Page 1

CoreBuilder™5000 Integrated

®

System Hub Installation and

Operation Guide

http://www.3com.com/

Part No. 17-00362-8

Published May 1997

Page 2

3Com Corporation

5400 Bayfront Plaza

Santa Clara, California

95052-8145

Copyright ©3Com Corporation, 1997. All rights reserved. No part of this documentation may be

reproduced in any form or by any means or used to make any derivative work (such as translation,

transformation, or adaptation) without permission from 3Com Corporation.

3Com Corporation reserves the right to revise this documentation and to make changes in content from

time to time without obligation on the part of 3Com Corporation to provide notification of such revision

or change.

3Com Corporation provides this documentation without warranty of any kind, either implied or

expressed, including, but not limited to, the implied warranties of merchantability and fitness for a

particular purpose. 3Com may make improvements or changes in the products or the programs described

in this documentation at any time.

UNITED STATES GOVERNMENT LEGENDS:

If you are a United States government agency, then this documentation and the software described

herein are provided to you subject to the following restricted rights:

For units of the Department of Defense:

Restricted Rights Legend: Use, duplication, or disclosure by the Government is subject to restrictions as

set forth in subparagraph (c) (1) (ii) for Restricted Rights in Technical Data and Computer Software Clause

at 48 C.F.R. 52.227-7013.

For civilian agencies:

Restricted Rights Legend: Use, reproduction, or disclosure is subject to restrictions set forth in

subparagraph (a) through (d) of the Commercial Computer Software – Restricted Rights Clause at

48 C.F.R. 52.227-19 and the limitations set forth in 3Com Corporation’s standard commercial agreement

for the software. Unpublished rights reserved under the copyright laws of the United States.

If there is any software on removable media described in this documentation, it is furnished under a

license agreement included with the product as a separate document, in the hard copy documentation,

or on the removable media in a directory file named LICENSE.TXT. If you are unable to locate a copy,

contact 3Com and a copy will be sent to you.

Federal Communications Commission Notice

This equipment was tested and found to comply with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference, in which case you must correct the

interference at your own expense.

Canadian Emissions Requirements

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment

Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel

brouilleur du Canada.

EMC Directive Compliance

This equipment was tested and conforms to the Council Directive 89/336/EEC for electromagnetic

compatibility. Conformity with this directive is based upon compliance with the following harmonized

standards:

EN 55022 – Limits and Methods of Measurement of Radio Interference

EN 50082-1 – Electromagnetic Compatibility Generic Immunity Standard: Residential, Commercial, and

Light Industry

Warning: This is a Class A product. In a domestic environment, this product may cause radio interference,

in which case you may be required to take adequate measures.

Compliance with this directive depends on the use of shielded cables.

Low Voltage Directive Compliance

This equipment was tested and conforms to the Council Directive 72/23/EEC for safety of electrical

equipment. Conformity with this directive is based upon compliance with the following harmonized

standard:

EN 60950 – Safety of Information Technology Equipment

ii

Page 3

VCCI Class 1 Compliance

This equipment is in the 1st Class category (information equipment to be used in commercial or industrial

areas) and conforms to the standards set by the Voluntary Control Council for Interference by

Information Technology Equipment aimed at preventing radio interference in commercial or industrial

areas.

Consequently, when the equipment is used in a residential area or in an adjacent area, radio interference

may be caused to radio and TV receivers, and so on.

Read the instructions for correct handling.

Fiber Cable Classification Notice

Use this equipment only with fiber cable classified by Underwriters Laboratories as to fire and smoke

characteristics in accordance with Section 770-2(b) and Section 725-2(b) of the National Electrical Code.

UK General Approval Statement

The CoreBuilder 5000 Integrated System Hub and ONline System Concentrator are manufactured to the

International Safety Standard EN 60950 and are approved in the U.K. under the General Approval

Number NS/G/12345/J/100003 for indirect connection to the public telecommunication network.

Trademarks

Unless otherwise indicated, 3Com registered trademarks are registered in the United States and may or

may not be registered in other countries.

3Com, Boundary Routing, CardFacts, EtherLink, LANplex, LANsentry, LinkBuilder, NETBuilder, NETBuilder II,

NetFacts, Parallel Tasking, SmartAgent, Star-Tek, TokenDisk, TokenLink, Transcend, TriChannel, and

ViewBuilder are registered trademarks of 3Com Corporation.

3TECH, CoreBuilder, EtherDisk, EtherLink II, FDDILink, MultiProbe, NetProbe, and ONline are trademarks

of 3Com Corporation.

3ComFacts is a service mark of 3Com Corporation.

The 3Com Multichannel Architecture Communications System is registered under U.S. Patent

Number 5,301,303.

DEC, DECnet, DELNI, POLYCENTER, VAX, VT100, VT220, and the Digital logo are trademarks of Digital

Equipment Corporation.

OpenView is a registered trademark of Hewlett-Packard Company.

Intel is a registered trademark of Intel Corporation.

AIX, IBM, and NetView are registered trademarks of International Business Machines Corporation.

Microsoft, MS-DOS, Windows, Windows 95, and Windows NT are registered trademarks of

Microsoft Corporation.

ONC, OpenWindows, Solaris, Solstice, Sun, Sun Microsystems, SunNet Manager, and SunOS are

trademarks of Sun Microsystems, Inc.

SPARCstation is a trademark licensed exclusively to Sun Microsystems Inc.

OPEN LOOK is a registered trademark of Unix System Laboratories, Inc.

UNIX is a registered trademark of X/Open Company, Ltd. in the United States and other countries.

Other brand and product names may be registered trademarks or trademarks of their respective holders.

Guide written by Jackie Bonin. Edited by Pam Taylor-Collins. Production by Tracey Taylor.

iii

Page 4

Page 5

CONTENTS

ABOUT THIS GUIDE

Audience 15

Structure of This Guide 15

Conventions 16

Related Documentation 17

3Com Documents 17

Reference Documents 18

1 INTRODUCTION

CoreBuilder 5000 Integrated System Hub Backplane Architecture 1-1

CoreBuilder 5000 Backplane Architecture 1-1

CoreBuilder 5000 Backplane Capabilities 1-2

CoreBuilder 5000 Integrated System Hub Model Numbers and Descriptions 1-4

Determining the Model Number of Your Hub 1-4

CoreBuilder 5000 Integrated System Hub Model Numbers and Descriptions 1-4

ONline Module Support 1-7

CoreBuilder 5000 Intelligent Cooling Subsystem 1-7

Active Controller Module Fan Indicators 1-8

Automatic CoreBuilder 5000 Module Power-Down 1-8

Enabling and Disabling CoreBuilder 5000 Module Power-Down 1-9

Active Controller Module Temp Indicators 1-9

Distributed Hub Management Architecture 1-10

CoreBuilder 5000 DMM Models 1-10

CoreBuilder 5000 Network Monitor Cards 1-11

Reporting Statistics 1-12

2 THEORY OF OPERATION

Management Capabilities 2-1

Module Configuration and Monitoring 2-1

Mastership in the CoreBuilder 5000 Integrated System Hub 2-1

ONline Master Management Module Status Display 2-3

ONline and CoreBuilder 5000 Module Configuration 2-4

Network Monitoring and Module Configuration Summary 2-6

Using Backup Management Modules 2-9

CoreBuilder 5000 Controller Module Descriptions 2-10

Controller Module Models 2-10

Active and Standby Controller Module Functionality 2-10

Identifying Controller Module Slots 2-11

Downloading Software to the Controller Module 2-12

Controller Module Fault-Tolerance 2-14

v

Page 6

CoreBuilder 5000 Module Poweron Strategy 2-16

Default CoreBuilder 5000 Module Poweron Strategy 2-16

Specifying CoreBuilder 5000 Module Poweron Order 2-17

CoreBuilder 5000 Module Power-off Response 2-17

Correcting a Power Deficit 2-17

Overheat Condition 2-20

3 INSTALLING THE HUB

How CoreBuilder 5000 Hubs are Shipped 3-1

Hub Shipments 3-1

Documents and Accessories Shipped with a Hub 3-4

Optional Cable Tray Kit 3-4

Selecting a Site 3-9

Location Requirements 3-10

Ventilation Requirements 3-11

Power Requirements 3-11

Installing the Hub 3-12

CoreBuilder 5000 Integrated System Hub Quick Installation 3-12

Removing the Hub and Components From the Shipping Box 3-13

Installing the Hub on a Table or Shelf 3-16

Installing the Cable Tray in a Rack 3-17

Installing the Hub in a Rack 3-19

4 INSTALLING POWER SUPPLIES

CoreBuilder 5000 Intelligent Power Subsystem 4-1

Intelligent Power Subsystem Features 4-1

CoreBuilder 5000 Power Supply Models 4-3

Determining the Model Number of Your Power Supply 4-4

Power Requirements 4-4

AC Power Requirements 4-4

DC Power Requirements 4-5

Load-Sharing Power Supplies 4-5

Power Supply Modes 4-5

Power Availability and Power Supply Capacity 4-7

Managing Power in the Hub 4-8

Establishing Power Fault-Tolerance 4-8

Power Supply Output in Non-Fault-Tolerant Mode 4-9

Power Supply Output in Fault-Tolerant Mode 4-11

Enabling and Disabling Power to Slots 4-12

CoreBuilder 5000 Module Power Class Settings 4-14

Installing Power Supplies 4-15

Installing a Load-Sharing AC Power Supply 4-15

Installing a -48 Volt DC Power Supply and Power Cord 4-19

Removing a -48 Volt DC Input Power Supply and Power Cord 4-22

vi

Page 7

Installing Power Supply Bay Grilles 4-23

Installing the Power Supply Bay Grille (17-slot Hub) 4-23

Installing the Power Supply Bay Grille (10-slot Hub) 4-23

Budgeting Power 4-24

Allocating Power for Installed Modules 4-24

Saved Power Management Configurations 4-26

Verifying Power Supply Operation 4-28

Saved Power Management Configurations 4-28

5 INSTALLING MODULES

Installing the Controller Module 5-1

Installing the Controller Module 5-1

Removing an Installed Controller Module 5-4

Monitoring the Controller Module Front Panels 5-4

Installing CoreBuilder 5000 Modules 5-11

Guidelines for Installing and Removing CoreBuilder 5000 Modules 5-11

Installing a CoreBuilder 5000 Module 5-13

Installing a Subsystem of ONline Modules 5-15

ONline Adapter Kits 5-16

Guidelines for Installing and Removing ONline Modules 5-17

Guidelines for Installing an ONline Subsystem 5-18

ONline Subsystem Quick Installation 5-20

Installing an ONline Subsystem 5-20

Verifying Module Installation 5-29

Verifying Controller Module Operation 5-30

Verifying Network Connectivity 5-30

6 MANAGEMENT COMMANDS

Management Command Conventions 6-1

Understanding Command Conventions 6-1

Using Terminal Keystrokes 6-1

Using the Command Completion Feature 6-2

Management Commands 6-2

Using Management Commands 6-2

Command Help 6-3

Completing a Command 6-4

Managing the Hub 6-5

Sample DMM Commands 6-6

Set Power 6-6

Reset 6-9

Show 6-10

Show Power 6-14

Show Inventory 6-17

vii

Page 8

7 TROUBLESHOOTING

Troubleshooting Fault Conditions 7-1

A SPECIFICATIONS

Supported Network Protocols A-1

Environmental Specifications A-1

Mechanical Specifications A-2

CoreBuilder 5000 17-slot Hub Models A-2

CoreBuilder 5000 10-slot Hub Models A-2

CoreBuilder 5000 7-slot Hub Models A-3

Power Requirements A-3

295 Watt AC Power Supply (Model Number 6000PS) A-3

415 Watt AC Power Supply (Model Number 6000PS-HO) A-3

295 Watt DC Power Supply (Model Number 6000PS-48V) A-3

Regulatory Compliance A-4

CoreBuilder 5000 Integrated System Hub Accessories A-4

B ONLINE MODULE POWER REQUIREMENTS

Voltages and Watts Consumed Per Module B-2

SwitchChannel Backplane Power Consumption B-5

PacketChannel Backplane Power Consumption B-5

ONline Module Power Consumption B-5

ONline Module Power Consumption B-5

Monitoring ONline Module Power Consumption B-6

Returning Unmanaged Power to the Power Budget B-6

C MAINTENANCE

Routine Maintenance C-1

Replacing a Defective Power Supply C-2

Replacing a Defective AC Power Supply C-2

Replacing a Defective DC Power Supply C-4

Replacing a Defective Fan Unit C-5

Removing Modules and Adapter Kit Components From an ONline Subsystem C-6

Removing Individual Subsystem Components C-6

Maintaining Hub System Components C-8

viii

Page 9

D TECHNICAL SUPPORT

Online Technical Services D-1

3Com Bulletin Board Service D-1

World Wide Web Site D-2

3ComForum on CompuServe D-2

3ComFacts Automated Fax Service D-2

Support From Your Network Supplier D-3

Support From 3Com D-3

Returning Products for Repair D-4

Accessing the 3Com ISD MIB D-4

Contacting 3Com Switching Systems Technical Publications D-4

INDEX

3COM CORPORATION LIMITED WARRANTY

ix

Page 10

Page 11

LIST OF FIGURES

3-1 CoreBuilder 5000 Hub Models 3-5

3-2 CoreBuilder 5000 Integrated System 17-slot Hub Front Panel 3-6

3-3 CoreBuilder 5000 Integrated System 17-slot Hub Rear Panel 3-6

3-4 CoreBuilder 5000 Integrated System 10-slot Hub Front Panel 3-7

3-5 CoreBuilder 5000 Integrated System 10-slot Hub Rear Panel 3-7

3-6 CoreBuilder 5000 Integrated System 7-slot Hub Front Panel 3-8

3-7 CoreBuilder 5000 Integrated System 7-slot Hub Rear Panel 3-8

3-8 CoreBuilder 5000 7-slot Hub Fan Assembly 3-9

3-9 Unpacking the 17-slot or 10-slot Hub Shipping Box 3-14

3-10 Unpacking the 7-slot Hub Shipping Box 3-15

3-11 Attaching a Rubber Foot to the CoreBuilder 5000 Integrated System Hub 3-16

3-12 Cable Tray Rack-Mount Positions 3-17

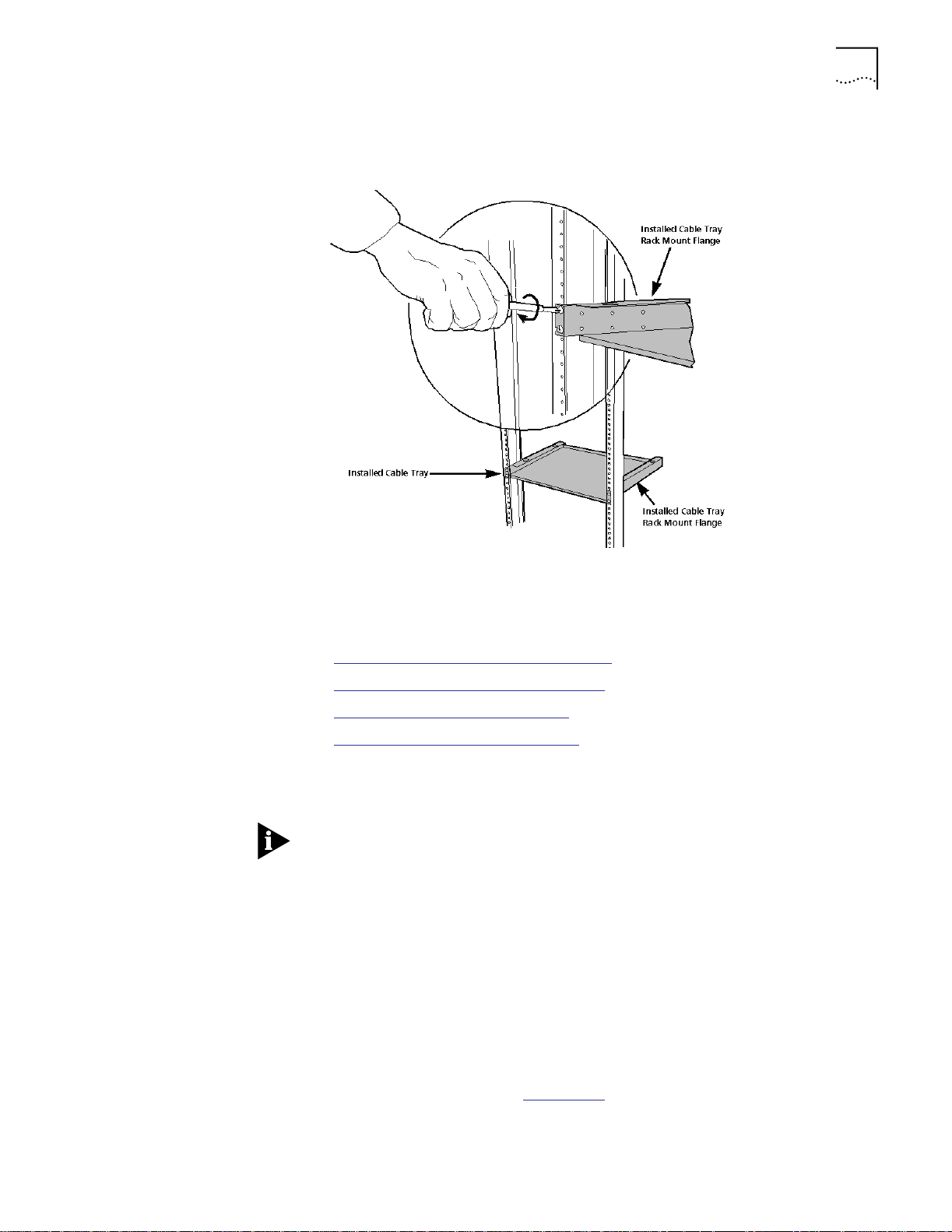

3-13 Installing the Cable Tray in a Rack 3-19

3-14 Installing a Clip Nut in the Rack 3-21

3-15 Rack-mounted 17-slot Hub With Cable Tray 3-23

3-16 Rack-Mounted 7-slot Hub With Cable Tray 3-24

4-1 Location of the ON Position Label for 7-slot Hubs 4-16

4-2 Installing a Load-Sharing Power Supply in a 17-slot Hub 4-17

4-3 Installing a Load-Sharing Power Supply in a 10-slot Hub 4-17

4-4 Installing a Load-Sharing Power Supply in a 7-slot Hub 4-18

4-5 -48 Volt DC Power Supply 4-20

4-6 -48 Volt DC Input Power Cord 4-21

4-7 Terminal Ring on Each Wire 4-21

4-8 Keyed Cable Connector 4-22

4-9 Installing the Power Supply Bay Grille (17-slot Hub) 4-23

4-10 Installing the Power Supply Bay Grille (10-slot Hub) 4-24

5-1 Installing a CoreBuilder 5000 Controller Module in a 17-slot Hub 5-2

5-2 Installing a CoreBuilder 5000 Controller Module in a 10-slot Hub 5-3

5-3 Installing a CoreBuilder 5000 Controller Module in a 7-slot Hub 5-4

5-4 CoreBuilder 5000 Controller Module Front Panels 5-6

5-5 CoreBuilder 5000 Module Ejectors (Open and Closed Positions) 5-12

5-6 Installing a CoreBuilder 5000 Module in a CoreBuilder 5000 Integrated System 17-slot

or 10-slot Hub 5-14

5-7 Installing a Module in CoreBuilder 5000 Integrated System 7-slot Hub 5-15

5-8 ONline Adapter Kit Components 5-17

5-9 Installed ONline Right Boundary Adapter 5-21

5-10 Installing an ONline Dual Slot Filler Plate 5-22

5-11 Lowering the Left Boundary Adapter into Position 5-23

5-12 Left Boundary Adapter Hook Installation 5-24

5-13 Installing an ONline Dual Slot Module Ejector Block 5-25

5-14 Installing an ONline Dual Slot Module 5-26

5-15 CoreBuilder 5000 17-slot Hub with Installed Components 5-27

xi

Page 12

5-16 CoreBuilder 5000 10-slot Hub with Installed Components 5-28

5-17 CoreBuilder 5000 7-slot Hub With Installed Components 5-29

C-1 Replacing a Defective Load-Sharing Power Supply C-3

C-2 Replacing a Defective Fan Unit C-6

xii

Page 13

LIST OF TABLES

1-1 CoreBuilder 5000 Hub Model Numbers and Backplane Configurations 1-2

1-2 CoreBuilder 5000 Integrated System Hub Backplane Descriptions 1-3

1-3 Upgradeable Hub Model Numbers 1-7

1-4 Active Controller Module LEDs 1-9

1-5 Supported Network Monitor Cards 1-11

2-1 Information Displayed by ONline Master Management Module 2-4

2-2 Management Module Capabilities on CoreBuilder 5000 Modules 2-7

2-3 Management Module Capabilities on ONline Modules 2-8

2-4 Identifying Controller Module Slots for DMMs 2-11

2-5 Identifying Controller Module Slots for ONline Management Modules 2-11

3-1 CoreBuilder 5000 Integrated System Hub Telco and Metric Rack Space

Requirements 3-11

3-2 Installing the CoreBuilder 5000 Integrated System Hub 3-12

Cable Tray Rack-Mount Settings 3-18

3-3

4-1 Intelligent Power Subsystem Features 4-1

4-2 CoreBuilder 5000 Integrated System Hub Power Supply Models 4-3

4-3 Number of Power Supplies in Each CoreBuilder 5000 Hub 4-5

4-4 Power Capacity for Modules in Power Non-Fault-Tolerant Mode (295 Watts) 4-9

4-5 Power Capacity for Modules in Power Non-Fault-Tolerant Mode (415 Watts) 4-10

4-6 Power Supply Requirements 4-10

4-7 Power Capacity for Modules in Non-Fault-Tolerant Mode (Mixed 295 and

415 Watts) 4-11

4-8 Power Capacity for Modules in Power Fault-Tolerant Mode (295 Watts) 4-11

4-9 Power Capacity for Modules in Power Fault-Tolerant Mode (415 Watts) 4-12

4-10 Power Capacity for Modules in Fault-Tolerant Mode (Mixed 295 and 415 Watts) 4-12

4-11 Selected DMM Power Management Commands 4-25

4-12 Saved Power Management Configuration Data 4-27

4-13 Saved Power Management Configuration Data 4-28

5-1 ONline Module Network LEDs (Controller LED Test) 5-9

5-2 CoreBuilder 5000 Network LEDs as Identified During DMM LED Test 5-10

5-3 ONline Subsystem Installation Sequence 5-19

5-4 Installing an ONline Subsystem 5-20

5-5 Network Activity LED Status 5-30

6-1 Command Conventions 6-1

6-2 Terminal Keystroke Functions 6-2

6-3 Show Power Commands 6-14

7-1 Troubleshooting Using the Controller Module Indicators 7-2

A-1 Supported Network Protocols A-1

A-2 Environmental Specifications (All Hub Models) A-1

A-3 Mechanical Specifications (17-slot Models) A-2

A-4 Mechanical Specifications (10-slot Models) A-2

A-5 Mechanical Specifications (7-slot Models) A-3

xiii

Page 14

A-6 Regulatory Certifications A-4

A-7 Hub Accessories A-4

B-1 ONline Ethernet Module Power Requirements B-2

B-2 ONline Token Ring Module Power Requirements B-3

B-3 ONline FDDI Module Power Requirements B-4

B-4 ONline Internetworking Module Power Requirements B-4

xiv

Page 15

ABOUT THIS GUIDE

The 3Com CoreBuilder5000 Integrated System Hub Installation and Operation

Guide provides instructions for installing, operating, and maintaining the 3Com

CoreBuilder

5000 Integrated System Hub. This guide also describes:

■ Principal features of both the CoreBuilder 5000 Integrated System Hub and the

■ Selected CoreBuilder 5000 Management Module commands and features that

The management component of both the CoreBuilder 5000 Distributed

Management Module (DMM) and a Distributed Management Module with

Ethernet Carrier (DMM-EC) is the same entity DMM. If a functional difference

exists (for example, Ethernet Network Monitor Card installation is possible on a

DMM-EC, but not on a DMM), the text specifies either DMM-EC or DMM, as

appropriate. Unless otherwise noted, CoreBuilder 5000 Distributed Management

Module is used to describe both the DMM and the DMM-EC.

®

3Com

enable you to use the CoreBuilder 5000 Integrated System.

CoreBuilder 5000 Controller Modules.

Audience The CoreBuilder 5000 Integrated System Hub Installation and Operation

Guide provides installation, operation, and maintenance information for service

personnel.

Structure of This

This guide contains the following chapters:

Guide

Chapter 1, Introduction – Introduces the features of all versions of the

CoreBuilder 5000 Integrated System Hub and the CoreBuilder 5000

Fault-Tolerant Controller Module.

Chapter 2, Theory of Operation – Describes the functionality of

CoreBuilder 5000 and ONline modules installed in the CoreBuilder 5000

Integrated System Hub. Provides information you need to know before installing

the hub.

Chapter 3, Installing the Hub – Provides illustrated procedures for installing

and verifying the operation of the CoreBuilder 5000 Integrated System Hub.

Discusses site selection criteria, and describes shipping box contents.

Chapter 4, Installing Power Supplies – Provides procedures for installing

CoreBuilder 5000 power supplies. Discusses load-sharing power supplies, power

management, and power requirements.

Page 16

16 ABOUT THIS GUIDE

Chapter 5, Installing Modules – Provides procedures for installing

CoreBuilder 5000 and ONline modules and accessory items available for use

with the hub.

Chapter 6, Management Commands – Presents an overview of hub

management and management commands for managing your hub. Discusses

some CoreBuilder 5000 distributed management commands.

Chapter 7, Troubleshooting – Provides information for detecting and resolving

problems affecting hub operation.

Appendix A, Specifications – Gives product dimensions, power requirements,

and other specifications for the hub and components.

Appendix B, ONline Module Power Requirements – Provides power

consumption values for the SwitchChannel and PacketChannel Backplane and

each type of ONline module available on the date this guide shipped.

Appendix C, Maintenance – Discusses routine maintenance requirements for

the hub and provides instructions for replacing power supplies and fan units.

Instructions for removing installed ONline modules and ONline Adapter Kit

components are also provided.

Appendix D, Technical Support – Lists the various methods for contacting the

3Com technical support organization and for accessing other product support

services.

Index

Limited Warranty

Conventions The following tables list conventions that are used throughout this guide:

Icon Notice Type Alerts you to...

Information note Important features or instructions

Caution Risk of personal safety, system damage, or loss of data

Warning Risk of severe personal injury

Convention Description

Synt ax Syntax means you must evaluate the syntax provided and supply the

appropriate values. Placeholders for values you must supply appear in

angle brackets. Example:

Enable RIPIP by using the following syntax:

SETDefault !<port> -RIPIP CONTrol = Listen

In this example, you must supply a port number for <port>.

Page 17

Related Documentation 17

Convention Description

Command s The word Command means you must enter the command exactly as

shown in text and press Return or Enter. Example:

To remove the IP address, enter the following command:

SETDef ault !0 -I P NETaddr = 0.0.0 .0

This guide always gives the full form of a command in uppercase and

lowercase letters. However, you can abbreviate commands by

entering only the uppercase letters and the appropriate value.

Commands are not case-sensitive.

Screen displays This typeface represents information as it appears on the screen.

The words enter

and type

[Key] names Key names appear in text in one of two ways:

Menu commands

and buttons

Words in italicized

type

Words in boldface

type

Enter means type something, and then press the Return or Enter key.

Do not press the Return or Enter key when an instruction says type.

■ Referred to by their labels, such as the Return key or the Escape

key

■ Written with brackets, such as [Return] or [Esc]

If you must press two or more keys simultaneously, the key names

are linked with a plus sign (+). Example:

Press [Ctrl]+[Alt]+[Del].

Menu commands or button names appear in italics. Example:

From the Help menu, select Contents.

Italics emphasize a point or denote new terms.

Bold text denotes key features.

Related Documentation

3Com Documents The following documents provide additional information on 3Com products:

This section provides information on supporting documentation, including:

■ 3Com Documents

■ Reference Documents

CoreBuilder 5000 Integrated System Hub Installation and Operation Guide –

Provides information on the installation, operation, and configuration of the

CoreBuilder 5000 Integrated System Hub. This guide also describes the principal

features of the CoreBuilder 5000 Fault-Tolerant Controller Module.

CoreBuilder 5000 Distributed Management Module User Guide – Provides

information on the CoreBuilder 5000 Distributed Management Module’s

operation, installation, and configuration. This guide also describes the software

commands associated with the Distributed Management Module.

CoreBuilder 5000 Distributed Management Module Commands Guide –

Describes each management command by providing detailed information on the

command’s format and use.

For a complete list of 3Com documents, contact your 3Com representative.

Page 18

18 ABOUT THIS GUIDE

Reference Documents The following documents supply related background information:

Case, J., Fedor, M., Scoffstall, M., and J. Davin, The Simple Network

Management Protocol, RFC 1157, University of Tennessee at Knoxville,

Performance Systems International and the MIT Laboratory for Computer

Science, May 1990.

Rose, M., and K. McCloghrie, Structure and Identification of Management

Information for TCP/IP-based Internets, RFC 1155, Performance Systems

International and Hughes LAN Systems, May 1990.

Page 19

1

INTRODUCTION

CoreBuilder 5000

Integrated System

Hub Backplane

Architecture

The 3Com CoreBuilder5000 Integrated System Hub is a modular chassis that

supports all components of the 3Com

Hub and all 3Com ONline™ modules, except the ONline Controller Module. The

CoreBuilder 5000 Integrated System Hub is available in the following versions:

■ 17-slot

■ 10-slot

■ 7-slot

The CoreBuilder 5000 Integrated System Hub also supports connections to the

ONline 17-slot and 6-slot System Concentrator.

This chapter contains the following sections:

■ CoreBuilder 5000 Integrated System Hub Backplane Architecture

■ CoreBuilder 5000 Integrated System Hub Model Numbers and Descriptions

■ ONline Module Support

■ CoreBuilder 5000 Intelligent Cooling Subsystem

■ Distributed Hub Management Architecture

This section describes:

■ CoreBuilder 5000 Backplane Architecture

■ CoreBuilder 5000 Backplane Capabilities

®

CoreBuilder 5000 Integrated System

CoreBuilder 5000

Backplane Architecture

The CoreBuilder 5000 Integrated System Hub is available in a variety of

backplane configurations.

Page 20

1-2 INTRODUCTION

Table 1-1 lists backplane configurations for all versions of the CoreBuilder 5000

Integrated System Hub.

Table 1-1 CoreBuilder 5000 Hub Model Numbers and Backplane Configurations

Enhanced

TriChannel/

Hub Model

Number

6017C-A yes yes no no

6017C-AC yes yes yes yes

6017C-AP yes yes no yes

6010C-A yes yes no no

6010C-AC yes yes yes yes

6010C-AP yes yes no yes

6007C-A yes yes no yes

6007C-AP yes yes no yes

FastChannel

Backplane

RingChannel

Backplane

SwitchChannel

Backplane

PacketChannel

Backplane

Each CoreBuilder 5000 hub equipped with a specific backplane supports the

following configurations:

CoreBuilder 5000

Backplane Capabilities

■ Enhanced TriChannel

®

and FastChannel Backplane and RingChannel

Backplane – Supports all ONline modules, CoreBuilder 5000 Ethernet

modules, CoreBuilder 5000 Token Ring modules, CoreBuilder 5000 Fast

Ethernetmodules, and the CoreBuilder 5000 Distributed Management

Module (DMM).

■ Enhanced TriChannel and FastChannel Backplane, RingChannel

Backplane, and SwitchChannel Backplane – Supports all ONline

modules, all CoreBuilder 5000 Ethernet and Token Ring modules, the

CoreBuilder 5000 Distributed Management Module (DMM), ATM cell

switching modules, and packet switching modules.

■ Enhanced TriChannel and FastChannel Backplane, RingChannel

Backplane, and PacketChannel

Backplane – Supports all ONline

modules, CoreBuilder 5000 Ethernet and Token Ring modules, and packet

switching modules.

Table 1-2

summarizes the capabilities of the following CoreBuilder 5000

backplanes:

■ Enhanced TriChannel Backplane

■ RingChannel Backplane

■ SwitchChannel Backplane

■ PacketChannel Backplane

■ FastChannel Backplane

Networks listed in Table 1-2

are available to each port and module in the

CoreBuilder 5000 Integrated System Hub. The maximum number of supported

networks is shown in each column. The maximum number of networks is the

maximum number of networks available per protocol (not the number of

networks that can exist concurrently).

Page 21

CoreBuilder 5000 Integrated System Hub Backplane Architecture 1-3

The maximum number of networks applies only to a hub in which one protocol

is used.

Table 1-2

describes CoreBuilder 5000 Integrated System Hub backplanes.

Table 1-2 CoreBuilder 5000 Integrated System Hub Backplane Descriptions

Enhanced

TriChannel

Backplane

Supports up to

6 Ethernets

1

3 Ethernets using

TriChannel

architecture

2

3 additional

Ethernets using

Enhanced

TriChannel

architecture

RingChannel

Backplane

Supports up to

8 Ethernets

1

6 Ethernets using

Enhanced

TriChannel

Backplane

2

2 additional

Ethernets using

RingChannel

Backplane

SwitchChannel

Backplane

Supports up to

8 Gigabits of cell

switching

capacity (ATM)

PacketChannel

Backplane

Supports up to

204 Ethernet

segments with

2 Gigabits of

packet

switching

capacity

(CoreBuilder 5000

modules only)

Supports up to

7 Token Rings

7 Token Rings

using Enhanced

TriChannel

Backplane (ONline

modules)

Supports up to

3

17 Token Rings

7 Token Rings using

Enhanced

TriChannel Backplane

10 additional Token

Rings using

3

Supports up to

2 Gigabits of

packet switching

capacity

Supports up to

64 shared and

34 switched

FDDI DAS (Dual

Attachment

Station)

connections

RingChannel

Backplane

(CoreBuilder 5000

modules only)

Up to 4 FDDI Rings

4 FDDI Rings

using Enhanced

TriChannel

Backplane for

ONline modules

Up to 4 FDDI Rings

4 FDDI Rings

using Enhanced

TriChannel

Backplane for

ONline modules

1

Enhanced TriChannel Backplane Ethernets 4, 5, and 6 can be used by CoreBuilder 5000

modules only. RingChannel Backplane Ethernets 7 and 8 can be used by

CoreBuilder 5000 modules only.

2

Enhanced TriChannel Backplane Ethernets 1, 2, and 3 can be used by both

CoreBuilder 5000 and ONline modules. CoreBuilder 5000 and ONline Ethernet modules

connected to these three Ethernet networks can communicate with each other across

the backplane.

3

Enhanced TriChannel Backplane Token Rings 1 through 7 can be used by ONline Token

Ring modules only.

Up to 4 FDDI Rings

4 FDDI Rings using

Enhanced

TriChannel

Backplane for

ONline modules

Up to 4 FDDI Rings

4 FDDI Rings using

Enhanced

TriChannel

Backplane for

ONline modules

Supports

redundant ATM

switches (17-slot

hubs only)

Supports

redundant ATM

switches (17-slot

hubs only)

Supports up to

64 fast Ethernet

connections

Supports up to

64 fast Ethernet

connections

FastChannel

Backplane

Part of

Enhanced

TriChannel

Backplane

Supports up

to 119 Fast

Ethernet

connections

Supports up

to 4 Fast

Ethernet

backplane

networks

Page 22

1-4 INTRODUCTION

CoreBuilder 5000

Integrated System

Hub Model Numbers

and Descriptions

Determining the Model

Number of Your Hub

This section describes:

■ Determining the Model Number of Your Hub

■ CoreBuilder 5000 Integrated System Hub Model Numbers and Descriptions

To establish the features and functionality your hub offers, you must determine

the hub model number. To determine the model number of your

CoreBuilder 5000 Integrated System Hub, check the sticker affixed:

■ To the immediate left of the left most power supply slot on a 17-slot hub

■ To the immediate right of the bottom power supply slot on a 10-slot hub

■ To the area below the fan exhaust at the rear of a 7-slot hub

Alternatively, to determine the model number of your hub after hub installation

(refer to Chapter 3), and if your hub is managed by a CoreBuilder 5000

Distributed Management Module (DMM):

1 Enter the SHOW HUB command or the SHOW INVENTORY command.

2 Press Enter.

Model Numbers 6010C-AC, 6017C-AP, and 6010C-AP require DMM software

Version v2.30 or later and Controller software Version v1.11 or later to support

the SHOW HUB and SHOW INVENTORY commands. Model Numbers 6007C-A

and 6007C-AP require DMM software Version v4.0 or later.

CoreBuilder 5000

Integrated System Hub

Model Numbers and

Descriptions

This section:

■ Lists hub model numbers

■ Describes features of each hub

■ Describes Distributed Management Module Software Support

■ Lists upgradeable hubs

CoreBuilder 5000 Integrated System Hub Model Numbers

This section describes the following hub model numbers:

■ Model Numbers 6017C-A, 6010C-A, and 6007C-A

■ Model Numbers 6017C-AP, 6010C-AP, and 6007C-AP

■ Model Numbers 6017C-AC and 6010C-AC

Model Numbers 6017C-A, 6010C-A, and 6007C-A Overview

Hub Model Numbers 6017C-A, 6010C-A, and 6007C-A are Advanced versions

of the CoreBuilder 5000 Integrated System 17-slot, 10-slot, and 7-slot hub.

These Advanced versions extend the capabilities of the ONline TriChannel

Backplane by providing additional networking services through the

CoreBuilder 5000 Enhanced TriChannel and CoreBuilder 5000 RingChannel

Backplanes.

Page 23

CoreBuilder 5000 Integrated System Hub Model Numbers and Descriptions 1-5

The CoreBuilder 5000 RingChannel Backplane provides additional ring

extensions to the TriChannel architecture for use by protocols that use a ring

topology. Up to 10 Token Rings and 8 Ethernets can run concurrently on hubs

equipped with both the Enhanced TriChannel Backplane and the

CoreBuilder 5000 RingChannel Backplane.

Model Numbers 6017C-A, 6010C-A, and 6007C-A Description

Hub model numbers 6017C-A, 6010C-A, and 6007C-A offer the following

features:

■ Support for up to 8 Ethernets, 17 Token Rings, 4 FDDI rings, and 4 fast

Ethernets.

■ ONline Ethernet Modules can use the first 3 Ethernet networks (ONline

Ethernet Modules and CoreBuilder 5000 Ethernet Modules can

communicate with each other on these 3 shared networks).

■ CoreBuilder 5000 Ethernet Modules can use all 8 Ethernet networks.

■ ONline Token Ring Modules can use the 7 TriChannel (ONline) Token Ring

networks.

■ CoreBuilder 5000 Token Ring Modules can use the 10 RingChannel

(CoreBuilder 5000) Token Ring networks.

■ ONline FDDI Modules can use 4 of the FDDI networks.

ONline Token Ring networks differ from CoreBuilder 5000 Token Ring

networks. Both support Token Rings (7 ONline and 10 CoreBuilder 5000);

however, ONline Token Ring does not use the same data path as

CoreBuilder 5000 Token Ring and can only connect to each other through

external Ring-In/Ring-Out cable.

Model Numbers 6017C-AP, 6010C-AP, and 6007C-AP Overview

Hub Model Numbers 6017C-AP, 6010C-AP, and 6007C-AP are versions of the

CoreBuilder 5000 Integrated System 17-slot, 10-slot, and 7-slot Hub with

support for:

■ Packet switching capabilities

■ Ethernet, Token Ring, and FDDI network connectivity

Model Numbers 6017C-AP, 6010C-AP, and 6007C-AP Description

Hub Model Numbers 6017C-AP, 6010C-AP, and 6007C-AP offer the following

features:

■ Up to 6 Ethernets, 7 Token Rings, and 4 FDDI rings.

■ ONline modules can use the first 3 Ethernet networks.

■ CoreBuilder 5000 modules can use all 6 Ethernet networks.

■ Only ONline modules use Token Ring and FDDI networks.

■ Provide up to 2 Gigabits of LAN packet switching capacity.

■ Support 10 additional port-switching Token Rings

■ Support 2 additional Ethernet networks

Page 24

1-6 INTRODUCTION

Model Numbers 6017C-AC and 6010C-AC Overview

Hub Model Numbers 6017C-AC and 6010C-AC are more advanced versions of

the CoreBuilder 5000 Integrated System 17-slot and 10-slot Hub that provide:

■ Cell switching capabilities

■ Packet switching capabilities

■ Full Ethernet, Token Ring, and FDDI network connectivity

Model Numbers 6017C-AC and 6010C-AC Description

Hub Model Numbers 6017C-AC and 6010C-AC offer the following features:

■ Support up to 8 Ethernets, 17 Token Rings, and 4 FDDI rings.

■ ONline Ethernet Modules can use the first 3 Ethernet networks (ONline

Ethernet Modules and CoreBuilder 5000 Ethernet Modules can

communicate with each other on these 3 shared networks).

■ CoreBuilder 5000 Ethernet Modules can use all 8 Ethernet networks.

■ ONline Token Ring Modules can use the 7 TriChannel (ONline) Token Ring

networks.

■ CoreBuilder 5000 Token Ring Modules can the 10 RingChannel

(CoreBuilder 5000) Token Ring networks.

ONline Token Ring networks differ from CoreBuilder 5000 Token Ring

networks. Both support Token Rings (7 ONline and 10 CoreBuilder 5000);

however, ONline Token Ring does not use the same data path as

CoreBuilder 5000 Token Ring and can only connect to ONline Token Ring

networks through a Ring-In/Ring-Out cable.

■ Only ONline modules can use the 4 available FDDI networks.

■ Support up to 8 Gigabits of ATM cell switching capacity.

■ Support redundant ATM switches (for 17-slot hub only).

■ Provide up to 2 Gigabits of LAN packet switching capacity.

Distributed Management Module Software Support

The following issues apply to Distributed Management Module (DMM) software

versions.

■ DMM software Version v1.0 does not identify Model Numbers 6010C-A and

6010C-AC as 10-slot CoreBuilder 5000 Integrated System Hubs (DMM

software Version v1.0 identifies incorrectly the 10-slot hub as a 17-slot hub).

■ DMM software Version v2.3 or later identifies the 10-slot and 17-slot hub

versions correctly.

■ DMM Version v4.0 and later identifies the CoreBuilder 5000 7-slot Hub

correctly.

Page 25

Upgradeable Hub Model Numbers

ONline Module Support 1-7

ONline Module Support

Table 1-3

lists upgradeable hub model numbers.

Table 1-3 Upgradeable Hub Model Numbers

Is Upgradeable to This Model

Hub Model Number...

6017C-B 6017C-BP 6017C-P-UPG

6010C-B 6010C-BP 6010C-P-UPG

6017C-A 6017C-AC 6017C-C-UPG

6010C-A 6010C-AC 6010C-C-UPG

6007C-A 6007C-AP 6007C-P-UPG

Number...

Using Upgrade Kit

Number...

You must use an adapter kit to use ONline modules in the CoreBuilder 5000

Integrated System Hub. Once you install the adapter kit, ONline modules use

most CoreBuilder 5000 Integrated System Hub capabilities, including:

■ Greater power availability

■ Extended monitoring

■ Extended manageability

■ Enhanced overall hub fault-tolerance

■ PacketChannel Backplane

CoreBuilder 5000

Intelligent Cooling

Subsystem

For more information on the adapter kit, refer to Chapter 5, the section titled

ONline Adapter Kits.

Some CoreBuilder 5000 features, such as a user interface to Controller-based

power management functionality, are only available if a CoreBuilder 5000

Distributed Management Module (DMM) is installed in the CoreBuilder 5000

hub. For example, the user can only take control of power management (assign

a power class to an installed CoreBuilder 5000 module) by entering

CoreBuilder 5000 power management commands at the CoreBuilder 5000

terminal prompt.

CAUTION: Do not install an ONline Controller Module in the CoreBuilder 5000

Integrated System Hub.

The default temperature threshold is the maximum internal hub temperature for

normal hub operation.

■ The allowable ambient temperature operating range is 0 °C to 50 °C (32 °F

to 122 °F).

■ An overheat condition exists when internal hub temperature exceeds the

default temperature threshold.

■ The default internal operating temperature threshold for the

CoreBuilder 5000 Integrated System Hub is 60 °C (140 °F) or higher.

Page 26

1-8 INTRODUCTION

The Intelligent Cooling Subsystem in the CoreBuilder 5000 Integrated System

Hub helps prevent:

■ Damage to the hub and all installed modules

■ Loss of configuration information

This section describes:

■ Active Controller Module Fan Indicators

■ Automatic CoreBuilder 5000 Module Power-Down

■ Enabling and Disabling CoreBuilder 5000 Module Power-Down

■ Active Controller Module Temp Indicators

Active Controller

Module Fan Indicators

Automatic

CoreBuilder 5000

Module Power-Down

Active Controller Module Fan indicators (LEDs or character display, depending on

Controller Module model) indicate that an installed fan has failed.

CoreBuilder 5000 17-slot and 10-slot hubs can temporarily run with two

functioning fans. The CoreBuilder 5000 7-slot hub has only two functioning

fans.

If one fan fails on a CoreBuilder 5000 7-slot Hub only, 3Com recommends that

you replace the fan within 48 hours of failure notification or contact your

service representative (refer to Appendix C, Maintenance).

Because the hub can run on just two fans, a warning provided by Active

Controller Module Fan indicators allows you adequate time to replace a faulty

fan at your convenience. For more information, refer to Chapter 7,

Troubleshooting.

Operate the hub with all fans running.

The Intelligent Cooling Subsystem operates as follows:

1 Active and Standby Controller Modules continually monitor the temperature

sensor located behind each fan unit, providing an accurate measurement of

internal hub temperature.

2 If the Distributed Management Module (DMM) command SET POWER

OVERHEAT_AUTO_POWER_DOWN MODE ENABLE is in effect, an overheat

condition may cause installed Controller Modules to power down selected

CoreBuilder 5000 modules. This condition continues until the cause of the

overheat condition is corrected and normal hub internal operating temperature

is restored.

The order in which CoreBuilder 5000 modules power down is determined by:

■ Individual CoreBuilder 5000 module power class settings

■ Relative slot location of each installed CoreBuilder 5000 module

For more information, refer to Chapter 4, the section titled Managing Power in

the Hub.

Page 27

CoreBuilder 5000 Intelligent Cooling Subsystem 1-9

Enabling and Disabling

CoreBuilder 5000

Module Power-Down

Active Controller

Module Temp Indicators

To enable or disable automatic power-down of CoreBuilder 5000 modules

caused by a hub overheat condition, issue the SET POWER

OVERHEAT_AUTO_POWER_DOWN MODE ENABLE (or DISABLE) command.

The default state is SET POWER OVERHEAT_AUTO_POWER_DOWN MODE

DISABLE, meaning that installed CoreBuilder 5000 modules do not power down

automatically during an overheat condition. For more information on overheat

conditions, refer to Chapter 2, the section titled Overheat Conditions.

The SET POWER OVERHEAT_AUTO_POWER_DOWN MODE command is only

available if you are using a Master DMM (indicated by RDY on the LCD display

of a DMM that has Mastership status). For a discussion of Master Management

Module functionality in the CoreBuilder 5000 Integrated System Hub, refer to

Chapter 2, Theory of Operation, the section titled Mastership in the

CoreBuilder 5000 Integrated System Hub.

The Temp indicator (LED or character display, depending on Controller Module

model) on the Active Controller Module warns you in the case of internal

overheat condition.

When hub internal operating temperature rises above the temperature

threshold, the following occurs:

1 A built-in temperature sensor detects the rise in hub internal operating

temperature.

2 The Fault-Tolerant Controller Module Temp LED blinks and the Master DMM

character display (for DMM Version v3.0 and later) shows the word TEMP.

3 The Active Controller Module sends an alert to the system administrator using

the Master Distributed Management Module (if installed).

The overheat indication stops when hub internal operating temperature falls

below the temperature threshold for at least 15 minutes. Correct the overheat

condition promptly to avoid possible hardware damage. (Only the Active

Controller Module indicators report hub operating conditions.)

Table 1-4

describes Controller Module LEDs associated with hub internal

operating temperature.

Tab le 1 -4 Active Controller Module LEDs

LED LED State Indicates

Temp LED or Character Display ON Hub temperature is normal.

LED = OFF Hub temperature is normal, or the

Temp LED is faulty

LED = Blinking or

Display = TEMP

Hub temperature is higher than the

allowable limit.

Page 28

1-10 INTRODUCTION

Table 1-4 Active Controller Module LEDs (continued)

LED LED State Indicates

Fan LED (1 through 3)

or

Character Display

Power Supply LED

(1 through 4) or

Character Display

ON Fan is present and operating.

LED = OFF Fan is not installed.

Fan LED is faulty.

LED = Blinking or

Display = FANn

(n = 1 to 3)

ON Power supply present and OK.

LED = OFF Power supply not installed.

LED = Blinking or

Display = PWRn

(n = 1 to 4)

Fan unit is malfunctioning or not

operational

Power supply LED failure.

Power supply present, but faulty.

Distributed Hub Management Architecture

CoreBuilder 5000 DMM

Models

Distributed hub management is a whole-system approach in which software and

hardware management functions are shared among functionally related

components. This design assures optimal fault-tolerance for the

CoreBuilder 5000 Integrated System Hub and all of the modules within it.

CoreBuilder 5000 Integrated System Hub network management architecture

enables you to manage multiple LAN segments from a single module. This

capability is managed through:

■ CoreBuilder 5000 Distributed Management Module (DMM or DMM-EC)

■ CoreBuilder 5000 Network Monitor Card (NMC)

■ CoreBuilder 5000 Advanced Ethernet Network Monitor Card (A-ENMC)

An Advanced Network Monitor Card is a high-performance daughter card

when installed on a CoreBuilder 5000 Ethernet media module or the

DMM-EC and provides high-speed, multi-segmented monitoring capabilities.

The CoreBuilder 5000 DMM is available in the following models:

■ Distributed Management Module (DMM, Model Number 6000M-MGT)

– The DMM consolidates media management for all media modules,

regardless of network communications protocol, onto a single card.

■ Advanced DMM/Controller Module (Model Number 6000M-CMGT) –

The Advanced DMM/Controller Module provides DMM functions with

performance enhancements, as well as hub controller functions, on a module

that installs in one of the controller bay slots in the CoreBuilder 5000 Hub.

■ DMM with Ethernet Carrier (DMM-EC, Model Number 6106M-MGT) –

The DMM-EC provides DMM functions as well as supporting the attachment

of up to six Ethernet Network Monitor Cards.

You can install a backup DMM for extra fault-tolerance. If a primary (Master)

DMM fails, the backup (Standby) DMM becomes the Master DMM and learns

the existing hub configuration.

Page 29

Distributed Hub Management Architecture 1-11

The rapid changeover from a failed Master DMM to a Standby DMM (which

becomes Master when the current Master DMM fails) occurs without causing

any loss of data. Nodes can still communicate with each other, but the DMM

interface is briefly unavailable during the changeover.

CoreBuilder 5000

Network Monitor Cards

A Network Monitor Card (NMC) is a circuit board that provides network

connectivity and gathers and reports statistics to an installed DMM. Network

Monitor Cards are optional. Install them only if you need to gather network

statistics and for network connectivity support. The NMC includes the following

features:

■ Can be physically attached (ENMC or A-ENMC only) to a CoreBuilder 5000

Ethernet Media Module, or to a CoreBuilder 5000 Distributed Management

Module with Ethernet Carrier (DMM-EC) installed in the hub.

■ Can be physically attached (TR-NMC only) to a CoreBuilder 5000 Token Ring

Media Module.

■ Does not consume a slot of its own. Rather, an NMC is a submodule that

shares slots with the CoreBuilder 5000 Media Module or DMM-EC to which

it is attached.

■ Monitors all activity on a network, gathering statistics and reporting them to

a protocol-independent CoreBuilder 5000 Distributed Management Module.

■ Communicates with an installed DMM using a high-speed management path

on the backplane, irrespective of the physical location of the NMC in the

hub.

■ Can be switched from one ring or network segment to another one having

the same protocol. This makes it possible to monitor multiple Ethernet or

multiple Token Ring networks, one at a time, using the same NMC. Switch

an NMC to monitor local (isolated_x) networks as well as backplane

networks when it is installed on the media module that the isolated_x

network exists on.

■ Provides full fault-tolerance capability. If an NMC fails, you can switch a

second NMC of the same protocol to the network previously monitored by

the failed NMC.

The network assignment of an installed Token Ring Network Monitor Card

(TR-NMC) is not switchable after the TR-NMC is installed on a CoreBuilder 5000

Token Ring Passive Media Module or on a CoreBuilder 5000 Token Ring Active

Per-Module Media Module. Under these circumstances, the network

assignment of the installed TR-NMC is the same as the network assignment of

the host media module to which the TR-NMC is attached.

Table 1-5

describes Network Monitor Cards supported by the CoreBuilder 5000

system.

Table 1-5 Supported Network Monitor Cards

Network Monitor Card Description

Ethernet Network Monitor Card

(ENMC)

Designed to reside on a CoreBuilder 5000 Ethernet

Media Module or on a DMM-EC. An ENMC monitors

the CoreBuilder 5000 or ONline Ethernet network to

which it is assigned, and reports statistics for that

network to a Master DMM.

Page 30

1-12 INTRODUCTION

Table 1-5 Supported Network Monitor Cards (continued)

Network Monitor Card Description

Advanced Ethernet Network

Monitor Card (ENMC)

Token Ring Network Monitor Card

(TR-NMC)

Designed to reside on a CoreBuilder 5000 Ethernet

Media Module or on a DMM-EC. An A-ENMC

monitors the CoreBuilder 5000 or ONline Ethernet

network to which it is assigned, and reports statistics

for that network to a Master DMM.

Designed to reside on a CoreBuilder 5000 Token Ring

Media Module. A TR-NMC monitors the

CoreBuilder 5000 or ONline network to which it is

assigned, and reports statistics for that network to a

Master DMM.

Reporting Statistics To report network statistics to a Master Distributed Management Module

(DMM):

1 Select Ethernet segments (CoreBuilder 5000 or ONline) or CoreBuilder 5000

rings to monitor.

2 Install one Network Monitor Card to gather statistics for each Ethernet segment

(CoreBuilder 5000 or ONline) or CoreBuilder 5000 ring you want to monitor.

Statistics Reporting Example

To gather statistics on one Token Ring network and two Ethernet networks,

install:

■ 1 DMM to fully manage all networks. This DMM is the Master DMM.

■ 1 TR-NMC to gather statistics for the Token Ring network. Install one

TR-NMC per segment.

■ 2 ENMCs or 1 A-ENMC to gather statistics for the 2 Ethernet segments.

Install one ENMC per segment.

Refer to Table 1-2

for a description of CoreBuilder 5000 and ONline backplane

network allocation in the CoreBuilder 5000 Integrated System Hub.

Page 31

2

THEORY OF OPERATION

This chapter describes the operation of specific hub components. The following

topics are described:

■ Management Capabilities

■ CoreBuilder 5000 Controller Module Descriptions

■ CoreBuilder 5000 Module Poweron Strategy

■ CoreBuilder 5000 Module Power-off Response

Management Capabilities

Module Configuration

and Monitoring

Mastership in the

CoreBuilder 5000

Integrated System Hub

This section contains the following topics:

■ Module Configuration and Monitoring

■ Mastership in the CoreBuilder 5000 Integrated System Hub

■ ONline Master Management Module Status Display

■ ONline and CoreBuilder 5000 Module Configuration

■ Network Monitoring and Module Configuration Summary

■ Using Backup Management Modules

Master management modules installed in the CoreBuilder 5000 Integrated

System Hub perform the following two primary functions:

■ Configuring – Configure and provide status reporting for modules and the

hub

■ Monitoring – Gather network statistics

This section describes:

■ Master Management Module

■ Master Distributed Management Module

■ Standby Distributed Management Module

■ Master ONline Management Module

If two or more DMMs are installed in the same CoreBuilder 5000 hub, only one

DMM is elected Master. All other DMMs in that hub are standby DMMs.

Table 2-2

and Table 2-3 list CoreBuilder 5000 and ONline management

capabilities in the CoreBuilder 5000 Integrated System Hub.

Page 32

2-2 CHAPTER 2: THEORY OF OPERATION

Master Management Module

A Master Management Module is the management module that manages and

controls the hub. The Master Management Module can be either a

CoreBuilder 5000 Distributed Management Module or an ONline Management

Module (see Ta bl e 2 -2

Master Distributed Management Module

A CoreBuilder 5000 Master Distributed Management Module (DMM) is the

CoreBuilder 5000 Management Module that manages and controls the hub. It

has the ability to fully manage hub conditions (for example, power

management, enabling power to slots, and setting hub operating temperature

parameters).

To take advantage of advanced DMM monitoring and configuration features,

install at least one DMM per hub.

An CoreBuilder 5000 Master DMM configures and provides status reporting for:

■ CoreBuilder 5000 Ethernet Modules and ONline Ethernet Modules.

and Table 2-3).

■ If the Ethernet Network Monitor Card (ENMC) assigned to an ONline

Ethernet network (networks 1, 2, or 3) is installed on a Distributed

Management Module with Ethernet Carrier (DMM-EC), you can gather

full statistics for that ONline Ethernet network.

■ If the ENMC is installed on a CoreBuilder 5000 Ethernet Module, you can

gather limited ONline Ethernet statistics.

■ Installed CoreBuilder 5000 and ONline Token Ring Media Modules. A Master

DMM can fully monitor CoreBuilder 5000 Token Ring networks, but an

ONline Token Ring Management Module (TRMM) is required to monitor

ONline Token Ring networks.

■ Installed ONline FDDI Media Modules. A Master DMM also gathers limited

ONline FDDI LAN statistics. An FDDI Management Module (FMM) is required

to gather full FDDI LAN statistics for ONline FDDI networks.

■ A Master CoreBuilder 5000 Distributed Management Module (DMM):

■ Monitors CoreBuilder 5000 networks and ONline Ethernet networks.

■ Requires a protocol-specific Network Monitor Card to monitor any

network. You can install Ethernet Network Monitor Cards on any

CoreBuilder 5000 Ethernet Media Module or on any CoreBuilder 5000

DMM-EC. You can only install Token Ring Network Monitor Cards on

CoreBuilder 5000 Token Ring Media Modules.

■ Incorporates an LCD display that shows RDY to indicate this is the Master

DMM.

■ Has limited control on ATM modules that are managed by the ATM

Control Point and Switch Module. A DMM has power management and

inventory management capabilities on ATM modules.

Page 33

Management Capabilities 2-3

Standby Distributed Management Module

A Standby Distributed Management Module (DMM):

■ Is any installed DMM that does not have mastership. The LCD display on a

Standby DMM shows STBY.

■ Is inactive until the Master DMM fails.

■ Cannot monitor any network. A Standby DMM does not communicate with

installed Network Monitor Cards.

Master ONline Management Module

A Master ONline Management Module:

■ Has more limited hub management capabilities.

■ Configures and provides status reporting for all installed ONline modules.

■ Monitors the ONline network to which it is assigned.

ONline modules monitor the following with or without mastership:

■ An ONline Ethernet Management Module monitors the ONline Ethernet

network to which it is assigned.

ONline Master

Management Module

Status Display

■ An ONline Token Ring Management Module monitors the ONline Token

Ring network to which it is assigned.

■ An ONline FDDI Management Module monitors the ONline FDDI network to

which it is assigned.

A DMM and any ONline Management Module (EMM, TRMM, FMM) can coexist

in the CoreBuilder 5000 Integrated System Hub with no loss of functionality.

However, the DMM is always the Master Management Module in such cases.

ONline Master Management Modules display:

■ Limited CoreBuilder 5000 hub status information

■ Limited CoreBuilder 5000 module status information

■ Full status information for all installed ONline modules

The following considerations apply to the status display:

■ An ONline Master Management Module reports that the Active Controller

Module is installed in slot 17 (CoreBuilder 5000 Integrated System 17-slot

hub) or in slot 10 (CoreBuilder 5000 Integrated System 10-slot hub) or in slot

7 (CoreBuilder 5000 Integrated System 7-slot hub).

■ An ONline Master Management Module does not report fan status.

■ The SET CONCENTRATOR PLATFORM command is disabled for all installed

ONline Management Modules because an ONline Management Module

knows it is installed in a CoreBuilder 5000 Integrated System hub (the ONline

Management Module must be Ethernet Version v4.0, Token Ring Version

v2.1, and FMM Version v2.0 or later).

■ If you enter RESET POWER SUPPLY from an ONline Management Module

prompt, the ONline Management Module generates an error message.

Page 34

2-4 CHAPTER 2: THEORY OF OPERATION

If you do not have the latest ONline Management Module software versions,

obtain a software upgrade. To obtain help, refer to Appendix D for details.

Table 2-1

summarizes the CoreBuilder 5000 module and CoreBuilder 5000 hub

status information you can display with the following:

■ ONline Master EMM software Version v4.0 or later

■ Master TRMM software Version v2.1 or later

■ Master FMM software Version v2.0 or later

Table 2-1 Information Displayed by ONline Master Management Module

ONline SHOW Command

(and selected fields)

SHOW CONCENTRATOR Yes Shows slot numbers for installed

Concentrator Type Yes 5006C, 5017C, 6017C, 6010C,

Primary Power Supply Status Yes Normal, Faulty

Backup Power Supply Status Yes Normal, Faulty, Removed

Temperature Sensor Status Yes Normal, Extreme

SHOW MODULE ALL Yes Shows only ONline modules

1

A Standby ONline Management Module monitors the network to which it is assigned, but it cannot

provide any of the information shown in Table 2-1.

Status Information

Available

1

Output Values

CoreBuilder 5000 modules

6007C

ONline and

CoreBuilder 5000

Module Configuration

When you install a DMM in a powered-on hub for the first time, and if that

DMM is then elected Master:

■ The DMM automatically learns the configurations of all installed

CoreBuilder 5000 and ONline modules.

■ The DMM saves the configuration information it has learned in on-board

non-volatile RAM storage (NVRAM).

When you install an ONline EMM, TRMM, or FMM in a powered-on hub for the

first time, and if it is then elected Master:

■ The ONline Master Management Module automatically learns the

configurations of all installed ONline modules.

■ The ONline Master Management Module then saves the learned

configuration in its NVRAM.

ONline Management Modules cannot save configurations for CoreBuilder 5000

modules.

You can configure any CoreBuilder 5000 module (except ATM modules) using a

Master DMM, then install that hot-staged CoreBuilder 5000 module into

another hub. This is possible because a CoreBuilder 5000 module stores

configuration information in on-board non-volatile RAM (NVRAM).

Page 35

Management Capabilities 2-5

ONline Module Configuration

When an ONline module powers on in a hub that is not managed:

■ The ONline module configures to DIP settings if the hub is already operating

when you install the ONline module.

■ The ONline module configures to DIP settings if the hub is not operating

when you install the ONline module (that is, if the hub powers on after you

install the ONline module).

When an ONline module powers on in a managed hub:

■ If a saved configuration is not available for this type of ONline module

installed in this slot, the new ONline module configures to defaults (isolated,

with all ports disabled).

■ For example, if you replace a faulty ONline BNC Module in slot 5 with a

functional ONline BNC Module installed in the same slot, and the Master

Management Module does not have a saved configuration for the

replacement ONline BNC Module, the replacement BNC Module

configures to defaults.

The ONline module configures to defaults if the hub is already operating

when you install the ONline module, or if the hub is not operating when

you install the ONline module (that is, if the hub powers on after you install

the ONline module).

■ If an installed Master DMM or Master ONline Management Module has a

saved configuration for this type of ONline module newly installed in this

slot, the Master DMM or Master ONline Management Module provides the

saved configuration to the newly installed ONline module.

■ For example, if you replace a faulty ONline BNC Module in slot 5 with a

functional ONline BNC Module installed in the same slot, the Master

Management Module provides a saved ONline BNC Module configuration

(if available) to the replacement module.

The new ONline module configures to the saved configuration if the hub is

already operating when you install the ONline module, or if the hub is not

operating when you install the ONline module (that is, if the hub powers on

after you install the ONline module).

The newly installed ONline module can be either a replacement module that has

been configured in another hub, or a new module that has never been

configured. If a usable saved configuration is not available, the new module

stays in the default state.

Both DMMs and ONline Management Modules have a ’configure to DIPs’ option

which allows media modules (ONline and CoreBuilder 5000) to configure to DIP

switch settings automatically, regardless of the saved configuration that

management might have for them.

Page 36

2-6 CHAPTER 2: THEORY OF OPERATION

CoreBuilder 5000 Module Configuration

CoreBuilder 5000 modules can save their own configurations. Once installed,

CoreBuilder 5000 modules first attempt to configure from either of the

following settings:

■ On-board DIP switch settings

■ A saved configuration stored in on-board non-volatile memory (NVRAM)

For each CoreBuilder 5000 module, the switch setting (to DIP or to NVRAM)

determines which configuration (DIP or NVRAM) is attempted.

If a Master DMM is present, the CoreBuilder 5000 module submits its

configuration (DIP or stored in NVRAM) to a Master DMM for approval.

■ If the Master DMM has a saved configuration for the CoreBuilder 5000

■ If the Master DMM does not have a saved configuration for the

module, it provides that configuration to the CoreBuilder 5000 module,

overriding the CoreBuilder 5000 module’s requested configuration.

CoreBuilder 5000 module, it allows the CoreBuilder 5000 module to

configure to its requested configuration, provided the requested

configuration is valid.

■ If the configuration requested by the CoreBuilder 5000 module has some

invalid settings, the CoreBuilder 5000 module reverts to defaults (isolated

with all ports disabled).

If a Master DMM is not present and the CoreBuilder 5000 module is set to:

■ DIP settings, then the CoreBuilder 5000 module uses the DIP configuration.

■ NVRAM and the CoreBuilder 5000 module has a stored configuration, the

CoreBuilder 5000 module configures to that stored configuration.

■ NVRAM and no configuration is stored there, the CoreBuilder 5000 module

configures to defaults (isolated with all ports disabled).

■ NVRAM and the stored configuration is invalid, the CoreBuilder 5000 module

configures to defaults (isolated with all ports disabled).

Network Monitor Cards do not store a configuration in NVRAM. During a

system reset in which all modules reboot, Network Monitor Cards set to defaults

and wait to be configured by a Master DMM.

A DMM elected to mastership learns all configuration information for all

installed modules (CoreBuilder 5000 and ONline), and automatically restores that

information to all modules or their replacements following a hub or module

failure.

Network Monitoring

and Module

Configuration Summary

Only a Distributed Management Module (DMM) elected to mastership has the

ability to configure modules. A CoreBuilder 5000 or ONline Management

Module not elected to mastership can only monitor the network to which it is

assigned.

Page 37

Management Capabilities 2-7

Table 2-2 and Table 2-3 provide a summary of the configuration and monitoring

capabilities of the DMM and CoreBuilder 5000 and ONline management

modules.

Table 2-2

summarizes the capabilities of a DMM and CoreBuilder 5000

Management Modules.

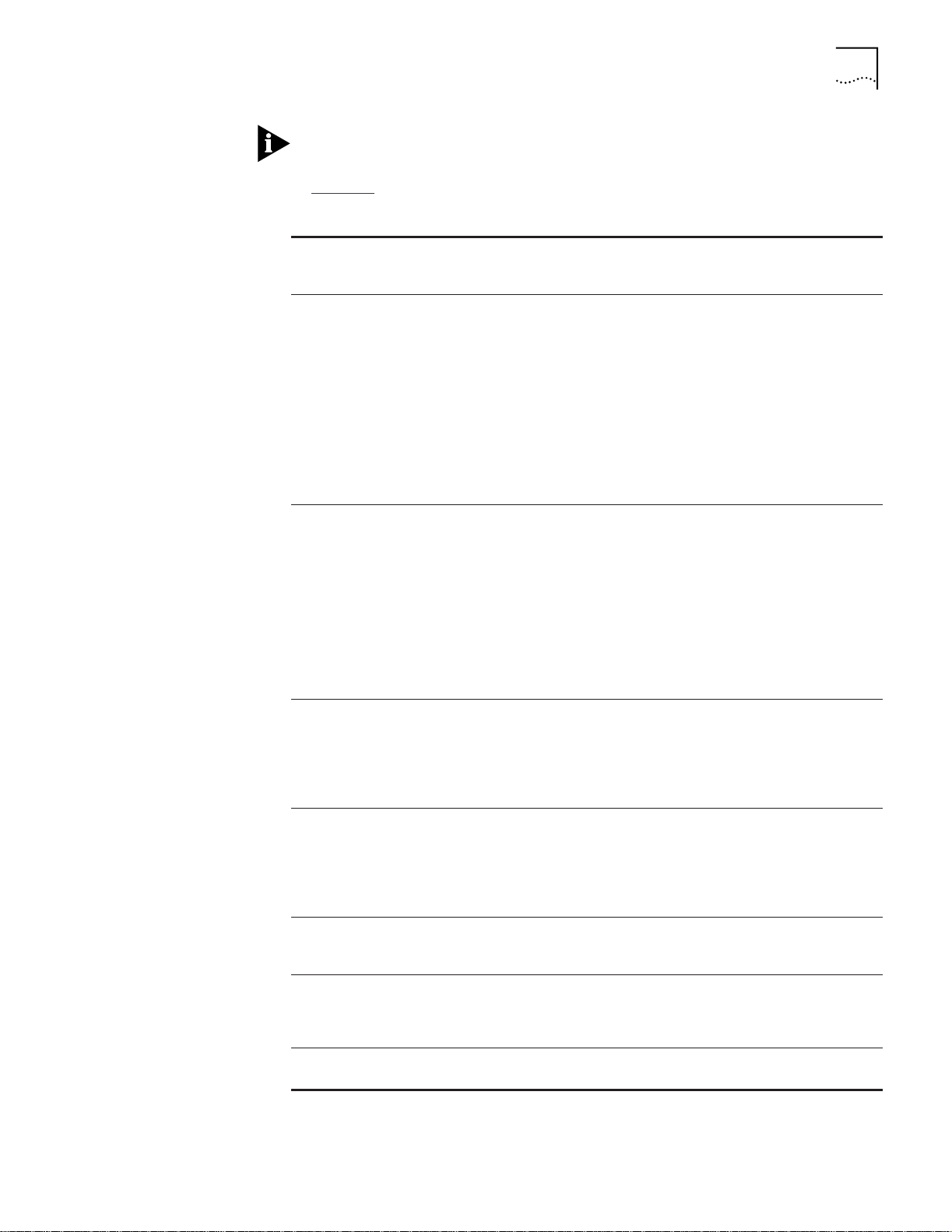

Table 2-2 Management Module Capabilities on CoreBuilder 5000 Modules

CoreBuilder 5000

1

Capability

Provide interface

DMM

Yes Yes

to Controller

Module

functionality

Configure

Yes No No No No

CoreBuilder 5000

Ethernet Modules

Monitor

CoreBuilder 5000

Yes

(with an ENMC)

Ethernet networks

Configure

Yes No No No No

CoreBuilder 5000

Token Ring

Modules

Monitor

CoreBuilder 5000

Yes

(with a TR-NMC)

Token Ring

networks

Monitor

No No No No Yes

CoreBuilder 5000

ATM Media

Modules

1

Must be a Master Management Module.

2

Can report limited hub status information and the presence of CoreBuilder 5000 modules

(a full management interface to the Controller Module is available only if you have an installed

Master DMM).

3

An ONline Management Module not elected to mastership can monitor the network to which it is

assigned.

4

Can gather limited statistics for the first 3 of the 8 Ethernet networks.

ONline

EMM

Yes

ONline

3

2

4

3

TRMM

2

Yes

No No No

ONline

FMM

2

Yes

CoreBuilder 5000

3

ATM CPSW

Yes

No No No No

Page 38

2-8 CHAPTER 2: THEORY OF OPERATION

Table 2-3 summarizes the capabilities of a DMM and ONline Management

Modules.

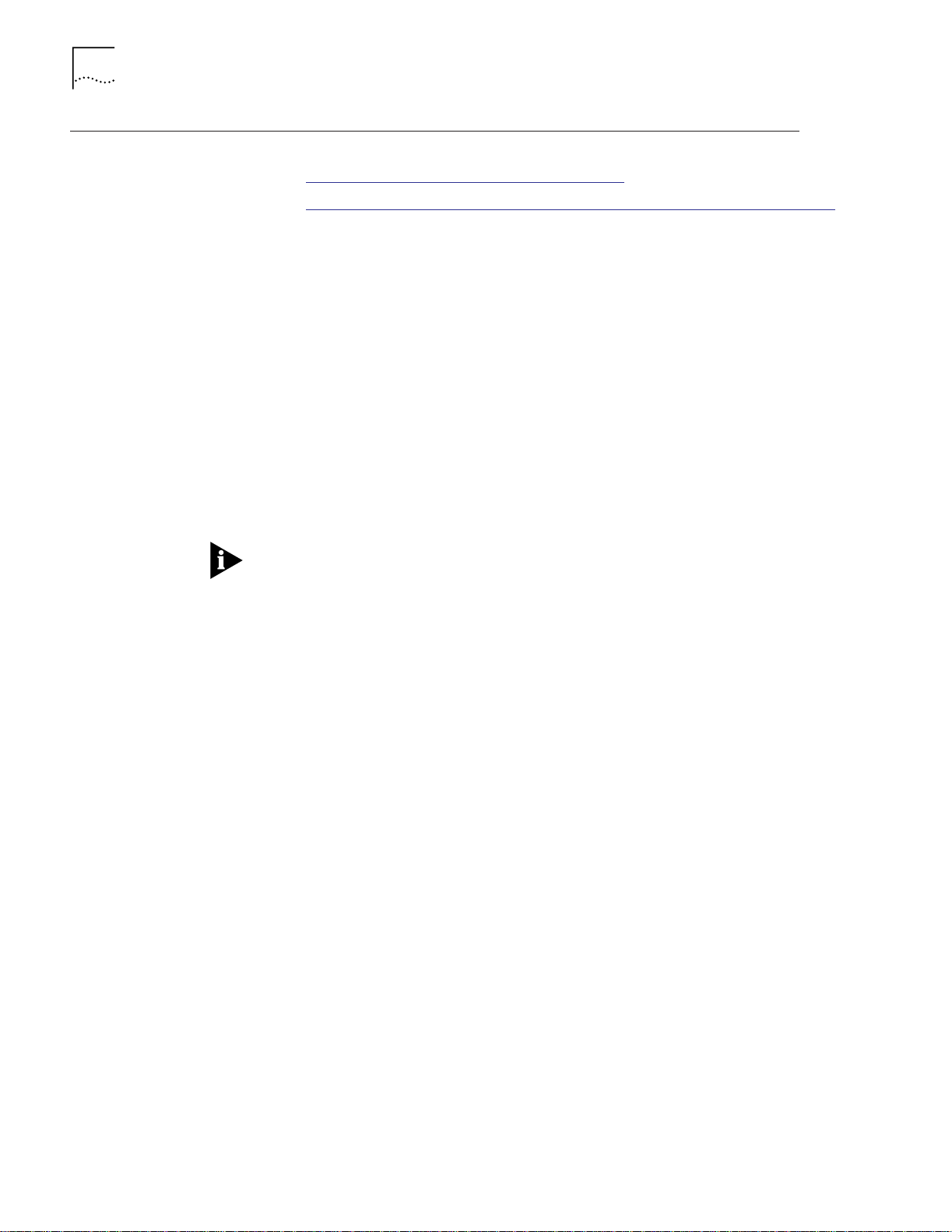

Table 2-3 Management Module Capabilities on ONline Modules

CoreBuilder 5000

1

Capability

Configure ONline

Ethernet modules

Monitor ONline

Ethernet networks

Configure ONline

Token Ring modules

Monitor ONline Token

Ring networks

Configure ONline FDDI

modules

Monitor ONline FDDI

networks

1

Must be a Master Management Module.

2 A CoreBuilder 5000 Distributed Management Module provides complete network monitoring for

ONline Ethernet Modules if the Ethernet Network Monitor Card you are using is installed on a

DMM-EC (rather than on a CoreBuilder 5000 Ethernet Media Module).

3

Install one EMM per ONline Ethernet segment to be monitored, one TRMM per ONline Token Ring

to be monitored, and one FMM per ONline FDDI ring to be monitored.

DMM

Yes Yes Yes Yes

2

Yes

Yes Yes Yes Yes

No No Yes

Yes Yes Yes Yes

No No No Yes

ONline

1

EMM

3

Yes

ONline

TRMM

No No

3

ONline

1

FMM

No

1

3

CoreBuilder 5000 Media Modules have limited on-board network configuration

capabilities. You can set on-board DIP switches to select the network to which

ports will be assigned.

For further information about CoreBuilder 5000 DMM functionality, refer to the

Distributed Management Module User Guide and the CoreBuilder 5000

Distributed Management Module Commands Guide.

For further information about ONline Management Module functionality, refer

to the ONline Network Management Module Installation and Operation Guide

that describes the ONline Management Modules or ONline Media Modules you

want to install.

Page 39

Management Capabilities 2-9

Using Backup

Management Modules

You can provide extra protection for your system by installing backup

management modules (two or more DMMs) in the hub. The Master DMM

(Distributed Management Module) provides configurations to all modules. One

or more additional DMMs back up the Master DMM if it fails.

■ Install more than one DMM-EC in your system to ensure that Ethernet

Network Monitor Cards (ENMC) or Advanced Ethernet Network Monitor

Cards (A-ENMC) installed on multiple DMM-ECs provide full monitoring for a

greater number of CoreBuilder 5000 and ONline Ethernet networks (each

DMM-EC can support up to 6 ENMCs).

If you back up an A-ENMC with an ENMC, features (for example, the security

feature) from the A-ENMC are not supported once the ENMC takes over. If you

want A-ENMC full-feature functionality, then use another A-ENMC for the n + 1

redundancy function.

■ Assign an ENMC as a standby ENMC in order to establish fault-tolerance for

an active ENMC.

■ Install additional Ethernet Network Monitor Cards on CoreBuilder 5000

Ethernet Media Modules.

A CoreBuilder 5000 Distributed Management Module provides full network

monitoring for ONline Ethernet Modules if the Ethernet Network Monitor Card

you are using is installed on a DMM-EC (rather than on a CoreBuilder 5000

Ethernet Media Module).

■ Install all Ethernet Network Monitor Cards on 2 DMM-ECs (6 ENMCs per

DMM-EC) to monitor all of the hub’s 8 Ethernet segments. This installation

approach centralizes the physical location of ENMCs in your hub and

simplifies maintenance.

Backup Management Module Example

Ethernet Network Monitor Cards installed on a DMM-EC in standby mode are

configured by the Master DMM to monitor Ethernet networks. When a

DMM-EC is in standby mode, only the DMM (management) component of the

DMM-EC is in standby mode. The Carrier component of the DMM-EC (the

component that supports the attachment of ENMCs) remains active.

If you remove a host DMM-EC to replace a defective Ethernet Network Monitor

Card, you can replace the faulty ENMC without disrupting port connections.

However, if you remove an installed CoreBuilder 5000 Ethernet Media Module

to replace a faulty Network Monitor Card, port connections are disrupted.

Page 40

2-10 CHAPTER 2: THEORY OF OPERATION

CoreBuilder 5000

Controller Module

Descriptions

Controller Module

Models

Active and Standby

Controller Module

Functionality

This section describes:

■ Controller Module Models

■ Active and Standby Controller Module Functionality

■ Identifying Controller Module Slots

■ Downloading Software to the Controller Module

■ Controller Module Fault-Tolerance

The Controller Module is available in the following models:

■ Fault-Tolerant Controller Module (Model Number 6000M-RCTL) –

Provides all controller functions as described in this section.

■ Advanced DMM/Controller Module (Model Number 6000M-CMGT) –

Provides all controller functions as described in this section, as well as DMM

functions with performance enhancements, on a module that installs in one

of the controller bay slots in the CoreBuilder 5000 hub.

Installed Active and Standby Controller Modules provide power management for

all installed CoreBuilder 5000 modules and maintain an accurate power budget