Page 1

SuperStack® II Hub 1000 SX

®

User Guide

A member of the 3Com SuperStack II System

http://www.3com.com/

Part No. 09-1354-000

Published March 1998

Page 2

3Com Corporation

5400 Bayfront Plaza

Santa Clara, California

95052-8145

Copyright © 1998, 3Com Corporation. All rights reserved. No part of this documentation may be reproduced

in any form or by any means or used to make any derivative work (such as translation, transformation, or

adaptation) without written permission from 3Com Corporation.

3Com Corporation reserves the right to revise this documentation and to make changes in content from time

to time without obligation on the part of 3Com Corporation to provide notification of such revision or change.

3Com Corporation provides this documentation without warranty of any kind, either implied or expressed,

including, but not limited to, the implied warranties of merchantability and fitness for a particular purpose.

3Com may make improvements or changes in the product(s) and/or the program(s) described in this

documentation at any time.

UNITED STATES GOVERNMENT LEGENDS:

If you are a United States government agency, then this documentation and the software described herein are

provided to you subject to the following:

United States Government Legend:

and developed solely at private expense. Software is delivered as Commercial Computer Software as defined

in DFARS 252.227-7014 (June 1995) or as a commercial item as defined in FAR 2.101(a) and as such is

provided with only such rights as are provided in 3Com’s standard commercial license for the Software.

Technical data is provided with limited rights only as provided in DFAR 252.227-7015 (Nov 1995) or FAR

52.227-14 (June 1987), whichever is applicable. You agree not to remove or deface any portion of any

legend provided on any licensed program or documentation contained in, or delivered to you in conjunction

with, this User Guide.

Unless otherwise indicated, 3Com registered trademarks are registered in the United States and may or may

not be registered in other countries.

3Com, the 3Com logo, EtherLink, Net Age, and SuperStack are registered trademarks of 3Com Corporation.

3ComFacts is a service mark of 3Com Corporation.

CompuServe is a registered trademark of CompuServe, Inc.

Other brand and product names may be registered trademarks or trademarks of their respective holders.

All technical data and computer software is commercial in nature

ii

Page 3

C

ONTENTS

BOUT THIS GUIDE

A

I

1

NTRODUCTION

Hub 1000 SX General Description 1-1

Downlinks and Uplink 1-2

Full-Duplex Operation 1-2

Flow Control 1-2

Asymmetric Flow Control 1-3

Symmetric Flow Control 1-3

Auto-Negotiation 1-3

Forced Link 1-3

Features and Functions 1-4

2

I

NSTALLING THE HUB

Safety Precautions 2-1

Package Contents 2-1

Hub Description 2-2

Front Panel 2-2

Rear Panel 2-3

Preparing the Site 2-3

Installing and Connecting the Hub 2-3

Mounting in a Rack 2-3

Placing on a Desktop 2-5

Interpreting Hub Indicators 2-5

Installing and Connecting a GBIC Module 2-7

Using Optional Power Systems 2-8

Advanced RPS 2-8

Power Modules 2-9

Cabling Options 2-9

Uninterruptible Power System 2-10

Page 4

M

3

A

AKING CONNECTIONS

Aggregating Servers 3-2

Connecting a Power Workgroup 3-2

Aggregating Switches 3-3

Mixing Connections 3-4

Connecting Through the Uplink 3-5

Troubleshooting 3-6

U

SING THE CONSOLE PORT

Requirements A-2

Connecting the Console Port A-2

With Power Connected A-2

With Power Disconnected A-3

POST Messages A-3

Logging On A-4

Changing the Password A-5

Configuring Port Settings A-5

Disabling Ports A-7

Disabling Auto-Negotiation A-8

Configuring the Uplink for Asymmetric Flow Control A-10

Displaying Hub Status A-12

Restoring the Factory Default Settings A-14

Updating the Firmware Image A-15

Checking the Firmware Version A-15

Transferring the Firmware Image File A-16

Logging Off A-17

Troubleshooting A-17

iv

Page 5

B

S

PECIFICATIONS

C

ECHNICAL SUPPORT

T

Online Technical Services C-1

World Wide Web Site C-1

3Com Bulletin Board Service C-1

Access by Analog Modem C-2

Access by Digital Modem C-2

3ComFacts Automated Fax Service C-2

3ComForum on CompuServe Online Service C-3

Support from Your Network Supplier C-3

Support from 3Com C-4

Returning Products for Repair C-5

G

LOSSARY

I

NDEX

3COM C

ORPORATION LIMITED WARRANTY

FCC C

LASS

A V

ERIFICATION STATEMENT

v

Page 6

Page 7

F

IGURES

2-1

Hub 1000 SX Front and Rear Panels 2-2

2-2

Attaching a Bracket for Rack Mounting 2-4

2-3

Rack Mounting the Hub 2-4

2-4

Sample GBIC Module 2-7

3-1

Server Farm Connection 3-2

3-2

Power Workgroup Connection 3-3

3-3

Aggregated Switches Connection 3-4

3-4

Mixed Connection 3-5

3-5

Connection to Another Hub 1000 SX 3-5

3-6

Uplink Connection to a 10/100 Mbps Switch 3-6

A-1

Console Port A-1

vii

Page 8

Page 9

T

ABLES

1

Notice Icons 1

2

Text Conventions 2

2-1

Downlink Connections 2-5

2-2

Hub 1000 SX Indicators 2-6

2-3

GBIC Modules 2-7

2-4

Advanced RPS Configuration Options 2-10

3-1

Gigabit Ethernet Maximum Cable Lengths 3-1

3-2

Troubleshooting Tips 3-6

A-1

Situations That Require Configuring Port Settings A-5

A-2

Port Configuration

A-3

Hub Status Information A-12

A-4

File Transfer Error Messages A-18

A-5

Fatal Error Messages A-18

Menu A-7

ix

Page 10

Page 11

BOUT

A

T

HIS

G

UIDE

This guide contains installation procedures and technical information

about the 3Com

full-duplex repeater (part number 3C510-SX).

It is assumed that the user knows basic precautions and procedures for

working with electrical equipment and has experience installing, using,

and managing an Ethernet network. It is also assumed that the user has

some knowledge of repeater technology.

If release notes are shipped with this product and the information in

the release notes differs from the information in this guide, follow

the information in the release notes.

Table 1 and Table 2 list conventions that are used throughout this guide.

Table 1

Icon

Notice Icons

Notice Type Description

Information note

Caution Information to alert you to potential damage to a

Warning Information to alert you to potential personal injury

®

SuperStack® II Hub 1000 SX Gigabit Ethernet

Important features or instructions

program, system, or device

Page 12

2

BOUT THIS GUIDE

A

Table 2

Text Conventions

Convention

Screen displays

Description

This typeface represents information as it appears on

the screen.

Commands

The word “command” means you must enter the

command exactly as shown in text and press Return

or Enter. For example:

To remove the IP address, enter the following

command:

SETDEFAULT !0 -IP NETaddr = 0.0.0.0

This guide always gives the full form of a command in

uppercase and lowercase letters. However, you can

abbreviate commands by entering only the uppercase

letters and the appropriate value. Commands are not

case sensitive.

The words “enter”

and “type”

When you see the word “enter” in this guide, you must

type something, and then press the Return or Enter key.

Do not press the Return or Enter key when an instruction

simply says “type.”

Keyboard key names If you must press two or more keys simultaneously, the key

names are linked with a plus sign (+). For example:

Press Ctrl+Alt+Del.

Menu commands

and

buttons

Words in

italicized

Menu commands or button names appear in italics.

Example:

From the

Help

menu, select

Contents

.

type Italics emphasize a point or denote new terms at the place

where they are defined in the text.

Words in

bold-face

Bold text denotes key features.

type

Page 13

1

NTRODUCTION

I

Gigabit Ethernet technology allows signal transmission at the rate of one

gigabit per second (1 Gbps, or 1000 Mbps), while continuing to support

IEEE 802.3 CSMA/CD local area networks. Using this technology, you can

add gigabit bandwidth to critical areas of a network and fully leverage

investments in Ethernet and Fast Ethernet products.

Hub 1000 SX

General Description

The 3Com® SuperStack® II Hub 1000 SX Gigabit Ethernet full-duplex

repeater (part number 3C510-SX) combines the low cost and simplicity

of a hub with the high performance and efficient throughput of a switch.

You can use the Hub 1000 SX to:

■

Aggregate servers

Aggregate 10/100 Mbps switches

■

■ Provide gigabit bandwidth to a power workgroup that is running a

high-bandwidth application such as medical imaging, video editing,

film postproduction, CAD/CAM, or digital prepress

The Hub 1000 SX is an eight-port repeater. All ports transmit and receive

at a speed of one gigabit per second. The hub forwards all incoming

packets (without filtering them) to all links except the originating

link, thus providing a shared bandwidth domain. Like a switch, the

Hub 1000 SX uses full-duplex ports and packet flow control to increase

bandwidth and ensure reliable performance.

The hub is ready to use and requires no configuration. However, some

configuration options are available through the console interface for use

in exceptional cases.

The Hub 1000 SX is part of the 3Com SuperStack II system and can

be used with the SuperStack II Advanced Redundant Power System

(Advanced RPS) and the SuperStack II Uninterruptible Power System (UPS),

which provide fail-safe operation and a constant power supply.

Page 14

1-2 CHAPTER 1: INTRODUCTION

Downlinks

and Uplink

Full-Duplex Operation

The hub’s eight 1000BASE-SX full-duplex downlink ports (downlinks) can

connect to servers or clients that are equipped with Gigabit Ethernet

network interface cards (NICs) or to 10/100 Mbps switches that are

equipped with Gigabit Ethernet uplink devices.

One uplink port (uplink) accepts an optional gigabit interface connector

(GBIC) module. The following types of GBIC modules are available:

■ 1000BASE-CX coaxial transmits over short-haul shielded balanced

copper cable (known as twinaxial STP).

■ 1000BASE-LX long-wavelength transmits over multimode fiber (MMF)

or single-mode fiber (SMF) cable.

■ 1000BASE-SX short-wavelength transmits over MMF cable.

The primary use of the uplink is to connect to a network backbone

through a Gigabit Ethernet switch such as the 3Com SuperStack II

Switch 9300.

Full-duplex operation allows frames to be transmitted and received

simultaneously and, in effect, doubles the bandwidth available on a link.

For Gigabit Ethernet devices, full-duplex operation allows a peak data

transmission rate of 2 Gbps. All Hub 1000 SX ports operate only in

full-duplex mode and receive frames from attached segments at a

speed of 1 Gbps.

Each port’s input buffer places received packets in an 18 KB input FIFO to

wait in a queue for the hub’s internal bus. The hub grants ports access to

the bus in a round-robin fashion. When a port has access to the bus, it

places the packet at the head of its input queue on the bus. All the other

ports transmit the packet out. Link-level flow control manages the queue.

Flow Control The Hub 1000 SX uses IEEE 802.3x flow control to prevent input buffers

from overflowing. Flow control uses pause frames to communicate buffer

status between linked transmitting and receiving devices (transmitters

and receivers). A receiver sends a pause frame—thereby using outgoing

flow control—to tell a transmitter to stop the transmission of data frames

for a specified period, allowing the receiver’s input port buffers to empty.

When a transmitter receives pause frames—using incoming flow

control—it suspends transmission for the specified period.

Page 15

Flow Control 1-3

When the receiver’s input buffers can store packets again, it can either

send another pause frame to tell the transmitter to resume transmission,

or wait for transmission to resume.

If the Hub 100 SX receives a pause frame, it does not remove the frame

from the network. Instead, it corrupts the frame’s CRC field and

retransmits the frame to all other ports.

Asymmetric

Flow Control

With asymmetric flow control, only one of two linked devices can use

incoming flow control to receive pause frames. Most full-duplex repeaters

default to asymmetric flow control. The Hub 1000 SX downlinks support

asymmetric, outgoing flow control only. The downlinks can send pause

frames to tell attached devices to stop transmission. They ignore any

pause frames that they receive, because acting upon them would stop

transmission to all ports, bringing hub operation to a halt.

Symmetric

Flow Control

With symmetric flow control, both linked devices can use incoming

and outgoing flow control to send and receive pause frames. The

Hub 1000 SX uplink defaults to symmetric flow control—also known

as bidirectional flow control—which prevents congestion at the core of

the network when the hub is connected to the network backbone.

The uplink can be reconfigured for asymmetric, outgoing flow control to

support a connection to a server or 10/100 Mbps switch.

Auto-Negotiation Related to flow control is the auto-negotiation capability, in which the

Hub 1000 SX ports and linked devices advertise their flow control

capabilities and automatically select the best common mode of

communication. During an auto-negotiation sequence, the Hub 1000 SX

downlinks advertise their capability for outgoing flow control and the

uplink advertises its capability for incoming and outgoing flow control.

For example, the result of an auto-negotiation sequence between a

Hub 1000 SX downlink and a SuperStack II Switch 3000 port is that the

downlink uses outgoing flow control and the switch port uses incoming

flow control.

Forced Link The Hub 1000 SX ports default to auto-negotiation. Rare cases (for

example, linking to a device that does not support auto-negotiation) may

require that auto-negotiation be disabled on a port, thereby enabling

forced link on that port. When forced link is enabled, linked devices must

have matching flow control capabilities. For example, a port that is set for

forced link and outgoing flow control can connect successfully only with

a port that is set for forced link and incoming flow control.

Page 16

1-4 CHAPTER 1: INTRODUCTION

Features and Functions

The hub can be mounted in a 19-inch standard rack or placed on a

flat surface. It supports the 1000 Mbps media access control (MAC)

as specified in the IEEE 802.3z standard. In addition, the hub has

these features:

■ LED indicators report the status of each port and of hub operations. A

meter shows the percentage of bandwidth being used within the hub.

■ The serial console interface allows limited options for port

configuration and, if necessary, firmware updates.

■ Power-on self-test (POST) diagnostics determine whether the hub is

functioning properly at power up.

■ Frame-aging firmware improves performance by minimizing

unnecessary frame aging and subsequent attempts to retransmit

packets at the protocol level.

■ Round-robin arbitration grants fair access for all ports to the hub’s

internal bus on a packet-by-packet basis.

■ Signal retiming restores the timing and amplitude of the received

signal before retransmitting the signal.

■ A carrier integrity monitor checks packets for invalid framing and

removes invalid frames from the network.

■ Jabber control inhibits overly long transmissions of data generated by

the hardware failure of an attached device.

Page 17

INSTALLING THE HUB

2

This chapter describes the Hub 1000 SX package contents and provides

installation procedures for the hub and for optional GBIC modules and

power systems.

No configuration is required to install and use the hub.

Safety Precautions To avoid personal injury or damage to the Hub 1000 SX unit, observe the

following safety precautions:

WARNING: Do not perform any maintenance on the hub while it is still

connected to a power source.

WARNING: Remove all jewelry from your hands and wrists before

installing the hub. Use insulated or nonconductive tools.

CAUTION: Power for the unit must be supplied by a grounded power

source. The hub should never be connected to an ungrounded AC outlet

or power supply.

Package Contents Remove the hub from the shipping package and verify that you have

received these items in good condition:

■ Hub 1000 SX unit

■ Rack mounting kit containing two brackets and four screws

■ Four rubber feet for desktop placement

■ AC power cord

■ SuperStack II Hub 1000 SX User Guide

Inspect each item for damage. If you find a problem, contact the network

supplier and the carrier that delivered the package.

Page 18

2-2 CHAPTER 2: INSTALLING THE HUB

If you need to return the hub to 3Com, pack it in the original (or

equivalent) packing material to maintain the warranty.

If you ordered a GBIC module or optional power system, it is packaged

separately from the hub.

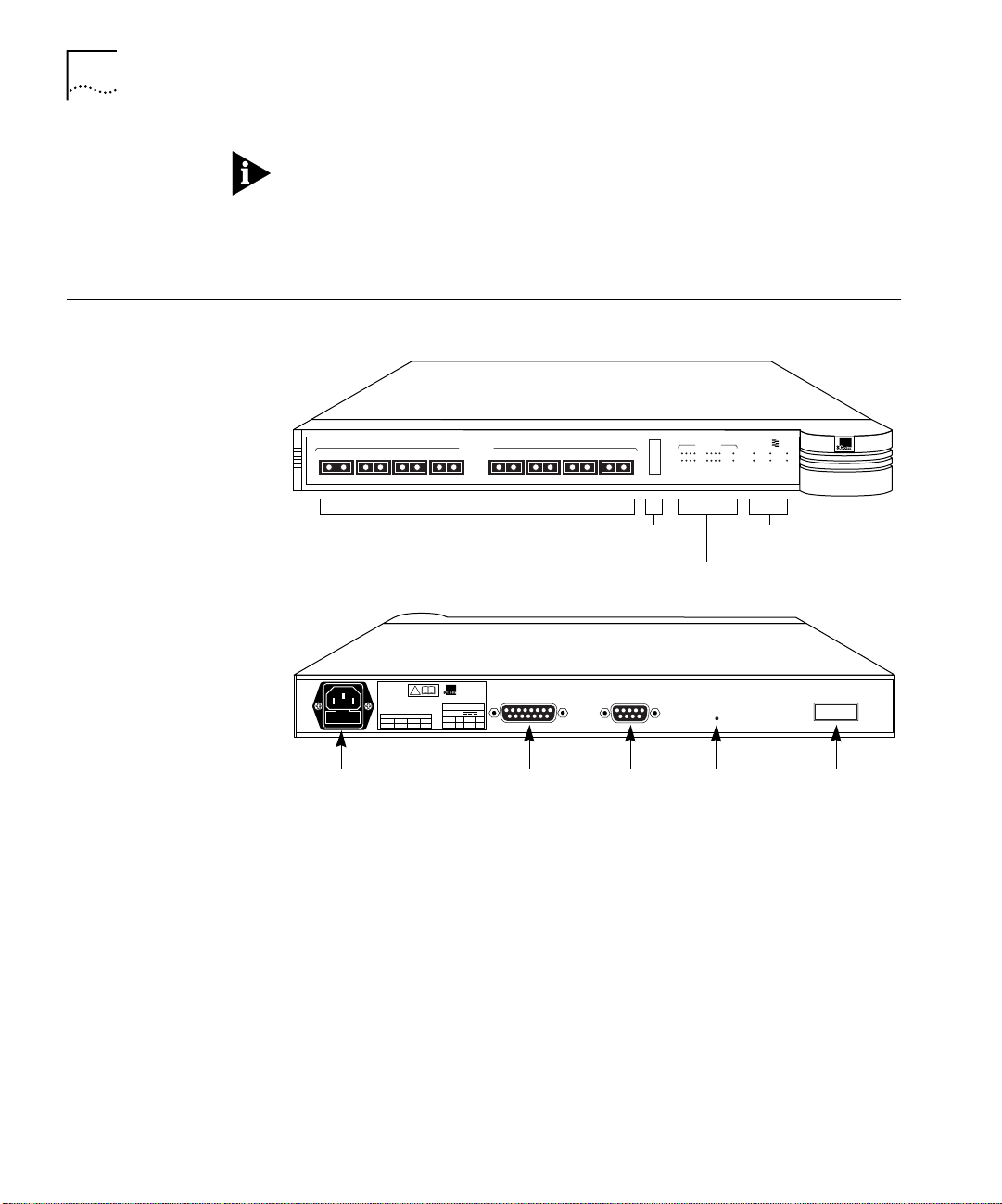

Hub Description The hub’s front and rear panels are shown in Figure 2-1.

Front panel

1

TX RX2TX RX3TX RX4TX RX

3C510-SX

1000BASE-SX downlink ports

1000BASE-SX

5

TX RX6TX RX7TX RX8TX RX

100

ACTIVITY

50

LINK

10

% BW USAGE

% BW

usage meter

PORT STATUS

1

234 5678 9

Hub operation

RPS ONOVERTEMP

SuperStack II

HUB 1000 SX

LEDs

SUPER

STACK

UNIT

STATUS

PAUSERPS FAILPWR

®

PORT STATUS

LEDs

Rear panel

AC

IN

REFER TO

INSTRUCTION MANUAL

FOR CORRECT

SELECTION OF

POWER CORD

CAUTION: For continued protection

against risk of fire use only with same

type and rating of of anti-surge fuse.

SUPPLY DATA

FUSE

2.0 AV~100-240Hz50/60A1.0

3Com Corporation

Santa Clara, CA

®

!

Made in USA

INPUT

A max58.5

DC POWER GBIC

V

+12

-12

2.5

1.0

CONSOLE

RESET

GBIC portAC input DC power Console Reset

Figure 2-1 Hub 1000 SX Front and Rear Panels

Front Panel Eight 850-nanometer (nm) fiber-optic 1000BASE-SX Gigabit Ethernet

downlink ports accept SC connectors and support 50/125 µ or

62.5/125 µ fiber-optic cable. The ports can connect to servers that

are equipped with Gigabit Ethernet NICs or to switches that are

equipped with Gigabit Ethernet uplink devices.

Indicators (see Table 2-2) show hub and port status when power is on.

Page 19

Preparing the Site 2-3

Rear Panel The AC input socket accepts a 100–240 V AC power cord. Power can

be supplied through optional 3Com SuperStack II Advanced Redundant

Power System (Advanced RPS) and SuperStack II Uninterruptible Power

System (UPS) units. These units use the DC power connector. See “Using

Optional Power Systems” later in this chapter.

The console port, a DB-9 standard male connector, can connect to a PC

through a null modem cable. For information on the console functions,

see Appendix A.

The Reset button resets the hub’s on-board CPU.

The GBIC port accepts an optional 3Com GBIC module that lets the hub

connect to a Gigabit Ethernet device.

Preparing the Site Make sure that the installation site meets the following conditions:

■ The hub is accessible and you can easily connect the cables.

■ The cables are away from:

■ Sources of electrical noise, such as: heating, ventilation,

and air conditioning (HVAC); radios; transmitters; and

broadband amplifiers

■ Power lines and fluorescent lighting fixtures

■ Water or moisture cannot enter the hub’s case.

■ Airflow around the unit and through the vents is not restricted.

Provide a minimum of 1-inch (2.5-cm) clearance on all four sides

of the unit.

■ No objects are placed directly on top of the unit.

Installing and Connecting the Hub

You can mount the hub in a standard 19-inch rack or place it on a desk

or table.

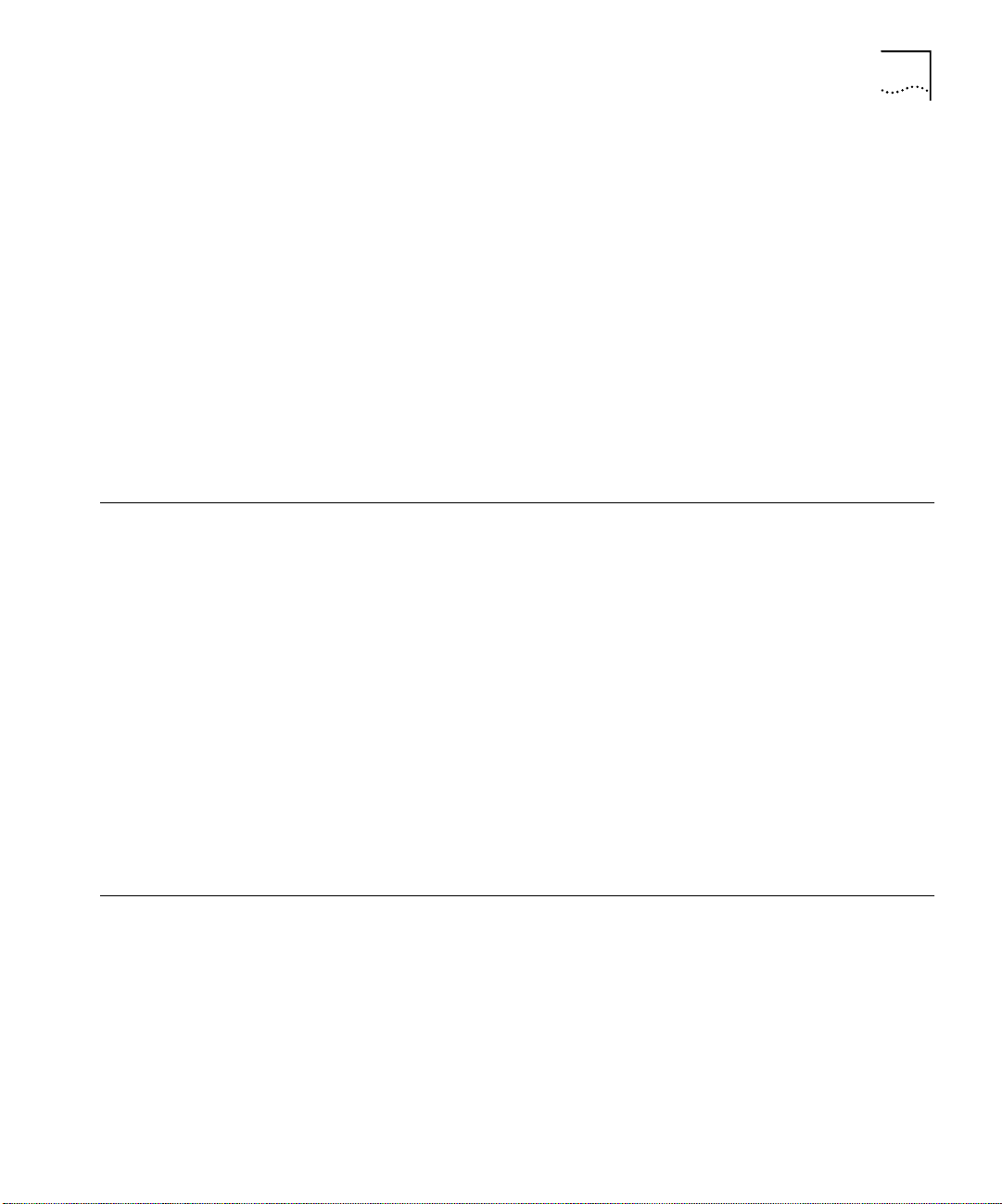

Mounting in a Rack Two brackets and four screws allow rack mounting in a standard

19-inch rack.

1 Place the hub on a level surface, with the front panel facing you.

2 Position a bracket over the mounting holes on one side of the hub,

as shown in Figure 2-2.

Page 20

2-4 CHAPTER 2: INSTALLING THE HUB

®

.

Figure 2-2 Attaching a Bracket for Rack Mounting

3 Insert the two screws and tighten with a screwdriver. Do not overtighten

the screws.

4 Repeat steps 2 and 3 for the other side of the hub.

5 Mount the hub in the rack and secure it with suitable screws, as shown in

Figure 2-3.

TX RX

1

TX RX

2

TX RX

3C510-SX

3

1000BASE-SX

TX RX

4

TX RX

5

TX RX

6

TX RX

7

100

TX RX

8

50

PORT STATUS

ACTIVITY

LINK

10

1

234 5678 9

% BW USAGE

SUPER

STACK

RPS ONOVERTEMP

UNIT

STATUS

PAUSERPS FAILPWR

®

SuperStack II

HUB 1000 SX

Figure 2-3 Rack Mounting the Hub

6 Remove the protective rubber cap from each downlink port and attach

the proper cable to make the desired network connection. Table 2-1

provides connector and cable information for downlink connections.

For guidelines on making typical connections, see Chapter 3.

Page 21

Table 2-1 Downlink Connections

Interpreting Hub Indicators 2-5

Connector

Type

SC Short-wavelength (850 nm) fiber-optic:

Cable Type

62.5/125 µ MMF

50/125 µ MMF

Maximum Cable

Length (Meters)

260

550

7 Apply power to the hub in either of these ways:

■ Plug one end of the power cord into the AC input socket and the

other end into a power source.

■ Connect the hub to a power supply, as described in “Using Optional

Power Systems” later in this chapter.

Placing on a Desktop If you place the hub on a desk or table, attach the supplied rubber feet to

each bottom corner of the hub. Remove the protective cap from each

downlink port and attach the proper cable to make the desired network

connection. (For connector and cable information, see Table 2-1. For

guidelines on making typical connections, see Chapter 3.) Apply power

to the hub in either of these ways:

■ Plug one end of the power cord into the AC input socket and the

other end into a power source.

■ Connect the hub to a power supply, as described in “Using Optional

Power Systems” later in this chapter.

Interpreting Hub Indicators

When power is applied, all the indicators on the front panel light

momentarily. The UNIT STATUS LED is amber while POST is running.

After approximately 30 seconds, the UNIT STATUS LED turns green.

Verify that the PWR (power) LED remains lit, indicating that the hub

is receiving power.

For explanations of the hub indicators, see Table 2-2.

Page 22

2-6 CHAPTER 2: INSTALLING THE HUB

Table 2-2 Hub 1000 SX Indicators

RPS ONOVERTEMP

SUPER

STACK

UNIT

STATUS

PAUSERPS FAILPWR

SuperStack II

HUB 1000 SX

100

50

10

% BW USAGE

PORT STATUS

ACTIVITY

LINK

1234 5678 9

Indicator Color Status Meaning

% BW usage meter Green Fluctuating The meter indicates the percentage of bandwidth that the

hub is using. Because the hub can be connected to multiple

network segments, this meter represents the aggregate

load on the hub.

PORT STATUS LEDs LEDs 1 through 8 show the status of the downlinks. LED 9

shows the status of the uplink.

ACTIVITY Green ON The port is receiving data.

OFF The port is not receiving data.

LINK Green ON A connection exists between the port and the end node.

OFF There is no connection between the port and the end node.

Hub operation LEDs

OVERTEMP Amber ON The internal temperature exceeds 158 °F (70 °C).

RPS ON Green ON The Advanced RPS is connected and turned on.

UNIT STATUS Amber ON The hub is performing POST diagnostics. If the amber LED

remains lit for longer than 30 seconds, POST has failed or

the CPU has halted.

Flashing An error has occurred.

Green ON The hub is operating normally.

Flashing A firmware update is proceeding.

Amber/Green Flashing A firmware update error occurred. See “Troubleshooting”

in Appendix A.

PWR Green ON The hub is receiving power.

RPS FAIL Amber ON The Advanced RPS is connected, but a failure

condition exists.

PAUSE Green ON The uplink port has received a pause frame. For an

explanation of pause frames, see “Flow Control” in

Chapter 1.

Page 23

Installing and Connecting a GBIC Module 2-7

Installing and

Connecting a

GBIC Module

Table 2-3 GBIC Modules

The gigabit interface connector (GBIC) port on the rear panel of the

Hub 1000 SX chassis accepts an optional 3Com GBIC module that

permits connection to a Gigabit Ethernet device. GBIC modules must

be ordered separately in either single-packs or six-packs.

By inserting the appropriate GBIC module in the hub’s rear-panel uplink

port, you can use various types of cabling to connect the hub to LAN

devices. For example, you can use the 1000BASE-LX module to reach

much greater distances than is possible with 1000BASE-SX connections.

A sample GBIC module appears in Figure 2-4. Table 2-3 lists the types of

GBIC modules available from 3Com.

Figure 2-4 Sample GBIC Module

3Com

Module Type

1000BASE-CX 3CGBIC4

1000BASE-LX 3CGBIC2

1000BASE-SX 3CGBIC1

Part Number

3CGBIC4-6PK

3CGBIC2-6PK

3CGBIC1-6PK

Connector

Type

HSSDC Shielded balanced twinaxial STP

SC Long-wavelength fiber-optic

SC Short-wavelength fiber-optic

Cable Type

(coaxial jumper)

(1300 nm):

62.5/125 µ MMF

50/125 µ MMF

SMF

(850 nm):

62.5/125 µ MMF

50/125 µ MMF

Maximum Cable

Length (Meters)

25

440

550

3000

260

550

Page 24

2-8 CHAPTER 2: INSTALLING THE HUB

To install and connect a GBIC module, follow these steps:

1 Disconnect all power to the Hub 1000 SX.

Disconnect the AC power cord. If you are using an Advanced RPS unit,

disconnect the RPS cable from the DC power connector.

2 Remove the GBIC module from its shipping container.

3 Slowly insert the module into the rear-panel uplink port, being careful not

to damage any of the components or connecting pins.

The module slides into the hub following the tracks in the slot. The

lettering that shows the module type must be positioned on top of the

connector openings when the module is in place.

4 Push the module all the way in until the connector makes contact.

5 Reattach the power cord and any power system cable to the hub.

6 Attach the proper cable to the module to make the desired

network connection.

Both ends of the connection must be of the same media type (CX, LX,

or SX).

Using Optional Power Systems

Advanced RPS A single SuperStack II Advanced RPS (part numbers 3C16070 and

7 Reconnect power to the hub.

You can ensure fail-safe operation and constant power to SuperStack II

components by using the SuperStack II Advanced Redundant

Power System (Advanced RPS) and the SuperStack II Uninterruptible

Power System (UPS). These units and associated Power Modules and

cabling must be purchased separately.

3C16071) can protect up to four SuperStack II Hub 1000 SX units from

internal power supply failures. If a SuperStack II unit’s internal power fails,

the Advanced RPS is capable of supplying all the unit’s power needs.

The Advanced RPS chassis is rack-mountable. It is fed by two independent

AC lines and remains operational if one of the AC lines fails. The front panel

provides LED indicators for monitoring temperature as well as power input

and output status.

Page 25

Using Optional Power Systems 2-9

Power Modules

At least one SuperStack II Advanced Redundant Power System

Power Module Type 2 is required for each SuperStack II hub that you

want to protect. The Hub 1000 SX requires the 100-watt, 3.3-volt version

of the module (part number 3C16074).

One Advanced RPS with Power Modules configured with straight cables for

standard usage can contain a maximum of four 100-watt Power Modules

(and four 60-watt Power Modules), or eight 60-watt Power Modules. If

each Power Module is configured for full redundancy with a SuperStack II

Advanced Redundant Power System Y Cable Type 2 (part number

3C16079), an Advanced RPS can contain a maximum of eight 100-watt

Power Modules, supporting as many as four Hub 1000 SX units.

Using the cable supplied with the Power Module, you connect the

Power Module to the DC power connector located on the rear panel

of the Hub 1000 SX. (For the DC power connector location, see

Figure 2-1.)

In the event of a failure in a Power Module, an alert is automatically

sent to the Advanced RPS management console software.

Cabling Options

You can supply AC power and DC power to the Hub 1000 SX

simultaneously, so that if an AC power failure occurs, the hub

switches to DC power supplied by the Advanced RPS unit. You can

also supply only DC power to the hub with the Advanced RPS unit.

Table 2-4 summarizes the Advanced RPS configuration options.

Page 26

2-10 CHAPTER 2: INSTALLING THE HUB

Table 2-4 Advanced RPS Configuration Options

Option Connection Description

Standard usage Disconnect the hub’s AC power cable from

the AC outlet. Use the straight DC cable

supplied with the Power Module to connect

the Power Module directly to the hub

through the DC power connector located

on the hub’s rear panel. (See “Rear Panel”

in this chapter.)

Managed redundancy Connect the hub’s AC power cable to a

standard AC outlet. Use the straight DC

cable supplied with the Power Module to

connect the Power Module directly to the

hub through the DC power connector

located on the hub’s rear panel. (See “Rear

Panel” in this chapter.)

Full redundancy Disconnect the hub’s AC power cable from

the AC outlet. Use a Y DC cable (part

number 3C16079) to connect the hub

directly to two Power Modules through the

DC power connector located on the hub’s

rear panel. (See “Rear Panel” in this chapter.)

The hub obtains DC power from a single

Power Module instead of being powered

directly from a standard AC source. If the

Power Module fails, you can swap the faulty

module for a new one. This swapping

method requires a reset of the hub, as in

a power cycle.

A cold Power Module supplies power after

about 5 seconds.

If the Hub 1000 SX internal power supply

fails, the hub’s auto-enable feature

automatically enables the Advanced RPS

and resets the hub, as in a power cycle.

This configuration offers full resilience for

mission-critical installations. The hub is

powered from both Power Modules instead

of being powered directly from a standard

AC source. If one of the Power Modules fails,

the other module takes the full load. The

faulty module can be hot-swapped,

returning the system to full redundancy

without the need for a power reset.

Uninterruptible

Power System

When switching from Advanced RPS (DC) to AC power or from AC power

to Advanced RPS power, the Hub 1000 SX unit resets itself. For example,

if both the RPS and AC cables are plugged in, and then either is removed,

the unit resets itself when it changes to the other power source.

The SuperStack II Uninterruptible Power System (UPS) (part number

3C16010, U.S. version) protects against building power outages,

brownouts, power surges, and spikes. If primary power fails or falters

for any reason, the UPS automatically provides power for as long as

7 minutes for up to four SuperStack II system units with 100-volt

50/60 Hz, 120-volt 60 Hz, or 230-volt 50/60 Hz power.

A hub connects to a UPS unit through the hub’s AC power cord.

Page 27

Using Optional Power Systems 2-11

You can connect a UPS unit to an Advanced RPS unit as long as you do

not exceed the maximum wattage (325 watts) for the UPS unit. To verify

that the UPS unit’s maximum wattage is not exceeded, calculate the total

power consumption of all units connected to the Advanced RPS. If the

result is less than 325 watts, your configuration is safe; if the result is

greater than 325 watts, then there are too many units connected to

the Advanced RPS.

To calculate the total power consumption of all units connected to the

Advanced RPS:

1 Calculate the total wattage of all the units connected to the Advanced RPS.

For example, one Hub 1000 SX has a maximum power consumption of

65 watts; two Hub 1000 SX units have a maximum power consumption

of 130 watts, and so forth.

2 Divide the total wattage of all units by 0.7, which is the efficiency rating

(70%) of the Advanced RPS.

If the result is less than 325 watts, your configuration is safe; if the result

is higher, then there are too many units connected to the Advanced RPS.

Page 28

Page 29

MAKING CONNECTIONS

3

This chapter contains guidelines for making typical Hub 1000 SX network

connections and for troubleshooting problems with the hub.

When making hub connections, follow the rules for maximum cable

lengths, which are summarized in Table 3-1. If you connect 10/100 Mbps

devices to the network, rules for Ethernet and Fast Ethernet connections

also apply.

Table 3-1 Gigabit Ethernet Maximum Cable Lengths

Cable Type

50/125 µ

Laser

Signal Type

1000BASE-SX Short

1000BASE-LX*Long

1000BASE-CX N/A HSSDC N/A N/A N/A 25 meters

* The 1000BASE-LX GBIC module requires an external patch cord for connection to MMF cable.

Wavelength

(850 nm)

(1300 nm)

Connector

Type

SC 550 meters 260 meters N/A N/A

SC 550 meters 440 meters 3 kilometers N/A

Multimode

Fiber

62.5/125 µ

Multimode

Fiber

Single-Mode

Fiber

Shielded

Balanced Pair

(Coaxial Jumper)

CAUTION: Connecting the downlink of one Hub 1000 SX to the uplink

of a second Hub 1000 SX degrades the performance of the second hub.

CAUTION: Connecting a Gigabit Ethernet switch downlink to a

Hub 1000 SX downlink degrades the performance on the link to

the switch.

Page 30

3-2 CHAPTER 3: MAKING CONNECTIONS

Aggregating Servers

You can use the Hub 1000 SX downlinks to aggregate servers into server

farms. First, install 3Com 3C985-SX Gigabit EtherLink

®

Server NICs in

each server. Then, connect up to eight servers through the downlinks.

The hub’s optional gigabit interface connector (GBIC) uplink can connect

to a 3Com SuperStack II Switch 9300 Gigabit Ethernet switch, thereby

connecting to the network backbone. See Figure 3-1.

SuperStack II

Switch 9300

SUPER

®

STACK

SuperStack II

9300 SX

Figure 3-1 Server Farm Connection

Single-mode fiber-optic cable

Maximum distance: 3 km

62.5/125 µ fiber-optic cable

Maximum distance: 260 m

Gigabit EtherLink Server NICs

SuperStack II

Hub 1000 SX

SUPER

STACK

SuperStack II

1000 SX

Servers with 3C985-SX

®

Connecting a

Power Workgroup

A power workgroup consists of a small number of servers, or a small

number of sophisticated users on high-end workstations. Such a

workgroup requires very high performance to run applications that

move and process massive amounts of data in real time (for example,

medical imaging, video editing, film postproduction, CAD/CAM, or

digital prepress).

You can provide gigabit bandwidth to a power workgroup as shown in

Figure 3-2.

Page 31

SuperStack II

Switch 9300

SUPER

®

STACK

SuperStack II

9300 SX

Single-mode fiber-optic cable

Maximum distance: 3 km

62.5/125 µ fiber-optic cable

Maximum distance: 260 m

Servers with 3C985-SX

Gigabit EtherLink Server NICs

Figure 3-2 Power Workgroup Connection

Aggregating Switches 3-3

High-end

workstations

SuperStack II

Hub 1000 SX

SUPER

®

STACK

SuperStack II

1000 SX

Aggregating Switches

You can use the Hub 1000 SX downlinks to aggregate 10/100 Mbps

switches such as the 3Com SuperStack II Switch 1000, Switch 3000,

or Switch 3900. The Switch 1000 and Switch 3000 units must be

equipped with Gigabit Ethernet uplink devices (SuperStack II Switch

Gigabit Ethernet SX Module, part number 3C16925). The Switch 3900

has one built-in Gigabit Ethernet port, which can be used to connect with

the Hub 1000 SX.

First, install 3C16925 uplink devices in the SuperStack II Switch 1000

or SuperStack II Switch 3000 switches. Then connect up to eight

switches to the Hub 1000 SX through the eight downlinks. The hub’s

optional GBIC uplink can connect to a 3Com SuperStack II Switch 9300

Gigabit Ethernet switch, thereby connecting to the network backbone.

See Figure 3-3.

The Hub 1000 SX does not support bandwidth aggregation (trunking).

Page 32

3-4 CHAPTER 3: MAKING CONNECTIONS

SuperStack II

Switch 9300

SUPER

®

STACK

SuperStack II

9300 SX

Single-mode fiber-optic cable

Maximum distance: 3 km

62.5/125 µ fiber-optic cable

Maximum distance: 260 m

SuperStack II

Hub 1000 SX

SUPER

®

STACK

SuperStack II

1000 SX

SuperStack II

®

Switch 1000

with 3C16925

uplink device

10/100 Mbps

SUPER

STACK

SuperStack II

1000 SX

SuperStack II

Switch 3900

SUPER

®

STACK

SuperStack II

3900

SuperStack II

Switch 3000

with 3C16925

uplink device

SUPER

STACK

SuperStack II

1000 SX

UTP links

Maximum distance: 100 m

Multiple 10/100 Mbps

clients

Multiple 10 Mbps

clients

Figure 3-3 Aggregated Switches Connection

Mixing Connections You can vary connections according to your requirements. For example,

you can connect a number of servers and 10/100 Mbps switches through

the downlinks, and connect to the network backbone through the

uplink, as shown in Figure 3-4.

®

Page 33

SuperStack II

Switch 9300

SUPER

STACK

SuperStack II

9300 SX

Servers with

3C985-SX Gigabit

EtherLink Server NICs

Connecting Through the Uplink 3-5

®

Single-mode fiber-optic cable

Maximum distance: 3 km

62.5/125 µ fiber-optic cable

Maximum distance: 260 m

SuperStack II

Hub 1000 SX

SUPER

®

STACK

SuperStack II

1000 SX

SuperStack II

Switch 3900

Connecting Through the Uplink

SUPER

®

STACK

SuperStack II

3900

SuperStack II

Switch 3000

with 3C16925

uplink device

SUPER

STACK

SuperStack II

1000 SX

®

SuperStack II

Switch 1000

with 3C16925

uplink device

SUPER

STACK

SuperStack II

1000 SX

10/100 Mbps

UTP links

Maximum distance: 100 m

Multiple 10/100 Mbps

clients

Multiple 10 Mbps

clients

Figure 3-4 Mixed Connection

The best use of the hub uplink is as a backbone connection to a 3Com

SuperStack II Switch 9300 Gigabit Ethernet switch, as shown earlier in

Figure 3-1 through Figure 3-2. Although two Hub 1000 SX units can be

connected to each other through their uplinks, as shown in Figure 3-5,

such a connection excludes connection to the network backbone.

Single-mode fiber-optic cable

Maximum distance: 3 km

SUPER

®

STACK

SuperStack II

1000 SX

SuperStack II

Hub 1000 SX

SUPER

®

STACK

SuperStack II

1000 SX

SuperStack II

Hub 1000 SX

®

Figure 3-5 Connection to Another Hub 1000 SX

Page 34

3-6 CHAPTER 3: MAKING CONNECTIONS

The Hub 1000 SX itself can be used as the network backbone by

connecting the uplink to a server equipped with a 3C985-SX Gigabit

EtherLink Server NIC or to a 10/100 Mbps switch equipped with a

3C16925 uplink device (see Figure 3-6). For these backbone connections,

reconfigure the uplink for asymmetric flow control, as described in

“Configuring Port Settings” in Appendix A.

Single-mode fiber-optic cable

Maximum distance: 3 km

SUPER

SuperStack II

Hub 1000 SX

®

STACK

SuperStack II

1000 SX

10/100 Mbps switch

with 3C16925 uplink device

100BASE-TX

SUPER

STACK

SuperStack II

3000 FX

Figure 3-6 Uplink Connection to a 10/100 Mbps Switch

Troubleshooting Table 3-2 summarizes some common problems and their solutions.

Table 3-2 Troubleshooting Tips

®

Symptom Explanation Solution

LINK LED does not light on

a port.

There is no link connection. You may be attempting to connect to equipment

that does not comply with Gigabit Ethernet

standards or does not support auto-negotiation.

Or, the link may be physically damaged (for example,

the cable may be damaged).

Disable auto-negotiation on the port (see Appendix A).

Configure the other end of the link for forced

configuration (see the configuration guidelines for

the device on the other end of the link). A restored

connection rules out physical damage.

ACTIVITY LED does not light

The port is not receiving data. Make sure that the link is connected at both ends.

on a port.

OVERTEMP LED is lit. The unit has overheated.

Return the unit to the supplier.

The fan may have failed.

Amber UNIT STATUS LED stays

lit longer than 30 seconds.

POST software may

be corrupted.

Use the command line interface (CLI) to confirm the

POST error. (See Appendix A.) If POST reports errors,

return the unit to the supplier.

PAUSE LED remains lit. A flickering PAUSE LED

indicates normal flow control.

Check for problems with the device attached to the

Hub 1000 SX uplink.

A PAUSE LED that remains lit

indicates that there is too

much traffic.

POST FAIL messages appear

in the CLI.

There is a fatal

hardware error.

Return the unit to the supplier.

Page 35

A

USING THE CONSOLE PORT

The Hub 1000 SX is ready to use and requires no configuration. However,

on rare occasions you may need to confirm a POST failure, change a

port’s configuration, or update the firmware image to install a bug fix or a

standards update. The console port provides access to a simple scrolling

command line interface (CLI). By connecting the console port to a PC, you

can perform these tasks:

■ Configure port settings

■ Display hub status

■ Update the firmware image

The console port (a DB-9 standard male connector) is located on the

Hub 1000 SX rear panel. See Figure A-1.

AC

IN

REFER TO

INSTRUCTION MANUAL

FOR CORRECT

SELECTION OF

POWER CORD

CAUTION: For continued protection

against risk of fire use only with same

type and rating of of anti-surge fuse.

SUPPLY DATA

FUSE

2.0 AV~100-240Hz50/60A1.0

3Com Corporation

Santa Clara, CA

®

!

Made in USA

INPUT

V

A max58.5

DC POWER GBIC

+12

-12

2.5

1.0

CONSOLE

RESET

Console

Figure A-1 Console Port

The console port default settings are:

■ 9600 baud

■ 8 data bits

■ 1 stop bit

■ No parity

Auto-baud and modem connections are not supported.

Page 36

A-2 APPENDIX A: USING THE CONSOLE PORT

Requirements To use the console port and CLI, you need:

■ A PC with a serial port

■ A null modem cable

■ A terminal-emulation program

If you need to perform a firmware update, the terminal-emulation

program must support one of these file transfer protocols: Xmodem,

Xmodem-1K, or Xmodem-CRC.

Connecting the Console Port

With Power

Connected

It is not necessary to disconnect the hub from the power source to

connect the console port. However, if you do disconnect the power,

you can watch POST messages when you reconnect the power.

To connect the console port while the hub is connected

to power:

1 Connect a null modem cable between the PC serial port and the console

port on the hub’s rear panel. (See Figure A-1.)

2 Turn on the PC.

3 Start the terminal-emulation program.

4 Configure the program with the same settings as the Hub 1000 SX

console interface port:

■ 9600 baud

■ 8 data bits

■ 1 stop bit

■ No parity

5 Press Enter.

The PC screen displays the CLI header and the password prompt:

****************************************************

* *

* SuperStack II (tm) *

* Hub 1000 SX *

* Copyright (c)1997 3Com Corporation *

* *

****************************************************

Enter password ->

Page 37

Connecting the Console Port A-3

With Power

Disconnected

To connect the console port when the hub is disconnected

from power:

1 Connect a null modem cable between the PC serial port and the

console port on the Hub 1000 SX rear panel.

2 Turn on the PC.

3 Start the terminal-emulation program.

4 Configure the program with the same settings as the Hub 1000 SX

console interface port:

■ 9600 baud

■ 8 data bits

■ 1 stop bit

■ No parity

5 Reconnect the hub to the power supply.

The PC screen displays POST messages, followed by the CLI header and

the password prompt.

POST Messages When you connect the hub to power or when you press the Reset button

on the hub’s rear panel, the PC screen displays messages while POST is

proceeding. When POST is finished, the CLI header appears, followed by

the password prompt. For example:

POST Level 0: PASS

Checking FDS ... valid.

Performing Level 1 Tests ...

Test: Port 0 - Pass.

Test: Port 1 - Pass.

Test: Port 2 - Pass.

Test: Port 3 - Pass.

Test: Port 4 - Pass.

Test: Port 5 - Pass.

Test: Port 6 - Pass.

Test: Port 7 - Pass.

Test: Port 8 - Pass.

Test: Port aliasing - Pass.

Test: MAC Address - Valid: 08004E2BA4D9

Test: Fan sense - Pass.

POST Level 1: PASS

Page 38

A-4 APPENDIX A: USING THE CONSOLE PORT

Hardware Version 0

Bootcode Version 1.00, 02/05/98

Firmware Version 1.00, 02/05/98

****************************************************

* *

* SuperStack II (tm) *

* Hub 1000 SX *

* Copyright (c)1997 3Com Corporation *

* *

****************************************************

Enter password ->

Any POST FAIL message indicates a fatal hardware error. If you see a FAIL

message, return the hub to the supplier.

Logging On The default password that is set at the factory is admin. If this is the first

time that anyone has logged on to the hub, enter the default password at

the prompt:

admin

Asterisks (*) instead of plain text appear at the prompt while you are

typing the password.

The Hub 1000 SX Configuration menu appears.

***************************************************

** Hub 1000 Configuration Menu **

***************************************************

[1] Configure port settings

[2] Display hub status

[3] Update firmware image

[4] Change password

[5] Logout

Enter choice ->

To select an option from the Configuration menu, enter the option

number at the prompt.

After 4 minutes of inactivity, the CLI logs off automatically.

Page 39

Changing the Password A-5

Changing the Password

You can change the password if you need to. The new password must be

eight characters or fewer and cannot contain spaces or tabs.

To change the password, enter:

4

You are prompted to enter the old password and then the new password,

as shown in this example:

***************************************************

** Hub 1000 Configuration Menu **

***************************************************

[1] Configure port settings

[2] Display hub status

[3] Update firmware image

[4] Change password

[5] Logout

Enter choice -> 4

Old password: *****

New password: *******

Re-enter new password: *******

Password changed.

The following sections show examples of how to use the Hub 1000 SX

Configuration menu.

Configuring

Port Settings

Table A-1 summarizes the situations that require you to configure port

settings through the Port Configuration menu.

Table A-1 Situations That Require Configuring Port Settings

Situation Action

You do not want a port to be connected. Disable the port.

A port cannot connect with a linked device. Disable auto-negotiation. (Force

A linked device does not support

auto-negotiation.

You are connecting to a server or a

10/100 Mbps switch through the uplink.

the link.)

Disable auto-negotiation. (Force

the link.)

Configure the uplink for

asymmetric flow control.

Page 40

A-6 APPENDIX A: USING THE CONSOLE PORT

To display the Port Configuration menu:

1 At the Configuration menu prompt, enter:

1

2 At the next prompt, enter the numbers of the ports that you want

to configure.

You can specify a single port number, multiple port numbers separated by

commas or spaces (for example: 5, 6 7), or a range of port numbers

separated with a hyphen (for example: 5-7).

The following example specifies ports 3, 5, 6, and 7:

***************************************************

** Hub 1000 Configuration Menu **

***************************************************

[1] Configure port settings

[2] Display hub status

[3] Update firmware image

[4] Change password

[5] Logout

Enter choice -> 1

Enter port number(s), from 1 to 9: 3 5-7

The Port Configuration menu appears, and the specified ports are

displayed. For example:

**** Port Configuration Menu ****

(1) Enable port

(2) Disable port

(3) Enable Auto-Negotiation

(4) Disable Auto-Negotiation (Force link)

(5) Show port settings

(6) Use factory default settings

(7) Save new port settings

(8) Exit without change to settings

(9) Apply changes and exit

Selected ports: 3, 5, 6, 7

Enter choice ->

Table A-2 summarizes the Port Configuration menu options.

Page 41

Configuring Port Settings A-7

Table A-2 Port Configuration Menu

Option Description

(1) Enable port Enable the port for linking. The factory

(2) Disable port Disable the port for linking.

(3) Enable auto-negotiation Enable auto-negotiation. The factory

(4) Disable auto-negotiation (force link) Disable auto-negotiation.

(5) Show port settings List the current settings for all ports.

(6) Use factory default settings Return selected ports to factory

(7) Save new port settings Save the settings. Select this option if you

(8) Exit without change to settings Exit to the Hub 1000 SX Configuration

(9) Apply changes and exit Apply the settings and exit to the

default is all ports enabled.

default is auto-negotiation enabled on

all ports.

default settings.

want settings to persist after a hub reset.

menu without applying or saving settings.

Hub 1000 SX Configuration menu.

If you want settings to persist after a hub

reset, you must select option 7 before

selecting option 9.

Disabling Ports The following example shows how to disable ports 3, 5, 6, and 7 and

apply the changes.

***************************************************

** Hub 1000 Configuration Menu **

***************************************************

[1] Configure port settings

[2] Display hub status

[3] Update firmware image

[4] Change password

[5] Logout

Enter choice -> 1

Enter port number(s), from 1 to 9: 3 5-7

**** Port Configuration Menu ****

(1) Enable port

(2) Disable port

(3) Enable Auto-Negotiation

(4) Disable Auto-Negotiation (Force link)

Page 42

A-8 APPENDIX A: USING THE CONSOLE PORT

(5) Show port settings

(6) Use factory default settings

(7) Save new port settings

(8) Exit without change to settings

(9) Apply changes and exit

Selected ports: 3, 5, 6, 7

Enter choice -> 2

**** Port Configuration Menu ****

(1) Enable port

(2) Disable port

(3) Enable Auto-Negotiation

(4) Disable Auto-Negotiation (Force link)

(5) Show port settings

(6) Use factory default settings

(7) Save new port settings

(8) Exit without change to settings

(9) Apply changes and exit

Selected ports: 3, 5, 6, 7

Enter choice -> 9

Changes applied

Disabling

Auto-Negotiation

Any time you select option 9 without selecting option 7, the settings will

return to the previous values in the event of a hub reset. This allows you

to experiment with port settings without specifying that they persist after

a hub reset. If you want settings to persist, select option 7 before

selecting option 9.

Disabling the auto-negotiation capability enables forced link on a port.

When forced link is enabled, linked devices must have matching flow

control capabilities. For example, a port that is set for forced link and

outgoing flow control can connect successfully only with a port that is

set for forced link and incoming flow control.

When you disable auto-negotiation on a Hub 1000 SX port, you also

need to set forced link on the connected device. On some devices, this

setting is called forced configuration or link negotiation. For details on

the correct configuration, see the configuration guidelines for the linked

device.

The following example shows how to disable auto-negotiation on port 1,

save the new port setting, and apply it.

Page 43

Configuring Port Settings A-9

***************************************************

** Hub 1000 Configuration Menu **

***************************************************

[1] Configure port settings

[2] Display hub status

[3] Update firmware image

[4] Change password

[5] Logout

Enter choice -> 1

Enter port number(s), from 1 to 9: 1

**** Port Configuration Menu ****

(1) Enable port

(2) Disable port

(3) Enable Auto-Negotiation

(4) Disable Auto-Negotiation (Force link)

(5) Show port settings

(6) Use factory default settings

(7) Save new port settings

(8) Exit without change to settings

(9) Apply changes and exit

Selected ports: 1

Enter choice -> 4

Enable Outgoing Flowcontrol (Y/N)? y

Port 1 is a downlink. Because downlinks support outgoing flow control only,

you can enable or disable outgoing flow control, but you cannot configure

incoming flow control. You might choose to disable outgoing flow control

if the port is linking to a device that does not support flow control.

**** Port Configuration Menu ****

(1) Enable port

(2) Disable port

(3) Enable Auto-Negotiation

(4) Disable Auto-Negotiation (Force link)

(5) Show port settings

(6) Use factory default settings

(7) Save new port settings

(8) Exit without change to settings

(9) Apply changes and exit

Selected ports: 1

Enter choice -> 7

Settings saved

Page 44

A-10 APPENDIX A: USING THE CONSOLE PORT

Because option 7 has been selected, the settings will persist after a

hub reset.

**** Port Configuration Menu ****

(1) Enable port

(2) Disable port

(3) Enable Auto-Negotiation

(4) Disable Auto-Negotiation (Force link)

(5) Show port settings

(6) Use factory default settings

(7) Save new port settings

(8) Exit without change to settings

(9) Apply changes and exit

Selected ports: 1

Enter choice -> 9

Changes applied

Configuring

the Uplink for

Asymmetric

Flow Control

The uplink (port 9) defaults to symmetric (both outgoing and incoming)

flow control. You must configure the uplink for asymmetric flow control

to connect it to a server or 10/100 Mbps switch. The server or switch

must have the appropriate NIC or uplink device, support flow control,

and be configured to receive pause frames.

The following example shows how to configure the uplink for asymmetric

flow control by disabling auto-negotiation, enabling outgoing flow

control, and disabling incoming flow control. With this configuration,

the uplink is set to forced link and can send pause frames but ignores

pause frames that it receives. (For more details on flow control, see “Flow

Control” in Chapter 1.)

***************************************************

** Hub 1000 Configuration Menu **

***************************************************

[1] Configure port settings

[2] Display hub status

[3] Update firmware image

[4] Change password

[5] Logout

Enter choice -> 1

Enter port number(s), from 1 to 9: 9

Page 45

Configuring Port Settings A-11

**** Port Configuration Menu ****

(1) Enable port

(2) Disable port

(3) Enable Auto-Negotiation

(4) Disable Auto-Negotiation (Force link)

(5) Show port settings

(6) Use factory default settings

(7) Save new port settings

(8) Exit without change to settings

(9) Apply changes and exit

Selected ports: 9

Enter choice -> 4

Enable Outgoing Flowcontrol (Y/N)? y

Enable Incoming Flowcontrol (Y/N)? n

**** Port Configuration Menu ****

(1) Enable port

(2) Disable port

(3) Enable Auto-Negotiation

(4) Disable Auto-Negotiation (Force link)

(5) Show port settings

(6) Use factory default settings

(7) Save new port settings

(8) Exit without change to settings

(9) Apply changes and exit

Selected ports: 9

Enter choice -> 7

Settings saved

Because option 7 has been selected, the settings will persist after a hub reset.

**** Port Configuration Menu ****

(1) Enable port

(2) Disable port

(3) Enable Auto-Negotiation

(4) Disable Auto-Negotiation (Force link)

(5) Show port settings

(6) Use factory default settings

(7) Save new port settings

(8) Exit without change to settings

(9) Apply changes and exit

Selected ports: 9

Enter choice -> 9

Changes applied

Page 46

A-12 APPENDIX A: USING THE CONSOLE PORT

Displaying

Hub Status

Hub status includes a matrix of information about the hub ports. In this

matrix, Y indicates yes and n indicates no. (See Table A-3.)

Table A-3 Hub Status Information

Category State Description

Port is enabled Y The port is enabled for linking.

n The port is disabled for linking.

Link state is up Y A link exists between the port and a device.

n No link exists between the port and

a device.

Auto-negotiate link

configuration

Advertise outgoing

flow control

Advertise incoming

flow control

Enable outgoing flow control Y or n If auto-negotiation is enabled, the result of

Enable incoming flow control Y or n If auto-negotiation is enabled, the result of

Y The port is set for auto-negotiation.

n The port is set for forced link.

Y The port signals outgoing flow

control capability.

n The port does not signal outgoing flow

control capability.

Y The port signals incoming flow

control capability.

n The port does not signal incoming flow

control capability.

– The port does not support incoming

flow control.

the negotiation between the port and the

linked device is shown. If auto-negotiation

is disabled, the flow control you specify

is shown.

the negotiation between the port and the

linked device is shown. If auto-negotiation

is disabled, the flow control you specify

is shown.

– The port does not support incoming

flow control.

Page 47

Displaying Hub Status A-13

Hub status also includes POST and fan status, bandwidth utilization,

hardware and firmware version, and MAC address.

The sample hub status display that follows is the result of the changes

made in the previous section. To view the hub status, enter:

2

When you have finished viewing the hub status, press Enter to continue

the CLI session.

***************************************************

** Hub 1000 Configuration Menu **

***************************************************

[1] Configure port settings

[2] Display hub status

[3] Update firmware image

[4] Change password

[5] Logout

Enter choice -> 2

Hub Status

Port Number: 1 2 3 4 5 6 7 8 9

=========== = = = = = = = = =

Port is Enabled: Y Y n Y n n n Y Y

Link state is up: Y Y n Y n n n Y Y

Auto-Negotiate link configuration: n Y Y Y Y Y Y Y n

Advertise outgoing flow control: Y Y Y Y Y Y Y Y Y

Advertise incoming flow control: - - - - - - - - n

Enable outgoing flow control: Y Y Y Y Y Y Y Y Y

Enable incoming flow control: - - - - - - - - n

Port has passed POST: Y Y Y Y Y Y Y Y Y

POST status: PASS

Fan status: Good

Bandwidth utilization: 0%

Hardware Version: 0

Firmware version: 1.00, 02/05/98

MAC Address: 08004E2BA4D9

Press Enter to continue ...

Page 48

A-14 APPENDIX A: USING THE CONSOLE PORT

Restoring the Factory Default Settings

To restore port settings to factory defaults:

1 At the Configuration menu prompt, enter:

1

2 Enter the numbers of the ports to be restored to factory defaults.

3 At the Port Configuration menu prompt, enter:

6

4 Apply the changes.

For example:

***************************************************

** Hub 1000 Configuration Menu **

***************************************************

[1] Configure port settings

[2] Display hub status

[3] Update firmware image

[4] Change password

[5] Logout

Enter choice -> 1

Enter port number(s), from 1 to 9: 1-9

**** Port Configuration Menu ****

(1) Enable port

(2) Disable port

(3) Enable Auto-Negotiation

(4) Disable Auto-Negotiation (Force link)

(5) Show port settings

(6) Use factory default settings

(7) Save new port settings

(8) Exit without change to settings

(9) Apply changes and exit

Selected ports: 1, 2, 3, 4, 5, 6, 7, 8, 9

Enter choice -> 6

Ports set to factory defaults

Page 49

Updating the Firmware Image A-15

**** Port Configuration Menu ****

(1) Enable port

(2) Disable port

(3) Enable Auto-Negotiation

(4) Disable Auto-Negotiation (Force link)

(5) Show port settings

(6) Use factory default settings

(7) Save new port settings

(8) Exit without change to settings

(9) Apply changes and exit

Selected ports: 1, 2, 3, 4, 5, 6, 7, 8, 9

Enter choice -> 9

Changes applied

If you want settings to persist after a hub reset, enter option 7 before

entering option 9.

Updating the Firmware Image

Checking the

Firmware Version

On rare occasions you may need to update the hub’s firmware image to

install a bug fix or a standards update. Firmware updates are made

available on the 3Com World Wide Web site:

http://www.3com.com/

To verify that the firmware version on the 3Com World Wide Web site

is more recent than the version installed on the hub, display the hub

status. At the Hub 1000 SX Configuration menu prompt, enter:

2

***************************************************

** Hub 1000 Configuration Menu **

***************************************************

[1] Configure port settings

[2] Display hub status

[3] Update firmware image

[4] Change password

[5] Logout

Enter choice -> 2

The firmware version is listed near the bottom of the Hub Status screen.

For example:

Firmware version: 1.00, 02/05/98

Page 50

A-16 APPENDIX A: USING THE CONSOLE PORT

Transferring the

Firmware Image File

Make sure that the terminal-emulation program supports one of

the following file transfer protocols: Xmodem, Xmodem-1K, or

Xmodem-CRC.

To transfer the firmware image file:

1 Obtain the file that contains the firmware image from the 3Com

World Wide Web site:

http://www.3com.com/

2 Copy the file to the PC.

3 Connect the console port to the PC. (See “Connecting the Console Port”

earlier in this appendix.)

4 Log on. (See “Logging On” earlier in this appendix.)

5 At the Hub 1000 SX Configuration menu prompt, enter:

3

***************************************************

** Hub 1000 Configuration Menu **

***************************************************

[1] Configure port settings

[2] Display hub status

[3] Update firmware image

[4] Change password

[5] Logout

Enter choice -> 3

The hub enters file transfer mode and prompts you to begin the

file transfer.

Please initiate XMODEM transfer now. Press <ESC> to abort.

C

The C character indicates that the hub is waiting for the

terminal-emulation program to send a file.

If you want to stop the file transfer at this point, press Esc.

6 From the terminal-emulation program, select the appropriate

command to send a file using the Xmodem, Xmodem-1K, or

Xmodem-CRC protocol.

This command varies, depending on the terminal-emulation program.

Some programs call this operation uploading a file.

Page 51

Logging Off A-17

7 When prompted, enter the filename of the firmware image file.

The terminal-emulation program begins to transfer the firmware image

file. If you want to stop the file transfer, use the appropriate command in

the terminal-emulation program.

After the transfer is finished, the CLI displays the following message:

File transfer successful.

Firmware update successful.

If the runtime software is corrupted (for example, if power is interrupted

during a firmware update), the CLI displays the following message:

Runtime image not valid.

The CLI prompts you to restart the file transfer, without requiring you to

log in again. To restart the file transfer, repeat steps 6 and 7.

Logging Off To log off the CLI, at the Hub 1000 SX Configuration menu

prompt, enter:

5

***************************************************

** Hub 1000 Configuration Menu **

***************************************************

[1] Configure port settings

[2] Display hub status

[3] Update firmware image

[4] Change password

[5] Logout

Enter choice -> 5

The screen returns to the CLI header and the password prompt.

Troubleshooting If a firmware update error occurs, the UNIT STATUS LED flashes

amber/green. Press the Reset button on the Hub 1000 SX rear panel and

repeat the procedure for updating the firmware. If the UNIT STATUS LED

continues to flash amber/green, return the unit to the supplier.

Table A-4 summarizes error messages that may appear during a file

transfer and actions you can take to correct the errors.

Page 52

A-18 APPENDIX A: USING THE CONSOLE PORT

Table A-5 lists fatal error messages. These messages indicate that the

memory unit has failed. If you see a fatal error message, return the unit

to the supplier.

Table A-4 File Transfer Error Messages

Message Meaning Action

Xmodem error: Timed out

sending NAK.

Xmodem error: Timed out

sending ACK.

Xmodem error: Timed out waiting

for packet.

Timed out waiting for transfer

to start.

Xmodem error: Got too many

errors to continue.

Xmodem error. A general protocol error occurred.

Abort key hit. Transfer aborted. The user pressed Esc to stop

Transfer aborted by file sender. The Xmodem operation in the

File too large. Transfer aborted. The file being transferred is too large

Downloaded file not valid. The firmware image file is corrupted,

The hub could not send a negative

acknowledgment.

The hub could not send an

acknowledgment.

The time limit for receiving a packet

was exceeded.

The time limit for starting the file

transfer was exceeded.

The hub error limit was exceeded.

the transfer.

terminal-emulation program stopped

the transfer.

for the hub’s memory.

or its format is incorrect.

For any of these errors, check the

following items and then restart

the transfer:

■ Make sure that the hub is in file

transfer mode (you selected

option 3 in the Hub 1000 SX

Configuration menu).

■ Make sure that you are using

the correct protocol in the

terminal-emulation program.

■ Verify that you copied the correct

file from the 3Com Web site. If

necessary, download the file from

the Web site again.

■ Check that cables are connected

properly.

■ Eliminate any interference that

may be coming from lighting or

from equipment operating near

the hub.

Table A-5 Fatal Error Messages

Message Context Action

Flash memory erase error. During firmware update. For any of these errors, return the

Flash memory programming error. During firmware update.

unit to the supplier.

Data storage error. While saving port settings or

changing the password.

System stopped! During firmware update.

Page 53

B

SPECIFICATIONS

This appendix lists the specifications for the SuperStack II Hub 1000 SX.

Physical Dimensions

Height: 4.37 cm (1.72 in.)

Width: 43.94 cm (17.3 in.)

Depth: 30.48 cm (12 in.)

Weight: 5.5 kg (12 lb)

Environmental Operating Ranges

Operating temperature: 0˚ to 50 ˚C (32˚ to 122 ˚F)

Storage temperature: –30˚ to 60 ˚C (–22˚ to 140 ˚F)

Operating humidity: 10% to 90% relative humidity, noncondensing

Storage humidity: 10% to 95% relative humidity, noncondensing

Electrostatic discharge: Does not exceed 25 kV

Operating altitude: –300 to 3000 meters (–296 to 9840 ft)

Power Requirements

AC input voltage: 90–264 V; 115–230 V nominal

Input frequency range: 47–63 Hz, single phase AC

Inrush current: 40 A peak maximum at cold start for half cycle

at any rated input voltage; no damage to the

supply from repeated on/off/on cycles under hot

or cold conditions

AC input isolation: Between primary and secondary circuits: 3000 V

Between primary circuit and chassis: 1500 V

Power consumption: 65 W maximum

Heat output: 90 BTU/hr

Fuse: Fast-blow, 250 VAC, 3.15 A, high

breaking capacity

Page 54

Page 55

C

TECHNICAL SUPPORT

3Com provides easy access to technical support information through a

variety of services. This appendix describes these services.

Information contained in this appendix is correct at time of publication.

For the very latest, we recommend that you access 3Com Corporation’s

World Wide Web site.

Online Technical Services

World Wide Web Site Access the latest networking information on 3Com Corporation’s

3Com Bulletin

Board Service

3Com offers worldwide product support 24 hours a day, 7 days a week,

through the following online systems:

■ World Wide Web site

■ 3Com Bulletin Board Service (3ComBBS)

■ 3ComFacts

■ 3ComForum on CompuServe online service

World Wide Web site by entering our URL into your Internet browser:

http://www.3com.com/

This service features the latest information about 3Com solutions and

technologies, customer service and support, news about the company,

Net Age

3ComBBS contains patches, software, and drivers for all 3Com products,

as well as technical articles. This service is available through analog

modem or digital modem (ISDN) 24 hours a day, 7 days a week.

SM

automated fax service

®

Magazine, technical documentation, and more.

Page 56

C-2 APPENDIX C: TECHNICAL SUPPORT

Access by Analog Modem

To reach the service by modem, set your modem to 8 data bits, no parity,

and 1 stop bit. Call the telephone number nearest you:

Country Data Rate Telephone Number

Australia up to 14400 bps 61 2 9955 2073

Brazil up to 14400 bps 55 11 5181 9666

France up to 14400 bps 33 1 6986 6954

Germany up to 28800 bps 4989 62732 188

Hong Kong up to 14400 bps 852 2537 5601

Italy up to 14400 bps 39 2 27300680

Japan up to 14400 bps 81 3 3345 7266

Mexico up to 28800 bps 52 5 520 7835

P.R. of China up to 14400 bps 86 10 684 92351

Taiwan, R.O.C. up to 14400 bps 886 2 377 5840

U.K. up to 28800 bps 44 1442 438278

U.S.A. up to 28800 bps 1 408 980 8204

3ComFacts

Automated

Fax Service

Access by Digital Modem

ISDN users can dial in to 3ComBBS using a digital modem for fast

access up to 56 Kbps. To access 3ComBBS using ISDN, use the

following number:

1 408 654 2703

3Com Corporation’s interactive fax service, 3ComFacts, provides data

sheets, technical articles, diagrams, and troubleshooting instructions on