Page 1

INKBUILDER

L

MSH

HASSIS

C

SER

U

G

UIDE

Part No. DUA1800-0AAA04

Published September 1994

Page 2

3Com Corporation ■ 5400 Bayfront Plaza ■ Santa Clara, California ■ 95052-8154

© 3Com Ireland, 1994. All rights reserved. No part of this documentation may be reproduced in any

form or by any means or used to make any derivative work (such as translation, transformation, or

adaptation) without permission from 3Com Ireland.

3Com Ireland reserves the right to revise this documentation and to make changes in content from

time to time without obligation on the part of 3Com Ireland to provide notification of such revision or

change.

3Com Ireland provides this documentation without warranty of any kind, either implied or expressed,

including, but not limited to, the implied warranties of merchantability and fitness for a particular

purpose. 3Com may make improvements or changes in the product(s) and/or the program(s) described

in this documentation at any time.

UNITED STATES GOVERNMENT LEGENDS:

If you are a United States government agency, then this documentation and the software described

herein are provided to you subject to the following restricted rights:

For units of the Department of Defense:

Restricted Rights Legend: Use, duplication or disclosure by the Government is subject to restrictions as

set forth in subparagraph (c) (1) (ii) for restricted Rights in Technical Data and Computer Software

clause at 48 C.F.R. 52.227-7013. 3Com Ireland, c/o 3Com Limited, Isolan House, Brindley Way, Hemel

Hempstead, Hertfordshire, HP3 9XJ, UK.

For civilian agencies:

Restricted Rights Legend: Use, reproduction or disclosure is subject to restrictions set forth in

subparagraph (a) through (d) of the Commercial Computer Software - Restricted Rights Clause at 48

C.F.R. 52.227-19 and the limitations set forth in 3Com’s standard commercial agreement for the

software. Unpublished rights reserved under the copyright laws of the United States.

3Com, CardFacts, LinkBuilder and RingBuilder are registered trademarks of 3Com Corporation.

Registered trademarks are registered in the United States, and may or may not be registered in other

countries.

LinkSwitch, FMS, MSH, and Transcend are trademarks of 3Com Corporation.

3ComFacts, Ask 3Com, NetFacts, and CardBoard are service marks of 3Com Corporation.

CompuServe is a registered trademark of CompuServe, Inc.

Other brand and product names may be registered trademarks or trademarks of their respective

holders.

Page 3

C

ONTENTS

A

BOUT THIS GUIDE

About This Guide ix

A Word About Safety ix

Special Messages x

How to Use This Guide x

W

HAT IS THE LINKBUILDER

1

The LinkBuilder MSH 1-1

The Chassis 1-4

The Backplane 1-5

The Modules 1-8

Power Supply Units (PSU) 1-8

The Display Panel 1-9

The Thermal Management Unit (TMU) 1-10

The Cable Support Tray 1-10

Management Of The LinkBuilder MSH 1-11

I

NSTALLING THE LINKBUILDER

2

Introduction 2-1

A Suitable Site For Installation 2-2

Installing The Chassis 2-2

Installation Into A 19 Inch Rack 2-4

The Locking Bar 2-5

Assembling The LinkBuilder MSH 2-6

Safety Information 2-6

The Power Supply Unit And Power Inlet Panel 2-8

Installing The Power Supply Unit 2-9

Removing The Power Supply Unit 2-12

The Display Panel 2-15

Removing The Display Panel 2-15

The Thermal Management Unit 2-17

MSH?

MSH

Page 4

The Cable Support Tray 2-20

Completing The Installation 2-23

Network Cabling 2-23

Power-up The LinkBuilder MSH 2-23

Storing The User Guides 2-24

I

3

NSTALLING MODULES INTO THE

Introduction 3-1

Ethernet Modules 3-2

Token Ring Modules 3-10

FDDI Modules 3-13

Handling Modules 3-15

Before You Begin 3-16

Blanking Plates 3-16

Choosing Slots For Modules 3-17

LinkBuilder MSH Modules 3-17

Installing/Removing A Module 3-18

Removing A Module 3-20

LinkBuilder ECS Modules 3-21

Installing/Removing LinkBuilder ECS Modules 3-21

U

4

SING THE DISPLAY PANEL

The Display Panel 4-1

The LEDs 4-4

Tes ti ng LE Ds 4- 5

Resetting The LinkBuilder MSH 4-6

Management 4-6

The Four-button Keypad 4-6

The RS232 Serial Port 4-7

The Network Manager 4-7

MSH C

HASSIS

P

5

ROBLEM SOLVING

Introduction 5-1

Spares 5-2

Spot Checks 5-2

Cleaning 5-3

Removing And Replacing Equipment 5-3

Page 5

Fault Diagnosis Using The LEDs 5-4

Obtaining Help 5-5

S

A

TANDARDS USED IN THE DESIGN

Standards and Approvals A-1

Safety A-1

Environmental A-1

Electromagnetic Compatability A-1

Functional A-2

BABT Approval A-2

T

B

ECHNICAL SPECIFICATION

MSH Chassis - 3C18000 and 3C18001 B-1

Display Panel - 3C18006 B-2

375W Power Supply Unit - 3C18011 B-2

525W Power Supply Unit - 3C18012 B-3

Thermal Management Unit - 3C18005 B-3

ECS - MSH Module Converter - 3C18082 B-4

Miscellaneous B-4

Weight of blanking panels B-4

MSH P

C

Calculating Power Consumption C-1

OWER CONSUMPTION LIMITS

PIN AND C

D

Ethernet RJ45 - Pin Assignments D-1

Ethernet Telco - Pin Assignments D-2

Token Ring RJ45 - Pin Assignments D-4

Ring-In and Ring-Out Pin Assignments D-4

RS232 Serial Port - Pin Assignments D-5

Status Input Connector D-5

O

E

RDERING INFORMATION

Product Numbers E-1

Chassis Components E-1

IRCUIT ASSIGNMENTS

Page 6

Ethernet Products E-2

Token Ring Products E-3

FDDI Products E-3

Suppliers E-4

T

F

ECHNICAL SUPPORT

On-line Technical Services F-1

3Com Bulletin Board Service (3ComBBS) F-1

Ask3Com on CompuServe F-2

3ComFacts Automated Fax Service F-2

3Com Documentation on CD-ROM F-3

Support from Your Network Supplier F-4

Support from 3Com F-4

Returning Products for Repair F-5

I

NDEX

R

ADIO FREQUENCY INTERFERENCE STATEMENTS

FCC Statement 1

CSA Statement 1

Information To The User 1

L

IMITED WARRANTY

Page 7

A

BOUT THIS

About This Guide

This guide is intended for use only by the following:

■ the Network Administrator responsible for the management and

maintenance of the network.

■ the installation engineer responsible for installing hardware.

This guide contains all the information you need to set up the

LinkBuilder MSH (Multi-Services Hub) and describes how:

■ the MSH works

■ to install the chassis, its ancillary components and modules

■ to identify problems and possible solutions to these problems.

G

UIDE

A Word About Safety

Please pay careful attention to the Warning and Safety

Information panels that appear throughout this user guide. These

panels give information that will protect you and the MSH

equipment.

They are always accompanied by this symbol:

Page 8

x A

BOUT THIS GUIDE

Special Messages

A special format indicates notes, cautions, and warnings. These

messages are defined as follows.

Notes call attention to important features or instructions.

CAUTION:

Cautions contain directions that you must follow to

avoid immediate system damage or loss of data.

WARNING:

Warnings contain directions that you must follow for

your personal safety. Follow all instructions carefully.

Throughout this guide,

are used to denote new terms or

italics

emphasis.

How to Use This Guide

The following list shows where to find specific information. Refer

to the documentation roadmap in the front of this guide for

information on related guides.

If you are looking for: Turn to:

Details of Multi-Services Hub functions and features, and add-on products Chapter One

How to install the chassis and the ancillary items Chapter Two

How to install and remove LinkBuilder MSH and ECS modules Chapter Three

How to use the display panel and what you can do with it Chapter Four

How to identify and resolve any problems Chapter Five

Standards used in the development of the MSH Appendix A

Technical specifications for LinkBuilder MSH products Appendix B

MSH power consumption limits Appendix C

Connector pin assignments Appendix D

Ordering information for products mentioned in this user guide. Appendix E

How you can contact 3Com Appendix F

DUA1800-0AAA04

Page 9

W

HAT IS THE LINKBUILDER

1

■ The LinkBuilder MSH and the services it provides

■

■ A brief explanation of the display panel, power supply units and

MSH?

This chapter introduces:

The modules

thermal management unit.

WARNING:

i.e., removal and replacement of modules, power supply units

and other ancillary components must only be carried out by

qualified personnel

AVERTISSEMENT:

MSH, comme par exemple, l'enlèvement et le remplacement des

modules, des fournitures électriques et des autres composants,

doivent être effectués uniquement par un personnel qualifié.

Installation and configuration of the MSH chassis,

L'installation et la configuration du châssis

The LinkBuilder MSH

The LinkBuilder MSH provides a central hub for network

interconnection and management.

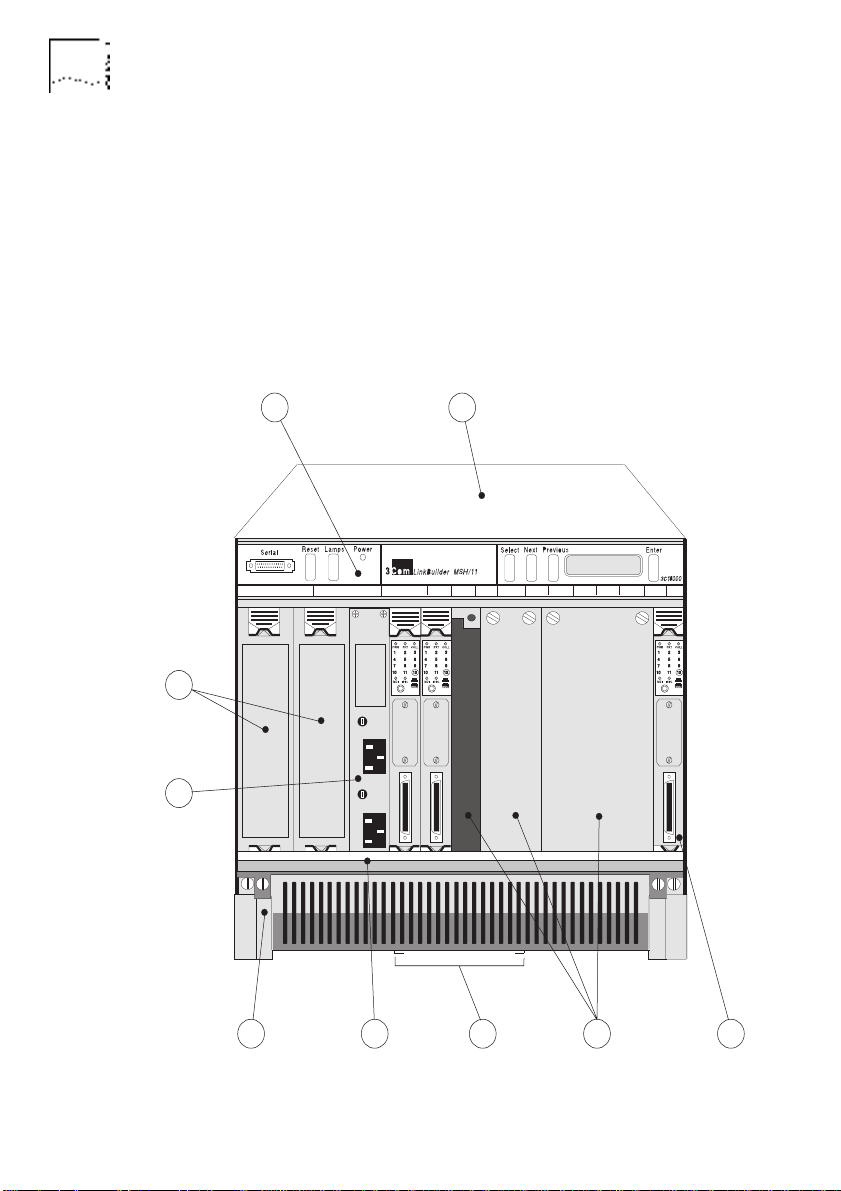

There is a diagram of an MSH and key to the compnents overleaf.

The basis of the MSH is the chassis, into which can be installed a

series of media specific modules. At the heart of the chassis is the

backplane onto which all modules connect. It is the backplane

which allows communication between the network segments

using the MSH. A locking bar fitted across the front of the MSH

chassis prevents removal of modules and power supply units by

unqualified personnel.

Page 10

1-2 C

HAPTER

HAT IS THE LINKBUILDER

1: W

MSH?

Power is supplied to the chassis via one or two

and the chassis is kept cool with a

Your local interface with the MSH is via a

convenience may be installed at the front or rear of the chassis.

This display panel provides simple local fault finding and

management status information and an RS232 port for

out-of-band management. Detailed management of the system is

available via a remote management tool such as the ISOVIEW

Network Manager.

2

thermal management unit

1

power supply units

display panel

.

which for

3

4

5

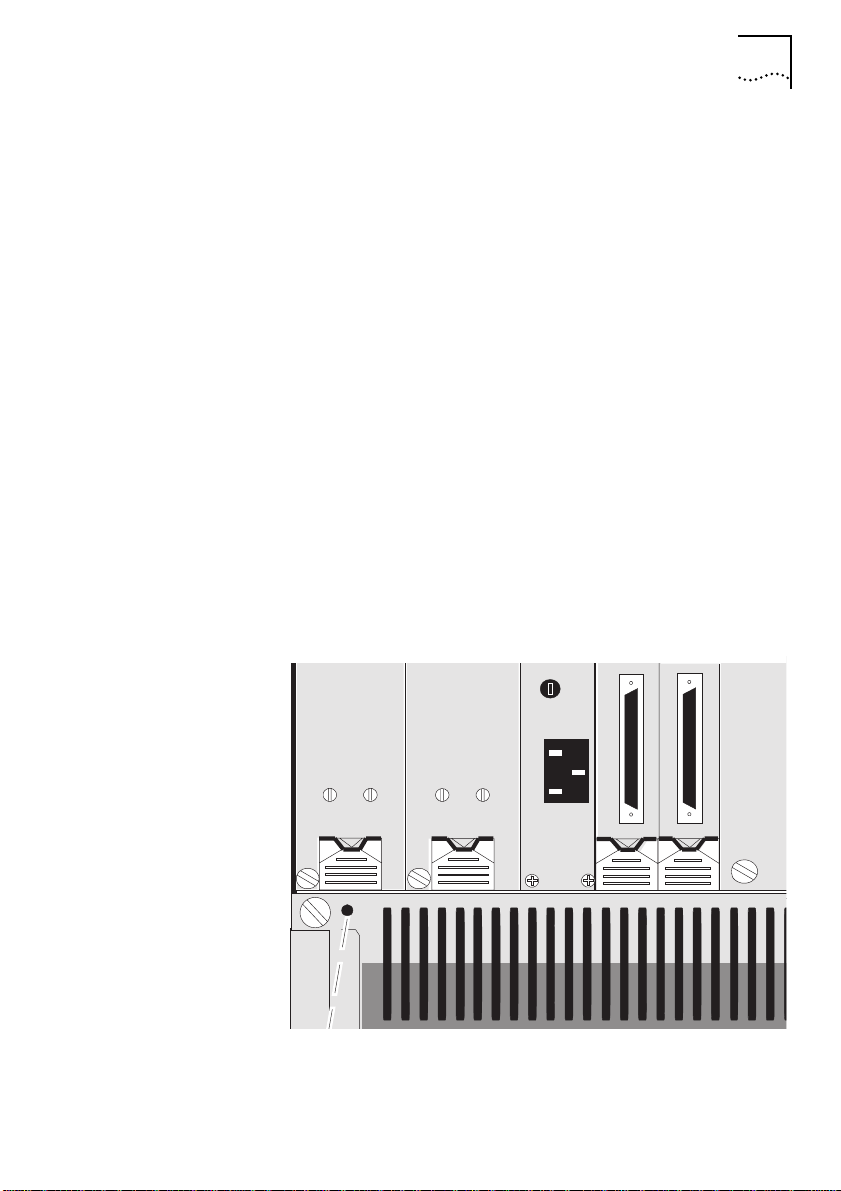

Figure 1-1 The LinkBuilder MSH

6

7

8

DUA1800-0AAA04

9

Page 11

The LinkBuilder MSH 1-3

MSH Chassis

1

which all components are installed. See

Display Panel

2

- The 11-slot chassis that holds the backplane into

The Chassis

on page 1-4

- Can be fitted front or back. Provides your local

interface to the control and management of the MSH. See

Display Panel

Power Supply Units

3

on page 1-9

.

- Distributes power to the other modules.

One unit is essential for operation, two are recommended for

resilience. See

Power Inlet Panel

4

sockets. See

page 2-8

Thermal Management Unit

5

air to the modules. See

page 1-10

Locking Bar

6

Power Supply Units (PSU)

on page 1-8

- Provides the power connection via two IEC

The Power Supply Unit And Power Inlet Panel

.

- A fan unit that supplies cooling

The Thermal Management Unit (TMU)

.

- This must be fitted to prevent removal of modules

and power supply units by unqualified personnel. See

Bar

on page 2-5

.

.

The Locking

The

on

on

7

8

9

DUA1800-0AAA04

Documentation Holder

guides. See

Storing The User Guides

Module Slot and Blanking Plate

- A useful place to store module user

on page 2-24

.

- There are eleven identical

slots that can take one of a range of modules. Blanking plates

that cover 1, 3 and 5 vacant slots are supplied.

For Modules

Module

Modules

- One of a wide range available from 3Com. See

on page 1-8.

on page 3-17

and Blanking Plates

See Choosing Slots

on page 3-16

The

Packaged with the MSH chassis, but not shown on Figure 1-1:

The Rack Mounting Kit

allow the MSH to be mounted into a 19 inch rack. See

Into A 19 Inch Rack

- Consists of a pair of brackets that

on page 2-4

.

Installation

.

Page 12

1-4 C

HAPTER

HAT IS THE LINKBUILDER

1: W

MSH?

Available to order, but not shown on Figure 1-1:

The Cable Support Kit

prevents strain on the connections.

on page 1-10

The MSH components are explained more fully in the sections

which follow.

The Chassis

The chassis has two versions. 3C18000 supports Ethernet and

Token Ring: 3C18001 supports FDDI as well. Upgrade from

3C18000 to 3C18001 is available. Ask your supplier for details.

Either chassis has eleven slots offering identical functionality to a

maximum of eleven modules if the unit is fully populated. Two

identical slots on the left-hand side of the chassis can each hold a

power supply unit (PSU). A power inlet panel located between the

right-hand PSU slot (PSU 2) and the module slots provides two IEC

sockets, one for each PSU. It is worth noting at this point that

connectivity modules

cannot

cannot

- Takes the weight of network cables and

See The Cable Support Tray

and Appendix E for ordering information.

cannot

be fitted into PSU slots, the PSU

be fitted into module slots and the power inlet panel

be moved from its position.

The chassis is suitable for installation into a standard 19 inch rack

system or stand-alone desk or shelf mounting and has been

designed so that you may decide which face of the unit is the

front. Blanking plates of various sizes are supplied to cover any

unused slots whilst the unit is in operation.

Underneath the chassis there is a storage position for holding up

to four module user guides. We suggest that you use this as a

way of keeping the useful information contained in the guides at

your finger-tips.

Fitted in the chassis and central to the operation of the MSH is the

backplane.

DUA1800-0AAA04

Page 13

The Backplane

p

The backplane provides the following services to the MSH:

■

Ethernet support via a medium speed CSMA/CD bus

■

Token ring support via a flexible high speed bus

■

FDDI support via a flexible high-speed bus (3C18001 or converted

3C18000)

■

Management via a separate management bus

■

Power

■

System control

Ethernet Support

The Ethernet bus has been designed to conform to the IEEE 802.3

standard for Local Area Networks. It supports three individual

paths which are tracked to all module slots. You can decide to

which Ethernet bus a module connects thus allowing multiple

segments within the one chassis..

The Chassis 1-5

DUA1800-0AAA04

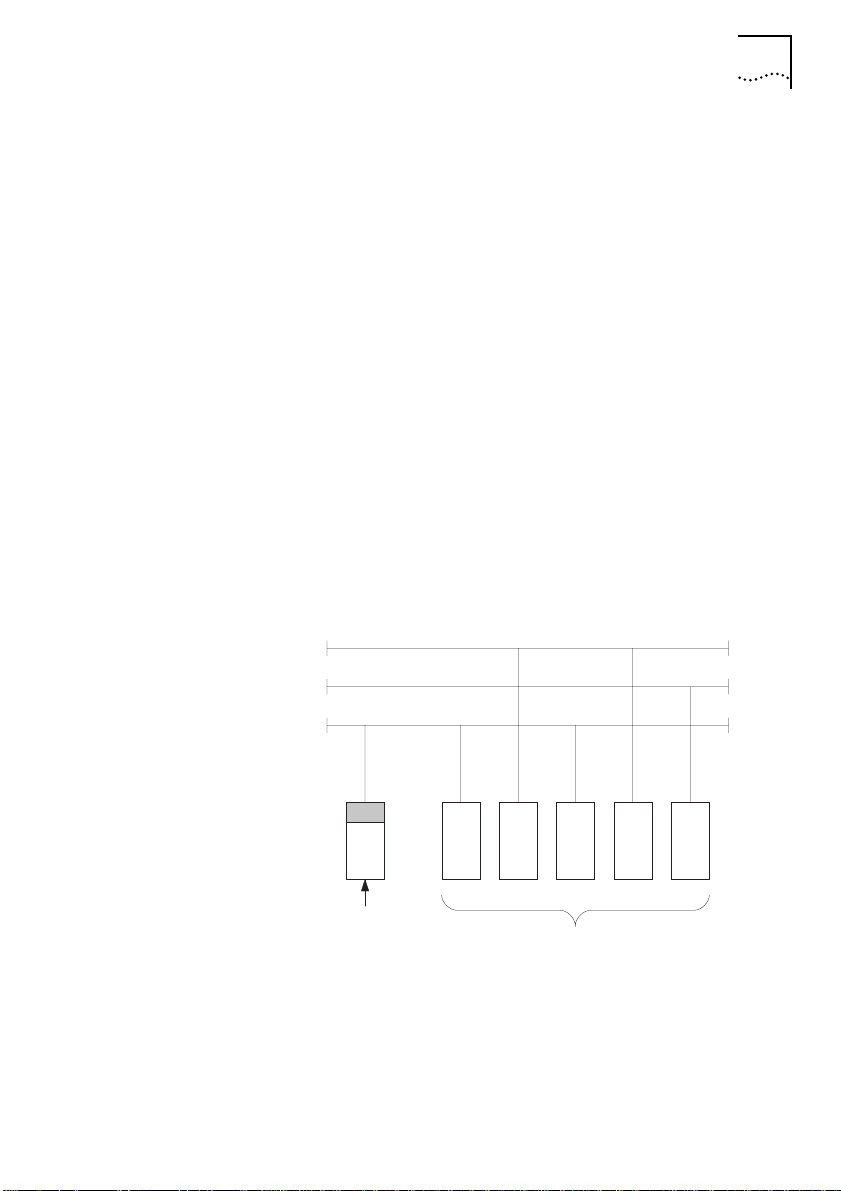

Bus 3

Bus 2

Bus 1

ECS module

Figure 1-2

with adap

Ethernet backplane operation

ter

MSH modules

Figure 1-2 shows an ECS module fitted with a converter

connecting into Bus E1 on the MSH Backplane, and MSH modules

connecting to any of the three ethernet buses.

Page 14

1-6 C

HAPTER

HAT IS THE LINKBUILDER

1: W

MSH?

ECS modules can connect to any of the three buses, however, you

should note that an ECS module attached to Buses E2 or E3 will

not have full statistics gathering facilities. Note also that an ECS

module should only be installed in slots 1 to 10 in the MSH

chassis.

Bus selection on MSH modules is controlled via link settings on

the board or through a remote management tool such as

Transcend software or using the front panel RS232 port.

You will find further information about this subject in Chapter 3,

The Modules

on page 1-8 in this user guide and in the user guide

that accompanies each module.

Token Ring Support

The MSH supports up to five individually managed token rings

using a bus tracked to all slots in the chassis. Token rings are

created using RingBuilder and MAU modules. Each RingBuilder

has a local ring section number associated with it, set by switches

on the RingBuilder or by the Management Module. Similarly all

MAU modules have local ring section numbers. A RingBuilder

combines all MAUs with local ring section numbers that match

the RingBuilder's local ring section number into one logical token

ring. Any MAUs with a local ring section number of zero, or one

that does not match the local ring section numbers of any

RingBuilder are left isolated as single, stand-alone token rings.

The MSH supports tokens rings at both 4Mbps and 16Mbps but

all modules in a local ring section must operate at the same

speed.

DUA1800-0AAA04

Page 15

The Chassis 1-7

.

DUA1800-0AAA04

Figure 1-3

Token ring backplane operation

You will find further information about this subject in Chapter 3,

The Modules

on page 1-8 in this user guide and in the user guide

that accompanies each module.

FDDI Support

The MSH chassis (3C18001) which is fitted with a FDDI

backplane, supports three managed 100Mbs FDDI rings.

Rings are created with an FDDI RingBuilder Module and one or

more port cards (fiber, UTP or any combination of these up to ten

modules). RingBuilder Modules may contain up to two FDDI

Media Modules, which connect to external FDDI devices. Port

cards associated with a RingBuilder Module must be to the left of

that RingBuilder Module. A special FDDI interface on the

backplane allows a LinkSwitch FDDI Module to communicate with

the associated RingBuilder Module on its left. The user guide

which accompanies your RingBuilder Module gives you a full

description of how to deploy the FDDI modules in an MSH

chassis. Management is through the MSH display panel RS232

Page 16

1-8 C

HAPTER

1: W

management port, a remote manager using Telnet or an SNMP

management application such as one of the 3Com Transcend

range.

The Modules

The range of modules available for installation into the

LinkBuilder MSH is constantly being extended. Please contact your

local supplier for further information.

If you already have a LinkBuilder ECS10 or ECS4, the modules

that you use for this system can be easily adapted for installation

into the MSH chassis. This is achieved by attaching a converter to

the ECS module which will allow it to connect to the MSH

backplane.

ECS modules are also known as line cards.

You will find further information about module functionality in

Chapter 3,

guide.

HAT IS THE LINKBUILDER

MSH?

LinkBuilder MSH Modules

on page 3-17 in this user

Power Supply Units (PSU)

Two slots are provided within the MSH chassis for power supply

units. The MSH can be configured with one PSU installed into

the chassis. However with two PSUs installed, each contributes

approximately half of the power requirement, enabling the load

to be shared. This increases the reliability of the power supply

units. Failure of one of the power supply units would result in the

other unit taking over the full load, without any interruption to

the operation of the MSH.

See Appendix C for details of the use of the two different capacity

PSUs and how to calculate power requirements for a particular

MSH configuration.

DUA1800-0AAA04

Page 17

Power is supplied to the chassis via two IEC sockets (the top

socket serves the left-hand PSU) on a fixed power inlet panel

fitted in the chassis between the right-hand PSU slot (PSU 2), and

the module slots. The two sockets provide resilience against

power supply cable or fuse faults.

The Display Panel

The display panel provides the following features:

■

Lamps Button

The Lamps button allows you to carry out an LED test which

shows you that all the LEDs on the display panel and on modules

installed into the chassis, are working. If an LED on the display

panel does not light, refer to Chapter 5 of this user guide; if it is a

problem with a module LED, refer to the user guide that

accompanies the product.

■

Reset Button

The Display Panel 1-9

■

DUA1800-0AAA04

Pressing the Reset button restarts the MSH. To prevent an

accidental reset of the modules, the Enter button on the

four-button keypad must be pressed at the same time as the

Reset button

.You should only need to reset the MSH immediately after

installation. It is advisable not to use the Reset button during

normal operation, as this could cause loss of data.

RS232 Port

This is a 25-way D-Type connector to which you may connect a

local management terminal directly or via a modem. Note that, in

order to use this port, a LinkBuilder MSH Management Module

must be installed into the chassis.

The display panel also gives you simple fault finding with a line of

comprehensive LEDs, which are explained in Chapters 4 and 5.

Page 18

1-10 C

HAPTER

HAT IS THE LINKBUILDER

1: W

MSH?

If you have a Management Module installed, you can access

read-only information telling you how the chassis is set up. More

details can be found in the user guide that accompanies the

Management Module.

For convenience, the display panel may be installed into the front

of the MSH chassis (the face of the chassis with cable connections

and module LEDs) or it may be fitted to the back of the chassis if

you wish to have network connections and cables kept behind

the MSH.

The Thermal Management Unit (TMU)

This is a fan unit which slides into the bottom of the MSH chassis

and supplies cooling air to the modules by forced circulation. Each

fan has its own failure detector. In the unlikely event of one of the

fans in the unit failing, a Fan Fail LED located on the display panel

at the top of the MSH chassis will light and a message will be sent

to network management stations. If a fan does fail, you should

contact your supplier immediately as the failure may lead to

overheating and subsequent damage to the modules.

Filters fitted over each fan, prevent dust and debris from entering

the chassis. These should be cleaned at regular intervals.

The Cable Support Tray

We recommend that all external cables from the LinkBuilder MSH

are provided with some form of strain relief. The

has been specifically designed for use with the MSH chassis.

tray

When fitted, the cable support tray also provides the correct

clearance underneath the unit so that cooling air can freely

circulate.

cable support

DUA1800-0AAA04

Page 19

Management Of The LinkBuilder MSH 1-11

Management Of The LinkBuilder MSH

You are advised to install a LinkBuilder Management Module into

the MSH. This will enable you to more effectively manage the

multiservice facilities of the MSH.

There are four possible methods of management.

■

If the MSH does not contain a Management Module:

■

you have access to simple monitoring, using the LED indicators

located on the display panel and on modules, and by manually

setting links on the modules.

■

If there is a Management Module installed in the MSH Chassis:

■

Remote Network Management, for instance ISOVIEW Network

Manager or Transcend applications for SunNet and HP

OpenView Managers, is the most powerful method of

management. It allows access to and control of a range of

features, including error and traffic rate triggers.

DUA1800-0AAA04

■

Using a local management terminal connected to the RS232

port on the display panel provides a method of accessing a

comprehensive set of management tools for out-of-band

management.

■

The 2-line x 24-character LCD panel displays read-only

information detailing statistics, port traffic, version numbers

etc. Refer to the user guides that accompany the Management

Module.

You will find further information in

Management

on page 4-6.

Page 20

1-12 C

HAPTER

HAT IS THE LINKBUILDER

1: W

MSH?

DUA1800-0AAA04

Page 21

I

NSTALLING THE LINKBUILDER

2

■

■

■ Details of how to install:

MSH

This chapter provides:

An overview of the steps needed to install the MSH

Details of how to install the chassis

■

a power supply unit

■

the display panel

■

the thermal management unit

■

the rack/cable mounting kit

WARNING:

must be carried out by qualified personnel only.

AVERTISSEMENT:

ce chapitre doivent être effectuées uniquement par un personnel

qualifié.

Maintenance operations described in this chapter

Les opérations de maintenance décrites dans

Introduction

We suggest that you carry out the following sequence of steps to

install and set up the LinkBuilder MSH:

If the MSH is to be installed on a new or extended network,

1

ensure that all the network cabling has been set up and tested

before starting the installation.

Install the chassis, and at least one power supply unit and check

2

that they are operating correctly.

Page 22

2-2 C

HAPTER

3

NSTALLING THE LINKBUILDER

2: I

Install modules and a Management Module if you are using one,

into the chassis, and check their operation

Attach your network cabling to the modules you have installed.

4

A Suitable Site For Installation

Before you install the MSH, make sure that the location you have

chosen is suitable. There should be:

Adequate ventilation. The chassis has three sets of ventilation

■

holes - one on the top of the chassis, one at the back and one

underneath. Ventilation panels and the air-intake at the front of

the fan tray must be free of obstructions at all times to allow

adequate circulation of cooling air.

Adequate clearance to allow for cable connections, viewing and

■

use of display panel and LEDs, and installation and removal of

modules.

Access to a power supply with two sockets.

■

MSH

No direct sources of electrical interference in the immediate area,

■

for example, machinery, power lines, transmitters.

No danger of condensation, liquids or excessive amounts of dust

■

entering the chassis.

Remember also that the MSH operates correctly in temperatures

between 0°C and 40°C (32°F and 104°F).

Installing The Chassis

A pair of brackets for mounting the MSH are supplied with the

chassis. The MSH can be:

Fitted into a standard 19 inch rack system.

■

Left as a stand-alone piece of equipment, for example, on a desk

■

or shelf.

DUA1800-0AAA04

Page 23

Introduction 2-3

If MSH chassis are mounted one above the other, there must be

adequate space between them for cooling air to pass. When

fitted, the cable support tray, which can be ordered from your

local LinkBuilder supplier, provides the correct spacing between

units. If you do not fit a cable support tray you should leave 1U

between units. (The height of standard 19 inch rack mountings

are measured in `U's. 1U is approximately 45 millimeters (1

3

/4”).)

If you decide to install the chassis into a 19 inch rack, you can also

determine which face of the chassis is the front. Throughout this

user guide, we assume that the front of the chassis is that face

which has the network connections and module LEDs. However,

you may find that, for your set-up, it is more convenient to have

all cable connections at the back of the unit.

Fitting The Mounting Brackets

Refer to Figure 2-1.

Figure 2-1

DUA1800-0AAA04

Position of the Mounting Brackets (lefthand side view)

Page 24

2-4 C

HAPTER

NSTALLING THE LINKBUILDER

2: I

MSH

There are two sets of holes on each side of the MSH chassis.

These allow for fitting the mounting brackets to two different

positions:

If you decide to have the face of the chassis that takes the cable

■

connections and shows module LEDs as the

, fit the brackets

front

to the holes near this face.

If you decide to have the face of the chassis that is clear of

■

connections as the front, fit the brackets using the set of holes

towards the rear face.

If you decide on this configuration, the display panel above the

module slots must be moved. Refer to The Display Panel on page

2-15.

Match the appropriate bracket with the holes on the side face of

1

the MSH chassis.

Locate the four slotted screws into the holes and tighten using a

2

flat-tipped screwdriver.

To remove the bracket, loosen the four screws, and lift it away.

Store both brackets and screws safely for future use.

Installation Into A 19 Inch Rack

Fit the mounting brackets that are supplied with the chassis to the

1

face which you have decided is the front of the chassis.

Refer to the manufacturer's documentation that accompanies the

2

19 inch rack for details of installation. If there is a door fitted to

the rack, it is essential that there is adequate clearance between

the door and the front of the MSH chassis to prevent damage to

cables and connectors.

DUA1800-0AAA04

Page 25

The Locking Bar

The MSH chassis is delivered with a locking bar fitted. Once the

MSH is fully assembled and installed, you must refit this locking

bar. This will prevent the removal and replacement of power

supplies, modules etc. by unqualified personnel.

Fitting The Locking Bar

1

Position the locking bar so that its two captive, fixing screws

align with holes in the thermal management unit. Note that for

clarity, the captive screws are shown removed from the bar in

Figure 2-2.

2

Locate two small screws into the appropriate holes and tighten

fully with a flat bladed screwdriver.

To remove the locking bar, loosen two screws and remove bar.

Introduction 2-5

DUA1800-0AAA04

Figure 2-2

Installing the Locking Bar

Page 26

2-6 C

HAPTER

NSTALLING THE LINKBUILDER

2: I

MSH

Assembling The LinkBuilder MSH

WARNING:

powered-up MSH must not be left unattended

Safety Information

WARNING:

power leads before servicing.

ATTENTION

The MSH cannot be powered from IT

are of the IT type, then the unit should be powered with 230V (2P

+ T) via an isolation transformer ratio 1:1, with the secondary

connection point labelled neutral, connected directly to earth.

‡

Impedance à la tierre

The MSH operates under SELV conditions (Safety Extra Low

Voltage) according to IEC 950, the conditions of which are

maintained only if the equipment to which it is connected is also

operating under SELV.

The power inlet panel is an integral part of the MSH chassis. Do

not make any attempt to remove it. If you suspect a problem is

related to the panel, please contact your supplier.

During installation and maintenance operations, the

This equipment must be earthed. Disconnect both

- Débrancher les 2 cordons avant entretien.

‡

supplies. If your supplies

The Power Lead - General1

The power lead must be approved for the country where it will be

■

used.

The appliance coupler (that is the connector to the device itself -

■

not the wall plug), must have a configuration for mating with a

EN 60320/IEC320 appliance inlet (Standard Sheet C14).

The Power Lead - USA and Canada

The power lead must be UL-listed and CSA-certified.

■

DUA1800-0AAA04

Page 27

Safety Information 2-7

■

The minimum specifications for the flexible lead are:

■

- No. 18 AWG

■

- Type SV or SJ

■

- 3-conductor

■

The power lead must have a rated current capacity of at least

10A.

■

The attachment plug must be an earth-grounding type with a

NEMA 5-15P (15A, 125V) or NEMA 6-15P (15A, 250V)

configuration.

The Power Supply Plug

If the power supply plug is unsuitable and you have to replace it,

you may find that the color coding for the replacement power

connector differs from the scheme used on the original

connector. Connect the power supply wire from the MSH

according to the following scheme:

DUA1800-0AAA04

■

Brown wire to the Live (Line) plug terminal which may be

marked with the letter L or colored red.

■

Blue wire to the neutral plug terminal which may be marked

with the letter N or colored black.

■

Yellow/Green wire to the Earth (Ground) plug terminal which

may be marked with the letter E or the earth symbol or

colored green/yellow.

WARNING:

It is essential that the power plugs of the final

installation remain nearby and easily accessible.

ATTENTION

- Il est essentiel que la prise principale de

l'installation finale soit située à proximité et facilement accessible.

The MSH is delivered with one power supply unit (PSU). It will

operate with one unit installed, but two units will provide a

resilient power supply in the unlikely event of a failure of one unit.

Page 28

2-8 C

HAPTER

NSTALLING THE LINKBUILDER

2: I

MSH

The Power Supply Unit And Power Inlet Panel

We recommend that you install two units. Further power supply

units are available from your LinkBuilder supplier: see Appendix E

Ordering Information

resilient supplies and calculating supply requirements.

One PSU installed into the MSH chassis can provide up to 375W

or 525W of power (maximum- depending on which PSU was

purchased), allowing the use of various types and numbers of

modules.

With two Units installed, each contributes approximately half of

the power requirement of the chassis. This enables the load to be

shared, increasing the reliability of the PSUs. Failure of one of the

PSUs would result in the other unit taking over the full load,

without any interruption to the operation of the MSH.

To ensure the operation of a resilient power supply in the MSH

chassis, you are advised to follow the instructions in Appendix C

and calculate total power and current consumptions before

installing the modules.

. See Appendix C for details of configuring

Power is supplied to the chassis via two IEC sockets on the power

inlet panel which is located between the right-hand PSU slot (PSU

2) and the first module slot. The top IEC socket supplies power to

the left-hand PSU (PSU 1), the lower socket supplies to the

right-hand PSU (PSU 2). The unit does not have an ON/OFF

switch, so it is isolated from power by disconnecting the

appropriate power supply cable. The power inlet panel also

contains two replaceable fuses: see the section entitled

The Power Supply Fuses

.

Replacing

The MSH PSU features automatic voltage selection according to

the supply that you are using.

A power lead terminated at both ends is supplied with the

chassis. Refer to the

Safety Information

on the previous pages.

DUA1800-0AAA04

Page 29

The Power Supply Unit And Power Inlet Panel 2-9

Installing The Power Supply Unit

We recommend that, if a single power supply unit is to be used

to power the MSH, the power supply unit should be installed into

the slot at the far left of the chassis. This position optimizes

ventilation within the chassis. MSH chassis are shipped without a

blanking plate covering this slot.

If you are installing a second power supply unit, it can be inserted

without powering down the MSH (this is known as

This will not cause any damage to your equipment, but packets of

data passing through the unit at the time of insertion could be

corrupted.

hot insertion

).

WARNING:

One PSU blanking plate is supplied. If you only have

one PSU installed, the adjacent vacant slot must be covered with

the blanking plate to allow cooling air to be directed onto the

installed PSU.

Hot insertion or removal of modules and/or PSUs may result in

code corruption in modules which contain microprocessors (e.g.

management or bridge modules). In the unlikely event that this

occurs, carry out a reset operation by depressing the `Enter' and

`Reset' buttons on the display panel simultaneously. The affected

modules will then resume their operational state.

We recommend that you use the following steps to install the

power supply unit. If you are hot inserting a second power supply

unit, ignore the first step.

1

Disconnect the power supply cable(s) from the IEC socket(s) on

the power inlet panel to ensure the MSH is powered down.

2

Undo two screws securing the locking bar and lift it away from

chassis.

3

The chassis offers two possible positions for power supply units;

the two left-most slots in the chassis. When a second power

DUA1800-0AAA04

Page 30

2-10 C

HAPTER

NSTALLING THE LINKBUILDER

2: I

MSH

supply unit is to be installed into the chassis, the blanking plate

covering the remaining power supply unit slot must be removed.

See

Blanking Plates

Orientate the power supply unit so that the ejector showing the

4

on page 3-16.

part number is at the top and the 11 way DIN connectors are

nearest to the unit. See Figure 2-3.

Figure 2-3

Raise the ejectors at the top and bottom of the PSU to the open

5

Inserting the PSU (3C18011 shown)

position. See Figure 2-4. With the unit located in the slot runners,

guide the power supply unit into the chassis until the hook on the

top of the ejector locates under the edge of the chassis. See

Figure 2-4. Ensure that the ejector at the bottom of the PSU is in a

similar position.

DUA1800-0AAA04

Page 31

The Power Supply Unit And Power Inlet Panel 2-11

DUA1800-0AAA04

Figure 2-4

Locking the PSU in position

Page 32

2-12 C

HAPTER

6

NSTALLING THE LINKBUILDER

2: I

Simultaneously, press the ejector flaps firmly down into the closed

position. See Figure 2-4. Check that the module has been

properly seated by placing both your thumbs on the front panel

and firmly pushing the module home. Check that the module

front panel is flush with the chassis and surrounding modules.

Using a suitable screwdriver, tighten the single security screw that

7

is at the foot of each PSU, adjacent to the ejector. This captive

screw is shown removed from the unit in Figure 2-3 for clarity.

Reposition locking bar and fully tighten the two screws to secure

8

it in place.

Once you have completed the installation of all components into

9

the chassis, you can power the MSH up and verify that it is

operating correctly. See

Completing The Installation

2-23.

Removing The Power Supply Unit

MSH

on page

Remove the power cord corresponding to the PSU you intend to

remove. The top socket feeds the left-hand PSU; the bottom one

the right-hand PSU. Remove the locking bar from the front of the

chassis. Loosen the security screw at the foot of the PSU. To

unlock the PSU ejector, press on the sprung catch and move the

flaps to the open position. This operation must be applied

simultaneously to both ejectors on the PSU

Removing one of the two power supply units from an operational

MSH will not cause any damage to your equipment. However,

packets of data passing through the unit at the time of removal

can be corrupted. Most network protocols will transparently

recover if this happens.

Before you power down the chassis make sure you inform

affected users or the Network Manager. The effect on end users

of powering down the MSH is varied. It is up to the Network

Manager to decide how best to deal with the situation.

DUA1800-0AAA04

Page 33

The Power Supply Unit And Power Inlet Panel 2-13

.

DUA1800-0AAA04

Figure 2-5

Removing the PSU

Replacing The Power Supply Fuses

Two fuses are fitted in removable cartridges located on the power

inlet panel.

WARNINGS:

The power inlet panel must not be removed from

the chassis; therefore fuse replacement must be carried out with

the panel in position.

Before replacing the fuse make sure you remove the power lead

immediately below the fuse to be replaced.

A defective fuse must be replaced with one of the same

manufacturer and type. The LinkBuilder MSH uses the following

fuses:

Manufacturer: LITTLEFUSE

Type: 314010, F10A H 250V

Page 34

2-14 C

HAPTER

NSTALLING THE LINKBUILDER

2: I

MSH

6.3 x 32mm, ceramic

Replace fuse ONCE only.

If the unit consistently blows fuses, there may be a problem.

Contact your supplier for advice.

Figure 2-6

Replacing Fuses - removing the cartridge

To replace one of these fuses proceed as follows:

Using a suitably sized screwdriver, unscrew the officeholder

1

cartridge from the power inlet panel (refer to Figure 2-6). Slide

the cartridge out of its position.

Pull the spent fuse from the cartridge and fit a new one of the

2

correct type as specified above.

DUA1800-0AAA04

Page 35

3

Replace the cartridge into the power inlet panel and secure using

the screwdriver.

The Display Panel

The display panel provides your local interface to the control of

the MSH. For a description of its functionality and instructions on

how to use it, please refer to Chapter 4.

The MSH is delivered with the display panel installed into the

chassis. However, if the panel fails for any reason or you want to

move the panel so that it is positioned on the other side of the

chassis, you will need to carry out the following procedures.

The Display Panel 2-15

Figure 2-7

WARNING:

Installing / removing the display panel

Installation or removal of the Display Panel must be

performed with the MSH powered down.

Removing The Display Panel

Refer to Figure 2-7.

You will need a small, cross-head screwdriver.

DUA1800-0AAA04

Page 36

2-16 C

HAPTER

1

NSTALLING THE LINKBUILDER

2: I

MSH

Remove the three screws that secure the display panel to the MSH

chassis.

Carefully disengage the flexi-ribbon connector taking care not to

2

bend the pins on the connector, and move the panel away from

the chassis.

Installing The Display Panel

Refer to Figure 2-7.

Before carrying out this procedure, you will need to decide which

installation position for the display panel best suits your set-up.

The display panel can be fitted to the front face (the face with the

network and power supply connections) or the rear face of the

MSH if you need to keep the front of the chassis free from cables.

However, remember that when the chassis is viewed from the

rear, module LEDs will not be visible, the only indication to the

user will be the single LED per slot on the display panel.

Fitting the display panel to the rear of the MSH. When fitting the

display panel to the rear of the unit, the ventilation panel must

first be removed and should be refitted into the position left by

the display panel at the front of the unit. The procedure for fitting

the ventilation panel is similar to that for the display panel.

To install the display panel, you will need a small, cross-head

screwdriver.

The procedure for installing the display panel is identical whether

you are installing it into the front or rear of the chassis.

Lift the display panel into position with the buttons and LCD

1

character display facing towards you.

Fit the flexi-ribbon connector, that emerges from the chassis to

2

the socket on the rear of the display panel and press firmly to

DUA1800-0AAA04

Page 37

ensure that the connection is good. The connector is keyed, so if

necessary turn it around to make it fit the socket.

3

Locate the display panel into position at the top of the chassis.

Secure using the three screws provided.

The Thermal Management Unit

The thermal management unit fits into the bottom of the MSH

chassis, underneath the module slots. It consists of an open-top

tray containing axial fans that draw in cooling air through a grill at

the front of the tray. The air circulates through the chassis and is

expelled through ventilation holes which must be kept free of

obstruction at all times.

The thermal management unit can be installed or replaced whilst

the MSH is powered up without any detrimental effect to its

operation. You should install or replace the TMU with minimal

delay when the MSH is powered up: serious damage can be

caused through overheating if the MSH is allowed to operate

without a TMU installed.

The Thermal Management Unit 2-17

DUA1800-0AAA04

On the underside of the unit, each fan is covered with a filter to

prevent dust from entering into the chassis. These filters should

be removed and inspected regularly and cleaned when necessary.

Cleaning The Filters

See

on page 2-19

.

The MSH is delivered with the thermal management unit

installed. However, in the unlikely event of a fan failure, you will

need to remove the unit and return it to your supplier. The

thermal management unit takes power from the MSH backplane.

This backplane connection also provides a detection service; an

LED located on the display panel will notify you immediately if a

fan has failed. If a Management Module has been fitted, a signal

will be sent to the module, which will in turn send an event to the

remote Network Manager.

Page 38

2-18 C

HAPTER

NSTALLING THE LINKBUILDER

2: I

MSH

WARNING:

You cannot replace individual fans in the thermal

management unit. If failure of a fan occurs, the entire unit must

be replaced as soon as possible.

Installing The Thermal Management Unit

You will need a flat-tipped screwdriver to install the thermal

management unit into the MSH chassis.

The unit can be hot-inserted; you do not have to power the MSH

down before installation. You should not run the MSH for more

than a short while without a working TMU installed.

With the grill at the front of the fan tray towards you and the

1

cut-outs in the top of the tray facing upwards, guide the unit into

the MSH chassis until it is fully home. See Figure 2-8.

With a screwdriver tighten the two captive screws. The captive

2

screws are shown removed from the unit in Figure 2-8 for clarity.

Fit the locking bar and tighten two screws fully.

3

Figure 2-8

Installing / removing the thermal management unit

DUA1800-0AAA04

Page 39

The Thermal Management Unit 2-19

Removing The Thermal Management Unit

Refer to Figure 2-8.

The MSH does not have to be powered down before carrying out

the procedure.

1

Loosen two screws to remove the locking bar.

2

Using a screwdriver loosen the two captive screws that secure the

thermal management unit in the MSH chassis.

3

Slowly withdraw the unit from the chassis.

WARNING:

A replacement thermal management unit must be

fitted immediately. If this is not possible, you must power down

the MSH to prevent damage from overheating.

Cleaning The Filters

WARNING:

It is important that the filters are kept clean. If dust is

allowed to build up, the air flow through the fans and the effect

of cooling of the MSH chassis will be reduced. This could cause

the MSH to overheat.

DUA1800-0AAA04

Page 40

2-20 C

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

HAPTER

NSTALLING THE LINKBUILDER

2: I

MSH

Figure 2-9

Remove the thermal management unit from the MSH chassis as

1

Removing/fitting filters

instructed previously and turn it upside down on a flat surface.

The filters are located in holders, one protecting each fan. Refer

2

to Figure 2-9. Unclip the cover of the filter holder and remove the

sponge filter.

The filter can be cleaned using clean water and, if required, a mild

3

detergent. When it is dry, fit it back into the holder and clip the

holder back into place. Repeat the procedure for each of the fans

within the unit.

Reinstall the thermal management unit as instructed previously.

4

The Cable Support Tray

Refer to Figures 2-10 and 2-11.

A cable support tray can be ordered from your LinkBuilder

product supplier. 3Com recommends its use, as it relieves any

strain on cables and therefore maintains good network

DUA1800-0AAA04

Page 41

The Thermal Management Unit 2-21

connections. When fitted, the cable support tray also provides the

correct clearance between chassis mounted one above the other.

If you decide to use the tray, the user guide holder that is located

underneath the chassis (see

Storing The User Guides

on page

2-24) must be moved as in this position the user guides will be

inaccessible.

To move the user guide holder:

1

Remove the user guide holder by loosening the four screws that

secure it in position underneath the chassis.

2

With the cable support tray upside down, slide the user guide

holder through the slot at the front of the tray until the four

screw holes align. Locate the four screws and tighten.

To fit the cable support tray:

1

Place the cable support tray onto a flat surface. Sit the MSH

chassis on the tray so that two screw holes on either side of the

tray match up with those on the chassis body.

2

1

2

DUA1800-0AAA04

Insert the four screws and tighten.

Fixing the cables:

The cable support tray can contain up to twelve adjustable cable

clips. Once you have fitted the tray, module cables can be secured

in two ways:

Figure 2-10: Let cables drop down the front of the chassis, insert

them through the front of the cable clip and route them out

through the back of the cable support tray. Tighten the cable clip.

Figure 2-11: The bracket that holds the cable clips can slide away

from the MSH chassis; undo the two thumb-screws, slide the

bracket out and retighten the thumb-screws. Let cables drop

down the front of the chassis, insert them through the back of

Page 42

2-22 C

HAPTER

NSTALLING THE LINKBUILDER

2: I

MSH

the cable clip, so leaving them at the front of the chassis. Tighten

the cable clip.

Multiple cables from an individual module can be secured into

one cable clip

Figure 2-10

Cables through the back of the MSH

DUA1800-0AAA04

Page 43

Completing The Installation 2-23

Figure 2-11

Cables at the front of the MSH

Completing The Installation

Complete the installation by fittiing the modules you require.

Refer to Chapter 3 of this user guide, and to the user guides

accompanying the individual modules and Management Module.

Network Cabling

Once you have installed the required modules in your chassis, you

can attach your network cable segments to the modules as

described in the user guide that accompanies each module.

You should ensure that all cables attached to the MSH are

correctly terminated, according to 802.3, 802.5 or ANSIX3T9.5

PMD requirements.

DUA1800-0AAA04

Page 44

2-24 C

HAPTER

NSTALLING THE LINKBUILDER

2: I

Power-up The LinkBuilder MSH

When you have completed all stages of installing the MSH as

outlined in this chapter, and have connected all the cable

segments to your modules, the MSH is ready for operation.

Check that all connections are secure and that all cables are

1

terminated correctly.

To power-up the unit connect the power lead to the IEC socket on

2

the power inlet panel and plug in to the wall socket. The upper

IEC socket supplies power to the left-hand PSU (PSU 1), the lower

IEC socket supplies to the right-hand PSU (PSU 2). Therefore if you

want to use two PSUs, you must have a power supply to both

sockets.

When the unit is powered up, the PWR indicator on each module

3

should light. If they do not, refer to the problem-solving section of

the appropriate user guide.

MSH

Storing The User Guides

On the underside of the MSH chassis, there is a storage position

for module user guides (if the cable support tray is fitted, this

holder should be moved. See

2-20). You can slide up to four guides into the holder, so that they

are readily available for fault diagnosis and LED interpretation.

The Cable Support Tray

DUA1800-0AAA04

on page

Page 45

Storing The User Guides 2-25

DUA1800-0AAA04

Figure 2-12

Putting the user guides into the holder

Page 46

I

NSTALLING

M

ODULES INTO THE

3

■

■

■ Instructions for fitting LinkBuilder ECS modules into the MSH

■ Instructions for fitting blanking plates

MSH C

This chapter provides:

An introduction to Ethernet, token ring and FDDI modules

A general overview for installing modules into the MSH chassis

chassis

WARNING:

out by qualified personnel only.

AVERTISSEMENT:

doivent être effectuées uniquement par un personnel qualifié.

Operations described in this chapter must be carried

HASSIS

Les opérations décrites dans ce chapitre

Introduction

The LinkBuilder range of MSH modules are specifically designed

to fit into your MSH chassis. However, if you currently have a

LinkBuilder ECS, you can also adapt modules that were designed

to fit into the ECS chassis, so that they are fully functional in the

MSH chassis. This does not apply to the Management Module;

ECS Management Modules cannot be used in the MSH.

ECS modules are also known as line cards.

Page 47

3-2 C

HAPTER

NSTALLING MODULES INTO THE

3: I

A Quick Check Before You Install Modules

As mentioned before you can insert up to eleven modules of

mixed media into the LinkBuilder MSH. The range of modules

that are available from 3Com allows many combinations and

permutations for a mixed media network.

However, you should check before installing the modules that the

total power and current consumptions required by the

combination of modules does not exceed the limits given in

Appendix C. These limits have been set to support a fault tolerant

power supply in the MSH chassis.

Ethernet Modules

Repeater Modules

Repeater modules provide all the standard functions within an

802.3 Repeater including the following:

MSH C

HASSIS

Frames are regenerated and retimed, allowing them to be

■

transmitted further than the maximum length of a single cable

segment.

Fragment extension extends undersized collision fragments so

■

that they can be detected by devices throughout the network.

Jabber lock-up protection prevents transceivers attached to the

■

MSH from locking up in the case of devices jabbering (jabbering is

the uncontrolled transmission of oversized frames to the

network).

The diagram opposite shows the functional blocks that make up

an Ethernet module

.

DUA1800-0AAA04

Page 48

Introduction 3-3

S

E

G

M

E

N

T

S

B

A

C

K

P

L

A

N

E

S

E

LED

display

G

M

E

N

T

S

Figure 3-1

Repeater Interface.

network

connections

Ethernet module functions

repeater

functions

isolation

This interface allows the transfer of

management

interface

repeater

interface

C

H

A

S

S

I

S

Ethernet packets, via the backplane, between the different

modules and the management module. Isolation logic allows a

module to act as a sub-network. See

Repeater Functions

on page

3-4.

Network Connection.

The network interface gives the module

a direct connection to the appropriate networking media.

Management Interface.

The management interface is available

if a management module is fitted. It allows modules to be

managed in any of the following ways (dependent on type):

B

A

C

K

P

L

A

N

E

■

Statistics relating to traffic status can be taken from each module

by the management module.

■

The management module can alter the status of any port on a

module. Ports can be enabled or disabled. The management

module can also test individual ports on a module.

■

Local working can be enabled by isolating network traffic over

cable segments from the backplane. Isolation logic allows the

module to act as a sub-network. See

3-4.

DUA1800-0AAA04

Repeater Functions

on page

Page 49

3-4 C

LinkBuilder MSH No. 1

LinkBuilder MSH No. 2

HAPTER

■

NSTALLING MODULES INTO THE

3: I

MSH C

HASSIS

Resilient links can be set up. See Figure 3-2 below. A resilient link

consists of a

main port

and a

stand-by port

which are both set up

locally via the display panel or remotely via a Network Manager.

The main port is the normally operational port; however, if a fault

occurs on the link and data cannot be passed over it, the stand-by

port will automatically take over. .

main port enabled

stand-by port disabled

Figure 3-2 Resilient links

Security features can be configured locally from the display panel

■

inter-repeater link

standby link

port enabled

port enabled

and monitored remotely by a network management tool such as

ISOVIEW Network Manager.

Limited management can be carried out locally at the MSH, by

means of the display or via the RS232 port. Implementation of the

full set of management functions available from the Management

Module require the use of a Network Manager. In both cases the

Management Module must be fitted to the MSH.

LED Display.

The LEDs provide visual information on the data

integrity and port status of each segment attached to a module.

The function of module LEDs is described in the user guide that

accompanies each module.

Repeater Functions.

Depending on type, MSH modules provide

the following features:

■

Auto Partition/Reconnection:

from faults such as cable breaks and faulty connectors which

would halt all network communication. In these circumstances,

the segment in which the fault occurs is isolated by partitioning it

from the rest of the network after 32 collisions.

The module provides protection

DUA1800-0AAA04

Page 50

Introduction 3-5

Partitioning of a segment from the rest of the network will occur

if the module detects thirty-two consecutive collisions on a

segment or if it detects a single collision of between 1,000 and

30,000 bit times.

Once a segment has been partitioned, the module will pass

network traffic onto the segment; but will not accept anything

from the segment for transmission to the rest of the network.

When a good packet is detected on the partitioned port, it will

automatically reconnect the port.

■

Isolation:

Modules can be isolated from the backplane and

therefore all other modules in the MSH chassis via a configurable

jumper. In Isolation mode, a module acts as a repeater for only

the segments attached to that module and data is not repeated

over the backplane. A module operating in Isolation mode does

not affect data travelling between the other slots in the MSH

chassis. Isolated modules can still be managed by the

management module.

■

Port Disable On Power-up:

This feature can be used as a

first-line security feature. Configurable jumpers mounted on the

module allow you to set ports to power-up in a disabled state.

This prevents unauthorized users from accessing your network via

unused ports.

■

DUA1800-0AAA04

If necessary, you can then enable these ports individually using a

management facility.

LAN Security Architecture (LSA):

A specific non-smart secure

module is supplied to support LSA. This provides twelve 10Base-T

ports over a 50-way telco connector. If LSA is needed over Optical

Fiber or AUI, the relevant secure ECS module fitted with a

converter can be used. Alternatively, you may fit a transceiver

module of the required connectivity to a secure MSH module.

LSA may be enabled or disabled using hardware links or Network

Manager.

When enabled, LSA operates in two ways to give you assurance

that your network is not being accessed by unauthorized users.

Page 51

3-6 C

HAPTER

NSTALLING MODULES INTO THE

3: I

Firstly, each frame is examined for the destination address, and

■

MSH C

HASSIS

passed intact to the port associated with that address. For

10Base-T, fiber or AUI, this is equivalent to passing direct to the

addressed device. Every other port transmits a frame of the

same length and network timing but with randomized bits:

this is undecipherable. No extra delays are introduced. The

frames are therefore sent securely on a need-to-know basis.

Secondly, if an unauthorized station appears on a segment

■

attached to a port, the Network Manager will be informed.

You may choose what action is taken by the Network

Manager. It may just note the fact, or it may automatically

disconnect the unauthorized device by disabling the port to

which that device is attached.

Resilience:

■

This feature is available for use on point-to-point

media, for example twisted pair and optical fiber. You specify

resilient pairs of ports, each pair consisting of a main port and a

stand-by port. If the management module detects a signal loss in

data transmitting over the segment attached to a main port, this

port will be automatically disabled and the data re-routed over

the segment attached to the stand-by port.

Ethernet Bus Selection:

■

The MSH Ethernet backplane contains

three separate buses, E1, E2 and E3. A configurable jumper on

the module (or converter if you are using ECS modules) allows

you to determine to which bus that module is routed. This allows

you to set up separate networks within the one MSH chassis.

When using this feature you should be aware that:

You will not be able to collect all statistics from LinkBuilder ECS

■

modules that are routed to Bus E2 or E3. If you require full

statistics gathering, you must connect ECS modules to Bus E1.

To ensure that the remote Network Manager has initial access

■

to the MSH management module and to ensure full statistics

gathering for ECS modules, you are advised to also attach the

management module to bus E1.

Internal Crossover:

■

Configured via a jumper located on a 10

Base-T Repeater module, this feature allows you to determine

DUA1800-0AAA04

Page 52

Introduction 3-7

whether a specified port on a module is connected to another

MSH (Inter-repeater Link) or to an end-station.

You will find further information in the user guides that

accompany Repeater Modules.

4 Port Ethernet Bridge

The 4 port bridge module connects the three Ethernet busses of