Page 1

CoreBuilder™ 5000

®

Ethernet 20-Port and

40-Port 10BASE-T Module

User Guide

http://www.3com.com/

Document Number 17-00540-3

Published May 1997

Page 2

3Com Corporation

5400 Bayfront Plaza

Santa Clara, California

95052-8145

Copyright © 3Com Corporation, 1997. All rights reserved. No part of this documentation may be

reproduced in any form or by any means, or used to make any derivative work (such as translation,

transformation, or adaptation) without permission from 3Com Corporation. Portions of this document are

reproduced in whole or part with permission from third parties.

3Com Corporation reserves the right to revise this documentation and to make changes in content from

time to time without obligation on the part of 3Com Corporation to provide notification of such revision or

change.

3Com Corporation provides this documentation without warranty of any kind, either implied or expressed,

including, but not limited to, the implied warranties of merchantability and fitness for a particular purpose.

3Com may make improvements or changes in the products or programs described in this documentation at

any time.

UNITED STATES GOVERNMENT LEGENDS:

If you are a United States government agency, then this documentation and the software described herein

are provided to you subject to the following restricted rights:

For units of the Department of Defense:

Restricted Rights Legend: Use, duplication, or disclosure by the Government is subject to restrictions as set

forth in subparagraph (c) (1) (ii) for Restricted Rights in Technical Data and Computer Software Clause at

48 C.F.R. 52.227-7013.

For civilian agencies:

Restricted Rights Legend: Use, reproduction, or disclosure is subject to restrictions set forth in subparagraph

(a) through (d) of the Commercial Computer Software – Restricted Rights Clause at 48 C.F.R. 52.227-19

and the limitations set forth in the 3Com Corporation standard commercial agreement for the software.

Unpublished rights reserved under the copyright laws of the United States.

If there is any software on removable media described in this documentation, it is furnished under a license

agreement included with the product as a separate document, in the hardcopy documentation, or on the

removable media in a directory file named LICENSE.TXT. If you are unable to locate a copy, please contact

3Com and a copy will be sent to you.

Federal Communications Commission Notice

This equipment was tested and found to comply with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference, in which case you must correct the interference

at your own expense.

Canadian Emissions Requirements

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment

Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur

du Canada.

EMC Directive Compliance

This equipment was tested and conforms to the Council Directive 89/336/EEC for electromagnetic

compatibility. Conformity with this directive is based upon compliance with the following harmonized

standards:

EN 55022 – Limits and Methods of Measurement of Radio Interference

EN 50082-1 – Electromagnetic Compatibility Generic Immunity Standard: Residential, Commercial, and

Light Industry

Warning: This is a Class A product. In a domestic environment, this product may cause radio interference, in

which case you may be required to take adequate measures.

Compliance with this directive depends on the use of shielded cables.

Low Voltage Directive Compliance

This equipment was tested and conforms to the Council Directive 72/23/EEC for safety of electrical

equipment. Conformity with this directive is based upon compliance with the following harmonized

standard:

EN 60950 – Safety of Information Technology Equipment

ii

Page 3

VCCI Class 1 Compliance

This equipment is in the 1st Class category (information equipment to be used in commercial or industrial

areas) and conforms to the standards set by the Voluntary Control Council for Interference by Information

Technology Equipment aimed at preventing radio interference in commercial or industrial areas.

Consequently, when the equipment is used in a residential area or in an adjacent area, radio interference

may be caused to radio and TV receivers, and so on.

Read the instructions for correct handling.

Fiber Cable Classification Notice

Use this equipment only with fiber cable classified by Underwriters Laboratories as to fire and smoke

characteristics in accordance with Section 770-2(b) and Section 725-2(b) of the National Electrical Code.

UK General Approval Statement

The CoreBuilder 5000 Integrated System Hub and ONline System Concentrator are manufactured to the

International Safety Standard EN 60950 and are approved in the U.K. under the General Approval Number

NS/G/12345/J/100003 for indirect connection to the public telecommunication network.

Trademarks

Unless otherwise indicated, 3Com registered trademarks are registered in the United States and may or may

not be registered in other countries.

3Com, Boundary Routing, CardFacts, EtherLink, LANplex, LANsentry, LinkBuilder, NETBuilder, NETBuilder II,

NetFacts, Parallel Tasking, SmartAgent, TokenDisk, TokenLink, Transcend, TriChannel, and ViewBuilder are

registered trademarks of 3Com Corporation.

3TECH, CELLplex, CoreBuilder, EtherDisk, EtherLink II, FDDILink, MultiProbe, NetProbe, and ONline are

trademarks of 3Com Corporation.

3ComFacts is a service mark of 3Com Corporation.

The 3Com Multichannel Architecture Communications System is registered under U.S. Patent

Number 5,301,303.

AT&T is a registered trademark of American Telephone and Telegraph Company.

Banyan and VINES are registered trademarks of Banyan Systems Inc.

CompuServe is a registered trademark of CompuServe, Inc.

DEC, DECnet, DELNI, POLYCENTER, VAX, VT100, VT220, and the Digital logo are trademarks of Digital

Equipment Corporation.

Hayes is a registered trademark of Hayes Microcomputer Products.

OpenView is a registered trademark of Hewlett-Packard Company.

Intel is a registered trademark of Intel Corporation.

AIX, IBM, and NetView are registered trademarks of International Business Machines Corporation.

Microsoft, MS-DOS, Windows, Windows 95, and Windows NT are registered trademarks of

Microsoft Corporation.

V30 is a trademark of NEC Corporation.

NetWare and Novell are registered trademarks of Novell, Incorporated.

IPX is a trademark of Novell, Incorporated.

OSF and OSF/Motif are registered trademarks of Open Software Foundation, Inc.

ONC, OpenWindows, Solaris, Solstice, Sun, Sun Microsystems, SunNet Manager, and SunOS are trademarks

of Sun Microsystems, Inc.

iii

Page 4

SPARCstation is a trademark licensed exclusively to Sun Microsystems Inc.

OPEN LOOK is a registered trademark of Unix System Laboratories, Inc.

UNIX is a registered trademark of X/Open Company, Ltd. in the United States and other countries.

Other brand and product names may be registered trademarks or trademarks of their respective holders.

iv

Page 5

CONTENTS

HOW TO USE THIS GUIDE

Audience 1

Structure of This Guide 2

Document Conventions 3

Related Documents 4

3Com Documents 4

Reference Documents 4

1 INTRODUCTION

CoreBuilder 5000 Ethernet 20/40-Port Module Description 1-2

CoreBuilder 5000 Ethernet 20/40-Port Module Features 1-2

CoreBuilder 5000 Ethernet 20/40-Port Module Benefits 1-3

20-Port Sample Module Application 1-5

Theory of Operation 1-6

Where to Go From Here 1-6

2 DESIGNING AND EXPANDING THE NETWORK

Understanding General Network Configuration Rules 2-1

Before Configuring Your Network 2-2

Basic Network Rules 2-2

LAN Product Distances 2-4

Configuring Fiber Backbone, Twisted Pair to-the-Desk 2-5

Fiber Backbone Configuration Rules 2-5

Configuration Example of Fiber Backbone, Twisted Pair

to-the-Desk 2-6

Fiber Backbone Configuration Verification 2-6

Configuring Twisted Pair Backbone, Twisted Pair to-the-Desk 2-7

Twisted Pair Backbone Configuration Rules 2-7

Configuration Example of Twisted Pair Backbone, Twisted

Pair-to-the-Desk 2-8

Page 6

Using Patch Panels 2-9

Using Module Workgroups 2-9

Workgroup Definition 2-9

Dividing the Network into Workgroups 2-10

Workgroup Example 2-10

Setting Redundant Links 2-13

Setting Redundancy Between Two Ports on One 40-Port

Module 2-14

Setting Redundancy Between Ports On Two 20/40-Port

Modules 2-15

Where to Go From Here 2-16

3 INSTALLING AND OPERATING THE MODULE

Precautionary Procedures 3-2

Unpacking Procedures 3-2

Quick Installation 3-3

Setting DIP Switches 3-4

Using DIP Switches 3-4

Setting the DIP Switches 3-4

DIP Switch Definition 3-5

Installing the Module 3-7

Configuring the Module 3-10

Enable/Disable/

Shutdown Ports 3-11

Set Port Redundancy 3-12

Set Remote Diagnostics 3-12

Enable/Disable Link Integrity 3-13

Set Alert Filter 3-13

Set Auto Polarity 3-14

Set Port Squelch 3-14

Network Selection 3-15

Assigning Ports On the Module to a Network 3-15

Assigning a Monitor Card to a Network 3-15

Showing Module Configurations 3-16

Show Module Command 3-16

vi

Page 7

Show Port Command 3-17

Attaching the Network Monitor Card 3-18

Gathering Statistics 3-19

Gathering Statistics 3-19

Monitoring the Network 3-19

Monitor Command 3-20

Show Counter Command 3-21

Monitoring the Front Panel 3-22

Module Status LED 3-22

Port Status and Activity LEDs 3-22

Verifying LEDs and the Network 3-24

Using the CoreBuilder 5000 Controller Module to Verify Bi-Color LED

Operation 3-25

Using the DMM to Verify Network Connections 3-25

Where to Go From Here 3-26

4 TROUBLESHOOTING

Troubleshooting Using the Module Status LED 4-2

Troubleshooting Using the Port Status LEDs 4-3

Technical Assistance 4-4

Where to Go From Here 4-4

A SPECIFICATIONS

Electrical Specifications A-1

Environmental Specifications A-2

Mechanical Specifications A-2

General Specifications A-2

Twisted Pair Connectors and Cables A-3

Twisted Pair Connectors A-3

Twisted Pair Cables A-4

Connecting Twisted Pair Cables A-4

vii

Page 8

B TECHNICAL SUPPORT

Online Technical Services B-1

World Wide Web Site B-2

3Com Bulletin Board Service B-2

Access by Analog Modem B-2

Access by Digital Modem B-2

3ComFacts Automated Fax Service B-3

3ComForum on CompuServe Online Service B-3

Support From Your Network Supplier B-4

Support From 3Com Corporation B-5

Returning Products for Repair B-6

Accessing the 3Com MIB B-6

Contacting 3Com Technical Publications B-7

INDEX

3COM CORPORATION LIMITED WARRANTY

viii

Page 9

FIGURES

1-1 CoreBuilder 5000 Ethernet 20-Port and 40-Port Module 1-4

1-2 Typical 20-Port Module Application 1-5

2-1 Sample Configuration Distance Calculation 2-6

2-2 Unshielded Twisted Pair Network 2-8

2-3 Typical Corporate Organizational Structure 2-10

2-4 20-Port Module Workgroup Port Allocation 2-12

2-5 Redundant Twisted Pair Configuration 2-14

3-1 20/40-Port Module and DIP Switch Location 3-5

3-2 Installing a CoreBuilder 5000 Module 3-8

3-3 Opened and Closed Module Ejectors 3-9

3-4 20-Port Module Cable Connection 3-10

3-5 Remote Diagnostics Example 3-12

3-6 Attaching the CoreBuilder 5000 Ethernet Monitor Card 3-18

3-7 20-Port and 40-Port Module Faceplate 3-23

A-1 RJ-45 Connector Pinouts A-4

ix

Page 10

Page 11

TABLES

2-1 Seven Basic Network Rules 2-2

2-2 LAN Product Equivalent Distances 2-4

2-3 Sample Network Reorganization 2-11

3-1 Quick Installation Checklist 3-3

3-2 Channel Select DIP Switch Settings 3-6

3-3 20/40-Port Module LED Interpretations 3-24

4-1 Module Status LED Troubleshooting 4-2

4-2 Port Status LED Troubleshooting 4-3

xi

Page 12

Page 13

HOW TO USE THIS GUIDE

This guide explains how to install and operate the 3Com

CoreBuilder

throughout this guide as the 20/40-Port module). This guide also

includes information on monitoring this module using a

3Com

appendix explains cabling guidelines and options for the 20/40-Port

module.

Before installing or using the 20/40-Port module, read Chapters 1, 2,

and 3 of this guide for basic installation and operation instructions.

5000 Ethernet 20/40-Port 10BASE-T Module (referenced

®

CoreBuilder 5000 Distributed Management Module. An

Audience This guide is intended for the following people at your site:

■ Network manager or administrator

■ Hardware installer

Page 14

2 HOW TO USE THIS GUIDE

Structure of This Guide

This guide contains the following chapters and appendix:

Chapter 1, Introduction – Introduces the functions and features of

the CoreBuilder 5000 Ethernet 20/40-Port 10BASE-T Module.

Chapter 2, Designing and Expanding the Network – Shows

possible network configurations using the CoreBuilder 5000 hub and

the CoreBuilder 5000 Ethernet 20/40-Port Module.

Chapter 3, Installing and Operating the Module – Provides

illustrated procedures for installing the 20/40-Port module into the

CoreBuilder 5000 hub. Also shows front panel LEDs and DIP switches

on the module and describes network management commands.

Chapter 4, Troubleshooting – Provides help in isolating and

correcting problems that may arise when installing or operating this

module.

Appendix A, Specifications – Provides electrical, environmental, and

mechanical specifications for the module. Provides information on RJ-45

connectors and twisted pair cables.

Appendix B, Technical Support – Lists the various methods for

contacting the 3Com technical support organization and for accessing

other product support services.

Index

Page 15

Document Conventions 3

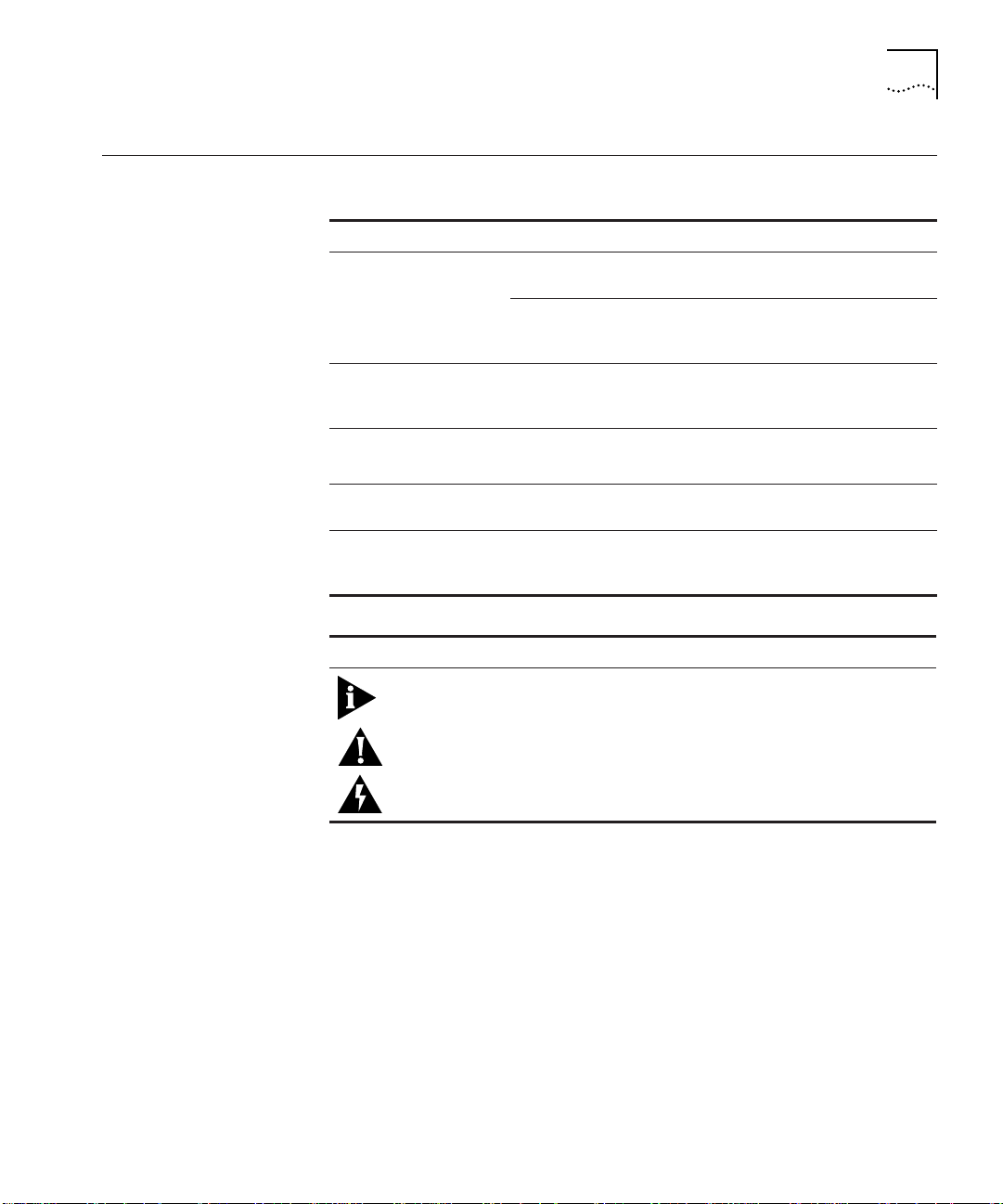

Document Conventions

The following document conventions are used in this manual:

Convention Indicates Example

Courier text User input In the Agent Information Form,

enter MIS in the New Contact field.

System output After pressing the Apply button, the

Bold command string Path names Before you begin, read the

User-substituted

identifiers

Capitalized text in plain

brackets

Italics Text emphasis,

Icon Notice Type Alerts you to...

Information note Important features or instructions

Keyboard entry by

the user

document titles

system displays the message

Transmitting data.

readme.txt file located in

/usr/s nm /agen ts.

Type your password and press

[ENTER].

Ensure that you press the Apply

button after you add the new

search parameters.

Caution Risk of personal safety, system damage, or loss

Warning Risk of severe personal injury

of data

Page 16

4 HOW TO USE THIS GUIDE

Related Documents This section provides information on supporting documentation,

including:

■ 3Com Documents

■ Reference Documents

3Com Documents The following documents provide additional information on 3Com

products:

CoreBuilder 5000 Integrated System Hub Installation and Operation

Guide – Provides information on the installation, operation, and

configuration of the CoreBuilder 5000 hub. This guide also describes

the principal features of the CoreBuilder 5000 Fault-Tolerant Controller

Module.

Distributed Management Module User Guide – Provides information

on the CoreBuilder 5000 Distributed Management Module’s operation,

installation, and configuration. This guide also describes the software

commands associated with the distributed management module.

Distributed Management Module Commands Guide – Describes each

management command by providing detailed information on the

command’s format, use, and description.

For a complete list of 3Com documents, contact your 3Com

representative.

Reference Documents The following documents supply related background information:

Case, J., Fedor, M., Scoffstall, M., and J. Davin, The Simple Network

Management Protocol, RFC 1157, University of Tennessee at Knoxville,

Performance Systems International and the MIT Laboratory for

Computer Science, May 1990.

Rose, M., and K. McCloghrie, Structure and Identification of

Management Information for TCP/IP-based Internets, RFC 1155,

Performance Systems International and Hughes LAN Systems, May

1990.

Page 17

1

INTRODUCTION

This chapter describes the 3Com CoreBuilder

10BASE-T Module (Model Number 6120M-TPP) and the 40-Port

10BASE-T Module (Model Number 6140M-TPP). For more information

on the CoreBuilder 5000 hub, refer to the CoreBuilder 5000 Integrated

System Hub Installation and Operation Guide.

This chapter contains the following sections:

■ CoreBuilder 5000 Ethernet 20/40-Port Module Description

■ CoreBuilder 5000 Ethernet 20/40-Port Module Features

■ CoreBuilder 5000 Ethernet 20/40-Port Module Benefits

■ Theory of Operation

■ Where to Go From Here

™

5000 Ethernet 20-Port

Page 18

1-2 INTRODUCTION

CoreBuilder 5000

Ethernet

20/40-Port Module

Description

CoreBuilder 5000

Ethernet

20/40-Port Module

Features

The 3Com® CoreBuilder 5000 Ethernet 20/40-Port 10BASE-T Module

is a port-switching module which:

■ Supports RJ-45 based 10BASE-T wiring

■ Enables users to assign a backplane segment at the port level of the

module

The CoreBuilder 5000 Ethernet 20-Port 10BASE-T Module offers a

single slot solution for networks utilizing RJ-45 connectors in their

10BASE-T installation. The CoreBuilder 5000 Ethernet 40-Port 10BASE-T

Module offers an additional 20 ports in a two slot solution for

networks with a large environment of RJ-45-based 10BASE-T wiring.

The 20/40-Port module connects up to 20 or 40 devices (PCs,

terminals, printers, modems) to the 3Com CoreBuilder 5000 hub. The

module provides 20 or 40 twisted pair Ethernet ports which may be

switched individually to any of the CoreBuilder 5000 backplane

channels or extended (isolated) segments.

The CoreBuilder 5000 Ethernet 20/40-Port 10BASE-T Module provides

the following features:

■ Remote Diagnostics Mode – Checks driver and receiver integrity.

■ Private Line Card – Supports security through the private line card

(PLC). The PLC provides continuous eavesdropping and intrusion

protection without impacting network performance.

■ Two Daughter Cards – Allows you to connect network monitor

cards for network management.

■ Hot swap capability – Allows you to install or remove the module

without having to power down the hub.

■ Scalable network management architecture – Enables you to

gather Ethernet and Remote Network Monitoring (RMON) network

statistics for any of the CoreBuilder 5000 backplane segments.

Includes up to two Network Monitor Cards (NMC) per module for in

depth monitoring of the network.

In addition, both modules support Repeater Management

Information Base (MIB) statistics without the need for a network

monitor card.

Page 19

CoreBuilder 5000 Ethernet 20/40-Port Module Benefits 1-3

CoreBuilder 5000

Ethernet

20/40-Port Module

Benefits

The CoreBuilder 5000 Ethernet 20/40-Port 10BASE-T Module provides

the following benefits:

■ Provides per-port switching to all eight of the CoreBuilder 5000

backplane segments and isolated segments. Supports up to eight

segments, simultaneously, in any combination.

■ Provides IEEE Repeater statistics gathering for monitoring of the

CoreBuilder 5000 hub’s security and network management

architecture.

■ Offers high port density at a low cost per port.

■ Supports up to 100 meters on 10BASE-T-compliant unshielded

twisted pair (UTP) wiring as well as shielded twisted pair (STP)

wiring.

■ Supports the CoreBuilder 5000 Private Line Card for private Ethernet

conversations.

■ Maintains inventory information for the 20/40-Port module in

non-volatile RAM (NVRAM). Information includes the module serial

number, power requirements, power class settings (for example,

powerup priority), and date of manufacture and a user note pad for

entering installation-specific information.

■ Supports CoreBuilder 5000 hub power management architecture

which enables administrators to prioritize the allocation of power to

modules.

Page 20

1-4 INTRODUCTION

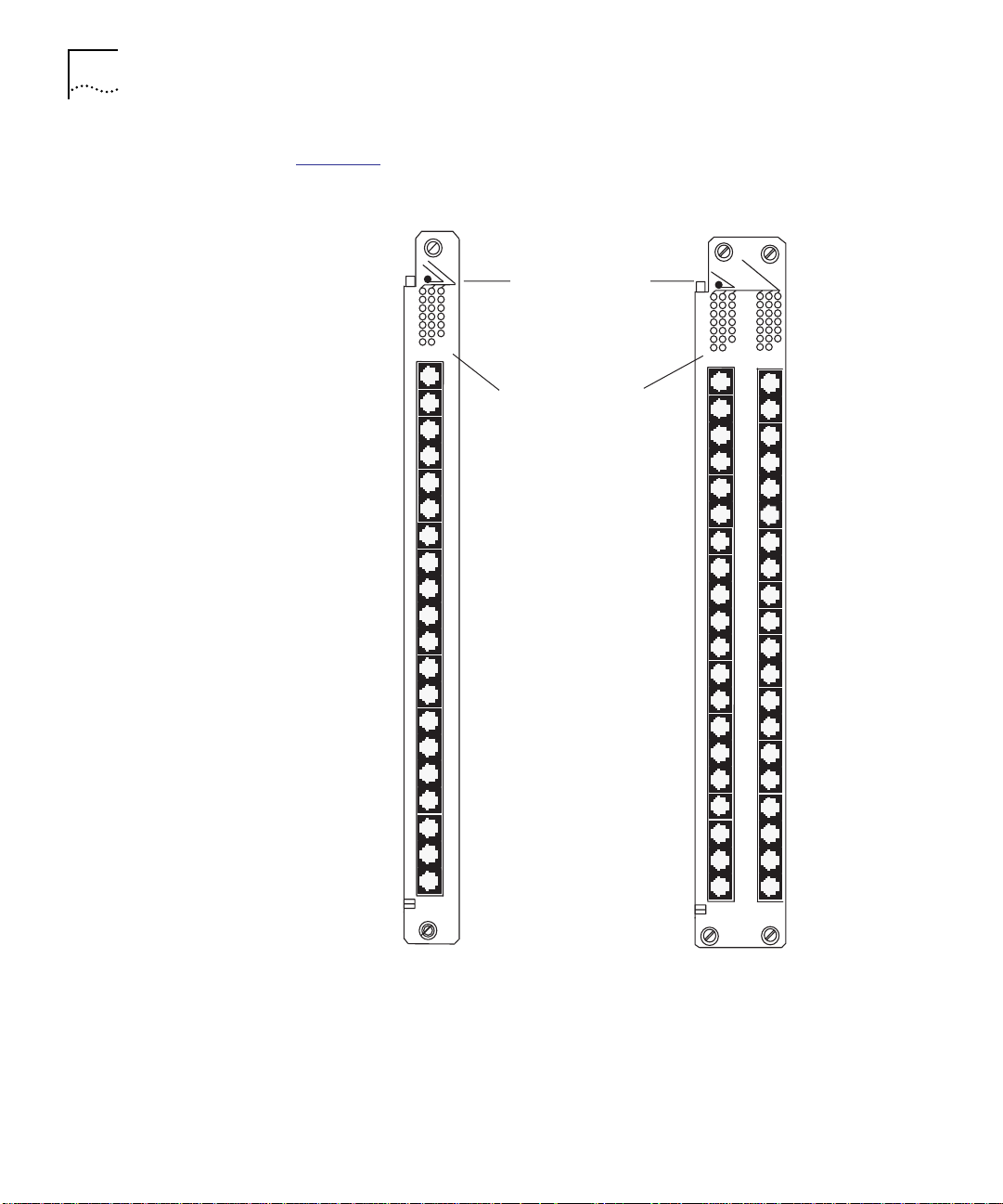

Figure 1-1 illustrates the CoreBuilder 5000 Ethernet 20-Port and

40-Port 10BASE-T Modules.

RJ-45

(ports 1 to 20)

1X

2X

3X

4X

5X

6X

7X

8X

9X

10X

11X

12X

13X

14X

15X

16X

17X

18X

19X

20X

1

4

7

10

13

16

19

10BASE-T

E20PS-TP

TRAFFIC STA

MOD STA

2X

3X

4X

5X

6X

7X

8X

9X

10X

11X

12X

13X

14X

15X

16X

17X

18X

19X

20X

Module Status LED

Bi-Color Port

Status/Activity LEDs

TRAFFIC STATUS

MODULE

STATUS

1

21

4

24

7

27

10

30

13

33

16

36

19

39

21X

1X

2X

2X

22X

23X

3X

3X

24X

4X

4X

25X

5X

5X

26X

6X

6X

27X

7X

7X

28X

8X

8X

29X

9X

9X

30X

10X

10X

31X

11X

11X

12X

12X

32X

13X

33X

13X

34X

14X

14X

35X

15X

15X

16X

16X

36X

17X

17X

37X

38X

18X

18X

39X

19X

19X

40X

20X

20X

RJ-45

(ports 1 to 40)

Figure 1-1 CoreBuilder 5000 Ethernet 20-Port and 40-Port Module

Page 21

CoreBuilder 5000 Ethernet 20/40-Port Module Benefits 1-5

20-Port Sample

Module Application

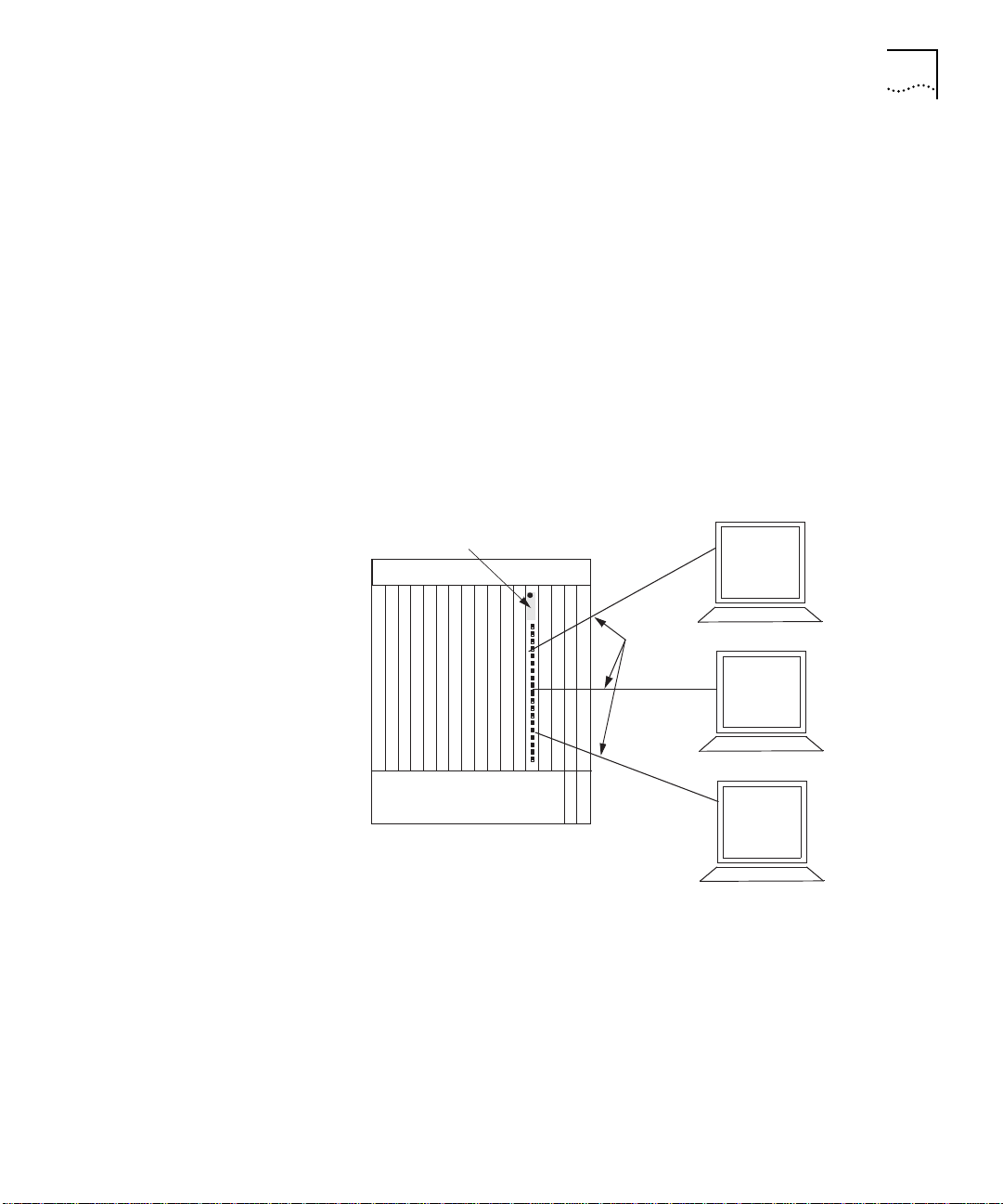

This section describes a sample application for the 20-Port module.

Attaching either CoreBuilder 5000 Ethernet 10BASE-T Module directly

to the hub using an RJ-45 cable provides the following connections:

■ 20-Port Module – Provides 20 twisted pair ports

■ 40-Port Module – Provides 40 twisted pair ports

You can attach the CoreBuilder 5000 Ethernet 20-Port 10BASE-T

Module using an RJ-45 cable directly to the hub which provides

connections for the 20 twisted pair ports. The CoreBuilder 5000

Ethernet 40-Port 10BASE-T Module has the same application except the

40-Port module offers an additional 20 ports and occupies a second

slot.

20-Port module

CoreBuilder 5000 hub

RJ-45 cables

Figure 1-2 Typical 20-Port Module Application

Page 22

1-6 INTRODUCTION

Theory of Operation

Where to Go From Here

The CoreBuilder 5000 Ethernet 10BASE-T 20/40-Port Module offers a

solution for customers utilizing RJ-45 connectors in their 10BASE-T

installation.

Both modules offer:

■ Per-port switching connectivity for STP and UTP 10BASE-T networks

■ Support for network monitoring and private line cards

■ Easy configuration using the CoreBuilder 5000 Manager

■ 20 or 40 twisted pair Ethernet ports which you can switch

individually to any of the 8 CoreBuilder 5000 backplane channels or

8 extended segments in any combination of 8

Once you are familiar with the CoreBuilder 5000 Ethernet 20/40-Port

10BASE-T Module, evaluate the environment in which you plan to use

the module and go to Chapter 2. Chapter 2, Designing and Expanding

the Network, describes cabling considerations and configuration

examples specific to the 20/40-Port module in the CoreBuilder 5000

hub.

Page 23

DESIGNING AND EXPANDING THE

2

NETWORK

This chapter describes how to configure networks that use the

CoreBuilder 5000 hub and the CoreBuilder 5000 Ethernet 20/40-Port

10BASE-T Module.

This chapter contains the following topics:

■ Understanding General Network Configuration Rules

■ Configuring Fiber Backbone, Twisted Pair to-the-Desk

■ Configuring Twisted Pair Backbone, Twisted Pair to-the-Desk

■ Using Patch Panels

■ Using Module Workgroups

■ Setting Redundant Links

■ Where to Go From Here

CAUTION: To ensure proper operation, install all equipment using only

approved cables. Refer to Appendix A, Specifications, for information

on twisted pair connector and cable requirements.

Understanding General Network Configuration Rules

This section describes general rules for configuring an Ethernet network

using fiber as the backbone medium, and twisted pair as the horizontal

medium. It also provides rules to ensure that your network

configuration conforms to distance limitations imposed by Ethernet and

networking equipment.

The following topics are discussed:

■ Before Configuring Your Network

■ Basic Network Rules

■ LAN Product Distances

Page 24

2-2 DESIGNING AND EXPANDING THE NETWORK

Before Configuring

Before configuring your network, consider your:

Your Network

■ Network size from end-to-end. Is it:

■ 100 meters

■ 1000 meters

■ 4000 meters

■ Greater than 4000 meters

■ Plans for expansion. Once the network expands beyond a certain

size, you may need to add a switch or an additional internetworking

device.

Basic Network Rules Table 2-1

■ The seven basic network rules to keep in mind when you construct

your network

■ 3Com recommendations for these rules

For hardware-specific information on the 20/40-Port module, refer to

Appendix A, Specifications.

Table 2-1 Seven Basic Network Rules

lists:

Rule Definition Recommendations/Notes

1 If possible, use 10BASE-FB

as the backbone medium.

Use 62.5 micron cable to conform with

IEEE 10BASE-F and ANSI FDDI standards.

Use ST-type connectors.

2 Wire the backbone in a star

topology for proper fault

isolation.

Make sure to lay extra fiber cables. The

extra cost is small and you need them as

your network grows.

The star topology conforms to Ethernet

and FDDI wiring. Ensure that you run at

least two FDDI fiber strands to each

backbone connection.

Page 25

Understanding General Network Configuration Rules 2-3

Table 2-1 Seven Basic Network Rules (continued)

Rule Definition Recommendations/Notes

3 The maximum fiber Ethernet

network diameter is

4200 meters of fiber cable.

4 Certain LAN devices on the

network shrink the

maximum Fiber Ethernet

network diameter to less

than 4200 meters.

5 Assume that 1 meter of

coaxial or twisted pair cable

is equal to 1 meter of fiber

cable.

6 The fiber link distances must

not exceed the limits

imposed by the optical

power budget.

7 When in doubt, use a switch

or bridge.

4200 meters is the maximum distance

between any two transceivers on the

network.

4200 meters does not include the

transceiver cable (that is, drop or patch

cable) that connects a device with an

external transceiver. Transceiver cables

can extend up to 50 meters. Thus, total

network diameter can be as much as

4300 meters (4200 m + 2 * 50 m)

between any two nodes.

Many LAN products delay the signal that

travels through them. This is known as

equivalent distance. Each microsecond

delay:

Reduces the maximum link distance

Shrinks the network diameter by

approximately 200 meters of fiber

cable

Table 2-2

3Com products.

A conservative rule. For example, the

actual equivalence is about 1.1 meters of

coaxial for each meter of fiber. For

simplicity, assume 1 meter.

For 62.5 micron cable, you can utilize up

to 4000 meters point-to-point using the

CoreBuilder 5000 or ONline fiber

modules. If you have poor quality cable or

cross several patch panels, you may have

to sacrifice some distance in cable length.

Some older Ethernet fiber optic products

are less powerful than CoreBuilder 5000

fiber module optics. If connecting to an

Ethernet fiber optic product, remember

that the least powerful device determines

the maximum point-to-point distance.

If you are not certain if you have

exceeded allowable network distances,

use a bridge to extend the network.

lists Equivalent Distances for

Page 26

2-4 DESIGNING AND EXPANDING THE NETWORK

LAN Product

Distances

When you configure your network, each product requires a different

LAN equivalent distance. LAN equivalence is the sum of the incoming

and outgoing module port signals. 3Com product modules have

different LAN equivalent distances. Ta b le 2 -2

lists the LAN product

equivalent distances required for each LAN product.

Table 2-2 LAN Product Equivalent Distances

Equivalent

LAN Product

CoreBuilder 5000 and ONline Ethernet 10BASE-T Modules 585

Incoming signal to TP port 420

Outgoing signal from TP port 165

CoreBuilder 5000 and ONline Ethernet 10BASE-FB Modules 190

Incoming signal to fiber port 140

Outgoing signal from fiber port 50

ONline Ethernet FOIRL Module 560

Incoming signal to fiber port 330

Outgoing signal from fiber port 230

ONline Ethernet Transceiver Module 0

ORnet Star Coupler (8 or 14 port) 180

ONline Ethernet BNC Module 900

Incoming signal to BNC port 450

Outgoing signal from BNC port 450

ONline Ethernet Repeater Module 800

Incoming signal to AUI port 600

Outgoing signal from AUI port 200

IEEE Repeater 800

Distance (meters)

Page 27

Configuring Fiber Backbone, Twisted Pair to-the-Desk 2-5

Configuring Fiber

Backbone, Twisted

Pair to-the-Desk

Fiber Backbone

Configuration Rules

This section describes:

■ Fiber Backbone Configuration Rules

■ Fiber Backbone Configuration Verification

■ Fiber Backbone Configuration Verification

When you configure a network with unshielded twisted pair cabling to

the desk and fiber for the backbone, the following rules apply:

■ Add a bridge if you will exceed 4 full repeater hops.

■ If traffic travels into a port on any repeater-based module and out

the backplane, then the module counts as a ½-repeater hop.

■ If traffic travels into the module through one port and out another

port on the same or a different module, then the module counts as

1 full repeater hop.

■ The equivalent fiber distance for the 3Com Ethernet 10BASE-FB

Modules (see Table 2-1

■ 140 meters for signals that enter a 10BASE-FB module port at the

, Rule 4) is:

front panel.

■ 50 meters for signals that internally enter a 10BASE-FB module

through the CoreBuilder 5000 hub backplane.

■ The equivalent fiber distance for the 20/40-Port modules

(see Table 2-1

■ 420 meters for signals that enter the 20/40-Port module port at the

, Rule 4) is:

front panel.

■ 165 meters for signals that internally enter a 20/40-Port module

through the CoreBuilder 5000 hub backplane.

For each pair of 20/40-Port modules that a signal travels through,

deduct a fiber equivalent distance of 585 meters (420 m + 165 m =

585 m) from the overall allowable network diameter. You must also

deduct fiber equivalent distance if a signal enters the 20/40-Port

module through one port and exits another port of the same

20/40-Port module. The fiber equivalent distance counts as 585 meters

of fiber equivalent distance, and as a full repeater hop.

Page 28

2-6 DESIGNING AND EXPANDING THE NETWORK

Configuration

Example of Fiber

Backbone, Twisted

Pair to-the-Desk

Fiber

backbone

1000 m

The sample configuration shown in Figure 2-1

illustrates how to

determine if the transceivers are within legal Ethernet distance limits.

The 24-gauge unshielded twisted pair cable is used to connect

10BASE-T Transceivers to the 20/40-Port modules in the hubs.

500 m

Fiber backbone

Hub A

Hub B

Hub C

Unshielded twisted pair

100 m

75 m

A

Unshielded twisted pair

B

Unshielded twisted pair

Configuration Distance

1. Maximum Diameter:

2. Equivalent Distances:

Hub A:

Hub B:

Hub C:

Total:

3. Amount of cable between

transceivers:

Total:

4. Remaining Distance:

470 m

305 m

190 m

965 m

1000 m

100 m

500 m

75 m

4200 m

1675 m

1560 m

C

Fiber Backbone

Configuration

Verification

Figure 2-1 Sample Configuration Distance Calculation

To determine if your network configuration is legal:

1 Identify the two transceivers that are the greatest fiber equivalent

distance apart. In Figure 2-1

, 10BASE-T transceivers A and B are the

farthest apart.

2 Set aside 4.2 km (4200 m) because this is the maximum network

diameter for a pure fiber network (Table 2-1

, Rule 3).

Page 29

Configuring Twisted Pair Backbone, Twisted Pair to-the-Desk 2-7

3 Determine the sum of each hub’s equivalent distance based on the

figures in Table 2-2

. For example, Hub A has an equivalent distance of

470 m. This total represents the sum of the incoming signal to the UTP

port (420 m) and the outgoing signal from the fiber port (50 m). Refer

to Figure 2-1

for details.

4 Subtract the total equivalent distance of each hub located between

transceivers A and B [inclusive (965 m)] from the maximum network

diameter (4200 m). In this case, the subtotal is 3235 m.

5 Determine the total amount of cable between transceivers A and B

(1675 m) and subtract this number from the subtotal determined in

step 4 (3235 m).

The remaining distance for legal expansion equals 1560 m.

Configuring

Twisted Pair

Backbone, Twisted

Pair to-the-Desk

Twisted Pair

Backbone

Configuration Rules

For the configuration shown in Figure 2-1

to function properly, the fiber

equivalent distance between Transceiver A and Transceiver B must be

less than 4200 meters. As a result of the calculation above,

1560 meters remain for expansion.

This section describes:

■ Twisted Pair Backbone Configuration Rules

■ Configuration Example of Twisted Pair Backbone, Twisted

Pair-to-the-Desk

When you configure a network with unshielded twisted pair cabling to

the desk and twisted pair for the backbone, the following rules apply:

■ Add a bridge if more than eight 20/40-Port modules are serially

connected. Each bridge creates a subnetwork. Each subnetwork can

have its own 4200 meter network diameter.

■ No more than eight 20/40-Port modules can be in the path between

any two transceivers due to Ethernet's four-repeater rule.

■ If traffic travels into a port on any repeater-based module and

out the backplane, the module counts as a ½-repeater hop.

■ If traffic travels into the module through one port and out

another port on the same or a different module, the module

counts as 1 full repeater hop.

Page 30

2-8 DESIGNING AND EXPANDING THE NETWORK

Configuration

Example of Twisted

Pair Backbone,

Twisted

Pair-to-the-Desk

Figure 2-2 illustrates an unshielded twisted pair network using

24-gauge cable.

B

100 m

100 m

Figure 2-2 Unshielded Twisted Pair Network

C

100 m

A

100 m

D

50 m

Although there is no fiber in the configuration illustrated in Figure 2-2,

you can calculate the fiber equivalent distance as follows:

1 Total amount of cable between workstations:

100 m + 100 m + 100 m + 100 m + 50 m = 450 m.

2 Total equivalent distance of the 20/40-Port modules:

Each hub has an equivalent distance of (420 m + 165 m) or 585 m

Four hubs with a total equivalent distance of (585 m * 4) or 2340 m

exist.

3 Total equivalent distance: 450 m + 2340 m = 2790 m.

1

Incoming signal to the UTP port on each hub = 420 m. Outgoing

signal from the UTP port on each hub = 165 m. Refer to Table 2-2

more information on LAN product equivalent distances.

Although the unshielded twisted pair network example in Figure 2-2

only uses 20/40-Port modules, it is also possible to use other 10BASE-T

modules.

1.

for

Page 31

Using Patch Panels 2-9

Because the total equivalent distance (2790 m) is less than

4200 meters, Figure 2-2

illustrates a legitimate configuration.

Using Patch Panels Patch panels make cable management easier when used in a

rack-installed hub. However, patch panels weaken signals that pass

through them, thereby reducing achievable link distances. 3Com

assumes the use of one patch panel in the 100 meter link distance

calculations specified in this guide. Each additional patch panel in the

link reduces the 100 meter link distance by approximately 10 meters.

Using Module Workgroups

In the example shown in Figure 2-2

, if you use two patch panels

between the top right PC and the top right hub, you must shorten the

link distance of 100 meters to 90 meters. This is because the maximum

allowable link distance on 24-gauge wire (using 10BASE-T signaling

with two intervening patch panels) is 100 meters minus approximately

10 meters.

A patch panel installed between the bottom right PC and the bottom

left hub does not affect the link because it is only 50 meters away.

Patch panels only affect lengths greater than 90 meters.

When you set up a 20/40-Port module as a fully configured workgroup

module, you are configuring a logical network that supports up to

eight workgroups (isolated networks) per module. Because a managed

CoreBuilder 5000 hub may contain as many as 16 CoreBuilder 5000

20-Port modules or eight CoreBuilder 5000 40-Port modules, it is

possible to configure your hub with a maximum of 128 workgroups.

This section describes:

■ Workgroup Definition

■ Dividing the Network into Workgroups

Workgroup

Definition

Workgroups are individual groups set up to divide your network layout

into smaller isolated networks.

Page 32

2-10 DESIGNING AND EXPANDING THE NETWORK

Workgroups:

■ Enable administrators to have more flexibility in organizing their

network.

■ Decrease the amount of traffic on the backplane segments of the

hubs in which the workgroups reside.

By creating module workgroup networks instead of separate backplane

segment networks, you can configure a maximum of 128 workgroups

per hub using little or no backplane traffic.

Although the CoreBuilder 5000 Ethernet 20/40-Port 10BASE-T Module

has access to eight backplane and eight isolated segments, the module

only supports per-port switching to eight segments simultaneously.

Dividing the Network

into Workgroups

The following example shows how workgroups help administrators to

efficiently organize users in their network.

Workgroup Example

Network administrator Jane Smith plans to reorganize the development

and support organizations in her company by dividing each department

within those organizations into separate workgroups. Currently, each

organization is connected to separate backplane segments (Figure 2-3

Backplane Segment 6

Backplane Segment 5

Backplane Segment 4

Hub C

Engineering

Technical

Support

Development

Organization

Marketing

Technical

Publications

Support

Organization

).

Figure 2-3 Typical Corporate Organizational Structure

Page 33

Using Module Workgroups 2-11

To divide the sample network into workgroups, Smith works as follows:

1 After studying each department’s needs, Smith decides to:

■ Create separate workgroups for each department within the two

organizations

■ Connect the workgroups to each other through an internal

bridge

Table 2-3

describes the reorganization of each department.

Table 2-3 Sample Network Reorganization

Module

Ethernet

Department

Engineering

Department

Technical

Support

Marketing 20-Port 1 WG4 2 to 20

Technical

Publications

2 As Ta b le 2 - 3

Module Type

20-Port 3 WG2 1 to 9

20-Port 6 WG3 1 to 18

20-Port 8 WG1 1 to 7

indicates, Smith assigns four organizations within her

Slot step

next

Workgroup

step next

company into separate workgroup numbers (WG1 to WG4). The

workgroups can share resources and communicate with each other

without using the hub backplane. Figure 2-4

illustrates each workgroup

configuration.

Ports Used

Page 34

2-12 DESIGNING AND EXPANDING THE NETWORK

Hub C

BR

Slot 4

1

2

3

4

5

WG2

6

7

8

9

10

WG4

KEY

WG = Module Workgroup Network (where x is the workgroup number)

BR = Internal Bridge

= Port allocated to internal bridge

11

12

13

14

15

16

17

18

19

20

Slot 1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Slot 3 Slot 6

WG3

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

WG1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Slot 8

= Workgroup

Figure 2-4 20-Port Module Workgroup Port Allocation

To enable all of the workgroups to communicate with other networks,

administrator Smith must connect at least one port per workgroup to

the bridge (see Figure 2-4

).

Page 35

Setting Redundant Links 2-13

By dividing the network into workgroups, Smith:

■ Increases the available number of backplane resources

■ Decreases overall backplane traffic

Setting Redundant Links

3 In Figure 2-4

, Smith configures four separate workgroups (WG1 to

WG4) and connects the workgroups to each other using an internal

bridge module (such as the CoreBuilder 5000 Multiprotocol Switching

Module).

The advantages of the configuration in Figure 2-4

■ Networks configured as module workgroups provide greater

include:

network capacity (8 backplane networks and 128 module

workgroup networks)

■ Network configuration is more flexible because workgroups can

communicate with other networks

■ Less backplane traffic because communication between each

department is isolated from the hub backplane

If Smith configured each workgroup on separate backplane segment

networks instead of separate module workgroup networks, 6 of the

hub’s 8 backplane segments would have been isolated from the rest of

the network.

When you set up a redundant twisted pair link between ports on

CoreBuilder 5000 hubs, you prevent a network failure. Figure 2-5

shows two examples of a redundant configuration.

It is also possible to enable redundancy between ONline modules in a

CoreBuilder 5000 hub.

Page 36

2-14 DESIGNING AND EXPANDING THE NETWORK

CoreBuilder 5000 hub

40-Port

module

Redundancy set up between two

ports on the same module

Figure 2-5 Redundant Twisted Pair Configuration

RJ-45

Twisted pair cable

CoreBuilder 5000 hub

20-Port

module

Redundancy set up between two

ports on different modules

Setting Redundancy Between Two Ports on One 40-Port Module

To set link redundancy between two ports on one 40-Port module:

1 To connect two links to two ports on the module using the SET PORT

{slot.port} MODE REDUNDANT {slot.port} network management

command.

2 Specify the primary link port and the backup link port.

For example, if you set up a redundant link using the following

command:

SET PORT 8.5 MODE REDUNDANT 8.7

Port 5 in slot 8 becomes the primary link and port 7 in slot 8 becomes

the backup link.

Page 37

Setting Redundant Links 2-15

Setting Redundancy Between Ports On Two 20/40-Port Modules

To set link redundancy between one 20-Port and one 40-Port module:

1 To connect two links to two ports between the modules using the SET

PORT {slot.port} MODE REDUNDANT {slot.port} network management

command.

2 Specify the primary link port and the backup link port.

For example, if you set up a redundant link using the following

command:

SET PORT 12.4 MODE REDUNDANT 8.9

Port 4 in slot 12 becomes the primary link and port 9 in slot 8 becomes

the backup link.

CAUTION: Setting redundancy on the 20/40-Port module is a

management module software function. Consequently, a network loop

could occur if the module is set to redundant mode and it is powered

off and then on without a 3Com distributed management module in

the hub.

Once you configure redundancy:

1 A switchover to the backup link occurs under two conditions:

■ Link failure

■ Port partition

2 Once the switchover occurs and the backup link becomes operational,

the system performs a switchover back to the primary link automatically

once the problem is resolved.

Although you can configure redundancy between two ports on a single

module, you should configure redundancy between two ports on two

different modules. This provides additional protection if, for example,

one of the modules becomes inoperative.

Refer to the CoreBuilder 5000 Distributed Management Module User

Guide for more information on setting redundancy between

20/40-Port module ports.

Page 38

2-16 DESIGNING AND EXPANDING THE NETWORK

Where to Go From Here

Once you complete this chapter, go to Chapter 3. Chapter 3, Installing

and Operating the Module, describes installation procedures and

explains how to set the DIP switches, configure the module through

network management, and monitor the front panel using the LEDs.

Page 39

INSTALLING AND OPERATING THE

3

MODULE

This chapter describes the installation of the CoreBuilder 5000

Ethernet 20/40-Port 10BASE-T Module.

A module reference card for the 20-Port module (Document

Number 17-00542) or a 40-Port module (Document Number 17-00523)

lists the DIP switch settings, 20/40-Port module management

commands, LED indicators, and other module information. Store the

card in the CoreBuilder 5000 reference binder in the Reference Card

area.

This chapter contains the following topics:

■ Precautionary Procedures

■ Unpacking Procedures

■ Quick Installation

■ Setting DIP Switches

■ Installing the Module

■ Configuring the Module

■ Showing Module Configurations

■ Attaching the Network Monitor Card

■ Gathering Statistics

■ Monitoring the Front Panel

■ Verifying LEDs and the Network

Read the precautionary procedures before unpacking the module.

Page 40

3-2 INSTALLING AND OPERATING THE MODULE

Precautionary Procedures

Unpacking Procedures

Electrostatic discharge (ESD) can damage static-sensitive devices on

circuit boards. Follow these precautions when you handle the

20/40-Port module.

CAUTION: Do not remove the board from its antistatic shielding bag

until you are ready to inspect or install it.

CAUTION: Handle the board by the faceplate only.

Use one of the following proper grounding techniques when you install

the 20/40-Port module:

■ Use a foot strap and grounded mat or wear a grounded static

discharge wrist strap

■ Touch the grounded rack or other source of ground just before you

handle the module

To unpack the 20/40-Port module:

1 Verify that the 20-Port module (Model Number 6120M-TPP) is the

model you ordered by checking the Model Number listed on the side of

the shipping carton. Repeat this step for the 40-Port module (Model

Number 6140M-TPP).

Note that the product model number printed on the shipping box

differs from the model number on the product. The model number on

the shipping box contains the prefix ’3C9’.

2 Remove the 20/40-Port module, in its antistatic bag, from the shipping

carton.

3 Remove the module from the antistatic shielding bag and inspect it for

damage.

Always handle the 20/40-Port module by the faceplate, being careful

not to touch the components. If the module appears to be damaged,

return it to the antistatic shielding bag, repack it in the shipping carton,

and contact your local supplier.

Keep the shipping carton and antistatic shielding bag in which your

module was shipped for future storage or shipment.

Page 41

Quick Installation 3-3

Record the serial number of your 20/40-Port module. The Hub Planning

Chart, located in the CoreBuilder 5000 reference binder, and the

module Planning Chart supplied with your module, are provided for this

purpose.

Quick Installation Table 3-1 outlines the steps for the installation of your module. If you

are familiar with installing CoreBuilder 5000 modules, use this table as

a checklist. Otherwise, consult the remainder of this chapter.

Table 3-1 Quick Installation Checklist

Step Procedure Chapter/Section

1 Verify that your network complies with the

basic rules for network design.

2 Unpack the module. Chapter 3, Unpacking

3 Configure the DIP switch settings. If you

have a network management module

installed in the hub, configure the module

using the management commands

described later in this chapter.

4 Enter the SHOW POWER1 command at the

5 Insert a 20-Port module into one open slot

6 Establish connections from the 20/40-Port

7 Verify LED status for normal operation. Chapter 3, Verifying LEDs

1

Refer to the CoreBuilder 5000 Integrated System Hub Installation and Operation Guide for

command line of the terminal. This

command displays current power

requirements for the hub.

or insert a 40-Port module into two

adjacent slots in the hub. Fasten the ejectors

and tighten the faceplate screws.

module to devices using the appropriate

connectors and cabling.

details on hub power requirements.

Chapter 2, Designing and

Expanding the Network

Procedures

Chapter 3, Setting DIP

Switches or Configuring

the Module

Chapter 3, Installing the

Module

Chapter 3, Installing the

Module

Chapter 3, Installing the

Module

and the Network

For information about potential problems, consult the troubleshooting

techniques in Chapter 4

.

Page 42

3-4 INSTALLING AND OPERATING THE MODULE

Setting DIP Switches

If you are using a management module and do not plan to use the DIP

configuration command, skip this section and proceed to Installing the

Module on page 3-7.

The CoreBuilder 5000 Ethernet 20/40-Port 10BASE-T Module has an

8-position DIP switch.

Using DIP Switches Use the DIP switch to:

■ Select a network for all ports on the 20-Port module or 40-Port

module

■ Configure all 20 or 40 ports of the module into one workgroup or

module segment

■ Choose the primary module configuration:

■ Non-volatile RAM configuration (software configuration)

■ DIP segment selection (DIP-specified module configuration)

You cannot assign ports to different networks using the DIP switches

on the 20/40-Port module. You must use network management

commands.

Use network management commands, rather than the DIP switches, to

configure the module. All of the DIP switch settings on the 20/40-Port

module are ignored if an appropriate CoreBuilder 5000 Distributed

Management Module (DMM Version v2.0 or later, for example) is

already installed in the hub.

Setting the DIP

Switches

To set the module to access the DIP switch settings when using a

management module, issue the SET DEVI CE DIP_CONFIGURATION

command from the management module.

If you do not have a CoreBuilder 5000 Distributed Management

Module installed in your hub, your hub configuration defaults to the

DIP switch settings on the module.

Page 43

Setting DIP Switches 3-5

Figure 3-1 shows the DIP switch locations on the module.

12345678

DIP switches

Off

12345678

0

1

On

Setting s

CH SEL 0

CH SEL 1

CH SEL 2

ISOLATE

NVRAM

NOT USED

NOT USED

NOT USED

Backplane DIN

connector

Figure 3-1 20/40-Port Module and DIP Switch Location

DIP Switch Definition Table 3-2 briefly describes the DIP switch settings. Each DIP switch

function is defined in Configuring the Module

Table 3-2

■ Switches 1 through 4 enable you to configure all ports for one of

lists DIP Switches 1 through 4.

on page 3-10.

the backplane segments (Ethernet 1 to Ethernet 8) or as a

workgroup (Isolate_1).

■ DIP Switch 5 enables you to switch between Non-volatile RAM

(NVRAM) or DIP-switch controlled configuration.

■ Switches 6, 7, and 8 are not used.

Page 44

3-6 INSTALLING AND OPERATING THE MODULE

Table 3-2 Channel Select DIP Switch Settings

Network

Selection

1 (default) Off Off Off Off

2 Off Off Off On

3 Off Off On Off

4 Off Off On On

5 Off On Off Off

6 Off On Off On

7 Off On On Off

8 Off On On On

Isolate_1 On x x x

1

By default, Switch 5 is set to NVRAM. When enabled, settings stored in NVRAM take

precedence over DIP Switch settings 4 through 1.

The DIP switch legend on the module refers to the backplane

connection as the channel selection (CH SEL). The channel setting and

the network setting are the same. Ports set to the same network

communicate with each other. If the switch labeled ISOLATE is ON, it

sets the module to Isolated_1.

Switch Settings

Switch 4 Switch 3 Switch 2 Switch 1

1

When the 20/40-Port module is first installed, the hub checks for

configuration settings in the DMM.

If:

The hub is unmanaged, then the 20/40-Port module checks for

configuration settings stored in NVRAM

There are no configuration settings in NVRAM or DIP Switch 5 is set to

DIP-switch controlled configuration, the 20/40-Port module checks the

DIP switches for configuration information

Page 45

Installing the Module 3-7

Installing the Module

You do not need to power off the CoreBuilder 5000 hub to install or

remove the 20/40-Port module. You can insert the module while the

hub is operating (this is called a hot swap).

To install the 20/40-Port module:

1 Use one of the following proper grounding techniques when you install

the 20/40-Port module:

■ Properly ground yourself prior to handling the 20/40-Port

module.

■ Attach a static wrist guard to yourself or touch a grounded static

mat prior to handling the 20/40-Port module.

2 Configure the 20/40-Port module:

■ If you plan to install the 20/40-Port module in a managed hub

(for example, DMM Version v2.0 or later), go to step 3 to

complete the installation. To configure the appropriate settings,

go to Configuring the Module

■ If you plan to insert the 20/40-Port module in an unmanaged

on page 3-10.

hub, configure the DIP switch settings on the module to the

desired settings (see Setting DIP Switches

on page 3-4 and go to

step 4.

3 To determine if the hub has enough power for the new module, from

the DMM command line, enter the SHOW POWER BUDGET command.

Refer to Appendix A, Electrical Specifications

, for detail on power

requirements for each of the specified watts ranges.

Refer to the Distributed Management Module Commands Guide for

information on the SHOW POWER BUDGET command.

4 Locate an open slot in the hub. You need:

■ One slot for the 20-Port module

■ Two slots for the 40-Port module

Remove the appropriate number of blank panels on the hub to expose

a slot for the module.

5 Insert the module into the board guides at the top and bottom of the

slot and slide it into the hub by pressing firmly at the top and bottom

of the faceplate. Figure 3-2

shows the installation of the module.

Page 46

3-8 INSTALLING AND OPERATING THE MODULE

Figure 3-2 Installing a CoreBuilder 5000 Module

Page 47

Installing the Module 3-9

6 Close the 20/40-Port module ejectors (Figure 3-3).

Open ed

Figure 3-3 Opened and Closed Module Ejectors

Clos ed

7 Fasten the spring-loaded screws on the front of the 20/40-Port module

faceplate to the hub using your fingers (do not overtighten).

8 Attach a twisted pair cable to the RJ-45 connectors on the front of the

module (Figure 3-4

).

Page 48

3-10 INSTALLING AND OPERATING THE MODULE

CoreBuilder 5000 hub

TRAFFIC STA

MOD STA

1

4

7

10

13

16

19

1X

2X

2X

3X

10X

11X

12X

13X

14X

15X

18X

19X

20X

4X

5X

6X

7X

8X

9X

16X

17X

3X

4X

5X

6X

7X

8X

9X

10X

11X

12X

13X

14X

15X

16X

17X

18X

19X

10BASE-T

E20PS-TP

RJ-45 connector

20X

2X

2X

2X

3X

3X

3X

4X

4X

4X

5X

5X

5X

6X

6X

6X

7X

7X

7X

8X

8X

8X

9X

9X

9X

10X

10X

10X

11X

11X

11X

12X

12X

12X

13X

13X

13X

14X

14X

14X

15X

15X

15X

16X

16X

16X

17X

17X

17X

18X

18X

18X

19X

19X

19X

20X

20X

20X

Configuring the Module

Figure 3-4 20-Port Module Cable Connection

This section describes how to configure the module using network

management commands.

The CoreBuilder 5000 Distributed Management Module (DMM)

provides network management for the CoreBuilder 5000 hub and its

modules. Use network management commands, rather than the DIP

switches, to configure the module. All of the DIP switch settings on the

20/40-Port module are ignored if an appropriate CoreBuilder 5000

Distributed Management Module (DMM Version v2.0 or later) is already

installed in the hub.

Page 49

Configuring the Module 3-11

Do not manage (get statistics or configure) this module from a slave

management module.

If network management is present when you first install the module,

the network defaults to isolated mode and the ports are automatically

disabled (so that users cannot join the network undetected by network

management). Therefore, you must enable the ports you wish to use

and set the module ports to the appropriate network using

management commands.

Use network management commands to configure the following

20/40-Port module features:

■ Enable/Disable/ Shutdown Ports

■ Set Port Redundancy

■ Set Remote Diagnostics

■ Enable/Disable Link Integrity

■ Set Alert Filter

Enable/Disable/

Shutdown Ports

■ Set Auto Polarity

■ Set Port Squelch

■ Network Selection

For additional information on network management commands refer to

the CoreBuilder 5000 Distributed Management Module Commands

Guide.

This command allows you to enable, disable, and shutdown each port

on the 20/40-Port module.

When a port is set to:

■ Enable – It transmits to and receives data from the network to

which the port is assigned.

■ Disable – It does not transmit or receive data. (Link Integrity is

unaffected.)

■ Shutdown – It turns off link integrity and the transmitter. The port

responds with status OFF at the terminal.

Page 50

3-12 INSTALLING AND OPERATING THE MODULE

Use the following command to enable, disable, or shutdown a port:

SET PORT {

slot .por t

{

slot

} MODE {disa ble}

.all} {enab le}

{shutdown}

Set Port Redundancy This command allows you to set redundancy between ports. When

you set two ports redundant to each other, the secondary port takes

over if the primary port fails.

Use the following command to set redundancy between ports:

SET PORT {

slot.port

} MODE {redundant} {

{non -red un dant }

slot.p or t

}

Refer to the section in Chapter 2, Setting Redundant Links, for an

example of port redundancy.

Set Remote

Diagnostics

On the 20/40-Port module, a port you configure for Remote

Diagnostics will only transmit Link Integrity if it receives Link Integrity.

This allows the 20/40-Port module’s Remote Diagnostic feature to be

used in a redundant configuration to provide even more fault

tolerance (Figure 3-5

).

ONline or CoreBuilder 5000 hub

Primary

port

Backup

port

transmit

receive

transmit

receive

CoreBuilder 5000 hub

receive

transmit

receive

transmit

Diagnostic

20/40-Port

Remote

Remote

Diagnostic

20/40-Port

Figure 3-5 Remote Diagnostics Example

For example, if the primary port’s transmit link fails, the remote

diagnostic port on the 20/40-Port module will stop transmitting Link

Integrity. The primary port will then sense the link failure and switch

over to the backup port.

Page 51

Configuring the Module 3-13

Use the following command to set remote diagnostics:

Enable/Disable Link

Integrity

SET PORT {

slot.port

} MODE {REMOTE_DIAGNOSTICS} {

{NON _REM OT E_DI AGN OSTI CS }

slot.port

}

The last variable, slot.port, in the command above is optional. When

Remote Diagnostic mode is enabled, it is referred to as a buddy port.

This command allows you to enable or disable Link Integrity for all

ports on the 20/40-Port module in networks that comply with the

10BASE-T standard.

You should:

■ Disable Link Integrity only when connecting to older equipment

that does not comply with the 10BASE-T standard.

■ Enable Link Integrity for all ports on your 10BASE-T module. You

must enable link integrity at one end of the connection.

Use the following command to enable or disable link integrity for each

port on the module:

SET PORT {

slot.port

{

slot.

all} {disabl e}

} LINK_INTE GRIT Y {enable }

Set Alert Filter This command allows you to override the PORT FILTER feature on a

port-by-port basis. The Port Filter feature enables or disables the DMM

delivery of port up and port down traps. You can use this command to

continue to monitor port status on crucial ports (file servers, for

example), while alerts from other ports are disabled.

Configure Set Alert Filter to:

■ Enable – To use the Port Alert filtering feature.

■ Disable – To cause all port up and port down alerts to display.

Use the following command to enable or disable the port up and port

down alerts for a port:

SET PORT {

slot .por t

{

slot.

all} {ena ble}

} ALERT_FI LT ER {disa ble}

Page 52

3-14 INSTALLING AND OPERATING THE MODULE

The following output is an example of the SET PORT ALERT_FILTER

command issued for port 1 of a module in slot 1:

CB5000> set port 1.1 a lert_filter disable [ ENTER]

Port 01 .01 Alert Filter set to DISABLE.

The SET ALERT PORT_UP_DOWN FILTER command should be set

before you use SET ALERT FILTER command.

For more information on this command, refer to the Distributed

Management Module Commands Guide.

Set Auto Polarity This command enables the 20/40-Port module to automatically switch

the polarity of twisted pair cabling. If, for instance, you erroneously

reverse the polarity of some twisted pair cabling while assembling it,

Auto Polarity enables you to automatically detect this problem and

reverse the polarity.

Use the following command to enable Auto Polarity for a port:

SET PORT {

slot.port

{

slot.

all} {enable}

} AUTO_POLARITY {disable}

Set Port Squelch This command allows you to establish the squelch level as either

normal (high) or low (sensitive) for ports on Ethernet 10BASE-T

modules. The squelch level is factory set to ''normal'' to conform to the

10BASE-T standard.

There are two Squelch settings:

■ Low setting – Allows ports to receive weaker signals, allowing

longer distances. Increases the achievable link distance (with the

added risk of losing packets to impulse noise).

■ Normal setting – Allows ports to receive signals compliant with the

10BASE-T standard.

Use the following command to set Squelch Mode for a port:

SET PORT {

slot.port

{

slot.

all} {low}

} SQUELCH {normal}

Page 53

Configuring the Module 3-15

Network Selection This command provides port-level configuration flexibility using the

CoreBuilder 5000 hub's unique architecture. You can assign ports

collectively or individually, to any of 8 backplane segments or any of

the 8 isolated segments. Supports up to 8 segments simultaneously, in

any combination. Refer to the CoreBuilder 5000 Integrated System

Hub Installation and Operation Guide, Chapter 1, for a complete

discussion of the CoreBuilder 5000 hub architecture.

The DIP switch settings on the module refer to the backplane

connection as the “channel” selection (CH SEL). The channel setting

and the network setting are the same.

Assigning Ports On the Module to a Network

Use the DIP switch settings on the 20/40-Port module to assign all

ports (collectively) on the module to network 1 through 8 or to an

extended segment. Network management, however, lets you assign

one or more ports to a network.

Use the following command to assign a port to a network:

SET PORT {

slot.port

{

slot.

all} {isolated_1..._8}

} NETWORK {ethernet_1..._8}

Use this command to assign users to backplane segments or isolated

segments (workgroups). For instance, to create a module segment

workgroup, you must assign all of the users in the workgroup to one

isolated network (for example, ISOLATED_1).

For more information on workgroups, refer to the section in Chapter 2,

''Module Workgroups''.

Assigning a Monitor Card to a Network

If you have a CoreBuilder 5000 Ethernet Network Monitor Card or

Private Line Card installed on this module, network management also

enables you to assign the monitor card to a network. The

CoreBuilder 5000 20/40-Port Module supports up to 2 daughter cards.

You can assign the daughter cards to any of the 8 backplane segments,

whether or not any of the ports are assigned to that segment. You can

also assign daughter cards to an isolated segment.

Page 54

3-16 INSTALLING AND OPERATING THE MODULE

Use the following command to assign a monitor card to a network:

Showing Module Configurations

Show Module

Command

SET MODULE {

slot.subslot

} NETW ORK {ethe rn et_1. .. _8}

{isola te d_1. .. _8}

The CoreBuilder 5000 Ethernet Network Monitor Card is configured as

subslot 2 or 3 on the 20/40-Port module. The default, subslot 1, refers

to the 20/40-Port module.

You cannot attach an Ethernet Private Line Card to an isolated network.

You can display status information about the 20/40-Port module using

the following network management commands:

■ SHOW MODULE

■ SHOW MODULE VERBOSE

■ SHOW PORT

■ SHOW PORT VERBOSE

This command enables you to display both brief and verbose

information about a particular module.

Use the following command to display module information:

SHOW MODULE {

slot.subslot

{

slot.

all} {no_ve rb ose}

} {ve rbos e}

The following output is an example of the SHOW MODULE VERBOSE

command issued for a 20-Port module installed in slot 10:

CB5000> sho w module 10 .1 verbos e [ENTER]

Slot Module Version N etwork G eneral Inf ormation

----- - --------- - ------- -- --------- ----- --------- --------

10.01 6 120M-TPP 1.00 PER_PO RT

6120M- TPP: CB500 0 Ethernet 2 0-Port 10 BASE-T Modul e

Boot Ve rsion: 1.00

Non-Volatil e DIP Sett ing: EN ABLED

Page 55

Showing Module Configurations 3-17

Show Port Command This command enables users to display brief and verbose information

on both individual ports and all ports collectively.

Use the following syntax to display port information:

SHOW PORT {

slot.port

{

slot.

all} {no_v erbos e}

} {ve rbos e}

The following output is an example of the SHOW PORT ALL VERBOSE

command issued for a 20-Port module installed in slot 4 (only the

output for ports 1, 2, and 3 are shown):

CB5000> sho w port 4.al l verbose [ENTER]

Port Di splay for Module 6120M -TPP :

Port Mode Status Network General Information

----- ----- ------- ------- -------------------

04.01 E NABLED OK AY ETHERNET_2

Port Al ert Filter : ENABLED

Port Co nnector: RJ-45

Networ k Dip Setti ng: ETHERNE T_1

Link In tegrity: ENABLED

Auto Po larity: ENABLED

04.02 E NABLED OK AY ET HERNET_2

Port Al ert Filter : ENABLED

Port Co nnector: RJ-45

Networ k Dip Setti ng: ETHERNE T_1

Link In tegrity: ENABLED

Auto Po larity: DISABLE D

04.03 E NABLED OK AY ET HERNET_5

Port Al ert Filter : ENABLED

Port Co nnector: RJ-45

Networ k Dip Setti ng: ETHERNE T_1

Link In tegrity: ENABLED

Auto Po larity: ENABLED

Page 56

3-18 INSTALLING AND OPERATING THE MODULE

Attaching the Network Monitor Card

To monitor Ethernet and RMON statistics on your 20/40-Port module,

you must attach the CoreBuilder 5000 Ethernet Network Monitor Card

(ENMC) to the network you wish to monitor. The ENMC enables you to

individually select and monitor each backplane segment of your

CoreBuilder 5000 hub.

Figure 3-6

provides a component side view of the 20/40-Port module

with the network monitor card orientation on the module. For details

on the installation, refer to the documentation that accompanies the

CoreBuilder 5000 Ethernet Network Monitor Card.

Screws

Standoffs

Monitor card

NMC

connector

Figure 3-6 Attaching the CoreBuilder 5000 Ethernet Monitor Card

Page 57

Gathering Statistics 3-19

Gathering Statistics This section describes the following capabilities of the 20/40-Port

module:

■ Gathering Statistics

■ Monitoring the Network

Gathering Statistics The 20/40-Port module gathers repeater statistics without the use of a

network monitor card. These repeater statistics include:

■ Network

■ Module

■ Port

The 20/40-Port module gathers repeater statistics for each port (for

example, collision, partition, late collision, data rate mismatch, and

short event statistics).

Unlike repeater statistics, Ethernet and RMON statistics are only

available when a Network Monitor Card is defined.

Monitoring the

Network

It is possible to install the monitor card on either the 20/40-Port

module or the Distributed Management Module for Ethernet

(DMM-EC). For more information on the DMM, refer to the Distributed

Management Module User Guide.

The CoreBuilder 5000 Ethernet Network Monitor Card does not provide

per-port statistics for ONline modules when it is installed on the

20/40-Port module. If, however, the card is installed on the DMM, it is

possible to collect per-port statistics for ONline modules.

The 20/40-Port module supports two daughter cards. You may assign

these cards to any of the eight networks (isolated or non-isolated

segments). The ability to support two cards provides greater flexibility in

both workgroup creation and module configuration.

Once the monitor card is attached to the 20/40-Port module, you may

monitor the network using the following commands:

■ Monitor

■ Show Counter

Page 58

3-20 INSTALLING AND OPERATING THE MODULE

Monitor Command

This command enables you to monitor each network (individually) by

specifying the backplane segment, isolated or non-isolated, to which

your ports are configured.

Use the following command to monitor a network:

MONI TOR {mm:s s} { ETH ERNE T} {eth er net_1 .. ._ 8}

The system-specified range of time allotted for monitoring the network

is 00 to 30 (minutes) and 05 to 59 (seconds). Use these ranges when

specifying a length of time to monitor your network.

The following output is an example of the MONITOR ETHERNET

command for a 20/40-Port module assigned to network Ethernet_1.

This example monitors ethernet_1 every 10 seconds.

{isola ted _1 ..._ 8}

{REPEA TER }

{RMO N}

CB5000 > monitor 0 0:10 ethernet et hernet_1 [ENTER]

Ethernet Statistics for ETHERNET_1

----------------------------------------------------------- Cumulative Last Time Interval

----------------------------------------------------------FCS Err ors 0 0

SQE Test Errors 0 0

Alignm ent Errors 0 0

Carrie r Sense Errors 0 0