3M FSCWS034ME-CAB Installation Manual

INSTALLATION AND OPERATING

MODELS:

FSCWS034ME-CAB

FSCWS075ME-CAB

INSTRUCTIONS

FSCWSME-CAB SERIES

WATER SOFTENERS

IN338 0807

Installer, please leave with owner.

a 3M company

SAFETY INFORMATION

CAUTION

WARNING

CAUTION

IMPORTANT NOTES

WARNING

CAUTION

Read, understand, and follow all safety information contained in these instructions prior to installation and use of the CUNO

Foodservice FSCWSME-CAB Series Water Softeners. Retain these instructions for future reference.

Intended use:

The CUNO Foodservice FSCWSME-CAB Series Water Softeners are intended for use in reducing hardness in water and have not

been evaluated for other uses. The system is intended for indoor installations near the entry point of a water line, and must be installed by qualifi ed professional installers according to these installation instructions.

EXPLANATION OF SIGNAL WORD CONSEQUENCES

WARNING

CAUTION

Indicates a potentially hazardous situation, which, if not avoided, could result in death or serious

injury and/or property damage.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate

injury and/or property damage.

CAUTION

To reduce the risk associated with ingestion of contaminants:

• Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the

system.

To reduce the risk associated with hazardous voltage:

• If the electrical system requires use of the cold water system as an electrical safety ground, a jumper must be used to ensure

a suffi cient ground connection across the softener installation piping — refer installation to qualifi ed personnel.

• Do not use the Water Softener if the wall-mounted power supply is damaged — contact qualifi ed service personnel

for repair.

To reduce the risk associated with back strain:

• Follow safe lifting procedures.

To reduce the risk associated with property damage due to water leakage:

• Read and follow Use Instructions before installation and use of this system;

• Installation must comply with existing state or local plumbing codes;

• Protect from freezing. Drain system when temperatures drop below 40°F (4.4°C);

• Do not install if water pressure exceeds 100 psi (689 kPa). If the system water pressure exceeds 100 psi, the installation must

use a pressure limiting valve. Contact a licensed plumbing professional if you are uncertain how to check your water pressure;

• Do not install system where water lines could be subjected to vacuum conditions without appropriate measures for vacuum

prevention;

• The system must be installed on cold water lines only, maximum temperature 100°F (38°C);

• When water supply is shut off, shut off fuel or electric power to water heater;

• Do not use torches or other heat sources near plastic plumbing, as damage may occur;

• Take care when using pliers or pipe wrenches to tighten plastic fi ttings, as damage may occur;

• On plastic fi ttings, use thread sealing tape only. Never use pipe sealant or pipe dope on plastic fi ttings, as damage may occur;

• Do not install this system in direct sunlight or outdoors without protection from precipitation.

To reduce the risk associated with property damage due to plugged water lines:

• Pay particular attention to correct orientation of control valve. Water fl ow should match arrow on control valve. The Inlet and

Outlet of other water treatment equipment products will vary depending on the control valve brand used.

Indicates a potentially hazardous situation, which, if not avoided, may result in property damage.

WARNING

CAUTION

IMPORTANT NOTES

• Failure to follow instructions may result in water leakage and will void warranty.

TABLE OF CONTENTS

IMPORTANT NOTES

SECTION DESCRIPTION

1 BEFORE INSTALLATION

2 INSTALLATION

3 CONTROL VALVE PROGRAMMING & REGENERATION

4 MAINTENANCE

5 UNIT & CONTROL VALVE SERVICE & TROUBLESHOOTING

6 SPECIFICATIONS & OPERATING DATA

7 PARTS

8 LIMITED WARRANTY

SECTION 1: BEFORE INSTALLATION

Congratulations! We believe your purchase of this water softener will prove to be a very wise choice. When properly installed, your new

softener will provide many years of virtually trouble-free service. Before starting the installation we suggest you read this manual all the

way through for an overview, and then follow the installation in proper sequence.

INSPECTING AND HANDLING YOUR SOFTENER:

Inspect the equipment for shipping damage. If damaged, notify the transportation company and request a damage inspection.

Handle the equipment with care. Damage can result if dropped or if the softener is set on sharp, uneven projections on the fl oor. When

handling, do not turn the water softener unit upside down.

MAKE SURE YOUR WATER HAS BEEN THOROUGHLY TESTED:

An analysis of your water should be made prior to the selection of your water conditioning equipment. Your dealer will generally perform

this service for you, and may send a sample to the factory for analysis and recommendations. Enter your analysis below for a permanent

record.

IMPORTANT NOTES

Softeners are designed to remove hardness but can handle reasonable amounts of soluble iron if consideration is given to content when

selecting model and regeneration settings. To treat sulfur (hydrogen sulfi de), bacterial iron, precipitated iron or very high levels of soluble

iron requires special equipment in addition to a water softener. For best results, a Chem-Free Iron Reduction Filter is recommended for

use on waters containing more than 2 ppm of iron.

Analysis Of Your Water

CONTAMINANT YOUR WATER

Hardness ___________gpg

Iron (Fe) ___________ppm

Manganese (Mn) ___________ppm

pH ___________

Tannins (Humic Acid) ___________ppm

Hydrogen Sulfi de (H

Other____________________ ___________ppm

Other____________________ ___________ppm

S) ___________ppm

2

1-1

Check Your Water Pressure:

CAUTION

IMPORTANT NOTE

CAUTION

Water pressure must be checked carefully to avoid unsatisfactory operation or equipment damage:

• MINIMUM water pressure required at the water softener inlet is 20 psi (137.9 kPa). IF WATER PRESSURE IS OVER 100 PSI (689 kPa),

A PRESSURE REDUCING VALVE MUST BE INSTALLED IN THE WATER SUPPLY LINE AHEAD OF THE WATER SOFTENER.

CAUTION

Do not install if water pressure exceeds 100 psi (689 kPa). If the system water pressure exceeds 100 psi, the installation must use a

pressure limiting valve. Contact a licensed plumbing professional if you are uncertain how to check your water pressure.

Do not install system where water lines could be subjected to vacuum conditions without appropriate measures for vacuum prevention.

IMPORTANT NOTE

If you have a municipal or a community water supply and daytime water pressure is 85 psi (586 kPa) or more, nighttime pressure may

exceed 100 psi (689 kPa). Call your local water department or plant operator to obtain pressure readings. Record your water pressure

data below:

Water Pressure:

Low psi High psi

Locate Water Conditioning Equipment Correctly:

Select the location of your water softener with care. Various conditions which contribute to proper location are as follows:

1) Locate as close as possible to water supply source.

2) Locate as close as possible to a drain.

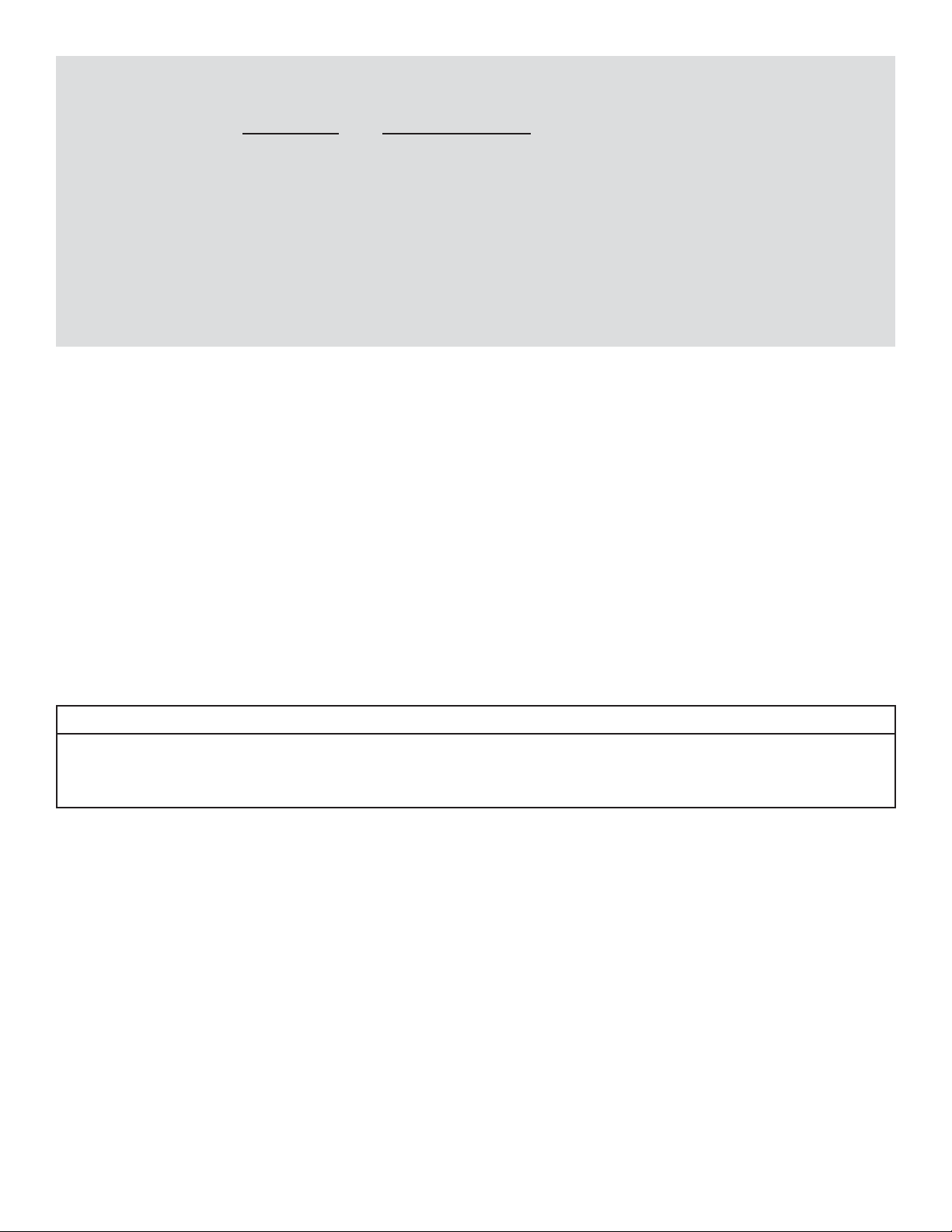

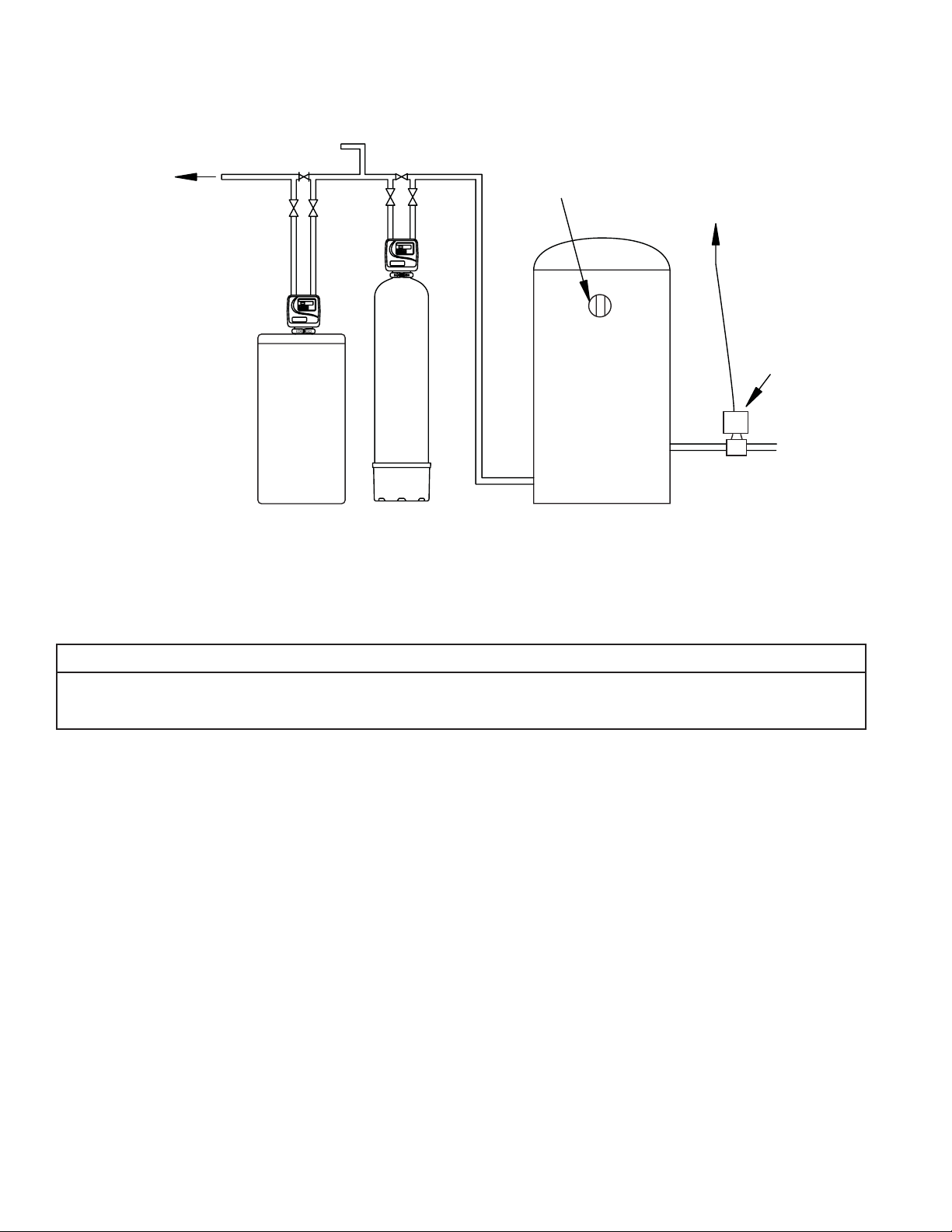

3) Locate in correct relationship to other water conditioning equipment (Figure 1).

4) Locate the softener in the supply line BEFORE the water heater. Temperatures above 100°F (38°C) will damage the softener and

void the warranty.

CAUTION

To reduce the risk associated with property damage due to water leakage:

• The system must be installed on cold water lines only, maximum temperature 100°F (38°C).

• Do not install this system in direct sunlight or outdoors without protection from precipitation.

5) DO NOT install the softener in a location where freezing temperatures occur. Freezing may cause permanent damage and will also

void the warranty.

6) Allow suffi cient space around the installation for easy servicing.

7) Provide a non-switched 110V, 60Hz (220V, 50Hz for specifi ed systems) power source for the control valve.

WARNING

To reduce the risk associated with ingestion of contaminants:

• Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

1-2

Facts to Remember While Planning Your Installation:

WARNING

CAUTION

IMPORTANT NOTE

WARNING

To reduce the risk associated with hazardous voltage:

If the electrical system requires use of the cold water system as an electrical safety ground, a jumper must be used to ensure a

suffi cient ground connection across the softener installation piping — refer installation to qualifi ed personnel.

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Installation must comply with existing state or local plumbing codes.

• Do not install if water pressure exceeds 100 psi (689 kPa). If the system water pressure exceeds 100 psi, the installation

must use a pressure limiting valve. Contact a licensed plumbing professional if you are uncertain how to check your water

pressure.

• Do not install system where water lines could be subjected to vacuum conditions without appropriate measures for vacuum

prevention.

• Do not use torches or other heat sources near plastic plumbing, as damage may occur.

• Take care when using pliers or pipe wrenches to tighten plastic fi ttings, as damage may occur.

• On plastic fi ttings, use thread sealing tape only. Never use pipe sealant or pipe dope on plastic fi ttings, as damage may occur.

To reduce the risk associated with property damage due to plugged water lines:

• Pay particular attention to correct orientation of control valve. Water fl ow should match arrow on control valve. The Inlet and

Outlet of other water treatment equipment products will vary depending on the control valve brand used.

If lawn sprinkling, a swimming pool, geothermal heating/cooling or water for other devices/activities are to be treated by the softener,

a larger model softener MUST be selected to accommodate the higher demands of these items. Consult your dealer for alternative

instructions if the pumping rate is insuffi cient.

Remember that the valve INLET is attached to the pipe that supplies water (i.e. runs to the pump) and OUTLET is the line that runs

toward the water heater or other water treatment equipment device.

Before commencing the installation, it is advisable to study the existing piping system and to determine the size, number and type of

fi ttings required. Typical system schematics shown in Figure 1 will be of assistance.

IMPORTANT NOTE

Sodium Information: Water softeners utilizing sodium chloride for regeneration add sodium to the softened water. Persons who

are on sodium restricted diets should consider the added sodium as part of their overall sodium intake. As a reference as to how

much sodium is added to softened water consider the following. For each grain per gallon of water hardness that is exchanged

from the water supply, 7.5 milligrams per liter of sodium will be added to the softened water. e.g. 10 grains per gallon (gpg) exchanged will add 75 milligrams of sodium to the softened water.

1-3

SECTION 2: INSTALLATION

CAUTION

FILTERED WATER

FILTERED

SOFT WATER

SOFTENER

AIR RELIEF VALVE

PRESSURE

FILTER

Figure 1. Installation Schematic

TANK

TO PUMP

CONTROLLER

PRESSURE

SWITCH

RAW

WATER

CAUTION

To reduce the risk associated with property damage due to plugged water lines:

• Pay particular attention to correct orientation of control valve. Water fl ow should match arrow on control valve. The Inlet and

Outlet of other water treatment equipment products will vary depending on the control valve brand used.

2-1

SECTION 2: INSTALLATION

WARNING

CAUTION

CAUTION

WARNING

Step 1

Remove the unit from the shipping box and remove all packaging. Ensure no freight damage has occurred since shipment from our

manufacturing facility. Locate the parts package and install the bypass and adapter fi ttings on the control valve to facilitate the connection to the customer’s water supply.

WARNING

To reduce the risk associated with ingestion of contaminants:

• Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before or after the

system.

Step 2

Verify all packaging materials have been removed.

Step 3

Shut off all water at main supply valve. Make certain pressure is relieved from the complete system by opening nearest faucet to drain

system.

CAUTION

To reduce the risk associated with property damage due to water leakage:

• When water supply is shut off, shut off fuel or electric power to water heater.

Step 4

Cut main supply line as required to fi t plumbing to INLET and OUTLET of unit.

Step 5

Attach plumbing. DO NOT apply heat to any fi tting connected to BYPASS or CONTROL VALVE as damage may result to internal

parts or connecting adapters. MAKE CERTAIN WATER FLOW ENTERS THROUGH INLET AND DISCHARGES THROUGH OUTLET.

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Do not use torches or other heat sources near plastic plumbing, as damage may occur.

• On plastic fi ttings, use thread sealing tape only. Never use pipe sealant or pipe dope on plastic fi ttings, as damage may occur.

To reduce the risk associated with property damage due to plugged water lines:

• Pay particular attention to correct orientation of control valve. Water fl ow should match arrow on control valve. The Inlet and

Outlet of other water treatment equipment products will vary depending on the control valve brand used.

WARNING

To reduce the risk associated with hazardous voltage:

• If the electrical system requires use of the cold water system as an electrical safety ground, a jumper must be used to ensure

a suffi cient ground connection across the softener installation piping — refer installation to qualifi ed personnel.

• Do not use the Water Softener if the wall-mounted power supply is damaged — contact qualifi ed service personnel

for repair.

Step 6

The controls allow for either a 3/4” NPT connection or 5/8” poly tubing for use as a drain line connection.

2-2

CAUTION

CAUTION

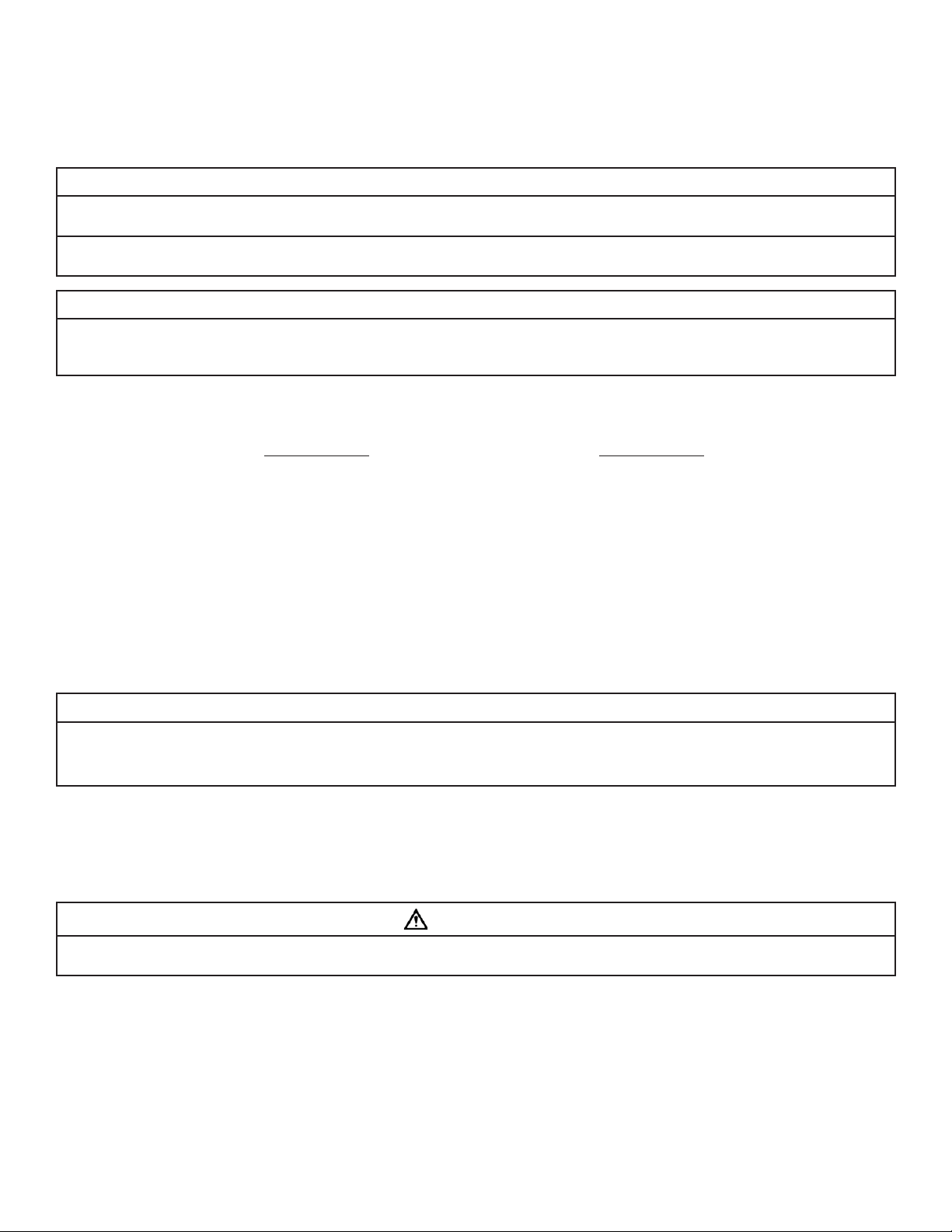

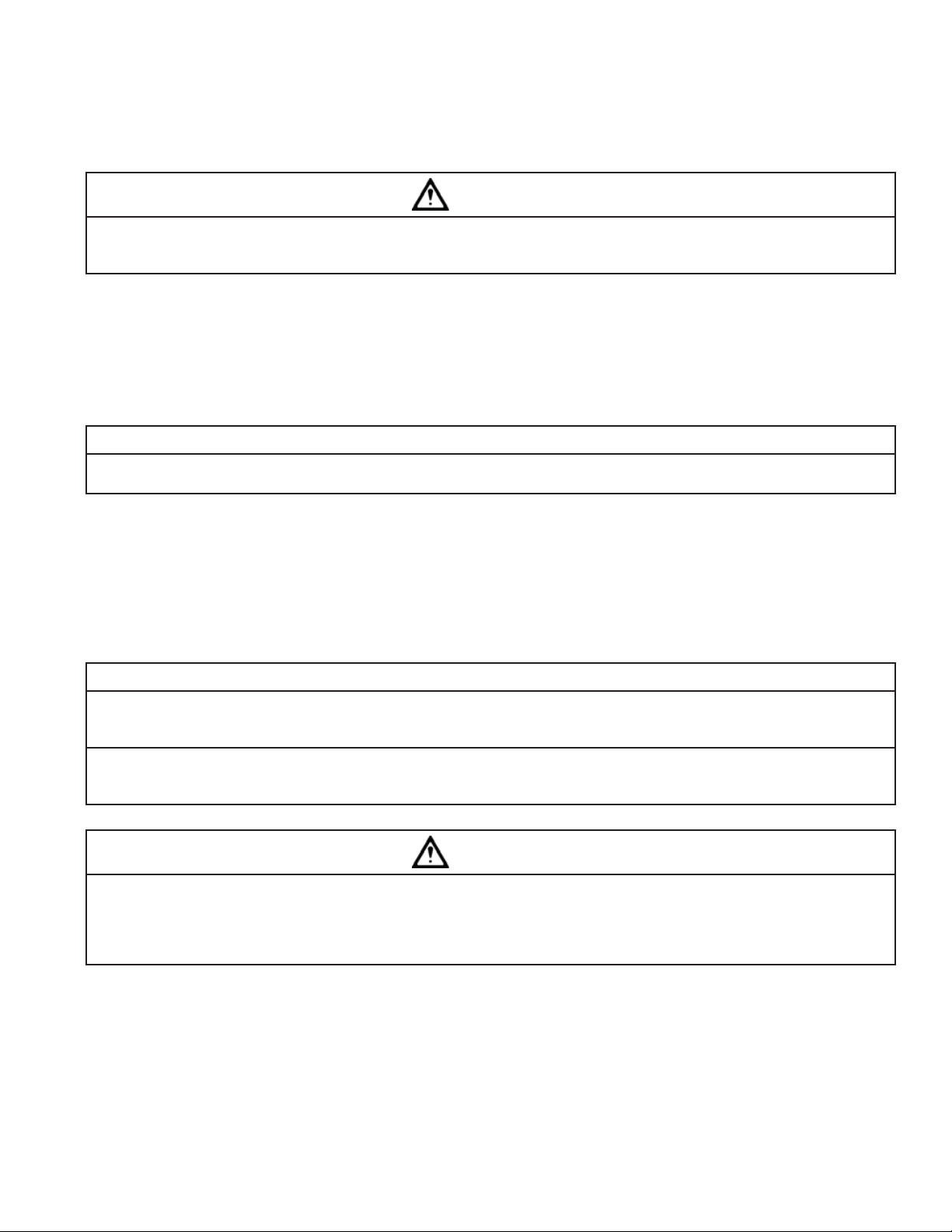

BRINE LINE

ELBOW

DRAIN LINE FLOW

CONTROL ASSEMBLY

SALT LID

INOUT

BYPASS VALVE

INJECTOR COVER

CONTROL VALVE BODY

BRINE LINE

BRINE

WELL

OVERFLOW

FITTING

SAFETY BRINE

VALVE

Treated

Water

(Untreated)

Water Exits

NORMAL

OPERATION

Exits

BYPASS

OPERATION

Supply

Figure 2. Softener, Top View

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Take care when using pliers or pipe wrenches to tighten plastic fi ttings, as damage may occur.

• On plastic fi ttings, use thread sealing tape only. Never use pipe sealant or pipe dope on plastic fi ttings, as damage may occur.

Supply

Water

Enters

Supply

Water

Enters

Step 7

Attach DRAIN LINE to DRAIN LINE FITTING. To prevent back pressure from reducing fl ow rate below minimum required for backwash,

DRAIN LINE MUST be sized according to run length and relative height. Be careful not to bend fl exible drain tubing sharply enough to

cause “kinking” (if kinking occurs DRAIN LINE MUST BE REPLACED). Typical examples of proper DRAIN LINE diameters are:

a) 1/2” ID lengths up to 15 feet and heighs lower or slightly higher than the control

valve.

b) 5/8” ID length up to 25 feet in length and up to 4 feet above the control valve.

c) For distances higher or longer than previously stated, relocated the softener closer

to the desired discharge point or consult factory for advice. Avoid overhead drain

lines as it may prevent desirable performance.

Some areas prohibit the use of fl exible drain lines. Check with local code offi cials prior

to installation.

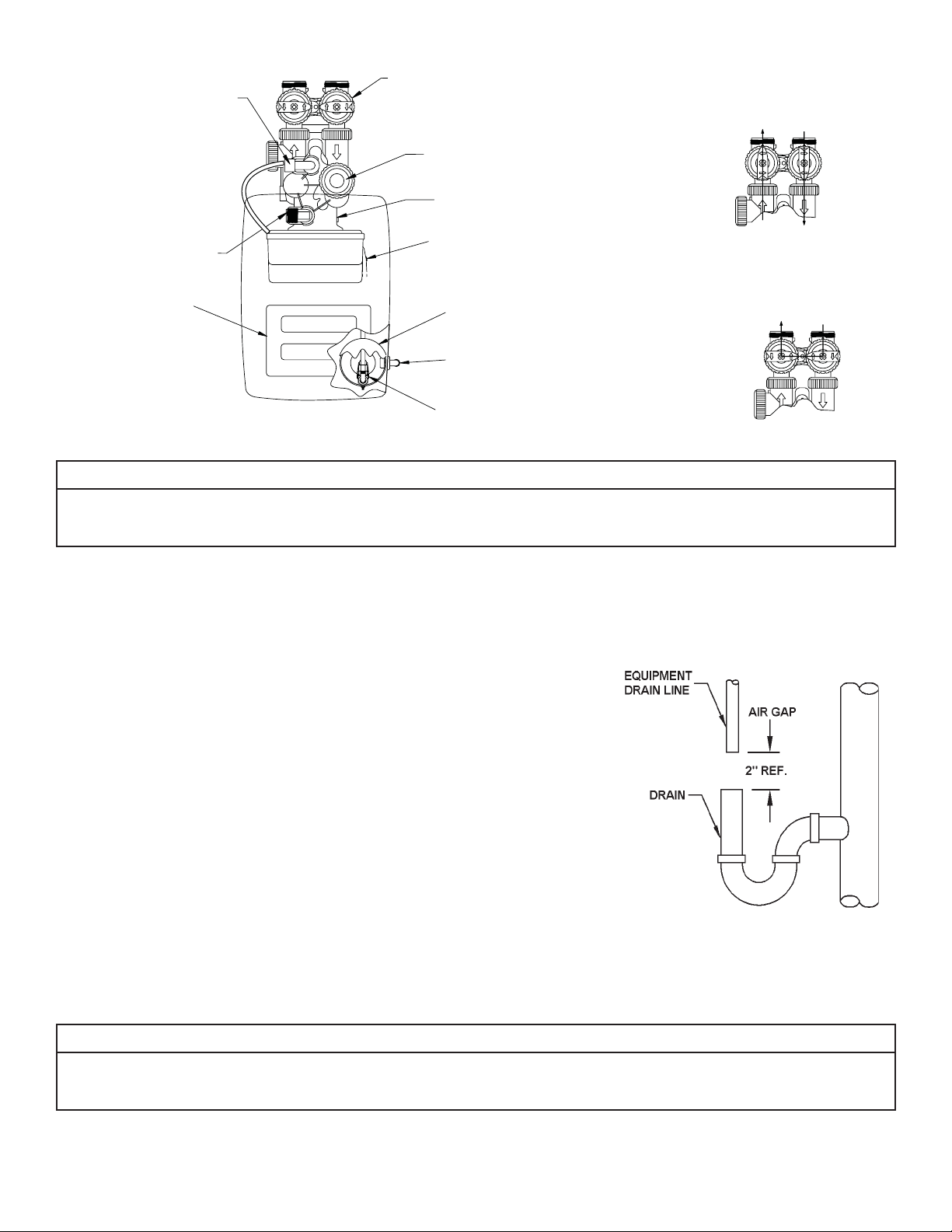

Step 8

Position DRAIN LINE over drain and secure fi rmly. To prevent backsiphoning of sewer

water, provide an air-gap of at least 2” or 2 pipe diameters between end of drain hose and

drain (Figure 3). DO NOT raise DRAIN LINE more than 10 ft. above fl oor.

Step 9

Connect one end of the 3/8” black Polyethylene tubing to the brine fi tting located on the

left side of the CONTROL VALVE. Connect the other end to the SAFETY BRINE VALVE ELBOW inside of the brine well in the brine tank.

To do so remove the retaining clip from the brine line fi tting on the control valve. The retaining clip is holding a plastic insert sleeve and

needs to be inserted into the polyethylene tubing before installing the tubing into the fi tting elbow. Hand tighten only.

Figure 3. Drain

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Take care when using pliers or pipe wrenches to tighten plastic fi ttings, as damage may occur.

• On plastic fi ttings, use thread sealing tape only. Never use pipe sealant or pipe dope on plastic fi ttings, as damage may occur.

Step 10

Install OVERFLOW LINE to brine tank OVERFLOW FITTING (Figure 2). Discharge of line must be lower than OVERFLOW FITTING. DO

NOT INTERCONNECT OVERFLOW LINE WITH VALVE DRAIN LINE.

2-3

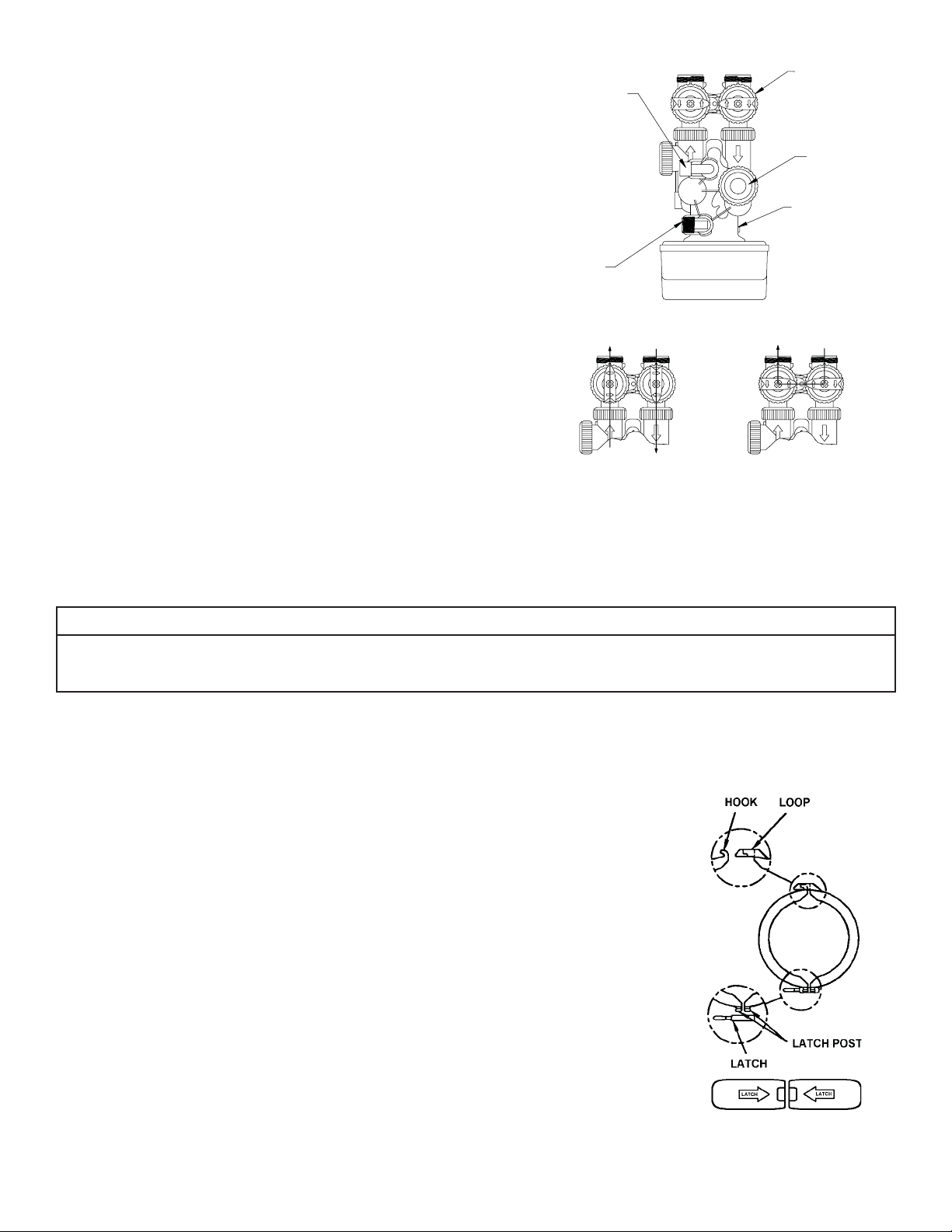

Step 11

IMPORTANT NOTE

Make certain BYPASS VALVE INLET and OUTLET KNOBS ARE IN

“BYPASS” position. After all plumbing connections have been completed, open main water shut-off valve. Check for leaks and correct as

necessary.

Step 12

Plug CONTROL VALVE POWER CORD into 120v/60Hz, non-switched

power source and set the time of day (See Set Time of Day on Page 3-

5). Manually stage control to BACKWASH POSITION and then unplug

power cord to prevent the unit from advancing automatically (see Manual

Regeneration on Page 3-5).

Step 13

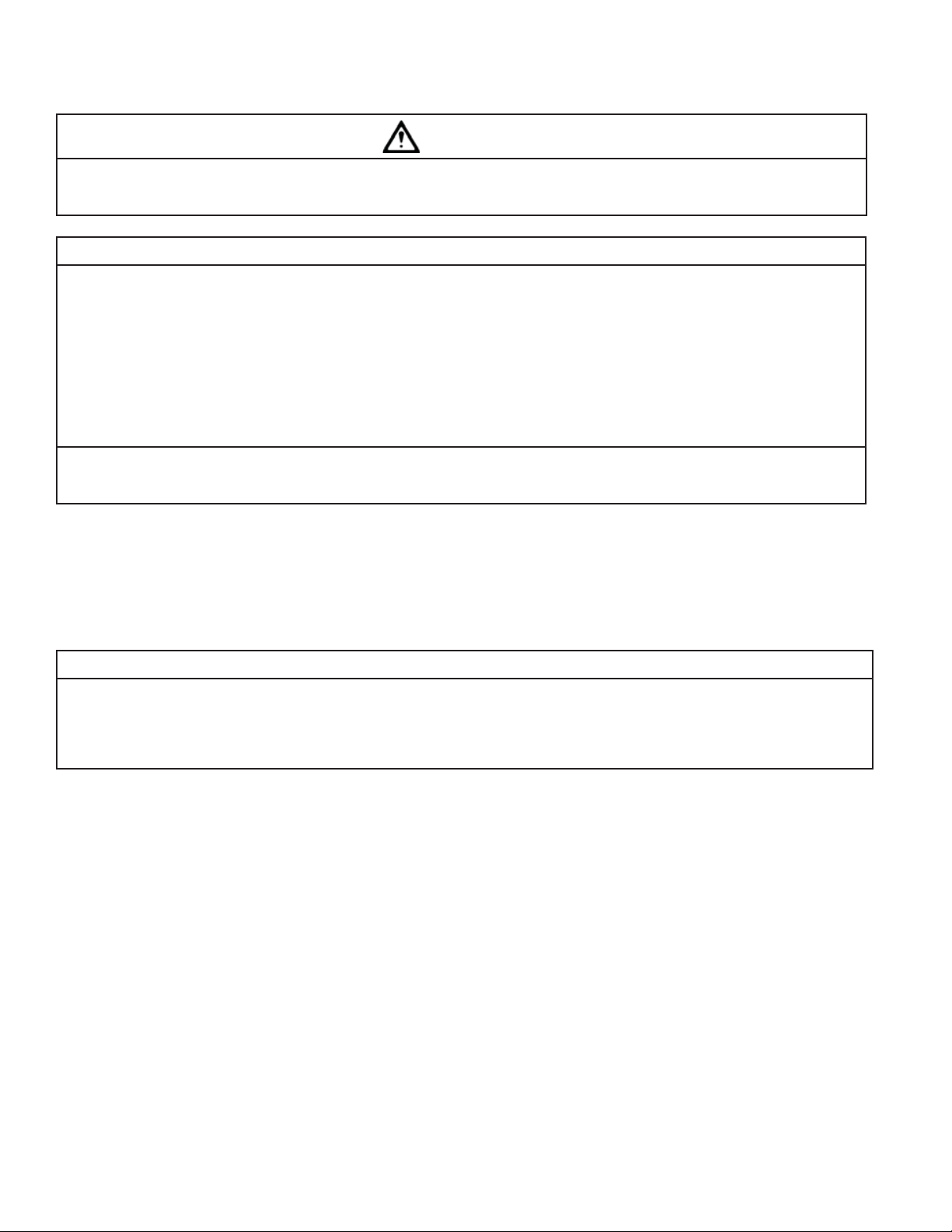

Partially open INLET knob on bypass valve (Figure 4). This will allow

the unit to fi ll slowly from the bottom up, reducing air entrapment. Allow

unit to fi ll slowly, failure to do so could result in loss of resin to the drain.

Once a steady stream of water, no air, is fl owing to drain the inlet and

outlet knobs on the bypass can be fully opened.

Step14

Plug the power cord back into the power source. Press the REGEN button and wait for the valve to advance to the next regeneration position.

Repeat the process until the valve is in Service Position (Time will be

on the display).

BRINE LINE

DRAIN LINE FLOW

CONTROL ASSEMBL

Treated Water

OUT

ELBOW

Y

NORMAL OPERATION BYPASS OPERATION

Exits

OFF

OFF

Supply Water

Enters

OFF

OFF

OFF

OFF

IN

OFF

OFF

Supply (Untreated)

Water Exits

BYPASS VALVE

INJECTOR COVER

CONTROL VALVE BO

OFF

OFF

OFF

Figure 4. BYPASS VALVE

Supply Water

Enters

OFF

DY

Step 15

Refer to Section 3: Control Valve Programming and Regeneration, on how to set control valve for proper set up and regeneration

settings.

IMPORTANT NOTE

Regeneration settings for the control valve are factory preset. The control valve design permits adjustment of the salt setting. This

adjustment may be necessary when unusual operating conditions exist, such as high concentrations of iron, manganese or hardness

and/or high fl ow rates or daily water consumption or California required salt effi ciency is desired.

SPECIAL SERVICE INSTRUCTIONS (FSCWS075ME-CAB Only):

Under normal circumstances removal of valve should not be required. However, if it must be

removed, it can be done by disassembling the quick release clamp, and latch. Pressure should

be relieved before attempting any disassembly. Upon reassembly, all o-rings should be lubricated

with silicone grease. Reassemble clamp as shown in Figure 5. MAKE SURE ARROWS ON

LATCHSIDE OF CLAMP ARE ALIGNED.

2-4

Figure 5. CLAMP ASSEMBLY

Loading...

Loading...