Page 1

INSTALLATION AND OPERATING

NWS RESIDENTIAL

WATER SOFTENERS

MODELS:

NWS100 NWS100M

NWS150 NWS150M

NWS200 NWS200M

INSTRUCTIONS

Installer, please leave with homeowner.

Homeowner, retain for future reference.

INSTR2208 0110

Page 2

Read, understand, and follow all safety information contained in these instructions prior to installation and use of the NWS Series Water Softener. Retain these

instructions for future reference. Failure to follow installation, operation and maintenance instructions may result in property damage and will void warranty.

Intended use:

The NWS Series Water Softener is intended for use in softening water in homes and has not been evaluated for other uses. The system must be installed

indoors near the point of entry of a home water line, and be installed by qualifi ed professional installers according to these installation instructions.

EXPLANATION OF SIGNAL WORD CONSEQUENCES

SAFETY INFORMATION

WARNING

CAUTION

CAUTION

To reduce the risk associated with choking:

• Do not allow children under 3 years of age to have access to small parts during the installation of this product.

To reduce the risk associated with ingestion of contaminants:

• Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

To reduce the risk of physical injury:

• Shut off inlet water supply and depressurize system as shown in manual prior to service.

To reduce the risk associated with a hazardous voltage:

• If the home electrical system requires use of the cold water system as an electrical safety ground, a jumper must be used to ensure a suffi cient ground connection across

the fi lter installation piping — refer installation to qualifi ed personnel.

• Do not use the system if the power cord is damaged — contact qualifi ed service personnel for repair.

To reduce the risk associated with back strain due to the heavy weight of the various system components:

• Follow safe lifting procedures.

Indicates a potentially hazardous situation, which, if not avoided, could result in death or serious injury and/or property damage.

Indicates a potentially hazardous situation, which, if not avoided, may result in minor or moderate injury and/or property damage.

Indicates a potentially hazardous situation, which, if not avoided, may result in property damage.

WARNING

CAUTION

To reduce the risk associated skin, eye, and respiratory tract irritation from gravel and fi lter media during installation:

• Gravel and several types of fi lter media may be used in this product, depending upon the application. During installation, dust may cause irritation to skin, eyes, and

respiratory tract.

• Utilize a NIOSH-approved dust fi lter mask, protective gloves, and appropriate eye protection when handling and pouring gravel and fi lter media.

• To request an MSDS relating to this product call 203-238-8965 or visit the web at http://solutions.3M.com/WPS/Portal/3M/EN_US/MSDS (click MSDS search). For

emergencies, call 800-364-3577 or 651-737-6501 (24 hours).

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Read and follow Use instructions before installation and use of this water treatment system.

• Installation and use MUST comply with existing state or local plumbing codes.

• Protect from freezing, relieve pressure and drain system when temperatures are expected to drop below 33°F (0.6°C).

• Do not install on hot water supply lines. The maximum operating water temperature of this fi lter system is 110°F (43.3°C).

• Do not install if water pressure exceeds 100 psi. If your water pressure exceeds 80 psi (552 kPa), you must install a pressure limiting valve. Contact a plumbing

professional if you are uncertain how to check your water pressure.

• Do not install where water hammer conditions may occur. If water hammer conditions exist you must install a water hammer arrester. Contact a plumbing professional if you are uncertain how to check for this condition.

• Where a backfl ow prevention device is installed on a water system, a device for controlling pressure due to thermal expansion must be installed.

• Do not use a torch or other high temperature sources near fi lter system, cartridges, plastic fi ttings or plastic plumbing.

• On plastic fi ttings, never use pipe sealant or pipe dope. Use PTFE thread tape only, pipe dope properties may deteriorate plastic.

• Take care when using pliers or pipe wrenches to tighten plastic fi ttings, as damage may occur if over tightening occurs.

• Do not install in direct sunlight or outdoors.

• Mount system in such a position as to prevent it from being struck by other items used in the area of installation.

• Ensure all tubing and fi ttings are secure and free of leaks.

• SHUT OFF FUEL OR ELECTRIC POWER SUPPLY TO WATER HEATER after water is shut off.

• Do not install system where water lines could be subjected to vacuum conditions without appropriate measures for vacuum prevention.

• Do not apply heat to any fi tting connected to bypass or control valve as damage may result to internal parts or connecting adapters.

• Install on a fl at/level surface. It is also advisable to sweep the fl oor to eliminate objects that could pierce the brine tank.

To reduce the risk associated with property damage due to plugged water lines:

• Pay particular attention to correct orientation of control valve. Water fl ow should match arrow on control valve. The Inlet and Outlet of other water treatment

equipment products will vary depending on the control valve brand used.

• Failure to follow instructions will void warranty.

IMPORTANT NOTES

Page 3

TABLE OF CONTENTS

IMPORTANT NOTES

SECTION DESCRIPTION

1 BEFORE INSTALLATION

2 INSTALLATION

3 REGENERATION INSTRUCTIONS (Timing Setting Instructions)

4 SERVICE INSTRUCTIONS

5 SPECIFICATION AND OPERATING DATA

6 PARTS

7 MAINTENANCE

8 LIMITED WARRANTY

• Professional Installation Required: Installation requires shutting water off to home, cutting home water supply pipe and

using a welding torch to add piping and fittings. Specialized tools and skills are required. Not a do-it-yourself type of project.

Professional installation required!

IMPORTANT: SECTION 1: BEFORE INSTALLATION

Congratulations! We believe your purchase of this water softener will prove to be a very wise choice. When properly installed, operated, and maintained, your

new softener will provide years of dependable service. Before starting the installation please read this manual all the way through for an overview, and then

follow the installation in proper sequence. Failure to follow instructions will void warranty.

Inspecting And Handling Your Softener:

Inspect the equipment for shipping damage. If damaged, notify the transportation company and request a damage inspection.

Handle the equipment with care. Damage can result if dropped or if the brine tank is set on sharp, uneven projections on the fl oor. When handling, do not

turn the water softener unit upside down.

Make Sure Your Water Has Been Thoroughly Tested:

An analysis of your water should be made prior to the selection of your water conditioning equipment. Your dealer will generally perform this service for you,

and may send a sample to the factory for analysis and recommendations. Enter your analysis below for your permanent record.

Analysis of Your Water:

Hardness gpg Tannins (Humic Acid) ppm

Iron (Fe) ppm Hydrogen Sulfi de (H2S) ppm

Manganese (Mn) ppm Other ppm

pH ppm

IMPORTANT NOTES

Hydrogen sulfi de (H2S) must be tested for at the well site. For accuracy, the sample must be drawn with the pump RUNNING, and the test be completed

within ONE minute after the sample is drawn.

Softeners are designed to reduce hardness but can handle reasonable amounts of soluble iron if consideration is given to content when selecting

model and regeneration settings. To treat sulfur (hydrogen sulfi de), bacterial iron, precipitated iron or very high levels of soluble iron requires special

equipment in addition to a water softener. For best results, 3MAPPM System is recommended for use on waters containing more than 2 ppm of iron.

Other ppm

1-1

Page 4

Check Your Pumping Rate and Water Pressure:

Two water system conditions must be checked carefully to avoid unsatisfactory operation or equipment damage:

1) MINIMUM water pressure required at the water softener inlet is 20 psi (138 kPa). IF WATER PRESSURE IS OVER 80 psi (552 kPa), A PRESSURE REDUCING VALVE MUST BE INSTALLED IN THE WATER SUPPLY LINE AHEAD OF THE WATER SOFTENER.

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Do not install if water pressure exceeds 100 psi. If your water pressure exceeds 80 psi (552 kPa), you must install a pressure limiting valve. Contact a plumbing professional if you are uncertain how to check your water pressure.

NOTE: If you have a municipal or a community water supply and daytime water pressure is 85 psi or more, nighttime pressure may exceed 100

psi. Call your local water department or plant operator to obtain pressure readings. If you have a private well, the gauge on the pressure tank will

indicate the high and low system pressure. Record your water pressure data below:

Water Pressure:

Low psi High psi

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Do not install system where water lines could be subjected to vacuum conditions without appropriate measures for vacuum prevention.

The installer should take appropriate measures if there is the possibility a vacuum may occur. This would include the installation of an appropriate

device in the supply line to the system, i.e., a vacuum breaker or backfl ow prevention device. Vacuum damage voids the factory warranty.

2) The pumping rate of your well must be suffi cient for satisfactory operation and BACKWASHING of the water softener. (See SPECIFICATIONS AND

OPERATING DATA, Section 6)

Locate Water Conditioning Equipment Correctly:

Select the location of your water softener with care. Various conditions which contribute to proper location are as follows:

1) Locate as close as possible to water supply source.

2) Locate as close as possible to a drain.

3) Locate in correct relationship to other water conditioning equipment (Figure 1, page 2-1).

4) Locate the softener in the supply line BEFORE the water heater. Temperatures above 110°F (43.3°C) will damage the softener and void the factory

warranty.

5) DO NOT install the softener in a location where freezing temperatures occur. Freezing may cause permanent damage and will also void the factory

warranty.

6) Allow suffi cient space around the installation for easy servicing.

7) Provide a non-switched 110V, 60Hz (220V, 50Hz for specifi ed systems) power source for the control valve.

WARNING

To reduce the risk associated with ingestion of contaminants:

• Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Protect from freezing, relieve pressure and drain system when temperatures are expected to drop below 33°F (0.6°C).

• Do not install on hot water supply lines. The maximum operating water temperature of this fi lter system is 110°F (43.3°C).

1-2

Page 5

Facts to Remember While Planning Your Installation:

1) All installation procedures MUST conform to local and state plumbing codes.

2) If lawn sprinkling, a swimming pool, or geothermal heating/cooling or water for other devices/activities are to be treated by the water softener, a larger

model MUST be selected to accommodate the higher fl ow rate plus the backwashing requirements of the water softener. Consult our Customer Service

Department at 1-866-990-9785 for alternative instructions if the pumping rate is insuffi cient.

3) Remember that the water softener INLET is attached to the pipe that supplies water (i.e. runs to the pump) and the OUTLET is the line that runs

toward the water heater.

CAUTION

To reduce the risk associated with property damage due to plugged water lines:

• Pay particular attention to correct orientation of control valve. Water fl ow should match arrow on control valve. The Inlet and Outlet of other water treatment

equipment products will vary depending on the control valve brand used.

4) Before commencing the installation it is advisable to study the existing piping system and to determine the size, number and type of fi ttings

required.

WARNING

To reduce the risk associated with a hazardous voltage:

• If the home electrical system requires use of the cold water system as an electrical safety ground, a jumper must be used to ensure a suffi cient ground connection

across the fi lter installation piping — refer installation to qualifi ed personnel.

5) Sweep the fl oor to eliminate objects that could pierce the brine tank.

IMPORTANT NOTE

Sodium Information: Water softeners utilizing sodium chloride for regeneration add sodium to the water softened water. Persons who are on sodium restricted diets should consider the added sodium as part of their overall sodium intake. As a reference as to how much sodium is added to softened water

consider the following. For each grain per gallon of water hardness that is exchanged from the water supply, 7.5 milligrams per liter of sodium will be added

to the softened water. e.g. 10 grains per gallon (gpg) exchanged will add 75 milligrams of sodium to the softened water.

1-3

Page 6

SECTION 2: INSTALLATION

CAUTION

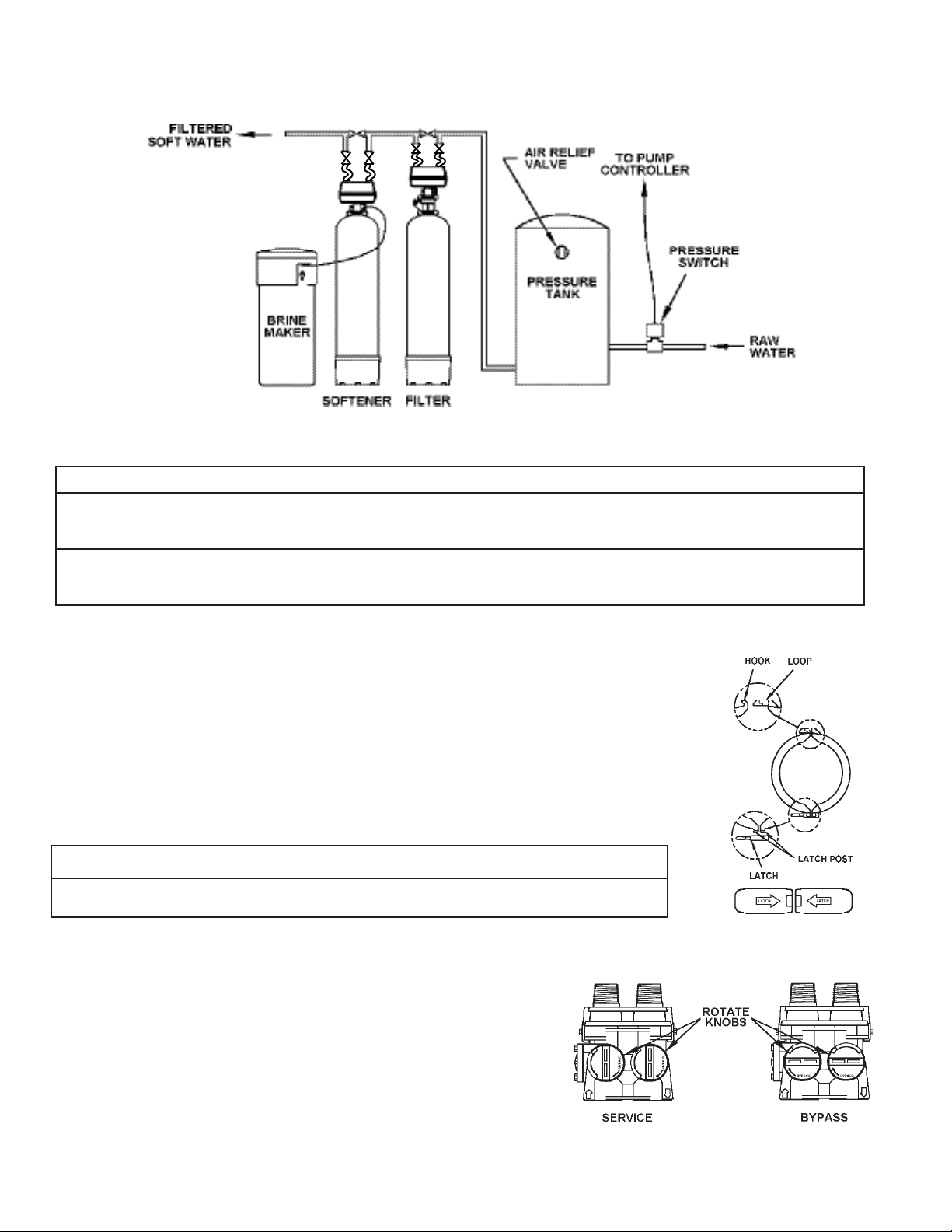

Proper installation sequence of water conditioning equipment is very important. Refer to the following diagram for your particular water supply.

Figure 1

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Read and follow Use instructions before installation and use of this water treatment system.

• Installation and use MUST comply with existing state or local plumbing codes.

To reduce the risk associated with property damage due to plugged water lines:

• Pay particular attention to correct orientation of control valve. Water fl ow should match arrow on control valve. The Inlet and Outlet of other water treatment

equipment products will vary depending on the control valve brand used.

Step 1

(a) Remove control valve by removing quick connect clamp and using a garden hose or bucket, to fi ll SOFTENER TANK

with water (this fi lling method prevents air entrapment that can cause loss of resin during initial regeneration procedure). Replace control valve. Make sure clamp is reassembled as shown in Figure 2 "LATCH" arrows should point

toward each other.

(b) Attach BYPASS VALVE/YOKE ASSEMBLY (Figure 3) using ADAPTER COUPLINGS, CLIPS and SCREWS to CONTROL VALVE

(Figure 4). On Meter initiated models, attach METER between BYPASS VALVE and CONTROL VALVE (Figure 4).

Step 2

Shut off all water at main supply valve. On a PRIVATE WELL SYSTEM, turn off power to pump and drain pressure tank.

Make certain pressure is relieved from complete system by opening nearest faucet to drain system.

CAUTION

To reduce the risk associated with property damage due to water leakage:

• SHUT OFF FUEL OR ELECTRIC POWER SUPPLY TO WATER HEATER after water is shut off.

Step 3

Cut main supply line as required to fi t plumbing INLET and OUTLET of BYPASS VALVE ASSEMBLY.

Use fl exible tubing connections to connect the valve to household plumbing (as shown in schematic).

Step 4

Solder or solvent weld plumbing. DO NOT apply heat to any fi tting connected to BYPASS or

CONTROL VALVE as damage may result to internal parts or connecting adapters. MAKE CERTAIN

WATER FLOW ENTERS THROUGH INLET AND DISCHARGES THROUGH OUTLET.

Figure 2. CLAMP ASSEMBLY

2-1

Figure 3. BYPASS VALVE

Page 7

OUT IN

INOUT

BYPASS

TIMER

INITIATED

BYPASS

METER

BYPASS

METER

INITIATED

ADAPTER

BYPASS

CABLE

METER

YOKE

ADAPTER

COUPLING

CLIP &

SCREW

Figure 4. Softener and Brine Tank Assembly, Top View

CAUTION

To reduce the risk associated with property damage due to plugged water lines:

• Pay particular attention to correct orientation of control valve. Water fl ow should match arrow

on control valve. The Inlet and Outlet of other water treatment equipment products will vary

depending on the control valve brand used.

BYPASS

VALV E

DRAIN LINE

FITTING

BRINE DRAW

B.L.F.C.,

D.L.F.C. &

INJECTOR

ASSEMBLY

OVERFLOW

BRINE

WELL

LINE

FITTING

BRINE

TANK

SAFETY BRINE

VALVE ASSEMBLY

Figure 5. TYPICAL DRAIN

2-2

Page 8

Step 5

Attach DRAIN LINE to DRAIN LINE FITTING. To prevent back pressure from reducing fl ow rate below minimum required for backwash, DRAIN LINE MUST be sized

according to run length and relative height. Be careful not to bend fl exible drain tubing sharply enough to cause "kinking" (if kinking occurs DRAIN LINE MUST

BE REPLACED). Typical examples of proper DRAIN LINE diameters are:

1) 1/2 in. ID up to 15 ft. when discharge is lower than INLET.

2) 5/8 in. ID up to 15 ft. when discharge is slightly higher than INLET.

3) 3/4 in. ID when drain is 25 ft. away and/or drain is installed overhead.

Some areas prohibit the use of fl exible drain lines. Check with local code offi cials prior to installation.

Step 6

Position DRAIN LINE over drain and secure fi rmly. To prevent backsiphoning of sewer water, provide an air-gap of at least 2 in. or 2 pipe diameters between end

of drain hose and drain (Figure 5). DO NOT raise DRAIN LINE more than 10 ft. above fl oor.

Step 7

Connect one end of the 3/8 in. poly brine line to BRINE VALVE located on right side of CONTROL VALVE. Connect other end to ELBOW inside of BRINE WELL. Brass

sleeves and plastic ferrules must be used where necessary. (See Figure 3 and CONTROL VALVE PARTS drawing, Section 6).

Step 8

Install OVERFLOW LINE to brine tank OVERFLOW FITTING (Figure 4). Discharge of line must be lower than OVERFLOW FITTING. DO NOT INTERCONNECT OVERFLOW LINE WITH VALVE DRAIN LINE (STEP 6).

Step 9

On time clock initiated models, set REGENERATION FREQUENCY. Refer to REGENERATION FREQUENCY SCHEDULES (Section 3) to determine correct frequency,

then refer to HOW TO SET TIME CLOCK REGENERATION CONTROL (Section 3) for instructions on setting frequency. For meter initiated models, refer to HOW TO

SET METER REGENERATION CONTROL.

NOTE: Regeneration settings for both time clock and meter initiated models are factory preset for the most effi cient salt use and minimum water consumption

used for regeneration (as little as 50 gallons/89 liters), and conform to the INDUSTRY SALT EFFICIENCY STANDARDS (required by some states). REGENERATION

FREQUENCY SCHEDULES are designed for use with factory regeneration settings (listed in SPECIFICATIONS AND OPERATING DATA, Section 5).

The control valve design permits adjustment of the salt dosage. This adjustment may be necessary when unusual operating conditions exist, such as high concentrations of iron or hardness and/or high fl ow rates or daily water consumption. This adjustment is easily performed by loosening the screw holding the white

cam (on backside of timer) and adjusting the pointer to the desired pounds of salt.

NOTE: For salt dosages greater than 15 lbs., grid leg extensions must be attached to bottom of grid legs.

Step 10

Set TIME OF DAY (refer to appropriate HOW TO SET TIME CLOCK/METER REGENERATION CONTROL, Section 3). When shifting to daylight saving time (and back),

you may wish to adjust TIME OF DAY accordingly.

NOTE: TIME OF REGENERATION is preset for 2:00 a.m. because at this time water consumption is generally minimal (a built-in hard

water bypass does, however, permit water to be drawn during regeneration). Should your lifestyle require regular use of water during

the 2:00 to 3:00 a.m. regeneration period, or if other water treatment equipment is also set for 2:00 a.m. regeneration, the TIME OF

REGENERATION will need changing. To change, adjust time of day on 24-HOUR GEAR ahead or behind actual time of day. For example, if 1:00 a.m. regeneration is desired and actual time of day is 10:00 a.m., advance 24-HOUR GEAR one hour to 11:00 a.m.; or,

should 3:00 a.m. regeneration be desired, set gear back one hour to 9:00 a.m.

Step 11

Before loading salt, using a pail or garden hose, add approximately 3 gals. water to brine tank (6 gals. for units with extended grid legs). Then add initial salt fi ll

to brine tank, and one cup full of laundry bleach.

Step 12

Put softener through a complete regeneration - to sanitize the system before use (refer to HOW TO SET TIME CLOCK (or METER) REGENERATION CONTROL for

instructions on manual regeneration.)

Installation is now complete, and your water softener is now ready for service!

2-3

Page 9

SECTION 3: REGENERATION INSTRUCTIONS

INSTRUCTIONS FOR USING REGENERATION FREQUENCY SCHEDULES:

(Time Clock Initiated Models Only)

1) Determine ADJUSTED HARDNESS by adding three (3) times the iron content in parts per million (ppm) to the hardness in grains per gallon (gpg). The

resulting number is ADJUSTED HARDNESS.

EXAMPLE: Hardness is 14 gpg and iron is 2 ppm. ADJUSTED HARDNESS is 20 gpg (14 plus 3 times 2).

2) Select REGENERATION FREQUENCY SCHEDULE corresponding to your model. Locate box intersected by NUMBER IN FAMILY and ADJUSTED HARDNESS (if ADJUSTED HARDNESS is between two numbers in schedule, use higher number). Number in box represents FREQUENCY or NUMBER OF

times per 12 DAYS timer should be set to regenerate. Refer to HOW TO SET TIME CLOCK REGENERATION CONTROL to set correct frequency.

EXAMPLE: You have Model NWS100, 4 in family and 20 gpg adjusted hardness. Refer to REGENERATION FREQUENCY SCHEDULE for Model Series 100 and

locate box intersected by 4 in family and 20 gpg adjusted hardness. The fi gure "3" in box indicates a REGENERATION frequency of THREE TIMES PER 12

DAYS (if a "1", "2", "4", etc. were in box, frequencies of once, twice and four times per twelve days, respectively, would be indicated.)

REGENERATION FREQUENCY SCHEDULES

(TIMES PER 12 DAYS)

Model(s) 100

HARDNESS — gpg

Persons In

Family

1 111112222222

2 112223334446

3 1223344666612

4 1233466612121212

5 1 2 3 4 6 6 12 12 12 12 12 12

6 2 3 4 6 6 12 12 12 12 12 12

7 2 3 4 6 6 12 12 12 12

8 2 3 6 6 12121212

5 1015202530354045505560

Model(s) 150

HARDNESS — gpg

Persons In

Family

1 111111111222222

2 111122223333344

3 111223334446666

4 11223344666661212

5 12233446661212121212

6 1233466612121212121212

7 12344661212121212121212

8 12346612121212121212

9 13466121212121212

10 234661212121212

5 1015202530354045505560657075

3-1

Page 10

Model(s) 200

HARDNESS — gpg

Persons In

Family

1 111111111112222222

2 111112222223333334

3 111222233334444666

4 1122233344466666612

5 11223344466661212121212

6 1223344666612121212121212

7 1 2 2 3 4 4 6 6 6 121212121212121212

8 1 2 3 3 4 6 6 6 12 12 12 12 12 12 12 12 12

9 1 2 3 4 4 6 6 1212121212121212

10 1 2 3 4 6 6 12 12 12 12 12 12 12

\

5 1015202530354045505560657075808590

HOW TO SET DAYS ON WHICH WATER SOFTENER IS TO REGENERATE:

Rotate the skipper wheel until the number “1” is at the red pointer. Set the days that regeneration is to occur by sliding tabs on the skipper wheel outward to

expose trip fi ngers. Each tab is one day. Finger at red pointer is tonight. Moving clockwise from the red pointer, extend or retract fi ngers to obtain the desired

regeneration schedule.

HOW TO SET THE TIME OF DAY:

1) Press and hold the red button in to disengage the drive gear.

2) Turn the large gear until the actual time of day is opposite the time of day pointer.

3) Release the red button to again engage the drive gear.

4) Time of regeneration is preset for 2:00 a.m.

HOW TO MANUALLY REGENERATE YOUR WATER SOFTENER AT ANY TIME.

Turn the manual regeneration knob clockwise.

A slight, clockwise movement of the manual regeneration knob engages the program wheel and starts the regeneration program.

The black center knob will make one revolution in the following approximately three hours and stop in the position shown in the drawing (SERVICE POSITION).

Even though it takes three hours for this center knob to complete one revolution, the regeneration cycle of your unit might be set only one-third of this time.

In any event, conditioned water may be drawn after rinse water stops fl owing from the water softener drain line.

3-2

Page 11

HOW TO SET METER GENERATION CONTROL:

TYPICAL RESIDENTIAL APPLICATION:

To program, just set the time, set the hardness and it automatically monitors system needs and regenerates only when necessary. To set time of day, press red

time set button and turn 24-hour gear until present time of day is opposite “time of day arrow.” Set program wheel by lifting the “people” dial and rotating it so

that the number of people in the household is aligned with the grains per gallon water hardness (adjusted hardness*) scale. Release the dial and check for fi rm

engagement at setting. (This method will provide reserve capacity of one day’s supply based on 75 gallons per person.)

OPTIONAL PROGRAMMING PROCEDURE:

Calculate the gallon capacity of the system, subtract the necessary one day’s reserve requirement and set the gallons available opposite the small white dot on

the program wheel gear. Note: drawing shows 850 gallon setting. The capacity (gallons) arrow denotes remaining gallons exclusive of fi xed reserve.

HOW TO SET THE TIME OF DAY:

1) Press and hold the red button in to disengage the drive gear.

2) Turn the large gear until the actual time of day is opposite the time of day pointer.

3) Release the red button to again engage the drive gear.

HOW TO MANUALLY REGENERATE YOUR WATER SOFTENER AT ANY TIME:

A slight, clockwise movement of the manual regeneration knob engages the program wheel and starts the regeneration process.

The black center knob will make one revolution in the following approximately three hours and stop in the position shown in the drawing.

Even though it takes three hours for this center knob to complete one revolution, the regeneration cycle of your unit might be set for only one-third of this time.

In any event, conditioned water may be drawn after rinse water stops fl owing from the water conditioner drain line.

NOTE: The backside of the timer is set the same as the standard time clock regenerated models.

* Adjusted hardness equals hardness in grains per gallon (gpg) plus 3 times the iron in parts per million (ppm).

3-3

Page 12

SECTION 4: SERVICE INSTRUCTIONS

Problem Cause Solution

1) Hard water, (unit NOT using salt;

liquid level in brine tank NOT too

high).

2) Hard water, (unit using salt; liquid

level in brine tank NOT too high).

3) Liquid level in brine tank TOO

high.

4) System regenerates at wrong

time-of-day.

5) Water continuously fl ows to

drain.

6) Water tastes salty. A. Salt setting too high. A. Reset program cycle.

7) White spots on glassware and

dark surfaces.

8) Low water pressure (low fl ow

rate).

9) “Rotten egg” smell (from hot

water ONLY).

10) “Rotten egg” smell (from both

hot and cold water).

11) Loss of resin through drain line. A. Air in water system. A. Assure that well system has proper air eliminator

A. Electrical service to unit interrupted. A. Assure permanent electrical service (check fuse, plug,

pull chain or switch.)

B. Timer not working. B. Replace timer motor.

C. Timer improperly set. C. Increase frequency of regeneration and/or salt setting.

D. Safety brine valve not opening. D. Replace safety brine valve.

E. Salt “bridged” in brine tank. E. Breakup salt.

A. Bypass open. A. Close bypass (replace if necessary).

B. Timer improperly set. B. Increase frequency of regeneration, or reset timer if

needed.

C. No salt in brine tank. C. Add salt; maintain above water level.

D. Excessive water usage. D. Increase frequency of regeneration and/or salt setting

(See HOW TO SET TIMER).

E. Unit installed backwards. E. Reinstall unit.

F. Unit undersized F. Replace with larger unit.

A. Brine valve not closing. A. Replace brine valve.

B. Salt setting too high. B. Reset timer.

C. Injector screen plugged. C. Clean injector and screen.

D. Drain line frozen, plugged or restricted. D. Free drain.

E. Salt "mushed" or sand from salt plugging

bottom of brine tank.

F. Incorrect brine line fl ow control (BLFC). F. Replace with correct fl ow control (See Specifi cations).

A. Power outage occurred. A.

A. Foreign material in control valve. Remove piston assembly and inspect bore; remove

B. Internal control leak. Replace seals and/or piston assembly.

C. Control valve jammed in brine or backwash

position.

B. Cyclone (distributor) tube too short. B. Replace.

A. Sodium residual resulting from water having

very high hardness or total dissolved solids

(TDS).

A. Iron build-up in line to water conditioner. A. Clean line to water conditioner.

B. Iron build-up in water conditioner. B. Clean control and add Iron-X Mineral Cleaner to resin

C. Well pumping sand. C. Install sand trap.

D. Pump losing capacity. D. Contact pump repair service.

A. Magnesium rod in water heater. A. Replace with aluminum rod or remove.

A. Hydrogen sulfi de ("sulfur") in water supply. A. Install Sulfur Reduction System.

B. Bacterial iron in water supply. B. Install Chem-Free Iron Reduction System.

C. Algae in water supply. C. Pour approximately 1/2 cup laundry bleach into brine

B. Incorrect Drain Line Flow Control (DLFC). B. Replace with correct DLFC.

E. Clean out brine tank (See Instructions).

Reset timer.

foreign material and check control in various regeneration positions.

Replace piston, seals and spacers.

A. Installation of additional water treatment equipment

such as reverse osmosis or demineralization.

bed; increase frequency of regeneration.

well just before regeneration as frequently as necessary.

control; check for dry well condition.

4-1

Page 13

SECTION 5: SPECIFICATION AND OPERATING DATA

Timer Initiated Meter Initiated

ITEM NWS100 NWS150 NWS200 NWS100M NWS150M NWS200M

Nominal Media Volume, cu. ft. (cu mtr) 1.0 (0.03) 1.5 (0.05) 2.0 (0.06) 1.0 (0.03) 1.5 (0.05) 2.0 (0.06)

Salt Dosage, lbs (kg):

Factory Setting (1)

Maximum Setting

Nominal Softening Capacity, Grains (2)

At factory salt setting

At maximum salt setting

Operating Flow Rates, gpm (lpm) (3)

Continuous (no duration limit)

Service (10 minutes or less)

Pressure Loss @ Operating Flow Rates, psi (kPa)

Continuous

Service

Regeneration Flow Rates, gpm (lpm)

Backwash (4)

Brine/Rinse

Rapid Rinse

Brine Refi ll

Approx Water Used

Inlet/Outlet Pipe Size, Inches (cm) 1.0 (2.5) 1.0 (2.5) 1.0 (2.5) 1.0 (2.5) 1.0 (2.5) 1.0 (2.5)

Mineral Tank Depth & Height w/Control Valve, Inches (cm) 8x44

Overall Depth & Height

w/ Control Valve, Inches (cm)

Brine Tank, W x D x H, Inches (cm) 15x15x34

Approx. Salt Storage, lbs. (kg)

Approximate Shipping Weight, lbs. (kg) 89 (40) 116 (53) 141 (64) 90 (41) 117 (53) 142 (64)

6.0 (2.7)

15.0 (6.8) )

18,600

30,000

4.0 (15)

7.0 (27)

6.0 (41)

15.0 (103)

1.5 (5.7)

0.33 (1.25)

1.5 (5.7)

0.5 (1.9)

64 (242

(20x112)

15x51

(38x130)

(38x38x86

160 (73) 160 (73) 160 (73) 160 (73) 160 (73) 160 (73)

9.0 (4.1)

24.0 (11)

27,900

45,000

6.0 (23)

8.0 (30)

8.0 (55)

15.0 (103)

2.4 (9.1)

0.33 (1.25)

2.4 (9.1)

0.5 (1.9)

90 (341)

10x44

(25x112)

15x51

(38x130)

15x15x34

(38x38x86

12.0 (5.4)

24.0 (11)

37,200

54,000

7.0 (27)

8.5 (32)

9.0 (62)

15.0 (103)

2.4 (9.1)

0.33 (1.25)

2.4 (9.1)

0.5 (1.9)

91 (344

10x54

(25x137)

15x61

(38x155

15x15x34

(38x38x86

6.0 (2.7)

15.0 (6.8) )

18,600

30,000

4.0 (15)

7.0 (27)

6.0 (41)

15.0 (103)

1.5 (5.7)

0.33 (1.25)

1.5 (5.7)

0.5 (1.9)

64 (242

8x44

(20x112)

17x51

(43x130

15x15x34

(38x38x86

9.0 (4.1)

24.0 (11)

27,900

45,000

6.0 (23)

8.0 (30)

8.0 (55)

15.0 (103)

2.4 (9.1)

0.33 (1.25)

2.4 (9.1)

0.5 (1.9)

90 (341)

10x44

(25x112)

17x51

(43x130

15x15x34

(38x38x86

12.0 (5.4)

24.0 (11)

37,200

54,000

7.0 (27)

8.5 (32)

9.0 (62)

15.0 (103)

2.4 (9.1)

0.33 (1.25)

2.4 (9.1)

0.5 (1.9)

91 (344

10x54

(25x137)

17x61

(43x155)

15x15x34

(38x38x86

Maximum operating temperature 110°F (43.3°C); Electrical requirements 110V/60Hz (220V/50Hz); Operating pressure 20-100 psi. All types water softener

salt may be used (See MAINTENANCE). Specifi cations subject to change without notice.

NOTES:

1) Meter Initiated Softeners: Dial settings based on this capacity. Consult dealer before changing salt dosage.

2) Actual capacity may vary substantially depending on water analysis and operating conditions. Softening capacities for systems containing 1.0 cubic feet

and larger are based on Radium 226/228, Barium and Softening.

3) For satisfactory performance indicated fl ow rates and duration should not be exceeded. Flow rates specifi ed are adequate for normal residential applications. Do not use Service Flow Rate when sizing commercial applications or if treated water is to supply a geothermal heat pump, swimming pool, etc.

(contact dealer before selecting equipment).

4) For system to operate properly, pumping rate of well pump MUST be suffi cient to backwash unit at rate specifi ed.

5-1

Page 14

SECTION 6: PARTS

COMPONENTS PARTS LIST TWO TANK MODELS (NS & NSM SERIES)

REF

NO.

1 Control Valve, Time Clock Initiation, with Cover, less Bypass Control

Valve, Meter Initiation, with Cover, less Bypass

2 Adapter Assy., Flg-Thrd (Incl. Ref. 3) FA45TX FA45TX FA45TX

3 O-Ring ORG-234 ORG-234 ORG-234

4 Clamp Assy. (Incl. Ref. 5) FC45XX FC45XX FC45XX

5 Latch, Clamp FC45C FC45C FC45C

6 Media Tank w/Base (Incl. Ref. 9) MTP0844FB MTP1044FB MTP1054FB

7 Media H-10P H-10P & H-050P H-10P(x2)

8 Cyclone Assy. C04N-44 C04N-44 C04N-54

9 Tank Base T06-8P T06-10P T06-10P

10 Brine Line Tubing 13000X 13000X 13000X

11 Brine Tank, Complete

Brine Tank, Complete w/Extension Kit

12 Overfl ow Fitting BT16 BT16 BT16

13 Brine Tank Shell w/Cover BT1534L BT1534L BT1534L

14 Brine Well w/Cap BT15BW BT15BW BT15BW

15 Grid Plate

Grid Plate w/Extension Kit

16 Safety Brine Valve, Complete BT15SBVA BT15SBVA BT15SBVA

17 Safety Brine Valve 60014 60014 60014

18 Float Assembly 60068X 60068X 60068X

19 Air Check Assembly 60002 60002 60002

20

21

DESCRIPTION NWS100

NWS100M

N100150-5W

N12J150-5W

BT1534X

--

BT15GP

--

Media Tank Jacket Cap T40BK-08 T40BK-10 T40BK-10

Media Tank Jacket T40BL0844P T40BL1044P T40BL1054P

NWS150

NWS150M

N100240-5W

N12N240-5W

BT1534X

--

BT15GP

--

NWS200

NWS200M

N100240-5W

N12R240-5W

--

BT1534X-EXT

--

BT15GP-EXT

NOTE: When ordering components, always specify model number.

6-1

Page 15

CONTROL VALVE

-12 DAY TIMER

6-3

Page 16

ONLY THOSE PARTS CIRCLED IN DRAWING AND/OR LISTED BELOW ARE STOCK ITEMS

ALL OTHERS ARE SPECIAL ORDER, NON-RETURNABLE

PARTS LIST - 12 DAY TIMER

REF PART No. DESCRIPTION

A 60353-13 Power Head Assy., Complete, L/Cover, NS/NLS Series (Incl. Ref. Items 2-37)

B 14381X Skipper Wheel Assy. (Incl. Ref. Items 4-10)

C 13010X 24-Hour Gear Assy. (Incl. Ref. Items 11-17)

D 13168-36X Brine Cam Assy. 6-36 lb. Salt (Incl. Ref. Items 10, 30 through 35)

E 14449-00X Control Valve Body Assy. (Incl. Ref. Items 38-81)

F 60102-00 Piston Kit (Incl. Ref. Items 42-46)

G 60125 Seal Kit (Incl. Ref. Items 47 & 48)

H 60084-50X Brine Valve Assy., 0.50 GPM (Incl. Ref. Items 52-81)

J 60022-50 Brine Line Flow Control Assy., 0.50 GPM, (Incl. Ref. Items 74-77)

K 10090X Adapter Coupling Assy. (Incl. 2 ea. Ref. Items 83-85 & 4 ea. Item 82)

L 60049/18706X

60049/18706-02X

1 22601X Valve Cover, Specify Model

26 18743 Motor, 120v/60 Hz

27 11384 Motor Mtg. & Ground Screw

29 13170 Main Gear

36 13547 Strain Relief

37 11842 Power Cord, 110V 60Hz

50 13304 Distributor Tube O-Ring

51 12281 Tank O-Ring

61 13497 Air Disperser

62 12638 Drain O-Ring

63 13301 Injector O-Ring

65 10914 Injector Throat - Specify Size

66 10227 Injector Screen

67 10913 Injector Nozzle - Specify Size

68 13303 Injector Cover O-Ring

69 13166 Injector Cover

70 13315 Injector Mounting Screw

71

12086

12088

72 13173 Drain Line Flow Control Retainer

73 12338 Drain Line Fitting

78 12767 Brine Line Screen

79 10332 Brine Line Tube Insert

80 10330 Brine Line Ferrule

81 10329 Brine Line Fitting Nut

82 13305 Adapter Coupling O-Ring

83 13709 Adapter Coupling

84 13255 Adapter Clip

85 13314 Adapter Coupling Screw

88 18706

18706-02

1" Bypass Valve Assy.

3/4" Bypass Valve Assy. (Optional)

Drain Line Flow Control Button:

1.5 GPM (1001 Two Tank)

2.4 GPM (1001 Space-Maker, 1501 & 2001 Two Tank)

Adapter Yoke, 1" NPT

Adapter Yoke, 3/4" NPT

6-4

Page 17

CONTROL VALVE

- METER INITIATED

6-5

Page 18

ONLY THOSE PARTS CIRCLED IN DRAWING AND/OR LISTED BELOW ARE STOCK ITEMS

ALL OTHERS ARE SPECIAL ORDER, NON-RETURNABLE

PARTS LIST - METER TIMER

REF PART No. DESCRIPTION

A 60354-13 Power Head Assy., Complete, L/Cover, NWS Series (Incl. Ref. Items 2-40)

B 14039X Program Wheel Assy. (Incl. Ref. Items 4-7, Specify "K" Label or Model)

C 13010X 24-Hour Gear Assy. (Incl. Ref. Items 8-14)

D 13168-36X Brine Cam Assy. 6-36 lb. Salt (Incl. Ref. Items 26, 28-33)

E 14449-00X Control Valve Body Assy. (Incl. Ref. Items 41-84)

F 60102-00 Piston Kit (Incl. Ref. Items 45-49)

G 60125 Seal Kit (Incl. Ref. Items 50 & 51)

H 60084-50X Brine Valve Assy., 0.50 GPM (Incl. Ref. Items 55-84)

J 60022-50 Brine Line Flow Control Assy., 0.50 GPM, (Incl. Ref. Items 77-80)

K 60086 Meter Assy. (Incl. Ref. Items 85-93)

L 60049/18706X

60049/18706-02X

1 22601X Valve Cover, Specify Model

23 18743 Motor, 120v/60 Hz

24 11384 Motor Mtg. & Ground Screw

27 13170 Main Gear

38 14043 Flexible Cable

39 13547 Strain Relief

40 11842 Power Cord, 110V/60Hz

53 13304 Distributor Tube O-Ring

54 12281 Tank O-Ring

65 13497 Air Disperser

66 12638 Drain O-Ring

67 13301 Injector O-Ring

68 10914 Injector Throat - Specify Size

69 10227 Injector Screen

70 10913 Injector Nozzle - Specify Size

71 13303 Injector Cover O-Ring

72 13166 Injector Cover

73 13315 Injector Mounting Screw

74

12086

12088

75 13173 Drain Line Flow Control Retainer

76 13308 Drain Line Fitting

81 12767 Brine Line Screen

82 10332 Brine Line Tube Insert

83 10330 Brine Line Ferrule

84 10329 Brine Line Fitting Nut

90 13314 Adapter Coupling screw

91 13255 Adapter Clip

92 13821 Meter Body

93 13305 Meter Body O-ring

102 18706

18706-02

1" Bypass Valve Assy.

3/4" Bypass Valve Assy. (Optional)

Drain Line Flow Control Button:

1.5 GPM (0751 Space-Maker, 1001 Two Tank)

2.4 GPM (1001 Space-Maker, 1501 & 2001 Two Tank)

Adapter Yoke, 1" NPT

Adapter Yoke, 3/4" NPT

6-6

Page 19

SECTION 7: MAINTENANCE

REPLENISHMENT OF SALT SUPPLY:

The salt storage capacity of the brine tank is approximately 160 lbs. During each regeneration a specifi c amount of salt is consumed, thus requiring its periodic

replenishment (the frequency is dependent on the regeneration schedule). Always replenish salt before the supply is exhausted to assure a continuous supply

of softened water.

TYPE OF SALT TO USE:

Any type of water softener salt may be used. There are advantages and disadvantages to every type of salt. Please ask your local dealer for his advice. Your

unit is designed to compensate for the disadvantages.

BRINE TANK CLEAN-OUT:

To prevent service problems the brine tank should be emptied and fl ushed out with a garden hose when dirt and other insolubles accumulate. The clean-out

frequency depends on the type salt used and regeneration frequency. The clean-out should be done when the salt level is low. Steps to follow:

1) Disconnect brine line at either end.

2) Turn brine tank upside down and discard old salt.

3) Rinse out with a garden hose.

4) Reconnect brine line.

5) Add about 3 gals. of water (6 gals. for units with extended grid legs) to brine tank before adding new salt. Perform approximately once a year if rock salt

is used; with other types of salt, approximately once every other year.

PREVENTING IRON-FOULING OF MINERAL BED:

If iron is present in the water supply, the softener mineral bed will eventually become iron-fouled, resulting in reduced softening capacity and rust-stained

fi xtures. Mixing one to two ounces of IRON-X Mineral Cleaner with every 80 lbs. of salt added to brine tank will minimize these problems from occurring.

IRON-X™ is available from your dealer.

PERIODICALLY CHECK TIME OF DAY SETTING:

Power outages will cause TIME OF DAY timer setting to become incorrect. To reset, refer to appropriate HOW TO SET TIME CLOCK (or METER) REGENERATION

CONTROL, Section 3.

MALFUNCTION OF UNIT:

Your water softener, under normal conditions, should provide years of trouble-free service; however, since it is a mechanical device, it can malfunction. (Refer

to Section 4, SERVICE INSTRUCTIONS, if necessary).

CHANGE OF OPERATING CONDITIONS:

Should your family size, your water usage habits, or your water quality change, the regeneration program settings may have to be adjusted. Consult your

dealer if any of the above occur.

7-1

Page 20

SECTION 8:

LIMITED WARRANTY

For any warranty questions, please refer to the enclosed warranty card or call 1-800-222-7880 or mail your request to:

3M Purifi cation Inc.

400 Research Parkway

Meriden, CT 06450

3M Purifi cation Inc.

400 Research Parkway

Meriden, CT 06450

1-800-222-7880

www.3Mpurifi cation.com

Aqua-Pure is a trademark of 3M Company used under license.

3M is a trademark of 3M Company.

© 2010 3M Company. All rights reserved.

Loading...

Loading...