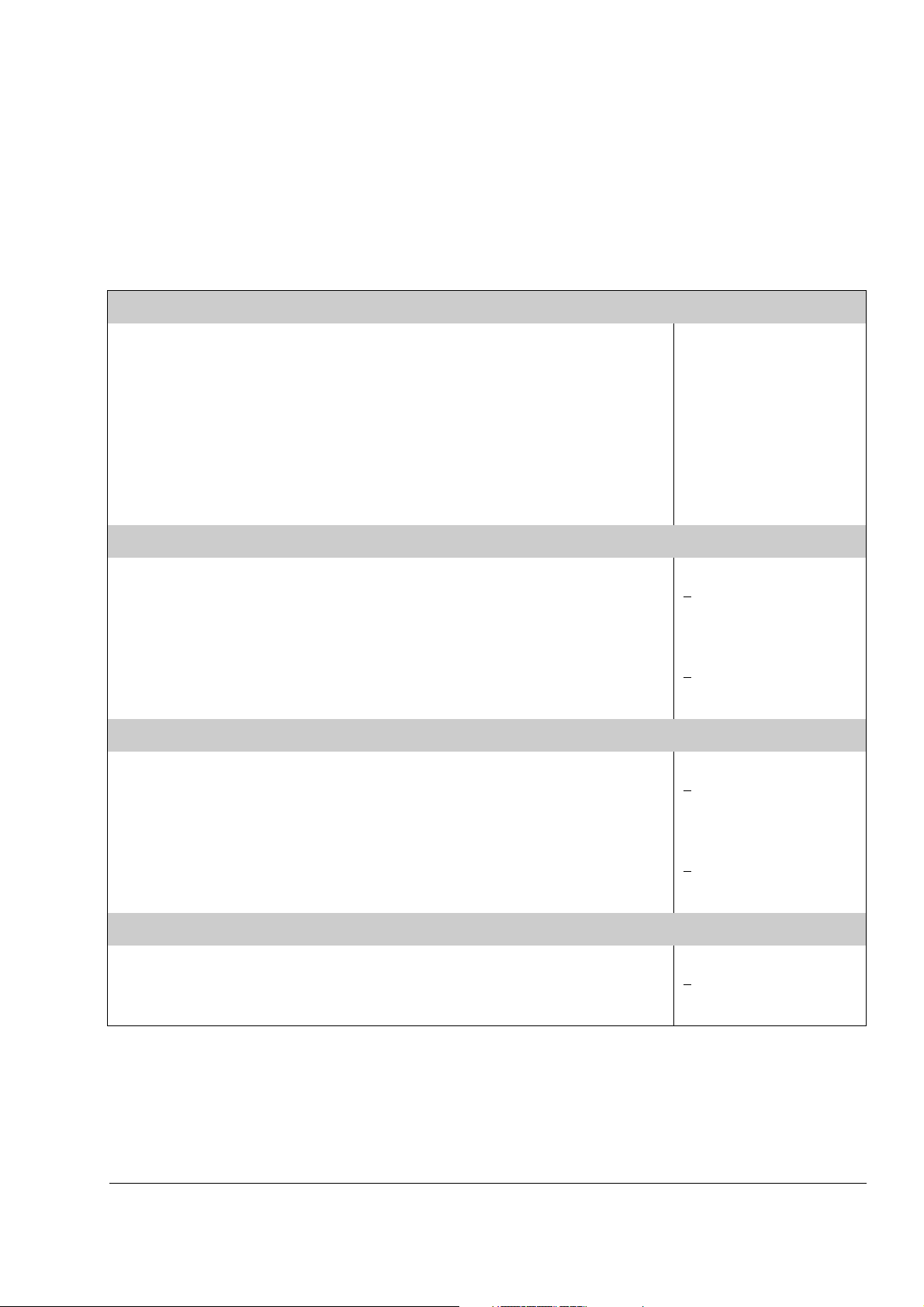

1367

5 24

The LCD type display has 4 lines of 20 characters.

The language is selected at start-up (parameter 99.01).

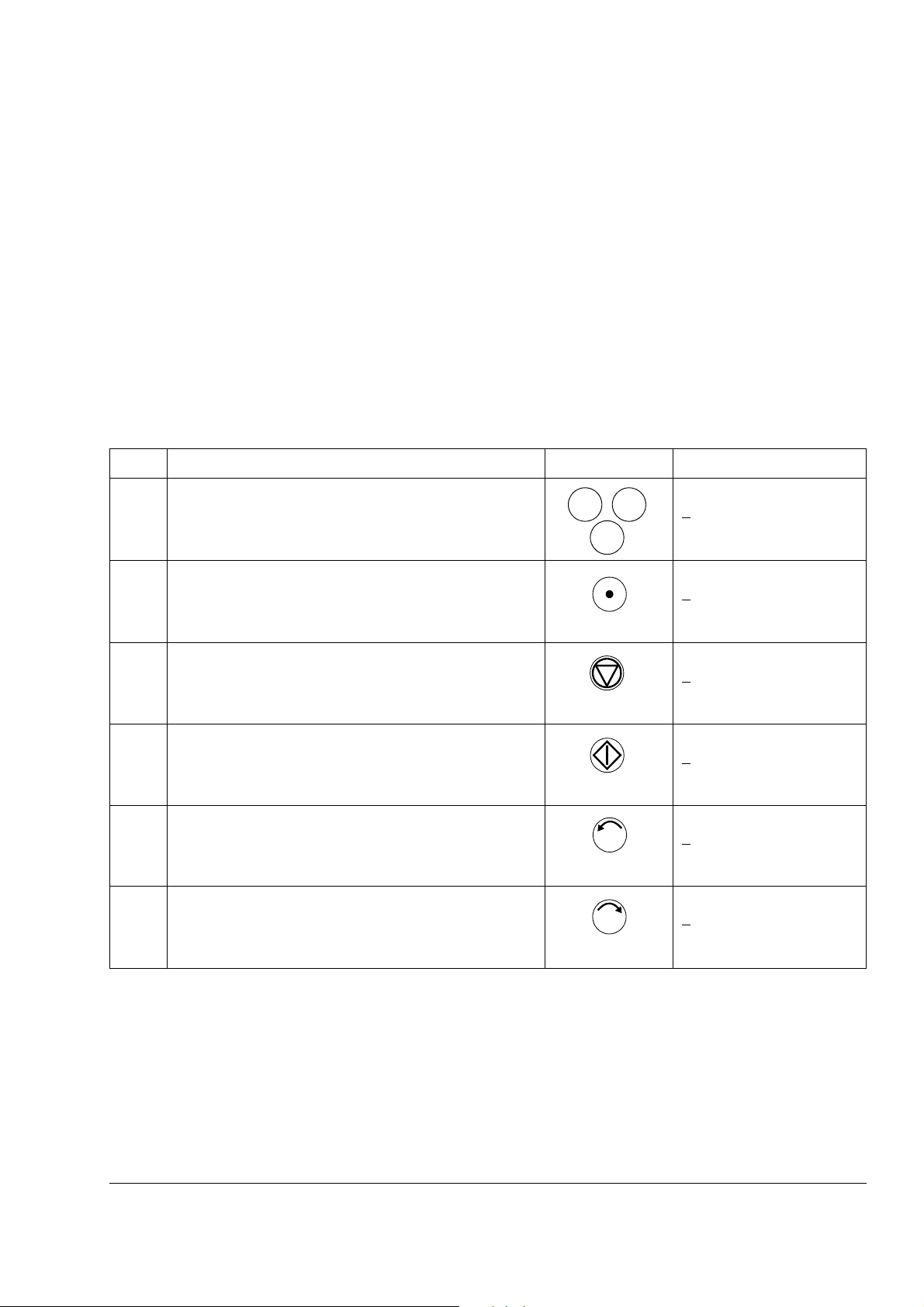

The control panel has four operation modes:

- Actual Signal Display Mode (ACT key)

- Parameter Mode (PAR key)

- Function Mode (FUNC key)

- Drive Selection Mode (DRIVE key)

The use of single arrow keys, double arrow keys and

ENTER depend on the operation mode of the panel.

The drive control keys are:

No. Use

1Start

2Stop

3 Activate reference setting

4 Forward direction of rotation

5 Reverse direction of rotation

6 Fault reset

7 Change between Local / Remote (external)

control

Chapter overview

The chapter describes how to use the control panel CDP 312R.

The same control panel is used with all ACS800 series drives, so the instructions

given apply to all ACS800 types. The display examples shown are based on the

Standard Control Program; displays produced by other application programs may

differ slightly.

Overview of the panel

25

Control panel

Page 26

26

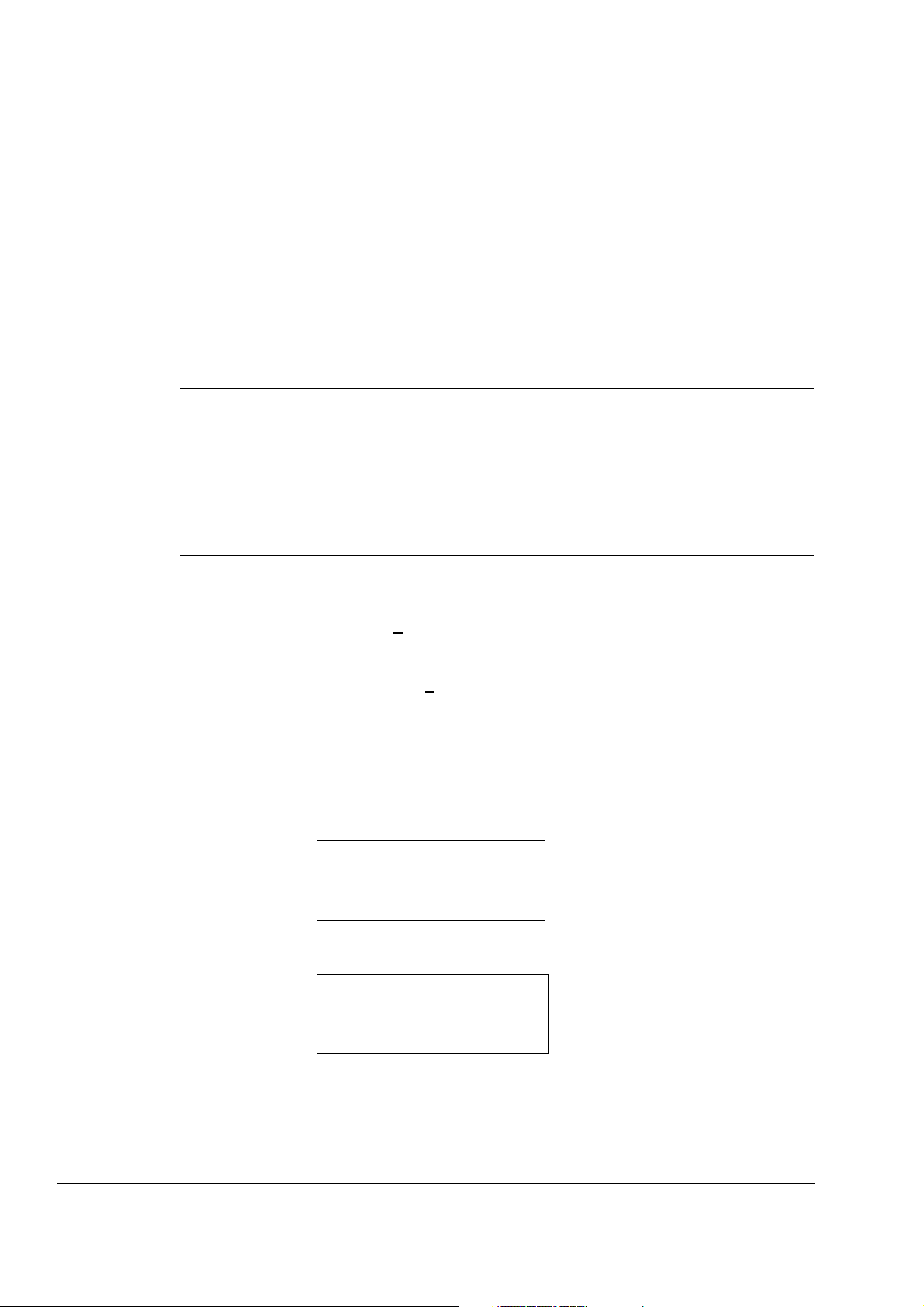

Parameter Mode

Function Mode

Drive Selection Mode

Act. signal / Fault history

Enter selection mode

Accept new signal

Group selection

Parameter selection

Enter change mode

Accept new value

Fast value change

Slow value change

Function start

Drive selection

Enter change mode

Accept new value

Actual Signal Display Mode

ENTER

ENTER

ENTER

ENTER

selection

ID number change

Status row

Status row

ACT

PAR

FUNC

DRIVE

1 L -> 1242.0 rpm O

F

REQ 45.00 Hz

CURRENT 80.00 A

POWER 75.00 %

1 L -> 1242.0 rpm O

10 START/STOP/DIR

01 EXT1 STRT/STP/DIR

DI1,2

1 L -> 1242.0 rpm O

Motor Setup

Application Macro

Speed Control EXT1

ACS800

ASXR7260 xxxxxx

ID NUMBER 1

Act. signal / Fault message

scrolling

Actual signal names

and values

Parameter group

Parameter

Parameter value

Status row

List of functions

Device type

SW loading package

name and ID number

Row selection

Page selection

Drive ID number

Drive control status

L = Local control

R = Remote control

“ “ = External control

Drive status

I = Running

O = Stopped

“ “ = Run disabled

1 L -> 1242.0 rpm I

Direction of rotation

-> = Forward

<- = Reverse

Drive reference

Panel operation mode keys and displays

The figure below shows the mode selection keys of the panel, and the basic

operations and displays in each mode.

Status row

The figure below describes the status row digits.

Control panel

Page 27

Drive control with the panel

ACT PA R

FUNC

LOC

REM

0

I

The user can control the drive with the panel as follows:

• start, stop, and change direction of the motor

• give the motor speed reference or torque reference

• give a process reference (when the process PID control is active)

• reset the fault and warning messages

• change between local and external drive control.

The panel can be used for control of the drive control always when the drive is under

local control and the status row is visible on the display.

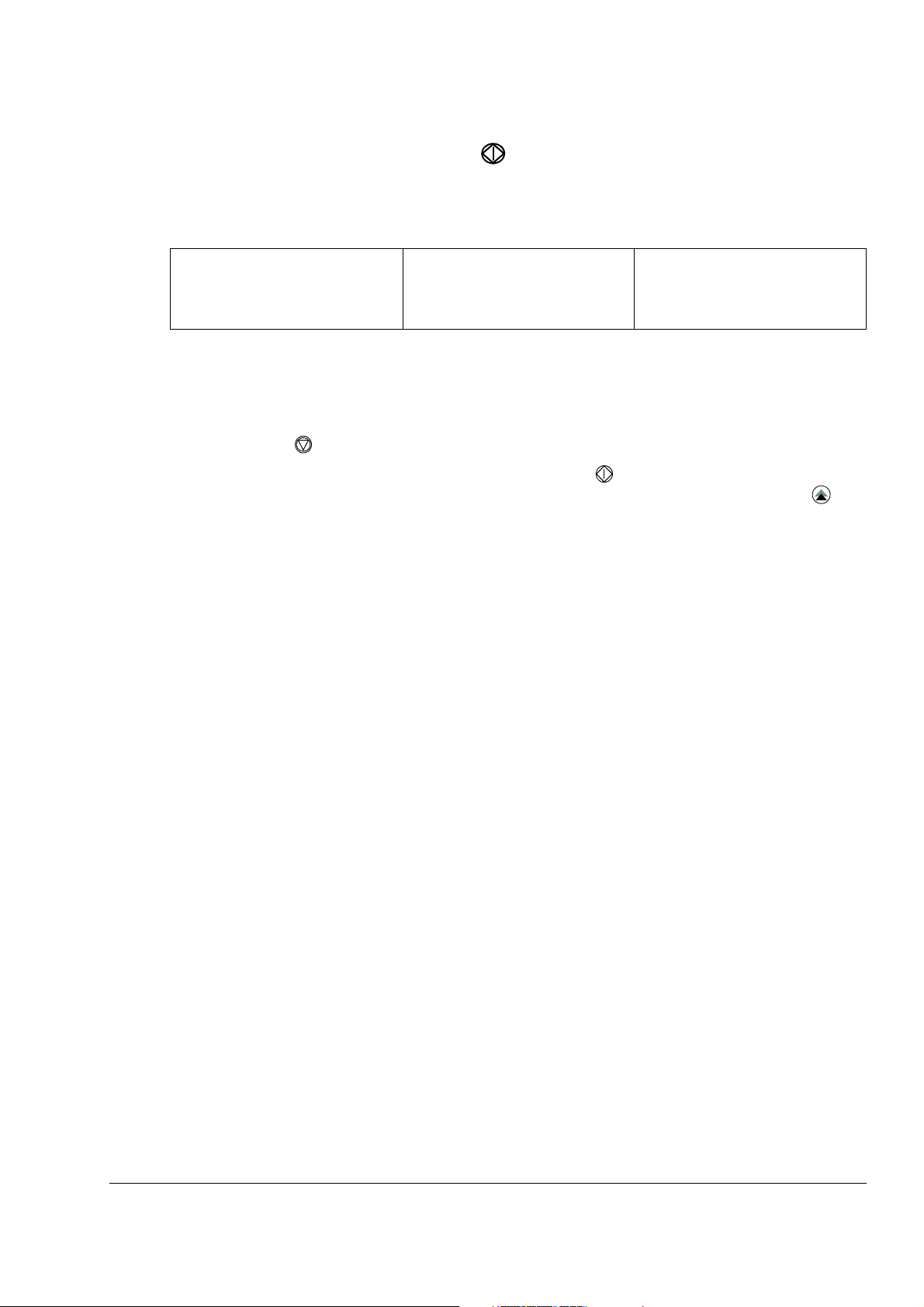

How to start, stop and change direction

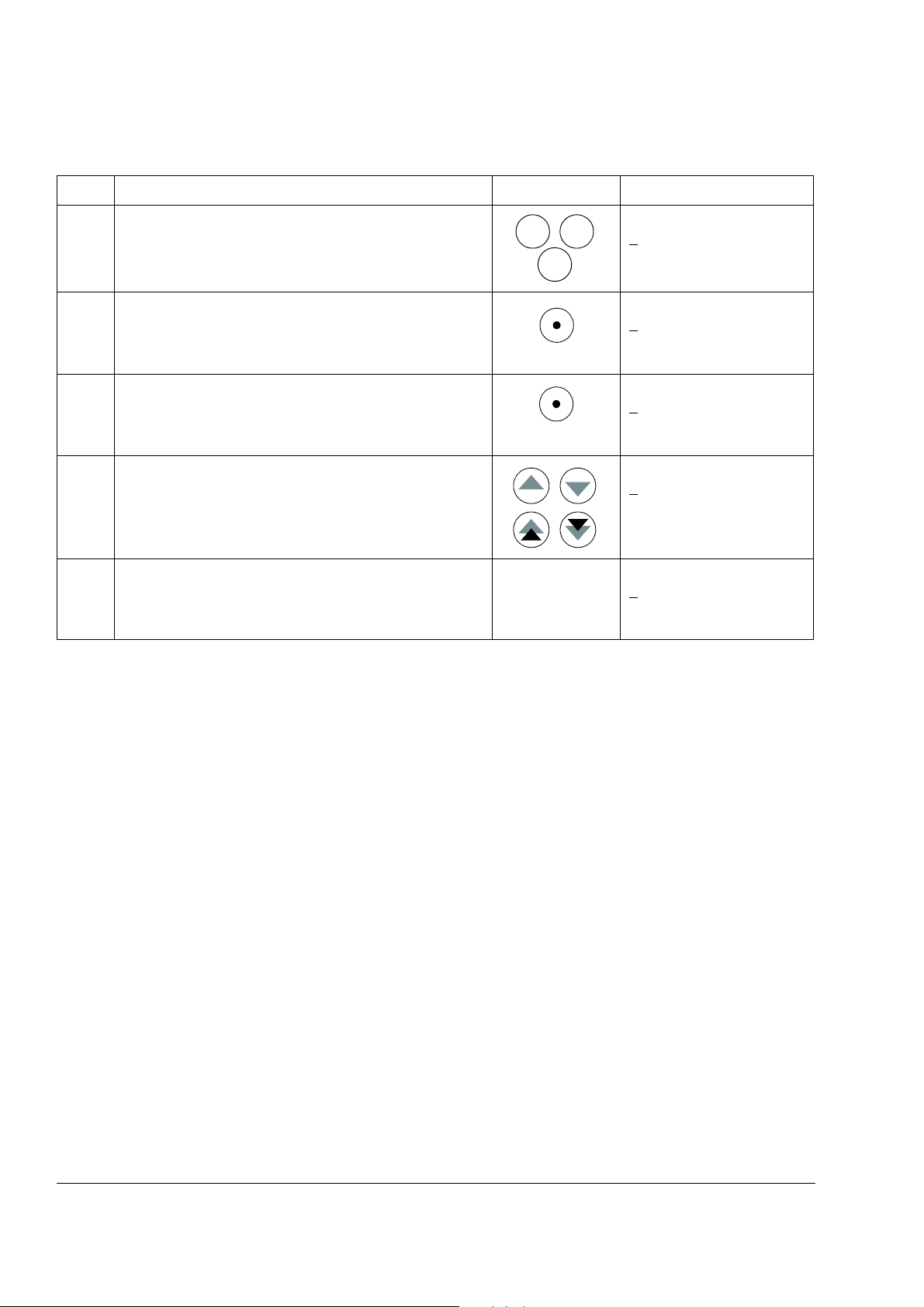

Step Action Press Key Display

1. To show the status row. 1 ->1242.0 rpm I

REQ 45.00 Hz

F

CURRENT 80.00 A

POWER 75.00 %

27

2. To switch to local control.

(only if the drive is not under local control, i.e. there is no L

on the first row of the display.)

3. To stop 1 L ->1242.0 rpm O

4. To start 1 L ->1242.0 rpm I

5. To change the direction to reverse. 1 L <-1242.0 rpm I

6. To change the direction to forward. 1 L ->1242.0 rpm I

1 L ->1242.0 rpm I

REQ 45.00 Hz

F

CURRENT 80.00 A

POWER 75.00 %

REQ 45.00 Hz

F

CURRENT 80.00 A

POWER 75.00 %

FREQ 45.00 Hz

CURRENT 80.00 A

POWER 75.00 %

REQ 45.00 Hz

F

CURRENT 80.00 A

POWER 75.00 %

FREQ 45.00 Hz

CURRENT 80.00 A

POWER 75.00 %

Control panel

Page 28

28

ACT PAR

FUNC

LOC

REM

REF

ENTER

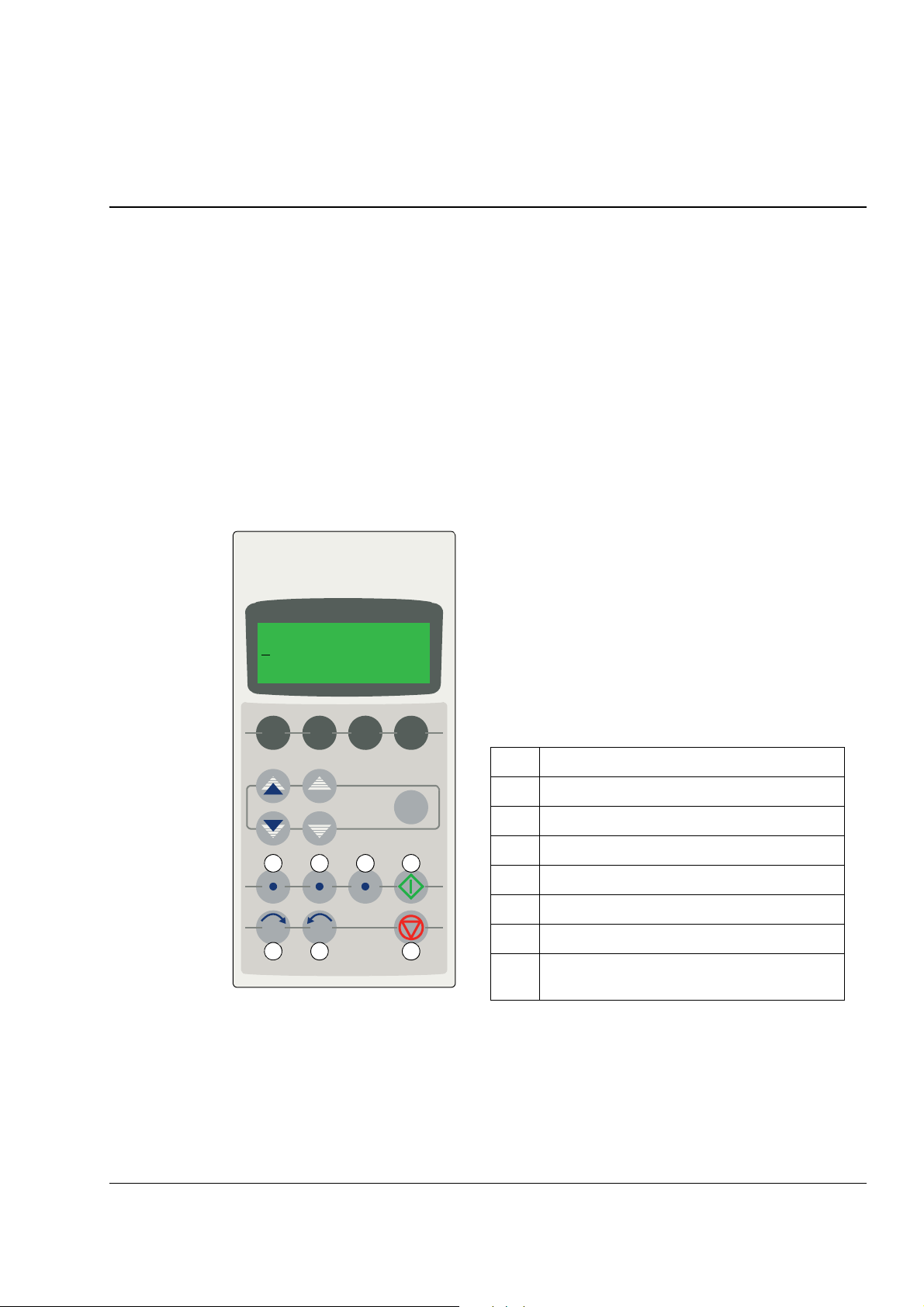

How to set speed reference

Step Action Press Key Display

1. To show the status row. 1 ->1242.0 rpm I

F

REQ 45.00 Hz

CURRENT 80.00 A

POWER 75.00 %

2. To switch to local control.

(Only if the drive is not under local control, i.e. there is no L

on the first row of the display.)

1 L ->1242.0 rpm I

REQ 45.00 Hz

F

CURRENT 80.00 A

POWER 75.00 %

3. To enter the Reference Setting function. 1 L ->[1242.0 rpm]I

REQ 45.00 Hz

F

CURRENT 80.00 A

POWER 75.00 %

4. To change the reference.

(slow change)

1 L ->[1325.0 rpm]I

F

REQ 45.00 Hz

CURRENT 80.00 A

POWER 75.00 %

(fast change)

5. To save the reference.

(The value is stored in the permanent memory; it is

restored automatically after power switch-off.)

1 L -> 1325.0 rpm I

REQ 45.00 Hz

F

CURRENT 80.00 A

POWER 75.00 %

Control panel

Page 29

Actual signal display mode

ACT

ENTER

ENTER

ACT

FUNC DRIVE

PAR

In the Actual Signal Display Mode, the user can:

• show three actual signals on the display at a time

• select the actual signals to display

• view the fault history

• reset the fault history.

The panel enters the Actual Signal Display Mode when the user presses the ACT

key, or if he does not press any key within one minute.

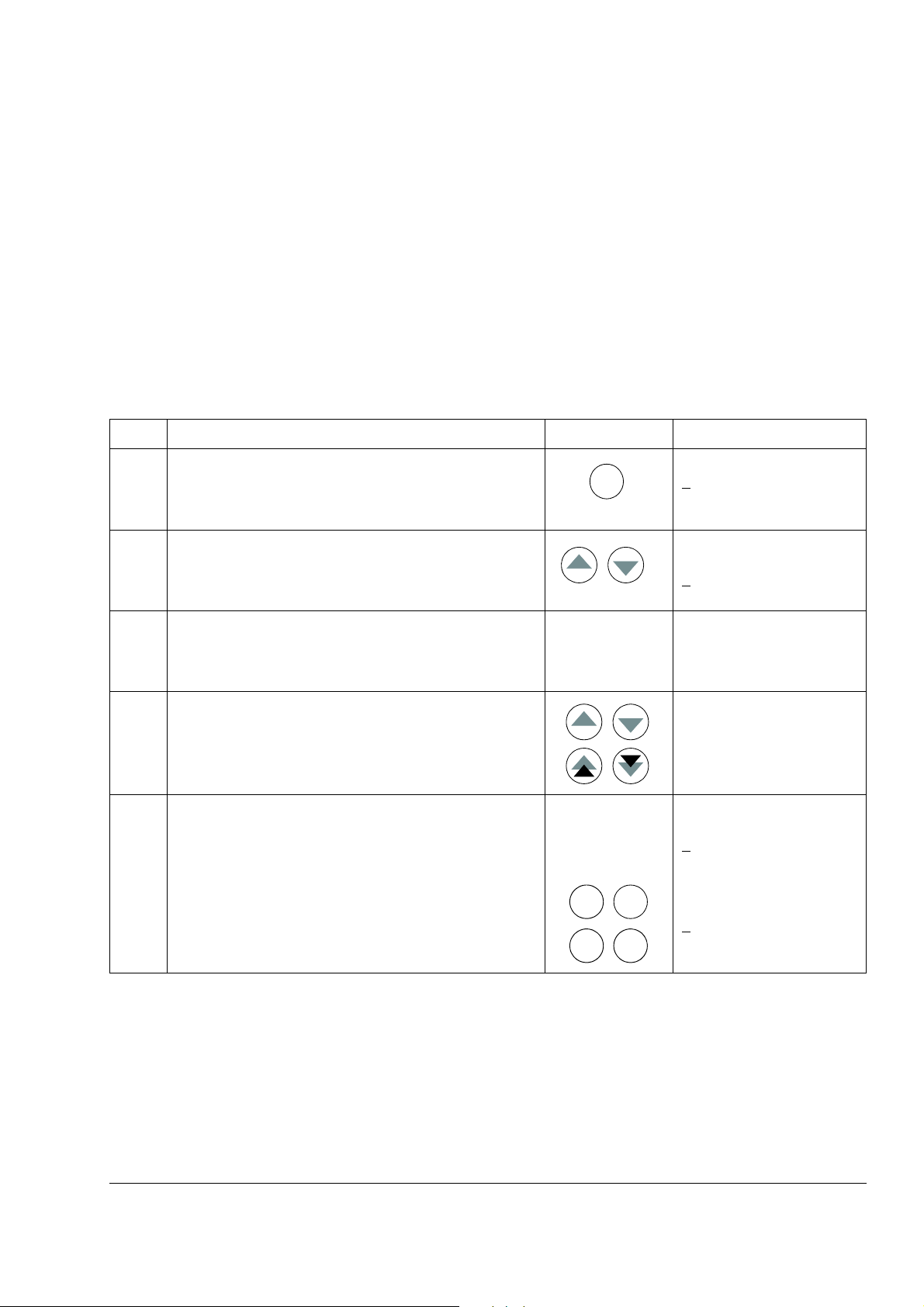

How to select actual signals to the display

Step Action Press key Display

1. To enter the Actual Signal Display Mode. 1 L -> 1242.0 rpm I

F

REQ 45.00 Hz

CURRENT 80.00 A

POWER 75.00 %

29

2. To select a row (a blinking cursor indicates the selected

row).

3. To enter the actual signal selection function. 1 L -> 1242.0 rpm I

4. To select an actual signal.

To change the actual signal group.

5.a To accept the selection and to return to the Actual Signal

Display Mode.

5.b To cancel the selection and keep the original selection.

The selected keypad mode is entered.

1 L -> 1242.0 rpm I

FREQ 45.00 Hz

URRENT 80.00 A

C

POWER 75.00 %

1 ACTUAL SIGNALS

04 CURRENT

80.00 A

1 L -> 1242.0 rpm I

1 ACTUAL SIGNALS

05 TORQUE 70.00 %

1 L -> 1242.0 rpm I

FREQ 45.00 Hz

ORQUE 70.00 %

T

POWER 75.00 %

1 L -> 1242.0 rpm I

FREQ 45.00 Hz

C

URRENT 80.00 A

POWER 75.00 %

Control panel

Page 30

30

ACT

ACT

ACT

RESET

How to display the full name of the actual signals

Step Action Press key Display

1. To display the full name of the three actual signals. Hold 1 L -> 1242.0 rpm I

F

REQUENCY

CURRENT

POWER

2. To return to the Actual Signal Display Mode. Release 1 L -> 1242.0 rpm I

FREQ 45.00 Hz

CURRENT 80.00 A

POWER 75.00 %

How to view and reset the fault history

Note: The fault history cannot be reset if there are active faults or warnings.

Step Action Press key Display

1. To enter the Actual Signal Display Mode. 1 L -> 1242.0 rpm I

REQ 45.00 Hz

F

CURRENT 80.00 A

POWER 75.00 %

2. To enter the Fault History Display. 1 L -> 1242.0 rpm I

1 LAST FAULT

+OVERCURRENT

6451 H 21 MIN 23 S

3. To select the previous (UP) or the next fault/warning

(DOWN).

1 L -> 1242.0 rpm I

2 LAST FAULT

+OVERVOLTAGE

1121 H 1 MIN 23 S

To clear the Fault History. 1 L -> 1242.0 rpm I

2 LAST FAULT

H MIN S

4. To return to the Actual Signal Display Mode. 1 L -> 1242.0 rpm I

REQ 45.00 Hz

F

CURRENT 80.00 A

POWER 75.00 %

Control panel

Page 31

How to display and reset an active fault

ACT

RESET

1 L -> 1242.0 rpm I

2 LAST FAULT

+DC OVERVOLT (3210)

1121 H 1 MIN 23 S

Event Information on display

Drive detects a fault and

generates a fault message

Sequential number of the event and

LAST FAULT text.

Name of the fault and a “+” sign in front

of the name.

Total power-on time.

User resets the fault message. Sequential number of the event and

LAST FAULT text.

-RESET FAULT text.

Total power-on time.

Drive generates a warning

message.

Sequential number of the event and

LAST WARNING text.

Name of the warning and a “+” sign in

front of the name.

Total power-on time.

Drive deactivates the warning

message.

Sequential number of the event and

LAST WARNING text.

Name of the warning and a “-” sign in

front of the name.

Total power-on time.

Sequential number

(1 is the most recent event)

Sign

Power-

on time

Name and

code

A Fault History View

WARNING! If an external source for start command is selected and it is ON, the

drive will start immediately after fault reset. If the cause of the fault has not been

removed, the drive will trip again.

Step Action Press Key Display

1. To display an active fault. 1 L -> 1242.0 rpm

ACS800

** FAULT **

ACS800 TEMP

2. To reset the fault. 1 L -> 1242.0 rpm O

REQ 45.00 Hz

F

CURRENT 80.00 A

POWER 75.00 %

About the fault history

The fault history restores information on the latest events (faults, warnings and

resets) of the drive. The table below shows how the events are stored in the fault

history.

31

Control panel

Page 32

32

PAR

ENTER

ENTER

ACT

FUNC DRIVE

PAR

Parameter mode

In the Parameter Mode, the user can:

• view the parameter values

• change the parameter settings.