Page 1

ACS 160 Installation and

Start-up Guide

RS485 and RS232

Adapter Module CFB-RS

Page 2

Page 3

RS485 and RS232

Adapter Module CFB-RS

Installation and

Start-up Guide

3BFE 64390431 R0125

EFFECTIVE: 23.3.2001

EN

Page 4

Page 5

Safety Instructions

Overview

This chapter states the safety instructions that must be followed when installing

and operating the RS485/RS232 adapter. If neglected, physical injury and

death may follow, or damage may occur to the frequency converter, the motor

and driven equipment. The material in this chapter must be studied before

attempting any work on, or with, the unit.

Warnings

Warnings are used to inform of conditions which can, if proper steps are not

taken, lead to a serious fault condition, physical injury and death.

Readers are informed of situations that can result in serious physical injury

and/or serious damage to equipment with the following symbols:

Dangerous Voltage Warning: warns of situations in which a high

voltage can cause physical injury and/or damage equipment. The

text next to this symbol describes ways to avoid the danger.

General Warning: warns of situations which can cause physical

injury and/or damage equipment by means other than electrical.

The text next to this symbol describes ways to avoid the danger.

RS485 and RS232 Adapter Installation and Start-up Guide i

Page 6

Safety Instructions

ii RS485 and RS232 Adapter Installation and Start-up Guide

Page 7

Table of Contents

Safety Instructions

Overview ...................................................................................................... i

Warnings ...................................................................................................... i

Chapter 1 –Introduction

Overview .................................................................................................. 1-1

Delivery Check ......................................................................................... 1-1

How to Use This Guide ............................................................................ 1-1

Chapter 2 – Installation

Mounting .................................................................................................. 2-2

Connectors and Switches ........................................................................ 2-3

Selecting the Communication Speed ....................................................... 2-4

Selecting RS485 or RS232 Mode ............................................................ 2-5

RS485 Bus Termination ........................................................................... 2-5

Installation to RS485 Bus......................................................................... 2-6

Installation to RS232 Bus......................................................................... 2-8

Earthing and Termination....................................................................... 2-11

Chapter 3 – Programming

General .................................................................................................... 3-1

Communication Settings .......................................................................... 3-2

Control Locations ..................................................................................... 3-5

Diagnostic Counters ................................................................................. 3-6

Chapter 4 – Communication

Introduction to Modbus............................................................................. 4-1

Register Read and Write .......................................................................... 4-1

Register Mapping ..................................................................................... 4-2

Exception Codes ...................................................................................... 4-3

Function Codes ........................................................................................ 4-4

The Control Word and the Status Word ................................................... 4-4

RS485 and RS232 Adapter Installation and Start-up Guide iii

Page 8

References............................................................................................... 4-8

Actual Values ......................................................................................... 4-11

Fault and Alarm Status .......................................................................... 4-13

Chapter 5 – Fault Tracing

Appendix A – Parameter Scaling

Effect of Resolution .................................................................................. A-1

Signed Values .......................................................................................... A-1

Appendix B– Technical Data

RS-485 Link ............................................................................................. B-1

CFB-RS.................................................................................................... B-1

Appendix C– Ambient Conditions

Operation ................................................................................................ C-1

Storage and Transportation .................................................................... C-1

iv RS485 and RS232 Adapter Installation and Start-up Guide

Page 9

Chapter 1 –Introduction

Overview

The RS485 and RS232 adapter is used for connecting the ACS 160 frequency

converter to a serial Modbus (RS232 or RS485) network. The adapter is IP65

protected for use in demanding environmental conditions.

Delivery Check

The option package includes:

• RS485/RS232 Adapter

• Installation and Start-up Guide for RS485 and RS232 Adapter

• Two M16 x 1,5 cable glands with O-ring.

• Two M4 x 12 mounting screws

How to Use This Guide

The purpose of this Guide is to provide the information necessary to install,

commission, use, and to fault diagnose the adapter.

Safety Instructions describe the formats for warnings and notations used within

this guide. This chapter also states the safety instructions which apply to the

installation and operation of the RS485/RS232 Adapter.

Chapter 1 – Introduction, the chapter you are reading now, contains a short

description of this manual and a list of related publications.

Chapter 2 – Installation contains instructions for mechanical and electrical

installation of the adapter.

Chapter 3 – Programming explains how to program the ACS 160 drive for

Modbus communication.

Chapter 4 – Communication describes the Modbus communication on

ACS 160 drives.

Chapter 5 – Fault Tracing describes how to diagnose the most common

problems with the adapter.

RS485 and RS232 Adapter Installation and Start-up Guide 1-1

Page 10

Chapter 1 –Introduction

Appendix A– Parameter Scaling describes the scaling when parameters are

accessed through the Modbus network.

Appendix B– Technical data of the module.

Appendix C– Ambient conditions.

Conventions Used in This Guide

This manual uses some terms and conventions which might not be known to

every user of this manual. Some of these terms are described below.

4XXXX Register Area

Modicon PLCs have a signed integer data table area, which is used for

Analogue Output modules and for storing temporary or set-point values. These

registers are in the address area starting from 40001. The last register address

available on PLCs depends on the available memory, but is less than 49999.

The ACS 160 drive simulates this area by providing a read and write access to

its parameters through this register address area.

Related Publications

ACS 160 User’s Manual.

1-2 RS485 and RS232 Adapter Installation and Start-up Guide

Page 11

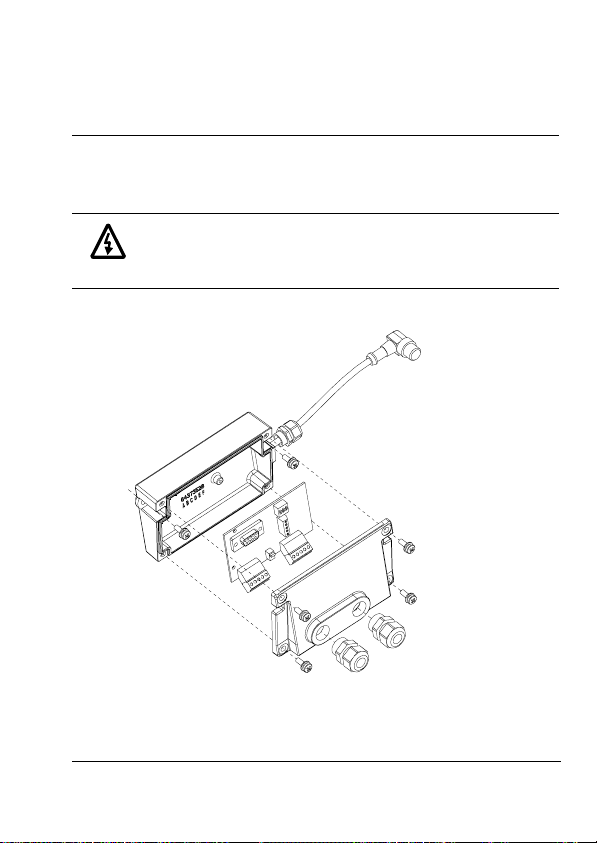

Chapter 2 – Installation

This chapter contains instructions for setting up the RS485/RS232 adapter.

WARNING! Verify that the ACS 160 is not powered before starting

the installation. Follow the safety instructions given in this Guide

and in the ACS 160 User’s Manual.

Drive connection Cable

Base

Circuit Board

Assembly

Figure 2-1 Exploded view of the CFB-RS Adapter Module

RS485 and RS232 Adapter Installation and Start-up Guide 2-1

Mounting Screws

(2 pcs)

Cover

Cover Screws

(4 pcs)

Cable Glands

for B us Cables

(2 pcs)

Page 12

Chapter 2 – Installation

Mounting

The CFB-RS can be mounted onto the ACS 160 drive with two screws as

shown in the ACS 160 User's Manual. This also provides the earthing of the

module housing.

The CFB-RS uses the control panel connector of the drive. The CFB-RS is

powered through this connector.

The CFB-RS provides two cable entries for the incoming and outgoing bus

cables. The cables are connected to a detachable terminal header.

If only one bus cable is connected, the unused cable entry should be plugged.

Remove the front cover to access the configuration switches and jumpers.

2-2 RS485 and RS232 Adapter Installation and Start-up Guide

Page 13

Chapter 2 – Installation

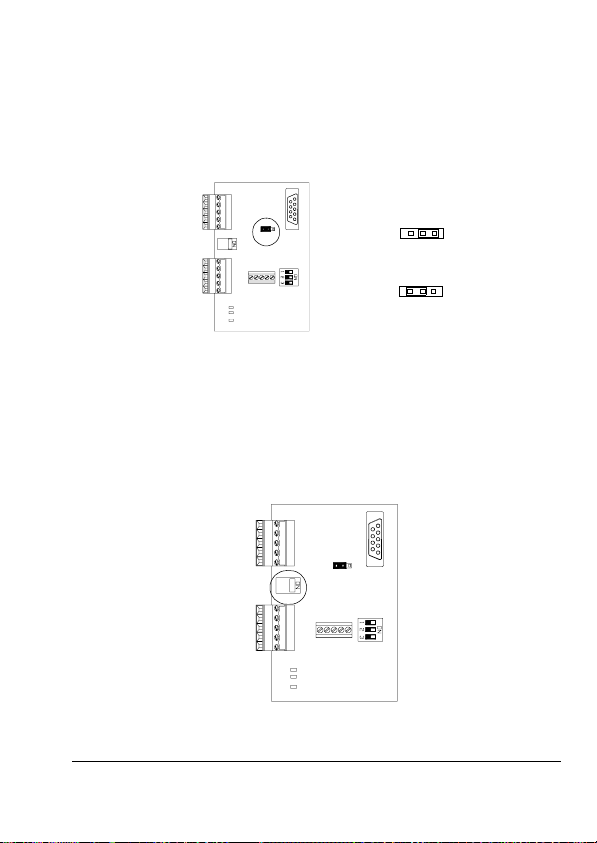

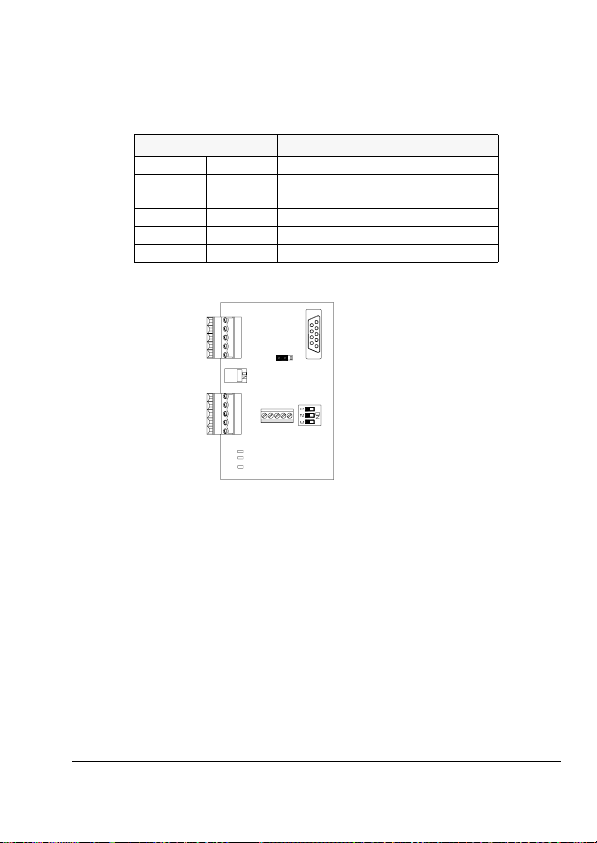

Connectors and Switches

The adapter operates either in RS232 mode or RS485 mode. The mode can be

selected with a jumper. By default, the adapter operates in RS485 mode at a

communication speed of 9600 bps (bits per second).

RS485 terminal X1

RS485 bus termination

switch S1

RS485 terminal X2

LEDs:

TxD

RxD

Powe r

1 2 3 4 5 1 2 3 4 5

RS232 terminal X4

RS323/RS485 mode

selection jumper S3

Communication

speed setting

DIP switch S2

Figure 2-2 Connectors and switches.

RS485 and RS232 Adapter Installation and Start-up Guide 2-3

Page 14

Chapter 2 – Installation

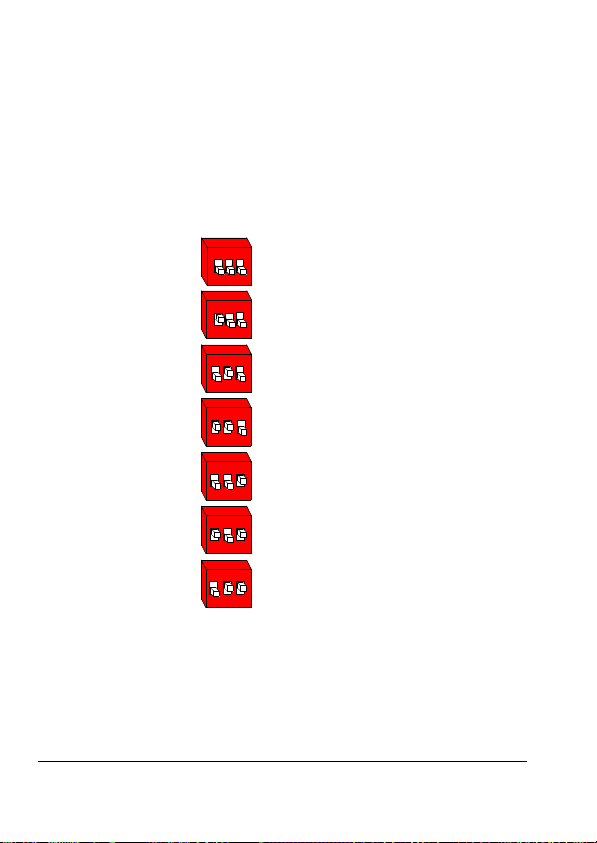

Selecting the Communication Speed

Communication speed is selected by DIP switch S2 and by parameter 5201

COMM SPEED. The factory setting for the communication speed is 9600 bps (bits

per second).

Communication speed setting using DIP switch S2 is needed only when the

adapter operates in RS485 mode.

DIP switch S2 Communication speed

ON

1 23

ON

1 23

ON

1 23

ON

1 23

ON

123

ON

123

ON

123

123

300 bps

600 bps

1200 bps

2400 bps

4800 bps

9600 bps

19200 bps

Figure 2-3 Selecting the communication speed for the adapter.

2-4 RS485 and RS232 Adapter Installation and Start-up Guide

Page 15

Chapter 2 – Installation

Selecting RS485 or RS232 Mode

The adapter operates either in RS232 mode or in RS485 mode, selectable by a

jumper. As a factory setting, the adapter operates in RS485 mode.

Jumper S3

S3

Mode

RS485

1

RS232

2

Figure 2-4 Selecting the operating mode.

RS485 Bus Termination

The RS485 bus must be terminated using 120 9 resistors at both ends of the

network. The adapter has built-in termination resistors that can be enabled by

the bus termination switch S1. Refer to 'Ear thing and Termination' on page 2-

11. By default, bus termination is enabled (ON).

Bus termination switch

S1

Figure 2-5 Selecting RS485 termination impedance.

RS485 and RS232 Adapter Installation and Start-up Guide 2-5

Page 16

Chapter 2 – Installation

Installation to RS485 Bus

1 Make sure power is not connected to the ACS 160.

2 Set the adapter switches:

• Confirm that the operation mode is RS485 (jumper S3)

• Set communication speed of the adapter with DIP switch S2

• If the termination is not needed, use switch S1 to disable it.

3 Mount the adapter on the side of the ACS 160. Leave the drive connection

cable disconnected.

4 Wire the adapter to the RS485 network (X1 and X2).

5 Connect the control panel to the drive.

6 Connect power to ACS 160.

7 Set up communication: Station number, communication speed of the drive

and parity. Refer to Chapter 3 – Programming.

8 Set up other drive parameters as needed. Refer to ACS 160 User’s Manual

and Chapter 3 of this manual.

9 Disconnect power from the ACS 160.

10 Disconnect control panel and connect drive connection cable of the adapter.

Wiring

The RS485 link is a daisy-chained bus, without dropout lines. The RS485 link

should also be ter minated on both physical ends of the wire to reduce the noise

on the network.

Modbus network should be wired using Belden 9841 or equivalent. Belden

9841 is a single twisted shielded pair cable with a wave impedance of 120

9.

The network should be connected according to Figure 2-6 below.

1 2 3 4 5

1 2 3 4 5

Figure 2-6 RS485 wiring.

2-6 RS485 and RS232 Adapter Installation and Start-up Guide

Page 17

Chapter 2 – Installation

Table 2-1 RS485 connection terminals. Terminals X1 and X2 are connected in

parallel.

X1, X2 Description

1 - No connection

2 C Common. Connected to ACS 160

3 A Data negative

4 B Data positive

5 Shield Cable shield

chassis through 100

9 impedance

RS485 terminal X1

RS485 terminal X2

Figure 2-7 RS485 connection terminals X1 and X2.

RS485 and RS232 Adapter Installation and Start-up Guide 2-7

Page 18

Chapter 2 – Installation

Installation to RS232 Bus

1 Make sure power is not connected to the ACS 160.

2 Confirm that the operation mode is RS232 (jumper S3).

3 Mount the adapter on the side of the ACS 160.

4 Connect the control panel to the drive.*

5 Connect power to ACS 160. *

6 Set up communication: Station number, communication speed of the drive

and parity. Refer to Chapter 3 – Programming. *

7 Set up other drive parameters as needed. Refer to ACS 160 User’s Manual

and Chapter 3 of this manual. *

8 Disconnect power from the ACS 160.

9 Disconnect control panel.

10 Connect drive connection cable of the adapter. Plug in the RS232 cable

(X4).

* These steps can be ignored when using DriveWindow Light PC tool, or when

the default communication settings are used.

2-8 RS485 and RS232 Adapter Installation and Start-up Guide

Page 19

Chapter 2 – Installation

Wiring

RS232 bus is a point-to-point type bus. Typical usage is to temporarily connect

the drive into the serial port of a PC. Cover of the adapter module can not be

closed when RS232 connector is used.

The maximum RS232 cable length is 3 meters. The RS232 cable is not

included in the delivery.

PC

ACS 160

Max Cable length 3 m

Serial Port

Figure 2-8 RS232 wiring.

RS485 and RS232 Adapter Installation and Start-up Guide 2-9

Page 20

Chapter 2 – Installation

X4

12345

6789

Figure 2-9 RS232 signals. DTR and DSR as well as RTS and CTS signals are

internally connected. The RS232 cable should not have TxD and RxD signals

connected across.

X4 Description

1NC

2TxD

3RxD

4DTR

5SGND

6DSR

7RTS

8CTS

9NC

2-10 RS485 and RS232 Adapter Installation and Start-up Guide

Page 21

Chapter 2 – Installation

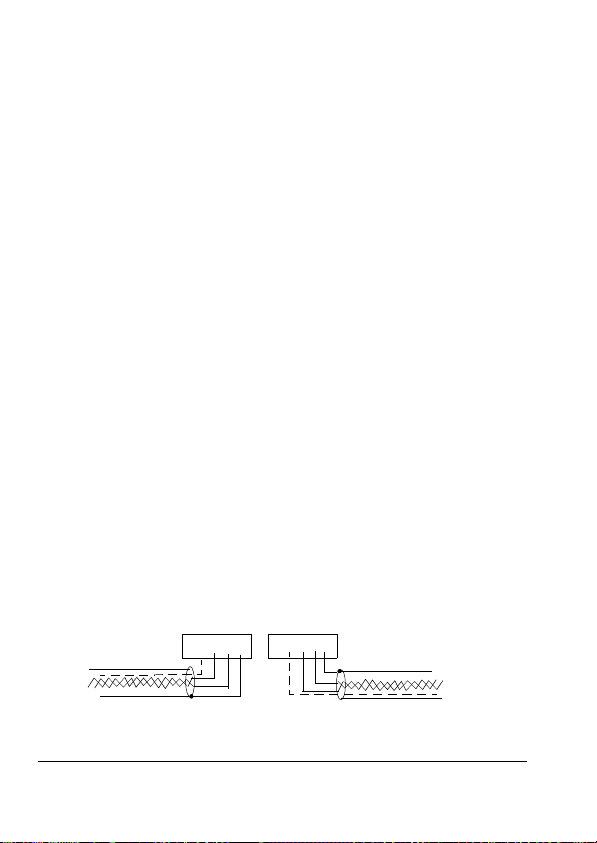

Earthing and Termination

RS485 Bus

The RS485 network should not be directly earthed at any point. All the devices

on the network should be well ear thed using their corresponding earthing

terminals.

As always, the earthing wires should not form any closed loops, and all the

devices should be earthed to a common earth.

The RS485 network must be terminated using 120

9 resistors at both ends of

the network as shown in Figure 2-10. These resistors are already resident on

the adapter. Use switch S1 to connect the termination resistors.

Terminated Terminated

Figure 2-10 Termination for the RS485 link.

The connections may only be made with the drive disconnected from the

power source.

RS485 and RS232 Adapter Installation and Start-up Guide 2-11

Page 22

Chapter 2 – Installation

2-12 RS485 and RS232 Adapter Installation and Start-up Guide

Page 23

Chapter 3 – Programming

This chapter describes how to program the ACS 160 drive for Modbus

communication.The reader should be already familiar with programming the

drive parameters using the control panel, and the way the parameters are

arranged in groups. For details, see the ACS 160 User’s Manual.

General

When power is connected, the ACS 160 will automatically check for the

presence of the panel.

If the panel is NOT detected in 7 seconds after power up, the ACS 160 will set

up Modbus communication normally, using the parameters 5201

COMM SPEED and 5203 PARITY. This communication setting is then used

5202

until the next power-down.

Note! If any of the parameters 5201 STAT ION ID, 5202 COMM SPEED and 5203

PARITY has been altered, the control panel will operate only if it is connected

before the power is applied to the ACS 160 (or immediately after power-up).

STATION ID,

Note! If any of the parameters 5201

PARITY is altered, the modification takes effect only on the next power-up, and if

STATION ID, 5202 COMM SPEED and 5203

the control panel is not connected when the power is applied.

RS485 and RS232 Adapter Installation and Start-up Guide 3-1

Page 24

Chapter 3 – Programming

Communication Settings

The configuration information is in Group 52. The contents of this group are

shown in Table 3-1 below.

Table 3-1 Communication parameters.

Code Name Range Default User

Group 52

SERIAL COMM

5201

5202

STATION NUMBER

COMM SPEED

1 - 247 1

3 = 300 bps

6 = 600 bps

12 = 1200 bps

96 (9600 bps)

24 = 2400 bps

48 = 4800 bps

96 = 9600 bps

192 = 19200 bps

5203

5204

5205

PARITY

COMM FAULT TIME

COMM FAULT FUNC

0 - 2 0 (NONE)

0.1 - 60.0 s 1.0 s

0 - 3 0 (NOT SEL)

3-2 RS485 and RS232 Adapter Installation and Start-up Guide

Page 25

Chapter 3 – Programming

Code Name

5201

STATION NUMBER

Sets the slave number for the ACS 160 in Modbus network.

Range: 1 - 247

Note! Modifications take effect only on the next power up.

5202

COMM SPEED

Defines the communication speed of the ACS 160 in bits per second

(bps).

3 = 300 bps 48 = 4800 bps

6 = 600 bps 96 = 9600 bps

12 = 1200 bps 192 = 19200 bps

24 = 2400 bps

Note! Modifications take effect only on the next power-up.

5203

PARITY

Defines the parity to be used in Modbus communication. Parameter also

defines the number of stop bits. In Modbus communication, the number

of stop bits is 2 with no parity bit, and 1 with even or odd parity.

0 =

NONE

1 = EVEN

2 = ODD

Note! Modifications take effect only on the next power-up.

5204

COMM FAULT TIME

Time limit for communication loss detection. This parameter is used

together with parameter 5205

operation when the communication with the master device in the Modbus

network is lost.

The master device in the Modbus network must signal its presence to

every slave device (ACS 160) in the network by periodically writing

COMM FAULT FUNC to define the ACS 160

Command Word, External Reference 1 or External Reference 2 to each

ACS 160 in the network. Maximum write period is set by this parameter.

Range: 0.1 - 60.0 s

Note! During the first 4 seconds after power-up, communication fault is

not evaluated to compensate for possible long system start-up delay.

RS485 and RS232 Adapter Installation and Start-up Guide 3-3

Page 26

Chapter 3 – Programming

Code Name

5205

COMM FAULT FUNC

Operation in case the communication with the master device is lost. The

time limit for communication loss detection is set by parameter 5204

COMM FAULT TIME.

NOT SEL

0 =

Communication loss is not detected.

FAULT

1 =

A fault indication is shown on the control panel display and included in the

Status Word. The ACS 160 coasts to stop.

2 =

CONST SPEED 7

A warning indication is shown on the control panel display and included in

the Status Word. The speed reverts to the level set by parameter 1208

CONST SPEED 7.

LAST SPEED

3 =

A warning indication is shown on the control panel display and included in

the Status Word. The speed reverts to the level set by the current

frequency reference.

Warning! If

CONST SPEED 7 or LAST SPEED is selected, ensure it

is safe to continue operation in case communication with the

master device fails.

3-4 RS485 and RS232 Adapter Installation and Start-up Guide

Page 27

Chapter 3 – Programming

Control Locations

The ACS 160 drive can receive control signals from multiple sources (such as

the digital and analogue inputs, the control panel, and a fieldbus adapter). The

user can separately determine the source for each type of control information.

Especially refer to parameter groups 10, 11 and 16 in the ACS 160 User’s

Manual for information on the selection parameters.

RS485 and RS232 Adapter Installation and Start-up Guide 3-5

Page 28

Chapter 3 – Programming

Diagnostic Counters

Diagnostic counters can be used for debugging the Modbus system.

Counters will roll over from 65535 to 0. The counter values are stored to

permanent memory when power is disconnected.

Counters can be reset from the control panel by pressing the UP and DOWN

buttons simultaneously when in parameter set mode, or by setting them to zero

via the serial communication channel.

Code Name Range User

Group 52

SERIAL COMM

5206 BAD MESSAGES 0 - 65535

5207 GOOD MESSAGES 0 - 65535

5208 BUFFER OVERRUNS 0 - 65535

5209 FRAME ERROS 0 - 65535

5210 PARITY ERROS 0 - 65535

5211 CRC ERROS 0 - 65535

5212 BUSY ERROS 0 - 65535

5213 SER FAULT MEM 1 0 - 3

5214 SER FAULT MEM 2 0 - 3

5215 SER FAULT MEM 3 0 - 3

Note! Parameters 5206 - 5212 are displayed in hexadecimal format by the

control panel. The panel displays three decimal points to indicate a

hexadecimal number control panel.

0.A.1.4

Figure 3-1 An example of the control panel displaying a hexadecimal number

A14 (2580 decimal).

3-6 RS485 and RS232 Adapter Installation and Start-up Guide

Page 29

Chapter 3 – Programming

Code Description

5206

BAD MESSAGES

This diagnostics counter increases by one every time the ACS 160 finds

any kind of communication error. During normal operation, this counter

hardly ever increases.

5207

GOOD MESSAGES

This diagnostics counter increases by one every time a valid Modbus

message has been received by the ACS 160. During normal operation, this

counter increases constantly.

5208

BUFFER OVERRUNS

The longest possible message length for the ACS 160 is 32 bytes. If a

message exceeding 32 bytes is received, this diagnostic counter increases

by one every time a character is received and cannot be placed in the

buffer.

5209

FRAME ERRORS

This diagnostic counter increases by one every time when a character with

a framing error is received from the bus.

• Communication speed settings of the devices connected to the bus

differ.

• Ambient noise levels may be too high.

5210

PARITY ERRORS

This diagnostic counter increases by one every time when a character with

a parity error is received from the bus.

• Parity settings of the devices connected in the bus differ.

• Ambient noise levels may be too high.

5211

CRC ERRORS

This diagnostic counter increases by one every time when a message with

a CRC error is received.

• Ambient noise levels may be too high.

• CRC calculation is not performed correctly.

RS485 and RS232 Adapter Installation and Start-up Guide 3-7

Page 30

Chapter 3 – Programming

Code Description

5212

BUSY ERRORS

In Modbus network, only one device can transmit at any given time. This

diagnostic counter increases by one every time the ACS 160 receives a

character from the bus while it is still processing the previous message.

5213

SER FAULT MEM 1

Last Modbus exception code sent. Refer to "Exception Codes" on page 4-3.

5214

SER FAULT MEM 2

Previous Modbus exception code sent.

5215

SER FAULT MEM 3

Oldest Modbus exception code sent.

3-8 RS485 and RS232 Adapter Installation and Start-up Guide

Page 31

Chapter 4 – Communication

This chapter describes the Modbus communication on ACS 160 drives.

Introduction to Modbus

Modbus is a serial, asynchronous protocol. The Modbus protocol does not

specify the physical interface. Typical physical interfaces are RS232 and

RS485, both of which are supported by the adapter.

Modbus is designed for integration with Modicon PLCs or other automation

devices, and the services closely correspond to the PLC architecture. The

ACS 160 drive ‘looks like’ a Modicon PLC on the network.

If detailed information regarding the Modicon Modbus protocol is required,

contact your ABB supplier for a copy of Modbus Protocol Guide.

Register Read and Write

The ACS 160 has all drive parameter, control and status information mapped

into a 4xxxx register area. This holding register area can be read from an

external device, and an external device can modify the register values by

writing to them.

There are no setup parameters for mapping the data to the 4xxxx register. The

mapping is pre-defined and corresponds directly to the ACS 160 parameter

grouping.

All parameters are available for both reading and writing. The parameter writes

are verified for correct value, and for valid register addresses. Some

parameters never allow writes (including Group 1 actual values), some

parameters allow write only when the drive is stopped (including Group 99

setup variables), and some can be modified at any time (including e.g. Group

22 acceleration and deceleration ramp times).

RS485 and RS232 Adapter Installation and Start-up Guide 4-1

Page 32

Chapter 4 – Communication

Register Mapping

The drive parameters are mapped to the 4xxxx area so that:

• 40001 – 40099 are reserved for drive control registers

• 40101 – 40199 is reserved for the actual values (parameter group 1)

• 40201 – 40299 is reserved for parameter group 2

• 40301 – 40399 is reserved for fault and alarm information

•… other parameter groups

• 49901 – 49999 is reserved for the start-up data

In this mapping, the thousands and hundreds correspond to the group number,

while the tens and ones correspond to the parameter number within a group.

Register addresses 4GGPP are shown in Table 4-1. In this table GG is the

group number, and PP is the parameter number within the group

Table 4-1 Parameter mapping.

4GGPP GG PP

40001 – 40006 00 Drive control registers 01 Command word

40102 – 40130 01 OPERATING DATA 02

41001 – 41003 10 COMMAND INPUTS 01 EXT 1 COMMANDS

41101 – 41108 11 REFERENCE SELECT 01 KEYPAD REF SEL

…… …

49901 – 49908 99 START-UP DATA 02

02 Reference 1

03 Reference 2

04 Status word

05 Actual value 1

06 Actual value 2

SPEED

…

30

OLDEST FAULT

02 EXT2 COMMA NDS

03 DIRECTION

…

08

CONST SPEED 7

APPLIC MACRO

…

08

MOTOR NOM SPEED

4-2 RS485 and RS232 Adapter Installation and Start-up Guide

Page 33

Chapter 4 – Communication

The register addresses between the groups are invalid. No reads or writes are

allowed for these addresses. If there is an attempt to read or write outside the

parameter addresses, the Modbus interface will return an exception code to the

controller.

Exception Codes

The ACS 160 supports the standard Modbus exception codes. These are

shown in Table 4-2.

Table 4-2 Exception codes.

Code Name Meaning

01 ILLEGAL

FUNCTION

02 ILLEGAL DATA

ADDRESS

03 ILLEGAL DATA

VAL UE

The function code received in the query is not an

allowable action for the slave.

ACS 160 : Unsupported Command.

The data address received in the query is not an

allowable address for the slave.

ACS 160 : Address outside groups

A value contained in the query data field is not an

allowable value for the slave.

ACS 160 : Value outside min-max limits

ACS 160 : Parameter is read-only

ACS 160 : Message is too long

ACS 160 : Parameter write not allowed when start is

active

ACS 160 : Parameter write not allowed when factory

macro is selected

RS485 and RS232 Adapter Installation and Start-up Guide 4-3

Page 34

Chapter 4 – Communication

Function Codes

The ACS 160 supports the Modbus function codes given in Table 4-3. If any

other function codes are used ACS 160 returns an exception response with

error code 01 (illegal function).

Table 4-3 Function codes.

Code Description

03 Read holding registers

06 Preset single register

16 (10 Hex) Preset multiple registers

The Control Word and the Status Word

Holding registers: 40001 (Control Word), 40004 (Status Word)

The Control Word (CW) is the principal means for controlling the drive from a

fieldbus system. It is effective when the drive is in external (remote) control and

the controlling commands are received through serial communication channel

(set by parameters 1001 EXT1 COMMANDS, 1002 EXT2 COMMANDS and

1102 EXT1/EXT2 SEL).

The Control Word (detailed in Table 4-4) is sent by the fieldbus master station

to the drive. The drive switches between its states according to the bit-coded

instructions of the Control Word. See also state machine in Figure 4-1.

The Status Word (SW) is a word containing status information, sent by the drive

to the master station. The composition of the Status Word is explained in Table

4-6.

Note! Operation of Control Word and Status Word conforms to ABB Drives

Profile with the exception of Control Word bit #10 (REMOTE_CMD), which is

not used by the ACS 160.

4-4 RS485 and RS232 Adapter Installation and Start-up Guide

Page 35

Chapter 4 – Communication

Table 4-4 The Control Word. See also the State machine in Figure 4-1.

Bit Value Description

01

11

21

30 -1

4

5 1

61

70 - 1

8 to 10

11 1

12 to 15

Enter READY TO OPERATE

Emergency OFF. Ramp to stop according to parameter 2203

0

DECELER TIME 1. Enter OFF1 ACTIVE; proceed to READY TO

SWITCH ON unless other interlocks (OFF2, OFF3) are active.

Continue operation (OFF2 inactive)

Emergency OFF, coast to stop.

0

Enter

OFF2 ACTIVE; proceed to SWITCH-ON INH IBITED.

Continue operation (OFF3 inactive)

Emergency stop. Drive ramps to stop according to parameter

0

2205

DECELER TIME 2. Enter OFF3 ACTIVE; proceed to SWITCH-ON

INHIBITED.

Enter OPERATION ENABLED (N ote that also the Run enable signal

must be present on a digital input – see parameter 1601

ENABLE.)

Inhibit operation. Enter OPERATION INHIBITED

0

Unused.

Normal operation.

Enter

RAMP FUNCTION GENERATOR: ACCELERATOR ENABLED

Halt ramping (Ramp Function Generator output held)

0

Normal operation. Enter OPERATING

Force Ramp Function Generator input to zero.

0

Fault reset (enter SWITCH-ON INHIBITED)

(Continue normal operation)

0

Unused

Select external control location 2 (EXT2)

Select external control location 1 (EXT1)

0

Unused

RUN

RS485 and RS232 Adapter Installation and Start-up Guide 4-5

Page 36

Chapter 4 – Communication

Example on Using the Control Word

The following example shows how to use the Control Word to star t the drive.

When the power is connected for the first time, the state of the drive (see the

state machine in Figure 4-1) is

to step through the state machine states until

NOT READY TO SWI TCH ON. Control Word is used

OPERATING state is reached,

meaning that the drive is running and follows the given reference.

Table 4-5 Using the Control Word.

Control Word Value Description

Step 1 CW = 0000 0000 0000 0110 When this value is written, drive

state changes to

bit 0bit 15

ON.

READY TO SWITCH

Step 2 Wait at least 100 ms before

proceeding.

Step 3 CW = 0000 0000 0000 0111 When this value is written, drive

state changes to

READY TO OPERATE.

Step 4 CW = 0000 0000 0000 1111 When this value is written, the drive

starts, but will not accelerate. Drive

state changes to

ENABLED.

OPERATION

Step 5 CW = 0000 0000 0010 1111 When this value is written, the ramp

function generator (RFG) output is

released. Drive state changes to

RFG: ACCELERATOR ENABLED.

Step 6 CW = 0000 0000 0110 1111 When this value is written, the ramp

function generator (RFG) input is

released. Drive state changes to

OPERATING. Drive will accelerate to

the given reference and will follow

the reference.

This example assumes that the ACS 160 is in remote control, that external

control place 1 (EXT1) is the active control place (as selected by parameter

1102), and that EXT1 start and stop commands are received through serial

communication (parameter 1001).

4-6 RS485 and RS232 Adapter Installation and Start-up Guide

Page 37

Table 4-6 The Status Word

Bit Value Description

01

11

21

30 - 1

41

51

61

71

81

91

10 1

11 1

12 1

13 to

ready to switch on

not ready to switch on

0

ready to operate

off1 active

0

operation enabled

Not ready (OPERATION INHIBITED)

0

fault

No fault

0

OFF2 inactive

OFF2 ACTIVE

0

OFF3 inactive

OFF3 ACTIVE

0

switch-on inhibited

0

Alarm is active. See Diagnostics section for a list of relevant

alarms.

No alarm

0

OPERATING. Actual value equals reference value (= is within

tolerance limits).

Actual value differs from reference value (= is outside tolerance

0

limits)

Drive control location: REMOTE

Drive control location: LOCAL

0

The value of first supervised parameter equals to or is greater than

supervision limit. Refer to Group 32 Supervision.

The value of first supervised parameter is below supervision limit

0

External control location 2 (EXT 2) selected

External control location 1 (EXT 1) selected

0

Run Enable signal received

No Run Enable signal received

0

Unused

15

Chapter 4 – Communication

RS485 and RS232 Adapter Installation and Start-up Guide 4-7

Page 38

Chapter 4 – Communication

References

References are 16-bit words comprising a sign bit and a 15-bit integer. A

negative reference (indicating reversed direction of rotation) is formed by

calculating the two’s complement from the corresponding positive reference

value.

Reference 1

Holding Register: 40002

Reference 1 can be used as the frequency reference

The signal source of external reference 1 (

external control location 1 (

EXT REF 1 SELECT and 1102 EXT 1/EXT2 SEL.

EXT1) must be activated. Refer to parameters 1103

REF1) must be set to COMM and

REF1 for the ACS 160.

Reference 2

Holding Register: 40003

Reference 2 can be used as the frequency reference

The signal source of external reference 2

External control location 2 (

EXT REF 2 SELECT and 1102 EXT 1/EXT2 SEL.

EXT2) must be activated. Refer to parameters 1106

REF2 must be set to COMM and

REF2 for the ACS 160.

4-8 RS485 and RS232 Adapter Installation and Start-up Guide

Page 39

Chapter 4 – Communication

Fieldbus Reference Scaling

Fieldbus references are scaled as follows:

Reference 1: 20000 EXT REF1 MAX (Hz, parameter 1105). Scaling

Parameter 1104 EXT REF1 MIN is not used.

Reference 2: 10000 EXT REF2 MAX (%, parameter 1108). Scaling Parameter

1107 EXT REF2 MIN is not used.

Fieldbus Reference

Fieldbus reference is selected by setting a reference selection parameter –

1103 EXT REF1 SELECT or 1106 EXT REF2 SELECT – to COMM,

COMM+AI1 or COMM*AI1. The latter two enable correction of the fieldbus

reference using analogue input AI1. The following table explains these

selections. Note that the analogue input value is a percentage value (0-100 %)

which can be seen in parameter 0118 AI1. When the analogue input is 50 %,

the correction is 0. When the input is <50 % (>50 %), the correction reduces

(respectively increases) the reference used.

Table 4-7 Correcting the fieldbus reference through analogue input.

Parameter

Setting

COMM None

COMM+AI1 Corrected fieldbus reference = give n fieldbus reference + analogue

COMM*AI1 Corrected fieldbus reference = given fieldbus reference * analogue

Effect of AI1 Value on Fieldbus Reference

input AI1 value

input AI1 value / 50 %

RS485 and RS232 Adapter Installation and Start-up Guide 4-9

Page 40

Chapter 4 – Communication

Example of the effect of AI1 value on fieldbus reference.

Assume that 2008

MAXIMUM FREQ = 50 Hz

Assume that fieldbus reference 1 is 5000 (corresponding to 25 % of full scale)

and voltage at AI1 is 3 V (corresponding to 30 % of full scale).

1. If setting

COMM+AI1 is used, then corrected fieldbus reference is 25 % + 30 %

- 50 % = 5 % or 2.5 Hz.

2. If setting

COMM*AI1 is used, then corrected fieldbus reference is 25 % * 30 %

/ 50 % = 15 % or 7.5 Hz.

REF

100 %

AI

+

m

m

o

c

I

A

*

50 %

.

2

.

1

50 %

m

m

o

c

FIELDBUS REFERENCE

AI1

100 %

4-10 RS485 and RS232 Adapter Installation and Start-up Guide

Page 41

Chapter 4 – Communication

Actual Values

Actual values are read-only values containing information on the operation of

the drive. Actual values are 16-bit words containing sign bit and a 15-bit

integer. A negative value is given as two’s complement of the corresponding

positive value.

Actual Value 1

Holding Register: 40005

Actual output frequency. Scaling: 5000 50 Hz.

Actual Value 2

Holding Register: 40006

Actual output current. Scaling: 10 1 A.

RS485 and RS232 Adapter Installation and Start-up Guide 4-11

Page 42

Chapter 4 – Communication

From any state

Emergency Stop

OFF3

(CW Bit2=0)

(SW Bit5=0)

f=0 / I=0

(SW Bit1=0)

f=0 / I=0

*This state transition occ urs also if the fault is reset

from any other source (e.g. digital input).

State I = Output current

CW = Control Word f = Output frequen cy

SW = Status Word RF G = Ramp Function Generator

OFF3

ACTIVE

From any state

OFF1

OFF1

ACTIVE

(SW Bit2=0)

From any state

Emergency Off

OFF2

(CW Bit1=0)

OFF2

(SW Bit4=0)

ACTIVE

(CW Bit0=0)

MAINS OFF

Power ON (CW Bit0=0)

ACD

(CW Bit3=0)

OPERATION

INHIBITED

CD

(CW Bit5=0)

D

(CW Bit6=0)

A

C

D

From any state

Fault

FAULT

(CW Bit7=1)*

SWITCH-ON

INHIBITED

NOT READY

TO SWITCH ON

(CW=xxxx xxxx xxxx x

READY TO

SWITCH ON

(CW=xxxx xxxx xxxx x

READY TO

OPERATE

(CW Bit3=1 and

SW Bit12=1)

OPERATION

ENABLED

(CW Bit5=1)

RFG: ACCELE RATOR

ENABLED

(CW Bit6=1)

OPERATING

(SW Bit3=1)

(SW Bit6=1)

(

SW Bit0=0

(SW Bit0=1)

(SW Bit1=1)

(SW Bit2=1)

(SW Bit8=1)

)

110

)

111

)

Figure 4-1The state machine for evaluation of start and stop signals.

4-12 RS485 and RS232 Adapter Installation and Start-up Guide

Page 43

Chapter 4 – Communication

Fault and Alarm Status

The ACS 160 provides fault and alarm status words for the external control

system. These data words are accessible only through the serial

communication link but not from the control panel.

Fault and alarm status words are located in parameter group 3. The group also

contains copies of the Control Word and Status Word. Group 3 parameters are

of read-only type; however, both alarm words can be reset by writing a zero to

them.

Table 4-8 Fault and alarm status words.

No Name Description

40301

40302

40305

40306

MAIN COMMAND

WORD

MAIN STATUS

WORD

FAULT WORD 1

FAULT WORD 2

Read-only copy of the Command Word

(40001). See page 4-4.

Read-only copy of the Status Word (40004).

See Table 4-6.

Fault information. When a fault is active

corresponding bit is set. Bit descriptions are

given in Table 4-9.

Fault information. When a fault is active, the

corresponding bit is set. Bit descriptions are

given in Table 4-9.

40308

ALARM WORD 1

Alarm information. When an alarm is active

corresponding bit is set. Bits remain set until

whole alarm word is reset by writing 0 to it.

See Table 4-10.

40309

ALARM WORD 2

Alarm information. When an alarm is active

corresponding bit is set. Bits remain set until

whole alarm word is reset by writing 0 to it.

See Table 4-10.

RS485 and RS232 Adapter Installation and Start-up Guide 4-13

Page 44

Chapter 4 – Communication

Table 4-9 Bit descriptions for fault words 1 and 2. See also the Diagnostics

section in the ACS 160 User’s Manual for more information about faults and

fault codes.

Bit # Fault Word 1 Fault Word 2

0 Overcurrent Underload

1 DC overvoltage Reserved

2 ACS160 overtemperature DDCS Link

3 Fault current Reserved

4 Output overload

5 DC undervoltage

6 Analogue input 1 fault

7 Analogue input 2 fault

8 Motor overtemperature Hardware error

9 Panel loss

10 Parameters inconsistent

11 DC bus ripple too large

12 Motor stall

13 Serial communication loss

14 External fault

15 Output earth fault

4-14 RS485 and RS232 Adapter Installation and Start-up Guide

Page 45

Chapter 4 – Communication

Table 4-10 Bit descriptions for alarm words 1 and 2. See also the Diagnostics

section for more information about alarms and alarm codes. .

Bit # Alarm Word 1 Alarm Word 2

0 Overcurrent controller alarm Overload alarm

1 Overvoltage controller alarm Autorest alarm

2 Undervoltage controller alarm PID sleep alarm

3 Direction lock alarm Autochange alarm. Reserved

4 Serial communication loss Interlock alarm. Reserved

5 Modbus exception Brake resistor overload alarm

6 Analogue input 1 loss

7 Analogue input 2 loss

8 Panel loss

9 ACS 160 overtemperature

10 Motor overtemperature

11 Underload

Reserved

RS485 and RS232 Adapter Installation and Start-up Guide 4-15

Page 46

Chapter 4 – Communication

4-16 RS485 and RS232 Adapter Installation and Start-up Guide

Page 47

Chapter 5 – Fault Tracing

This chapter gives step-by-step diagnostics information for finding out the

causes and corrections to the most common problems with the adapter.

Power LED of the adapter is illuminated, but Receive

(RxD) and Transmit (TxD) LEDs are not blinking

• The master device is not transmitting.

• The cable is not correctly connected to connector X1/

X2 (in RS485 mode) or X4 (in RS232 mode).

• Operation mode (RS485 or RS232) of the adapter is

not correct: Check jumper S3.

Receive LED blinks but there is no response from the

ACS 160 (Transmit LED is not blinking)

• The master device is not using the same communication settings as the ACS 160.

• The ACS 160 is using the communication settings of

the control panel: Turn power off and then on again.

Receive and Transmit LEDs are blinking, but the drive

does not follow commands given by the master device

• The drive is not in remote control mode.

• The drive parametering is incorrect: Control com-

mands are not accepted from the serial communication

channel.

RS485 and RS232 Adapter Installation and Start-up Guide 5-1

Page 48

Chapter 5 – Fault Tracing

Receive and Transmit LEDs are blinking, but the

responses ACS 160 sends are not intelligible

• DIP switch S2 and parameter 5202 COMM SPEED do not

have the same speed setting.

• Ambient noise level is too high.

The control panel is not operating and panel display blinks

• Panel is not properly connected to the drive.

• The drive is using different communication settings from

the panel: Connect the panel and then turn power off and

then on again.

Group 52 is not visible on the control panel

• Make full parameter set visible by selecting menu function

-LG- and pressing and holding ENTER button down until

display blinks.

Take advantage of the group 52 diagnostic counters. If necessary, use

parameter 9902

APPLIC MACRO to restore the parameter settings of the

ACS 160 to their default values and then reconfigure the drive.

5-2 RS485 and RS232 Adapter Installation and Start-up Guide

Page 49

Appendix A – Parameter Scaling

This chapter is intended for people who are using the drive data through the

Modbus connection, and need to know in what units the data is available for

reading and writing.

Effect of Resolution

Parameter values are read and written through serial communication using

integer values. When the given parameter resolution is 0.1, desired value must

be multiplied by 10 to produce the integer value.

For example, to set parameter 2202

value of 60.5 s, value 605 must be written through serial communication.

Signed Values

Normally, parameter values are represented as signed integers. Negative

values are given in the 2’s complement format. To calculate the 2’s

complement, take the corresponding positive value, negate it and add 1.

Signed integer values range from -32768 to 32767.

Note! Diagnostic counter values (parameters 5206 - 5215) are represented as

unsigned integers. In this case values extend from 0 to 65535.

The parameters and their resolutions are listed in the ACS 160 User’s Manual.

ACCELER TIME 1 (resolution 0.1 s) to the

RS485 and RS232 Installation and Start-up Guide A-1

Page 50

Appendix A – Parameter Scaling

A-2 RS485 and RS232 Installation and Start-up Guide

Page 51

Appendix B– Technical Data

RS-485 Link

Compatible devices: All devices compatible with Modbus protocol

Size of the link: 247 stations including repeaters (31 stations and 1 repeater per

segment)

Medium: Shielded, twisted pair RS-485 cable (Belden 9841 or equivalent)

Termination: Built in CFB-RS module

Maximum bus length: 1200 m

Topology: Multi-drop

Serial communication type: Asynchronous, half duplex

Transfer rate: 300 bit/s, 600 bit/s, 1200 bit/s, 2400 bit/s, 4800 bit/s, 9600 bit/s,

19200 bit/s.

Protocol: Modbus

CFB-RS

Enclosure: Cast aluminium

Dimensions: 124 x 79 x 42 mm (without cable glands)

Degree of protection: IP65

Mounting: Onto ACS 160 drive

Settings: Via drive interface (control panel)

Current consumption: 100 mA

Connectors: Two Phoenix Contact MC 1,5/5-ST-3,81 (5-pole, cross-section

2

max) screw terminal blocks.

1,5 mm

RS485 and RS232 Installation and Start-up Guide B-1

Page 52

Appendix B– Technical Data

X1, X2 Description

1 - No connection

2 C Common

3 A Data negative

4 B Data positive

5 Shield Cable shield

General: Complies with EMC standards EN50081-1 and EN50082-2

B-2 RS485 and RS232 Installation and Start-up Guide

Page 53

Appendix C– Ambient Conditions

Operation

The following conditions apply to stationar y use of the module.

Installation Site Altitude: 0 to 2000 m above sea level. If the installation site is

higher than 2000 m above sea level, please contact your local ABB

representative for further information.

Temperature: -10 to +50

Contamination Levels (IEC 721-3-3):

Chemical gases: Class 3C3

Solid particles: Class 3S3

Sinusoidal Vibration

(IEC 721-3-3, 2nd Edition 1994-12):

Max 3 mm (2 to 9 Hz)

Max 10 m/s

Shock (IEC 721-3-3, 2nd Edition 1994-12):

Max 250 m/s

2

(9 to 200 Hz)

2

, 6 ms

Storage and Transportation

The following conditions apply to storage and transportation of the module in

the protective package.

Temperature: -40 to +70

Contamination Levels (IEC 721-3-3):

Storage:

Chemical gases: Class 1C2

Solid particles: Class 1S3

Transportation:

Chemical gases: Class 2C2

Solid particles: Class 2S2

Shock (IEC 721-3-3, 2nd Edition 1994-12):

Max 300 m/s

2

, 18 ms

°C

°C

RS485 and RS232 Installation and Start-up Guide C-1

Page 54

Appendix C– Ambient Conditions

C-2 RS485 and RS232 Installation and Start-up Guide

Page 55

Page 56

ABB Industry Oy

P.O.Box 184

FIN-00381 Helsinki

FINLAND

Telephone: +358 10 222 000

Fax: +358 10 222 2681

3BFE 64390431 R0125ENEFFECTIVE: 23.3.2001

Loading...

Loading...