Page 1

3

Motorized Man ual Highway Tape

Applicator (MMHTA-18)

Information Folder 5.15

July 1995

Description

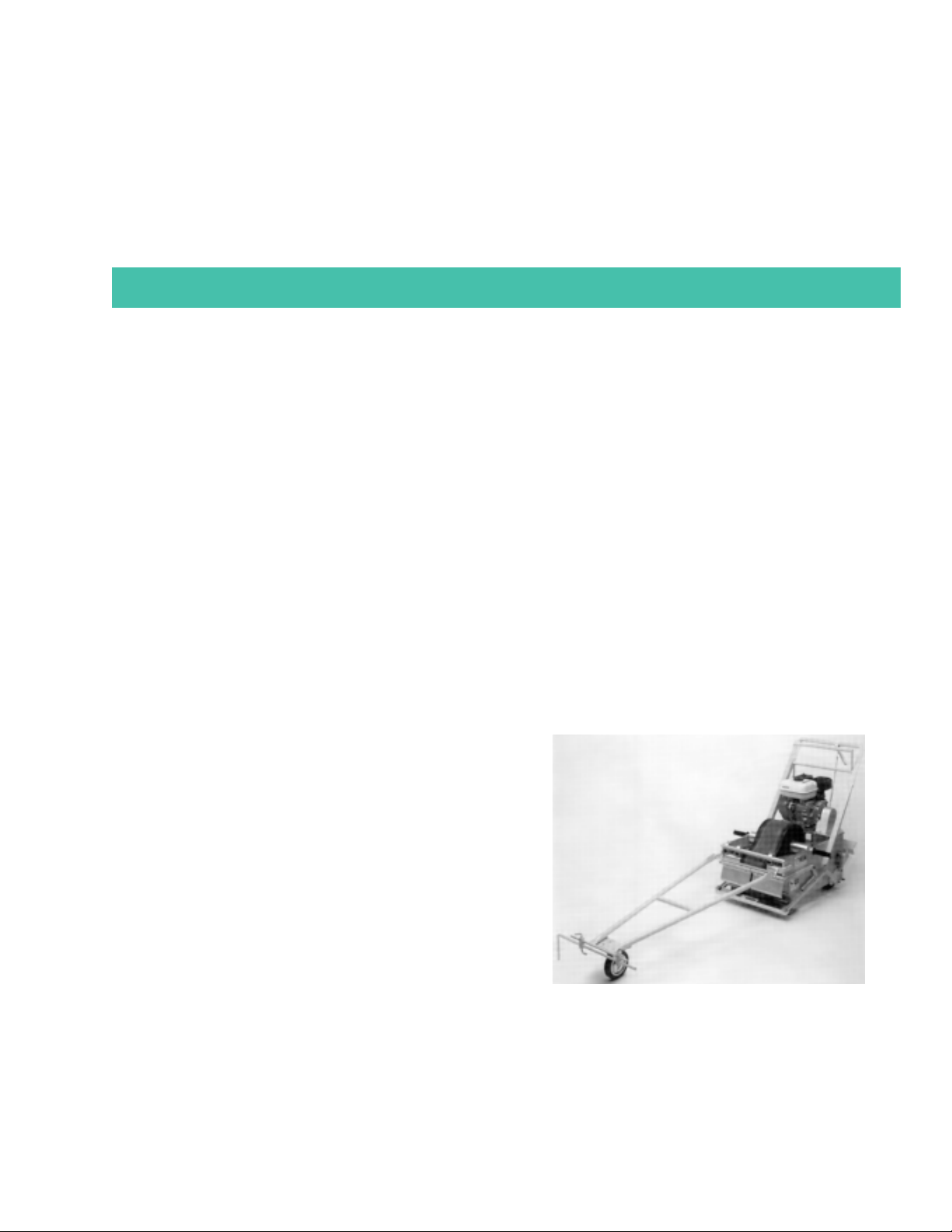

The 3M™ Motorized Manual Highway Tape

Applicator (MMHTA-18) is a motorized, twowheeled device for applying 3M™ Stamark™ and

Scotch-Lane™ pavement marking tapes (See

Figure 1). The device is specifically designed to

apply pavement markings precoated with pressure

sensitive adhesive during and immediately following asphalt resurfacing operations. It can also be

used to apply pressure sensitive adhesive coated

markings on existing surfaces or temporary markings used in construction work zones.

Table of Contents

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 1

Product Width and Spacing . . . . . . . . . . . . . . . . . . . . . . . Page 2

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 2

Application Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . Page 2

Application Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . Page 2

Pre-Application Preparation . . . . . . . . . . . . . . . . . . . . . . . Page 3

Tape Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 3

Tape Cutting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 3

Tamping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 4

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 4

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 5

Shipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 5

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 5

Side View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 8

Top View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 9

Figure 1

Page 2

2

Application Techniques (Refer to

Diagram A)

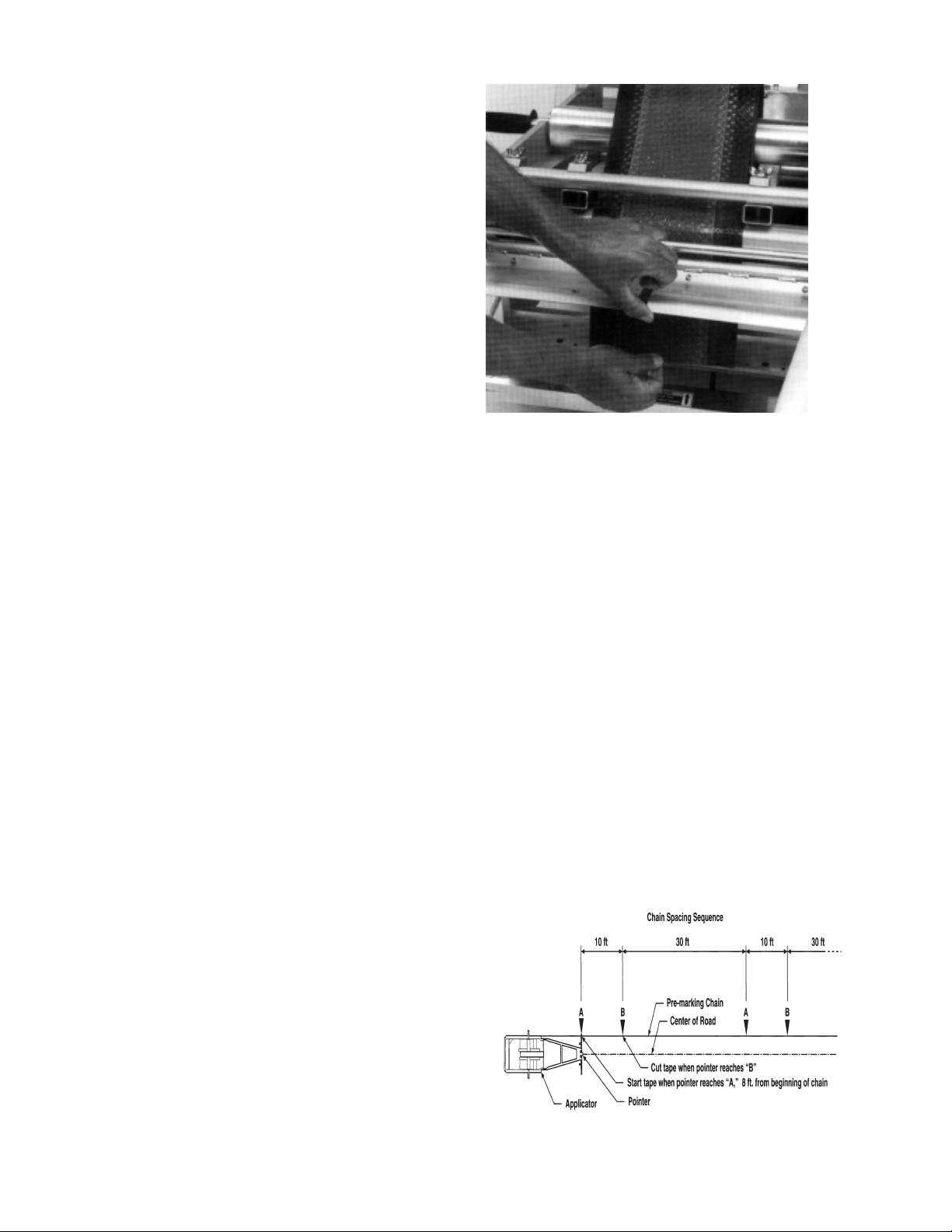

Pre-marking:

Using 200-250 ft. (60-70 m) of light rope, chain or

thin wire cable for a guideline, mark the skip

sequence on the chain to be followed. Example:

A sash chain marked to the proper sequence with

1-inch (2.54 cm) spiral key rings.

Example: For a 10 ft. (3 m) skip line and a 30 ft.

(9 m) space (10-30 sequence):

1) Mark point (A), the beginning of the first skip

line, about 8 feet (2.44 m) from the beginning

of the chain to line up applicator.

2) Measure 10 ft. (3 m) and mark point (B), the

end of the skip line.

3) Measure 30 ft. (9 m) and mark point (A), the

beginning of the next skip line.

4) Repeat steps 2 and 3 throughout the remaining

length of the guideline so that the last mark is

at point (A).

Figure 2

Diagram A

Product Width and Spacing

Several combinations of tape widths and spacing

can be applied using the MMHTA-18. Combinations of solid and skip lines may be applied simutaneously. The 3M™ Manual Highway Tape

Applicator can be used to apply all Stamark and

Scotch-Lane pavement marking tapes at maximum

standard roll lengths. NOTE: If special ordering

tape, the maximum roll diameter cannot exceed 20

inches (50.8cm) if the material is to be applied

with a MMHTA-18. Consult your 3M representitive to determine the availbility of the MMHTA-18

in your area.

Operation

The tape applicator can be operated by one person.

The following application rates are based on

asphalt paver speeds of 25 - 50 ft./min. and a

walking speed of 100 ft./min.

10:30 Skip 750 ft./hr.

15:25 Skip 1125 ft./hr.

Solid Line 1500 ft./hr.

Solid / Skip (NPZ) 2500 ft./hr.

Double Solid 3000 ft./hr.

Overall Average 1000 ft./hr.

NOTE: The application rates shown are intended

as guidelines and may vary with project conditions.

Procedure for Application of Pavement

Markings

Load the tape and thread it over the 2-inch (5.08

cm) diameter aluminum roll, adhesive side up (See

Figure 2). Feed the tape through the CLAMP to

the CUTTER PLATE. Adjust the GUIDE BARS at

the sides of the tape rolls to hold them securely in

position. The guide bars should be adjusted to

allow the roll to rotate freely, but not move side to

side. Stamark pavement marking tapes can be

ordered with the adhesive side of the tape wound

inward or wound outward. Both types of rolls will

work with the MMHTA-18; however, the tape

wound adhesive side out is recommended. The

tape wound adhesive side out will develop a natural curl that positions it to curve toward the silicone

applicator roll as it passes through the cutting

plate.

CAUTION: Do not activate the cutting knife with

the foot pedal while threading tape.

Page 3

3

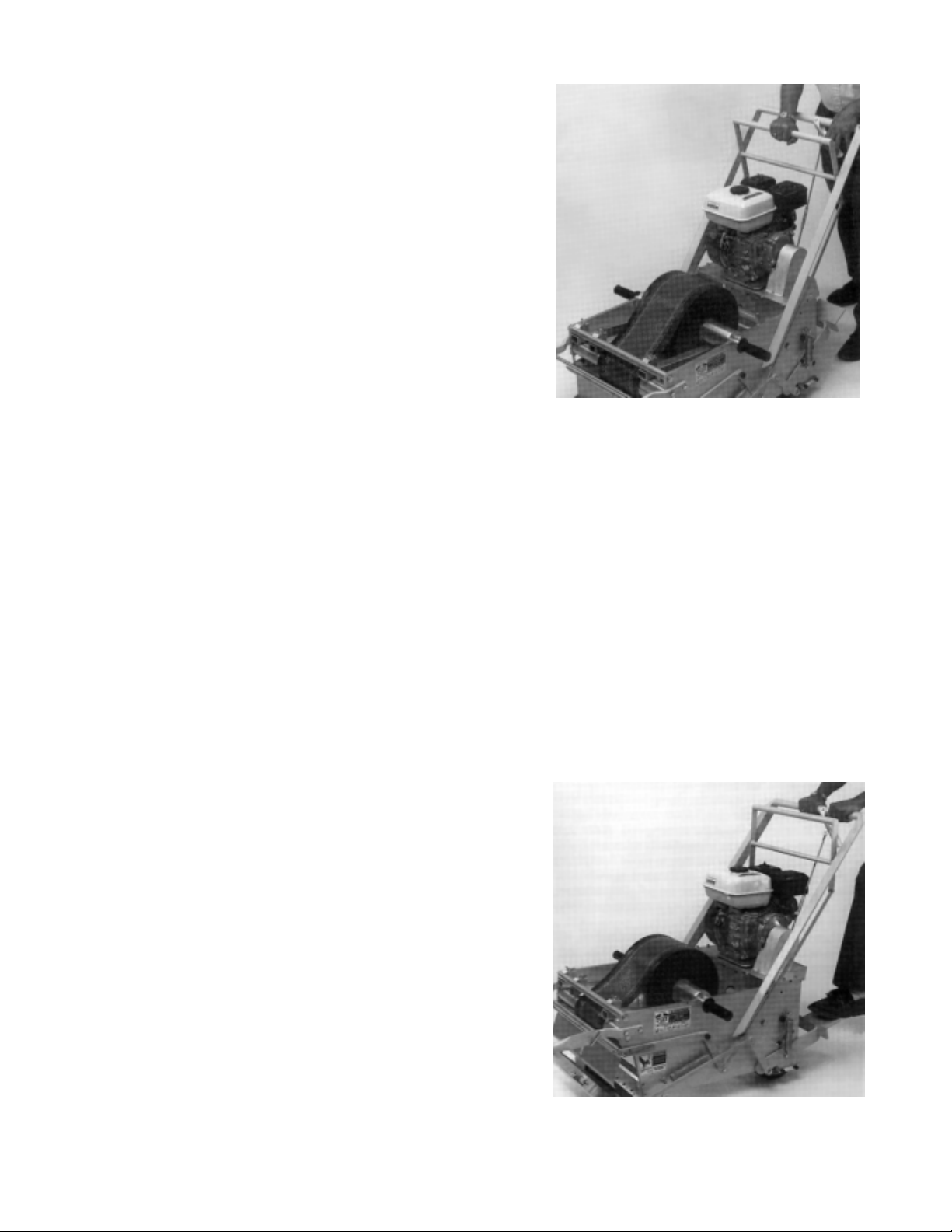

Figure 3

Pre-Application Preparation

1. Inspect cutting blades, clean and adjust if necessary. See Maintenance.

2. Check all fastening hardware and tighten if

necessary. Do not overtighten. Use self-locking hardware if replacing missing nuts or bolts.

3. Engine pre-operation check. See Maintenance

for maintenance intervals.

A. Oil: Use Honda 4-stroke oil, or equivalent

detergent, premium quality motor oil. SAE

10W/30 is recommended for general all-temperature use.

- Remove the oil filler cap/dipstick and wipe clean.

- Insert the dipstick into the oil filler neck, but do

not screw it in.

- If oil level is low, fill to the top of the oil filler

neck with recommended oil.

B. Air Cleaner: Check the air cleaner elements to

be sure they are clean and in good condition.

Clean or replace the elements if necessary.

C. Fuel: Remove the f iller cap and check the fuel

level. Refill the tank if the fuel level is low. Do

not f ill above the shoulder of the fuel strainer.

Tape Application

1. Determine where the first skip or long line

starts by measuring from the last existing skip

or reference mark and the side of the road.

Offset the premarked chain at least 12 inches

(30 cm) from the center of where the new

markings will be applied.

2. Lay the guideline out and adjust the pointer to

the side of the applicator. Position the applicator even with the pre-marking chain, and position the pointer to the side as shown.

3. To star t application, position the right hand in

the center of the clamp handle when moving

the handle forward to aid in keeping the applicator moving in a straight line when star ting

tape application (See Figure 3). Slowly move

the clamp handle forward while squeezing the

clutch lever to move the applicator forward at

about the same speed. After tape application

has begun, immediately release the clamp handle to allow the tape to move freely. As the

tape applicator is moved forward, start the

pavement marking each time the pointer passes

over “A,” and cut the pavement marking each

time the pointer passes over “B.”

4. When the last mark on the guideline is reached,

start the next pavement marking, stop the

machine and again lay the guideline out in

front of the pointer.

Tape Cutting

Release the clutch bar and bring the applicator to a

complete stop over the proper marking. Back-up

1/2 inch (1.27 cm) before cutting the tape and

release the foot pedal slowly. Do not attempt to

cut the tape while moving. Cutting the tape in

motion will stretch and tear the tape, causing the

next line to start off center.

When cutting a single line or both lines of a double line, depress either the right or left foot pedal

to the lowest position (See Figure 4).

When cutting a single line while applying a double

line, depress the corresponding foot pedal.

Depressing the foot pedal too far will cut both

markings.

Figure 4

Page 4

4

Tamping

When inlaying pavement markings in new asphalt

concrete surfaces, tamp the markings during the

f inal compaction (finishing roller) of the mat.

After application of markings on existing surfaces,

tamp the tape thoroughly with the 3M™ Roller

Tamper Car t (RTC-2) with a minimum 200 lb.

(90 kg) load, or slowly (2-3 mph) drive over the

tape three times with a vehicle tire. The vehicle

must be equipped with a pointing device to aid in

keeping the vehicle on the tape, making three

passes forward over the tape. Use a vehicle tire on

long line markings only. Do not attempt to tamp

intersection markings with a vehicle tire.

Tamping is most important!

When using the RTC-2 Roller Tamper Cart with

200 lbs. (90 kg.) of weight:

• Do not twist or turn the tamping device on the

tape.

• Make three passes back and forth over each part

of the tape.

• When tamping symbols, start in the center and

work to the outside edges.

• Make sure all edges are fir mly adhered.

• Open road to traffic as soon as tamping is

complete.

Maintenance

Keep All Fasteners Tight

Lubrication:

All the pivot points and sliding areas

should be kept lubricated with light oil penetrant

such as 3M™ Five-Way Penetrant or similar penetrants such as WD-40.

Cleaning: The r ubber application roller wheels

and cutting mechanism must be kept clean. 3M™

Citrus Base Industrial Cleaner or any natural citrus

based cleaner may be used on the wheels and

knives. Solvents may be used occasionally for diff icult cleaning problems. A spray bottle of cleaner

is useful to prevent asphalt buildup on the wheels

and adhesive buildup on the knives during operation.

Caution: Do not use solvents or petroleum products on the silicone application roller when working on new, hot asphalt surfaces. A paint scraper or

putty knife should be used to clean the asphalt

buildup from the scraper and cutter mounting bar.

To prevent asphalt buildup around the roller, additional clearance can be provided by loosening the

scraper mounting screws and sliding the scraper

back. Tighten the screws. Second, remove the cutter mounting bar and grind 1/8 inch (3.175 mm)

off the bottom. Replace the bar.

Each Every 50 Every 100

Use Hour Hours

Engine Oil Check Level X X

Change*

Air Cleaner Check X X

Clean*

Spark Plug Clean and X

Readjust

*Service more frequently when used in dusty areas.

Adjustments

The SCRAPER BAR, which is readjusted by the

manufacturer to prevent excess materials from accumulating on the application roller, should be periodically checked for wear and rotated if necessary. The bar should contact the rubber roller

across the full length of the roller.

The KNIVES are readjusted by the manufacturer

to slide across each other with a minimum of friction in a scissors action. Adjustment is needed

when foil construction tapes are not cleanly cut.

Either the STATIONARY KNIFE or the SLIDING

KNIFE may be adjusted (See Figure 5). To adjust

the stationary knife, loosen the mounting screws

slightly. Turn the set screws to bring the cutting

edge down, and retighten the mounting screws.

The same procedure is followed to adjust the sliding knife. Each knife has two cutting edges. The

knives may be removed and new cutting edges

exposed. The knives may be sharpened after the

cutting edges are dull.

Figure 5

Page 5

5

Troubleshooting

Tape Does Not Advance:

1. If the clamp springs have been overly stretched,

there will not be enough tension to advance the

tape. The springs should be replaced.

2. If the GUIDE BARS are too tight to the roll,

the tape will not advance properly. The bars

should be positioned so that the tape can

advance freely but hold the tape from moving

side to side.

3. If the teeth on the clamp are severely worn,

there will not be enough force to advance the

tape. See Replacement Parts or call your 3M

representative.

4. Check to see if the tape releases from itself

properly. There should be no adhesive picking

from the back side of the tape to the topside of

the next layer.

Tape Does Not Cut:

The tape will not cut cleanly if cutting is done

while the applicator is in motion. If the knife edges

are dull or out of alignment, the knives should be

sharpened and adjusted. (See Adjustments.) Clean

adhesive buildup from knives. (See Maintenance.)

Shipping

The MMHTA-18 must have the fuel drained prior

to shipment in an enclosed area. It is recommended to transport the MMHTA-18 using a utility

trailer.

Replacement Parts

The following is a complete listing of available replacement parts for the 18-inch (45.72 cm) wide

Motorized Manual Highway Tape Applicator

(MMHTA-18). When ordering, please note the

“MH-x” number in the right column. A complete

description of all parts included for each order

entry number is provided. Some parts are not

available separately, so take time to find the proper order number that contains all the parts needed.

Alphabetical Listing of Title Items: See the

chart on the following page for a complete listing.

Aluminum Roll Assembly MH-41

Bar Guide Assembly MH-4

Cartridge Bearing MH-56

Clamp Assembly MH-46

Clamp Pivot Shaft MH-47

Clamp Spring (small) MH-61

Clamp Spring (large) MH-10

Clutch Rod Assembly MH-55

Cutter Bar MH-45

Cutter Blade - Top MH-43

Cutter Blade - Bottom MH-44

Cutter Spring Assembly MH-14

Drive Axle Assembly MH-51

Drive V-Belt MH-57

Engine - 5.5 HP Honda MH-59

Guide Clamp (front) MH-12

Guide Clamp (rear) MH-13

Idler Pulley Assembly MH-54

Pointer MH-25

Pointer Assembly MH-39

Pointer Clamp Assembly MH-18

Power Transfer Shaft Assembly MH-53

Roller Chain Assembly MH-58

Side Frame Connecting Rod MH-49

Silicone Rubber Roll MH-50

Stock Roll Shaft MH-40

Stop Clamp MH-20

Swivel Caster Assembly MH-16

Tape Guide MH-11

Vibration Mount MH-60

Wheel Assembly MH-52

NOTE:After locating the proper replacement

part, check the following table to see a complete

listing of hardware included with each assembly.

Page 6

6

Code Description

MH-4 Bar Guide Assembly

(2) Screw, Soc. Hd. Cap, Stl, Zinc

Plt., 1/4-20 x 1-1/4

(1) Screw, Soc. Hd. Cap, Stl., Zinc

Plt., Loc-Wel, 1/4-20 x 5/8

MH-10 Clamp Spring (large) Assembly

(1) Screw, Hex Hd. Cap, Stl., Zinc

Plate 1/4-20 x 7/8 Lg.

(1) Nut, Hex, Stl., Zinc Plt., 14-20

MH-11 Tape Guide

(1) Tape Guide

MH-12 Guide Clamp (front) Assembly

(1) Wing Nut, Stl., Zinc Plt., 3/8-16

MH-13 Guide Clamp (rear) Assembly

(1) Wing Nut, Stl., Zinc Plt. 3/8-16

MH-14 Cutter Spring Assembly

(2) Screw, Hex Hd. Cap, Stl., Zinc

Plt., 1/4-20 x 3/4 Lg.

(2) Nut, Hex, Stl., Zinc Plt., 1/4-20

MH-16 Swivel Caster Assembly

(4) Screw, Hex Hd. Cap, Stl., Zinc

Plt., 1/4-20 x 3/4 Lg.

(4) Nut, Hex, Stl., Zinc Plt. 1/4-20

(4) Lockwasher, Stl., Zinc Plt., 1/4

MH-18 Pointer Clamp Assembly

(1) Pointer Clamp

(2) L-Screw

MH-20 Stop Clamp

(2) Stop Clamp

MH-25 Pointer

(1) Pointer

(2) Pointer Clamp

(4) L-Screw

MH-39 Pointer Assembly

(1) Pointer Frame

(1) Pointer

(2) Pointer Clamp

(1) Pointer Pin

(4) L- Screw

(1) Swivel Caster

(4) Cap Screw, Hex. Hd., Stl., Zinc

Plt., 1/4-20 x 3/4 Lg.

(4) Nut, Hex., Stl. Zinc Plt., 1/4-20

(4) Washer, Lock-Stl., Zinc Plt. 1/4

(1) Hitch Pin Clip, Stl., Zinc Plt.,

.093 Wire x 1-3/4 Lg.

MH-40 Stock Shaft Roll

(1) Stock Roll shaft

MH-41 Aluminum Roll Assembly

(1) 2 inch (5.08cm) Diameter Roll

(2) Flanged Bearing-Oilite No.

FF-1014

(2) Set Screw-Hex. Soc., Cup Point

1/4-20 x 3/8

Code Description

MH-43 Cutting Blade - Top

(9) Cap Screw-Hex. Soc., Stl., Zinc

Plt. #10-24 x 5/16 Lg Loc-Wel

(10) Set Screw-Hex. Soc.,

CupPoint Zinc Plt., #10-24 x 3/8

Lg. Loc-Wel

MH-44 Cutting Blade - Bottom

(9) Cap Screw-Hex. Soc., Stl., Zinc

Plt. #10-24 x 1/2 Lg. Loc-Wel

(8) Set Screw-Hex. Soc., CupPoint

Zinc Plt., #10-24 x 3/8 Lg. LocWel

MH-45 Cutting Bar

(1) Cutting Bar

MH-46 Clamp Assembly

(1) Windscreen

(2) Cap Screw-Hex. Soc., Stl., Zinc

Plt., #10-24 x 5/16 Lg. Loc-Wel

MH-47 Clamp Pivot Shaft Assembly

(2) Screw, Soc. Hd. Cap, Loc-Wel,

Stl., Zinc Plt., 1/4-20 x 3/4 Lg.

MH-49 Side Frame Connecting Rod

(2) Cap Screw-Hex. Hd., Stl., Zinc

Plt. 1/2-13 x 1 Lg.

MH-50 Silicone Rubber Covered Roll

Assembly

(3) Roll, Silicone Rubber Covered 4 in. dia.

(6) Bearing, Flange Series - General

#32662-88

(2) Set Screw, Hex. Soc., Cup Point

Zinc Plt. 1/4-20 x 3/8

MH-51 Drive Axle Assembly

(1) Axle

(4) Washers

(1) Key - 3/16" Sq.l X 1.2 Long

(1) Sprocket, 30 Tooth 3/4" Bore

Boston #SSC75

(1) Collar, Set Screw - 3/4" Dia.

Boston #SSC75

(4) Inner Race, Torrington #IR-1224

MH-52 Wheel Assembl y

(1) Wheel - Modified

(1) Spacer - Wheel Bearing

(2) Bearing, Torrington #JHTT-1614

(2) Bearing - Clutch Torrington

#RC-162110

MH-53 Power Transfer Shaft Assembly

(1) Shaft - Power Transfer

(2) Bearing - Roller Torrington

#JTT-1410

MH-54 Idler Pulley Assembly

(1) Pulley - Idler

(2) Pulley - Bearing Fafnir

#FS-3-KDD

(1) E-Ring - 3/8 Dia. Shaft, Truarc

#5133-37

Page 7

7

Code Description

MH-55 Clutch Rod Assembly

(1) Rod - Clutch (Upper)

(1) Rod - Clutch (Lower)

(1) Turn Buckle - McMaster

#30125T4

(2) Clevis - Rod - Bimba

#D-10139-A

(3) Nut, Lock, Grade 2 Toplock 1/420 Unc, Stl, Zinc Plt.

MH-56 Cartridge Bearing

(1) Cartridge Bearing, Fafnir

RCJC-3/4

MH-57 Drive V-Belt

(1) V-Belt, Gpl Premium, Dayco

#L430

MH-58 Roller Chain Assembly

(1) Chain, Roller, ANSI #40 1/2 in.

Pitch, 2 ft. Long

(1) Chain Link #40, +in. Pitch

Code Description

MH-59 Engine - 5.5 HP Honda

Engine 5.5 HP, 6:1 Reduction,

Exhaust Deflector, Honda

#GX160-K1HX2

MH-60 Vibration Mount

Vibration Mount, 70 Durometer,

McMaster #64875K64

MH-61 Clamp Spring (small) Assembly

(2) Lee Spring #LE-037D-9-MW

(4) Screw, Bottom Hd. Cap, Stl.,

Zinc Plt. 1/4-20 x 3/4 Lg.

(2) Screw, Soc. Hd. Cap, Stl., Zinc

Plt., #10-24 x 1/2 Lg.

(1) Blue Line Print of Drawing

For fur ther information, contact: 3M Traff ic

Control Materials Division,1-800-553-1380.

Follow instructions to reach Technical Service

for Pavement Markings. In Canada call 1-519452-6201.

Page 8

8

Page 9

9

Page 10

3M assumes no responsibility for any injury, loss or damage arising out of the use of a product that is not of our manufacture.

Where reference is made in literature to a commercially available product, made by another manufacturer, it shall be the user’s

responsibility to ascertain the precautionary measures for its use outlined by the manufacturer.

Important Notice

All statements, technical information and recommendations contained herein are based on tests we believe to be reliable, but the

accuracy or completeness thereof is not guaranteed, and the following is made in lieu of all warranties, express or implied.

Seller’s and manufacturer’s only obligation shall be to replace such quantity of the product proved to be defective. Neither seller nor

manufacturer shall be liable for any injury, loss or damage, direct or consequential, arising out of the use of or the inability to use the

product. Before using, user shall determine the suitability of the product for his/her intended use, and user assumes all risk and

liability whatsoever in connection therewith.

Statements or recommendations not contained herein shall have no force or effect unless in an agreement signed by officers of seller

and manufacturer.

3

Traffic Control Materials Division

3M Center, Building 225-5S-08 3M Canada 3M Mexico, S.A. de C.V.

P.O. Box 33225 P.O. Box 5757 Apartado Postal 14-139 Printed on recycled paper

St. Paul, MN 55133-3225 London, Ontario N6A 4T1 Mexico, D.F. 07070 75-0300-1799-2

Loading...

Loading...