Page 1

Instructions and Parts List

Important Safety

Information

™

3M-Matic

r70 Type 10700

Random

Case Sealer

with

™

AccuGlide 2+

BEFORE INSTALLING OR

OPERATING THIS

EQUIPMENT

Read, understand, and follow

all safety and operating

instructions.

Spare Parts

Taping Heads

Serial No.

For reference, record machine serial number here.

3M Industrial Adhesives and Tapes

3M Center, Building 220-5E-06

St. Paul, MN 55144-1000

It is recommended you

immediately order the spare

parts listed in the "Spare

Parts/Service Information"

section. These parts are

expected to wear through

normal use, and should be

kept on hand to minimize

production delays.

"3M-Matic"and "AccuGlide" are Trademarks

of 3M, St. Paul, MN 55144-1000

Printed in U.S.A.

© 3M 2007 44-0009-2062-7 (D)

Page 2

Page 3

Replacement Parts and Service Information

To Our Customers:

This is the 3M-Matic™/AccuGlide™/Scotch equipment you ordered. It

has been set up and tested in the factory with Scotch tapes. If technical

assistance or replacement parts are needed, call or fax the appropriate

number listed below.

Included with each machine is an Instructions and Parts List manual.

Technical Assist ance:

Call the 3M-Matic™ Helpline at 1-800-328-1390. Please provide the customer

support coordinator with the machine number, machine type, model number, and

serial number. If you have a technical question that does not require an

immediate response, you may fax it to 651-736-7282.

Replacement Parts and Additional Manuals

Order parts by part number, part description, and quantity required. When

ordering parts or additional manuals, include the machine name, model number,

and type. A parts order form is provided at the back of this manual.

3M Tape Dispenser Parts

241 Venture Drive 1-800-344-9883

Amery, WI 54001-1325 Fax: 715-268-8153

Minimum billing on parts orders will be $25.00. Replacement part prices available on request.

$10.00 restocking charge per invoice on returned parts.

Note : Outside the U.S., contact the local 3M subsidiary for parts ordering information.

3M Industrial Adhesives and Tapes

3M Center, Building 220-5E-06

St. Paul, MN 55144-1000

"3M-Matic", "AccuGlide" and “Scotch” are trademarks

of 3M, St. Paul, Minnesota 55144-1000

Printed in U.S.A.

© 3M 2005 44-0009-1851-4(G)

Page 4

Page 5

Replacement Parts And Service Information

To Our Customers:

This is the 3M-Matic™/AccuGlide™/Scotch® equipment you ordered. It has

been set up and tested in the factory with Scotch

occur when operating this equipment and you desire a service call or

phone consultation, call, write, or fax the appropriate number listed

below.

Included with each machine is an Instructions and Parts List manual.

SERVICE, REPLACEMENT PARTS, AND ADDITIONAL MANUALS

AVAILABLE DIRECT FROM:

®

tapes. If any problems

Order parts by part number, part description, and quantity required. Also, when

ordering parts or additional manuals, include machine name, model number, and

type.

3M Industrial Adhesives and Tapes

3M Center, Building 220-5E-06

St. Paul, MN 55144-1000

"3M-Matic", "AccuGlide" and “Scotch” are trademarks of

3M, St. Paul, Minnesota 55144-1000

Printed in U.S.A.

© 3M 2007 44-0009-1852-2 (E)

Page 6

Page 7

Instruction Manual

r70, Random Case Sealer, Type 10700

This instruction manual is divided into two sections as follows:

Section I Includes all information related to installation, operation and parts for the case sealer.

Section II Includes specific information regarding the AccuGlide™ 2+ STD 2 Inch Taping Heads.

Table of Contents Page

Section

Intended Use ................................................................................................................................... 1

Equipment Warranty and Limited Remedy ...................................................................................... 2

Contents—r70 Random Case Sealer ................................................................................................ 2

Important Safeguards ....................................................................................................................... 3–5

Specifications .................................................................................................................................. 6–8

Installation and Setup....................................................................................................................... 9–15

I – r70 Random Case Sealer

Receiving and Handling ....................................................................................... 9

Machine Setup .................................................................................................... 9–15

Required Tools........................................................................................... 9

Packaging and Separate Parts .................................................................. 9-10

Infeed Conveyor Assembly......................................................................... 11

Centering Guides....................................................................................... 11

Machine Bed Height .................................................................................. 12

Tape Leg Length........................................................................................ 12

Electrical Connection and Controls ............................................................ 13

Space Requirements ................................................................................. 13

Operator Working Position......................................................................... 13

Pneumatic Connection .............................................................................. 14

Taping Head Setup .................................................................................... 15

Initial Startup of Case Sealer ..................................................................... 15

Operation ......................................................................................................................................... 16–21

Controls, Valves, and Switches ........................................................................... 17–19

Tape Loading/Threading....................................................................................... 20

Theory of Operation ............................................................................................. 20–21

Box Sealing ........................................................................................................ 21

(Table of Contents continued on next page)

i

Page 8

Table of Contents (Continued) Page

Maintenance .................................................................................................................................... 22–24

Cleaning .............................................................................................................. 22

Lubrication .......................................................................................................... 22

Circuit Breaker .................................................................................................... 23

Knife Replacement, Taping Head......................................................................... 23

Box Drive Belt Replacement................................................................................ 23-24

Adjustments ................................................................................................................................... 25–28

Box Drive Belt Tension ........................................................................................ 25

Taping Head Adjustments ................................................................................... 27–28

Centering Rail Timing Adjustment........................................................................ 29

Removing Taping Heads ................................................................................................................... 29

Troubleshooting Guide...................................................................................................................... 30–31

Electrical Diagram............................................................................................................................ 32

Pneumatic Diagram.......................................................................................................................... 33

Replacement Parts and Service Information ..................................................................................... 34

Spare Parts......................................................................................................... 34

Label Kit.............................................................................................................. 34

Tool Kit ............................................................................................................... 34

Options and Accessories ................................................................................................................. 35

Replacement Parts Illustrations and Parts Lists ...................................................... (Yellow Section) 37–67

Section II – AccuGlide™ 2+ STD 2 Inch Taping Heads

(See Section II for Table of Contents)

ii

Page 9

Intended Use

The 3M-MaticTM r70 Random Case Sealer with AccuGlideTM 2+ Taping Heads is designed to apply a “C” clip of

Scotch® pressure-sensitive film box sealing tape to the top and bottom center seam of regular slotted containers.

The r70 automatically adjusts to a wide range of box sizes. See "Specifications Section—Box Weight and Size

Capacities".

3M-MaticTM r70 Random Case Sealer, Type 10700

1

Page 10

Equipment Warranty and Limited Remedy: THE FOLLOWING WARRANTY IS MADE IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE AND ANY IMPLIED WARRANTY ARISING OUT

OF A COURSE OF DEALING, CUSTOM OR USAGE OF TRADE:

3M sells its 3M-Matic

™

r70 Adjustable Case Sealer, Type 10700

with the following warranties:

1. The drive belts and the taping head knives, springs and rollers will be free from defects in material and

manufacture for ninety (90) days after delivery.

2. All other taping head parts will be free from defects in material and manufacture for three (3) years after

delivery.

3. All other parts will be free from defects in material and manufacture for two (2) years after delivery.

If any part is defective within this warranty period, your exclusive remedy and 3M’s and seller’s sole obligation shall be,

at 3M’s option, to repair or replace the part. 3M must receive actual notice of any alleged defect within a reasonable

time after it is discovered, but in no event shall 3M have any obligation under this warranty unless it receives such notice

within five (5) business days after the expiration of the warranty period. All notices required hereunder shall be given to

3M solely through the 3M-Matic™ Helpline (800-328-1390). To be entitled to repair or replacement as provided under

this warranty, the part must be returned as directed by 3M to its factory or other authorized service station designated

by 3M. If 3M is unable to repair or replace the part within a reasonable time after receipt thereof, 3M, at its option, will

replace the equipment or refund the purchase price. 3M shall have no obligation to provide or pay for the labor required

to remove any part or equipment or to install the repaired or replacement part or equipment. 3M shall have no obligation

to repair or replace those parts failing due to normal wear, inadequate or improper maintenance, inadequate cleaning,

non-lubrication, improper operating environment, improper utilities, operator error or misuse, alteration or modification,

mishandling, lack of reasonable care, or due to any accidental cause.

Limitation of Liability: Except where prohibited by law, 3M and seller will not be liable for any loss or damage arising

from this 3M equipment, whether direct, indirect, special, incidental, or consequential, regardless of the legal theory

asserted, including breach of warranty, breach of contract, negligence, or strict liability.

Note: The foregoing Equipment Warranty and Limited Remedy and Limitation of Liability may be changed only by a

written agreement signed by authorized representatives of 3M and seller.

Contents – r70 Random Case Sealer

(1 ) r70 Random Case Sealer, Type 10700

(1) Upper Tape Drum/Bracket/Hardware

(2 ) Column Bumper Bracket/Hardware

(1 ) Tool/Spare Parts Kit

(1 ) Instruction and Parts Manual

Scotch®, AccuGlideTM, and 3M-MaticTM are Trademarks of 3M, St. Paul, Minnesota 55144-1000

2

Page 11

Important Safeguards

This safety alert symbol identifies

important messages in this manual.

READ AND UNDERSTAND THEM BEFORE

INSTALLING OR OPERATING THIS

EQUIPMENT.

Explanation of Signal Word Consequences

WARNING:

CAUTION:

Indicates a potentially hazardous

situation, which, if not avoided,

could result in death, serious

injury, or property damage.

Indicates a potentially hazardous

situation, which, if not avoided,

may result in minor or moderate

injury, or property damage.

WARNING

• To reduce the risk associated with

mechanical and electrical hazards:

− Read, understand and follow all safety and

operating instructions before operating or

servicing the case sealer.

− Allow only properly trained and qualified

personnel to operate and service this

equipment.

WARNING (continued)

• To reduce the risk associated with impact

hazards:

− Always use appropriate supporting means

when working under the upper drive

assembly.

• To reduce the risk associated with sharp

blade hazards:

− Keep hands and fingers away from tape

cutoff blades under orange blade guards.

The blades are extremely sharp.

• To reduce the risk associated with fire and

explosion hazards:

− Do not operate this equipment in potentially

flammable or explosive environments.

• To reduce the risk associated with muscle

strain:

− Use the appropriate rigging and material

handling equipment when lifting or

repositioning this equipment.

− Use proper body mechanics when removing

or installing taping heads that are moderately

heavy or may be considered awkward to lift.

CAUTION

− Turn electrical and air supply off and

disconnect before performing any

adjustments, maintenance, or servicing the

machine or taping heads.

• To reduce the risk associated with pinches

and entanglement hazards:

− Do not leave the machine running while

unattended.

− Turn the machine off while not in use.

− Never attempt to work on any part of the

machine, load tape, or remove jammed

boxes from the machine while the machine

is running.

• To reduce the risk associated with

hazardous voltage:

− Position electrical cord away from foot and

vehicle traffic.

• To reduce the risk associated with pinches

and entanglement hazards:

− Keep hands clear of the upper head support

assembly as boxes are transported through

the machine.

− Always feed boxes into the machine by

pushing only from the end of the box.

− Keep hands, hair, loose clothing, and jewelry

away from moving belts and taping heads.

• To reduce the risk associated with pinches

and impact hazards:

− Keep away from the pneumatically controlled

upper drive assembly and box centering

guides when air and electric supplies are on.

3

Page 12

Important Safeguards (Continued)

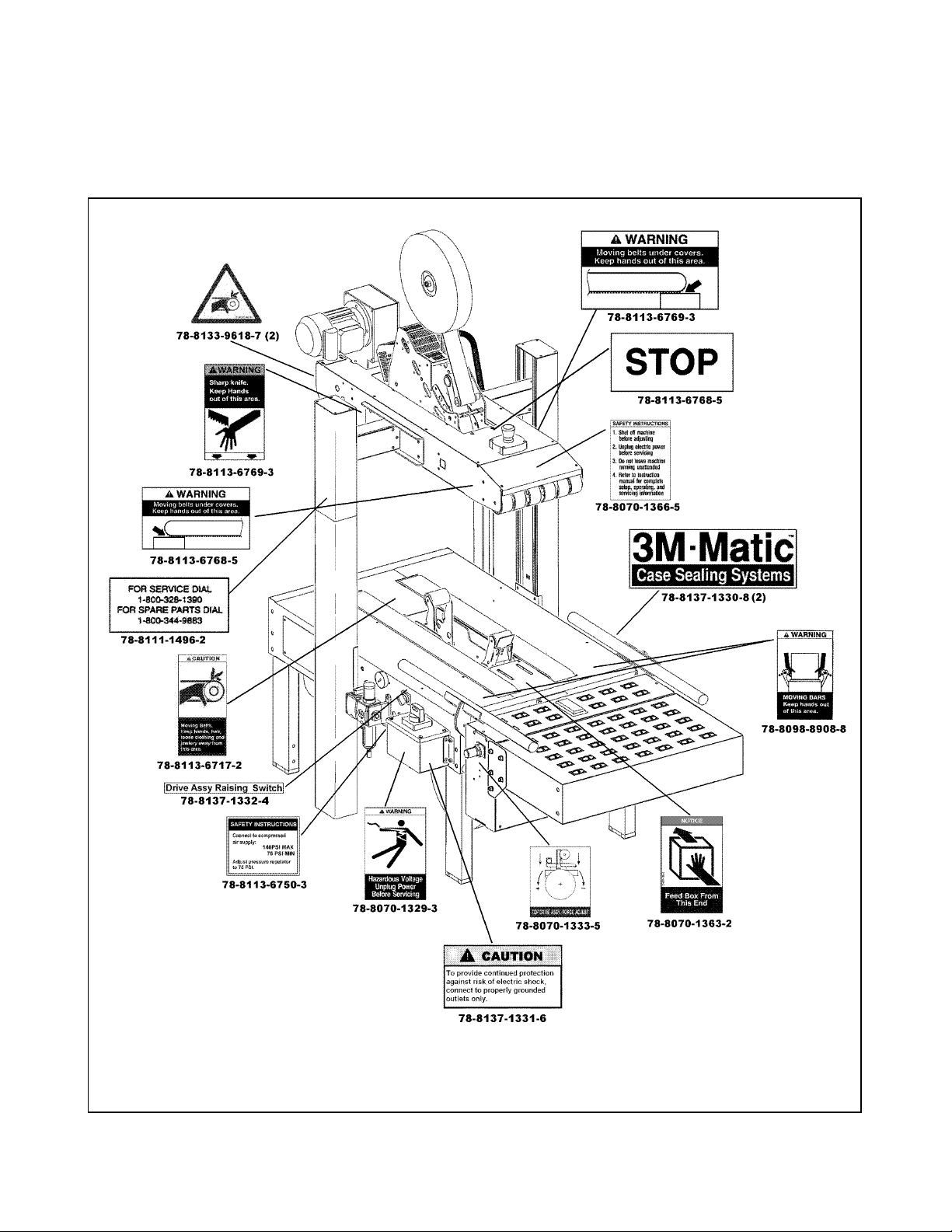

If the following safety labels are damaged or destroyed, they must be replaced to ensure operator safety. Replace-

ment part numbers for individual labels are shown in Figures 1-1 through 1-3. A label kit, part number 78-8137-12565, is available that includes all labels used on the case sealer. See "Safety and Information Labels," at the end of

Parts Illustration List, Section I.

Figure 1-1 Replacement Labels and 3M Part Numbers

4

Page 13

Important Safeguards (Continued)

WARNING

• To reduce the risk associated with

mechanical and electrical hazards:

− Allow only properly trained and qualified

personnel to operate and service this

equipment.

Operator Skill Level Descriptions

Skill 1: Machine Operator

This operator is trained to use the machine with the

machine controls, to feed cases into the machine,

make adjustments for different case sizes, to change

the tape and to start, stop, and restart production.

Important: The factory manager must ensure

that the operator has been properly trained on

all the machine functions before starting work.

Skill 2: Mechanical Maintenance Technician

This operator is trained to use the machine as the

MACHINE OPERATOR and in addition is able to work

with the safety protection disconnected, to check and

adjust mechanical parts, to carry out maintenance

operations and repair the machine. He is not allowed

to work on live electrical components.

Skill 2a: Electrical Maintenance Technician

This operator is trained to use the machine as the

MACHINE OPERATOR and is able to work with the

safety protection disconnected, to make adjustments,

to carry out maintenance operations and repair the

electrical components of the machine. He is allowed

to work on live electrical panels, connector blocks,

and control equipment.

Skill 3: Specialist From the Manufacturer

Skilled operator sent by the manufacturer or its agent

to perform complex repairs or modifications, when

agreed with the customer.

Operator's Skill Levels Required to Perform the Main Operations on Machine

noitarepOsutatSenihcaM

putesdnanoitallatsnienihcaM

uR

tnemecalperepaT

tnemecalperedalBdetc

ytefashtiwgninn

delbasidsnoitcetorp

ehtgnisserpybdeppotS

nottubPOTSYCNEGREME

ennocsidrewopcirtcelE21

tnemecalpertlebevirDdetcennocsidrewopcirtcelE21

ecnanetniamyranidrOdetcennocsidrewopc

ecnanetniamlacinahcemyranidroartxE

irtcelE21

ytefashtiwgninnuR

delbasidsnoitcetorp

deriuqeR

llikSrotarepO

forebmuN

srotarepO

a2dna22

11

31

anidroartxE

ecnanetniamlacirtceleyr

5

ytefashtiwgninnuR

delbasidsnoitcetorp

a21

Page 14

Specifications

1. Power Requirements:

Electrical: 115 VAC, 60 Hz, 5.6 A (680 watts)

Pneumatic: 5 bar gauge pressure [70 PSIG]

110 liter/min @ 21° C, 1.01 bar [3.75 SCFM] at 15 boxes per minute

A pressure regulator is included

The machine is equipped with two 1/6 HP motors and comes with an 2.4 m [8 foot] standard neoprene covered

power cord and a grounded plug. Contact your 3M Representative for power requirements not listed above.

2. Operating Rate:

Up to 15 boxes per minute. Actual production rate is dependent on box size, box size mix, and operator

dexterity.

Box drive belt speed is approximately 0.38 m/s [75 FPM]

3. Operating Conditions:

Use in dry, relatively clean environments at 4°C to 50°C [40°F to 120°F] with clean, dry, boxes.

Note: Machine should not be washed or subjected to conditions causing moisture condensation on

components.

WARNING

• To reduce the risk associated with fire and

explosion hazards:

− Do not operate this equipment in potentially

flammable or explosive environments.

4. Tape:

Scotch® pressure-sensitive film box sealing tapes.

5. Tape Width:

36 mm or 1.5 inches minimum to 50 mm [2 inches] maximum

6. Tape Roll Diameter:

Up to 405 mm [16 inches] maximum on a 76.2 mm [3 inches] diameter core.

(Accommodates all system roll lengths of Scotch® film tapes.)

7. Tape Application Leg Length—Standard:

70 mm ± 6 mm [2.75 inches ± 0.25 inches]

Tape Application Leg Length—Optional:

(See "Special Setup Procedure")

50 mm ± 6 mm [2 inches ±1/4 inches]

(Specifications continued on next page)

6

Page 15

Specifications (Continued)

8. Box Board:

Style: regular slotted containers, RSC

125 to 275 P.S.I. bursting test, single wall or double wall B or C flute.

23-44 lbs. per inch of width Edge Crush Test (ECT)

9. Box Weight and Size Capacities:

A. Box Weight Range 5 lbs.–65 lbs. [2.3 kg–29.5 kg]. Contents must support flaps.

B. Box Size: Minimum Maximum

Length: 150 mm [6.0 inches] Unlimited

Width: 150 mm [6.0 inches]* 550 mm [21.5 inches]

Height: 120 mm [4.75 inches]** 550 mm [21.5 inches]

* Cartons narrower than 250 mm [10 inches] in width may require more frequent belt replacement

because of limited contact area.

** 95 mm [3.75 inches] height with heads adjusted to apply 50 mm [2 inches] tape leg lengths. See "Special

Setup Procedure".

Note: The case sealer can accommodate most boxes within the size range listed above. However, if the box

length (in direction of seal) to box height ratio is 0.5 or less, then several boxes should be test run to ensure

proper machine performance.

DETERMINE THE BOX LIMITATIONS BY COMPLETING THIS FORMULA:

BOX LENGTH IN DIRECTION OF SEAL = SHOULD BE GREATER THAN 0.5

BOX HEIGHT

Any box ratio approaching this limitation should be test run to ensure proper performance.

(Specifications continued on next page.)

7

Page 16

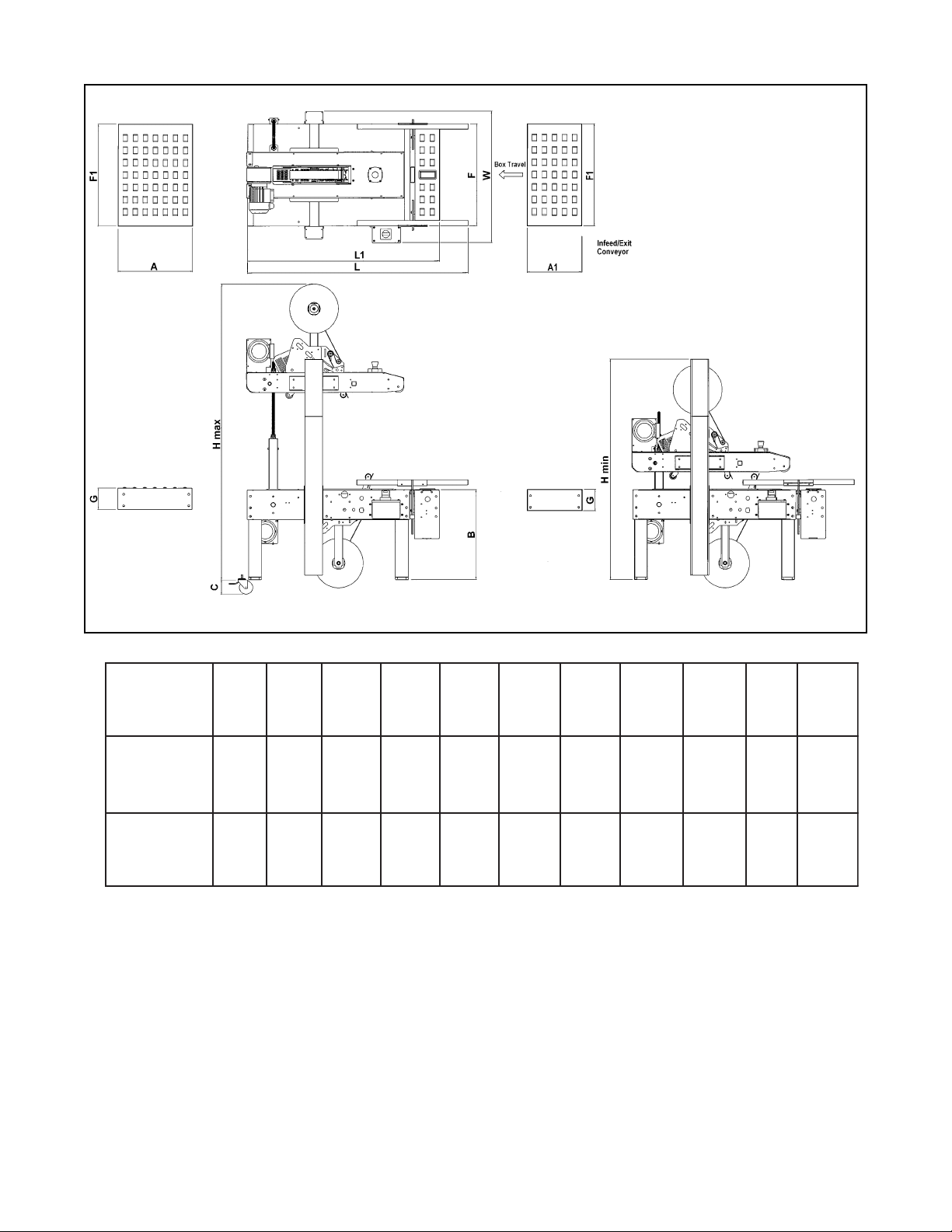

Specifications (Continued)

10. Machine Dimensions:

WL H A 1AB **CF 1FGT

muminiM

mm

)sehcni(

mumixaM

mm

)sehcni(

508

)23(

----0971

0631

5.35

0431

)8.25(

)5.07(

* Exit conveyor is optional

** Casters are optional

Weight – 193 kg [425 lbs.] crated (approximate)

170 kg [375 lbs.] uncrated (approximate)

11. Setup Recommendations:

• Machine must be level.

064

)1.81(

----008

633

)2.31(

545

)5.12(

)5.13(

601

)2.4(

----------

026

)4.42(

026

0

31

)4.42(

)2.5(

0461

)6.46(

• Customer supplied infeed and exit conveyors (if used) should provide straight and level box entry and exit.

• Exit conveyors (powered or gravity) must convey sealed boxes away from machine.

8

Page 17

Installation and Setup

Receiving And Handling

After the machine has been uncrated, examine the

case sealer for damage that might have occurred

during transit. If damage is evident, file a damage

claim immediately with the transportation company

and notify your 3M Representative.

Machine Setup

WARNING

• To reduce the risk associated with

mechanical and electrical hazards:

− Read, understand, and follow all safety and

operating instructions before operating or

servicing the case sealer.

The following instructions are presented in the order

recommended for setting up and installing the case

sealer, as well as for learning the operating functions

and adjustments. Following them step-by-step will

result in thoroughly understanding the case sealer

and installing it in a manner that best utilizes its

many features. Refer to Figure 3-1 to identify the

various components of the case sealer.

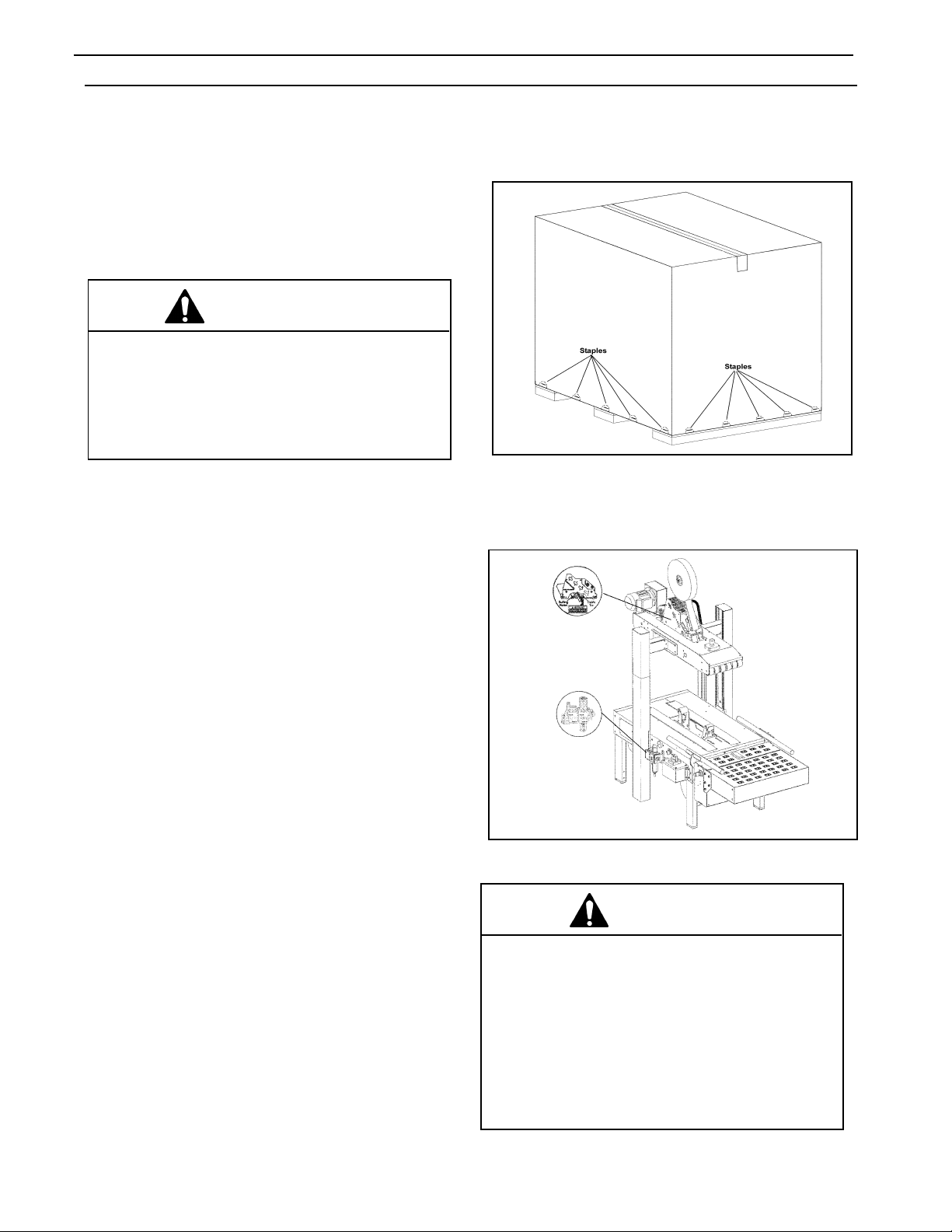

PACKAGING AND SEPARATE PARTS

1. Remove the staples from the shipping carton or

cut around them.

Figure 2-1—Remove Staples

2. Remove the shipping carton from the pallet and

from the machine.

REQUIRED TOOLS

A 17 mm and 21 mm open-end wrench and a 17

mm hex socket wrench are provided with the

machine.

The following customer-supplied tools are required

for machine setup, maintenance, and

adjustments.

• 3 mm hex wrench

• 4 mm hex wrench

• 5 mm hex wrench

• 6 mm hex wrench

• 7 mm combination wrench

• 8 mm combination wrench

• 10 mm combination wrench

• 13 mm combination wrench

• 17 mm combination wrench

• #2 Phillips screwdriver

Figure 2-2—r70 Frame Setup

W ARNING

• To reduce the risk associated with muscle

strain:

− Use the appropriate rigging and material

handling equipment when lifting or

repositioning this equipment.

− Use proper body mechanics when removing

or installing taping heads that are moderately

heavy or awkward to lift.

9

Page 18

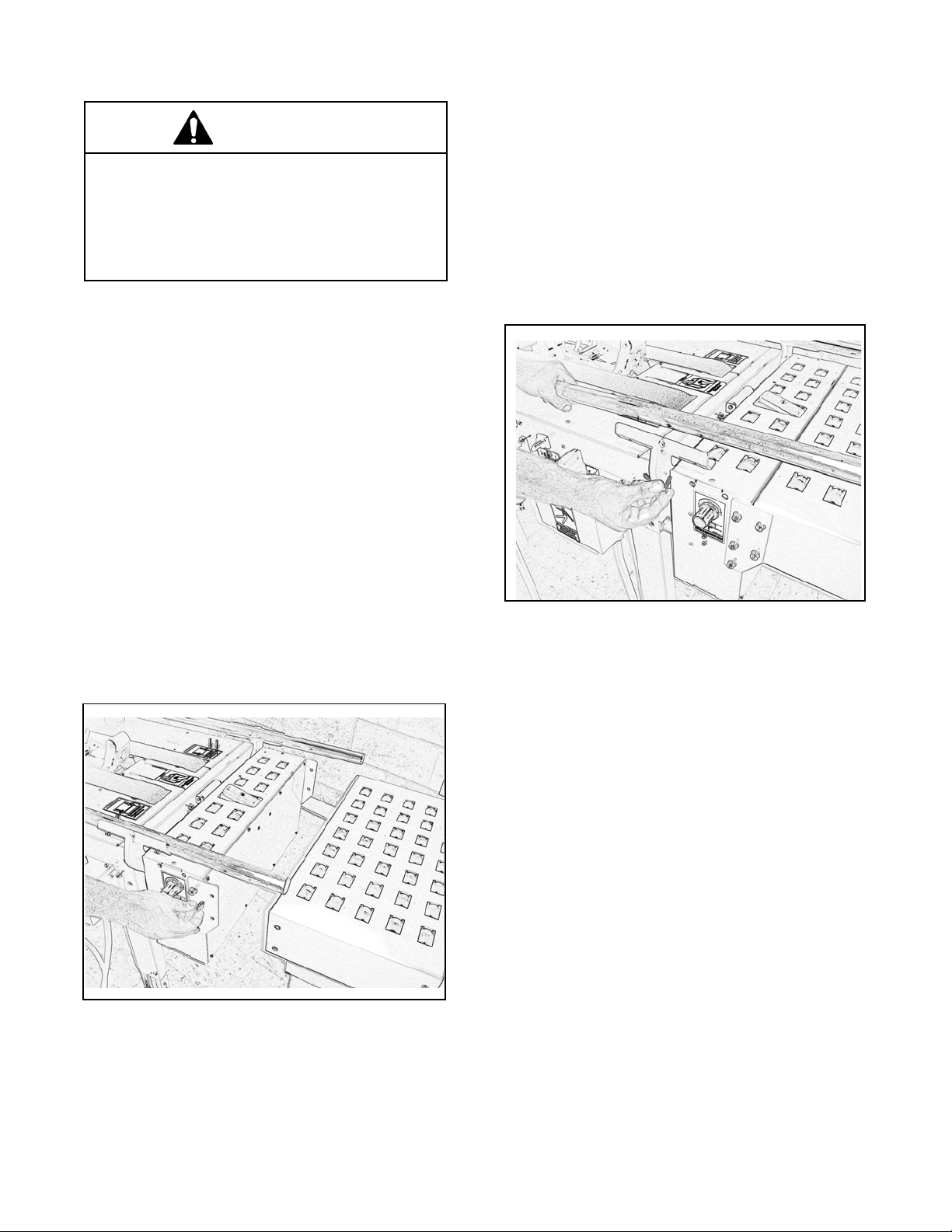

Installation and Setup (Continued)

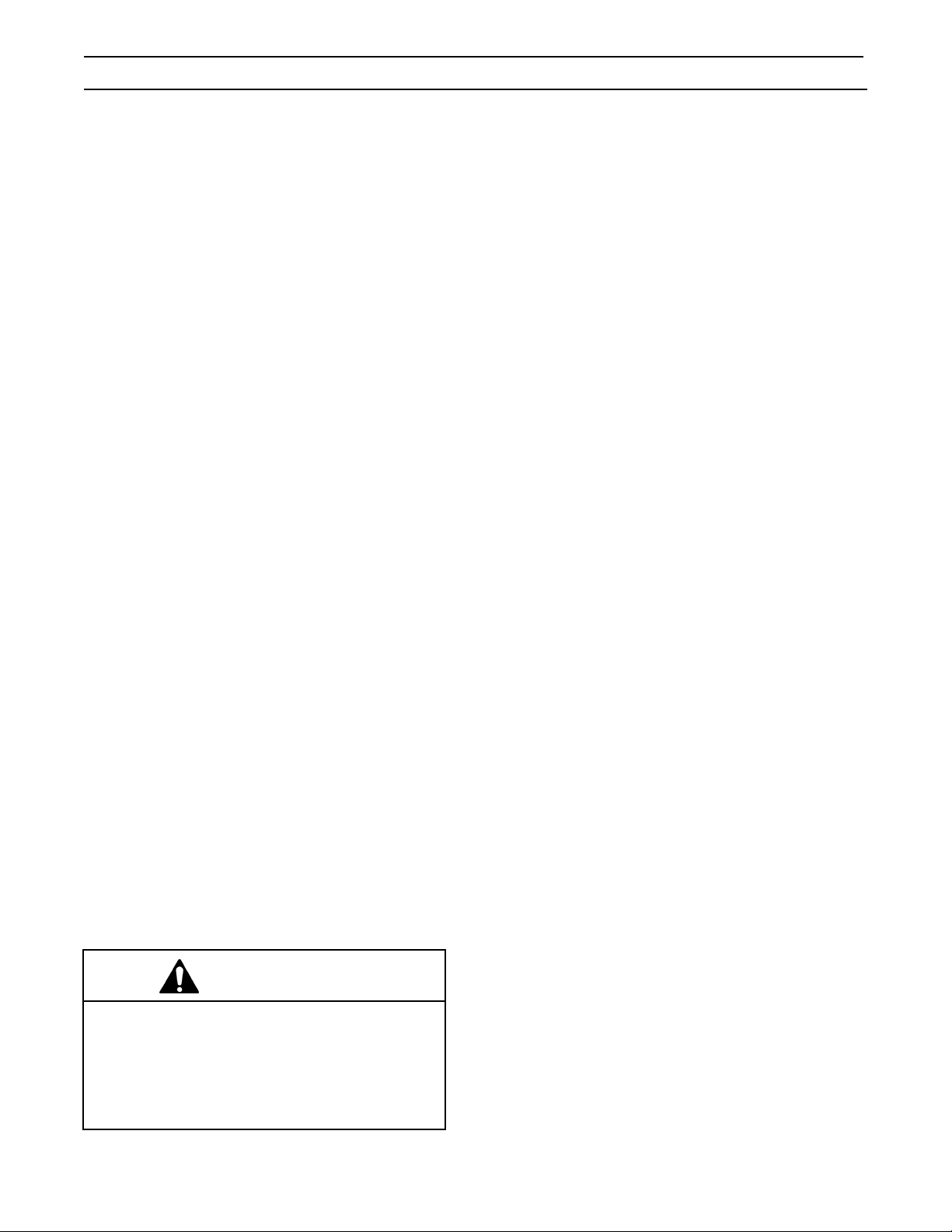

3. Using a 10 mm combination wrench, remove the

fasteners that secure each of the case sealer legs to

the pallet as shown in Figure 2-3.

Figure 2-3—Remove Fasteners

6. Cut the plastic straps that attach the top head to

the frame as shown in Figure 2-4. Retain the tool

and spare parts kit for later use.

4. Remove the leg height adjustment cap screws and

replace with the cap screws from the tool kit.

Remove and replace them one at a time to keep

the inner threaded plate in position.

5. Remove the machine from the pallet and move it

into position.

Important: Whenever the machine is lifted with a

fork truck, ensure that the forks span completely

across the machine frame and do not contact any

wiring or mechanism under the machine frame. In

some cases, the lower taping head may need to

be removed to avoid damage.

WARNING

• To reduce the risk associated with sharp

blade hazards:

− Keep hands and fingers away from tape cutoff

blades under orange blade guards. The

blades are extremely sharp.

Figure 2-4—Cut the Plastic Straps

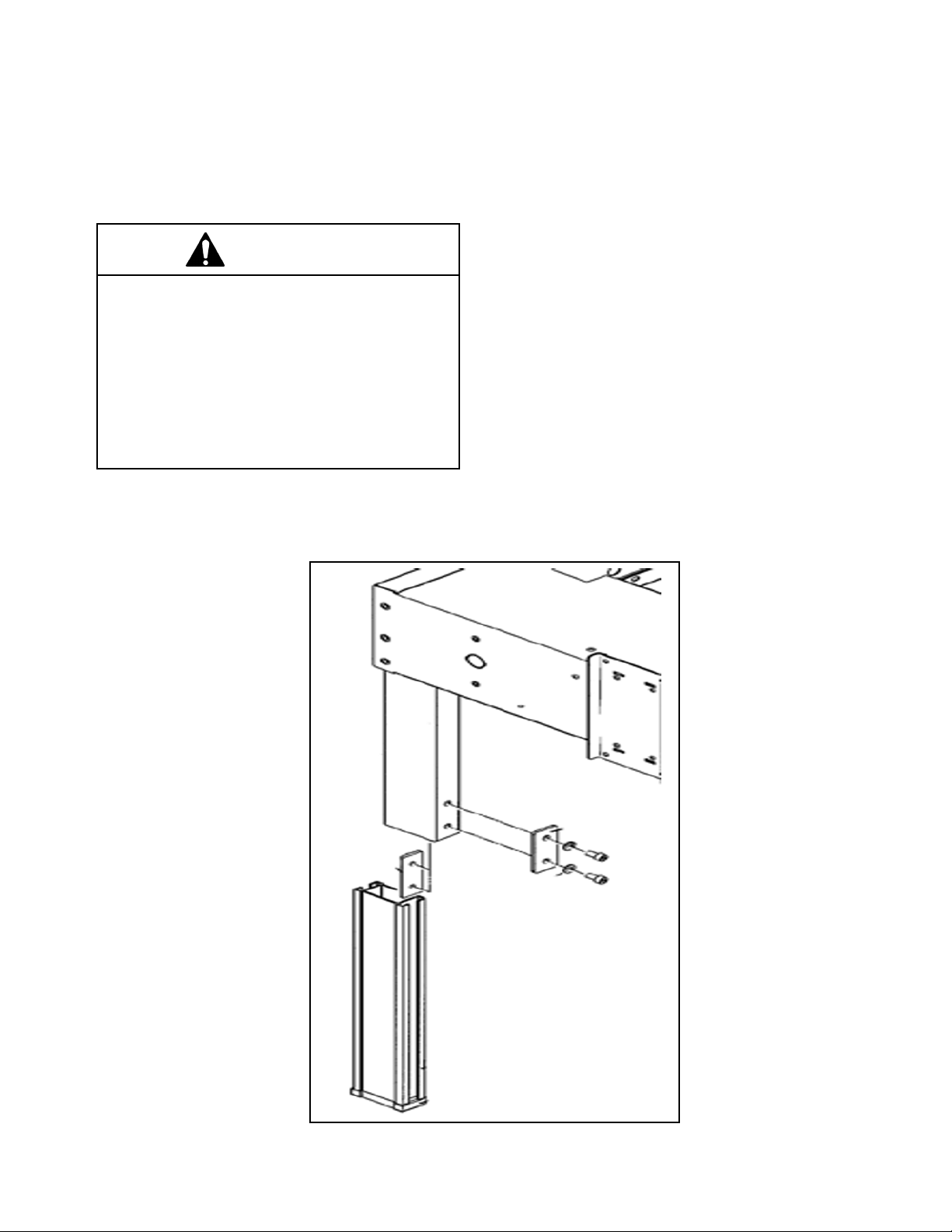

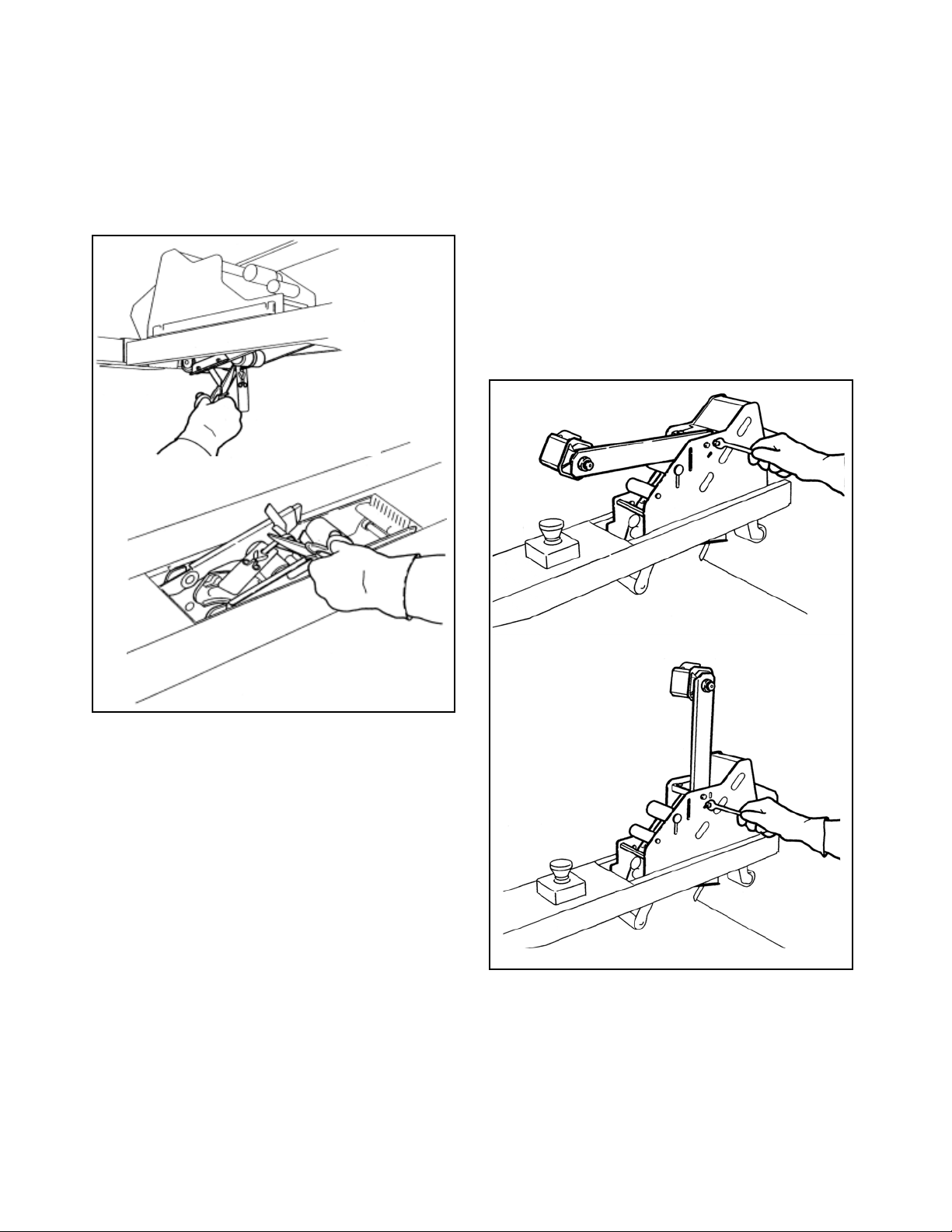

7. Assemble the column cap onto the column as

shown in Figure 2-5.

8. Fasten the column setscrews as shown in Figure 2-

6.

Figure 2-5—Column Cap Setscrews

10

Page 19

Installation and Setup (Continued)

W ARNING

• To reduce the risk associated with muscle

strain:

− Use the appropriate rigging and material

handling equipment when lifting or

repositioning this equipment.

INFEED CONVEYOR ASSEMBLY

1. Remove the conveyor and the package of parts

from the carton.

2. Verify that the package contains two flat plates,

ten M8 x 20 hex socket head screws, and ten

M8 flat washers.

3. To assemble the infeed conveyor, refer to

Figure 2-2 and locate the three bolt holes on the

infeed end of the case sealer frame and the two

bolt holes on the infeed conveyor.

CENTERING GUIDES

1. Remove the two centering guides and four

M6 x 20 socket head screws from the package.

2. Using a 5 mm hex wrench, attach the centering

guides to the rails with four M6 x 20 screws (two

in each guide) as shown in

Figure 2-3.

4. Place the flat plates over the conveyor and the

frame on each side and secure them with five M8

x 20 screws and M8 washers.

5. Insert a M8 x 20 screw in each hole so that only

a few threads take hold.

Figure 2-3—Centering Guides

Figure 2-2—Infeed Conveyor

11

Page 20

Installation and Setup (Continued)

MACHINE BED HEIGHT

The case sealer is equipped with four adjustable

legs that are located at the corners of the

machine frame. The legs can be adjusted to

obtain different machine bed heights. See the

"Specifications" section.

W ARNING

• To reduce the risk associated with muscle

strain:

− Use the appropriate rigging and material

handling equipment when lifting or

repositioning this equipment.

− Use proper body mechanics when removing

or installing taping heads that are moderately

heavy or may be considered awkward to lift.

To adjust the machine bed height, do the

following:

1. Use appropriate material handling equipment

and blocking techniques to raise the machine

frame to allow adequate leg adjustment.

2. Using a 6 mm hex wrench, loosen the socket

head screws that hold the inner leg assembly

to the machine as shown in Figure 2-10.

3. Adjust the leg length for the desired machine

bed height. Adjust all four legs equally.

4. Retighten the screws.

Note: It is not necessary to fasten the

machine to the floor.

TAPE LEG LENGTH

Taping heads are preset to apply 70 mm

[2.75 inches] long tape legs. To change tape leg

length to 50 mm [2.0 inches], refer to Section II,

"Special Setup Procedure—Changing the Tape

Leg Length".

Figure 2-10—Machine Bed Height Adjustment

12

Page 21

Installation and Setup (Continued)

ELECTRICAL CONNECTION AND CONTROLS

The electrical control box (with circuit breaker)

and "On/Off" switch are located on the left side of

the machine frame. See Figure 3-1. If desired, for

operator convenience, the "On/Off" switch can be

relocated to the right side of the machine frame.

A standard three-conductor power cord with plug

is provided at the back of the electrical control

box. The receptacle providing this service shall be

properly grounded. Before the power cord is

plugged into a 115 Volt, 60 Hz outlet, verify that

all packaging materials and tools are removed

from the machine. Do not plug electrical cord

into outlet until ready to run machine.

Use of an extension cord is not recommended.

However, if one is needed for temporary use, it

must have a wire size of 1.5 mm diameter

[AWG 16 ], have a maximum length of 30.5 m

[100 ft], and must be properly grounded.

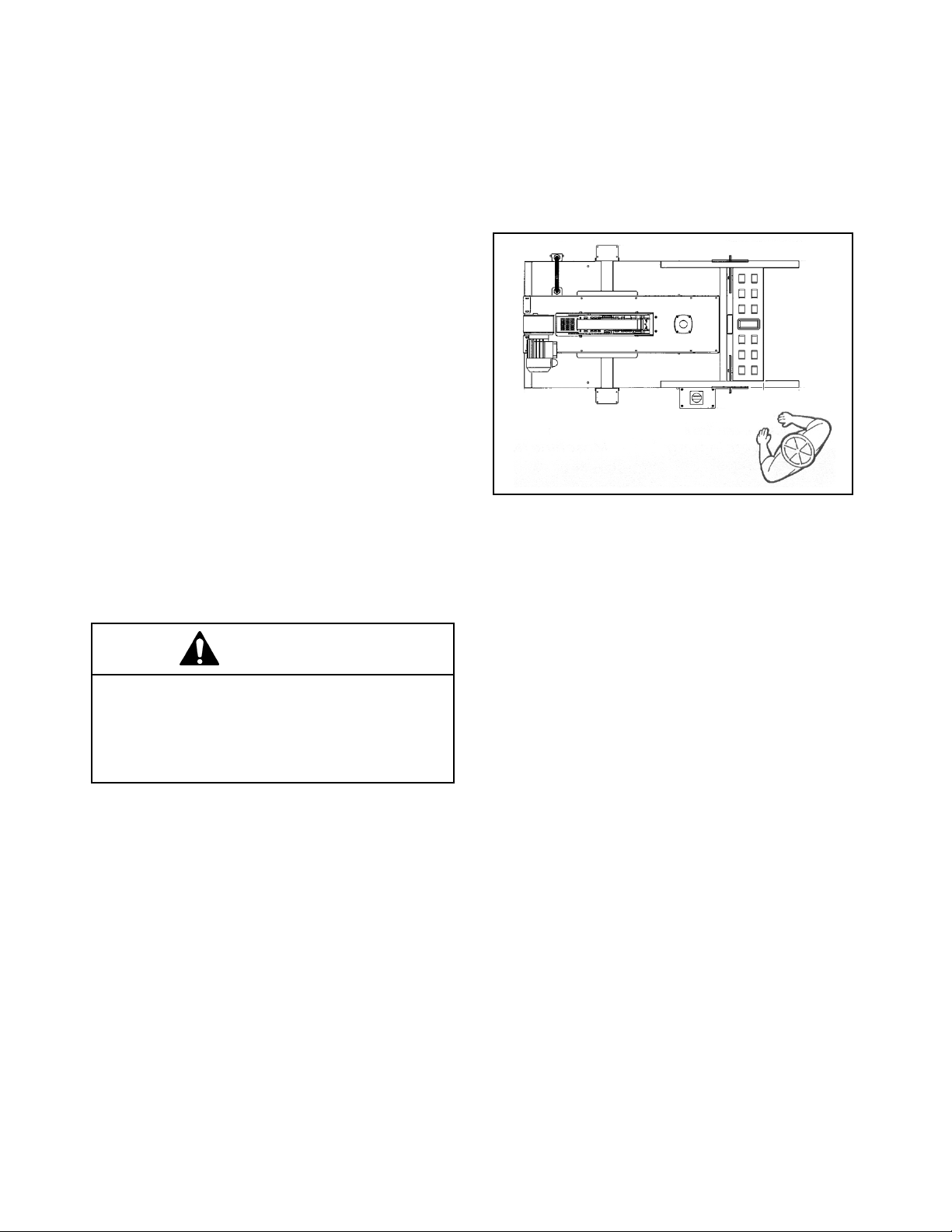

OPERATOR WORKING POSITION

Figure 2-11 illustrates the correct operator

working position.

Figure 2-11—Operator Working Position

WARNING

• To reduce the risk associated with

hazardous voltage:

− Position electrical cord away from foot and

vehicle traffic.

Note: Machines outside the U.S. may be

equipped with 220/240 Volt, 50 Hz systems or

other electrical requirements compatible with

local practice.

SPACE REQUIREMENTS

The left side of the machine must be a minimum

of 1.0 m (39.4 inches) from the nearest wall.

The right side of the machine must be a minimum

of 0.7 m (27.6 inches) from the nearest wall.

The machine requires a minimum of 2.7 m (106.3

inches) height.

13

Page 22

Installation and Setup (Continued)

PNEUMATIC CONNECTION

Important: Use care when working with

compressed air.

The case sealer requires a 5.2 bar gauge

pressure 110 liter/min [75 PSIG], @ 21°C, 1.01

bar [3.75 SCFM] compressed air supply. As

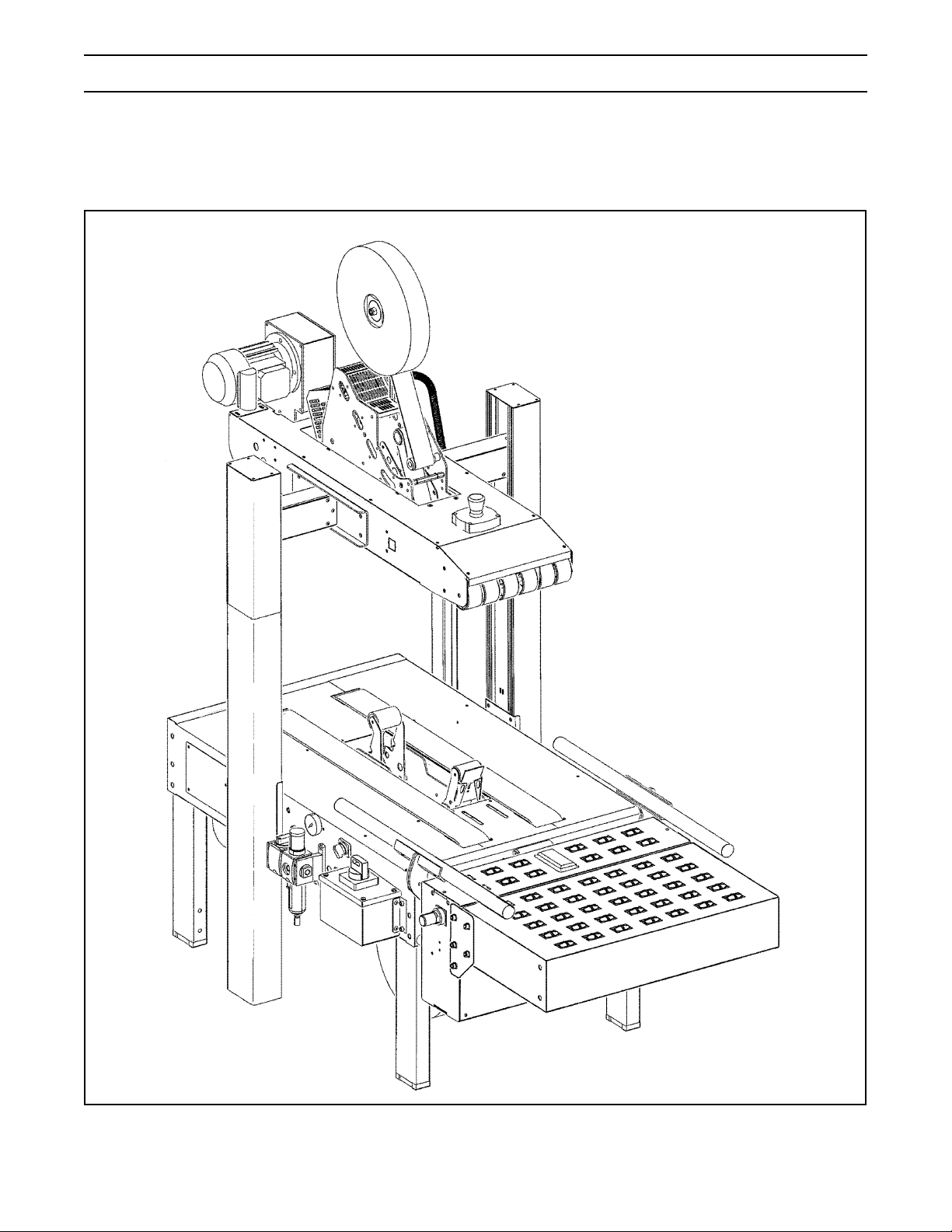

shown in Figure 3-1, an on/off valve, pressure

regulator, and filter are provided to service the air

supply.

Note: A precision regulator is used to balance

the top drive assembly. Due to the selfrelieving feature of this regulator, a small

amount of air continually vents to the atmosphere. This is normal and amounts to

approximately 3 liter/min. [0.1 SCFM].

1. Read and remove safety tag from pneumatic

"On/Off" valve.

2. Connect the main air supply line to the inlet

side of the On/Off valve using the barbed

fitting and hose clamp provided. The

customer supplied air hose

(8 mm [5/16 inches] Inner Diameter) must be

clamped tightly to the barbed fitting.

4. Raise the upper drive assembly to full Up position

by turning the drive assembly raising switch

clockwise.

If another type of connector is desired, the

barbed fitting can be removed and replaced

with the desired 1/4-18 NPT threaded

connector.

Always turn the air valve Off when the air

supply line is being connected or

disconnected.

3. Turn the air supply on by turning the air On/Off

valve to On.

Note – The air valve has provisions for lock

out/tag out according to plant regulations.

WARNING

• To reduce the risk associated with impact

hazards:

− Always use appropriate supporting means

when working under the upper drive

assembly

14

Page 23

Installation and Setup (Continued)

TAPING HEAD SETUP

1. Cut the plastic ties holding the upper and lower

taping heads in position, as shown in Figure 2-8.

Hold taping head Buffing Roller while cutting the

plastic tie. Allow buffing/applying arms to extend

slowly.

2. Verify that the upper and lower taping heads

move freely by pushing the buffing roller into the

taping head.

3. Using a 10 mm open-end wrench, loosen the

capscrew on the tape drum bracket assembly

and move the assembly to the vertical position,

as shown in Figure 2-9. Install additional

capscrews from the tool kit. The tape drum

bracket assembly can be pivoted as necessary

to provide tape roll clearance from the floor or

overhead obstacles.

Figure 2-8—Cut the Plastic Ties

Figure 2-9—Lower Tape Drum Bracket Position

INITIAL STARTUP OF CASE SEALER

After completing the "Installation and Setup"

procedure, continue through "Operation" for tape

loading and startup to ensure that the case sealer

is properly adjusted to run boxes.

15

Page 24

Operation

WARNING

• To reduce the risk associated with mechanical and electrical hazards:

− Read, understand, and follow all safety and operating instructions before operating or

servicing the case sealer

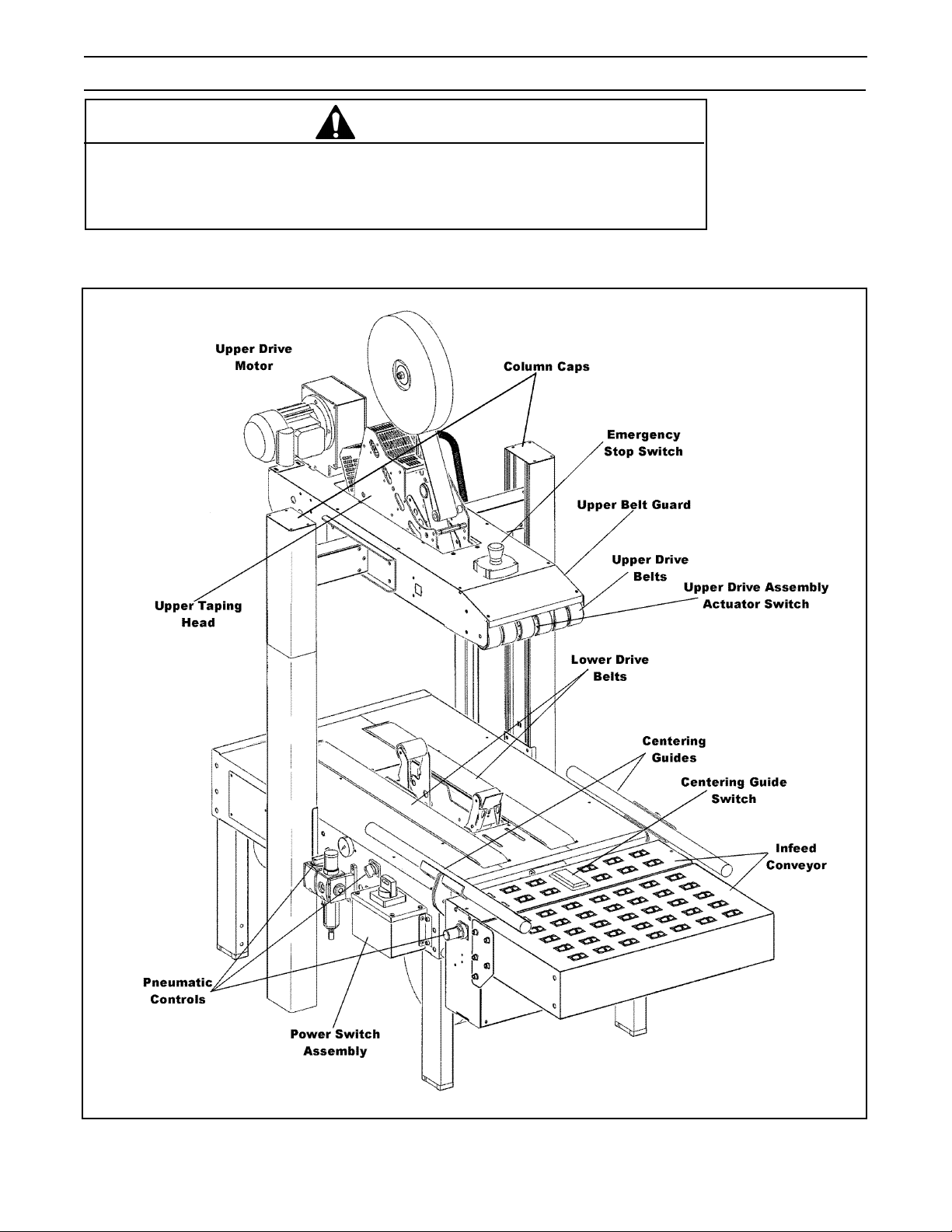

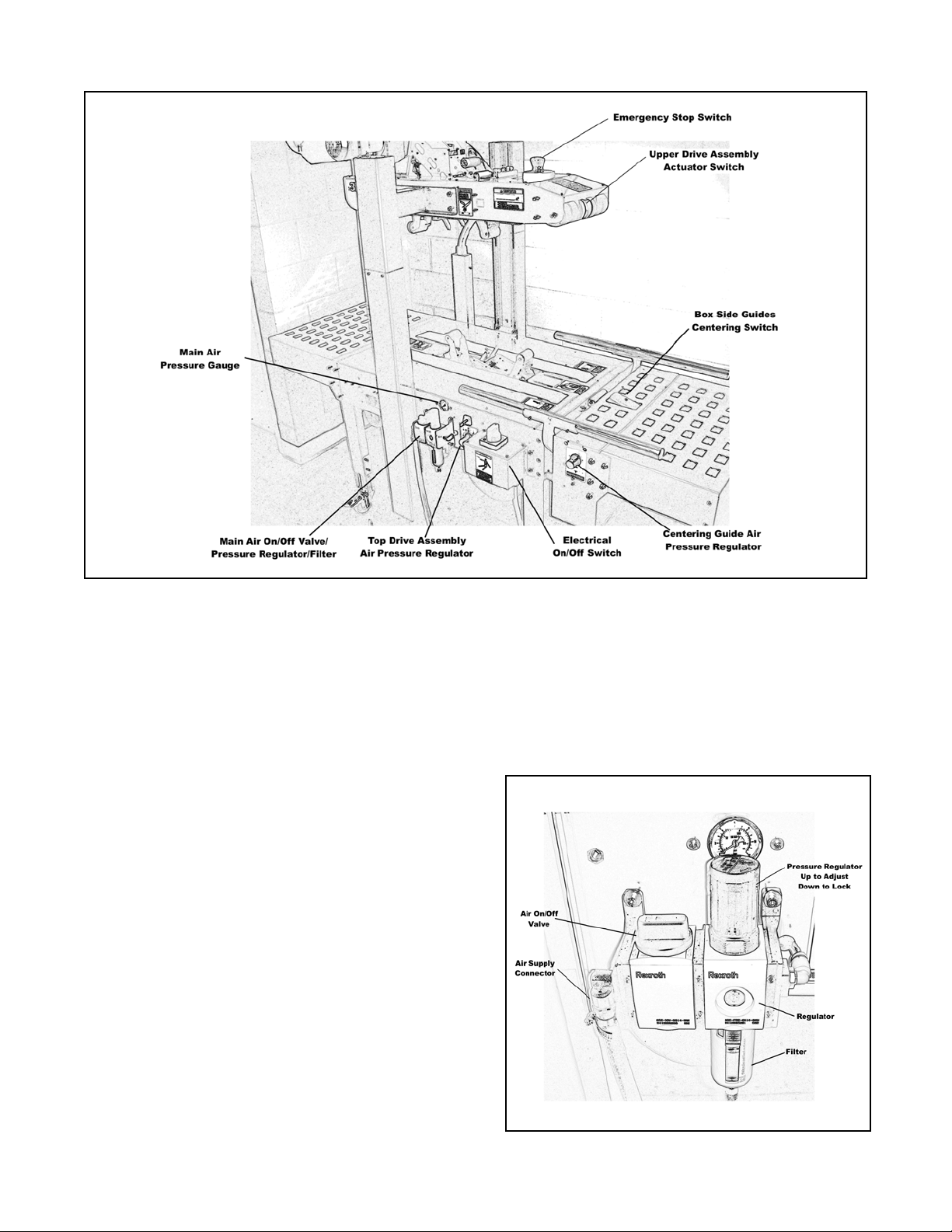

Refer to Figure 3-1 and 3-2 below to acquaint yourself with the various components and controls of the case

sealer. Also see Figures 3-1 and 3-2 in Section II for taping head components.

Figure 3-1—r70 Case Sealer Components (Left Front View)

16

Page 25

Operation (Continued)

Figure 3-2—Controls, Valves and Switches

Electrical On/Off Switch (Figure 3-2)

The box drive belts are turned on and off with the

electrical switch on the side of the machine

frame.

The case sealer has a circuit breaker located in

the electrical enclosure on the left side of the

machine frame. If circuit becomes overloaded

and circuit

electrical

After two minutes, plug machine electrical cord

into outlet and restart machine by rotating the

On/Off switch to Off (O) then On (I).

Main Air On/Off Valve/Pressure Regulator/

Filter (Figure 3-3)

This set of pneumatic components controls,

regulates and filters plant air supply to the two

separate control circuits of the case sealer.

On/Off Valve (Figure 3-2)

On—turn arrows on switch toward the front of the

machine; Off—turn arrows on switch toward the

left side of the machine.

breaker trips, unplug the machine

cord and determine cause of overload.

Always turn off the air when machine is not in

use, when servicing the machine, or when

connecting or disconnecting air supply line.

Note: The air valve has provisions for lockout/

tagout according to plant regulations.

Note: Turning air supply off automatically bleeds

air pressure from the case sealer air circuits.

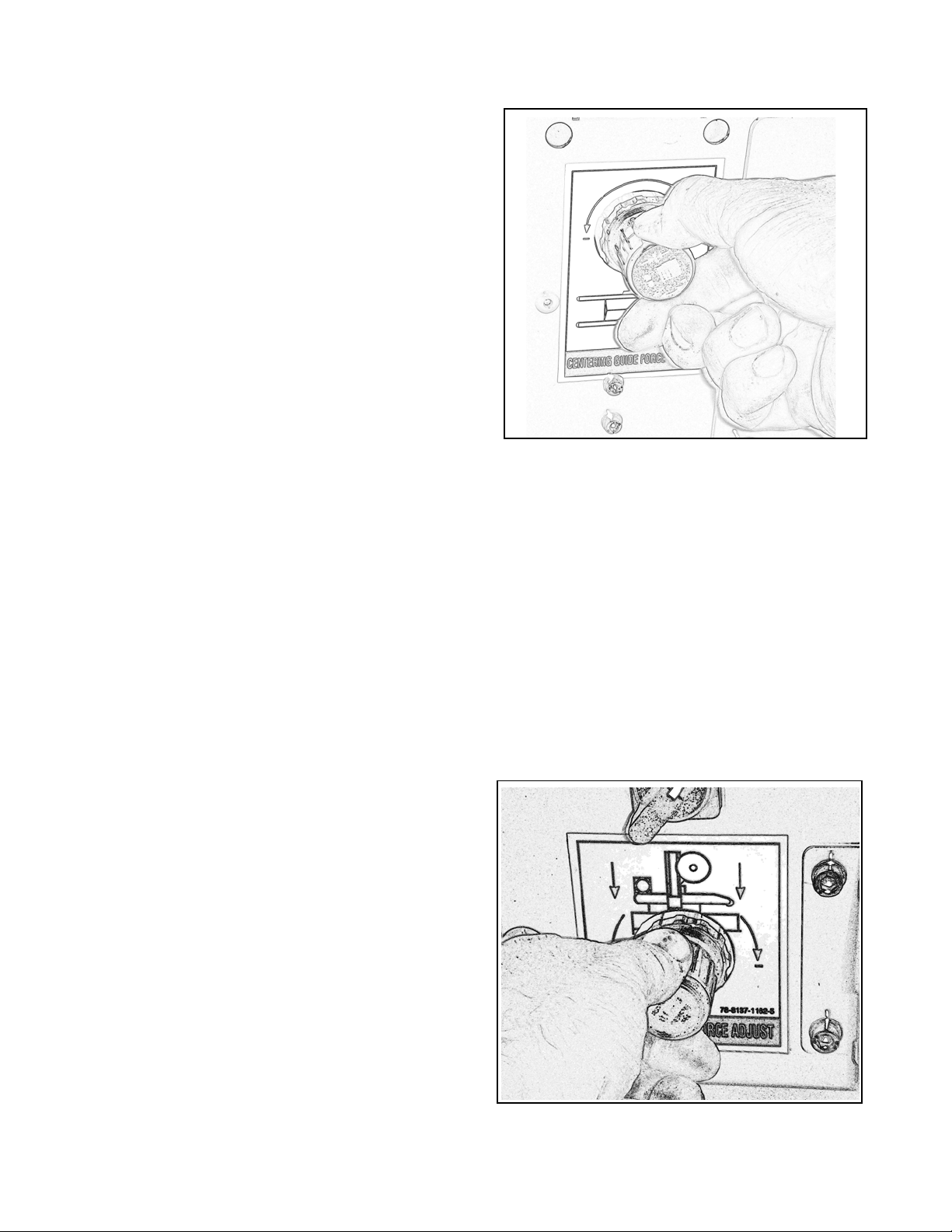

Figure 3-3—On/Off Valve/Regulator/Filter

17

Page 26

Operation (Continued)

Pressure Regulator (Figure 3-3)

Regulates main air pressure to the machine to

adjust pressure, pull knob up and turn; push

down to lock setting.

Filter (Figure 3-3)

Removes dirt and moisture from plant air before

it enters the case sealer pneumatic circuits. If

water collects in bottom of bowl, unscrew the

valve on the bottom of bowl to drain. When

empty, retighten valve.

Emergency Stop Switch (Figure 3-2)

The machine electrical supply can be turned off

by pressing the latching emergency stop

switch. To restart machine, rotate emergency

stop switch a quarter turn clockwise to releases switch latch. Restart machine by

turning the switch to the "O" (Off) position then

to "I" (On).

Figure 3-4—Air Regulator, Centering Guides

Upper Drive Assembly Actuator Switch

(Figure 3-2)

This switch, when touched by the leading edge

of a box , pneumatically raises the upper drive

assembly to allow insertion of the box under

the drive belts. As the box moves under the

switch, releasing it, the upper drive assembly

descends on the box and the drive belts

convey the box through the machine. When

switch is turned, the upper drive assembly

rises. When the switch is released, the upper

drive assembly descends to its rest position.

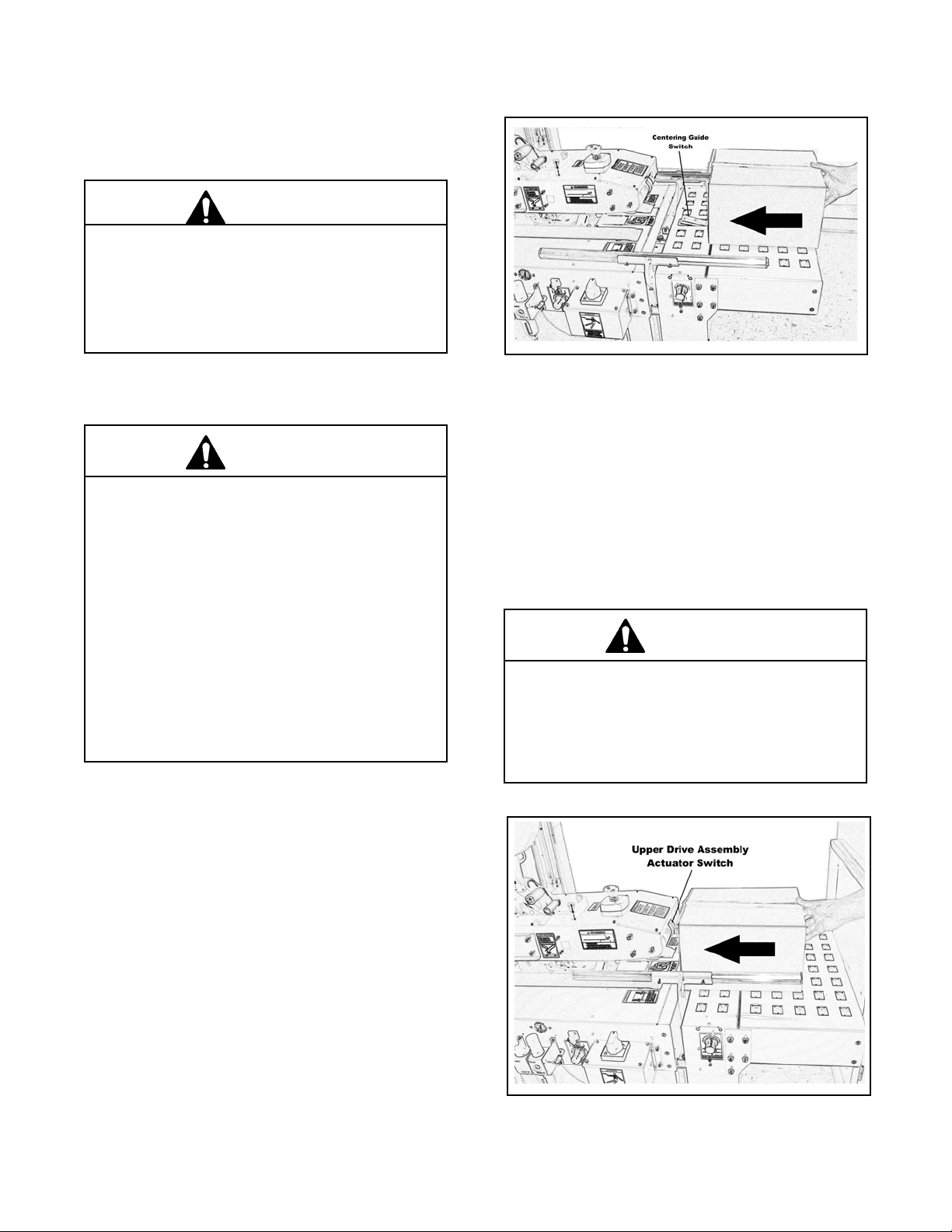

Centering Guide Switch (Figure 3-7)

This pneumatic switch controls the box

centering guides. When switch is activated by

a box entering the case sealer, the centering

guides close (centering the box), and released

(after box passes over switch), the guides

open.

Air Pressure Regulator, Centering Guide

Force Adjustment (Figure 3-4)

This regulator is used to adjust centering

guides according to weight of boxes. Pressure

should be adequate to center boxes, but low

enough to allow easy pushing of boxes under

taping head.

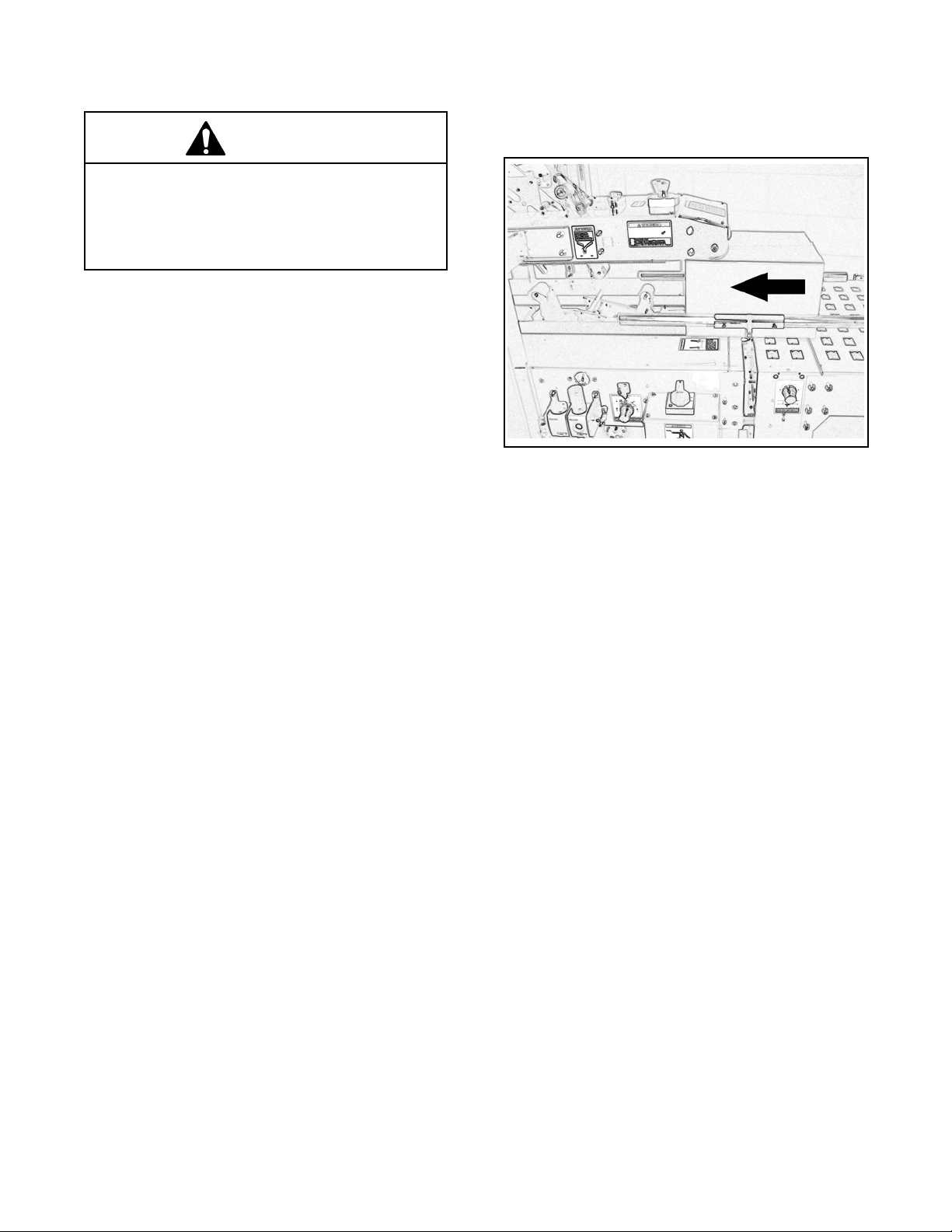

Air Pressure Regulator, Top Drive Assembly

Force Adjustment (Figure 3-5)

Set nominally to control the "down" movement of

top drive assembly and the pressure exerted

against the box as shown in Figure 3-5. The

regulator setting is changed as necessary for the

boxes being sealed to provide adequate drive belt

pressure against the box to positively convey the

boxes through the machine. If the boxes stop or

hesitate while being conveyed, decrease the

regulator pressure. This increases the drive belt

force on the box for more friction between the box

and drive belts. Adjust the pressure setting as

necessary to get continuous movement of boxes

through the machine.

To adjust the regulator setting, pull the knob

outward, rotate the knob to the desired setting.

Push the knob inward to lock it and prevent

unintentional adjustment.

Figure 3-5—Air Regulator/Gauge, Top Drive

Assembly

18

Page 27

Operation (Continued)

For boxes which are fully packed with products

that support the top flaps, the adjustment of this

regulator is not critical since the boxes can

support the pressure of the upper frame (drive

belts) at a wide range of regulator settings.

However, if under-filled or fragile boxes are

sealed, this regulator can be used to set the

upper frame pressure to a reduced level that is

still adequate to positively convey the box and to

prevent damage of boxes. The regulator setting

can be locked by pushing the knob inward.

Note: A precision regulator is used to

balance the top drive assembly. Due to

the self relieving feature of this regulator a

small amount of air will continually vent to

the atmosphere. This is normal and

amounts to approximately 3 liter/min

[0.1 SCFM ].

Figure 3-6—Mechanical Latch, Upper

Drive Assembly

Main Air Pressure Gauge (Figure 3-2)

Indicates main air regulator pressure setting. Air

regulator should be adjusted so gauge reads 5.2

bar gauge pressure [75 PSIG].

Pneumatic Valve, Drive Assembly Raising

Switch (Figure 3-6)

The Pneumatic Valve Drive Assembly Raising

Switch is used to hold the upper drive assembly

to its fully raised position for tape threading and

maintenance.

To raise the drive assembly, turn the switch to

the right. To lower the drive assembly to its fully

lowered position, turn the switch to the left.

19

Page 28

Operation (Continued)

Tape Loading/Threading

See Section II.

WARNING

• To reduce the risk associated with muscle

strain:

− Use proper body mechanics when removing

or installing taping heads that are moderately

heavy or may be considered awkward to lift.

Theory of Operation

Figure 3-7—Centering Guide Switch

CAUTION

• To reduce the risk associated with pinches

and entanglement hazards:

− Always feed boxes into the machine by

pushing only from the end of the box.

− Keep hands clear of the upper head support

assembly as boxes are transported through

the machine.

• To reduce the risk associated with pinches

and impact hazards:

− Keep away from the pneumatically controlled

upper drive assembly and box centering

guides when air and electric supplies are on.

The air supply powers movement of the centering

guides and upper drive assembly to automatically

adjust the case sealer to the box size being sealed

as follows:

1. A box centering switch in the center of the

infeed roller conveyor actuates movement of the

centering guides. When the operator pushes a

box onto the infeed conveyor, as shown in

Figure 3-7, the lever is depressed causing the

air cylinder powered centering guides to move

inward, centering the box.

2. Once the box is centered by the guides, the

operator pushes the box against the raising

switch on the upper drive assembly, as shown in

Figure 3-8, two air cylinders raise the upper drive

assembly. The upper taping head will continue

to rise above the box height so the operator can

insert the box underneath the upper drive belts.

CAUTION

• To reduce the risk associated with pinches

and entanglement hazards:

− Keep hands clear of the upper head support

assembly as boxes are transported through

the machine

Figure 3-8—Upper Drive Assembly Actuator

Switch

20

Page 29

Operation (Continued)

CAUTION

• To reduce the risk associated with pinches

and entanglement hazards:

− Keep hands, hair, loose clothing, and jewelry

away from moving belts and taping heads

3. Once the box is pushed under the upper taping

head, the upper drive assembly actuator switch

is releases to lower the upper drive assembly to

descend onto the box top, as shown in

Figure 3-9, allowing the drive belts to convey the

box through the upper and lower taping heads for

application of the tape seals.

4. As the box is conveyed through the machine, the

centering guide switch is released causing the

centering guides to return to their full open

position, ready for insertion of the next box.

5. Once the box is conveyed from under the upper

taping head, the upper drive assembly descends

to its rest position, ready for insertion of the next

box.

At this point it is recommended that the centering

guides and upper drive assembly switches be

manually actuated to better understand their

functions. Depress the centering guide switch to

close the guides. Release the switch to open the

guides. Depress the upper drive assembly raising

switch to raise the upper drive assembly. Release

the upper drive assembly raising switch to lower the

drive assembly.

Figure 3-9—Box Conveyed Through Machine

Machine or taping head adjustments are described

in "Adjustments" Section I for machine or Section

II for taping heads.

Note: Box drive motors are designed to run at

a temperature somewhat above ambient

room temperature. A motor may feel hot

to the touch during normal operation.

Box Sealing

1. Turn main air valve to (On).

Important: Before turning drive belts on, be sure

no tools or other objects are on the conveyor bed.

2. Turn the switch on side of machine frame to start

drive belts.

3. Feed boxes to machine. Always allow previous

box to exit machine BEFORE feeding next box.

4. Turn air and electrical supplies "Off" when

machine is not in use.

5. Reload and thread tape as necessary.

6. Be sure machine is cleaned and lubricated

according to recommendations in "Maintenance"

section of this manual.

21

Page 30

Maintenance

The case sealer has been designed for long, trouble

free service. The machine performs best when it

receives routine maintenance and cleaning.

Machine components that fail or wear excessively

should be promptly repaired or replaced to prevent

damage to other portions of the machine or to the

product.

WARNING

• To reduce the risk associated with

mechanical and electrical hazards:

− Turn electrical and air supply off and

disconnect before performing any

adjustments, maintenance, or servicing the

machine or taping heads.

• To reduce the risk associated with impact

hazards:

− Always use appropriate supporting means

when working under the upper drive

assembly.

Lubrication

The machine bearings, including the drive motor, are

permanently lubricated and sealed and do not require

additional lubricant.

Cleaning

Note – Never attempt to remove dirt from

the machine by blowing it out with

compressed air. This can cause the dirt to

be blown inside the motor and onto sliding

surfaces which may cause premature

equipment wear. Never wash or subject

equipment to conditions causing moisture

condensation on components. Serious

equipment damage could result.

Regular slotted containers produce a great deal of

dust and paper chips when processed or handled in

equipment. If this dust is allowed to buildup on

machine components, it can cause component wear

and overheating of drive motor. The dust buildup can

best be removed from the machine by a shop vacuum.

Depending on the number and type of boxes sealed in

the case sealer, this cleaning should be done approximately once per month. If the boxes sealed are dirty,

or if the environment in which the machine operates is

dusty, cleaning on a more frequent basis may be

necessary. Excessive dirt buildup that cannot be

removed by vacuuming should be wiped off with a

damp cloth.

22

Page 31

Maintenance (Continued)

WARNING

• To reduce the risk associated with mechanical and electrical hazards:

− Turn electrical and air supply off and disconnect before performing any adjustments, maintenance, or

servicing the machine or taping heads

Circuit Breaker

The case sealer is equipped with a circuit breaker

which trips if the motors are overloaded. Located

inside the electrical enclosure on the side of the

machine frame. The circuit breaker has been preset

at the factory to 4.5 amps and requires no further

maintenance.

If circuit is overloaded and circuit breaker trips:

1. Determine cause of overload and correct.

2. Rotate the switch mechanism to the "O" (Off)

position then to "I" (On). If circuit breaker will

not reset, wait 2 minutes and retry.

Knife Replacement, Taping Head

See Section II, "Maintenance—Blade (Knife)

Replacement."

Box Drive Belt Replacement

3M recommends replacing drive belts in pairs,

especially if belts are unevenly worn.

DRIVE PULLEY RINGS

Before installing a new belt, check the orange plastic

drive pulley rings for wear. If torn, broken, or worn

smooth, replace the rings.

Figure 4-1—Drive Pulley Rings

23

Page 32

Maintenance (Continued)

WARNING

• To reduce the risk associated with mechanical and electrical hazards:

− Turn electrical and air supply off and disconnect before performing any adjustments, maintenance, or

servicing the machine or taping heads.

LOWER DRIVE BELTS

1. Using a 17 mm open end wrench, loosen, but do

not remove the lock nut as shown in Figure 4-2.

2. Using a 6 mm hex wrench, loosen tension screw

until all belt tension is removed as shown in

Figure 5-2.

3. Pull out belt splicing pin.

Tip: The old belt may be used to install the new

belt. Attach the new belt to the old belt and pull

the new belt into the position while removing the

old belt.

4. If the old belt cannot be used to install a new belt,

remove the upper drive cover. If using the old belt,

continue with the next step.

5. Place new belt over pulleys with laced splice at

top.

6. Insert splicing pin.

Important: Pin must not extend beyond edge of

belt.

7. Adjust belt tension as explained in

"Adjustments—Box Drive Belt Tension."

UPPER DRIVE BELTS

1. Using a 17 mm open end wrench, loosen, but

do not remove the lock nut as shown in Figure

4-3.

2. Using a 6 mm hex wrench, loosen tension

screw until all belt tension is removed as shown

in Figure 5-3.

3. Move compression roller assembly out to full

open position (If installed).

4. Pull out belt splicing pin.

Tip: The old belt may be used to install the new

belt. Attach the new belt to the old belt and pull

the new belt into the position while removing the

old belt.

5. If the old belt cannot be used to install a new

belt, remove the upper drive cover. If using the

old belt, continue with the next step.

6. Place new belt over pulleys with laced splice at

top.

7. Insert splicing pin.

Important: Pin must not extend beyond edge of

belt.

Figure 4-2—Lower Drive Belt Replacement

8. Adjust belt tension as explained in

"Adjustments—Box Drive Belt Tension."

Figure 4-3—Upper Drive Belt Replacement

24

Page 33

Adjustments

WARNING

• To reduce the risk associated with mechanical and electrical hazards:

− Turn electrical and air supply off and disconnect before performing any adjustments, maintenance, or

servicing the machine or taping heads.

Box Drive Belt Tension

The four continuously moving drive belts convey boxes through the tape applying mechanism. The box drive belts

are powered by electric motors.

Tension adjustment of these belts may be required during normal operation. Belt tension must be adequate to

positively move the box through the machine and the belts should run fully on the surface of the pulleys at each end

of the frame. The idler pulleys on the infeed end are adjusted in or out to provide proper belt tension. Each belt is

adjusted separately.

Belt tension is obtained by tightening the adjustment screw so that a moderate pulling force of 3.5 kg [7 lbs.]

applied at the midspan, as shown in Figure 5-1, will deflect the belt 25 mm [1 inch]. This ensures positive contact

between the belt and the drive pulley on the discharge end of the drive assembly. Figure 5-1 illustrates the lower

drive belts. The upper drive belts are adjusted in the same manner.

Figure 5-1—Box Drive Belt Tension Adjustment

25

Page 34

Adjustments (Continued)

WARNING

• To reduce the risk associated with mechanical and electrical hazards:

− Turn electrical and air supply off and disconnect before performing any adjustments, maintenance, or

servicing the machine or taping heads.

Refer to Figures 5-2 and 5-3 and adjust belt tension as follows:

1. Using a 17 mm open end wrench, loosen, but do not remove, the M10 lock nut. Refer to Figures 4-2 and 4-3.

2. Reset the tension on the drive belts as needed. Using a 6 mm long shank hex wrench (approximately 9 inches

[230 mm] long), adjust the M8 tension screws in (clockwise) to increase tension or out (counterclockwise) to

decrease tension.

3. Tighten the M10 lock nut to secure the tension setting.

Figure 5-2—Box Drive Belt Tension Adjustment, Lower Belts (Infeed End)

26

Page 35

Adjustments (Continued)

WARNING

• To reduce the risk associated with mechanical and electrical hazards:

− Turn electrical and air supply off and disconnect before performing any adjustments, maintenance, or

servicing the machine or taping heads.

Figure 5-3—Box Drive Belt Tension Adjustment, Upper Belts (Infeed End)

Taping Head Adjustments: Refer to Section II

WARNING

• To reduce the risk associated with sharp blade hazards:

− Keep hands and fingers away from tape cutoff blades under orange blade guards. The blades are

extremely sharp.

TAPE WEB ALIGNMENT: Section II

TAPE DRUM FRICTION BRAKE: Section II

APPLYING MECHANISM SPRING: Section II

ONE-WAY TENSION ROLLER: Section II

TAPE LEG LENGTH ADJUSTMENT: Section II

27

Page 36

Adjustments (Continued)

WARNING

• To reduce the risk associated with mechanical and electrical hazards:

− Allow only properly trained and qualified personnel to operate and service this equipment.

− Turn electrical and air supply off and disconnect before performing any adjustments, maintenance, or

servicing the machine or taping heads.

Centering Rail Timing Adjustment

The centering rails position and hold the box in the

center of the infeed conveyor until it contacts the drive

belts. A flow control valve located at the front of the

machine determines the amount of time that these

guides are in contact with the box. This valve is preset

at the factory. However, changes to the plant air

supply and adjustments to the case sealer pneumatic

system for your specific application may alter performance of the centering rails.

The centering rails should close against the box until

the drive belts engage and then release the box.

Indications of improper operation include the rails

moving away from the box before the drive belts pull the

box through the machine (short box applications) and

the rails moving inward after the box passes through

the centering rails.

To adjust the Centering Rail timing, do the following:

1. Turn off the air supply and unplug the power cord.

2. Remove Entrance conveyor (if installed).

3. Remove Infeed Frame Cover Plate.

4. Turn the Flow Regulator knob (Figure 5-5) clockwise slightly to increase the dwell time or counterclockwise slightly to decrease the dwell time.

5. Replace cover temporarily to prevent access to

moving parts.

6. Turn on the air supply and plug in the power cord.

7. Run a box through the machine and observe the

operation.

8. Repeat steps 1–7 until the centering rails operate

properly.

9. Replace Infeed Frame Cover plate and Entrance

conveyor (if installed).

Figure 5-4—Timing Adjustment

28

Page 37

Removing Taping Heads

WARNING

• To reduce the risk associated with mechanical and electrical hazards:

− Turn electrical and air supply off and disconnect before performing any adjustments, maintenance, or

servicing the machine or taping heads.

• To reduce the risk associated with sharp blade hazards:

− Keep hands and fingers away from tape cutoff blades under orange blade guards. The blades are extremely

sharp.

WARNING

• To reduce the risk associated with muscle strain:

− Use proper body mechanics when removing or installing taping heads that are moderately heavy or may be

considered awkward to lift.

1. Remove tape from upper taping head and raise

upper assembly to a convenient working height.

2. Loosen the thumb screws and move the clamp

that secures the upper taping head as shown in

Figure 6-1.

Figure 6-1—Loosen Thumb Screws

3. Slide the taping head forward and lift upward to

remove.

4. Raise upper assembly to provide working room

around lower taping head and remove tape from

taping head.

5. Lift the lower taping head, shown in Figure 6-3

straight up to remove it from the case sealer

bed.

7. Replace taping heads in the reverse order of

disassembly.

Figure 6-2—Remove Upper Taping Head

Figure 6-3—Remove Lower Taping Head

29

Page 38

Troubleshooting Guide

The Troubleshooting Guide lists some possible machine problems, causes, and corrections. Also see Section II

"Troubleshooting" for taping head problems.

melborPesuaCnoitcerroC

sexobworraN

nahtreworranerasexoB

gnisuac,dednemmocer

tamerpdnaegappils

.raew

sgnirnoitcirfrostlebevirdnroW

sgnir

tonodstlebevirD

sexobyevnoc

thgit

hgih

tonodstlebevirD

nrut

gnittes

hgnipatpoT

.erusserphguone

gnissim

simronroW

wolootnoisnettlebevirD

tcennocsidlacirtcelE

ylppatonseoddae

eldnahknarcehtgnisu

ootsrellornoisserpmocpalfpoT

redlohgnirpsgniylppadaehgnipaT

gnirpsgniylppadaehgnipaT

sgnirnoitcirfgnis

tcerroctatonrekaerbtiucriC

oottes

wopkcehC

redlohgnirpsecalpeR

erusserpgnirpsecudeR

sgnirnoitcirfecalpeR

noisnettlebtsujdA

.snoitacificepsenihcamkcehC

tleberu

noitcirfrostlebevirdecalpeR

tnemtsujdathgiehxobehttsujdA

srellornoisserpmoctsujdaeR

gulplacirtcelednare

eulavtnerructcerrocotteS

fretni

rehto

sa

(Continued)

gninruttonrotoM

re

kaerbtiucriC

roticapacrotoM

detnedrevocnafrotoM

rewoldnareppU

daehgnipat

smsinahcem

hcaehtiwere

kaerbstlebevirD

maj

pitsexobthgiL

ixenokcab

t

esiongnikaeuqS

ssapsexob

enihcamhguorht

deretnectonepaT

maesxobno

rafoot

gnitteshtgnel

tlebnroW

srellornoisserpmocyrD

sgniraebnmulocyrD

deretnectonmurdepaT

sediuggniretneC

potsthgiehmuminims'enihcaM

geldaehepathctamtonseod

gnittes

tlebecalpeR

otsexobgnisuacputesreporpmI

nwodylbmessadaehreppureppU

buL

sgniraebnmulocevitcefeD

deretnecton

htgnellauqenufospalfxoB

hctamsdaehgnipat

ylbmessadaeh

murdepatnoitisopeR

sediuggniretnectsujdA

tcerrocdnamelborpetaulavE

erusekamotlaunamkcehC

enihcam

reppurepputsujdaylluferaC

srellornoisserpmocetacir

sgniraebnmulocetacirbuL

sgniraebnmulocecalpeR

snoitacificepsxobkcehC

30

Page 39

Troubleshooting Guide (Continued)

melborPesuaCnoitcerroC

erusserpriarewoL

evirdreppU

tonseodylbmessa

sevomropuevom

ylwolspu

daehgnipatreppU

evomtonseod

fodneehttanwod

t

elcycgnipateh

itcefeD

daeh

rotalugertsujda

srednilycgnisiar

thgiloottesrotaluger

.evlavgnisiardaehev

evlav

rotautcaevlavgnisiardaehkroW

tsuahxedegamadrodeggolC

ehtfosdnereppuehtnosrelffum

evlavrewopdaehevitcefeD

tsujdaecrofylbmessaevirdreppU

ecrofylbmessaevirdpotevitcefeD

srelffum

evlavecalpeR

erronaelC

evlavrewop

colcretnuoc

rotalugerecalpeR

.ylppusriaehttcennocsiD

erusserprianiamehttahtyfireV

.orezsdaerrotaluger

tsujdadnaylppusriatcennoceR

.)rab5(GISP07otrotaluger

gnisiardaehecalperronaelC

tsuahxeecalp

daehehtecalperronaelC

ylbmessaevirdreppuehtnruT

rotalugertsujdaecrof

ehtesaercniotesiwk

.xobehtfopotehttsniagaecrof

aw-enoevitcefeD

U

evirdrepp

sevomylbmessa

rotsafootnwod

drahoot

sediuggniretneC

nahtrewolsevom

.lamron

vitcefeD

evlav

evlavy

evlavrewopdaehevitcefeD

tsujdaecrofylbmessaevirdreppU

T

hgihoottesrotaluger

ylbmessaevirdreppue

rotalugertsujdaecrof

detsujdaylreporpmiwercsnoihsuC

gnissimwercsnoihsuC

tsujdaecrofediuggniretneC

woloottesrotaluger

dnilycediuggniretneC

deepsre

detsujdayltcerroctonslortnoc

rewopediuggniretnecevitcefeD

jdA

wercsecalpeR

rotalugertsujdA

evlavecalperronaelC

evlavecalperronaelC

ylbmessaevirdreppuehtnru

esiwkcolcrotalugertsujdaecrof

tsniagaecrofehtesaercedot

.xobehtfopoteht

rotalugerecalpeR

wercsnoihsuctsu

detnuomslortnocdeepstsujdA

rednilycediuggniretnecno

evlavecalperronaelC

31

Page 40

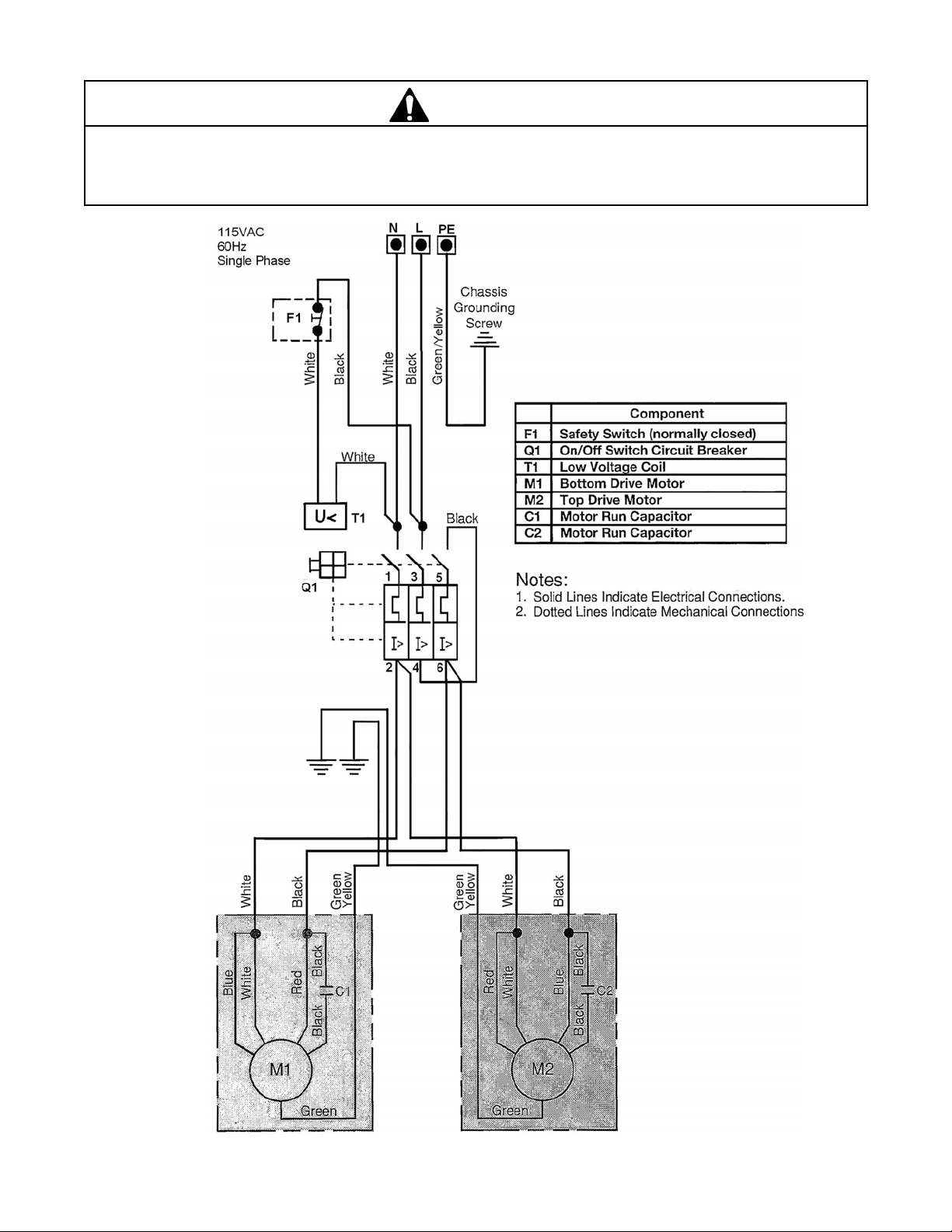

Electrical Diagram

WARNING

•

To reduce the risk associated with mechanical and electrical hazards:

− Turn electrical and air supply off and disconnect before performing any adjustments, maintenance, or

servicing the machine or taping heads.

32

Page 41

Pneumatic Diagram

WARNING

• To reduce the risk associated with mechanical and electrical hazards:

− Turn electrical and air supply off and disconnect before performing any adjustments, maintenance, or

servicing the machine or taping heads.

Figure 8-1—Pneumatic Diagram

33

Page 42

Replacement Parts and Service Information

Spare Parts

The following parts are normal wear items and should be ordered and kept on hand as required.

Qty. Ref. No. Part Number Description

4 10677-8 78-8070-1531-4 Belt, Drive, with Pin

In addition, a tool and spare parts kit supplied with the r70 Random Case Sealer contains the following spare parts:

Qty. Ref. No. Part Number Description

1 10387-10 (Sec. II) 78-8070-1274-1 Spring, Upper Extension (Silver)

1 10389-10 (Sec. II) 78-8070-1273-3 Spring, Lower Extension (Black)

2 10391-2 (Sec. II) 78-8017-9173-8 Knife, 65 mm (2.56 inches)

4 10391-12 (Sec. II) 78-8052-6602-6 Spring, Cutter

All the above listed parts can be ordered separately and when used should be ordered and kept on hand for

spares.

Refer to Section II for recommended taping head spare parts.

Label Kit

If any labels are damaged or destroyed, they must be replaced to ensure operator safety. A label kit (part number

78-8137-1256-5) is available as a stock item. It contains all the safety labels used on the r70 Random Case Sealer.

Tool Kit

A tool kit, part number 78-8098-8868-4, is available for the machine. The kit contains the necessary open end and

hex socket wrenches for use with the metric fasteners on the case sealer. The threading tool, part number 78-80764726-4, contained in above kit is also available as a replacement stock item.

Replacement Parts Ordering Information and Service

Refer to the first page of this instruction manual "Replacement Parts and Service Information".

34

Page 43

Options and Accessories

For additional information on the options and accessories listed below, contact your 3M Representative.

Part Number Option/Accessory

70-0064-2998-2 Caster Kit Attachment

70-0064-2999-0 Conveyor Extension Attachment (exit only)

70-0064-0353-2 AccuGlide™ 2+ STD 2 Inch Upper Taping Head, Type 10500

70-0064-0354-0 AccuGlide™ 2+ STD 2 Inch Lower Taping Head, Type 10500

70-0064-3000-6 Compression Roller Kit

78-8098-8868-4 Tool and Parts Kit

78-8076-4834-6 6 mm Long Shank hex wrench

35

Page 44

THIS PAGE IS BLANK

36

Page 45

Replacement Parts – Illustrations and Parts Lists

r70 Random Case Sealer, Type 10700

Frame Assemblies

To Order Parts:

1. Refer to first illustration, Frame Assemblies, for the Figure Number that identifies a specific portion of the

machine.

2. Refer to the appropriate Figure or Figures to determine the parts required and the parts reference number.

3. The Parts List that follows each illustration, includes the Reference Number, Part Number, and Part

Description for the parts on that illustration.

Note: The complete description has been included for standard fasteners and some commercially

available components. This has been done to allow obtaining these standard parts locally, if desired.

4. Order parts by Part Number, Part Description, and Quantity required. Also include machine name, number,

and type.

5.. Refer to the first page of this instruction manual “Replacement Parts and Service Information” for

replacement parts ordering information.

IMPORTANT – Not all the parts listed are normally stocked items. Some parts or assemblies shown are

available only on special order. Contact 3M/Tape Dispenser Parts to confirm item availability.

37

Page 46

THIS PAGE IS BLANK

38

Page 47

r70 Random Case Sealer

Frame Assemblies

39

Page 48

r70 Random Case Sealer

Figure 10676/1

40

Page 49

Figure 10676/1

Ref. No. 3M Part No. Description

10676/1-1 78-8137-0653-4 Frame, L/H Gearbox

10676/1-2 78-8054-8977-6 Spacer

10676/1-3 78-8054-8975-0 Spacer

10676/1-4 26-1003-5820-4 Screw, Special, M5

10676/1-5 78-8137-0654-2 Frame, R/H Gearbox

10676/1-6 78-8054-8980-0 Pulley Timing Belt

10676/1-7 78-8054-8979-2 Housing, Bearing

10676/1-8 78-8054-8577-4 Washer, Special

10676/1-9 26-1001-9843-6 Screw, Flat, M6

10676/1-10 78-8028-8244-5 Key

10676/1-11 78-8054-8981-8 Sprocket

10676/1-12 78-8054-8877-8 Washer

10676/1-13 26-0001-5862-1 Screw, M5

10676/1-14 78-8054-8978-4 Pulley, with Bearing

10676/1-15 78-8076-4531-8 Shaft, Timing Pulley

10676/1-16 78-8016-5855-6 E-Ring

10676/1-17 78-8005-5741-1 Washer, Flat, M5

10676/1-18 78-8032-0382-3 Screw, Special, M5

10676/1-19 78-8010-7193-3 Screw, Special, M6

10676/1-20 78-8042-2919-9 Washer, Triple, M6

10676/1-21 78-8046-8267-8 Motor

10676/1-22 26-1004-5507-5 Washer, M8

10676/1-23 78-8017-9301-5 Screw, M8

10676/1-24 78-8005-5736-1 Lockwasher,, M8

10676/1-25 26-1003-6904-5 Nut, M8

10676/1-26 78-8054-8982-6 Pulley, Timing

10676/1-27 26-1003-8816-9 Screw, Set M5 x 6

10676/1-28 78-8057-5808-9 Belt, Timing 187L100

10676/1-29 78-8057-5724-8 Belt, Timing 187L050

10676/1-30 78-8137-0655-9 Cover, Front

10676/1-31 78-8137-0656-7 Cover, Rear

10676/1-32 78-8076-4580-5 Nut, M8

10676/1-33 78-8054-8987-5 Chain

41

Page 50

r70 Random Case Sealer

Figure 10676/2

42

Page 51

Figure 10676/2

Ref. No. 3M Part No. Description

10676/2-1 78-8137-0657-5 Drive Shaft

10676/2-2 78-8076-5105-0 Pulley Assembly, Drive

10676/2-3 78-8060-8416-2 Nut, Special M20 x 1

10676/2-4 78-8076-4581-3 Shaft, Gear Box

10676/2-5 78-8054-8984--2 Bushing

10676/2-6 78-8054-8986-7 Sprocket, 3/8" Pitch, 28 Teeth

10676/2-7 78-8057-5811-3 Key, 6 x 6 x 20 mm

10676/2-8 78-8054-8983-4 Flange, Radial Ball Bearing

10676/2-9 78-8057-5739-6 Key, M5 x 5 x 30 mm

10676/2-10 78-8052-6713-1 Ring, Polyurethane

43

Page 52

r70 Random Case Sealer

Figure 10677

44

Page 53

Figure 10677

Ref. No. 3M Part No. Description

10677-1 78-8137-0658-3 Conveyor

10677-2 78-8137-0659-1 Tension Belts, Assembly

10677-3 78-8017-9318-9 Washer, 8 mm

10677-4 78-8094-6145-8 Screw, Phillips M5

10677-5 78-8076-4503-7 Screw, M6

10677-6 78-8137-0660-9 Cover

10677-7 78-8137-0661-7 Gear Box, Assembly

10677-8 78-8070-1531-4 Belt, with Hook

10677-9 26-1003-7964-8 Screw, M8

10677-10 78-8114-4633-1 Screw, Hex. Soc. Hd., M8 x 100

10677-11 78-8137-0663-3 Tension Belt, Support

10677-12 78-8137-0664-1 Plate

10677-13 78-8137-0665-8 Shaft, Pulley

10677-14 78-8137-0666-6 Nut, Special, M25

10677-15 78-8052-6710-7 Roller

10677-16 78-8137-0667-4 Washer, Flat, M25

10677-17 78-8070-1518-1 Spacer, Shaft

10677-18 26-1004-5510-9 Washer, Flat, M10

10677-19 26-1003-6918-5 Nut, Plastic Insert M10

10677-20 78-8052-6709-9 Washer, Special

10677-21 78-8010-7435-8 Washer, M6

10677-22 26-1003-7957-2 Screw, M6

45

Page 54

r70 Random Case Sealer

Figure 10678/1

46

Page 55

Figure 10678/1

Ref. No. 3M Part No. Description

10678/1-1 78-8091-0790-3 Frame, L/H

10678/1-2 78-8091-0789-5 Frame, R/H

10678/1-3 78-8054-8975-0 Spacer

10678/1-4 78-8054-8977-6 Spacer

10678/1-5 78-8005-5741-1 Washer, Flat, M5

10678/1-6 26-1003-5820-4 Screw, Hex Hd. M5 x 12

10678/1-7 26-0001-5862-1 Screw, Flat Soc. Hd., M5 x 12

10678/1-8 78-8076-4585-4 Support, Right, Bearing

10678/1-9 78-8076-4586-2 Support, Left, Bearing

10678/1-10 78-8032-0382-3 Screw, Hex. Soc. Hd., M5 x 16 Zinc. Pl

10678/1-11 78-8054-8978-4 Pulley with Bearing 6203-2RS/17

10678/1-12 78-8076-4531-8 Shaft, Timing Pulley

10678/1-13 78-8016-5855-6 E-Ring, 10 mm

10678/1-14 78-8054-8980-0 Pulley, Timing Belt

10678/1-15 78-8054-8979-2 Housing, Bearing

10678/1-16 78-8054-8577-4 Washer, Special

10678/1-17 26-1001-9843-6 Screw Flat Soc. Hd., M6 x 16

10678/1-18 78-8028-8244-5 Key, 4 x 4 x 10 mm

10678/1-19 78-8054-8981-8 Sprocket, 3/8 Pitch, 11 Teeth

10678/1-20 78-8054-8877-8 Washer, 5, 5/20 x 4

10678/1-21 78-8046-8267-8 Motor, 110/110 V, 50/60 Hz

10678/1-22 78-8042-2919-9 Washer, Triple, M6

10678/1-23 78-8010-7193-3 Screw, Metric, M6 x 20, Hex. Hd.

10678/1-24 26-1004-5507-5 Washer M8

10678/1-25 78-8017-9301-5 Screw, Hex Head, M8 x 25

10678/1-26 78-8005-5736-1 Lockwasher, for M8 Screw

10678/1-27 26-1003-6904-5 Nut, Hex, M8

10678/1-28 78-8054-8982-6 Pulley, Timing 11 Teeth

10678/1-29 26-1003-8816-9 Screw, Set, M5 x 6

10678/1-30 78-8091-0598-0 Cover, Gearbox

10678/1-31 78-8091-0713-5 Cover, Upper

10678/1-32 78-8076-4580-5 Nut, Self-Locking, M8

47

Page 56

r70 Random Case Sealer

Figure 10678/2

48

Page 57

Figure 10678/2

Ref. No. 3M Part No. Description

10678/2-1 78-8137-0657-5 Shaft Assembly

10678/2-2 78-8076-5105-0 Pulley Assembly, Drive

10678/2-3 78-8060-8416-2 Nut, Special, M20 x 1

10678/2-4 78-8076-4581-3 Shaft, Gear Box

10678/2-5 78-8054-8984-2 Bushing

10678/2-6 78-8054-8986-7 Sprocket, 3/8" Pitch, 28 Teeth

10678/2-7 78-8057-5811-3 Key, 6 x 6 x 20 mm

10678/2-8 78-8054-8983-4 Flange, Radial Ball Bearing

10678/1-9 78-8057-5739-6 Key, M5 x 5 x 30 mm

10678/2-10 78-8052-6713-1 Ring, Polyurethane

49

Page 58

r70 Random Case Sealer

Figure 10682

50

Page 59

Figure 10682

Ref. No. 3M Part No. Description

10682-1 78-8137-0601-3 Box, Switch

10682-2 78-8137-0602-1 Cover, Box, Switch

10682-3 78-8137-0606-2 Lockable, Twist Knob, Allen Bradley

10682-4 78-8137-0603-9 Switch, Terminal, Allen Bradley, 2.5-4 A

10682-5 78-8137-0604-7 Coil, Under Voltage 120 V 60 Hz 140M-C-UCD

10682-6 78-8094-6384-3 Terminal

10682-7 78-8094-6145-8 Screw, Phillips, M5 x 12

10682-8 78-8005-5741-1 Washer, Flat, M5

10682-9 78-8129-6469-6 Nut, Special, M20 x 1.5

10682-10 78-8137-0607-0 Grip, Cord, Skintop

10682-11 78-8060-8053-3 Wire, 3-Pole, 5 Meters Length

10682-12 78-8028-7909-4 Power Cord U.S.A.

10682-13 78-8060-7785-1 Plug

10682-14 26-1000-0010-3 Washer, Flat M6

10682-15 26-1003-7957-2 Screw, Soc. Hd. Hex Hd. M6 x 16

10682-16 78-8137-0608-8 Box, E-Stop, Yellow, Allen Bradley

10682-17 78-8137-0609-6 Switch, E-Stop, 40 800FM-MT44

10682-18 78-8137-0610-4 Terminal Switch

10682-19 26-1003-7943-2 Screw, Soc. Hd. M4 x 12

10682-20 78-8060-8488-1 Screw, Hex.Hd. M5 x 20

10682-21 78-8137-0611-2 Washer, Safety “S” (Schnorr) 5 F144

10682-22 78-8005-5741-1 Washer, Flat, M5

10682-23 78-8010-7417-6 Nut, Metric, Hex Stl., M5

51

Page 60

r70 Random Case Sealer

Figure 10730

52

Page 61

Figure 10730 (Page 1 of 2)

Ref. No. 3M Part No. Description

10730-1 78-8137-0746-6 Roller, Tappert

10730-2 78-8137-0747-4 Shaft

10730-3 78-8137-0748-2 Lever, Infeed

10730-4 78-8010-7210-5 Screw, Hex. Soc. Hd., M6 x 20

10730-5 78-8076-4649-8 Guide, Infeed

10730-6 78-8054-8779-6 End, Cap

10730-7 78-8137-0750-8 Frame, Infeed

10730-8 78-8017-9318-9 Washer, Plain, 8 mm

10730-9 78-8137-0751-6 Screw, M8

10730-10 78-8137-0752-4 Caps

10730-11 26-1003-7957-2 Screw, Hex. Soc. Hd., M6 x 16

10730-12 78-8137-0713-6 Valve, Assembly, 5/2 R70

10730-13 26-1003-7946-5 Screw, Soc. Hd., M4 x 25

10730-14 78-8137-0753-2 Shaft

10730-15 78-8017-9257-9 Screw, Phillips, M4 x 10

10730-16 78-8091-0537-8 Screw, Hex, M5 x 25

10730-17 78-8137-0754-0 Nut, Special

10730-18 78-8060-8480-8 Pad, Foot

10730-19 78-8137-0755-7 Support

10730-20 78-8137-0746-5 Rubber, Valve

10730-21 26-1000-0010-3 Washer, Flat M6

10730-22 78-8010-7418-4 Nut, Metric, Hex, STL., M6

10730-23 78-8137-0757-3 Support

10730-24 78-8137-0758-1 Shaft, Spring

10730-25 78-8137-0759-9 Spring

10730-26 78-8137-0722-7 Valve, Assembly 5/2 R70

10730-27 78-8005-5740-3 Washer Plain, Nickel, Metric 4 mm

10730-28 26-1003-6914-4 Nut, Plastic Insert, M4

10730-29 78-8129-6124-7 Screw, Cup Hd., M8 x 16

10730-30 78-8059-5617-0 Set Screw M6 x 8

10730-31 78-8076-4571-4 Sprocket, Z=20

10730-32 78-8054-8588-1 Washer, 8,5/40 x 6

10730-33 78-8057-5716-4 Screw, Flat Soc. Hd., M8 x 15

10730-34 26-1003-5807-1 Screw, Hex Hd., M3 x 20

10730-35 78-8054-8785-3 Rod, Threaded R/L

10730-36 78-8056-3945-3 E-Ring, M4

10730-37 78-8054-8787-9 Chain Link

10730-38 26-1003-5808-9 Screw, Hex Hd., M3 x 25

10730-39 78-8054-8783-8 Washer, Special

10730-40 78-8054-8788-7 Connector, Chain

53

Page 62

Figure 10730 (Page 2 of 2)

Ref. No. 3M Part No. Description

10730-41 78-8137-0760-7 Cover

10730-42 78-8137-0761-5 Screw, M5 x 10

10730-43 78-8054-8777-0 Chain, 3/8" Pitch, 41 Pitch

10730-44 26-1003-7945-7 Screw, Soc. Hd., M4 x 20

10730-45 78-8137-0702-9 Flow Regulator

10730-46 78-8137-0762-3 Frame, Infeed

10730-47 78-8010-7209-7 Screw, Soc. Hd., M6 x 12

10730-48 78-8010-7435-8 Washer, Metric Lock, M6

10730-49 78-8137-0723-5 Lever Cylinder, Assembly

10730-50 26-1003-7964-8 Screw, Hex Soc. Dr. Hd., M8 x 20

10730-51 78-8042-2919-9 Washer, Triple, M6

10730-52 78-8137-0720-1 Reductor, Assembly

10730-53 78-8010-7435-8 Shaft

10730-54 78-8137-0735-9 Pin, Cotter

10730-55 78-8060-7692-9 Roller, Tapered

10730-56 78-8137-0764-9 Shaft

10730-57 78-8137-0765-6 Lever, Infeed

10730-58 78-8137-0766-4 Washer

10730-59 78-8060-8416-2 Nut, Special, M20 x 1

10730-60 78-8137-0767-2 Shaft

10730-61 78-8137-0768-0 Spacer

10730-62 78-8137-0769-8 Shaft

10730-63 78-8137-0770-6 Support

10730-64 78-8137-0771-4 Stud, Joint

10730-65 78-8137-0701-1 Mount, Cylinder Rod End

10730-66 78-8005-5741-1 Washer, Flat, M5

10730-67 26-1003-7948-1 Screw, Hex Soc. Hd., M5 x 10

10730-68 12-7997-0272-0 E-Ring, M-25

10730-69 78-8070-1530-6 Radial Ball Bearing

10730-70 78-8137-0772-2 Spacer

10730-71 78-8114-4704-0 Union, 3140A0800

10730-72 78-8137-0699-7 Joint, Type An 10

10730-73 78-8137-0700-3 Reduction Tube 10/4

10730-74 78-8137-0773-0 Stud, Joint

10730-75 78-8137-0774-8 Spacer

10730-76 78-8091-0555-0 Nut, Special, M12

10730-77 78-8076-4570-6 Key, 6 x 6 x 15

54

Page 63

THIS PAGE IS BLANK

55

Page 64

r70 Random Case Sealer

Figure 10731

56

Page 65

Figure 10731

Ref. No. 3M Part No. Description

10731-1 78-8005-5741-1 Washer, Flat, M5

10731-2 26-1003-7949-9 Screw, Hex Soc. Hd., M5 x 12

10731-3 26-1003-7954-9 Screw, M5 x 45

10731-4 78-8137-0743-3 Support, Valve

10731-5 78-8137-0703-7 Valve Assembly 5/2