Page 1

Page 2

Microfluor®II Critical Sterilizing Grade PTFE

Cartridge and Capsule Membrane Filters

Microfluor II PTFE membrane filters offer the ultimate in

microorganism retention for air and gas streams while

providing superior air flow capacity.

CUNO’S Microfluor II filters with flow enhanced

?

construction allow use of smaller, more economical air

filter assemblies compared to competitive air filters.

Microfluor II filters provide absolute retention based on

?

liquid bacteria challenge and aerosol bacteriophage

challenge.

Microfluor II filters are available in a wide range of

?

cartridge and capsule configurations to provide the most

New flow enhanced cartridge and capsule filter construction

provides lower differential pressure than competitive filters

economical solution to air, gas and aggressive liquid

filtration applications.

Cartridge and Capsule Configurations to Meet Any Process Requirement

Microfluor II membrane filters are available in 5 through 40 inch cartridges, 2.5 and 5 inch Mini Cartridges and

2.5, 5, 10, 20 and 30 inch capsules. With the exceptionally high Microfluor II flow rates, smaller and more

economical assemblies can provide the same air flow as larger, more costly competitive PTFE filters.

Feature Benefit

?

Unique flow enhancing layer construction

?

Liquid validation of B. diminuta retention

?

Hydrophobic PTFE membrane

?

21 CFR Materials of Construction, USP

Biological Safety Test, Validation Guide

and Drug Master File Listing

?

Higher air flow for fermenter aeration and smaller,

more economical vent filter assemblies

?

Reliable sterilizing performance in wet or dry

conditions

?

Membrane will not become blocked with moisture

?

Eases validation and regulatory submissions

2

Page 3

Microfluor®II Cartridge and Capsule Filter Applications

(

)

(

)

Microfluor II filters are optimized for applications requiring sterilization of air, gas, or aggressive solvents and

chemicals. The hydrophobic PTFE filter membrane prevents wetting with aqueous liquids or moisture that can

block free air flow. Some applications, however, may require filtration of aggressive fluids such as acids or bases.

Depending on compatibility, Microfluor II filters can be used to provide sterile filtration of these fluids by

prewetting the membrane with a low surface tension fluid such as alcohol. A list of Microfluor II filter applications

includes:

Sterile venting of process tanks

>

Sterile filtration of process air and aseptic filling lines

>

Sterile venting of lyophilizers

>

Sterile venting of autoclaves

>

Sterile air filtration on blow, fill, and seal machines

>

Sterilizing filtration of fermentation inlet and exhaust air

>

Sterile filtration of aggressive liquids

>

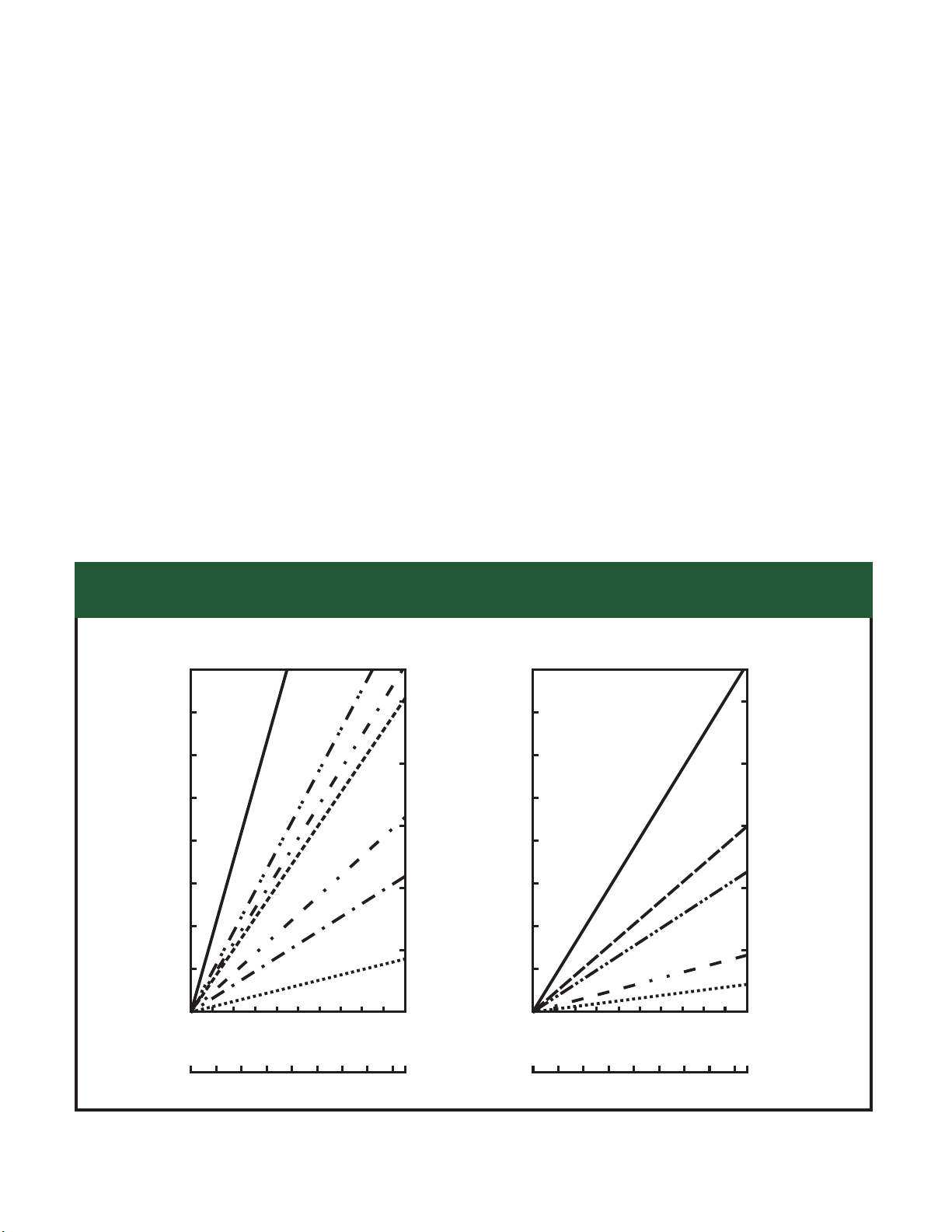

Microfluor II filters have been designed to provide exceptionally high flow rates with low differential pressures

(Figure 1). Microfluor II filters are available in a range of cartridge and capsule filter configurations to meet any

process requirement. Shown in Figure 1 are flow curves for cartridge and capsule filter assemblies at atmospheric

(vent) and compressed air conditions. For details of sizing vent and compressed air assemblies, please ask for

CUNO Automated Sizing Program assistance.

Figure 1. - Microfluor II Air Flow vs. Diffferential Pressure*

Microfluor II Filter

Air Flow @ Vent Conditions

4.0

3.5

3.0

2.5

2.0

1.5

2.5” Mini Cartridge & Capsules

Differential Pressure (psid)

1.0

0.5

0

0 20406080100

5” Mini Cartridge

5” Capsule

5” Cartridge

10” Capsule

10” Cartridge

20” Cartridge

Air Flow (SCFM)

40 60 80 100 120 140 160

20

0

0.25

0.20

0.15

0.10

0.05

0

Differential Pressure (bar)

Microfluor II Filter

4.0

3.5

3.0

2.5

2.0

1.5

Differential Pressure (psid)

1.0

0.5

0

0 20406080100

Air Flow @ 30 psi

2.5” Mini Cartridge

5” Mini Cartridge

5” Cartridge

10” Cartridge

20” Cartridge

Air Flow (SCFM)

40 60 80 100 120 140 160

20

0

0.25

0.20

0.15

0.10

0.05

0

Differential Pressure (bar)

3

Air Flow

* Cartridge airflow values with housing pressure loss subtracted (excluding capsules).

Nm /hr

3

Air Flow

3

Nm /hr

Page 4

The Microfluor®II Membrane Advantage

Microfluor II filter cartridges and capsules combine high flow

with a liquid validated, bacteria retentive, hydrophobic PTFE

filter membrane. Capsule and cartridge filter structural

components are polypropylene, optimized for long on-stream

air service. The most important characteristics for a

sterilizing grade air filter include:

Validated PTFE Membrane

Microfluor II filters are validated by liquid bacteria challenge

for complete retention. Liquid bacteria challenge represents

the most severe test of filter performance and provides the

highest assurance level of reliable sterilizing performance. In

addition, Microfluor II filters have demonstrated complete

aerosol retention of the bacteriophage ΦX-174. For complete

details, request the Microfluor II Validation Guide

(LITVGMR2). The scanning electron micrograph (Photo 1)

shows the structure of the PTFE membrane with a tortuous

pore pathway of flow channels.

Photo 1. - SEM of Microfluor II PTFE membrane

Hydrophobicity

Free air flow with little resistance requires that the filter

membrane not wet with water or moisture. Membrane

wetting can result in filter pore blockage, which in turn

prevents free air flow and can cause filter failure. In order to

prevent pore blockage, an extremely hydrophobic PTFE

membrane is used which prevents wetting with water or

moisture. Graph 1 shows the relative hydrophobicity of

filter media used in air filters. As can be seen, PTFE offers

the highest level of hydrophobicity ensuring optimum air

flow service.

High Air Flow

Efficient performance requires maximum air flow at

minimum pressure drop. Microfluor II air filters utilize a

patent pending construction to achieve higher

air flow vs. pressure drop compared to

competitive air filters. This unique CUNO

development involves the use of specially

designed PTFE filter membrane and

polypropylene flow enhancing layers. This

construction is applied to Microfluor II

cartridge and capsule filters. Photo 2 shows

how each layer is positioned within the

cartridge and capsule filters.

Photo 2. - Microfluor II Filter Construction

Graph 1. - Comparative Hydrophobicity

0.06

0.05

0.04

0.03

0.02

0.01

1/Critical Surface Tension (dynes/cm)

0

Air Filter Hydrophobicity

PTFE PVDF Polypropylene

Flow Distribution

Layer

Downstream Support

Layer

PTFE Media

Upstream Support

Layer

4

Page 5

Superior Flow Rate Performance

f

Microfluor II filter cartridges and capsules offer outstanding flow rate performance at low differential pressures.

Whether used for tank venting, lyophilizer or autoclave vacuum breaking, blow, fill, seal machines or fermentation

air sterilization, filter flow rate is a critical parameter. Using the design enhancements described, Microfluor II

filters provide maximum flow performance. Graph 2 presents the comparison of Microfluor II cartridge and capsule

filter performance to competitive air filters.

Graph 2. - Air Flow Rate Comparisons

luor II 20”Cartridges

Micro

Microfluor II Cartridges

Outperform Competitive

Cartridge Filters

Provide Comparable

Performance to Domnick

Hunter 30” Cartridge Filters

Microfluor II Capsules

Significantly Outperform

Competitive Capsule Filters

Microfluor II 5 Inch Capsule

Microfluor II 2.5 Inch Capsule

Domnick Hunter Tetpor 5 Inch Capsule

Pall Kleenpak™ Emflon KA3 Capsule

Millipore Opticap 4 Inch Capsule

®

®

®

100

SCFM/0.5psid @ 30 psig

80

60

40

20

Microfluor II 10 Inch Cartridge

Microfluor II 5 Inch Cartridge

Domnick Hunter ZCHT 10 Inch Cartridge

®

Pall Emflon PFR10 Inch Cartridge

Millipore Aervent™ 10 Inch Cartridge

200

160

120

80

SCFM/0.5psid @ 30 psig

40

0

0

Microfluor II

20 Inch Cartridge

Domnick Hunter

30 Inch Cartridge

25

20

15

10

SCFM/0.5psid @ Vent

5

0

Reliable Microorganism Retention Performance.

Microfluor II filters are validated for sterilizing performance using a liquid bacteria (B.diminuta) challenge test

method. Liquid bacteria retention testing is the most critical test of sterilizing filter performance and provides the

user with the utmost assurance that critical product or fermentation broth will be protected from contamination. In

addition to demonstrating sterilizing performance in liquid, Microfluor II filters were tested for complete

bacteriophage retention using aerosol challenge test methods. Aerosol retention performance assures users that

Microfluor II filters will provide reliable air and gas sterilization. Aerosol challenge testing was performed using

ΦX-174 bacteriophage which are small organisms that infect bacteria cells and can ruin bacteria fermentation

processes. Complete retention of bacteriophage was observed as shown in Table 1. For complete details request the

CUNO Microfluor II Validation Guide (LITVGMR2).

Table 1. - Microfluor II Retention Performance

Test Method Test Organism Test Result

Liquid Bacteria Challenge B. diminuta Sterile

Aerosol Virus Test

Emflon and Kleenpak are trademarks of Pall Corporation, Aervent and Opticap are trademarks of Millipore Incorporated, and Tetpor is a trademark of Domnick

Hunter Group plc

.

ΦX-174 Bacteriophage

5

0 Plaque Forming Units

Page 6

Robust Filter Construction

Mini Cartridge

End Cap

Inner Core

& Outer Cage

Support

Layers

Microfluor II

PTFE Filter

Media

Mini Cartridge

Microfluor II

PTFE Filter

Media

Flow

Distribution

Layer

Inlet

Vent

Valve

Support

Layers

Outlet

Capsule

Microfluor

PTFE Filter

Media

Flow

Distribution

Layer

Flow

Distribution

Layer

End Cap

Adapter

Various O-Ring

Materials

316 Stainless Steel

Reinforcing Ring

Support

Layers

Inner Core

& Outer Cage

Standard Cartridge

Many applications for air filtration require steam sterilization of filter cartridges. In vent or fermentation air service

applications, filters may be steam sterilized multiple times. For fermentation processes, air sterilizing filters may

be used for up to two years, and if sterilization is performed weekly, this results in exposure to over 100 steam

cycles. Microfluor II air filters were tested for ability to withstand multiple forward and reverse steam cycles and

were demonstrated to retain integrity for 200 steam cycles at 145°C. For complete details, request the Microfluor II

Validation Guide (LITVGMR2).

Microfluor II Cartridge and Capsule Filter Configurations

Cartridge Filters

Microfluor II filters are available in 5 through 40 inch cartridge filters with a variety of end fittings and o-ring

options to meet hardware and process requirements.

Mini-Cartridges

CUNO 2.5” and 5” Microfluor II Mini Cartridges can be installed in existing Pall

Sealkleen™ housings or CUNO Mini Cartridge housing (LITZRMCH).

Capsule Filters

Microfluor II filters are available in 2.5, 5, 10, 20 and

30-inch capsule filter configurations. Capsule filters

may be autoclave sterilized and offer a convenient, easy

to use format for air sterilization. As with Microfluor II

cartridge filters, the capsule filters have been specially

designed to provide optimum air flow. Capsules are not

recommended for continuous compressed gas service.

Quality and Reliability

Microfluor II filters are manufactured to an ISO 9000

registered quality system and are 100% diffusion flow

tested prior to shipment. All materials of construction

are 21 CFR listed and cartridge and capsule filter

components have been tested in accordance with United

States Pharmacopoeia (USP) Class VI Biological Safety. All

Microfluor II cartridge and capsule filters are shipped with a

Certificate of Quality affirming compliance with rigid manufacturing

quality specifications. Supporting Drug Master File (DMF) documentation

is on file with the United States Food and Drug Administration (FDA). A

complete Microfluor II Validation Guide is available upon request

(LITVGMR2).

Integrity Testing

Microfluor II cartridge and capsule filters can be easily and

automatically tested to verify filter integrity pre and post use

using the CUNOCheck

®

2 integrity test instrument. Filters can

be tested using diffusive flow, pressure hold, bubble point or

water intrusion test (WIT) methods. Refer to CUNO

publication LITTDMR2INTG - Integrity Testing Microfluor II

Cartridge and Capsule Filters.

Sealkleen is a trademark of Pall Corporation

6

Page 7

Operating Parameters and Specifications

Filter Configuration

Filter Rating

Materials of Construction

Membrane

Membrane Support Layer

Core, cage, end caps, and adaptors

Adapter Reinforcing Ring

Filtration Surface Area -ft

Cartridge Operating Parameters

Maximum Differential Pressure

Forward Pressure

Reverse Pressure

Maximum Operating Temperature

Integrity Test Parameters - Diffusion Flow Test - @ 25°C and 1 atm.***

25%/75% TBA/Water @ 16 psig (1.11 bar)

55%/45% IPA/Water @ 16 psig (1.11 bar)

Autoclave Conditions

In-situ Steam Conditions

* per 10 inch element **not for continuous compressed gas service. *** Consult factory for other methods

2(m2

)

Cartridge Mini Cartridge Capsules**

5to40"

Stainless Steel NA

11 (1.02)* 1.8 (0.17) 3.7 (0.34) 2.8 (0.26) 5.5 (0.51) 11 (1.02) 22 (2.04) 33 (3.06)

80 psid (5.5 bar) @ 75°F (25°C)

25 psid (1.7 bar) @ 180°F (80°C)

65 psid (4.5 bar) @ 75°F (25°C)

8.7 cc/min.* 1.4 cc/min. 2.9 cc/min. 2.2 cc/min. 4.4 cc/min. 8.7 cc/min. 17.5 cc/min. 26.2 cc/min.

14.7 cc/min.* 2.4 cc/min. 5.0 cc/min. 3.8 cc/min. 7.4 cc/min. 14.7 cc/min. 29.5 cc/min. 44.2 cc/min.

2.5" 5" 2.5" 5" 10" 20" 30"

180°F (80°C) 104°F (40°C)

Up to 259°F (126°C)

Up to 293°F (145°C)

CUNO Filter Housings

0.2 µm

PTFE

Polypropylene

Polypropylene

75 psid (5.2 bar) @ 104°F (40°C)

65 psid (4.5 bar) @ 75°F (25°C)

Do not In-situ steam

A complete line of sanitary design, stainless steel filter housings is available for Microfluor II cartridge

filters. Options are available for heat traced (electrical and steam jacketed) housings where condensate is

a concern. Specialized configurations and housing designs are also available for high flow, fermentation

air filtration applications.

Housing Model Mini ZMS ZMS ZWC ZWB ZVS Mini Cartridge Housing

For 5 inch

Cartridge

Basic Part Number /

Cartridge Capacity

Housing Style T-line Sanitary type connection Sanitary type in-line

Equivalent Cartridge

Lengths

Materials of

Construction

Pressure &

Temperature Ratings

Literature # LITZRHZMS2 LITZRH.104 LITZRH.106 LITZRH.104 LITZRHMCH

70236 / 1

5 inch 10, 20, 30, and 40 inches 2.5 inches 5 inches

150 psi (10 bar) @ 300°F (149°C)

70220-01 / 1 70180 / 4 70192 / 4 70221-01 / 1

70220-02 / 1 70189 / 8 70193 / 8 70221-02 / 1

70220-03 / 1 70190 / 11 70194 / 11 70221-03 / 1

70220-04 / 1 70191 / 21 70195 / 21 70221-04 / 1

For 10, 20. 30, and 40 inch cartridges For 2.5 inch Mini Cartridges For 5 inch Mini Cartridges

7023502 / 1 7023501 / 1

316L Stainless Steel

75 psi (5 bar)

@ 200°F

(90°C)

150 psi (10 bar)

@ 200°F (90°C)

150 psi (10 bar)

@ 300°F (149°C)

150 psi (10 bar) @ 300°F (149°C)

150 psi (10 bar) @ 300°F

(149°C)

Scientific Applications Support Services (SASS)

CUNO's 90 years of experience are synonymous with quality, performance and high-level technical support. The

cornerstone of CUNO's philosophy is service to customers, not only in product quality and prompt delivery, but

also in validation assistance, applications support and in the sharing of scientific information. CUNO's Scientific

Applications Support Services group works closely with customers to solve difficult separations problems and to

recommend the most economical and efficient filter system. SASS Specialists are skilled in performing on-site

testing and relating test results to full-scale manufacturing operations.

7

Page 8

Microfluor II Cartridge Ordering Guide

Grade

Designation

PFS020 A

Configuration

Height

(Inches)

01 -10 B - 226 O-ring & Spear A - Silicone

02 -20 C - 222 O-ring & Spear B - Fluorocarbon

03 -30 F - 222 O-ring & Flat Cap C - EPR

04 -40 J - 226 O-ring & Flat Cap D - Nitrile

50 -5 K - Teflon Encapsulated Viton

Microfluor II Mini Cartridge Ordering Guide

Grade

Designation

PFS020 R

Configuration

Height

(Inches)

01 - 2.5

02 -5

Microfluor II Capsule Ordering Guide

Grade

Designation

PFS020 J

Configuration

Height

(Inches)

01 -10

02 -20 B - Fluorocarbon

03 -30 C - EPR

25 - 2.5

50 -5

End Modification O-Ring Material

End Modification Package Quantity

AN 06 - 6 Pack

End Modification

A - Sanitary Fitting

Vent O-Ring

Option

A - Silicone

Package

Quantity

01 -1 Pack

CUNO: A World Leader in Fluid

Purification

CUNO's manufacturing sites have ISO 9000

registered quality systems. Global

manufacturing together with trained stocking

distributors and state-of-the-art laboratory

support bring quality solutions to existing and

challenging new filtration applications.

CUNO Filtration Asia Pte Ltd

18 Tuas Link 1 (3 Floor)

Singapore 638599

Cuno Filtration Shanghai Co, Ltd

No. 2 Xin Miao San Rd,

Song Jiang District,

Shanghai. China. 201612

rd

Xin Miao Town,

CUNO Pacific Pty Ltd

140 Sunnyholt Road

Blacktown, NSW 2148

CUNO K.K.

Hodogaya Station

Building 6F

1-7 Iwai-cho, Hodogaya-ku

Yokohama 240 Japan

Australia

WARRANTY

Seller warrants its equipment against defects in workmanship and material for a

period of 12 months from date of shipment from the factory under normal use

and service and otherwise when such equipment is used in accordance with

instructions furnished by Seller and for purposes disclosed in writing at the time

of purchase, if any. Any unauthorized alteration or modification of the

equipment byBuyer will void thiswarranty. Seller's liability under this warranty

shall be limited to the replacement or repair, F.O.B. point of manufacture,of any

defective equipment or part which, having been returned to the factory,

transportation charges prepaid, has been inspected and determined by the Seller

to be defective. THIS WARRANTY IS IN LIEU OF ANY OTHER

WARRANTY, EITHER EXPRESSED OR IMPLIED, AS TO DESCRIPTION,

QUALITY, MERCHANTABILITY, FITNESS FOR ANY PARTICULAR

PURPOSE OR USE, OR ANY OTHER MATTER. Under no circumstances

shall Seller be liable to Buyer or any third party for any loss of profits or other

direct or indirect costs, expenses, losses or consequential damages arising out of

or as a result ofany defects inor failure of its products or any part or partsthereof

or arising out of or as a result of parts or components incorporated in Seller's

equipment but not supplied by the Seller.

a 3M company

CUNO Latina Ltda

Rua Amf Do Brasil 251

18120 Mairinque-Sp

Brazil

CUNO Ltd

21 Woking Business Park

Albert Drive

Woking, Surrey GU215JY

United Kingdom

CunoIncorporated

400 Research Parkway

Meriden, CT 06450, U.S.A.

Tel: (800) 243-6894

(203) 237-5541

Fax: (203) 630-4530

www.cuno.com

© CUNO Incorporated, 2002 - ALL RIGHTS RESERVED LITCMR2.1202

Loading...

Loading...