Page 1

SuperStack® 3

Switch 4400 Series

Getting Started Guide

Switch 4400 (3C17203)

Switch 4400 (3C17204)

Switch 4400 PWR (3C17205)

Switch 4400 SE (3C17206)

Switch 4400 FX (3C17210)

http://www.3com.com/

Part No. DUA1720-3AAA06

Published June 2003

Page 2

3Com Corporation

5500 Great America

Parkway, Santa Clara,

California 95052-8145

Copyright © 2003, 3Com Corporation. All rights reserved. No part of this documentation may be reproduced

in any form or by any means or used to make any derivative work (such as translation, transformation, or

adaptation) without written permission from 3Com Corporation.

3Com Corporation reserves the right to revise this documentation and to make changes in content from time

to time without obligation on the part of 3Com Corporation to provide notification of such revision or change.

3Com Corporation provides this documentation without warranty, term, or condition of any kind, either

implied or expressed, including, but not limited to, the implied warranties, terms or conditions of

merchantability, satisfactory quality, and fitness for a particular purpose. 3Com may make improvements or

changes in the product(s) and/or the program(s) described in this documentation at any time.

If there is any software on removable media described in this documentation, it is furnished under a license

agreement included with the product as a separate document, in the hard copy documentation, or on the

removable media in a directory file named LICENSE.TXT or !LICENSE.TXT. If you are unable to locate a copy,

please contact 3Com and a copy will be provided to you.

UNITED STATES GOVERNMENT LEGEND

If you are a United States government agency, then this documentation and the software described herein are

provided to you subject to the following:

All technical data and computer software are commercial in nature and developed solely at private expense.

Software is delivered as “Commercial Computer Software” as defined in DFARS 252.227-7014 (June 1995) or

as a “commercial item” as defined in FAR 2.101(a) and as such is provided with only such rights as are

provided in 3Com’s standard commercial license for the Software. Technical data is provided with limited rights

only as provided in DFAR 252.227-7015 (Nov 1995) or FAR 52.227-14 (June 1987), whichever is applicable.

You agree not to remove or deface any portion of any legend provided on any licensed program or

documentation contained in, or delivered to you in conjunction with, this User Guide.

Unless otherwise indicated, 3Com registered trademarks are registered in the United States and may or may

not be registered in other countries.

3Com, the 3Com logo and SuperStack are registered trademarks of 3Com Corporation.

Intel and Pentium are registered trademarks of Intel Corporation. Microsoft, MS-DOS, Windows, and Windows

NT are registered trademarks of Microsoft Corporation. Novell and NetWare are registered trademarks of

Novell, Inc. UNIX is a registered trademark in the United States and other countries, licensed exclusively

through X/Open Company, Ltd.

IEEE and 802 are registered trademarks of the Institute of Electrical and Electronics Engineers, Inc.

Netscape Navigator is a registered trademark of Netscape Communications.

JavaScript is a trademark of Sun Microsystems.

All other company and product names may be trademarks of the respective companies with which they are

associated.

ENVIRONMENTAL STATEMENT

It is the policy of 3Com Corporation to be environmentally-friendly in all operations. To uphold our policy, we

are committed to:

Establishing environmental performance standards that comply with national legislation and regulations.

Conserving energy, materials and natural resources in all operations.

Reducing the waste generated by all operations. Ensuring that all waste conforms to recognized environmental

standards. Maximizing the recyclable and reusable content of all products.

Ensuring that all products can be recycled, reused and disposed of safely.

Ensuring that all products are labelled according to recognized environmental standards.

Improving our environmental record on a continual basis.

End of Life Statement

3Com processes allow for the recovery, reclamation and safe disposal of all end-of-life electronic components.

Regulated Materials Statement

3Com products do not contain any hazardous or ozone-depleting material.

Environmental Statement about the Documentation

The documentation for this product is printed on paper that comes from sustainable, managed forests; it is

fully biodegradable and recyclable, and is completely chlorine-free. The varnish is environmentally-friendly, and

the inks are vegetable-based with a low heavy-metal content.

Page 3

CONTENTS

ABOUT THIS GUIDE

Before You Start 7

Release Notes 7

About Your CD-ROM 8

Conventions 8

Related Documentation 9

Accessing Online Documentation 10

Documentation Comments 10

Product Registration 11

1 INTRODUCING THE

S

UPERSTACK 3 SWITCH 4400

About the Switch 4400 14

Summary of Hardware Features 14

Switch 4400 — Front View Detail 15

10BASE-T/ 100BASE-TX Ports 16

100BASE-FX Ports 16

LEDs 17

Switch 4400 — Rear View Detail 19

Power Socket 19

Redundant Power System Socket 19

Console Port 19

Expansion Module Slots 19

Default Settings 20

2 INSTALLING THE SWITCH

Package Contents 24

Choosing a Suitable Site 24

Rack-mounting 25

Placing Units On Top of Each Other 27

Stacking Units 27

Page 4

How To Stack Units 27

Rules For Stacking Units 29

The Power-up Sequence 30

Powering-up the Switch 4400 30

Checking for Correct Operation of LEDs 30

Connecting a Redundant Power System 30

Using Power over Ethernet 31

Choosing the Correct Cables (Switch 4400, 4400 SE and

4400 PWR) 32

Choosing the Correct Cables (Switch 4400 FX) 33

3 SETTING UP FOR MANAGEMENT

Setting Up Overview 36

IP Configuration 37

Preparing for Management 38

Manually Configuring IP Information 39

Connecting to a Front Panel Port 39

Connecting to the Console Port 42

Viewing Automatically Configured IP Information 46

Using 3Com Network Supervisor 46

Connecting to the Console Port 46

Methods of Managing a Switch 49

Command Line Interface Management 49

Web Interface Management 50

SNMP Management 50

Setting Up Command Line Interface Management 50

CLI Management via the Console Port 50

CLI Management over the Network 51

Setting Up Web Interface Management 52

Pre-requisites 52

Web Management Over the Network 53

Setting Up SNMP Management 53

Pre-requisites 53

Default Users and Passwords 54

Changing Default Passwords 54

Page 5

4 PROBLEM SOLVING

Solving Problems Indicated by LEDs 56

Solving Hardware Problems 57

Solving Communication Problems 60

Solving Software Upgrade Problems 61

A SAFETY INFORMATION

Power Cord Set — Japan 63

Important Safety Information 64

L’information de Sécurité Importante 66

Wichtige Sicherheitsinformationen 68

B PIN-OUTS

Null Modem Cable 71

PC-AT Serial Cable 71

Modem Cable 72

RJ-45 Pin Assignments 72

C TECHNICAL SPECIFICATIONS

Switch 4400 (24-port) and Switch 4400 SE 75

Switch 4400 PWR (24-port) 77

Switch 4400 (48-port) 78

Switch 4400 FX 79

D TECHNICAL SUPPORT

Online Technical Services 81

World Wide Web Site 81

3Com Knowledgebase Web Services 82

3Com FTP Site 82

Support from Your Network Supplier 82

Support from 3Com 83

Internet Support 83

Telephone Support 83

Returning Products for Repair 85

Contacting 3Com Support 86

Page 6

INDEX

REGULATORY NOTICES

Page 7

ABOUT THIS GUIDE

This guide provides all the information you need to install and use the

following switches in their default state:

■ SuperStack® Switch 4400 (3C17203)

■ SuperStack® Switch 4400 (3C17204)

■ SuperStack® Switch 4400 PWR (3C17205)

■ SuperStack® Switch 4400 SE (3C17206)

■ SuperStack® Switch 4400 FX (3C17210)

All procedures described in this guide apply to all models except where

stated.

The guide is intended for use by network administrators who are

responsible for installing and setting up network equipment;

consequently, it assumes a basic working knowledge of LANs (Local Area

Networks).

Before You Start This section contains information about the documents and CD-ROM

that accompany your Switch 4400.

Release Notes The Release Notes provide important information about the current

software release, including new features, modifications, and known

problems. You should read the Release Notes before installing the Switch

in your network.

If the information in the Release Notes differ from the information in this

guide, follow the instructions in the Release Notes.

Page 8

8 ABOUT THIS GUIDE

About Your CD-ROM The CD-ROM contains the following:

■ Online documentation for the Switch 4400 — refer to Related

Documentation on page 9 for details.

■ 3Com Network Supervisor — a powerful and easy-to-use network

management platform.

■ A number of other useful applications.

Most user guides and release notes are available in Adobe Acrobat

Reader Portable Document Format (PDF) or HTML on the 3Com

World Wide Web site:

http://www.3com.com/

Conventions Table 1 and Table 2 list conventions that are used throughout this guide.

Tab le 1 Notice Icons

Icon Notice Type Description

Information note Information that describes important features or

Caution Information that alerts you to potential loss of data or

Warning Information that alerts you to potential personal injury

instructions

potential damage to an application, system, or device

Tab le 2 Text Conventions

Convention Description

Screen displays This typeface represents information as it appears on the

Syntax The word “syntax” means that you must evaluate the syntax

Commands The word “command” means that you must enter the

screen.

provided and then supply the appropriate values for the

placeholders that appear in angle brackets. Example:

To change your password, use the following syntax:

system password <password>

In this example, you must supply a password for <password>.

command exactly as shown and then press Return or Enter.

Commands appear in bold. Example:

To display port information, enter the following command:

bridge port detail

Page 9

Related Documentation 9

Tab le 2 Text Conventions (continued)

Convention Description

The words “enter”

and “type”

When you see the word “enter” in this guide, you must type

something, and then press Return or Enter. Do not press

Return or Enter when an instruction simply says “type.”

Keyboard key names If you must press two or more keys simultaneously, the key

names are linked with a plus sign (+). Example:

Press Ctrl+Alt+Del

Words in italics Italics are used to:

■ Emphasize a point.

■ Denote a new term at the place where it is defined in the

text.

■ Identify menu names, menu commands, and software

button names. Examples:

From the Help menu, select Contents.

Click OK.

Related Documentation

In addition to this guide, each Switch documentation set includes the

following:

■ SuperStack 3 Switch Implementation Guide

This guide contains information on the features supported by your

Switch and how they can be used to optimize your network. It is

supplied in PDF format on the CD-ROM that accompanies the Switch.

■ SuperStack 3 Switch Management Quick Reference Guide

This guide contains:

■ a list of the features supported by the Switch.

■ a summary of the web interface and command line interface

commands for the Switch.

■ SuperStack 3 Switch Management Interface Reference Guide

This guide provides detailed information about the web interface and

command line interface that enable you to manage the Switch. It is

supplied in HTML format on the CD-ROM that accompanies the

Switch.

■ Release Notes

Page 10

10 ABOUT THIS GUIDE

These notes provide information about the current software release,

including new features, modifications, and known problems. The

Release Notes are supplied in hard copy with your Switch.

There are other publications you may find useful, such as:

■ Documentation accompanying the Advanced Redundant Power

system.

■ Documentation accompanying the Expansion Modules.

■ Documentation accompanying 3Com Network Supervisor. This is

supplied on the CD-ROM that accompanies the Switch.

Accessing Online

Documentation

Documentation Comments

To access the documentation on the CD-ROM supplied with your Switch,

do the following:

1 Insert the CD-ROM into your CD-ROM drive. If your PC has auto-run

enabled, a splash screen will be displayed automatically.

2 Select the Documentation section from the contents page.

If the online documentation is to be accessed from a local drive or server,

you will need to access the CD-ROM contents via the root directory and

copy the files from the CD-ROM to a suitable directory.

■ The HTML Reference Guide is stored in the Docs/reference

directory on the CD-ROM. The documentation is accessed using the

contents.htm file.

■ The PDF Implementation Guide is stored in the

Docs/implementation directory of the CD-ROM.

3Com recommends that you copy the Docs/reference directory as a

whole to maintain the structure of the files.

Your suggestions are very important to us. They will help make our

documentation more useful to you. Please e-mail comments about this

document to 3Com at:

pddtechpubs_comments@3com.com

Please include the following information when commenting:

■ Document title

Page 11

Product Registration 11

■ Document part number (on the title page)

■ Page number (if appropriate)

Example:

Part Number DUA1720-3AAA06

SuperStack 3 Switch 4400 Series Getting Started Guide

Page 21

Please note that we can only respond to comments and questions about

3Com product documentation at this e-mail address. Questions related to

technical support or sales should be directed in the first instance to your

network supplier.

Product Registration

You can now register your SuperStack 3 Switch on the 3Com web site to

receive up-to-date information on your product:

http://www.3com.com/register

Page 12

12 ABOUT THIS GUIDE

Page 13

1

INTRODUCING THE SUPERSTACK 3 SWITCH 4400

This chapter contains introductory information about the Switch 4400

and how it can be used in your network. It covers summaries of hardware

and software features and also the following topics:

■ About the Switch 4400

■ Switch 4400 — Front View Detail

■ Switch 4400 — Rear View Detail

■ Default Settings

Page 14

14 CHAPTER 1: INTRODUCING THE SUPERSTACK 3 SWITCH 4400

About the Switch 4400

Summary of

Hardware Features

The Switch 4400 is a stackable 10/100 Mbps Ethernet switch and

provides high-performance workgroups with a backbone to server

connection. The Switch 4400 allows Cascade, Gigabit Ethernet or Fast

Ethernet Fiber connections when expansion modules are installed in the

expansion slots on the rear of the unit. You can also add the Switch 4400

®

to any SuperStack

system as your network grows.

The Switch 4400 PWR (3C17205) supports Power over Ethernet on all

front panel ports. If you plug in a compatible (IEEE 802.3af compliant)

device, it will be automatically detected and power supplied to it. Power

over Ethernet is enabled on each port by default.

The Switch 4400 FX (3C17210) has 24 100BASE-FX MT-RJ ports. These

allow easy connection of 100 Mbps fiber-optic links.

Table 3 summarizes the hardware features that are supported by the

Switch 4400.

Tab le 3 Hardware features

Feature Switch 4400

Addresses ■ Up to 8000 supported

■ Up to 64 permanent entries

Auto-negotiation ■ Supported on all ports

■ Auto MDI/MDI-X (not 3C17210)

Forwarding Modes Store and Forward

Duplex Modes Half and full duplex on all front panel ports

Flow Control In full duplex operation all ports are supported

Smart Auto-sensing Supported on all ports

Traffic Prioritization Supported (using the IEEE Std 802.ID, 1998 Edition):

Power over Ethernet Supported on all front panel ports (3C17205 only).

Ethernet and Fast Ethernet

Ports

RPS Support Connects to SuperStack 3 Advanced Redundant

Mounting 19-inch rack or stand-alone mounting

Stacking All Switch units in the stack can be managed as a

4 queues per port

Auto-negotiating 10BASE-T/100BASE-TX ports or

100BASE-FX ports (3C17210)

Power System (ARPS) (3C16071B)

single entity with one IP address

Page 15

Switch 4400 — Front View Detail 15

Switch 4400 —

Front View Detail

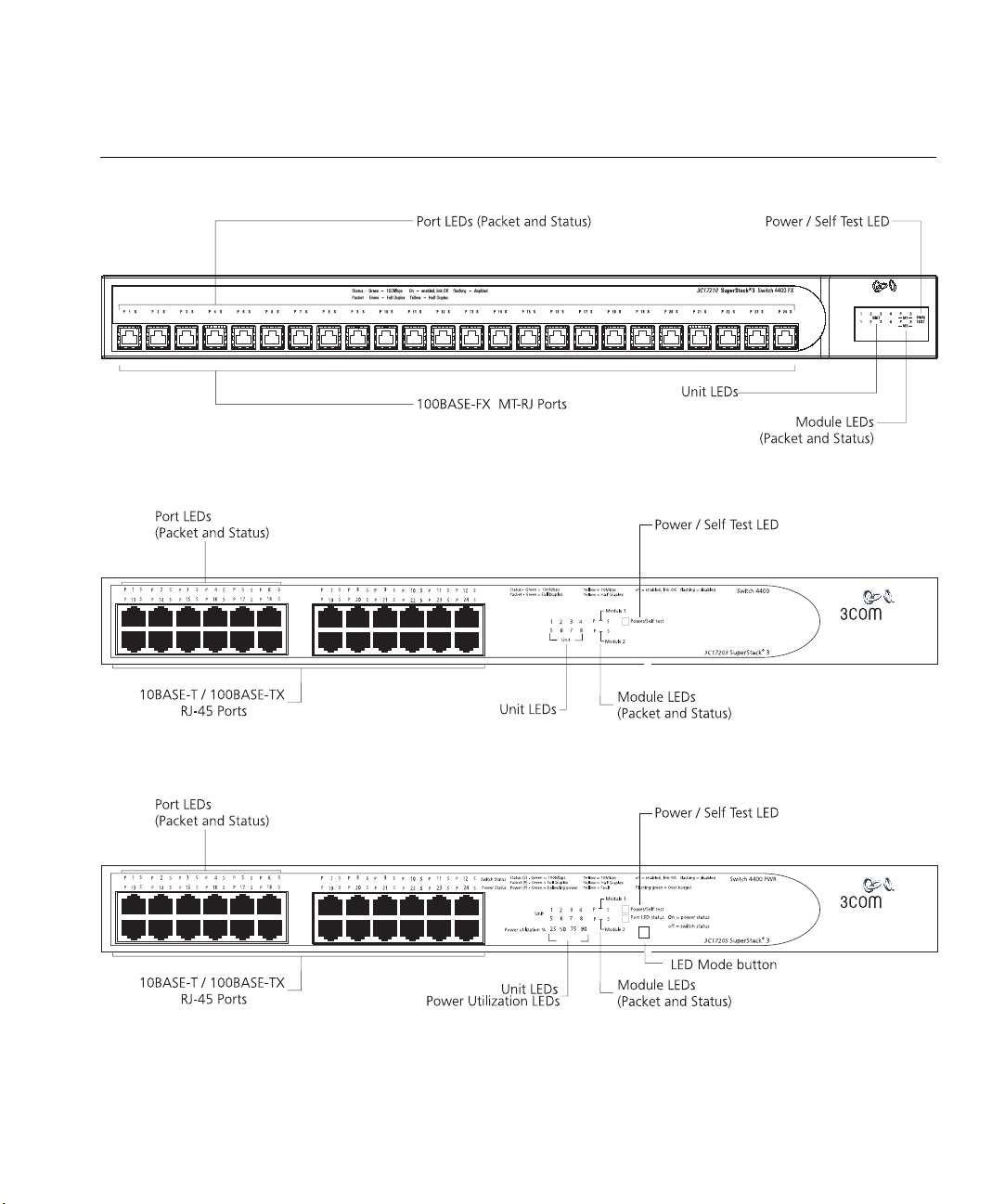

Figure 1 Switch 4400 FX — front view

Figure 2 Switch 4400 (24-port) / Switch 4400 SE — front view

Figure 3 Switch 4400 PWR — front view

Page 16

16 CHAPTER 1: INTRODUCING THE SUPERSTACK 3 SWITCH 4400

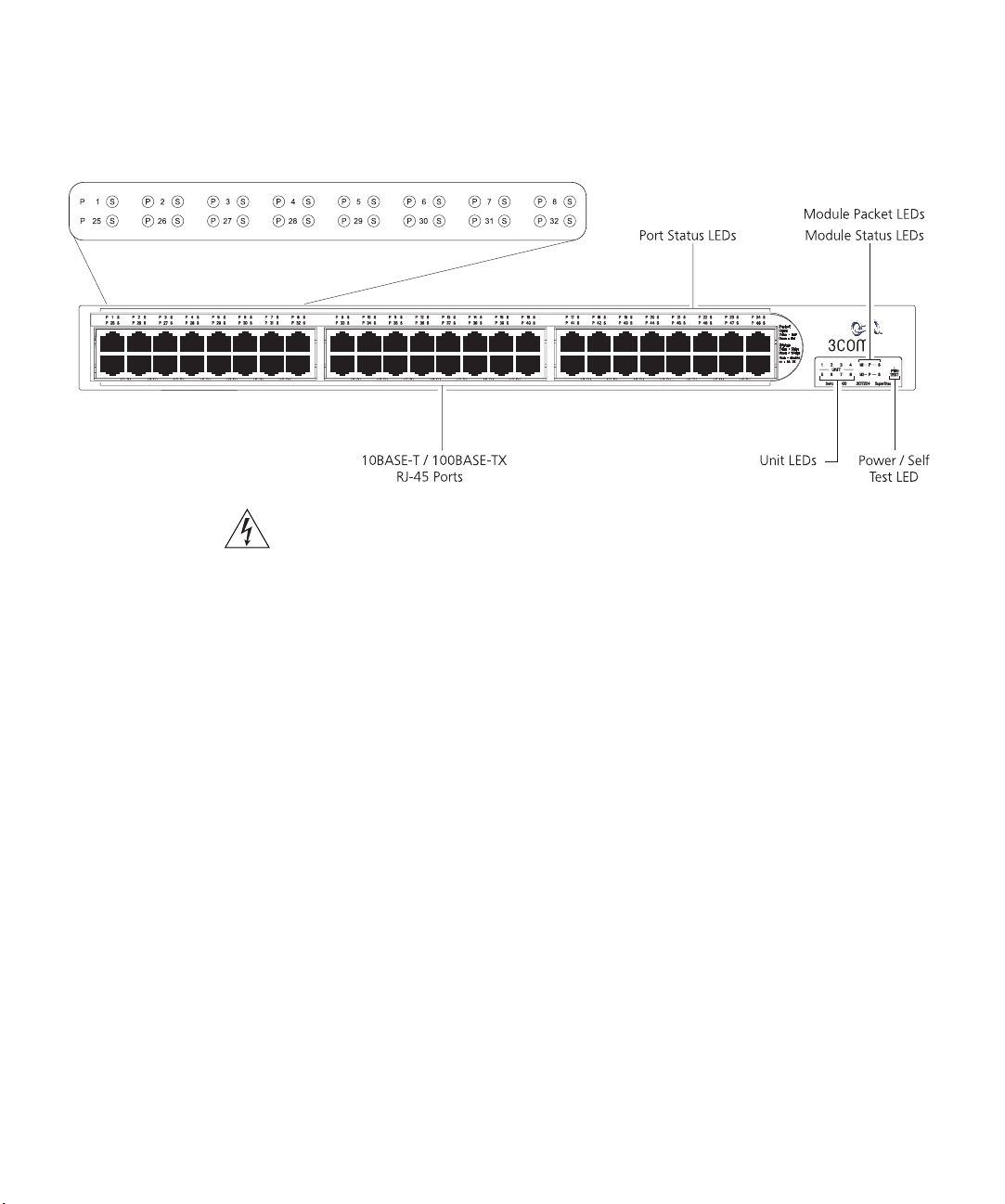

Figure 4 Switch 4400 (48-port) — front view

WARNING: RJ-45 Ports. These are shielded RJ-45 data sockets. They cannot

be used as standard traditional telephone sockets, or to connect the unit to a

traditional PBX or public telephone network. Only connect RJ-45 data

connectors, network telephony systems, or network telephones to these

sockets.

Either shielded or unshielded data cables with shielded or unshielded

jacks can be connected to these data sockets.

10BASE-T/

100BASE-TX Ports

The Switch 4400, 4400 SE and 4400 PWR have 24 or 48

auto-negotiating 10BASE-T/100BASE-TX ports configured as Auto MDIX

(cross-over). These ports automatically provide the appropriate

connection. Alternatively, you can manually set these ports to 10BASE-T

half duplex, 10BASE-T full duplex, 100BASE-TX half duplex or

100BASE-TX full duplex. The maximum segment length is 100 m (328 ft)

over Category 5 twisted pair cable.

The 4400 PWR will supply up to 15.4W of power through any of the 24

front panel ports in conformance to the 802.3af specification. The Switch

4400 PWR incorporates a LED Mode Button on the front panel, which

when pressed changes the mode of the front panel port LEDs

functionality between Switch and Power mode.

100BASE-FX Ports The Switch 4400 FX has 24 100BASE-FX MT-RJ ports. These are

100 Mbps fiber-optic ports that can use standard multi-mode fiber-optic

cable of up to 2 kilometers (1.2 miles). They use the standard MT-RJ

Page 17

Switch 4400 — Front View Detail 17

connector that allows both the transmit and the receive fibers to be

connected in the same space as an RJ-45 port.

LEDs Table 4 lists LEDs visible on the front of the Switch, and how to read their

status according to color. For information on using the LEDs for problem

solving, see “Solving Problems Indicated by LEDs” on page 56.

Tab le 4 LED behavior

LED Color Indicates

Power/Self Test LED

Green The Switch is powered-up and operating normally.

Green flashing The Switch is either downloading software or is initializing

(which includes running a Power On Self Test).

Yellow The Switch has failed its Power On Self Test

or

A port has failed and has been automatically disabled. You

can verify this by checking that the Port LED Status LED is

quickly flashing Yellow. If a port fails the Switch passes its

Power On Self Test and continues to operate normally.

Off The Switch is not receiving power or there is a fault with the

Port LEDs

Packet Green Full duplex packets are being transmitted/received on the

Yellow Half duplex packets are being transmitted/received on the

Off No packets are being transmitted/received on the port.

Status Green A high speed (100 Mbps) link is present, and the port is

Green flashing A high speed (100 Mbps) link is present, but the port is

Yellow A low speed (10 Mbps) link is present, and the port is

Yellow flashing A low speed (10 Mbps) link is present, but the port is

Yellow flashing

(fast)

Off No link is present.

Power Supply Unit.

port.

port.

enabled.

disabled.

enabled (not 4400 FX).

disabled (not 4400 FX).

The port has failed and has been automatically disabled. The

Switch passes its Power On Self Test and continues to

operate normally even if one or more ports are disabled.

Page 18

18 CHAPTER 1: INTRODUCING THE SUPERSTACK 3 SWITCH 4400

LED Color Indicates

Port LEDs — Power over Ethernet mode (3C17205 only)

Packet Green Power is being delivered to the port.

Green flashing Exceeded port power limit (overCurrent MIB state) or unable

to supply power due to unit over budget (denyLowPriority

MIB state).

Yellow Power over Ethernet error, no power supplied on port.

Off No power is being delivered.

Status Yellow flashing Power over Ethernet POST error on port. Flash rate is 4 Hz

Module LEDs

Packet Refer to the user documentation accompanying the module,

Status Refer to the user documentation accompanying the module,

Off There is no module installed in the expansion module slot.

Yellow flashing

(fast)

Unit LEDs

1–8 Green When the Switch forms a stack with other Switch 4400

Green

sequential

Green

flashing

Off A fault has occurred.

Port LED Status LED (3C17205 only)

Green Port LEDs are operating in power mode

Yellow flashing Port LEDs are operating in normal mode. One or more ports

Off Port LEDs are operating in normal mode.

if installed.

if installed.

The module has failed and has been automatically disabled.

The Switch passes its Power On Self Test and continues to

operate normally even if one or more modules are disabled.

units, the LED indicates the position of the unit in the stack

and that a link is present.

When the Switch is stand-alone and not part of a stack, LED

1 is on.

When a software upgrade is in progress, the Unit LEDs of the

unit that is being upgraded flash on and off in the following

sequence —

1,2,4,6,8,7,5,3 (24-port)

1,2,3,4,8,7,6,5 (48-port)

The Switch physically forms a stack with other Switch 4400

units, but cannot be managed as part of that stack until all

units have been upgraded to software version 2.0 or later.

has a Power over Ethernet error.

Page 19

LED Color Indicates

Power Utilization LEDs (3C17205 only)

Green 4 LEDs showing total power being delivered as a percentage

of maximum possible.

Switch 4400 — Rear View Detail 19

Switch 4400 — Rear

View Detail

Power Socket The Switch automatically adjusts its power setting to any supply voltage

Redundant Power

System Socket

Console Port The console port allows you to connect a terminal and perform remote or

Figure 5 Switch 4400 (all models) — rear view

in the range 90-240 VAC.

To protect against internal power supply failure, you can use this socket

to connect a Switch 4400 to a SuperStack 3 Advanced Redundant Power

System (RPS). See “Connecting a Redundant Power System” on page 30.

local out-of-band management. The console port uses a standard null

modem cable and is set to auto-baud, 8 data bits, no parity and 1 stop

bit.

Expansion Module

Slots

You can use these slots to install Expansion Modules. These allow the

Switch to support various forms of connection and add extra functionality

to your Switch. For example you can install a Cascade module to enable

the Switch to be stacked with other Switches. Please note that Power

over Ethernet is not supported on expansion modules on the Switch 4400

PWR (3C17205). Contact your supplier for more information.

Page 20

20 CHAPTER 1: INTRODUCING THE SUPERSTACK 3 SWITCH 4400

WARNING: When an Expansion Module is not installed, ensure the

blanking plate is fitted by tightening all screws with a suitable tool.

Default Settings Table 5 shows the default settings for the Switch 4400:

Tab le 5 Default Settings

Feature Switch 4400

Automatic IP Configuration Enabled

Port Status Enabled

Port Speed 10/100 Mbps ports are auto-negotiated

TR-RJ ports (3C17210) are fixed at 100 Mbps

Duplex Mode All fixed 10BASE-T and 100BASE-TX ports are

auto-negotiated

100BASE-FX ports default to full-duplex mode

(100 FD) and must be manually set to half-duplex

mode (100 HD) if required.

Power over Ethernet Enabled (3C17205 only)

Flow Control ■ Enabled in half-duplex mode

■ Auto-negotiated in full-duplex mode

Broadcast Storm Control Enabled

Virtual LANs (VLANs) All ports belong to the untagged Default VLAN

(VLAN 1) with IEEE Std 802.1Q-1998 learning

operational

Link Aggregation Control

Protocol (LACP)

IP Multicast Filtering Filtering enabled

Rapid Spanning Tree Protocol Enabled

Fast Start ■ Enabled on front panel ports

RMON Alarm Enabled

Smart Auto-Sensing Enabled

Webcache Support Disabled

Traffic Prioritization All ports prioritize NBX VoIP traffic (LAN and IP).

Port Security Disabled per port

Configuration Save and

Restore

Disabled per port

■ Disabled on rear panel port

All ports set to “best effort” for all other traffic.

Disabled

Page 21

Default Settings 21

To make Webcache Support, Traffic Prioritization and Configuration Save

and Restore available on the SuperStack 3 Switch 4400 SE, upgrade the

product to the Switch 4400 SE Enhanced Software Upgrade (3C17207).

If you initialize a Switch unit by selecting System > Control > Initialize in

the Web interface or by entering system control initialize

in

the Command Line Interface, the following settings are retained to allow

you to connect to and manage the Switch:

■ IP Address

■ Subnet Mask

■ Default Router

Page 22

22 CHAPTER 1: INTRODUCING THE SUPERSTACK 3 SWITCH 4400

Page 23

2

INSTALLING THE SWITCH

This chapter contains the information you need to install and set up the

Switch 4400. It covers the following topics:

■ Package Contents

■ Choosing a Suitable Site

■ Rack-mounting

■ Placing Units On Top of Each Other

■ Stacking Units

■ The Power-up Sequence

WARNING: Safety Information. Before installing or removing any

components from the Switch 4400 or carrying out any maintenance

procedures, you must read the safety information provided in Appendix A

of this guide.

AVERTISSEMENT: Consignes de sécurité. Avant d'installer ou d'enlever

tout composant du Switch 4400 ou d'entamer une procédure de

maintenance, lisez les informations relatives à la sécurité qui se trouvent

dans l'Appendice A de ce guide.

VORSICHT: Sicherheitsinformationen. Bevor Sie Komponenten aus

dem Switch 4400 entfernen oder dem Switch 4400 hinzufuegen oder

Instandhaltungsarbeiten verrichten, lesen Sie die Sicherheitsanweisungen,

die in Appendix A (Anhang A) in diesem Handbuch aufgefuehrt sind.

Page 24

24 CHAPTER 2: INSTALLING THE SWITCH

Package Contents ■ Switch unit

■ CD-ROM (includes documentation related to your Switch)

■ Getting Started Guide (this guide)

■ Management Quick Reference Guide

■ Release Notes

■ Unit Information Labels

■ Warranty Information

■ Power Cord

■ 2 x Mounting brackets

■ 4 x Screws

■ 4 x Rubber feet

Choosing a Suitable Site

The Switch is suited for use on a desktop, either free standing or

mounted in a standard 19-inch equipment rack. Alternatively, the Switch

can be mounted in a wiring closet or equipment room, as an aggregator

for other Hubs and Switches. A rack-mounting kit containing two

mounting brackets is supplied with the Switch.

CAUTION: Ensure that the ventilation holes are not obstructed.

When deciding where to position the Switch, ensure that:

■ Cabling is located away from:

■ sources of electrical noise such as radios, transmitters and

broadband amplifiers.

■ power lines and fluorescent lighting fixtures

■ The Switch is accessible and cables can be connected easily.

■ Water or moisture cannot enter the case of the Switch.

■ Air flow is not restricted around the Switch or through the vents in the

side of the Switch. 3Com recommends that you provide a minimum of

25mm (1in.) clearance.

■ Air temperature around the Switch does not exceed 40 °C (104 °F).

If the Switch is installed in a 19-inch rack or closed assembly its local air

temperature may be greater than room ambient temperature.

Page 25

Rack-mounting 25

■ The air is as free from dust as possible.

■ The unit is installed in a clean, air conditioned environment.

■ No more than eight Switch units are placed on top of one another, if

the units are free-standing.

■ The Switch is situated away from sources of conductive (electrical)

dust, for example laser printers.

■ The AC supply used by the Switch is separate to that used by units

that generate high levels of AC noise, for example air conditioning

units and laser printers.

Rack-mounting The Switch 4400 is 1U high and will fit in most standard 19-inch racks.

CAUTION: Disconnect all cables from the Switch before continuing.

Remove all self adhesive pads from the underside of the Switch if they

have been fitted.

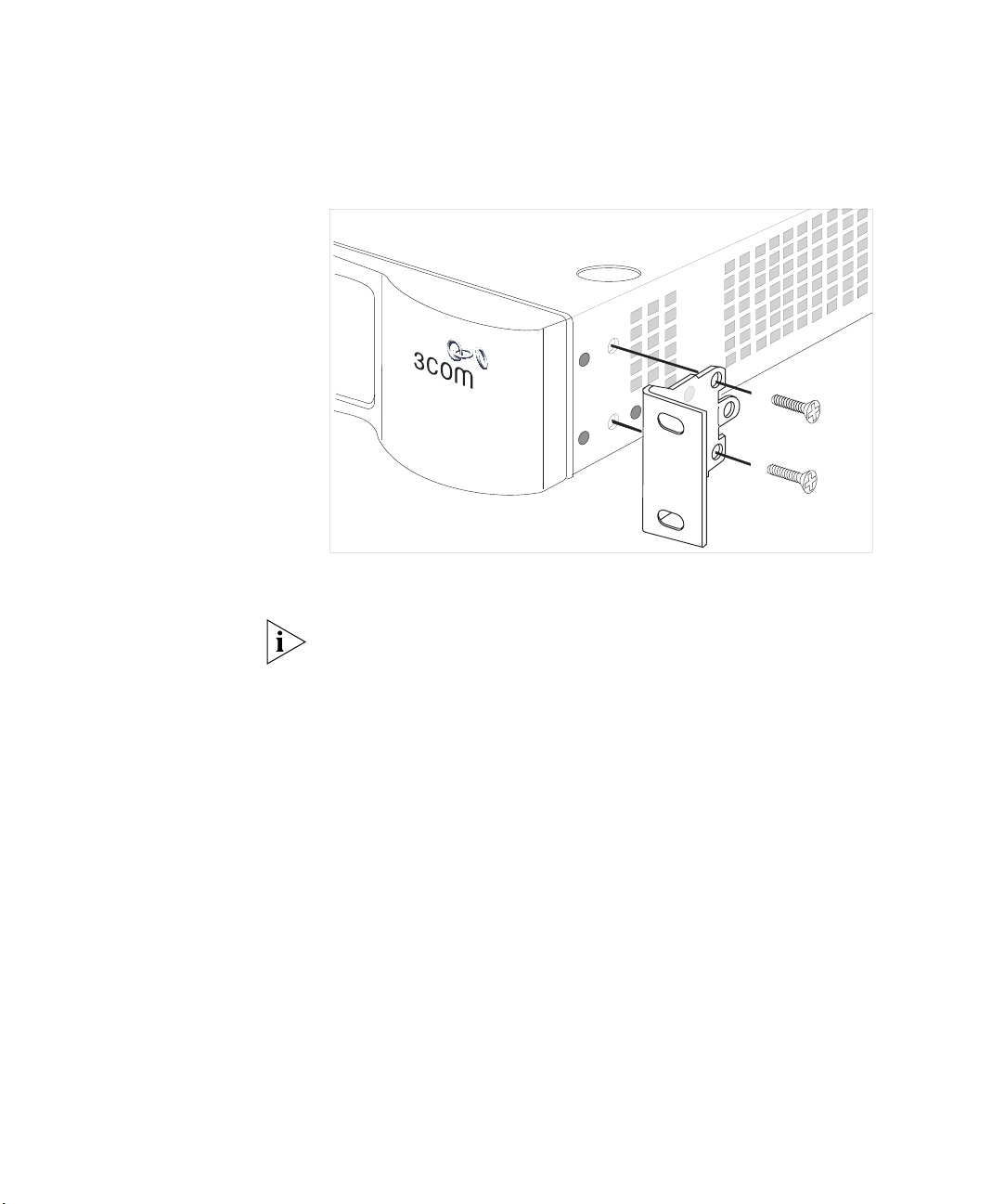

To rack-mount your Switch:

1 Place the Switch the right way up on a hard flat surface, with the front

facing towards you.

2 Locate a mounting bracket over the mounting holes on one side of the

Switch, as shown in Figure 6.

Page 26

26 CHAPTER 2: INSTALLING THE SWITCH

Figure 6 Fitting a bracket for rack-mounting

3 Insert the two screws and tighten with a suitable screwdriver.

You must use the screws supplied with the mounting brackets. Damage

caused to the unit by using incorrect screws invalidates your warranty.

4 Repeat steps 2 and 3 for the other side of the Switch.

5 Insert the Switch into the 19-inch rack and secure with suitable screws

(not provided). Ensure that ventilation holes are not obstructed.

6 Connect network cabling.

7 Finally place a unit information label on the unit in an easily accessible

position. The unit information label shows the following:

■ The 3Com product name of the Switch

■ The 3Com 3C number of the Switch

■ The unique MAC address (Ethernet address) of the Switch

■ The serial number of the Switch

You may need this information for fault reporting purposes.

Page 27

Placing Units On Top of Each Other 27

Placing Units On Top of Each Other

If the Switch units are free-standing, up to eight units can be placed one

®

on top of the other. If you are mixing a variety of SuperStack

3 Switch

and Hub units, the smaller units must be positioned at the top.

If you are placing Switch units one on top of the other, you must use the

self-adhesive rubber pads supplied. Apply the pads to the underside of

each Switch, sticking one in the marked area at each corner. Place the

Switch units on top of each other, ensuring that the pads of the upper

unit line up with the recesses of the lower unit.

Stacking Units Switch 4400 units can be stacked together and then treated as a single

manageable unit with one IP address. Any combination of 24-port and

48-port units is allowed in a single stack, as long as the total number of

front panel ports does not exceed the limit of 192 ports. The following

combinations are allowed:

■ 4 x 48-port Switches

■ 3 x 48-port Switches and 2 x 24-port Switches

■ 2 x 48-port Switches and 4 x 24-port Switches

■ 1 x 48-port Switch and 6 x 24-port Switches

■ 8 x 24-port Switches

The SuperStack 3 Switch 4400 SE can only be stacked with non-SE

Switches if it has been upgraded using the Switch 4400 SE Enhanced

Software Upgrade (3C17207). An upgraded Switch 4400 SE cannot be

stacked with a normal Switch 4400 SE.

How To Stack Units To stack two Switch 4400 units you will need to order the SuperStack 3

Switch Cascade Stacking Kit (3C17227). The kit consists of two Cascade

Modules and a Cascade Cable. Both Switches must have an unused

expansion slot to allow a Cascade Module to be fitted.

Page 28

28 CHAPTER 2: INSTALLING THE SWITCH

Figure 7 Stacking two Switch 4400 units

To stack more than two Switch units you will need to order one

SuperStack 3 Cascade Extender Kit (3C17228) for each additional unit.

This Kit consists of one Cascade Module, one Cascade Cable and one

Cascade Extender Unit. The Cascade Module is installed into the

expansion slot at the rear of the Switch and the Cascade Extender Unit

plugs into the Cascade Module.

Module 2

3C17224

U

P

SuperStack 3 Cascade Module

Switch 2

Module 2

3C17224

DOW

N

SuperStack 3 Cascade Module

Switch 1

Figure 8 Stacking more than two Switch 4400 units

M

odule 2

3C17224

U

P

SuperStack 3 Cascade Module

M

odule 2

3C17224

3

3C17224

C

1

7

22

U

4

P

SuperStack 3 Cascade Module

UP

3C17224

3

UP

3C17224

SuperStack 3 Cascade Module

D

O

W

N

M

odule 2

C

1

7

2

U

2

P

4

SuperStack 3 Cascade Module

D

O

W

N

M

odule 2

DOWN

SuperStack 3 Cascade Module

Switch 4

Switch 3

Switch 2

Switch 1

For information on ordering the Cascade Kits contact your supplier. For

illustrations and information on how to install the Cascade Kits, refer to

the user documentation that accompanies these Kits.

Page 29

Stacking Units 29

Rules For Stacking

Units

This information is also provided in the user documentation that

accompanies the Cascade Kits.

■ The number of Switch units in a stack is limited to a maximum of 192

front panel ports in the stack.

■ Only one Cascade Module can be installed per Switch. If Cascade

Modules are fitted to both expansion slots in a Switch then both

Modules will be disabled.

■ Cascade Modules are NOT hot-swappable or hot-insertable. Ensure

that the Switch is powered off before inserting or removing a Cascade

Module.

■ The Cascade Extender Unit is hot-insertable. This allows its host

Switch unit to be removed and replaced without disturbing the rest of

the stack.

■ Only 3Com

®

Cascade Cables can be used to connect between

Cascade Modules/Cascade Extender Units.

■ Due to the length of the Cascade Cables, you must insert all of the

Cascade Modules into Expansion Module Slot 1 or all of the Cascade

Modules into Expansion Module Slot 2 on the Switches.

■ It is not possible to stack a Switch 4400, Switch 4400 SE,

Switch 4400 PWR or Switch 4400 FX unit with SuperStack II or other

SuperStack 3 products using the Cascade Stacking Kit (3C17227) or

Cascade Extender Kit (3C17228).

■ 3Com strongly recommends that you upgrade all Switch 4400 units

(24-port and 48-port) in a stack to the latest software agent.

■ 3Com recommends that you initialize a Switch 4400, Switch 4400 SE,

Switch 4400 PWR or Switch 4400 FX unit that has previously been

used elsewhere in your network before you add it to an existing stack.

If you do not initialize the unit, problems may be caused by conflicting

Switch configurations.

■ When the Switch 4400s are stacked together they are assigned a unit

number from bottom-to-top for management purposes. When further

Switches are added to the stack, they can be positioned at the bottom

of the stack or at the top. Either way, the Switch management

software will re-order the Switch unit numbers into a logical order

again (from bottom to top).

Page 30

30 CHAPTER 2: INSTALLING THE SWITCH

The Power-up Sequence

Powering-up the

Switch 4400

Checking for Correct

Operation of LEDs

The following sections describe how to get your Switch 4400

powered-up and ready for operation.

Use the following sequence of steps to power-up the Switch.

1 Plug the power cord into the power socket at the rear of the Switch.

2 Plug the other end of the power cord into your power outlet.

The Switch powers-up and runs through its Power On Self Test (POST),

which takes approximately 10 seconds.

During the Power On Self Test, all ports on the Switch are disabled and

the LEDs light in a set sequence.

When the POST has completed, check the Power/Self Test LED to make

sure that your Switch is operating correctly. Table 6 shows possible colors

for the LED.

Tab le 6 Power/Self Test LED colors

Color State

Green The Switch is powered-up and operating normally.

Yellow The Switch has failed its Power On Self Test.

Off The Switch is not receiving power.

Connecting a

Redundant Power

System

If there is evidence of a problem, see “Solving Problems Indicated by

LEDs” on page 56.

You can connect a SuperStack 3 Advanced Redundant Power System

(3C16071B) to the Switch. This unit, which is also known as an RPS, is

designed to maintain the power to your Switch if a power supply failure

occurs.

For normal redundancy, the Switch 4400, Switch 4400 SE, and

Switch 4400 FX require one Type 2A Power Module (3C16074A). For full

redundancy, the Switch 4400, Switch 4400 SE, and Switch 4400 FX

require two type 2A Power Modules combined using a Type 2 Y-Cable.

The Switch 4400 PWR (3C17205) requires one Type 3 Power Module

(3C16075) for normal redundancy and two Type 3 Power Modules for

full redundancy.

Page 31

The Power-up Sequence 31

CAUTION The Switch has no ON/OFF switch; the only method of

connecting or disconnecting mains power is by connecting or

disconnecting the power cord.

CAUTION: The Switch can only use a SuperStack Advanced Redundant

Power System output.

Using Power over

Ethernet

The Switch 4400 PWR can power any IEEE 802.3af compliant device

through any of its front panel ports. The Switch will support the following

3Com 802.3af equipment:

■ Wireless:

■ 3Com 11 Mbps Wireless LAN Access Point 8000 (3CRWE80096B)

■ 3Com 11 Mbps Wireless LAN Access Point 8200 (3CRWE820096A)

■ 3Com 11 Mbps Wireless LAN Access Point 8500 (3CRWE850096A)

■ 3Com Wireless LAN Building to Building Bridge (3CRWE91096B)

■ Voice Over IP Telephones:

■ 3Com 11 Mbps Wireless LAN Access Point 8000 (3CRWE80096B)

■ 3Com 11 Mbps Wireless LAN Access Point 8200 (3CRWE820096A)

■ 3Com 11 Mbps Wireless LAN Access Point 8500 (3CRWE850096A)

■ 3Com Wireless LAN Building to Building Bridge (3CRWE91096B)

■ The following 3Com NBX phones are also supported using the 3Com

NBX VoIP Phone Module (3CNJVOIPMOD-NBX):

■ 3Com NBX 1102 Business Phone (3C10121)

■ 3Com NBX 1102B Business Phone (3C10281B)

■ 3Com NBX 2101Basic Phone (3C10248B)

■ 3Com NBX 2102 Business Phone (3C10226A)

■ 3Com NBX 2102-IR Business Phone with IR (3C10228IRA)

■ 3Com NBX 2102B Business Phone (3C10226B)

■ 3Com NBX 2102-IRB Business Phone with IR (3C10228IRB)

■ Network Jacks:

■ 3Com NJ95 (3CNJ95)

■ 3Com NJ100 (3CNJ100, 3CNJ100-CRM)

■ 3Com NJ200 (3CNJ200, 3CNJ200-CRM)

Page 32

32 CHAPTER 2: INSTALLING THE SWITCH

For the latest list of supported devices, go to the product page on the

3Com web site

For further information about Power Over Ethernet, refer to “Power

Management and Control” in the Switch Implementation Guide supplied

on the CD-ROM that accompanies your Switch. Power over Ethernet

management is available using the web interface or the command line

interface (CLI).

http://www.3com.com/.

Choosing the Correct

Cables (Switch 4400,

4400 SE and

4400 PWR)

All of the ports on the front of the Switch 4400, 4400 SE and 4400 PWR

are Auto-MDIX, that is they have a cross-over capability. The port can

automatically detect whether it needs to operate in MDI or MDIX mode.

Therefore you can make a connection to a port with a straight-through

(MDI) or a cross-over cable (MDIX).

The Auto-MDIX feature only operates when auto-negotiation is enabled.

If auto-negotiation is disabled, all the Switch ports are configured as

MDIX (cross-over). If you want to make a connection to another MDIX

port, you need a cross-over cable. Many ports on workstations and

servers are configured as MDI (straight-through). If you want to make a

connection to an MDI port, you need to use a standard straight-through

cable. See Table 7.

WARNING: The 4400 PWR (3C17205) supports Power over Ethernet on

all front ports. These ports should only be used for ethernet wiring within

the same building. The Rear Module ports of the Switch 4400 PWR can

be used for ethernet wiring between buildings.

3Com recommends that you use Category 5 twisted pair cable — the

maximum segment length for this type of cable is 100 m (328 ft).

Page 33

The Power-up Sequence 33

Tab le 7 Cables required to connect the Switch 4400 to other devices if

auto-negotiation is disabled

Cross-over Cable Straight-through Cable

Switch to Switch

(MDIX to MDIX)

Switch to Hub

(MDIX to MDIX)

Switch to PC (NIC)

(MDIX to MDI)

✓

✓ ✕

✕

✕

✓

CAUTION: If you want to install the Switch using a Category 5E or

Category 6 cable, 3Com recommends that you briefly connect the cable

to a grounded port before connecting network equipment. If you do not,

the cable’s Electrostatic Discharge (ESD) may damage the Switch’s port.

You can create a grounded port by connecting all wires at one end of a

UTP cable to an earth ground point, and the other end to a female RJ-45

connector located, for example, on a Switch rack or patch panel. The

RJ-45 connector is now a grounded port.

Choosing the Correct

Cables

(Switch 4400 FX)

All of the ports on the front of the Switch 4400 FX are 100BASE-FX

MT-RJ multi-mode ports. The MT-RJ port is a small form factor fiber-optic

port with the transmit and receive fibers in the same cable. Unlike many

fiber-optic systems, only one MT-RJ cable is needed to connect two

MT-RJ ports together.

To connect a front-panel port to another 100BASE-FX MT-RJ multi-mode

port, or to a patch panel, a single MT-RJ multi-mode pinless jumper cable

is required. Since standard MT-RJ cables are cross-over cables, no

Auto-MDIX sensing is required. The maximum cable length is

2 kilometers (1.24 miles).

CAUTION: Do not connect pinned MT-RJ connectors into any port on the

Switch 4400 FX as this may damage the unit. The ports have locator pins

fitted and are designed for standard (pinless) connectors.

To connect a front-panel port to a 100BASE-FX single mode port, or to a

port that does not have an MT-RJ connector, an adaptor will be required.

It is not possible to connect a front panel port to a 1000BASE-FX port.

Page 34

34 CHAPTER 2: INSTALLING THE SWITCH

Page 35

3

SETTING UP FOR MANAGEMENT

Your Switch can operate in its default state, that is, you can install it and

it will work straight away (plug-and-play). However, to make full use of

the features offered by the Switch, and to change and monitor the way it

works, you have to access the management software that resides on the

Switch. This is known as managing the Switch.

Managing the Switch can help you to improve the efficiency of the

Switch and therefore the overall performance of your network.

This chapter explains the initial set up of the Switch and the different

methods of accessing the management software to manage a Switch. It

covers the following topics:

■ Setting Up Overview

■ Manually Configuring IP Information

■ Viewing Automatically Configured IP Information

■ Methods of Managing a Switch

■ Setting Up Command Line Interface Management

■ Setting Up Web Interface Management

■ Setting Up SNMP Management

■ Default Users and Passwords

Page 36

36 CHAPTER 3: SETTING UP FOR MANAGEMENT

Setting Up Overview

This section gives an overview of what you need to do to get your Switch

set up and ready for management when it is in its default state. The

whole setup process is summarized in Figure 9. Detailed procedural steps

are contained in the sections that follow. In brief, you need to:

■ Configure IP information manually for your Switch or view the

automatically configured IP information

■ Prepare for your chosen method of management

Figure 9 Initial Switch Setup and Management Flow diagram

Power Up the Switch.

Plug and Play Setup

How do you want to connect to the Switch?

Connect to a front

panel port and use the

Web Interface or

Initial IP Information Setup

Command Line Interface.

See page 39

Yes

Connect to the console

port and use the

Command Line

IP Information is automatically configured.

Interface.

See page 39

See page 37

Do you want to manually

configure the IP information?

Use 3Com Network

No

How do you want to view the automatically

configured IP information?

Supervisor (3NS).

See page 46

Connect to the console

port and use the

Command Line

Interface.

See page 46

Feature Management

Connect via the

console port.

Command Line Interface

See page 50

How do you want to manage your Switch? See page 49

SNMP

See page 53

Connect over the

network via Telnet.

See page 51

Web Interface

Connect over the

network.

See page 53

Page 37

Setting Up Overview 37

CAUTION: To protect your Switch from unauthorized access, you must

change all three default passwords as soon as possible, even if you do not

intend to actively manage your Switch. For more information on default

users and changing default passwords, see “Default Users and

Passwords” on page 54.

IP Configuration You can use one of the following methods to allocate IP information to

your Switch (essential if you wish to manage your Switch across the

network).

Manual IP Configuration

You can choose to configure the IP information yourself. The Switch

remembers the information that you enter until you change it again or

set the configuration method to Automatic.

You should use the Manual IP configuration method if:

■ you do not have a DHCP or BootP server on your network, or

■ you want to remove the risk of the IP address ever changing, or

■ your DHCP or BootP server does not allow you to allocate static IP

addresses. (Static IP addresses are necessary to ensure that the Switch

is always allocated the same IP information.)

For most installations, 3Com recommends that you configure the Switch

IP information manually. This makes management simpler and more

reliable as it is not dependent on a DHCP or BootP server, and eliminates

the risk of the IP address changing.

If you wish to manually enter IP information for your Switch, work

through the “Manually Configuring IP Information” section on page 39.

Automatic IP Configuration

By default the Switch tries to configure itself with IP information without

requesting user intervention. It tries to obtain an IP address from a DHCP

or BootP server on the network.

If neither server is found, the Switch will configure itself with its default IP

address 169.254.100.100 if it is operating in a standalone mode, and/or

no other Switches on the network have this IP address. If this default IP

address is already in use on the network then the Switch detects this and

configures itself with an IP address in the range 169.254.1.0 to

169.254.254.255.

Page 38

38 CHAPTER 3: SETTING UP FOR MANAGEMENT

This process is known as Auto-IP and is the same mechanism used by

Windows 98 and Windows 2000. IP addresses configured by Auto-IP are

temporary as they cannot be routed but are useful for small networks

which are not connected to other networks, or for initial configuration.

However, as soon as a DHCP or BootP server is detected, the Switch will

configure itself with the IP address allocated by that server.

When using automatic IP configuration it is important that the IP address

of the Switch is static, otherwise you will not know what the IP address is

and it will be difficult to manage. Most DHCP and BootP servers allow

static IP addresses to be configured so that you know what IP address will

be allocated to the Switch. Refer to the documentation that accompanies

your DHCP/BootP server.

For a detailed description of how automatic IP configuration operates,

please refer to the Implementation Guide on the CD-ROM that

accompanies your Switch or on the 3Com Web site.

You should use the automatic IP configuration method if:

Preparing for

Management

■ your network uses DHCP or BootP to allocate IP information, or

■ flexibility is needed. If the Switch is re-deployed onto a different

subnet, it will automatically reconfigure itself with an appropriate IP

address, instead of you having to manually reconfigure the Switch.

If you use the automatic IP configuration method, you need to discover

the automatically allocated IP information before you can begin

management. Work through the “Viewing Automatically Configured IP

Information” section on page 46.

Once your Switch’s initial set up is complete you can set up your chosen

management method as described in “Methods of Managing a Switch”

on page 49.

For detailed information about the specific web interface operations and

command line interface commands and problem solving, refer to the

“SuperStack

3 Switch Management Interface Reference Guide” on the

CD-ROM that is supplied with the Switch or on the 3Com Web site.

Page 39

Manually Configuring IP Information 39

Manually Configuring IP Information

Connecting to a Front

Panel Port

You can manually configure the Switch IP information in the following

ways:

■ Connecting to a front panel port — Connect a workstation using an

Ethernet cable to a front panel port of the Switch. You can then

manually enter IP information using the web interface or the

command line interface (CLI).

■ Connecting to the console port — Connect a workstation using a

console cable to the console port of the Switch. You can then

manually enter IP information using the command line interface (CLI).

To set up your Switch manually you can make a connection to a front

panel port. You must do this whilst the Switch is offline, that is, before

you connect the Switch to a network.

The procedure described in this section assumes the unit has been

powered up in standalone mode and has the default IP address of

169.254.100.100.

Pre-requisites

■ A workstation running Windows 95/98/2000, Windows NT or

Windows XP.

■ A Network Interface Card (NIC).

■ A Category 5 twisted pair Ethernet cable with RJ-45 connectors.

■ A suitable Web browser — refer to “Choosing a Browser”on page 52.

■ You need to have the following so that you can manually set up the

Switch with IP information:

■ IP address

■ subnet mask

■ default gateway

Page 40

40 CHAPTER 3: SETTING UP FOR MANAGEMENT

Connecting the Workstation to the Switch

1 Connect the workstation to a front panel port using an Ethernet cable as

shown in Figure 10.

Figure 10 Connecting a workstation to the Switch via a front panel port

To connect the cable:

a Attach an RJ-45 connector at one end of the Ethernet cable to the

Network Interface Card (NIC) in the workstation.

b Connect the RJ-45 connector at the other end of the cable to one of

the front panel ports on the Switch.

Do not interconnect the Switch to any other unconfigured Switch.

Configuring the Workstation with IP Information

You need to change the IP address and subnet mask of the workstation

that you have connected to the Switch. Make a note of the existing

settings so you can return to them later. Change the workstation to the

following settings:

■ IP address — 169.254.100.99

■ Subnet mask — 255.255.0.0

Setting Up the Switch with IP Information

You are now ready to manually set up the Switch with IP information.

You can do this using the Web interface or the command line interface

(CLI) via telnet.

Using the Web Interface

1 Power-up the Switch. This takes approximately one minute.

2 Open a suitable Web browser and enter 169.254.100.100 in the

Location Address field. This is the default IP address that is automatically

assigned to an offline unit.

Page 41

Manually Configuring IP Information 41

If there is no response, wait for one minute then re-enter the default IP

address.

3 At the login and password prompts, enter admin as your user name and

press Return at the password prompt (default user name and password).

If you have logged on correctly, a set of Getting Started pages are

displayed.

4 The Getting Started pages allow you to enter basic setup information for

the Switch. Select Manual and then enter the IP address, subnet mask,

and default gateway that you want the Switch to use when it is

connected to the network. The final page displays a summary of the

information entered.

The initial set up of your Switch is now complete and the Switch is ready

for you to set up your chosen management method. See “Methods of

Managing a Switch” on page 49.

Using Command Line Interface via Telnet

1 To start a Telnet session to the unit, click Start in Microsoft Windows

95/98/2000/NT/XP.

a Click Run.

b In the dialogue box that appears type the default IP address of the

unit, that is: Telnet 169.254.100.100

c Click OK.

2 Press Enter to open a login prompt.

If the login prompt does not begin immediately, press Return a few times

until it starts.

3 At the login and password prompts, enter admin as your user name and

press Return at the password prompt. If you have logged on correctly, the

top-level menu of the command line interface is displayed as shown in

the example in Figure 11.

Page 42

42 CHAPTER 3: SETTING UP FOR MANAGEMENT

Figure 11 Example top-level command line interface menu

4 At the Select menu option prompt you can either:

■ enter the protocol ip basicConfig command. At the Enter

configuration method prompt enter manual. The screen

prompts you to enter IP information.

or

■ enter the gettingStarted command. At the Enter

configuration method prompt enter manual. The screen

prompts you to enter IP information.

Connecting to the

Console Port

5 Enter the IP address, subnet mask, and gateway IP address for the Switch.

The screen displays a summary of the information entered.

If using the gettingStarted command you will then be prompted to

enter system information, change passwords, and then given the option

to carry out advanced configuration.

The initial set up of your Switch is now complete and the Switch is ready

for you to set up your chosen management method. See “Methods of

Managing a Switch” on page 49.

To set up your Switch manually you can alternatively make a connection

to the console port (this example describes a local connection to the

console port, rather than a remote one via a modem). You can do this

whilst the Switch is offline, that is, before you connect the Switch to a

network, or whilst the Switch is online, that is, connected to a network.

Page 43

Manually Configuring IP Information 43

Pre-requisites

■ A workstation with terminal emulation software installed, such as

Microsoft Hyperterminal. This software allows you to communicate

with the Switch via the console port directly, or through a modem.

■ Documentation supplied with the terminal emulation software.

■ A suitable cable:

■ A standard null modem cable — if you are connecting directly to

the console port, or

■ A standard modem cable — if you are connecting to the console

port using a modem.

You can find pin-out diagrams for both cables in Appendix B on page 71.

■ You need to have the following so that you can manually set up the

Switch with IP information:

■ IP address

■ subnet mask

■ default gateway

Connecting the Workstation to the Switch

1 Connect the workstation to the console port using a standard null

modem cable as shown in Figure 12.

Figure 12 Connecting a workstation to the Switch via the console port

To connect the cable:

a Attach the female connector on the cable to the male connector on

the console port of the Switch.

b Tighten the retaining screws on the cable to prevent it from being

loosened.

c Connect the other end of the cable to one of the serial ports (also

known as a COM port) on your workstation.

Page 44

44 CHAPTER 3: SETTING UP FOR MANAGEMENT

2 Open your terminal emulation software and configure the COM port

settings to which you have connected the cable. The settings should be

set to match the default settings for the Switch, which are:

■ 19,200 baud

■ 8 data bits

■ no parity

■ 1 stop bit

■ no hardware flow control

Refer to the documentation that accompanies the terminal emulation

software for more information.

Setting Up the Switch with IP Information

You are now ready to manually set up the Switch with IP information

using the command line interface.

1 The command line interface login sequence begins as soon as the Switch

detects a connection to its console port.

If the login prompt does not begin immediately, press Return a few times

until it starts.

2 At the login and password prompts, enter

admin as your user name and

press Return at the password prompt. If you have logged on correctly, the

top-level menu of the command line interface is displayed as shown in

the example in Figure 13.

Page 45

Manually Configuring IP Information 45

Figure 13 Example top-level command line interface menu

3 At the Select menu option prompt you can either:

■ enter the protocol ip basicConfig command. At the Enter

configuration method prompt enter manual. The screen

prompts you to enter IP information.

or

■ enter the gettingStarted command. At the Enter

configuration method prompt enter manual. The screen

prompts you to enter IP information.

4 Enter the IP address, subnet mask, and gateway IP address for the Switch.

The screen displays a summary of the information entered.

If using the gettingStarted command you will then be prompted to

enter system information, change passwords, and then given the option

to carry out advanced configuration.

The initial set up of your Switch is now complete and the Switch is ready

for you to set up your chosen management method. See “Methods of

Managing a Switch” on page 49.

If you do not intend to use the command line interface via the console

port to manage the Switch, you can disconnect the serial cable and close

the terminal emulator software.

Page 46

46 CHAPTER 3: SETTING UP FOR MANAGEMENT

Viewing Automatically Configured IP Information

Using 3Com Network

Supervisor

If you allow the Switch to automatically configure its own IP information

you need to discover and view the IP information before you can begin to

manage the Switch. You can discover the IP information in two ways:

■ Using 3Com Network Supervisor — This application will auto-discover

the Switch and display the automatically allocated IP information

assigned to the Switch.

■ Connecting to the Console Port — Connect a workstation using a

console cable to the console port of the Switch. You can then view the

IP information automatically assigned to the Switch using the

command line interface (CLI).

You can use the 3Com Network Supervisor application provided on the

CD-ROM that accompanies your Switch to discover the automatically

allocated IP information.

1 Connect your Switch to the network.

2 Power-up the Switch and wait for two minutes.

3 Launch 3Com Network Supervisor and run the Auto-discovery wizard.

3Com Network Supervisor will auto-discover the new Switch and display

the IP information that has been automatically allocated to the Switch.

Most DHCP and BootP servers allow static IP addresses to be configured

so that you know what IP address the Switch will be given. Refer to the

documentation that accompanies your DHCP or BootP server.

Connecting to the

Console Port

If your network does not have a DHCP or BootP server, the workstation

running 3Com Network Supervisor must be on the same subnet as the

Switch, because Auto-IP addresses are non-routable.

Alternatively, you can view the automatically configured IP information

via the command line interface (CLI) through a connection to the console

port. (This example describes a local connection to the console port,

rather than a remote one via a modem.)

Pre-requisites

■ A workstation with terminal emulation software installed, such as

Microsoft Hyperterminal. This software allows you to communicate

with the Switch via the console port directly, or through a modem.

■ Documentation supplied with the terminal emulation software.

Page 47

Viewing Automatically Configured IP Information 47

■ A suitable cable:

■ A standard null modem cable — if you are connecting directly to

the console port, or

■ A standard modem cable — if you are connecting to the console

port using a modem.

You can find pin-out diagrams for both cables in Appendix B on page 71.

■ A Category 5 twisted pair Ethernet cable with RJ-45 connectors to

connect your Switch to the network.

Connecting the Workstation to the Switch

1 Connect the workstation to the console port using a standard null

modem cable as shown in Figure 14.

Figure 14 Connecting a workstation to the Switch via the console port

To connect the cable:

a Attach the female connector on the cable to the male connector on

the console port of the Switch.

b Tighten the retaining screws on the cable to prevent it from being

loosened.

c Connect the other end of the cable to one of the serial ports (also

known as a COM port) on your workstation.

2 Open your terminal emulation software and configure the COM port

settings to which you have connected the cable. The settings should be

set to match the default settings for the Switch, which are:

■ 19,200 baud

■ 8 data bits

■ no parity

■ 1 stop bit

■ no hardware flow control

Refer to the documentation that accompanies the terminal emulation

software for more information.

Page 48

48 CHAPTER 3: SETTING UP FOR MANAGEMENT

Viewing IP Information via the Console Port

You are now ready to view the automatically allocated IP information

using the command line interface.

1 Connect your Switch to the network using an Ethernet cable. As soon as

a network connection is made the Switch begins the automatic IP

configuration process.

The automatic IP configuration process usually completes within one

minute.

If there is no response from a DHCP server within 30 seconds, the Auto-IP

configuration mechanism attempts to allocate the default IP address

169.254.100.100. If this address is not available, it then allocates an IP

address in the range of 169.254.x.y (where x is in the range 1 to 254, and

y is in the range 0 to 255).

2 The command line interface login sequence begins as soon as the Switch

detects a connection to its console port.

If the login prompt does not begin immediately, press Return a few times

until it starts.

3 At the login and password prompts, enter

admin as your user name and

press Return at the password prompt. If you have logged on correctly, the

top-level menu of the command line interface is displayed as shown in

the example in Figure 15.

Figure 15 Example top-level command line interface menu

4 At the Select menu option prompt enter the protocol ip

interface summary command. At the Select IP interfaces

prompt enter all. A summary of the automatically allocated IP

information is displayed. Make a note of the Network IP Address.

Page 49

Methods of Managing a Switch 49

The initial set up of your Switch is now complete and the Switch is ready

for you to set up your chosen management method. See “Methods of

Managing a Switch” on page 49.

If you do not intend to use the command line interface via the console

port to manage the Switch, you can logout, disconnect the serial cable

and close the terminal emulator software.

Methods of Managing a Switch

Command Line

Interface

Management

Once you have completed the initial set up of your Switch, you can

decide how you wish to manage the Switch. You can use one of the

following methods:

■ Command line interface management

■ Web interface management

■ SNMP management

Each Switch has a command line interface (CLI) that allows you to

manage the Switch from a workstation, either locally via a console port

connection (see Figure 16), or remotely over the network (see Figure 17).

Figure 16 CLI management via the console port

Figure 17 CLI management over the network

Refer to “Setting Up Command Line Interface Management” on

page 50.

Page 50

50 CHAPTER 3: SETTING UP FOR MANAGEMENT

Web Interface

Management

SNMP Management You can manage a Switch using any network management workstation

Each Switch has an internal set of web pages that allow you to manage

the Switch using a Web browser remotely over an IP network (see

Figure 18).

Figure 18 Web interface management over the network

Refer to “Setting Up Web Interface Management” on page 52.

running the Simple Network Management Protocol (SNMP) as shown in

Figure 19. For example, you can use the 3Com Network Supervisor

software that is provided on the CD-ROM that accompanies your Switch.

Figure 19 SNMP management over the network

Setting Up Command Line Interface Management

CLI Management via

the Console Port

Refer to “Setting Up SNMP Management” on page 53.

This section describes how you can set up command line interface

management using a local console port connection or over the network.

To manage a Switch using the command line interface via the local

console port connection:

1 Ensure you have connected your workstation to the console port correctly

as described in “Connecting to the Console Port” on page 42.

2 Your Switch is now ready to continue being managed and/or configured

through the CLI via its console port.

Page 51

Setting Up Command Line Interface Management 51

CLI Management over

the Network

To manage a Switch using the command line interface over a network

using Telnet:

1 Ensure you have already set up the Switch with IP information as

described in “Setting Up Overview” on page 36.

2 Check that you have the IP protocol correctly installed on your

management workstation. You can check this by trying to browse the

World Wide Web. If you can browse, the IP protocol is installed.

3 Check you can communicate with the Switch by entering a ping

command at the DOS prompt in the following format:

c:\ ping xxx.xxx.xxx.xxx

(where xxx.xxx.xxx.xxx is the IP address of the Switch)

If you get an error message, check that your IP information has been

entered correctly and the Switch is powered up.

4 To open a Telnet session via the DOS prompt, enter the IP address of the

Switch that you wish to manage in the following format:

>telnet xxx.xxx.xxx.xxx

(where xxx.xxx.xxx.xxx is the IP address of the Switch)

If opening a Telnet session via third party software you will need to enter

the IP address in the format suitable for that software.

5 At the login and password prompts, enter

admin as your user name and

press Return at the password prompt (or the password of your choice if

you have already modified the default passwords).

If the login prompt does not display immediately, press Return a few

times until it starts.

6 If you have logged on correctly, the top-level menu of the command line

interface for the Switch you wish to manage is displayed as shown in

Figure 13 on page 45.

Page 52

52 CHAPTER 3: SETTING UP FOR MANAGEMENT

Setting Up Web Interface Management

Pre-requisites

Netscape 4.76

Netscape 6.2

Internet Explorer

5.0, 5.5 and 6.0

This section describes how you can set up web interface management

over the network.

■ Ensure you have already set up the Switch with IP information as

described in “Setting Up Overview” on page 36.

■ Ensure that the Switch is connected to the network using a Category

5 twisted pair Ethernet cable with RJ-45 connectors.

■ A suitable Web browser.

Choosing a Browser

To display the web interface correctly, use one of the following Web

browser and platform combinations:

Tab le 8 Supported Web Browsers and Platforms

Windows NT 4Windows

Windows 95 Windows 98

2000

Windows XP

✓ ✓ ✓ ✓ ✓ ✓

✕ ✓ ✓ ✓ ✓ ✕

✓ ✓ ✓ ✓ ✓ ✕

Solaris

2.6

For the browser to operate the web interface correctly, JavaScript™ and

Cascading Style Sheets must be enabled on your browser. These features

are enabled on a browser by default. You will only need to enable them if

you have changed your browser settings.

To enable style sheets in Netscape Navigator 4.76 on Solaris 2.6, open

Netscape Navigator and select Edit > Preferences > Fonts. Select the Use

document-specified fonts, including Dynamic Fonts radio button. You

should also set the font sizes as follows:

■ Variable Width Font - Size 10.0

■ Fixed Width Font - Size 12.0

This ensures that the text spacing is correct. Finally in the Advanced

category ensure that Enable Java Script and Enable style sheets are

checked.

Page 53

Setting Up SNMP Management 53

Web Management

Over the Network

Setting Up SNMP Management

To manage a Switch using the web interface over an IP network:

1 Check that you have the IP protocol correctly installed on your

management workstation. You can check this by trying to browse the

World Wide Web. If you can browse, the IP protocol is installed.

2 Check you can communicate with the Switch by entering a ping

command at the DOS prompt in the following format:

c:\ ping xxx.xxx.xxx.xxx

(where xxx.xxx.xxx.xxx is the IP address of the Switch)

If you get an error message, check that your IP information has been

entered correctly and the Switch is powered up.

3 Open your web browser and enter the IP address of the Switch that you

wish to manage in the URL locator, for example, in the following format:

http://xxx.xxx.xxx.xxx

4 At the login and password prompts, enter admin as your user name and

press Return at the password prompt (or the password of your choice if

you have already modified the default passwords).

5 Click on the Device View button to display the web management options.

Any network management application running the Simple Network

Management Protocol (SNMP) can manage a Switch if:

Pre-requisites

■ The correct Management Information Bases (MIBs) are installed on the

management workstation.

■ The management workstation is connected to the Switch using a port

in VLAN 1 (the Default VLAN). By default, all ports on the Switch are in

VLAN 1.

You can use the 3Com Network Supervisor application that is provided on

the CD-ROM that accompanies your Switch to provide SNMP

management for your Switch. If you use 3Com Network Supervisor it

automatically loads the correct MIBs and necessary files onto your

workstation.

■ Documentation supplied with the SNMP network management

application software.

Page 54

54 CHAPTER 3: SETTING UP FOR MANAGEMENT

To manage your Switch using an SNMP network management

application, you need to specify SNMP community strings for the users

defined on the Switch. You can do this using the command line interface

system management snmp community command — refer to the

command line interface section of the “SuperStack 3 Switch

Management Interface Reference Guide” for more information.

Default Users and Passwords

If you intend to manage the Switch using the web interface or the

command line interface, or to change the default passwords, you need to

log in with a valid user name and password. The Switch has three default

user names, and each user name has a different password and level of

access. These default users are listed in Table 9.

CAUTION: To protect your Switch from unauthorized access, you must

change all three default passwords as soon as possible, even if you do not

intend to actively manage your Switch

Tab le 9 Default Users

User

Name

monitor monitor monitor — the user can view all manageable parameters,

manager manager manager — the user can access and change the

admin (no

Default

Password

password)

Access Level

except special/security features, but cannot change any

manageable parameters

operational parameters but not special/security features

security — the user can access and change all manageable

parameters

Use the admin default user name (no password) to login and carry out

initial Switch setup.

Changing Default

Passwords

You can change the default passwords using either:

■ The gettingStarted command on the CLI, or

■ The security device user modify command on the CLI, or

■ The Security > Device > User > Modify operation on the web interface.

For more information about default users and passwords, refer to the