Page 1

Installation Addendum

For ET 355 Monitor HL

About this addendum

This document supplements information in the ET 350

Monitor User’s Installat ion Gui de with detail s that pe rtain

to the 3M Dynapro

Important

If there appears to be a conf lict between information in the ET

350 Moni tor User’s Install ation Guide and this Installation

Addendum: ET 355 Industrial Monitor HL (for hazardous

locations), this addendum takes precedence.

If there appears to be a conf lict between inf ormation in this

addend um and the Installation Addendum for the ET 350 Monitor

with Hea ter and ET 355 Mo ni tor HL w ith He ate r, the latter tak es

precedence.

Translations of intended use and product safety information

Translations of intended use and product safety

information are at the end of this document (starting on

page 8). Defin itions of saf ety symbo ls tha t are use d on t he

ET 355 Monitor HL are on page 4 in English and other

languages.

Intended Use

The ET 355 Monitor HL (hereafter, ET 355 monitor) is

intended to provi de touch screen functions for ind ustrial

applicati ons in hazardous locat ions when the monitor is

connected to a host computer.

The ET 355 monitor is suitable for use in non-hazardous

locations and also in the following types of hazardous

locations. Using the monitor in locations other than these

will invalidate the warranty and will be sol ely the user’s

risk and responsibility:

Class I, Division 2, Groups A, B, C, and D hazardous locations;

temperature code T6 (less than or equal to 85°C).

volatile flammabl e liquids or flammable gases or vapors

exist, but are normally confined within closed containers;

TM

ET 355 Monitor HL.

Where:

ignitable conc entrations of gases , vapors or liquids are

normally prevented by positive mechanica l ventilation;

adjacent to a Class I, Divisi on 1 loc ation , where i gnit able

concentrati ons might be occasionally communicated.

Class II, Division 2, Groups F and G hazardous locati ons;

temper ature code T6 (less than or equal to 85°C)

combustible dust is not normally in the air in ignitable

. Where:

concentrations;

dust accumulat ions are normally insuf f icient to interf ere

with normal operation of electrical equipment;

dust may be in suspension in the air as the result of

infrequent malfunctioning of equipment; or

dust accumulation may be sufficient to interfere with safe

dissipation of hea t or may be ignitable by abnormal

operation.

Important

For more detailed definitions of hazardous locations, refer to the

UL

web site <http://www.ul.com>.

Important

The ET 355 monitor HL is a component. Af ter the monitor is

installed in a hazardous location for which it is certified, the whole

system or end product of which it is a part must be inspected to

confirm seal ratings and complianc e with all electrical codes. If

your ET 35 5 moni t or H L come s w ith th e KVM exte nd er opti on , it

is not ne cessary to have the KVM local unit evaluat ed since the

local unit is not to be situated in a hazardous location.

Wiring methods must be in accordance with Class I,

Division 2 wiring methods, Article 501-4(b) of the

National Electric Code, NFPA 70 for installations in the

U.S. , or as s p ecified in Sec tion 18- 1 J 2 of th e Cana di a n

Electrical Code for installations within Canada and in

accordance with the authority having juris diction.

Accessory connections must be evaluat ed in the end

application (i.e. nonincendive circuits).

Read and understand all safety information before installing and using this product.

3M Touch Systems Proprietary Information

1

Page 2

Installation Addendum

Product safety information

DANGER

To reduce the risks associated with fire and explosion which, if not

avoided, will cause death or serious injury and/or property damage:

Do not open the ET unit (or hatch, if applicable) while the circuit is live

unless the area is known to be non-hazardous.

Do not use an external keyboard or mouse unless the area is known to be

non-hazardous.

Do not operate the ET unit’s OSD switches, DIP switch, KVM extender

remote board, or potentiometer on the KVM extender remote board unless

the area is known to be non-hazardous.

Do not disconnect equipment unless power has been switched off or the

area is known to be non-hazardous.

Do not replace the fuse unless the power has been disconnected and the

area is known to be non-hazardous.

Do not use the ET unit in Class I, Division 1; Zone 0; or Zone 1 hazardous

locations.

WARNING

To reduce the risks associated with electrical shock, fire, or

explosion which, if not avoided, could result in de ath or serious

injury and/or property damage:

Follow all product and accessory installation instructions, including

instructions for mounting the unit with a NEMA 4X panel gasket (ships with

all ET 355 monitors) and instructions that accompany the NEMA 4X hatch

kit.

The procedures described in this document should be performed only by

trained personnel. Failure to perform all operations correctly could

damage the unit and invalidate the warranty.

For servicing or other procedures not described in this document, in the

ET 350 Monitor User’s Installation Guide, or in other ET 35X instructions,

return the ET unit to 3M Touch Systems for servicing.

Read and understand all safety information before installing and using the

ET unit.

Engineer the installation of the ET unit to take into account the operating

environment (e.g., hazardous location, shock/vibration factors).

Properly install the ET unit with a NEMA 4X gasket that is clean,

undamaged, and effective.

Do not modify the ET unit.

Do not substitute components. Substitution of components may impair

suitability for a Class I, Division 2; Class II, Division 2; or Zone 2 hazardous

location.

When replacing a fuse or other part, use a part of the type and rating

specified by 3M Touch Systems.

Provide a clean, reliable ground.

Use locking devices on connectors.

To ensure compliance with electrical codes and safe operation of the

monitor, have a licensed journeyman electrician familiar with local codes

perform all wiring and installation tasks.

When connecting power with fixed field wiring in the NEMA 4X hatch, the

field wiring must be double insulated. A clear, flexible insulator (supplied)

must cover the portion of the cable that is not double insulated when

connecting to a terminal strip connector.

After making an opening in the NEMA 4X hatch, make sure that there are

no metal shavings in the hatch.

When installing the ET unit, ensure that specifications for supply circuit

overcurrent protection and wiring are not exceeded.

Choose listed (UL) conduit hub or Notified Body Certified gland rated

NEMA 4X/IP66 that is suitable for use in hazardous locations, and provide

adequate strain relief for wiring.

Properly install the ET unit so that it is environmentally sealed to the

NEMA 4X/IP66 standard. Do not use the ET unit with mounting options

that are not rated for NEMA 4X/IP66 in environments that require such a

seal. Use the NEMA 4X hatch with ET 35X monitors with heater.

If a KVM extender is used with the ET unit, the KVM local unit should be

located in an area known to be non-hazardous.

Do not use flammable or combustible cleaners on or near the ET unit.

WARNING

To reduce the risks associated with electrical shock or fire which, if

not avoided, could result in death or serious injury and/or property

damage:

If the ET unit is mounted using a NEMA 4X panel gasket, install the unit in

a Listed (UL) enclosure.

If the ET unit will be used in corrosive environments, it is the responsibility

of the user to test and evaluate the unit in those environments. The

monitor, as shipped, has not been evaluated for use in excessively

corrosive environments. Using it in such environments, without evaluation

and testing, may lead to unsafe conditions.

WARNING

To reduce the risks associated with electric shock and/or burnrelated injury that could result in death or serious injury and/or

property damage:

Avoid contact with connectors on power terminal strip unless the power

has been disconnected.

Avoid exposed electrical contacts inside the ET unit.

WARNING

To reduce the risks associated with electrical shock which, if not

avoided, could result in death or serious injury and/or property

damage:

Make sure that the ground potential difference between the ET unit and

the host computer is less than 2V.

Before removing the ET unit from its mounting or performing any other

service to the monitor, disconnect power to the unit.

Provide adequate strain relief for all field wiring in accordance with Class

I, Division 2 wiring methods Article 501-4(b) of the National Electric Code,

NFPA 70 for installations in the U.S., or as specified in Section 18-1J2 of

the Canadian Electrical Code for installations within Canada and in

accordance with the authority having jurisdiction.

WARNING

To reduce the risks associated with electrical shock or mechanical

function whi ch, i f no t avoi ded, c ould res ult in dea th or s er ious i njur y

and/or proper ty damage:

Apply a “safe touch” setting, especially if the ET unit is running an

application or is in a setting where safety is a concern.

Do not use a non-Windows operating system screen saver that may affect

the “safe touch” setting and could in turn cause connected peripheral

equipment to start or stop inadvertently.

Set the safe touch setting correctly, with the number of minutes entered

for the Windows operating system’s energy saver being at least one

minute greater than the time entered for the Windows operating system

screen saver.

If your ET unit has a display power management system (DPMS) that is

configurable from the display’s on-screen Utility menu, do not turn off the

DPMS.

WARNING

To reduce the risks associated with electric shock and/or burnrelated injury that could result in death or serious injury and/or

property damage:

Do not open the power supply in the ET unit. It contains hazardous

voltage/hazardous energy. The power supply has no user-serviceable

parts or adjustments inside.

WARNING

To reduce the risks associated with mechanical function which, if not

avoided, could result in property dama ge:

Do not operate the ET unit in conditions outside of the operational

specifications.

3M Touch Systems Proprietary Information

2

Page 3

WARNING

To reduce the risks associated with skin contact or swallowing of

cleaning soluti ons or fluids which, if not avoided, may result in minor

or moderate injury and/or cause property damage:

Refer to the cleaner manufacturer’s material safety data sheet (MSDS)

and follow all instructions and recommendations.

CAUTION

To reduce the risks associated with muscle strain which, if not

avoided, may result in minor or moderate injury:

Avoid using the ET unit for long periods of time without breaks.

CAUTION

To reduce the risks associated with eye strain which, if not avoided,

may result in minor or moderate injury:

Use the ET unit where there is neither too much ambient light nor glare on

the screen.

CAUTION

To reduce the risks associated with environmental contamination

which, if not avoided, may result in minor or moderate injury and/or

cause property damage:

Dispose of the ET unit according to applicable governmental regulations.

3M Dynapro ET 355 Monitor HL

3M Touch Systems Proprietary Information

3

Page 4

Installation Addendum

Safety labels

The following safety symbols are used on the exterior and

interior of the 3M Dynapro

Symbol Meaning

Consult user instructions.

Consulter le mode d'emploi.

Consulte las instrucciones para el usuario.

Raadpleeg de instructies voor de gebruiker.

Benutzeranweisungen beachten.

Consultare le istruzioni per l'utente.

Обратиться к инструкциям для

пользователя.

參照使用者明。

Caution: Risk of electric shock.

Mise en garde : risque de décharges

électriques.

Precaución: Riesgo de descarga eléctrica.

Let op: Risico van elektrische schokken.

Vorsicht: Elektroschock-Gefahr.

Avvertenza: rischio di scosse elettriche.

Внимание! Опасность поражения

электрическим током.

小心:電擊危險。

Lifting hazard.

Risque associé au levage.

Cancelación del peligro

Gevaarlijk om op te tillen

Gefahr des Überhebens

adottate le necessarie misure di protezione.

Опасность при подъеме

提升危險

TM

ET 355 Monitor HL:

Symbol Meaning

Caution: Item is susceptible to electrostatic

discharge (ESD) damage if proper precautions

are not taken.

Mise en garde : à défaut de prendre des

mesures de précaution appropriées, le produit

risque de subir des dommages par suite de

décharges électrostatiques.

Precaución: El artículo es susceptible a daños

por descargas electrostáticas (ESD) si no se

toman las precauciones debidas.

Let op: Het item is gevoelig voor beschadiging

door elektrostatische ontlading (ESD) als er

geen goede voorzorgsmaatregelen worden

genomen.

Vorsicht: Das Gerät kann durch

elektrostatische Entladungen (ESD) Schaden

nehmen, wenn keine geeigneten

Vorsichtsmaßnahmen getroffen werden.

Avvertenza: il componente può essere

danneggiato dalle scariche elettrostatiche

(ESD) nel caso in cui non vengano adottate le

necessarie misure di protezione.

Внимание! Объект подвержен повреждению

электростатическим разрядом, если не

предпринять соответствующих мер

предосторожности.

小心:若不采取適當預防措施則易於

受到靜電釋放(ESD)損壞。

3M Touch Systems Proprietary Information

4

Page 5

3M Dynapro ET 355 Monitor HL

Instruct ions for installin g th e ET 355 monitor

User’s Installation Guide

This document is an addendum to the ET 350 Monitor

User’s Installation Guide. It is not m eant to stand alone.

For a summary of to pics covered in the Installation Guide

and this Addendum, see Table A:

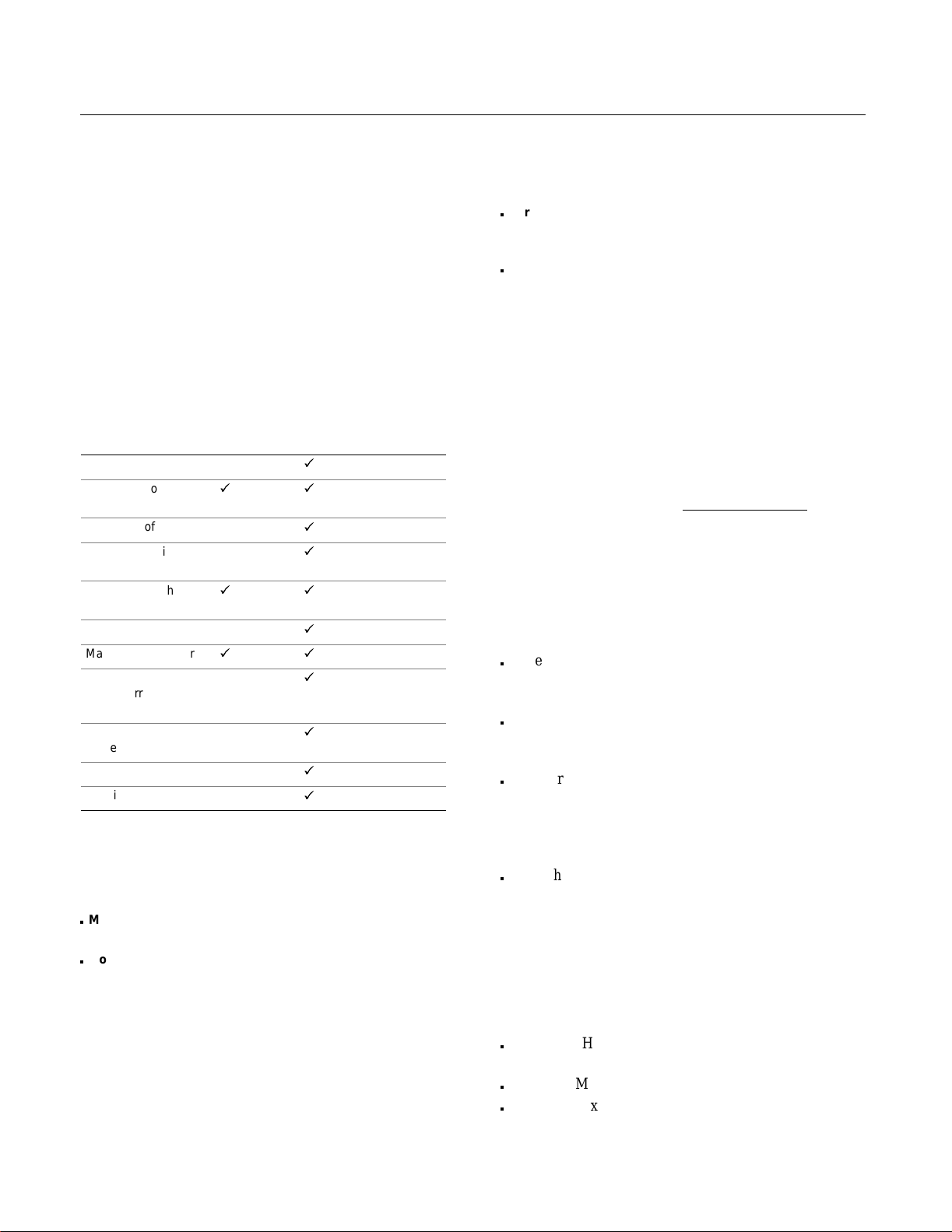

T able A: T opics covered in ET 350 User’s Installation

Guide and those covered in this Addendum

Topic This

document

Connec t in g ca bl es

Adjusting monitor

display settings

Installing software

Installing monitor with

KVM extender

Setting backlights

saver and “safe touch”

Checking gaskets

Maint aining monitor

Replacing a

TouchSurround

graphic underlay

Troubleshooting

strategies

Connector pin-outs

Specifications

Mounting instructions

There are also doc uments available to as s ist you in

mounting ET 35X monitors with heater:

Mountin g usi ng a NEMA 4X pa nel gasket: Install ing the

NEMA 4X Panel Gask et. Shi ps with al l E T 35X mon it ors.

Mount i ng us ing a N E MA 4X h at c h: Insta lli ng t he NEMA 4X

Hatch. Ships with all ET 35X monitors with heater.

Software guides

The ET 350 Monitor User’s Installation Guide explains

how to install touch screen software that will run with

operating sy st em s supported by ET 35X monitors with

heater.

ET 350 Monitor

User’s Installation

Guide

For information on how to customize the software, refer to

one of the following software guides:

For Windows XP Professional and Windows 2000

Profess iona l ope rati ng sy ste ms :

MicroTouch NFI

Software Guide for WindowsXP and Windows 2000

For Windows NT 4.0, Windows 98, and Windows 95

operating systems:

Configuration Utilities User’s Guide

Information online

The ET 350 Monitor User’s Installation Guide and the

NEM A 4X Pane l G asket instructions for the ET 355

monitor accompany all ET 355 monitors.

Installing the NEMA 4X Hatch for the ET 355 monitor

ships with all units that are ordered with the optional hatch

kit.

All of these documents and the software guides are

available for download from www.3Mtouch.com

.

Guideli n e s fo r ma intain ing t he ET 355 Monitor HL

To minimize factors that might cause the monitor to

malfunction, follow these guidelines for performing

regular preven tive maintenance:

To reduce the risk of electromagnetic interferenc e, do not

place electrical noise-generating equipment near the

monitor.

Check all connections regularly, especially in

environments wher e shock and/ or vi bration might lo osen

connections.

The more rugged the environment in which the unit is

located, the more freque ntly preventive maintenance

should be pe rform ed. For example, if the monitor is used

in a wet location, it should be maintai ned more often than

if it is located in a dry, cle an area.

Clean the front of the touch screen with a mild windowcleaning solution or other cleaner that will not leave

residue on the screen or corr ode it. Be careful not to

scratch the surface of the screen.

Options

Options availa ble from 3M T ouch Systems for use with th e

ET 355 monitor are:

NEMA 4X Hatch (comes with instructions for ins talling

in ET 355 monitor)

Single KVM extender

Dual KVM extender

3M Touch Systems Proprietary Information

5

Page 6

Moisture deflector

25-foot serial/VGA cables

50-foot serial/VGA cables

Security hardware (including security screws)

Note: A NEMA 4X panel gasket mounting kit ships with

all ET 355 monitors.

For details on the options, re f er to the ET 350 Monitor

User’s Installation Guide.

Important

All options, including VGA and serial cables, must be

considered in the end product.

Wiring methods must be considered in the end product.

Consid er con du ctin g a he at in g test in t he end pr o duc t of whi ch

the ET 355 monitor is a part.

Specifications,certifications, and standards

The specific ati on and certification information below

shows only points that apply to the ET 355 monitor and is

different from s pecifications and certifications that appear

in the ET 350 Monitor User’s Insta llation Guide and the

Installatio n Addendu m for the E T 350 Monit or with Heater

and ET 355 Monitor HL with Heater.

For additional details on specifi cations, standards, and

certificati ons, refer to the ET 350 Monitor User’s

Installatio n Guide and, if you have an ET 35X monit or with

heater, th e Ins tallation Addendum for the ET 350 Monit or

with Heater and ET 355 Monitor HL wit h Heater.

Installation Addendum

Marks for ET 355 Monitor HL with DC Power Supply

UL Recognized component

cUL

CE

Class I Division 2; Groups A, B, C, D; T6

Class II Division 2; Groups F, G; T6

Class I Zone 2

Ex II 3 G/D

DEMKO 02 ATEX 021046 U; EEx nC IIC

1

Standards

UL reco gnized component1 for Pollution Degree 3

environments if:

installed and tested with panel gasket in an e nclosure that

meets NEMA 4X/IP66 ratings;

installed with the NEMA 4X hatch kit

UL 60950; Safety Information Technology Equipment

CSA 22.2 No. 60950; Safe ty of Information Technology

Equipment

EN60950; Safety of Information Technology Equipment

USR (U.S. Recognized) — UL 60950

UL 160 4: El ectr ica l Equi pmen t f or Us e in Class I a nd II , Div isio n

2 and Class III Hazar dous (Classified) Locations.

CSA 22.2 No. 213-M1987: Non-Incendive Electrical

Equipment for Use in Class I, Division 2 Hazar dous Locations.

UL 2279, Pt. 15; Standard for Ele c trical Equipment for Use in

Class I, Zone 0, 1, and 2 Hazardous (Classified) Locations

CSA-E79-15; Electrical Apparatus for Explosive Gas

Atmospheres

EN50021; Electrical Apparatus for Potentially Explosive

Atmospheres

EN50281; Electrical Apparatus for Use in the Presence of

Combustible Dust

1

For use in Pollution Degree 3 environments if installed with the

NEMA 4X hatch kit or the NEMA 4X pa nel gasket in a UL Listed

enclos ure that meets NEMA 4X/IP66 rating.

AC or DC power supply specifications

Power source: 3 terminal strip

Certification marks and standards for ET 355 Monitor HL

Marks for ET 355 Monitor HL with AC Power Supply

UL reco gnized component1

cUL

CE

Class I Division 2; Groups A, B, C, D; T6

Class II Division 2; Groups F, G; T6

3M Touch Systems Proprietary Information

3M Touch Systems support services

3M Touch Systems provides extensive support s ervices

through our web site and technical support organization.

Visit www.3Mtouch.com

software and drivers, obtain regularly updated technical

documentation on 3M Touch Systems products, and le arn

more about our company.

Whenever you contact Technical Support, pleas e provide

the following information:

Part number and serial number

Current driver version

6

, to download touch screen

Page 7

Operating system and applications being run

Information on peripherals and installed cards

Customer and technical support for

3M Dynapro products

3M Dynapro ET 355 Monitor HL

Returning products

All returned 3M DynaproTM industrial products must be

accompanied by a Return Authorization number. Fo r

details, contact Customer Service at 3M Touch Systems.

Technical Su pport for 3M DynaproTM products i s avai lable

Monday through Friday from 7:30 a.m. to 4:00 p.m.,

Pacif i c Time. To contact cus t o mer service and tec h ni cal

support for 3M Dynapro products, refer to the following

table:

Area Contact information

USA and Canada General information

Tel 800-667-03 74 (toll free)*

Fax 604-521-4629

E-mail etsales@mmm.com

Web site www.3Mtouch.com

Custom er se r vic e

Tel 800-667-03 74 (toll free)*

Fax 604-521-4629

E-mail 3MTScustomerservic e@mmm.com

Technical service

Tel 800-667-03 74 (toll free)*

Fax 604-521-4629

E-mail 3Mdynaprotechsupport@mmm.com

Outside USA and

Canada

*Call be tw ee n 7:30 a.m. and 4:0 0 p. m., Pacifi c Time

General information

Tel 604-521-3962*

Fax 604-521-4629

E-mail etsales@mmm.com

Custom er se r vic e

Tel 800-667-0374*

Fax 604-521-4629

E-mail 3MTScustomerservic e@mmm.com

Technical service

Tel 604-521-3962*

Fax 604-521-4629

E-mail 3Mdynaprotechsupport@mmm. com

3M Touch Systems Worldwide Offices

All offices can be reac hed through the web site:

www.3Mtouch.com

Country Telephone

United States 978-659 - 90 00

Australia +61 39 5-82-47 99

Canada 604-521-3962

France +33 (1) 45-13-90-30

Germany +49 (0) 21 1-59907-0

Hong Kong/China (852) 2333-6138

Italy +39 (0) 39-230-2230

Japan +81 (4) 4811-1133

Korea +822 552 3198

Singapore +65-96279173

Spain +34 934-15-6285

T aiwan +886-2-2704-9011

.

3M Touch Systems Proprietary Information

7

Page 8

Intended Use and Produc t Safety Information French

Utilisation

Le monit

eur HL ET 355 ( ci-aprè s désign é par moni teur ET 35 5) est con çu

pour offrir des fonctions à l'écran pour les applications industrielles

installées dans des locaux dan ger eux, lorsque le moni teur est connecté à

un ordinate ur hôte.

L

’utilisation du monit eur ET 355 est indiquée pour les locaux nondangereux, ainsi que pour les types de locaux dangereux répertoriés cidessous.

L’utilisation du moniteur dans des locaux autres que ceux-ci annule

la garantie

propres risques et périls

et engage uniquement la responsabilité de l’utilisateur, à ses

:

Endroits à risque de catégorie I, division 2, groupes A, B, C, et

D; code de temp érat ure T6 (égal e ou in féri eure à 85°C ( 185°F) ),

où :

il existe des liquides, gaz ou vapeurs inflammables volatiles, mais ceuxci sont généralement confinés dans des récipients scellés;

les concentrations de gaz, vapeurs ou liquides inflammabl es s ont

généralement éliminées par une ventilation mécanique positive;

ils sont adjacents à un endroit de catégorie I, division 1, où les

concentrati ons inflammables peuvent être occasionnellement

transmises.

Endroits à risque de catégorie II, division 2, groupes F et G;

code de te mpér atur e T6 (éga le ou inféri eure à 85 °C (18 5°F )), où

les concen trations de pous sière com bustibl e se tro uvant dan s l'ai r ne sont

pas normalement inflammables;

les accumula ti ons de poussièr e s ont généralement insuffisantes pour

nuire au fonctionnement nor m al de l'équipem ent électrique;

la poussière peut demeurer en s us pension dans l'air suite au mauvais

fonctionnement occasionnel de l'équipement ; ou

l'accumulation de poussière peut être suffis ante pour nuire à la

dissipati on s écuritaire de la chaleur ou peut être rendue inflammable

suite à une anoma lie.

Important

Pour de plus amples définitions des endroits à risque, consulter le site Web

de UL <http://www.ul.com>.

Important

Le moniteur HL ET 355 est un composant. Après l’installation du terminal

dans un endroit à risque pour lequel il a été homologué (voir "Endroits à

risque"), il faut procéder à la vérification de l’ensemble du système dont il

fait partie afin d’en certifier l’étanchéité nominale et la conformité aux codes

locaux de l’électricité. Si le moniteur HL ET 355 est doté d’une carte

d’extension KVM optionnelle, il n'est pas nécessaire de procéder à la

vérification de l'appareil local KVM car celui-ci ne sera pas installé dans un

endroit à risque.

Les méthodes d e câbl age du moni teur H L ET 35 5 ave c élément ch auffan t

doive nt être co nformes au x méthod es de câ blage de ca t é g or ie I, divis ion

2, article 501-4(b) du National Electric Code, NFPA 70, pour les

installations effectuées aux États-Unis, ou tel que spécifié à l'article 181J2 du Code é lectrique cana dien pour les installations eff ectuées au

Canada et con fo rmément aux autorités ayant juridiction.

Les raccords accessoires doivent êtr e évalués dan s l'application finale (c .à.-d., circuits ininflammables).

Consignes de sécurité du produit

DANGER

Pour réduire les risques d’explosion et d’incendie susceptibles, faute

de précaution, de causer la mort, des blessures graves et/ou des

dommages matériels :

Ne pas ouvrir le terminal ET (ou le trappe, s'il y a lieu) pendant que le circuit

est sous tension à moins que l'endroit ait été jugé sécuritaire.

Ne pas utiliser de clavier ou de souris externe à moins que l'endroit ait été

jugé sécuritaire.

Ne pas faire fonctionner les commutateurs OSD, les commutateurs DIP, la

carte d’extension à distance KVM ou le potentiomètre sur la carte

d’extension à distance KVM à moins que l'endroit ait été jugé sécuritaire.

Ne pas débrancher l'équipement à moins que la tension n'ait été coupée

ou que l'endroit ait été jugé sécuritaire.

Ne pas remplacer le fusible à moins que la tension n'ait été coupée et que

l'endroit ait été jugé sécuritaire.

Ne pas utiliser l'appareil ET dans un endroit à risque de catégorie I,

division 1, zone 0 ou zone 1.

AVERTISSEMENT

Pour réduire les risques de décharges électriques, d’explosion et

d’incendie susceptibles, faute de précaution, de causer la mort, des

blessures graves et/ou des dommages matériels :

Suivre toutes les consignes d'installation des accessoires et du produit, y

compris le mode d'assemblage de l'appareil avec un joint NEMA 4X

(expédié avec tous les moniteurs ET 355) et toutes les consignes

accompagnant la trappe NEMA 4X (nécessaire d'assemblage optionnel)

pour le moniteur ET 355.

Les procédures décrites dans ce document doivent être réalisées par un

technicien agréé. Toute opération effectuée de façon inadéquate pourrait

endommager l'appareil et annuler la garantie.

Pour tout entretien ou toute procédure qui n'est pas décrite dans ce

document, dans le Guide d'installation du moniteur ET 350, ou dans les

autres consignes ET 35X, retourner l'appareil à 3M Touch Systems.

AVERTISSEMENT

Pour réduire les risques de décharges électriques, d’explosion et

d’incendie susceptibles, faute de précaution, de causer la mort, des

blessures graves et/ou des dommages matériels :

Lire et comprendre toutes les consignes de sécurité avant d'installer et

d'utiliser le moniteur ET.

Superviser l'installation du moniteur ET en tenant compte du milieu de

service (ex., endroit à risque, exposition aux chocs et aux vibrations).

Installer solidement le moniteur ET avec un joint NEMA 4X propre, intact et

fonctionnel.

Ne pas modifier le moniteur ET.

Ne pas remplacer de composants car cela pourrait nuire à l'applicabilité

dans un endroit à risque de catégorie I, division 2; catégorie II, division 2;

ou zone 2.

Pour remplacer un fusible ou un autre composant, utiliser une pièce de

rechange de type et de capacité nominale prescrits par 3M Touch Systems.

Fournir une mise à la terre fiable et propre.

Utiliser des dispositifs de verrouillage sur les connecteurs.

Pour s’assurer du fonctionnement sécuritaire du terminal ET et de sa

conformité aux codes de l’électricité, demander à un électricien compétent

agréé familier avec les codes locaux et fédéraux d’en effectuer le câblage.

Lors du branchement à l’alimentation dans la trappe NEMA 4X au moyen

d’un dispositif de câblage à champ en zone fixe, le câble d’alimentation

doit comporter une double gaine isolante. Un isolant transparent et flexible

(fourni) doit recouvrir la portion du câble ne comportant pas de double

gaine isolante lors du branchement à un connecteur de bornier.

AVERTISSEMENT

Pour réduire les risques de décharges électriques, d’explosion et

d’incendie susceptibles, faute de précaution, de causer la mort, des

blessures graves et/ou des dommages matériels :

Après avoir ouvert la trappe NEMA 4X, s'assurer qu'il n'y a pas d'ébarbage

dans celle-ci.

Lors de l’installation du terminal ET, veiller à ne pas dépasser les normes

de câblage et de protection contre les surcharges du circuit d’alimentation.

Choisir une entrée de conduit ou un fouloir certifié compatible avec la

norme NEMA 4X/IP66 susceptible d'être utilisée dans un endroit à risque

et utiliser un réducteur de tension adéquat pour le câblage.

Procéder à l'installation adéquate du terminal ET de façon à ce que le joint

soit conforme à la norme NEMA 4X/IP66. Ne pas utiliser un terminal ET

avec des options d'assemblage incompatibles avec la norme NEMA

4X/IP66 dans un milieu de service nécessitant l’emploi d’un joint conforme

à cette norme. Utiliser la trappe NEMA 4X avec les moniteurs ET 35X avec

élément chauffant.

AVERTISSEMENT

Pour réduire les risques d’explosion et d’incendi e susceptibles, faute

de précaution, de causer la mort, des blessures graves et/ou des

dommages matériels :

Si une carte KVM est utilisée avec le terminal ET, l'appareil local KVM ne

doit pas se trouver dans un endroit à risque.

Ne pas utiliser de produits de nettoyage inflammables ou combustibles sur

le terminal ET ou à proximité de celui-ci.

AVERTISSEMENT

Pour réduire l es risques de décharges électriques ou d’incendie

susceptibles, faute de précaution, de causer la mort, des blessures

graves et/ou des dommages matériels :

Si le terminal ET a été assemblé à l'aide d'un joint NEMA 4X, installer le

terminal dans un endroit homologué UL.

3M Touch Systems Proprietary Information

8

Page 9

Intended Use and Produc t Safety Information French

Si le terminal ET doit servir dans une atmosphère corrosive, il incombe à

l’utilisateur de le mettre à l’essai et d’en évaluer l’efficacité dans un tel

milieu. Le terminal ET d’origine n’a pas fait l’objet d’une mise à l’essai en

atmosphère corrosive et son emploi dans un tel milieu, sans évaluation ou

essai préalable, risque de le rendre non sécuritaire.

AVERTISSEMENT

Pour réduire les risques d’électrocution et/ou de blessure par brûlure,

pouvant entr aîner des dommages matéri

mort :

Évitez tout contact avec les barrettes d’alimentation des connecteurs

lorsque le courant électrique n’est pas déconnecté.

Évitez tout contact avec les raccordements électriques non-isolés à

l’intérieur de l’unité ET.

AVERTISSEMENT

Pour réduire les risques de décharges électriques susceptibles, faute

de précaution, de causer la mort, des blessures graves et/ou des

dommages matériels :

Veiller à ce que la tension de masse entre le terminal ET et l’ordinateur hôte

soit inférieure à 2 volts.

Couper l’alimentation du terminal ET avant de le détacher de son dispositif

de montage ou d’y effectuer une réparation quelconque.

Fournir un réducteur de tension adéquat pour le câblage d'alimentation

conforme aux méthodes de câblage de catégorie I, division 2, article 5014(b) du National Electric Code, NFPA 70, pour les installations effectuées

aux États-Unis, ou tel que spécifié à l'article 18-1J2 du Code électrique

canadien pour les installations effectuées au Canada et conformément aux

autorités ayant juridiction.

AVERTISSEMENT

Pour réduire les risques de décharges électriques ou de problème

mécanique susceptibles, faute de précaution, de causer la mort, des

blessures graves et/ou des dommages matériels :

Sélect ionn er un régl age "sa fe t ouc h", surt ou t si le term ina l ET ou l'or di nat eu r hô te

exécute une application ou si le réglage de la sécurité est en question.

Utiliser seulement un économiseur d'écran pour système d'exploitation

Windows qui ne pourrait pas affecter le réglage "safe touch" et faire

démarrer et stopper les périphériques qui y sont branchés par

inadvertance.

Régler correctement les paramètres "safe touch" où le nombre de minutes

entrées pour l'économiseur d'énergie du système d'exploitation Windows

doit être au moins une minute de plus que le temps entré pour

l'économiseur d'écran du système d'exploitation Windows.

Si votre unité ET est équipée d’un système DPMS ( Display Power

Management System, Système de gestion d’

configurable à partir du menu Utilitaires, ne désactivez pas le DPMS.

AVERTISSEMENT

Pour réduire les risques de problème mécanique susceptibles, faute de

précaution, de causer des dommages matériels :

Ne pas faire fonctionner le moniteur ET 350 avec élément chauffant ou le

moniteur HL ET 355 avec élément chauffant dans des conditions

différentes de celles qui sont spécifiées.

AVERTISSEMENT

Pour réduire les risques de décharges électriques ou de brûlures

susceptibles, faute de précaution, de causer la mort, des blessures

graves et/ou des dommages matériels :

Ne pas ouvrir le bloc d'alimentation du moniteur ET 350 car il comporte des

tensions dangereuses. Le bloc d'alimentation ne renferme aucune pièce ni

aucun dispositif de réglage remplaçable par l'utilisateur.

AVERTISSEMENT

Pour réduire les risques de contact avec la peau ou d'absorption de

solutions de nettoyage susceptibles, faute de précaution, de causer

des blessures mineures ou modérées :

Consulter la fiche technique des substances dangereuses (FTSS) émise

par le fabricant du produit de nettoyage et suivre toutes les consignes et

recommandations.

AVERTISSEMENT

Pour réduire les risques de problème mécanique susceptibles, faute de

précaution, de causer la mort, des blessures graves et/ou des

dommages matériels :

Ne pas faire fonctionner le terminal ET 350 dans des conditions différentes

de celles qui sont spécifiées.

MISE EN GARDE

Pour réduire les risques de tension musculaire susceptibles, faute de

précaution, de causer des blessures légères ou modérées :

Éviter d’utiliser le terminal ET pendant de longues périodes de temps sans

pause.

els et/ou corporels graves ou la

alimentation de l

’écran)

MISE EN GARDE

Pour réduire les risques de fatigue oculaire susceptibles, faute de

précaution, de causer des blessures légères ou modérées :

Utiliser le terminal ET là où la lumière ambiante ne produit aucun effet

d’éblouissement à l’écran.

MISE EN GARDE

Pour réduire les risques de contamination environnementale

susceptibles, faute de précaution, de causer des blessures légères ou

modérées ou des dommages matériels :

Mettre le terminal ET au rebut en suivant les règles gouvernementales en

vigueur.

3M Touch Systems Proprietary Information

9

Page 10

Intended Use and Produc t Safety Information Spanish

Uso

El monitor HL ET 355 (d e aquí en adel ante, mo nitor ET 355 ) fue diseña do

para prop orcionar funci ones de pantalla táctil al conectarse a una

computadora host en un entorno industrial que no presente riesgo alguno.

El monitor ET 355 puede utilizarse en lu

gares qu e no so n pe ligro sos y

también en los siguientes tipos de lugares peligrosos.

El uso del monitor en otros lugares que no s ean estos, anulará la garantía

y el equi po corre r á po r cu e nta y ries g o de l us u a r io:

Lugares peligrosos Clase I, División 2, Grupos A, B, C, y D;

código de temperatura T6 (menor o igual a 85° C). Condiciones:

hay presencia de líquidos, gases o vapores inflamables

volátiles pero por lo general están almacenados en contenedores

cerrados;

se evita las concentraciones de gases, vapores o líquidos inflamables

mediante ventilación mecánica positiva;

contiguo a u n lugar Cl ase I, Di visión 1 e n donde ocas ional mente podr ían

comunicarse co ncentraciones inflamables.

Lugares peligrosos Clase II, División 2, Grupos F y G; código

de temperatura T6 (menor o igual a 85° C). Condiciones:

por lo general no existen concentraciones inflamables de polvo

combustibl e en el aire;

las acumulaciones de pol vo por lo general no son suficientes para

interferir con el funciona miento normal de l equipo eléctrico;

es posible que haya presencia de polvo en el aire como

consecuencia de mal funcionamiento en situaciones esporádicas, o

la acumulación de polvo puede ser suficiente para evitar que el calor se

disipe de man era s egur a o pue de i ncendi arse como con secu encia d e mal

funcionamiento..

Importante

Para obtener definiciones más detalladas de los lugares peligrosos,

consulte el sitio web UL <http://www.ul.com>.

Importante

El monitor HL ET 355 es un componente. Después de que se instale en un

lugar peligroso para el cual esté certificado (consulte “Lugares peligrosos”),

es necesario revisar el sistema completo o el producto final del cual forma

parte para confirmar que los indicadores del sellado sean los correctos y

que se cumpla con todos los códigos de electricidad. Si el monitor HL ET

355 incluye la opción de extensor KVM, no será necesario evaluar la

unidad local KVM ya que ésta no se coloca en lugares peligrosos.

Los métodos de cableado para el monitor HL ET 355 deben cumplir con

los métodos de cablead o Clase I , Divisi ón 2, Artí culo 50 1-4(b) d el Código

de Electri cidad Nacional, NFPA 70 para instalaciones en los Es tados

Unidos, o bien, según las especificaciones de la Sección 18-1J2 del

Código d e Ele ctrici da d Can adi ense para ins tala ciones den tro de Ca nadá y

de con for m idad co n l a autorida d que pose a la ju r is d i c c i ó n.

Información de seguridad sobre los productos

PELIGRO

Para reducir los riesgos asocia dos con incendios y explosiones, los

cuales si no se evitan, pueden ocasionar la muerte, lesiones serias o

daños a la propiedad:

No abra la unidad ET (o la compuerta, si se aplica) mientras esté activo el

circuito a menos que el área no sea peligrosa.

No utilice un teclado externo o un mouse a menos que el área

no sea peligrosa.

No opere los interruptores OSD de la unidad ET, el interruptor DIP, la

tarjeta remota del extensor KVM, o el potenciómetro de la tarjeta remota

del extensor KVM a menos que el área no sea peligrosa.

No desconecte el equipo a menos que se haya interrumpido la energía o

que el área no sea peligrosa.

No reemplace el fusible a menos que se haya desconectado la energía y

el área no sea peligrosa.

No utilice la unidad ET en lugares peligrosos Clase I, División 1; Zona 0 o

Zona 1.

ADVERTENCIA

Para reducir los riesgos asociados con descargas eléctricas, incendios

o explosiones, los cuales, de no evitarse, pueden ocasionar la muerte,

lesiones graves o daño a la propiedad:

Siga todas las instrucciones de instalación del producto y de los

accesorios, incluso las instrucciones para montar la unidad con un

empaque para panel NEMA 4X (se incluye con todos los monitores ET

355) y las instrucciones que se incluyen con el kit de compuerta NEMA 4X

(kit opcional de montaje) para el monitor ET 355.

Únicamente personal capacitado debe hacerse cargo de los

procedimientos descritos en este documento. La realización incorrecta de

los procedimientos podría dañar la unidad y anular la validez de la

garantía.

Para obtener instrucciones sobre cómo darle servicio al equipo u otros

procedimientos que no estén descritos en este documento, en la Guía de

instalación de monitores ET 350 para el usuario, o en otras instrucciones

de ET 35X, devuelva la unidad ET a 3M Touch Systems para hacerle

servicio.

ADVERTENCIA

Para disminuir los riesgos asociados con descargas eléctricas,

incendios o explosiones, los cuales, si no se evitan, pueden ocasionar

la muerte, lesiones graves o daños a la propiedad:

Lea y asegúrese de entender toda la información sobre seguridad antes de

instalar o usar la unidad ET.

Diseñe la instalación de la unidad ET para tener en cuenta el entorno de

funcionamiento (por ej., lugares peligrosos, factores de descarga o

vibración).

Instale correctamente la unidad ET con un empaque NEMA 4X que esté

limpio, en perfectas condiciones y que sea eficaz.

No modifique la unidad ET.

No sustituya componentes. La sustitución de componentes puede impedir

su adecuación a lugares peligrosos Clase I, División 2; Clase II, División 2;

o Zona 2.

Al reemplazar un fusible o cualquier otra pieza, utilice una que sea del

mismo tipo y clasificación especificados por 3M Touch Systems.

Provea una conexión a tierra limpia y confiable.

Utilice servicios de bloqueo en los conectores.

Para garantizar el cumplimiento con los códigos de electricidad y el

funcionamiento seguro del monitor, encargue el cableado y las tareas de

instalación a un electricista autorizado que esté familiarizado con los

códigos locales .

Al conectar energía con cables de campo fijo en la compuerta NEMA 4X

los cables que se utilicen deben tener doble aislamiento. Un aislante

transparente y flexible (incluido) debe cubrir la porción del cable que no

tiene doble aislamiento al conectarlo a un conector de regleta de

terminales.

ADVERTENCIA

Para disminuir los riesgos relacionados con descargas eléctricas,

incendios o explosiones, los cuales, si no se evitan, pueden ocasionar

la muerte, lesiones severas o daño a la propiedad, haga lo siguiente:

Después de hacer una abertura en la compuerta NEMA 4X, asegúrese de

que no queden residuos de metal en la misma.

Al instalar la unidad ET, asegúrese de que no se excedan las

especificaciones para protección y cableado de sobrecorriente del circuito

de alimentación.

Elija centros conductores certificados (UL) o una estructura NEMA 4X/IP66

certificada por un Organismo de Notificación que sea adecuada para

lugares peligrosos; permita la holgura necesaria en los cables.

Instale adecuadamente la unidad ET de manera que quede sellada contra

el ambiente según la norma NEMA 4X/IP66. No utilice la unidad ET con

opciones de montaje que no cumplan con la norma NEMA 4X/IP66 en

entornos que necesiten ese sello. Utilice la compuerta NEMA 4X con

monitores ET 35X con calentador.

ADVERTENCIA

Para disminuir los riesgos relacionados con incendios o explosiones,

los cuales, si no se evitan, pueden ocasionar la muerte, lesiones

severas o daño a la propiedad, haga lo siguiente:

Si se utiliza un extensor KVM con la unidad ET, la unidad local KVM debe

estar ubicada en un área que no sea peligrosa.

No utilice limpiadores inflamables o combustibles en la unidad ET ni cerca

de ella.

3M Touch Systems Proprietary Information

10

Page 11

Intended Use and Produc t Safety Information Spanish

ADVERTENCIA

Para disminuir los riesgos relacionados con descargas eléctricas o

incendios, los cuales, si no se evitan, pueden ocasionar la muerte,

lesiones severas o daño a la propiedad, haga lo siguiente:

Si la unidad ET está montada con un empaque de panel NEMA 4X,

instálela en un lugar certificado (UL).

Si la unidad ET se utilizará en ambientes corrosivos, es responsabilidad del

usuario probar y evaluar la unidad en esos ambientes. La unidad ET, tal

como se envía, no ha sido evaluada para ser utilizada en ambientes

excesivamente corrosivos. Su uso en estos ambientes sin la debida

evaluación y prueba puede ocasionar condiciones de riesgo.

ADVERTENCIA

Para disminuir los riesgos relacionados con descargas eléctricas o

quemaduras, los cuales pueden ocasionar la muerte, lesiones severas

o daño a la propiedad:

Evite el contacto con conectores en las regletas de las terminales de

energía a menos que la energía esté desconectada.

Evite co

ntactos eléctricos expuestos dentro de la unidad

ADVERTENCIA

Para disminuir los riesgos relacionados con descargas eléctricas, los

cuales, si no se evitan, pueden ocasionar la muerte, lesiones severas o

daño a la propiedad, haga lo siguiente:

Asegúrese de que la diferencia del potencial de la conexión a tierra entre

la unidad ET y la computadora host sea menos de 2V.

Antes de retirar la unidad ET de donde está montada, o bien, antes de

darle servicio a la misma, desconecte la energía de la unidad.

Permita suficiente holgura en todo el cableado de campo según los

métodos de cableado Clase I, División 2 Artículo 501-4(b) del Código de

Electricidad Nacional, NFPA 70 para instalaciones en EE.UU. o tal como

se especifica en la Sección 18-1J2 del Código de Electricidad Canadiense

y de conformidad con la autoridad que posea la jurisdicción.

ADVERTENCIA

Para disminuir los riesgos relacionados con descargas eléctricas o

funcionamiento mecánico, los cuales, si no se evitan, pueden

ocasionar la muerte, lesiones severas o daño a la propiedad:

Aplique una configuración de “seguridad táctil”, en especial si la unidad ET

o la computadora host ejecuta una aplicación o está en un lugar donde la

seguridad es importante.

No utilice protectores de pantalla que no sean compatibles con el sistema

operativo Windows que pudieran afectar la configuración de “seguridad

táctil” y pudieran a su vez ocasionar que los dispositivos periféricos

conectados se enciendan o se apaguen inesperadamente.

Establezca la configuración de seguridad táctil correctamente: que el

número de minutos establecido para la opción de ahorro de energía del

sistema operativo Windows sea al menos un minuto más que el tiempo

especificado para el protector de pantalla de Windows.

Si su unidad ET cuenta con un sistema de administración de energía del

monitor (DPMS) que se puede configurar desde el menú en pantalla

Utilidades del monitor, no apague el DPMS.

ADVERTENCIA

Para disminuir los riesgos relac ionados con el fu ncionamiento

mecánico, los cuales, si no se evitan, pueden ocasionar daño a la

propiedad:

No haga funcionar el monitor ET 350 con calentador o el monitor HL ET

355 con monitor en condiciones que no estén dentro de las

especificaciones de uso.

ADVERTENCIA

Para disminuir los riesgos relacionados con descargas eléctricas o

quemaduras, los cuales, si no se evitan, pueden ocasionar la muerte,

lesiones severas o daño a la propiedad:

No abra la unidad de suministro de energía de la unidad ET, pues contiene

energía o voltaje peligroso. El suministro de energía no contiene piezas a

las que pueda dar servicio ni ajustes que pueda hacer el usuario.

ADVERTENCIA

Para disminuir los r iesgo s rel acio nados con el cont ac to con la p iel o la

ingestión de soluciones o líquidos de limpieza , los cuales, si no se

evitan, pueden ocasionar lesiones leves o moderadas:

Consulte la hoja de datos de seguridad de materiales del fabricante

(MSDS) y siga todas las instrucciones y recomendaciones.

ADVERTENCIA

Para disminuir los riesgos relac ionados con el fu ncionamiento

mecánico, los cuales, si no se evitan, pueden ocasionar daño a la

propiedad:

No haga fun ciona r la unid ad ET en cond icio nes qu e se salg an de

las especificaciones de us o.

ET.

PRECAUCIÓN

Para disminuir los riesgos relacionados con tensión muscular , los

cuales, si no se evitan, pueden ocasionar lesiones leves o moderadas:

Evite utilizar la unidad ET durante largos períodos sin descanso.

PRECAUCIÓN

Para disminuir los riesgos relacionados con el cansancio de la vista,

los cuales, si no se evitan, pueden ocasionar lesiones leves o

moderadas:

Utilice la unidad ET en lugares donde no haya demasiada luz ni reflejo

sobre la pantalla.

PRECAUCIÓN

Para disminuir los r iesgo s rel acio nados con cont a minac ión am biental,

los cuales, si no se evitan, pueden ocasionar contaminación de los

mantos de agua, lesiones leves o moderadas o daño a la propiedad:

Deseche la unidad ET según las normas gubernamentales

correspondientes

3M Touch Systems Proprietary Information

11

Page 12

Intended Use and Produc t Safety Information Dutch

Bedoeld ge b ruik

De ET 355-monitor HL (hierna de ET 355-monitor genoemd)

voorziet in functies op het aanraakscherm voor industri

ë

le

toepassingen op gevaarlijke locaties als de monitor is aangesloten

op een hostcomputer.

De ET 355-mon it or is geschikt voor gebruik op niet-gevaarl ijke locaties

en tevens op de volgende typen gevaarlijke locaties.

Gebruik va n de mo ni tor op h ie rvan afw ijke nde loc at ies maakt de gara ntie

ongeldig en is uitsluitend voor het risico en de verantwoordelijkheid van

de gebr uiker:

Gevaar lijke locaties van Class I, Division 2, Group A, B, C en

D; temperatuurcode T6 (lager dan of gelijk aan 85°C). Waar:

vluchtige br andbare vloeist of fen of brandbar e gas s en of dampen

aanwezig zijn , maar die zich gewoonlijk in gesloten houders bevinden;

ontvlamb are conc ent r atie s ga ss en, dam p en of vl oeisto f fe n gewoo n lijk

worden voorkomen door positieve mechanische ventilatie;

aangrenzend aan een loca tie van Clas s I, Divi sion 1, z o nu e n d an sprak e

is van ontvlambare concentraties.

Gevaar lijke locaties van Class II, Divi sion 2, Group F en G;

temperatuurcode T6 (lager dan of ge lijk a a n 85°C). Waar:

gewoonlijk geen brandbaar stof in ontbrandbare concentraties in de

lucht aanwezi g is;

gewoonlijk onvoldoende stofophopingen zijn om de normale werking

van elektrische apparatuur te beïnvloeden;

zwevend stof in de lucht aanwezig is tengevolg e van zelden

voorkomende storingen bij apparatuur; of

stofophopi ngen zodanig z ijn dat ze veilige war mtedissipa ti e

beïnvloeden of dat ze kunnen ontbranden door abnormal e werking.

Belangrijk

Raadpleeg de website <http://www.ul.com> van UL voor uitgebreidere

definities van gevaarlijke locaties.

Belangrijk

De ET 355-monitor HL is een component. Nadat de monitor is geïnstalleerd

op een gevaarlijke locatie waarvoor deze is gecertificeerd (zie “Gevaarlijke

locaties”), moet het gehele systeem of het eindproduct waarvan deze deel

uitmaakt, worden gecontroleerd om na te gaan of aan alle

afdichtingswaarden en voorschriften betreffende elektriciteit is voldaan. Als

de ET 355 monitor HL is voorzien van de KVM-uitbreidingsoptie, is het niet

nodig om de lokale KVM-eenheid te laten testen aangezien de lokale

eenheid niet op een gevaarlijke locatie mag worden geplaatst.

De bedradingsmethoden voor de ET 355-monitor HL moeten in

overeenstemming zijn met Cl as s I, Division 2 wiring methods, Ar ticle

501-4(b ) van de National Electric C ode, NFPA 70 voor installaties in de

VS, of zo als gespecificeerd in Section 18-1J2 van de Canadian Electrical

Code voor installaties in Canada en in overeenstemming met de bevoegde

autoriteiten.

Verbindingen met randapparatuur dienen in de eindtoepassing (d.w.z.

niet-bra ndgevaarlijke circuits) te worden gecontroleer d.

Productveiligheidsinformatie

GEVAAR

Neem het volgende in acht om de risico's van brand en explosies te

reduceren die, indien deze niet worden voorkomen, ernstig letsel, de

dood en/of schade aan eigendommen tot gevolg hebben:

Maak de ET-eenheid (of het ET-luik indien van toepassing) niet open

wanneer het circuit onder spanning staat, tenzij bekend is dat de omgeving

niet gevaarlijk is.

Gebruik geen extern toetsenbord of externe muis tenzij bekend is dat de

omgeving niet gevaarlijk is.

Gebruik van de ET-eenheid niet de OSD-schakelaars, DIP-schakelaar,

externe KVM-uitbreidingskaart of de potentiometer op de externe KVMuitbreidingskaart tenzij bekend is dat de omgeving niet gevaarlijk is.

Koppel de apparatuur niet los, tenzij de voeding is uitgeschakeld of bekend

is dat de omgeving geen gevaar oplevert.

Vervang de zekering niet, tenzij de eenheid van de voeding is losgekoppeld

of bekend is dat de omgeving geen gevaar oplevert.

Gebruik de ET-eenheid niet op gevaarlijke locaties van Class I, Division 1;

Zone 0; of Zone 1.

WAARSCHUWING

Neem het volgende in acht om de risico's van elektrische schokken,

brand of explosies te reduceren die, indien deze niet worden

voorkomen, ern sti g let sel, de dood en/o f sch ade aan e igendomm en tot

gevolg kunnen hebben:

Volg alle installatie-instructies voor het product en de accessoires op, met

inbegrip van de instructies om bij montage van de eenheid het paneel met

een NEMA 4X-pakking uit te rusten (wordt bij alle ET 355-monitors

geleverd) en de instructies die zijn bijgesloten bij de NEMA 4X-luikset

(optionele bevestigingsset) voor de ET 355-monitor.

De in dit document beschreven procedures mogen uitsluitend door

getraind personeel worden uitgevoerd. Het niet correct uitvoeren van alle

handelingen kan schade aan de eenheid tot gevolg hebben waardoor de

garantie ongeldig wordt.

Voor onderhouds- of andere procedures die niet worden beschreven in dit

document, in de Installatiehandleiding voor de gebruiker van de ET 350-

monitor of in andere instructies voor de ET 35X, dient u de ET-eenheid

retour te sturen aan 3M Touch Systems voor service.

WAARSCHUWING

Neem het volgende in acht om de risico's van elektrische schokken,

brand of explosies te reduceren die, indien deze niet worden

voorkomen, ern sti g let sel, de dood en/o f sch ade aan e igendomm en tot

gevolg kunnen hebben:

Voordat de ET-eenheid wordt geïnstalleerd en gebruikt, moet alle

veiligheidsinformatie zijn gelezen en begrepen.

Houd bij het plannen van de installatie van de ET-eenheid rekening met de

werkconfiguratie (bijv. gevaarlijke locatie en factoren als schokken en

vibratie).

Installeer de ET-eenheid op juiste wijze met een schone, onbeschadigde

en effectieve NEMA 4X-pakking.

Breng geen modificaties in de ET-eenheid aan.

Vervang componenten niet door andere. Het vervangen van componenten

kan de geschiktheid voor gevaarlijke locaties van Class I, Division 2; Class

II, Division 2; of Zone 2 nadelig beïnvloeden.

Gebruik ter vervanging van zekeringen of andere onderdelen uitsluitend

onderdelen van het type en met de toegestane waarde die door 3M Touch

Systems zijn opgegeven.

Zorg voor een schone, betrouwbare aarding.

Gebruik connectors met vergrendelingen.

Laat alle bedradings- en installatiewerkzaamheden uitvoeren door een

erkende, gerenommeerde elektricien die bekend is met de lokale

voorschriften om er zeker van te zijn dat aan alle voorschriften betreffende

elektriciteit wordt voldaan en om een veilige werking van de monitor te

garanderen.

Als de voeding wordt aangesloten via vaste veldbedrading in het NEMA

4X-luik, moet de veldbedrading dubbel geïsoleerd zijn. Bij aansluiting op

een stripconnector van de terminal moet een doorzichtige, flexibele isolator

(bijgeleverd) het gedeelte van de kabel bedekken dat niet dubbel

geïsoleerd is.

WAARSCHUWING

Neem het volgende in acht om de risico's van elektrische schokken,

brand of explosies te reduceren die, indien deze niet worden

voorkomen, ern sti g let sel, de dood en/o f sch ade aan e igendomm en tot

gevolg kunnen hebben:

Zorg ervoor dat na het maken van een opening in het NEMA 4X-luik er

geen metalen spaanders in het luik achterblijven.

Zorg ervoor dat bij de installatie van de ET-eenheid de specificaties voor

beveiliging tegen overbelasting en voor bedrading van het voedingscircuit

niet worden overschreden.

Kies de aangegeven (UL) verdeeldoos of de door de bevoegde instantie

gecertificeerde nominale afdichting NEMA 4X/IP66 die geschikt is voor

gebruik op gevaarlijke locaties en zorg dat de bedrading voldoende

trekontlasting heeft.

Installeer de ET-eenheid zodanig dat deze is afgedicht voor de omgeving

volgens de NEMA 4X/IP66-standaard. Gebruik in omgevingen waarin

dergelijke afdichtingen vereist zijn de ET-eenheid alleen met

bevestigingopties die voldoen aan NEMA 4X/IP66. Gebruik het NEMA 4Xluik met ET 35X-monitors met verwarming.

WAARSCHUWING

Neem het volgende in acht om de risico's van brand en explosies te

reduceren die, indien deze niet worden voorkomen, ernstig letsel, de

dood en/of schade aan eigendommen tot gevolg kunnen hebben:

Als de ET-eenheid in combinatie met een KVM-uitbreiding wordt gebruikt,

moet de lokale KVM-eenheid in een omgeving worden geplaatst waarvan

bekend is dat deze niet gevaarlijk is.

Gebruik geen ontvlambare of brandbare reinigingsmiddelen voor of in de

buurt van de ET-eenheid.

3M Touch Systems Proprietary Information

12

Page 13

Intended Use and Produc t Safety Information Dutch

WAARSCHUWING

Neem het volgende in acht om de risico's van elektrische schokken of

brand te reduceren die, indien deze niet worden voorkomen, ernstig

letsel, de dood en/of schade aan eigendommen tot gevolg kunnen

hebben:

Als de ET-eenheid wordt gemonteerd en er wordt voor het paneel een

NEMA 4X-pakking gebruikt, dient u de eenheid in een aangegeven (UL)

behuizing aan te brengen.

Als de ET-eenheid in een corrosieve omgeving wordt gebruikt, is het de

verantwoordelijkheid van de gebruiker de eenheid in die omgeving te

testen en onderzoeken. De ET-eenheid is, zoals deze wordt verzonden,

niet getest voor gebruik in een extreem corrosieve omgeving. Het gebruik

in een dergelijke omgeving zonder tests en onderzoek kan tot onveilige

omstandigheden leiden.

WAARSCHUWING

Neem het volgende in acht om de risico's van elektrische schokken

en/of brandwonden te reduceren die ernstig letsel, de dood en/of

schade aan eigendommen tot gevolg kunnen hebben:

Raak de connectors op de voedingsterminalstrip niet aan, tenzij de voeding

is losgekoppeld.

Raak blootliggende elektrische contacten in de ET-eenheid niet aan.

WAARSCHUWING

Neem het volgende in acht om de risico's van elektrische schokken te

reduceren die, indien deze niet worden voorkomen, ernstig letsel, de

dood en/of schade aan eigendommen tot gevolg kunnen hebben:

Zorg ervoor dat het verschil in aardpotentiaal tussen de ET-eenheid en de

hostcomputer niet meer dan 2 V bedraagt.

Voordat de ET-eenheid van de steun wordt verwijderd of er onderhoud aan

de eenheid wordt uitgevoerd, moet de voeding van de ET-eenheid worden

losgekoppeld.

Zorg voor voldoende trekontlasting van alle veldbedrading in

overeenstemming met Class I, Division 2 wiring methods Article 501-4(b)

of de National Electric Code, NFPA 70 voor installaties in de VS, of zoals

gespecificeerd in Section 18-1J2 van de Canadian Electrical Code voor

installaties in Canada en in overeenstemming met de bevoegde

autoriteiten.

WAARSCHUWING

Neem het volgende in acht om de risico's van elektrische schokken of

mechanische werking te reduceren die, indien deze niet worden

voorkomen, er nsti g let sel, de dood en/o f schad e aan e igendom men tot

gevolg kunnen hebben:

Kies een “safe touch”-instelling (aanraakbeveiliging), vooral als de ETeenheid of hostcomputer een toepassing uitvoert of in een omgeving staat

waarin veiligheid een rol speelt.

Gebruik geen andere schermbeveiliging dan een van het Windowsbesturingssysteem, omdat deze de “safe touch” instelling kan beïnvloeden

waardoor aangesloten randapparatuur onbedoeld in werking kan treden of

kan stoppen.

Stel de safe touch-instelling correct in, waarbij het ingevoerde aantal

minuten voor de energiebesparende functie van het Windowsbesturingssysteem minimaal één minuut groter is dan de ingevoerde tijd

voor de schermbeveiliging van het Windows-besturingssysteem.

Als de ET-eenheid over een Display Power Management System (DPMS)

beschikt dat vanuit het menu Utility (Hulpprogramma) op het scherm van

het display kan worden geconfigureerd, schakel dan het DPMS niet uit.

WAARSCHUWING

Neem het volgende in acht om de risico's van mechanische werking te

reduceren die, indien deze niet worden voorkomen, schade aan

eigendommen tot gevolg kunnen hebben:

Gebruik de ET 350-monitor met verwarming of de ET 355-monitor HL met

verwarming niet onder omstandigheden die buiten de bedrijfsspecificaties

vallen.

WAARSCHUWING

Neem het volgende in acht om de risico's van elektrische schokken

en/of brandwonden te reduceren die ernstig letsel, de dood en/of

schade aan eigendommen tot gevolg kunnen hebben:

Maak de voedingsbron in de ET-eenheid niet open. Hierin is een gevaarlijk

vermogen en/of een gevaarlijke spanning aanwezig. In de voedingsbron

bevinden zich geen onderdelen waaraan door de gebruiker onderhoud

mag worden uitgevoerd of die door de gebruiker mogen worden afgesteld.

WAARSCHUWING

Neem het volgende in acht om het risico op huidcontact met of het

inslikken van reinigingsoplossingen of -vloeistoffen te vermi nderen,

die indien ze niet worden voorkomen licht tot middelzwaar letsel tot

gevolg kunnen hebben:

Raadpleeg het Material Safety Data Sheet (MSDS) van de fabrikant en volg

alle instructies en aanbevelingen op.

WAARSCHUWING

Neem het volgende in acht om de risico's van mechanische werking te

reduceren die, indien deze niet worden voorkomen, schade aan

eigendommen tot gevolg kunnen hebben:

Gebrui k de ET 350-eenheid niet onder omstan digheden die

buiten de bedrijfsspecificaties vallen.

LET OP

Neem het volgende in acht om de risico's van spierbelasting te

reduceren die, indien deze niet worden voorkomen, licht tot

middelzwaar letsel tot gevolg kunnen hebben:

Gebruik de ET-eenheid niet langdurig zonder pauze te nemen.

LET OP

Neem het volgende in a cht om de risic o's van as thenopie te reduc eren

die, indien deze niet wor den voorkome n, licht tot middelz waar let sel tot

gevolg kunnen hebben:

Gebruik de ET-eenheid niet in een omgeving met te veel omgevingslicht of

reflecties op het scherm.

LET OP

Neem het volgende in acht om de risico's op milieuverontreiniging te

reduceren die, indien deze niet worden voorkomen, verontreiniging van

het grondwater, licht tot middelzwaar letsel en/of schade aan

eigendommen tot gevolg kunnen hebben:

Voer de ET-eenheid af in overeenstemming met de van toepassing zijnde

overheidsbepalingen.

3M Touch Systems Proprietary Information

13

Page 14

Intended Use and Produc t Safety Information German

Einsatzbereiche

Der ET 355-Monitor HL (im Folgenden ET 355-Monitor genannt)

bietet Touch-Screen- Funktionen f ür industrielle Anwendungen, wenn er

an einen Host-Co

mputer angeschlossen ist.

Der ET 355-Monitor HL ist geeignet für den Betrieb in einer

ungefähr lichen Umgebung sowie in Gefa hr enzonen

folgender Art.

Falls der Monitor in einer anderen als der beschriebenen

Umgebungen eingesetzt wird, erlischt damit die Gara

ntie und der

Benutzer trägt für die entstehenden Risike n die alleinige Verantwortung:

Klas se I , Ab t ei l ung 2 , G efahrenzonen de r Gruppen A, B , C un d

D; Temperatur-Code T6 (bis zu 85°C). Unter folgenden

Bedingungen:

flüchtige entflammbare Flüssigkeiten oder Dämpfe sind vorhanden,

werden aber normalerweise in geschlossenen B e hältern aufbewahrt;

entflammba re Konzent rationen von Gase n, Dämpfen oder Flüss igkeiten

werden normalerw eise durch eine po s it ive mechanische Be lüftung

verhindert;

Einsatzort gr enzt an einen Ort der Kl as s e I , Abteilung 1 an, an dem

entflammbare Konzentrationen gelegentlich verbreitet werden können.

Klasse II, Abteilung 2, Gefahrenz one n der Gru ppe n F und G;

Temperatur-Code T6 (bis zu 85°C). Unter folgenden

Bedingungen:

brennbarer S taub befindet sich normalerweise i n entflammbarer

Konzentration in der Luft;

Die Stauban sammlun g reich t norma lerweise nich t aus, um den normalen

Betrieb ele ktr isc her Gerä te zu störe n ;

Staub befindet sich in der Luf t infolge manchmal auftretender

Fehlfunktion von Geräten; oder

Die Staubans ammlung reicht aus , um eine sichere Dissipation der

Wärme zu bee inträcht igen ode r wird durch au ßergewöhn liche Vo rgänge

entflammbar.

Wichtig

Genauere Definitionen für Gefahrenzonen finden Sie auf der UL-Website

unter <http://www.ul.com>.

Wichtig

Der ET 355-Monitor HL ist eine Komponente. Nach der Installation des

Monitors in einer Gefahrenzone, für die er zugelassen ist (siehe

"Gefährliche Einsatzorte") muss das gesamte System oder Endprodukt zu

dem es gehört inspiziert werden, um die Dichtungsstufe und Kompatibilität

mit allen elektrischen Codes zu gewährleisten. Wenn Ihr ET 355-MonitorHL die KVM-Umschalter-Option enthält, ist es nicht erforderlich, die lokale

KVM-Einheit zu evaluieren, da sich die lokale Einheit nicht an einem

gefährlichen Ort befindet.

Die Verkabelungsart des ET 355-Monitor HL muss sich bei Installationen

in den USA in Üb er einstimmung mit den Verkabelungs m ethoden der

Klasse 1, A bteilung 2 (" Class I, Divisi on 2), Artike l 501-4(b) des

"National Electric Code, NFP A 70" und bei Installat ion in Kanada mit

Abschnitt 18-1J2 des "Canadian Electrical Code" sowie in

Übereinstimmung mit den zuständigen Behörden befinden.

Zubehöra nschlüs se müssen b ei der Endabn ahme begut achtet werden ( z.B.

nicht entzündbare Stromkreise).

Produktsicherheitshinweise

GEFAHR

Maßnahmen zum Schutz vor Feuer- und Explosionsgefahren, die zu

schweren Unfäl len mit T odes- oder Ver letzungsfolge bzw . Sachsch äden

führen können:

Den ET-Monitor (oder ggf. Schutzgehäuse) nicht öffnen, solange der

Stromkreis aktiv ist, es sei denn, es steht fest, dass der Bereich

ungefährlich ist.

Keine externe Tastatur oder Maus verwenden, es sei denn, es steht fest,

dass der Bereich ungefährlich ist.

OSD-Schalter des ET-Monitors, DIP-Schalter, das KVM-UmschalterRemote Board oder das Potentiometer auf dem KVM-Umschalter-Remote

Board nur bedienen, wenn fest steht, dass der Bereich ungefährlich ist.

Gerät nur ausstecken, wenn der Strom ausgeschaltet ist oder fest steht,

dass der Bereich ungefährlich ist.

Sicherungen nur wechseln, wenn die Stromzufuhr unterbrochen ist und

fest steht, dass der Bereich ungefährlich ist.

ET-Monitor nicht in Gefahrenzonen der Klasse I, Abteilung 1; Zone 0; oder

Zone 1 verwenden.

WARNUNG

Maßnahmen zum Schutz vor Elektroschock-, Feuer- und

Explosionrisiken, die zu schweren Unfällen mit Todes- oder

Verletzungsfolge bzw. Sachschäden führen können:

Alle Installationsanweisungen für Produkt und Zubehör beachten,

einschließlich der Anweisungen zum Aufbau der Einheit mit einer Dichtung

gem. NEMA 4X (wird mit allen ET 355-Monitoren mitgeliefert) und der

Anweisungen, die mit dem Schutzgehäuse gem. NEMA 4X (optionales

Montage-Kit) für den ET 355-Monitor mitgeliefert werden.

Die in diesem Dokument beschriebenen Maßnahmen sind nur von

ausgebildeten Mitarbeitern auszuführen. Falls die Maßnahmen nicht

korrekt ausgeführt werden, können Beschädigungen an der Einheit

entstehen und die Garantie kann ungültig werden.

Zur Durchführung von Wartungsarbeiten und anderen nicht in diesem

Handbuch, in der ET 350-Monitor-Installationsanleitung für den Benutzer

oder in anderen ET 35X-Anweisungen beschriebenen Prozeduren, ETMonitor an 3M Touch Systems senden.

WARNUNG

Maßnahmen zum Schutz vor Elektroschock-, Feuer- und

Explosionsrisiken, die zu schweren Unfällen mit Todes- oder

Verletzungsfolge bzw. Sachschäden führen können:

Vor der Installation des ET-Monitors alle Sicherheitshinweise sorgfältig

lesen.

Planen Sie bei der Installation des ET-Monitors die Betriebsumgebung ein

(z.B. Gefahrenzone, Stoß -und Erschütterungsfaktoren).

Installieren Sie den ET-Monitor mit einer sauberen, unbeschädigten und

leistungsfähigen Dichtung gem. NEMA 4X.

Verändern Sie den ET-Monitor nicht.

Ersetzen Sie keine Komponenten. Der Ersatz von Komponenten kann die

Eignung für Gefahrenzonen der Klasse I, Abteilung 2; Klasse II, Abteilung

2; oder Zone 2 beeinträchtigen.

Beim Ersetzen von Sicherungen oder anderen Teilen sind nur Teile

einzusetzen, die dem von 3M Touch Systems angegebenen Typ und

Nennwert entsprechen.

Sorgen Sie für saubere und zuverlässige Erdung.

Verwenden Sie Arretierungen für die Steckverbindungen.

Um die Übereinstimmung mit den elektrischen Regelungen und einen

sicheren Betrieb zu gewährleisten, ist die Verkabelung und Installation von

einem qualifizierten Handwerker durchführen zu lassen, der mit den

lokalen Regelungen vertraut ist.

Beim Netzanschluss mit dauerhaftem Kabelanschluss im NEMA 4X

Schutzgehäuse muss das Netzkabel doppelt isoliert sein. Ein

durchsichtiger und flexibler Isolator (mitgeliefert) muss beim Anschluss an

die Klemmenleiste jeweils das nicht doppelt isolierte Kabelteil abdecken.

WARNUNG

Maßnahmen zum Schutz vor Elektroschock-, Feuer- und

Explosionsrisiken, die zu schweren Unfällen mit Todes- oder

Verletzungsfolge bzw. Sachschäden führen können:

Nachdem Sie das NEMA 4X-Schutzgehäuse mit einer Öffnung versehen

haben, vergewissern Sie sich, dass keine Metallspäne im Gehäuse liegen.

Achten Sie beim Installieren des ET-Monitors darauf, dass die

Spezifikationen für den Netzstromschutz und die Verkabelung nicht

überschritten werden.

Wählen Sie eine gelistete (UL) Verbindungs-Hub oder eine gemeldete

Buchse gem. NEMA 4X/IP66 mit geprüftem Gehäuse, die für den Einsatz

in Gefahrenzonen geeignet ist und achten Sie auf eine geeignete

Zugentlastung der Kabel.

Installieren Sie den ET-Monitor ordnungsgemäß so, dass sie den

Umweltversiegelungsbestimmungen der Norm NEMA 4X/IP66 entspricht.

Verwenden Sie den ET-Monitor nicht mit Monatageoptionen, die nicht dem

NEMA 4X/IP66-Standard entsprechen in einer Umgebung, in der dieser

Standard erforderlich ist. Verwenden Sie bei ET 35X-Monitoren mit

Heizung das NEMA 4X-Gehäuse.

WARNUNG

Maßnahmen zum Schutz vor Feuer- und E xplosionsrisike n, die zu

schweren Un fällen mi t Todes- oder Ve rletzun gsfolge bzw. Sachschäd en

führen können:

Wenn ein KVM-Umschalter mit dem ET-Monitor verwendet wird, ist die

lokale KVM-Einheit an einem Ort unterzubringen, von dem fest steht, dass

er ungefährlich ist.

Keine entzündlichen oder brennbaren Reinigungsmittel an oder in der

Nähe des ET-Monitors verwenden.

3M Touch Systems Proprietary Information

14

Page 15

Intended Use and Produc t Safety Information German

WARNUNG

Maßnahmen zum Schutz vor Elektroschock- und Feuerrisiken, die zu

schweren Unfäl len mit T odes- oder Ver letzungsfolge bzw . Sachsch äden

führen können:

Wenn der ET-Monitor mit Hilfe einer Dichtung gem. NEMA 4X montiert

wird, installieren Sie die Einheit in einem eingetragenen (UL) Gehäuse.

Wenn der ET-Monitor in einem korrosiven Umfeld eingesetzt wird, liegt das

Testen und Evaluieren der Einheit unter solchen Bedingungen in der

Verantwortung des Benutzers. Der gelieferte ET-Monitor wurde für einen

Einsatz in einer extrem korrosiven Umgebung nicht entworfen. Eine

Verwendung in einer solchen Umgebung ohne Evaluierung und Test kann

zu gefährlichen Zuständen führen.

WARNUNG

Maßnahmen zum Schutz vor Elektroschock - bzw. V erbrennungsris iken,

die zu schweren Unfällen mit Todes- oder Verletzungsfolge bzw.

Sachschäden führen können:

Die Verb

indungen auf der Klemmleiste nur berühren, wenn die

Stromzufuhr unterbrochen ist.

Vermeiden Sie freiliegende elektrische Kontakte innerhalb des ETMonitors.

WARNUNG

Maßnahmen zum Schutz vor Elektroschockrisiken, die zu schweren

Unfällen mit Todes- oder Verletzungsfolge bzw. Sachschäden führen

können:

Vergewissern Sie sich, dass der Spannungsunterschied zwischen dem ET

350-Monitor und dem Hauptrechner nicht mehr als 2 V beträgt.

Vor dem Entfernen des ET-Monitors vom Gestell und vor der Durchführung

von Wartungsarbeiten Netzstecker ziehen.

Achten Sie auf geeignete Zugentlastung der Verkabelung in den USA in

Übereinstimmung mit den Verkabelungsmethoden der Klasse 1, Abteilung

2 ("Class I, Division 2), Artikel 501-4(b) des "National Electric Code, NFPA

70" und bei Installation in Kanada mit Abschnitt 18-1J2 des "Canadian

Electrical Code" sowie in Übereinstimmung mit den zuständigen Behörden.

WARNUNG

Maßnahmen zum Schutz vor Elektroschock- und mechanischen

Risiken, die zu schweren Unfällen mit Todes- oder Verletzungsfolge

bzw. Sachschäden führen können:

Stellen Sie eine "Sichere Berührung" ein, besonders wenn der Monitor oder

Hauptrechner mit einer Anwendung läuft oder in einer Umgebung

aufgestellt ist, bei denen Sicherheitsbedenken bestehen.

Benutzen Sie keinen Bildschirmschoner, eines anderen Betriebssystems

als Windows, da die Einstellung "Sichere Berührung" beeinträchtigt werden