appears

sounds,

changes

e

Check

Model

holds

from

Rate

e

Rate

accuracy.

obtain a stopwatch.

moving,

e

Verify

seconds)

3100,

e

Disconnect

in

Message

volume

to 3 mL/h.

burette

3000.

If

25

mL

+1/2

bottom

Accuracy:

accuracy

of

When

start

alarm

occurs

if

checking a Model

alarm

should

and

and

checking a Micro

can

stopwatch.

Display,

to

be

infused

Press

Hold.

verify a volume

mL.

Remember

meniscus.

be

verified

setting

up

for

When

the

at 2 minutes,

occur

at

drain

burette.

non-insistent

display

at

pumping

3000.

15

of

3100,

to

take

same

volume

56.6

If

minutes

is

0,

and

49

mL,

verify

measurement

time

accuracy,

indicator

seconds

checking a Micro

(+18

audio

alarm

rate

+1

mL,

burette

as

volume

also

starts

(+3

seconds).

on

5.8

Table

action

Infusion

3M

properly

you

troubleshooting

Electronic

circuit

and

component

Troubleshooting

5-2

lists

problems,

for

troubleshooting

Pumps.

recommends

functioning

have.

board.

Model

that

These

test

when

malfunctions

Because

3100

are

level

repair

CAUTION

The

functional

following

infusion

and

any

significant

pumps.

CAUTION

Electrostatically

manufacture

electrostatic

handling

printed

sensitive

of

3M

discharge

circuit

possible

the

you

maintain a complete

circuit

boards

circuit

should

the

circuit

primarily

is

not

accuracy

disassembly

infusion

(ESD)

boards.

causes,

Model

boards

can

be

board

be

narrowed

boards

surface

recommended.

check

components

pumps.

must

and

3000

and

for

each

useful

for

repairs

are

in

the

mount

should

or

repair

are

Protection

be

provided

corrective

Micro

3100

set

of

model

pump

diagnostic

indicated,

to a specific

Model

3000

technology,

be

performed

of

3M

used

in

the

against

when

ath

學

5-8

004)

Table

Situation

No

AC

shooting).

No

(disconnect

shooting).

Battery and

not

power

DC

power

AC

power

light

and

5-2

up

before

cord

up,

battery

battery

Charge

Troubleshooting

(disconnect

trouble-

charge

light

light

is

before

lights

on

trouble-

both

Cause

1.

2.

3.

4.

does

lit. 1.

1.

2.

3.

4.

Battery

connection

Wire

and

P104

Open

battery

Q2

on

Power

faulty.

Open

AC

CPU

board

‘Wire

connection

filter

and

Open

thermal

former.

Open

connection

Faulty

18

will

on

fuse

(open

Power

volt

not

I/O

Guide

maintain

between

board.

fuse

F101

on

Supply/CPU

F1

on

Power

AC

fuse

>

between

Supply/CPU

fuse

within

in

AC

power

regulator.

charge.

battery

I/O

board.

board

Supply/

F2).

RFI

line

board.

trans-

cord.

Solution

Replace

1.

Repair

1.

wire

assembly.

1.

Replace

I.

Replace

1.

Replace

1.

Repair

1.

Replace

|1.

Replace

1.

Replace

battery.

.

connection

wire

battery

Power

AC

fuse.

wire

connection.

Power

AC

power

Power

.

replace

or

fuse.

Supply/CPU

.

Supply/CPU

cord,

Supply/CPU

board.

board.

board.

Battery

Dead

battery

Battery”

plug

Low

battery

(Low

battery/

plug

No

keypad

Loading

|tubing

will

not

charge.

alarm

too

in

cora).

alarm

in

cord).

response.

problem/check

set

low/

1.

Faulty

2.

Faulty

1.

Goto

baitery

2.

JP402

connected,

3.

Faulty

Display

1.

Go

battery

2.

Faulty

3.

Faulty

Display

i.

Faulty

membrane

2.

Faulty

1.

Cassette

(flat

battery.

U109

on

JO

board.

options

to

options

side

screen

and

test.

on

Display

U408, A to D converter

board.

test.

U415

U408, A to D converter

board.

connection

membrane

loaded

inward),

board

screen

on

Display

between

switch

and

switch.

in

backwards

dis-

and

board.

Display

perform

on

perform

on

|

board.

1.

Replace

|1.

Replace

1.

If

1.

Repair

1.

Replace

1.

If

1.

Replace

1.

Replace

1.

Repair

1.

1.

battery.

JO

battery

connection.

Display

battery

Display

Display

connection.

Replace

Properly

membrane

board.

is

low,

is

low,

load

cassette.

charge

board.

charge

board.

board.

switch.

battery.

battery.

2...

Faulty

connection

micro

switch.

3.

Faulty

U414,

Motor

stalls

/

Yom

to

pressure

U409

on

Display

in

reverse.

1.94.5

plk

plate

board.

1.

ror

BD

Repair

Replace

connection

Display

Repair

wire

11Ο

board (motor

Replace

Replace

Replace

YO

Display

motor.

to

micro

board.

connection

board.

at

wires),

board.

switch.

P103

59699)

on

A

Table

Situation

Air

No

Primary

sounds,

‘Primary

sounds,

Back

5-2

in

cassette

flow/above

z

audio

system

audio

system

Up/Continuous

pump

failure

(Back

error

is

failure

(primary

error

is

audio

Troubleshooting

Cause

1.

Up

audio}

displayed.

audio | 1.

displayed.

failure.

Cassette

(flat

2.

Faulty

3.

Faulty

1.

Faulty

2.

Open

3.

Contact

4.

Faulty

5.

Contaminant

1.

Faulty

CPU/Power

Faulty

Supply

1.

Open

loaded

side

inward).

U103,

optical

connection

contact

out

U104,

U16,

US,

board.

fuse

Guide - Continued

in

U107

detector.

wire.

of

position.

U105

on

top

Q8, Q9,

Supply

U10,

U11

(F101)

|

backwards

,

on

I/O

board.

at

P102,

on

YO

board.

piston

shaft.

Q12,

Q13

board.

on

CPU/Power

on

I/O

board.

on

Solution

1.

1.

1.

1.

1.

1.

1.

1.

1.

|1.

.

1. | Replace

Properly

Replace

Replace

emitter.

Repair

“Repair

Reposition

Replace

Clean

Replace

Replace

load

YO

optical

connection.

wire

JO

top

CPU/Power

CPU/Power

fuse.

cassette.

board.

detector

i

connection.

contact

piston

in

board.

shaft.

and

guide

Supply

Supply

slot.

board.

board.

ilocclusion/bélow

|

Close

clip

Door

‘clamp!/Load

open

pump

safety

2.

Loose

fuse

(F101).

1.

Faulty

2.

3.

4.

| 1.

2.

3.

4.

1.

2.

3.

4.

pressure

Faulty

wire

sensor,

Faulty

connection

Faulty

U409

Faulty

micro

Faulty

wire

Faulty

connection

Faulty

U104

Faulty

micro

Faulty

switch.

wire

Faulty

Faulty

connection

U104

sensor.

connection

on

switch.

connection

on

switch,

connection

on

to

to

J404.

Display

at

P102.

I/O

board.

at

P102,

I/O

board.

pressure

board.

to

micro

to

micro

1.

Tighten

holder.

1.

Replace

1.

Repair

1.

Repair

1.

Replace

1.

Replace

1.

Repair

1.

Repair

1.

Replace

1.

Replace

1.

1.

1.

Repair

Repair

Replace

・

contact

wire

connection.

wire

connection.

connection.

connection.

between

pressure

Display

micro

I/O

micro

YO

plate.

connection.

board.

switch.

connection.

board.

switch.

board.

fuse

and

-5-10

(3/94)

5.9

DANGER

Potentially

pump

in.

transformer

board;

nects.

injury

power

Disassembly

©

Reassembly

.

dangerous

housing

These

voltages

the

RFI

To

avoid

or

death,

cord

is

open

and

line

electric

avoid

is

plugged

are

AC

filter

voltages

and

the

present

fuse

on

where

shock

touching

in.

and

Instructions

are

exposed

AC

power

in

the

the

CPU/Power

the

with

potential

these

following

power

cord

areas

when

is

areas:

supply

cord

for

when

the

plugged

con-

severe

the

the

board;

nects.

injury

beginning

2.

Unplug

scribed

filter

a

3.

AC

on

long

Front

the

To

avoid

or

death,

Fuse

pump

in

CPU/Power

nose

RFT

line

filter

electric

always

djsassembly

from

AC

step

1.

AC

fuse

Supply

pliers (see

Housing

where

shock

unplug

of

the

power.

is

located

board;

Figure

the

with

AC

3M

pumps.

Remove

5-2).

power

potential

power

cord

battery

directly

it

can

above

be

removed

cord

for

as

con-

severe

before

de-

RFI

line

with

CAUTION

The

Functional

formed

of

-

NOTE

3M

attend a Service

service

1.

The

short

serew

door

‘slide

from

procedure

following

the

3M

Infusion

or

Battery

3M

infusion

duration

which

toward

battery

battery

infusion

repair

bottom

to

DANGER

-

Potentially

housing

These

transformer

dangerous

is

open

voltages

and

Accuracy

any

significant

pumps.

Therapy

recommends

Training

of

this

product,

Removal

pumps

come

use.

Unplug

holds

battery

of

pump.

partially

terminals and

replace

out

the

battery

©-

voltages

and

the

are

present

and

AC

fiise

Seminar

with a 12

the

AC

door

Remove

of

pump.

remove

AC

power

in

the

on

the

Check

in

should

disassembly

that

prior

volt

power

cord.

place

and

battery

Pull

lead

battery.

(see

Figure

are

present

cord

following

CPU/Power

be

per-

or

repair

technicians

to

beginning

battery

slide

connectors

Reverse

5-2).

is

plugged

Remove

battery

clamp

the

when

the

areas:

supply

for

and

in.

the

CAUTION

Do

not

use a screwdriver

separate

may

CAUTION

Electrostatically

3M

discharge

printed

Remove 2 screws

cover

and 1 screw

Figure

The

the

CPU/Power

front

The

being

cover.

functional

complete

the

front

occur.

pump

design.

(ESD)

circuit

near

5-2).

front

SPI

ribbon.cable.

housing

front

careful

Before

boards.

bottom

from

Pull

housing

supply

assembly.

housing

not

replacing

and

accuracy

housing

and

sensitive

Protection

must

from

left

battery

front

remains

is

to

reassembly.

or

other

rear

housing

components

against

be

provided

pump

handle, 1 screw

corner

of

door

on

housing

This

board

reinstalled

damage

away

connected

must

(P200)

the

screws

check

sharp

instrument

or

pump

are

electrostatic

when

handling

AC

cord

connector

bottom

be

to

by

gasket

in

If

check

of

the

from

rear

to

the

rear

disconnected

completely

reversing

retainers

housing,

perform

is

satisfactory,

damage

used

in

from

rear

cover,

pump

housing.

housing

from

free

the

the

procedure,

on

the

the

to

the

(see

by

the

front

5-11

4)

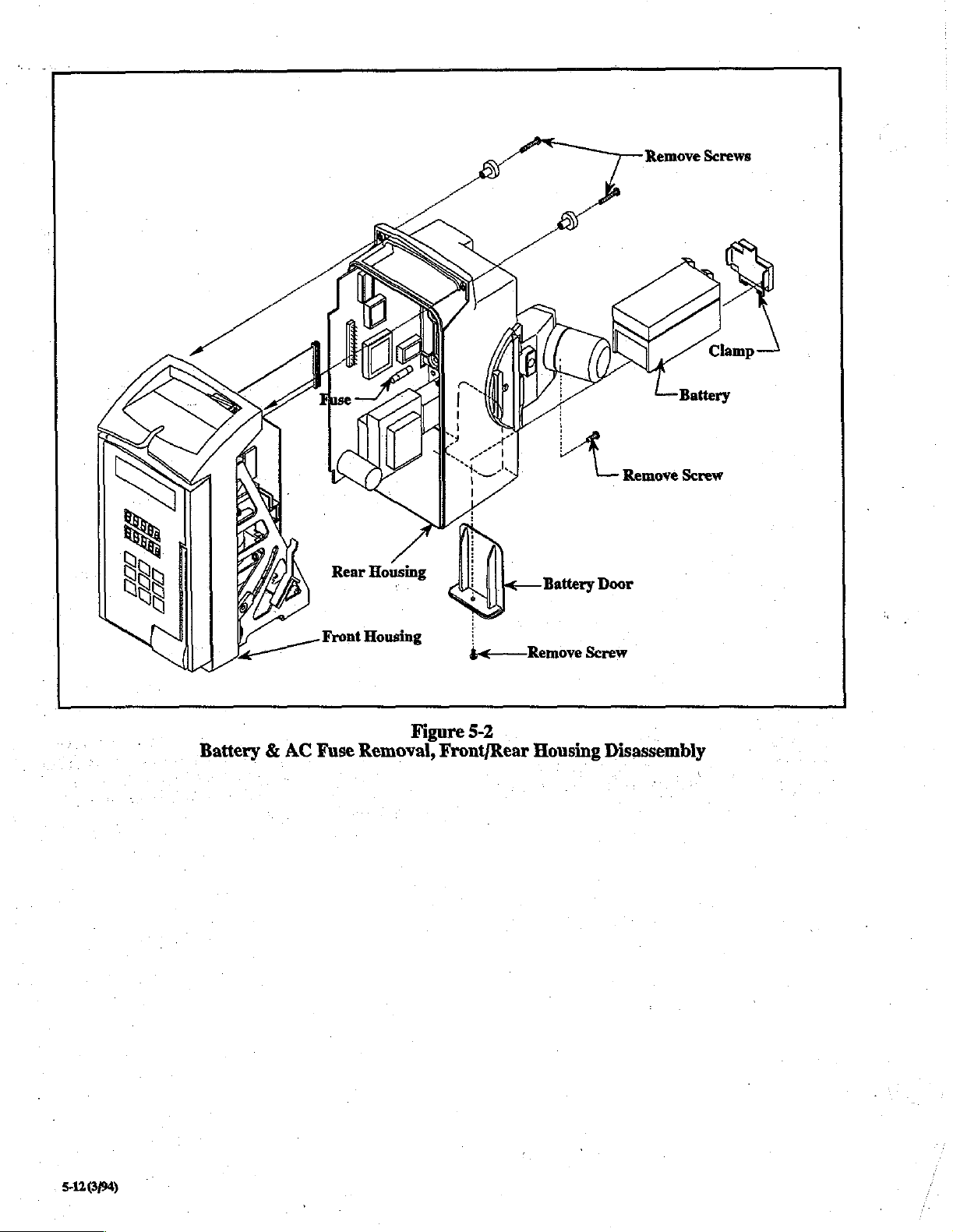

Remove

Screws

Battery & AC

Front

Fuse

Housing

Figure

Removal,

5-2

Front/Rear

Housing

Disassembly

512694

©

4.

Door

See

Figure

Open

door.

slide

door

and

remove

and

CPU

Separate

nect

wire

plate

switch.

To

remove

fasten

it

Assembly

5-3

for

the

following

Remove 2 screws

out.

Remove 2 screws

handle.

board.

front

assemblies

pressure

to

rear

Disconnect

Remove 4 screws

and

rear

from

plate

door

housing.

from lower

door

housings

pressure

assembly,

discussion.

hinge

from

door

latch/handle,

SPI cable

from

from

rear

door

slightly,

transducer

remove 4 screws

bracket

I/O

board

housing.

then

discon-

and

pressure

and

which

Reverse

cover

slides

the

process

into

the

for

front

reassembly,

pump

housing.

Membrane

being

Door

Switch

sure

the

ESD

Front

ESD

Cover

Remove

Screws

(4)

Door

Latch

(Handle)

Figure

Door

Disassembly

5-3

5133/94)

|

5.

CPU/Power

Assembly

Supply

Circuit

Board

assembly

bly

from

board

to

from

P102

pump

P103

on

I/O

on

I/O

board.

mechanism.

board,

and

sensor

Remove 4 screws

wire

assem-

fastening

DANGER

Unplug

bly

to

the

avoid

AC

risk

CAUTION

Handling

during

discharge

damage

CAUTIONBattery

be

disconnected

to

avoid

To

board,

Disconnect

threaded

nut,

and

From

filter

Slide

Reassemble

Before

tional

housing

of

the

disassembly;

(ESD)

could

circuit

remove

the

remove

SPI

Panel

and

internal

nut.

Remove 2 screws

inside

rear

wires

from

CPU/Power

in

replacing

and

accuracy

reassembly.

result.

CPU/Power

front

Lockout

reverse

power

cord

of

electric

printed

protection

must

be

connection

before

disassembling

damage.

housing

cable

from

Button

tooth

washer.

cover,

disconnect

CPU/Power

supply

order.

screws

in

check.

before

shock.

circuit

boards

provided

P104

supply,

first.

P200.

(turn

Remove

from

RS232

Supply

out

of

rear

pump

If

check

beginning

is

required

against

electrostatic

or

circuit

on 1/O

the

VO

Board,

On

rear

of

counter

audio

connector.

brown

and

board.

cover.

housing,

perform

is

satisfactory,

disassem-

board

board

must

circuit

or

pump,

boards

RS232

remove

clockwise),

volume

blue

knob

RFI

func-

complete

line

Reassemble

Before

functional

complete

7.

Membrane

in

replacing

and

housing

DANGER

Unplug AC

avoid

CAUTION

Handling

disassembly;

(ESD)

result.

risk

of

must

power

of

printed

be

CAUTION

Battery

nected

circuit

See

The

electronic

graphics.

removed

must

damage

connection

before

damage.

Figure

5-3

membrane

switch

Once

as a single

not

be

reinstalled

during

reverse

accuracy

order.

screws

in

pump

check.

reassembly.

Switch

cord

before

electric

protection

shock.

circuit

against

provided

P104

or

on

disassembling

for the

following

switch

consists

and

the

upper

in

place

on

the

unit.

The

after

removal

is

likely

housing,

If

check

perform

is

satisfactory,

Replacement

opening

boards

electrostatic

circuit

1/O

board must

the circuit

discussion.

of

two

overlay

door

original

removal

to

pump

is

required

board

damage

boards

parts;

with

assembly,

membrane

because

occur.

the

housing

during

discharge

could

be

discon-

to

avoid

the

lower

keypad

they

are

switch

electrical

to

6.

1/0

Board

:

DANGER

Unplug

avoid

AC

risk

CAUTION

-

Handling

disassembly;

(ESD)

must

result.

CAUTION

Battery

nected

circuit

The

(see

Disconnect

board

5-14

connection

before

damage.

I/O

board

Figure

and

(3/94)

Assembly

power

of

of

5-4).

SPI cable

P101

cord before

electric

printed

protection

be

provided

P104

disassembling

is

mounted

on

WO

shock.

circuit

boards

against

or

circuit

on

to

the

from

P200

board.

opening

is

required

electrostatic

board

I/O

board

must

the

circuit

back

of

the

on

CPU/Power

Disconnect

pump

discharge

damage

be

boards

pump

motor

housing

during

could

discon-

to

avoid

assembly

supply

wire

to

The

door

in

order

to

assembly

display

peel

residual

To

board,

up

and

adhesive

replace

below:

1.

Peel

release

(front

of

liner

on

2.

Thread

3.

Apply

around

vertically

tool

(see

pressure

4.

Once

electrical

release

from

back

must

be

disassembled

replace

is

opened,

then

discard

off

the

membrane

liner

membrane

front

must

ribbon

cable

membrane

outer

edges,

between

Section

on

domes

switch

liner

from

of

graphics

the

membrane

remove

remove

old

display

membrane

of

housing.

switch,

off

back

switch

not

be

removed

through

switch

to

around

rows

of

5.5

Special

themselves.

portion

its

front.

overlay.

(see step 4 Door

switch.

ribbon

connector

board.

switch.

follow

of

electronic

has

raised

domes).

at

this

slot

provided

door

front.

display

domed

Also,

windows,

switches

Tools).

is

firmly

remove

Avoid

Assembly)

Once

door

from

P403

On

front

of

Clean

any

the

instructions

switch

portion

Release

time.

on

door

Press firmly

and

using

keypad

excess

in

place,

remove

release

liner

on

door,

front.

5.

Place

graphics

making

portion.

windows,

keypad

excessive

6.

Connect

Press

Reassemble

and

housing

8.

DANGER

Unplug

avoid

CAUTION

Handling

disassembly;

(ESD)

result.

sure

Press

and

tool (see

pressure

ribbon

board

door

accuracy

reassembly.

Pump

AC

risk

of

must

©

Assembly

power

of

printed

be

overlay

to

line

it

up

firmly

around

vertically

Section

on

cable

to

firmly

into

as

described

check.

If

check

cord

electric

.

protection

shock,

circuit

provided

over

electrical

correctly

outer

between

5.5

Special

keypads

P403

on

board

retainers.

in

is

satisfactory,

before

boards

against

or

circuit

switch

portion,

with

electrical

edges,

around

rows

of

numbers

Tools).

themselves.

back

step

4.

opening

is

electrostatic

board

Avoid

of

display

Perform

complete

pump

required

damage

switch

display

using

board.

functional

housing

during

discharge

to

could

CAUTION

Battery

nected

circuit

‘The

assembly.

removal

pump

The

the

1.

‘2.

Reverse

housing.

functional

complete

connection

before

damage.

pump

assembly

Separation

of

the

assembly

pump

assembly

following

Remove

retaining

pin.

linkage

Remove 4 screws

assembly

screw from

ring

Raise

assembly

out.

the

procedure

Before

and

housing

arm

P104

on

disassembling

consists

of

the

front

YO

board

are

(see

Section

is

separated

manner:

linkage

from

connecting

of

the

drop-in

can

be

removed

from

cassette

to

reassemble

replacing

accuracy

reassembly.

screws

check.

I/O

board

the

circuit

of

the

cam

and

rear

required

5.9,

steps

from

the

assembly

link,

guide

from

housing

pump

in

housing,

If

check

must

be

discon-

boards

housing/motor

housings

prior

3'and

rear

and

remove

(see

frame

is

to

to

removing

6).

housing

upper

link

Figure

5.4)

assembly.

and

lift

pump

assembly

perform

satisfactory,

avoid

and

in

from

so

to

the

the

rear

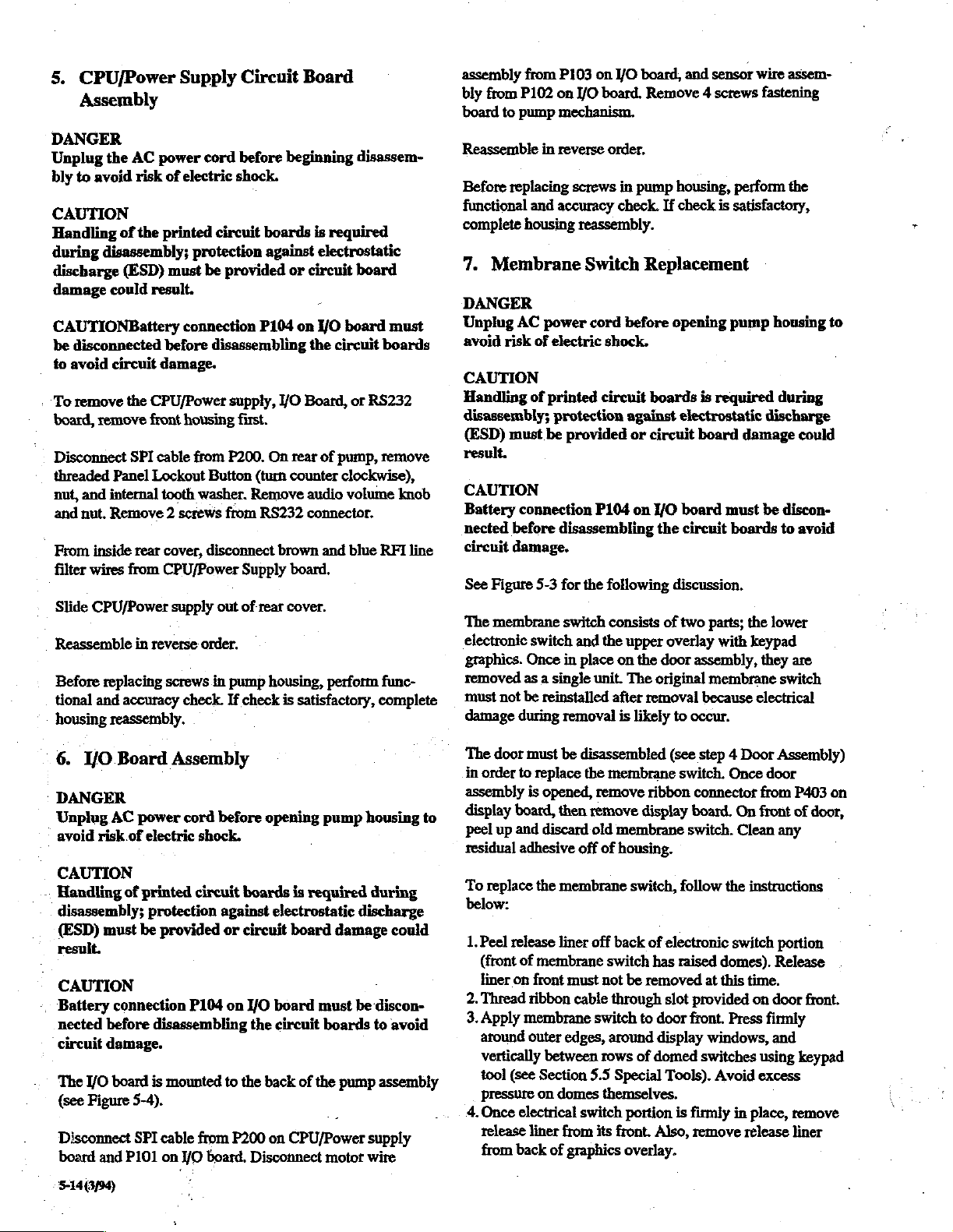

Pump

Assembly

Front

(MotorAssembly

shown

attached)

Housing

not

Remove

,

Connecting

Connectin;

Screw

Mount

Point

Link

Assembly

< — Retaining

of

Pivot

Ring

{<

^

Mount

Frame

Point

of

Assembly

.

Pump

Figure

Assembly

5-4

Removal

Close-up

Link

Assembly

of

Pivot

CEN

©

5150/94)

.

9.

Motor

Assembly

DANGER

Unplug

avoid

AC

risk

of

power

CAUTION

Handling

disassembly;

(ESD)

result.

CAUTION

Battery

nected

circuit

See

The

disassembied

Section

’

Remove 4 motor

out.

Remove

swing

of

must

connection

before

damage.

Figure

front

housing,

5.9,

Next,

remove

coupler

arm

printed

be

5-5

numbers

assembly

cord

before

electric

protection

disassembling

in

shock.

circuit

provided

P104

for

the

following

pump

order

to

3,

mounting

swing

gear.

Finally,

intact.

against

or

on

assembly,

remove

6,

and

screws

arm

opening

boards

circuit

I/O

damper

is

required

electrostatic

board

board

the

circuit

discussion.

and

the

motor

8).

and

take

from

remove

mounting

pump

damage

must

boards

I/O

board

assembly

motor

coupler

housing

during

discharge

could

be

discon-

to

avoid

must

be

(see

assembly

gear.

plate

with

to

Screw

Set

Coupler

yy,

A

;

Hub

i

i

(attached

cam

一

hteerfaee

一

人

я

>,

ring

Gap

Mounting

5-5

Gear

一

之 8 :

Figure

Motor

©

"<

i

Assembly

Coupler

shaft)

Here

Swing

to

end

of

Coupler

Damper

Arm

Platej

Arm

Reverse

NOTE

When

properly

the

sequence

assembling

align

CAUTION

Realignment

the

motor

and

inch

spacing

attached

which

coupler.

required

must

mounting

Reverse

all

cable

Reassemble

screws

check.

reassembly.

to

is

located

Repositioning

to

be

maintained

plate.

the

procedure

cables

and

clamps

in

housing,

If

check

the

achieve

the

to

reassemble.”

the

motor,

over

the

overpressure

of

the

motor

cam

shaft

is

required

cam

shaft

between

of

this

between

to

connectors

on

the

left

side

front

and

perform

is

satisfactory,

the

swing

coupler

have

between

and

the

the

spacing,

reassemble

and

of

rear

the

is

been

the

the

interface

motor

hub

coupler

Also a .125

the

coupler

secure

the

the

pump

housings.

functional

complete

arm

must

valve

shaft.

necessary

disassembled. A .002

hub

(sprocket)

the

pump.

SPI

housing.

Before

and

housing

whenever

coupler

coupler,

and

may

be

inch

gear

and

Reconnect

cable

with

replacing

accuracy

that

hub

gap

the

is

10.

Cassette

To

disassemble

board,

and

See

Figure

Remove

Slide

and

cassette

Reverse

11.

retaining

shaft

detector

housing.

the

Safety

DANGER

Unplug

avoid

AC

risk

CAUTION

Battery

nected

circuit

connection

before

damage.

Housing

the

cassette

pump

mechanism

5-6

for

the

following

ring

out

of

cassette

assemblies

procedure

Mechanism

Clip

power

cord

of

electric

shock.

P104

disassembling

housing,

from

one

housing.

from

to

assemble

before

on

the

must

be

removed

discussion.

end

of

Remove

cassette

`

I/O

the

housing

the

opening

board

circuit

front

housing,

first.

each

cassette

optical

and

cassette

pump

must

boards

housing.

be

I/O

shaft.

emitter

remove

housing

discon-

to

avoid

to

5-16(3/94)

See

Figure

The

front

cassette

clip

housing

mechanism.

5-6

for

the

housing,

must

following

pump

mechanism,

be

removed

discussion.

I/O

board,

to

disassemble

and

the

safety

‘The

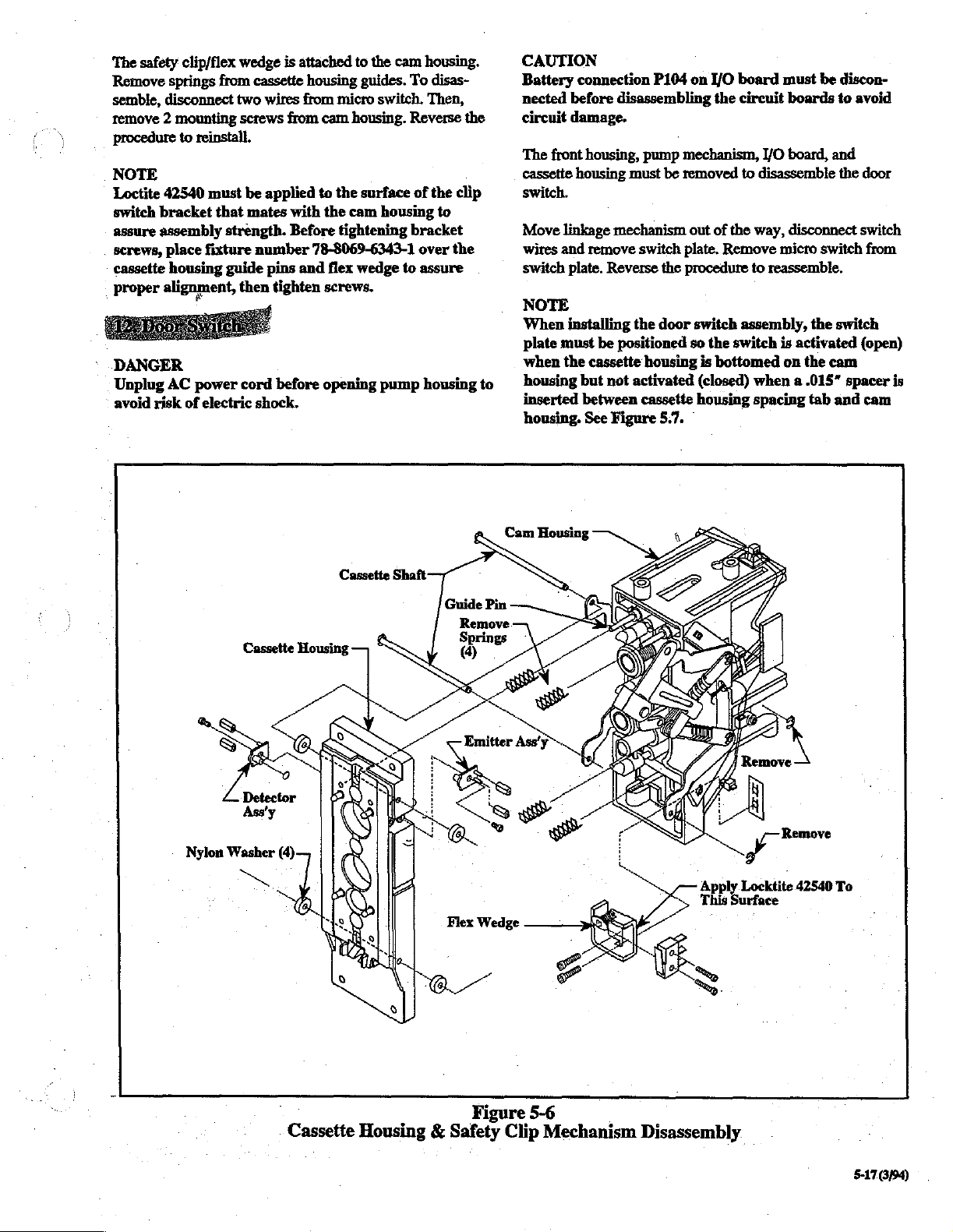

safety

clip/flex

Remove

semble,

remove 2 mounting

procedure

NOTE

Loctite

switch

assure

screws,

cassette

proper

DANGER

Unplug

avoid

springs

disconnect

to

reinstall.

42540

must

bracket

assembly

place

housing

alignment,

AC

risk

that

fixture

power

of

electric

from

strength.

guide

wedge

is

attached

cassette

two

screws

be

mates

number

then

cord before

shock.

housing

wires

from micro

from

applied

with

Before

pins

and

tighten

to

the

cam

guides.

cam

housing.

to

the

surface

the

cam

tightening

78-8069-6343-1

flex

wedge

screws.

opening

To

switch.

Reverse

of

housing

bracket

to

pump

housing.

disas-

Then,

the

the

clip

to

over

the

assure

housing

.

to

CAUTION

Battery

nected

circuit

The

cassette

switch.

Move

wires and

switch

NOTE

When

plate

when

housing

inserted

housing.

connection

before

damage.

front

housing

linkage

plate.

installing

must

the

disassembling

housing,

must

mechanism

remove

Reverse

the

be

positioned

cassette

but

not

activated

between

See

Figure

P104

on I/O

pump

mechanism,

be

removed

out

switch

plate.

the

procedure

door

switch

so

housing

cassette

5.7.

board

the

circuit

to

of

the

Remove

to

assembly,

the

switch

is

bottomed

(closed)

housing

when a .015"

spacing

must

be

boards

I/O

board,

disassemble

way,

disconnect

micro

switch

reassemble.

the

is

activated

on

the

cam

tab

discon-

to

avoid

and

the

door

switch

from

switch

(open)

spacer

and

cam

is

Cassette

Figure

Housing & Safety

5-6

Clip

Mechanism

yer

Apply

Locktite

This

Surface

Disassembly.

42540

To

511099

5.10

The

be

necessary

month

Calibration

also

CAUTION

The

should

ment

NOTE

3M

attend a Service

Infusion

service

Calibration

Checks

following

functional

be

Functional

of

Infusion

calibration

if

indicated

and

adjustment

performed

and

be

performed

any

of

the

Therapy

therapy

or

repair

and

following

following

Training

Service

of

this

and

adjustment

during

accuracy

of

affected

disassembly

Accuracy

following

components.

recommends

Seminar,

Center,

product.

and

the

check

Check

calibration

Voltage

procedures

recommended

(see

Section

components

arid

(see

that

technicians

offerred

prior

to

Insert

Two

Door

repair.

Section

and

beginning

Switch

may

twelve-

5.7).

must

5.7)

adjust-

by

the

015"

Points

Figure

3M

Spacer

(top & bottom)

Disassembly

Between

5-7

1.

Power

DANGER

Potentially

housing

To

avoid

severe

cord

DANGER

Unplug

avoid

NOTE

There

voltage

Diodes

logic

different

dangerous

is

opened

electric

injury

before

AC

risk

of

are

no

checks.

D9,

D10,

circuitry.

when

Supply

beginning

power

These

Voltage

and

shock

or

death,

cord

electric

required

and

Source

the

pump

shock.

D11

power

Check

voltages

the

with

always

disassembly

before

adjustments

is

are

AC

power

the

potential

unplug

opening

direct

voltage

to

the

operated

present

of

.

logic

on

cord

for

the

the

3M

pump

for

the

to

the

circuitry

battery

when

the

is

plugged

causing

AC

power

pumps.

housing

following

pump’s

is

than

when

in.

to

it

5-18(3/94)

is

operated

checks

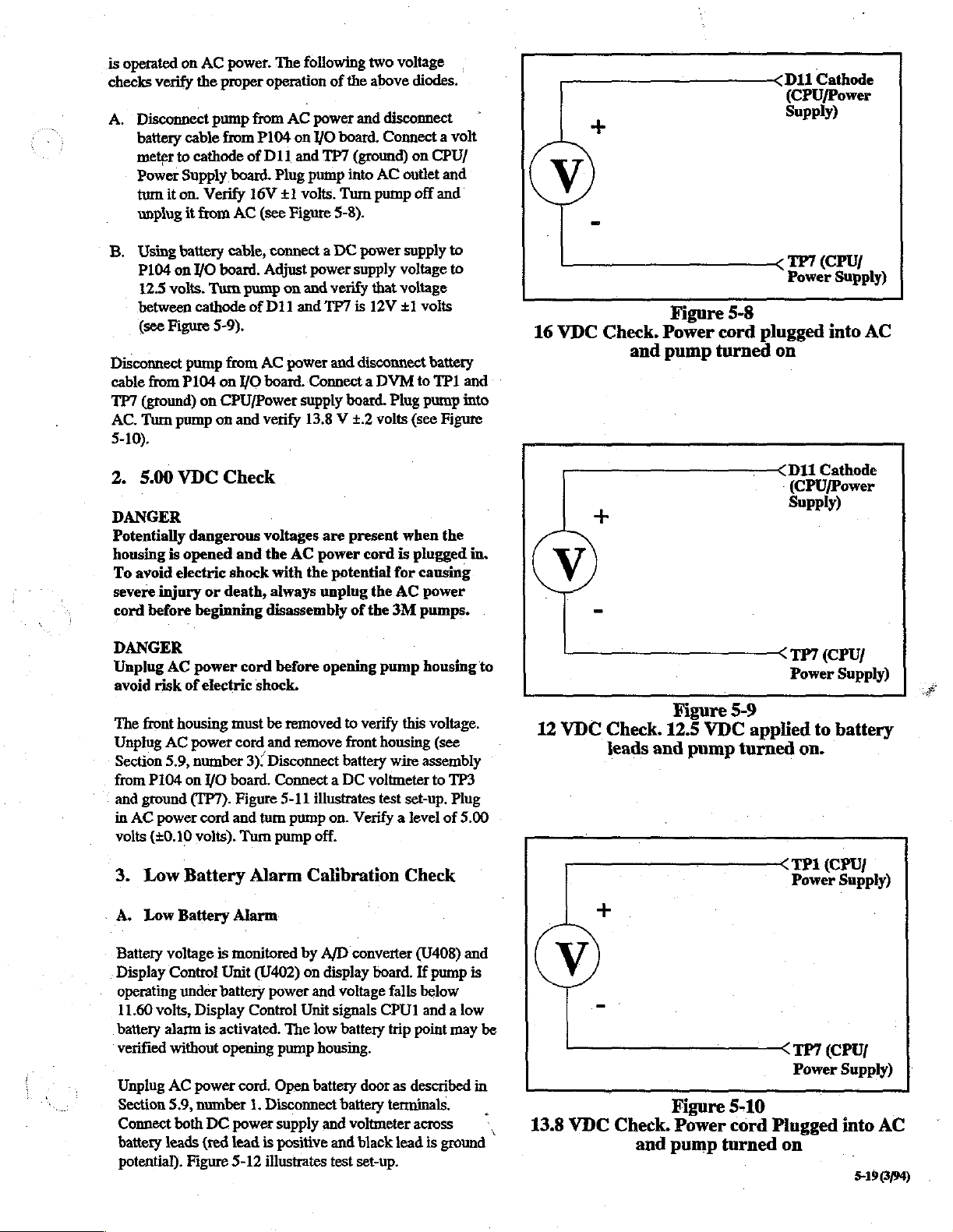

A.

B.

Disconnect

cable

TP7

AC.

5-10).

2.

DANGER

Potentially

housing

To

severe

cord

on

verify

‘Disconnect

battery

meter

Power

turn

unplug

Using

P104

between

avoid

cable

to

Supply

it

on.

it

battery

on

12.5

volts.

(see

Figure

pump

from

P104

(ground)

Turn

pump

5.00

VDC

is

opened

electric

injury

before

AC

power.

the

proper

pump

from

from

cathode

from

VO

cathode

board.

Verify

AC

cable,

board.

Turn

pump

5-9),

from

on

YO

on

CPU/Power

on

and

of

16V

of

Check

dangerous

and

shock

or

death,

beginning

The

following

operation

AC

power

P104

on

I/O

D11

and

TP7

Plug

pump

£1

volts.

(see

Figure

connect a DC

Adjust

power

on

and

D11

and

TP7

AC

power

board.

Connect a DVM

supply

verify

13.8 V +.2

・

voltages

the

with

always

disassembly

AC

are

power

the

unplug

two

of

the

above

and

disconnect

board.

Connect a volt

(ground)

into

AC

Turn

pump

5-8).

power

supply

verify

that

is

12V

and

disconnect

board.

Plug

volts

present

cord

potential

the

of

the

3M

voltage

diodes.

on

CPU/

outlet

off

and

supply

voltage

voltage

+1

volts

battery

to

TP1

pump

(see

Figure

when

is

plugged

for

causing

AC

power

pumps.

|,

and

to

to

the

and

into

in.

V

16

VDC

Check.

and

Figure

Power

pump

5-8

cord

plugged

turned

-

D1i

Cathode

(CPU/Power

Supply)

TP7

(CPU/

Power

Supply)

into

on

D11

Cathode

(CPU/Power

Supply)

AC

DANGER

Unplug

avoid

The

Unplug

Section

from

<

and

in

volts

3.

“A.

Battery

Display

operating

11.60

battery

verified

Unplug

Section

Connect

battery

potential).

risk

front

P104

ground

AC

power

(+0.10

Low

Low

volts,

AC

AC

5.9,

voltage

Control

alarm

without

AC

5.9,

leads

power

of

electric

housing

power

number

on

I/O

(TP7).

cord

volts).

Battery

Battery

is

Unit

under

battery

Display

is

activated.

opening

power

number

both

DC

(red

Figure

cord

before

shock.

must

be

removed

cord

and

remove

3):

Disconnect

board.

Connect a DC

Figure

5-11

and

tum

pump

Tum

pump

Alarm

Alarm

monitored

(402)

power

Control

The

pump

cord.

Open

1.

Disconnect

power

supply

lead

is

positive

5-12

illustrates

opening

illustrates

on.

off.

pump

to

verify

front

housing

battery

wire

voltmeter

test

Verify a level

Calibration

by

A/D

converter

on

display

and

Unit

low

housing.

battery

and

board.

voltage

signals

battery

door

battery

voltmeter

and

black

test

set-up.

falls

CPU1

trip

as

terminals.

housing

this

voltage.

(see

assembly

to

set-up.

of

Check

(U408)

If

pump

below

and a low

point

described

across

lead

is

ground

TP3

Plug

5.00

and

is

may

to

be

in

、

|

12

VDC

13.8

VDC

Check.

leads

+

Check.

and

Figure

12.5

and

Figure

Power

pump

VDC

pump

turned

5-9

applied

turned

5-10

cord

TP7

(CPU/

Power

to

on.

TP1

(CPU/

Power

ТРУ

(СРО!

Power

Plugged

on

Supply)

battery

Supply)

Supply)

into

AC

5-19

3/94)

у

TP3

(CPU

Power

Supply)

The

dead

battery

activation

scribed

audio

supply

low/plug

audio

4.

of

in

A,

alarm.

voltage. A dead

alarm)

Cam

alarm

initial

low

above.

Press

Continue

in

cord

must

activate

Housing

trip

point

battery

Silence

gradual

battery

in

Message

at

11.0

Switch

may

be

verified

alarm

as

previously

to

reset

non-insistent

reduction

alarm

(Battery

Display

volts

(+.2

of

DC

Adjustment

following

de-

power

too

and

insistent

volts).

5.00

VDC

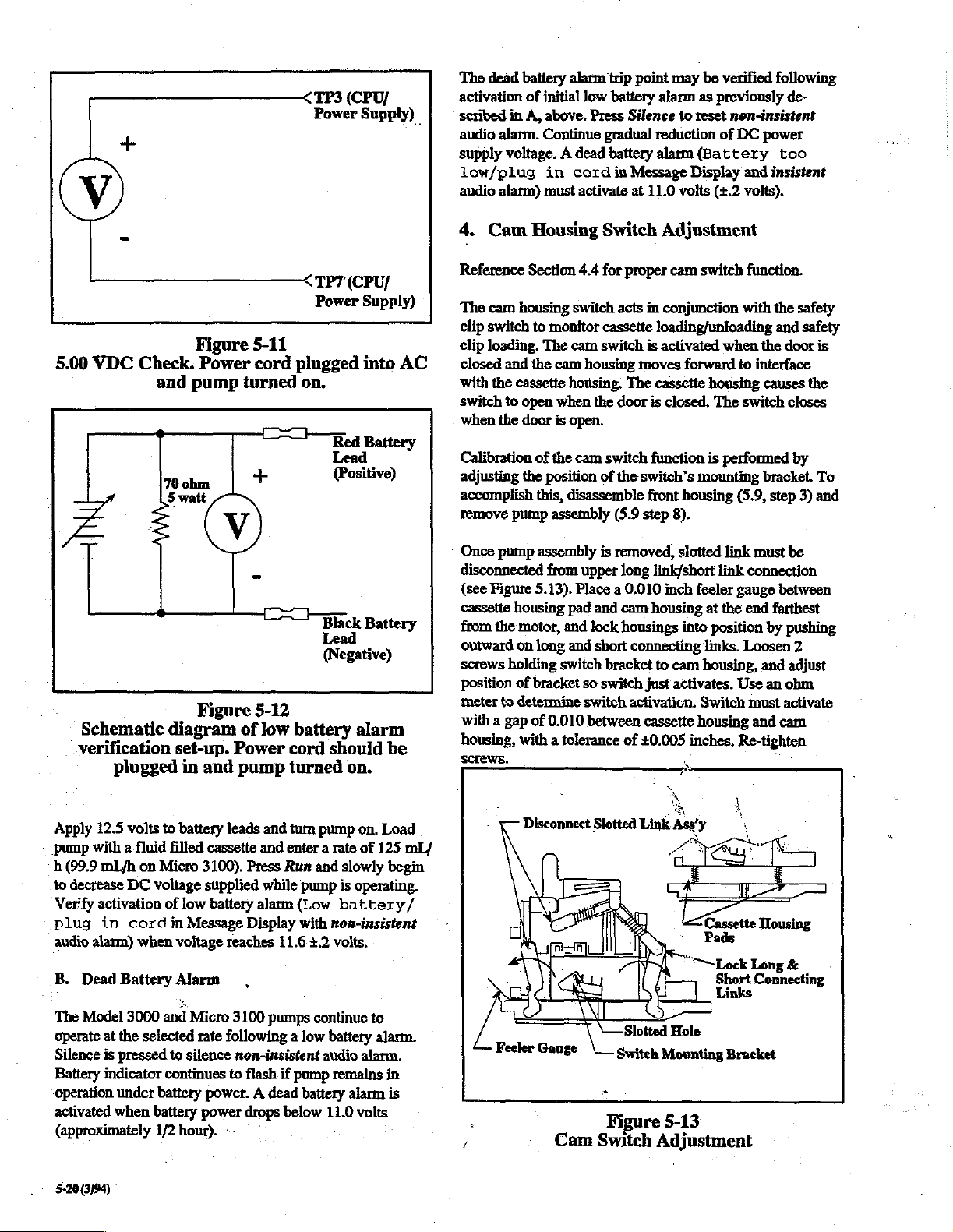

Schematic

verification

plugged

Check.

and

pump

diagram

set-up.

in

Figure

Power

turned

Figure

of

Power

and

pump

5-11

cord

5-12

low

TP7

Power

plugged

on.

Red

Lead

(Positive)

Black

Lead

(Negative)

battery

cord

should

turned

(CPU/

Supply)

into

Battery

Battery

alarm

on.

AC

be

Reference

The

clip

switch

clip

loading.

closed

with

switch

when

Calibration

adjusting

accomplish

remove

Once

disconnected

{see

cassette

from

outward

screws

position

meter

with a gap

housing,

Section

cam

housing

to

monitor

The

and

the

cam

the

cassette

to

open

when

the

door

is

of

the

the

position

this,

disassemble

pump

assembly

pump

assembly

from upper

Figure

5.13).

housing

the

motor,

and

on

long

holding

to

switch

of

bracket

determine

of

0.010

with a tolerance

4.4

for

proper

switch

acts

in

cassette

cam

switch

is

housing

housing.

open.

cam

Place a 0.010

pad

lock

and

so

switch

between

moves

The

the

door

switch

of

the

(5.9

is

removed,

long

and

cam

housings

short

connecting

bracket

switch

activation.

of

switch’s

step

just

cassette

+0.005

cam

switch

conjunction

loading/unloading

activated

forward

cassette

is

closed.

function

mounting

front

housing

8).

slotted

link/short

inch

feeler

housing

into

to

cam

activates.

Switch

housing

inches,

function.

with

when

to

interface

housing

The

switch

is

performed

(5.9,

link

must

link

connection

gauge

at

the

end

position

links.

Loosen

housing,

Use

must

and

Re-tighten

the

causes

bracket.

by

and

an

the

safety

and

safety

door

is

the

closes

by

To

step

3)

and

be

between

farthest

pushing

2

adjust

obm

activate

cam

Apply

12.5

volts

pump

with a fluid

h

(99.9

mL/h

on

to

decrease

Verify

plug

audio

B.

The

operate

Silence

Battery

operation

activated

(approximately

5-20

DC

activation

in

cord

alarm)

when

Dead

Battery

Model

3000

at

the

is

pressed

indicator

under

when

(3/94)

voltage

selected

battery

to

battery

filled

Micro

of

in

voltage reaches

Alarm

and

to

continues

battery

1/2

hour).

leads

cassette

3100).

supplied

low

battery

Message

|,

Micro

3100

rate

following a low

silence

non-insistent

to

power. A dead

power

--

and

turn

and

enter a rate

Press

Run

while

alarm

Display

11.6

pumps

flash

if

drops

below

|

pump

and

slowly

pump

is

(Low

battery/

with

non-insistent

+.2

volts.

continue

battery

audio

pump

remains

battery

alarm

11.0

on.

Load.

of

125

mL/

begin

operating.

to

alarm.

alarm.

jn

is

volts

Disconnect

Feeler

.

/

Gauge

Cam

Slotted

Link

ρα

©

Slotted

Switch

Mounting

Figure

Switch

5-13

Adjustment

Asy'y

*

“Lock

Short

Links

Hole

Long

8

Connecting

Bracket

Insert a 0.016

pads

and

cam

If

the

switch

of

less

than 0.010.

5.

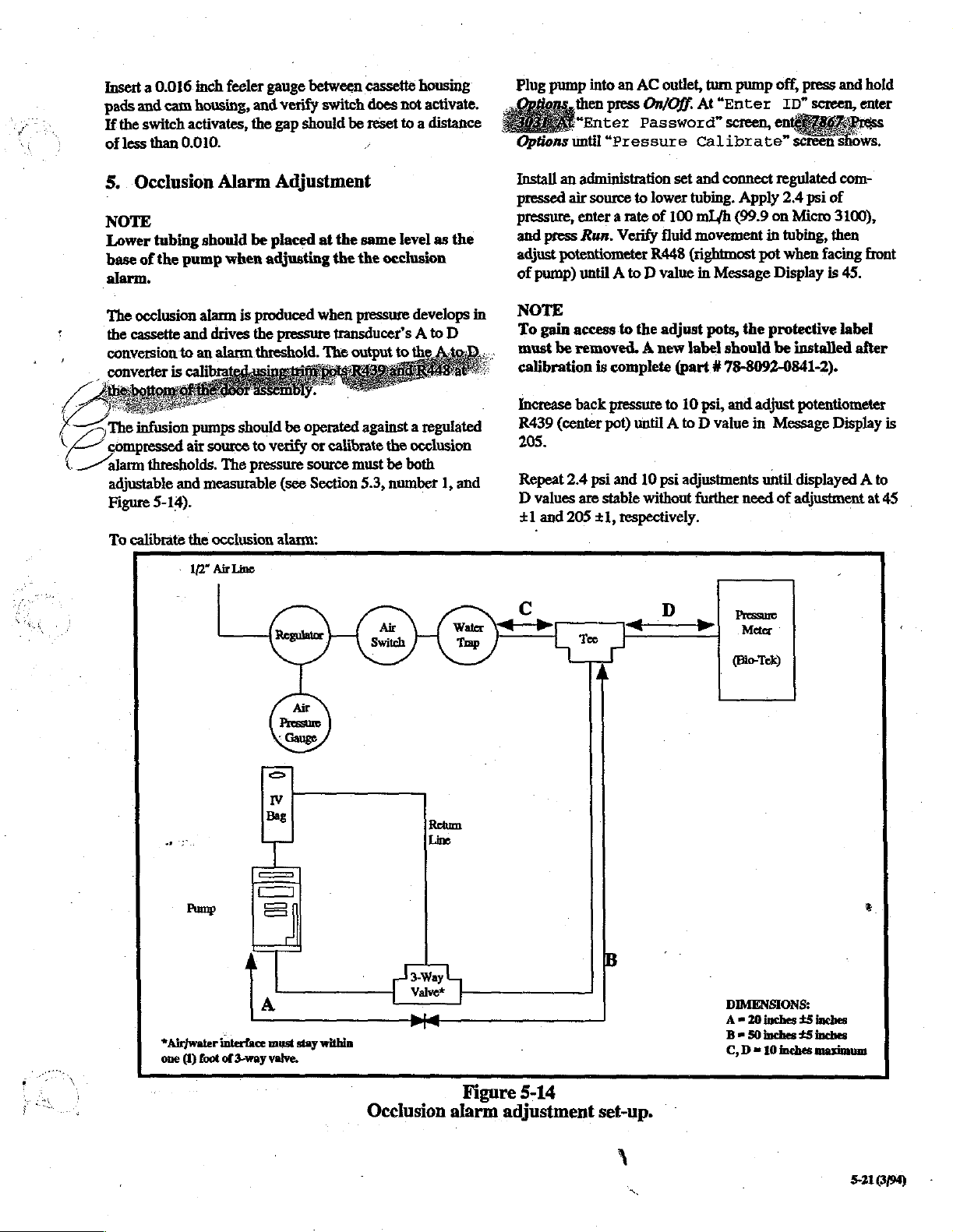

Occlusion

NOTE

Lower

base

alarm.

tubing

of

the

pump

inch

feeler

housing,

activates,

should

and

the

Alarm

be

when

gauge

between

verify

switch

gap

should

Adjustment

placed

adjusting

at

the

the the

cassette

does

be

reset

っ

same

occlusion

housing

not

activate.

to a distance

level

as

the

Plug

pump

Options

Install

pressed

pressure,

and

press

adjust

of

pump)

into

an

AC

outlet,

then

press

On/Off.

“Enter

until

an

administration

air

source

enter a rate

Run.

potentiometer

until A to D value

Password”

“Pressure

to

lower

of

Verify

fluid

R448

turn

At“Enter

screen,

Calibrate”

set

and

connect

tubing.

100

mL/h

movement

(rightmost

in

Message

pump

Apply

(99.9

in

pot

off,

press

ID”

screen,

en

screen

regulated

2.4

psi

of

on

Micro

tubing,

when

Display

then

facing

is

and

hold

enter

shows.

com-

3100),

front

45.

The

occlusion

the

cassette

conversion

の

Ls

he

infusion

impressed

im

adjustable

Figure

To

calibrate

alarm

and

drives

to

an

pumps

air

source

thresholds.

and

measurable

5-14).

the

>

1/2”

Pump

4

*Air}water

foot

(1)

one

is

produced

the

alarm

threshold.

should

to

verify

The

pressure

occlusion

Air

Line

>

Iv

Bag

[=>

E

E

A

A

©

interface

of

3-way

must

valve.

when

pressure

(see

alarm:

transducer’s A to

The

be

operated

or

calibrate

source

Section

|

E

within

stay

pressure

output

against a regulated

must

5.3,

develops

to

the

the

occlusion

be

both

number

D

A

1,

Line

:

3Way

Valve*

pré

Occlusion

in

and

Figure

alarm

NOTE

To

gain

access

must

be

removed. A new

calibration

Increase

R439

205.

Repeat

D

+1

back

(center

2.4

values

and

205

psi

are

5-14

adjustment

to

the

adjust

is

complete

pressute

pot)

and

stabie

+1,

to

until A to D value

10

psi

without

respectively.

B

set-up.

pots, the

label

(part # 78-8092-0841-2).

10

psi,

adjustments

further

protective

should

and

be

adjust

in

Message

until

need

of

Pressure

Meter

(Bio-Tek)

installed

potentiometer

displayed A to

adjustment

DIMENSIONS:

inches

20

=

A

B=

50

inches

2

10

=

C,D

+5

£5

inches

inches

inches

maximum

label

Display

e

after

is

at

45

>

À

=.

5-21

3/94)

6.

Empty

NOTE

Before

top

solution,

The

spring

piston

is

the

during

The

The

-

calibrating

piston

moves

etc.

empty

bag

contact.

as

its

mounted

wire

depressions

pronounced

the

minor

only

major

Calibration

require

5.9,

accomplished

the

cam

switch.

to

contact

each

cam

which

perimeter

depression.

when

the

depression.

and

that

the

number

housing

Bag

Contacts

the

empty

freely

contacts

The

wire

drive

(metering)

the

cam

housing.

briefly

touches

revolution

of

(see

and

upper

front

3).

by

of

drives

the

the

metering

Figure

is

called

The

piston

adjustment

housing

Calibration

turning

just

above

Adjustment

bag

and

is

consist

contact

cam

the

cam

upper

cam

5-15).

One

the

major

empty

shaft

of

the

be

of

the

the

dog

and

contact,

not

impeded

of a rigid

moves

tums.

Its

position

the

spring

shaft

piston

is

depression

depression.

bag

is

in

empty

disassembled

empty

point

to

the

verify

wire

with

The

is

contact

(see

Figure

is

the

designed

contacts

contact

bag

bag

set

screw

rear

of

that

by

dried

contact

the

spring

calibrated

metering

with

is

must

with

contacts

(see

contacts

the

upper

contact

once

4-3).

two

more

The

other

touch

the

Section

located

cam.

and

cam.

is

the

a

so

is

on

Calibrate

©

Turn

and

e

Connect

and

e

Manually

Upper

held

metering

@

Adjust

perform

Empty

filled,

of

level

(the

handle).

flow

these

for

clockwise.

Hf

lower

inches

flow

mL.

position

pump

connector

pin 6 of

piston

inward

dog

bag

non-checkvalve

999

mL/h

in

the

top

of

The

above

conditions,

less

sensitivity

the

pump

the

above

above

of

spring

off

and

partially

P102

an

ohmmeter

connector

rotate

cam

is

spring

so

that

cam

during

point

set

as

specified

calibration

(99.9

mL/h

bag

at 6

5/8

the

pump

is

pump

should

pump”

the

empty

by

runs

for 6 mL

solution

top

pump”

level

of

Micro

contact

on

I/O

board.

between

P102

shaft

while

loaded

its

shaft

maintains

rotation.

screw

until

on

Figure

should

be

set

and

on

Micro

inches

defined

run

alarm.

bag

tuming

the

under

to 2 5/8

3100).

alarm

as

follows:

disconnect

TP8

(pin L is

to

5.15.

tested

operating

wire

(ground

at

observing

out

position.

contact

empty

bag

by

the

3100),

above

the

top

as

the

flat

area

for 6 mL

If

contact

inches

before

without a “No

an

alarm

should

dogpoint

the

above

above

You

should

the

pump

assembly

potential)

top).

ohmmeter.

It

must

be

with

contacts

installing a fluid

pump

at a rate

with

the

fluid

of

the

pump

below

the

occurs

under

be

adjusted

set

screw

conditions,

the

pump

(3/8

get a “No

infuses

3

Empty

when

bag

upper

A=

contacts

piston

shaft

Major

Depression

MUST

touch

is

here.

Metering

Cam

Figure

Related

as

Empty

when

5-15

Empty

to

bag

contacts

upper

B = Minor

Contacts

Bag

piston

MUST

shaft

is

here.

Depression

NOT

touch

yi

-

5-22

(494)

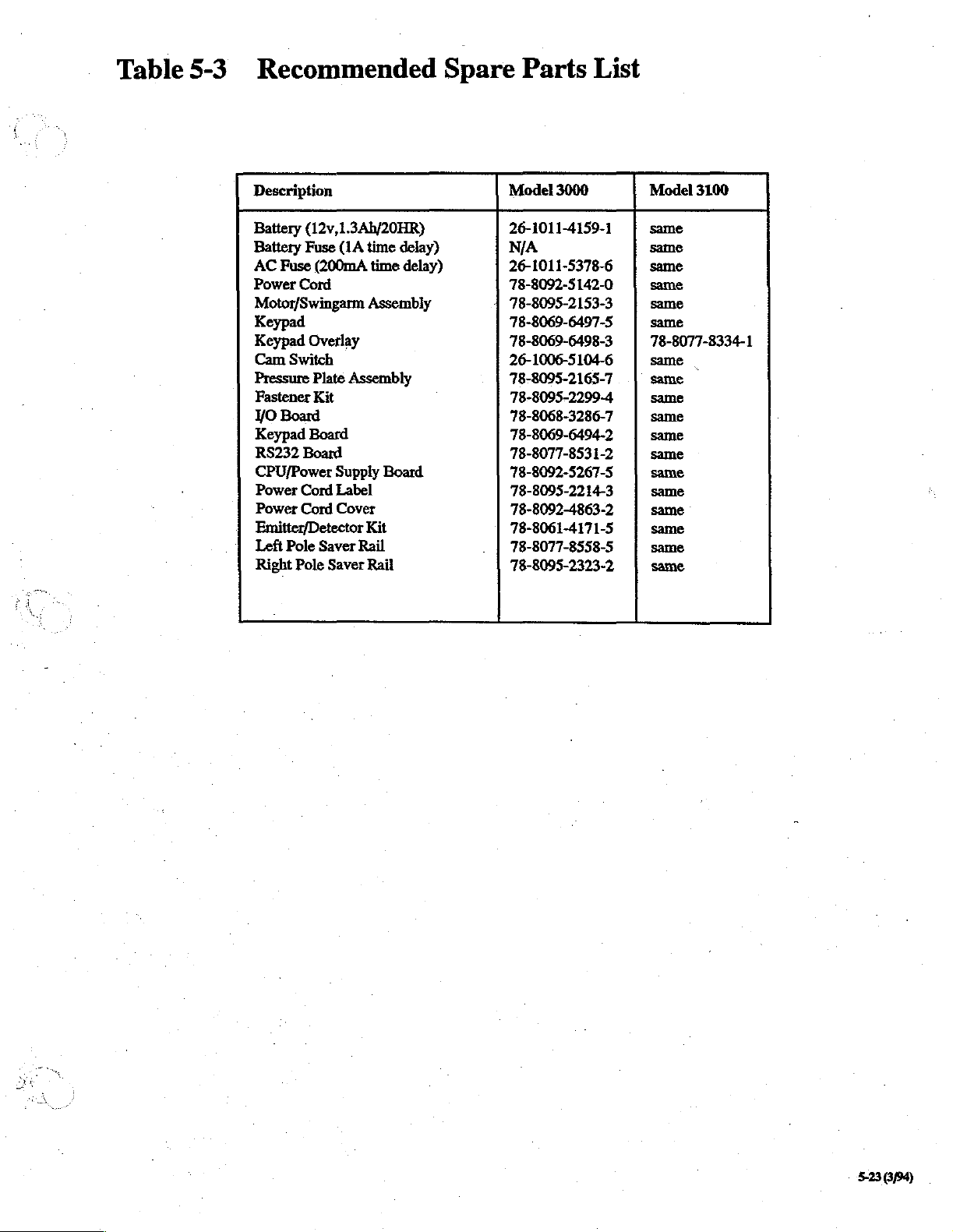

Table

5-3

Recommended

Description

Battery

Battery

AC

Power

Motor/Swingarm

Keypad

Keypad

Cam

Pressure

Fastener

YO

Keypad

RS232

CPU/Power

Power

Power

Emitter/Detector

Left

Right

(12v,1.3Ah/20HR)

Fuse

(1A

Fuse

(200mA

Cord

Overlay

Switch

Plate

Assembiy

Kit

Board

Board

Board

Supply

Cord

Label

Cord

Cover

Pole

Saver

Rail

Pole

Saver

time delay)

time

delay)

Assembly

Board

Kit

Rail

Spare

Model

26-1011-4159-1

N/A

26-1011-5378-6

78-8092-5142-0

78-8095-2153-3

78-8069-6497-5

78-8069-6498-3

26-1006-5104-6

78-8095-2165-7

78-8095-2299-4

78-8068-3286-7

78-8069-6494-2

78-8077-8531-2

78-8092-5267-5

78-8095-2214-3

78-8092-4863-2

78-8061-4171-5

78-8077-8558-5

78-8095-2323-2

Parts

3000

List

Model

3100

same

same

same

same

same

same

78-8077-8334-1

same

|

same

same

same

same

same

same

same

same

same

same

same

5-23

8/94)

This

Page

Intentionally

Left

Blank

5-24(3/94)

Section

6:

Parts

Lists

and

Diagrams

Model

3000

and

Micro

3100

6.1

The

structural

Volumetric

are

(see

NOTE

Pump

may

and any

mailed

products.

CAUTION

Because

Micro

mount

recommended.

Mechanical

following

parts

Infusion

available

Section

be

from

5.1).

specifications

changed

instructions

to

you

the

3100

Infusion

technology,

tables

of

the

Pumps.

3M

without

as

required

circuit

boards

component

and

and

figures

3M

Model

Current

Infusion

and

parts

notice.

required

for

used

Pumps

Structural

identify

3000

Therapy

of

for

proper

are

level

mechanical

and

parts

Customer

the

3M

Updated

this

manual

service

in

the

Model

primarily

repair

Parts

Micro

3100

aid

price

infusion

tables,

will

of

these

3000

surface

is

not

and

lists

Service

pumps

figures,

be

and

61604

Table

o

6-1

Reference

From

Figure

2

3

4

5

7

15

24

33

Designation

6-1

1

6

8

9

10

il

12

13

14

16

17

18

19

20

21

2

23

25

26

27

28

29

30

31

32

34

Pump

Description

Cassette

Cassette

Emitter/Detector

Clip

Cassette

E-Ring

Modified

Link - Short

Ribbon

Cable

Tapered

Double

Valve/Piston

Empty

Assembly

Housing

Washer - Nylon

Guide

Shaft

(1/8")

Link - Long

Cable

Clamp

Cam

Back

Foam

Cam

Housing

Coil

Flat

Washer

C-Ring

(1/16)

Spring

Bag

Contact

Empty

Bag

Contact

Bearing

Spacer

Molded

Special

YO

Switch

Snap Switch

Pivot

Switch

Spring

Flat

Modified

Shaft/Molded

Empty

Optical

Flange

Ring

Cam

#10

Board

Wiring

Plate

Link

Assembly

Bracket

Valve

Assembly

Shaft/Molded

Bag

Filter

Assembly

Flat

Spring

Assembly

Assembly

Guide

Shaft

Tape

Spring

Washer

Harness

Clip

Piston

Assembly

Piston

Parts

Model

3000

78-8092-4839-2

26-1011-4189-8

78-8061-4171-5———

78-8077-8384-6

78-8077-8284-8

NA

78-8092-4970-5

78-8077-8278-0

N/A N/A

N/A

78-8077-8274-9

78-8005-3202-6

78-8077-8275-6

78-8061-4232-5

N/A

N/A

78-8637-2811-6

78-8061-4230-9

78-8061-4225-9

78-8077-8347-3

78-8079-5879-4

‘78-8079-5989-1

78-8079-6410-7

78-8092-0789-3

78-8095-2289-5

26-1006-5104-6

78-8092-4995-2

78-8095-2212-7

78-8003-8346-1

78-8092-4945-7

78-8092-4855-8

78-8079-6005-5

78-8061-4288-7

78-8079-5958-6

Micro

3100

same

same

|-

same

same

same

N/A

same

same

N/A

same

same

same

same

N/A

N/A

same

same

same

same

same

same

same

same

same

same

same

same

same

same

same

зате

same

same

6-2

м.

(394)

Loading...

Loading...