Page 1

|

Table

of

Contents

Model

3000

and

Micro

3100

Warespey & Service

Section

1.1

1.2

1.3

Section

"Table

Section

3.1

3.2

3.3

Front

1:

General

3M

Infusion

Micro

3100

Epidural

Precautions.

Installation......................

1.

2.

Operational

Controls & Indicators.

1.

Options

Administration.

2:

Specifications

2olocoocccocacanonocconenconoronosnorenronenensornoroerraonor

3:

Installation & Operation

AC

Power

Portable

Panel

Controls

Message

Key..

Policy.

Description

Therapy

System

Models

Description.

Connection...

Operation & M

Description.

€:

Indicators

Display.

Occlusion

Primary

Secondary

2.

3.

Rate

Volume

“Number

“+

(Decimal)

>

Run

Hold

。

*

4.

Battery

5.

Inside

Pump

1.

2.

Back

Panel

1,

2.

Photo

Pumping

SY

Door

Cassette

Safety

Alarm

Computer

Keypad

Alarm

Setting

Key & Indicator...

Key & Indica

Sensor...

Key & Numeric

to

Keys

Key & Indicator..

Key

dz

(Charge)

Indicator.........

Latch

Door

Clip

Controls

Volume

το

Indicat

be

Infused

(0-9).

Key......

Indicator.

у.

(Handle)...

Loading

Retention

Port........

Key & Numeric

Indicator.

Pins...

Control.

바

Button.

Display...

Slot.

Key.

3000

&

roer

Display.

rosrness

2-2

.

1

te

ča

Pe

の

の

や

の

の

ыы

Un

a

CA

CA

CA

いい

ふい

ar Ad

Alerts:

1.

2.

3.

4.

Alarms:

5.

6.

7.

8.

5,

10.

11.

12.

13.

14.

Table

3-1

3.7

Options.

2.

Time

3.

Message

4.

Battery

5.

Quick

6.

Rate

Biomedical

1.

2.

5.

6.

7.

8

.

8.

9.

10.

11,

КУО

Low

Rate

Secondary/was

Pump

System

Occlusion/below

Air

Door

On

Battery

Close

Loading

Summary

System

Snapshot

Pump

Volume

Charge

On

Pressure

Baud

Language

Battery

Display

mi

battery/Plug

change/not

needs/service.

in

open...

Hold...

clamp!/Load

Remaining

Test

rate

Taper

Time.

Rate

/this

in

completed.

set.

check/Tum

pump...

cassette..........

too

low/Plug

problem/Check

of

Alarm

Display

Special

History

Display

Light

Optional

Change

Optional

Warning

Screen-a..

Infused,

History

(Calibrate

Use

Model

Optional

Function........

and

Display - Hours

Loading

Display - AC,

Selection...

Selection.

Display.

Ni

infusion.

cord...

off

then

in

Safety

Conditions.

Optional

Function................

Punction..

error

у...

Mode)

on.

cord.

Cl

tubing

.

optional

Function

Function.

Function.

code

Cycles..................

Display.

display.

of

operation,

Charge,

3-14

-14

3-14

-14

-14

-14

….

~

3-29

Battery

3-29

"3.29

3-29

3-30

Page 2

-4.13

Pole

Clamp.........

4.14

‘Modular

Electronic

4.15

4.16

4.17

4.18

4.19

4.20

4.21

4.22

Circuit

i

System

Power..............

Interface

Interconnection

Detailed

CPU/Power

4.22.1

4:22.2

Control...

System

Motor

System.

Description.

designs.

(017

Table

4-1

Miscellaneous

Control

4.22.3

Nonvolatile

4.22.4

Audio

4.22.5

Power

-

4.22.6

4.23

4.24

425

Section

5.1

Service

5.2

Materials

5.3

Recommended

5.4

Recommended

5.5

Special

Periodic

5.6

Cleaning...........….….

‘Table

5.7

Recommended

1

2

3.

4.

5.

6.

7

8.

Power

VO

Board...............

4.23.1

Motor

4.23.2

Switch

4.23.3

Battery

Display

4.24.1

4.24.2

4.24.3

4.244

4.24.5

RS232

5-1

Board...

Keypad

Analog

7-Segment

4.24.3.1

LCD

Pressure

Interface.

5:

Maintenance

Information.

Return

Tools.....

Maintenanc

Recommendation

on

3M

Record

Audio

Power

LCD

pump

Alarm

Up & Self

Contrast & LED

/

Descriptions

Summary.

Supply

Control

Monitor

Uni

Microprocessor

49

VO

Signals

Unit

Circuit..

Supply.

Control.

Control.

Sensor

Charger.

(U15)

Memory.

Interface.

Unit...

Sensor

Display

Unit

Plate

Procedure.

Test

Troubleshooting

Pump'Exterior........................vuie

12-Month

Test.....

Unit...

Display

иен

Position

Equipment...

for

history.

Test...

on

System

Unit...

Control

Functional

Unit.

Sensor.

eee

Cleaning

Brightness.

Agents

and

411

4-11

4-12

4-12

4-13

4-13

4-13

4-14

4-14

4-14

4-15

4-15

4-15

4-15

4-16

so

5-2

5-2

52

5-2

5-3

34

54

5-4

5.8

Table

5-9

5.10Calibration

Table

Section

6.1

Table

Table

Table

Table

Table

Table

Table

Table

Section

Section

.

8.1.

Section

9.

Valve

10.

Pressure

Point.

11.

Check

12.

Motor

13.

Empty

14.

Air

15.

KVO

Accuracy.

Integrity

Occlusion

Torque

Bag

Detect

Aiam,

Test...

Plate

Position

Test....

Check..

Alarm...

Volumetric

Settings.

Troubleshooting.

5-2

Troubleshoo!

Disassembly

1.

Battery

2.

AC

Fuse...

3.

Front

Housing

4.

Door

Assembly...

5.

CPU/Power

6.

I/O

Board

7.

‘Membrane

8.

Pump

9.

10.

11.

12.

1.

Power

2.5.00

3.

Low

A.

B.

4.

Cam

5.

Occlusion

6.

Empty

5-3

Mechanical

6-1

6-2

6-3

6-4

6-5

6-6

6-7 1/0

6-8

Sample

Assembly.

Motor

Assembly

Cassette

Safety

Clip

Door

Switch...

Supply

VDC

Battery

Low

Dead

Housing

Bag

Recommended

6:

Parts

Pump

Swingarm

Front/Rear

Pole

Display

Power

PWB

RS232

7:

Electrical

8:

Wavé

Wave

9:

Message

and

Reassembly

Removal.

Housing...

Supply

AssembiY....................

Switch

Mechanism.

Board

Replacement.

and

Vo

5

Voltage

Check...

Alarm

Battery

Battery

Switch

Alarm

Contacts

Lists

and

Structural

Assembly

Assembly

Clamp

PWB.......................

Supply

Parts...

Serial

Diagrams

Form

Forms...

Display,Screens

Check.

Calibration

Alarm...

Alarm..

Adjustment..

Adjustment.....

Adjustment.

Spare

and

Diagrams

Parts...

Housing

Assembly

CPU

Interface

Diagrams

Sensor

Breakopen

and

Rate

.

Assembly.

Check...

Parts

List..

Parts..

Parts...

Assembly

Parts

PWB

Parts..

ttt

PWB

Parts.

mom

©.

_

i

5-5

ve

3-5

5-5

5-7

5-7

5-7

-7

pinta

ae

o

oo

No

o%

>

Tables & Charts

2-1

Pump

3-1

Gü

mary © of

5-1

ュー

TBC-2

Recommendations

-

Pump

-2:

Troubleshooting

Recommended

(3/94)

Specifications.

Alarm

Conditions..

for

Cleaning

Exteribi!.............

Guide.

Spare

Parts

List.

。

-

Agents

on

3M

.

„5-9

.

-

Figures

3-2

Front

3-3

Back

4-1

Linkage

4-2

Cassette

5-1

Functional

5-2

Battery & AC

Housing

7053

5-4

Door

Pump

we

ge

Pant « Door.

Panel

Controls.

Systém/Safety

Housing & Doo

and

Accuracy

Fuse

Disassembly...

Disassembly

Assembly

Clip

Switc

Check...

Removal,

ο.

Removal..

Front/Rear

56.

\

°

3

Page 3

や

し:

mí

5-5

Motor

Assembly

5-6

Cassette

Disassembly...

5-7

Door

Switch

5-8

16.5

VDC

pump

5-9

5-10

5-11

5-12

5-13

5-14

5-15

6-1

turned

11.8

VDC

and

pump

13.8

pump

5.00

A

Schematic

set-up.

turned

Cam

Occlusion

Metering

Pump

Assembly.

μμ

μμυμϱῥ-----

Housing & Safety

Disassembly.

Check.

Check.

turned

VDC

turned

VDC

Power

on.

Switch

Power

on.

12.5

VDC

On...

Check.

Check.

diagram

alarm

cam

Power

OD...

Power

A

of

cord

should

Adjustment...

adjustment

as

Related

Clip

Mechanism

co

app!

cord

cord

low

battery

be

plugged

set-up.

to

Empty

plugged

nent

plugged

alarm

5-16

---

into

AC

and

5-19

into

AC

and

5-20

verification

in

and

pump

…

3-20

Bag

6-2

Swingarm

6-3

Front/Rear

6-4

Pole

6-5A

Display

6-SB

Display

6-6

Power

6-7A

VO

6-7B

YO

6-8

RS232

7-1

Functional

7-2

Power

7-3

Electrical

7-4

Electrical

8-1

Air

8-2

Air

8-3

Motor

8-4

Motor

8-5

Motor

8-6

Empty

8-7

Interrupter

Assembly.

Housing

Clamp

Assembly......

PWB,

PWB,

Suppiy/CPU

PWB,

Side

Board,

Serial

Block

Routing......

Routing.

System

Detect - Emitter,

Detect - Detector,

Drive

Pulses,

Drive

Pulses,

Drive

Pulses,

Bag,

P102

Detector,

Assembly.

Side

1

Side

2

PWB.

1...

Side

2..

Interface

Diagram.

Schematics.

TP3

TP2

TP7

TP7

TP7

Pin

6,

TP4,

on

on

on

YO

on

VO

Board.

on

YO

/O

Board.

I/O

Board.

I/O

Board.

Board...

YO

Board.....

Board..

a

o

Çapa

og

фоном

Ho

wo

Page 4

This

Page

Intentionally

Left

Blank

“TBC-4

6/94)

Page 5

Section

A:

Warranty

Service

&

Information

Model

3000

and

Micro

3100

3M

Infusion

Warranty

Service

3M

Limited

manufacture

Infusion

3M

Infusion

tions.

However,

apply

if

the

Limitation

If,

within

or,

at

tion

Infusion

Minnesota

THESE

TAL

Of

one

3M°s

(RMA)

Device,

55112-6933.

ARE

DAMAGES

option,

Agreement

One

Therapy

and

device

year

number

(3M)

material.

3M

does

has

Remedies

after

refund

from

freight

YOUR

OF

Therapy

and

Therapy

Year

3M

not

been

shipment,

the

the

and

The

ONLY

ANY

Warranty

warrants

also

watrants

warrant

altered,

this

purchase

3M

Infusion

insurance

repaired

REMEDIES.

KIND.

Service

Options

that

for

one

year

following

that

this

Infusion

that

this

device

is

misused,

device

price.

prepaid,

or

replaced

or

is

defective

To

obtain

Therapy

to

3M

Infusion

3M

WILL

repaired

warranty

Service

Infusion

|

Policy

shipment

Device

fit

for

any

by

persons

in

manufacture

service,

Center.

Therapy

Device

NOT

will be

BE

&

its

is

fit

other

not

or

you

Reference

Service

shipped,

LIABLE

|

Infusion

for

use

in

particular

authorized

material,

must

request a Returned

the

RMA

Center,

freight

FOR

CONSEQUENTIAL

Device

accordance

3M

will

purpose.

by

3M.

will

repair

number

3800

North

prepaid,

be

free

with

This

or

when

Dunlap,

to

of

defects

its

written

warranty

replace

Material

retuming

you.

OR

in

instruc-

does

the

device

Authoriza-

your

St.Paul,

INCIDEN-

not

Service

The

3M

Infusion

e

Service

e

Technical

e

Preventive

e

Technical

Warranty

To

A.

B.

service

initiate

service

Contact

the

1-800-752-7867

Request a Retumed

is

issued.

Clearly

-

-

-

-

reference

RMA

purchase

written

name

Therapy

and

Service

repair

assistance

maintenance

training

will

be

performed

and

repair:

3M

Infusion

Material

on

all

number

order

number

description

and

address

Center

of

all

3M

Infusion

and

consultation

when

Therapy

Sn

-

Authorization

shipping

of

problem

of

contact

performs

Devices

in

accordance

Service

documents:

person

Center

LTÉE

(RMA)

within

C

the

following

with

at

number. A purchase

your

hospital

functions:

3M

Infusion

or

|

Therapy's

order

organization

Вы

-

Warranty.

will

be

requested

№

o

3931

7461

过

before

Ser

ㆍ.

an

EN

RMA

|

number

41699

Page 6

-

Carefully

C.

Material”

D.

Ship

complete

package

label

the

pump(s),

3M

Infusion

3800

North

St.

Paul,

MN

name

and

the

each

to

freight

Therapy

Dunlap

55112-6933

return

pump(s)

carton

prepaid,

Service

address

in

shipped.

of

original

the

by

traceable

Center

organization.

shipping

means,

carton,

to

other

or

appropriate

-

container,

and

a

affix

“Returned

3M

Service

Loaner”

Any

warranty,

this

pumps

When

the

and

repair

while

chargeable

will

when

calling

will

also

other

than

type

of

shipment

Limited

3M

Infusion

tently

the

service

Infusion

Limitation

If

any

will

correctly

3M’s

(RMA)

Device,

55112-6933.

Therapy

and

in

accordance

center

Device

Of

failure

option,

number

freight

to

refund

The

is

generally

your

pump

is

repairs

not

be

on

be

performed

in

for

the

retumed

normal

requested.

means

Service

(3M)

with

will

be

free

serviced

Remedies

meet

the

Limited

re-perform

from

and

repaired

the

the

purchase

the

3M

insurance

completed

being

repaired, a loaner

pumps

under

without

RMA

number.

freight

prepaid,

of

shipment

Warranty

warrants

in

cases

service

or

replaced

that

industry

from

Infusion

prepaid,

standards.

defects

where a complete

Service

identified,

price.

Therapy

to

Infusion

within 4 working

warranty

customer

all

Warranty

To

3M

or

authorization.

Pumps

under

however a shipping/handling

is

requested

service

in

obtain

and

3M

manufacture

Policy

repair

warranty

Service

Infusion

Device

days

must

be

requested

contract,

also

or

or

warranty

by

the

repair

performed

warrants

or

material.

overhaul

appears

repiace

service,

Center.

Therapy

will

be

shipped,

upon

repairs

If

an

or

customer,

for a period

has

within

defective

Reference

Service

receipt

when

estimated

“estimate

contract

not

you

are

charge

an

additional

by

the

This

warranty

been

ninety

parts

must

the

Center,

freight

by

the

service

calling

to

exceed

is

required

returned

will

service

of

ninety

performed.

(90)

provided,

request a Returned

RMA

number

3800

prepaid,

in

for the

freight

be

added

charge

center

(90)

covers

days

replace

North

to

you.

center.

$150.00

before

days

following

when

Dunlap,

If

you

RMA

number.

on

work

prepaid.

to

the

repair/charge

is

assessed

will

be

performed compe-

that

only

that

service

the

Infusion

Material

returning

St.

need a “Service

pumps

out

of

is

performed”

Out

of

warranty

invoice.

depending

parts

furnished

portion

Paul,

of

the

or

repair,

Device

Authorization

your

Infusion

Minnesota

state

upon

by

3M

or,

at

THESE

TAL

Service

Contact

ARE

DAMAGES

Device

:

Service

Technical

Preventive

Service

Loaners

the

3M

YOUR

Offerings

Training

Assistance

Maintenance

Atena

ONLY

OF

ANY

Seminars

Maintenance

Agreements

Infusion

Therapy

REMEDIES.

KIND.

Agreements

Service

3M

Center

WILL

NOT

BE

at

1-800-752-7867

SMS

BELTE

LIABLE

for

details.

C

FOR

CONSEQUENTIAL

OR

INCIDEN-

Page 7

Section

1:

General

Description

Model

3000

and

Micro

3100

1.1

3M

Infusion

Models

3100

The

3M

Modular

3000

and

Micro

with

various

Infusion

professionals

of

fluid

epidural

programmable

the

dose

The

key

flexible,

may

also

the

pump

Precise

by

the

pumping

patient.

The

pumps

situations.

audible

alert

situations, a separate

indicator

alarm/alert

in

Section

‘The

Model

features.

Change.

life,

total

remaining

continuously

darkened

designed

recordkeeping.

3M

Systems

in

and

medications.

delivery

is

delivered.

component

three-chambered

be

used

due

to

control

mechanical

mechanism

provide

In

alarm

alarm

sounds,

is

displayed,

indicators

3.5

and

3000

These

In

addition,

volume

this

light

rooms. The

to

aid

Therapy

3000 & Micro

System

Infusion

3100

infusion

administration

are

intended

the

intravenous

(see

1.2,

control

over

of

the

for

gravity

their

valveless

over

delivery

manipulation

results

for

monitoring

situations,

and a visual

and

and

3.6.

and

Micro

include

Options

delivered

infusion,

the

display

Biomedical

service

Description

System

pumps

sets.

for

use

and

In

addition,

below).

both

volume

administration

cassette.

administration

design.

rate

and

of

in

smooth

fluid

audible

fluid

delivery

audible

3100

Rate

Tapering

allows

over

several

and a feature

panel

personnel

consists

Both

3M

the

of

alarm

alarm

alarms

also

Special

in

of the

used

in

conjunction

The

3M

Modular

by

trained

intra-arterial

they

pumps

and

administration

volume

flexible

fluid

several

delivery

sounds,

continues.

offer

and

you

infusions,

which

for

easier

troubleshooting

medical

may

be

offer

rate

set

is

the

independent

is

provided

cassette.

delivery

alarm/alert

stops,

is

displayed.

are

fully

several

Quick

to

check

allows

reading

Functions

Model

delivery

used

for

user

at

which

unique,

sets

of

The

to

the

an

In

an

alert

These

explained

optional

Rate

battery

time

you

to

in

are

and

accidentally

for

ambulatory

1.2

The

Model

be

used

Anesthetics

Epidural

term

catheters

delivery

Analgesics

Epidural

with

long-term

e

To

epidural

which

e

Differentiate

epidural

routes

cut

off.

patients.

Epidural

3000

for

epidural

administration

(not

to

exceed

specifically

of

anesthetic

administration

indwelling

prevent

catheters

delivery

infusion

use,

contain

delivery

of

administration.

WARNING

When

delivering

those

medications

Epidural

serious

1.3

administration

patient

injury.

Precautions

DANGER

Never

operate

bathing,

Use

of

the

severe

electric

such conditions,

to

power

this

showering,

pump

shock.

the

pump.

Battery

power

also

Administration

and

Micro

3100

Infusion

administration.

of

anesthetics

96

hours)

indicated

drugs.

of

analgesics

specifically

of

analgesic

of

drugs

do

not

use

IV

injection

the

drugs

specifically

pump

under

only

pump

and

from

those

in | the

of

on

or

otherwise

such

If a pump

DC

(battery)

sites.

other

infusion

AC

conditions

is

with

for

short-term

is

indicated

drugs.

not

indicated

administration

IV

set

being

being

epidural

indicated

drugs

power

immersed

must

power

provides

limited

used

portability

Pumps

may

limited

be

to

short-

indwelling

epidural

to

use only

for

for

sets

used

for

for

other

space,

use

for

epidural

could.result

while

patient

in

liquid.

could

lead

used

under

may

be

also

short-

or

only

use.

in

is

to

used

Both

pumps

delivery

administration

to

primary

attached

patented

connect

infusion

power,

you

to

can

when

used

set,

rate

and

to

an

IV

Modular

up

to 3 pumps

lines

are

or

with

the

continue

be

used

for

secondary

with a checkvalve

switching automatically

volume.

pole

Connection

required.

built-in

infusion

The

using

the

System

together

The

battery.

even

if

pumps

built

for

easy

pumps

Battery

AC

power

(piggyback)

and

in

allows

can

piggyback

from

are

typically

pole

clamp.

you

use

when

be

used

power

fails

secondary

The

to

multiple

on

AC

allows

or

is

DANGER

Place

the

pump

avoid

explosion

DANGER

Electric

Internal

fied,

unplug

shock

servicing

3M

Infusion

AC

away

from

hazard.

hazard

should

Therapy-trained

power

cord

all

exists

if

be

before

flammable

pump

housing

performed

beginning

only

personnel.

anesthetics

is

by

Always

disassembly.

to

opened.

quali-

11699)

Page 8

WARNING

Replace

protect

against

WARNING

The

air

detection

detect

air

used

in

the

side

or

back

fuses

at

the

upright

during

only

fire

system

top

with

fuses

of

hazard.

of

the

of

the

cassette

position.

operation.

Do

same

pumps

when

not

lay

type

are

the

the

and

rating

designed

pump

is

pump

on

to

to

its

WARNING

The

occlusion

pressure

detect

infiltration.

policies

inspect

changes,

detection

in

the

administration

and

procedures,

patient’s

and/or

infusion

other

In

WARNING

Pump

users

should

beginning

of

the

use

pumps

of

any

could

CAUTION

Electrostatically

design

Discharge

printed

CAUTION

Do

not

this

of

the

circuit

autoclave,

pump

pumps.

(ESD)

boards.

in

any

sensitive

must

ethylene

liquid

CAUTION

To

avoid

unnecessary

200

millimeters

pressure

using

the

100

mmHg).

cuff

Low

of

above

Occlusion

sensor

accordance

operator

site

signs

receive

lead

Mercury

inservice

medical

to

injury.

components

Protection

be

provided

oxide

or

pump

Occlusion

the

patient’s

Alarm

detects

set,

for

of

infiltration.

equipment.

(mmHg)

downline

but

is

with

institution’s

must

periodically

swelling,

training

are

against

when

sterilize,

damage

alarms,

when

venipuncture

Setting,

.

back-

not

designed

temperature

prior

Improper

used

Electrostatic

handling

or

submerge

will

occur.

do

not

using

do

not

to

use

in

the

exceed

a

site

when

exceed

to

CAUTION

-

The

Model

cause

this

reason,

autotransfusion

level

flow

below

3000

from

the

the

CAUTION

Federal

the

1-2

(USA)

order

of a physician

(3/94)

and

the

fluid

pumps

system

pump.

law

restricts

Micro

container

should

in

or

3109

not

which

this

other

require

to

the

be

used

blood

is

device

to

licensed

gravity

pump.

collected

use

practitioner.

as

part

by

or

to

For

of

at

on

an

a

Page 9

Section

Table

2-1

lists

Model

3000

NOTE

‘All

pump

specifications

notice.

2:

operating

and

Micro

Specifications

and

design

3100

are

specifications

Infusion

subject

Pumps.

to

change

of

the

without

Model

3000

and

Micro

3100

21699)

.

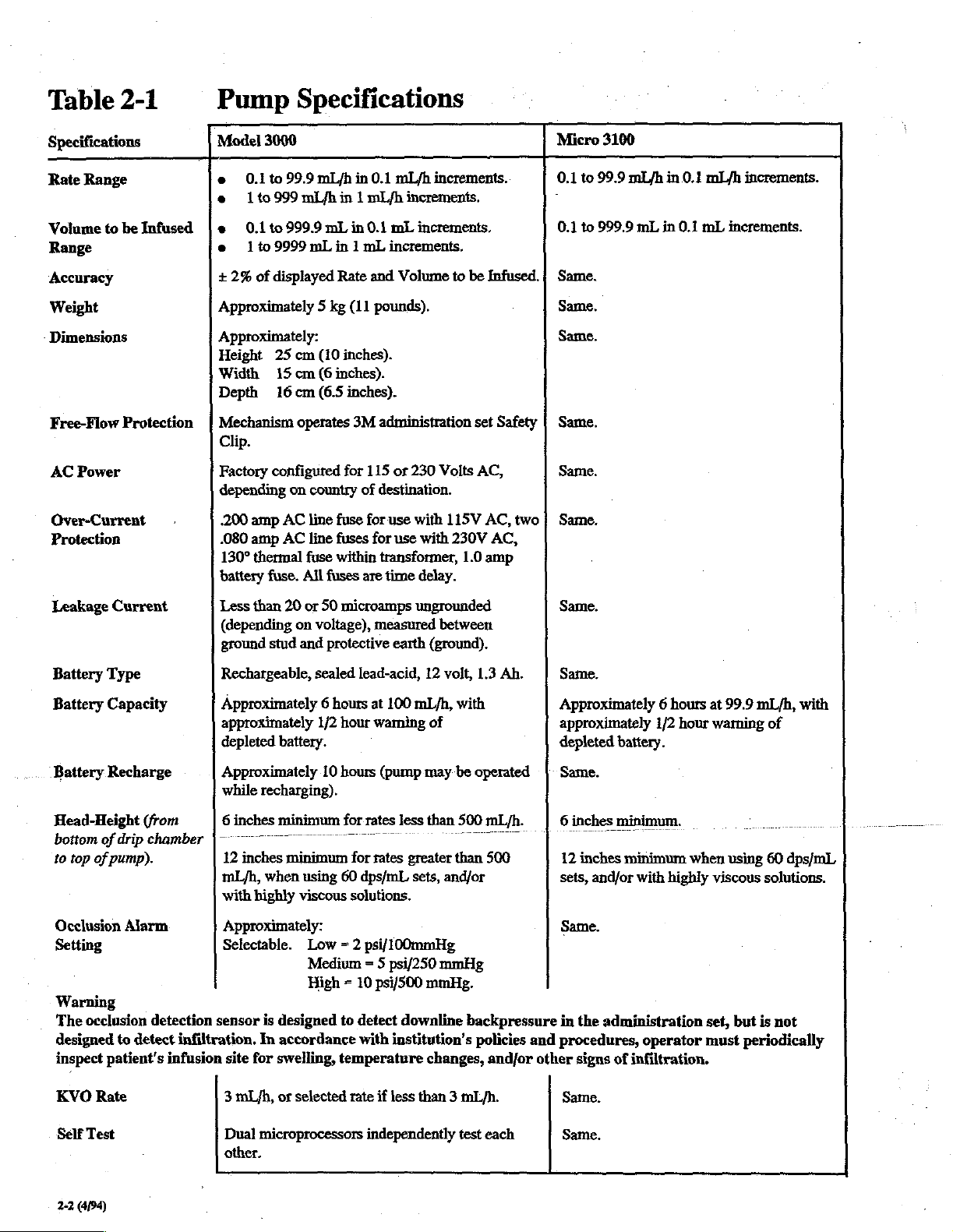

Page 10

1

Table

Specifications

Rate

2-1

Range

Pump

Model

e

0.1

e | [to

9 .

Specifications

3000

to

99.9

mL/h

in

0.1

mL/h

999

mř/h

in | mish

increments.

increments.

Micro

0.1

to

-

3100

99.9

mLyh

in

0.1

mL/h

increments.

Volume

Range

Accuracy

Weight

Dimensions

Free-Flow

AC

Over-Current

Protection

Leakage

Battery

to

Power

Type

be

Infused | +.

Protection | Mechanism

Current

0.1

e

109999

+

2%

of

Approximately 5 kg

Approximately:

Height

Width

Depth

Clip.

Factory

depending

200

amp

.080

amp

130°

thermal

battery

Less

than

(depending

ground

Rechargeable,

to

999.9

mL

mL

displayed

25

cm

(10

15

cm

(6

16cm

(6.5

operates

configured

on

country

AC

line

AC

line

fuse

fuse.

All

fuses

20

or

50

on

voltage),

stud

and

protective

sealed

in

0.1

mL

in 1 mL

Rate

inches).

fuse

fuses

within

microamps

increments.

and

(11

pounds).

inches).

inches).

3M

administration

for

115

or

of

destination.

for

use with

for

use

transformer,

are

time

measured

earth

lead-acid,

increments.

Volume

to

230

Volts

115V

with

230V

delay.

ungrounded

between

(ground).

12

volt,

be

Infused. | Same.

set

Safety | Same.

AC,

AC,

two | Same.

AC,

1.0

amp

1.3

Ah.

0.1

to

Same.

Same.

Same.

Same.

Same.

999.9

mL

in

0.1

mL

increments.

Battery

Battery

Head-Height

bottom

to

Occlusion

Setting

Warning

The

designed

inspect

KVO

Self

Capacity

Recharge

of

drip

top

of

pump).

occlusion

to

patient's

Rate

Test

Alarm

(from

ehamber

detection

detect

infiltration.

infusion

Approximately 6 hours

approximately

depleted

Approximately

while

recharging).

6

inches

|

12

inches

mL/h,

when

with

highly

Approximately:

Selectable.

sensor

is

In

site

for

3

mL/h,

Dual

microprocessors

other.

1/2

battery.

10

minimum

0

minimum

using

viscous

Low

Medium = 5

High = 10

designed

accordance

swelling,

or

selected

at

100

hour

waming

hours

(pump

for

rates

less

for

rates

greater

60

dps/mL

solutions.

= 2

psi/100mmHg

psi/250

psi/500

to

detect

downline

with

institution's

temperature

rate

if

less

independently

mL/h,

with

of

may

be

operated

than

500

than

sets,

and/or

mmHg

mmHg.

backpressure

policies

changes,

than 3 mL/h.

test

mL/h.

500

and/or

each

Approximately 6 hours

approximately

depleted

Same.

6

inches

o

12

inches

sets,

and/or

Same.

1/2

battery.

minimum.

minimum

with

hour

when

highly

at

99.9

waming

using

viscous

in

the

and

procedures,

other

signs

Same.

Same.

administration

operator

of

infiltration.

set,

must

mL/h,

with

of

60

dps/mL

solutions.

but

is

not

periodically

2-2

(4/94)

Page 11

Section

3:

Installation

&

Operation

Model

3000

and

Micro

3100

3.1

1.

The

eguipped

prong,

minimize

wire.

The

manufacture,

safety

tetainer

retainer

or

unreliable.

If

Replacements

order

leakage

important

cords,

connection.

the

connections.

2.

Installation

AC

Power

3M

Model

with a detachable

hospital

leakage

power

cord

testing

is

attached

must

replaced,

the

power

Portable

or

cord

becomes

to

maintain

current.

to

adapter

Always

cord,

System

The

pumps

“operation,

The

infusion

horizontal

tion

set

the

pump

greater

when

solutions).

IV pole

TV pole

portable

are

or

surface,

drip

(12

than

using

Typically,

using

mounting

for

Connection

3000

and

Micro

3100

power

cord,

grade

plug.

The

power

current

is

but

can

of

the

be

reinstalled

ground

should

grounding

Integrity

prevent

plugs,

as

inducing

secured

over

pulling on

to

be

removed

cord

itself

the

and

power

damaged,

be

made

of

electric

or

attempt

hold

the

potentials

the

rear

from

become

cord

by

four

whenever

connections

replace

using

safety

and

the

three-prong

shock.

Do

to

defeat

plug

itself

the

cord

original

Operation & Modular

equipped

in

the

pumps

chamber

inches

500

mL/h,

60

drops/mL

the

patient

with a 12

event

AC

may

be

provided

is

at

may

be

or

on

sets

however,

pole

clamp

and

battery

mobility.

volt

power

fails

operated

the

bottom

least 6 inches

required

both

the

and/or

highly

the

pump

on

the

pump's

operation

Infusion

cord

housing

the

necessary. A cord

the

it

could

while

on

Micro

Pumps

which

has a three-

is

designed

on

the

ground

during

pump

should

screws.

cord

immediately.

acceptable

not

the

when

battery

or

of

above

the

make

The

is

reattached

may

equipment

level

plug

is

use

extension

plug’s

unplugging

damage

for

portable

is

unavailable.

standing

the

administra-

the

3000

with

3100-and

viscous

is

attached

rear

housing.

the

pumps

become

also

ground

top

plug

on

to

are

to

cord

in

of

any

of

rates

3000

an

tip.

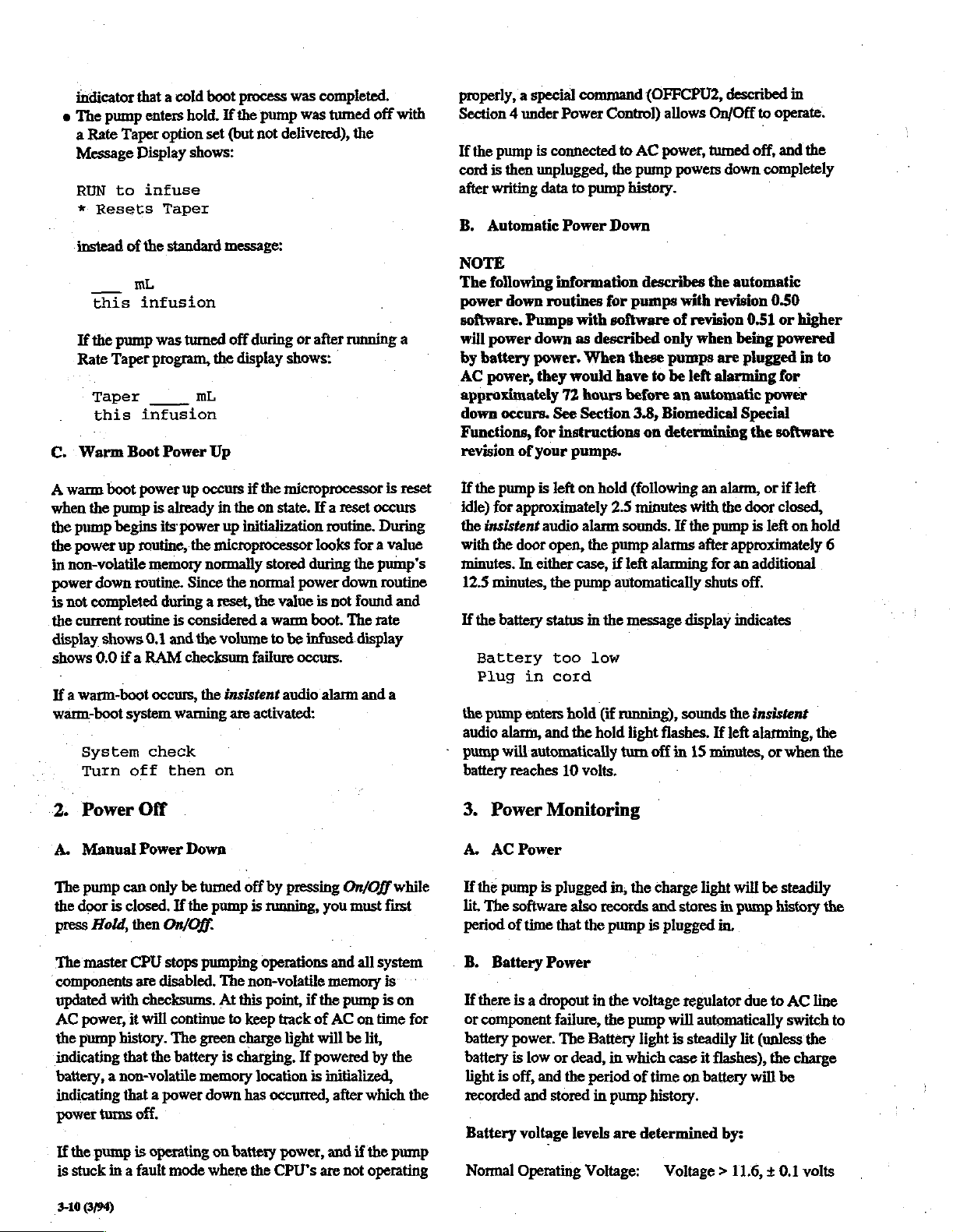

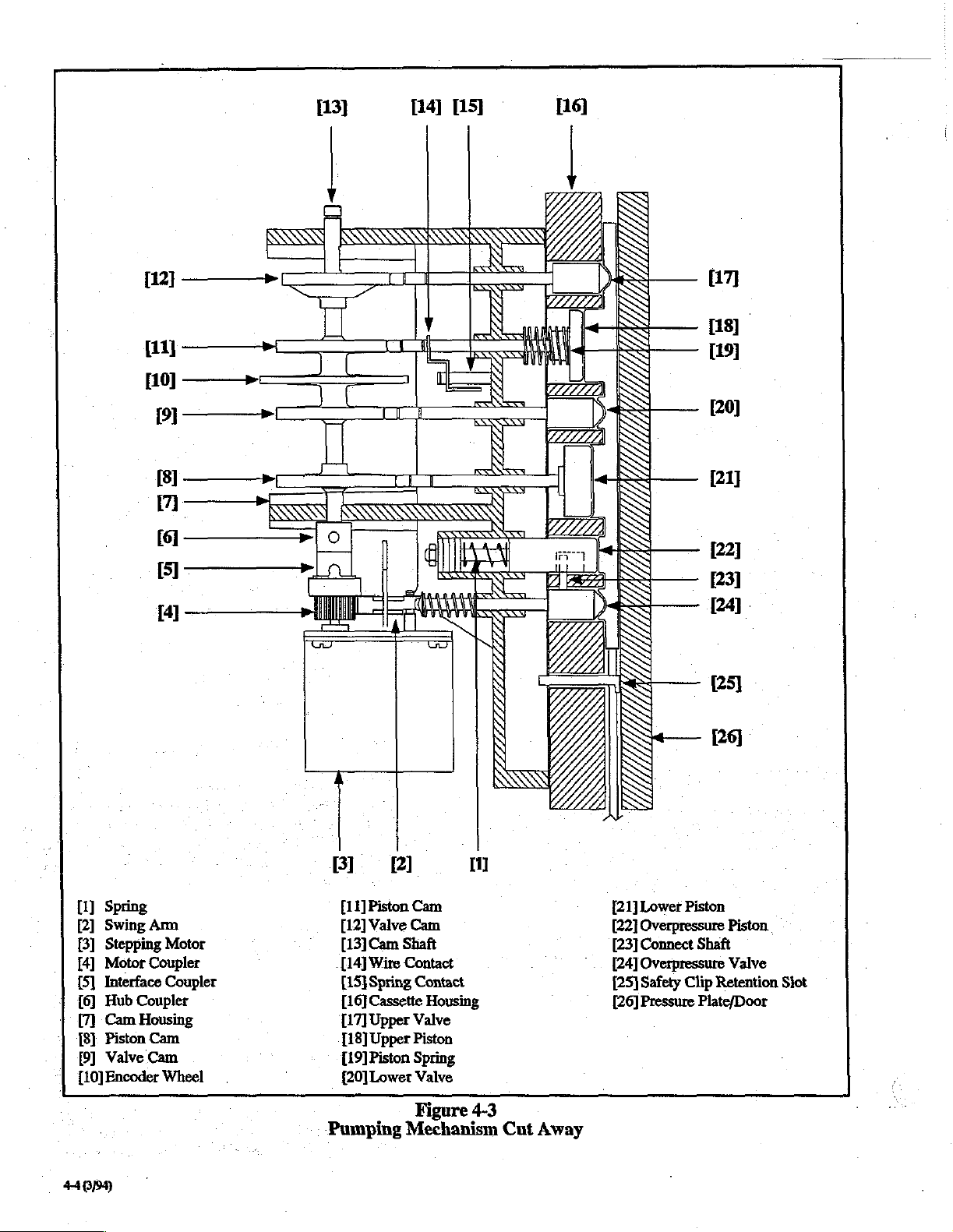

3.2

The

central

peripheral

and

microprocessor

alarm

tions.

The

motor

Smooth

forward

is

When

off”

accept a fluid

Completion

Teverse

during

the

upstream

lower

mechanism

The

Clip

and

mechanics

Safety

loading

door

When

lower

when

Operational

Model

3000

system

fail-safe

condition

central

which

running.

you

to

the

the

pumping

fluid

Free-Flow:

(located

the

Clip

is

closed

the

tubing,

the

controller

microprocessors

system

controls

sensors,

microprocessor

is

used

fluid

delivery

rotation

open

load

position.

filled

of

cassette

rotation

mechanical

of

loading

mechanism

pressure

pathway

and

reopens

Prevention

under

on

the

must

the

cassette,

the

door

is

thus

administration

WARNING

To

minimize

always

door,

close

the

the

and

Micro

microprocessor

monitoring

all

and

to

operate

is

accomplished

of

the

pumping

the

door,

the

The

cassette

loading

the

motor

process)

prepares

release,

lower

be

Safety

opened,

preventing

possibility

lower

during

upon

the

cassette

clip

retention

portion

placed

or

the

Clip

the

set

roller

the

System

pump

Description

3100

Infusion

used

for

(CPU2).

user

programmable

interprocessor

also

controls a 4-phase

the

pumping

mechanism

pumping

pistons

when

in

results

as

pressure

on

the

cassette

for

overpressure

reverse

initial

consists

on

slot

of

the

in

the

clip

will

opens

Safety

unrestricted

is

removed

of

unrestricted

clamp

Pumps

(CPU1),

display

rotation

the

control

The

communica-

mechanism.

by

uninterrupted

when

mechanism

are

best

the

load

in

some

(which

is

delivery.

valve

of

forward

of

administration

and

associated

cassette

retention

not

operate.

to

allow

Clip

closes

fluid

from

before

contain

with

two

(CPU3)

central

functions,

stepping

the

pump

“backs

positioned

position.

additional

develops

reduced

rotation.

the

fluid

the

and

To

facilitate

seals

the

pumping

Safety

set)

housing.

slot

when

When

delivery.

over

the

flow

even

pump.

the

The

.

gravity

opening

flow,

the

a

to

the

The

Model

Modular

to 3 pumps

required,

that

pump.

pole)

connecting

Connection

The

any

pump

Only

will

accept

3000

and

for

situations

Modular

can

be a Center,

the

Center

attachment

too

many

Micro

3100

System

which

when

Connector

pump

(pump

of

pumps,

which

are

equipped

allows

multiple

Left,

another

infusion

System

or

Right

which

pump.

could

with

a

connection

lines

is

designed

mounted

is

attached

This

prevents

cause

IV

poles

of

are

so

to

up

IV

to

The

microprocessor

insistent

nine

sages

detail

‘e

.. @ Occlusion

audio

alarm

displayed

in

Section

System

stops

alarm

conditions

during

3.6):

zero

Warning

the

when

is

detected

an

alarm

pump

one

or

condition

and

more

(note

sounds

of

-

the

are

the

the

following

actual

discussed

mes-

in

31694)

Page 12

e

Air

e

Empty

Bag

e

Door Open

e

On

Hold

e

Dead

Battery

e

Safety

Clip

e

Pressure

Detection

the

e

e

e

»

During

run

or

Run

Downline

the

monitored

monitoring

mounted

activated

level.

pressure,

point,

of

microprocessor

On

Battery

Low

Battery

Rate

Change

KVO

(Keep

these

and

the

audio

(see

Section

pressure

upper

two

at

is

in

the

if

pressure

The

pump

which

the

pump

WARNING

The

occlusion

pressure

detect

policies

inspect

changes,

in

infiltration.

and

patient’s

and/or

(no

flow

above

Plate

Position

the

following

to

sound

Not

Completed

Vein

Open)

four

alert

conditions

alarm

can

3.6

for

is

developed

cassette

the

performed

middle

door

assembly.

chambers,

cassette

by

exceeds

briefly

backs

minimizes

stops

and

detection

the

administration

In

accordance

procedures,

infusion

other

signs

pump)

Switch

four

alert

the

non-insistent

be

silenced

visual

by

and

chamber.

the

pressure

The

the

user

off

to

fluid

bolus

fluid

delivery

sensor

detects

set,

operator

site

for

of

infiltration.

conditions

the

pump

will

by

pressing

alarm

descriptions).

the

pumping

is

continuously

Occlusion

transducer

Occlusion

selected

reduce

downline

to

the

ceases.

downline

but

is

not

with

institution’s

must

periodically

swelling,

will

cause

audio

alarm:

continue

Silence

pistons

alarm

at

is

threshold

patient.

At

that

back-

designed

temperature

to

to

pressed

original

audio

within

rate

alarm

and display

The

Rate

not

Model

change

completed

3000

programmed

solutions.

to

the

selections.

delivery,

primary

KVO

solution.

There

plained

3.3

Front

(Reference

The

secondary

Then,

the

solution

alarm

are

additional

in

the

Controls

Panel

Figure

NOTE

Only

those

labeled

as

to

below.

1.

Message

The

Message

display,

infusion

consisting

status,

10

seconds

will

reappear

will

sound,

and

Micro

for

automatic

secondary

program

rather

pump

switches

according

occurs

following

message

Options

Controls

3-1.)

controls

and

function

Display

Display

of 2 lines

visual

of

entering

in

the

and

the

3100

sequential

medication

of

rate

than

entering

to

Primary

to a separate

delivery

and

section

of

And

And

Indicators

indicators

are

called

is

an

alphanumeric

by

alarms,

options,

the

new

rate,

display,

Message

have

the

non-insistent

Display

the

capability

delivery

is

delivered

and

volume

KVO

after

and

delivers

to

program.

of

the

primary

pumping

this

options

manual.

Indicators

not

specifically

out

using

numbers

liquid

16

characters.

and

other

the

will

flash

to

of

two

according

be

infused

secondary

the

The

ex-

crystal

It

shows

messages,

be

During

continuously

Display

(as

counts

up).

current

the

be

the

volt

operation,

will

fluid

is

down

Also,

status

data

in

stored

pump

lithium

shown

show

delivered,

as

status

the

in

nonvolatile

is

turned

battery

chip.

The

Running

change

Rate

while

sor

to

receive

using

the

display,

rate.

Press

3-2

(3/94)

rates

without

the

number

but

the

Run

Rate

the

in

volume

the

volume

lights

of

the

pump.

Message

on.

which

Change

interrupting

pump

new

rate

keys,

pump

to

lock

rate

and

the

Numeric

infused

the

Volume

in

will

be

When

Display

memory

The

memory

is

integrated

feature

is

operating

input.

the

new

will

continue

in

the

volume

to

be

infused

Displays.

for the

current

to

be

Infused

the

Message

appropriately

the

and

and

Display

lit

pump

is

Numeric

displayed

is

maintained

with

allows

you

fluid

delivery.

readies

After entering

rate

new

will

to

infuse

rate

setting.

the

the

appeat

will

be

The

Message

infusion

display

counts

to

show

the

turned

off,

Displays

again

the

to

will

when

by

a 3

memory

instantly

Pressing

microproces-

new

rate

in

the

at

the

original

If

Run

is

not

The

Message

and

when

for

approximately 1 minute.

The

backlight

when

the

AC

Power

With

the

backlight

with

the

approximately 1 minute.

the

Message

DC

Power

When

the

pump

pump

will

door

(Battery)

on

battery

Display

door

is

time

out

is

on

on

hold,

always

open,

the

Display

power,

is

opened.

feature

AC

be

backlight

approximately 1 minute

When

the

pump

is

running,

briefly,

The

then

general

rule

the

display

is

that

backlit

and

backlight

whether

reverts

informational

The

has

power

with

on.

With

After

timeout,

the

backlight

some

when

any key

backlight

different

and

battery

the

door

the

pump

will

time

will

tum

the

door

messages

to

the

messages

will

standard

is

pressed,

will

remain

characteristics

power:

closed,

if

the

on

out

door

the

hold,

after

is

and

on.

time

out

after

is

open

or

not.

are

displayed

message.

will

be

on

closed,

Page 13

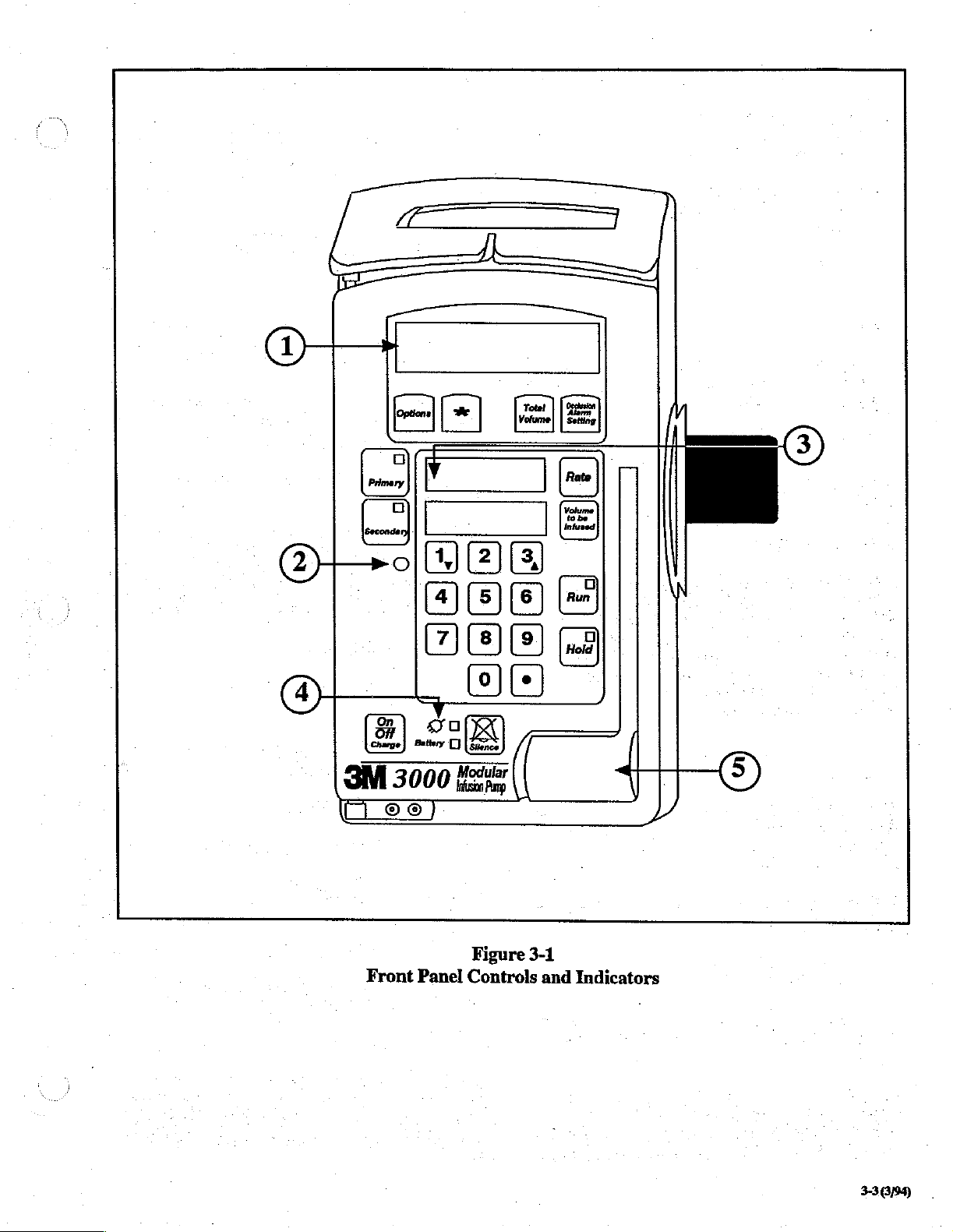

ES

ЗМ

Gee)

Front

3000

3000

Mes

Panel

"odiar

ir

Figure

Controls

3-1

and

Indicators

330684

.

Page 14

displayed

which

for 5 seconds,

require

Pressing a key

it

will

cause

its

or

10

second

During

on

and

audio

The

various

9.

an

off

has

timeout

alarm

with

been

Message

input

will

which

has a different

screen

to

has

or

alert

the

audible

silenced.

Display

and

messages

be

displayed

be

instantly

expired

condition,

on

alarms

screens

with

for

10

display

displayed

the

first

the

backlight

and

remain

are

listed

instructions

or

seconds,

associated

before

with

the

message.

will

flash

on

after

the

in

Section

5

Occlusion

With

the

pump

Alarm

Setting

occlusion

desired

pressing

While

Setting

ever,

settings

setting

Run.

the

shows

the

setting

on hold.

pump

Alarm

on

hold,

advances

in

is

shown

is

the

setting

cannot

Setting

repeatedly

through

the

Message

in

the

running,

pressing

which

be

changed

Key

pressing

Low,

Display.

Message

Ocelusion

is

currently

until

Occlusion

Medium,

When

Display,

in

use.

the

pump

and

High

the

select

Alarm

How-

is

placed

it

by

Options

Pressing

functions.

Key

Options

To

instructions

Кеу

“The

(|

key

functions

Total

Press

(Primary,

delivered

displays

since

checked

‘pump

the

and

Volume

Total

Secondary,

since

total

the

display

when

on

hold,

Message

m.

Press

allows

select

in

the

Message

is

used

when

Key

Volume

it

was

hours

was

the

pump

the

total

Display

oh

*

to

you

to

scroll

and

set

up

desired

Display

in

the

programming

clearing Total

to

display

and

last

and

last

as

the

Rate

Taper)

cleared.

minutes

cleared.

is

running

volume

follows:

and

the

m

clear

through

option(s),

.

of

optional

Volume.

cumulative

which

Total

volume

pump

has

Total

volume

or

on

hold.

time

will

the

optional

follow

volume

has

been

also

been

may

With

be

shown

`

in

use

be

the

the

in

The

Occlusion

downline

the

pump

Low

means

teaches

and

The

when

The

rates.

viscous

100

High = 500

pump

tumed

Low

When

solutions,

“Occlusion

Occlusion

Primary

Selects

light

Ifa

the

primary

on

the

secondary

primary

Alarm

pressure

Setting

allowed

determines

in

the

alarms.

the

pump

will

alarm

mmHg

automatically

(2

mmHg

psi),

Medium = 250

(10

psi).

defaults

on.

setting

is

infusing

below

Alarm

Setting

designed

at

and/or

pump”

to

higher

with

alarm

if

not

Key & Indicator

delivery

key.

infusion

settings

as

shown

is

running,

momentarily.

the

administration

when

downline

mmHg

to

the

Medium

be

used

at

lower

flow

rates,

with

small

diameter

may

activate.

appropriate

by

the

for

green

press Primary

amount

set

of

before

pressure

(5

psi),

setting

infusion

more

catheters,

Change

infusion.

indicator

to

view

the

the

To

clear

total

is

not

pressed,

Occlusion

to

the

standard

With

the

pump

displayed

“The

standard

as

total

message

message.

Volume.

In

either

case,

volume

the

exceeds

pump

was

is

99

3-4(3/94)

volume,

Alarm

message.

running,

follows:

m.

infusions

remains

the

last

cleared.

tumed

hours,

press

pressing

Setting)

oh.

The

time

59

will

the

om

for 5 seconds

pump

displayed

It

on,

whether

minutes,

Total

Volume,

any

other

return

total

volume

must

is

includes

on

hold

the

display

key

the

before

be

on

the

time

all

time

or

then

press

(except

Options

Message

and

time

reverting

hold

to

clear

since

during

running.

shows

[X).

If

or

Display

will be

to

the

Total

total

which

If

time

100+hrs.

Secondary

Selects

Press

the

2.

The

adjusts

Located

secondary

Secondary

secondary

Photo

photo

the

3.

Pumping

on

indicator,

downward

the

rate.

consisting

pumping

Sensor

sensor

intensity

the

fashion

Key & Indicator

delivery

while

rate

momentarily.

constantly

of

the

the

as

shown

primary

measures

LED

displays

Indicator

left

side

of

the

Rate

of

three

horizontal

to

indicate

‘indicator

is

fluid

approximately

by

the

yellow

line

is

running

room

light

accordingly.

Display,

delivery.

the

lines,

The

moves

proportional

light.

to

view

and

pumping

in

a

speed

of

to

the

Page 15

Rate

Key & Numeric

The

Rate

Numeric

which

the

current

With

the

pump

display and

-is

entered

approximately

readies

the

display.

Display

infusion

on hold,

the

pump

will

10

seconds.

Display

shows

is

being

pressing

Rate

for

rate

default

the

rate,

in

delivered.

blanks

entry.

to

the

old

rate

mL/h,

the

If

no

at

rate

new

after

rate

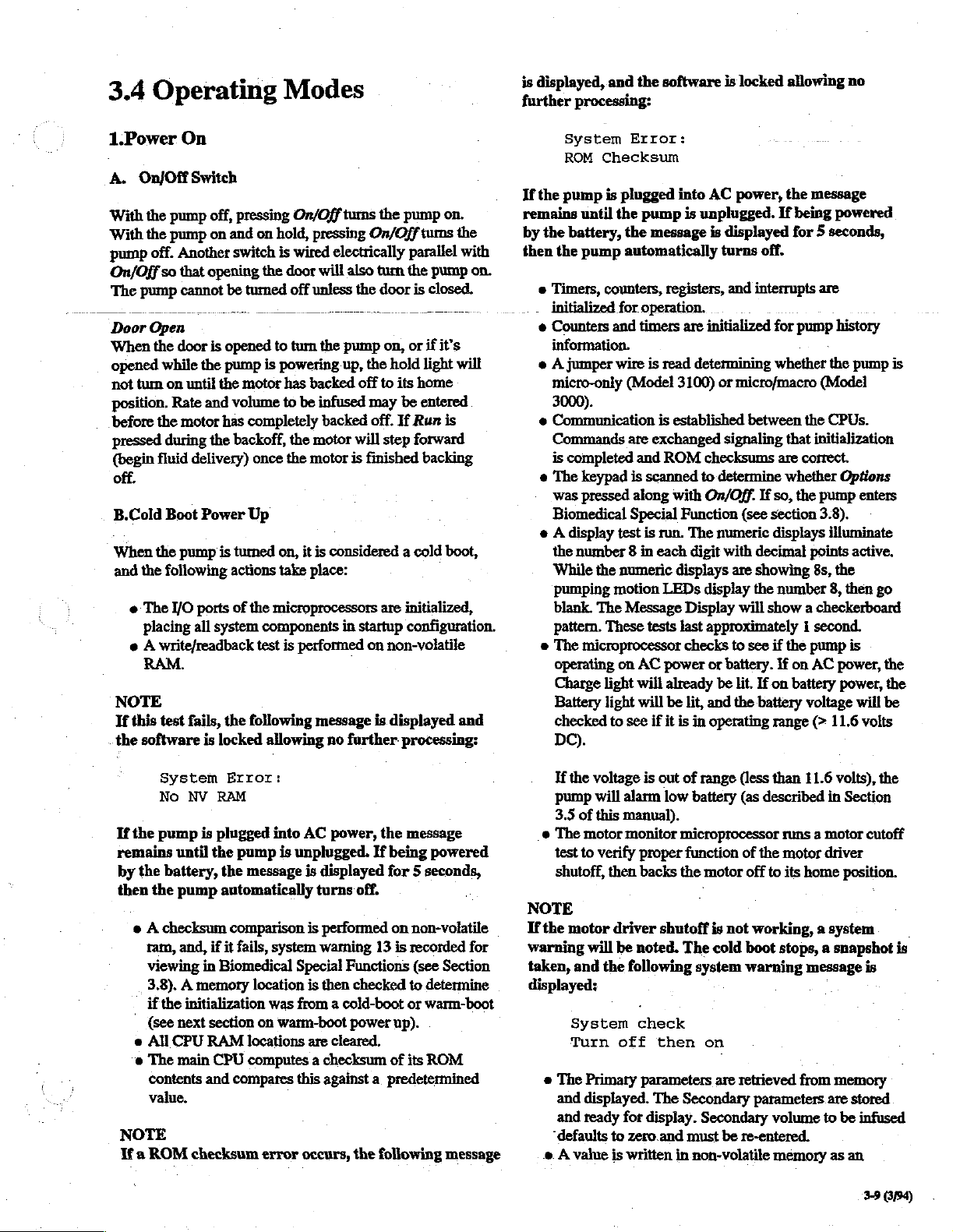

On/Off

On/Off

the

routine.

Another

that

the

door

is a software

central

On/Off

switch

opening

pump

is

closed.

Key

controlled

microprocessor’s

is

deactivated

is

wired

electrically

the

door

when

on.

The

pump

cannot

switch.

power

while

the

pump

be

Pressing

up

and

the

pump

parallel

is

off

tumed

off

power

is

with

will

also turn

unless

it

activates

down

running.

On/Off

so

the

Volume

The

volume,

counts

running.

With

blanks

infused

restore

Number

The

Infused,

The 1 and 3 keys

indicators

«

(decimal)

Press

ml/h.

to

Volume

in

down

the

pump

the

display

entry.

the

number

and

for

the

decimal

be

to

be

mL,

which

from

on hold,

Pressing

previously

Keys

keys

when

use

Key

Infused

Infused

remains

the

initial

pressing

and

readies

Volume

set

Volume

(0-9)

are

used

working

are

also

marked

during

Quick

key

to

enter

Key & Numeric

Numeric

setting

to

in

Display

to

be

when

Volume

the

pump

to

be

to

set

Rate,

certain

with

Rate

rates

and

shows

delivered.

the

Te

for

volume

Infused

be

Infused.

Volume

Options.

up

and

Change.

volumes

Display

the

The

display

pump

is

Be

Infused

to

twice

will

To

Be

down

in

10ths

be

DANGER

Potentially

the

pump

plugged

These

transformer

board,

nects.

ning

dangerous

housing

in,

regardless

voltages

and

and

the

Always

disassembly.

CAUTION

Turning

circuits,

transformer.

charging

is

Silence

Press

used

pump

the

before

the

but

circuit

plugged

Key

Silence

when

on

hold

pump

must

plugging

pump

does

in,

it

is

voltages

is

opened

of

are

present

AC

fuse

RFI

filter

unplug

The

regardless

to

undesirable

(e.g.,

remain

the

off

removes

not

remove

transformer

are

energized

silence

it

the

when a low

on

in).

are

and

the

on

or

in

the

on

the

CPU/power

where

the

AC

power

power

AC

and

whenever

of

on/off

audio

alarm.

or

unnecessary

battery

battery

operation

exposed

the

power

off

state

following

power

cord

before

from

power

from

12

volt

the

state.

Silence

to

alarm

for a short

whenever:

cord

is

of

the

pump.

areas:

the

supply

cord

con-

begin-

most

the

battery

power

cord

can

be

place

the

occurs

and

time

Run

Key & Indicator

Press

Run

to

will be

programmed

rate.

If

not

Run

Hold

lit

steadily

the

door

is

in

place,

or

is

also

used

Change.

Key & Indicator

Pressing

on

pump

When

will

Hold

hold,

temporarily

is

on hold,

the

flash

until

pump

begin

when

rate,

and

not

closed,

pump

to

stops

the

is

either

infusing.

fluid

flashes

the

set

up

set a new

the

infusion

silences

red

indicator

alarming,

Hold,

Silence,

The

green

indicator

is

being

delivered

when

delivering

administration

is

incomplete,

rate

during

or,

an

audio

on

the

indicator

if

the

alarm.

the

or

Run

set

Run

Running

pump

key

light

is

on

at

the

at

the

safety

is

disabled,

Rate

is

already

When

will

be

on

the

pressed.

the

KVO

clip

the

lit.

key

key

is

4.

sy

The

green

in

and

the

pump

is

Battery

The

yellow

being

powered

When

battery

power

cord

5.

Door

Pulling

housing

position

set

from

pumping

(charge)

charge

indicator

battery

on

Indicator

the

and

is

the

mechanism

is

or

off.

Battery

by

power

is

plugged

Latch

door

latch

pumping

used

to

pump.

the

install

Indicator

lights

charging,

indicator

internal

is

(Handle)

to

mechanism

Pushing

to

regardless

is

lit

battery.

low,

the

indicator

in.

the

open

the

administration

the

latch

the

operate

when

the

of

whenever

will

position

to

the

load

closed

position.

pump

is

whether

the

pump

flash

moves

position.

set

or

moves

plugged

the

is

until

the

cam

This

remove

the

3-5

6/54)

the

a

Page 16

If

the

pump

is

running

and

the

door

is

opened,

the

4.

Ground

Stud

Door

alarm

is

activated.

alarm.

Once a set

placed

safety

is

pulled

preventing

in

the

clip

open,

is

to

CAUTION

To

prevent

upper

clamp

door.

Inside

Pump

(Reference

1.

Cassette

Place

four

holes

pins

and

press

open

Pressing

loaded

retention

allow

for

the

safety

gravity

pump

on

the

Door

Figure

flow

and/or

3-2.)

Loading

on

cassette

cassette

Silence

into

the

slot,

closing

fluid

delivery.

clip

through

cassette

administration

pump

is

allowed

the

or

and

the

damage,

Pins

(flat

side

into

place.

Hold

the

door

When

set.

set

out)

will

safety

opens

the

to

close,

open

before

over

silence

clip

is

the

door

latch

thus

the

closing

four

loading

the

the

The

ground

current

5.

Pole

Turn

the

an

IV

6.

Modular

The

modular

pumps

7.

Modular

Press

to

stud

and

ground

Clamp

pole

clamp

pole.

connection

together

disconnect

is

used

as a test

line

resistance

clockwise

Connection

allows

for

multiple

Disconnect

pumps

from

point

levels.

firmly.to

you

to

infusion

lines.

Button

each

other.

to

measure

secure

connect

leakage

the

pump

up

to

to

3

2.

Safety

Place

administration

completely

Clip.is

correctly

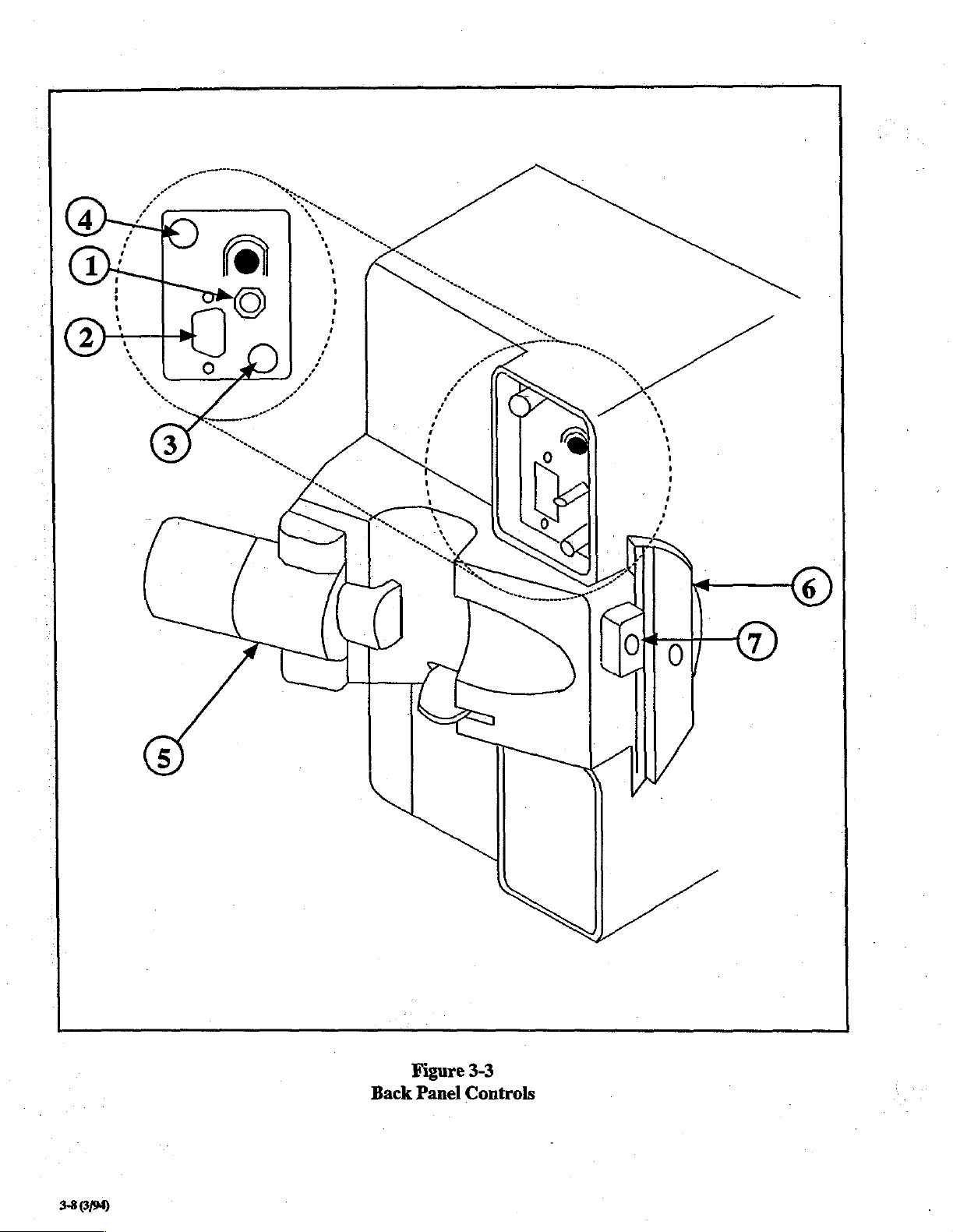

Back

Panel

(Reference

1.

Alarm

Turn

to

alarm

cannot

2.

Computer

This

is

an

3.

Keypad

Pressing

Lockout

display

‘

entries

are

will

timeout

Clip

forward.

loaded.

Controls

Figure

Volume

increase

RS

be

232

or

completely

Leckout

the

button

feature.

will

read

allowed.

and

Retention

set

Safety

Pump

will

3-3.)

Control

decrease

audio

silenced.

Port

Port

for

computer

Button

activates

When

Keypad

After 5 seconds,

revert

(or

the

button

lockout,

to

standard

Slot

Clip

in

slot

and

not

operate

alarm

deactivates)

is

message.

unless

volume.

connection.

the

pressed,

the

the

and

no

Message

push

Safety

Audio

Keypad

message

keypad

Display

Pressing

and

restores

message

3-6

(3/94)

the

button

all

keypad

display

again

when

deactivates

functions.

the

lockout

the

There

is

feature

lockout

feature

no

change

is

deactivated.

to

the

Page 17

Figure

Inside

Pump

3-2

Door

37889

Page 18

Figure

Back

3-8

(3/94)

Panel